Lightweight low-temperature fancy golden silk white glazed porcelain and manufacturing process

A production process and light-weight porcelain technology, applied in the field of ceramic glazes, can solve the problems of intense titanium oxide glaze effect and decreased body strength, and achieve the effects of increasing sales prices, improving product grades, and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0035] Low-temperature light porcelain kiln changed into gold wire white glaze porcelain, the ceramic body is successively provided with a base glaze and a top glaze from the inside to the outside;

[0036] The composition of the base glaze is as follows in parts by weight: 28 parts of nepheline, 21 parts of burnt talc, 18 parts of feldspar, 13 parts of iron, 8 parts of ashes, 3 parts of kaolin, 2 parts of barium, 4 parts of manganese carbonate, and 3 parts of cyanite.

[0037] The composition of the glaze is as follows in parts by weight: 36 parts of potash feldspar, 26 parts of albite, 12 parts of calcite, 12 parts of transparent frit, 6 parts of talc, 3 parts of zinc, 2 parts of manganese, and 3 parts of titanium.

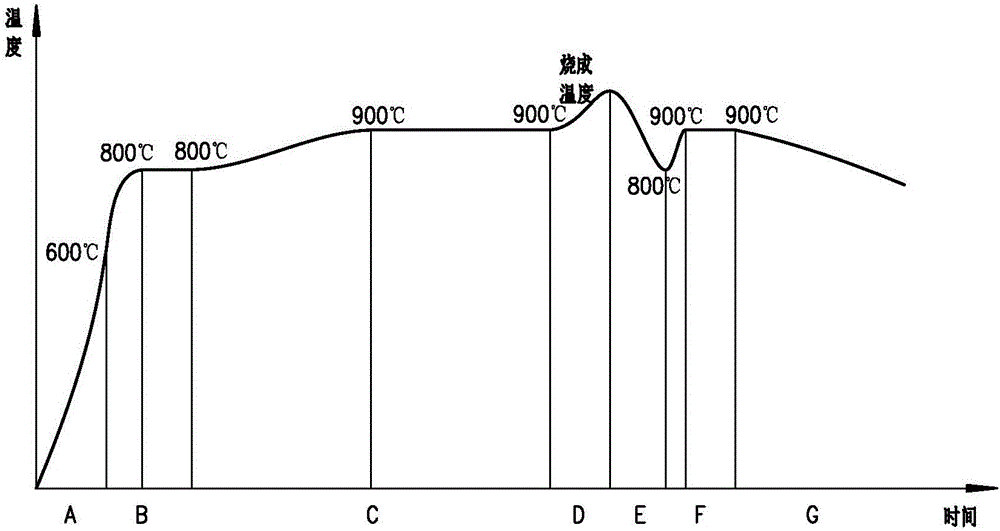

[0038] The manufacturing process of the above-mentioned light-weight porcelain low-temperature kiln changed gold wire white glaze porcelain includes the following steps:

[0039] Step 1, according to the black gold sand glaze base glaze raw material formula, weigh the pr...

specific Embodiment 2

[0046] Low-temperature light porcelain kiln changed into white glaze porcelain with gold wire, the ceramic body is successively provided with a base glaze and a top glaze from the inside to the outside;

[0047] The composition of the base glaze is as follows in parts by weight: 23 parts of nepheline, 28 parts of burnt talc, 16 parts of feldspar, 15 parts of iron, 6 parts of ashes, 5 parts of kaolin, 3 parts of barium, 3 parts of manganese carbonate, 1 part of sylvite ;

[0048] The composition of the glaze is as follows in parts by weight: 40 parts of potash feldspar, 28 parts of albite, 11 parts of calcite, 10 parts of transparent frit, 5 parts of talc, 1 part of zinc, 2 parts of manganese, and 3 parts of titanium.

[0049] The process of making light porcelain with white glaze from a low-temperature kiln with gold wire includes the following steps:

[0050] Step 1, according to the black gold sand glaze base glaze raw material formula, weigh the proportions, mix the raw materials e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com