Patents

Literature

126242 results about "Pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pollution is the introduction of contaminants into the natural environment that cause adverse change. Pollution can take the form of chemical substances or energy, such as noise, heat or light. Pollutants, the components of pollution, can be either foreign substances/energies or naturally occurring contaminants. Pollution is often classed as point source or nonpoint source pollution. In 2015, pollution killed 9 million people in the world.

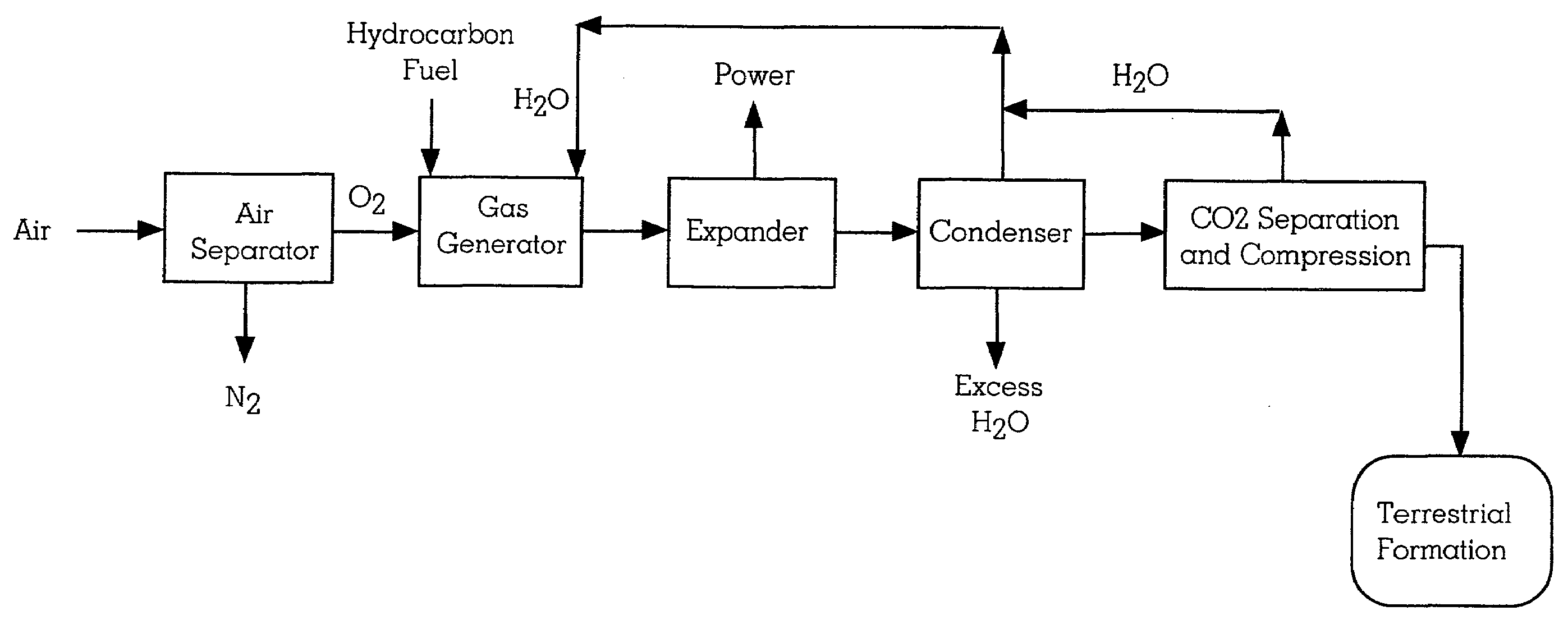

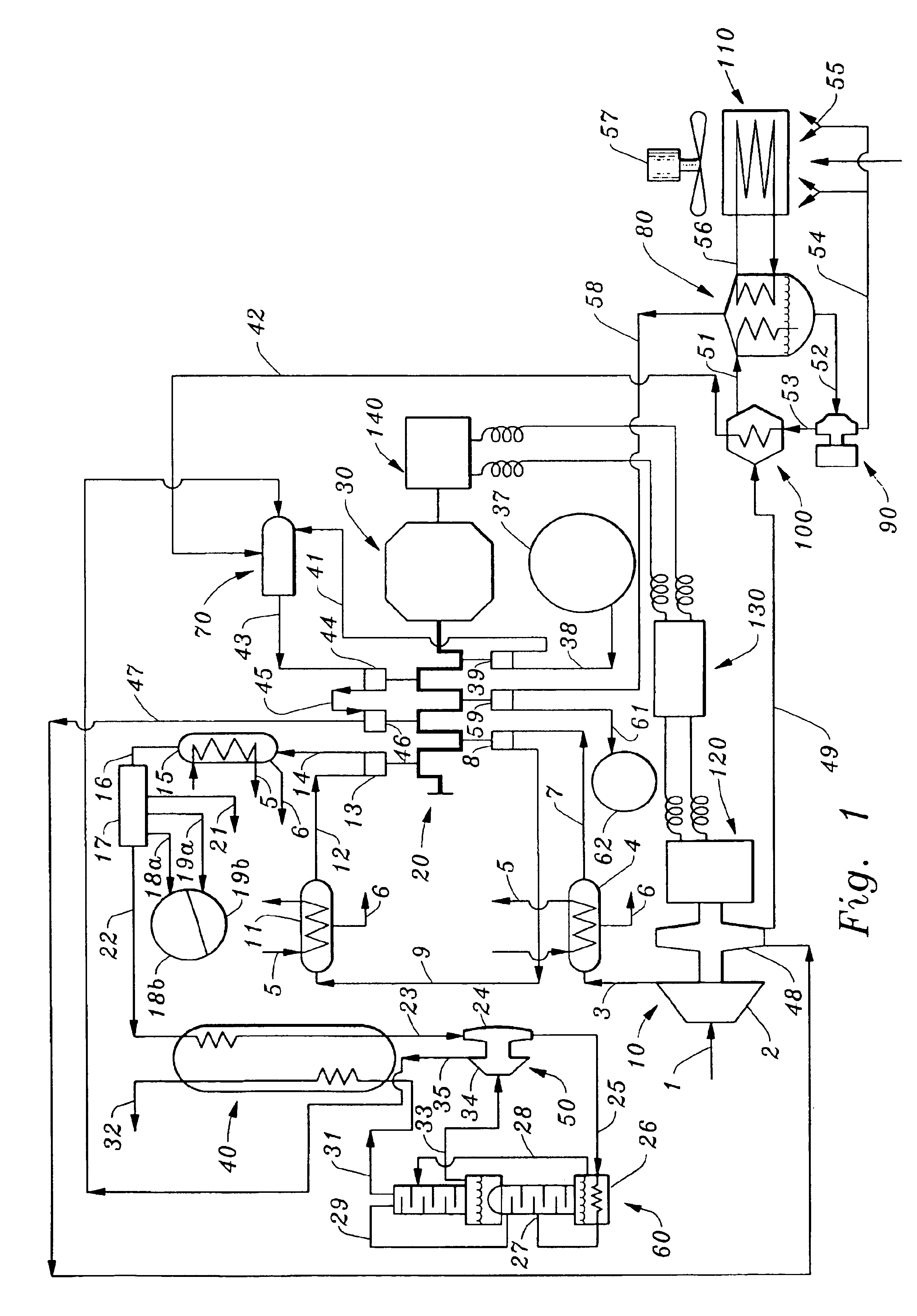

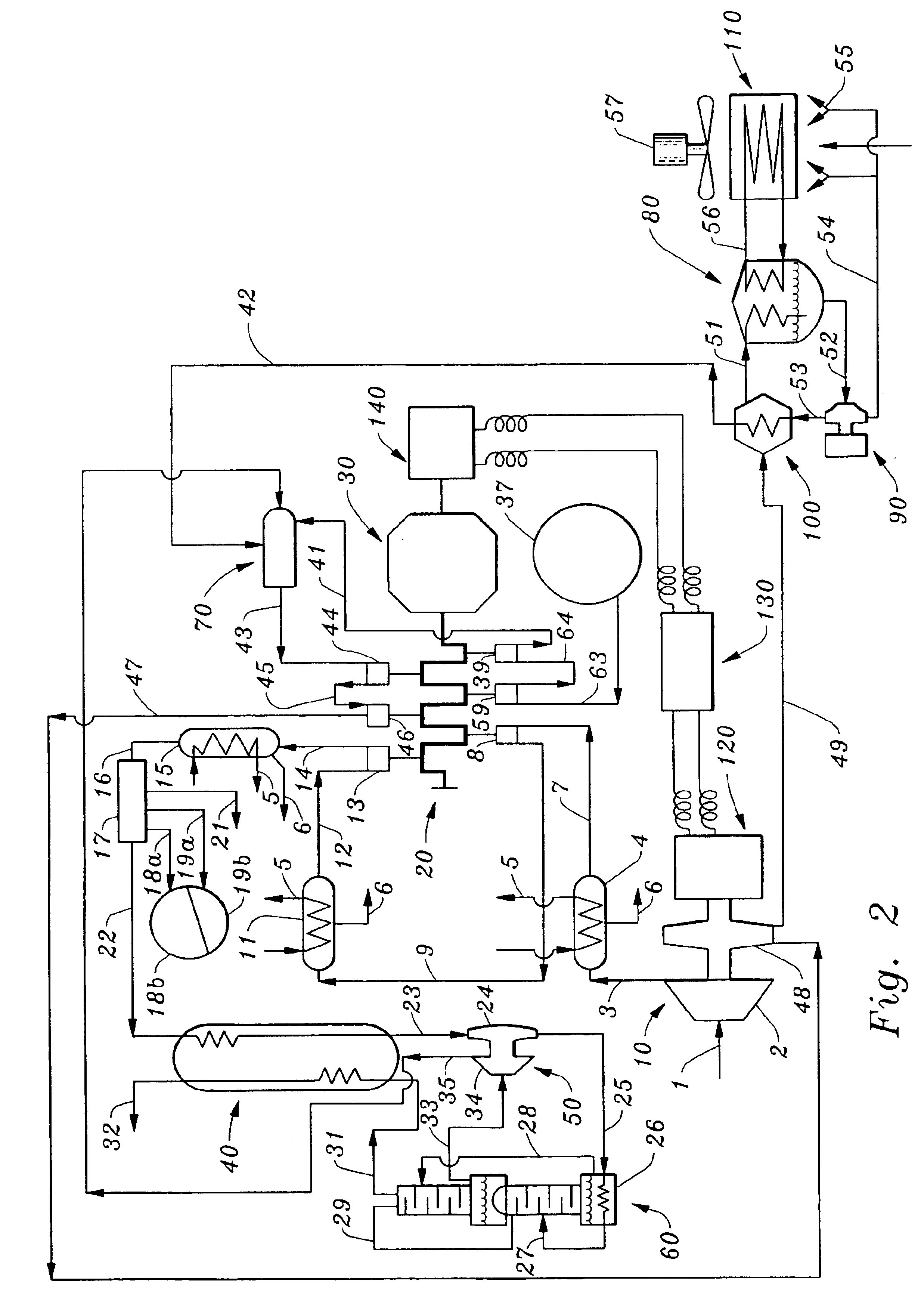

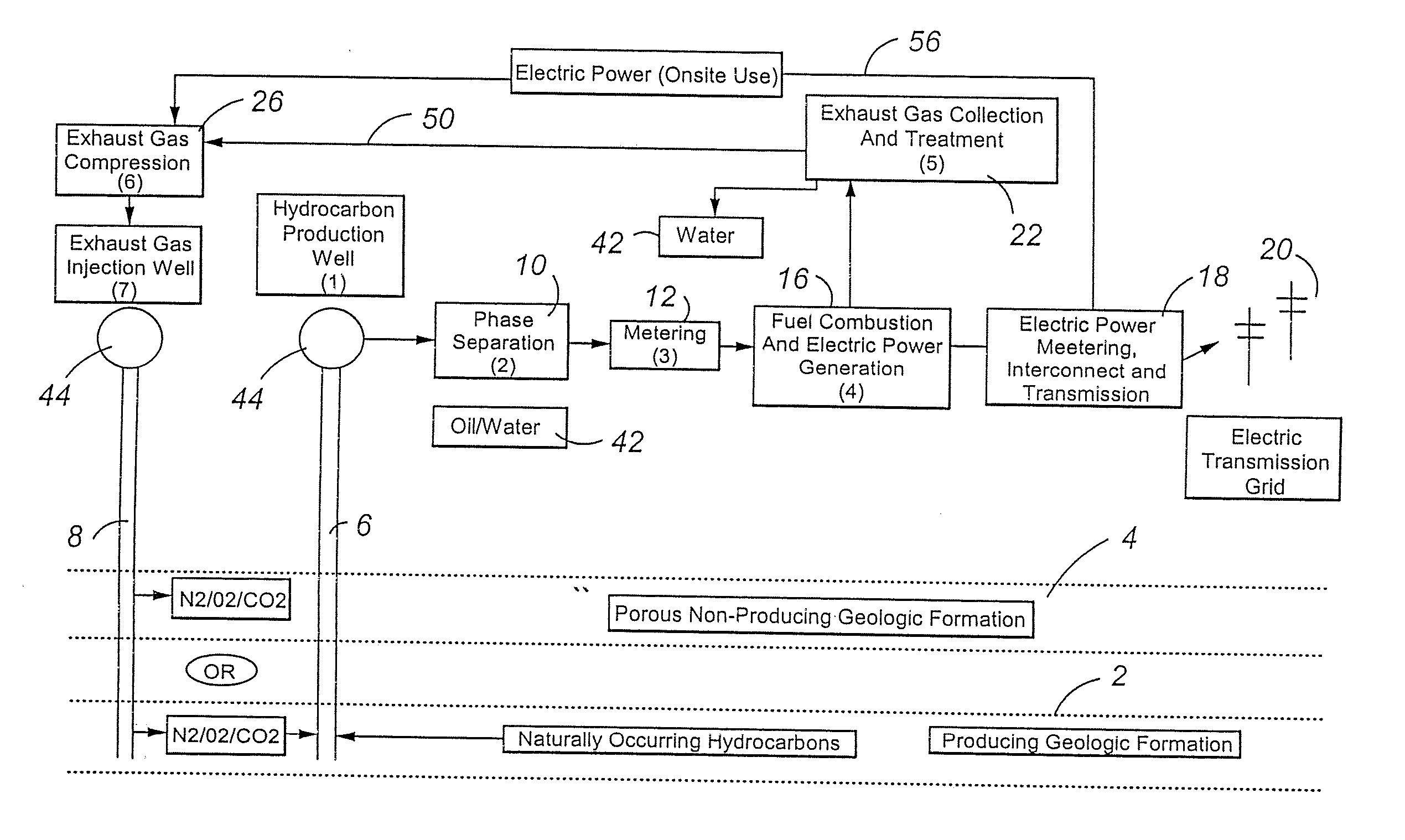

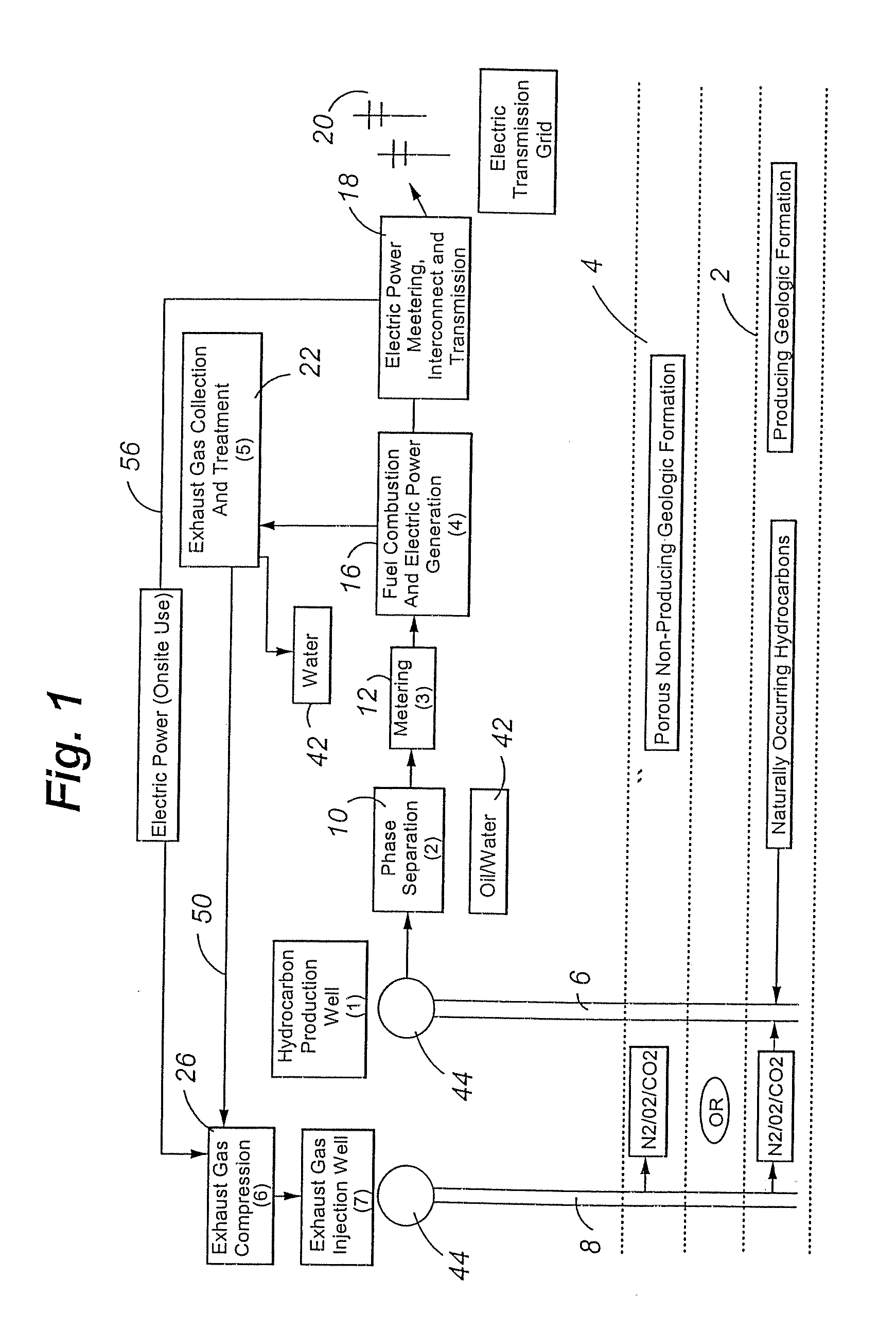

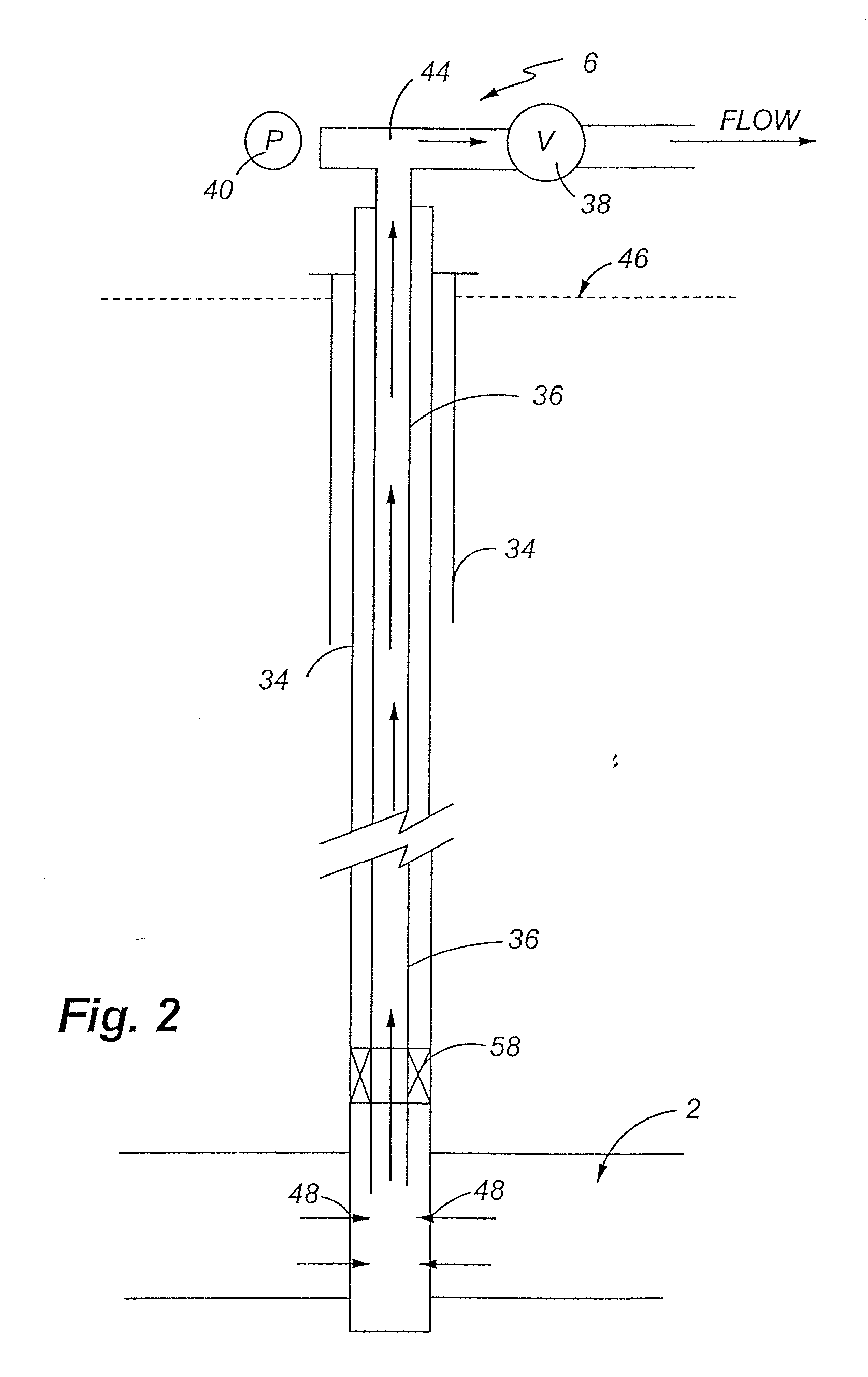

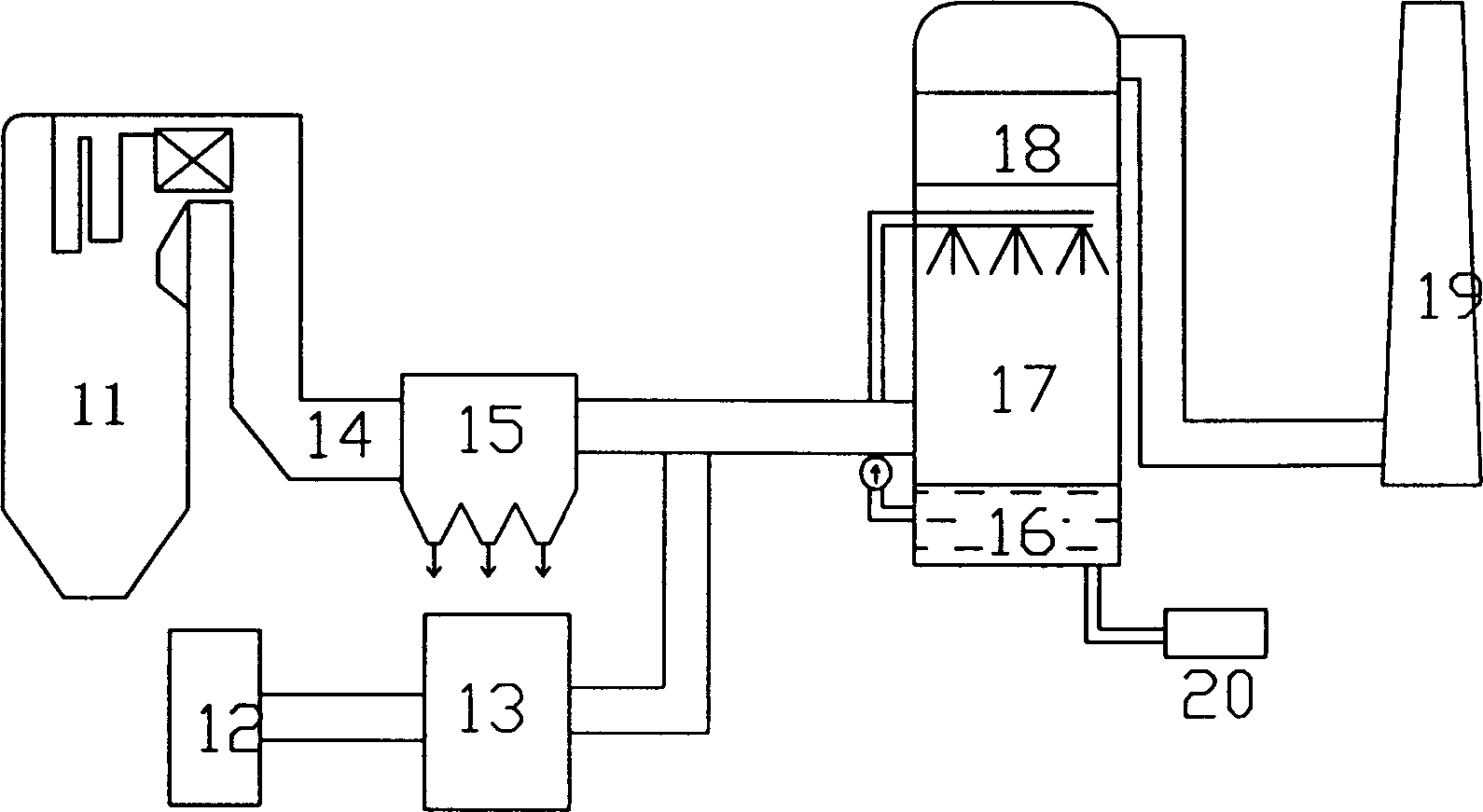

Hydrocarbon combustion power generation system with CO2 sequestration

InactiveUS7043920B2Eliminate needReduce electricity demandReciprocating combination enginesSolidificationAtmospheric airOxygen

A low or no pollution engine is provided for delivering power for vehicles or other power applications. The engine has an air inlet which collects air from a surrounding environment. At least a portion of the nitrogen in the air is removed. The remaining gas is primarily oxygen, which is then routed to a gas generator. The gas generator has inputs for the oxygen and a hydrocarbon fuel. The fuel and oxygen are combusted within the gas generator, forming water and carbon dioxide. The combustion products are then expanded through a power generating device, such as a turbine or piston expander to deliver output power for operation of a vehicle or other power uses. The combustion products are then passed through a condenser where the steam is condensed and the carbon dioxide is collected or discharged. A portion of the water is routed back to the gas generator. The carbon dioxide is compressed and delivered to a terrestrial formation from which return of the CO2 into the atmosphere is inhibited.

