Patents

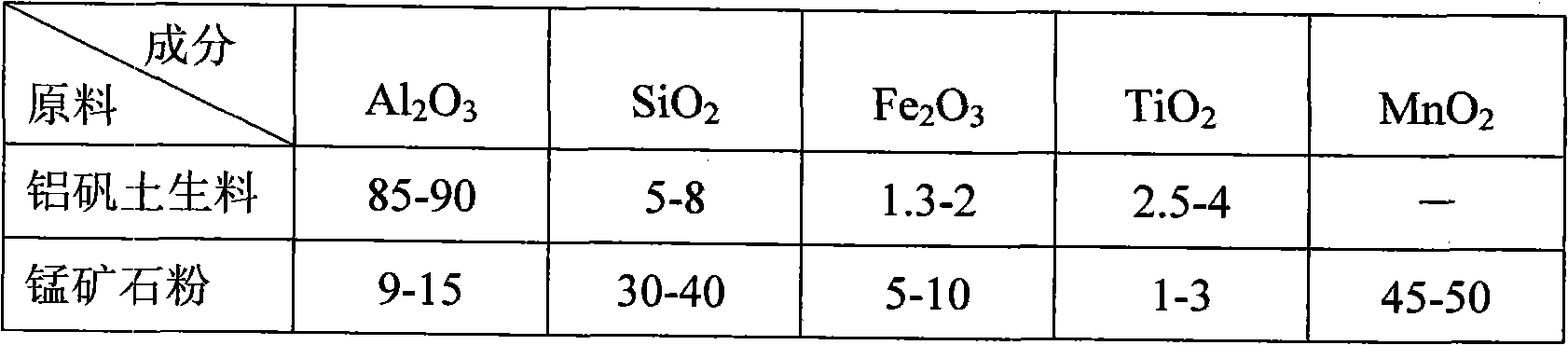

Literature

4326 results about "Alum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An alum (/ˈæləm/) is a type of chemical compound, usually a hydrated double sulfate salt of aluminium with the general formula XAl(SO₄)₂·12H₂O, where X is a monovalent cation such as potassium or ammonium. By itself, "alum" often refers to potassium alum, with the formula KAl(SO₄)₂·12H₂O. Other alums are named after the monovalent ion, such as sodium alum and ammonium alum.

Efficient water treatment flocculant

InactiveCN101327976AEfficient purificationPromote generationWater/sewage treatment by flocculation/precipitationWater qualityHigh intensity

The invention relates to a high efficiency water treatment flocculant for drinking water and water treatment comprising a metal cation flocculant which is characterized in that the high efficiency water treatment flocculant also comprises a high efficiency adsorption component and an assistant medicament to be remixed, inwhich the weight ratio is: the high efficiency adsorption component 5-15%, the metal cation flocculant 50-85%, the assistant medicament 5-15%. The obvious characteristics of the invention are that each component can play the advantages of high intensity of the flocs of the inorganic flocculant and large flocs of the polymeric flocculant, overcomes the drawback of small flocs of the inorganic flocculant and low intensity of the flocs of the organic flocculant. The existence of the high adsorption component plays the action of adsorption of the organic compounds and heavy metal ion which are difficult to flocculat and precipitate, also plays the role of aid-coagulation, decoloration and deflavour. Thus the flocculant of the invention has advantages of good coagulation effect, large alum blossom, rapid settling velocity, good effluent quality and few dosage or the like.

Owner:郭振岳 +1

Iron-based ionic liquid catalysts for hydroprocessing carbonaceous feeds

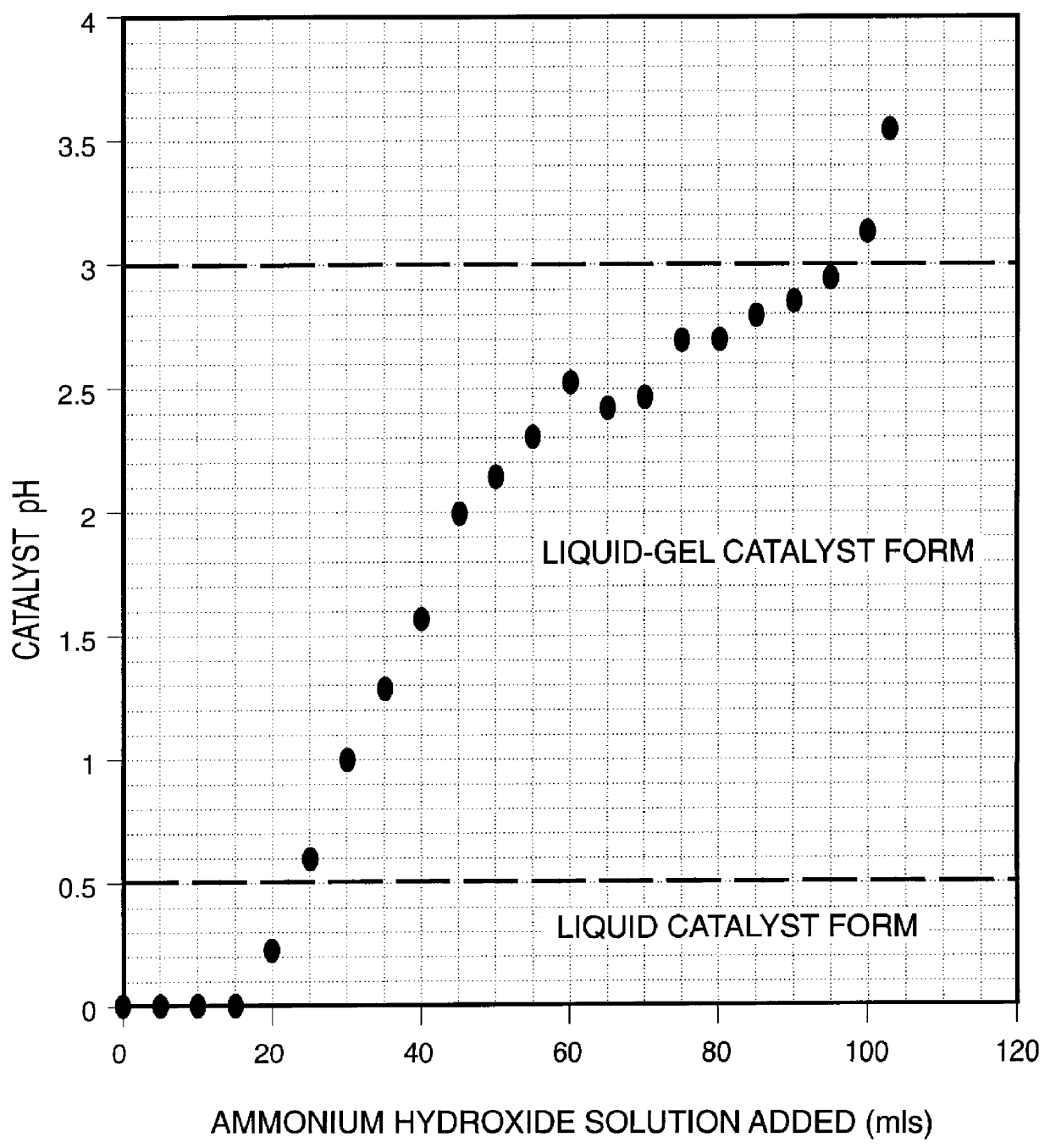

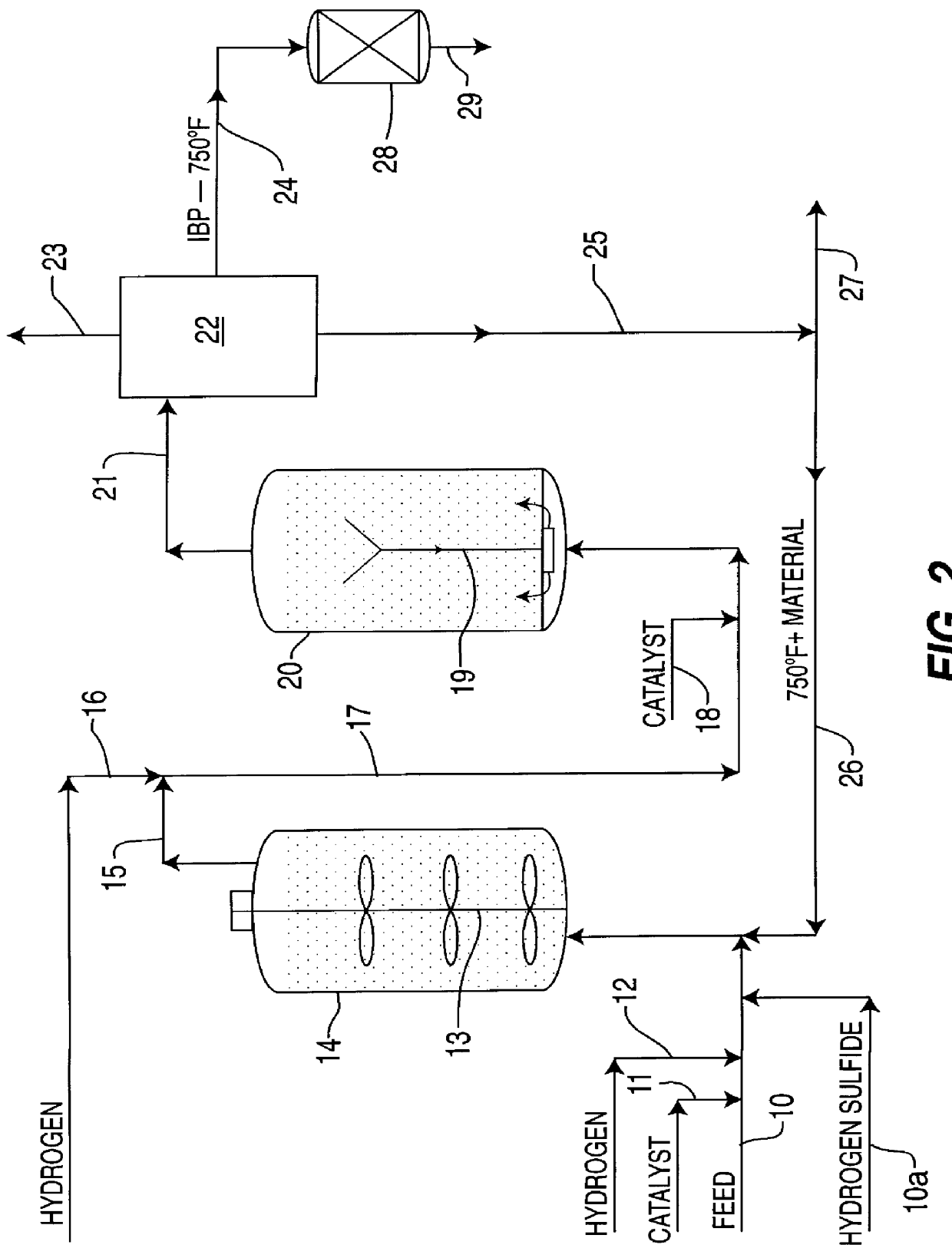

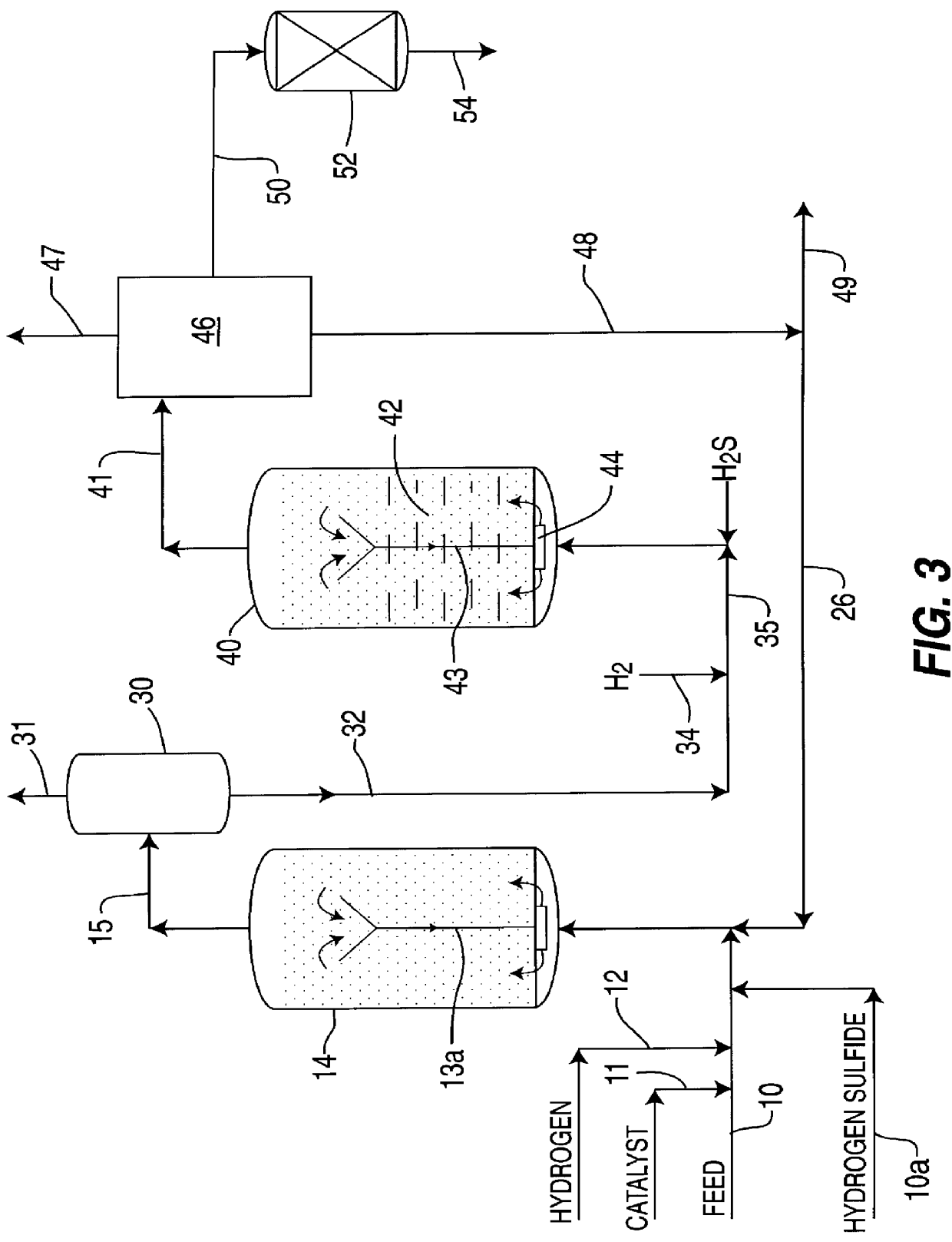

InactiveUS6139723AIncrease hydrocracking ability of catalystIndirect and direct heating destructive distillationCatalyst activation/preparationLiquid productIron salts

A highly dispersed iron-based ionic liquid or liquid-gel catalyst which may be anion-modified and metals-promoted has high catalytic activity, and is useful for hydrocracking / hydrogenation reactions for carbonaceous feed materials. The catalyst is produced by aqueous precipitation from saturated iron salt solutions such as ferric sulfate and ferric alum, and may be modified during preparation with anionic sulfate (SO42-) and promoted with small percentages of at least one active metal such as cobalt, molybdenum, palladium, platinum, nickel, or tungsten or mixtures thereof. The resulting catalyst may be used in a preferred ionic liquid form or in a liquid-gel form, and either fluidic form can be easily mixed and reacted with carbonaceous feed materials such as coal, heavy petroleum fractions, mixed plastic waste, or mixtures thereof. The invention includes methods for making the ionic liquid or liquid-gel catalyst, and processes for using the fluidic catalysts for hydroprocessing the carbonaceous feed materials to produce desirable low-boiling hydrocarbon liquid products.

Owner:HEADWATERS CTL

Formulation useful as a natural herbal tooth powder

InactiveUS6264926B1Not produce any adverse effectPleasant smellCosmetic preparationsBiocideSpilanthesUsnea longissima

The present invention relates to a formulation of herbal toothpowder or toothpaste for gums and teeth, which comprises of powder or paste of Zanthoxylum armatum (20-25%), Zingiber officinale (25-30%), Santalum album (8.25-8.5%), Spilanthes calva (2.0-2.5%), Pistacia lentiseus (2.0-2.5%), Quercus infectoria (8.0-8.5%), Usnea longissima (1-4%), as well as roasted alum and common salt.

