Patents

Literature

246results about How to "Reduce the amount of water added" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grouting material for connecting steel bars in low temperature environment, and preparation method and application thereof

The invention discloses a grouting material for connecting steel bars in a low temperature environment, and an application thereof. The grouting material for connecting steel bars in the low temperature environment comprises, by weight, 35-55 parts of cement, 5-20 parts of a mineral admixture, 0-30 parts of an early strength component, 30-50 parts of aggregates, 0.1-0.5 part of a water reducer, 0-0.03 part of a plastic expansion agent, 0-0.1 part of an antifoaming agent, 0-0.05 part of a stabilizer, 0-0.05 part of an air entraining agent, 0-1 part of a setting retarder and 0-0.05 part of a setting accelerator. The fluidity of a grouting material mixture prepared after adding 0 DEG C water to the grouting material in a -5 DEG C environment and mixing the grouting material and the water is more than 260 mm 30 min later, so sufficient grouting time at a low temperature is ensured; the grouting material has the characteristics of low water-to-feed ratio and high fluidity, and the groutingmaterial still has an expansion performance and a good low-temperature hydration characteristic in a subzero temperature environment, is suitable for steel bar grouting connection construction in a -10-10 DEG C environment, and solves the problem of grouting construction in the low temperature environment, especially the below 0 DEG C environment; and the grouting material contains no chlorine salt and other early-strength components corroding the steel bars.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

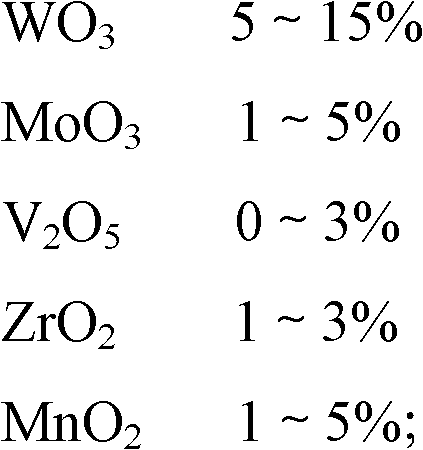

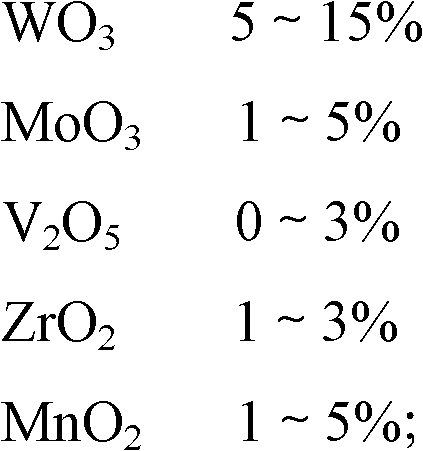

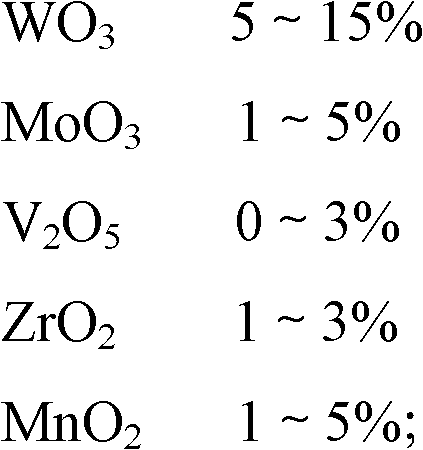

Monolithic cellular catalyst for SCR smoke denitration and preparation technology thereof

ActiveCN102380370AReduce dry molding conditionsHigh mechanical strengthDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsGlass fiberDry mixing

The invention discloses a monolithic cellular catalyst for SCR smoke denitration, which adopts TiO2 powder as a substrate. The catalyst is added with active ingredients and additive at the same time. The active ingredients comprise TiO2, WO3, MoO3, V2O5, ZrO2 and MnO2. The additive comprises water reducer, binder, pore-forming agent, extrusion assistant and glass fiber. The invention further discloses a preparation technology for the monolithic cellular catalyst for SCR smoke denitration, comprising the following steps: dry mixing, kneading and pugging to obtain a mud section with good plasticity and a compact structure; extruding to obtain the blank of the monolithic cellular catalyst; drying and baking to obtain the monolithic cellular catalyst for SCR smoke denitration. The invention has simple preparation technology, greatly reduces the water quantity during the kneading process through adding the water reducer which is adopted as one active ingredient, reduces the maintaining conditions of the catalyst after being formed, and improves the strength, abrasion resistance and yield for forming the catalyst.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

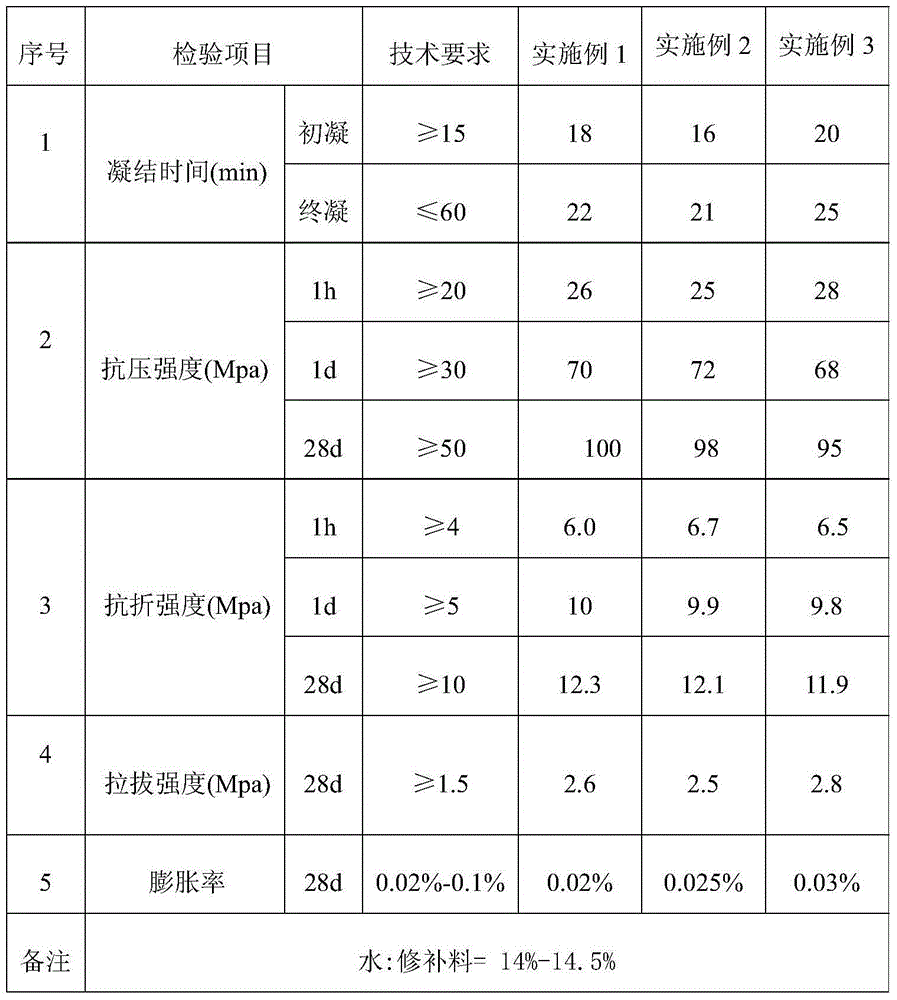

Pavement/bridge deck concrete fast mending material and application thereof

The invention relates to a pavement / bridge deck concrete fast mending material and application thereof. The mending material comprises the following raw materials by weight: 20 to 30 parts of sulphoaluminate cement, 8 to 10 parts of ordinary Portland cement 52.5, 5 to 10 parts of polymer powder, 0.5 to 1.5 parts of aluminium sulphate, 1 to 2 parts of water glass, 0.1 to 1 part of organic silicon, 1 to 2 parts of gypsum, 2 to 3 parts of slag, 0.1 to 0.5 part of silica micropowder, 0.5 to 1 part of an HPCA high-performance concrete expansive material, 3 to 5 parts of fly ash, 20 to 30 parts of washed-out and dried sand, 25 to 30 parts of corundum, 3 to 5 parts of composite fiber, 1 to 3 parts of a polycarboxylate superplasticizer, 0.1 to 0.5 part of boric acid, 0.1 to 0.3 part of sodium gluconate, and 0.2 to 1 part of lithium carbonate. The mending material is high in early strength, and has the advantages that traffic can be opened fast only 1 to 2 hours after mending is completed, so as to reduce traffic jams, and effectively reduce the generation of traffic accidents.

Owner:HENAN HUINENG ROAD & BRIDGE TECH CO LTD

Tunnel fireproof paint

InactiveCN101747675AGood construction performanceConstruction stabilityFireproof paintsCalcium formateToxic material

The invention relates to fireproof paint, in particular to tunnel fireproof paint, which is prepared from the following ingredients: a major bonding agent (ordinary Portland cement), inorganic heat insulation filling materials (expanded perlite, expanded vermiculite, meerschaum, kaoline and wollastonite powder) and addition agents (calcium formate, starch ether, redispersible latex powder, methyl cellulose ether and polypropylene fiber). Through the unique addition agent combination and the prescription mixture ratio, the tunnel fireproof paint has the advantages that the construction performance is obviously improved, at the same time, the integral overall performance of the tunnel fireproof paint is greatly improved, and the tunnel fireproof paint has the characteristics of stable fireproof performance, high adhesion intensity and stable physicochemical performance. Simultaneously, the product per se generates no toxic substance in the construction and burning processes, has the effects of environment protection and high practicability, and can be widely used for the fireproof protection of buildings such as highways, railways, subway tunnels and the like.

Owner:江西三星气龙新材料有限公司

3D printing gypsum ink and preparation method thereof

The present invention belongs to the technical field of 3D printing materials, and relates to a 3D printing gypsum ink, and the 3D printing gypsum ink is prepared from the following components by weight: 60% to 93% of gypsum powder, 2% to 20% of filler, 4% to 18% of a modifying solvent and 0.5% to 5% of a coagulant. The present invention also discloses a preparation method of the 3D printing gypsum ink, and all the raw materials are mixed and stirred evenly to obtain the 3D printing gypsum ink. The problems of low strength, poor mobility, coarse particles, poor toughness and high cost in the prior art can be solved, and an economical 3D printing forming material with industrial potential, high speed, good precision and low use cost is developed.