Owner:CLEAN ENERGY SYST

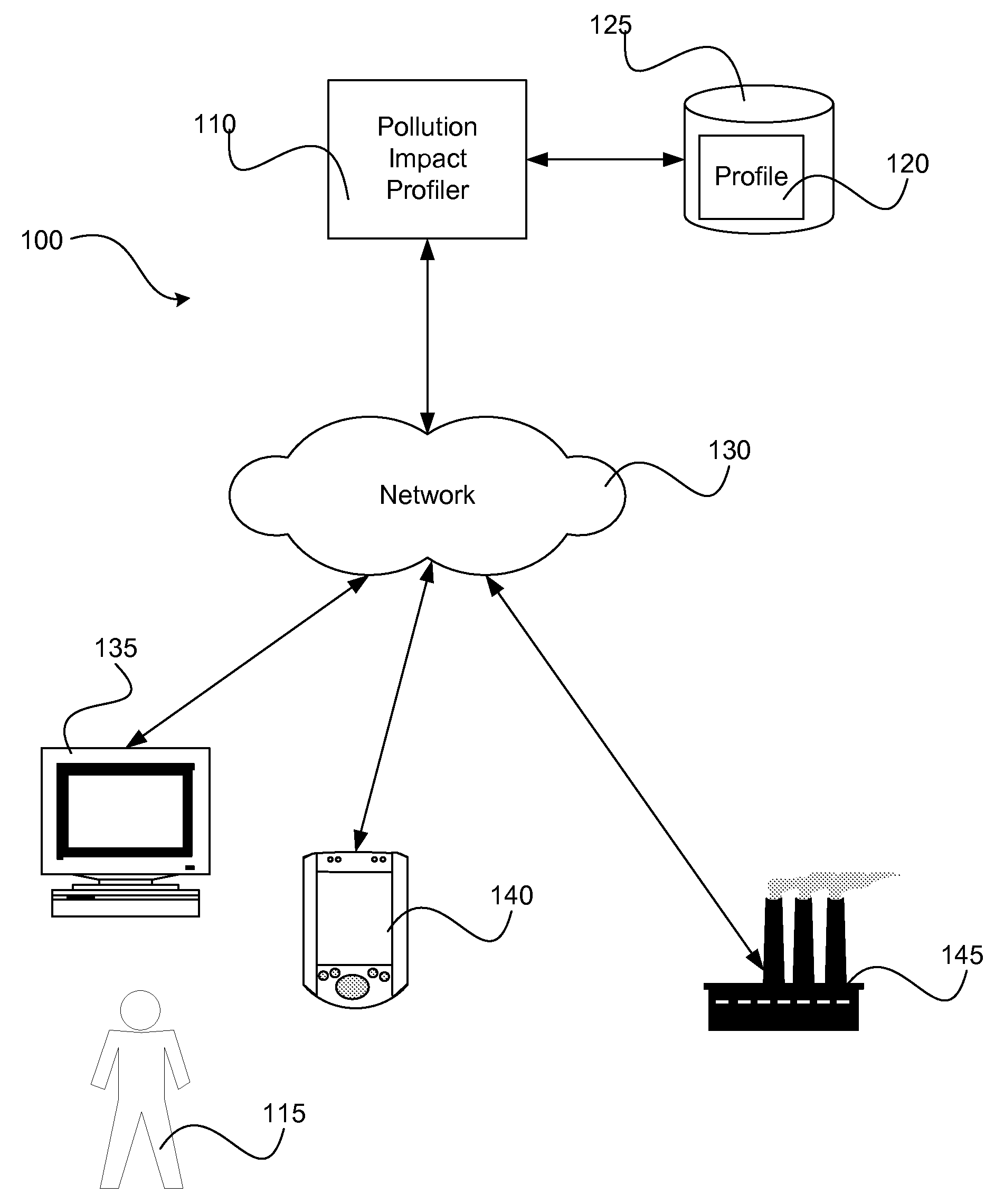

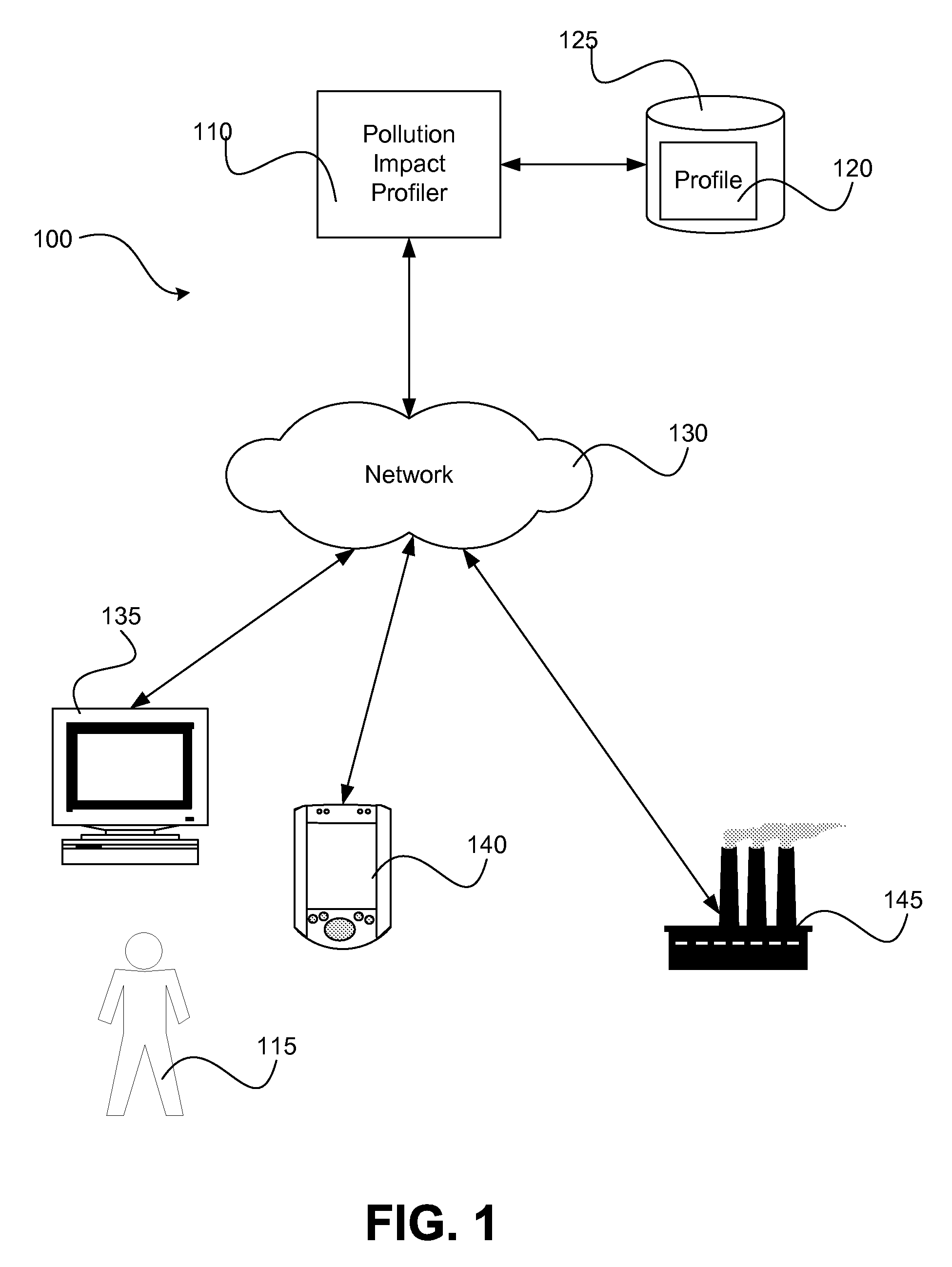

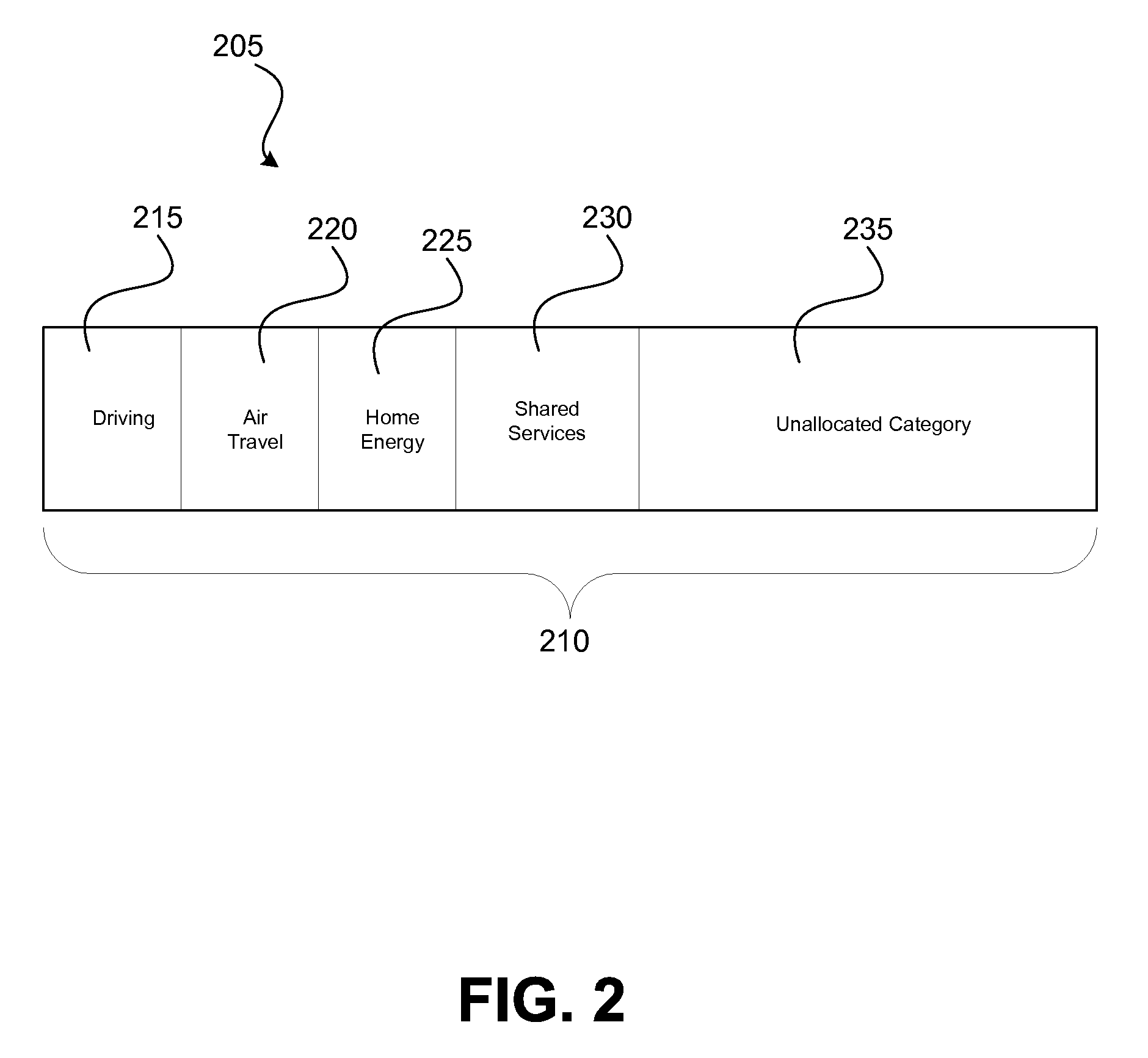

Consumer Pollution Impact Profile System and Method

InactiveUS20070255457A1Pollution footprintSampled-variable control systemsComputer controlEngineeringPollution

A system and method developing an ongoing relationship with a consumer for assessing the pollution impact attributable to the consumer. The ongoing relationship is provided utilizing a pollution impact profile. In one example a pollution impact profile represents a pollution impact attributable to the consumer. The pollution impact profile may be based on a plurality of categories of pollution impact, each category of pollution impact including an impact arising from one or more pollution-related activities and having an initial value of impact. A pollution impact profile may be associated with one or more pollution offsetting services. A pollution impact profile may be configured to allow a consumer to have an ongoing relationship with information related to an associated pollution impact attributed to the consumer.

Owner:BRIGHT PLANET NETWORK

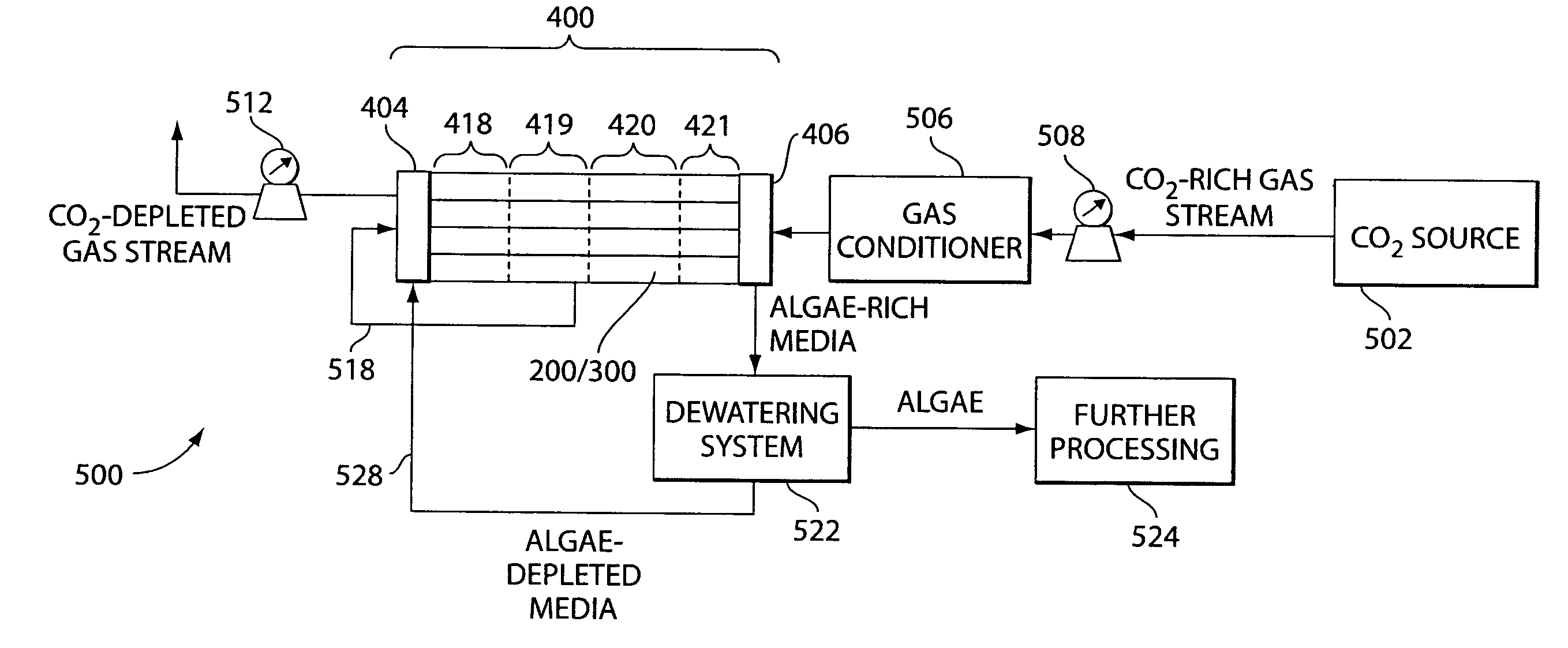

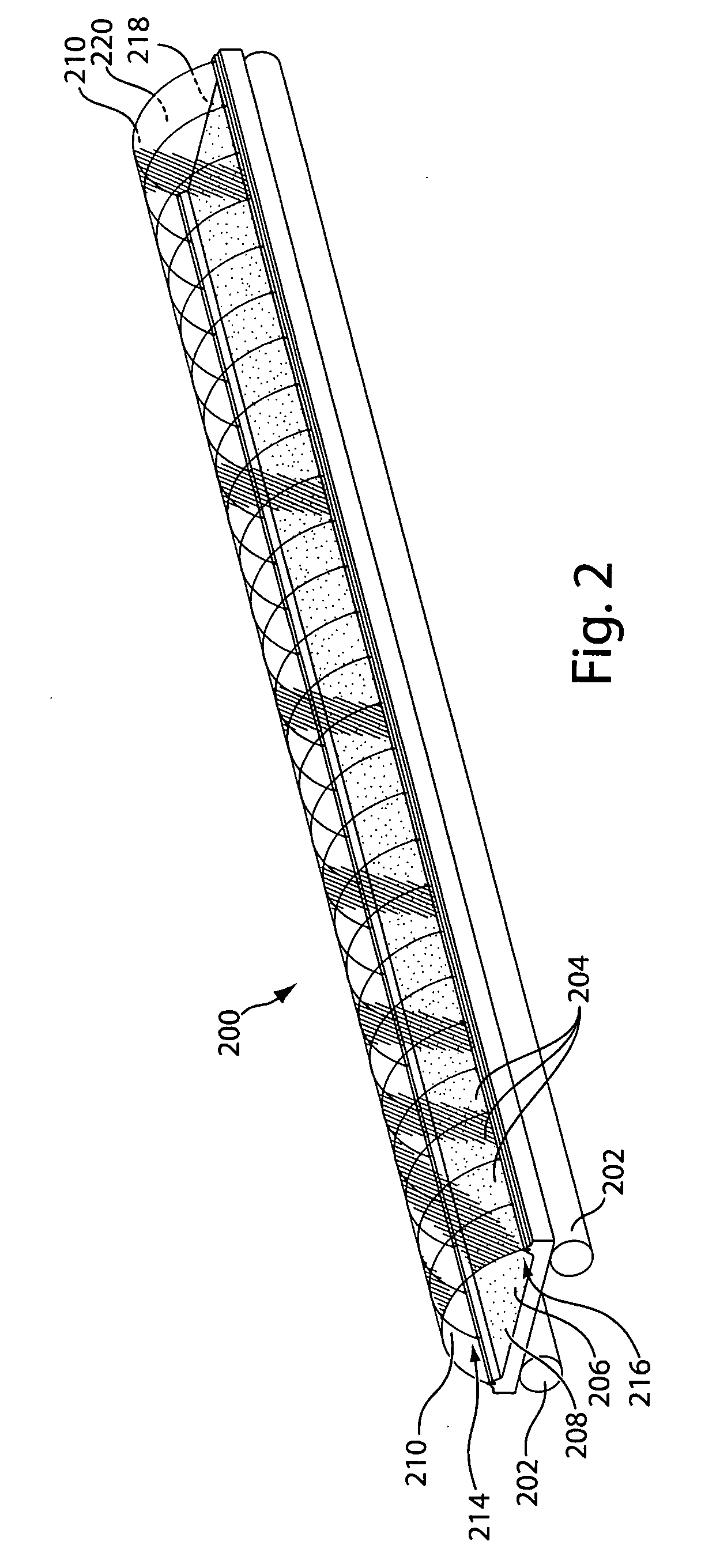

Integrated photobioreactor-based pollution mitigation and oil extraction processes and systems

InactiveUS20080009055A1Bioreactor/fermenter combinationsBiological substance pretreatmentsBiodieselLiquid medium

Integrated systems including a photobioreactor system designed to contain a liquid medium comprising at least one species of phototrophic organism therein, and a facility associated with extracting and / or processing oil extracted from mixtures of oil and solid material, such as an oil sands facility, are described. Processes for using a photobioreactor system as part of a gas-treatment process and system able to at least partially remove certain undesirable pollutants from a byproduct gas stream produced by an oil sands facility are also described. Examples of such pollutants that may be removed include compounds contained within combustion gases, e.g., CO2 and / or NOx. These pollutants processed with the photobioreactor system, and, in some embodiments, biomass produced with the photobioreactor system may be utilized to produce a fuel source (e.g., biodiesel) and cutting stock for further operation of or use in the oil sands facility. Such uses of certain embodiments can provide an efficient means for recycling carbon, thereby reducing CO2 emissions, fuel, and / or cutting stock requirements for a given quantum of energy produced. In addition, in some cases the photobioreactor can be integrated with a holding pond and waste heat from the oil extraction process can be used to maintain the photobioreactor temperature and / or provide energy for other processes. Accordingly, embodiments described herein can improve the overall environmental and economic profile of the oil sands facility.

Owner:GREENFUEL TECHNOLOGIES CORPORATION

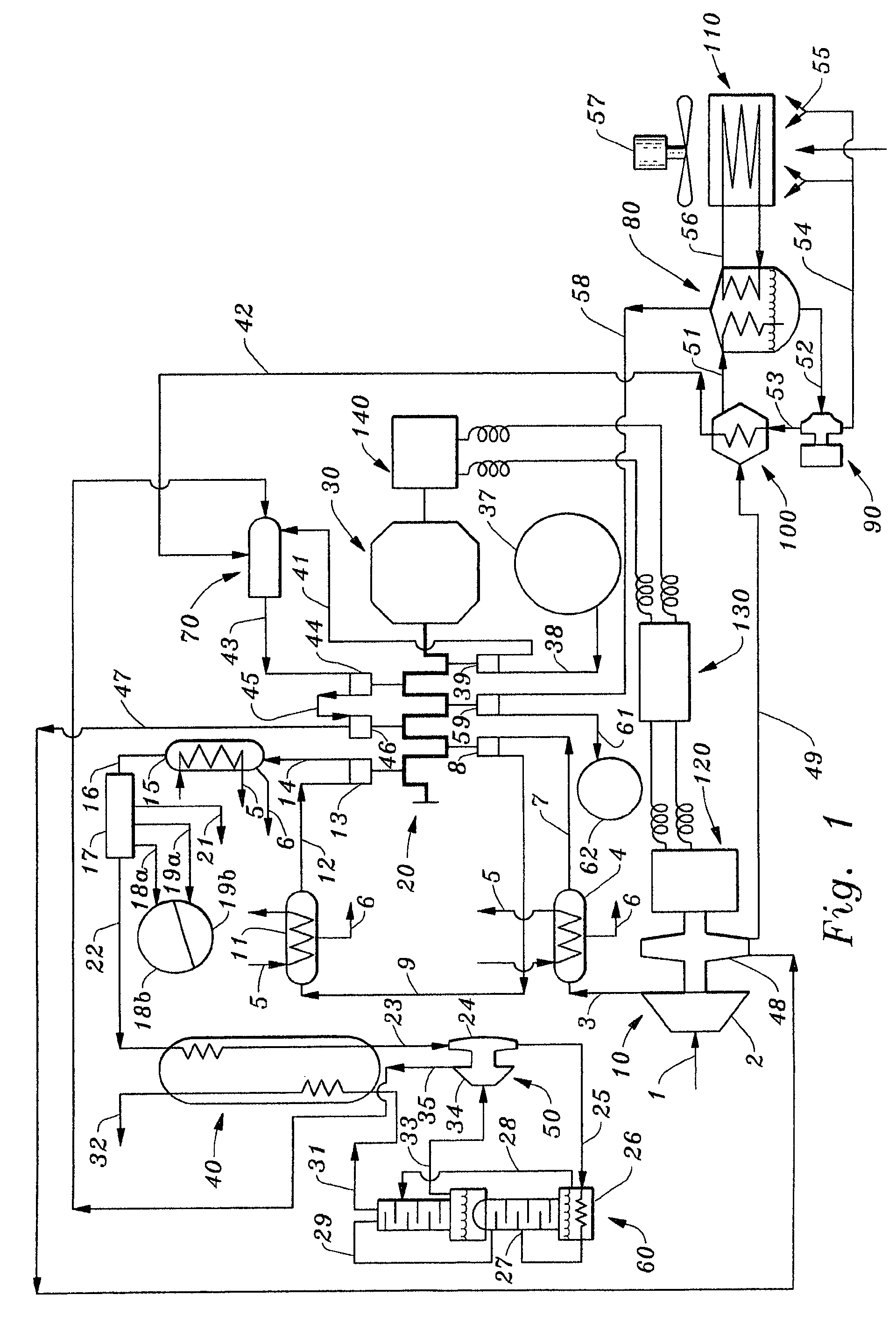

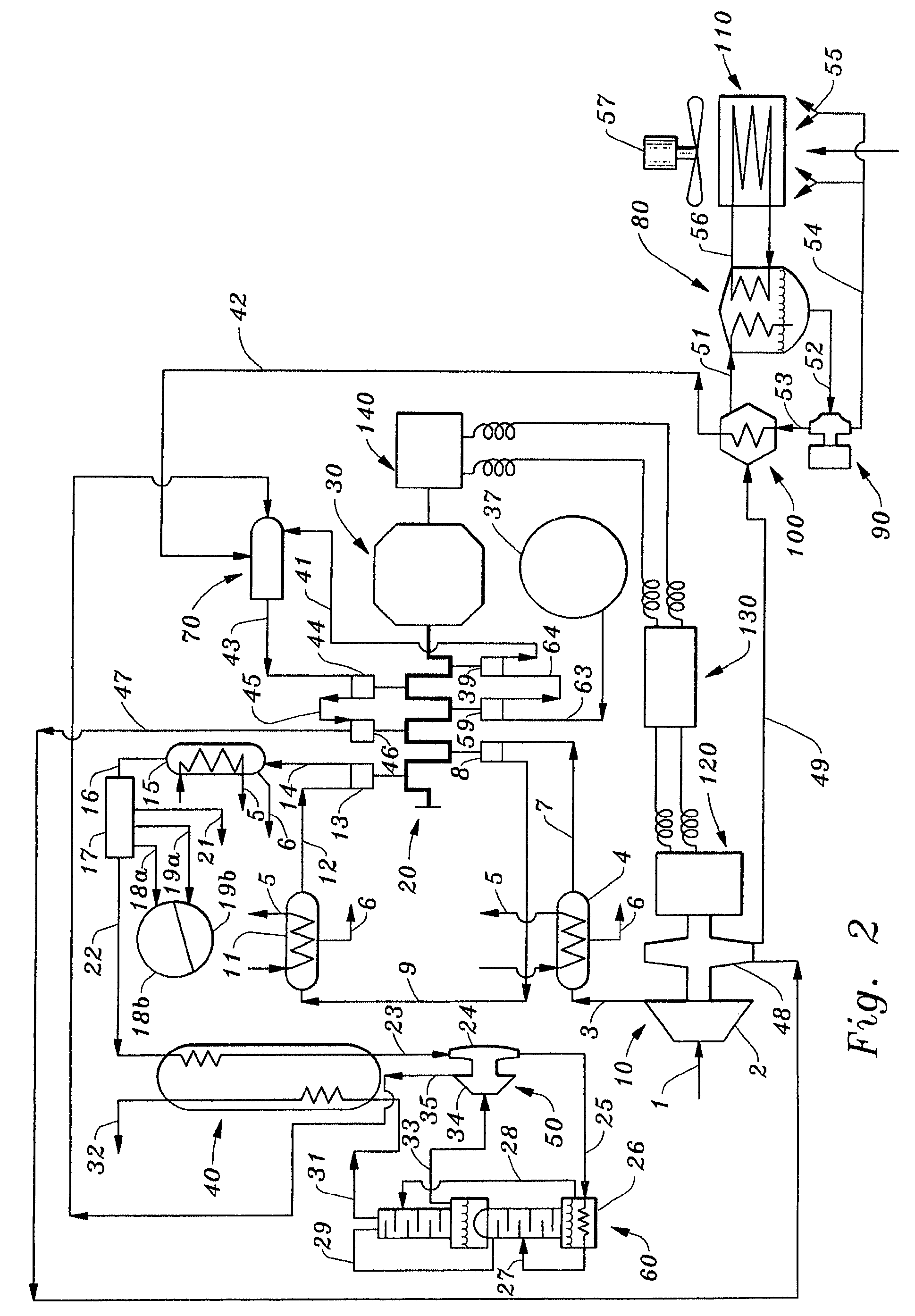

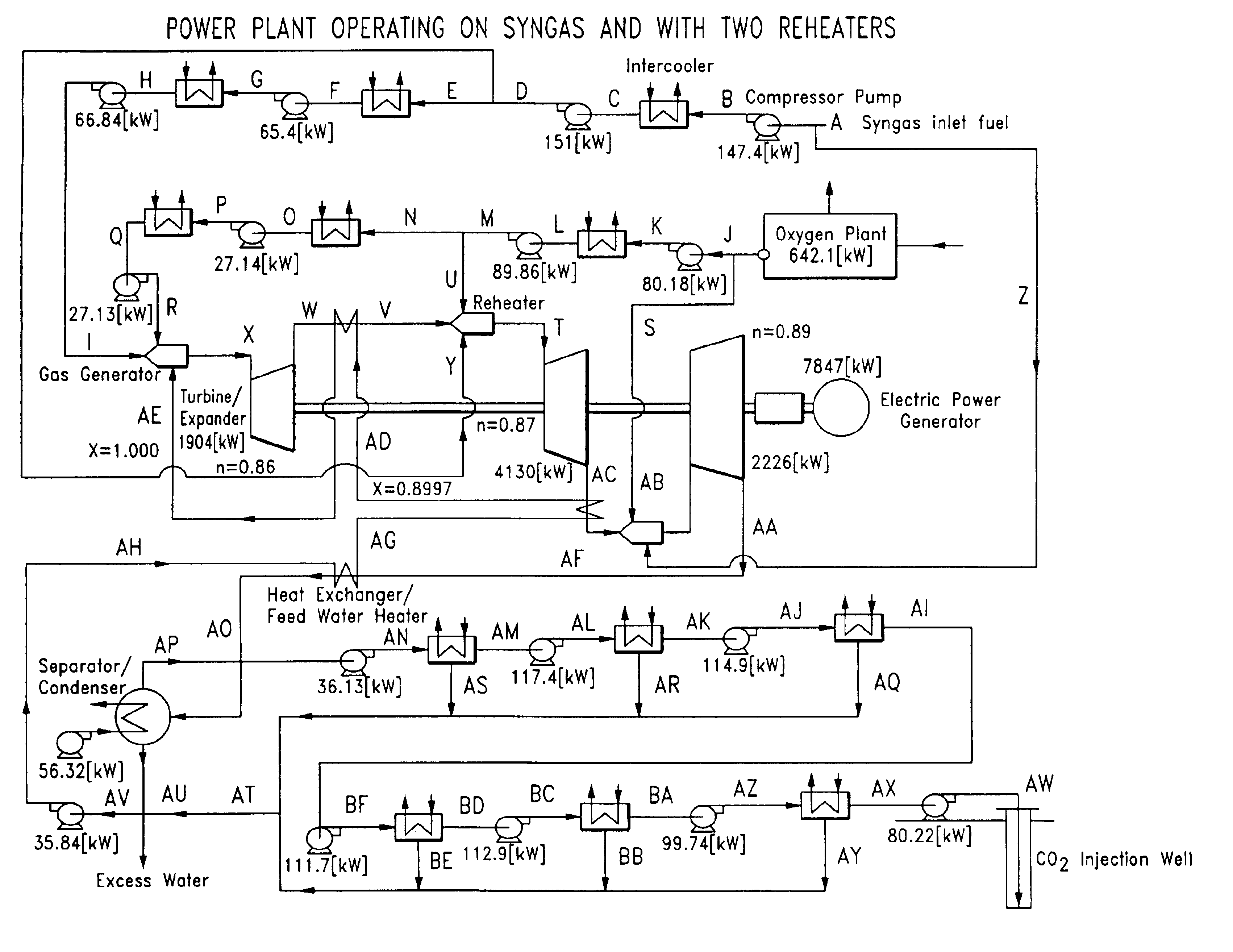

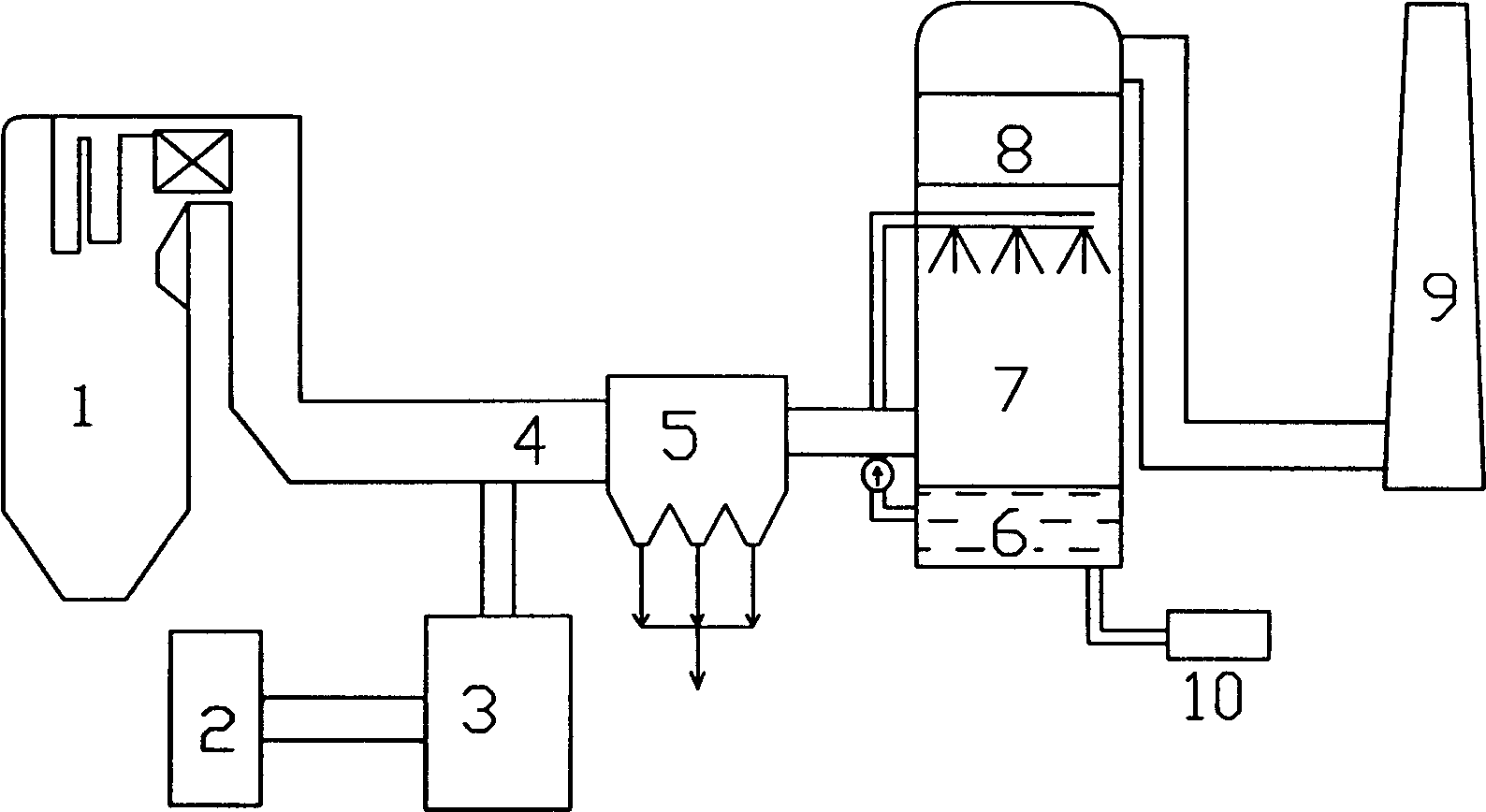

Low pollution power generation system with ion transfer membrane air separation

InactiveUS6945029B2Nitrogen oxideReduce electricity demandSolidificationLiquefactionPollutionCombustion products

A low or no pollution power generation system is provided. The system has an air separator to collect oxygen. A gas generator is provided with inputs for the oxygen and a hydrocarbon fuel. The fuel and oxygen are combusted within the gas generator, forming water and carbon dioxide. Water or other diluents are also delivered into the gas generator to control temperature of the combustion products. The combustion products are then expanded through at least one turbine or other expander to deliver output power. The combustion products are then passed through a separator where the steam is condensed. A portion of the water is discharged and the remainder is routed back to the gas generator as diluent. The carbon dioxide can be conditioned for sequestration. The system can be optimized by adding multiple expanders, reheaters and water diluent preheaters, and by preheating air for an ion transfer membrane oxygen separation.

