Patents

Literature

437 results about "Sylvite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sylvite, or sylvine, is potassium chloride (KCl) in natural mineral form. It forms crystals in the isometric system very similar to normal rock salt, halite (NaCl). The two are, in fact, isomorphous. Sylvite is colorless to white with shades of yellow and red due to inclusions. It has a Mohs hardness of 2.5 and a specific gravity of 1.99. It has a refractive index of 1.4903. Sylvite has a salty taste with a distinct bitterness.

Method for tobacco slice cigarette paper coloring by adopting Millard reaction

Disclosed is a method for tobacco slice cigarette paper coloring with Millard reaction. The method comprises the following steps: (1) tobacco patches or stems are put into hot water with temperatures from 40 degrees to 70 degrees and extracted for 20 minutes-40 minutes, and extract liquor is obtained. (2) The extracted tobacco patches or the stems are put into the hot water with 1 to 3 times total weight of the tobacco patches or the stems after being shoved initially by a shoving machine. The temperature of the hot water is controlled at 45 DEG C + / - 5 DEG C. The tobacco patches or the stems are extracted for 20 minutes. The tobacco patches or the stems are pulped from 25 degrees SR to 40 degrees SR by the pulping machine after the tobacco patches or the stems are shoved, thus tobacco syrup is obtained. (3) Additional fibers are pulped by the pulping machine to 40 degrees SR to 75 degrees SR. Cigarette paper is mixtured by mixturing the additional fibers and the tobacco syrup. (4) Extracted liquors are concentrated after the extracted liquors are combined. Sylvite, compound Millard reaction liquid and spices are added to the concentrated extracted liquors and made into coating liquid. The coating liquid is coated on the cigarette paper with the way of coating. (5) The coated cigarette paper is put under temperature condition of from 70 DEG C to 130 DEG C to conduct the Millard reaction.

Owner:HUBEI XINYE TOBACCO SLICE DEV +1

Method for preparing potassium dehydroandrographolide succinate or potassium sodium dehydroandroan drographolide succinate

The invention discloses a method for preparing potassium dehydroandrographolide succinate or potassium sodium dehydroandroan drographolide succinate, which comprises that firstly, andrographolide serves as a raw material, the andrographolide reacts with succinic anhydride to produce dehydroandroan drographolide disuccinate in a specific non-pyridine solvent under the heating reflux in the presence of a catalyst, and the usage amount ratio (W / W) of the andrographolide and the catalyst is (1:10)-(1:1); and secondly, the purified dehydroandroan drographolide disuccinate reacts with potassium hydroxide, sodium hydroxide, alkalinity sylvite or alkalinity sodium salt to produce the potassium dehydroandrographolide succinate or the potassium sodium dehydroandroan drographolide succinate in methanol, ethanol or hydrosolvent. The method is practical, convenient to operate, low in cost and nontoxic. The potassium dehydroandrographolide succinate or the potassium sodium dehydroandroan drographolide succinate is prepared easily under the normal atmosphere through usage of the solvent, the product quality is guaranteed, and the method is suitable for industrial production particularly.

Owner:HUBEI HOPE PHARMA

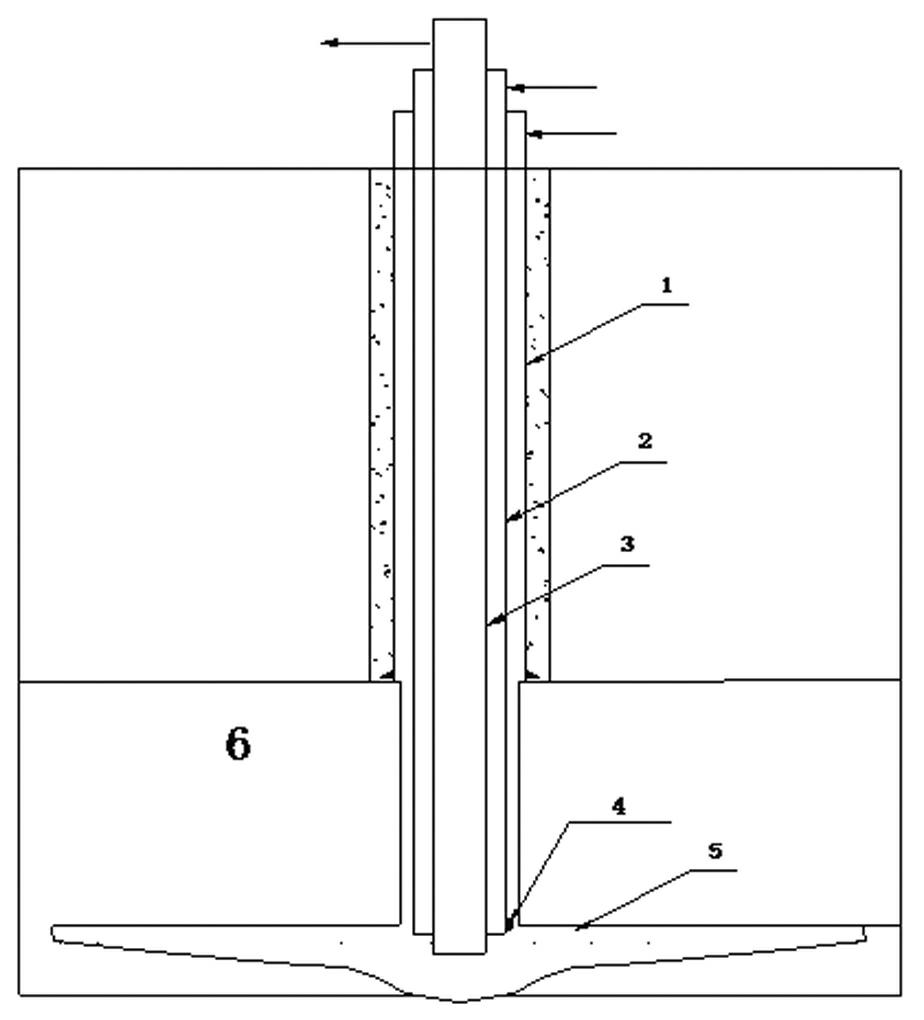

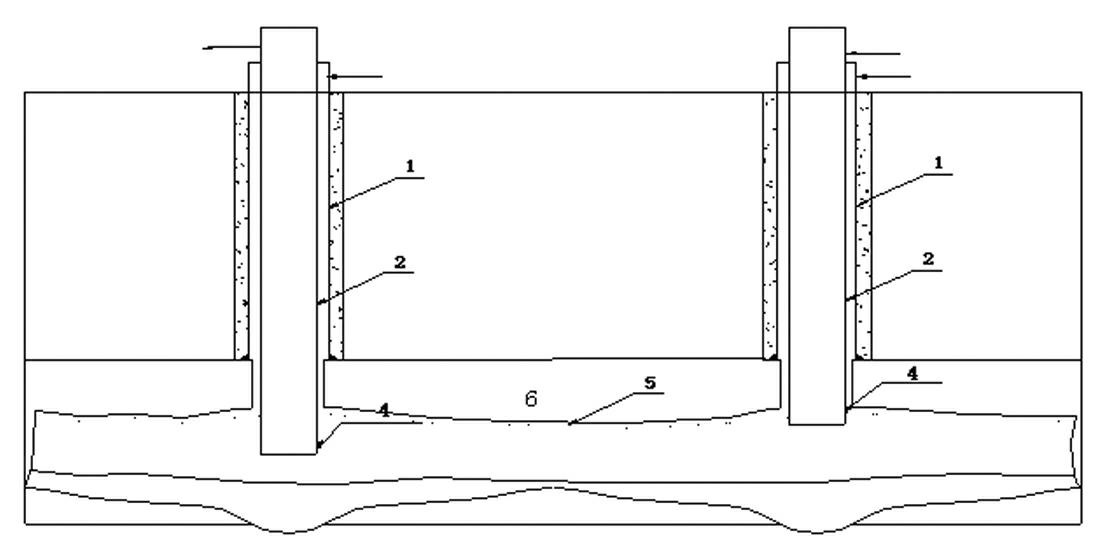

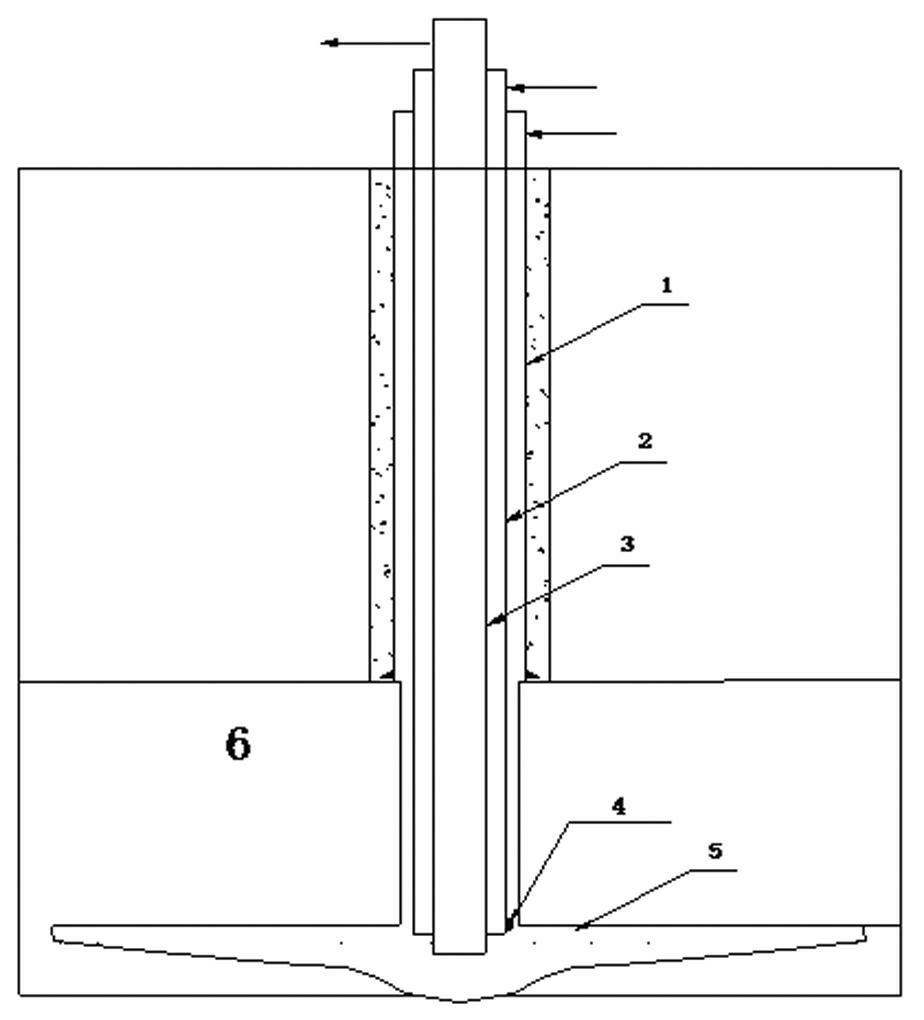

Method for mining sylvite in underground carnallite ore

The invention discloses a method for mining sylvite in underground carnallite ore, which comprises the following steps of: (1) building wells, namely, taking three-pipe structures as well bodies, wherein the three pipes include a technical sleeve pipe, a production sleeve pipe and a central pipe; (2) building a groove on a single well, namely, filling normal-temperature water in annular space of the central pipe and the production sleeve pipe, and discharging dissolved brine from the central pipe; (3) mining by non selective dissolution at normal temperature; (4) selectively mining by hot melting at high temperature, namely, communicating two wells or well groups, pulling out the central pipe, filling a sodium chloride and magnesium chloride containing filler of 75 to 90 degrees centigrade into a well, and discharging the brine for processing from the other well in the well group; and (5) refilling a mother solution into the wells. The method for mining the sylvite in the underground carnallite ore provided by the invention realizes selective mining of potassium chloride; and, the method saves energy resources and reduces production cost; moreover, the refilling process of the mother solution realizes zero discharge of the mother solution and facilitates environment protection.

Owner:中水电海外投资有限责任公司 +1

Drilling fluid and preparation method thereof

ActiveCN103773332ANo biological toxicityInhibition of hydrationDrilling compositionEpoxyPolymer science

The invention discloses a drilling fluid and a preparation method thereof. The drilling fluid comprises, by weight, 2.0 to 6.0 parts of bentonite, 0.1 to 1 part of sodium carboxymethylcellulose, 0.2 to 0.8 part of a zwitter-ion sulphonate copolymer, 0.03 to 0.4 part of sodium hydroxide, 0.1 to 0.8 of a polyamine polymer, and 100 parts of water; the polyamine polymer is a polymer of terminal diamine, a cyclic ether, and an epoxy alkyl halide. The preparation method comprises following steps: the polyamine polymer is prepared firstly, wherein the polyamine polymer is prepared via copolymerization of terminal diamine, the cyclic ether, and the epoxy alkyl halide; and then an aqueous solution containing bentonite, sodium carboxymethylcellulose, the zwitter-ion sulphonate copolymer, sodium hydroxide, the polyamine polymer, and water is prepared according to the stoichiometric ratio so as to obtain the drilling fluid. The drilling fluid is excellent in system inhibition performance and collapse resistance, and contains no sylvite, so that subsequent processing on high salt content is unnecessary.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation and application of catalyst for selective hydrodesulfurization of gasoline

ActiveCN101905165AHigh desulfurization activityInhibit carbon depositionCatalyst activation/preparationRefining to eliminate hetero atomsEthylene diamineHydrodesulfurization

The invention relates to preparation and application of a catalyst for selective hydrodesulfurization of gasoline. The catalyst comprises the following components in percentage by weight: 6 to 20 percent of CoO+MoO, 0.1 to 5 percent of K2O, 0.1 to 5 percent of MgO, 0.1 to 5 percent of P2O5, and the balance of ZrO2-Al2O3 composite carrier, wherein the ZrO2 accounts for 0.1 to 20 percent of the weight of the composite carrier. The preparation of the catalyst comprises the following steps of: preparing the composite carrier by adopting a complex precipitation method; adding sylvite, sesbania powder and de-ionized water into the composite carrier, uniformly mixing and kneading, extruding and drying the mixture at the temperature of between 100 and 150 DEG C and roasting the mixture at the temperature of between 450 and 550 DEG C to prepare a catalyst carrier; adding ammonia, EDTA (Ethylene Diamine Tetraacetic Acid) complexing agent to prepare stable Co-Mo co-immersion liquid which contains phosphorus and magnesium; and preparing the catalyst by using an isometric spraying immersion method. The catalyst has high selectivity and stability, and can reduce saturation of olefin to the utmost extent, and has a good desulfurization effect.

Owner:PETROCHINA CO LTD

Preparation method of scouring agent for aluminum and aluminum alloy

The invention relates to a preparation method of a scouring agent for aluminum and an aluminum alloy, which comprises the following steps: firstly, selecting ingredients according to the following percentages by weight: 30-85% of NaCl, 5-40% of Na2SiF6, 5-40% of Na2SO4, 2-20% of CaF2 and 0.5-10% of C6Cl6; uniformly mixing and fully stirring the selected ingredients; placing the mixture into a crucible, carrying out overheat melting to eliminate crystal water, and preserving the temperature for 30-60 minutes; and finally, processing after cooling to obtain the scouring agent. The method has the advantages of simple process and low cost. The prepared scouring agent does not contain sylvite, so that sylvite can not be introduced into the scouring and purifying treatment procedures, and therefore, an aluminum electrolysis cell can not be seriously corroded as a result of the introduction of sylvite when aluminum ash is directly recycled in the cell.

