Patents

Literature

2522 results about "Gas holder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A gas holder, or gasometer, is a large container in which natural gas or town gas is stored near atmospheric pressure at ambient temperatures. The volume of the container follows the quantity of stored gas, with pressure coming from the weight of a movable cap. Typical volumes for large gas holders are about 50,000 cubic metres (1,800,000 cu ft), with 60 metres (200 ft) diameter structures.

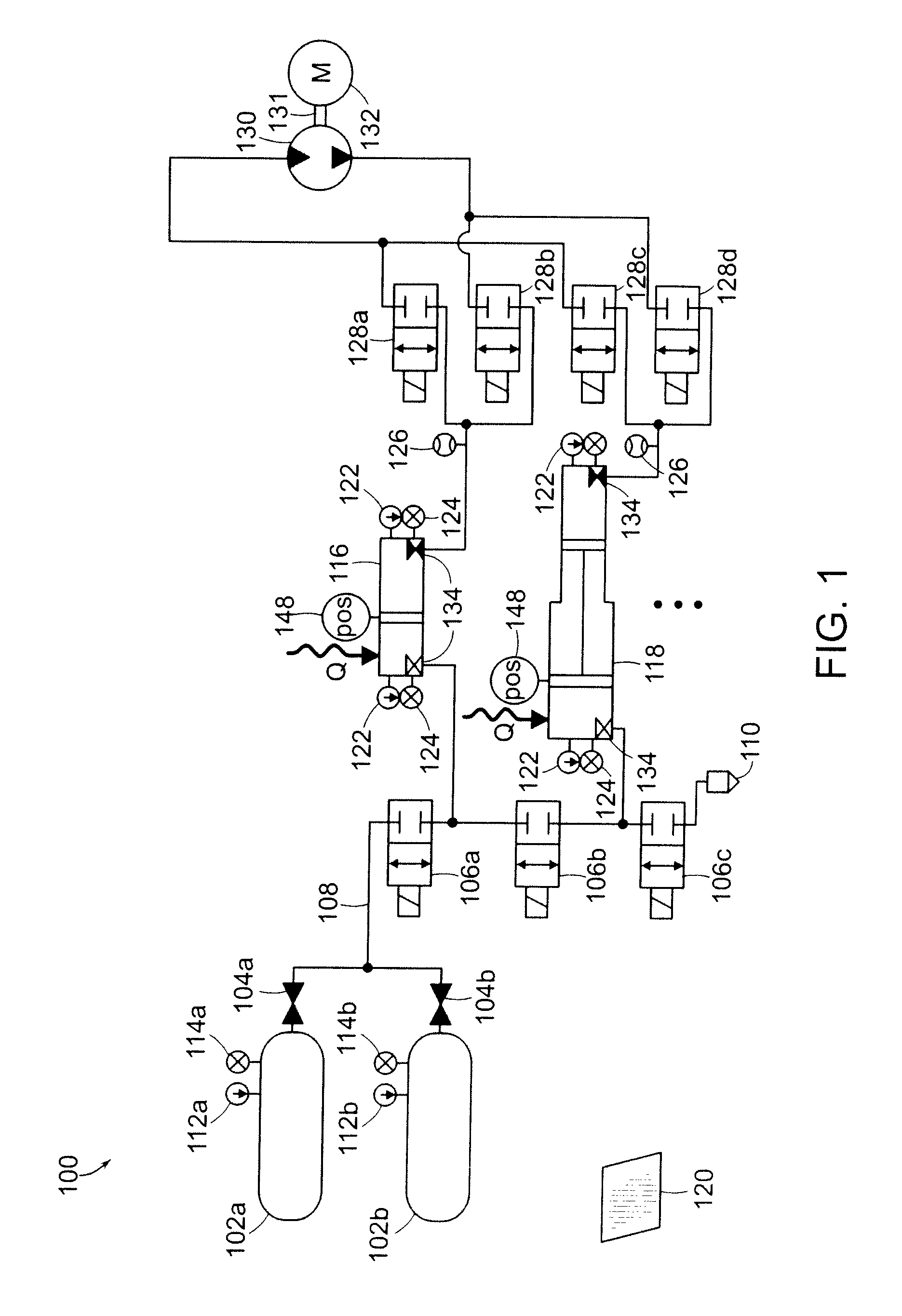

Systems and methods for energy storage and recovery using compressed gas

InactiveUS7832207B2Increase energy densityExpand/compress the gas more evenlyFluid couplingsAccumulator installationsEngineeringHigh pressure

