Patents

Literature

1138results about How to "Good moisture permeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

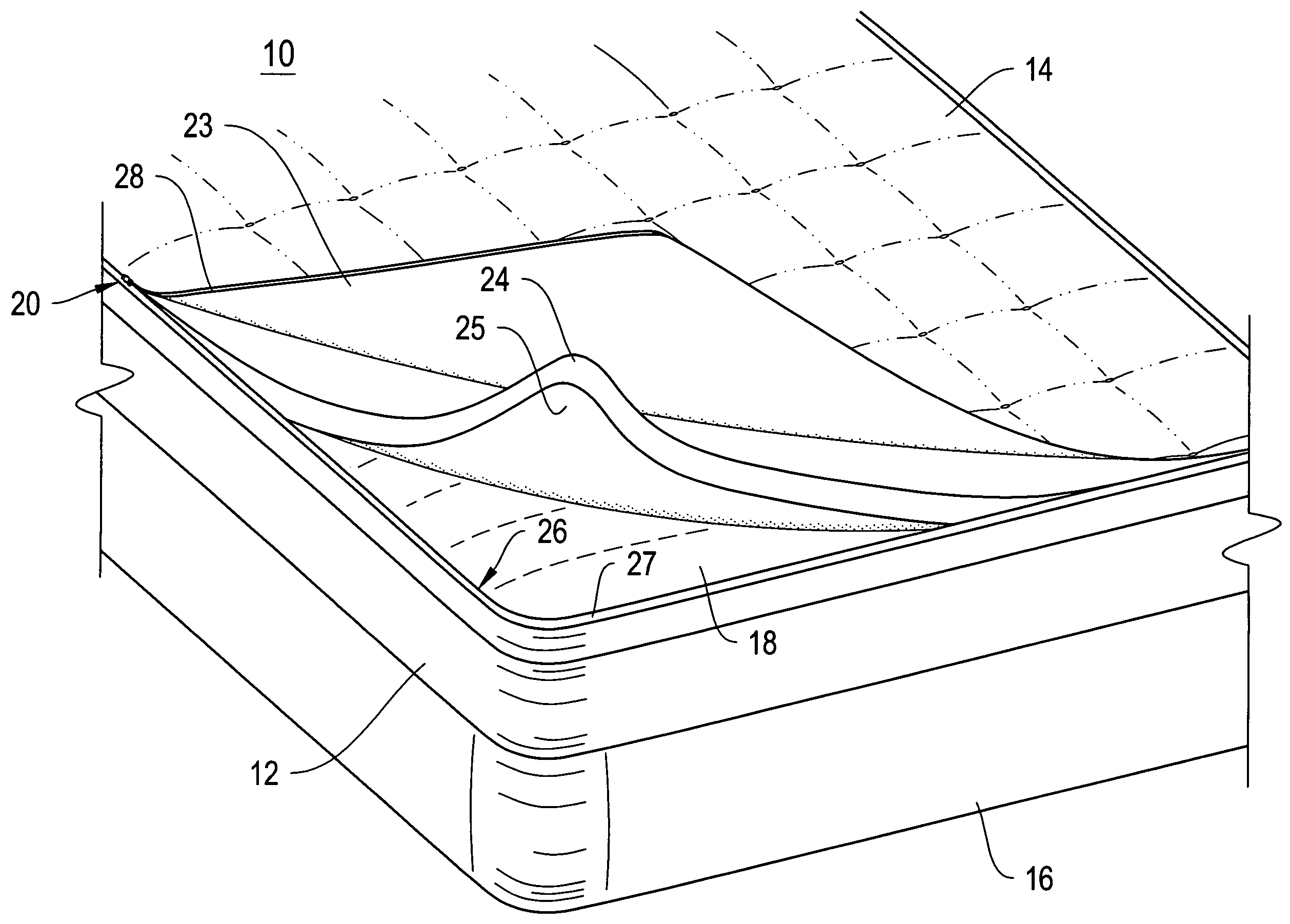

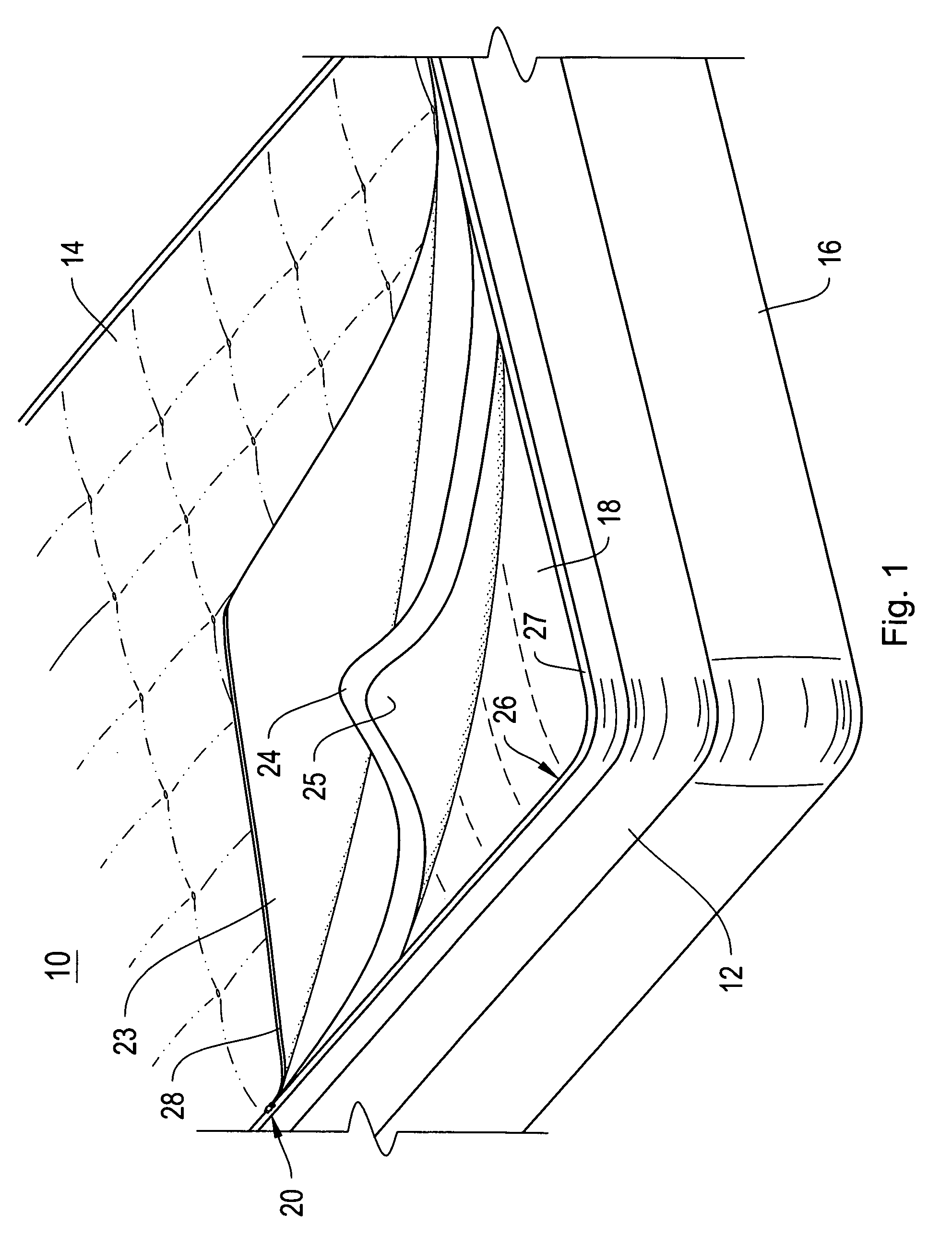

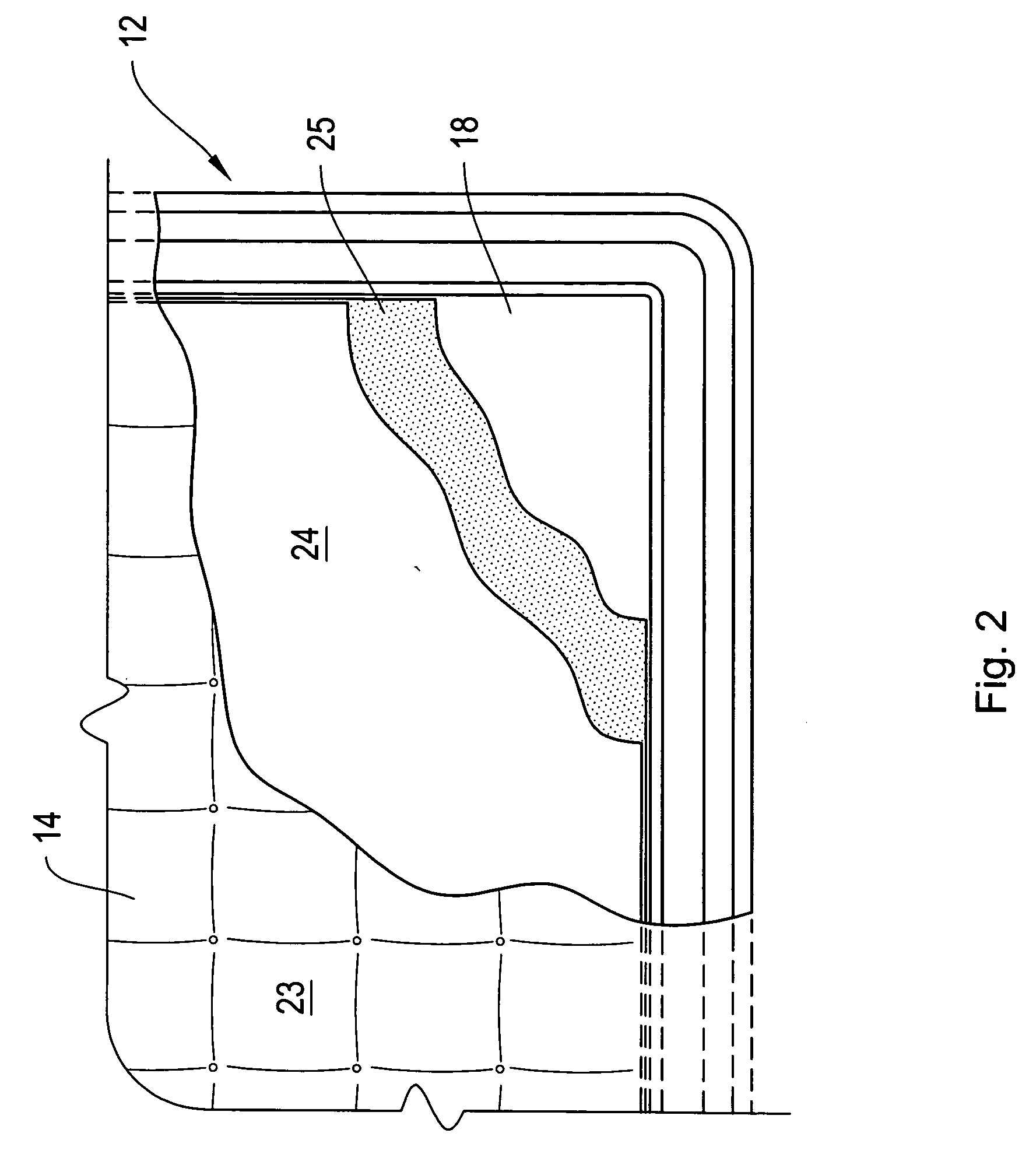

Mattress with removable top

ActiveUS20060010608A1Improve breathabilityGood moisture permeabilityStuffed mattressesSpring mattressesMoisture barrierFastener

A mattress is constructed from a mattress body having an upper and a lower deck, which is preferably pervious to moisture and air. A removable panel, which includes a top layer of breathable fabric, a bottom layer of a fabric that forms a moisture barrier, and a batting layer, is placed on at least the upper deck of the mattress body. The removable panel is removably attached along the perimeter of the deck or decks by a fastener, such as a zipper. The panel can be removed from the deck for cleaning and folded and secured by the fastener in an inverted configuration, with the top layer facing outward.

