Patents

Literature

935 results about "Polybutylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polybutylene (polybutene-1, poly(1-butene), PB-1) is a polyolefin or saturated polymer with the chemical formula (C₄H₈)ₙ. It should not be confused with polybutene, a low molecular weight oligomer. Polybutylene is produced by polymerisation of 1-butene using supported Ziegler–Natta catalysts. PB-1 is a high molecular weight, linear, isotactic, and semi-crystalline polymer. PB-1 combines typical characteristics of conventional polyolefins with certain properties of technical polymers.

Composite materials comprising polar polymers and single-wall carbon nanotubes

InactiveUS6936653B2Improve conductivityMaterial nanotechnologyIndividual molecule manipulationPolyesterPolymer science

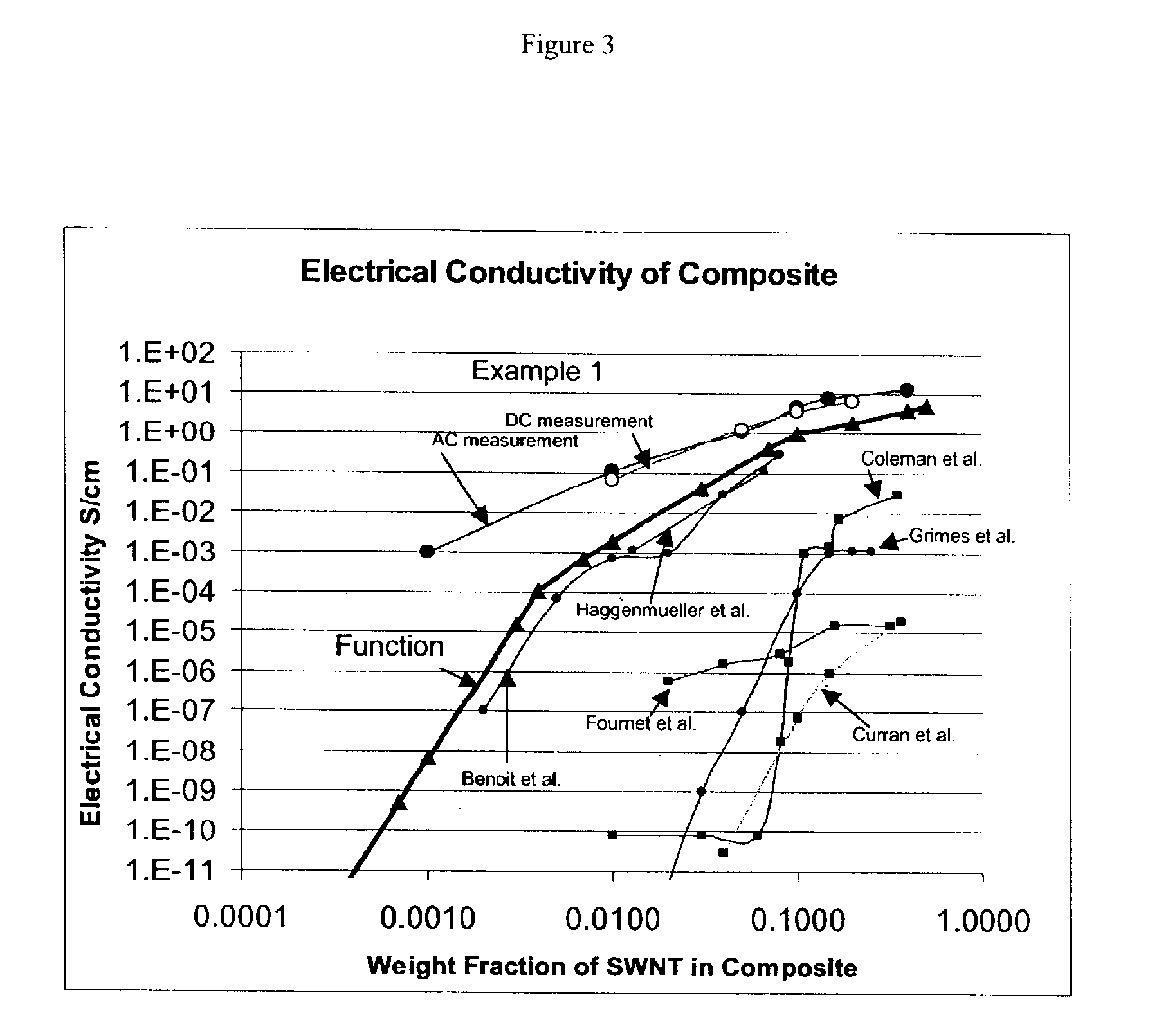

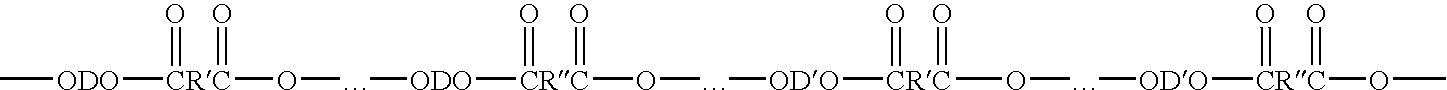

The invention relates to a composite comprising a weight fraction of single-wall carbon nanotubes and at least one polar polymer wherein the composite has an electrical and / or thermal conductivity enhanced over that of the polymer alone. The invention also comprises a method for making this polymer composition. The present application provides composite compositions that, over a wide range of single-wall carbon nanotube loading, have electrical conductivities exceeding those known in the art by more than one order of magnitude. The electrical conductivity enhancement depends on the weight fraction (F) of the single-wall carbon nanotubes in the composite. The electrical conductivity of the composite of this invention is at least 5 Siemens per centimeter (S / cm) at (F) of 0.5 (i.e. where single-wall carbon nanotube loading weight represents half of the total composite weight), at least 1 S / cm at a F of 0.1, at least 1×10−4 S / cm at (F) of 0.004, at least 6×10−9 S / cm at (F) of 0.001 and at least 3×10−16 S / cm (F) plus the intrinsic conductivity of the polymer matrix material at of 0.0001. The thermal conductivity enhancement is in excess of 1 Watt / m-° K. The polar polymer can be polycarbonate, poly(acrylic acid), poly(acrylic acid), poly(methacrylic acid), polyoxide, polysulfide, polysulfone, polyamides, polyester, polyurethane, polyimide, poly(vinyl acetate), poly(vinyl alcohol), poly(vinyl chloride), poly(vinyl pyridine), poly(vinyl pyrrolidone), copolymers thereof and combinations thereof. The composite can further comprise a nonpolar polymer, such as, a polyolefin polymer, polyethylene, polypropylene, polybutene, polyisobutene, polyisoprene, polystyrene, copolymers thereof and combinations thereof.

Owner:SAMSUNG ELECTRONICS CO LTD

Ternary polymer blend, the film containing it, and the easy-to-open package made therewith

InactiveUS6476137B1Easy opening strengthImprove the immunitySynthetic resin layered productsPackagingPolymer sciencePolybutylene

Object of the present invention is an extrudable blend comprising (i) a copolymer of ethylene and acrylic acid or methacrylic acid (ii) a modified EVA copolymer and (iii) a polybutylene. Included are the films comprising said blend in the sealant layer or in a layer directly adhered to the sealant layer, and the easy-to-open packages obtained therefrom.

Owner:CRYOVAC INC

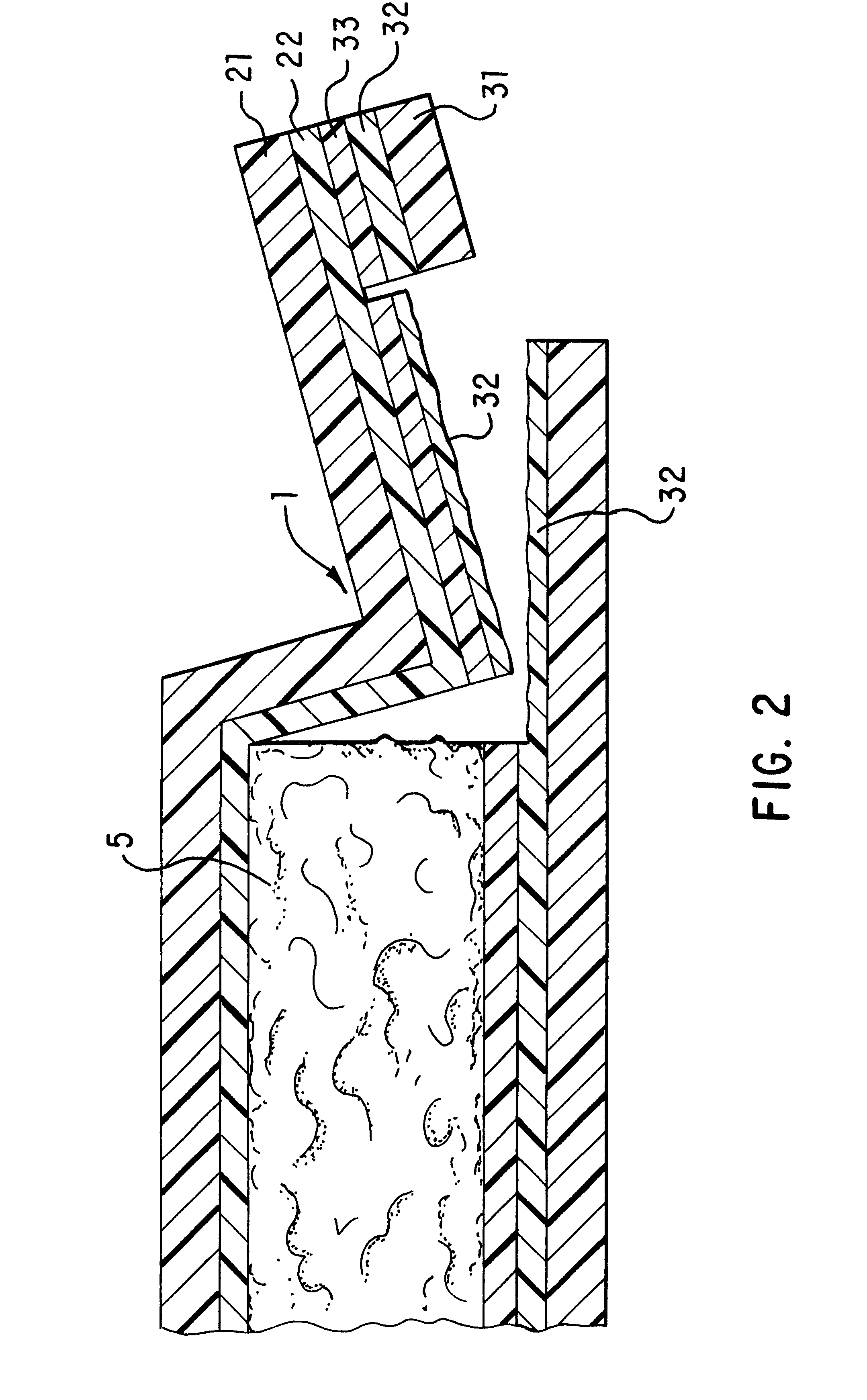

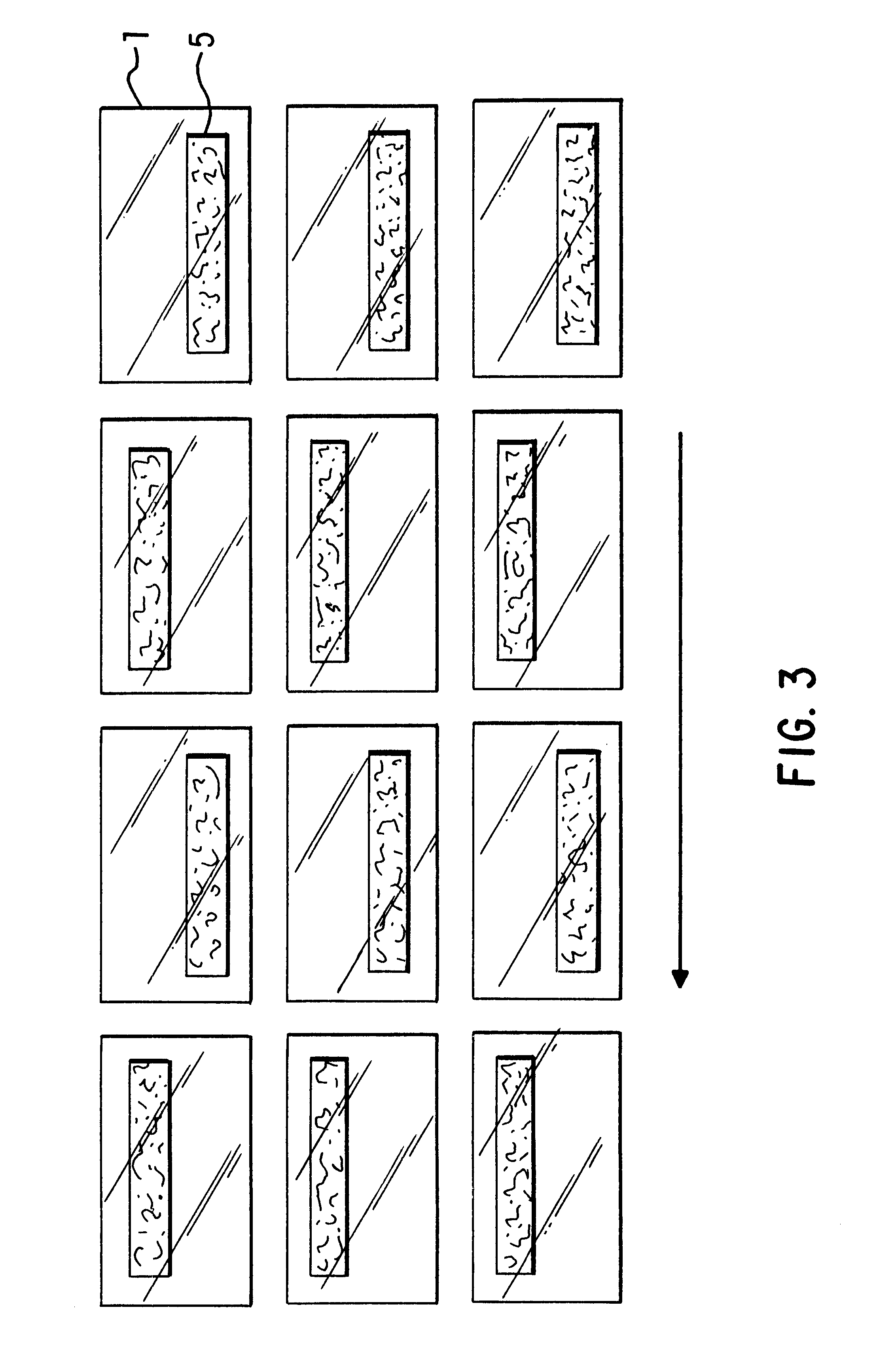

Scaffold for tissue engineering cartilage having outer surface layers of copolymer and ceramic material

InactiveUS6692761B2High mechanical strengthEfficient transportBiocideJoint implantsPolyesterPolytetramethylene terephthalate

A biodegradable, biocompatible porous matrix as a scaffold for tissue engineering cartilage is formed of a copolymer of a polyalkylene glycol and an aromatic polyester such as a polyethylene glycol / polybutylene terephtalate copolymer. A ceramic coating such as a calcium phosphate coating may be provided on the scaffold by soaking the scaffold in a solution containing calcium and phosphate ions. A composite scaffold which is preferably a two-layer system may be formed having an outer surface of a layer of the porous matrix formed of the copolymer, and an outer surface of a layer of a ceramic material. The composite scaffold may be prepared by casting the copolymer on top of the ceramic material in a mould. Cells are preferably seeded on the scaffold prior to implanting, and the scaffold may contain bioactive agents that are released on degradation of the scaffold in vivo.

