Patents

Literature

1668 results about "Carbon nanomaterials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon nanomaterials are a family of carbon-based materials with at least one dimension in the nanomater range. One of the most widely studied and used carbon nanomaterials are carbon nanotubes and nanofibres.

Method of forming a carbon nano-material layer using a cyclic deposition technique

ActiveUS20050003089A1Well formedEasy to disassemblePolycrystalline material growthChemical vapor deposition coatingChemisorptionCarbon nanomaterials

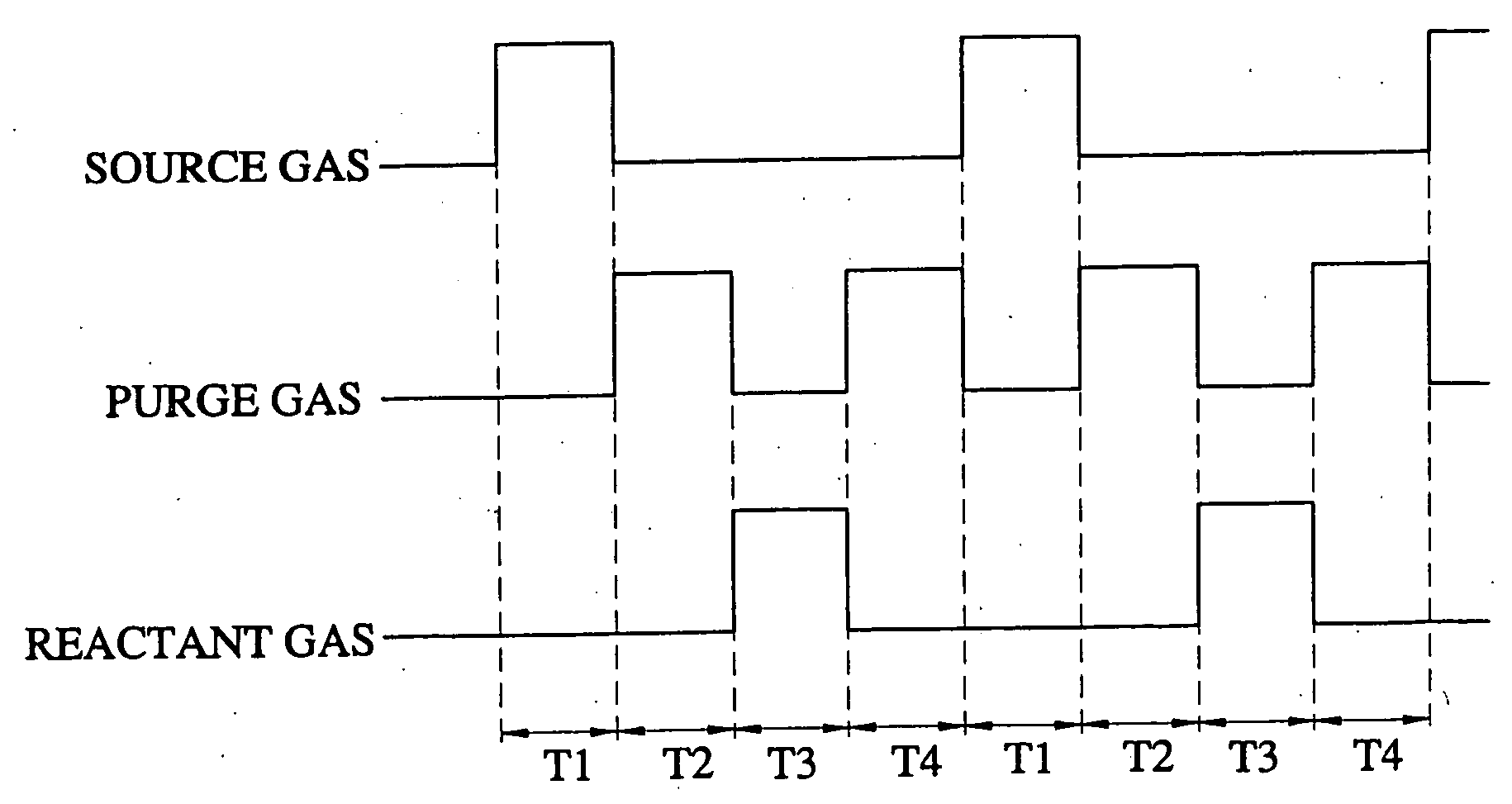

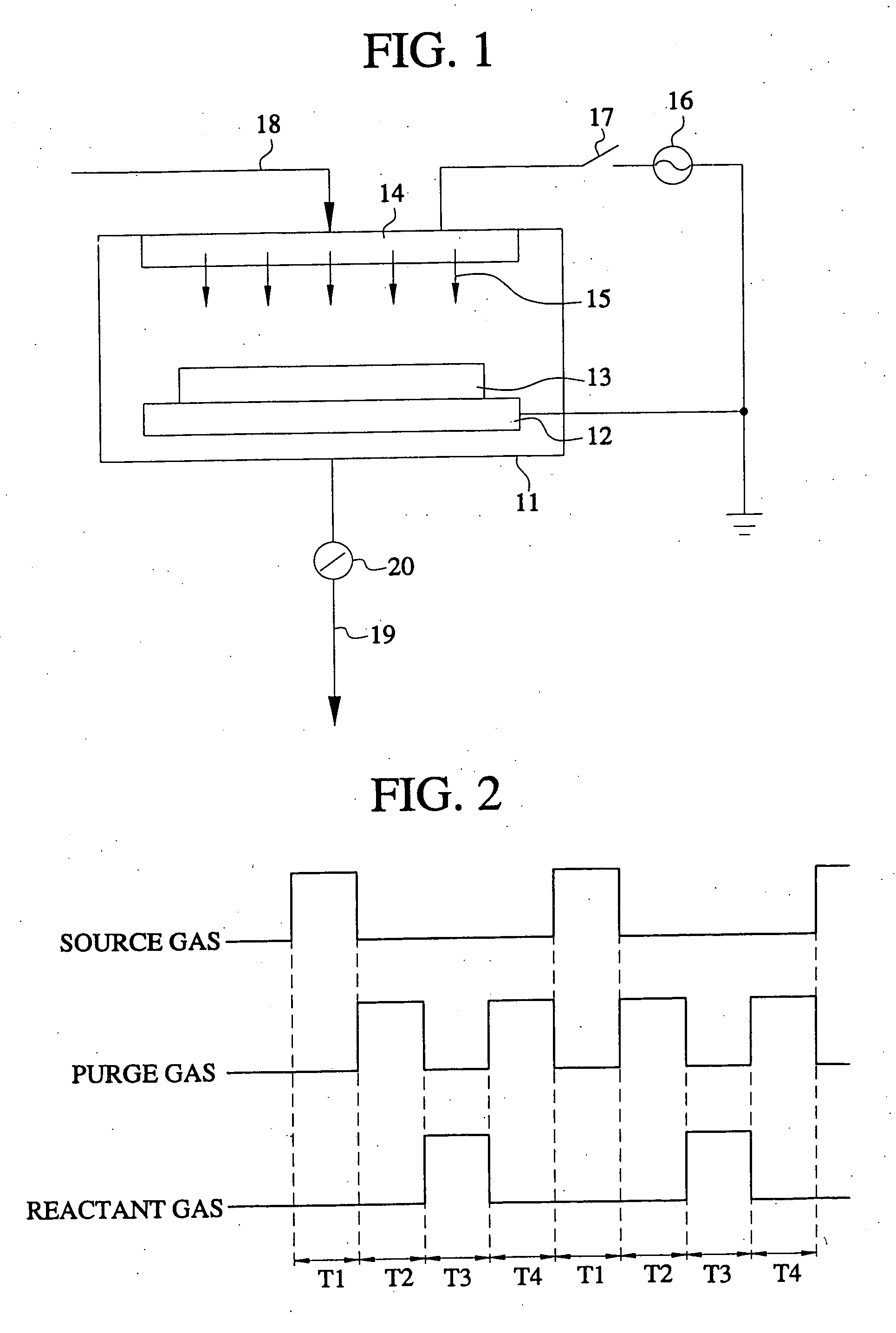

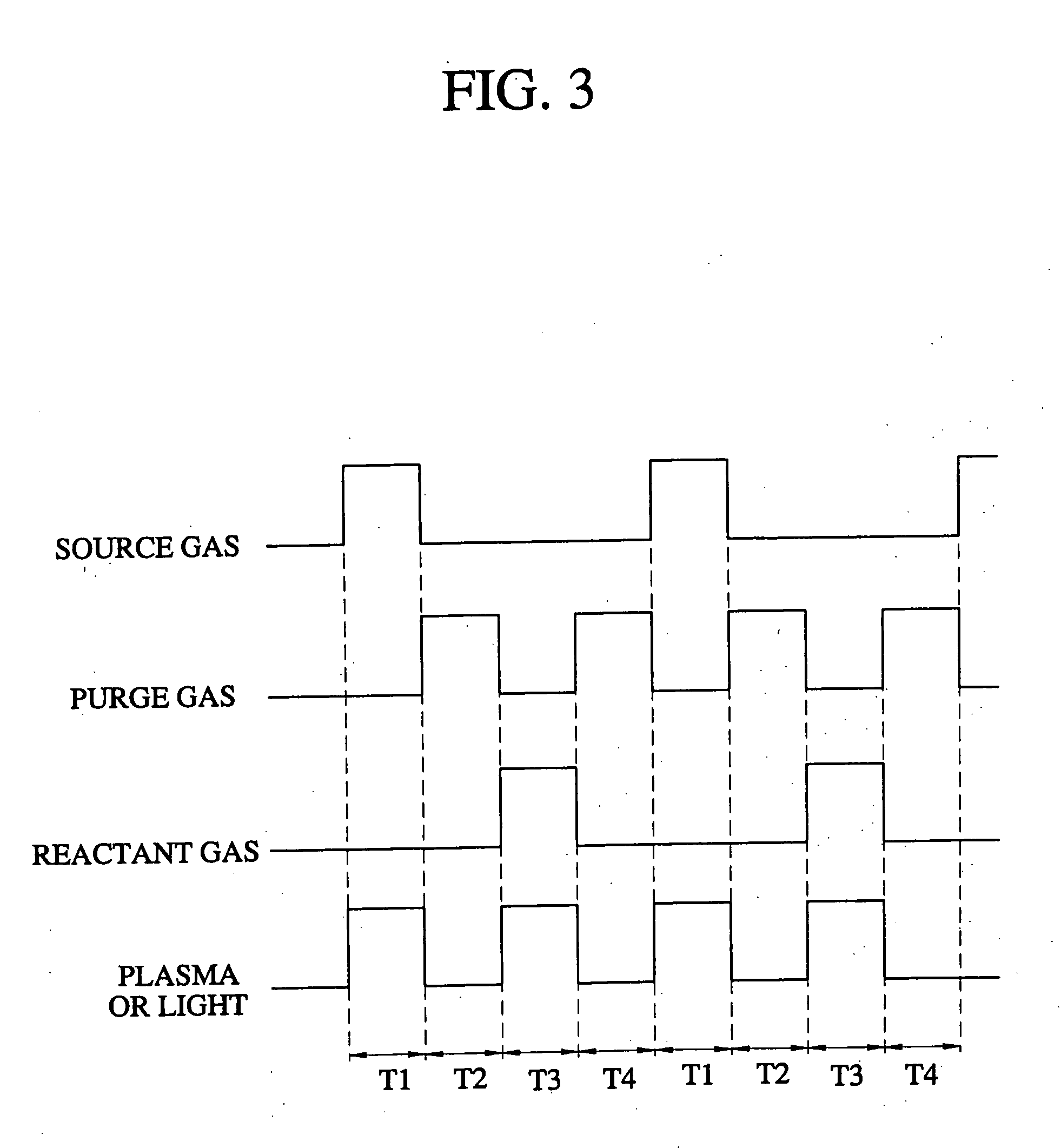

A method of forming a carbon nano-material layer may involve a cyclic deposition technique. In the method, a chemisorption layer or a chemical vapor deposition layer may be formed on a substrate. Impurities may be removed from the chemisorption layer or the chemical vapor deposition layer to form a carbon atoms layer on the substrate. More than one carbon atoms layer may be formed by repeating the method.

