Patents

Literature

40results about How to "Solve the problem of excess" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Numerical reservoir simulation method for measuring flowing situation of a plurality of intersected discrete cracks

InactiveCN103400020ADoes not affect calculation resultsSolve the problem of excessSpecial data processing applicationsLine segmentOil well

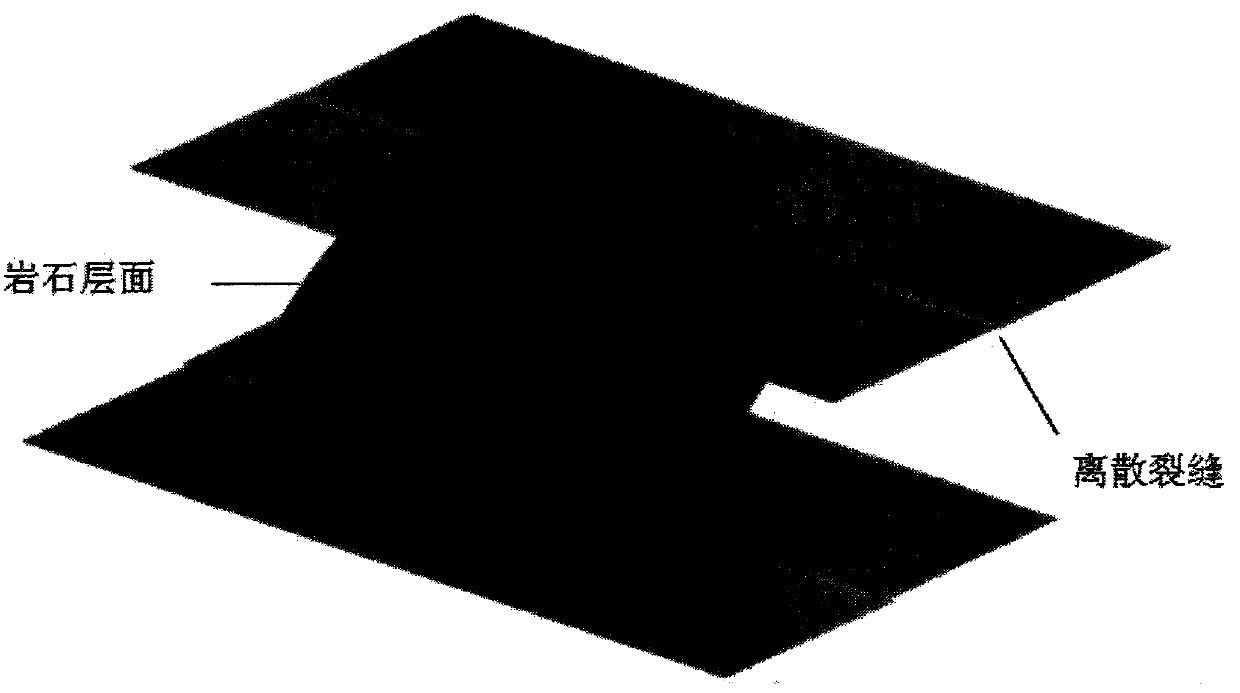

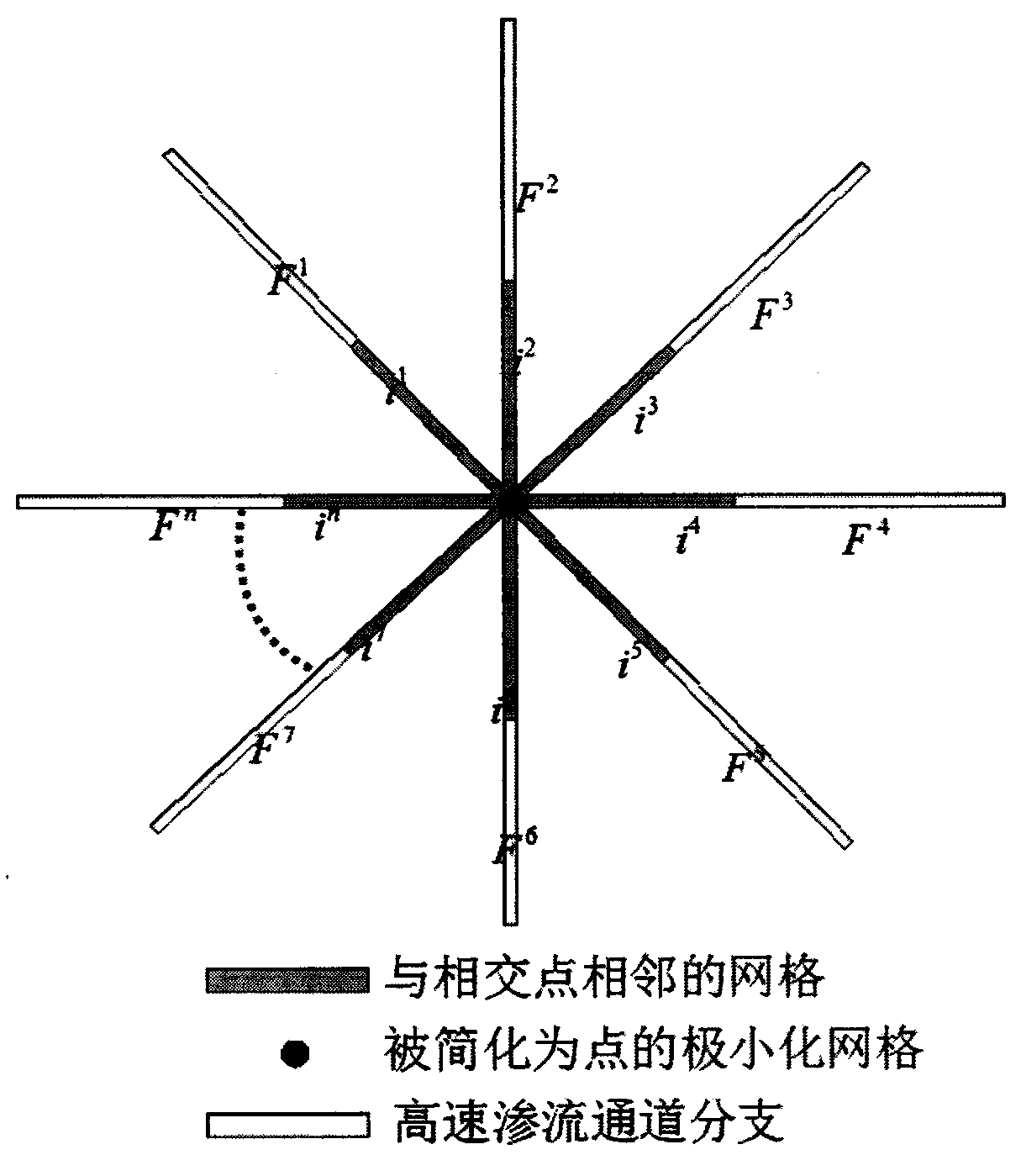

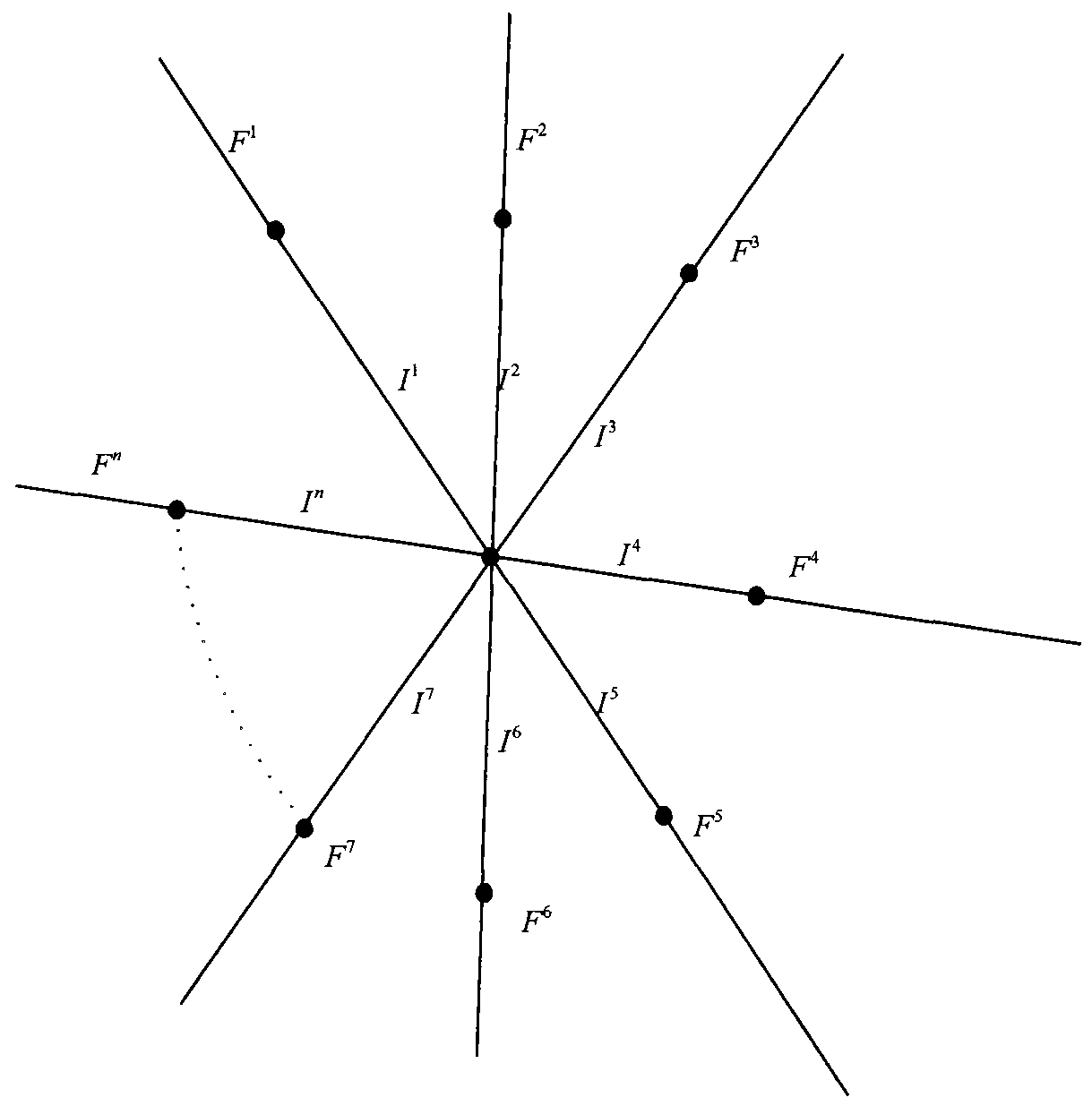

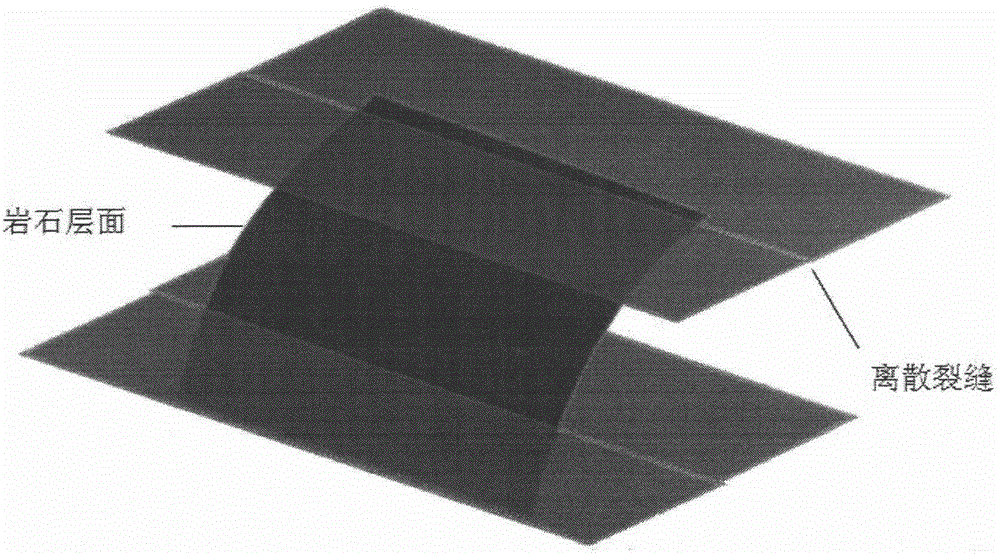

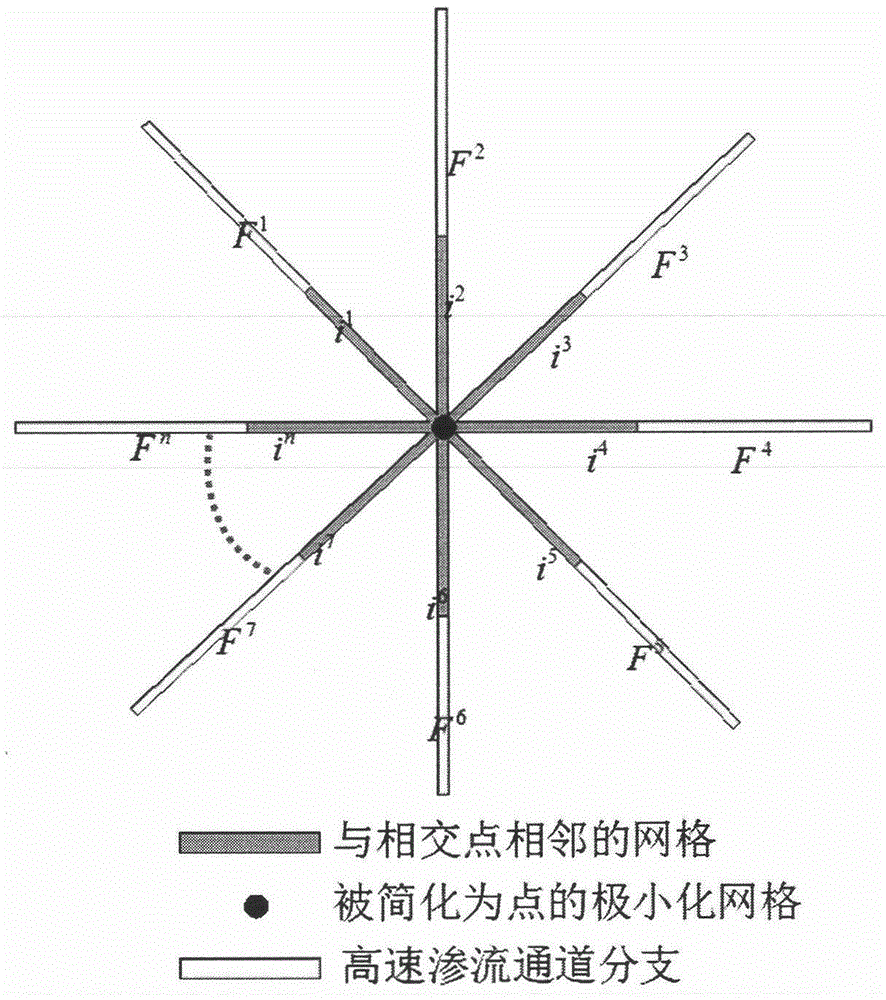

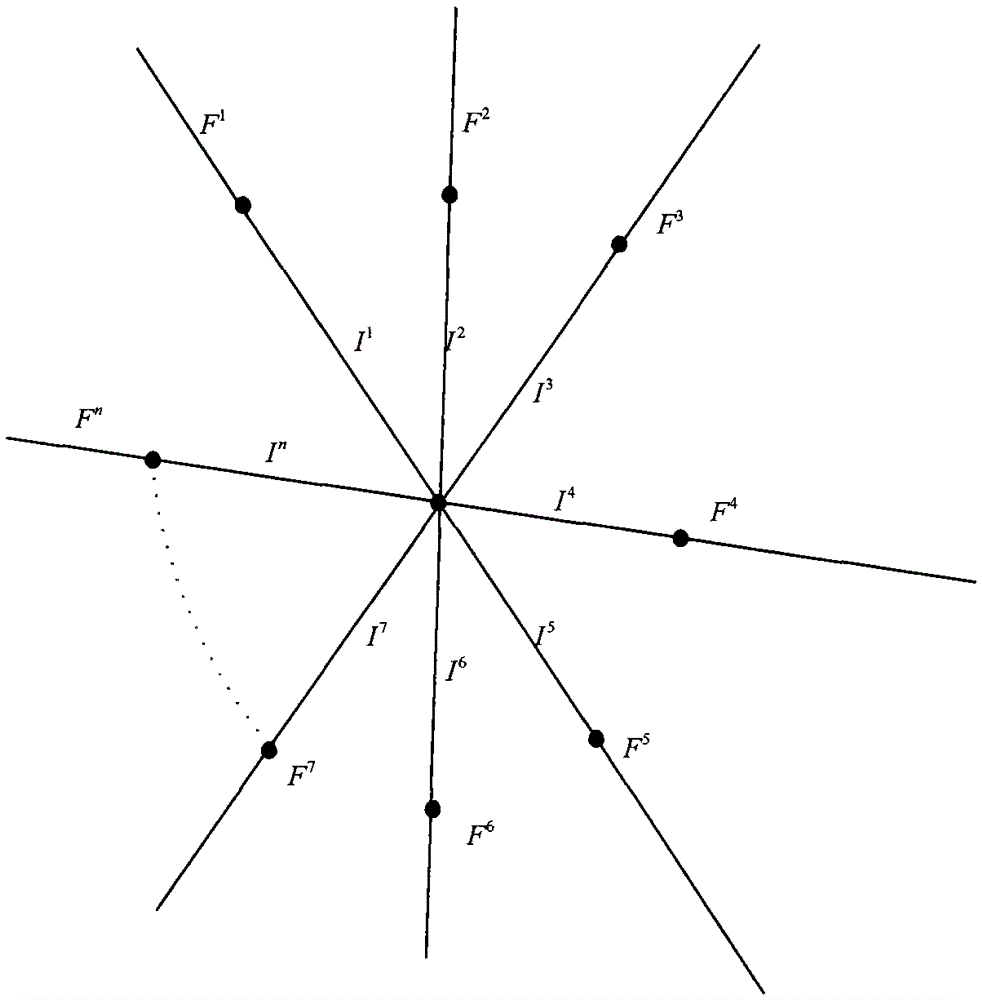

The invention discloses a numerical reservoir simulation method for measuring the flowing situation of a plurality of intersected discrete cracks. The method comprises the steps that a reservoir is divided into a continuous medium and a discrete crack medium; in order to remove extremely small grids, when a reservoir grid is created, a discrete crack endpoint is deformed or is simplified to be a segment by neglecting the thickness, then a rock stratum face grid is established, and a three-dimensional reservoir grid is established; practically measured reservoir parameters of holes, leakage, saturation and the like are input into a simulator, then a real value instead of a grid display value is used as the width of each discrete crack, and accuracy of a measured and calculated result is not lowered by deformation processing; the volume of the intersecting area of the discrete cracks is neglected, and a flow formula of the discrete cracks in the intersecting area is established; the reservoir parameters are corrected by utilizing the history fitting method; then well yield and remaining oil gas distribution and reserves are measured and calculated. The numerical reservoir simulation method can solve the problems that the discrete crack value simulation technology is prone to interruption and failure and is long in consumed time for measurement and calculation, so that the technology can achieve measurement and calculation in the whole process of full three-dimensional reservoir development, and improves accuracy of the measured and calculated result.

