Patents

Literature

3761 results about "Rutile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rutile is a mineral composed primarily of titanium dioxide (TiO₂), and is the most common natural form of TiO₂. Other rarer polymorphs of TiO₂ are known including anatase, akaogiite, and brookite. Rutile has one of the highest refractive indices at visible wavelengths of any known crystal and also exhibits a particularly large birefringence and high dispersion. Owing to these properties, it is useful for the manufacture of certain optical elements, especially polarization optics, for longer visible and infrared wavelengths up to about 4.5 μm.

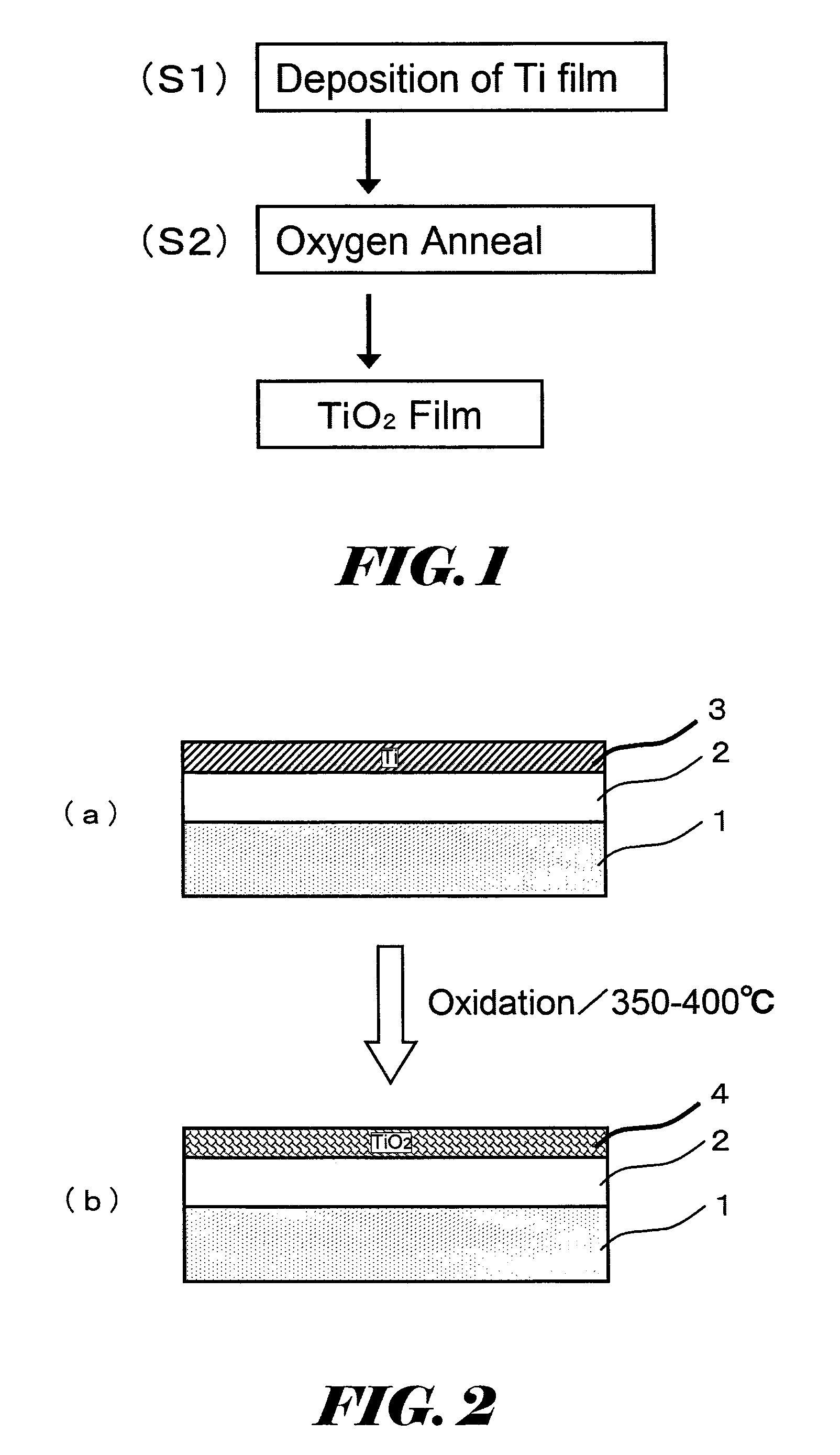

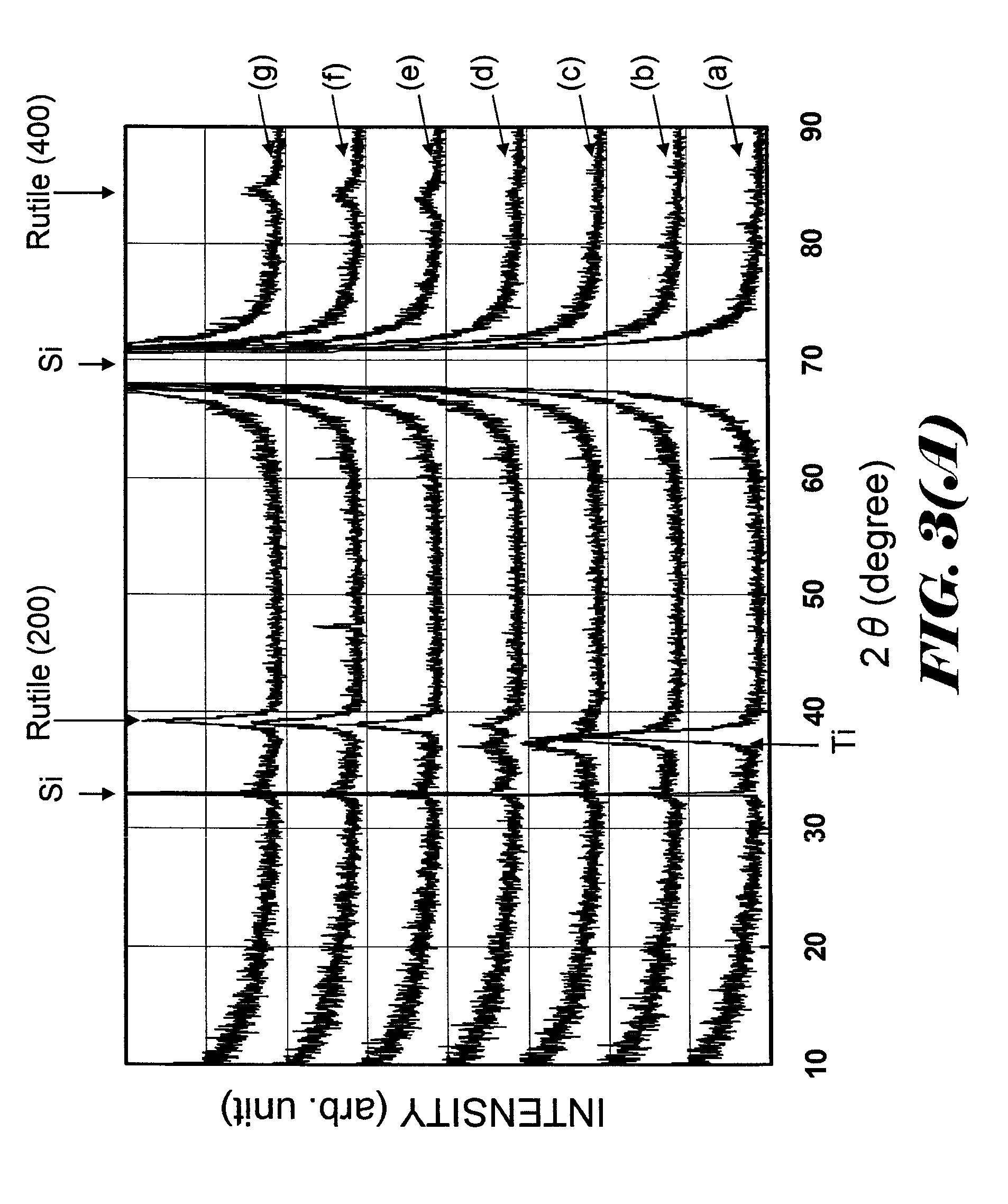

Method of manufacturing capacitive insulating film for capacitor

InactiveUS8198168B2Increase capacitanceReduce adverse effectsThin/thick film capacitorSemiconductor/solid-state device manufacturingCapacitanceCrystal structure

According to the invention, a Ti film is formed on a substrate and is annealed at the temperatures of 350° C.-400° C. under oxidative environment, so that a TiO2 film having a rutile crystal structure is formed. Since the TiO2 film having a rutile crystal structure has a high dielectric constant, it is useful for a capacitive insulating film for a capacitor.

Owner:PS4 LUXCO SARL

Process for making durable rutile titanium dioxide pigment by vapor phase deposition of surface treatment

The present invention relates to a process for making durable titanium dioxide pigment by vapor phase deposition of surface treatments on the titanium dioxide particle surface by reacting titanium tetrachloride vapor, an oxygen containing gas and aluminum chloride in a plug flow reactor to form a product stream containing titanium dioxide particles; and introducing silicon tetrachloride into the reactor at a point down stream of the point where the titanium tetrachloride and oxygen were contacted and where at least 97% of the titanium tetrachloride has been converted to titanium dioxide or where the reaction temperature is no greater than about 1200° C., and preferably not more than about 1100° C.