Owner:SAMSUNG ELECTRONICS CO LTD

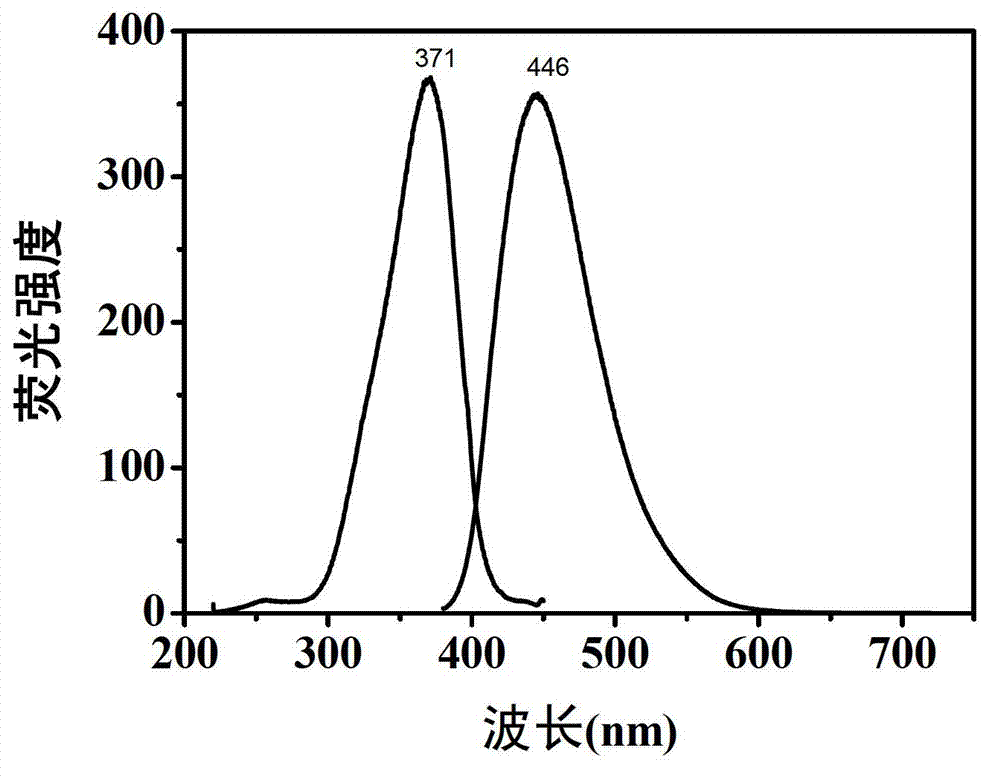

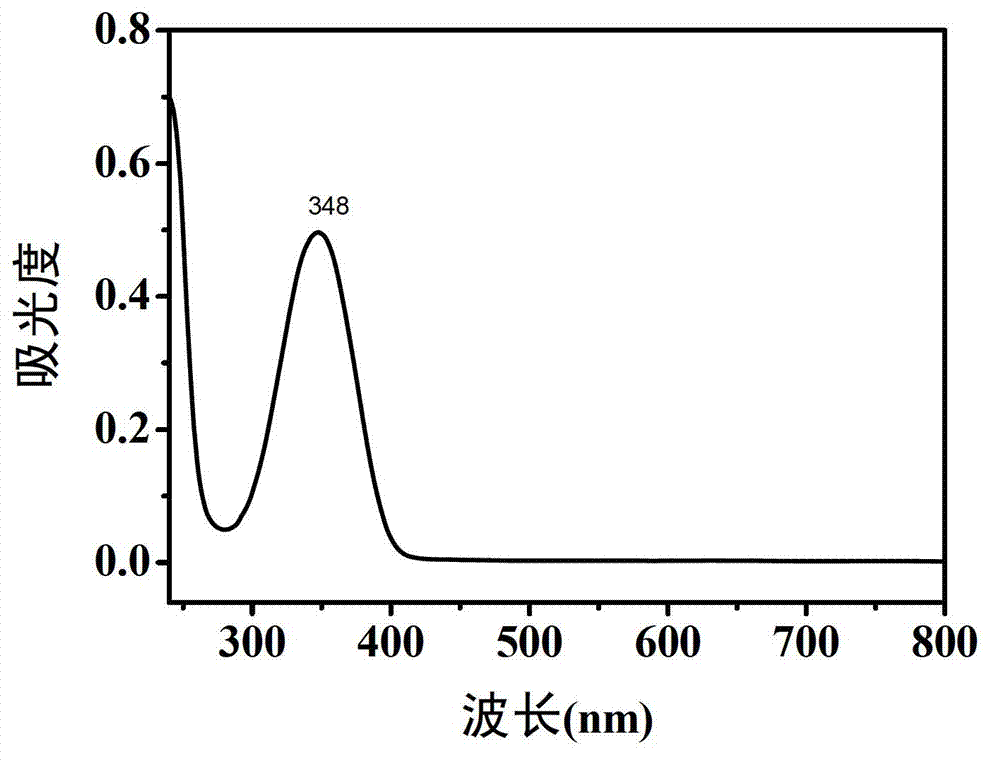

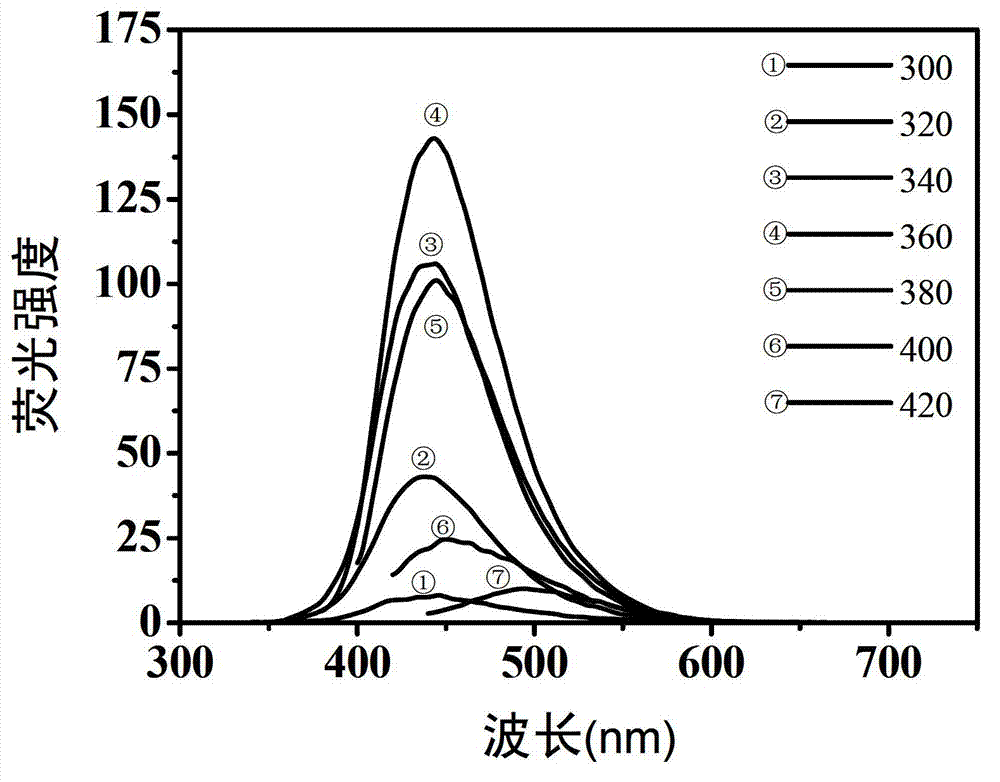

Preparation method of carbon dot having high fluorescent quantum yield

The invention belongs to the technical field of preparation of a carbon nano material, and particularly relates to a method for preparing a carbon dot having a high fluorescent quantum yield from citric acid and different nitrogen-containing molecules. The method comprises the following steps: weighing 1-10 mmol of solid citric acid, and dissolving in 10 ml of deionized water; weighing 1-10 mmol of ethylenediamine, ethylamine, propylamine, butanediamine, n-hexylamine, p-phenylene diamine or urea, adding into the citric acid solution, and uniformly stirring; transferring the solution into a hydrothermal or high-pressure microwave reaction kettle, reacting under hydrothermal or microwave conditions, and naturally cooling the reaction kettle to room temperature, thus obtaining a yellow or brown carbon dot water solution; and finally, purifying the carbon dot water solution, evaporating, and drying to obtain pure carbon dot solid powder. The carbon dot solution can send out bright blue fluorescence under the irradiation of a handheld ultraviolet lamp. The invention has wide application prospects in the fields of biological imaging, fluorescent printing and the like.

Owner:JILIN UNIV

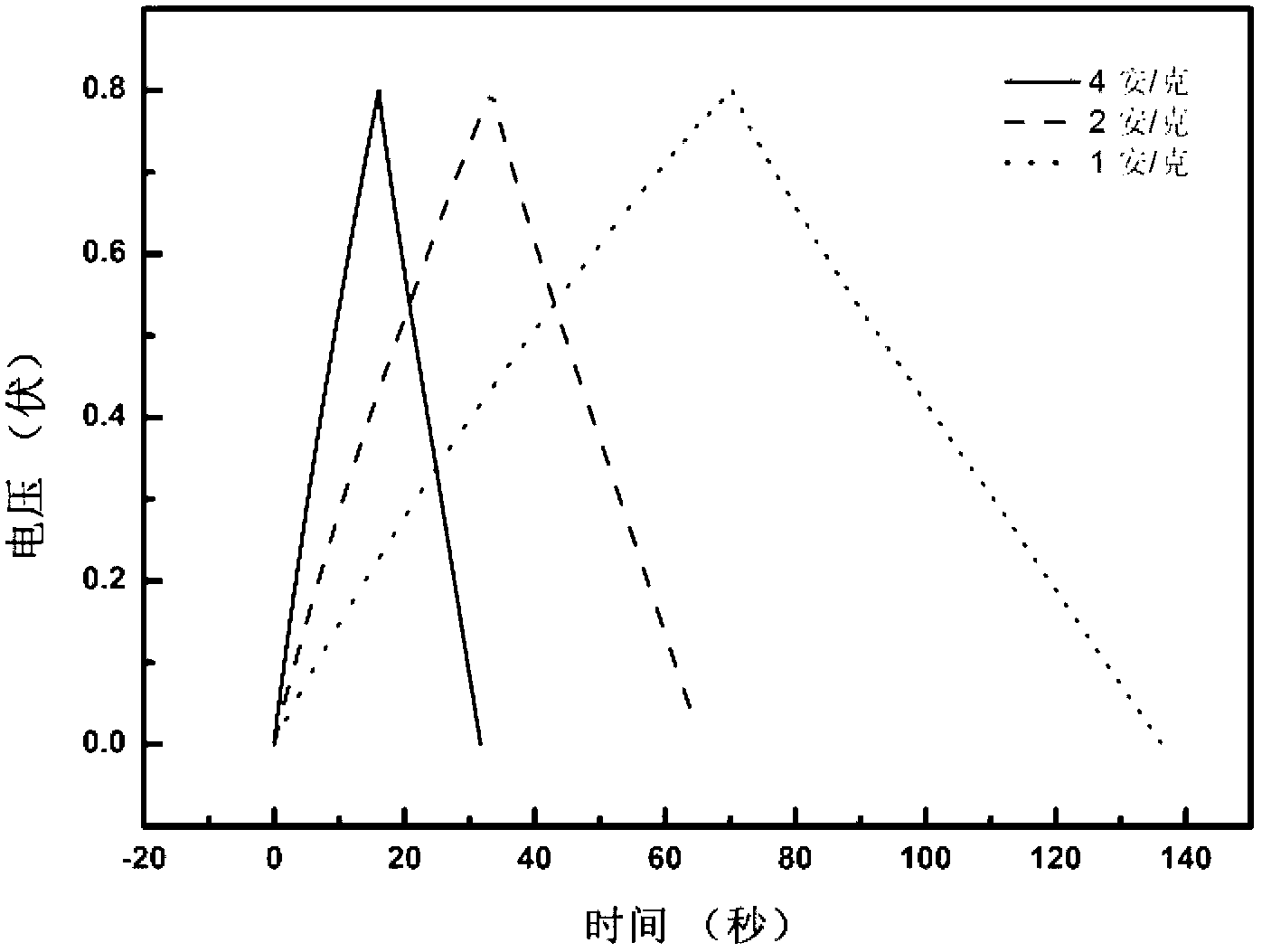

High performance ultracapacitors with carbon nanomaterials and ionic liquids

InactiveUS20080192407A1Excellent electrolyte accessibilityImprove performanceHybrid capacitor electrolytesElectrolytic capacitorsSupercapacitorCarbon nanomaterials

The present invention is directed to the use of carbon nanotubes and / or electrolyte structures comprising ionic liquids in various electrochemical devices, such as ultracapacitors.