Owner:COUNCIL OF SCI & IND RES

Multiple-effect pollute-removing water purification agent and use method thereof

InactiveCN101327984AImprove compactnessHigh turbidity removal rateWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionEutrophicationSorbent

The invention relates to a multi-effect pollution removal purifying agent and a method for applying the same. The purifying agent is complexly formed by a strong oxidant, an effective adsorbent and an assistant medicament by a weight percentage of strong oxidant 10-80%, effective adsorbent 10-70% and assistant medicament 5-50%. The surface water treatment process of using multi-effect pollution removal purifying agent of the invention comparing with the common flocculants has the following advantages: effectively improving the turbidity removal ratio, increasing the flcos formation amount and alum blossom density for the difficult coagulated surface water, improving the deposition efficiency, oxidizing and removing the organic matters in the water, eliminating the chroma and odor caused by the pollution, increasing the effluent conventional indexes, obviously improving the indexes such as oxygen consumption and ammonia nitrogen, wherein the removal rate of oxygen consumption and ammonia nitrogen can reach 25-60%, the removal rate of small organic molecules, benzenes and phenols can reach more than 80%, playing an obvious roll for the algae inactivation of lake water and reservoir water which are serious eutrophic, improving the algae removal efficiency of the deposition and filtration technologies with an algae removal rate of 80-90%, improving the coagulation efficiency, reducing 20-30% of the common flocculant dosage, effectively adsorbing the codeposition heavy-metal ion. The adding equipment of the invention is easy and convenient to use with little investment and fast effect.

Owner:南通立源水业科技发展有限公司

An externally applied ointment

InactiveCN1879856AShort course of treatmentQuick resultsHeavy metal active ingredientsOrganic active ingredientsOrpimentMyrrh

The invention discloses an externally-used plaster which is prepared from more than 80 kinds of Chinese medicinal materials including frankincense, myrrh, mercurous chloride, dragon's blood resin, camphor, boneol, orpiment, sulfur, gamboge, lead monoxide, native copper, white alum, colophony, dragon's blood resin, musk, orpiment, lead monoxide, alkanna tinctoria, colophony, buck grass, wasp's nest, camphor, mercurous chloride, wood louse, and can be used for treating rheumatic arthritis and proliferative arthritis.

Owner:杨树民

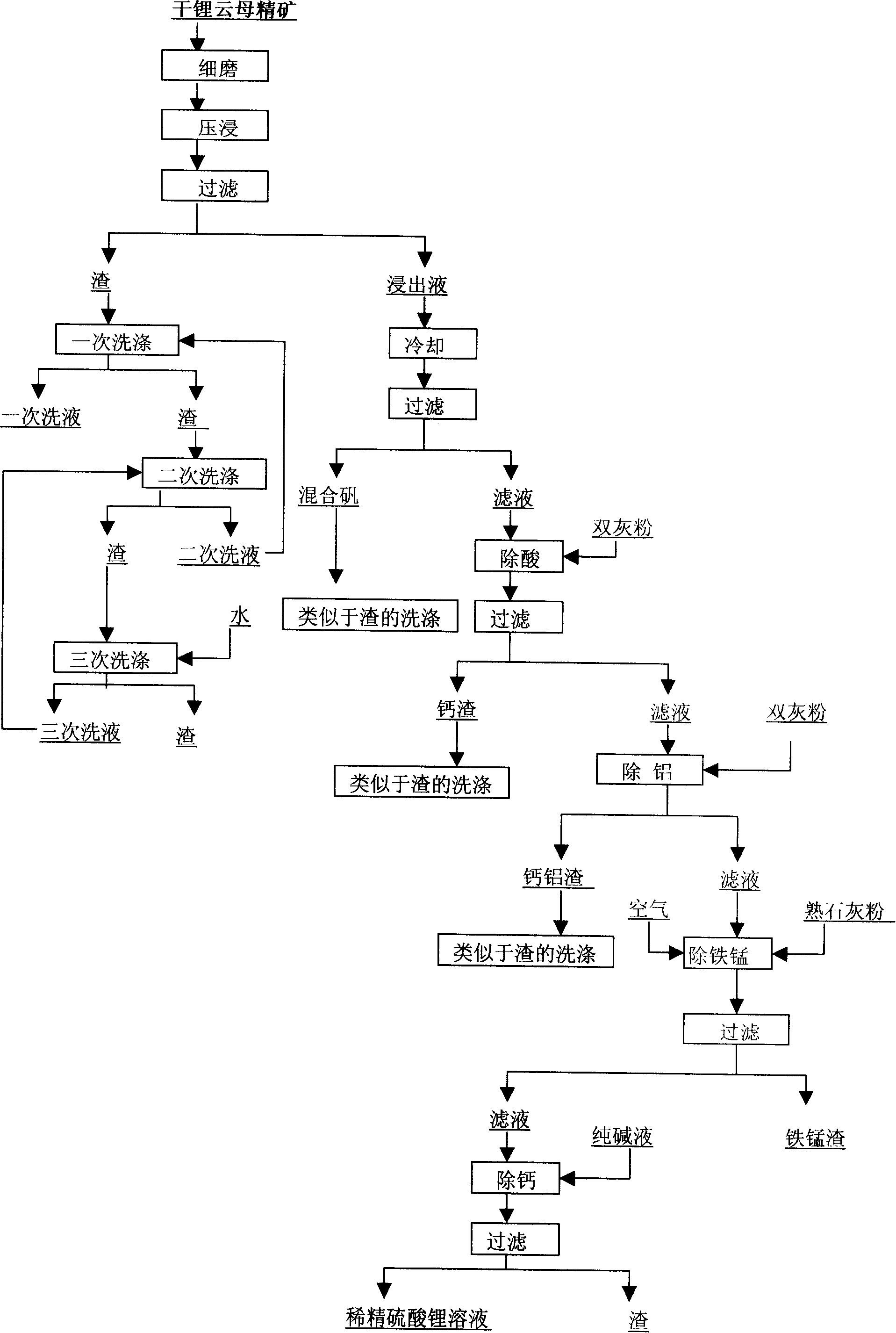

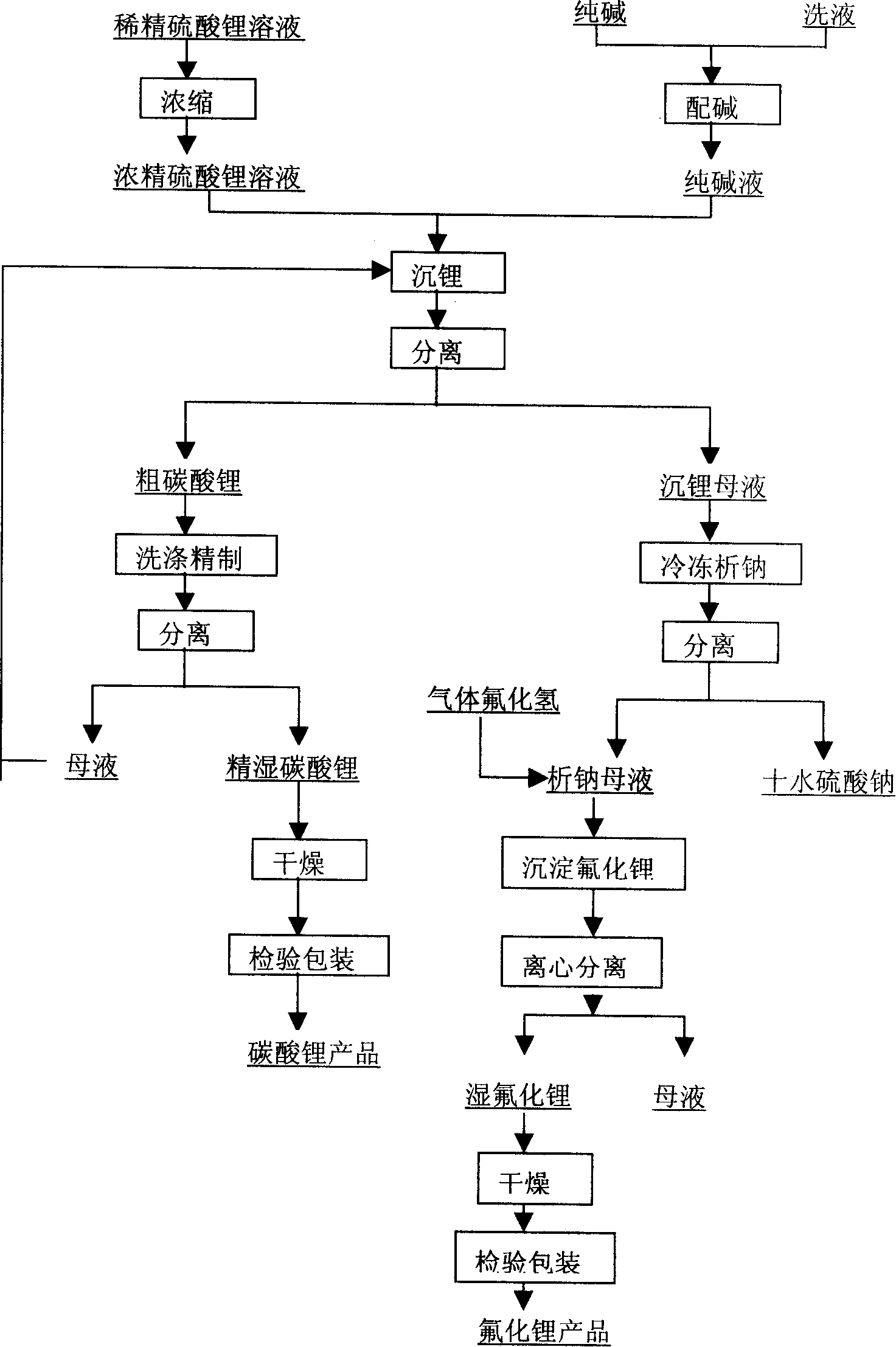

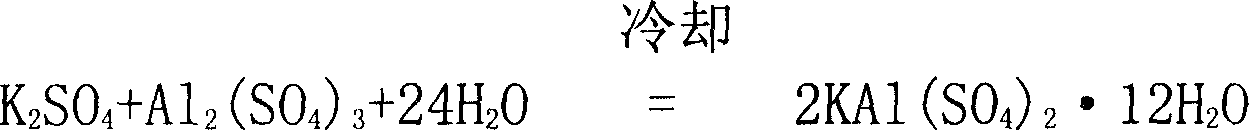

Method for producing refined lithium sulfate solution used in lepidolite lithium-extracting technique by sulfuric acid process

Provided is a process for producing refined lithium sulfate solution of lepidolite lithium extracting technology with sulfuric acid process, which takes lepidolite clean ore as raw material and sequentially includes the following steps, including leaching, alum cooling and decanting, acid removing, aluminum removing, decontaminating and deliming, thereby achieving refined lithium sulfate solution. The alum cooling and decanting process of the invention can precipitate kalium, rubidium and caesium in alum form, thereby the separation of lithium and kalium, rubidium and caesium is easily achieved, and the achieved alum dregs of kalium, rubidium and caesium are blend alum with high purity, which creates perfect condition for comprehensive utilization and simultaneously reduces the burdens of the separation of lithium and aluminum. The aluminum removing process can easily achieve the separation of lithium and aluminum. The process of the invention has the advantages that the energy consumption is relatively low, and the lithium yield is relatively high, most of the residues can be used and the process is favorable for comprehensive utilization. The invention further provides a process for producing lithium carbonate and lithium fluoride with the achieved refined lithium sulfate solution.

Owner:GANFENG LITHIUM CO LTD

Saline-alkali soil amendment

InactiveCN101624523ALow costImprove convenienceOther chemical processesOrganic fertilisersAmmonium ferrous sulfateAlkali soil

The invention discloses a saline-alkali soil amendment, and relates to a soil amendment. The soil amendment of the invention solves the problem of the waste of land resources caused by a condition that saline-alkali soil is wasted and can not be used throughout the year because only artemisia anethifolia can grow in the saline-alkali soil at present, while other plants can not grow thereon. Besides, the existing saline-alkali soil amendment is mainly prepared from alum which has high cost and poor soil amendment effect. The saline-alkali soil amendment of the invention is prepared by weight percent from aluminum sulfate, ammonium ferrous sulfate and magnesium sulfate, which are mixed, and the weight ratio of the three materials is 1-1.8:1-2:0.2-0.5. The saline-alkali soil amendment of the invention can ensure that crop plants can be planted in the saline-alkali soil; thus, the saline-alkali soil, a wide land resource, can be made good use of. In addition, the saline-alkali soil amendment of the invention has the advantages of low cost and obvious effect of soil amendment.

Owner:张炳辉

Lotion for treating female vagina inflammation

ActiveCN101612343AConvenient treatmentGood treatment effectInorganic boron active ingredientsHydroxy compound active ingredientsSide effectPeppermints

The invention relates to lotion for treating female vagina inflammation, aiming at providing lotion which has obvious clinical curative effect for treating gynecologic inflammation, has small side effect to the body and does not destroy the self defense function of the human body. The invention has the technical scheme that the lotion is external-application lotion prepared from the following raw materials according to parts by weight: 10 to 20 parts of coptis root, 10 to 20 parts of yellow-corktree bark, 10 to 20 parts of baikal skullcap root, 20 to 40 parts of cnidium fruit, 20 to 40 parts of broom cypress fruit, 5 to 15 parts of dried alum, 20 to 40 parts of cordate houttuynia, 20 to 40 parts of kuhseng, 20 to 40 parts of wild chrysanthemum flower, 20 to 40 parts of radix gentianae, 20 to 40 parts of smilax glabra rhizoma, 10 to 20 parts of stemona root, 20 to 40 parts of zanthoxylum, 20 to 40 parts of dandelion, 15 to 25 parts of radix sileris, 20 to 40 parts of borax, 10 to 20 parts of peppermint, 20 to 40 parts of angelica, 20 to 40 parts of radix arnebiae seu lithospermi and 10 to 20 parts of licorice. The invention is suitable for clinically common gynecologic inflammation.

