Patents

Literature

205results about How to "Raise the selling price" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

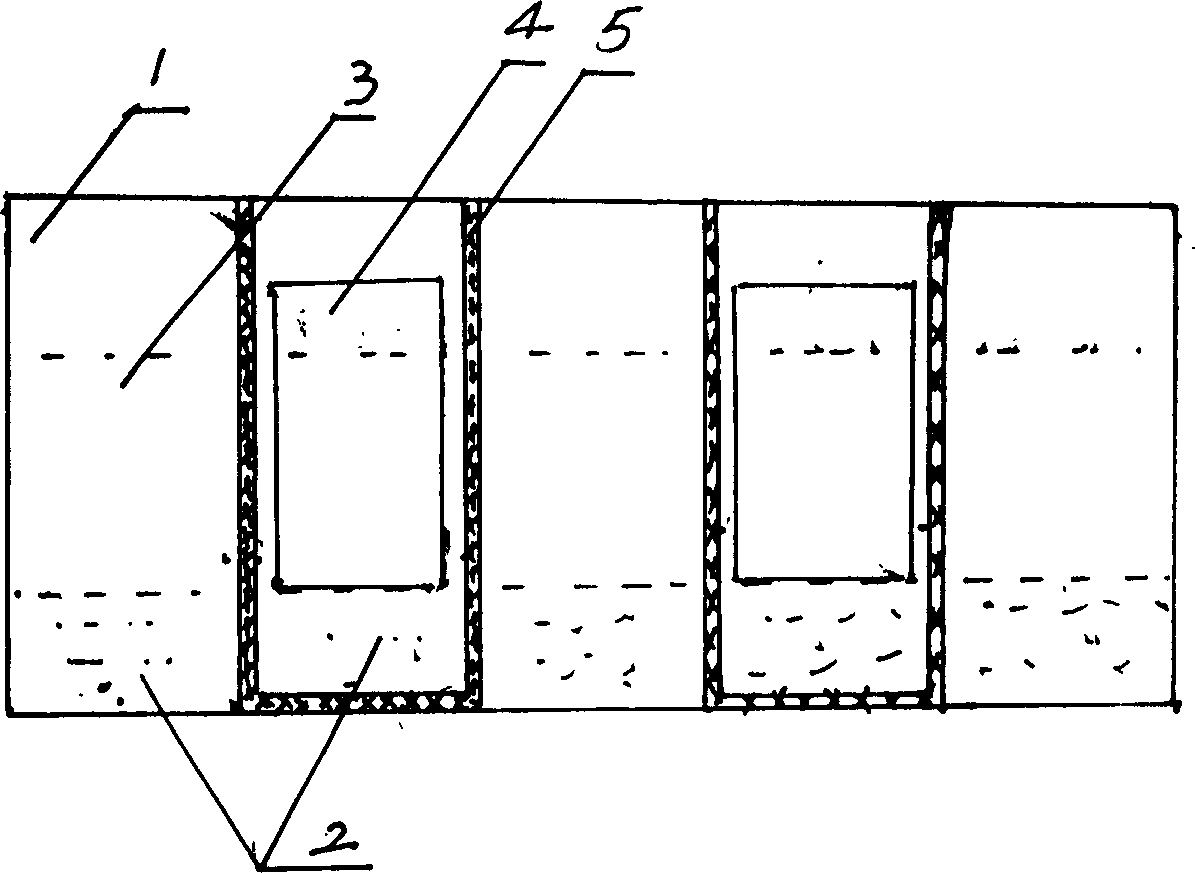

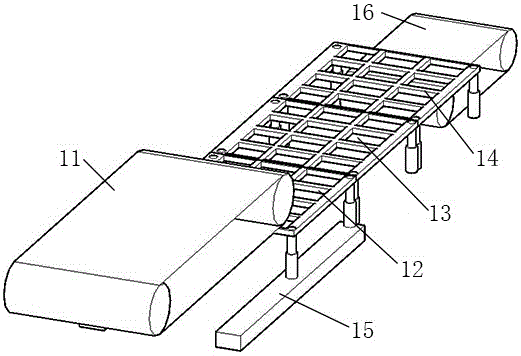

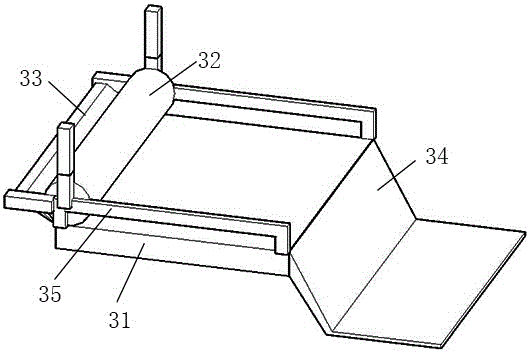

Operation method of electric peeling device for protective cores of waste cables

ActiveCN106329410AReduce labor intensitySave labor costsApparatus for removing/armouring cablesEngineeringProtective relay