Owner:QINGHAI MINGYANG ENVIRONMENTAL TECH GRP CO LTD

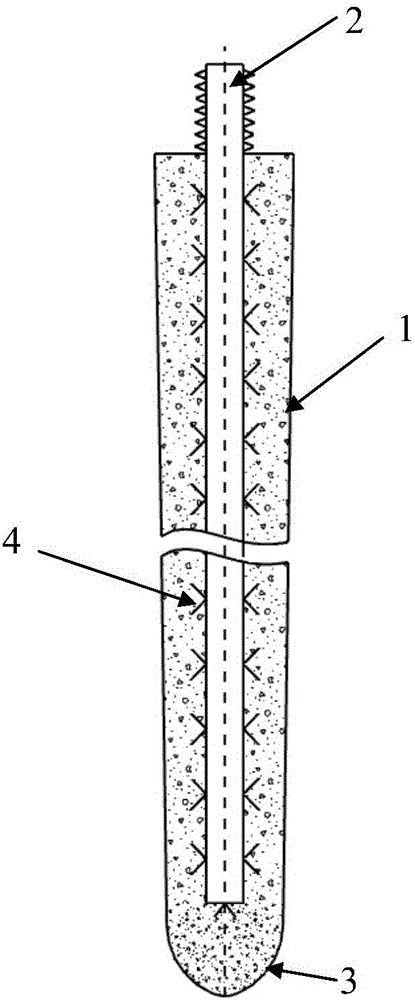

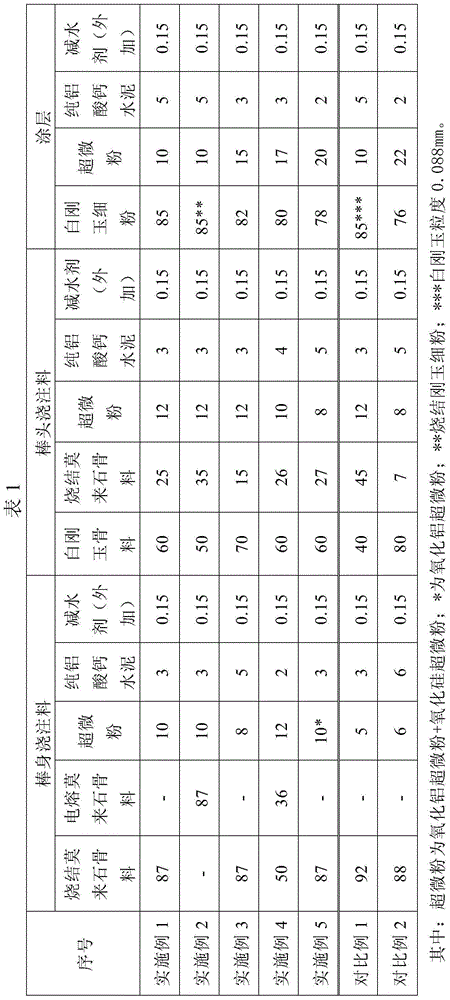

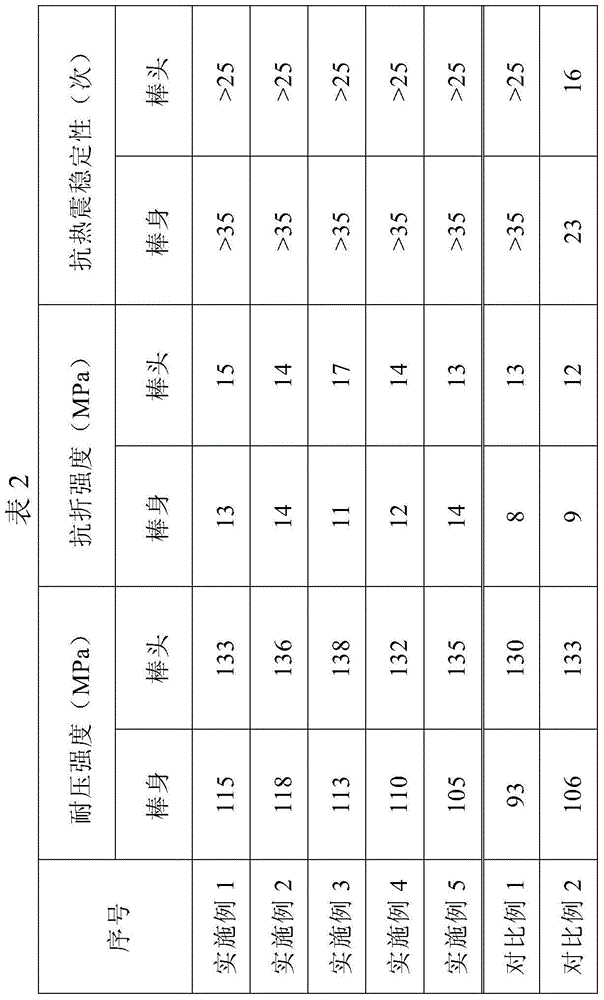

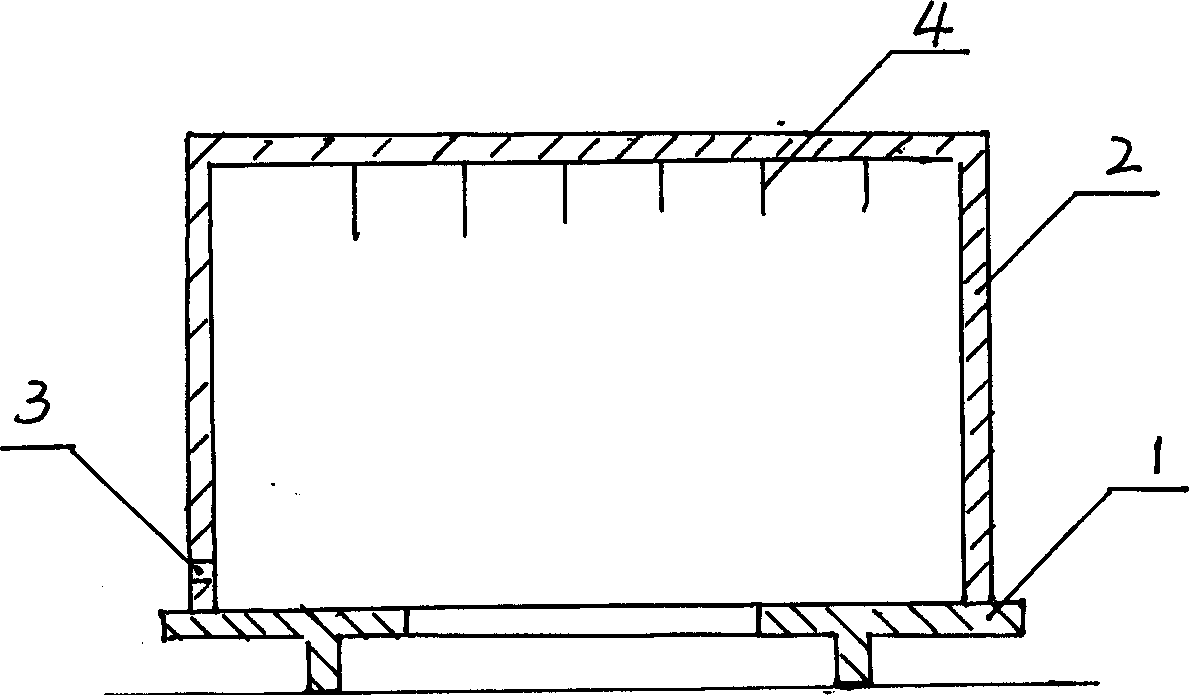

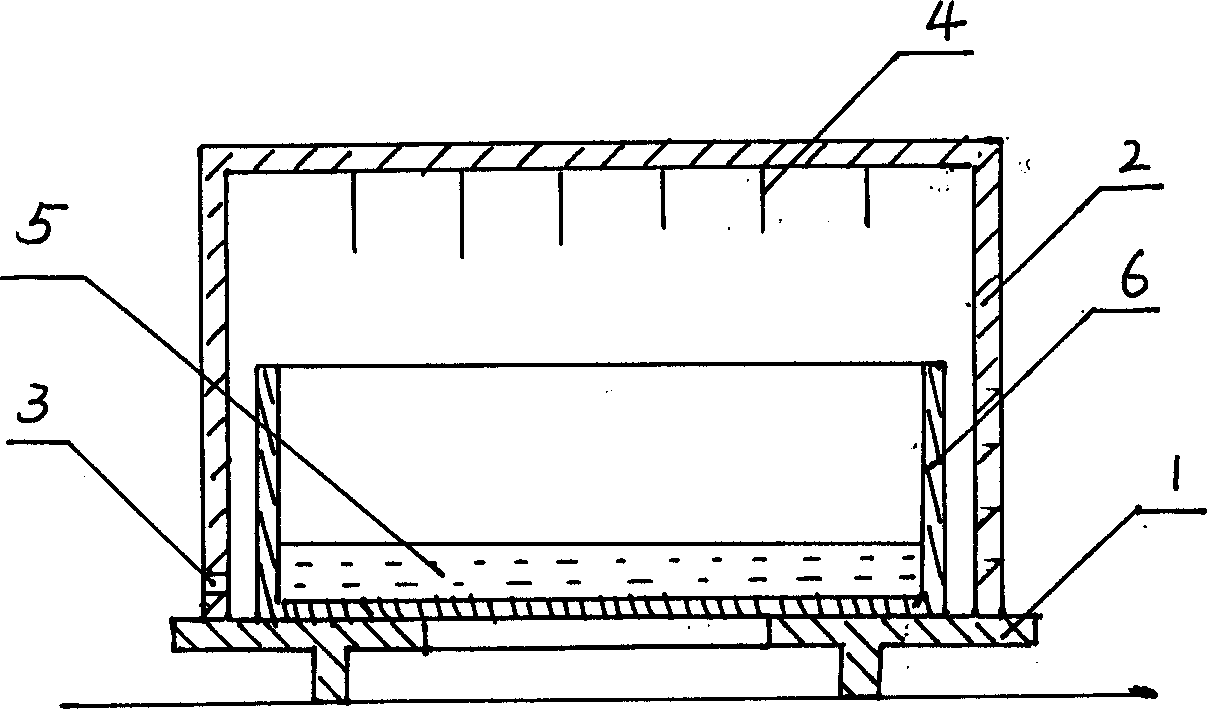

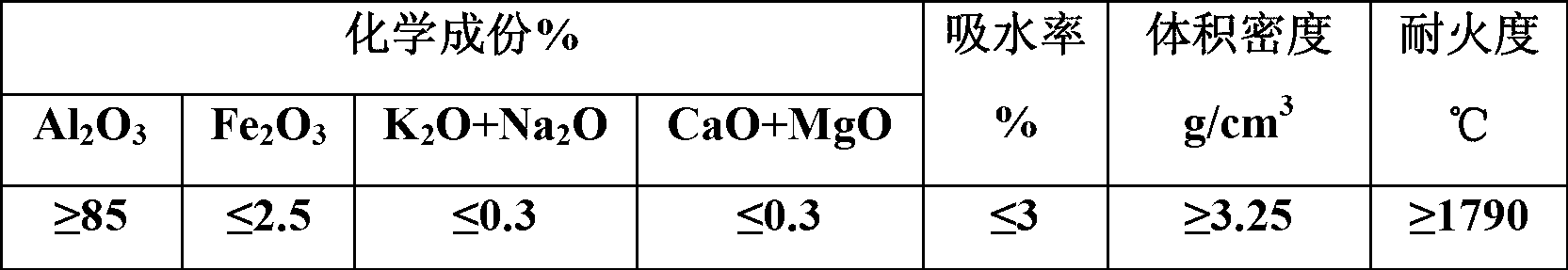

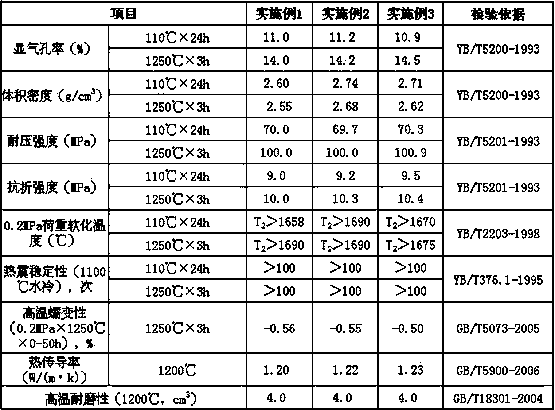

Continuous casting monolithic stopper and method of manufacture thereof

ActiveCN105753489AImprove thermal shock resistanceImprove erosion resistanceMelt-holding vesselsBrickMullite

The invention discloses a continuous casting monolithic stopper and a method of manufacture thereof.The monolithic stopper comprises a stopper body, a steel core inserted into the stopper body and a head connected to the lower end of the stopper body, the surface of the steel core is provided with an anchor, the surface of the monolithic stopper is coated with Al2O3 coating; the stopper body is made by casting castables comprising mullite, the head is made by casting castables comprising corundum and sintered mullite, and the monolithic stopper is manufactured by monolithic casting.The stopper obtained herein is good in monolithicity, is free of brick joint and head shedding problems of sleeve brick stoppers, has good thermal shock resistance, high strength and good resistance to molten steel scour erosion, is simple to manufacture and low in cost, and is suitable for stopping a tundish nozzle under low continuous casting, high-oxygen steel continuous casting and skid flow control.

Owner:BAOSHAN IRON & STEEL CO LTD

Method of producing mixed grain steamed bread

InactiveCN101223898AIncrease the volume of bunsSoft tasteDough treatmentPre-baking dough treatmentYeastCalcium

The invention discloses a production method of steamed bread made of coarse cereals, which is prepared by the following raw materials by weight proportion: 40-50 portions of medium-strength wheat flour, 40-50 portions of coarse cereals powder, 5-10 portions of soybean flour, 1-5 portions of konjak powder, 0.1-1 portion of the mixture of calcium stearyl lactylate and sodium stearyl lactate and 0.5 portion of yeast. The weight ratio of alcium stearyl lactylate to sodium stearyl lactate is 10:1-1:10.

Owner:河南兴泰科技实业有限公司

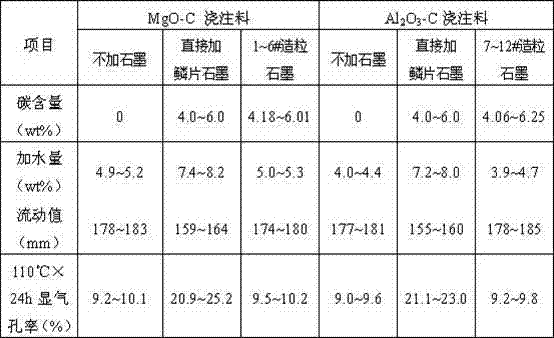

Magnesium carbon pouring material

The invention relates to a magnesium carbon pouring material. The magnesium carbon pouring material is characterized in that the component ratio is counted by weight part and the processing steps are as follows: (1) removing deteriorated layers and steel slag from used magnesium carbon bricks, and then crushing, grinding, magnetically separating and screening the magnesium carbon bricks, thereby obtaining waste brick grains being more than 1 mm and less than 1 mm, and sending the waste brick grains being less than 1 mm to an air separating machine so as to perform air separation and obtain the light components with the average weight less than or equal to 2.4 and the heavy components with the average weight more than or equal to 2.8; and (2) mixing 54-92 parts of magnesium sand, 3-15 parts of aluminum oxide powder and / or spinelle powder, 2-25 parts of heavy component and 2.5-6 parts of bonding agent, thereby obtaining the magnesium carbon pouring material. In the invention, the components with magnesium sand clinkers as main ingredients are separated from the waste magnesium carbon bricks; few graphite carbons and bonding agent carbons are also contained in the components; and the components are added into the magnesium carbon pouring material, so that the quantity of water added during the forming process of the magnesium carbon pouring material is lower and the density of the formed material is higher.