Owner:CLEAN ENERGY SYST

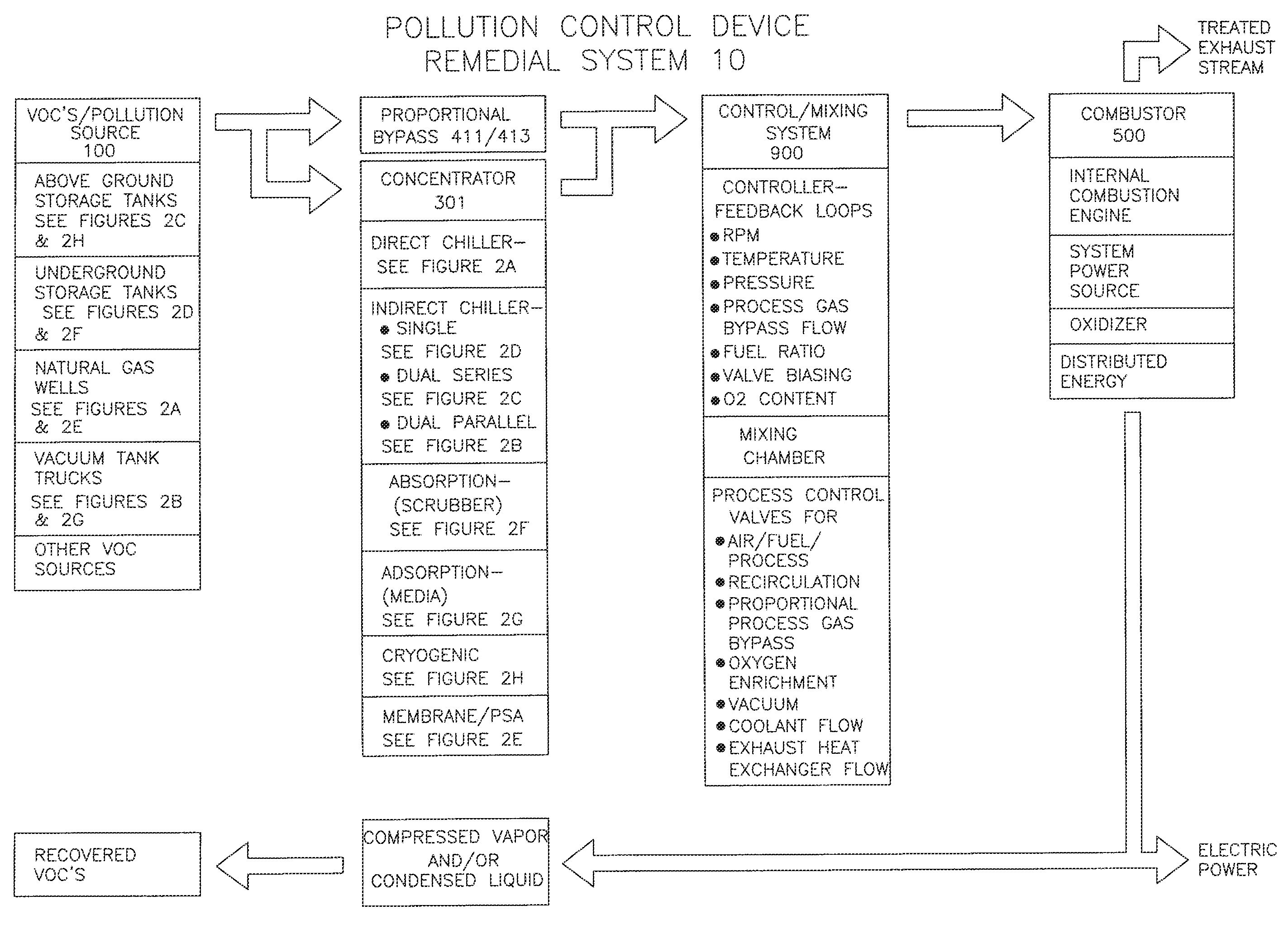

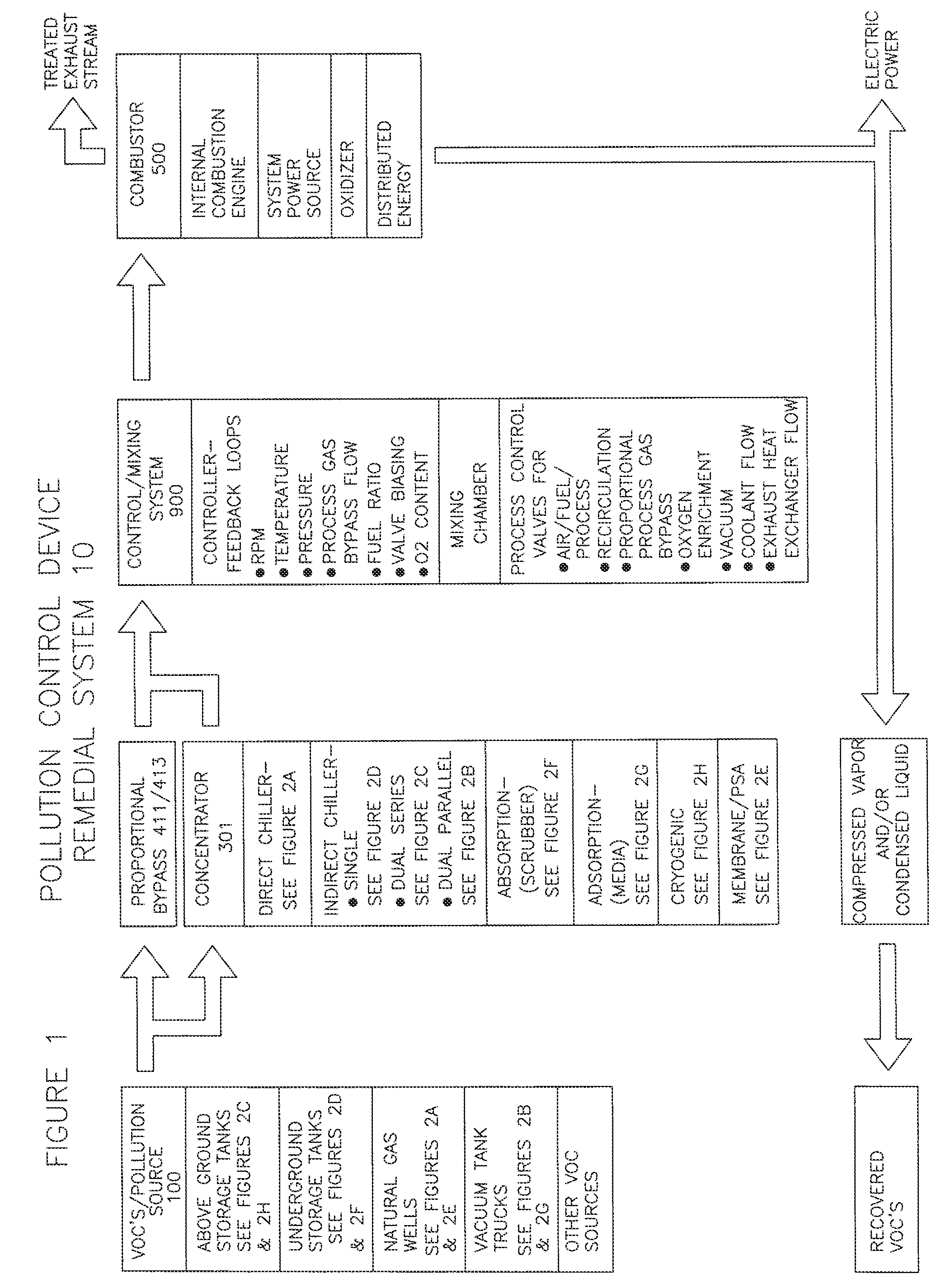

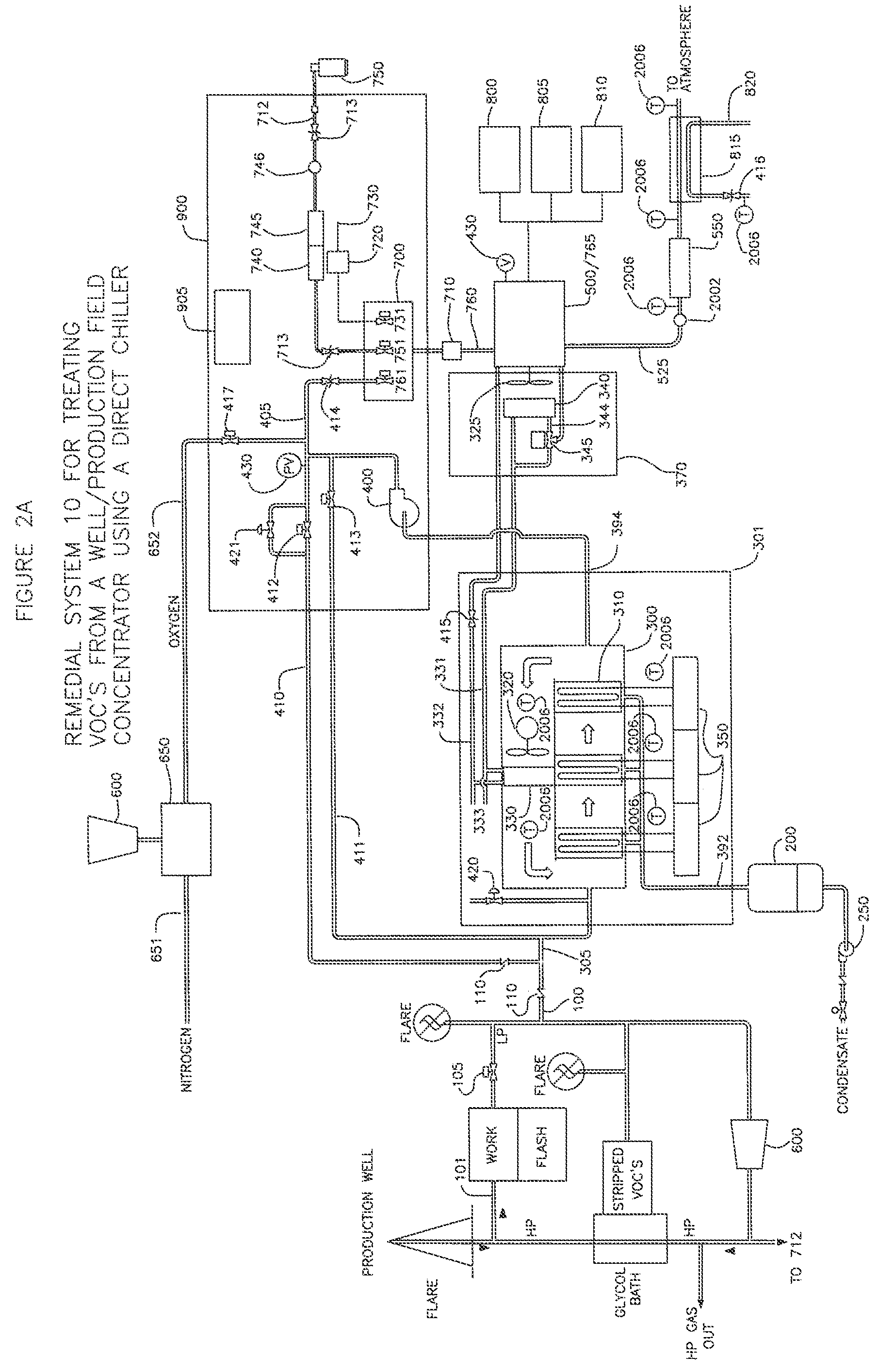

Remedial system: a pollution control device for utilizing and abating volatile organic compounds

ActiveUS8776734B1Easy to useTreatment safetyGas treatmentNon-fuel substance addition to fuelHybrid systemControl system

A remedial pollution control system for treating volatile organic compounds that may include a vapor concentrator connected to a line that is laden with volatile organic compounds, the concentrator has an organic condensate output line and a vapor output line; a mixing chamber adapted to receive air provided from an air supply line, combustible fuel from an alternate fuel supply line, and a vapor stream from the vapor output line to produce a mixed fuel supplied to an internal combustion engine, a control mixing system with a controller for producing a proper air to fuel ratio in the mixed fuel supply, and power generated to operate other devices used to more efficiently abate volatile organic compounds and reduce greenhouse gas emissions.

Owner:INNOVATIVE ENVIRONMENTAL SOLUTIONS LLC DBA REMEDIATION SERVICE INTL

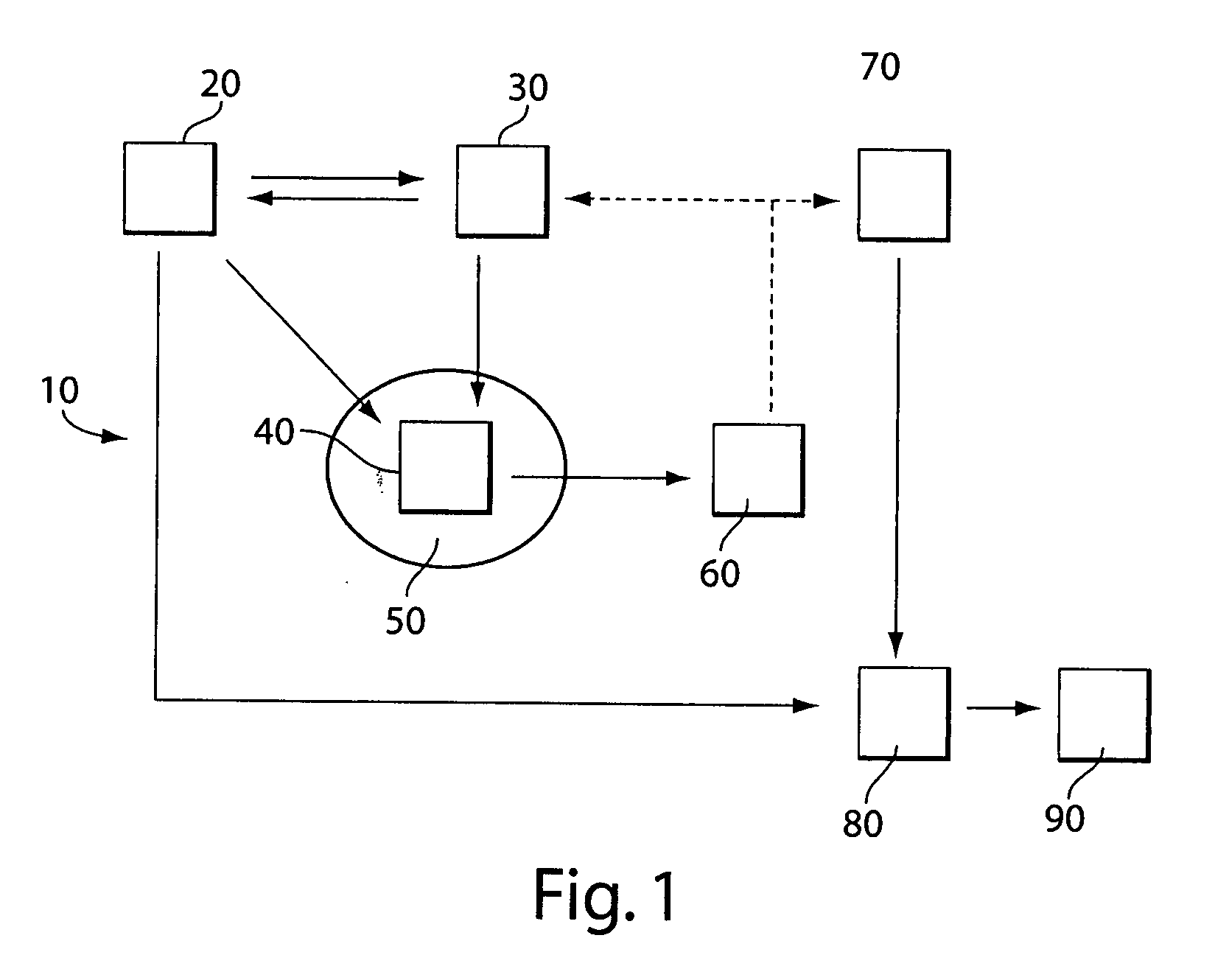

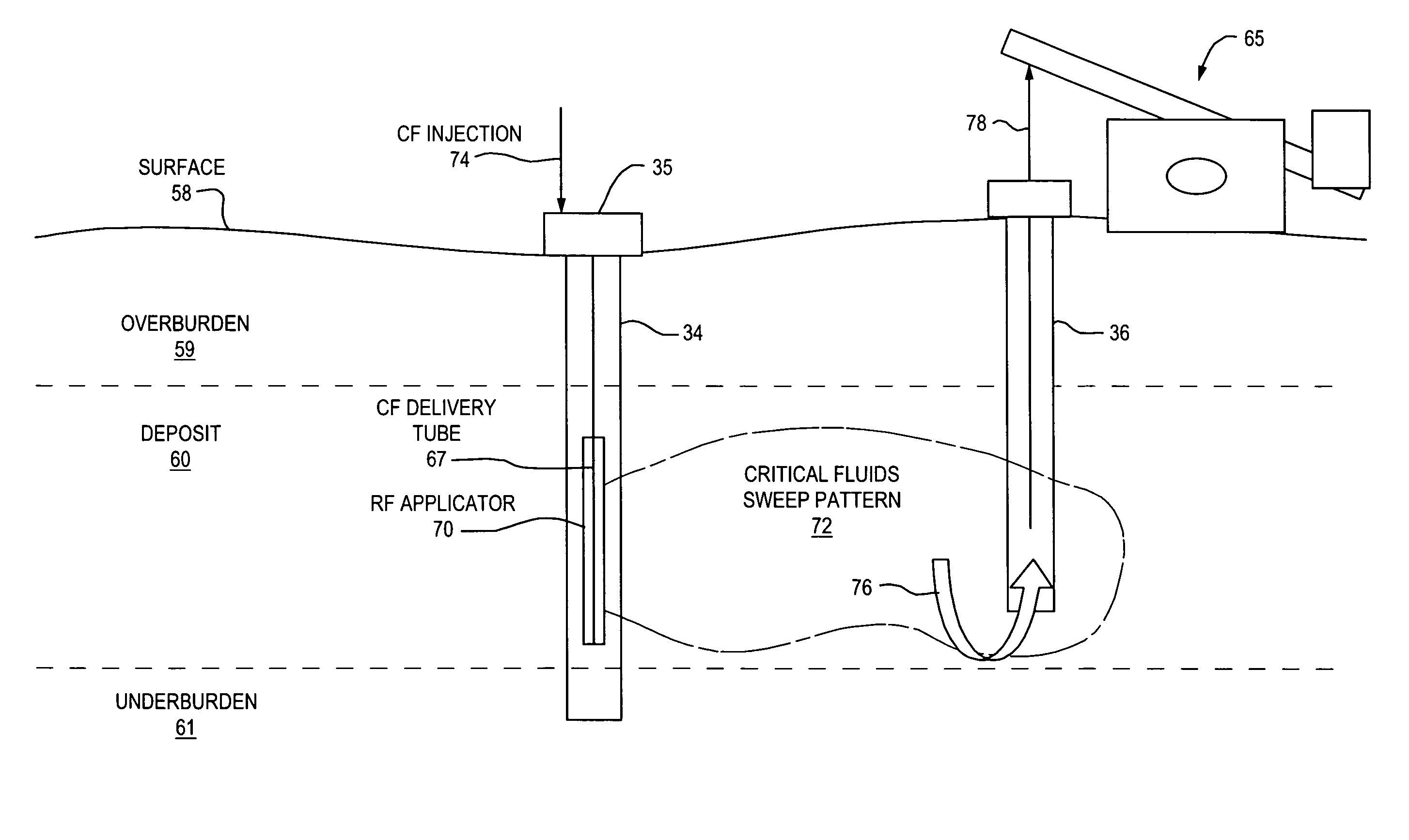

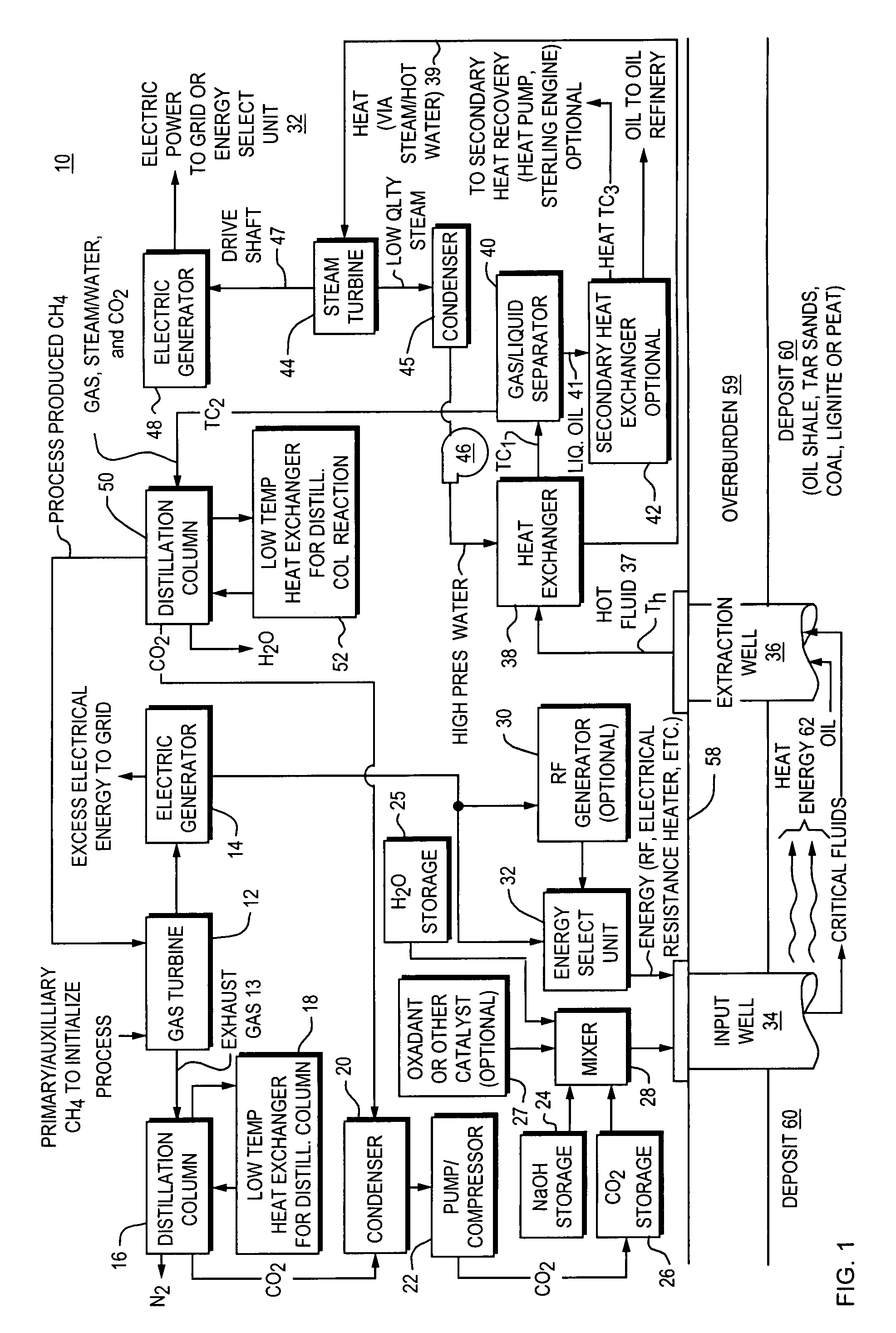

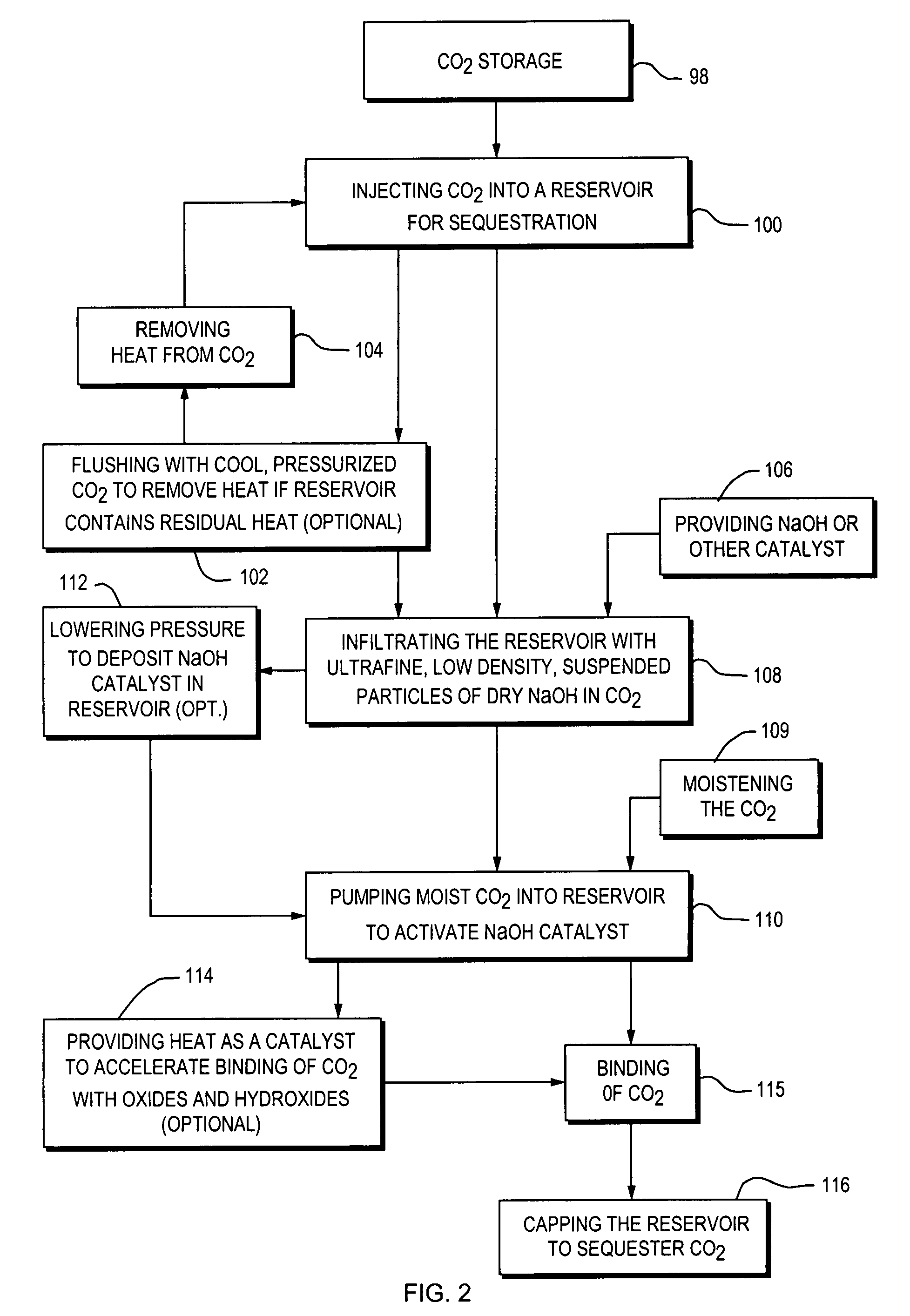

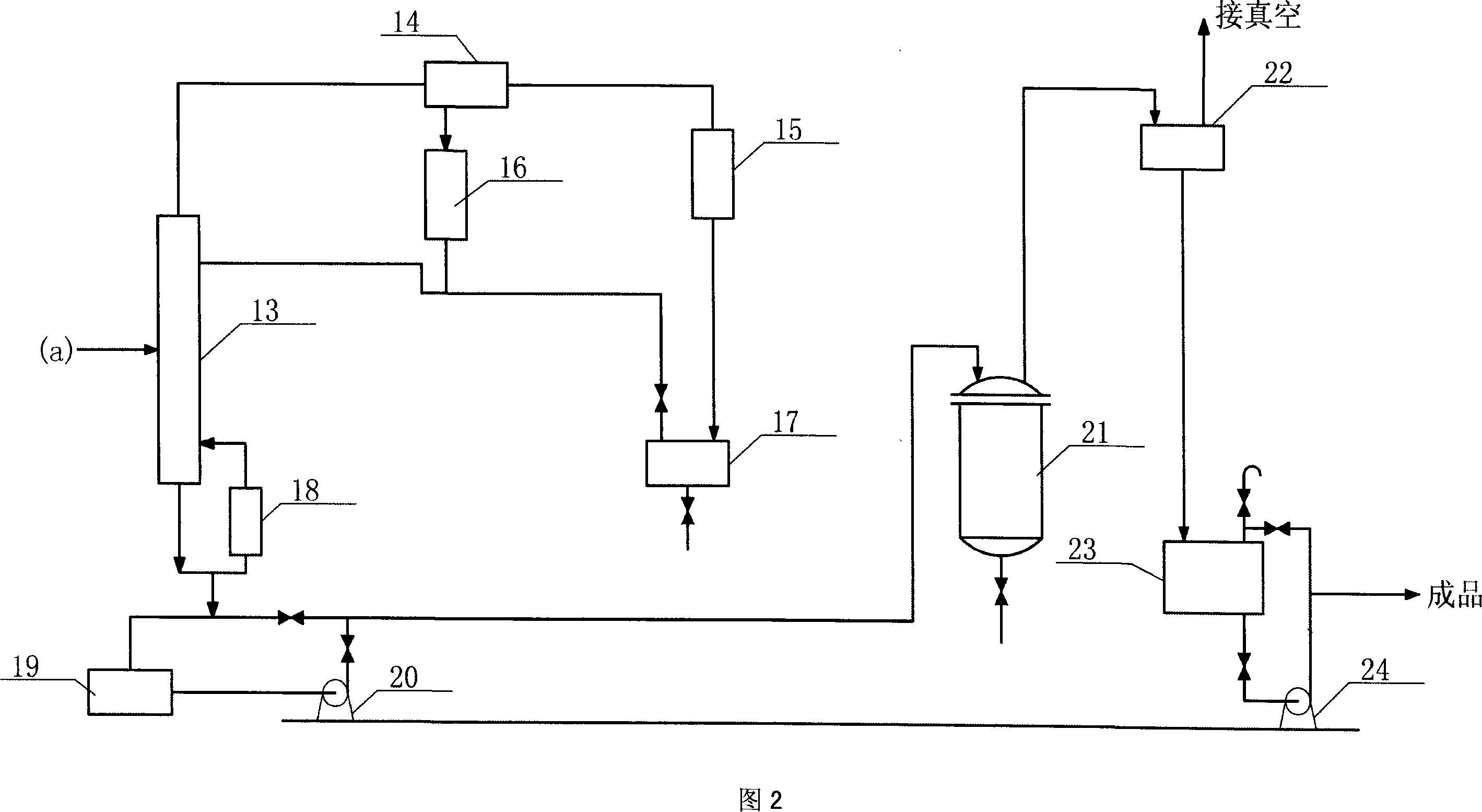

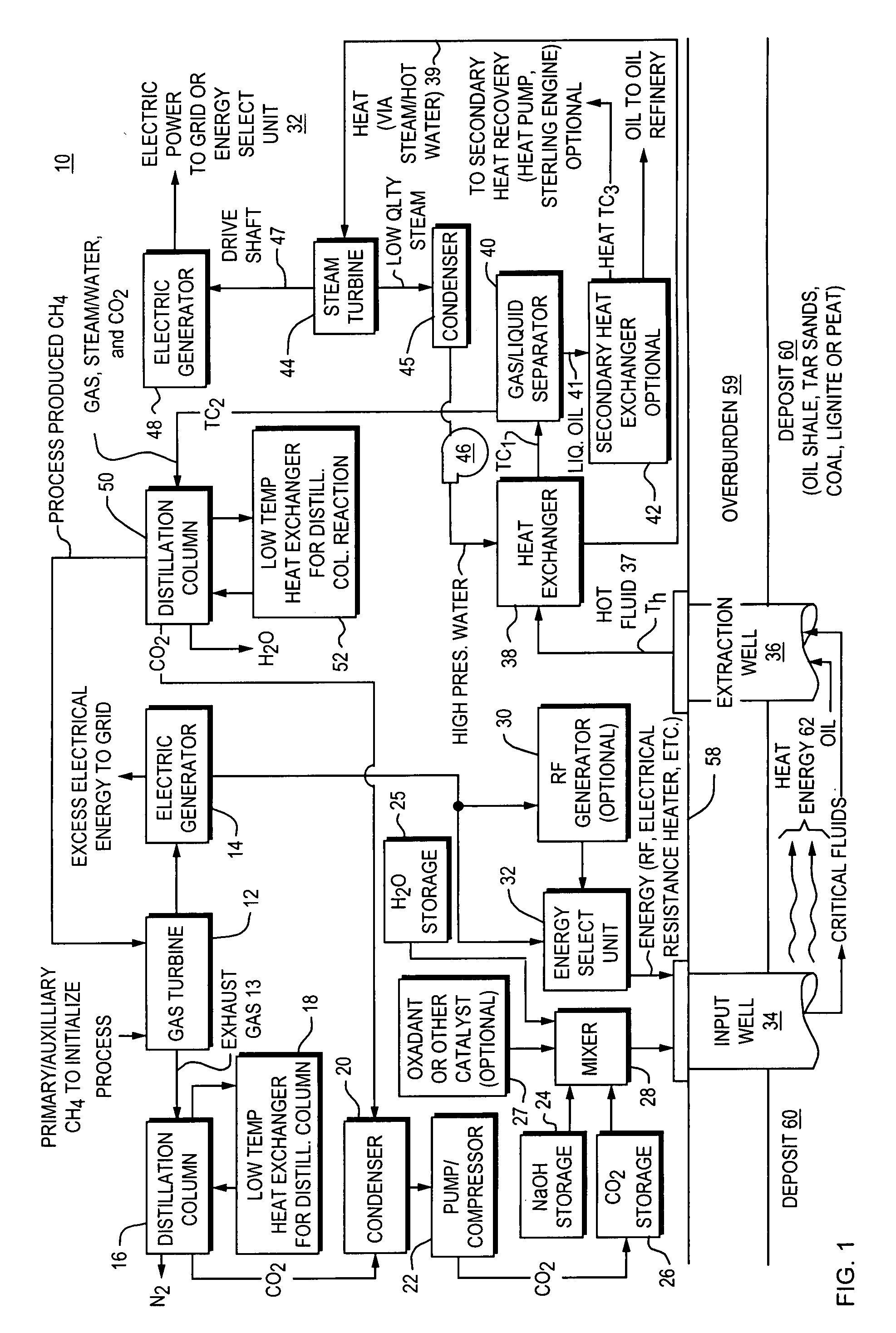

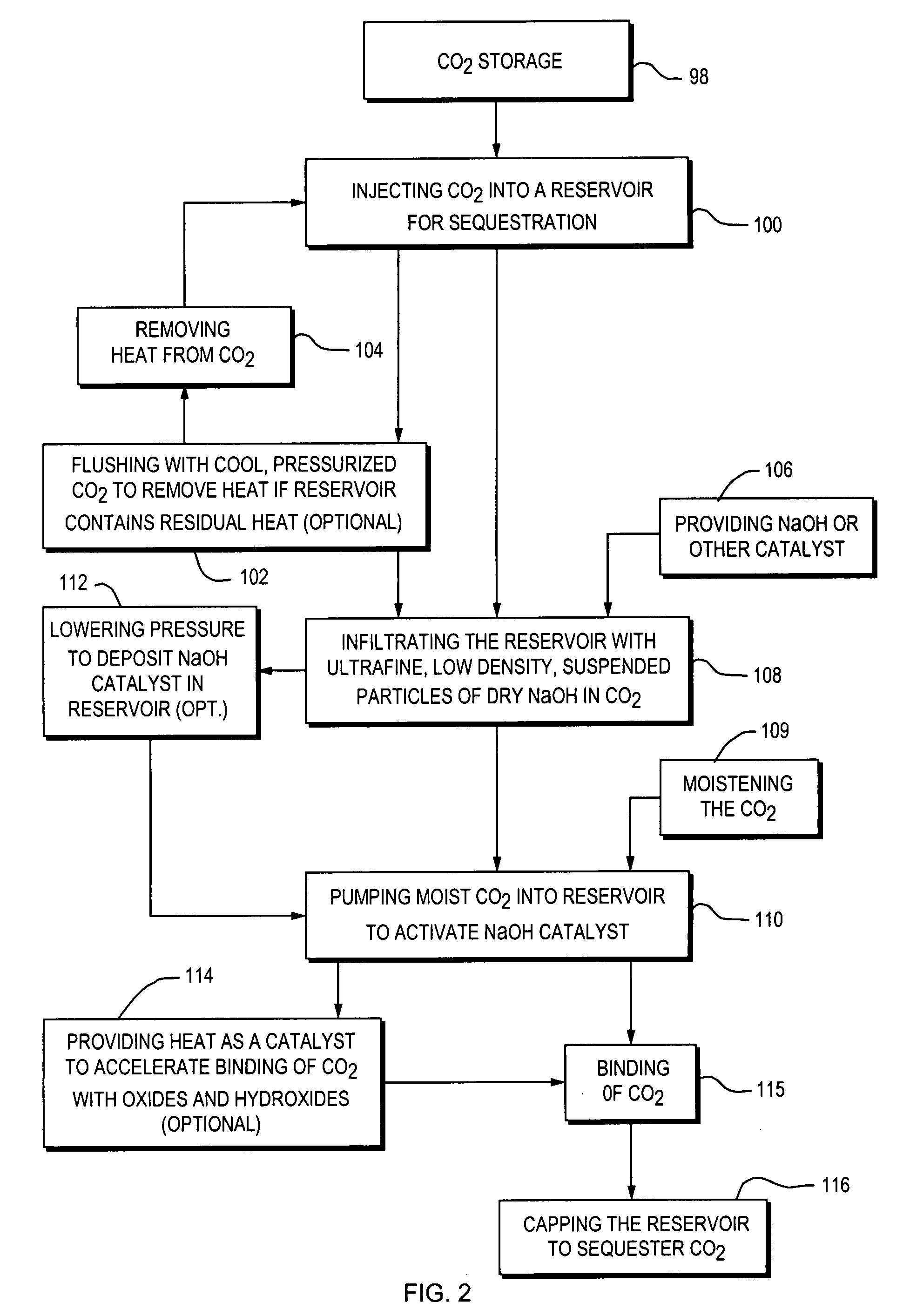

Method and apparatus for capture and sequester of carbon dioxide and extraction of energy from large land masses during and after extraction of hydrocarbon fuels or contaminants using energy and critical fluids

