Patents

Literature

1975 results about "Vinyl ester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vinyl ester refers to esters formerly derived from vinyl alcohol. Commercially important examples of these monomers are vinyl acetate, vinyl propionate, and vinyl laurate.

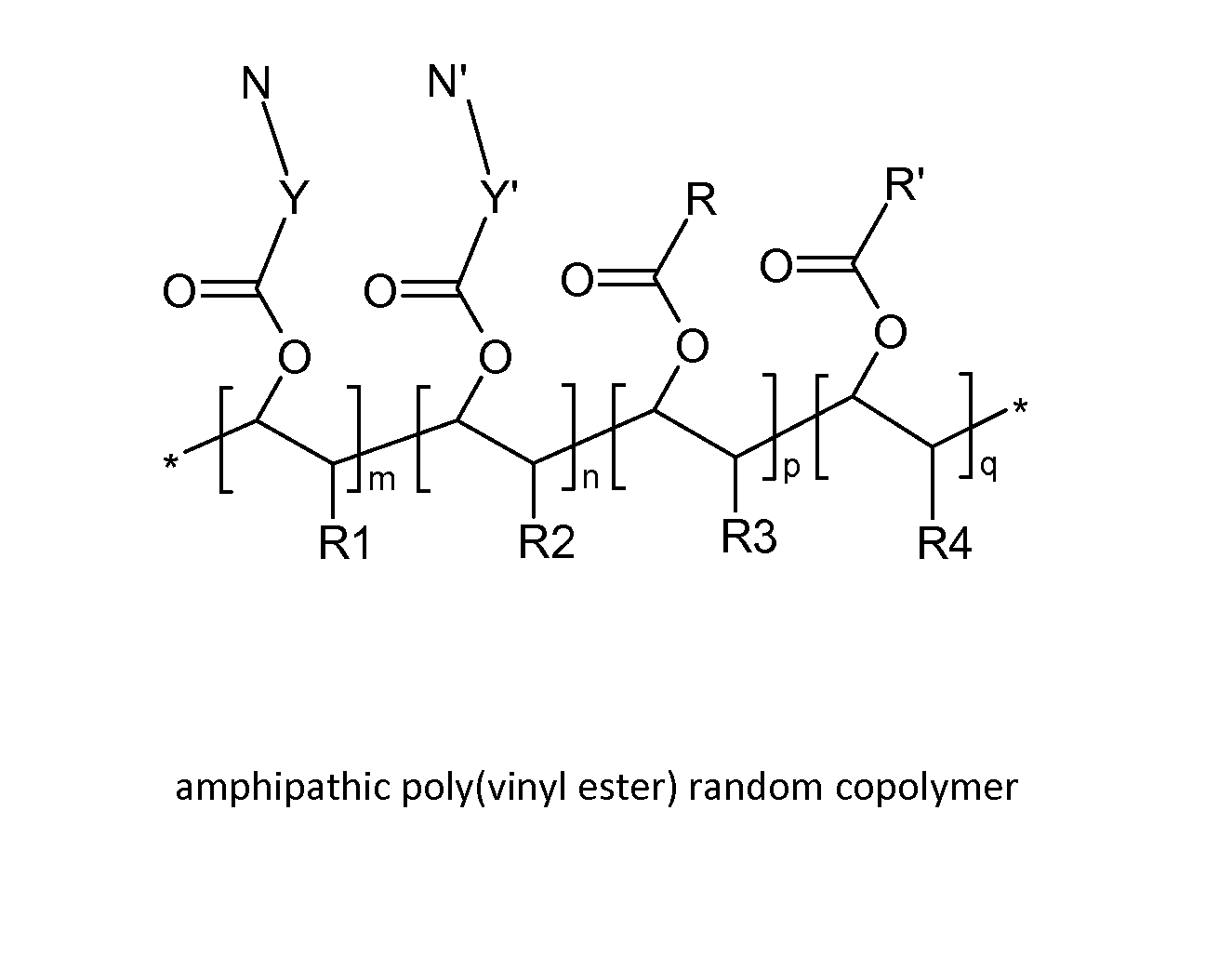

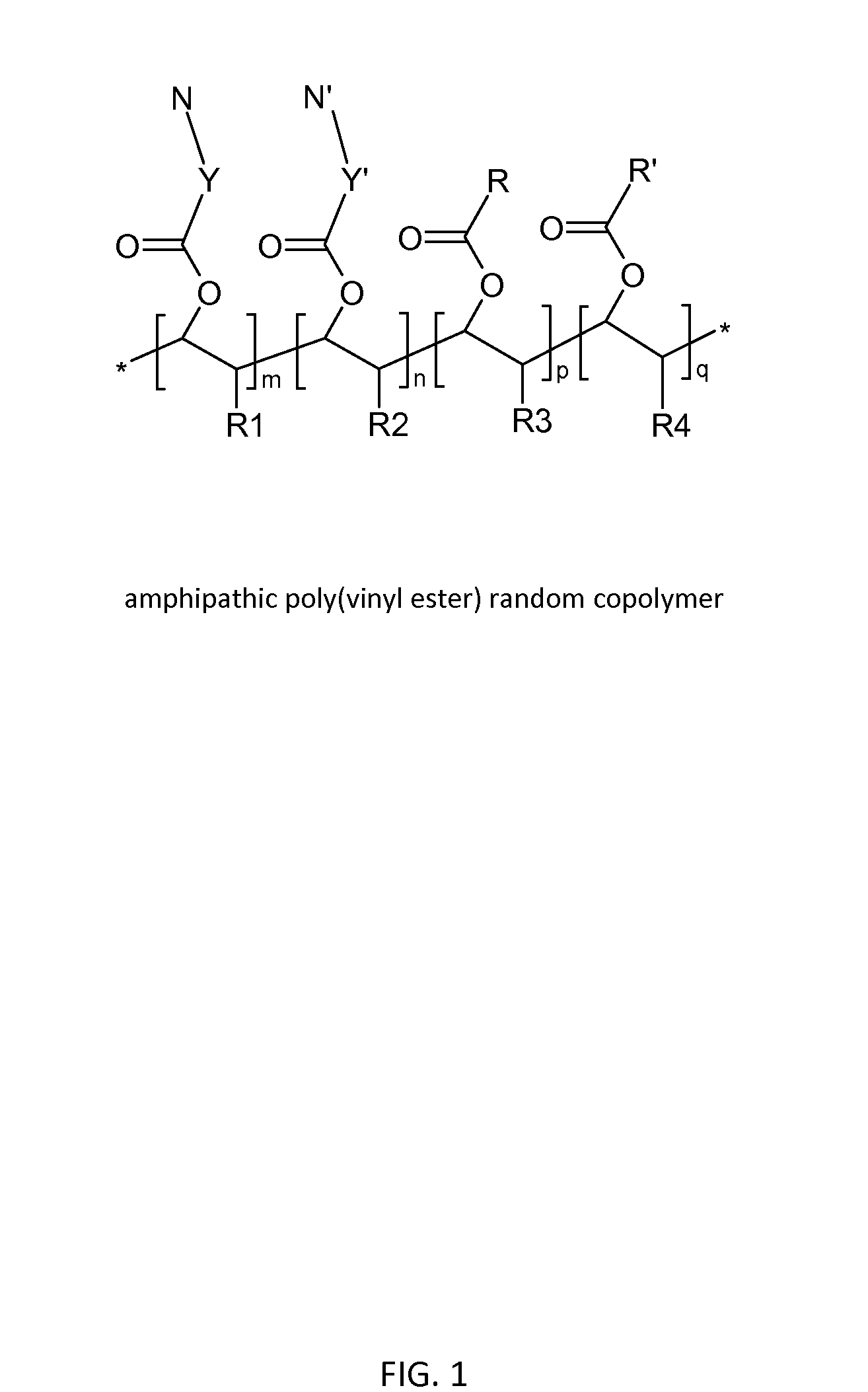

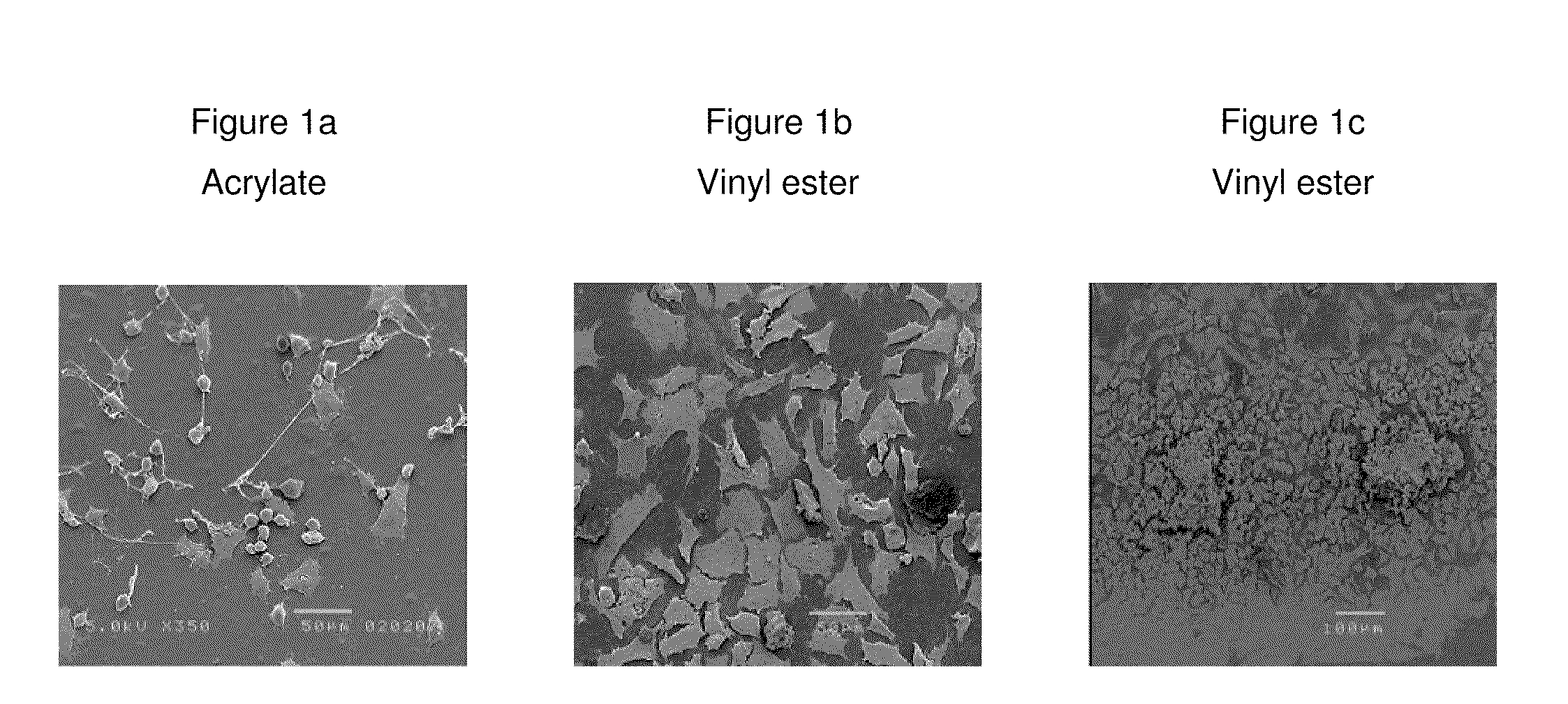

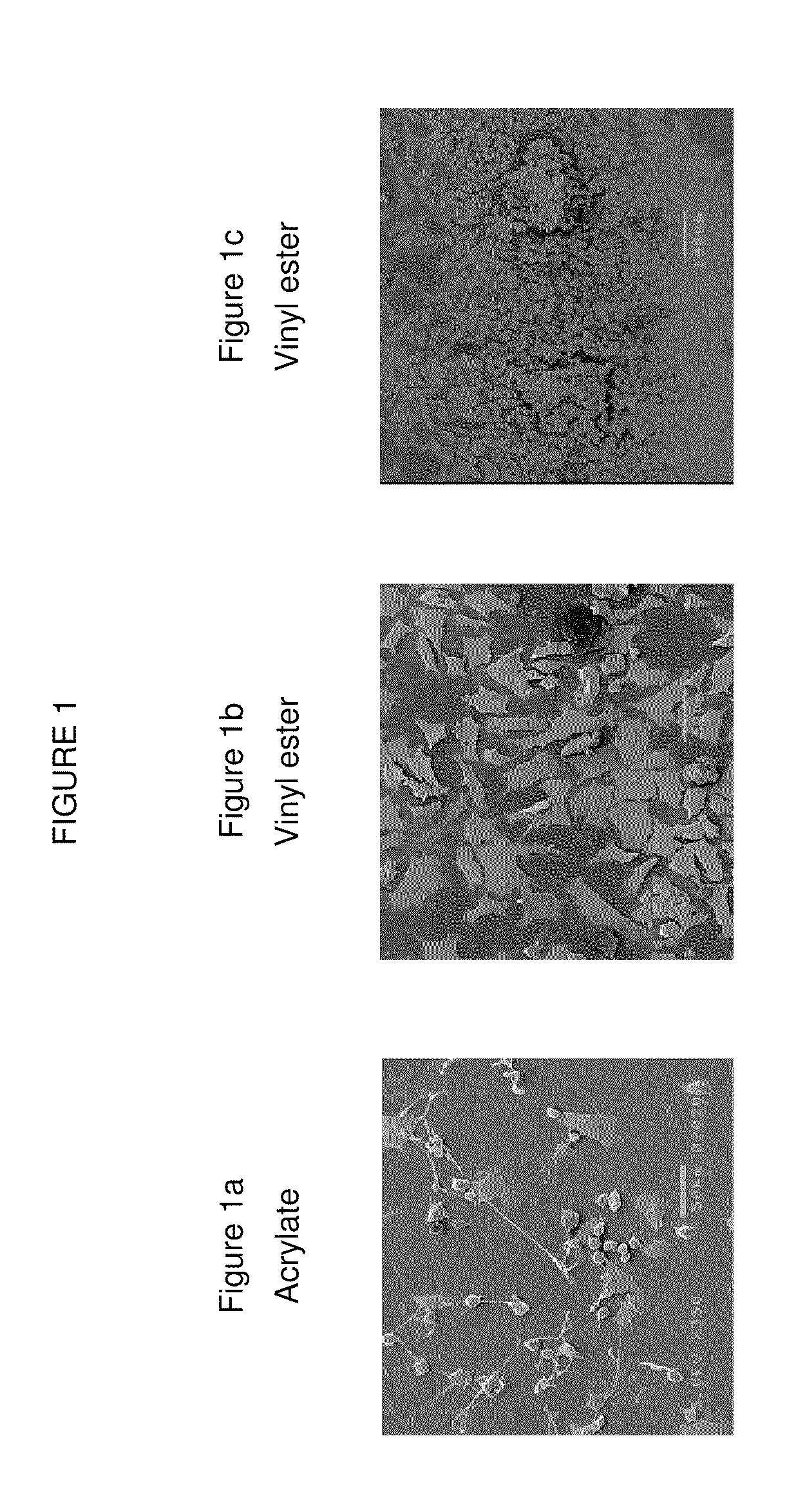

Poly(vinyl ester) Polymers for In Vivo Nucleic Acid Delivery

ActiveUS20130121954A1Suppression problemBeneficial level of expressionPharmaceutical non-active ingredientsDrug compositionsMembrane activityVinyl ester

The present invention is directed membrane active poly(vinyl ester) polymers and compositions for targeted delivery of RNA interference (RNAi) polynucleotides to cells in vivo. RNAi polynucleotides are conjugated to the poly(vinyl ester) polymers and the polymers are reversibly modified to enable in vivo targeted delivery. Membrane activity of the poly(vinyl ester) provides for movement of the RNAi polynucleotides from outside the cell to inside the cell. Reversible modification provides physiological responsiveness.

