Patents

Literature

796results about "Extraction purification/separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

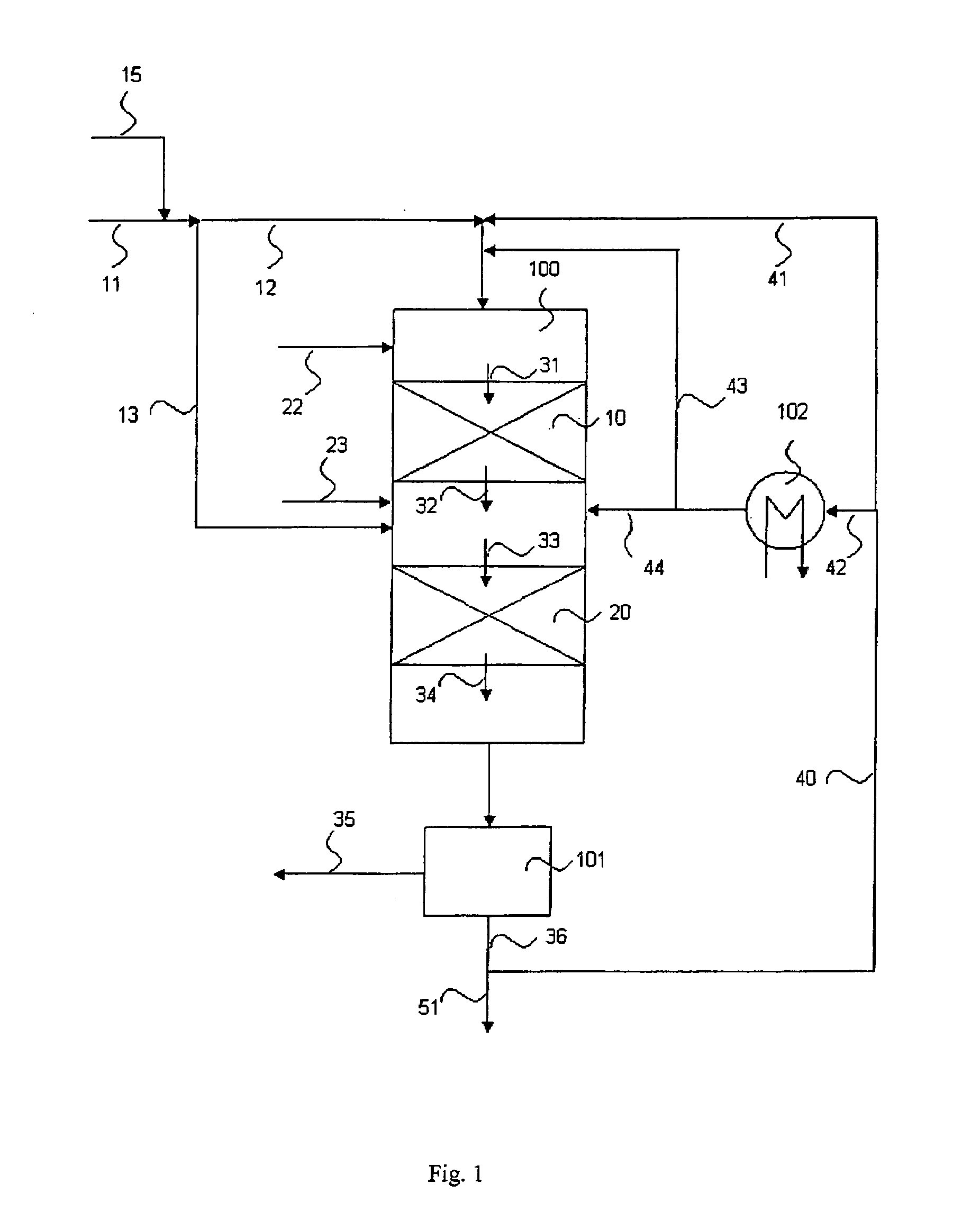

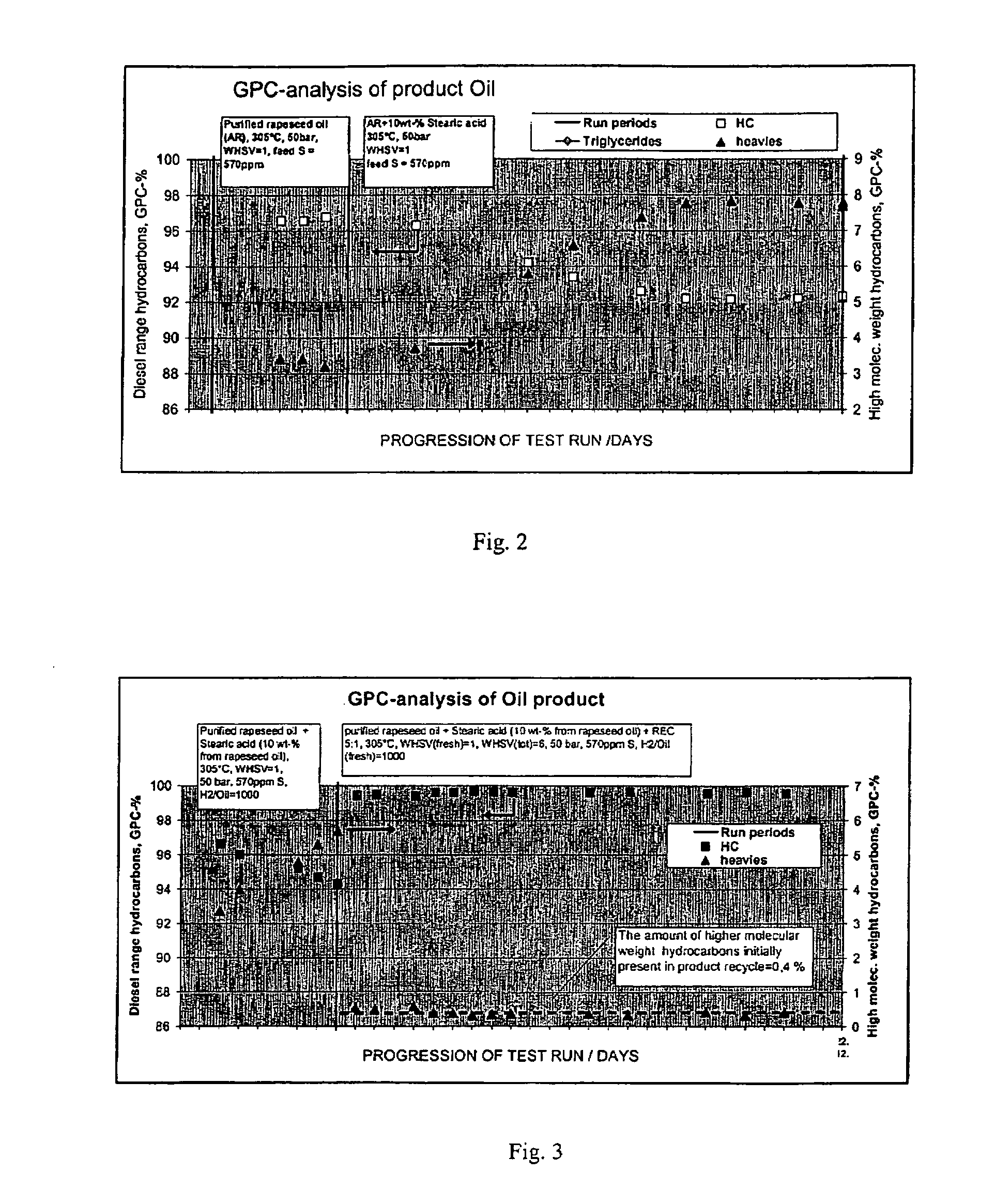

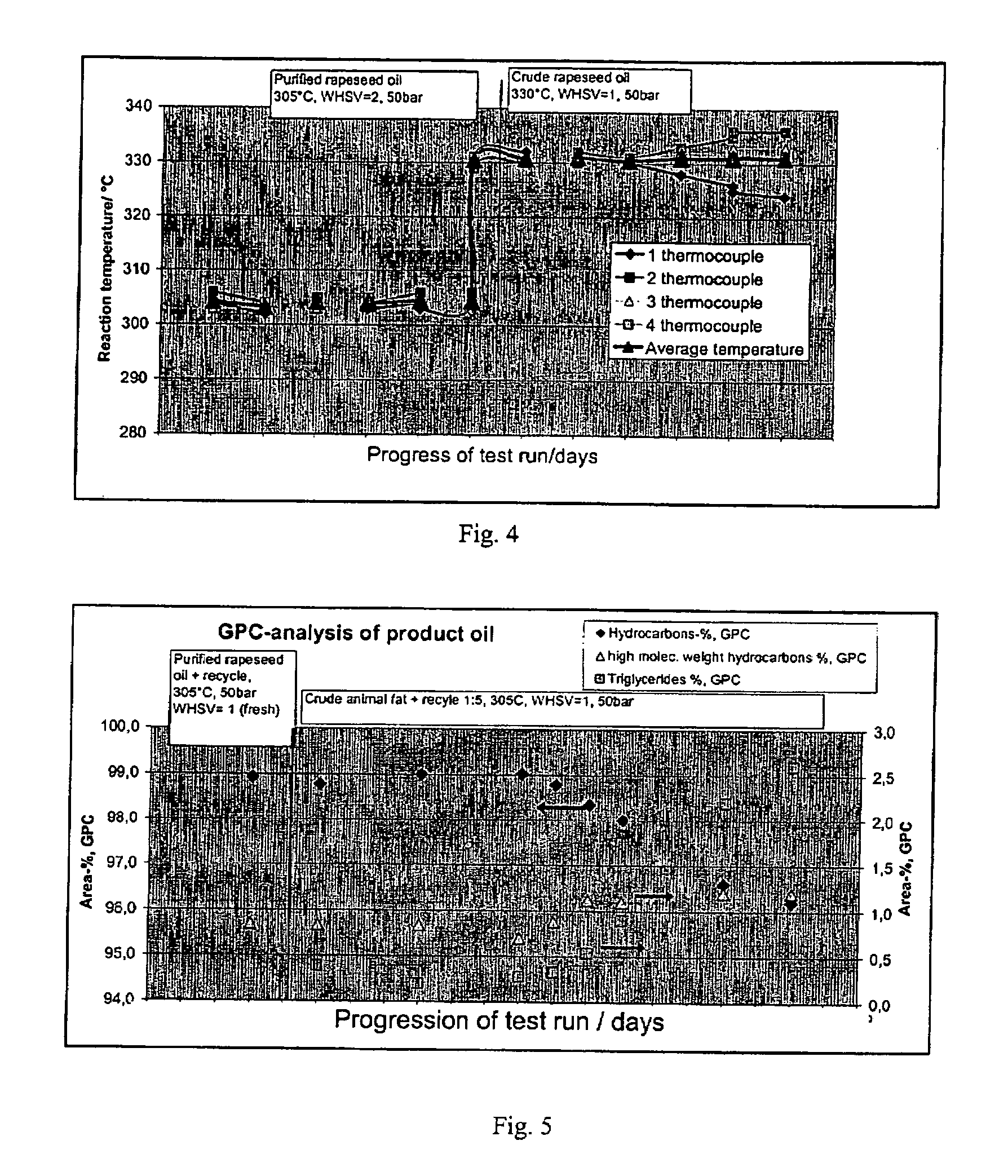

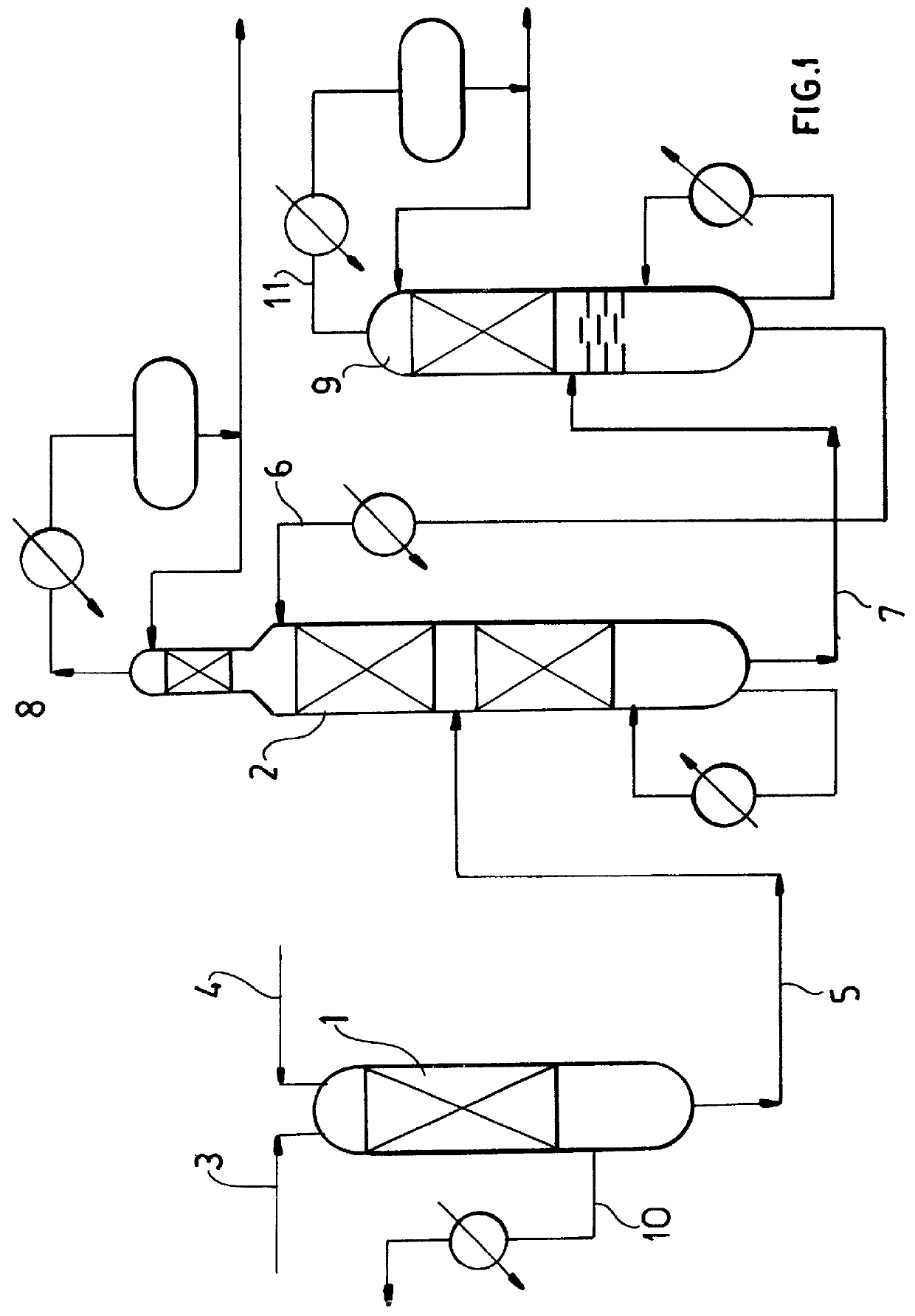

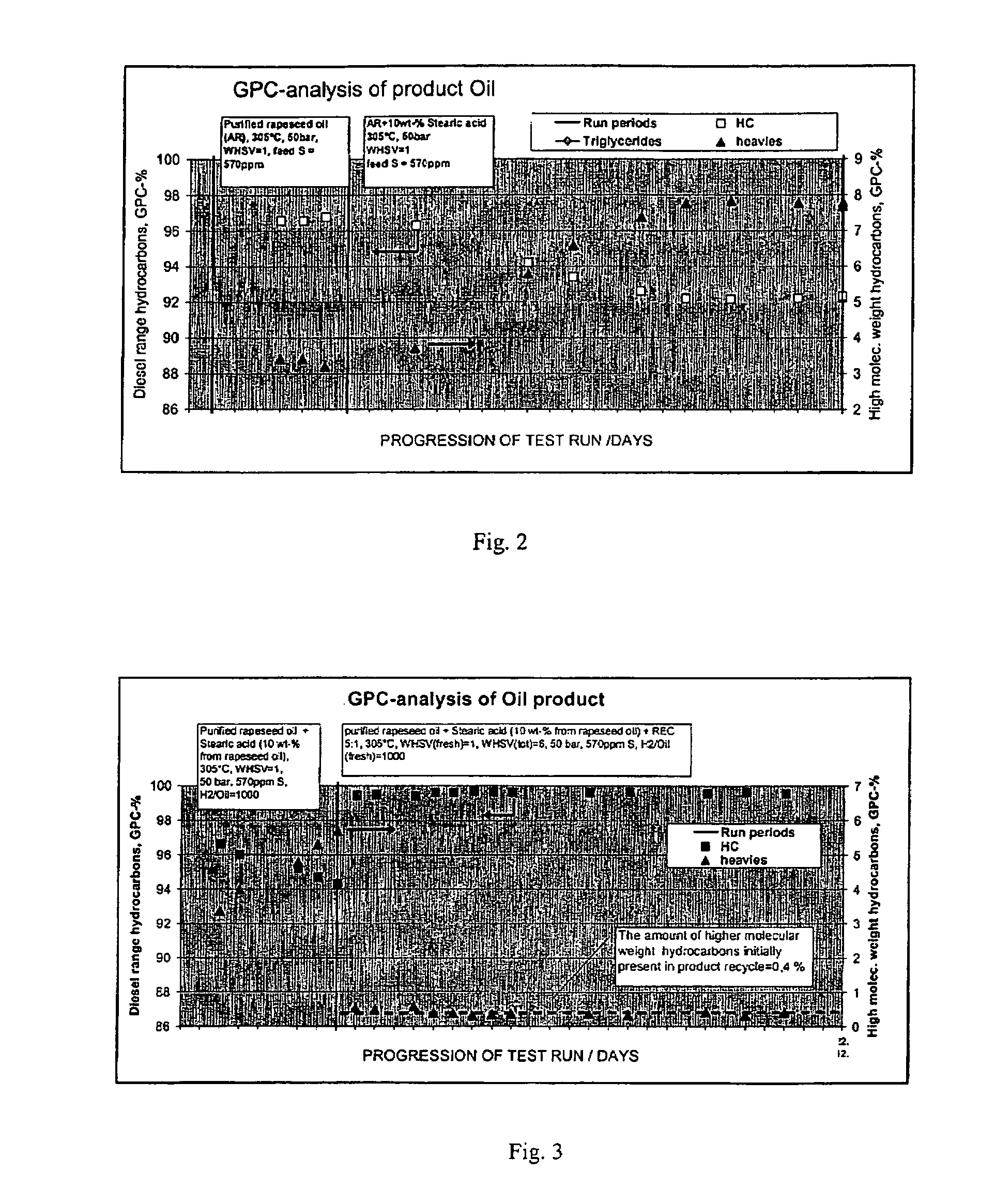

Process for the manufacture of diesel range hydrocarbons

ActiveUS20070010682A1Fatty oils/acids recovery from wasteHydrocarbon by isomerisationIsomerizationReaction temperature

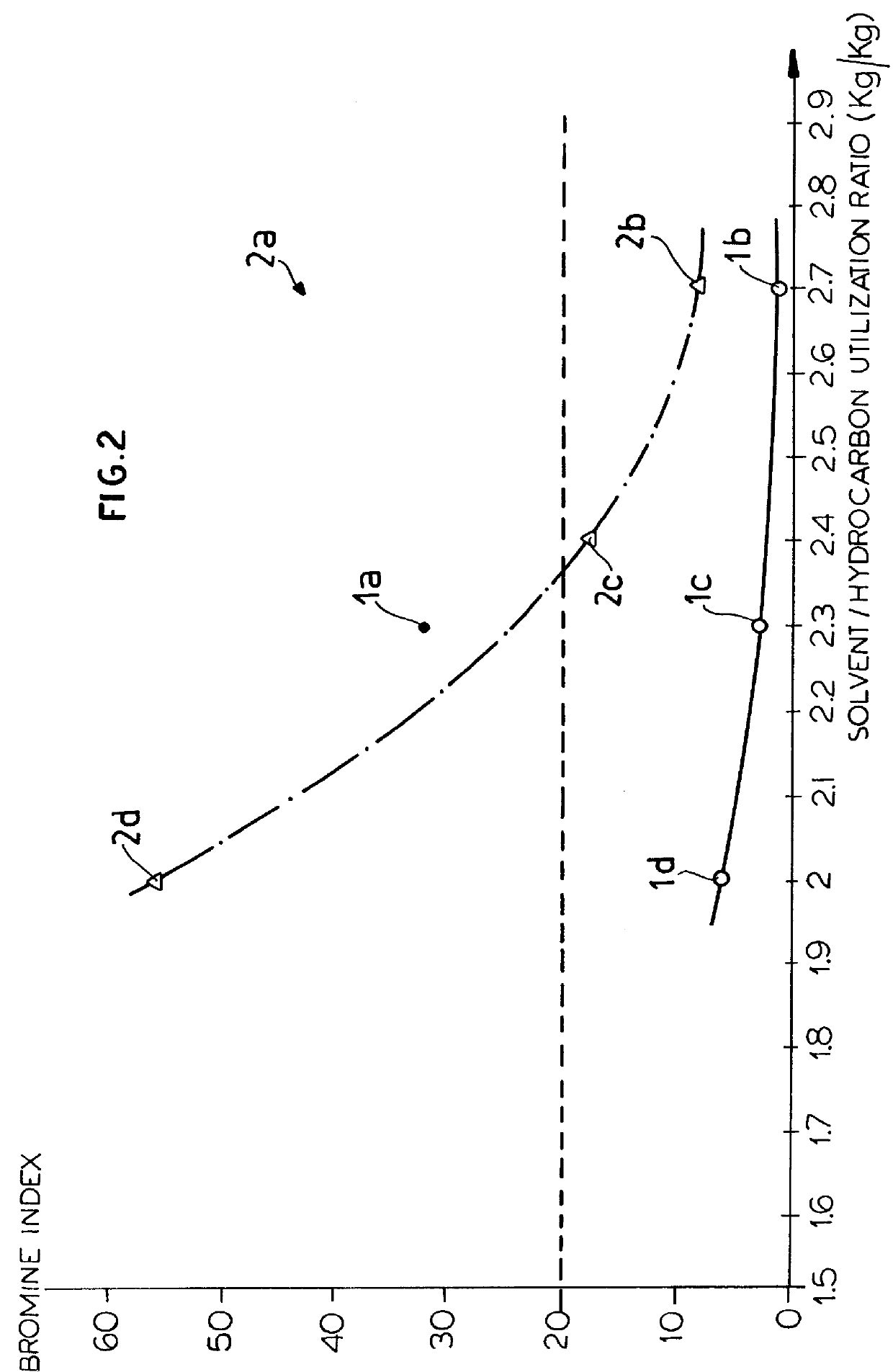

The invention relates to a process for the manufacture of diesel range hydrocarbons wherein a feed is hydrotreated in a hydrotreating step and isomerised in an isomerisation step, and a feed comprising fresh feed containing more than 5 wt % of free fatty acids and at least one diluting agent is hydrotreated at a reaction temperature of 200-400° C., in a hydrotreating reactor in the presence of catalyst, and the ratio of the diluting agent / fresh feed is 5-30:1.