Owner:OCTOPLUS SCI

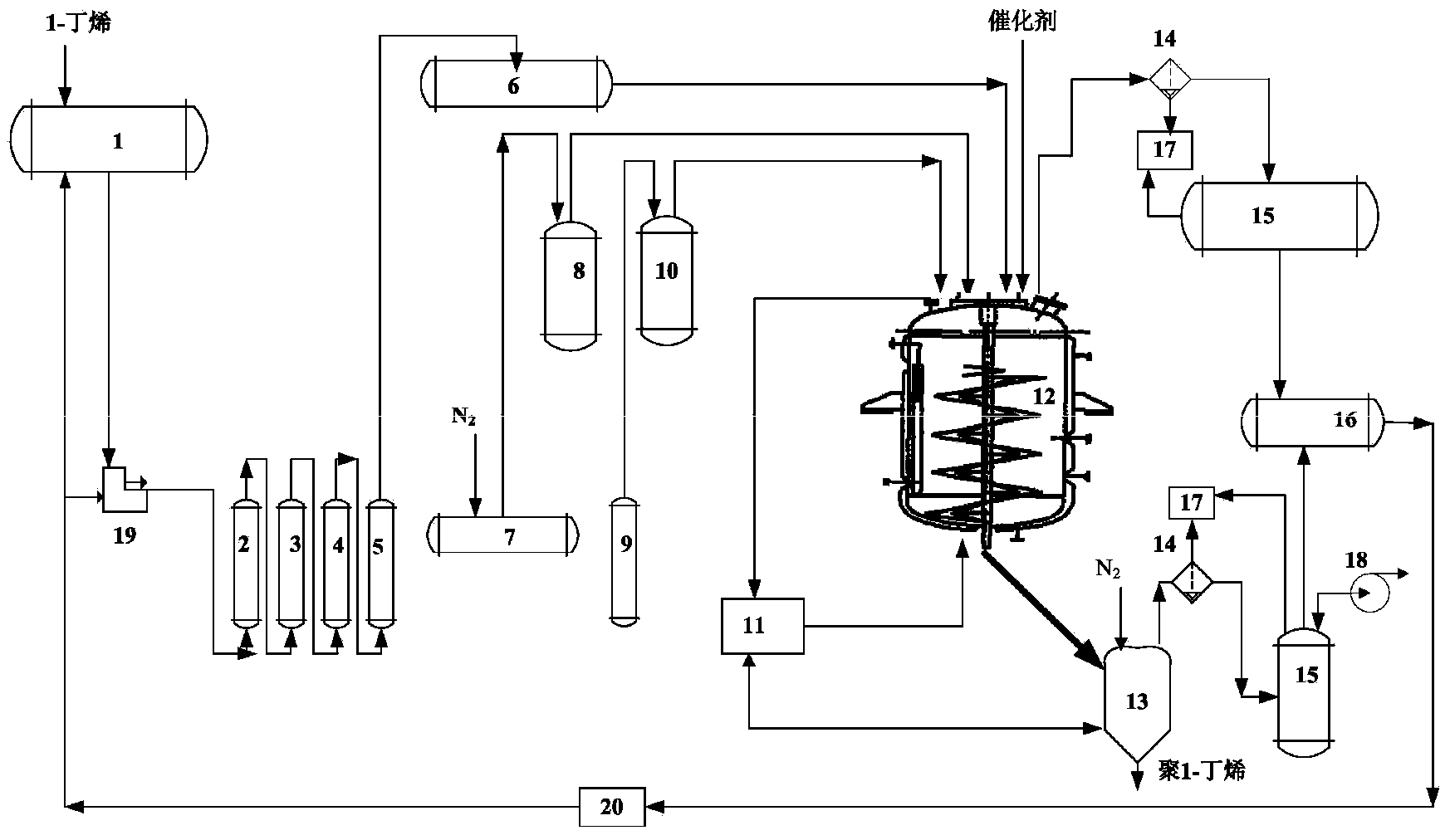

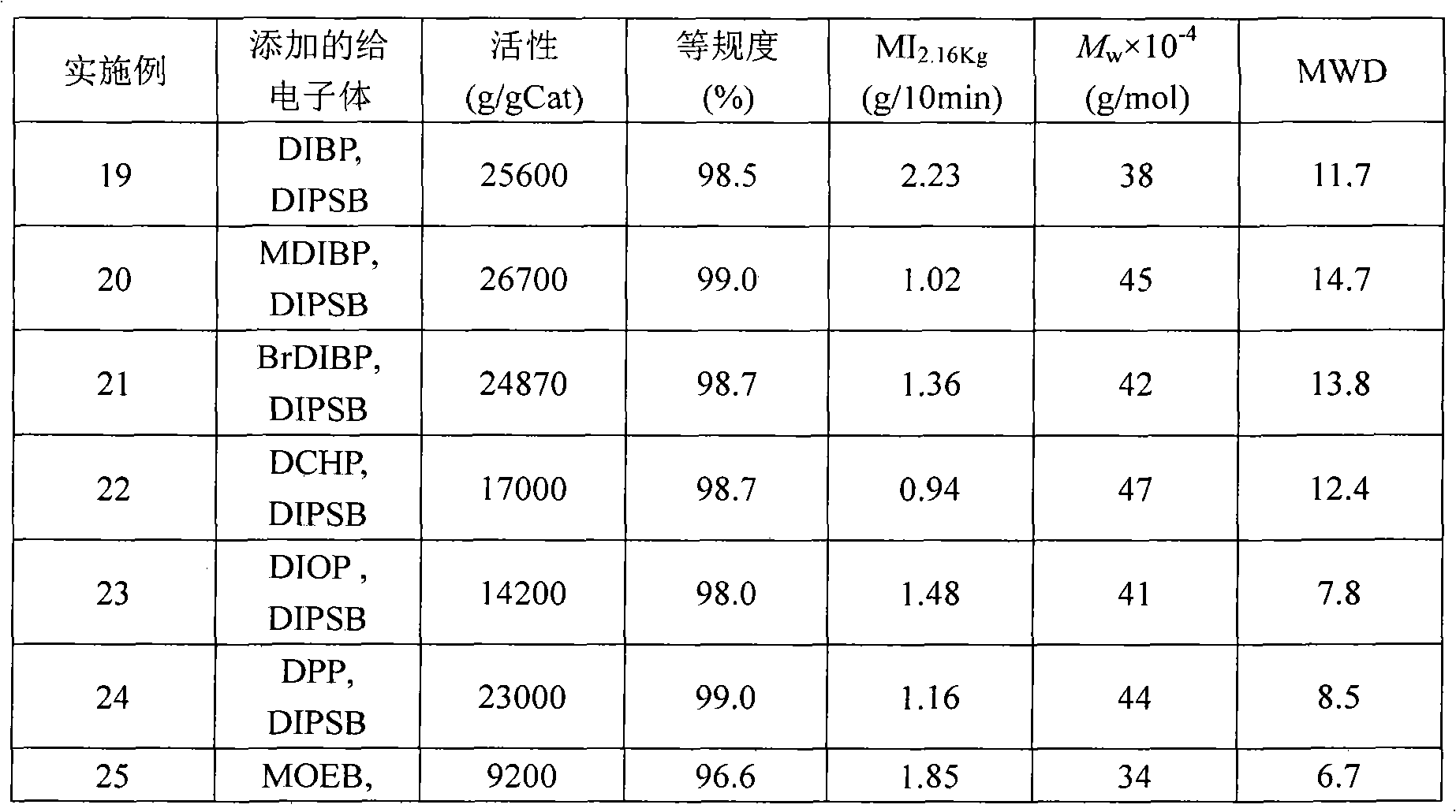

Bulk depositing synthesis process of isotactic polybutylene-1

The present invention is bulk depositing synthesis process of isotactic polybutylene-1, and belongs to the field of polymer technology. The powdered isotactic polybutylene-1 product is obtained through bulk depositing polymerization of butylene-1 as the monomer and reactant medium at 0-70 deg.c in the presence of supported titanium catalyst, and the subsequent flash evaporation to eliminate unpolymerized monomer. The catalyst system may have organic aluminum AlR3 as co-catalyst, added electron donor compound, and hydrogen as molecular weight regulator. The polymerization reaction is performed in a polymerizing kettle with stirring screw belt. The present invention has simple technological process, high efficiency and low cost, and the prepared isotactic polybutylene-1 has high stereoregularity degree, crystallization degree higher than 60 %, and smelting point of 127.5 deg.c.

Owner:SHANDONG ORIENT HONGYE CHEM +1

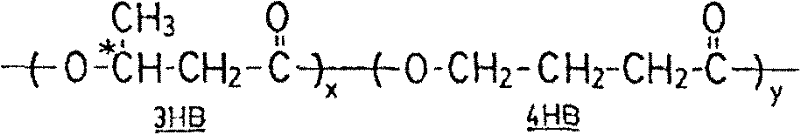

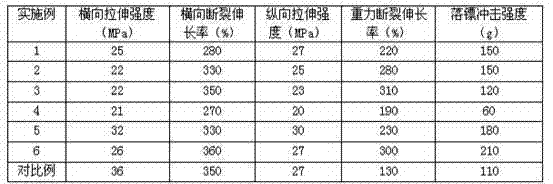

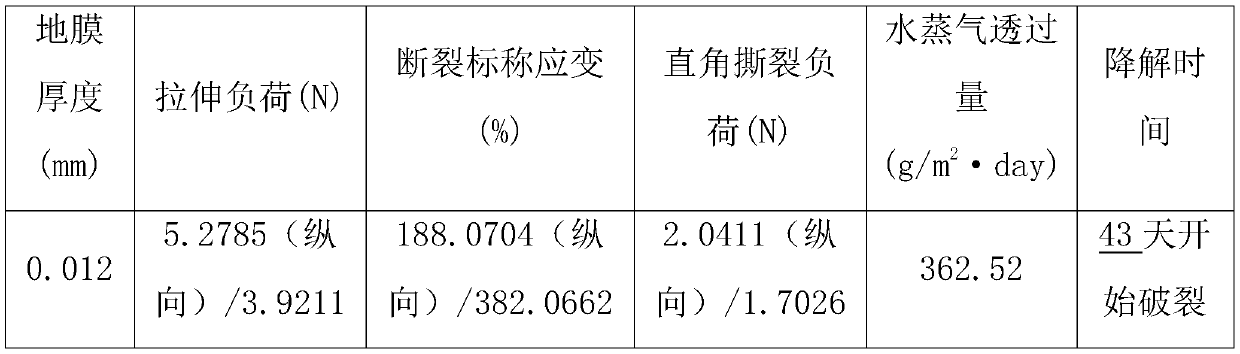

Biological degradable film and laminated material

ActiveCN102675839AImprove mechanical propertiesHigh elongationSynthetic resin layered productsNon-woven fabricsMicroorganismPolymer science

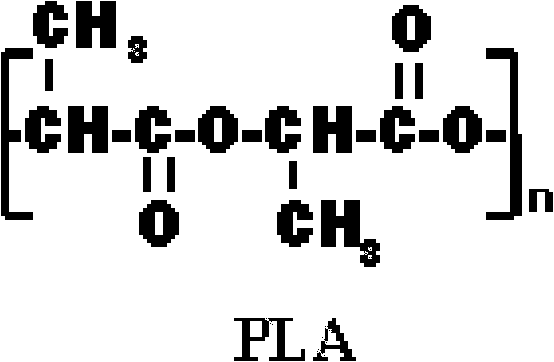

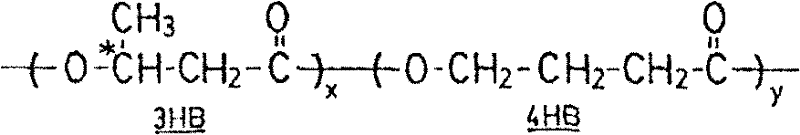

The invention discloses a biological degradable film, enhancement type biological degradable fabrics and a laminate material, and the enhancement type biological degradable fabrics and the laminate material are made of the laminated biological degradable film. The biological degradable film mainly comprises polybutylene adipate terephthalate (PBAT) or poly butylenes succinate (PBS) or a mixture of PBAT and PBS, and polylactic acid (PLA) and other degradable macromolecular polymers such as PBSA, PCL, PCL-BS and PHA, and accordingly the PLA, and a novel mixture of PLA and polyhydrooxyalkonates (PHAs), or a mixture of PLA, PBAT and PBS, or a mixture of PLA, PHAs, PBAT and PBS or other degradable macromolecular polymers are made. The enhancement type biological degradable fabrics and the laminate material have strong biological degradable performances in the environment containing microorganisms and can have good quality guarantee period, strength, flexibility and toughness.

Owner:U S PACIFIC NONWOVENS IND

Filler masterbatch used for increasing polarity of polypropylene and preparation method thereof

The invention discloses a filler masterbatch used for increasing the polarity of polypropylene and a preparation method thereof. The filler masterbatch is characterized by comprising the following components by weight percent: 50%-79% of inorganic filler, 15%-30% of carrier, 5%-17% of polar additive and 1%-3% of processing additive; and the polar additive is one or more of thermoplastic polyurethane resin (TPU), maleic anhydride grafted polypropylene, epoxy resin, ethylene acrylate, ethylene vinyl acetate, polyether amine and polybutylene polyol. In the preparation method of the invention, the added carrier can not improve the polarity of polypropylene, the inorganic filler is used to increase the rigidity of the material; the key is to introduce the polar additive with high unipolarity, thus the filler masterbatch used for increasing the polarity of polypropylene can be prepared; when the filler masterbatch is combined with the polypropylene material for production, the surface polarity of the filled and modified polypropylene material can be increased, the surface energy of the filled and modified polypropylene can be reduced, the dimension stability can be increased, the modified polypropylene material can have good paint adhesion and the material can be used to form exterior trimming parts such as bumpers and interior trimming parts such instrument panels.

Owner:KINGFA SCI & TECH CO LTD +3

Full-biodegradable film and preparation method thereof

The invention relates to a composition of a high-tenacity full-biodegradable film and a preparation method thereof. The film is prepared from polylactic acid (PLA), poly propylene carbonate (PPC), polybutylene adipate terephthalate (PBAT) and a heat stabilizer. Blending modification sections are prepared by adopting a twin-screw extruder, blow molding is carried out by adopting a single-screw extruder, the prepared film has excellent tenacity and full biodegradable performance, and meanwhile the cost is low, so that the film is an ideal substitute for a current non-degradable film packing material.

Owner:NANTONG LONGDA BIO TECH NEW MATERIALS CO LTD

Uniformly tacky filter media

InactiveUS6136058AImprove filtration efficiencyImprove filtering effectDispersed particle filtrationOther chemical processesFiberglass meshFiber

A filter medium, a tackified binder composition and a method for providing a uniformly distributed tackifier on the glass fibers of an unwoven fiberglass web for improving filtration capacity and efficiency. An emulsified tackifier, such as polybutene, is mixed with a conventional binder composition and applied to the fibers before they are expanded into the web. The binder is cured in the conventional manner and the tackifier migrates to the surface on each fiber to enhance particle adsorption.

Owner:SUPERIOR FIBERS

Process for making polybutylene terephthalate (PBT) from polyethylene terephthalate (PET)

The invention relates to a process for making modified polybutylene terephththalate random copolymers from a polyethylene terephthalate component. The invention relates to a three step process in which a diol component selected from the group consisting of ethylene glycol, propylene glycol, and combinations thereof reacts with a polyethylene terephthalate component under conditions sufficient to depolymerize the polyethylene terephthalate component into a first molten mixture; and where the first molten mixture is combined with 1,4-butanediol under conditions that create a second molten mixture that is subsequently placed under subatmospheric conditions that produce the modified polybutylene terephthalate random copolymers. The invention also relates to compositions made from the process.