Owner:THE CHEMOURS CO FC LLC

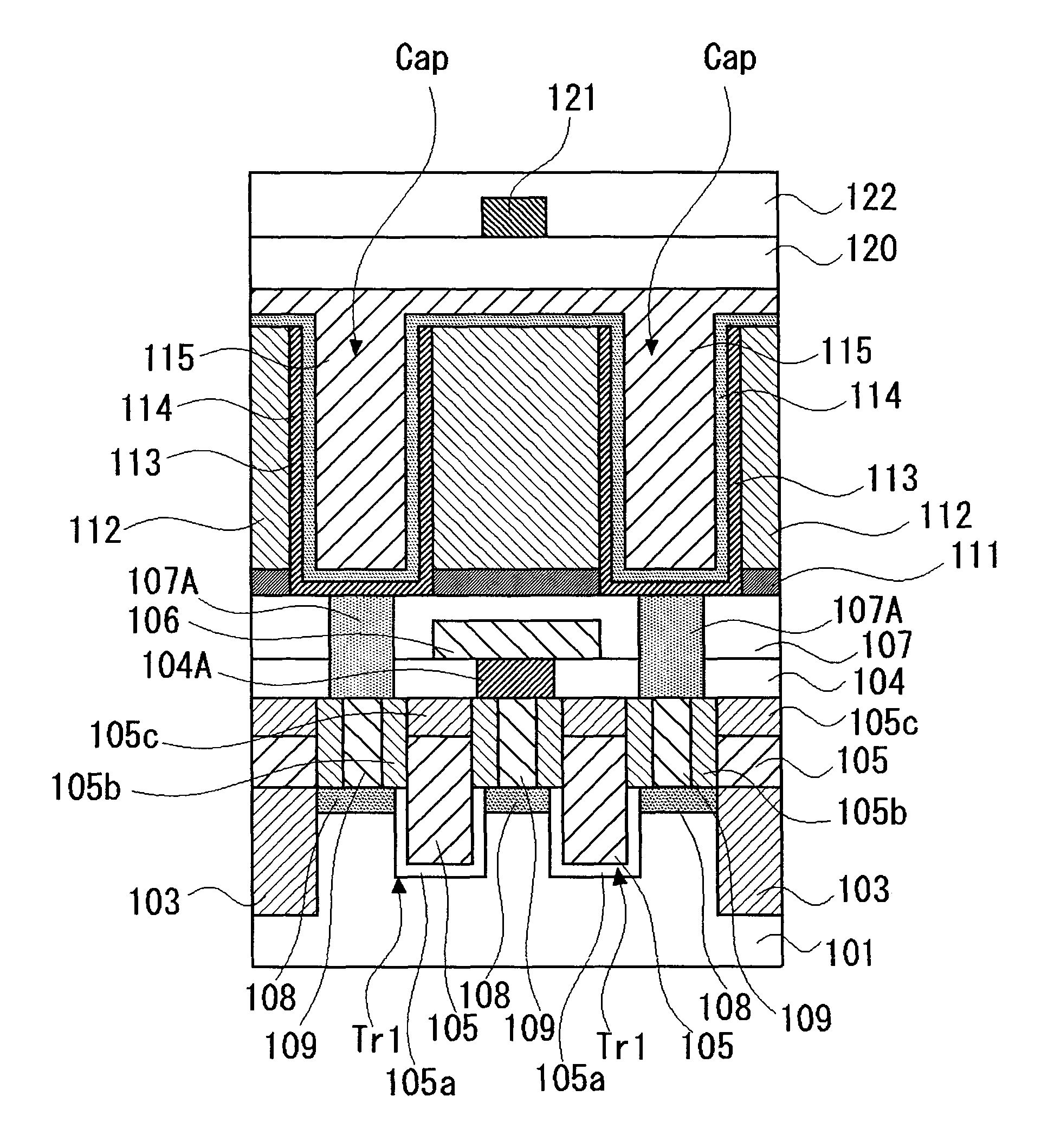

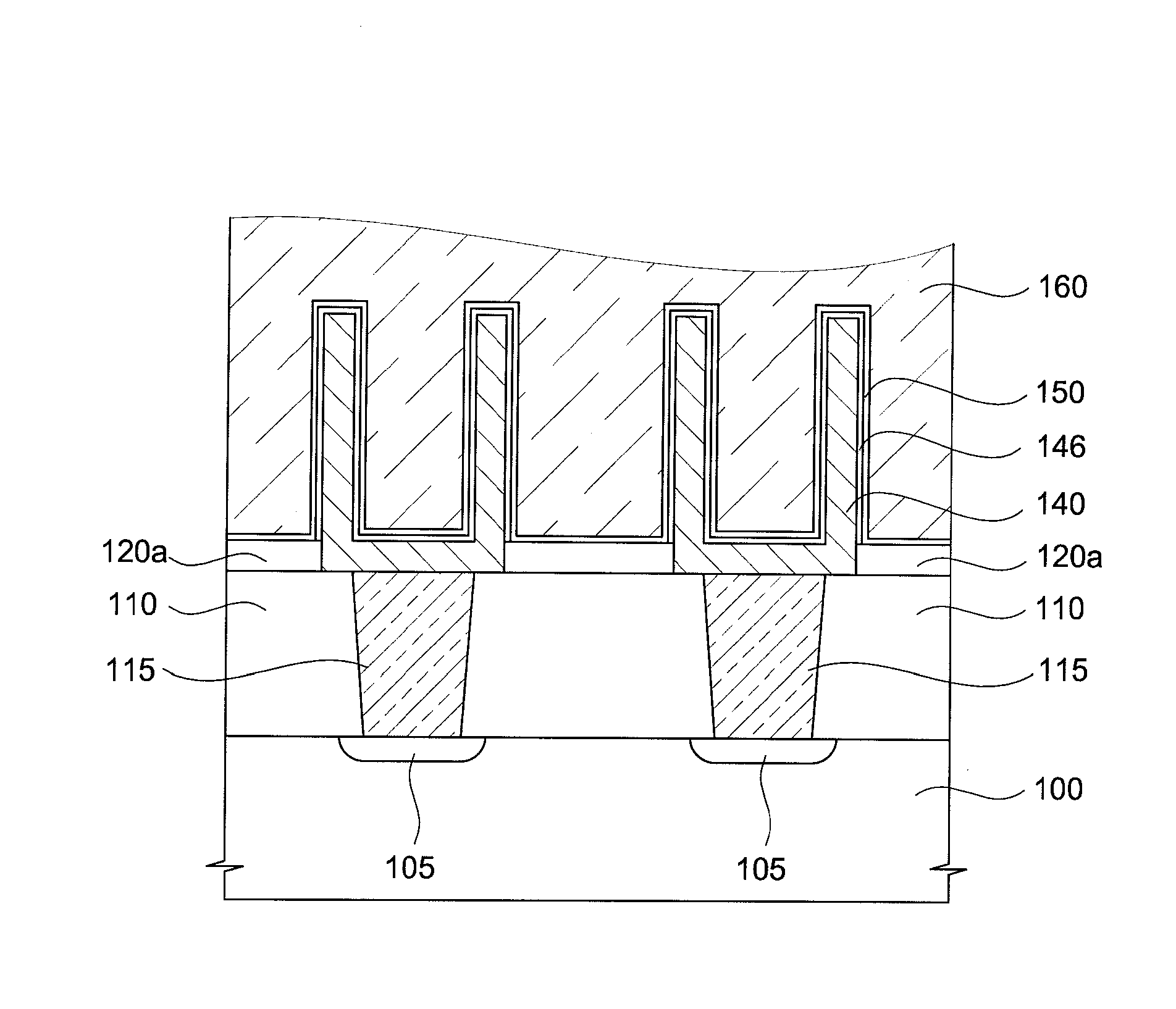

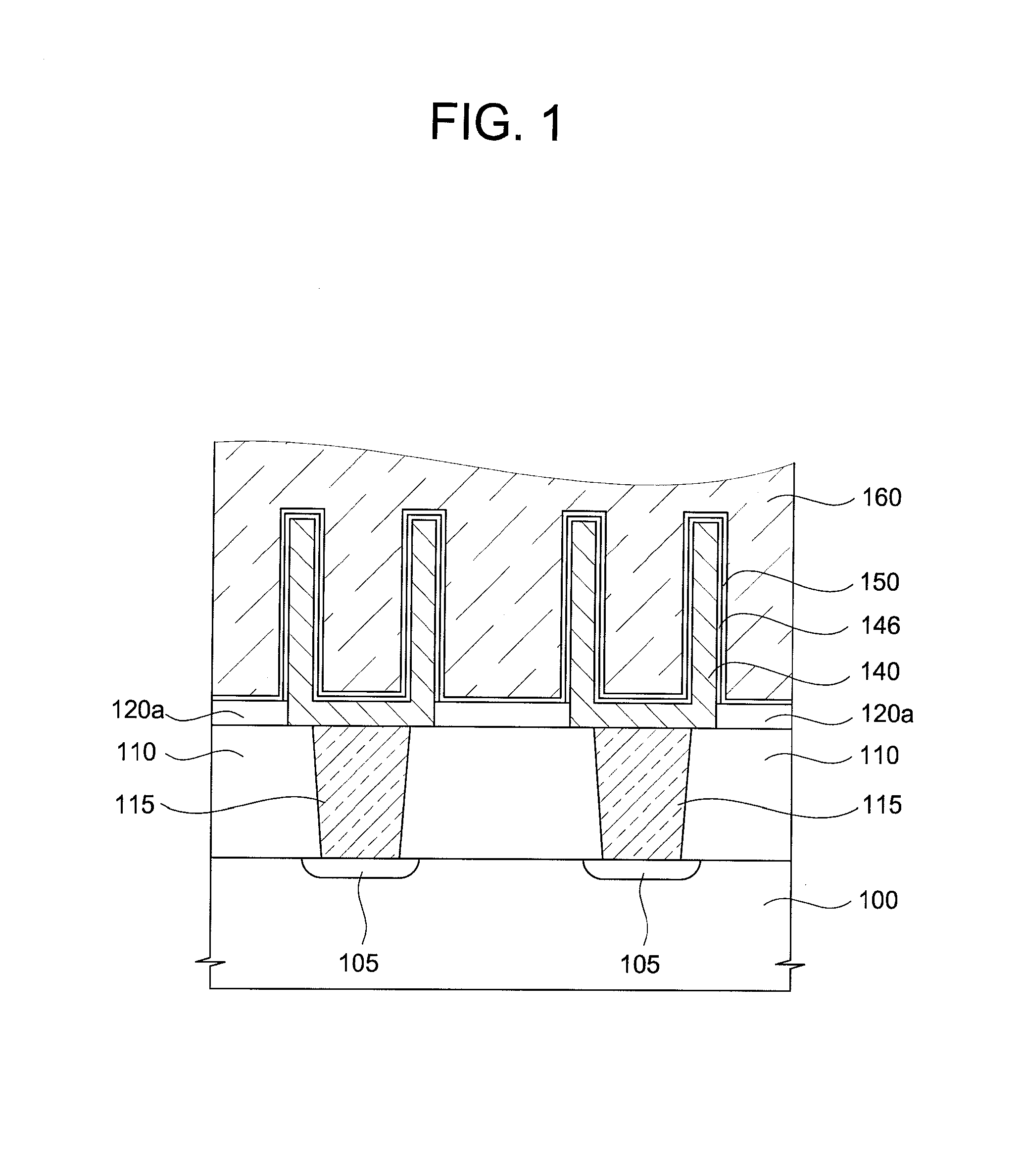

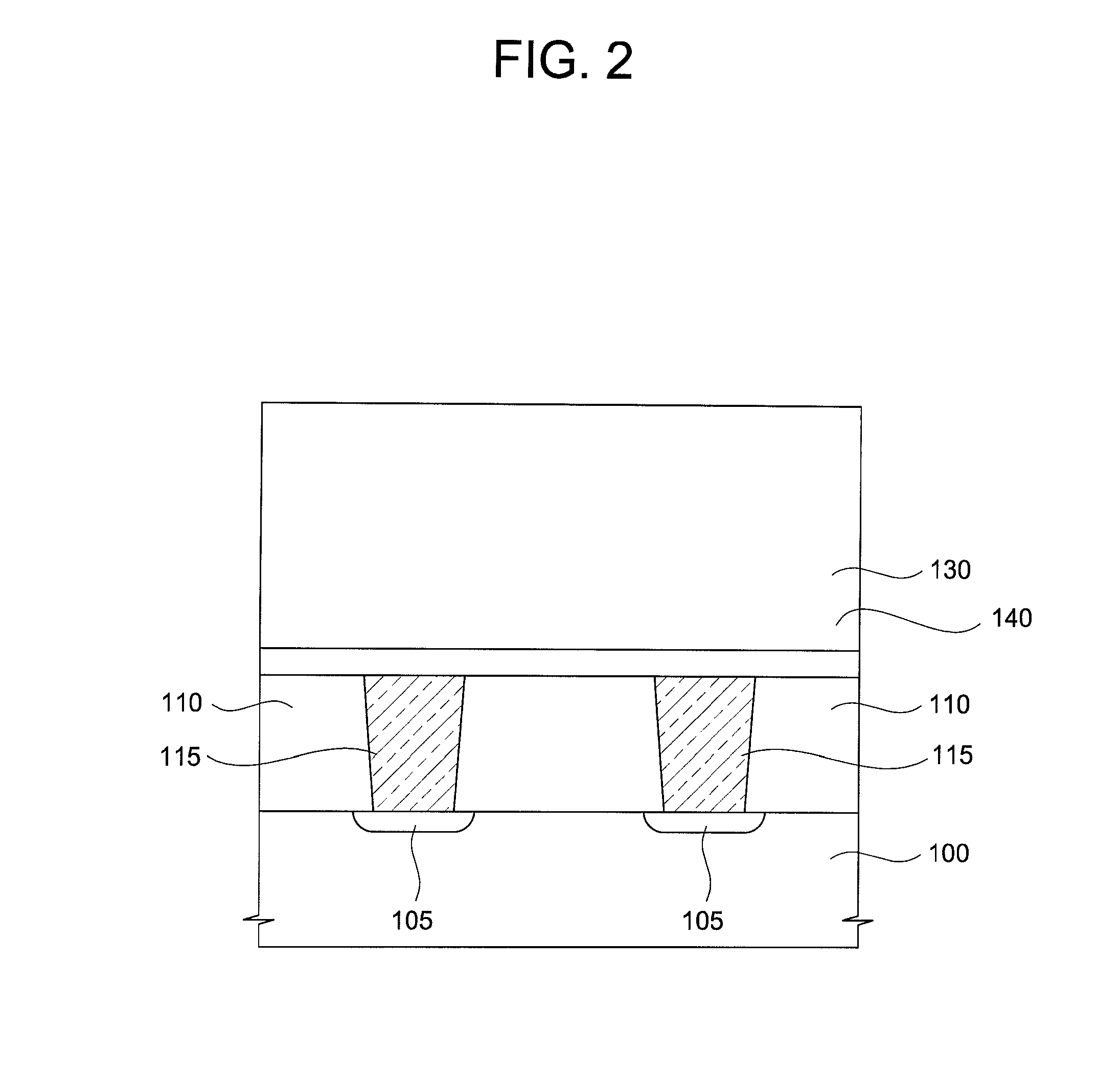

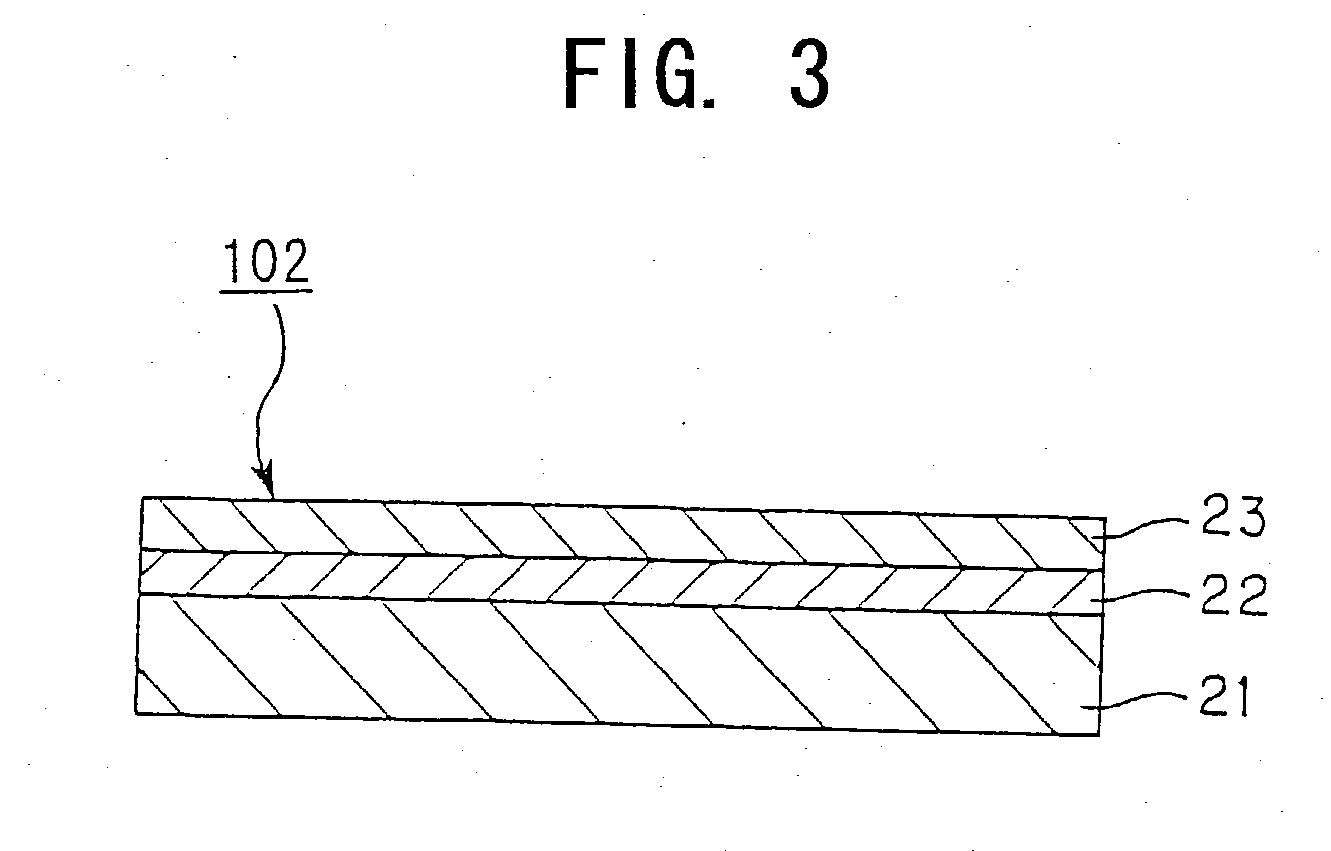

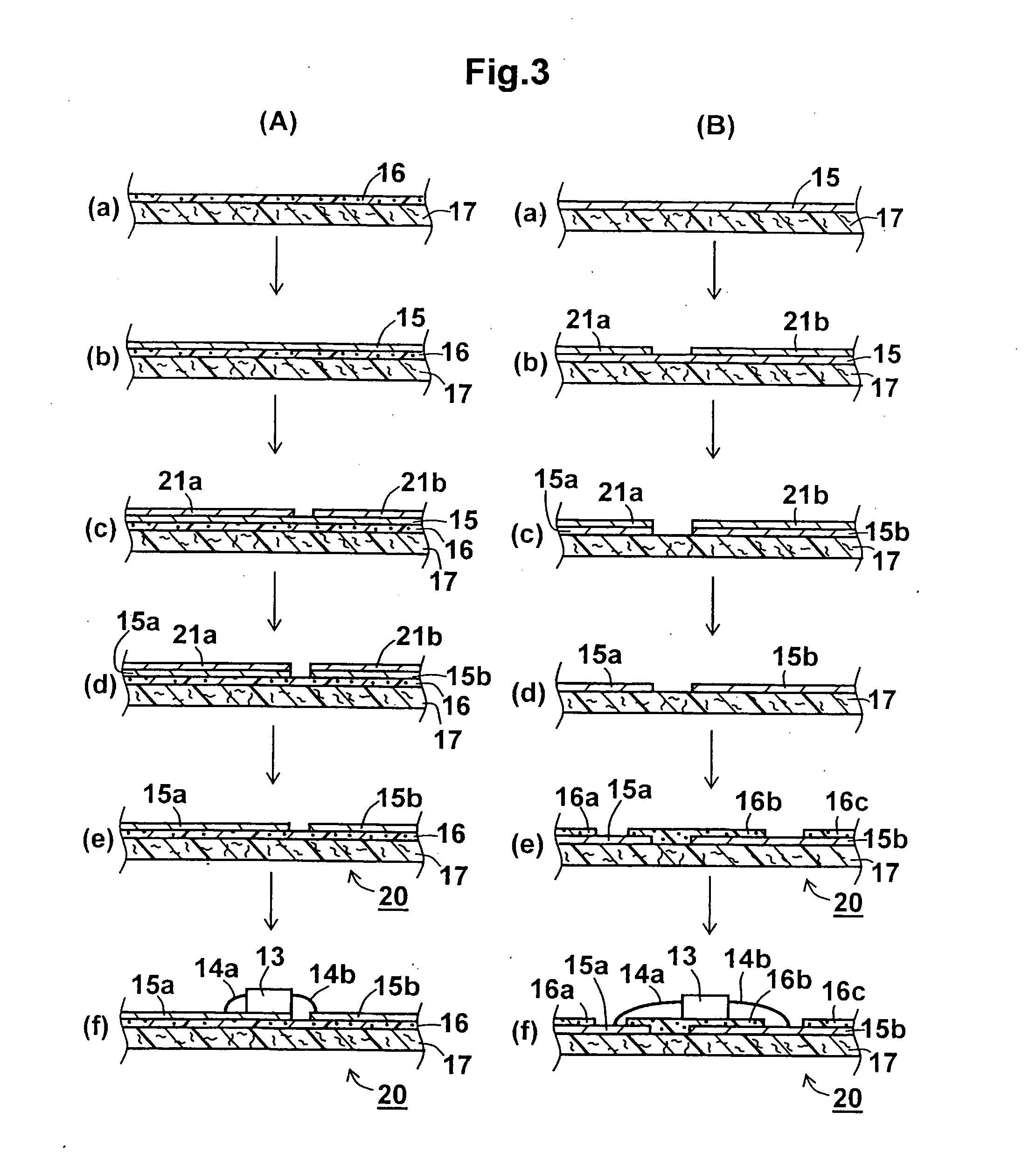

CAPACITOR HAVING Ru ELECTRODE AND TiO2 DIELECTRIC LAYER FOR SEMICONDUCTOR DEVICE AND METHOD OF FABRICATING THE SAME

InactiveUS20090065896A1Simple structureHigh dielectric constantSolid-state devicesSemiconductor/solid-state device manufacturingCrystal structureDielectric layer

Provided are a capacitor of a semiconductor device using a TiO2 dielectric layer and a method of fabricating the capacitor. The capacitor includes a Ru bottom electrode formed on a semiconductor substrate, an rutile-structures RuO2 pretreated layer which is formed by oxidizing the Ru bottom electrode, a TiO2 dielectric layer which has a rutile crystal structure corresponding to the rutile crystal structure of the RuO2 pretreated layer and is doped with an impurity, and a top electrode formed on the TiO2 dielectric layer. The method includes forming a Ru bottom electrode on a semiconductor substrate, forming a rutile-structured RuO2 pretreated layer by oxidizing a surface of the Ru bottom electrode, forming a TiO2 dielectric layer to have a rutile crystal structure corresponding to the rutile crystal structure of the RuO2 pretreated layer on the a RuO2 pretreated layer and doping the TiO2 dielectric layer with an impurity, and forming a top electrode on the TiO2 dielectric layer.

Owner:SEOUL NAT UNIV R&DB FOUND

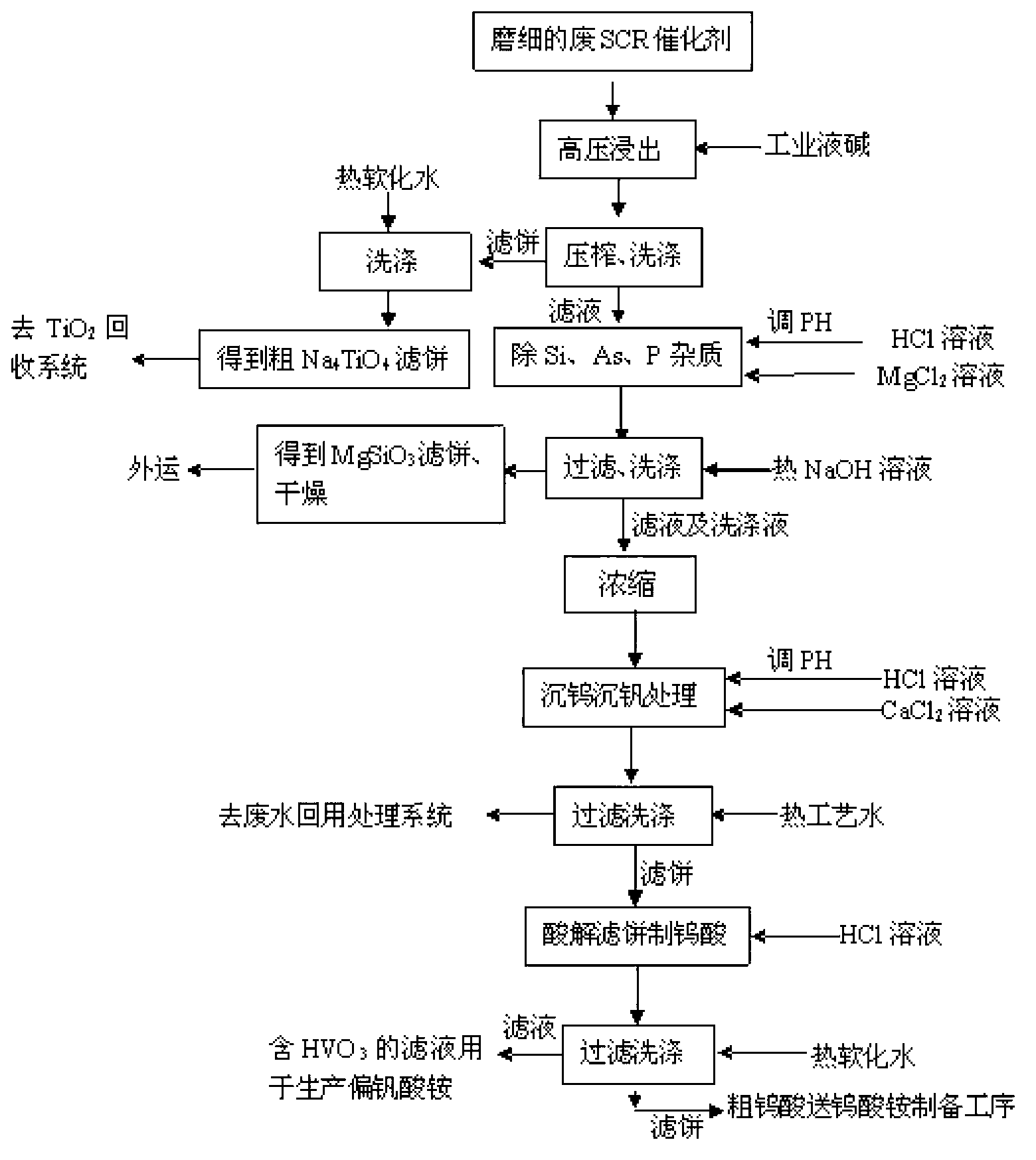

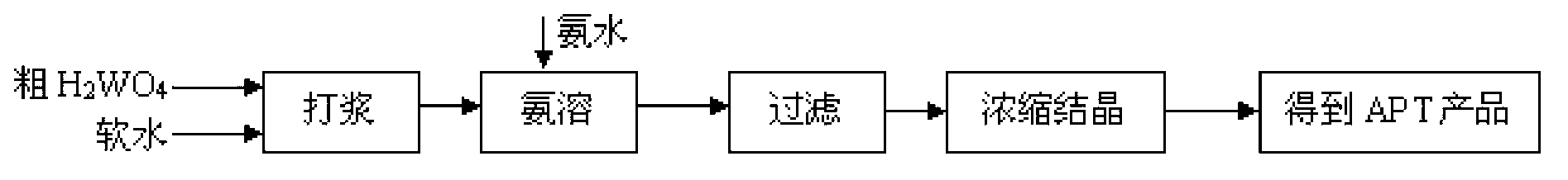

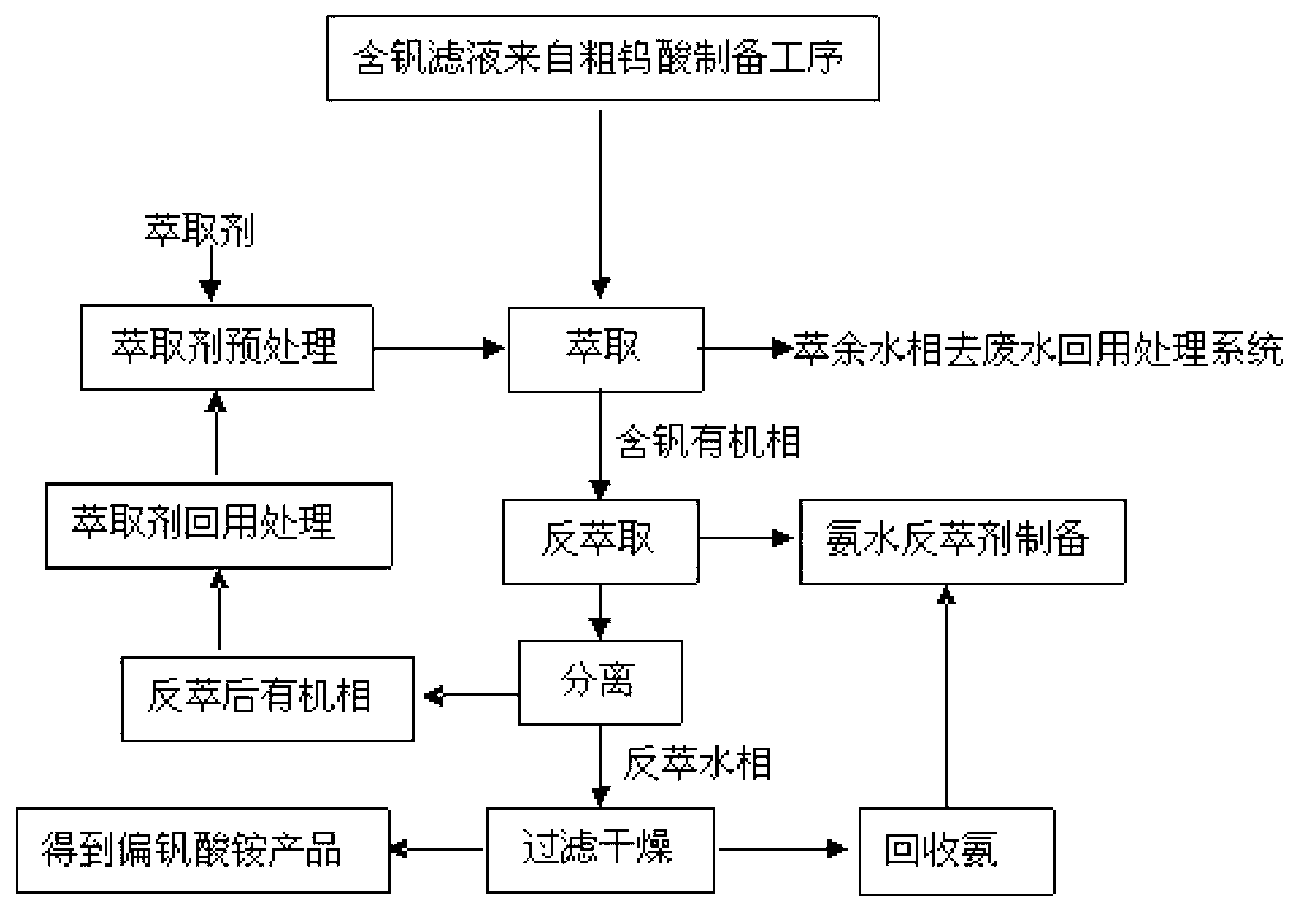

Recovery process of honeycomb type selective catalytic reduction (SCR) waste catalyst containing tungsten, vanadium and titanium

InactiveCN102936039AHigh purityHigh recovery rateTitanium dioxideVanadium compoundsHigh concentrationAmmonium paratungstate

The invention discloses recovery process of honeycomb type selective catalytic reduction (SCR) waste catalyst. The process includes the following steps: a, preprocessing the SCR waste catalyst and leaching at the high temperature and under high pressure; b, adding hydrochloric acid into leaching liquid, adjusting pH, and removing impurities; c, adding hydrochloric acid into the leaching liquid, reacting, calcining and preparing rutile titanium dioxide; d, preparing ammonium paratungstate; e, preparing ammonium metavanadate; and f, recycling and treating waste water. Main products of ammonium paratungstate, ammonium metavanadate and rutile titanium dioxide obtained in the process are high in purity and recovery rate. By-products of silicon magnesium slags, salty mud, high-concentration sodium chloride liquid and barium sulfate dregs are high-purity harmless useful goods. The process is free of harmful secondary pollutant emission, environment-friendly and capable of circulating, has high economical and social benefit and is practicable.

Owner:曾瑞

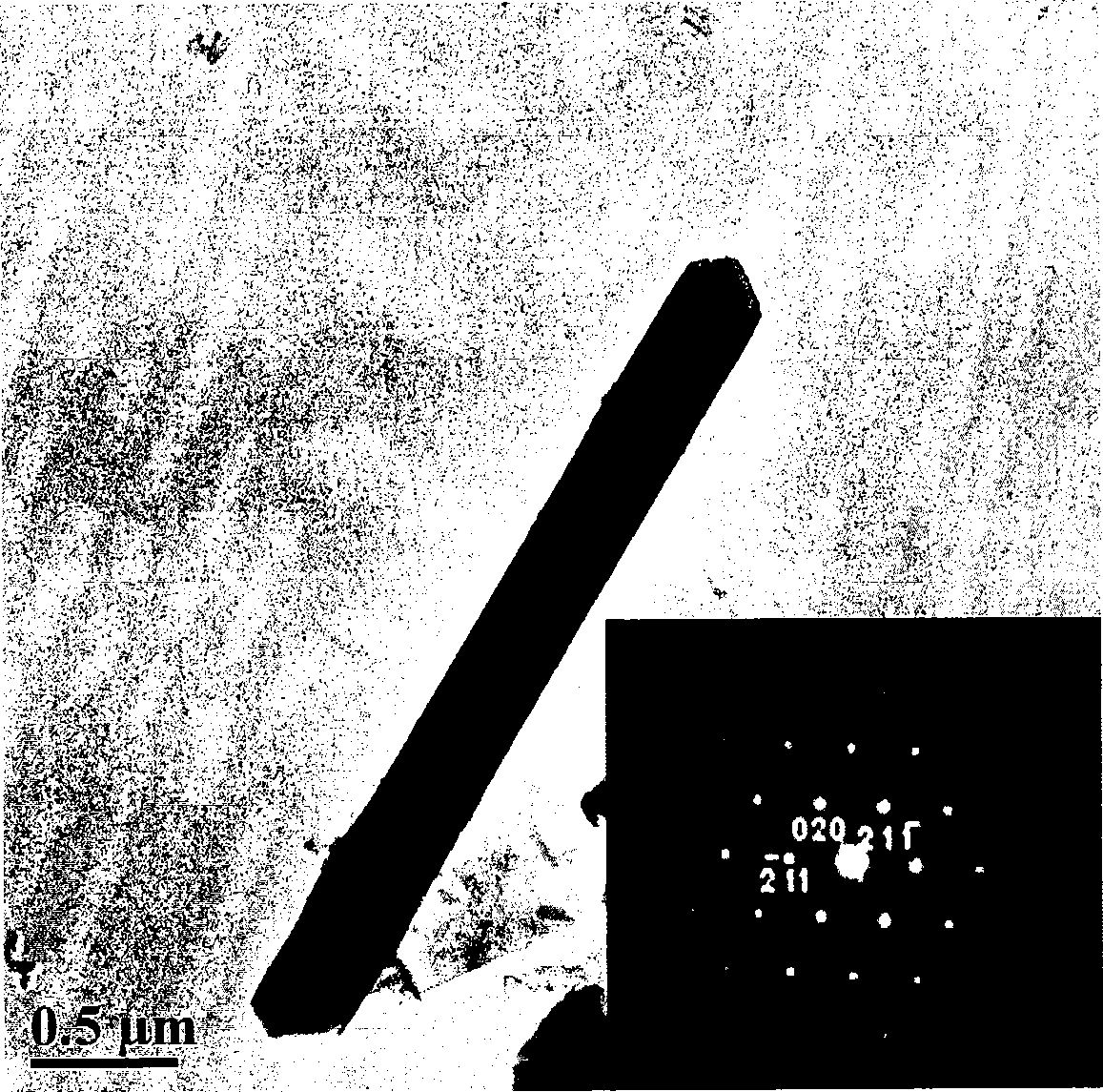

Process for preparing titanium dioxide nano-belts

The invention provides a method for preparing a titanium dioxide nano belt, belonging to the nano material technical field. The prior methods for preparing the titanium dioxide nano belt comprise the hydro-thermal method and the combination method of the sol-gel method and the hydro-thermal method. The prior electrostatic spinning method is applied to the preparation of nano fibers. The invention comprises three steps that: 1. a spinning solution is prepared; the mixture of polymethylmethacrylate and vinylpyrrolidone is used as a macromolecule template, and the mixture of chloroform and N,N-dimethylformamide is used as a solvent; 2. a titanium alkoxide / macromolecule template compound nano belt is prepared; the electrostatic spinning method is used, and the technical parameters are as follows: the voltage is between 15 and 25kV and the curing distance is between 15 and 30cm; 3. a TiO2 nano belt is prepared; the heat treatment method is used, and the technical parameters are as follows: the rate of temperature rise is between 0.5 and 2 DEG C / min and the heat preservation time at the temperature of between 500 and 900 DEG C is between 10 and 15h; for the TiO2 nano belt prepared, the width is between 5 and 15mu m, the thickness is between 30 and 60nm and the length is more than 200mu m; the TiO2 nano belt comprises a pure phase anatase type TiO2 nano belt and a pure phase rutile type TiO2 nano belt.

Owner:CHANGCHUN UNIV OF SCI & TECH

Multifunctional high-efficiency thermal insulation insulating mold paint

The invention relates to a multifunctional high-efficiency heat-preservation heat-insulation coating material. The compositions in percentage by weight of the coating material are: 10 to 20 percent of water, 0.1 to 0.2 percent of multifunctional auxiliary agent, 0.1 to 0.2 percent of wetting agent, 0.5 to 0.8 percent of dispersing agent, 0.3 to 0.5 percent of antifoam agent, 1.5 to 3.0 percent of propylene glycol, 16 to 20 percent of rutile-type titanium pigment, 3 to 5 percent of mica powder, 6 to 8 percent of hollow glass microballoon, 3 to 5 percent of infrared powder, 3 to 4 percent of fire retardant, 35 to 40 percent of elastic acrylic acid emulsion, 3 to 5 percent of opaque polymer, 0.5 to 0.8 percent of film-forming auxiliary agent, 0.2 to 0.3 percent of bactericide and preservative and 0.3 to 0.6 percent of thickening agent. The multifunctional high-efficiency heat-preservation heat-insulation coating material is of aqueous monocomponent and does no harm to human body and the environment so as to be an environment-friendly product; meanwhile, the coating material also has excellent waterproof and fire-retardation functions, convenient and quick construction, excellent adhesion strength, outstanding crack resistance, infrequent pollution and service life as long as 15 years; moreover, during practical use, the coating material can effectively reduce solar heat accumulated in a house by approximately 8 to 15 DEG C, and can greatly reduce energy consumption.

Owner:董善刚

Heat-insulating energy-saving paint for vehicle and method for producing the same

InactiveCN101195725AIncrease reflectionInsulate heat radiationFireproof paintsPolyester coatingsRadiant heatAbsorption rate

The invention relates to heat insulating and energy saving coating used for the vehicle, and the preparation method thereof. The invention takes organic resin film forming material as the main material, the coating at least includes infrared reflection pigment, hollow ceramic micro-spheres and silicon dioxide aerogel, an organic resin film having low sunlight absorption rate is formed in the coating through the organic resin film forming material with high transparency, the visible light and the near infrared ray in the sunlight are reflected through the infrared reflection pigment, the rutile type titanium dioxide and the hollow ceramic micro-spheres, and simultaneously a compact vacuum layer and an inert gas layer are formed on the surface of a coated object through the hollow ceramic micro-spheres and the silicon dioxide aerogel, so as to effectively isolate the radiant heat of the sun, and to reduce the heat conduction of air, and finally the heat insulating and energy saving coating used for the vehicle is formed, which not only can effectively reflect the energy in the sunlight, but also can effectively isolate the radiant heat of the sun and reduce the heat conduction of air, and simultaneously has good weather resistant performance, chemicals resistant performance, mechanical property and decorative property.

Owner:ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

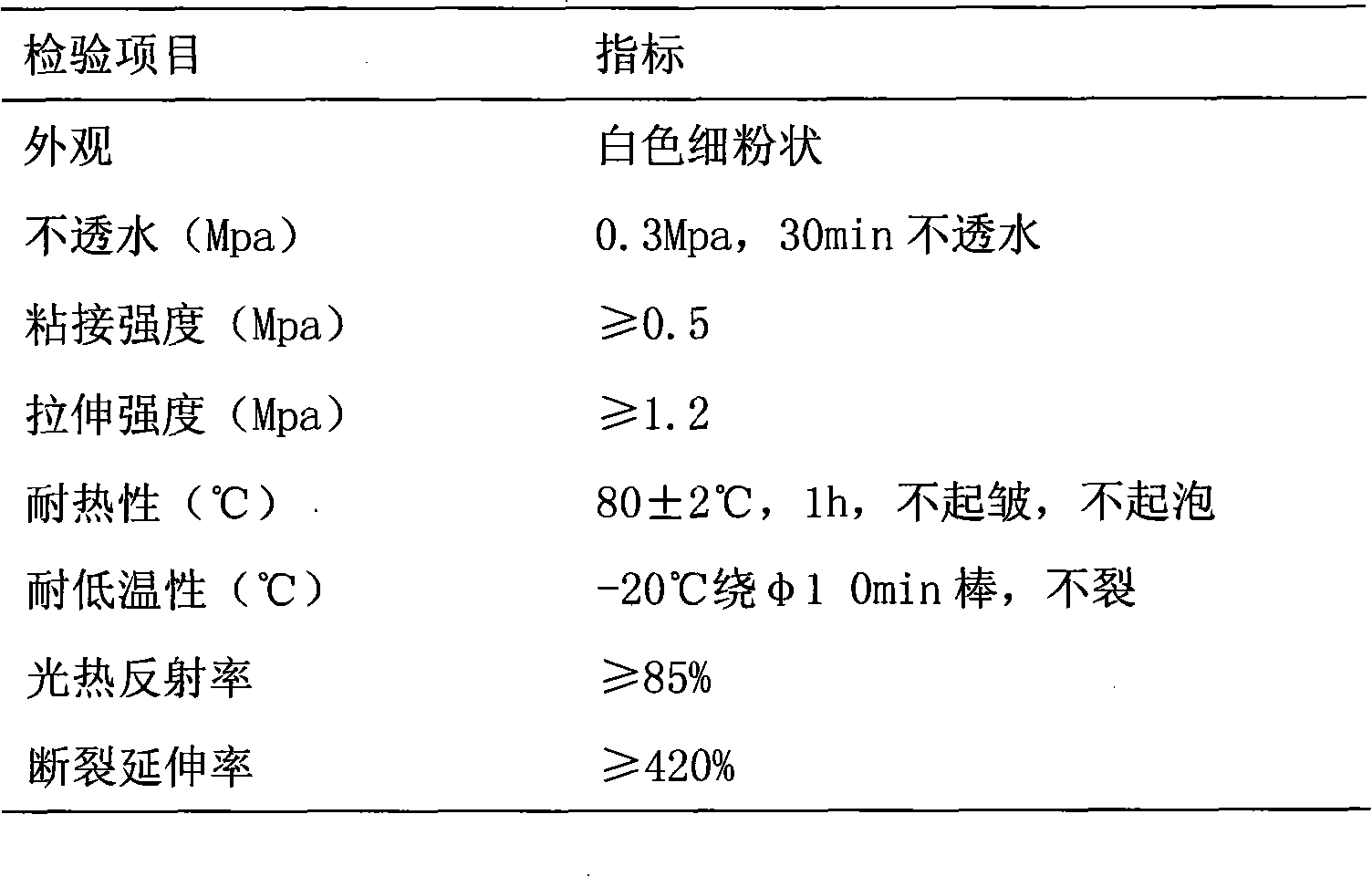

Dry-type heat-insulating waterproof coating

InactiveCN101648794AGood heat insulation and waterproof effectImprove waterproof performancePliabilityTalc

The invention relates to a dry-type heat-insulating waterproof coating which comprises the following raw materials in percentage by weight: 0-5.5 dispersible polymer powder, 10-20 hollow filling beads, 5-20 sepiolite powder, 5-10 mica powder, 5-30 heavy calcium carbonate powder, 5-15 light calcium carbonate powder, 0.5-1.5 rutile titanium dioxide, 10-20 talc powder and 10-40 white cement. A coat formed by the coating of the invention has favorable heat-insulating waterproof effect (lowers indoor temperature by 4-20 DEG C) and excellent flexibility, impermeability, weathering resistance and bonding strength to a substrate as well as high strength, good brightness, uniform luster, smooth and tender touch feeling, waterproof washing and rubbing, and the like. The dry-type coating has the advantages of simple production process, convenient transportation, long storage time, convenient construction, and the like, no toxicity or pollution, environment-friendly trend suitability, low cost, low VOC and high performance, thereby becoming a new-generation building coating product.

