Patents

Literature

1212results about How to "Process parameters are easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A kind of preparation method and product thereof of lithium iron phosphate material with high capacity and high compaction density

InactiveCN102275887ASolve the problem of impurityReduce manufacturing costCell electrodesPhosphorus compoundsElectrical batteryPhosphate

The invention belongs to the field of positive electrode materials for lithium ion batteries, and discloses a method for preparing lithium iron phosphate materials with high capacity and high compaction density, including (1) combining lithium source, Fe3+ source, phosphate, dopant and organic carbon source Mixing, and then spray granulation, (2) prepare calcined product, (3) mix and sand the calcined product and inorganic carbon source, and then spray dry to obtain secondary spray powder, (4) secondary spray The powder is heat-treated in vacuum or in a protective atmosphere, and sintered at a constant temperature; (5) After the above-mentioned sintered semi-finished product is passed through secondary ball milling or jet milling, a lithium iron phosphate product is obtained. The invention solves the defects of increased product cost, difficult coating and low compaction density of pole pieces caused by the use of divalent iron source, and has the characteristics of low production cost and good processability, electrical conductivity and electrochemical performance of prepared pole pieces .

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

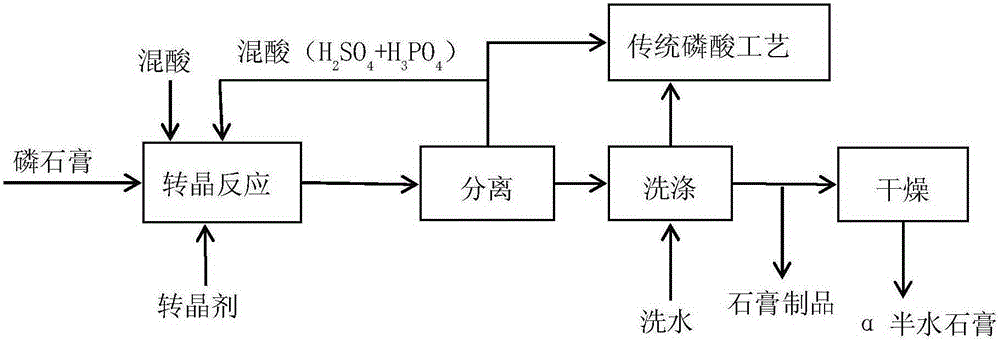

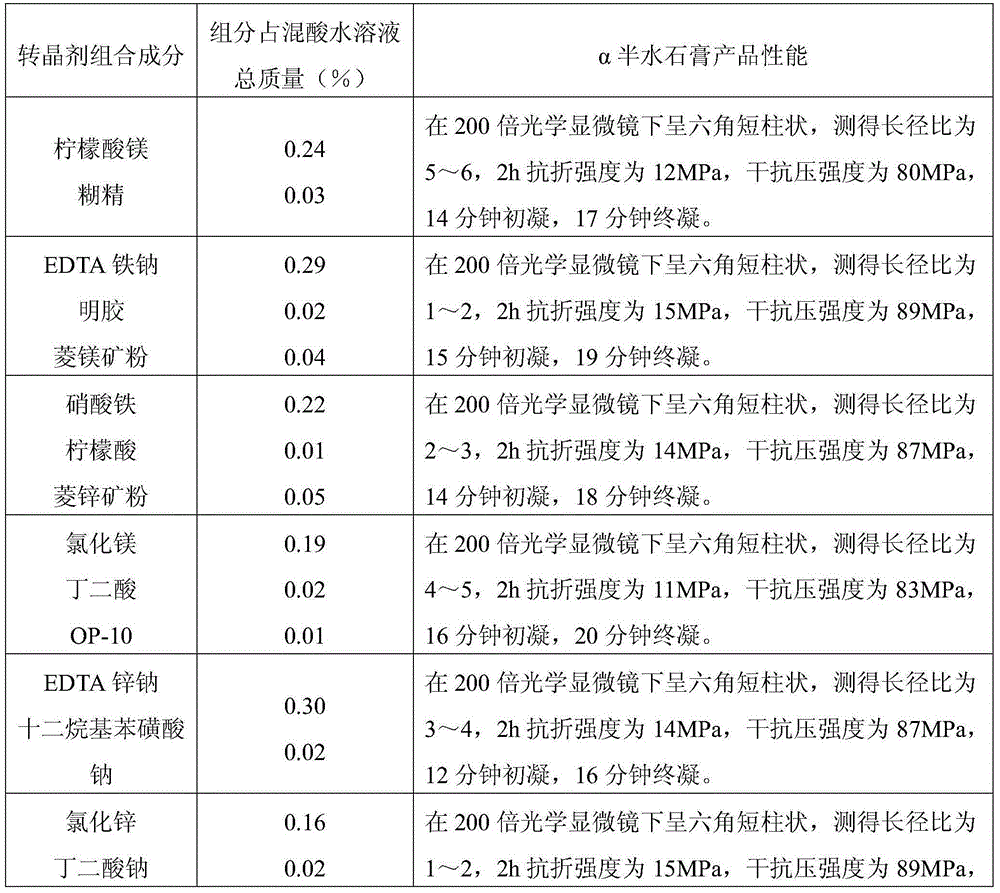

Method for preparing alpha semi-hydrated gypsum from dihydrate gypsum

The invention relates to a method for preparing alpha semi-hydrated gypsum from dihydrate gypsum. The method comprises the following steps: adding dihydrate gypsum and a crystal modifier into a mixed acid water solution containing sulfur acid and phosphoric acid to carry out crystal transformation, carrying out solid-liquid separation, returning a part of liquid phase into a crystal transformation tank for crystal transformation, and conveying another part of liquid phase to an acidolysis tank for use, wherein the acidolysis tank is used for preparing phosphoric acid by decomposing phosphorite by virtue of sulfuric acid; adding washing water to wash a solid phase, and introducing the washing water into the liquid phase for use. The washed solid phase can be prepared into alpha semi-hydrated gypsum powder through drying and can be prepared into gypsum products such as gypsum boards, gypsum blocks, gypsum components and the like by directly adding water without drying. According to the method, the alpha semi-hydrated gypsum is prepared in the mixed acid water solution containing sulfur acid and phosphoric acid, procedures including desulfuration, removal of impurity and the like on raw gypsum can be omitted, furthermore, mixed acid can be recycled, and the obtained alpha semi-hydrated gypsum product is high in strength and stable in quality.

Owner:贵州正磷科技有限公司

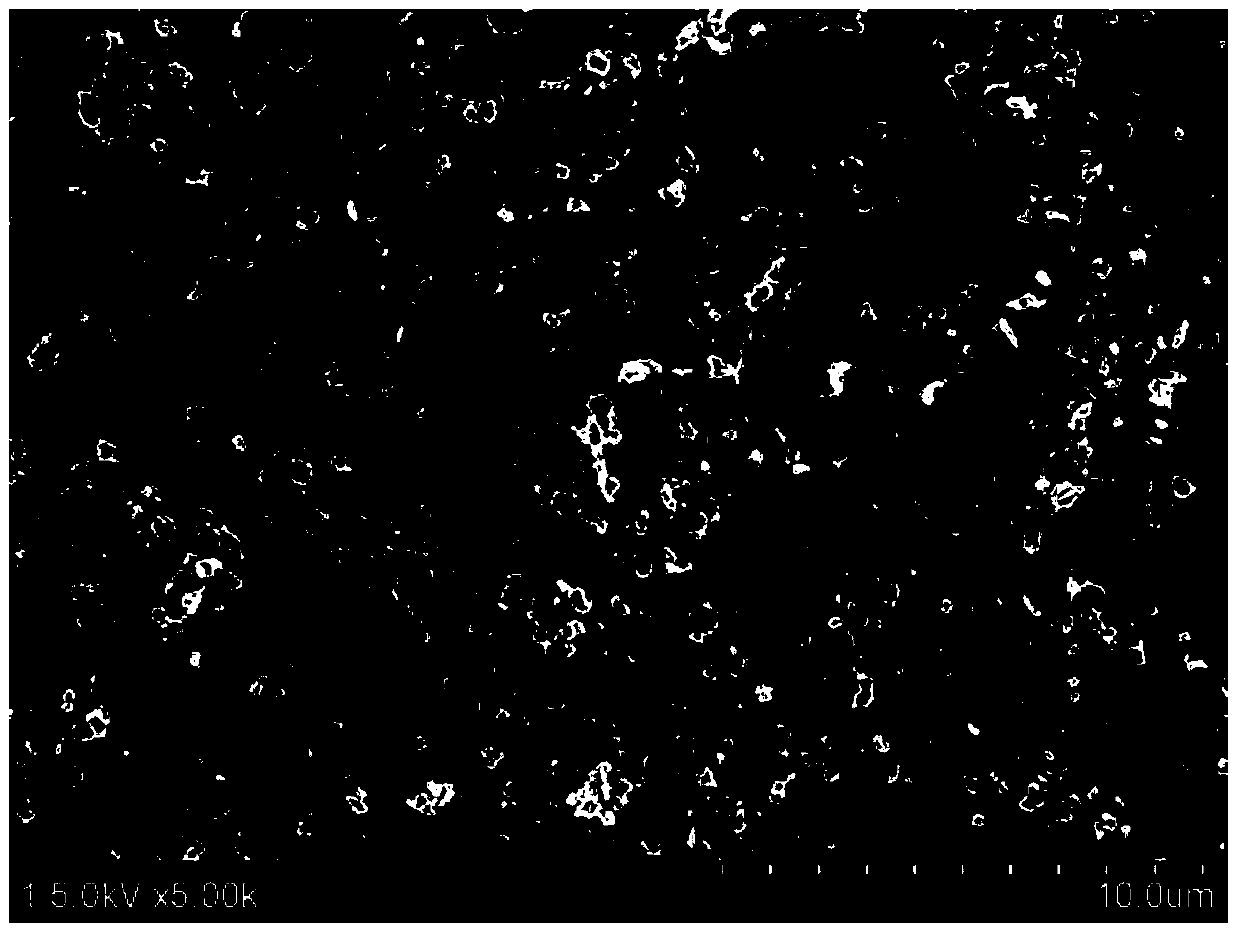

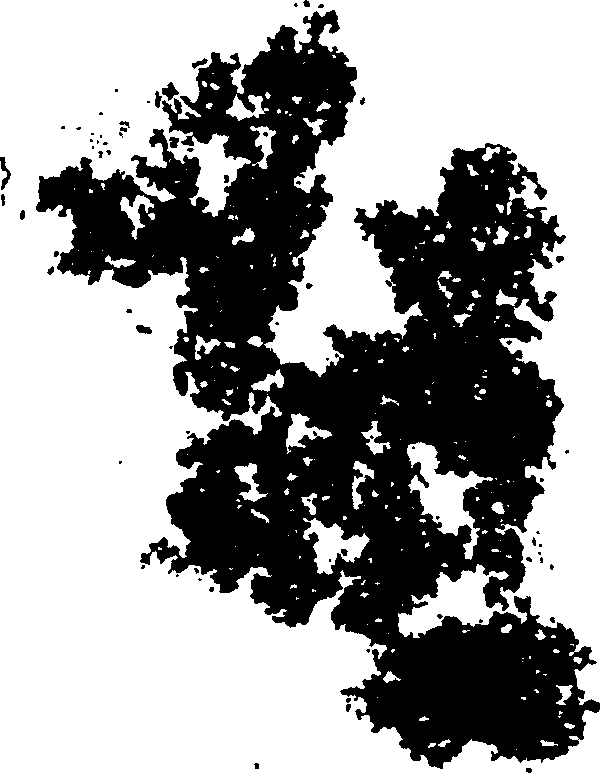

Amino-protected crosslinking magnetic chitosan composite adsorbent and preparation method thereof

InactiveCN102744044ASimple preparation processProcess parameters are easy to controlOther chemical processesAlkali metal oxides/hydroxidesPolymer scienceEpichlorohydrin

The invention relates to an amino-protected crosslinking magnetic chitosan composite adsorbent and a preparation method of the amino-protected crosslinking magnetic chitosan composite adsorbent. The preparation method comprises the following steps: enabling formaldehyde and amino on the chitosan to react to generate Schiff's base protected amino; crosslinking by using epichlorohydrin; and finally, carrying out acidolysis to remove the Schiff's base to recover the amino to obtain the amino-protected crosslinking magnetic chitosan composite adsorbent. The amino-protected crosslinking magnetic chitosan composite adsorbent comprises a magnetic chitosan and probably comprises a high molecular compound and / or an inorganic material. The amino-protected crosslinking magnetic chitosan composite adsorbent has the characteristics that the preparation process of the composite adsorbent is simpler, and the process parameters are easy to control; the adsorption capacity and the adsorption speed of the composite adsorbent are large and high, and the composite adsorbent can be recovered through an external magnetic field, so the reusability of the composite adsorbent is good. The composite adsorbent can be hopefully used for treating waste water containing heavy metal ions, protein and dye.

