Patents

Literature

3086 results about "Sepiolite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sepiolite, also known as meerschaum (/ˈmɪərʃɔːm/ MEER-shawm, /-ʃəm/ -shəm; German: [ˈmeːɐ̯ʃaʊm] ; meaning "foam of the sea"), is a soft white clay mineral, often used to make tobacco pipes (known as meerschaum pipes). A complex magnesium silicate, a typical chemical formula for which is Mg₄Si₆O₁₅(OH)₂·6H₂O, it can be present in fibrous, fine-particulate, and solid forms.

an air purifier

InactiveCN103861421BLarger than surface and uniformGood adsorption and decomposition effectOther chemical processesDispersed particle separationActivated carbonHazardous substance

Owner:QINGDAO CHUANSHAN NEW MATERIALS

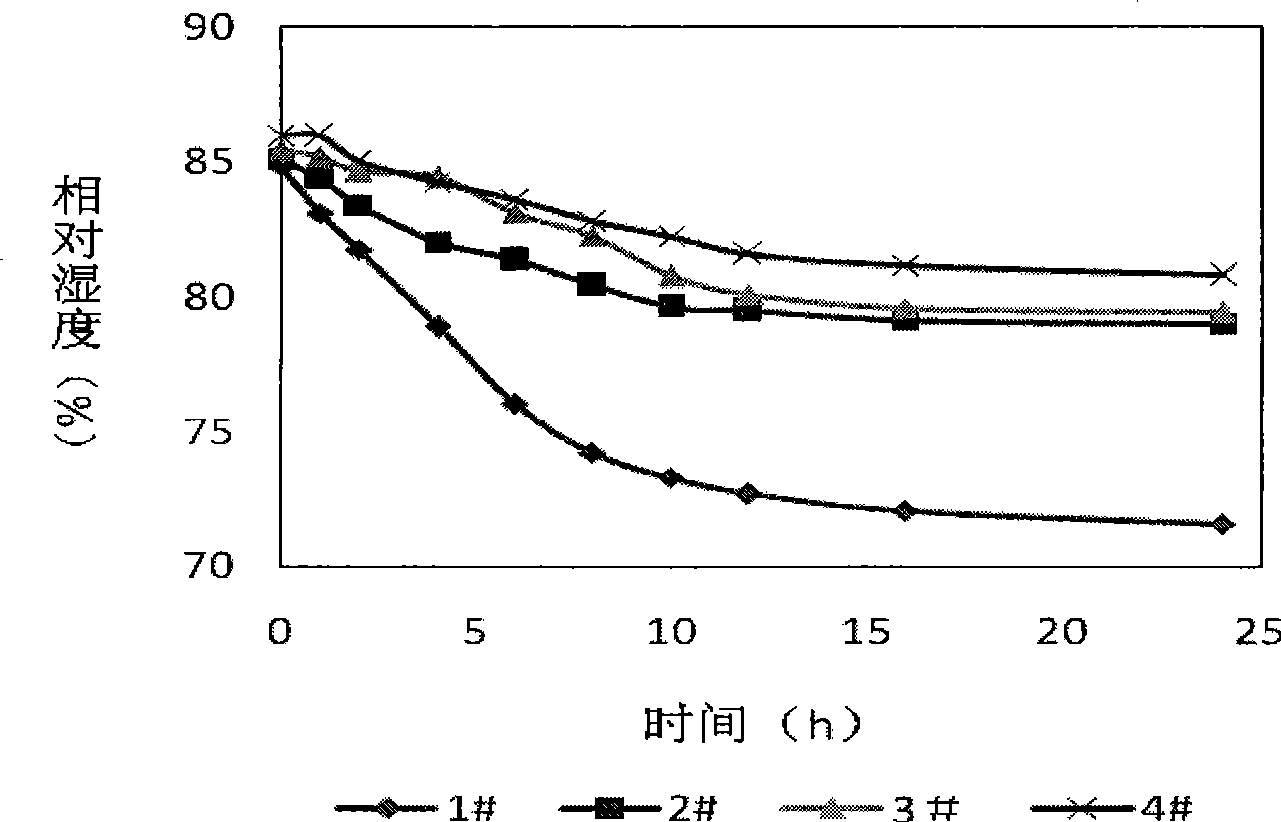

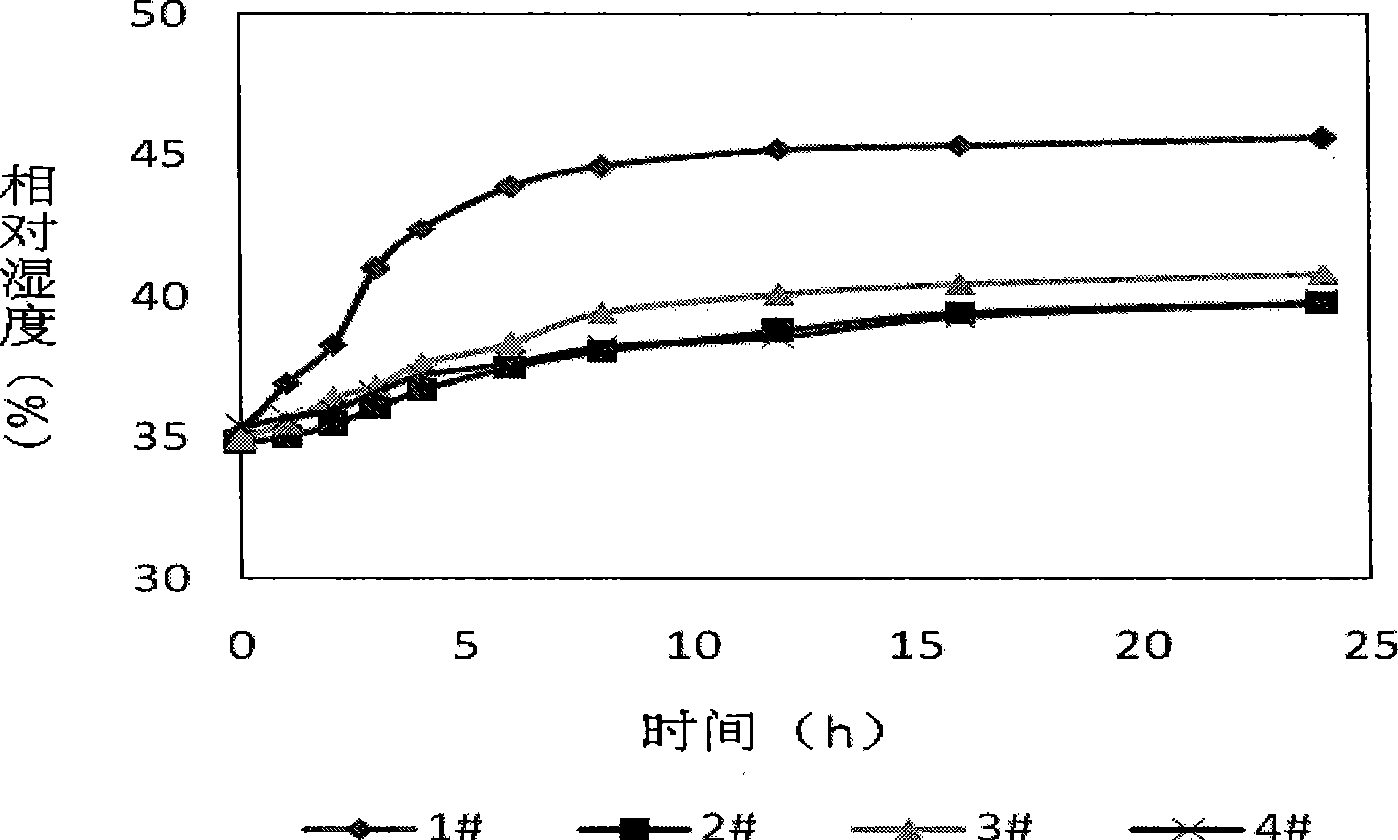

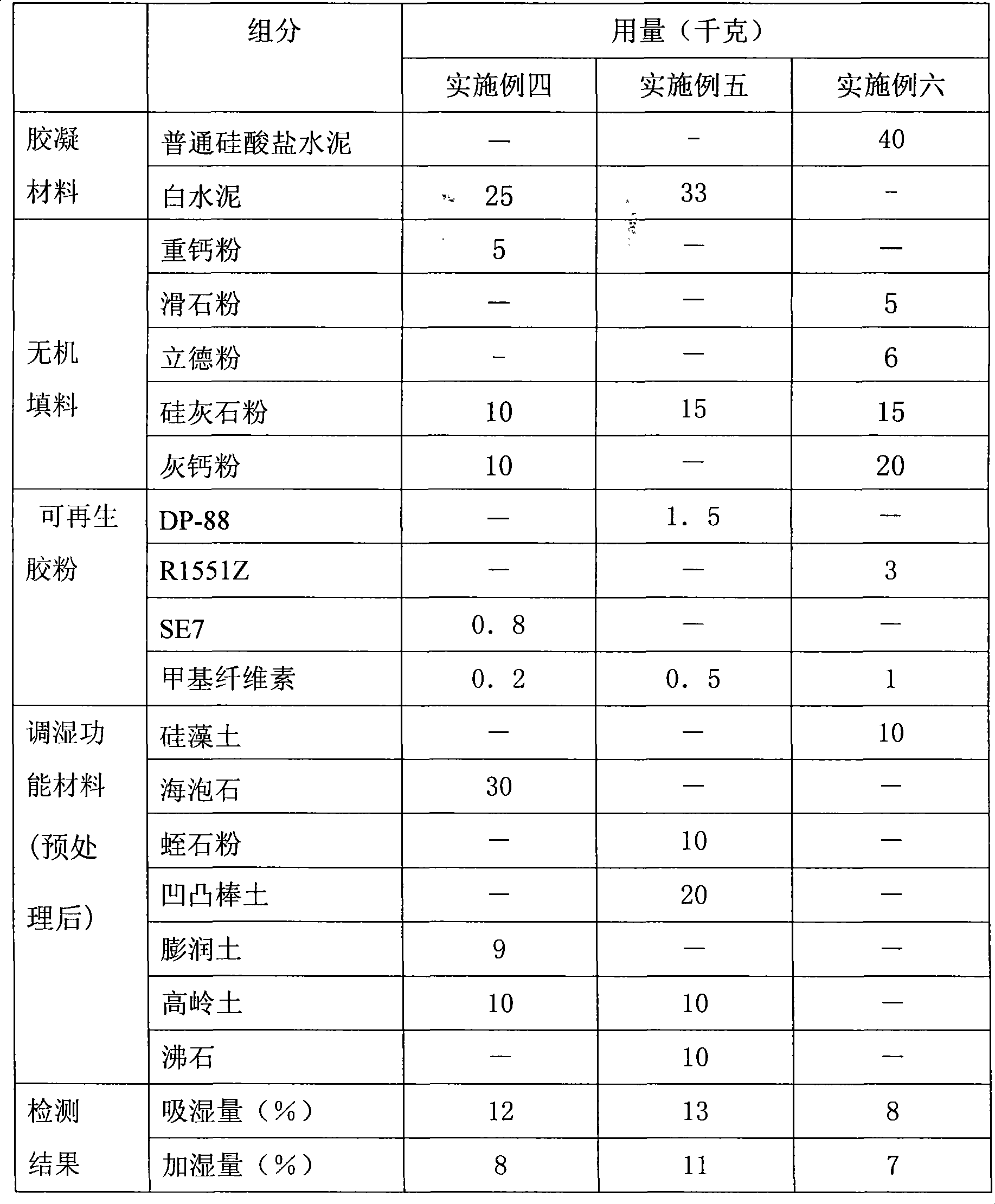

Inorganic putty powder with function of governing humidness

ActiveCN101368014AEffective regulation of relative humidityGood environmental protectionFilling pastesCement coatingsSodium BentoniteMetallurgy

The invention relates to interior wall putty powder with air humidity regulating function, which belongs to the field of building materials. The putty powder is composed of 10 to 50 weight portions of humidity regulating material, 15 to 50 weight portions of inorganic binding material, 15 to 50 weight portions of inorganic filler, and 1 to 5 weight portions of sub divisible rubber powder; the humidity regulating material comprises one type or more than one type of diatomite, sepiolite, attapulgite, vermiculite, zeolite powder, kaolin and bentonite. Because of the environment protection and humidity regulating functions, the multi-pore inorganic mineral material is taken as humidity regulating material and applied in the building interior wall putty powder. With water added in, the putty powder is mixed into lacquer putty and applied on the wall surface, which can effectively regulate the indoor air humidity, so that the indoor air humidity is controlled within the scope which is beneficial to the health of human body; meanwhile, the putty powder has no pollution, no VOC released and can be directly used for decoration.