Owner:ADA TECH

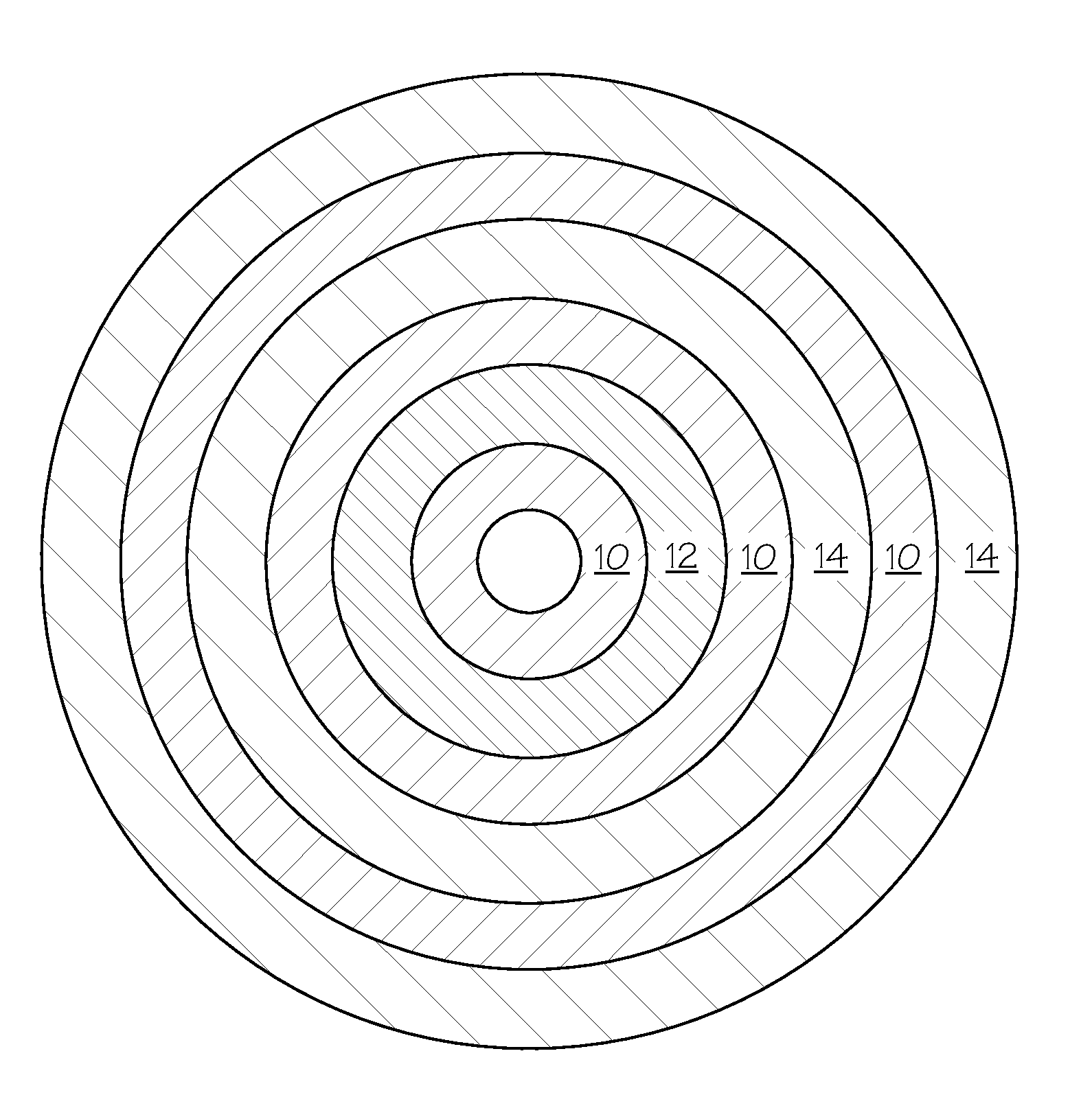

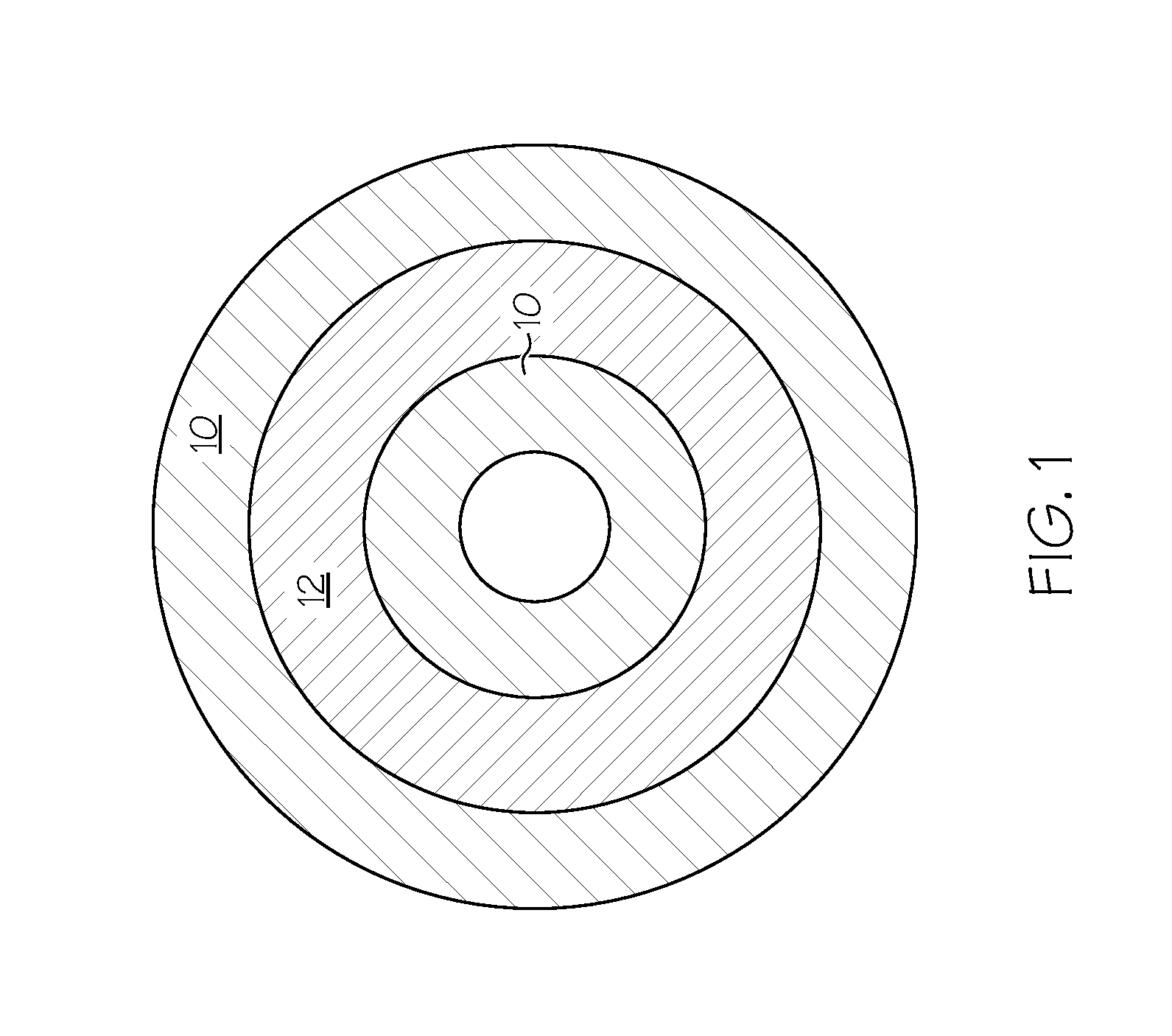

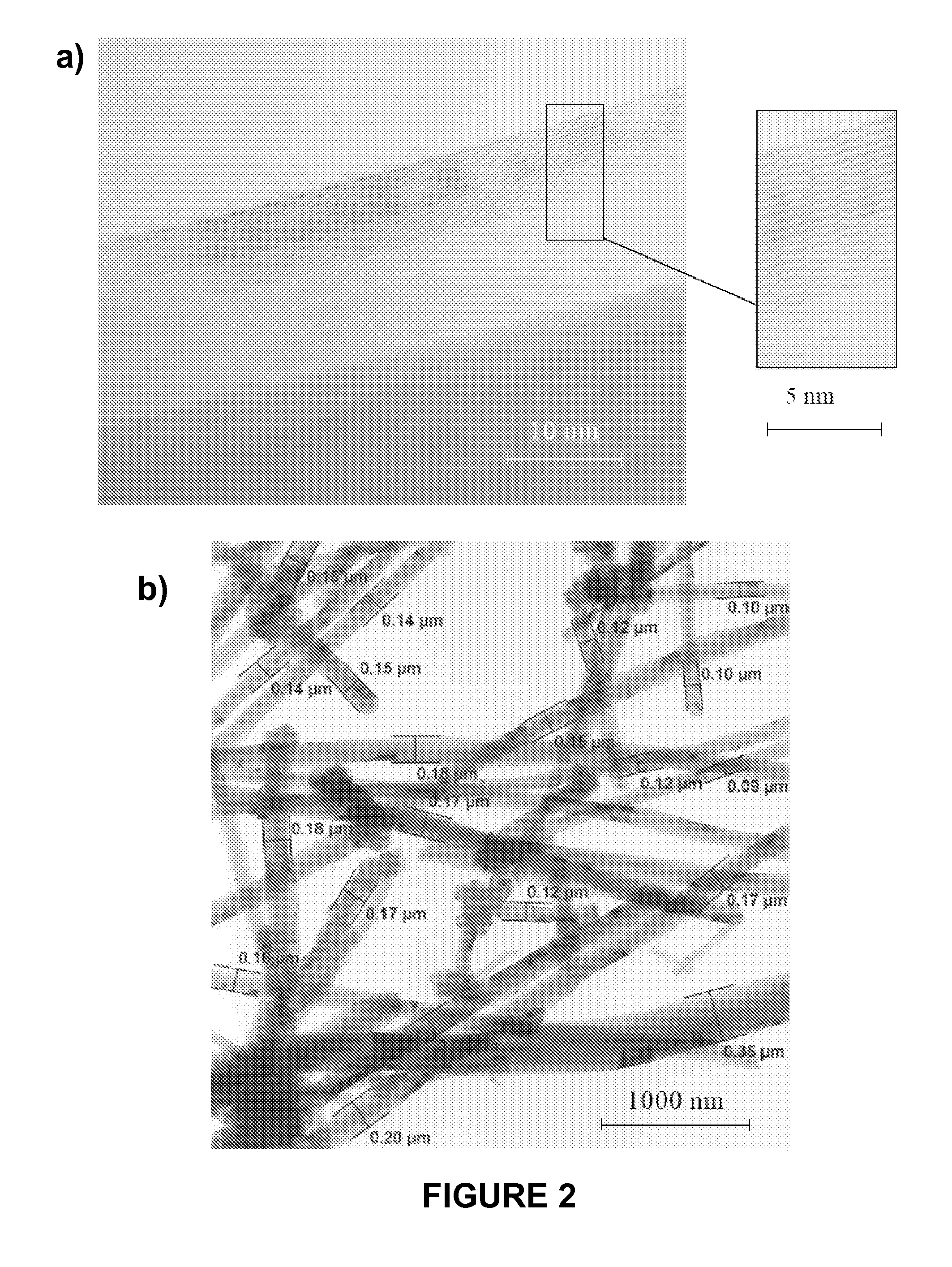

Method of depositing silicon on carbon nanomaterials

InactiveUS20120264020A1Increase surface areaHigh pore volumeMaterial nanotechnologyLiquid surface applicatorsCarbon coatingGas phase

A method of depositing silicon on carbon nanomaterials such as vapor grown carbon nanofibers, nanomats, or nanofiber powder is provided. The method includes flowing a silicon-containing precursor gas in contact with the carbon nanomaterial such that silicon is deposited on the exterior surface and within the hollow core of the carbon nanomaterials. A protective carbon coating may be deposited on the silicon-coated nanomaterials. The resulting nanocomposite materials may be used as anodes in lithium ion batteries.