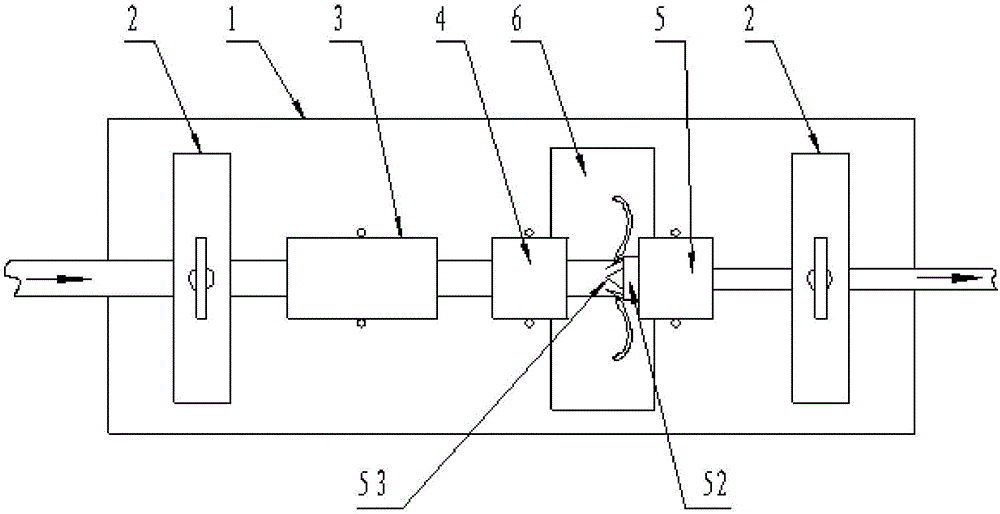

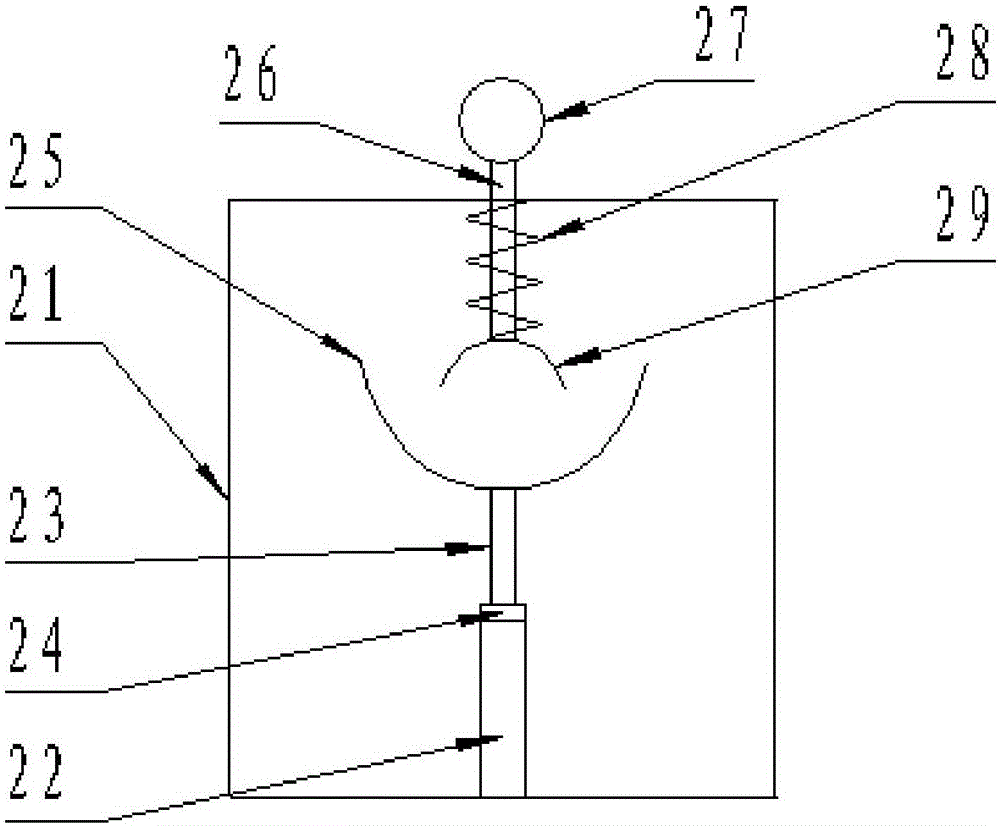

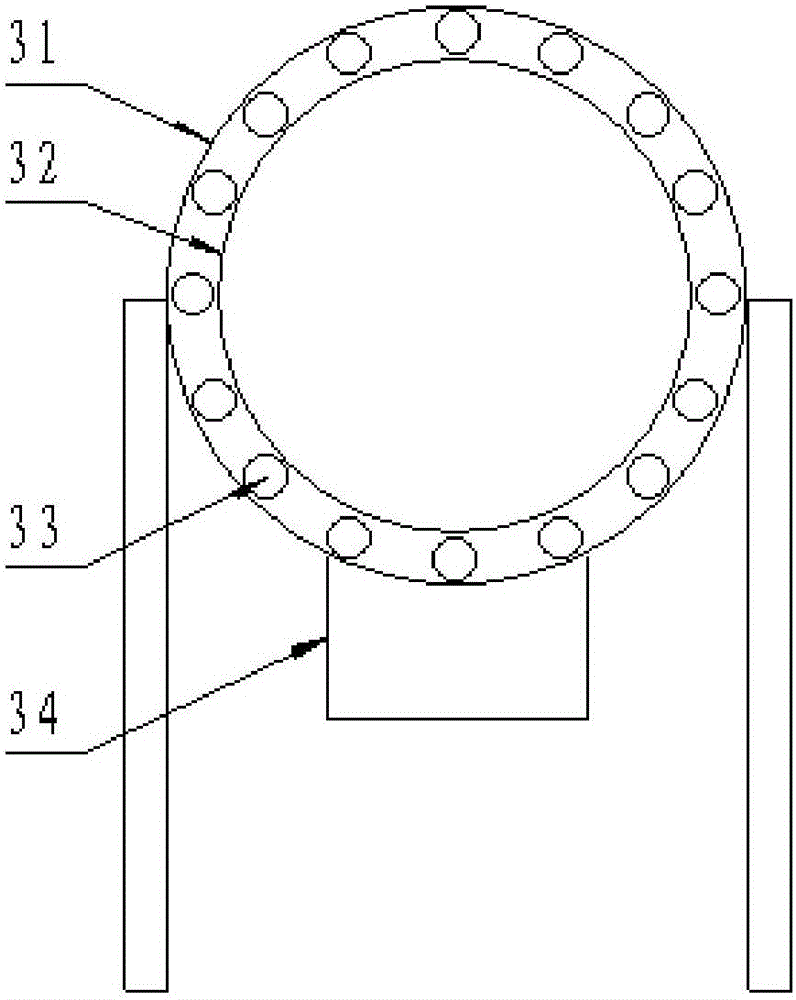

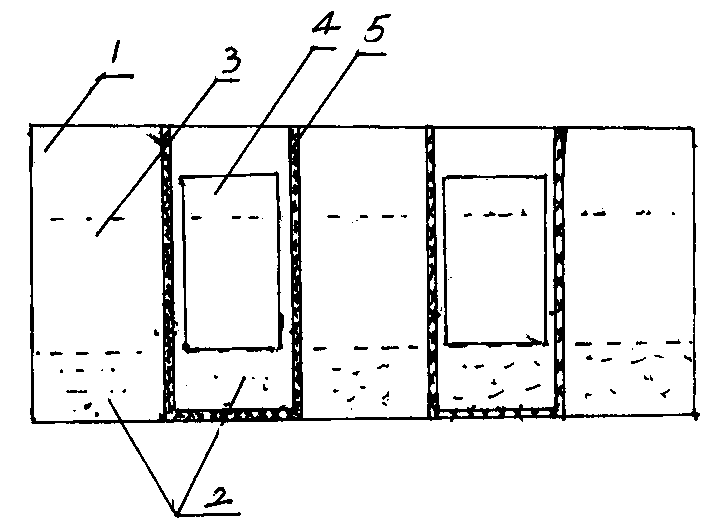

Provided is an operation method of an electric peeling device for the protective cores of waste cable. Clamping mechanisms are arranged at the two ends on an operation table. A heater, a cutting mechanism and a stripping mechanism are sequentially arranged along the running direction of cables between the two clamping mechanisms. An insulating layer collection hole is arranged between the cutting mechanism and the stripping mechanism. The operation method comprises the following steps: adjusting the height of the telescopic rods on the clamping mechanisms; adjusting the distance between the blade of a cutter on the cutting mechanism and the inner core of a cable and the distance between the blade of a separator on the stripping mechanism and the inner core of the cable; adjusting the centers of the mechanisms to the same axis line; and heating, cutting and stripping the insulating layer of a to-be-processed cable in sequence. The device has a simple structure. The operation method is simple. The use effect is good. Operation by workers is facilitated. The labor intensity of workers is reduced greatly. The stripping effect is good, and the production efficiency is high. The method is suitable for stripping the rubber sheaths of all kinds of cables. High cable core recovery efficiency is achieved.

Owner:HUATONG CABLE INC

High-immune anti-stress turtle complete feed

ActiveCN103039730AImprove survival rateImprove stress resistanceAnimal feeding stuffAnti stressVitamin C

The present invention relates to a high-immune anti-stress turtle complete feed, including a base material. The base material includes red fish meal, white fish meal, cod meal, skim fish meal, chicken meal, alpha-starch, fermented soybean meal, extruded soybean, vital gluten and yeast wall-broken meal; and further comprises by weight: 1.2-2% of calcium dihydrogen phosphate, 0.3-0.6% of choline chloride, 0.4-0.6% of glucose, 0.15-0.4% of compound probiotics, 0.1-0.2% of vitamin C, 0.2-0.3% of a compound hepatobiliary preparation, 0.2-0.3% of compound immunopotentiator, 2.5-3.5% of compound vitamins, and 5-6.5% of a compound mineral salt. By using the feed, the survival rate and anti-stress of the turtle can be significantly improved, the occurrence of white abdominal shell, leukoderma and enteritis of the turtle is reduced, specification and quality of the products are improved, and the economic efficiency is increased.

Owner:深圳市澳华集团股份有限公司

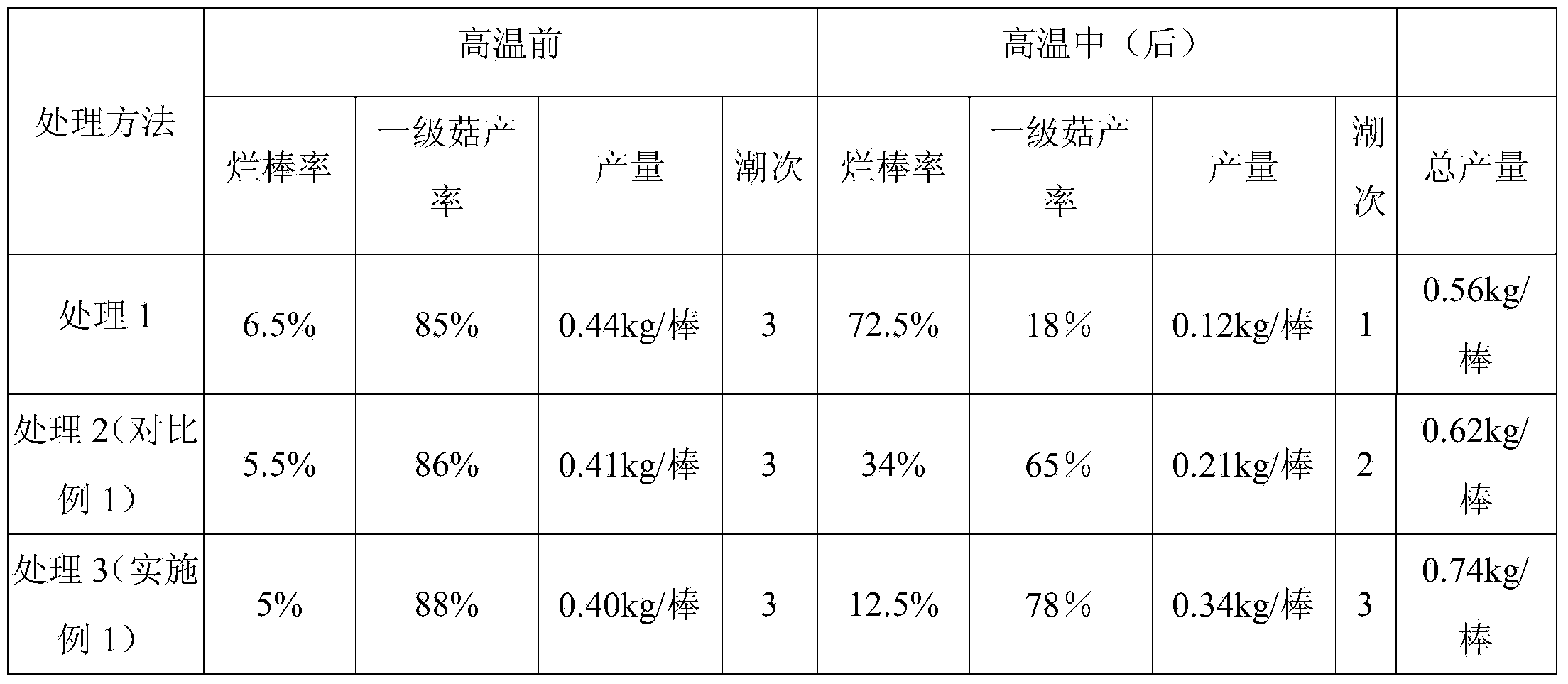

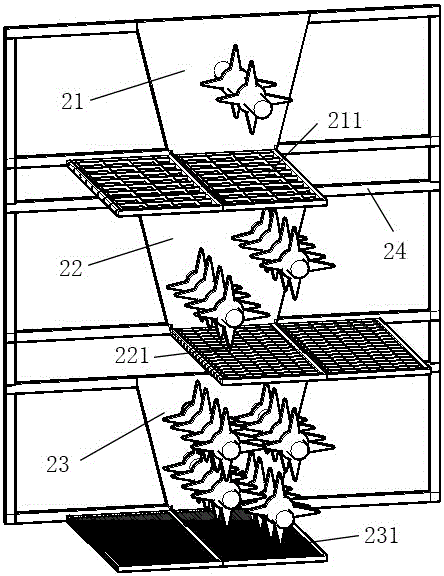

Method for cultivating shitake mushrooms by segmental fruiting

The invention discloses a method for cultivating shitake mushrooms by segmental fruiting. The method comprises the following steps of: making bags and inoculating from September to November each year; fruiting and harvesting at the first segment from April to June next year; making the plant dormant in summer from July to August; fruiting and harvesting at the second segment from September to November; stimulating fungus bags during fruiting at the second segment when the minimum air temperature drops to below 23 DEG C in early September to promote the fruiting at the second segment; injecting deep well water at constant temperature of 24 DEG C once to the fungus bags by using water injection needles from 20 O' clock to 7 O'clock next day, wherein the time is controlled to be less than 10S, and a great amount of yellow water seeps from the fungus bags; managing the fruiting after injecting the water; continuously harvesting for 2 to 3 times. According to the method, the two-segment fruiting technology is adopted, two-segment fruiting of the shitake mushrooms from May to June and from September to November is achieved, the yield is improved by 40 percent compared with that of the conventional cultivating method, and the efficiency is increased by 90 percent.

Owner:WUYI INNOVATION EDIBLE FUNGUS

Complete feed for tilapia

The invention relates to a complete feed of tilapia. The technical scheme of the complete feed disclosed by the invention is as follows: the complete feed comprises the following components in percentage by weight: 0.5-4% of fish meal, 16-23.5 of soybean meal, 22-31% of rapeseed meal, 5-6% of peanut meal, 5-7% of rice bran, 5-14% of wheat bran, 14.61-20.63% of high-protein flour, 5-6% of DDGS (Distillers Dried Grains with Soluble) and 1.3-2.2% of soybean oil. The complete feed of the tilapia, disclosed by the invention, has the advantages of simple formula and easy production; in addition, through the complete feed of the tilapia, disclosed by the invention, the contents of DHA (Docose Hexaenoie Acid) and EPA (Eicosapntemacnioc Acid) in the fish flesh can be remarkably increased so that the selling price of the tilapia is increased and the economic benefit of a tilapia raiser is remarkably improved.

