Industrial production method of high isotactic polybutylene and device for implementing method

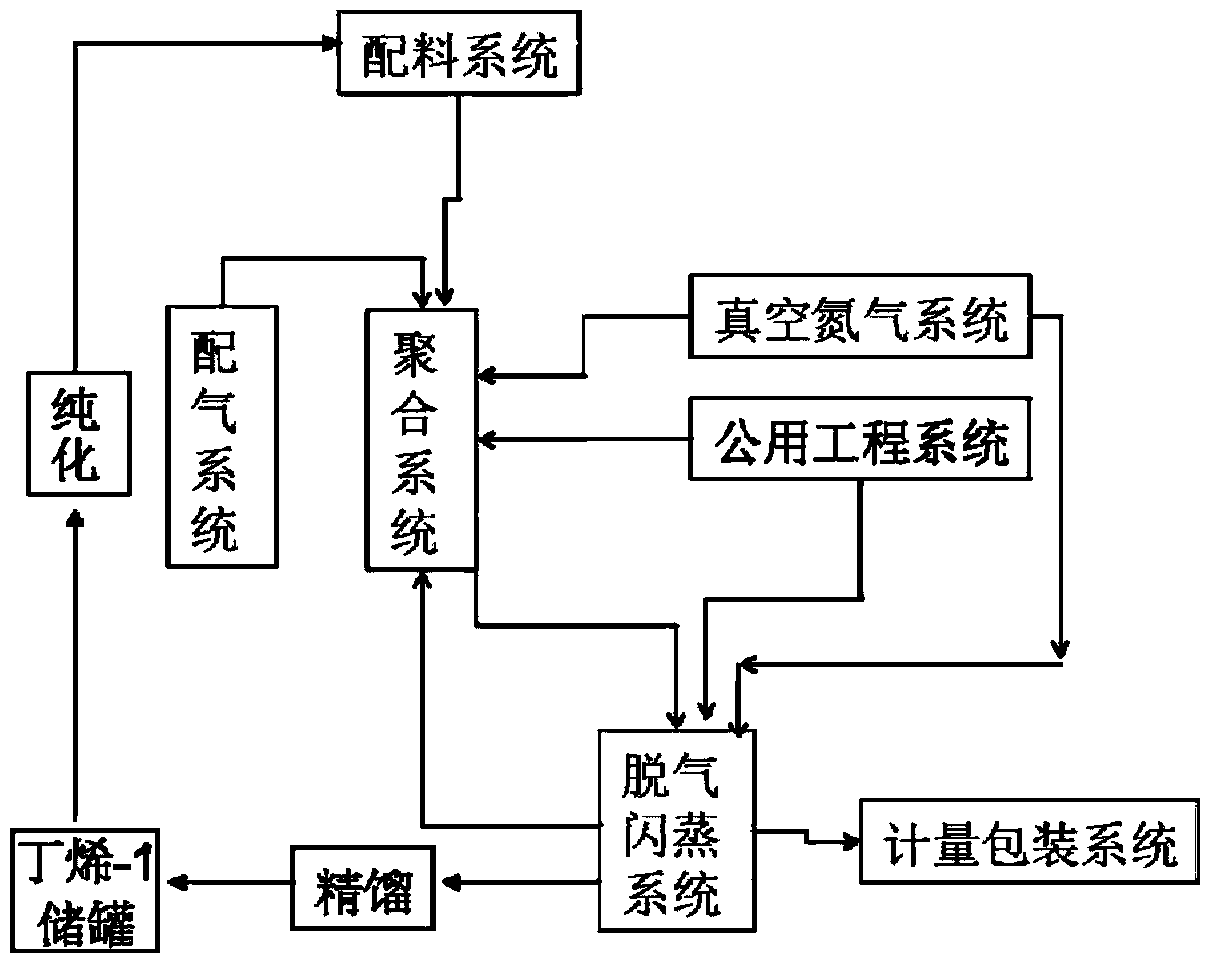

A technology of high tactic polybutene and production method, applied in the field of tactic polybutene, can solve the problems of mass transfer, heat transfer difficulty, harm to workers, low monomer concentration and partial pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