Owner:APPLIED SCI

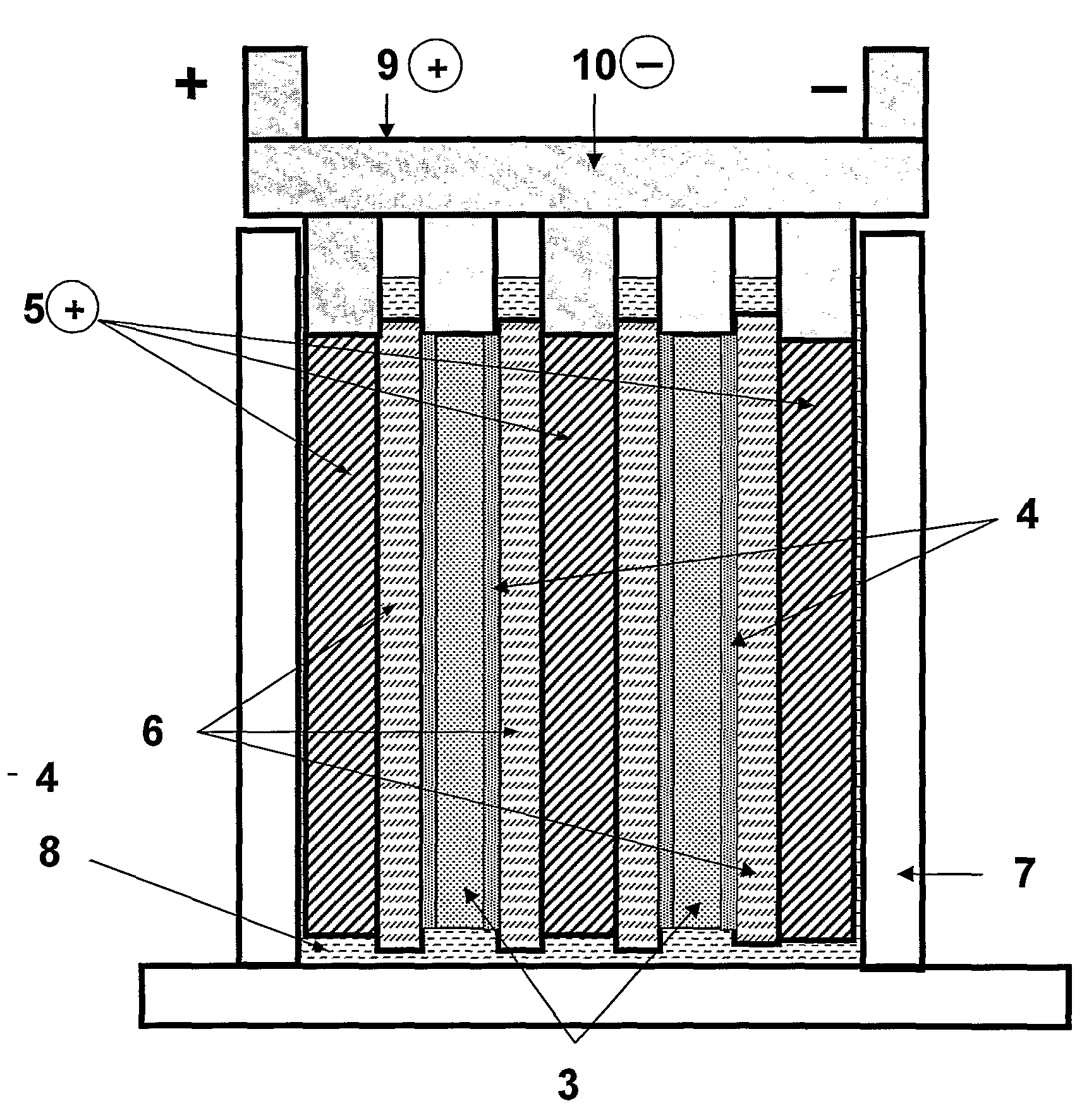

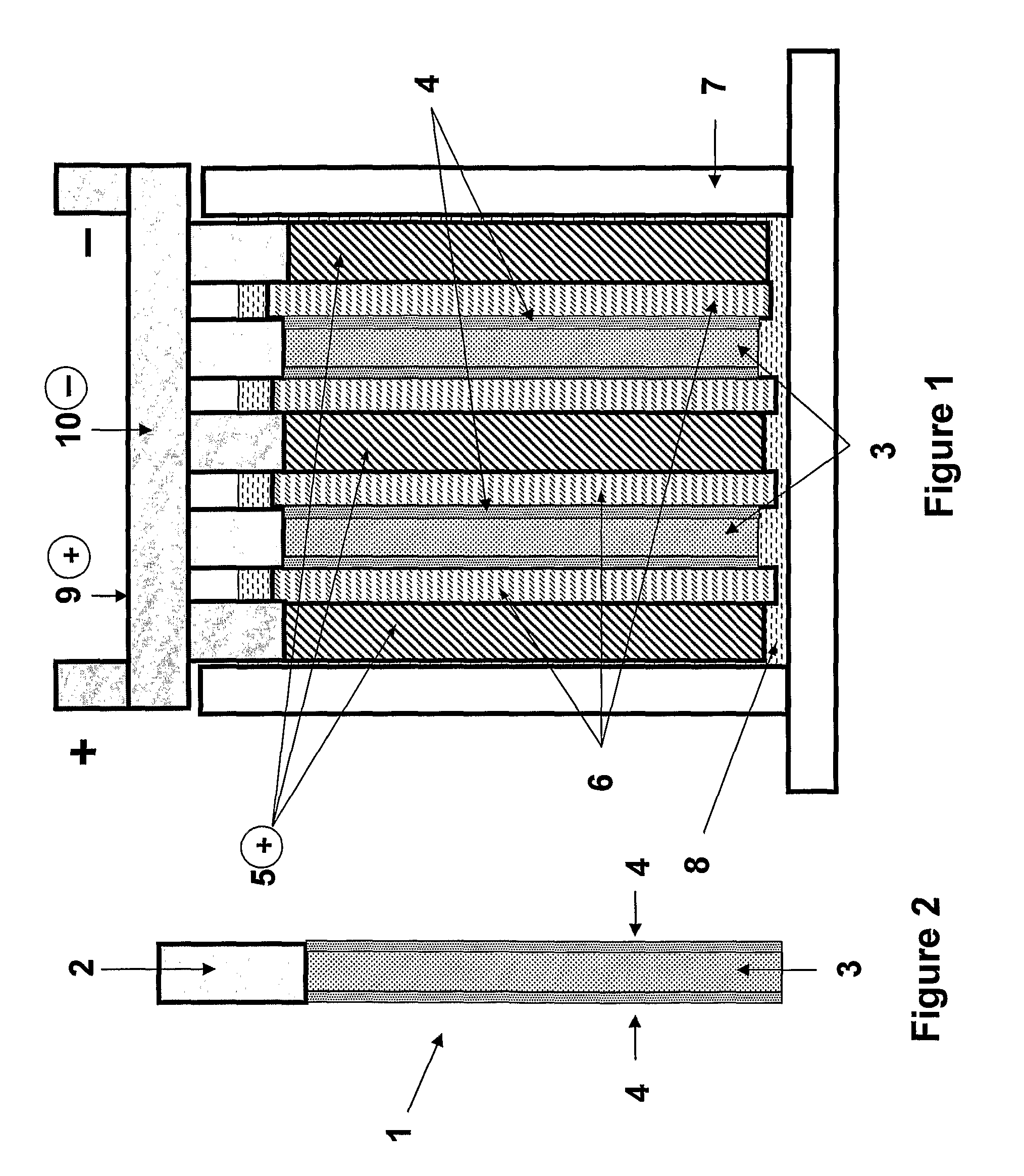

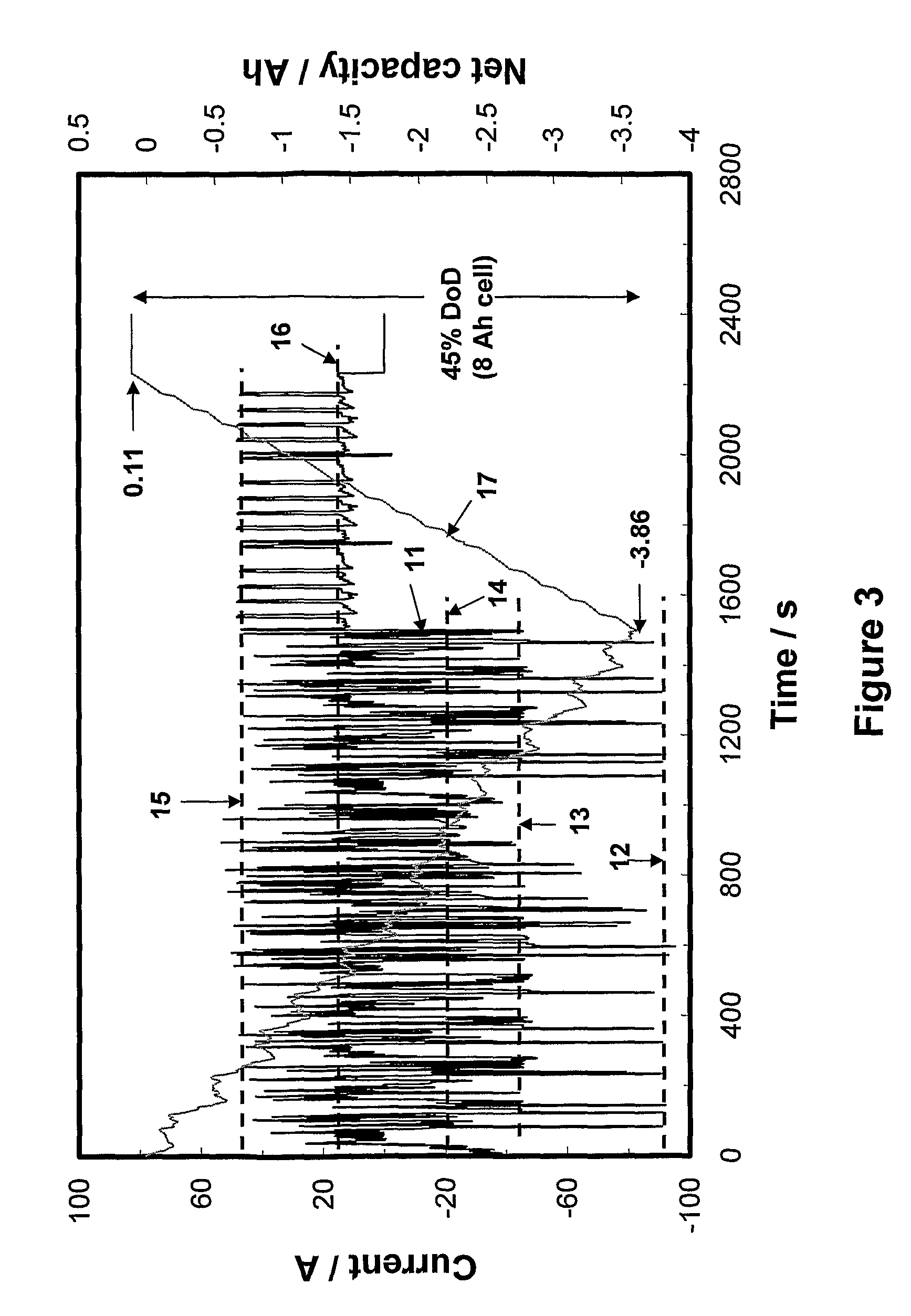

Energy storage device

ActiveUS20100203362A1Reduce heatImprove conductivityLead-acid accumulatorsCapacitor and primary/secondary cellsTin dioxideConductive materials

An energy storage device comprising at least one negative electrode, wherein each negative electrode is individually selected from (i) an electrode comprising negative battery electrode material; (ii) an electrode comprising capacitor electrode material; (iii) a mixed electrode comprising either—a mixture of battery and capacitor electrode material or—a region of battery electrode material and a region of capacitor electrode material, or—a combination thereof, and wherein the energy storage device either comprises at least one electrode of type (iii), or comprises at least one electrode of each of types (i) and (ii),—at least one positive electrode, wherein the positive electrode comprises positive battery electrode material and a charging ability-increasing additive, such as one or a mixture of: (a) carbon nanomaterial, vapour grown carbon fibre, fullerene, or a mixture thereof, and (b) tin dioxide conductive materials.