Owner:ARROWHEAD MADISON

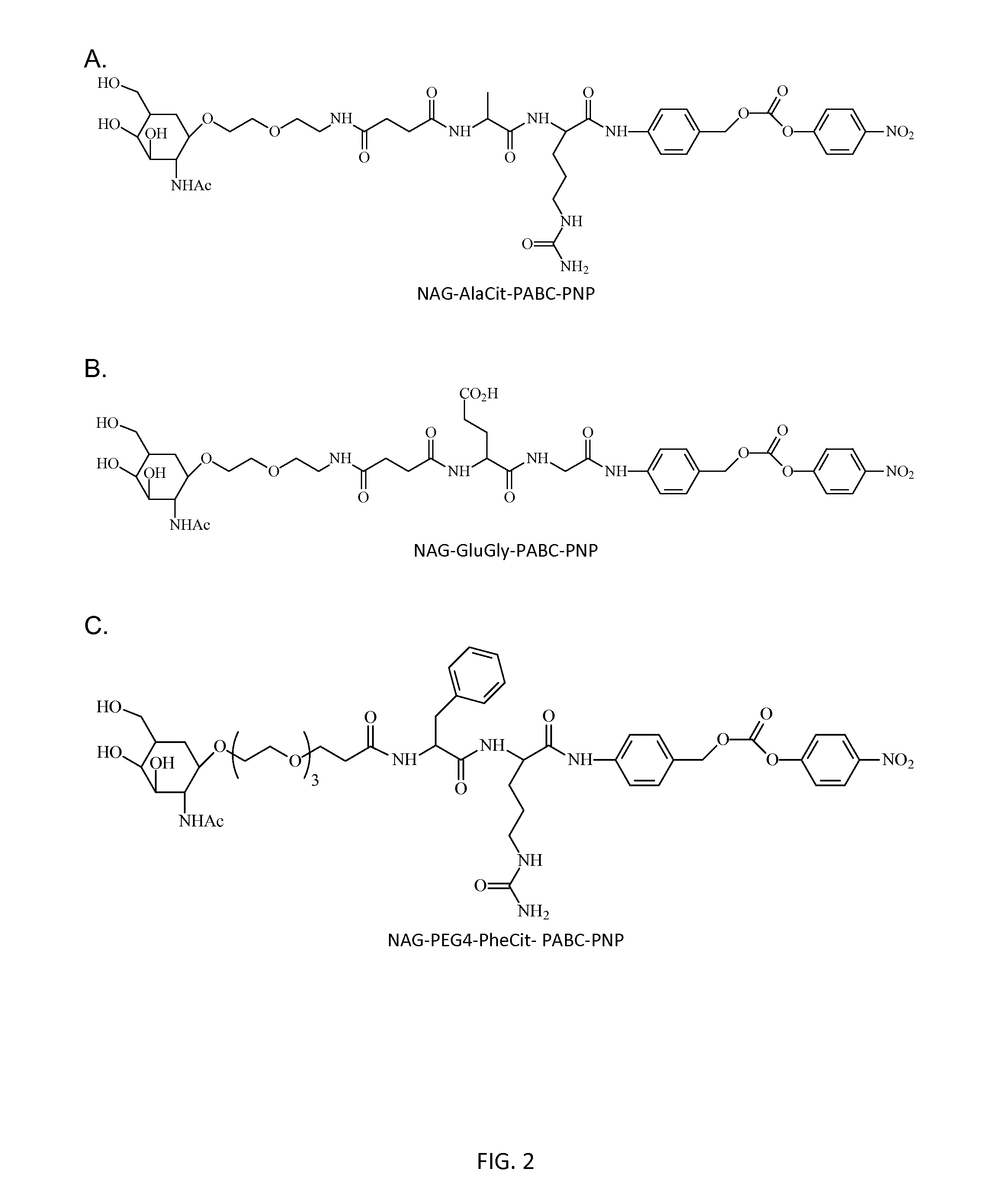

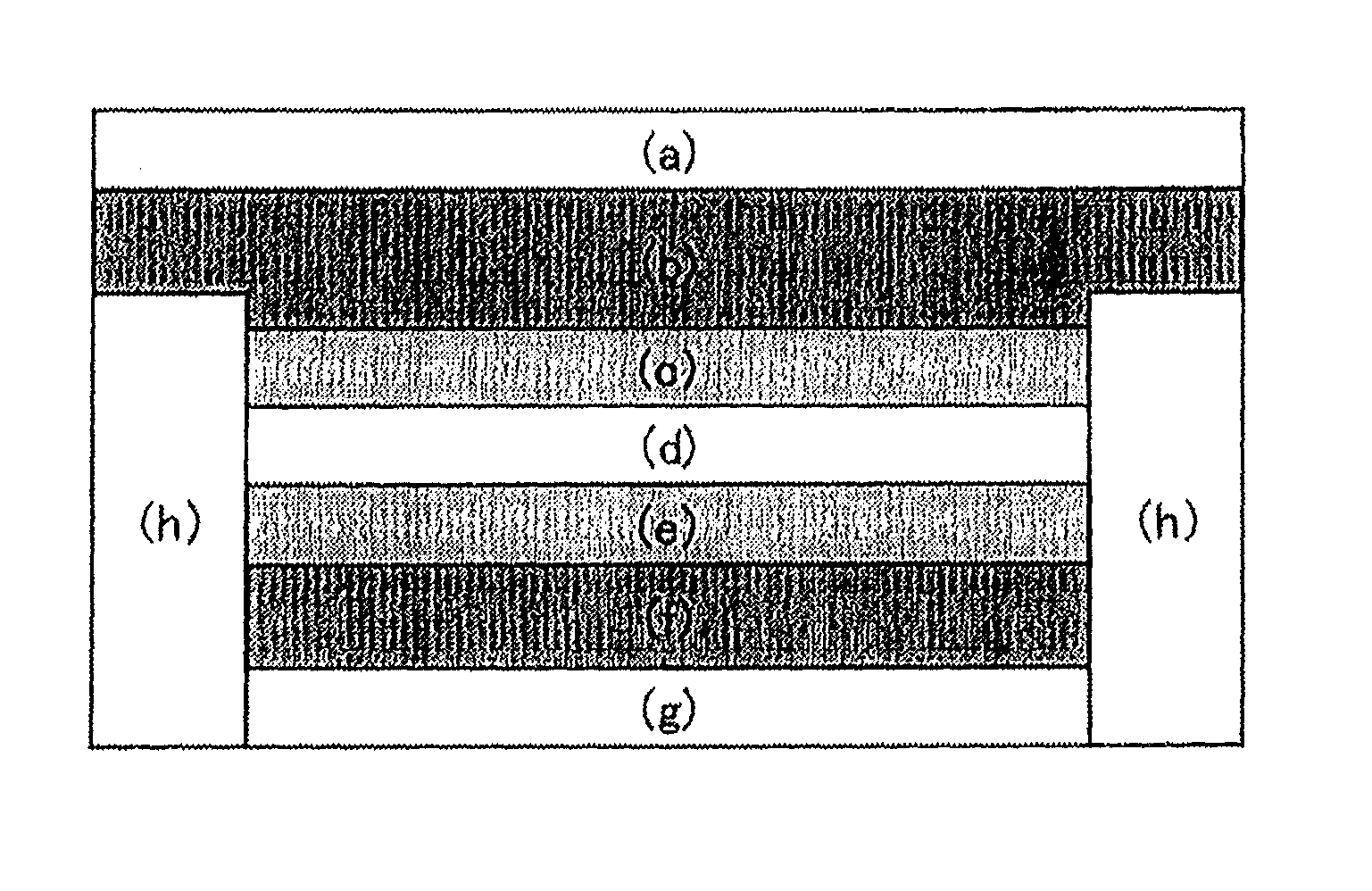

Composite bipolar plate for electrochemical cells

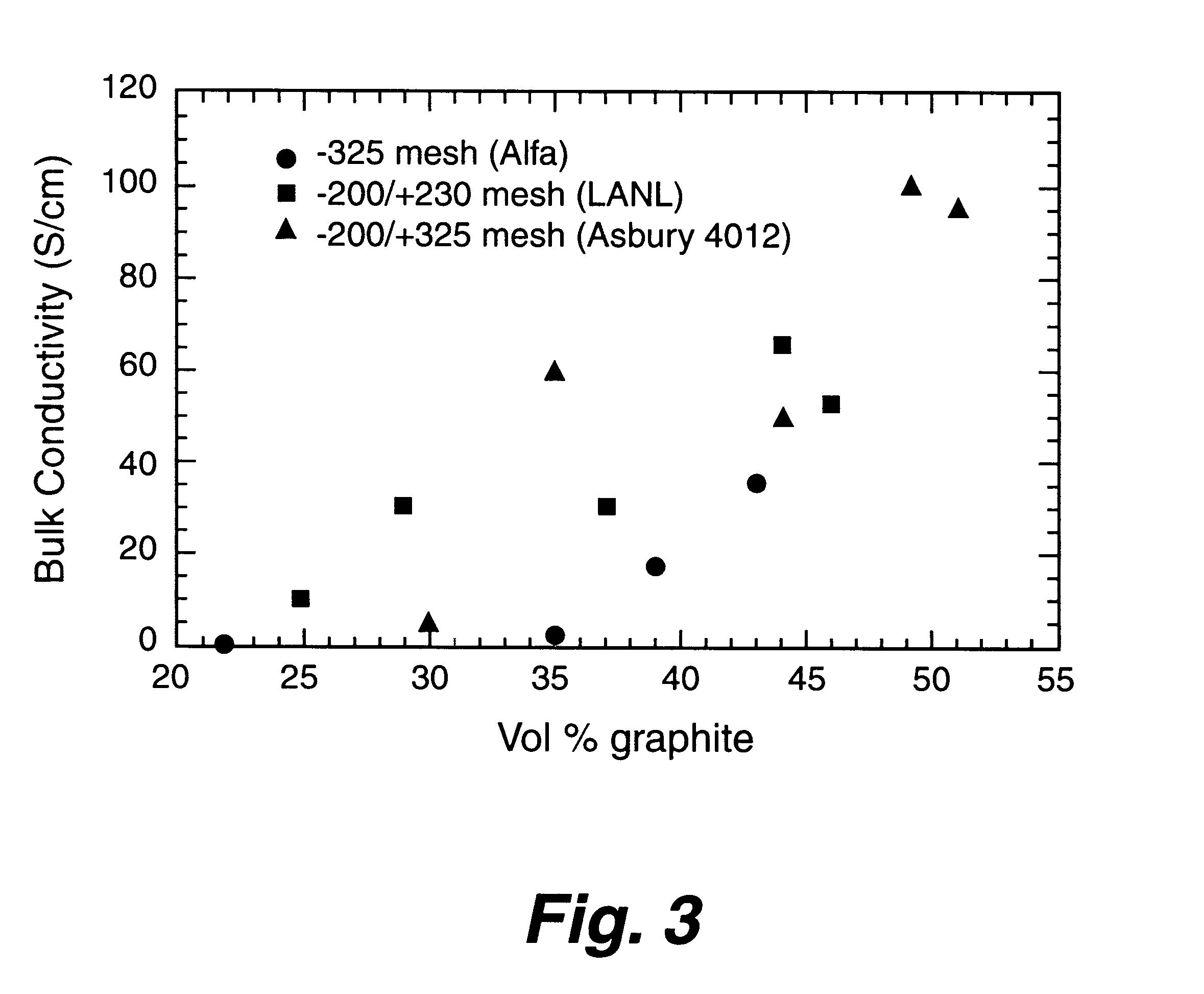

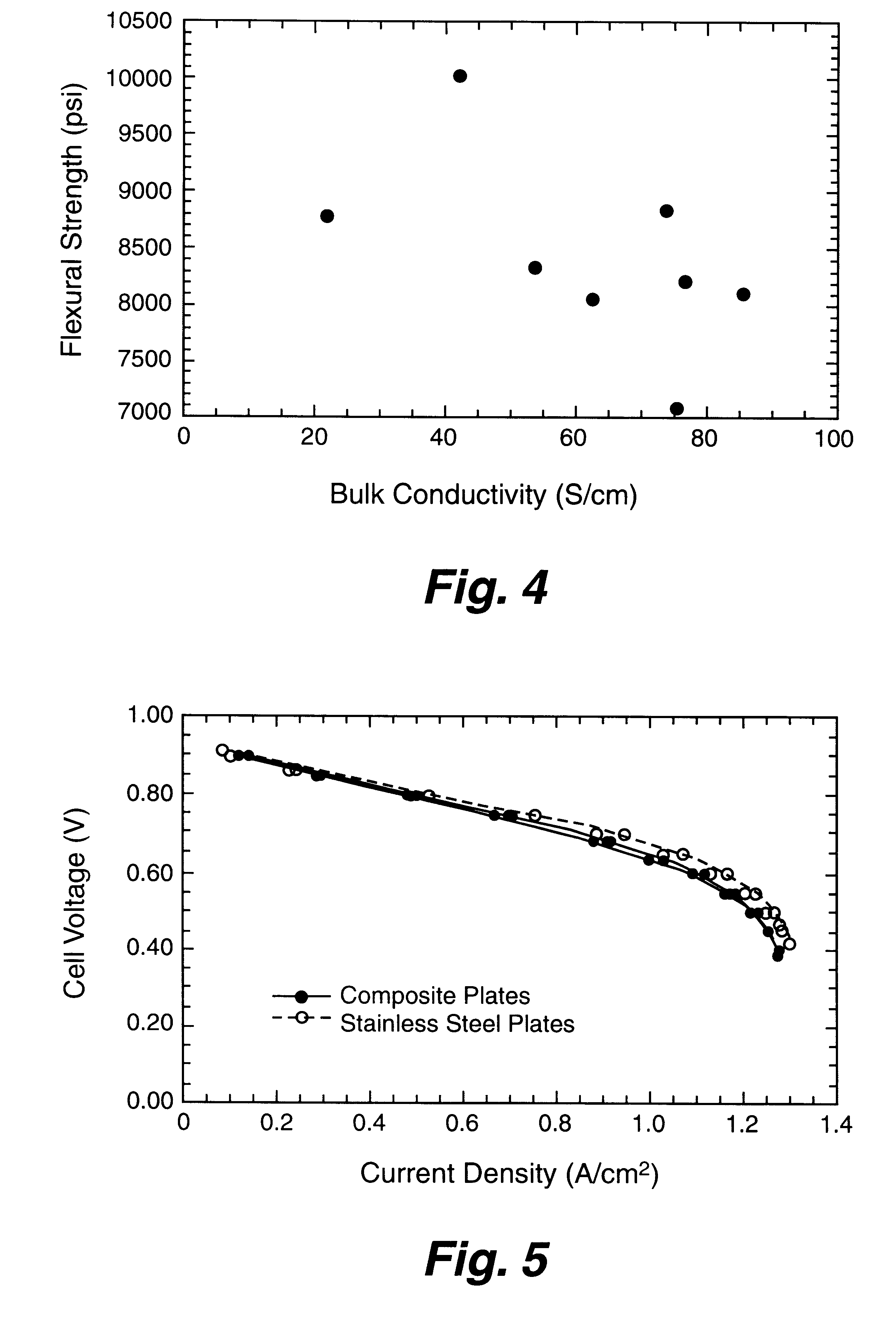

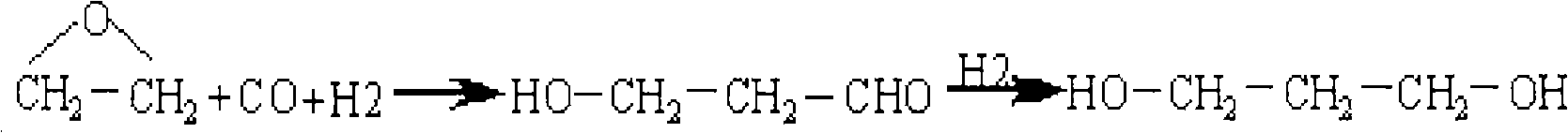

A bipolar separator plate for fuel cells consists of a molded mixture of a vinyl ester resin and graphite powder. The plate serves as a current collector and may contain fluid flow fields for the distribution of reactant gases. The material is inexpensive, electrically conductive, lightweight, strong, corrosion resistant, easily mass produced, and relatively impermeable to hydrogen gas. The addition of certain fiber reinforcements and other additives can improve the properties of the composite material without significantly increasing its overall cost.

Owner:TRIAD NAT SECURITY LLC

Flame retardant composition

Owner:NIPPON YUNIKAA

Toughened poly(lactic acid) compositions

Toughened poly(lactic acid) resin compositions comprising poly(lactic acid) and an impact modifier comprising an ethylene copolymer made from monomers (a) ethylene; (b) one or more olefins of the formula CH2═C(R1)CO2R2, where R1 is hydrogen or an alkyl group with 2-8 carbon atoms and R2 is an alkyl group with 1-8 carbon atoms, such as methyl, ethyl, or butyl; and (c) one or more olefins of the formula CH2═C(R3)CO2R4, where R3 is hydrogen or an alkyl group with 1-6 carbon atoms, such as methyl, and R4 is glycidyl. The ethylene copolymer may further be made from carbon monoxide monomers. The compositions may further comprise one or more ethylene / acrylate and / or ethylene / vinyl ester polymers, ionomers, and cationic grafting agents.

Owner:PERFORMANCE MATERIALS NA INC

Toughened polyoxymethylene-poly(lactic acid) compositions

Toughened polyoxymethylene-poly(lactic acid) resin compositions comprising polyoxymethylene, poly(lactic acid), and an impact modifier comprising an ethylene copolymer impact modifier made from monomers (a) ethylene; (b) one or more olefins of the formula CH2═C(R1)CO2R2, where R1 is hydrogen or an alkyl group with 2-8 carbon atoms and R2 is an alkyl group with 1-8 carbon atoms, such as methyl, ethyl, or butyl; and (c) one or more olefins of the formula CH2═C(R3)CO2R4, where R3 is hydrogen or an alkyl group with 1-6 carbon atoms, such as methyl, and R4 is glycidyl. The ethylene copolymer impact modifier may further be made from carbon monoxide monomers. The compositions may further comprise one or more ethylene / acrylate and / or ethylene / vinyl ester polymers, ionomers, and cationic grafting agents.