Owner:HAINAN YUBAO HIGHEST QUALITY AQUACULTURE FEED

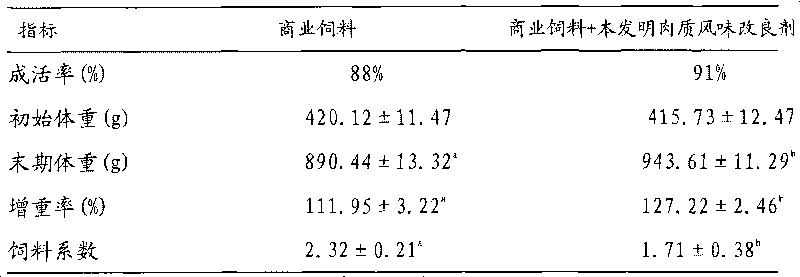

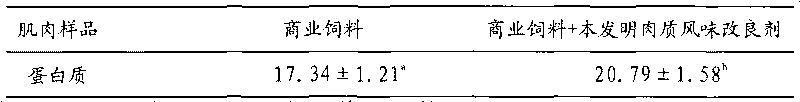

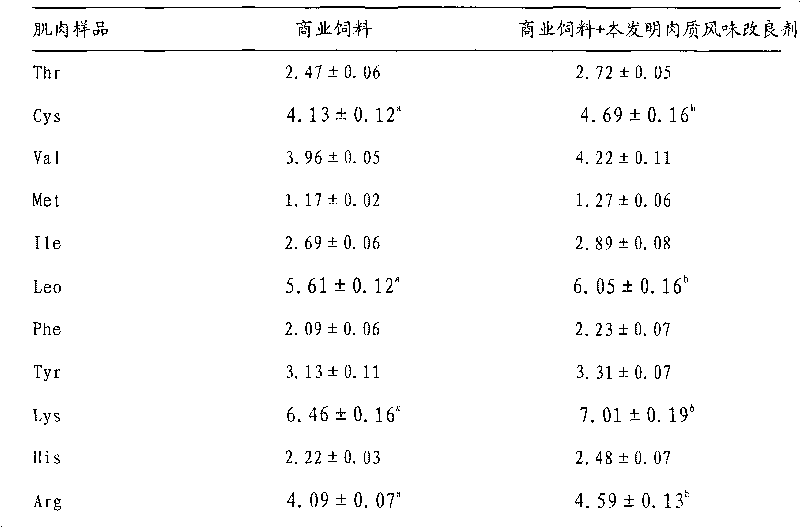

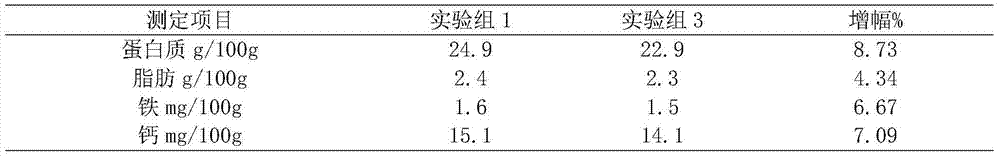

Meat quality flavor modifying agent for grass carp or carp and preparation method thereof

ActiveCN101744145AIncrease attractivenessImprove immunityAnimal feeding stuffBiotechnologyAquaculture industry

The invention relates to a feed additive of aquaculture industry, in particular to a meat quality flavor modifying agent for grass carp or carp and a preparation method thereof. Each kilogram of modifying agent comprises the following components: 30 to 50g of seaweed extract, 10 to 20g of combination of inosinic acid and guanylic acid, 20 to 30g of carnitine, 15 to 30g of glycin, 10 to 20g of alanine and the balance of zeolite powder. The preparation method comprises the following steps: firstly, crushing solid materials in the seaweed extract, the combination of inosinic acid and guanylic acid, the carnitine, the glycin, the alanine and the zeolite powder materials and sieving the crushed solid materials through a sieve with 80 to 100 meshes for later use; and secondly, mixing and stirring the crushed solid materials in the proportion to ensure that the coefficient of variation CV of the uniformity is less than 5 percent to obtain the product. The modifying agent can effectively improve protein content, content of total amino acids, content of essential amino acids and content of delicious amino acid in muscles of the grass carp and the carp.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Green control method of citrus diseases and insects

ActiveCN102812874AGood control effectReduce usagePlant protectionInsect catchers and killersDiseaseEcological environment

The invention discloses a green control method of citrus diseases and insects, wherein the method comprises the following steps: 1) changing a citrus garden from dense to sparse; 2) trimming large branches; 3) cultivating swards; 4) treating mites by mites; 5) trapping and killing insects; 6) reasonably applying chemicals. Because of adopting the green and environment-friendly control method, the green control method of citrus diseases and insects provided by the invention is capable of resolving a problem of green control on the citrus diseases and insects, crops are protected, the use of chemical pesticides is decreased, the ecological environment is protected, the safety of human and livestock is protected, the control effect on main citrus diseases and insects is higher than 90%, the control effect is increased by 15-20%, the use times of the chemical pesticides is decreased by more than 50%, the soluble solid of the citrus is increased by 2-3%, the rate of high-quality fruits is increased by 5%, and the economic benefit, the social benefit and the ecological benefit are obvious.

Owner:曹诗红 +4

Method for accelerating two maturations in one year of Chinese jujube in winter warm type big shack

InactiveCN101049072ARaise the selling priceBig fruitCultivating equipmentsHorticultureZiziphus jujubaPruning

A method for promoting the jujube tree to bear the jujubes twice in one year by use of the big plastic film shed warming the in winter and regulating temp and humidity includes such steps as removing the plastic film after the first batch of jujubes is picked up in order to update the tree, promoting second blossom and fruit bearing, covering film in the last 10 days of the October, picking up the second batch of jujubes, pruning, covering film in the day and removing film at night for forcing the dormancy of jujube tree, and warming from the middle 10 days of the December.

Owner:陈福志

Method for cultiating recifield eel in ecological net cage

InactiveCN1418540AImprove the growing environmentImprove qualityClimate change adaptationPisciculture and aquariaFinless eelMaggot

The present invention relates to an ecological cage culture method of finless eel, including lotus rhizome, finless eel, interval culture and using engineering fly-maggot as feed. Said invention provides a good culture environment for grwoth of finless eel, use high-quality high protein engineering fly-maggot as feed so as to can greatly raise finless eel culture density, can shorten feeding period, and its yield can be raised by 50-100%.

Owner:HAOYUNDAO SPECIFIC CULTIVATION SCI & TECH WUHAN

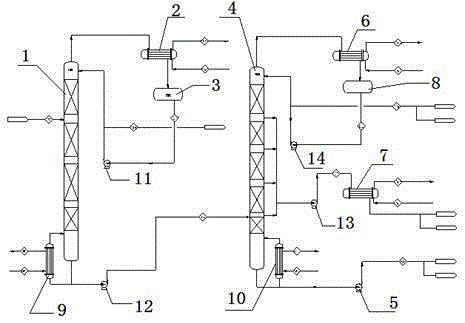

Refining purifying device and method used for continuously producing battery grade dimethyl carbonate

ActiveCN105384639AAddressing Purity IssuesSettlement yieldCarbonic/haloformic acid esters purification/separationHigh energyReboiler

The invention relates to a refining purifying device and method used for continuously producing battery grade dimethyl carbonate. The device is characterized in that the top of a light component removal column is connected with an overhead condenser; the overhead condenser is connected with the light component removal column by a first reflux drum and a first reflux pump and is connected with a light component removal outlet; the bottom of the light component removal column is connected with a first reboiler; the first reboiler is used for conveying raw materials subjected to light component removal to a rectifying column via a column reactor pump; the rectifying column is connected with a second reflux drum by a rectifying column condenser; the second reflux drum is connected with the rectifying column by a second reflux pump; the bottom of the separate column reactor is connected with a second column reactor pump by a second reboiler; the middle part of the separate column reactor is connected with a side condenser by a side withdrawing pump. The device and the method have the beneficial effects that the problems of low product purity, low yield, high energy consumption and generation of solid waste pollutants in traditional production processes are solved; the purity of the dimethyl carbonate product is improved 99.99% or more after removing light components by the light component removal column and then carrying out purifying refining by the rectifying column.

Owner:DONGYING HI TECH SPRING CHEM IND

Method for quickly culturing stools of asparagus officinalis, promoting germination of tender stems and cultivating same of asparagus officinalis

InactiveCN103704100ARaise the selling priceReduce consumptionAgriculture gas emission reductionCultivating equipmentsGreenhouseOfficinalis

The invention discloses a method for quickly culturing stools of asparagus officinalis and promoting germination of tender stems and cultivating the same of the asparagus officinalis, and belongs to the technical field of plant cultivation. The method includes selecting asparagus officinalis varieties with short dormant periods, protecting roots of the asparagus officinalis to quickly cultivate seedlings of the asparagus officinalis by the aid of artificial substrates, transplanting the seedlings at the age of 70-90 days into cultivation tanks to cultivate the seedlings by the aid of soilless mixed substrates in a root restriction manner and cultivating healthy and strong underground stems of the annual asparagus officinalis; promoting spouting of the tender stems in greenhouses or sunlight greenhouses by means of artificial warming, producing green asparagus officinalis under natural light conditions in winters and springs or producing white asparagus officinalis in a mulching manner by the aid of sunshade films. The method has the advantages that the method is combined with technologies for storing the stools of the asparagus officinalis by means of low-temperature moisture retention and the like, the asparagus officinalis can be cultivated in a batched manner in different seasons in controllable environments, accordingly, the high-quality asparagus officinalis can be produced industrially and intensively, purposes of producing and supplying the asparagus officinalis throughout the year can be achieved, and the produced asparagus officinalis is excellent in commercial property, good in quality and free of pollution and has an excellent planting benefit.

Owner:ZHEJIANG UNIV

Preparation method of biodegradable aliphatic-aromatic copolyester

The invention relates to a preparation method of a biodegradable aliphatic-aromatic copolyester, comprising the following steps of: a) carrying out polymerization between aliphatic dibasic acid, ester, acid anhydride or their mixture and dihydric alcohol to obtain an aliphatic polyester with a certain molecular weight, adding aromatic diacid, ester, acid anhydride or their mixture into dihydric alcohol for ester interchange or esterification, and carrying out vacuum-pumping for copolymerization to obtain the biodegradable aliphatic-aromatic copolyester; or b) carrying out copolymerization between aromatic diacid, ester, acid anhydride or their mixture and dihydric alcohol to obtain the aromatic polyester with a certain molecular weight; adding aliphatic dibasic acid, ester, acid anhydride or their mixture into dihydric alcohol for ester interchange or esterification, and carrying out vacuum-pumping for copolymerization to obtain the biodegradable aliphatic-aromatic copolyester. The product prepared by the method provided by the invention can be used in biodegradable molded products and for a purpose of mixing it with starch.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Maturation promoting method for Dongzao jujube

InactiveCN1526265AExtended harvest periodExtended sales periodCultivating equipmentsHorticultureFruit treeZiziphus jujuba

The present invention belongs to fruit cultivating method. The method of promoting maturation of Dongzao jujube includes the main measures of selecting stunted and premature Dongzao jujube variety, setting plastic house in winter and spring to increase temperature, topping off after germination of the tree, tip pruning after the branch grows to 9 leaves to promote early flower to bear, and top dressing with phosphate fertilizer and potash fertilizer. The said method can move up the maturation phase by over 30 days to reach high marketing profits.