Owner:HANGZHOU PYRAMIX BIOTECH

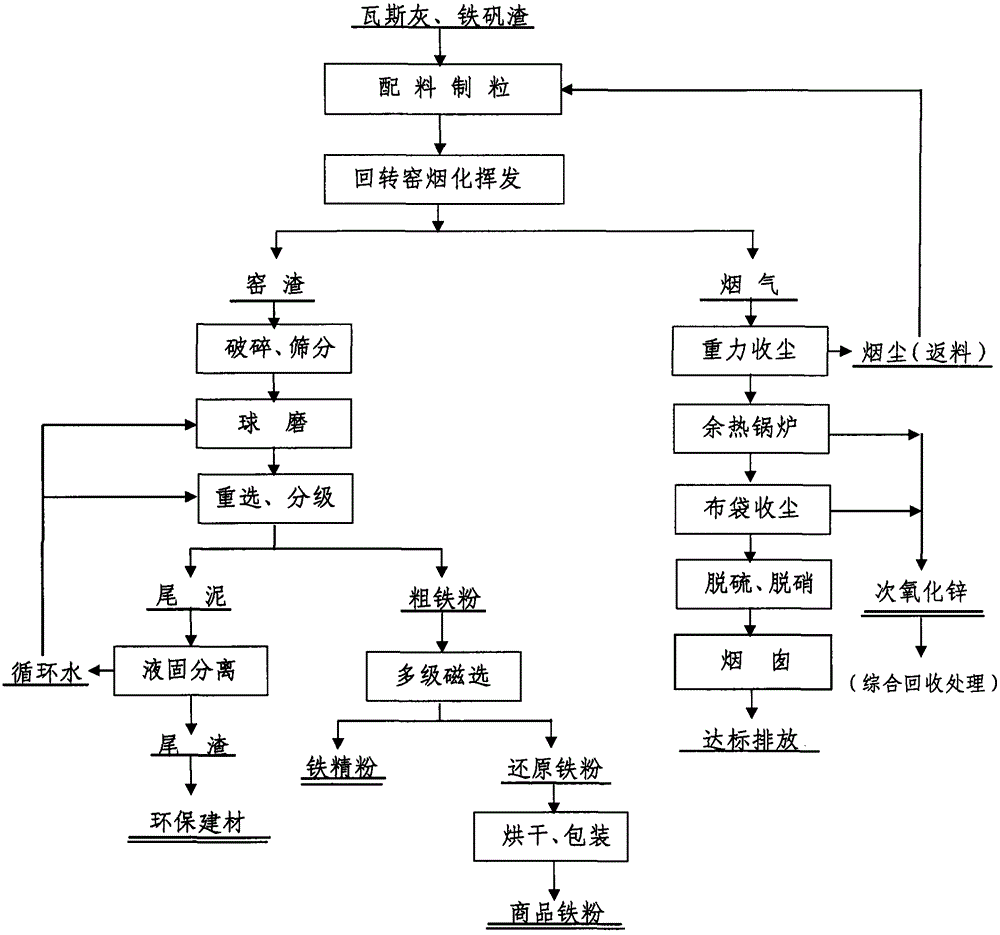

Comprehensive recovery technology of solid waste gas ash and zinc-containing ferrovanadium slag

ActiveCN104911356AImprove the level of comprehensive utilizationAchieve reductionProcess efficiency improvementSlagHigh energy

The invention provides a comprehensive recovery technology of solid waste gas ash and zinc-containing ferrovanadium slag. By combining advantages of low iron content and rich carbon of gas ash and characteristics of high iron content and rich precious metals of ferrovanadium slag, and by the adoption of a rotary-kiln fire method fuming enrichment technology, the material undergoes comprehensive recovery. Advanced equipment such as a waste heat boiler, a negative-pressure bag collector, a pneumatic emulsification desulfurization tower and the like are configured to carry out efficient recovery and harmless environmental-protection processing of flue gas so as to achieve the purpose of clean production. By a beneficiation combined method, iron-containing kiln slag undergoes high added-value exploitation. Thus, the environmental protection problem of resource disposition is solved, and the effect of comprehensive utilization with low energy consumption, high yield and high added-value is achieved. Problems of short kiln age, high energy consumption and low concentration of SO2 during the treating process of ferrovanadium slag can be solved by the technology provided by the invention, and problems of poor iron separation effect and overhigh content of fluorine and chlorine in zinc hypoxide also can be solved. The technology has good economic benefit and high popularization and practical value.

Owner:北京事竟成有色金属研究所

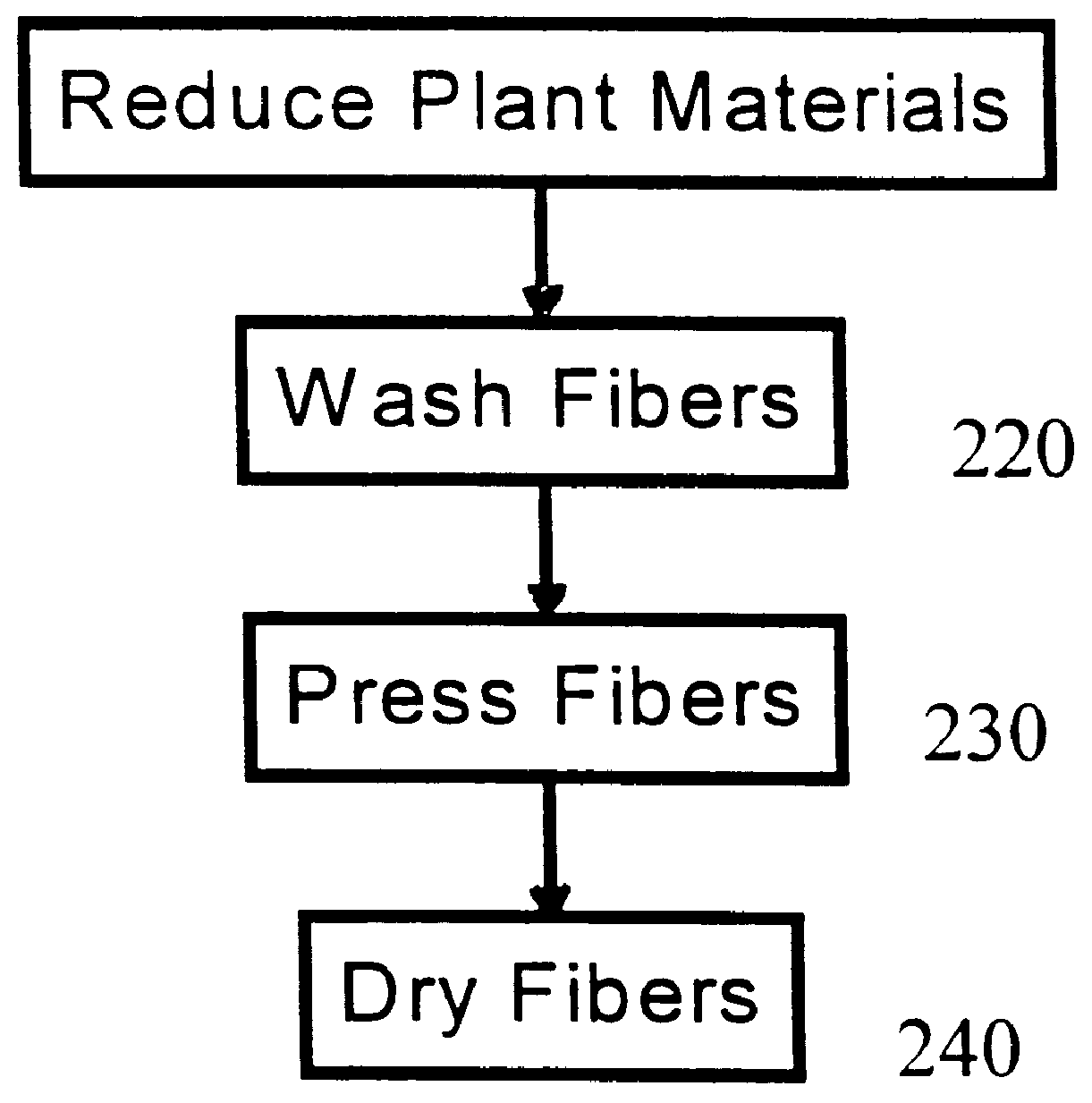

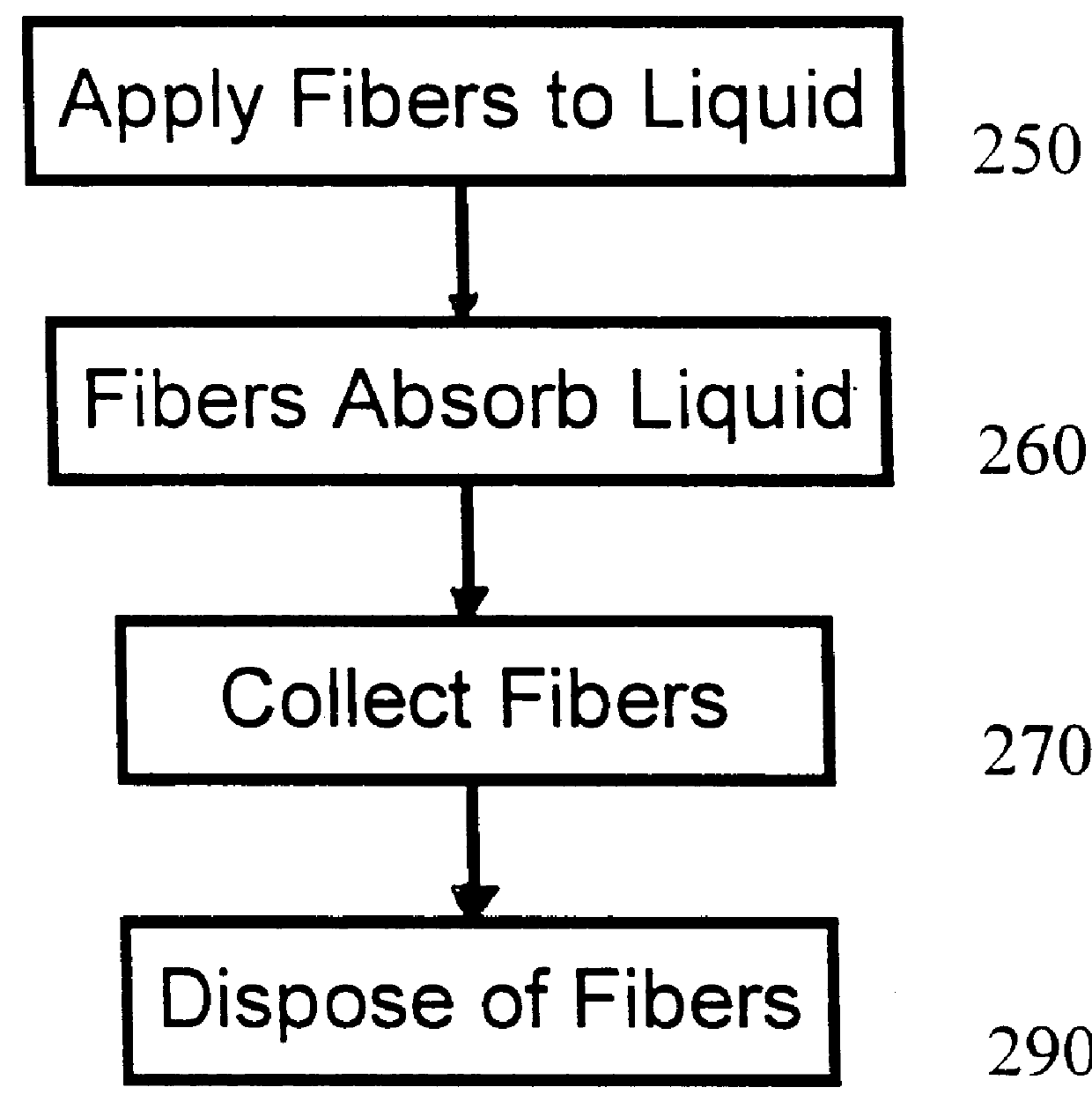

Process for sorbing liquids using tropical fibers

A process is described for using tropical fibers to recover spilled oil, gasoline, kerosene, hydrocarbons, pentachlorophenol, creosote or other hazardous liquids from land or water. The sorbent fiber material is produced from agricultural byproducts from cultivation of banana, plantain, cavendish plant, pineapple, coconut, palm, or other tropical fruit bearing plants. The sorbent fibers are produced by separating the raw plant materials; washing the separated fibers in a solution of 1% alum; pressing the fibers to extract liquids and natural juices; further separating the fibers by beating or agitating; and drying the fibers. The sorbent fibers have a water and natural liquid content of less than 10% by weight and may be applied to the surface or periphery of an oil or chemical spill, whereupon they will sorb the oil or chemical. Once the oil or chemical is sorbed the fibers may be collected and the oil or chemical may be partially recovered by compressing the fibers. The fibers may be disposed of by landfilling or may be thermally treated. When thermally treated in a boiler or furnace, the liquid laden fibers may also be a valuable source of fuel.

Owner:KEMRON ENVIRONMENTAL SERVICES INC +1

Edible packing membrane, and its preparing method and use

ActiveCN1743379ADoes not change appearanceNo change in flavorFood preparationNutritive valuesGenipin

The invention relates to food pachaging material, in particular edible packing film prepared from soybean protein isolate and glutin and its preparing method and use. The packing film is composed mainly of soybean protein isolate and glutin. Film solution for preparing the film is obtained by mixing two solutions of soybean protein isolate and glutin. The film solution contains soybean protein isolate, glutin, and further adding auxiliary haulages for improving film property, such as glycerin, crosslinking agnet (genipin,transglutaminase or alum), alkaline matter(sodium carbonate, sodium hydroxide).The film appearance is similar to plastic film, can be solved in 30-100deg.C water, and has certain nutritive value. The invention makes the best of advantage of glutin and soybean protein isolate, and obtains edible packing film with definite mechanical stength and low cost.

Owner:BAOTOU DONGBAO BIO TECH CO LTD

Method for making raw paper of heat sublimation transfer printing paper

InactiveCN102767120AEasy to useOptimize copying parametersSpecial paperWater-repelling agents additionPulp and paper industryAlum

The invention discloses a method for making raw paper of heat sublimation transfer printing paper. The method comprises the following steps of: slurrying a needle leaf wood-pulp board and a broad leaf wood-pulp board, and respectively beating the needle leaf wood-pulp board and the broad leaf wood-pulp board to 15 to 25 degrees SR and 18 to 28 degrees SR; then mixing the two beaten pulps, mixing the mixture and chemimechanical pulp (CTMP) which is beaten to 22 to 32 degrees SR in advance, and uniformly stirring the mixture with wet strength agent polyamide epoxy resin (PAE), white alum and sizing agent cation rosin size to obtain paper pulp; and putting the paper pulp onto a net, controlling the net part to be dehydrated and molded, and performing squeezing, surface sizing and drying to obtain the heat sublimation transfer printing paper. The indexes of the finished paper can meet the requirement of the heat sublimation transfer printing paper by optimizing the beating degree, the using amounts of various additives during papermaking and making parameters of a paper maker.

Owner:ZHEJIANG JINCHANG SPECIALTY PAPER CO LTD

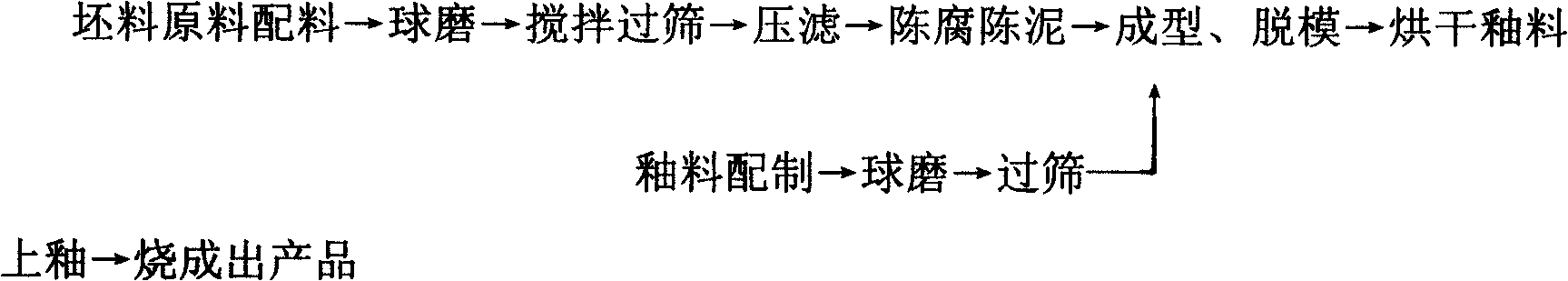

Heat resisting red porcelain chinaware

The invention discloses a heat-resistant purple sand ceramic tool. The manufacture material includes stock and glaze; wherein, the stock is formed by the following components according to weight percentage: 1 to 15 percent of purple sand soil, 25 to 38 percent of triphane, 5 to 30 percent of bauxite clay, 5 to 30 percent of kaolin, 2 to 6 percent of talc, 5 to 20 percent of alum clay, 5 to 20 percent of grog and 5 to 25 percent of attaclay; the glaze is formed by the following components according to weight percentage: 20 to 35 percent of paste, 10 to 25 percent of petalite, 15 to 25 percent of grog, 8 to 15 percent of clinker, 12 to 25 percent of yellow earth, 6 to 9 percent of iron red, 0 to 0.15 percent of trimeric sodium phosphate and 1 to 2 percent of water glass. The adoption of triphane in the material of ceramics can largely enhance the heat-resistant capability, and the ceramics can be heated by electricity or fire and even the firing without water causes no crack. The heat-resistant purple sand ceramics can be adopted either as tableware or as drinking vessel.