Owner:SOUTHWEST PETROLEUM UNIV +1

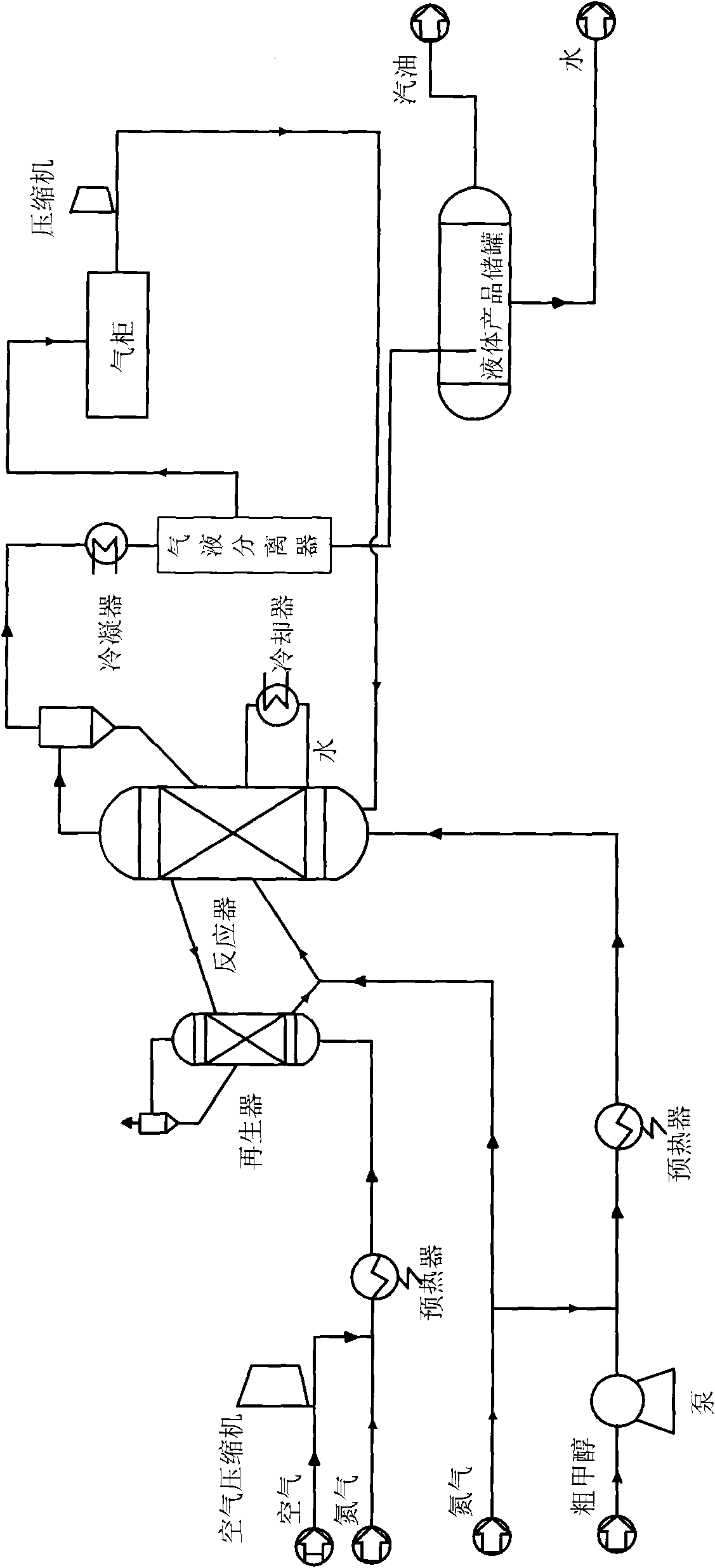

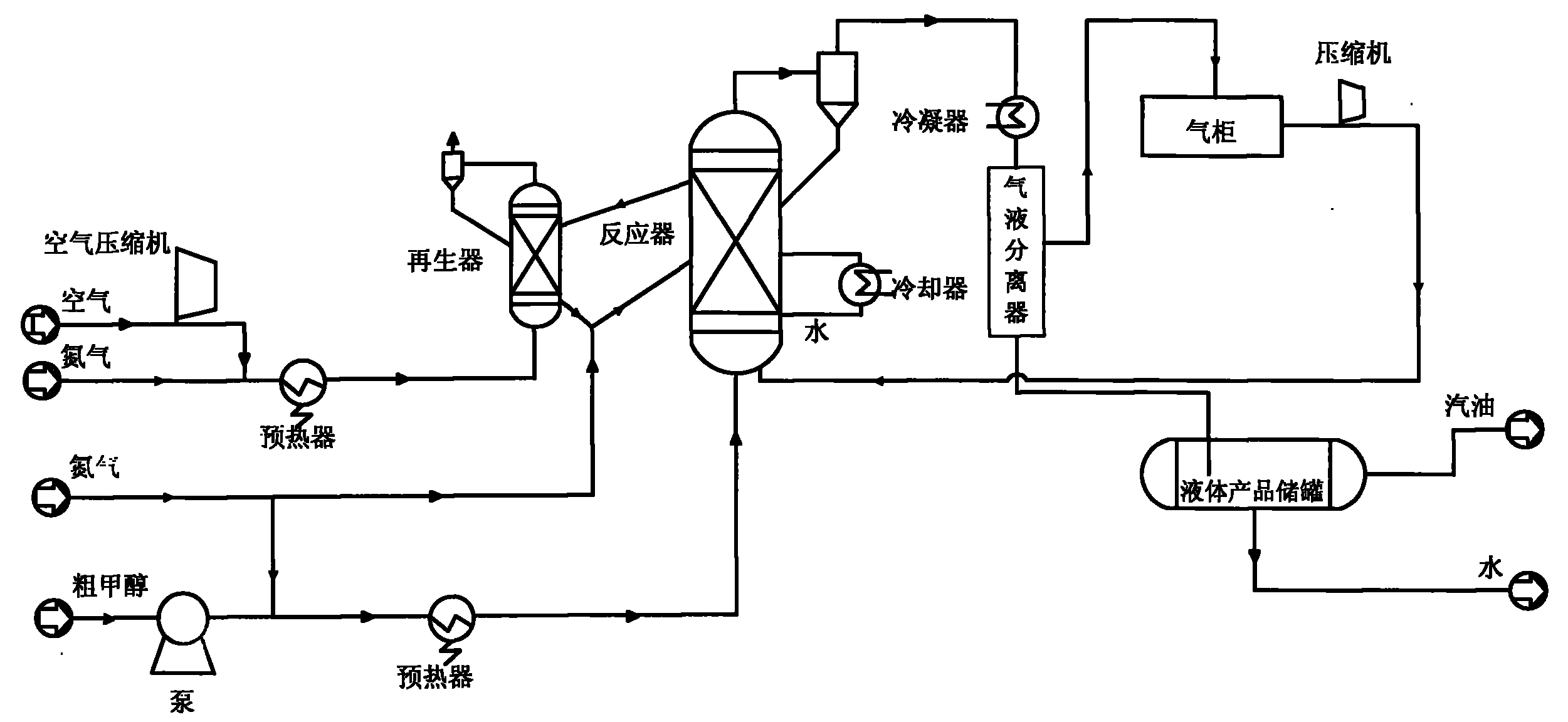

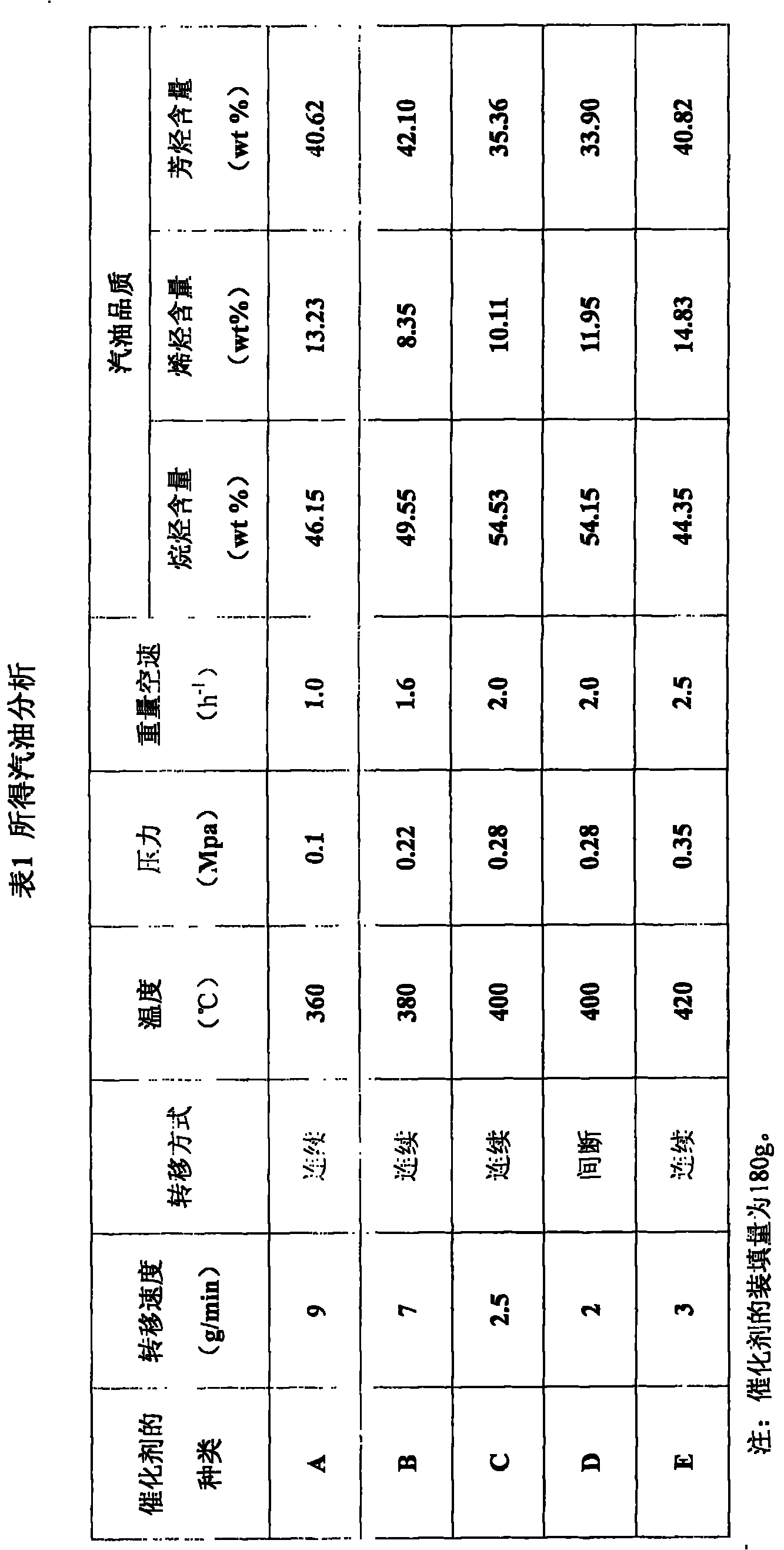

Method of producing gasoline by fluidized bed process methanol

InactiveCN101775310ASolve the problem of excess methanolSolve the problem of excessLiquid hydrocarbon mixture productionBio-feedstockFluidized bedGasoline

The invention relates to a method of producing gasoline by fluidized bed process methanol, in which crude methanol steam enters a fluidized bed reactor from the lower part to be contacted and reacted with a catalyst; a part of the catalyst after reaction is taken out continuously or discontinuously from the upper part of the reactor in a certain output amount for regeneration, and then the catalyst is supplemented with the same output amount from the lower part of the reactor by the regenerator, which is repeated and circulated. Reaction products flow out from the top of the fluidized bed reactor, and after gas-solid separation, the obtained catalyst powder enters the fluidized bed reactor again, gas firstly enters to be cooled, then gas-liquid separation is carried out, separated light hydrocarbon gas is collected by a gas holder and then is sent by compression into the fluidized bed reactor for light hydrocarbon circulation, and liquid separation is carried out on the separated liquid to obtain the gasoline and water. The technology used in the invention has the advantages that the catalyst can be regenerated continuously, a spare reactor is not needed, the nature of the catalyst is constant, the quality of the gasoline is high (octane value RON 93 plus), the conversion rate of the methanol is 100 percent, and the heat transfer intensity is high.

Owner:山西天和煤气化科技有限公司

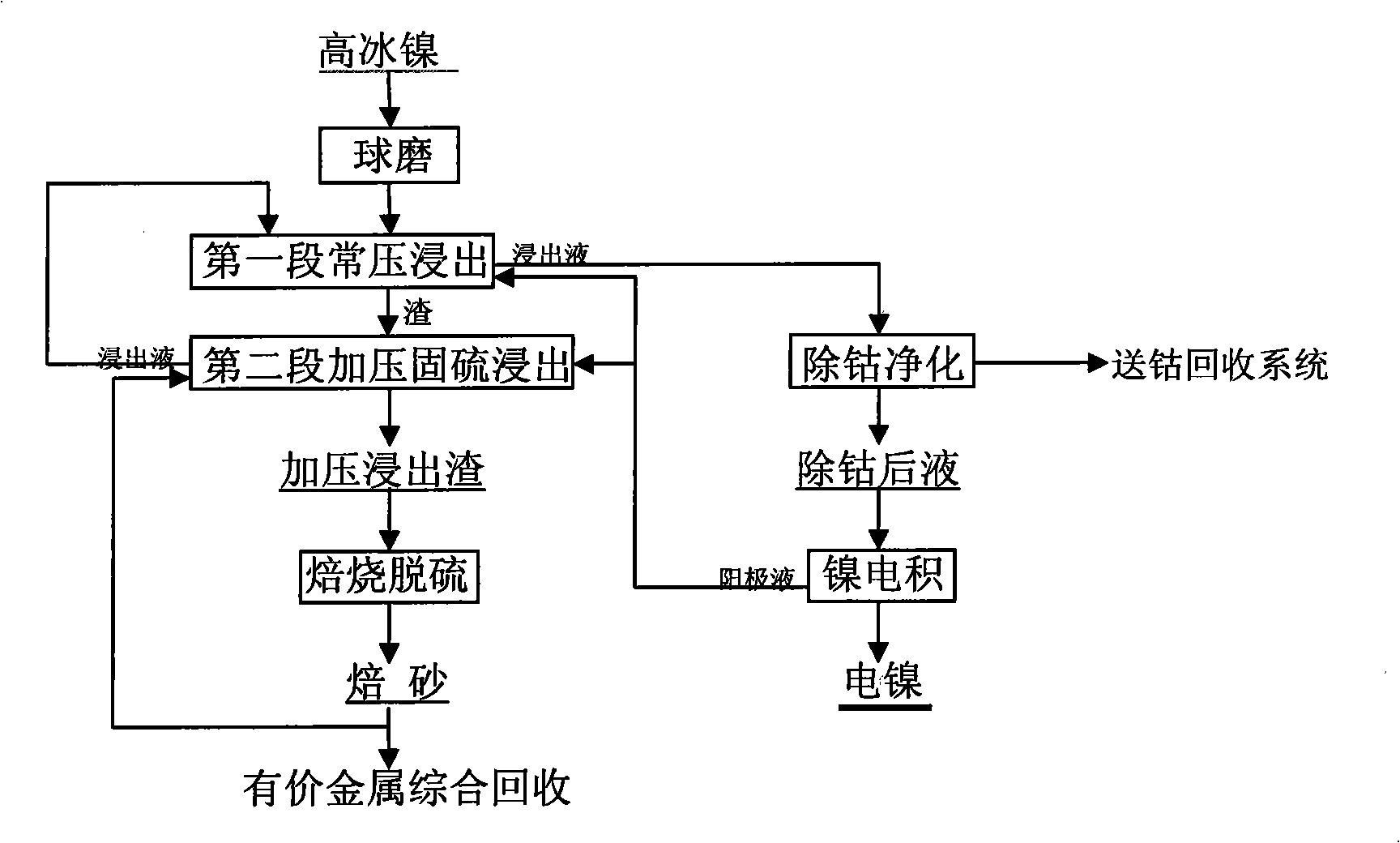

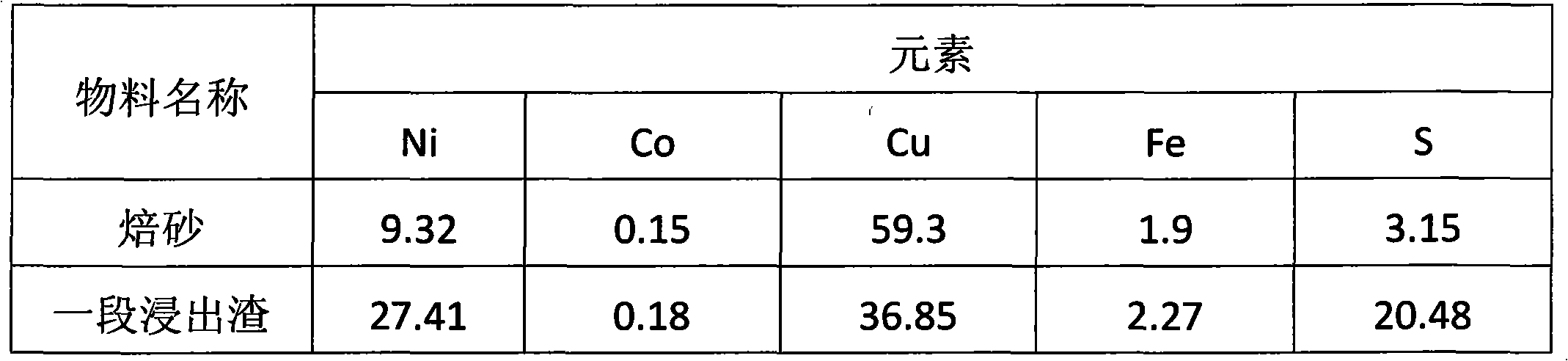

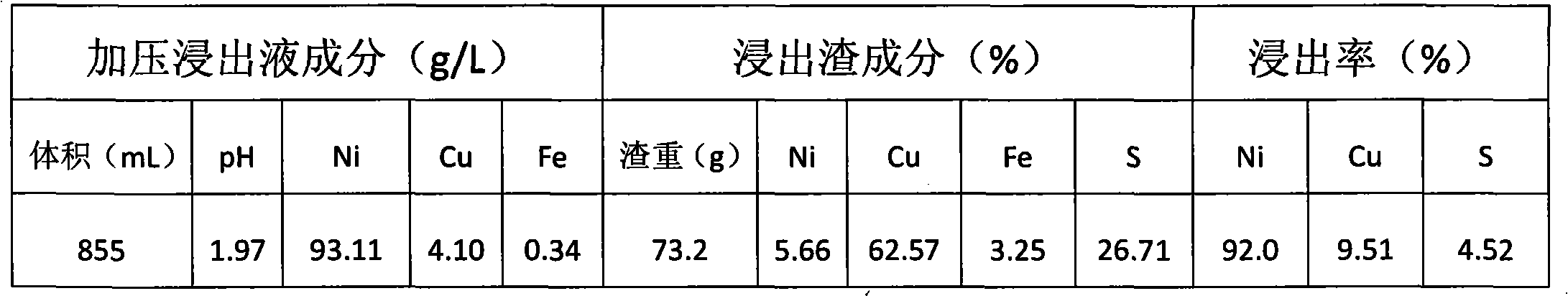

Method for producing cathode nickel by selective leaching-electrodeposition of high nickel matte

InactiveCN101886167AHigh recovery rateAdaptablePhotography auxillary processesProcess efficiency improvementPregnant leach solutionSelective leaching

The invention discloses a method for producing cathode nickel by the selective leaching-electrodeposition of high nickel matte, which relates to a method for producing the cathode nickel by hydrometallurgical refining of the high nickel matte. The method is characterized in that the cathode nickel production process comprises the following steps of: (1) performing first-stage normal-pressure leaching on the high nickel matte; (2) removing cobalt from first-stage normal-pressure leachate for purification and producing electric nickel by electrodeposition; (3) adding a sulphur fixing agent into a first-stage leaching residue to perform second-stage pressing and sulphur fixing leaching, and returning the leachate which is obtained by the second-stage pressing and sulphur fixing leaching to perform first-stage normal-pressure leaching; and (4) desulfurating and roasting the leaching residue obtained by the second-stage pressing and sulphur fixing leaching to obtain a roasted product, and returning the roasted product which is used as the sulphur fixing agent in the step (3). The method of the invention effectively solves the problem of acid excess of a production system, has a high nickel recovery rate and low production cost, is highly adapted to different high nickel matte raw materials and favorable for environmental protection, and can obviously reduce the waste water emission in the production.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