ActiveUS7562708B2Reduce energy consumptionMinimal pollutionSurveyOther gas emission reduction technologiesClosed loopUltra fine

A closed loop system for increasing yield, reducing post process pollution, reducing energy consumed during and after extraction of fuels or contaminants in formations and for sequestering of carbon dioxide C02 from various sources is converted to a critical fluid for use as a flushing and cooling medium. Electrical energy heats a hydrocarbon rich formation resulting in the extraction of hot fluids which are fed to heat exchangers, gas / liquid separator, and steam turbine whereby oil, electric power, carbon dioxide and methane are produced for reuse in the system or for external use. Further, a method for sequestering of carbon dioxide in a formation comprises the steps of injecting CO2 into the reservoir, flushing with cool pressurized CO2 for heat removal, infiltrating with ultra-fine low density suspended catalyst particles of dry sodium hydroxide in CO2, pumping water moistened CO2 into the reservoir to activate the catalysts, binding the CO2 with reacting materials and capping the reservoir.

Owner:RAYTHEON CO

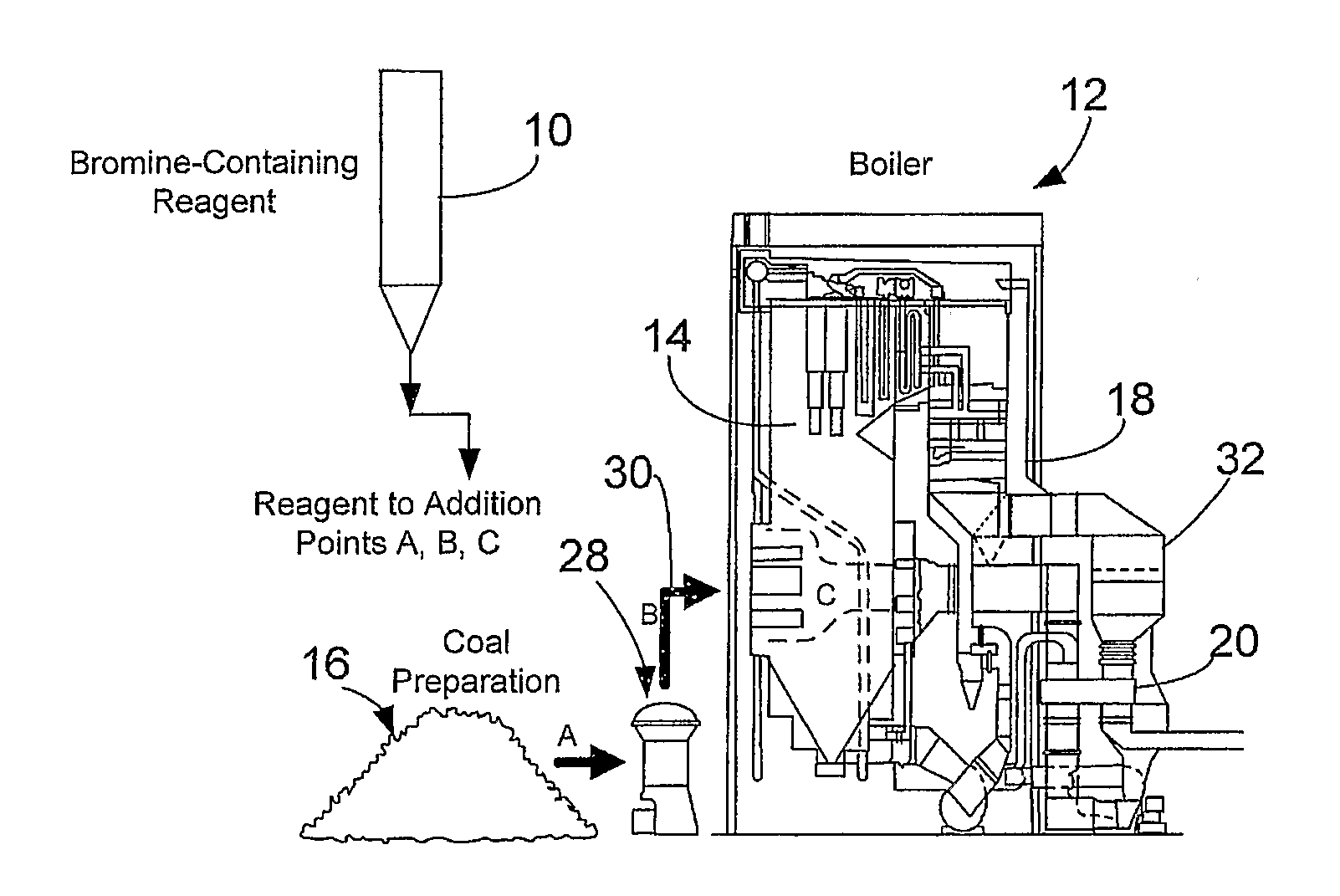

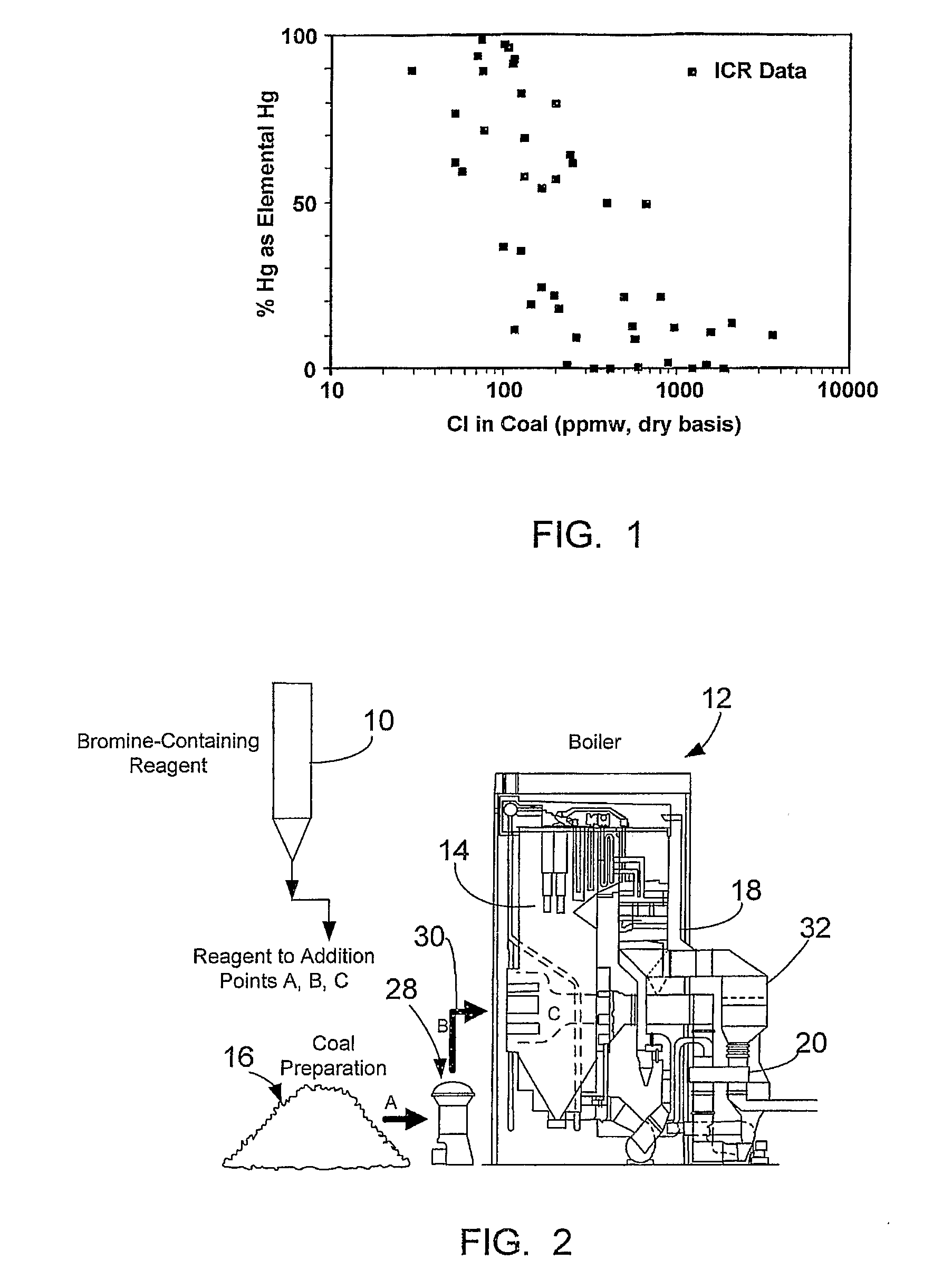

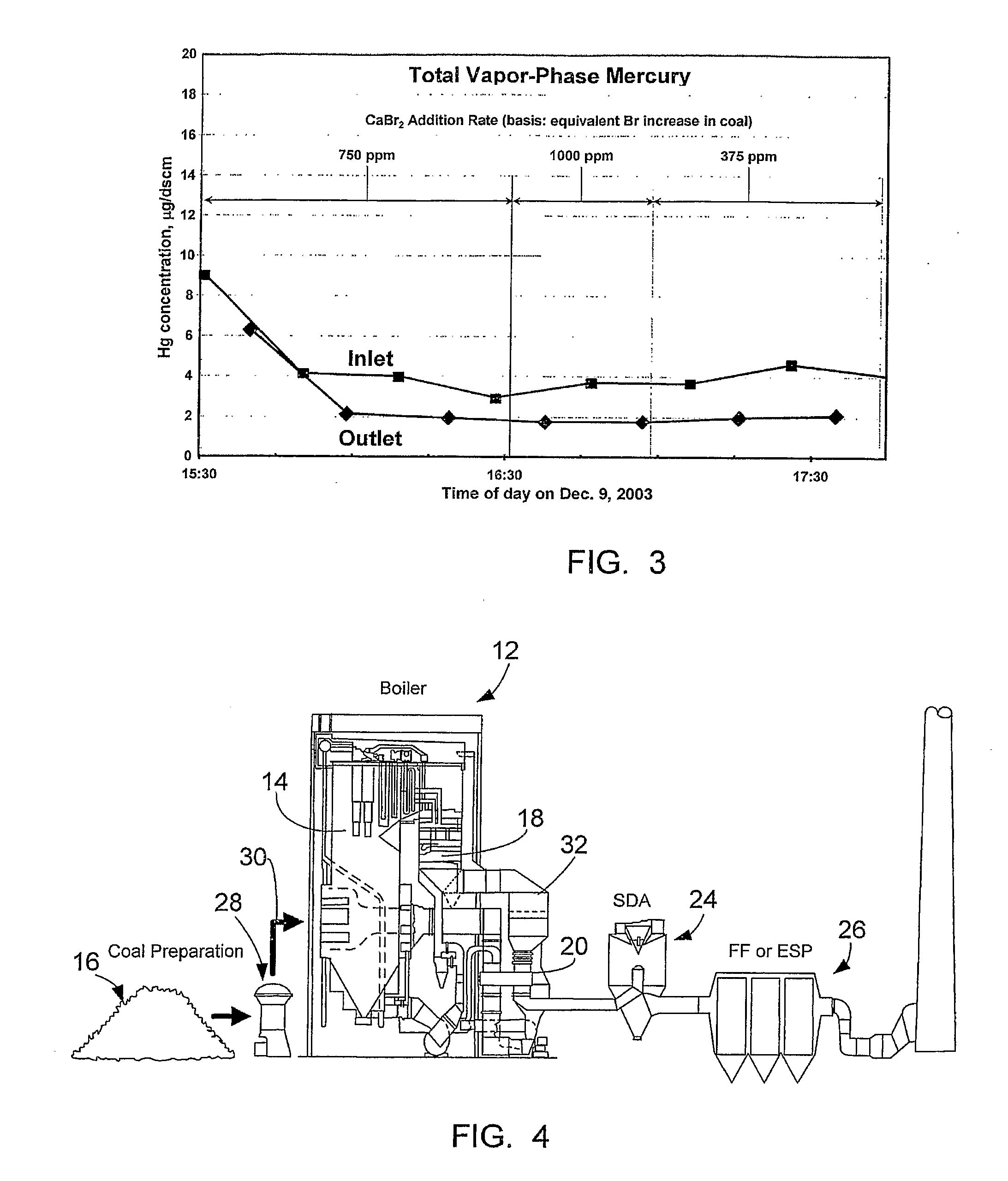

Bromine Addition for the Improved Removal of Mercury from Flue Gas

InactiveUS20080107579A1Significant technicalSignificant commercial advantageGas treatmentUsing liquid separation agentCombustionFlue gas

Bromine-containing compounds, added to the coal, or to the boiler combustion furnace, are used to enhance the oxidation of mercury, thereby enhancing the overall removal of mercury in downstream pollution control devices. The method is applicable to utility power plants equipped with wet FGD systems, as well as those plants equipped with spray dryer absorber FGD systems.

Owner:THE BABCOCK & WILCOX CO

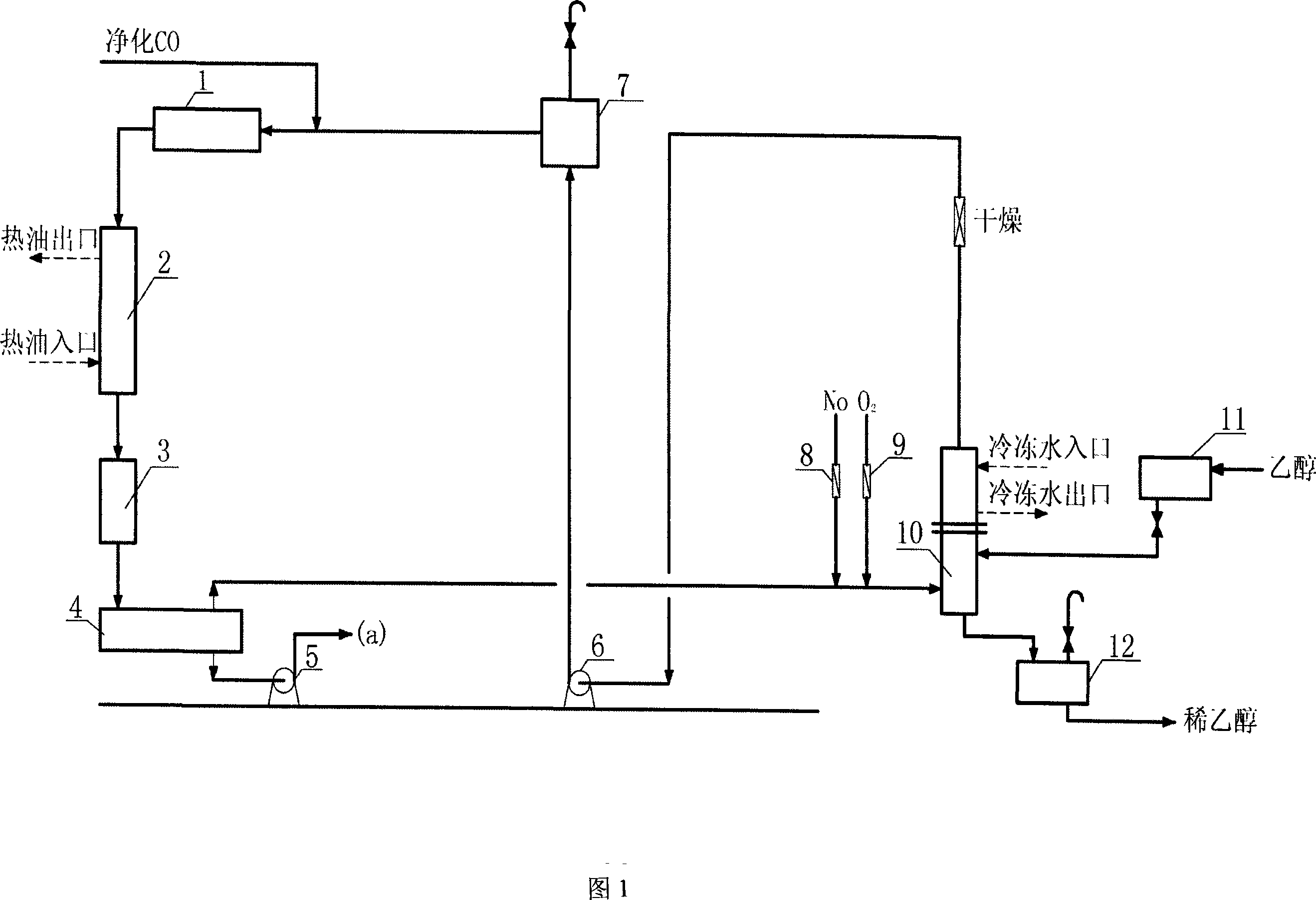

Method for preparing diethyl oxalate by coupling CO

ActiveCN101143821ANo pollution in the processImprove efficiencyPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsCyclic processContinuous use

The invention discloses a method for preparing diethyl oxalate by CO coupling reaction. By applying a gas phase method, CO is coordinated with ethyl nitrite and is catalyzed by bimetallic supported catalyzer to couplingly generate crude diethyl oxalate, the reaction is a self-sealing circulation process, the CO gas mixed with the ethyl nitrite coming from a regeneration reactor is preheated and then enters into a coupling reactor, after the reaction, the gas is separated by condensation, so that the colorless and transparent condensed diethyl oxalate liquid is produced, and the uncondensed gas containing NO enters into the regeneration reactor to react with ethanol and oxygen in order to generate ethyl nitrite which is again circulated back to the coupling reactor for continuous use. The invention is carried out on the basis of previous laboratory research and under the background of industrial production and fulfils the continuous run examination of the bench scale test and pilot magnification under the condition of industrial operation, the temperature of the coupling reaction is low, and the concentration of products is increased. The method has the advantages of more energy saving, no pollution and high benefit. The total conversion rate of the CO generated by reaction is one hundred percent, and the selectivity of diethyl oxalate is over ninety six percent.

Owner:TIANJIN UNIV

Method and apparatus for capture and sequester of carbon dioxide and extraction of energy from large land masses during and after extraction of hydrocarbon fuels or contaminants using energy and critical fluids

ActiveUS20070261844A1Weaken energyReducing critical fluid requirementSurveyOther gas emission reduction technologiesClosed loopUltra fine

A closed loop system for increasing yield, reducing post process pollution, reducing energy consumed during and after extraction of fuels or contaminants in formations and for sequestering of carbon dioxide C02 from various sources is converted to a critical fluid for use as a flushing and cooling medium. Electrical energy heats a hydrocarbon rich formation resulting in the extraction of hot fluids which are fed to heat exchangers, gas / liquid separator, and steam turbine whereby oil, electric power, carbon dioxide and methane are produced for reuse in the system or for external use. Further, a method for sequestering of carbon dioxide in a formation comprises the steps of injecting CO2 into the reservoir, flushing with cool pressurized CO2 for heat removal, infiltrating with ultra-fine low density suspended catalyst particles of dry sodium hydroxide in CO2, pumping water moistened CO2 into the reservoir to activate the catalysts, binding the CO2 with reacting materials and capping the reservoir.

Owner:RAYTHEON CO

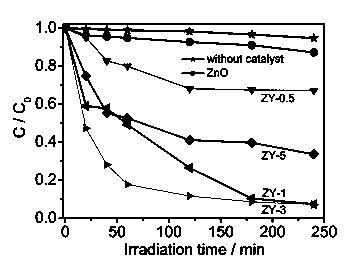

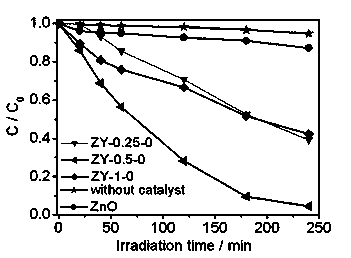

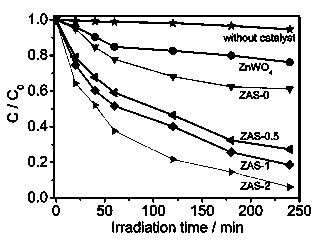

Visible light photocatalyst and preparation method therefor

InactiveCN103623803AHigh removal rateEasy to scale applicationWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsSemiconductor materialsVisible light photocatalytic

Provided is a visible light photocatalyst and a preparation method therefor. The visible light photocatalyst comprises down conversion materials and semiconductor materials. The mass percent of the down conversion materials to the semiconductor materials is 0.5%-5%. The visible light photocatalyst with down conversion functions is advantaged by high visible light catalytic degradation rate, no pollution, simple preparation method and low cost. The invention also provides a preparation method for the visible light photocatalyst with down conversion functions.

Owner:上海纳晶科技有限公司 +1

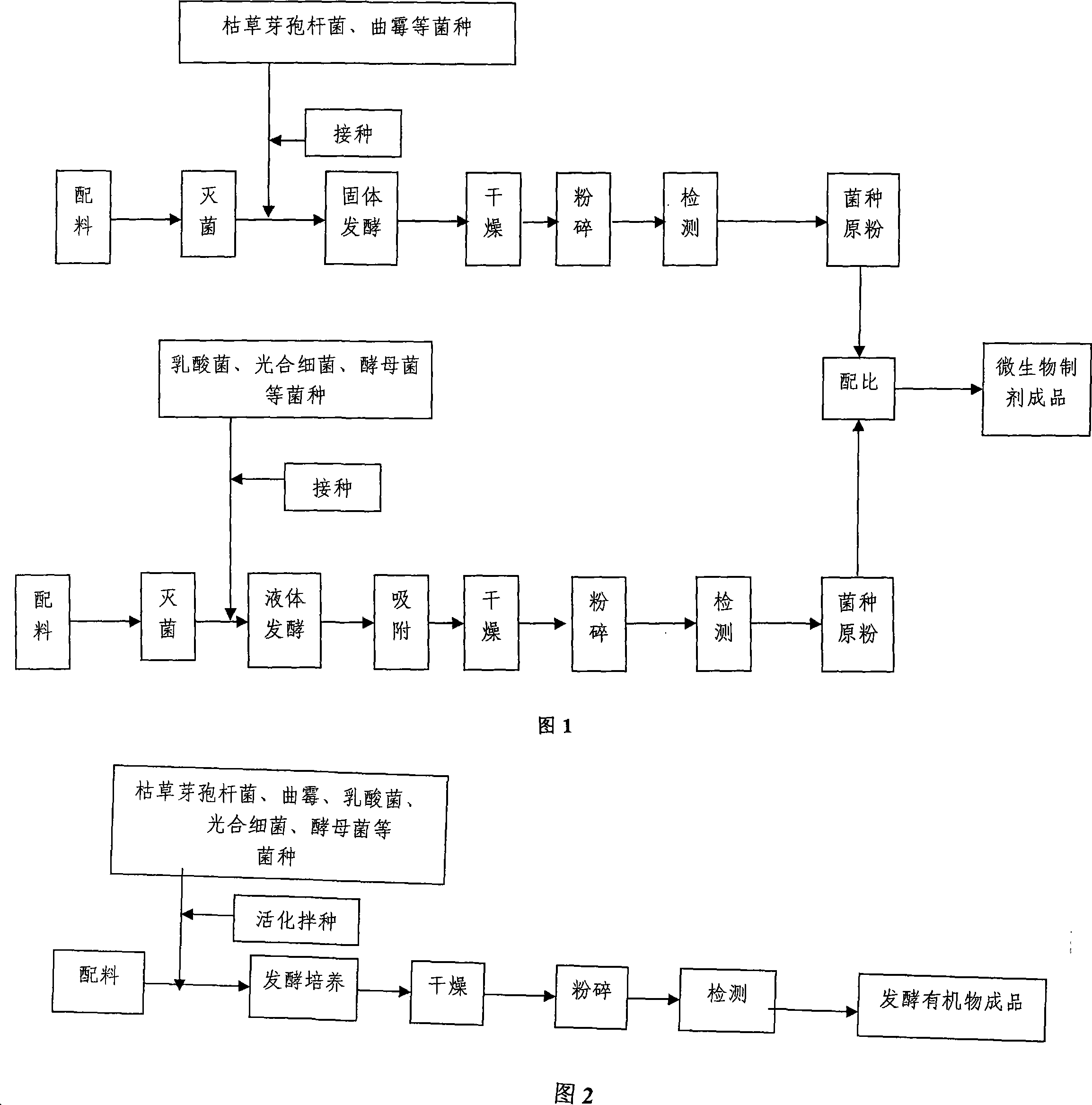

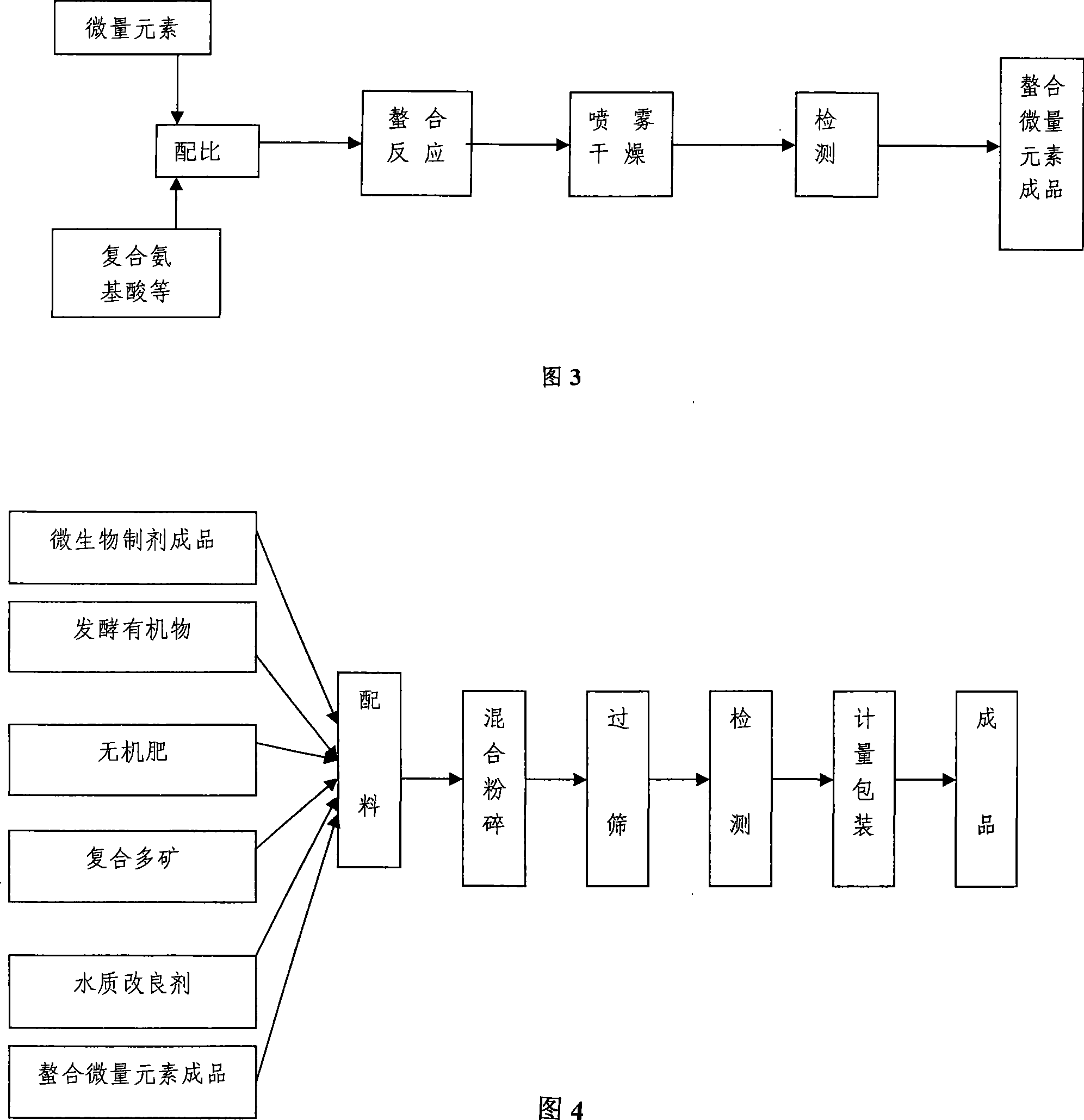

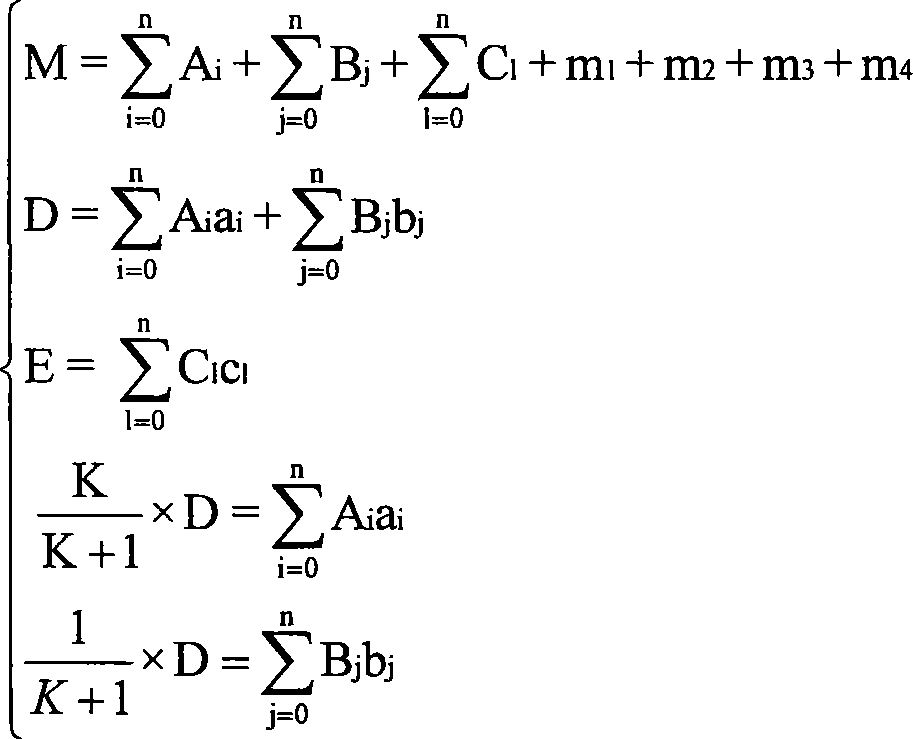

Special biological fish-fertilizer for aquaculture and preparation method thereof

ActiveCN101225007AMatching scienceIncrease profitClimate change adaptationPisciculture and aquariaDiseaseWater quality

The invention discloses a special biological fish fertilizer and a preparation method for the fertilizer used in aquiculture; wherein, the biological fish fertilizer mainly comprises raw materials as follows: microbiological preparation, inorganic fertilizers, fermentation organics, micro-mineral amino acid chelate, mineral composites, and water quality improver. The preparation method for the special biological fish fertilizer in aquiculture comprises steps as follows: microbiological preparation is produced; fermentation organics is then produced, and the micro-mineral amino acid chelate is produced, eventually the finished products are made. The special biological fish fertilizer has the advantages of limiting the growth and reproduction of the harmful algae, promoting the large-scale growth and reproduction of the suitable food for fish, effectively improving the water quality and purifying the water environment, strengthening the fish immunity, reducing the diseases, reducing cost due to the small use level, convenient use, mild odor, no pollution to the water, and environment protection. By combining the modern bioengineering technique, low-temperature drying technique, spray-drying technique, and super-fine crushing techniques, the preparation method has the advantages of stable quality for the fish fertilizers and lower overall cost.