Owner:包头市一禾稀土铝业科技材料有限公司

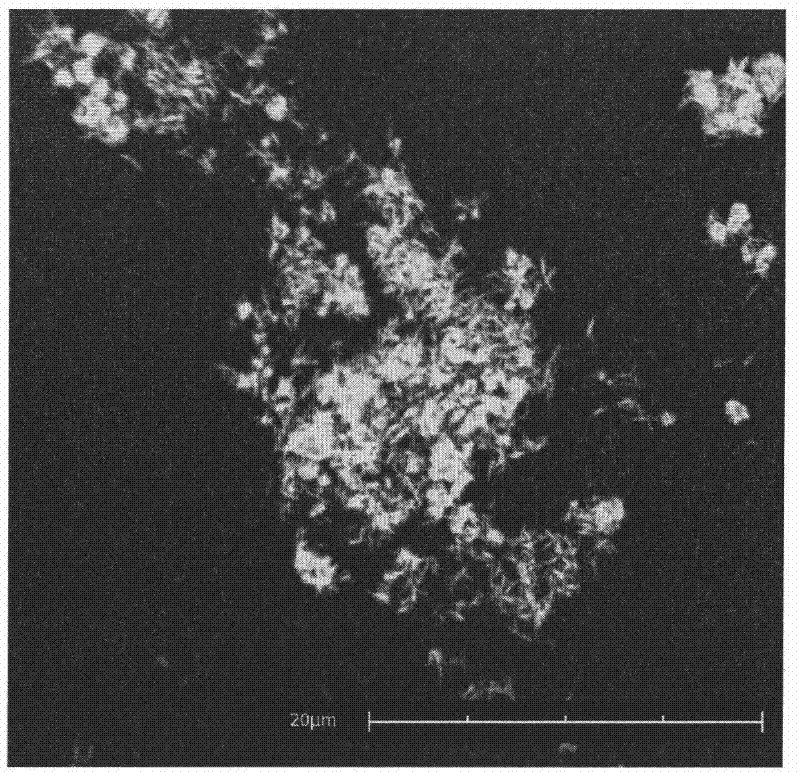

Method for preparing one-dimensional alloy nanometer wire

The invention relates to a method for preparing a one-dimensional alloy nanometer wire. A chloroformic solution of hexadecyl trimethyl ammonium bromide (abbreviated as CTAB), an aqueous solution of chloroplatinic acid or platinichloride and soluble salt, sylvite, sodium salt or an acidic solution of Ni, Pd, Au, Pb, Fe and Ru metallic ions are injected into a flask and are subjected to mechanical or magnetic stirring; after the solution is evenly mixed, the solution is added with a sodium borohydride solution for reduction, and the mixture is continuously stirred for certain time to obtain the corresponding alloy nanometer wire. The whole preparation process is convenient to operate, can be used for preparing various kinds of the alloy nanometer wires and can realize batch production. The method realizes large-scale preparation of the one-dimensional Pt-M(M=Ni, Pd, Au, Pb, Fe and Ru) alloy nanometer wire. The method has simple operation and low cost; the diameter of the obtained alloy nanometer particle is between 1.5 and 4 nm; and the alloy nanometer particle has large specific surface and thus has high application value in the field of catalysts and other fields.

Owner:XI AN JIAOTONG UNIV

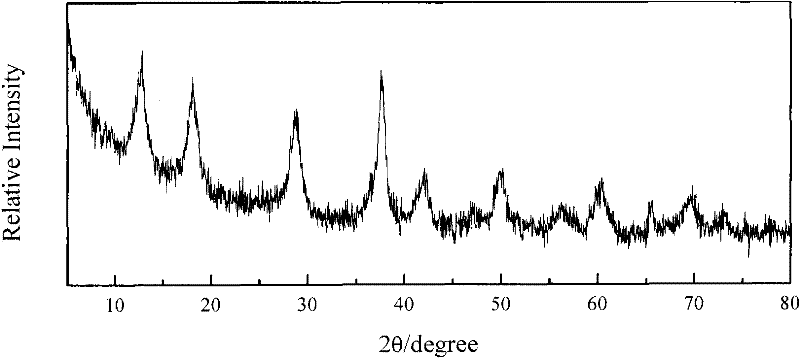

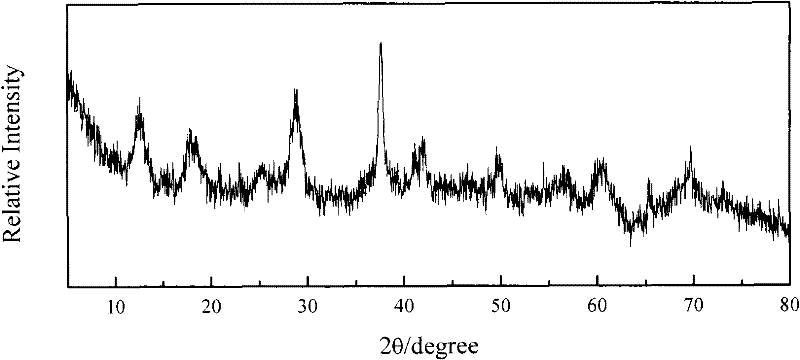

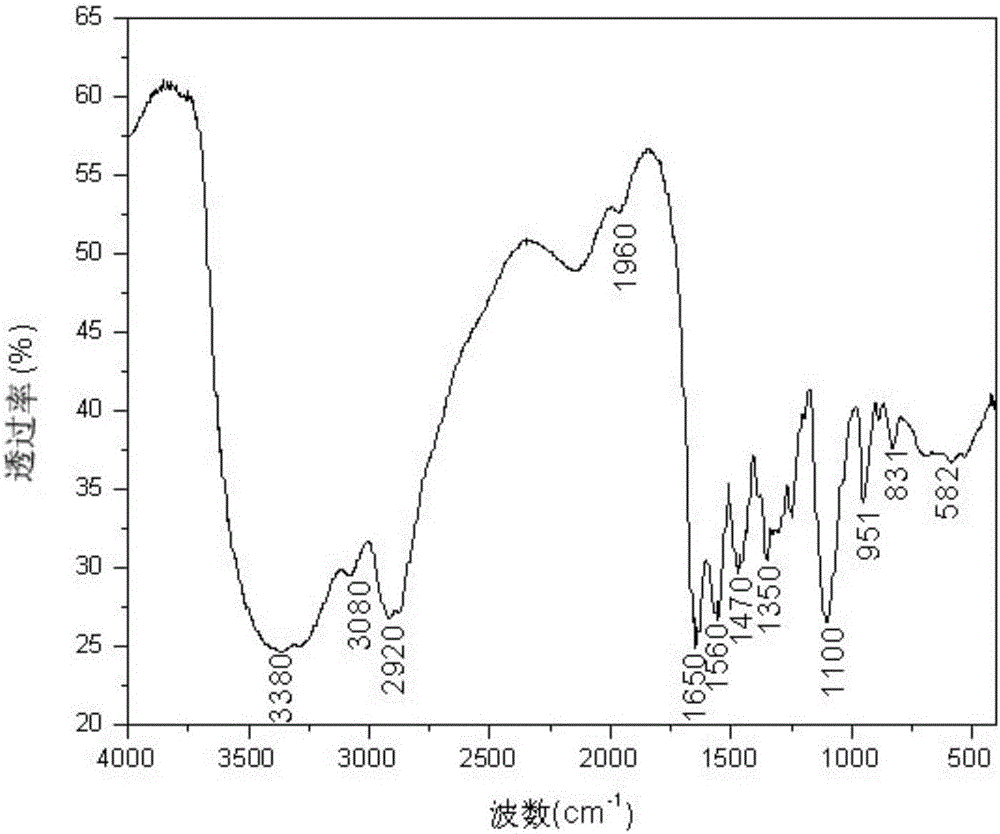

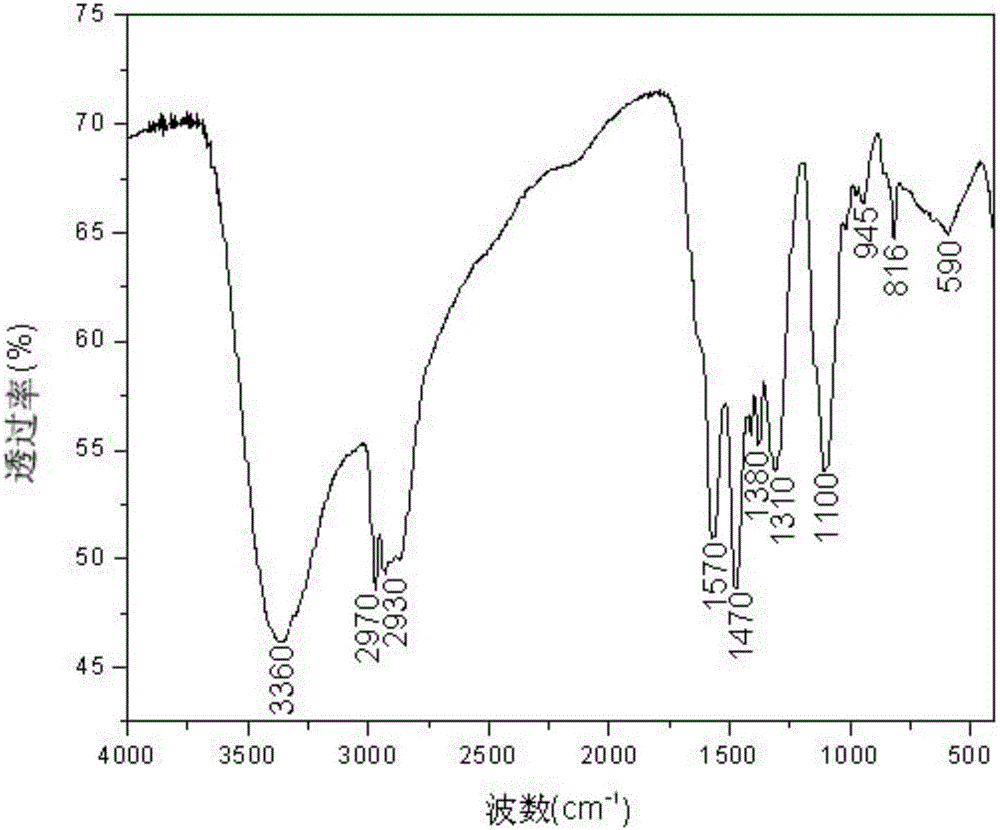

Method for synthesizing OMS-2 manganese oxide octahedral molecular sieve

InactiveCN102476831ANot volatileImprove securityMolecular-sieve and base-exchange compoundsManganese oxides/hydroxidesMolecular sievePERMANGANATE ION

The invention relates to a method for synthesizing an OMS-2 manganese oxide octahedral molecular sieve. By special solvent properties and reductibility of an ionic liquid, the OMS-2 manganese oxide octahedral molecular sieve with specific appearance and physicochemical performance can be synthesized. During the synthesis process, the ionic liquid is used as a reaction medium and a reducing agent to be uniformly mixed with permanganate and sylvite; crystallization is carried out at a certain temperature for a certain time; and washing and drying are then carried out to obtain the OMS-2 manganese oxide octahedral molecular sieve. The manganese oxide octahedral molecular sieve can be used as a catalyst for a plurality of selective oxidation reactions.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

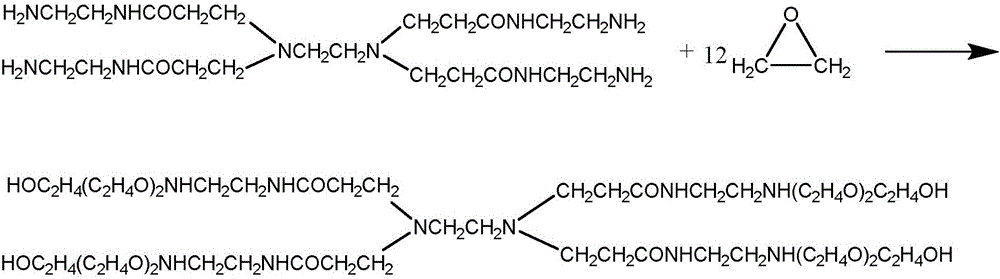

Dendritic polyether clay shale inhibitor and preparation method and application thereof

ActiveCN106520085AInhibits hydration swellingInhibition of dispersionDrilling compositionDendritic PolymersMaterials science

The invention discloses a dendritic polyether clay shale inhibitor and a preparation method and an application thereof. The inhibitor is the dendritic polyether clay shale inhibitor obtained by reacting an amino-terminated dendritic polymer and alkyleneoxide. The dendritic polyether clay shale inhibitor has excellent shale inhibition performance, can obviously inhibit hydration expansion and dispersion of the clay shale, has good synergistic inhibition with sylvite, and has advantages of outstanding performance, good environment acceptability, and long aging effect.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

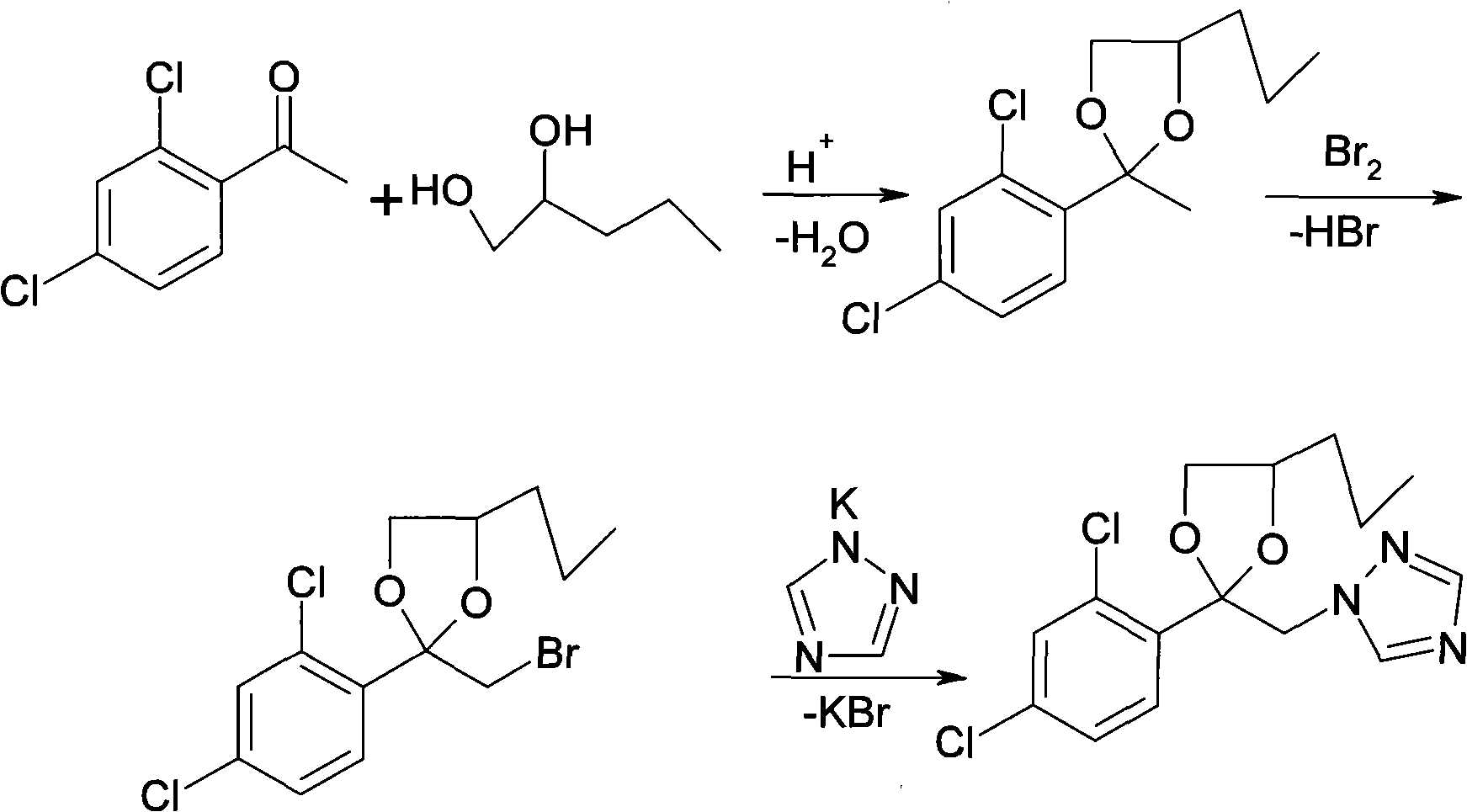

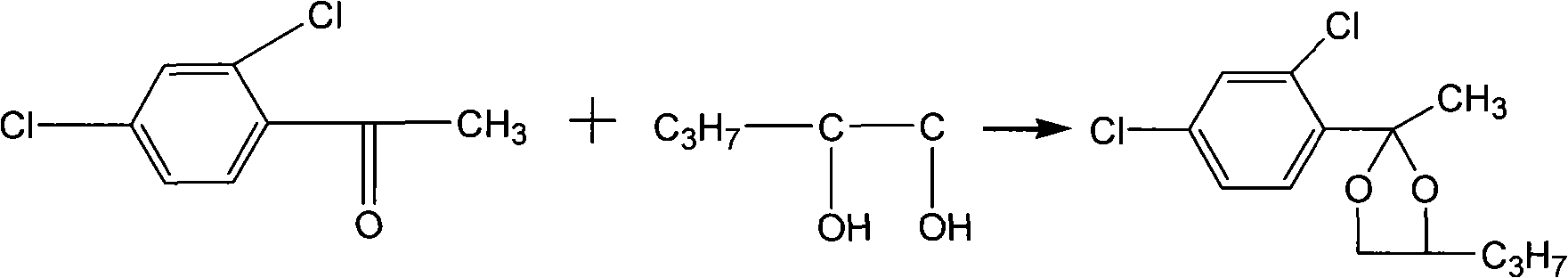

Preparation of bactericide propiconazole

InactiveCN101323612AAvoid recycling lossNo harmOrganic chemistryFungicidesPropiconazoleOrganic solvent