Owner:WUHAN UNIV

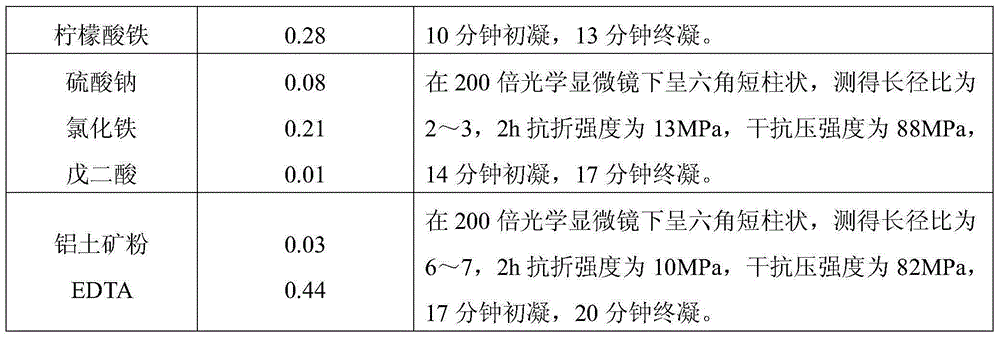

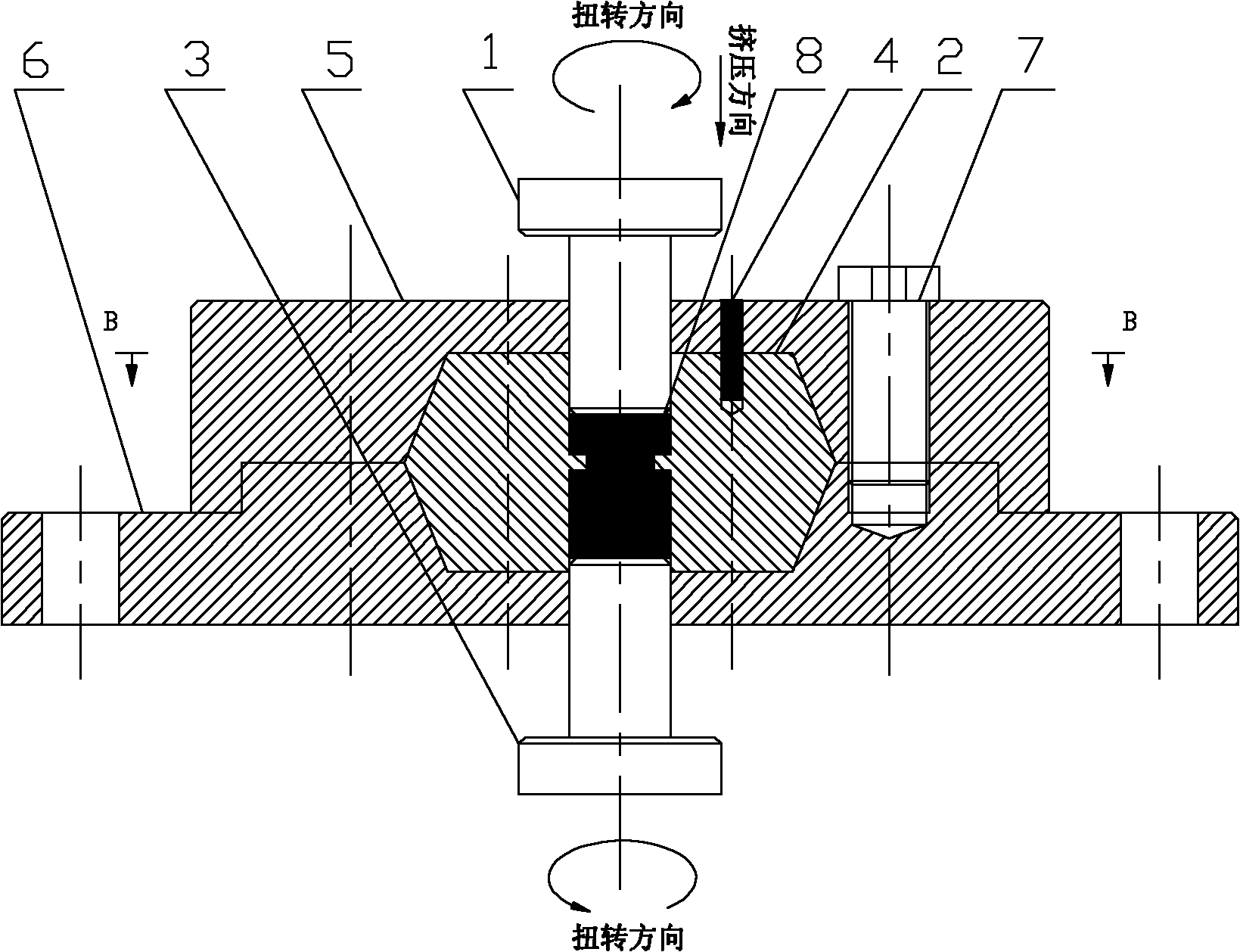

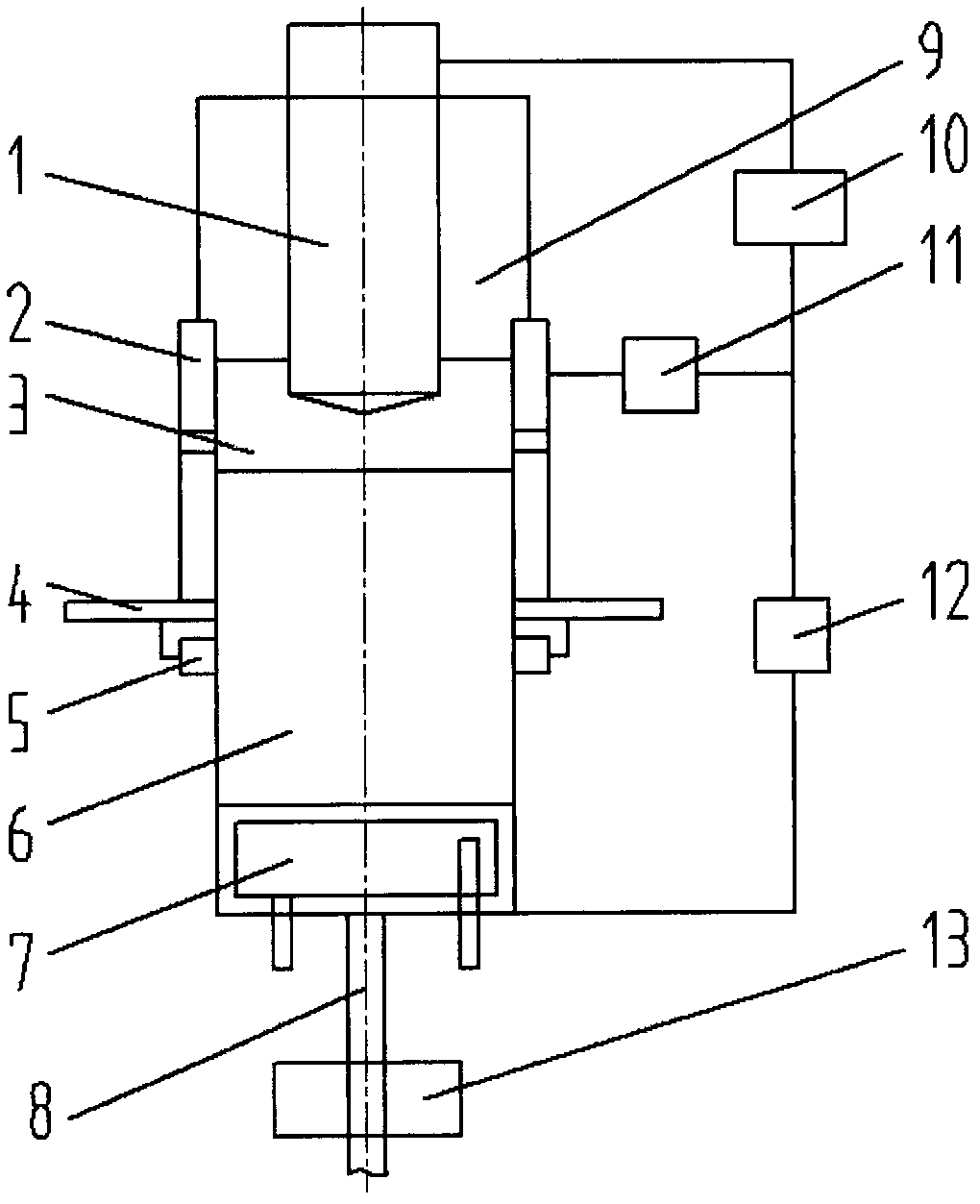

Torsion type reciprocating extrusion device and process method thereof

ActiveCN101966536AAddressing Smaller Size LimitationsImprove toughnessExtrusion profiling toolsExtrusion control devicesEngineeringUltra fine

The invention discloses a torsion type reciprocating extrusion device and a process method thereof, belonging to the technical field of plastic formation. The device comprises a cavity die, a cavity die cover plate and a cavity die fixing plate, wherein the cavity die fixing plate is fixed on a work table, and the cavity die with a variable section spindle structure is arranged between the cavity die fixing plate and the cavity die cover plate. The process method makes materials generate the compound formation of reciprocating extrusion and torsion shearing so as to prepare ultra-fine grained materials with larger volume and uniform tissue.

Owner:SHANGHAI JIAO TONG UNIV

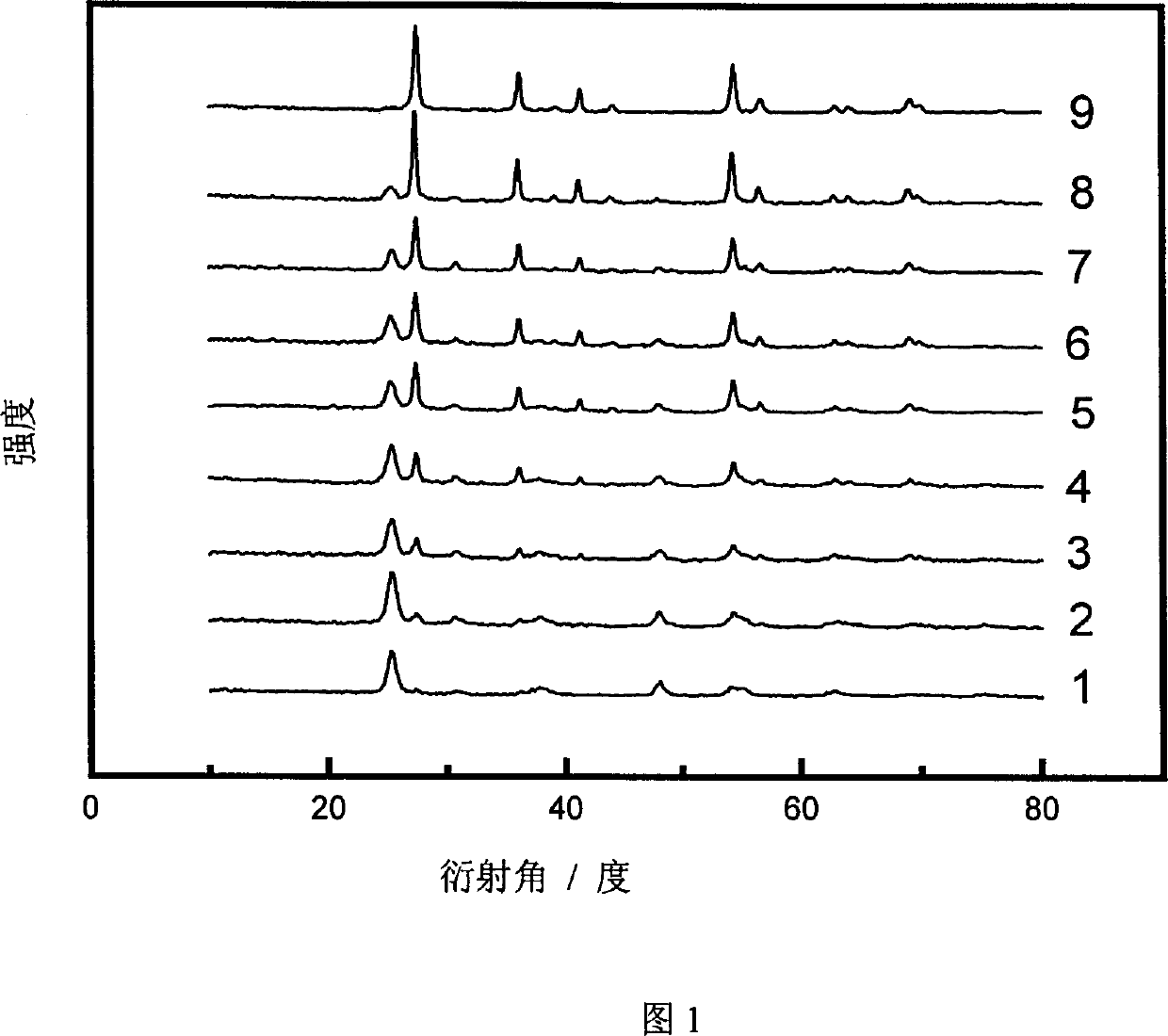

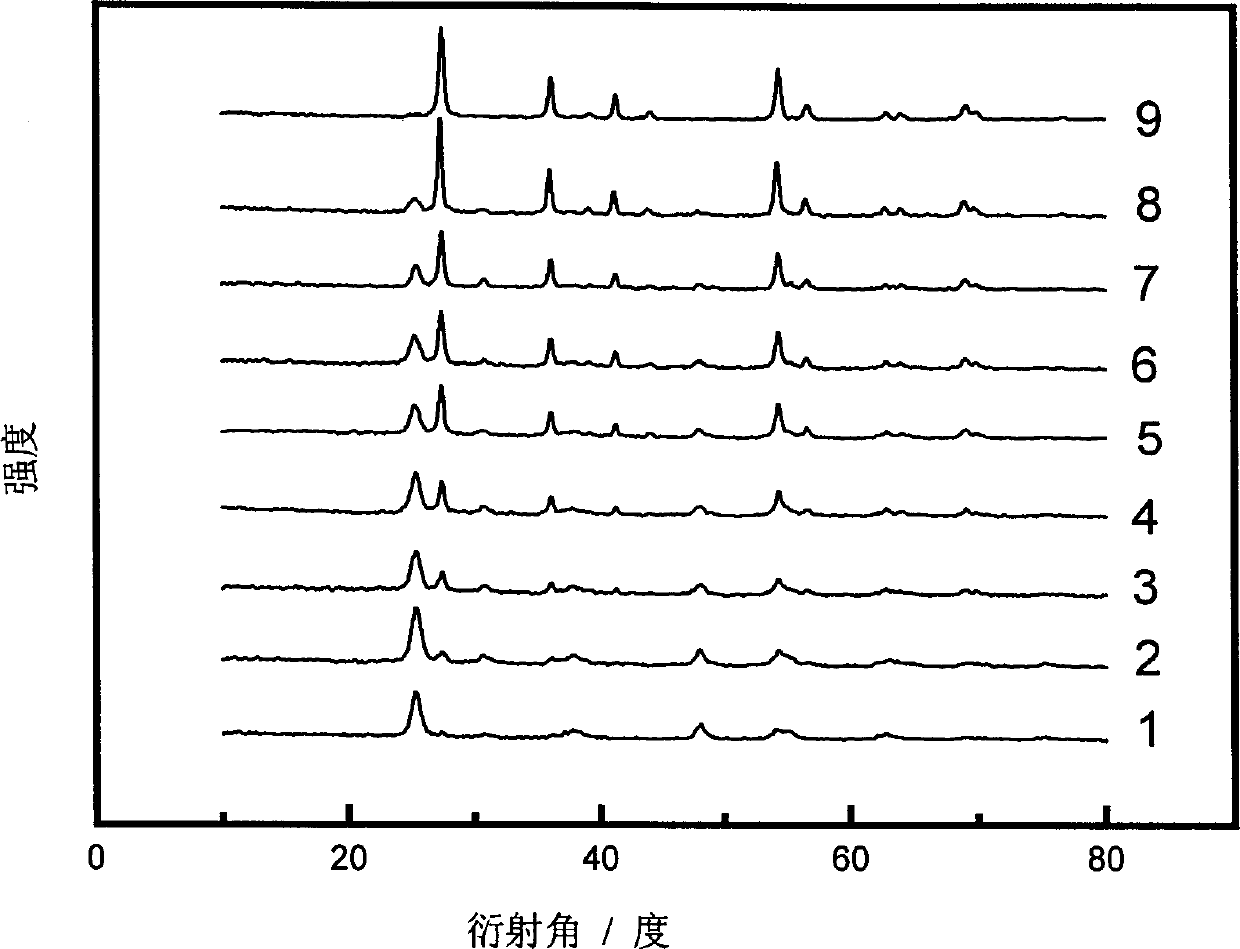

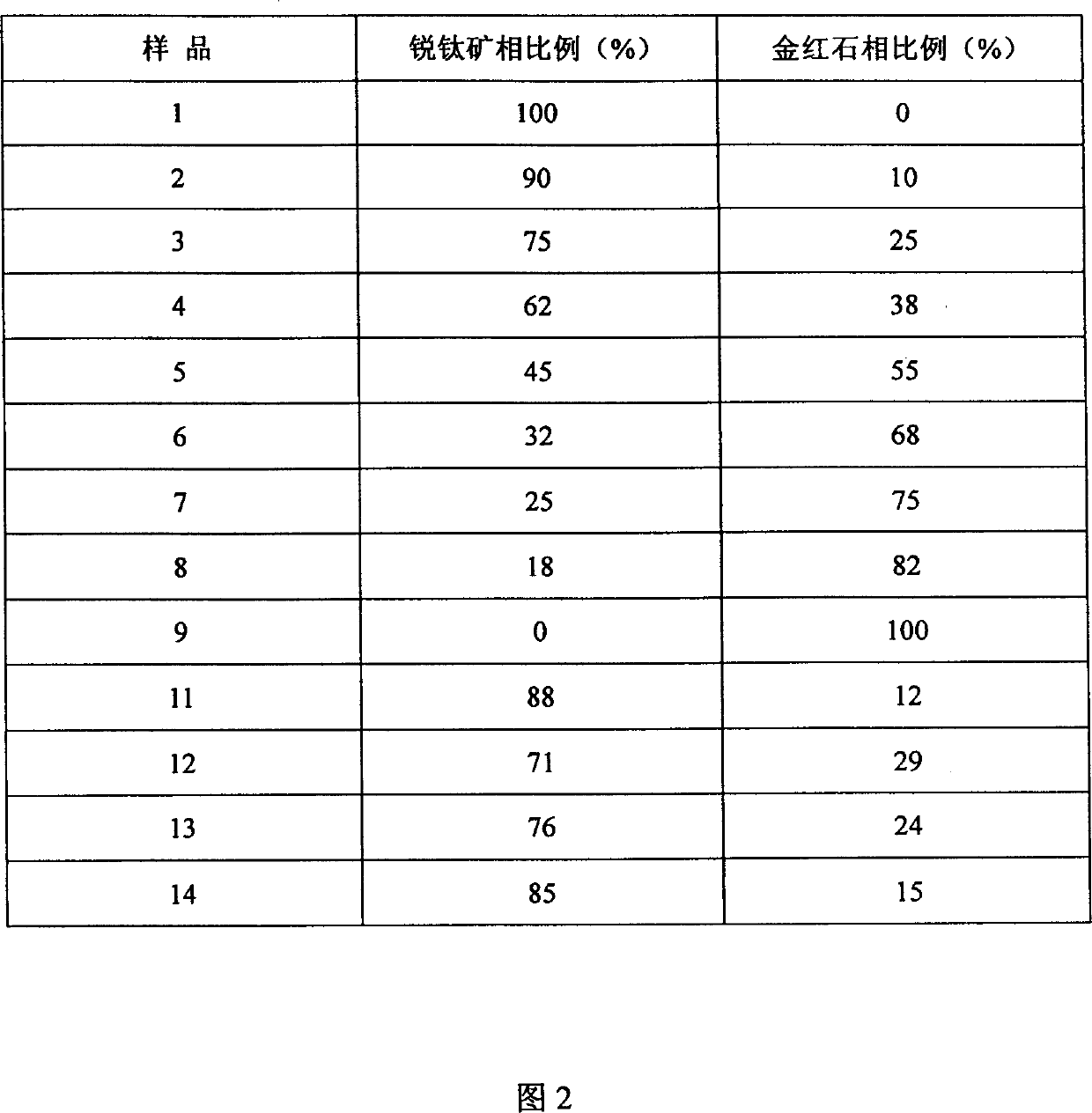

Preparation method of crystal phase controllable titanium dioxide nanometer crystal

InactiveCN1478725AMild preparation conditionsSimple preparation equipmentTitanium dioxideAlcoholTitanium

A process for preparing the crystal phase controllable TiO2 nanocrystals includes such steps as hydrolyzing the Ti-cotnained compound in the aqueous solution of alcohol to obtain amorphous TiO2 powder, adding inorganic acid, hydrothermal treating, filtering, washing and drying. Its resultant TiO2 nanocrystal has the continuously regulatable ratio of anatase phase to rutile phase.