Owner:NESTE OIL OY

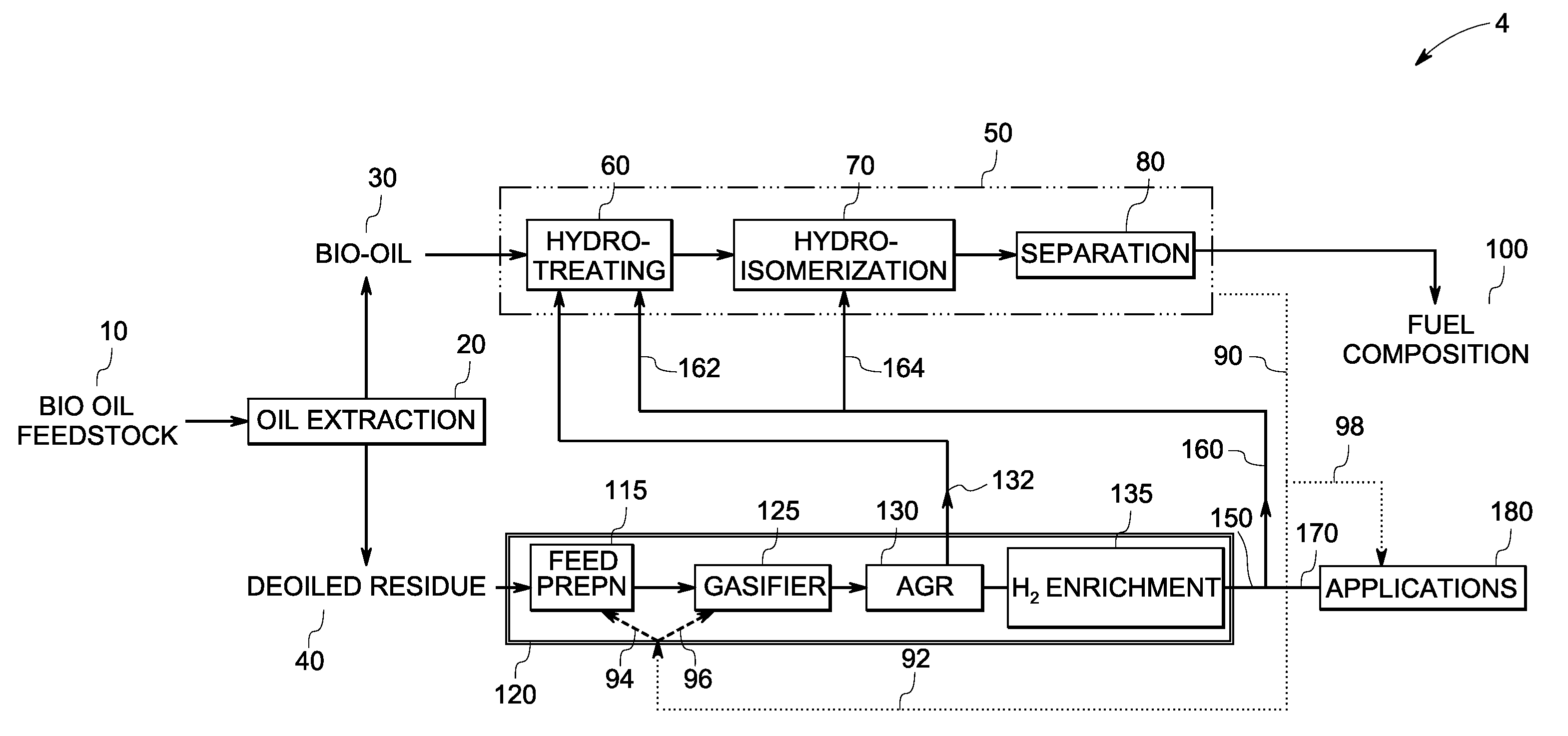

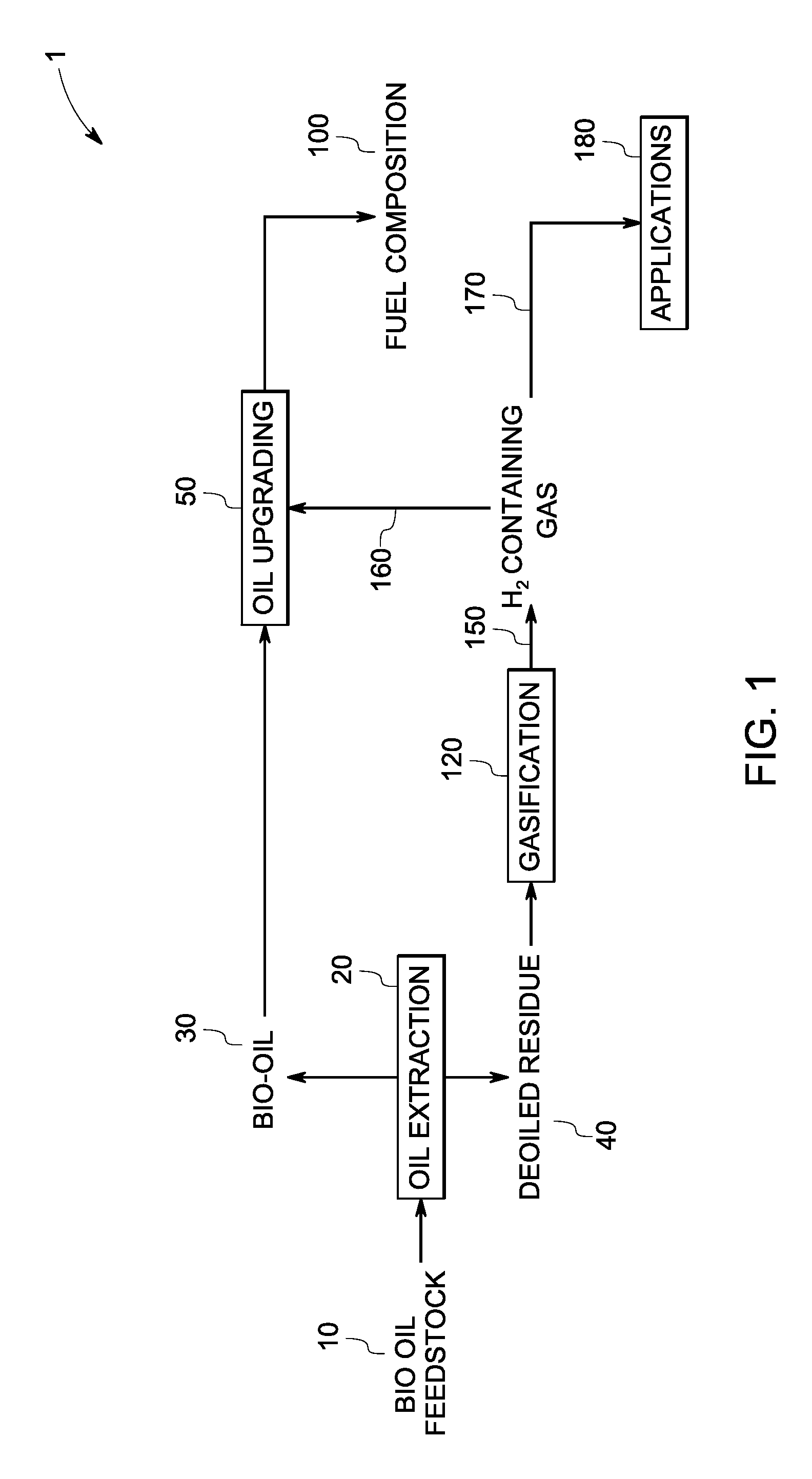

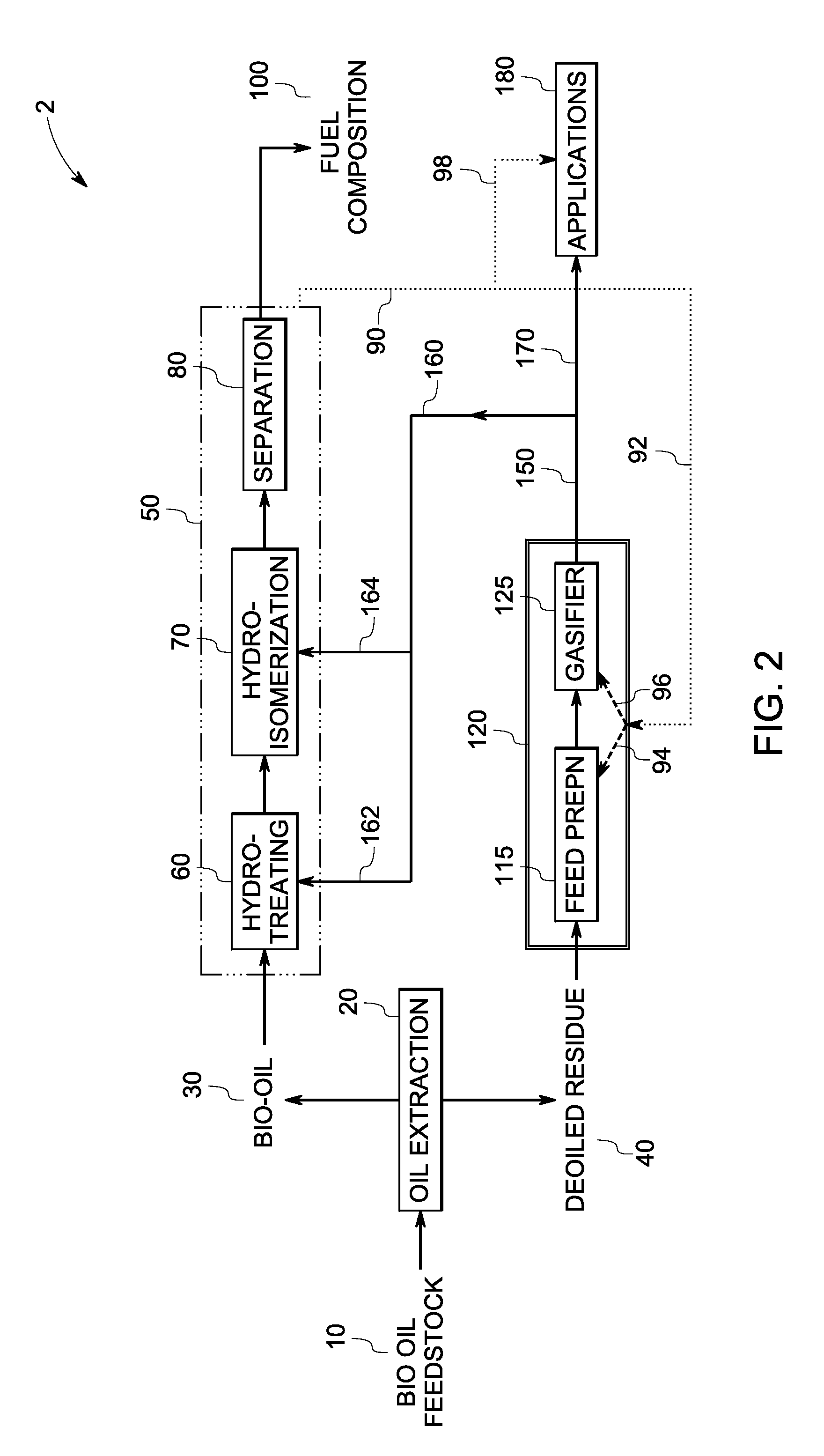

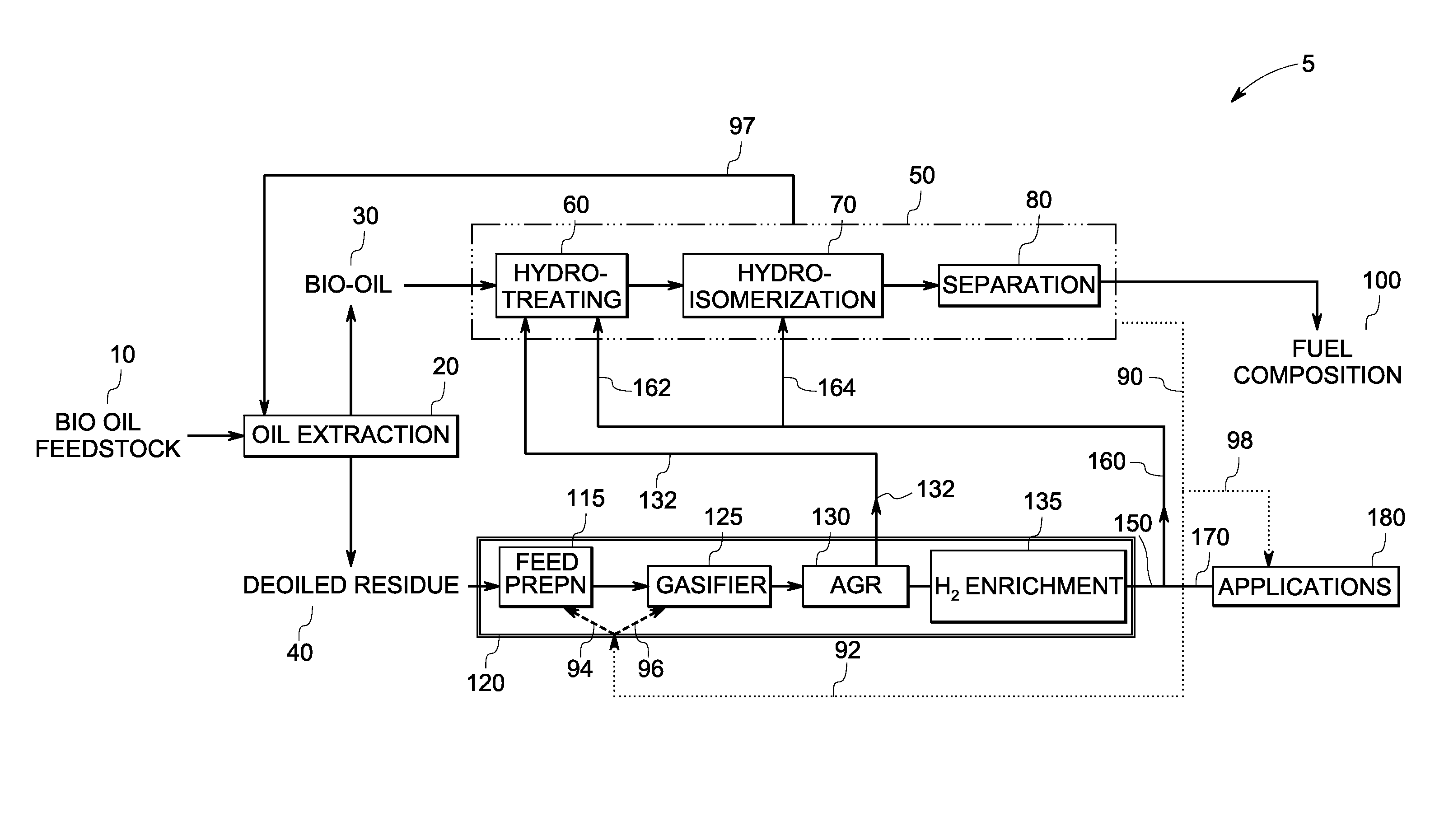

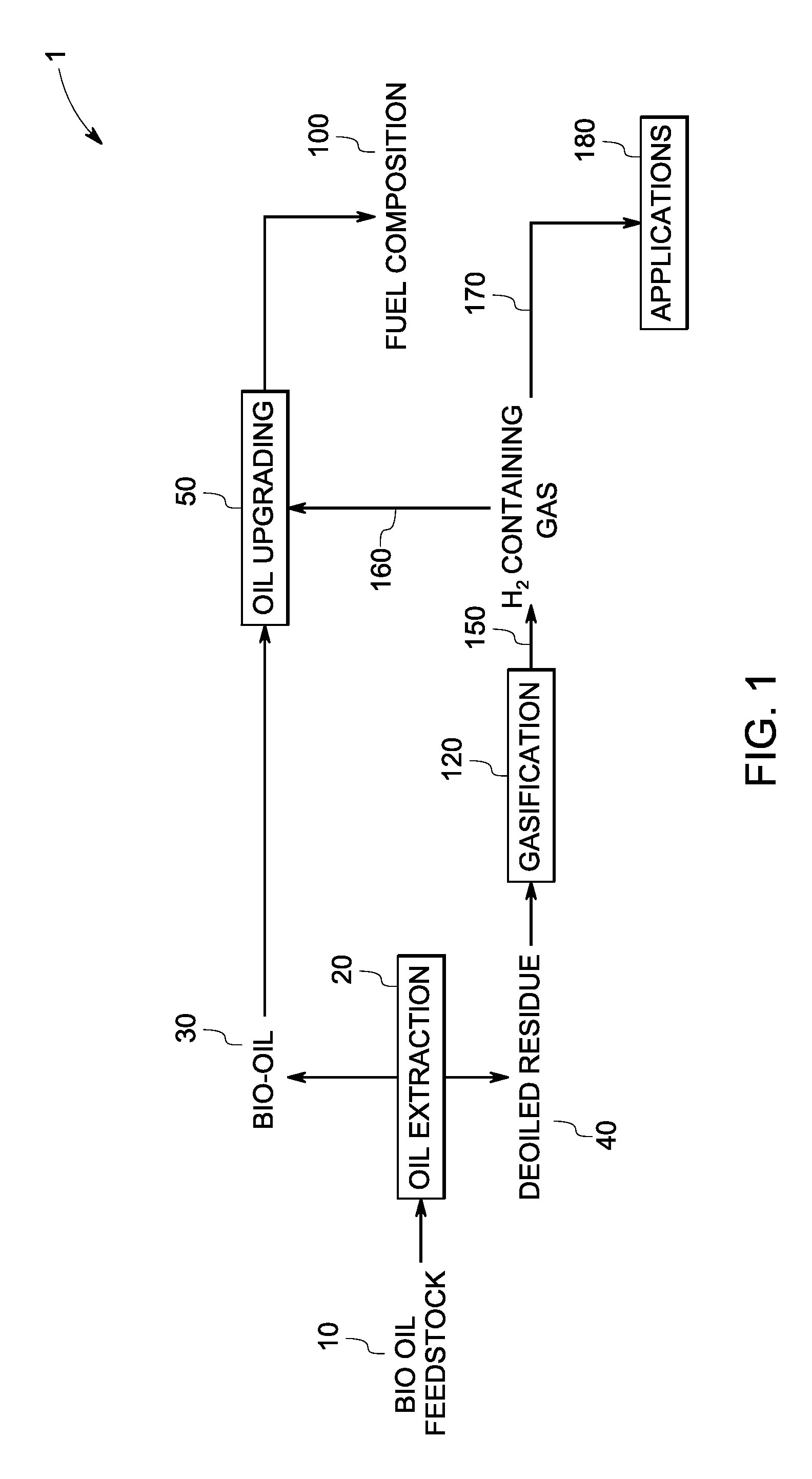

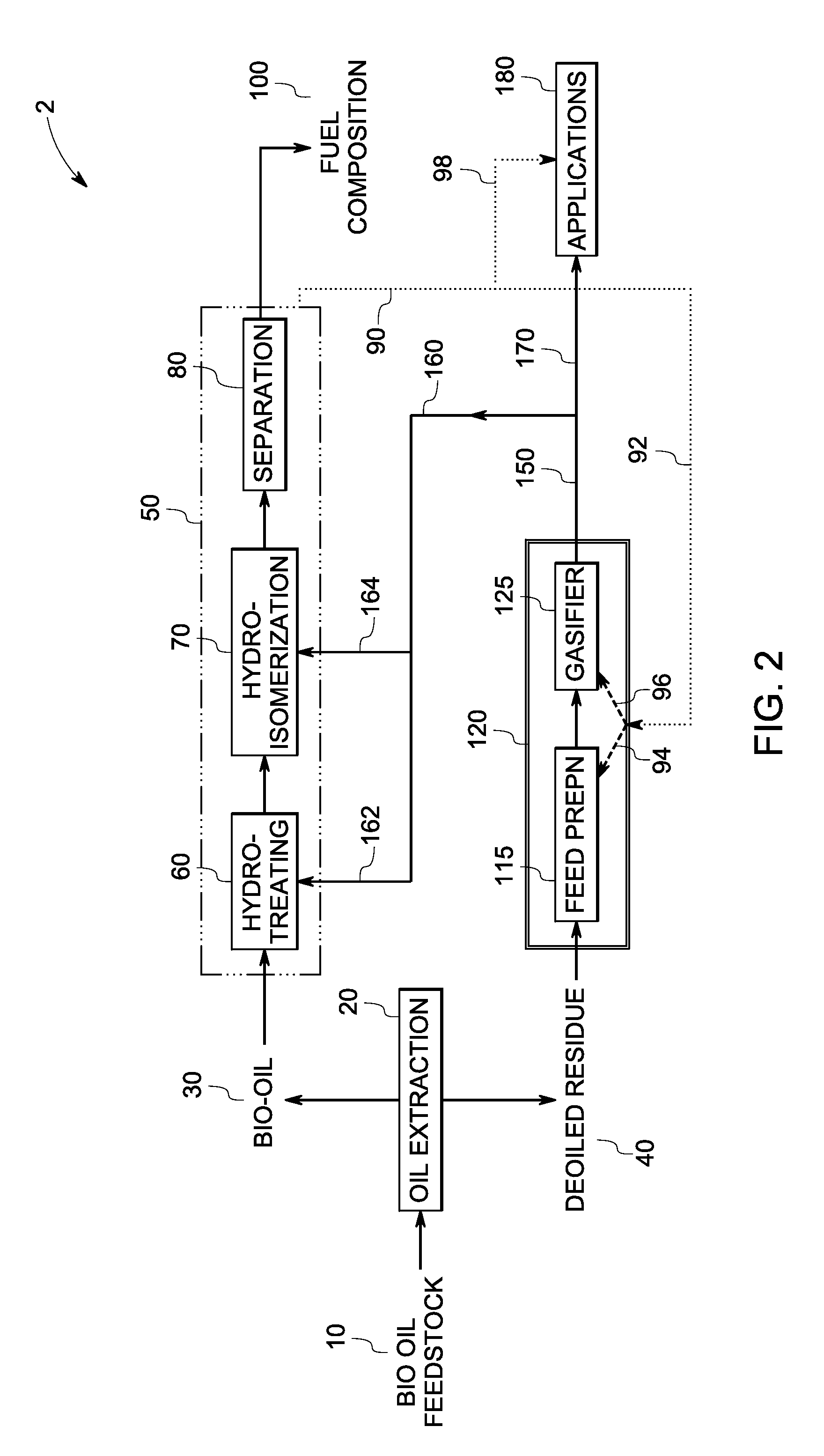

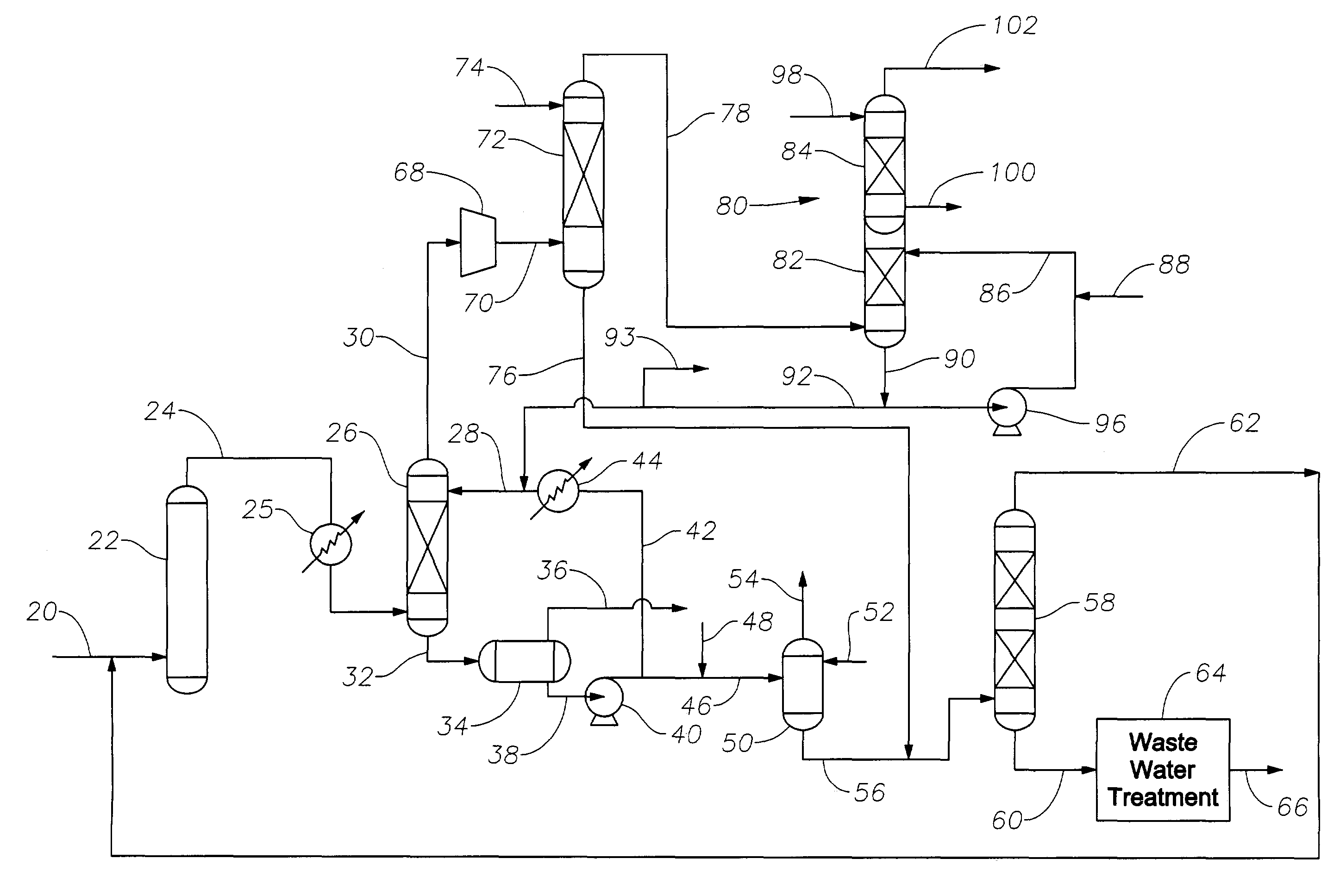

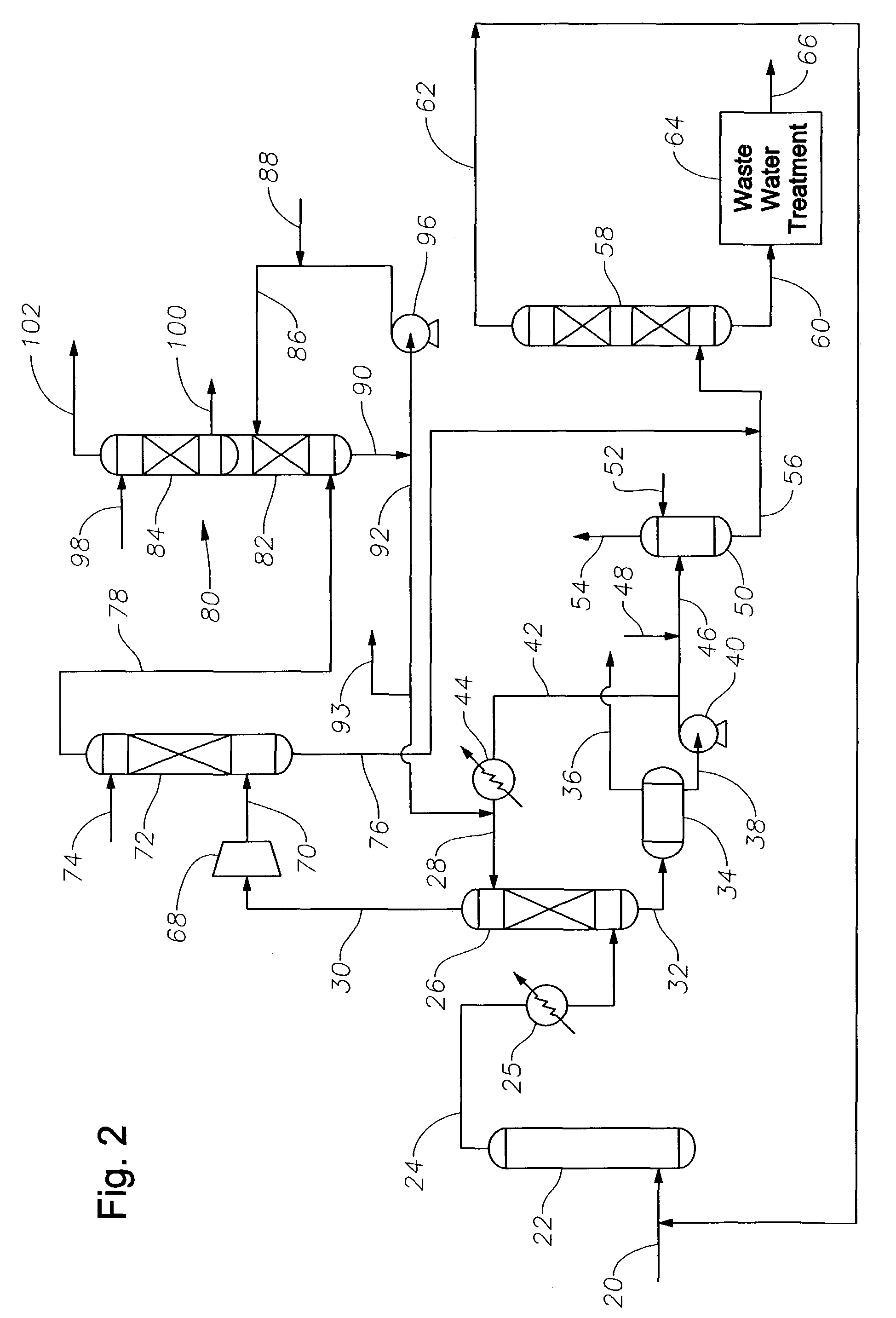

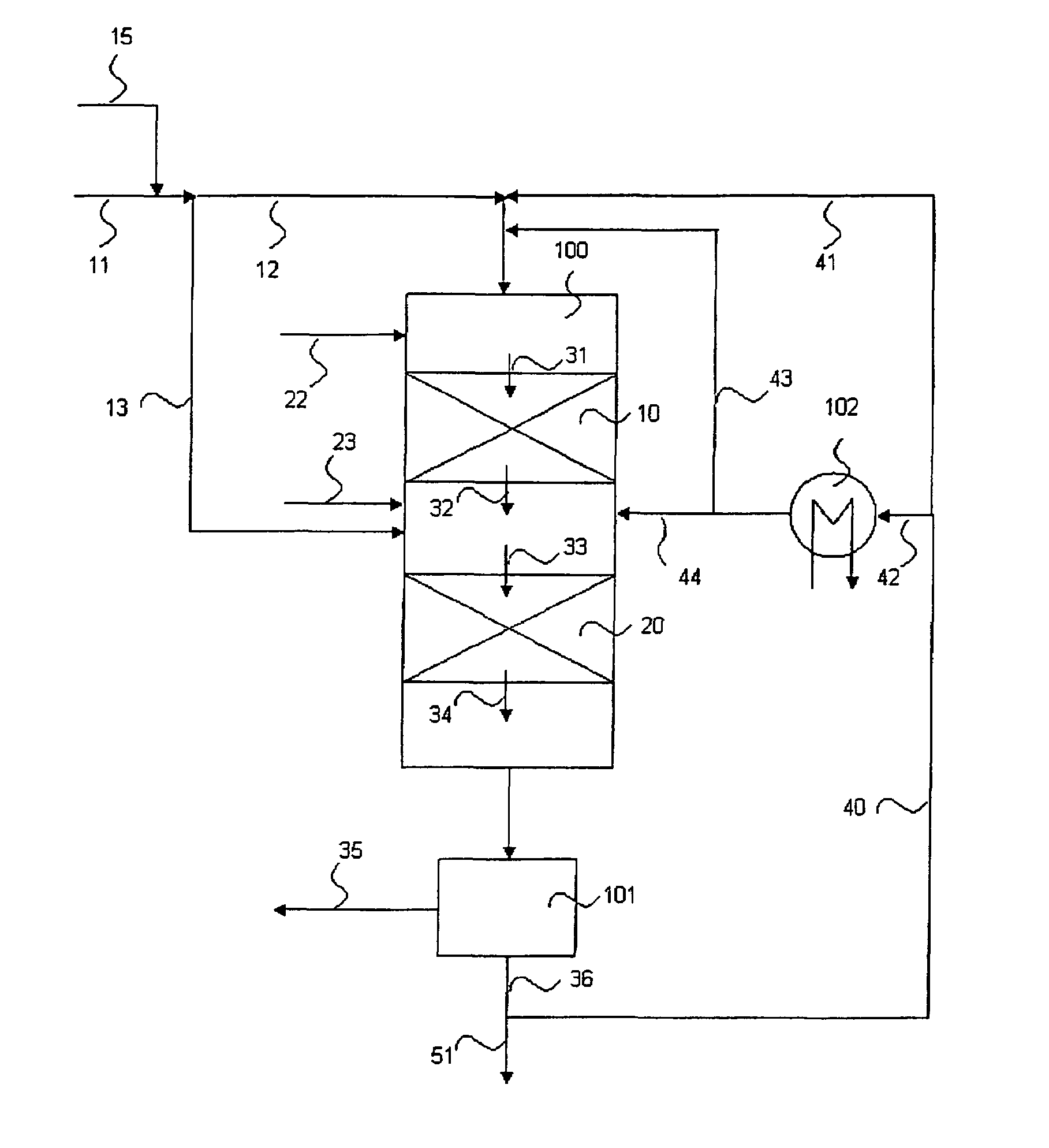

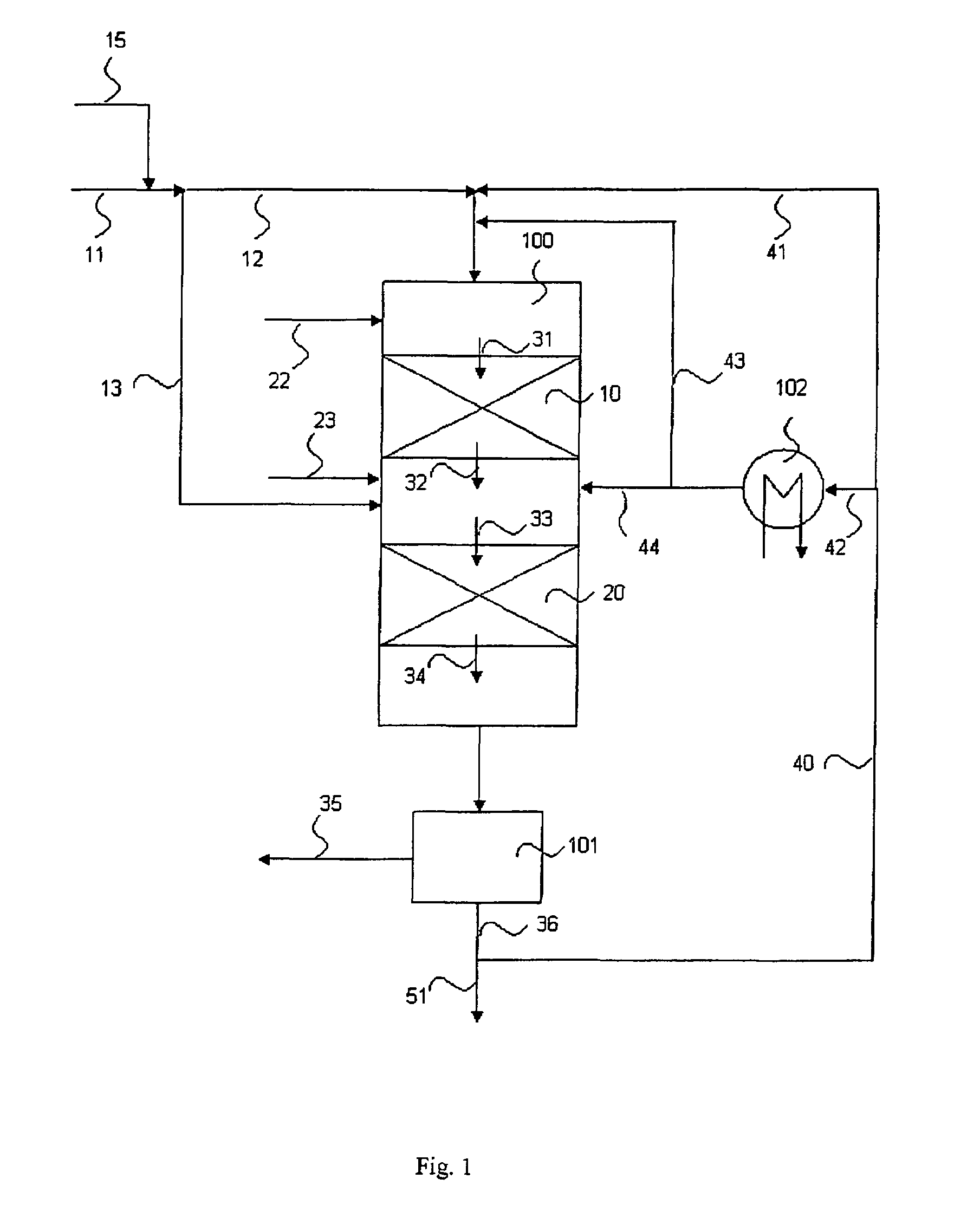

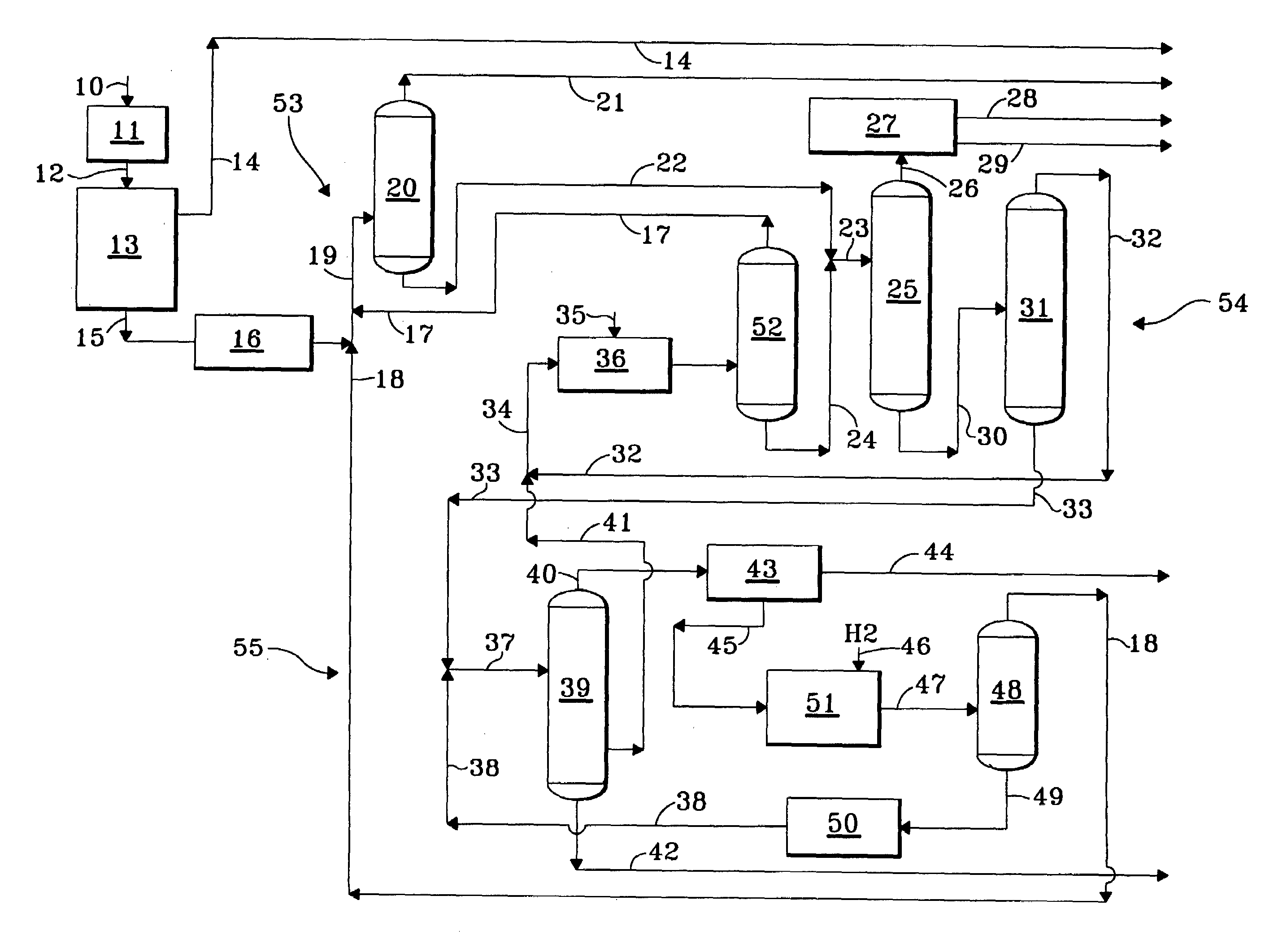

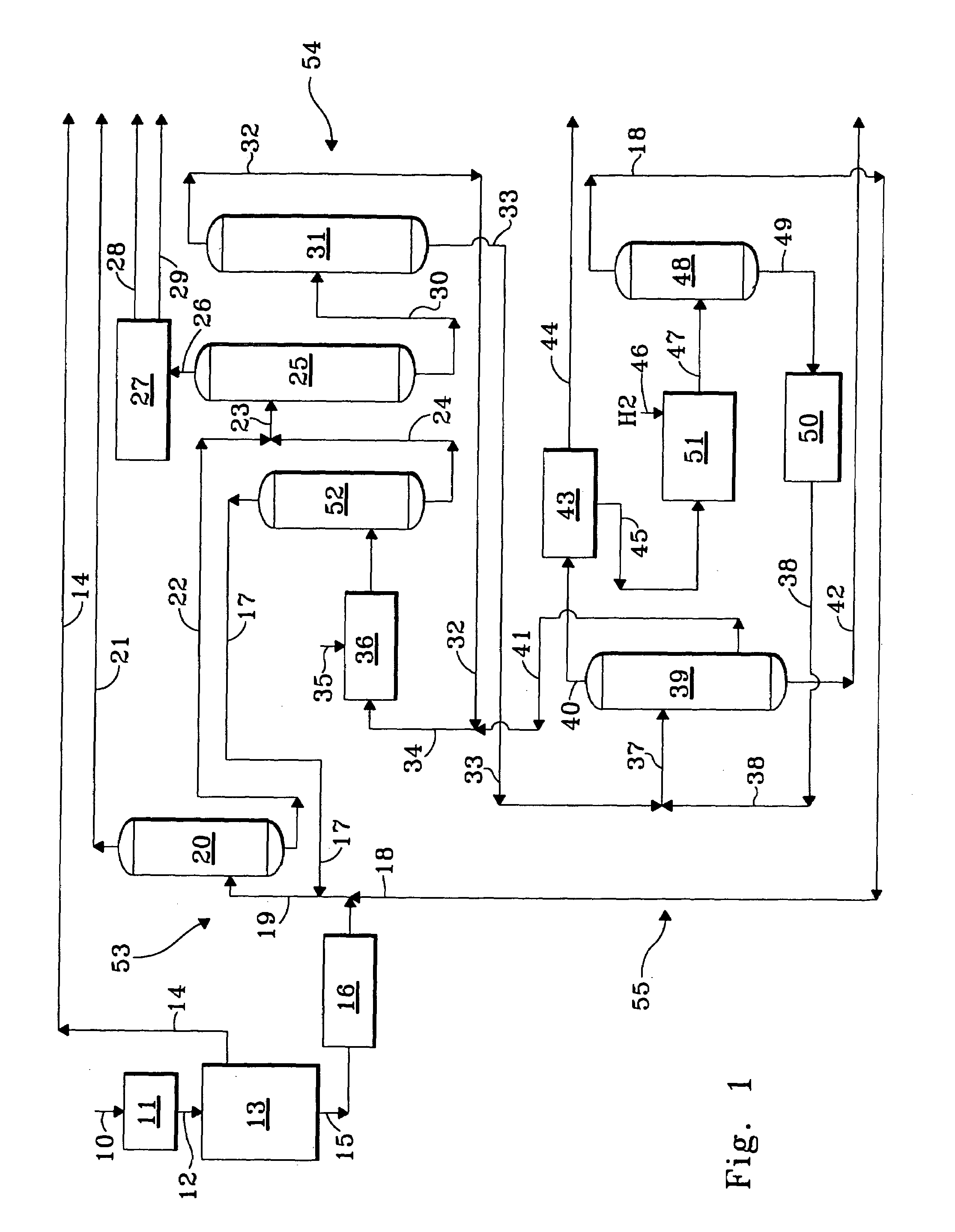

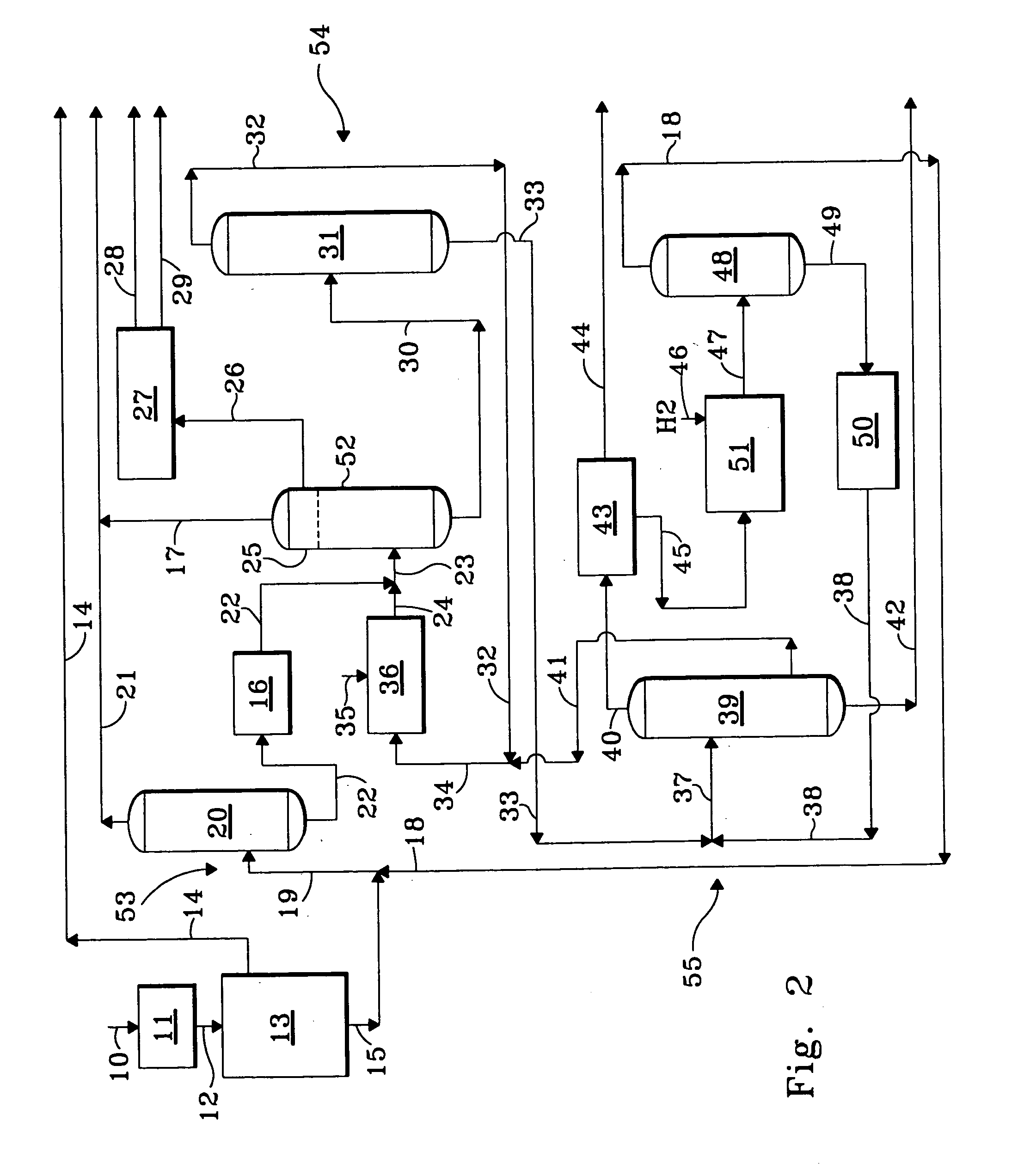

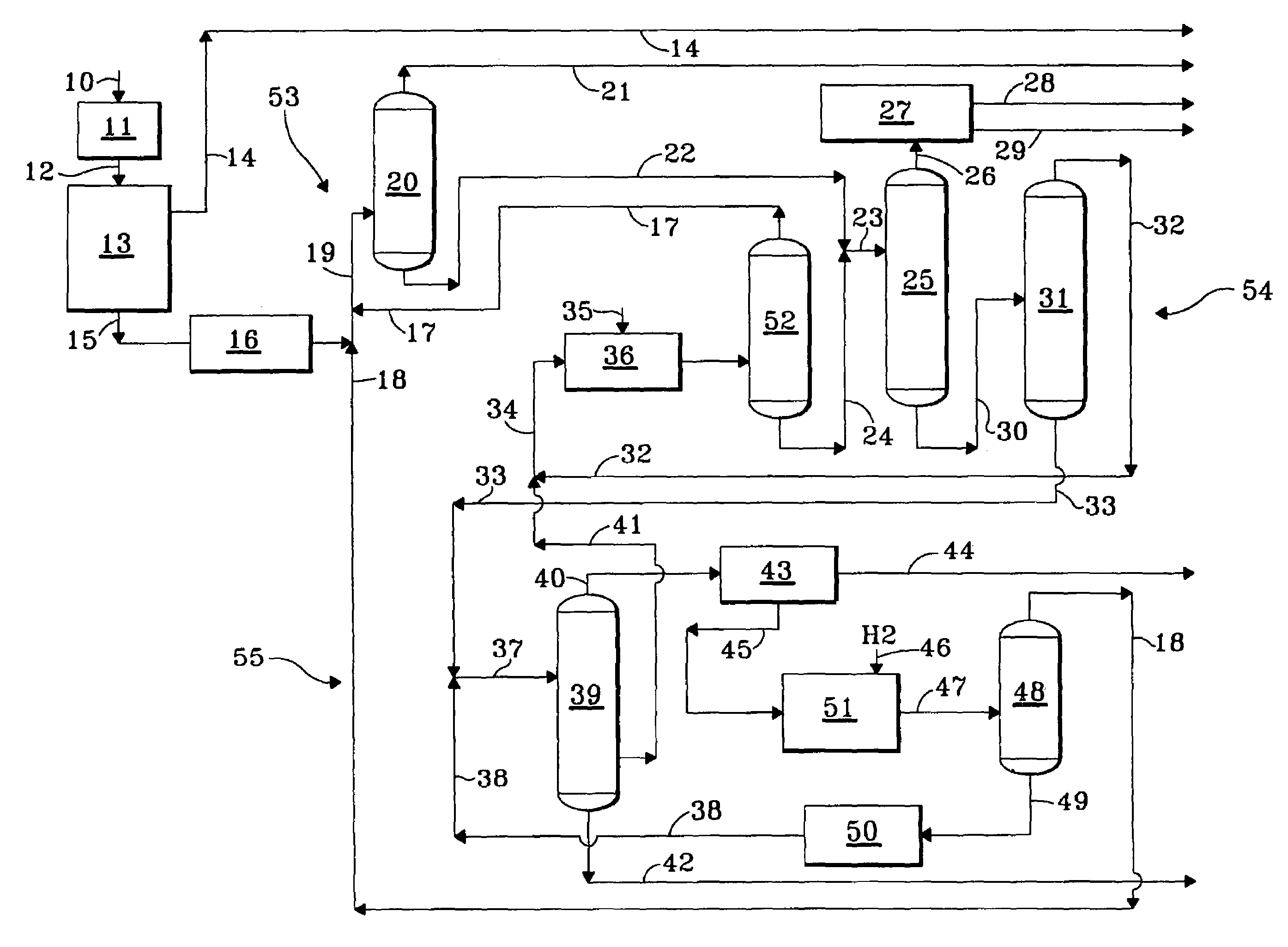

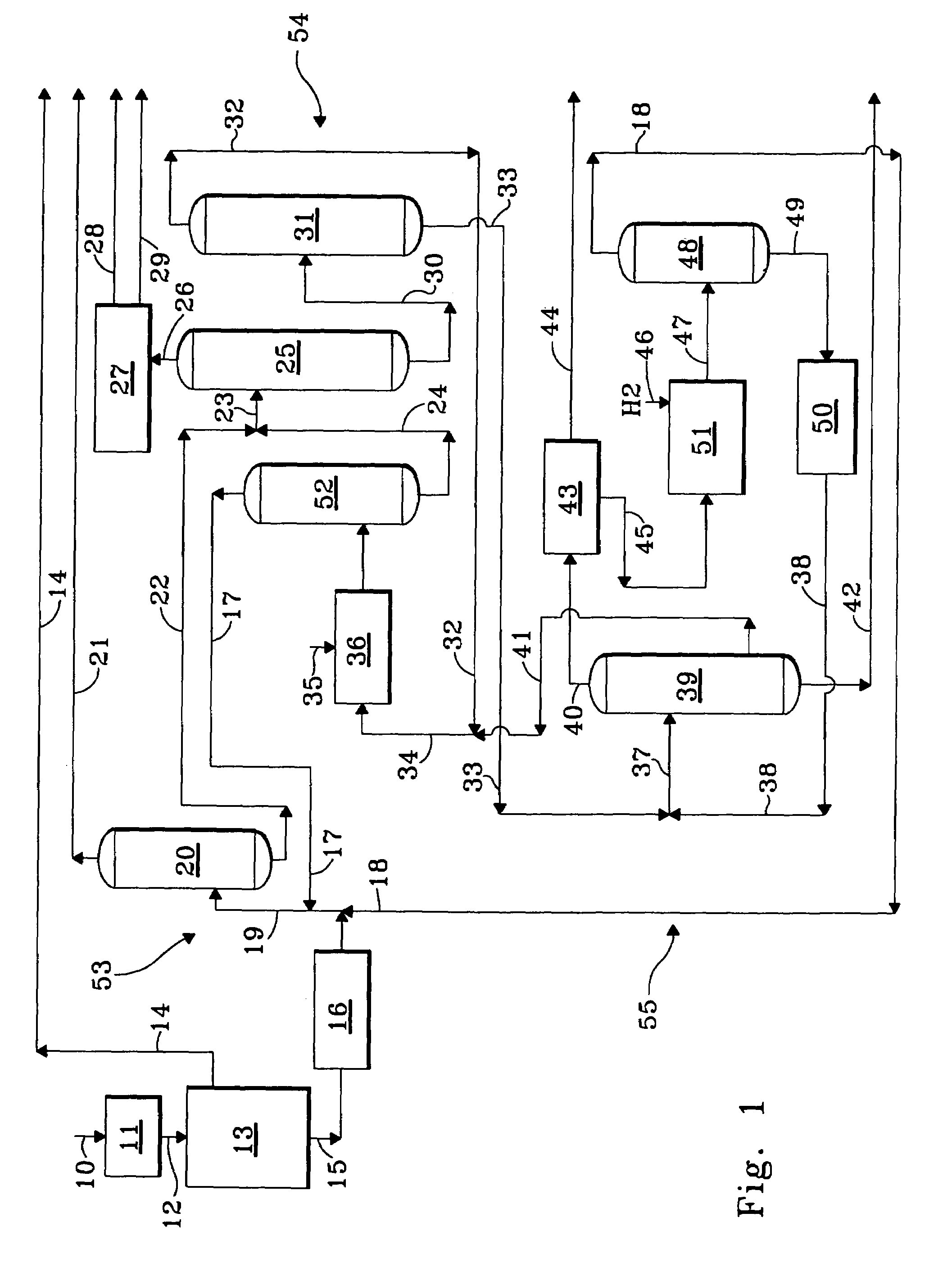

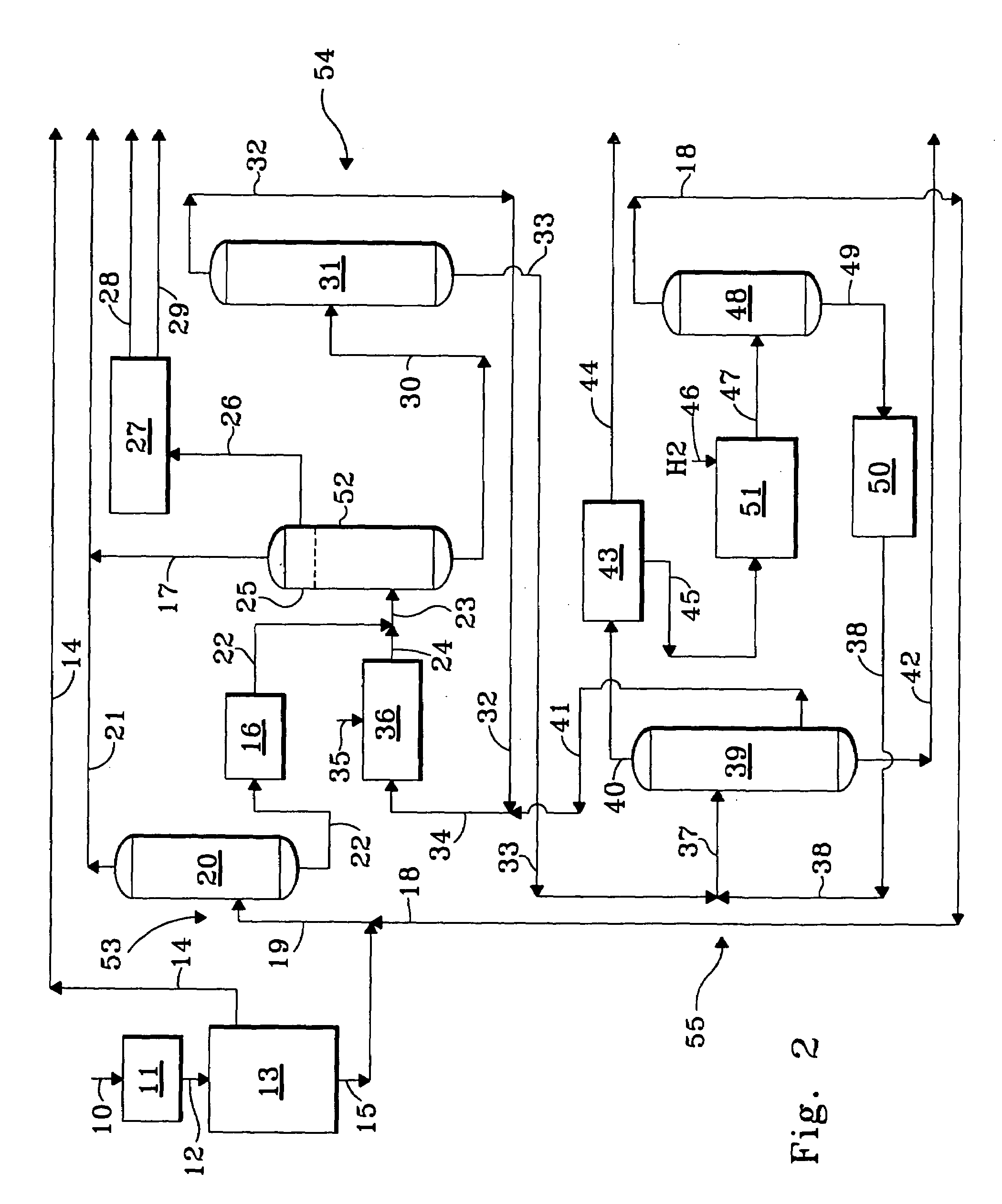

Integrated system and method for producing fuel composition from biomass

InactiveUS7888540B2Reduce formationHydrocarbon by isomerisationCombustible gas catalytic treatmentHydrogenTar

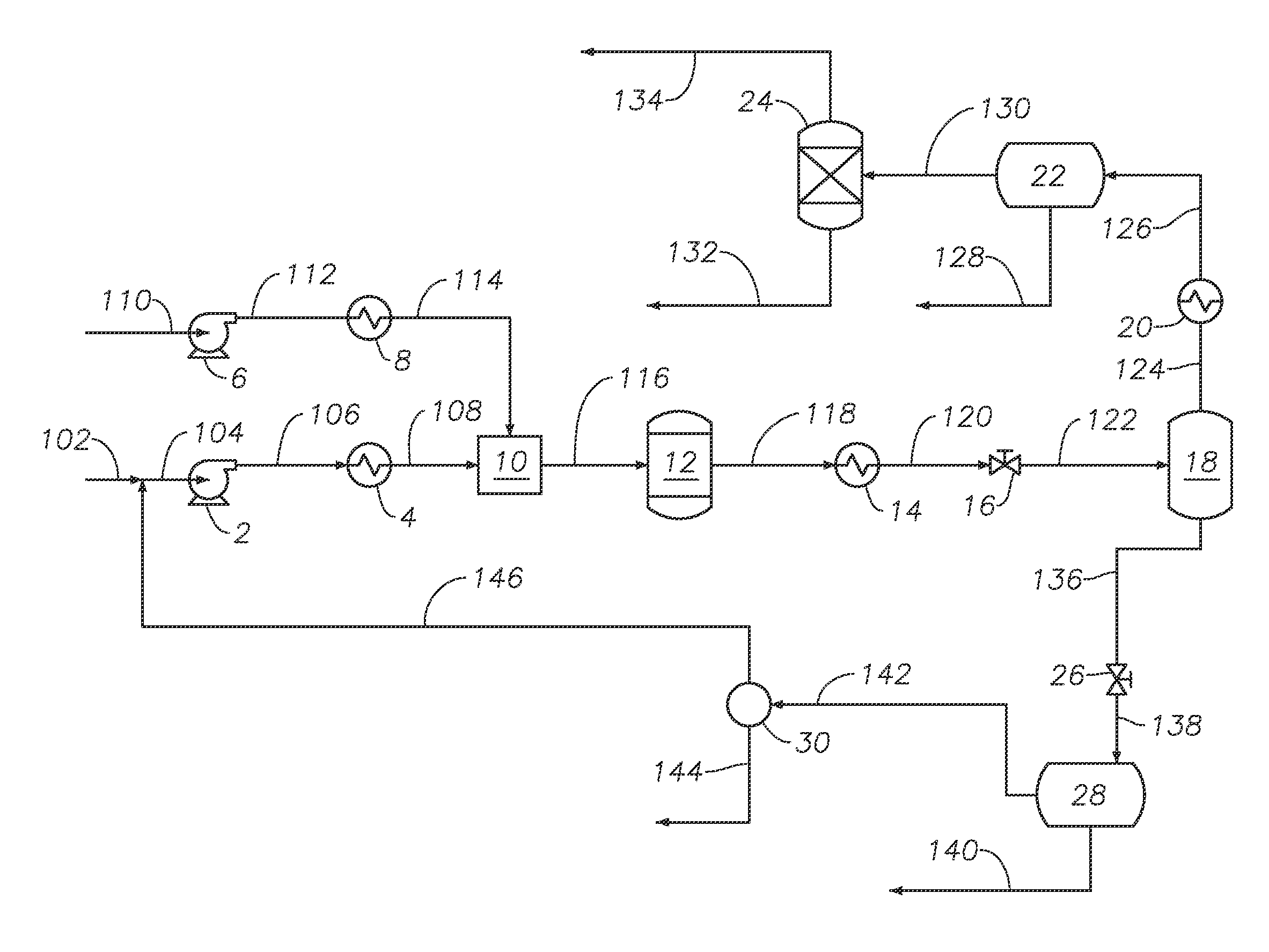

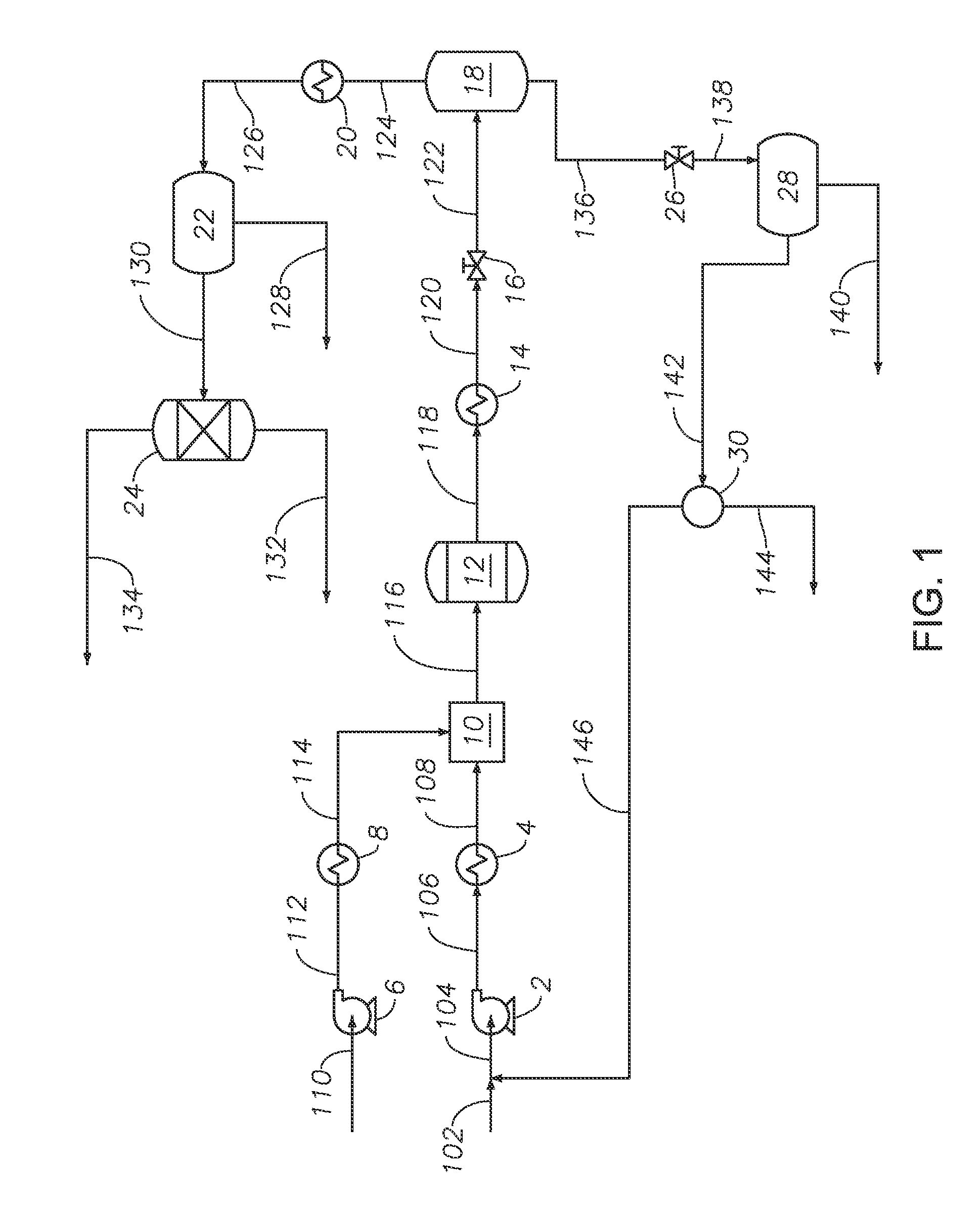

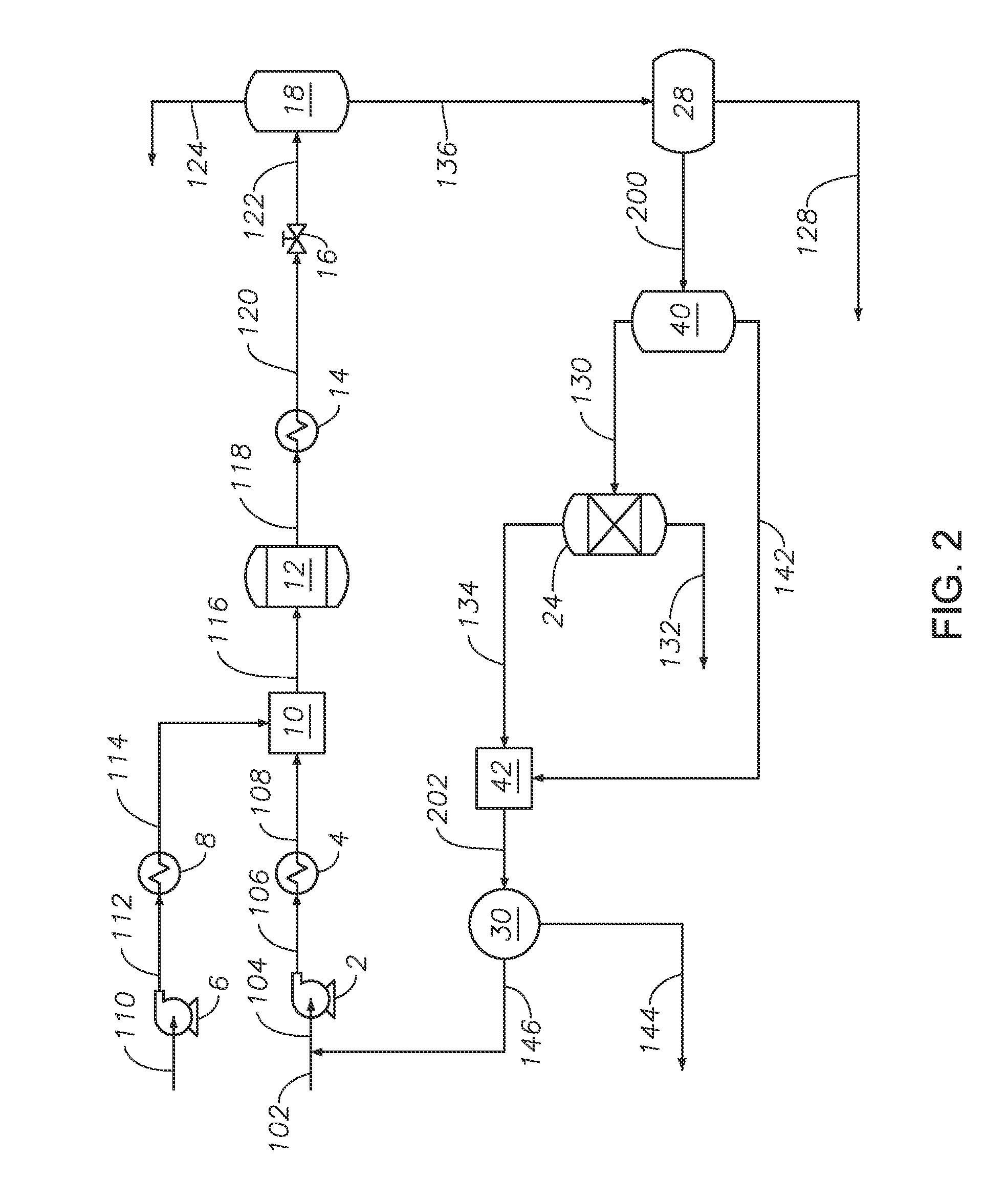

A method of producing a fuel composition from a bio-oil feedstock is provided, wherein the bio-oil feedstock is subjected to a step of oil extraction to produce a bio-oil and deoiled residue. At least a portion of the deoiled residue is gasified to produce a hydrogen-containing gas. The bio-oil is subjected to an upgrading process to ultimately produce a fuel composition. At least a part of the hydrogen-containing gas produced in the gasification of deoiled residue is used in the upgrading process of producing a fuel composition. The upgrading process, which can involve hydro-treating, hydroisomerization and at least one separation step, produces light hydrocarbons in addition to the product fuel composition. The light hydrocarbons can be used in the gasification operation, e.g., to reduce tar formation.

Owner:GENERAL ELECTRIC CO

Process for the removal of nitrogen compounds from a fluid stream

ActiveUS7205448B2Increase capacityReduce accumulationMolecular sieve catalystsHydrocarbonsMolecular sieveNitrite