Owner:DREAMWELL

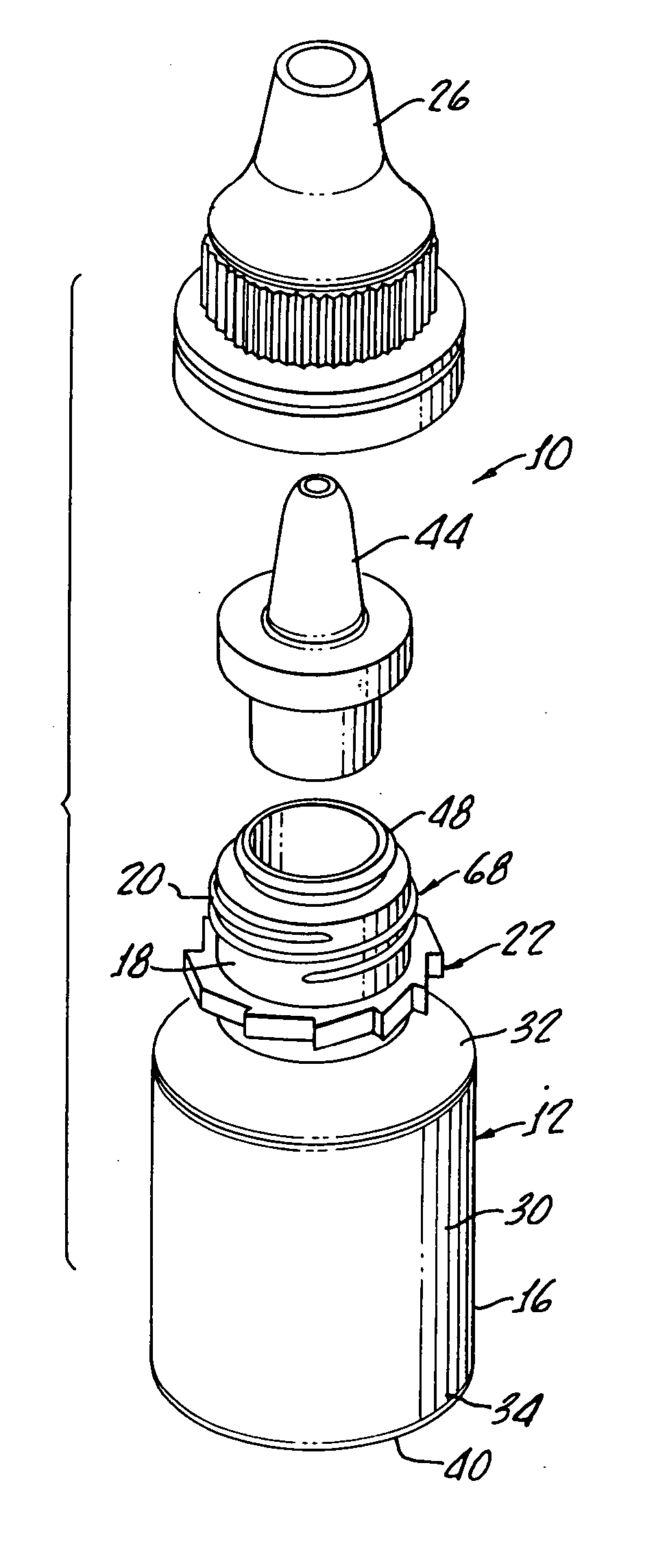

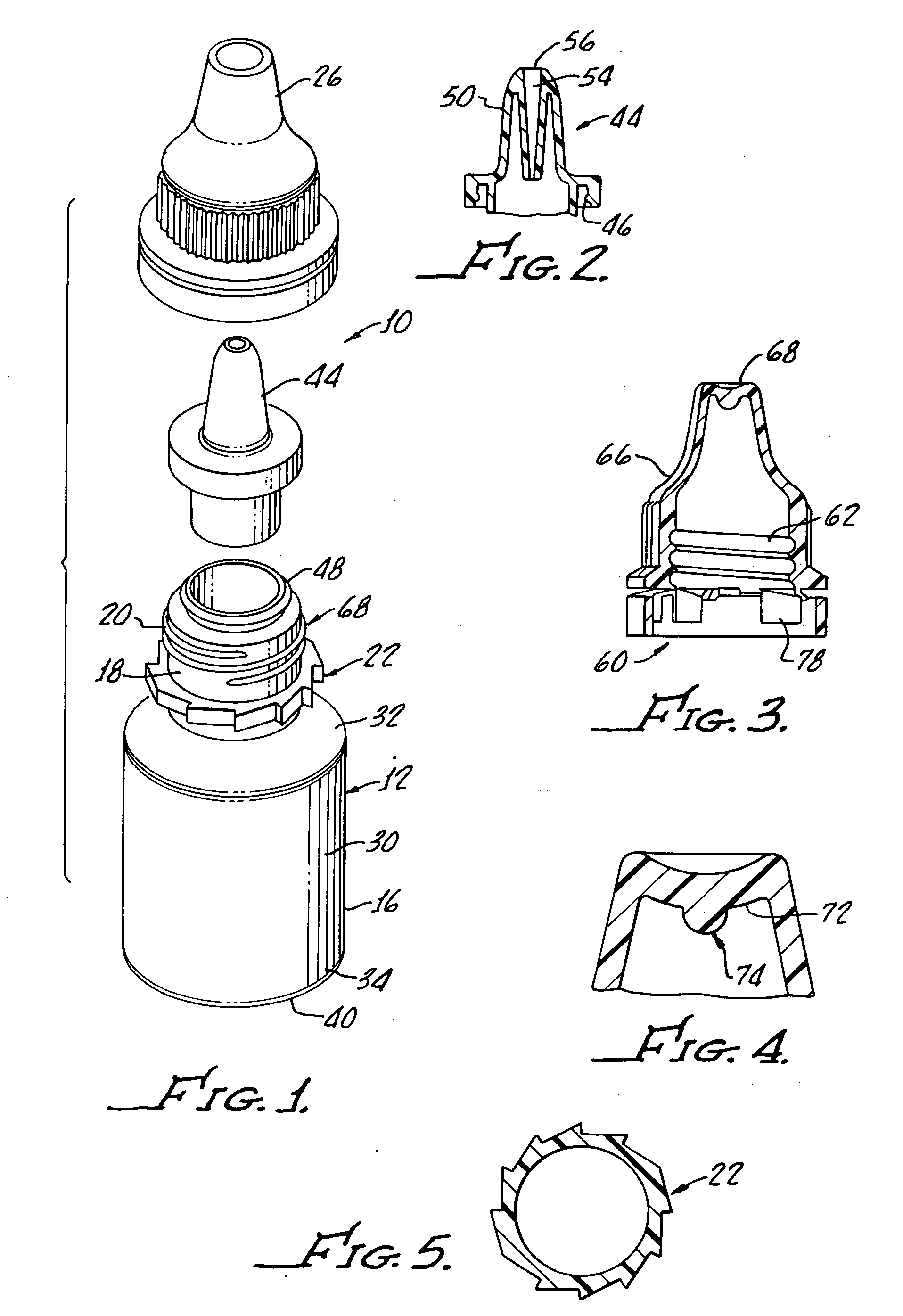

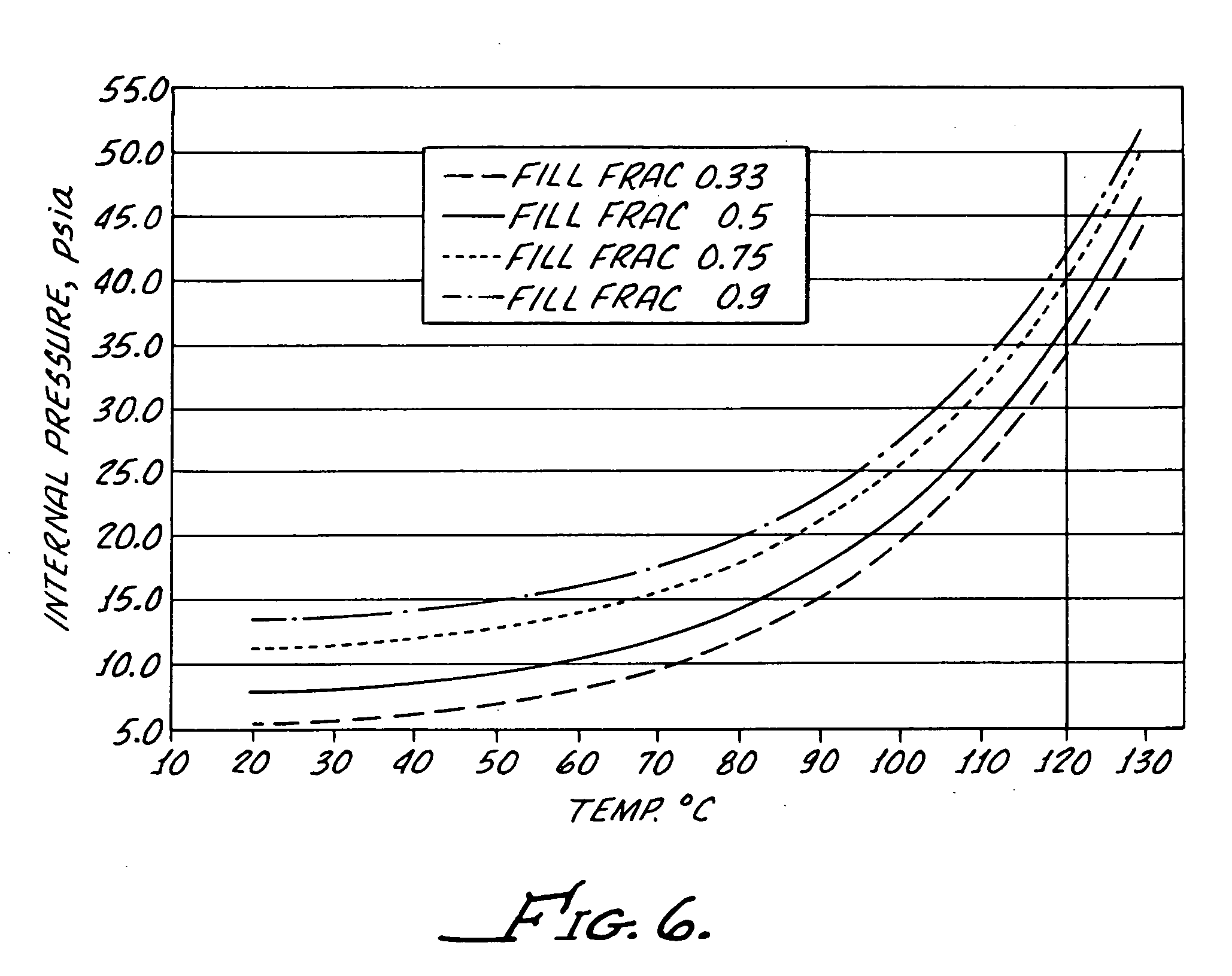

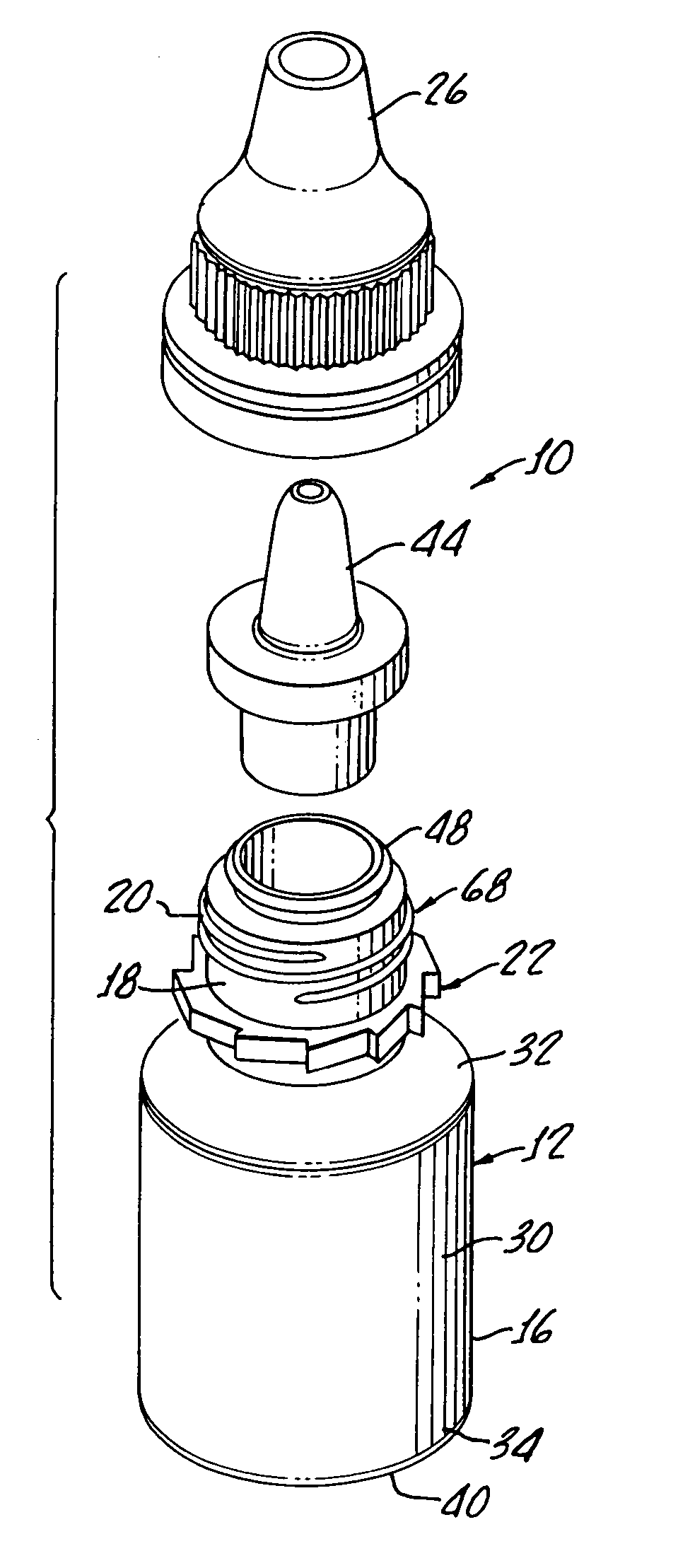

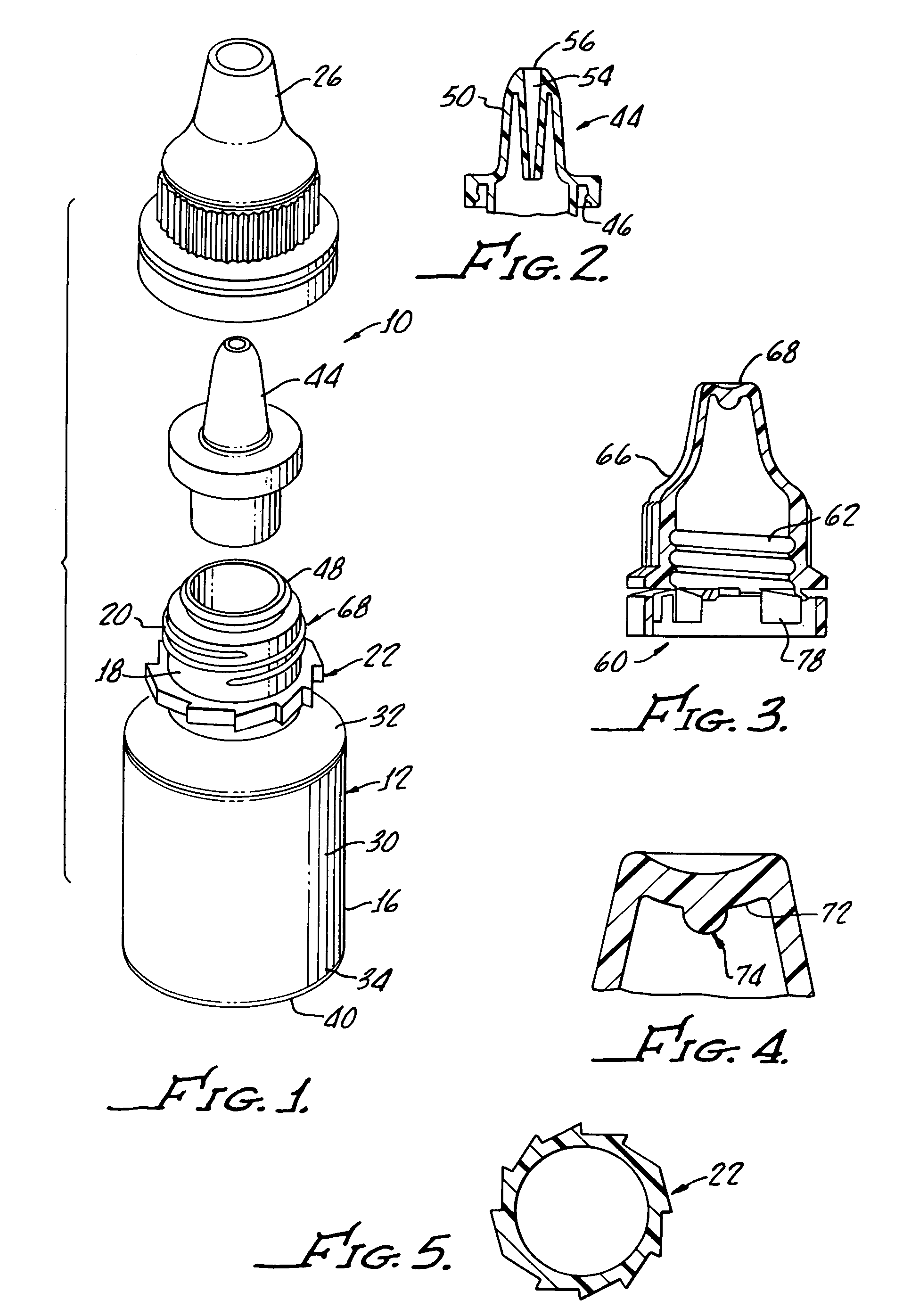

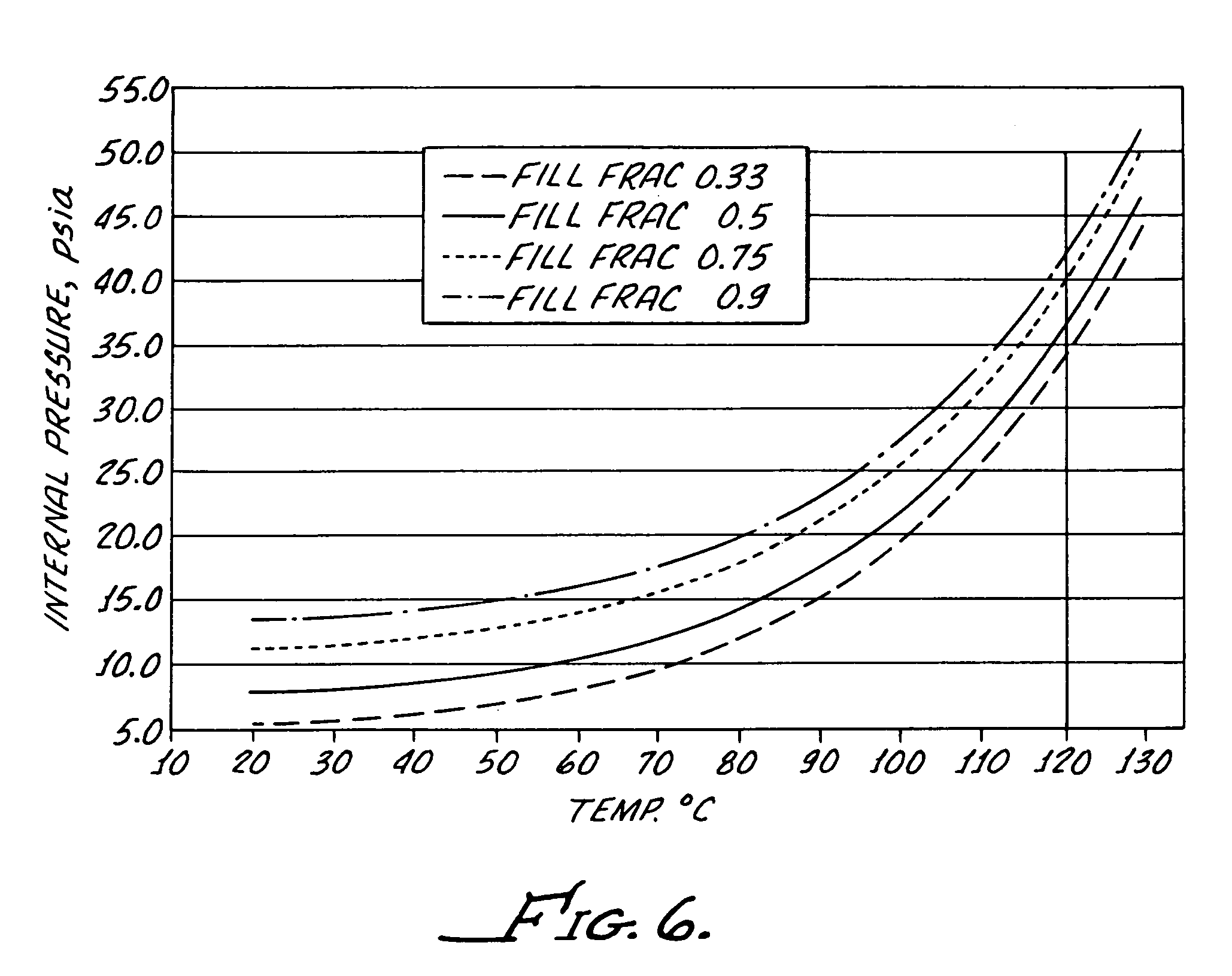

Autoclaveable small-volume dropper bottle

ActiveUS20060111680A1Short lifeLow acceptabilityClosuresLiquid flow controllersEngineeringHigh pressure

A terminally sterilizable container includes a polypropylene bottle having a body with a manually squeezable sidewall and a thickness preventing water loss. The bottle body includes shoulders for providing autoclave produced pressure distribution and deformation resistance along with an elongated tips outfitted to a neck of the body and having a lumen therethrough with a drop dispensing orifice. A cap enclosed the elongated tip and includes enclosed with a nub for sealing the orifice to prevent autoclave produced pressure leaks.

Owner:ALLERGAN INC

Production method for liner gloves aqueous polyurethane coating connection material

InactiveCN101328383ABreathableGood moisture permeabilityPolyurea/polyurethane coatingsWater basedPropanoic acid

The invention discloses a production method for insert gloves water-based polyurethane coating bonding materials. The method comprises the following steps of: under the protection of dry nitrogen, adding polyether glycols (including polyether diatomic alcohol and / or polyether triatomic alcohol) having undergone vacuum dewatering and isocyanate into a reaction vessel; heating the mixture up to between 80 and 100 DEG C for reaction after even mixing; then adding a hydrophilic chain extender such as dihydromethyl propionic acid (DMPA) and a catalyst for reaction at a temperature of between 80 and 100 DEG C; finally adding the chain extender and a solvent into the mixture for reaction at a temperature of between 55 and 65 DEG C until the NCO content of the isocyanate group does not change; discharging the reactant after temperature reduction to obtain an ionomer; neutralizing a preformed polymer with triethylamine or diethanolamine or triethanolamine and then adding water the mixed solution for emulsification to obtain water-based polyurethane latex; and carrying out reduced pressure distillation to remove the solvent and obtain the product. The synthesized water-based polyurethane resin which serves as a gloves coating has the advantages of good air and moisture permeability, excellent mechanical performance, solvent resistance, ageing resistance, resistance to corrosion caused by chemical mediators, oil resistance, resistance to hooking, cutting and piercing, excellent abrasion resistance, odorlessness, innocuous and nondestructive for contacting with skin, etc.

Owner:ANHUI UNIVERSITY +1

Pressure-sensitive adhesive tape and pressure-sensitive adhesive composition for medical adhesive tape

InactiveUS20060216523A1Good moisture permeabilityLess generationSurgical adhesivesPolyureas/polyurethane adhesivesVitrificationOligomer

An adhesive composition for medical adhesive tapes, comprising a base polymer containing a pressure-sensitive adhesive polymer obtained by crosslinking or curing a precursor containing a urethane acrylate oligomer and an ultraviolet (UV) initiator, the base polymer having a glass transition temperature (Tg) of 0° C. or less.

Owner:3M INNOVATIVE PROPERTIES CO

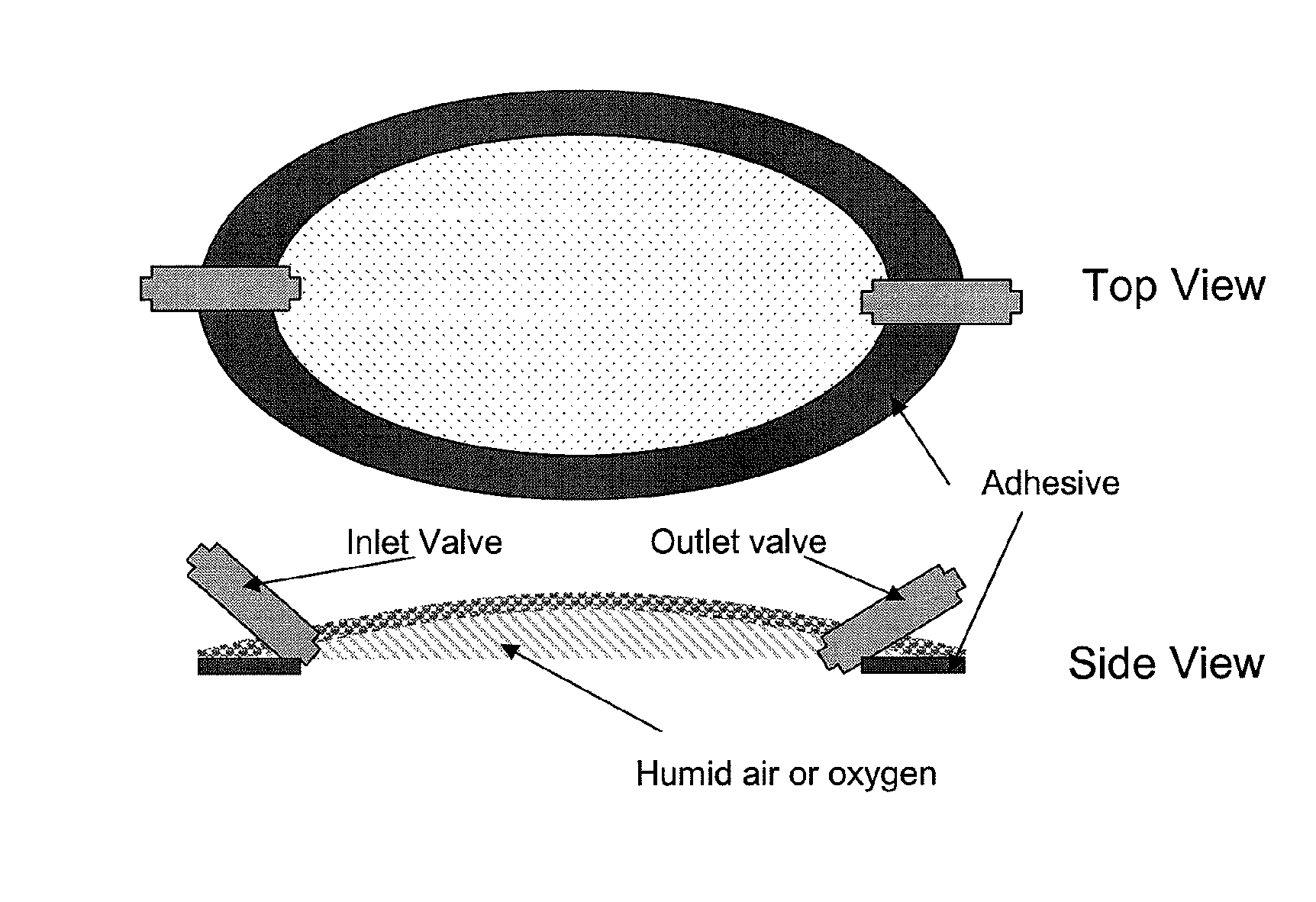

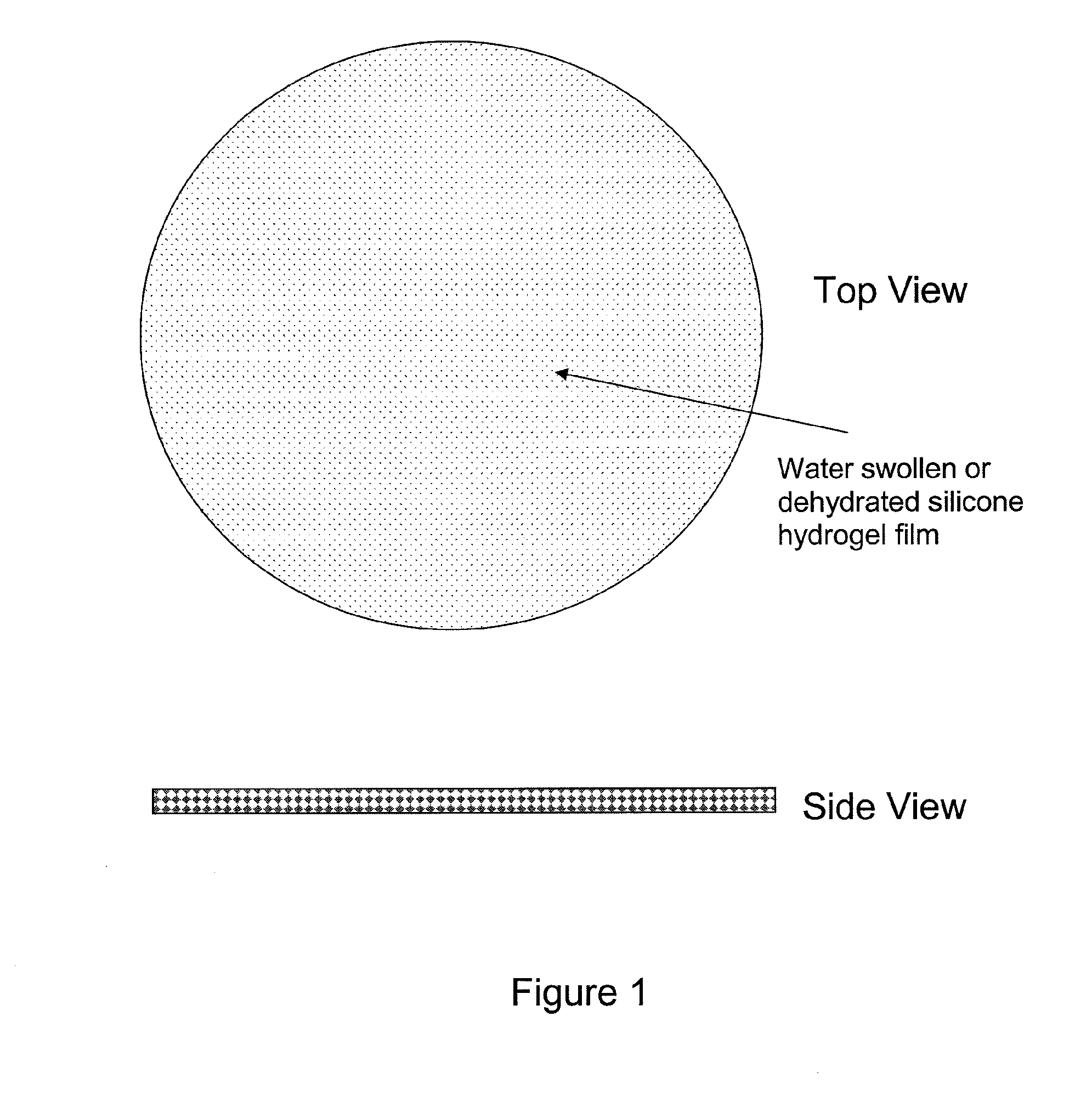

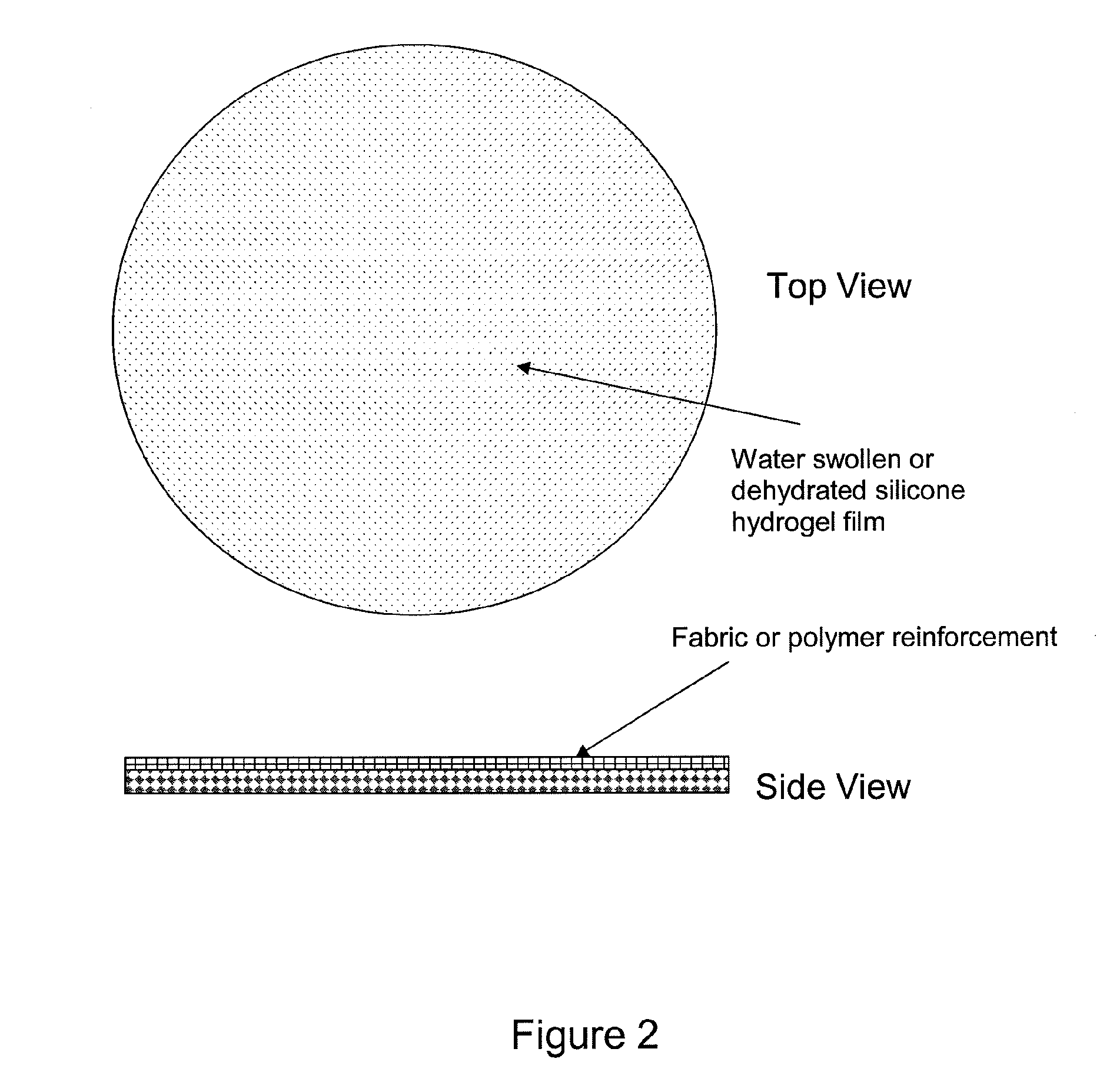

Silicone hydrogels for tissue adhesives and tissue dressing applications

InactiveUS20110086077A1Provide strengthFacilitated releaseBiocidePeptide/protein ingredientsWound dressingSilanes