The invention discloses a preparation method of propiconazole that is a bactericide, which comprises four steps: first of all, under the action of an acid catalyst, atmospheric refluxing dehydration is carried out to 2, 4-dichloroacetophenone and 1, 2-pentanediol which are in an organic solvent so as to obtain ketal reaction solution which then reacts with bromine to generate bromide ketal which then reacts with 1, 2, 4- triazole sylvite in a polar solvent under the action of a phase transfer catalyst to obtain a propiconazole crude product; finally, under the action of an antioxidant, the propiconazole crude product is distilled under high vacuum and high temperature to obtain the propiconazole finished product. The preparation method of the invention reduces the varieties and dosage of the solvents necessary for reactions as well as the yield of wastewater resulted from cleaning during the reactions, thus realizing the goal of clean production.

Owner:JIANGSU SEVENCONTINENT GREEN CHEM CO LTD

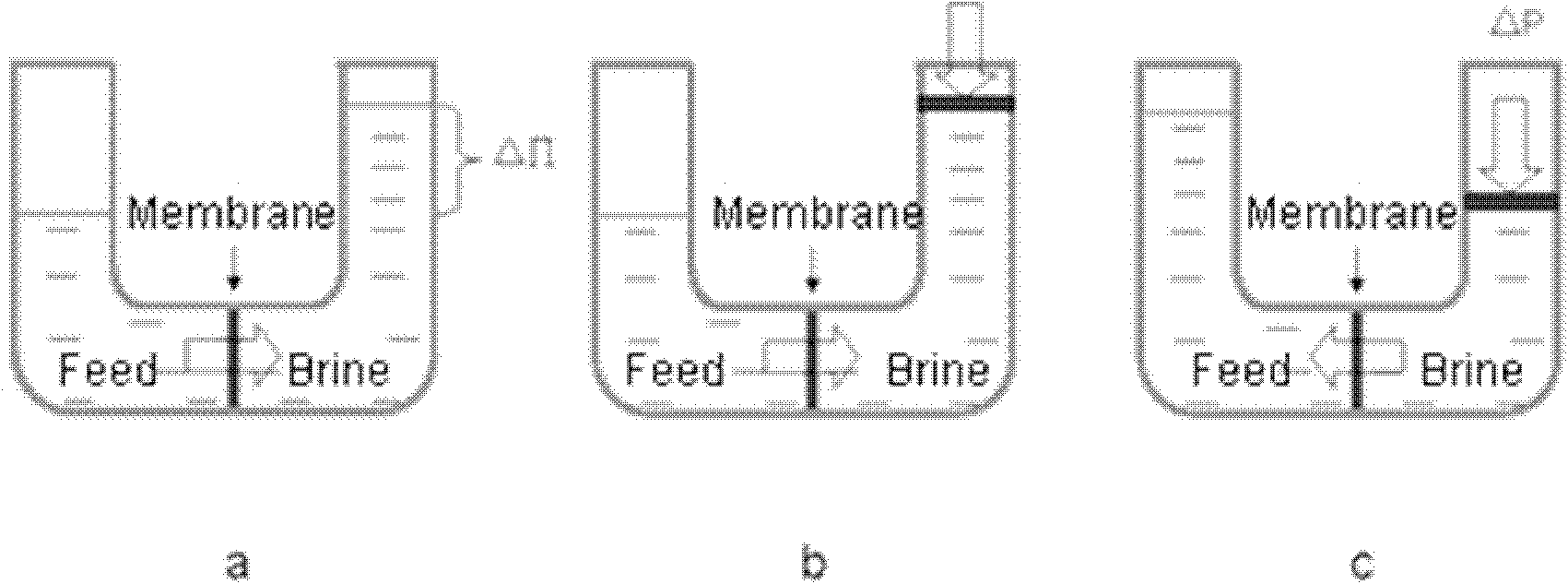

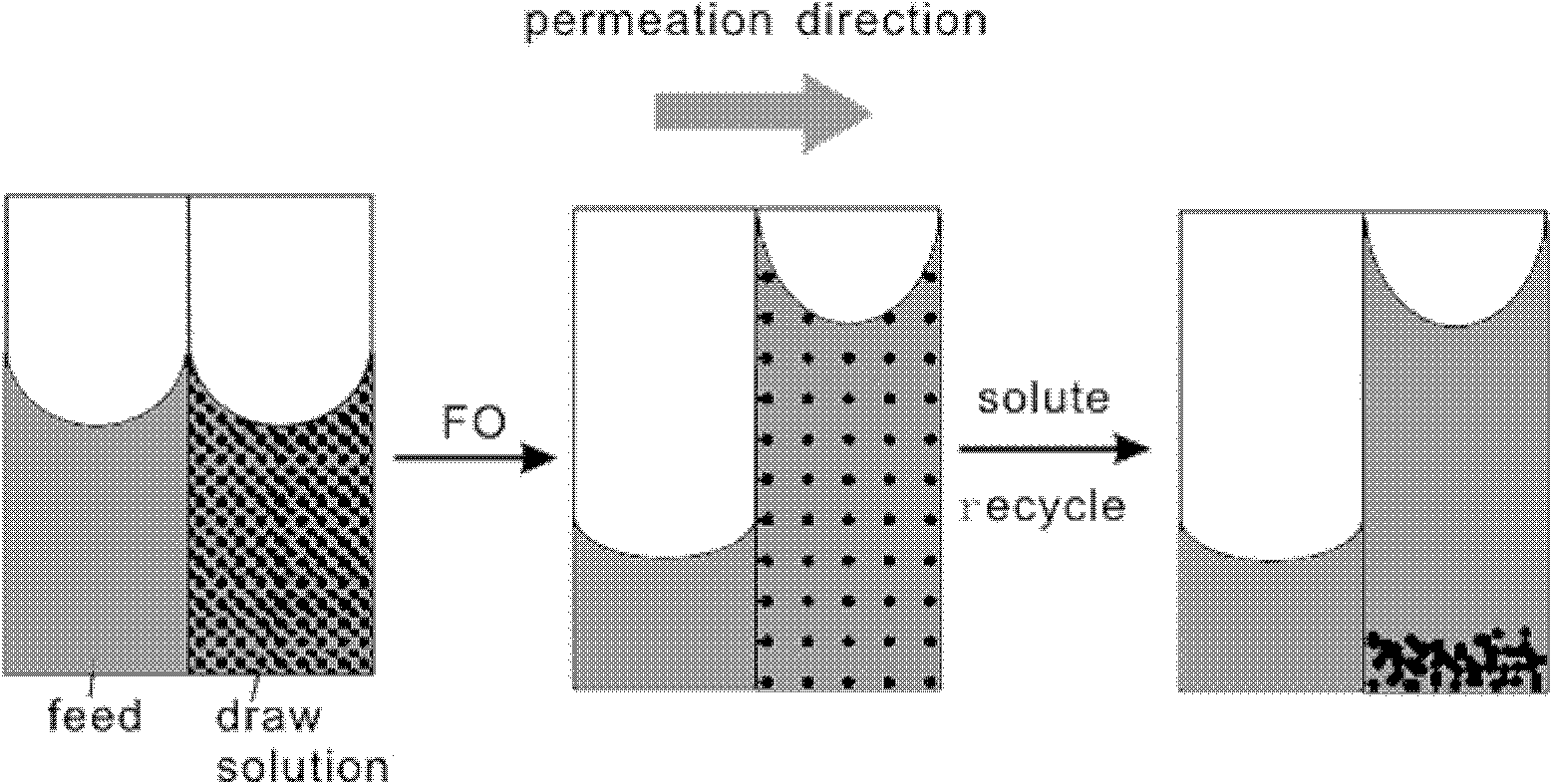

Composite fine particles of forward osmosis driving solution system and application thereof

InactiveCN101891281AAchieve fadeReduce energy consumptionWater/sewage treatment bu osmosis/dialysisChemical structurePolyvinyl alcohol

The invention relates to composite fine particles of a forward osmosis driving solution system. Fine particle cores are fully or partially coated by a separable outer layer; an outer layer shell provides an osmotic pressure; and the cores provide a separable characteristic. The solution system has the characteristics that: (1) the system has the composite fine particles having core-shell structures; (2) the diameters of the composite fine particles are less than 500 microns; and (3) the cores of the fine particles comprise particle cores of polymer particles, chitosan, nonmetal particles, metal or alloy; the shells of the fine particles comprise sodium polystyrene sulfonate, polyvinylamine hydrochloride, polyacrylic acid sodium salt, sylvite, calcium salt, polymethylacrylic acid sodium salt or sylvite, polyvinyl alcohol or polyaniline hydrochloride; the surfaces of the fine particle shells are provided with grafted groups, namely, chemical substances having ionization performance are grated on the surfaces of the particle shells by a chemical method; chemical structures having ionization performance are selected from the following chemical substances: Cl<->, COO<-> or SO<3->; and corresponding counter ions are H<+>, Na<+>, K<+>, Ca<2+> or quaternary ammonium salt according to the properties of the groups.

Owner:NANJING UNIV OF TECH +1

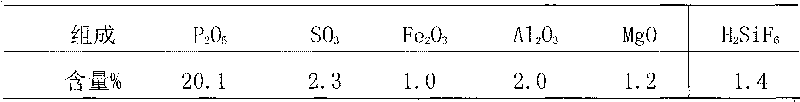

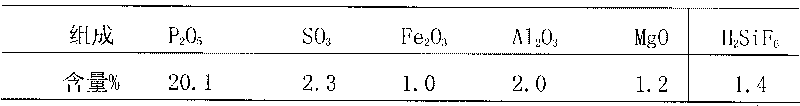

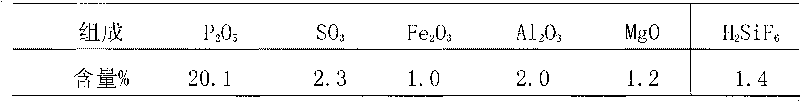

Method for producing defluorinated sulfenyl nitrogen-phosphorus-potassium compound fertilizer

InactiveCN101717290AIncrease profitSave resourcesFertilizer mixturesChemical industryPhosphoric acid

The invention relates to a method for producing defluorinated sulfenyl nitrogen-phosphorus-potassium compound fertilizer, which belongs to the technical field of production in the chemical industry. The method comprises the following steps of: firstly, adding soluble sylvite (or sodium salt) into fluosilicic acid in wet phosphoric acid to generate potassium fluosilicate (or sodium fluosilicate) precipitate, wherein after separating the potassium fluosilicate (or sodium fluosilicate) precipitate, the potassium fluosilicate (or sodium fluosilicate) precipitate is used as byproduct; then mixing the defluorinated wet phosphoric acid with converted potassium bisulfate at low temperature, carrying out neutralization reaction on mixed acid and gas ammonia; and granulating, drying, sieving, cooling and packing the neutralized slurry to prepare the defluorinated sulfenyl nitrogen-phosphorus-potassium compound fertilizer. The invention is mainly used for producing chemical fertilizers.