At lower temperatures an acidic molecular sieve adsorbent preferentially adsorbs water and basic organic nitrogen compounds over weakly basic organic nitrogen compounds such as nitrites. Elevated temperatures improve the capacity of acidic molecular sieve adsorbents to adsorb nitrites in the presence of water.

Owner:UOP LLC

Integrated system and method for producing fuel composition from biomass

InactiveUS20090259082A1Reduce formationHydrocarbon by isomerisationCombustible gas catalytic treatmentThermodynamicsProcess engineering

A method of producing a fuel composition from a bio-oil feedstock is provided, wherein the bio-oil feedstock is subjected to a step of oil extraction to produce a bio-oil and deoiled residue. At least a portion of the deoiled residue is gasified to produce a hydrogen-containing gas. The bio-oil is subjected to an upgrading process to ultimately produce a fuel composition. At least a part of the hydrogen-containing gas produced in the gasification of deoiled residue is used in the upgrading process of producing a fuel composition. The upgrading process, which can involve hydro-treating, hydroisomerization and at least one separation step, produces light hydrocarbons in addition to the product fuel composition. The light hydrocarbons can be used in the gasification operation, e.g., to reduce tar formation.

Owner:GENERAL ELECTRIC CO

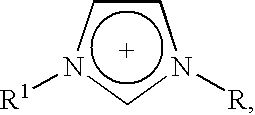

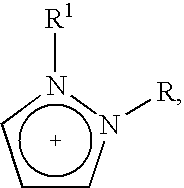

Process for removing polar impurities from hydrocarbons and mixtures of hydrocarbons

InactiveUS7553406B2Improve efficiencyMild process conditionsOrganic compounds purification/separation/stabilisationSolvent extractionHydrocotyle bowlesioidesIonic liquid

This invention relates to a process for removing polarizable impurities from hydrocarbons and mixtures of hydrocarbons using ionic liquids as an extraction medium. By way of extraction, the degree of contamination of the hydrocarbon or mixture of hydrocarbons is reduced to a low or very low level. The specific ionic liquids are compounds of the Formula 1, which are organic salts that are liquid or can be melted to form a liquid and that can form at least a biphasic mixture with a hydrocarbon. The process is suitable for purifying a wide range of hydrocarbons under a wide range of process conditions.

