Method for simultaneously producing 1,3-propylene glycol and 1,2-propylene glycol

A technology of propylene glycol and alkanoyloxy propanol, applied in the production field of propylene glycol, can solve problems such as low selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

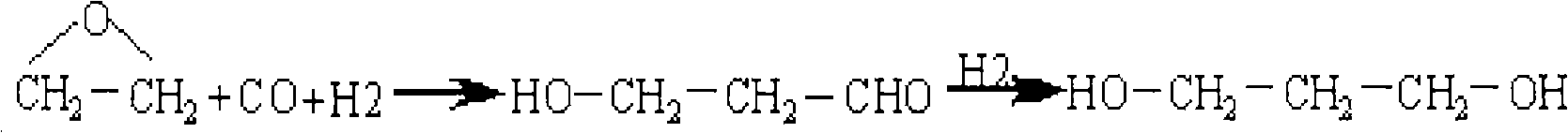

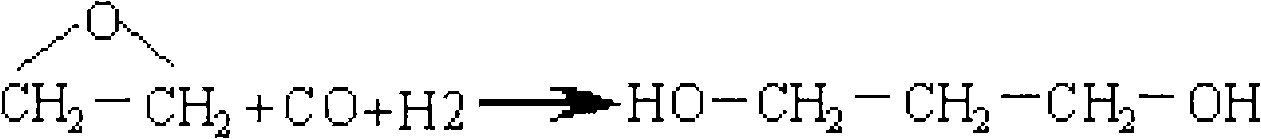

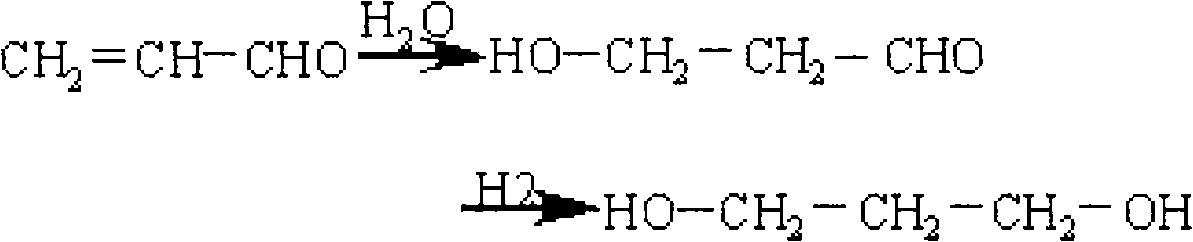

Method used

Image

Examples

Embodiment 1

[0113] Step 1: In a 100ml reactor, add 20ml of vinyl acetate as the raw material of vinyl carboxylate, 20ml of toluene as the solvent, and 0.2g of Co 2 (CO) 8 It is an olefin hydroformylation catalyst, and the reaction kettle is sealed. Replaced with nitrogen 3 times, with CO+H 2 (by mol ratio, CO:H 2=1:1) replacement 3 times, and with CO+H 2 The pressure was charged to 2.0MPa, and the temperature was raised to 115°C reaction temperature. The reactor CO+H is passed through the pressure regulator valve 2 The pressure was adjusted and stabilized at 7.0MPa reaction pressure, the stirring speed was adjusted to 800rmp, and the hydroformylation reaction was started. CO+H consumed by the reaction 2 Indicated by the pressure change of the gas storage tank until the gas is no longer consumed as the end of the reaction. The reaction kettle is lowered to room temperature, discharges unreacted gas, analyzes the reaction product composition with gas chromatography, quantifies by int...

Embodiment 2

[0117] Implement the first step of the present invention, wherein the solvent is changed into 20ml chlorobenzene, and all the other conditions are with embodiment 1. The reaction results are: the conversion rate of vinyl acetate is 98.5%, and the selectivities of 2-acetoxypropionaldehyde and 3-acetoxypropionaldehyde are 42.0% and 57.1%, respectively.

Embodiment 3

[0119] Implement the first step of the present invention, wherein the solvent is changed into 20ml methylcyclohexane, all the other conditions are with embodiment 1. The reaction results showed that the conversion rate of vinyl acetate was 98.0%, and the selectivities of 2-acetoxypropionaldehyde and 3-acetoxypropionaldehyde were 47.0% and 52.2%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com