A silicone hydrogel formulation may contains random and / or block copolymers or oligomers or macromers. The silicone copolymer is copolymerized or blended with other polymers or monomers or macromers to obtain final formulation. The silicone hydrogel may contain crosslinking groups to provide a complete or partially crosslinked final structure. The silicone hydrogel formulation may be pre-formed as a film or other structure, or it may be polymerized during application as in the case of an adhesive formulation. A wound dressing comprising a silicone hydrogel formed as a film, either prior to application to a wound or in situ on a wound, which film has gas permeability, moisture permeability, and high water content, wherein said silicone hydrogel is formed from a polymerizable silicone such as a difunctional polydimethylsiloxane methacrylate and crosslinking agents such as N,N-dimethyllacrylamide (DMA), 2-hydroxyethyl methacrylate (HEMA), and trimethylsiloxy silane (TRIS).

Owner:DSM IP ASSETS BV

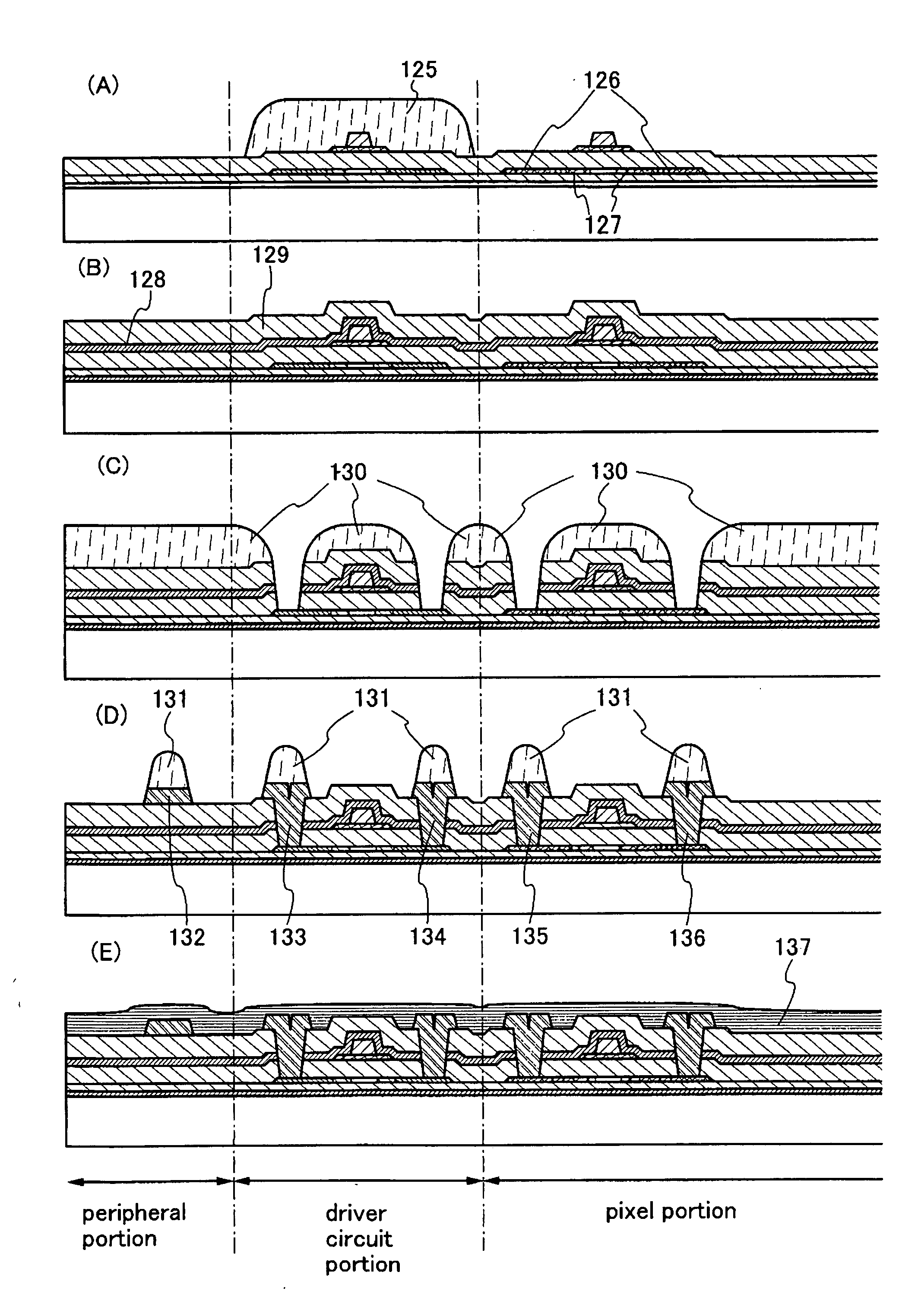

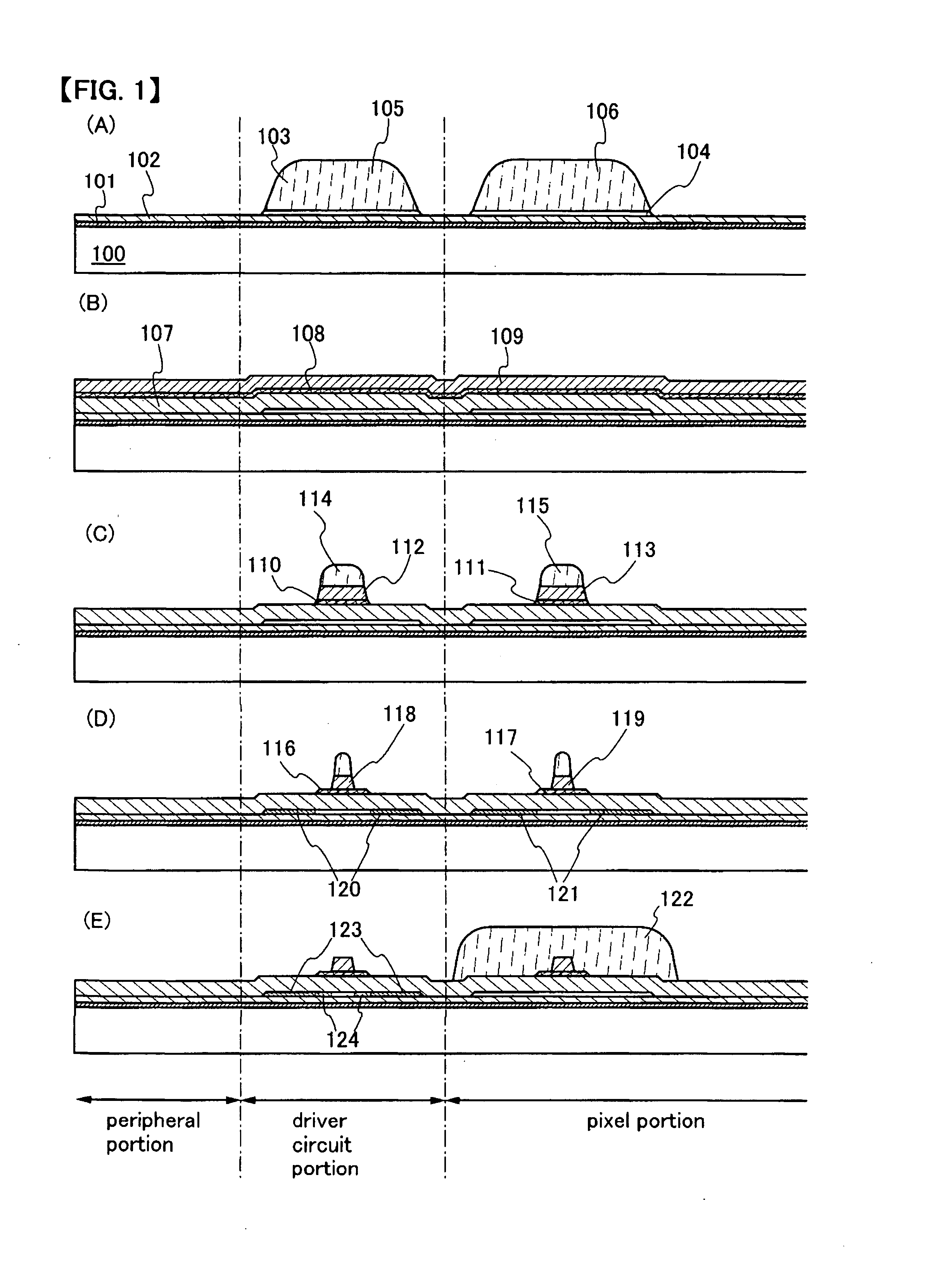

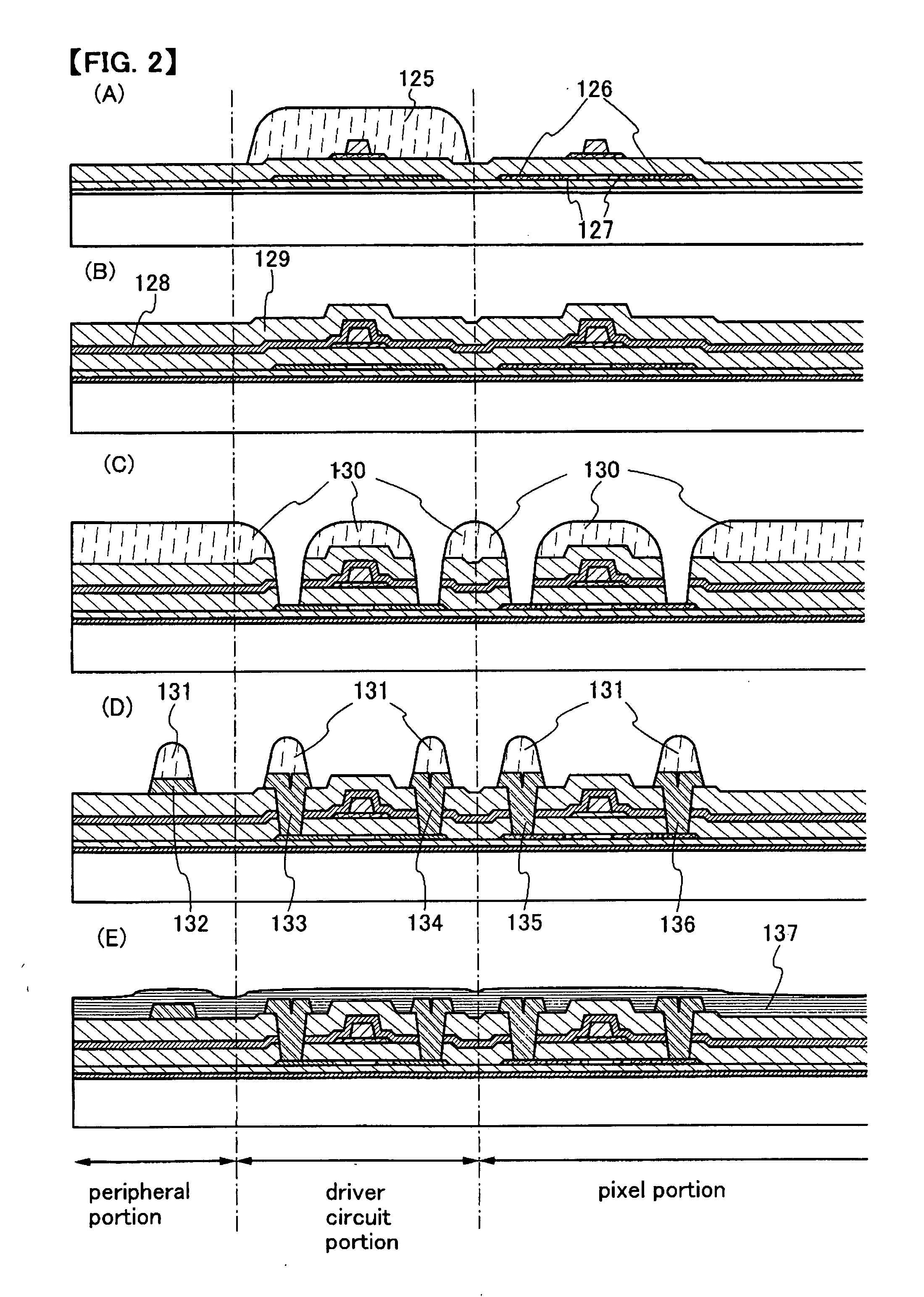

Display device and manufacturing method of the same

ActiveUS20060186413A1Easy to operateGood moisture permeabilityStatic indicating devicesSolid-state devicesDisplay deviceMoisture permeability

It is an object of the present invention to provide a method for manufacturing a display device in which unevenness generated under a light-emitting element does not impart an adverse effect on the light-emitting element. It is another object of the invention to provide a method for manufacturing a display device in which penetration of water into the inside of the display device through a film having high moisture permeability can be suppressed without increasing processing steps considerably. It is another object of the invention to provide a display device and a method for manufacturing a display device satisfying the above two simultaneously. A display device of the present invention to solve the above problems comprising a thin film transistor and a light-emitting element over an insulating surface formed on a substrate, wherein the light-emitting element includes a light-emitting laminated body interposed between a first electrode and a second electrode; wherein the first electrode is formed over an insulating film formed over the thin film transistor; and wherein a planarizing film is formed in response to the first electrode between the first electrode and the insulating film.

Owner:SEMICON ENERGY LAB CO LTD

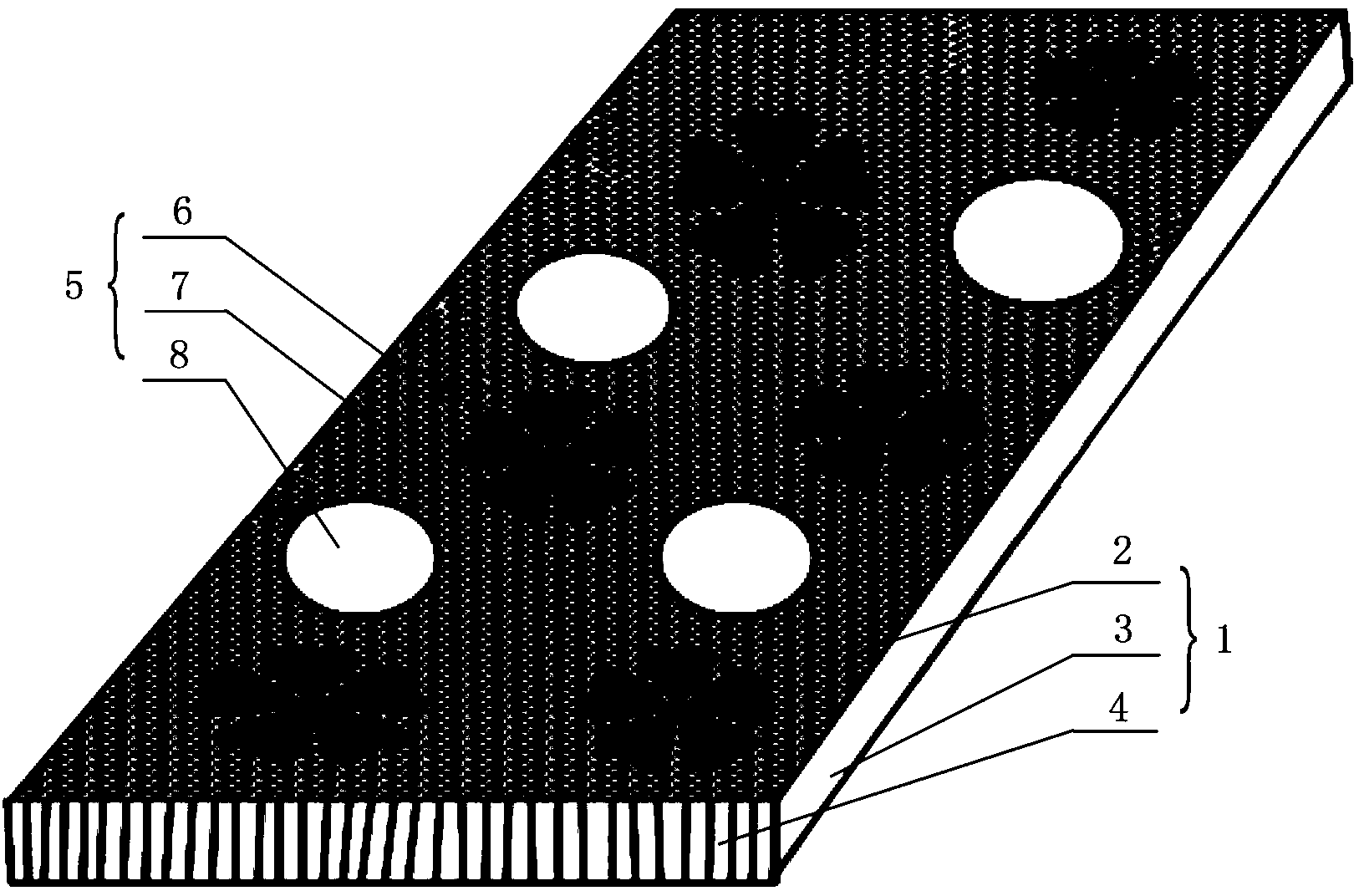

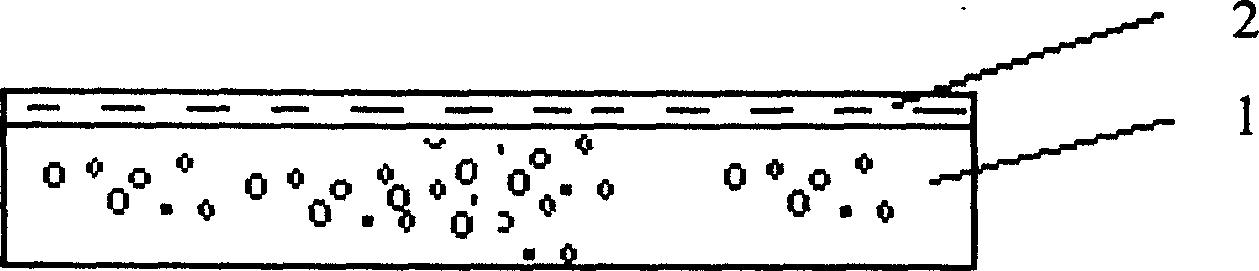

Multifunctional ventilating type protection material and preparation method thereof

The invention relates to a multi-functional vented protective material and a preparation method thereof. The protective material of the invention consists of a multi-functional protective textile layer, a barrier layer and an adsorption layer. The protective material of the invention has a plurality of functions and realizes the harmony, uniform and duration of the functions by organically combining filming, composition and arrangement. The vented NBC protective material prepared by the method of the invention has a plurality of functions, simple process technique, low cost and evident economic and social benefits.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME +1

Method for manufacturing synthetic leather and synthetic leather

InactiveCN101941321AAchieving water-basedRealize cleaner productionSynthetic resin layered productsTextiles and paperLeather industryPolymer science