Owner:SHANDONG HONGRI ACRON CHEM

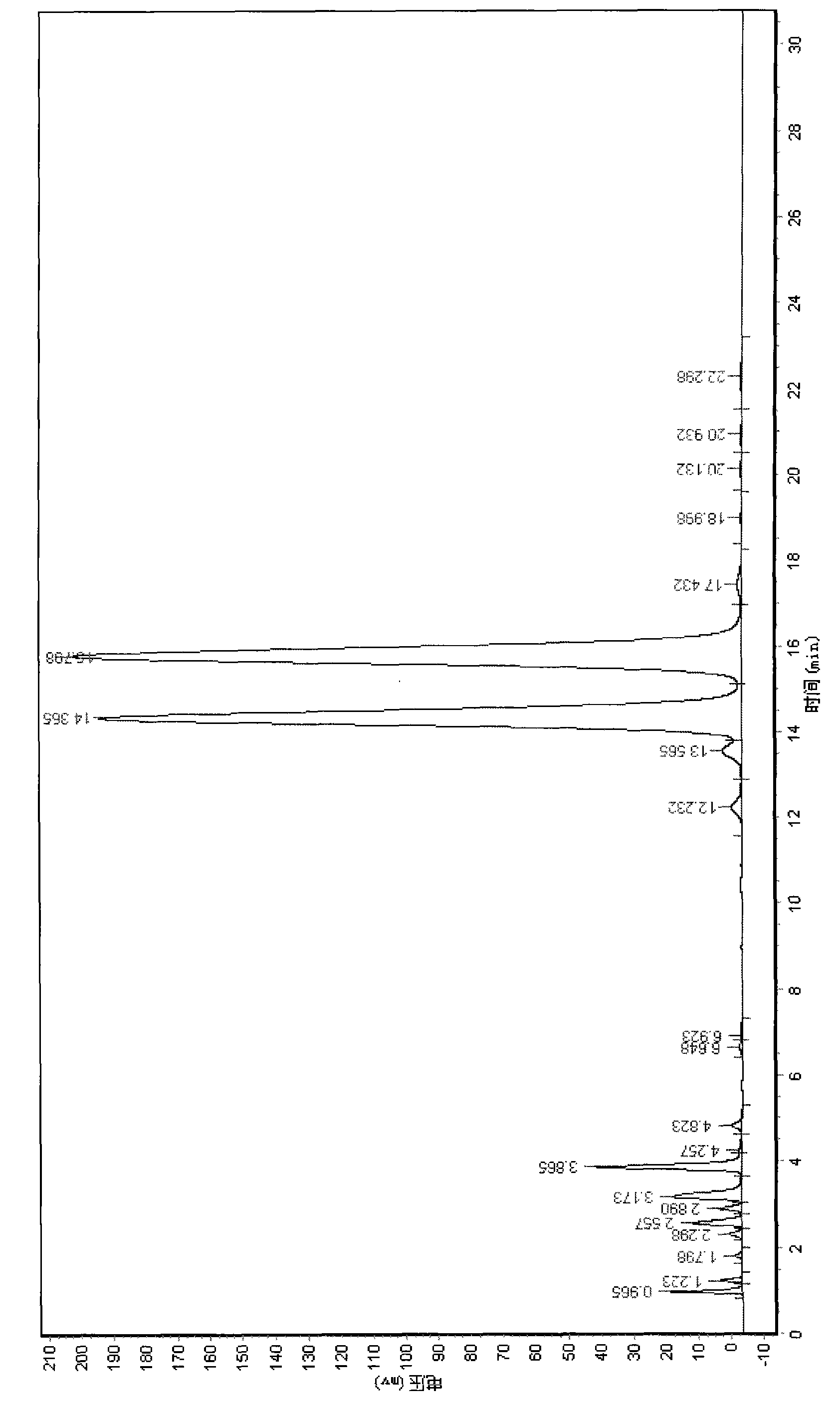

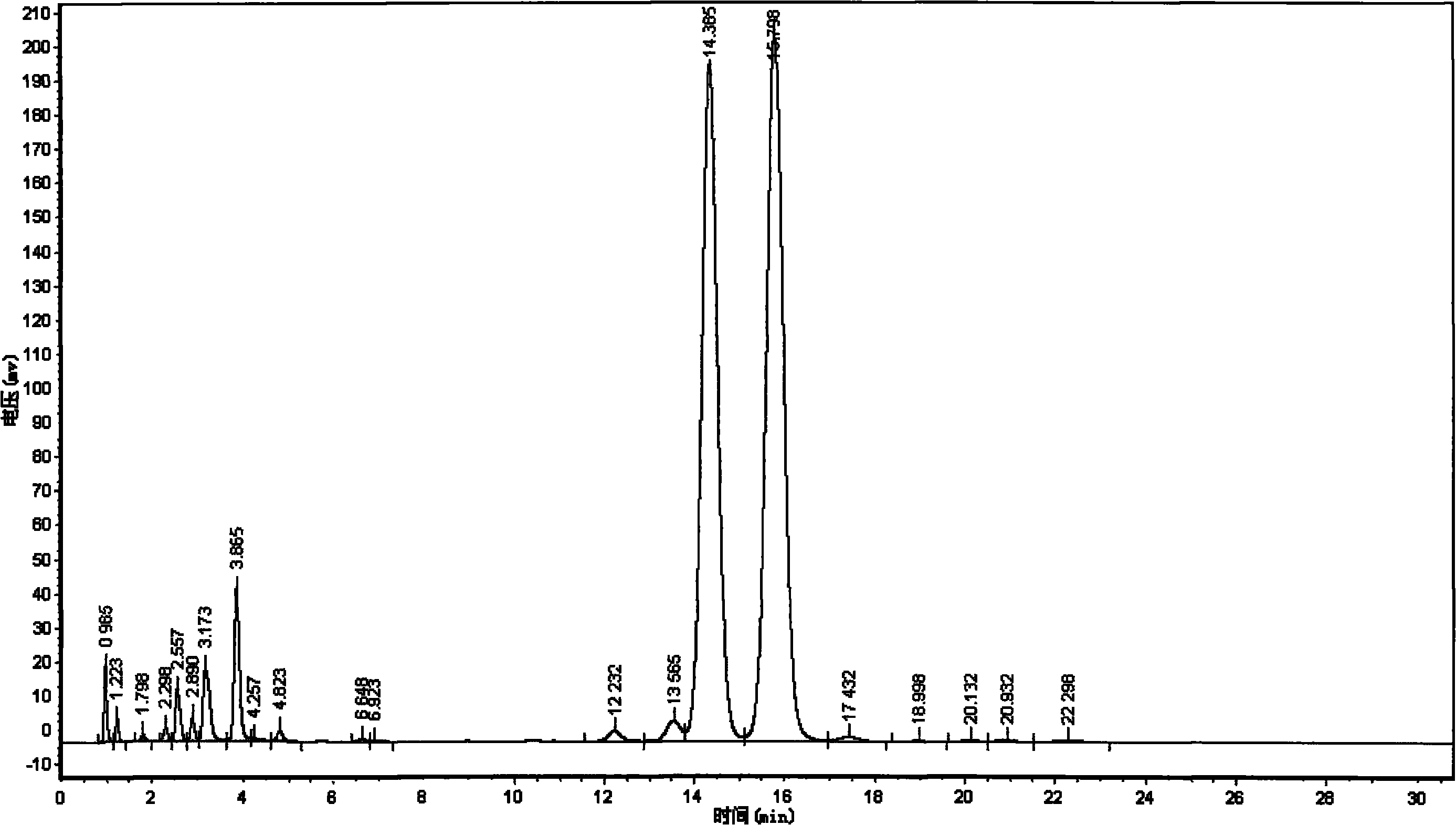

New method for producing propiconazole

ActiveCN101781290ASolve the problems of long reaction time, high water content and sticky materialsSimple processOrganic chemistryPropiconazoleBromine

The invention discloses a new method for producing propiconazole, comprising the following steps of: cyclizing 2,4-dichloroacetophenone and 1,2-pentanediol, brominating with bromine to generate 2-brooethyl-(2,4-dichlorophenyl)-4-propyl-1,3-dioxolane, then condensing with 1,2,4-tolyltriazole sylvite to prepare a crude product, and desolventizing, washing and distilling the crude product in vacuum to obtain the propiconazole. When the brominating reaction is carried out after the cyclizing reaction is finished, the bromine is added for twice, firstly the bromine accounting for 1%-10% of the total weight of the bromine is added in a reaction system for brominating induction reaction, and then the residual bromine is added. The bromine is added for twice during brominating reaction, firstly the bromine accounting for 1%-10% of the total weight of the bromine is added for initiating the whole system, the brominating induction reaction guides the direction of the brominating reaction so that monobromides and dibromides generating ketone due to the repeated resolution of cyclized matter are reduced, and finally the method achieves the purpose of improving the yield of the brominating reaction; and the conversion rate of the bromides is high and can be greater than 97%.

Owner:利民化学有限责任公司

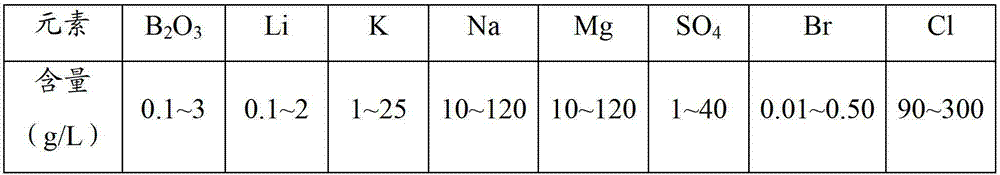

Multi-ion health-preserving solution and preparation method and application thereof

ActiveCN102068019AGood technical effectConvenient treatmentCosmetic preparationsToilet preparationsDiseaseSeawater

The invention discloses a multi-ion health-preserving solution, which contains alkaline concentrated solution and acidic concentrated solution; and the multi-ion health-preserving solution is characterized in that: the alkaline concentrated solution contains the following components in part by weight: 800 to 1200 parts of concentrated seawater mother liquor; 280 to 420 parts of sylvite; 18 to 33 parts of wollastonite; and 0.15 to 0.45 parts of germanium oxide; and the acidic concentrated solution contains the following components in part by weight: 400 to 600 parts of calcium ion water; 145 to 225 parts of citric acid solution; 0.4 to 0.6 parts of germanium oxide; 14 to 26 parts of tourmaline; 24 to 36 parts of sugar; and 280 to 420 parts of white vinegar. The invention also discloses a preparation method and application of the multi-ion health-preserving solution. The multi-ion health-preserving solution has the effects of radical conversion, toxin expulsion and balance-circulation synergism, and products made from the multi-ion health-preserving solution as additive, such as drinking water, cosmetic solution, washing water, food and antialcoholic products, have disease-preventing-and-treating, senility-deferring, cosmetic and body-building effects.

Owner:上海心动能科技有限公司

High-content organic/inorganic compound fertilizer

InactiveCN101172900AMeet growth needsIncrease contentAnimal corpse fertilisersClimate change adaptationSesamum orientaleAlkali soil

The invention belongs to agricultural fertilizer, in particular to high content organic and non-organic composite fertilizer, which comprises the substances as follow counted in weight: 30 parts of furfural dregs, 10 parts of sheep droppings, 4 parts of plant ashes, 3 parts of bean cakes, 3 parts of sesame cakes, 5 parts of excrementum bombycises, 15 parts of sylvites, 10 parts of ammonium nitrates, 20 parts of powdered rock phosphates. The fertilizer has high nutrient content, with total nutrient of 50 percent. The fertilizer can be used as basic fertilizer or used for fertilizing. The fertilizer can satisfy the growth demand of various crops, and is particularly suitable to corns and beams planted in alkali soil northeast of china, without packaging with the soil and having protection function for the soil. The fertilizer takes a grain shape, thereby being used as the basic fertilizer together with seeds conveniently.

Owner:辽宁乌兰山生物技术有限公司

Method for preparing lithium salt ore from plateau sulfate type salt lake brine

ActiveCN103204523ANo pollution in the processReduce manufacturing costChemical industryLithium sulfates/sulfitesHigh magnesiumThenardite

The invention discloses a method for preparing lithium salt ore from plateau sulfate type salt lake brine. The method comprises the following steps of: evaporating sulfate type salt lake brine to be in the sodium chloride saturated state, freezing in winter to separate out mirabilite, and carrying out solid-liquid separation when the content of the sulfate ion in the brine is controlled to be 1g / L to 7g / L; evaporating the brine from which the mirabilite is separated out, so as to separate sodium chloride; evaporating the brine from which the sodium chloride is separated out, so as to separate out sylvine, carnallite and epsomite, carrying out solid-liquid separation when the lithium ion concentration in the brine is controlled to be greater than or equal to 6g / L, wherein the brine subjected to solid-liquid separation is the brine with high magnesium chloride content; mixing the brine with high magnesium chloride content with the mirabilite to react so as to separate out sodium salt and magnesium salt, and carrying out solid-liquid separation when the magnesium-lithium ratio in the solution is controlled to be less than or equal to 8:1, so as to obtain boron-lithium-rich brine; and reacting the boron-lithium-rich brine with water to separate out boron rock, carrying out solid-liquid separation so as to obtain lithium-rich brine; and introducing the lithium-rich brine into a lithium salt pool, and evaporating so as to separate out the lithium salt ore.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

Method for producing magnesium-zirconium inter mediate alloy

A production method of magnesium zirconium interalloy deals with the operational difficulties of smelting magnesium alloy now, the difficulties of controlling the quality and environmental pollution. The production method is: take magnesium and sylvite into reduction furnace with the weight composition of 1:0.5-1.5, when degree of vacuum is no more than 1Pa, stop vacuumizing, heat tetrazirconium chloride, vaporize it,; when reduction furnace opens inert gas, heat magnesium and sylvite 2-5 hours, up to 650-950 deg.C, take the vaporized tetrazirconium chloride into reduction furnace to react with fusing magnesium, 8-14 hours, then, mechanically stir 0.5-1 hours, cool down to room temperature, gain magnesium zirconium interalloy of this invention.

Owner:锦州市金属材料研究所

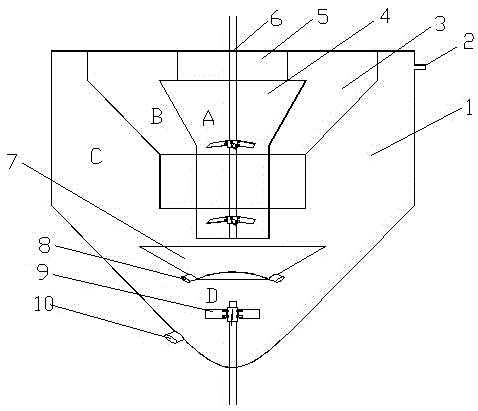

Mechanical crystallizer for sylvite industry

ActiveCN105597362ARelatively well separatedReduce entrainmentSolution crystallizationProcess engineeringPotassium sulfate

The invention relates to a mechanical crystallizer for sylvite industry. The mechanical crystallizer for sylvite industry comprises a crystallizer body, an outer barrel, a guide cylinder, a feeding baffle plate, a main stirring apparatus, a bowl-shaped baffle plate and a discharged material stirring device, wherein the outer barrel, the guide cylinder, the feeding baffle plate and the bowl-shaped baffle plate are fixedly connected with the crystallizer body, the main stirring apparatus and the discharged material stirring device are connected with the crystallizer body by a support and a bearing, a mother solution overflow opening is formed at the upper end of the crystallizer body, a discharge hole is formed at the bottom of the crystallizer body, the bowl-shaped baffle plate is arranged just under the guide cylinder, and the bottom of the bowl-shaped baffle plate is of an arched-shaped structure which is high in the middle and low at the periphery and is provided with material communication holes at the periphery. The mechanical crystallizer is used for crystallization production of potassium chloride and potassium sulfate and makes the feeding size of raw materials be increased to 8mm, circulating paste for crystallization is relatively separated from crystallized products, the mass concentration of the circulating paste and the handling capacity of the crystallizer can be effectively increased, the particle size of the crystallized products is increased, the entrainment rate of the raw material in the crystallized products is reduced and good crystallization effect is achieved.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

