Waterproof, oil resistant, and moisture permeable garment fabric

A water- and oil-repellent, water-repellent and oil-repellent technology, applied in the textile field, can solve the problems of poor moisture permeability, low temperature and cold, and decreased mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

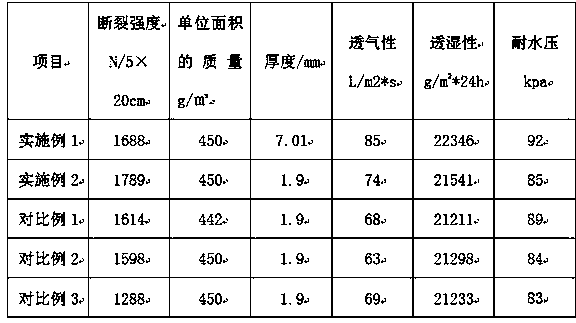

Examples

Embodiment 1

[0020] A water-repellent, oil-proof and moisture-permeable clothing fabric, comprising the following components by weight: 80 parts of superfine polyester fiber, 40 parts of mulberry fiber, 20 parts of polyvinylidene chloride fiber, 15 parts of chitin and graphene regenerated fiber 15 parts of prime, 0.5 parts of water and oil repellent.

[0021] A water-repellent, oil-proof and moisture-permeable clothing fabric, the preparation method of which comprises the following steps: the first step, pre-treatment: first dipping and rolling each fiber raw material twice in the pre-waterproof treatment liquid, and after the liquid rolling rate is 70%, bake at 100°C After drying, use a coating treatment agent to coat the superfine polyester fiber, mulberry fiber, polyvinylidene chloride fiber, chitin and graphene regenerated cellulose fiber respectively, and then dry it in an oven at 150°C. After adding it into the water-repellent treatment solution, dipping and rolling twice, and after ...

Embodiment 2

[0027]A water-repellent, oil-proof and moisture-permeable clothing fabric, comprising the following components by weight: 60 parts of superfine polyester fiber, 30 parts of mulberry fiber, 10 parts of polyvinylidene chloride fiber, 10 parts of chitin and graphene regenerated fiber 10 parts of prime, 0.5 parts of water and oil repellent.

[0028] A water-repellent, oil-proof and moisture-permeable clothing fabric, the preparation method of which comprises the following steps: the first step, pre-treatment: first dipping and rolling each fiber raw material twice in the pre-waterproof treatment liquid, and after the liquid rolling rate is 70%, bake at 100°C After drying, use a coating treatment agent to coat the superfine polyester fiber, mulberry fiber, polyvinylidene chloride fiber, chitin and graphene regenerated cellulose fiber respectively, and then dry it in an oven at 150°C. After adding it into the water-repellent treatment solution, dipping and rolling twice, and after t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com