Owner:江苏苏嘉集团新材料有限公司

Steel ladle cover light mullite castable material and preparation method thereof

The invention discloses a steel ladle cover light mullite castable material including an aggregate and a matrix and including the components in parts by weight: the aggregate comprising 30-70 parts of light mullite balls, and the matrix comprising 0-15 parts of tabular corundum, 0-15 parts of mullite particles, 5-15 parts of an alumina micro powder, 5-15 parts of a mullite micro powder, 0-8 parts of a silicon micro powder, 5-15 parts of a binder, and 0.1-0.4 part of a water reducer. The invention also discloses a preparation method of the steel ladle cover light mullite castable material, wherein the preparation method comprises the following steps: firstly, mixing the matrix parts evenly; and then adding the light mullite balls, and then mixing evenly and packing. The steel ladle cover light mullite castable material has the advantages of simple production, high production efficiency, convenient field construction, low volume density, low thermal conductivity coefficient, excellent thermal shock resistance, high strength, and good high temperature volume stability and the like, and has the use temperature reaching up to 1550 DEG C.

Owner:ZHEJIANG ZILI HIGH TEMPERATURE TECH CO LTD

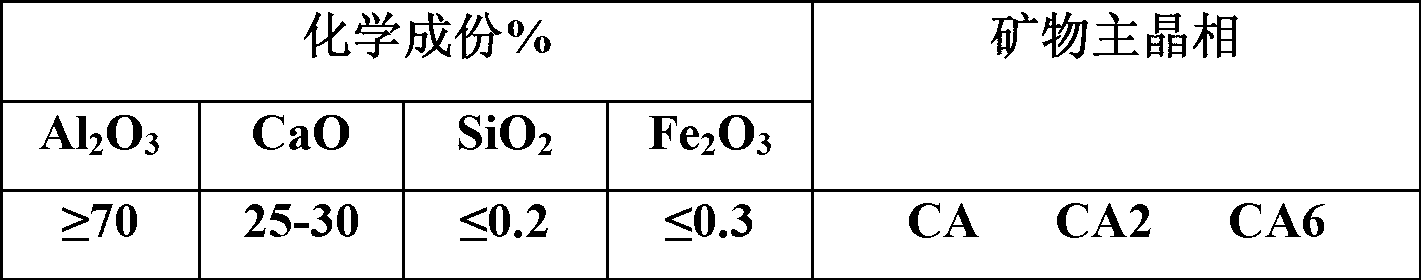

High-temperature walking beam furnace beam and column insulation lining slag-adhesion-preventing coating

The invention discloses a high-temperature walking beam furnace beam and column insulation lining slag-adhesion-preventing coating. The coating comprises the raw materials of, by weight: 55-60% of the bauxite clinker, 5-10% of magnesium aluminate spinel, 5-10% of calcined anthracite, 2-5% of flake graphite, 3-6% of silicon carbide, 4-6 % of alpha-Al2O3 powder, 4-6% silica micro-powder, 5-7% of calcium aluminate cement, 0.5-1.5% of metal silicon powder, 2.5-3.5% of water-soluble epoxy resin and water-soluble curing agent, 0.05-0.10% of explosion-proof fiber, 0.1-0.15% of sodium hexametaphosphate, 0.05-0.10% of an organic reducing agent, and 0. 04-0.07% of an organic silane coupling agent. With the slag-adhesion-preventing coating, the comprehensive targets are achieved, that service lives of the furnace beam and the column insulation lining are prolonged, furnace energy consumption and insulation lining surface slag adhesion amount are reduced, furnace maintenance cost is reduced, and high-temperature-oriented silicon steel production efficiency is improved.

Owner:武汉钢铁有限公司

Method for producing potassium chloride, sodium chloride and magnesium sheet from bittern extracted from carnallite mine

ActiveCN102491373AReduce consumptionReduce dosageMagnesium chloridesAlkali metal chloridesSolubilityEvaporation

The invention discloses a method for producing potassium chloride, sodium chloride and a magnesium sheet from bittern extracted from a carnallite mine. The method provided by the invention comprises the following steps of 1, decomposing carnallite, 2, carrying out evaporation concentration, 3, separating carnallite, 4, preparing a mining injection agent, 5, carrying out heating dissolution and crystallization to obtain potassium chloride, 6, carrying out salt-leaching and drying to obtain sodium chloride, and 7, carrying out magnesium sheet processing. The method provided by the invention has the advantages that the hot mining injection agent is utilized for ore dissolution and thus a yield of sodium chloride and magnesium chloride is greatly reduced in production of per unit amount of potassium chloride because the solubility of potassium chloride is far greater than the solubility of sodium chloride and the solubility of magnesium chloride; a waste salt discharge amount of a follow-up process is reduced; a backfill amount is reduced obviously; a cost is reduced; comprehensive utilization of potassium and magnesium resources of carnallite is realized; and the economic benefits are high.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN +1

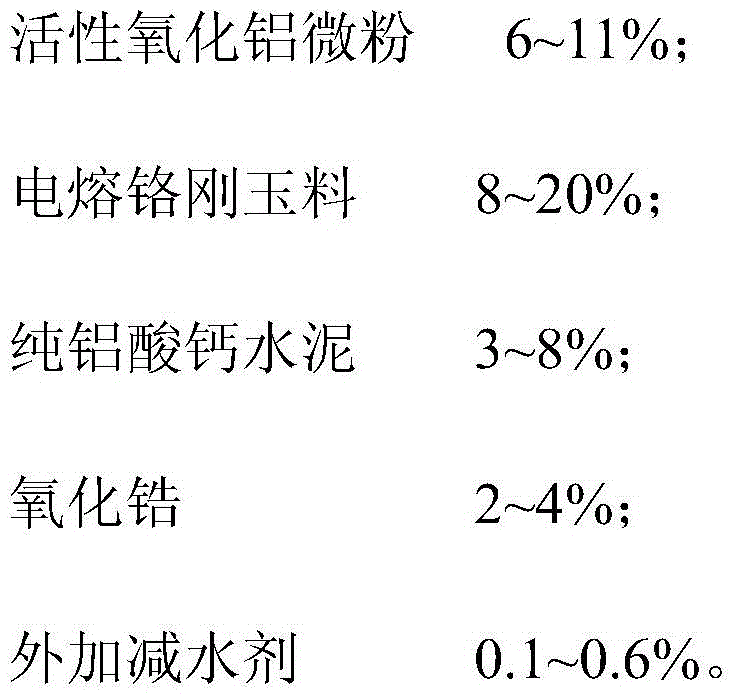

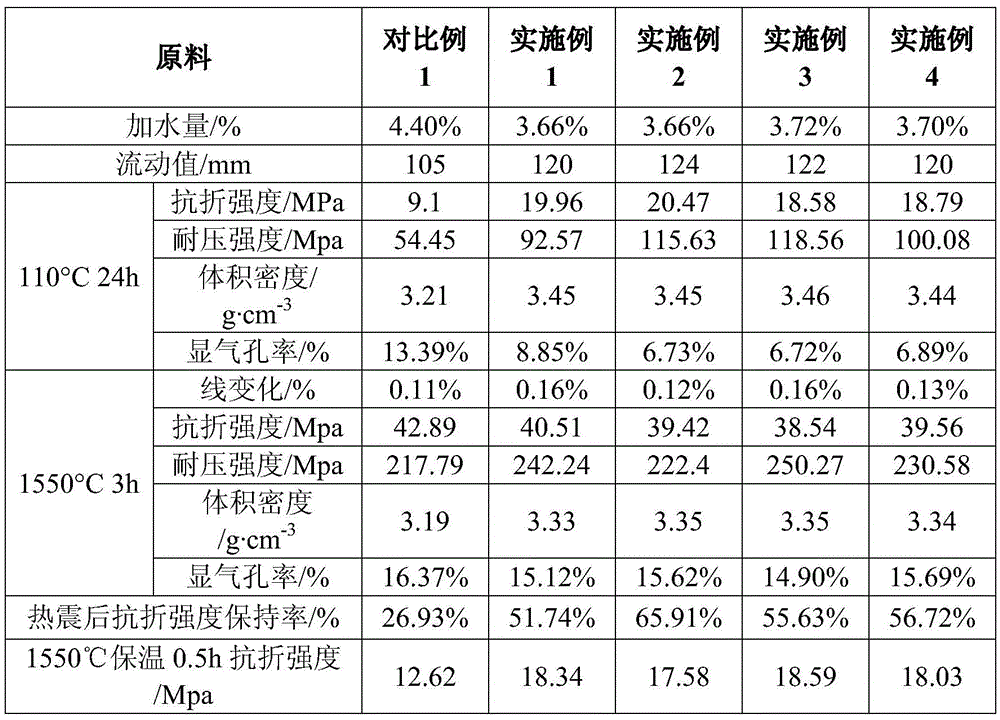

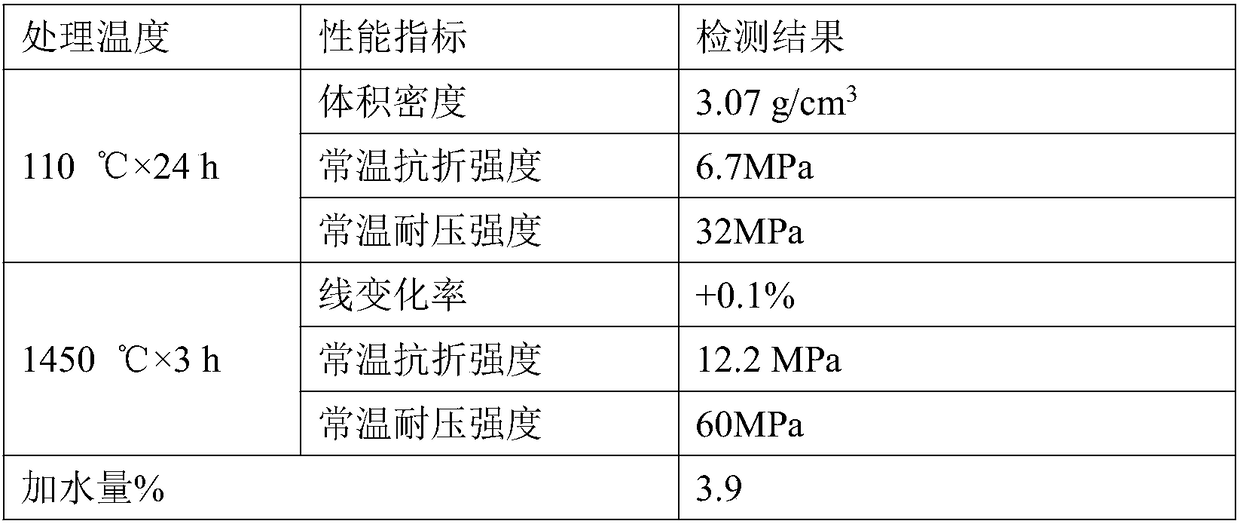

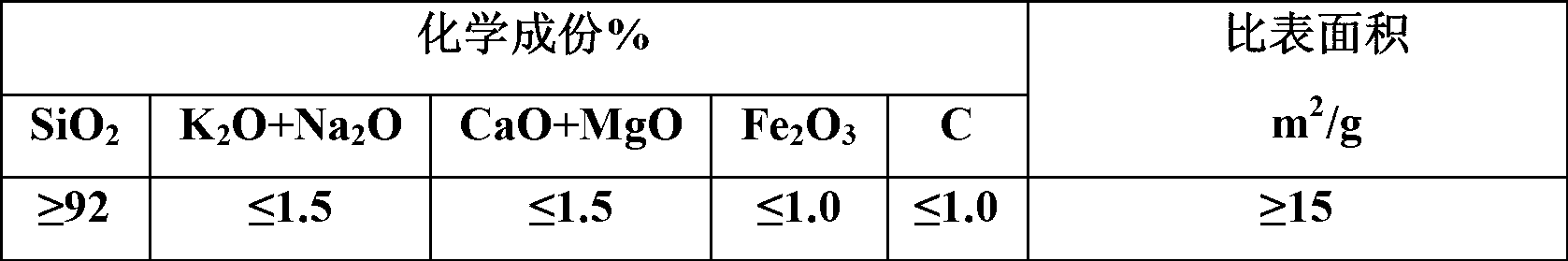

Air brick for special steel refining and preparation method thereof

InactiveCN105645977AReduce the amount of water addedImprove liquidityMelt-holding vesselsBrickCalcination

The invention relates to an air brick for special steel refining, particularly an air brick for special steel refining and a preparation method thereof. The air brick is composed of the following components in percentage by mass: 60-75% of corundum particle and fine powder, 6-11% of activated alumina micropowder, 8-20% of electrofused chrome corundum material, 3-8% of pure calcium aluminate cement, 2-4% of zirconium oxide and 0.1-0.6% of additional water reducing agent. The air brick is suitable for smelting of special steel grades, and has the advantages of excellent high-temperature properties, excellent air permeability, low breaking possibility, favorable high-temperature folding strength and favorable thermal shock resistance. By adopting the curing schedule, the cement in the material can be sufficiently hydrated, thereby enhancing the strength of the semifinished product, and avoiding generating microcracks of possible collisions in the transportation process (the cracks can further extend in the high-temperature calcination process). The firing schedule is adopted to prevent the air brick cracks from generation and enhance the yield of the air bricks.