Owner:DUPONT POLYMERS INC

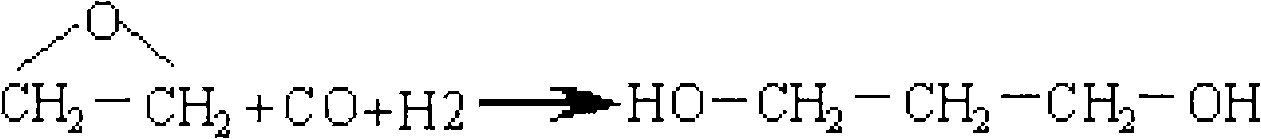

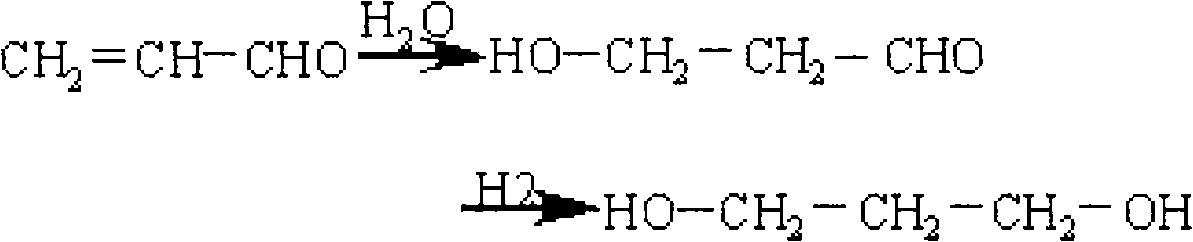

Method for simultaneously producing 1,3-propylene glycol and 1,2-propylene glycol

The invention relates to a chemical material production method, in particular to a method for simultaneously producing 1,3-propylene glycol and 1,2-propylene glycol. Alkyl carboxylic acid vinyl ester carries out hydroformylation with carbon monoxide and hydrogen under the action of olefin hydroformylation catalyst, so that 3-alkylacyloxy propaldehyde and 2- alkylacyloxy propaldehyde are produced, the 3-alkylacyloxy propaldehyde and the 2- alkylacyloxy propaldehyde react with hydrogen under the action of aldehyde hydrogenation catalyst, so that 3-alkylacyloxy propyl alcohol and 2-alkylacyloxy propyl alcohol are produced, and the 3-alkylacyloxy propyl alcohol and the 2-alkylacyloxy propyl alcohol are hydrolyzed under the action of esterolytic catalyst, so that the 1,3-propylene glycol and the 1,2-propylene glycol are produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Pvp copolymer for harsh chemical packaging

A water soluble film useful in unit-dose chemical packaging is disclosed. The film may include: a water soluble saccharide and a polyvinyl alcohol copolymer consisting essentially of: (a) from 80 to 99 mole percent of vinyl alcohol and vinyl ester monomer; and (b) from 1 to 20 mole percent of a pyrrolidone comonomer. Such compositions may be used to provide a water-soluble film simultaneously satisfying requirements in regard to water solubility, biodegradability, and physical properties, even when used for packaging of harsh, oxidizing chemicals.

Owner:SEKISUI SPECIALTY CHEM AMERICA

Toughened poly(lactic acid) compositions

Toughened poly(lactic acid) resin compositions comprising poly(lactic acid) and an impact modifier comprising an ethylene copolymer made from monomers (a) ethylene; (b) one or more olefins of the formula CH2═C(R1)CO2R2, where R1 is hydrogen or an alkyl group with 2-8 carbon atoms and R2 is an alkyl group with 1-8 carbon atoms, such as methyl, ethyl, or butyl; and (c) one or more olefins of the formula CH2═C(R3)CO2R4, where R3 is hydrogen or an alkyl group with 1-6 carbon atoms, such as methyl, and R4 is glycidyl. The ethylene copolymer may further be made from carbon monoxide monomers. The compositions may further comprise one or more ethylene / acrylate and / or ethylene / vinyl ester polymers, ionomers, and cationic grafting agents.