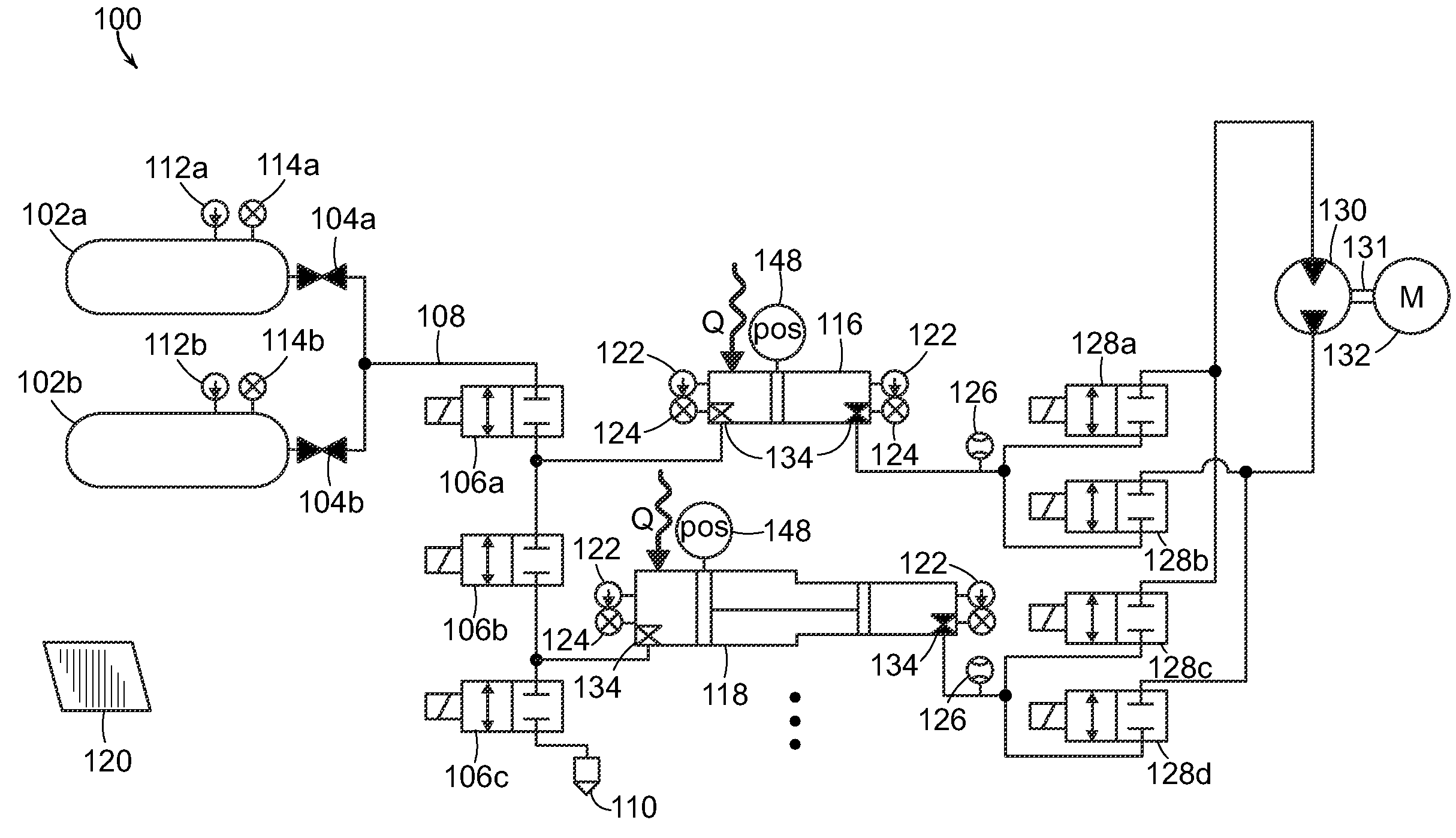

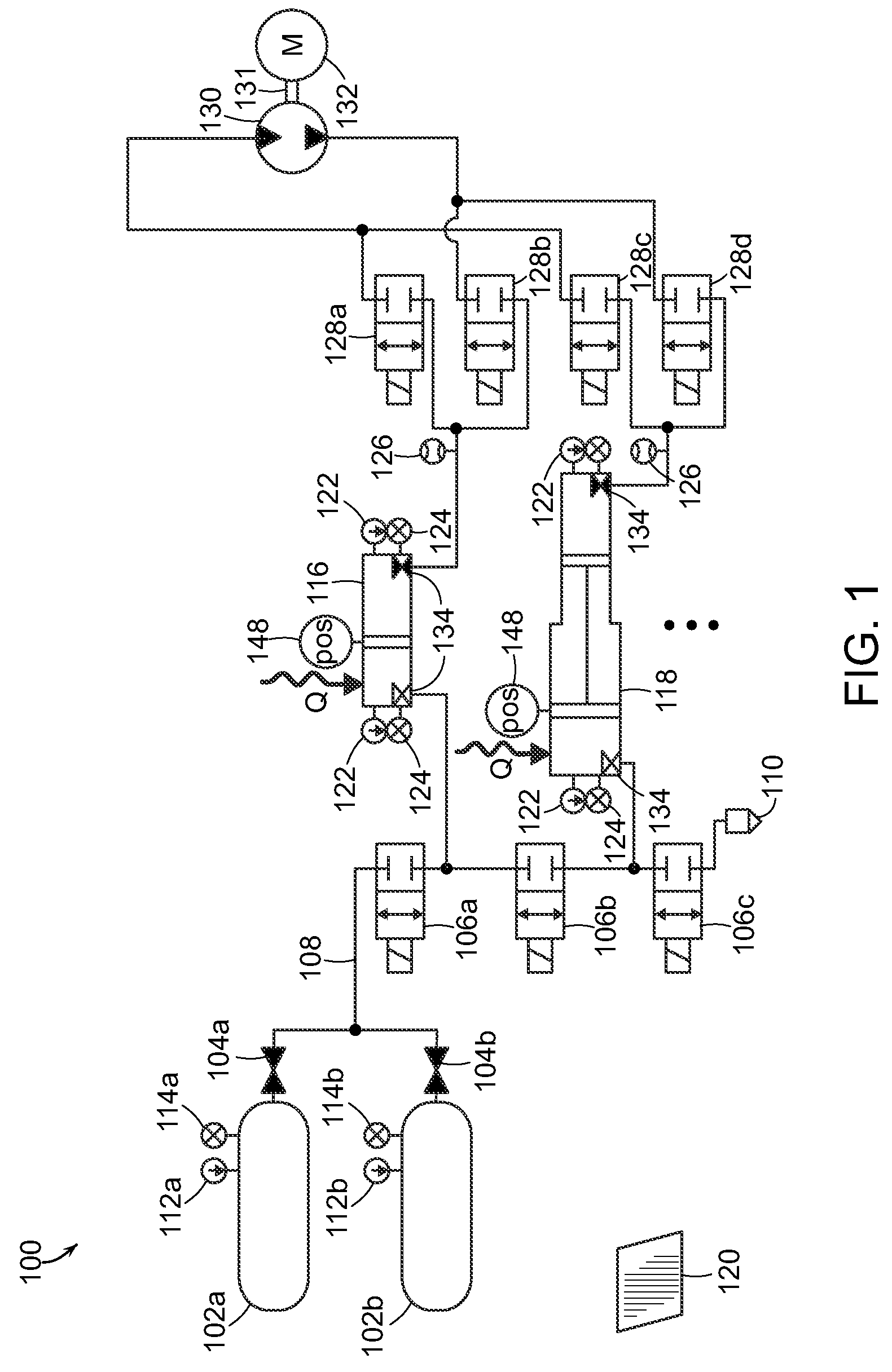

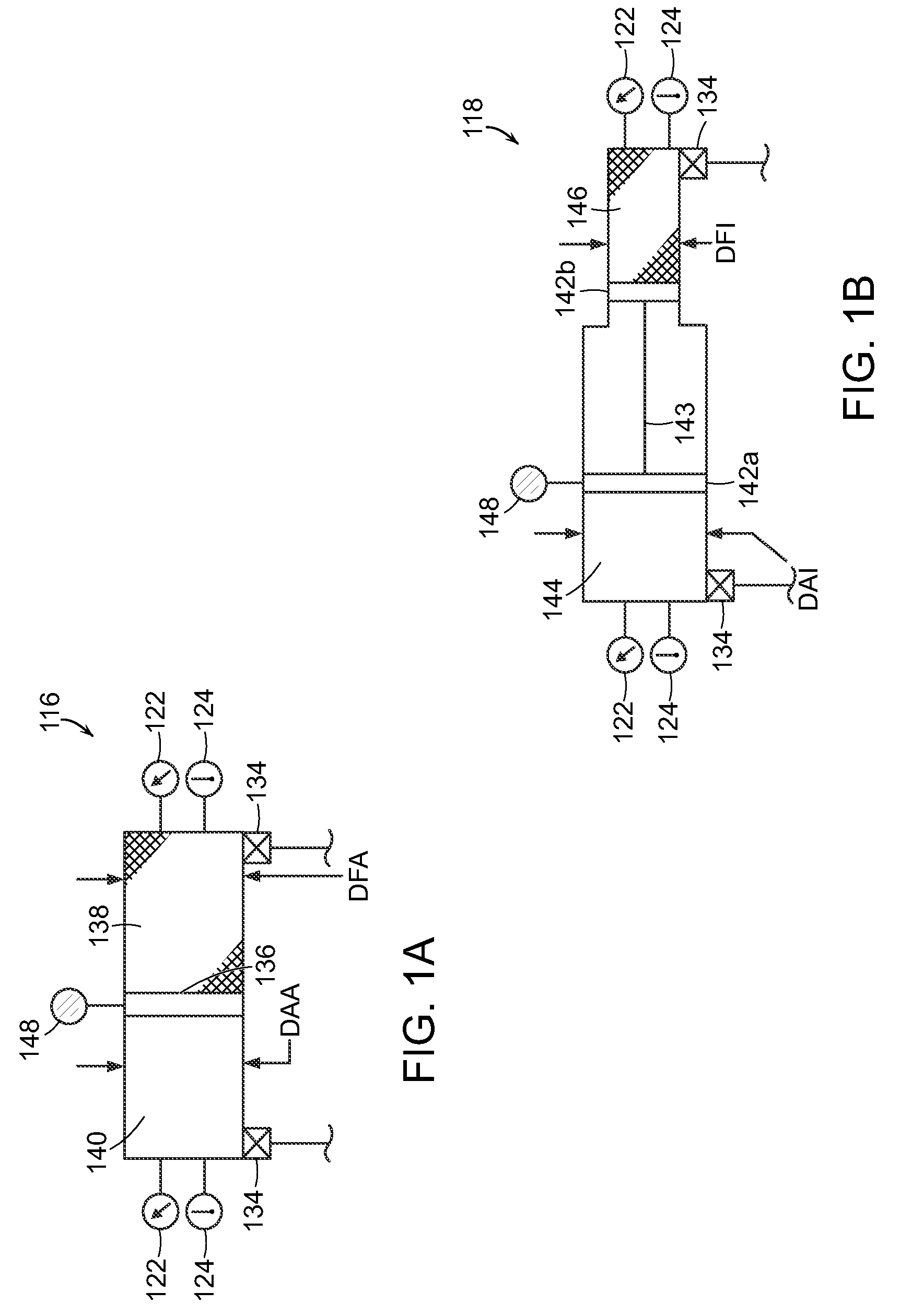

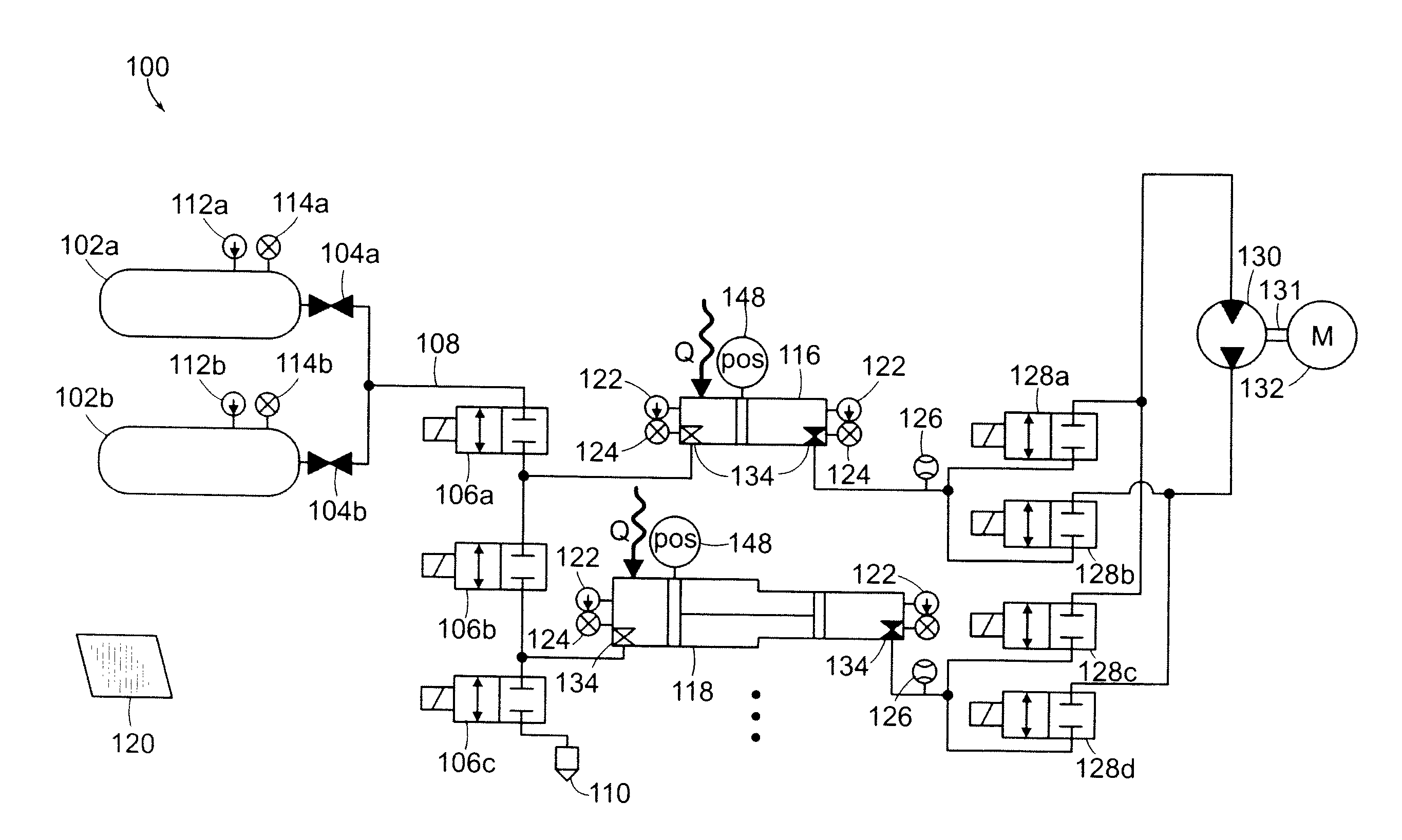

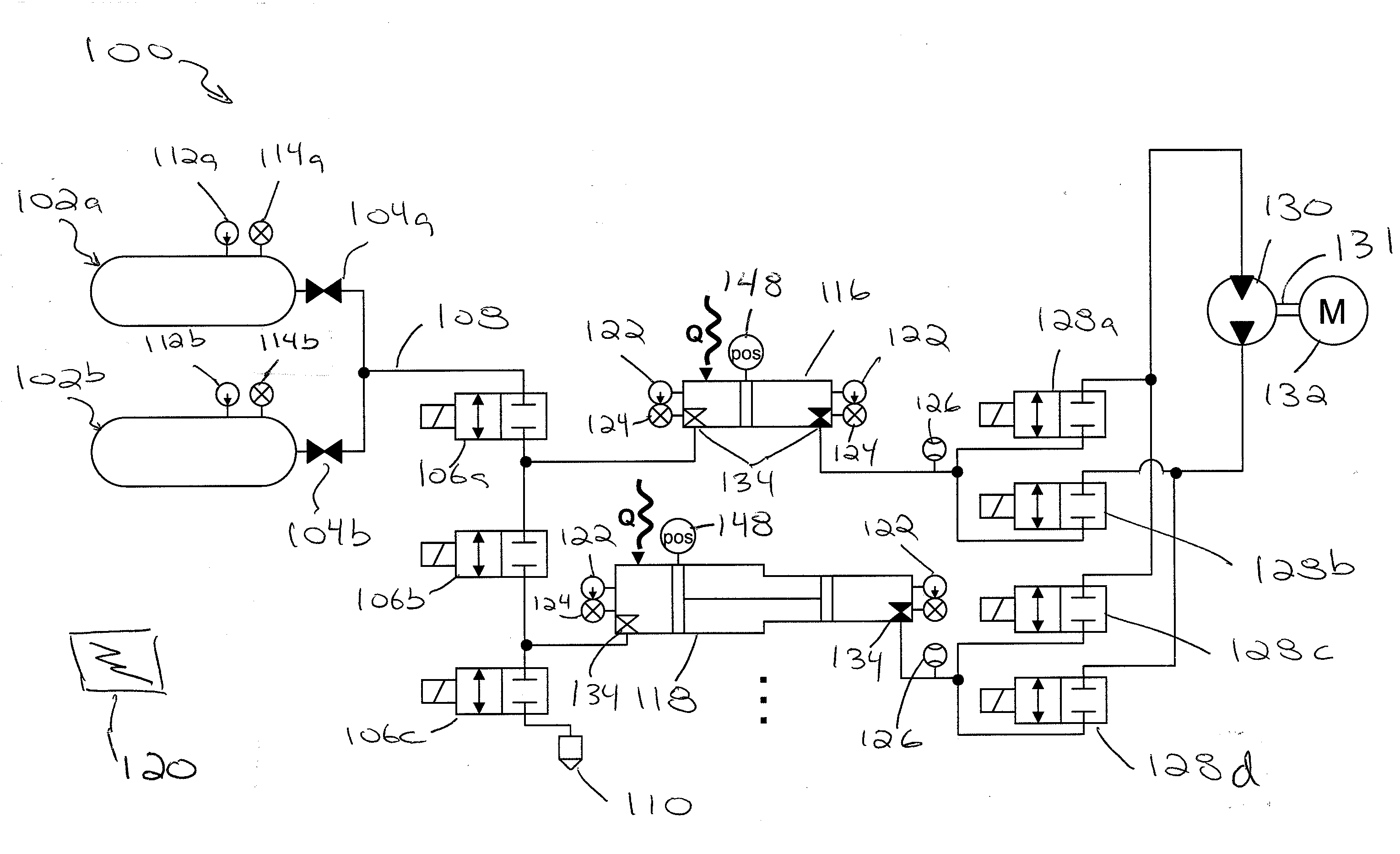

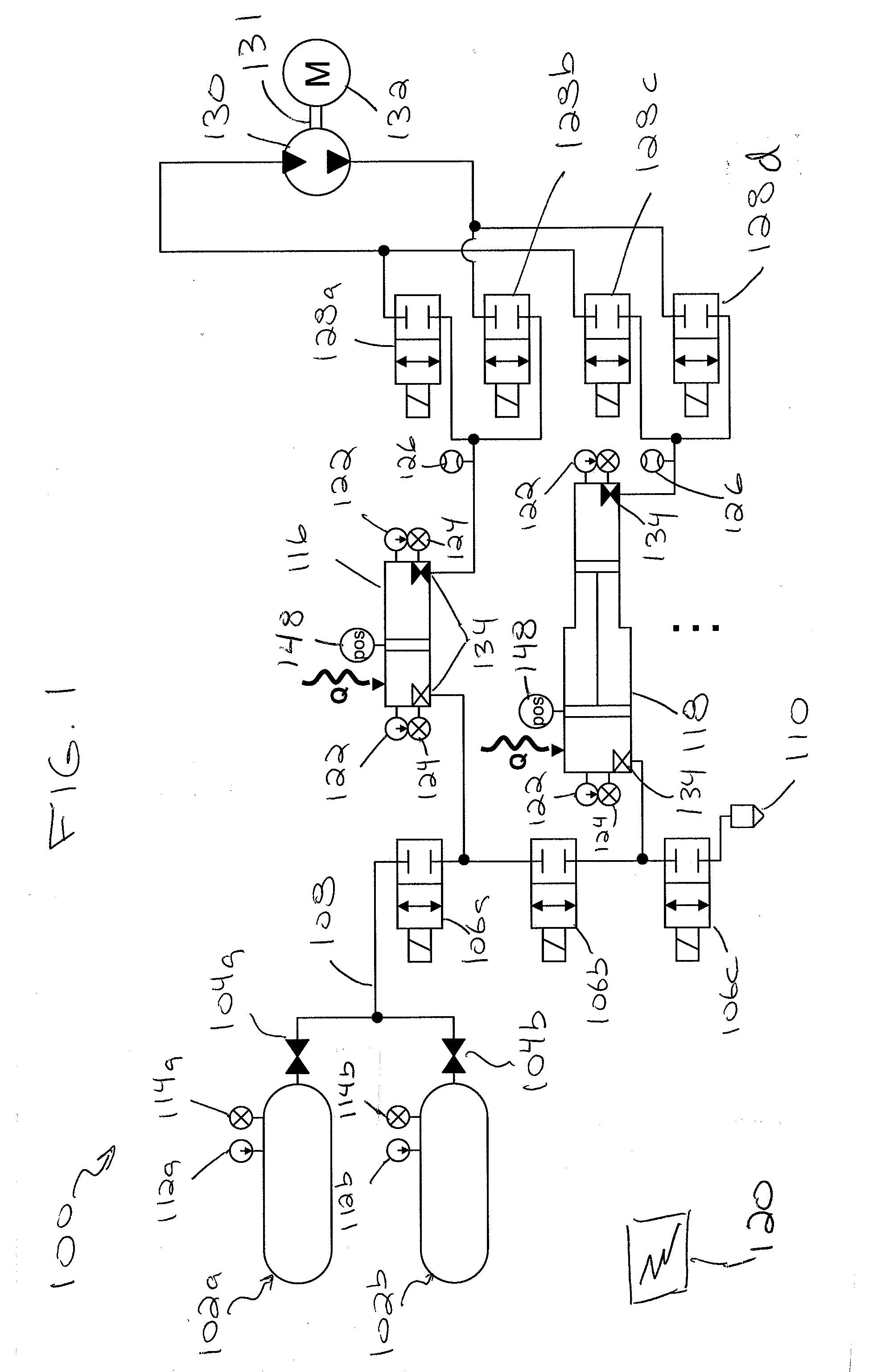

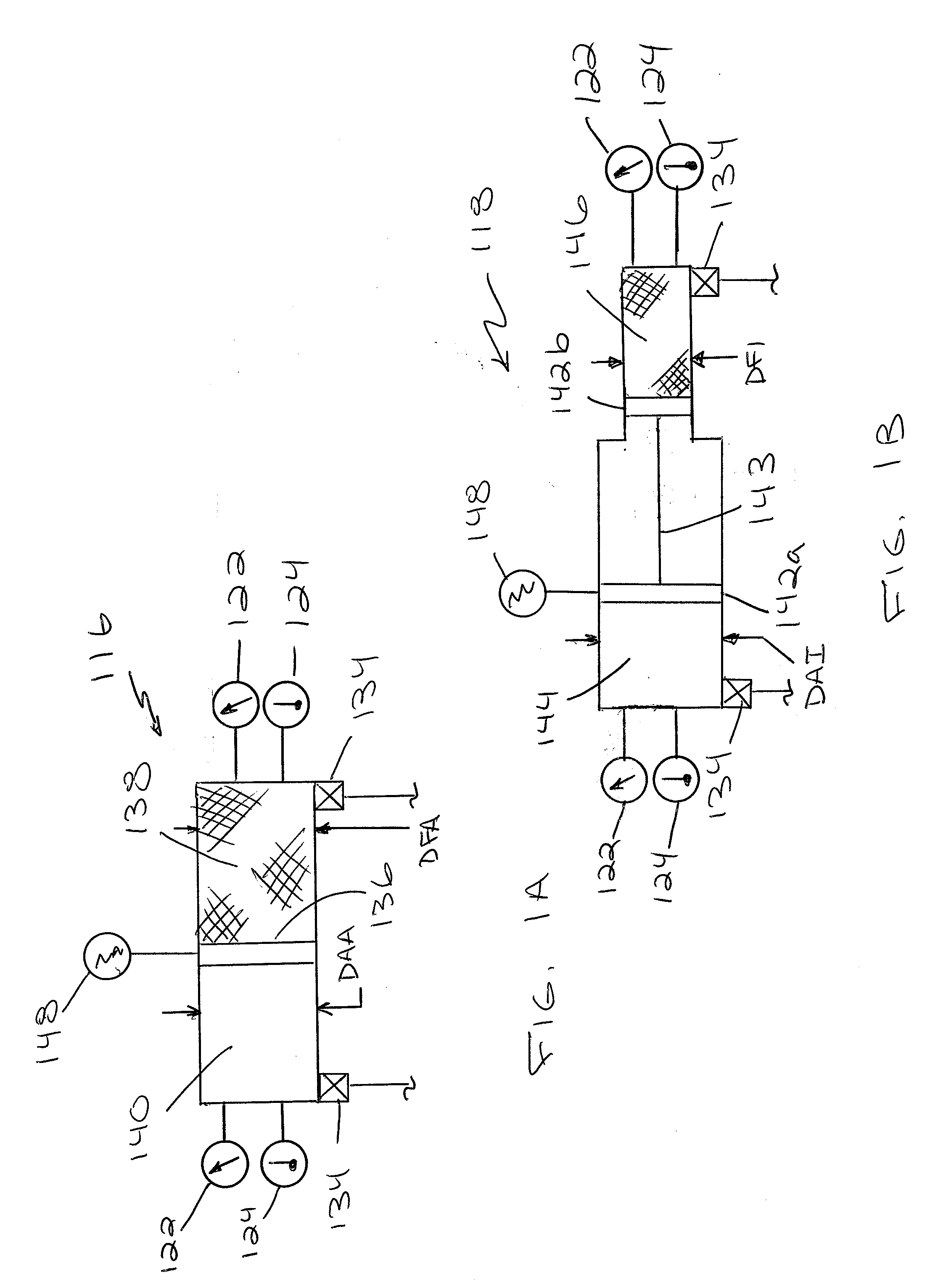

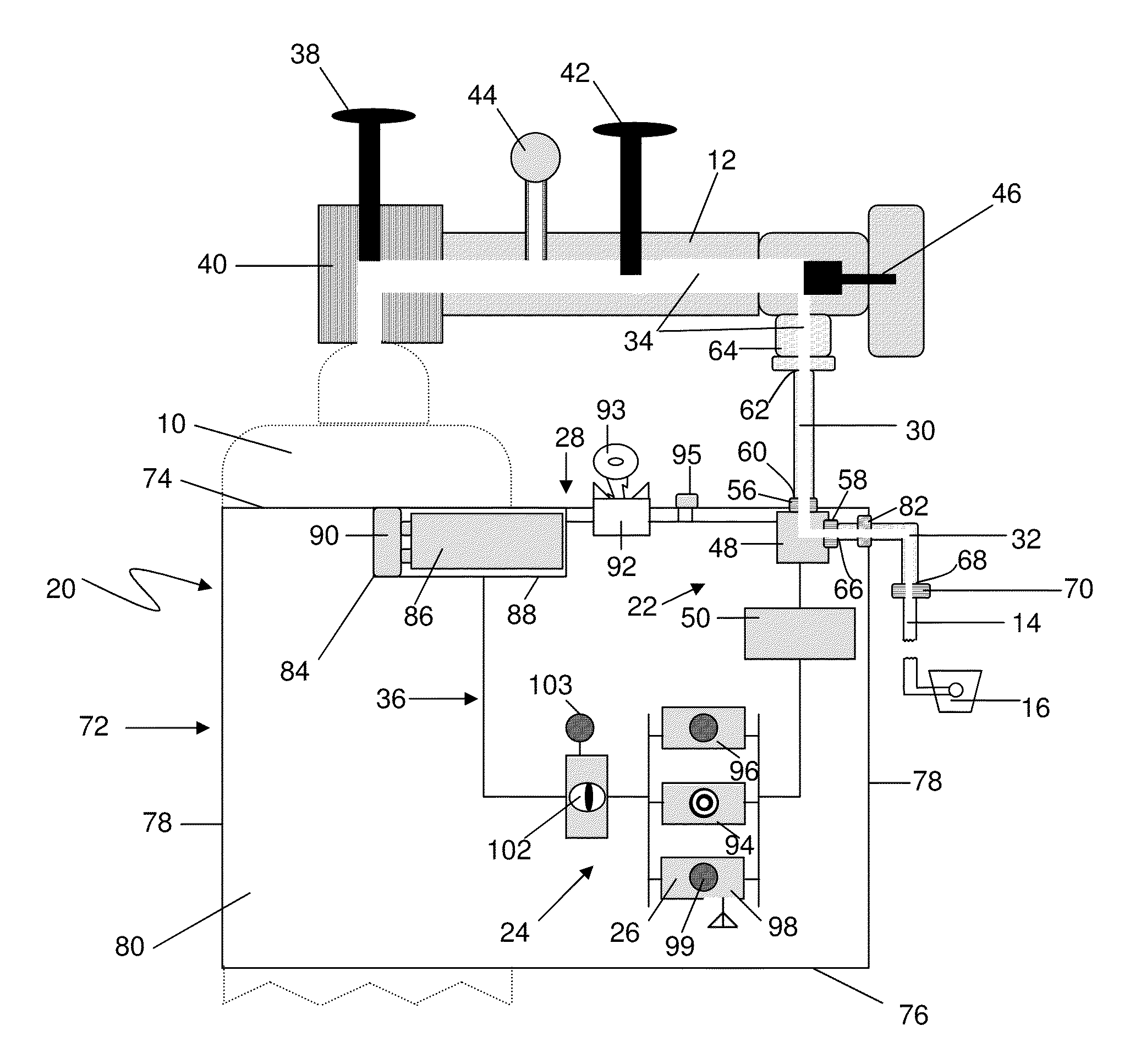

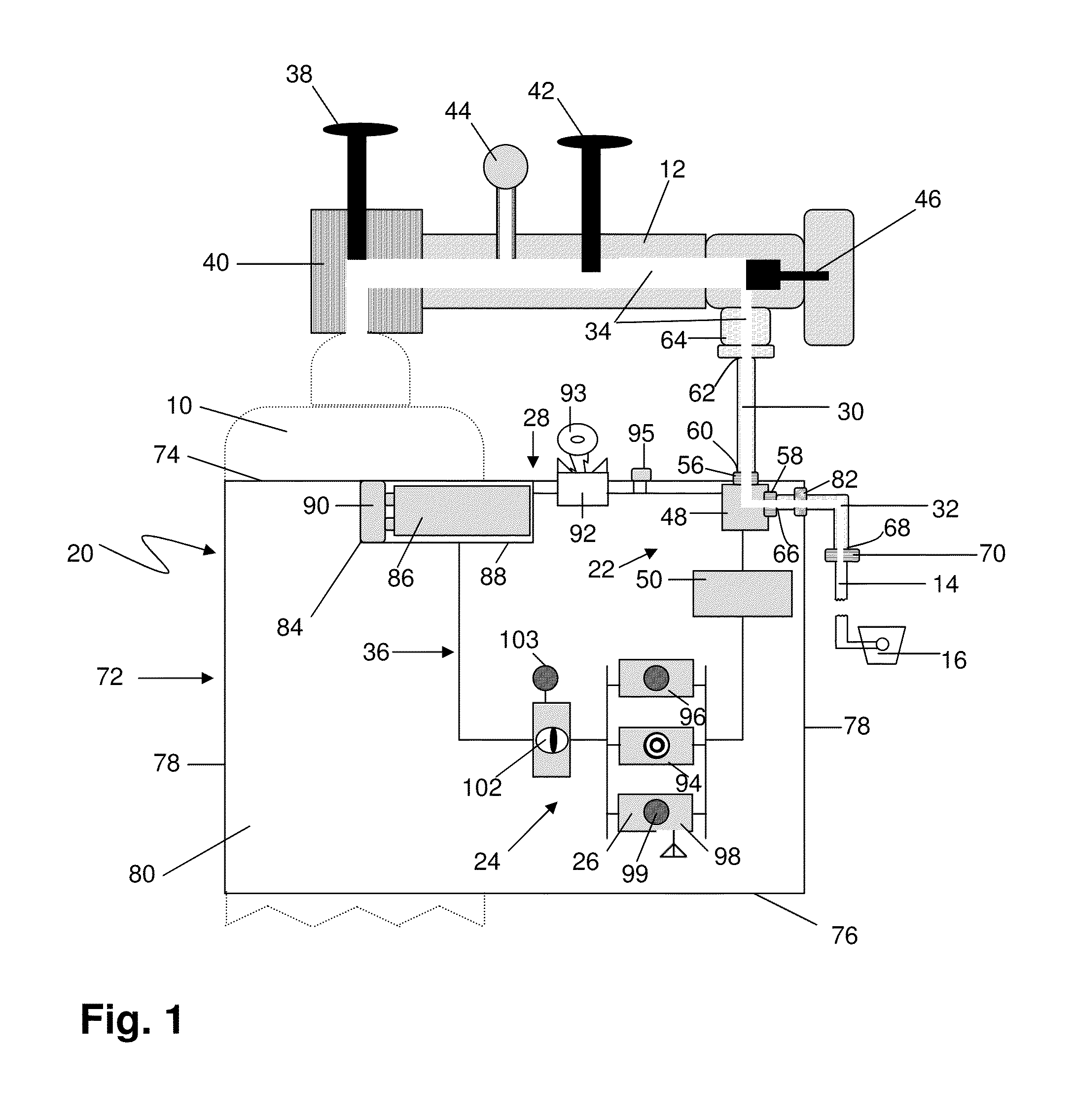

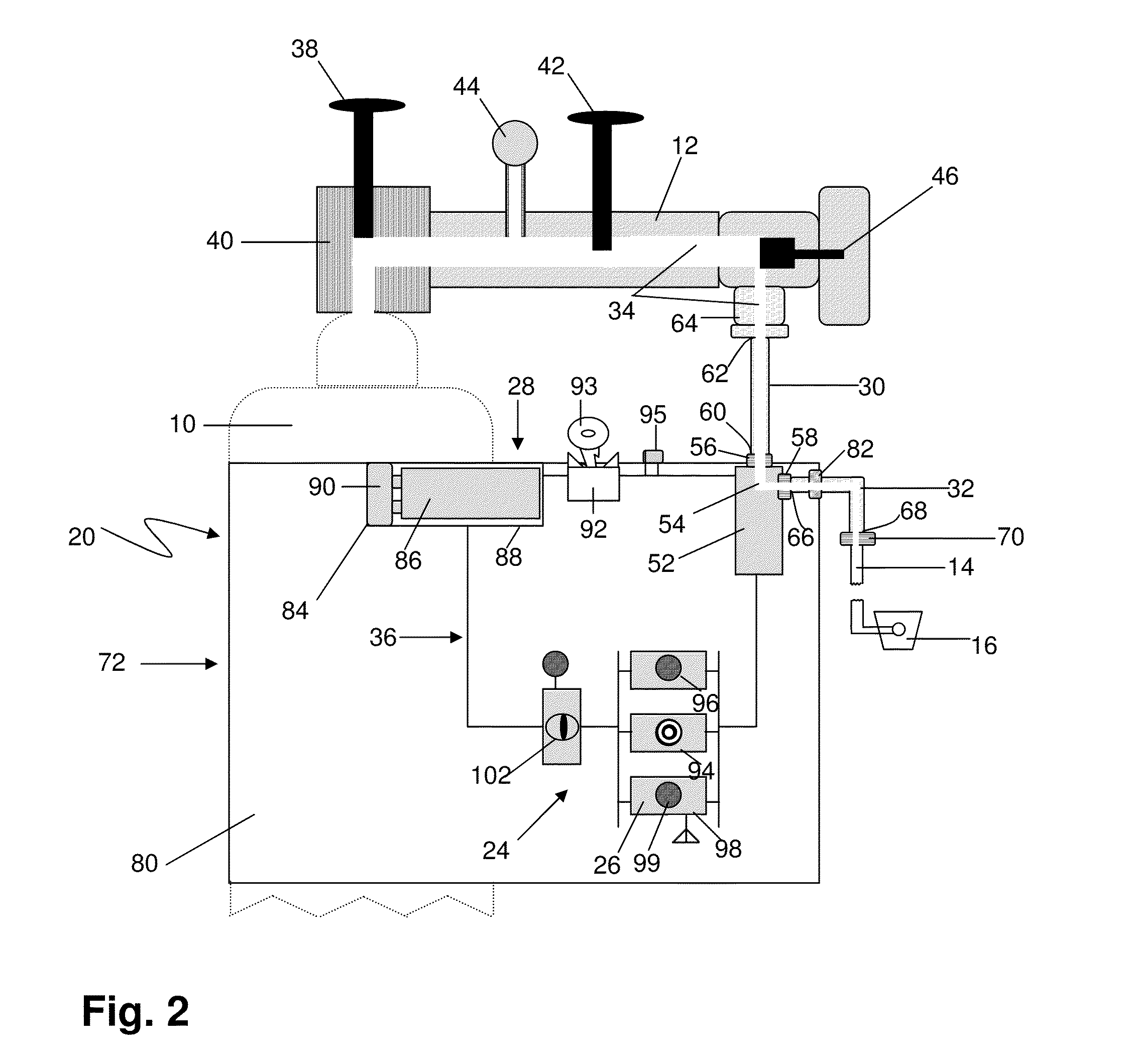

The invention relates to methods and systems for the storage and recovery of energy using open-air hydraulic-pneumatic accumulator and intensifier arrangements that combine at least one accumulator and at least one intensifier in communication with a high-pressure gas storage reservoir on a gas-side of the circuits and a combination fluid motor / pump, coupled to a combination electric generator / motor on the fluid side of the circuits.

Owner:SUSTAINX

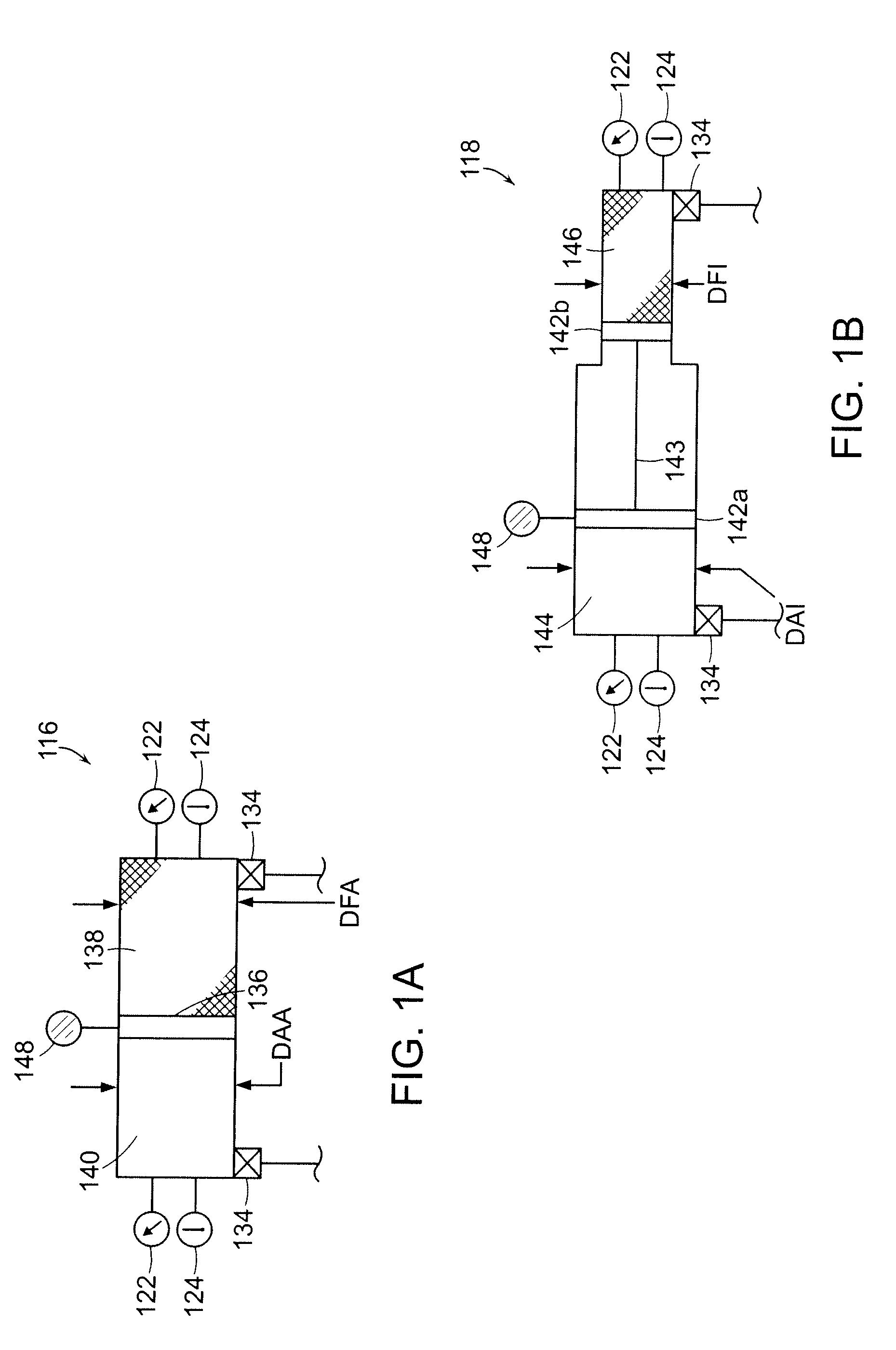

Systems and Methods for Energy Storage and Recovery Using Rapid Isothermal Gas Expansion and Compression

InactiveUS20100089063A1Increase energy densityHigh outputElectrical storage systemInternal combustion piston enginesProduct gasEngineering

The invention relates to systems and methods for rapidly and isothermally expanding and compressing gas in energy storage and recovery systems that use open-air hydraulic-pneumatic cylinder assemblies, such as an accumulator and an intensifier in communication with a high-pressure gas storage reservoir on a gas-side of the circuits and a combination fluid motor / pump, coupled to a combination electric generator / motor on the fluid side of the circuits. The systems use heat transfer subsystems in communication with at least one of the cylinder assemblies or reservoir to thermally condition the gas being expanded or compressed.

Owner:SUSTAINX

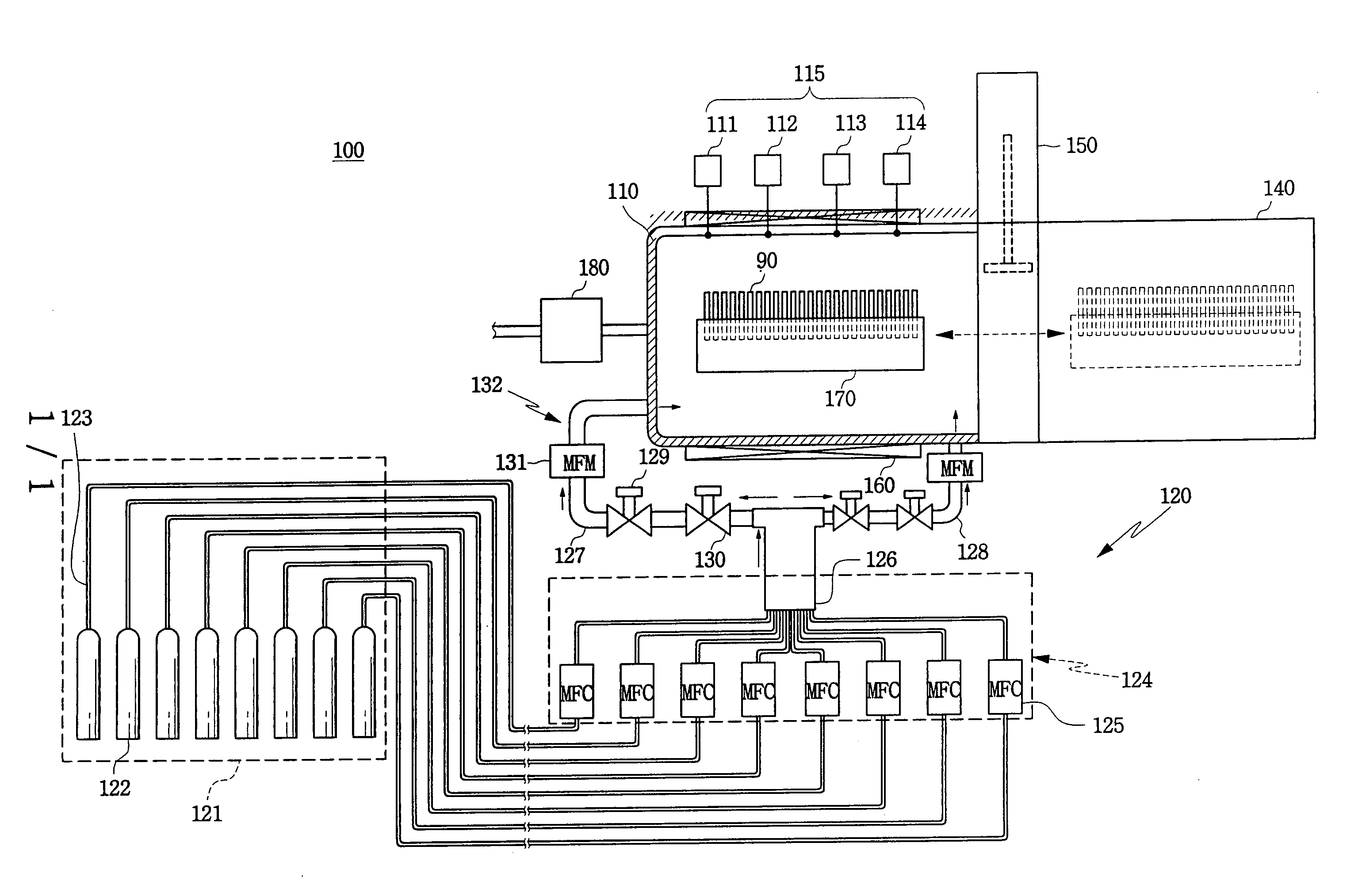

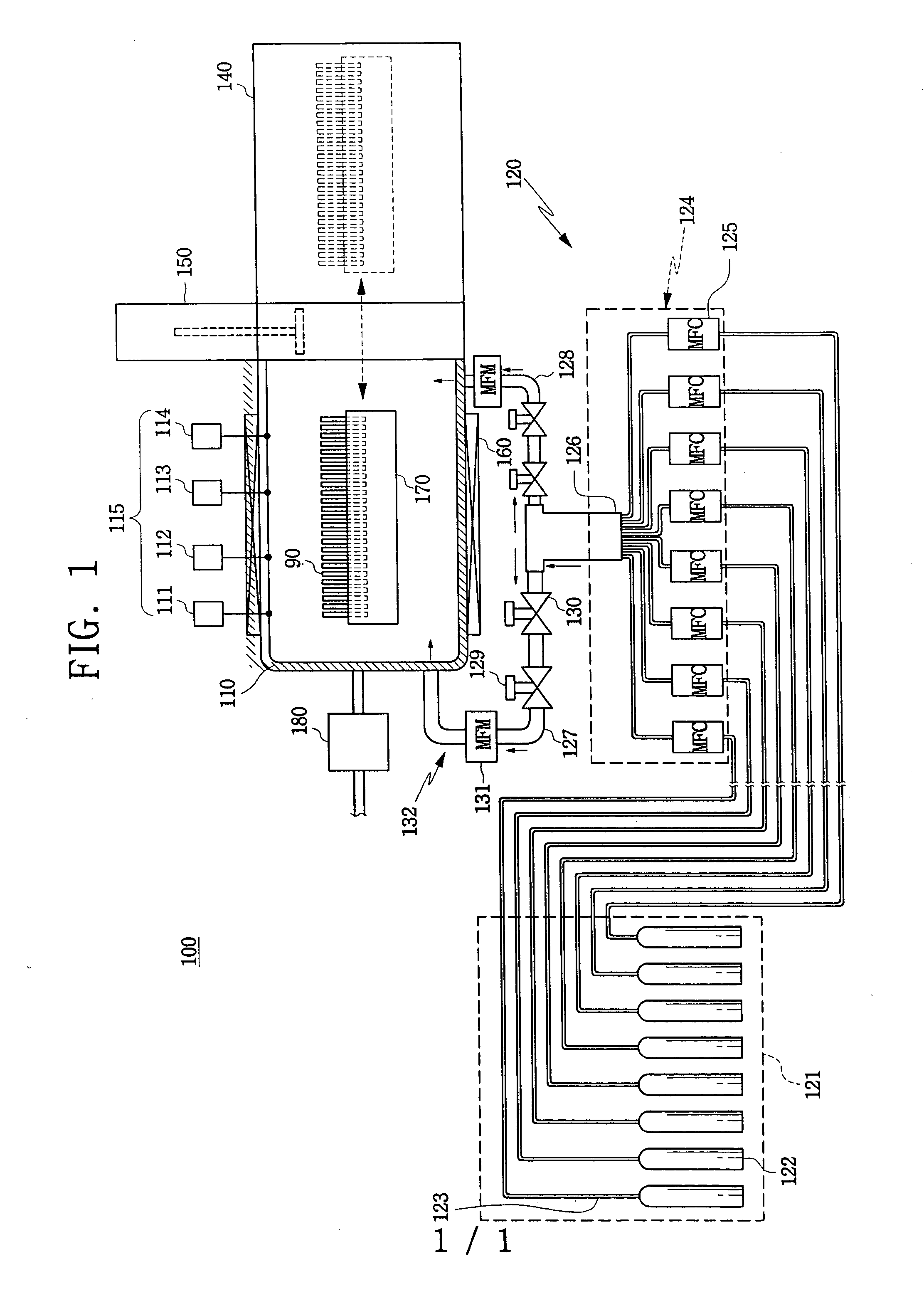

Gas supply unit and semiconductor device manufacturing apparatus using the same

InactiveUS20050016452A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDevice materialManufactured apparatus

A semiconductor device manufacturing apparatus is provided. The semiconductor device manufacturing apparatus comprises a furnace having a closed predetermined space for seating a wafer, a loading device located at one side of the furnace to load the wafer on which a prior process may have been performed, a gate valve interposed between the furnace and the loading device to selectively open / close a pathway between the furnace and the loading device, a heater for heating an interior of the furnace, a vacuum pump for maintaining the interior of the furnace with a suitable pressure necessary to the process, a gas reservoir for storing individually various kinds of reaction gases supplied from an exterior of the space, a gas mixing device connected to the gas reservoir to mix the various kinds of reaction gases supplied from the gas reservoir with an even mixing ratio, at least two mixed gases supply pipes connected to the gas mixing device to supply the reaction gases mixed in the gas mixing device to each direction of the furnace, and a mixed gases flow control unit installed at the mixed gases supply pipe to control the flow of the reaction gases supplied through the mixed gases supply pipe.

Owner:SAMSUNG ELECTRONICS CO LTD

Systems and Methods for Energy Storage and Recovery Using Compressed Gas

InactiveUS20090282822A1Increase energy densityExpand/compress the gas more evenlyFluid couplingsAccumulator installationsThermodynamicsGas cylinder

The invention relates to methods and systems for the storage and recovery of energy using open-air hydraulic-pneumatic accumulator and intensifier arrangements that combine at least one accumulator and at least one intensifier in communication with a high-pressure gas storage reservoir on a gas-side of the circuits and a combination fluid motor / pump, coupled to a combination electric generator / motor on the fluid side of the circuits.

Owner:SUSTAINX

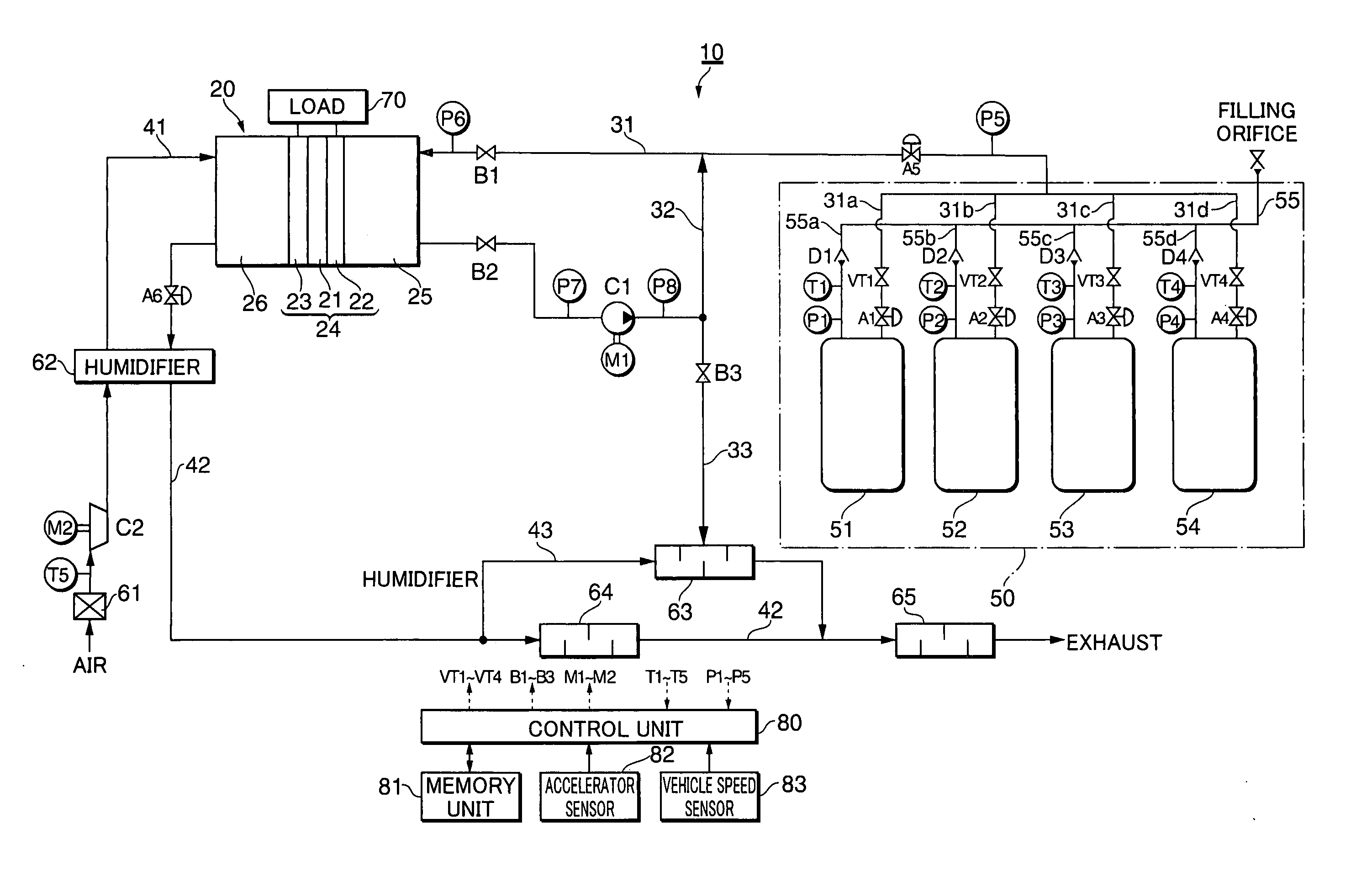

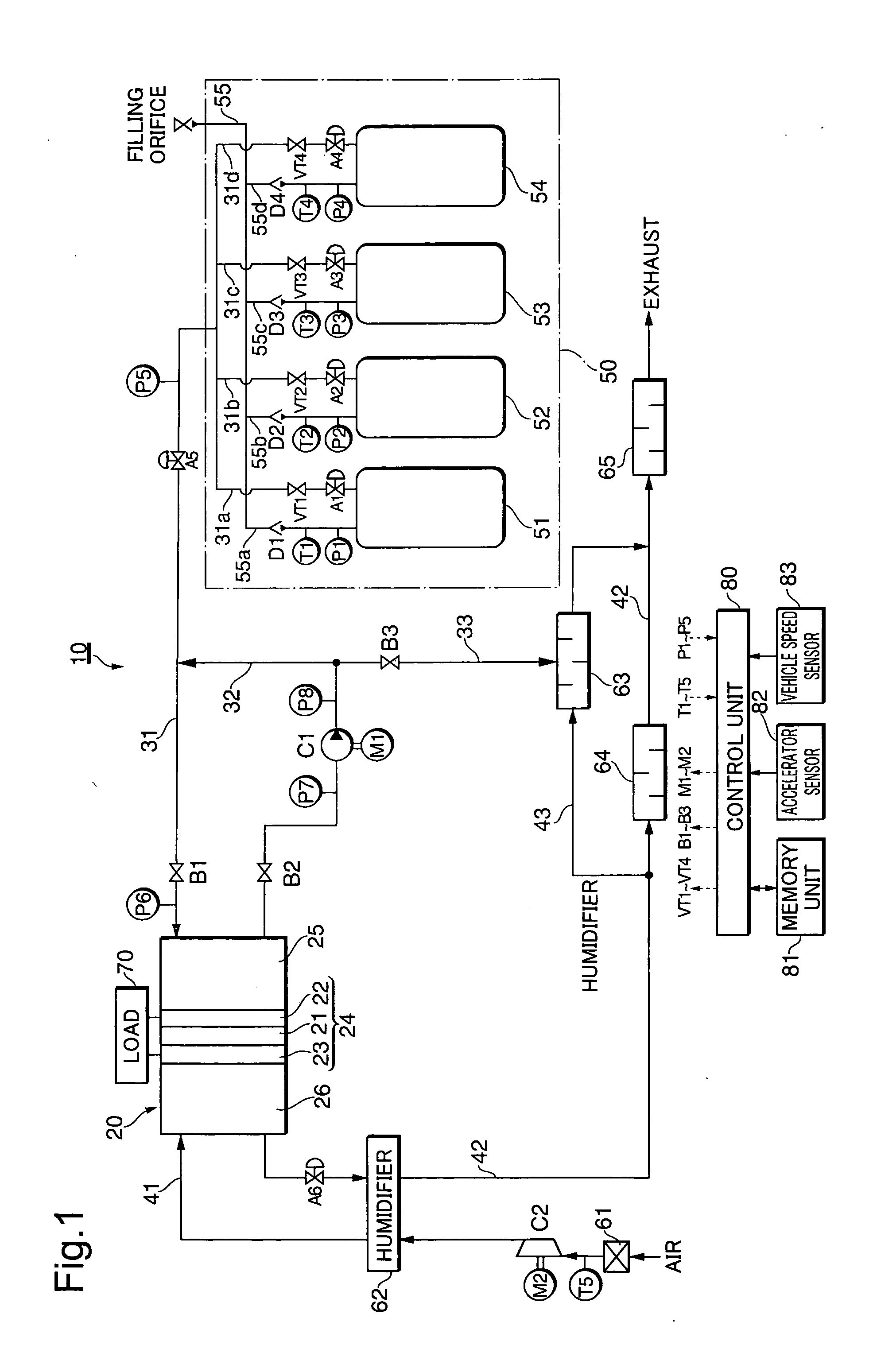

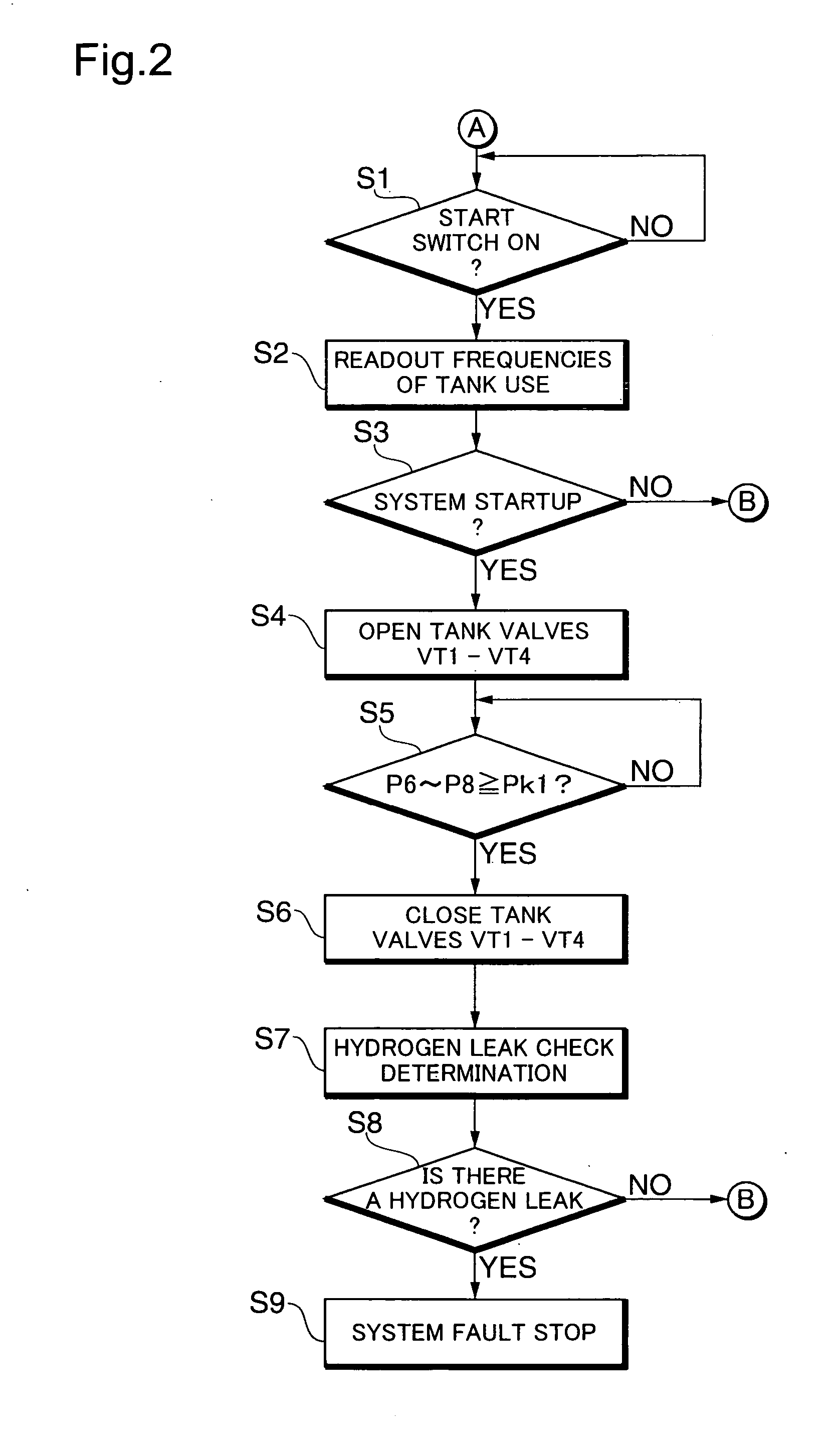

Gas supply apparatus

InactiveUS20060246177A1Reduce supplyReduce pressureGas handling applicationsSpecial dispensing meansProcess engineeringGas holder

A gas supply apparatus including: a tank unit that includes a tank storing a gas and a discharge mechanism discharging the stored gas to the outside of the tank at a reduced pressure of the stored gas; a temperature detector that detects a temperature of the tank; and a supply regulator that regulates supply of the gas from the tank according to the detected tank temperature.