Owner:LUOYANG LIER REFRACTORY MATERIAL

Microwave heating process and special moisture maintainer for producing rice bran stably

InactiveCN1347661AImprove cooling effectPromote passivationFood preservationFood preparationWood splinterFree cooling

The rice bran producing process of regulating the moisture content of rice bran to 15-24 % includes spreading sieved rice bran in a container, setting the container inside one special moisture maintainer, microwave heating for 2.5-3.5 min to 101-120 deg.c and final natural cooling. The special moisture maintainer consists of one horizontal hollow shelf and one cover with pendulous splinters. The present invention is superior in that heating rice bran in a special moisture maintainer to form stable steam environment is favorable to deactivation of enzyme in rice bran, reduce water and microwave power consumption.

Owner:南京经济学院

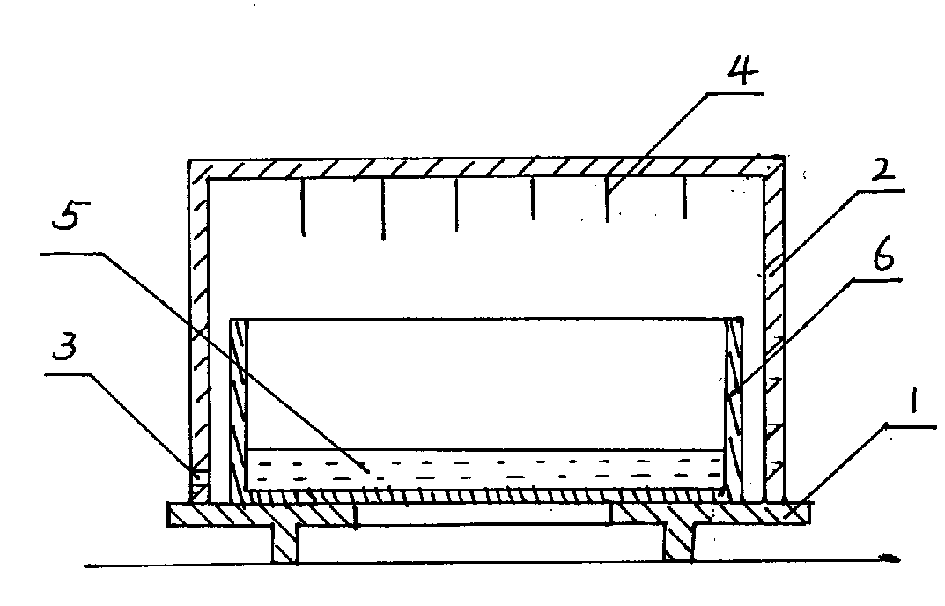

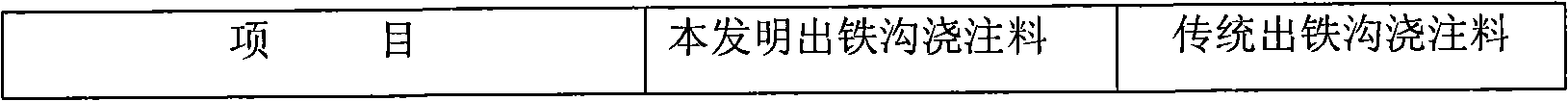

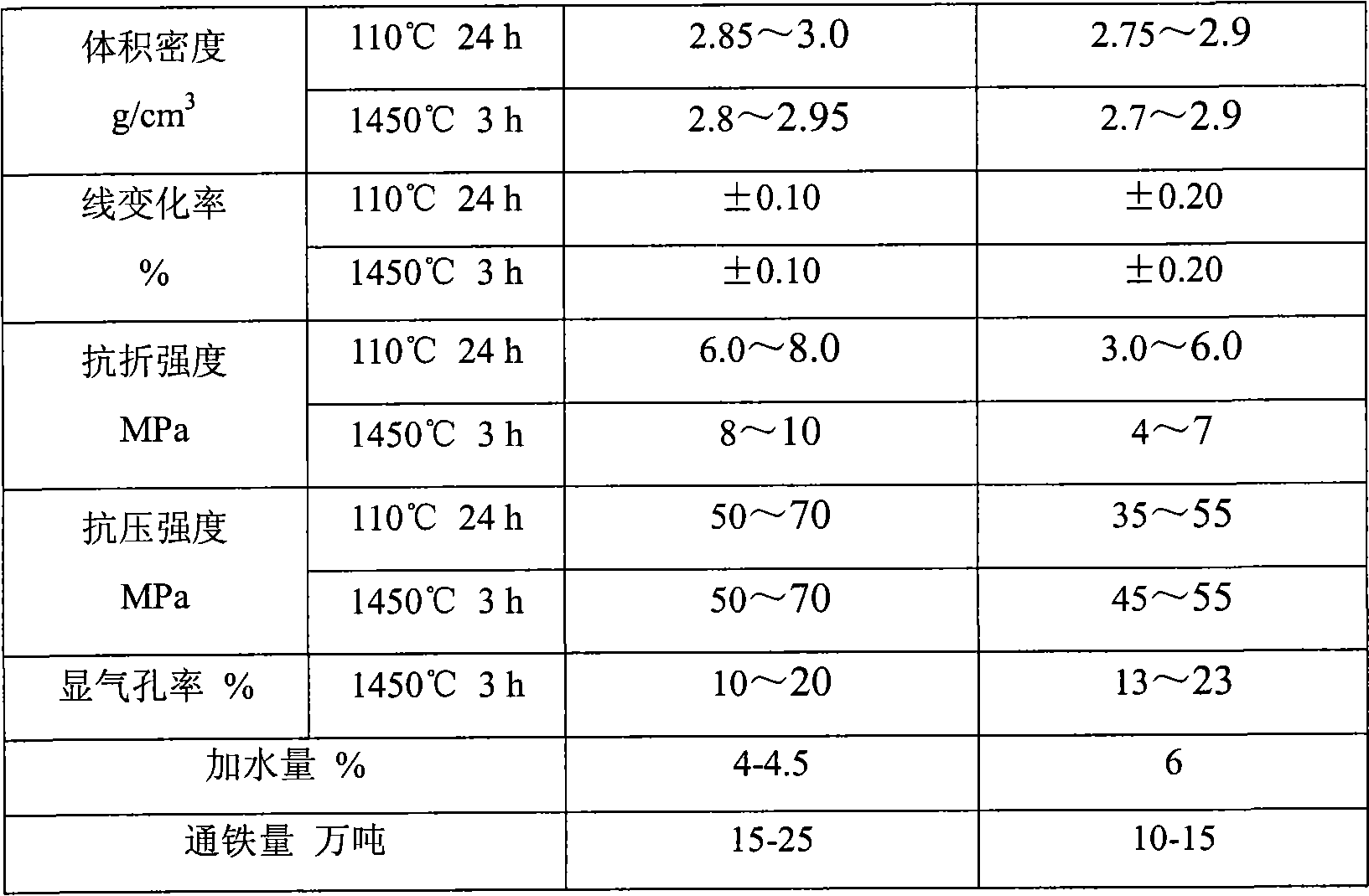

Tapping channel casting material with good oxidation resistance

The invention provides a tapping channel casting material with good oxidation resistance. The casting material comprises the following raw materials in percentage by mass: 60 to 70 percent of white corundum granules with a diameter of 0 to 8 millimeters, 2 to 8 percent of silicon carbide with a diameter of 0 to 1 millimeter, 10 to 16 percent of fine silicon carbide powder of 200 to 325 meshes, 2 to 6 percent of Al2O3 super-micro powder, 2 to 4 percent of SiO2 super-micro powder, 2 to 4 percent of asphalt, 2 to 4 percent of aluminate cement, 1 to 2 percent of clay powder, 1 to 3 percent of metal nitride, and 0.05 to 0.2 percent of polycarboxylic acid water reducing agent. The tapping channel casting material has the advantages that: the water consumption of the casting material is obviously reduced, the porosity of the casting material is reduced, the compactness and the strength of the casting material are improved, the flowing property of the casting material is improved, and the constructability of the casting material is improved; the casting material has excellent oxidation resistance and corrosion resistance to molten slag and molten iron; and the service life of the casting material is greatly improved.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

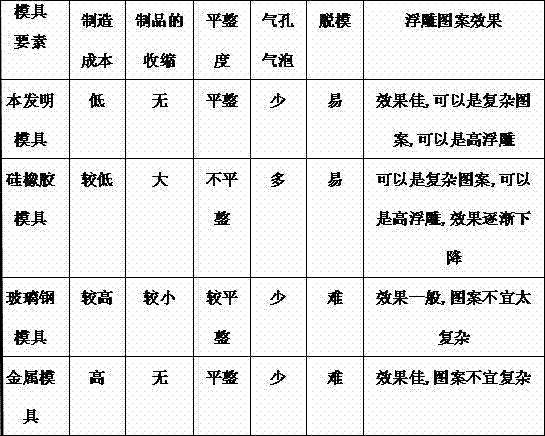

Production method of gypsum relief product

InactiveCN102343758AImprove surface strengthHigh strengthDecorative surface effectsOrnamental structuresFiberWeather resistance

The invention, belonging to the field of ornaments, relates to a method for producing a gypsum relief product, comprising the following steps: (1) preparing slurry, (2) making a die, (3) grouting, and (4) surface protection of the product. The step of preparing slurry comprises the following steps: 1, material preparation: high strength gesso a, redispersible polymer powder b, peach gum c, sodium tetraborate d, chopped fiber e, and water f; 2, preparation method: mixing f, b, c, d, and e with the weight ratio of f to b to c to d to e of 1000 to (40-50) to (3-5) to (2-3) to (15:20) to obtain a mixed emulsion g, and mixing a with g with the weight ratio of a to g of 1 to 1 to obtain slurry h. The gypsum relief product disclosed herein has the advantages of high surface hardness, scratch resistance, good toughness, impact resistance, strong weatherability, water resistance, and light weight.

Owner:义乌市项羽工艺品厂

Fiber-reinforced composite refractory castable for molten iron desulphurization lance and preparation method of fiber-reinforced composite refractory castable

The invention relates to a fiber-reinforced composite refractory castable for a molten iron desulphurization lance and a preparation method of the fiber-reinforced composite refractory castable. According to the technical scheme, the method comprises the steps of dispersing the following raw materials in parts by weight: 1-4 parts of mullite powder, 3-5 parts of kyanite, 5-8 parts of fused dense corundum powder, 5-8 parts of alpha-Al2O3 micro powder, 4-7 parts of silica powder, 1-4 parts of silicon carbide powder and 5-7 parts of pure aluminum silicate cement and an additive into a flat container and mixing evenly by using a rake; adding the following raw materials in parts by weight: 10-15 parts of first-level bauxite chamotte, 30-38 parts of natural fused mullite, 20-25 parts of andalusite and 1-2 parts of high-purity fused mullite particles; and pouring the mixed materials into a stirrer for stirring to obtain the fiber-reinforced composite refractory castable for the molten iron desulphurization lance. The fiber-reinforced composite refractory castable is low in cost and wide in raw material source, the obtained product is good in mechanical property and thermal shock resistance, the service life of the molten iron desulphurization lance can be prolonged, and the desulphurization cost can be reduced.

Owner:WUHAN UNIV OF SCI & TECH

Castable for ladle deslagging plate, and preparation method and applicable of castable

The invention discloses a castable for a ladle deslagging plate, and a preparation method and an applicable of the castable. The castable for the ladle deslagging plate comprises the following components in parts by weight: 50-70 parts of mullite, 10-20 parts of andalusite, 10-20 parts of bauxite powder, 3-5 parts of pure calcium aluminate cement, 4-6 parts of aluminum oxide micropowder, 3-5 parts of silicon carbide micropowder and 2-3 parts of compound additive, wherein the compound additive is a combination of two or more of organic fiber, steel fiber, and sodium tripolyphosphate or sodium hexametaphosphate. When the castable is cast on the outer surface of the ladle deslagging plate, the service life of the ladle deslagging plate can be prolonged and the preparation cost can be reduced; and the preparation method of the castable for the ladle deslagging plate is simple, and easy to operate.

