Microorganism composite flocculant coagulation bacterium application method

A technology of microbial flocculants and composite flocculants, applied in biochemical equipment and methods, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problem of large pollution load of target water, and achieve improved water transparency, strong Flocculation and adsorption, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] a. Preparation of flocculant solution A: dissolving the flocculant in water to obtain flocculant solution A; wherein, the flocculant is at least one of a macromolecular inorganic flocculant, a macromolecular organic flocculant, and a microbial flocculant;

[0027] b. Preparation of engineering bacteria suspension B: mix and stir the engineering bacteria powder with water to obtain engineering bacteria suspension B; wherein, the engineering bacteria powder is obtained by adsorbing engineering bacteria with an adsorbent; the adsorbent is zeolite Powder, diatomite powder at least one; said engineering bacteria are photosynthetic bacteria, photosynthetic bacteria, lactic acid bacteria, yeast, bacillus, acetic acid bacteria, bifidobacteria, actinomycetes, nitrifying bacteria, denitrifying bacteria at least one of

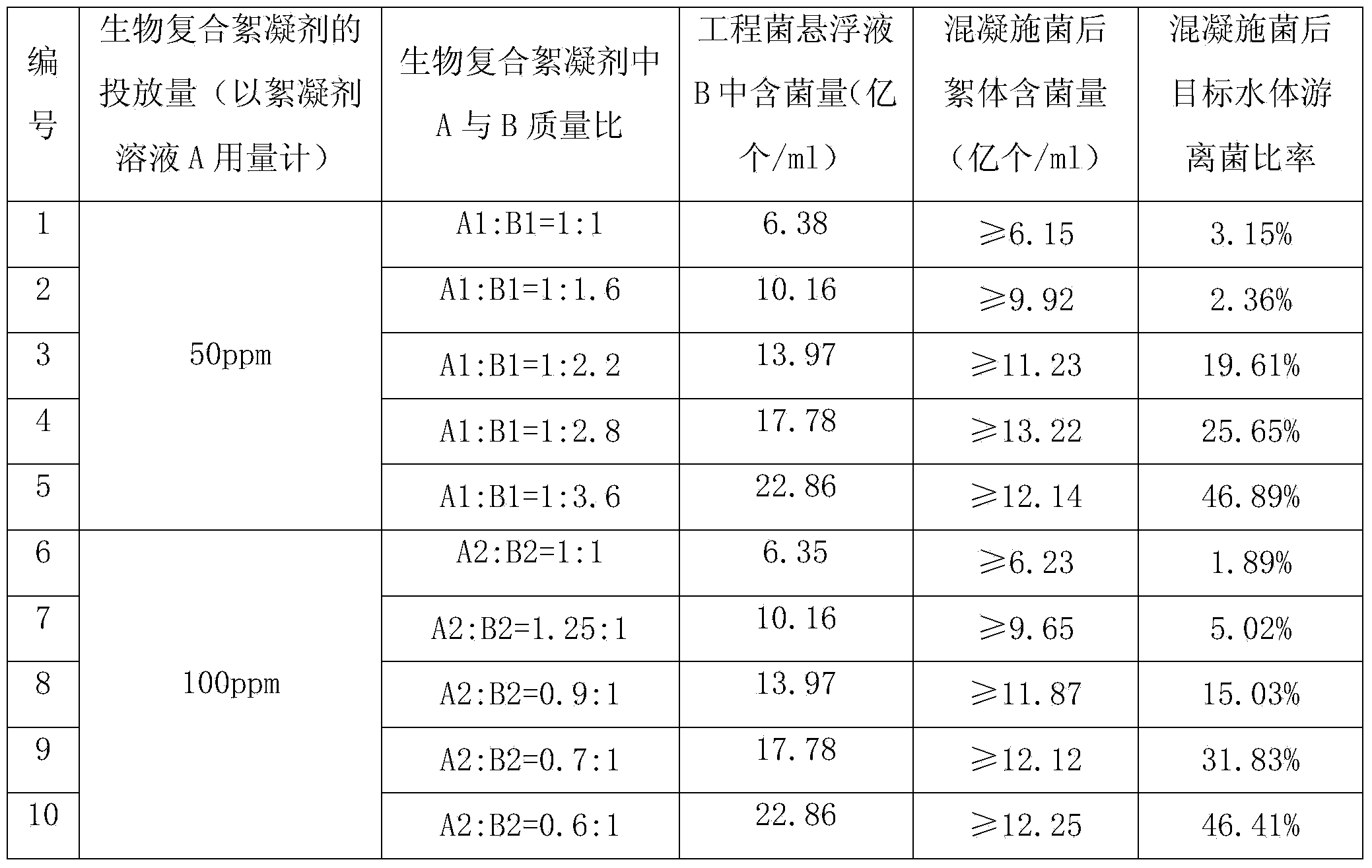

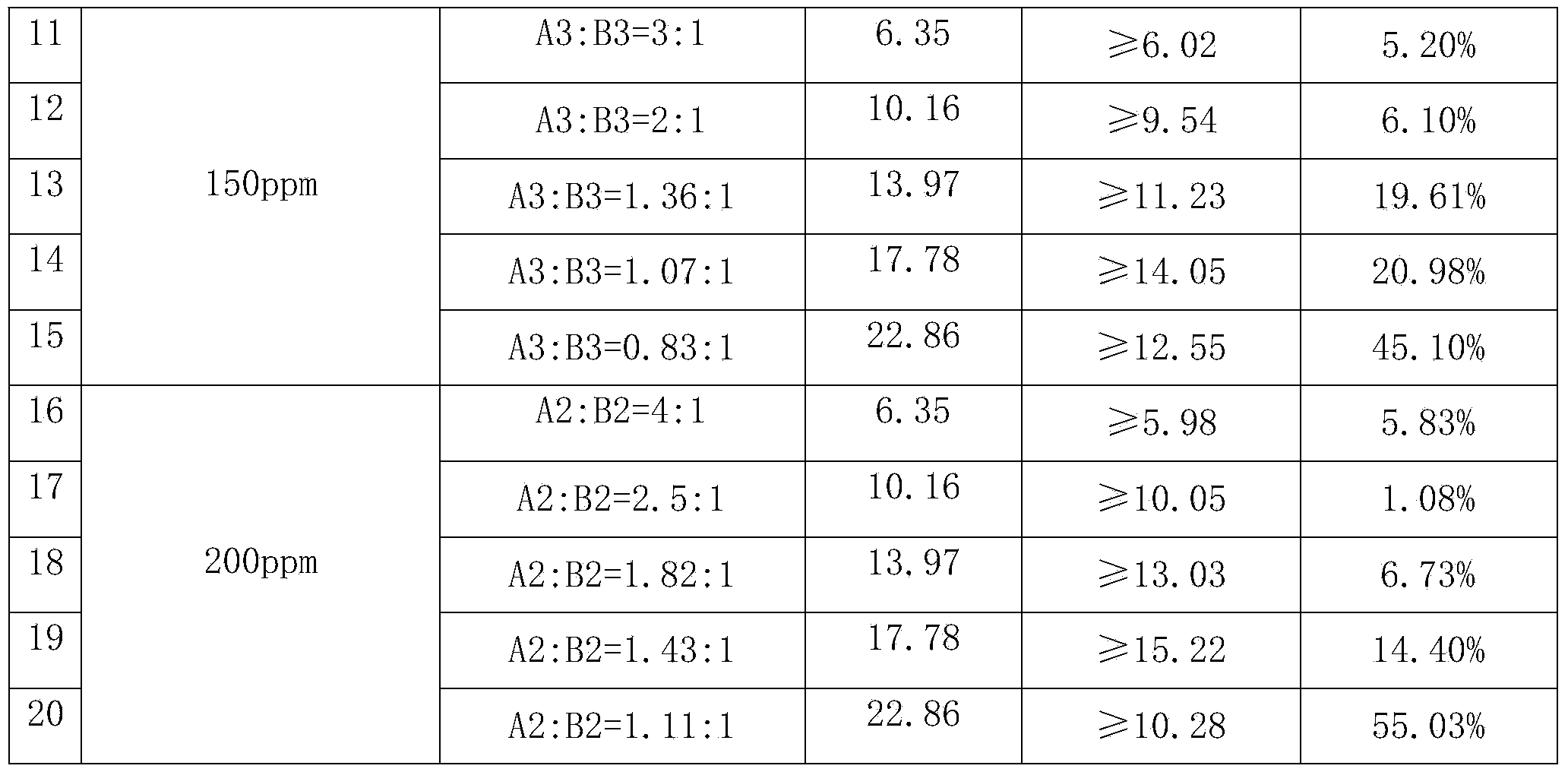

[0028] c. Coagulation and bacteria application: Mix the flocculant solution A and the engineering bacteria suspension B, and stir to obtain alum flowers, which are ...