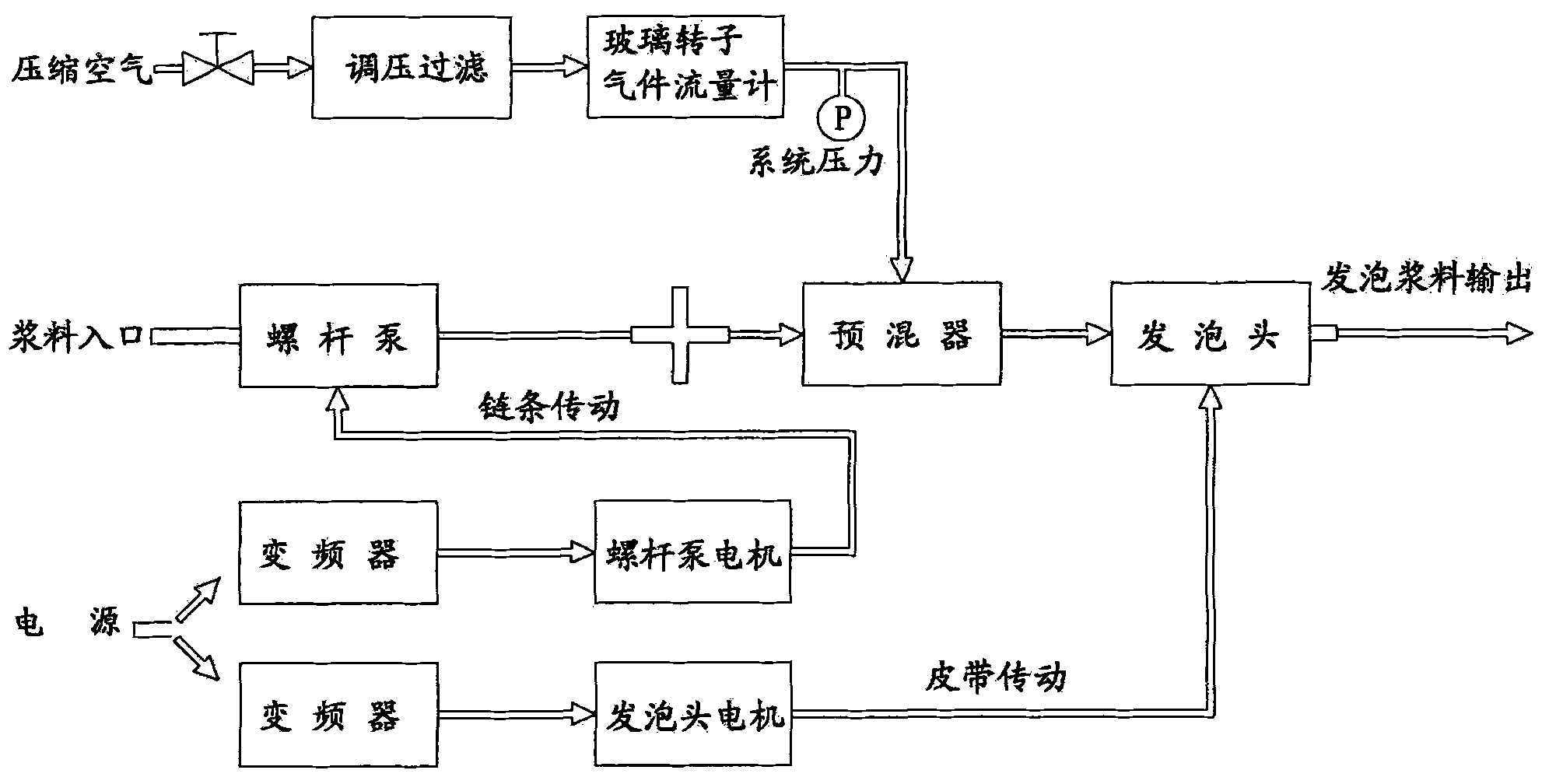

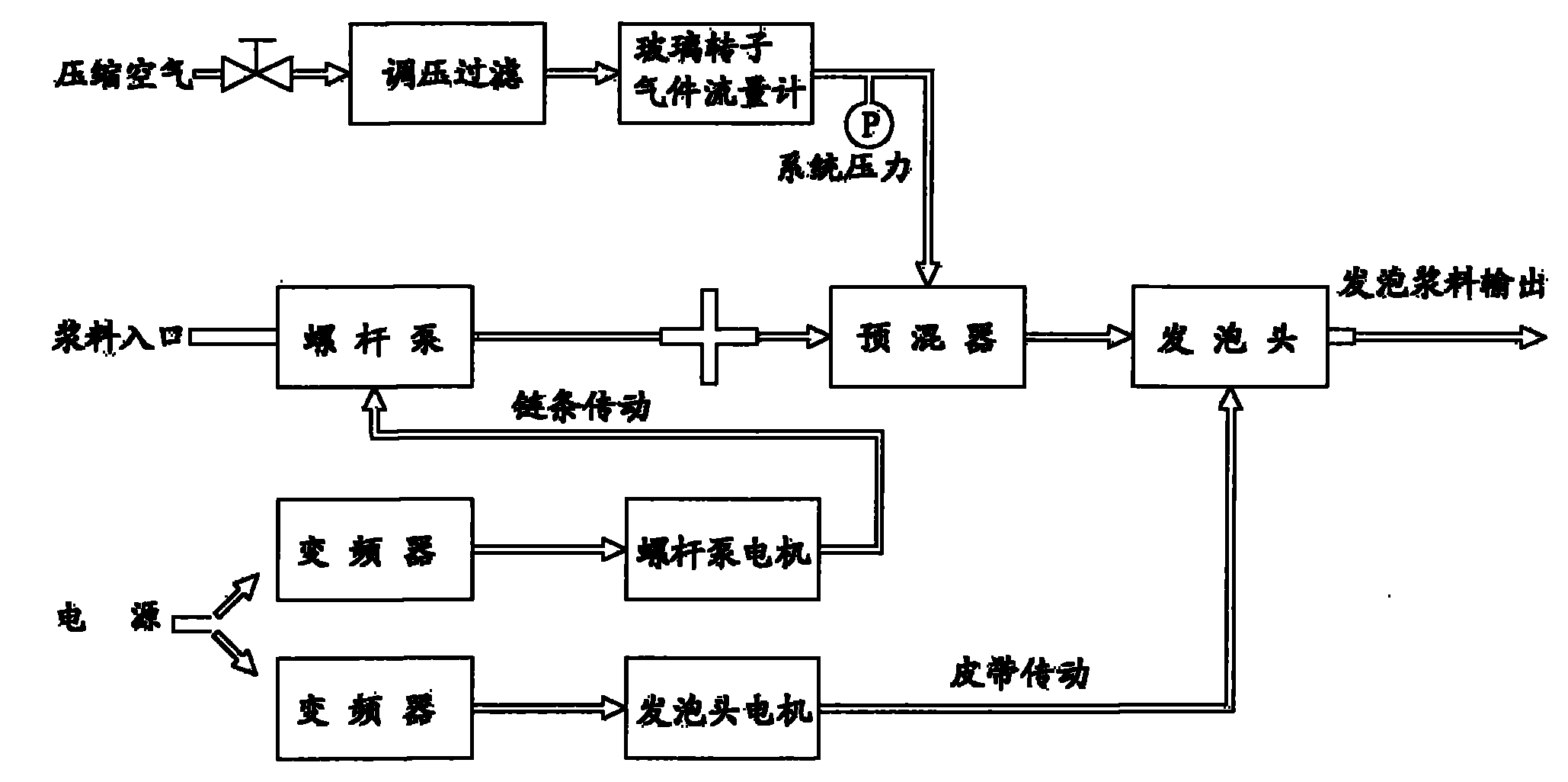

The invention provides a method for preparing synthetic leather and the synthetic leather prepared by the method. The method comprises the following steps: (1) coating slurry containing surface waterborne polyurethane resin on the surface of release paper, and drying to form a finishing coat; (2) mixing and foaming the slurry containing the foaming waterborne polyurethane resin with air by using a foaming machine, and coating the foamed slurry on the surface of the finishing layer, and drying to form a medium foaming layer; and (3) adhering the surface of the foaming layer and a basic fabric by using an adhesive containing waterborne polyurethane resin, and drying. The method uses the waterborne resin foaming layer to replace the Base leather manufacturing process, avoids using toxic and harmful organic solvents, such as dimetbyl formamide (DMF), toluene and the like, solves the pollution problem in the synthetic leather industry, and realizes clean manufacture of the synthetic leather.

Owner:丽水市优耐克水性树脂科技有限公司

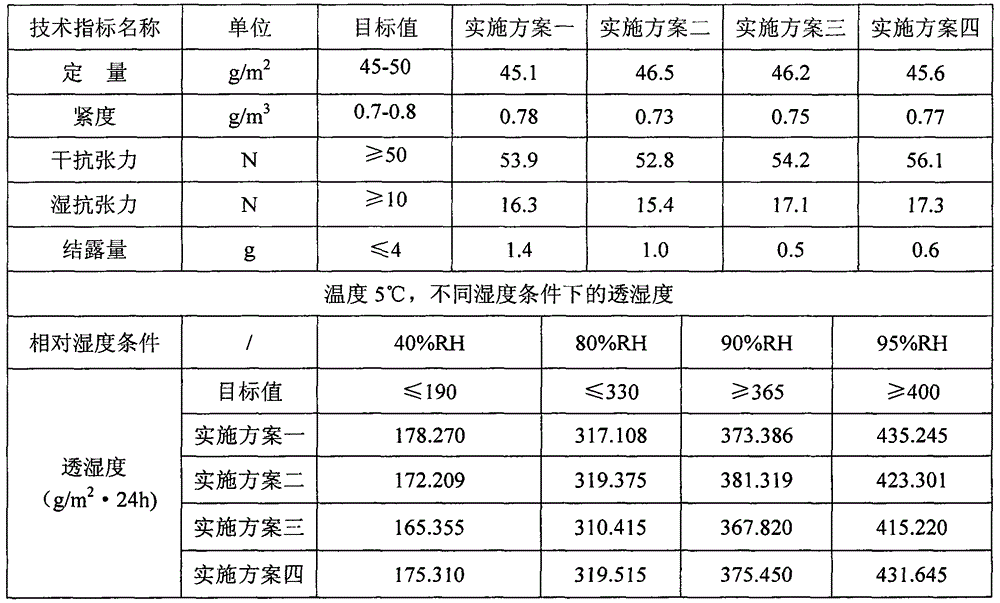

Method for manufacturing fruit and vegetable humidity-adjusting fresh-keeping film

ActiveCN105986511AReduce dosageSimple production operationWater-repelling agents additionReinforcing agents additionRefrigerated temperatureFruits and vegetables

The invention discloses a method for manufacturing a fruit and vegetable humidity-adjusting fresh-keeping film. Body paper is prepared through papermaking by means of plant fiber as the raw material and by adding a proper wet strength agent and a proper dry strength agent. The body paper is prepared into the humidity-adjusting fresh-keeping film by coating a mixed glue solution composed of a hydrophilic water-retention natural high-molecular polymer and a water-insoluble, safe and environment-friendly mildew-proof antibacterial agent. The manufacturing method is environmentally friendly and simple, and the special humidity-adjusting fresh-keeping film is used for a fruit and vegetable box with a fresh-keeping function and a refrigerator with the fresh-keeping fruit and vegetable box. The fruit and vegetable humidity-adjusting fresh-keeping film can make fruits and vegetables in the fruit and vegetable box hold moisture and kept fresh when relative humidity is small, moisture permeability is remarkably increased when relative humidity is large, and condensation and rotting are prevented. The humidity-adjusting fresh-keeping film can be completely and naturally degraded.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

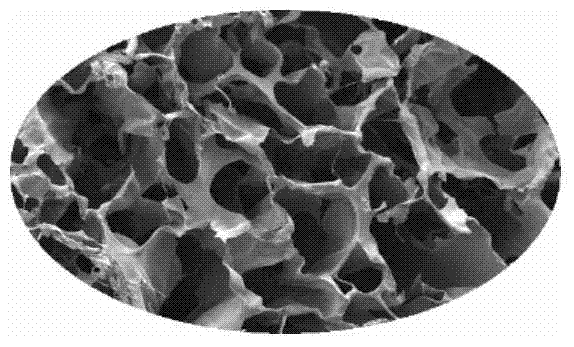

Porous complex gel-nanofiber oxygen permeation dressing and preparation method thereof

ActiveCN104491914AHigh oxygen permeabilityImprove antibacterial propertiesAbsorbent padsBandagesWound dressingFreeze-drying

The invention discloses a porous complex gel-nanofiber oxygen permeation dressing and a preparation method thereof. The method comprises the following steps: obtaining a collagen nanofiber membrane by adopting a collagen solution by virtue of an electrostatic spinning method; performing chemical crosslinking on two natural and non-toxic macromolecule polysaccharides such as chitosan and alginic acid, and preparing complex gel; and preparing the porous sponge-nanofiber double-layer composite material in a freeze-drying mode, wherein the upper gel layer of the dressing is in a sponge state during drying and is in a gel state after moisture absorption. The biological wound dressing is prepared under the condition that any toxic chemical crosslinking agent is not added, the process is simple, and the safety is high. The prepared biological wound dressing disclosed by the invention has the characteristics of excellent oxygen permeation performance, water-absorbing quality, water permeability, moisture penetrability and high biocompatibility, a physiological wet environment of the wound surface can be maintained, wound healing and effective haemostasis are promoted, wound infection can be avoided, the recovery is accelerated, the wound surface can be effectively recovered, and the dressing is applied to multiple wound surfaces such as trauma, burns and ulceration.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Waterproof moisture permeation polyurethane paint used for textiles and preparation method

The invention relates to waterproof moisture permeation polyurethane paint used for textiles and a preparation method. The waterproof moisture permeation polyurethane paint is prepared from methyl diphenylene diisocyanate, toluene di-isocyanate, polyether glycol (with the molecular weight of 2000), linear dihydroxylated alkylsiloxane (with the molecular weight of 1000), polyester dihydric alcohol (with the molecular weight of 2000), trimethylolpropane, chain extending agents, sealing compounds, dibutyl tin laurate and solvents through the processes of pre-polymerization reaction, chain extension reaction and sealing reaction. The production process is simple, and the products have the advantages of self-crosslinking effect, soft hand feeling, good cold resistance performance, high moisture permeation performance, high water pressure resistance and little reduction after water pressure resistance washing.

Owner:郯城丰润粮机配件有限公司

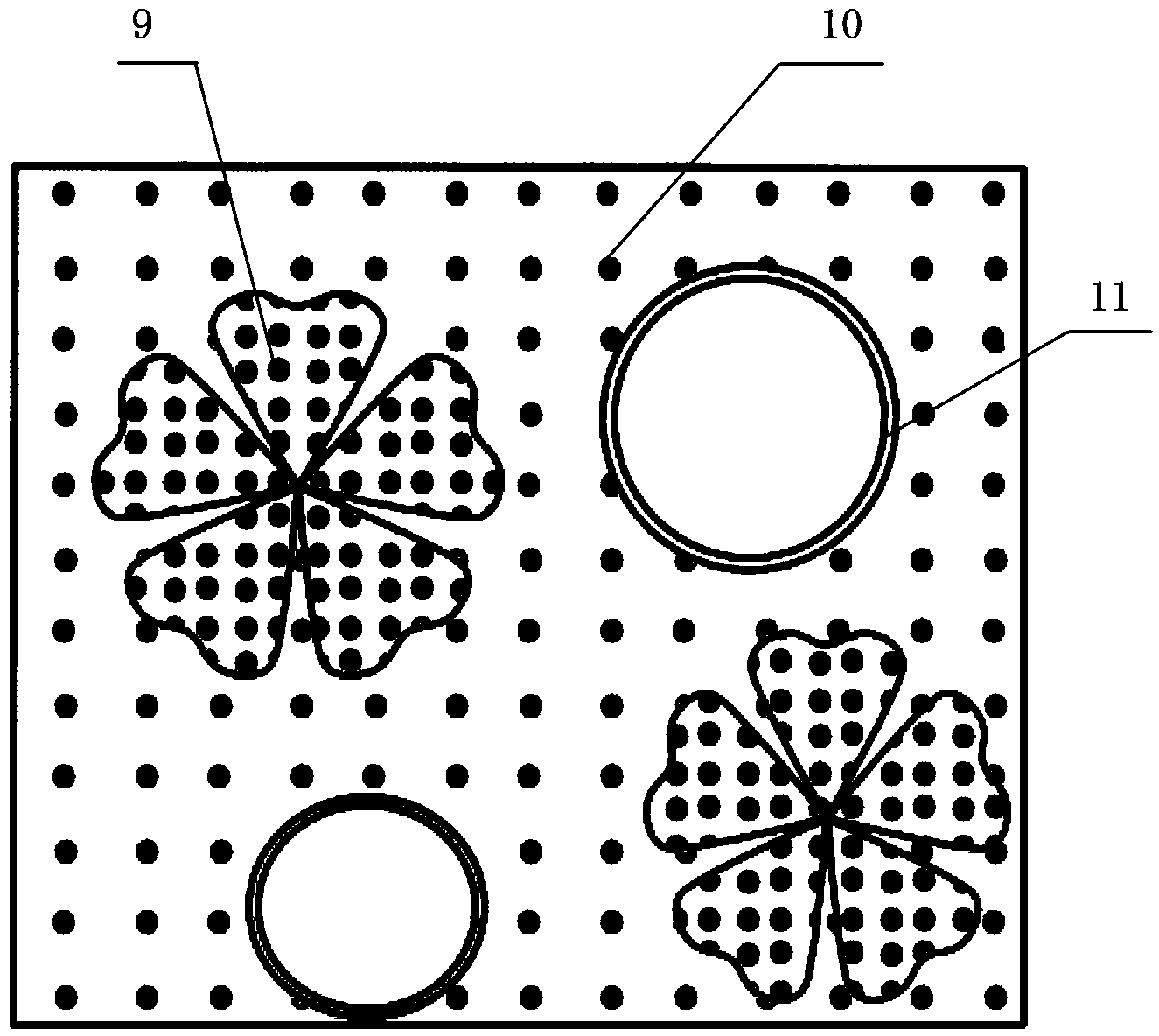

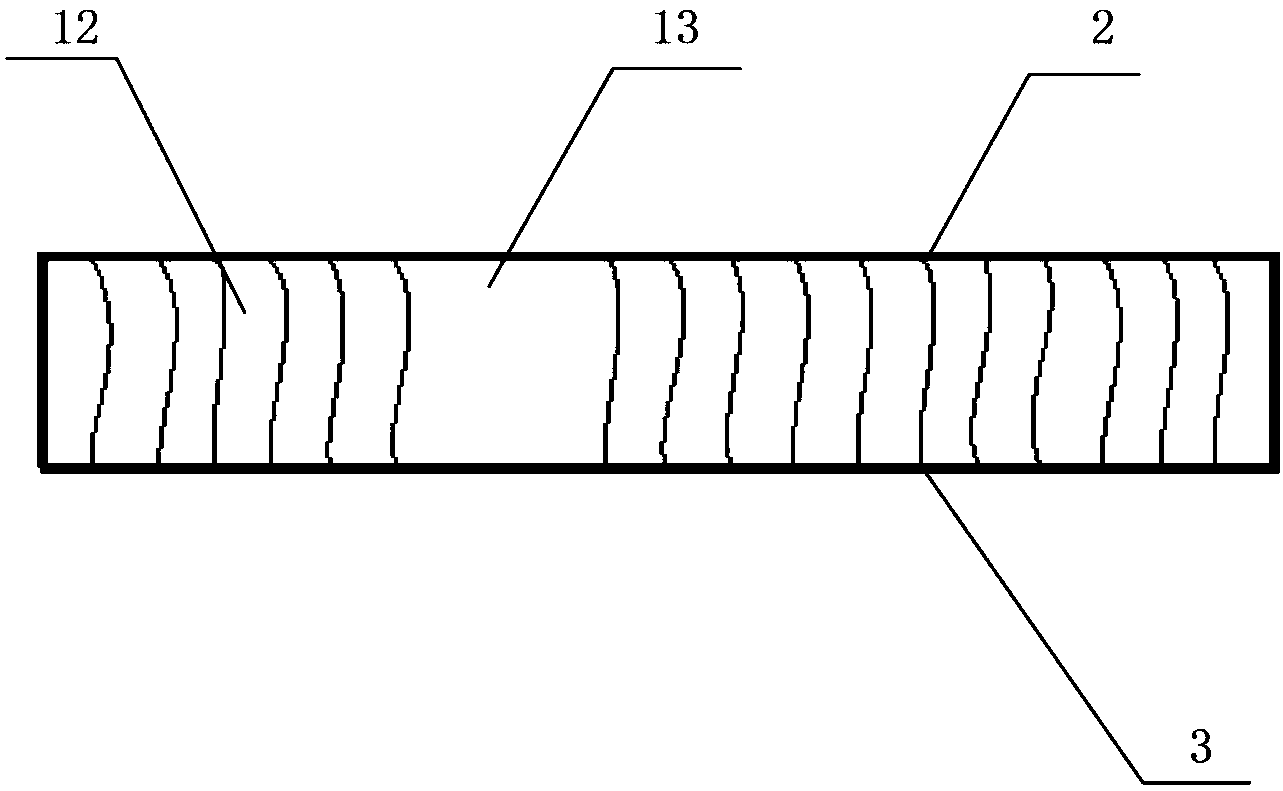

Three-dimensional jacquard sandwich fabric

The invention discloses three-dimensional jacquard sandwich fabric. The fabric comprises an upper layer structure, a lower layer structure and a middle layer structure, wherein the upper layer structure and the lower layer structure form a transparent bottom cloth which is knitted by transparent micro-thin filaments; the middle layer structure adopts synthetic multi-filaments with certain elasticity as a woven material; the synthetic multi-filaments are combined according to certain patterns, so as to form various floral designs by adopting needle front and needle back migration of a jacquard needle; the fabric surface is exposed through the transparent upper layer bottom cloth and lower layer bottom cloth; the embossing jacquard effect is formed on the surface, thereby generating a good effect of hollow three-dimensional patterns in a three-dimensional structure. The fabric disclosed by the invention is strong in pattern stereo perception, and is mainly applied to the fields such as lady brassieres and shoe materials; the hand feeling, the comfort and the functionality of the fabric are obviously improved.