Owner:CHINA BUILDING MATERIALS ACAD

Heat insulation wall integral pouring material and construction method

InactiveCN101376582AImprove insulation effectEarly benefitsSolid waste managementFiberCrack resistance

The invention discloses an insulation wall body integral-casting material and a construction method thereof. The insulation wall body integral-casting material is characterized in that the ratio of a binder, an insulation aggregate and an additive is 1000:(5-5000):(0-300); the binder is a cement-based binder or a gypsum-based binder; the constitutes of the cement-based binder are 300-1000 parts of cement, 0-200 parts of silica fume, 0-400 parts of fly ash, 0-700 parts of slag powder, 0-300 parts of zeolite powder, 0-200 parts of ash-calcium powder and 0-40 parts of gypsum; the constituent of the gypsum-based binder is 1000 parts of gypsum; and the constituents of the insulation aggregate are 0-100 parts of expanded polystyrene granules, 0-1500 parts of expanded perlite, 0-1500 parts of expanded vermiculite, 0-1500 parts of expanded vitrified microspheres, 0-5000 parts of expanded ceramisite and 0-200 parts of sepiolite fibers. The invention also comprises the construction method. The wall bodies casted by the insulation wall body material have good insulating and thermal performances, higher strength, and good water resistance, crack resistance and permeability resistance performances, as well as good compatibility and good security towards the subsequent decorating process.

Owner:湖南江盛新型建筑材料有限公司

Heat preservation and energy saving type lightweight, gas filled wall bricks, and preparation method

This invention relates to a method for preparing heat-insulating and energy-saving lightweight aerated wall bricks, which are prepared from aggregate, gelation agent, aeration agent, heat-insulating material and water. The aggregate is composed of slag or river sand, glass microbeads, floating beads, closed perlite, and expanded perlite. The gelation agent is composed of cement, gypsum and lime. The aeration agent is Al powder. The fiber heat-insulating material is composed of high-Al powder, tripolite, ceramic fibers, mineral wool, sepiolite, expanded vermiculite, glass cotton and palygorskite. The wall bricks have such advantages as high compressive strength, low heat conductivity, high heat-insulating performance, high fireproof and damp-proof performances, rapid and convenient construction, and no need for composite heat-insulating layer.

Owner:徐振飞

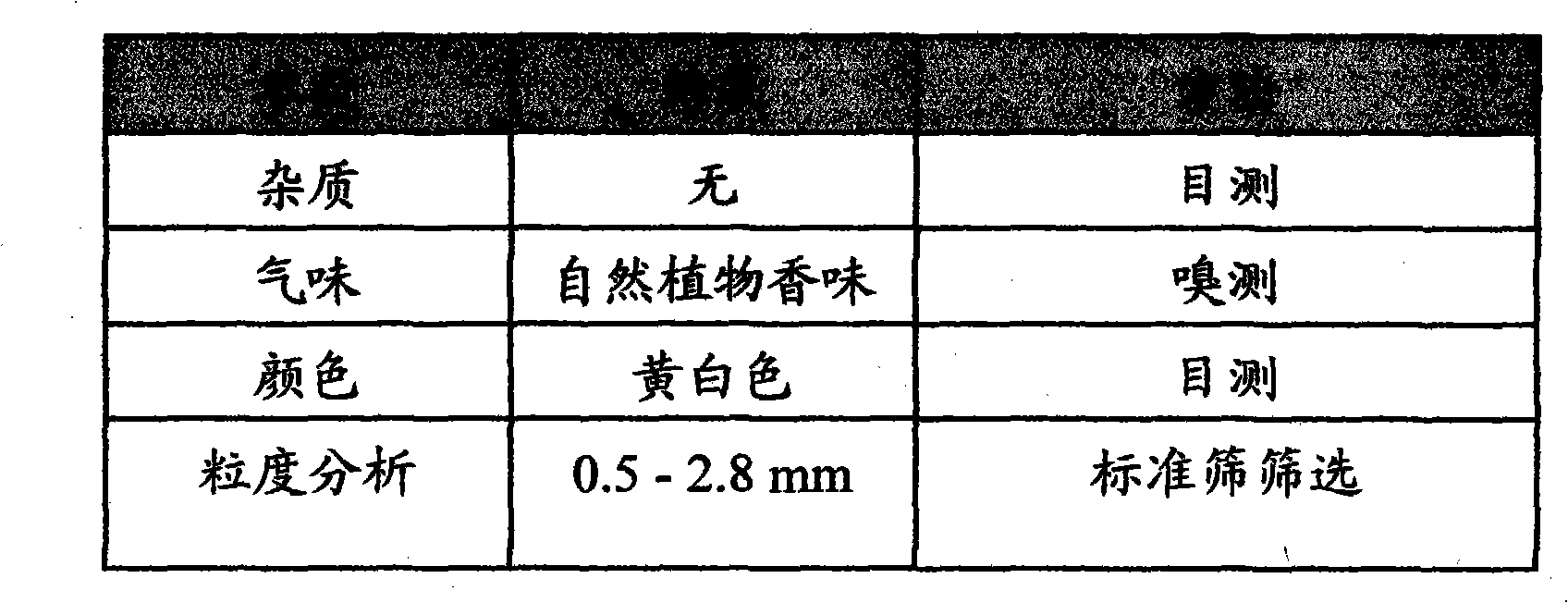

Cat litter and making method thereof

InactiveCN102150627AEnhanced adsorption and deodorization abilityImprove deodorization abilityAnimal housingSodium BentoniteSilica gel

The invention discloses cat litter comprising a composition prepared from the following components in percent by weight: 50-80% of inorganic clay, 5-15% of silica gel, 5-20% of organic substrate and 8-20% of mineral matter, wherein the inorganic clay is selected from one or a mixture of attapulgite, bentonite, kaolinite and sepiolite; the organic substrate is selected from one or a mixture of corncob, corn, wheat, clover, peanut hull, walnut shell, pine wood shavings and broadleaved tree wood shavings; and the mineral matter is selected from one or a mixture of perlite, diatomite, pumice and other low-density mineral matters. The cat litter disclosed by the invention has the following advantages of largely strengthened adsorption deodorization capacity due to the addition of the silica gel component, stronger deodorization capacity by utilizing the adsorbability of natural materials, natural fragrance, small weight and strong caking capability, in particular no dust and easiness for treatment; and the cat litter disclosed by the invention is 40% lighter than the traditional bentonite cat litter.

Owner:QINGDAO FRANK FINE CHEM

Aerogel heat insulation composite material and preparation method thereof

The invention relates to an aerogel heat insulation composite material and a preparation method thereof, which belong to the technical field of aerogel heat insulation composite materials. The aerogel heat insulation composite material comprises silicon dioxide aerogel, an infrared sunscreen titanium dioxide and a fortifying fiber which does not react with sols. The aerogel heat insulation composite material is characterized by further comprising the following raw materials which do not react with the sols: the silicon dioxide aerogel, the infrared sunscreen titanium dioxide, the fortifying fiber, and a packing material in a ratio of 1:0.1-0.5:0.5-3:0.5-2, wherein the packing material is one or a mixture of any two of kaolin, attapulgite, sepiolite, wollastonite, diatomite and silicon micro-powder. The aerogel heat insulation composite material has good heat insulation performance and high mechanical strength, and the serviceability temperature thereof can reach 1,000 DEG C.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

255 DEG C superhigh temperature resistant water-based drilling fluid and construction process thereof

ActiveCN103160259AHas ultra-high temperature stabilityGood plugging and anti-collapse performanceFlushingDrilling compositionWater basedSodium Bentonite