Owner:COMMONWEALTH SCI & IND RES ORG +1

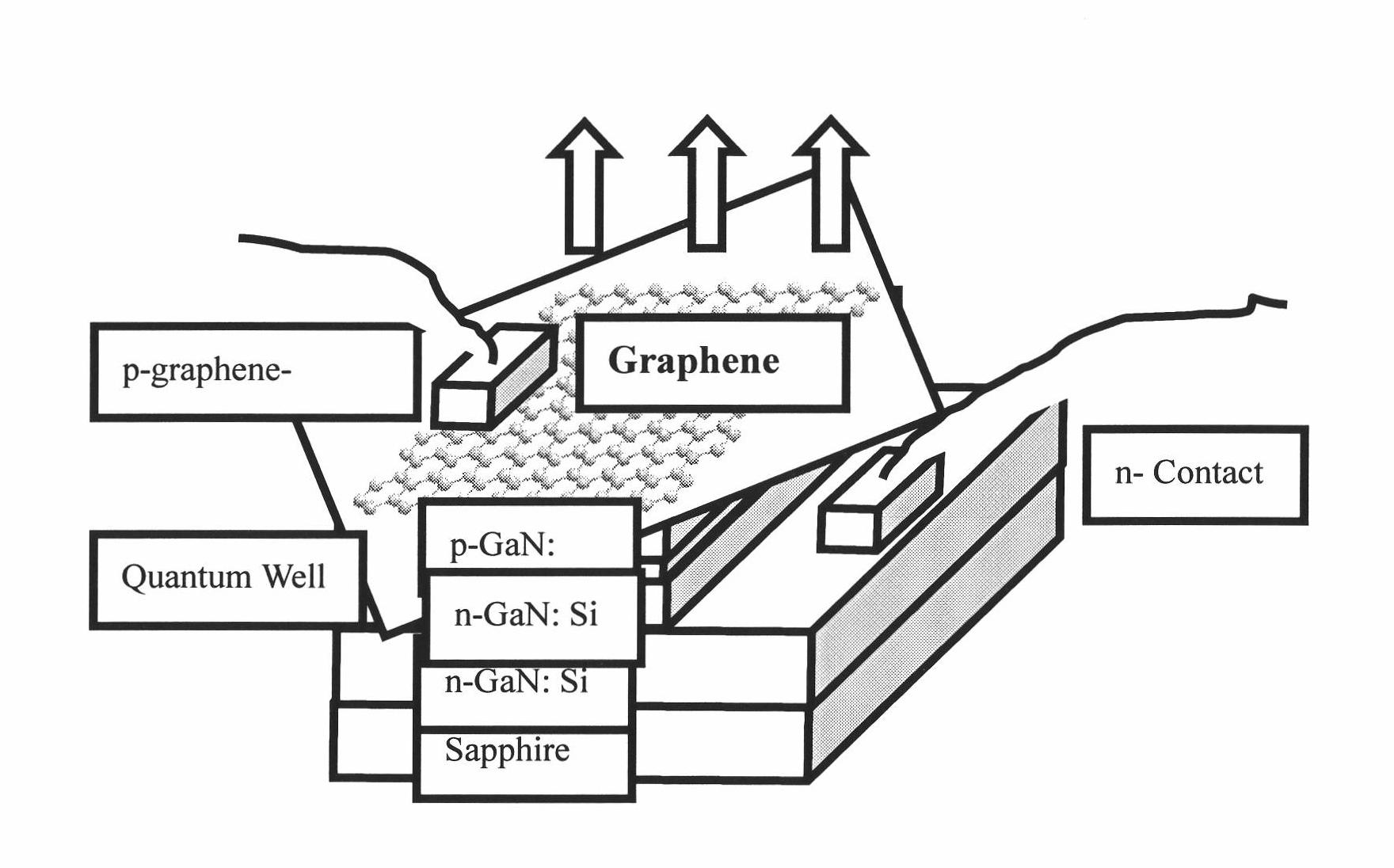

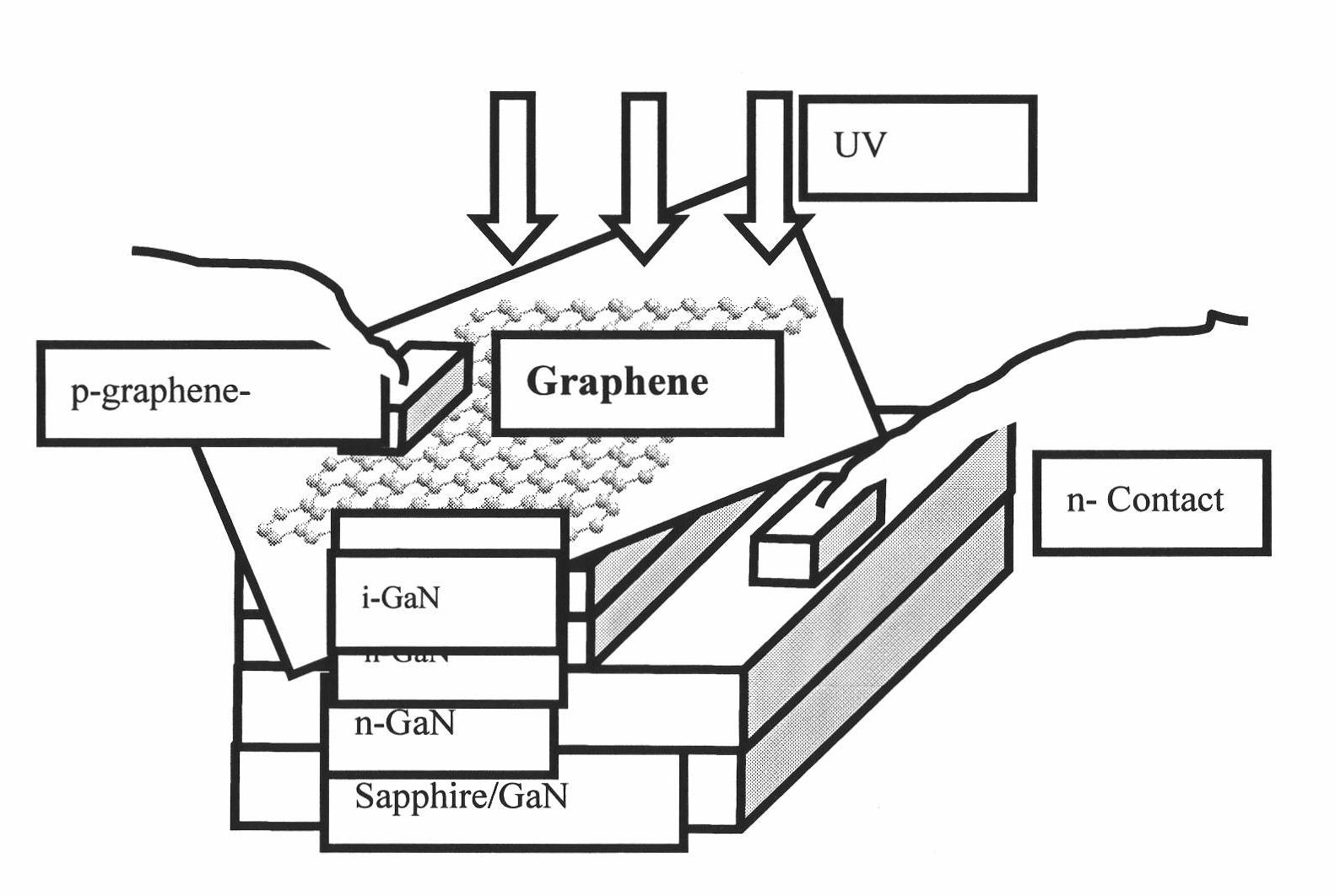

Transparent conducting electrode based on graphene and manufacture method and applications thereof

InactiveCN101859858ALow costIncrease brightnessFinal product manufactureSemiconductor devicesEtchingGas phase

The invention discloses a transparent conducting electrode using a graphene film as a GaN-based LED (light-emitting diode) or ultraviolet light detector and a manufacture method and applications thereof. The graphene film is solidified and bonded on the surface of the GaN substrate of the LED or ultraviolet light detector. The transparent graphene conducting film is prepared by adopting a chemical vapor deposition or reduction-oxidation method, and the GaN-based LED or ultraviolet light detector is manufactured by utilizing a micromachining photoetching, etching and metal deposition method; the graphene film is moved to the p-type GaN-based substrate of the LED or ultraviolet light detector to serve as the transparent conducting electrode instead of ITO or Ni / Au. In the invention, the graphene film is used as the transparent conducting electrode, which can realize low-cost and high-brightness luminescent devices and expands the applications of carbon nanometer materials in the field of GaN-based photoelectric devices.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