Owner:PERFORMANCE MATERIALS NA INC

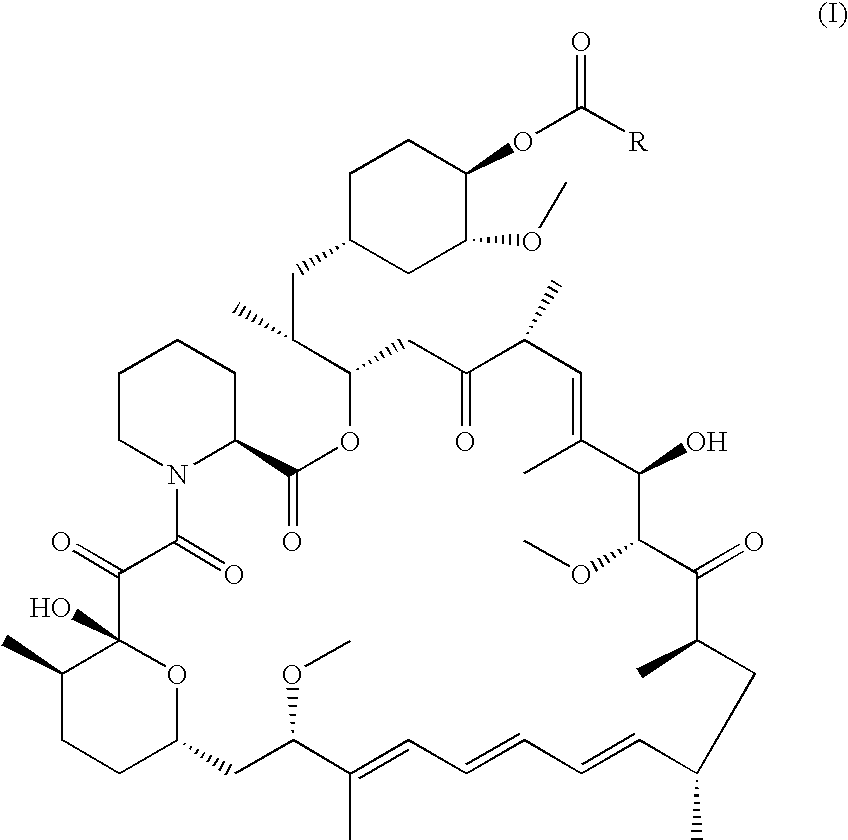

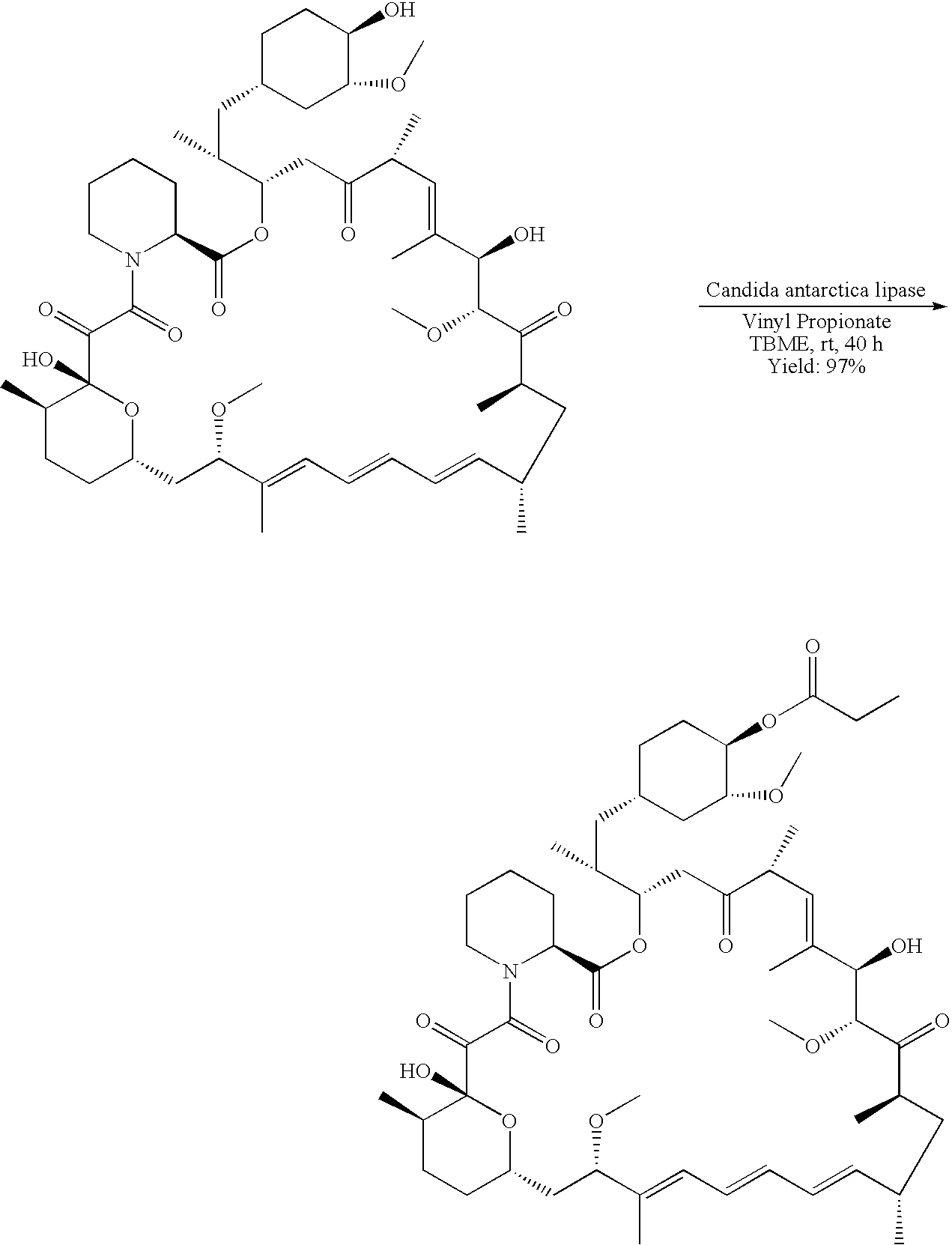

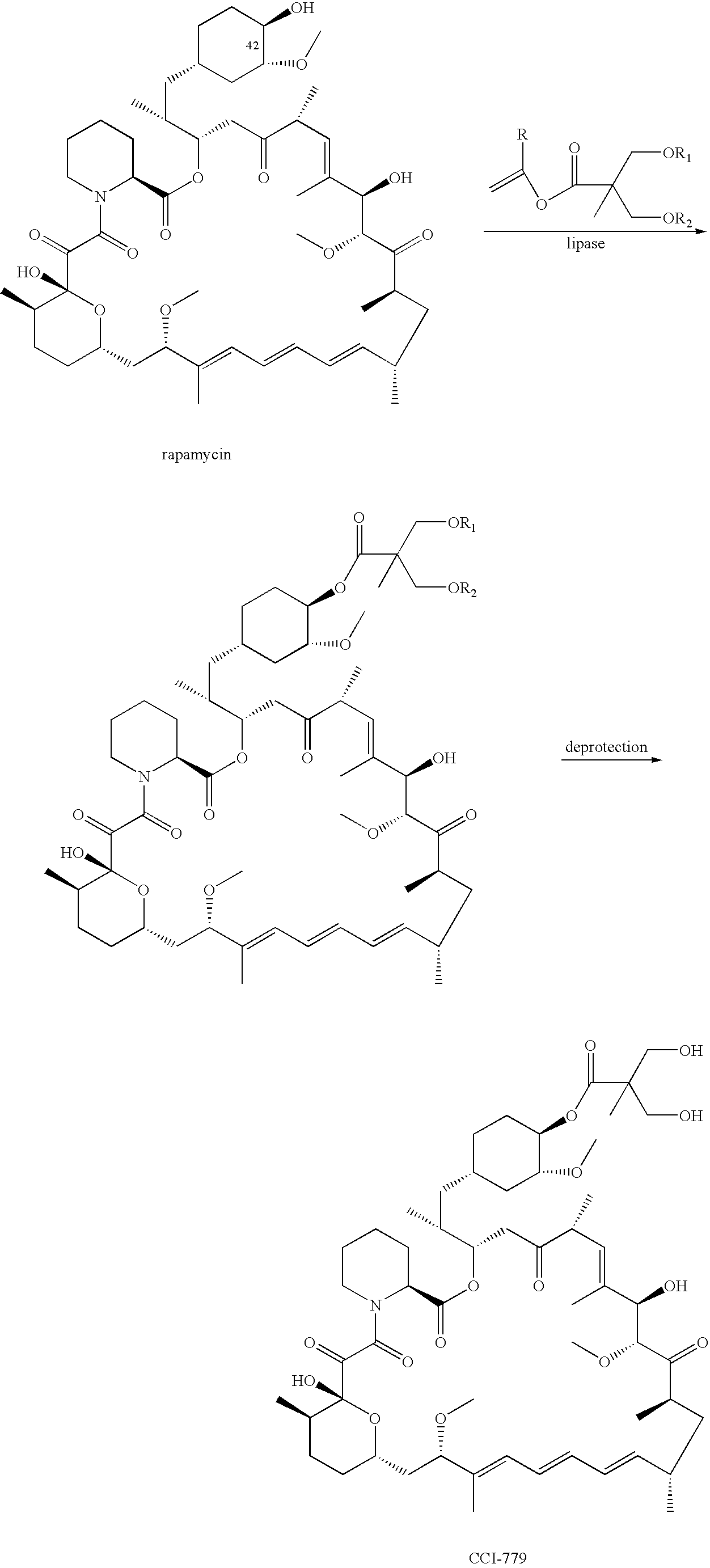

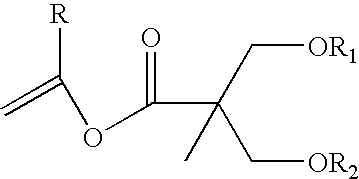

Regiospecific synthesis of rapamycin 42-ester derivatives

A method for the regiospecific synthesis of rapamycin 42-ester derivatives is described. The method involves lipase-catalyzed acetylation of 42-hydroxy of rapamycin with an acyl donor such as a vinyl ester, an isopropenyl ester or an anhydride in a suitable organic solvent.