Owner:MERCK PATENT GMBH

Equipment and method for extracting biologically active ingredients from subcritical fluid

InactiveCN101905091AKeep intactGuaranteed production costExtraction purification/separationSolid solvent extractionAutomatic controlSeparation technology

The invention discloses equipment and a method for extracting biologically active ingredients from subcritical fluid, aims to solve the problems of low extraction efficiency and the like existing in the aspects of biologically active ingredient separation technology in the prior art and provides a set of subcritical equipment which comprises an extracting agent supply system, an entrainer supply system, an extraction system, a separation system, a solvent recycling system, a desolvation system, a heat supply system, a computer control system and the like, has high automatic control degree and is used for extracting the biologically active ingredients. Simultaneously, the invention also provides a new technological method for extracting the biologically active ingredients by adopting a subcritical extraction process. The method has the advantage of relatively low cost on the conventional extraction of an organic solvent, and the equipment has the characteristics of no solvent residue, no pollution, high bioactivity and the like in a product obtained by supercritical CO2 extraction technology and has the advantages of low investment on production equipment, high production efficiency within unit time, low energy consumption, flexible operation, high degree of automation and the like.

Owner:XINJIANG UNIVERSITY +1

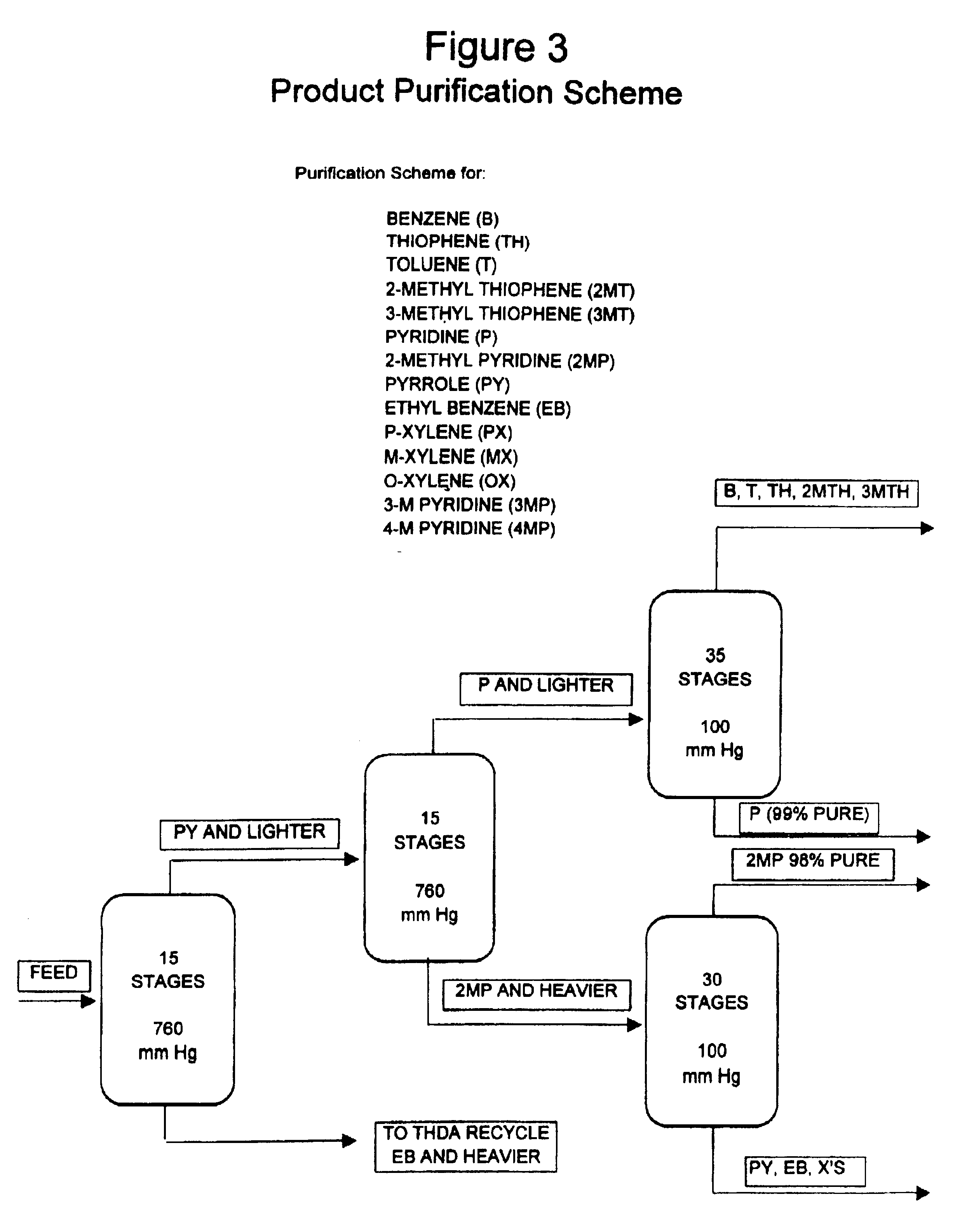

Process for generating pure benzene from reformed gasoline

InactiveUS6124514AReduce benzene contentAchieve separationThermal non-catalytic crackingCatalytic crackingBenzeneExtractive distillation

A process is disclosed for generating pure aromatic compounds from a reformed gasoline which contains aromatic compounds, olefins, diolefin, and triolefins, which comprises the steps of: (a) selectively hydrogenating the olefins, diolefins and triolefins in the reformed gasoline to obtain a mixture of hydrogenated, non-aromatic compounds and aromatic compounds; and (b) separating the aromatic compounds from the hydrogenated, non-aromatic compounds in the mixture formed during step (a) by either extractive distillation, liquid-liquid extraction or both to obtain the pure aromatic compounds.

Owner:BASF AG

Process to produce aromatics from crude oil

ActiveUS20150321975A1Low impurity contentHigh API gravityThermal non-catalytic crackingTreatment with plural serial stages onlyVapor–liquid separatorWater flow

A process for producing aromatics from a hydrocarbon source in the presence of supercritical water comprising the steps of mixing a pressurized, pre-heated water stream with a pressurized, pre-heated petroleum feedstock, the pressurized, pre-heated water stream at a pressure above the critical pressure of water and a temperature above the critical temperature of water, feeding the combined stream to a supercritical water reactor to create a modified stream, cooling and depressurizing the modified stream, separating the depressurized stream in a vapor-liquid separator, condensing the vapor stream, separating the condensed stream into a water recovery stream and a light product recovery stream, extracting the aromatics from the light product recovery stream, depressurizing the liquid stream, separating the depressurized liquid stream in a heavy separator into an upgraded product stream, and recycling part of the upgraded product stream to the pressurized, pre-heated petroleum feedstock as a product recycle.

Owner:SAUDI ARABIAN OIL CO

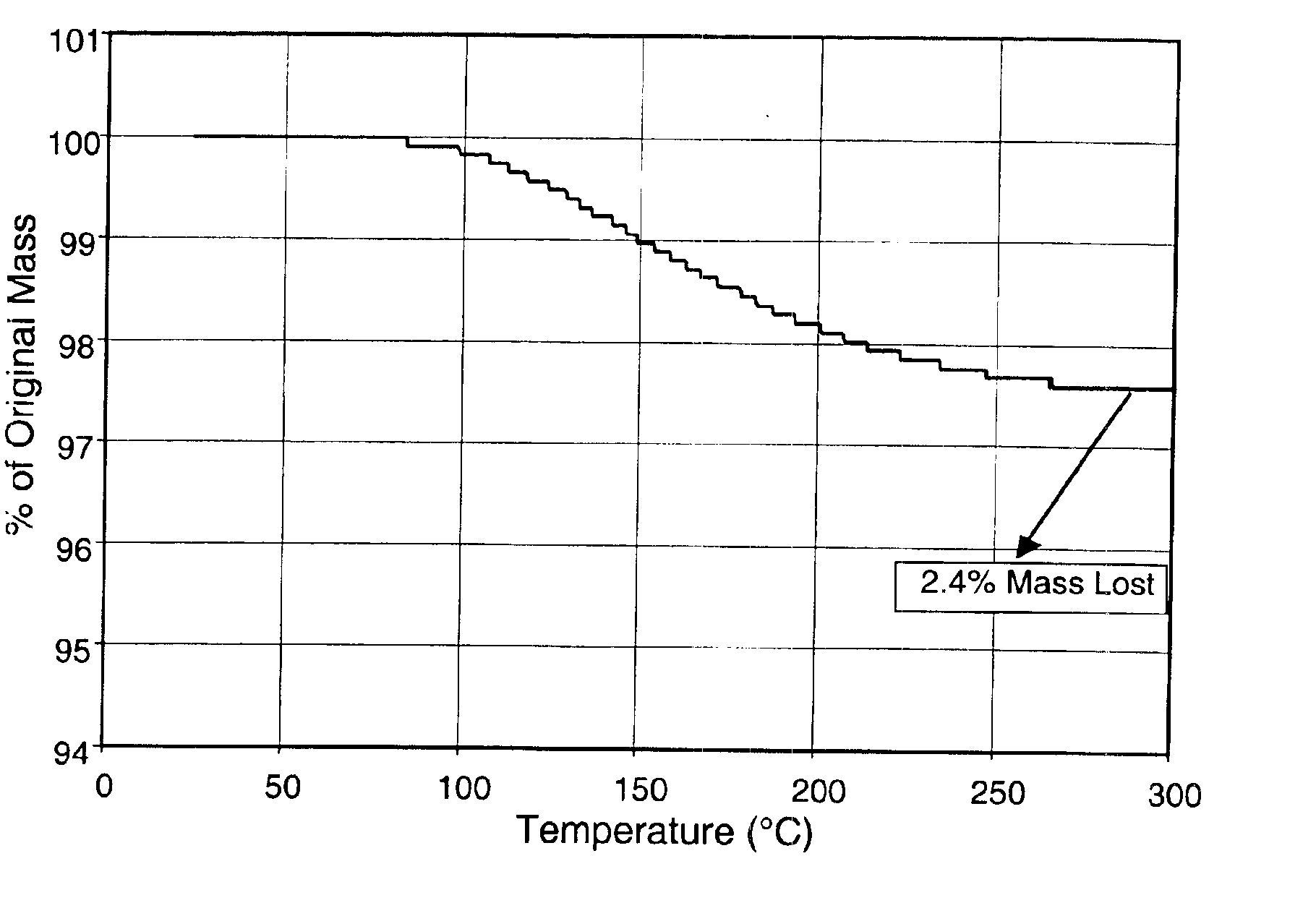

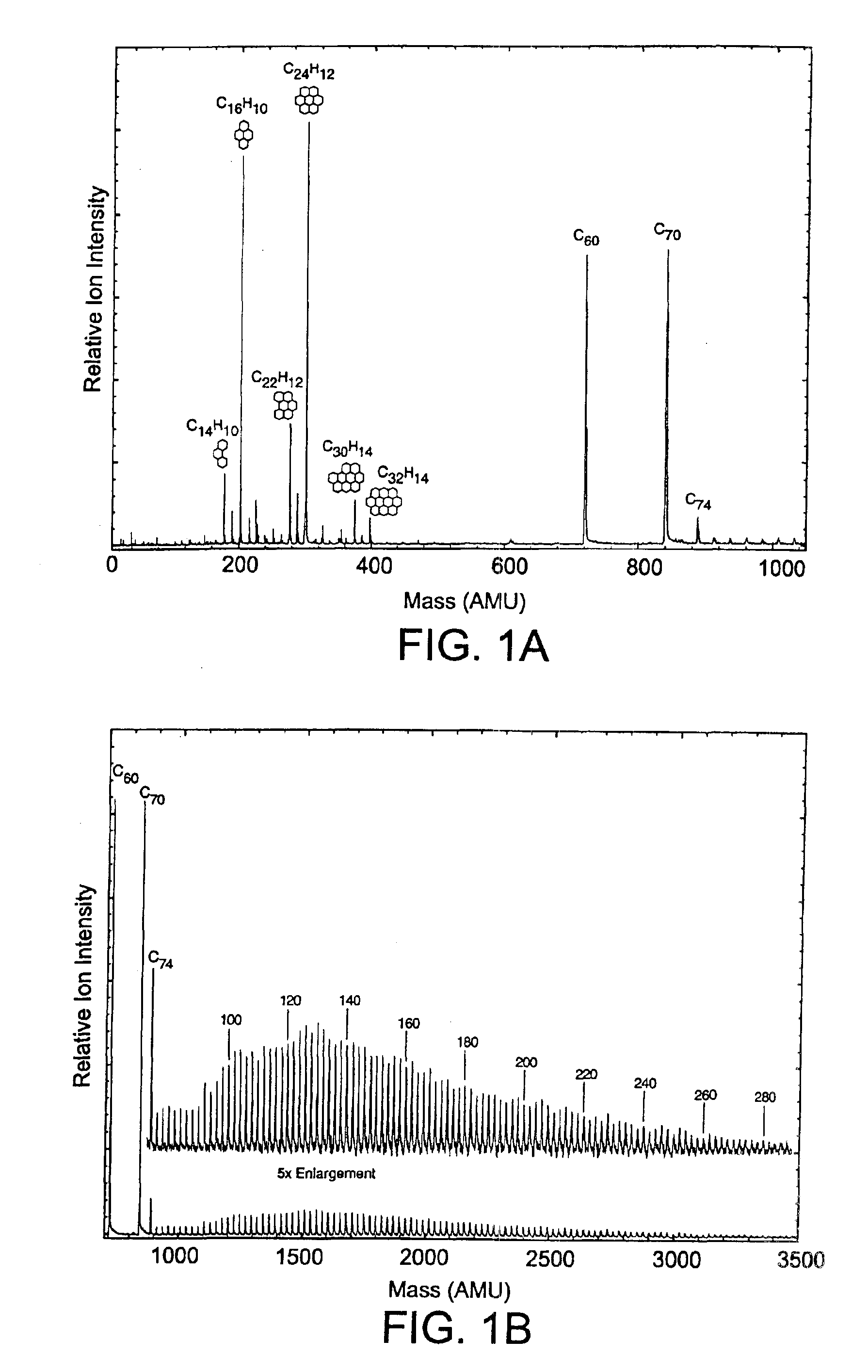

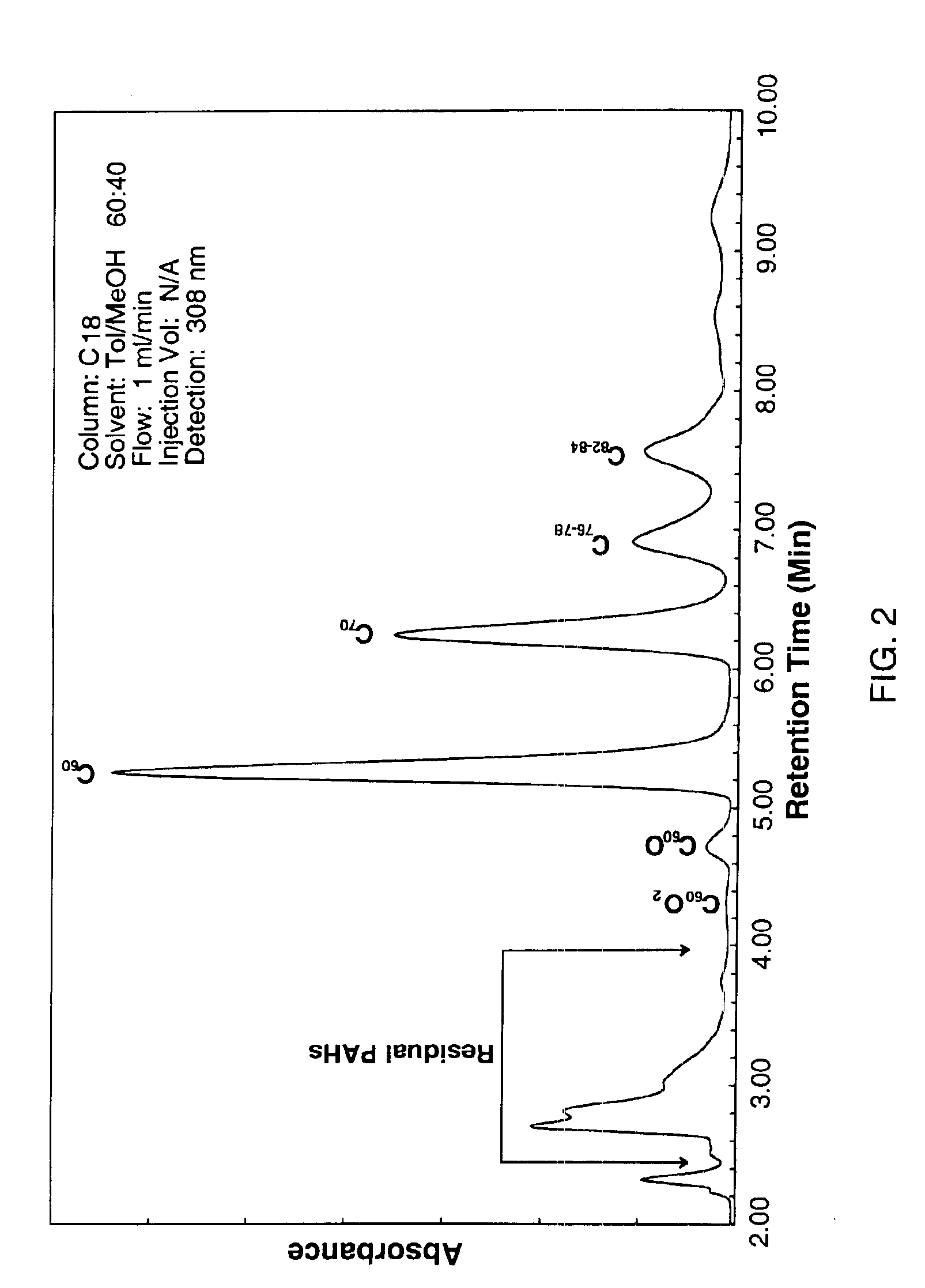

Process for the removal of impurities from combustion fullerenes

InactiveUS6923915B2Without incurring undo costEfficient removalMaterial nanotechnologyFullerenesO-XylenePurification methods

The invention generally relates to purification of carbon nanomaterials, particularly fullerenes, by removal of PAHs and other hydrocarbon impurities. The inventive process involves extracting a sample containing carbon nanomaterials with a solvent in which the PAHs are substantially soluble but in which the carbon nanomaterials are not substantially soluble. The sample can be repeatedly or continuously extracted with one or more solvents to remove a greater amount of impurities. Preferred solvents include ethanol, diethyl ether, and acetone. The invention also provides a process for efficiently separating solvent extractable fullerenes from samples containing fullerenes and PAHs wherein the sample is extracted with a solvent in which both fullerenes and PAHs are substantially soluble and the sample extract then undergoes selective extraction to remove PAHs. Suitable solvents in which both fullerenes and PAHs are soluble include o-xylene, toluene, and o-dichlorobenzene. The purification process is capable of treating quantities of combustion soot in excess of one kilogram and can produce fullerenes or fullerenic soot of suitable purity for many applications.

Owner:FRONTIER CARBON CORP

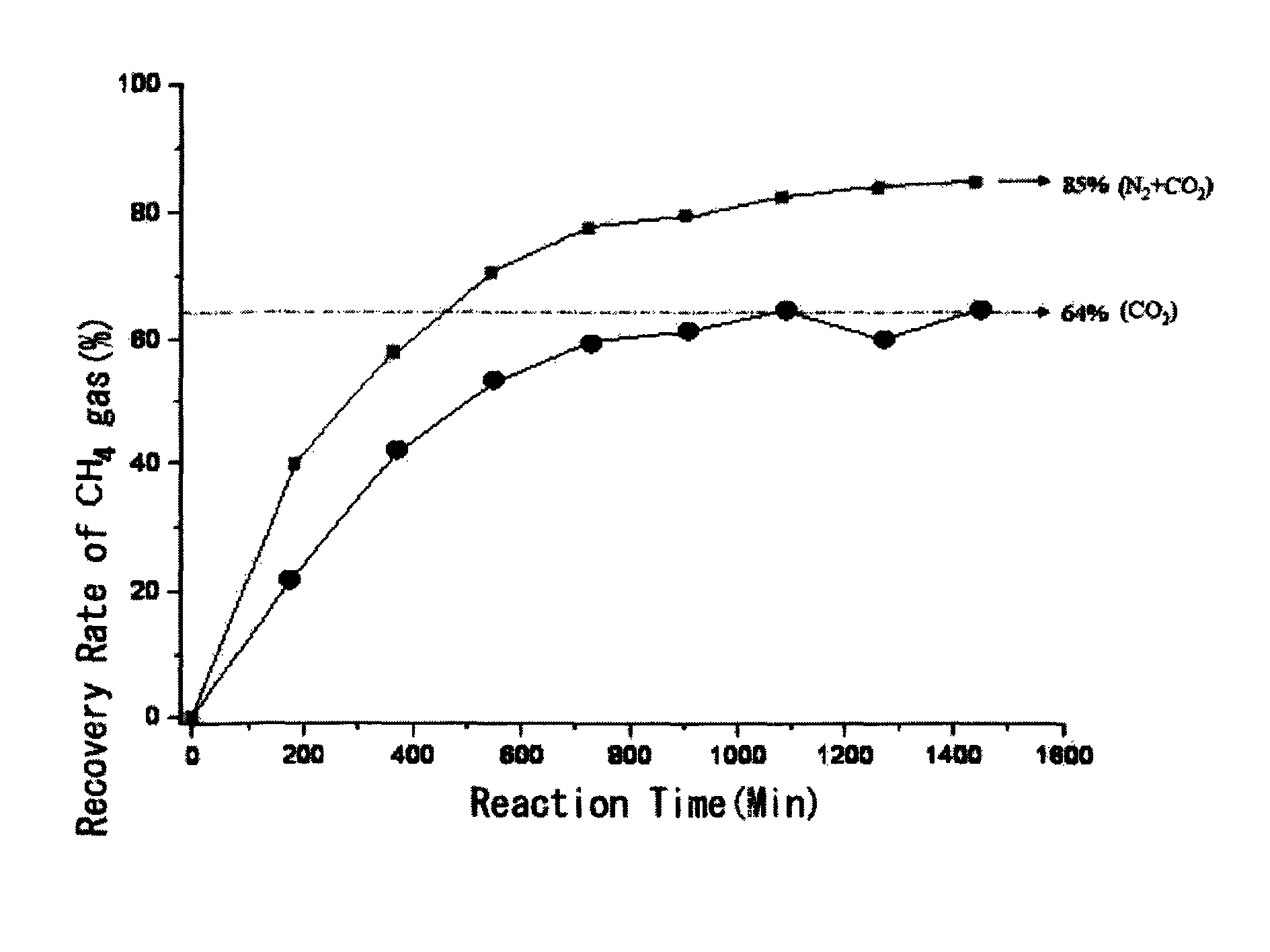

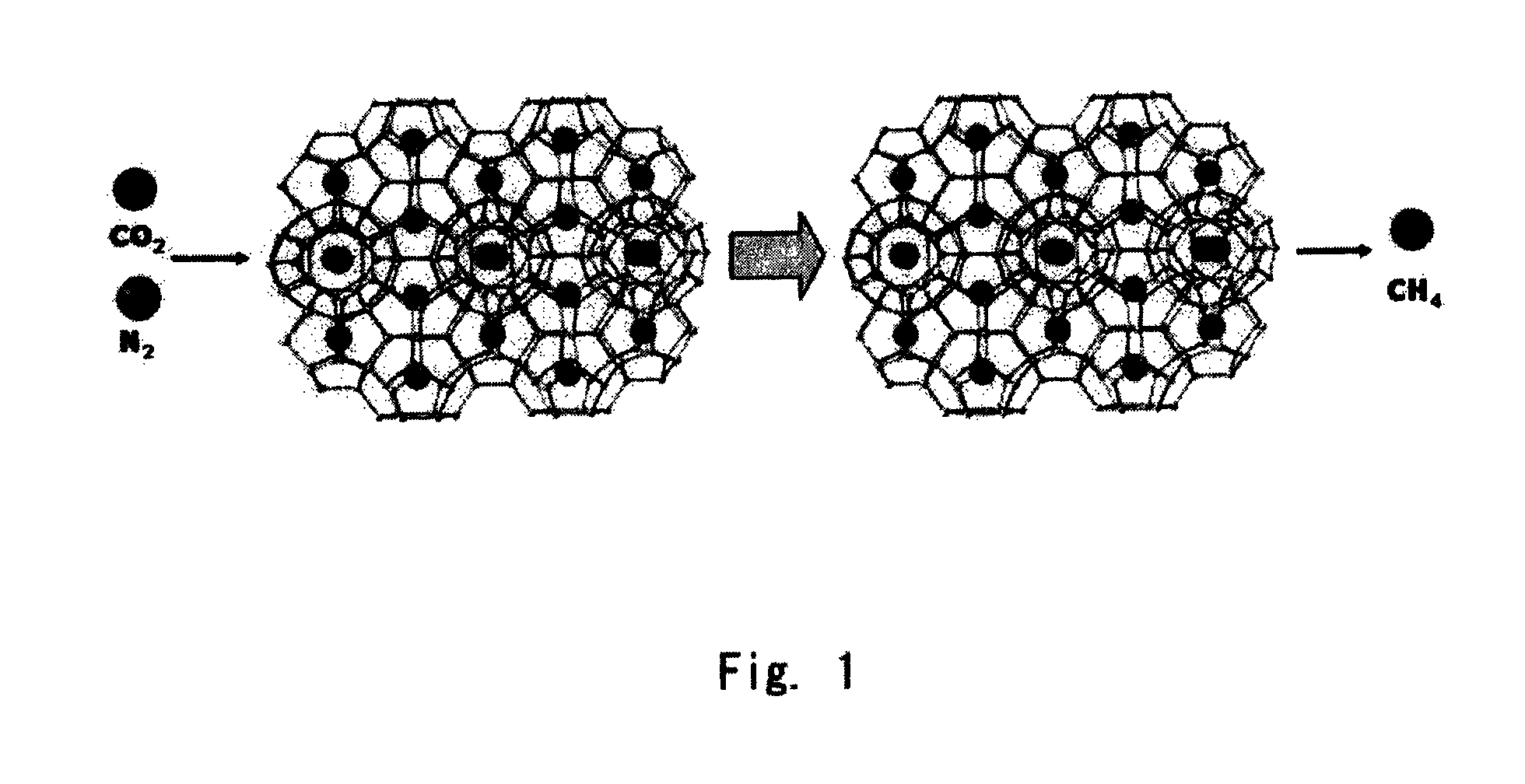

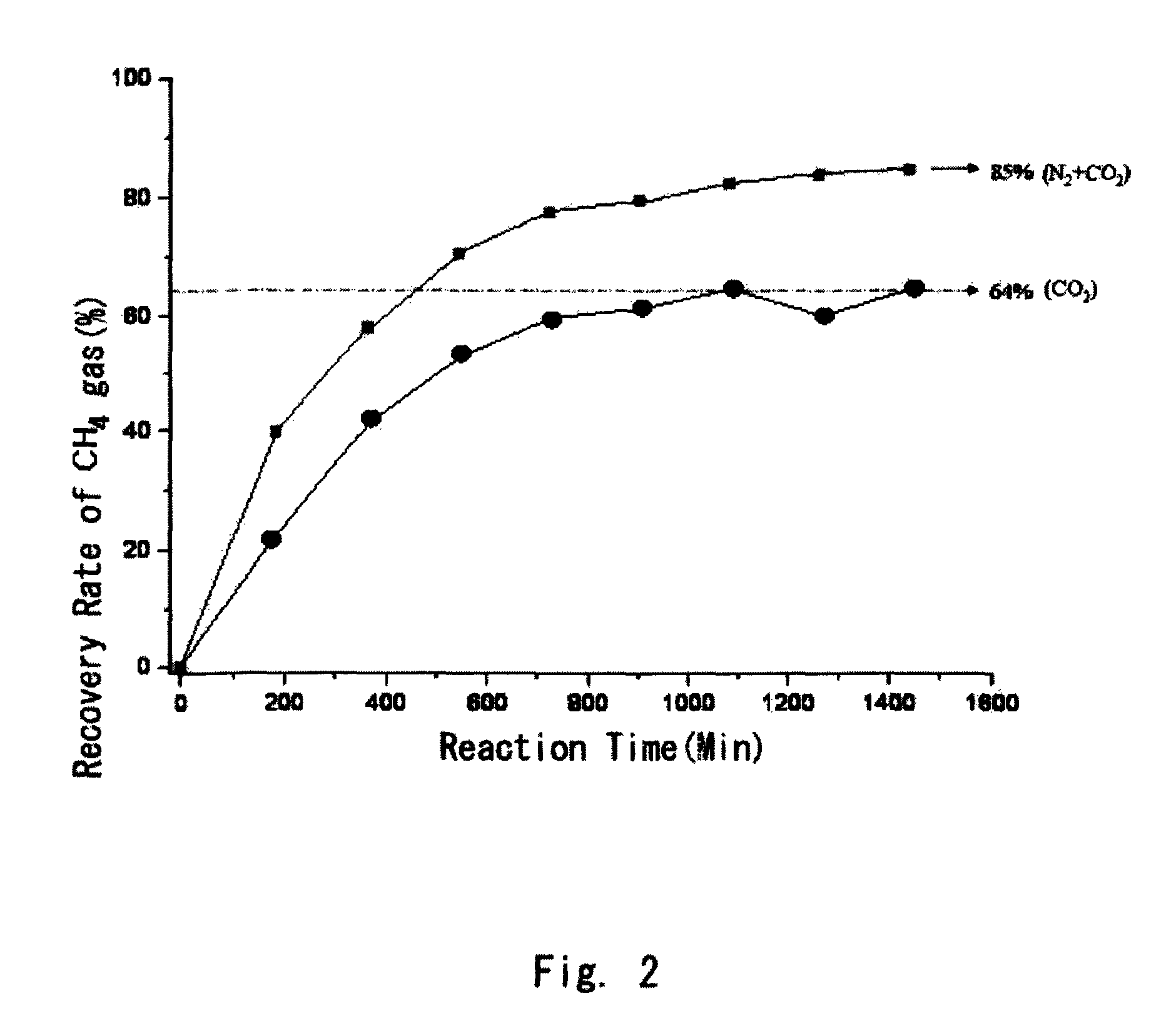

Method for recovering methane gas from natural gas hydrate

The present invention relates to a method for recovering methane gas by adding a gas mixture containing N2 and CO2 gases to natural gas hydrate and reacting them. The method for recovering methane gas from natural gas hydrate of the present invention comprises the step of replacing CH4 gas in natural gas hydrate with a gas mixture containing N2 and CO2 gases by adding the gas mixture to the natural gas hydrate. The method for recovering methane gas of the invention assures a recovery rate of CH4 gas much higher than prior art method without dissociating natural gas hydrate layer and utilization of flue gas as a gas mixture containing N2 and CO2 gases, which makes possible its practical application for the production of natural gas in terms of economy and environmental protection.

Owner:KOREA ADVANCED INST OF SCI & TECH

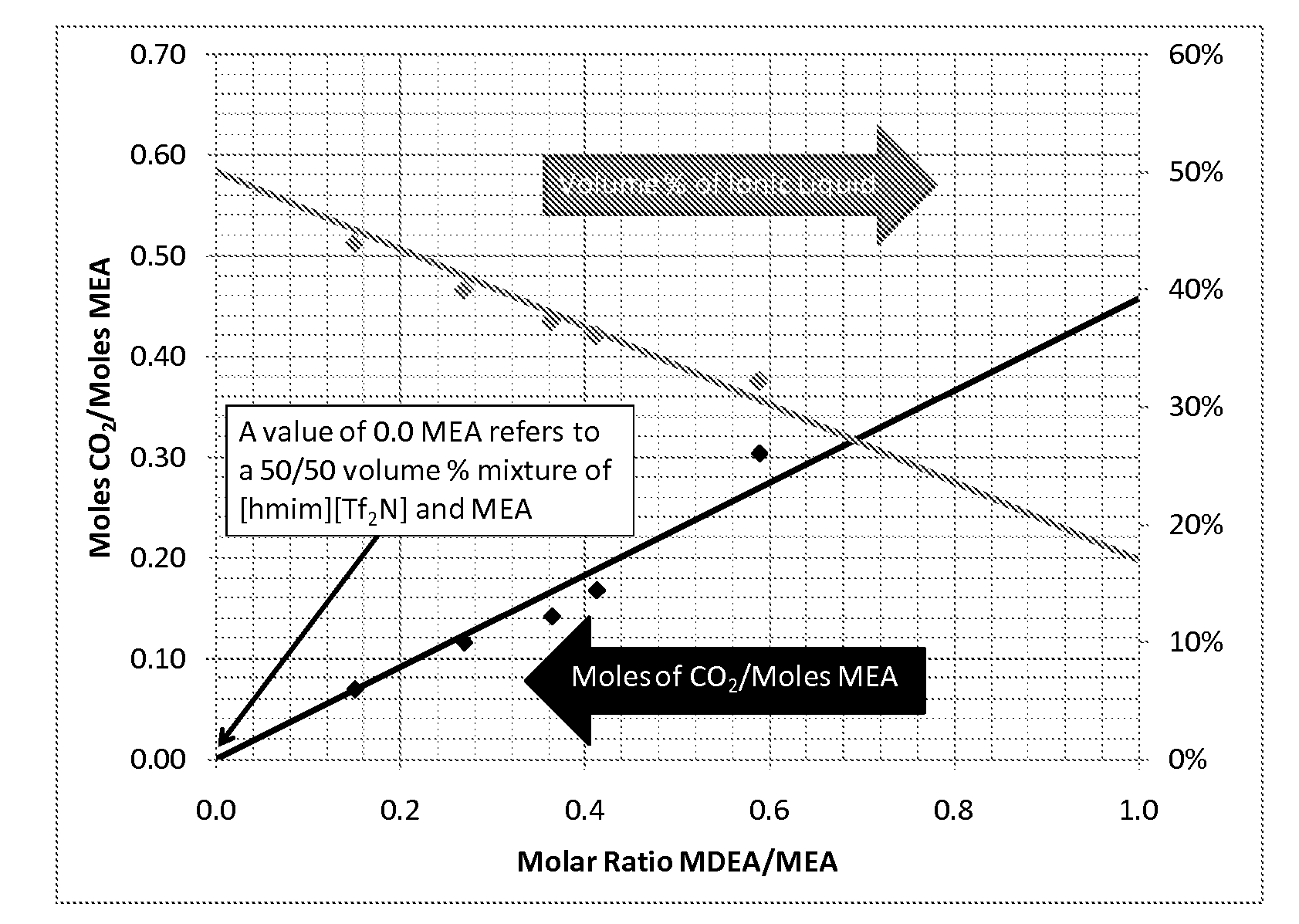

Ionic Liquids and Methods For Using the Same

InactiveUS20090291872A1Reducing and removing impurityReducing and removing and materialOrganic detergent compounding agentsLiquid degasification with auxillary substancesSolid substrateIonic liquid

The present invention provides compositions comprising ionic liquids and an amine compound, and methods for using and producing the same. In some embodiments, the compositions of the invention are useful in reducing the amount of impurities in a fluid medium or a solid substrate.