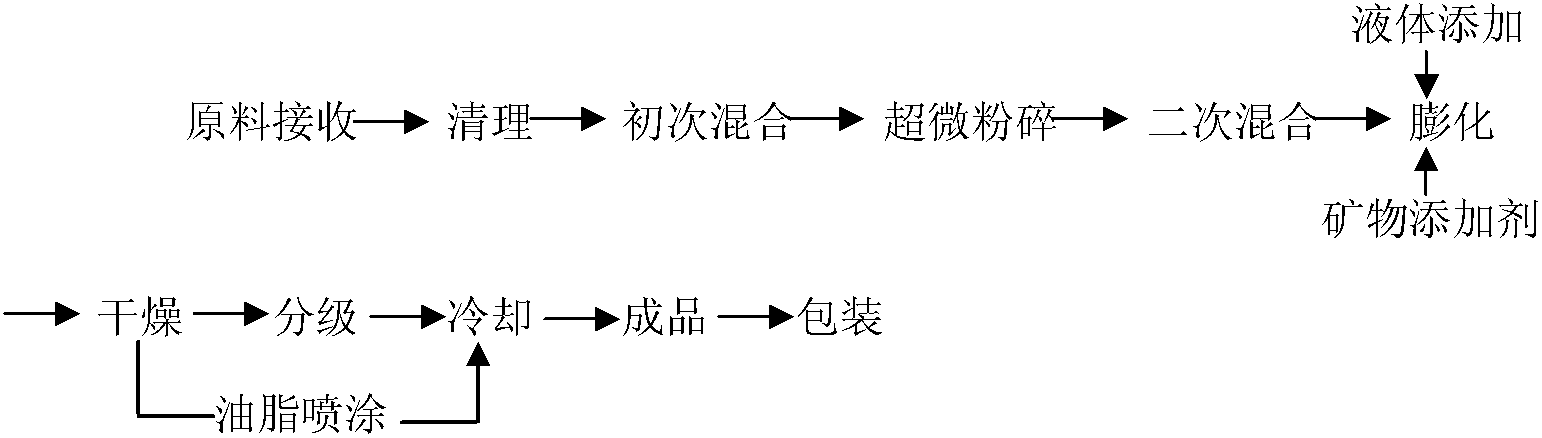

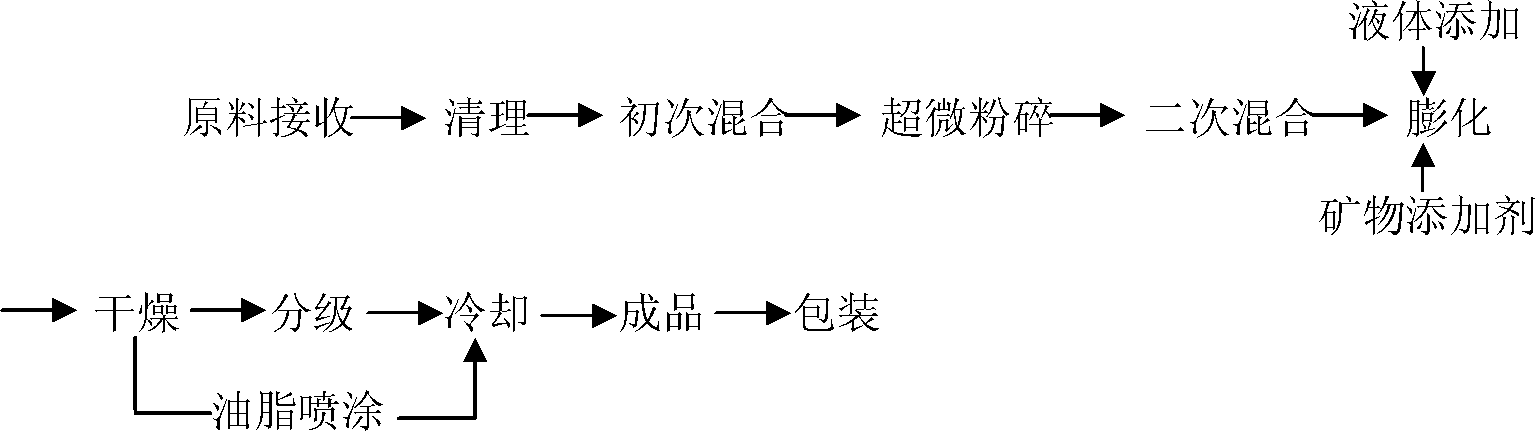

Black fish expansion compound feed

The invention relates to a black fish expansion compound feed, and is specifically suitable for a new species of No. 1 Hang Channa. The black fish expansion compound feed is a mixture prepared from various raw materials by an expansion granulated feed processing method, and comprises the following raw materials in part by weight: 30 to 50 parts of fish meal, 20 to 40 parts of soya bean meal, 15 to 25 parts of flour, 2 to 10 parts of meat and bone meal, 2 to 4 parts of soybean oil or fish oil, 1 to 2 parts of calcium biphosphate, 0.8 to 1 part of sylvite, 0.8 to 1 part of sodium salt, 0.8 to 1 part of multivitamins, and 0.5 to 1 part of squid paste. The invention has the advantages that: the feed is prepared by finely selecting high-quality raw materials according to a scientific formula and the requirement of each growth stage of the No.1 Hang Channa, has high stability in water, comprehensive nutrition, high attractant performance, and high digestive absorption performance, and can meet the requirement of No. 1 Hang Channa for nutrition, improve bait efficiency, reduce breeding cost, and reduce breeding water body pollution and water change amount.

Owner:HANGZHOU HAIHUANG FEED DEV

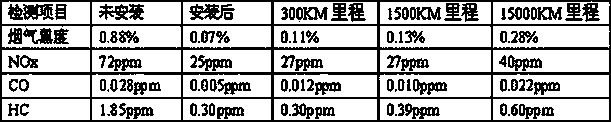

Automobile exhaust soot particle trapping burner

ActiveCN103758613ALow activation temperatureLow costInternal combustion piston enginesExhaust apparatusTrappingManganese

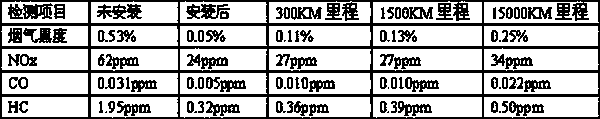

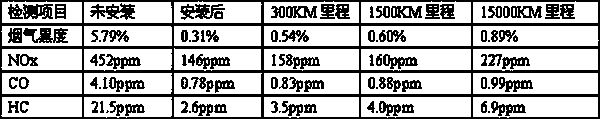

The invention discloses an automobile exhaust soot particle trapping burner. The automobile exhaust soot particle trapping burner comprises a shell, a cellular carrier and a three-way catalyst. The shell is filled with the cellular carrier. The three-way catalyst is attached to the carrier and prepared through a method which includes the steps that water-soluble copper salt, water-soluble manganese salt, water-soluble sylvite, water-soluble cerium salt and water-soluble zircon salt are taken and are then dissolved in water, citric acid and polyethylene glycol are added, the water is removed through evaporation after the water-soluble copper salt, the water-soluble manganese salt, the water-soluble sylvite, the water-soluble cerium salt and the water-soluble zircon salt are completely dissolved to obtain gel, and the gel is dried and roasted to obtain the three-way catalyst. The automobile exhaust soot particle trapping burner has a low activation temperature, can be externally connected to the tail end of an automobile exhaust pipeline to trap and burn soot, can remove 80%-95% of soot, 70%-90% of CO, 80%-90% of HC and 50%-70% of NOx at the early use stage, and is easy and convenient to install; the automobile exhaust soot particle trapping burner can still work after an automobile runs for twenty thousand to thirty thousand kilometers, and the cost of the automobile exhaust soot particle trapping burner is far lower than that of an existing three-way catalytic converter.

Owner:广东联南环保科技有限公司

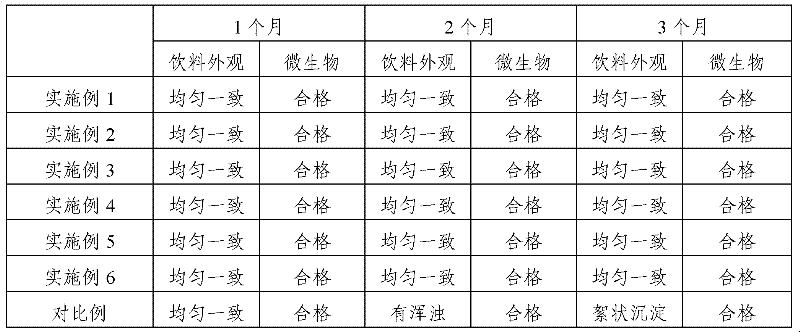

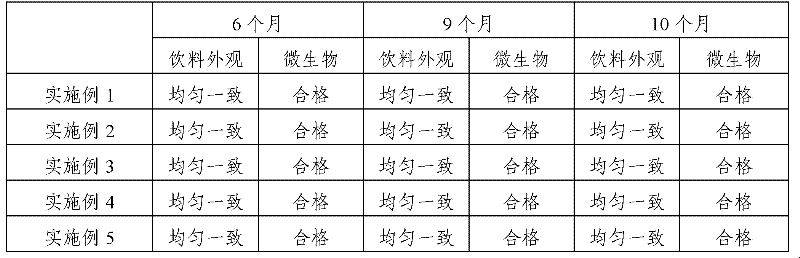

Sports beverage containing whey protein and preparation method thereof

The invention provides sports beverage containing whey protein and a preparation method thereof. The sports beverage comprises the following components in parts by weight: 10-30 parts of whey protein powder or 200-350 parts of fresh whey, 0.01-0.5 part of mineral substance, 0.001-0.07 part of vitamin, 0.03-0.3 part of L-carnitine and 0.001-0.005 part of lycopene, wherein sodium salt and sylvite at a ratio of (1-4):1 contained in the mineral substance form a sodium / potassium ion buffer system. The obtained sports beverage containing mineral substance, vitamin and animal and plant nutrients has the advantages that the added value of the sports beverage is improved, and proportion of all nutrients is reasonable, sweet and sour degrees are moderate and the mouthfeel is fresh and cool.

Owner:BEIJING SANYUAN FOOD

Oil gas recycling special activated carbon and preparation method thereof

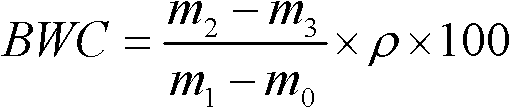

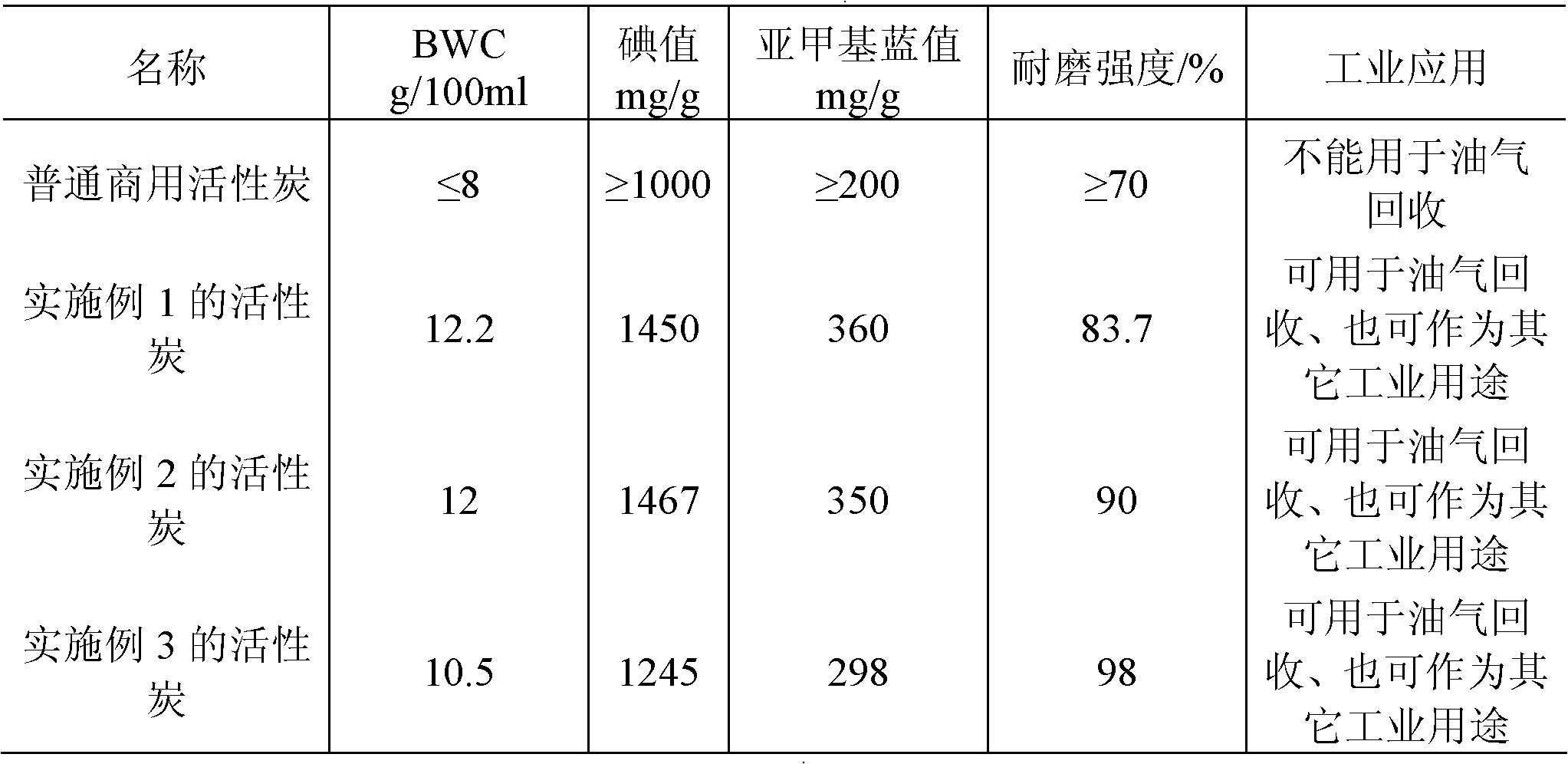

The invention discloses an oil gas recycling special activated carbon and preparation method thereof. The method comprises steps as follows: (1) mixing raw coal and additive, crushing and grinding to obtain mixed material, extrusion molding the powder material to obtain molded material, wherein the additive is at least one selected from the group consisting of sodium hydroxide, potassium hydroxide, urea, sylvite and ammonium salt; (2) carbonizing the molded material to obtain carbonized material; and (3) activating the carbonized material to obtain activated carbon. The oil gas recycling special activated carbon has excellent indexes, is particularly suitable to be used as oil gas recycling adsorbent, provides precondition for localization of the oil gas recycling adsorbent and adds novelproduct for serial product of activated carbon. The invention has simple content and technique, wide additive source and low cost, is feasible in industry and is product with low cost and high performance, and has large economic value and social significance.

Owner:CCTEG CHINA COAL RES INST

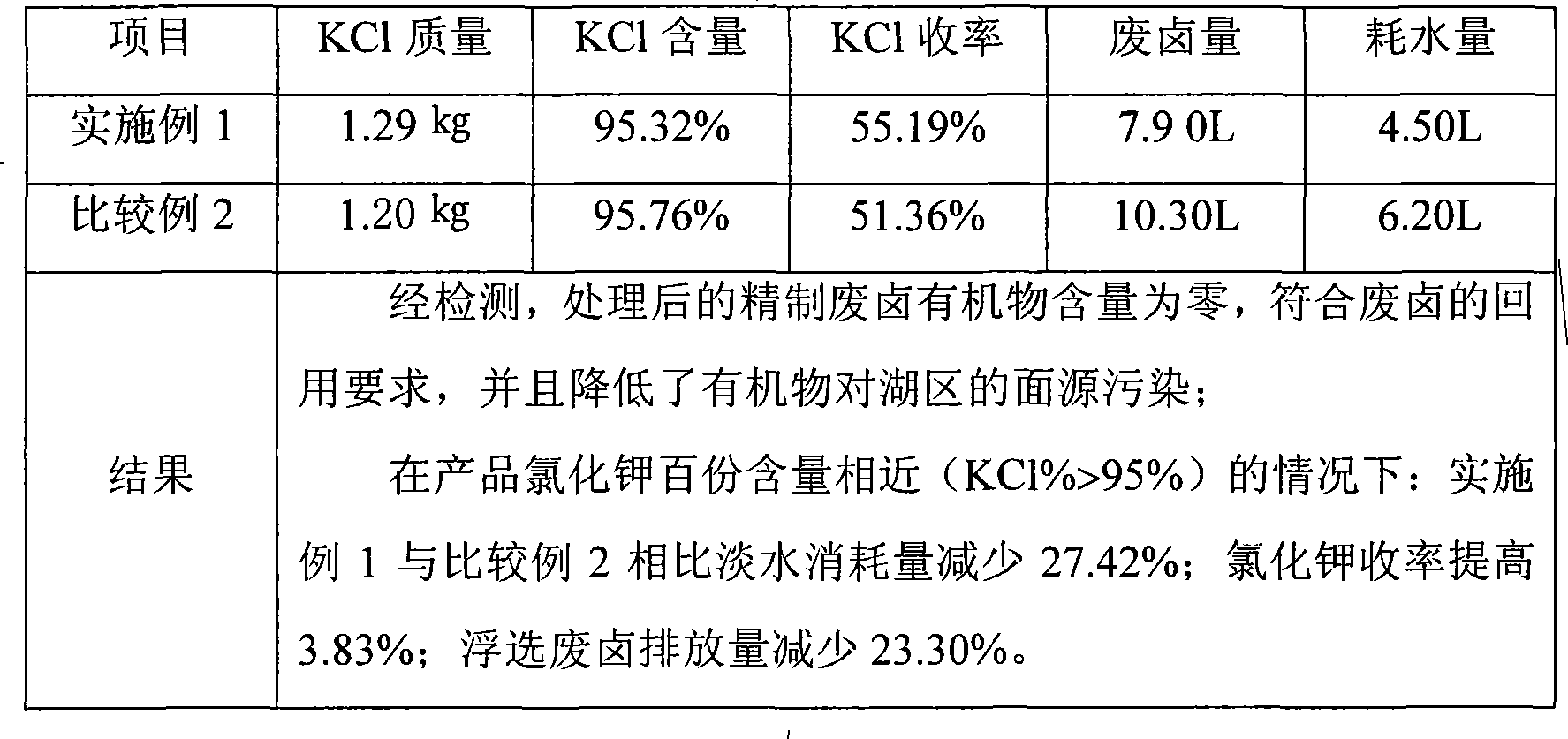

Production method of potassium salt

ActiveCN101249972AReduce the amount of water addedReduced water consumption throughout the processAlkali metal chloridesAlkali metal halide purificationCentrifugationResource utilization