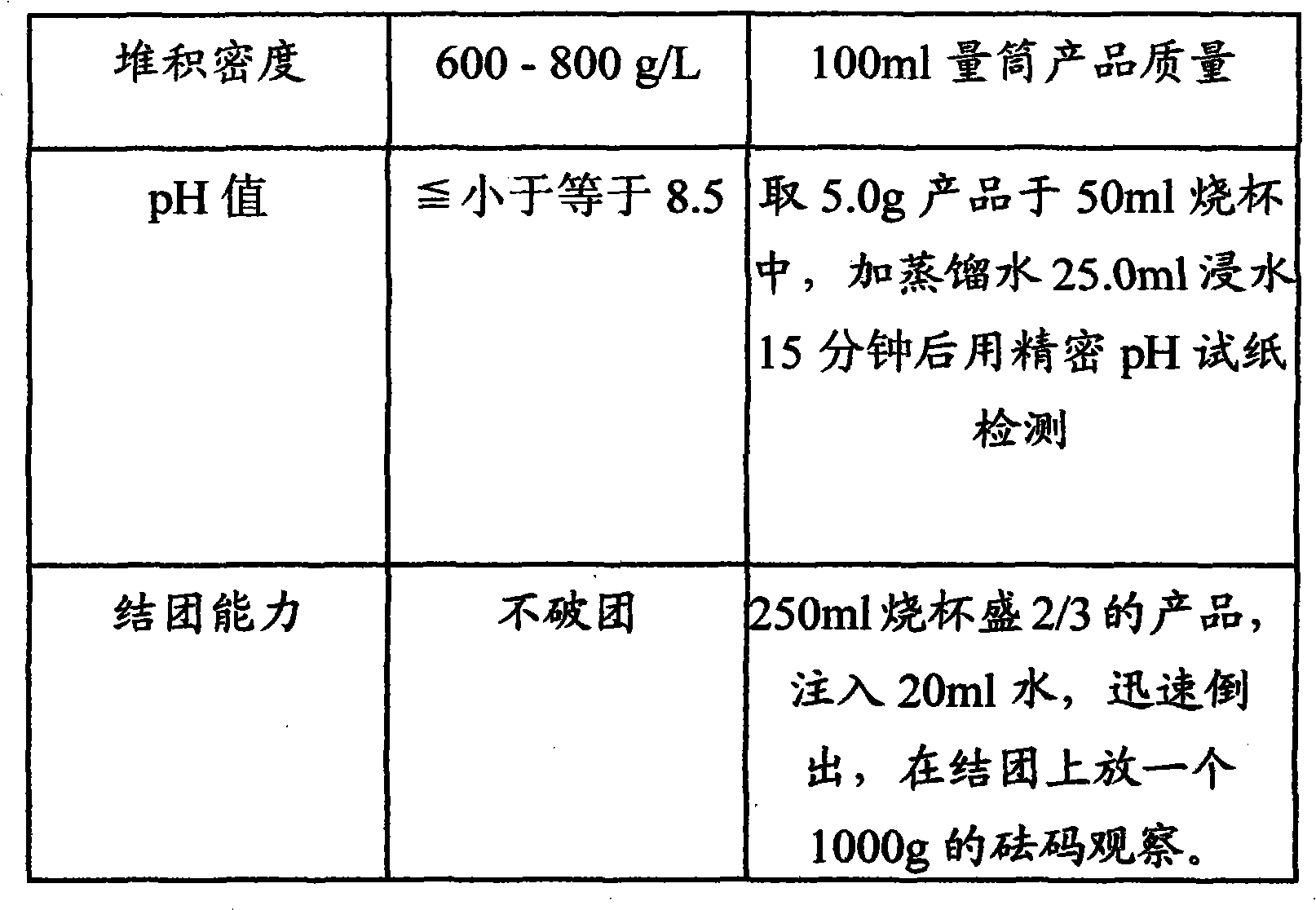

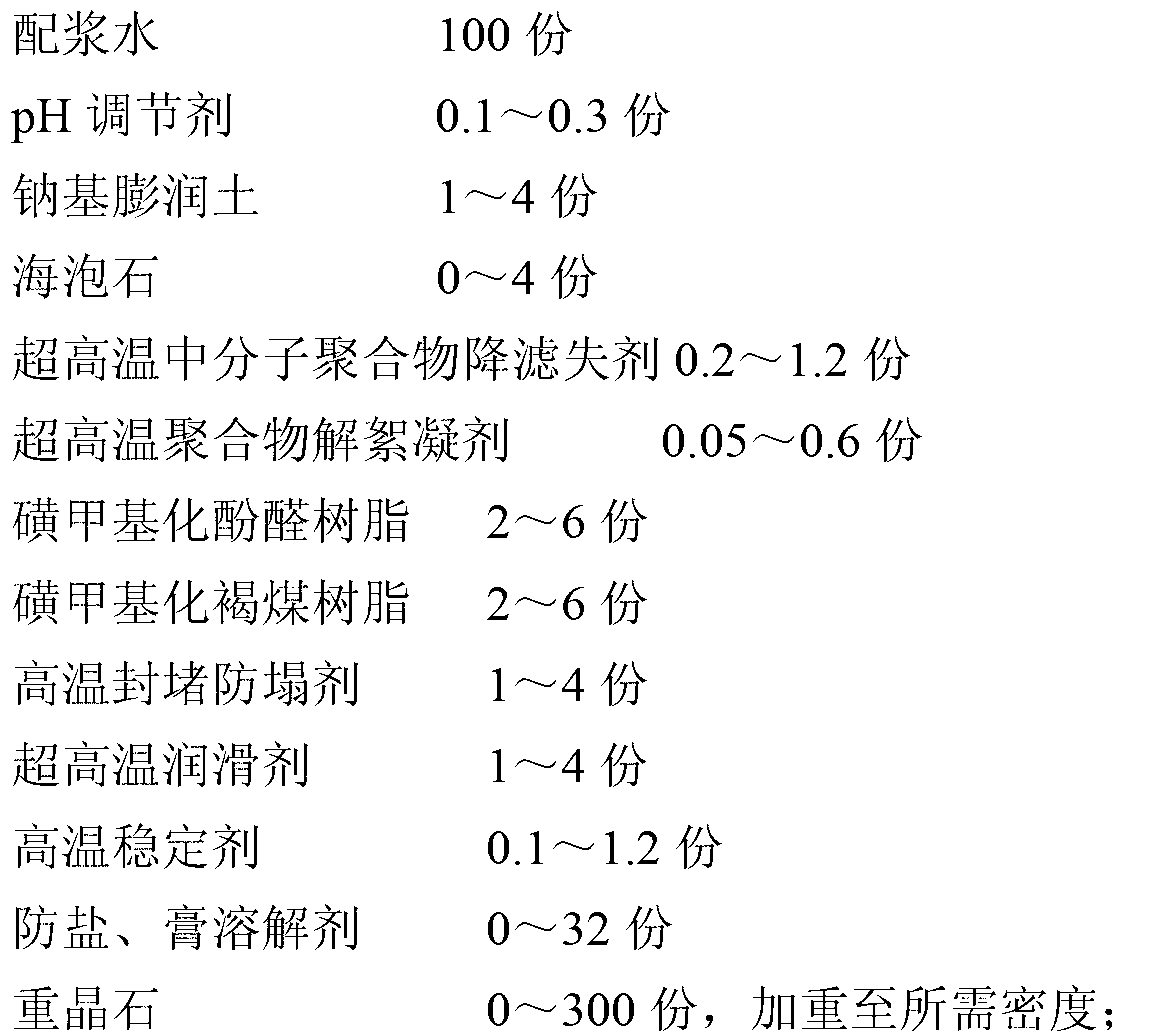

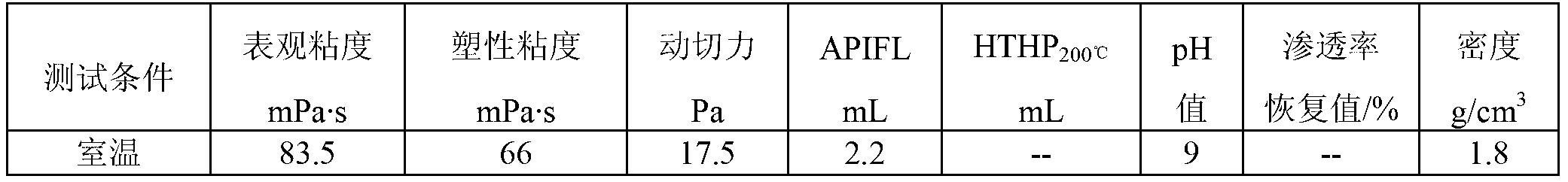

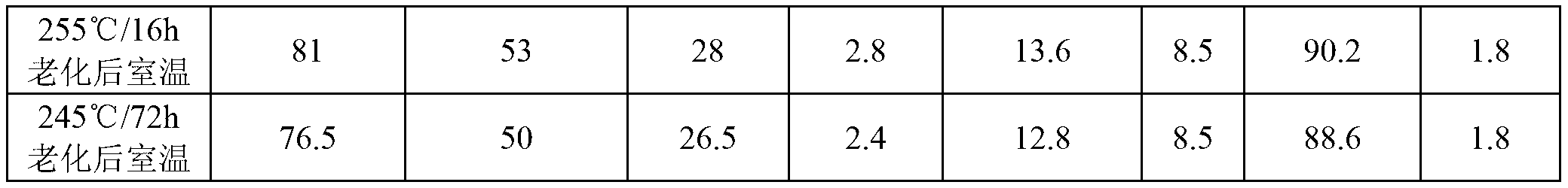

The invention relates to a 255 DEG C superhigh temperature resistant water-based drilling fluid and a construction process thereof. The drilling fluid comprises the following raw material in parts by weight: 100 parts of blending water, 0.1-0.3 part of a pH regulator, 1-4 parts of sodium bentonite, 0-4 parts of sepiolite, 0.2-1.2 parts of a superhigh-temperature middle-molecule polymer filtrate reducer, 0.05-0.6 part of superhigh-temperature polymer deflucculating agent, 2-6 parts of sulfomethylated phenolic resin, 2-6 parts of sulfomethylated walchowite, 1-4 parts of high-temperature plugging anti-collapse agent, 1-4 parts of a superhigh-temperature lubricant, 0.1-1.2 parts of a high-temperature stabilizer, 0-32 parts of an anti-salt / cream dissolving agent,and barites added to a required density. The invention also provides a construction process of the drilling fluid in the process of application. The 255 DEG C superhigh temperature resistant water-based drilling fluid disclosed by the invention is applied to deep well and ultra deep well drilling, and the applicable temperature is 245-255 DEG C. The drilling fluid is strong in stability under superhigh temperature conditions, good in rheological property and easy to control.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

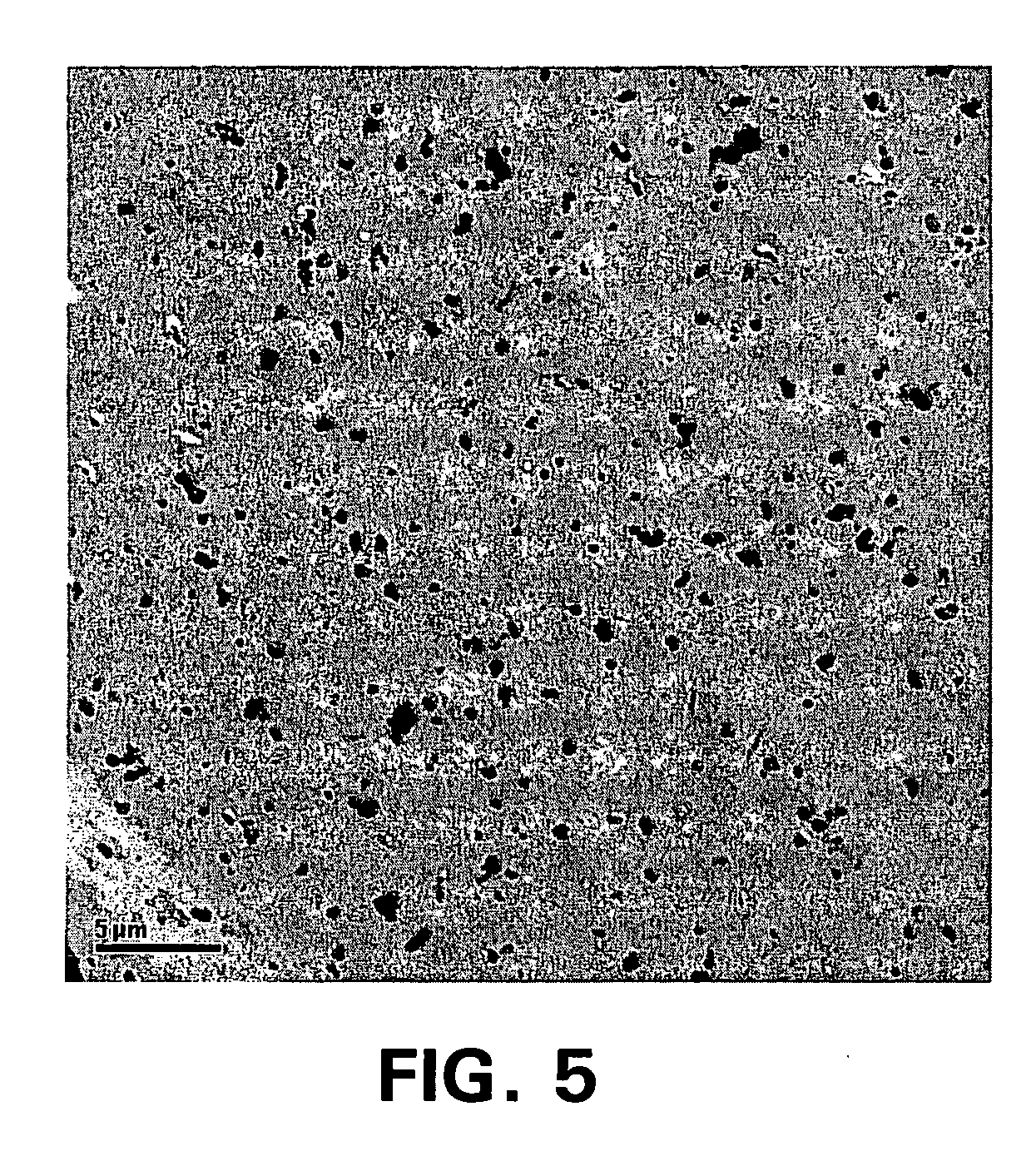

Process for the production of polyester nanocomposites

InactiveUS20080315453A1Increase polyester molecular weightHigh molecular weightMaterial nanotechnologyRotary stirring mixersCompound aMasterbatch