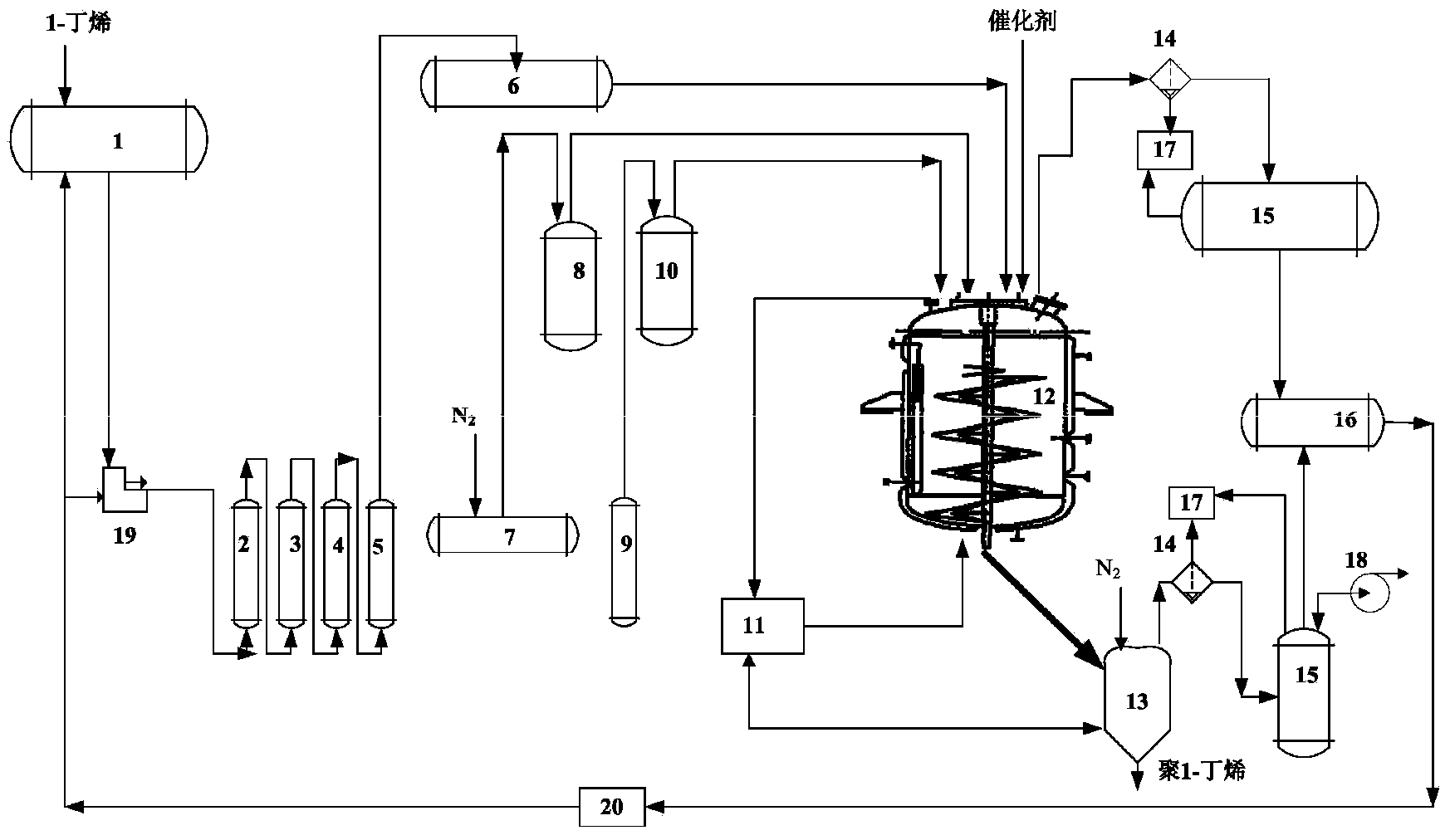

[0047] After the 12 cubic meter polymerization kettle was treated by the vacuum nitrogen system, 3.4 tons of purified butene monomer was introduced into the polymerization kettle through the batching system at one time, and 2.8kg of triethylaluminum was added in sequence, and the external electron donor diphenyl dimethyl Oxysilane 0.3kg, MgCl 2 Loaded TiCl 4 Catalyst (titanium loading: 3.2wt.%) 0.36kg, add hydrogen 5MPa as a molecular weight regulator through the gas distribution system, raise the temperature of the polymerization tank to 50°C through the utility system and react under this condition for 3h. After the reaction is over, the polymerization tank is decompressed, and part of the unreacted monomer is flashed off, and then enters the butene gas holder. Then transfer the polybutene to the flash tank to continue the further flash evaporation of the monomer. After the combustible gas is detected and there is no monomer residue, a certain amount of nitrogen is introduc...

Embodiment 2

[0052] In addition to the cocatalyst being 2.8kg of diethylaluminum chloride, the external electron donor being 0.3kg of methyltriethoxysilane, and the main catalyst being MgCl 2 Load VCl 4 Catalyst (2.5wt.% vanadium load) 0.36kg, polymerization time 4 hours, other parameters and polymerization process steps are the same as in Example 1. The weight of the synthesized polymer is 3.04 tons, and the conversion rate is about 89.4%. The bulk density of polybutene is 367kg / m 3 , The melt flow rate is 0.53g / 10min, the tested polybutene isotacticity is 96.8%, and the ash content is less than 100ppm. After two flashes, 345kg of monomers were recovered, and the monomer loss per ton of polymer was calculated to be only 4.9kg. The polymerization parameters and product physical parameters are shown in Table 1.

Embodiment 3

[0054] After the 12 cubic meter polymerization kettle was treated by the vacuum nitrogen system, 3.4 tons of butene monomer was introduced into the polymerization kettle through the batching system at one time, and after the temperature of the polymerization kettle was raised to 60°C through the public engineering system, triisobutyl Aluminum 2.0kg, external electron donor cyclohexylmethyldimethoxysilane 0.2kg, MgCl 2 Loaded TiCl 4 Catalyst (titanium loading: 3.2wt.%) 0.2kg, add hydrogen 3MPa as a molecular weight regulator through the gas distribution system. React under these conditions for 6h. After the reaction is over, the polymerization tank is decompressed, and part of the unreacted monomer is flashed off, and then enters the butene gas holder. Then transfer the polybutene to the flash tank to continue the further flash evaporation of the monomer. After the combustible gas is detected and there is no monomer residue, a certain amount of nitrogen is replaced in the fla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com