Owner:FUDAN UNIV

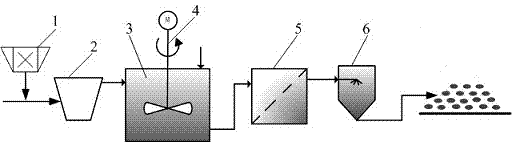

Method and device for preparing formed sludge fuel

InactiveCN102212403AImprove dehydration effectImplement resourcesSludge treatment by de-watering/drying/thickeningBiofuelsSludgeSolid fuel

The invention discloses a process method for preparing a derived solid fuel by using sludge, and the method comprises the following steps: feeding dehydrated wet sludge with the moisture content of 70-85% and biomass at a weight ratio of 50:(1-10) into a tempering kettle, introducing less water, evenly stirring, adding a tempering agent the mass of which is 0-20% of that of dried solid sludge, stirring for 2-10 minutes continuously, removing most of water by a dehydrator, forming, and naturally drying for 24 hours, thus obtaining the derived sludge solid fuel. The invention also discloses a device for preparing a formed sludge fuel. The device comprises a straw crusher, a feeder, the tempering kettle, the stirrer, the fuel hydrator and a fuel forming machine, wherein the stirrer is positioned at the top of the tempering kettle, a stirring shaft is coincident with the axis of the tempering kettle and inserted into the tempering kettle, the outlet of the straw crusher is connected with the inlet of the feeder, the outlet of the feeder is connected with the inlet of the tempering kettle, the outlet of the tempering kettle is connected with the inlet of the fuel dehydrator, and the outlet of the fuel dehydrator is connected with the inlet of the fuel forming machine.

Owner:JIANGSU XINFA ENVIRONMENTAL PROTECTION TECHCO

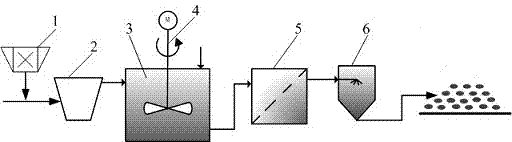

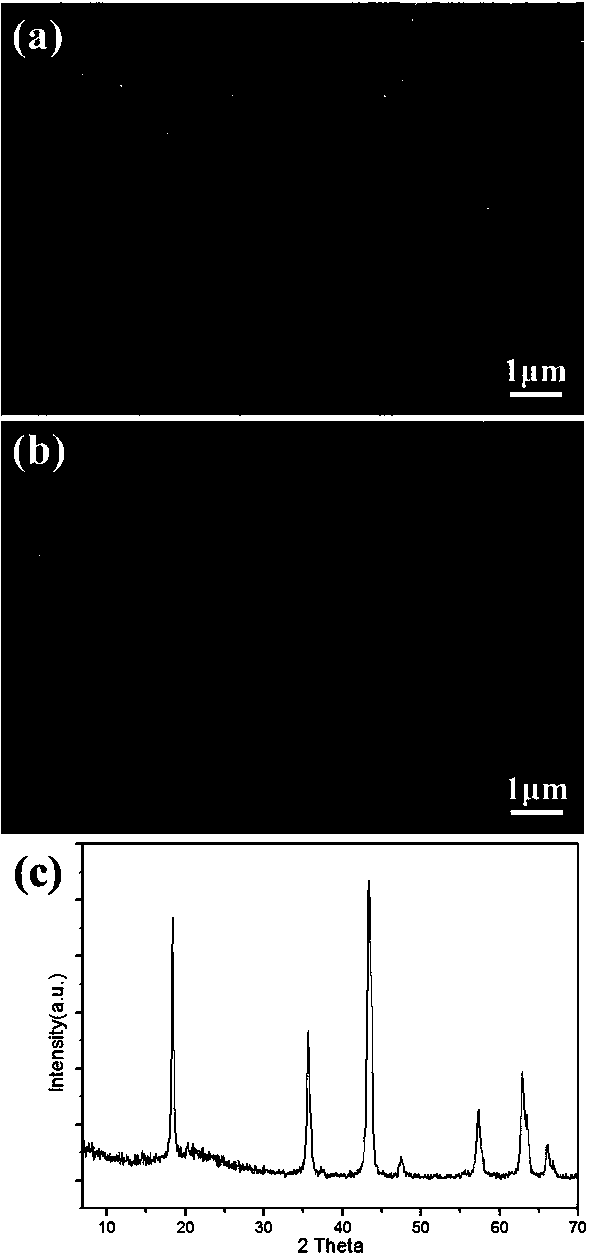

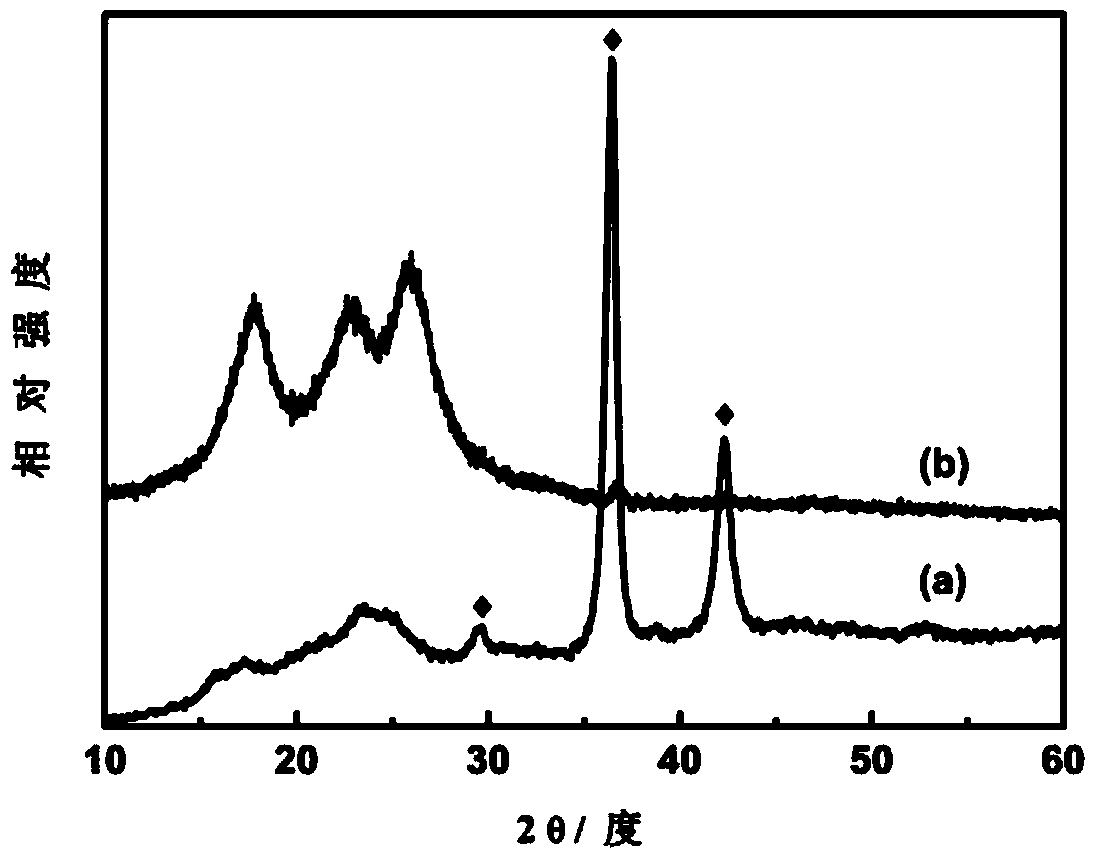

Method for preparing spinel lithium titanate

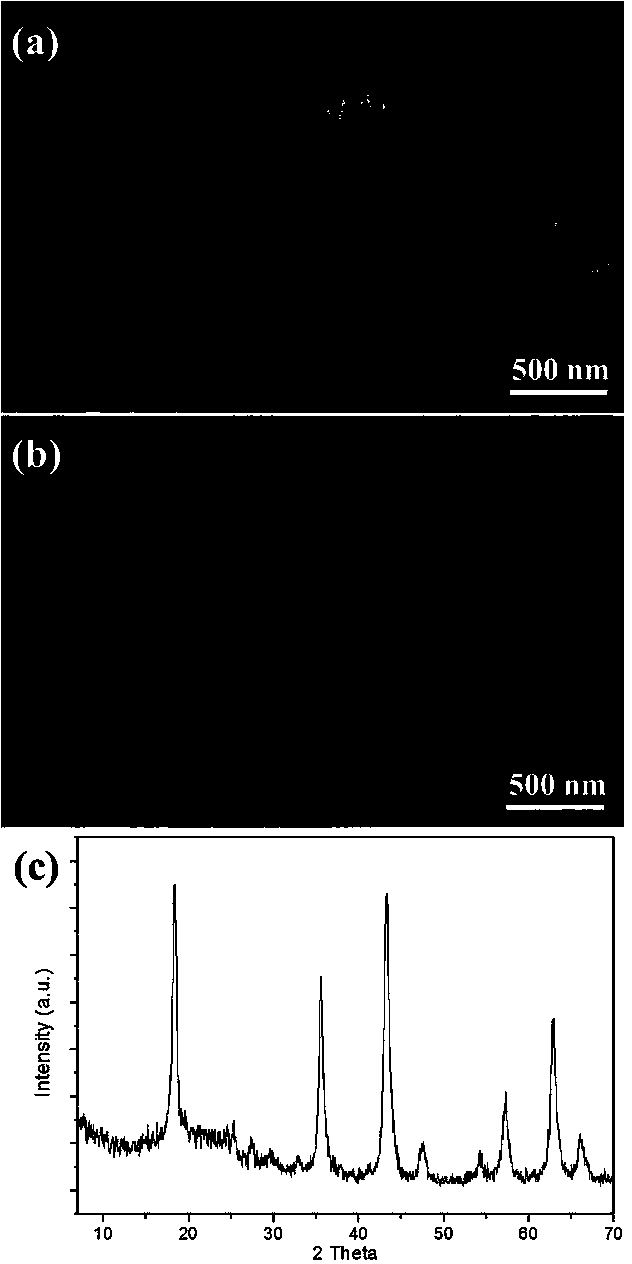

InactiveCN104201364AOvercome conductivityLow priceMaterial nanotechnologyAlkali titanatesLithiumNanowire

The invention discloses a method for preparing spinel lithium titanate. The method is characterized by comprising the steps of S1, performing hydrolysis reaction on a titanium source to obtain hydrated titanium acid sediments; S2, dispersing the hydrated titanium acid sediments into lithium ion-containing hydrogen peroxide aqueous solution to obtain a mixture; S3, performing hydrothermal reaction on the mixture to obtain nanowire type lithium titanate and / or lithium titanate with a nano differential level structure; S4, annealing the nanowire type lithium titanate and / or the lithium titanate with the nano differential level structure to obtain nanowire type spinel lithium titanate and / or the spinel lithium titanate with the nano differential level structure. According to the method, both spinel lithium titanate nanowires and the spinel lithium titanate with the nano differential level structure can be prepared.

Owner:李建明

Method for preparing ultra-fine calcium sulfate crystal whisker by using phosphogypsum

ActiveCN101792932ALarge diameterSmall diameterPolycrystalline material growthSingle crystal growth detailsFiltrationWhiskers

The invention discloses a method for preparing ultra-fine calcium sulfate crystal whiskers by using phosphogypsum. The method comprises that the phosphogypsum is ultra-fine treated to powder with grain size of 0.1-100 mum, water is added into the powder to prepare slurry with weight percent of 5-15 percent, pH value is regulated to be 3-5, reaction is kept for 3-5h at 125-145 DEG C and under 2-3MPa, pumping filtration is conducted when the obtained product is hot, and the filtered product is dried at 120-250 DEG C to obtain the calcium sulfate crystal whiskers. Moreover, crystal promoter with weight 0.10-0.20 time of the weight of the phosphogypsum and seed crystal with weight 0.1-0.2 time of the weight of the phosphogypsum can be added. The invention has the advantages of low production cost, simple production method and good comprehensive performance.