Owner:WUHAN KEYANG BIOTECH

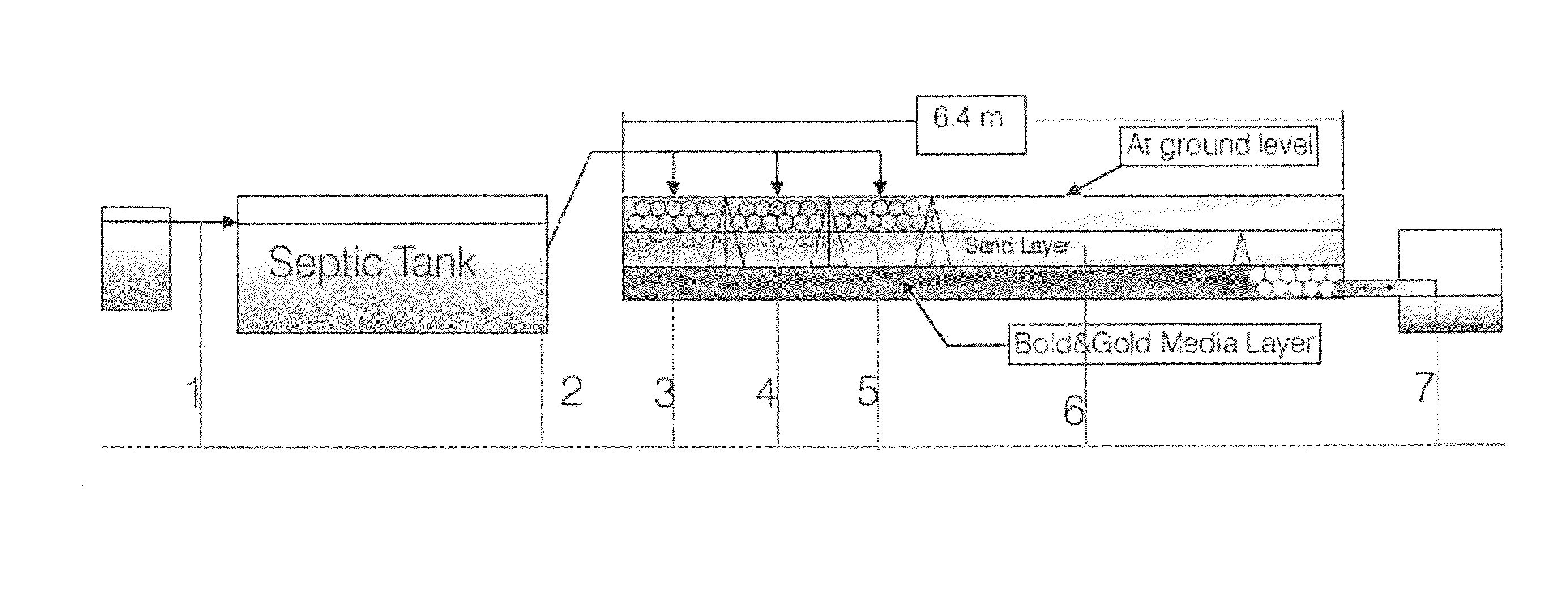

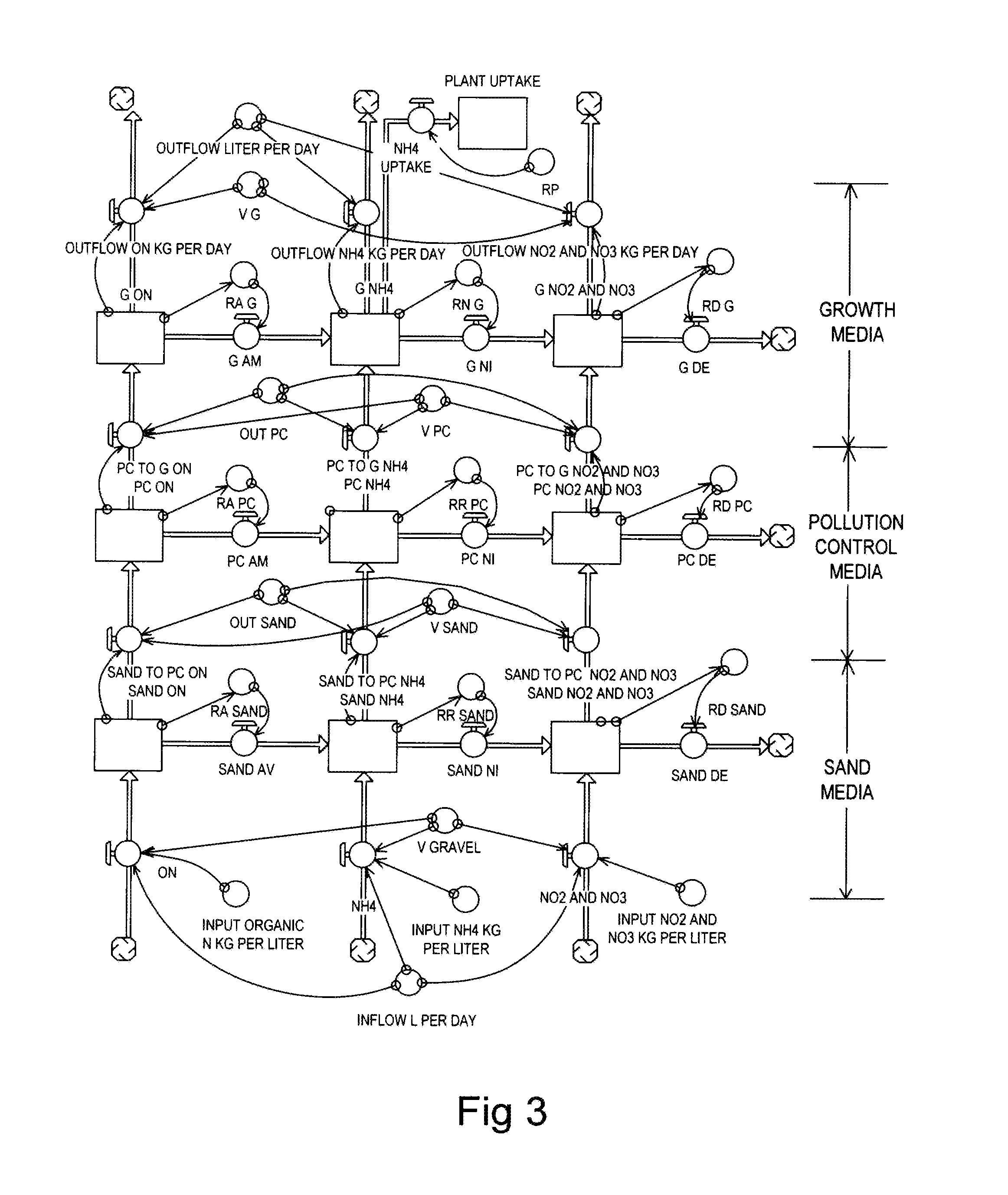

Subsurface upflow wetland system for nutrient and pathogen removal in wastewater treatment systems

ActiveUS8252182B1Low maintenance burdenHigh benefit cost ratioWater cleaningContaminated soil reclamationFecesTotal suspended solids

Methods and systems for a subsurface upflow wetland for wastewater treatment that includes a series of parallel treatment cells, each cell including from bottom to top, a layer of gravel, a layer of sand over the gravel to remove pathogens from a septic effluent, a pollution control medium above the sand layer to remove nutrients, total suspended solid, and biochemical oxygen demand and a growth media mixture layered on top of the pollution control media to grow plants, and a gravity distribution system to distribute effluent to the series of parallel treatment cells. The pollution control medium includes at least one recycled material and at least one naturally occurring material. In an embodiment it includes recycled tire crumb, sand and limestone or recycled tire crumb, compost, sand and limestone.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

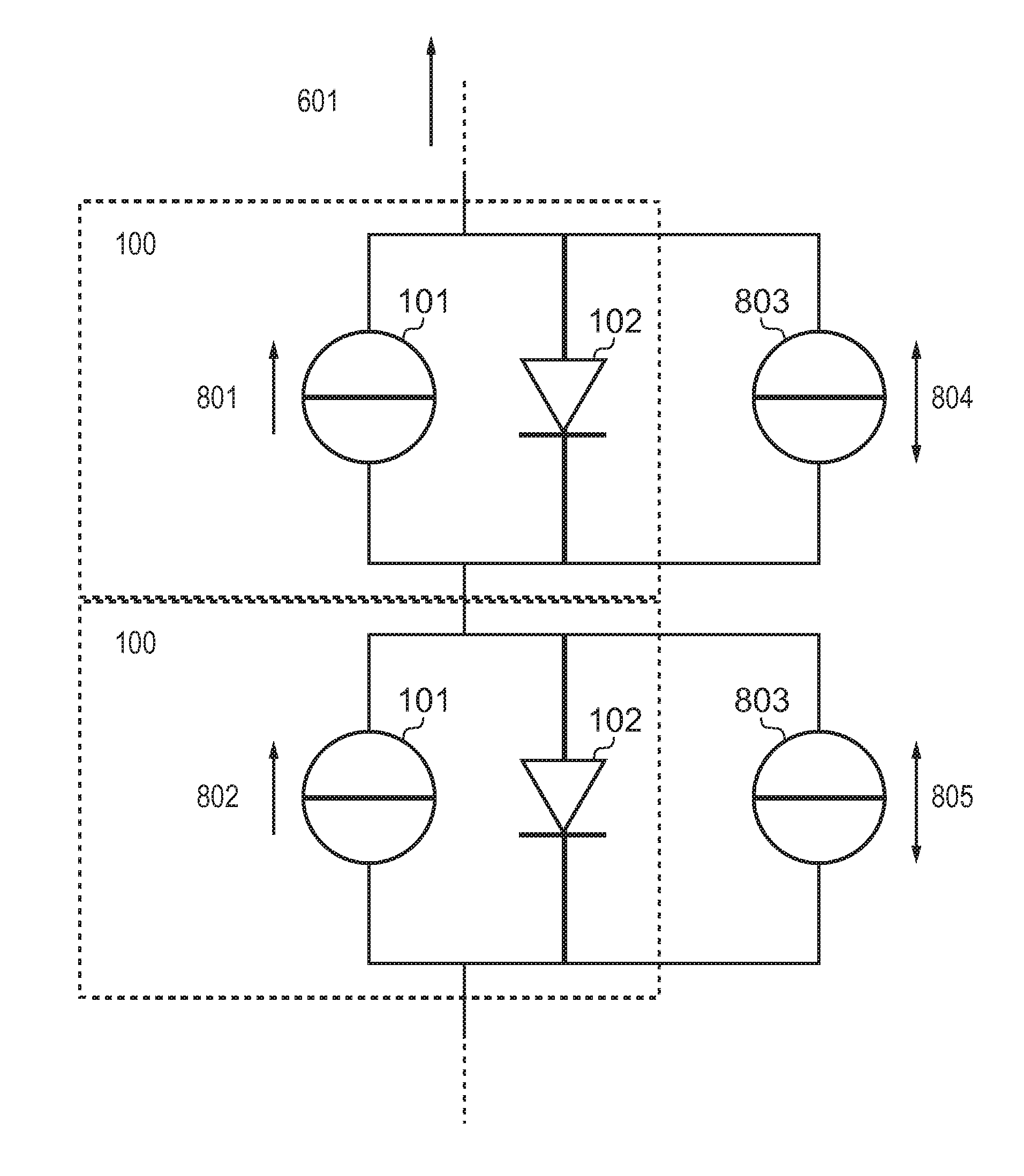

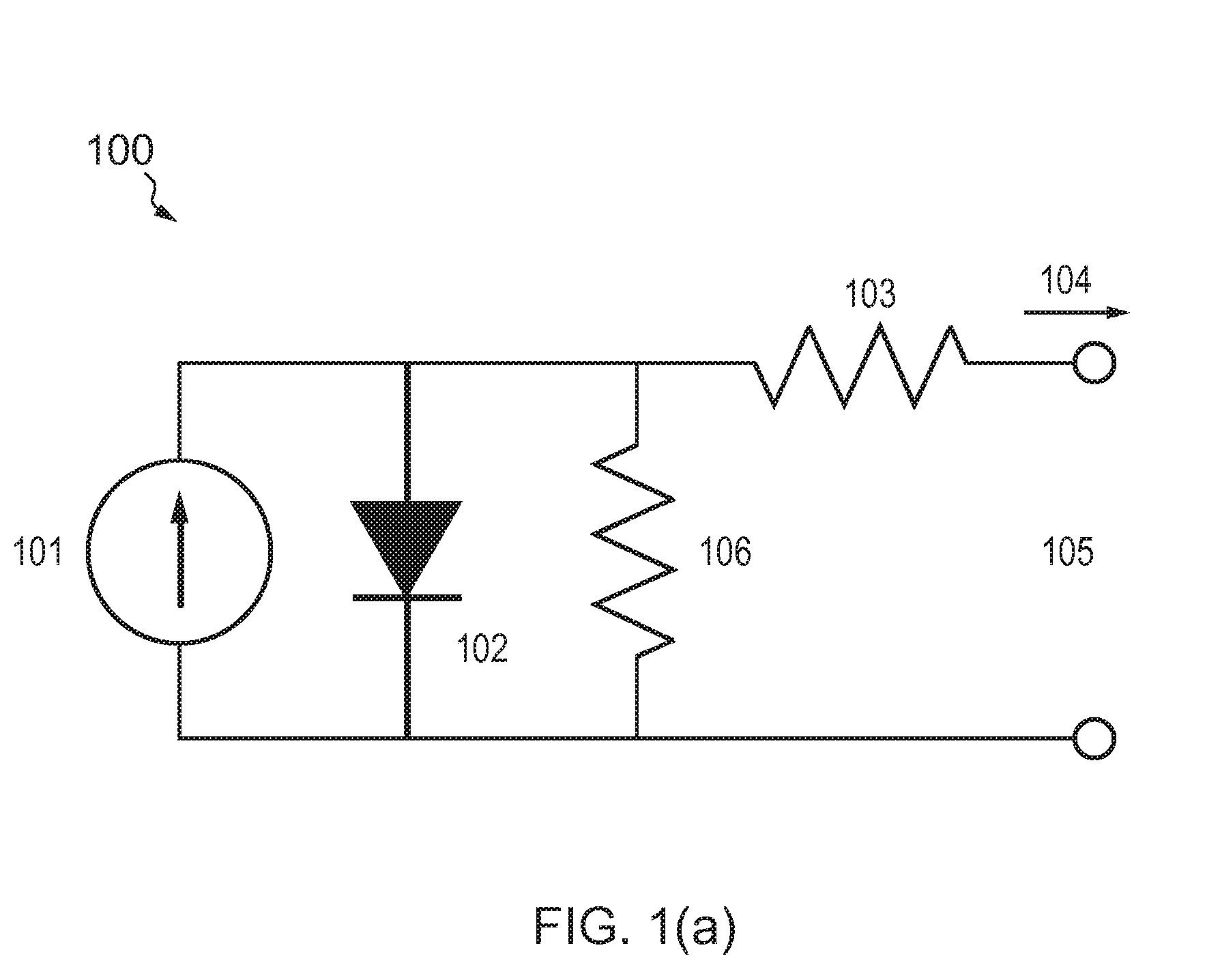

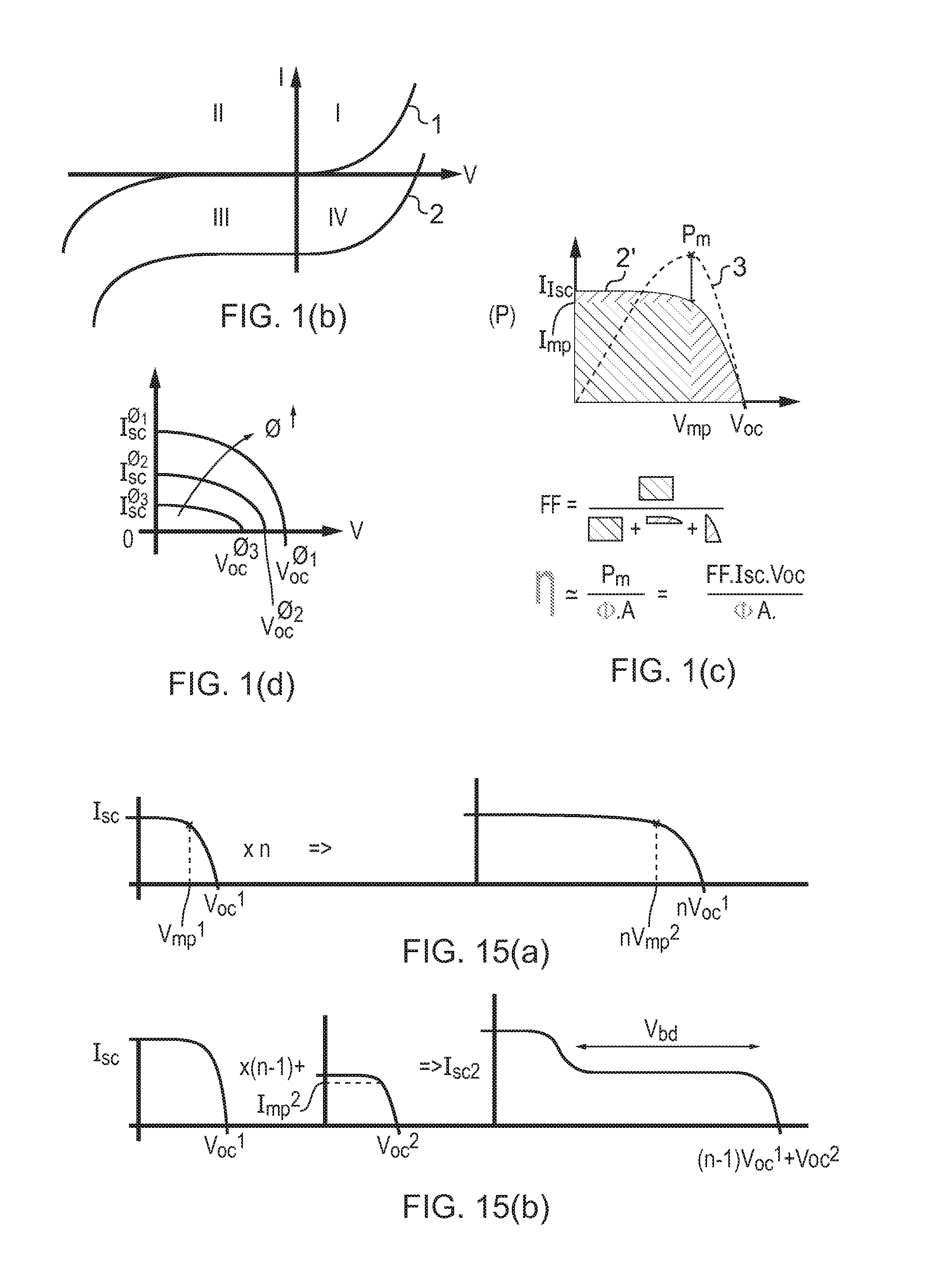

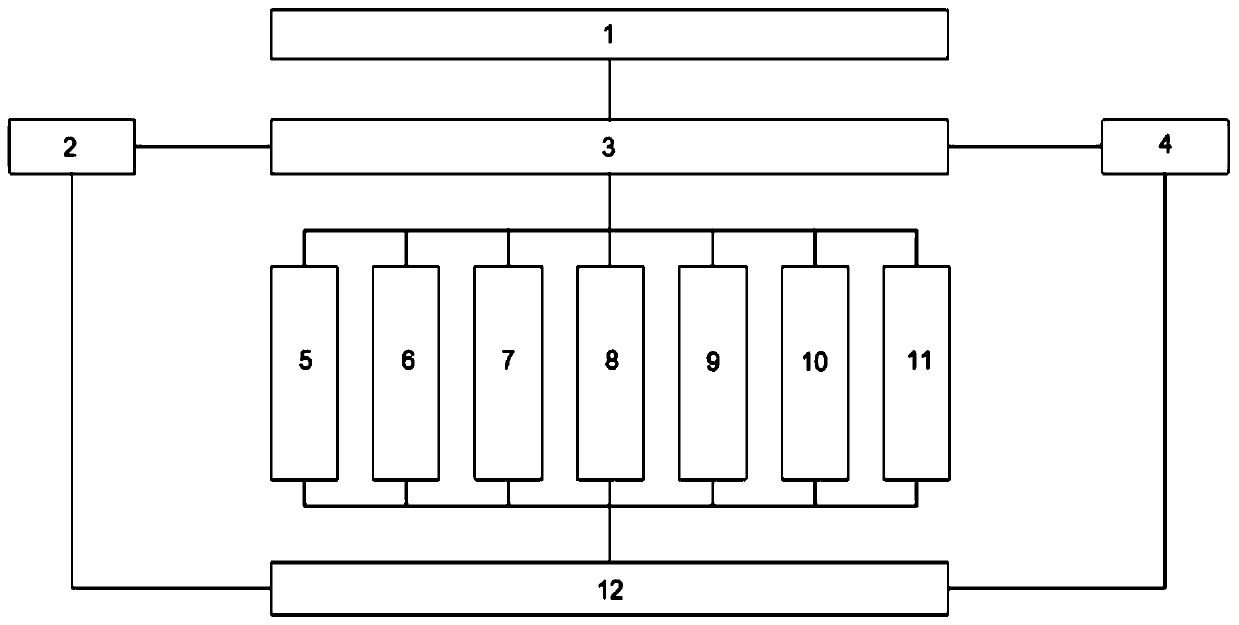

Photovoltaic units, methods of operating photovoltaic units and controllers therefor

InactiveUS20120098344A1Low costUnnecessary to performBatteries circuit arrangementsPhotovoltaicsElectrical batteryComputer module

The present invention relates to the field of photovoltaic systems with solar cell (s) or modules having insolation differences or mismatch. Each solar module is formed by placing a large number of solar cells in series. The PV system is then formed by placing a number of solar modules in series in a string and sometimes by placing multiple strings of series-connected solar modules in parallel, depending on the desired output voltage and power range of the PV system. In practical cases, differences will exist between output powers of the solar cells in the various modules, e.g. due to (part of) the modules being temporarily shaded, pollution on one or more solar cells, or even spread in solar-cell behaviour that may become worse during aging. Due to the current-source-type behaviour of solar cells and their series connection these differences will lead to a relatively large drop in output power coming from the PV system. This invention addresses this problem by adding DC-DC converters (803) on a single or multiple solar-cell level that source or sink difference currents thereby increasing the output power of the complete PV system. In embodiments, the efficiency of photovoltaic systems with solar cell (s) or modules is improved by compensating for output-power loss caused by insolation difference and mismatch.

Owner:NXP BV

Surface anti-corrosion sol for aeronautic aluminum alloy material and treatment method thereof

The invention discloses surface anti-corrosion sol for an aeronautic aluminum alloy material and a treatment method thereof in the technical field of aluminum alloy surface treatment. The sol comprises the following components in percentage by weight: 1-15 percent of organosiloxane, 45-93 percent of organic solvent, 0.1-10 percent of additive, 0.5-10 percent of rare earth salt, 5-50 percent of deionized water and 0.1-5 percent of catalyst. In the invention, a coating with a compact netlike crosslinking structure is formed on the surface of an aluminum alloy matrix and has high chemical stability and thermal stability, so that influence of an external acidic and alkaline environment and temperature variation on the coating can be resisted; and the coating has higher mechanical strength, rain washing resistance, friction resistance and scratch resistance. The technical method is simple, is easy and convenient to operate, does not have high requirement on equipment and is environmentally-friendly and pollution-free.

Owner:SHANGHAI JIAO TONG UNIV +1

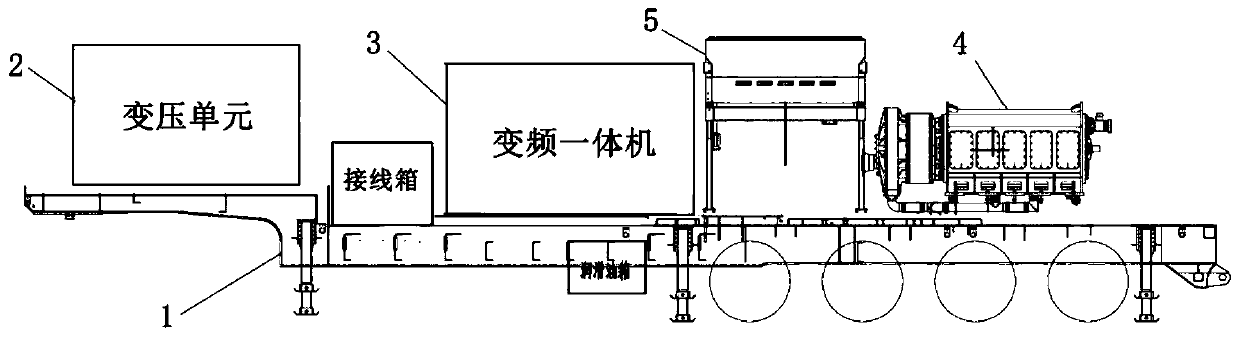

Electric drive fracturing semi-trailer of frequency conversion integrated machine

PendingCN110608030AOptimize layoutNo emission pollutionPositive displacement pump componentsFluid removalFrequency changerEngineering

The invention discloses an electric drive fracturing semi-trailer of a frequency conversion integrated machine. The optimization and integration of the traditional power supply semi-trailer and the fracturing semi-trailer realize the functions of power supply and fracturing of one semi-trailer without using the complete set of the power supply semi-trailer and the fracturing semi-trailer, the electric drive fracturing semi-trailer is more flexible in actual use, and the well field layout of oil and gas fields is greatly optimized; the transportation is convenient; only a set of high-voltage cables can be connected with the high-voltage power supply to reach a working state, and the wiring installation is faster; compared with diesel-driven fracturing, and the noise of the electric drive fracturing is low without exhaust emission pollution; the driving source is power, which has lower cost than the diesel; the electric drive fracturing semi-trailer adopts an integrated design of a motorand a frequency converter (namely, the frequency conversion integrated machine), the space occupied by the electric motor and the inverter in the prior art is reduced effectively, so the installing part of the electric drive fracturing semi-trailer has smaller volume and the transportation is more convenient, and can also provide space guarantee for installing other equipment on the semi-trailerbody.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

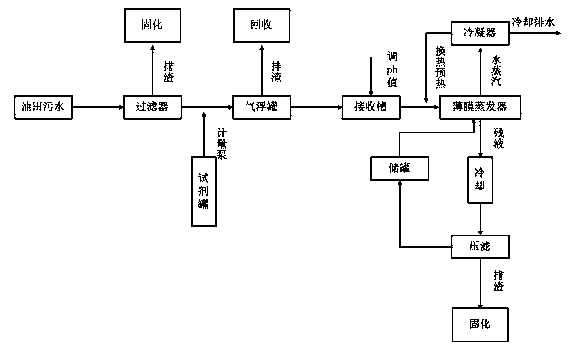

Processing method of sewage in oil fields by using film evaporator

InactiveCN103420532AReduce processing costsReduce consumptionWaste water treatment from quariesMultistage water/sewage treatmentSlagWastewater

The invention discloses a processing method of sewage in oil fields by using a film evaporator. The processing method is characterized by comprising following technology steps: filtering sewage with a filtering device, removing oil by the air-floating method, separating and condensing sewage by the thin-film evaporating method, and processing residual slag, is mainly used for evaporating processing of sewage in oil fields, and is capable of continuously processing oil-containing sewage. The liquid phase and solid phase after being processed can be discharged without causing pollution to the environment.