Owner:SHPP GLOBAL TECH BV

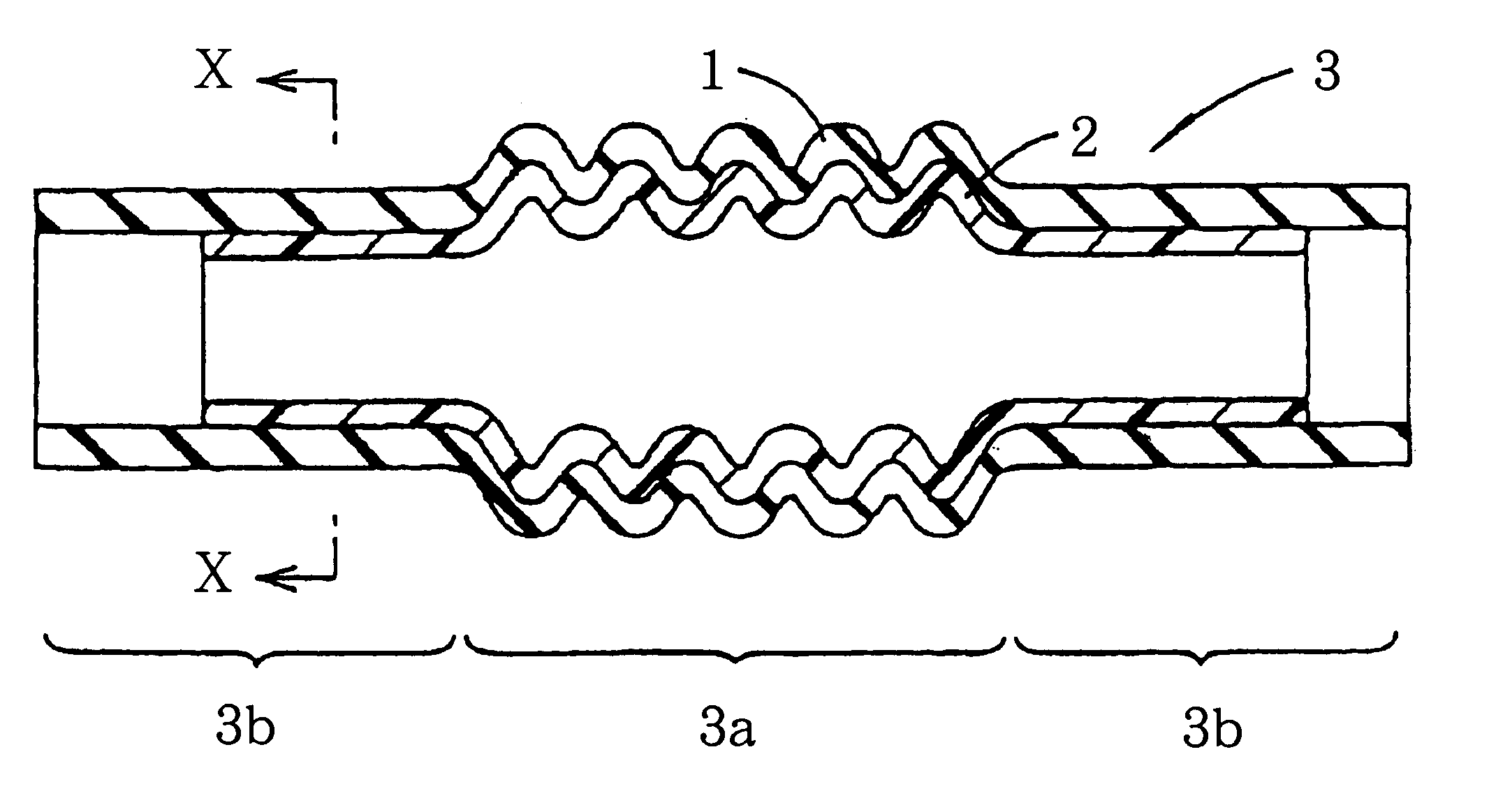

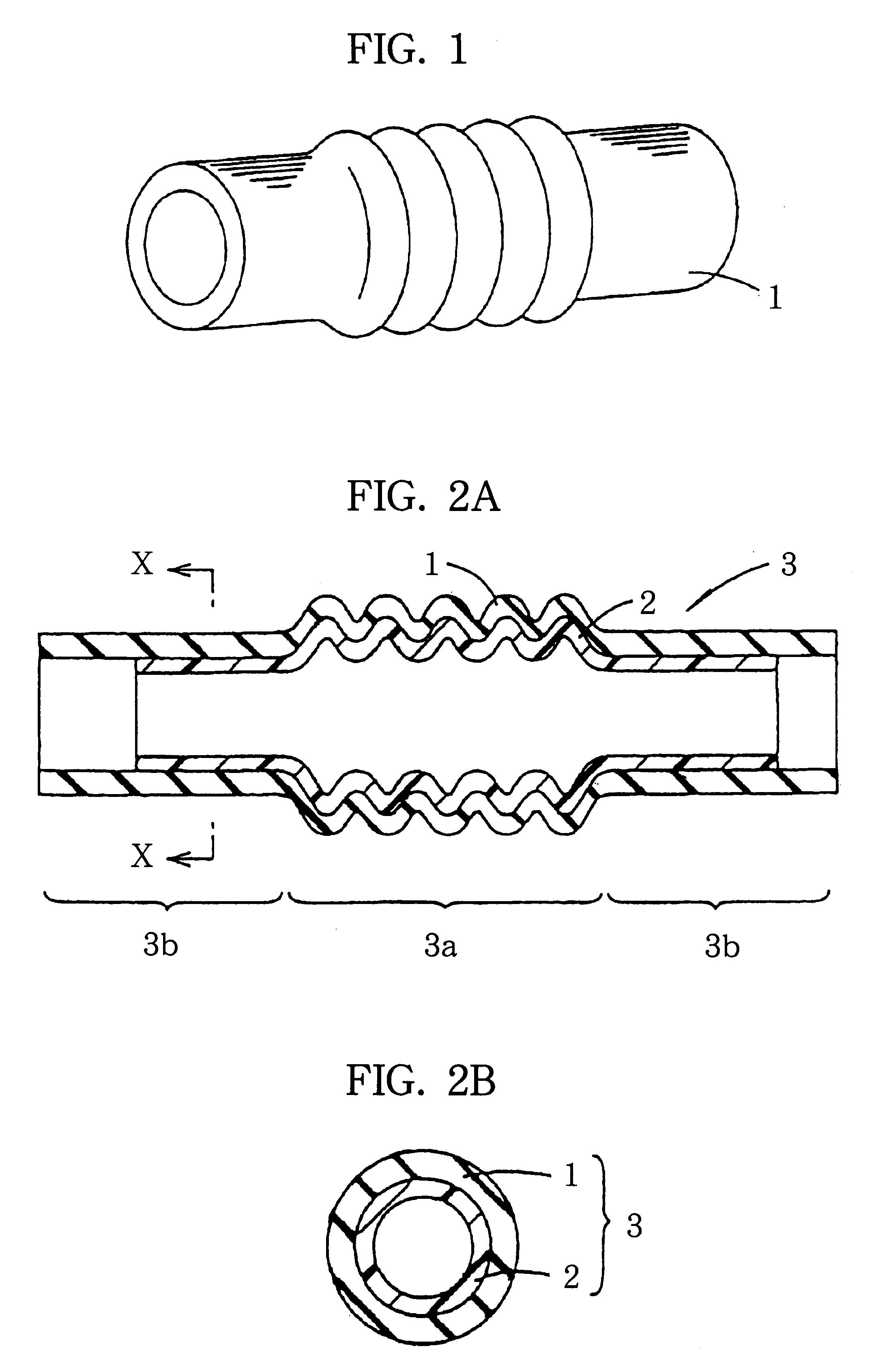

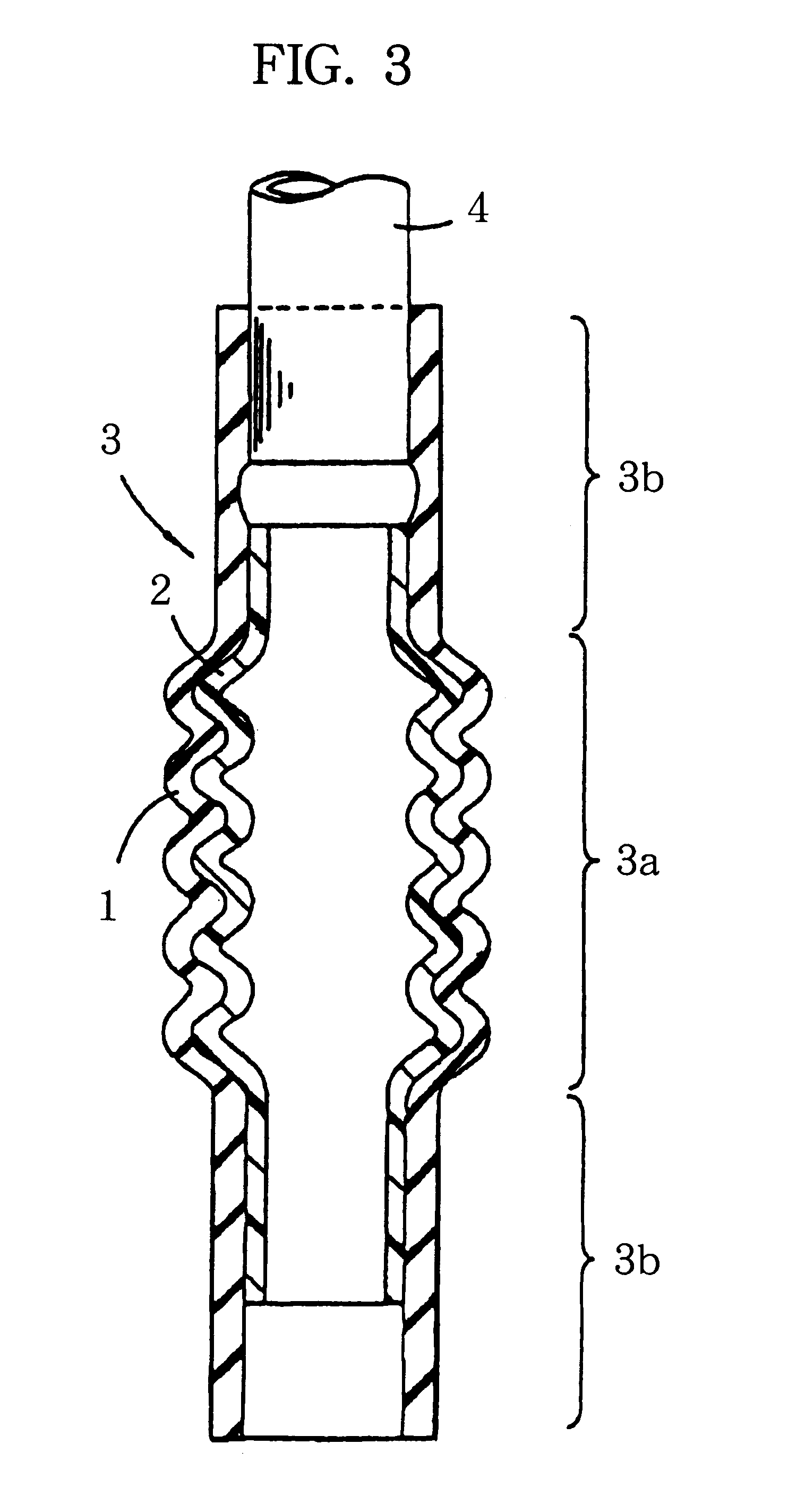

Fuel hose

InactiveUS6279615B1Excellent ozone resistanceLow melting pointHeat exhanger conduitsFlexible pipesAlcoholPolybutylene

A fuel hose comprises a single layered or multi-layered tubular rubber body and a thin film resin layer formed on the inner circumferential surface of the innermost layer of the tubular rubber body. The resin layer is formed of a resin such that an amount of permeation of 10% ethanol-mixed gasoline is 2 mg / cm2 / day (at 60° C.) or less when the thickness of the resin layer is 0.1 mm. A preferred example of such a resin is EVOH with an ethylene content of from 35 to 50 mol % or polybutylene aromatic ester. The fuel hose has necessary flexibility and shows excellent impermeability even to an alcohol-mixed gasoline.

Owner:SUMITOMO RIKO CO LTD

Material capable of completely biodegrading and preparation method thereof

The invention relates to a material capable of completely biodegrading, containing the following parts by weight:100 of polyester resin, 5-100 of polylactic resin and the multipolymer thereof, 10-80 of compounding converted starch, 10-60 of inorganic fillers and 0.1-0.9 of resin acceptor, wherein the polyester resin is at least one of polybutylene succinate resin, polybutylene adipate resin and the multipolymer thereof. The invention also provides a preparation method of the material. The material capable of completely biodegrading can combine the advantages of each component and has high intensity, modules, elongation at break and toughness, good heat resistance, and the like, thereby meeting the property requirements of a plurality of plastic products in the market and in particular products, such as non-returnable containers, mess kits, agricultural films, and the like, which cause serious white pollution, retaining the complete biodegradability of the material and reducing the production cost under the precondition of no influence on the property requirement.

Owner:深圳市未名北科环境材料有限公司 +1

Laundry detergent compositions comprising amphiphilic graft polymers based on polyalkylene oxides and vinyl esters

InactiveUS20090005288A1Negatively impacting general cleaning capabilityLower surfactant levelOrganic detergent compounding agentsDetergent solventsOrganic solventPolybutylene

A laundry detergent composition comprising a graft copolymer of polyethylene, polypropylene or polybutylene oxide with vinyl acetate in a weight ratio of from about 1:0.2 to about 1:10; from about 0.2% to about 8% of organic solvent; and from about 2% to about 20% of a surfactant system; wherein said detergent composition is in a form selected from: liquid; gel; and combinations thereof.

Owner:THE PROCTER & GAMBLE COMPANY

Electrode and preparation method therefor

ActiveCN107437622AImprove the high conductivity at room temperatureHigh strengthCell electrodesSecondary cellsLow-density polyethyleneEpoxy

The invention provides an electrode and a preparation method therefor. The electrode comprises a current collector and an active material layer arranged on the current collector; the electrode also comprises a coating layer arranged between the current collector and the active material layer; the coating layer comprises a polymer substrate and a conductive agent; the polymer substrate is selected from one or more of low-density polyethylene, high-density polyethylene, epoxy resin, polyvinylidene fluoride, an ethylene-ethyl acrylate copolymer, an ethylene-vinyl acetate copolymer, polybutylene, cellulose acetate and polyamide; and the conductive agent is selected from one or more of acanthosphere-shaped Ni powder, acanthosphere-shaped Cu powder, acanthosphere Al powder and acanthosphere-shaped tungsten carbide. The electrode has the advantages of low normal-temperature resistor and high PTC strength, so that improvement of safety performance of a lithium ion battery can be facilitated.

Owner:CONTEMPORARY AMPEREX TECH CO

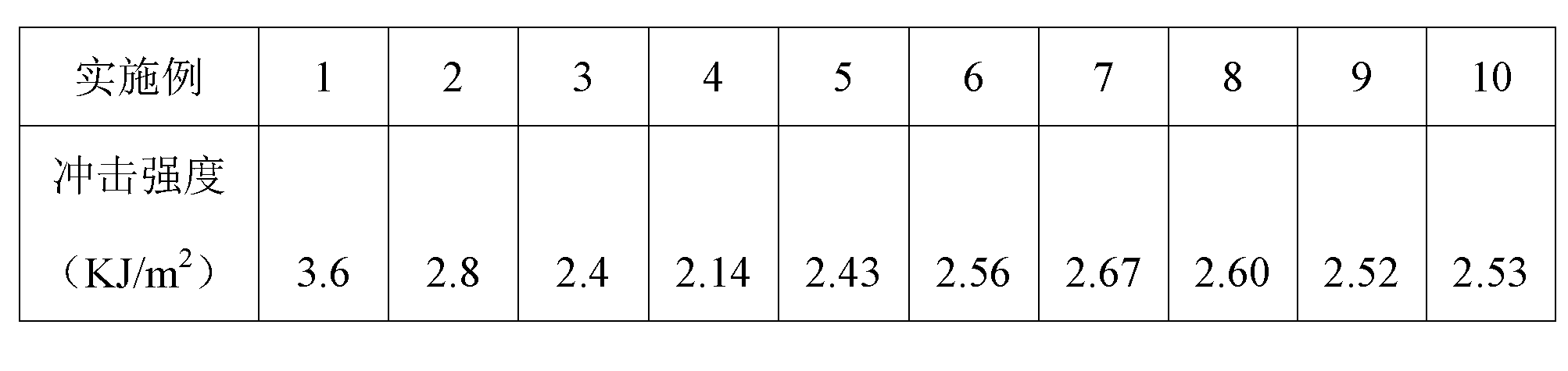

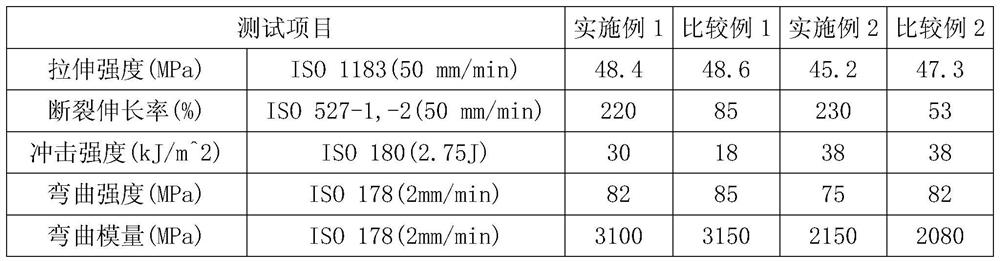

High-shock resistance polypropylene/polybutylene composite material as well as preparation method and purposes thereof