Owner:熊禄生

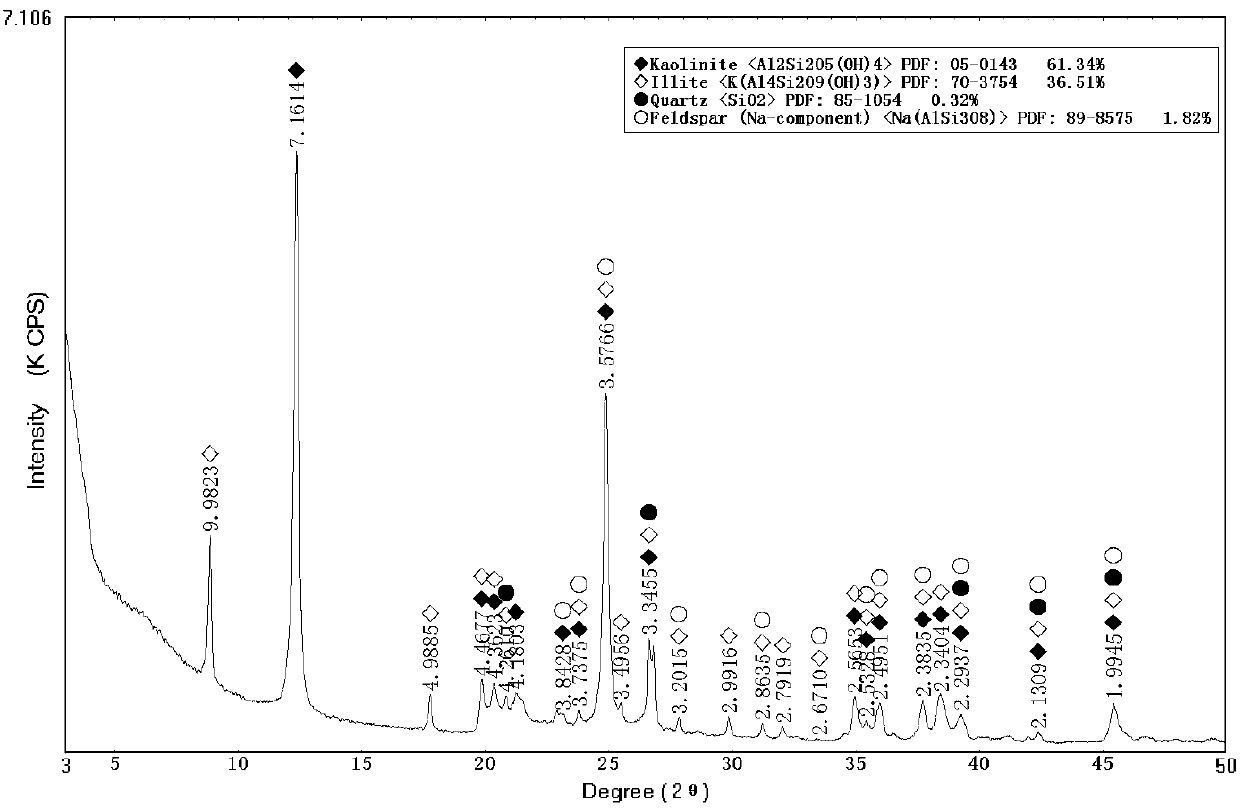

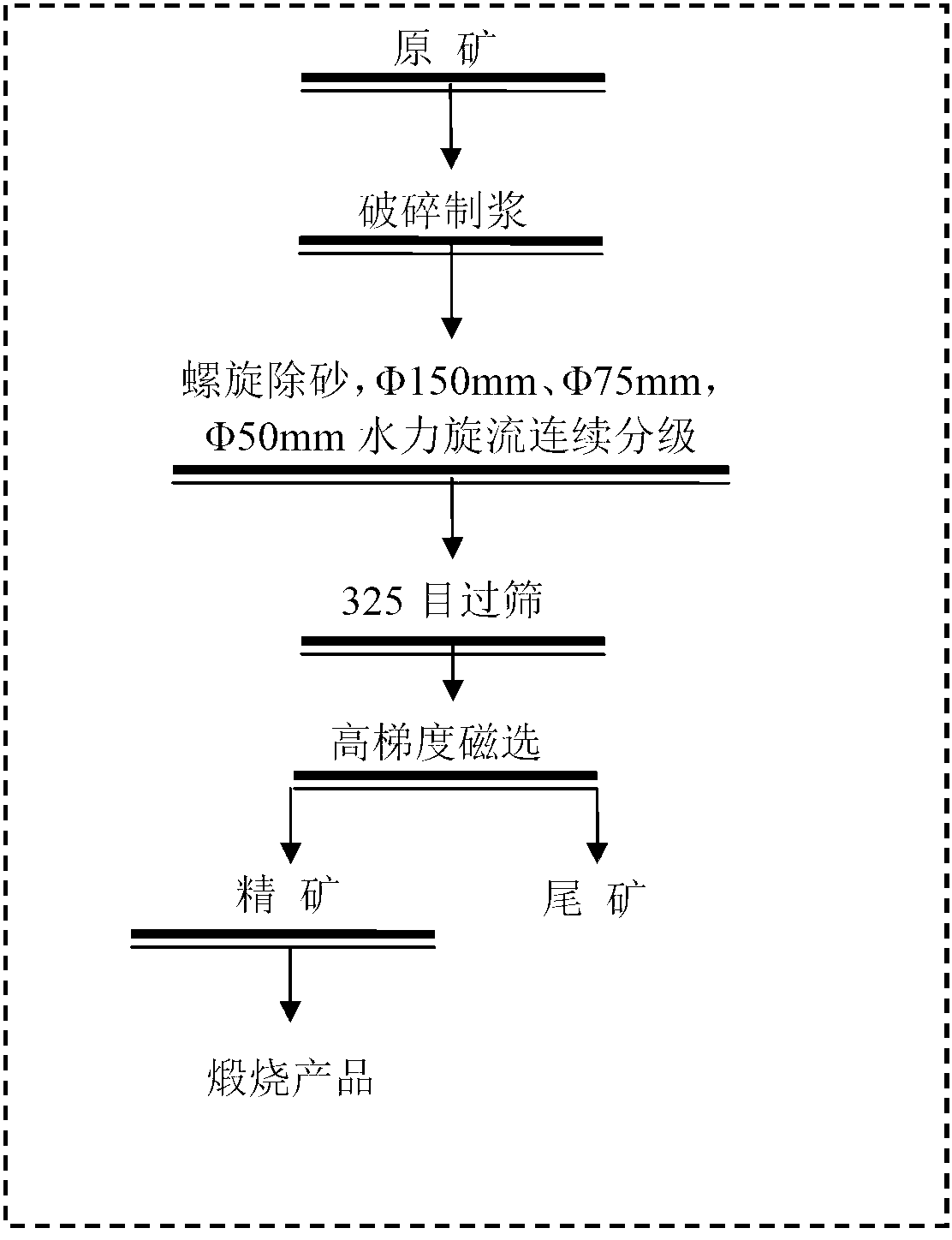

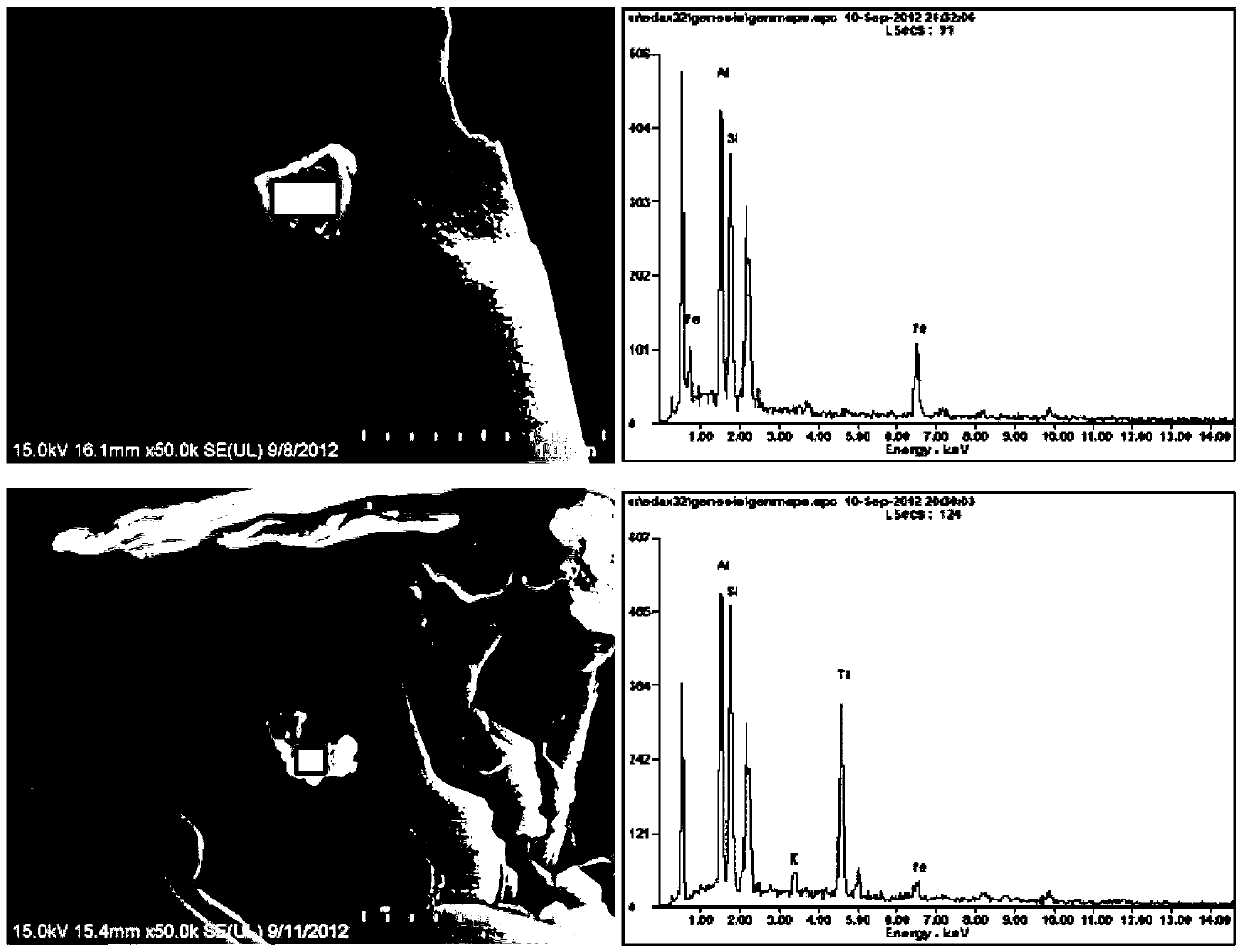

Technique for efficiently removing iron from kaolin

The invention relates to a technique for efficiently removing iron from kaolin by magnetic separation, which is characterized by comprising the following steps: (1) purifying kaolin raw ore to obtain a magnetic separation raw material; (2) adding water to the magnetic separation raw material obtained in the step (1) to prepare a mixed slurry with the solid content of 10-20 wt%, adding sodium hexametaphosphate accounting for 0.2-0.6 wt% of the magnetic separation raw material, slurrying, stirring for 20 minutes, and passing through a 325-mesh wet sieve; (3) carrying out high-gradient magnetic separation on the undersize slurry of the 325-mesh sieve in the step (2): while controlling the magnetic field intensity of the high-gradient magnetic separator at 1.0-1.8T and the slurry flow rate at 0.8-1.8cm / s, the slurry is subjected to magnetic separation by the high-gradient magnetic separator to obtain a concentrate slurry; (4) adding alum accounting for 1-6 wt% of the concentrate slurry into the concentrate slurry obtained in the step (3), flocculating, carrying out pressure filtration, drying, and packaging to obtain a magnetic concentrate; and (5) calcining the magnetic concentrate obtained in the step (4) to obtain the calcined kaolin. The technique has the advantages of high iron removal efficiency and obvious whitening effect.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

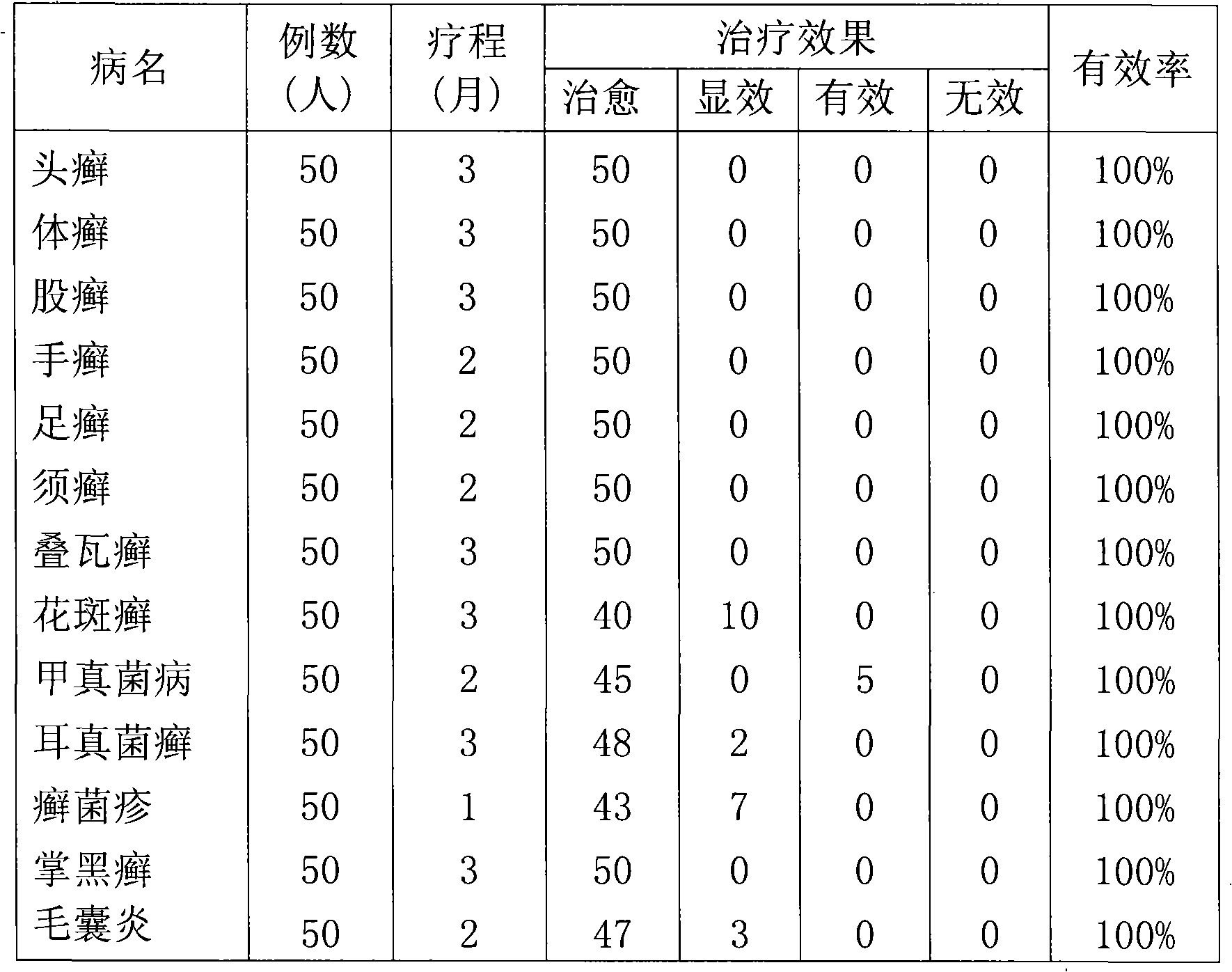

Chinese medicine for curing fungal dermatopathy

InactiveCN101274093ANo side effectsImprove immunityHeavy metal active ingredientsAntimycoticsDiseaseBaical Skullcap Root

The invention relates to a traditional Chinese medicine for curing fungal dermatosis, which is characterized in that: the components of the medicine comprise Group A for oral taking: dyers woad leaf, woad root of dyer, hedyotis diffusa willd, pearl barley, radix rehmanniae, honeysuckle, black ants, red peony, salvia, cogongrass rhizome, joss robe, rhizoma ligustici wallichii, tangerine peel, gardenia, suberect spatholobus, angelica sinensis, Virgate Wormwood Herb; Group B for external application: geranium strictipes, cortex dictamni radicis, belvedere fruit, lightyellow sophora root, cortex pseudolaricis, paniculate swallowwort root, pericarpium zanthoxyli, baical skullcap root, stemona, golden larch bark, notopterygium root, common cnidium fruit, corktree, chrysanthemum, tokyo violet herb, siberian cocklebur fruit, common St. Paulswort herb, dandelion, dried alum, peach seed, olibanum, commiphora myrrha, safflower, hernquecksilvea, sulfur, realgar, galla chinensis, dried ginger and goldthread. The Chinese medicine is applicable to fungal dermatosis and has no toxicity or side effect on human body and can fulfill the purpose of curing diseases.