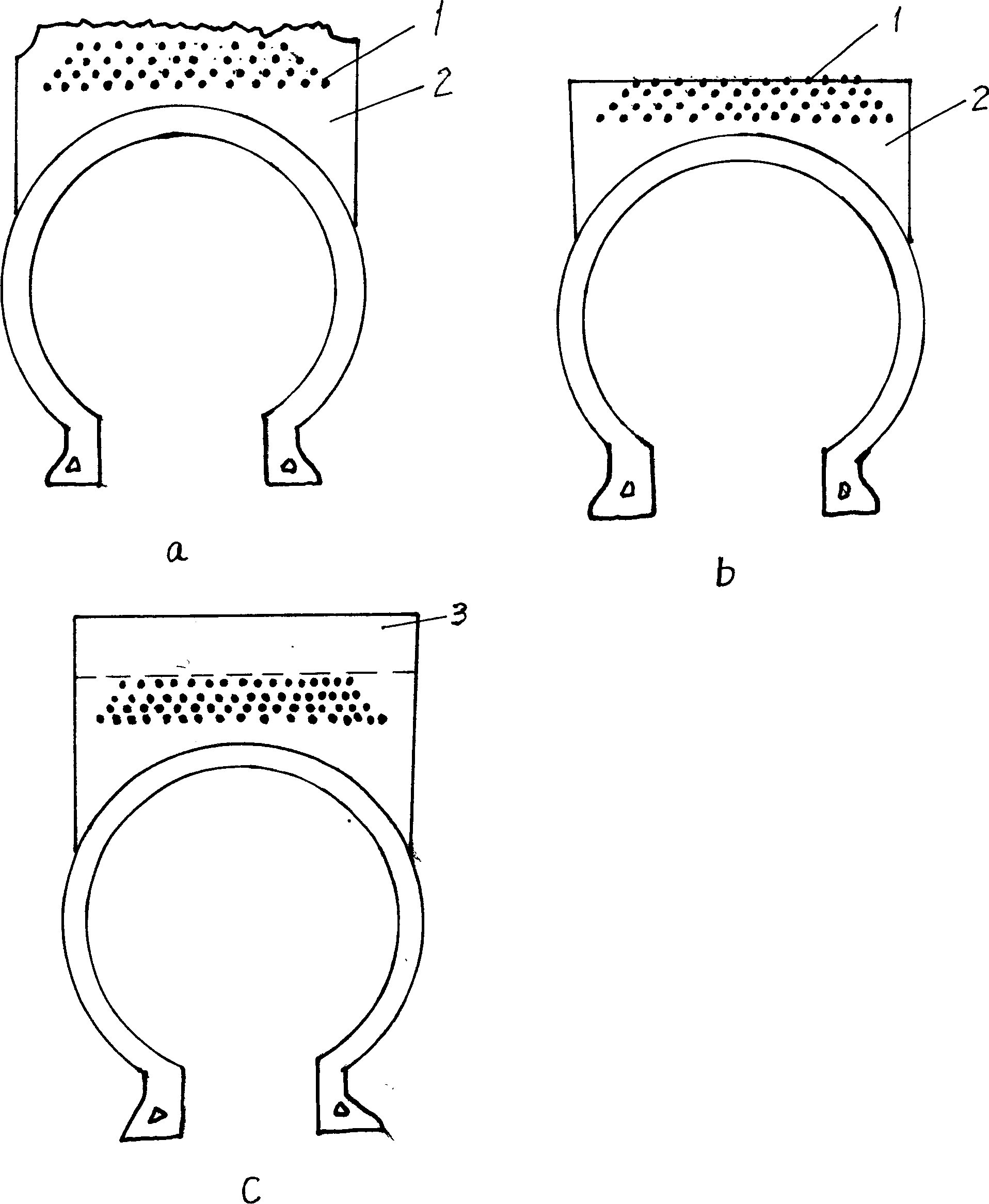

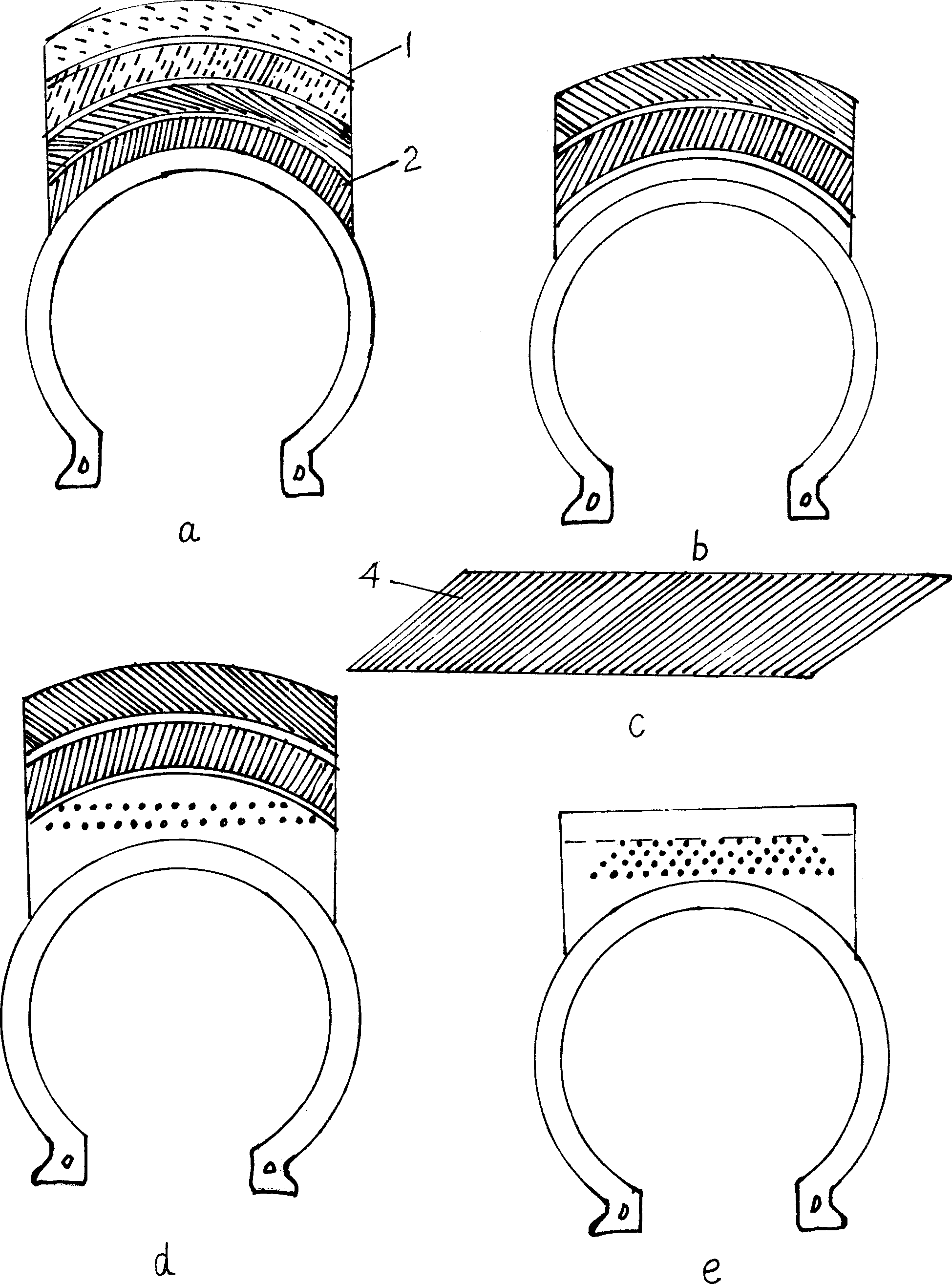

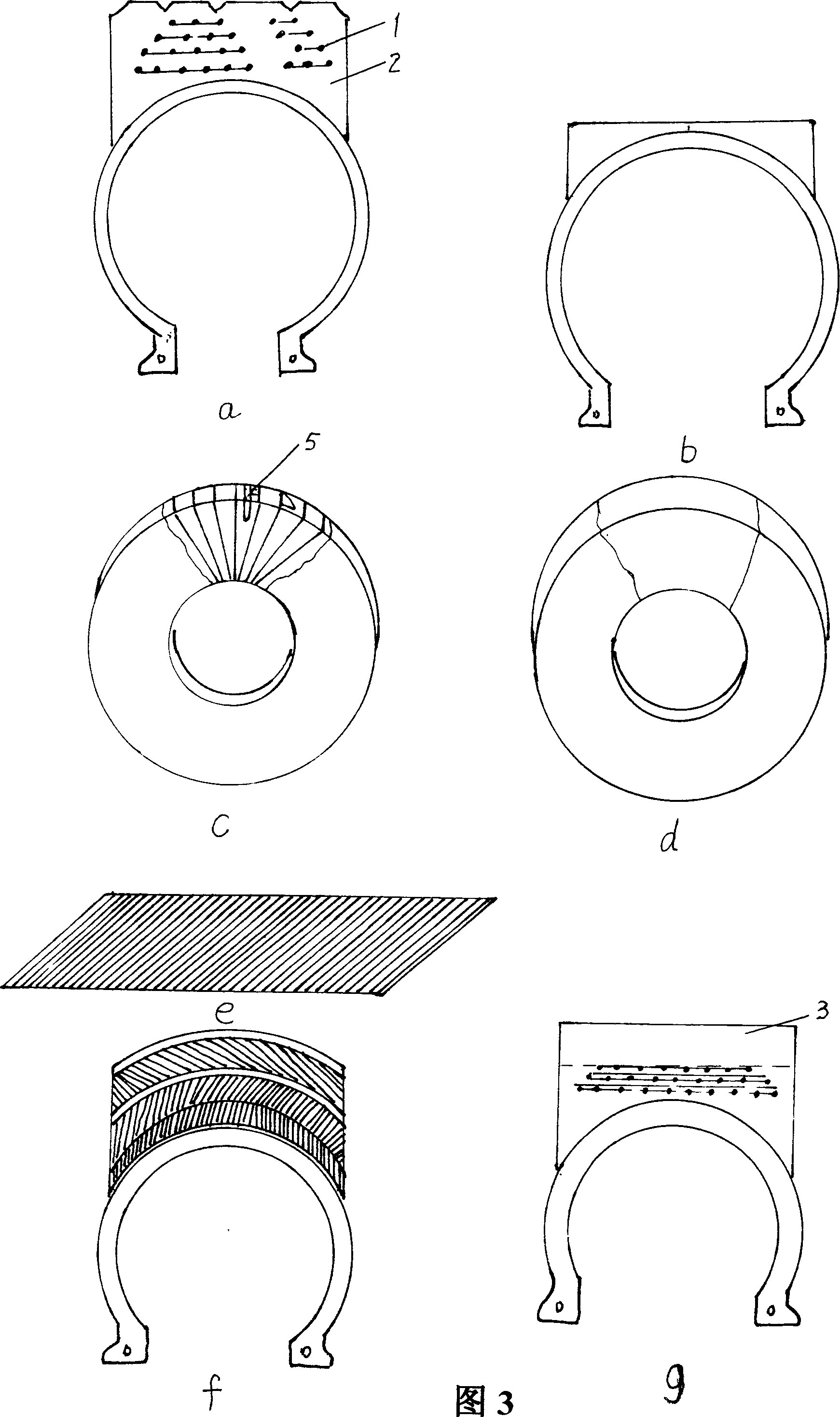

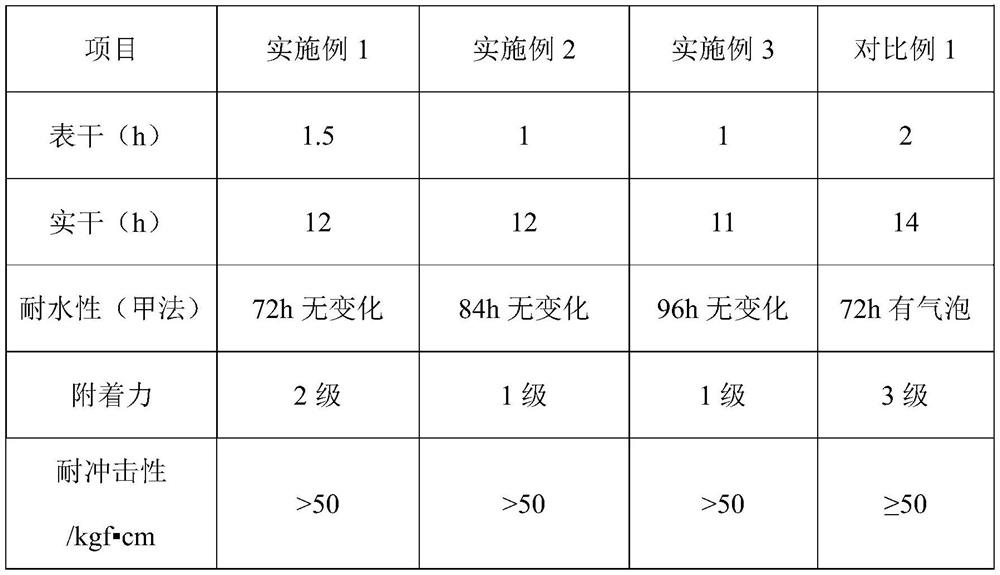

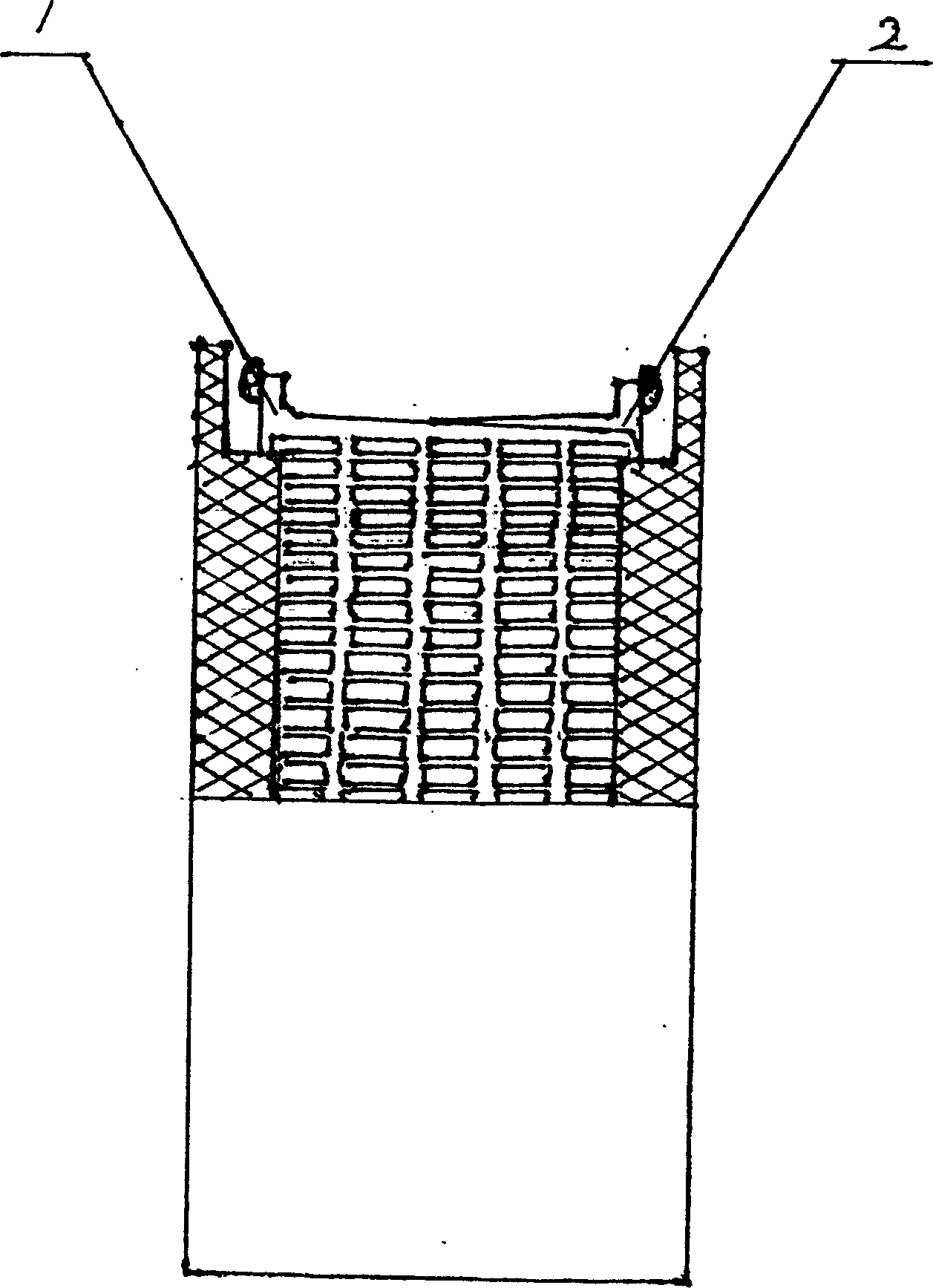

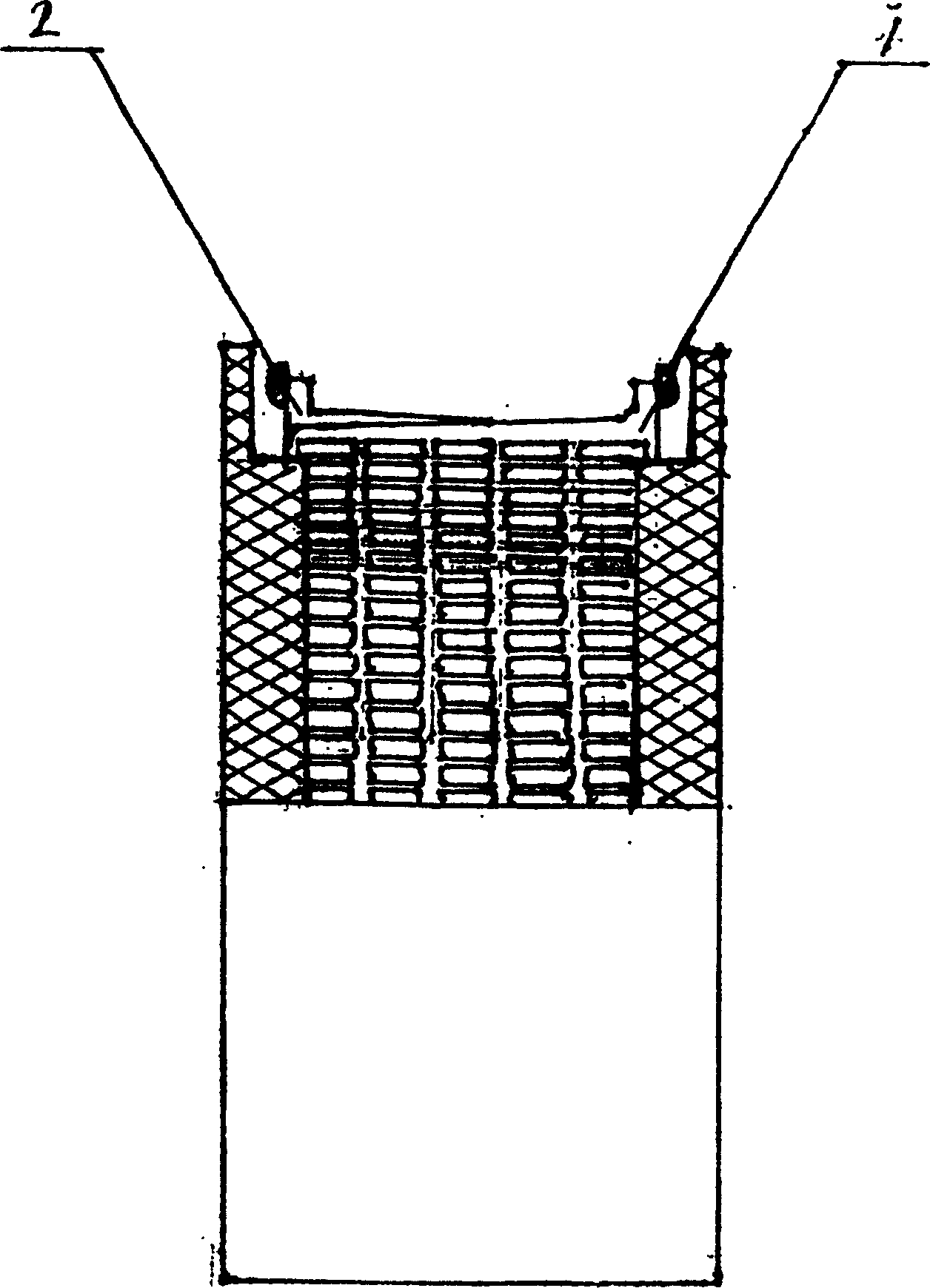

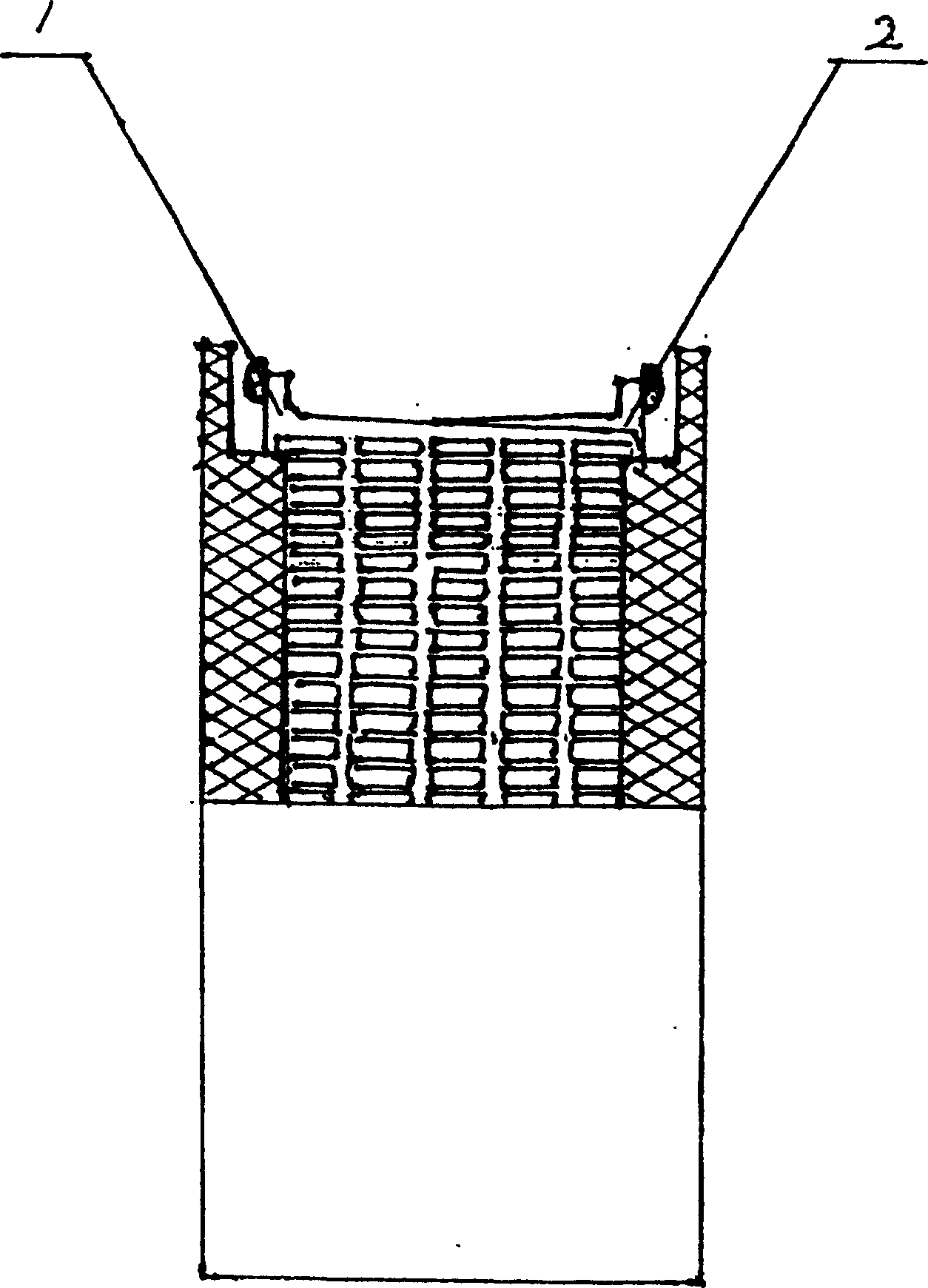

New method for repairing waste tyre

A method to repair the waste tyre is disclosed the invention. First it divides the waste tyre into the first, second, third and forth degree, then to treat the old skin to expose the oblique steel mesh, next to dry the tyre, then to cover with the adhesives twice, next to lay the cushion glue and main tyre face in the way of the pressure, last to sulphurate. The invention can repair the waste tyre without the main tyre face, it can improve the using ratio of the waste tyre to 90%, and the quality can reach the fist grade of the recovery tyre.

Owner:海启和

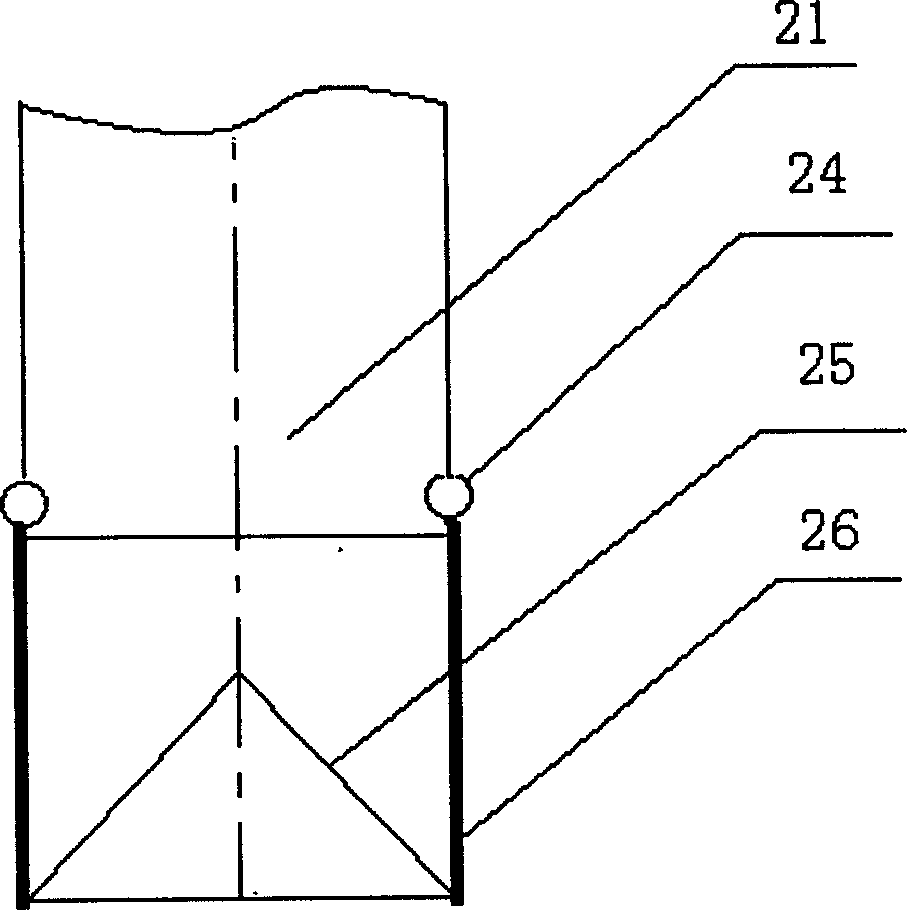

Method for oil deposit flow state digifax calculating with discrete fracture line processing

InactiveCN103399970AReduce in quantityFewer segmentation failuresSpecial data processing applicationsLine segmentOil well

The invention discloses a method for oil deposit flow state digifax calculating with discrete fracture line processing. First, an oil deposit storage layer is divided into continuous media and discrete fracture media; in order to remove minimum meshes, discrete fracture thicknesses are ignored when oil deposit meshes are established, the section of a discrete fracture on a plane is changed to a line segment, then rock stratum meshes are established, three-dimensional oil deposit meshes are then established; oil deposit parameters such as practical measuring holes, leakage, saturation are recorded into a simulator, wherein real values are used for discrete fracture widths, mesh display values are not used, accuracy of calculating results is not lowered by deformation; the oil deposit parameters are corrected through a history fitting method; then oil well yield, surplus oil-gas distribution and storage amount are calculated. The problems that a discrete fracture numerical simulation technique can be easily interrupted and fail, calculating time is long can be solved, the whole process of practical oil deposit development can be really calculated through the technology, so that accuracy of oil deposit flow state calculating is improved, and accordingly an effective development scheme is formulated to improve oil deposit development effect.