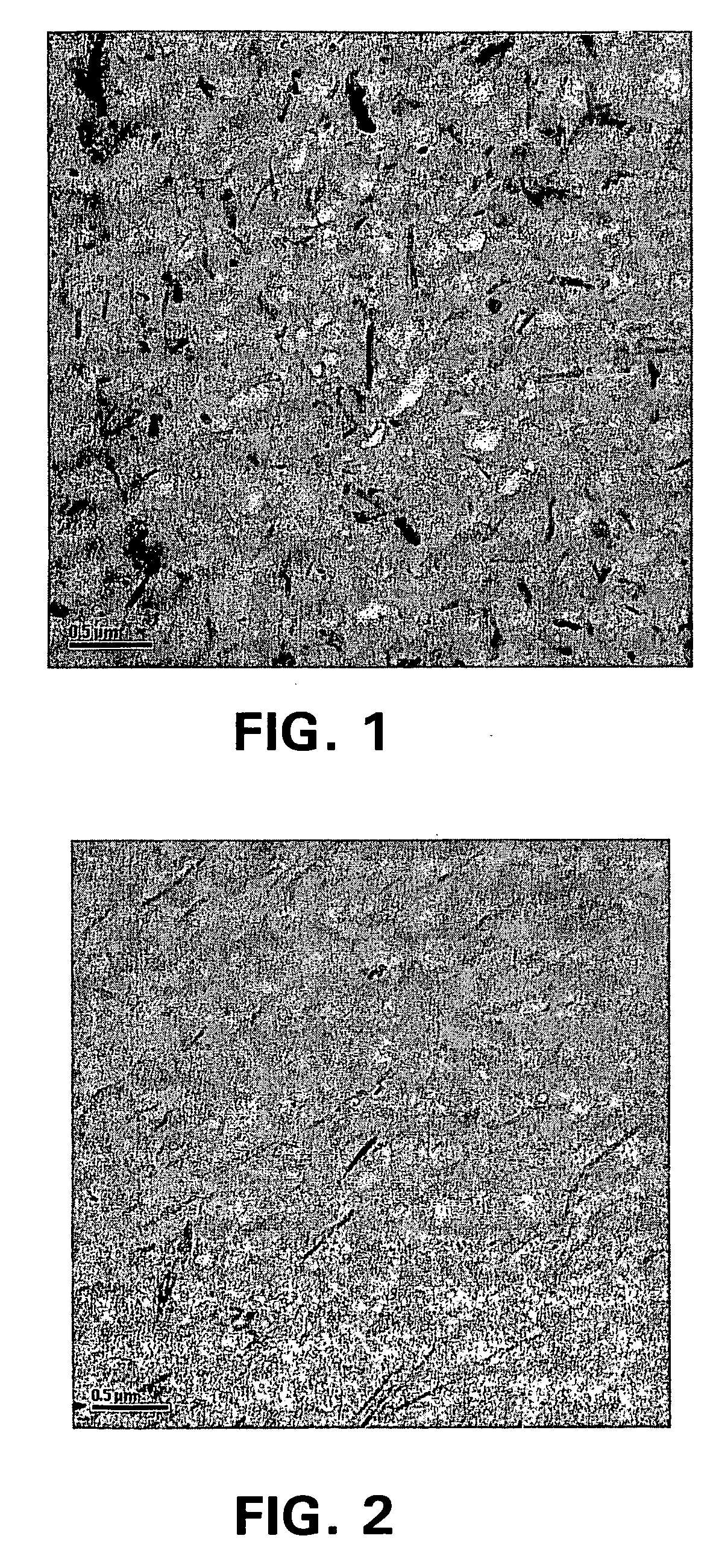

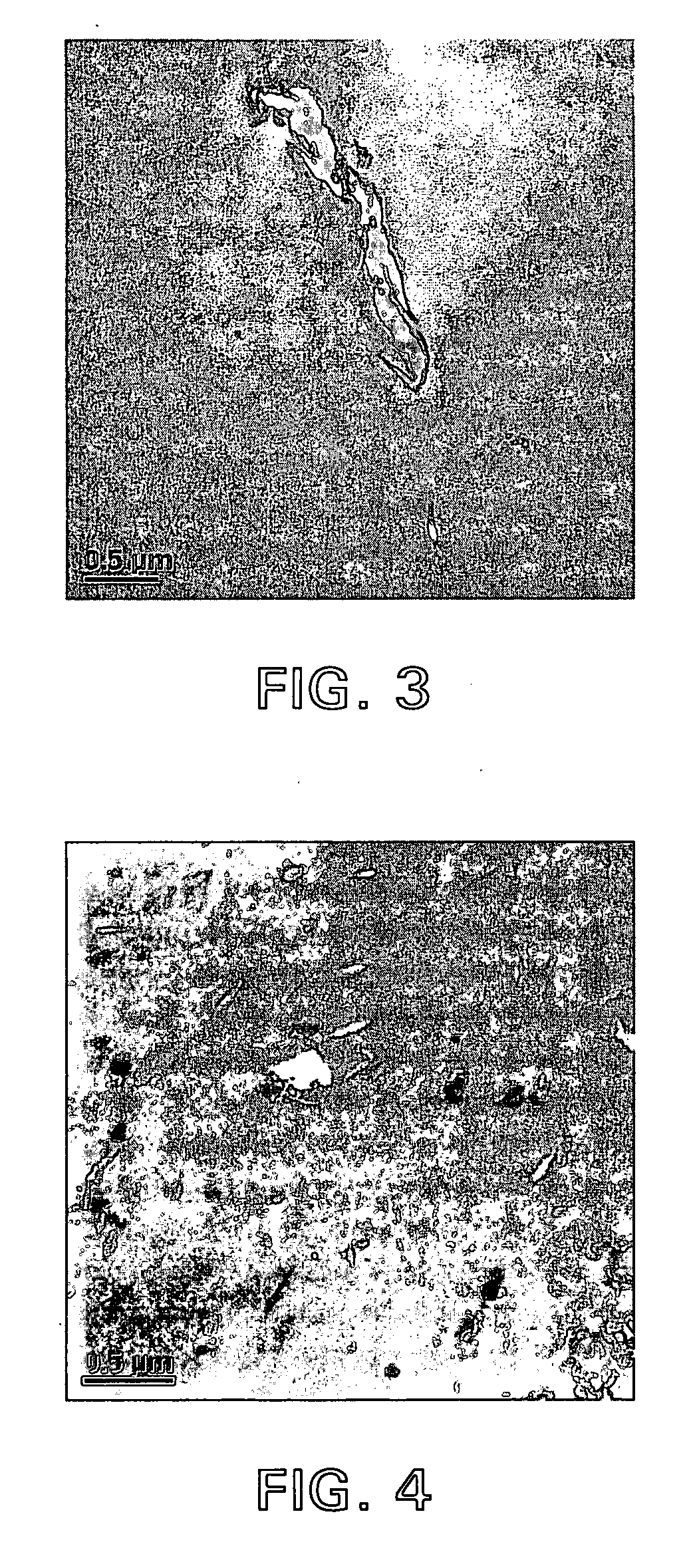

A method for dispersing sepiolite-type clay particles in a polyester matrix by melt-compounding a mixture of: sepiolite-type clay, at least one linear polyester oligomer, and at least one polyester polymer to produce a nanocomposite composition; and, optionally, subjecting said nanocomposite composition to solid state polymerization to increase polyester molecular weight. Further described is a method for preparing a polyester nanocomposite composition from a masterbatch, comprising melt-compounding a mixture of: sepiolite-type clay, at least one polyester oligomer, and at least one polyester polymer to produce a nanocomposite composition containing a greater concentration of sepiolite-type clay than is desired in the final resin composition; optionally, subjecting said nanocomposite composition to solid state polymerization to increase the polyester molecular weight; and further melt compounding said nanocomposite composition with polyester polymer and, optionally, additional ingredients.

Owner:EI DU PONT DE NEMOURS & CO

Dry-type heat-insulating waterproof coating

InactiveCN101648794AGood heat insulation and waterproof effectImprove waterproof performancePliabilityTalc

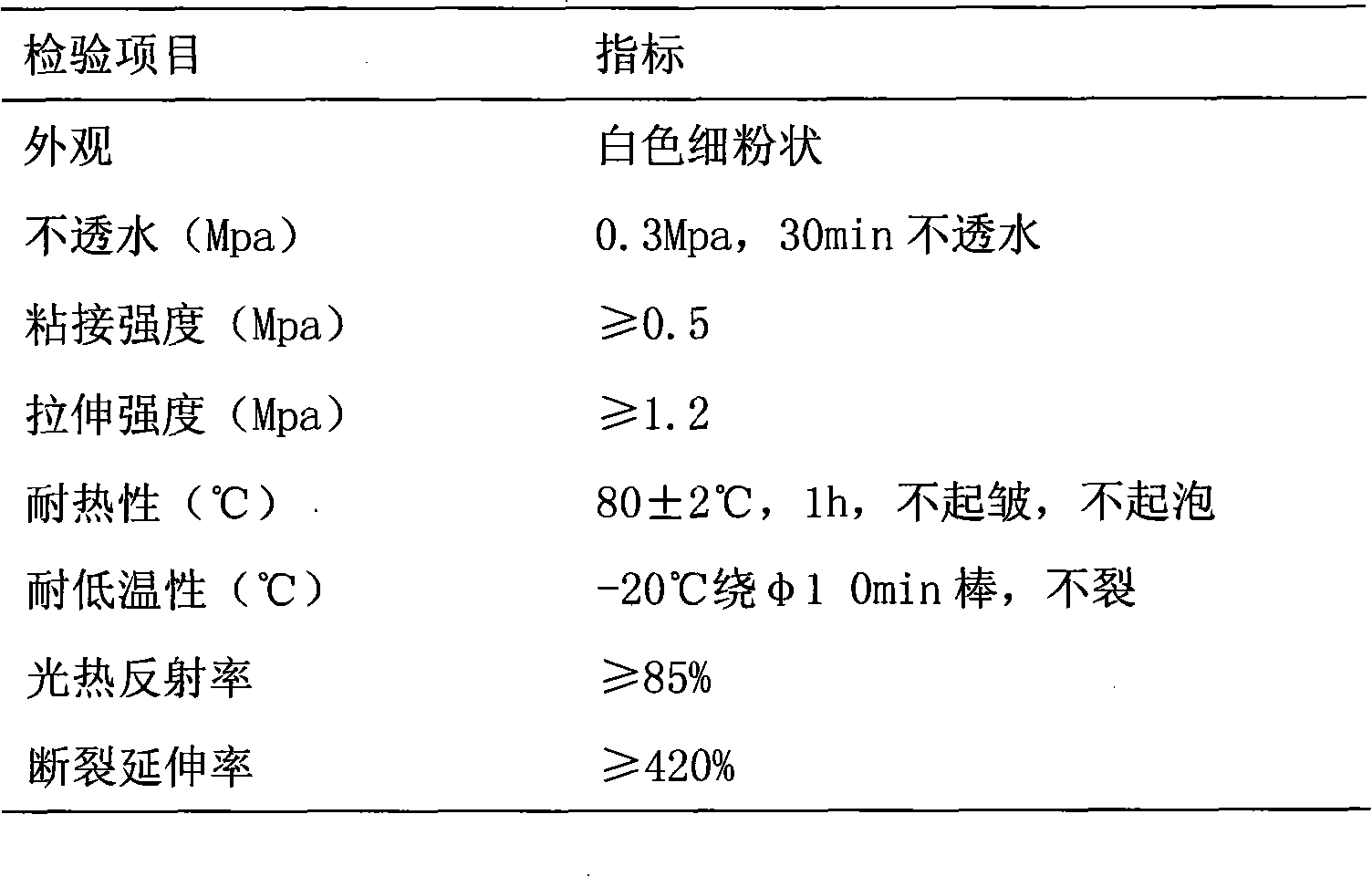

The invention relates to a dry-type heat-insulating waterproof coating which comprises the following raw materials in percentage by weight: 0-5.5 dispersible polymer powder, 10-20 hollow filling beads, 5-20 sepiolite powder, 5-10 mica powder, 5-30 heavy calcium carbonate powder, 5-15 light calcium carbonate powder, 0.5-1.5 rutile titanium dioxide, 10-20 talc powder and 10-40 white cement. A coat formed by the coating of the invention has favorable heat-insulating waterproof effect (lowers indoor temperature by 4-20 DEG C) and excellent flexibility, impermeability, weathering resistance and bonding strength to a substrate as well as high strength, good brightness, uniform luster, smooth and tender touch feeling, waterproof washing and rubbing, and the like. The dry-type coating has the advantages of simple production process, convenient transportation, long storage time, convenient construction, and the like, no toxicity or pollution, environment-friendly trend suitability, low cost, low VOC and high performance, thereby becoming a new-generation building coating product.

Owner:吕海涛

Integral honeycombed catalyst for SCR flue-gas denitration and preparation method therefor

ActiveCN101444727AImprove catalytic performanceIncrease contact areaDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSodium BentoniteFlue gas

The invention relates to an integral honeycombed catalyst for SCR flue-gas denitration and a preparation method therefor. Titanium dioxide, bentonite and meerschaum are taken as carries, soaked for loading active components, formed, dried and baked to prepare the integral honeycombed catalyst. The carries comprise titanium dioxide 60-90%, bentonite 0-20% and meerschaum 0-10% by weight; the active components comprise WO3 5.0-10.0% OR MoO3 5.0-9.0%, V2O5 0.3-5.0%, and CeO2 0.0-2.0% or Nb2O5 0.0-1.0% by weight; and the total of the components is 100%. The catalytic activity is high, the denitration efficiency is high, and the service life is long; titanium dioxide, bentonite and meerschaum are taken as the carries, soaked for loading the active components, formed, dried and baked to prepare the integral honeycombed catalyst; and the preparation method is scientific, reasonable, simple and feasible.

Owner:ZHONGCAI HIGH NEW MATERIAL +1

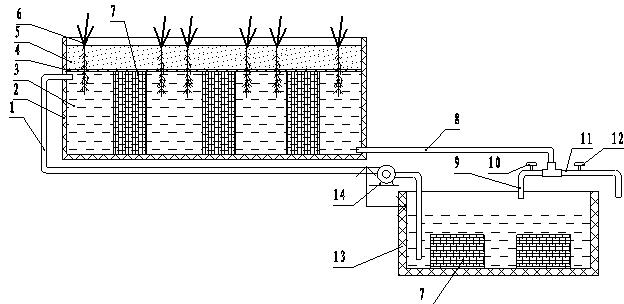

Small soilless culture method and device

ActiveCN102119651AIncrease the concentration of inputFewer deliveriesAgriculture gas emission reductionCultivating equipmentsSlagPeat

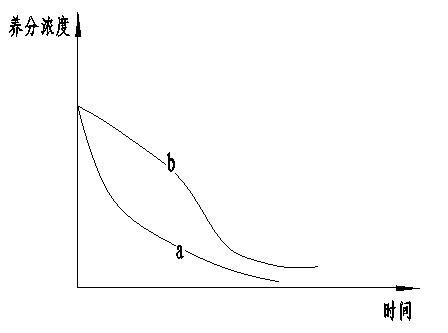

The invention relates to a small soilless culture method and device. A nutrient solution is contained in a culture disk or a nutrient solution storage pool; crops are planted into the nutrient solution; a soil copy material is added into the nutrient solution; the soil copy material comprises the following raw materials in parts by weight: 20-90 parts of organic matter and 2-80 parts of nonmetal mineral substance, wherein the organic matter is one or mixture of peat, fermented straw, fermented bagasse and fermented livestock and poultry manure; the nonmetal mineral substance is one or mixtureof coal ash, steel slag, zeolite, bentonite, opal, attapulgite mineral soil, pearlite, vermiculite, rectorite clay, sepiolite clay and kieselguhr; and the proportion of the nutrient solution to the soil copy material is (5-2):1. By adding the soil copy material into the nutrient solution, the nutrient charge concentration can be improved, the nutrient charge frequency is reduced, and the labor cost is reduced; meanwhile, when the concentration is reduced due to the absorption of the nutrients, the concentration reduction range is slower, and a deficiency symptom caused by lacking nutrients ofplants is lightened; in addition, trace elements needed by plants can be also supplemented.

Owner:杜友萍

Non-glue diatom ooze building material

The invention discloses non-glue diatom ooze building material, which is used for wall decoration, surface dressing of boards and intermediate sandwich of the boards, and comprises the following components in parts by weight: 4-90 parts of kieselguhr below 10000 mesh, 20-60 parts of bentonite below 2000 mesh, 10-40 parts of kaolin below 2000 mesh, 5-30 parts of activated clay below 2000 mesh, 10-60 parts of quartz sand below 200 mesh, 5-40 parts of sepiolite below 800 mesh, 5-40 parts of calcium carbonate below 800 mesh, 5-30 parts of medical stone powder below 800 mesh, 2-20 parts of nanosized titania powder below 20000 mesh, 0.1-3 parts of fiber with the length being 5mm or below, 4.5-40 parts of attapulgite below 800 mesh, 2-20 parts of hydroxypropyl methyl cellulose, and 1-20 parts ofpigment. According to the non-glue diatom ooze building material, the kieselguhr and other porous natural materials with adsorption capacity are selected to manufacture interior building materials, the proportion is reasonable, chemical adhesive agents are not needed, and adhesive forming is realized through characteristics of the natural materials, so that porous structures of the natural materials can be maintained, indoor pollution can be eliminated, indoor humidity can be adjusted, odor can be removed, noise can be isolated, and flame retardant is realized.