Owner:吕海涛

Process for preparation of nano multiporous silicon dioxide aerogel block

The process of producing silica aerogel block adopts the materials including polysiloxane E-40 as Si source, ethanol, water and hydrofluoric acid; and includes preparing silica aerogel grain via sol-gel and surface modification process at normal pressure, mixing the grain with calcium silicate slurry, rutile type titanium dioxide powder, ceramic fiber, glass fiber and porous cement via powerful stirring, and pressing into block with aerogel content greater than 90 vol%. High strength skeleton may be embedded into the block if necessary. The present invention may be used in insulation, sound isolation and adsorption.

Owner:TONGJI UNIV

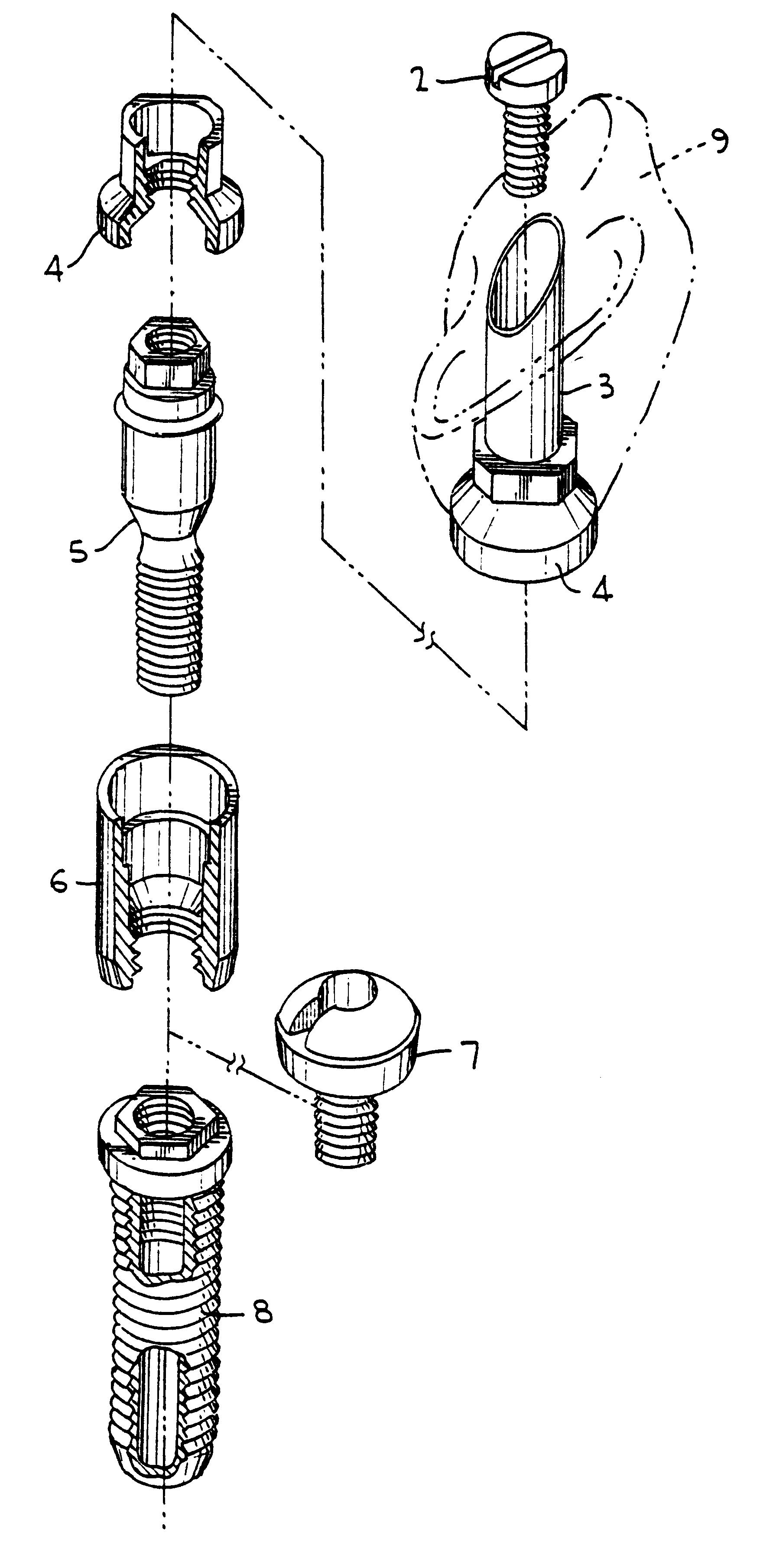

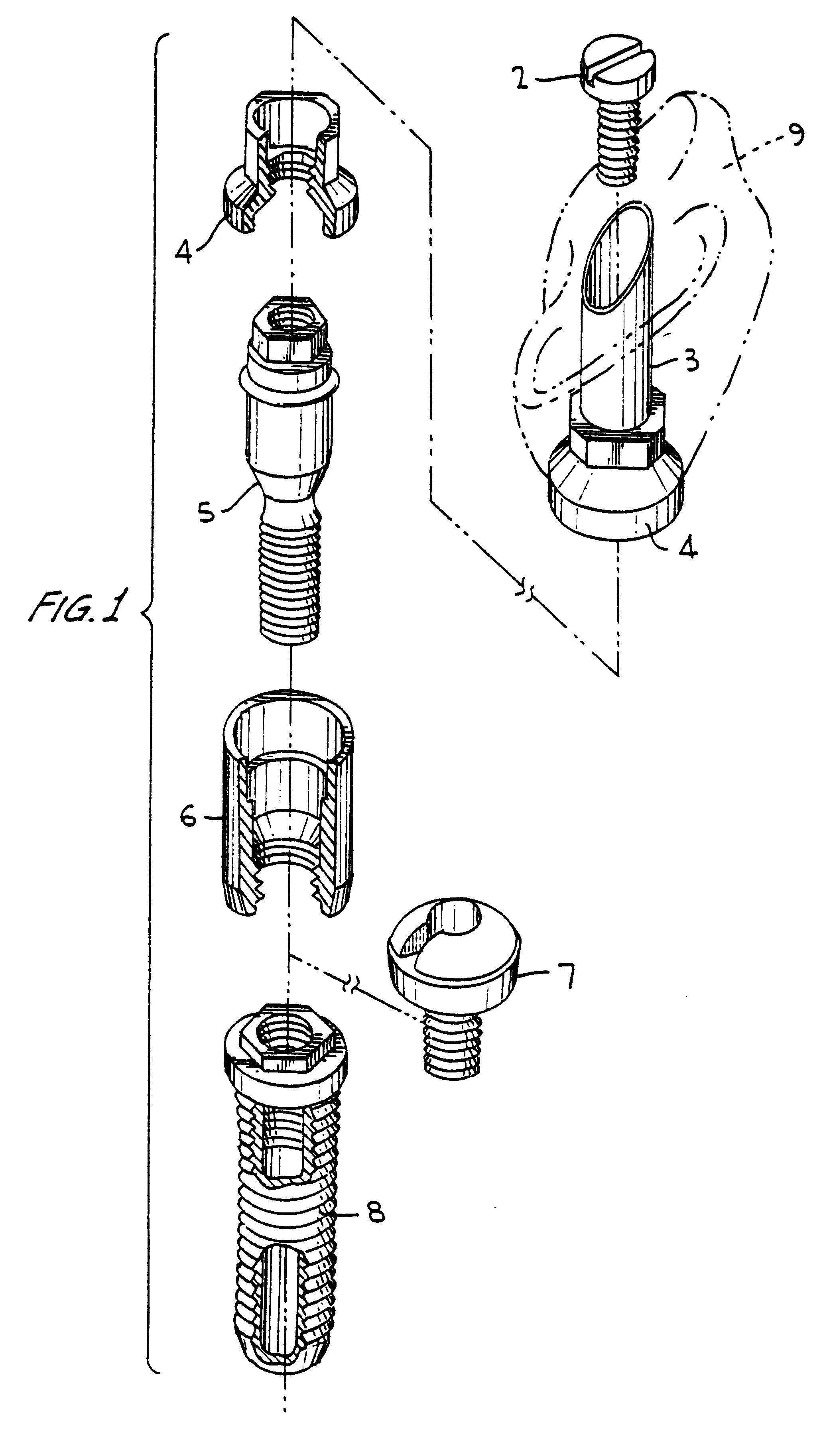

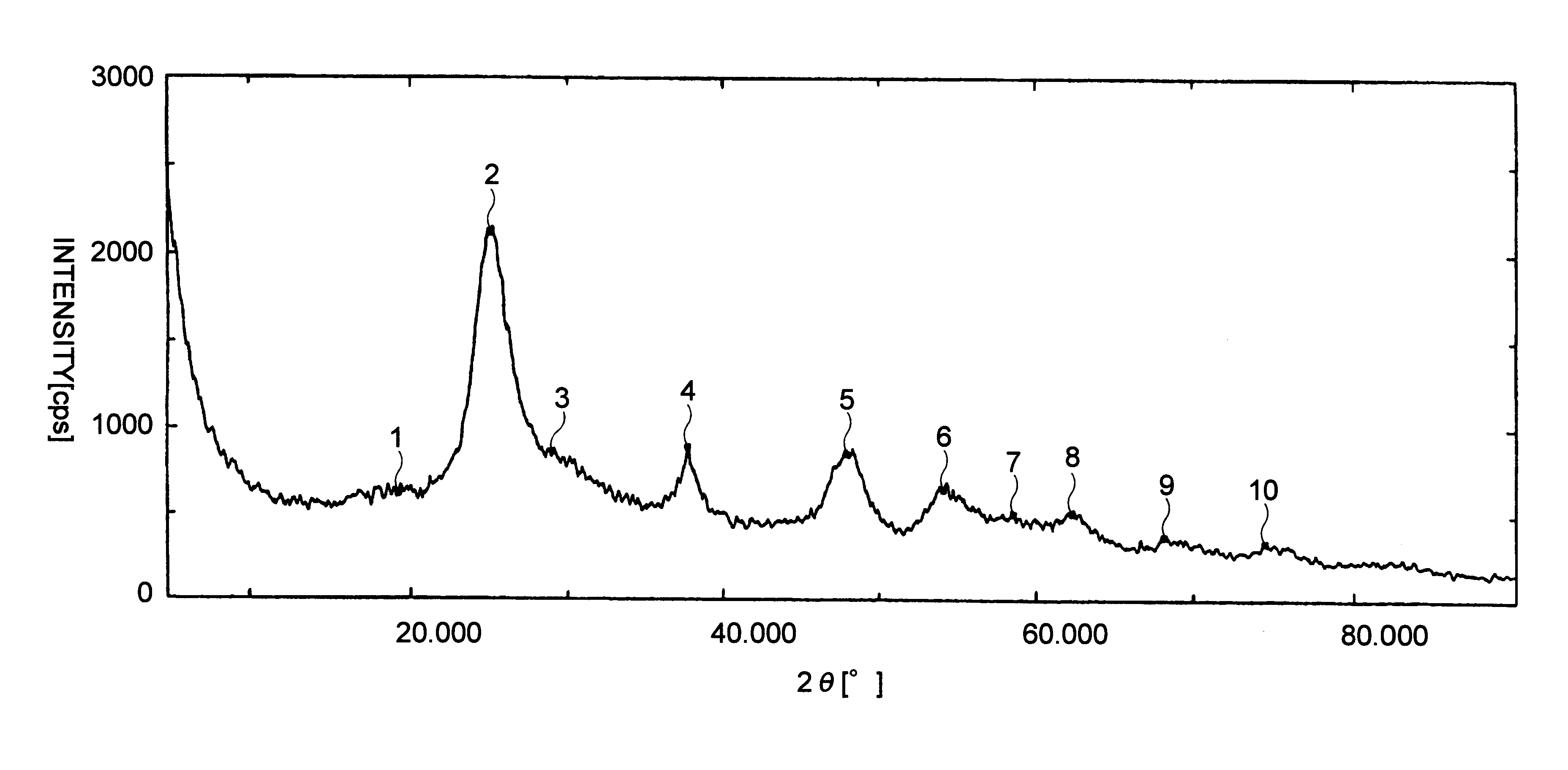

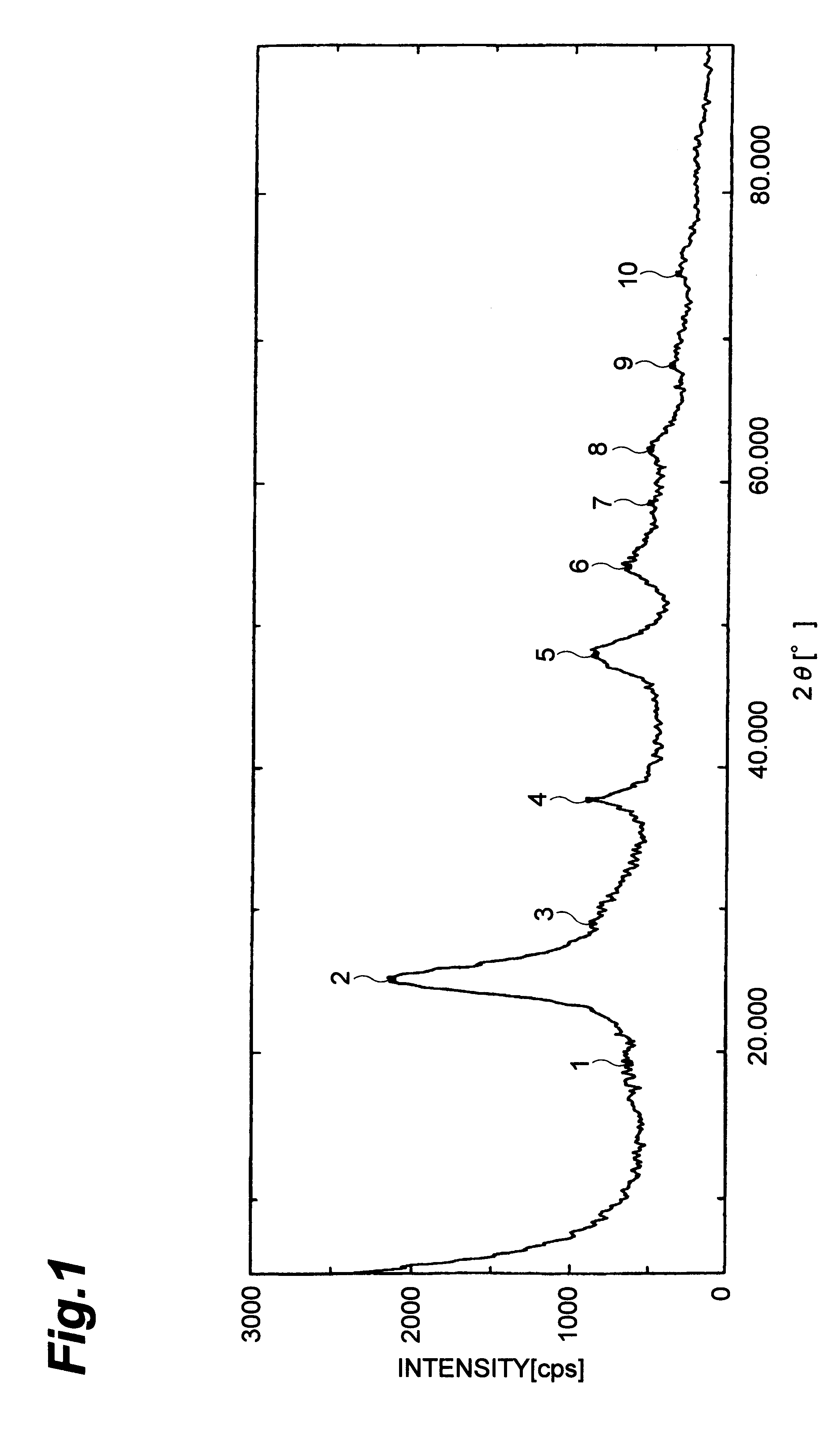

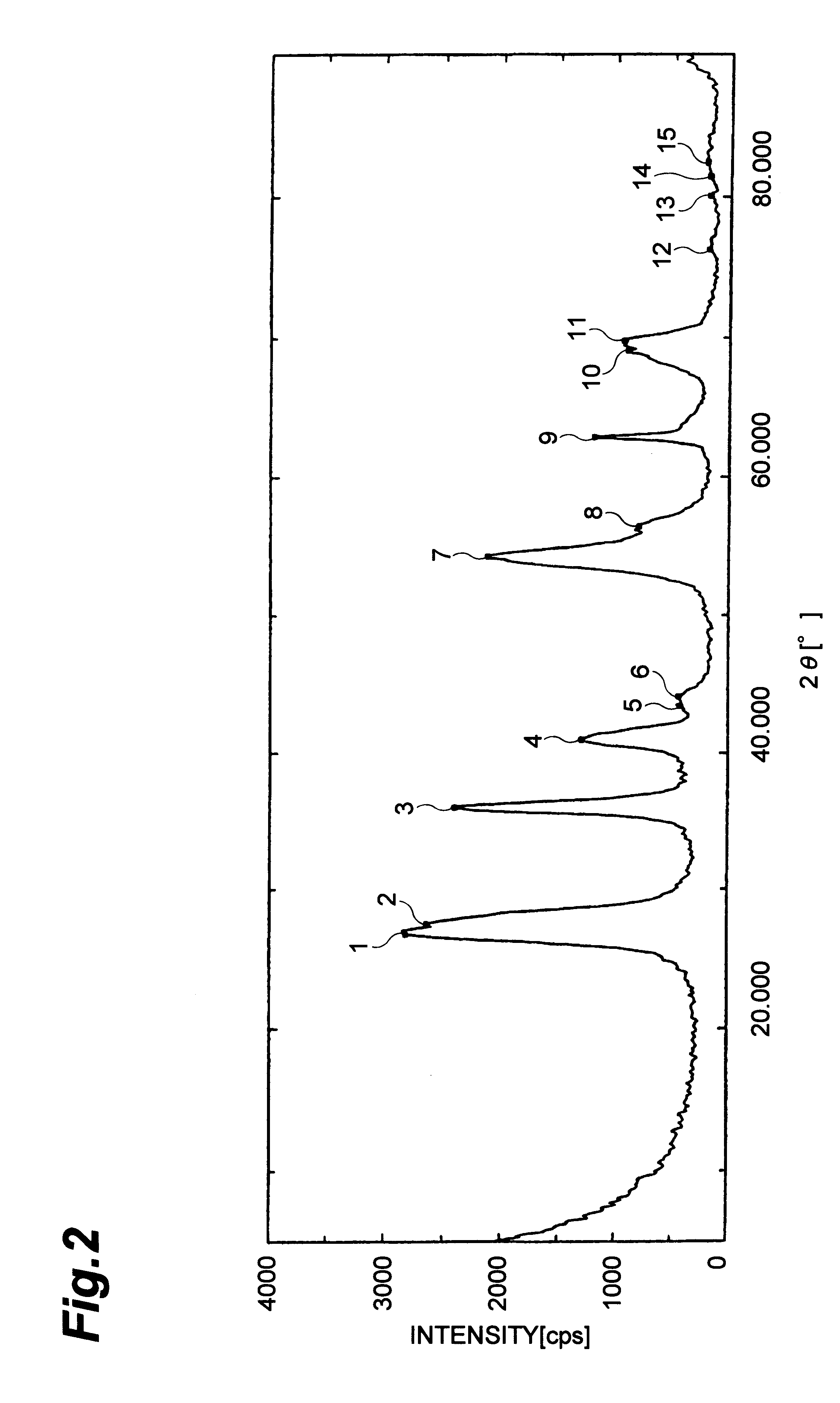

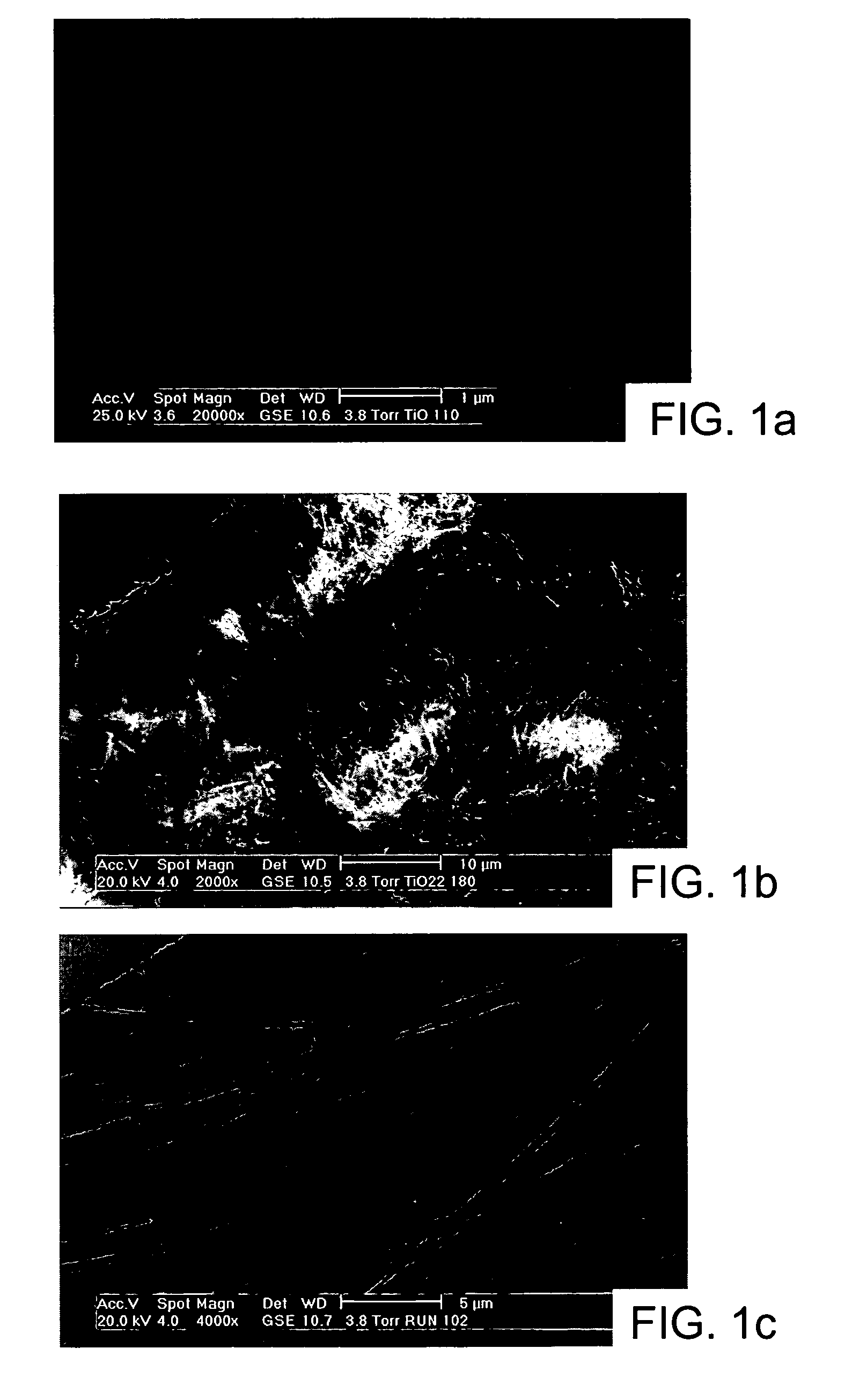

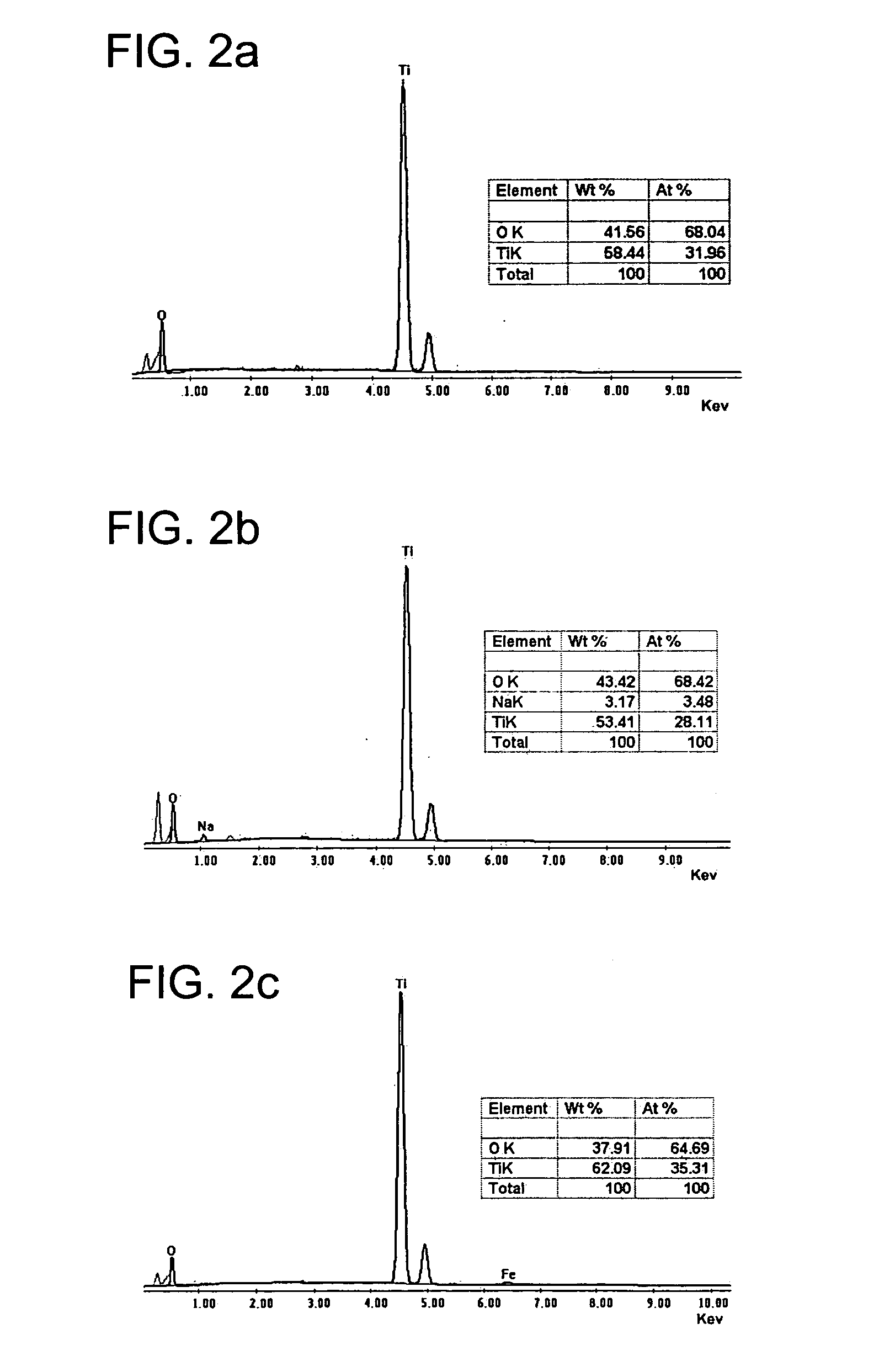

Titanium material implants

One of many universal requirements of dental or orthopedic implants, wherever they are used in the vital body, is that the implant system should be biologically functioning. To achieve the biological functionality, the implant should meet several requirements for compatibility. These include biological compatibility and mechanical compatibility. It has now been recognized that morphological compatibility and crystallographic compatibility should be added to these two compatibility requirements. Hence, the present invention provides a method of forming a certain type of crystalline structure of titanium oxide and controlled surface roughness to meet both morphological and crystallographic compatibilities. It has been further determined that a chemical treatment (using sodium hydroxide) alone or followed by in-air oxidation, or acid treatment (a mixed aqueous solution of hydrofluoric acid and nitric acid), followed by sodium hydroxide treatment, furthermore followed by in-air oxidation provide for advantageous surface modifications to create a complex mixture of rutile with anatase and / or brookite types of titanium oxide and provide a most favorable surface for wettability and an acceptable range of surface roughness.