Owner:JEREH ENERGY SERVICES

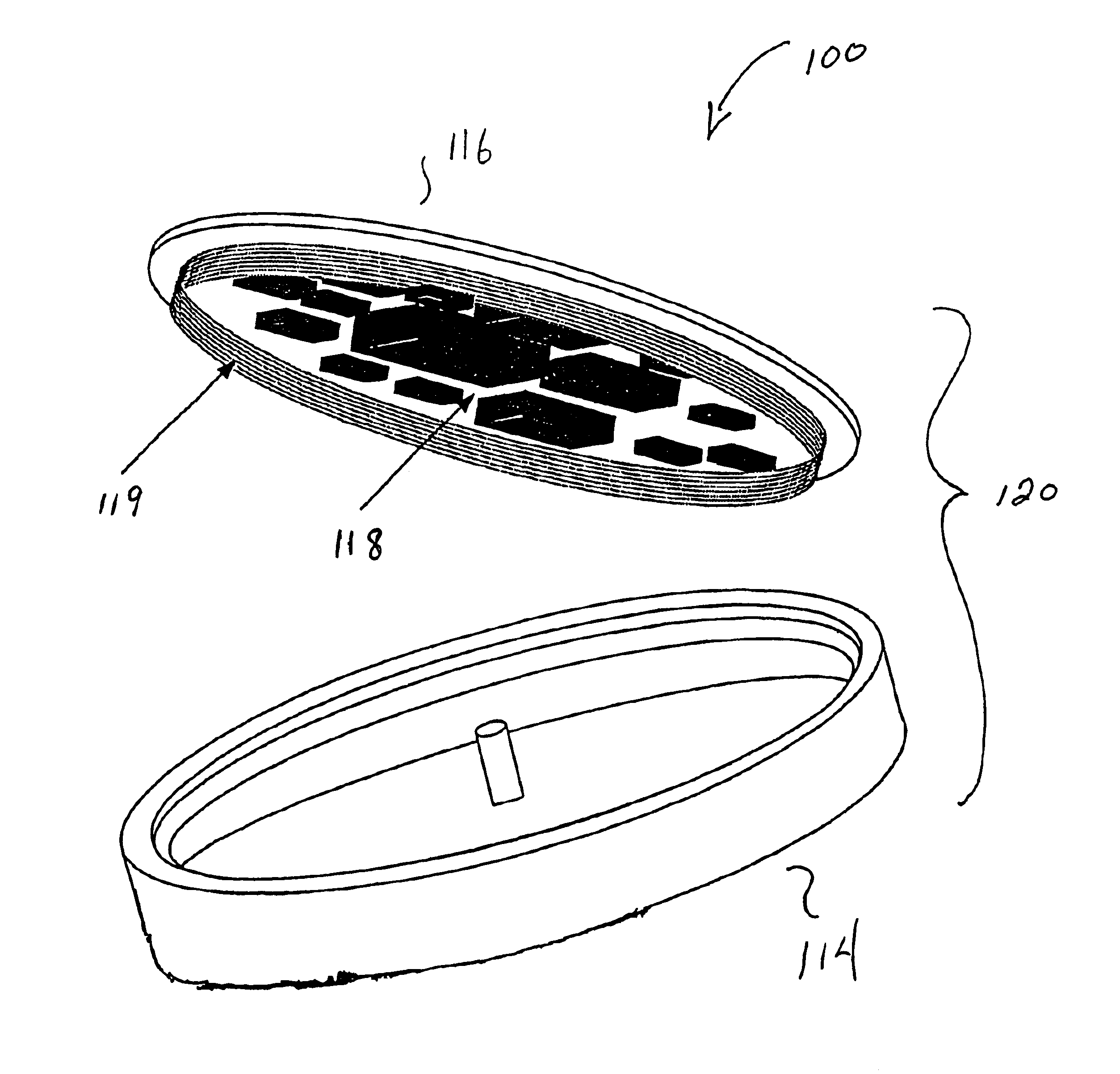

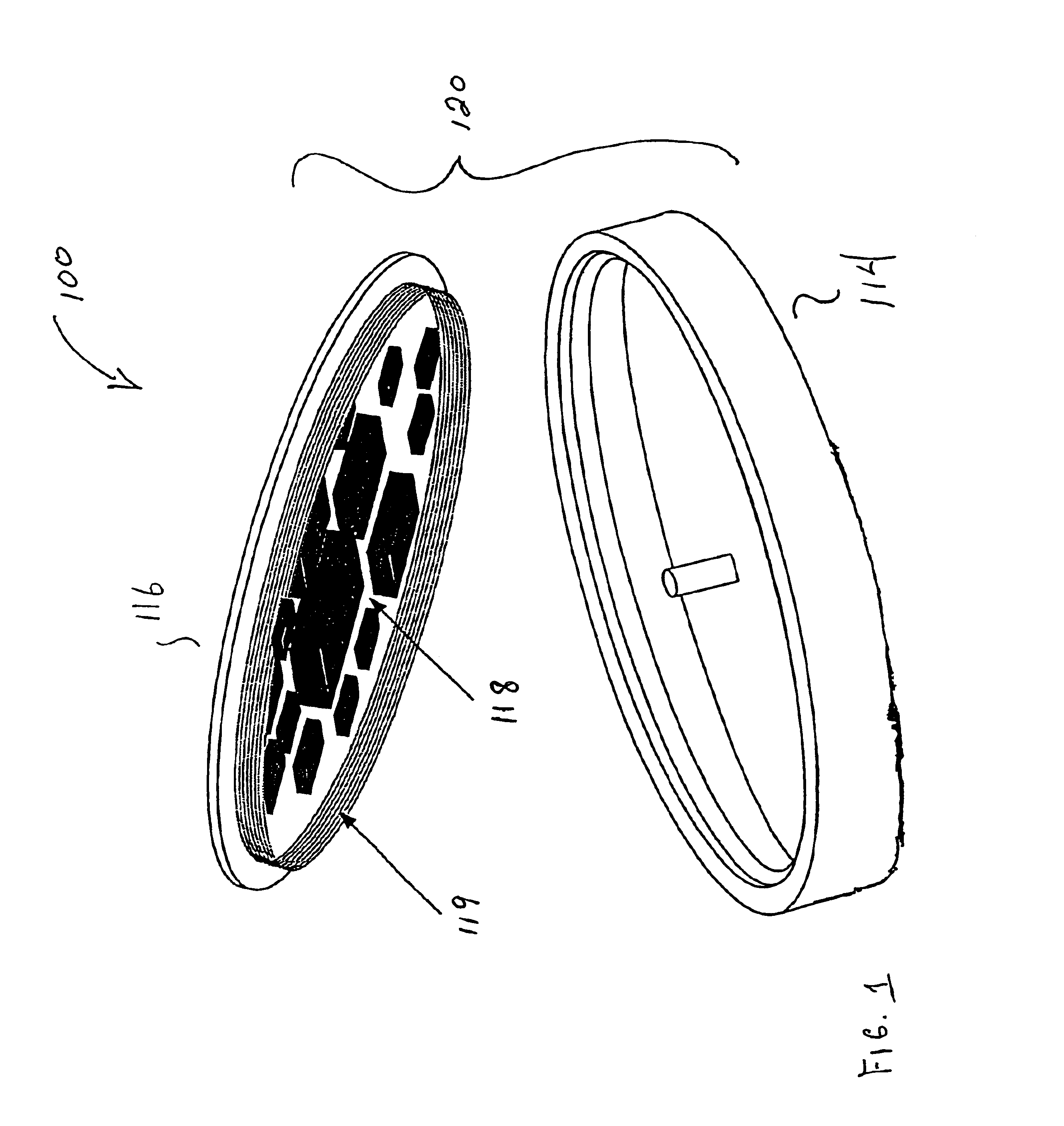

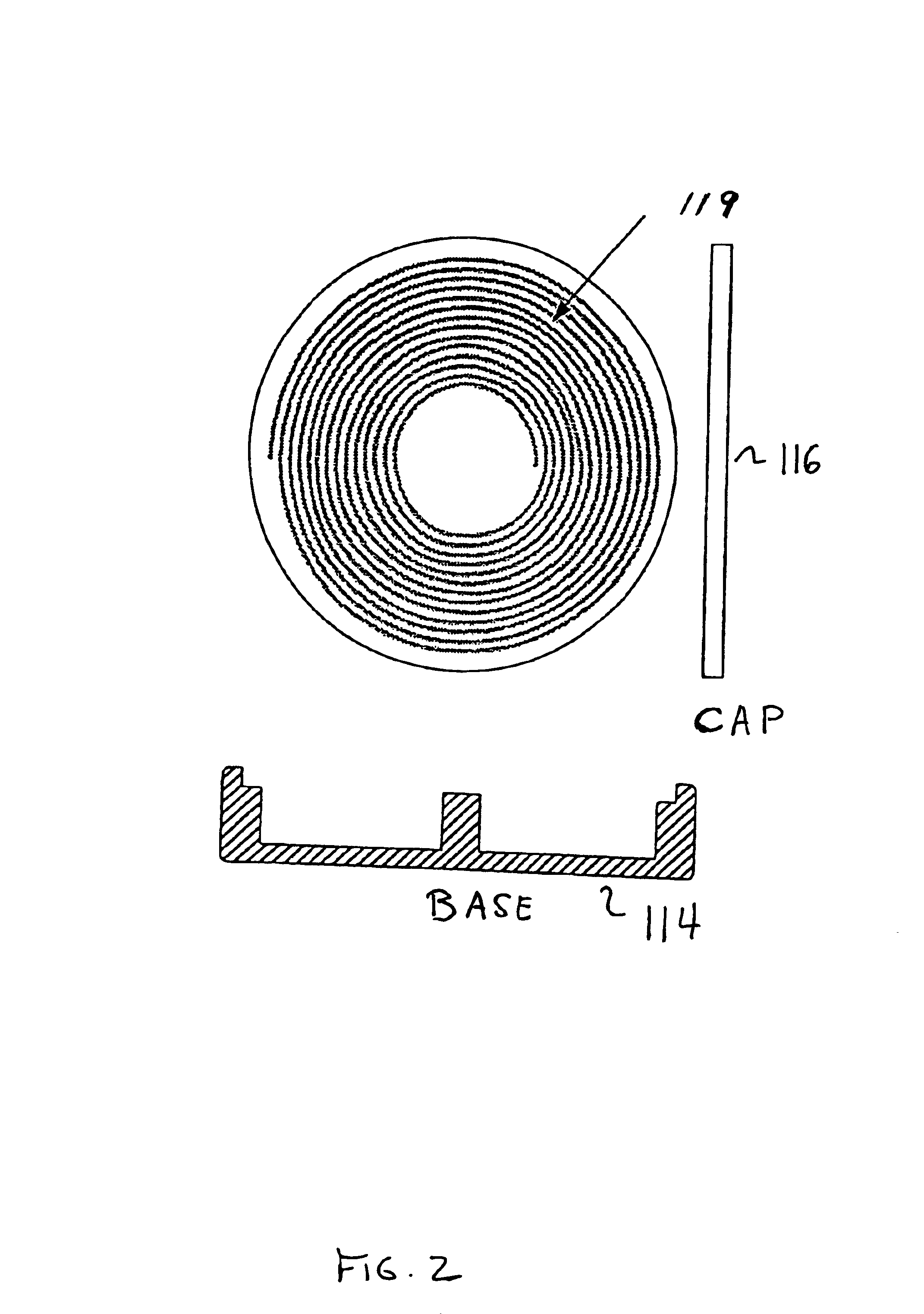

Wireless multi-functional sensor platform, system containing same and method for its use

InactiveUS6796187B2Small sizeLow costElectric signal transmission systemsForce measurementLine sensorTransmitted power

A multi-functional sensor system for simultaneously monitoring various parameters such as the structural, chemical and environmental conditions associated with a medium to be monitored, e.g., bridges, high-rise buildings, pollution zones, is provided wherein the system includes at least a plurality of wireless multi-functional sensor platforms embedded in the medium in which an interrogation unit transmits power and receives responses. Each wireless multi-functional sensor platform includes multiple channels for accommodating a plurality of sensor types to simultaneously monitor the parameters associated with the medium. Thus, the wireless sensor platforms are formed to include those sensor types which are considered germane to the intended medium to be monitored.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Minitype gas turbine generator wellhead shale gas supply device control system

PendingCN111350595AMeet the requirements of water hydrocarbon dew pointGuaranteed uptimeTurbine/propulsion fuel valvesGas turbine plantsMicro gas turbineHydrocarbon dew point

The invention discloses a minitype gas turbine generator wellhead shale gas supply device control system. A control protection system comprises a particle liquid drop control system, a temperature control system, a pressure control system, a liquid level control system, a water hydrocarbon dew point control system, a fine treatment control system and a system safety protection system which are independently arranged side by side, a working condition parameter signal acquisition system transmits acquired signals to a logic judgment command system, the logic judgment command system is correspondingly connected with a parameter setting system, the control protection system and a data storage remote transmission system, and a micro gas turbine power generation system is correspondingly connected with the parameter setting system, the control protection system and the data storage remote transmission system. The control system has the beneficial effects that stable control over the water hydrocarbon dew point is achieved, and normal and stable operation of the micro gas turbine is guaranteed; the pollution discharge is accurately controlled according to the fluctuation condition of theactual working condition, and the overall operation cost is reduced; and automatic liquid drainage under different working condition fluctuations is achieved, and the risks of tripping and blow-by arereduced.

Owner:JEREH OIL & GAS ENG

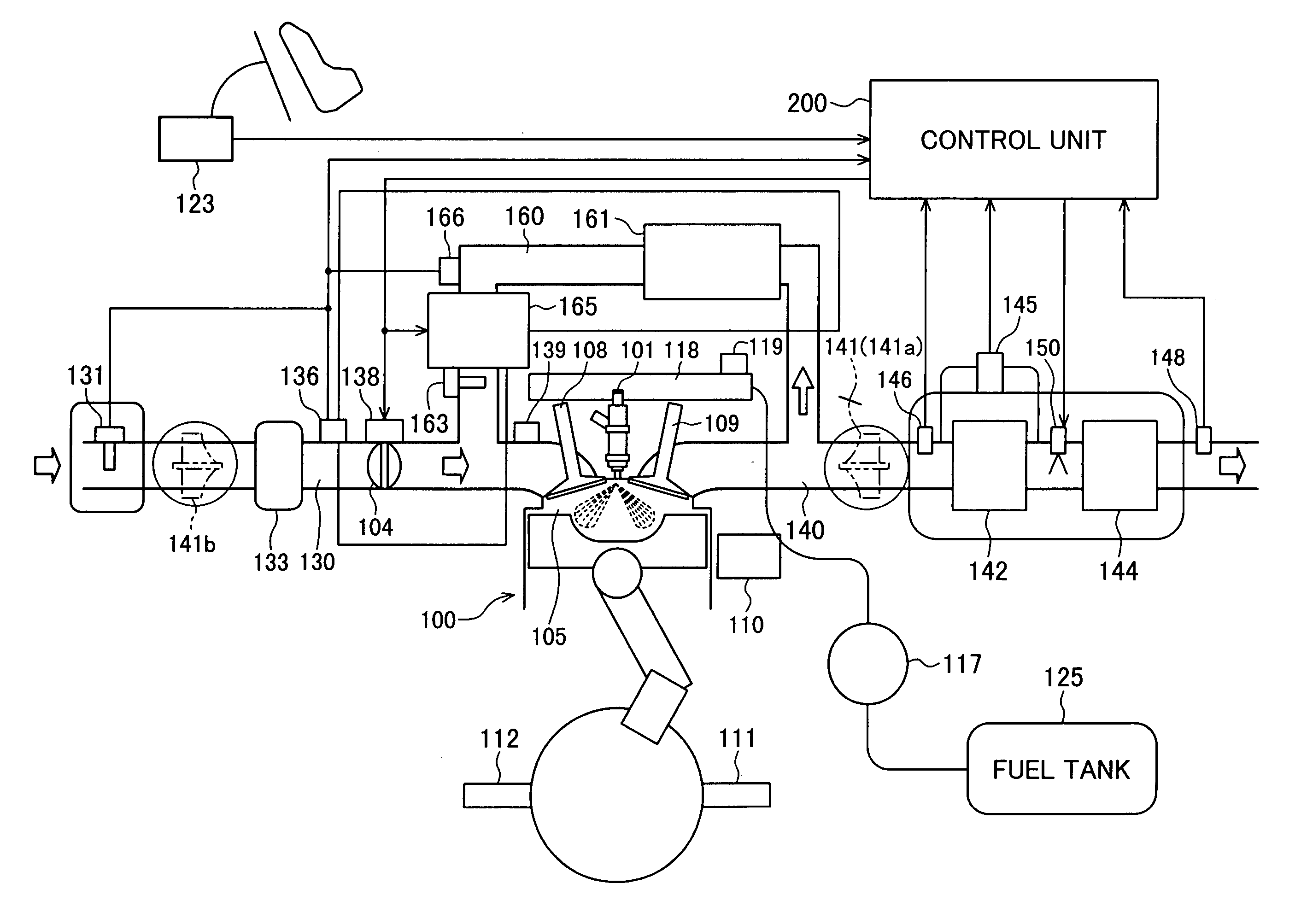

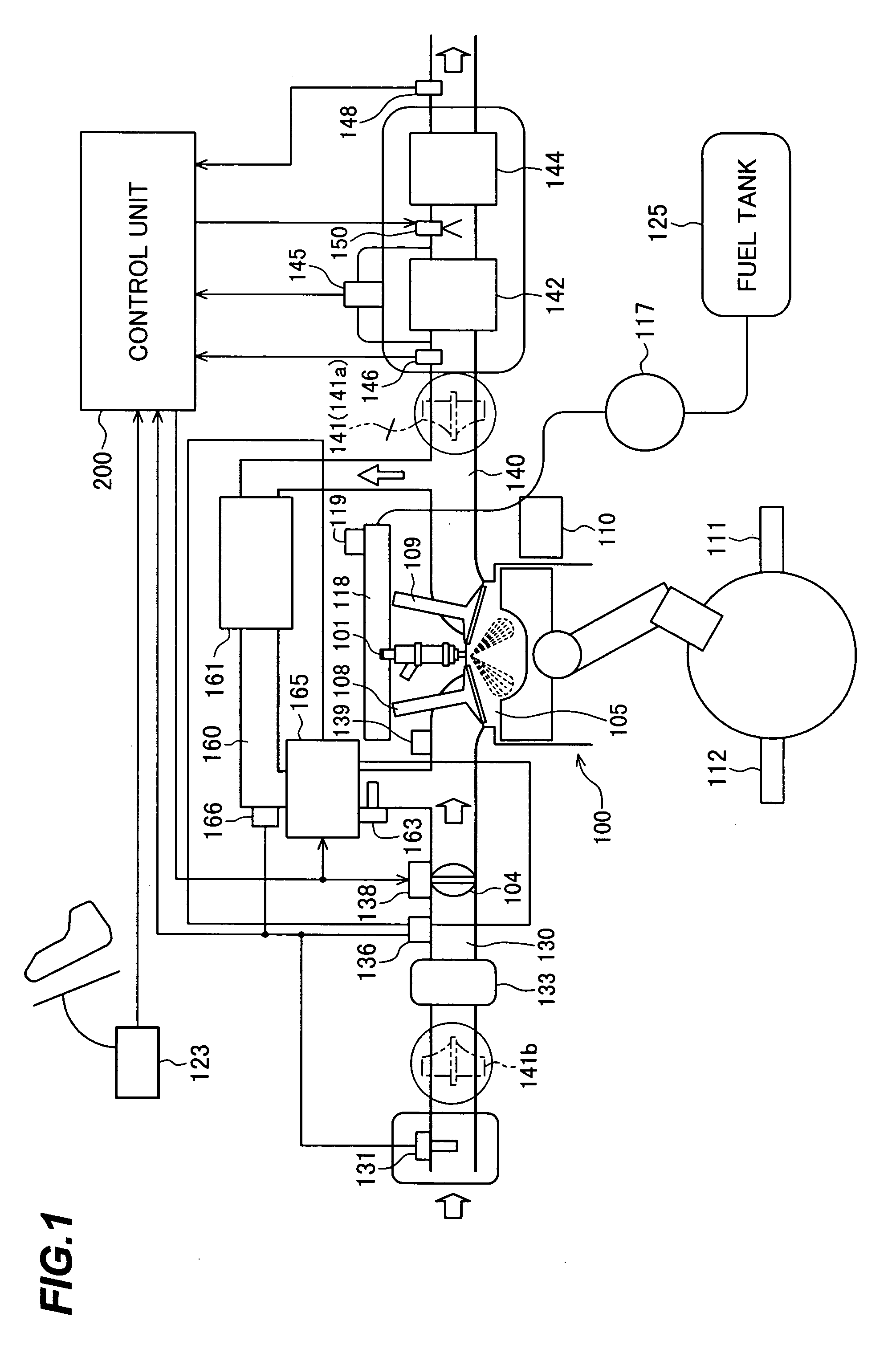

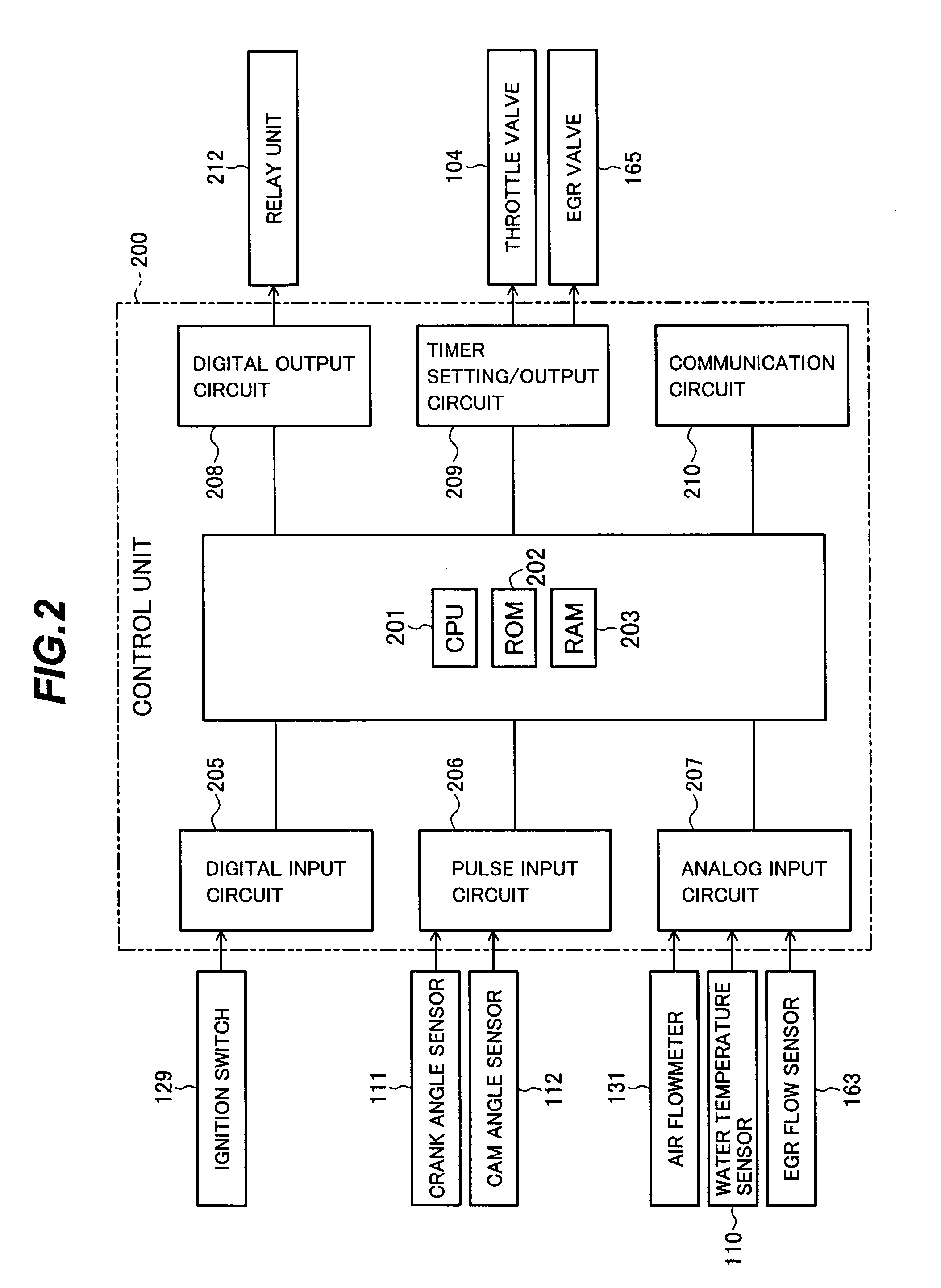

Engine exhaust gas cleaning method and system

InactiveUS20060086080A1Emission reductionReduce cleaning rateElectrical controlNon-fuel substance addition to fuelExhaust fumesEnvironmental engineering

An engine exhaust gas cleaning method and system, which can effectively reduce emission amounts of particular components, such as NOx, contained in exhaust gas by adding an additive, such as urea water or light oil, into an exhaust passage, which is adaptable for a reduction of the cleaning rate caused by deterioration of a catalyst, which can always maintain a high cleaning rate during acceleration and deceleration as well, and which can minimize environmental pollution with use of the additive in the least necessary amount. The engine exhaust gas cleaning system comprises a catalyst for removing a particular component, represented by NOx, contained in exhaust gas of an engine, an additive adding unit for adding, to the exhaust gas, an additive for reducing the particular component represented by NOx, and an EGR amount adjusting unit for adjusting an EGR amount. An addition amount of the additive and the EGR amount are set depending on an operating state and deterioration of the catalyst with time. The catalyst is regenerated when a cleaning capability of the catalyst has reduced to a predetermined value or below.

Owner:HITACHI LTD

Sensor system for measuring and monitoring indoor air quality

InactiveUS6941193B2Accurate inductionAccurate measurementMechanical apparatusLighting and heating apparatusIndoor air qualityBuilding under construction

An apparatus for accurately sensing room conditions and positioned in the air stream to the return air plenum. The apparatus is a combination of a temperature and volatile organic compound (VOC) sensor. The sensor module is built into a ceiling grid system with the body of the sensor module extending into the return air plenum. The ceiling grid has a slot fabricated into its face which allows the air stream from the room to flow by the sensors on its way to the plenum. This enables both the temperature and the composition of the air to be monitored at the optimal location. A portable pollution sensor device that measures and monitors leading indicators of indoor air quality and the extent of pollution is used in conjunction with the ceiling grid mounted sensor modules. The portable device documents and benchmarks air quality both in buildings under construction and in existing buildings. The portable device is network-enabled so as to simultaneously transmit the data to various control devices. In addition to its use to monitor areas not otherwise covered by the ceiling grid mounted sensors, the hand-held sensor can be used during building construction to determine the best locations in the ceiling grid system for mounting of the fixed pollution sensors.