Owner:无棣县科学技术局

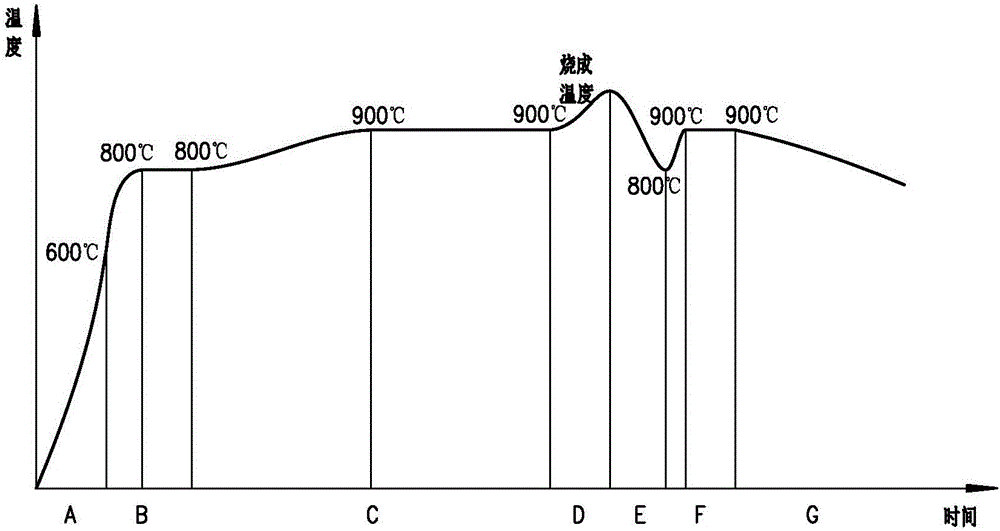

Lightweight low-temperature fancy golden silk white glazed porcelain and manufacturing process

The invention belongs to the field of ceramic glaze and specifically relates to lightweight low-temperature fancy golden silk white glazed porcelain widely applicable to art ceramics or ceramics for household purpose and a manufacturing process thereof. According to the lightweight low-temperature fancy golden silk white glazed porcelain, by the combination of ground glaze and overglaze, the black galaxy effect is realized. The fired lightweight low-temperature fancy golden silk white glazed porcelain has black ground color, which is covered with golden sand particles. The golden sand particles are polygonal particles when examined under a microscope, and the light-reflecting effect is good. Relative to the black ground color, there is a striking contrast and a unique artistic effect is achieved. In addition, the service life of the lightweight low-temperature fancy golden silk white glazed porcelain is long due to the combination of the ground glaze and overglaze. According to the manufacturing process of the lightweight low-temperature fancy golden silk white glazed porcelain, the effect of the overglaze can be adjusted through the formula and thickness of the ground glaze and overglaze. Then, yield of black galaxy glaze is high, firing temperature is low, energy conservation and environment protection are achieved, and energy consumption is reduced.

Owner:福建省德化县臻晖陶瓷有限公司

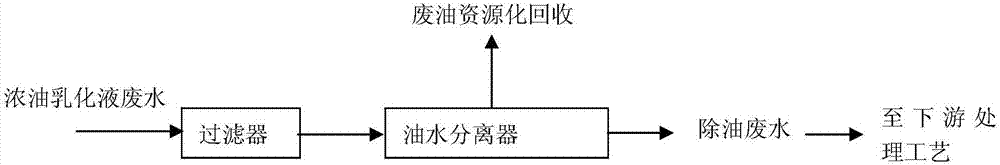

Deoiling method for cold rolling oil-rich emulsion wastewater, and device thereof

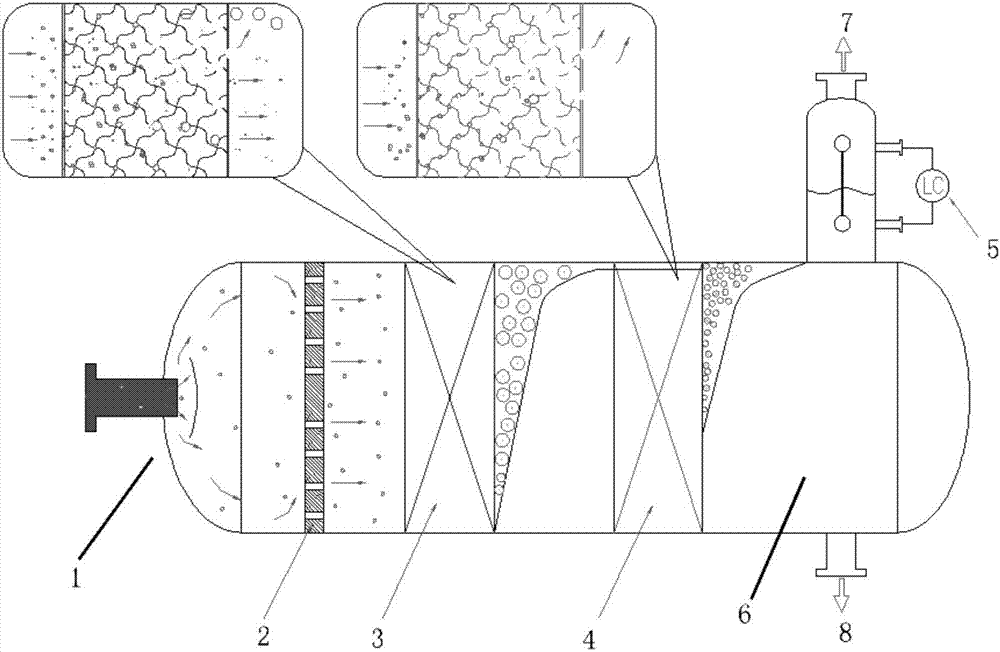

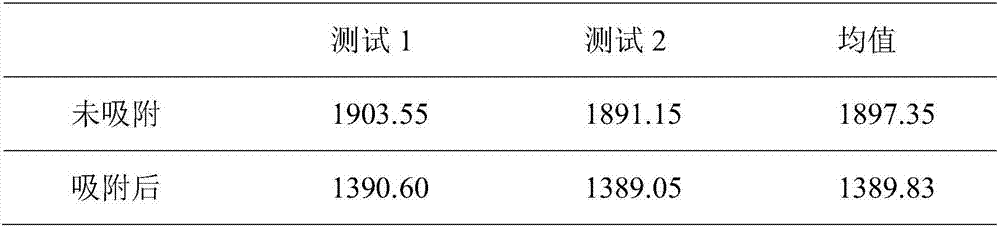

ActiveCN107540105AAchieve separationReduce distractionsWaste water treatment from metallurgical processMultistage water/sewage treatmentTherapeutic effectEngineering

The invention relates to a deoiling method for cold rolling oil-rich emulsion wastewater, and a device thereof. The method comprises the following steps: 1, filtering pretreatment; 2, oil-water separation; and 3, waste oil recycling. An oil-water separator comprises an oil-water rectifier, a porous filled area and a multilayer folded plate oil-water separation area, the porous filled area and themultilayer folded plate oil-water separation area are filled with functional nano-fiber filter cores, and every functional nano-fiber filter core is a 304 stainless steel wire fiber and modified polypropylene fiber hybrid fabric filter layer, wherein the denier (fiber diameter) of each of the 304 stainless steel wire fiber and the modified polypropylene fiber is 50-500 nm. The method and the device thereof have the advantages of good treatment effect, low running cost, no secondary pollution, and realization of waste oil recovery.

Owner:BAOSHAN IRON & STEEL CO LTD

Fertilizer application formulas for different growth stages of garlic

The invention discloses fertilizer application formulas for different growth stages of garlic. The different fertilizer application formulas for six stages including a planting stage, a seedling stage, a flower bud and bulb differentiation stage, a pedicel elongating stage, a bulbus expansion stage and a quiescent stage are respectively provided according to characteristics of demands of plants to fertilizer in different stages during a garlic growing process, application proportions of azophoska in each stage is controlled, on one hand, the growth of garlic in each stage is promoted, limitation to plant growth caused by less application of a fertilizer can be avoided, and cost increase caused by fertilizer waste due to excess application of a fertilizer can also be prevented, and on the other hand, the garlic grown-up period is shortened, garlic can enter into market in advance and has a stronger superiority of price competitiveness; garlic yield and quality are enhanced due to reasonable fertilizer application and allocation in different stages, the ripening period is shortened, fertilizer cost for the process of garlic planting is reduced, the selling price is higher, and a strong practical signification is achieved.