Owner:TOYOTA JIDOSHA KK

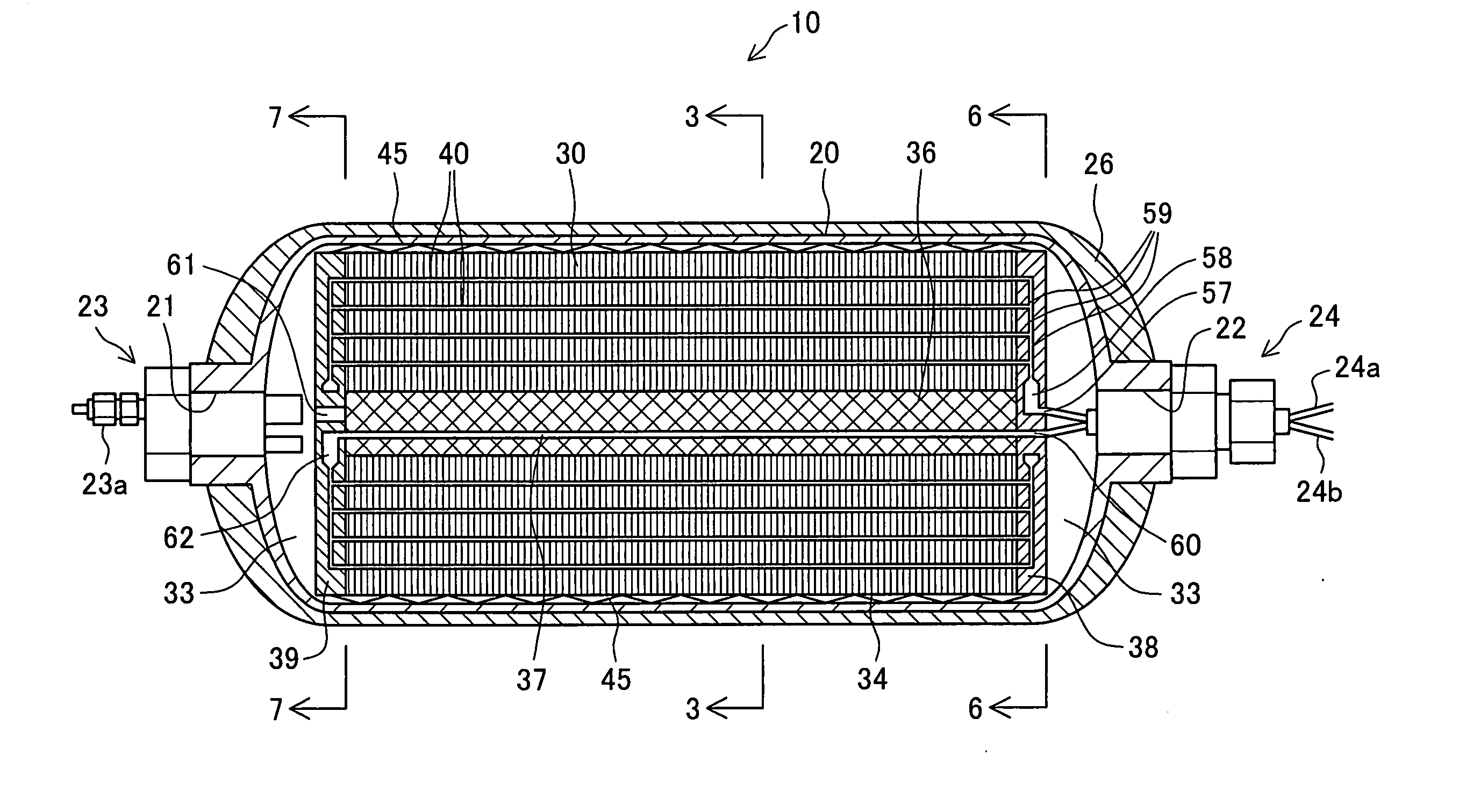

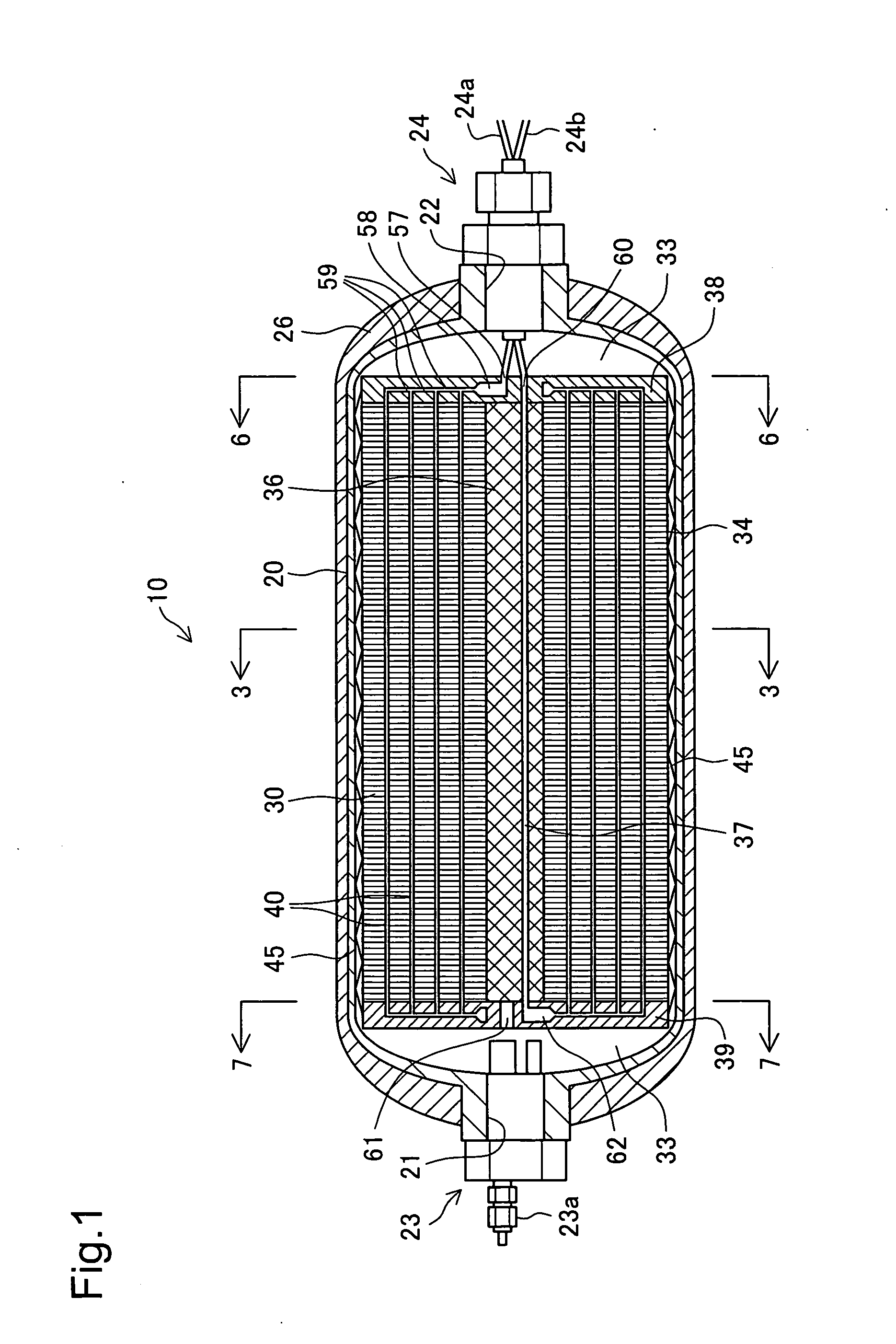

Gas storage tank and method of manufacturing the same

InactiveUS20050000970A1Drawback can be obviatedSufficient performanceReversible hydrogen uptakeCombustion enginesWater coolingHigh pressure

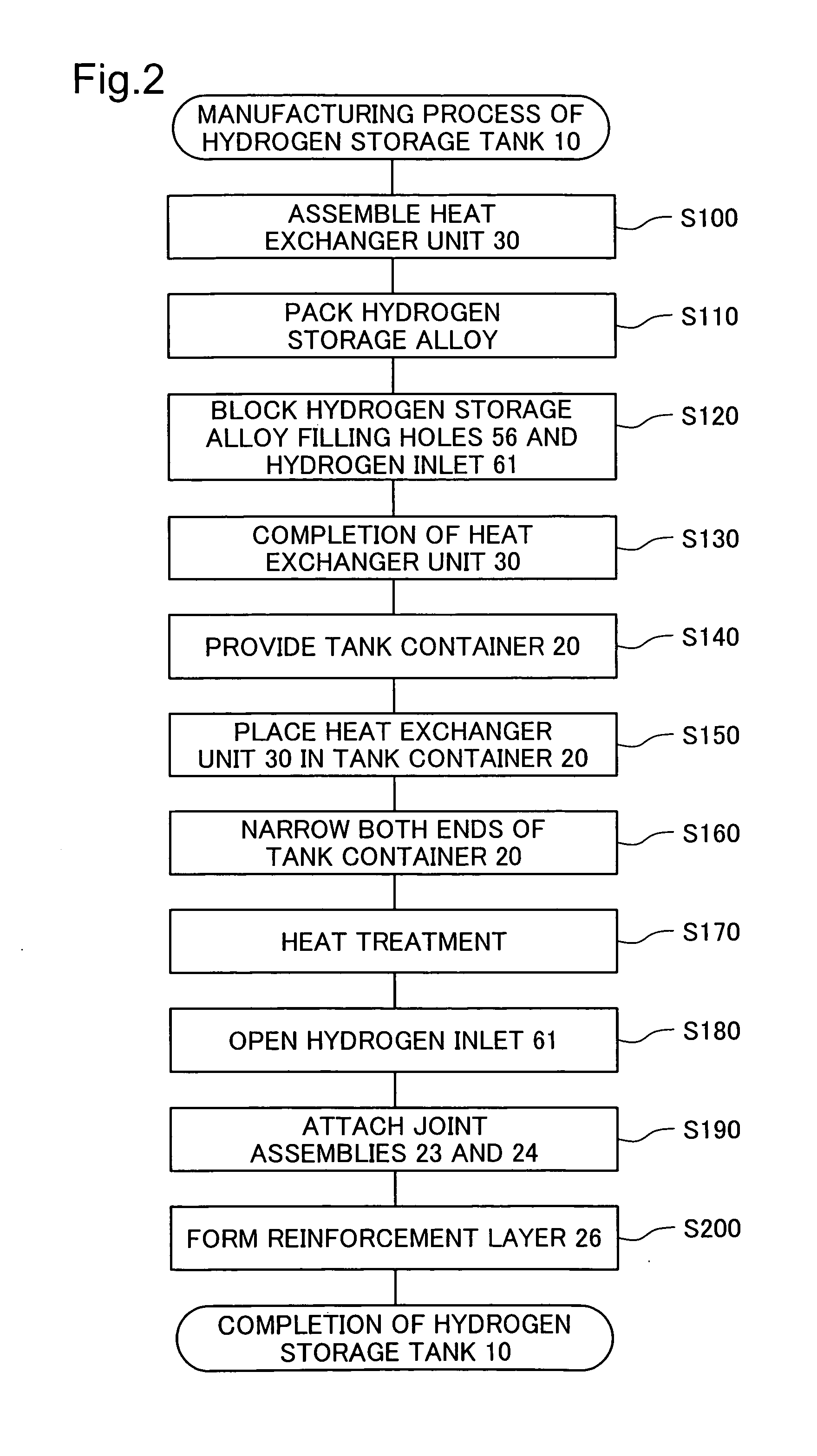

The technique of the invention manufactures a gas storage tank, which includes a gas absorbent / adsorbent and is capable of storing a high-pressure gas. The manufacturing process of a hydrogen storage tank first assembles a heat exchanger unit and packs the particles of hydrogen storage alloy into the heat exchanger unit. The manufacturing process then blocks hydrogen storage alloy filling holes used for packing the hydrogen storage alloy in the heat exchanger unit and attaches a detachable cover member to a hydrogen inlet. The manufacturing process subsequently locates the heat exchange unit filled with the hydrogen storage alloy in a cylindrical tank and narrows both ends of the tank to form joint openings. The manufacturing process then heat-treating the tank under water cooling and detaches the cover member. The manufacturing process attaches joint assemblies to the joint openings and forms a reinforcement layer around the outer circumference of the tank to complete the hydrogen storage tank.

Owner:TOYOTA JIDOSHA KK +1

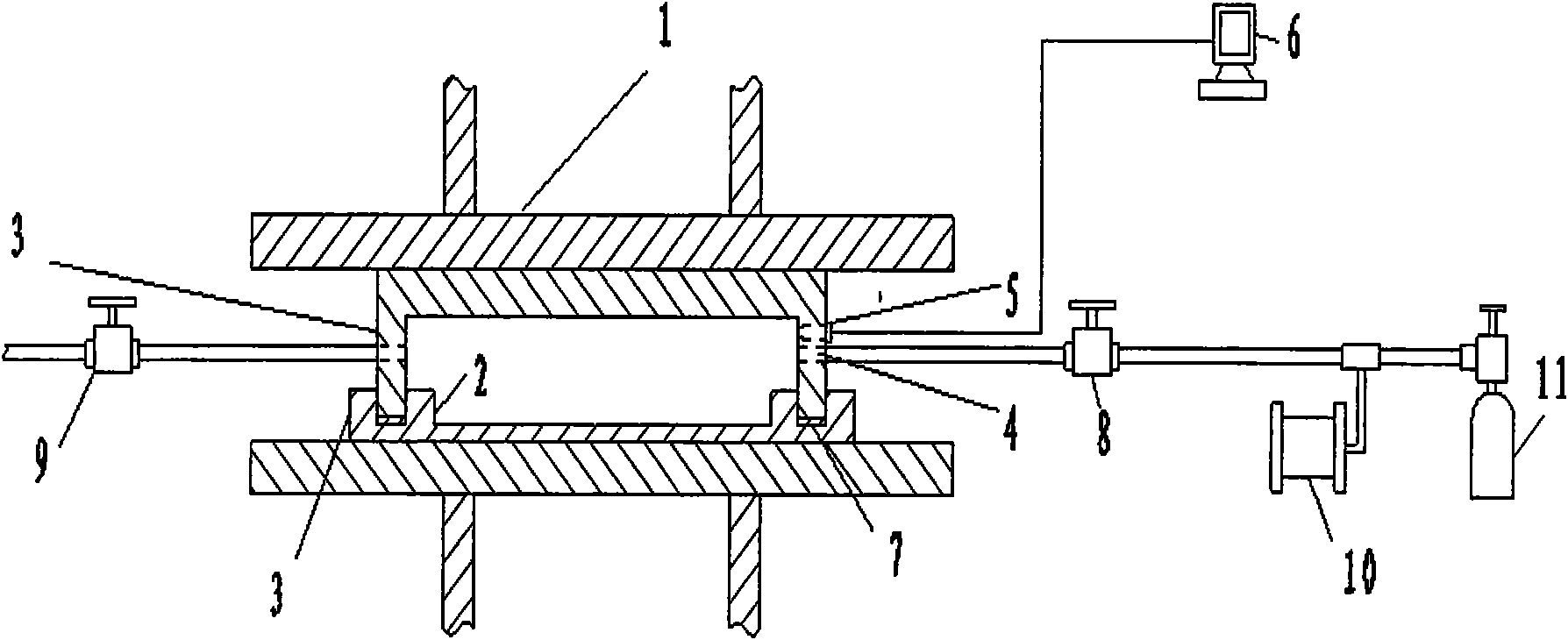

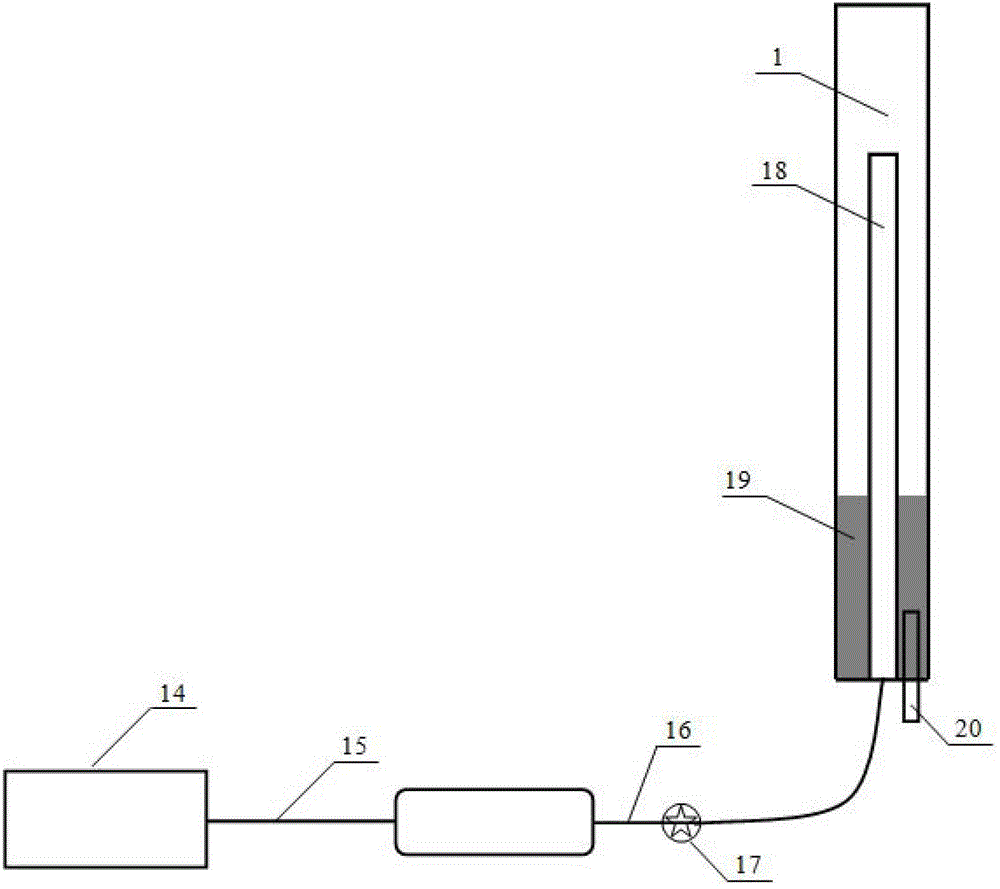

Testing device and measuring and calculating method for gas permeability of compact rock material

ActiveCN103163057AEasy to operateWide range of confining pressurePermeability/surface area analysisRock sampleGas holder

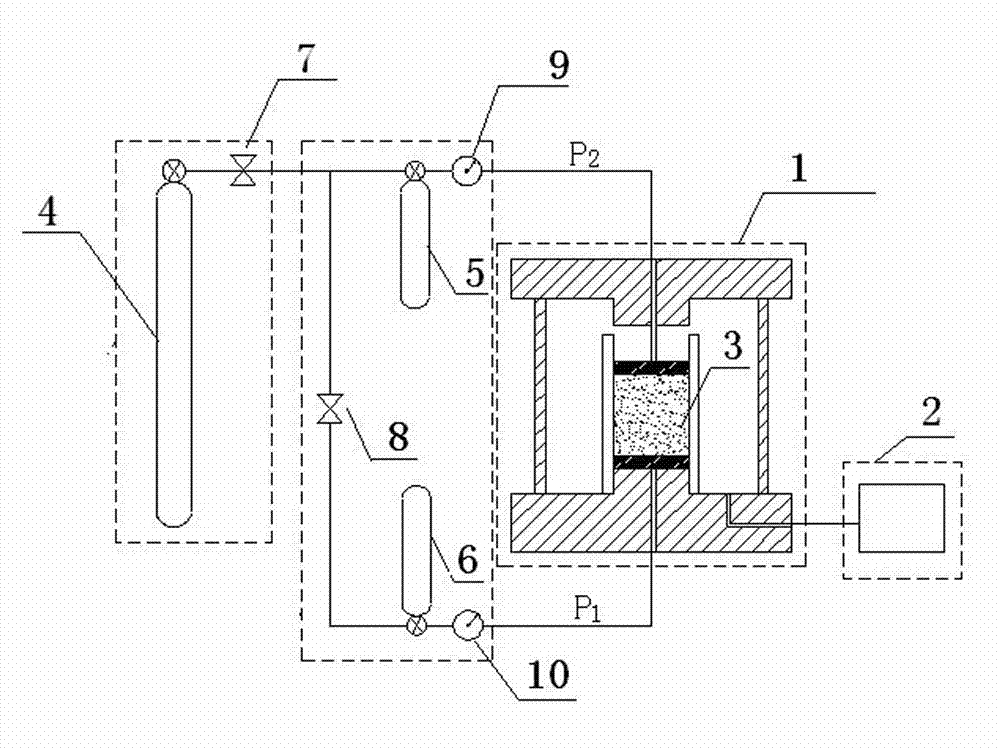

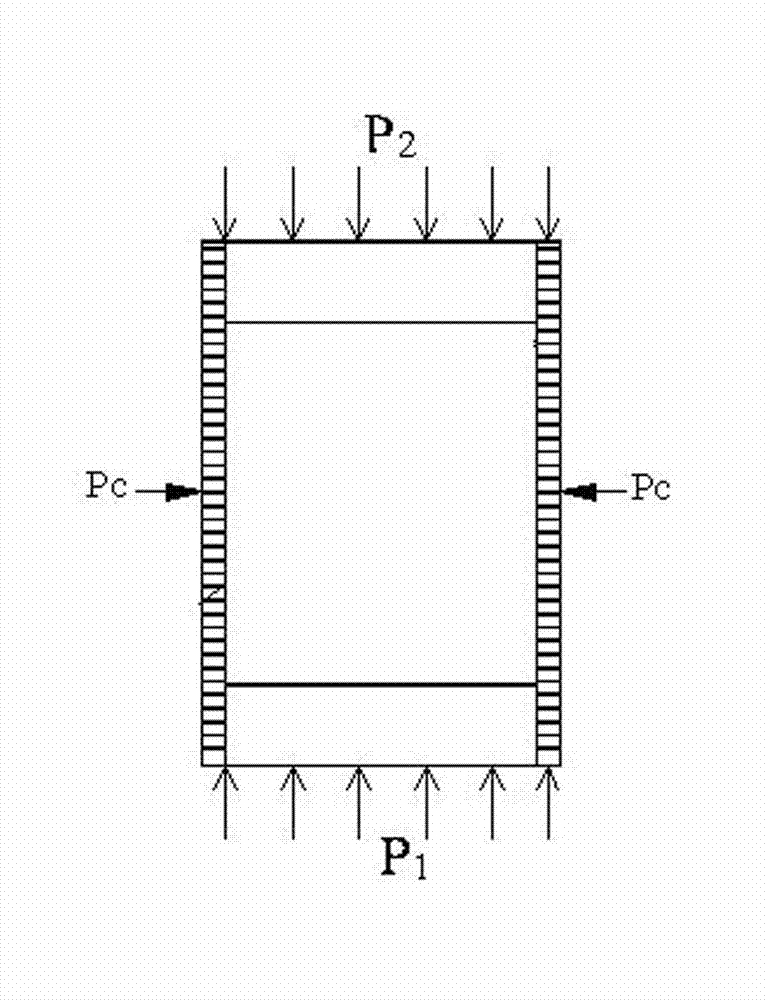

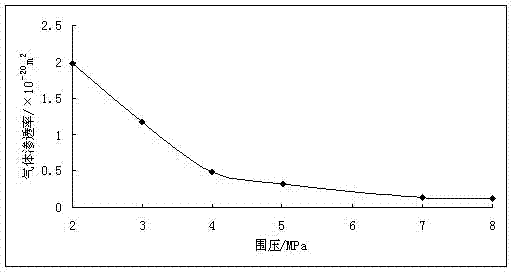

The invention discloses a testing device and a measuring and calculating method for the gas permeability of compact rock material. Under the condition that the gas pressure at two ends of a rock sample are controlled to be the same, a gas pressure pulse is applied to the lower surface of the rock sample by a gas pressure control panel. When gas penetrates through the rock sample and enters a known pressure air storage tank under the action of the pressure of the pulse, the gas permeability of the rock sample is calculated by recording the change of the pressure of the pulse with time. The testing device and the measuring and calculating method are applicable to the measurement of permeability of mediums with low permeability, such as the storage of underground petroleum and natural gas, the storage of CO2, the disposal of nuclear waste, the storage of shale gas and the like and the measurement and calculation of the permeability of other compact rock mediums. Materials the permeability of mediums is between around 10-24m2 can all be measured and calculated by the device system.

Owner:HOHAI UNIV

Gas flow and pressure error alarm

A gas flow warning alarm device to produce an alarm indication when the gas flow rate in a pressurized gas system violates at least one predetermined limit. The alarm device includes a gas flow sensing and error signaling subassembly to generate an error signal upon sensing a violative gas flow rate, and an indicator subassembly activatable by an error signal to produce an alarm indication. The gas flow warning alarm device responds both to the depletion of a pressurized gas reservoir and to blockages and disconnections in a gas line downstream of a regulator. A method for detecting gas flow malfunctions in a pressurized gas system. A reservoir changing device to open a filled reserve reservoir of gas to a pressurized gas system upon receiving an alarm indication that pressure in a primary gas reservoir has fallen below a predetermined limit.