Owner:WENGFU (GRP) CO LTD +1

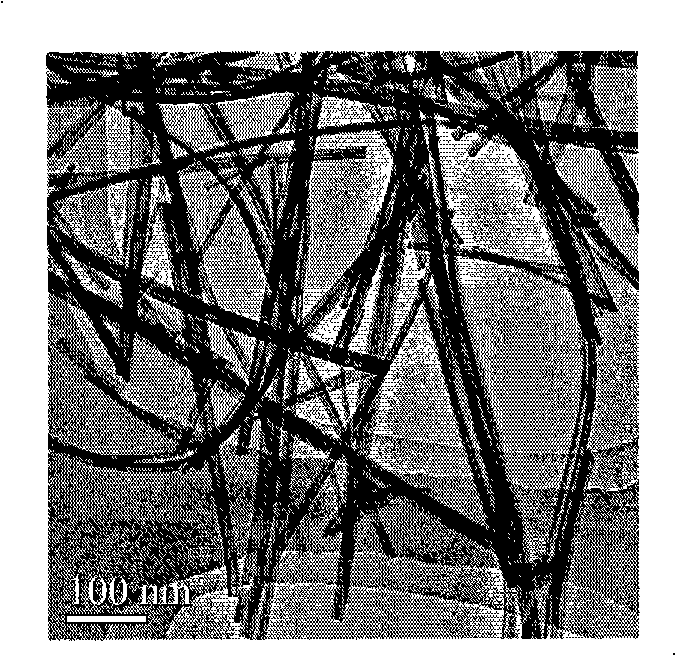

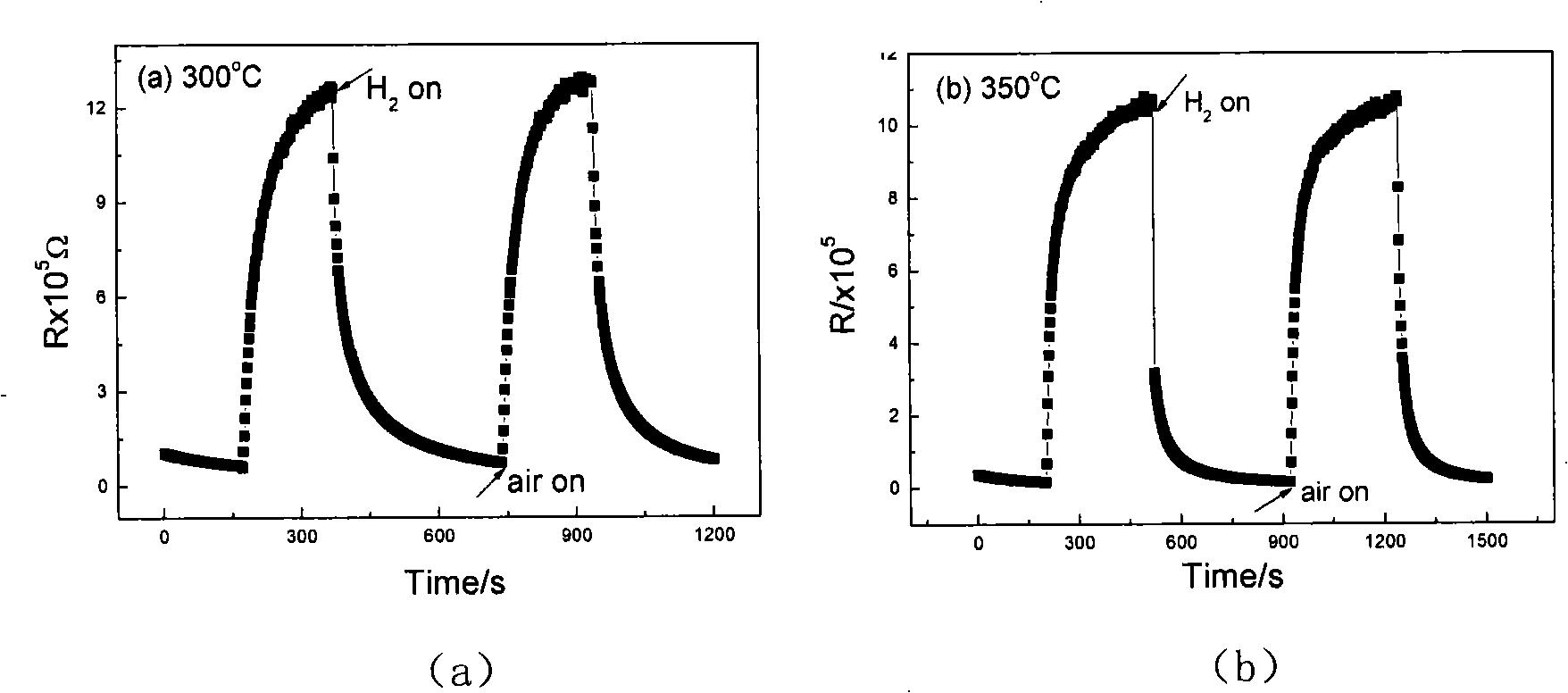

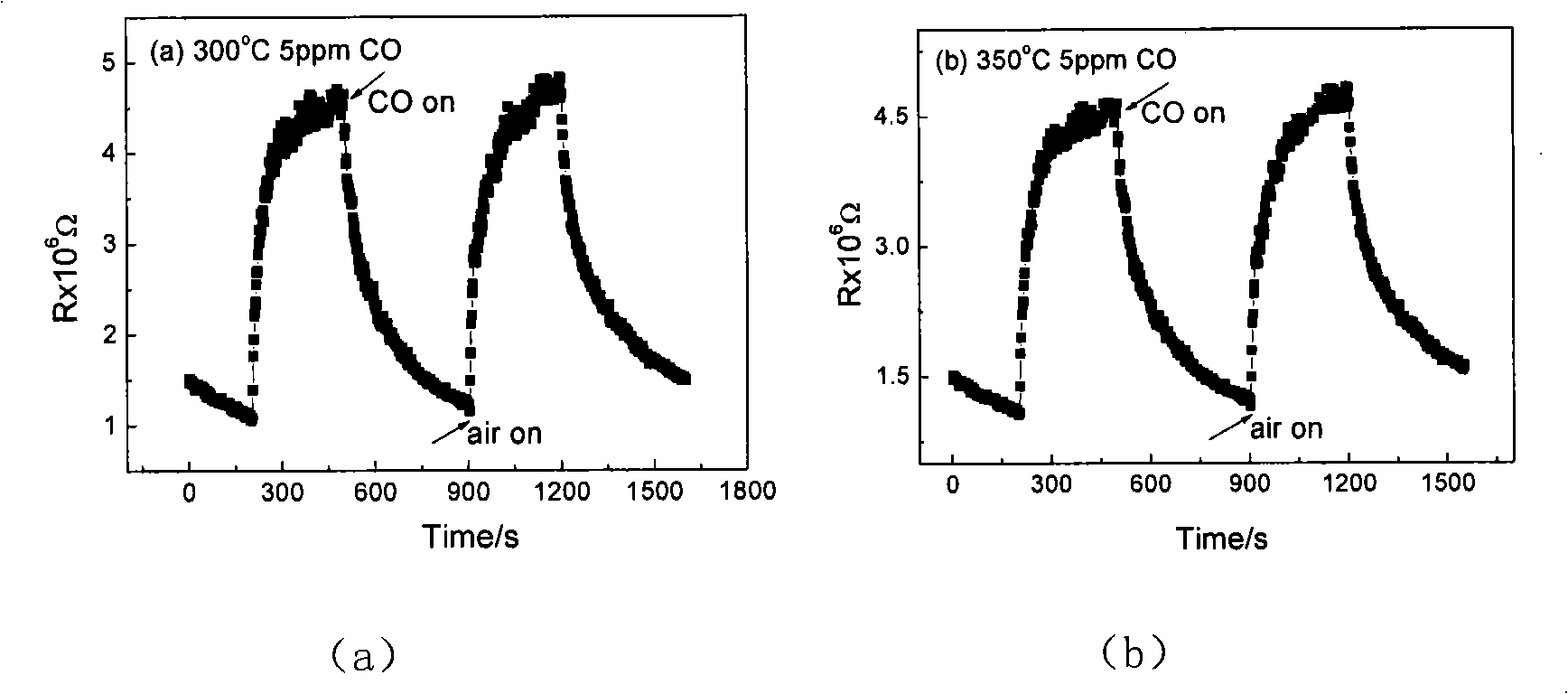

Tungstic oxide nano-wire and method for preparing tungstic oxide nano-wire gas-sensitive sensor

InactiveCN101318704AReduce consumptionLarge specific surface areaTungsten oxides/hydroxidesMaterial analysis by electric/magnetic meansAdhesiveMicellar solutions

The invention relates to a method for preparing a tungsten oxide nano-wire and a tungsten oxide nano-wire ammonia-sensitive sensor, belonging to the one dimensional nano oxide material preparation and gas-sensitive technical field. The method comprises the following steps that: sodium tungstate is dissolved in deionized water to prepare a sodium tungstate solution; a hydrochloric acid is dripped slowly to prepare a flaxen micellar solution which is then centrifugally separated; products are uniformly dispersed in a potassium sulfate solution which is then transferred into a reaction kettle for hydrothermal reaction, and then the tungsten oxide nano-wire is prepared; adhesives and frit are added into the tungsten oxide nano-wire, and then the tungsten oxide nano-wire ammonia-sensitive sensor is prepared after element sintering and ageing. The method has simple steps, easily controlled technological parameters during the preparation process, and very low energy consumption during the whole preparation process; the tungsten oxide nano-wire prepared has a large specific surface area and high thermal stability; and the tungsten oxide nano-wire ammonia-sensitive sensor prepared has high sensitivity on low-concentration (between 1 and 100 pars per million) H2, CO and NH3, good repeatability and high stability.

Owner:TSINGHUA UNIV

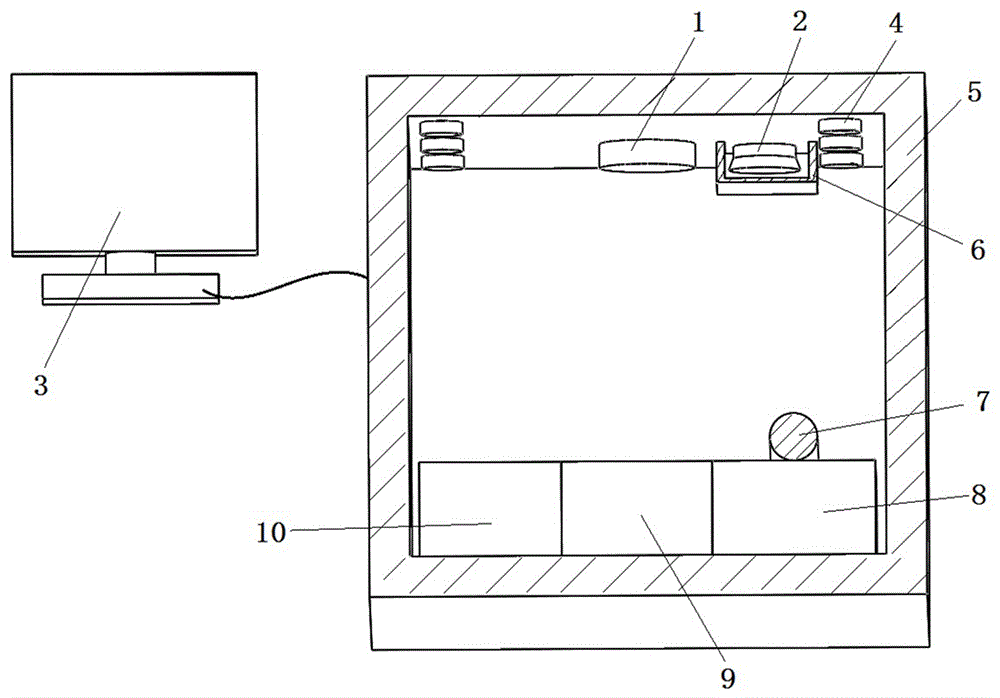

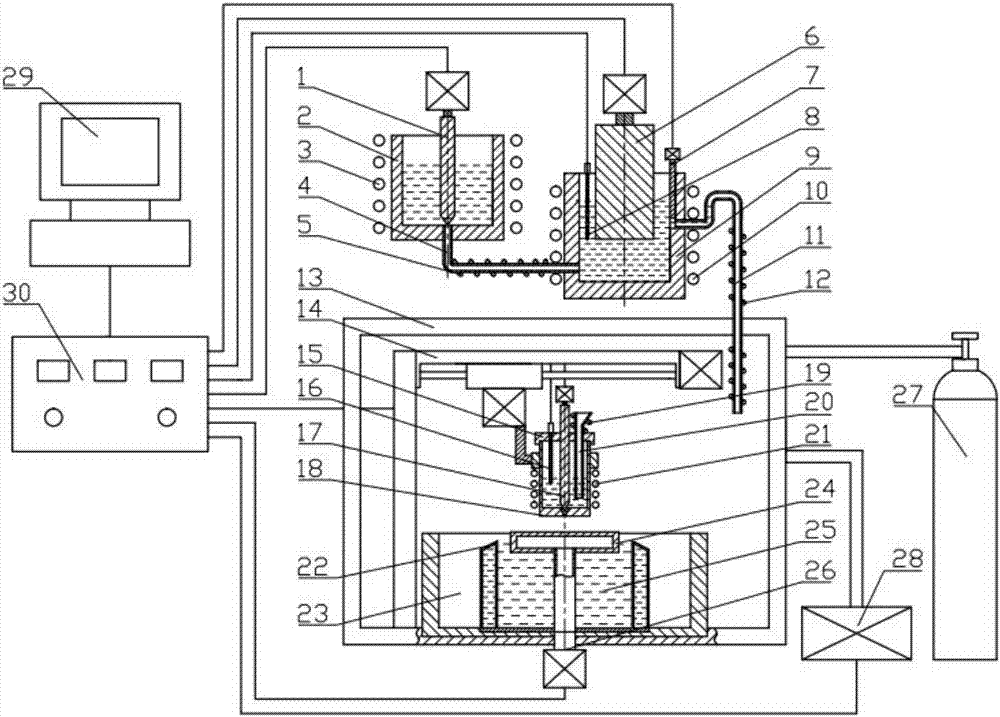

Laser fast forming detection system and method for powder laying evenness

ActiveCN106041076AReal-time monitoring of contour sizeHigh forming precisionAdditive manufacturing apparatusMaterial analysis by optical meansControl systemOptoelectronics

The invention relates to a laser fast forming detection system and method for powder laying evenness and belongs to the technical field of laser fast forming powder laying detection. The laser fast forming detection system and method for powder laying evenness are provided and can monitor whether powder is laid flatly or not in real time and effectively improve the forming quality. According to the adopted technical scheme, a powder laying device, a powder supplying cylinder, a forming cylinder and a material collecting cylinder are arranged in a forming cavity; a laser device and an image collecting device are arranged on the top of the forming cavity; light supplementing lamps are arranged on the two sides of the forming cavity; and the laser device, the image collecting device and the light supplementing lamps are connected with the control system. The laser fast forming detection system and method for powder laying evenness can be widely applied to powder laying evenness detection for laser fast forming.

Owner:山西阳宸中北科技有限公司

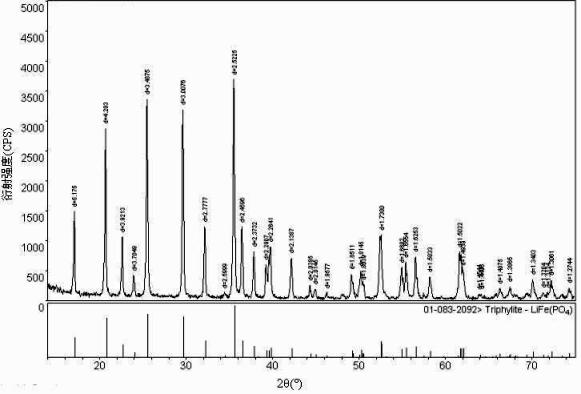

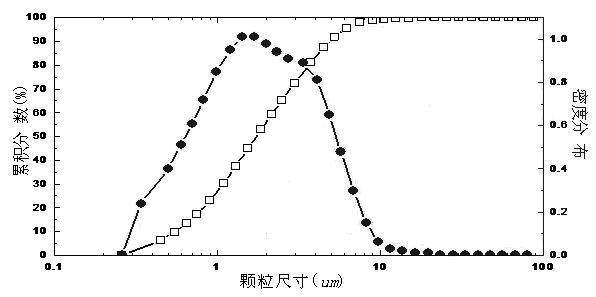

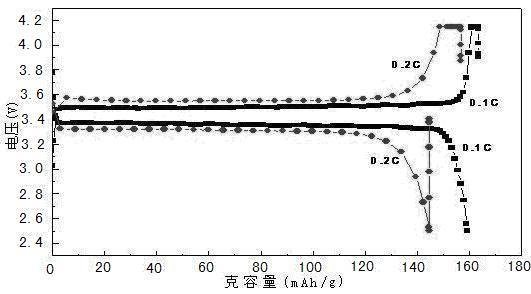

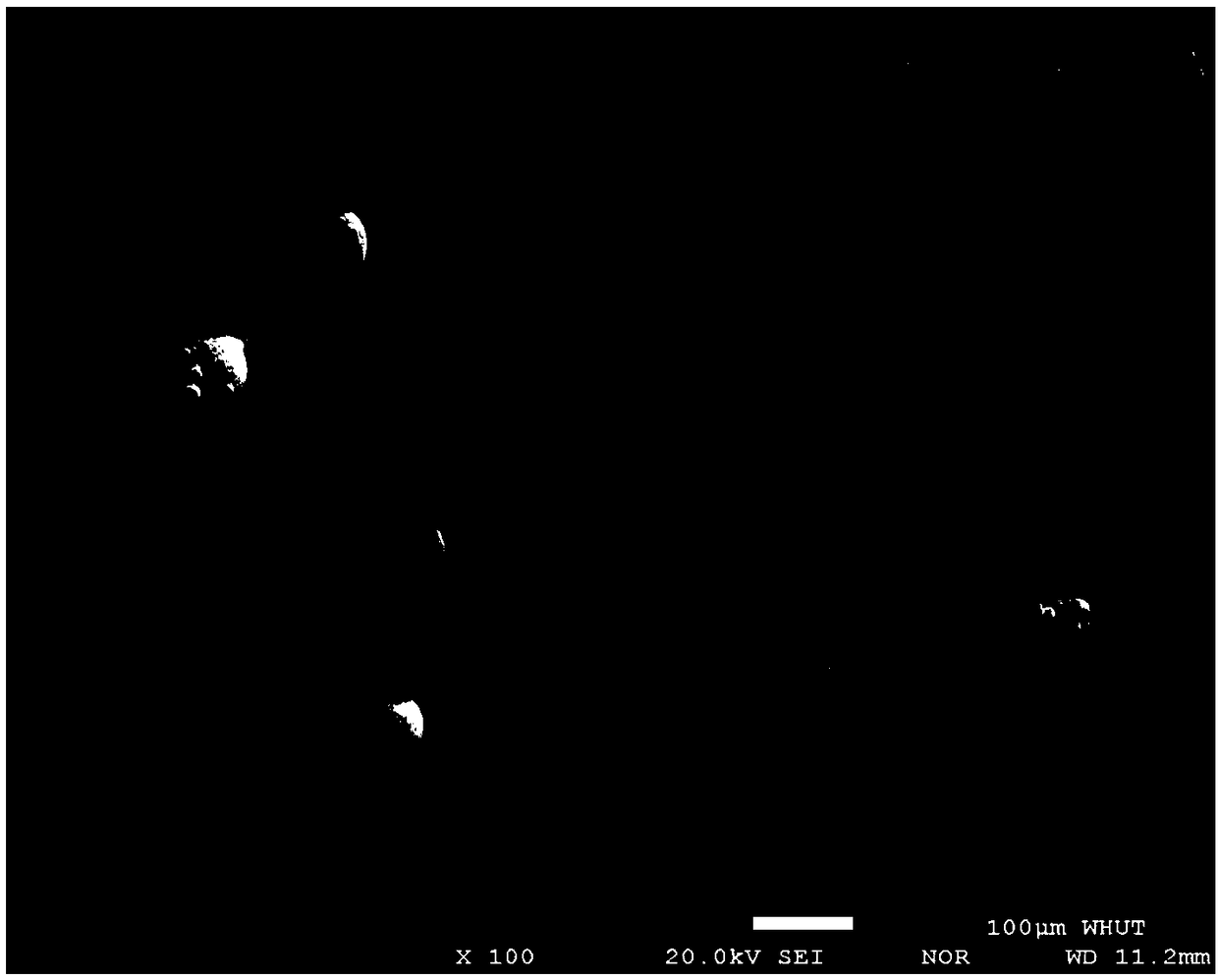

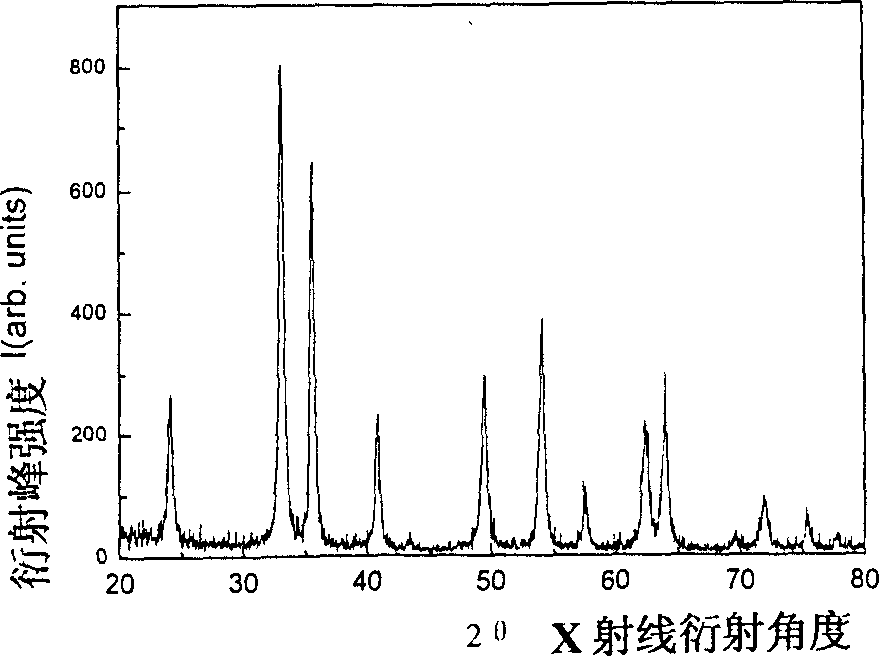

Hydrothermal synthesis method for preparing iron phosphate lithium as anode material of lithium ion battery

InactiveCN101764215AProcess parameters are easy to controlExtensive sources of raw materialsCell electrodesHydrothermal synthesisLithium electrode

The invention relates to a hydrothermal synthesis method for preparing iron phosphate lithium as an anode material of lithium ion battery, which belongs to the technical field of new energy materials. The hydrothermal synthesis method comprises the following steps of: mixing an iron source with phosphate, adding a lithium source, and after uniform agitation, putting the mixture into a high-pressure reaction kettle; then, adding a reducing agent, and maintaining the temperature at 180-200 DEG C for 8-12 h to produce spherical iron phosphate lithium, wherein the mol ratio of the lithium source to the iron source to the phosphate is 3:1:1. The invention provides a simple and one-step method for directly preparing iron phosphate lithium. The technological parameters of the method used for preparation are easily controlled; compared with a process using ferric iron as a raw material, the resource of ferrous iron as the raw material is wider; the prepared iron phosphate lithium powder particles have small mean particle diameter which is about 3-5 mu m, the particles are evenly distributed, the tap density can reach 2.0-2.5 g / cm<3>, the battery performance is high, and the specific capacity for the first charge and discharge cycle is 140-160 mAh / g.