Owner:OSHIDA YOSHIKI

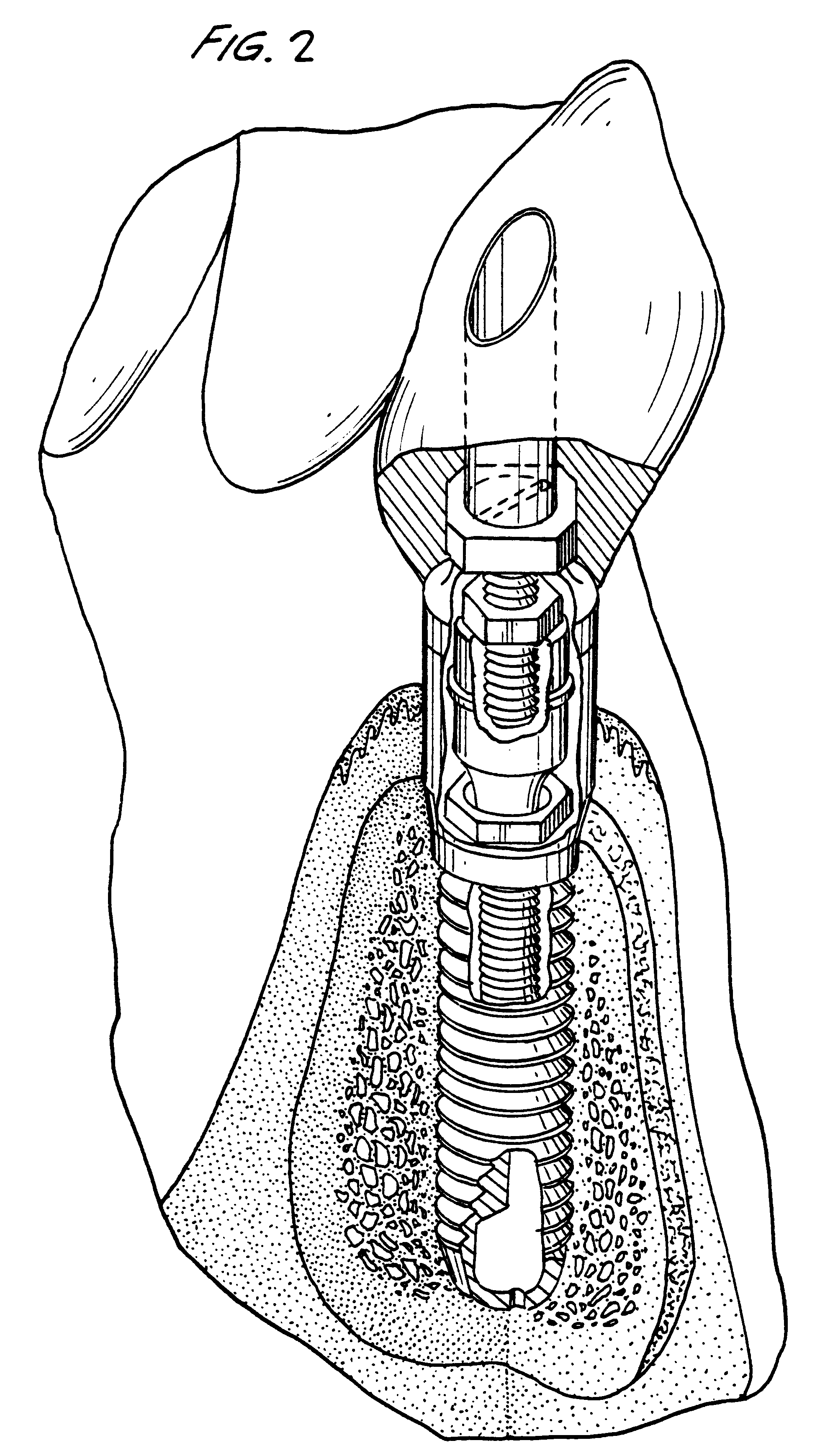

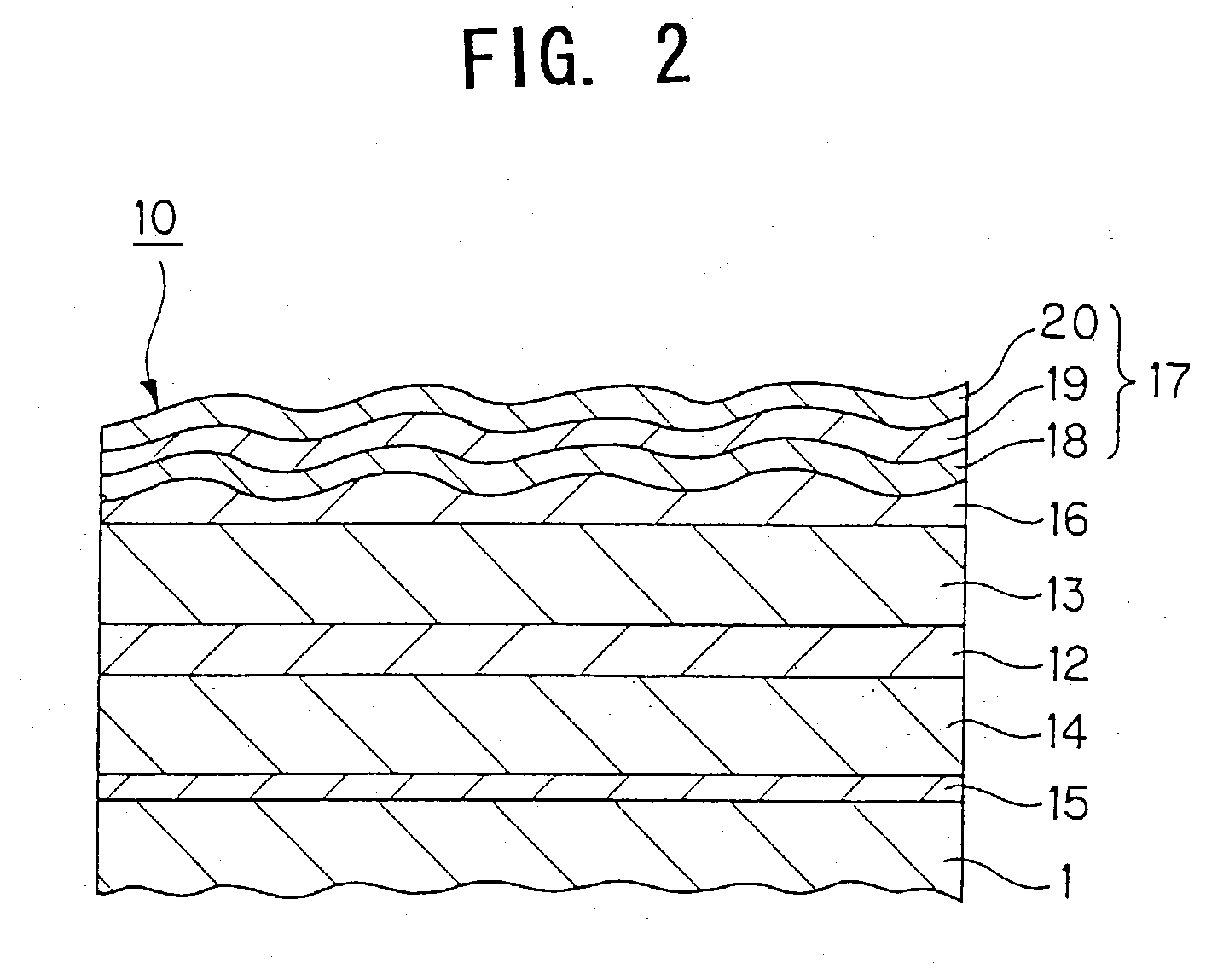

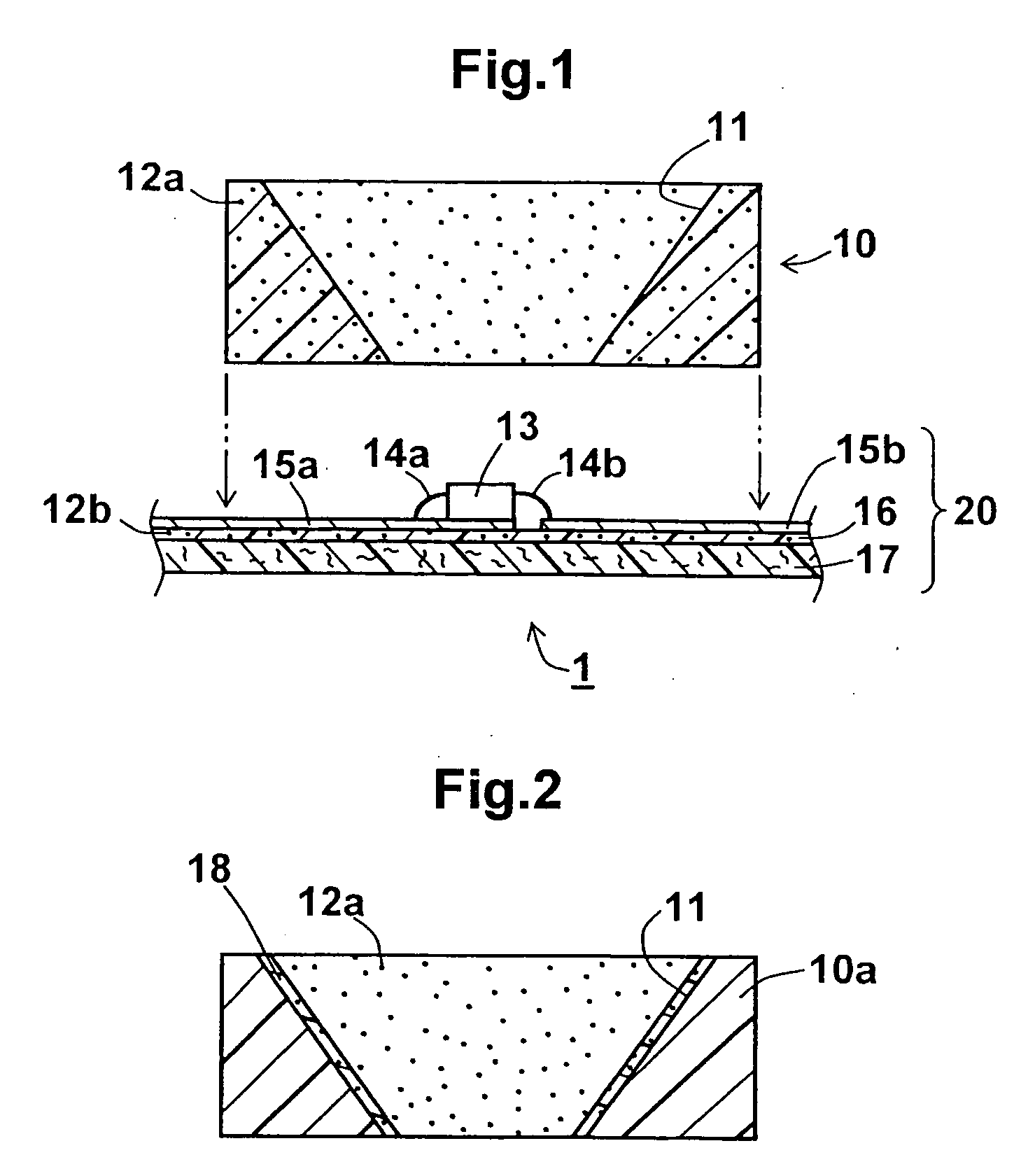

Coating composition, coating film thereof, antireflection coating, antireflection film, image display, and intermediate product

InactiveUS20030096102A1Good dispersibilityGood dispersionSynthetic resin layered productsCellulosic plastic layered productsMetallurgyRefractive index

A coating material capable of forming a high-quality thin film having a regulated refractive index; a coating film formed from the coating material; an antireflection coating comprising the coating film; an antireflection film to which the antireflection coating is applied; and an image display. The coating composition comprises (1) rutile-form titanium oxide having primary particle diameter of 0.01 to 0.1 mum and coated with an inorganic compound for reducing or eliminating the photocatalytic activity and with an organic compound having an anionic polar group and / or an organometallic compound, (2) a binder ingredient curable with an ionizing radiation, (3) a dispersant having an anionic polar group, and (4) an organic solvent. The coating film formed from the coating composition is suitable for forming a light-transmitting layer constituting or contained in a single- or multi-layer antireflection coating (17), in particular, a medium-refractive-index layer (18), high-refractive-index layer (19), or hard coat layer (16) having a high refractive index.