Owner:JIANGNAN UNIV

Water-proof moisture-permeation coating agent composition and application thereof

InactiveCN101104752AGood hygroscopicityGood anti-adhesionNatural rubber coatingsPolyurea/polyurethane coatingsFiberHigh resistance

The invention relates to a waterproof and moisture-permeable coating agent composition, wherein, a certain amount of microporous lignocellulose fine powder is added into the coating agent with waterproof function, so that the coating agent has moisture permeable performance. The waterproof and moisture-permeable coating agent composition which is used as the coating agent for non-woven fabric, knitted fabric or woven fabric can be made into coated fabric and synthetic leather with waterproof and moisture permeable performances. Compared with the prior at, the invention has the advantages that: 1. the raw material is easy to be added, the process is available with high adaptability, no need to add new equipment; 2. on the premise that the waterproof performance is not decreased, the amount of moisture permeated is increased obviously and the anti-adhesion is improved; 3. the coated fabric and superfine fiber and artificial cover synthetic leather made by the invention has the advantages of fine moisture permeability, high resistance to water pressure and that the physical performance does not decrease.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

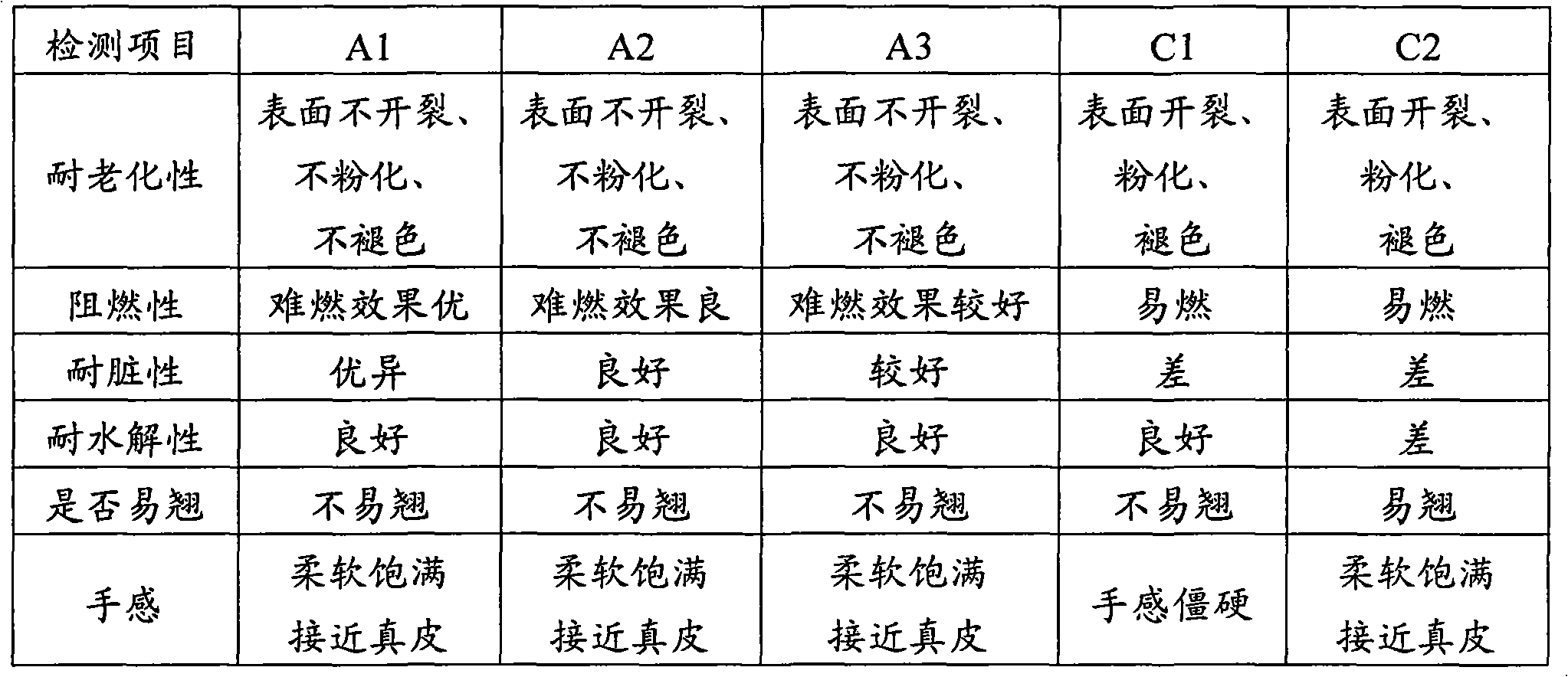

Interior wall adornment leather and preparation method

The invention provides interior wall adornment leather and a preparation method. The interior wall adornment leather comprises base fabric, a foaming layer and a surface layer, wherein an adhesive layer is arranged between the base fabric and the foaming layer; the foaming layer contains foamed water-borne polyurethane resin; the surface layer contains inflaming retardant water-borne polyurethane resin; and the adhesive layer contains adhesive water-borne polyurethane resin. The interior wall adornment leather not only has the advantages of traditional wallpaper sound insulation, heat preservation, gorgeousness and easy adornment, but also has the advantages of safety, environment protection, endurance, ageing resistance and fame resistance, which are incomparable with the traditional wallpaper, and can effectively overcome the defects that the traditional wallpaper is easy to raise margins, does not resist dirt and damp, has poor handfeel, and can not be repaired after wrinkling and the like.

Owner:丽水市优耐克水性树脂科技有限公司

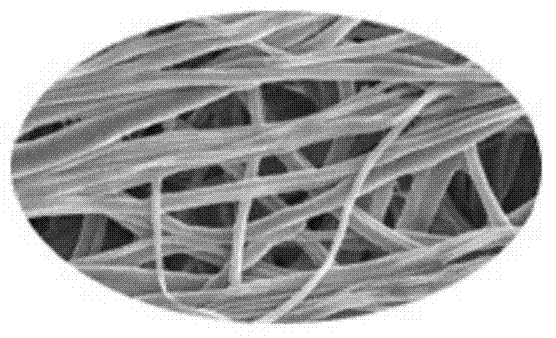

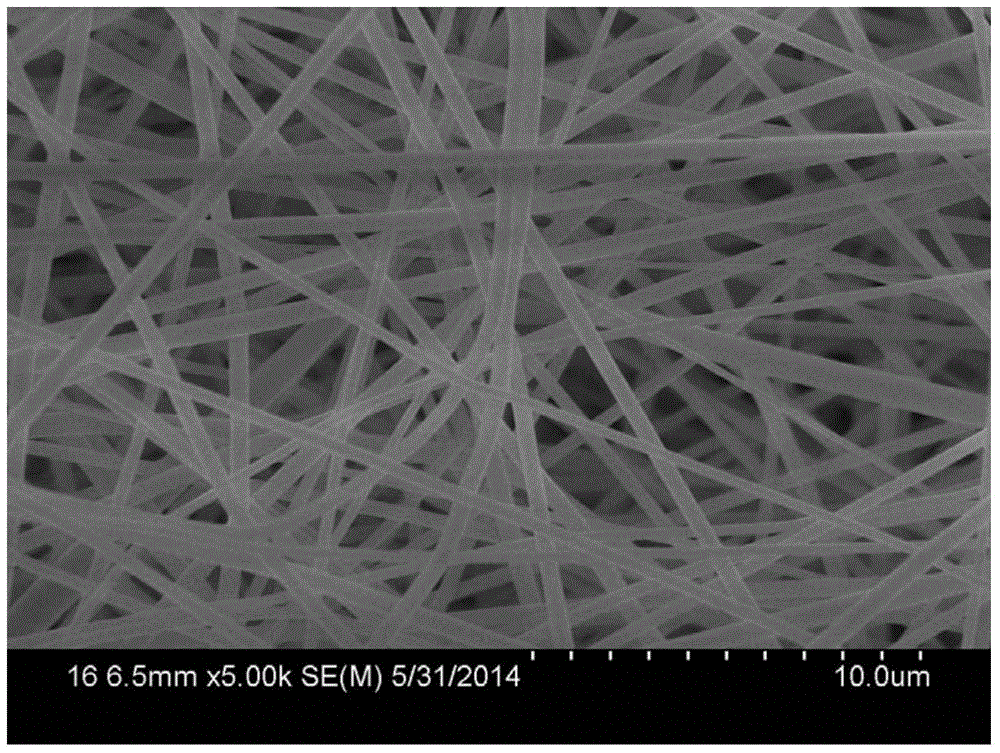

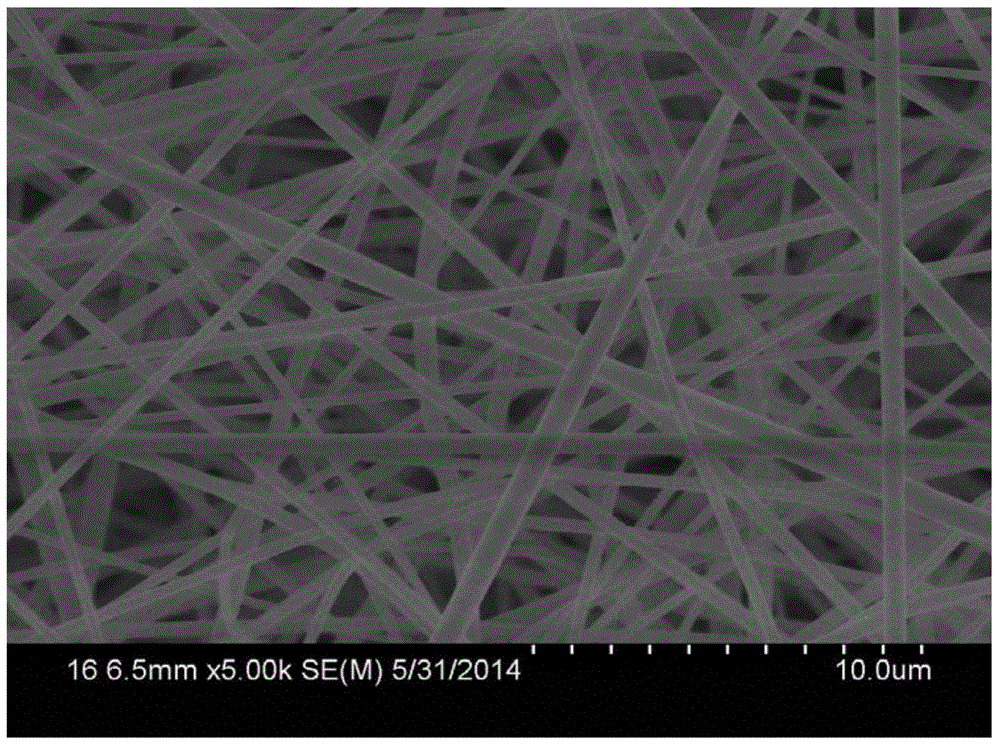

Waterproof and moisture permeable membrane, preparation method of waterproof and moisture permeable membrane, waterproof and moisture permeable fabric and preparation method of waterproof and moisture permeable fabric

InactiveCN104207390AImprove waterproof performanceGood moisture permeabilitySynthetic resin layered productsNon-woven fabricsFiberElectrospinning

The invention provides a waterproof and moisture permeable membrane which sequentially comprises a nano-fiber hydrophilic layer and a nano-fiber hydrophobic layer. The nano-fiber hydrophilic layer is prepared from a hydrophilic polymer by electrostatic spinning; the nano-fiber hydrophobic layer is prepared from a hydrophobic polymer by electrostatic spinning. The waterproof and moisture permeable membrane provided by the invention has good moisture permeability and air permeability; an experiment result shows that the moisture permeability of the waterproof and moisture permeable membrane provided by the invention can reach 10,000g / m<2>24h, and the air permeability of the waterproof and moisture permeable membrane can reach 0.29mL / cm<2>s. The invention also provides a preparation method of the waterproof and moisture permeable membrane. According to the preparation method provided by the invention, the nano-fiber hydrophilic layer and the nano-fiber hydrophobic layer which are prepared by electrostatic spinning are subjected to hot-pressing compounding, so that the obtained waterproof and moisture permeable membrane has better performance and can be integrally formed without being adhered by an adhesive; the production process is simplified; the waterproof and moisture permeable membrane is easy for industrial production. The invention also provides a waterproof and moisture permeable fabric and a preparation method thereof.

Owner:ZHEJIANG WEIXING IND DEV

Method for producing speical-finished pure cotton rapid-drying intelligent textile

ActiveCN1580384AGood moisture permeabilityImprove breathabilityGarment special featuresWeft knittingYarnIsomerisms

A method to produce special modified purified cotton high-speed drying intelligent tissue, the keypoint is:first water the surface purified cotton yarn, getting surface hydrophilic yarn, drainage collating internal, getting drainage collating yarn, then getting double layer isomerism tissue using special weaving tech. The invention adopts different collating method to collate double layer isomerism tissue,getting yarn of heterogeneity;the internal layer is discharging purified cotton yarn,which is of good moisture penetrability and permeability; the surface is hydrophilic purified cotton yarn,is of good water absorption. So the difference forms and offers power to transmit water. Internal moisture can impregnate into surface quickly,internal layer keeps dry, so is the sweating function. The tissue is made of 100% purified cotton face fabric,and of good hand feeling and comfortability.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

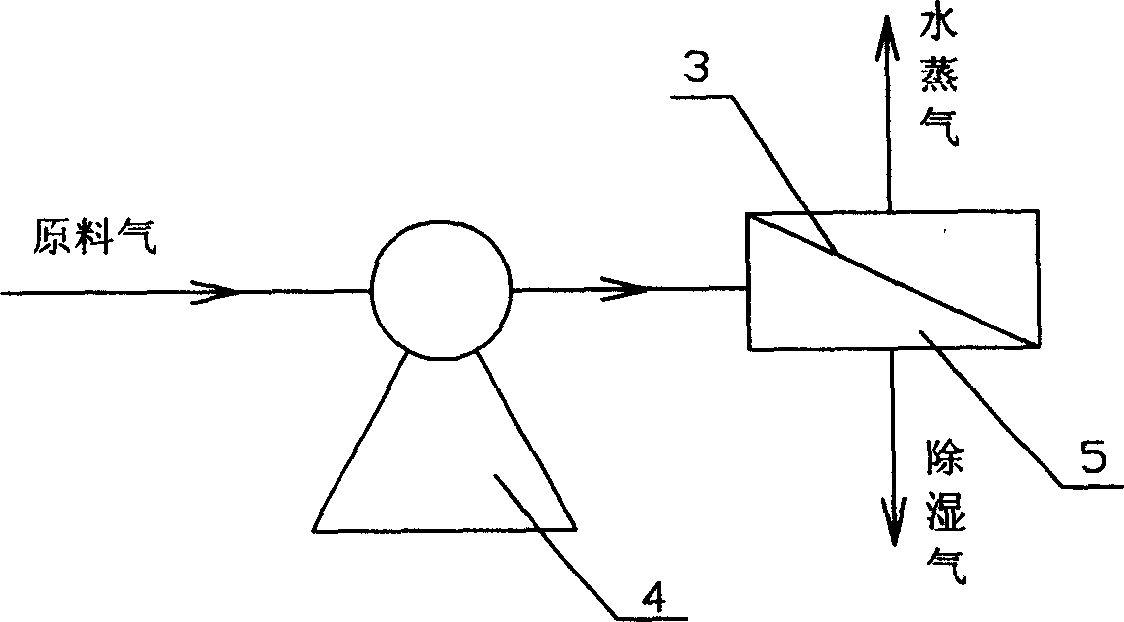

A hydrophilic-hydrophobic bipolar composite membrane and method for preparing same

InactiveCN1864829ASpeed up penetrationReduced Diffusion ResistanceSemi-permeable membranesLighting and heating apparatusChemical industrySupporting system

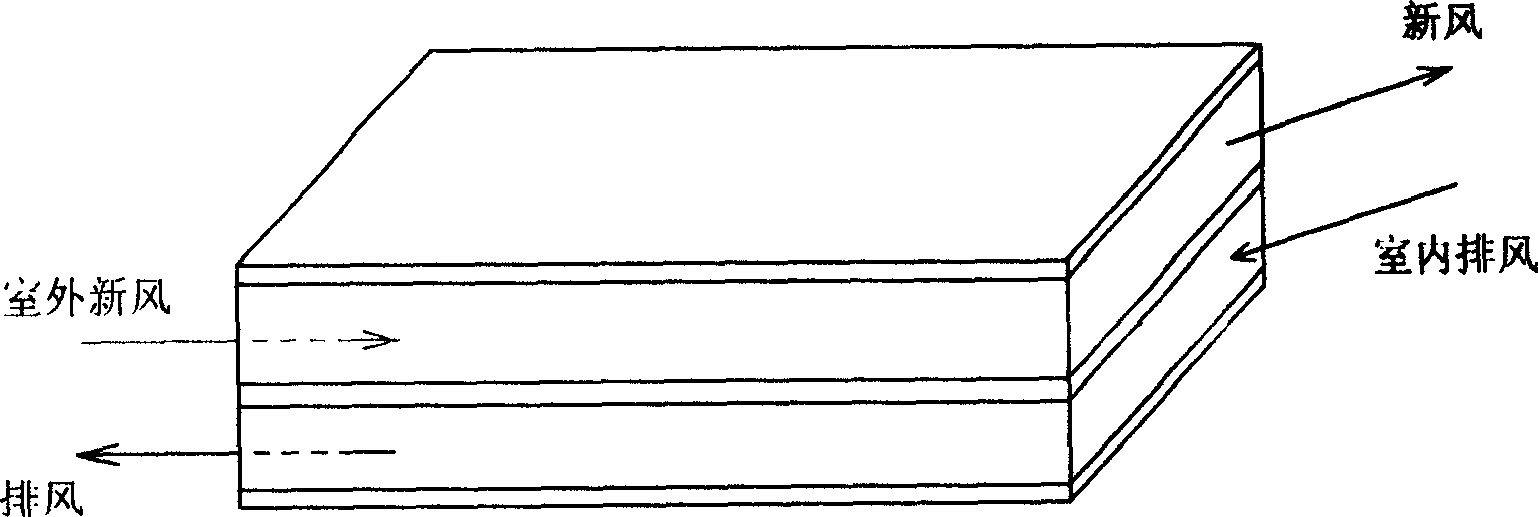

The invention discloses a hydrophilic-hydrophobic bipolar complex membrane and the method for preparing the same. Said complex membrane comprises two layers, the bottom one is porous supporting system, and upper one is ultra-fine cerebral cortex; said porous supporting system is hydrophobic membrane and nonpolar, to avoid condensation of water vapour; ultra-fine membrane is hydrophilic membrane and polar, and LiCl with 1-5% by weight of main component can be doped to increase polarity; the thickness of porous supporting system is 30-100 um, and that of ultra-fine cerebral cortex is 5-20 um. The invention is characterized by simple process and low cost. The prepared bipolar complex membrane is characterized by good penetration property and gas selectivity, high intensity and wide application in water treatment, air conditioner engineering, energy, chemical industry, metallurgy and biochemical engineering. The product is especially suitable for air dehumidification and heat recycle of air cinditioner new gas.

Owner:SOUTH CHINA UNIV OF TECH

Production of coating fabrics with high-peneration and waterproofing functions

InactiveCN1940174AImprove waterproof performanceGood moisture permeabilityTextiles and paperSocial benefitsOrganic solvent

This invention was a public high permeability high waterproof coating fabrics manufacturing methods, including polyurethane polymer, an organic solvent, allocation of water, as agent, crosslinking agents, other agents, water mixed into a fabric coating agents will be made of fabric coated with the coating in uniform as coating on the fabric, Fabric coating agent had dried occasion of the coating for drying processing steps. The invention manufactured coated fabric is not only an excellent waterproof and good moisture permeability but also has good rubbing sex and the feeling of fullness soft features. Product hydrostatic pressure 5000mm H2O over Al permeability to 8000g / m2 . 24hr above Tolerance washing and rubbing. Such coated fabric has broad prospects for sales, which can be used to produce rainwear, breathable, ski clothes, cool suits. Have greater economic and social benefits.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