Owner:孙琦

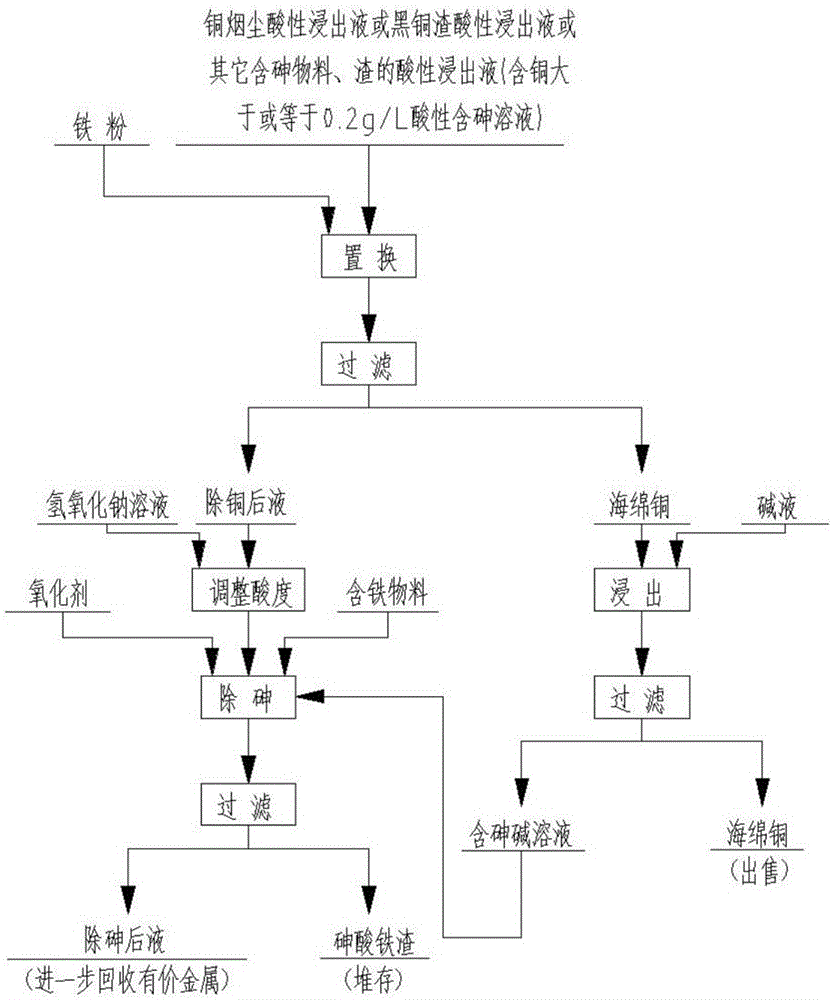

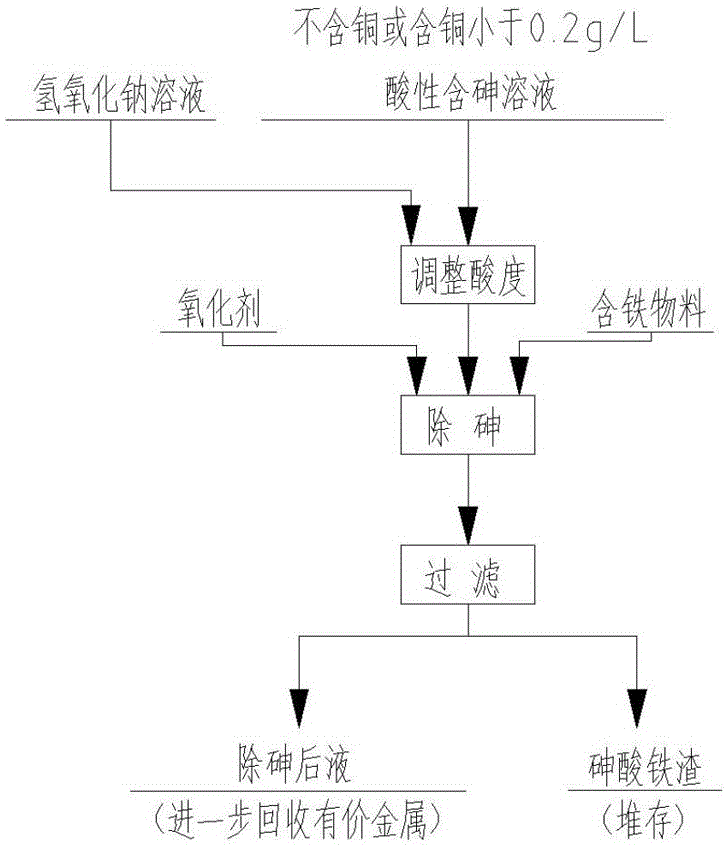

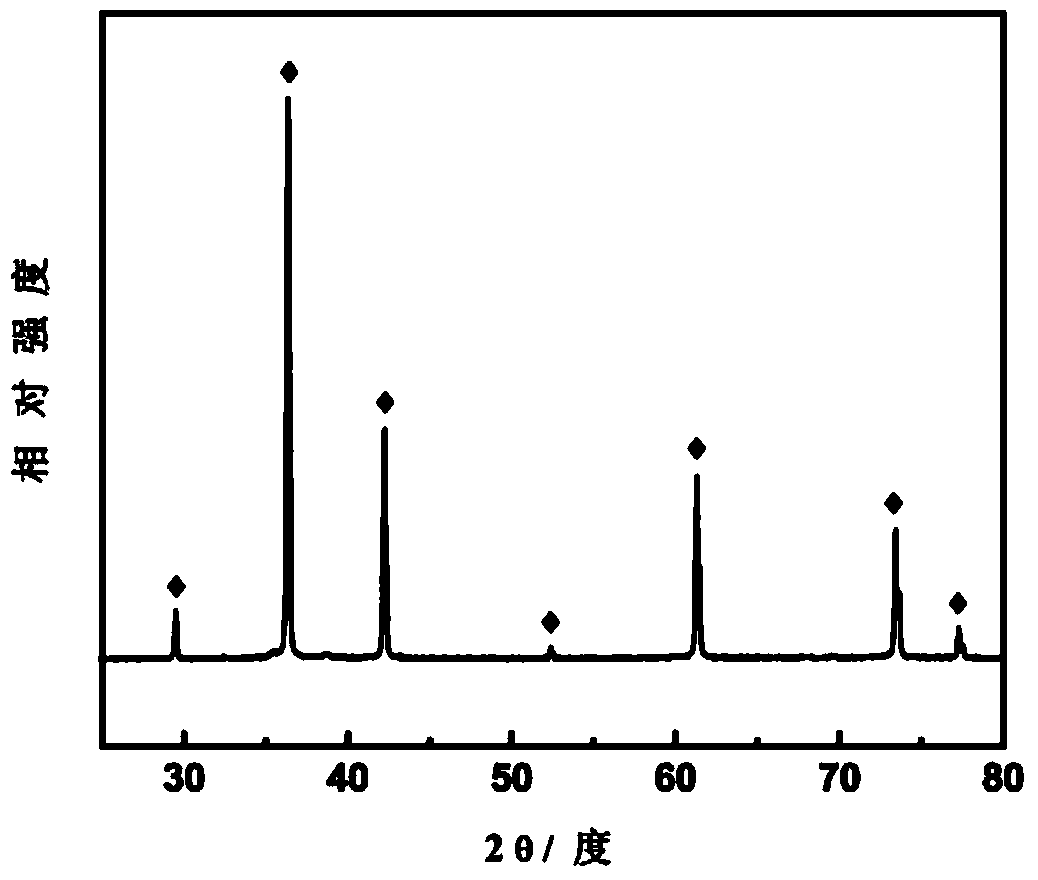

Method of removing arsenic from acid arsenic-containing solution

InactiveCN106148705ASimple processProcess parameters are easy to controlProcess efficiency improvementArsenateCopper

The invention discloses a method of removing arsenic from an acid arsenic-containing solution. The method comprises the following steps: the pH value of the acid arsenic-containing solution is adjusted to be 1.0-5.0, an iron-containing material and an oxidizing agent are added, the temperature of the solution is controlled at 25-90 degrees, after reaction, ferric arsenate sediment and arsenic-removed post liquid are obtained, and the removal of arsenic is realized. When copper contained in the acid arsenic-containing solution is greater than or equal to 0.2g / L, iron powder replacement copper removal treatment is required to be carried out first. The method has the advantages that the method is simple in process, low in cost and high in arsenic removal rate and obtained ferric arsenate sediment is stable; valuable metals can be recycled effectively; and the method has very high practicability and economic value.

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

Edible antibacterial ink

InactiveCN101709184ASimple preparation processProcess parameters are easy to controlInksPrinting inkRaw material

The invention relates to an edible antibacterial ink prepared by blinding, mixing, grinding, adjusting, inspecting and processing raw materials. The raw material comprises the following component in percentage by weight: 20-65 percent of edible binder, 10-40 percent of edible addition agent, 20-50 percent of edible coloring material and 2-40 percent of diluting agent, wherein the binder is gadoleic acid solution of chitosan. The edible antibacterial ink not only has common characteristics of ink, but also can directly upholster the surfaces of food and medicines, avoid the safe problem of the food and medicines caused by printing ink, improve the grade of the food and the medicines and simultaneously has the functions of inhibiting and sterilizing strains which often exist in the food and keeping freshness and ensuring the quality.

Owner:WUHAN UNIV

Composite coating with friction-decreasing function and biological-foul and seawater resistances and its production

InactiveCN101074331AImprove the protective effectResistant to microbial foulingAntifouling/underwater paintsPaints with biocidesComposite ceramicAlloy

A composite coating against biological fouling and seawater corrosion and its production are disclosed. The composition consists of oxide based-phase ceramic powder 80-95 wt% and powder against biological fouling 5-20 wt% with Cu, CuO or Cu2O powders. The composite coating comprises binding bottom layer, composite ceramic coating and surface sealing layer; ZnNi alloy powder is sprayed on metal substrate of binding bottom layer by supersonic flame; Composite ceramic power against biological fouling and sea-water corrosion is sprayed on bottom of composite ceramic coating by plasma; Inorganic or organic sealer with low surface energy is sprayed on surface sealing layer. An insulating ceramic transient layer is added between binding bottom layer and composite ceramic coating when Cu powder is adopted. It's simple and cheap and can be used for industrial production.

Owner:WUHAN UNIV OF TECH

Cuprous oxide base antibacterial fibers and preparation method thereof

InactiveCN103741242AEasy to prepareProcess parameters are easy to controlMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterPhysical chemistry

The present invention relates to cuprous oxide base antibacterial fibers and a preparation method thereof. The preparation method comprises: (1) adding cuprous oxide powder, a dispersant and a modifier to an aqueous medium, and carrying out grinding, dispersion, modification and drying to obtain modified cuprous oxide powder; (2) uniformly mixing the modified cuprous oxide powder in the step (1) and master batches (such as polyester, nylon and the like) with different varieties according to a mass ratio of 1:1-1:50, and carrying out granulation to obtain antibacterial master batches (such as polyester, nylon and the like) with different varieties; and (3) uniformly mixing the prepared antibacterial master batches and ordinary master batch according to a mass ratio of 1:1-1:50, adding the obtained mixture to high speed spinning equipment, and carrying out melt-spinning and winding to obtain the fiber product. According to the present invention, the method has characteristics of simple process and easy industrial production; and the fibers prepared by the method have characteristics of original fiber characteristic maintaining and broad-spectrum antibacterial property, wherein the antibacterial rate is more than 99%.

Owner:TAICANG RONGWEN SYNTHETIC FIBER

Zirconium oxide thermal barrier coating for turbine buckets of gas turbine and preparation method thereof

ActiveCN102094170AProcess parameters are easy to controlComposition controllableBlade accessoriesVacuum evaporation coatingZirconium hydrideThermal barrier coating

The invention relates to a zirconium oxide thermal barrier coating for turbine buckets of a gas turbine and a preparation method thereof. The zirconium oxide thermal barrier coating for the turbine buckets of the gas turbine is characterized in that adhesive layer materials and ceramic layer materials are plated on a metal surface; the adhesive layer materials include the following materials in percentage by weight: 15-30% of Co, 20-30% of Cr, 6-16% of Al, 0.2-1.0% of Y, and the balance of Ni; and the ceramic layer materials are zirconium oxide (ZrO2 / (5-8%)Y2O3) with stable yttrium oxide. The prepared zirconium oxide thermal barrier coating has compactness, good combining capacity with a base body and good thermal cycle resisting capacity and high temperature corrosion resisting capacity.

Owner:沈阳天贺新材料开发有限公司

Prepn of nanometer aggregated zirconia powder for hot spraying

InactiveCN1637080AControl growthStructure does not growLiquid surface applicatorsCoatingsThermal sprayingMass ratio

The preparation process of nanometer aggregated zirconia powder for spraying includes: mixing nanometer zirconia powder stabilized with 20-60 nm granularity yttrium oxide and adhesive in the mass ratio of 95:5 to 98:2 and adding pure water of 1-1.3 times the mixture weight to compound slurry; spraying at 110-300 deg.c to form micron level aggregated powder; and final plasma nodulizing or sintering to form compact powder of 40-90 micron granularity and with the nanometer crystal structure maintained. The obtained powder may meet the technological requirement of plasma spraying or flame spraying. The technological process is simple, great in output, safe, reliable, low in cost and suitable for continuous industrial production.

Owner:WUHAN UNIV OF TECH

Vacuum/gas shield electroslag remelting continuous directional solidification device and method

ActiveCN102021348AEliminate aggregationEliminate coagulation and looseningElectricityHigh volume manufacturing

The invention relates to an electroslag remelting technique, in particular to a vacuum / gas shield electroslag remelting continuous directional solidification device and method. The device comprises a power supply, a consumable electrode (1), a water-cooling crystallizer (2) and a gas shield system, wherein the lower part of the water-cooling crystallizer (2) is provided with a water-cooling chassis (7) and a stripping device (13), and a two-circuit control mode is adopted by the consumable electrode (1) to make the stripping speed equivalent with the solidification speed of a cast ingot. The invention has simple operation and low cost, is convenient to control, can be used for producing large-dimension low-segregation directional solidification cast ingots and is suitable for mass production and application.