Owner:WYETH

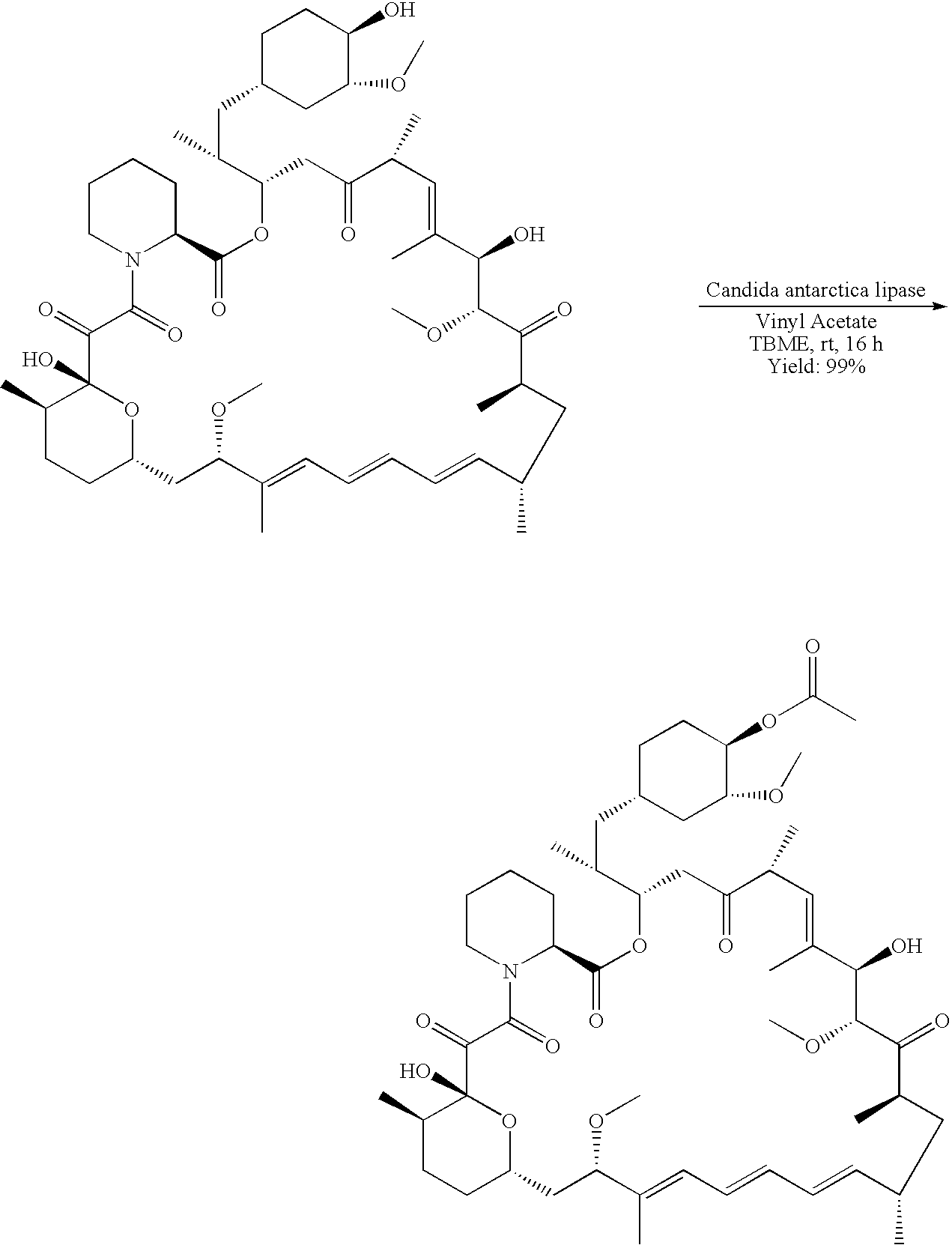

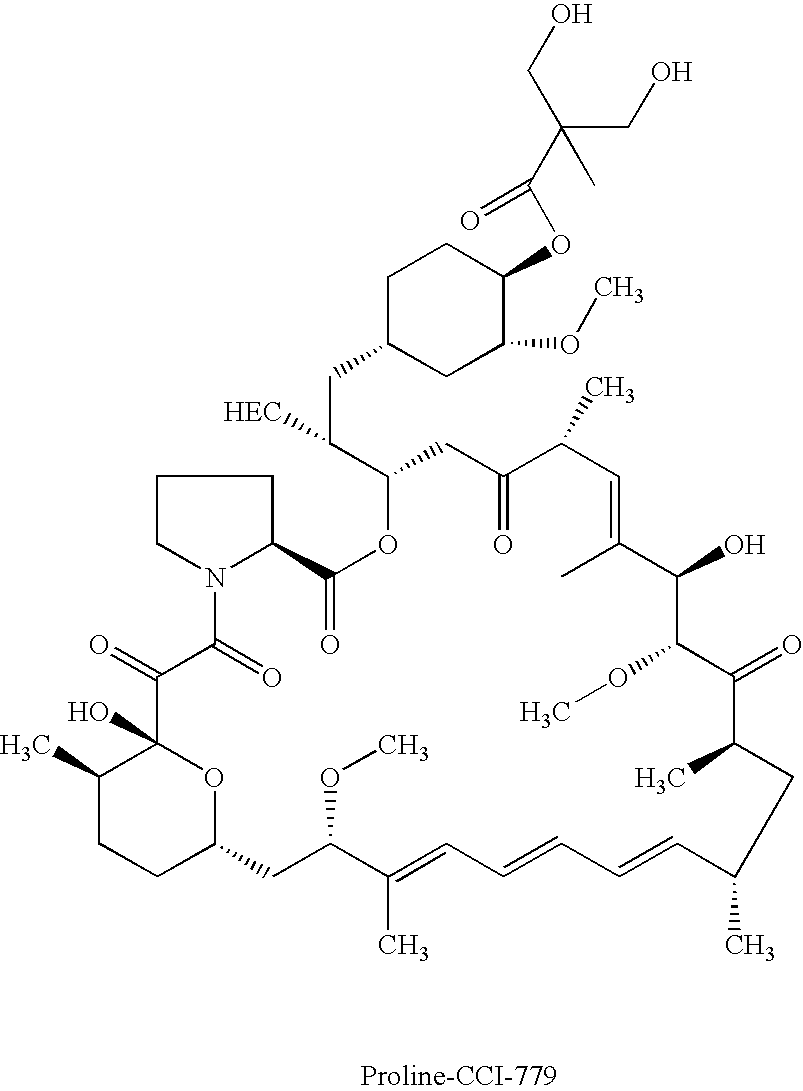

Proline CCI-779, production of and uses therefor, and two-step enzymatic synthesis of proline CCI-779 and CCI-779

Methods for the synthesis of CCI-779 and proline-CCI-779 are described, including a method involving lipase-catalyzed acetylation of 42-hydroxy of rapamycin with a vinyl ester of 2,2-bis(hydroxymethyl) propionic acid in an organic solvent followed by deprotection. Also provided are products containing proline-CCI-779 and uses thereof.

Owner:WYETH LLC

Process for producing fast curing molding compounds bonded with phenolic resin

A process is provided for producing fast curing bonded with phenolic resin, which comprises pulverulent phenolic resins mixed with or applied to the substrate to be adhered together with pulverulent addition polymers selected from the group consisting of polyvinyl alcohols and addition polymers, stabilized by hydroxyl-containing protective colloids of at least one monomer selected from the group consisting of the vinyl esters of branched or unbranched carboxylic acids of 1 to 12 carbon atoms, the esters of acrylic acid and methacrylic acid with branched or unbranched alcohols of 1 to 12 carbon atoms, vinylaromatics, vinyl halides, olefins and dienes, and subsequently, by the employment of elevated temperature and optionally elevated pressure, cured and processed into a shaped article.

Owner:WACKER CHEM GMBH

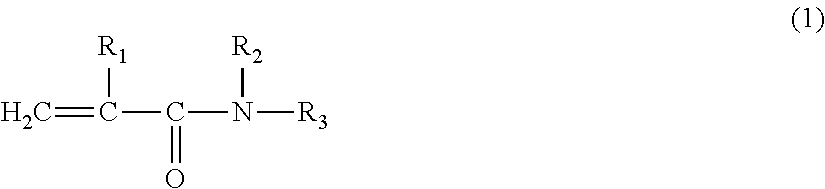

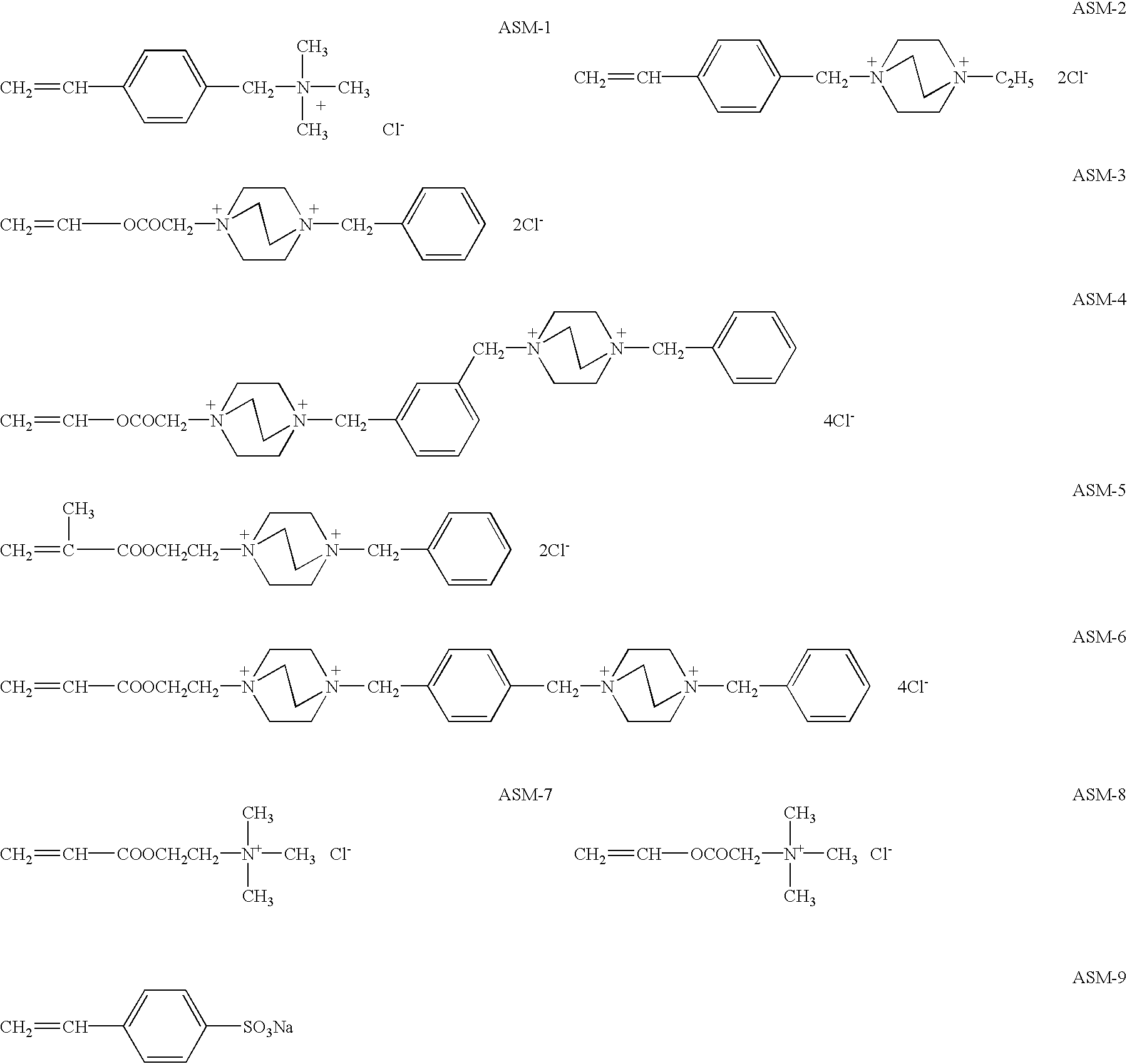

Acrylic polymer for use in pressure-sensitive adhesive composition for touch screen panel

InactiveUS20130211028A1High dielectric constantHigh transparencyNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceAcid value

An object of the invention is to provide a pressure-sensitive adhesive sheet. Provided is an acrylic polymer for use in a pressure-sensitive adhesive composition for a touch screen panel, the acrylic polymer being obtained by copolymerizing monomer components comprising (a) a (meth)acrylic acid ester monomer having a C1-12 hydrocarbon group, (b) a hydroxy group-containing (meth)acrylic acid ester monomer, (c) an amide group-containing monomer, and (d) a vinyl ester monomer. The acrylic polymer has an acid value of 0.1 mg KOH / g or less, a weight-average molecular weight of 400,000 to 2,000,000, a Tg of −80 to 0° C., and a permittivity of 3 to 6.

Owner:DAIDOU KASEI KOGYO KK

Metal base material corrosion-resistant coating and preparation method thereof

InactiveCN102391779AWeather resistantAnti-corrosionAnti-corrosive paintsEpoxy resin coatingsVinyl esterBis epoxide

The invention discloses metal base material corrosion-resistant coating and a preparation method thereof. The metal base material corrosion-resistant coating comprises the following components in parts by weight: 25 to 30 pats of epoxy modified organic silicon resin, 15 to 20 parts of modified vinyl resin, 1 to 2 parts of nano material, 1 to 3 parts of corrosion-resistant particulate filler, 15 to 18.5 percent of pigment and filler, 1 to 2 parts of antisettling agent, 0.3 to 0.5 part of dispersing agent, 0.5 to 0.8 part of stabilizing agent, 3 to 4 parts of aid and 23 to 26 parts of solvent, wherein the modified vinyl resin comprises according to the weight percentage 50 to 70 % of phenolic aldehyde epoxy vinyl ester resin and 30 to 50 % of flexible vinyl ester resin. The metal base material corrosion-resistant coating is prepared by multiple flows of weighing the raw materials in parts by weight, mixing the raw materials according to certain sequence, dispersing, grinding and the like. The metal base material corrosion-resistant coating has high temperature tolerance, wet resistance, corrosion resistance, weldability and constructability and can be applied in the technical fieldsof processing of various different metals.

Owner:资阳赛特化工有限公司

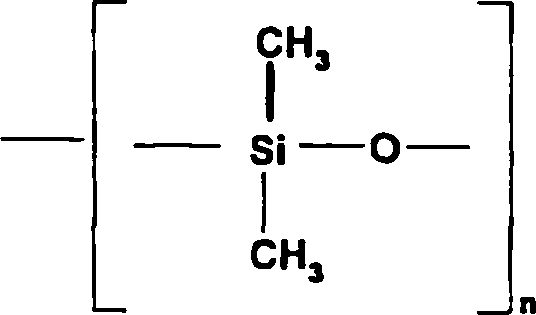

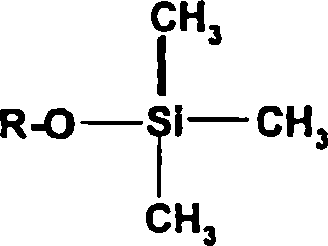

Anti-pollution flashover normal-temperature cured fluorocarbon resin coating and preparation method thereof

ActiveCN102010636AImprove hydrophobicityExcellent hydrophobic migrationAntifouling/underwater paintsSynthetic resin layered productsResin coatingDibutyltin dilaurate

The invention discloses a normal-temperature cured fluorocarbon resin coating, which consists of the following components in percentage by weight: 35 to 70 percent of tetrafluorochloroethylene-vinyl ester polymer, 5.5 to 12 percent of curing agent, 2 to 10 percent of coupling agent, 1 to 10 percent of pigment, 1 to 30 percent of hydrophobic particles, 0.03 to 3 percent of aid, 20 to 40 percent ofsolvent and 0.001 to 1 percent of catalyst, wherein the coupling agent is fluorosilane with a -CF3 group and a -CF2 group; the aid is a flatting agent, an antifoaming agent and a dispersing agent; the solvent is butyl acetate and methyl isobutyl ketone; the catalyst is dibutyltin dilaurate; and the curing agent is aliphatic diisocyanate. By adopting a specific coating formula, due to the combinedaction of the fluorosilane coupling agent and the hydrophobic particles, the anti-pollution flashover fluorocarbon resin coating has a static contact angle theta of 120 degrees, is excellent in hydrophobic performance and hydrophobic migration property, high in anti-pollution flashover performance, high in coating leveling property, smooth in surface, and high in self-cleanliness, chemicals resistance and hot-water resistance, and has an adhesive force reaching a zero level.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Laundry detergent compositions comprising amphiphilic graft polymers based on polyalkylene oxides and vinyl esters

InactiveUS20090005288A1Negatively impacting general cleaning capabilityLower surfactant levelOrganic detergent compounding agentsDetergent solventsOrganic solventPolybutylene

A laundry detergent composition comprising a graft copolymer of polyethylene, polypropylene or polybutylene oxide with vinyl acetate in a weight ratio of from about 1:0.2 to about 1:10; from about 0.2% to about 8% of organic solvent; and from about 2% to about 20% of a surfactant system; wherein said detergent composition is in a form selected from: liquid; gel; and combinations thereof.