Owner:WUGANG REFRACTORY CO LTD

Wear resistant pouring material and method of preparing same

ActiveCN101337801ALower sintering temperatureReduce the amount of water addedWear resistantRotary furnace

The invention discloses a wearable castable material, which comprises the following components by weight: 15 to 25 parts of porcelain granule of 0 to 1mm; 10 to 20 parts of porcelain granule of 1 to 5mm; 35 to 55 parts of calcined andalusite granule of 1 to 5mm; 4 to 6 parts of 1000-mesh Alpha aluminum micro-powder; 3 to 5 parts of silicon micro-powder; 4 to 5 parts of pure calcium aluminate cement; 0.1 to 0.3 parts of a water reducer of silicate type; 5 to 7 parts of water. The invention further discloses a preparation method of the wearable castable material. The wearable castable material has high alkali-proofness, resistance to erosion of chlorine, fire resistance, and abrasive resistance, and is applicable for masonry of various large cement rotary furnaces and destructors.

Owner:无锡远能耐火材料有限公司

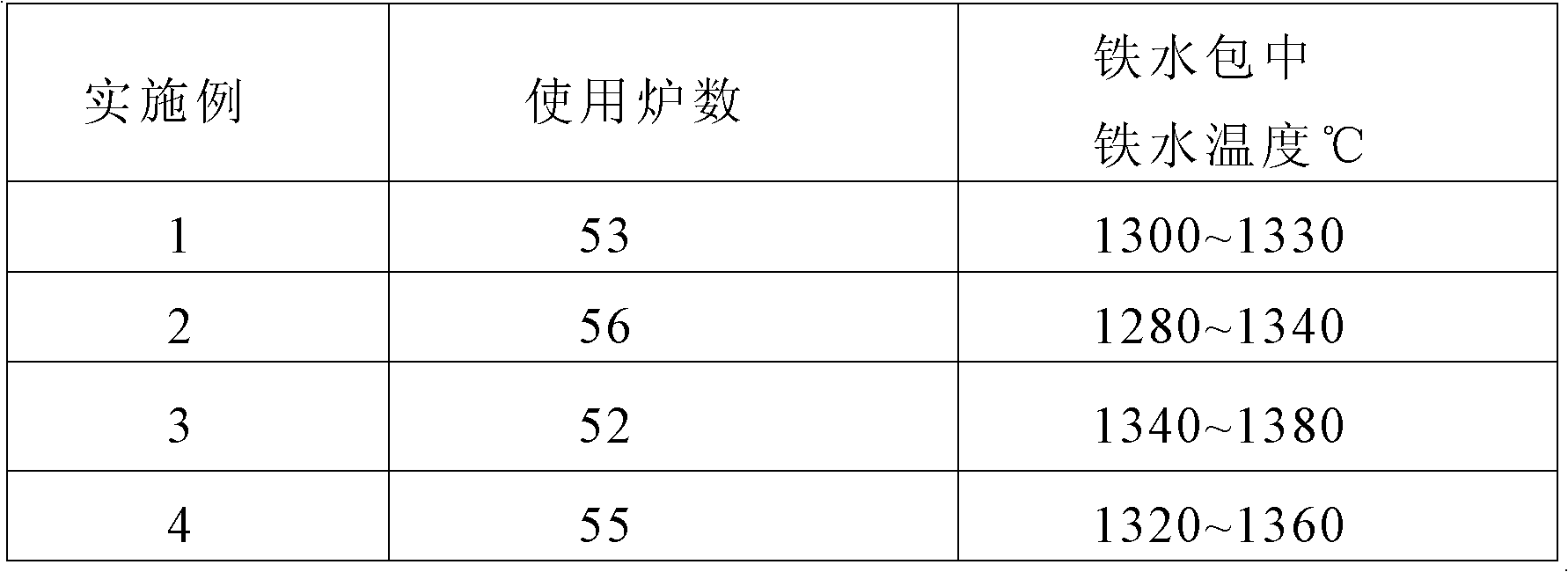

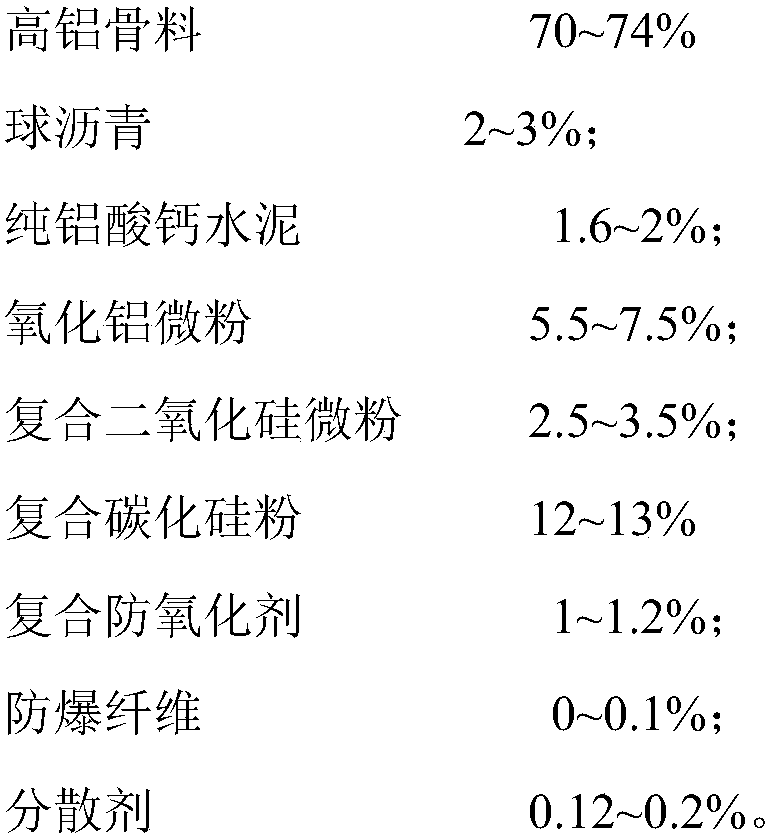

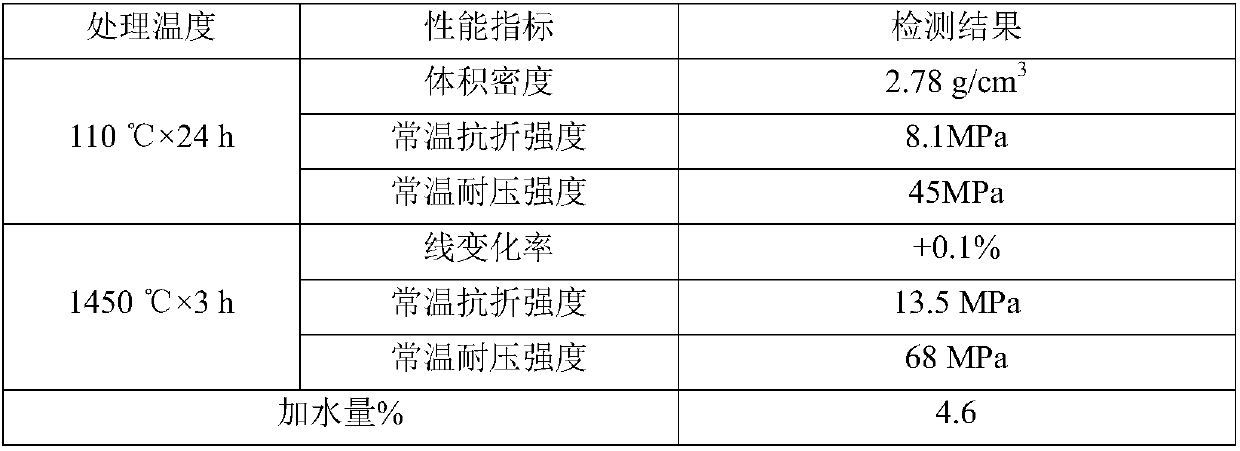

Iron trough castable containing 70% or above of high-aluminum aggregates

The invention belongs to the field of unshaped refractory materials and in particular relates to an iron trough castable containing 70% or above of high-aluminum aggregates. The iron trough castable comprises the components in percentage by mass: 70-74% of high-aluminum aggregates, 2-3% of spherical asphalt, 1.6-2% of calcium aluminate cement, 5.5-7.5% of alumina micropowder, 2.5-3.5% of compositesilicon dioxide micropowder, 12-13% of composite silicon carbide powder, 1-1.2% of composite antioxidant, 0-0.1% of anti-explosion fibers and 0.12-0.2% of dispersant. By combining with a plurality ofimprovement means, the addition amount of the high-aluminum aggregates can be effectively increased (the addition amount can reach 70% or above), and the water addition amount used when the castableis prepared is reduced; and proved by actual industrial applications, the use effect of the iron trough castable in a non-impact region of a main trough reaches the use effect of a common corundum iron trough castable, so that the production cost of the iron trough castable and the whole contracting cost of an iron trough can be greatly reduced.

Owner:中冶武汉冶金建筑研究院有限公司

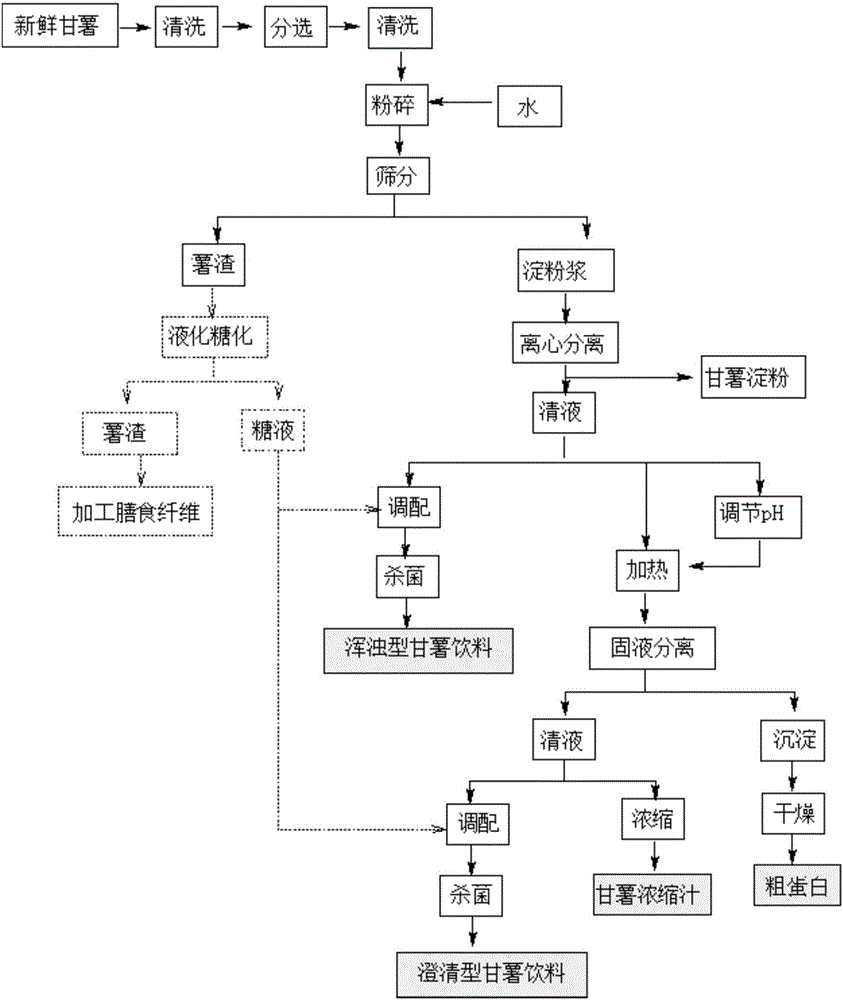

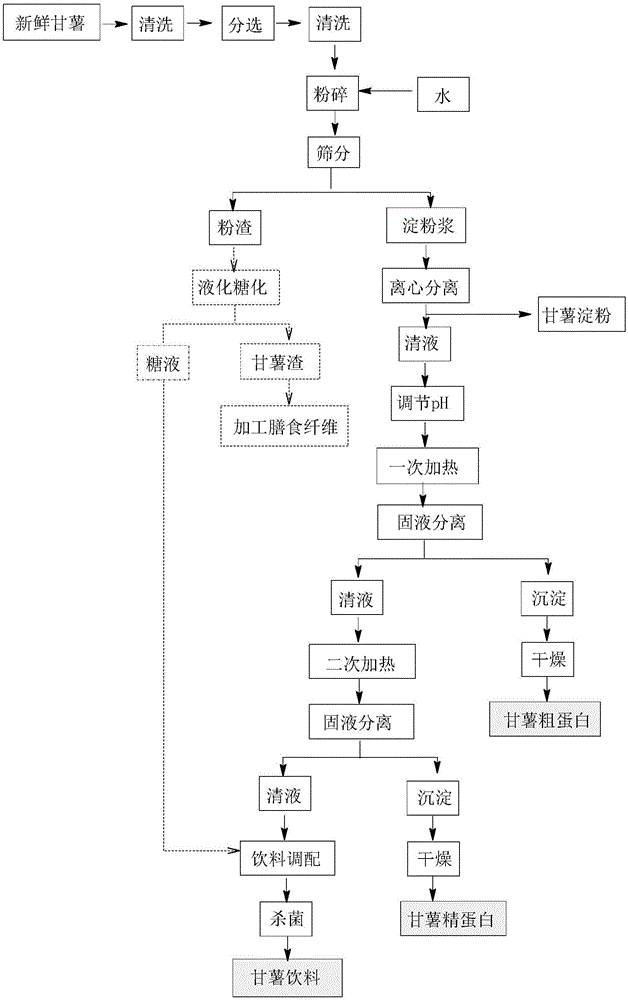

Sweet potato beverage preparation method

The invention discloses a sweet potato beverage preparation method. According to the characteristics of sweet potato starch processing, a processing technology in prior art is partly adjusted as follows: material washing and selection are strengthened, and slurry quality is improved; water adding amount in a crushing stage is appropriately reduced, soluble solid content of starch slurry separation liquid is increased, and the part clear liquid is further processed into a sweet potato beverage. By pH regulation, heating and other processing, proteins in the sweet potato starch processing separation liquid can be separated, and then a clear type sweet potato beverage is prepared by allocation, or a turbid-type sweet potato beverage is prepared by direct allocation. By the process, sweet potato starch processing wastewater is turned into wealth from waste, emissions of organic wastewater with high concentration in sweet potato starch processing process can be greatly reduced, the produced sweet potato beverage can bring considerable economic benefits to enterprises, and the sweet potato beverage preparation method has very good promotion and application value in sweet potato starch processing enterprises.