Owner:UNIV OF COLORADO THE REGENTS OF

Process for removal of catalyst residues from poly-alpha-olefins

ActiveUS20050101761A1Reduce raw material usageOperation efficiency can be improvedHydrocarbonsAdsorption purification/separationCalcium silicateHalogen

A method is disclosed for reducing levels of residual halogen and Group IIIb metals in a crude poly(α-olefin) polymerized in the presence of a catalyst comprising the halogen and Group IIIb metals, wherein the method comprises: A) washing the crude poly(α-olefin) with water; B) separating the aqueous and organic phases; C) then adding an adsorbent selected from the group consisting of magnesium silicates, calcium silicates, aluminum silicates, aluminum oxides, and clays to the organic phase to form a slurry; D) heating the slurry under reduced pressure at a temperature of at least about 180° C. for at least about thirty minutes; and then E) separating the adsorbent from the slurry.

Owner:CHEMTURA CORP

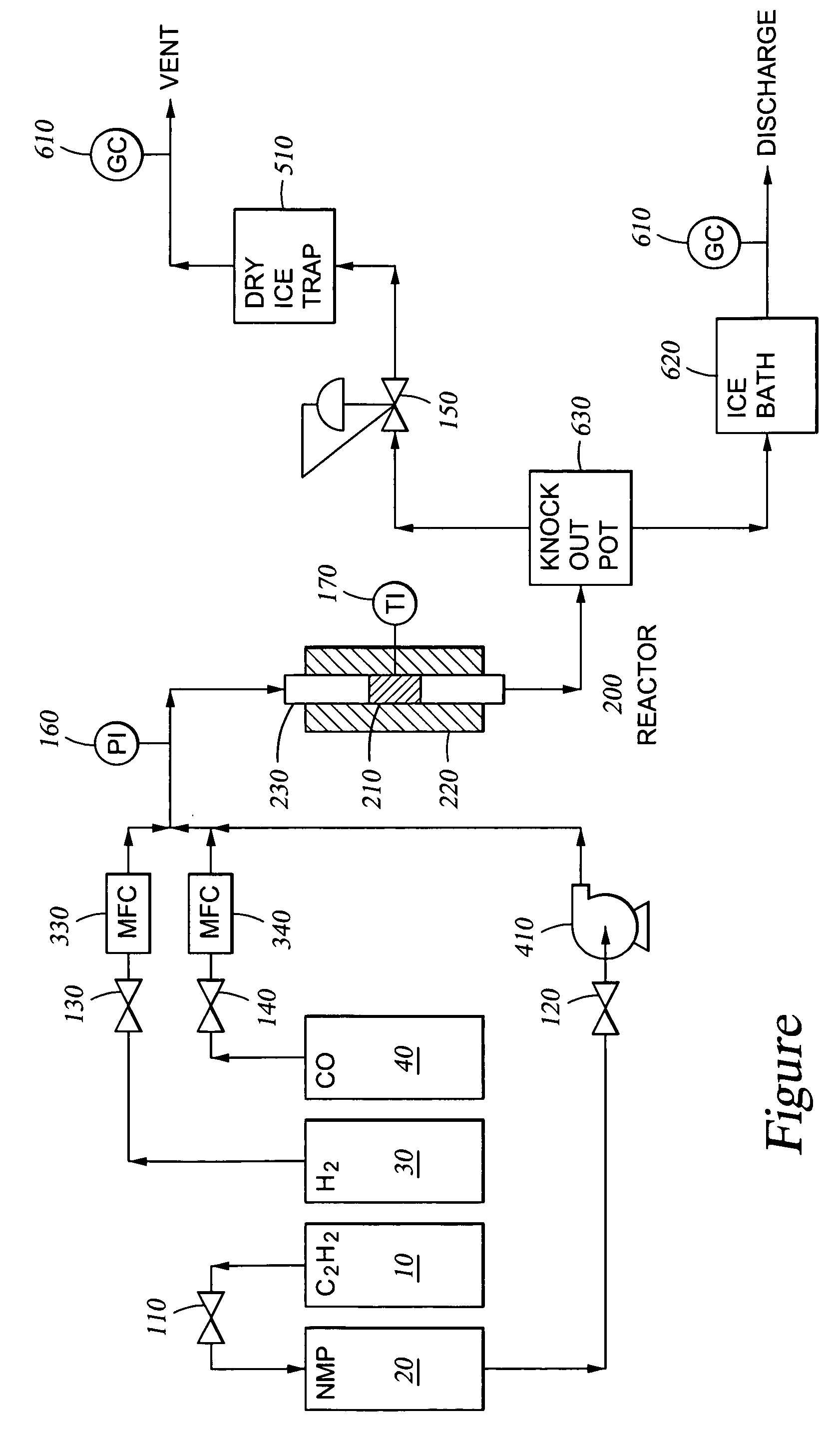

Process for liquid phase hydrogenation

A process for the liquid phase selective hydrogenation of alkynes to alkenes with high selectivity to alkenes relative to alkanes, high alkyne conversion, and sustained catalytic activity comprising a reactant comprising an alkyne and a non-hydrocarbon solvent / absorbent, contacting the reactant stream with a hydrogen-containing stream in the presence of a supported, promoted, Group VIII catalyst, removing the solvent / absorbent, and recovering the alkene product.

Owner:SYNFUELS INT

Isolation of carotenoid crystals

InactiveUS7015014B2Reduce usageIncrease carotenoid contentOrganic active ingredientsBiocideMicroorganismAnti solvent

The present invention relates to a crystalline carotenoid compound, such as β-carotene, with a purity of at least 95% and with substantially no solvent enclosed in the crystal lattice. The present invention further describes a process to prepare such a highly pure crystalline carotenoid compound from microbial biomass, without the use of a solvent extraction and / or an anti-solvent crystallization process.

Owner:DSM IP ASSETS BV

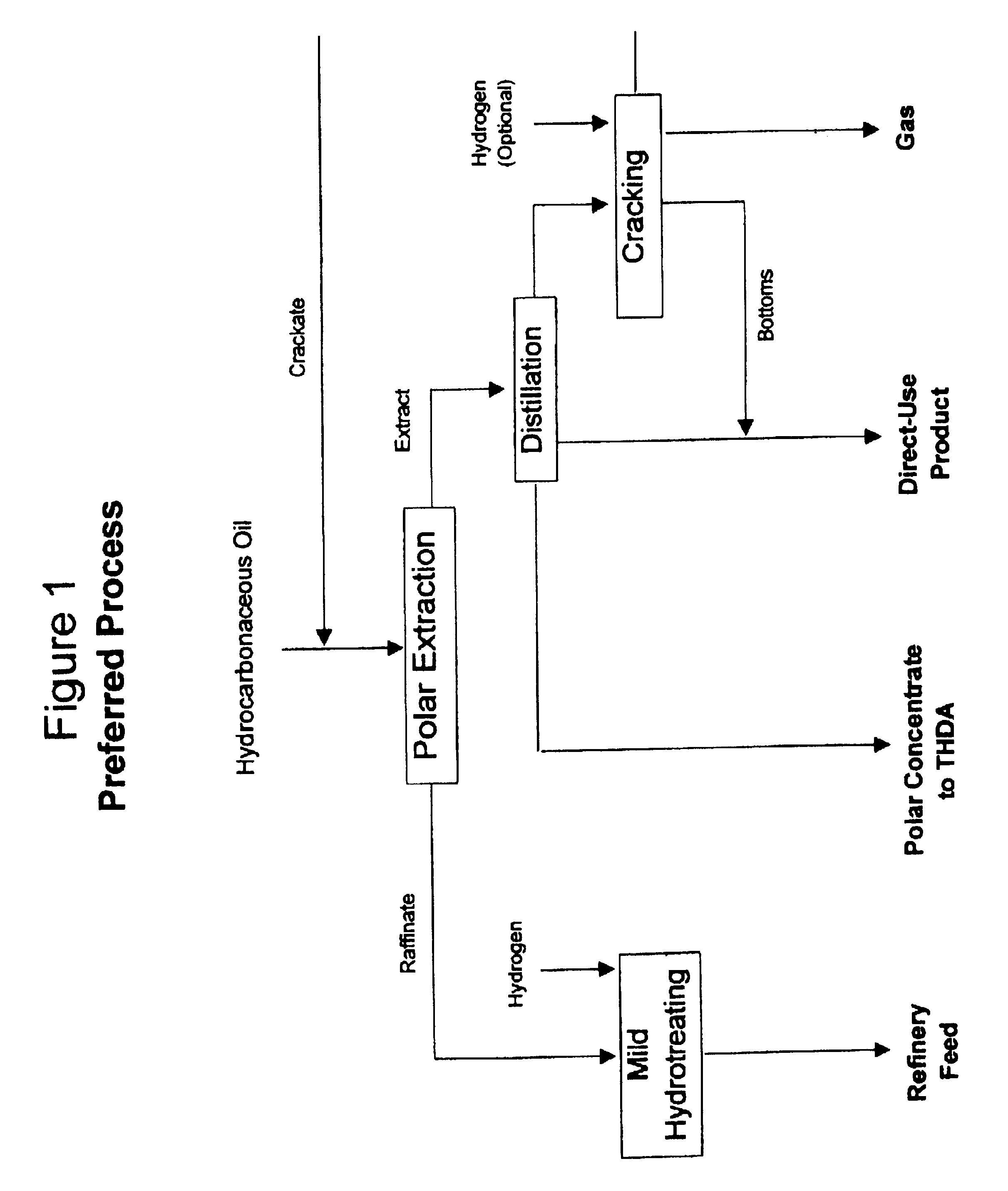

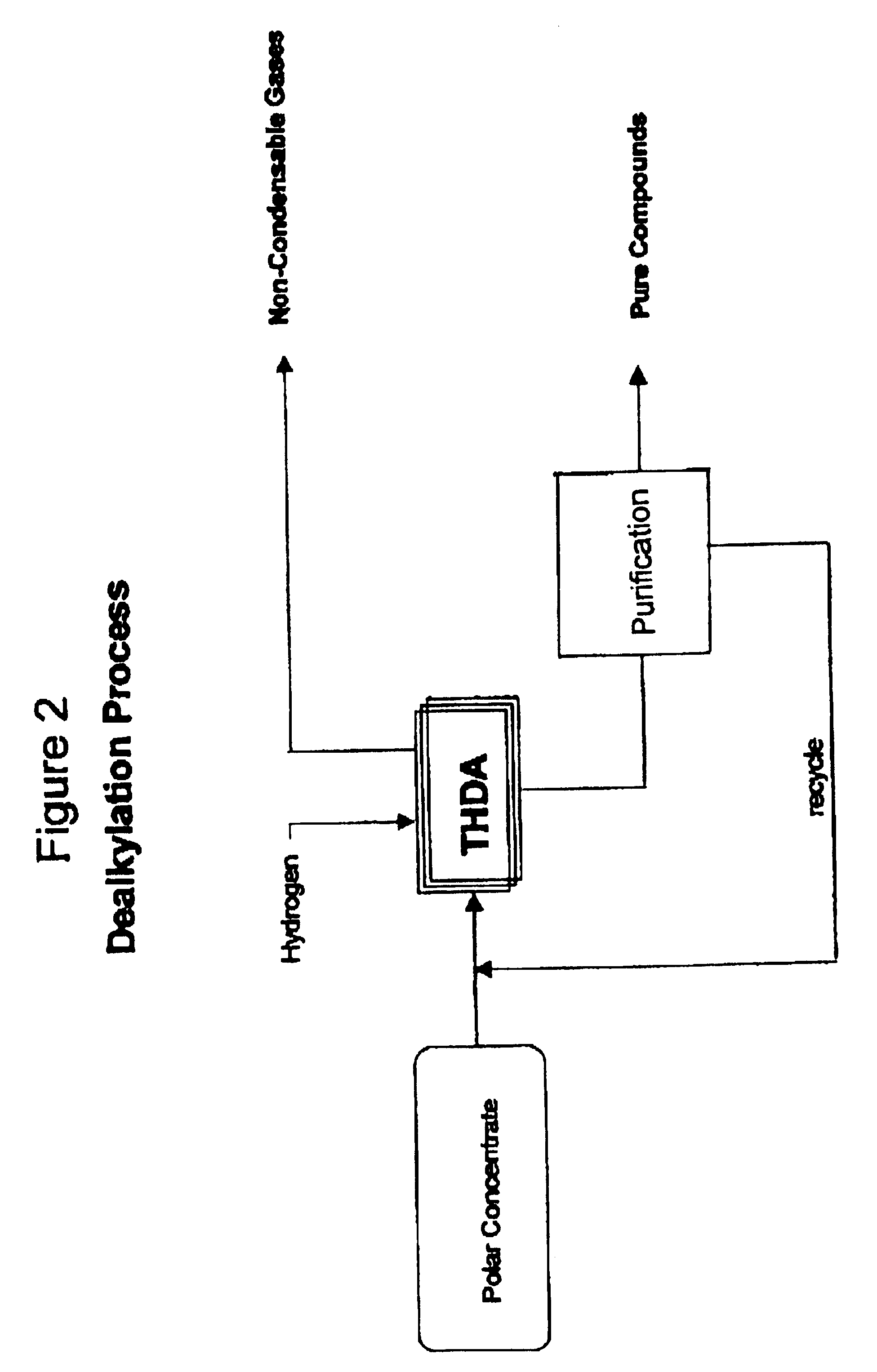

Process for enhancing the value of hydrocabonaceous natural recources

InactiveUS6875341B1Little and valueReduce total process throughputRefining with acid-containing liquidsHydrocarbonsSolubilitySolvent free

Owner:JWBA

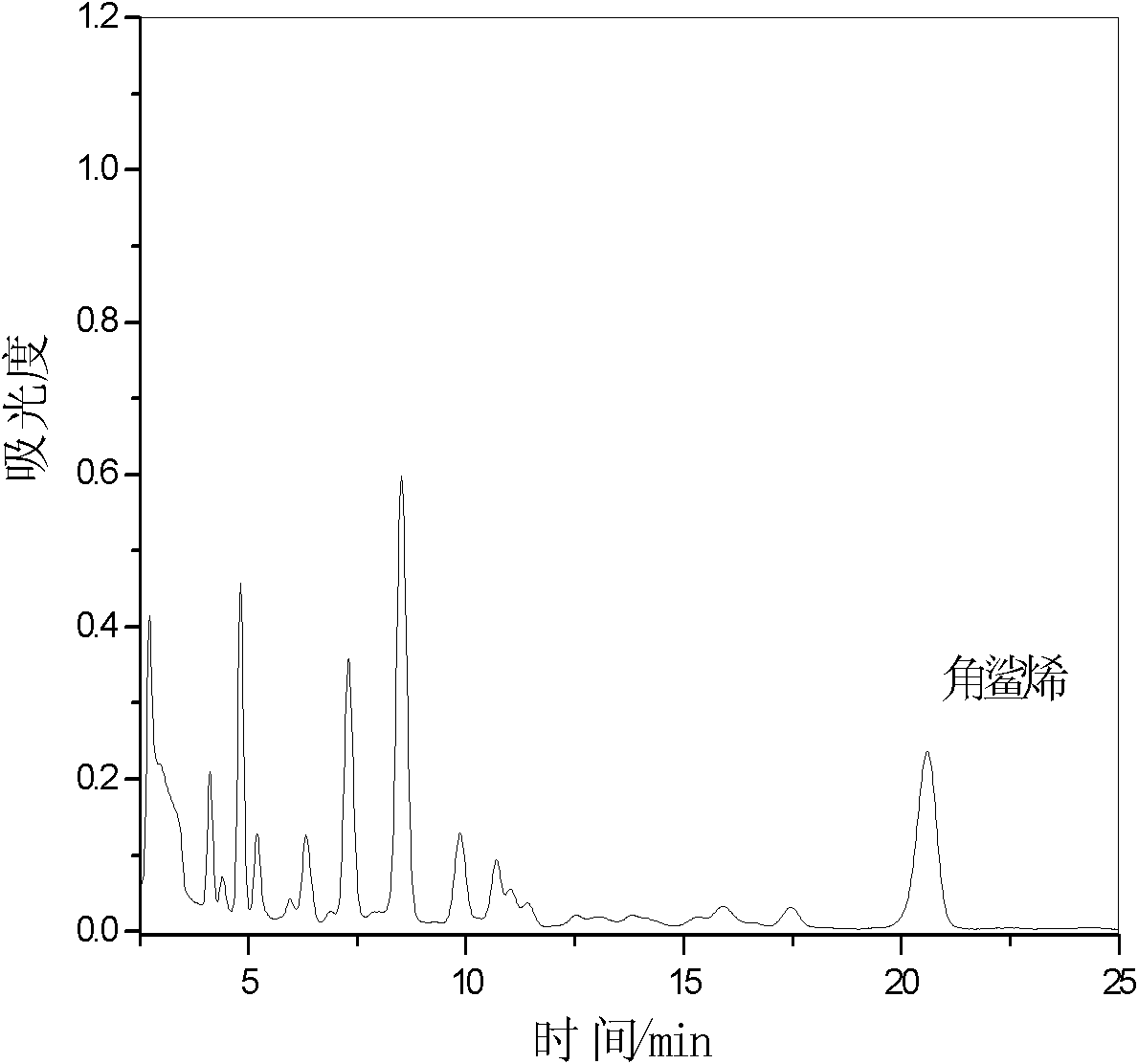

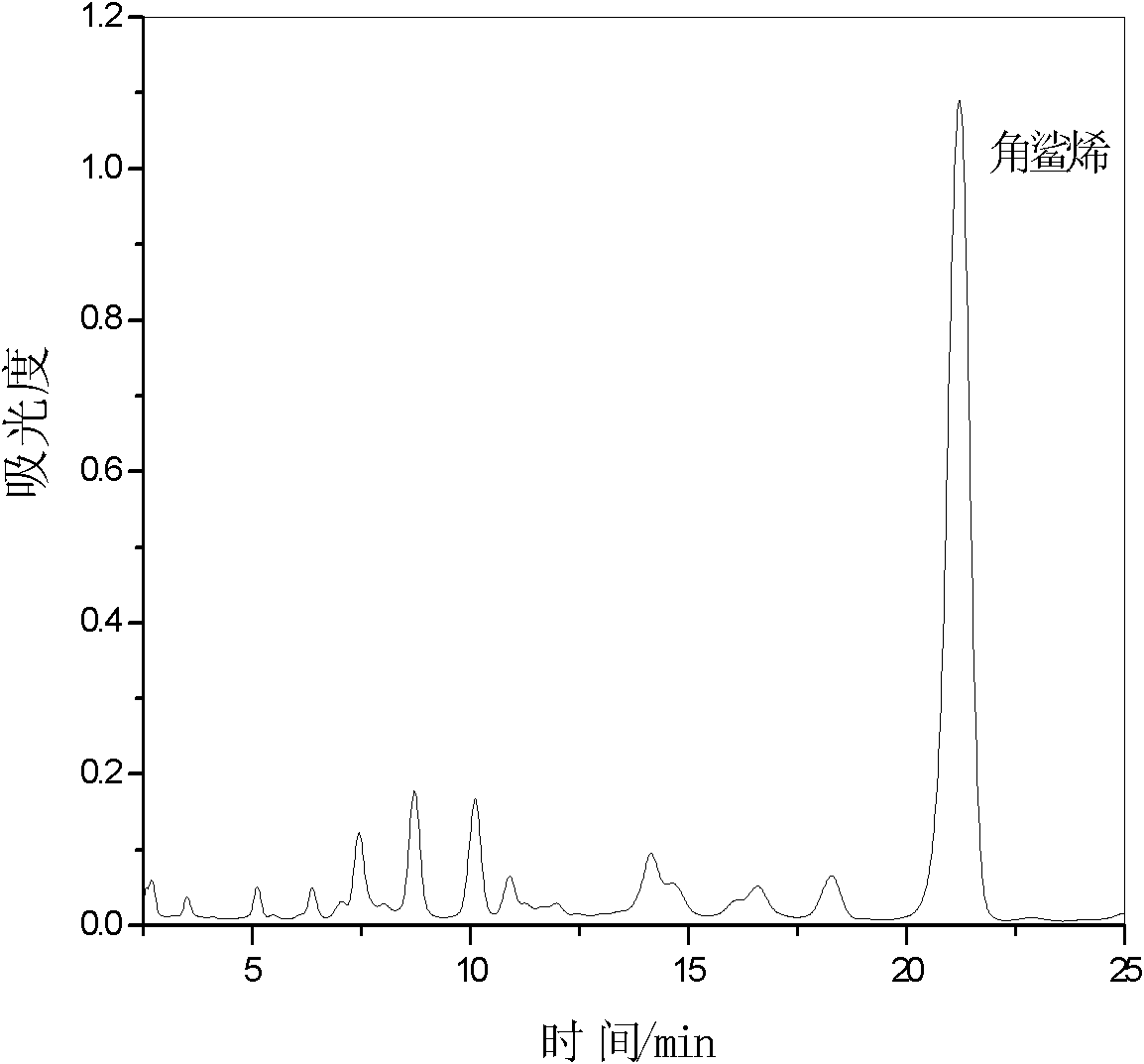

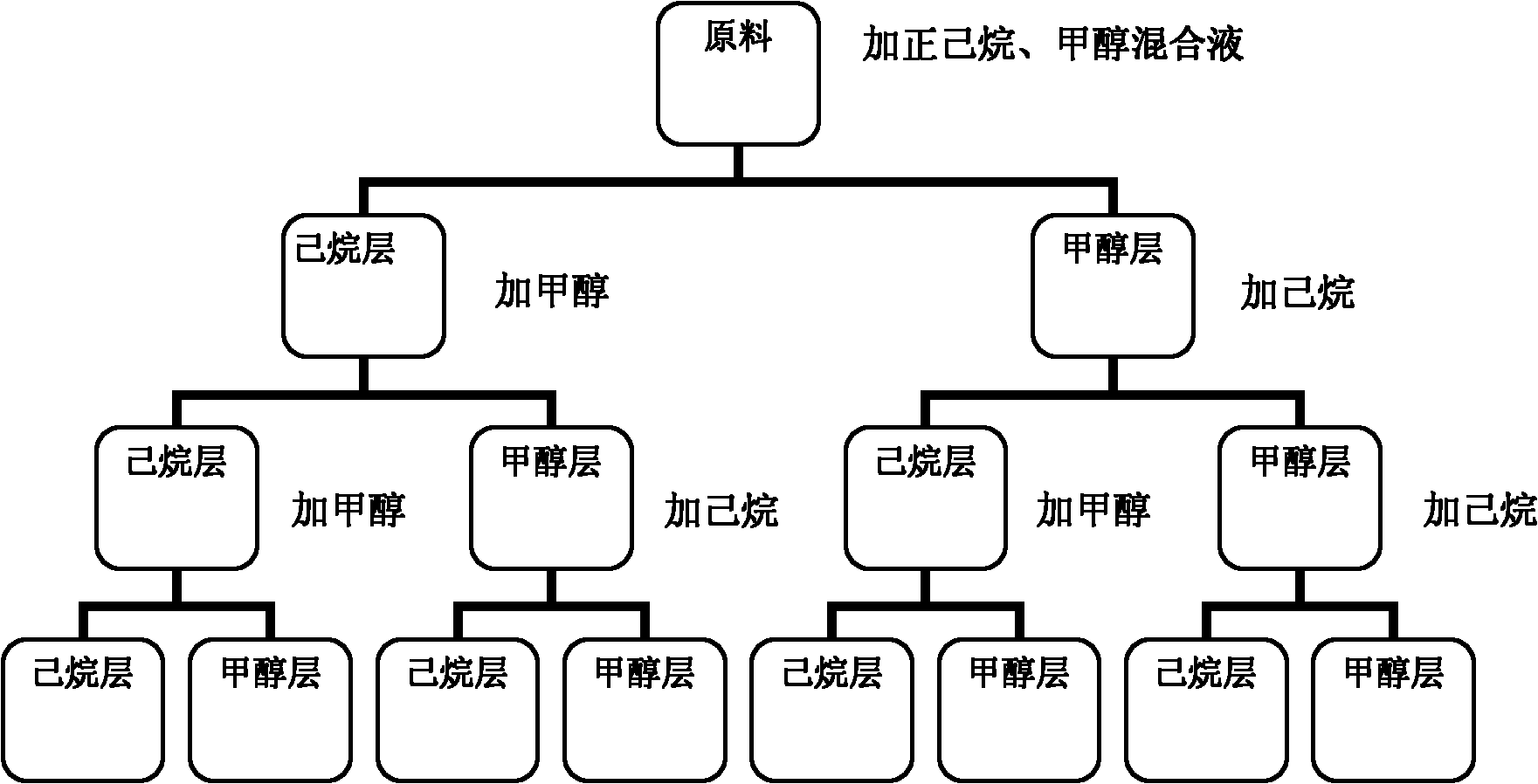

Method for extracting squalene from vegetable oil deodorized distillate

InactiveCN101830770AIdeal yieldIncrease contentDistillation purification/separationExtraction purification/separationHigh concentrationVegetable oil

The invention relates to a method for extracting squalene from vegetable oil deodorized distillate. A process method of combining molecular distillation with extraction and crystallization is used to extract high-concentration squalene and recover natural vitamin E and phytosterol with a certain purity from vegetable oil deodorized distillate. The method comprises the following steps of: carryingout a saponification reaction of the raw material; twice molecularly distilling unsaponifiable matter obtained by extraction; using the distillate obtained during the second distilling as a raw material for cold crystallization to obtain phytosterol; recovering squalene and mixed tocopherol from the filtrate; and extracting with multi-stage solvents to respectively enrich squalene and vitamin E in two phases. The process has simple flows, low-prices raw material and higher separation efficiency and recovery rate and comprehensively utilizes useful contents in the deodorized distillate.