Owner:句容市和春园农业机械专业合作社

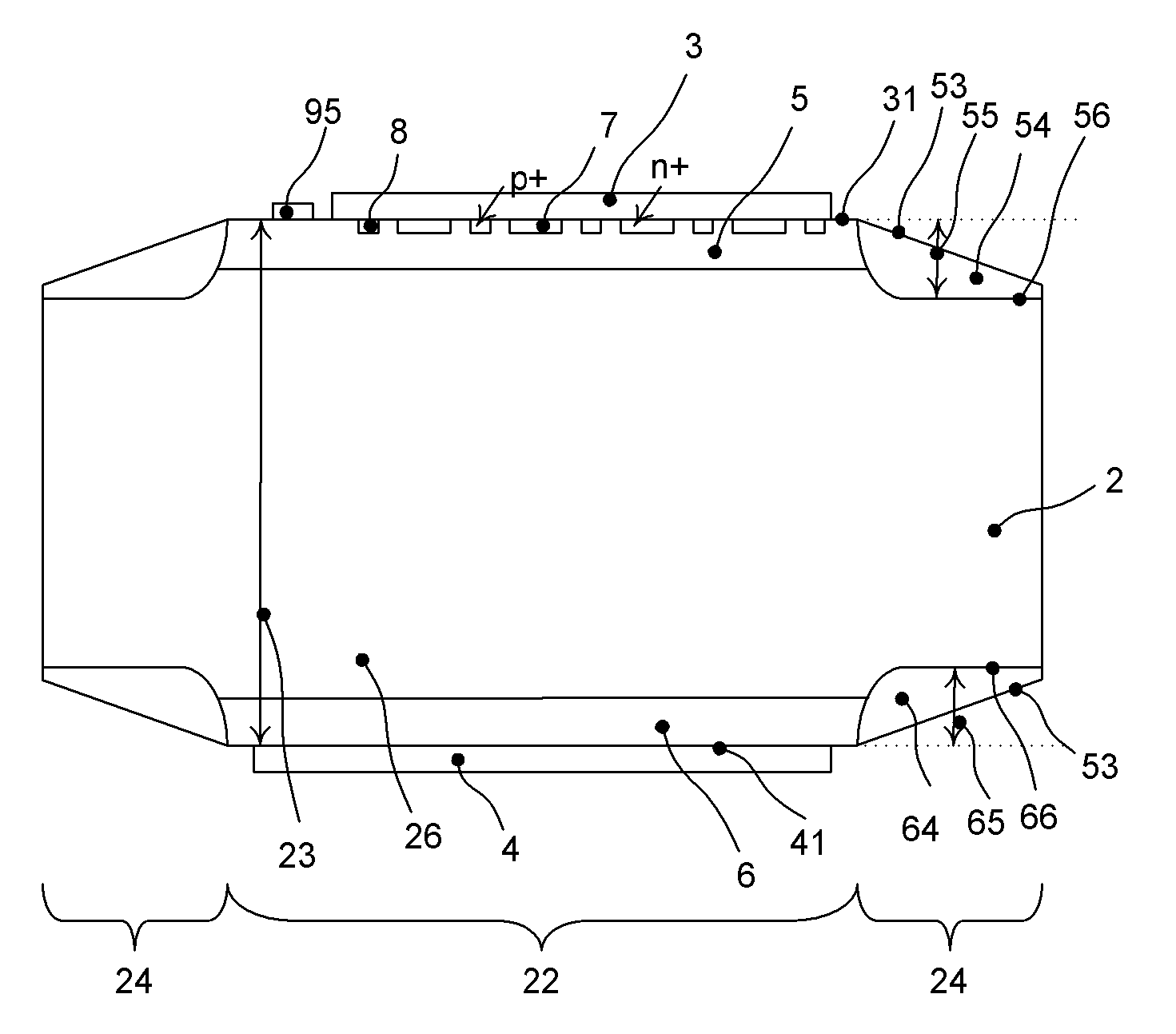

Bipolar non-punch-hrough power semiconductor device

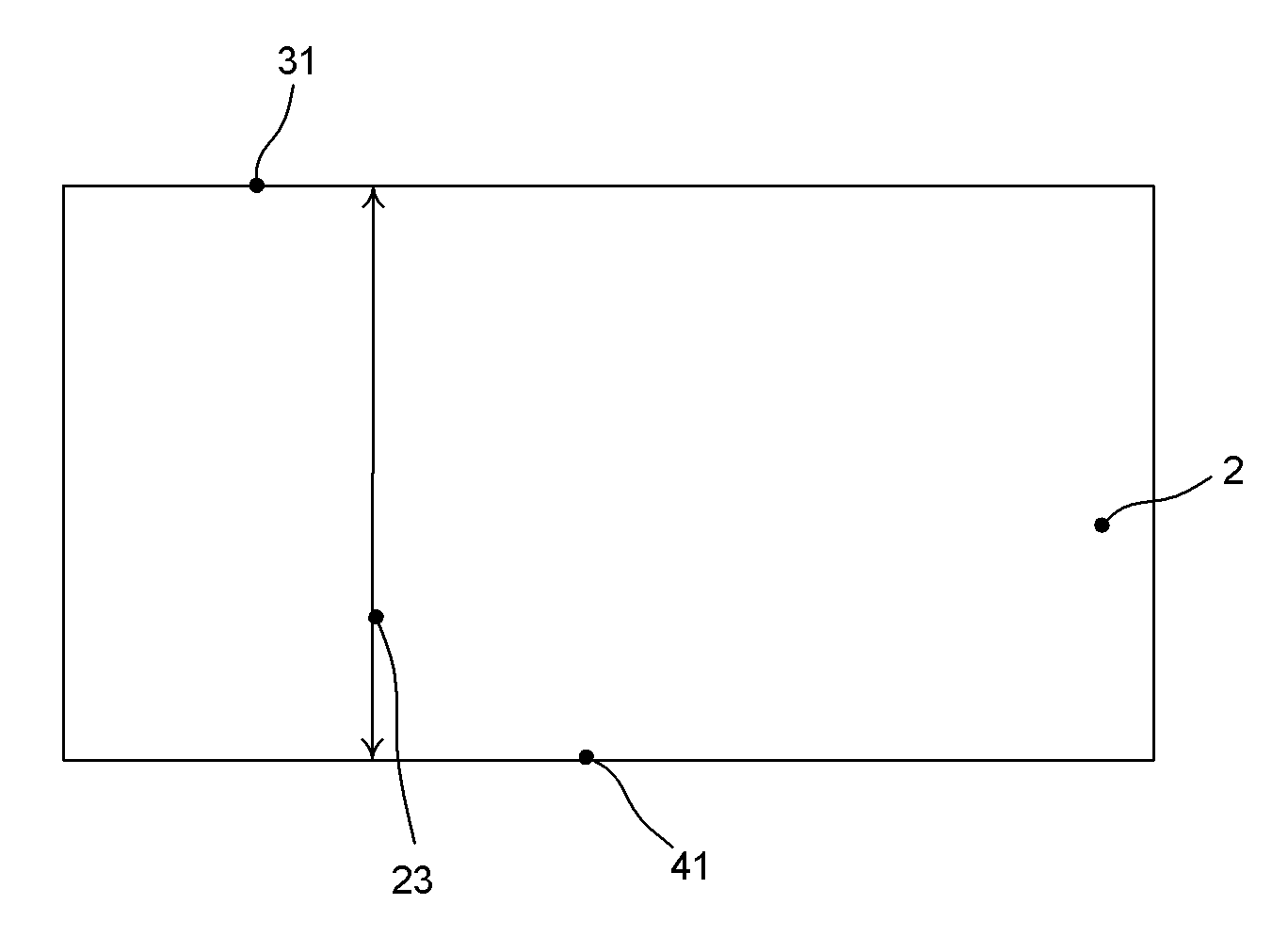

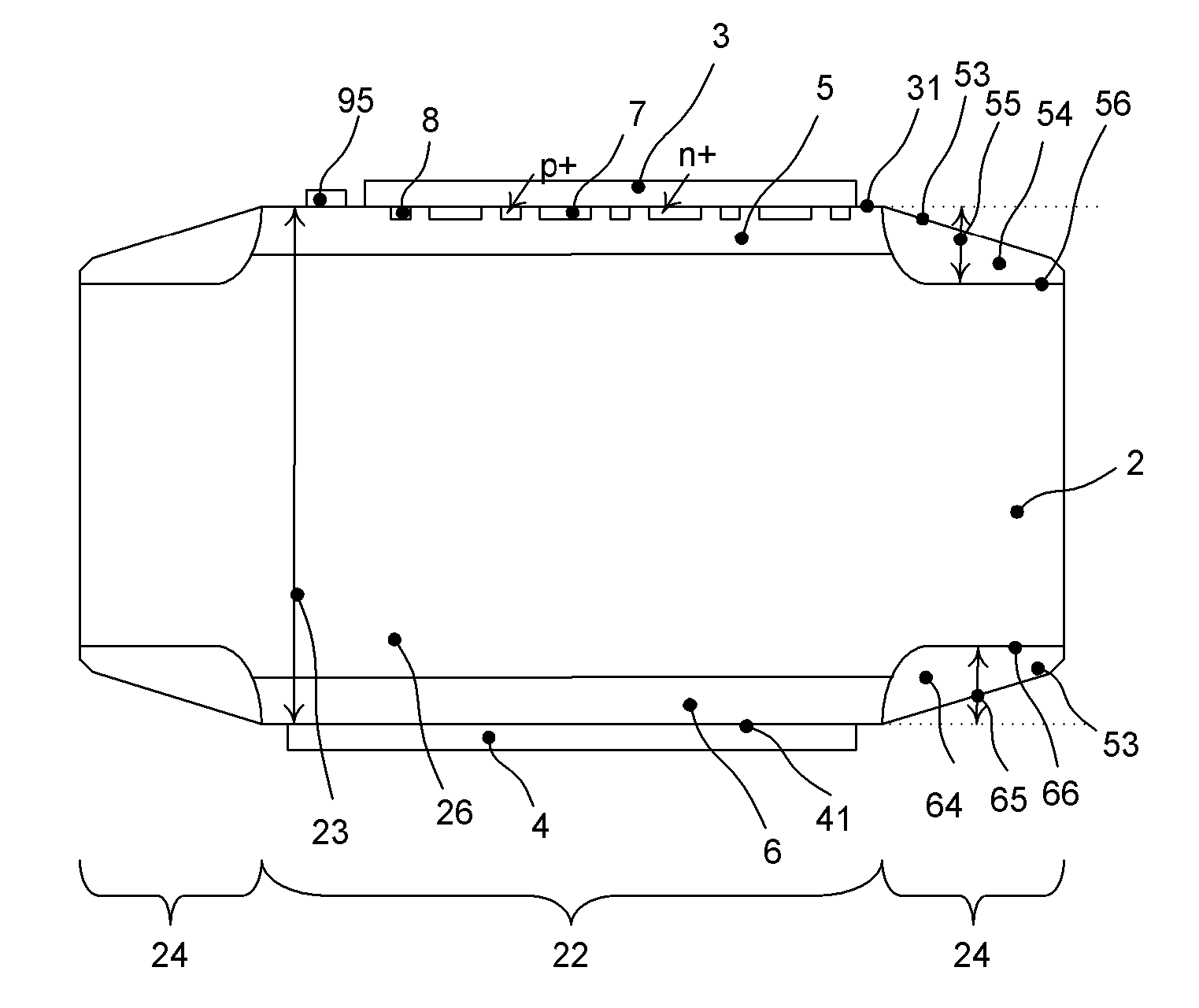

ActiveCN103222056AReduce on-state voltage dropLower thermal budgetThyristorSemiconductor/solid-state device manufacturingPower semiconductor deviceSemiconductor

A bipolar non-punch-through power semiconductor device is provided. It comprises a semiconductor wafer (2) and a first electrical contact on a first main side and a second electrical contact on a second main side. The wafer (2) comprises an inner region (22) with a wafer thickness (23) and a termination region (24), which surrounds the inner region (22) and in which the wafer thickness (23) is reduced at least on the first main side with a negative bevel. The semiconductor wafer (2) comprises at least a two-layer structure with layers of different conductivity types: - a drift layer (26) of a first conductivity type, a first layer of a second conductivity type directly connected to the drift layer (26) on the first main side and contacting the first electrical contact, which first layer extends to a first layer depth, and - a second layer of the second conductivity type, which is arranged in the termination region (24) on the first main side up to a second layer depth. The second layer depth is larger than the first layer depth, which first layer depth is at most 45 [mu]m. The doping concentration of the second layer is lower than the doping concentration of the first layer.

Owner:HITACHI ENERGY SWITZERLAND AG

Breeding method for honey plum

InactiveCN102870641AIncrease productionSweetness enoughCultivating equipmentsFruit maturationRipeness

The invention relates to a breeding method for a honey plum. The shapes of honey plum trees are pruned, a three-bough open-center shape or a two-bough open-center shape is adopted as the main tree shape, flower thinning is carried out at the big bud stage, fruit thinning is carried out two weeks after blossom drop to the core-hardening stage, and fruits are bagged and debagged; after setting, the fruits are bagged in time, and the sequence of bagging is that the early-ripening fruits are bagged before the late-ripening fruits are bagged; the bags are normally removed 25 to 30 days before harvesting, the suitable harvesting time is determined according to the ripeness degree of the fruits and the market demand, and after being harvested, the fruits are preserved, packaged and put into the market. The plum bred by the method is big, sweet, fragrant and delicious, has thick pulp, and has the advantages of high yield, enough sweetness, good fruit shape and high sale price.