Owner:ADVANCED INTERACTIVE RESPONSE SYST

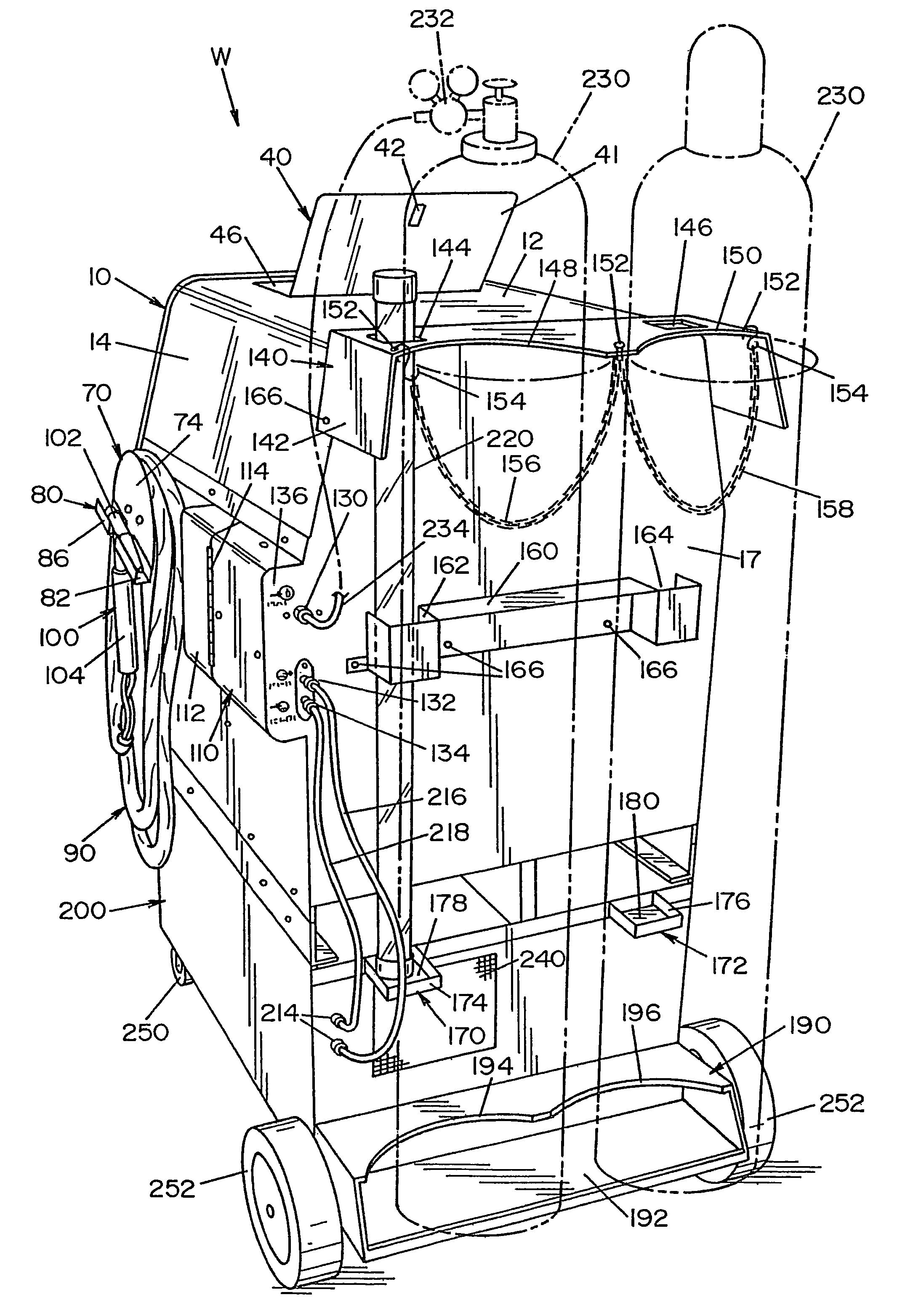

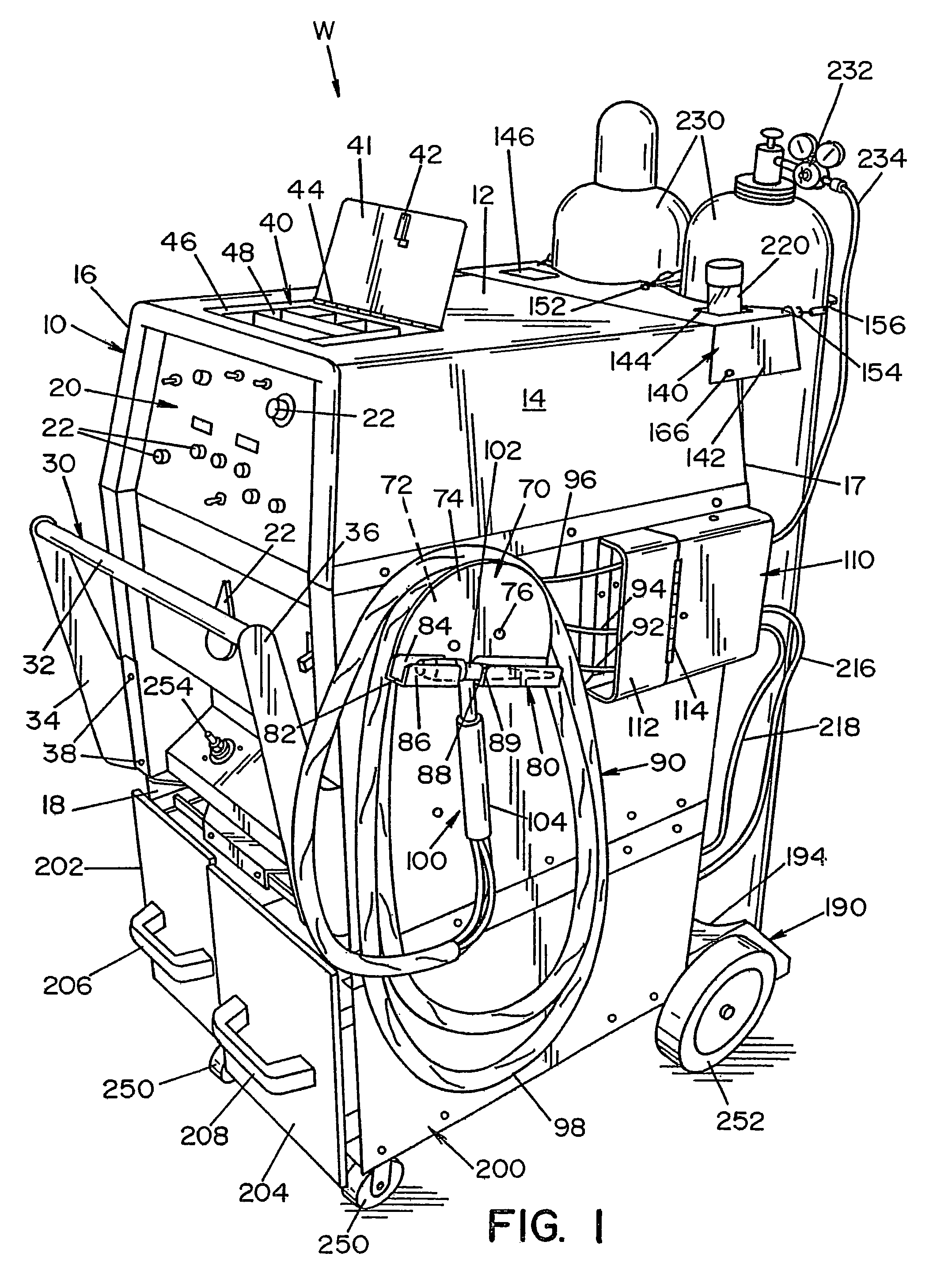

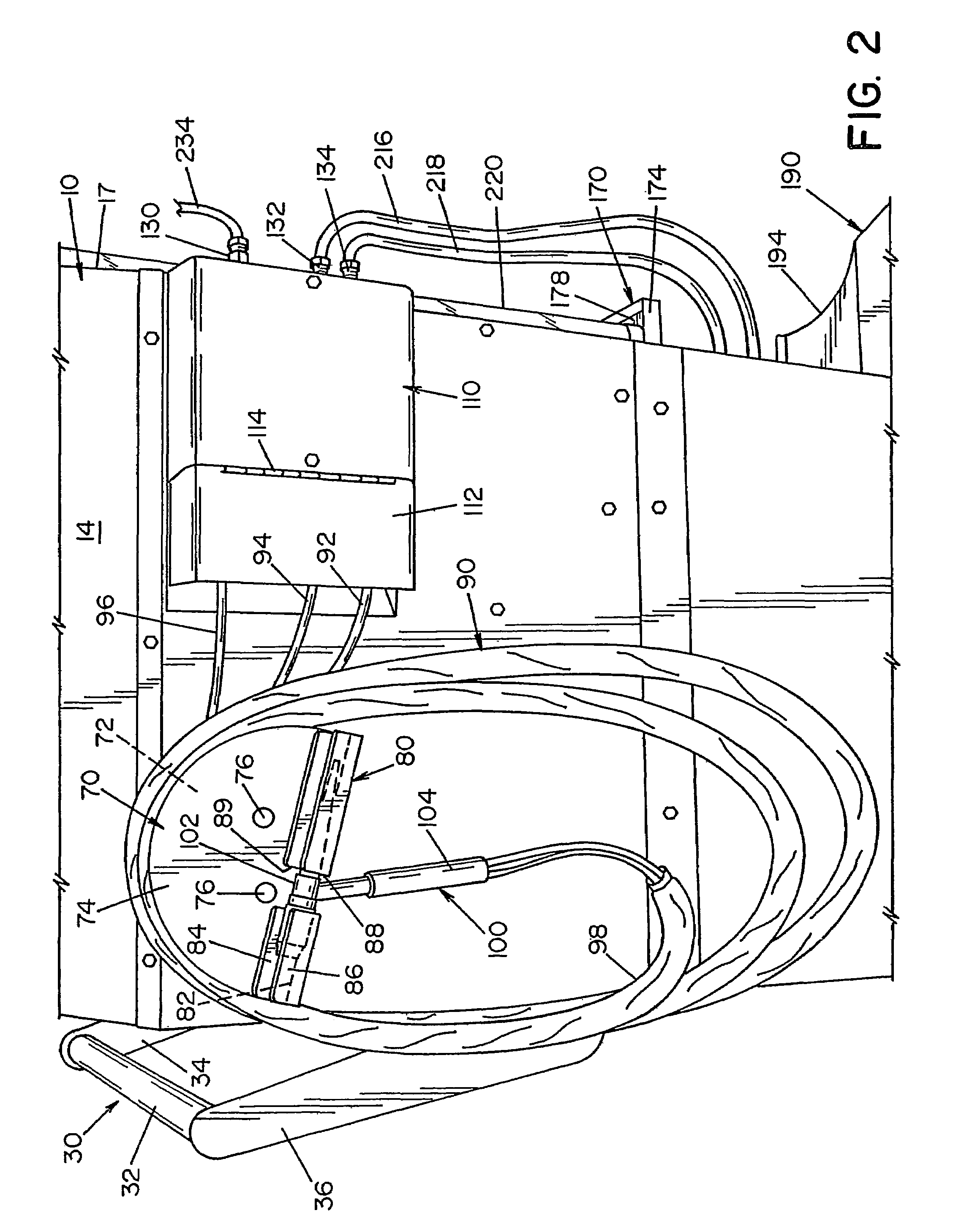

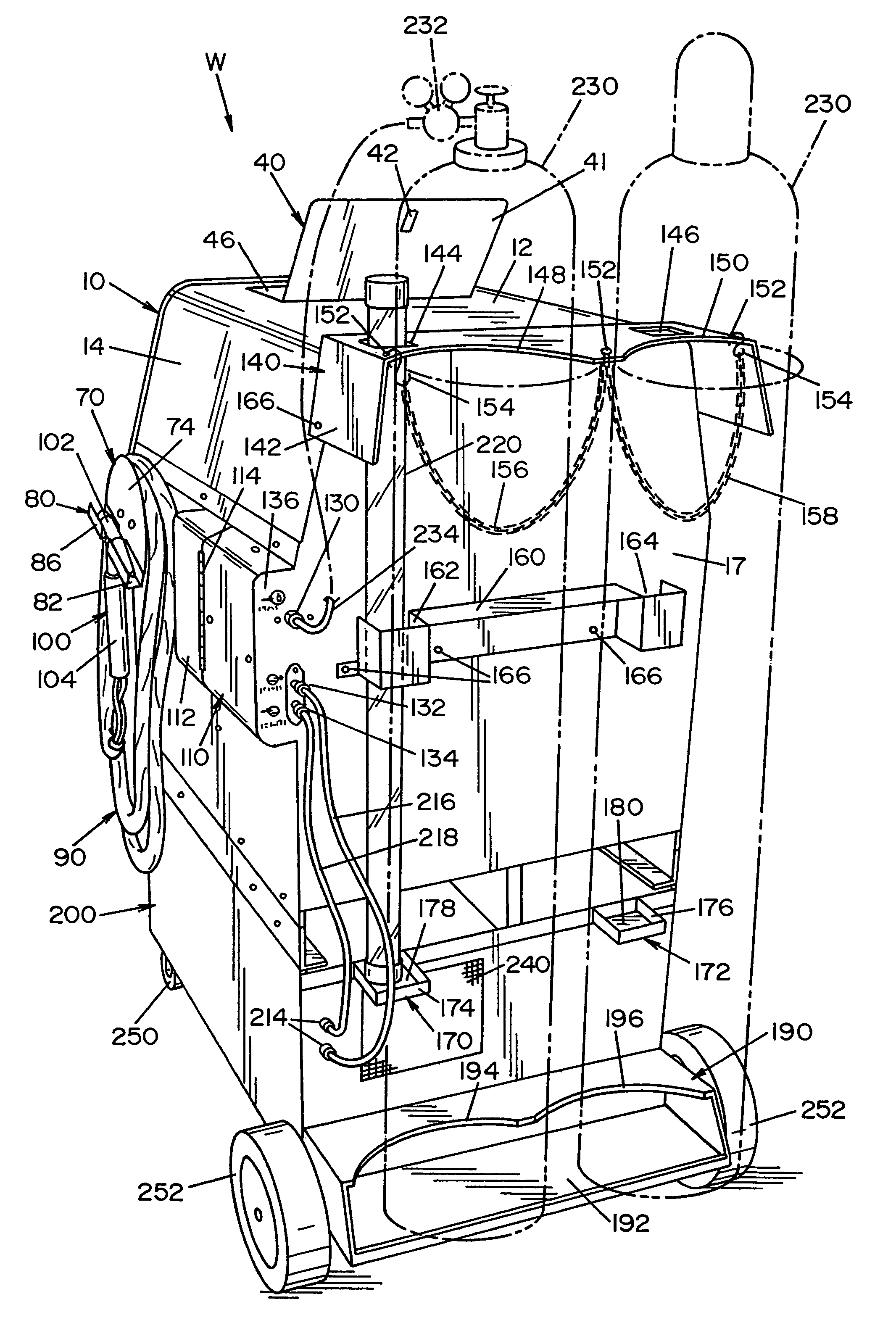

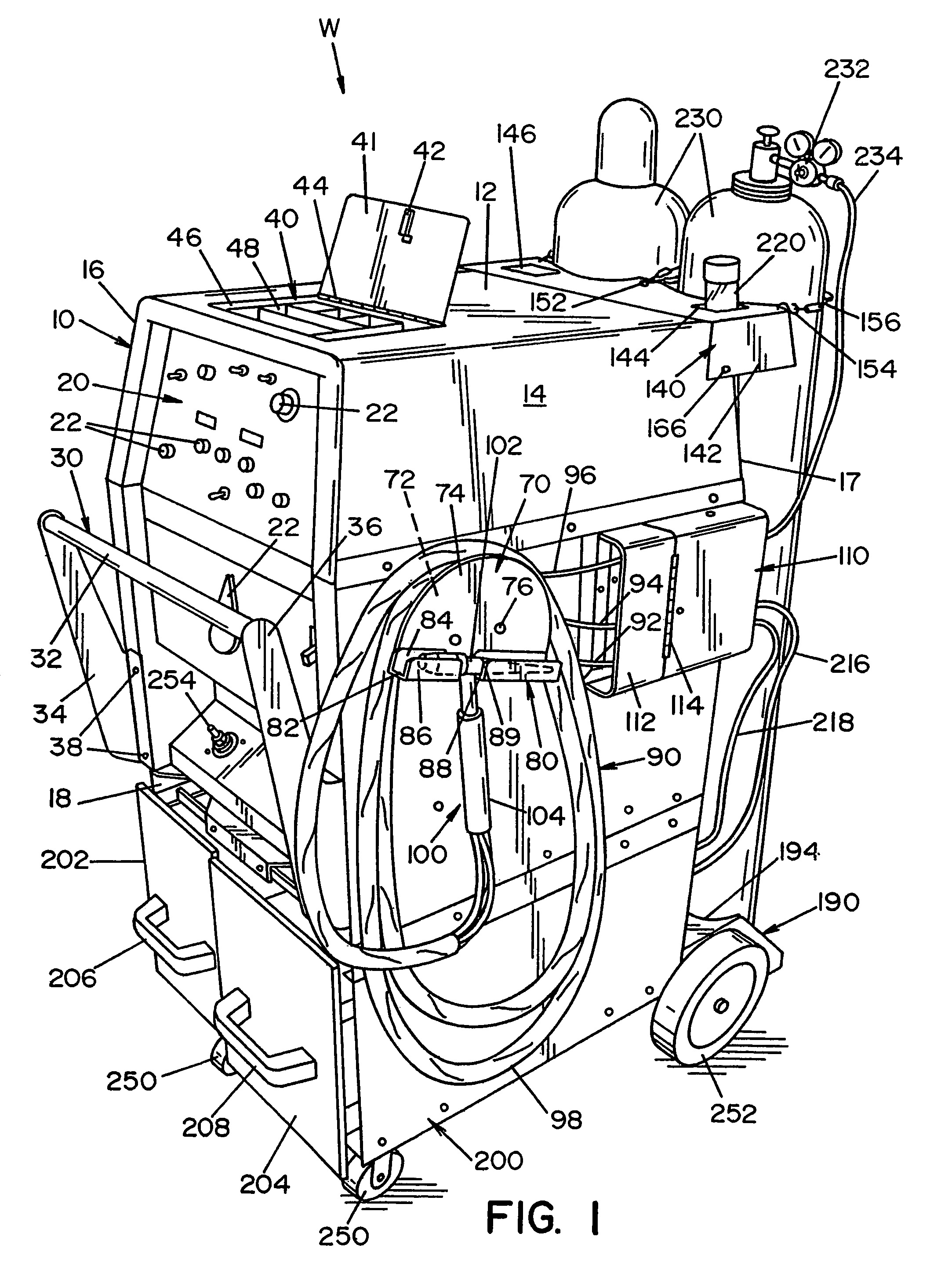

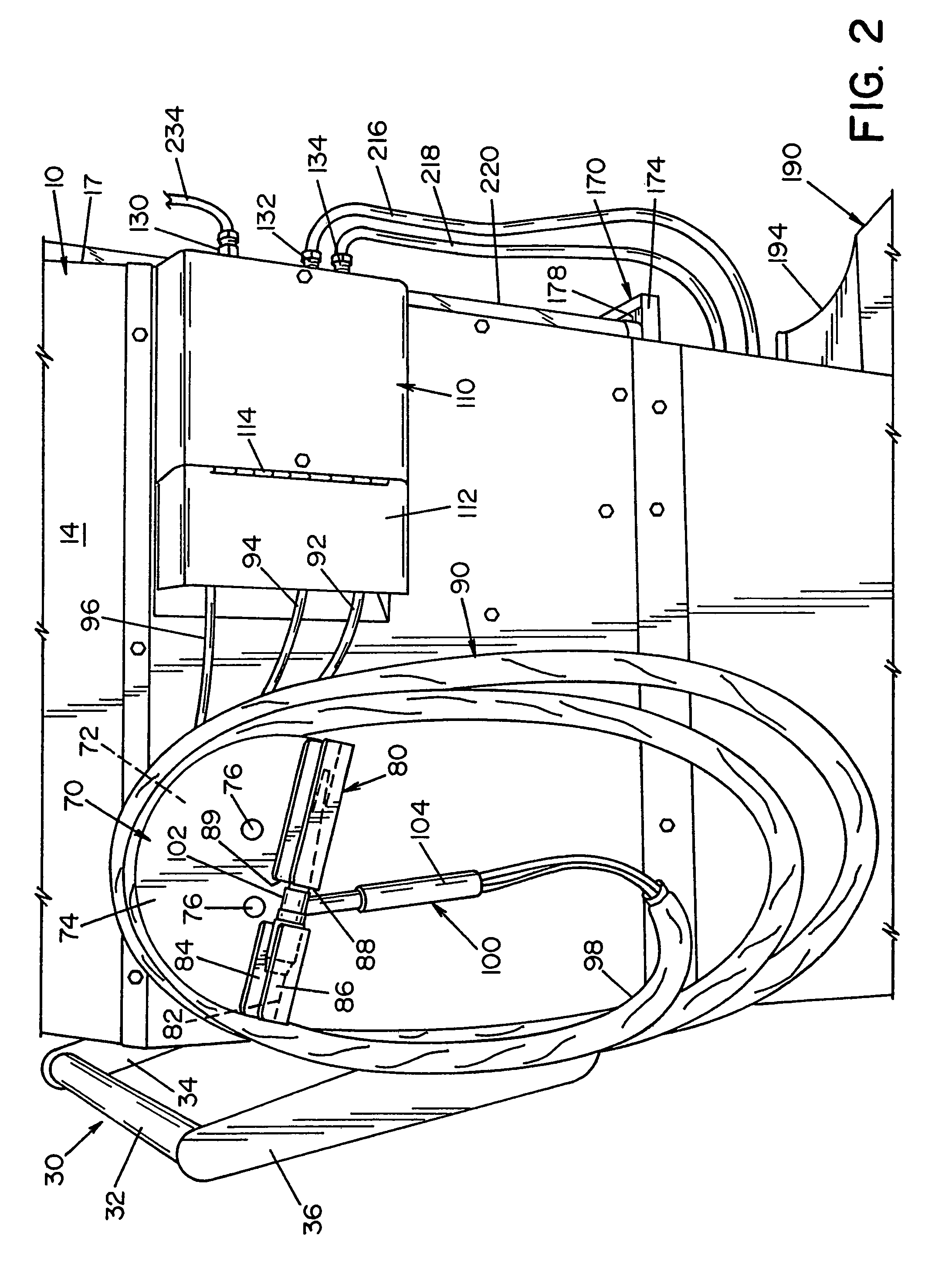

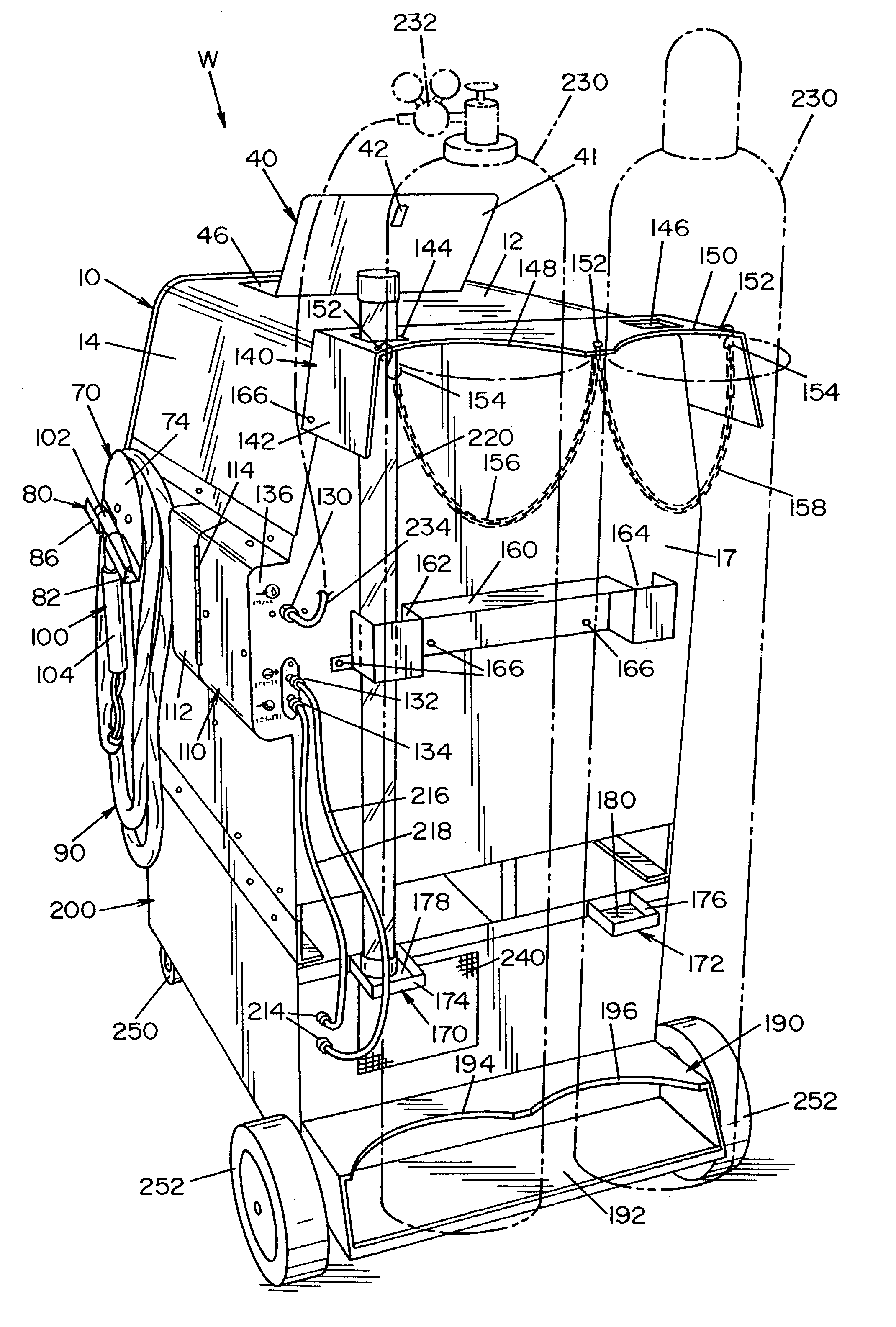

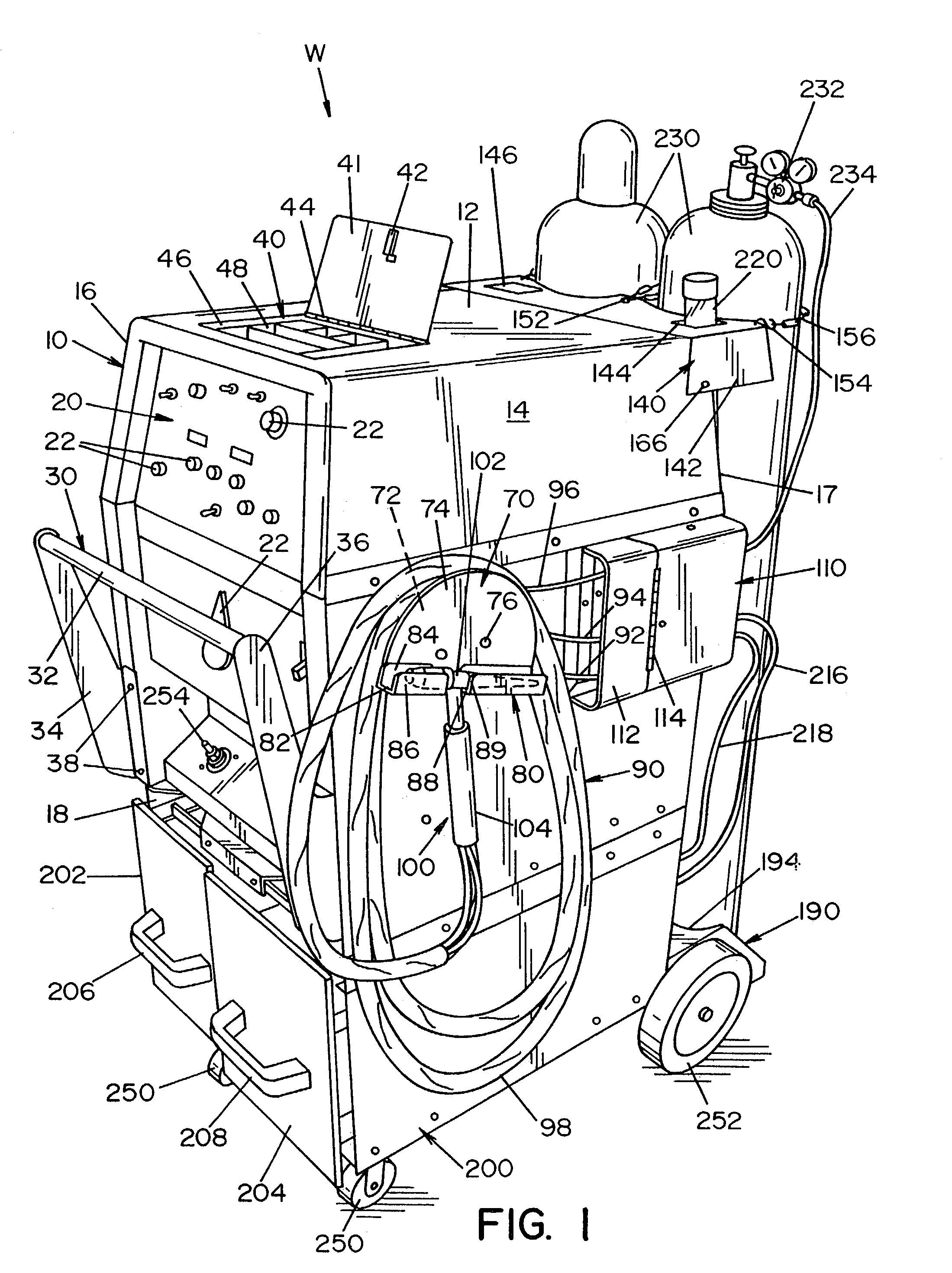

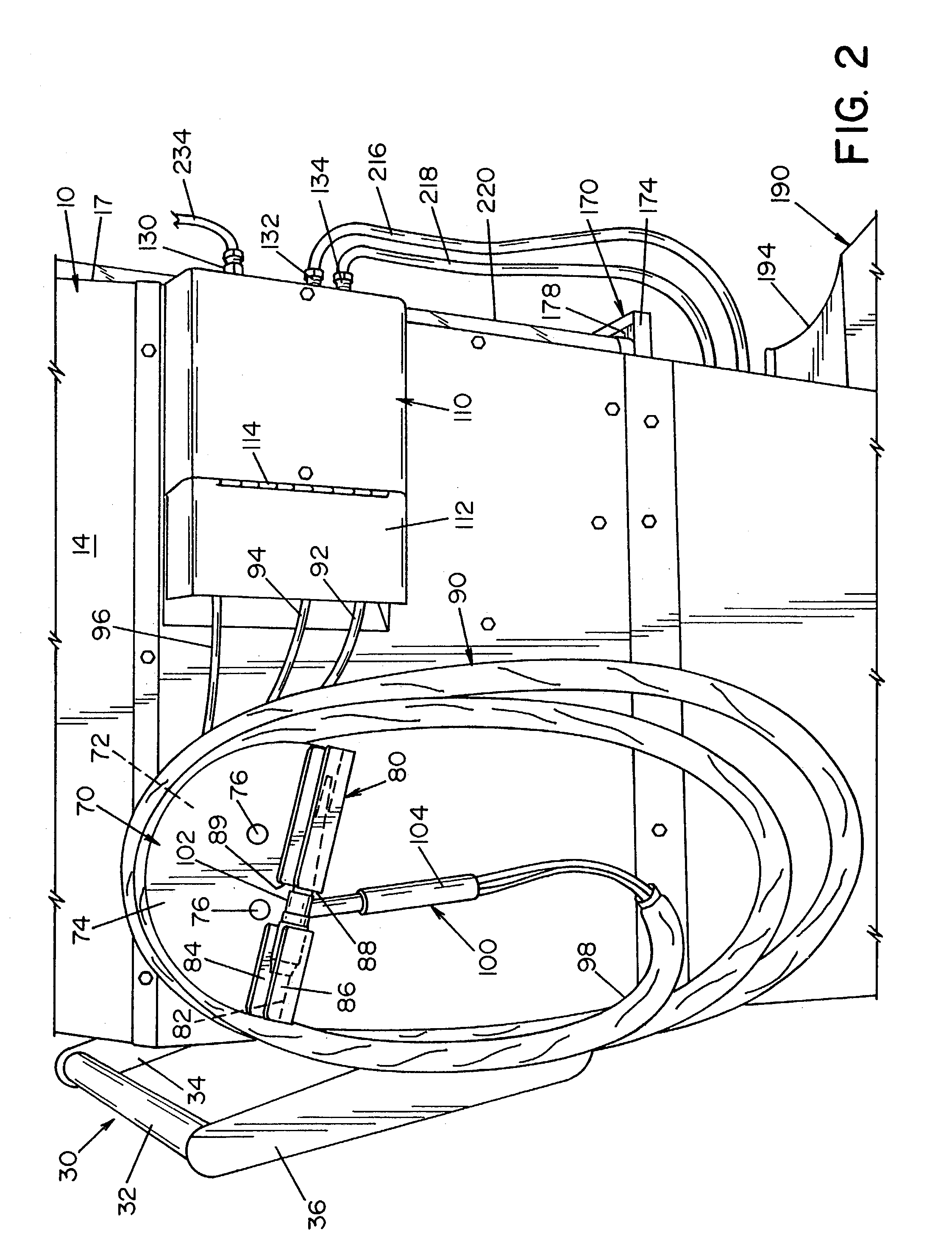

Welding accessory arrangement

InactiveUS7241973B1Easy to transportConveniently and more easily transportWelding/cutting auxillary devicesAuxillary welding devicesEngineeringGas holder

A welding accessory system for a welder that includes a welder having a welder housing and at least one welding accessory support connected to the welder housing to support at least one welding accessory of a welder. The one or more welding accessory supports include a cable holder, an electrode holder, a cooling fluid holder, a cylinder gas holder, a cable connector box, and / or a tool holder.

Owner:LINCOLN GLOBAL INC

Welding accessory arrangement

A welding accessory system for a welder that includes a welder having a welder housing and at least one welding accessory support connected to the welder housing to support at least one welding accessory of a welder. The one or more welding accessory supports include a cable holder, an electrode holder, a cooling fluid holder, a cylinder gas holder, a cable connector box, and / or a tool holder.

Owner:LINCOLN GLOBAL INC

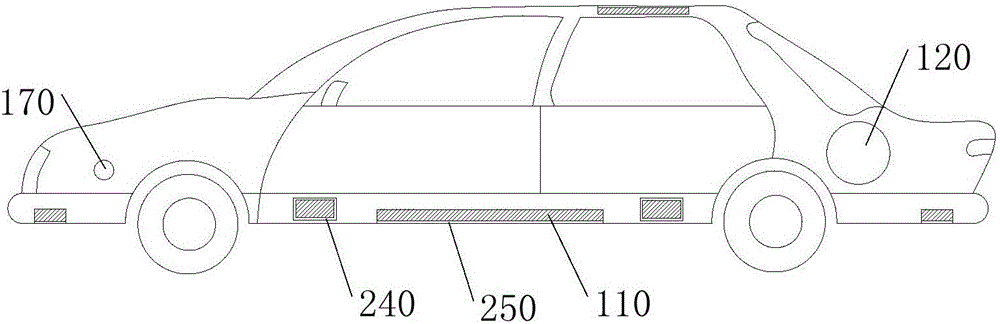

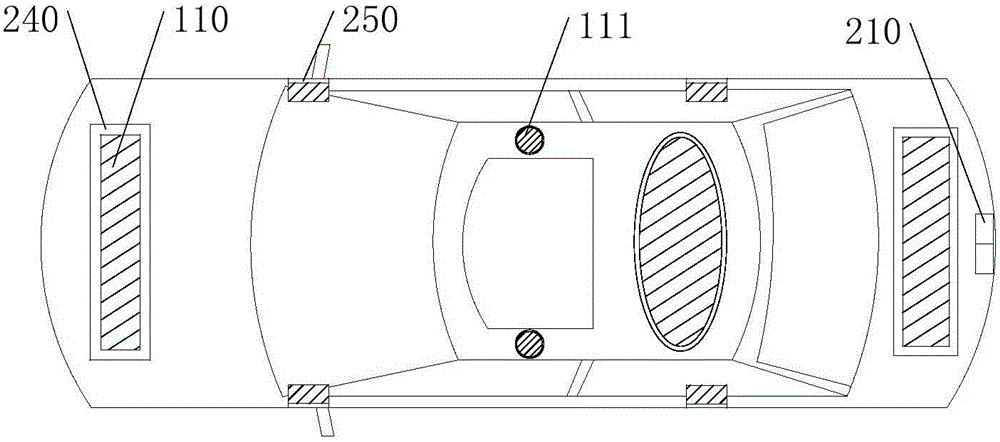

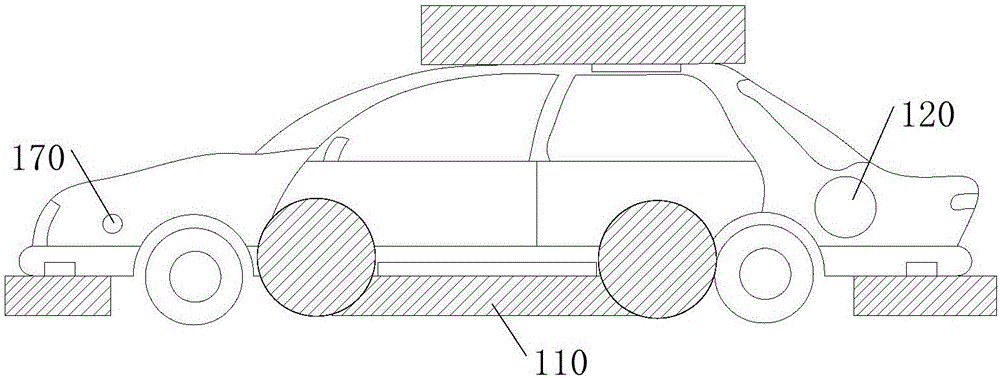

Anti-settling protection device and automobile

PendingCN106740629AAlleviate underinflationAlleviate problems caused byLife-buoysPedestrian/occupant safety arrangementElectricityEngineering

The invention provides an anti-settling protection device, and relates to the technical field of automobile security devices. The anti-settling protection device comprises an air storage tank and a plurality of air bags, wherein the air bags are arranged at the chassis, top and two sides of the automobile, and all communicate with the air storage tank via air-guide tubes; an inflation control valve is arranged on each air-guide tube, and electrically connected with an automobile controller; and a water detection element is arranged on the automobile chassis, and electrically connected with the automobile controller. The invention also discloses an automobile comprising an automobile body and an anti-settling protection device installed on the automobile body. By installing the settling protection device on the automobile body, the inflation device can be started before the automobile falls into water or after the automobile falls, so that the air storage tank can inflate each air bag, the automobile can be lifted up or reduced in settling speed under the effect of buoyancy of water, and thus life security of personnel in the automobile is ensured.

Owner:周小平

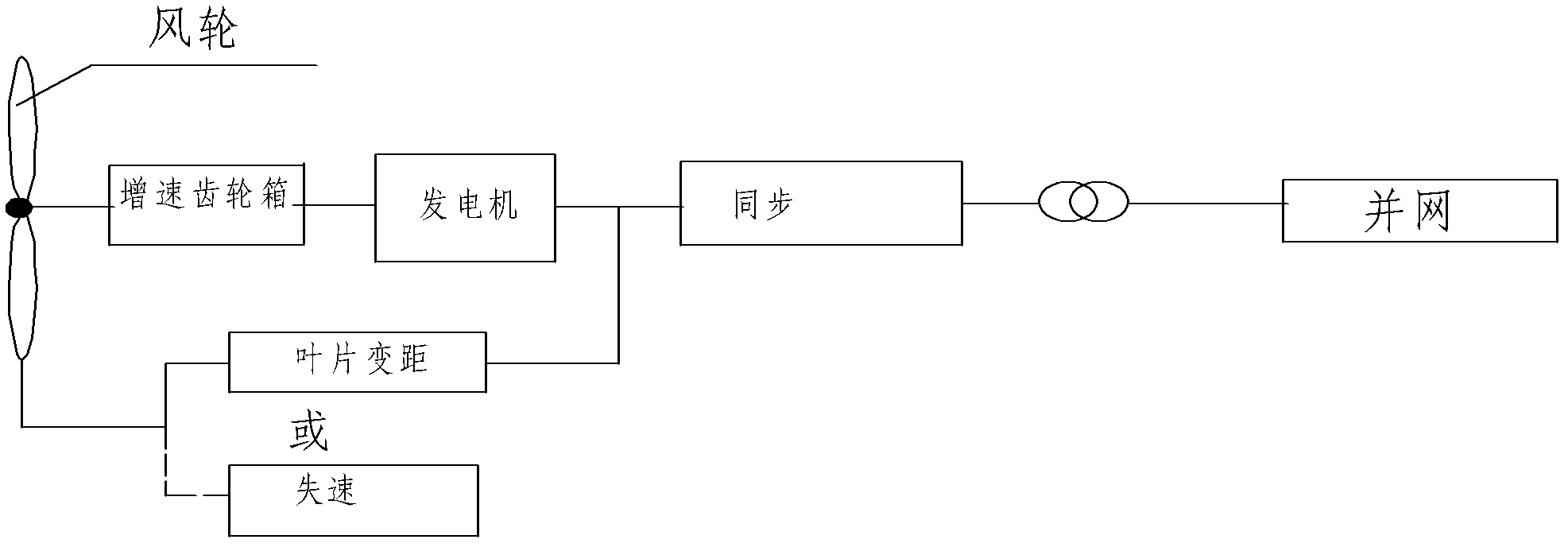

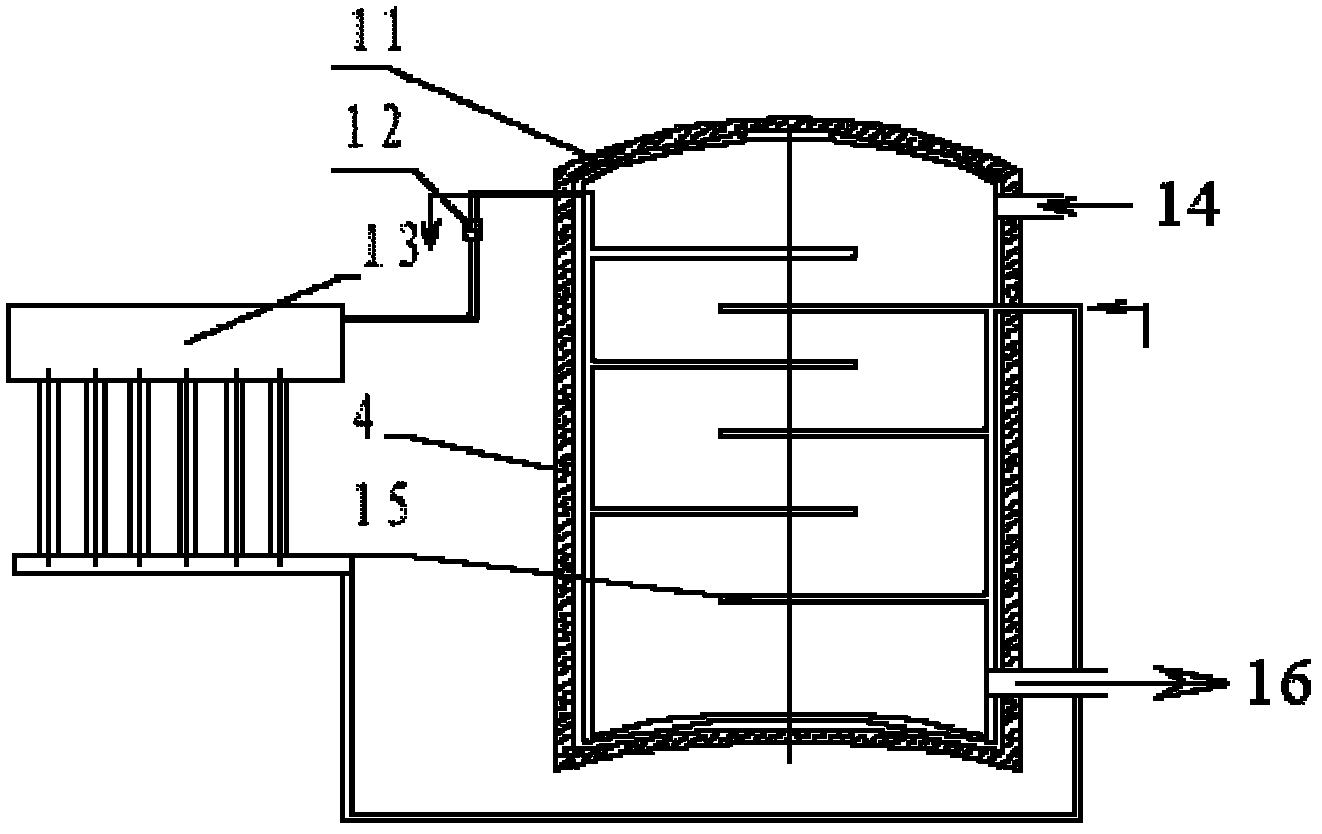

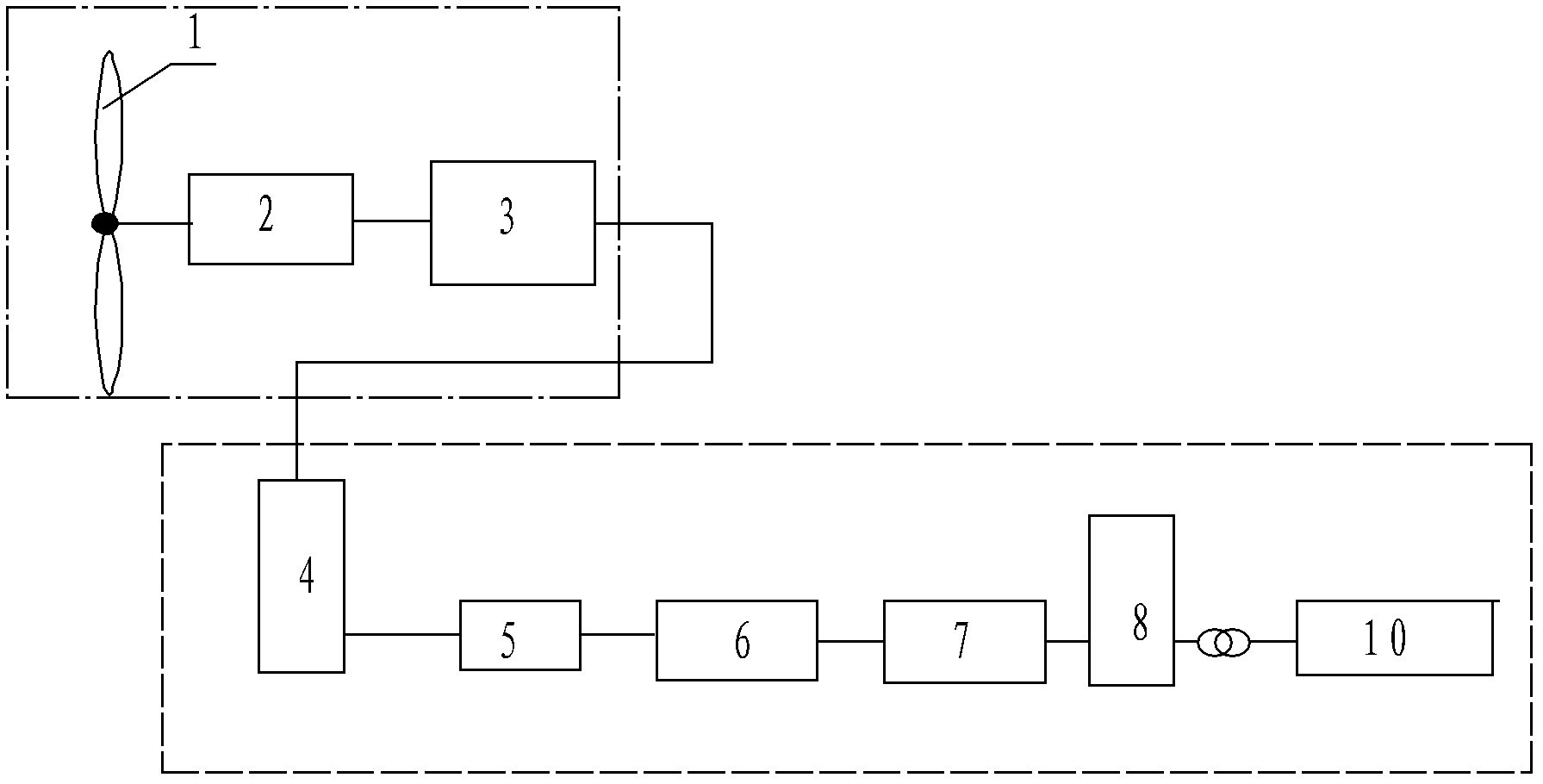

Air compression energy storage wind power generation method and generating set thereof

InactiveCN102305193AImprove efficiencySmall radius of rotationFrom solar energyFinal product manufactureMechanical energyAir compressor

The invention discloses an air compression energy storage wind power generation method and a generating set thereof for overcoming the rotation rate limitation and the problems of a rigid drive system in the prior art. The air compression energy storage wind power generation method comprises the following steps: 1, wind wheels convert the kinetic energy of wind into mechanical energy; 2, the wind wheels drive an air compressor to work so as to generate compressed air; 3, an air storage tank stores the compressed air; 4, the compressed air drives an air motor or a steam turbine; 5, the air motor or the steam turbine drives the generator to generate electricity; and 6, the surplus electric energy is stored. The invention also provides an air compression energy storage wind power generating set and a surplus electric energy storage device. The air compression energy storage wind power generating set comprises wind wheels, a speed increasing gear case, an air compressor, an air storage tank, an electric control valve, an air motor or a gas turbine and a generator. In the surplus electric energy storage device, the wind wheels and the speed increasing gear case of the air compression energy storage wind power generating set are replaced by electromotors, and other parts are the same as those of the air compression energy storage wind power generating set.