Owner:SOUTHWEST PETROLEUM UNIV +1

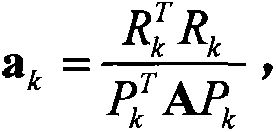

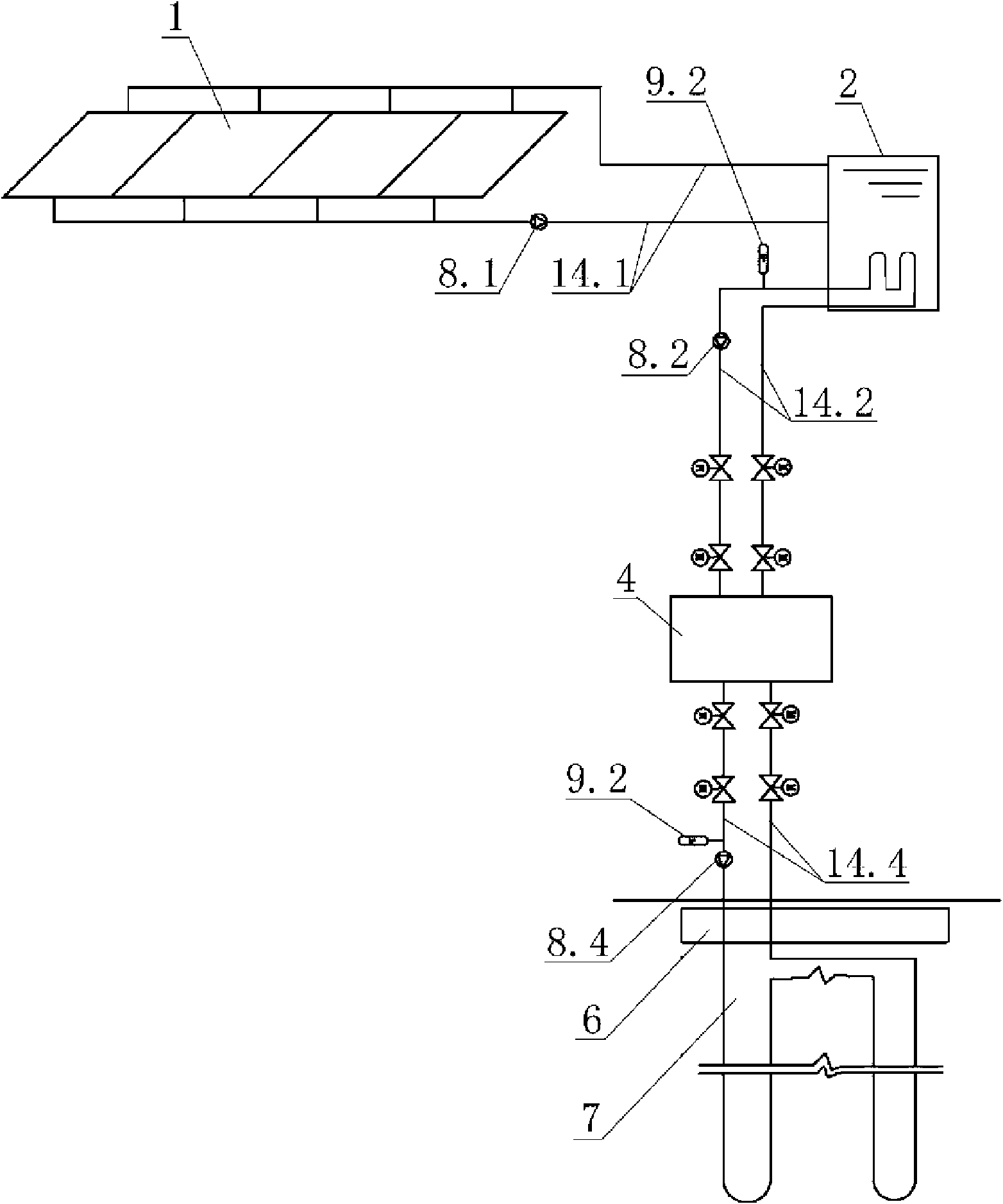

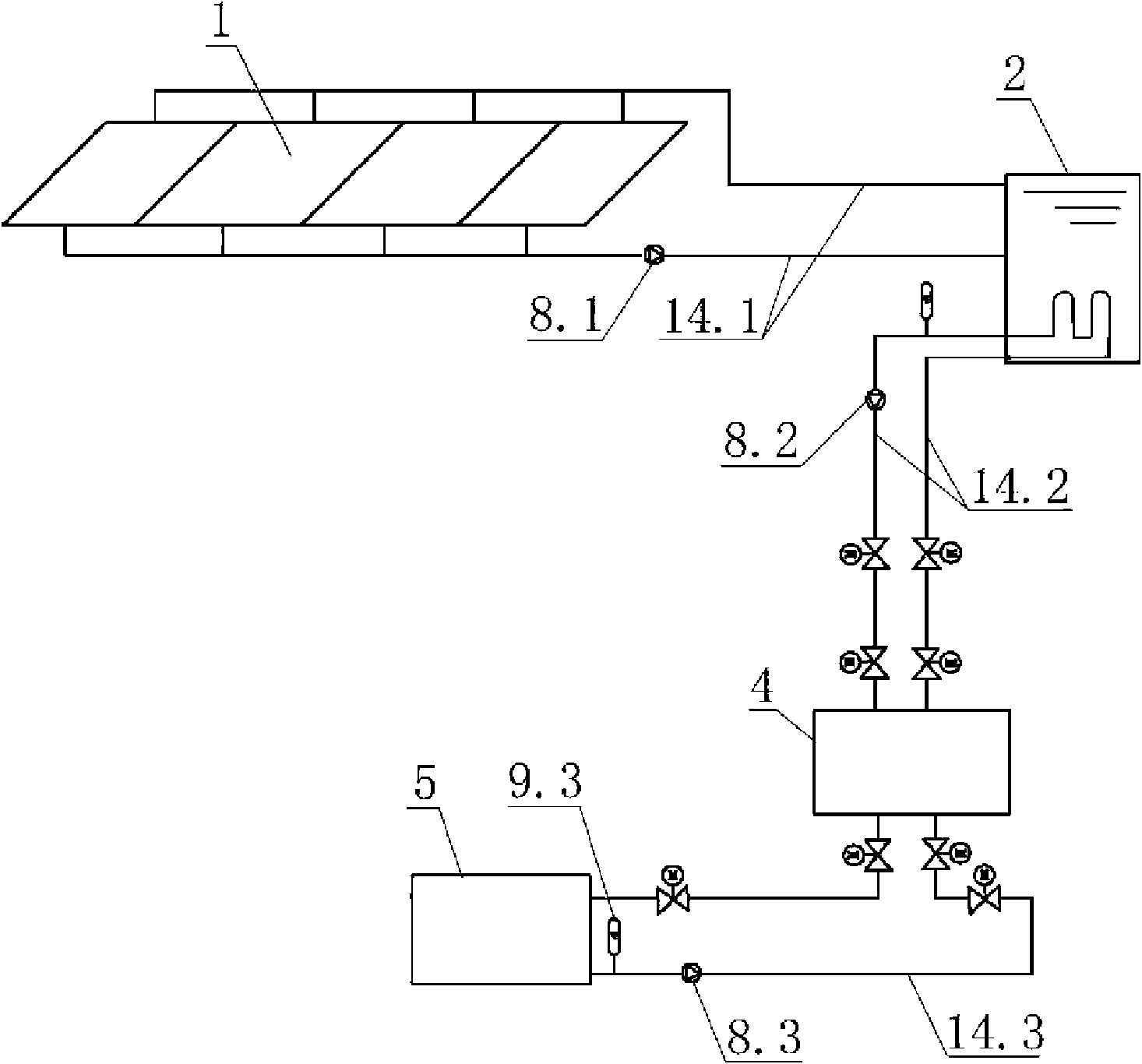

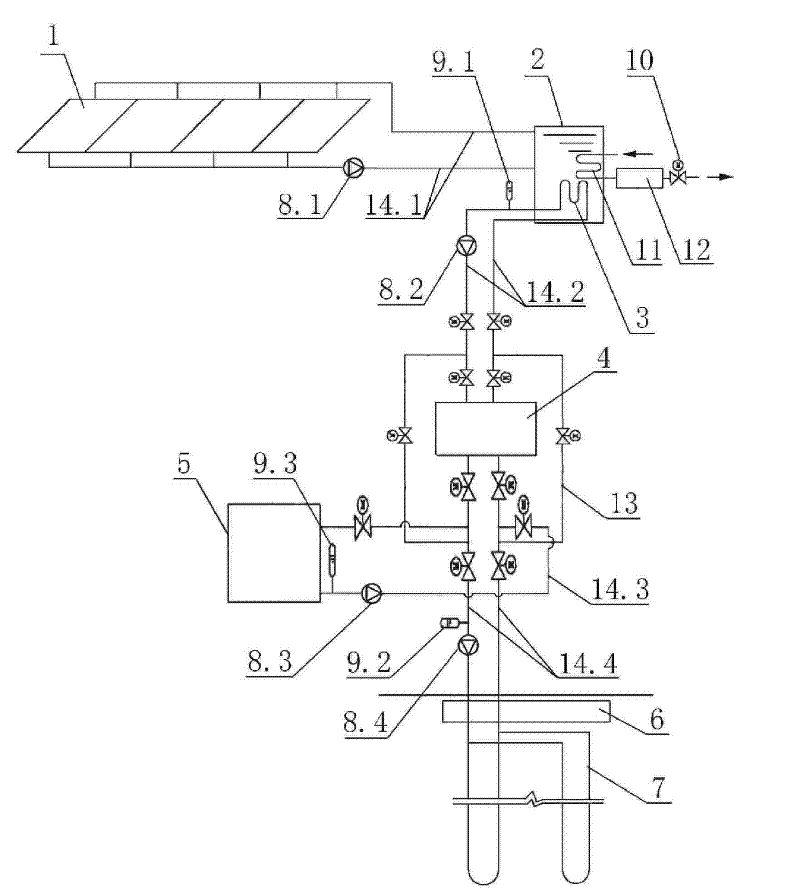

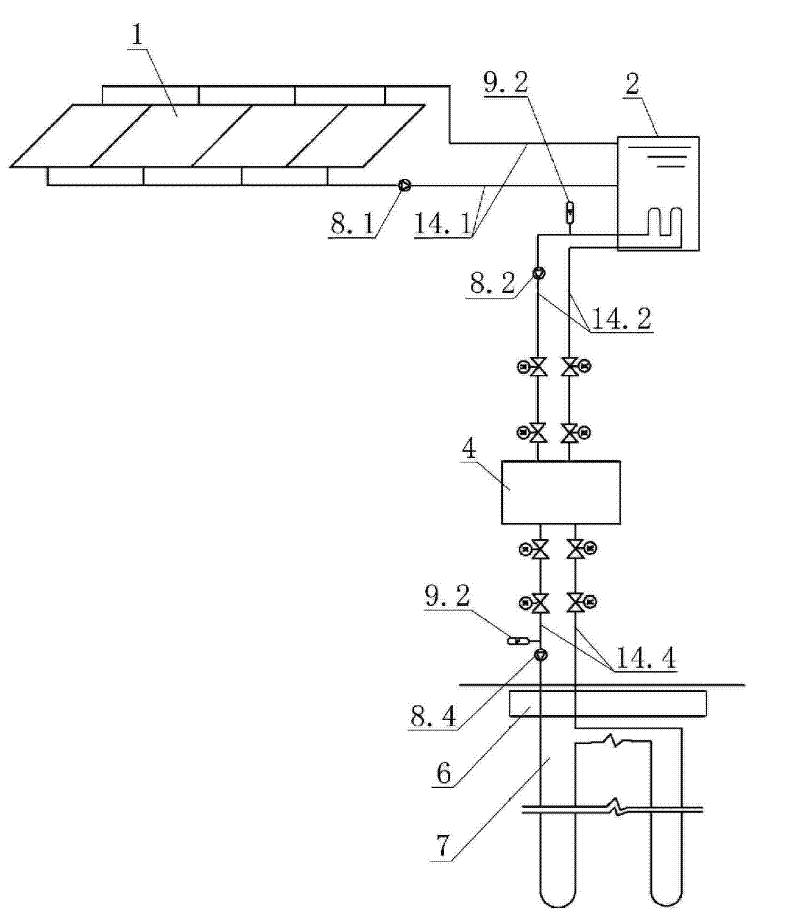

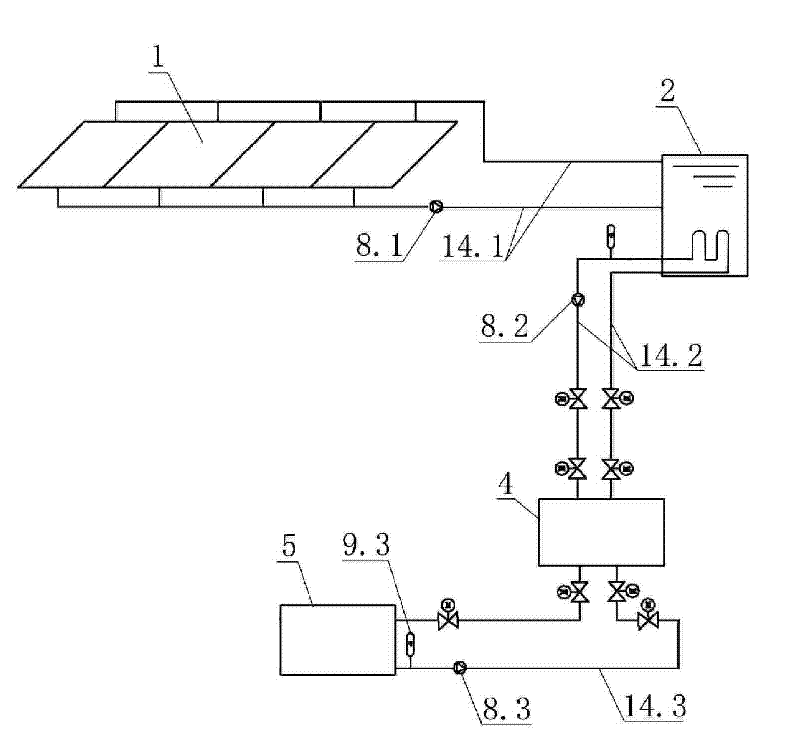

Solar energy-soil source heat pump seasonal balance heating system

InactiveCN101634466ALong-term solutionAvoid stabilityOther heat production devicesSolar heat devicesMagnetic valveEngineering

The invention discloses a solar energy-soil source heat pump seasonal balance heating system comprising a solar energy heat collector, a water tank and a solar energy heating heat-exchange coil pipe, wherein a ground source heat-pump heat-exchange coil pipe is arranged in the water tank and communicated with a plate heat exchanger by a second circulation pipeline; a second water pump, a second water pump, a first constant pressure tank and a magnetic valve are arranged on the second circulation pipeline; the plate heat exchanger is communicated with a heat pump assembly by a third circulation pipeline; a third water pump, a third constant pressure tank and a magnetic valve are arranged on the third circulation pipeline; the plate heat exchanger is communicated with an underground burying pipe by a fourth circulation pipeline; the underground burying pipe is buried underground and is provided with an underground insulating device; and a fourth water pump, a second constant pressure tank and a magnetic valve are arranged on the fourth circulation pipeline. The solar energy-soil source heat pump seasonal balance heating system can store redundant heat generated by a summer solar energy heat collecting system in winter to use, effectively save energy sources, increase the use efficiency of solar energy and solve the detects of the traditional earth source heat pump.