Owner:AWI LICENSING

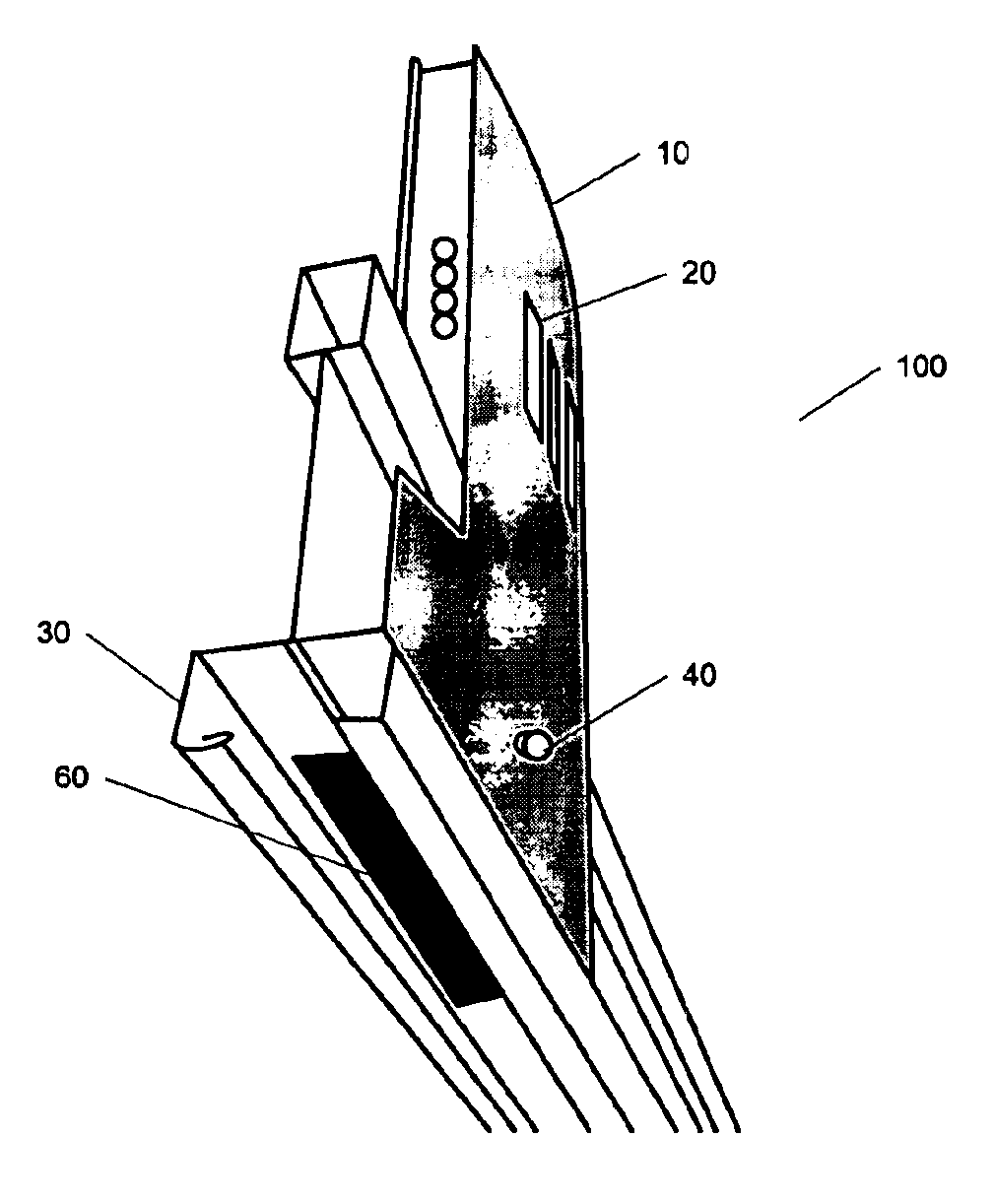

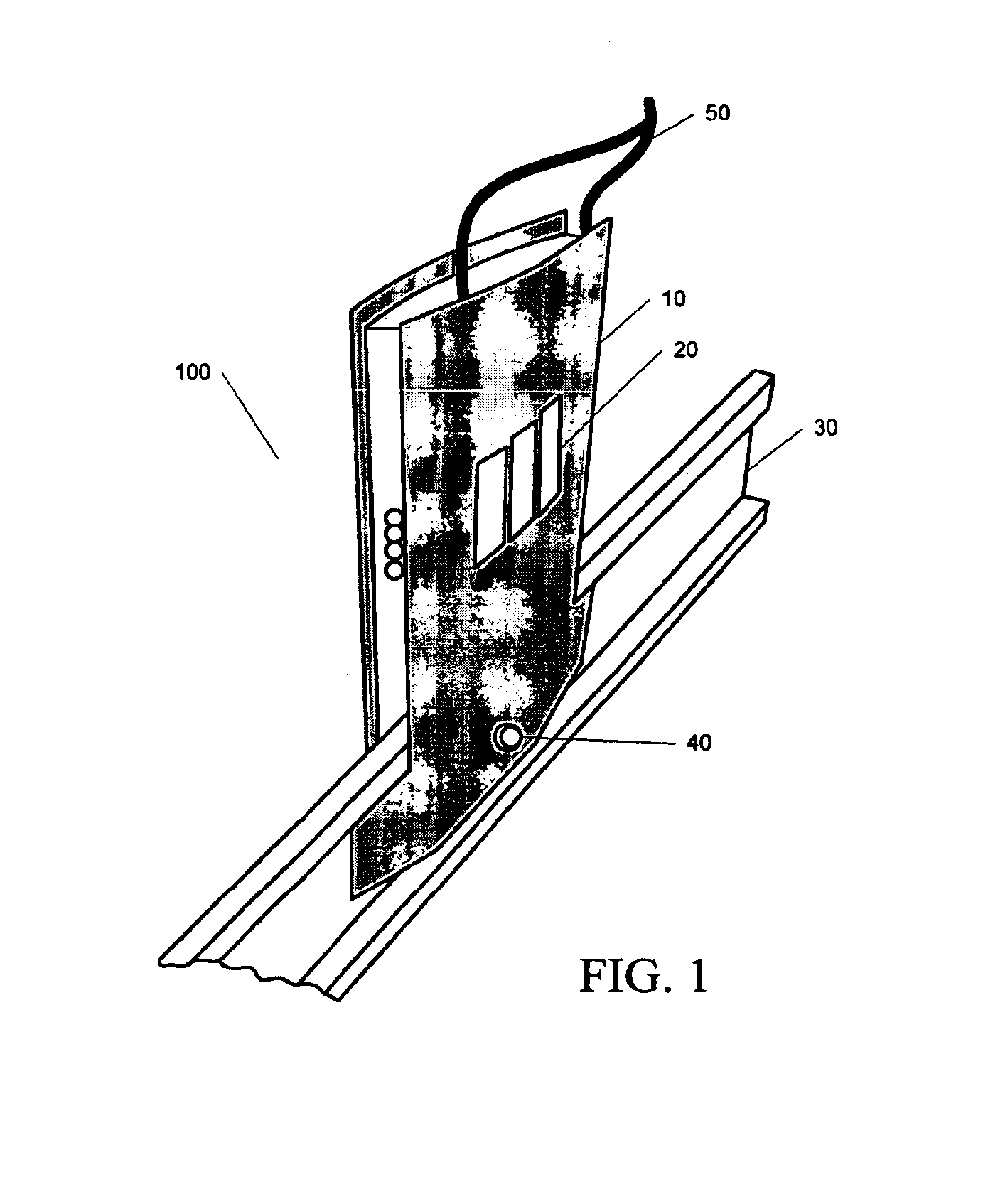

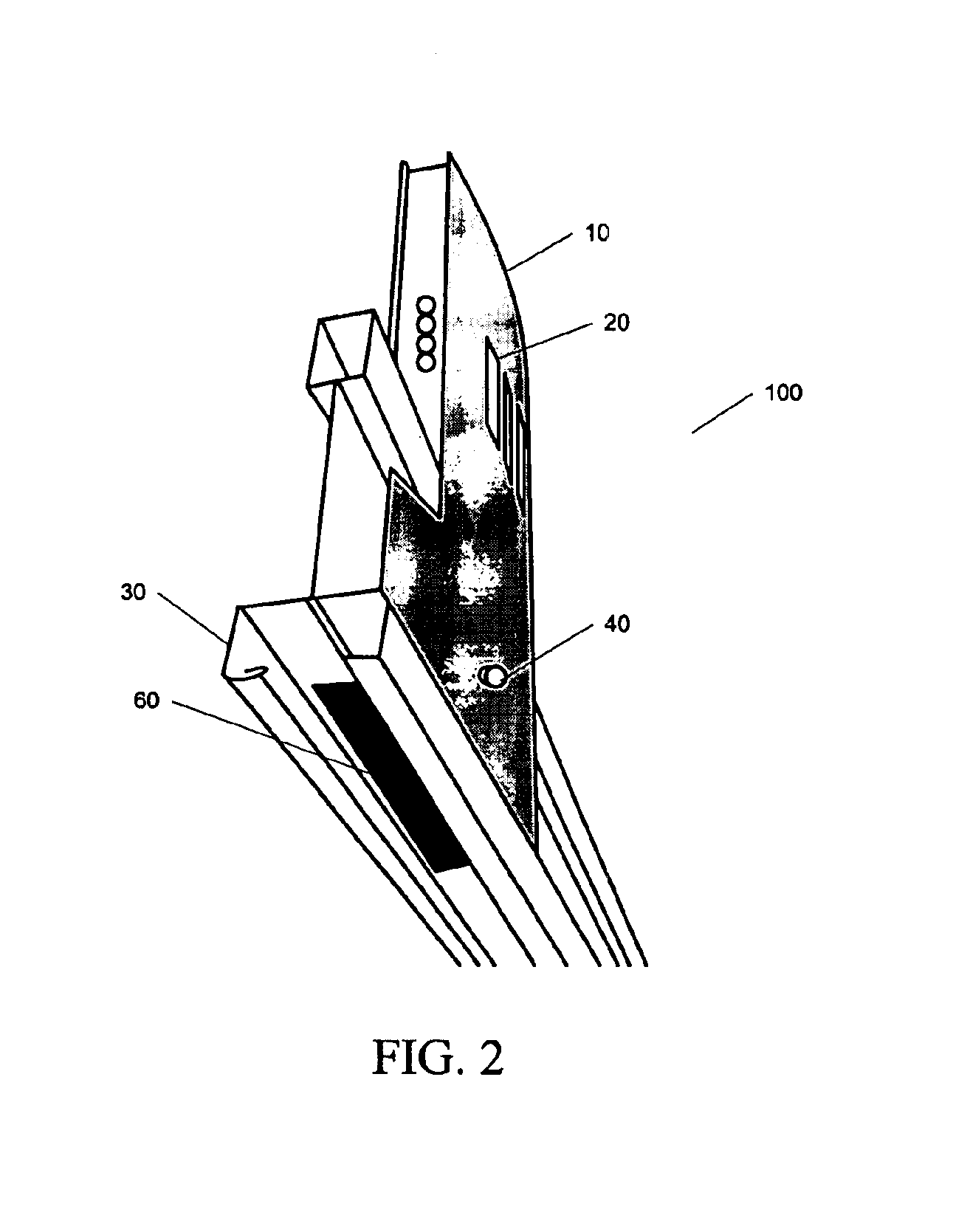

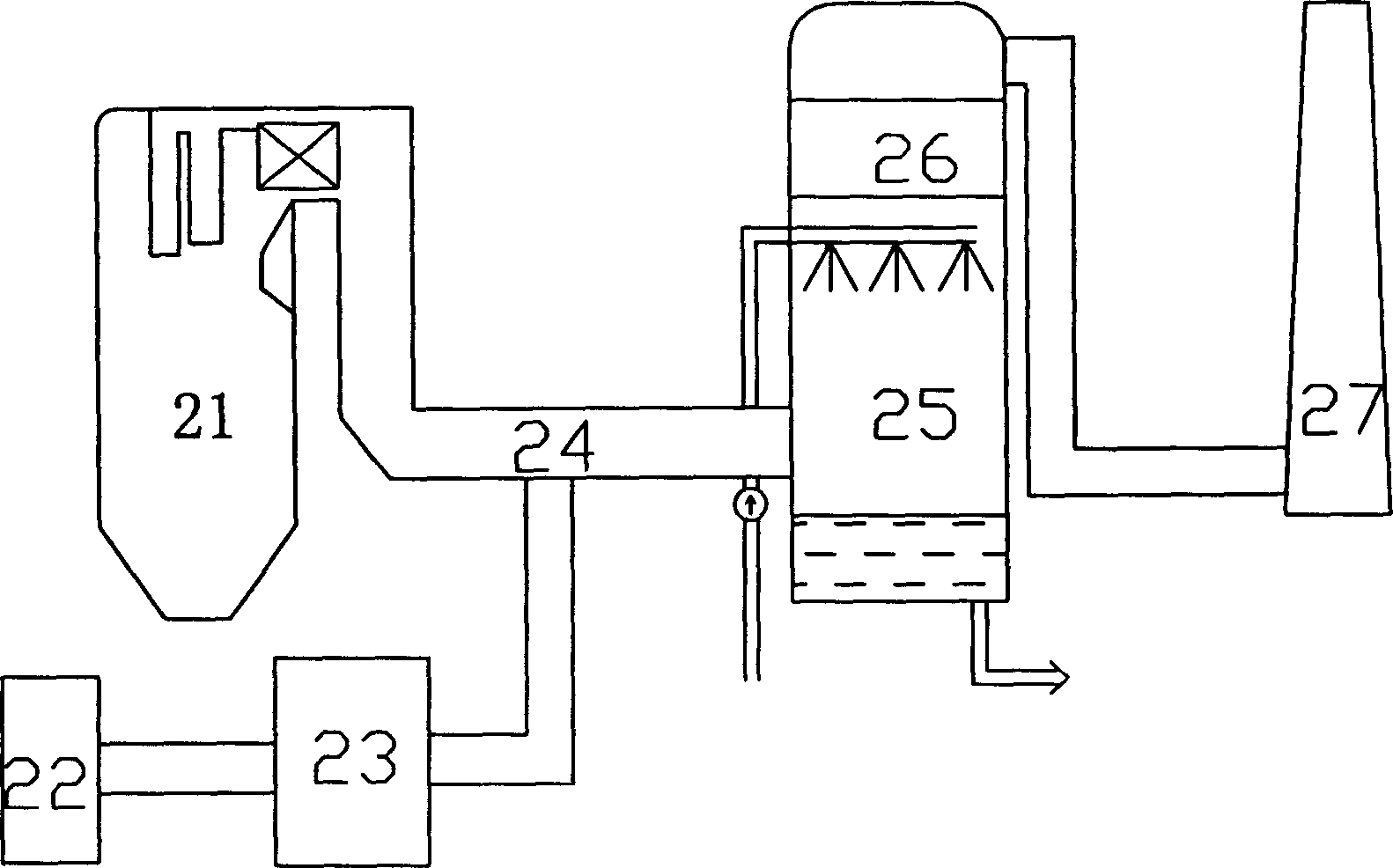

Method and apparatus for generating pollution free electrical energy from hydrocarbons

InactiveUS20080017369A1Cost effectivePollution free energyFluid removalThermal energyHydrocotyle bowlesioides

The present invention relates to the generation of substantially pollution free energy by utilizing hydrocarbons to create electrical energy, while reinjecting exhaust fumes or other byproducts into a subterranean formation. The present invention further relates to managing and supplying this electrical energy to at least one of a variety of subprocesses for producing a fuel product, such as hydrogen or ethanol. Alternatively, electrical power can be generated from a non-hydrocarbon source such as thermal, solar, wind or other power source to produce electrical energy, which in turn may be used to produce fuel products or other forms of usable energy. Thus, remote, low reserve oil and gas fields may be exploited and produced without requiring the construction of expensive gas transmission lines.

Owner:PRODN RESOURCES

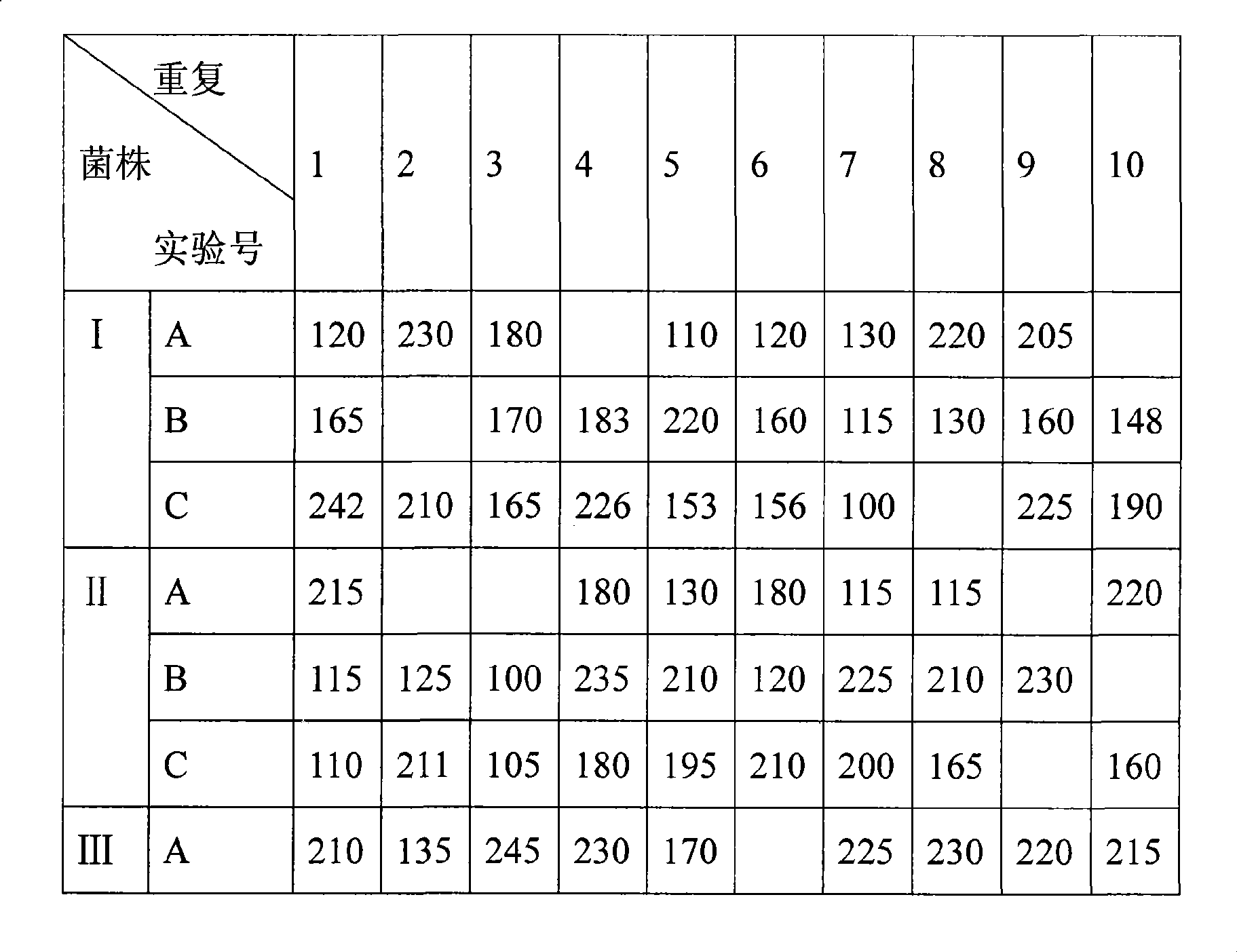

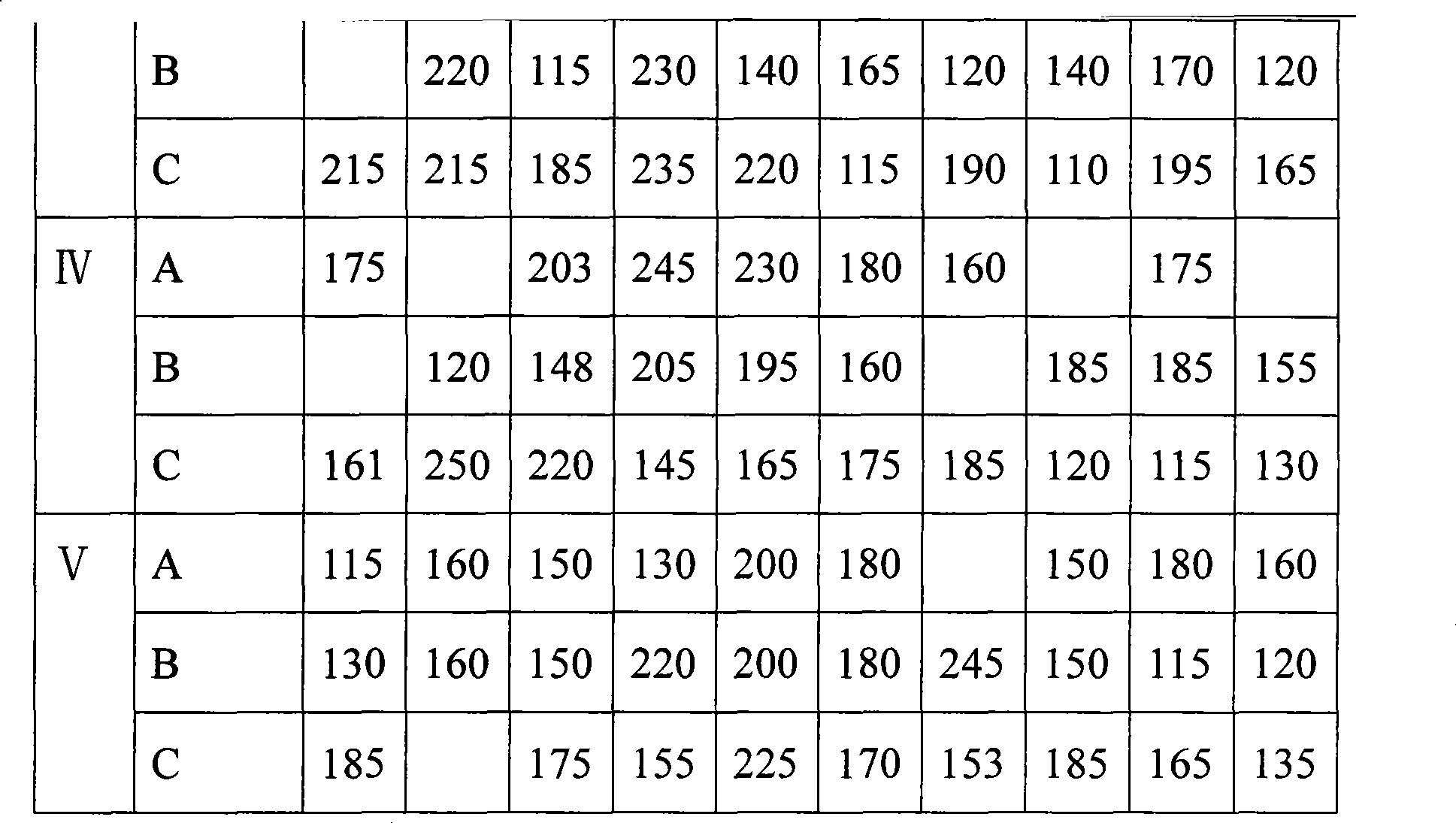

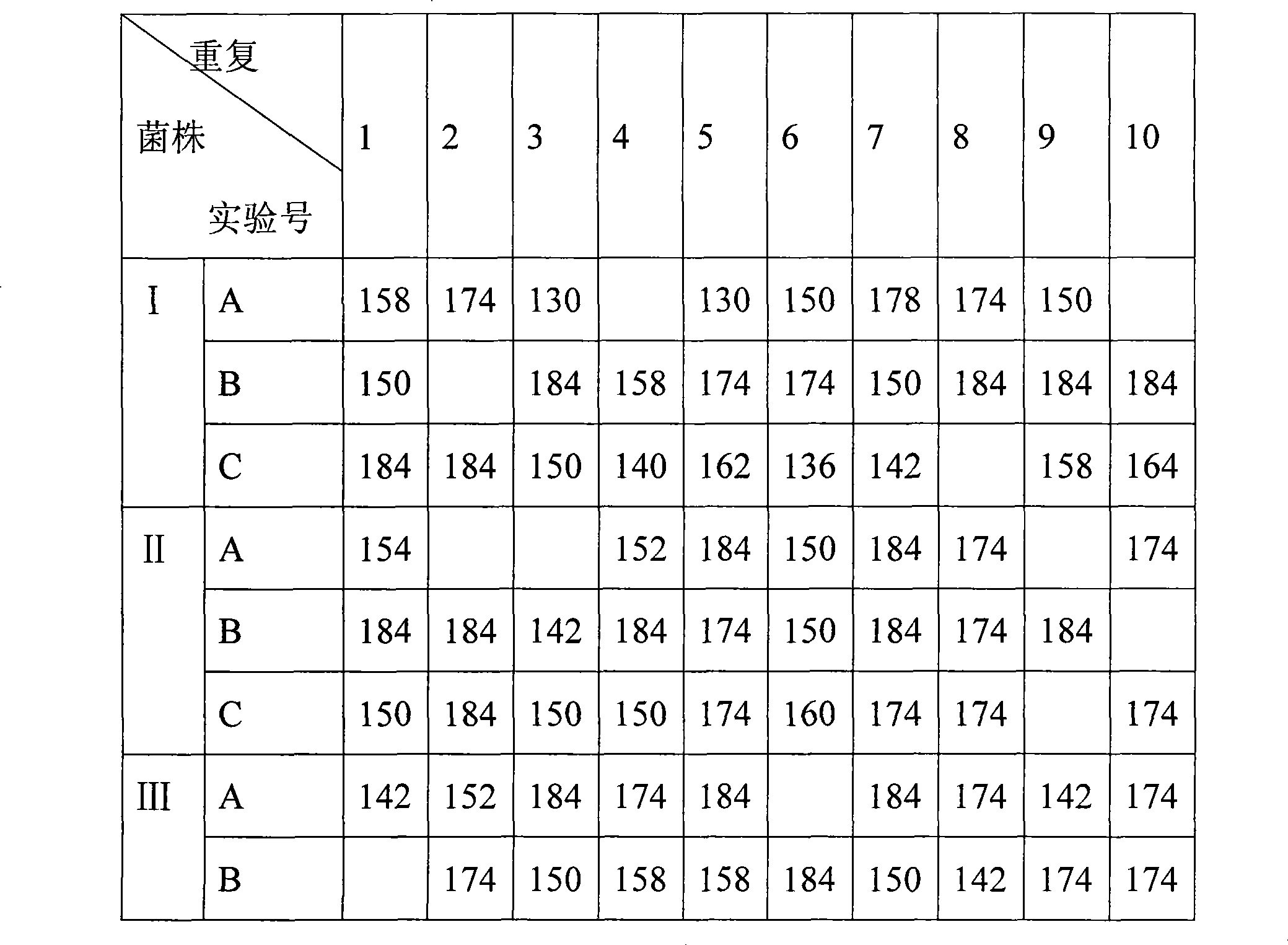

Clear-white gold needle mushroom cultivation method

InactiveCN101366346AAvoid pollutionNo diseaseBio-organic fraction processingOrganic fertiliser preparationSucroseSaccharum

The invention discloses a method for cultivating pure white needle mushrooms. The method comprises the following steps: a strain is prepared; a culture material is prepared; bagging and sterilization are carried out; inoculation is carried out; a mycelium is cultured; nutrition, humidity, temperature, light, air and other culture conditions are strictly controlled during a fruiting period; and harvesting is carried out in an optimum period. the formulation of the culture material is 0 to 32 percent of weed tree sawdust, 0 to 93 percent of cotton seed hulls or wheat straw, straw, corncob and other crop straw, 0 to 20 percent of wheat bran, 0 to 10 percent of corn meal, 0 to 10 percent of soybean meal, 0 to 1 percent of calcium carbonate, 0 to 0.2 percent of monopotassium phosphate, 0 to 0.2 percent of magnesium sulfate, 1 to 1.2 percent of sucrose, 0 to 10 percent of rice bran, 0 to 1 percent of plaster and 0 to 0.02 percent of urea. Quicklime and wettable carbendazim are added during the preparation of the culture material so as to prevent the pollution of undesired bacteria. The technical proposal aims to select proper breeds, popularize local large scale planting and improve cultivation benefit.

Owner:WUHU YESHULIN BIOTECH

Ozone oxidation and denitration method of boiler flue gas

The invention provides a method for processing de-nitration on the boiler smoke, belonging to the environmental protective technique. The method comprises: ejecting ozone O3 into the low-temperature section of smoke channel of boiler whose temperature ranges from 110-150Deg. C; oxygenizing the nitric oxide NO into high-state nitrogen oxide as NO2, NO3 or N2O5; washing the smoke with alkali liquor to remove the nitrogen oxide in the smoke. Compared to other de-nitration method, said invention has higher efficiency, lower cost, and non-secondary pollution, while the absorption effect combined with alkali liquor can reach more than 80%. In addition, the invention can apply variable boiler devices, which is not relative to the burning condition of boiler.

Owner:ZHEJIANG UNIV

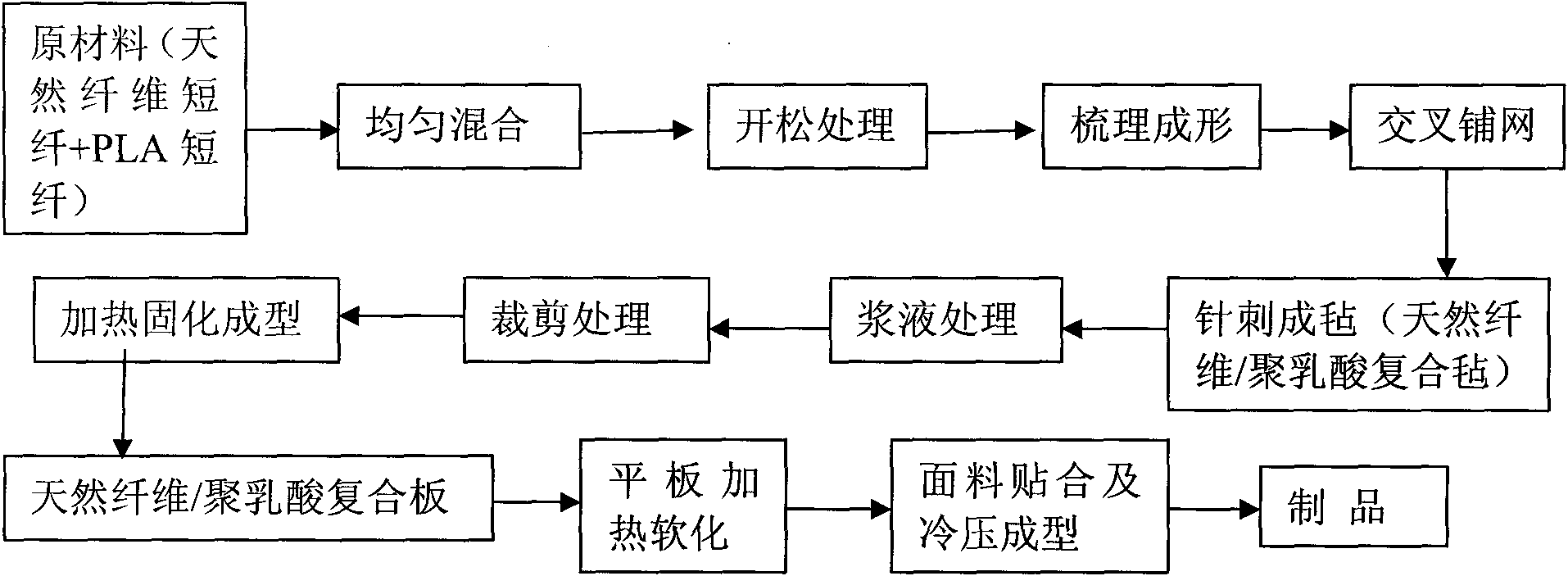

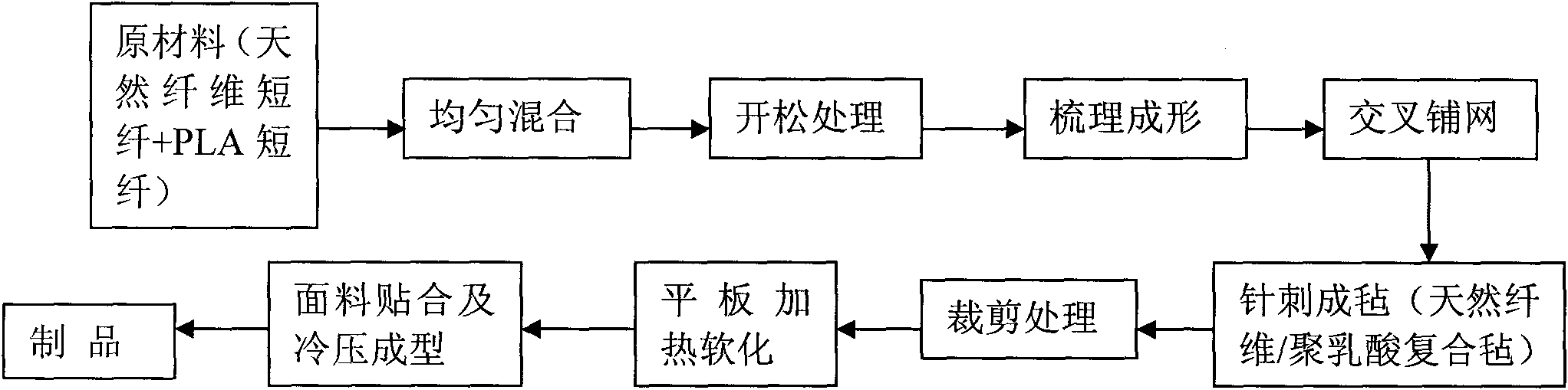

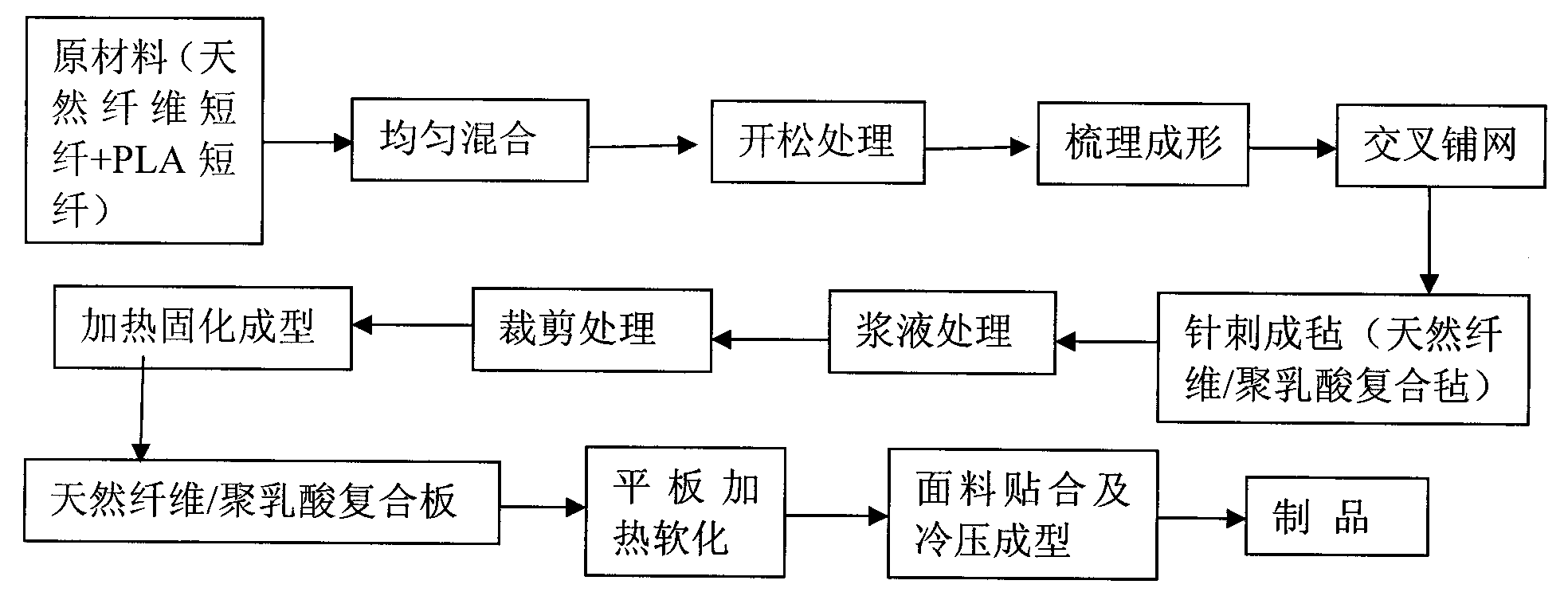

Composite material for automobile interior part and production method thereof

ActiveCN101812773ANo pollution in the processReduce lossVehicle componentsNon-woven fabricsMetallurgySlurry

The invention discloses a formula of a composite material for an automobile interior part. The formula consists of the following materials in percentage by weight: 40 to 60 percent of polylactic acid fiber and 40 to 60 percent of natural fiber. The production method of the invention comprises the following steps: uniformly mixing the raw materials; putting the mixture into an opener for opening, combing and shaping the obtained product, feeding the product into a lapping machine for cross lapping and feeding the cross-lapped product into a needling machine for needling to form a felt; immersing the fiber felt into a processing slurry; drying the immersed coiled material through hot blast and cutting the dried material into pieces of required size; placing the cut material into a mould for curing and shaping by heating; demoulding the material to form a composite plate; and softening the composite plate by flat panel heating, covering the plate with a surface decorative layer and performing cold molding on the plate through a product mould to manufacture the finished product finally; or softening the cut fiber felt by the flat panel heating directly, covering the plate with the surface decorative layer and performing the cold molding to manufacture the finished product finally. The composite material for the automobile interior part of the invention has the advantages of no toxicity, no pollution, simple processing technique, small energy consumption and high environment protection performance.