Owner:DAI NIPPON PRINTING CO LTD

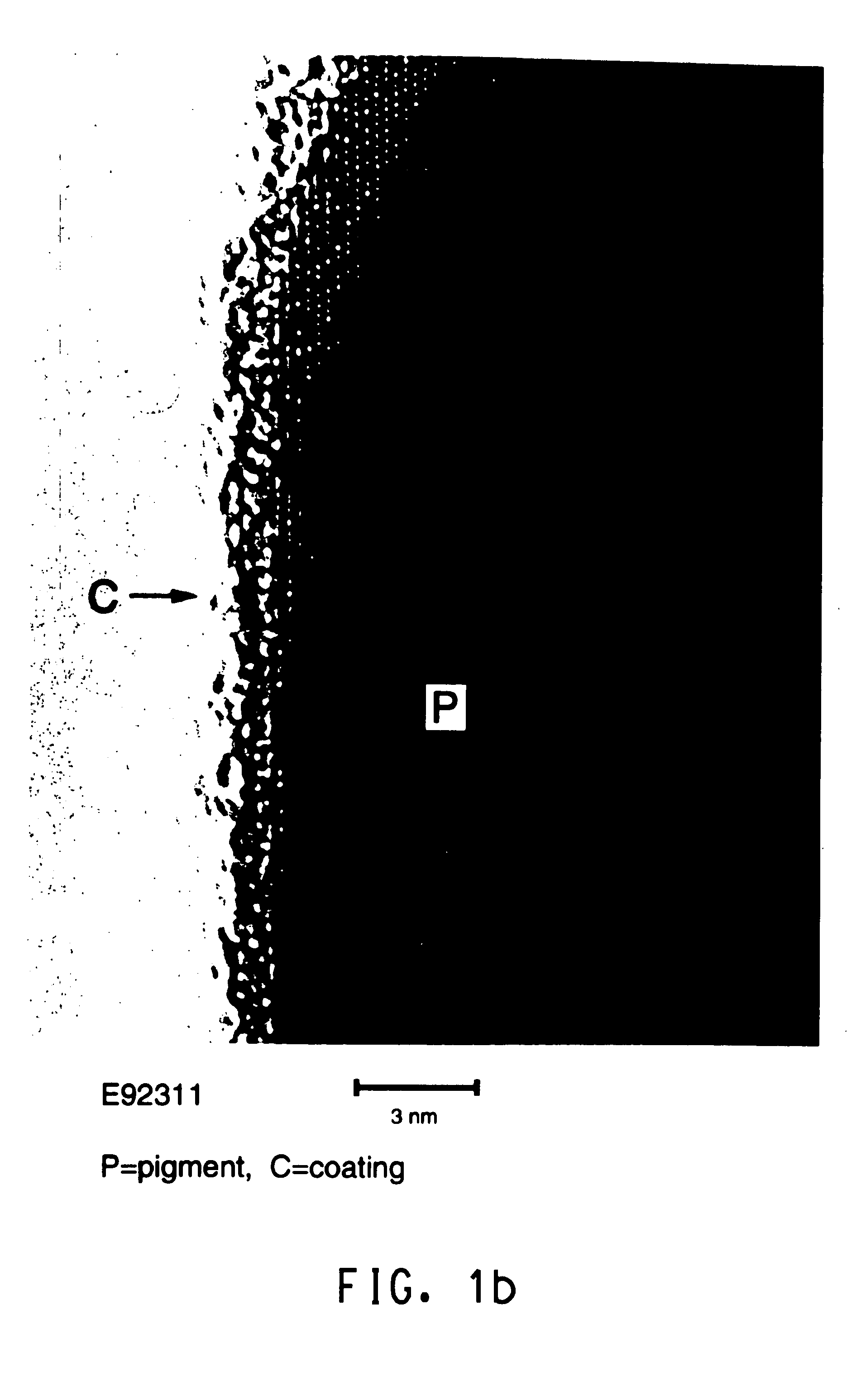

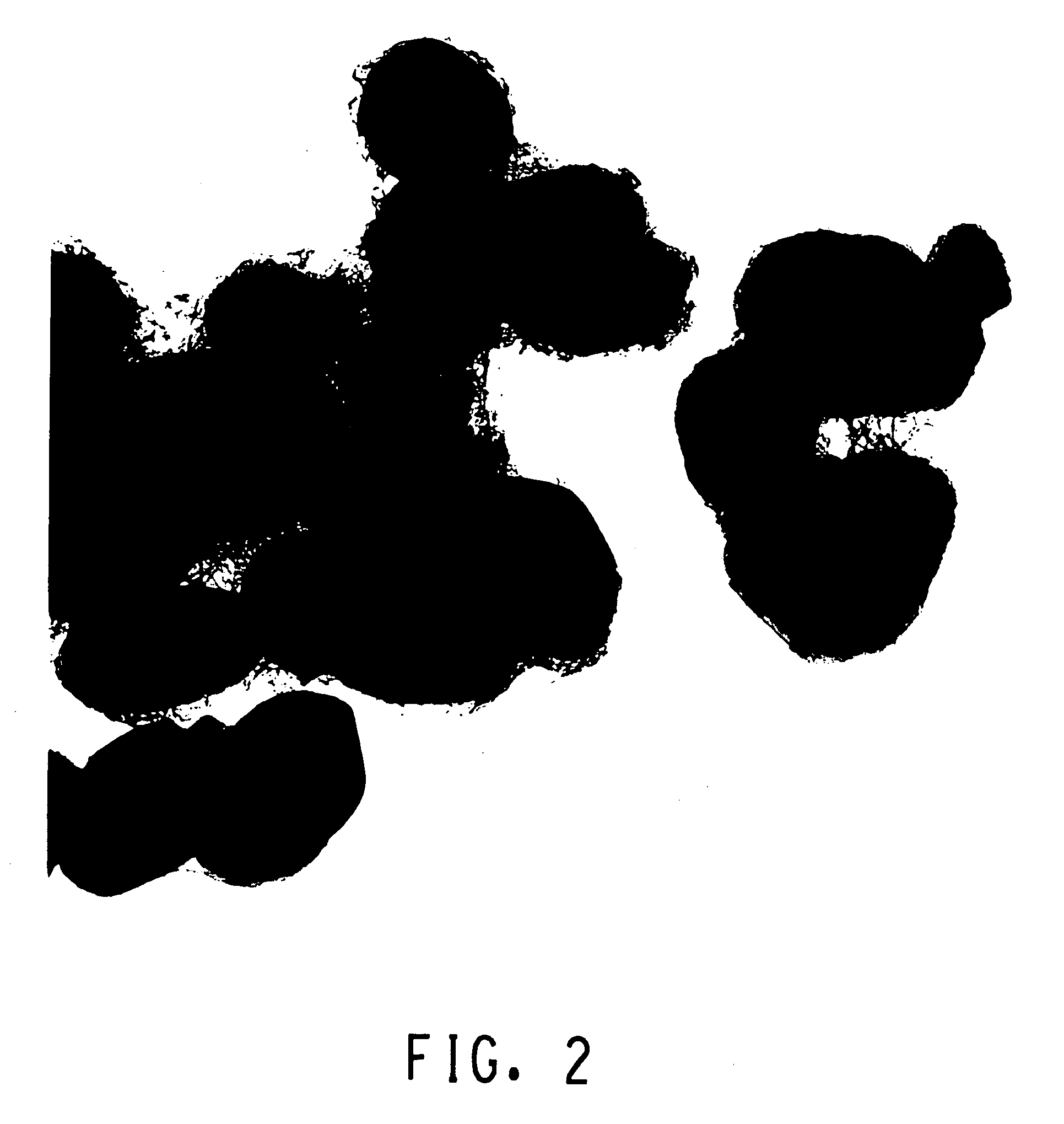

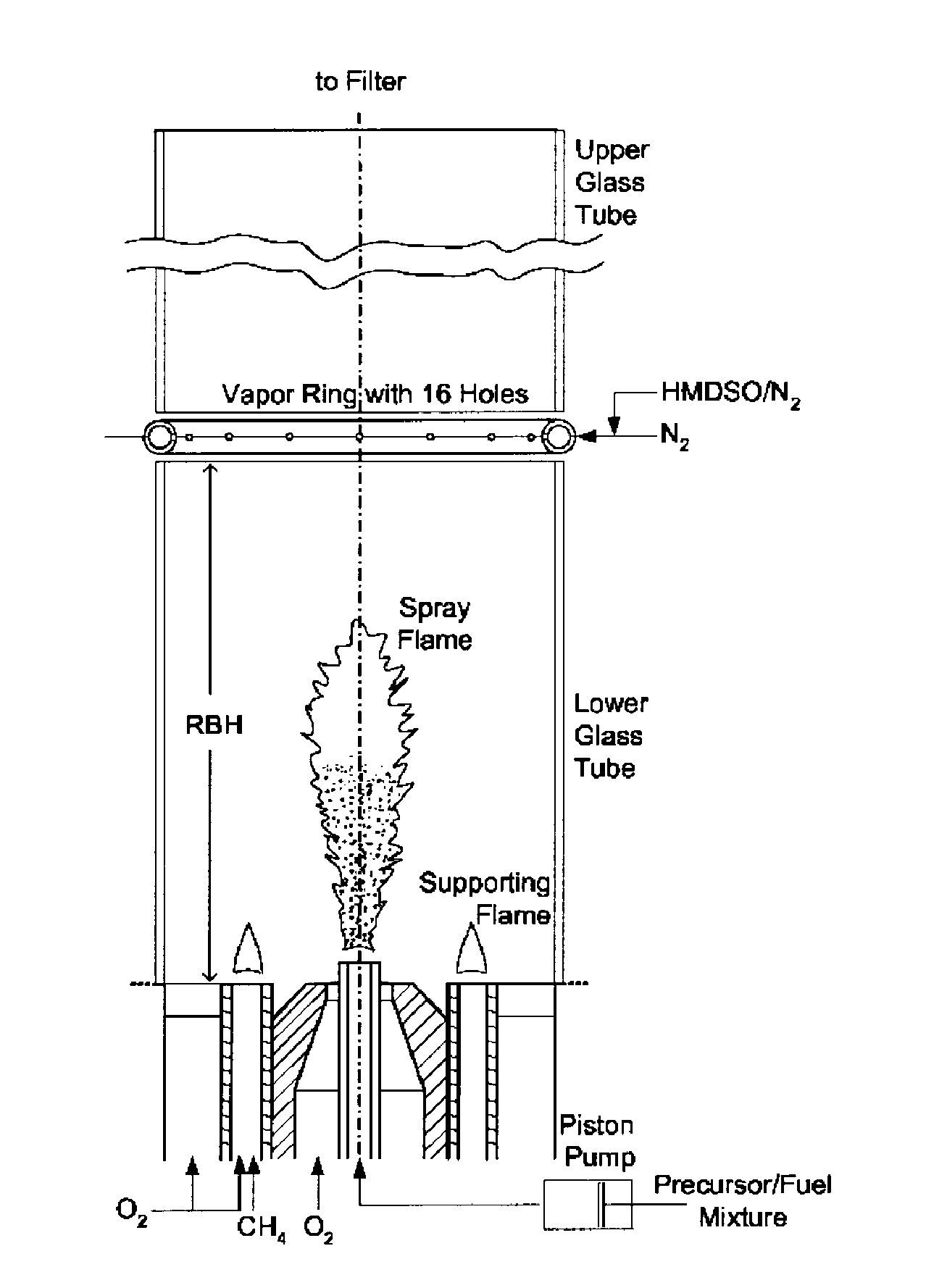

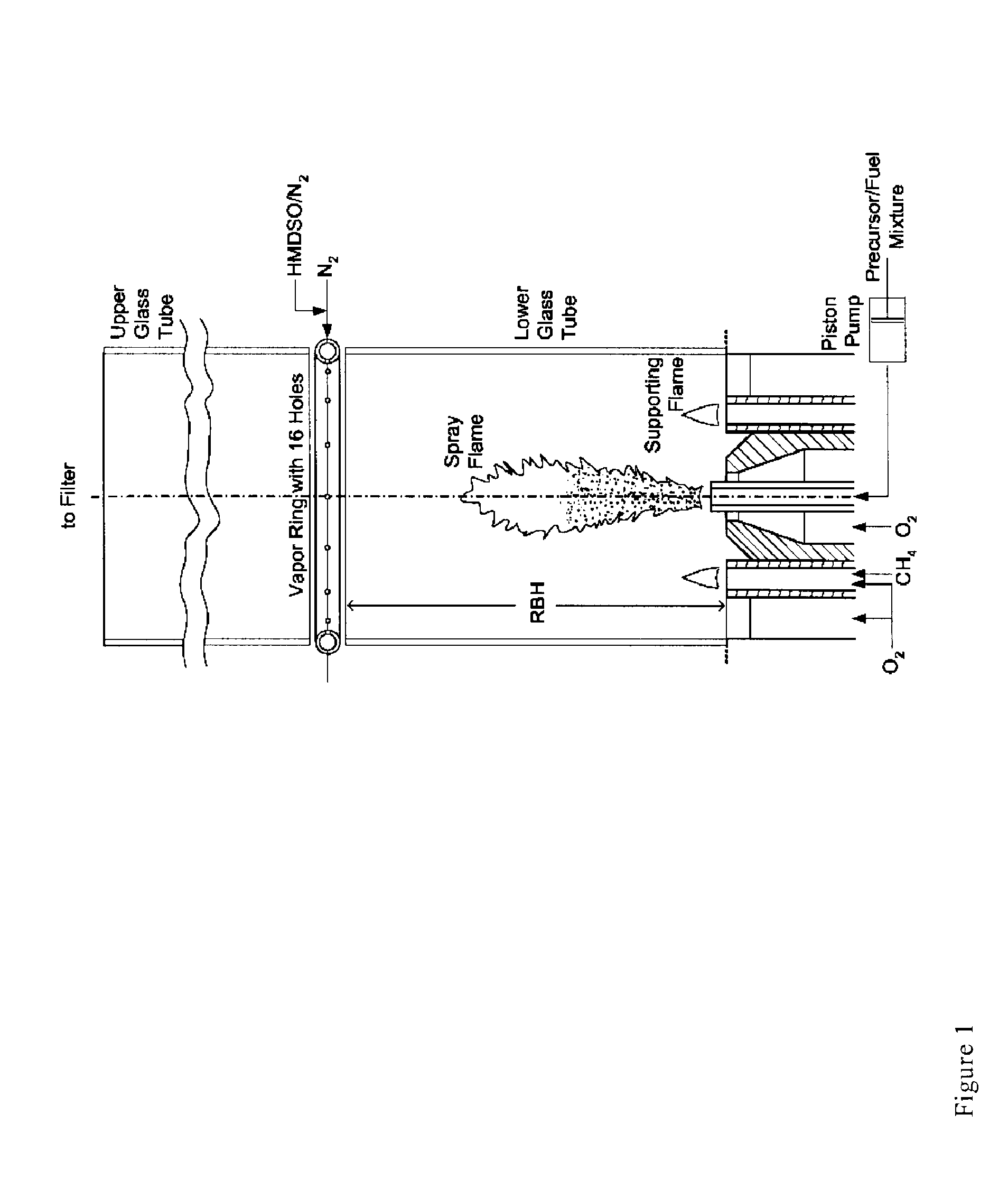

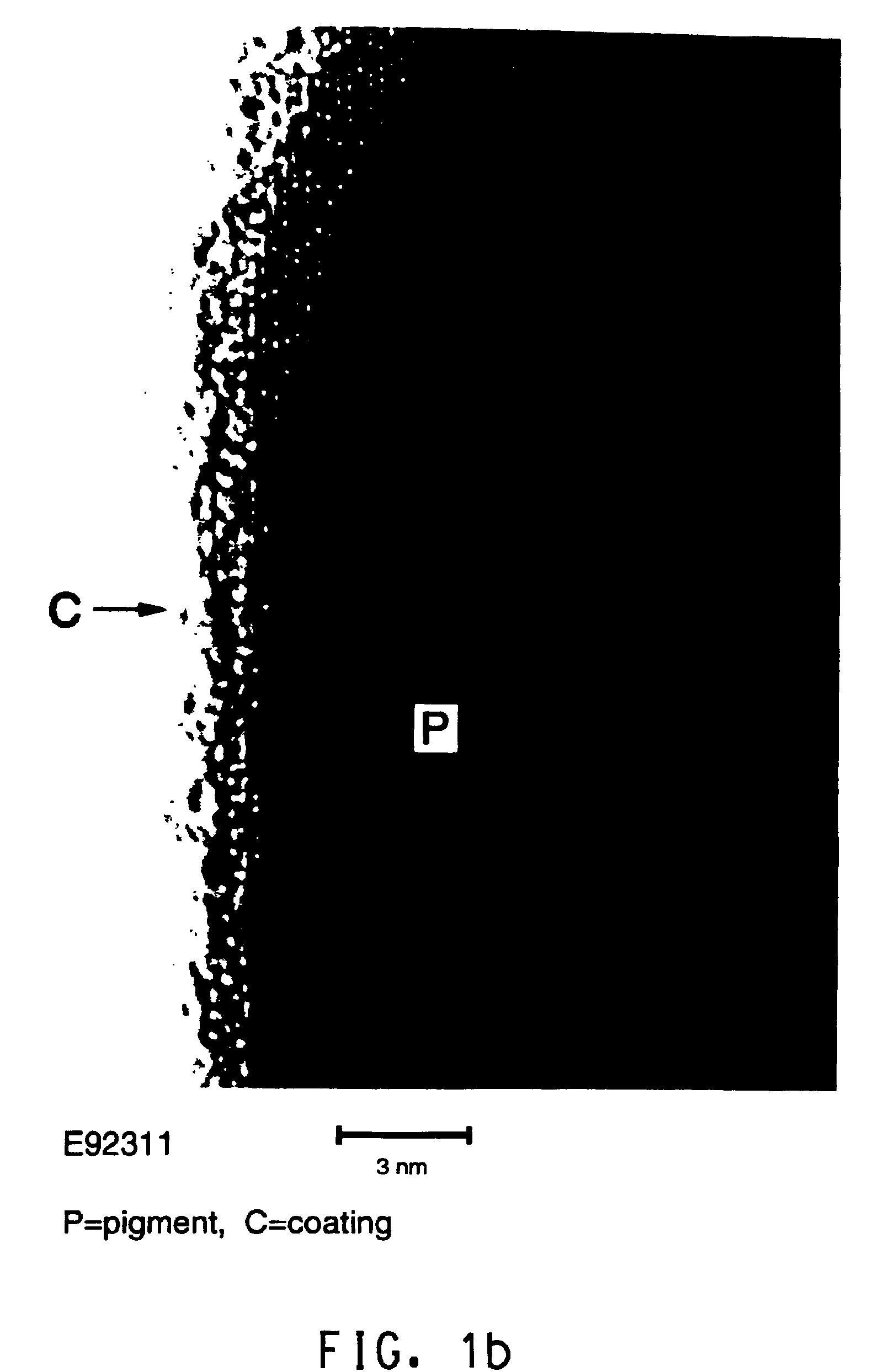

Gas phase production of coated titania

InactiveUS20090126604A1Not to wasteDesired characteristicPigmenting treatmentMaterial nanotechnologyGas phaseSpray pyrolysis

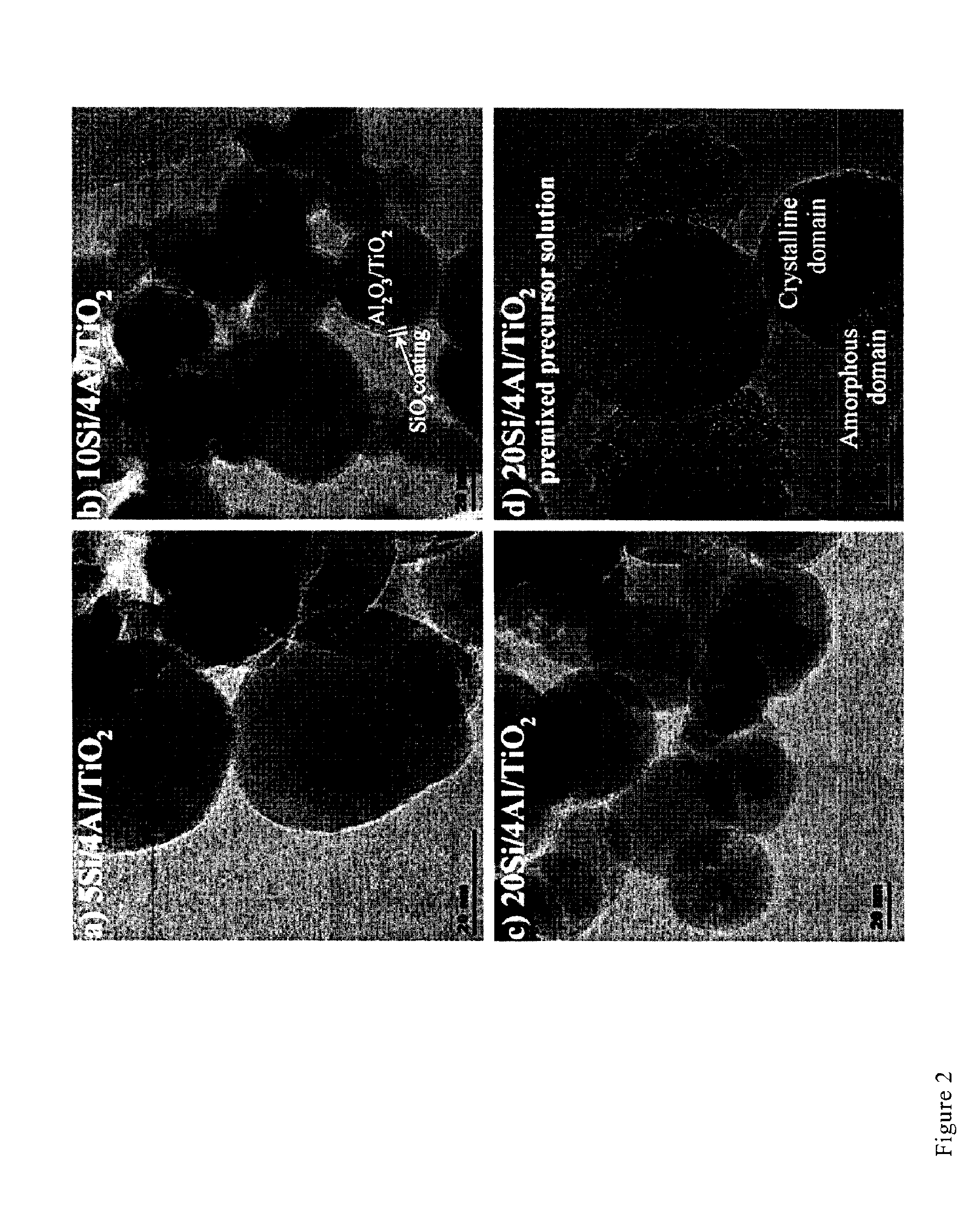

A flame spray pyrolysis process for the preparation of ultrafine titania particles coated with a smooth, homogeneous coating of one or more metal oxides is provided. The metal oxide coating is achieved by contacting the titania particles with a metal oxide precursor downstream of the titania formation zone, after the titania particles have formed. The process provides titania particles with a high rutile content and a smooth and homogeneous coating of a metal oxide.

Owner:TRONOX LLC

Photocatalyst air freshing coating and preparation method thereof

InactiveCN101423690AEfficient antibacterial and antibacterialTo achieve the purpose of anti-pollution and easy cleaningDeodrantsCoatingsRutileIndoor air

The invention provides a photocatalytic air fresh coating and a preparation method thereof, and belongs to the field of indoor coating material, in particular to a coating for purifying air through a photocatalytic material and an anion generating material. The coating comprises the following raw materials in weight portion: 20 to 32 portions of deionized water, 1 to 2.0 portions of antifreeze agent, 0.1 to 0.2 portion of wetting agent, 0.5 to 0.6 portion of dispersing agent, 0.2 portion of preservative, 0.1 to 0.2 portion of pH regulator, 1 portion of nano titanium dioxide, 2 to 2.5 portions of the anion generating material, 20 to 25 portions of rutile titanium dioxide powder, 2 to 2.5 portions of diatomite, 12 to 15 portions of coarse whiting, 1 to 2 portions of film forming auxiliary, 25 to 45 portions of acrylic acid latex and 1 to 2 portions of thickening agent. The coating can keep the indoor air fresh for a long time and reach the first class indoor air environment standard of the nation. The anion releasing quantity of the coating reaches 2,626 / cm<3> and the antibacterium and bacteriostasis ratio of the coating reaches more than 97 percent.

Owner:XINHE NEW MATERIALS CO LTD

Aquosity elastic heat preserving insulating paint and its preparing process

A water-base and elastic heat insulation coating and the preparation method are provided. The invention adopts the elastic pure emulsion and the silicone-acrylate emulsion as the film former and also adopts the materials such as insulating materials and rutile type titanium pigment talc. The preparation process is that water is added with a dispersant, an antifoamer A, a pH regulator with right amount, propylene glycol and titanium pigment in turns under the stirring speed of 500r / min; the rotary speed is adjusted to 1500r / min and the dispersive degree below 25Mum; then an antifoulant, a mildewproof agent, an antifoamer B, silicone-acrylate emulsion, elastic emulsion and a film forming additive are added to stirred for 10min under the rotary speed of 500r / min and then the rotary speed is adjusted to 300r / min, and two third of the insulating materials are added to stir for 20min; at last, the remaining insulating materials are added to stir for 20min under the rotary speed of 300r / min, and the thickeners A, B are added to stir for 15min; the pH value is adjusted to 7.5 to 9 and a preservative is added to stir for 10min to produce the coating of the invention.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

Method for producing special rutile type titanium white powder for power coating

ActiveCN101880479ALattice stabilizationGood dispersionPigment treatment with organosilicon compoundsPigment physical treatmentSlurryZircon

The invention discloses a method for producing special rutile type titanium white powder for power coating, which comprises the following steps of: preparing slurry of which titanium dioxide concentration is 300 to 400g / l by using bleached metatitanic acid, and adding a calcining auxiliary agent into the slurry; filtering the obtained metatitanic acid, then calcining solid, and grinding the solidto obtain a primary product; preparing titanium dioxide slurry of which titanium dioxide concentration is 650 to 850g / l by using the obtained primary product, adding a wetting agent into the titaniumdioxide slurry, and performing dispersion and grinding; heating the obtained titanium dioxide slurry to between 40 and 90 DEG C, adding dispersant, zircon salt or titanium salt, silicon salt and aluminum salt into the slurry in turn, adjusting the pH value to between 5 and 9, ageing the mixture, and adjusting the pH value to between 7 and 8; and then filtering, washing and drying the mixture, treating the dried product by an organic surface treatment agent, and vaporizing the product to obtain the rutile type titanium white powder. Compared with the prior art, the rutile type titanium white powder obtained by the method has the properties of stable crystal lattice, good dispersion, heat and yellowing resistance, and good oily whiteness, reducing power, covering power and weather resistance and the like; the appearance and properties of the rutile type titanium white powder are close to that of the rutile type titanium white powder prepared by a chlorination process; and the productionmethod has the advantages of easily obtained process raw materials and stable process control.

Owner:NINGBO XINFU TITANIUM DIOXIDE

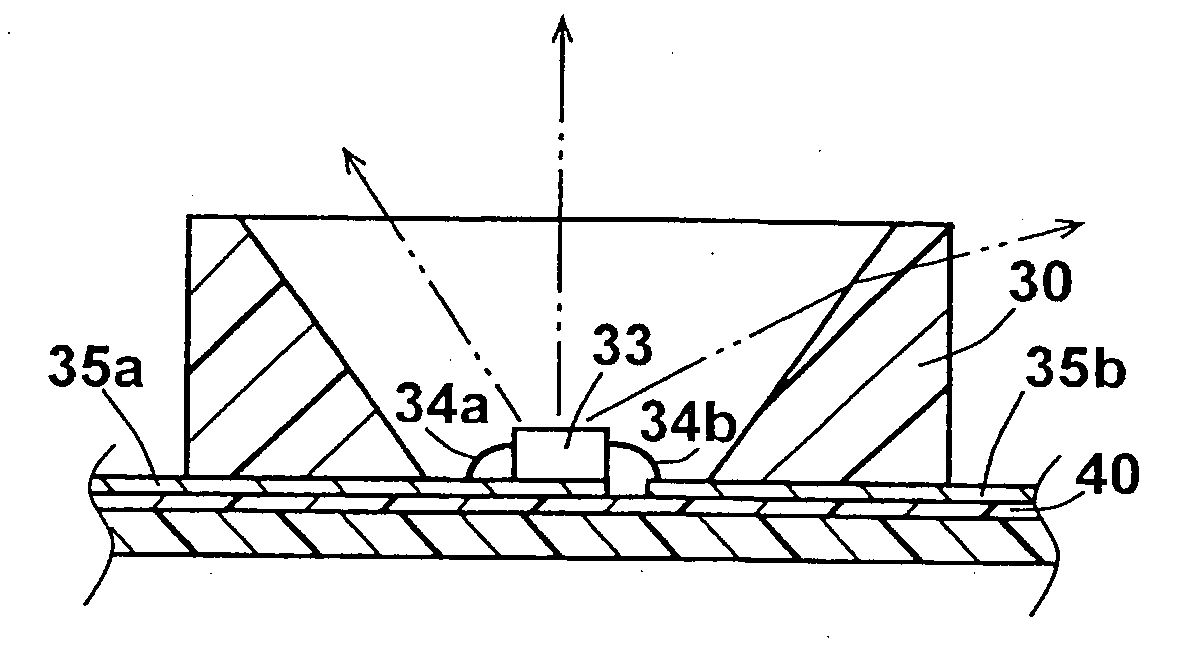

Optical system for optical recording

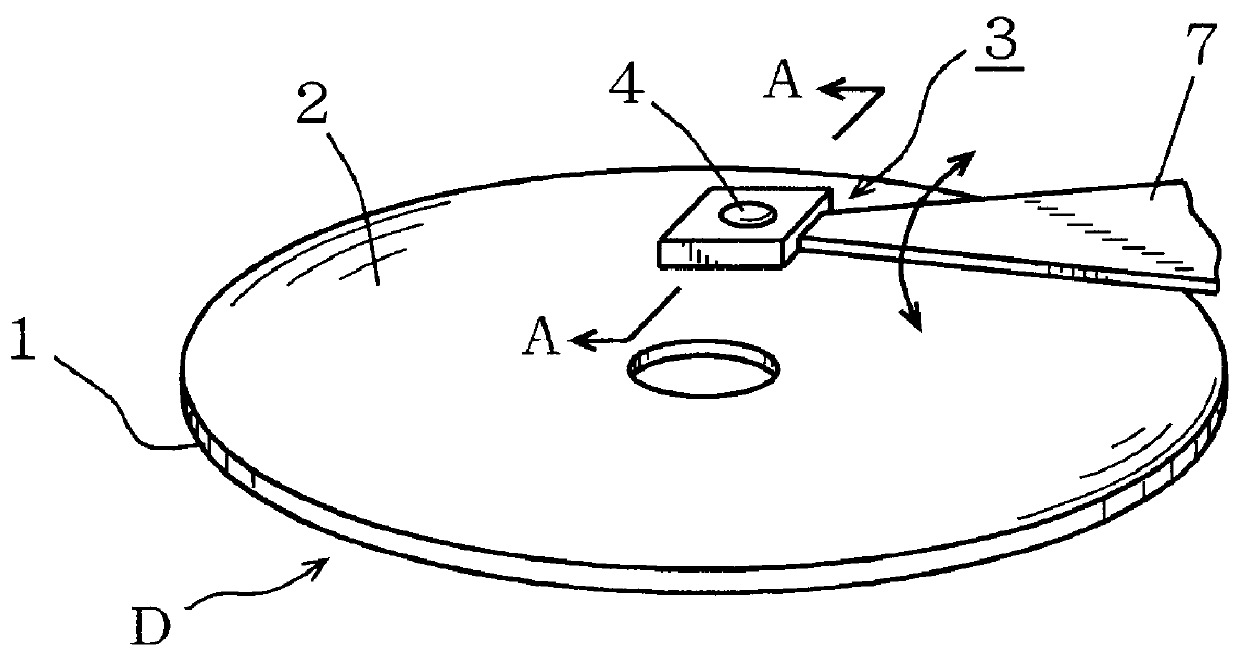

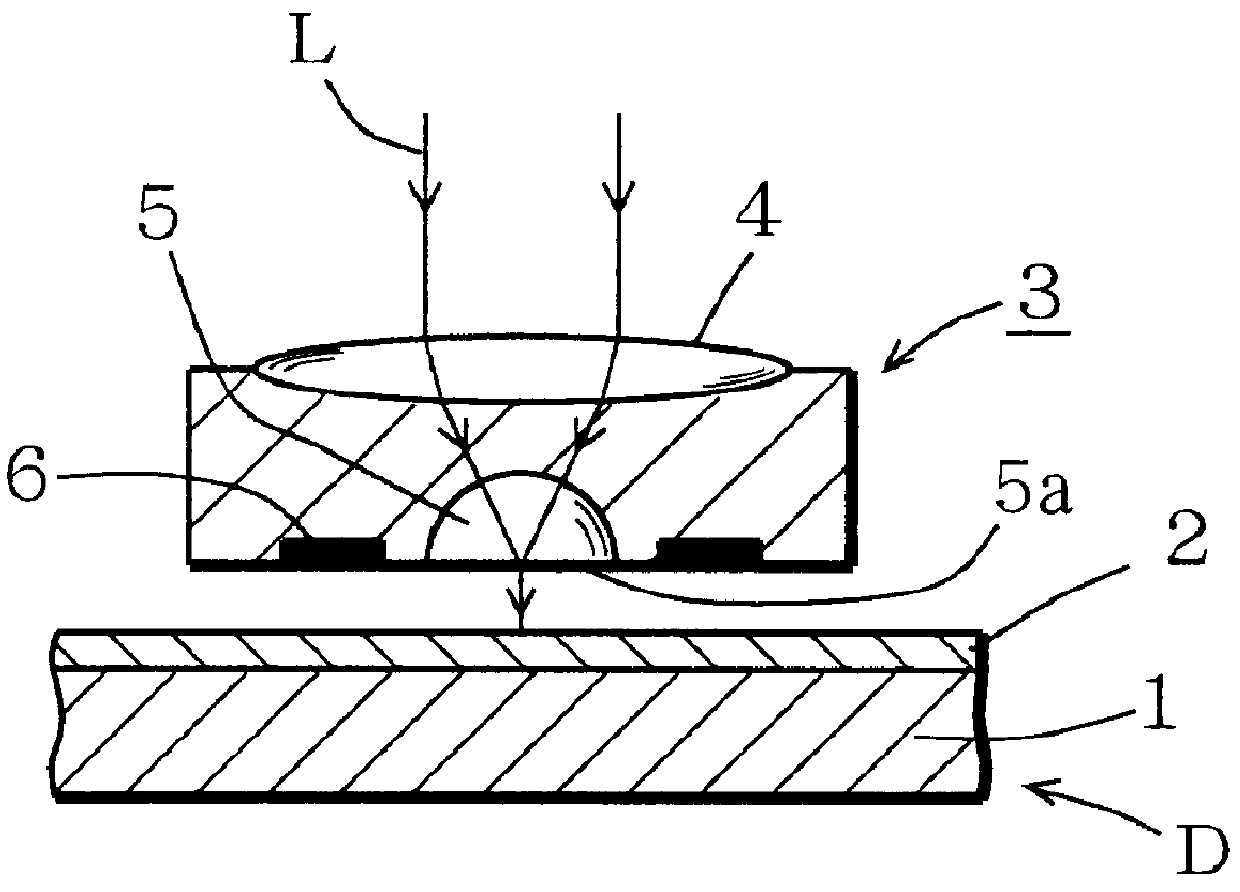

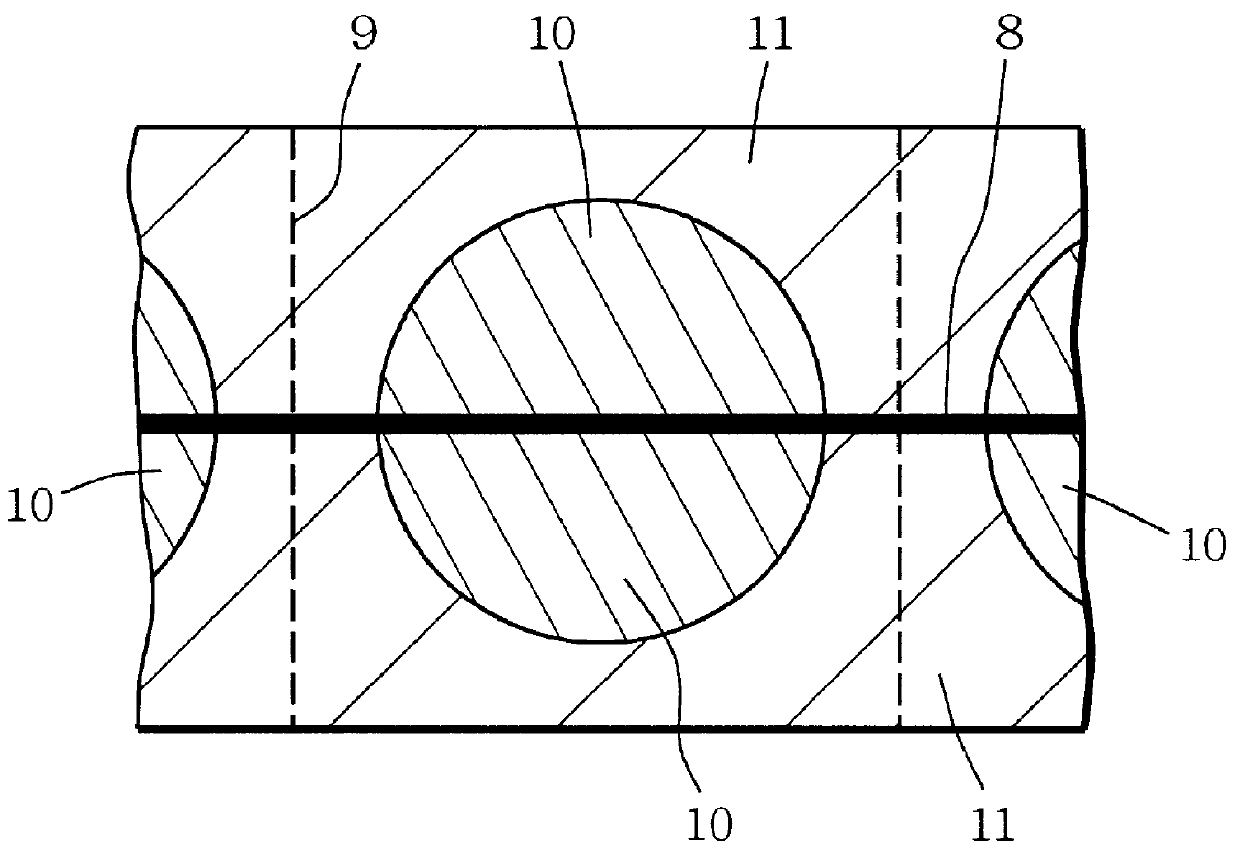

InactiveUS6043940AHigh refractive indexSuitable for massRecord information storageOptical beam guiding meansRefractive indexSingle crystal

A hemispheric lens of a single crystal having a refractive index of 2.0 or over is used as a SIL lens of an optical system for optical recording. The single crystal is LiNbO3, LiTaO3, rutile phase TiO2, PbMoO4, TeO2, SrTiO3, ZrO2, SrNbO3, SrTaO3, CaNbO3, CaTaO3, CaTiO3, KNbO3, KTaO3, BaZrO3, SrZrO3, CaZrO3, KNbO3, KTaO3, BaZrO3, SrZrO3, CaZrO3, ZnWO4, ZnMoO4, CdWO4, CdMoO4, PbWO4, Bi20SiO12, Bi20GeO12, Bi4Si3O12, Bi4Ge3O12, GaP, ZnTe, ZnSe, Cu3TaSe4 or ZnS.