Owner:青岛泉佳美硅藻泥科技有限公司

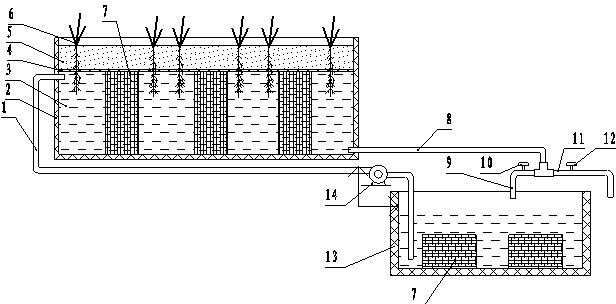

Composite material thermal insulation plate

InactiveCN1511808ANo pollution in the processStrong self-breathing functionThermal insulationSolid waste managementAdhesiveHeat conducting

The thermal insulating plate of composite material is produced with waste foamed phenolic plastic powder as basic heat insulating material, flyash as stuffing, expanded perlite as aggregate, mineral wool, glass wool, sepiolite and palygorskite as reinforcing material, neutral water glass or silica sol as inorganic adhesive and guar gum, methylcellulose or CMC as organic adhesive, and through high speed dispersion, stirring, mixing, molding, forming and drying. The thermal insulating plate has low heat conducting coefficient, is non-inflammable, smell-less, non-toxic, long in service life and wide in application range. The production process adopts industrial waste as main components and produces no waste, and used plate may be reused, so that the present invention is significant in environment protection.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

Compound feed for piglets

The invention discloses a compound feed for piglets, which consists of the following components in part by weight: 20 to 30 parts of corn, 20 to 30 parts of soybean meal, 5 to 10 parts of sesame meal, 5 to 10 parts of fermented soybean meal, 10 to 20 parts of wheat bran, 10 to 20 parts of rice bran, 10 to 15 parts of DDGS, 5 to 10 parts of sepiolite powder, 1 to 2 parts of soybean oil and 1 to 2 parts of traditional Chinese medicine preparation, wherein the traditional Chinese medicine preparation consists of the following components: 3 to 7 parts of oyster, 3 to 7 parts of radish seed, 3 to 7 parts of the stem of noble dendrobium, 3 to 7 parts of fragrant solomonseal rhizome, 3 to 7 parts of codonopsis pilosula, 3 to 7 parts of Indian buead, 3 to 7 parts of lily, 3 to 7 parts of Chinese angelica, 3 to 7 parts of white paeony root, 3 to 7 parts of officinal magnolia bark, 3 to 7 parts of bitter orange, 3 to 7 parts of cuttlebone and 3 to 7 parts of cablin potchouli herb. Since the compound feed is added with the traditional Chinese medicines and scientifically prepared, the compound feed has the function of spleen activation and appetite stimulation, and can reduce the diarrhoea of piglets, enhance disease-resisting capability and increase the growing speed of piglets.

Owner:许雪姣

Multiple-aperture carbon granule air purification agent and preparation method thereof

ActiveCN101947433AReasonable designImprove adsorption capacityGas treatmentOther chemical processesSorbentFar infrared

The invention relates to a multiple-aperture carbon granule air purification agent and a preparation method thereof, belonging to the technical field of air purification agents. The multiple-aperture carbon granule air purification agent is prepared from carbon powder, attapulgite, sepiolite, zeolite, cationic surfactant, pore-forming material and bamboo vinegar. The multiple-aperture carbon granule air purification agent has reasonable design. After the carbon powder (containing plant charcoal and active carbon), and nanometer mineral matters of attapulgite, sepiolite, zeolite, and the like are treated, the adsorptive capacity of the original plant charcoal is improved by more than 5 times, the adsorptive capacity of the active carbon is improved by more than twice, and the added cationic surfactant and bamboo vinegar increase the effects of sterilization and bacteriostasis. Compared with other adsorbents in the prior art, the air purification agent still has higher adsorption capacity even in higher temperature and lower adsorbate partial pressure, and remains the functions of releasing negative ions and far infrareds of the plant charcoal at the same time, and the prepared granule has rigid characters without dust and does not pollute contactants and a human body.

Owner:ZHEJIANG JIANZHONG BAMBOO IND

Adsorbing material for effectively adsorbing formaldehyde and other harmful substances in air

The invention relates to an adsorbing material for effectively adsorbing formaldehyde and other harmful substances in the air, belonging to the field of the adsorbing material for improving the air quality. The adsorbing material has the technical scheme that the material is characterized by comprising the raw materials based on the parts by weight: 10-20 parts of zeolite, 20-30 parts of sepiolite, 15-25 parts of diatomite, 10-15 parts of bentonite, 15-25% of active carbon and 6-12 parts of silicasol, wherein the silicasol is nanoscale silicon dioxide colloid water solution. The technical scheme also comprises the raw materials based on the parts by weight: 10-15 parts of higher molecular weight organic amine polymer with the molecular weight of 1800-50000, 5-10 parts of active carbon fiber and 10-20 parts of non-woven fabrics. The invention selects the substances with very strong adsorbing function and designs a set of formulation according to the different adsorption capacity and selectivity of the substances, so as to lead the substances to be matched with each other for adsorbing common indoor pollution gases such as formaldehyde, benzenes, hydrocarbons, other organic gas molecules larger than oxygen and nitrogen molecules in the air as well as virus bacterium and fine dust, thus purifying the indoor air, preventing decoration disease and improving the health level of residents.

Owner:傅桂云 +1

In situ restoring agent for heavy metal polluted soil

ActiveCN1631561AGuarantee continuous developmentSimple handling of equipmentContaminated soil reclamationMicroorganismCoal

The invention concerns the repairing dose to repair the soil polluted by heavy metal, which belongs to the technique field of repairing soil polluted by heavy metal. The repairing dose mainly includes: Na unit soil, haibao stone, stick stone, coal powder and microorganism germ root. Every composition' rate by weight is: Na unit soil15--40%, haipao stone 10--50%, stick stone 10--30%, coal powder 5--30%, microorganism germ root 0--40%. The repairing dose in the invention has the advantages of low cost of material, simple working equipment, good effect and no second pollution.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

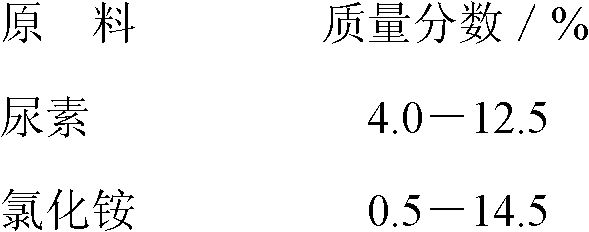

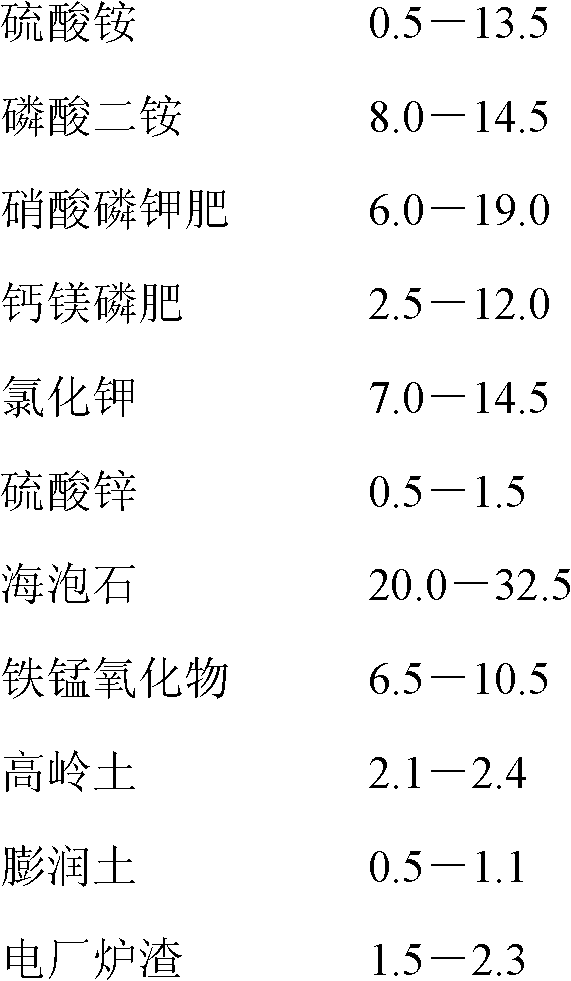

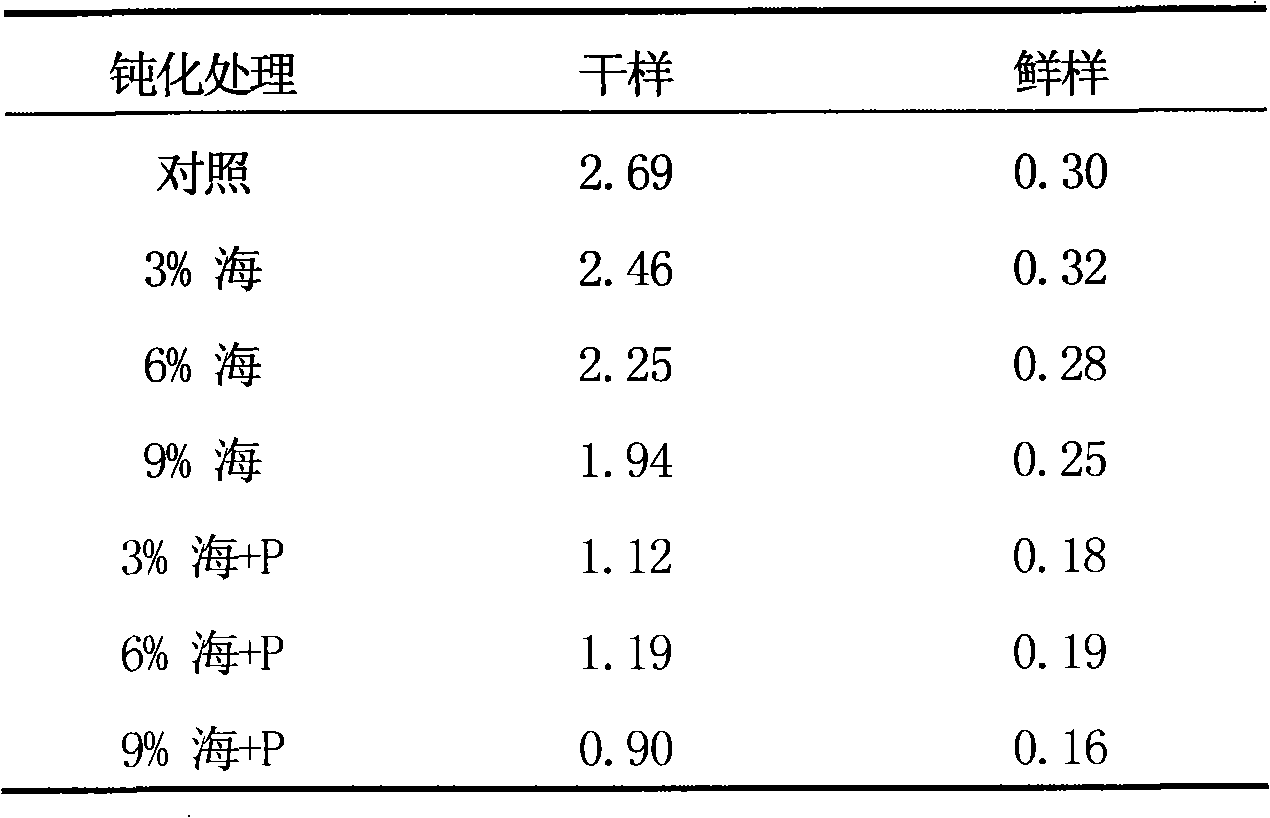

Compound fertilizer capable of reducing cadmium content in rice with overproof cadmium and preparation method thereof

The invention discloses a compound fertilizer capable of reducing cadmium content in rice with overproof cadmium and a preparation method thereof. The fertilizer is prepared from urea, ammonium chloride, ammonium sulfate, diammonium phosphate, nitrophoska, a calcium magnesium phosphate fertilizer, potassium chloride, zinc sulfate, sepiolite, ferrimganic oxide, kaolin, bentonite and power plant slags in a certain proportion. The preparation method comprises the following steps: A, preparing the sepiolite; B, preparing the ferrimganic oxide; C, preparing the kaolin; D, preparing the bentonite; and E, preparing the power plant slags. In addition, scale production is carried out by a compound fertilizer process flow namely extrusion and granulation. The compound fertilizer is characterized in that 38.5-50.5% of passivator such as sepiolite, ferrimganic oxide, calcium magnesium phosphate fertilizer, kaolin, bentonite, power plant slags and the like (wherein the sepiolite accounts for 20-32.5%) are contained; the content of the total nutrition (N+P2O5+K2O) is 25%, the soil activated cadmium in the rice with the overproof cadmium is reduced by 31.9-58.5%, rice cadmium is reduced by 28.7-51.7% (the content is less than 0.2mg / kg); and the compound fertilizer has huge popularization and application value in light-grade cadmium-polluted areas.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

Fresh-keeping packaging material and products thereof

InactiveCN101701082AHigh strengthHigh air permeabilityFlexible coversWrappersDispersitySodium Bentonite

The invention relates to a fresh-keeping packaging material and products thereof, belonging to the technical field of packaging. The invention has the technical scheme that a certain proportion of mineral micropowder of kieselguhr or sepiolite or medical stone or bentonite or tephros or perlite and the like is doped into plastics of PE, PP, PVC and the like and paper pulp, and then the mixture is made into thin films, packaging paper or packaging bags or packaging boxes or packaging cases, trays and the like; the characteristics of dispersity, air permeability, adsorbability, far infrared ray and positive and negative ion function and the like of the mineral micropowder are utilized to enable the packaging material to generate micropores, and therefore, the packaging material has a certain air permeability and adsorbability or generates positive and negative ions or far infrared rays; gas and a small quantity of moisture which are generated from packaged articles are discharged from the micropores, and harmful gas is absorbed and transferred, and thereby, the heat value of the packaged articles can be effectively lowered; microbes are killed or restrained, thereby meeting the demands of keeping fresh of live and fresh food and prolonging storage life.