Owner:BEIJING CISRI GAONA TECH

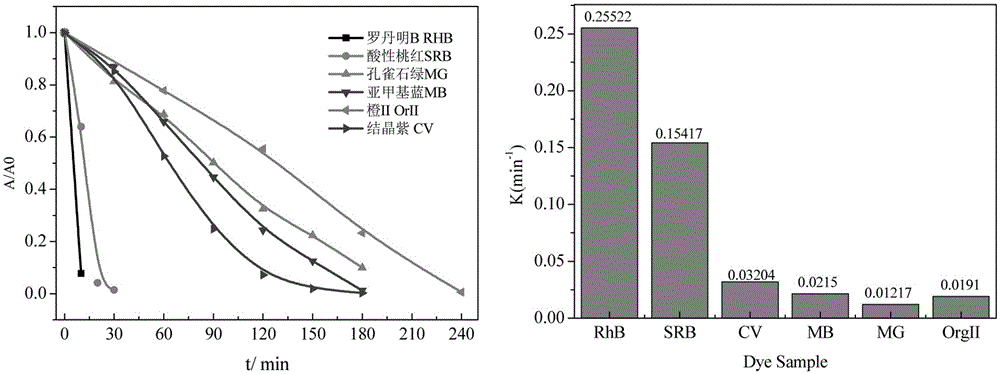

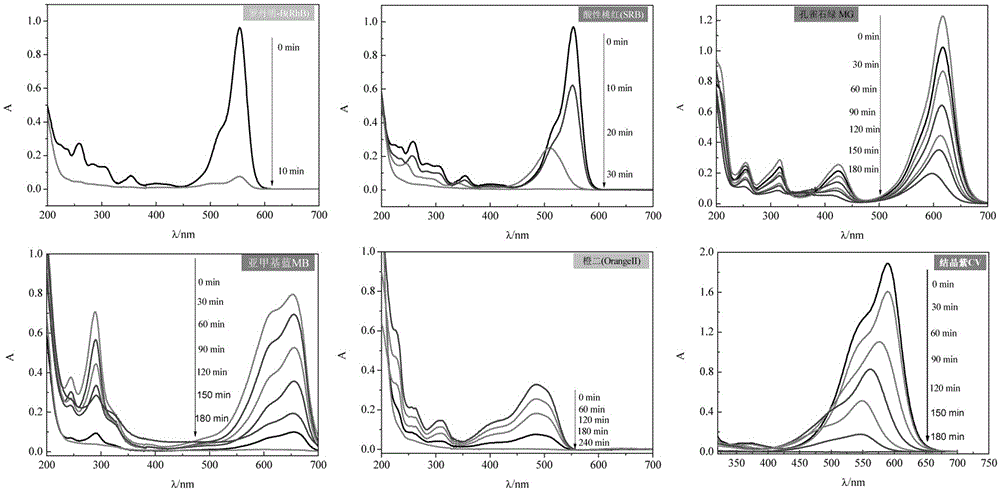

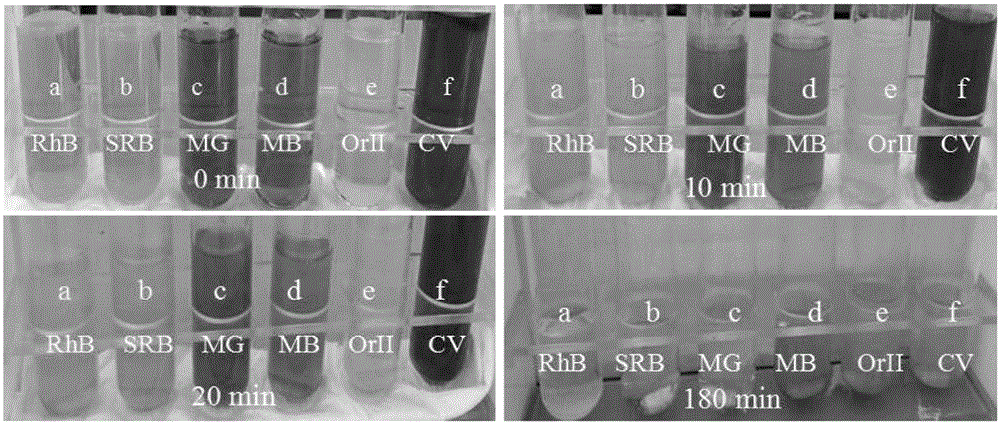

Preparation method and application of BiVO4-BiOBr photocatalyst

InactiveCN104998665AGuaranteed stabilityGood UV-Vis catalytic activityPhysical/chemical process catalystsWater/sewage treatment by irradiationUltraviolet lightsNanostructure

The invention discloses a preparation method of BiVO4-BiOBr photocatalyst has a visible-light response, wherein the catalyst may be used under visible light, ultraviolet light, or sunlight. The preparation method of BiVO4-BiOBr photocatalyst that is in a multilevel nest-like nanostructure and is formed by nanosheets is: heating for 8 to 24 h under an alcohol-heating temperature of 100 to 200 DEG C with pH of 5 to 10. The catalyst of the invention can decompose water-soluble organic pollutant containing chlorine and sulfur, water-soluble organic pollutant of azo, xanthene, and anthraquinone type, and biological contaminant microcystic toxins generated by harmful algal bloom.

Owner:CHINA THREE GORGES UNIV

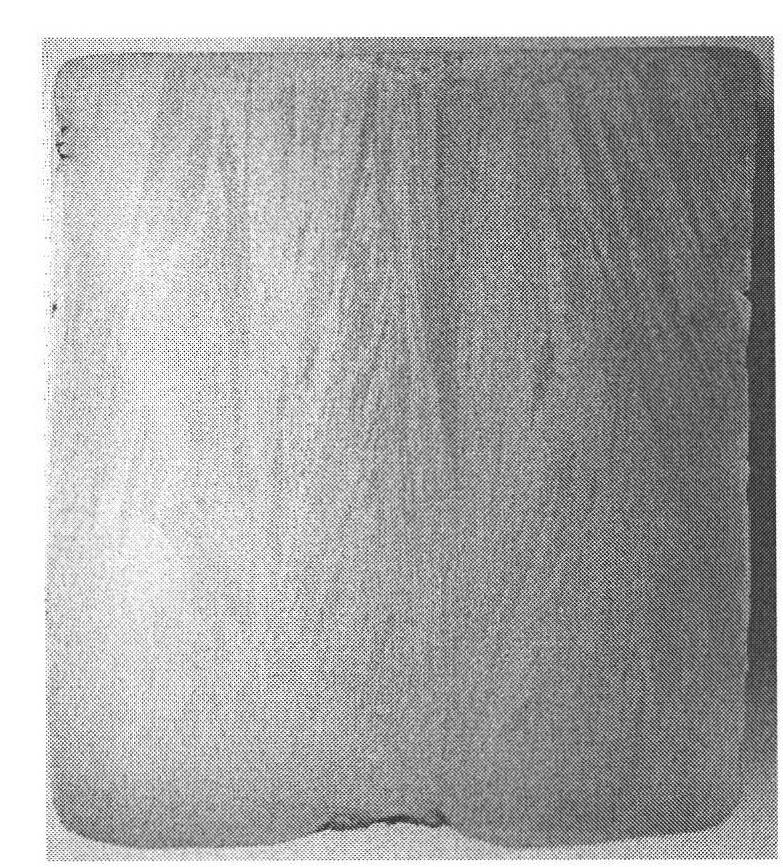

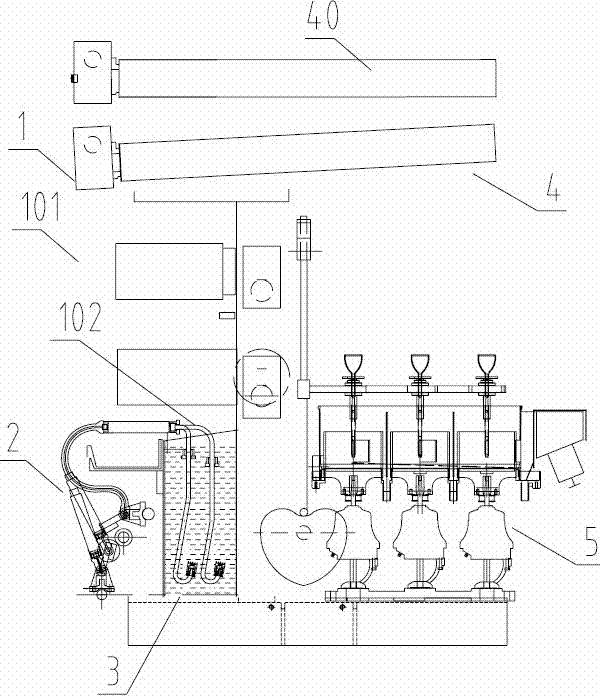

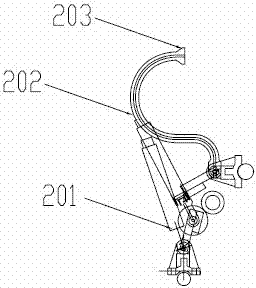

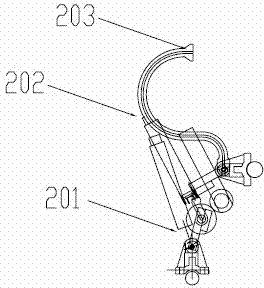

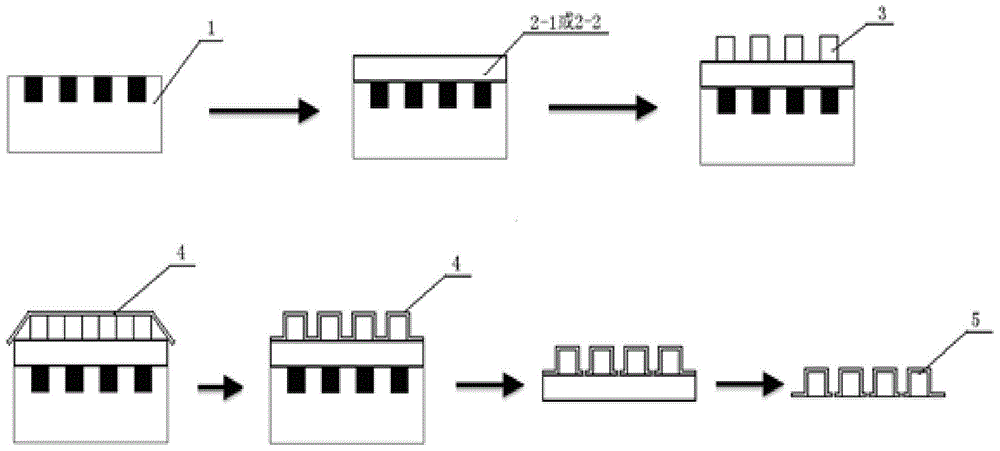

Semi-continuous high-speed spinning machine

ActiveCN103290501AEasy to operateControllableNew-spun product collectionArtificial thread manufacturing machinesEngineeringMechanical engineering

The invention relates to spinning equipment, in particular to a semi-continuous high-speed spinning machine. The semi-continuous high-speed spinning machine comprises a rack, a glue supply device, a strip forming device, a spinning device and a winding device, wherein a spinning roller of the spinning device is horizontally arranged relative to an operating surface of a spinning surface. The operating surface of the spinning surface is a horizontal working surface in a spinning surface area, and the fact that the spinning roller is horizontally arranged relative to the operating surface of the spinning surface refers to that the spinning roller is horizontally installed relative to spinning workers when the spinning workers face towards the winding device. According to the semi-continuous high-speed spinning machine, the spinning roller is horizontally arranged relative to the operating surface of the spinning surface, and two ends of the horizontally arranged spinning roller are fixed, so that the spinning speed can be increased on the basis of the semi-continuous high-speed spinning machine, the spinning roller is ensured to rotate stably without shaking, and the problems of intertwining and breakage of strips caused by shaking of the spinning roller during spinning are solved.

Owner:YIBIN HIEST FIBER +2

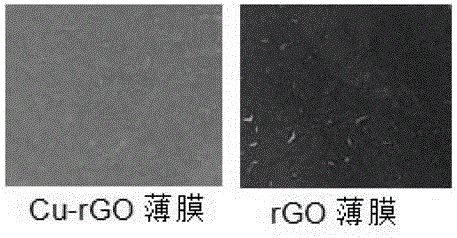

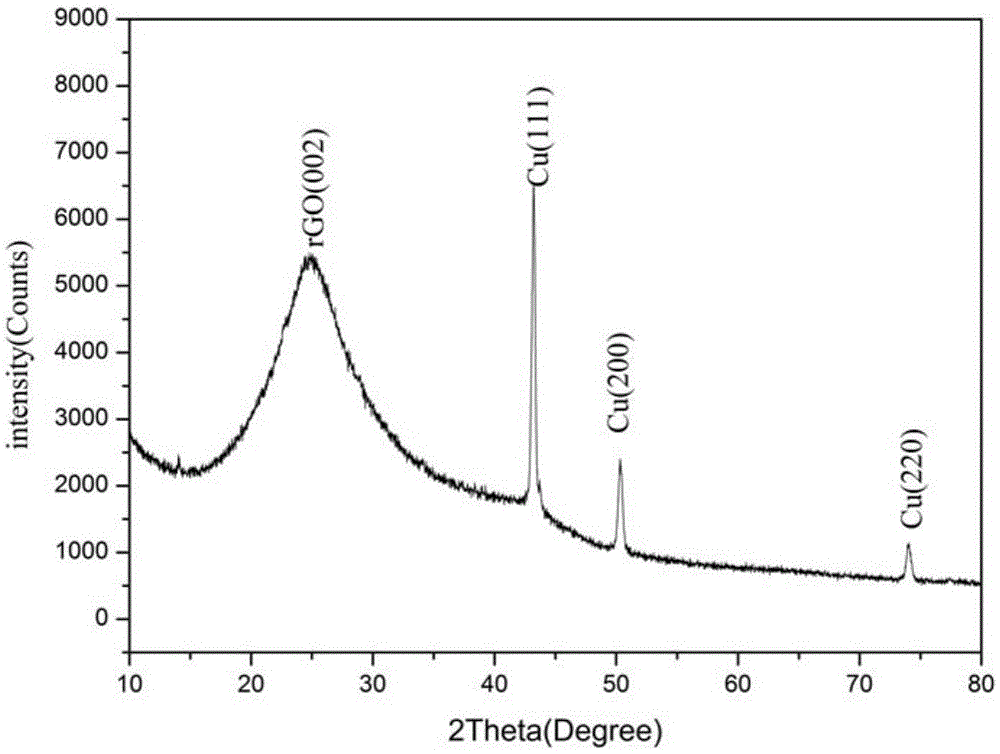

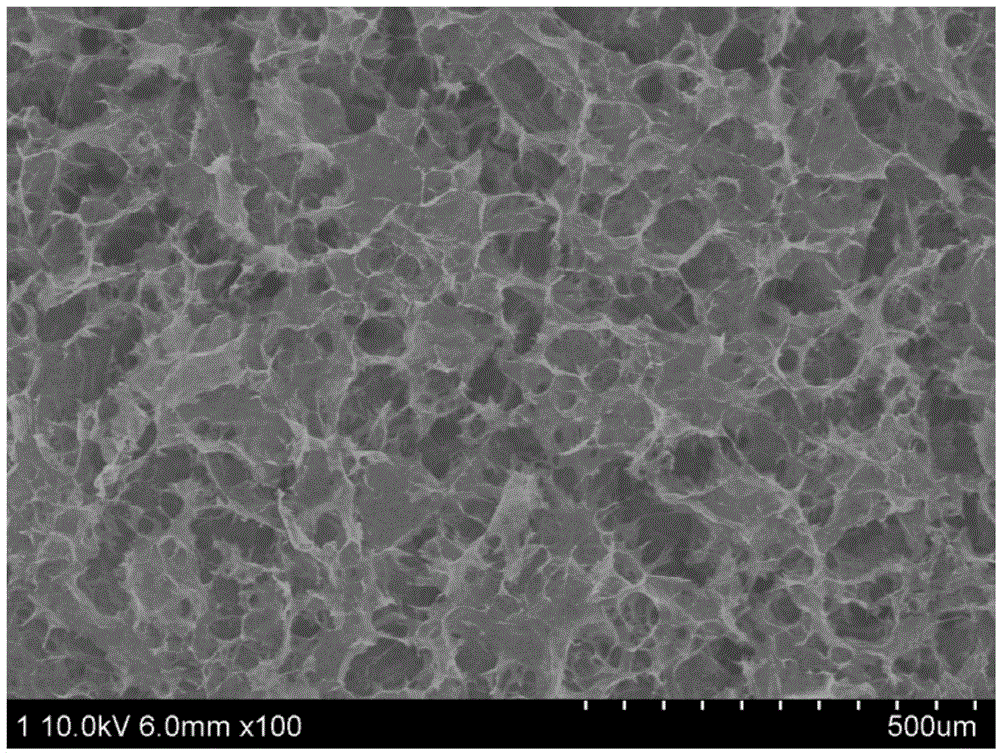

Preparation method and application of Cu nanowire-reduced graphene oxide three-dimensional porous film

InactiveCN105583408ALarge specific surface areaMild conditionsElectrical/magnetic solid deformation measurementComposite filmFiltration

The invention provides a preparation method of a Cu nanowire-reduced graphene oxide-PDMS composite strain sensor, and belongs to the field of reduced graphene oxide composite sensors. The preparation method comprises the steps that copper nanowires are added into graphene oxide containing ascorbic acid, Cu nanowire-reduced graphene oxide hydrogel is obtained after reducing, and a Cu nanowire-reduced graphene oxide film with the three-dimensional porous appearance is obtained through washing, stir-breaking and suction filtration film formation; and then liquid PDMS is poured, vacuum filtration is carried out to remove bubbles, the liquid PDMS is subjected to cross-linking and curing at the temperature of 70 DEG C, and finally the Cu nanowire-reduced graphene oxide-PDMS composite strain sensor is obtained. The composite film is large in specific surface area and excellent in electric conductivity and mechanical performance, and the preparation method of a Cu nanowire-reduced graphene oxide-PDMS composite is mild in condition, simple, practical, controllable in process parameter, low in cost and high in repeatability.

Owner:ZHEJIANG SCI-TECH UNIV

A highly conductive thermal insulating metal base printed circuit board

ActiveCN103338588AIncrease productivityProcess parameters are easy to controlVacuum evaporation coatingSputtering coatingPrinted circuit boardMetal substrate

The invention relates to a highly conductive thermal insulating metal matrix printed circuit board comprising a metal base body. A ceramic layer formed through a reaction magnetron sputtering method and a metal conducting layer formed on the ceramic layer are sequentially formed on the metal base body. According to the invention, through the adoption of the reaction magnetron sputtering deposition method, a transition layer and a highly thermal conducting layer are deposited on a metal substrate, and the metal substrate is regarded as a circuit board substrate to form an integrated printed circuit board with a high integration degree. The manufacturing method of the invention facilitates the control of technological parameters, and is simple in procedures. The product quality is stable and reliable. The production efficiency is high, and the preparation cost is low.