Owner:初立森

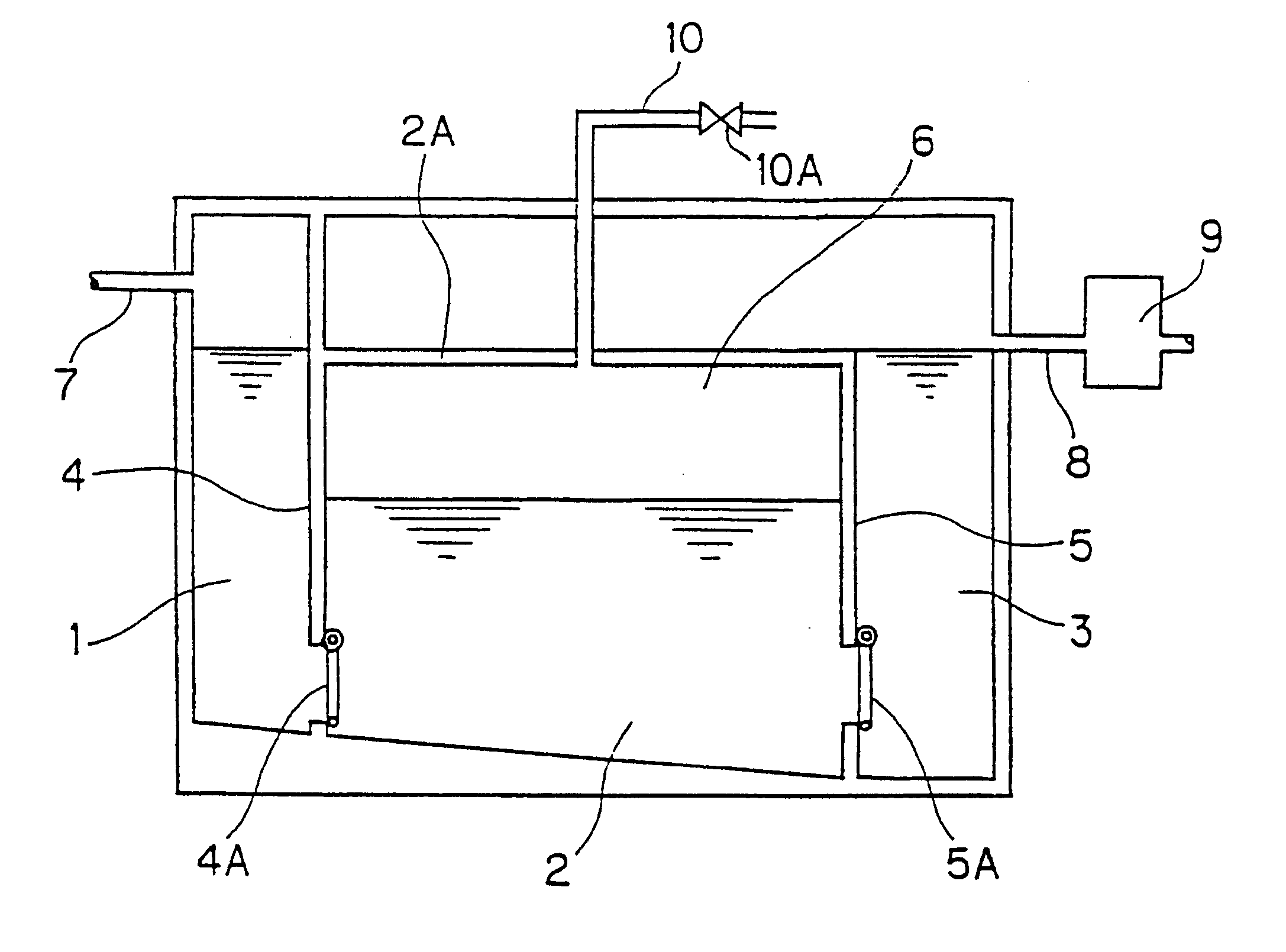

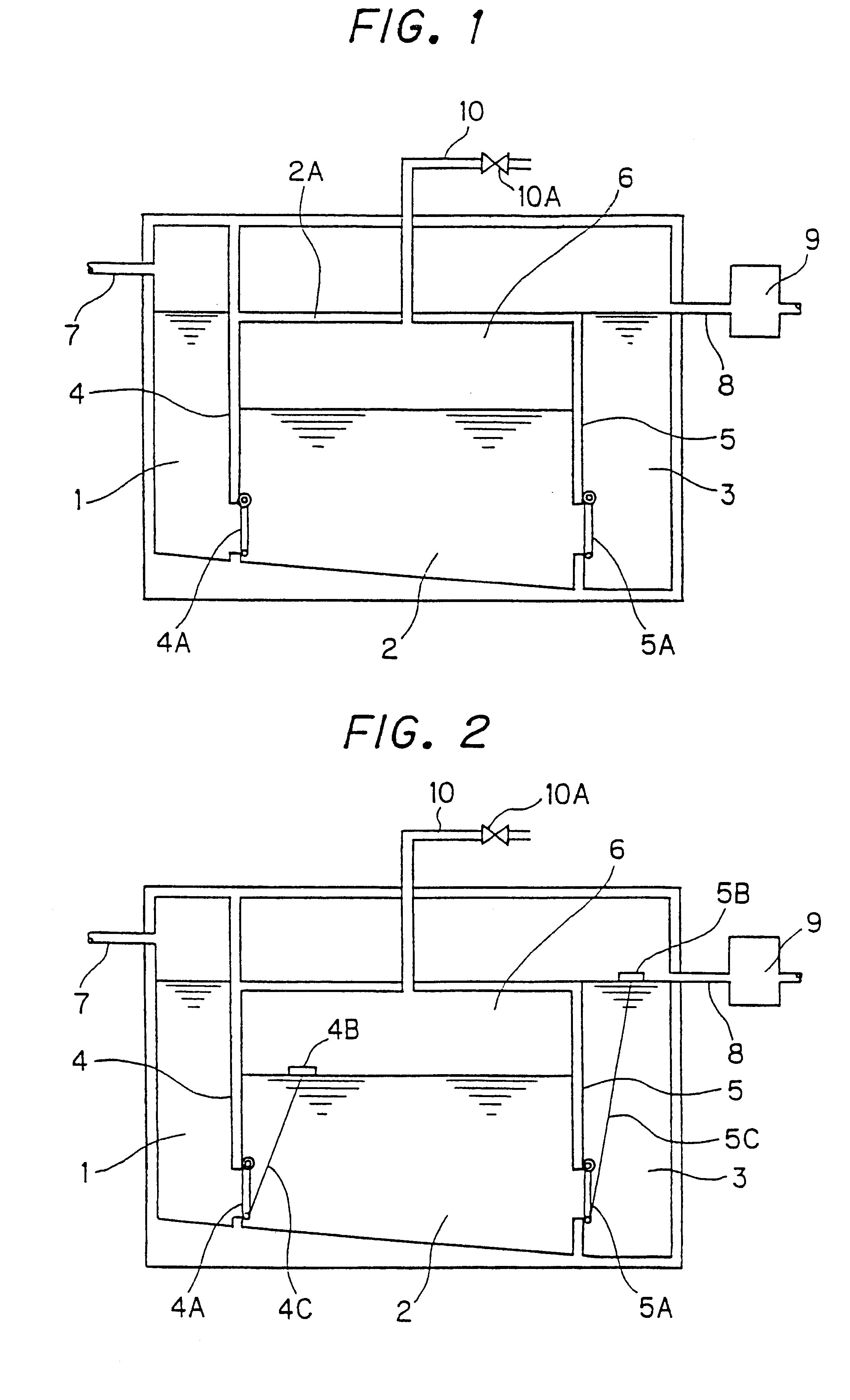

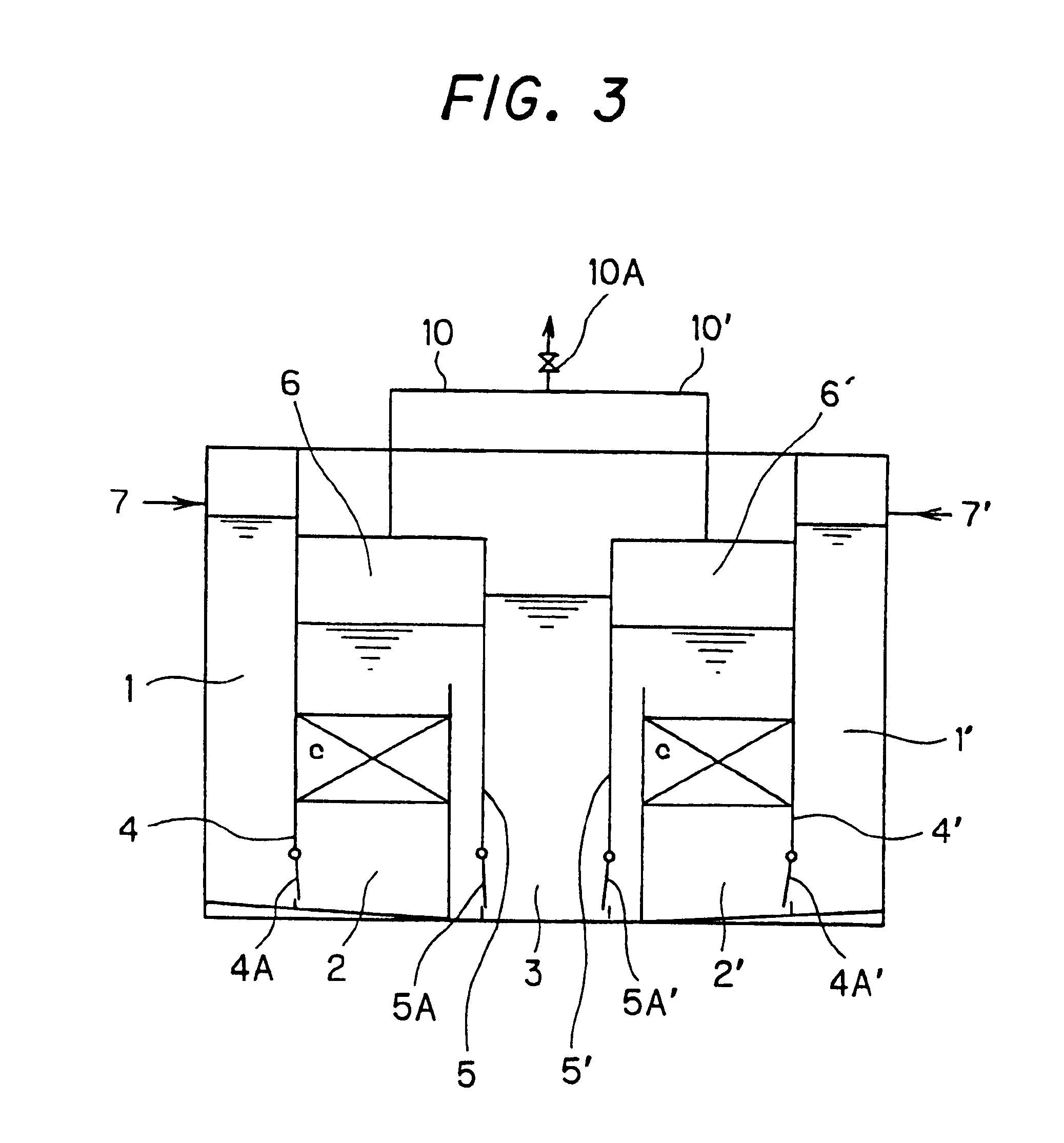

Two-phase type methane fermentation reactor

InactiveUS6660518B1Improve efficiencyLarge capacityBioreactor/fermenter combinationsBio-organic fraction processingMethane fermentationMethane gas

Provided by the invention is a reactor for two-phase methane fermentation of organic waste materials such as livestock excrements which can be operated for a long period with stability. The apparatus comprises an acid fermentation tank (1) connected to a feed tank, a methane fermentation tank (2) partitioned from the acid fermentation tank (1) with a partition wall (4) having a gate valve (4A) and a settling tank (3) partitioned from the methane fermentation tank (2) by a second partition wall (5) having a gate valve (5A) and the space in the upper part of the methane fermentation tank (2) serves as a gas holder (6). The methane gas generated in the methane fermentation tank (2) and collected in the gas holder (6) is taken out from a methane outlet pipeline (10) opening in the canopy of the gas holder (6).

Owner:DAISHIN DESIGN CORP

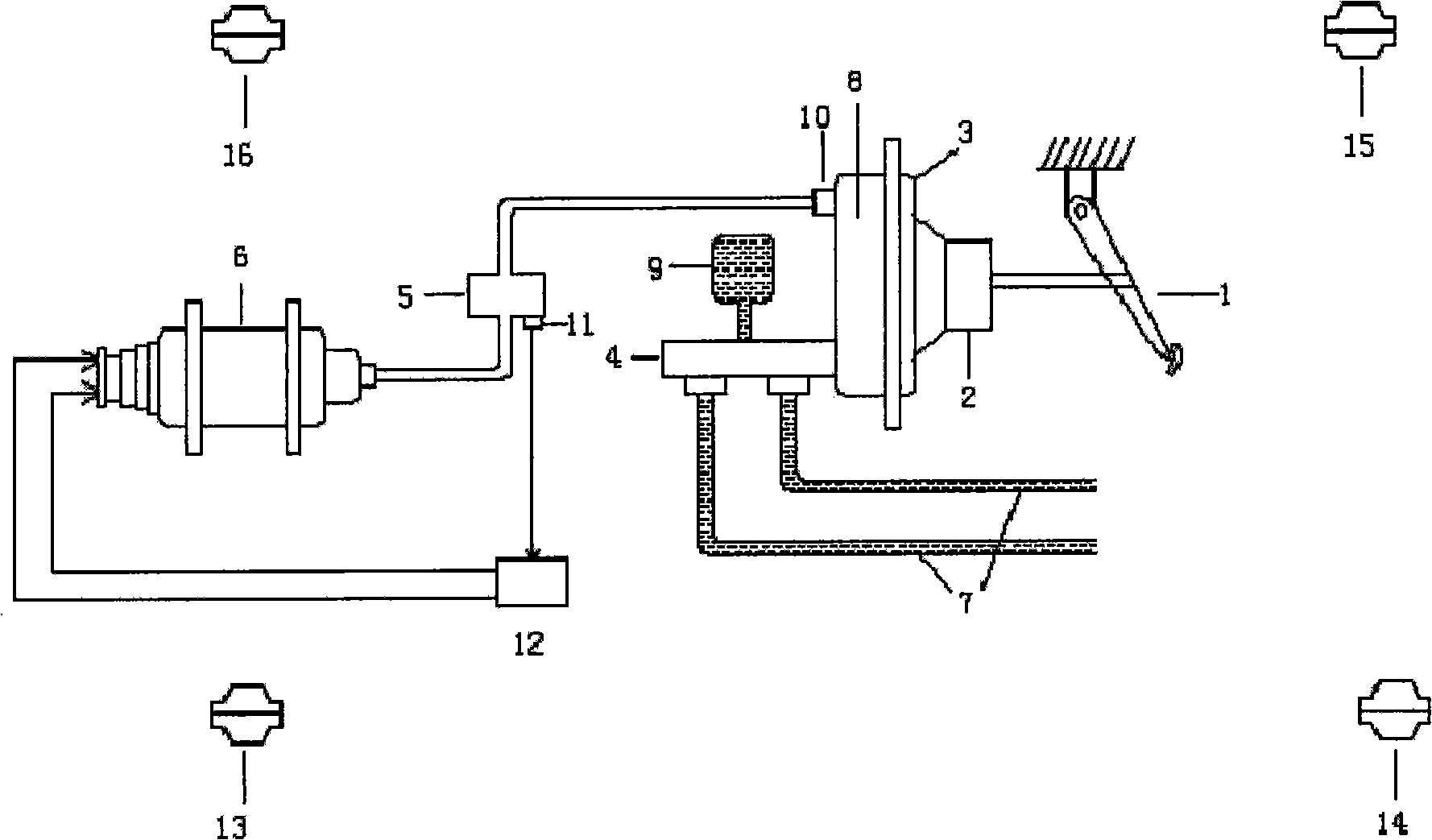

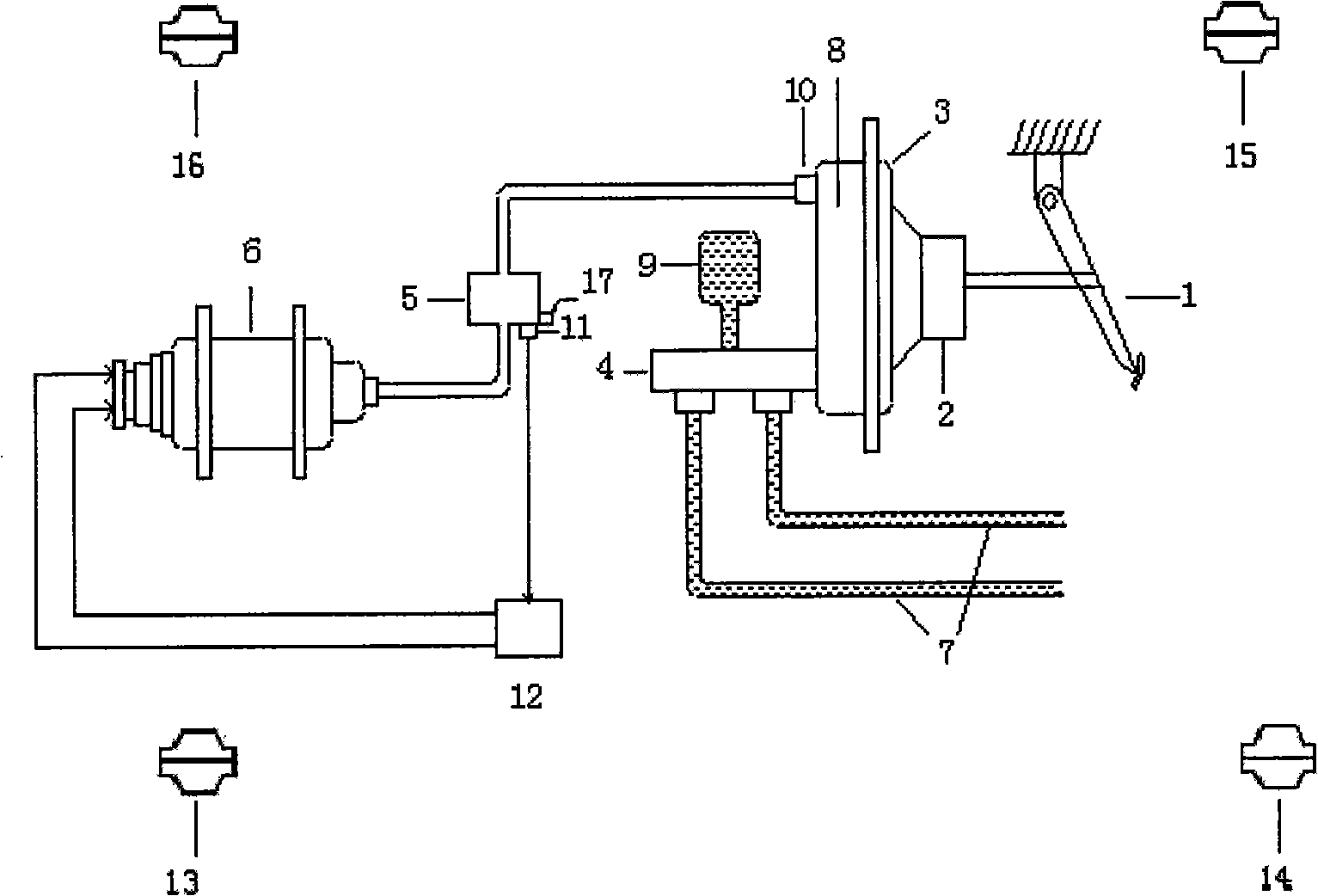

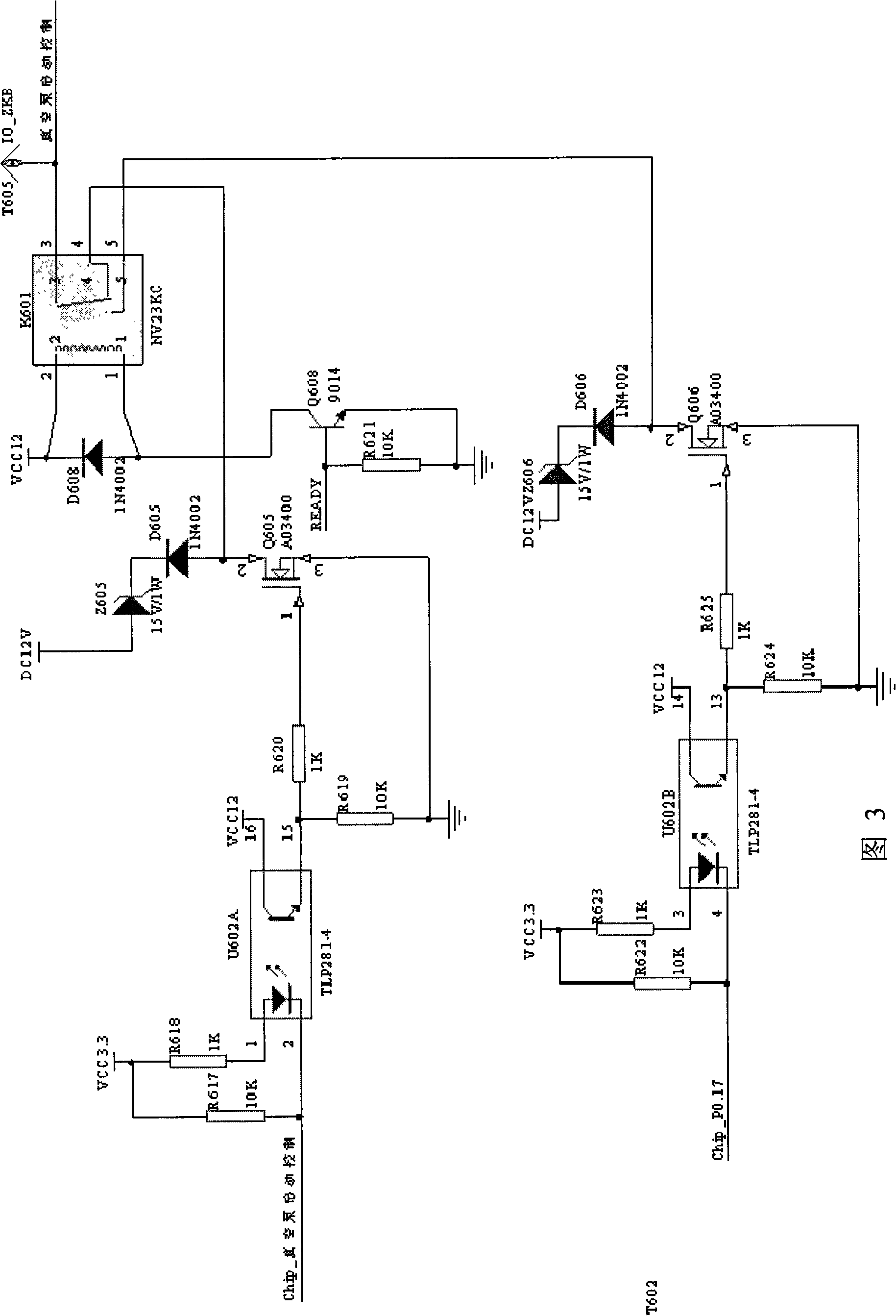

Brake vacuum booster device for electric automobile and control method thereof

ActiveCN101357630AAvoid error controlAvoid untimelyBraking action transmissionEngineeringGas chamber

The invention provides a brake vacuum boosting device used for an electric automobile and a control method thereof. The device comprises a vacuum booster, a vacuum pump, a gas holder, a main control ECU and a plurality of pressure sensors, wherein, the vacuum booster is used for providing assistance for brake; the vacuum pump is used for extracting and removing gases from a vacuum servo gas chamber; the pressure sensors are used for measuring gas pressure in the gas holder, wherein, a plurality of pressure sensors are respectively independently used for measuring the gas pressure in the gas holder; the main control ECU is used for receiving the gas pressure in the gas holder measured by a plurality of pressure sensors, judging whether at least one of the pressure sensors works normally and determining whether the starting of the vacuum pump is controlled according to the gas pressure in the gas holder measured by the pressure sensors and determining which pressure sensors are subject to. The device and the method of the invention can cause the brake vacuum boosting device to have relatively high reliability, thereby enhancing driving safety.

Owner:BYD CO LTD

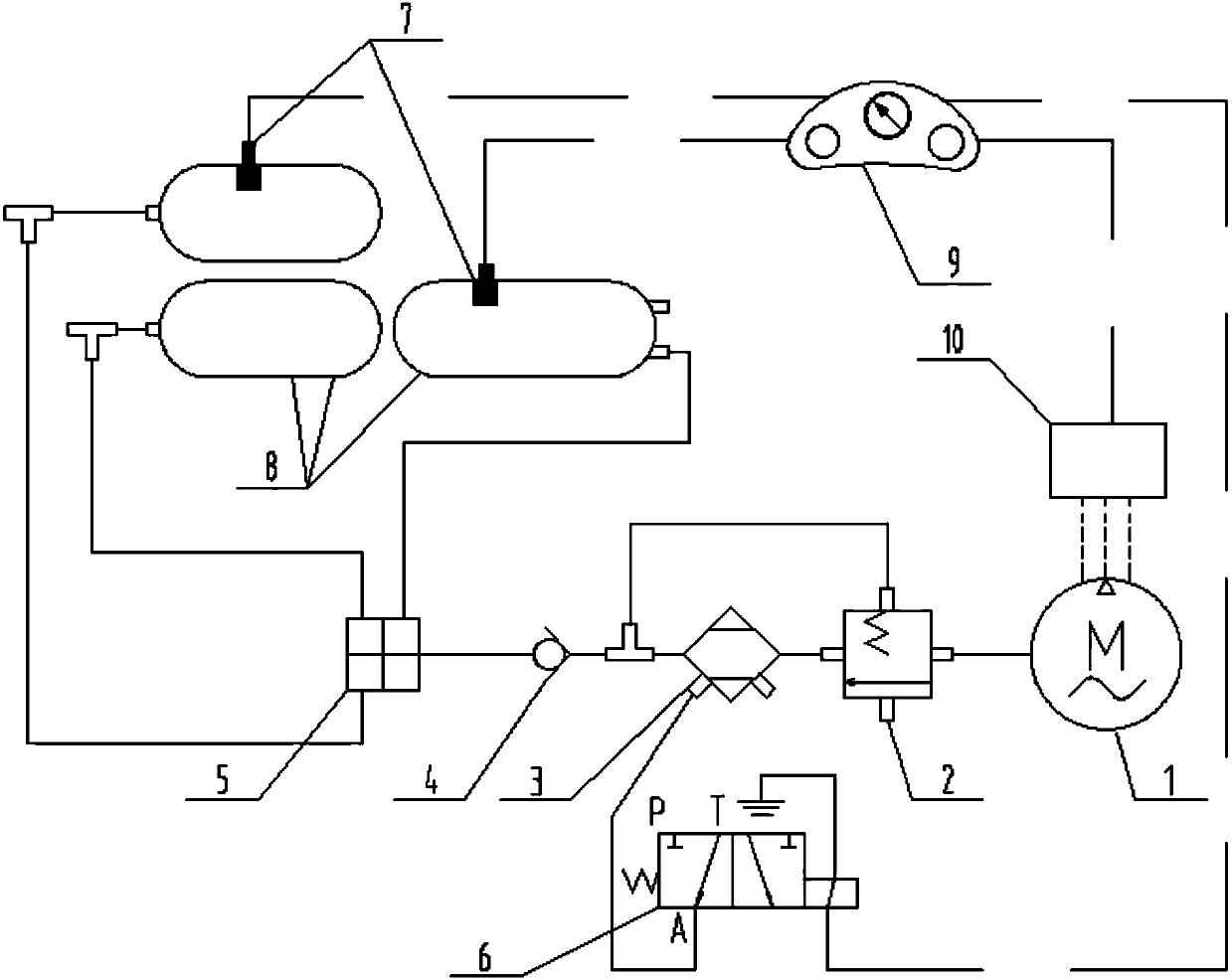

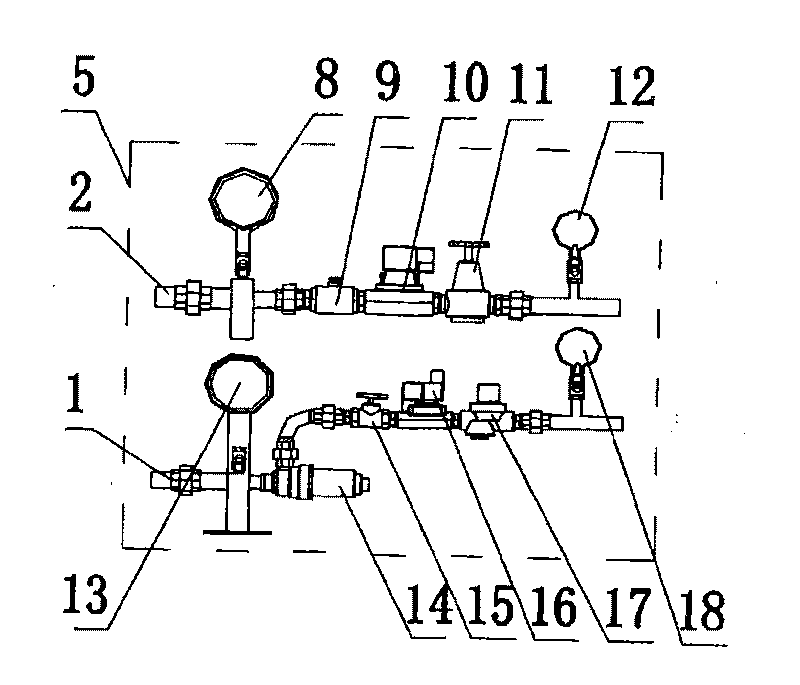

Gas path-electric air compressor integrated control system and control method

ActiveCN103437986APrecise switching pressureControl start and stopPositive displacement pump componentsPump controlControl systemControl engineering

The invention particularly discloses a gas path-electric air compressor integrated control system and control method. The system comprises an electric air compressor, wherein the electric air compressor is connected with a pressure regulating valve; an outlet of the pressure regulating valve is connected with a dryer; an output end of the dryer is connected with a one-way valve; the one-way valve is connected with a four-loop protective valve; output ends of the four-loop protective valve are respectively connected with an air storage tank; two of the air storage tanks are respectively provided with an air pressure transducer which is connected with a digital instrument through an electric circuit; a pressure relief port of the dryer is connected with an electromagnetic valve; and the other end of the electromagnetic valve is communicated with atmosphere. The electromagnetic valve is added to the air outlet of the dryer to ensure that the discharge pressure of the dryer can be achieved in every air inflation, so that the dryer can discharge air and water, thereby prolonging the service life of the dryer.

Owner:ZHONGTONG BUS HLDG

Thermoplastic resin physical foaming material preparation device and preparation method thereof

The invention discloses a thermoplastic resin physical foaming material preparation device and preparation method thereof and is characterized in that the device comprises a hot pressing (1), a high pressure container (2) and a gas pressurization system (10); wherein, the high pressure container is arranged between an upper press plate and a lower press plate of the hot pressing, one end of the high pressure container is provided with a gas inlet (4) and connected with the gas pressurization system and a gas tank (11) through a gas control valve (8), the other end of the high pressure container is provided with a gas outlet (3) and connected with a depressurization control valve (9), the high pressure container is a mould which is combined by an upper mould plate and a lower plate mould and a sealing ring is arranged between the two mould plates. The preparation method comprises the following steps: placing the thermoplastic resin in a high pressure container of which the volume is 25 times or more than 25 times of the total volume of the particles, injecting 5-30MPa of gas at 110-170 DEG C, keeping the temperature and the pressure for 2-60min and then relieving the pressure in a speed of 5-20MPa / s to the normal pressure to obtain the thermoplastic resin foaming material.