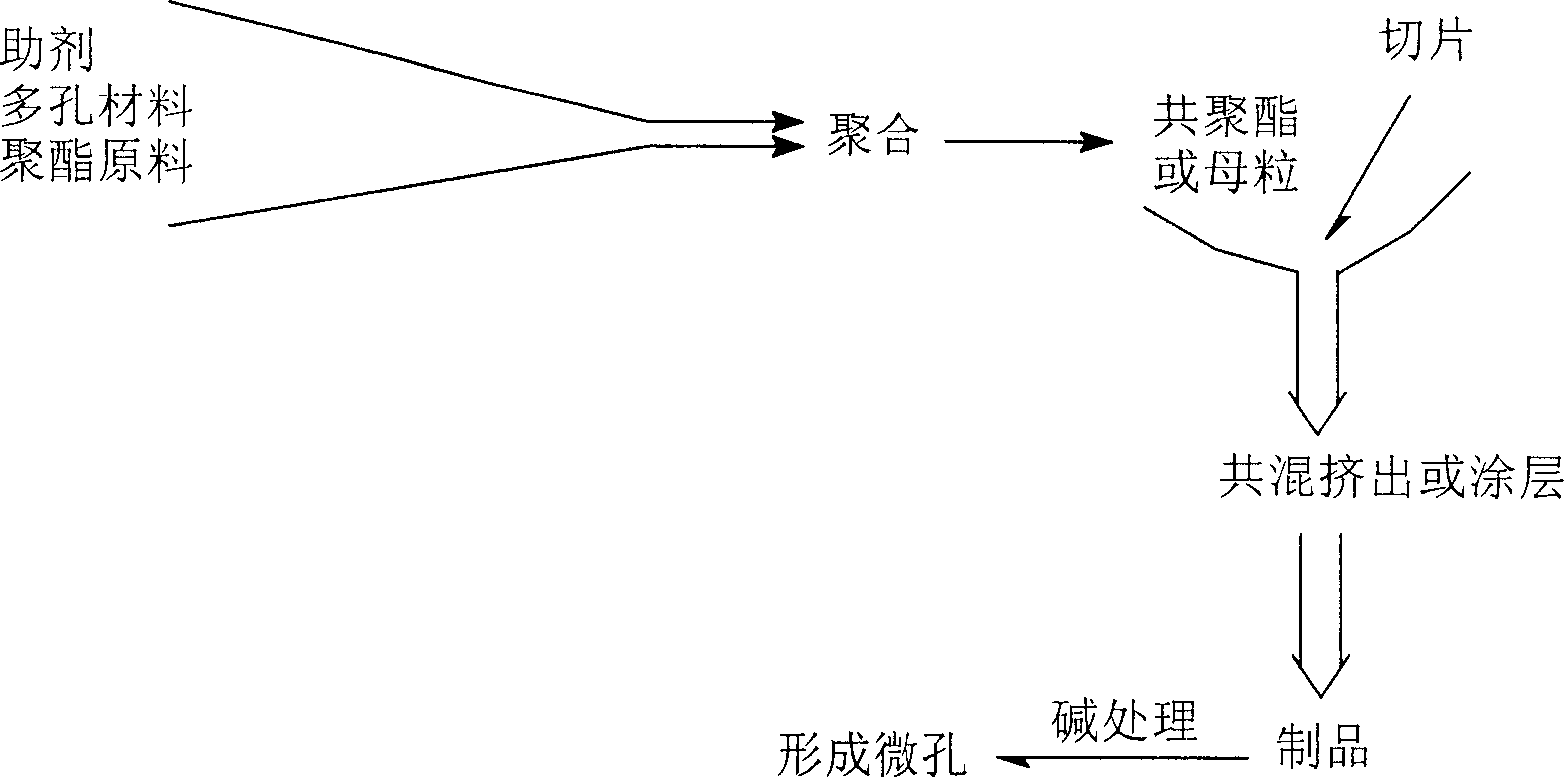

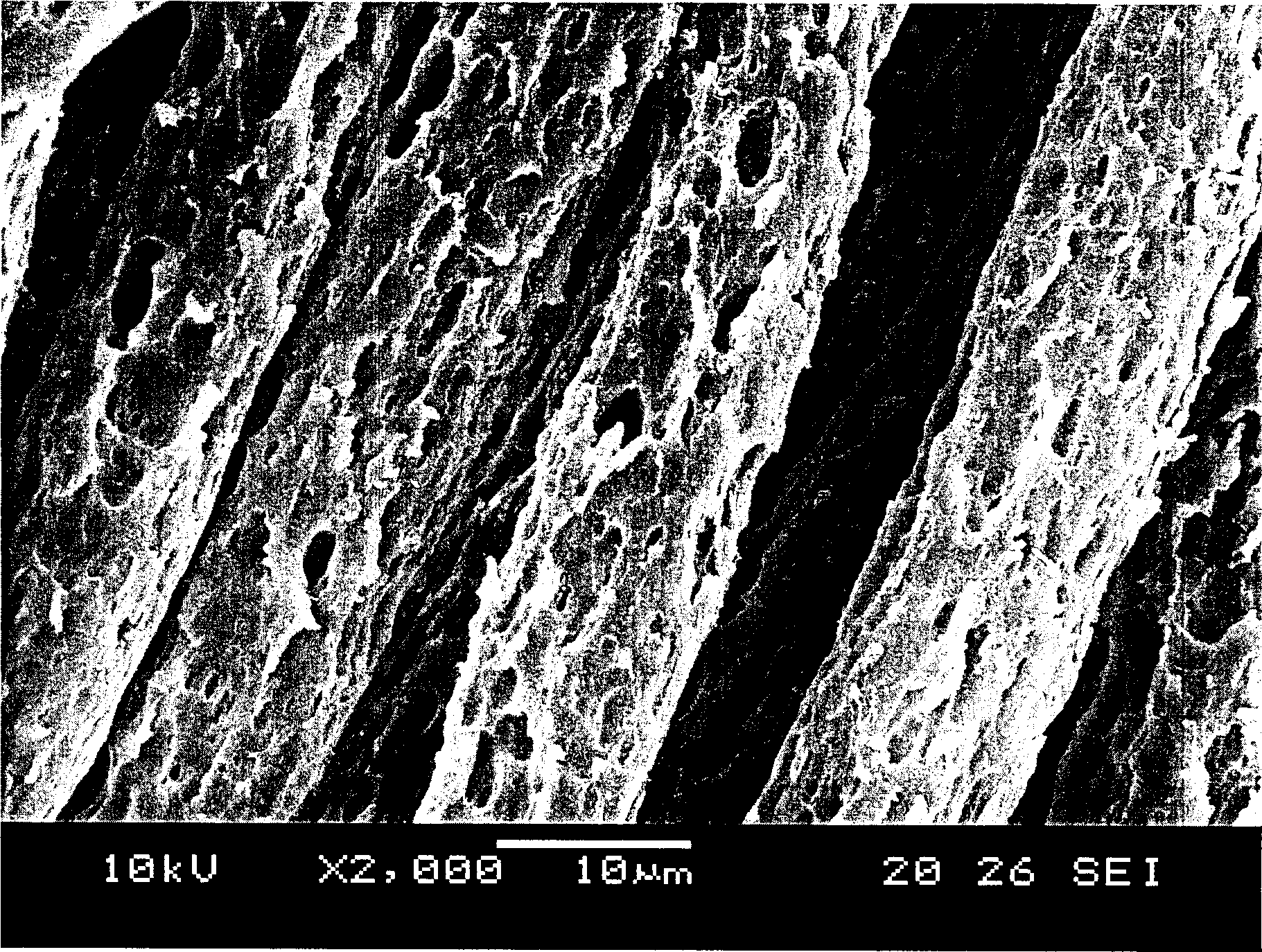

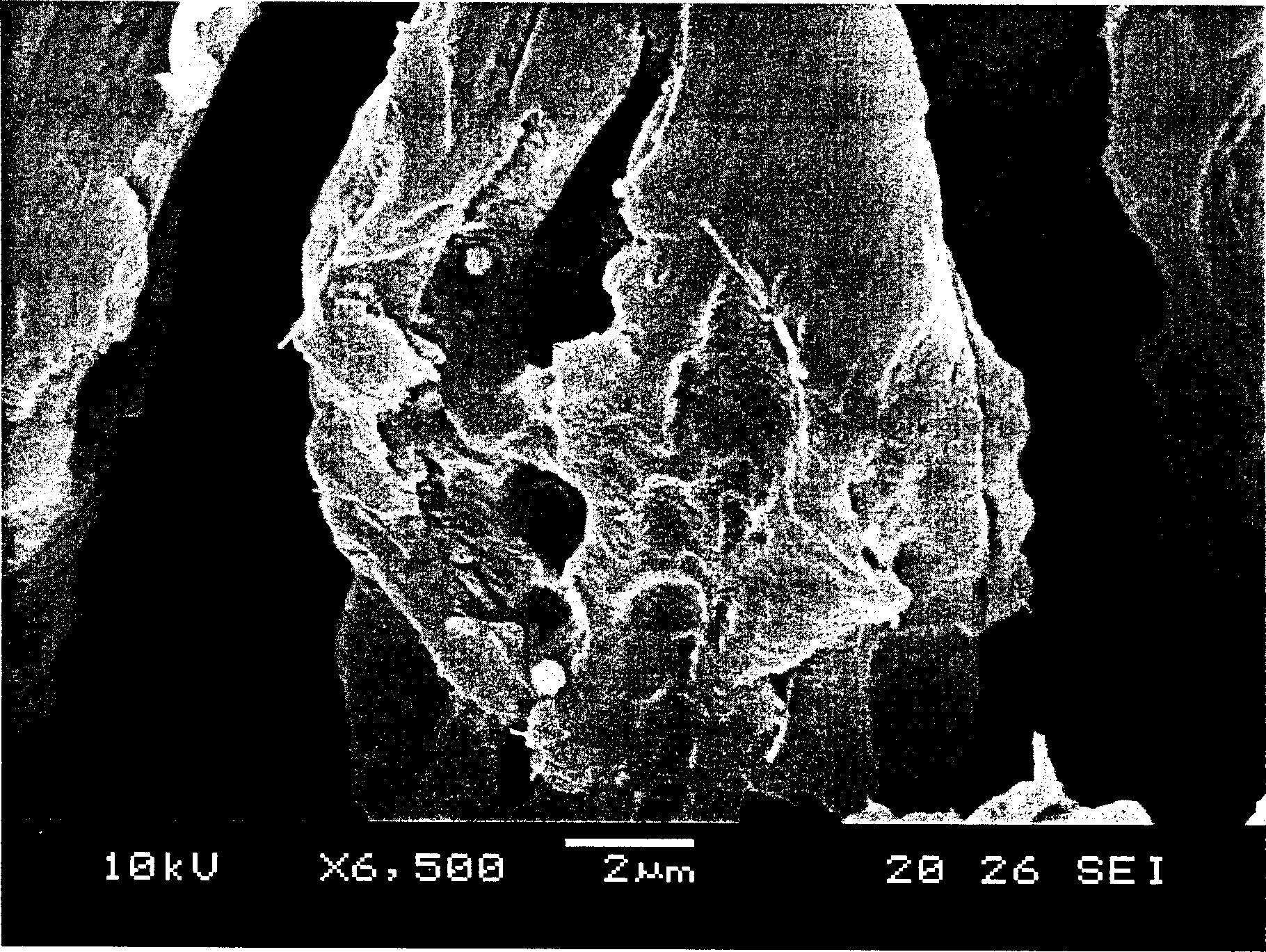

Preparation method of functional polyester fiber

ActiveCN103789868AAdequate responseHigh apparent viscosityArtificial filament heat treatmentMelt spinning methodsPolymer scienceMoisture absorption

The invention relates to a preparation method of a functional polyester fiber. The preparation method comprises the following steps: performing esterification by stages, wherein dihydric alcohols, polyhydric alcohols and functional inorganic powder are mixed according to a certain mole ratio, in the first esterification stage, acid is slightly excess to ensure that monomers with low capability of participating in esterification reaction in the polyhydric alcohols fully react and are grafted into polyester molecular chains, and in the second esterification stage, the dihydric alcohols are replenished to control the terminal carboxyl group of copolyester. The preparation method has the advantages that polyhydric functional groups can improve the apparent viscosity of a system and play a role in wrapping the introduced functional inorganic powder (such as far infrared ceramic inorganic powder, titanium dioxide powder and zinc oxide antibacterial powder), thus improving the dispersion uniformity of particles; settlement is unlikely to happen in the polymerization process and then functional polyester is prepared through condensation polymerization; the functional polyester fiber is finally prepared by carrying out melt spinning on the prepared polyester, has good moisture absorption property and flexibility and can be widely used for preparing far-infrared moisture absorbing and sweat releasing antistatic and antibacterial fabrics next to the skin.

Owner:JIANGSU HENGZE COMPOSITE MATERIALS TECH

Emergency wound dressing and its preparation method

InactiveCN1830409AImprove breathabilityGood moisture permeabilityAdhesive dressingsAbsorbent padsWound dressingInter layer

A dressing for the first aid to wound is a composite non-woven cloth consisting of an internal layer made of the mixture of chitosan fibers and alginate fibers, a middle layer made of the hydroscopic fibers mixed with high-hydroscopicity resin, and an external layer made of hydrophobic fibers. Its preparing process is also disclosed.

Owner:SANITARY EQUIP INST ACAD OF MILITARY MEDICAL SCI PLA

Clear and smooth blended yarn and production process thereof

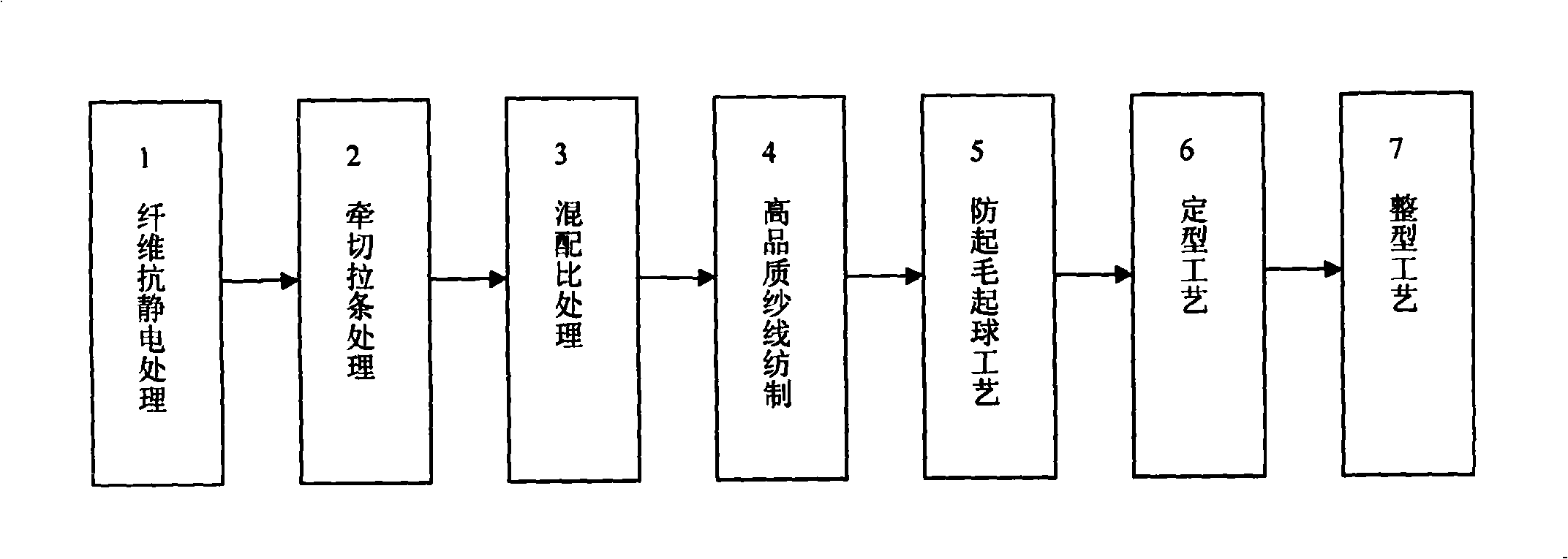

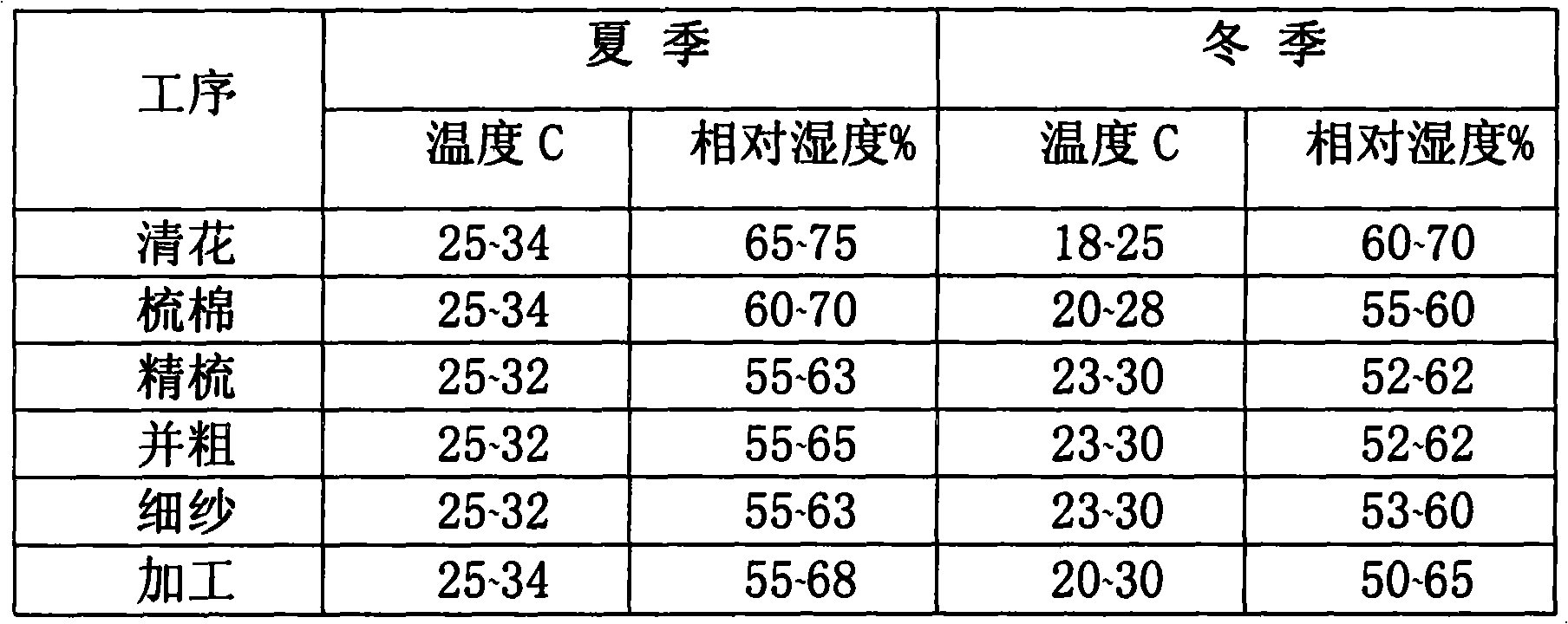

The invention relates to a cotton textile-engineering field in the textile industry, in particular to a pure nylon blended yarn composed of the blended fabric of natural and chemical fibers and the production process of the pure nylon blended yarn, which has the technical scheme that through the changes of process parameters in the yarn spinning process and the special production processes of anti-static fiber blending treatment, yarn spinning twisting, double-twisting, modeling, integrating and other process steps in sequence, a special yarn with crepe twisting is produced in which the twisting coefficient range is 600 to 760 and the range of yarn count is 20s to 80s (yarns) is produced. The utility model is mainly to resolve the relevant technology issue that how to increase the twisting coefficient of spinning yarn substantially. The invention has the advantages that the twisting coefficient range of pure nylon blended yarn can reach 600 to 760 and the production yarn range thereof can reach the single and double yarns of 20s to 80s, which can be widely applied in circular knitting machines, flat knitting machines, tatting and other woven fabric series to fill in a gap in this domestic product category.. Therefore, the invention has the advantages the evaporation and permeability are increased with strong emotional cold feeling, unique luster, bright color and strong wear resistance. The moisture absorption and perspiration can be increased to facilitate the metabolic functions.

Owner:SHANGHAI HEYE TEXTILE

Moisture-absorption, heat-generating, quick-drying, moisturizing and thermal fabric and preparation method thereof

ActiveCN103952845AImprove hydrophilicityGood wicking and moisture-wicking functionSucessive textile treatmentsWeft knittingYarnPolyester

The invention discloses a moisture-absorption, heat-generating, quick-drying, moisturizing and thermal fabric and a preparation method thereof. The fabric is formed by weaving first yarns, second yarns, third yarns and fourth yarns, wherein the first yarns are regenerated cellulose fiber type blended yarns formed by blending linen, wool or cashmere, one or more types of cotton fibers and regenerated cellulose fibers, or regenerated cellulose multi-filaments, or regenerated cellulose staple fiber yarns; the second yarns are modified polyester fiber yarns with non-circular cross sections; the third yarns are cotton fiber type blended yarns formed by blending one or two of polyester staple fiber yarns or polyacrylonitrile fibers and cotton fibers, or all cotton yarns; the fourth yarns are polyurethane fiber yarns. The moisture absorption and heat-generating value of the fabric exceeds national standards, the moisture absorption and quick-drying performance is excellent, and the thermal insulation rate meets national standards; the fabric also has comfortable elasticity and soft and smooth hand feeling of one surface next to the skin. Meanwhile, the preparation method is simple in process, and convenient to operate.

Owner:武汉爱帝针纺实业有限公司

Polyester composition and its uses

ActiveCN1789330AImprove adsorption capacityGood hygroscopicityMelt spinning methodsMonocomponent polyesters artificial filamentFiberPolyester

The invention relates to a polyester composition and its use, wherein the polyester composition contains polyester or polymeric compound with polyester as the main body, and porous material whose content is 0.1-10% of the total weight of the composition. The polyester composition can be used for the preparation of fabrics, thin film and coating composite material, which are obtained through polyester composition extrusion formation and alkaline treatment.