Owner:苏州汾湖投资集团有限公司

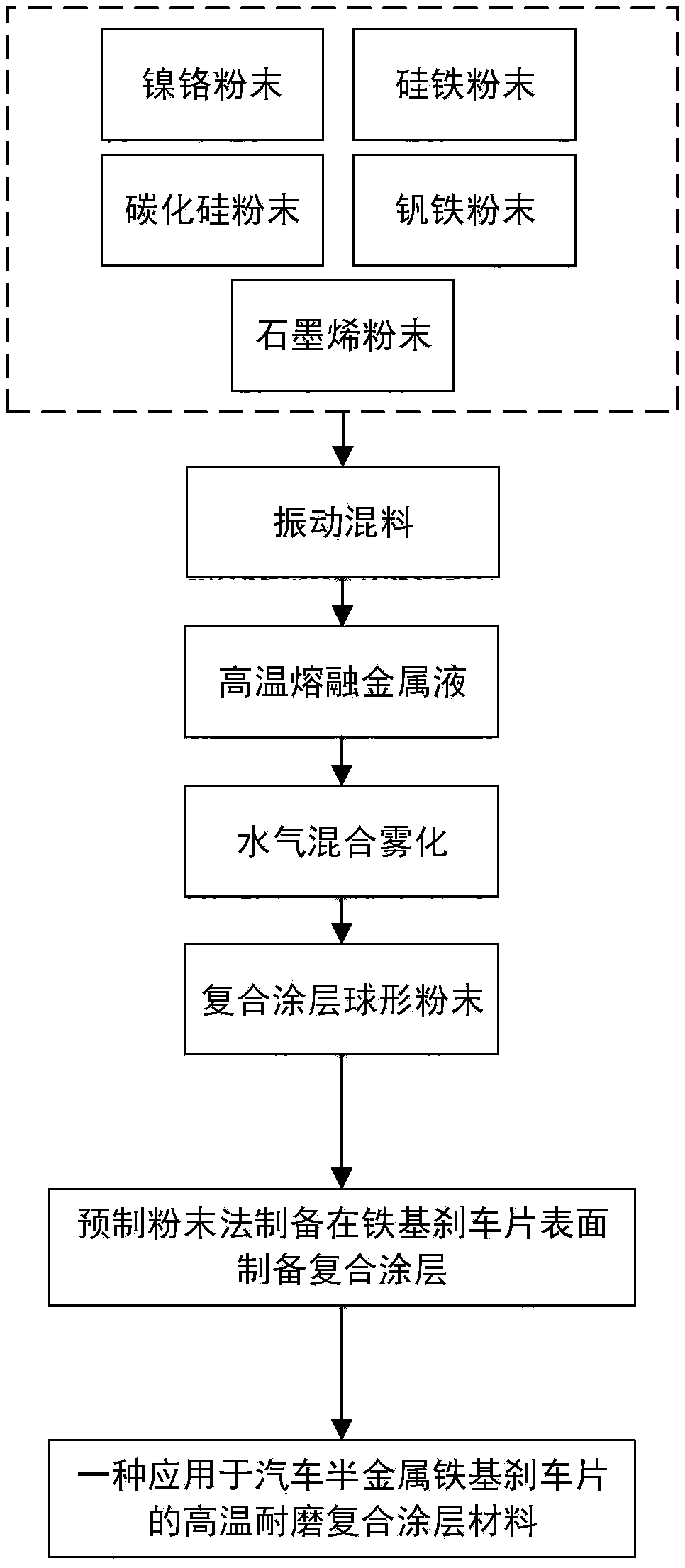

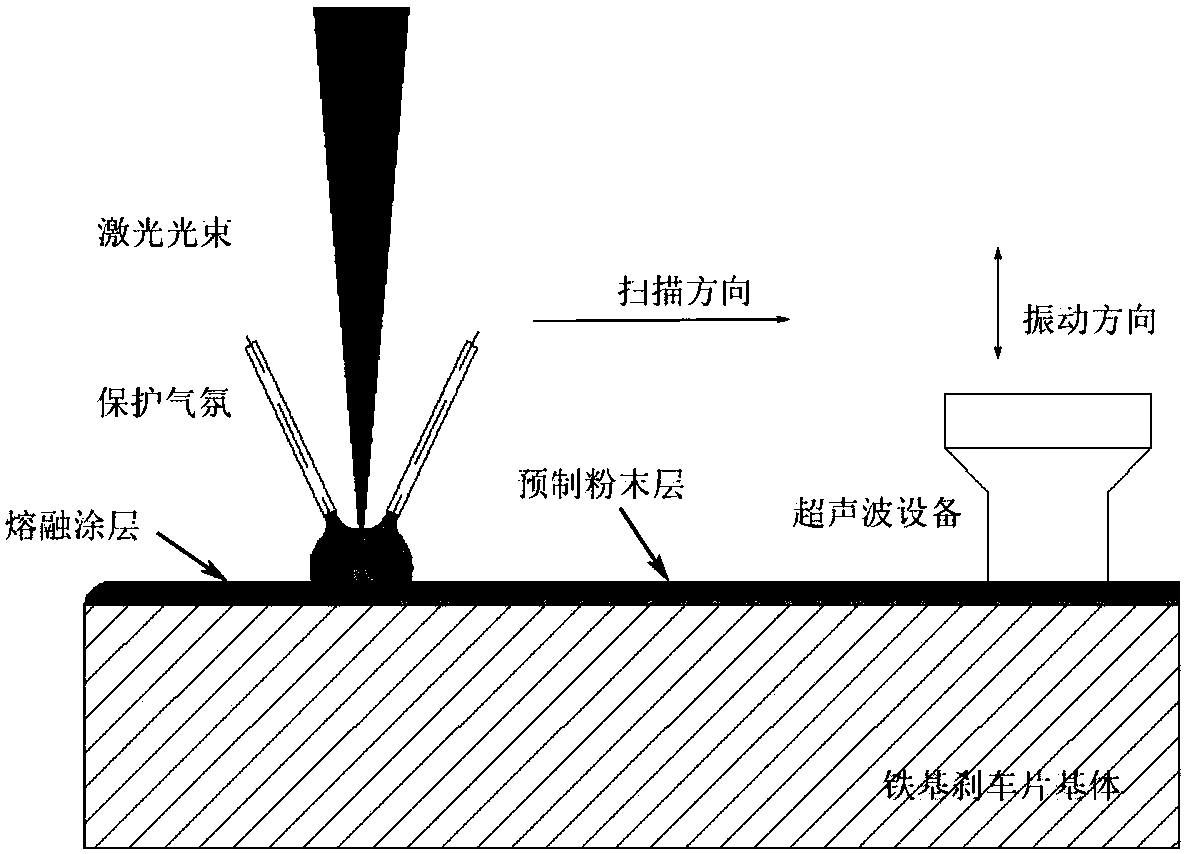

Composite coating material applied to semi-metal iron-based brake pads and preparation method for composite coating material

ActiveCN108127123AStable brakingImprove toughnessTransportation and packagingMetal-working apparatusWater vaporFerrosilicon

The invention discloses a composite coating material applied to semi-metal iron-based brake pads. The composite coating material is formed by nickel-chrome alloy powder, chromium carbide powder, ferrosilicon, ferrovanadium, aluminite powder and graphene being subjected to high temperature melting, water vapor mixing atomization, bonding batter-mixing brushing and laser melting. The raw materials comprise the ingredients of, in percentage by mass, 12-50% of nickel-chromium, 15-28% of chromium carbide, 6-10% of ferrosilicon, 5-8% of ferrovanadium, 20-40% of aluminum and 1-2% of graphene. By means of the composite coating material applied to the semi-metal iron-based brake pads and a preparation method for the composite coating material, a metal alloy powder coating formed on the surface of the semi-metal iron-based brake pads has good physical and mechanical performance and has good friction performance and thermal stability under high temperature conditions, and dust after friction is convenient to treat, furthermore, process parameters are easy to control in the preparation process, and the composite coating material applied to the semi-metal iron-based brake pads and the preparation method for the composite coating material are suitable for popularization and application.

Owner:WUHAN UNIV OF TECH

High-efficiency metal 3D printing equipment and method

ActiveCN106925783AHigh precisionLow costAdditive manufacturing apparatusIncreasing energy efficiencySpray nozzleEngineering

The invention discloses high-efficiency metal 3D printing equipment and a method, and belongs to the technical field of 3D printing. Through such measures as separation of a supply system of metal 3D printing equipment from a discharge system, separation of a printing forming area from a cooling medium, positioning of the supply system out of a forming room and capability of controlling the size of a discharge port of a nozzle according to sizes of products, based on direct melt supply and cooling medium cooling, the high-efficiency metal 3D printing equipment and method adopt 3D printing to form high-quality metal products with high efficiency and low cost, and in particular, are suitable for high-efficiency formation of large metal products. The 3D printing equipment is flexible in mechanism actions, fast in operating speed, high in flexibility, high in sensitivity and low in manufacturing cost; the 3D printing forming process is high in efficiency; process parameters are liable to control; and the metal products formed by printing are excellent in quality and repeatability and low in production cost.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing nano iron oxide red

InactiveCN1508192AQuick buildUniform dispersionPigmenting treatmentReaction temperatureBuffer solution

The invention relates to a nano iron oxide red preparing method, fully mixing crystal converting agent and lye under normal temperature and pressure, then stirring and adding the product obtained by oxidizing soluble trivalent or bivalent ferric salt solution at the same time to form gelatin, then adding in buffer solution, maintaining the pH value of the mixed liquid within 8-12, heating and maintaining the reaction temperature within 85-110 deg.C aging for 5-20minutes, centrifugating turbid liquid by centrifugal pump, washing for 3-5times, drying for 1.5-3hours under 25-50 deg.C, and grinding to obtain single disperse nano alpha-Fe2O3 particles. The particle size can be regulated and controlled within 10-100nm, the distribution even.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

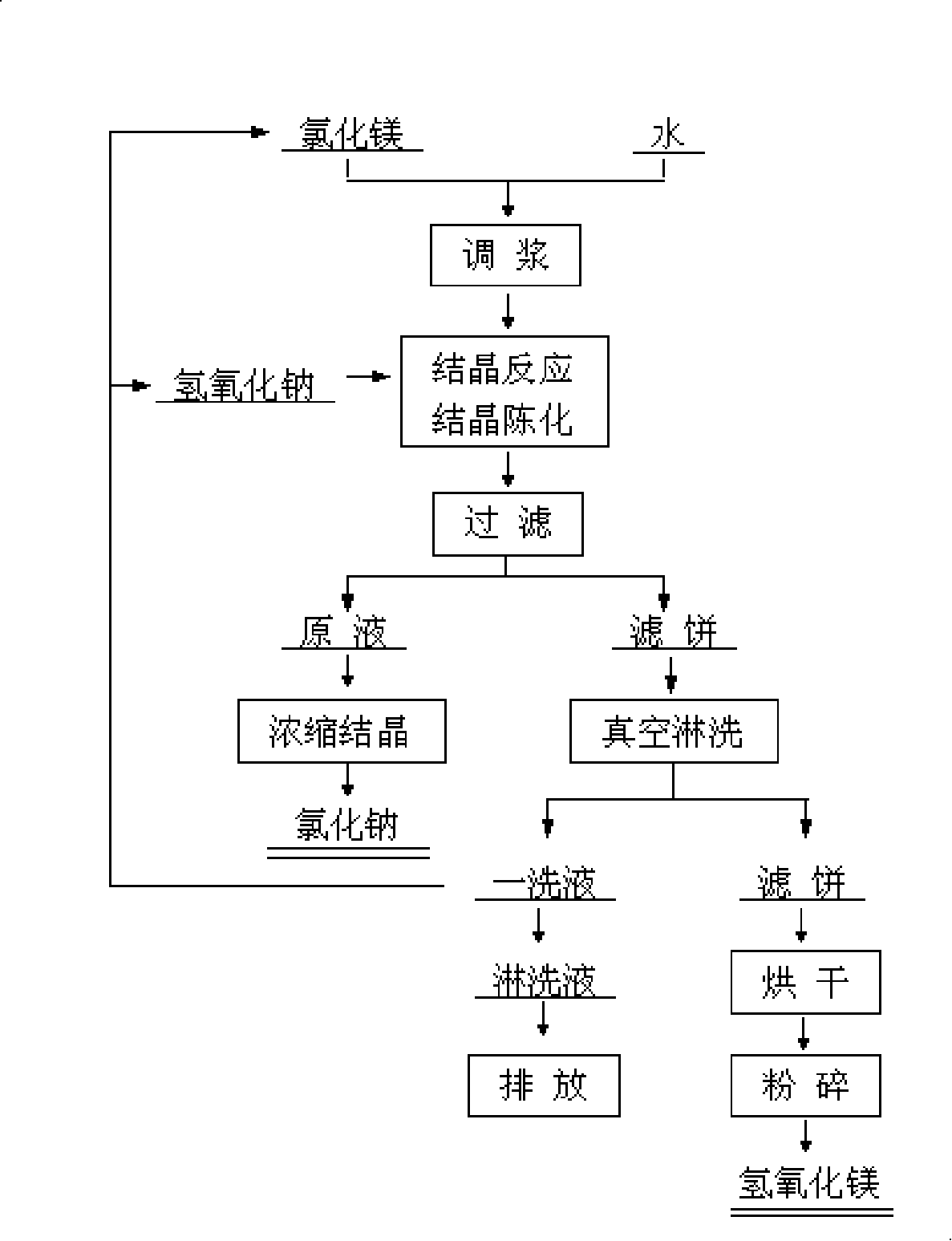

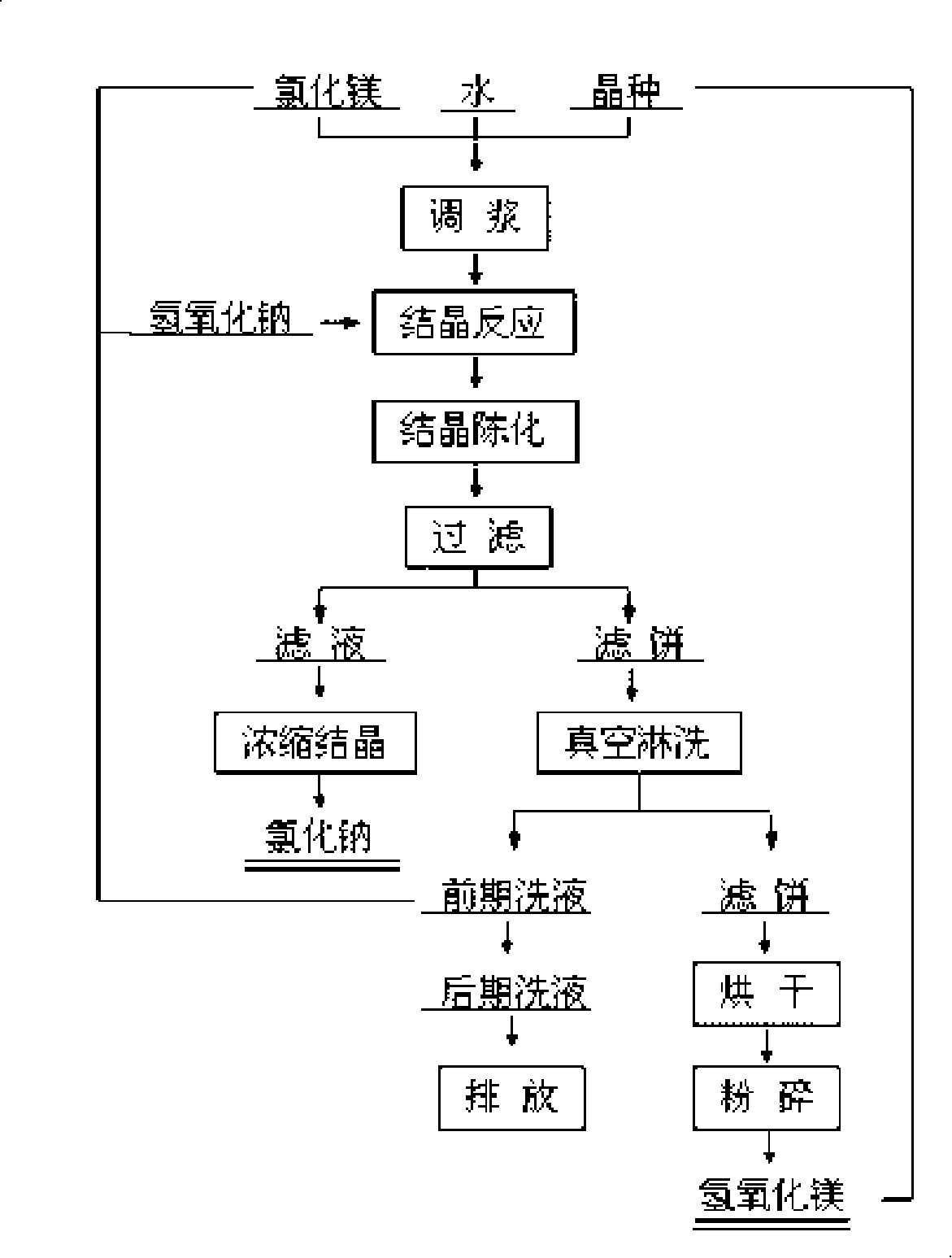

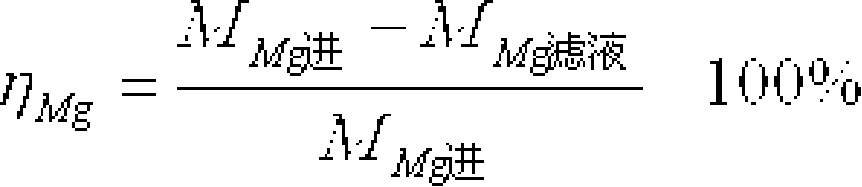

Technique for preparing high purity ultra-fine magnesium hydroxide by sodium hydroxide method

InactiveCN101234769ASpeed up the distribution balance stateHigh purityMagnesium hydroxideDecompositionSlurry

The invention discloses a process for preparing high-purity ultrafine magnesium hydroxide by a sodium hydroxide method; by using a crystal seed decomposition method, purified brine and crystal seed of the magnesium hydroxide are added to a reaction pool to be mixed and temperature is kept at 60-80 DEG C; then solution of the sodium hydroxide is added to the reaction pool to carry out the precipitation reaction, crystallization and aging; after the reaction is finished, slurry of the magnesium hydroxide is filtered and washed; cake after filter is dried and crashed, the crystal product of the magnesium hydroxide is obtained. Compared with the prior art, the process for preparing the high-purity ultrafine magnesium hydroxide accelerates agglomeration and growth of the magnesium hydroxide crystal by adding the crystal seed, solves the problem of the difficulty for filtering and washing the filter cake by using the prior sodium hydroxide method to produce the magnesium hydroxide, and directly utilizes the slurry of the magnesium hydroxide generated by the reaction as the crystal seed to carry out cyclic decomposition. The process flow is simple and the process parameter can be easily controlled. The production process is pro-environment without producing pollutant. At the same time, the purity of the magnesium hydroxide obtained by the process and the recovery rate of the magnesium are very high; furthermore, the purity of the by-product sodium chloride is high. The process for producing the magnesium hydroxide has great development prospect.