Owner:广冬云

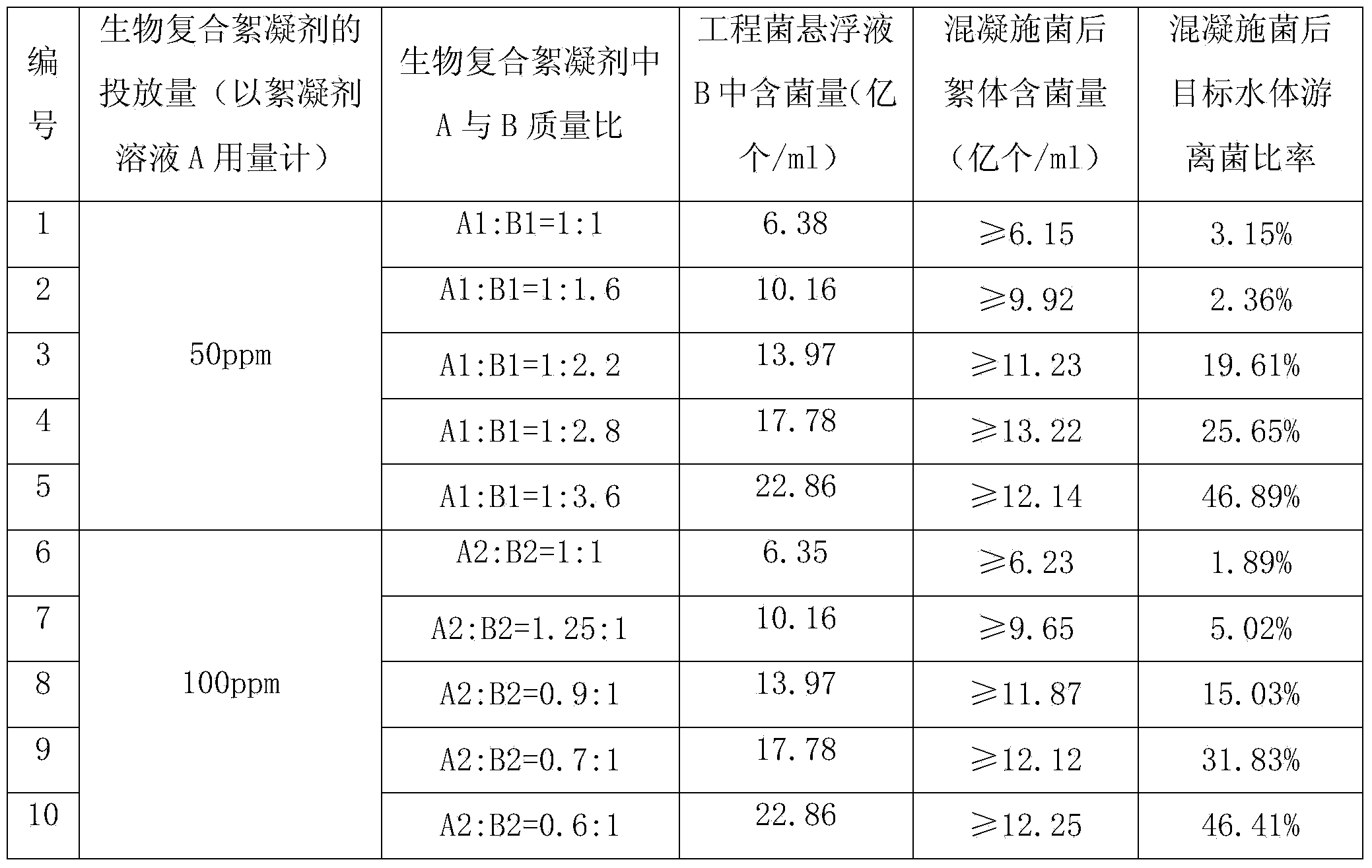

Microorganism composite flocculant coagulation bacterium application method

ActiveCN103922489ADecomposition Strengthening and AccelerationStrengthen and accelerate degradabilityEnergy based wastewater treatmentOn/in organic carrierMicroorganismSewage

Owner:SICHUAN QINGHE TECH

Modified phosphogypsum and its preparation

The present invention discloses a modified phosphogypsum and its preparation process. Its main weight composition is formed from 10-30% of additive (one, two or three kinds of aluminium sulfate slag, alum stone, plant ash, bentonite, slag, dickite, waste liquor and waste residue of paper mill and soda plant, white mud and sepiolite) and 70-90% of phosphogypsum. The phosphogypsum and additive are mixed together, and stacked at a certain temp. so as to obtain the modified phosphogypsum. If said modified phosphogypsum is closed-heated at 30-100 deg.C for 8-48 hr., and formed, dried and can be made into the cement retarded, and if the modified phosphogypsum closed-heated for 8-24 hr, is calcined at 600-900 deg.C, and can be made into cement reinforcing agent.

Owner:孙国庆 +1

Alum-free sweet potato vermicelli capable of invigorating stomach and promoting digestion and preparation technology thereof

InactiveCN104705550AHigh economic valueImprove toughnessFood ingredient functionsFood preparationAdditive ingredientPhosphate

The invention discloses alum-free sweet potato vermicelli capable of invigorating stomach and promoting digestion. The alum-free sweet potato vermicelli is characterized by being prepared from the following raw materials in parts by weight: 400-450 parts of sweet potato starch, 20-22 parts of green bean starch, 1.6-2 parts of xanthan gum, 1.2-1.4 parts of composite phosphate, 20-30 parts of carrot, 10-14 parts of tomato, 14-18 parts of hyacinth bean, 15-25 parts of mushroom, 3-5 parts of lilium pollen, 5-7 parts of gelatine powder, 10-14 parts of water caltrop starch, 14-16 parts of polished round-grained rice, 8-10 parts of coloured malt, 6-8 parts of Chinese yam, 5-7 parts of medicated leaven and 7-9 parts of hawthorn. By the method of replacing alum with green bean starch, xanthan gum and composite phosphate for the sweet potato vermicelli, not only can the toughness and elasticity of vermicelli be increased, but also the bar breaking rate of vermicelli in boiling is reduced; the added raw materials including carrot, tomato, hyacinth bean and the like are capable of increasing the nutritional value of vermicelli; the added traditional Chinese medicine components including coloured malt, Chinese yam and the like are capable of enabling the vermicelli to have the health efficacies of invigorating stomach and promoting digestion and the like, and increasing the economic value of the sweet potato vermicelli.

Owner:陈予诺

Composite cementitious material of desulfurated waste residue and mortar prepared from same

The invention relates to the field of building material, and particularly discloses a composite cementitious material of desulfurated waste residue, wherein the composition of the composite cementitious material of desulfurated waste residue comprises ingredients in the following ratios by weight: 25-40% of desulfurated waste residue, 60-75% of industrial chemical gypsum, 0-20% of inorganic mineral additive and 0-2% of chemical additive. The desulfurated waste residue is at least one of dry-process desulfurated ash, wet-process desulfurated gypsum and semidry-process desulfurated ash; the inorganic mineral additive is at least one of cement, fly ash, mineral powder and steel slag; and the chemical additive is at least one of K2SO4, Al2(SO4)3 and alums. The performances such as compressive strength and tensile bond strength of the mortar prepared from the cementitious material are basically the same as the performances of cement mortar, and the mortar can achieve related standards and requirements. In the composite cementitious material of desulfurated waste residue disclosed by the invention, solid waste is efficiently utilized for preparing composite cementitious material high in performances and low in cost by burning-free treatment process and efficient excitation pre-treatment technology, so that pollution can be reduced and energy can be saved.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

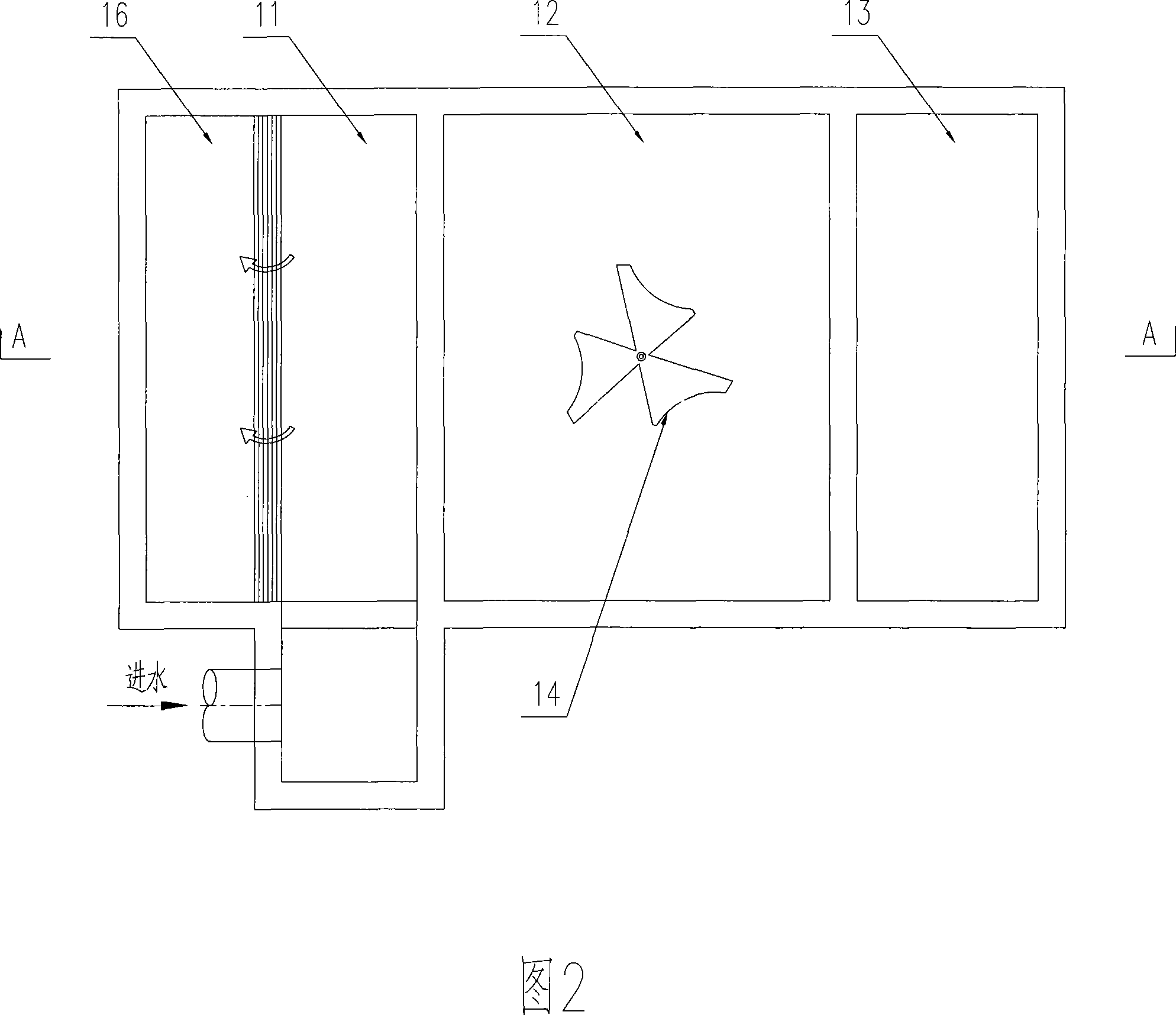

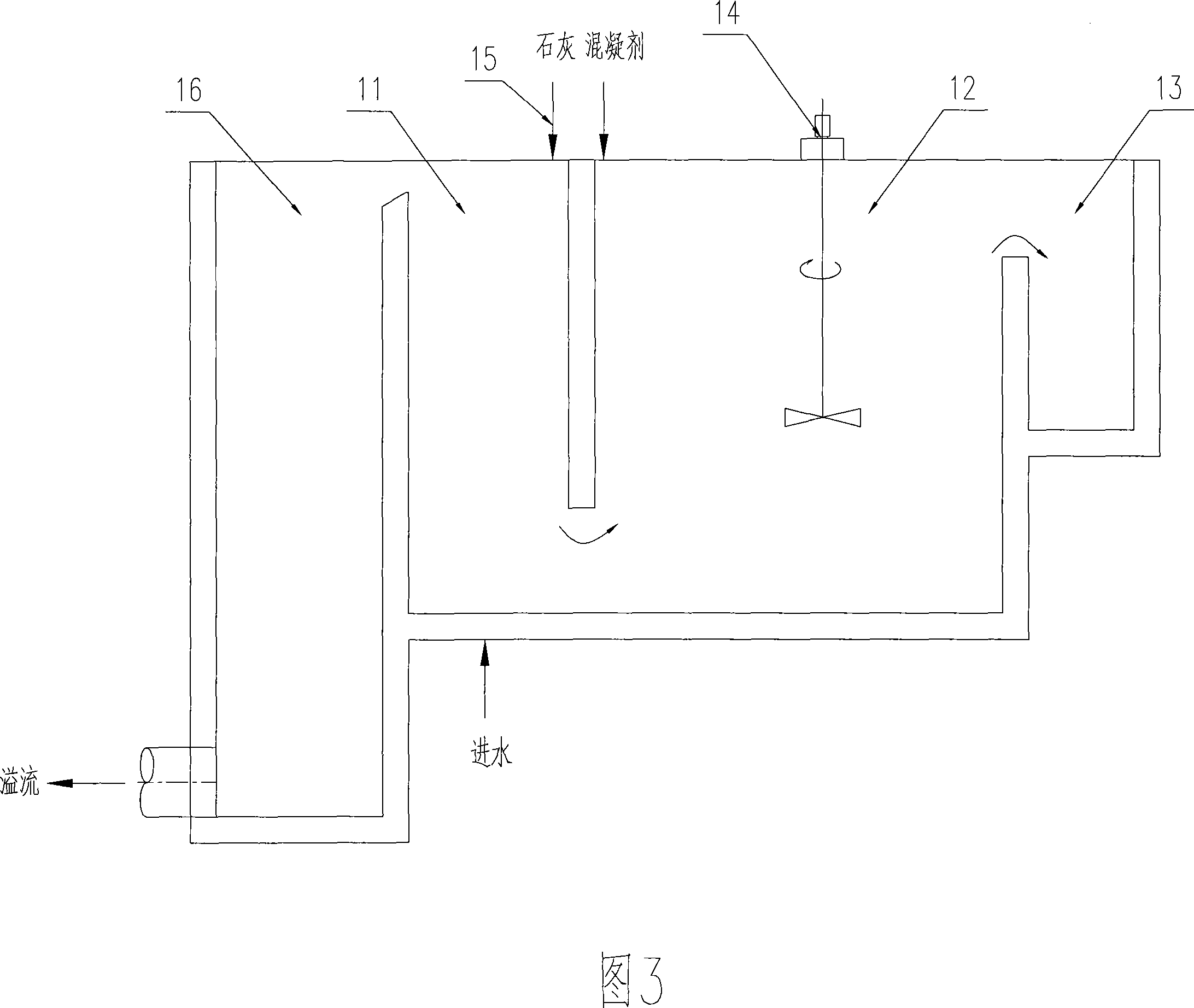

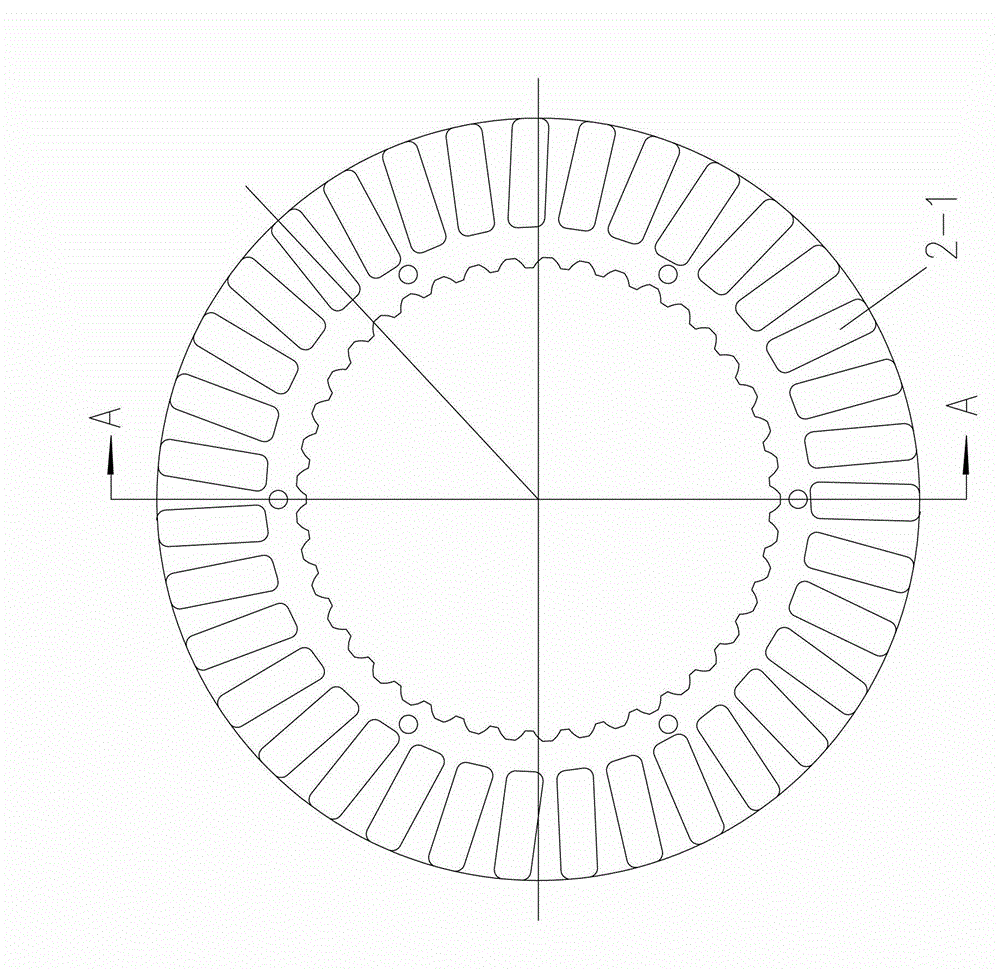

Method and equipment for purifying recirculated cooling water or town B-grade sewage