Owner:张发开

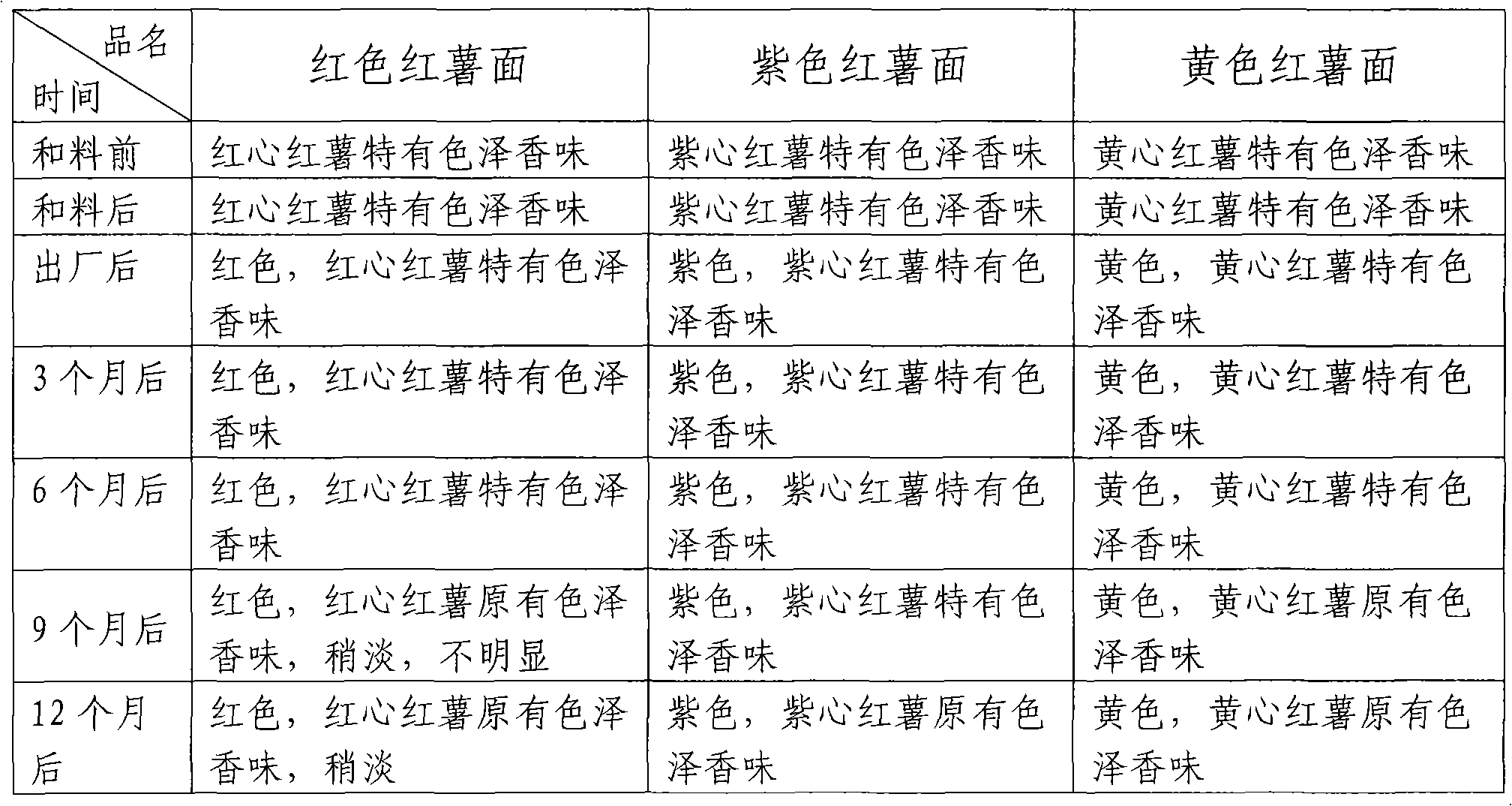

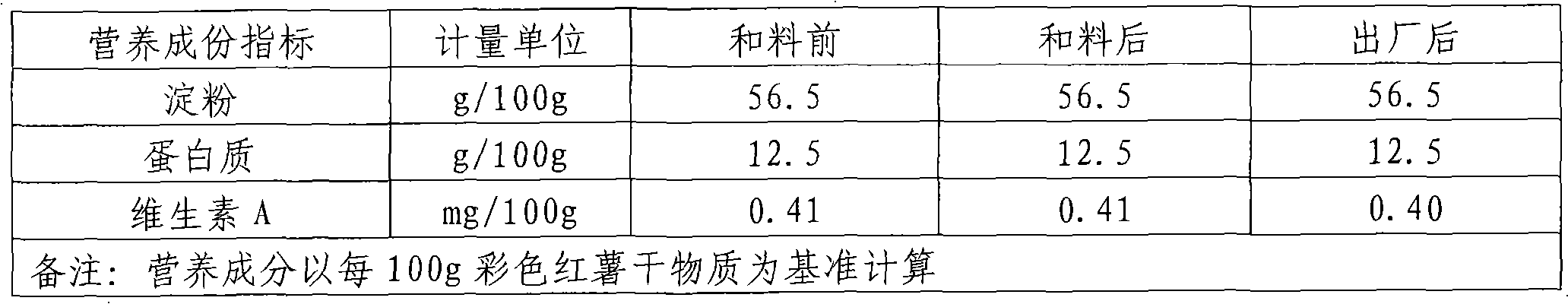

Production process of colored sweet potato noodles

InactiveCN101849634ARetain nutritionImprove qualityDough treatmentFood preparationSalt waterHigh intensity

The invention relates to a production process of colored sweet potato noodles, which belongs to the technical field of noodle processing. The production process comprises the following steps: 1 selecting sweet potatoes with a single type of color in colored sweet potatoes, and adding edible salt water into the sweet potatoes to be ground into cooked and mashed sweet potatoes after being steamed and cooled; 2 mixing the cooked and mashed sweet potatoes, wheat gluten and high-strength wheat flour into a dough kneading machine to be sufficiently and uniformly stirred; 3 curing the materials for 10 to 30 minutes; 4 carrying out composite rolling and noodle cutting; 5 baking the noodles for 6 hours to obtain fine dried noodles; and 6 carrying out cutting and package to obtain finished products of colored sweet potato noodles. When the method of the invention is used for production, most nutrient substances in the sweet potatoes and special fragrance and color of the colored sweet potatoes can be maintained, and the invention has the characteristics of high intensity of the noodles, difficult fracture, boiling resistance, clear soup, high flour intensity and exquisite mouth feeling.

Owner:CHENZHOU YUXIANG NOODLE

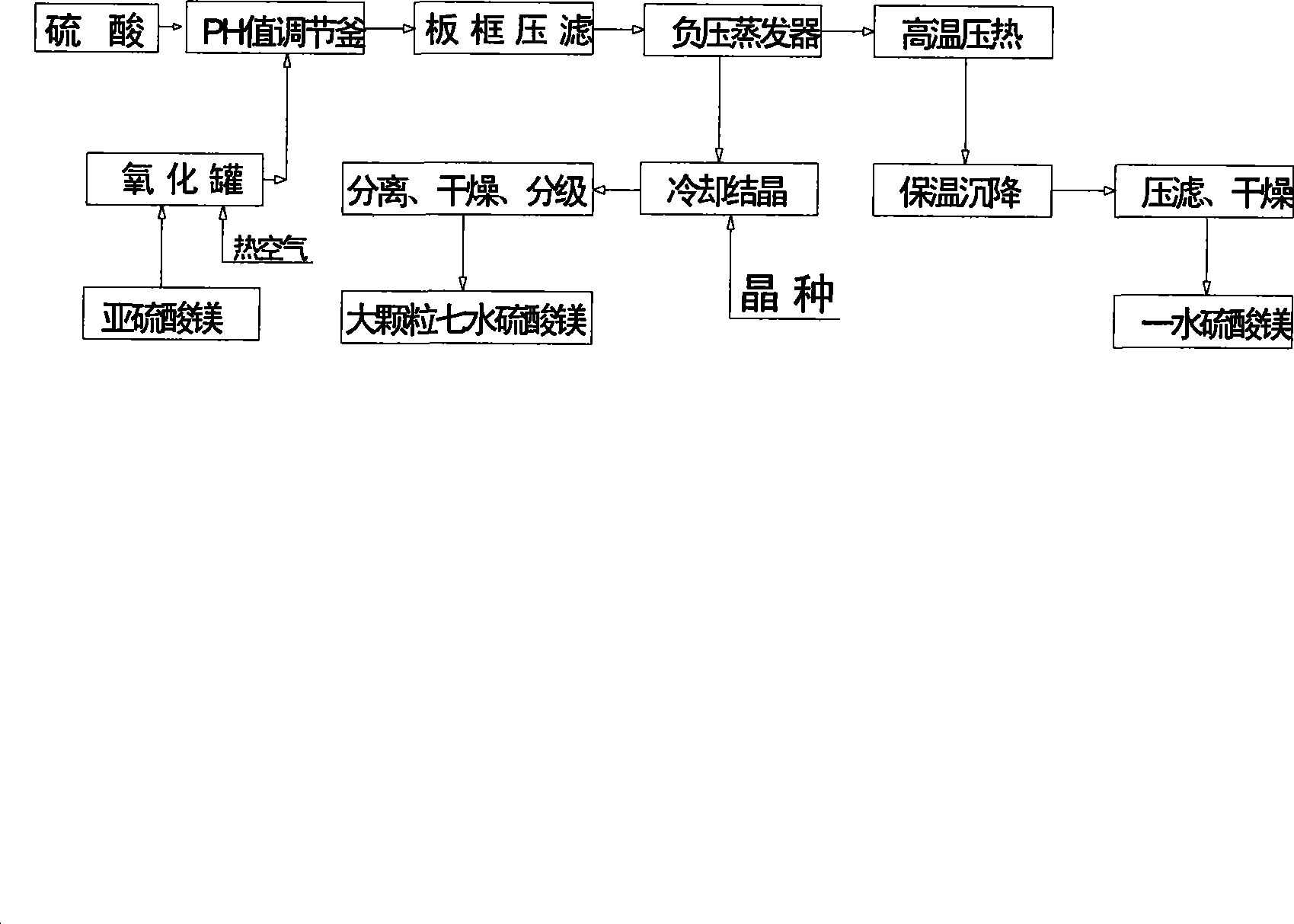

Method for producing large particles of heptahydrate magnesium sulfate and monohydrate magnesium sulfate from magnesium sulfate solution

InactiveCN101214980AImprove product qualityQuality improvementMagnesium sulfatesSocial benefitsPhysical chemistry

The invention discloses a method for producing magnesium sulfate, which is a method for producing macroaggregated magnesium sulfate heptahydrate and magnesium sulfate mono-hydrate from magnesium sulfate solution, in particular to a method for producing macroaggregated magnesium sulfate heptahydrate and magnesium sulfate mono-hydrate by employing solid containing magnesium sulfite (the chemical name is MgSO3) to obtain solution containing magnesium sulfate after oxidation treatment. The method of the invention comprises high temperature oxidizing magnesium sulfite, adding acid to adjust pH value, filtering solution, negative pressure evaporating and high temperature heating or seeding cooling for producing magnesium sulfate heptahydrate. The invention is simple in method and easy in operation. The product of magnesium sulfate produced by the method is high in product quality, and the selling price is increased. The method sufficiently employs byproduct of desulphurization process with magnesium as raw material, thereby decreasing the investment of environmental equipment in the desulphurization process with magnesium and operation cost, also decreasing the production cost of magnesium sulfate industry and achieving the win-win purpose of social benefit and economic benefit. The problems that in the existing method the product quality is low and macroaggregated magnesium sulfate heptahydrate can not be produced are resolved.