Owner:钟爱民

Purified filtering agent for seawater desalination by using natural mineral

InactiveCN101049984AGood fade effectHigh strengthSeawater treatmentWater contaminantsWater desalinationFiltration

This invention discloses a natural mineral filter agent for desalting seawater, which is composed of attapulgite, smectite, zeolite, diatomite, mainfanite and sepiolite. The natural mineral filter agent is prepared by: pulverizing the above components, soaking, pressing, air-drying, crushing, sieving, torrefying, cooling and packaging. The contents of NaCl, KCl, Ns2SO4 and Na2CO3 in seawater are effectively decreased by ion exchange between Na+ / K+ in seawater and the natural mineral filter agent. Heavy metals such as Hg, Pb and As, chlorides and residual pesticides can be adsorbed by the natural mineral filter agent. The natural mineral filter agent can be used for late-stage purification and filtration of seawater desalting, as well as brackish water desalting in China northwestern regions.

Owner:陶韬

Silicic acid mud interior wall decorating material and preparation method thereof

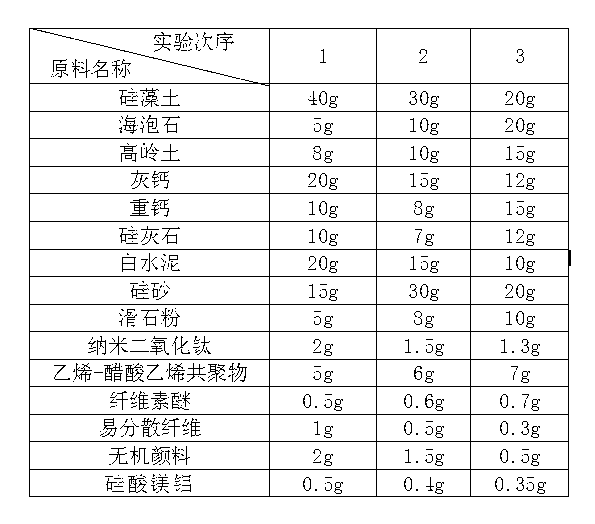

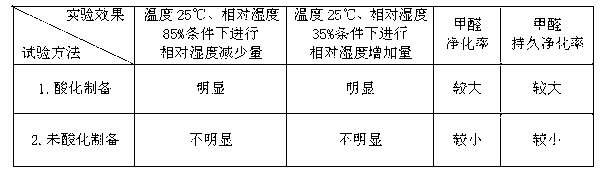

The invention relates to a silicic acid mud interior wall decorating material and a preparation method thereof. The silicic acid mud interior wall decorating material mainly comprises diatomite, sepiolite, kaolin, sierozem, coarse whiting, wollastonite, white cement, silica sand, talcum powder, nanometer titanium dioxide, ethylene-vinyl acetate copolymer, cellulose ether, aluminium-magnesium silicate, easily dispersed fiber, inorganic pigments and has the functions of humidity control and air purification. The preparation method comprises the following steps of: firstly acidizing the diatomite, the sepiolite and the kaolin, removing harmful ingredients in the diatomite, the sepiolite and the kaolin, improving the activation property of the material, then filtering, washing, drying and crushing, and finally adding the diatomite, the sepiolite and the kaolin and the other components to a dry powder blender for uniformly stirring. When being used, water is added to powder, so that the powder is prepared into paste or emulsion; the silicic acid mud interior wall decorating material is suitable for roll coating, spray finishing, blade coating and the like in interior wall decoration and has the functions of indoor humidity adjustment, peculiar smell elimination, removal of harmful gases such as formaldehyde and toluene in air and lasting environmental protection and simultaneously has the characteristics of rich color, strong sense of texture and environmental friendliness.

Owner:商志民

Compositions of polyesters and sepiolite-type clays

Compositions of thermoplastic polyesters and sepiolite-type clay in which the clay is dispersed in the polyester as often fibrous particles whose smallest dimension is less than 100 nm are made by polymerizing the polyester precursors in the presence of the clay. The compositions have good physical properties and can be melt molded into various articles. Many of these articles may be coated (painted) and are especially useful for appearance parts such as visible exterior automotive body parts.