Owner:CHINA ARCHITECTURE DESIGN & RES GRP CO LTD +1

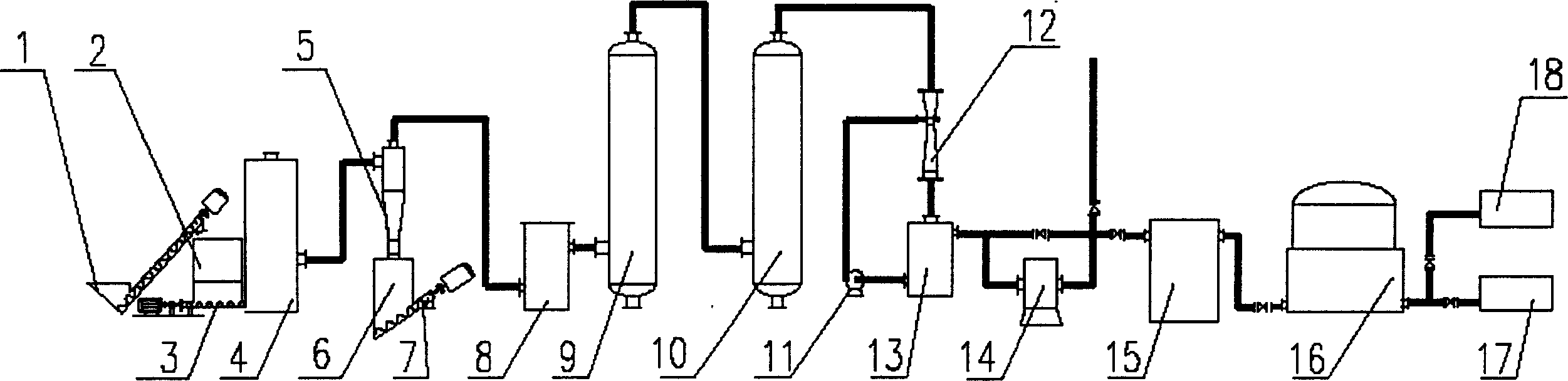

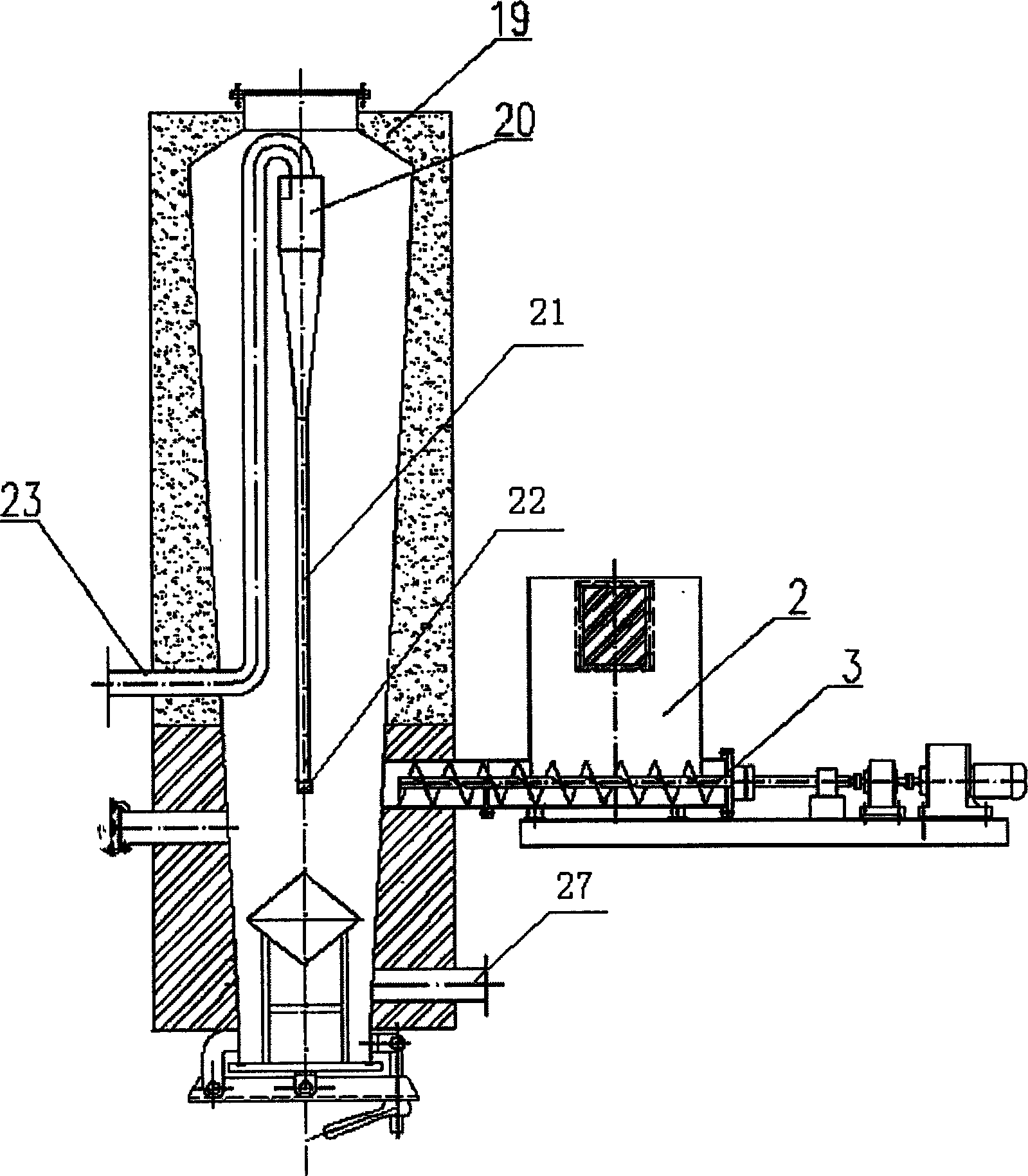

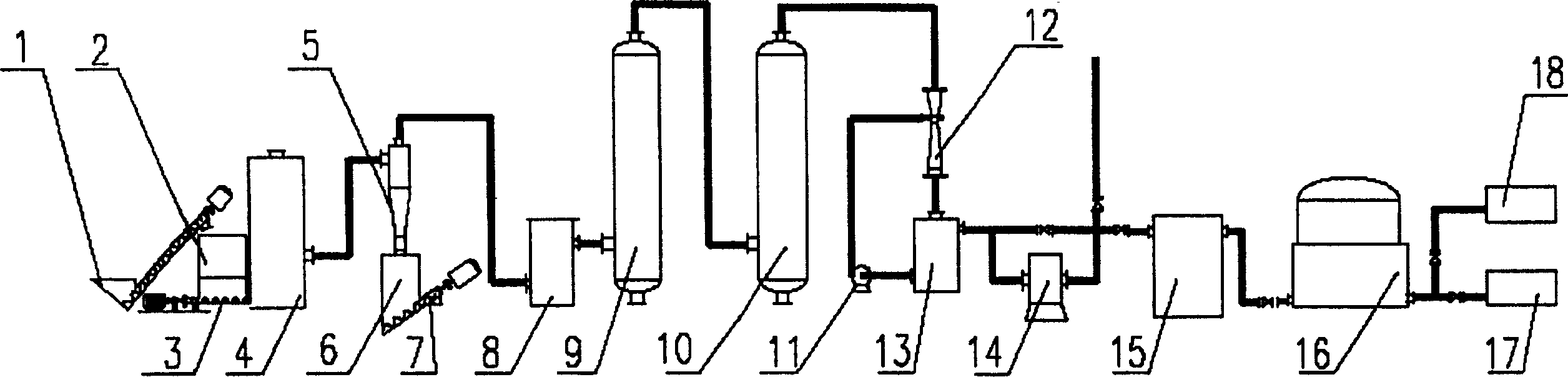

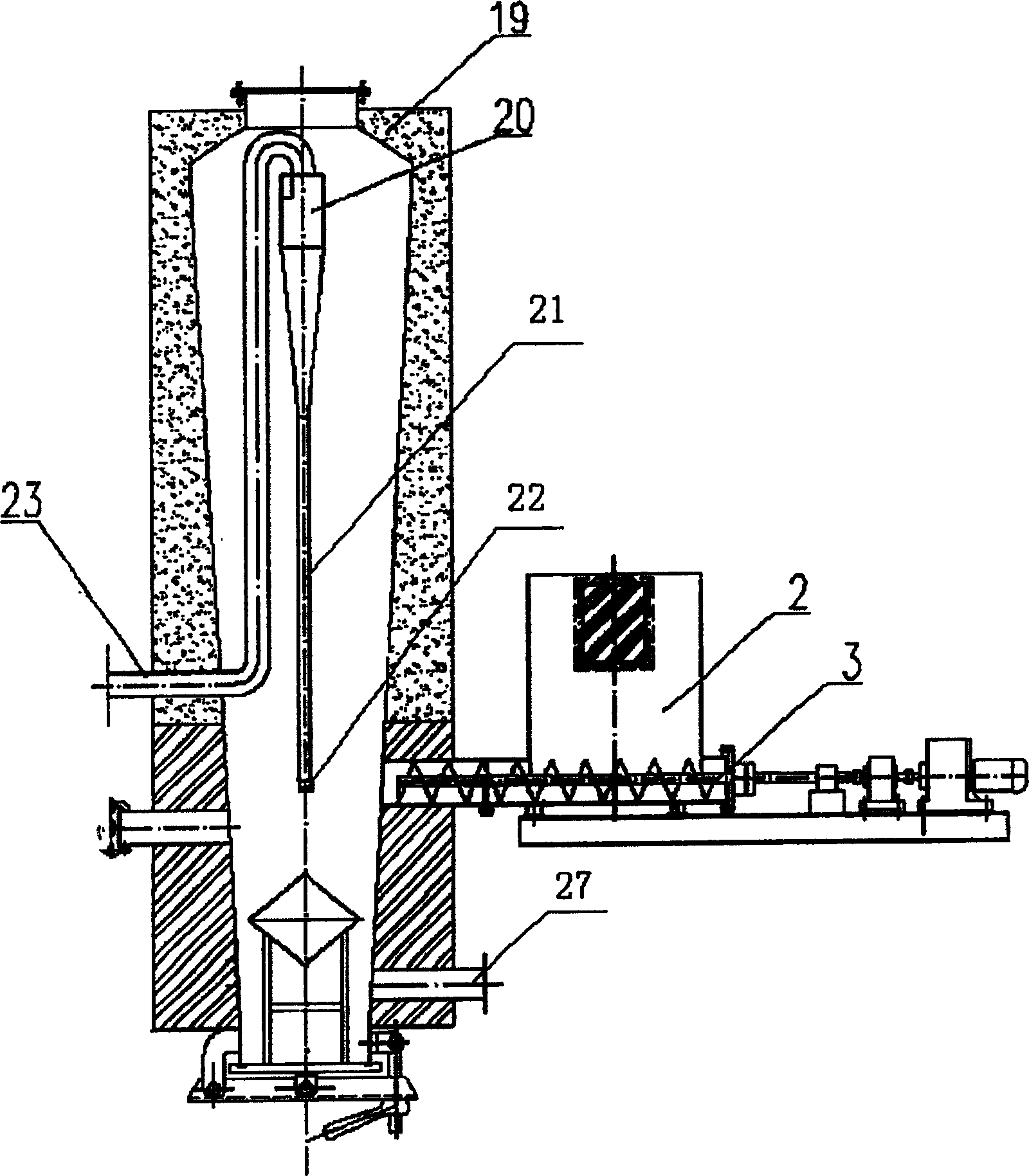

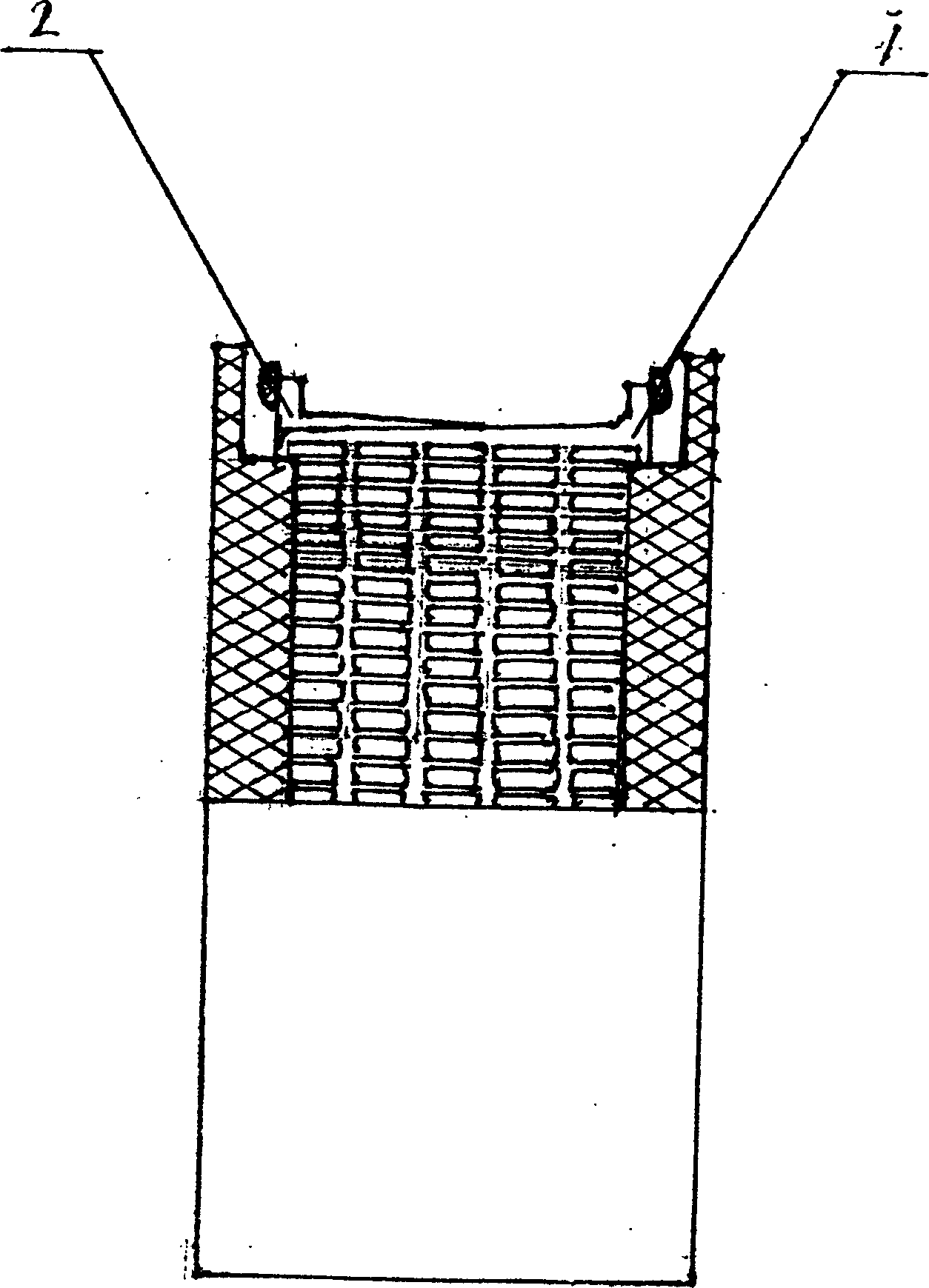

Process and apparatus for preparing coal gas by using bulky biomass materials

InactiveCN1603388ASimple structureLow costSpecial form destructive distillationPhysical strengthCoal gasification

The invention discloses a kind of use fluffy biology raw material preparation coal gas craft and the equipment. The craft including the raw material pretreatment, the raw material gasification, is divided the principle to leave the dregs, the coal gas purifies, the coal gas transportation step; The equipment including the raw material pretreatment system, the coal gas has the system, the coal gas purification system, the coal gas transportation storing system. In this invention uses sets at the type fast fluidized gasification furnace and furnace accessories to have the production intensity in a big way, the gasified efficiency high, the gas tar content low, the operation stability is good and so on the characteristic. The gasification responded completes under the physical strength transfer rate, in sets at in the type separator realization gasification stove fresh material raw material fast circulation, the coal gas purification uses the method which the laundering and the organic solvent washes unifies, has tar removing rate to be high, in the coal gas the tar content change undulates slightly and so on the characteristic. The invention craft and the equipment may continuously gasify the fluffy fresh material raw material, gasifies the coal gas which produces to be possible to serve as the fuel gas generator the gas source, also may pass the pipe network to all around the side inhabitant user air feed.

Owner:NANJING TECH UNIV

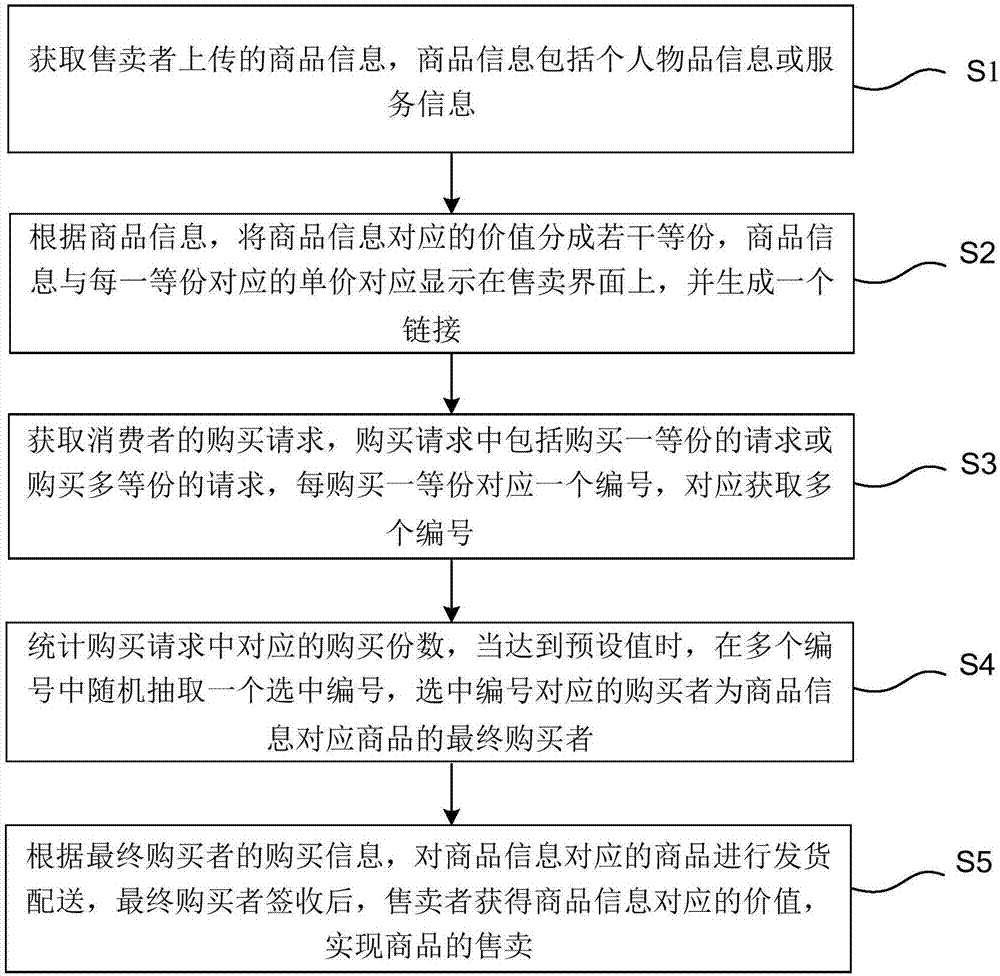

Crowdfunding commodity transaction method and system based on user direct initiation

InactiveCN107169841ARaise the selling priceImprove experienceBuying/selling/leasing transactionsModern lifeSerial code

The invention provides a crowdfunding commodity transaction method and system based on user direct initiation. The method comprises steps of acquiring commodity information uploaded by sellers; dividing values corresponding to the commodity information into multiple equal parts, and acquiring buying requests of buyers, where the buying requests comprise requests for buying one equal part or requests for buying multiple equal parts and every bought equal part corresponds to one serial number and correspondingly acquiring multiple serial numbers; collecting corresponding buying quantity in the buying requests, and selecting buyers corresponding to the serial numbers as the final buyers of the commodities corresponding to the commodity information; and according to the buying information of the final buyers, achieving selling the commodities. According to the invention, users can directly propose to sell the commodities in a crowdfunding manner, so a problem of surplus personal belongs caused by aimless consumption in modern life is avoided. More users are attracted to sell own commodities in the crowdfunding manner, so selling price of the commodities is increased and user experience is improved.

Owner:孙夕欣

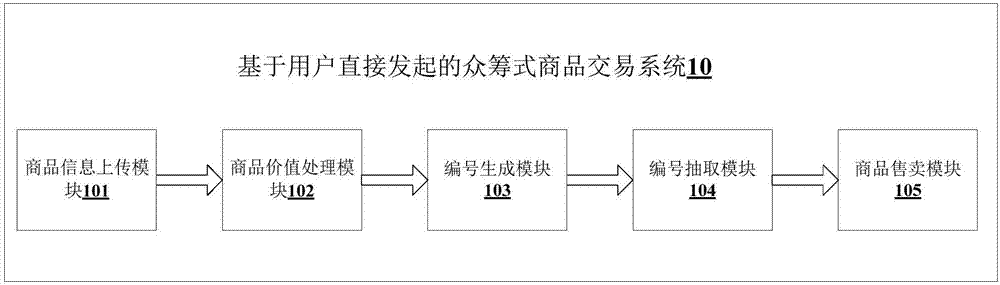

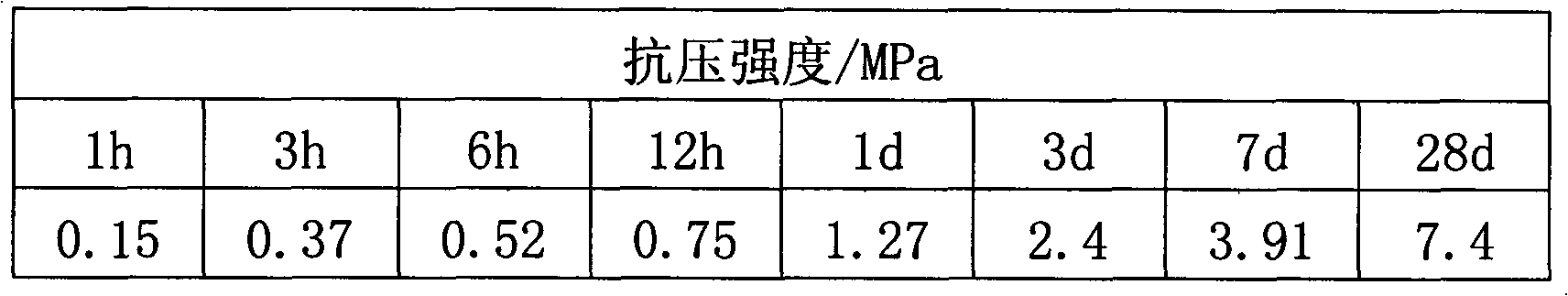

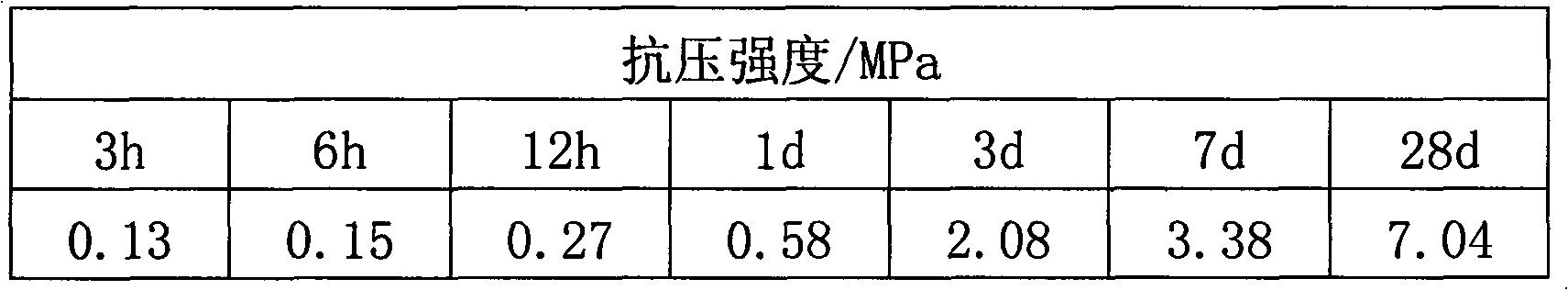

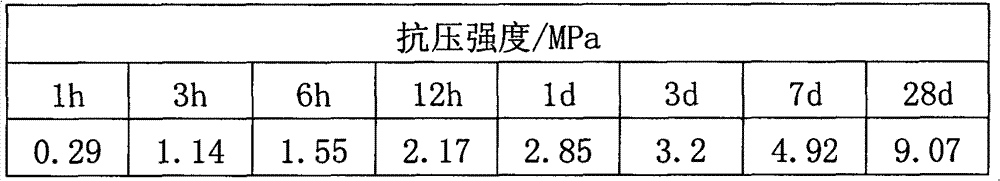

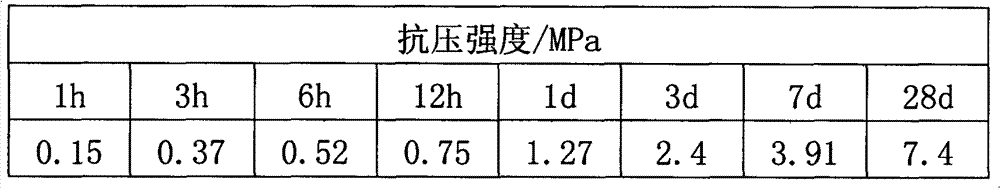

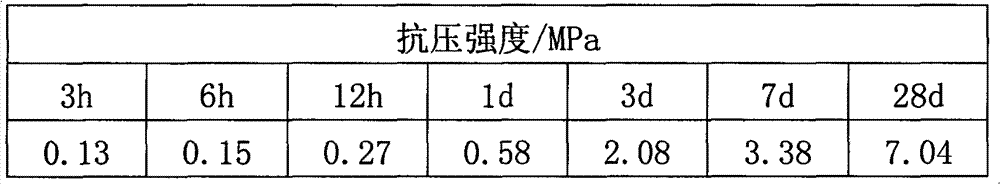

Double-fluid rapid hardening slurry for roadway grouting and mollisol compaction grouting

InactiveCN101974319AGuaranteed durabilityImprove grouting processDrilling compositionSodium silicateCoal

The invention discloses double-fluid rapid hardening slurry for roadway grouting and mollisol compaction grouting, remedying the defects that a cement-sodium silicate slurry concrement body has poor durability, and the grouting process is complicated. The slurry contains fluids A and B; the fluids A and B are injected at equal volume, and the on-site operation is simple. The fluid A contains 50 percent of portland cement, 0.5-0.75 percent of inorganic sodium salt, 0.025-0.05 percent of organic alcohol early strength agent and the balance of water; and the fluid B contains 43.6-48.8 percent of coal ash, 13.9-20.05 percent of sodium silicate and the balance of water. The performances of the slurry are shown as follows: the gelation time is adjustable within the range of 36s-124s, the concrement rate is 100 percent and the early compression strength is high; moreover, the concrement body has good durability and does not crack or pulverize. Compared with the original cement-sodium silicate slurry, the grouting process is simple, the durability of the slurry concrement body is obviously improved, the sodium silicate consumption is saved and the grouting cost is greatly reduced.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

