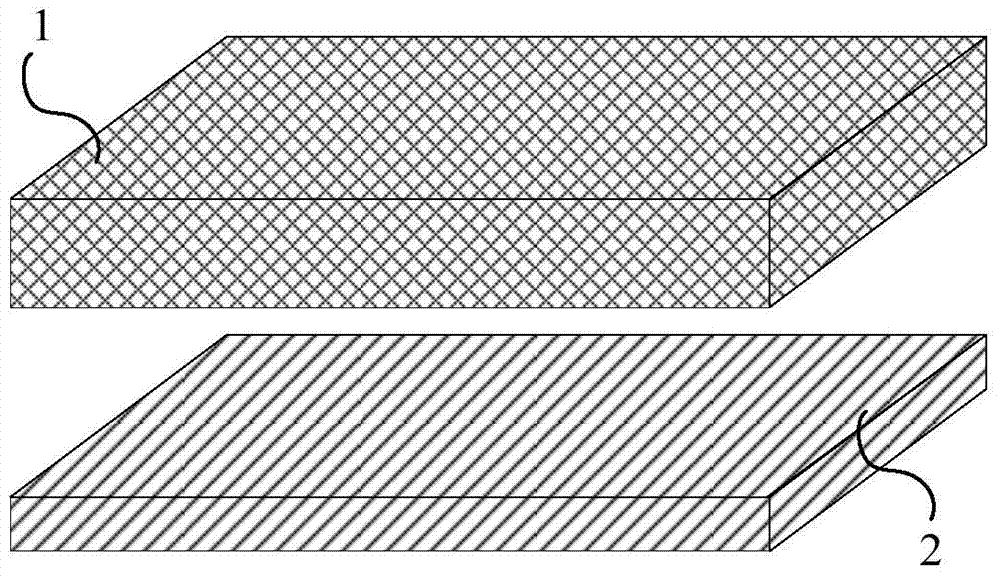

Porous complex gel-nanofiber oxygen permeation dressing and preparation method thereof

A composite gel and nanofiber technology, which is applied in the fields of natural polymer materials and biomedical materials, can solve the problem of not significantly improving the oxygen permeability of medical wound dressings and composite dressings with micro-nano structures, obvious wound scars, and long healing periods. problems, achieve excellent oxygen permeability, promote wound healing, and prevent wound infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

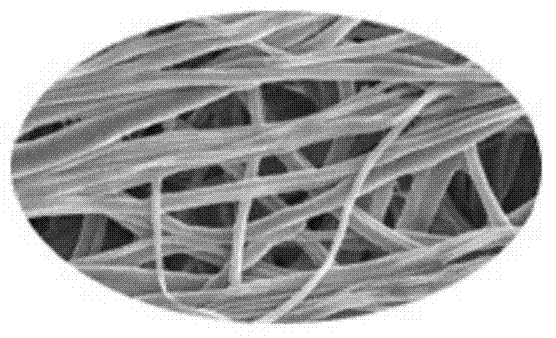

[0037] (1) Collagen is placed in the acetic acid solution that mass fraction is 1mol / L, is mixed with the collagen solution that mass concentration is 8% (w / w);

[0038] (2) Pour the collagen solution obtained in step (1) into a 10mL syringe, control the flow rate to 1mL / h, the electrospinning voltage is 30kV, the receiving distance is 15cm, and the electrospinning time is 24h. Collagen nanofibers were prepared by electrospinning, and the temperature and relative humidity of electrospinning were 25°C and 45% respectively;

[0039] (3) Place the nanofibrous membrane prepared in step (2) in a vacuum drying oven, and dry at 30°C for 6 hours to remove residual solvent; then cross-link in glutaraldehyde vapor, the volume concentration of glutaraldehyde 1%, the cross-linking time is 6h;

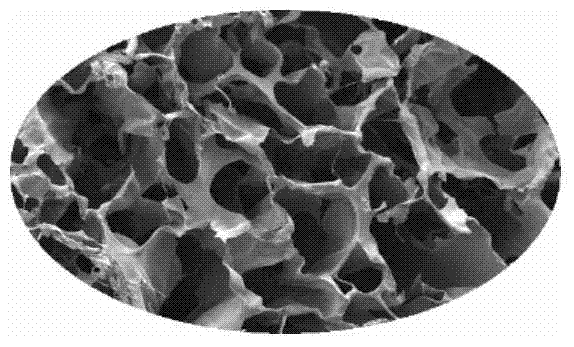

[0040] (4) dissolving chitosan in a mass concentration of 2% glacial acetic acid aqueous solution to prepare a mass concentration of 2% chitosan solution, the prepared 1mg / mL calcium chloride aque...

Embodiment 2

[0044] (1) Collagen is placed in the acetic acid solution that mass fraction is 1mol / L, is mixed with the collagen solution that mass concentration is 8% (w / w);

[0045] (2) Pour the collagen solution obtained in step (1) into a 10mL syringe, control the flow rate to 1mL / h, the electrospinning voltage is 30kV, the receiving distance is 15cm, and the electrospinning time is 48h. Collagen nanofibers were prepared by electrospinning, and the temperature and relative humidity of electrospinning were 25°C and 45% respectively;

[0046] (3) Place the nanofibrous membrane prepared in step (2) in a vacuum drying oven, and dry at 30°C for 12 hours to remove residual solvent; then cross-link in glutaraldehyde vapor, the volume concentration of glutaraldehyde is 2%, and the cross-linking time is 12h;

[0047] (4) dissolving chitosan in a mass concentration of 2% glacial acetic acid aqueous solution to prepare a mass concentration of 2% chitosan solution, the prepared 1mg / mL calcium chlo...

Embodiment 3

[0051] (1) Collagen is placed in the acetic acid solution that mass fraction is 1mol / L, is mixed with the collagen solution that mass concentration is 8% (w / w);

[0052] (2) Pour the collagen solution obtained in step (1) into a 10mL syringe, control the flow rate to 1mL / h, the electrospinning voltage is 30kV, the receiving distance is 15cm, and the electrospinning time is 24h. Collagen nanofibers were prepared by electrospinning, and the temperature and relative humidity of electrospinning were 25°C and 45% respectively;

[0053] (3) Place the nanofibrous membrane prepared in step (2) in a vacuum drying oven, and dry at 30°C for 6 hours to remove residual solvent; then cross-link in glutaraldehyde vapor, the volume concentration of glutaraldehyde 1%, the cross-linking time is 6h;

[0054] (4) dissolving chitosan in a mass concentration of 2% glacial acetic acid aqueous solution to prepare a mass concentration of 2% chitosan solution, the prepared 1mg / mL calcium chloride aque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com