Owner:SHANDONG FOOD & FERMENT IND RES & DESIGN INST

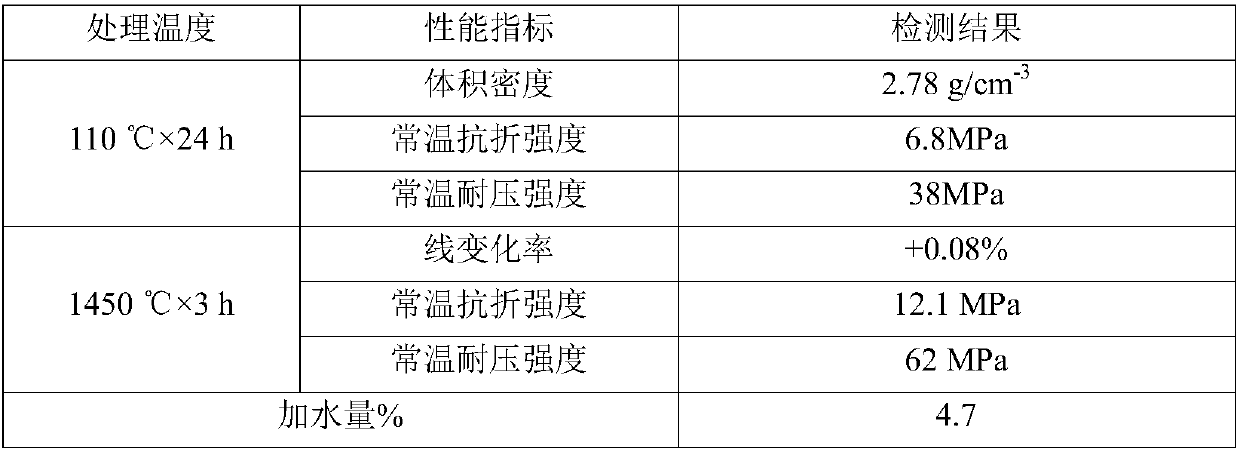

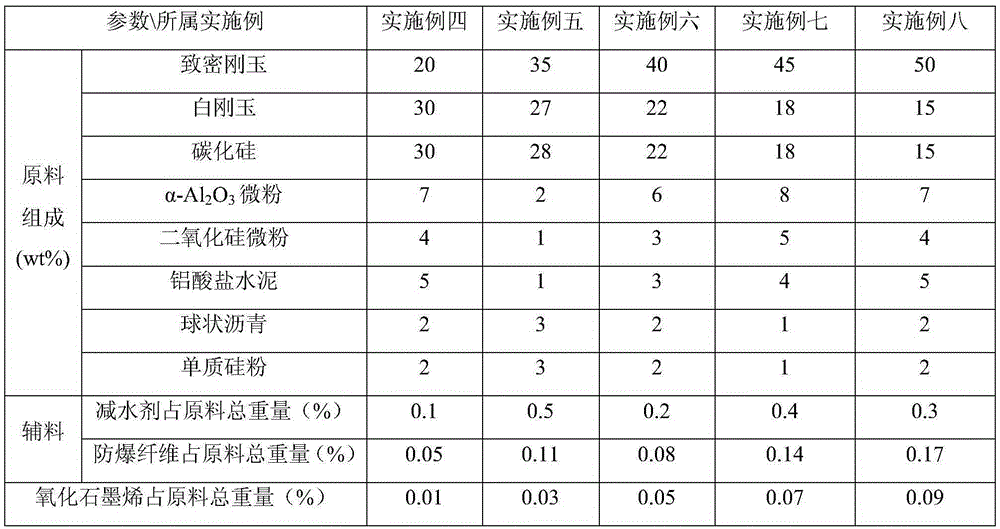

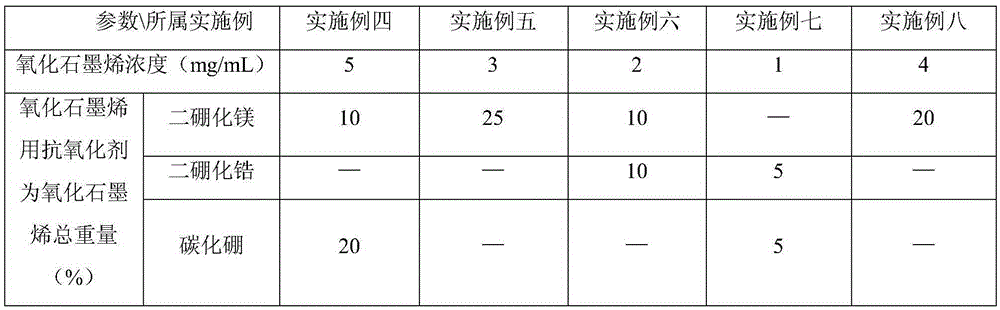

Preparation method of iron runner castable containing graphene oxide

ActiveCN105294134ASimple manufacturing process stepsProcess parameters are easy to controlFiberPorosity

The invention provides a preparation method of an iron runner castable containing graphene oxide, comprising the following steps: step 1: premixing materials, and mixing raw materials and auxiliary materials evenly, wherein the raw materials contain dense corundum, white corundum, carborundum, alpha-Al2O3 micropowder, silicon dioxide micropowder, aluminate cement, ball pitch and monatomic silicon powder, and the auxiliary materials comprise a water reducer and explosion-proof fiber; step 2, adding graphene oxide solution and an antioxidant for the graphene oxide. By applying the technical scheme, the preparation method has the following effects: (1) preparation steps are simplified, and are suitable for industrial production; (2) the added graphene oxide can reduce the usage amount of common carbonaceous materials such as the ball pitch, and the production of poisonous and carcinogenic gas can be reduced when the iron runner castable is used in a high temperature environment; (3) the content of carbon in the castable can be effectively increased by the addition of the graphene oxide, the additive quantity of water and the porosity of the iron runner castable can be reduced, and the structural strength, thermal shock resistance and corrosion resistance of the iron runner castable are enhanced.

Owner:CENT SOUTH UNIV

Environment-friendly castable for blast furnace iron runners

The invention belongs to the field of refractory materials, and mainly relates to an environment-friendly castable for blast furnace iron runners. The castable is composed of, by weight, 50 parts to 85 parts of corundum raw materials, 8 parts to 30 parts of silicon carbide based raw materials, 1 part to 10 parts of palletized carbon black, 2 parts to 6 parts of silica fume, 1 part to 5 parts of calcium aluminate cement, 0.3 part to 3 parts of antioxidants, 0.1 part to 0.3 part of water reducing agents, 0.01 part to 0.2 part of wetting agents and 3.2 parts to 5 parts of water. The environment-friendly castable has the advantages of being low in water addition, high in carbon content, compact in structure, large in hot strength and excellent in anti-scouring performance, not causing site environment pollution in a construction utilization process, and being environment-friendly.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