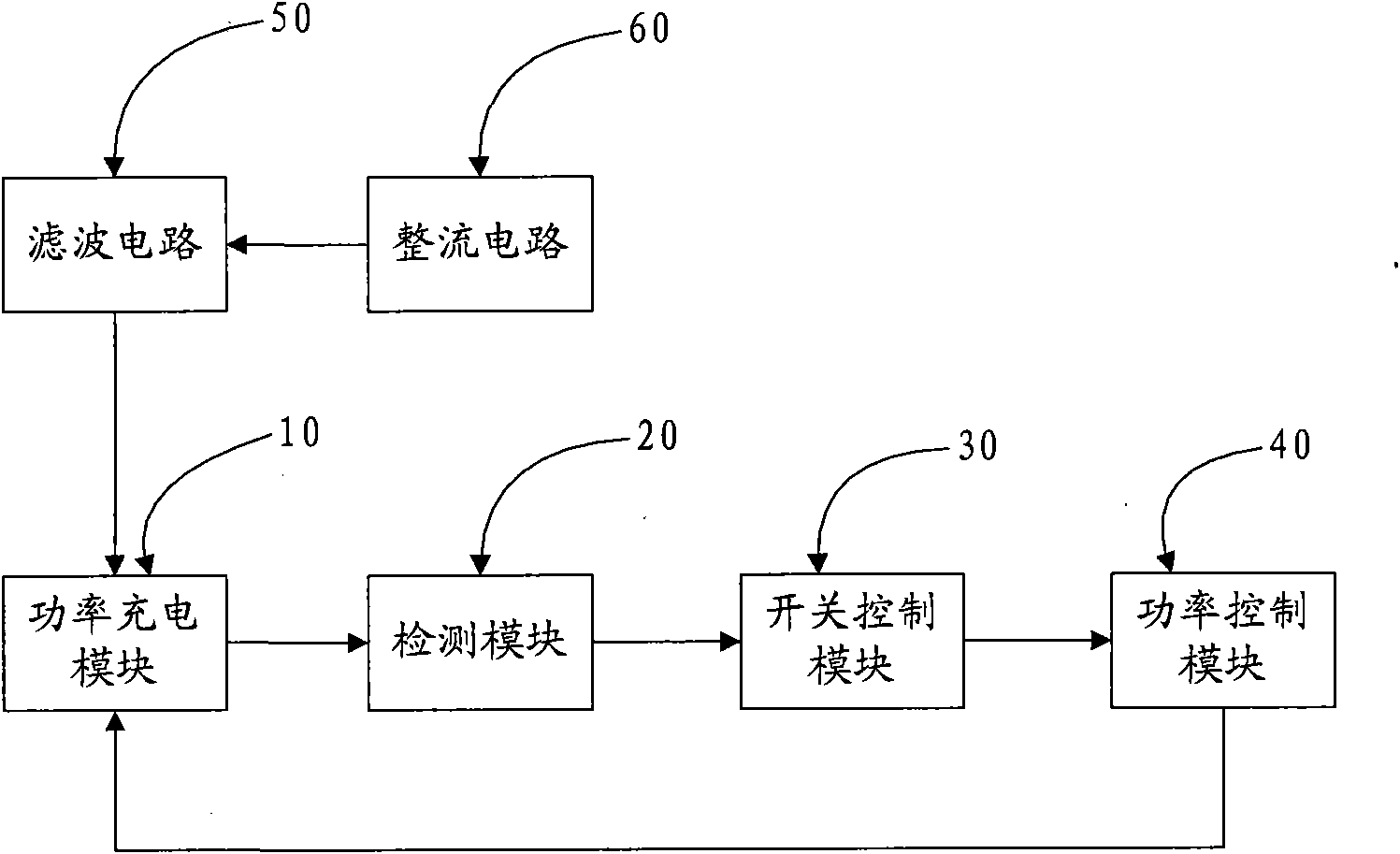

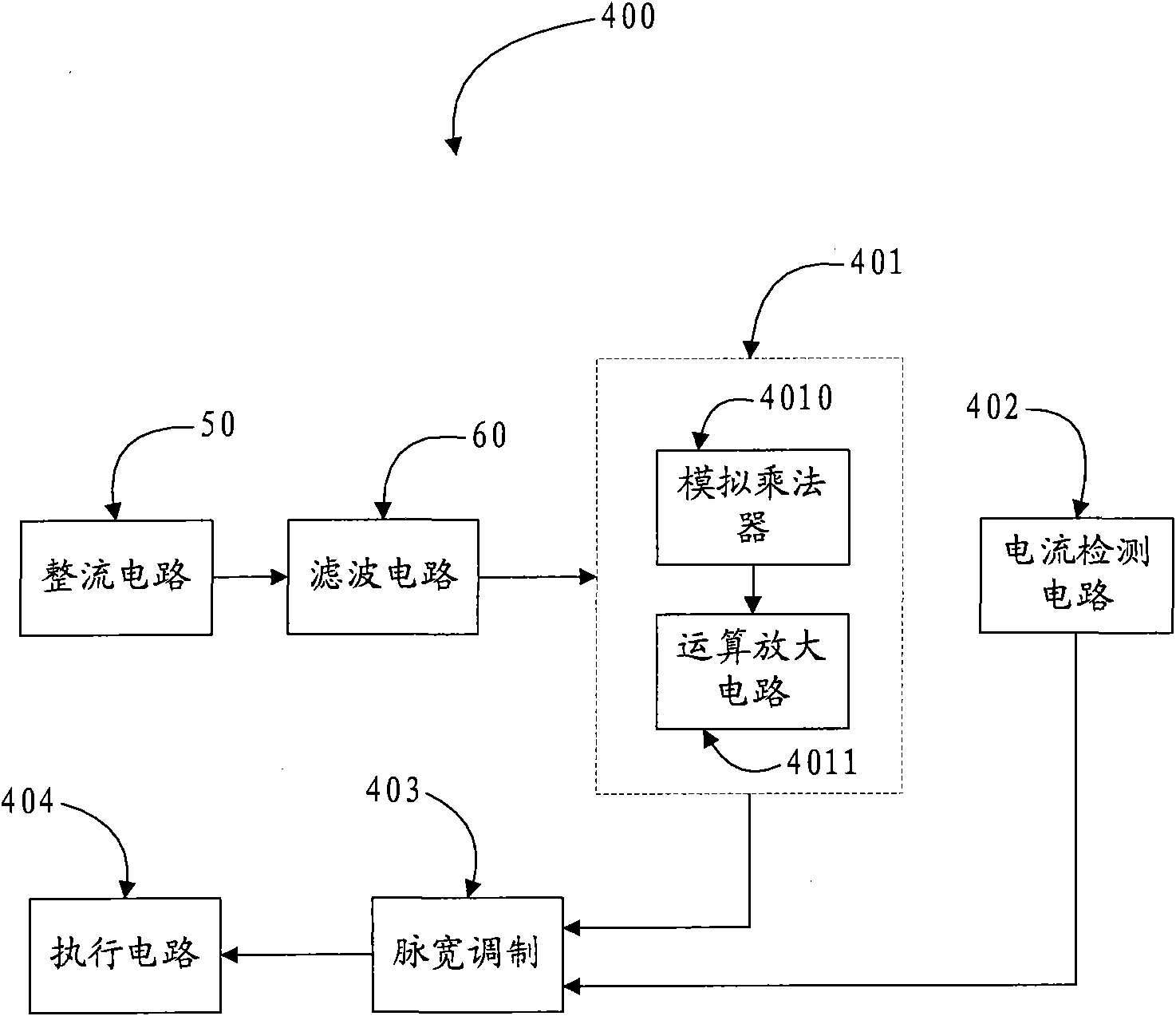

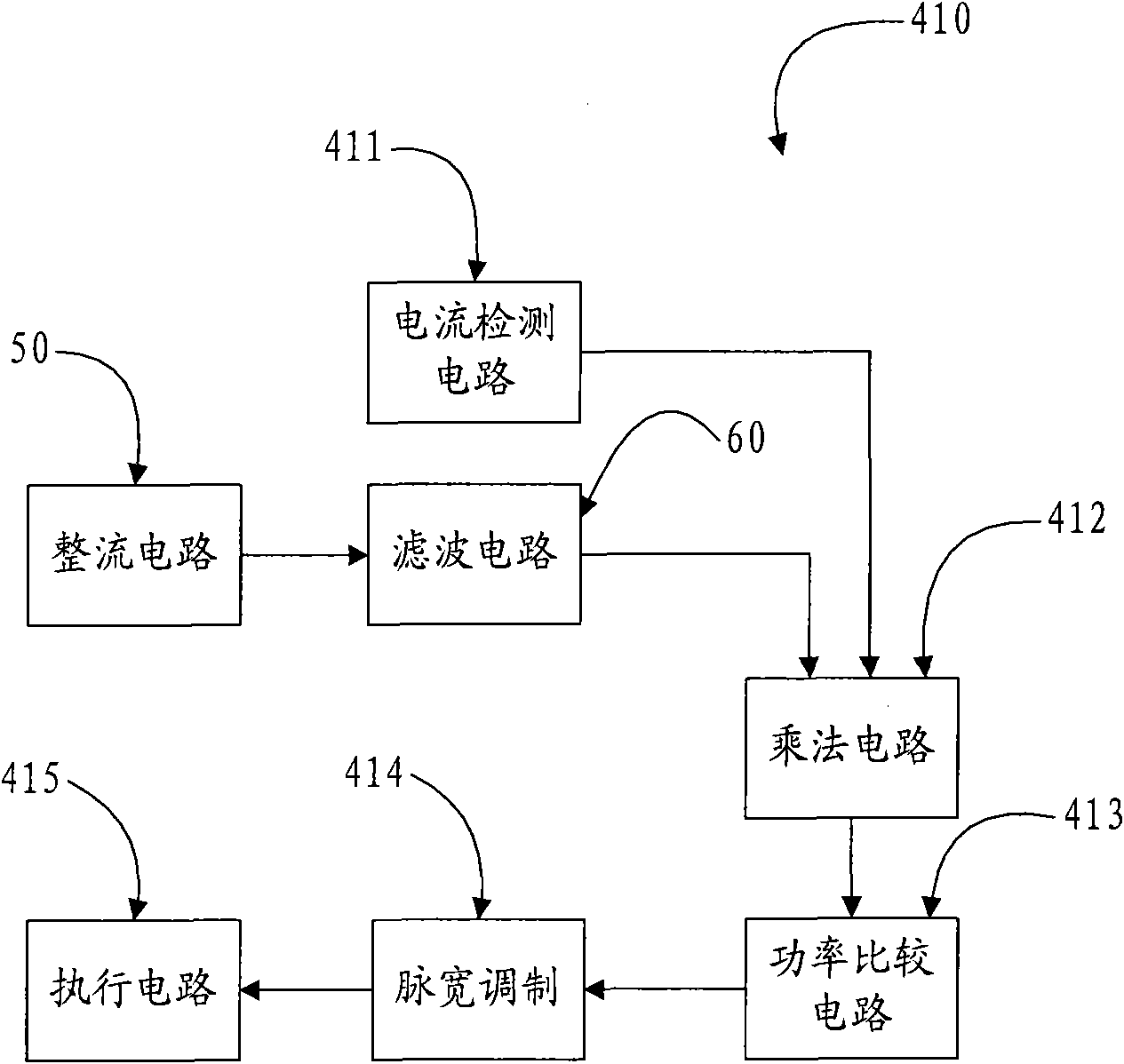

Laser power supply device with constant power charge

InactiveCN101626167AConstant charging powerSolve insufficient charging capacityElectrical storage systemConstant powerControl signal

The invention relates to a laser power supply device capable of realizing constant power charge. The laser power supply device comprises a rectifying circuit, a filter circuit, a power charging module, a detection module, a switching control module and a power control module. The rectifying circuit rectifies a voltage of an external power grid to acquire a pulse direct-current voltage. The filter circuit filters the pulse direct-current voltage generated by the rectifying circuit to acquire a smooth direct-current voltage with small pulse. The power charging module charges an energy storage element by using the direct-current voltage generated by the filter circuit. The detection module detects the power charging module to generate a detection signal. The switching control module receives the detection signal generated by the detection module to generate a switching control signal. The power control module receives the switching control signal generated by the switching control module and generates a power control signal, and carries out debugging control for the charging power of the energy storage element by using the power control signal to keep the charging power of the energy storage element stable.

Owner:UNITED WINNERS LASER CO LTD

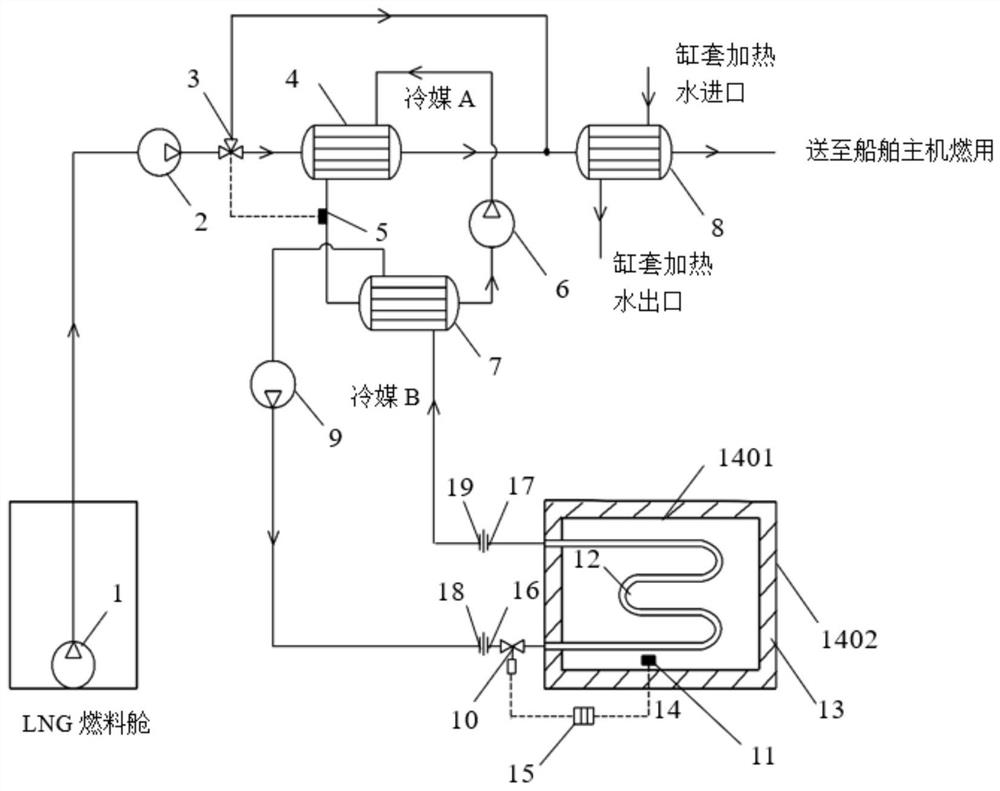

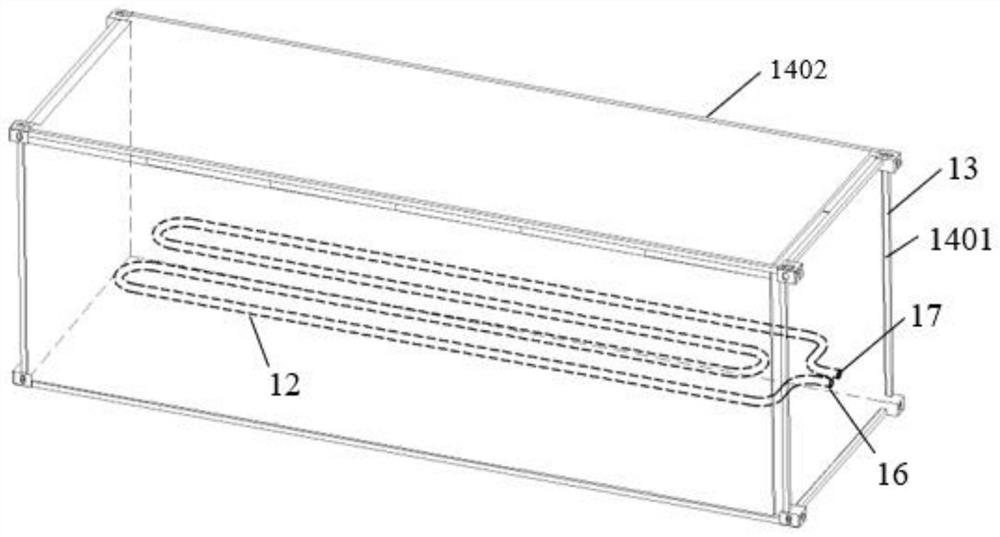

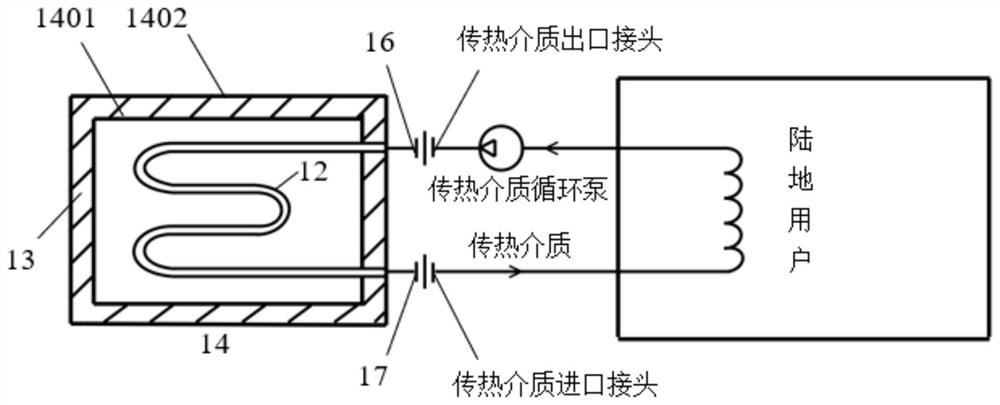

Cold storage system and method of LNG (Liquefied Natural Gas) power container ship

PendingCN112815574AIncrease powerIncrease consumptionMechanical apparatusRefrigeration componentsCombustion systemMarine engineering

The invention discloses a cold storage system and method for an LNG power container ship. The system comprises an LNG combustion system, an LNG heat exchange system and a cold storage system body. For the problems that the LNG power container ship is high in power, the LNG fuel consumption is large and a large amount of released cold energy cannot be utilized, the system stores excessive cold energy on the LNG power container ship in a cold storage box ice making manner, and the problem of excessive cold energy of the LNG power container ship is solved. Through the method, the cold energy of LNG fuel on the ship can be used for land requirements, so that the cold energy of an LNG can be fully utilized, and power consumption of refrigeration equipment of a user needing the cold energy on land is saved; and along with large-scale development of the container ship, the main motor power of the LNG power container ship is higher and higher, and the consumption of the LNG fuel is larger and larger, so that the released cold energy is more and more, and the cold storage system and method disclosed by the invention have relatively good application value.

Owner:QINGDAO UNIV OF SCI & TECH

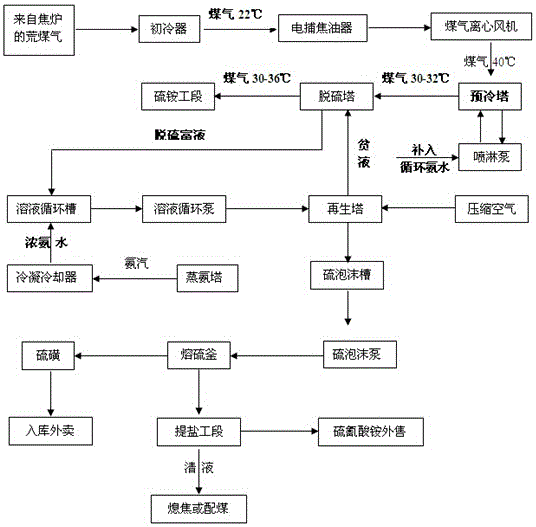

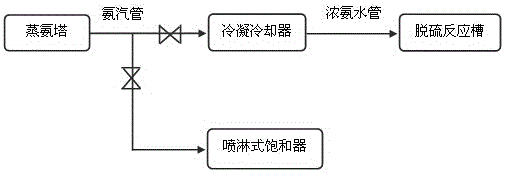

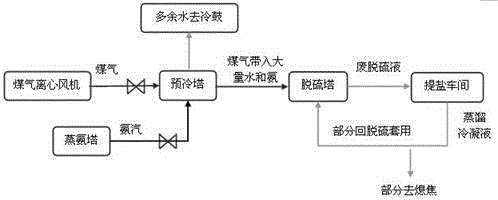

Process for solving coal gas desulfuration liquid expansion in coking industry and system for process

InactiveCN105694988AReduce the amount of waterAchieve water balanceGas treatmentDispersed particle separationChemical industryLiquid waste

The invention belongs to the technical field of chemical industry, and in particular relates to a process for solving the expansion of gas desulfurization liquid in the coking industry. The invention adopts gas blowing and desorption method to remove ammonia in concentrated ammonia water, and the gas after desorbing ammonia is sent to the desulfurization tower as an alkali source for desulfurization, while the remaining water is discharged from the bottom of the tower, thereby realizing the purpose of gas blowing ammonia. Compared with the technology in the prior art, the present invention firstly solves the problem of insufficient alkali source of desulfurization in technology one; secondly, solves the problem that the water balance of the spray saturator cannot be controlled and the ammonium sulfate mother liquor is excessive. The amount of water brought into the desulfurization system by the device of the present invention is less, and the desulfurization system is short of water, and the distilled condensed liquid produced by extracting salt from the desulfurization waste liquid can be fully reused in the desulfurization system, and no excess waste water will be generated for coal blending or coke quenching. Satisfactory results have been achieved.

Owner:JINNENG SCI & TECH

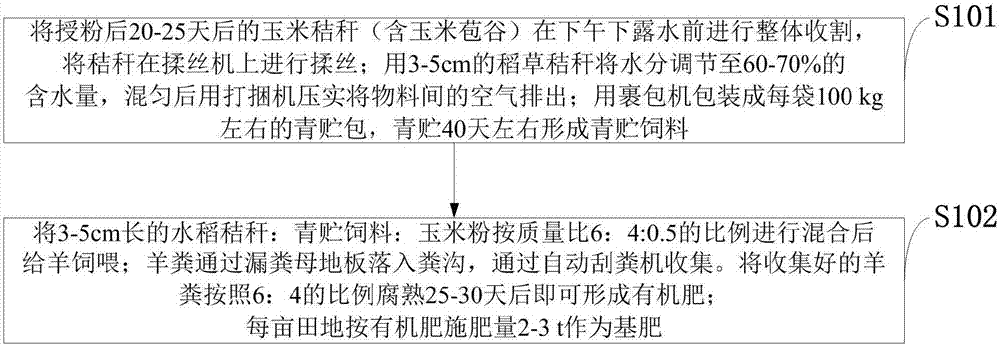

Method for returning double straw to field by abdomen-passing-through through sheep

PendingCN106995355ASolve the problem of excessSolve the shortageBio-organic fraction processingCrop conditionersAgricultural scienceDecomposition

The invention belongs to the technical field of returning straw to fields, and discloses a method for returning double straw to a field by abdomen-passing-through through a sheep. Maize straw and rice straw are formed into silage feed, which is high in nutrient and good in palatability, through a mixed ensiling technique; subsequently, the silage is formed into excrement through the digestion of the sheep; afterwards, the excrement is promoted to be thoroughly decomposed according to the ratio of the excrement to the rice straw, which is 6 to 4; organic fertilizer is formed and is returned to the field. By using the method, environmental pollution and waste problems which are brought when the maize straw and the rice straw in a hilly area are treated are solved; palatable feed for herbivorous livestock is produced; the problem that the feed for the sheep in the hilly area is short is solved; meanwhile, the organic fertilizer is formed by utilizing two kinds of straw and through an abdomen-passing-through technique and thorough decomposition; the production and the return to the field of the organic fertilizer are realized; the cyclic development of planting and breeding industries are prompted; the silage feed is formed by utilizing nutrient substances in the maize and rice straw; the problem that grass lacks for the herbivorous livestock in the hilly area is solved; the environmental pollution problem in processes of the incineration, the accumulation and the like of rural straw are also solved.