Owner:THE PROCTER & GAMBLE COMPANY

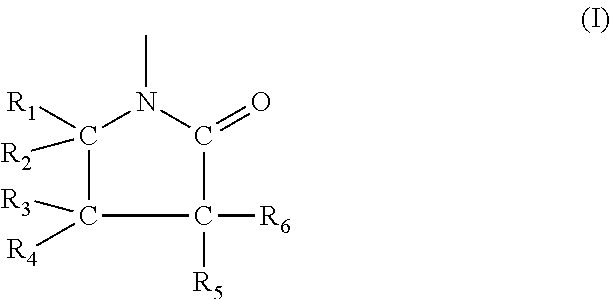

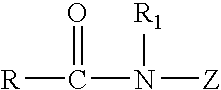

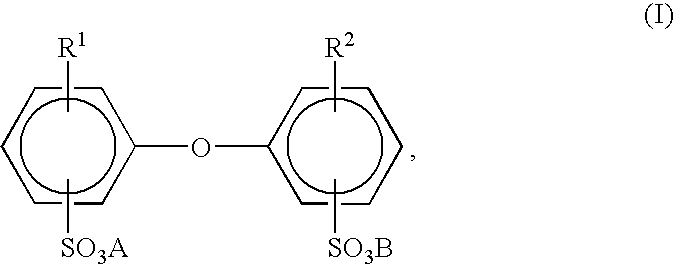

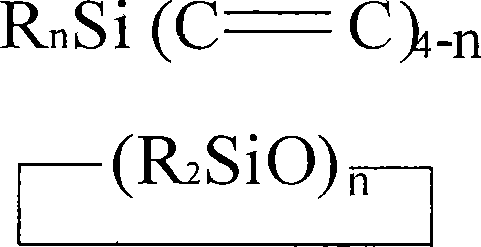

Composition that can be cured by polymerisation for the production of biodegradable, biocompatible, cross-linkable polymers on the basis of polyvinyl alcohol

ActiveUS20100303804A1Improve adhesionPromote cell adhesionImpression capsCarbamic acid derivatives preparationSolventVinyl ester

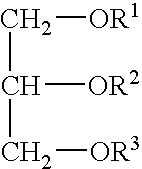

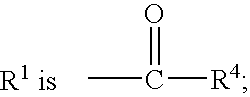

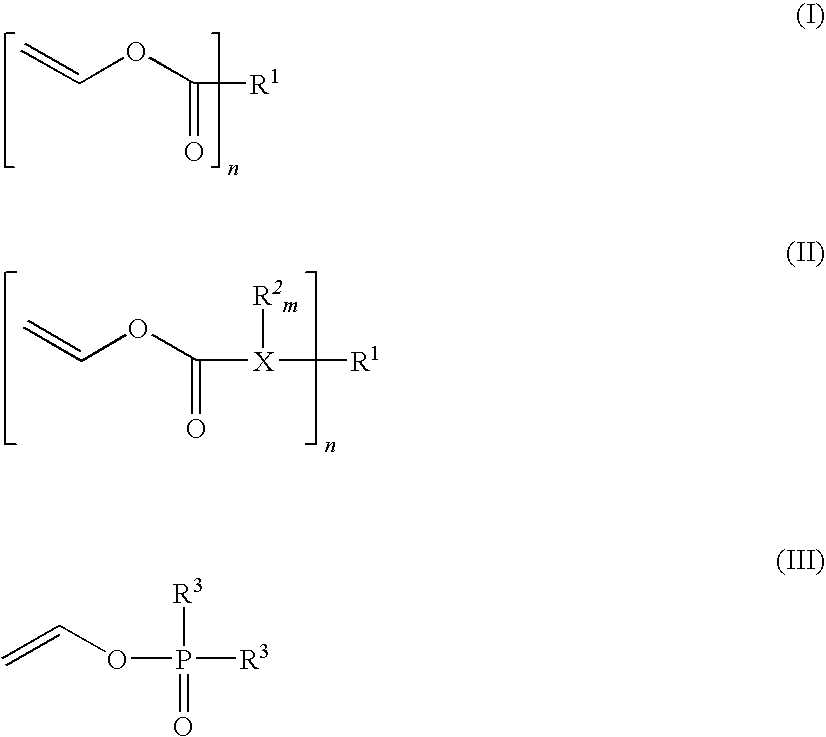

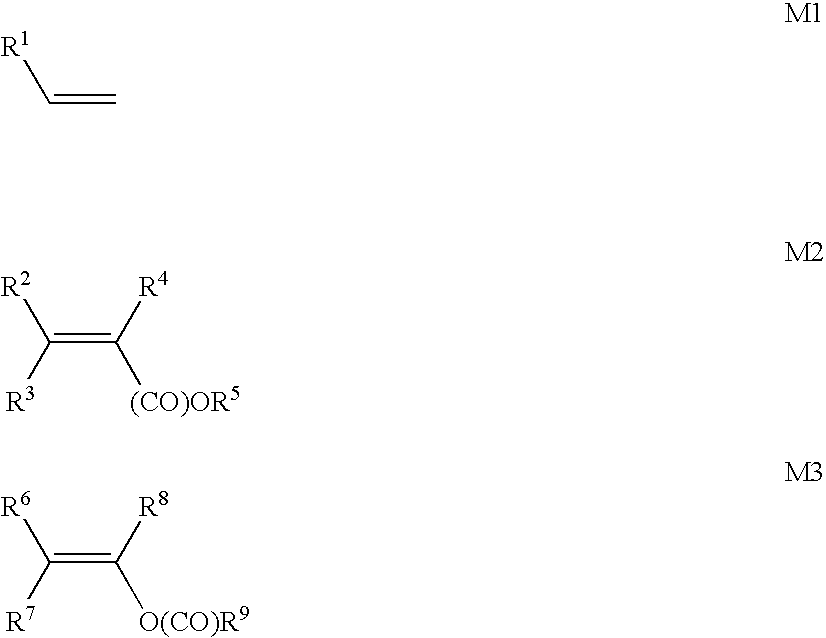

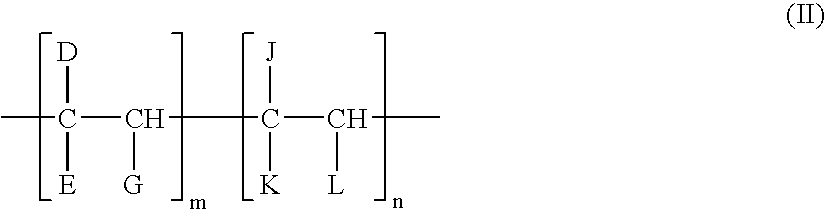

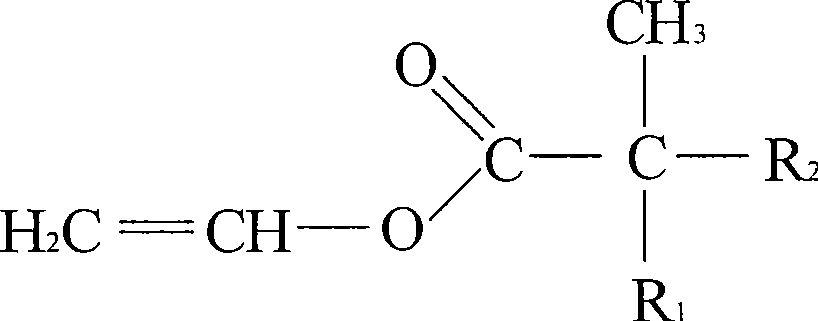

The present invention relates to a polymerization-curable composition for the preparation of biodegradable, biocompatible, cross-linked polymers on the basis of polyvinyl alcohol comprising: 5 to 100% by weight of (a) vinyl ester monomer(s) of one of the general formulas (I) to (III):wherein X is oxygen, sulfur, nitrogen, or phosphorus; n is 1 to 1000, at least 20% of the n being ≧2; the R1 are selected from hydrogen; straight, branched or cyclic, saturated or unsaturated, n-valent hydrocarbon groups having 1 to 30 carbon atoms, which optionally have heteroatoms and are optionally substituted with one or more substituents selected from —OH, —COON, —CN, —CHO, and ═O, and n-valent radicals of biodegradable, biocompatible oligomers and polymers; m is an integer from 1 to 5; the R2 are selected from hydrogen, —OH, ═O, and the options listed for R1; and the R3 are selected from hydrogen, —OH, and the options listed for R1; 0 to 50% by weight of ethylenically unsaturated co-monomers; 0 to 10% by weight of (a) polymerization initiator(s); and 0 to 95% by weight of solvent(s).