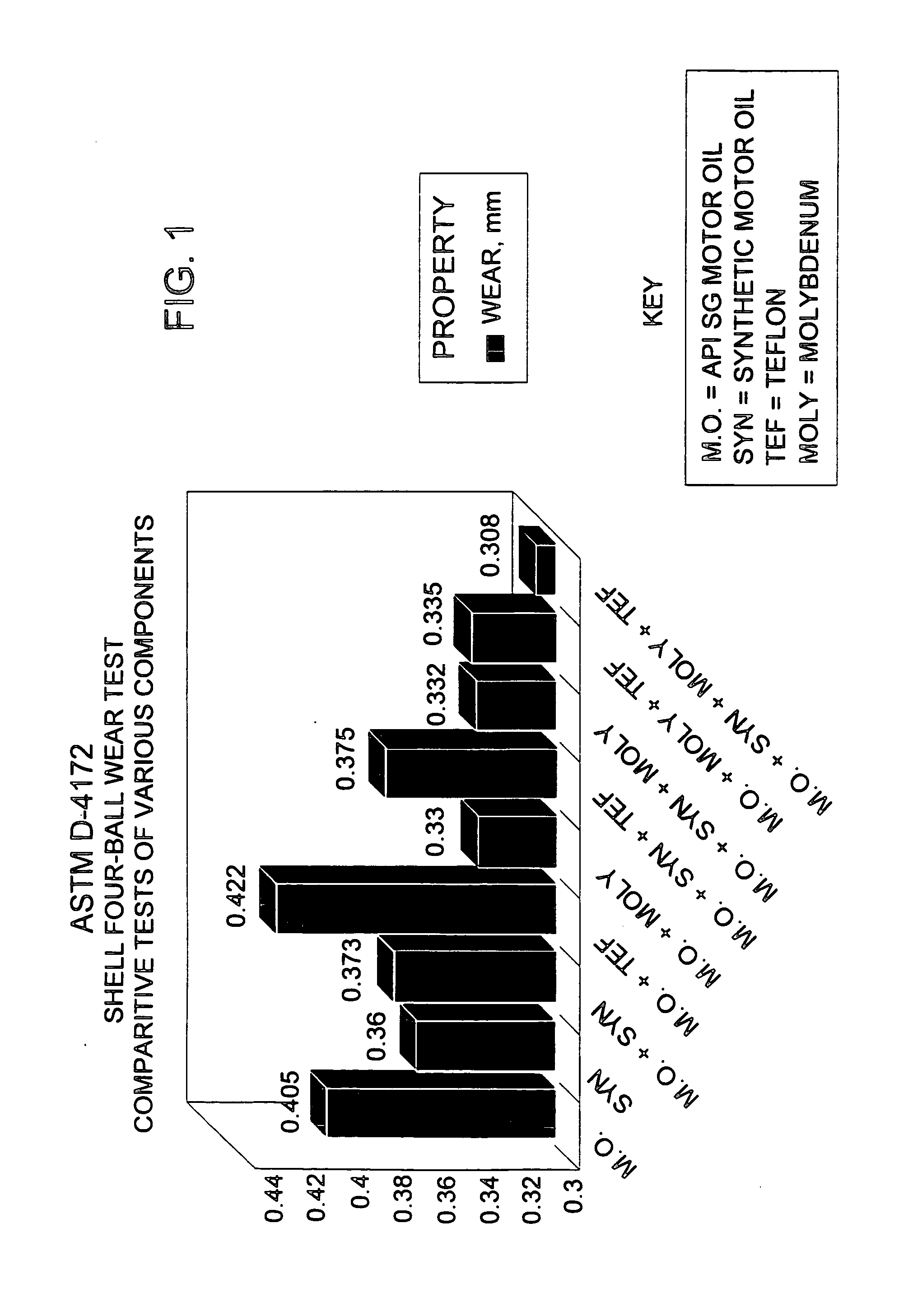

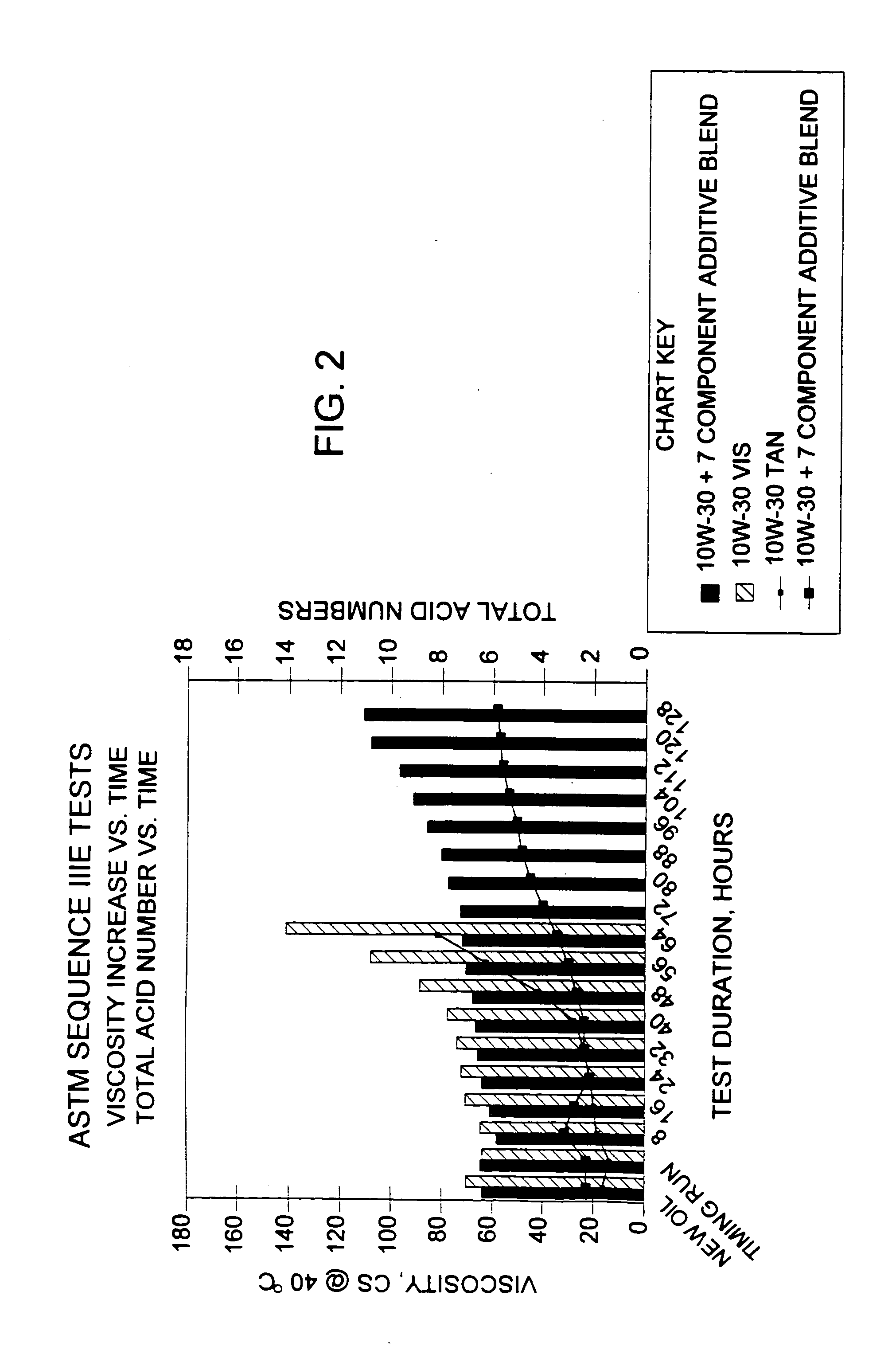

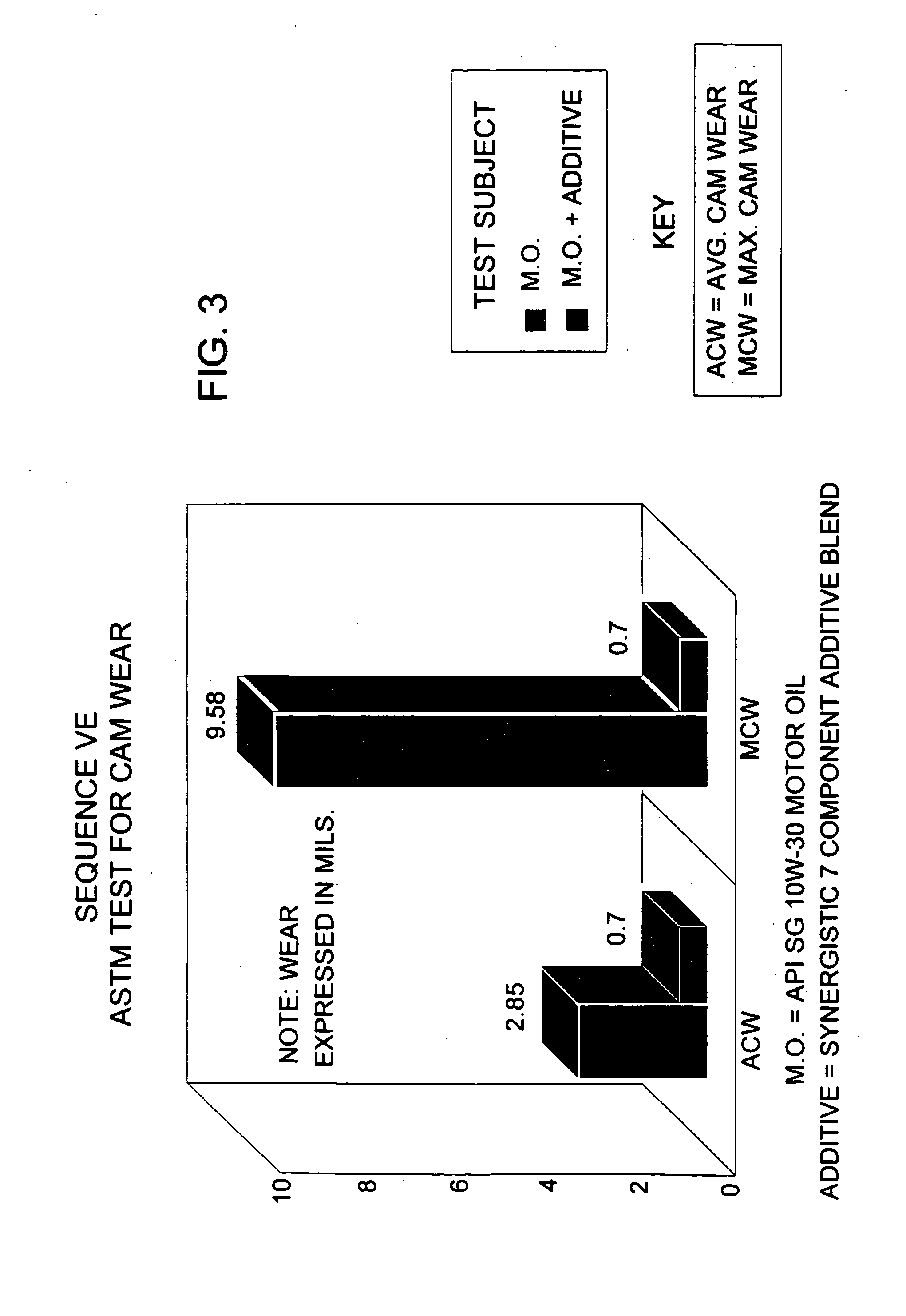

Lubricant and additive formulation

InactiveUS20050124504A1Improve the lubrication effectImprove engine performanceMaterial nanotechnologyAdditivesSuspended particlesNanostructure

A lubricant composition for use as a concentrate and motor oil having an enhanced thermal conductivity. One preferred composition contains a lubricant composition, nanomaterial, and a dispersing agent or surfactant for the purpose of stabilizing the nanomaterial. One preferred nanomaterial is a high thermal conductivity graphite, exceeding 80 W / m in thermal conductivity. Carbon nano material or nanostructures such as nanotubes, nanofibrils, and nanoparticles formed by grounding and / or milling graphite to obtain a mean particle size less than 500 nm in diameter, and preferably less than 100 nm, and most preferably less than 50 nm. Other high thermal conductivity carbon materials are also acceptable. To confer long-term stability, the use of one or more chemical dispersants or surfactants is useful. The graphite nanomaterials contribute to the overall fluid viscosity and providing a very high viscosity index. Particle size and dispersing chemistry is controlled to get the desired combination of viscosity and thermal conductivity increase from the lubricant. The resulting fluids have unique properties due to the high thermal conductivity and high viscosity index of the suspended particles, as well as their small size.