Owner:KYOCERA CORP

Method for producing fine particles of metal oxide

A method for producing fine particles of metal oxide characterized in that metal halide is hydrolyzed in the presence of organic solvent. According to this invention, under hydrolysis of titanium tetrachrolide, anatase type titanium oxide can be obtained by selecting hydrophilic organic solvent, and rutile type titanium oxide can be obtained by selecting hydrophobic organic solvent.

Owner:SHOWA DENKO KK

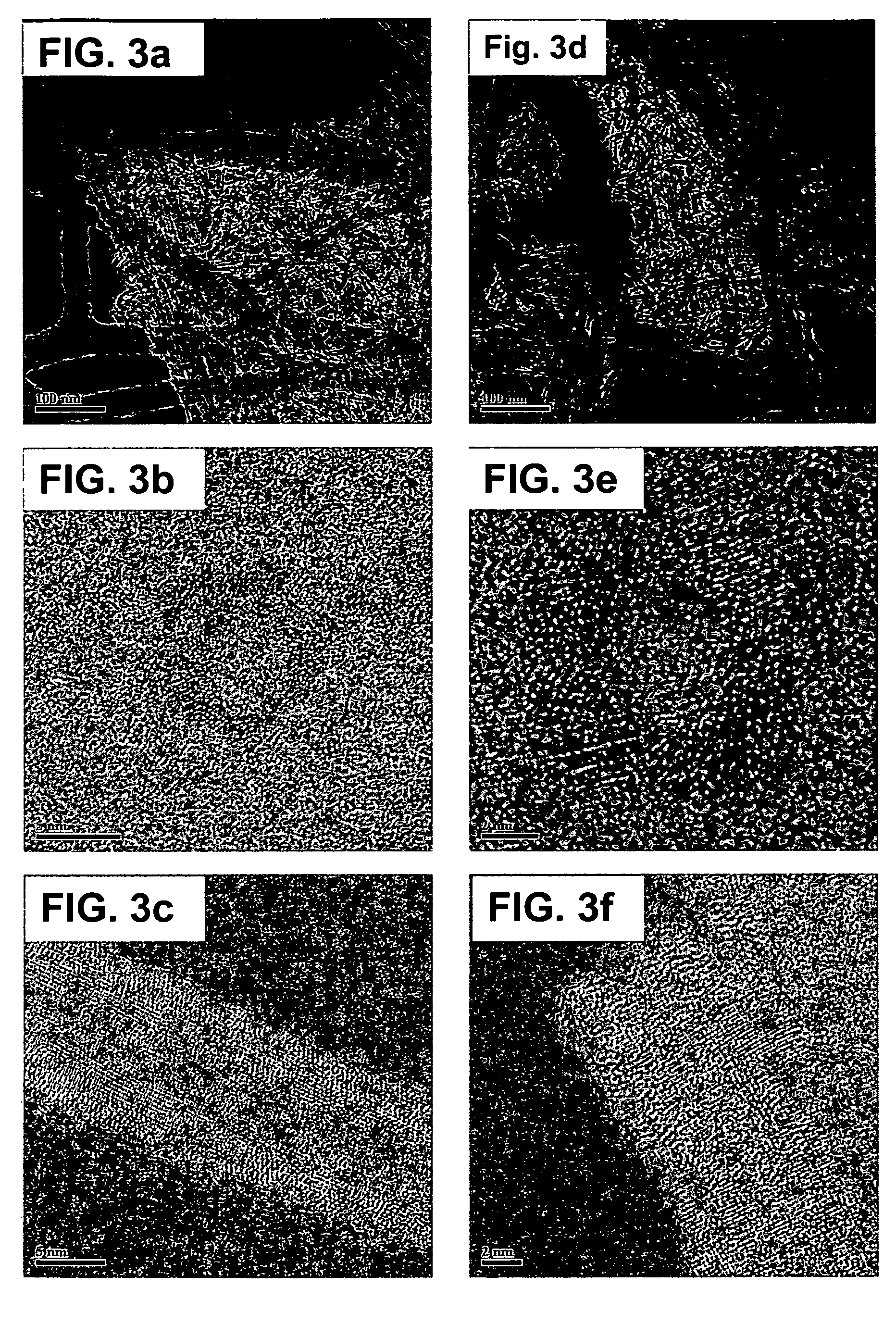

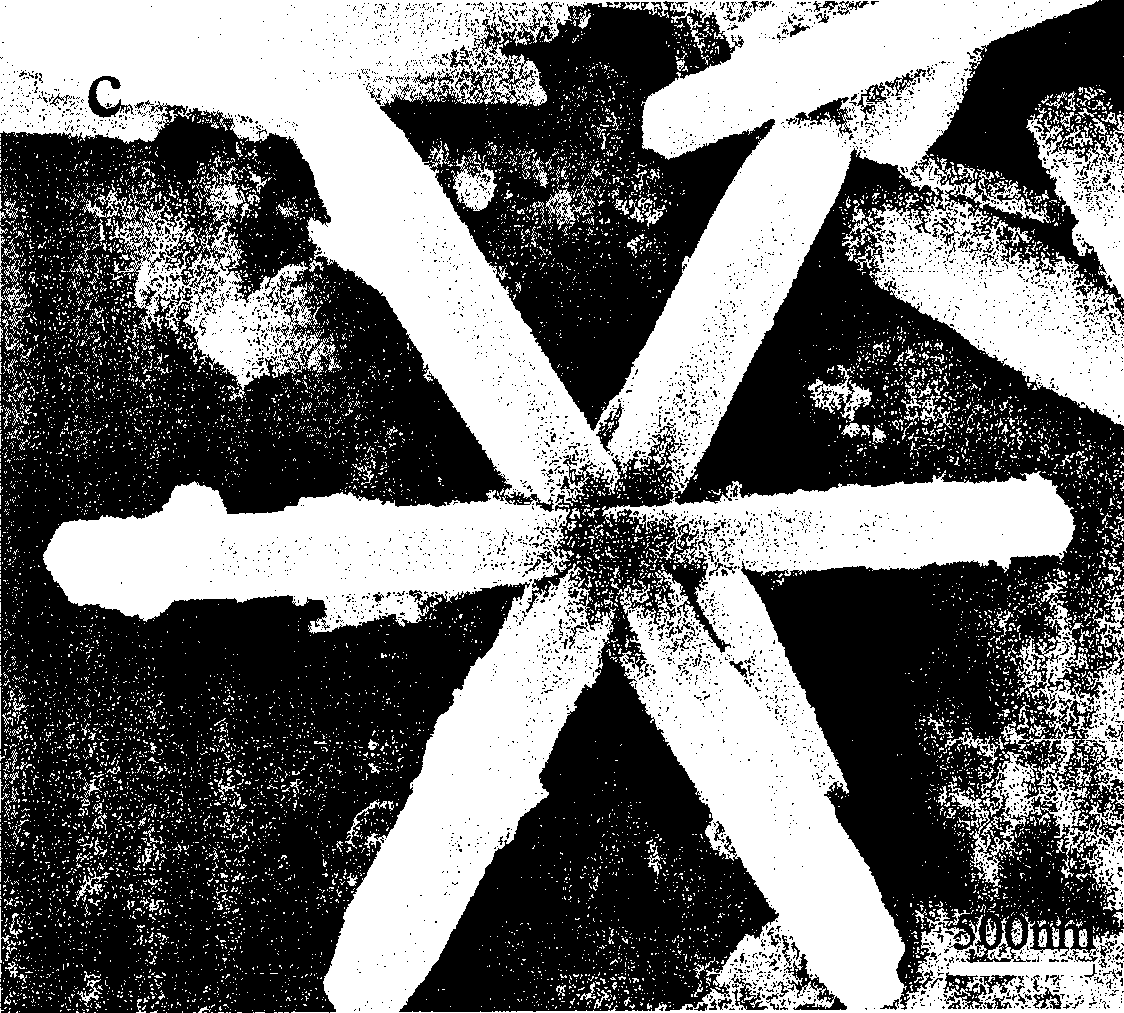

Nanostructured titanium oxide material and its synthesis procedure

ActiveUS20060078726A1Stable nanotubular structureLarge specific surface areaMaterial nanotechnologyLayered productsFiberNanowire

Nanomaterials of the JT phase of the titanium oxide TiO2-x, where 0≦x≦1 having as a building block a crystalline structure with an orthorhombic symmetry and described by at least one of the space groups 59 Pmmn, 63 Amma, 71 Immm or 63 Bmmb. These nanomaterials are in the form of nanofibers, nanowires, nanorods, nanoscrolls and / or nanotubes. The nanomaterials are obtained from a hydrogen titanate and / or a mixed sodium and hydrogen titanate precursor compound that is isostructural to the JT crystalline structure. The titanates are the hydrogenated, the protonated, the hydrated and / or the alkalinized phases of the JT crystalline phase that are obtained from titanium compounds such as titanium oxide with an anatase crystalline structure, amorphous titanium oxide, and titanium oxide with a rutile crystalline structure, and / or directly from the rutile mineral and / or from ilmenite. The titanates are submitted to dynamic thermal treatment in an inert, oxidizing or reducing atmosphere to produce the JT phase of the TiO2-x, where 0≦x≦1 with an orthorhombic structure.

Owner:INST MEXICANO DEL GASOLINEEO

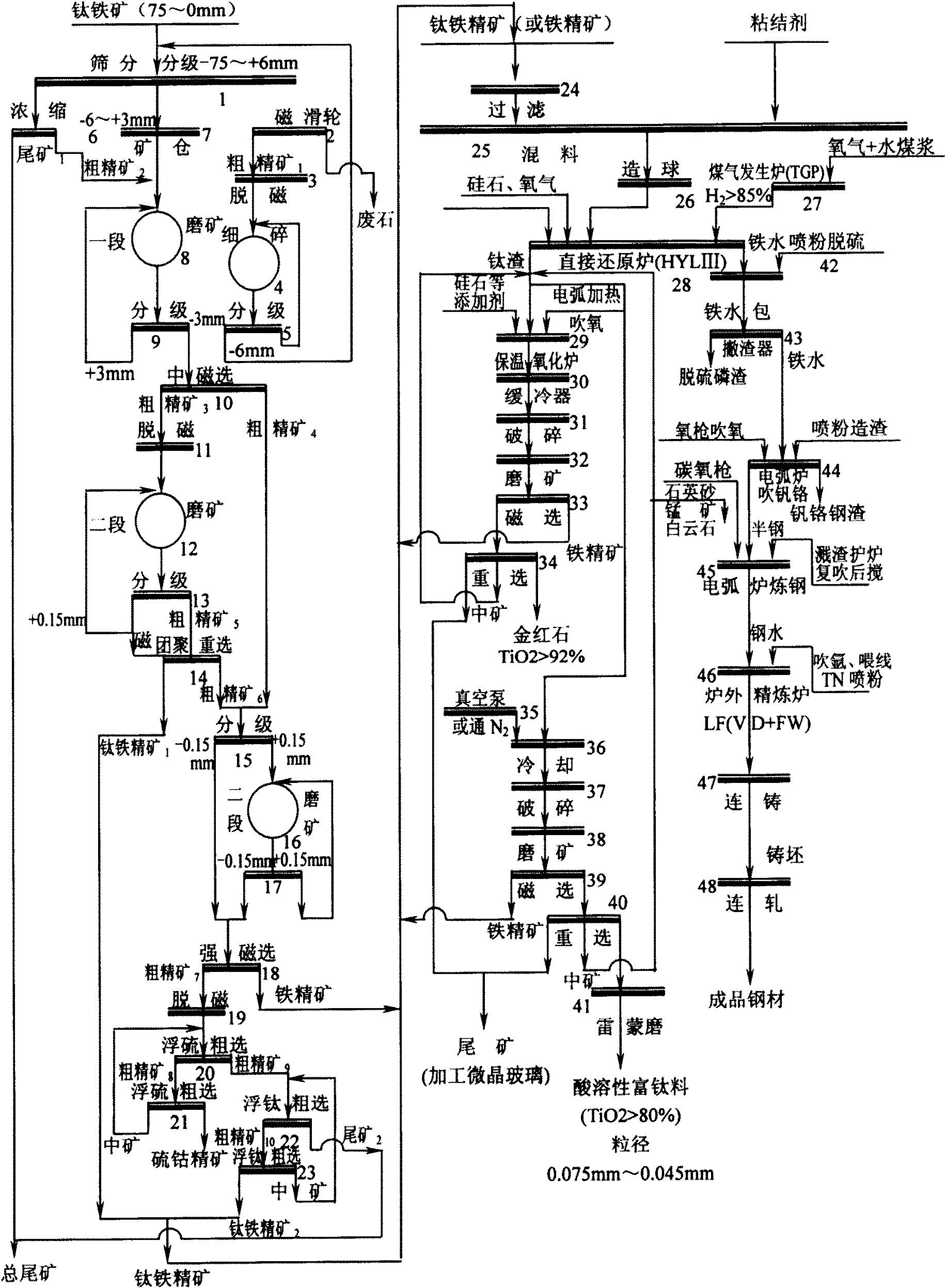

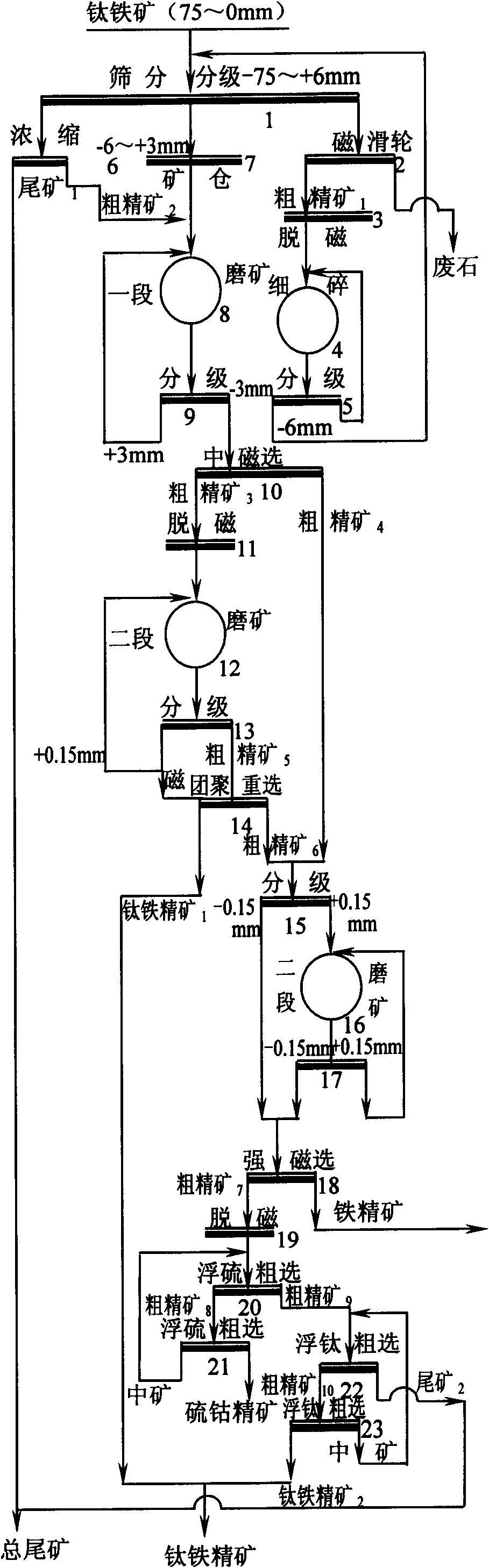

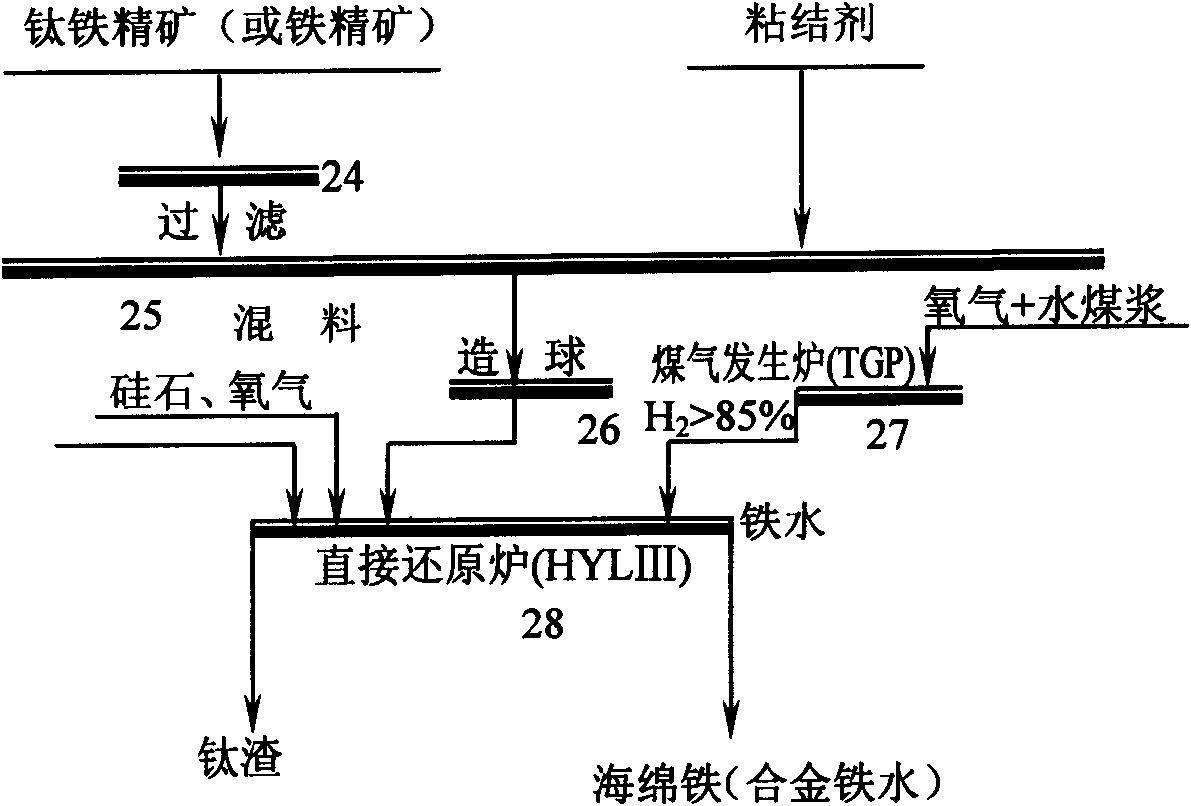

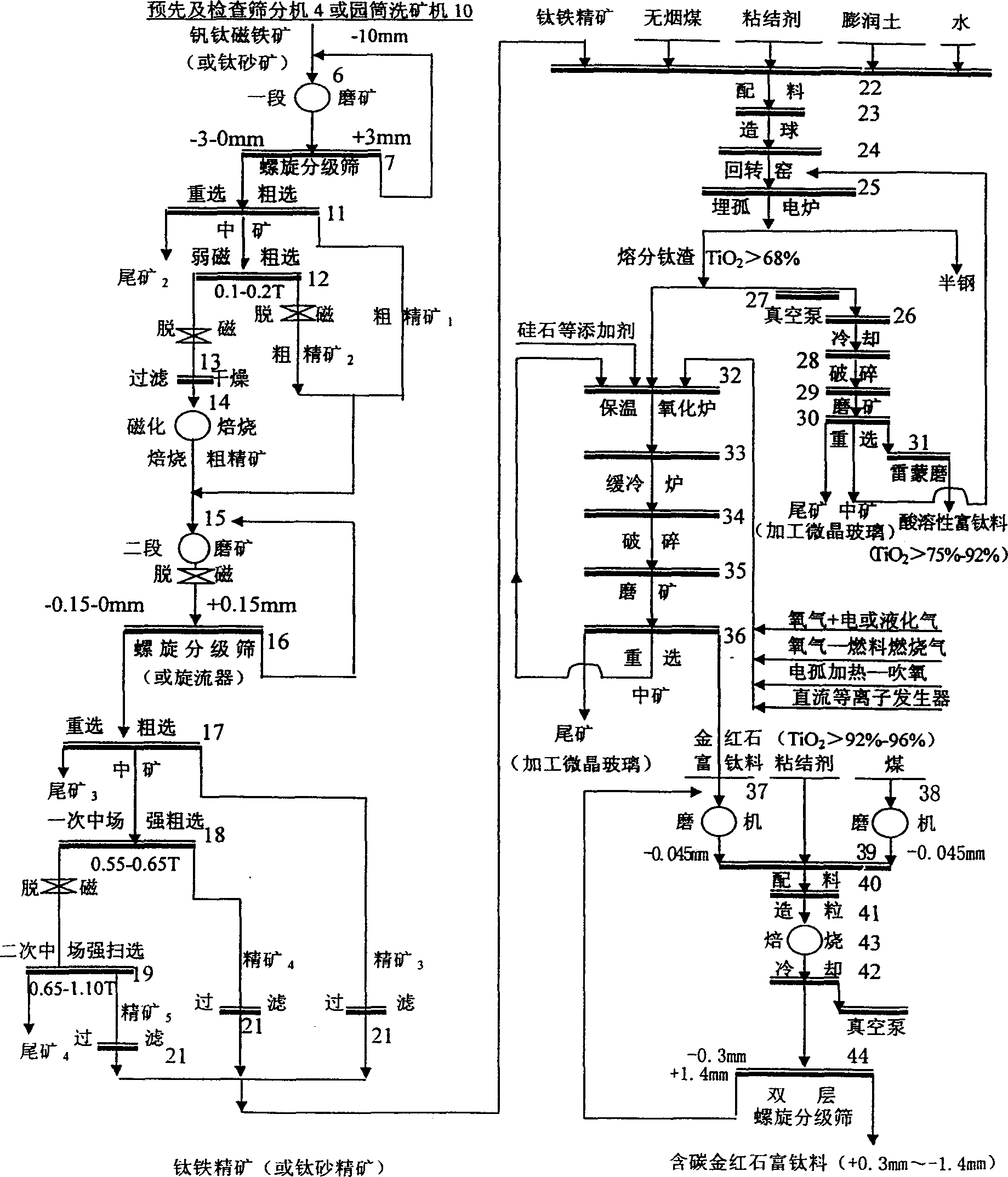

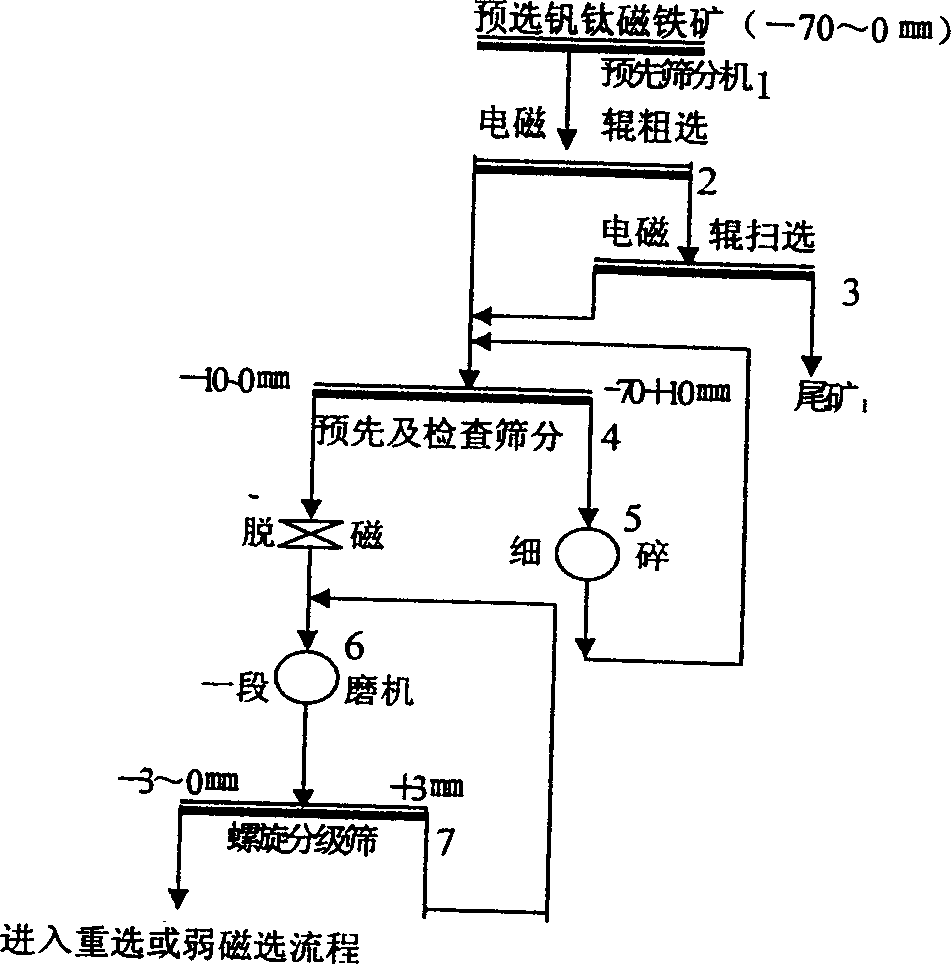

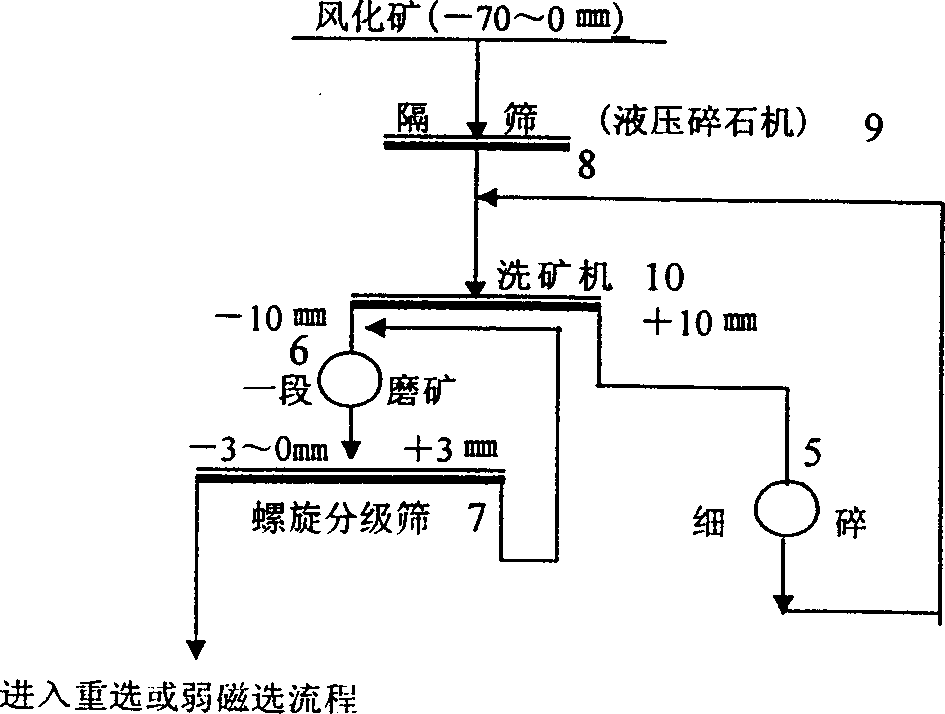

Method for producing titanium and steel products by utilizing titanium and iron ores

InactiveCN101613825AIncrease profitHigh recovery rateProcess efficiency improvementElectric furnaceRutileContinuous rolling

The invention discloses a method for producing titanium and steel products by utilizing titanium and iron ores, which belongs to the field of technical innovation of mining, dressing and smelting full process flow of the titanium and iron ores. Ordinary blast furnaces are not suitable for the smelting of high-titanium and medium-titanium schreyerite; and schreyerite mining, dressing and smelting enterprises in Panxi region extract rich parts and discard poor parts, and discard weathered ore of submarginal ore which accounts for over 95 percent of that of raw ore and is taken as mining mullock. The method comprises the following step: directly reducing titaniferous iron concentrate dressed from the mining mullock (TiO2 is over 5 percent, and TFe is over 13 percent) of the schreyerite, electric furnace melt producing titanium slag and molten water with electric furnace melt components, and producing a titanium-rich material and rutile with the titanium slag through mineral dressing by a fire method; producing alloy molten iron with the molten iron through electric smelting and vanadium-chrome steel slag blowing; and producing various alloy steel products the alloy molten iron in a continuous casting and continuous rolling mode through the electric smelting. The recovery rates of titanium, iron and vanadium are improved to 80 percent from 3.86 percent, improved to 70 percent from 34.5 percent and improved to 70 percent from 20.90 percent respectively.