Owner:绵阳市农业科学研究院

A method for preparing biodiesel from bio-oil

ActiveCN103881827BSolve the problem of excessIncrease profitFatty acid esterificationBiofuelsOil and greaseEnvironmental resistance

The invention discloses a method for preparing biodiesel from biolipid and relates to the field of renewable new energy sources. The method comprises the three steps of (1) preprocessing the raw material biolipid; (2) carrying out an ester exchange reaction under the conditions that the mol ratio of the standard raw material lipid to dimethyl carbonate is 1: (3-9), the dosage of a solid alkali catalyst is 0.01-0.2% of the mass of the standard raw material lipid, the reaction temperature ranges from 250 to 300 DEG C, the reaction pressure ranges from 2 to 5 MPa and the reaction time is 8 to 30 minutes; (3) decoloring the crude diesel. The method solves the problem of glycerol excess in the production of the biodiesel with a short-chain alcohol as an ester-exchange reagent and also realizes the production possibility that the reaction yield is higher than 90% under the condition of a low ester-oil ratio; the obtained by-products can be directly used without being separated subsequently; the color of the prepared biodiesel can be between standard color solutions No. Y5 and No. Y6; in short, the method is a new green and environment-friendly method for preparing the biodiesel from the biolipid.

Owner:GUANGZHOU TAISHENG BIOTECH

Double-fluid rapid hardening slurry for roadway grouting and mollisol compaction grouting

The invention discloses double-fluid rapid hardening slurry for roadway grouting and mollisol compaction grouting, remedying the defects that a cement-sodium silicate slurry concrement body has poor durability, and the grouting process is complicated. The slurry contains fluids A and B; the fluids A and B are injected at equal volume, and the on-site operation is simple. The fluid A contains 50 percent of portland cement, 0.5-0.75 percent of inorganic sodium salt, 0.025-0.05 percent of organic alcohol early strength agent and the balance of water; and the fluid B contains 43.6-48.8 percent ofcoal ash, 13.9-20.05 percent of sodium silicate and the balance of water. The performances of the slurry are shown as follows: the gelation time is adjustable within the range of 36s-124s, the concrement rate is 100 percent and the early compression strength is high; moreover, the concrement body has good durability and does not crack or pulverize. Compared with the original cement-sodium silicate slurry, the grouting process is simple, the durability of the slurry concrement body is obviously improved, the sodium silicate consumption is saved and the grouting cost is greatly reduced.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

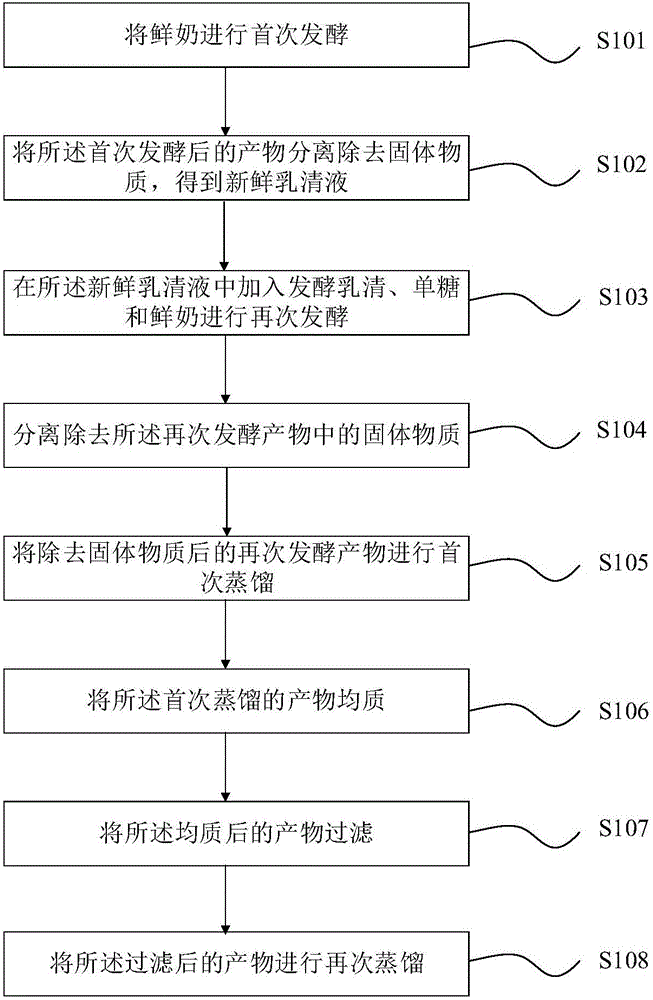

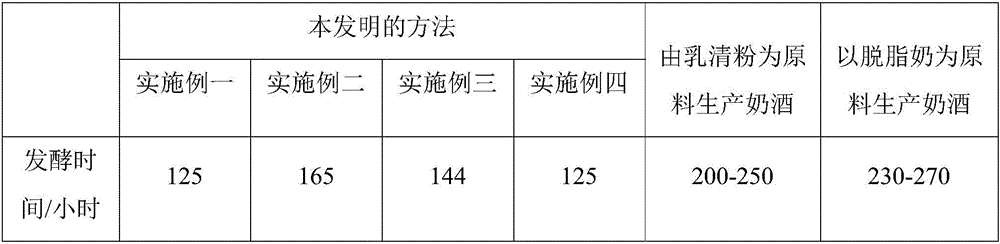

Method for producing milk wine

InactiveCN105950418AHigh nutritional valueShorten fermentation timeAlcoholic beverage preparationChemistryDistillation

The invention relates to a method for producing milk wine. The method is characterized by comprising the following steps: carrying out primary fermentation on fresh milk; separating products after the primary fermentation to remove solid substances so as to obtain fresh whey; adding fermented whey, monosaccharide and fresh milk into the fresh whey for secondary fermentation; separating and removing the solid substances in products of secondary fermentation; carrying out primary distillation on the products of secondary fermentation after the solid substances are removed; homogenizing products of primary distillation; filtering the homogenized products; carrying out secondary distillation on the filtered products, wherein the time for the primary fermentation is 40-60 hours, and the time for the secondary fermentation is 85-105 hours. The method for producing milk wine provided by the invention is short in fermentation time, so that the production period of the milk wine is shortened, and the problem of excess milk source is effectively solved.

Owner:盖哈木西格图

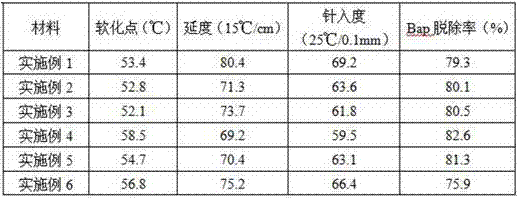

Benzyl benzoate waste mixed modified asphalt and preparation method thereof

ActiveCN107245245ASolve the problem of excessAlleviate supply shortagesBuilding insulationsBenzyl benzoatAlkylphenol

The invention relates to a benzyl benzoate waste mixed modified asphalt. The modified asphalt is prepared from the following raw materials by weight: 40-60 parts of petroleum asphalt, 20-40 parts of coal pitch, 40-80 parts of benzyl benzoate waste, 15-30 parts of ethylene glycol monomethyl ether, 10-15 parts of ethylene glycol, 2-5 parts of alkylphenol polyoxyethylene ether, 1-3 parts of aluminum isopropoxide, and 1-3 parts of zinc stannate. The method provided by the invention has the advantages that: 1. the process is simple, the equipment requirement is low, the method can realize large-scale production of modified asphalt, and the modified asphalt finished product can meet the requirements of national regulations and can be used for asphalt road pavement construction; 2. the method also can reduce the content of polycyclic aromatic hydrocarbon 3, 4-benzopyrene (Bap) in mixed asphalt; and 3. more importantly, benzyl benzoate waste is utilized to replace expensive raw materials to serve as the modifier.

Owner:HUBEI GREENHOME MATERIALS TECH INC

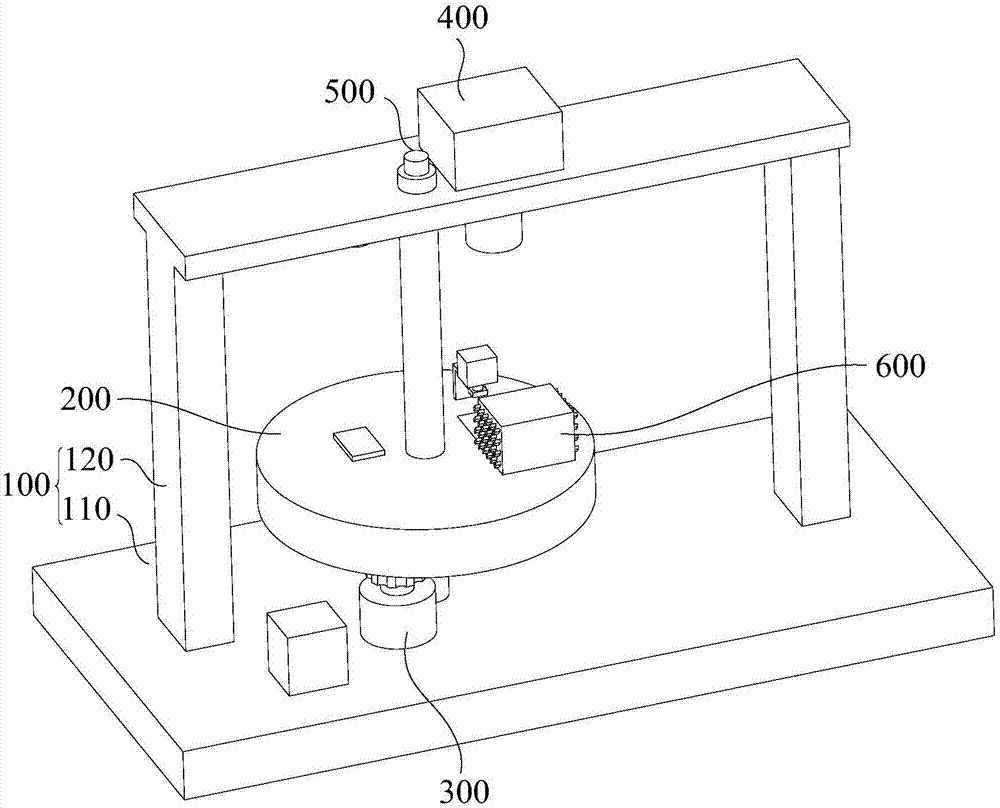

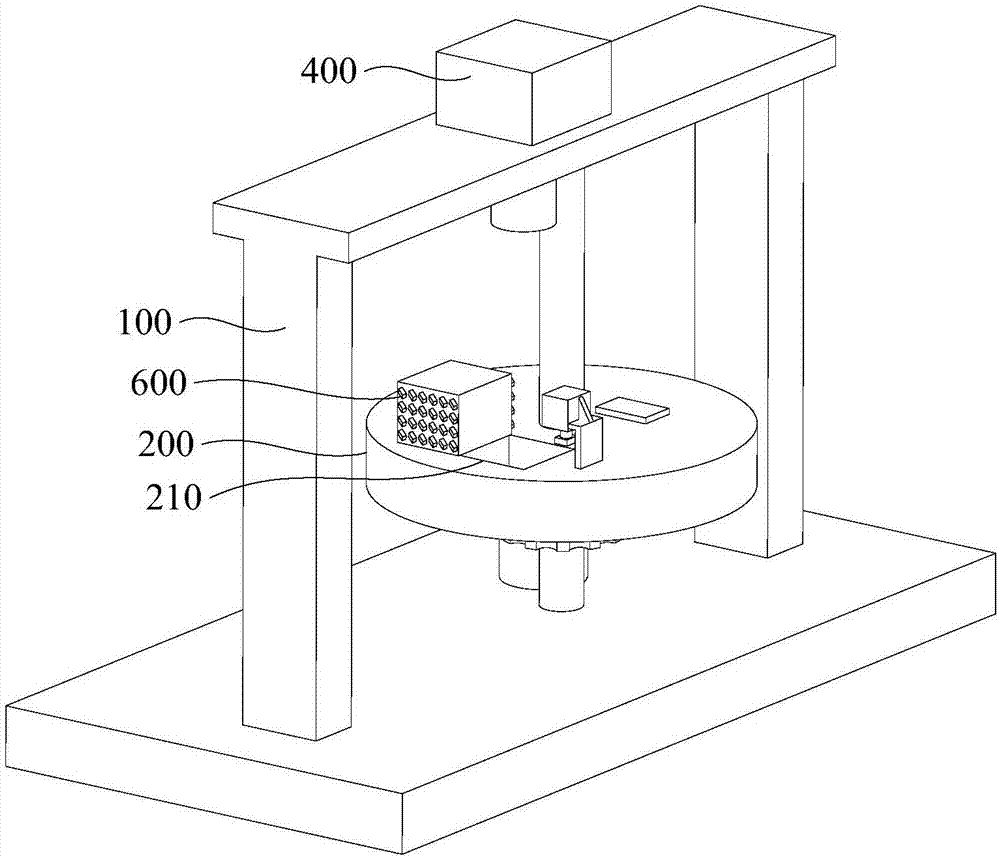

Arc-shaped welding machine

InactiveCN107262923AImprove welding precisionSolve the shortcomings of the welding pathLaser beam welding apparatusEngineeringLaser beams

The invention relates to an arc welding machine. The above-mentioned arc welding machine is used for welding products, and the arc welding machine includes a frame, a turntable, a driving mechanism, a laser mechanism, an angle sensor and a heat conduction mechanism. The turntable is rotatably connected to the frame, and there is a storage slot for placing products on the turntable; the drive mechanism is set on the frame, and the drive mechanism drives the turntable to rotate relative to the frame; the laser mechanism is set on the frame, and the laser mechanism is used for The product is welded; the angle sensor is set on the turntable, and the angle sensor is used to measure the rotation angle of the turntable; when the rotation angle is equal to a predetermined value, the angle sensor generates the first induction signal to control the laser mechanism to stop generating the laser beam; the heat conduction mechanism includes a heat conduction matrix and multiple The heat-conducting substrate is arranged on the turntable; the above-mentioned arc welding machine avoids the problem that the product is easily warped and deformed during the welding process, so that the flatness of the product is better, and the problem that the product is easily scrapped is solved.

Owner:惠州市格农科技有限公司

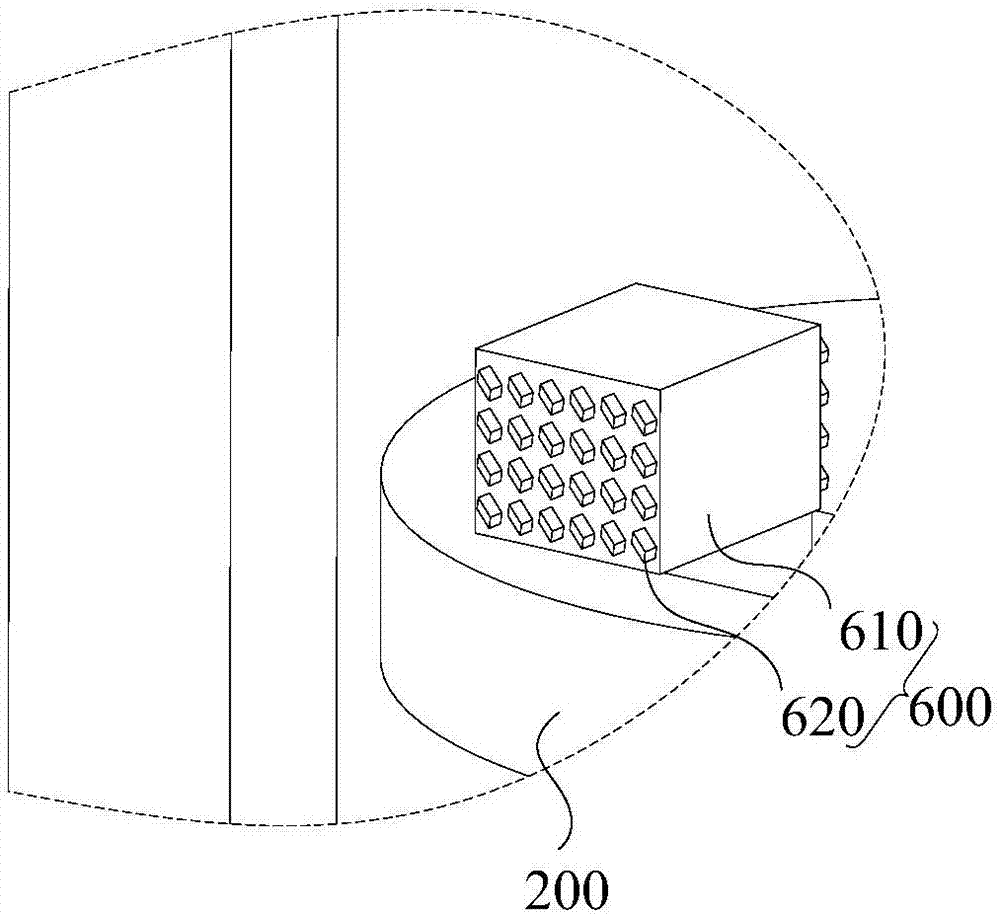

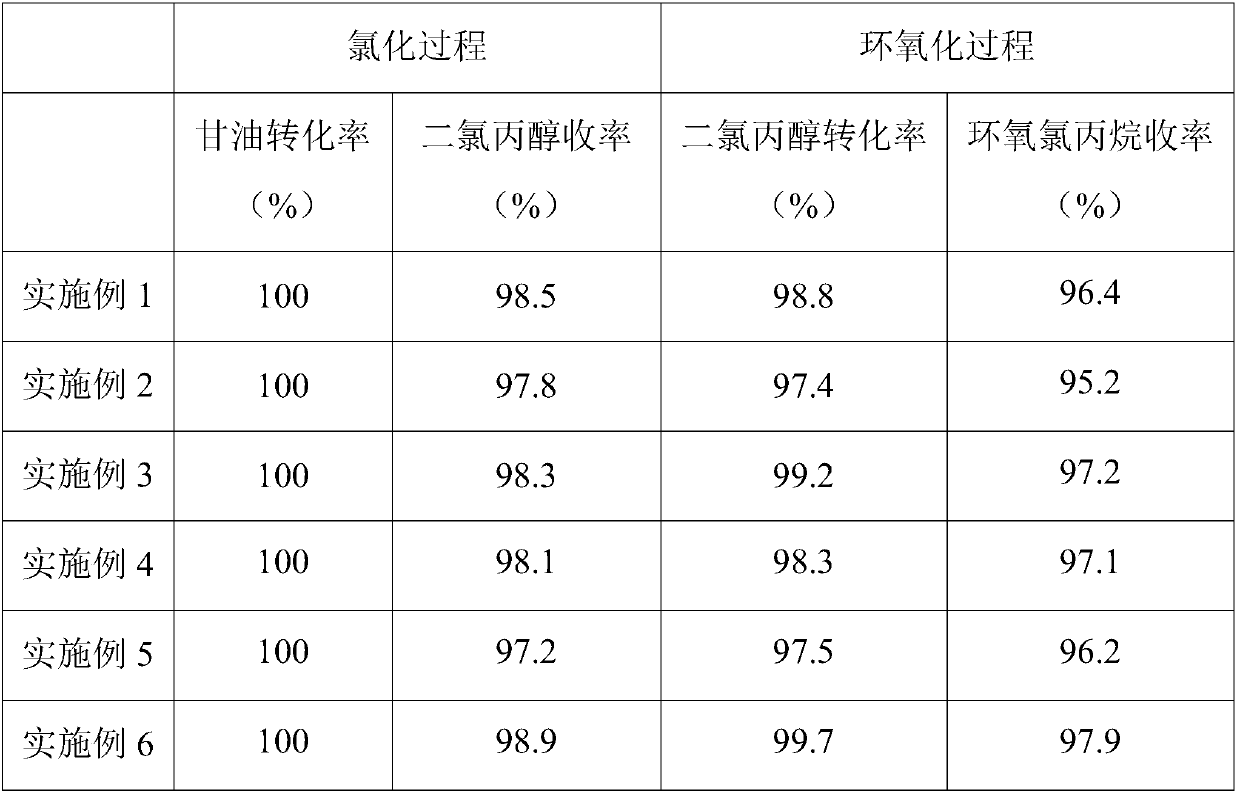

Method for preparing chloropropylene oxide from biomass glycerol

The invention provides a method for preparing chloropropylene oxide from biomass glycerol. The method comprises the following steps: first mixing biomass glycerol with organic acid, carrying out heating to 90-140 DEG C, maintaining the temperature, introducing hydrogen chloride gas into the obtained system and starting a bubbling reaction, wherein tail gas is absorbed with alkali liquor; cooling amaterial obtained in the previous step to room temperature, then transferring the material to another reactor, heating the material to 30-90 DEG C, and adding a KOH solution with a concentration of 6-10 mol / L for a reaction; and at the end of the reaction, removing solids through filtration so as to obtain a filtrate which is a chloropropylene oxide solution. The method of the invention has the advantages of simple process, easy availability of raw materials, low cost and good industrialization prospects.