Owner:ASHLAND LICENSING & INTPROP LLC

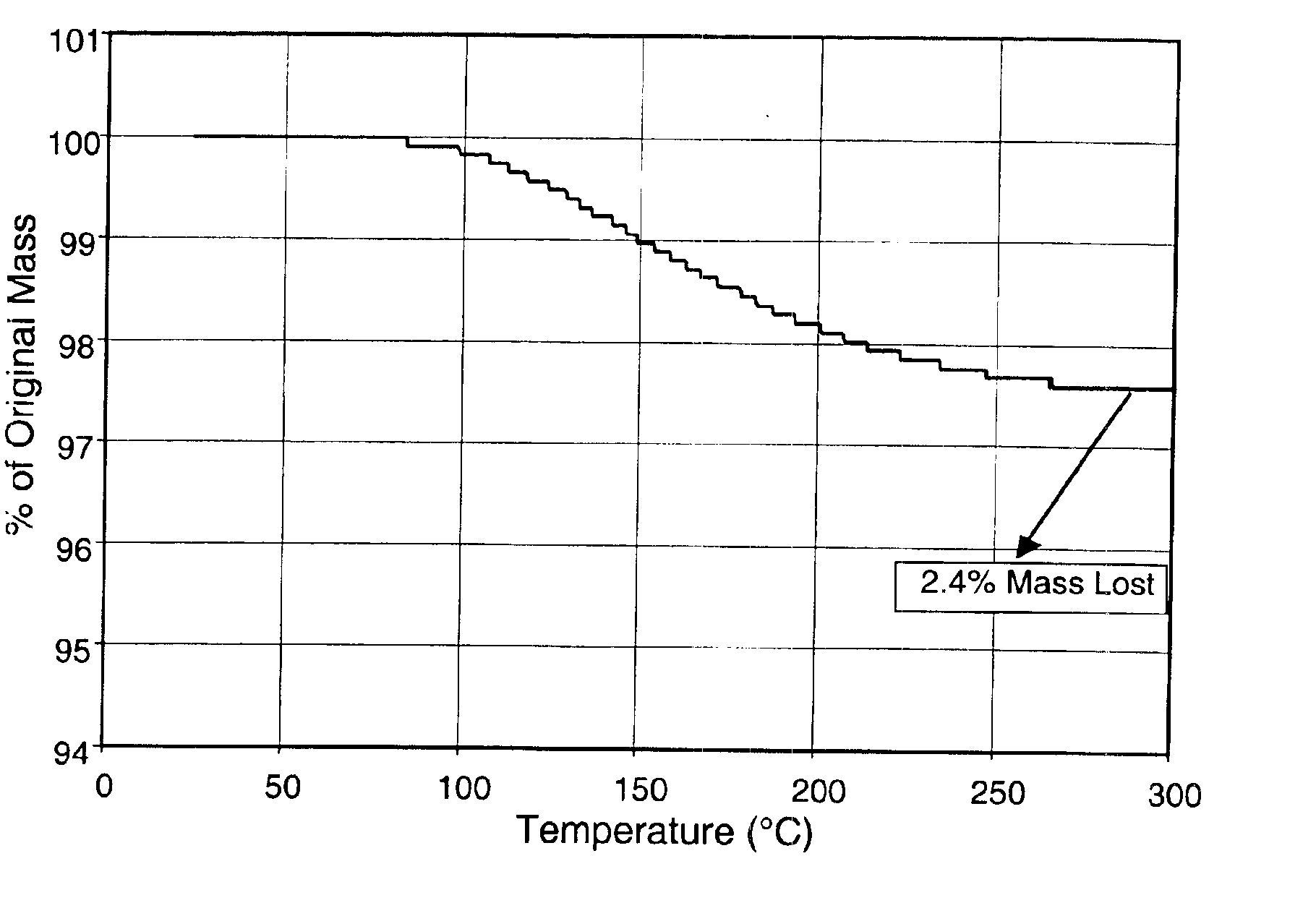

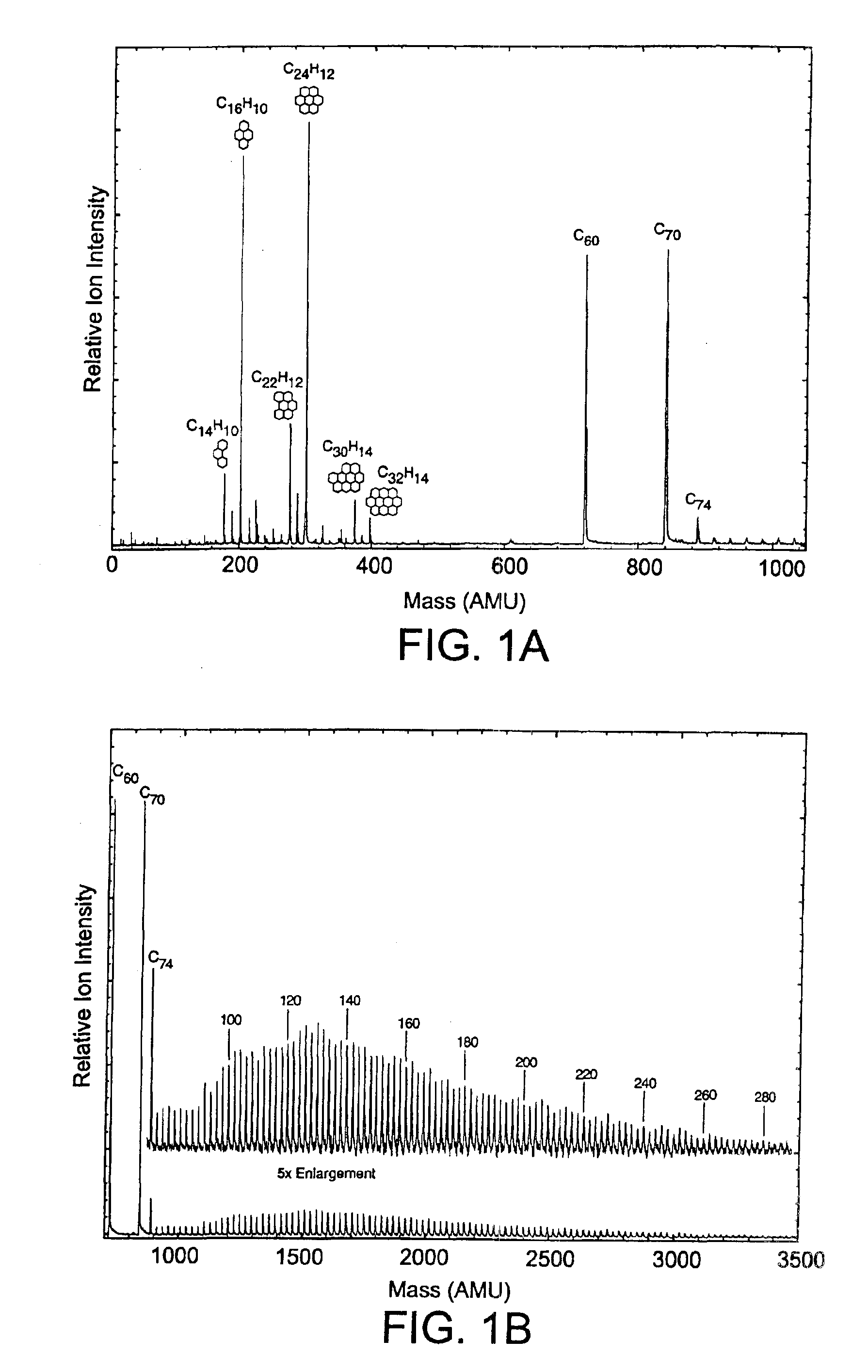

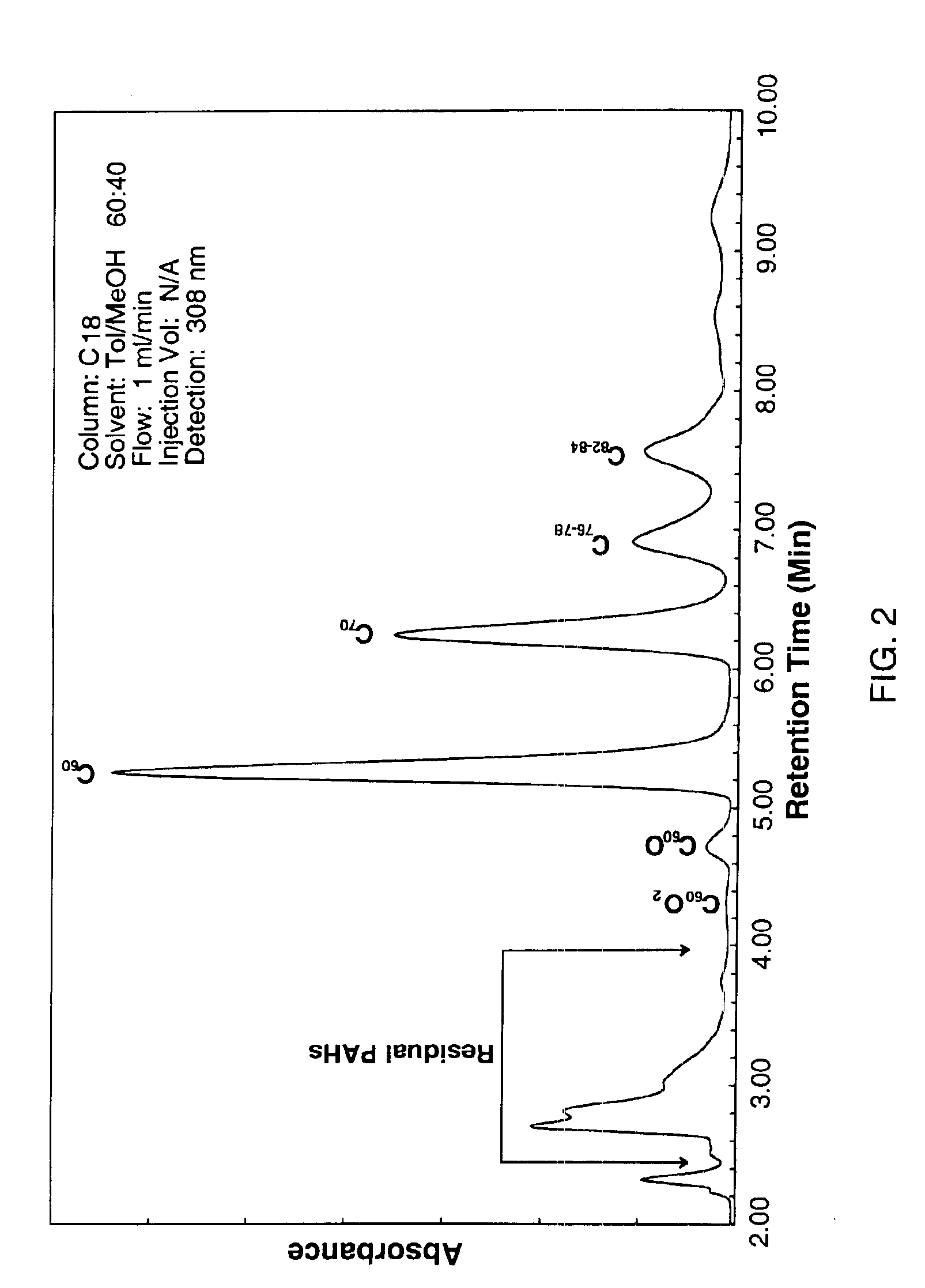

Process for the removal of impurities from combustion fullerenes

InactiveUS6923915B2Without incurring undo costEfficient removalMaterial nanotechnologyFullerenesO-XylenePurification methods

The invention generally relates to purification of carbon nanomaterials, particularly fullerenes, by removal of PAHs and other hydrocarbon impurities. The inventive process involves extracting a sample containing carbon nanomaterials with a solvent in which the PAHs are substantially soluble but in which the carbon nanomaterials are not substantially soluble. The sample can be repeatedly or continuously extracted with one or more solvents to remove a greater amount of impurities. Preferred solvents include ethanol, diethyl ether, and acetone. The invention also provides a process for efficiently separating solvent extractable fullerenes from samples containing fullerenes and PAHs wherein the sample is extracted with a solvent in which both fullerenes and PAHs are substantially soluble and the sample extract then undergoes selective extraction to remove PAHs. Suitable solvents in which both fullerenes and PAHs are soluble include o-xylene, toluene, and o-dichlorobenzene. The purification process is capable of treating quantities of combustion soot in excess of one kilogram and can produce fullerenes or fullerenic soot of suitable purity for many applications.

Owner:FRONTIER CARBON CORP

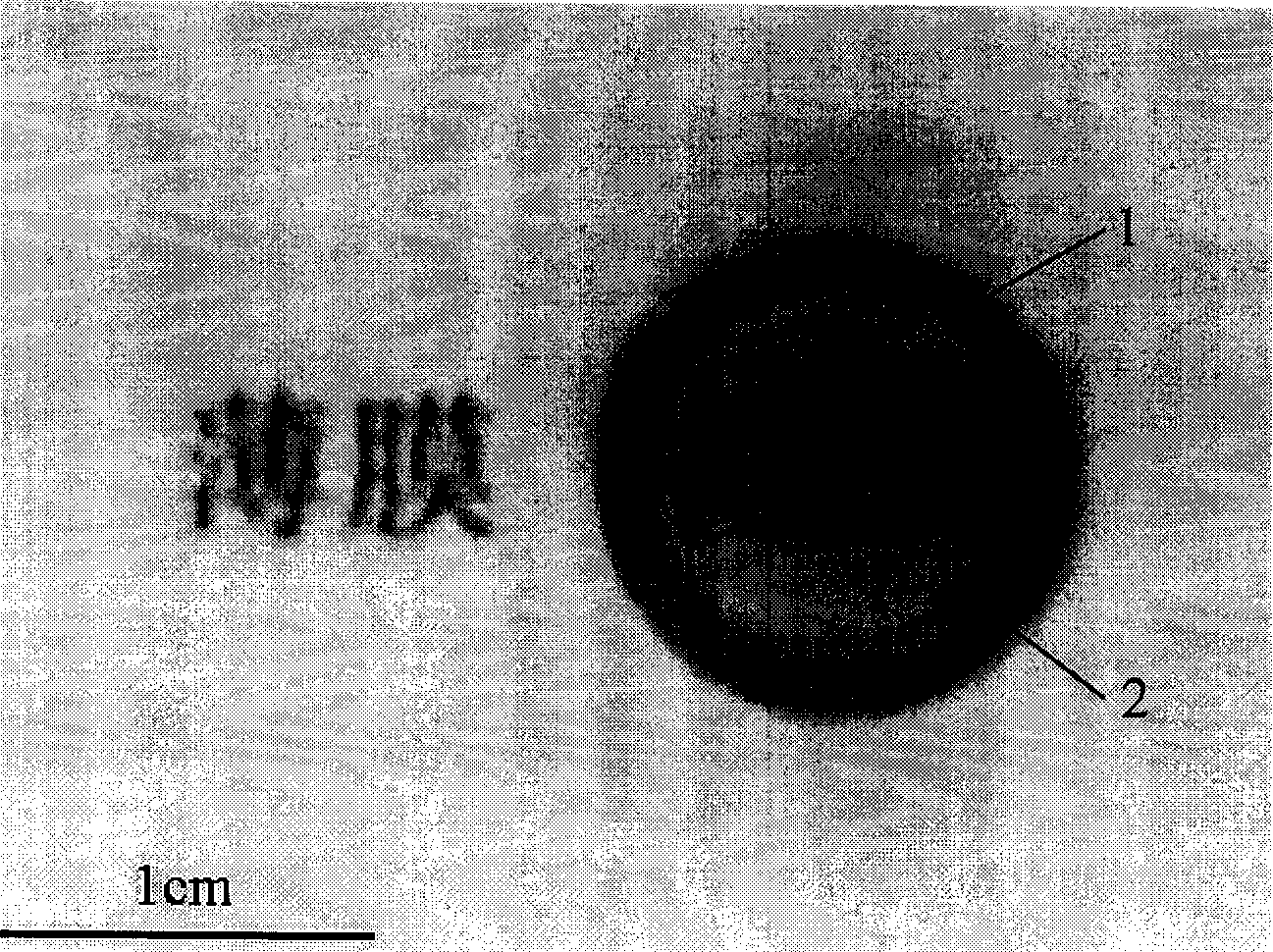

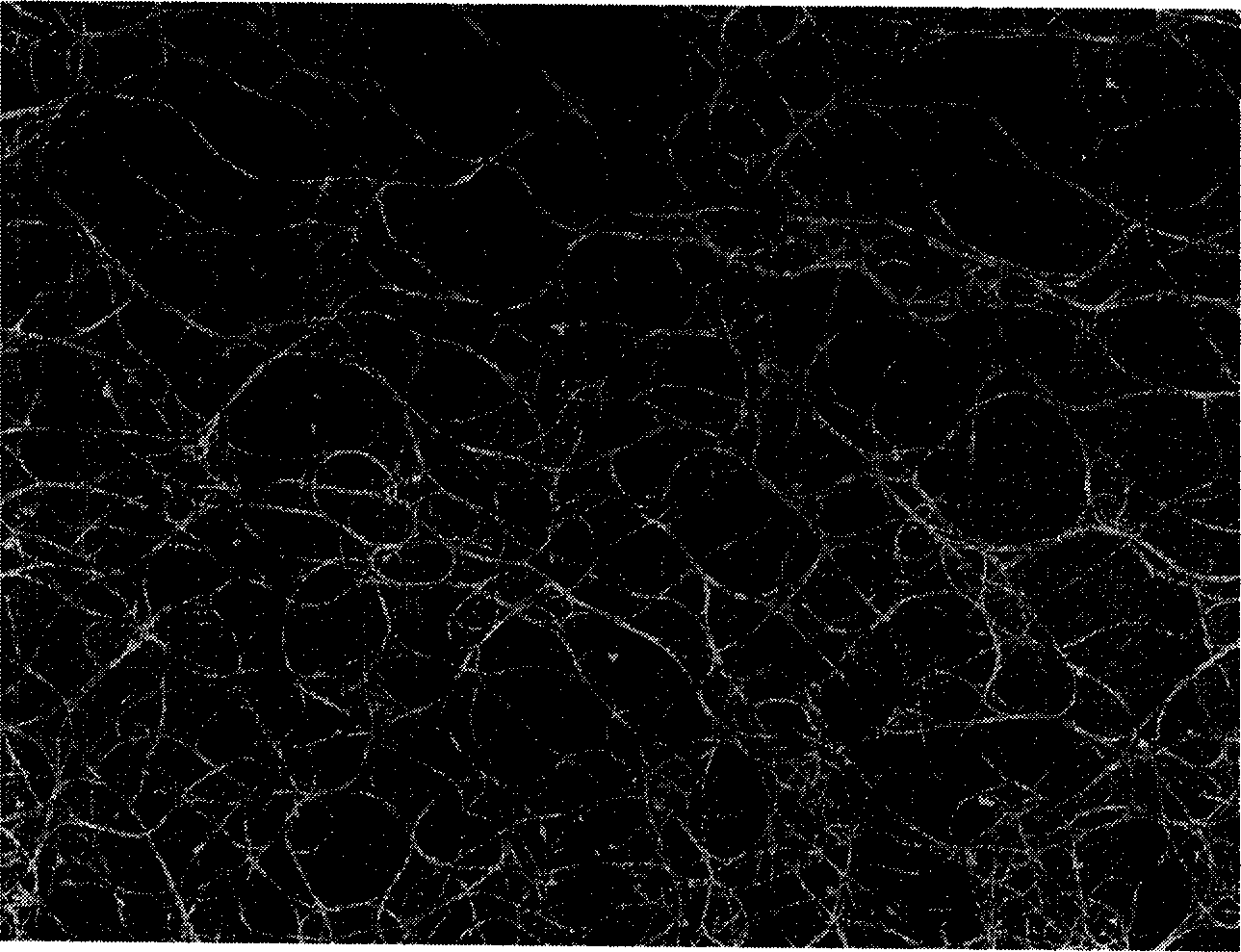

Large-area ultra-thin carbon nanotube film and its preparation process

The large-area untrathin nano carbon tube film with well feature in microcosmic level comprises nano carbon tubes with centimeter-level length and more then 90wt% purity. Wherein, the least thickness of single-layer film can achieve 20nm with near transparent color and more then 10cm2 film area; there are multiple functional groups on tube surface. It also discloses the opposite preparation technique: with the macroscopic body of nano carbon tube, oxidating the macroscopic body in air; then, dipping into hydroperoxide; adding strong acid to poach till the liquid shows neutrality; finally, adding alcohol or acetone into the liquid to float the tube and form the film.