Owner:PANZHIHUA JINTAI HI TECH

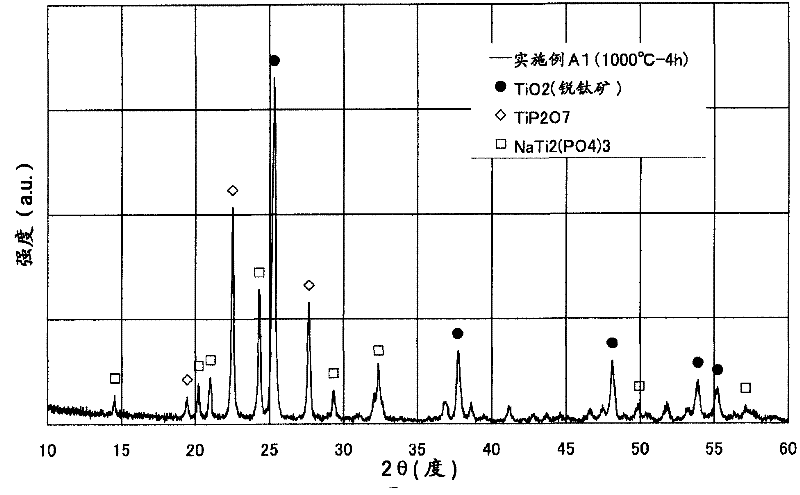

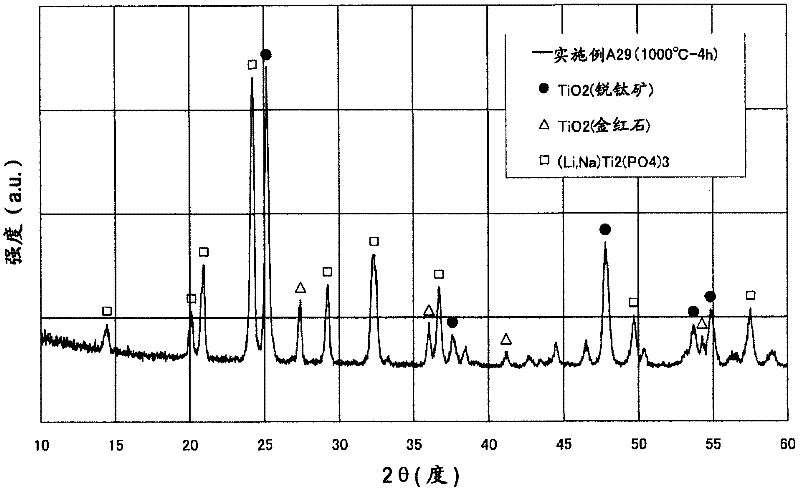

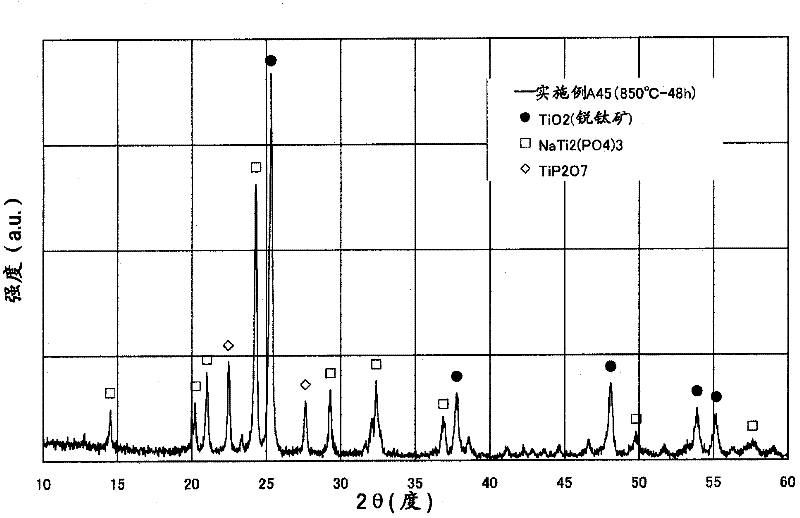

Glass ceramics and process for production thereof, process for producing sintered glass ceramics, process for producing complex, molded article having photocatalytic function, and hydrophilic molded article

InactiveCN102177102APromote precipitationCatalytic performance does not deterioratePhysical/chemical process catalystsBrookiteTitanium

Disclosed is a process for producing a glass ceramics which has a surface having excellent durability and has at least one titanium oxide crystal phase selected from those of anatase type, rutile type and brookite type. Also disclosed are a molded article having a photocatalytic function and a hydrophilic molded article each of which comprises the glass ceramics produced by the process. The glass ceramics comprises 15.0 to 95.0% by mol inclusive of a TiO2 component and 3.0 to 85.0% by mol inclusive of a P2O5 component and / or an SiO2 component in terms of oxide contents relative to the total amount of the glass ceramics.

Owner:OHARA

Method of producing titanium enriched material using titanium mineral

InactiveCN1429919AEfficient recyclingImprove resource utilization efficiencyMagnetic separationAdhesiveMagnetite

A process for preparing Ti-enriched material from V-Ti magnetite through preseparating to obtain Ti-Fe ore concentrate, proportionally mixing it with V-Ti-Fe core concentrate, adhesive and carbon reducer, smelting to obtain high-Ti slag and semi-steel, blowing V-Cr to melten alloy iron to obtain V-Cr contained steel slag, separating V and Cr, fire metallurge of high-Ti slag to obtain artificial rutile and microcrystal glass, ball grinding of artificial rutile and coal while adding adhesive to obtain C-contained Ti particles, calcining, cooling and classifying.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

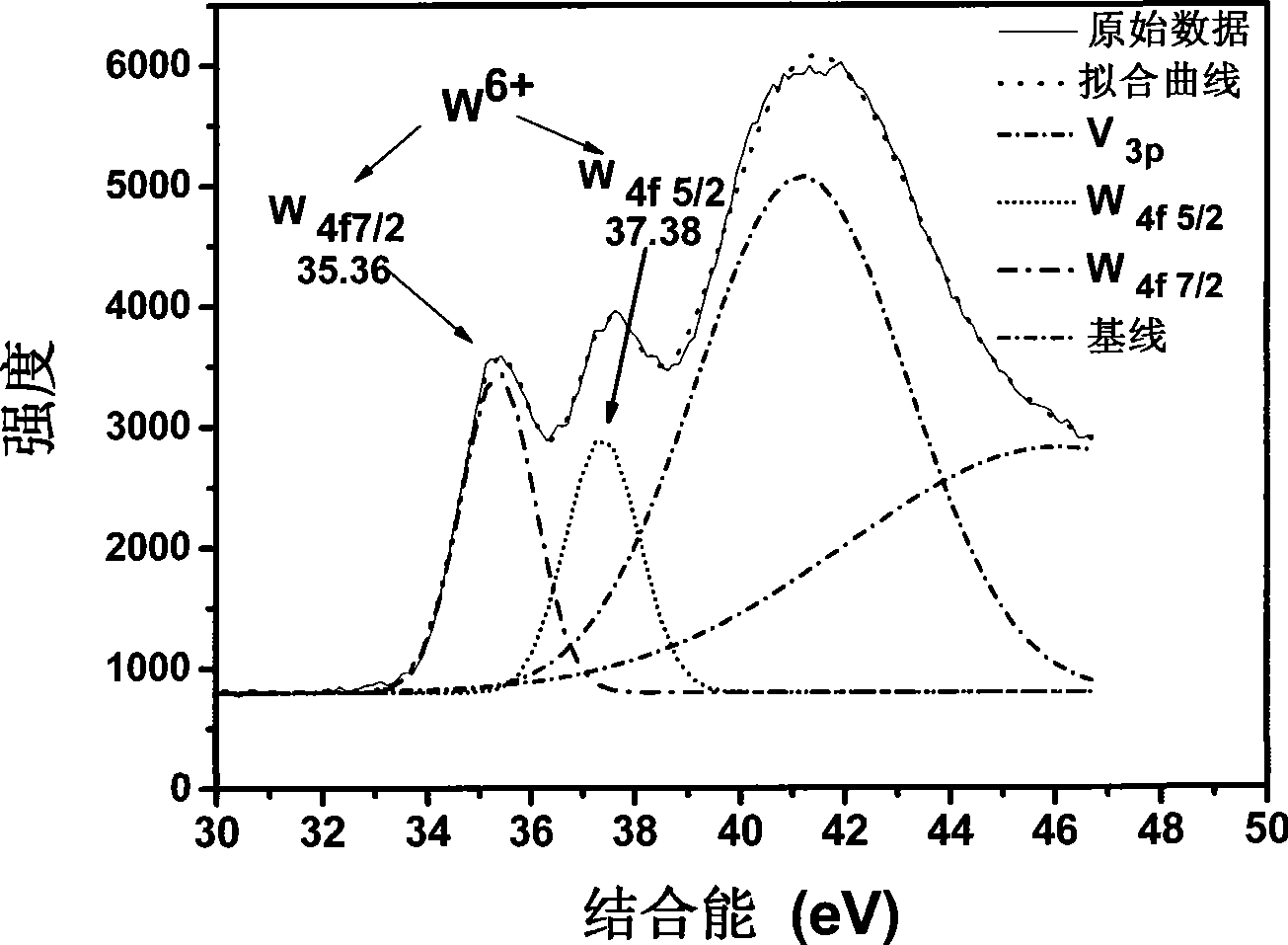

Method for preparing rutile phase hypovanadic oxide powder

The invention relates to a method for preparing rutile-phase vanadium dioxide powder, in particular to a method for preparing rutile-phase vanadium dioxide powder through a hydrothermal method. The method for preparing rutile-phase vanadium dioxide powder adopts the conditions of different vanadium materials, dopants and doping ratios, and the like, to obtain rutile-phase vanadium dioxide powders with good crystallization performance and in shapes of grains, nanometer rods and snowflake-shaped grains. The temperature for transforming the powder from semiconductor phase to conductor phase can be reduced approximately to the room temperature.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

White color reflecting material and process for production thereof

ActiveUS20120138997A1Improve heat resistanceImprove light resistanceDiffusing elementsSolid-state devicesUltravioletRutile

A general-use white color reflecting material, and a process for production thereof are provided. The white color reflecting material, without troublesome surface treatment such as formation of a reflective layer by plating, is capable of reflecting a near-ultraviolet ray of a wavelength region of 380 nm or longer or a near-infrared ray sufficiently without light leakage; does not become yellow even when exposed to near-ultraviolet rays; has excellent lightfastness, heat resistance, and weatherability; has high mechanical strength and chemical stability; is capable of maintaining a high degree of whiteness; and is easily moldable at a low cost. Further a white color reflecting material used as an ink composition for producing the white color reflecting material in a film shape is also provided. The white color reflecting material comprises; a silicone resin or silicone rubber formed from titanium oxide-containing silicone composition, in which anatase-type or rutile-type titanium oxide particles are dispersed.