Owner:CHINESE TEXTILE ACAD +1

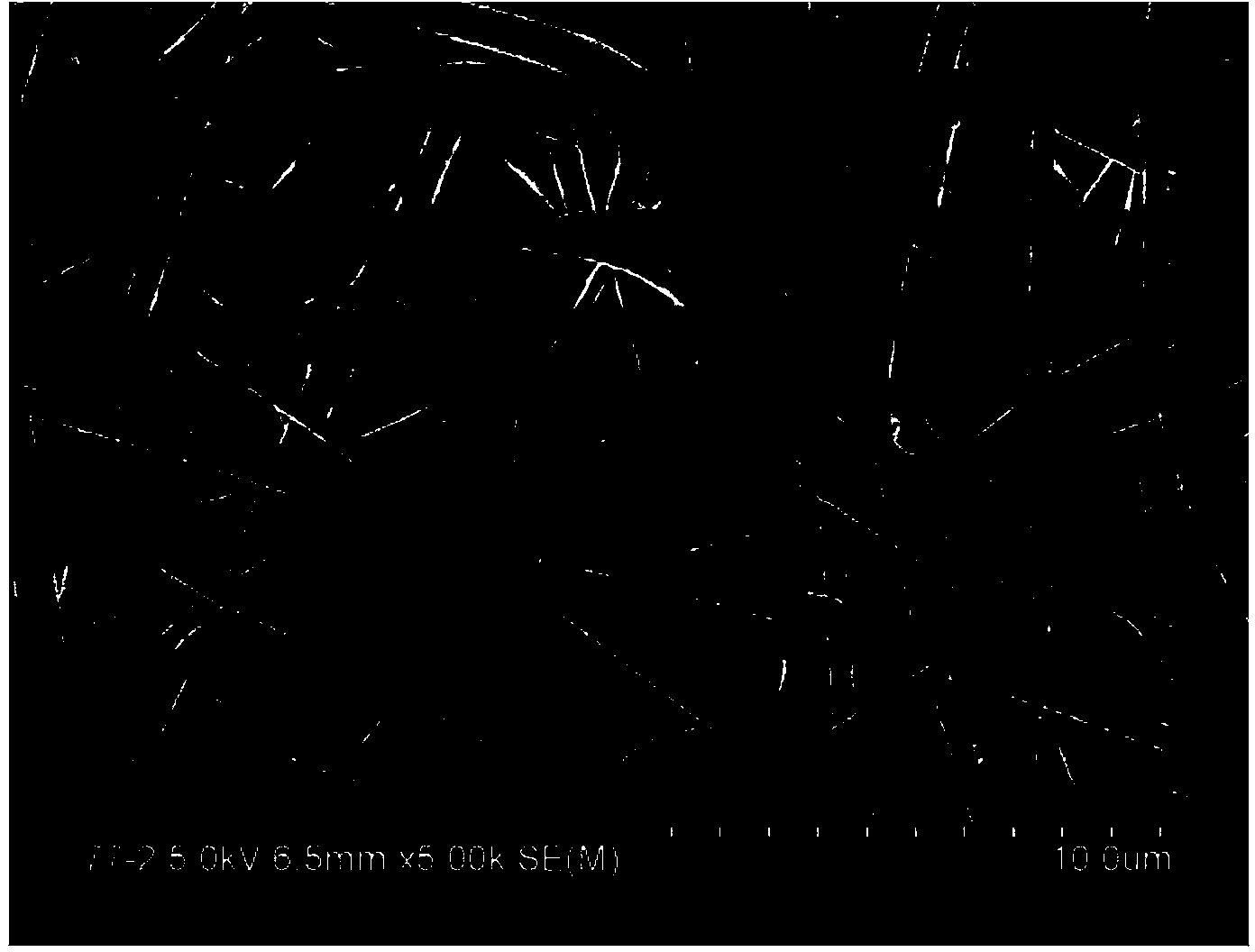

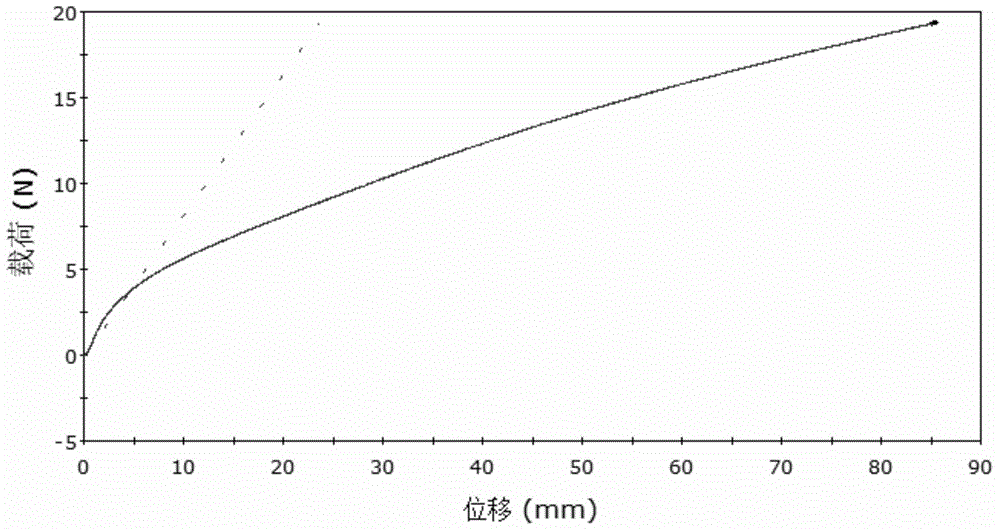

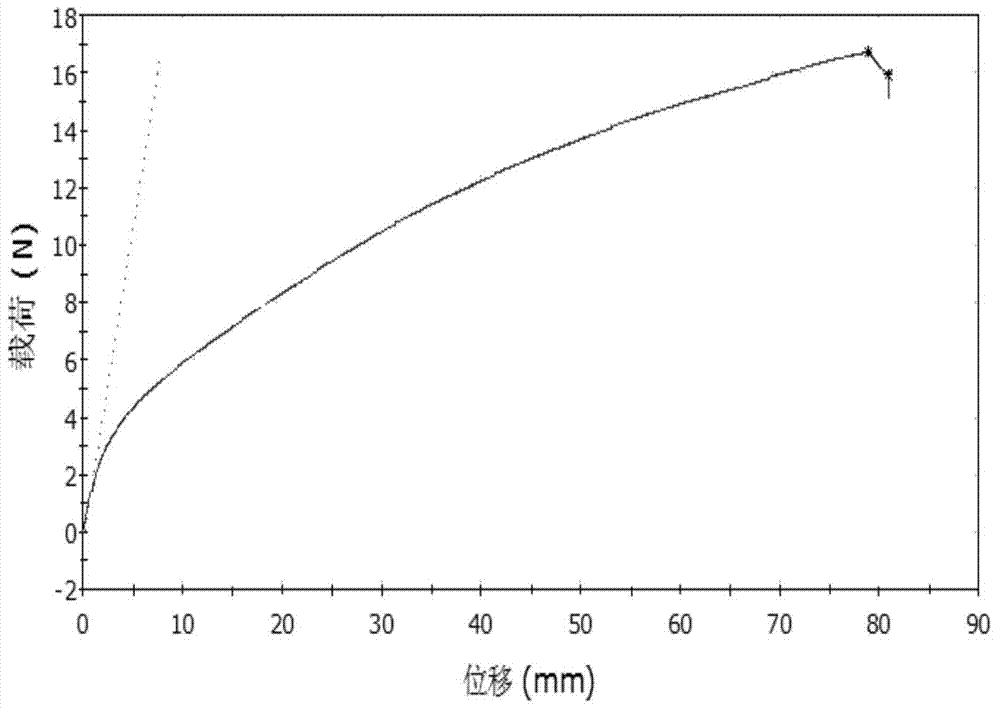

Nanofiber membrane and preparation method thereof, nanofiber composite and preparation method thereof

ActiveCN104099725AStrong air purification abilityImprove waterproof performanceSynthetic resin layered productsNon-woven fabricsSorbentNanofiber

The invention provides a nanofiber membrane. The nanofiber membrane is made of mixture by spinning. The mixture includes polymers and nanofiber materials in the mass ratio of 1:(0.01-0.2). The nanofiber materials are composed of photocatalyst and adsorbent. The adsorbent and the photocatalyst are used in the nanofiber membrane, the adsorbent can adsorb harmful gas in an adsorption chamber, the photocatalyst is capable of degrading and adsorbing harmful organics in holes of the adsorbent into carbon dioxide and water under the condition of indoor light rays and irradiation of a daylight lamp, and activates and regenerates the adsorbent in situ when decomposing the harmful organics on the adsorbent in the meantime, so that the adsorbent and the photocatalyst are reusable, and the nanofiber membrane has excellent air purification capacity. The invention further provides a preparation method of the nanofiber membrane and a nanofiber composite and a preparation method thereof.

Owner:ZHEJIANG WEIXING IND DEV

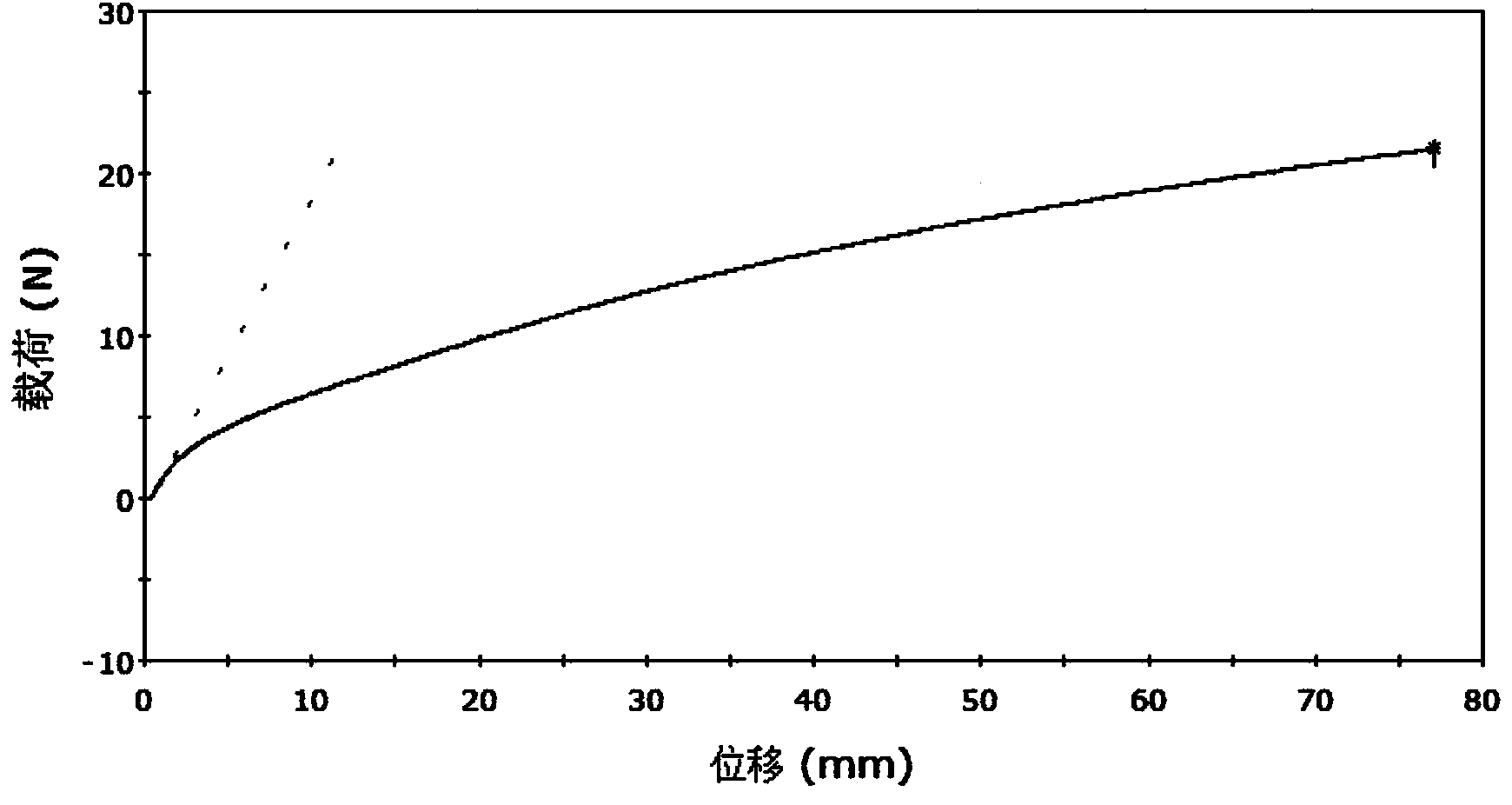

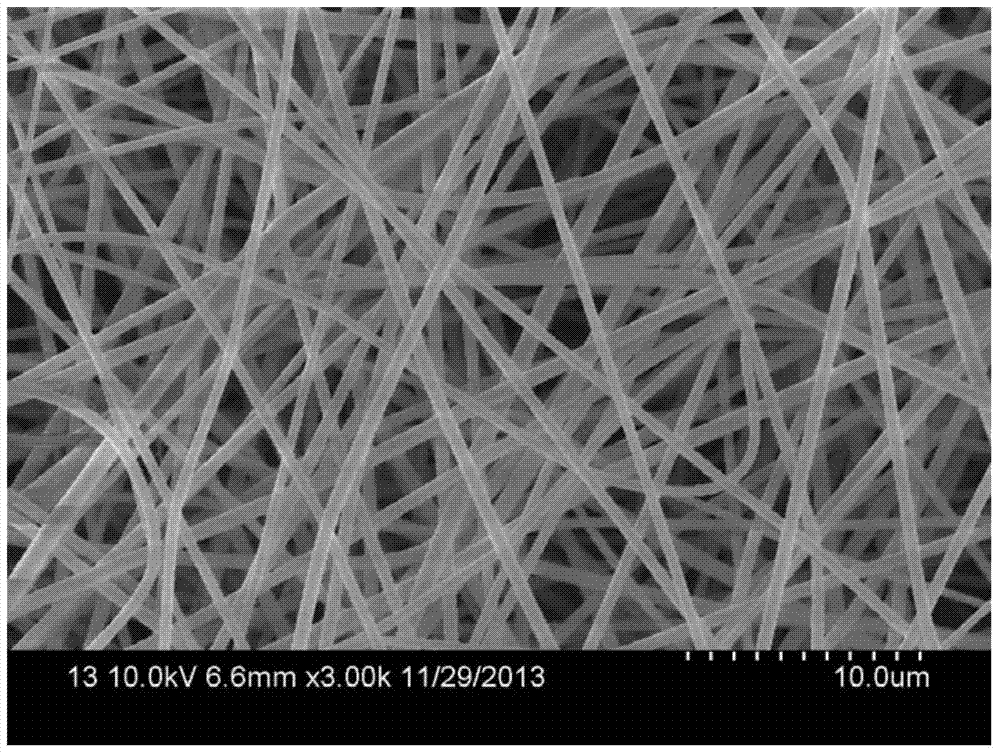

Nanofiber composite membrane and preparation method thereof

InactiveCN104727016AWide range of usesHigh hydrostatic pressure resistanceNon-woven fabricsAdhesivesPolymer scienceNanofiber

The invention provides a preparation method of a nanofiber composite membrane. The method includes the steps that a spinning solution and melt of a high-melting-point polymer are provided, a spinning solution and melt of a low-melting-point polymer are provided, and the melting point difference of the high-melting-point polymer and the low-melting-point polymer is not smaller than 10 DEG C; the spinning solution of the high-melting-point polymer and the spinning solution of the low-melting-point polymer are subjected to electrostatic spinning, and accordingly an electrostatic spinning high-melting-point polymer fiber membrane and an electrostatic spinning low-melting-point polymer fiber membrane are obtained; the low-melting-point polymer melt and the high-melting-point polymer melt are subjected to melt-blowing spinning, so that a melt-blowing spinning low-melting-point polymer fiber membrane and a melt-blowing spinning high-melting-point polymer fiber membrane are obtained; the melt-blowing spinning high-melting-point polymer fiber membrane and the electrostatic spinning low-melting-point polymer fiber membrane undergo composite hot pressing, or the melt-blowing spinning low-melting-point polymer fiber membrane and the electrostatic spinning high-melting-point polymer fiber membrane undergo composite hot pressing, and thus the nanofiber composite membrane is obtained. The nanofiber composite membrane has high tensile strength which reaches up to 22 MPa-32 MPa.

Owner:ZHEJIANG WEIXING IND DEV

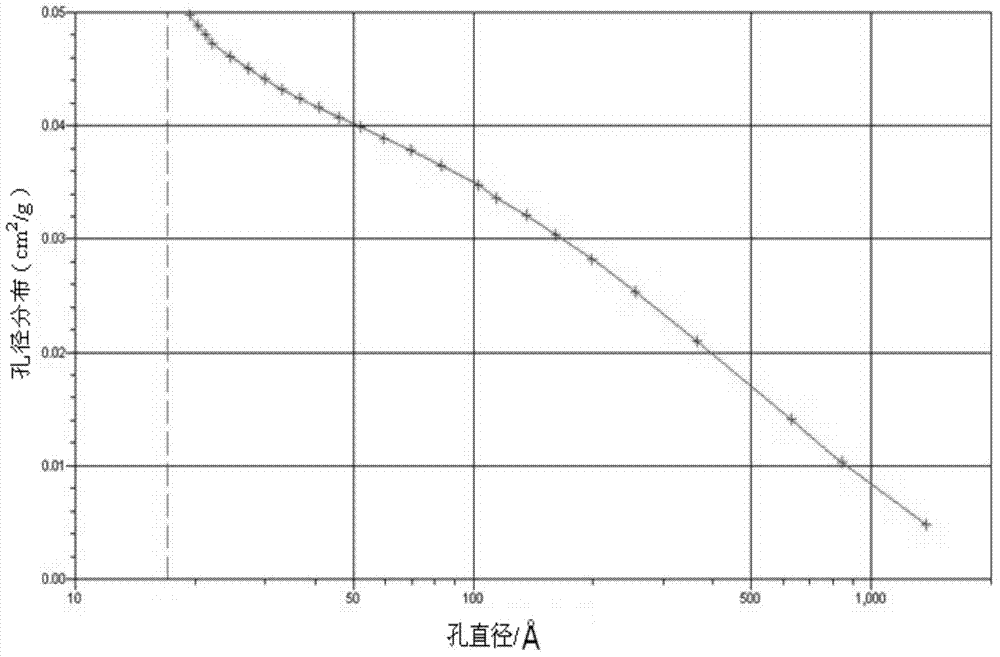

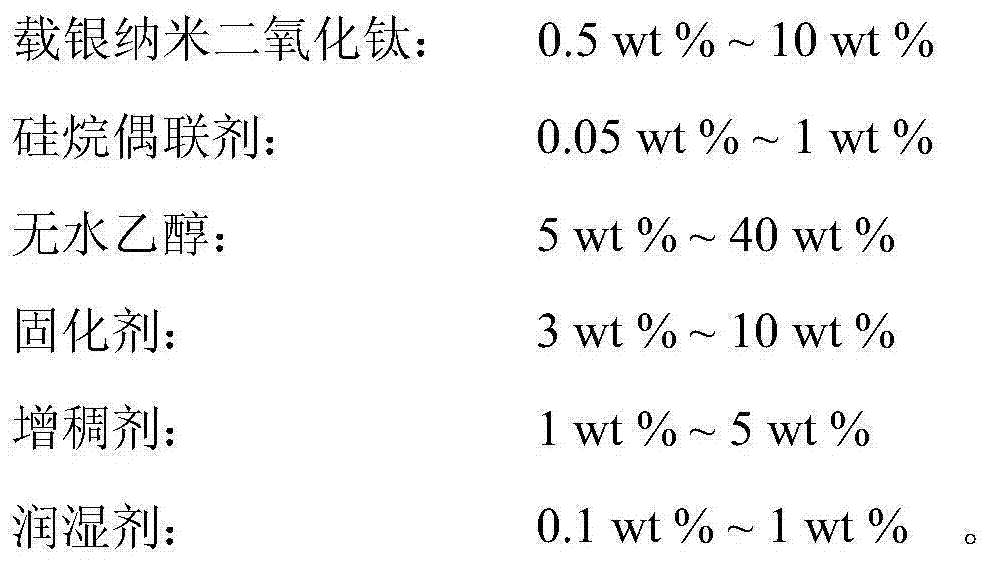

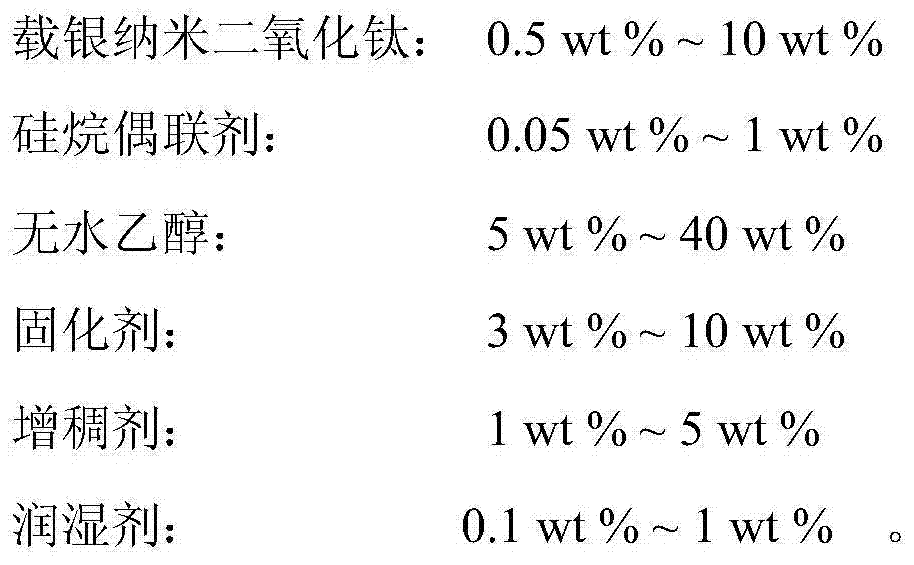

Waterproof moisture-penetrable antibacterial anti-ultraviolet waterborne polyurethane material and preparation method thereof

ActiveCN104727150AImprove mechanical propertiesGood water resistanceVegetal fibresChemistrySilane coupling

The invention provides a waterproof moisture-penetrable antibacterial anti-ultraviolet waterborne polyurethane material for dry method coating finishing of cotton and terylene textiles and a preparation method of the waterproof moisture-penetrable antibacterial anti-ultraviolet waterborne polyurethane material. The material is obtained by blending waterproof moisture-penetrable waterborne polyurethane resin with silver-loaded nano titanium dioxide accounting for 0.5wt%-10wt% of the resin, a silane coupling agent accounting for 0.05wt%-1wt% of the resin, anhydrous ethanol accounting for 5wt%-40wt% of the resin, a curing agent accounting for 3wt%-10wt% of the resin, a thickening agent accounting for 1wt%-5wt% of the resin and a wetting agent accounting for 0.1wt%-1wt% of the resin. The highly moisture-penetrable antibacterial anti-ultraviolet waterborne polyurethane material provided by the invention is finished into a textile, and an obtained coated textile is good in waterproof moisture-penetrability and has antibacterial, anti-ultraviolet and other functions at the same time.