Owner:JIANGSU SOPO GRP +1

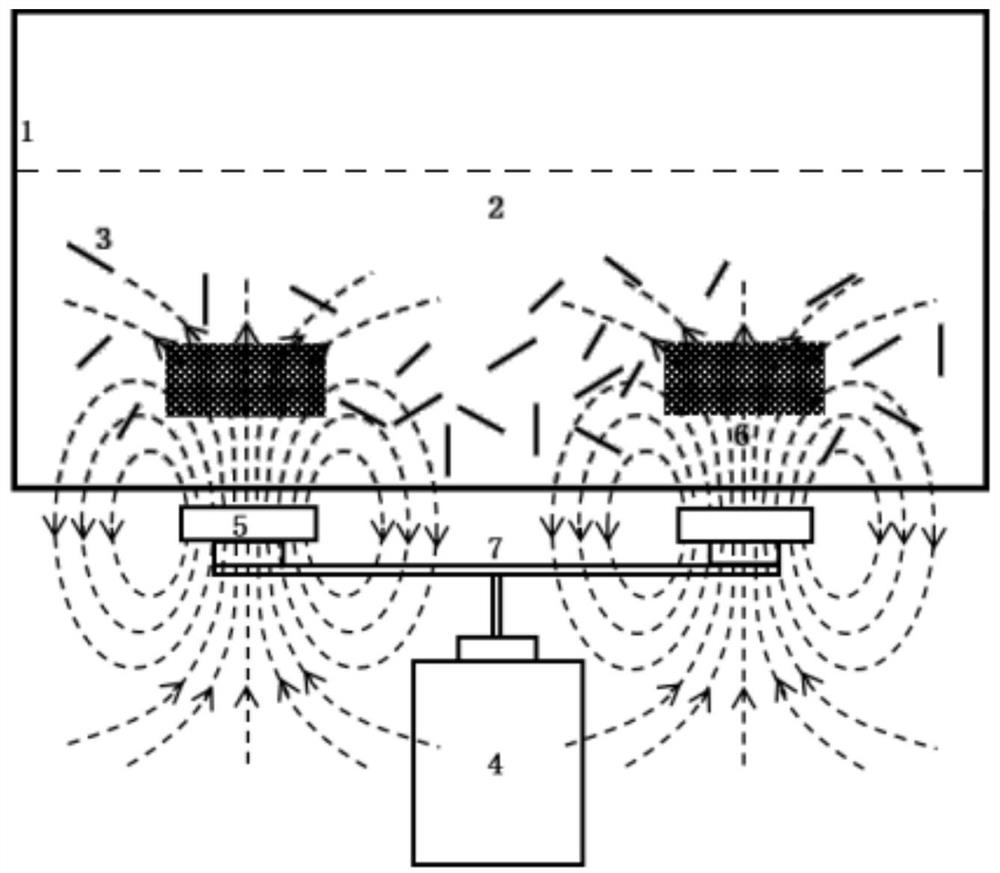

Method for removing carbon deposition on turbine blade of aircraft engine through magnetic needle grinding

InactiveCN113235098ASolve pollutionSolve the problem of excessEdge grinding machinesPolishing machinesTurbine bladeProcess engineering

The invention discloses a method for removing carbon deposition on a turbine blade of an aircraft engine through magnetic needle grinding. The method for removing the carbon deposition on the turbine blade of the aircraft engine through magnetic needle grinding comprises the steps that the turbine blade is soaked in a dissolved cleaning solution, so that the surface of the turbine blade is infiltrated; a magnetic needle is poured into the cleaning solution, the magnetic needle impacts the surface of the turbine blade under a rotating electromagnetic field and rotates forwards and reversely at intervals for cleaning, and the carbon deposition on the surface of the turbine blade is removed; and the turbine blade is taken out after cleaning is completed, the carbon deposition and the cleaning solution attached to the surface of the turbine blade are washed away through a high-pressure water gun, and then the turbine blade is dried. According to the method for removing the carbon deposition on the turbine blade of the aircraft engine through magnetic needle grinding, the carbon deposition of the turbine blade is removed under the condition that a strong oxidant and strong alkali are not used; an abrasive material adopted for magnetic needle grinding is slender, so that the abrasive material cannot enter the turbine blade through heat dissipation holes of the turbine blade; in addition, batch treatment of the turbine blades can be achieved, manual grinding is not needed, and therefore the cleaning efficiency of the carbon deposition of the turbine blades is greatly improved.

Owner:SHANGHAI HANGYI HI TECH DEV RES INST CO LTD

Isomerization process of butene in etherified liquefied petroleum gas

InactiveCN103739432BSolve the problem of excessFull recoveryHydrocarbon by isomerisationMolecular sieveButene

The invention discloses an isomerization process of butene in etherified liquefied petroleum gas. Materials at an outlet of an etherification device for producing MTBE (Methyl Tert-Butyl Ether) contain a large amount of n-butene, and skeletal isomerization is carried out on the materials rich in n-butene to produce isobutene so as to reach the purpose of increasing the isobutylene production. An isomerization reactor is a fixed bed reactor, a catalyst is a ZSM-5 molecular sieve with a molar ratio of SiO2 / Al2O3 being 200-500, the specific surface is 300-500m<2> / g, and the average pore diameter is 2-8nm.

Owner:YUHUA CHEM PLANT BINZHOUSNDONG PROV

Apparatus for preparing coal gas by using bulky biomass materials

InactiveCN1279145CSimple structureLow costSpecial form destructive distillationGranular/pulverulent flues gasificationRaw materialWater washing

The invention discloses a process and device for preparing coal gas using fluffy biomass raw materials. The process includes raw material pretreatment, raw material gasification, slag separation, gas purification, and gas transportation steps; the device includes a raw material pretreatment system, a gas generation system, a gas purification system, and a gas transportation and storage system. The built-in rapid fluidized bed gasifier used in the present invention has the characteristics of high production intensity, high gasification efficiency, low gas tar content, and good operating stability. The gasification reaction is completed at pneumatic conveying speed, and the built-in separator realizes rapid circulation of biomass raw materials in the gasification furnace. The gas purification method uses a combination of water washing and organic solvent washing, which has a high tar removal rate and a low tar content in the gas. Characteristics include small changes and fluctuations. The process and equipment of the present invention can continuously gasify fluffy biomass raw materials, and the gas generated by gasification can be used as a gas source for gas generators, and can also be used to supply gas to surrounding residential users through the pipeline network.

Owner:NANJING TECH UNIV

Isomerization process of butene in etherified liquefied petroleum gas

InactiveCN103739432ASolve the problem of excessFull recoveryHydrocarbon by isomerisationMolecular sieveButene

The invention discloses an isomerization process of butene in etherified liquefied petroleum gas. Materials at an outlet of an etherification device for producing MTBE (Methyl Tert-Butyl Ether) contain a large amount of n-butene, and skeletal isomerization is carried out on the materials rich in n-butene to produce isobutene so as to reach the purpose of increasing the isobutylene production. An isomerization reactor is a fixed bed reactor, a catalyst is a ZSM-5 molecular sieve with a molar ratio of SiO2 / Al2O3 being 200-500, the specific surface is 300-500m<2> / g, and the average pore diameter is 2-8nm.

Owner:YUHUA CHEM PLANT BINZHOUSNDONG PROV

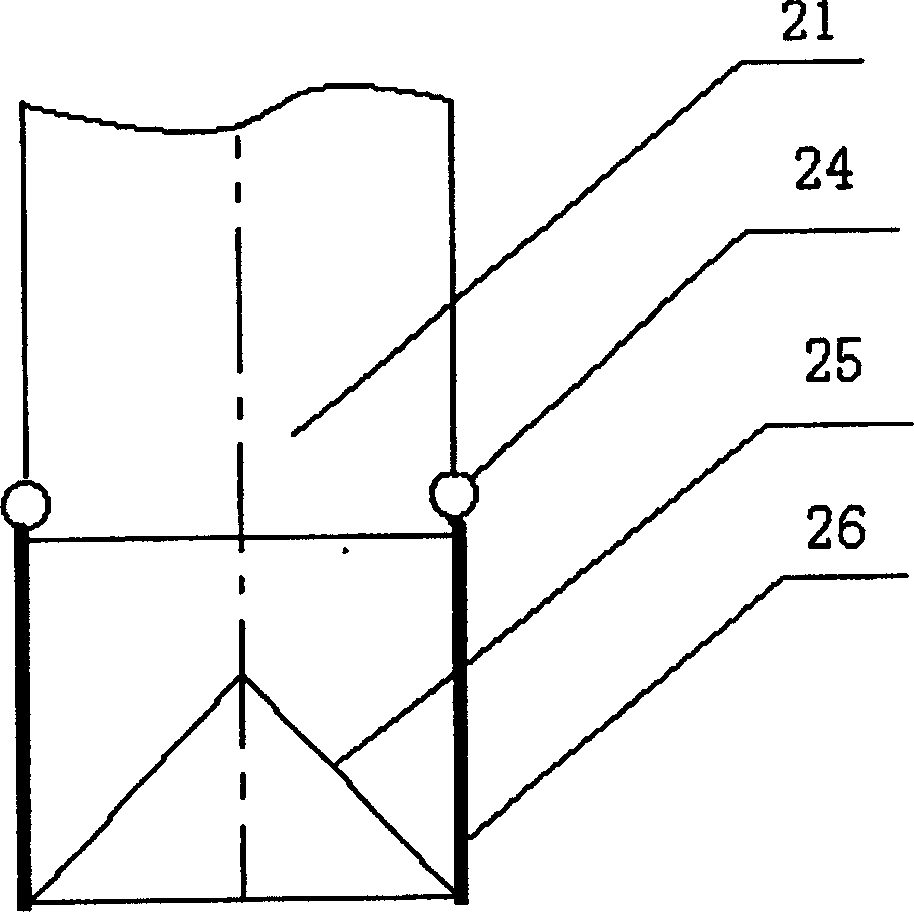

A kind of water-based alkyd resin and preparation method thereof

ActiveCN111995738BAdjustable functionalityControl reaction ratePolyester coatingsPolymer scienceMonomethyl ether

The invention provides a water-based alkyd resin and a preparation method thereof. The water-based alkyd resin is prepared by taking vegetable oleic acid, polyhydric alcohols other than glycerol monomethyl ether, glycerol monomethyl ether and polyacids or acid anhydrides as reaction raw materials, and using water-carrying agents as reflux solvents through multi-step reactions. The water-based alkyd resin has improved water resistance and adhesion, and the method realizes the reuse of glycerin and improves the utilization value of glycerin.

Owner:TANGSHAN XUYANG CHEM IND CO LTD +1

High-calcium yeast powder and preparation method of high-calcium yeast powder

The present invention relates to the technical field of foods and particularly relates to high-calcium yeast powder and a preparation method of the high-calcium yeast powder. The high-calcium yeast powder mainly comprises the following components in parts by weight: 10-50 parts of flour, 5-10 parts of animal bone paste, 1-3 parts of yeasts, and 1-2 parts of cheese. In the high-calcium yeast powderobtained by the formula and technology, probiotic species are increased, at the same time, some hydroxyapatite crystals and amorphous calcium hydrogen phosphate in bones are converted into higher-quality calcium lactate, amino acid calcium, calcium acetate, etc., and besides, calcium amount supplemented with cooked wheaten food belongs to a safe and reasonable range. The production technology ofthe product fully utilizes existing devices of existing bone marrow powder production enterprises, and does not need much investment and many device layout changes. The high-calcium yeast powder can be sold and displayed in the same manner as ordinary yeast powder, can also be sold as a novel type of probiotics-enriched and high-quality calcium-source bone marrow powder, and has a larger market space.

Owner:JIANGSU NUOPULE BIOTECH CO LTD

Method for producing balance together negative-positive plate of battery

InactiveCN1599104ASolve the problem of excessAchieve balanceElectrode manufacturing processesFinal product manufactureEngineeringCathode

The invention relates to a balanced tie-in manufacturing method of negative and positive plates of the storage batteries. It replaces the positive plates with the slab lattices to produce the negative plates alone or replaces the negative plates with the slab lattices to produce the positive plates alone. When the positive plates are superfluous during producing the storage battery, replace the anode plates with the slab lattices, take the cathodes as the negative plates and produce the negative plates alone with between 4.33% and 7.13% of PbO in normal formation condition. When the negative plates are superfluous, replace the cathode plates with the slab lattices, take the anodes as the positive plates and produce the positive plates alone with between 77.68% and 85.21% of PbO2 in normal formation condition. By adopting the invention to produce the negative and positive plates, can get stable index, reliable technology, pay the cost of between 0.26RMB and 0.30RMB per monolithic for the profit of more than 1RMB pre monolithic and is a good method of balanced arrangement of the negative and positive plates of the storage batteries and increasing the benefit.

Owner:广西华锡集团股份有限公司

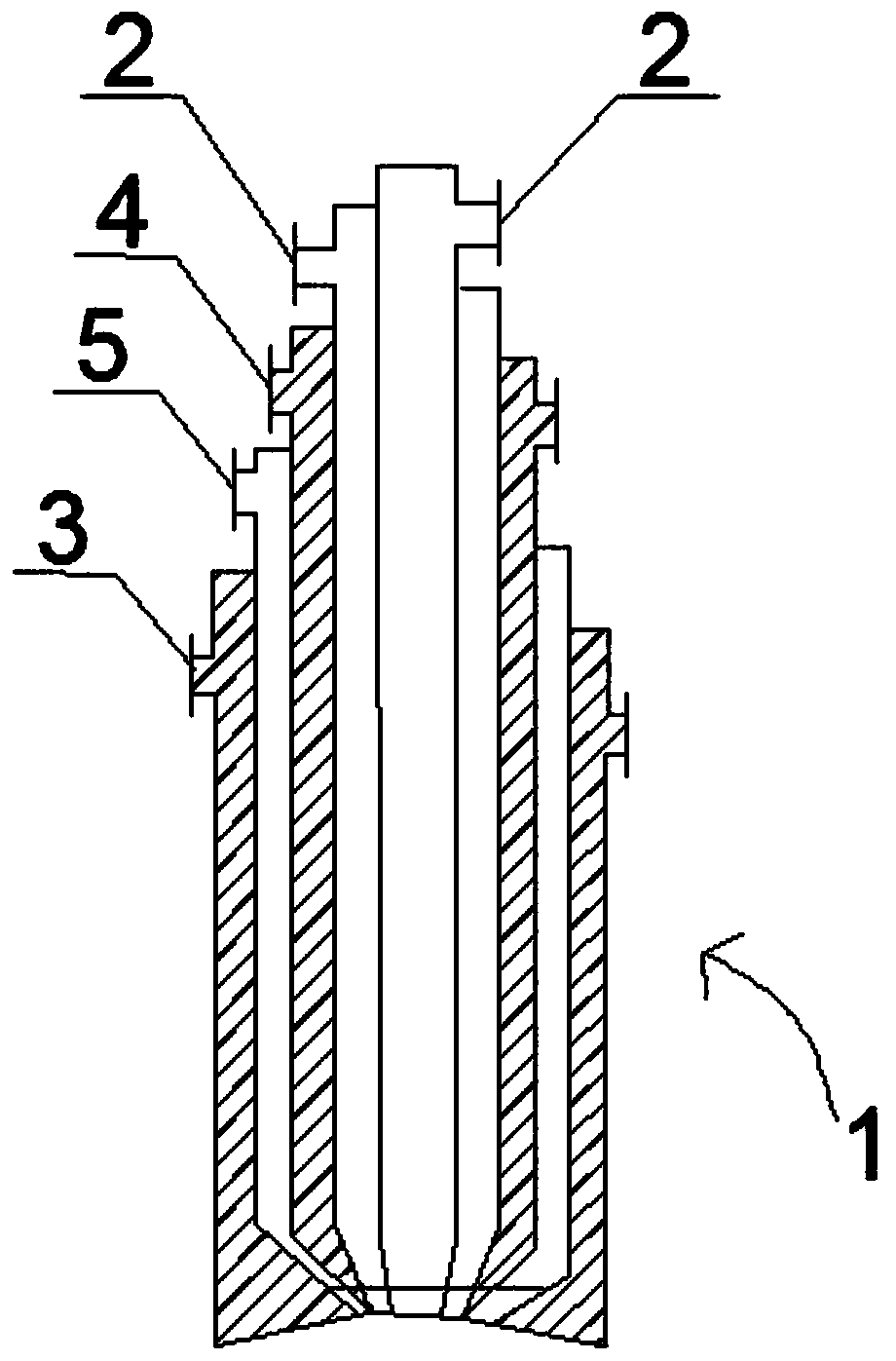

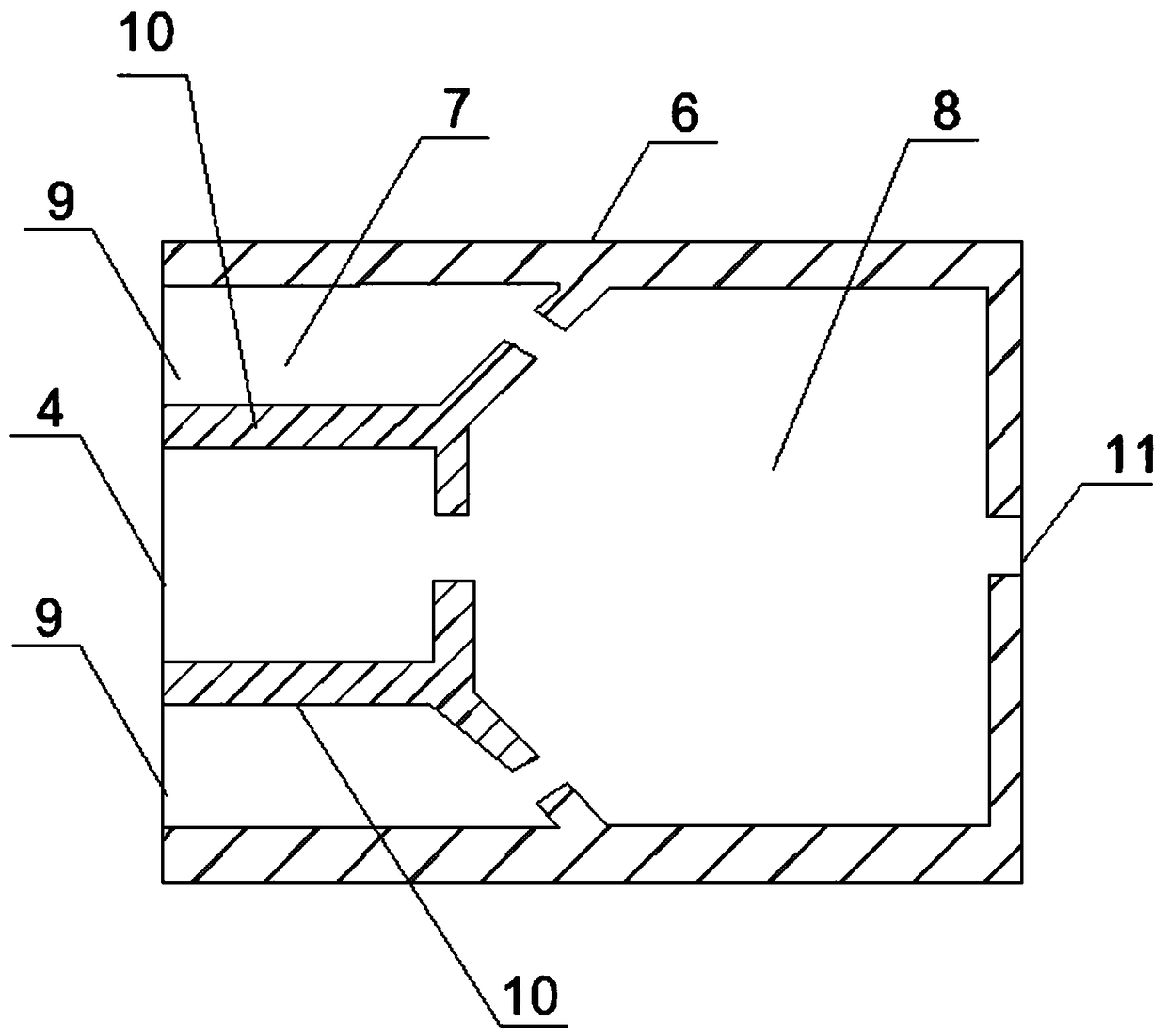

Novel technological burner system

InactiveCN109504456AEvenly heatedExtended service lifeGasification processes detailsGasification apparatus detailsCoal waterWater channel

The invention provides a novel technological burner system. The novel technological burner system comprises a technological burner, wherein the technological burner comprises a middle oxygen channel,an outer ring oxygen channel and a coal water slurry channel located between the middle oxygen channel and the outer ring oxygen channel; a cooling water channel is arranged between the outer ring oxygen channel and the coal water slurry channel; the front end of the technological burner is further connected with a mixed atomizer; the mixed atomizer comprises a mixing chamber and a pre-mixing chamber; the mixing chamber consists of CO2 channels at two sides and the coal water slurry channel located between the CO2 channels; a separation plate between every two adjacent channels is Y-shaped; the pre-mixing chamber is located at the rear end of each channel and a discharge hole is formed in the rear end of the pre-mixing chamber; the discharge hole is communicated with a feeding opening of the technological burner. By adopting the technological burner, the contact specific surface area between CO2 and oxygen gas can be larger and gasification reaction is more rapid, so that the problem that the oxygen gas is excessive in a combustion region and local area is greatly solved.

Owner:江苏中友讯华信息科技有限公司

Method for producing balance together negative-positive plate of battery

InactiveCN1293654CSolve the problem of excessAchieve balanceElectrode manufacturing processesFinal product manufactureEngineeringCathode

Owner:GUANGXI HUAXI GRP CO LTD

A Reservoir Numerical Simulation Method for Calculating the Flow of Multiple Intersecting Discrete Fractures

InactiveCN103400020BDoes not affect calculation resultsSolve the problem of excessSpecial data processing applicationsLine segmentStreamflow

The invention discloses a numerical reservoir simulation method for measuring the flowing situation of a plurality of intersected discrete cracks. The method comprises the steps that a reservoir is divided into a continuous medium and a discrete crack medium; in order to remove extremely small grids, when a reservoir grid is created, a discrete crack endpoint is deformed or is simplified to be a segment by neglecting the thickness, then a rock stratum face grid is established, and a three-dimensional reservoir grid is established; practically measured reservoir parameters of holes, leakage, saturation and the like are input into a simulator, then a real value instead of a grid display value is used as the width of each discrete crack, and accuracy of a measured and calculated result is not lowered by deformation processing; the volume of the intersecting area of the discrete cracks is neglected, and a flow formula of the discrete cracks in the intersecting area is established; the reservoir parameters are corrected by utilizing the history fitting method; then well yield and remaining oil gas distribution and reserves are measured and calculated. The numerical reservoir simulation method can solve the problems that the discrete crack value simulation technology is prone to interruption and failure and is long in consumed time for measurement and calculation, so that the technology can achieve measurement and calculation in the whole process of full three-dimensional reservoir development, and improves accuracy of the measured and calculated result.

Owner:SOUTHWEST PETROLEUM UNIV +1

Solar-earth source heat pump seasonal balance heating system

InactiveCN101634466BLong-term solutionAvoid stabilityHeat pumpsOther heat production devicesPlate heat exchangerMagnetic valve

The invention discloses a solar energy-soil source heat pump seasonal balance heating system comprising a solar energy heat collector, a water tank and a solar energy heating heat-exchange coil pipe, wherein a ground source heat-pump heat-exchange coil pipe is arranged in the water tank and communicated with a plate heat exchanger by a second circulation pipeline; a second water pump, a second water pump, a first constant pressure tank and a magnetic valve are arranged on the second circulation pipeline; the plate heat exchanger is communicated with a heat pump assembly by a third circulation pipeline; a third water pump, a third constant pressure tank and a magnetic valve are arranged on the third circulation pipeline; the plate heat exchanger is communicated with an underground burying pipe by a fourth circulation pipeline; the underground burying pipe is buried underground and is provided with an underground insulating device; and a fourth water pump, a second constant pressure tank and a magnetic valve are arranged on the fourth circulation pipeline. The solar energy-soil source heat pump seasonal balance heating system can store redundant heat generated by a summer solar energy heat collecting system in winter to use, effectively save energy sources, increase the use efficiency of solar energy and solve the detects of the traditional earth source heat pump.

Owner:CHINA ARCHITECTURE DESIGN & RES GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com