ActiveCN101117250APromote productionEasy to quantifyWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationPurification methodsWater quality

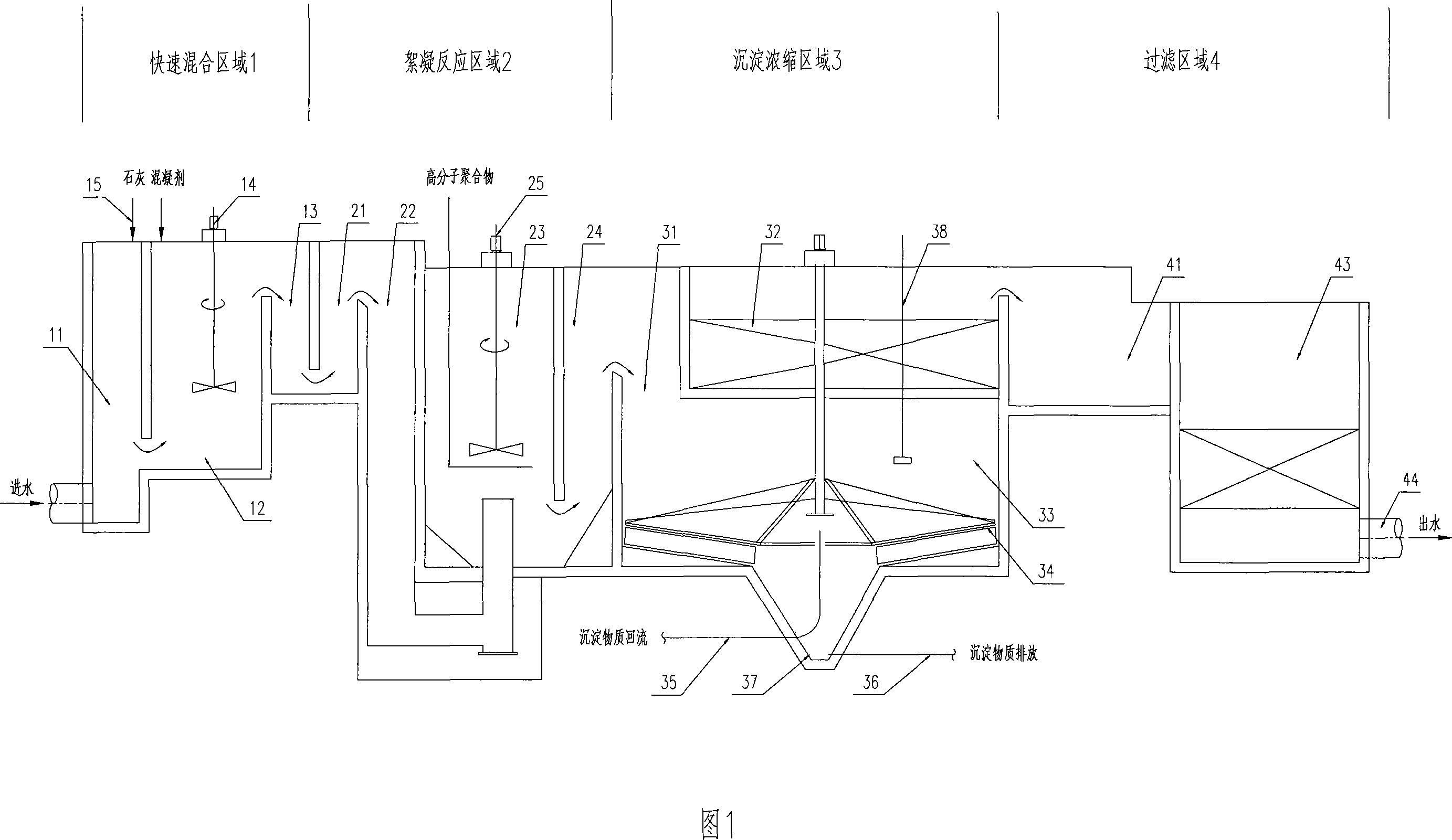

The invention relates to a purification method and equipment for cool circulating water or town secondary sewage water, and is characterized in that the invention has the following steps: a quick mixing zone 1 for mixing a ready treated liquid and a mixing medicament, a flocculating reaction zone 2 for mixing and flocculating a mixed liquid with a backflow deposit substance to get a compact alum at an outlet of the zone, a depositing and concentrating zone 3 for separating a supernatant liquor and a suspension solid and for returning and draining a deposit substance, and a filtering facility zone 4 for purifying the supernatant liquor; the equipment of the invention mainly comprises the quick mixing zone, a high efficient clarification tank and a filtering zone; the invention designs the purification method and equipment for liquid and water; the water quality from the invention is stable, the cost is lower, which changes the prior purification method for liquid and water.

Owner:华电水务(天津)有限公司

Comprehensive recovery method for extracting ferrovanadium from stone coal acid immersion liquid

InactiveCN102127657AEasy to separateEasy to recycleProcess efficiency improvementRecovery methodSlag

The invention relates to a comprehensive recovery method for extracting ferrovanadium from stone coal acid leaching liquid. The process mainly comprises the following steps of: crystallizing a stone coal sulfuric acid leaching liquid into ammonium aluminum alum sulfate and adding a pH value regulator to the crystallized liquid at a room temperature; oxidizing, precipitating and separating out crystallized liquid into a mixture containing ammonium jarosite and ammoniojarosite, leaching the vanadium-contained mixture separated from the precipitate in alkaline to obtain alkaline leaching liquid and alkaline leaching slag; adding sulphuric acid to the alkaline leaching liquid to acidify and precipitate vanadium pentoxide, calcining, washing and drying the vanadium pentoxide to obtain a refined vanadium product, calcining the alkaline leaching slag to obtain ferric oxide or adding sulphuric acid to dissolve, concentrate and crystallize to obtain polymerase ferric sulfate; and transforming the ammonium aluminum alum sulfate and regenerating vanadium precipitation mother liquor alkali, and the like. The invention has the advantages of good product quality, less reagent amount, low production cost, environmental protection, and the like.

Owner:CENT SOUTH UNIV

Method for preparing boil proof vermicelli without alum

A process for preparing the high-toughness alum-free long-thread vermicelli includes such steps as proportionally mixing starch, konjak starch, Arabic gum, straight-chain starch, modified soybean phosphoride, sodium dihydrogen phosphate, sodium carbonate and water, stirring, gelatinizing, cooling, ageing, cutting to become long-thread vermicelli, drying, moistening, drying again and cutting short.

Owner:SHENYANG POLYTECHNIC UNIV

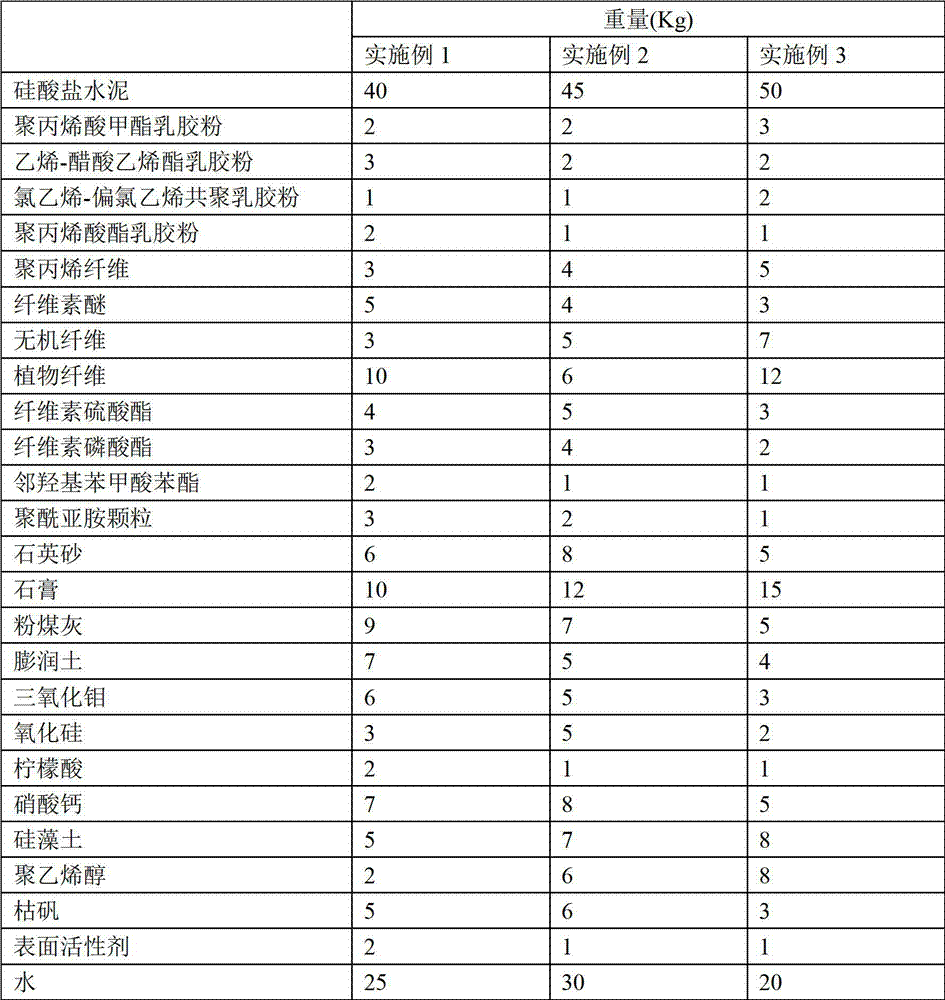

Corrosion-resistant polymer waterproof mortar

The invention provides a corrosion-resistant polymer waterproof mortar, which comprises the following components by weight: 40-50 parts of portland cement, 2-3 parts of polymethyl acrylate latex powder, 2-3 parts of ethylene-vinyl acetate latex powder, 1-2 parts of vinyl chloride-vinylidene chloride copolymerized latex powder, 1-2 parts of polyacrylate latex powder, 3-5 parts of polypropylene fibers, 3-5 parts of cellulose ether, 3-7 parts of inorganic fibers, 6-12 parts of plant fibers, 3-5 parts of cellulose sulfate, 2-4 parts of cellulose phosphate, 1-2 parts of phenyl salicylate, 1-3 parts of polyimide particles, 5-8 parts of quartz sand, 10-15 parts of gypsum, 5-9 parts of fly ash, 4-7 parts of bentonite, 3-6 parts of molybdenum trioxide, 2-5 parts of silicon oxide, 1-2 parts of citric acid, 5-8 parts of calcium nitrate, 5-8 parts of diatomite, 2-8 parts of polyvinyl alcohol, 3-6 parts of dried alum, 1-2 parts of a surfactant, and 20-30 parts of water.

Owner:WUJIANG TIANYUAN PLASTIC

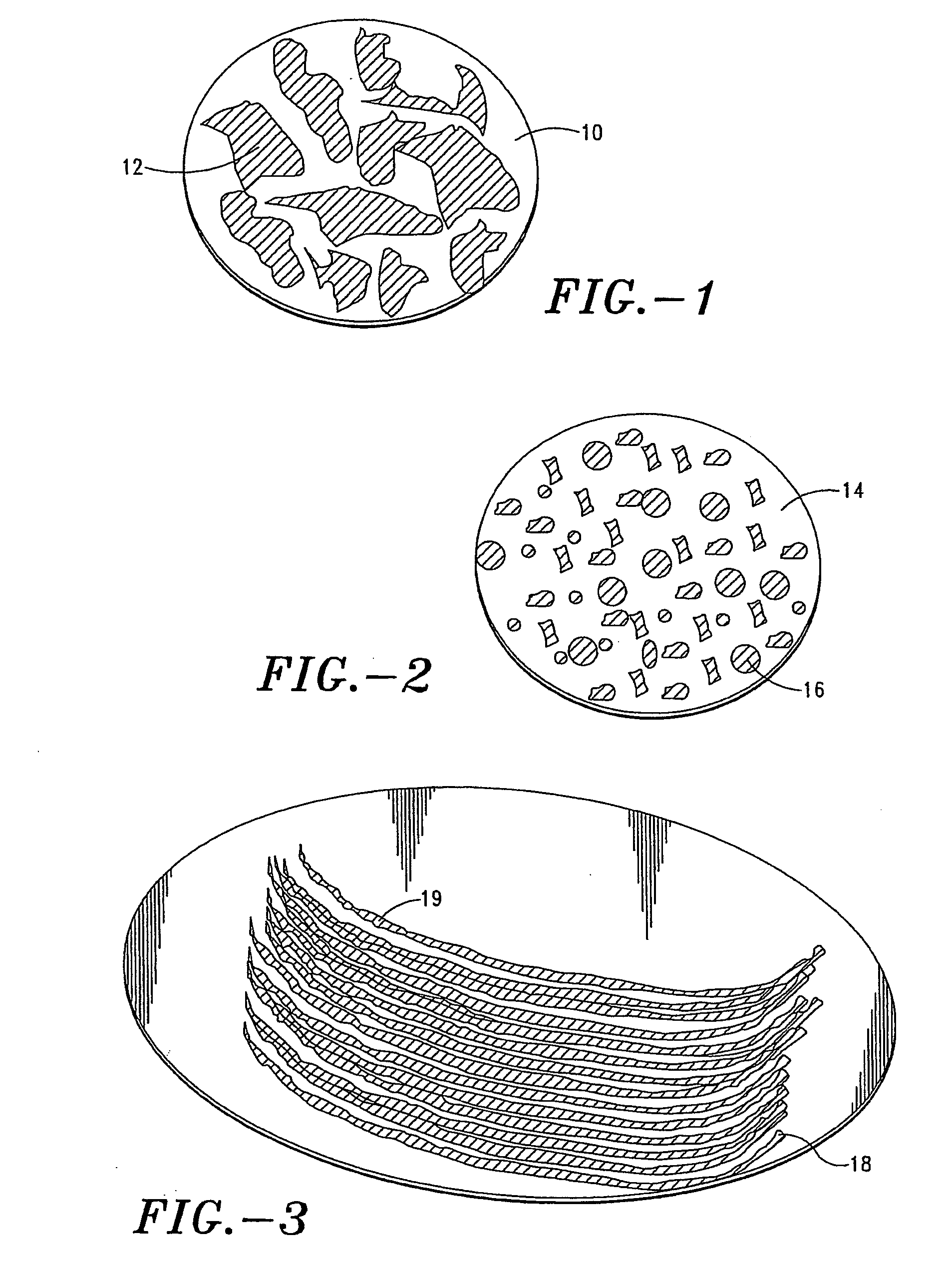

Ceramic-fiber-paper-based friction plate and production method thereof

ActiveCN102878232AGuaranteed stabilityGuaranteed oil conductivityNon-macromolecular organic additionPaper/cardboardAdhesiveBoron carbide

The invention relates to a ceramic-fiber-paper-based friction plate and a production method thereof and aims to provide the friction plate which is high in friction coefficient and fine in wear resistance and the production method which is simple in procedure and easy and convenient for production. According to the technical scheme, the ceramic-fiber-paper-based friction plate comprises ceramic fiber, carbon fiber, aramid pulp fiber, long staple cotton paper, diatomite, cashew shell oil friction powder, calcium carbonate whisker, boron carbide, potassium feldspar powder, rubber granule, iron sulfide, mica, alum, magnesia, cashew shell oil modified phenolic resin, powdered fluorine rubber, butyronitrile rubber latex, boron-tung oil modified phenolic resin and moderate additives. The production method includes the steps of firstly, producing pretreatment material, mixing material and size and performing papermaking to produce raw paper of ceramic-fiber-paper-base friction material; and secondly, soaking the raw paper in adhesive, cutting into strips after hot-pressing solidification, and adhering to a friction plate core plate to obtain the ceramic-fiber-paper-based friction plate.