Owner:QINGDAO UNIV OF SCI & TECH

Controllable fully biodegradable mulching film and preparation method thereof

InactiveCN110330773AHigh water vapor barrierHigh tensile strengthClimate change adaptationPlant protective coveringsPolymer sciencePolybutylene

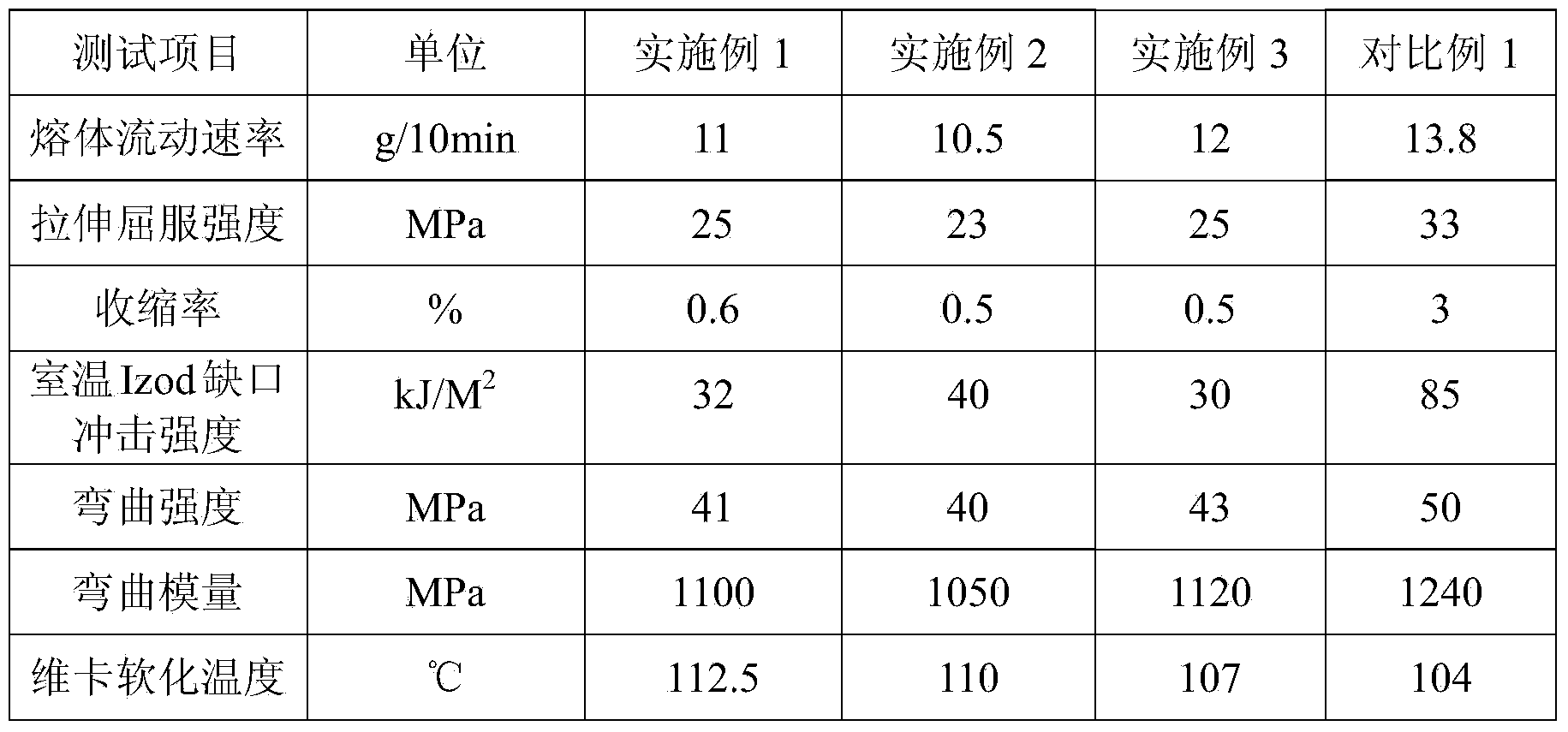

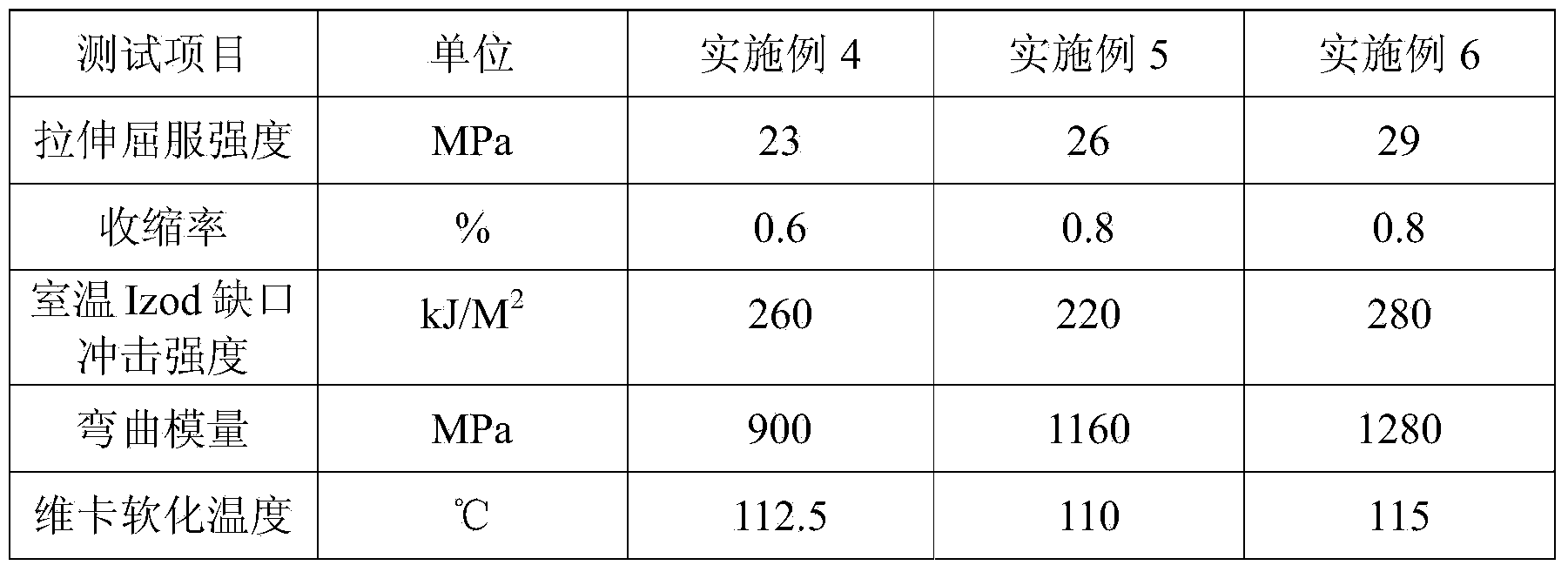

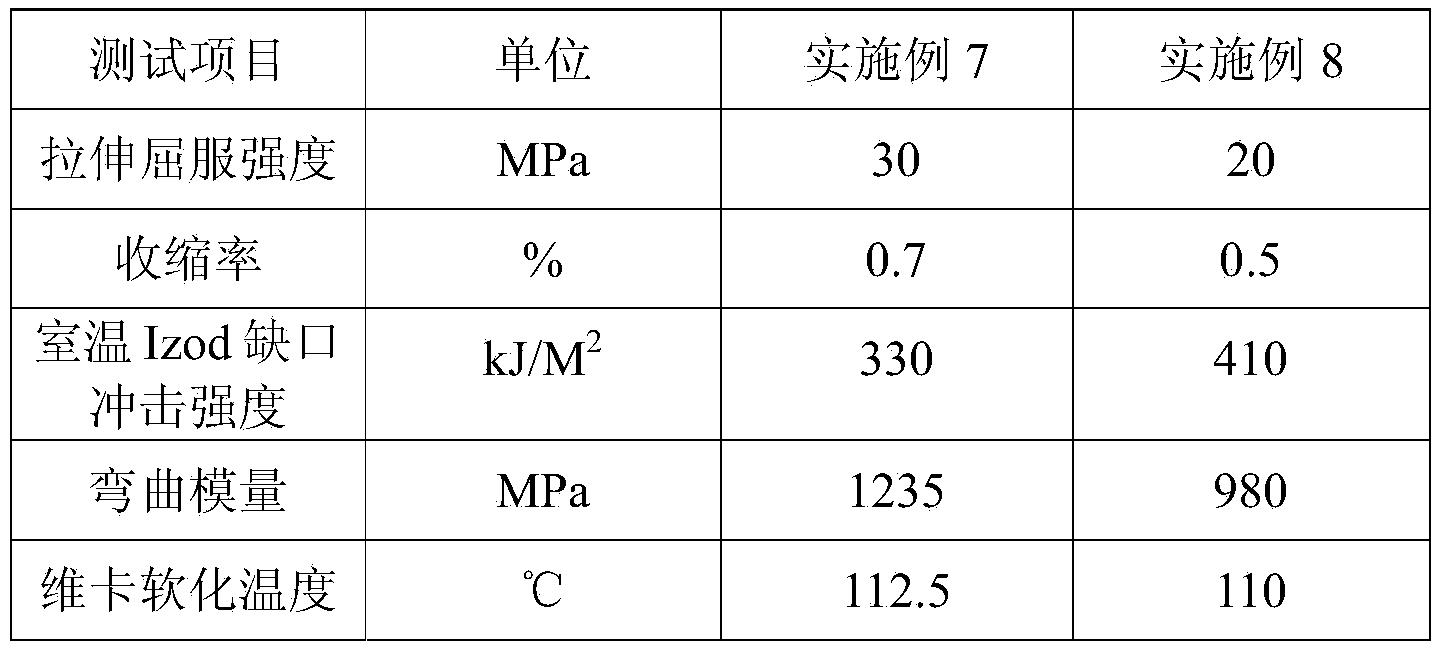

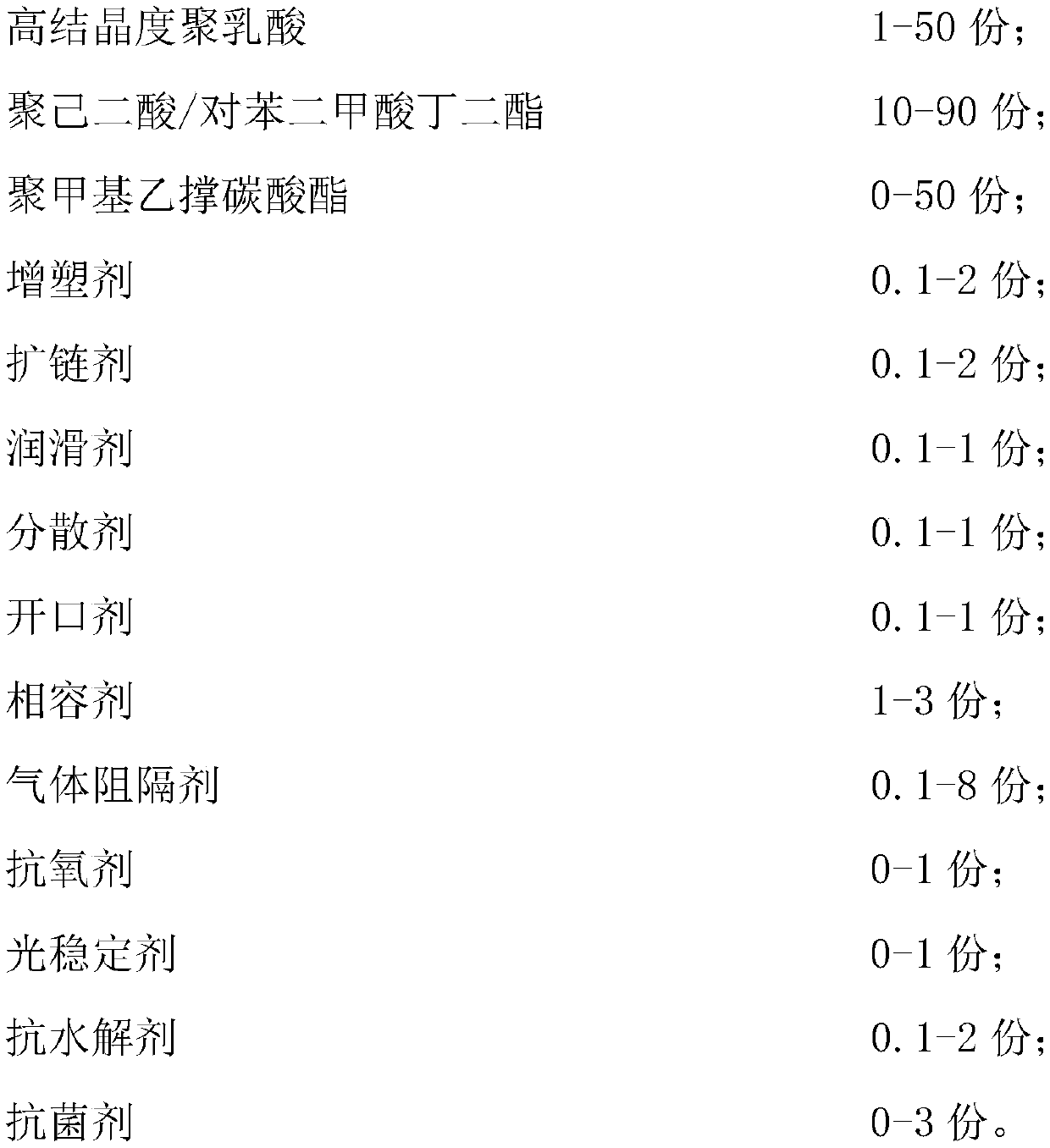

The invention belongs to the technical fields of biodegradable material modification and application, and relates to a controllable fully biodegradable mulching film and a preparation method thereof.The controllable fully biodegradable mulching film comprises the following raw materials in parts by weight: 1-50 parts of high-crystallinity polylactic acid, 10-90 parts of polybutylene adipate / butylene terephthalate, 0-50 parts of poly propylene carbonate, 0.1-2 parts of a plasticizer, 0.1-2 parts of a chain extender, 0.1-1 part of a lubricant, 0.1-1 part of a dispersant, 0.1-1 part of an opening agent, 1-3 parts of a compatibilizer, 0.1-8 parts of a gas barrier, 0-1 part of an antioxidant, 0-1 part of a light stabilizer, 0.1-2 parts of an anti-hydrolysis agent and 0-3 parts of an antibacterial agent. The raw materials are pretreated and uniformly mixed, the controllable fully biodegradable mulching film is obtained by extrusion and blow molding, and the thickness of the mulching film is0.005 to 0.020 mm. The fully biodegradable mulching film provided by the invention has good mechanical properties, excellent heat preservation and moisture retention performance, and can be completely degraded by itself; the mulching film degradation rate can be regulated according to the 'mulching film function period' of different crop mulching films in different regions to meet the needs of different crops in different regions.