Owner:张荣阳 +2

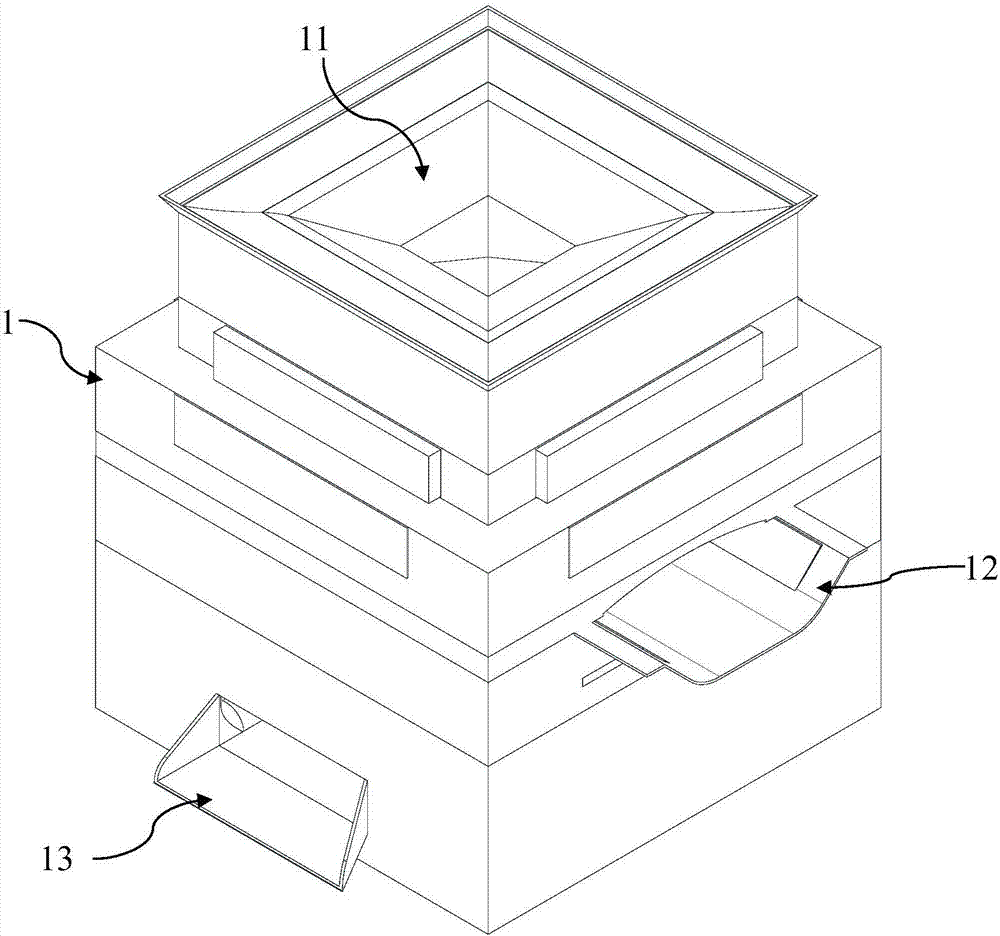

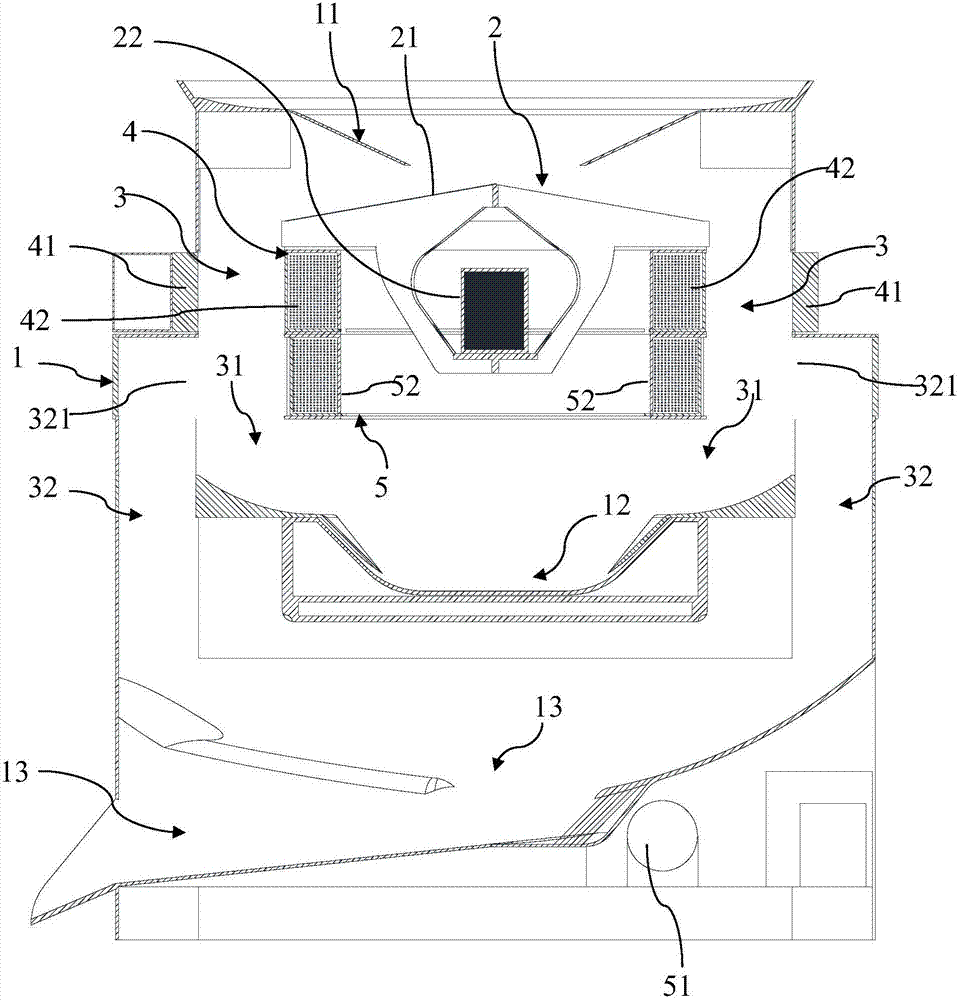

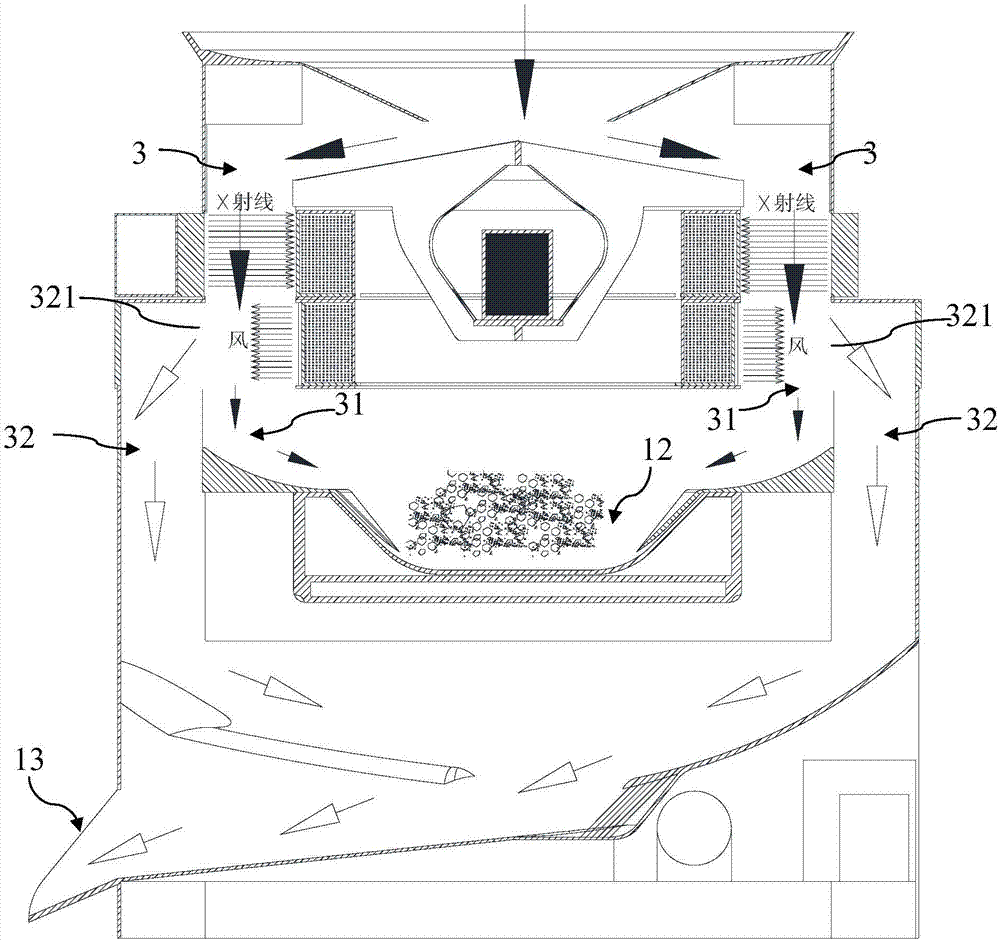

Coal preparation equipment and method

The invention discloses a coal preparation equipment, which comprises a casing, a vibrating bed, a main drop channel, a coal block discharge hopper, a coal block drop channel, a gangue discharge hopper, a connection to the drop channel, a gangue identification system and a gangue sorting system, and a gangue identification system. The system includes an X-ray emitting device, an X-ray receiving device and a central controller; the gangue sorting system includes an air compressor, an air nozzle and a solenoid valve for controlling the opening and closing of the air nozzle; the air compressor is set in the casing, and the air nozzle is located The X-ray receiving device is connected to the coal drop channel, the air nozzle and the air compressor are connected through an air supply pipeline, and the solenoid valve is respectively connected to the central controller and the air nozzle for signals. The invention discloses a coal preparation method. The coal preparation equipment and coal preparation method provided by the invention realize the automation of gangue selection or coal preparation process, replace manual gangue selection, save human resources, reduce labor costs, and improve the quality and efficiency of gangue selection.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Forming method and forming system for straw pellets

ActiveCN106635233AImprove briquetting qualityEfficient removalBiofuelsSolid fuelsProcess engineeringBriquette

The invention relates to the technical field of straw processing, in particular to a forming method and a forming system for straw pellets. The forming system for the straw pellets comprises a straw clearing device, a straw crushing device, a straw cleaning pool, a straw filament grinding device, a straw briquetting machine and a straw drying device which are sequentially connected according to the process sequence; the straw clearing device comprises a straw inputting device, a first straw clearing frame, a second straw clearing frame, a third straw clearing frame, a straw outputting device and a moving mechanism connected with the bottom of the first straw clearing frame; the straw crushing device comprises a second straw inputting device, a second straw outputting device as well as a first cutting box, a second cutting box and a third cutting box which are sequentially arranged from top to bottom. The forming system for the straw pellets, disclosed by the invention, comprises the straw clearing device, the straw crushing device, the straw filament grinding device, the straw briquetting machine and the straw drying device, and can be used for automatically and efficiently performing briquetting processing on the straws; high-quality straw briquettes can be obtained.

Owner:湖州吉能生物质燃料有限公司

High temperature mushroom culture method

InactiveCN101926265APromote growthFill a gap in the marketHorticultureTime to marketEconomic benefits

The invention relates to a high temperature mushroom culture method, which mainly comprises the following steps of: building a mushroom shed; erecting a shed frame; selecting seeds; propagating original seeds; seeding; covering soil; managing in the fruiting period; controlling pests; managing after mushroom picking, and the like. The method is favorable for the growth of high temperature mushroom, can improve the mushroom yield and survival rate, makes the time-to-market of the high temperature mushroom about 40-45 days earlier than that of conventionally cultured mushroom, and has obvious economic benefit.

Owner:陈爱山

Anti-season penaeus vanmamei factory culture method

InactiveCN104621024ALow climate impactAvoid cross infectionClimate change adaptationPisciculture and aquariaPathogenic microorganismLand resources

The invention relates to an anti-season penaeus vanmamei factory culture method. The anti-season penaeus vanmamei factory culture method comprises the following steps: (1) selecting the site of a culture field, and designing a culture workshop and a penaeus vanmamei pond; (2) preparing before releasing young penaeus vanmamei; (3) temporarily culturing by putting the young penaeus vanmamei into the penaeus vanmamei pond; (4) managing in a growing period; and (5) harvesting. Anti-season penaeus vanmamei culture can be carried out in a northern area through the anti-season penaeus vanmamei factory culture method disclosed by the invention; compared with traditional culture, the anti-season penaeus vanmamei factory culture method is not limited by seasons and temperature and is capable of controlling the environmental conditions, such as temperature, illumination and dissolved oxygen, in a most proper penaeus vanmamei growing environment, preventing cross infection of pathogenic microorganisms and reducing disease occurrence; by means of high-density intensive culture, the yield is obviously increased; concentrated appearance of penaeus vanmamei on the market is avoided; the market supply is adjusted; the rural income is increased easily; simultaneously, culture is carried out by effectively utilizing the idle time in winter; and therefore, the utilization rate of land resources is greatly increased.