Owner:浙江博发新材料股份有限公司

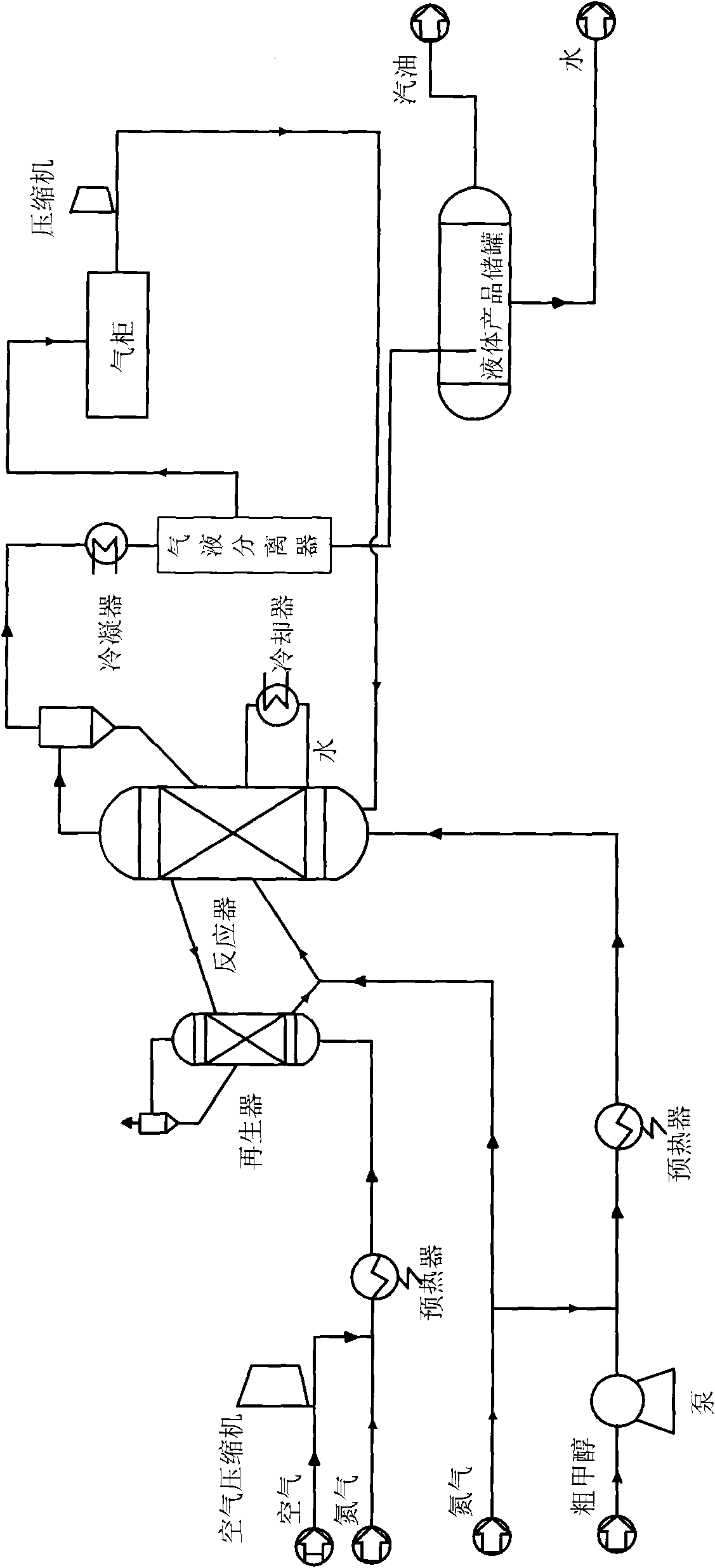

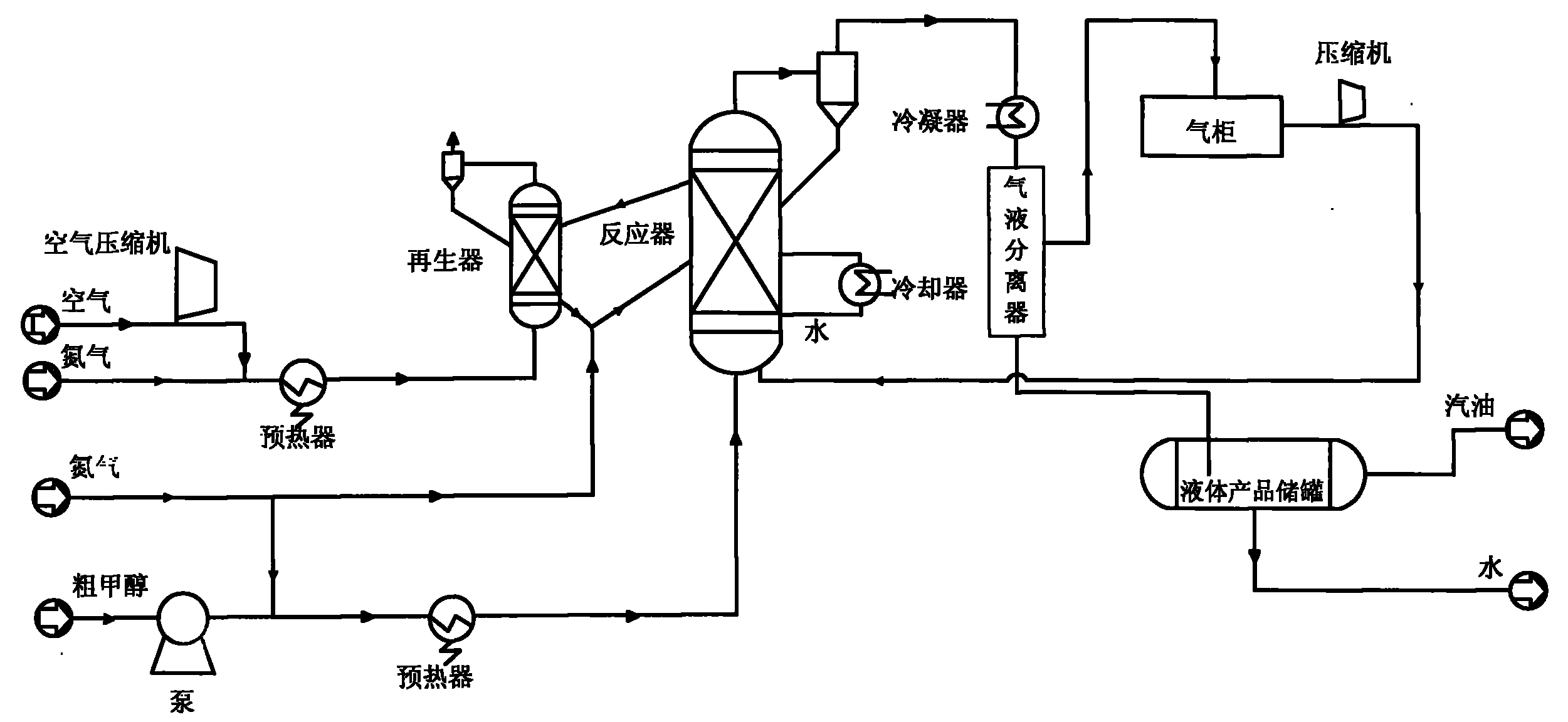

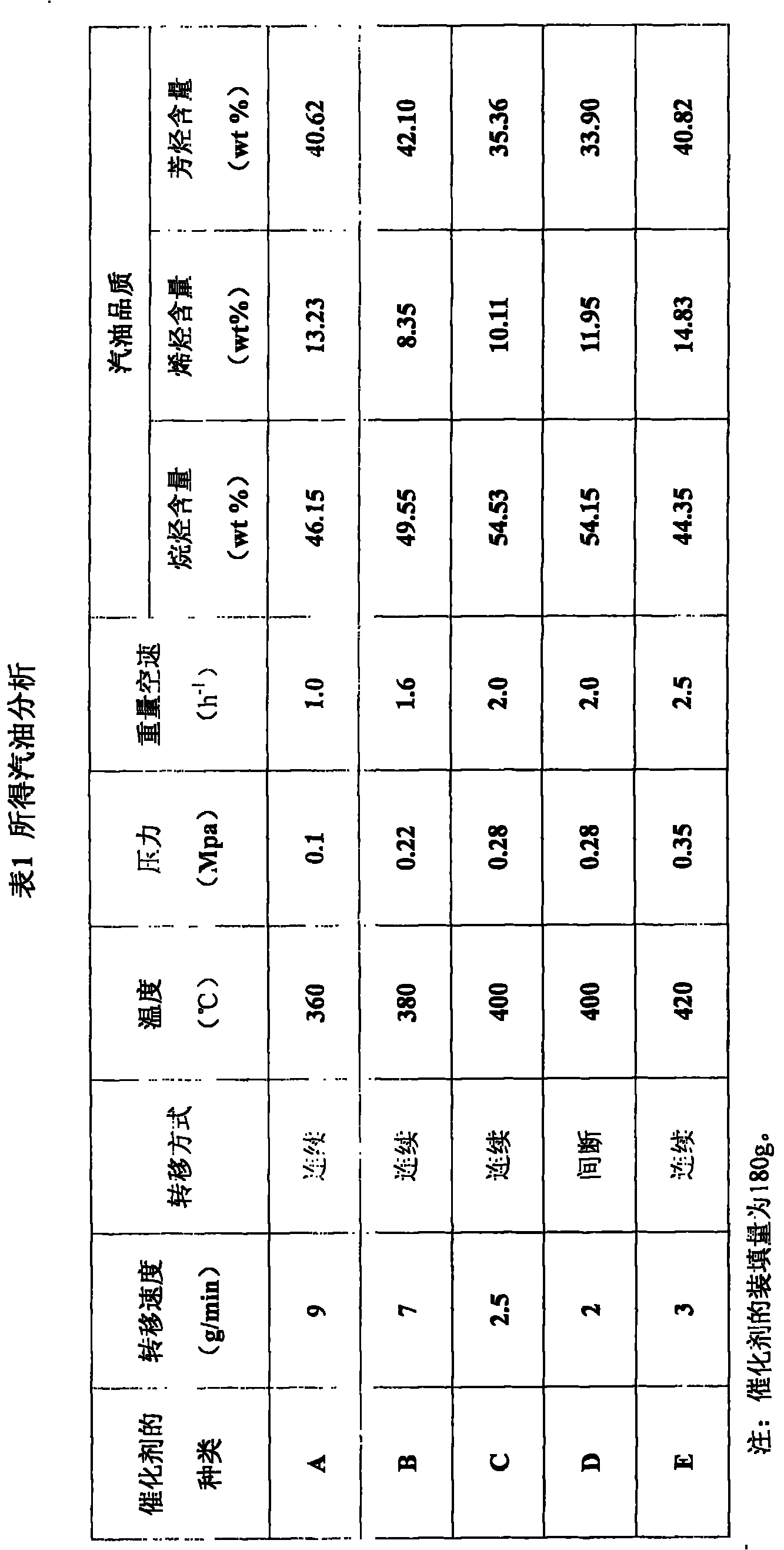

Method of producing gasoline by fluidized bed process methanol

InactiveCN101775310ASolve the problem of excess methanolSolve the problem of excessLiquid hydrocarbon mixture productionBio-feedstockFluidized bedGasoline

The invention relates to a method of producing gasoline by fluidized bed process methanol, in which crude methanol steam enters a fluidized bed reactor from the lower part to be contacted and reacted with a catalyst; a part of the catalyst after reaction is taken out continuously or discontinuously from the upper part of the reactor in a certain output amount for regeneration, and then the catalyst is supplemented with the same output amount from the lower part of the reactor by the regenerator, which is repeated and circulated. Reaction products flow out from the top of the fluidized bed reactor, and after gas-solid separation, the obtained catalyst powder enters the fluidized bed reactor again, gas firstly enters to be cooled, then gas-liquid separation is carried out, separated light hydrocarbon gas is collected by a gas holder and then is sent by compression into the fluidized bed reactor for light hydrocarbon circulation, and liquid separation is carried out on the separated liquid to obtain the gasoline and water. The technology used in the invention has the advantages that the catalyst can be regenerated continuously, a spare reactor is not needed, the nature of the catalyst is constant, the quality of the gasoline is high (octane value RON 93 plus), the conversion rate of the methanol is 100 percent, and the heat transfer intensity is high.

Owner:山西天和煤气化科技有限公司

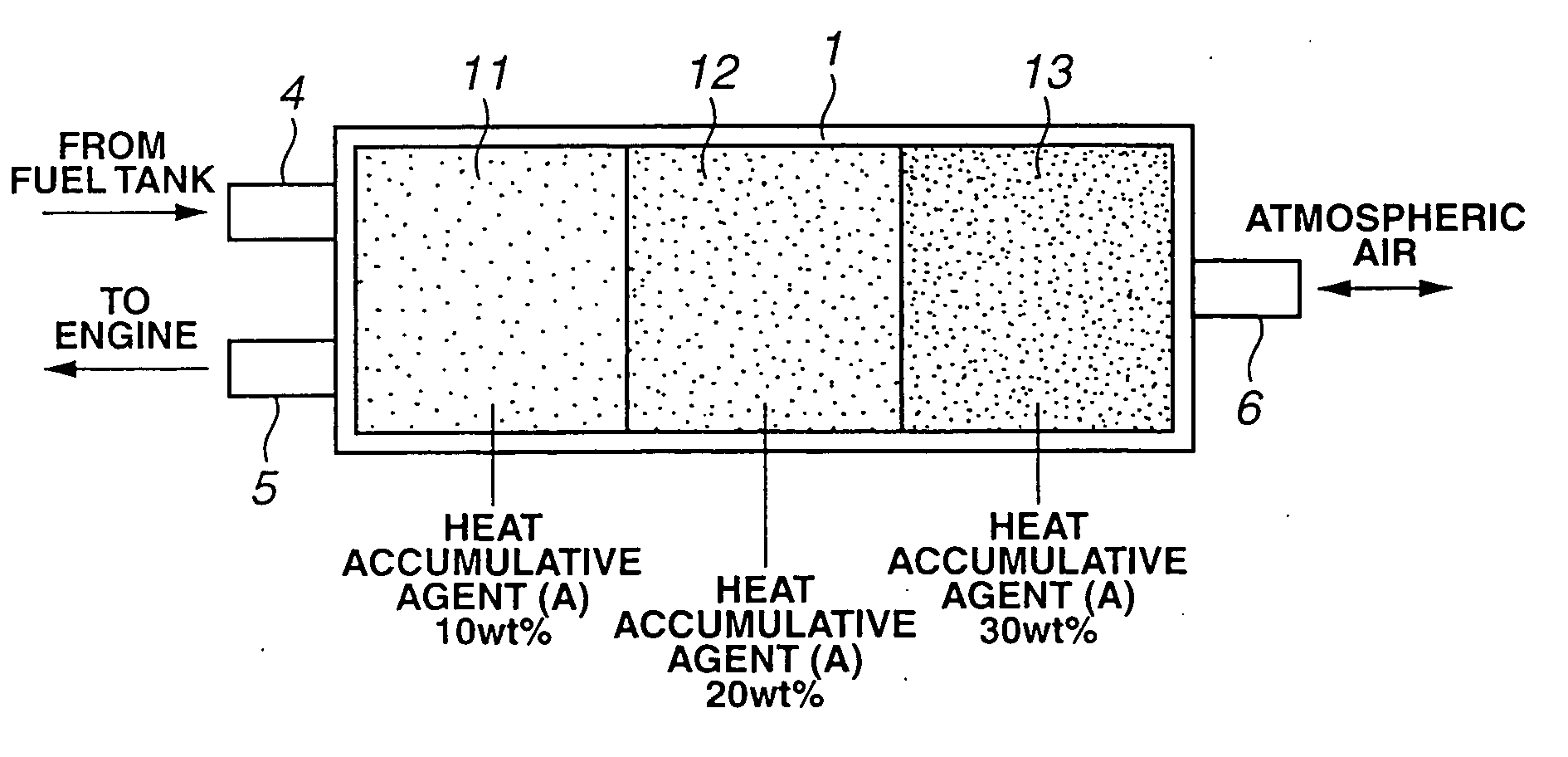

Gas storage canister

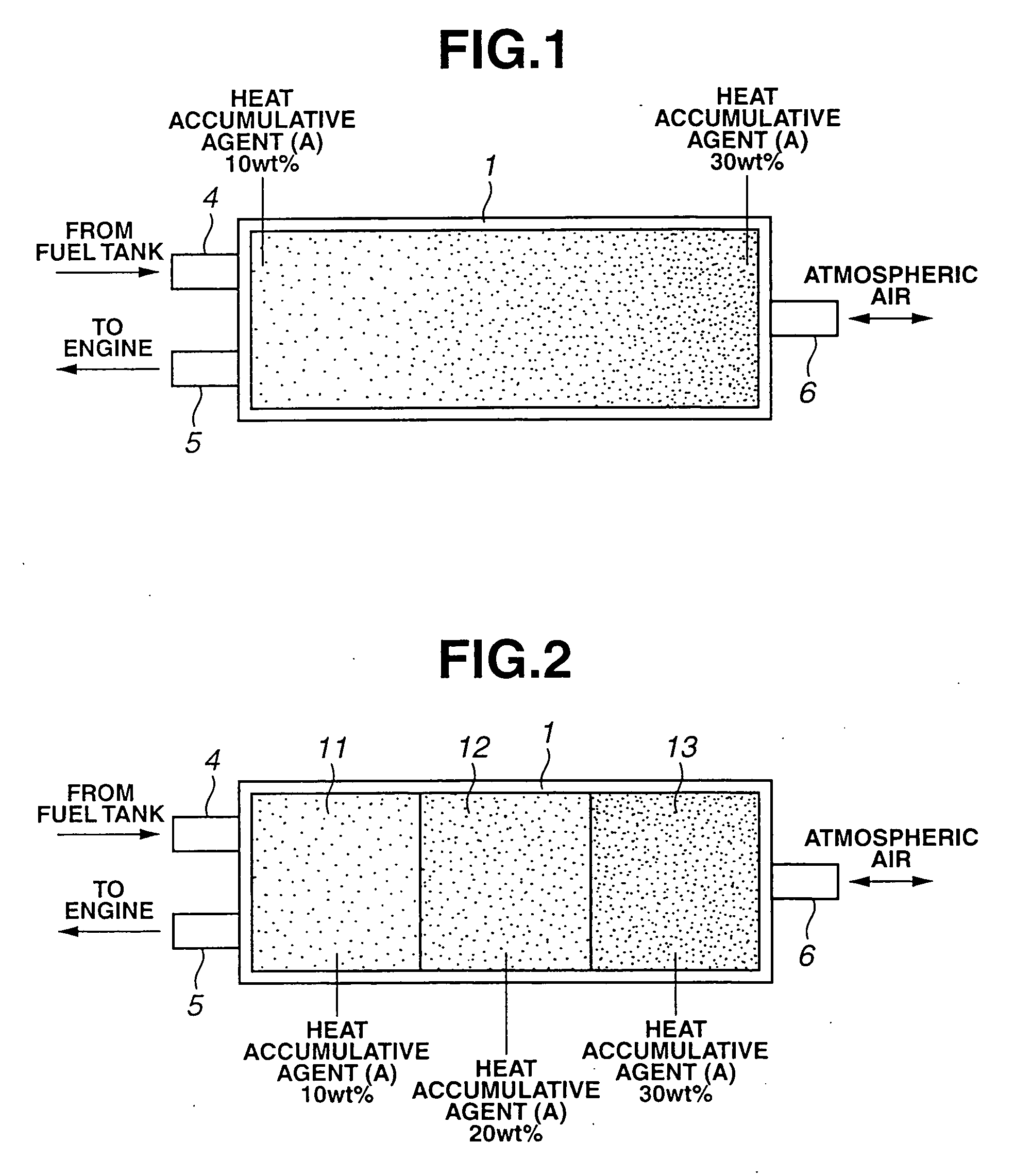

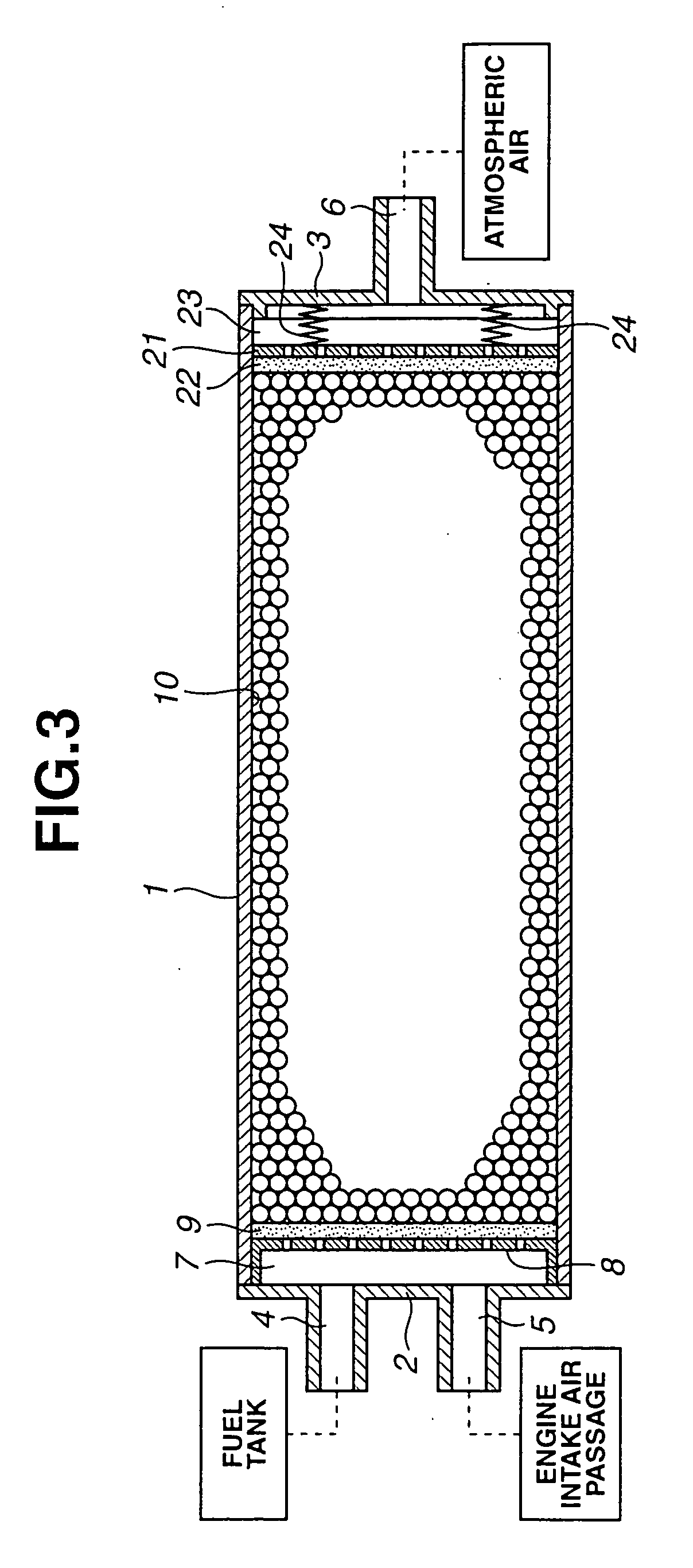

ActiveUS20050223900A1Effectively overcome drawbacksInhibit temperature riseNon-fuel substance addition to fuelFuel injection apparatusLatent heatPhase-change material

A gas storage canister for use in an automotive vehicle, includes a case having first and second end sections which are opposite to each other in a direction of flow of gas. The first end section has a gas inflow port and a gas outflow port. The second end section has an atmosphere-opened port. A gas adsorbing material is disposed inside the case. Additionally, a heat accumulative agent is provided including a phase changing material which causes absorption and release of latent heat to occur in accordance with a temperature variation. The heat accumulative material is mixed with the gas adsorbing material and disposed inside the case. Here, a mix proportion of the heat accumulative agent changes in the gas flow direction between the first and second end sections.

Owner:OSAKA GAS CO LTD

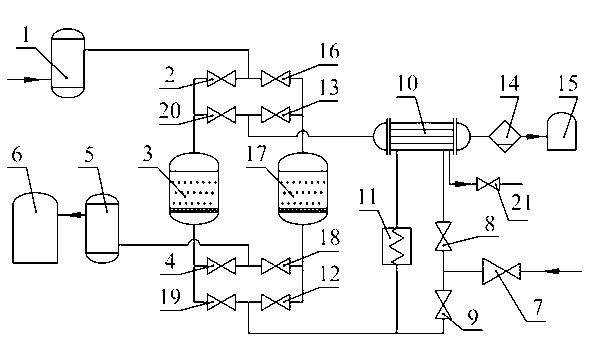

Natural gas absorbent regeneration and energy conservation technology and device

InactiveCN103071475AAvoid wastingReduce dosageGaseous fuelsCombustible gas purificationCompressed natural gasNatural gas dehydration

The invention relates to a natural gas absorbent regeneration and energy conservation technology and a natural gas absorbent regeneration and energy conservation device. The technology and the device can overcome the defects that the energy consumption is great and the heating time is long when the absorbent is regenerated. The technical scheme is as follows: a process of two towers is adopted, one tower is used for dehydration of natural gas and the other one is used for regeneration of natural gas. The two towers are switched for dehydration and regeneration of natural gas. During dehydration of natural gas, compressed natural gas first enters into the dehydration tower A to be dehydrated and obtain dried natural gas after being separated by a front filter separator, then the natural gas enters into a gas storage tank after being separated by a back filter separator; during heating and regeneration of absorbent, after flow reduction and depressurization, the regenerated natural gas is first heated in a heat exchanger and a heater and enters into the dehydration tower B to regenerate the absorbent, then, the natural gas enters into the heat exchanger to be cooled, and finally the natural gas enters into a recovery tank after being separated by a condensation separator; and during cold blowing and regeneration of the absorbent, after flow reduction and depressurization, the regenerated natural gas enters into the dehydration tower B to cold blow and reduce the temperature of the absorbent. According to the technology, complementary utilization of energy is achieved, energy consumption in absorbent regeneration is reduced, and energy-saving operation of the device is realized.

Owner:SOUTHWEST PETROLEUM UNIV

Welding accessory arrangement

A welding accessory system for a welder that includes a welder having a welder housing and at least one welding accessory support connected to the welder housing to support at least one welding accessory of a welder. The one or more welding accessory supports include a cable holder, an electrode holder, a cooling fluid holder, a cylinder gas holder, a cable connector box, and / or a tool holder.

Owner:LINCOLN GLOBAL INC

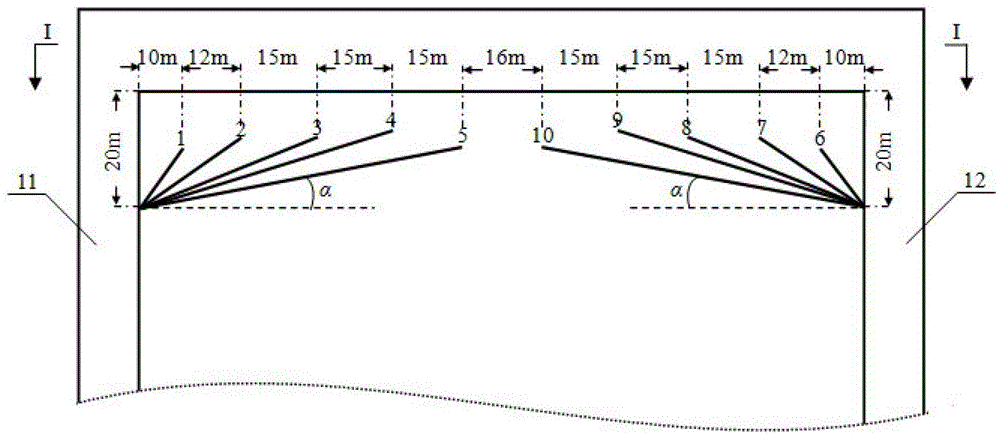

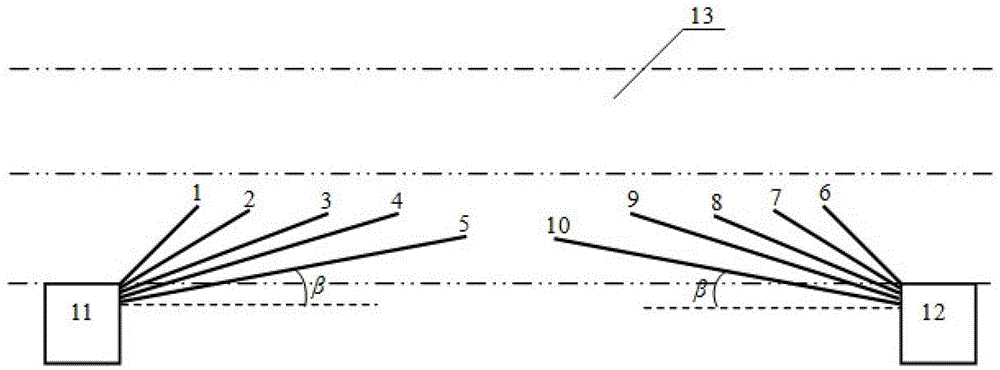

High-pressure gas blasting-based coal seam roof advance presplitting method

ActiveCN103334790ASmall power disturbanceGood pre-cracking effectMining devicesChemical explosiveExplosive Agents

The invention discloses a high-pressure gas blasting-based coal seam roof advance presplitting method, which belongs to the technical field of mine safety. The method is performed according to the following steps: (1) forming a group of drilled holes in a coal seam roof every a certain distance on a conveying roadway and a track roadway of a working face, wherein each group of drilled holes is arranged in a fan shape and faces towards a goaf; (2) placing a gas detonation gun which is connected with a high-pressure gas compression system in the drilled hole and sealing the hole by using high-strength fast setting concrete or resin; (3) starting the high-pressure gas compression system and instantaneously releasing high-pressure gas in a high-pressure gas storage tank in the drilled hole through the gas detonation gun to blast so as to communicate the crack around the drilled holes with adjacent drilled holes; and (4) repeating the steps (2) and (3) on each group of drilled holes in sequence to finish advance presplitting of the coal seam roof. According to the method, the potential spark hazard of chemical explosive blasting is eliminated; and since the pressure of the high-pressure gas is controllable and impact blasting can be repeatedly performed on the rock body, the dynamic disturbance of a coal seam is small, the roof presplitting effect is good, and the method is environment-friendly, safe and reliable.