Owner:深圳利峰达科技发展有限公司

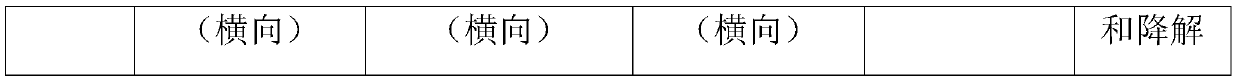

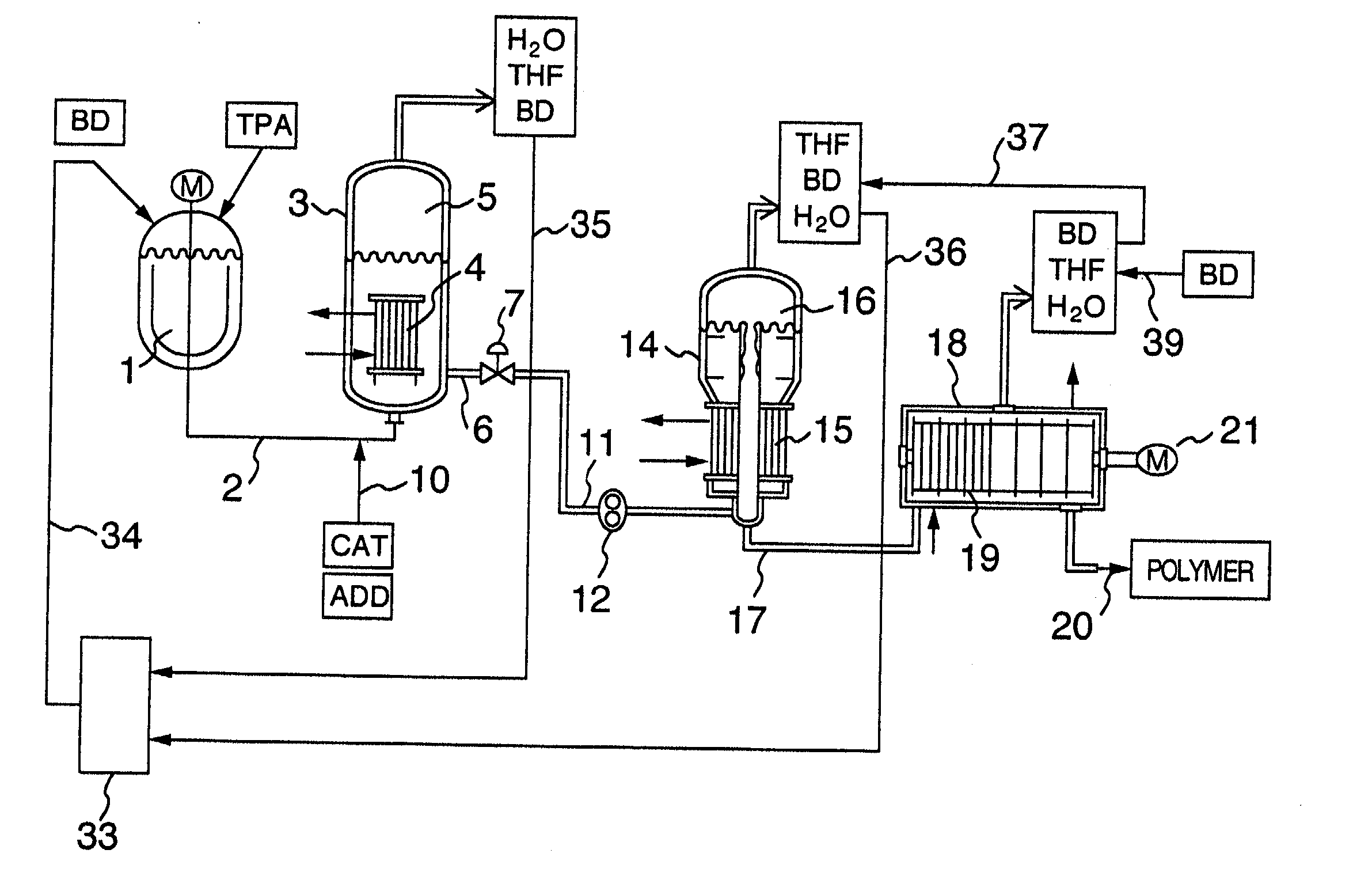

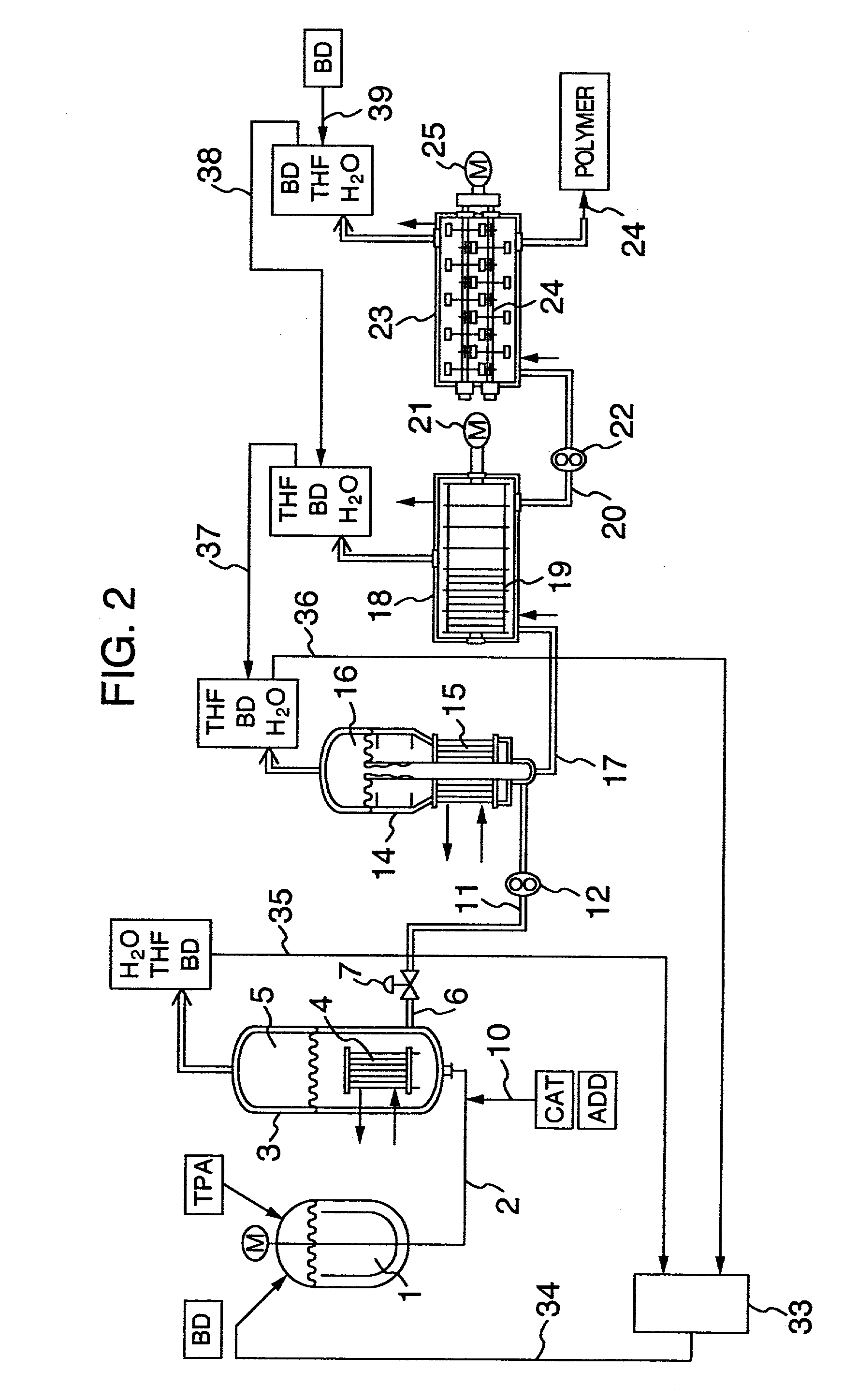

Process for continuously producing polybutylene terephthalate

InactiveUS20020128399A1Improve effectivelyGood molding effectChemical/physical/physico-chemical stationary reactorsLiquid-gas reaction processesPolytetramethylene terephthalatePolybutylene

Polybutylene terephthalate having good heat stability and excellent hydrolysis resistance is continuously produced in a series of a first reactor for reacting an aromatic dicarboxylic acid comprising terephthalic acid as a main ingredient or a derivative thereof with a glycol comprising 1,4-butanediol as a main ingredient, thereby producing an oligomer with an average degree of polymerization of 2.2 to 5, a second reactor for polycondensating the oligomer from the first reactor, thereby preparing a low polymerization product with an average degree of polymerization of 25 to 40, and a third reactor for further polycondensating the low polymerization product from the second reactor, thereby producing a high molecular weight polyester with an average degree of polymerization of 70 to 130, or followed by a fourth reactor for further polycondensing the polyester from the third reactor to an average degree of polymerization of 150 to 200, thereby producing a high molecular weight polyester. Another third reactor or a plurality of third reactors can be provided in parallel to the third reactor, thereby producing different kinds of polybutylene phthalate with different degrees of polymerization from that produced in the main line of the third and fourth reactors or adjusting operating conditions of each of a plurality of the third reactors to increase kinds, precise quality.

Owner:HITACHI LTD

Ultra quick quenching oil and preparation method thereof

InactiveCN102212662AFast coolingFast medium temperature cooling speedQuenching agentsPolybutyleneAntioxidant

The invention relates to ultra quick quenching oil and a preparation method thereof. The ultra quick quenching oil comprises the following raw materials in percentage by weight: 80 to 97 percent of refined mineral oil, 1 to 10 percent of cooling catalyst, 1 to 5 percent of antioxidant and 1 to 6 percent of anionic surfactant. The kinematic viscosity of the refined mineral oil at the temperature of 40 DEG C is 6 to 9 mm<2> / s; the cooling catalyst is a mixture of oily phenolic resin and polybutylene; the antioxidant is alkylated diphenylamine; and the anionic surfactant is petroleum sodium sulfonate. The preparation method of the ultra quick quenching oil is simple and convenient; the obtained quenching oil has the advantages of ultra high cooling speed, good thermal oxidation stability, long service life and continuous and stable property retention; little peculiar smell, smog and carbon deposit are produced, and the take-out consumption of a workpiece is low; and after the workpiece is quenched by adopting the quenching oil, the workpiece has the advantages of high and uniform surface hardness, deep quenching layer, low deformation, metallographic structure, good mechanical property and good brightness, the surface of the workpiece does not become black, and the workpiece is easily cleaned.