Owner:ASAHI RUBBER

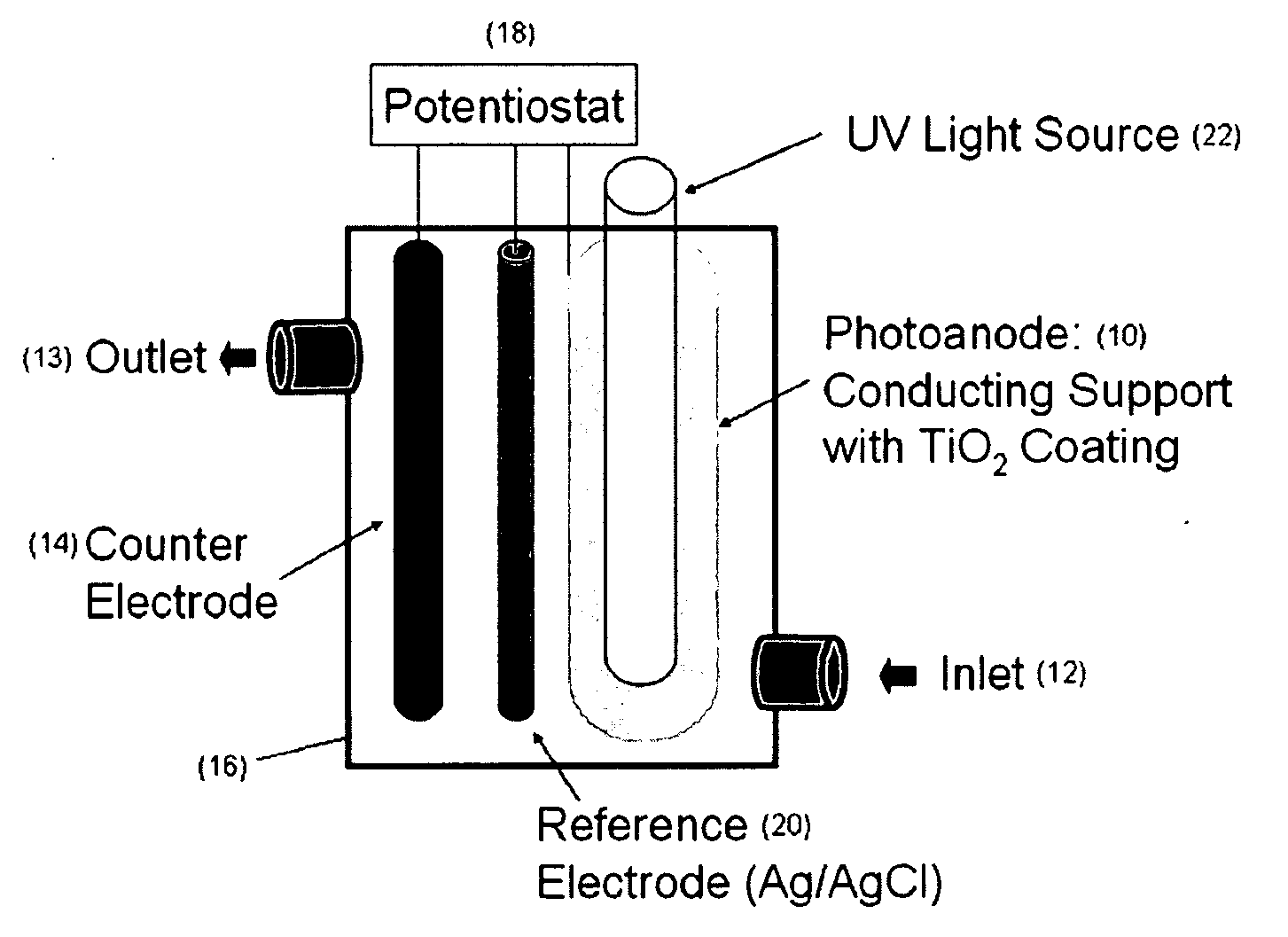

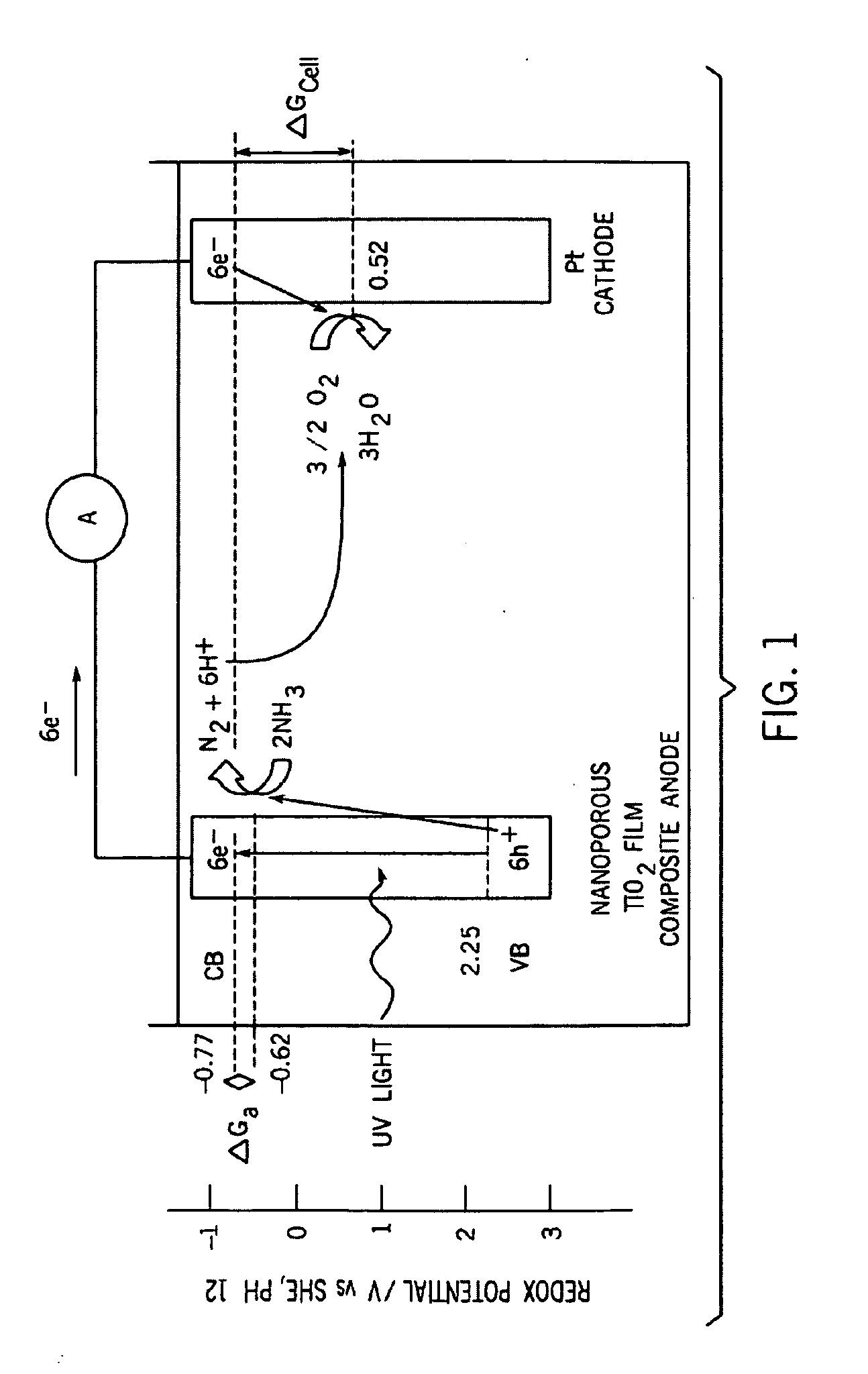

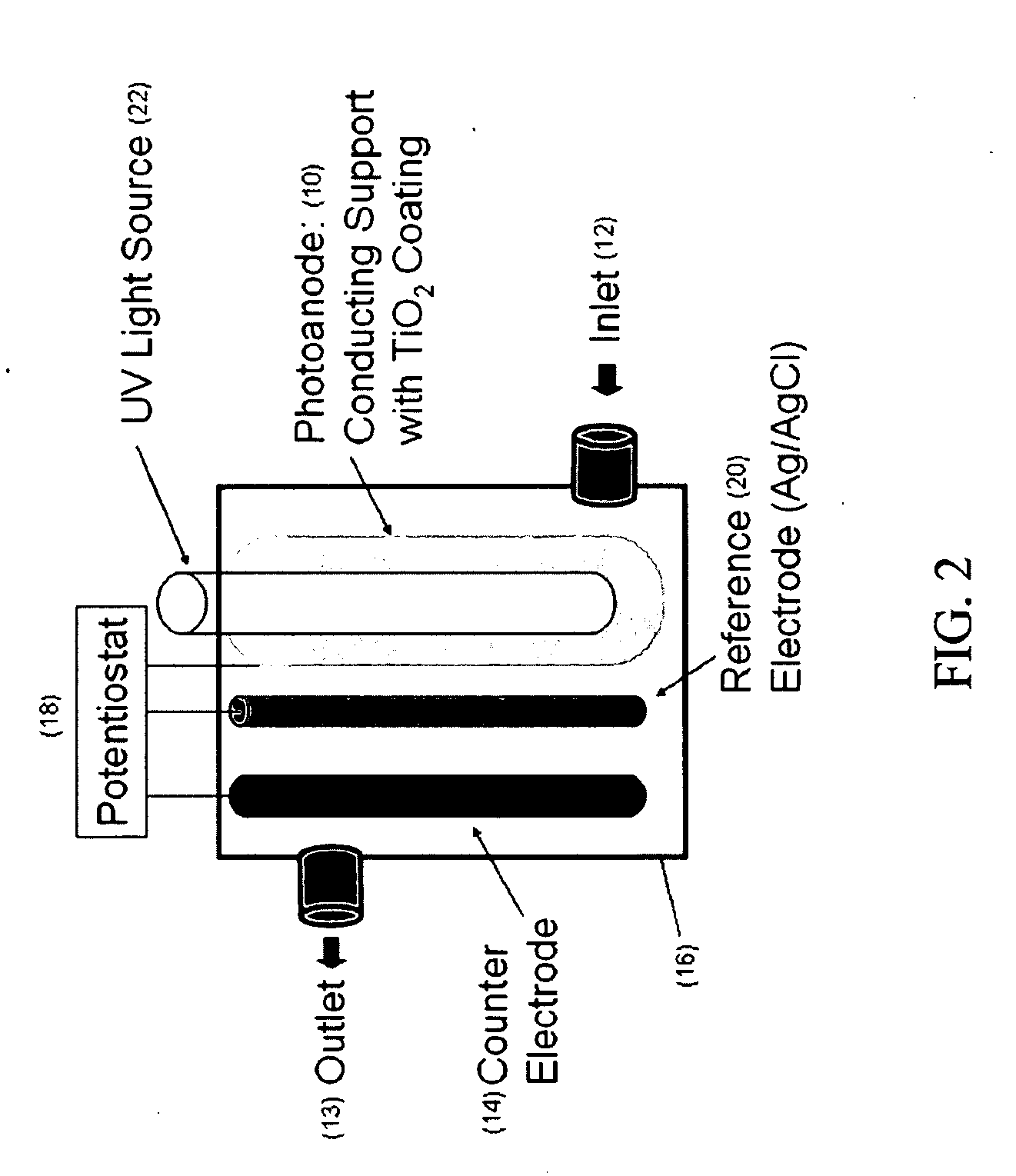

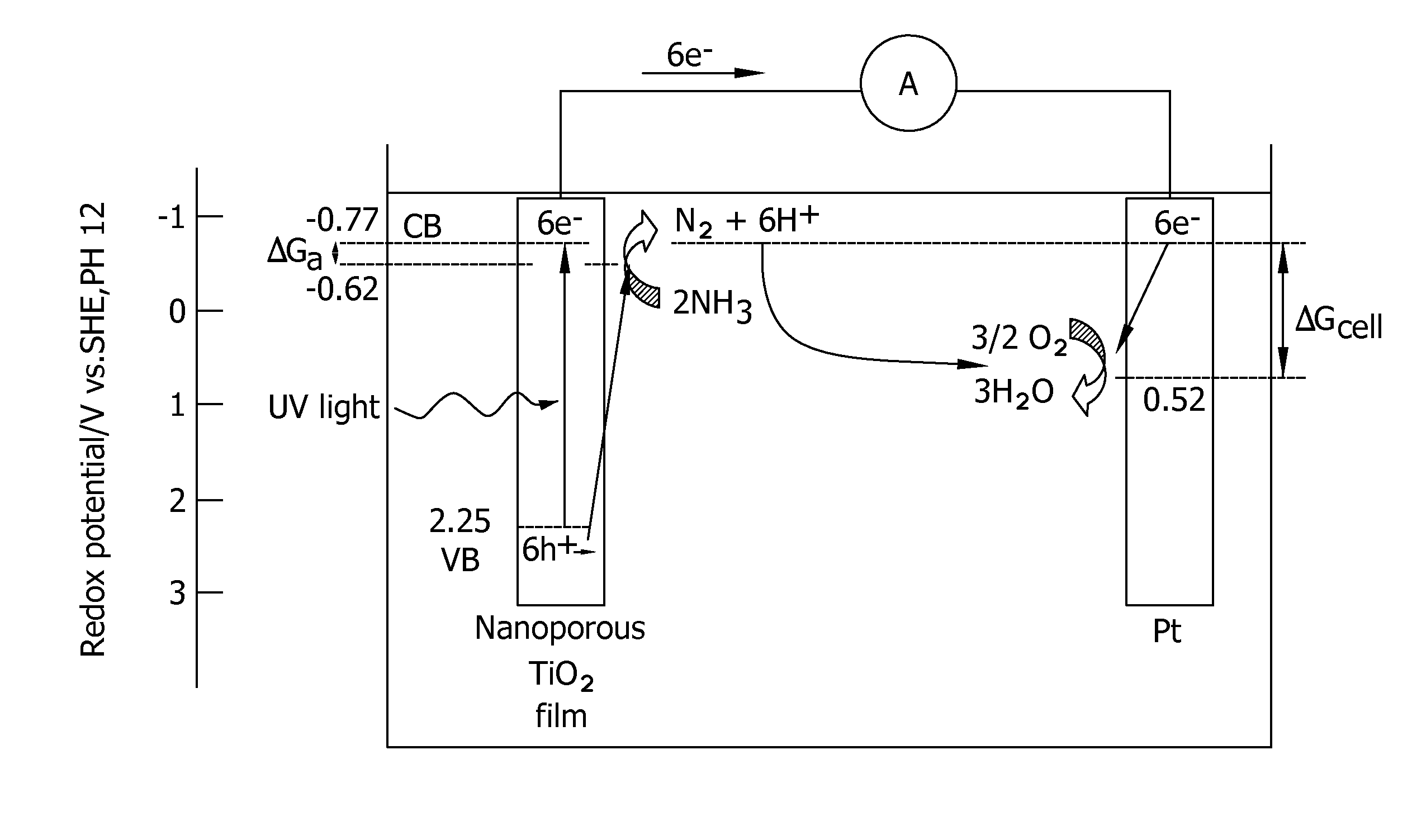

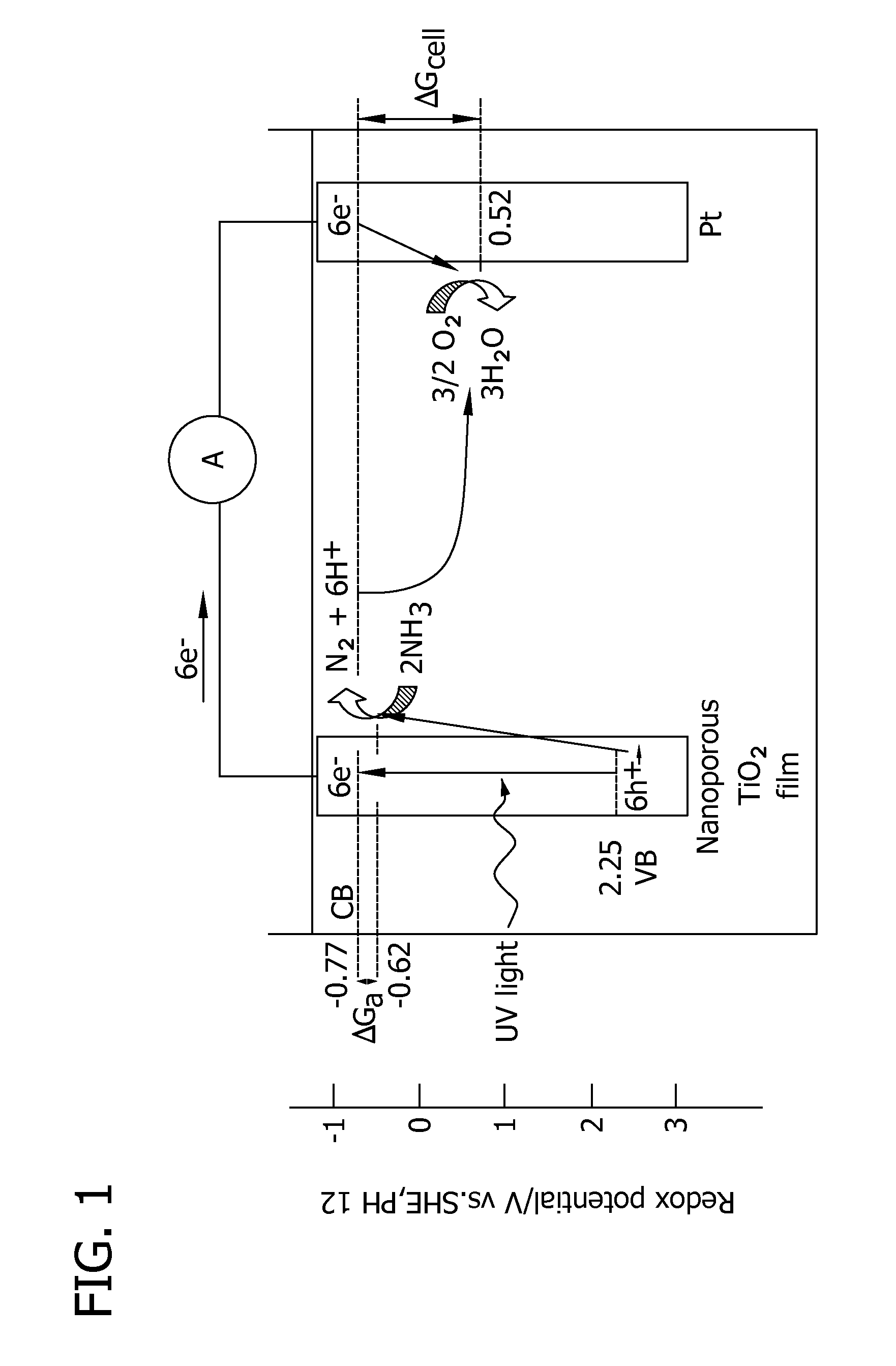

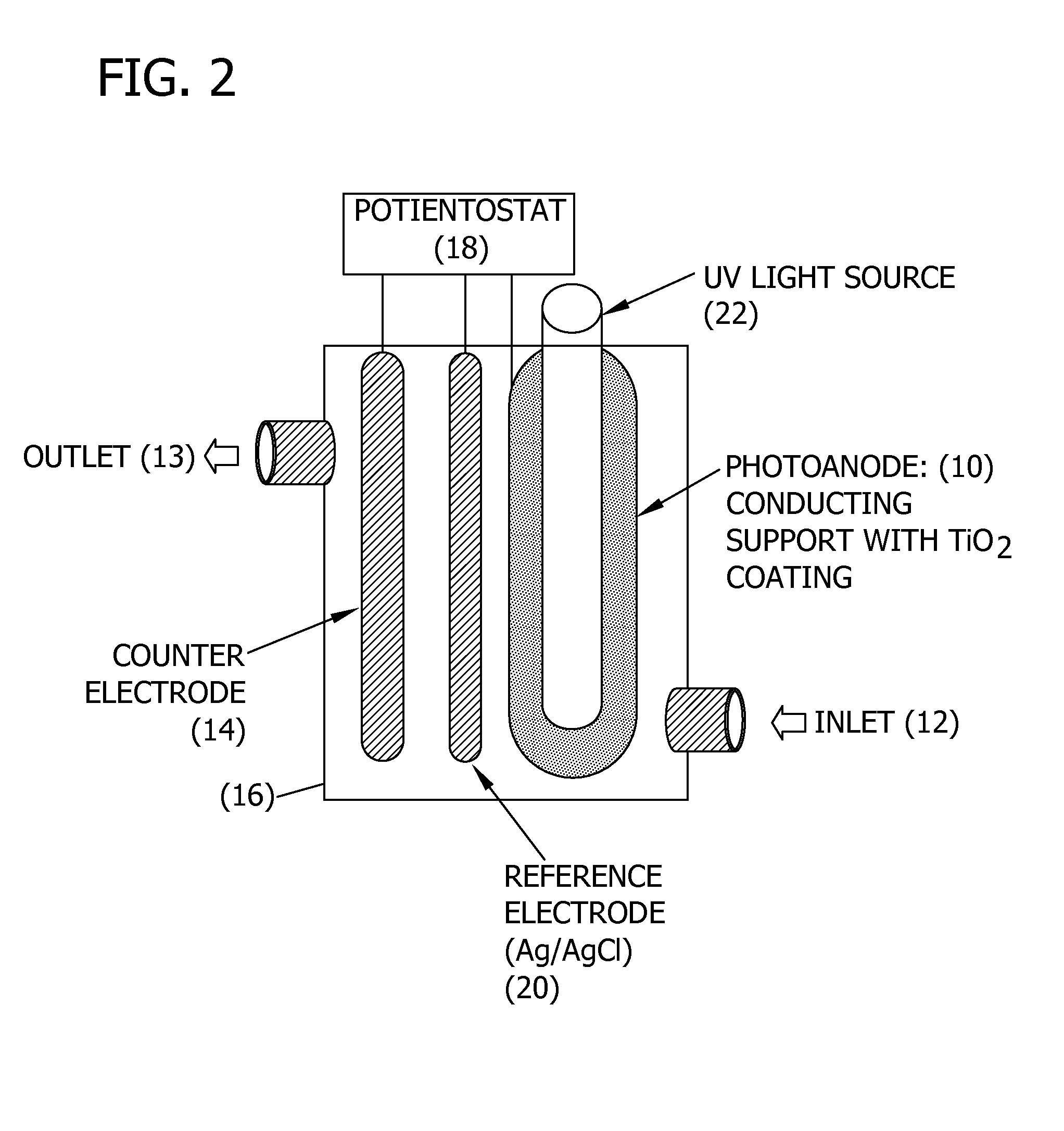

PHOTOELECTROCATALYTIC OXIDIZER DEVICE HAVING COMPOSITE NANOPOROUS TiO2 COATED Ti PHOTOANODE AND METHOD OF REMOVING AMMONIA FROM WATER IN AQUARIA AND RECIRCULATION AQUACULTURE SYSTEMS

InactiveUS20090314711A1Improve performanceWater treatment parameter controlElectrolysis componentsComposite electrodeNanoporous membrane

A photoelectrocatalytic oxidizing device having a photoanode being constructed from an anatase or rutile polymorph of Ti as the support electrode. Alternatively, the photoanode is a composite electrode comprising an anatase or rutile polymorph of Ti as the support electrode coated with a thin film of sintered nanoporous TiO2 derived from a stable, dispersed suspension of nanoparticulate TiO2. The device being useful for removing ammonia, protein and other contaminants from water in aquariums and aquacultures thereof. The device being cylindrical in shape and having a flow-through configuration. The method being directed at reducing the amount and concentration of ammonia in an aquarium or aquaculture system comprising providing an aqueous solution comprising water, NH3, NH4+ and 1 ppb to 200 g / L NaCl, and, photoelectrocatalytically oxidizing the NH3 and NH4+ to produce N2 gas, NO2− and NO3−, wherein the NH3 and NH4+ are oxidized on the surface of a photoanode constructed from an anatase polymorph of Ti, a rutile polymorph of Ti, or a nanoporous film of TiO2.

Owner:WISCONSIN ALUMNI RES FOUND

Nickel-based welding electrode for welding nickel-chromium-molybdenum alloy

ActiveCN102430876AExcellent heat crack resistanceEasy to useWelding/cutting media/materialsSoldering mediaCrack resistanceNiobium

The invention relates to a nickel-based welding electrode which comprises the following component by weight percent (wt%): 50.0-68.0% of Ni, 18.0-23.0% of Cr, 6.0-11.0% of Mo, 3.0-6.0% of Nb, 2.50-9.00% of Fe, 0.01-0.1% of C, 0.10-1.00% of Mn, 0.010-0.10% of Si, 0.015% of S or less, 0.015% of P or less, 0.01-0.10% of Cu, 0.003-0.010% of Co and the balance of impurities. The coat of the nickel-based welding electrode comprises the following components by weight percent of the welding core: 12-18% of marble, 10-15% of fluorite, 12-18% of barium carbonate, 5.0-6.4% of rutile, 3.5-5.0% of ferroniobium, 3.3-4.5 of chromium metal powder, 0.45-0.65% of sodium carbonate, 0.45-0.65% of electrolytic manganese and 1.3-1.8% of zircon sand, and the adhesion agent is 10-20% of the total weight of the power. The nickel-based welding electrode is prepared by mixing, wrapping mixture on the welding core and baking at low and high temperature. The nickel-based welding electrode disclosed by the invention is used for nickel-chromium-molybdenum alloy steel welding, ensures that the excellent mechanical properties, the excellent corrosion resistance, the excellent thermal crack resistance and the hightensile strength of the welding seam match with those of the base material, has good welding process performance, guarantees attractive molding and can be used for the welding of the steel (with 9% of Ni) working at low temperature.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

Process for making durable rutile titanium dioxide pigment by vapor phase deposition of surface treatments

The present invention relates to a process for making durable titanium dioxide pigment by vapor phase deposition of surface treatments on the titanium dioxide particle surface by reacting titanium tetrachloride vapor, an oxygen containing gas and aluminum chloride in a plug flow reactor to form a product stream containing titanium dioxide particles; and introducing silicon tetrachloride into the reactor at a point down stream of the point where the titanium tetrachloride and oxygen were contacted and where at least 97% of the titanium tetrachloride has been converted to titanium dioxide or where the reaction temperature is no greater than about 1200° C., and preferably not more than about 1100° C.

Owner:THE CHEMOURS CO FC LLC

A nano-modified highly stain-resistant elastic coating and its preparation method

InactiveCN102286233AOvercome sticking backImprove stain resistanceCoatingsPigment treatment with organosilicon compoundsColloidal silicaAluminum Carbonate

The invention provides a nano-modified highly stain-resistant elastic paint and a preparation method thereof, belonging to the technical field of building paint preparation. The composition and mass percent of the elastic coating provided by the present invention are: emulsion 40-50; water-based nano-colloidal silicon; 2-5; ultrafine aluminum carbonate; 15-25; modified nano-calcium carbonate 5-10; rutile titanium White powder; 8~15; pH regulator; 0.30~35; film-forming aid 0.50~0.65; elastic defoamer; 0.35~0.40; wetting agent 0.20~0.30; ; Leveling agent; 0.30~0.45; Bactericidal preservative; 0.10~0.15; Thickener; 0.10~0.20; Water; Balance. The nano-modified highly stain-resistant elastic paint provided by the present invention well achieves a balance among elasticity, stain resistance, water resistance, adhesion and practicability.

Owner:CHINA MCC17 GRP

Methods for removing contaminants from aqueous solutions using photoelectrocatalytic oxidization

InactiveUS20110180423A1Improve performanceImprove photoanode performanceWater treatment compoundsSpecific water treatment objectivesComposite electrodeNanoporous membrane

A photoelectrocatalytic oxidizing device having a photoanode being constructed from a conducting metal such as Ti as the support electrode. Alternatively, the photoanode is a composite electrode comprising a conducting metal such as Ti as the support electrode coated with a thin film of sintered nanoporous TiO2. The device is useful in methods for treating an aqueous solution such as groundwater, wastewater, drinking water, ballast water, aquarium water, and aquaculture water to reduce amounts of a contaminant. The method being directed at reducing the amount and concentration of contaminants in an aqueous solution comprising providing an aqueous solution comprising at least one contaminant, and, photoelectrocatalytically oxidizing the contaminant, wherein the contaminant is oxidized by a free radical produced by a photoanode constructed from an anatase polymorph of Ti, a rutile polymorph of Ti, or a nanoporous film of TiO2.

Owner:WISCONSIN ALUMNI RES FOUND

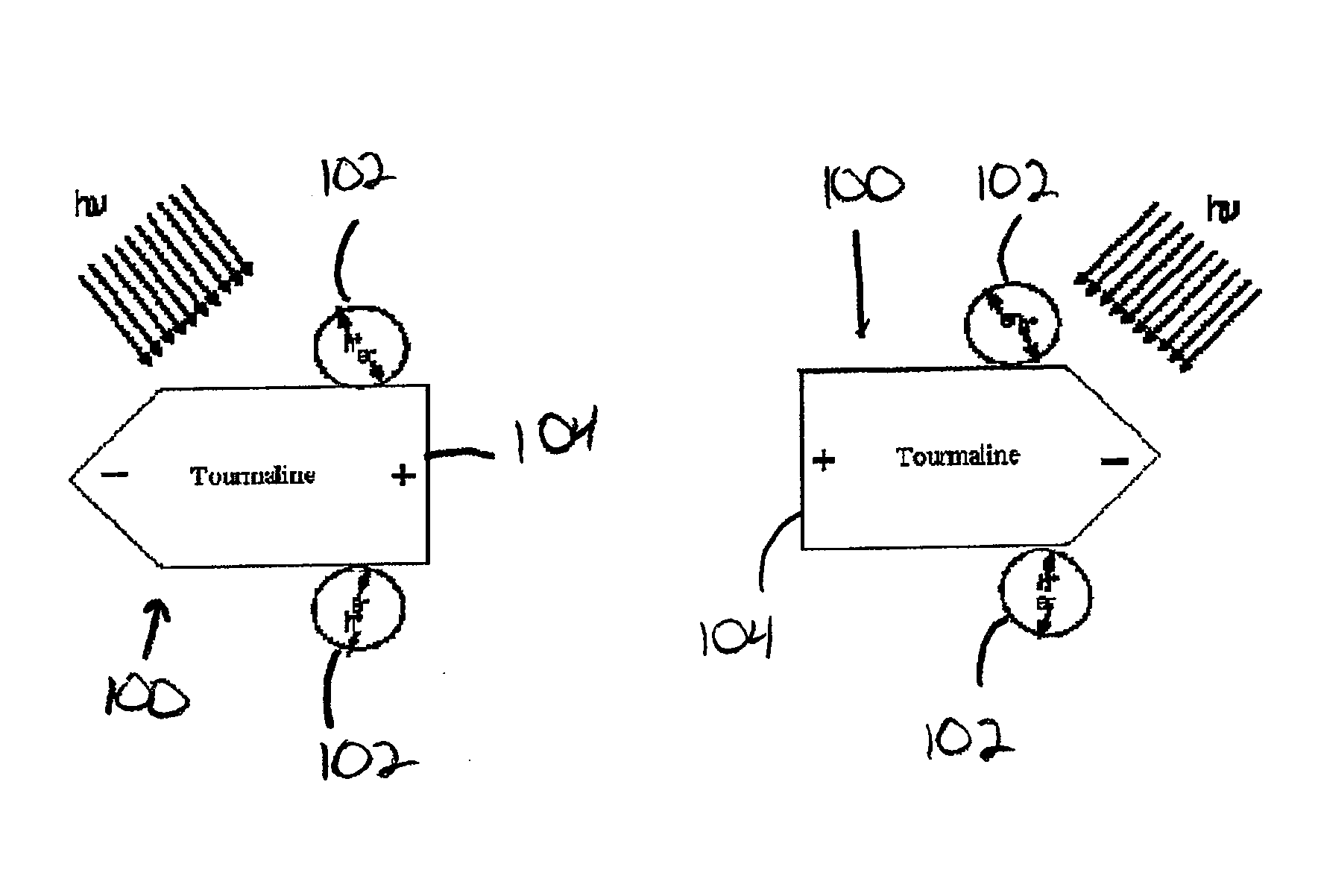

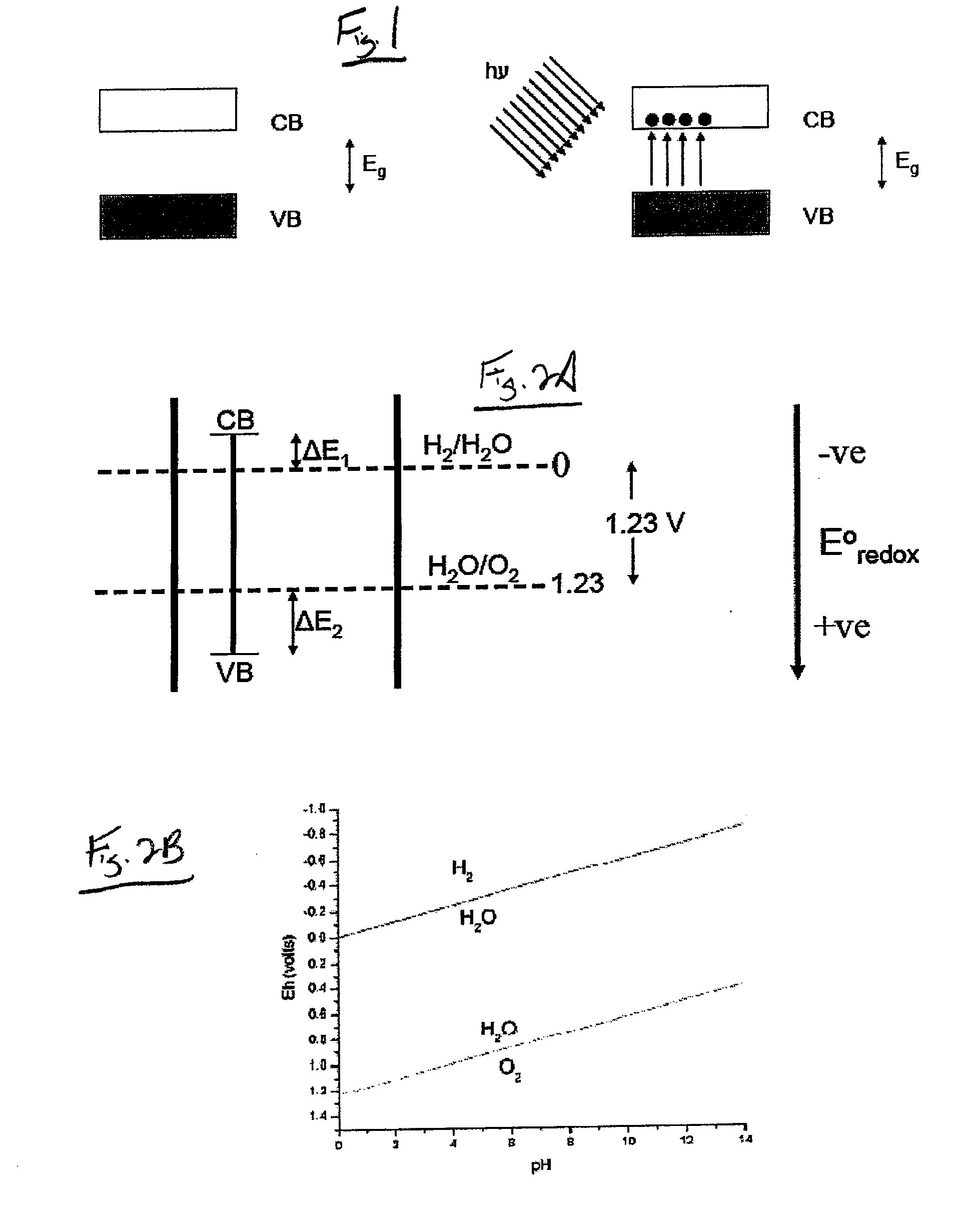

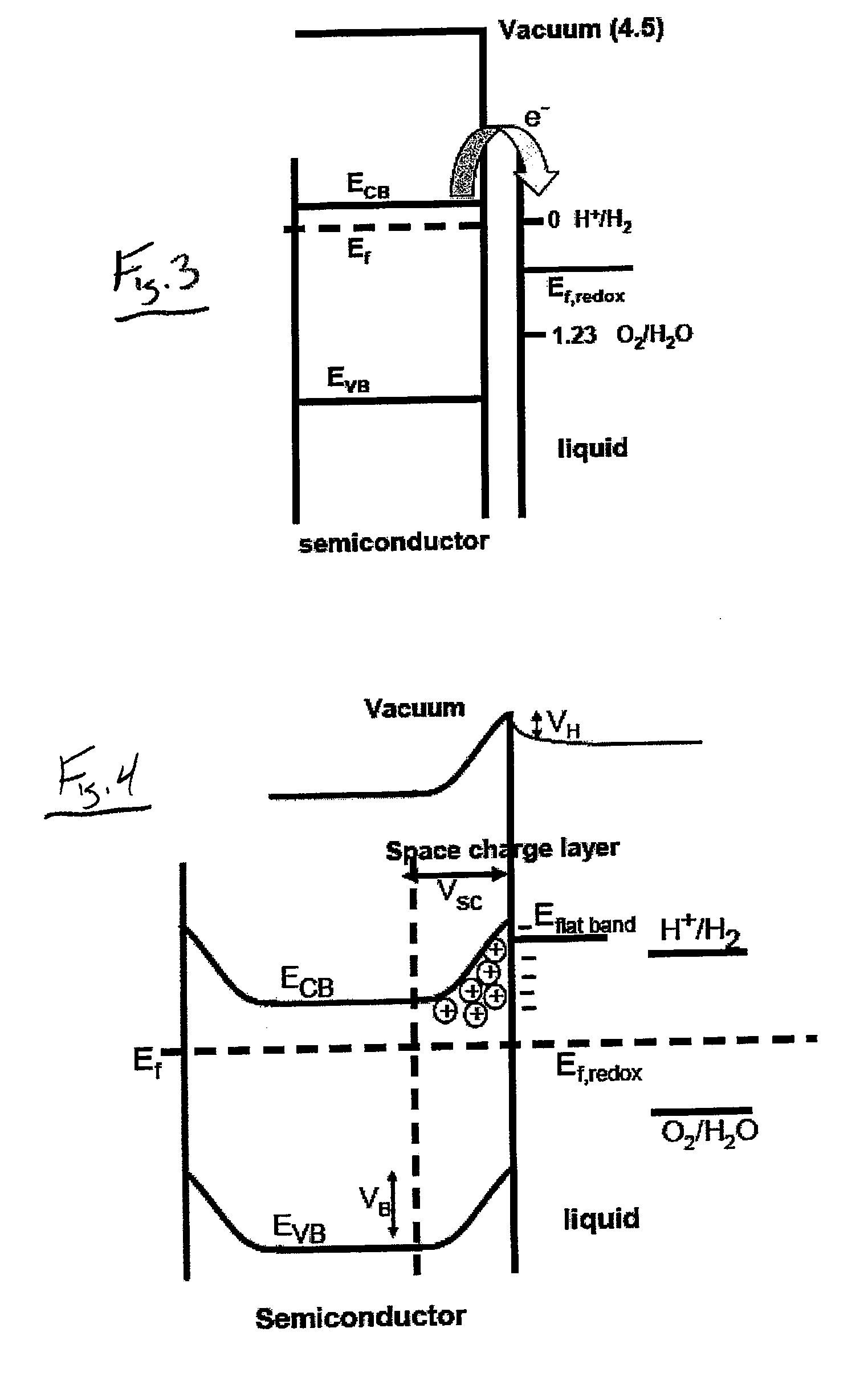

Photocatalyst Having Improved Quantum Efficiency and Method for Use in Photocatalytic and Photosynthetic

InactiveUS20080223713A1Easy to separateImprove quantum efficiencyHydrogenGas treatmentPhotocatalytic reactionNanostructure

The present invention involves increasing the quantum efficiency in titania photocatalysts for photocatalytic (oxidation of acetaldehyde) and photosynthetic (photosplitting of water) reactions by integrating the titania photocatalyst with a polar mineral having surface electrical fields due to pyroelectric and piezoelectric effects, and by adjusting the nanostructure of the photocatalyst materials. The photocatalytic reactivity of titania powder is increased due to the effect of electric field present on the surface of polar mineral material on the photocatalytic effect of commercial titania with respect to photolysis of water. Additionally, the photocatalytic performance of pure phase rutile and anatase nanostructures with well defined morphologies was found to improved with respect to certain photocatalytic reactions in comparison with non-structured titania.

Owner:XU HUIFANG +2

Heavy-duty anticorrosive coating for flue gas desulphurization equipment and preparation technology thereof

InactiveCN102690586AStrong adhesionImprove water resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyPlasticizer

The invention discloses a heavy-duty anticorrosive coating for flue gas desulphurization equipment and a preparation technology thereof. The heavy-duty anticorrosive coating comprises components of a novolac epoxy vinyl ester resin, a plasticizer, a diluent, a curing agent, a promoter, glass flakes, rutile titanium dioxide, nano-silica, alumina powder, silicon carbide, talcum powder and auxiliary agents. The preparation technology comprises that the components are dispersed by a high-speed dispersion kettle and then are mixed into the heavy-duty anticorrosive coating. The heavy-duty anticorrosive coating is convenient for construction, can be cured at a normal temperature, has good mechanical properties and excellent anti-permeability performances, is stable in an acid medium for a long time and has good protection effects on a matrix material.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com