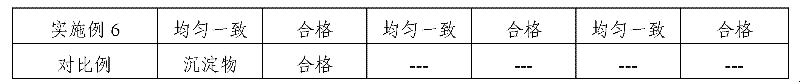

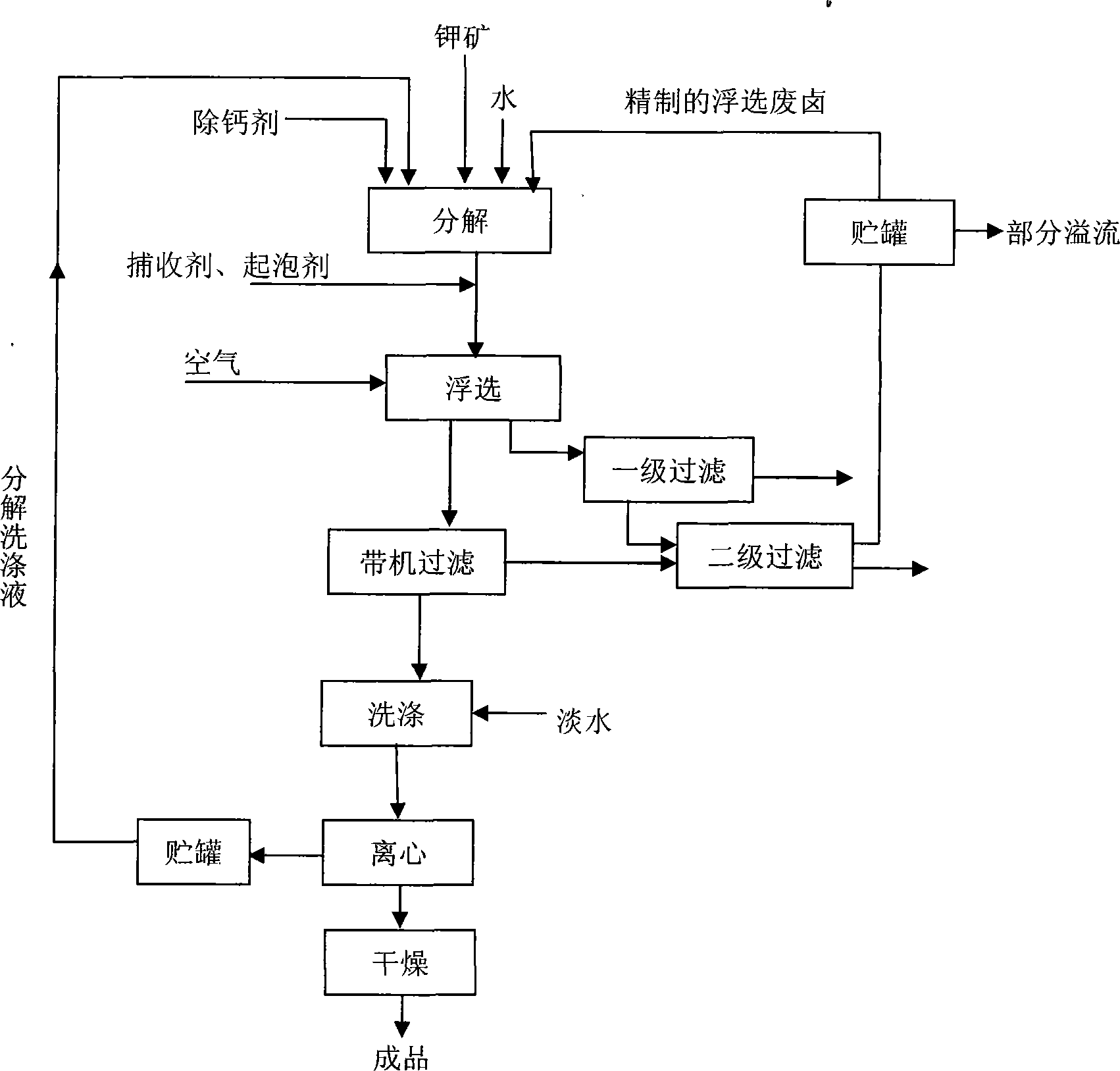

The invention provides a manufacturing method of sylvite, the steps comprise potassium mineral decomposition, froth flotation, dual-level filtration and reusing of waste and brine, wet materials filtration, washing, centrifugation and drying, and then the product is obtained. The invention solves the problems that the existing production technique for sylvite is high in fresh water consumption, high in potassium ion loss, high in froth flotation waste and brine discharge amount and polluted in organic pollution in salt field and the like. The manufacturing method of sylvite is simple in routing, low in fresh water consumption, high in potassium ion recovery rate, low in froth flotation waste and brine discharge amount, high in availability of resources and the like.

Owner:SHANXI UNIV

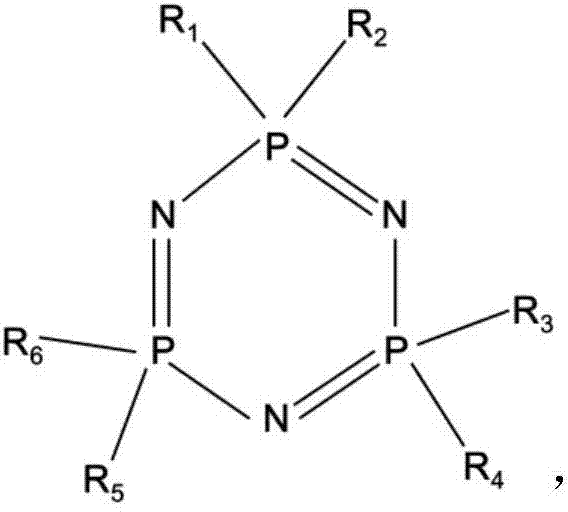

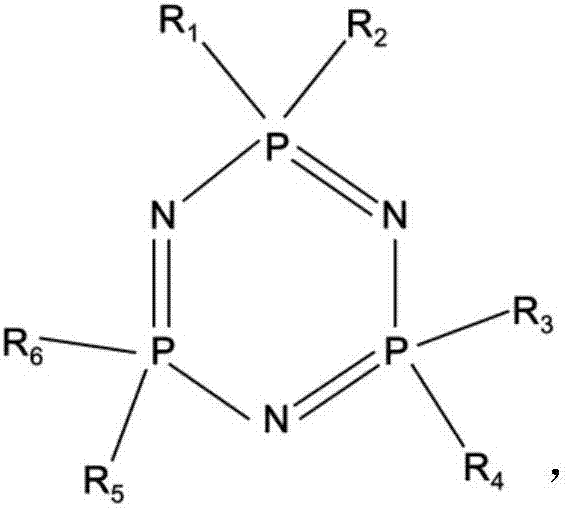

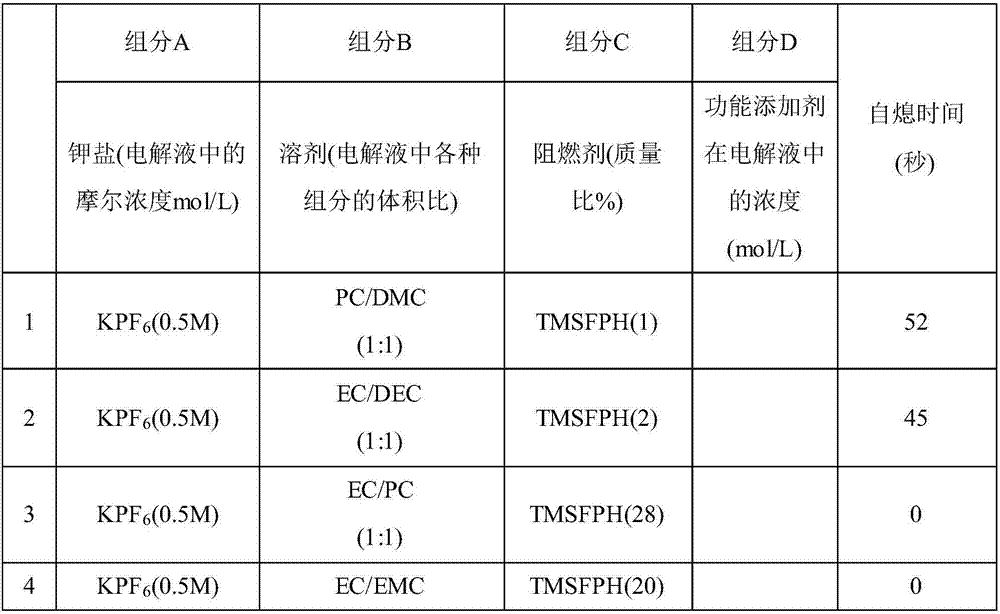

Flame-retardant potassium ion battery electrolyte and preparation method thereof

InactiveCN106935909AImprove flame retardant performanceLittle impact on electrochemical performanceOrganic electrolyte cellsSecondary cellsAlkylphosphatePhenyl group

The invention discloses a flame-retardant potassium ion battery electrolyte and a preparation method thereof. The flame-retardant potassium ion battery electrolyte comprises an organic solvent, sylvite and a flame retardant. The organic solvent is a carbonic ester organic solvent and / or an ether organic solvent. The flame retardant accounts for 0.1-50% of total mass of the flame-retardant potassium ion battery electrolyte. The general structural formula of the flame retardant is as shown in the specification, wherein R1-R6 all can be alkyl groups, alkyloxy group, halogenated alkyl group, halogenated alkyloxy group, halogenated alkylene group, phenyl group, biphenyl group, halogenated phenyl group, halogenated biphenyl group, alkyl silicon, alkyloxy silicon, alkyl phosphate, alkyloxy boron or amide group. According to the flame-retardant potassium ion battery electrolyte, safety of a potassium ion battery can be raised, and cycling stability of the battery and battery capacity retention ratio also can be enhanced.

Owner:SHANDONG UNIV

High-efficiency environment-friendly additive for smelting aluminum alloy

The invention provides am additive for smelting aluminum and aluminum alloy, which comprises metal powder and a halogen salt fluxing agent. The invention is characterized in that a small amount of sulfur powder is used as an auxiliary fluxing agent, the additive comprises the following components: approximately 70-80% of metal powder, approximately 20-30% of sylvite and 0.03-1% of sulphur powder, wherein particles of the components are 80 meshes or so, and the sum of all the components are 100%. The metal powder can be one or more out of manganese, copper, iron, nickel, titanium and the like. As potassium fluoroaluminate is used as the fluxing agent of the sylvite, thus causing no damages to the production environment and the fitness of working people, thereby achieving the goal of environmental friendliness. The use of the moderate amount of sulphur powder provides a very good bonding effect to the medal powder, thereby effectively preventing the pulverization of the metal powder, simultaneously driving the additive to ascend or descend in the melt, and reducing the descent speed. Therefore, the smelting rate is improved by more than one time, and the recovery efficiency of the metal powder reaches more than 98%.

Owner:于翔

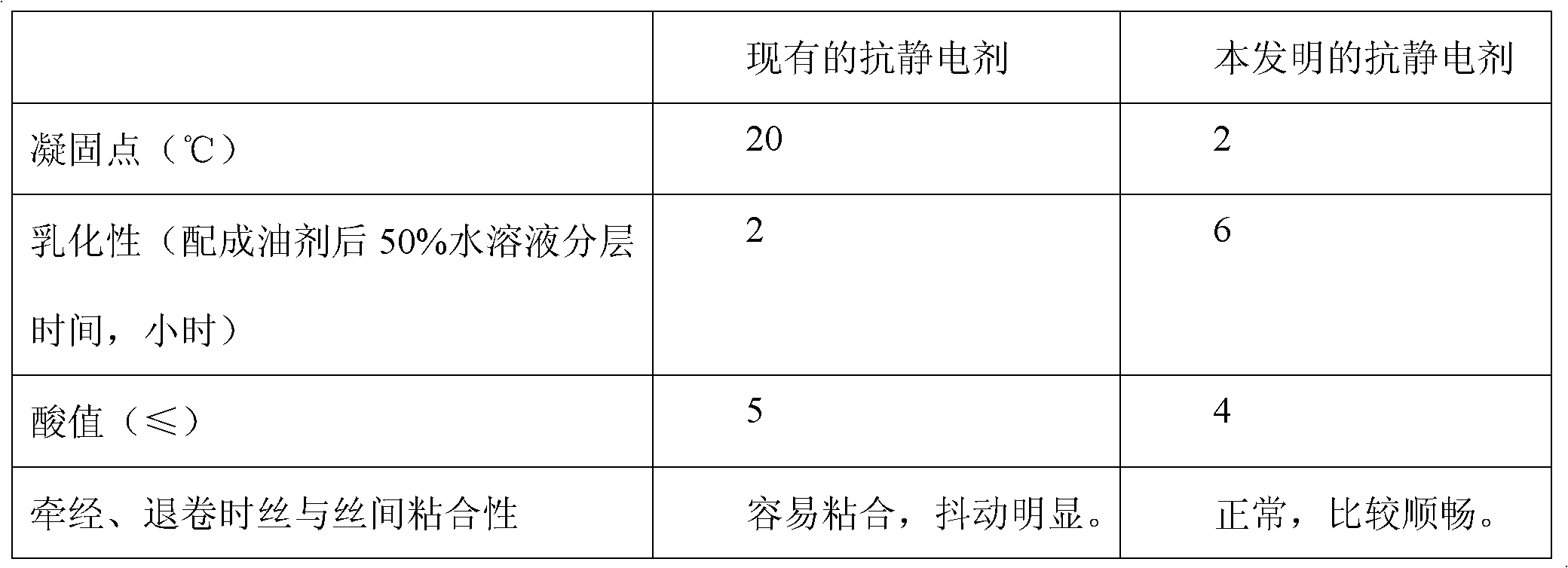

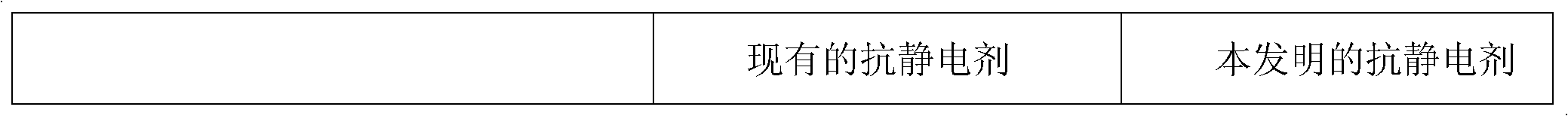

Antistatic agent for polyester elasticizing oiling agent and manufacturing method thereof

InactiveCN102182059ALow costImprove conductivityFibre typesPhosphorus organic compoundsPolyesterAlcohol

The invention discloses an antistatic agent for a polyester elasticizing oiling agent. The antistatic agent comprises the following components in part by weight: 30 to 40 parts of fatty alcohol, 10 to 12 parts of ethylene oxide, 40 to 50 parts of phosphorus pentoxide, 1 to 3 parts of potassium hydroxide and 2 to 5 parts of deionized water. The manufacturing method comprises the follow steps of: firstly, synthesizing the fatty alcohol and the ethylene oxide to obtain fatty alcohol-polyoxyethylene ether; secondly, synthesizing the fatty alcohol-polyoxyethylene ether and the phosphorus pentoxide to obtain fatty alcohol-polyoxyethylene ether organic phosphate; thirdly, synthesizing the fatty alcohol-polyoxyethylene ether organic phosphate and the ethylene oxide to obtain fatty alcohol-polyoxyethylene ether organic phosphate alcohol-polyoxyethylene ester; and fourthly; and fourthly, synthesizing the fatty alcohol-polyoxyethylene ether organic phosphate alcohol-polyoxyethylene ester and the potassium hydroxide to obtain fatty alcohol-polyoxyethylene ether organic phosphate alcohol-polyoxyethylene ester sylvite. The antistatic agent produced by the method has the advantages of high efficiency, low cost, strong frost resistance, easiness in emulsification and capability of meeting series of requirements of post-processing such as elasticizing.