Owner:CHERY COMML VEHICLE ANHUI

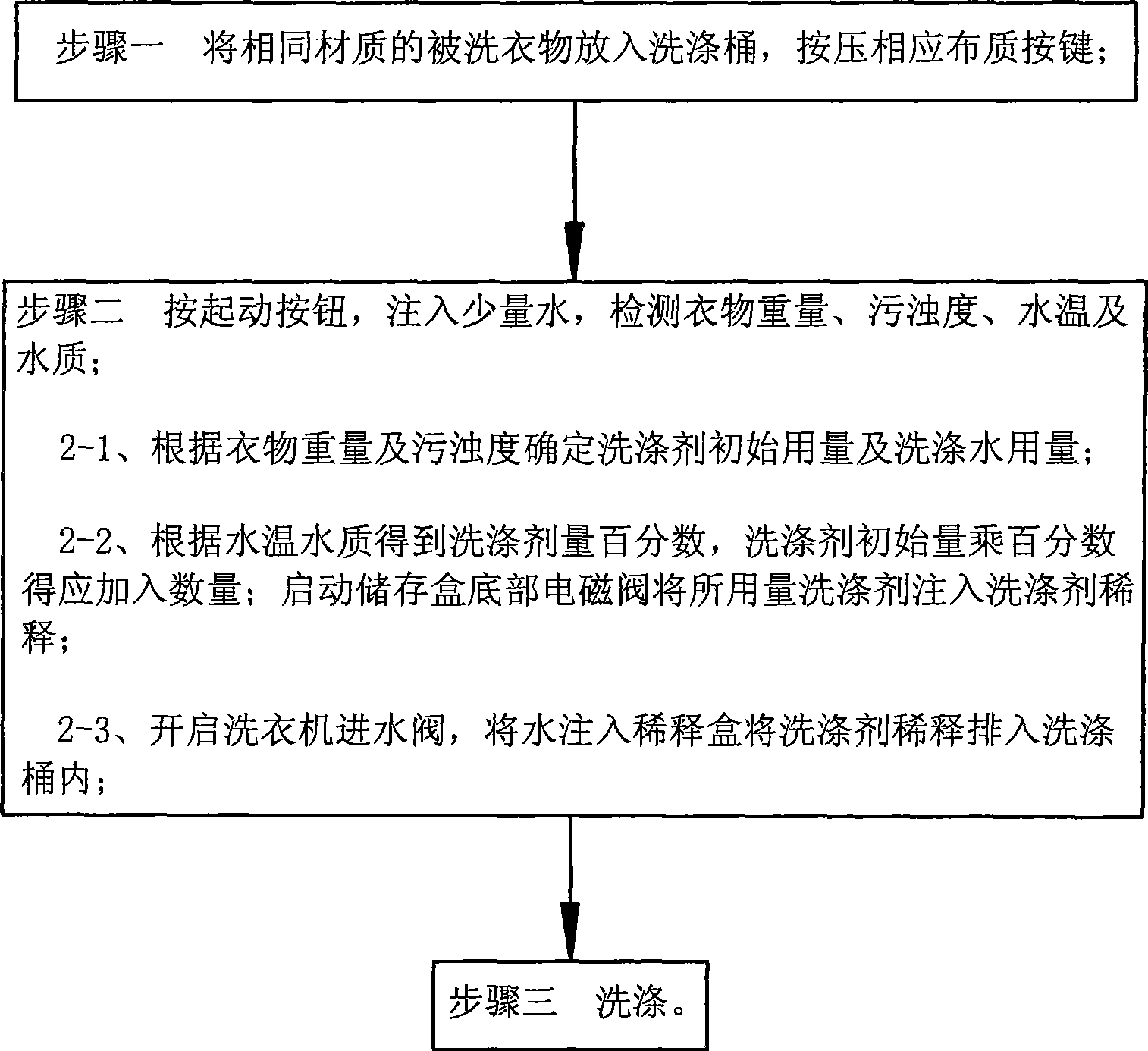

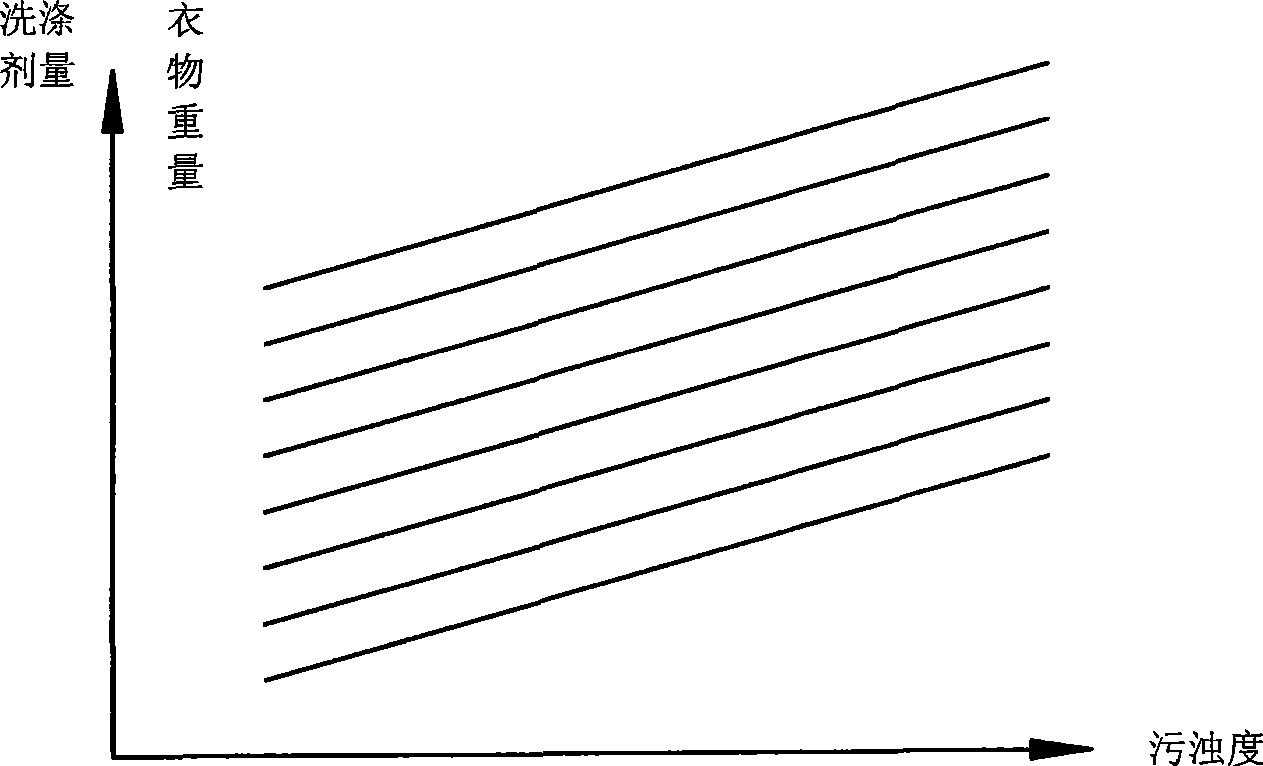

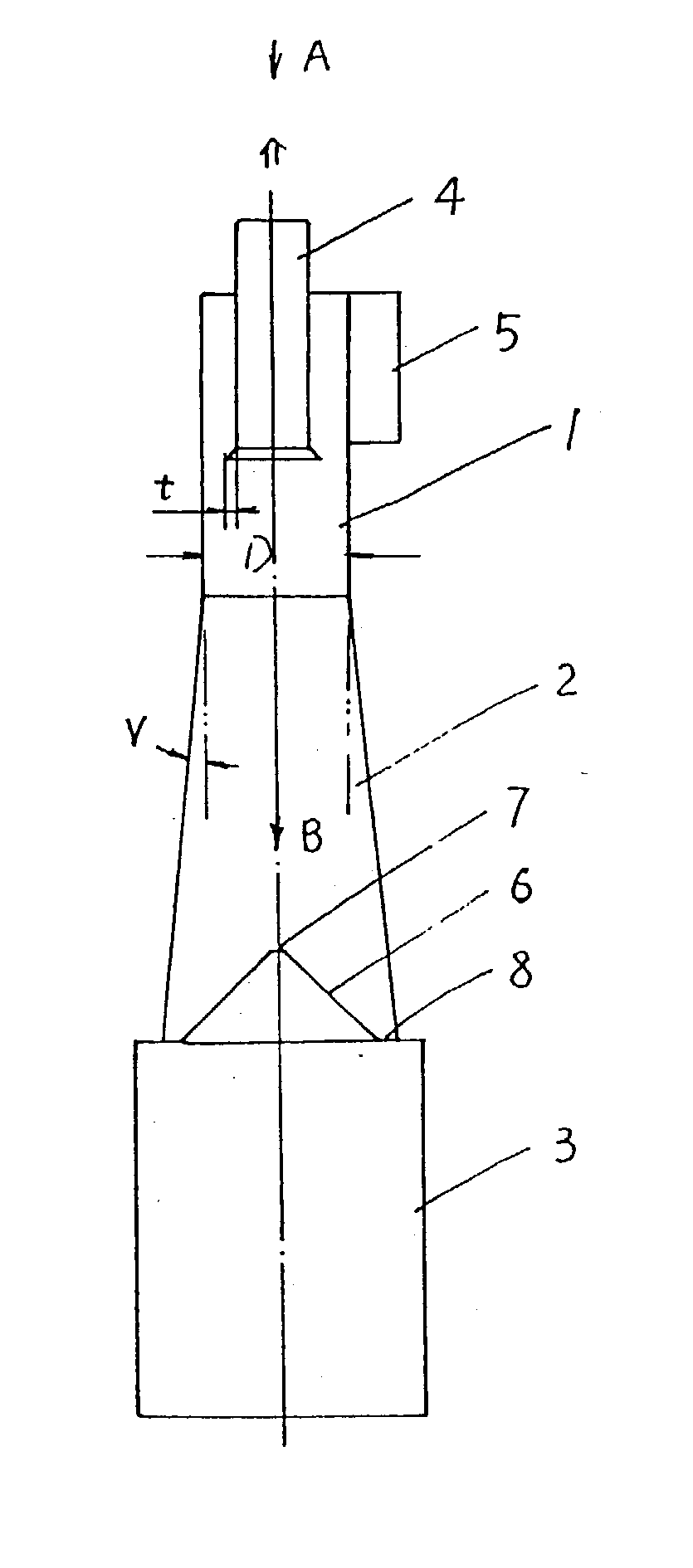

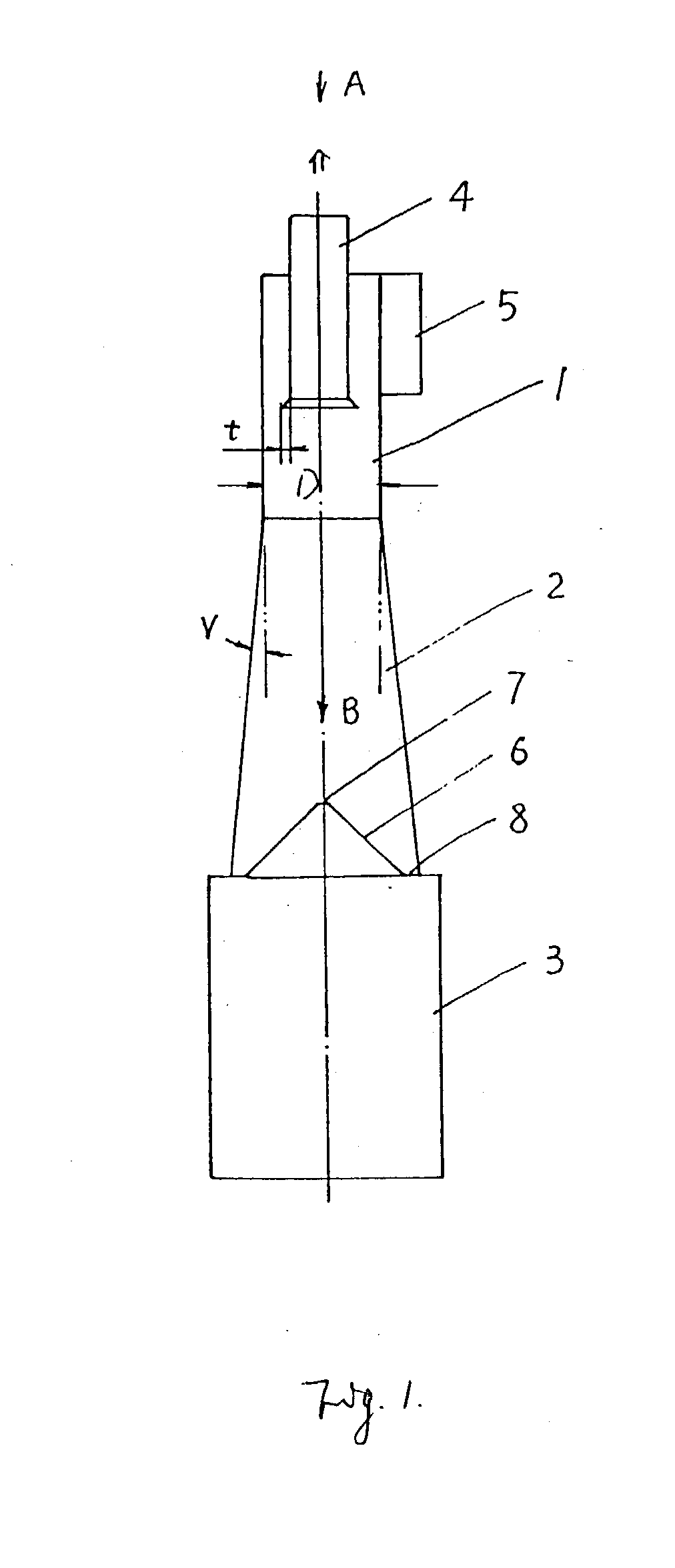

Washing machine for auto-adding washing agent and washing method for auto-adding washing agent

ActiveCN101381939APrevent too littlePrevent the situationOther washing machinesControl devices for washing apparatusPulp and paper industryHardness

The invention relates to an automatic detergent-adding washing machine and a washing method, in particular to a washing method which automatically adds detergent according to five factors, namely the weight, dirty degree, cloth characters of clothes, as well as the temperature and hardness of washing water. Due to the technical proposal, the invention provides the automatic detergent-adding method which automatically adds the most reasonable detergent on the premise of without affecting washing effects, prevents the circumstances that the detergent manually added is too little or excessive, saves resources, and reduces the pollution of discharged washing water on environment.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Decelerated centrifugal dust removing apparatus for dust cleaner

InactiveUS20030200736A1Avoid secondary pollutionSmooth rotationCombination devicesAuxillary pretreatmentLow noiseFilter system

The present invention discloses a decelerated centrifugal dust removing apparatus for a dust cleaner. It comprises a cylinder, a conical cylinder and a dust collector box connected in the given order from the upper part to the lower part, as well as an air outlet pipe and an air inlet pipe on the cylinder body. The conical cylinder has a small upper end and a large lower end. In the conical cylinder, on the lower part of the air outlet pipe (under the air outlet pipe) there is an umbrella-shaped reflector in the center of which is provided a hole for air returning. Between the periphery of the umbrella reflector and the side wall is provided an annular gap for the falling down of dust. The apparatus features small loss of air flow pressure, good effectiveness of air suction, high quality of dust filtering, and low noise. With the apparatus, the secondary pollution of the cleaned air can be effectively prevented, and it is especially suitable for use in a secondary stage filtering system of the dust cleaner and for separating small and fine dust particles.

Owner:SUZHOU KINGCLEAN FLOORCARE

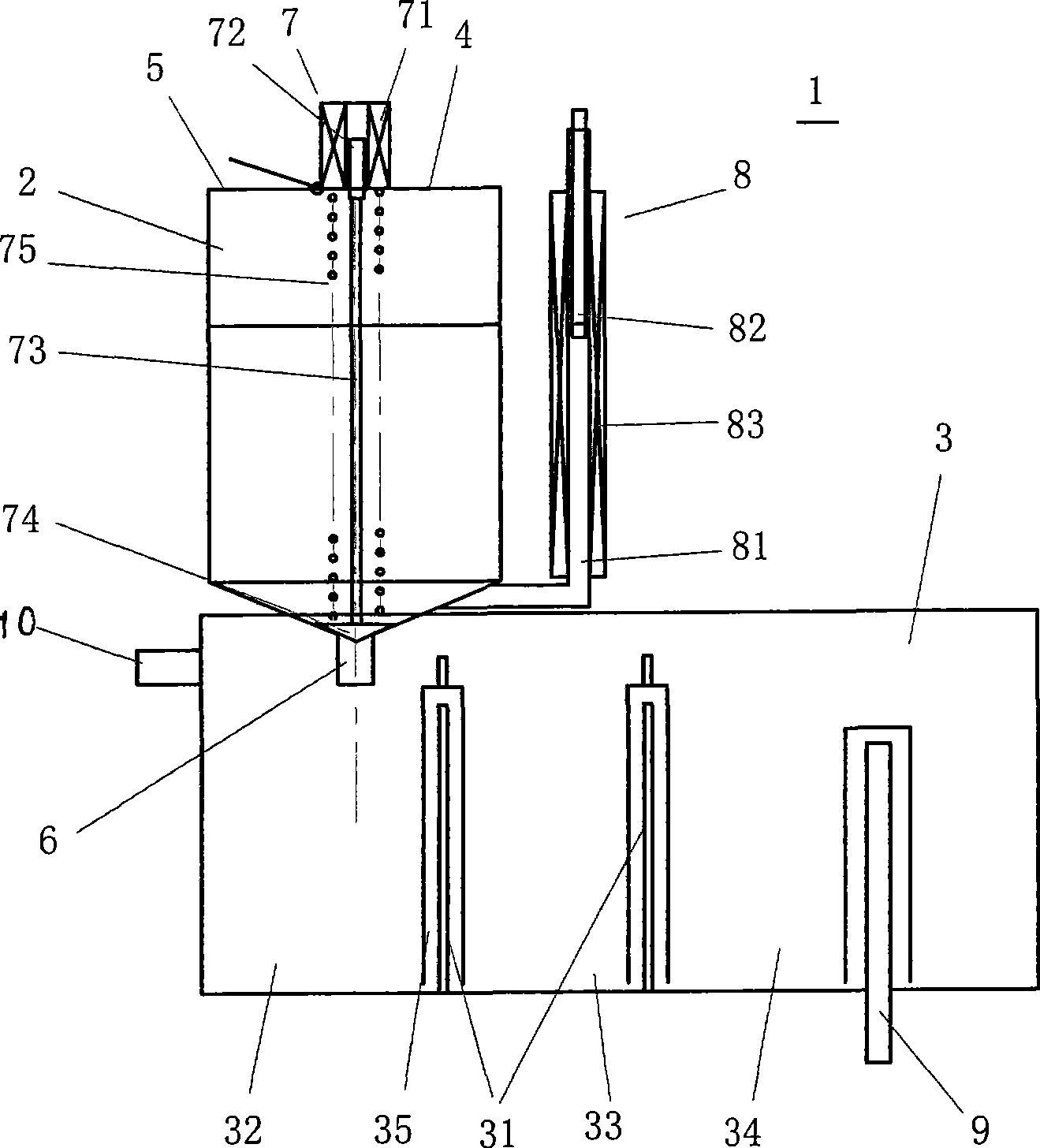

Equipment and method for extracting biologically active ingredients from subcritical fluid

InactiveCN101905091AKeep intactGuaranteed production costExtraction purification/separationSolid solvent extractionAutomatic controlSeparation technology

The invention discloses equipment and a method for extracting biologically active ingredients from subcritical fluid, aims to solve the problems of low extraction efficiency and the like existing in the aspects of biologically active ingredient separation technology in the prior art and provides a set of subcritical equipment which comprises an extracting agent supply system, an entrainer supply system, an extraction system, a separation system, a solvent recycling system, a desolvation system, a heat supply system, a computer control system and the like, has high automatic control degree and is used for extracting the biologically active ingredients. Simultaneously, the invention also provides a new technological method for extracting the biologically active ingredients by adopting a subcritical extraction process. The method has the advantage of relatively low cost on the conventional extraction of an organic solvent, and the equipment has the characteristics of no solvent residue, no pollution, high bioactivity and the like in a product obtained by supercritical CO2 extraction technology and has the advantages of low investment on production equipment, high production efficiency within unit time, low energy consumption, flexible operation, high degree of automation and the like.

Owner:XINJIANG UNIVERSITY +1

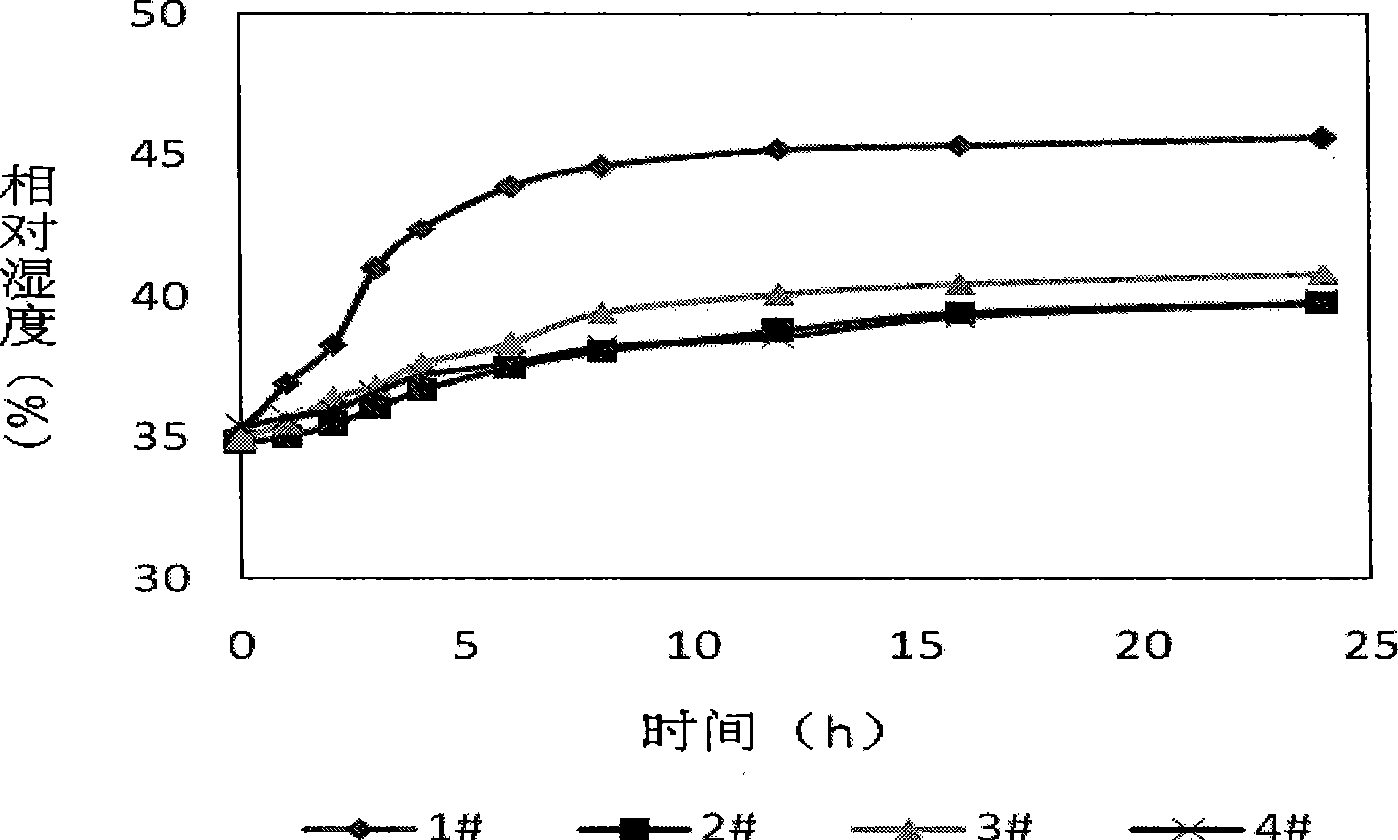

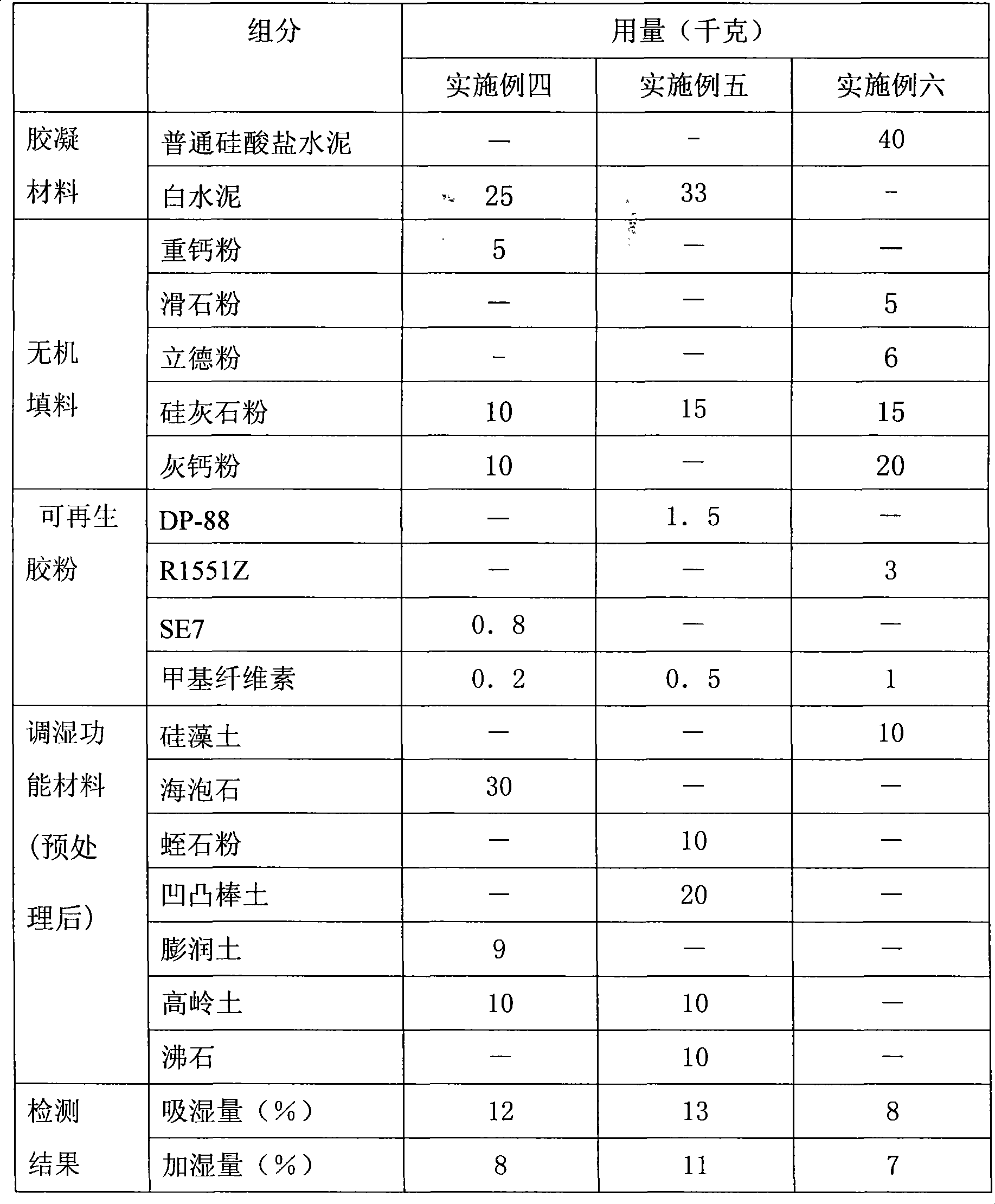

Inorganic putty powder with function of governing humidness

ActiveCN101368014AEffective regulation of relative humidityGood environmental protectionFilling pastesCement coatingsSodium BentoniteMetallurgy

The invention relates to interior wall putty powder with air humidity regulating function, which belongs to the field of building materials. The putty powder is composed of 10 to 50 weight portions of humidity regulating material, 15 to 50 weight portions of inorganic binding material, 15 to 50 weight portions of inorganic filler, and 1 to 5 weight portions of sub divisible rubber powder; the humidity regulating material comprises one type or more than one type of diatomite, sepiolite, attapulgite, vermiculite, zeolite powder, kaolin and bentonite. Because of the environment protection and humidity regulating functions, the multi-pore inorganic mineral material is taken as humidity regulating material and applied in the building interior wall putty powder. With water added in, the putty powder is mixed into lacquer putty and applied on the wall surface, which can effectively regulate the indoor air humidity, so that the indoor air humidity is controlled within the scope which is beneficial to the health of human body; meanwhile, the putty powder has no pollution, no VOC released and can be directly used for decoration.

Owner:CHINA BUILDING MATERIALS ACAD

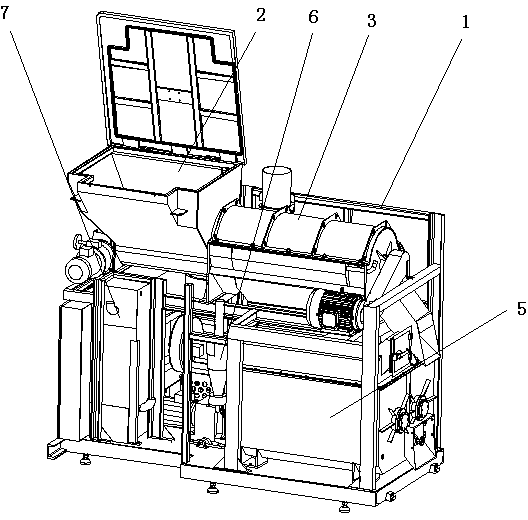

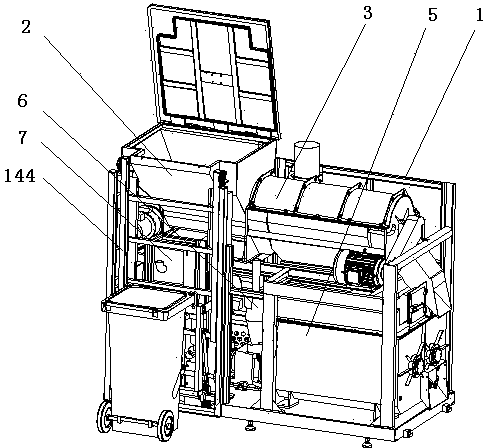

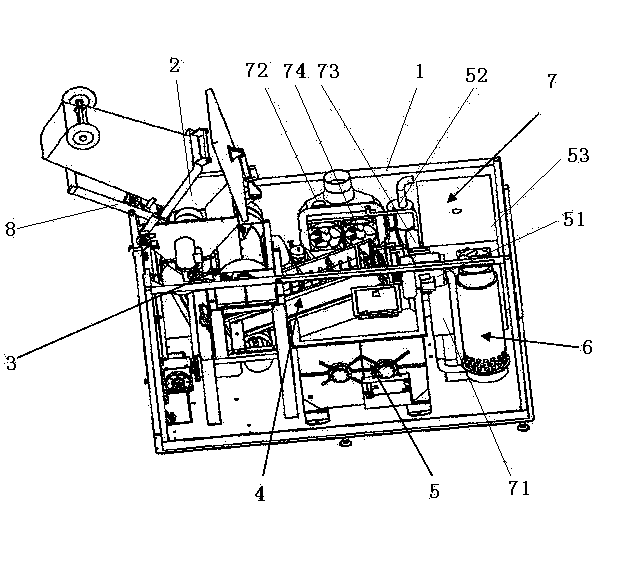

Kitchen waste pretreatment device

ActiveCN103464449ADeodorization up to standardWith automatic sortingSolid waste disposalControl systemOil water

The invention discloses a kitchen waste pretreatment device. The kitchen waste pretreatment device comprises a closed shell and a control system. The kitchen waste pretreatment device is characterized in that the upper end of the shell is provided with a feeding funnel and a feeding motor; the shell is internally provided with an automatic sorting device, a biological fermentation drying device, an oil-water separation device, an ionization deodorization device and a gas condensation device; the feeding funnel is communicated with a kitchen waste charge hole of the automatic sorting device through a discharge hole; the automatic sorting device is communicated with a charge hole of the biological fermentation drying device through a kitchen waste outlet; the automatic sorting device is communicated with the oil-water separation device through a liquid outlet; the biological fermentation drying device is communicated with the gas condensation device through a gas exhaust opening; the gas condensation device is communicated with the ionization deodorization device, so that the effects of automatic sorting, rapid fermentation treatment speed, uniform fermentation, rapid heating speed, capability of oxygenating in fermentation, standard gas deodorization and environment protection and no pollution are achieved.

Owner:SHANDONG MINGLIU KITCHEN WASTE TREATMENT EQUIP CO LTD

Temporary blocking agent for hydrocarbon reservoir crack

InactiveCN101311243AWide range of temporary blockingTemporary blocking range is smallDrilling compositionFiberWell drilling

The invention relates to a hydrocarbon zone protective agent specific to fractured hydrocarbon zone in oil and gas drilling, in particular to a fractured temporary plugging additive, which is mixed by the components with the following mixture ratio: 40-85 percent of 60-1100 meshes of calcium carbonate superfine powder, 10-40 percent of plant fibers and 5-20 percent of oxidized asphalt. After the temporary plugging additive of the invention enters the stratum with the drillingfluid, a layer of compact and tenacious mud cake is quickly formed near the well wall for ensuring the original permeability of the stratum near the well wall to rapidly reduce to be nearly zero, thus preventing the intrusion of drilling fluid filter, various finishing agents, rock debris and the like which causes the reduction of oil and gas yield and capacity. The temporary plugging additive of the invention reaches more than 99 percent of temporary plugging rate to fractured core and more than 80 percent of pressure flowback and acidification flowback rate. Furthermore, the temporary plugging additive is characterized by wild temporary plugging range, little dosage, low cost and no pollution, thus being an ideal hydrocarbon zone protective agent.

Owner:浙江仁智股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com