Owner:LIAONING TECHNICAL UNIVERSITY

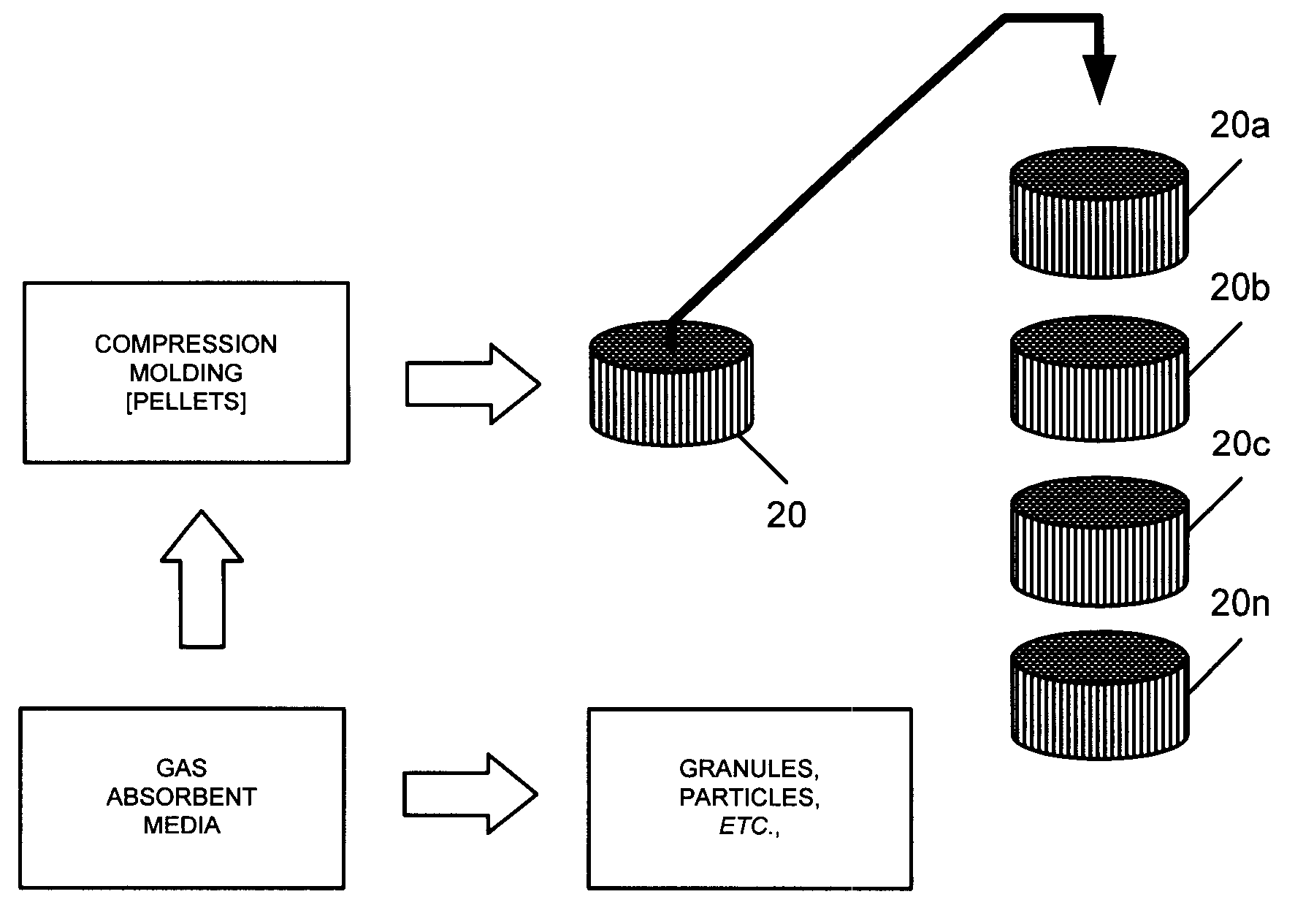

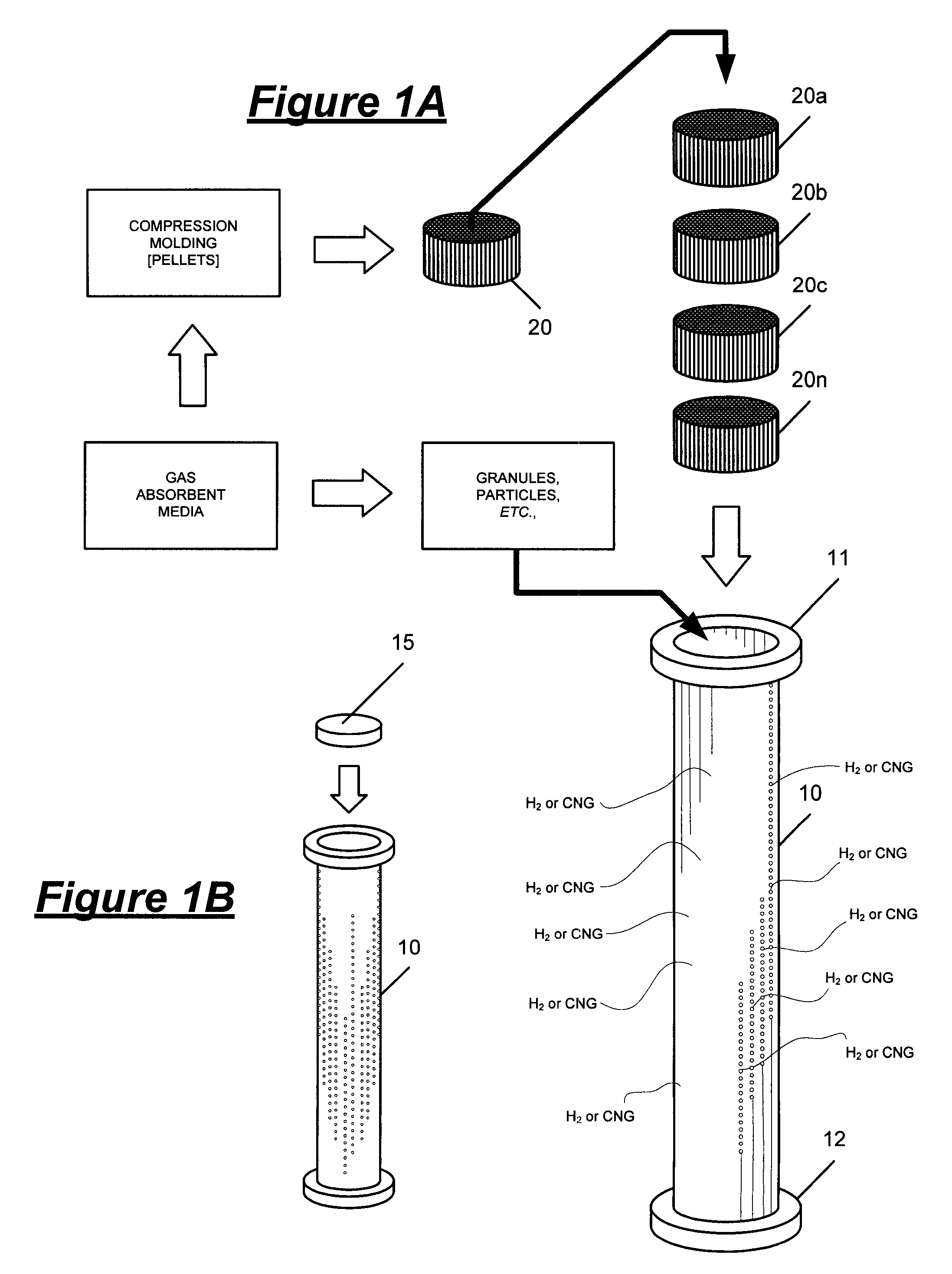

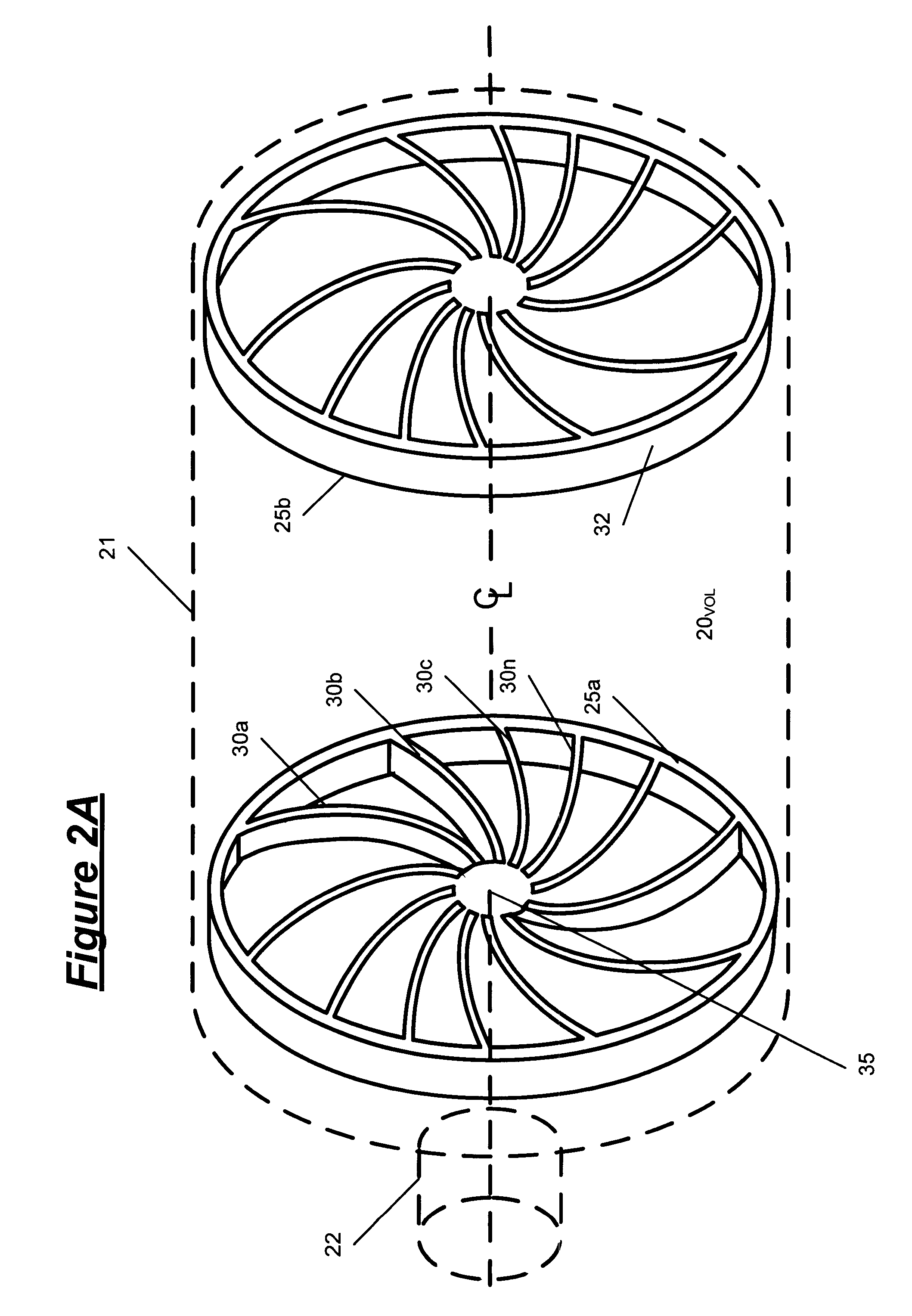

Installation of Gas Absorbent in a High Pressure Tank

Tubes packed with gas absorbent media are installed in radial sectors in a high pressure gas tank interior. When a tank is fully packed with gas absorbent tubes in all sectors, interstices in the internal spaces between the tubes, an internal heat exchanger may be centrally installed within the tank having conduits for high pressure gas flow in the tank in a configuration in accordance with the cooling and heating requirements of the particular tank system. Flanged ends on the tubes maintain spacing of the tubes, facilitating gas flow and absorption.

Owner:HONDA MOTOR CO LTD

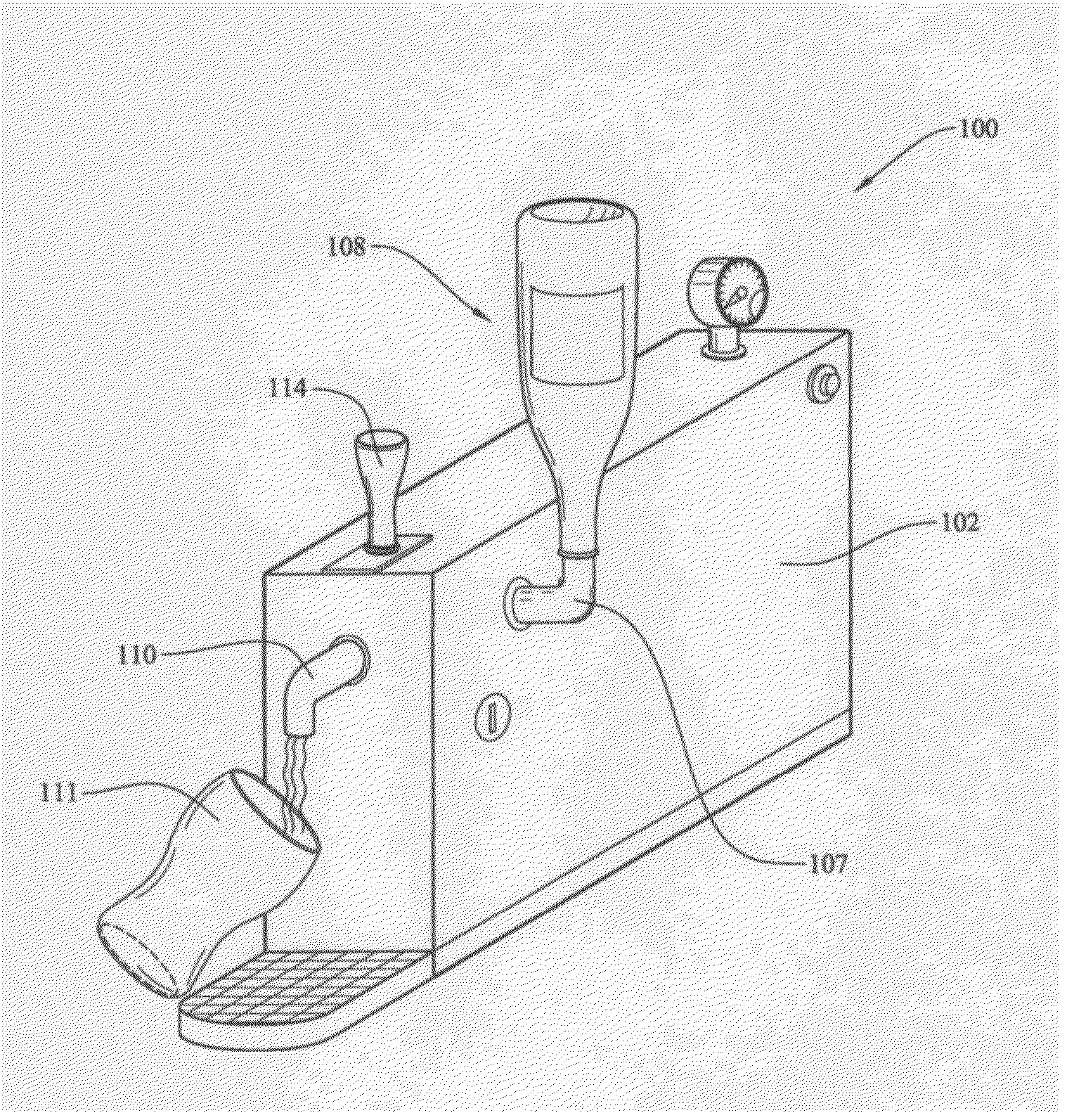

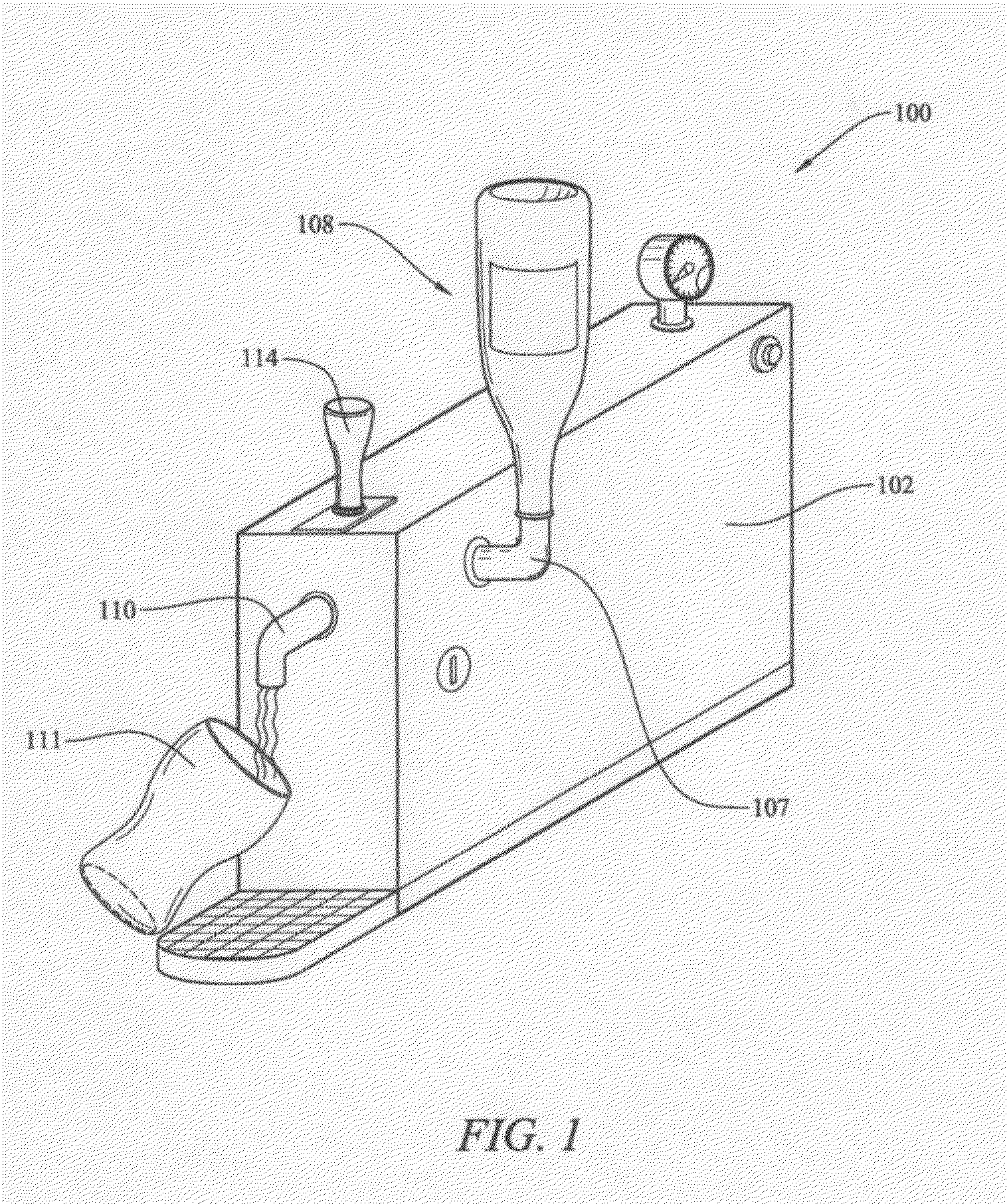

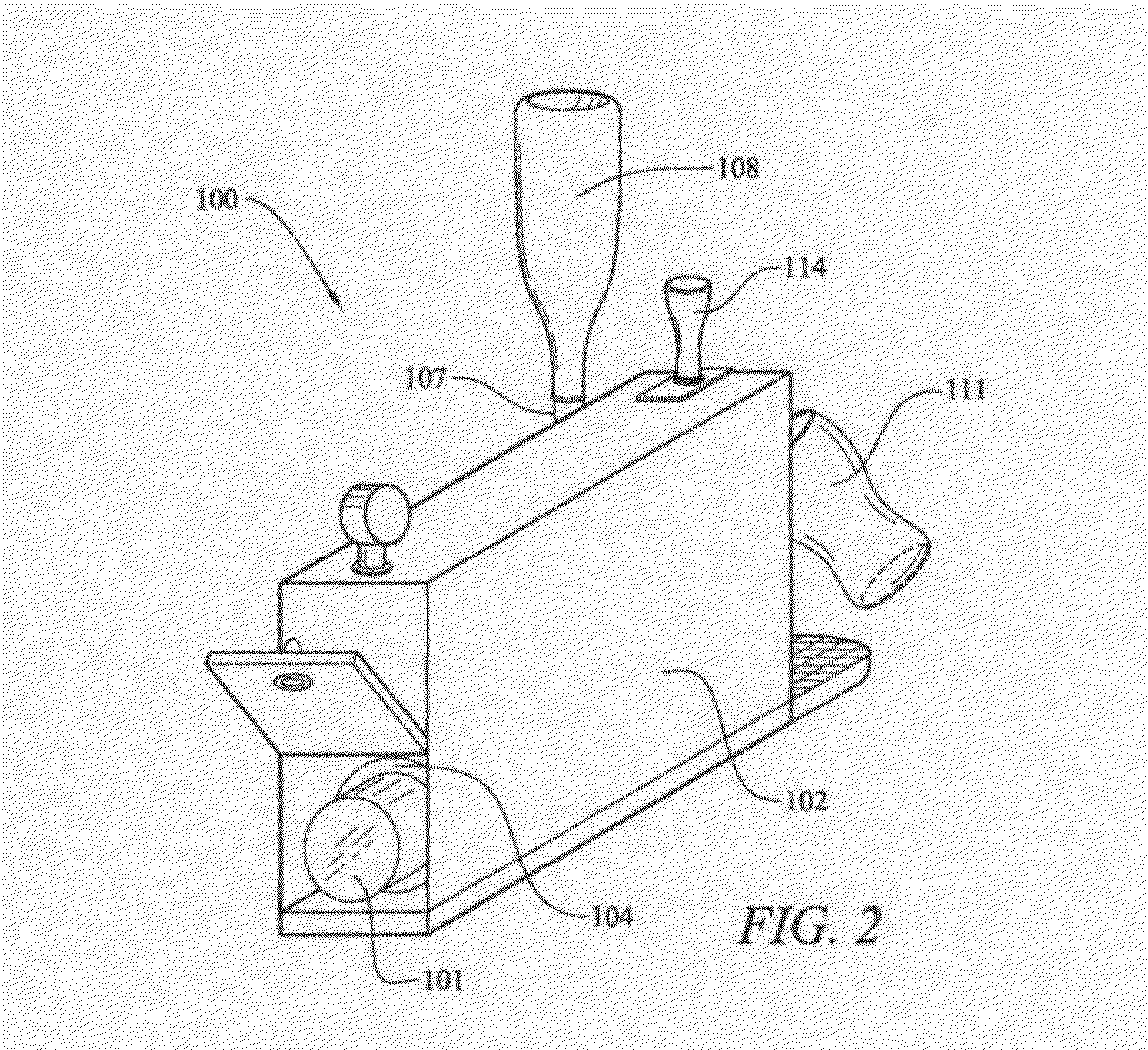

Single serve carbonation apparatus

InactiveUS20140103549A1Improve aspectAdd flavorLighting and heating apparatusUsing liquid separation agentProduct gasEngineering

The present invention is related to a single serve carbonation apparatus comprising a carcass that supports components including a removable pressurized gas canister, a canister receiver that regulates the flow of gas, an operative spigot to receive the bottled beverage and provide the gas inlet, a tap handle mechanism, and internal tubing to provide the channeling of gas and pressurized liquid throughout the process. With gas canister inserted and the selected beverage attached to the operative spigot, the circuit is then switched on allowing the gas into the bottle creating a pressurized flow of draught-like beverage, dispensed via the tap handle, into the glass. The present apparatus allows users to enjoy any bottled beverage at any time. The installation and removal of said canister is easy, keeping the unit small, portable and affordable. There is no need to power the unit since the bottles are already chilled.

Owner:STANELAND BENJAMIN DAVID

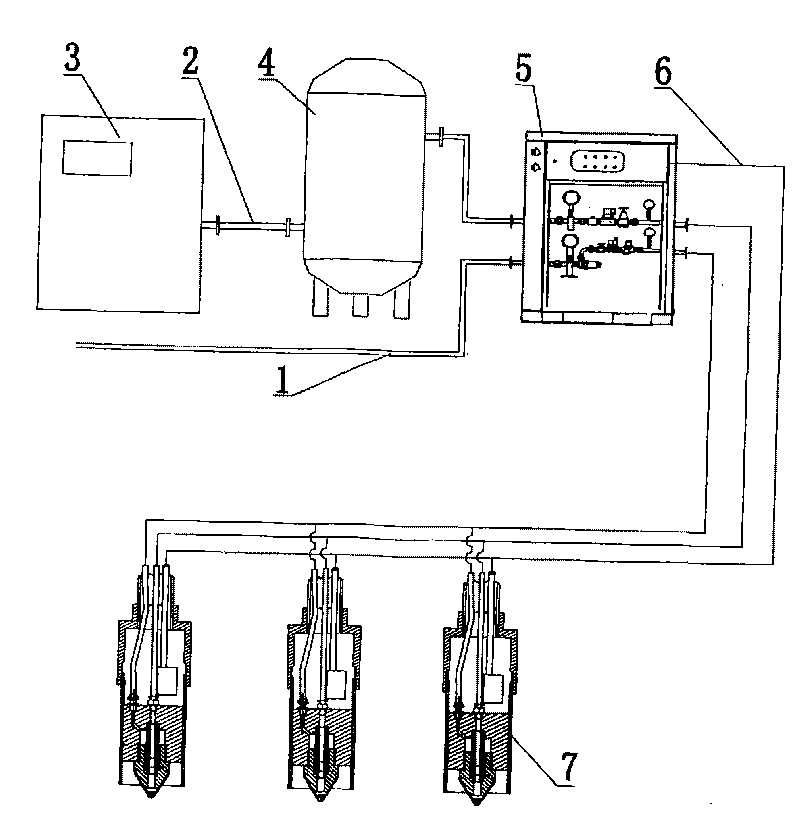

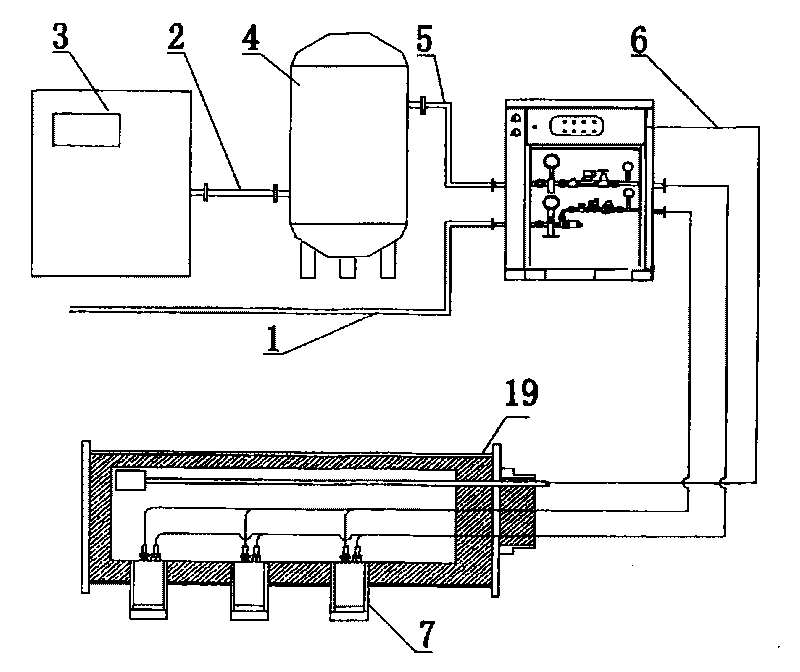

Method and equipment for suppressing dust with dry mist

InactiveCN101757825ASimple system structureLow water consumptionUsing liquid separation agentDirt cleaningElectrical controlSystem structure

The invention relates to a method and equipment for suppressing dust with dry mist. The method for suppressing dust with dry mist is characterized in that a plurality of atomizing nozzles are arranged in parallel on a disorderly discharged dust drift outlet of a dust generation point and are used for spraying the dry mist having the particle size of less than 10 Mum and making the sprayed dry mist form into a dry mist curtain to prevent the dust generated in the dust generation point from diffusing outwards to pollute the environment. The equipment for suppressing dust comprises a water supplying pipeline, an air supplying pipeline, an air compressor, an air storage tank and a control box. The air supplying pipeline, the water supplying pipeline and an electrical control pipeline which are led out of the control box are respectively connected with the air inlets, the water inlets and tracing band inlets of the atomizing nozzles which are arranged in parallel. The micro-size dry mist is sprayed to form a dry mist curtain to suppress dust. The micro-size dry mist spraying system equipment adopts the air compressor to supply compressed air, and the water and the air enter the atomizing nozzles in two branches. The micro-size dry mist spraying system equipment has simple structure, low running cost, wide application range and good dust suppression effect, consumes less water and works stably and reliably.

Owner:QINHUANGDAO CAPITAL STARLIGHT ENVIRONMENTAL TECH CO LTD

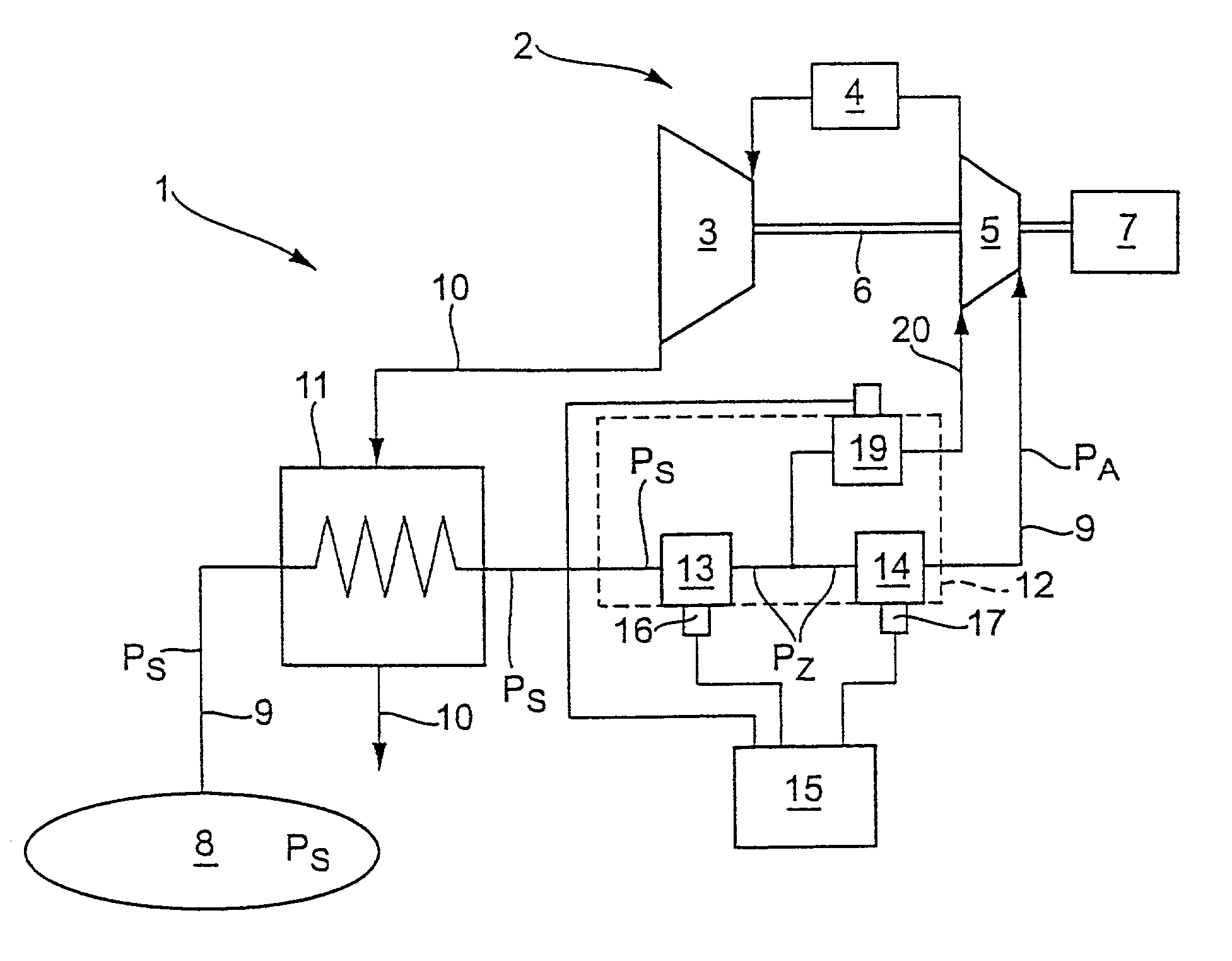

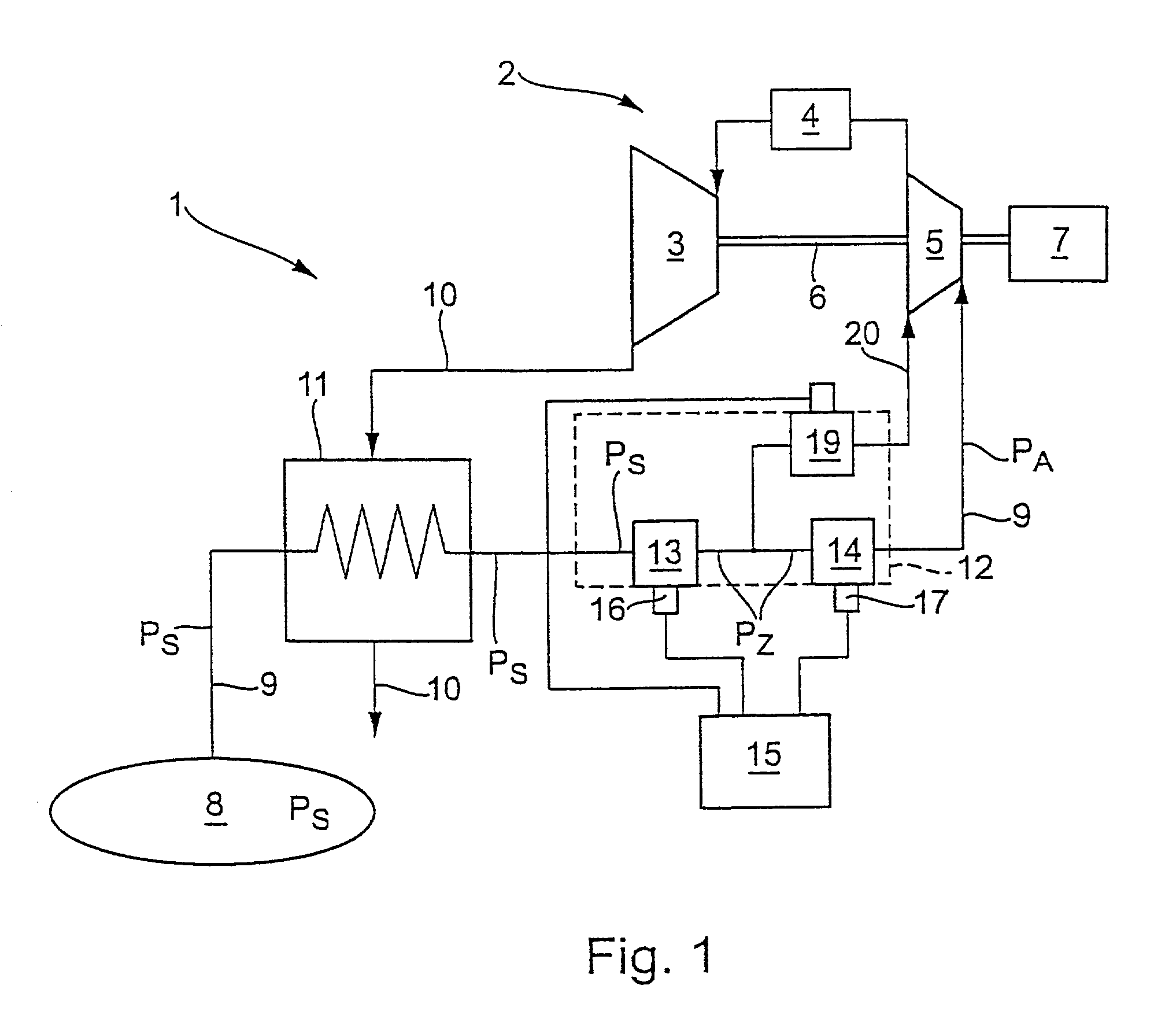

Gas-storage power plant

InactiveUS20030033809A1Closed-loop control simplifiedOpen-loop control simplifiedGas turbine plantsFluid pressure control without auxillary powerProduct gasEngineering

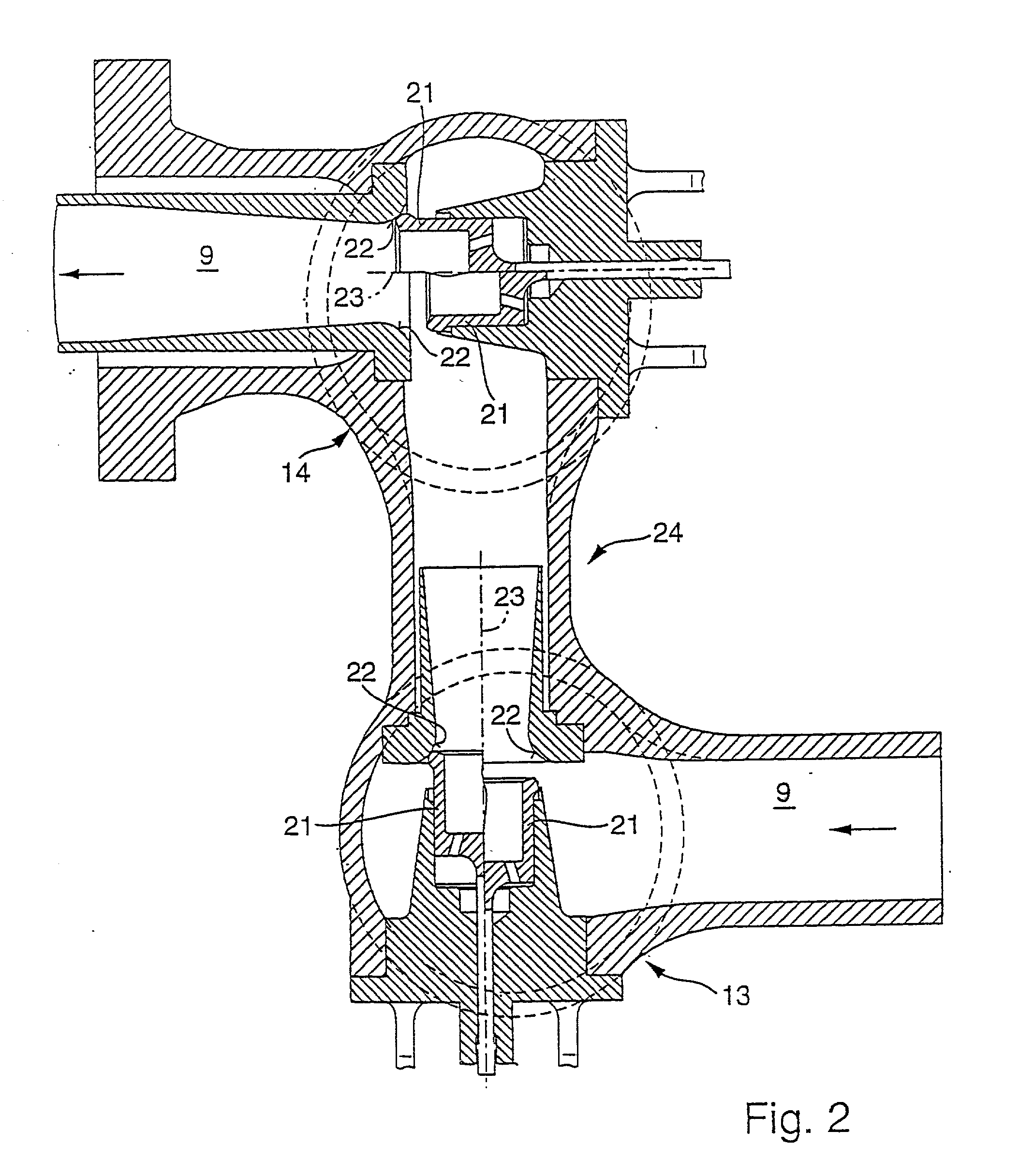

The present invention relates to a gas-storage power plant, comprising a gas reservoir (8) in which a gas can be stored under pressure, a turbogroup (2) which has at least one turbine (3, 5), a gas-supply line (9) which leads from the gas reservoir (8) to the turbogroup (2), and a valve arrangement (12) which is arranged in the gas-supply line (9) and throttles a storage pressure (PS) applied on the inlet side to a working pressure (PA) by closed-loop and / or open-loop control. In order to improve the reliability of the valve arrangement (12), it has at least two control valves (13, 14) arranged in series. A leading first control valve (13) throttles the storage pressure (PS) applied on the inlet side to an intermediate pressure (PZ) by closed-loop or open-loop control. A subsequent second control valve (14) throttles the pressure (PZ) applied on the inlet side to the working pressure (PA) by closed-loop control.