Owner:TONGXIANG HENGLONG CHEM CO LTD

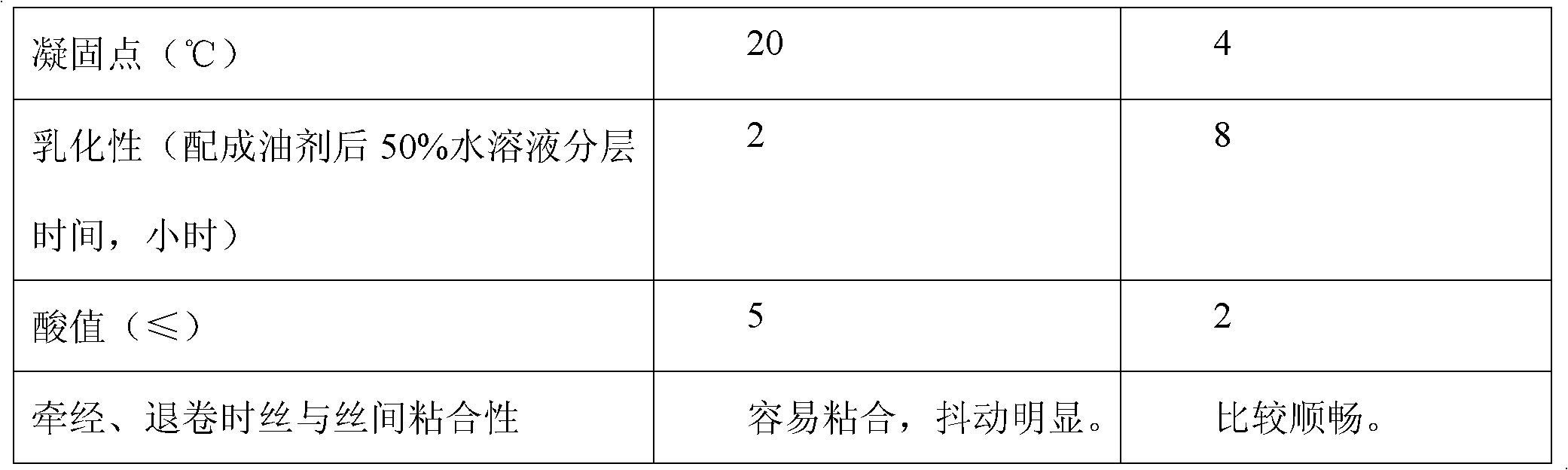

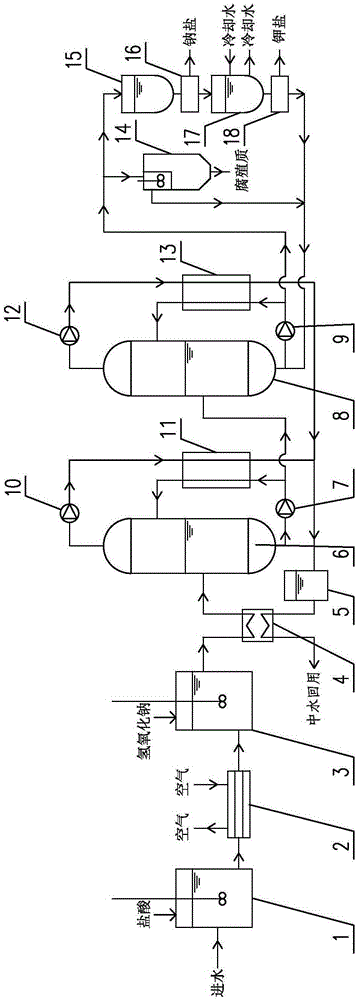

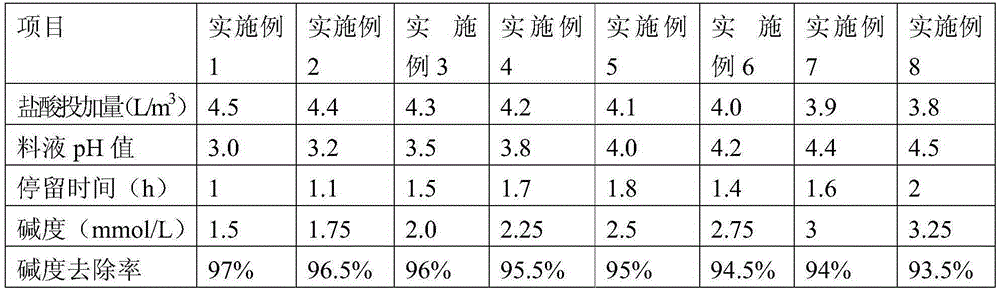

Garbage leachate reverse-osmosis concentrate treatment method

ActiveCN106630332AAvoid redissolutionEliminate the effects ofMultistage water/sewage treatmentContaminated groundwater/leachate treatmentHigh concentrationEvaporation

The invention relates to a garbage leachate reverse-osmosis concentrate treatment method, which comprises the following steps: pouring acid into a reverse-osmosis concentrate to reduce alkalinity of the concentrate, introducing the feed liquid into a degassing membrane tube, removing carbon dioxide gas and discharging the degassed concentrate into a sealed neutralization tank, pouring alkali into the neutralization tank, adjusting pH of the feed liquid to 6.5-7.5, preheating and letting the feed liquid enter a first-stage mechanical compression evaporator to carry out forced-circulation heat-exchange evaporation, carrying out forced-circulation heat-exchange evaporation by a second-stage mechanical compression evaporator, controlling liquid-solid rate to 28-35%, carrying out quality-based crystallization to obtain sodium salt and sylvite, processing high-concentration mother liquor and recovering humus, and pumping a separating medium or a supernatant inside a coagulative precipitation tank back into the second-stage mechanical compression evaporator and continuously evaporating. Operation load of each stage can be effectively reduced, the influence of humus accumulation in the concentrate and other unfavorable factors is reduced, continuous and stable operation of the evaporation system can be guaranteed, and zero emission of the reverse-osmosis concentrate can be realized.

Owner:WELLE ENVIRONMENTAL GRP CO LTD

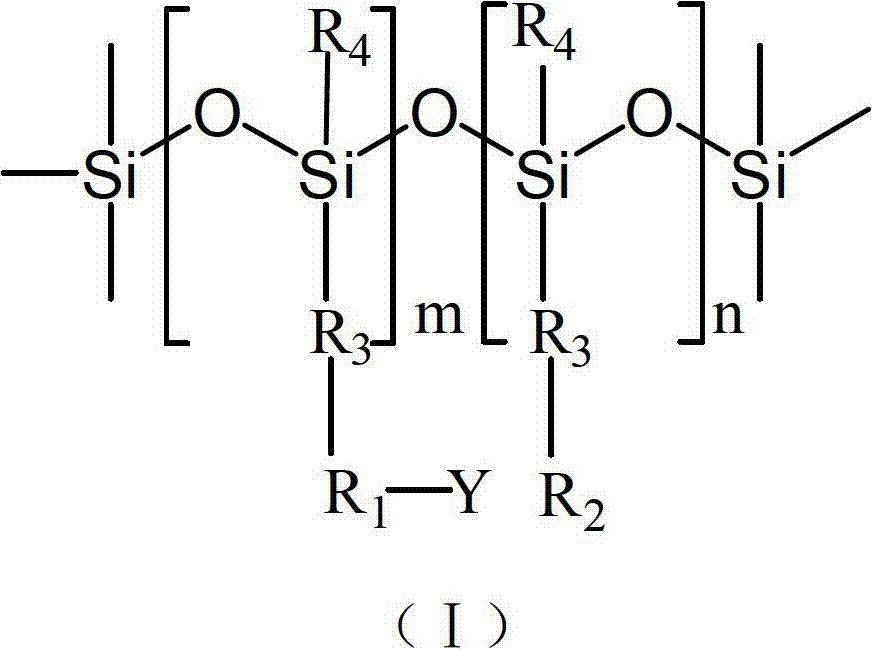

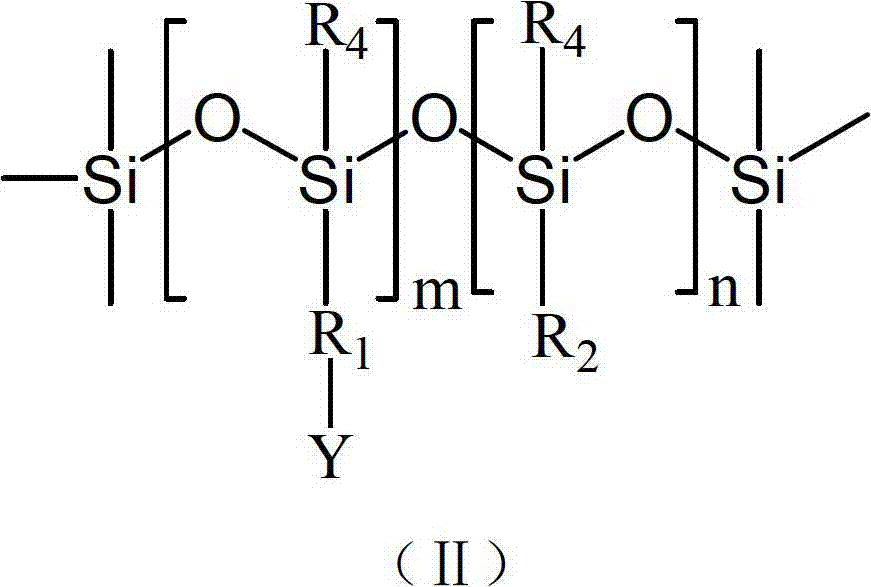

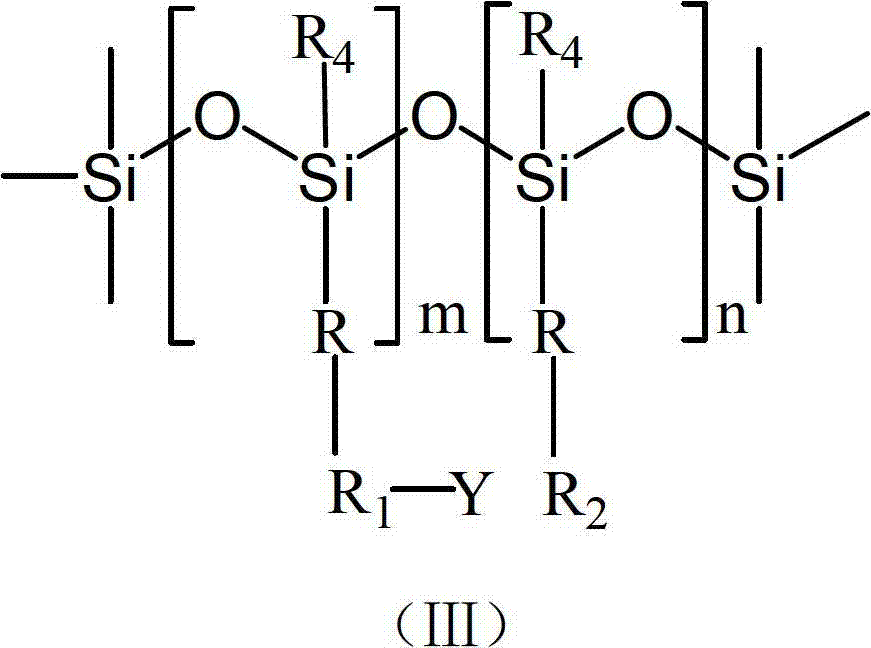

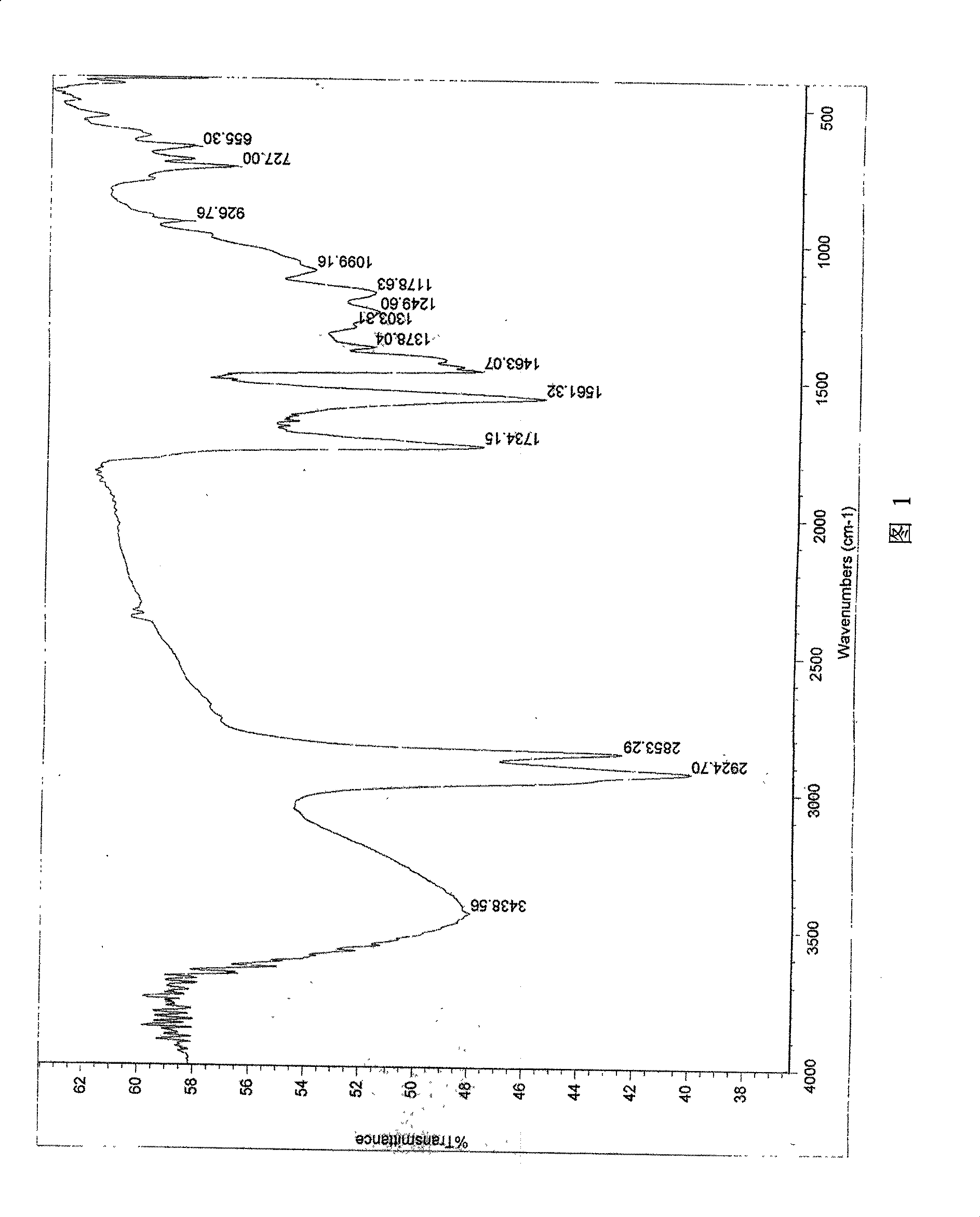

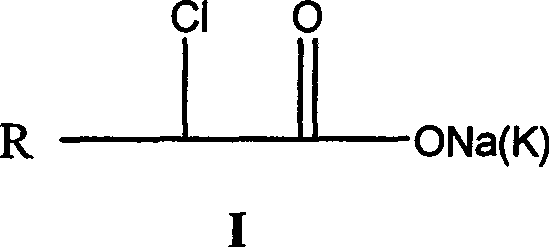

Polysiloxane, preparation method, application and bacteriacide containing same

InactiveCN102875814AWide range of sterilizationFast sterilizationFibre treatmentQuaternary ammonium cationSide chain