Embodiment 1

[0044] a. Preparation of flocculant solution A: Dissolve 1kg of polyaluminum ferric silicate in 30kg of water and stir for 30min at a rate of 30r / min to obtain flocculant solution A1;

[0045] b. Preparation of engineering bacteria suspension B: 1 kg of engineering bacteria powder was mixed with 30 kg of water, and stirred at a rate of 30 r / min for 10 min to obtain engineering bacteria suspension B1; wherein, the engineering bacteria powder was produced by Sichuan Qinghe Technology Co., Ltd. The produced EPSB engineering bacteria (concentrate) is mixed and adsorbed with zeolite powder; the bacteria content in the engineering bacteria powder is 3 billion / g; the particle size of the zeolite powder is 120 mesh.

Embodiment 2

[0047] a. Preparation of flocculant solution A: Dissolve 1 kg of polyaluminum chloride in 40 kg of water and stir for 20 min at a rate of 60 r / min to obtain flocculant solution A2;

[0048] b. Preparation of engineering bacteria suspension B: mix engineering bacteria powder with water, stir at a rate of 30-100r / min for 5-10min, and obtain engineering bacteria suspension B2; wherein, said engineering bacteria powder is composed of Bacillus subtilis , Bacillus detritus and Rhodopseudomonas concentrated bacterial liquid mixed with diatomaceous earth fine powder and adsorbed; the bacteria content in the engineering bacteria powder is 3 billion / g; the particle size of the adsorbent is 120 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com