Owner:杭州克尔菲利科技有限公司

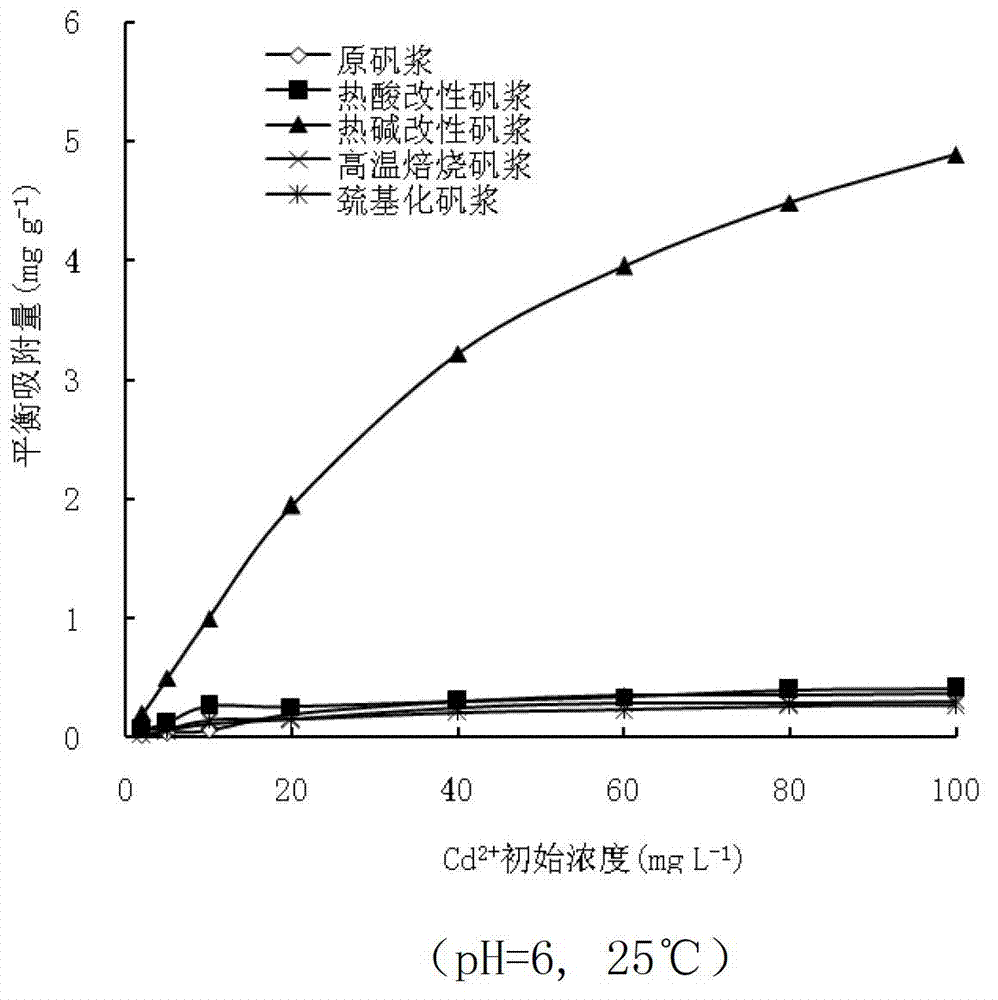

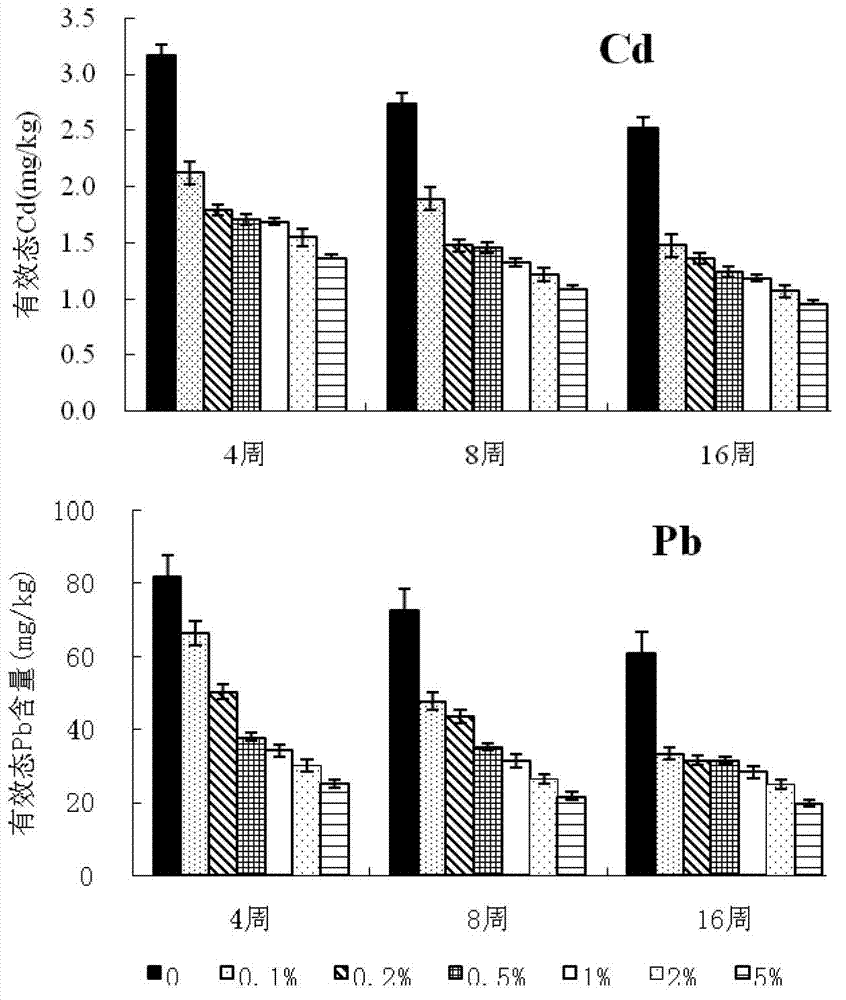

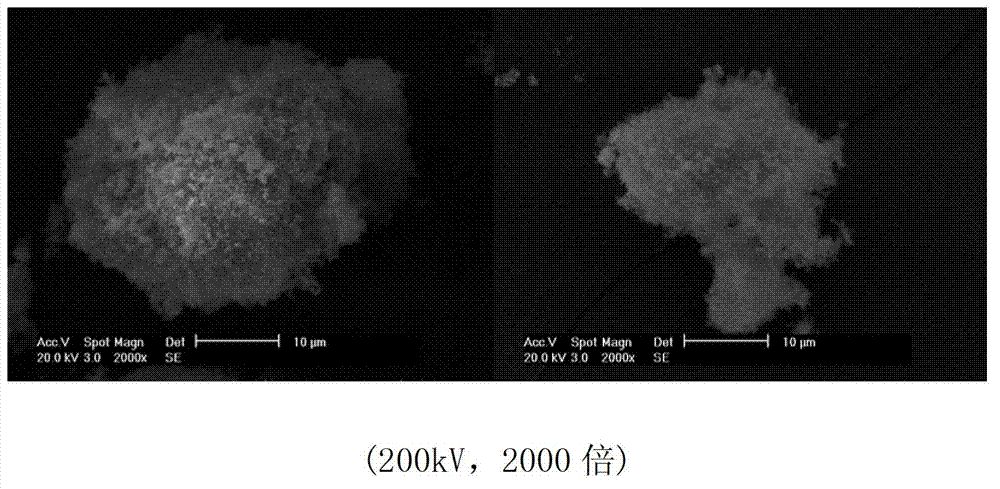

Method for remedying cadmium (Cd) and lead (Pb) polluted soil by alum pulp in situ

InactiveCN102962250AImprove adsorption capacityImprove passivation effectContaminated soil reclamationIn situ remediationAlum

The invention discloses a method for remedying cadmium (Cd) and lead (Pb) polluted soil by alum pulp in situ and belongs to the technical field of in-situ remediation of heavy metal polluted soil. The method comprises the following steps: (1) preparation of hot-alkali modified passivant of heavy metal polluted soil; (2) selection of Cd and Pb polluted soil suitable to in-situ remediation by alum pulp passivant; and (3) in-situ remediation of heavy metal Cd and Pb polluted soil. In the method, the by-product alum pulp in the production of alum is taken as a raw material which is activated and modified by hot alkali to form an efficient heavy metal passivant, and by the passivant, the contents of the exchangeable Cd and Pb in the soil can be lowered by over 60% and 65% respectively in one to four months; and the method has the characteristics of low raw-material cost, simple production technology, stable passivation effect, operation simpleness and the like. The method can be popularized and used in farmland soil with medium-low Cd and Pb pollution.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

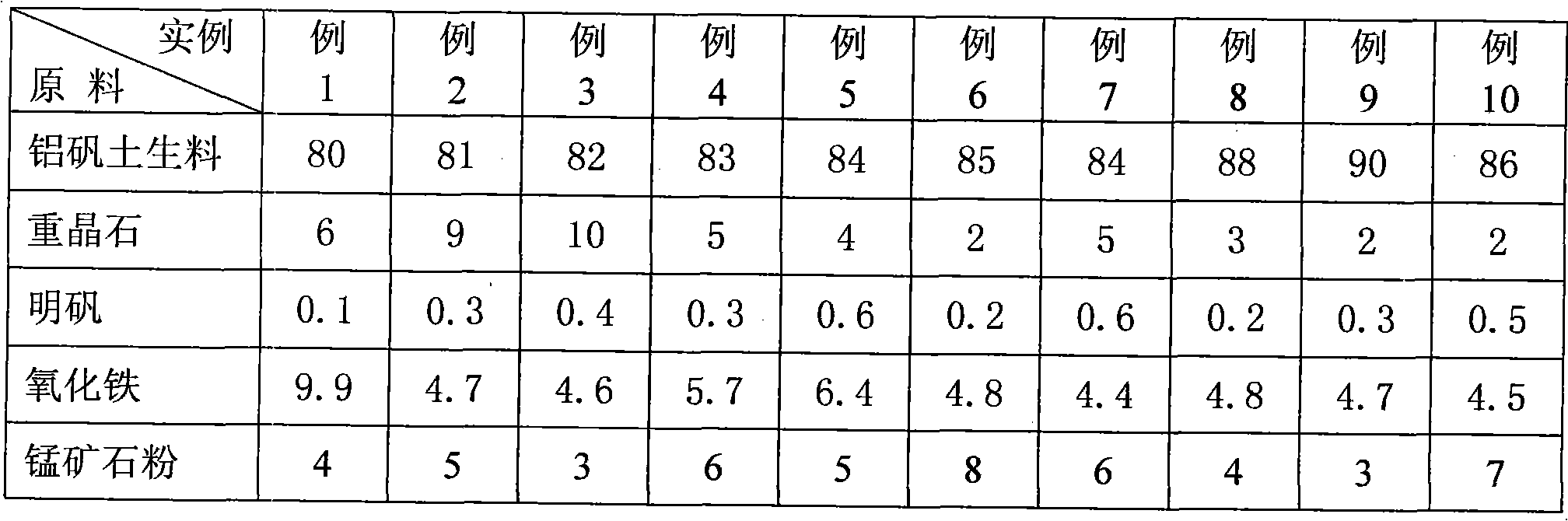

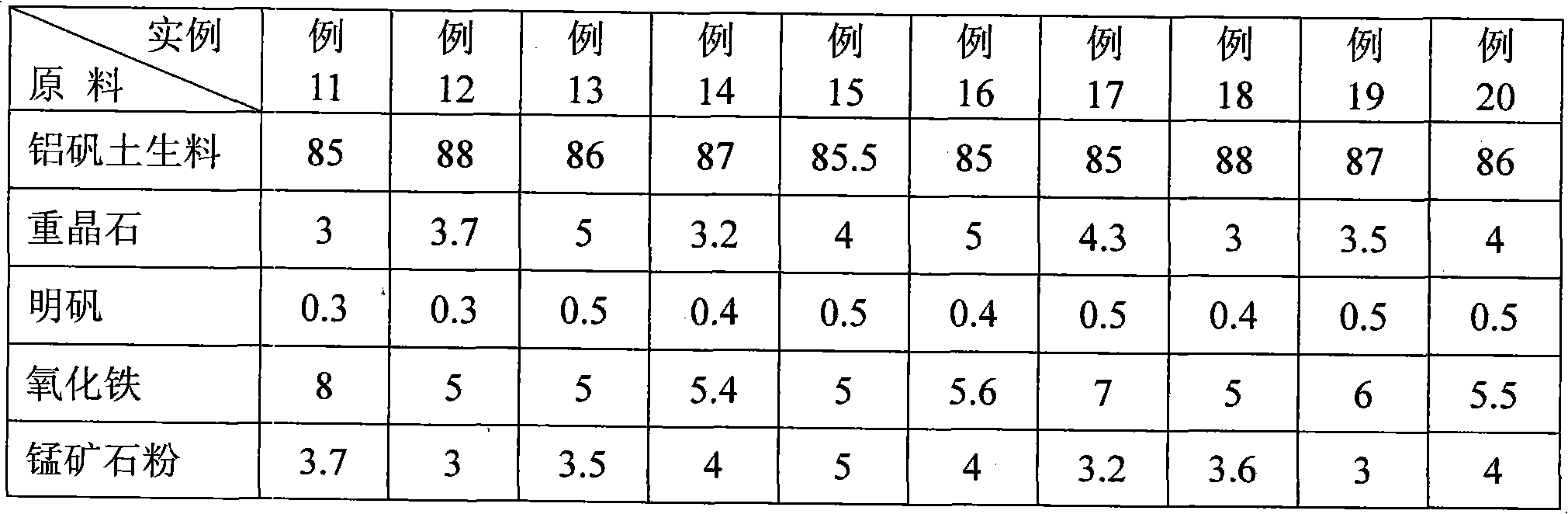

High-strength ceramsite propping agent and production method thereof

ActiveCN101914374AHigh compressive strengthThe ingredients are well matchedFluid removalHigh surfacePetroleum

The invention relates to a high-strength ceramsite propping agent and a production method thereof. The high-strength ceramsite propping agent is prepared from the following components in percentage by weight: 80-90 percent of raw bauxite raw material, 2-10 percent of barite, 0.1-0.6 percent of alum, 4-10 percent of iron oxide and 3-8 percent of manganese powder. The invention adopts carefully chosen raw materials and reasonable component matching, the ceramsite propping agent forms more porzite phases and partial jade phases at a high temperature by adding the barite, the alum and the iron oxide under the catalysis of the manganese powder so as to greatly improve the compressive strength. The crushing rates of the product under the pressure of 69 MPa, 86 MPa and 100 MPa are respectively lower than 3.5 percent, 6.5 percent and 9.5 percent, and the product has higher surface smoothness, effectively improved product quality, decreased oil cracking cost, less raw materials, easily obtained raw materials, simplified production process, small investment, low cost and easy popularization and implementation.