Owner:TIANJIN UNIV

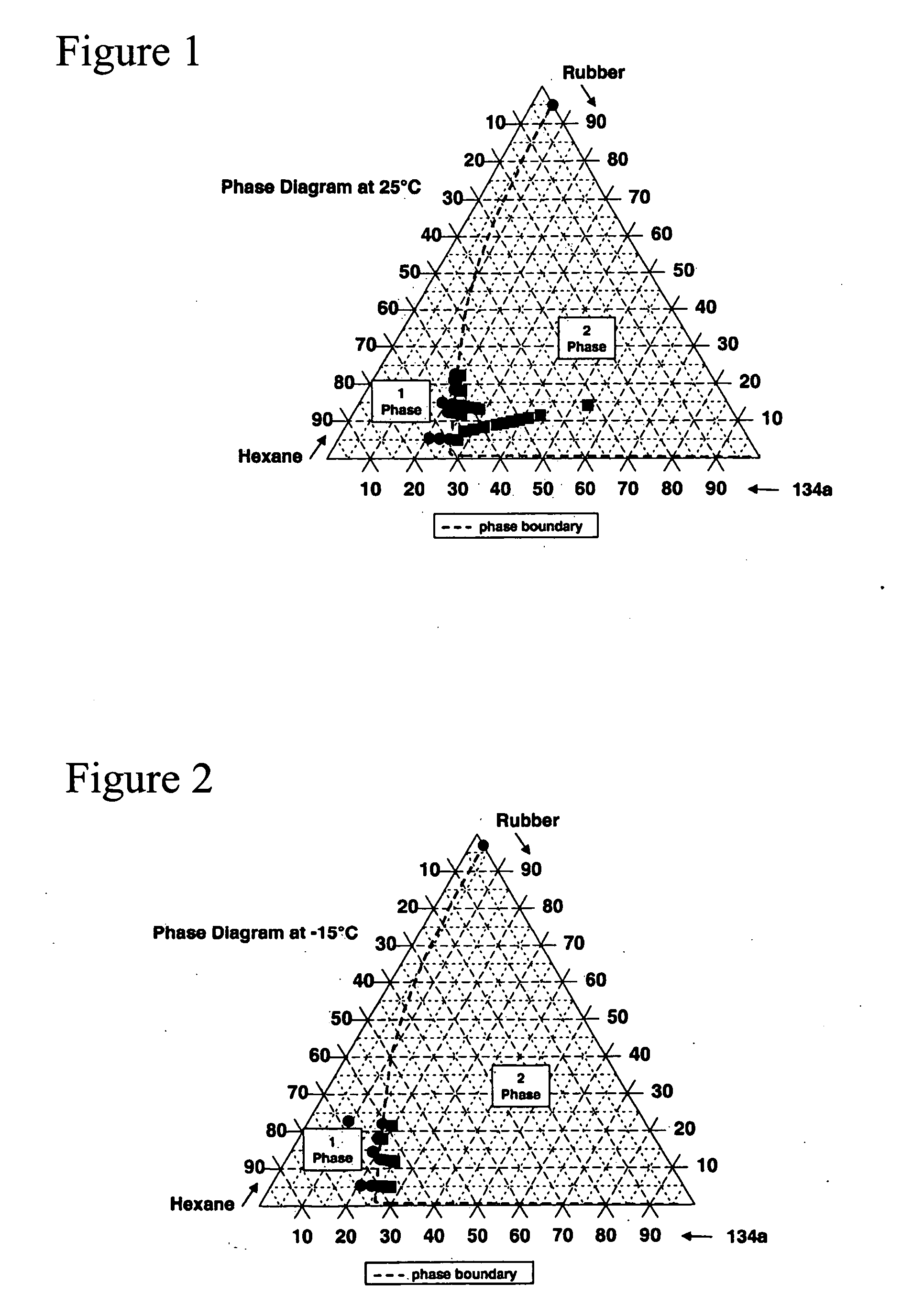

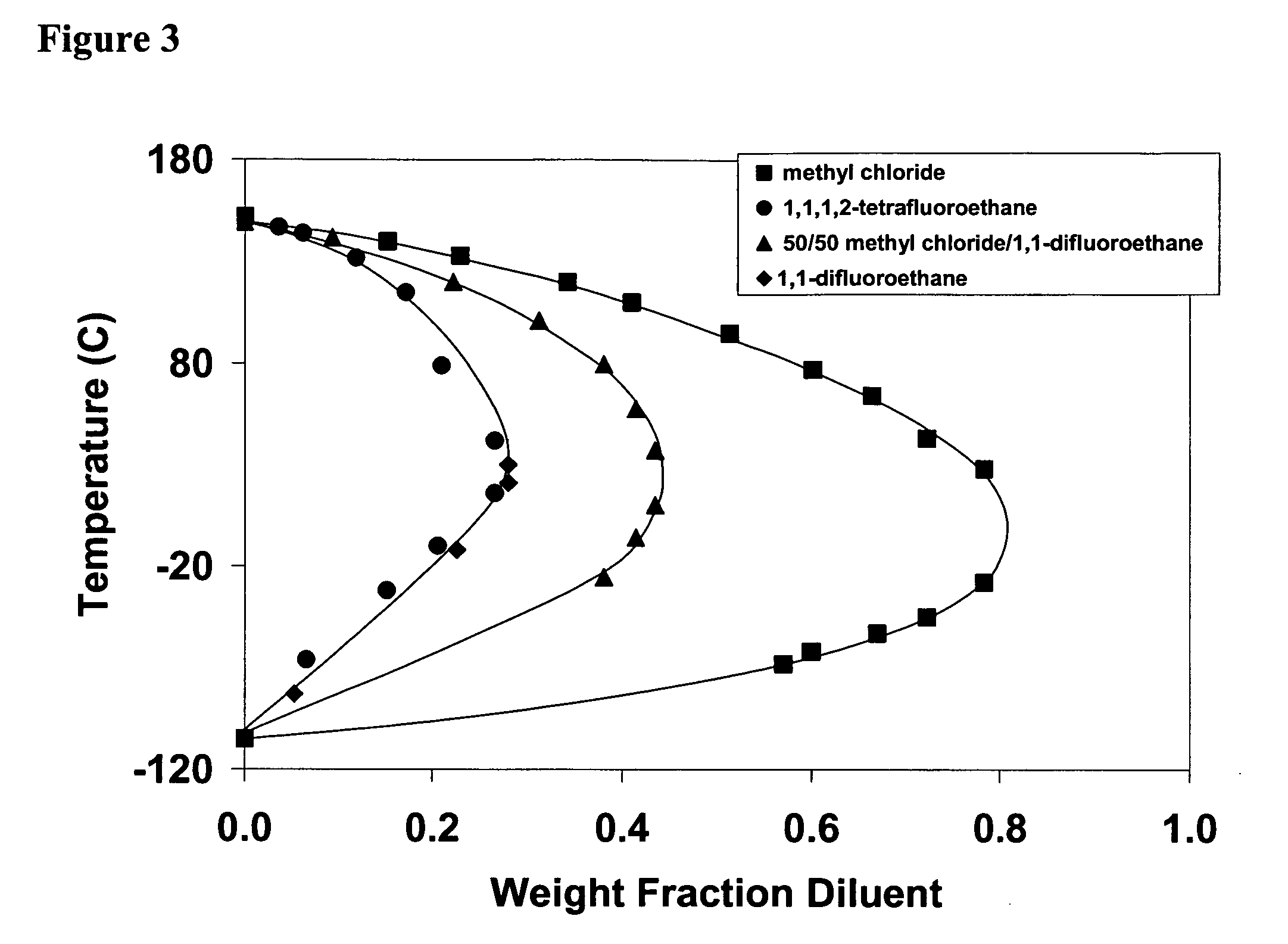

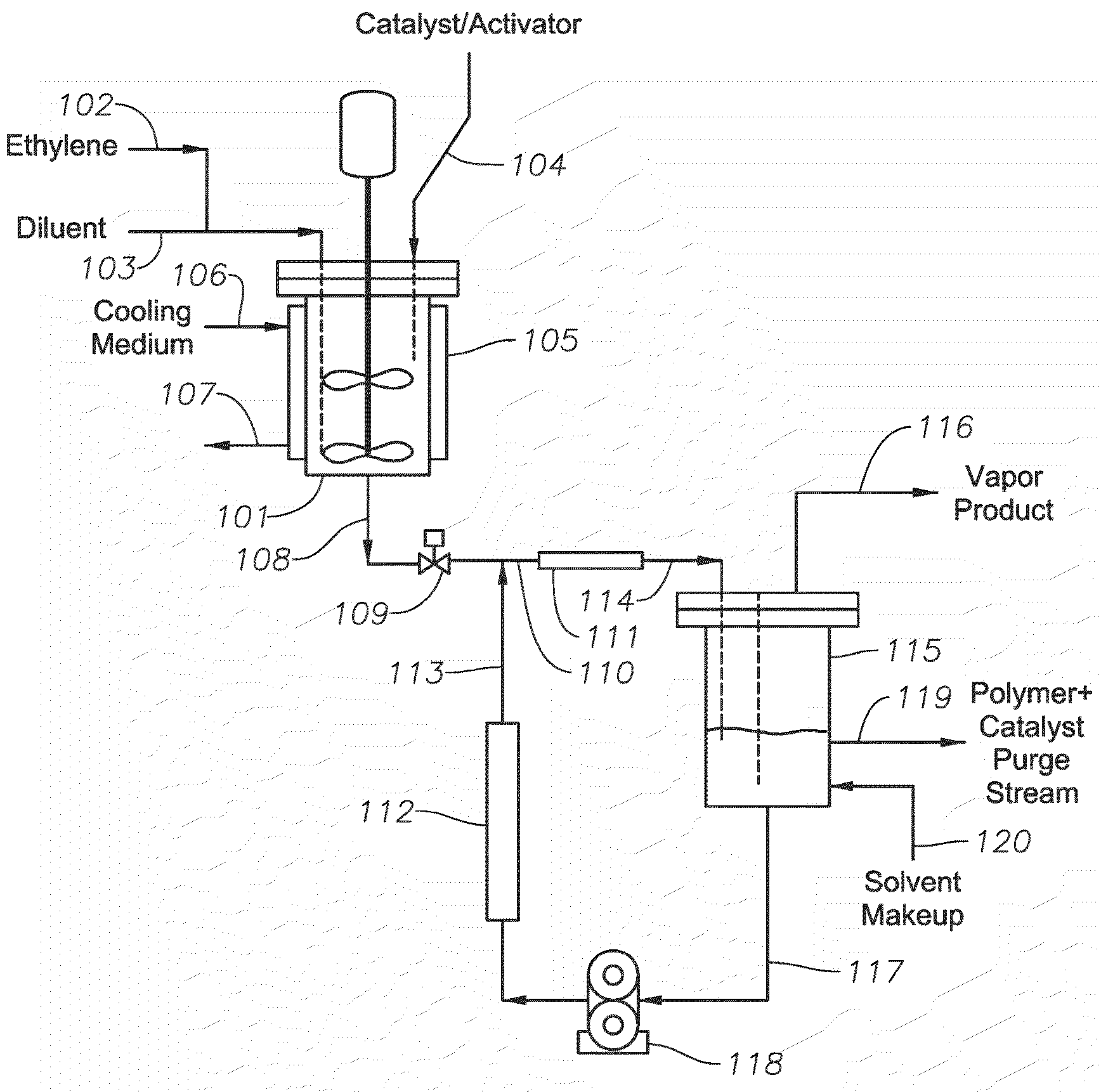

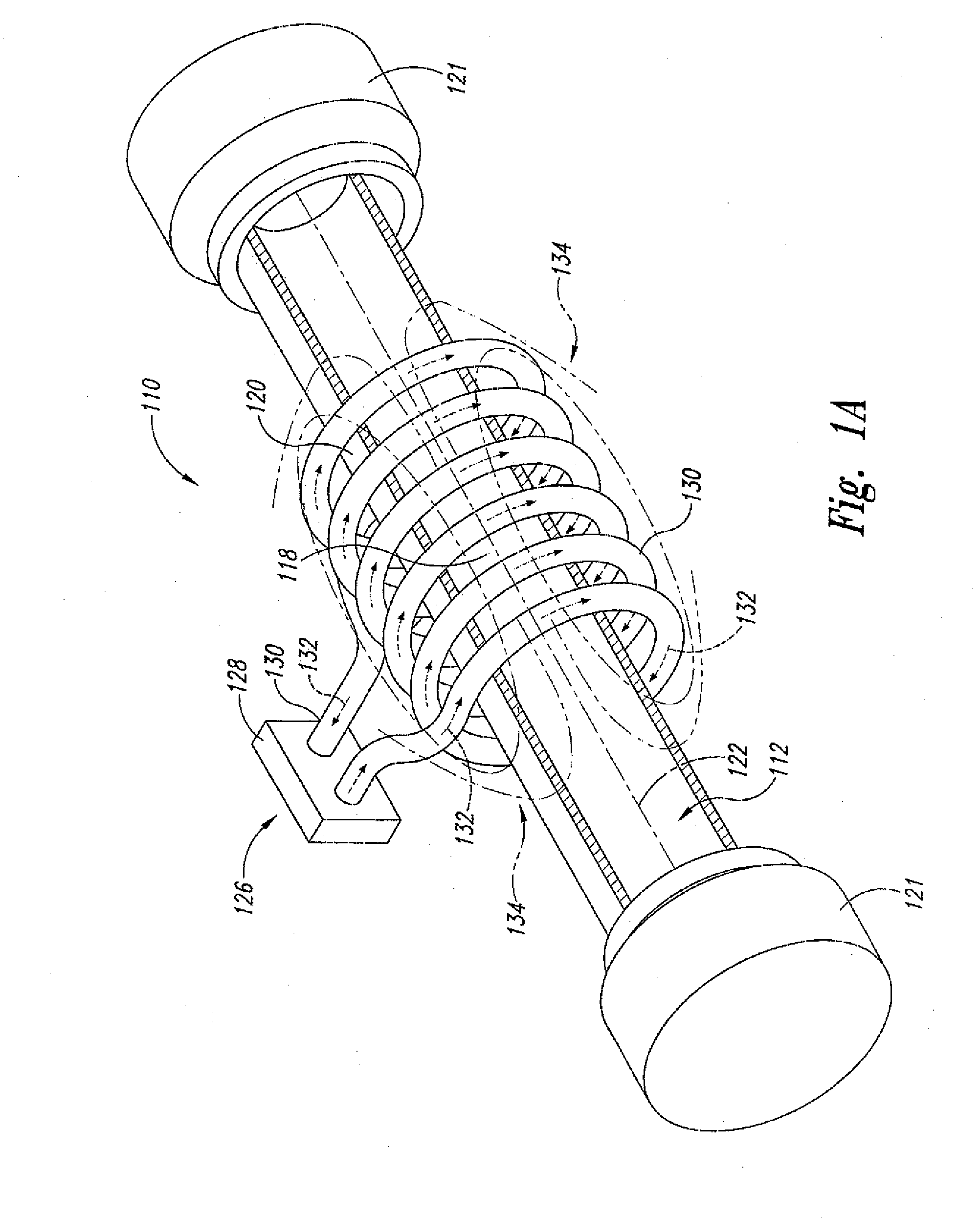

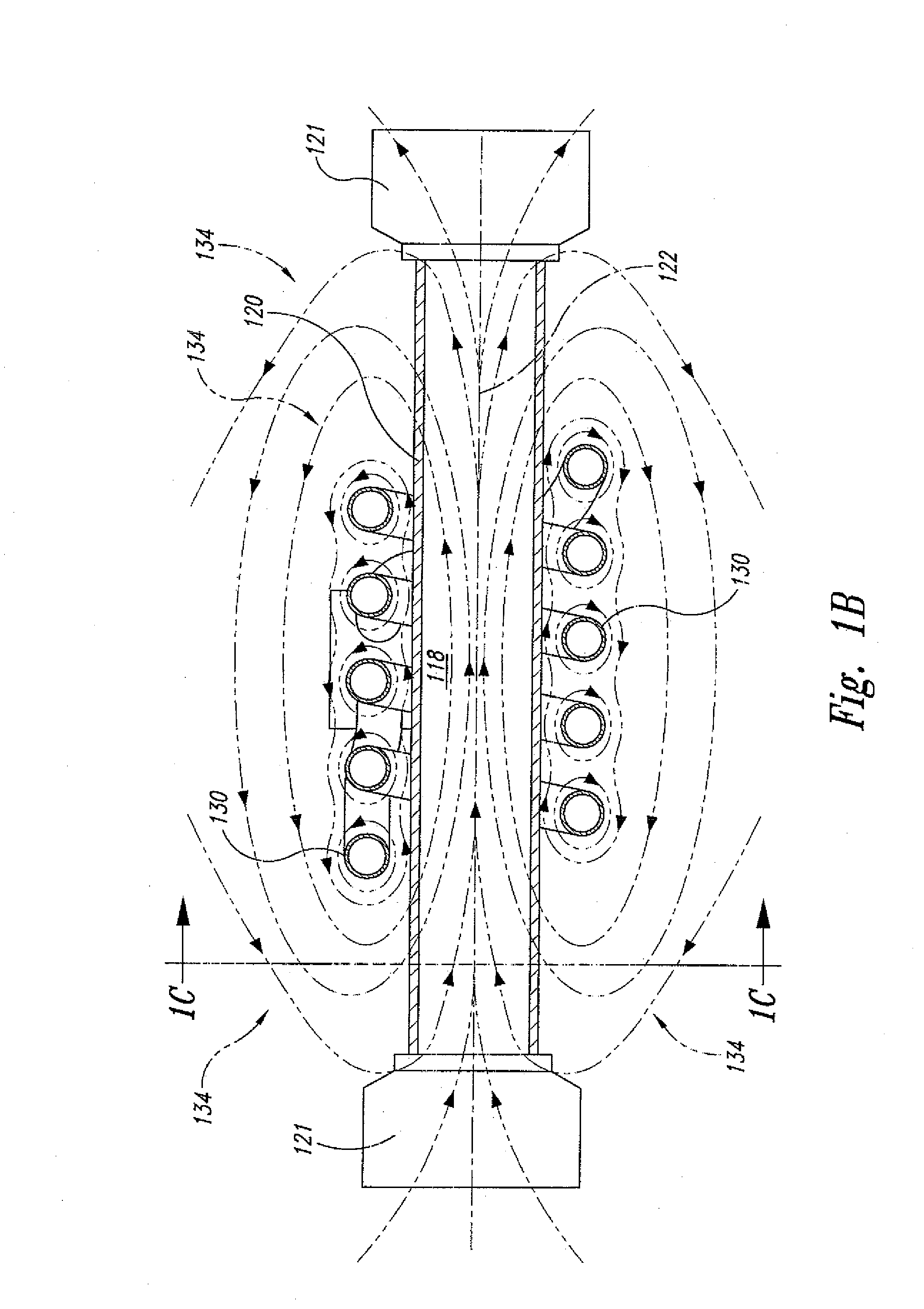

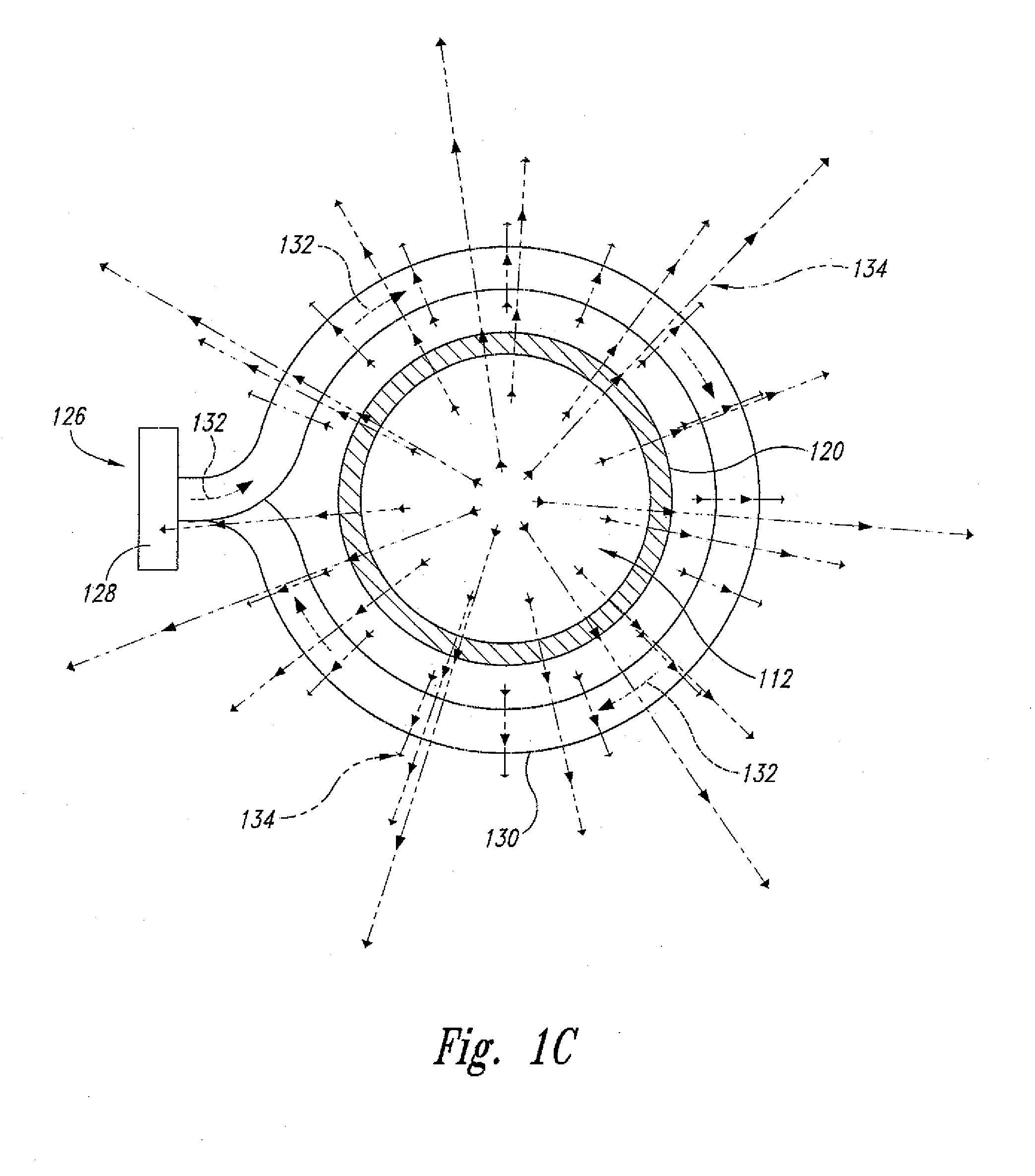

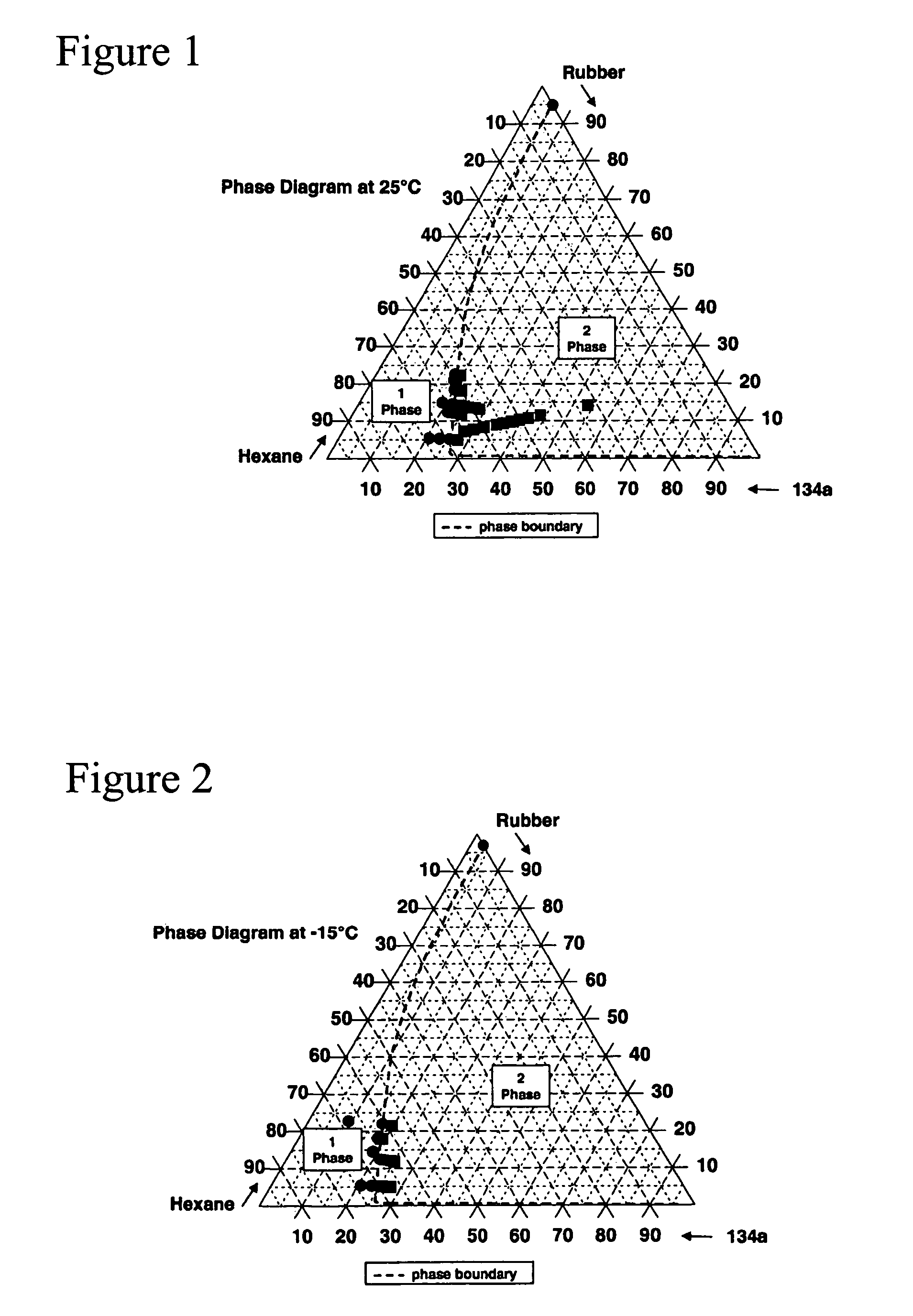

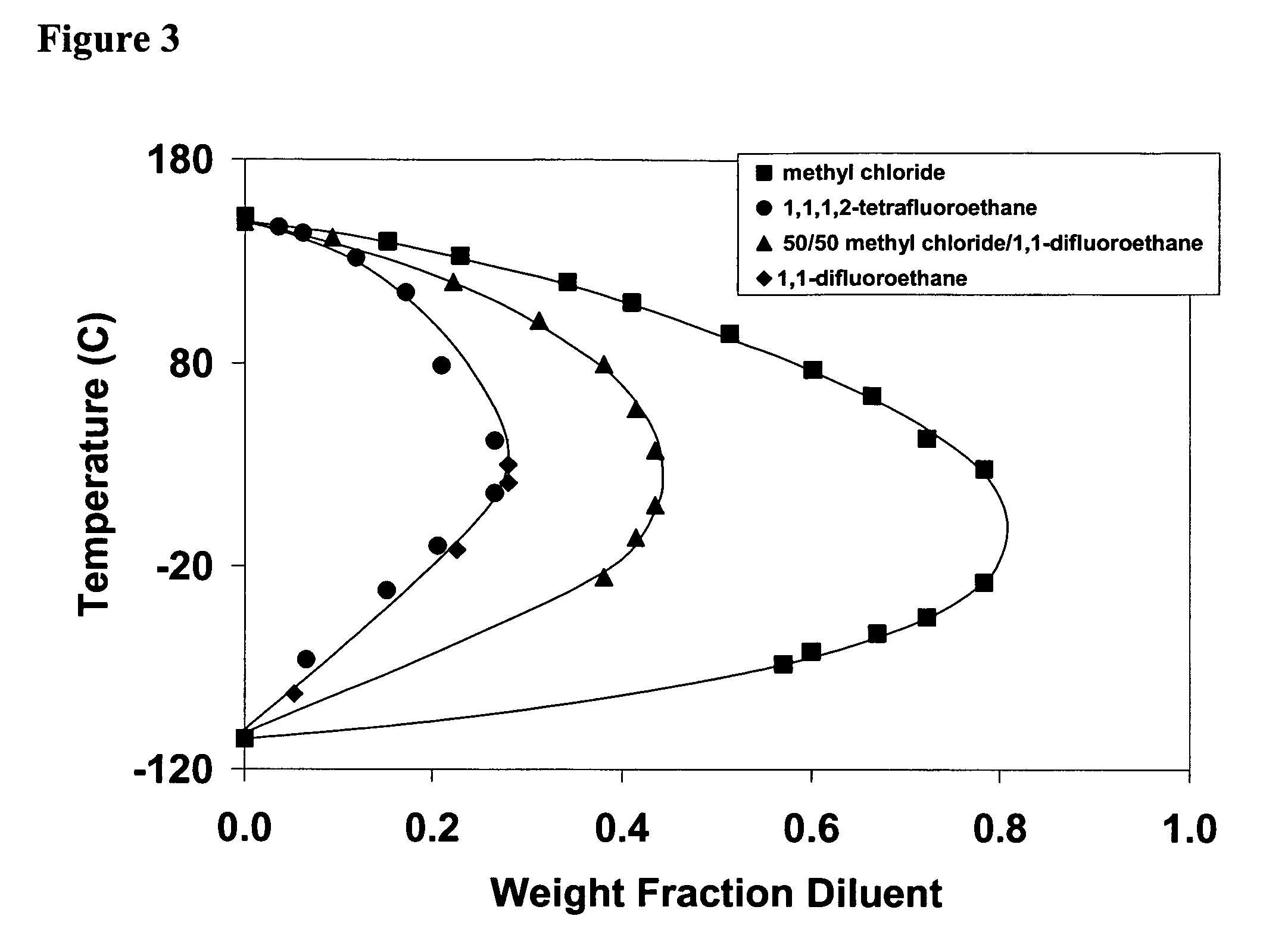

Phase separation process utilizing a hydrofluorocarbon

ActiveUS20070299161A1Easy to appreciateSpecial tyresMultistage water/sewage treatmentHydrocarbon solventsPhase separation process

Provided for herein is a process for separating a hydrocarbon-rubber from a hydrofluorocarbon diluent comprising contacting a polymer slurry comprising the hydrocarbon-rubber dispersed within the hydrofluorocarbon diluent with a hydrocarbon solvent capable of dissolving the hydrocarbon-rubber, to produce a first liquid phase and a second liquid phase, and separating the first liquid phase from the second liquid phase.

Owner:EXXONMOBIL CHEM PAT INC

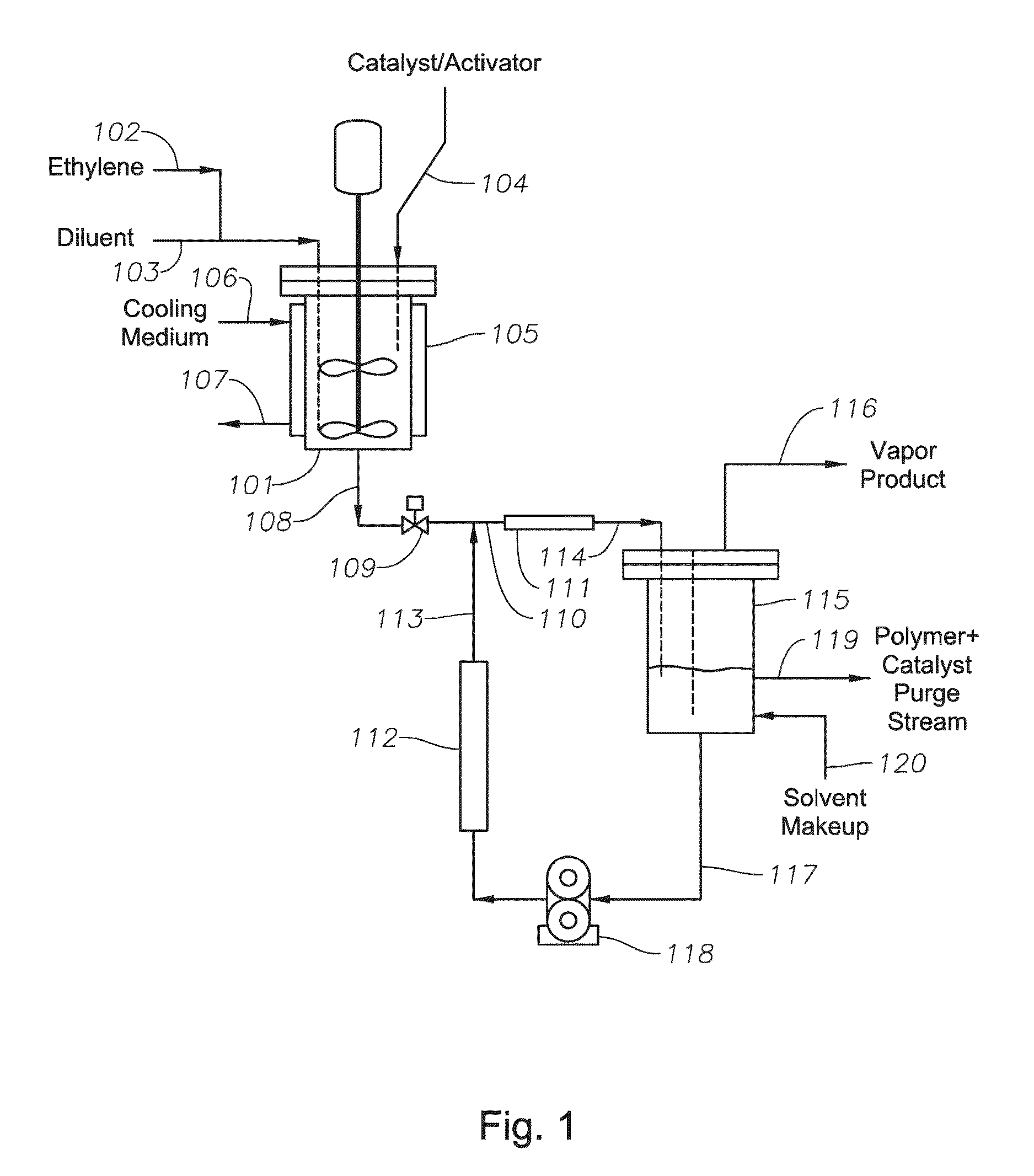

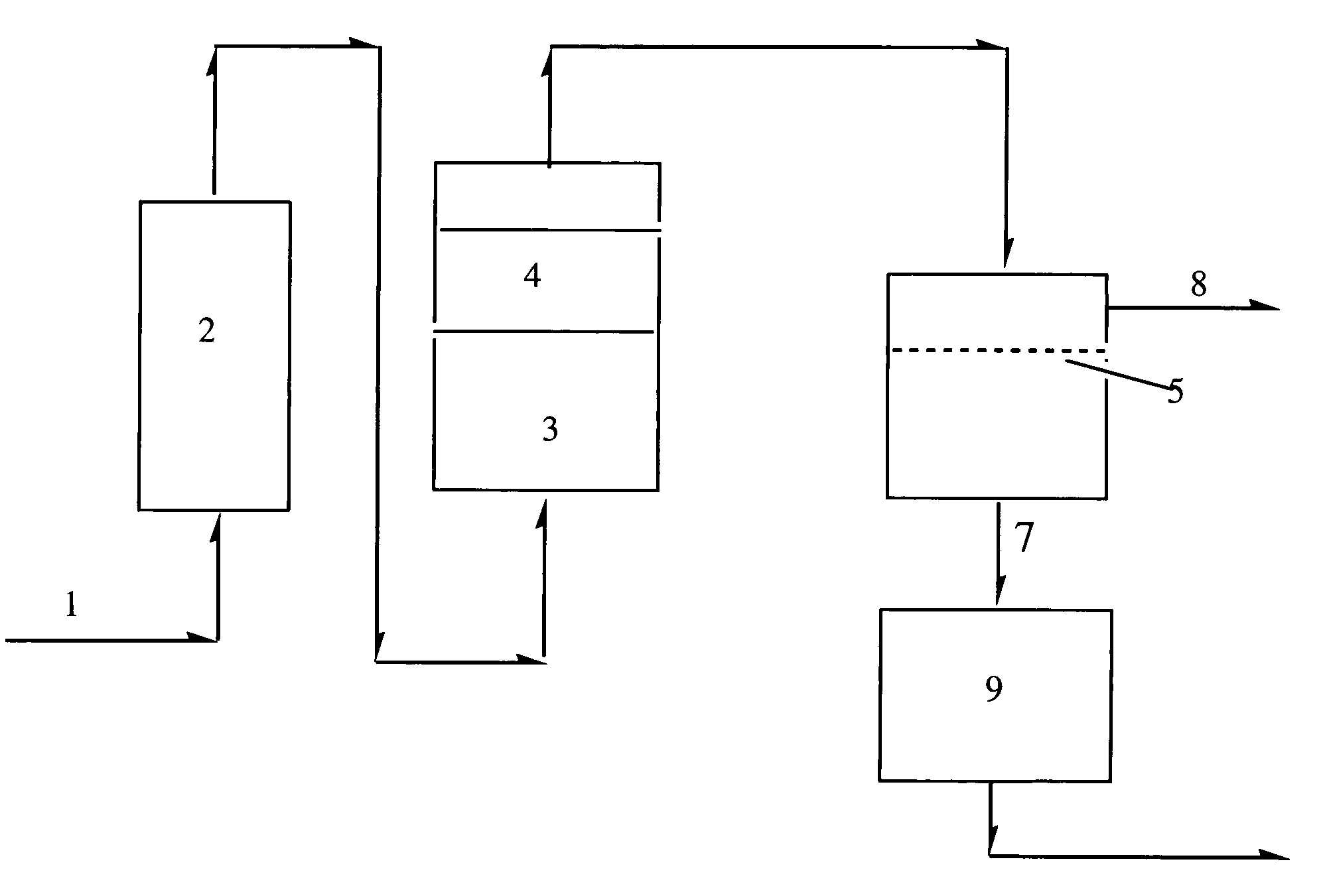

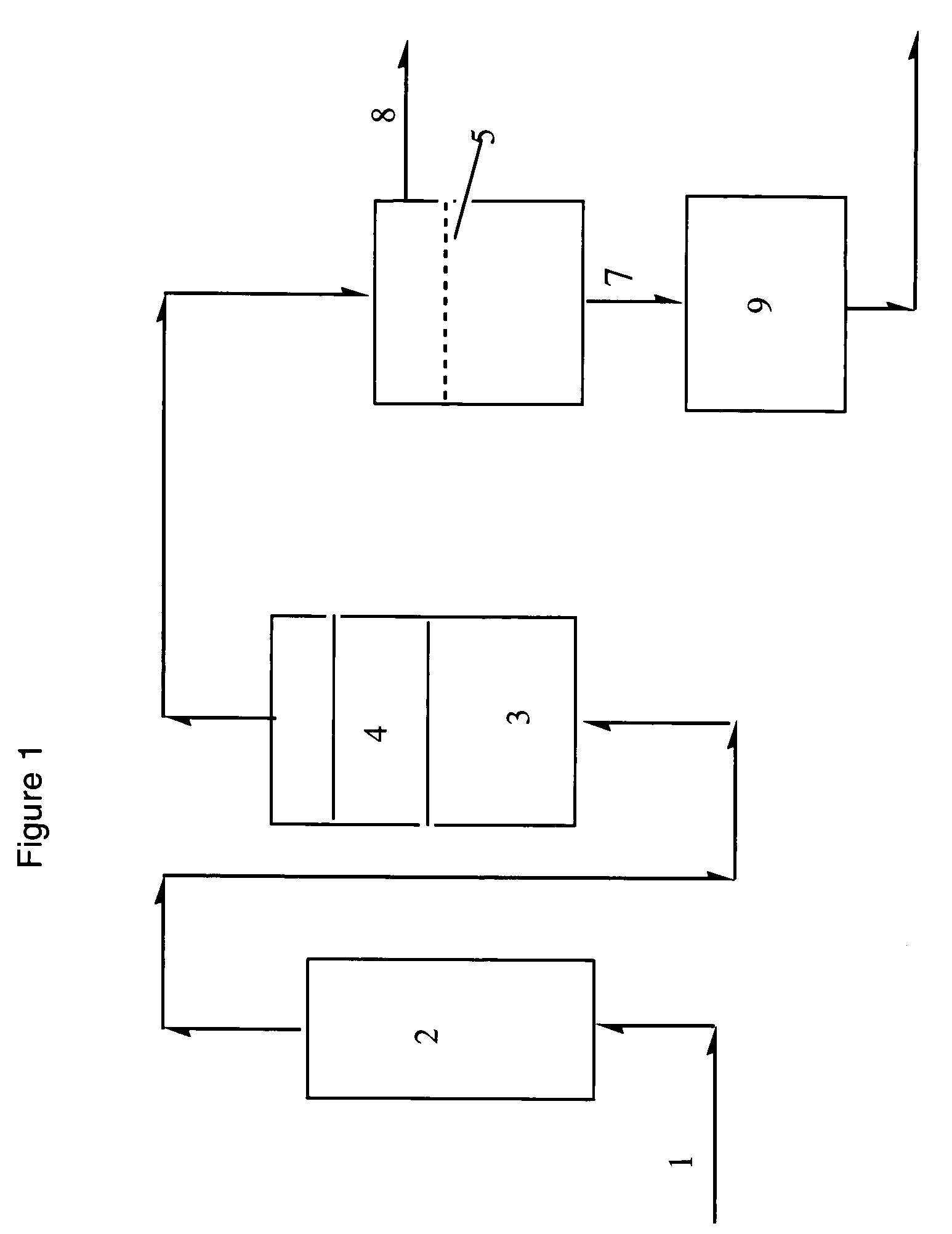

System and method for selective trimerization

ActiveUS8658750B2Distillation purification/separationMolecular sieve catalystsReactor systemDownstream processing