Owner:上海德润宝特种润滑剂有限公司

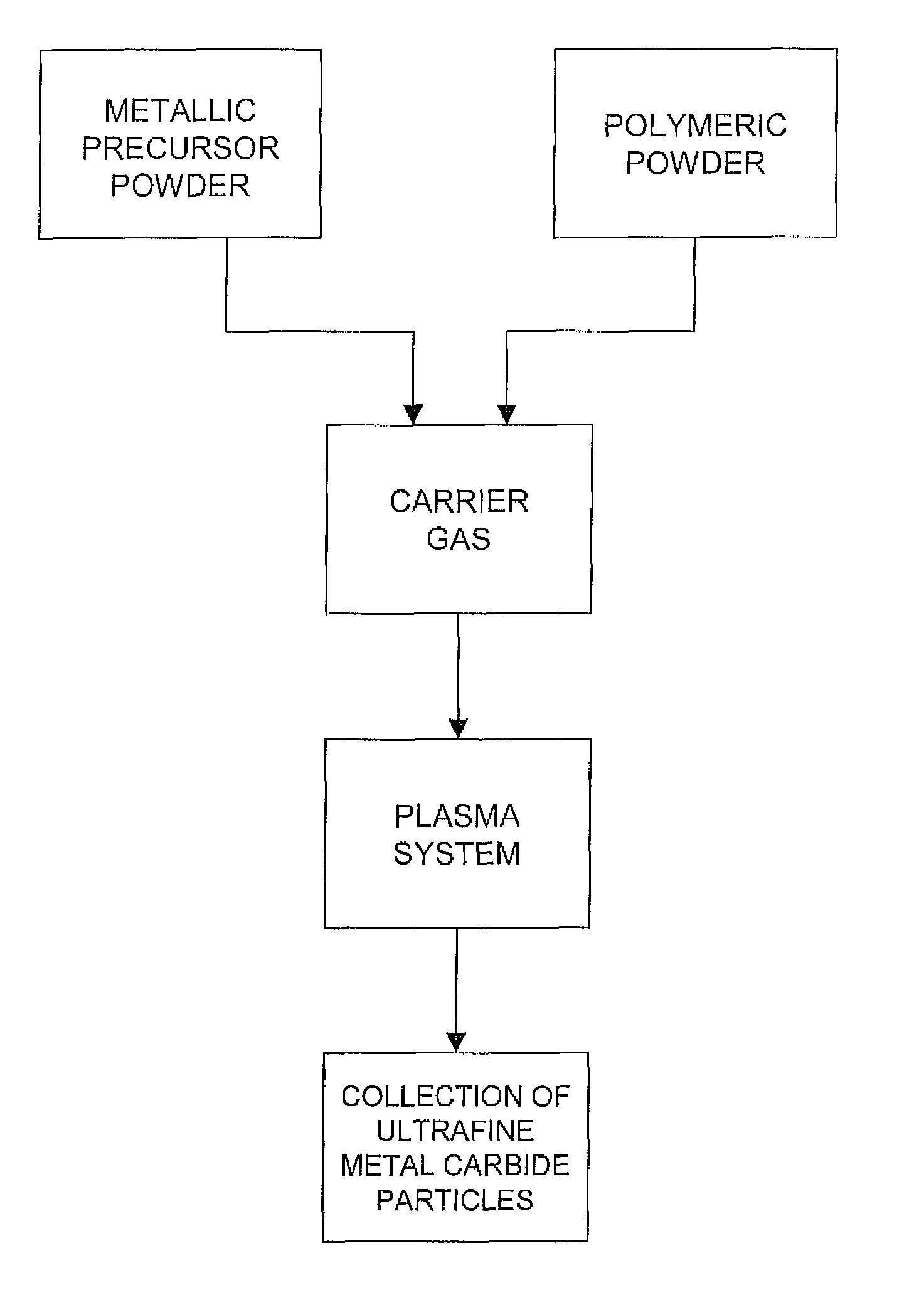

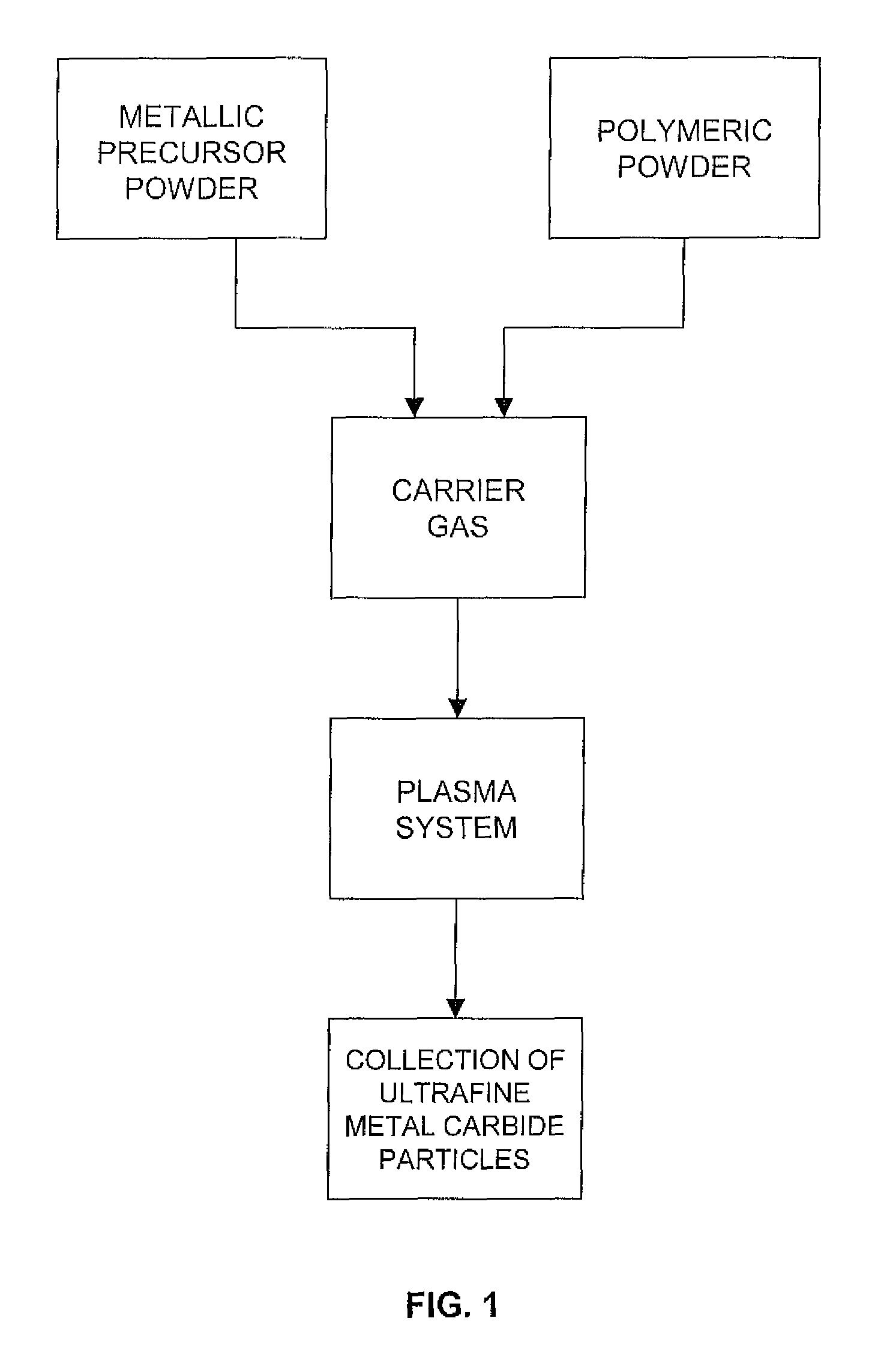

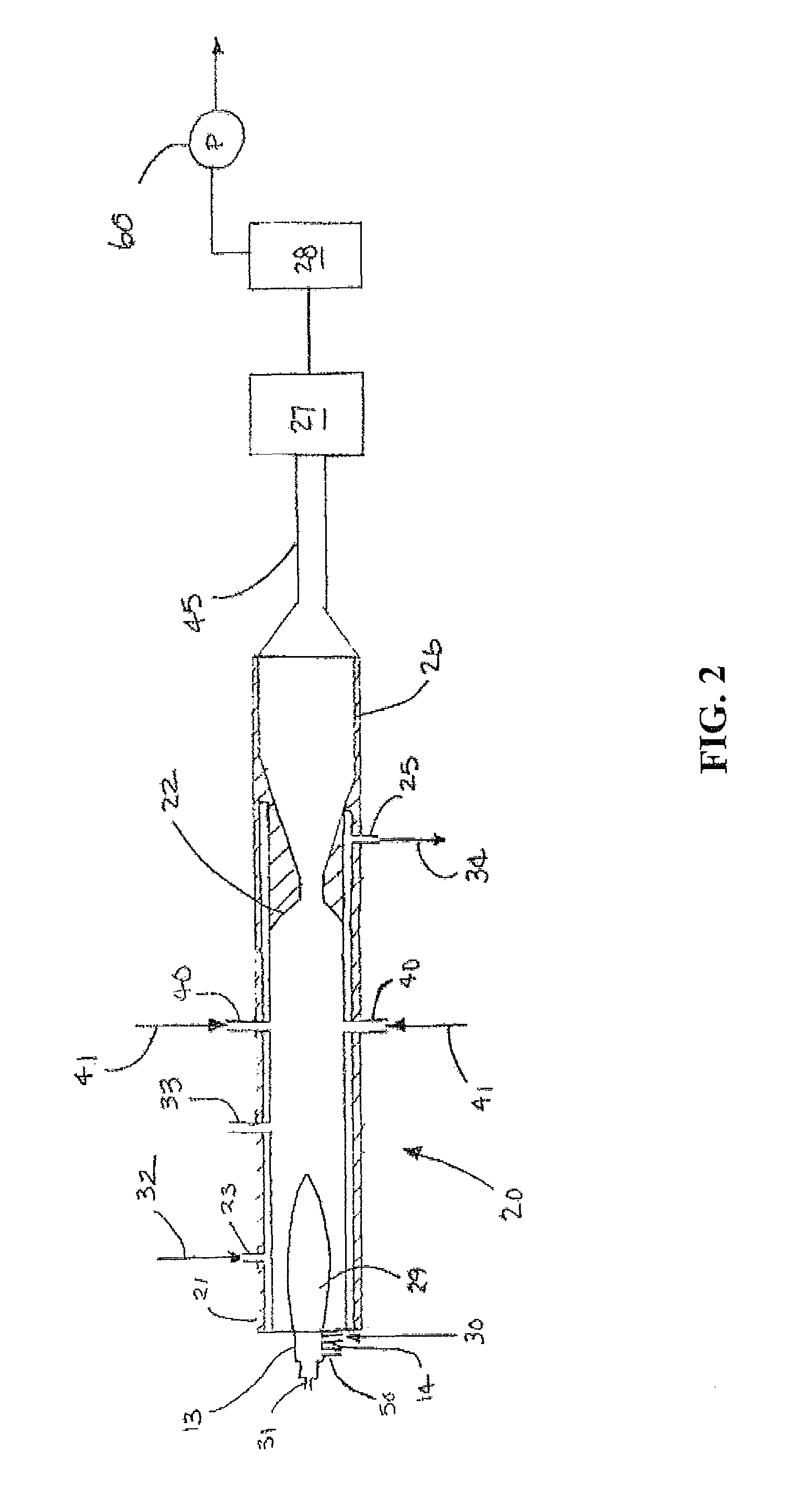

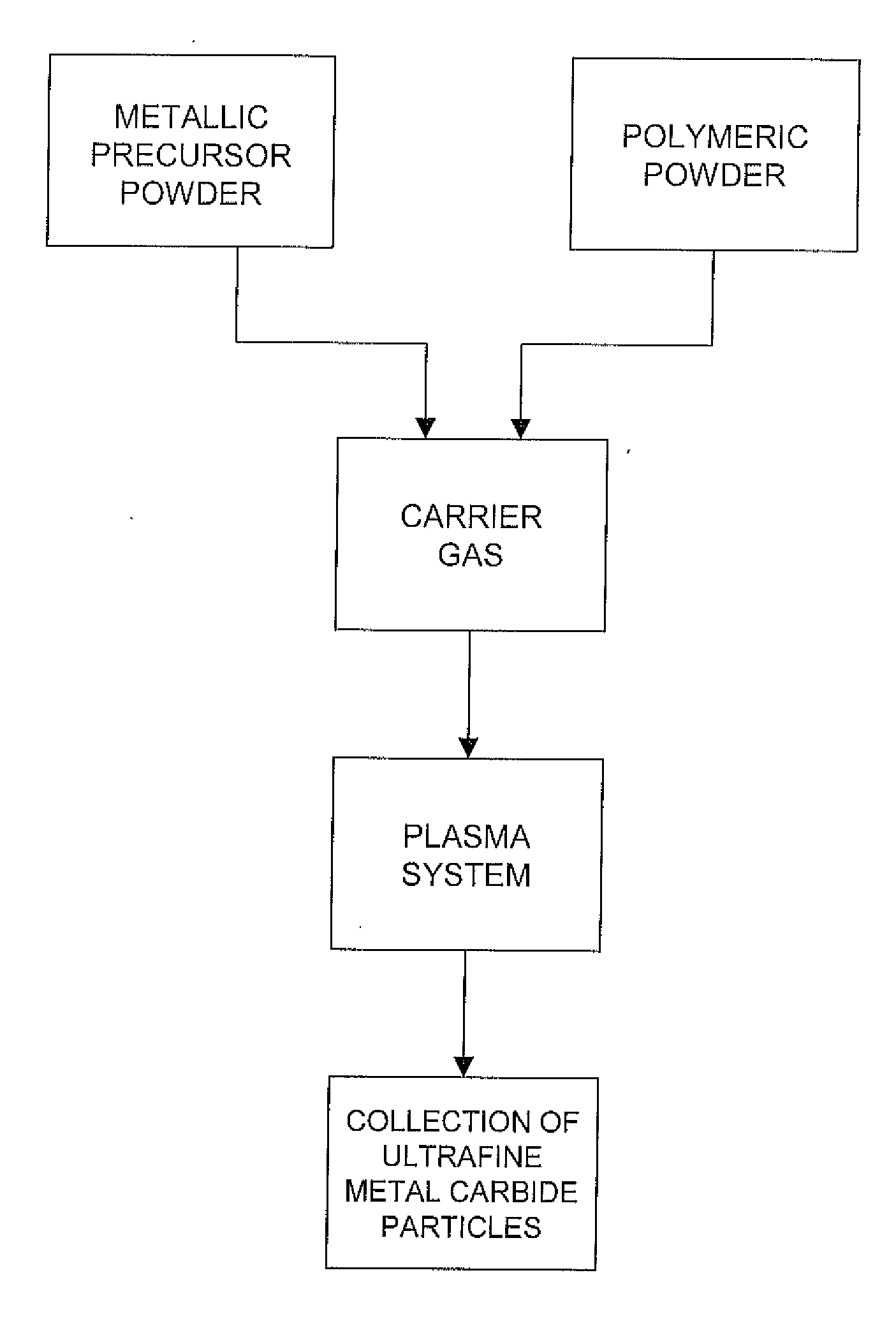

Production of ultrafine metal carbide particles utilizing polymeric feed materials

The production of ultrafine metal carbide powders from polymeric powder and metallic precursor powder starting materials is disclosed. In certain embodiments, the polymeric powder may comprise polypropylene, polyethylene, polystyrene, polyester, polybutylene, nylon, polymethylpentene and the like. The metal precursor powder may comprise pure metals, metal alloys, intermetallics and / or metal-containing compounds such as metal oxides and nitrides. In one embodiment, the metal precursor powder comprises a silicon-containing material, and the ultrafine powders comprise SiC. The polymeric and metal precursor powders are fed together or separately to a plasma system where the feed materials react to form metal carbides in the form of ultrafine particles.

Owner:PPG IND OHIO INC

Full-biodegradable material and preparation method thereof

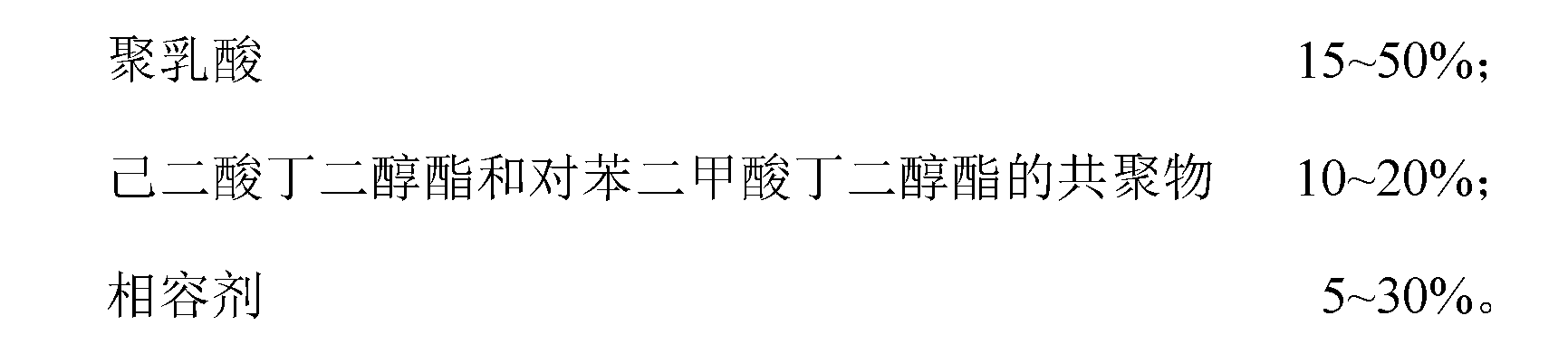

The invention relates to a full-biodegradable material which is characterized by comprising the following raw materials in percentage by weight: 30-65% of starch, 5-15% of vegetable oil, 15-50% of polylactic acid, 10-20% of polybutylene adipate-polybutylene terephthalate copolymer and 5-30% of compatilizer. Preferably, the compatilizer accounts for 5-20% of the total weight of the raw materials. The full-biodegradable material has the advantages of excellent and stable properties and low cost, is biodegradable, well gives consideration to economic benefit and environmental benefit, and has wide application prospects. The invention also provides a preparation method of the full-biodegradable material. The preparation method is easy to implement, operate and control, can easily implement industrial production, and is beneficial to lowering the cost of the full-biodegradable material.

Owner:ECOTA ENVIRONMENTAL TECH

Gas barrier pet composition for monolayer bottle and process thereof

InactiveUS20060182911A1Suitable for applicationLow pointSynthetic resin layered productsThin material handlingPolyethylene terephthalate glycolPolybutylene

Novel alloy / blends barrier resins consisting of a composition of Polyethylene Terephthalate (PET) and Polytrimethylene Naphthalate (PTN) or PET and Polybutylene Naphthalate (PBN) exclusively for packaging beverages like beer in a monolayer bottle outperforming the existing other barrier multi-layer bottles is described. The alloy / blends of PET / PTN and PET / PBN are produced by using in situ polymerization or melt blending the two polymers or compounding the two polymers to get the PTN and PBN in a PET polymer matrix. The composition of PET alloy / blends with PTN and PBN additionally contains other barrier improving additives. Incorporating a suitable oxygen scavenger in these new alloy / blends and converting to a stretch blow molded bottle, with or without heat setting, allows this monolayer bottle to be tunnel pasteurized for protecting beverages like beer filled at specific gas pressure to its maximum shelf life of >180 days keeping under control both oxygen ingress and carbon dioxide egress. The recyclability of used bottles into bottles, fibres and strappings has been established.

Owner:FUTURA POLYESTERS LTD

Multilayer composite having a barrier action

A multilayer composite comprising at least the following layers:I. a layer I of a polyamide molding composition andII. a layer II of a polyester molding composition, where the layers are firmly bonded to each other without use of an additional layer of bonding agent, wherein the polyester molding composition comprises a mixture of:a) from 80-99% by weight of a polyalkylene 2,6-naphthalate selected from the group consisting of polyethylene 2,6-naphthalate and polybutylene 2,6-naphthalate, andb) from 1-20% by weight of one or more compounds containing at least two isocyanate groups, wherein, in addition, the isocyanate groups from component IIb are present in layer II in a concentration of from 0.03-3% by weight.

Owner:DEGUSSA AG

Production of ultrafine metal carbide particles utilizing polymeric feed materials

The production of ultrafine metal carbide powders from polymeric powder and metallic precursor powder starting materials is disclosed. In certain embodiments, the polymeric powder may comprise polypropylene, polyethylene, polystyrene, polyester, polybutylene, nylon, polymethylpentene and the like. The metal precursor powder may comprise pure metals, metal alloys, intermetallics and / or metal-containing compounds such as metal oxides and nitrides. In one embodiment, the metal precursor powder comprises a silicon-containing material, and the ultrafine powders comprise SiC. The polymeric and metal precursor powders are fed together or separately to a plasma system where the feed materials react to form metal carbides in the form of ultrafine particles.

Owner:PPG IND OHIO INC

LOW APPLICATION TEMPEARATURE AMORPHOUS POLY-a-OLEFIN ADHESIVE

It has been discovered that amorphous polybutene copolymers that have a softening point of from about 70 to about 105° C. and viscosity of less than about 1,900 cP at 190° C. possesses desirable properties and may be used to make a low application temperature hot melt adhesive for disposable absorbent articles.

Owner:HENKEL KGAA

Chub packaging film

InactiveUS20040157077A1High impact strengthLow production costSynthetic resin layered productsDomestic containersLow-density polyethyleneLinear low-density polyethylene

Owner:FLEXOPACK PLASTICS IND

Polybutylenes resin, tubing and pipe fitting made from it

The present invention provides polybutene resin, which is characterized by: (1) more than 80-100 mol% of 1-butene units and 20 mol% of α-alkene (except 1-butene) units with 2-10 carbon atoms The following composition; (2) The melt flow rate (MFR) is 0.01-10g / 10min; (3) The molecular weight distribution represented by the ratio (Mw / Mn) of the weight average molecular weight (Mw) to the weight average molecular weight (Mn) is above 6 and (4) when the molecular weight distribution curve is drawn according to the chromatogram of gel permeation chromatography (GPC), measure the total area enclosed by the curve and the abscissa, and the part whose weight average molecular weight is 6×105 or more accounts for the total area More than 20%. The present invention also provides pipes and pipe fittings made of the above resin.