Owner:郑州德赛尔陶粒有限公司

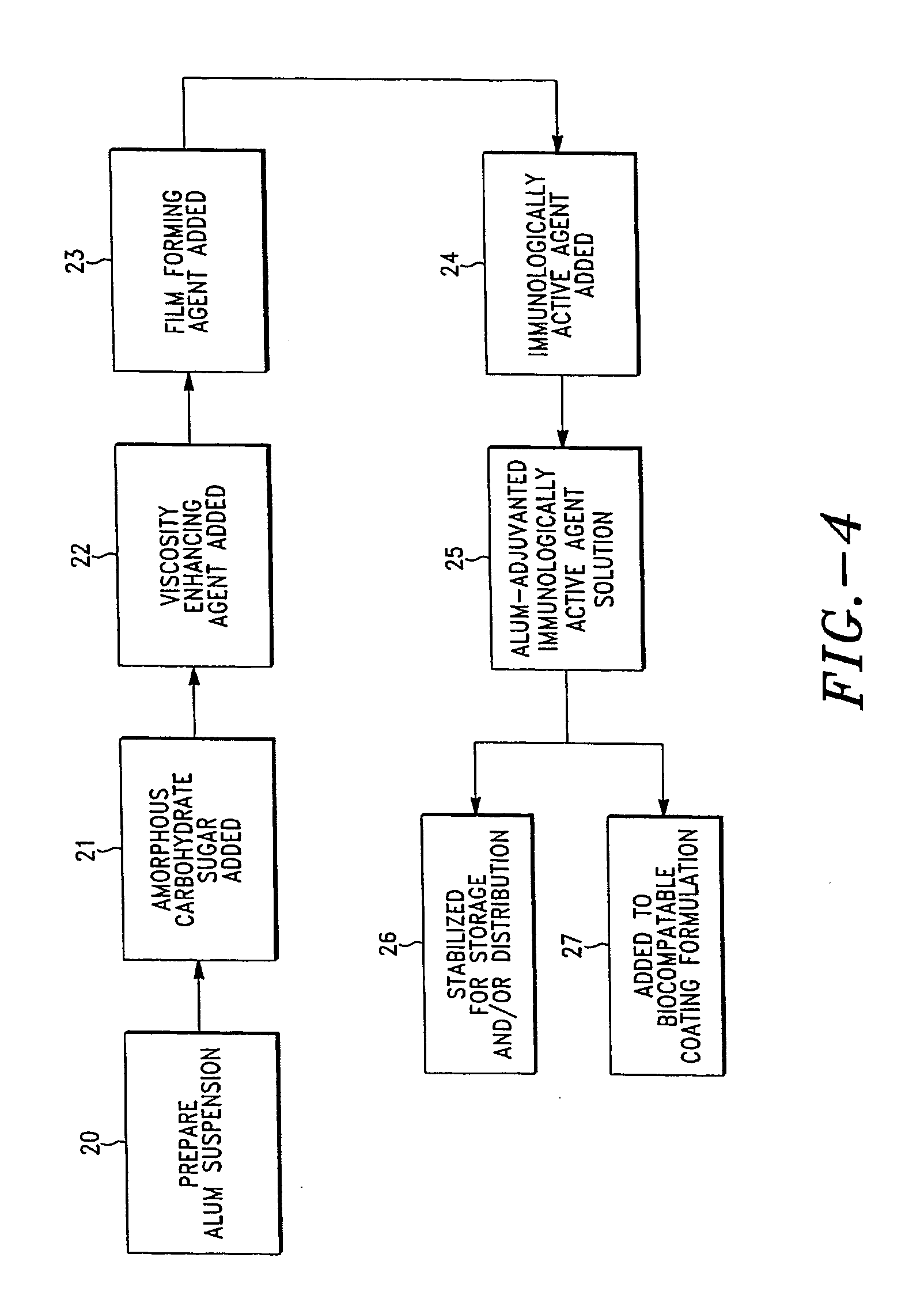

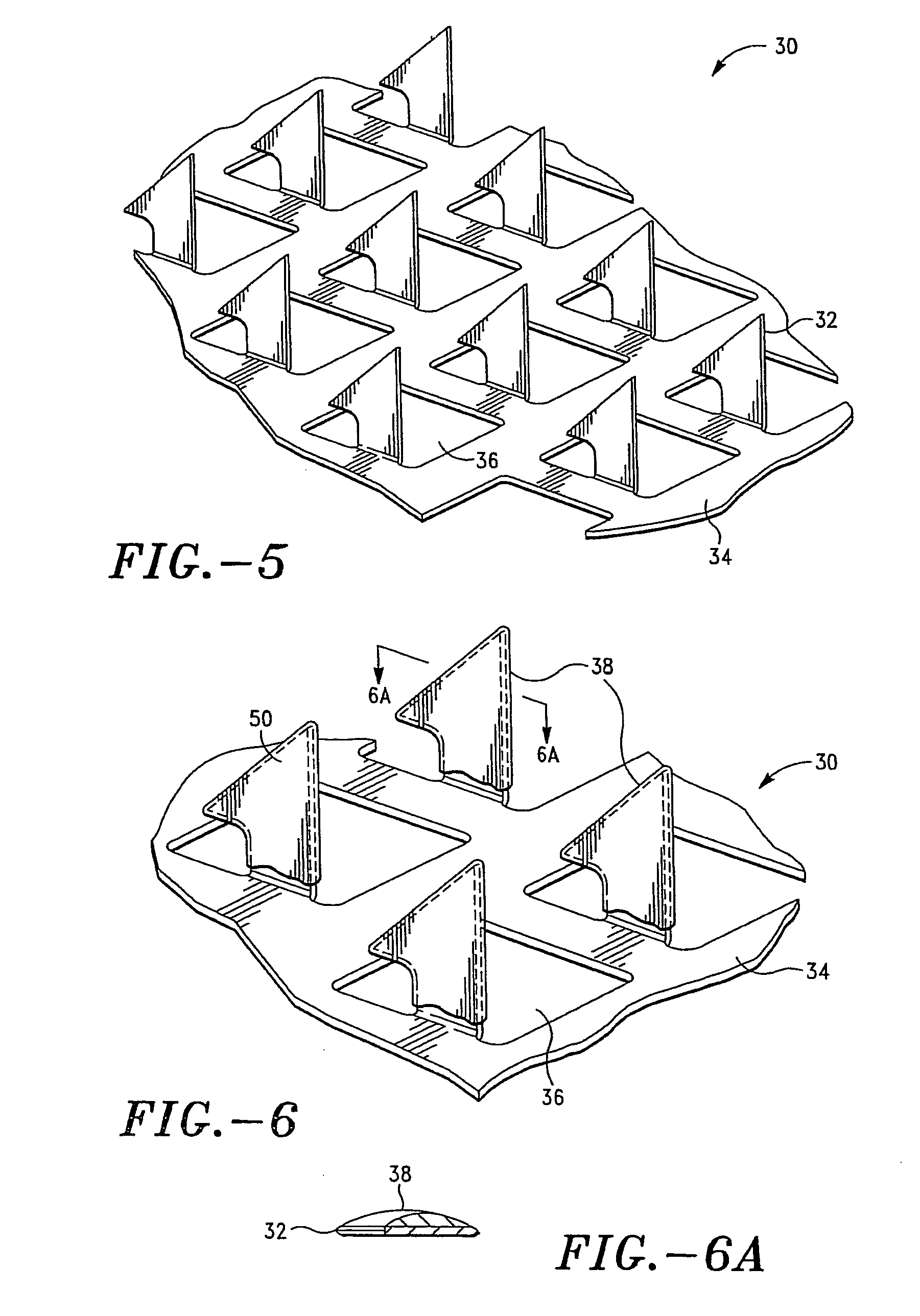

Stabilization of alum-adjuvanted immunologically active agents

InactiveUS20060067943A1Improve the level ofEnhancement is mitigated or avoidedBiocideOrganic active ingredientsAdjuvantAlum adjuvant

A composition and method for formulating and delivering an adjuvanted immunological active agent, especially a vaccine, wherein adjuvant coagulation and concomitant loss of vaccine efficacy enhancement is mitigated or avoided. The adjuvanted, immunologically-active agent can be subjected to freezing, drying, freeze-drying, or lyophilization, and when reconstituted, retains a high level of potency. The present invention further provides for a composition and method for formulating and delivering a stable, adjuvanted, immunologically-active agent capable of being deposited on a transdermal delivery device or microprojection or array thereof.

Owner:ALZA CORP

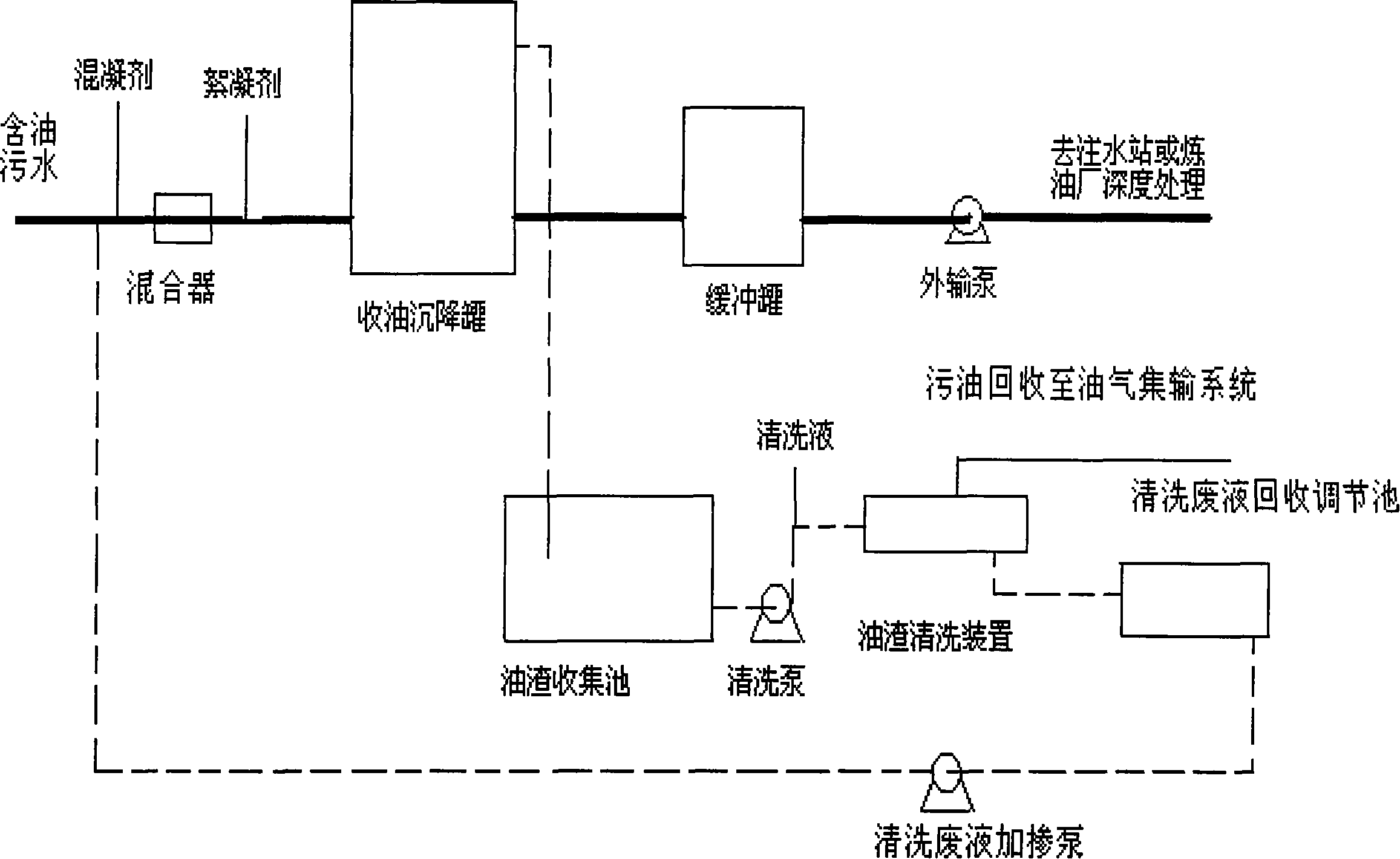

Oily sewage processing method

InactiveCN101139142AReduce processing costsDoes not affect operationFatty/oily/floating substances removal devicesMultistage water/sewage treatmentLiquid wasteSewage

The present invention relates to a treatment method of oil-bearing sewage. Megadose coagulants are added in the oil-bearing sewage so as to carry out gel and milk breaking on the sewage and to form small alum flowers, and then polymer organic flocculating agents are added toenlarge the small alum flowers and then oil residues are formed in an oil-receiving flow tank to separate from water, thus sewage is purified. The oil residues are recycled in an oil residue collecting pool by a dirty oil collecting device and then pumped to an oil residue cleaning device, and oil residue cleaning liquor is added after being pumped to enter the oil residue cleaning device again. The oil residues are cleaned and the ''clean'' dirty oil acquired enters an oil gas gathering system then. The cleaning waste liquor acquired after the oil residues are cleaned is added into flow inlet water through a pump according to a certain proportion. The cleaning waste liquor is added in the inlet water as the coagulant to lead the coagulants originally added to be recycled. The present invention leads the treatment of water containing high oil stain to generate no secondary discharge pollution. The oil stain recycling rate reaches to 99 percent and the present invention has the advantages of low sewage treatment cost, few device and technics alternation and low alternation cost. The dirty water after treated meets corresponding standards.

Owner:洪骧龙

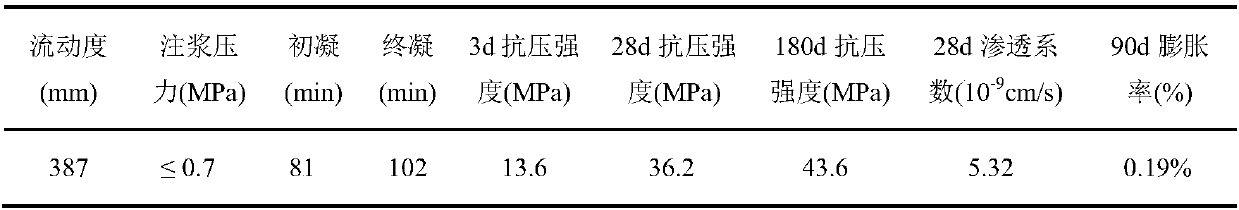

High-performance superfine cement based grouting material for microfissuring and silty fine sand soil grouting treatment and application of grouting material

The invention discloses a high-performance superfine cement based grouting material for microfissuring and silty fine sand soil grouting treatment, and application of the grouting material. The grouting material comprises the following ingredients in parts by weight: 50-79 parts of Portland cement clinker, 19-48 parts of an auxiliary cementing material and 2-7 parts of desulfurized gypsum, whereinthe auxiliary cementing material comprises the following ingredients in parts by weight: 25-57 parts of mineral slag, 8-21 parts of steel slag, 18-36 parts of pulverized fuel ash, 6-12 parts of limestone flour, 1-8 parts of silica fume and 2.5-12.8 parts of a high-performance composite regulator; the high-performance composite regulator comprises the following ingredients in parts by weight: 5-16parts of sodium hydroxide, 4-12 parts of sodium silicate, 4-14 parts of potassium metaaluminate, 12-21 parts of calcium chloride, 11-18 parts of lithium chloride, 4-12 parts of triethanolamine, 21-27parts of alum, 18-29 parts of aluminum sulfate, 0.2-1.5 parts of hydroxypropyl methyl cellulose, 0.1-3.0 parts of viscous polymer, 0-0.8 parts of polypropylene fiber and 0.5-3.0 parts of a superplasticizer; and the viscous polymer is an acrylic ester polymer or an ethylene-vinyl acetate copolymer.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com