Disclosed herein is a method for separating from the reactor effluent of an olefin oligomerization procedure those catalyst materials and polymeric by-products which can cause difficulties in the downstream processing of such effluent. Polymer by-products and catalyst in the effluent are separated from reaction products by flash vaporization utilizing an in-situ hot solvent which is contacted with the effluent and serves as the heating medium to promote this flash vaporization step. Subsequent processing of a liquid portion of the effluent which is left after flash vaporization involves recovery of catalyst and polymeric by-products therefrom in a steam stripping vessel. Also disclosed is a multiple reactor system which can be used for continuous trimerization of ethylene to 1-hexene while at the same time washing polymeric by-products from one of the reactors in the series using a wash oil solvent.

Owner:EXXONMOBIL CHEM PAT INC

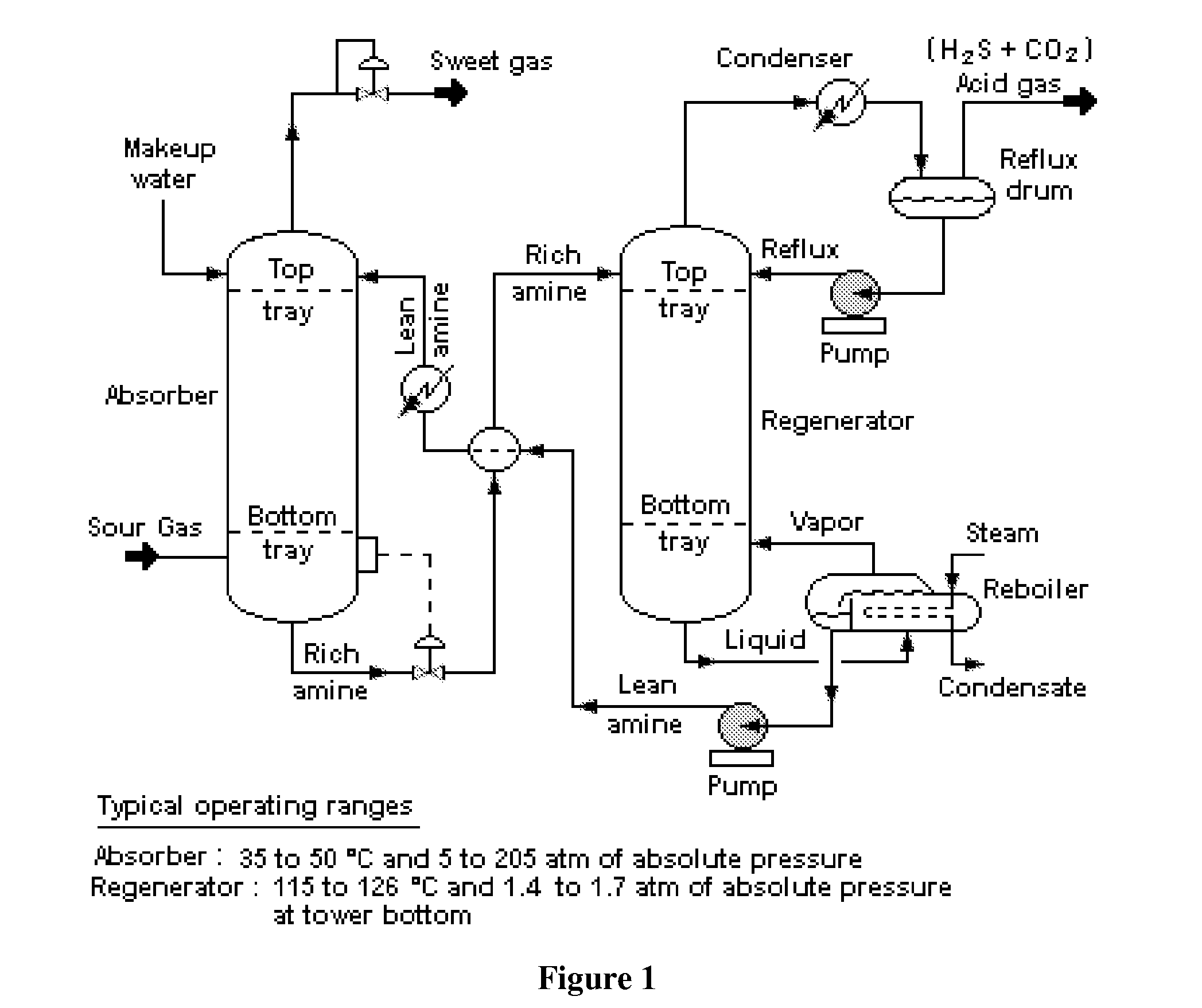

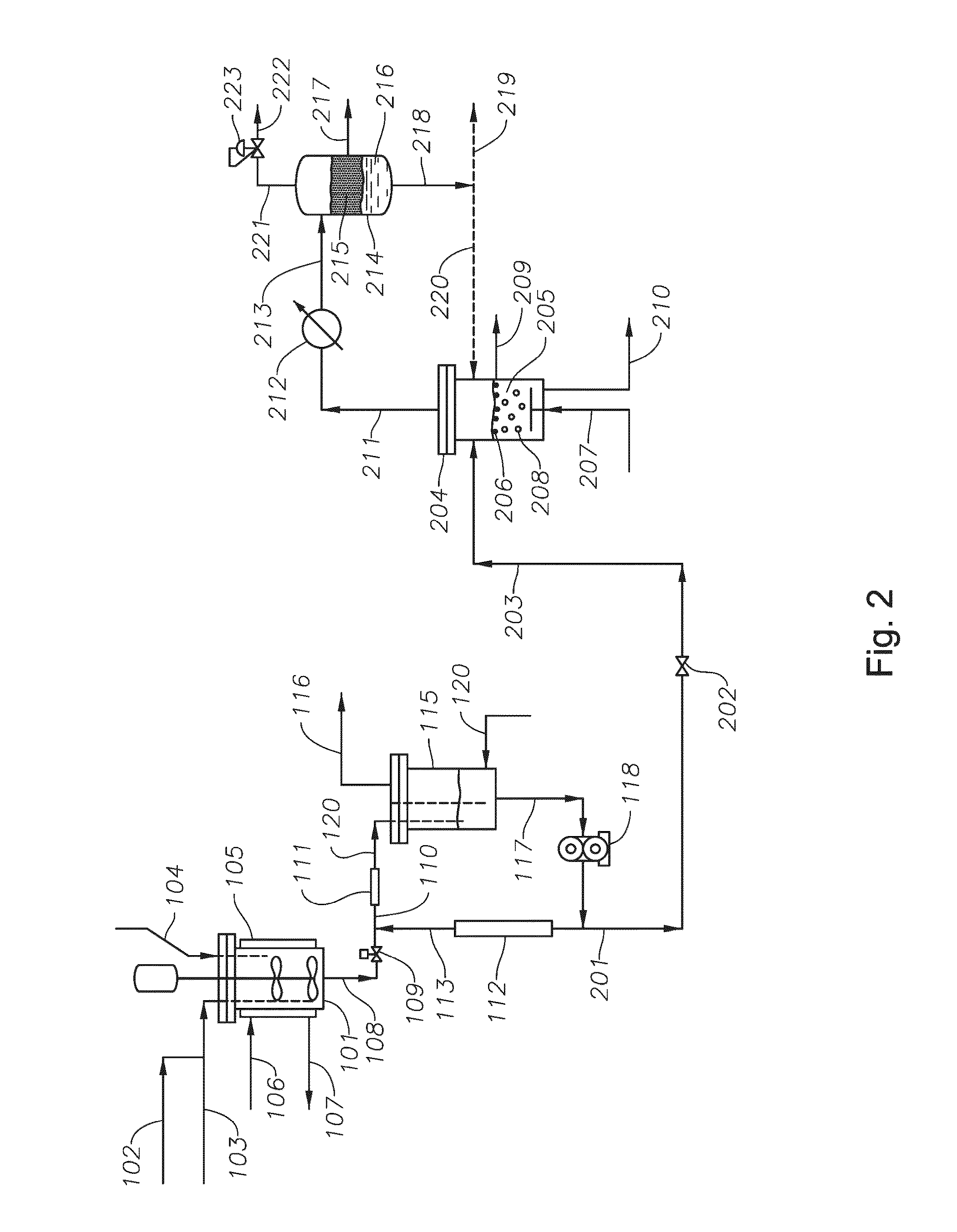

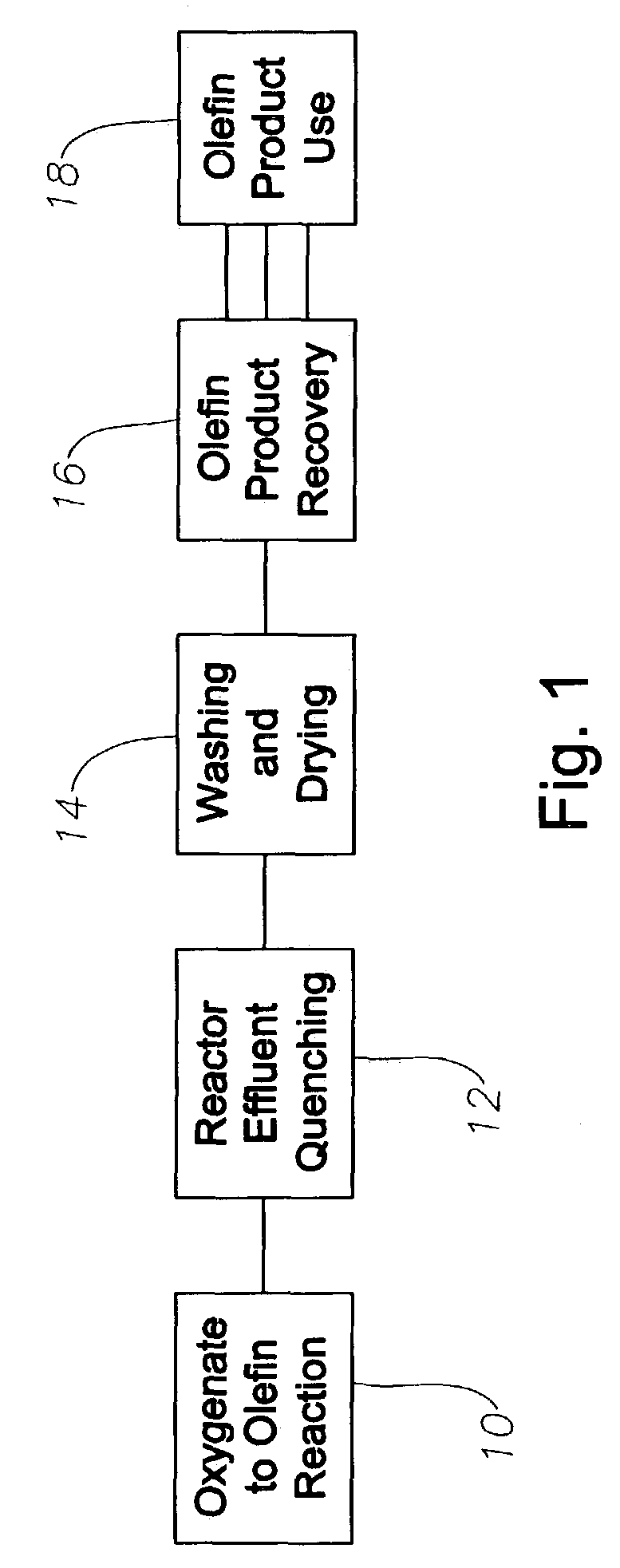

Process for separating carbon dioxide from an oxygenate-to-olefin effluent stream

InactiveUS7135604B2Conserve alkalineEfficient removalLiquid hydrocarbon mixture productionEthylene productionOxygenateAlkene

The present invention is a process for removal of carbon dioxide from a reactor effluent stream comprising water, carbon dioxide and olefin(s), where a portion of the carbon dioxide is removed in a quenching step with a quench medium and more carbon dioxide is removed by contacting the quenched effluent stream with an alkaline stream. A portion of the alkaline stream is added to the quench medium.

Owner:EXXONMOBIL CHEM PAT INC

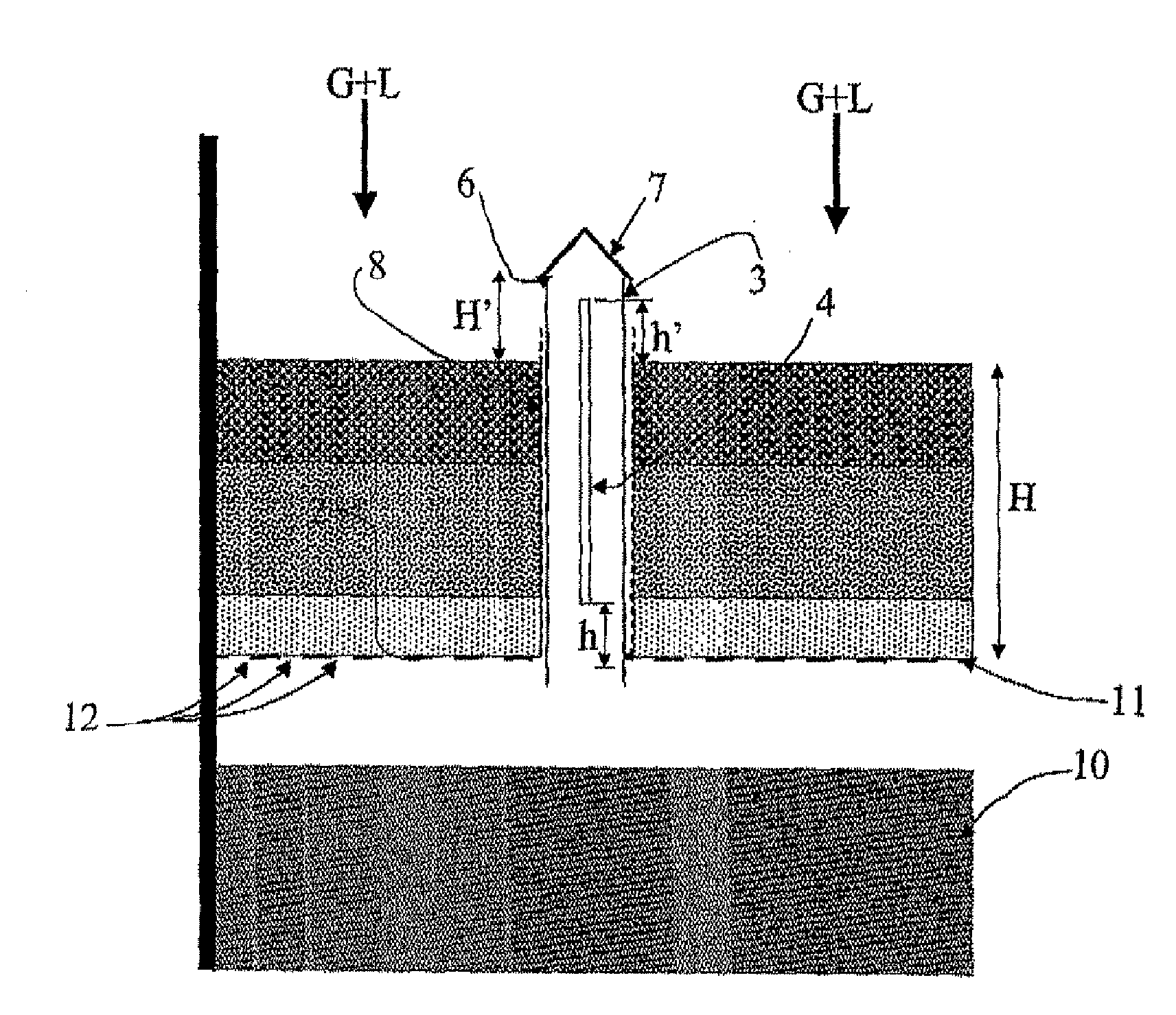

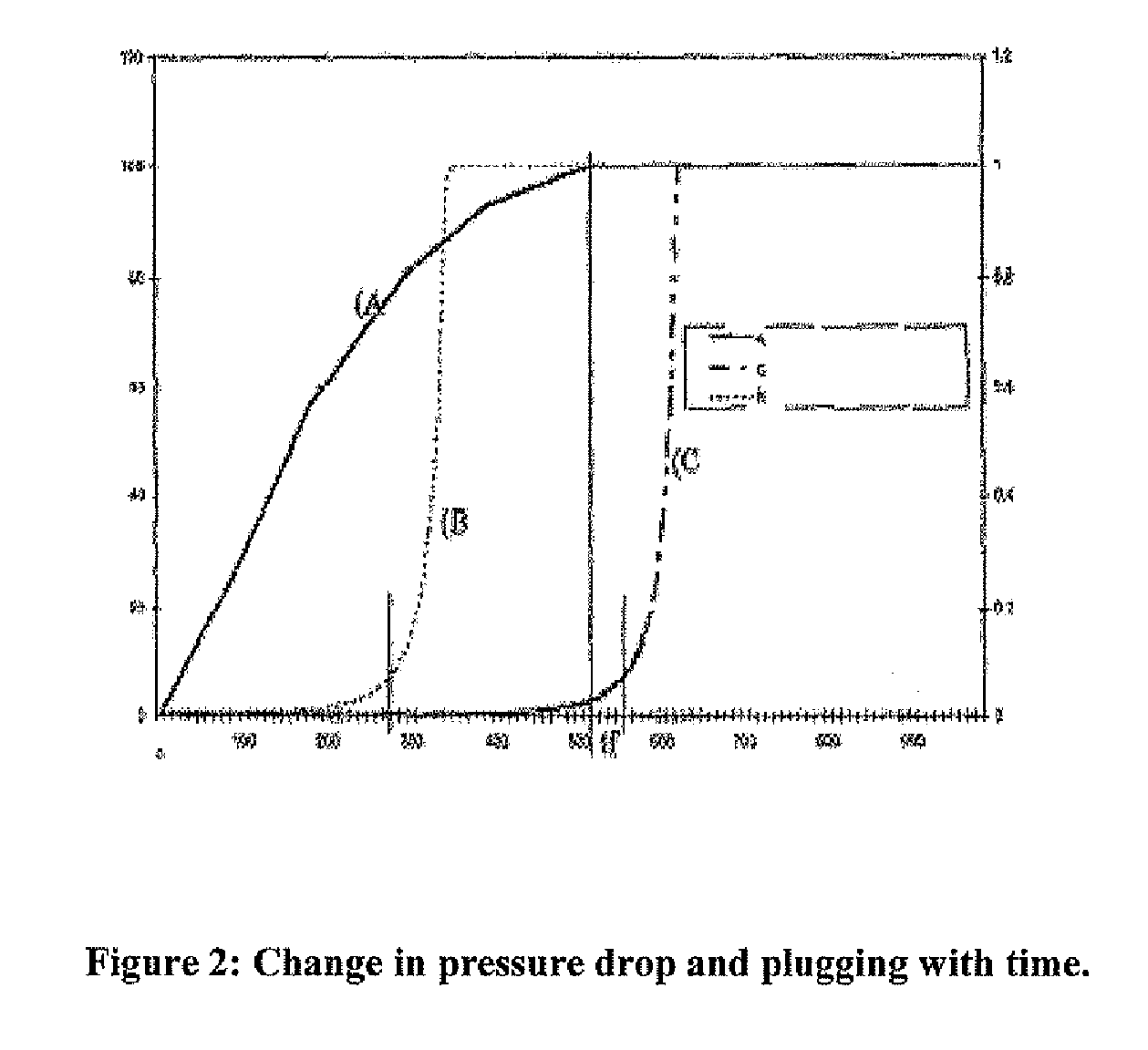

Filtration tray for fixed bed reactor with a co-current down-flow of gas and liquid

The device described in the present invention can trap plugging particles contained in the liquid feed supplying a reactor functioning in gas and liquid co-current down-flow mode using a specific distributor tray comprising a filtration medium.The present device is of particular application to the selective hydrogenation of feeds containing acetylenic and dienic compounds.

Owner:INST FR DU PETROLE

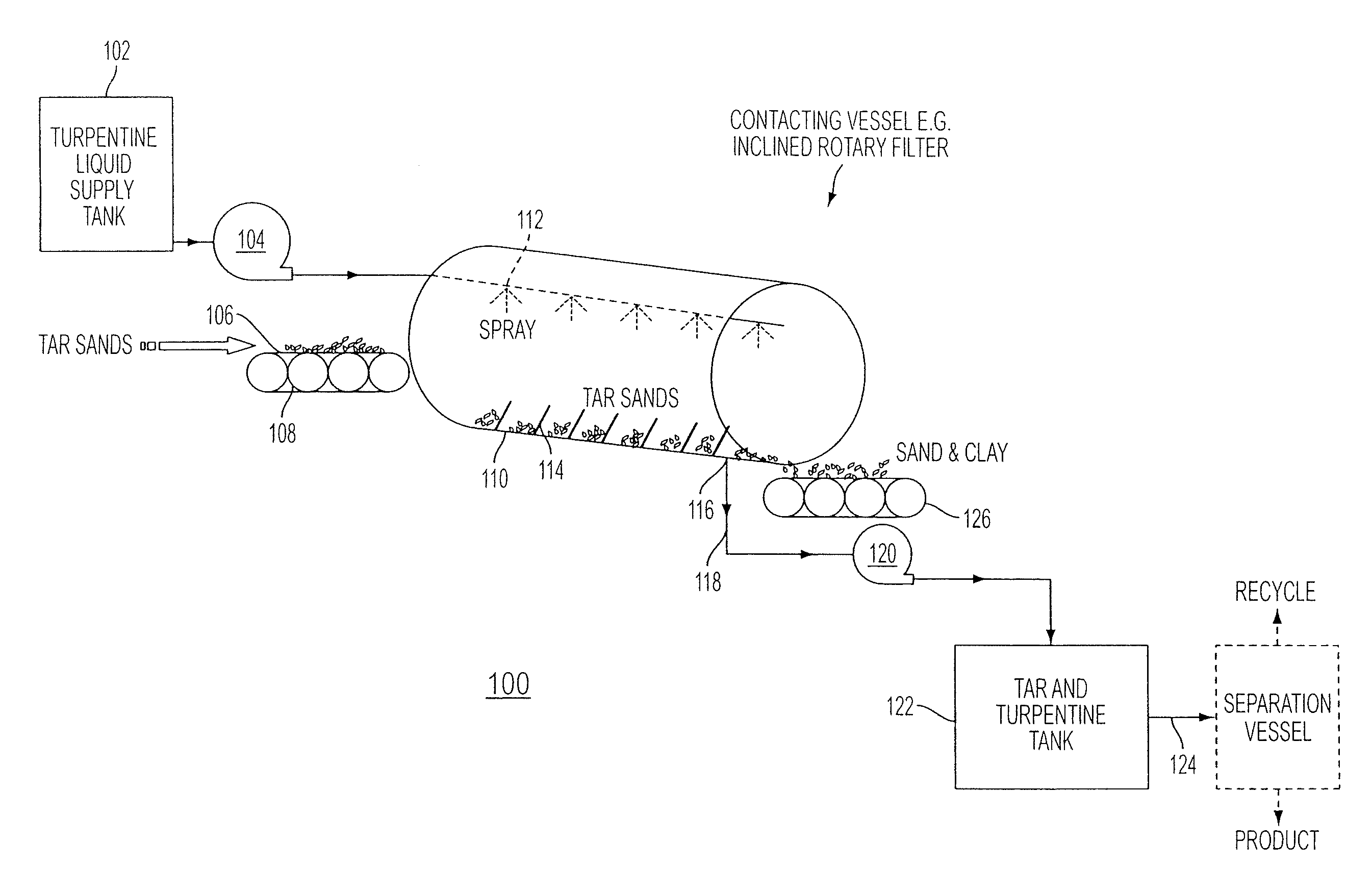

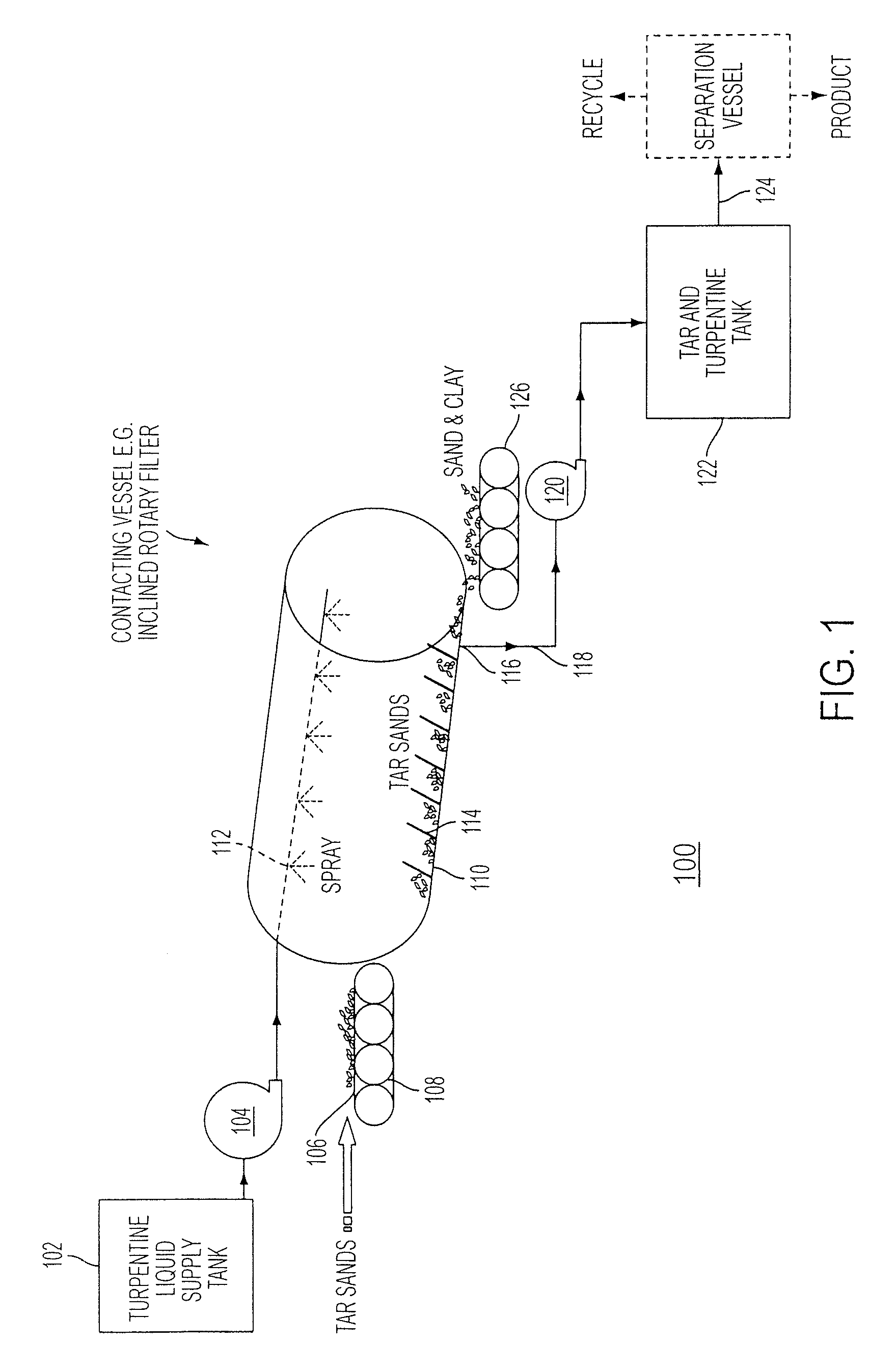

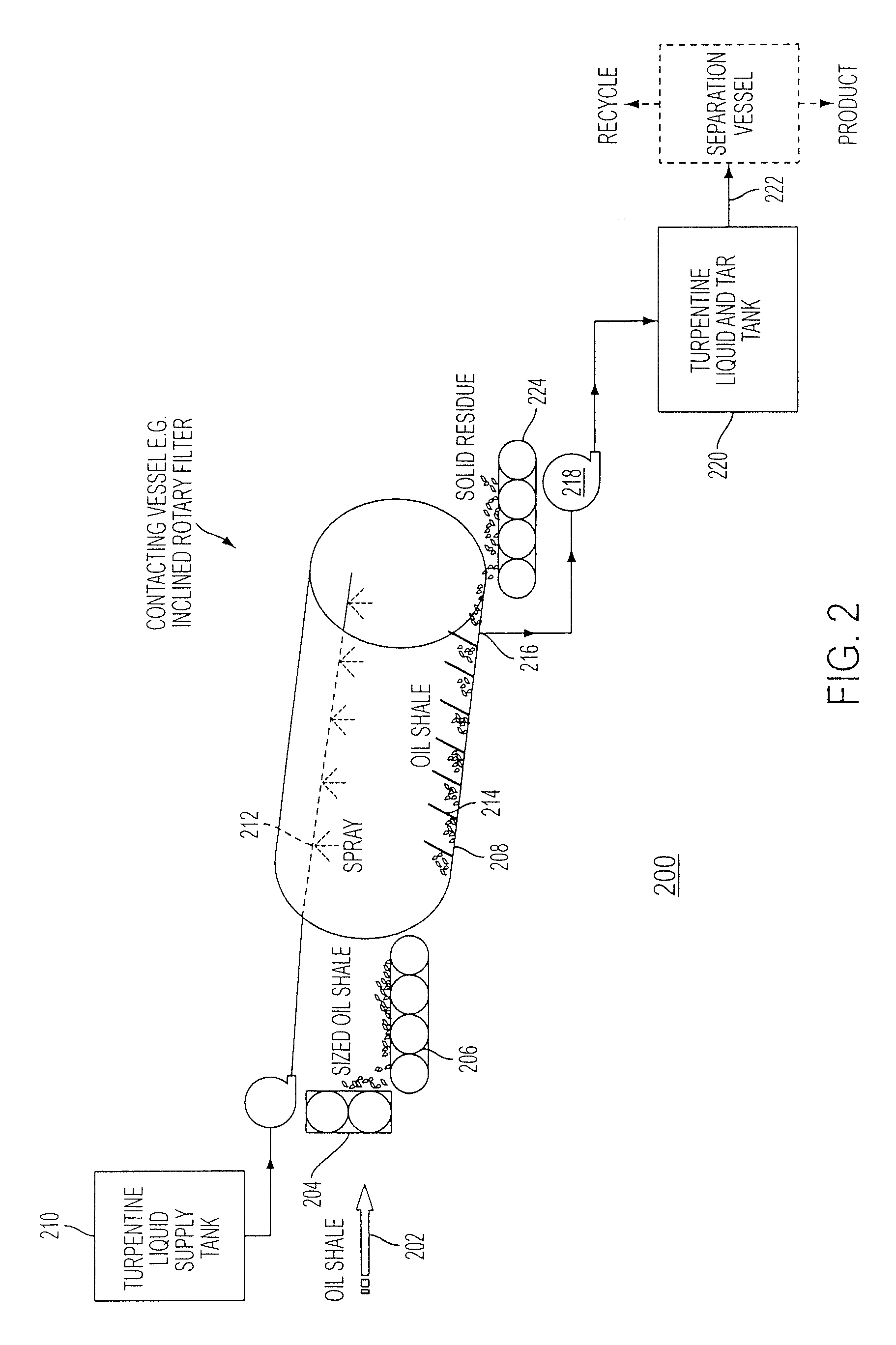

Extraction of Hydrocarbons from Hydrocarbon-Containing Materials and/or Processing of Hydrocarbon-Containing Materials

ActiveUS20090250381A1Low corrosion rateLow costFluid removalLiquid hydrocarbon mixture productionTurpentineOrganic matter

A method of extracting hydrocarbon-containing organic matter from a hydrocarbon-containing material includes the steps of providing a first liquid comprising a turpentine liquid; contacting the hydrocarbon-containing material with the turpentine liquid to form an extraction mixture; extracting the hydrocarbon material into the turpentine liquid; and separating the extracted hydrocarbon material from a residual material not extracted.