Owner:TIANJIN BOHAI SEA FISHERIES RES INST

Grass cloth processing process

This invention discloses one grass cloth processing method. It causes H2O2 to carry on chemistry blanch front processing and acidic cellulase carries on the enzyme preparation post-processing blanch reorganization grass cloth gray clothes. Chemistry blanch front processes carries on two times, H2O2 joins the quantity for to process according the rate of the cotton material weight 20 - 30%, but also joins the processing cotton material weight's 3 ~ 5% stabilizer Na2Sio3.9H2O2, bath to compare 1: 25 ~ 30, temperature 95 ~ 100 DEG C, total blanch time is 35 ~ 45 minutes; When enzyme preparation post-processing the acidic cellulase joins the quantity for process according the rate cotton material weight 1.0 ~ 2%, the bath compares 1: 15 ~ 20, temperature 48 ~ 52 DEG C, pH value 4.5 ~ 4.8, process time is 10 ~ 20 minutes; Afterwards carries on inactivate, inactivate when adjusts the pH value to 9.0, temperature 80 DEG C, time 15 ~ 20 minutes. Uses this invention method can be able basically to eliminate grass cloth embryo cloth's sol, the red root, the spot fault, the solution grass cloth rigidity is hard, has the itch feeling question; Process time short, even, has processed the grass cloth is easy to colour; no pollution, remains without the chemical agent.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI +1

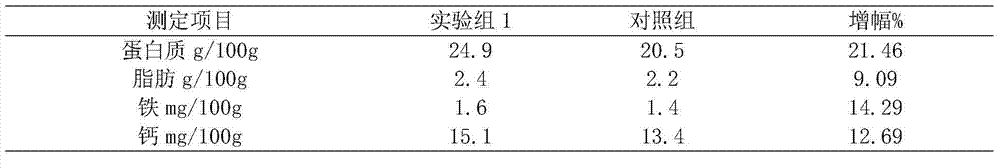

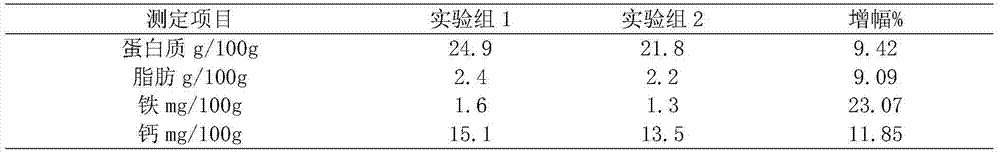

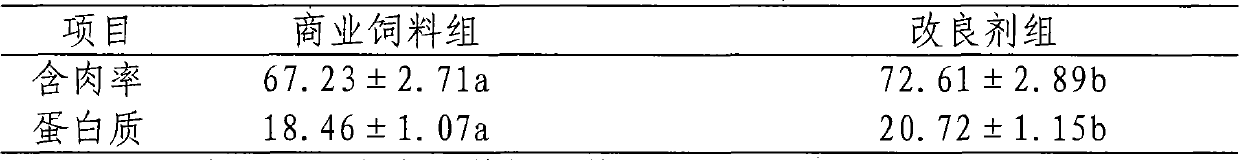

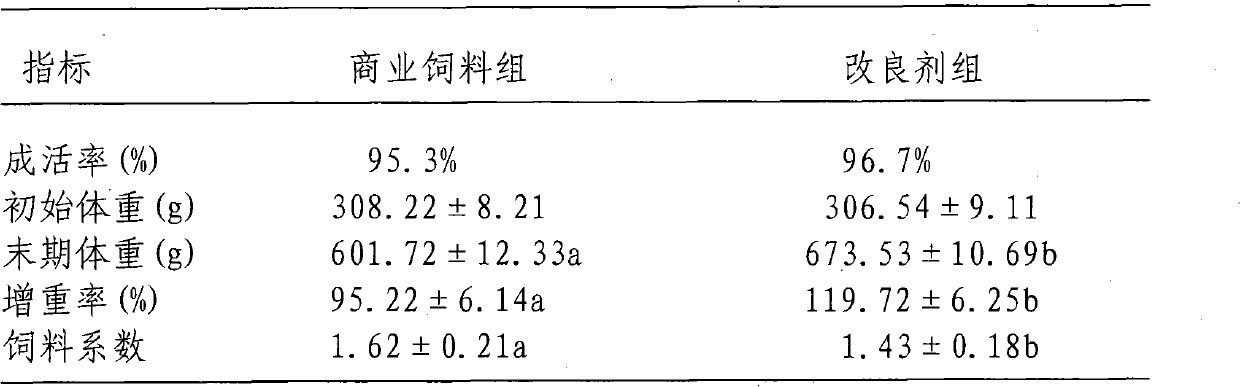

Quality improver for low-salt or freshwater aquiculture of Litopenaeus vannamei Boone and preparation method thereof

The invention relates to feed additives in aquiculture, in particular to a quality improver for low-salt or freshwater aquiculture of Litopenaeus vannamei Boone and a preparation method thereof. one kilogram of the improver comprises the following components: 30-50g of freeze-dried green algae powder, 20-50g of krill powder, 200-300g of eucommia ulmoides powder, 10-20g of inosinic acid, 10-20g ofsodium glutamate and the balance of zeolite powder. By adoption of the quality improver, the content of bromophenol which is a seafood flavor substance in muscle of low-salt or freshwater cultivated Litopenaeus vannamei Boone can be effectively increased, the content of inosinic acid which is a main seafood flavor substance in muscle of Litopenaeus vannamei Boone can be effectively enhanced, the body color of Litopenaeus vannamei Boone can be effectively improved, the contents of protein and flavoring amino acid in muscle of Litopenaeus vannamei Boone can be effectively increased, the attraction effect of feed of Litopenaeus vannamei Boone can be promoted and the growth property of Litopenaeus vannamei Boone can be improved to a certain extent, and the taste and flavor of Litopenaeus vannamei Boone can be improved finally.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Compound probiotic for raising chicken

InactiveCN103766651AShortened growth periodRaise the selling priceAnimal feeding stuffMicroorganismMicrobiological Techniques

The invention belongs to the technical field of microorganisms and more particularly relates to a compound probiotic for raising poultries, particularly chicken. The compound probiotic is applied in manners of feed fermentation, feed stirring and feeding, feed drinking, atomization deodorization, fecal treatment and the like.

Owner:陕西万源生物农业科技有限公司

Selenium-rich black fungus culture material and preparation method thereof

InactiveCN104402639AReasonable ratioMeet the needs of cultivationSuperphosphatesCalcareous fertilisersPhosphoric acidGypsum

The invention relates to a selenium-rich black fungus culture material and a preparation method thereof. The culture material is prepared from the following raw materials in percentage by weight: 65-73% of corn cob, 18-24% of selenium-rich lucerne meal, 5-11% of wheat straw, 0.8-1.2% of calcium superphosphate, 0.2-0.8% of gypsum and 0.3-0.9% of lime. The selenium-rich black fungus culture material has the advantages of reasonable raw material proportioning, balanced nutrients and high utilization ratio of selenium; and the C / N ratio satisfies the culture demands for black fungus. The selenium content of the black fungus produced by the culture material according to the conventional bag-type culture technique reaches 0.15-3.0 mg / kg which is 5-100 times of the common black fungus; the black fungus has rich nutrients, and is an excellent selenium-supplementing green health-care product; the sales price is 10% higher than that of the common black fungus; and the culture material has wide development prospects.

Owner:HENAN UNIV OF ANIMAL HUSBANDRY & ECONOMY

Plum tree planting method

InactiveCN106386367AGuaranteed pollination rateGuaranteed fruit set rateCultivating equipmentsPlant protectionPesticideFruit tree

The invention discloses a plum tree planting method, and belongs to the technical field of fruit tree planting. The method comprises the following steps: garden construction; seed selection: a mainly cultivated variety accounts for 80 percent, and pollination trees account for 10 to 20 percent; planting: a, transplanting annual grafted nursery-grown plants; water, fertilizer and soil management: applying a fertilizer in March, May, August and October, irrigating the nursery-grown plants after fertilization, and covering plum trees with grass after the irrigation; trimming; pollination management: after early-spring irrigation, spraying a white pigment preparation on tree trunks and boughs before sprouting, spraying a mixed solution of 0.1 percent borax and 0.1 percent ammonium molybdate once on leaf surfaces 15 to 20 days before a full-bloom stage, and manually spraying sugar water of which the concentration is 5 to 10 percent at the full-bloom stage; pest management: preventing and controlling pests by a grapholitafunebrana sex pheromone and a pesticide, and trapping and killing the pests by a black light lamp and sweet lure. Through combination of grafted plant transplanting, water and fertilizer management, pollination management and pest management, the survival rate and fruit set percentage of the plum trees are increased effectively, the survival rate of nursery-grown plants is 98 percent, the fruit setting percentage is 50 percent, and the unit yield per mu is 500 to 800 kg.

Owner:GUIZHOU SHANLIHONG FRUIT & VEGETABLE DEV

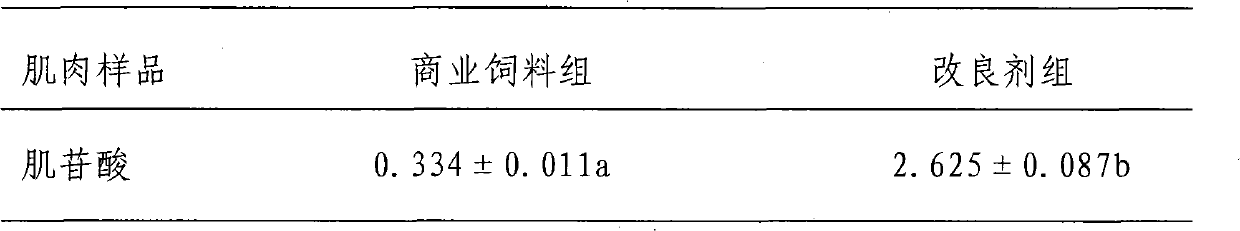

Meat quality and flavor improver for tilapia mossambica and preparation method thereof

The invention relates to a feed additive in aquaculture industry, in particular to a meat quality and flavor improver for tilapia mossambica and a preparation method thereof. Each kilogram of improver comprises 50-100 g of ulva powder, 20-30 g of carnitine, 30-50 g of dimethylpropiothetin, 15-25 g of cysteamine HCl, 200-300 g of sodium chloride and the balance of zeolite powder. The preparation method comprises the following steps of: firstly, pulverizing the ulva powder, the carnitine, the dimethylpropiothetin, the cysteamine HCl and the sodium chloride, and sieving with a 100-mesh sieve; secondly, mixing the pulverized solid materials according to the proportions; and finally, mixing and stirring the mixed solid materials and the zeolite powder so that the coefficient of variation (CV) of uniformity of the mixture is less than 5%. The improver can efficiently increase the content of inosinic acid as a delicate flavor substance in tilapia mossambica meat, can efficiently increase the content of proteins, the content of essential amino acids and the content of taste amino acids in the tilapia mossambica meat, can improve the taste and the flavor of the tilapia mossambica meat, and can eliminate fishy smell.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com