The invention relates to polysiloxane containing halamine and quaternary ammonium salt on a side chain. The polysiloxane has the structure as shown in the general formula (I). The invention also relates to a preparation method of the polysiloxane. The preparation method comprises the steps as follows: carrying out reaction between the raw material and R1 sylvite and then between the raw material and long-chain primary amine, so as to obtain the polysiloxane containing both N-halamine and quaternary ammonium salt characteristic functional groups on the side chain. The polysiloxane integrates the advantages of the N-halamine and quaternary ammonium salt on bactericidal performance, and has the characteristics of being wide in bactericidal range, high in sterilization speed and capable of regenerating; and the polysiloxane can be widely applied to various cleaning agents and bacteriacides and porous and hard surface coatings.

Owner:LUMIGENEX (SUZHOU) CO LTD

Chloro-sodium soap/sylvite flotation agent and method for producing the same

InactiveCN101429114AHigh activityImprove solubilityFlotationCarboxylic acid salt preparationOrtho positionHard water

The invention relates to a chlor-sodium soap / sylvine floatation agent and a preparation method thereof. The floatation agent is mainly prepared from colza oil, a strong alkali solution, concentrated sulfuric acid and chlorine; the molar ratio of raw materials of the colza oil, to the strong alkali solution to the concentrated sulfuric acid to the chlorine is 1 to 10.2-12.9 to 4.2-5.4 to 9-12. Compared with the prior art, the method has the following advantages: for alpha substitution (-Cl or-OH), the alpha substitution of carboxylic acid strengthens the activity of anions, improves the chelating capacity of the floatation agent, increases the electric conductivity of a compound, reduces surface tension, increases the foam performance and improves surface activity; the adaptability to Ca<2+> ions and Mg<2+> ions is increased so that floatation can be carried out at lower temperature in hard water; if two polar groups are in ortho position, the section on one end of the polar group of the floatation agent is increased to strengthen the selectivity of a drug; after a hydrophilic polar group is introduced to the alpha position, the dependence of the floatation agent on the temperature is greatly reduced.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

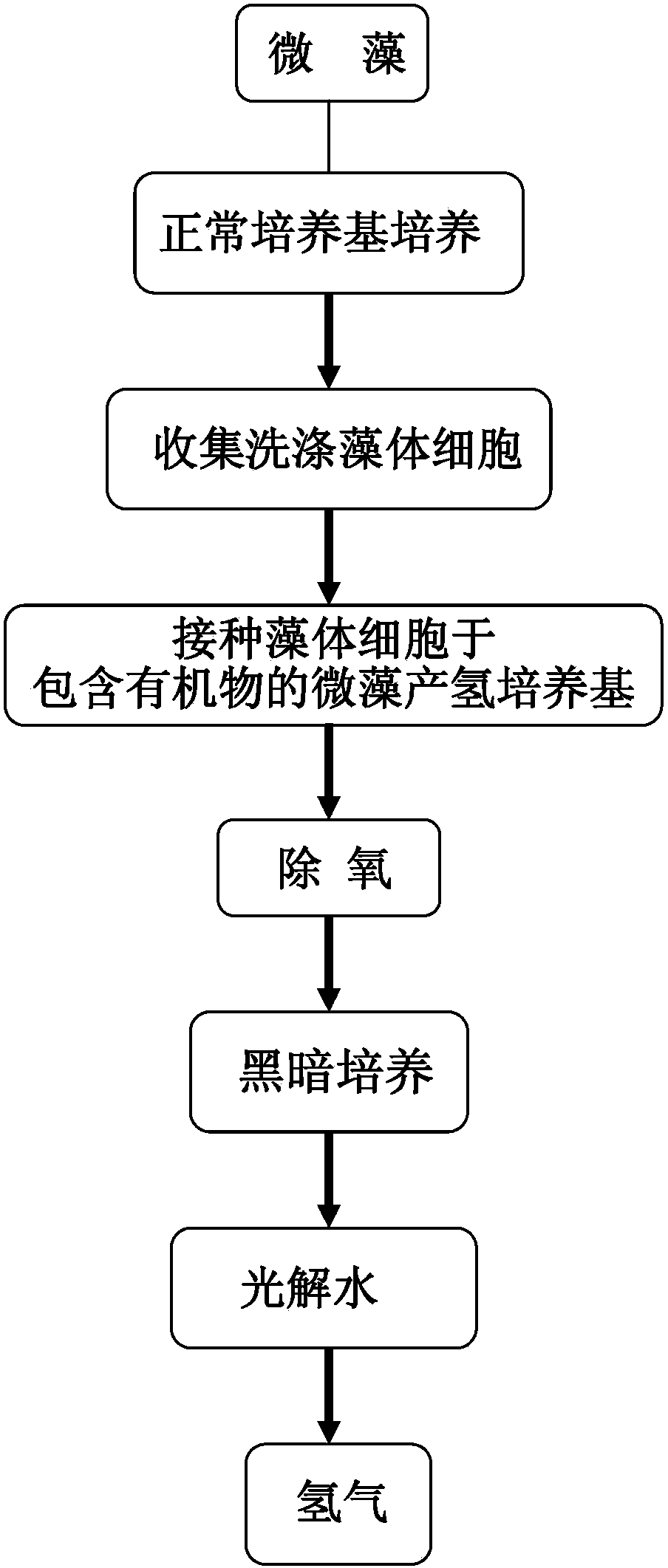

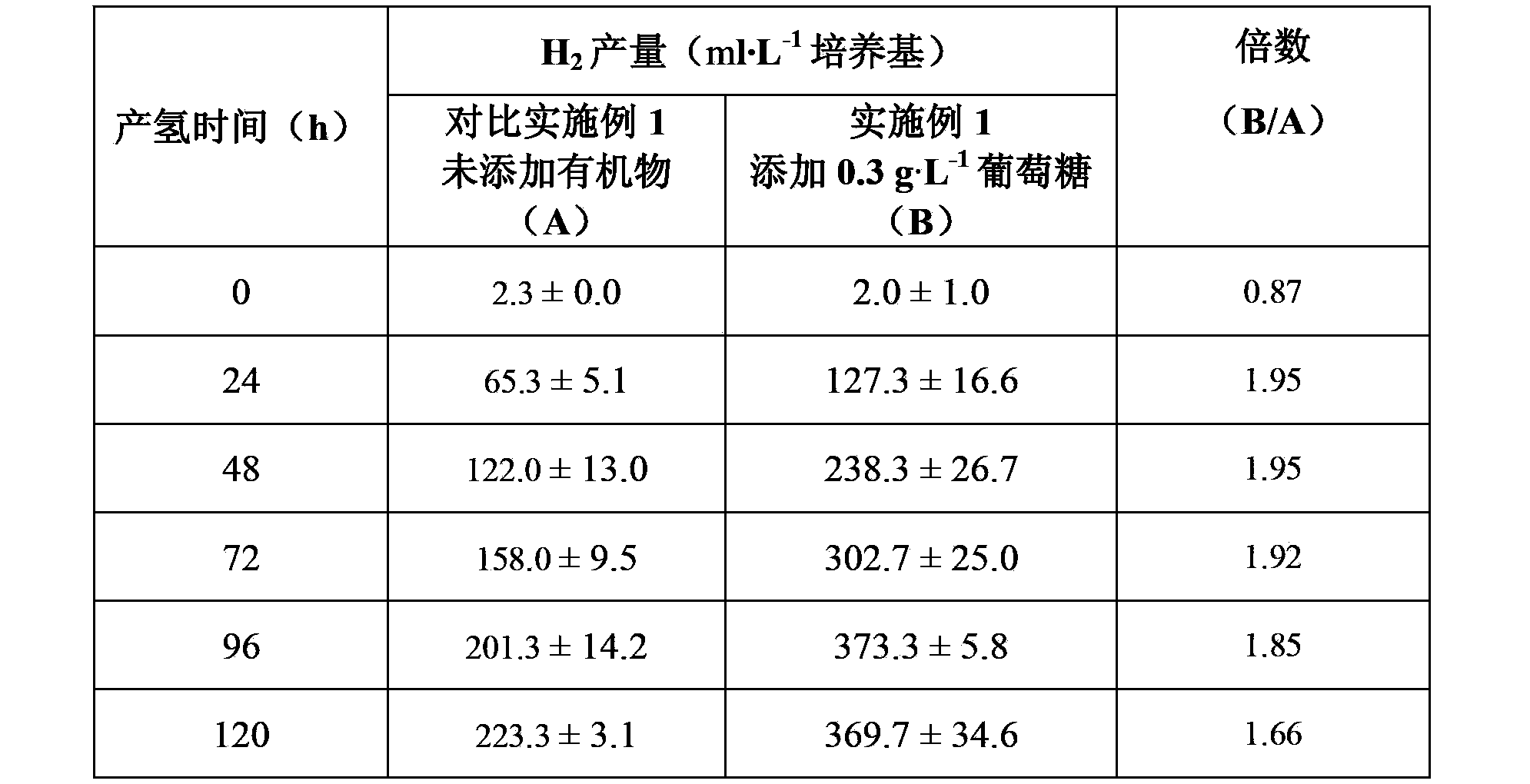

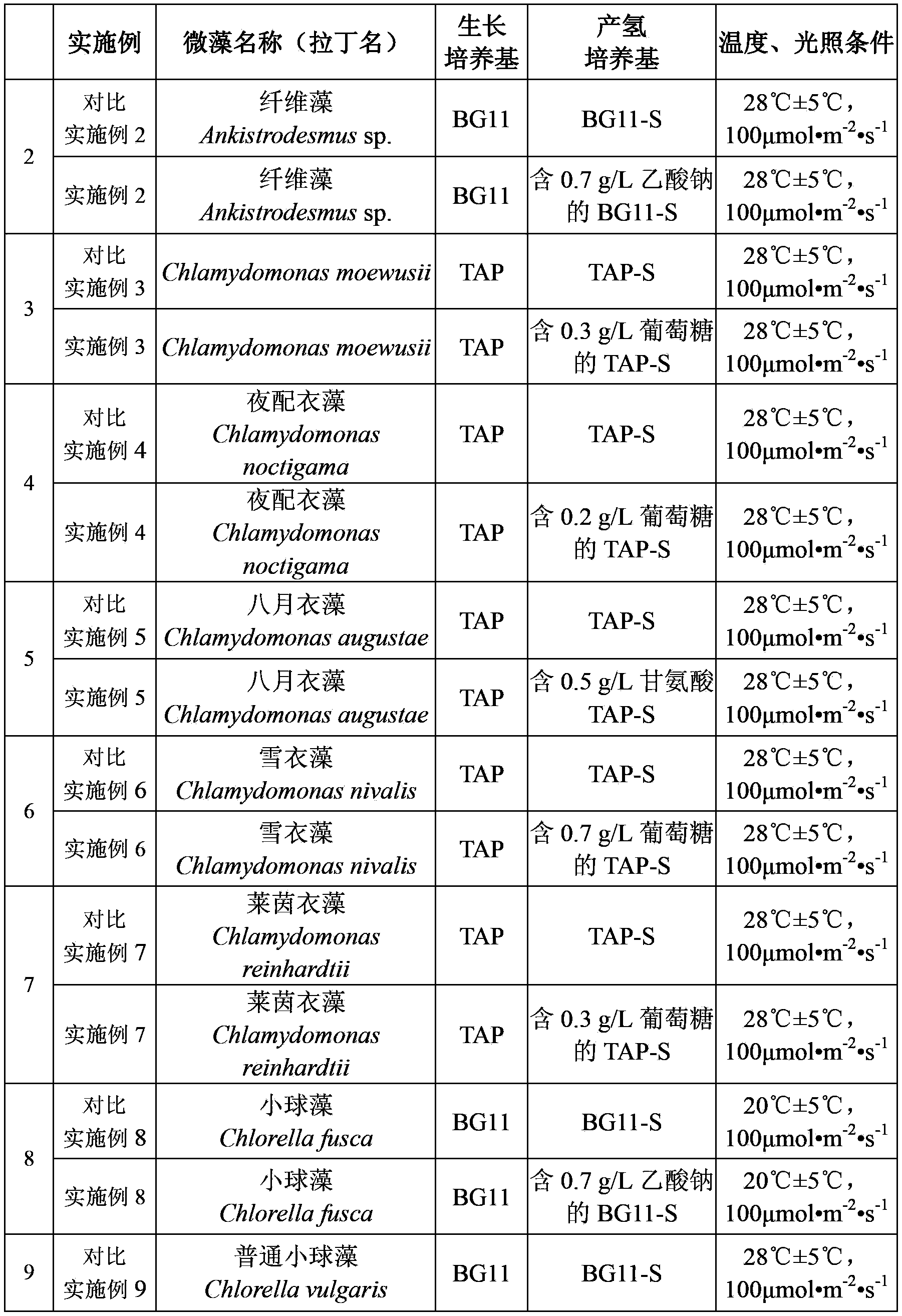

Method for raising hydrogen production efficiency of microalgae

InactiveCN104046651AImprove hydrogen production efficiencyEfficient photolysis of waterMicroorganism based processesFermentationNew energyDecomposition

The invention discloses a method for raising hydrogen production efficiency of microalgae and belongs to the field of a biological energy source. The method comprises the following steps: hydrogen-production microalgae cells are cultured in a medium until the exponential growth phase; the microalgae cells are collected, and the microalgae cells are transferred to a microalgae hydrogen-production medium containing organic matters, deoxygenization and sealing are carried out, and the microalgae cells are continuously cultured in a dark environment for a certain time, wherein the organic matters contain at least one of glucose, fructose, acetate, pyruvic acid, 3-phosphoglycerate, malic acid and amino acid and at least one of sodium salts and sylvite of the above organic matters; and finally, the microalgae cells are again placed in a light environment to induce water decomposition to produce hydrogen. It is verified through experiments that hydrogen production efficiency of microalgae can be remarkably raised by adding the organic matters to the microalgae hydrogen-production medium. The method has characteristics of novel technology and remarkable effect and the like, is simple and reliable, and has important practical application value in the field of new energy.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com