Owner:VIENNA UNIVERSITY OF TECHNOLOGY

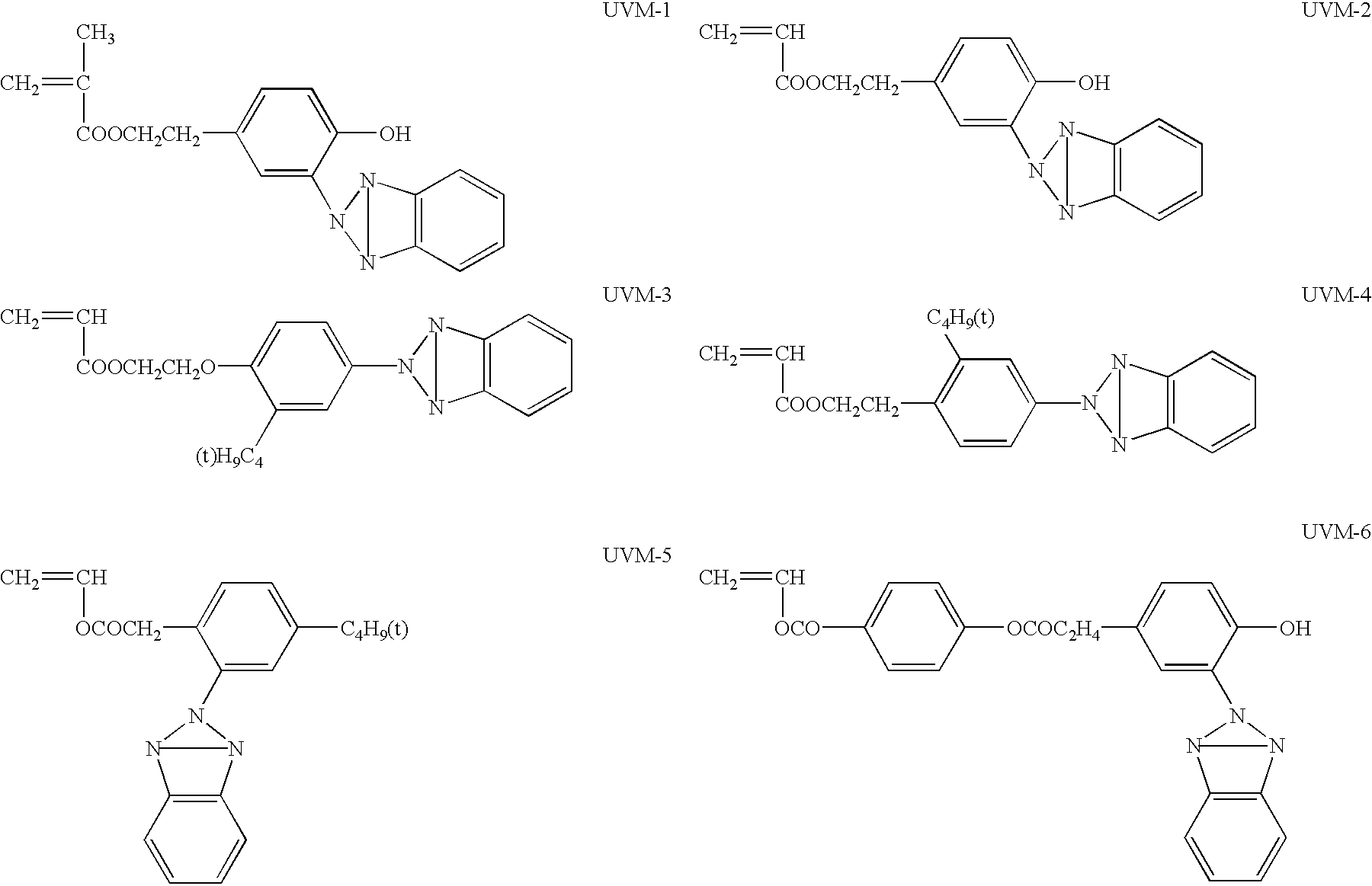

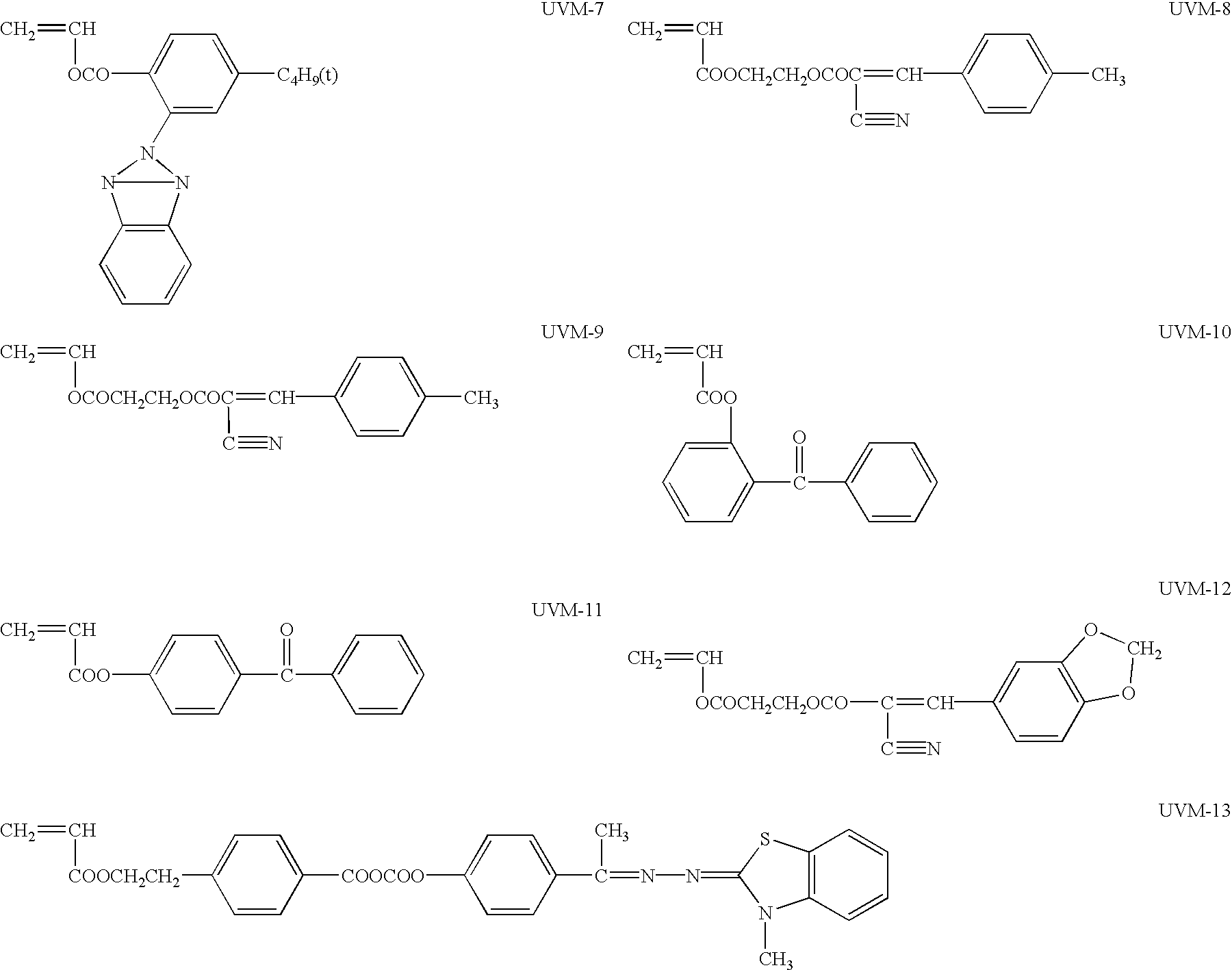

Cellulose ester film, cellulose ester dope, protective film of polarizing plate and polarizing plate

InactiveUS6974608B2Reduce penetrationImprove retentionLiquid crystal compositionsOptical filtersTectorial membraneCellulose ester membrane

Disclosed is a cellulose ester film comprising a polymer prepared by polymerizing at least one ethylenically unsaturated monomer selected from vinyl esters, vinyl esters having a functional group, acrylic esters, and acrylic esters having a functional group, wherein the polymer has a weight average molecular weight of not more than 5,000.

Owner:KONICA CORP

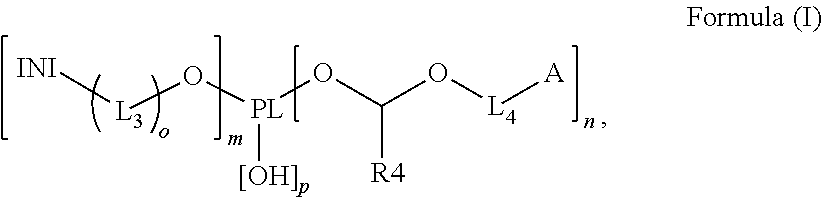

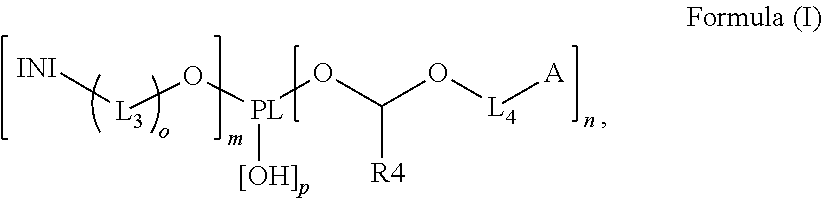

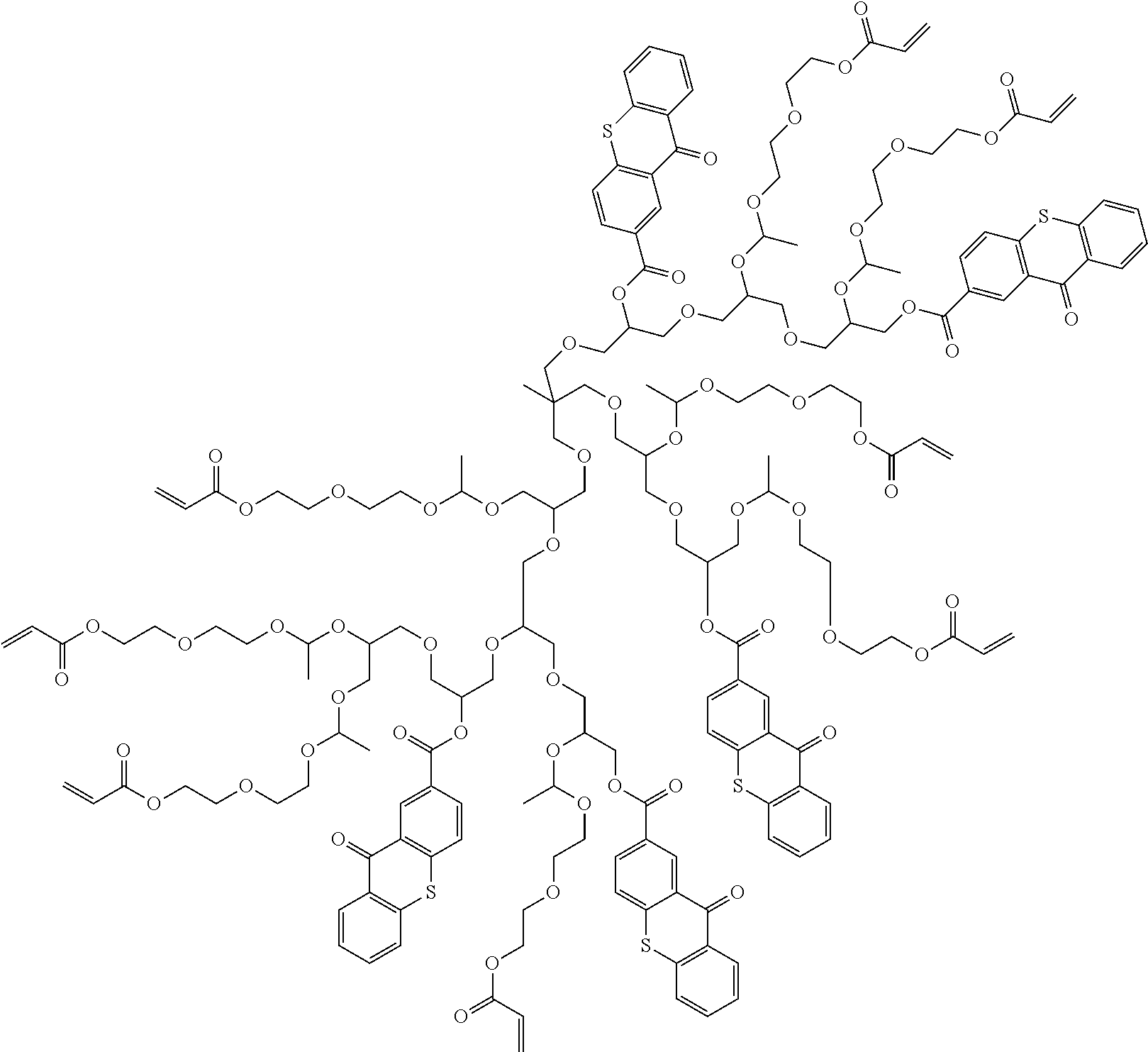

Polymerizable polymeric photoinitiators and radiation curable compositions

InactiveUS20120046376A1Simple and cost efficient procedureAvoiding unecological removal of solventInksVinyl etherPhosphine oxide

A polymerizable polymeric photoinitiator according to Formula (I):wherein:PL represents an n+m+p-functional polymeric core;n and m independently represent an integer from 1 to 30;p represents an integer from 0 to 10;o is 0 or 1;INI represents a group selected from the group consisting of a benzophenone, a thioxanthone, a carbazole, a anthraquinone, a camphor quinone, an α-hydroxyalkylphenone, an α-aminoalkylphenone, an acylphosphine oxide, a bisacyl phosphine oxide, an acylphosphine sulfide, a phenyl glyoxalate, a benzoin ether, a benzyl ketal, an α-dialkoxyacetophenone, a carbazolyl-O-acyl-oxime, an α-haloarylketone and an α-haloaryl sulfone;L3 and L4 represent a substituted or unsubstituted divalent linking group comprising 1 to 14 carbon atoms;A represents a radically polymerizable functional group selected from the group consisting of an acrylate, a methacrylate, a styrene, an acryl amide, a methacryl amide, a maleate, a fumarate, an itaconate, an vinyl ether, an allyl ether, an allyl ester, a maleimide, a vinyl nitrile and a vinyl ester; andR4 represents a substituted or unsubstituted alkyl group.Radiation curable compositions containing the polymerizable polymeric photoinitiator and methods for preparing the polymerizable polymeric photoinitiator are also disclosed.

Owner:AGFA NV

Adhesive compositions for bonding and filling large assemblies

InactiveUS20050014901A1Reduced tendency to gasReduce boilingEster polymer adhesivesOrganic non-macromolecular adhesiveMethacrylateVinyl ester

Adhesive composition for bonding and filling large assemblies, including a mixture of about 5 percent to about 75 percent by weight of a thermoplastic polymer, about 0.5 percent to about 35 percent by weight of a polyester resin or vinyl ester resin, and about 20 percent to about 80 percent by weight of an alkyl acrylate or methacrylate monomer.

Owner:IPS STRUCTURAL ADHESIVES

High solids dispersion for wide temperature, pressure sensitive adhesive applications

A pressure-sensitive adhesive polymer comprising a reaction product of a C1 to C20 alkyl (meth)acrylate, an ethylenically unsaturated carboxylic acid, a C2 to C8 hydroxyalkyl (meth)acrylate, a vinyl aromatic, optionally a ethylenically unsaturated monomer containing sulfonic acid, and optionally a vinyl ester of a carboxylic acid. The pressure-sensitive adhesive polymer can provide adhesion and cohesion in a temperature range from −30° C. to 50° C. for the All-temperature pressure-sensitive adhesive market.