Owner:MITSUI CHEM INC

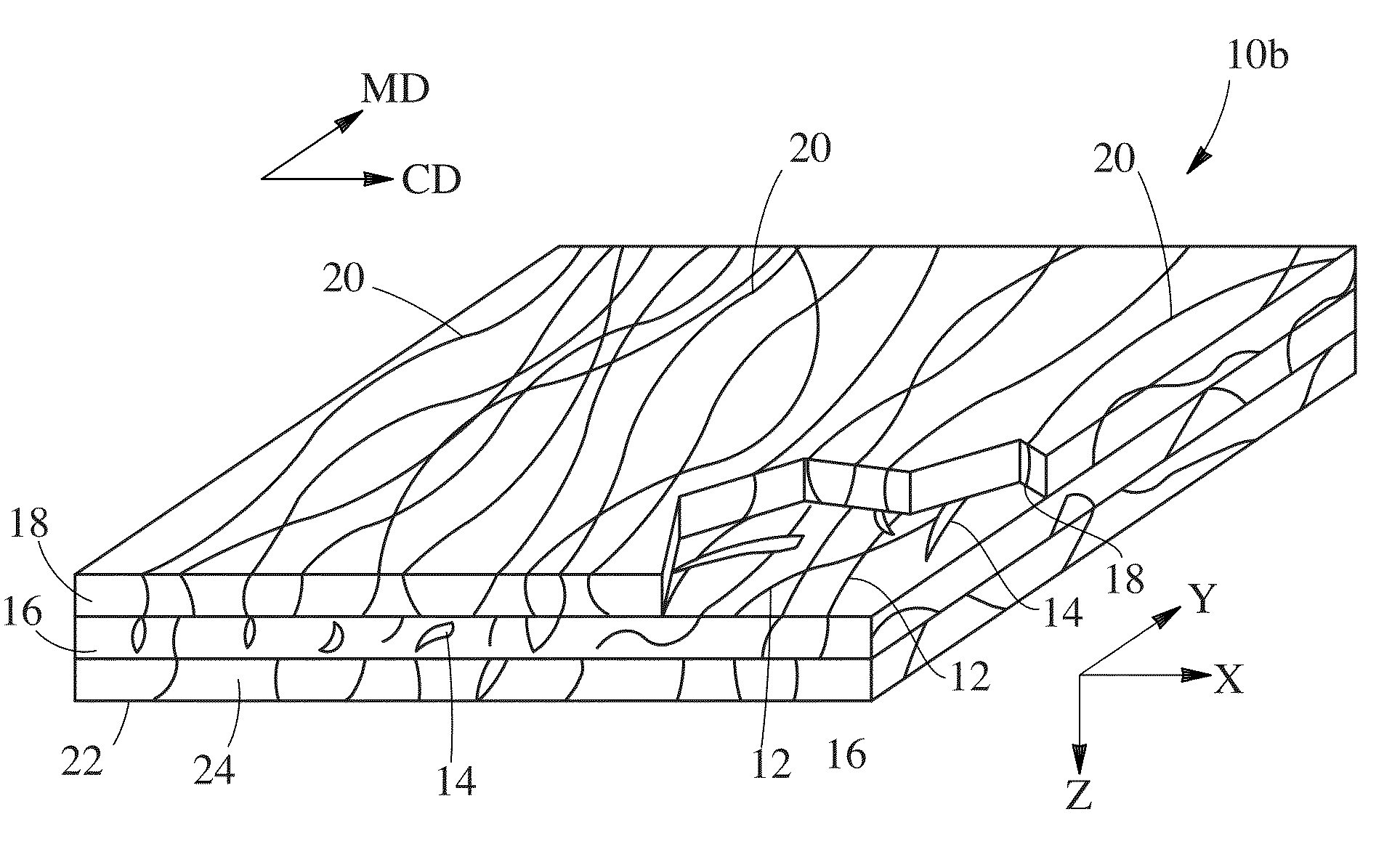

Fibrous structures derived from renewable resources

Disclosed herein are co-formed fibrous structures that are composed of (a) a plurality of filaments that have a biobased content of at least about 25% and selected from the group consisting of polypropylene, polyethylene, polymethylpentene, polybutylene-1, polyisobutylene, ethylene propylene copolymer, ethylene propylene diene monomer copolymer or rubber, and mixtures thereof; and, (b) a solid additive including a cellulosic fiber. The solid additive is present in an amount of at least about 30 wt. %, based on the total weight of the fibrous structure. The co-formed fibrous structures of the invention can themselves be articles, such as, paper, fabrics, and absorbent pads.

Owner:THE PROCTER & GAMBLE COMPANY

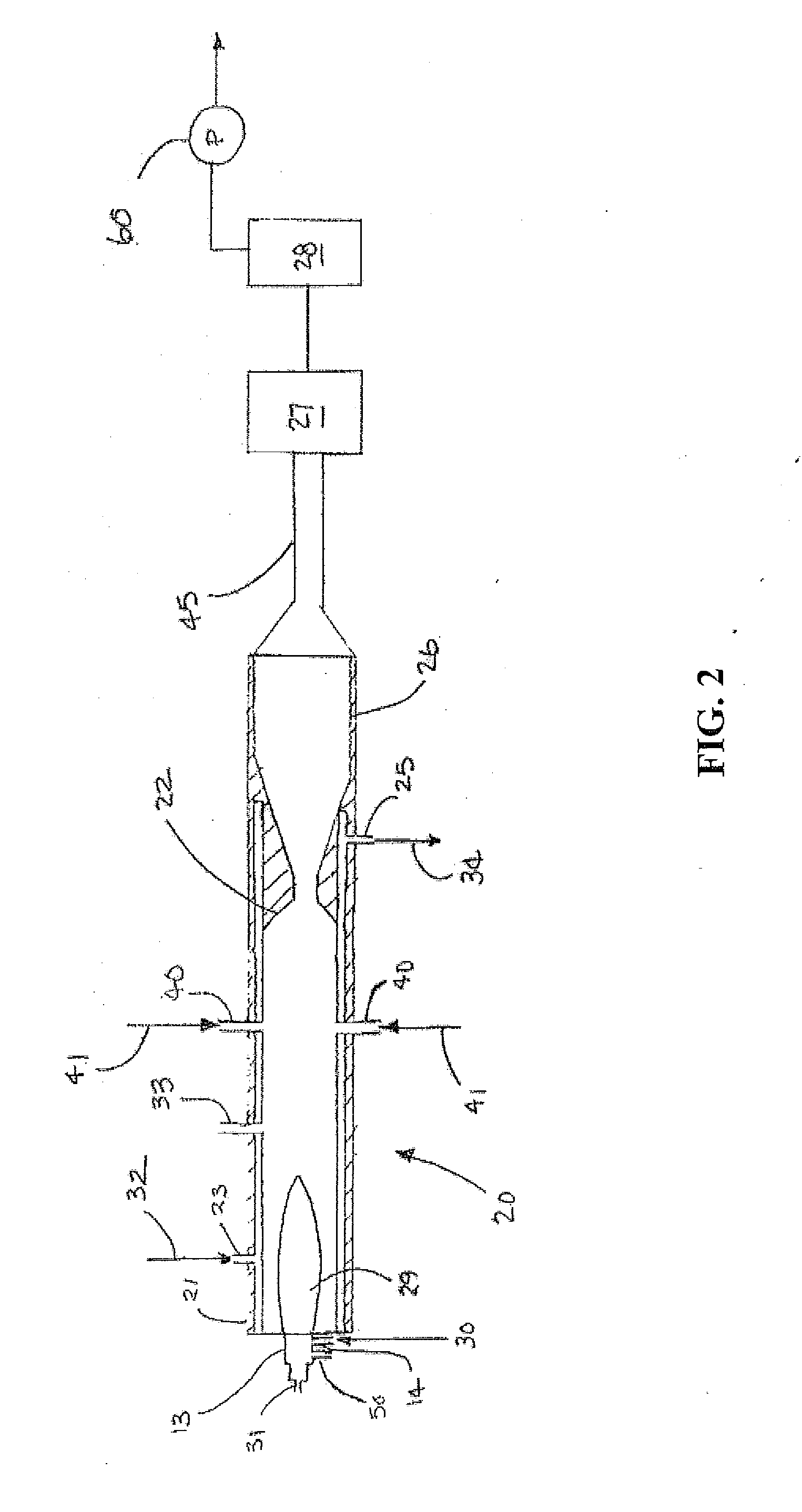

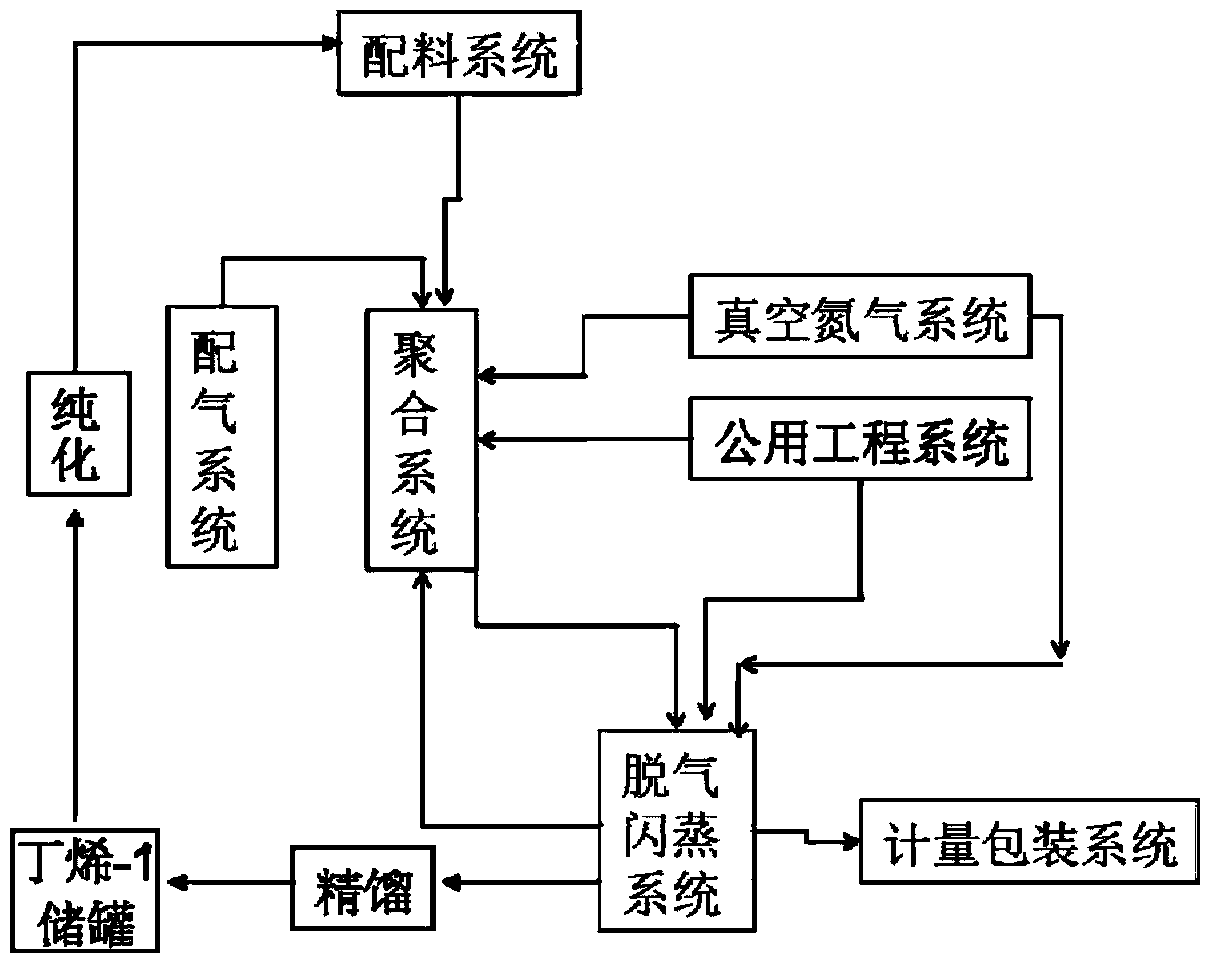

Industrial production method of high isotactic polybutylene and device for implementing method

The invention discloses an industrial production method of high isotactic polybutylene and a device for implementing the method. The production method comprises the process flows of carrying out bulk polymerization on a liquid-phase butylene-1 monomer in a polymerization kettle at the temperature of 10 DEG C below zero to 70 DEG C above zero to synthesize isotactic polybutylene, and recovering part of unreacted butylene-1 into a butylene gasometer through primary pressure reduction after polymerizing for a certain period of time; then, transferring high isotactic polybutylene from the polymerization kettle to a flash distillation kettle, carrying out reduced-pressure flash distillation, and further recovering the unreacted butylene-1 monomer into the butylene gasometer; sequentially introducing nitrogen gas and air into the flash distillation kettle to replace, discharging a granular high isotactic polybutylene product through an emptying valve at the bottom of the kettle, and packaging. The device comprises a proportioning system, a polymerization system, a gas distribution system, a vacuum nitrogen system, a degassing and flash distillation system and a utility system. Through the industrial production method and the device, the industrial synthesis of the high isotactic polybutylene can be realized, and no organic solvents, waste gases, waste water and waste residues are discharged; in addition, the industrial production method belongs to a green and clean production process.