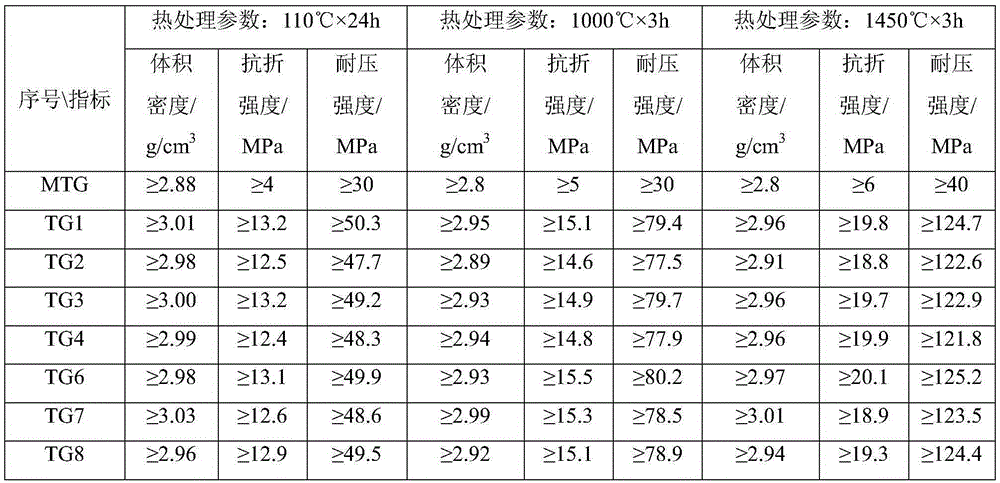

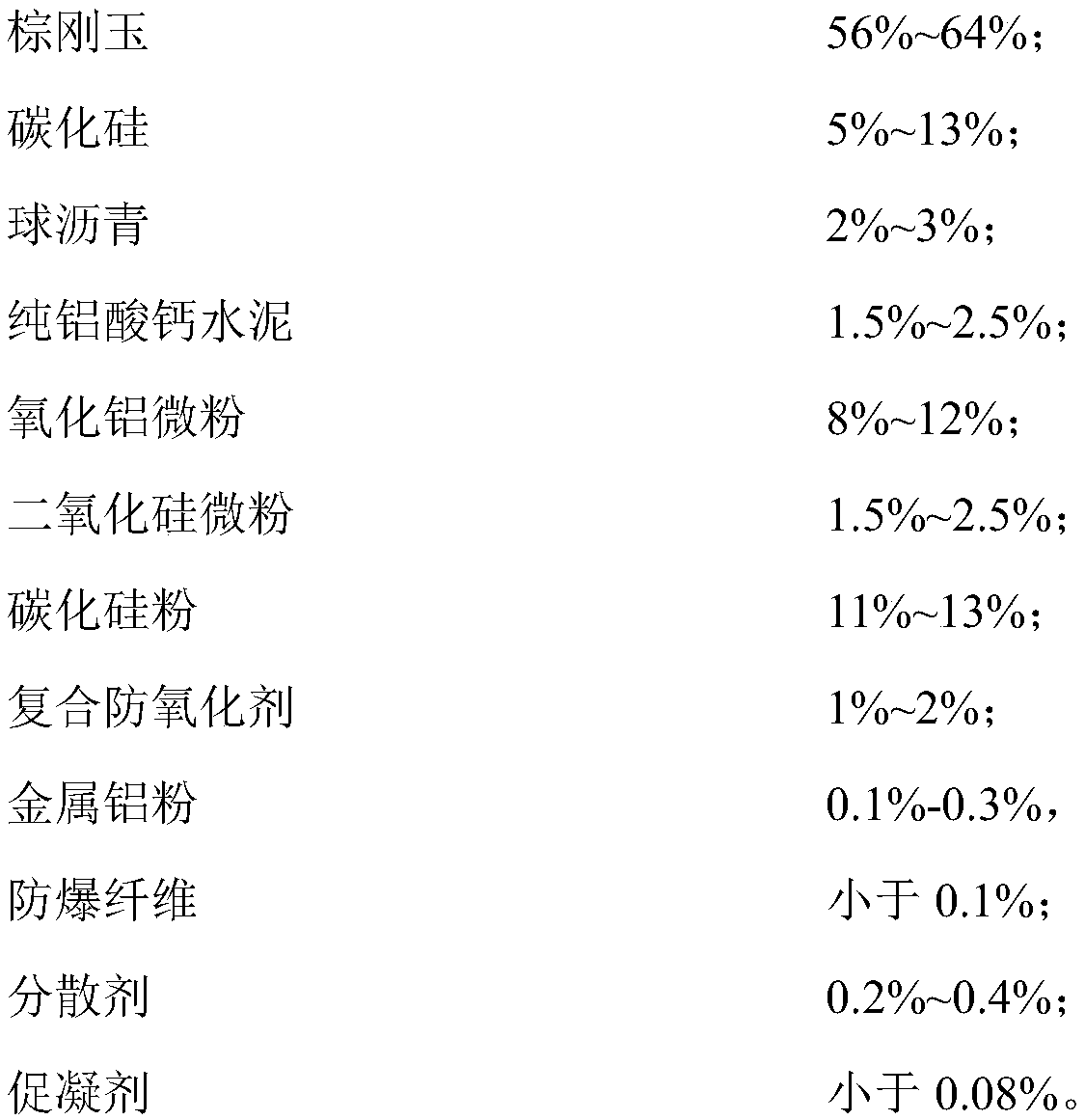

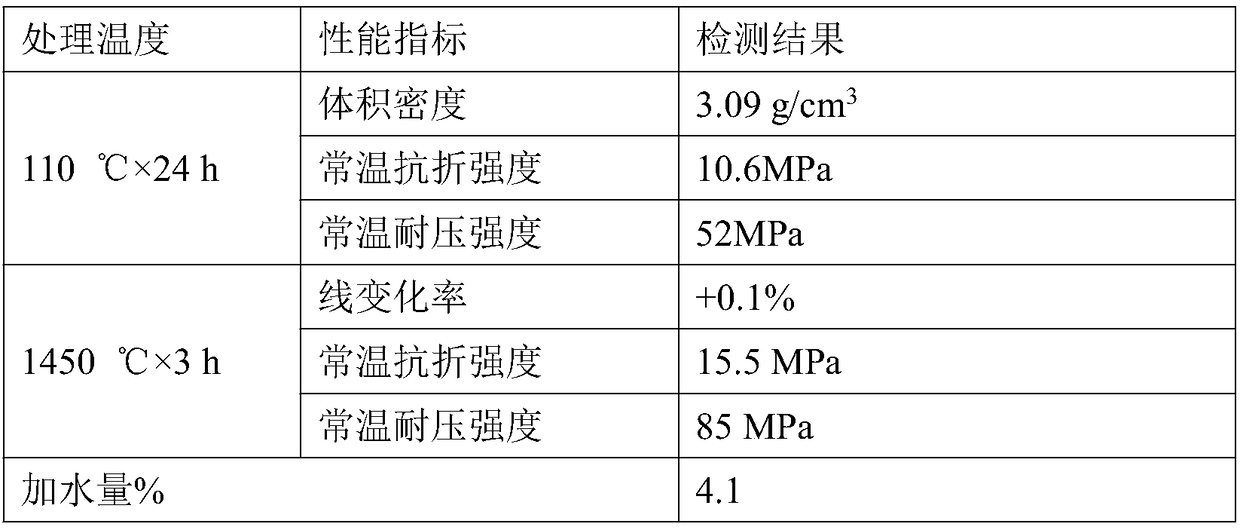

Long-service-life iron runner castable for hot repair

The invention discloses a long-service-life iron runner castable for hot repair. The long-service-life iron runner castable for hot repair comprises the following components in percentage by mass: 56%-64% of brown fused alumina, 5%-13% of silicon carbide, 2%-3% of ball pitch, 1.5%-2.5% of calcium aluminate cement, 8%-12% of alumina micro-powder, 1.5%-2.5% of silicon dioxide micro-powder, 11%-13% of silicon carbide powder, 1%-2% of a composite antioxidant, 0.1%-0.3% of metal aluminum powder, less than 0.1% of explosion-proof fibers, 0.2%-0.4% of a dispersing agent and 0.08% of a coagulant. Thenovel coagulant is used for the iron runner castable, thus, the metal aluminum powder in the iron runner castable produces hydrogen ahead of time, the gas is generated to open an exhaust hole when thecastable is not cured, then, the castable is matched with the suitable metal aluminum powder and the low-melting-point explosion-proof fibers, and it ensures that the castable has excellent high-temperature usability while meeting the condition of construction.

Owner:中冶武汉冶金建筑研究院有限公司

Full resource utilization method of sweet potato starch processing wastewater

ActiveCN106333193AIncrease sewage treatment loadReduce environmental loadPeptide preparation methodsPlant peptidesProtein contentChemistry

The invention discloses a full resource utilization method of sweet potato starch processing wastewater. Sweet potato protein is extracted by the utilization of sweet potato juice liquor. Firstly, part of sweet potato protein is separated by pH regulation and low-temperature heating, protein content is about 50-60%, and the separated sweet potato protein is used as a feed protein product; residual liquor is continuously heated to 95-105 DEG C, and protein ingredient is precipitated out and the part of protein with high content (85% and above) and good condition can be used as excellent sweet potato protein to be used for food processing; and liquor obtained after separation of protein is used for preparing a sweet potato beverage. Other nutritional ingredients in the liquor are maintained. By the method, the sweet potato starch high-concentration wastewater resource is utilized to the maximum.

Owner:SHANDONG FOOD & FERMENT IND RES & DESIGN INST

Microporous high-penetration-resistance high-aluminum casting material, and preparation method and application method thereof

The invention discloses a microporous high-penetration-resistance high-aluminum casting material, and a preparation method and an application method thereof. The casting material is prepared from the following components in parts by weight: 51-95 parts of aggregate, 23.5-41.5 parts of powder, 3-6 parts of composite dewetting agent and 0.02-0.4 part of composite water reducing agent, wherein the aggregate is superfine bauxite chamotte; and the powder contains 180-mesh superfine bauxite fine powder, 800-mesh superfine bauxite fine powder, CA-70 cement, alpha-Al2O3 micro powder and SiO2 micro powder. A lining cast by the microporous high-penetration-resistance high-aluminum casting material provided by the invention is low in porosity, small in pore size of air pores and high in resistance to aluminum alloy liquid-state or vapor-state element penetration and corrosion; the aluminum alloy melt penetration resistance is improved; the mechanical strength is high, the high-temperature volume is stable, and the thermal shock resistance is favorable; and nodulation and bulge phenomena at the three-phase juncture can be effectively avoided.

Owner:贵阳联合高温材料有限公司

Wear-resistant and thermal shock-resistant lining for air supply branch pipe of iron-making blast furnace and preparation method thereof

The invention relates to a wear-resistant and thermal shock-resistant lining for an air supply branch pipe of an iron-making blast furnace and a preparation method thereof. The wear-resistant and thermal shock-resistant lining comprises the following raw materials in percentage by weight: 20.65-31.85 percent of substrate, 65-72 percent of aggregate, 0.05-0.15 percent of explosion-proof fiber, 3-7 percent of a bonding agent and 0.1-0.2 percent of a dispersing agent. The preparation method of the wear-resistant and thermal shock-resistant lining comprises the following steps: mixing the raw materials with a certain weight of water into pouring material; after pouring, curing and carrying out thermal treatment to prepare the lining for the air supply branch pipe. In the wear-resistant and thermal shock-resistant lining, the substrate is composed of andalusite fine powder with 200 meshes, corundum fine powder, alpha-Al2O3 micro powder and SiO2 micro powder; the aggregate is composed of clay clinker particle and andalusite particle with a grain size grade of 3-0.074 mesh. The wear-resistant and thermal shock-resistant lining and the preparation method thereof have the benefits that in the use process, mullite converted from the andalusite can form a weaving structure with the other raw materials and can play bridging and toughening roles, so that the thermal shock resistance of raw material products is improved; the expansion effect of the mullite is durable, the volume stability is good, and the service life of the lining is long.

Owner:ZHENGZHOU ANNEC IND

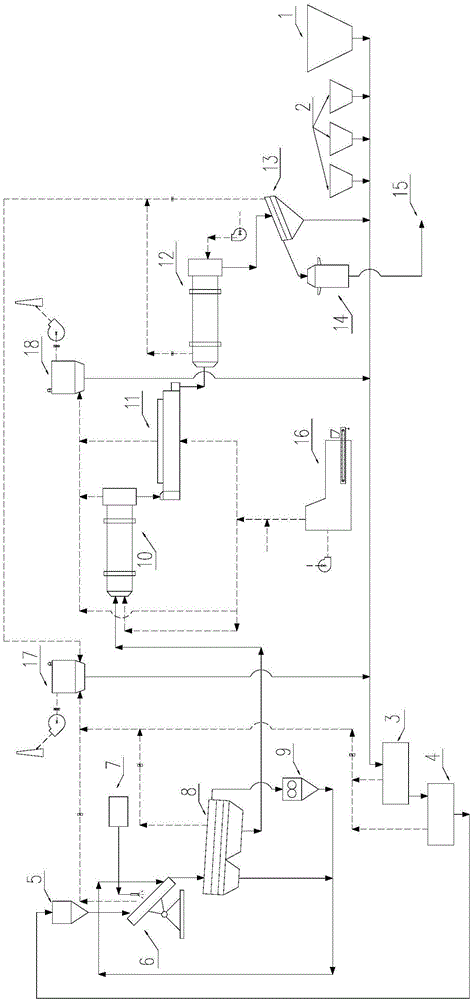

Round granule ore fertilizer pelleting process and device

ActiveCN106495811AAvoid cloggingHigh ball rateCalcareous fertilisersMagnesium fertilisersEngineeringUltimate tensile strength

The invention discloses a round granule ore fertilizer pelleting process which comprises the following steps: I) preparing raw materials; II) performing stirring mixing; III) performing pelleting; IV) screening wet granules; V) performing first-stage drying; VI) performing second-stage drying; VII) cooling; VIII) screening a finished product; IX) packaging the finished product. The invention further discloses a pelleting device with the process. The pelleting device comprises a mixing machine, a disc pelleting machine, a staged rotary screen, a rotary drying machine, a vibration fluid bed dryer, a rotary cooling machine and a vibration screen. The round granular ore fertilizer pelleting process is high in pelleting disc balling yield, low in granule crushing rate in the drying procedure, high in yield of the whole system, advanced in pelleting process, low in drying cost, small in water amount, high in granule strength of a round granule ore fertilizer product, good in sphericity degree and high in market acceptance degree.

Owner:TIANJIN CEMENT IND DESIGN & RES INST +1

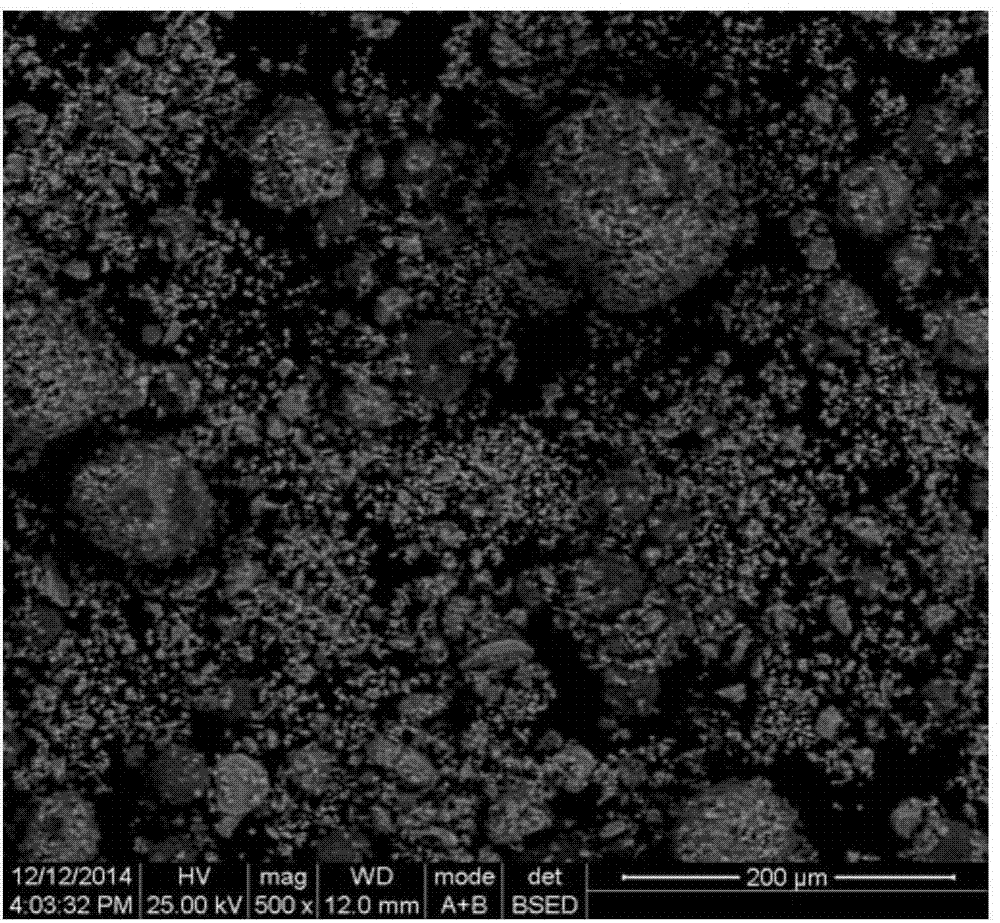

Preparation method of dispersive aluminum oxide for castable and castable

The invention discloses a preparation method of dispersive aluminum oxide for a castable. The method comprises the following steps: mixing aluminum oxide powder, a water reducing agent and a thickening time control agent to obtain the dispersive aluminum oxide, wherein the granularity of the aluminum oxide powder simultaneously meet the following formula requirements: D50 is smaller than or equal to 10 micrometers and D90 is smaller than or equal to 20 micrometers. The dispersive aluminum oxide is prepared from the following constituents in parts by weight: 60-95 parts of the aluminum oxide powder, 5-40 parts of the water reducing agent and 0-5 parts of the thickening time control agent. The preparation method provided by the invention is simple in technology and low in cost; the prepared dispersive aluminum oxide can uniformly disperse in the castable; the additive quantity of water in the castable can be obviously reduced; the coagulation performance of the castable can be effectively regulated; the constructability, anti-bleeding property and early strength of the castable are improved.