Owner:GENERAL ELECTRIC TECH GMBH

Gas drainage method and equipment with alternative drainage

ActiveCN102352768AIncrease the extraction radiusIncrease the total amount of extractionGas removalHigh pressureDrainage amount

The invention discloses a gas drainage method and equipment with alternative drainage, which are applicable to increasing the drainage diameter of a gas drainage drilling hole and improving the total gas drainage amount of the drilling hole. A main drainage pipeline at the front part and the rear part of a gas pump is connected with bypass pipelines in parallel by a front three-way ball valve anda rear three-way ball valve; the main drainage pipeline at the front part of the front three-way ball valve is connected with a high-pressure gas storage tank; the rear part of the high-pressure gas storage tank is connected with a gas filling pipeline controlled by a gas filling control ball valve; the gas filling pipeline is connected onto the main drainage pipeline between the rear three-way ball valve and the gas pump; a gas drainage pipe in the gas drainage drilling hole is connected with the main drainage pipeline to carry out gas drainage; in the operation process of the gas pump, by controlling the states of the front three-way ball valve, the rear three-way ball valve, the gas filling control ball valve and an outlet control ball valve, extracted gas flow and pressed-in gas flow occur alternatively on the gas drainage drilling hole, the cracks of coal bodies around the drilling hole are enlarged continuously under the action of alternative stress and develop gradually towardsthe deep part, so that the total gas drainage amount of the drilling hole is improved. The method and the equipment are simple, the operation is convenient and the cost is low.

Owner:CHINA UNIV OF MINING & TECH

Flare gas safe recovery and discharge system

ActiveCN101672478ARealize automatic controlSafe recyclingIncinerator apparatusAutomatic controlProcess engineering

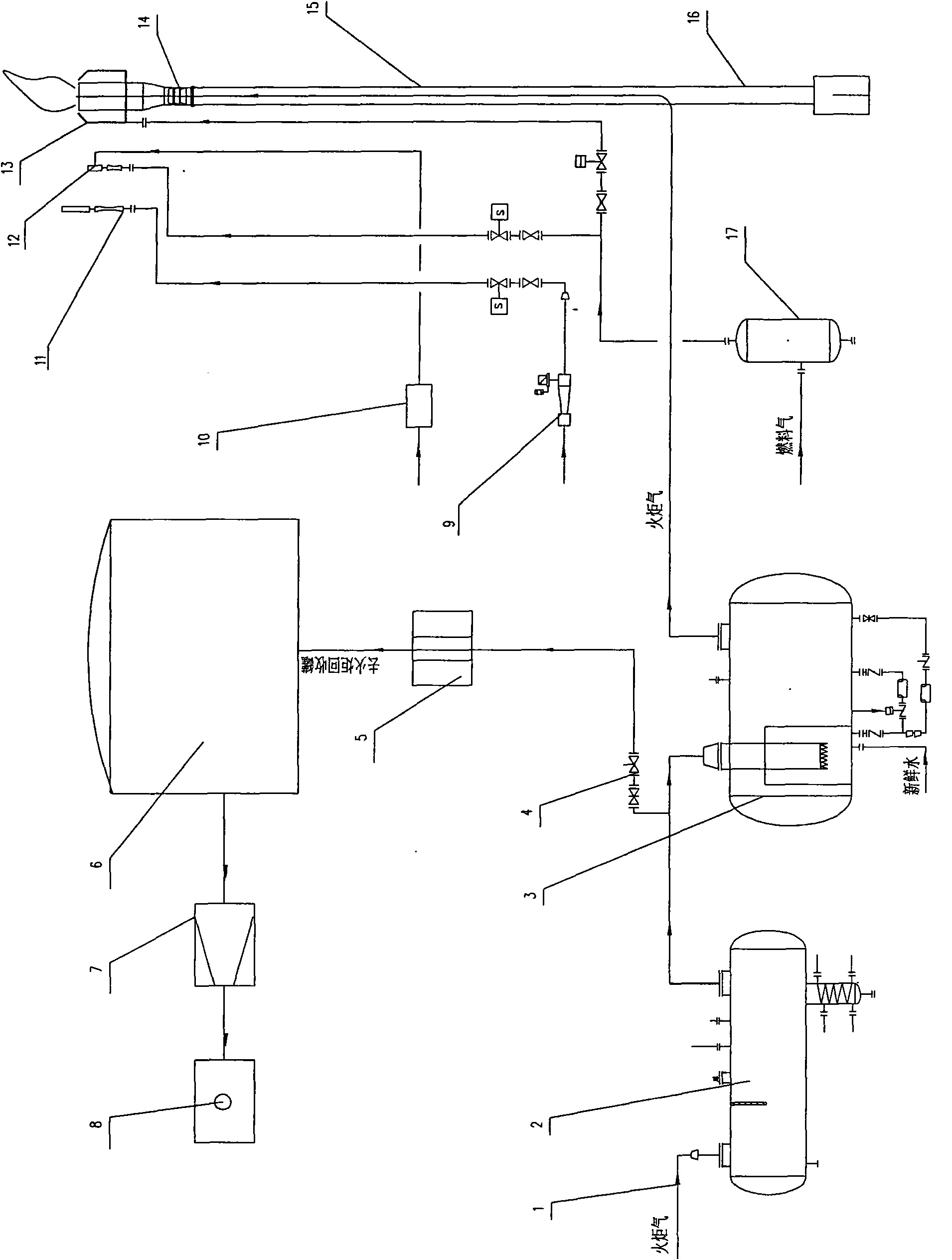

The invention provides a flare gas safe recovery and discharge system, which comprises a flare gas delivery flask (2), an automatic control water-sealed valve (3), a gas holder (6) and a flare tip (13) and is characterized in that the gas inlet end of the flare gas delivery flask (2) is connected with a flare gas source by a flare gas main pipe (1); one path of the output end of the flare gas delivery flask (2) is connected with a gas torch (6), and the other path thereof is connected with the flare tip (13) via the automatic control water-sealed valve (3); an automatic control valve (4) and aflare gas filtering tank (5) are mounted on the pipeline connecting the flare gas delivery flask (2) with the gas torch (6); the output end of the gas torch (6) is connected with a compressor (7); and the output end of the compressor (7) is connected with a gas appliance (8). The invention has the advantages of simple system structure, convenient manufacturing and installation and safe usage; andthe invention also has the characteristics of being favor of preventing environment, saving energy and the like.

Owner:JIANGSU SUNPOWER TECH

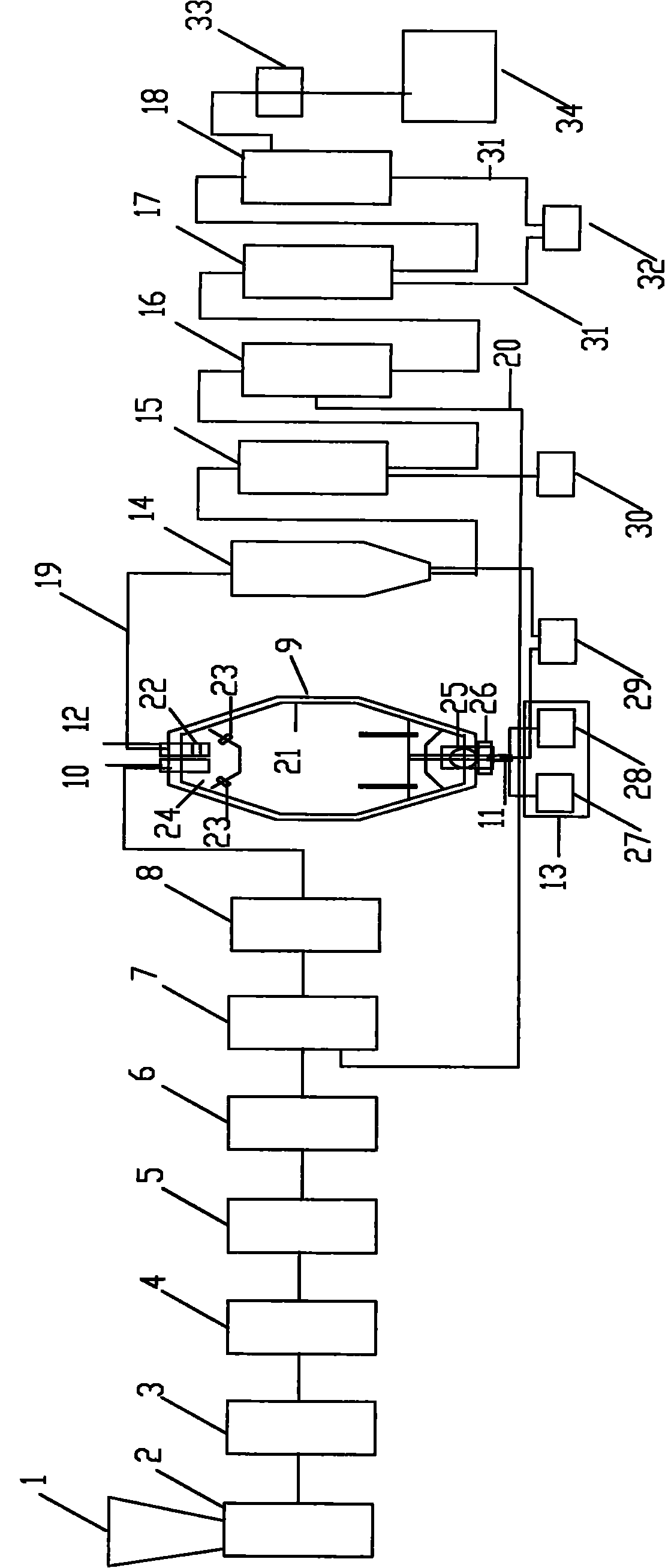

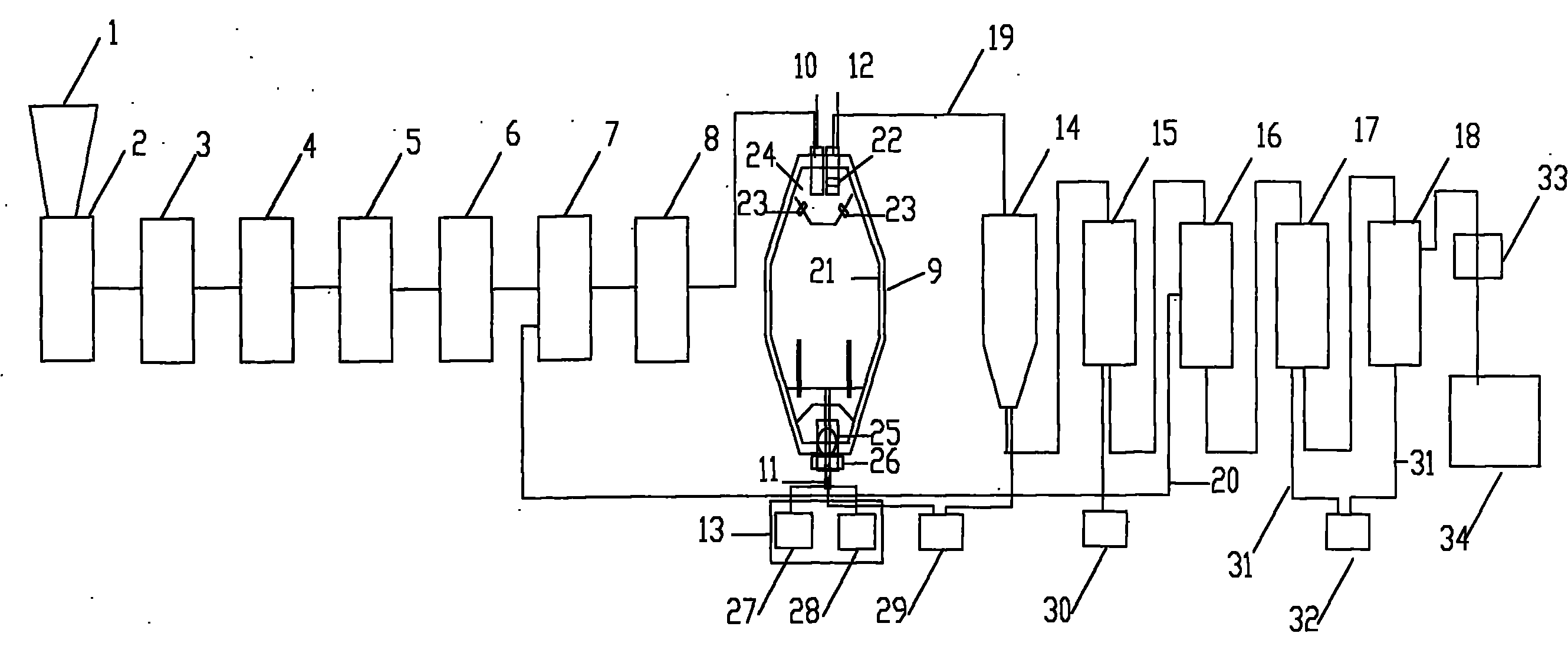

Gasification treatment device for household refuse

InactiveCN101817012ASolve intractableGood environmental benefitsSolid waste disposalCombustible gas purificationRefuse-derived fuelBrick

The invention discloses a gasification treatment device for household refuse. Combustible materials in the household refuseare treated and processed into refuse derived fuel RDF, and the RDF is subjected to pyrolysis gasification of a fixed bed gasifier and purification into clean gas. The device comprises an RDF processing system, a gasification system and a gas purification system, wherein the RDF processing system comprises a discharge hopper, a plate feeder, a refuse breaker, a rotary screen, a magneticseparator, a dehydrator, a rotary dryer and a refuse press; the gasification system comprises a normal-pressure fixed bed gasifier, a feeding hole, a slag hole, a gas hole and a blower device; and the gas purification system comprises a cyclone dust collector, an electrical tar precipitator, a heat exchanger, a washer and an adsorption tower. The RDF is subjected to pyrolysis gasification of the fixed bed gasifier to form combustible gas, the combustible gas is purified by the gas purification system, and finally the gas is delivered to a gas holder through a Roots blower; the slag after the gasification is delivered to a brick making device for producing building materials; and wastewater generated by gas purification enters a wastewater tank for further treatment.

Owner:SHANGHAI SHENGONG ENVIRONMENTAL PROTECTION CO LTD

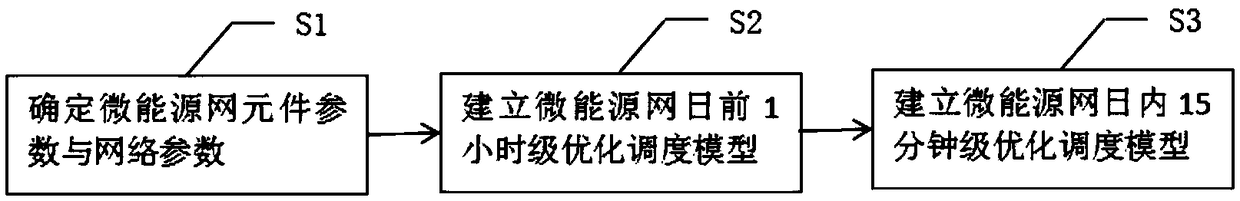

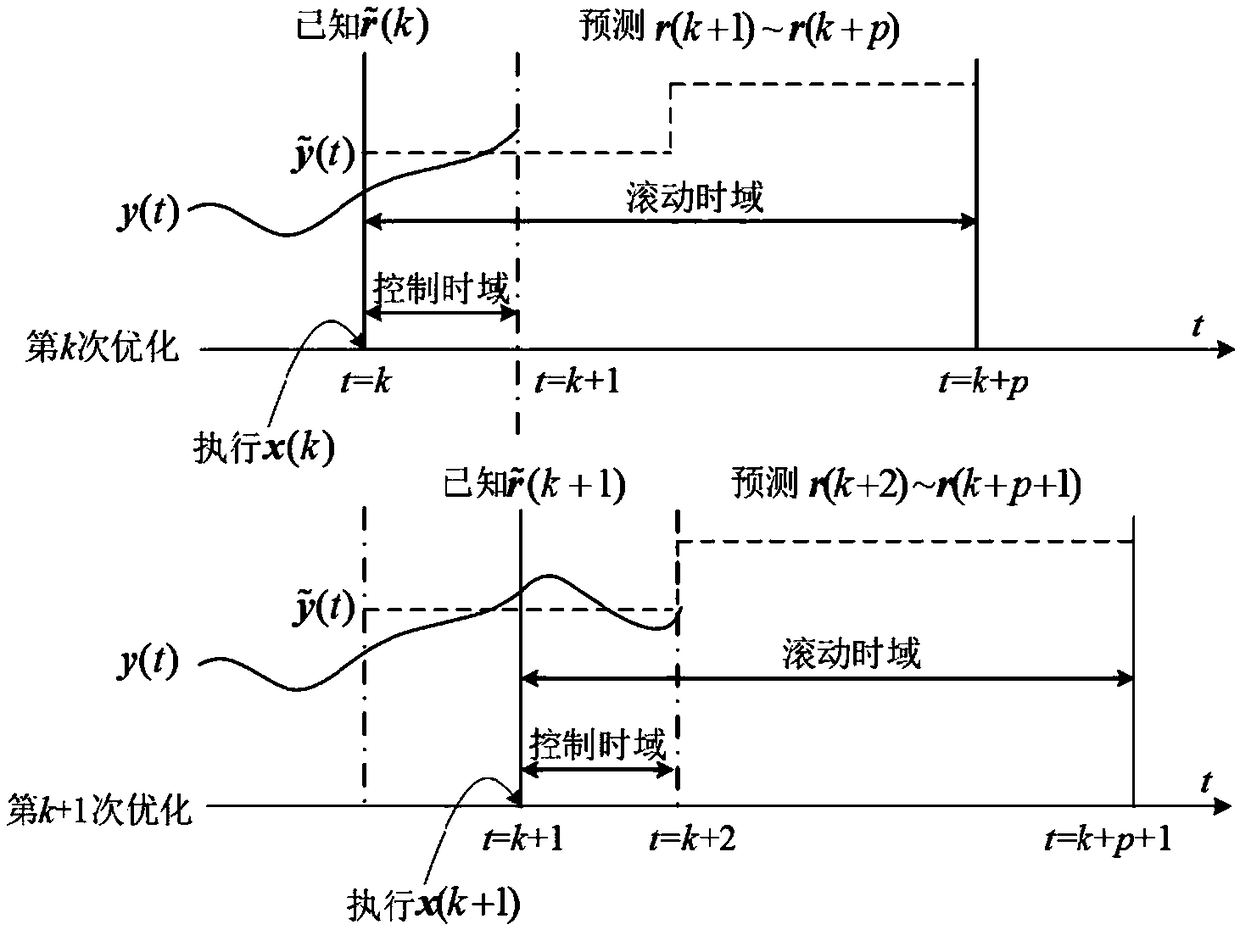

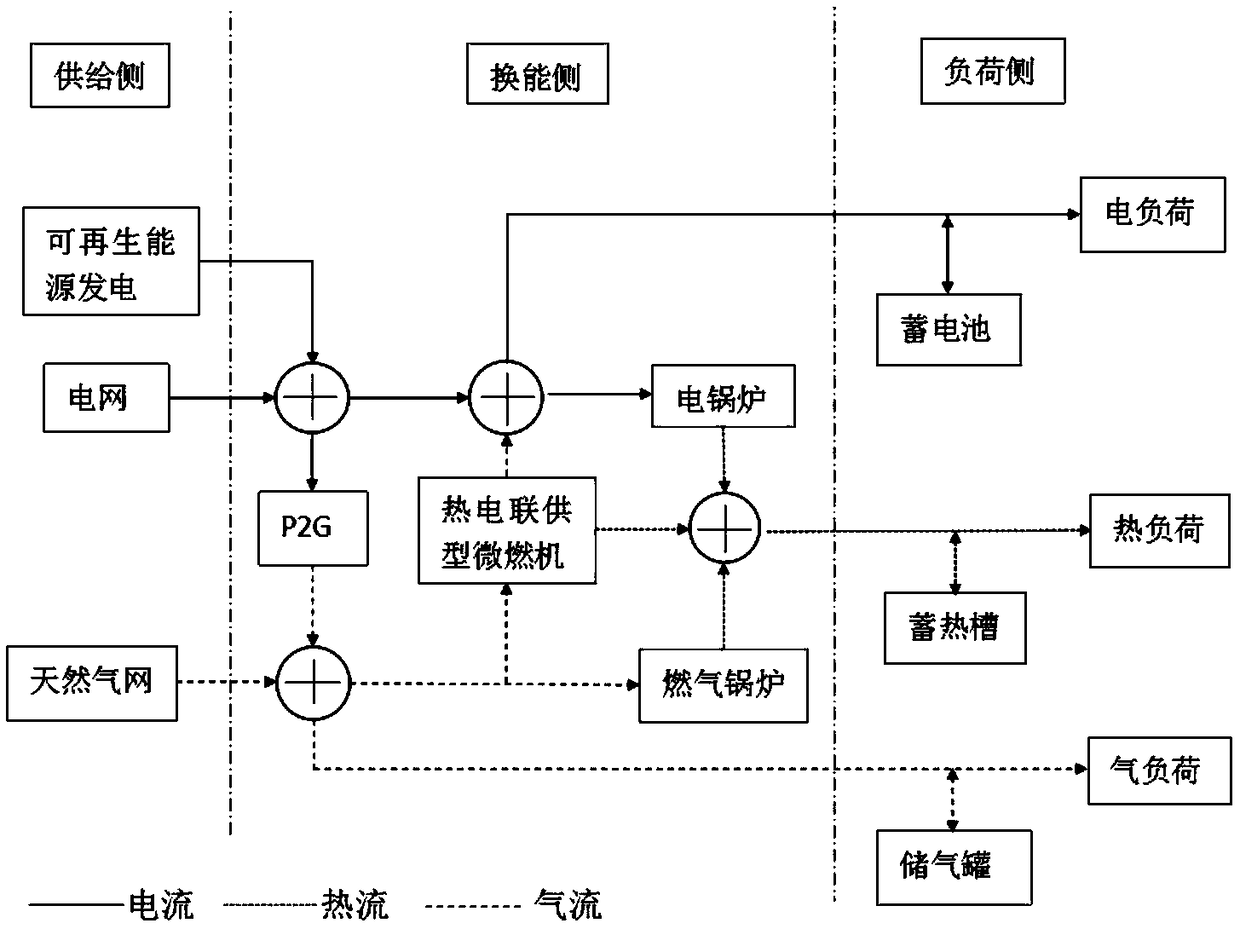

Optimal scheduling model of micro-energy grid with multi-energy storage under multi-time scales

ActiveCN109088442AEffective response powerDealing with Errors EffectivelySingle network parallel feeding arrangementsEnergy storageEnergy balancingDaily operation

The invention discloses an optimal scheduling model of a micro-energy grid with multi-energy storage under multi-time scales, which relates to the field of energy internet optimization operation. Themicro-energy network comprises three energy forms of electricity, heat and gas, including P2G equipment, a heat and power co-generation micro-combustion engine, an electric boiler, a gas boiler, an accumulator, a heat storage tank and a gas storage tank. The multi-time scale considers two time scales, one hour before the day and 15 minutes within the day. The process of establishing the optimal scheduling model of the micro-energy grid comprises the following steps: 1, determining the component parameters and the network parameters of the micro-energy network; 2, establishing an hour-level optimized dispatch model before that day of the micro-energy grid; 3, establishing a micro-energy grid intra-day 15-minute level optimal scheduling model. The invention effectively deals with the power fluctuation of the renewable energy and the load prediction error on the premise of ensuring the daily operation energy balance of each energy storage device, and improves the absorbing capacity of themicro-energy grid to the wind power and the photovoltaic.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY RIZHAOPOWER SUPPLY +1

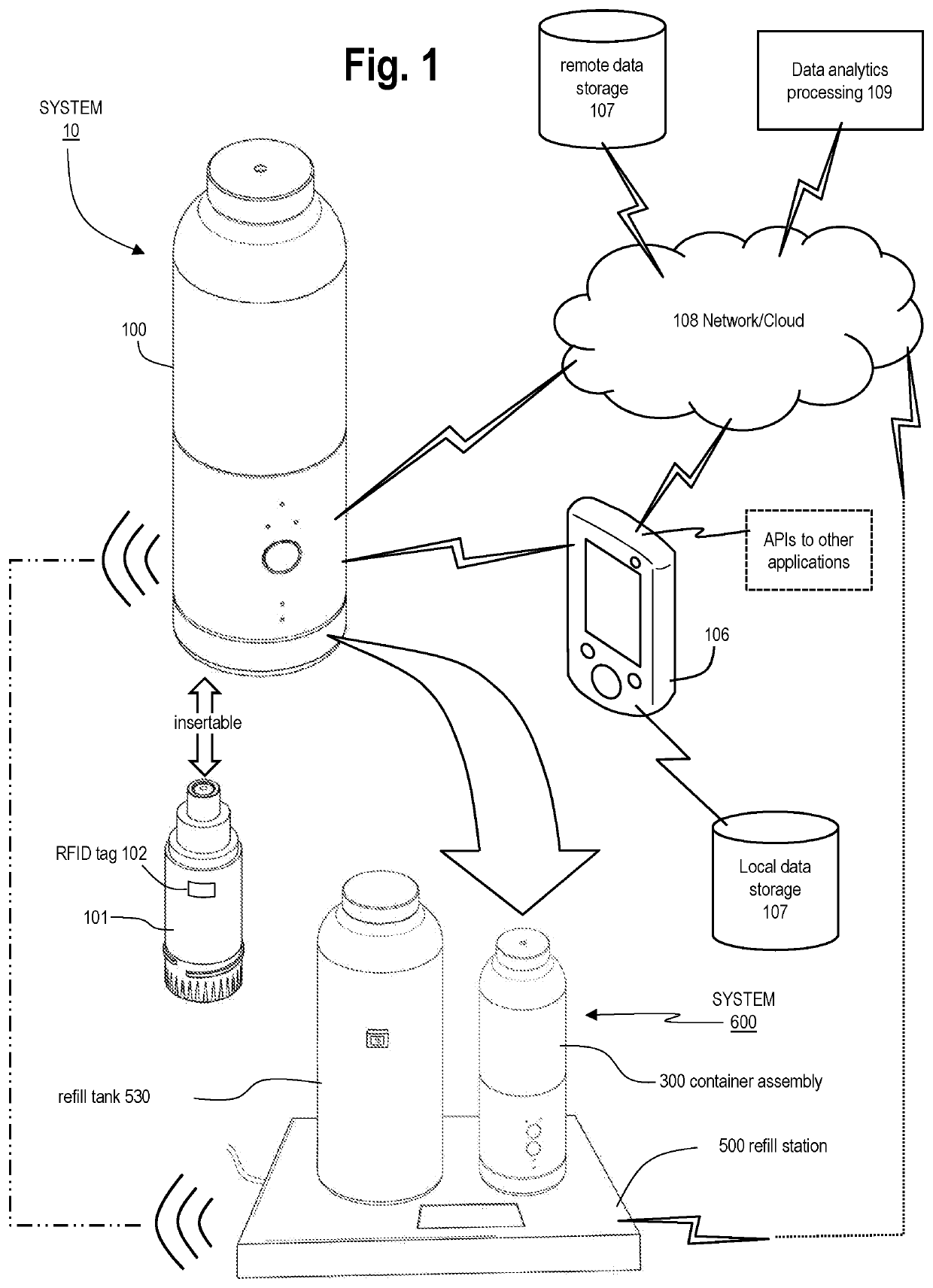

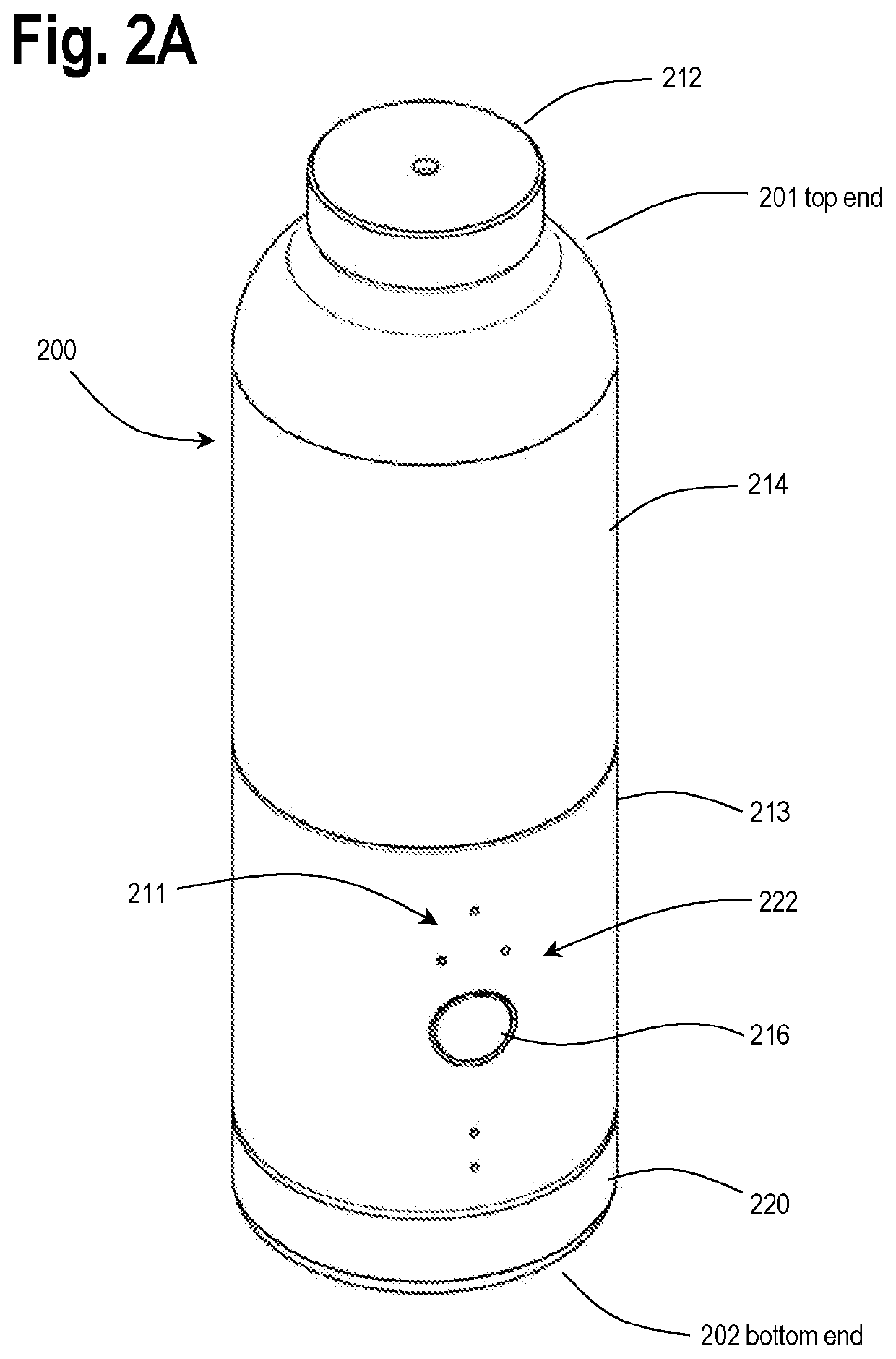

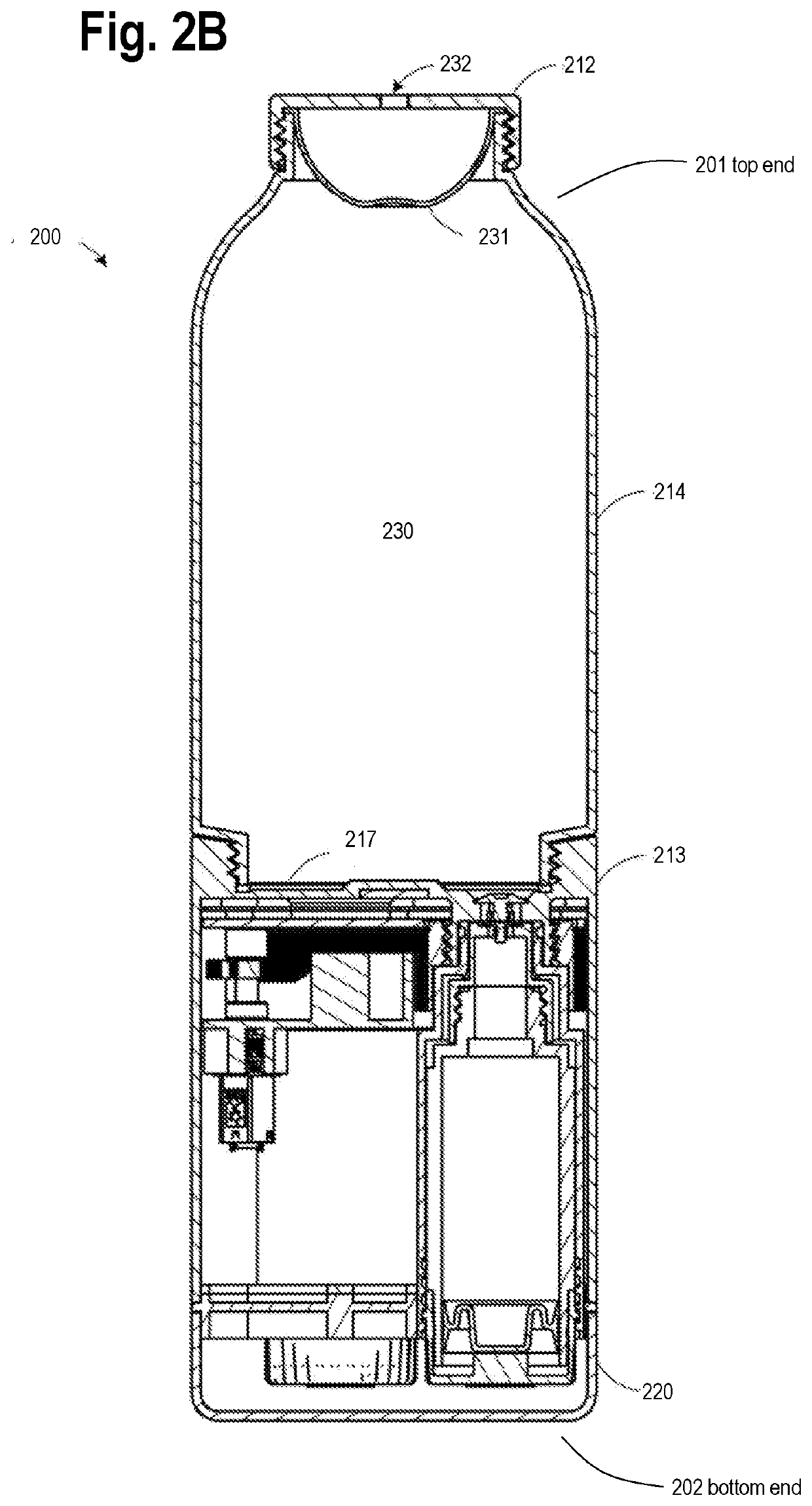

Portable systems and methods for adjusting the composition of a beverage

The systems and methods provide a container assembly comprising: a container having a known storage capacity for storing a liquid; an additive dispensing assembly, the additive dispensing assembly dispensing variable, non-zero quantities of one or more additives into the liquid stored in the container; one or more vessels that each contain one of the additives, of the one or more additives, to be dispensed into the liquid; and a gas dispensing assembly, the gas dispensing assembly releasing a gas into the liquid stored in the container, and the gas dispensing assembly including: an onboard gas tank; a valve assembly; and a gas outlet, and the valve assembly controlling flow of gas from the onboard gas tank, through the valve assembly, and to the gas outlet so as to output the gas into the liquid; and wherein the valve assembly, to perform the controlling the flow of gas, is movable between: an open position, in which flow of gas is allowed to flow from the onboard gas tank to the gas outlet; and a closed position in which the flow of gas is prevented to flow from the onboard gas tank to the gas outlet.

Owner:CIRKUL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com