Owner:SHANDONG ORIENT HONGYE CHEM +1

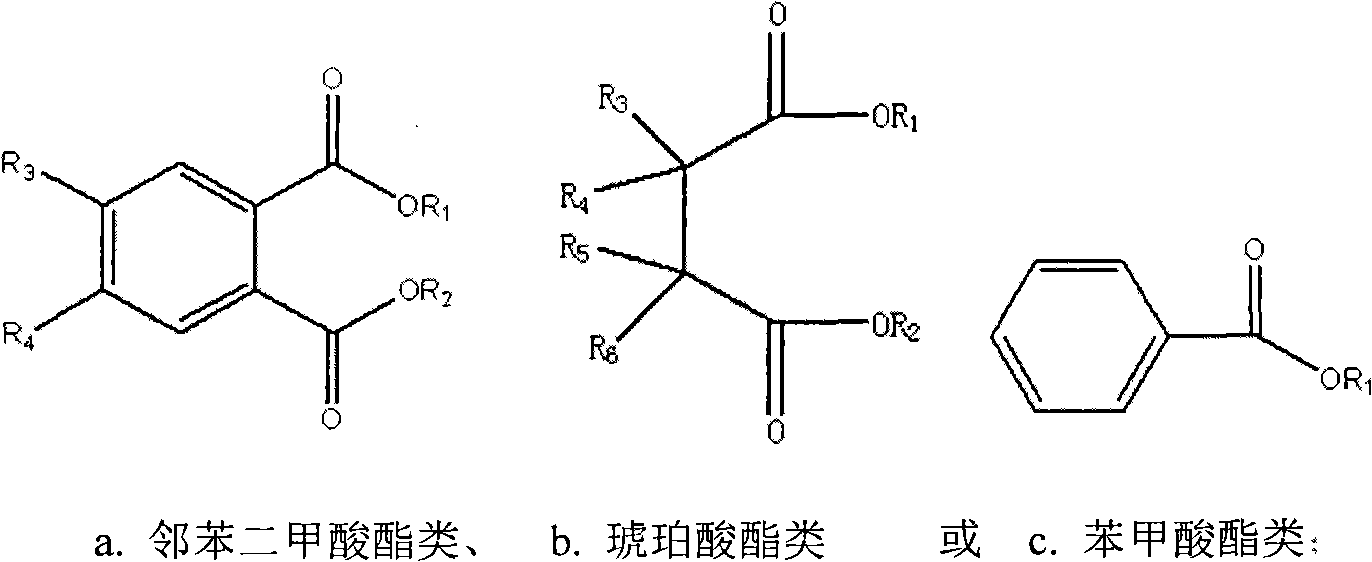

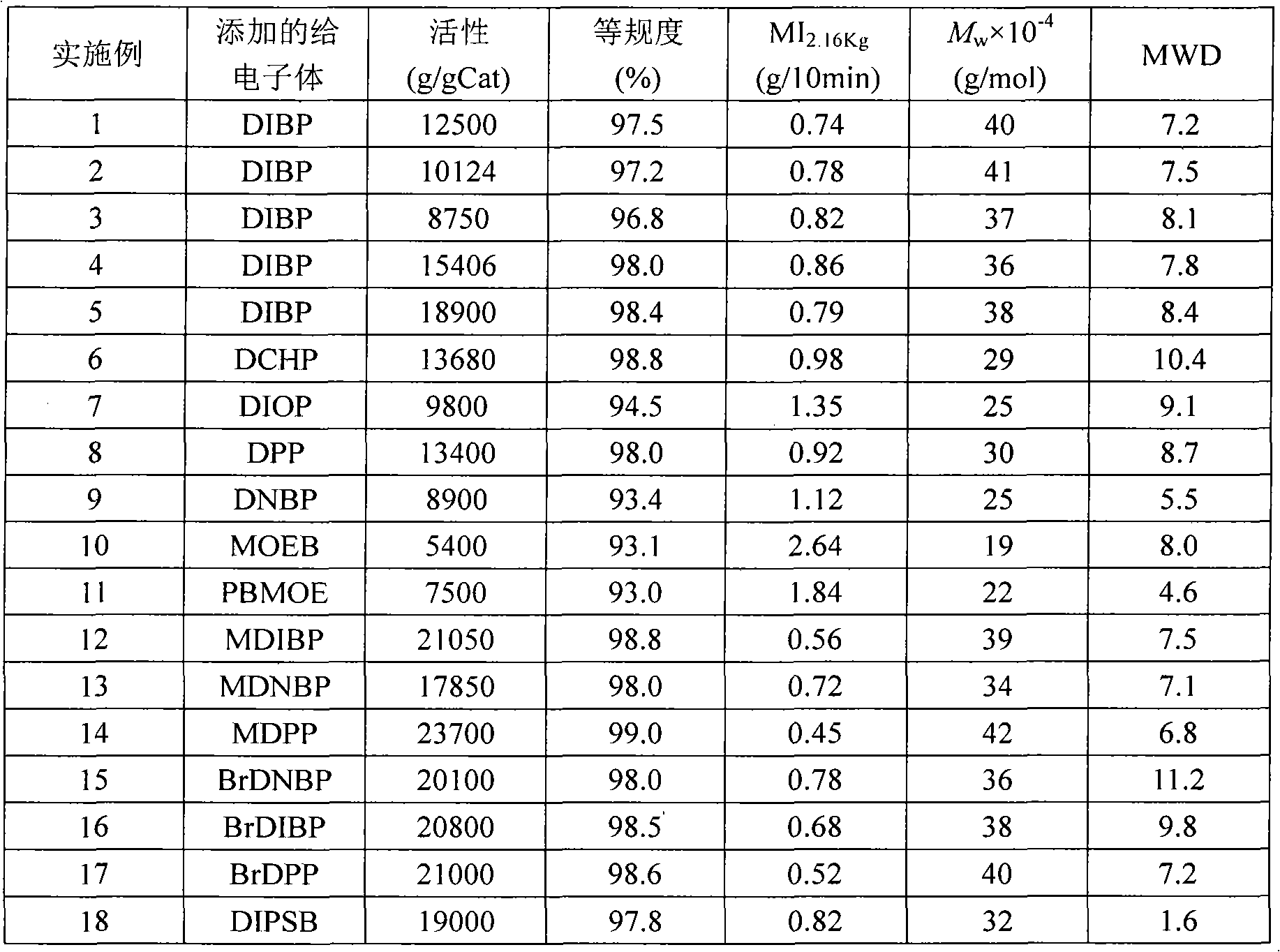

Spherical catalyst for 1-butene polymerization as well as preparation method and application thereof

The invention relates to polymerization of 1-butene, in particular to a spherical catalyst of polybutylene-1. The catalyst consists of a carrier, an active component and a modifier, wherein the active component is titanium tetrachloride, the carrier is a magnesium chloride spherical carrier and the modifier is an electron donor compound; and the catalyst comprises the major components in percentage by mass of: 1.1-4.5% of Ti and 0.15-12.37% of electron donors. The spherical catalyst suitable for butane-1 polymerization solves the problems that the activity of the general catalyst is low, the normality of polymer is difficult to control, and the molecular weight of the polymer and the molecular weight distribution are difficult to control. The obtained polybutylene polymer has very high steric regularity, the normality of polybutylene is as high as 99%, the crystallinity of the polybutylene-1 polymer is greater than 60% and the fusion point is 130.5 DEG C. The invention can simplify the polymerizing process and save the production cost.

Owner:HEBEI UNIV OF TECH

PLA/PBAT biodegradable composite material and product thereof

The invention relates to the technical field of high polymer materials, and particularly discloses a PLA / PBAT biodegradable composite material and a product thereof. The PLA / PBAT biodegradable composite material is prepared from 33 to 95.9 parts by mass of polylactic acid (PLA), 3 to 60 parts by mass of polybutylene adipate terephthalate (PBAT), 1 to 5 parts by mass of a compatilizer and 0.1 to 2parts by mass of a chain extender. The PLA / PBAT biodegradable composite material has the characteristics of PLA and PBAT, and is high in impact strength and good in toughness.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

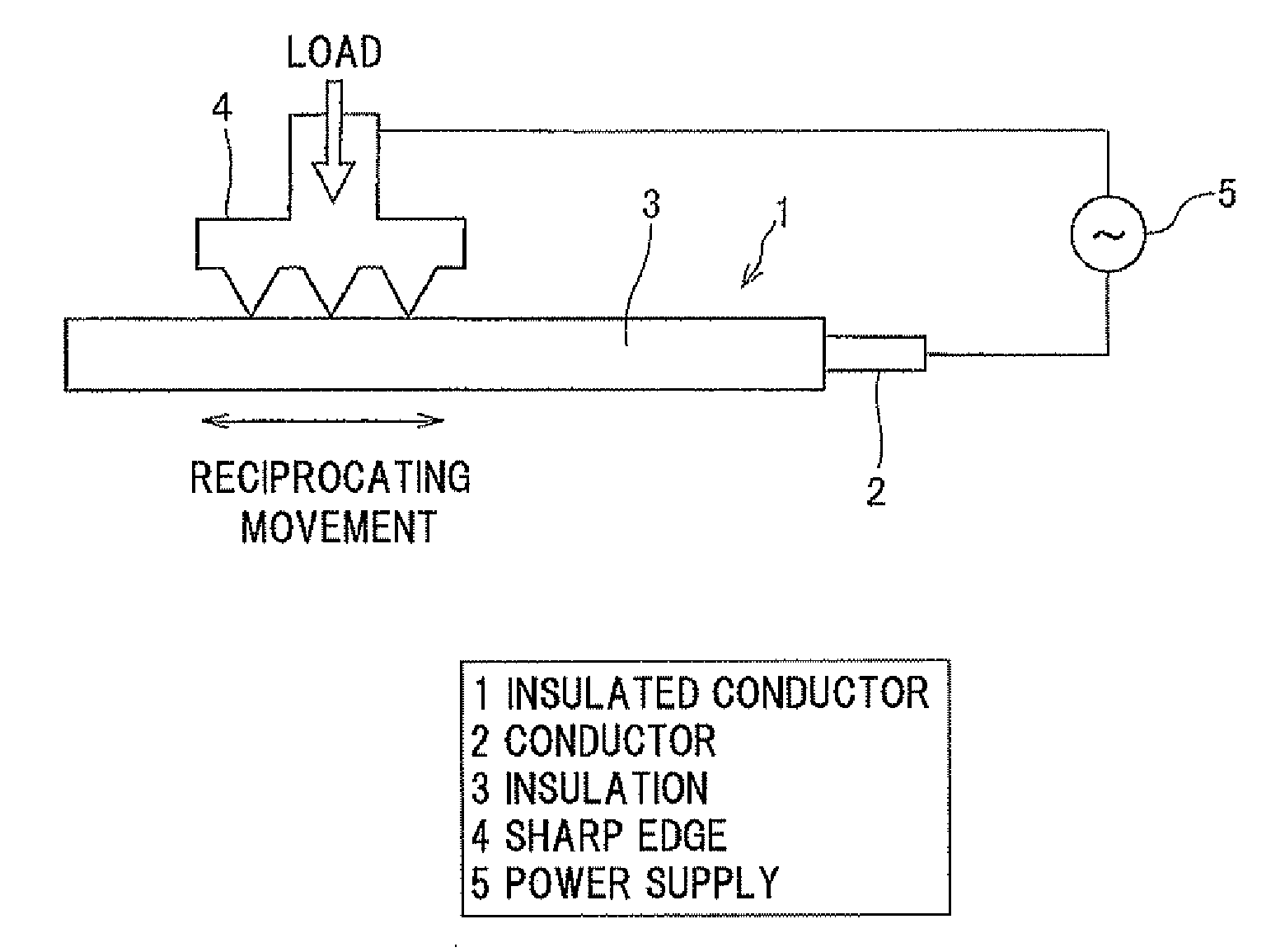

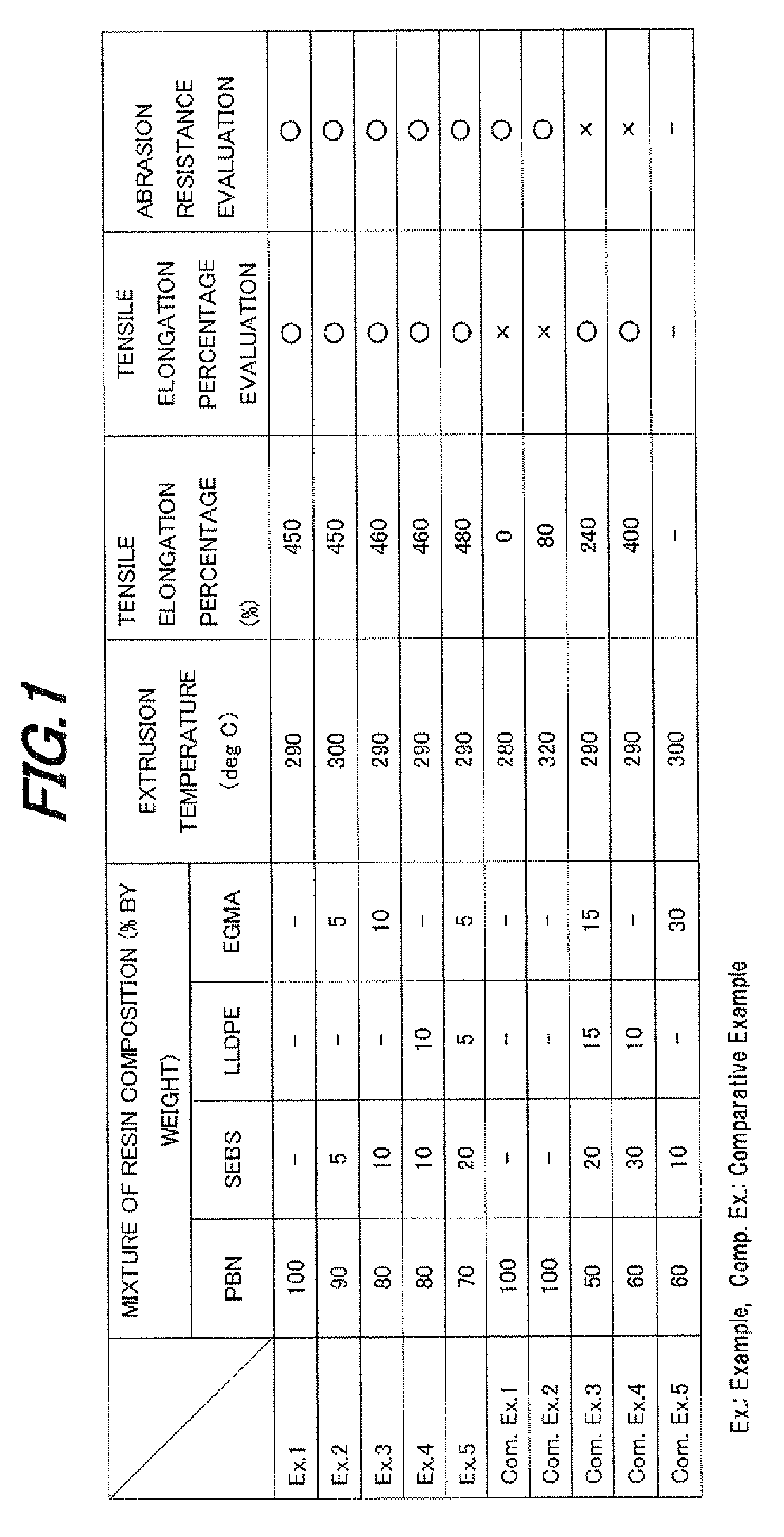

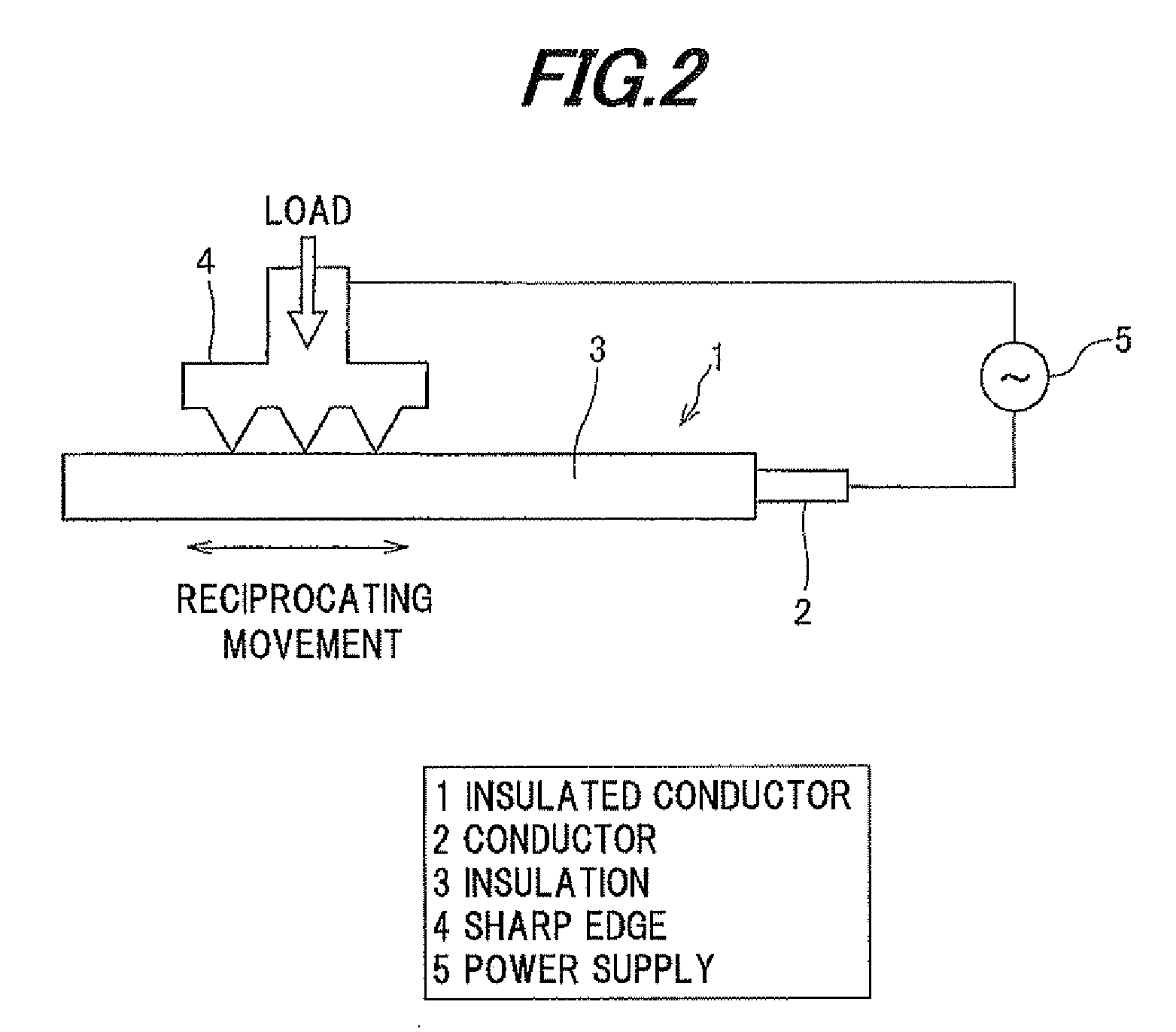

Insulated conductor and method for manufacturing same

InactiveUS20090004472A1Excellent characteristicsIncrease resistanceRecord information storageLight beam reproducingPolyolefinElectrical conductor

An insulated conductor includes a conductor, and an insulation covering the conductor and formed of a resin composition. The resin composition includes more than 60% by weight of polybutylene naphthalate resin. The resin composition further includes a hydrogenated block copolymer that a block copolymer including a styrene and a diene system compound is saturated by hydrogenation, and at least one of a polyolefin and a compound including a glycidyl group. A method for manufacturing the insulated conductor includes forming on the conductor the insulation including the resin composition by extrusion in a range of 290° C. to 310° C.

Owner:HITACHI METALS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com