Owner:EI DU PONT DE NEMOURS & CO

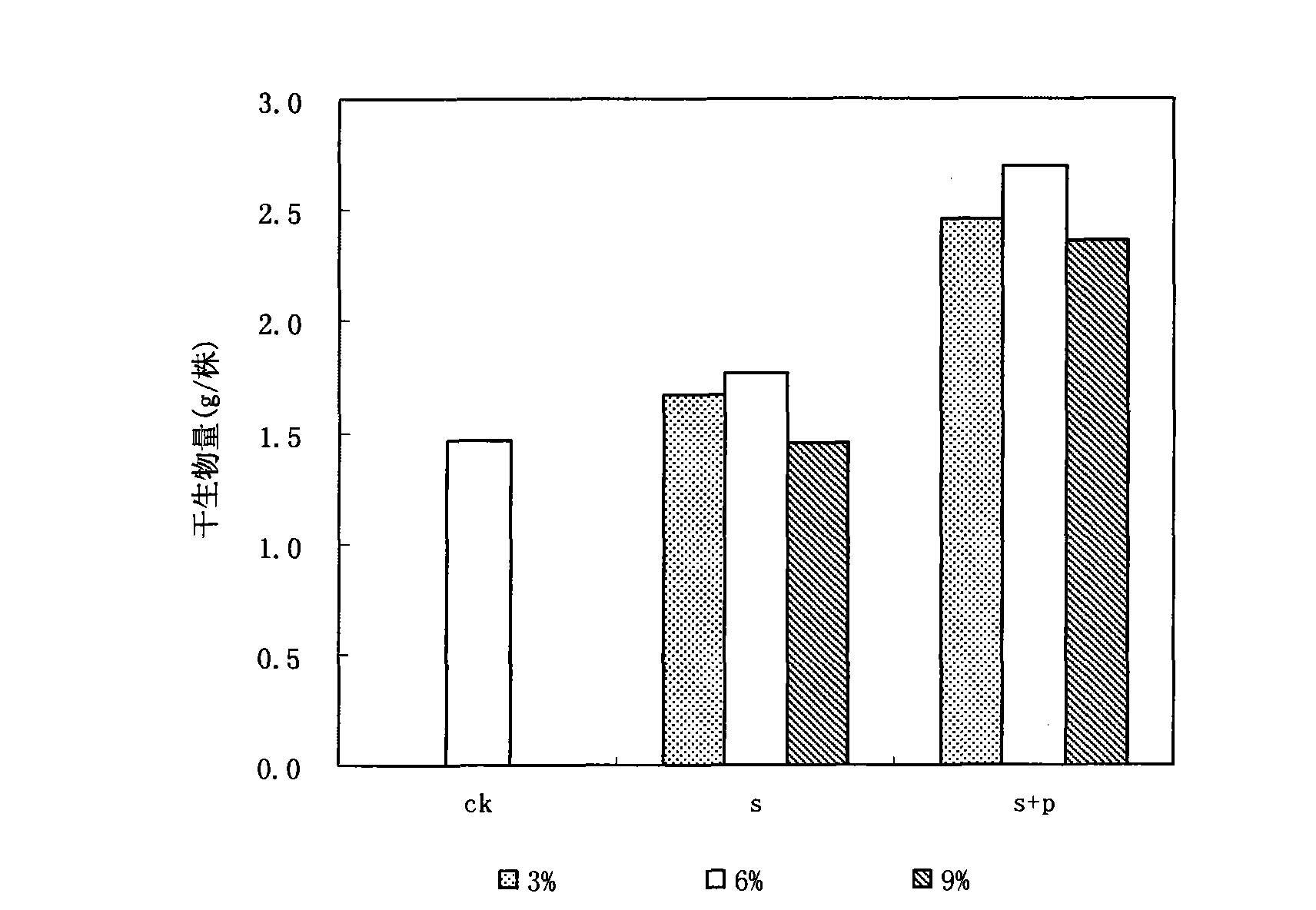

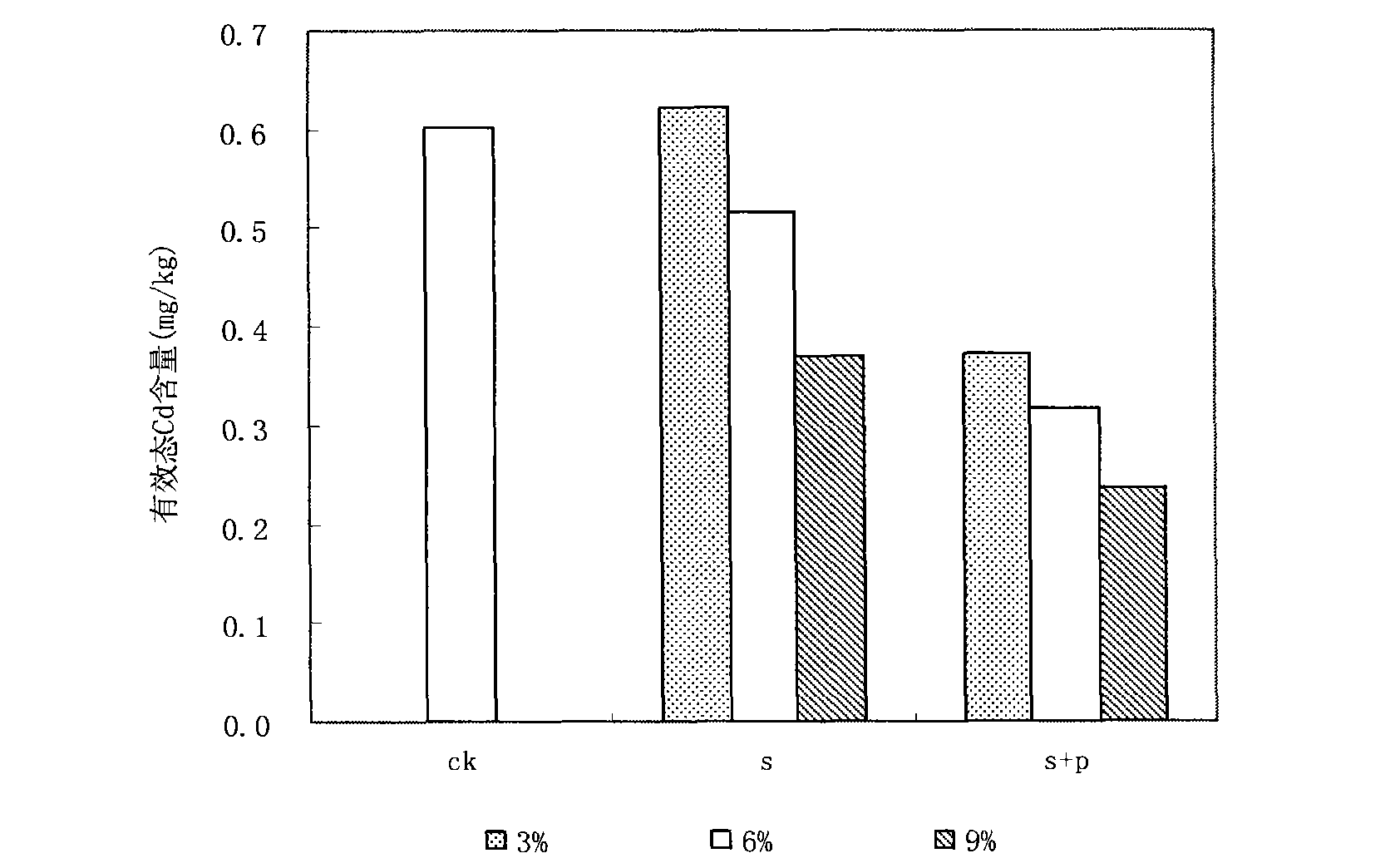

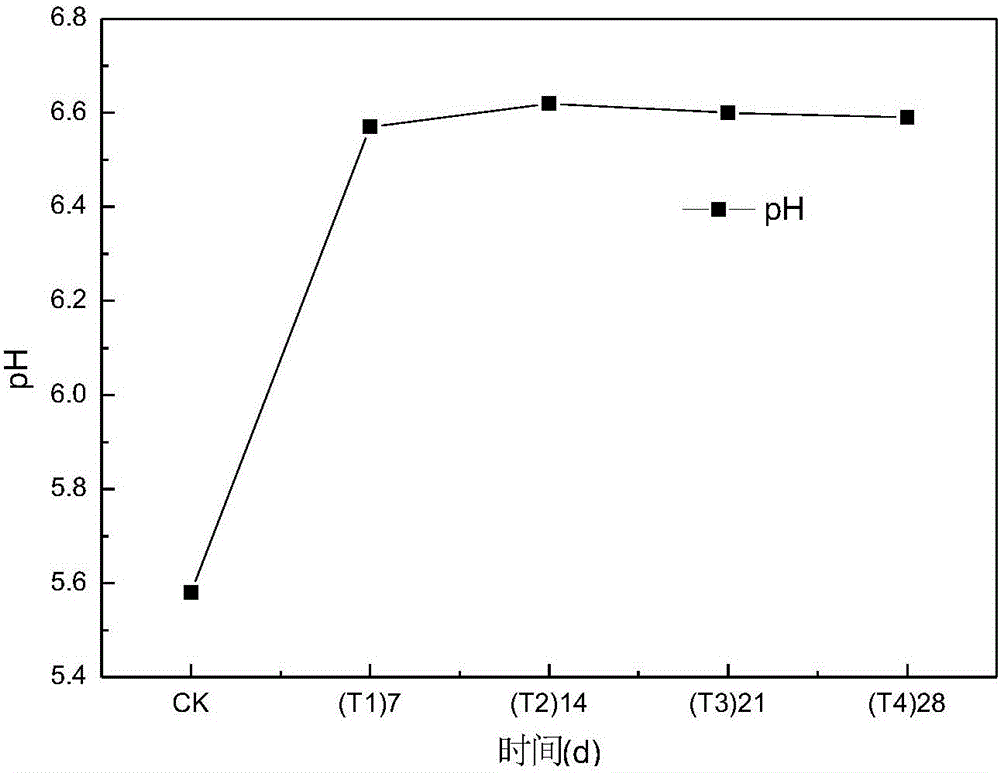

Method for restoring heavy metal pollution of vegetable field soil with in-situ passivation method

ActiveCN101664757AImprove self-cleaning abilityQuality improvementContaminated soil reclamationSoil heavy metalsMonocalcium phosphate

The invention provides a method for restoring heavy metal pollution of vegetable field soil with an in-situ passivation method. The method comprises the step of applying sepiolite and monocalcium phosphate in the vegetable field soil to be restored according to the proportions of 3-9 percent and 0.25 percent of the dry soil according to the specific pollution condition and mixing evenly the sepiolite and monocalcium. The invention reasonably uses passivation materials of sepiolite and monocalcium, remarkably reduces the bioavailability and transferability of the soil heavy metal by reactions of absorption, complexation and precipitation, and the like between the sepiolite and monocalcium and the heavy metal element, simultaneously improves the self-cleaning capacity of the soil, improves the soil fertility condition so as to produce high-quality and high-yield vegetables and restore the ecological function and industrial function of the vegetable field soil. The invention has the advantages of wide material source, simple use method, low cost, favorable restoring effect, wide application range, no secondary pollution and favorable ecological benefits and economical benefits.

Owner:AGRO ENVIRONMENTAL PROTECTION INST OF MIN OF AGRI

Technology for preparing zeolite-containing inorganic insulation mortar

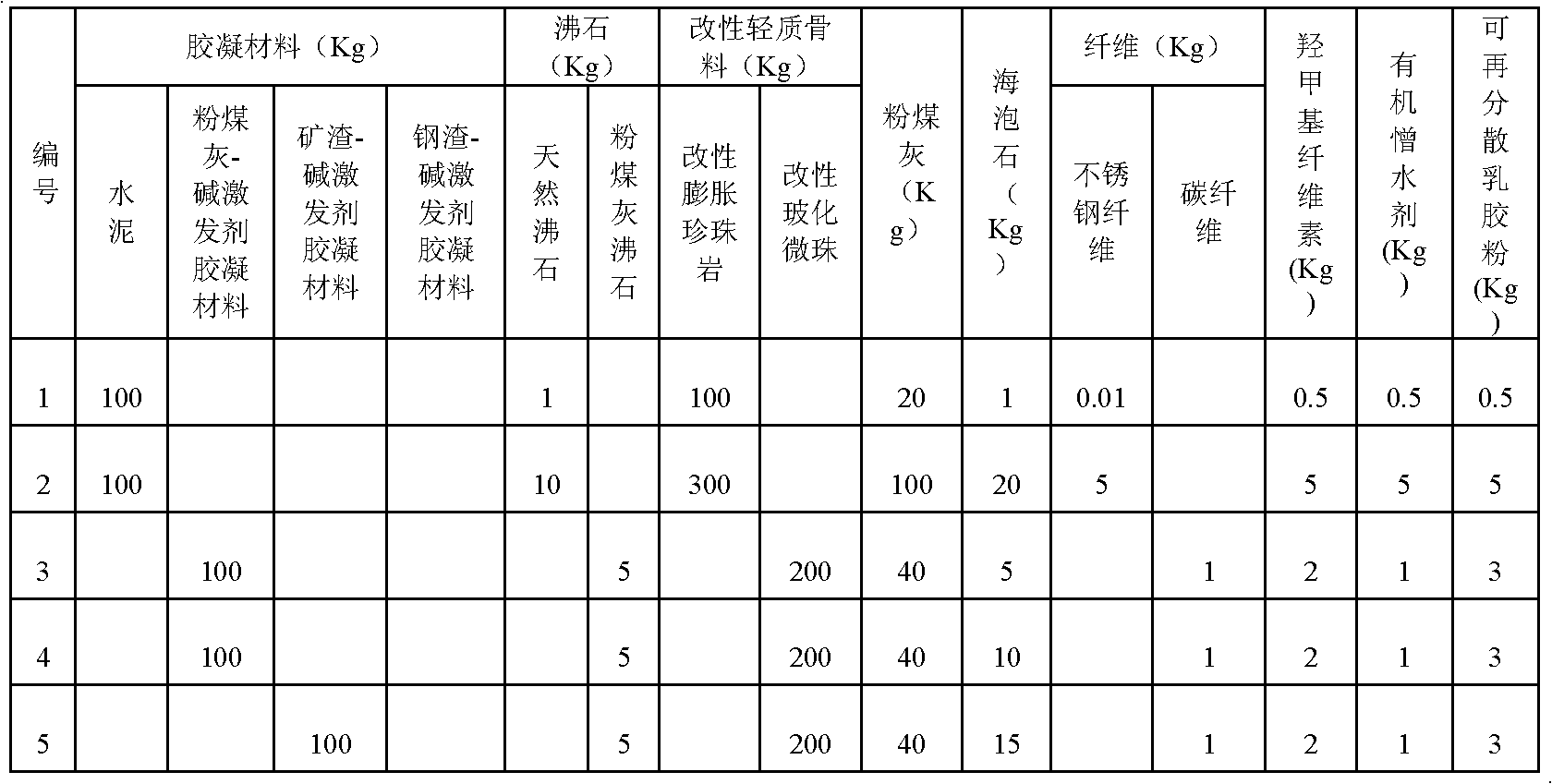

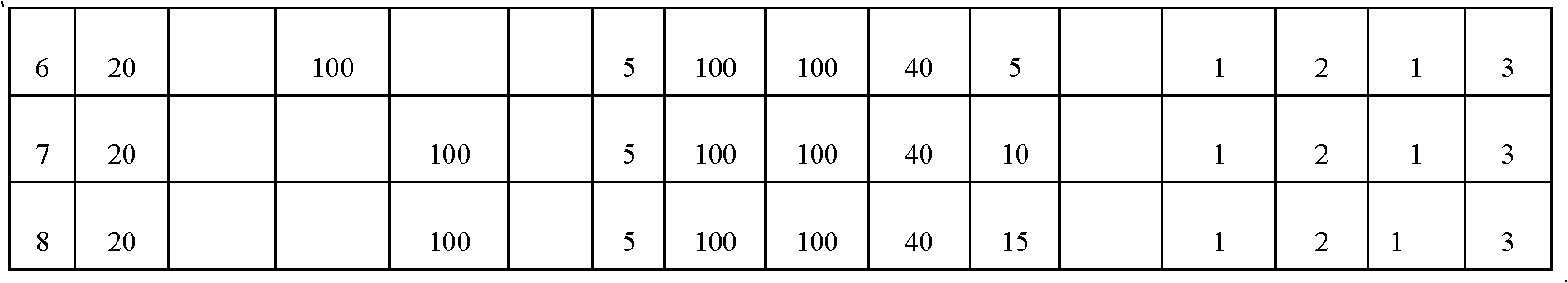

The invention discloses a technology for preparing zeolite-containing inorganic insulation mortar. The technology is characterized by comprising the following steps of: adding zeolite, modified lightweight aggregate, fly ash, sepiolite, conductive fiber, hydroxymethyl cellulose, organic water repellent and re-dispersible latex powder into a gel material, stirring uniformly, and thus obtaining the dry powder inorganic insulation mortar, wherein based on the mass of the gel material, the inorganic insulation mortar contains 1 to 10 percent of zeolite, 100 to 300 percent of modified lightweight aggregate, 20 to 100 percent of fly ash, 1 to 20 percent of sepiolite, 0.01 to 5 percent of fiber, 0.5 to 5 percent of hydroxymethyl cellulose, 0.5 to 5 percent of organic water repellent and 0.5 to 5 percent of re-dispersible latex powder.

Owner:SHAANXI UNIV OF TECH

Air purifying agent

InactiveCN103861421ALarger than surface and uniformGood adsorption and decomposition effectOther chemical processesDispersed particle separationActivated carbonHazardous substance

The invention relates to an air purifying agent which comprises the following raw materials by mass: kieselguhr powder, zeolite powder, medical stone powder, tourmaline powder, activated carbon power, sepiolite powder and titanium dioxide powder. The air purifying agent is prepared by the steps of (1) mixing the kieselguhr powder, the zeolite powder, the medical stone powder, the tourmaline powder, the activated carbon power, the sepiolite powder and the titanium dioxide powder; (2) granulating a mixture obtained in the step (1); and (3) drying the granulated mixture obtained in the step (2). The air purifying agent disclosed by the invention is large in specific surface area and uniform, has a good effect for adsorbing and decomposing harmful substances in air and is an ideal selected material suitable for environment purification in closed spaces such as a room and an automobile and for various air purifiers.