Owner:SOUTHEAST UNIV

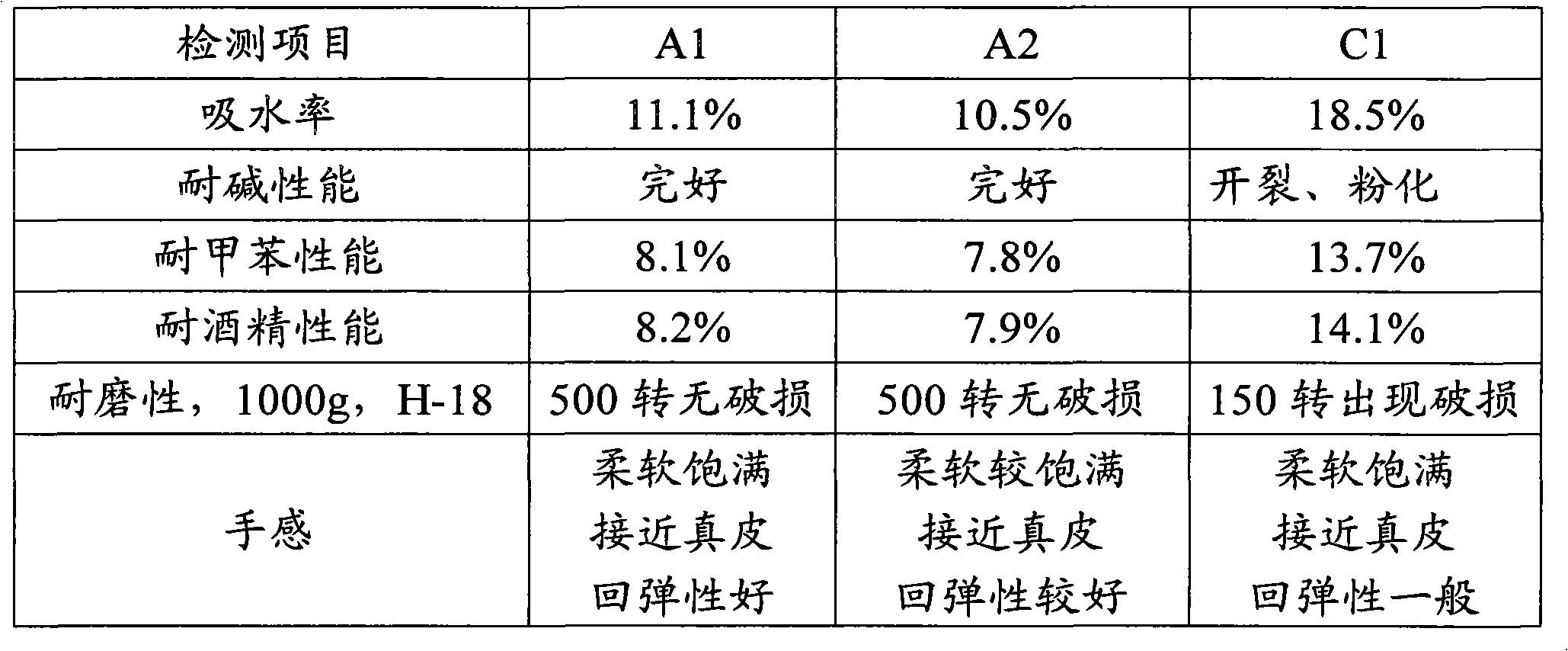

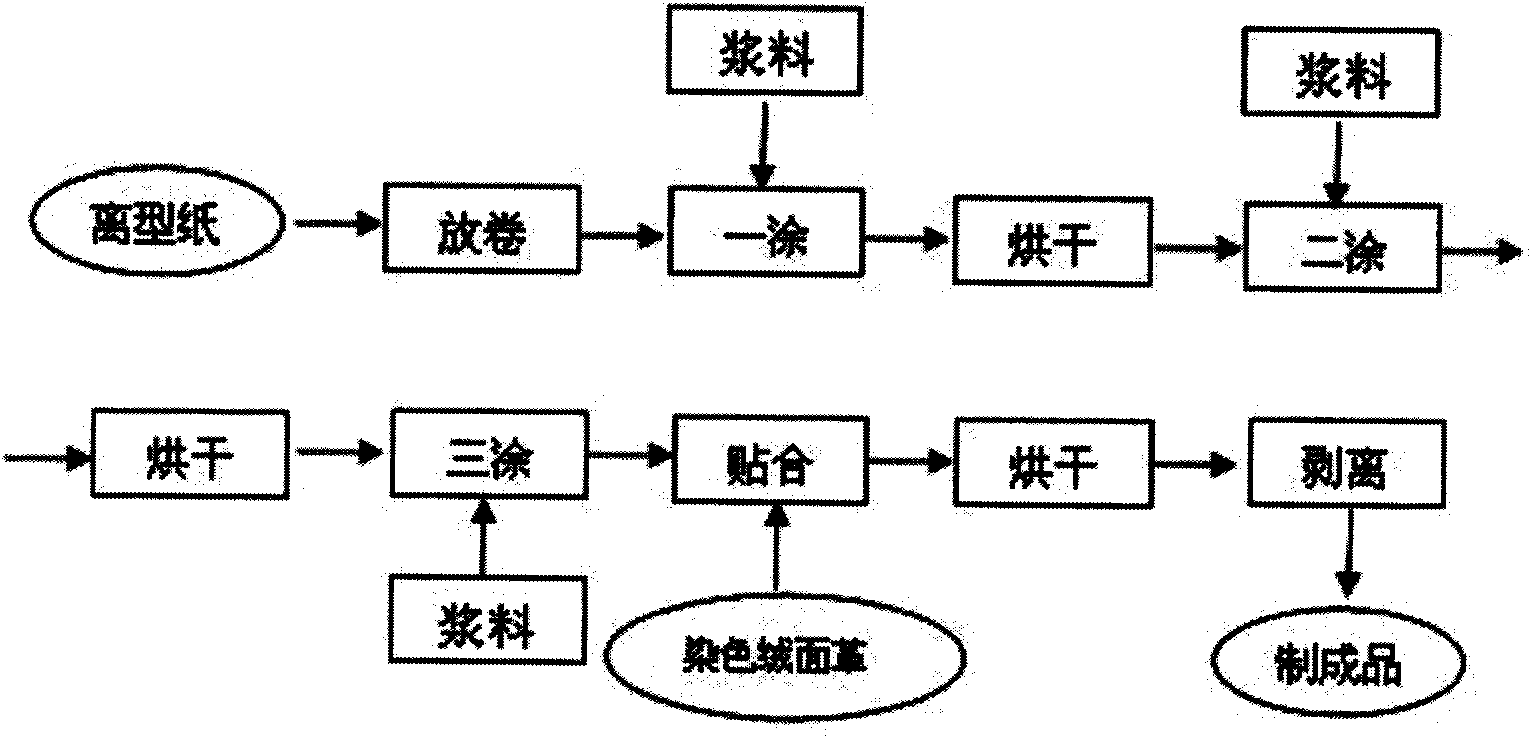

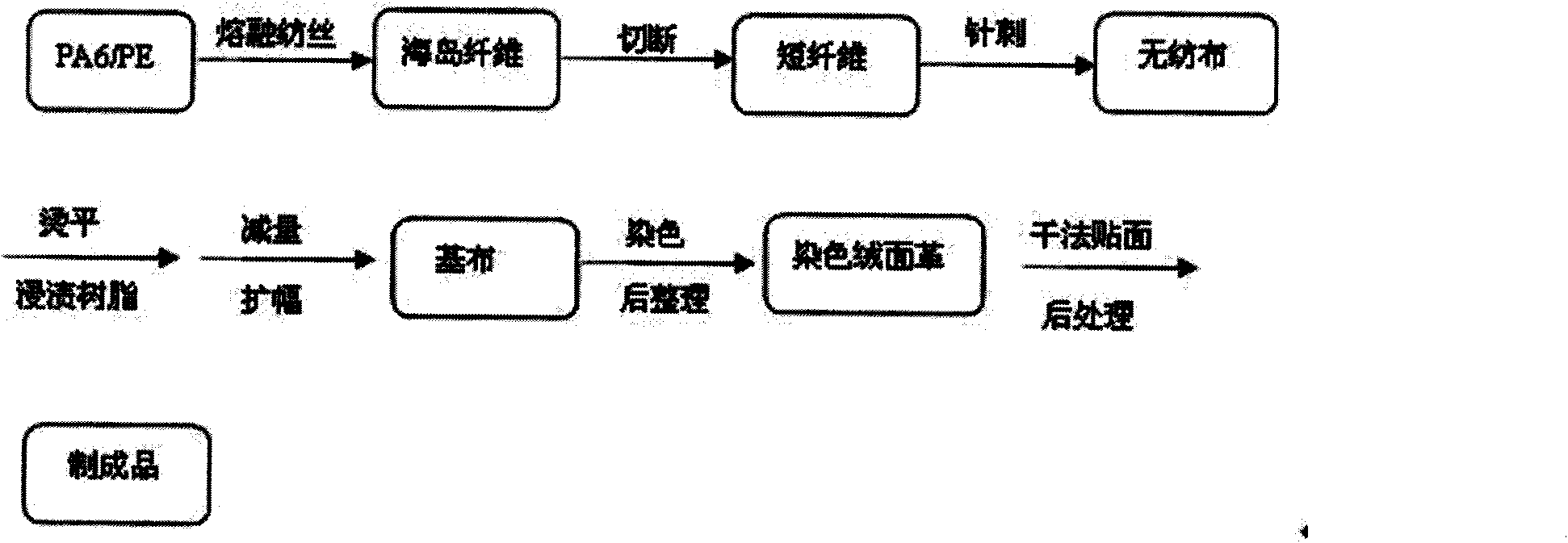

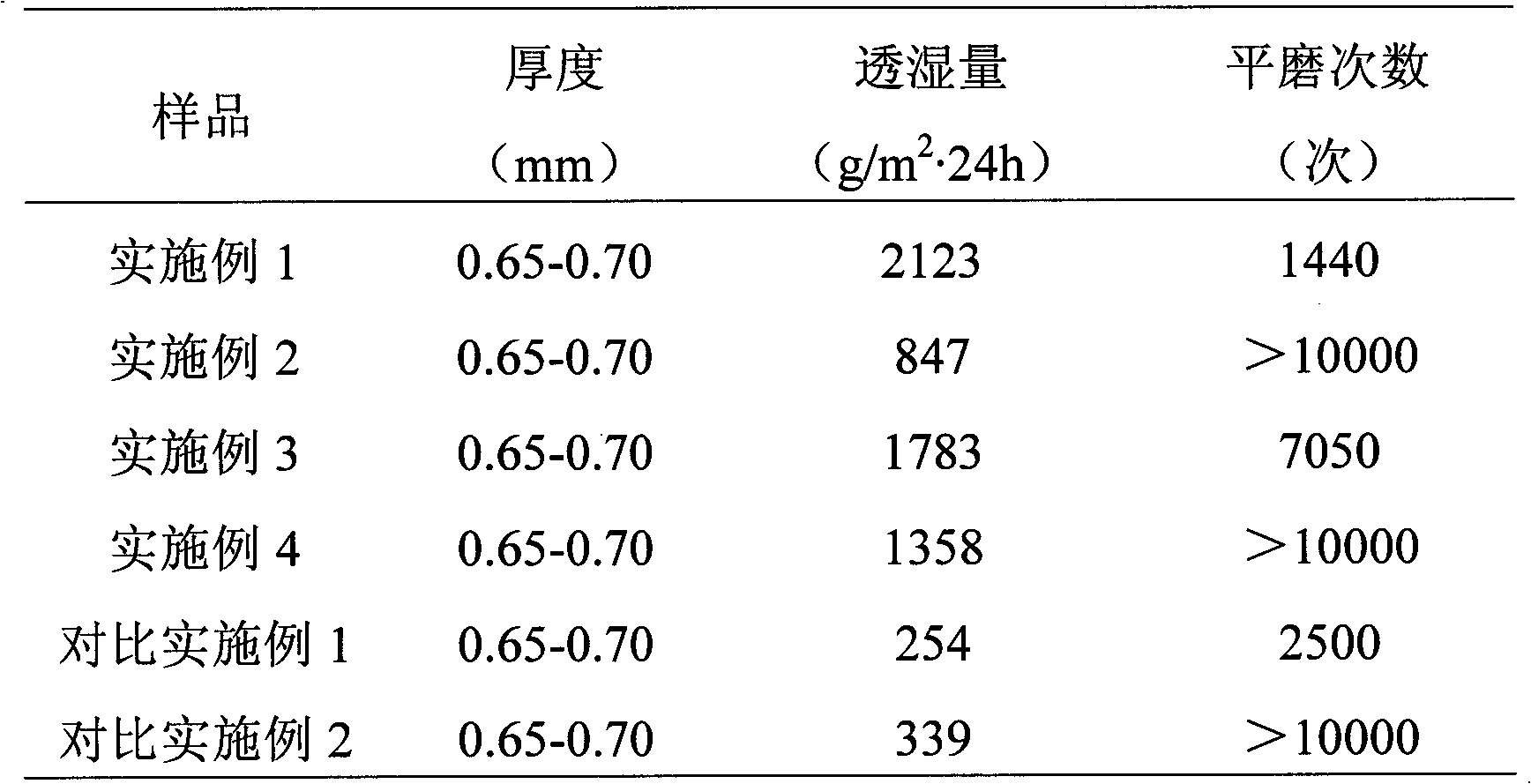

Superfine fiber leather and preparation method thereof

InactiveCN102102301AImprove comfortGood moisture permeabilitySynthetic resin layered productsTextiles and paperFiberWear resistant

The invention discloses a preparation method of superfine fiber leather, which comprises the steps of: coating a surface layer, a middle layer and an adhesive layer on a piece of release paper; laminating the release paper with dyed suede leather; drying; and removing the release paper to obtain the superfine fiber leather, wherein a sizing agent of the surface layer and the middle layer contains 100 parts of polyurethane resin, 10 to 60 parts of polar solvent, 1 to 6 parts of friction resistant additive and 0.5 to 5 parts of hydrophilic additive; a sizing agent of the adhesive layer contains 100 parts of polyurethane resin, 10 to 60 parts of polar solvent, 1 to 6 parts of friction resistant additive, 0.5 to 5 parts of hydrophilic additive and 70 to 90 parts of absorbent resin; a fluorine modified polyethylene wax substance is adopted as the friction resistant additive; and a hydrophilic organic silicon substance is adopted as the hydrophilic additive. The invention also discloses superfine fiber leather which has the moisture permeability higher than or equal to 850 grams per square meter for every 24 hours, which is higher than that of the natural leather. The preparation method disclosed by the invention can also improve the wear resistant time which is higher than 10000 times in the preferable embodiment of the invention.

Owner:HUAFON MICROFIBER SHANGHAI

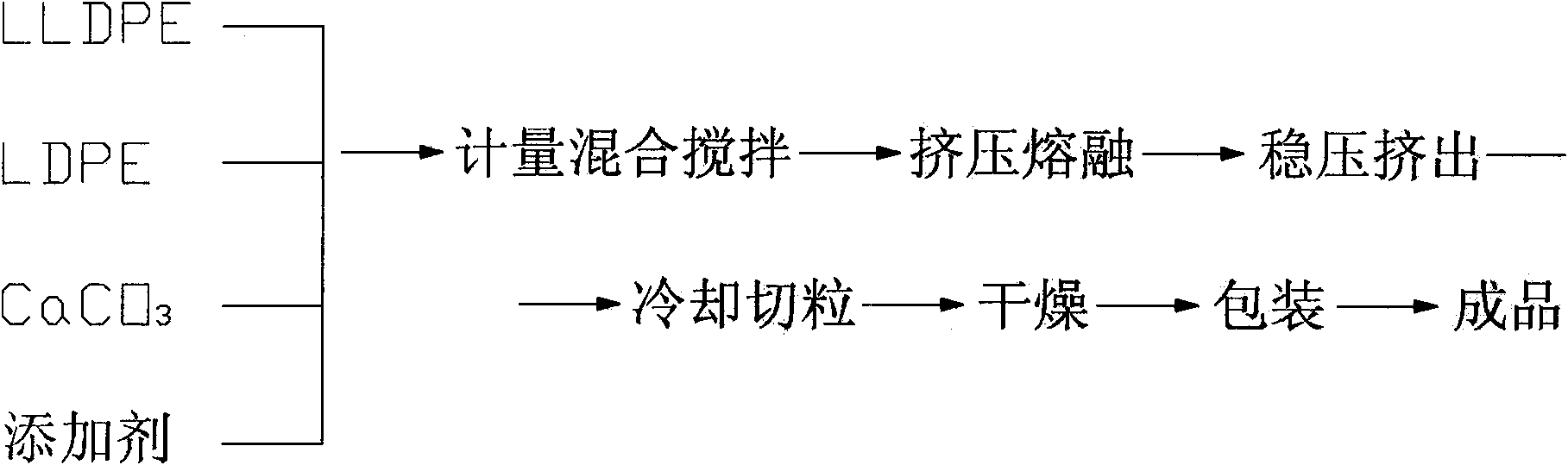

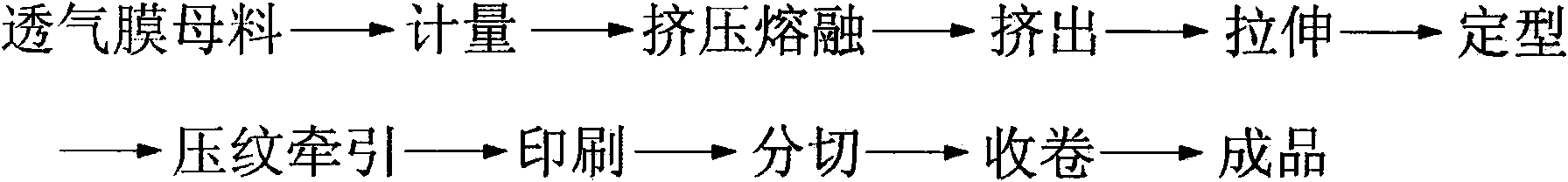

Ultrathin high porosity film and preparation method thereof

The invention discloses an ultrathin high porosity film and a preparation method thereof. The film comprises the following components by weight percent: 40-50% of : PE(LLDPE / LDPE), 45-55% of calcium carbonate and 3-5% of modified additives (plastic additive and film forming additive). The preparation method of the invention comprises the following steps: (1) breathable film master batch process flow and (2) breathable film process flow. The product of the invention can replace imported products, thus reducing the production cost of the breathable film, improving the current dilemma of foreignmonopoly, filling the domestic blank to develop and produce the breathable film material with independent intellectual property rights and having practical and great economic benefit and social benefit.

Owner:ZHEJIANG YUEHAN TECH BREATHABLE MATERIAL

Autoclaveable small-volume dropper bottle

A terminally sterilizable container includes a polypropylene bottle having a body with a manually squeezable sidewall and a thickness preventing water loss. The bottle body includes shoulders for providing autoclave produced pressure distribution and deformation resistance along with an elongated tips outfitted to a neck of the body and having a lumen therethrough with a drop dispensing orifice. A cap enclosed the elongated tip and includes enclosed with a nub for sealing the orifice to prevent autoclave produced pressure leaks.

Owner:ALLERGAN INC

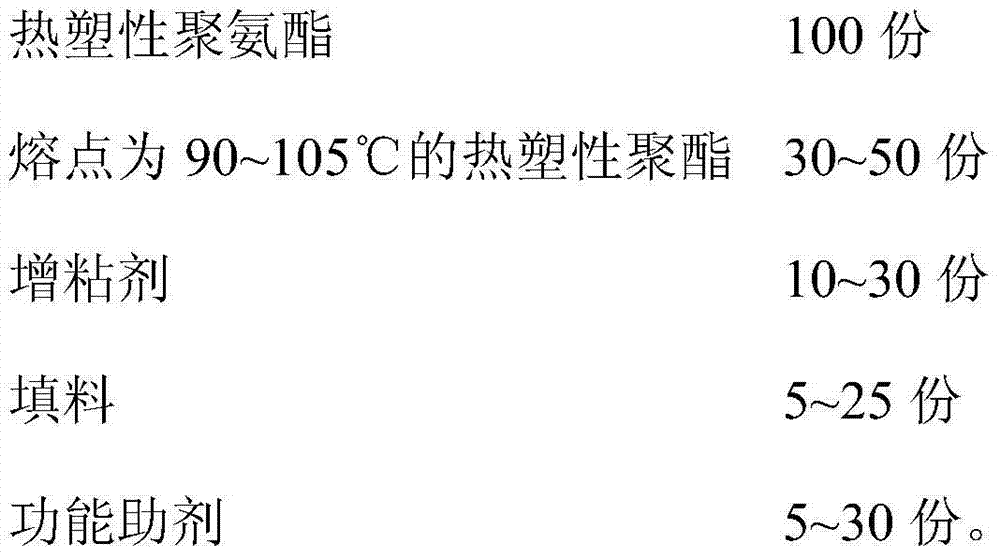

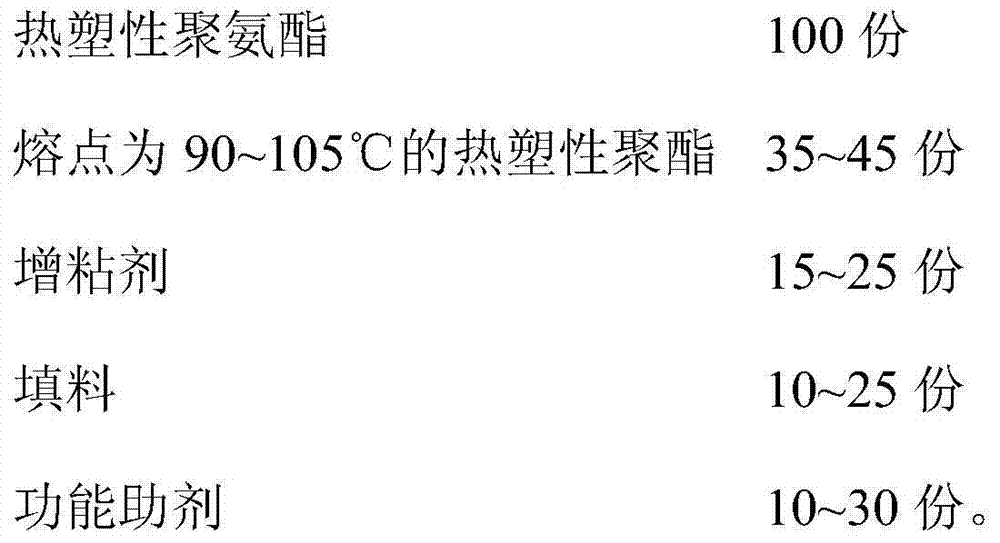

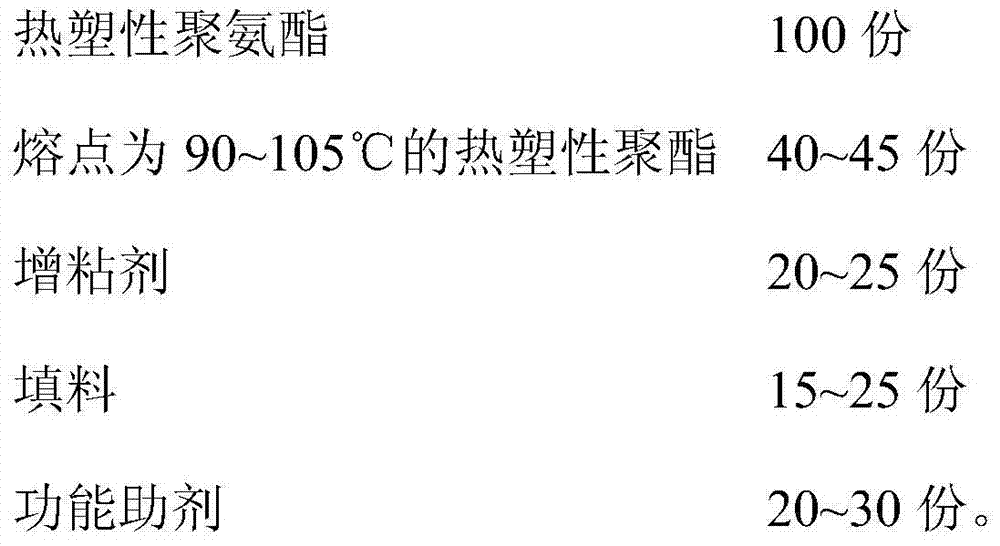

Low-melting-point and high-bonding-strength TPU (thermoplastic polyurethane) hot melt adhesive membrane and preparation method thereof

ActiveCN104263259AUniform thicknessSimple bonding processNon-macromolecular adhesive additivesFilm/foil adhesivesChemistryPolyester

The invention provides a TPU (thermoplastic polyurethane) hot melt adhesive membrane. The TPU hot melt adhesive membrane is mainly prepared from the following raw materials in parts by weight: 100 parts of TPU, 30-50 parts of thermoplastic polyester of which the melting point is 90-105 DEG C, 10-30 parts of a tackifier, 5-25 parts of a filling material and 5-30 parts of a functional auxiliary agent. The hot melt adhesive membrane prepared by using the method provided by the invention is of a thermoplastic adhesive, is uniform in thickness and simple in bonding process, is suitable for bonding by adopting an automatic production line, is high in production efficiency and large in peeling strength after bonding, can resist water, heat and salt fog aging in an outdoor harsh environment, is durable in bonding, and can be used for significantly improving the bonding strength of the hot melt adhesive membrane adhered to fabrics.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com