Owner:GUIZHOU UNIV

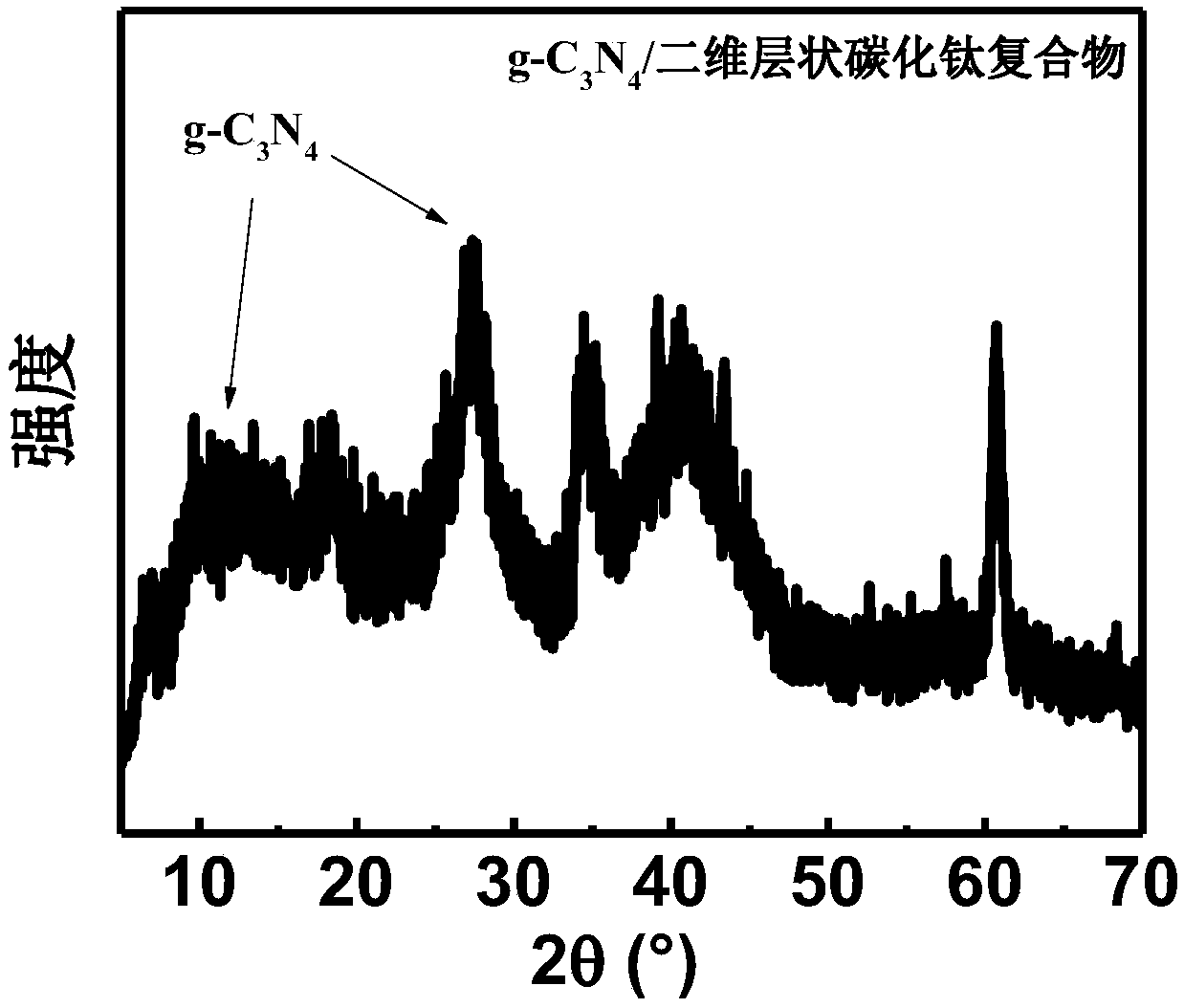

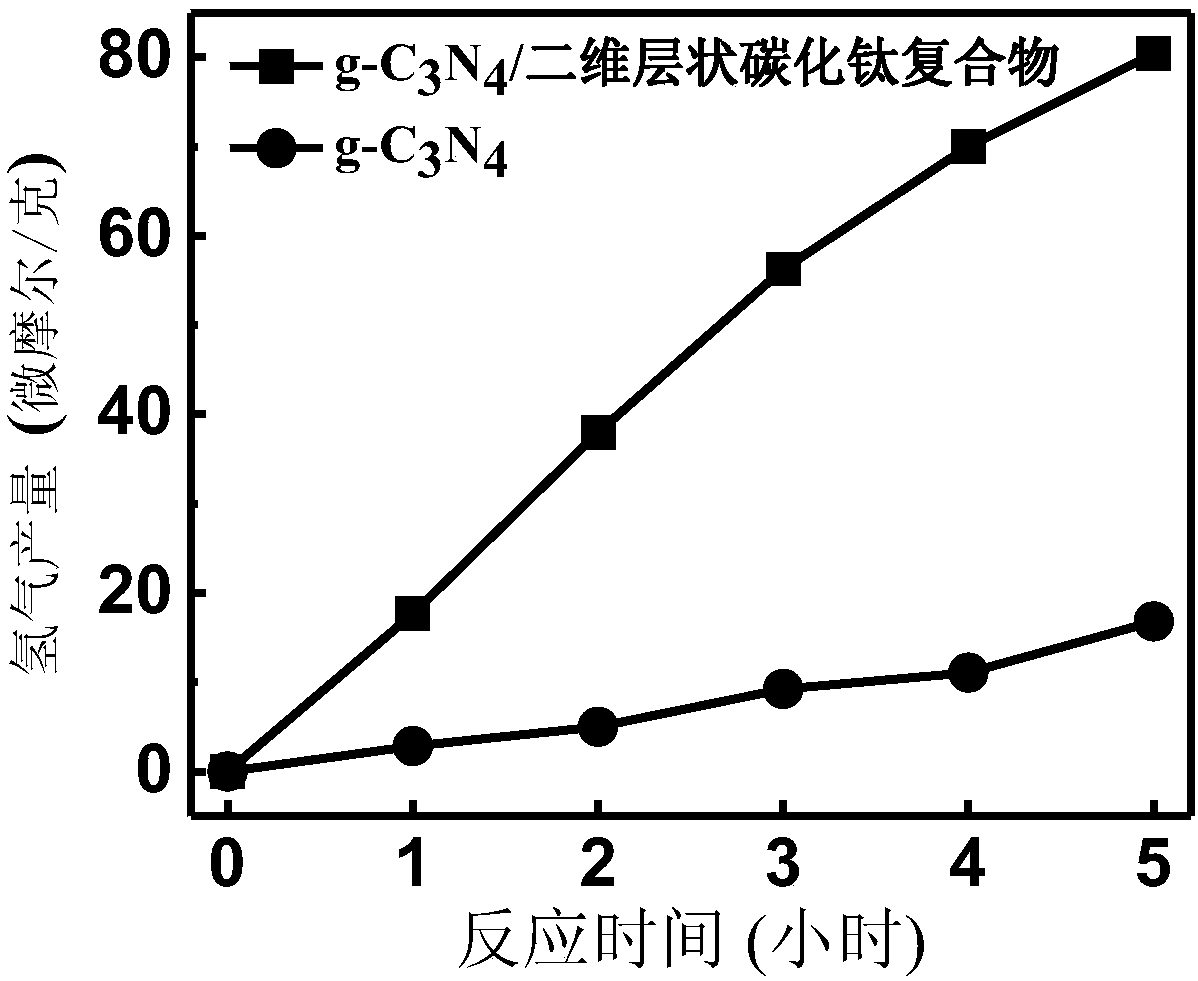

Preparation method of g-C3N4/MXene composite material

InactiveCN108499588AImprove separation efficiencyIncrease contactCatalyst activation/preparationWastewaterNanotechnology

The invention relates to a preparation method of a g-C3N4 / MXene composite material. The preparation method comprises the following steps of preparing an MXene material, preparing a mixture of MXene and g-C3N4 precursor matters, and preparing the g-C3N4 / MXene composite material. The preparation method has the advantages that the preparation method is simple, the technology parameters are easy to control, the cost is low, and the large-scale industrialized production is easy to implement; the prepared g-C3N4 / MXene composite material has good crystallizing property, fine particles, uniform distribution, large specific surface area, good conductivity, good photocatalysis property, good biophile property, and application value in the fields of photocatalysis, wastewater treatment, biological sensors and the like.

Owner:DONGHUA UNIV

High heat conducting and insulating metal matrix printed circuit board

ActiveCN103327735AIncrease productivityProcess parameters are easy to controlPrinted circuit manufactureCircuit susbtrate materialsElectrically conductiveMetal substrate

The invention relates to a high heat conducting and insulating metal matrix printed circuit board. The circuit board comprises a metal substrate, a metal transition layer, a ceramic layer and a metal conducting layer, wherein the ceramic layer is formed through a CVD method, the metal conducting layer is formed on the ceramic layer in sequence, and the heat conducting coefficient of the ceramic layer is larger than 50W / mK. By depositing the metal transition layer and the ceramic layer with high heat conductivity on the metal substrate, the integrated printed circuit board with high integration level can be formed to serve as a circuit board substrate. In addition, a preparation method and a technological parameter of the high heat conducting and insulating metal matrix printed circuit board are easy to control, and the high heat conducting and insulating metal matrix printed circuit board is simple in step, reliable and stable in production quality, high in production efficiency and low in manufacturing method.

Owner:苏州汾湖投资集团有限公司

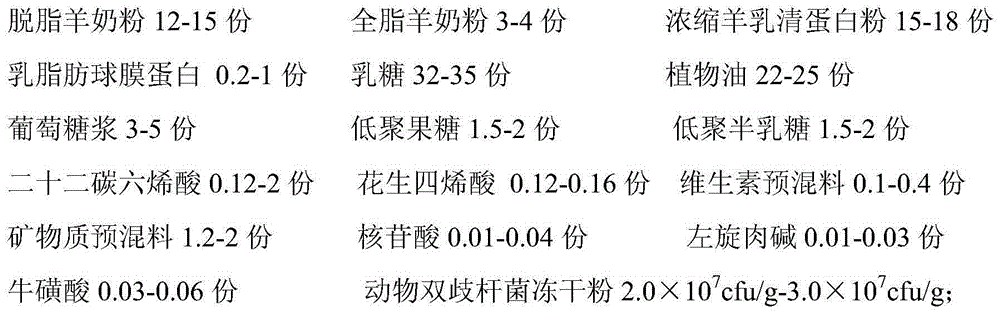

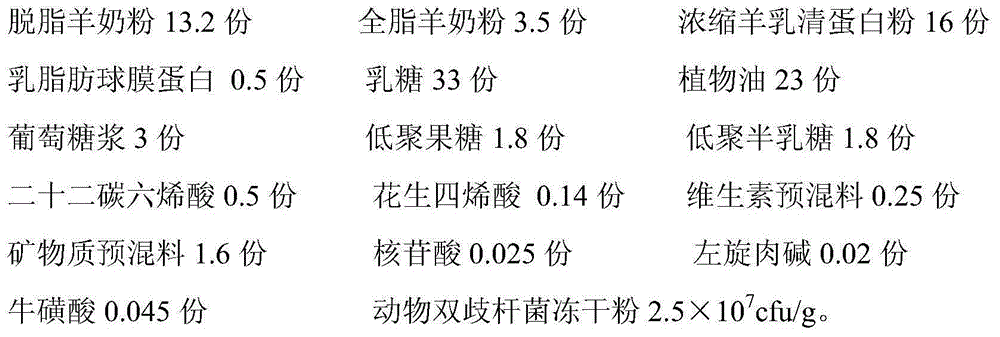

Infant formula ewe milk powder and production method thereof

PendingCN105053217AReduces risk of intestinal inflammation and lactose intoleranceTo promote metabolismMilk preparationChemistryMilk fat globule

The first purpose of the invention is to provide an infant formula ewe milk powder. The material includes the following component: skim ewe milk powder, whole ewe milk powder, concentrated ewe whey protein powder, milk fat globule membrane protein, docosahexaenoic acid, arachidonic acid, vitamin premix, mineral premix, lyophilized bifidobacterium animalis powder and the like, and moreover, Betal-casein in each of the skim ewe milk powder, the whole ewe milk powder and the concentrated ewe whey protein powder is only A2 Betal-casein. Since the invention adopts the skim ewe milk powder, the whole ewe milk powder and the concentrated ewe whey protein powder, the Betal-casein of which is only the A2 Betal-casein, the protein ingredient of the infant formula ewe milk powder is closer to breast milk; the addition of the milk fat globule membrane protein has a positive effect on the cognitive development of infants and decreasing the incidence of part of diseases. The second purpose of the invention is to provide a production method for the infant formula ewe milk powder, the process is simplified, process parameters are easy to control, the production method is suitable for mass production, and practicability is high.

Owner:HYPROCA NUTRITION CO LTD

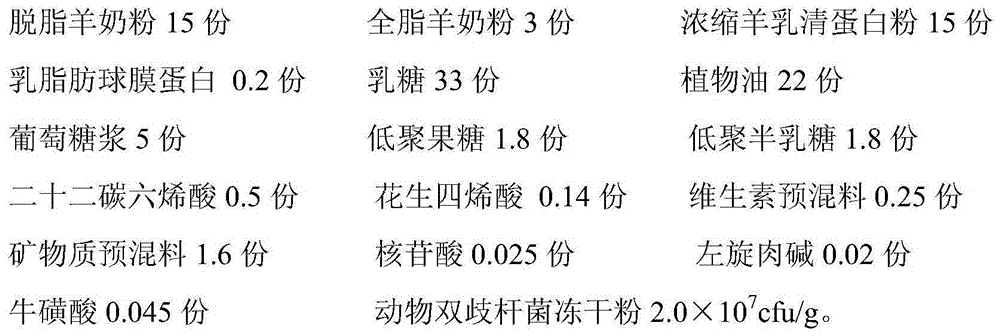

Preparation method for inverted LED white-light chip of chip scale package

ActiveCN104900783AHigh batch stabilityConsistent color temperatureSemiconductor devicesPhosphorEngineering

The invention discloses a preparation method for an inverted LED white-light chip of chip scale package, and the method comprises the following steps: temporarily fixing an UV solidifying adhesive tape (2-1) on the upper surface of a die bonding positioning light cover (1); setting flip chips (3) on the upper surface of the UV solidified adhesive tape (2-1) according to the position of the die bonding positioning light cover (1); employing a fluorescent glue film (4) to cover the flip chips (3); carrying out vacuumizing and heating, and enabling the fluorescent glue film (4) to be solidified and packaged on the flip chips (3); carrying out cutting along gaps among the all packaged flip chips (3); removing the die bonding positioning light cover (1); carrying out UV irradiation and enabling the UV solidified adhesive tape (2-1) to be solidified, and obtaining the inverted LED white-light chip (5) of chip scale package. The method simplifies the technological flow, avoids glue mixing and dispensing in the original technology, improves the production efficiency and yield, and greatly reduces the production cost. The method completely avoids the sinking of phosphor, enables the batch stability of the inverted LED white-light chips (5) to be high, and enabling the color temperature of the inverted LED white-light chips (5) to be consistent.

Owner:TECORE SYNCHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com