Owner:QINGDAO CHUANSHAN NEW MATERIALS

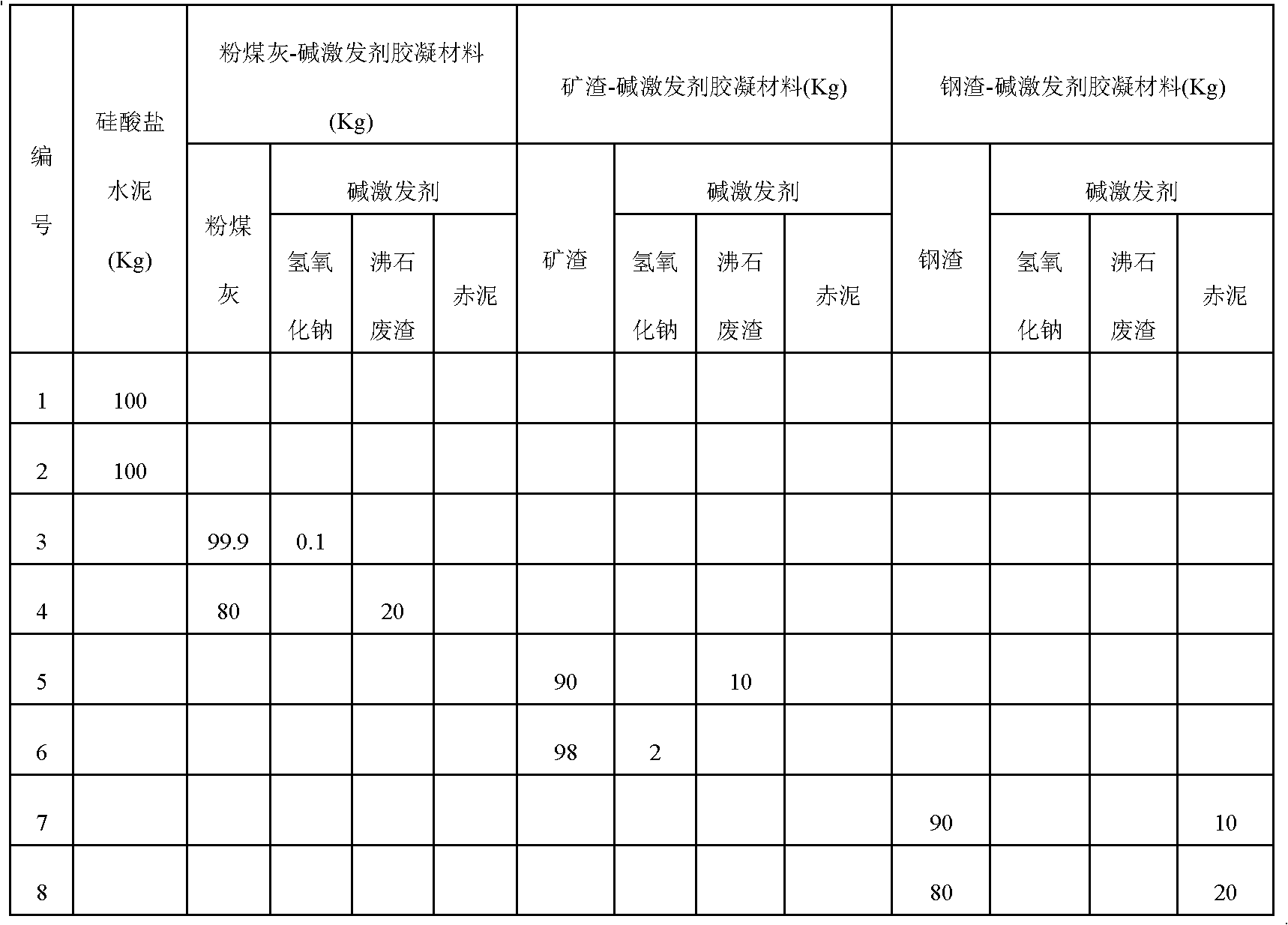

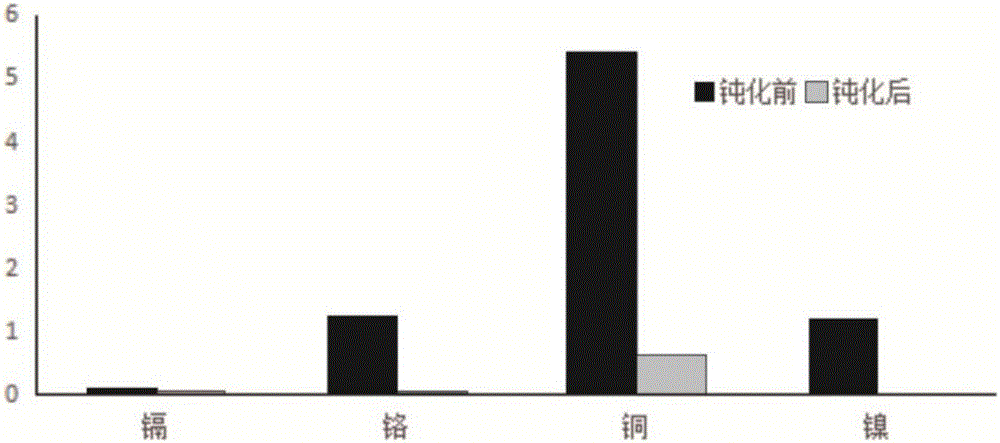

Passivator for remediation of farmland soil subjected to combined pollution of heavy metals, and preparation method and use method of passivator

InactiveCN106800933AImprove adsorption capacityImprove water retentionAgriculture tools and machinesMagnesium fertilisersIon exchangeBinding state

The invention relates to a passivator for remediation of farmland soil subjected to combined pollution of heavy metals such as cadmium, chromium, copper and nickel, and a preparation method and a use method of the passivator. The passivator is prepared from a passivator A and a passivator B, wherein the passivator A is prepared from montmorillonite, kieselguhr, sepiolite, illite and ferrous sulfate; the passivator B is prepared from periclase, calcite, calcium magnesium phosphate fertilizer, plant ash and calcium hydroxide; the passivator is suitable for the farmland soil subjected to the combined pollution of the cadmium, the chromium, the copper and the nickel, and is prepared from the multiple different porous absorption materials with specific contents and a passivation material; the components of the passivator have complementary advantages, and the principles such as absorption and stabilization are combined; the combination forms of the heavy metals are effectively enhanced by ion exchange, complexing, chelating and adsorption methods, and the combination forms are converted into more stable strong organic binding states and residue states, so that the effective state contents of the heavy metals in the farmland soil are effectively reduced, and the passivation effect is long-acting and stable; therefore, the passivator has a great repair effect for the farmland soil subjected to combined pollution of the cadmium, the chromium, the copper and the nickel.

Owner:SICHUAN YIKE ENVIRONMENTAL PROTECTION SCI ANDTECH

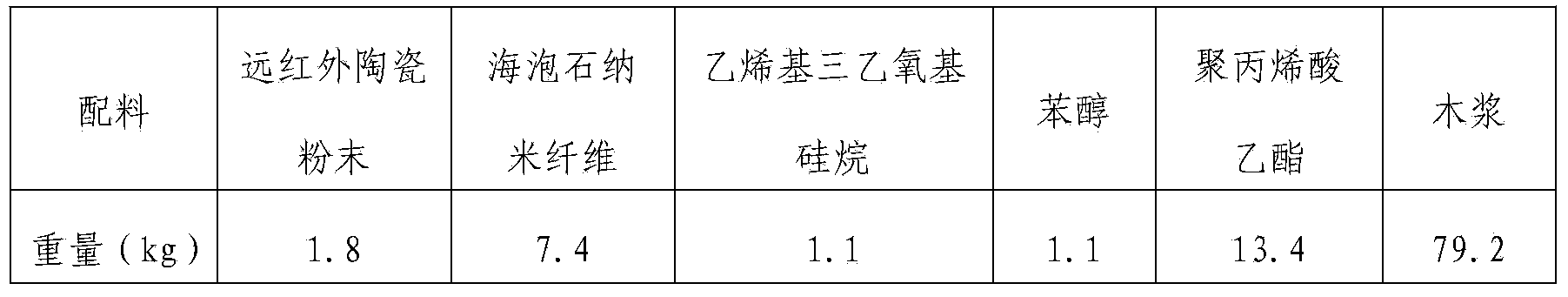

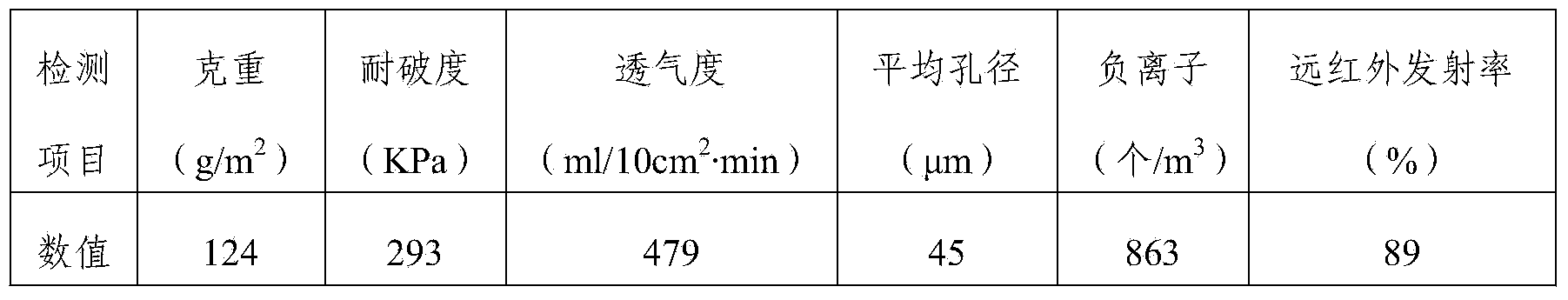

Filter paper for environmental-friendly automobile filter and preparation method of filter paper

InactiveCN103774503ASimple processHigh filtration precisionInorganic fibres/flakesWater-repelling agents additionExhaust gas emissionsEmission standard

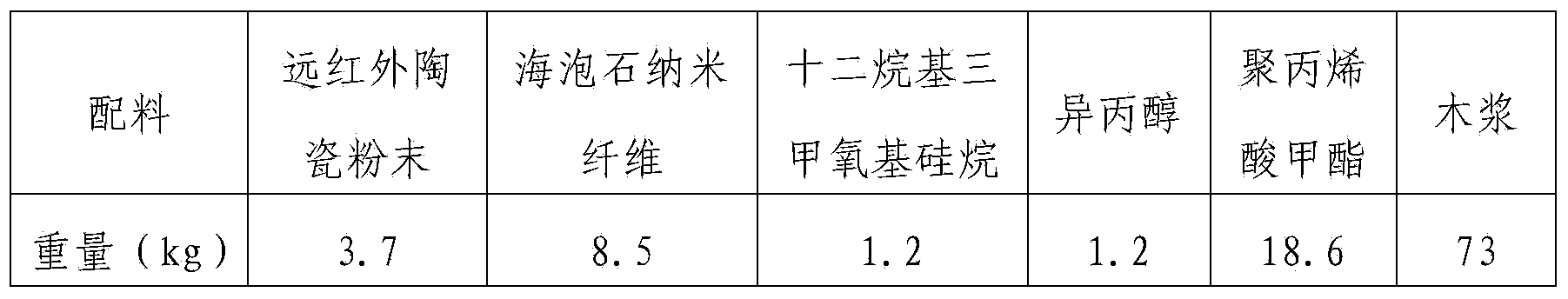

The invention relates to filter paper for an environmental-friendly automobile filter. The filter paper for the environmental-friendly automobile filter is prepared from the following components in parts by weight: 1-5 parts of far infrared ceramic powder, 2-20 parts of sepiolite nanofibers, 0.8-1.6 parts of a silane coupling agent, 0.8-1.6 parts of a diluent, 9-20 parts of a sizing agent and 60-96 parts of wood pulp. Air, fuel oil and engine oil filters made of the filter paper are obvious in comprehensive effect; pollutants generated by exhaust gas emission of an automobile are reduced by 16-47%; the dynamic performance is improved by 6-12%; fuel oil can be saved by 2-5%; the emission standard reaches the European IV standard.

Owner:北京联飞翔科技股份有限公司

Nano crystallite composite filter material and supplement of manufacture method thereof

The invention extends the connotation range required to be protected on the basis of a previously issued patent ZL200710025045.4, i.e., a nanometer microcrystalline composite filter material and a preparation method thereof, belonging to the field of a water disposal technique material. According to weight percentage, the nanometer microcrystalline composite filter material comprises 3-95 percent of attapulgite clay, 5-80 percent of sepiolite clay, 2-25 percent of kaolinite clay, 2-97 percent of tubular halloysite, 5-75 percent of diatomite, 5-75 percent of natural zeolite (clinoptilolite, mordenite and the like), 0-25 percent of pillared montmorillonite, 0-50 percent of expanded vermiculite, 0-5 percent of expanded perlite and 0-50 percent of active carbon or bamboo carbon powders. All raw materials which are powder shapes are mixed according to proportion and stirred to granulate by adding an inorganic adhesive, then sintered and activated at the temperature of 900-500 DEG C (inert gas is required for sintering and activating the filter material added with active carbon). The nanometer microcrystalline composite filter material has smooth shape, rough surface and uniform particle size, with the diameter of 1-10mm, and is used for biological filter tanks and high-class adsorption filter materials in deep purification systems of drinking water and reclaimed water sewage disposal systems.

Owner:傅成义

Modified phosphogypsum and its preparation

The present invention discloses a modified phosphogypsum and its preparation process. Its main weight composition is formed from 10-30% of additive (one, two or three kinds of aluminium sulfate slag, alum stone, plant ash, bentonite, slag, dickite, waste liquor and waste residue of paper mill and soda plant, white mud and sepiolite) and 70-90% of phosphogypsum. The phosphogypsum and additive are mixed together, and stacked at a certain temp. so as to obtain the modified phosphogypsum. If said modified phosphogypsum is closed-heated at 30-100 deg.C for 8-48 hr., and formed, dried and can be made into the cement retarded, and if the modified phosphogypsum closed-heated for 8-24 hr, is calcined at 600-900 deg.C, and can be made into cement reinforcing agent.

Owner:孙国庆 +1

Steelwork fire-retardant paint using self-crosslinking silicone-acrylic compound emulsion as substrate and preparation thereof

InactiveCN101205441AGood thermal oxidation resistanceGood cohesive energyFireproof paintsFiberMelamine phosphate

The invention relates to the fire retardant coating technical field, in particular to steel-structure fire retardant coating taking self-crosslinkable silicone-acrylate composite emulsion as substrate as well as a preparation method thereof. The invention adopts polysiloxanes and self-crosslinkable polyacrylate composite emulsion as film-forming materials; moreover, based on the commonly used composite fire retardant comprising ammonium polyphosphate, melamine and pentaerythritol, melamine phosphate and early stage foaming agent with excellent carbonizing and foaming performances are added in the fire retardant coating, thereby greatly increasing the foaming capacity of the coating with the thickness of the foaming layer 20 times to 35 times of the prior coating; meanwhile, titanium pigment, sepiolite and aluminium silicate fiber are adopted as high temperature resistant filler, and propylene glycol is adopted as film-forming auxiliary agent; in addition, the fire endurance of the formed fire retardant coating can reach 90min (when coating thickness is 2mm). The coating has simple preparation method, no pollution, low cost and wide application.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com