Owner:BASF AG

Heavy-duty anticorrosive coating for flue gas desulphurization equipment and preparation technology thereof

InactiveCN102690586AStrong adhesionImprove water resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyPlasticizer

The invention discloses a heavy-duty anticorrosive coating for flue gas desulphurization equipment and a preparation technology thereof. The heavy-duty anticorrosive coating comprises components of a novolac epoxy vinyl ester resin, a plasticizer, a diluent, a curing agent, a promoter, glass flakes, rutile titanium dioxide, nano-silica, alumina powder, silicon carbide, talcum powder and auxiliary agents. The preparation technology comprises that the components are dispersed by a high-speed dispersion kettle and then are mixed into the heavy-duty anticorrosive coating. The heavy-duty anticorrosive coating is convenient for construction, can be cured at a normal temperature, has good mechanical properties and excellent anti-permeability performances, is stable in an acid medium for a long time and has good protection effects on a matrix material.

Owner:BEIJING UNIV OF CHEM TECH

Preparation of fuel cell composite bipolar plate

ActiveUS20050001352A1Improve thermal stabilityImprove mechanical propertiesNon-metal conductorsConductive materialPolymer electrolytesFuel cells

A composite bipolar plate of polymer electrolyte membrane fuel cells (PEMFC) is prepared as follows: a) preparing a bulk molding compound (BMC) material containing a vinyl ester resin and a graphite powder, the graphite powder content of BMC material ranging from 60 wt % to 80 wt %, based on the compounded mixture; b) molding the BMC material from step a) to form a bipolar plate having a desired shape at 80-200° C. and 500-4000 psi, wherein the graphite powder is of 40 mesh-80 mesh.

Owner:IND TECH RES INST +1

Fuel oil compositions with improved cold flow properties

InactiveUS20070094920A1Improve performanceLiquid carbonaceous fuelsFuel additivesFuel oilCarboxylic acid

The use is described of polymers which contain, in copolymerized form, an α-olefin, a vinyl ester and an ester of an α,β-unsaturated carboxylic acid as an additive for fuel oils and lubricants and in particular as a cold flow improver in fuel oils. In addition, the fuel oils and lubricants additized with these polymers; and also additive packages comprising such polymers are described.

Owner:BASF AG

Article comprising poly(hydroxyalkanoic acid)

Disclosed are oriented films comprising toughened poly(hydroxy-alkanoic acid) resin compositions comprising poly(hydroxyalkanoic acid) and an impact modifier comprising an ethylene copolymer made from monomers (a) ethylene; (b) one or more olefins of the formula CH2═C(R3)CO2R4, where R3 is hydrogen or an alkyl group with 1-6 carbon atoms, such as methyl, and R4 is glycidyl; and optionally (c) one or more olefins of the formula CH2═C(R1)CO2R2, where R1 is hydrogen or an alkyl group with 2-8 carbon atoms and R2 is an alkyl group with 1-8 carbon atoms, such as methyl, ethyl, or butyl. The ethylene copolymer may further be made from carbon monoxide monomers. The compositions may further comprise one or more ethylene / acrylate and / or ethylene / vinyl ester polymers, ionomers, and cationic grafting agents. Also disclosed are packaging materials and containers comprising the oriented films.

Owner:PERFORMANCE MATERIALS NA INC

Elastomer compositions for use in a hydrocarbon resistant hose

InactiveUS20050059764A1Improve impermeabilityGood oil resistanceSynthetic resin layered productsSpecial tyresElastomerPolymer science

A heat tolerant, pressure resistant elastomeric composition comprising a blend of a first ethylene-vinyl ester copolymer and a second copolymer selected from the group consisting of chlorosulfonated polyethylene (CSM), chlorinated polyethylene (CPE), polychloroprene (CR), ethylene-acrylic elastomer (AEM), alkyl-acrylate copolymer (ACM), polyvinyl acetate (PVA), nitrile-butadiene rubber (NBR), hydrogenated nitrile-butadiene rubber (HNBR), and mixtures thereof, a hose manufactured therefrom; and a method for preparing the hose are described.

Owner:FLUID ROUTING SOLUTIONS

Toughened poly(lactic acid) compositions

Toughened poly(lactic acid) resin compositions comprising poly(lactic acid) and an impact modifier comprising an ethylene copolymer made from monomers (a) ethylene; (b) one or more olefins of the formula CH2═C(R1)CO2R2, where R1 is hydrogen or an alkyl group with 2-8 carbon atoms and R2 is an alkyl group with 1-8 carbon atoms, such as methyl, ethyl, or butyl; and (c) one or more olefins of the formula CH2═C(R3)CO2R4, where R3 is hydrogen or an alkyl group with 1-6 carbon atoms, such as methyl, and R4 is glycidyl. The ethylene copolymer may further be made from carbon monoxide monomers. The compositions may further comprise one or more ethylene / acrylate and / or ethylene / vinyl ester polymers, ionomers, and cationic grafting agents.

Owner:PERFORMANCE MATERIALS NA INC

Adhesive and sealant systems

Adhesive and sealant systems based on epoxy resins, polyurethane, silane-terminated polymers, silicones, unsaturated polyester resins, vinyl ester resins, acrylates, polyvinyl acetate, polyvinyl alcohol, polyvinyl ether, ethylene vinyl acetate, ethylene-acrylic acid copolymers, polyvinyl acetates, polystyrene, polyvinyl chloride, styrene-butadiene rubber, chloroprene rubber, nitrile rubber, butyl rubber, polysulfide, polyethylene, polypropylene, fluorinated hydrocarbons, polyamides, saturated polyesters and copolyesters, phenol-formaldehyde resins, cresol- / resorcinol-formaldehyde resins, urea-formaldehyde resins, melamine-formaldehyde resins, polyimides, polybenzimidazoles, polysulfones, which contain 1 wt.% to 15 wt.% of a compacted, hydrophobic pyrogenic silica.

Owner:DEGUSSA AG

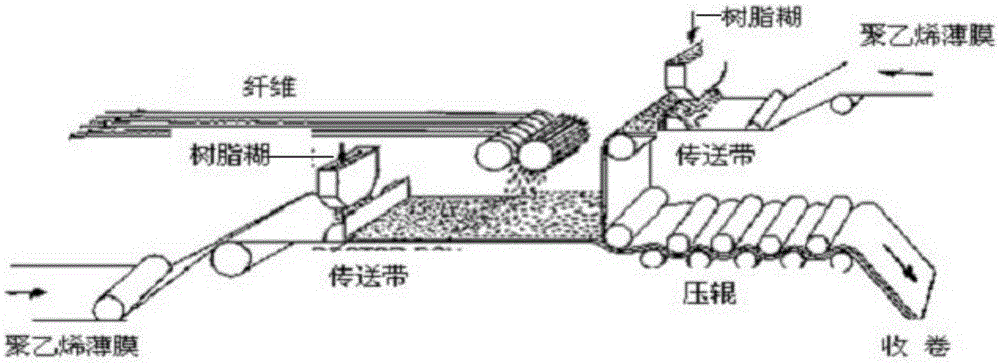

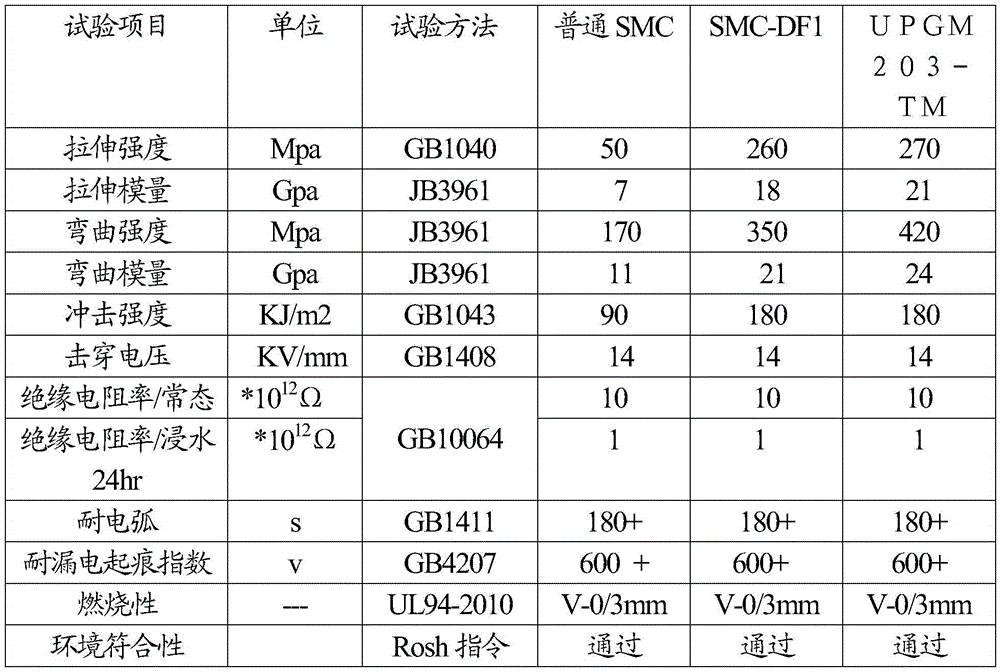

Unsaturated polyester resin fiber reinforced sheet-shape molding compound and preparation method thereof

The invention discloses an unsaturated polyester resin fiber reinforced sheet-shape molding compound, comprising unsaturated polyester resin, a low shrinkage agent, a filler, a curing agent, a thickener, a mold release agent, a reinforcing material, a colorant and an additive. The unsaturated polyester resin is characterized by comprising one or more of o-phenylene resin, m-phenylene resin and vinyl ester resin in mixing; the filler is modified aluminium hydroxide; the reinforcing material is made of one or more selected from the group containing alkali-free chopped glass fiber, alkali-free untwisted continuous glass fiber rove, high silica glass fiber and Kevlar fiber. The molding compound combines light weight, high strength, retardance, corrosion resistance and insulation, has the advantages of high weight percentage of reinforced material, good electrical properties, significantly improved mechanical properties, tensile strength of not less than 100Mpa, bending strength of not less than 300Mpa, impact strength not less than 260 KJ / m<2>, dielectric strength of not less than 12KV / mm, flame retardance of UL94V-0 and product thickness of up to 60mm, and can be used for compression molding of electrical insulation structural parts.

Owner:SICHUAN D&F ELECTRICAL TECH

Toughened poly(hydroxyalkanoic acid) compositions

Disclosed are toughened poly(hydroxyalkanoic acid) resin compositions comprising poly(hydroxyalkanoic acid), such as polylactic acid, and an impact modifier comprising an ethylene copolymer made from monomers (a) ethylene; (b) one or more olefins of the formula CH2═C(R1)CO2R2, where R1 is hydrogen or an alkyl group with 2-8 carbon atoms and R2 is an alkyl group with 1-8 carbon atoms, such as methyl, ethyl, or butyl; and (c) one or more olefins of the formula CH2═C(R3)CO2R4, where R3 is hydrogen or an alkyl group with 1-6 carbon atoms, such as methyl, and R4 is glycidyl. The ethylene copolymer may further be made from carbon monoxide monomers. The compositions may further comprise one or more ethylene / acrylate and / or ethylene / vinyl ester polymers, ionomers, and cationic agents.

Owner:PERFORMANCE MATERIALS NA INC

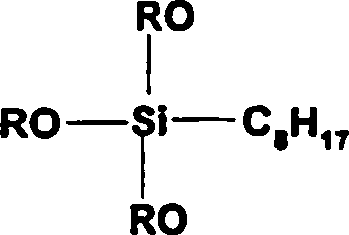

Organosilicon modified tert-fluoro emulsion and preparation of luminescent coating with the emulsion as base material

InactiveCN101463108ATake advantage ofNo pollution in the processLuminescent paintsCarboxylic acidSolvent

The invention discloses an organosilicon modified tert-fluoro emulsion and a preparation method of a luminescent coating which takes the emulsion as a base material. The emulsion takes vinyl ester of tertary carboxylic acid, an organosilicon monomer, an organic fluorine monomer and an acrylic monomer to perform graft copolymerization, the prepared emulsion takes water as a solvent, does not contain organic solvent and is an environment-friendly product, and emulsion particles are of a core-shell structure. The production method of the luminescent coating comprises the following steps: mixing and blending the emulsion with super-efficiency afterglow luminescent powder and other coating additives, the prepared luminescent coating has corrosion prevention and self-cleaning functions, and can be applied to the fields such as building decoration, advertisement signs, factory instruments, airfield runways, road rails, handicraft articles and the like. The coating has the advantages of excellent cost performance ratio, convenient production and construction and easy implementation and popularization.

Owner:NORTHWEST NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com