Owner:GREEN SOURCE HLDG LLC

Process for the manufacture of diesel range hydrocarbons

ActiveUS8022258B2Fatty oils/acids recovery from wasteHydrocarbon by isomerisationIsomerizationHydrocotyle bowlesioides

The invention relates to a process for the manufacture of diesel range hydrocarbons wherein a feed is hydrotreated in a hydrotreating step and isomerised in an isomerisation step, and a feed comprising fresh feed containing more than 5 wt % of free fatty acids and at least one diluting agent is hydrotreated at a reaction temperature of 200-400° C., in a hydrotreating reactor in the presence of catalyst, and the ratio of the diluting agent / fresh feed is 5-30:1.

Owner:NESTE OIL OY

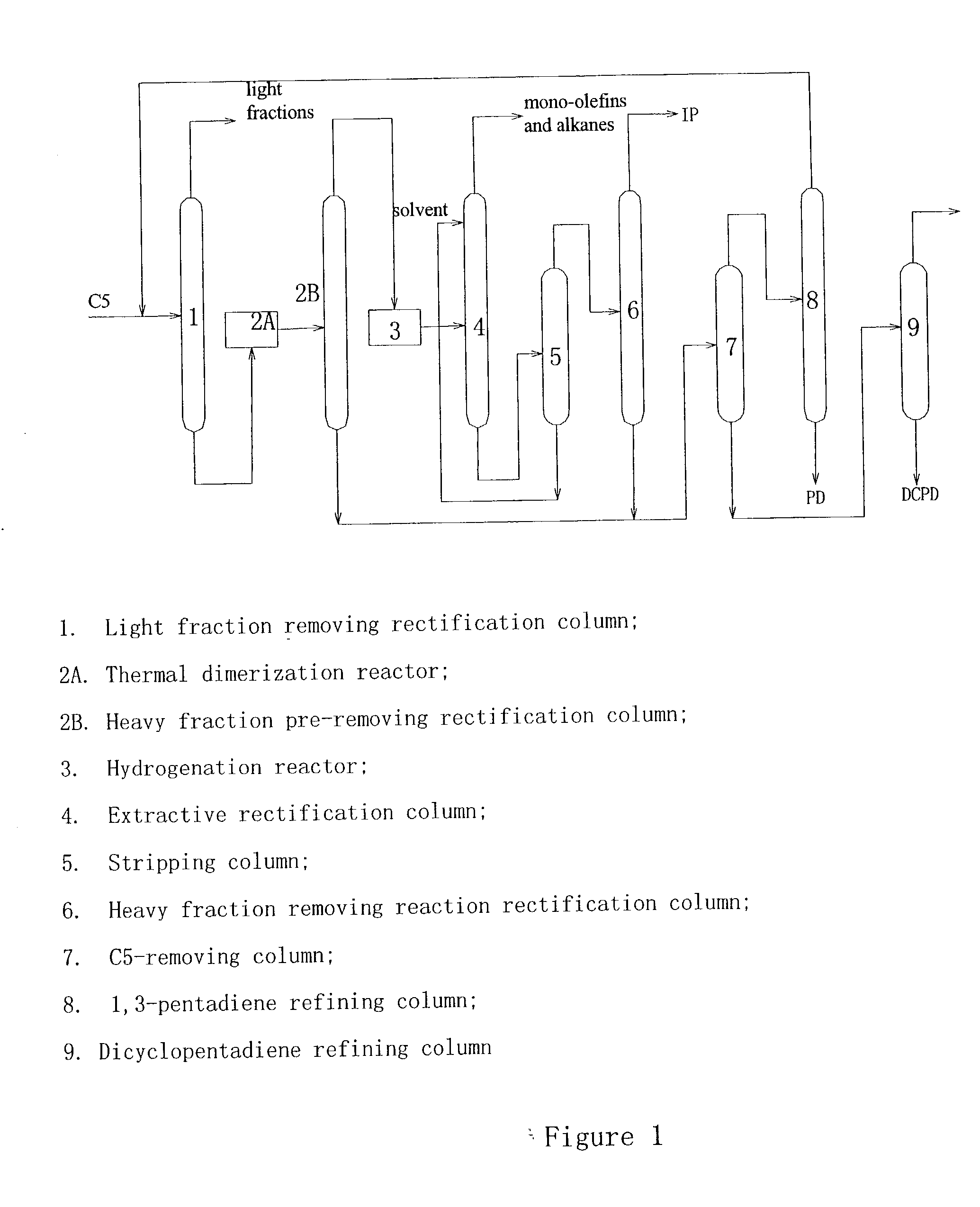

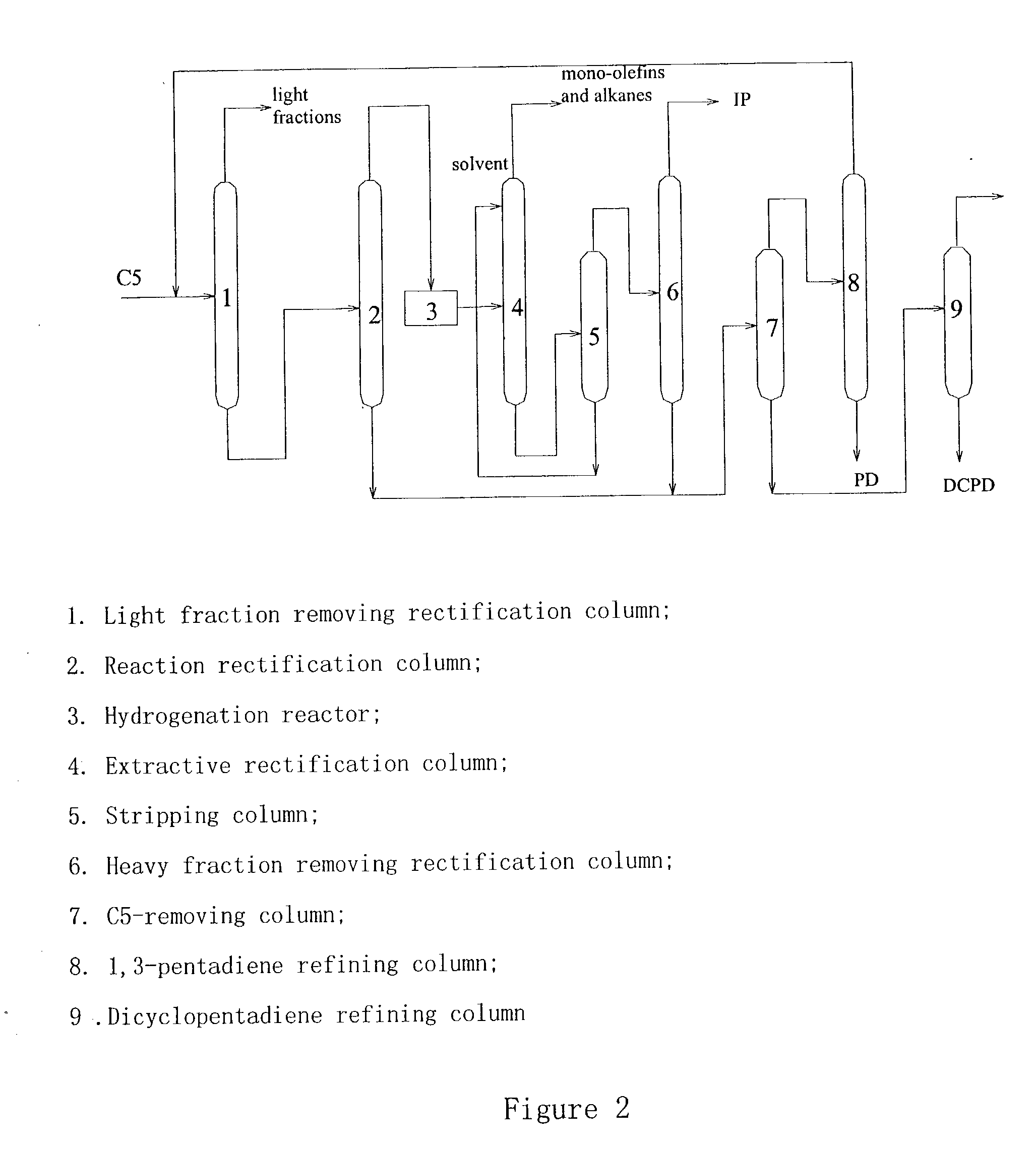

Process for separating C5 cuts obtained from a petroleum cracking process

ActiveUS20030100809A1Improve catalytic performanceHigh activityLiquid hydrocarbon mixtures productionDistillation purification/separationAlkyneSolvent

The present invention relates to a process for separating the isoprene, 1,3-pentadiene and dicyclopentadiene from a C5 cuts, comprising dimerization of the cyclopentadiene and selective catalytic hydrogenation. The second extractive rectification step can be omitted, because the alkynes are removed through selective catalytic hydrogenation prior to the extractive rectification. As a result, the solvent-recovering units can be simplified, and thus the process as a whole can be optimized. Correspondingly, the investment and energy consumption, the operation cost, and finally the production cost can be substantially reduced.

Owner:CHINA PETROCHEMICAL CORP +1

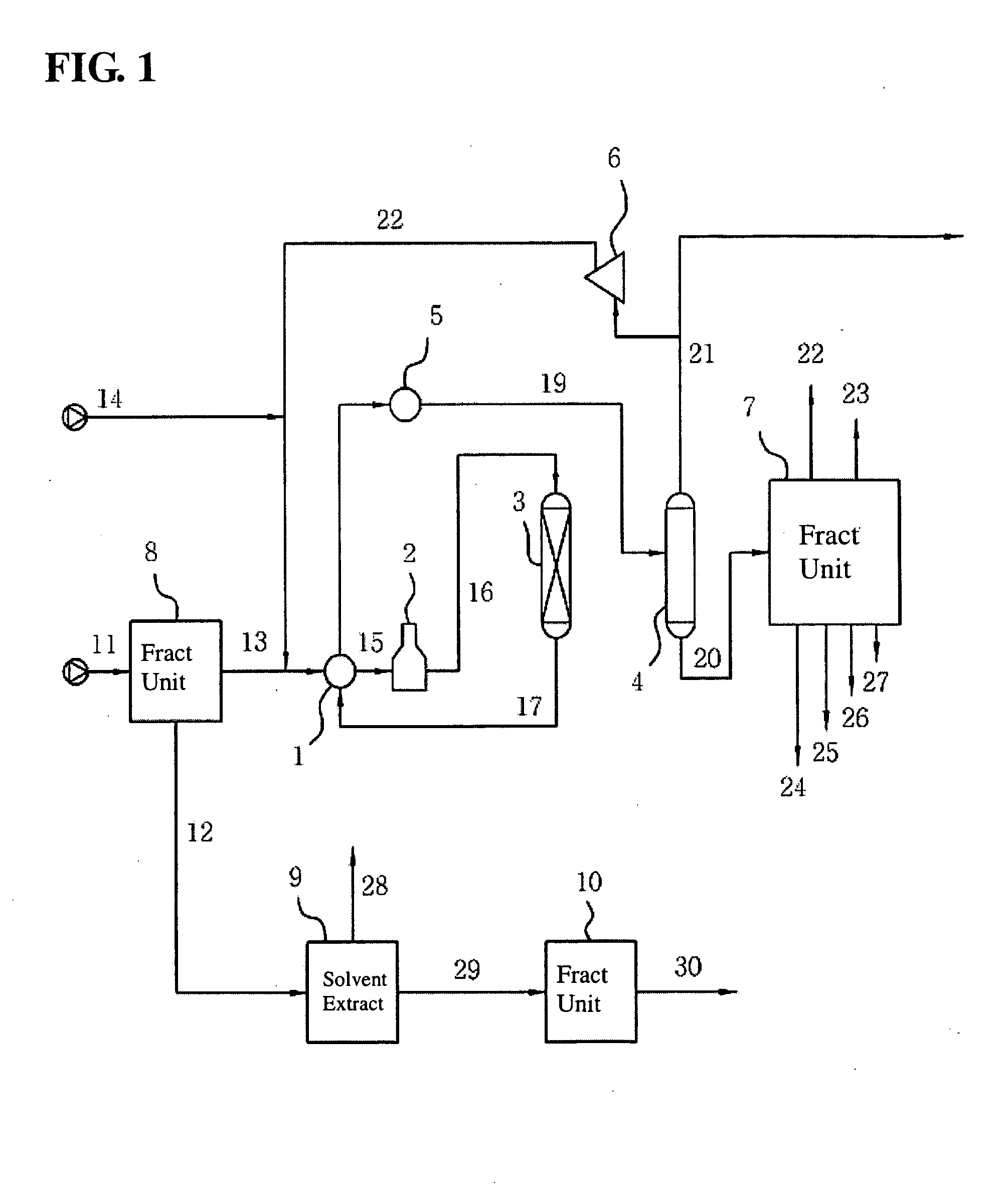

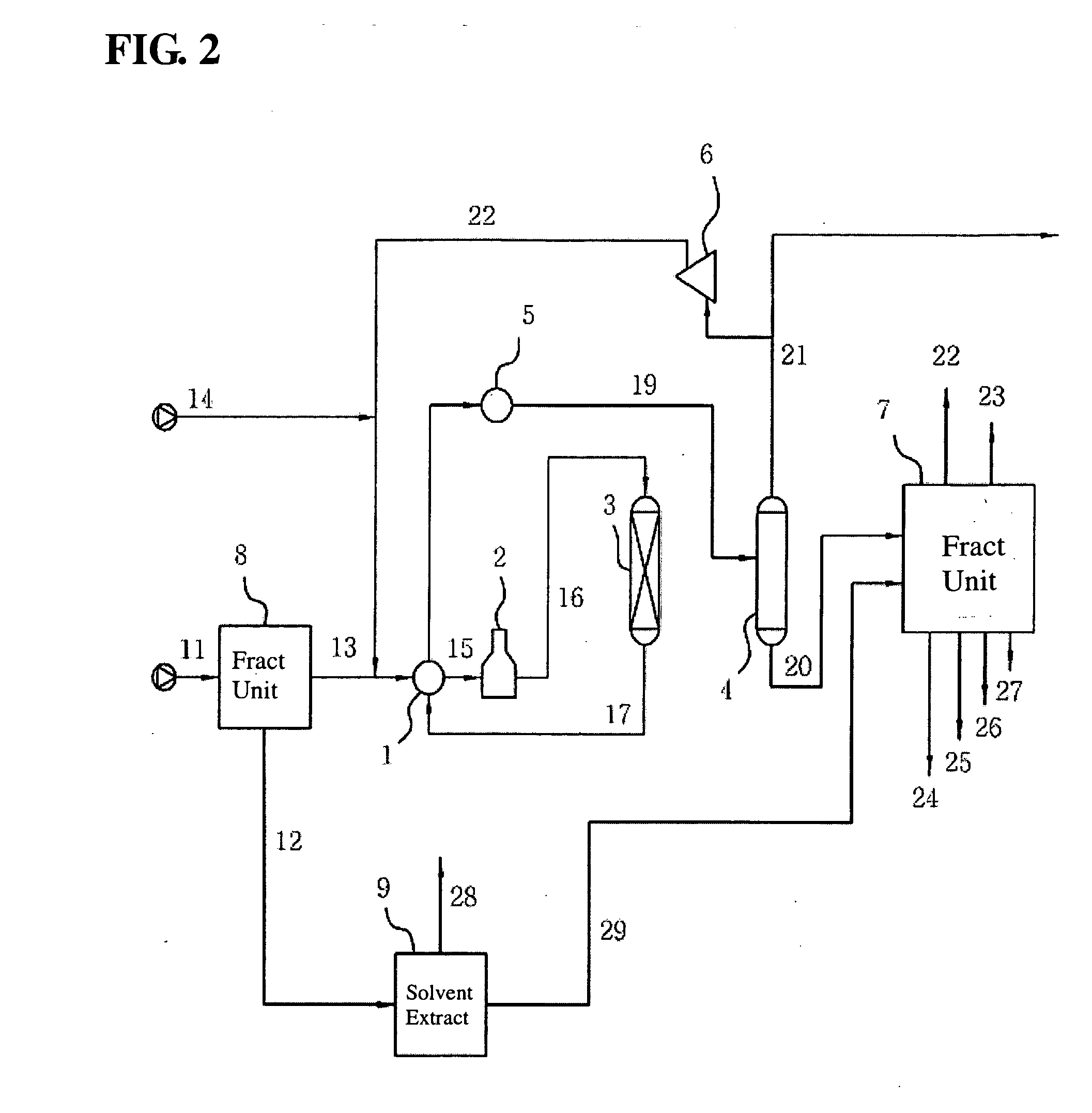

Process for increasing production of benzene from hydrocarbon mixture

ActiveUS20060287564A1Increase productivityImprove efficiencyHydrocarbon by isomerisationRefining to change hydrocarbon structural skeletonBenzeneHydrocarbon mixtures

A process for increasing the production of benzene from a hydrocarbon mixture. A process for producing an aromatic hydrocarbon mixture and liquefied petroleum gas (LPG) from a hydrocarbon mixture, and a solvent extraction process for separating and recovering polar hydrocarbons from a hydrocarbon mixture containing polar hydrocarbons (that is, aromatic hydrocarbons) and nonpolar hydrocarbons (that is, non-aromatic hydrocarbons) are integrated, thereby it is possible to increase the production of benzene.

Owner:SK INNOVATION CO LTD

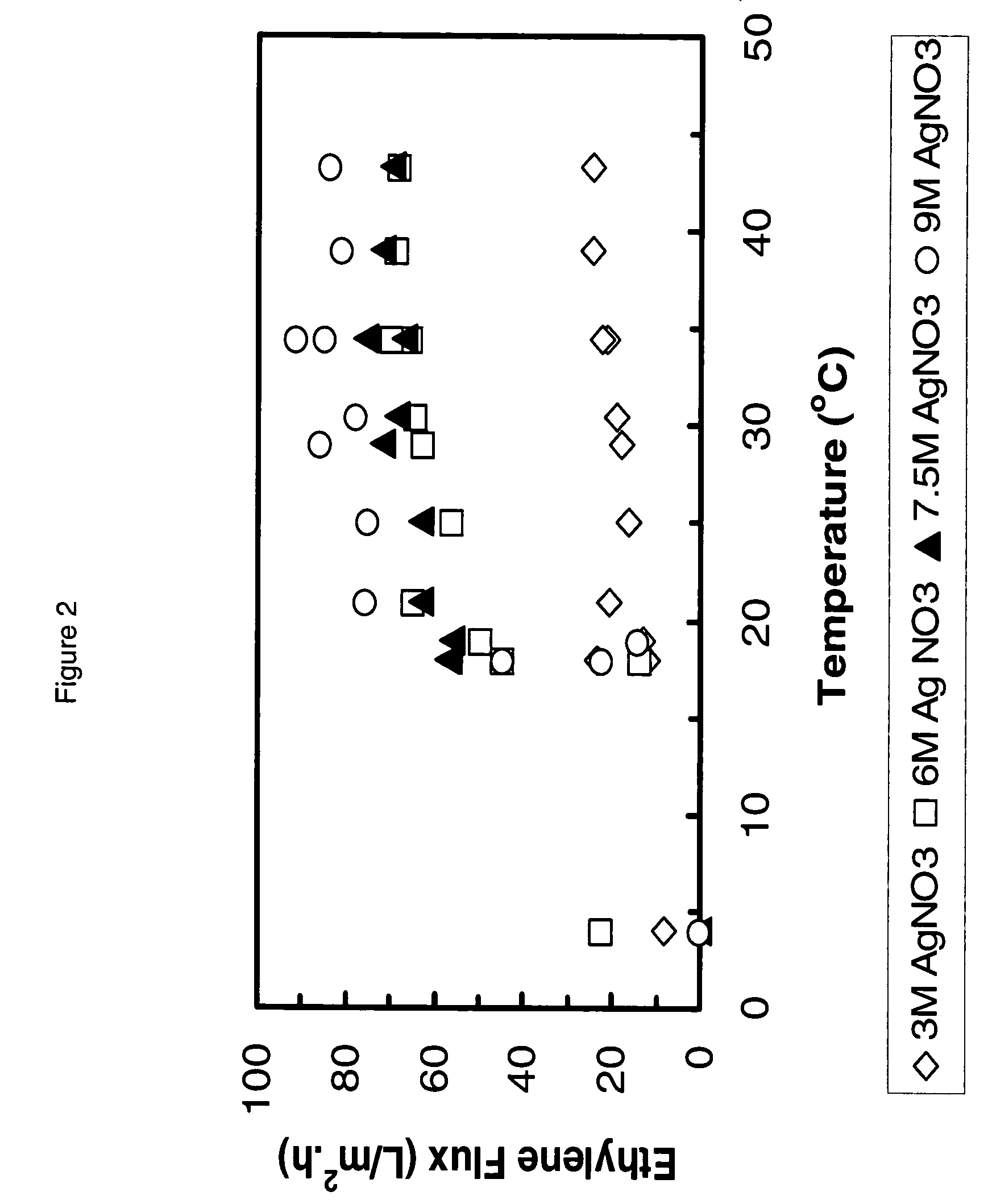

Process for the separation of olefins from paraffins using membranes

Chitosan membranes chelated with silver or cuprous material may be used to separate olefins from a mixture of olefins and paraffins. The feed stream is humidified, demisted, treated to remove sulfur compounds and passed to a cell having a chitosan membrane containing chelated silver or cuprous compounds. The process has a reasonable flux rate and is operable at reasonable temperatures and pressures. The process could be used in an olefin separation train.

Owner:IMTEX MEMBRANES CORP

Integrated apparatus for aromatics production

Enabling a transalkylation process to handle both C10 alkylaromatics and unextracted toluene permits the following improvements to be realized. No longer extracting toluene allows a reformate-splitter column to be eliminated. The extraction unit can be moved to the overhead of a benzene column and integrated together with the transalkylation unit to reduce costs. No longer requiring a rigorous split between C9 and C10 alkylaromatics allows a heavy aromatics column to be eliminated. Such an enabled transalkylation process requires stabilization of a transalkylation catalyst through the introduction of a metal function. These improvements result in an aromatics complex apparatus with savings on inside battery limits curve costs and an improvement on the return on investment in such a complex.

Owner:UOP LLC

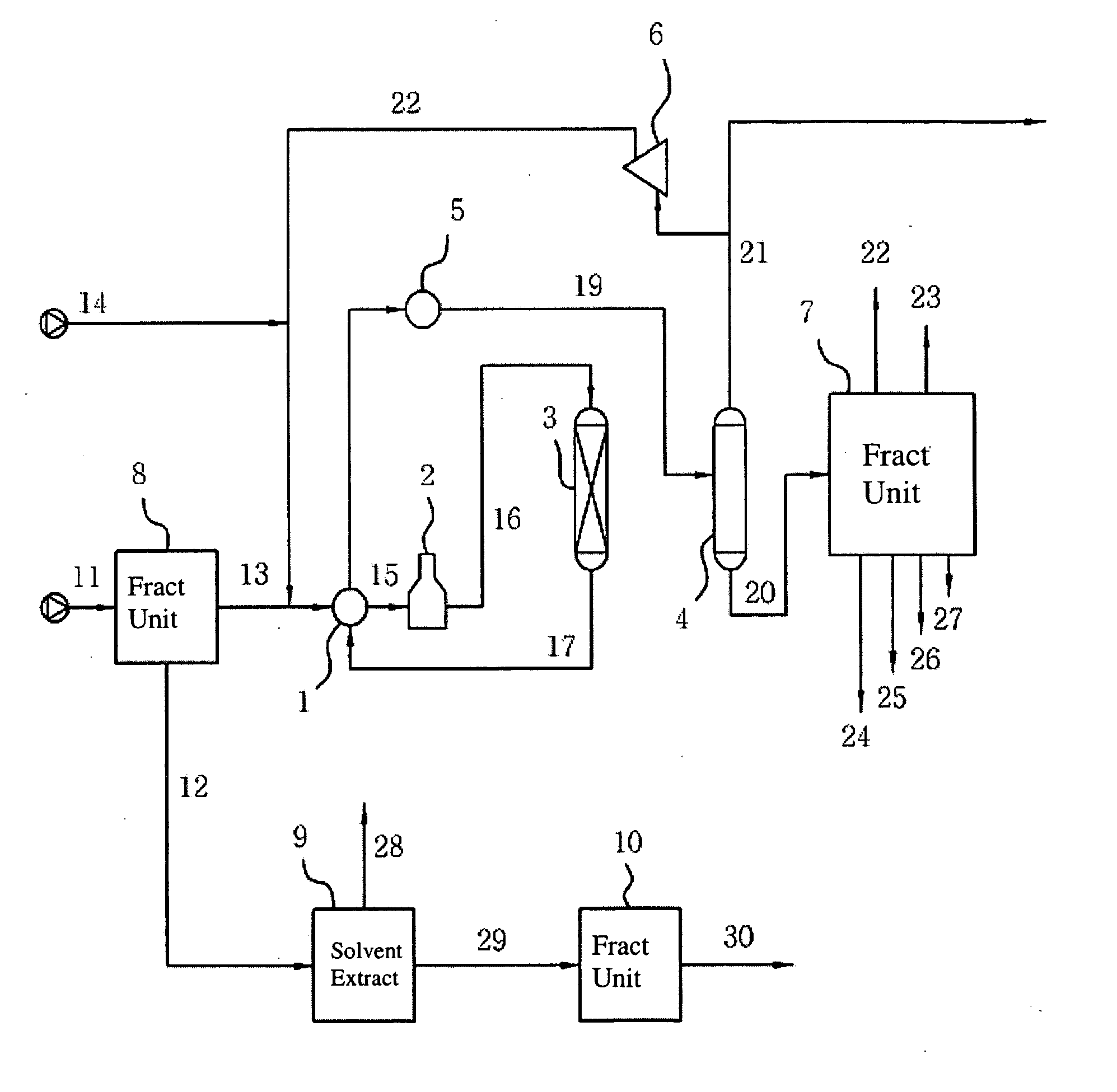

Biomass and waste plastics to neodiesel and valuable chemicals via supercritical water

ActiveUS20100329938A1Enhances the rapid cleavage and depolymerizationSolvent extractionLiquid displacementDepolymerizationChemical reaction

A supercritical fluid polymer depolymerization machine is disclosed herein, which machine is capable of converting a wide range of biomass and / or waste plastic materials into a plurality of reaction products (liquid and gaseous) including fermentable sugars, hydrocarbons, and various aromatic substances that, in turn, are readily convertible into liquid transportation fuel known as “neodiesel.” In one embodiment, a supercritical fluid reaction apparatus for transforming a selected polymeric material flowstream into a plurality of reaction products is disclosed and comprises, in fluidic series: an extruder; a supercritical fluid reaction zone fluidicly connected to the extruder, the supercritical fluid reaction zone being proximate to a circumferentially positioned heater, with the heater being configured to transfer heat to the selected polymeric material flowstream admixed together with water to supercritical conditions to thereby facilitate chemical reaction; and a reaction products separation chamber fluidicly connected to the supercritical fluid reaction zone.

Owner:XTRUDX TECH

Phase separation process utilizing a hydrofluorocarbon

ActiveUS7629397B2Easy to appreciateSpecial tyresMultistage water/sewage treatmentHydrocarbon solventsPhase separation process

Provided for herein is a process for separating a hydrocarbon-rubber from a hydrofluorocarbon diluent comprising contacting a polymer slurry comprising the hydrocarbon-rubber dispersed within the hydrofluorocarbon diluent with a hydrocarbon solvent capable of dissolving the hydrocarbon-rubber, to produce a first liquid phase and a second liquid phase, and separating the first liquid phase from the second liquid phase.

Owner:EXXONMOBIL CHEM PAT INC

Method for fast extracting lycopene

InactiveCN101121631AReduce processing timeReduce consumptionNatural dyesExtraction purification/separationMicrowaveLycopene

A method for quickly extracting lycopene belongs to the technical field of food ingredients. The present invention extracts lycopene from raw materials rich in lycopene. After preliminary treatment of the raw materials rich in lycopene, ultrasonic / microwave collaborative technology is used to assist solvent reflux to extract lycopene, and the lycopene oleoresin is obtained after concentration. products; and recover solvents. The method of the invention has simple steps, greatly shortens the extraction time, and avoids the loss of lycopene during the extraction process; the extraction rate is high, and the highest extraction rate can reach 97%; the extraction process adopts a closed system, consumes less solvent, reduces costs, and at the same time increases It ensures the safety of production; using microwave as the heating source, the energy directly acts on the extraction system, reducing the waste of energy and having the characteristics of energy saving.

Owner:JIANGNAN UNIV

Integrated apparatus for aromatics production

Enabling a transalkylation process to handle both C10 alkylaromatics and unextracted toluene permits the following improvements to be realized. No longer extracting toluene allows a reformate-splitter column to be eliminated. The extraction unit can be moved to the overhead of a benzene column that is also closely integrated with the transalkylation unit. No longer requiring a rigorous split between C9 and C10 alkylaromatics allows a heavy aromatics column to be eliminated. Such an enabled transalkylation process requires stabilization of a transalkylation catalyst through the introduction of a metal function. These improvements result in an aromatics complex apparatus with savings on inside battery limits curve costs and an improvement on the return on investment in such a complex.

Owner:UOP LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com