Owner:浙江自立新材料股份有限公司

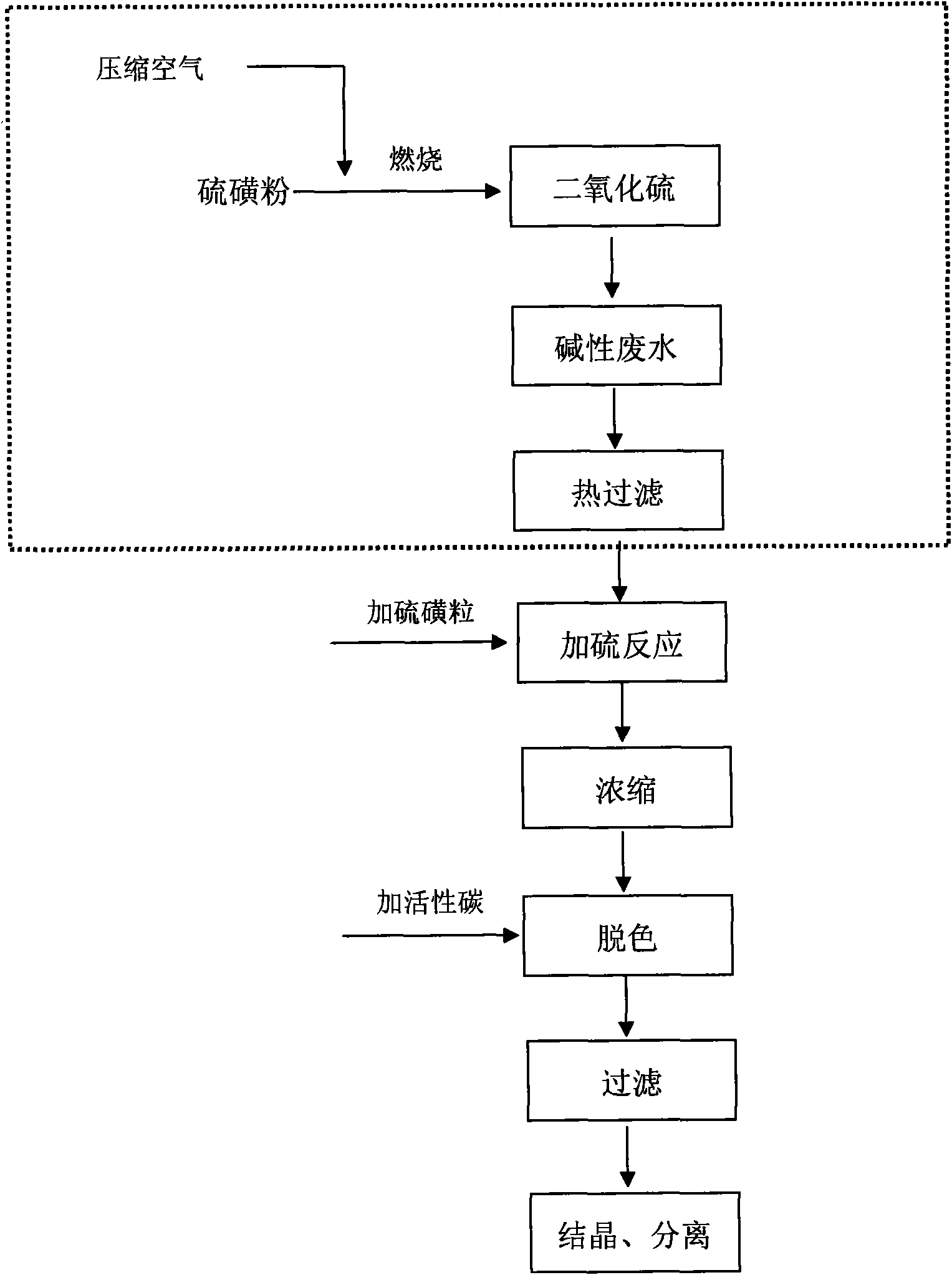

Method for producing sodium thiosulfate

InactiveCN101654227AReduce and electricity consumptionReduce and power consumptionThiosulfates/dithionites/polythionitesChemical industryNitro compound

The invention relates to an improved process for producing sodium thiosulfate in the field of the chemical industry. The improved process uses alkali waste water deoxidized by an aromatic nitro compound sodium sulfide as a raw material and comprises the process steps of sulfur oxidization, introduction of sulfur dioxide into the alkali waste water, heat filtration, sulfur treatment, concentration,active carbon decoloration, filtration, crystallization and separation. The improved process is characterized in that the technological processes of the sulfur oxidization and the introduction of sulfur dioxide into the alkali waste water comprise the following steps: crushing solid sulfurs and then inputting the crushed sulfur into a combustion furnace; introducing air into the furnace so as toensure that the sulfur powder is oxidized into a sulfur dioxide gas; imputing the sulfur dioxide gas into a reaction kettle to react with sodium hydrate and sodium sulfide in the alkali waste water soas to generate sodium sulfite; and then obtaining the finished product of the sodium thiosulfate through the process steps of the heat filtration, the sulfur treatment, the concentration, the decoloration, the filtration, the crystallization and the separation. The process saves energy resources and reduces the cost.

Owner:陈小毛

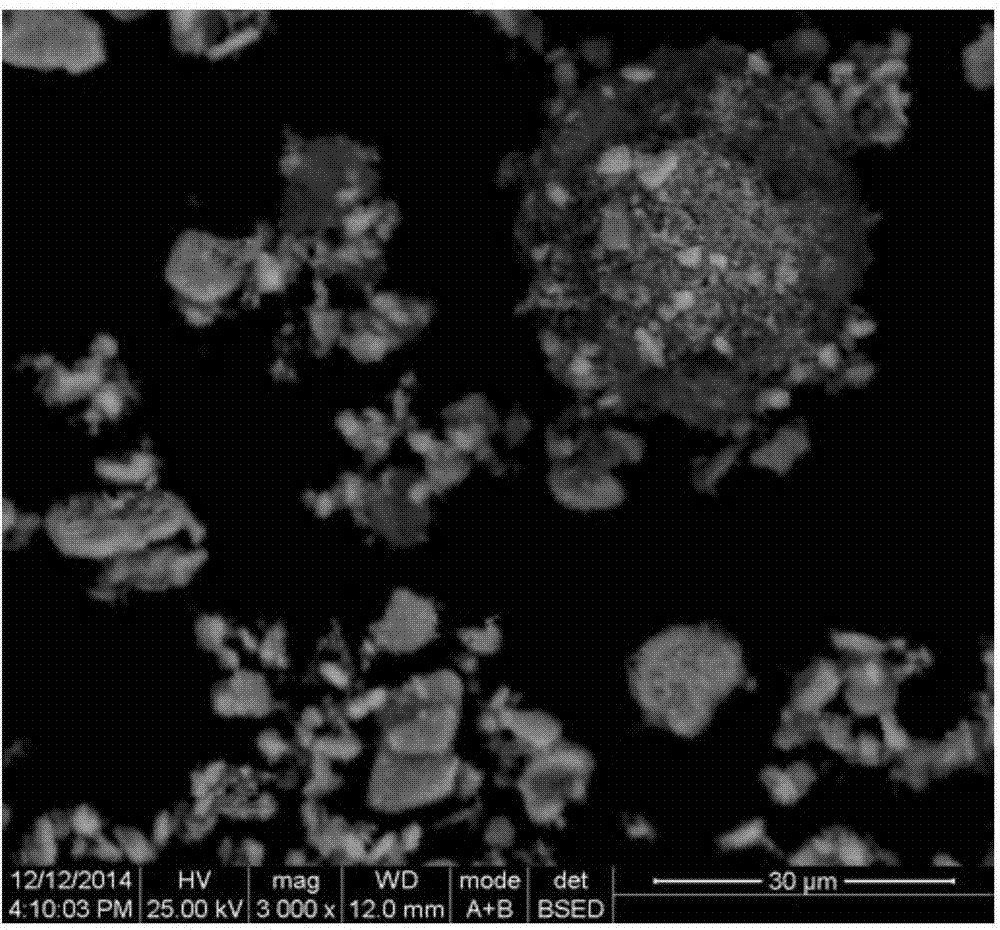

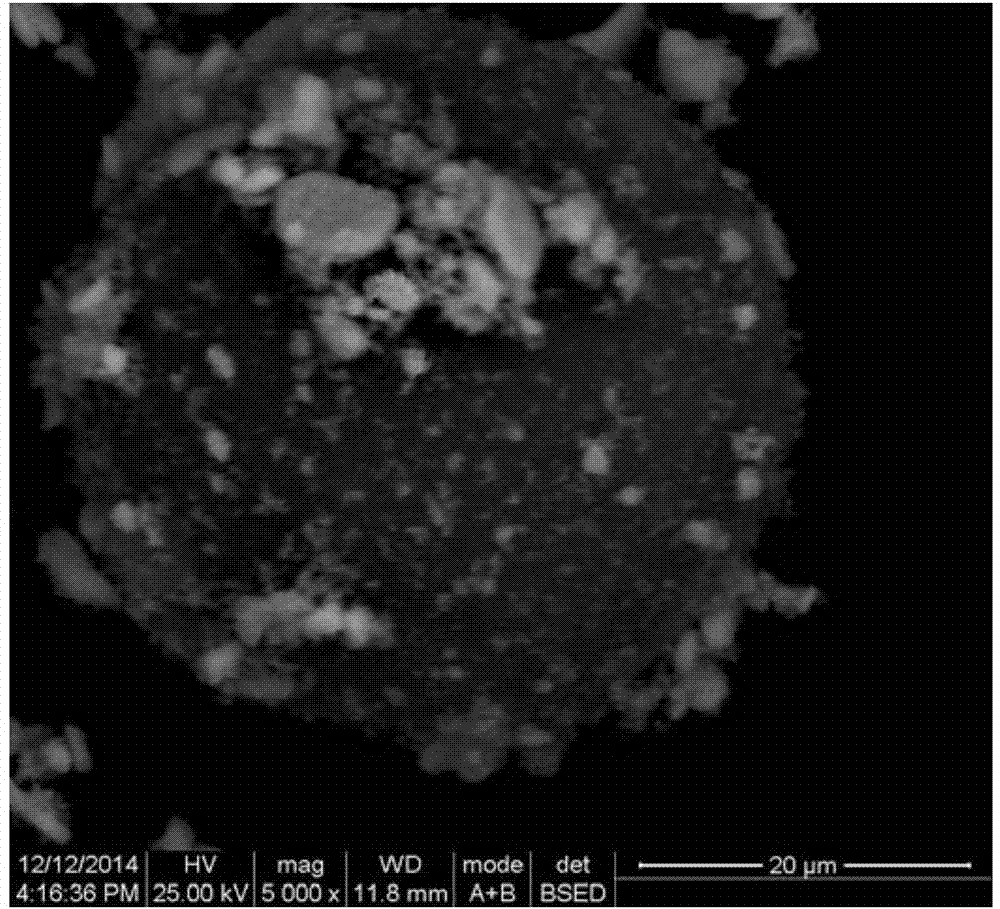

Preparation method of granulated graphite used in refractory castable

The invention belongs to the filed of refractory materials, and relates to a preparation method of granulated graphite used in a refractory castable. The granulated graphite is prepared from raw materials of, by mass: 34-52% of refractory raw material fine powder, 25-40% of flake graphite, 0-9% of solid-state phenol formaldehyde resin powder, 0-15% of an additive, and 22-31% of refractory raw material particles. Also, liquid-state phenol formaldehyde resin which takes 8.5-14.0% of the total weight of the solid raw materials is added. The preparation method comprises steps that: the refractory raw material fine powder, the flake graphite, the solid-state phenol formaldehyde resin powder and the additive are well mixed in a high-speed mixing granulator; a mixture is fetched for later use; the refractory raw material particles and the liquid-state phenol formaldehyde resin are well mixed in the high-speed mixing granulator according to the proportions; mixed powder obtained in the previous steps is placed in the high-speed mixing granulator; coating and granulating are carried out; an obtained material is dried in air, and is baked under a temperature of 100-200 DEG C, such that granulated graphite with a carbon content of 27.1-41.7wt% is obtained.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com