Owner:TSINGHUA UNIV +1

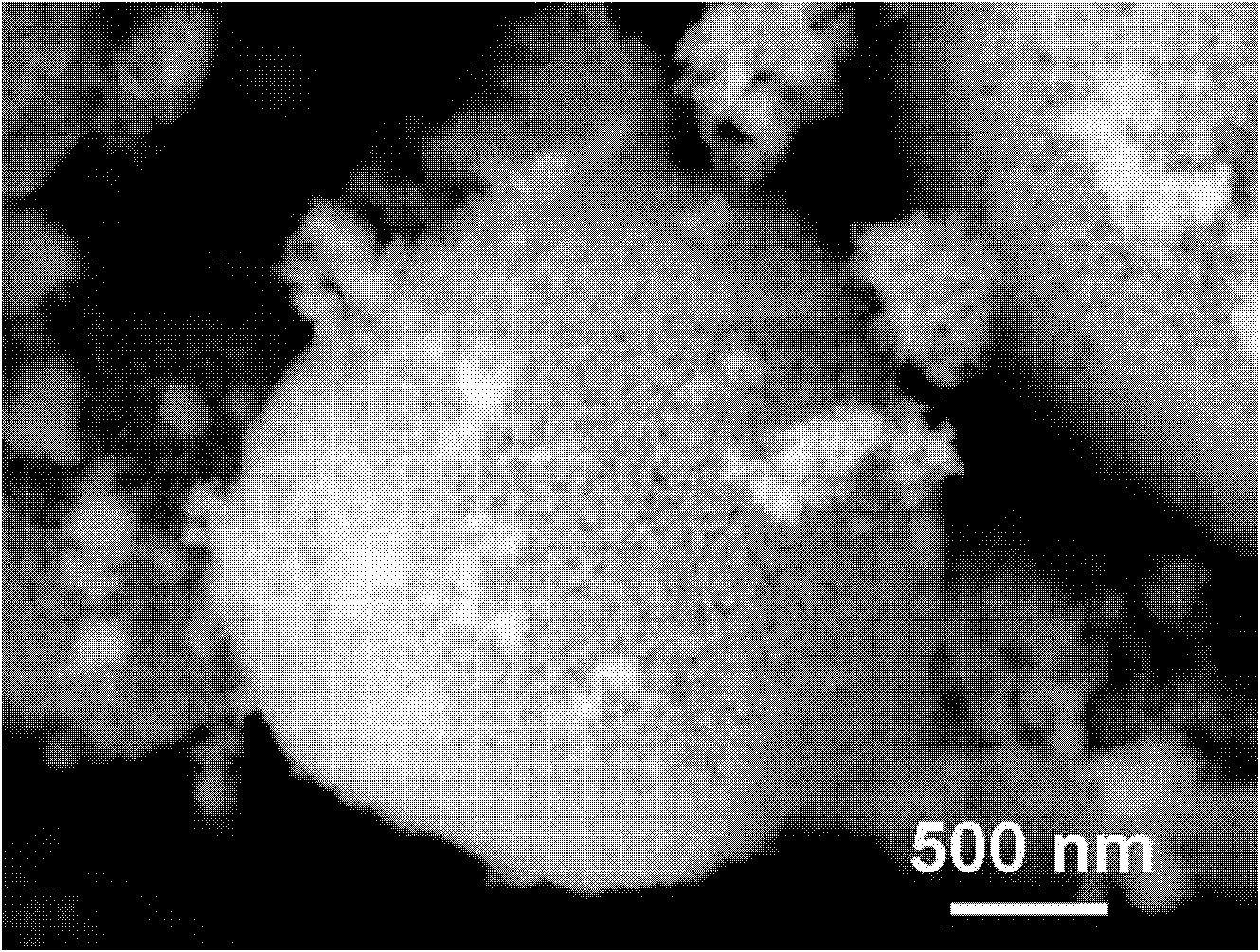

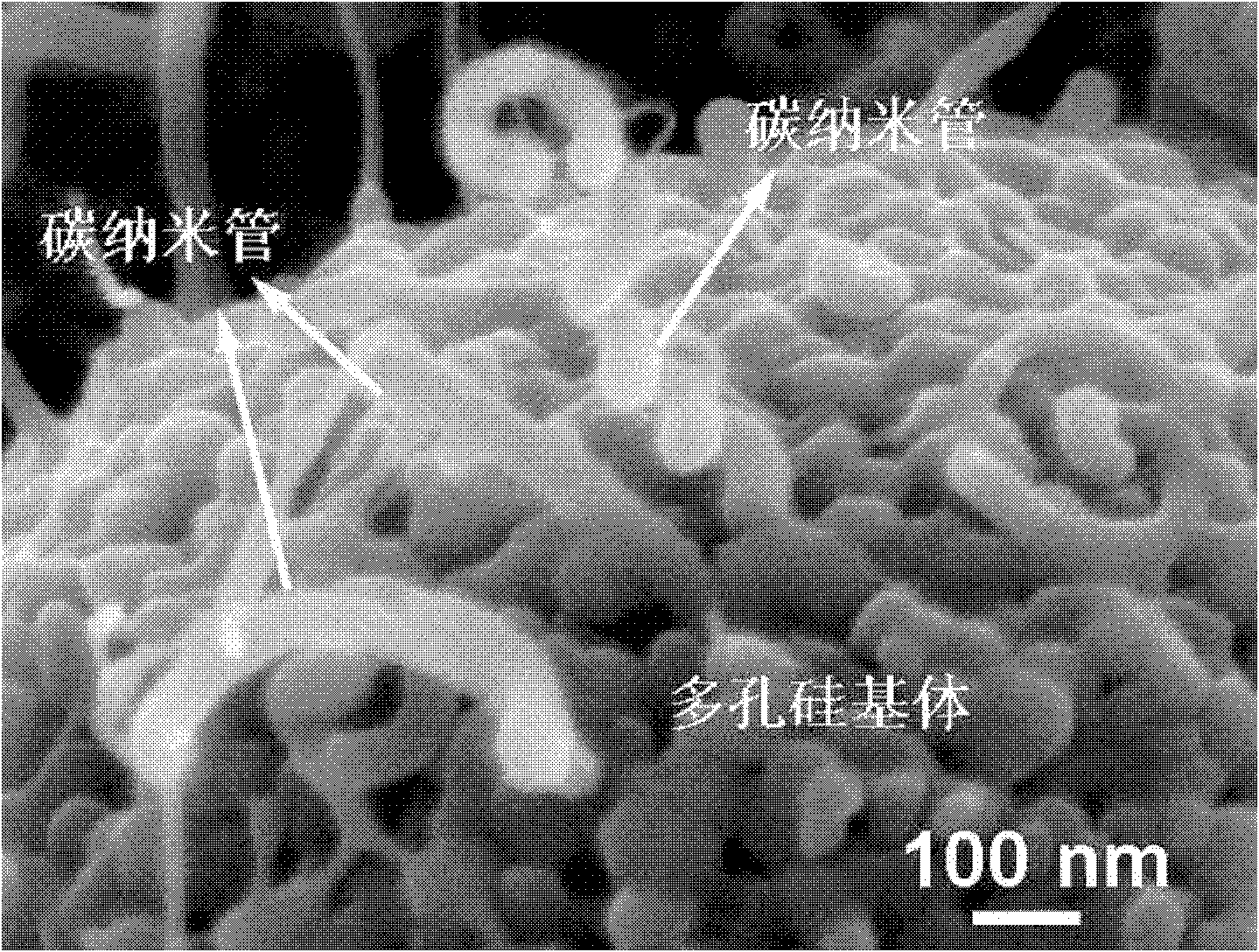

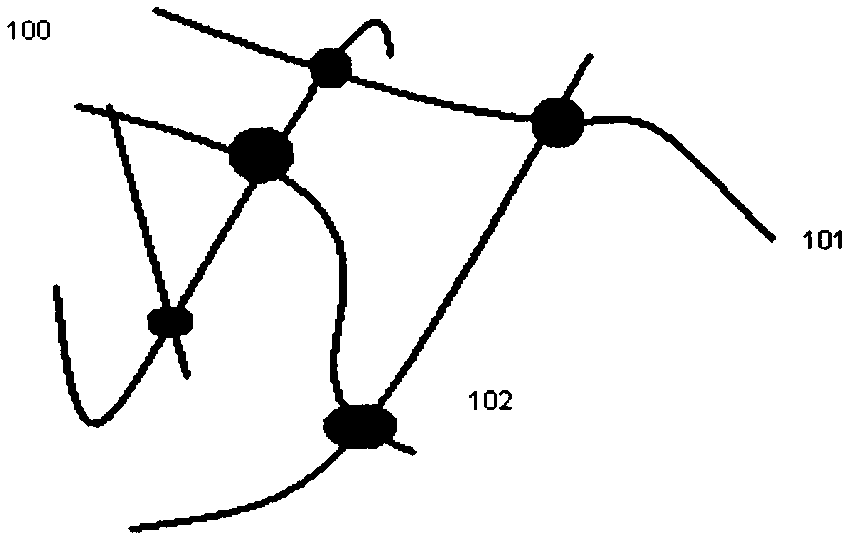

Silicon carbon composite material and preparation method thereof

ActiveCN102185128AIncrease productivityReduce manufacturing costCell electrodesFiberCarbon composites

The invention discloses a silicon carbon composite material and a preparation method thereof. The material disclosed by the invention comprises a porous silicon substrate, a one-dimensional carbon nano material and amorphous carbon, wherein the one-dimensional carbon nano material is a carbon nano tube or carbon nano fiber. The preparation method disclosed by the invention comprises the following steps: preparing the porous silicon substrate; loading a catalyst precursor; and carrying out the chemical vapor deposition. The one-dimensional carbon nano material directly grows on the porous silicon substrate, and the one-dimensional carbon nano material and the porous silicon substrate are coated with the amorphous carbon. The silicon carbon composite material provided by the invention is suitable for the cathode material of a lithium ion battery, and has the advantages of high capacity and stable circulation performance. A constant-current charge and discharge test is carried out under the 300mA / g current density, and the silicon carbon composite material disclosed by the invention has the characteristics that the first reversible capacity is 1149mAh / g; the reversible capacity is 1087mAh / g after the circulation is carried out for 100 times; and the capacity conservation rate is up to 95%.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

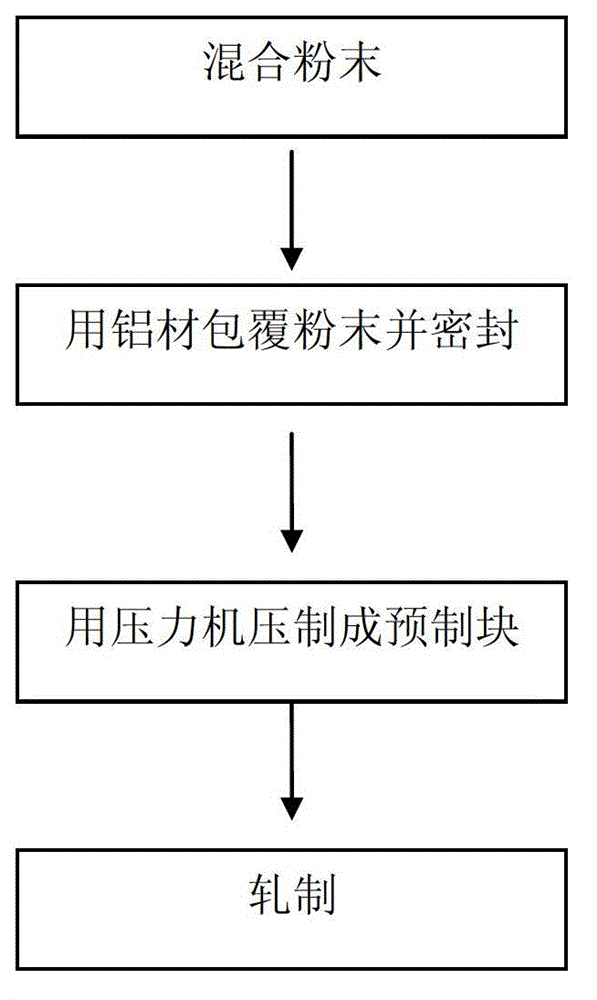

Preparation method for carbon nanomaterial enhanced aluminum base composite material

The invention discloses a preparation method for a carbon nanomaterial enhanced aluminum base composite material, which is similar to a powder metallurgy method, i.e. an aluminum material cladding powder processing and forming method. The preparation method is mainly used for solving the problem of precise mould requirement in the powder metallurgy process. The method is realized by the following steps of: 1) carrying out annealing treatment to pure aluminum or aluminum alloy material, carrying out alkali liquor cleaning and clean water cleaning to the surface of the pure aluminum or aluminum alloy material, and airing or drying after cleaning; 2) fully mixing and evenly stirring the pure aluminum or aluminum alloy powder with carbon nanomaterial at a certain ratio, i.e. at the mass fraction of the carbon nanomaterial of 0.1-8%; 3) cladding mixed powder by the pure aluminum or aluminum alloy material processed in step 1, compacting, sealing, and pressing into a precast block by a press; and 4) rolling the precast block obtained in step 3 into a final finished product. The preparation method for the carbon nanomaterial enhanced aluminum base composite material, which is disclosed by the invention, has the advantages of low cost, short flow, simpleness in operation and easiness in realizing industrialization.

Owner:NORTHEASTERN UNIV

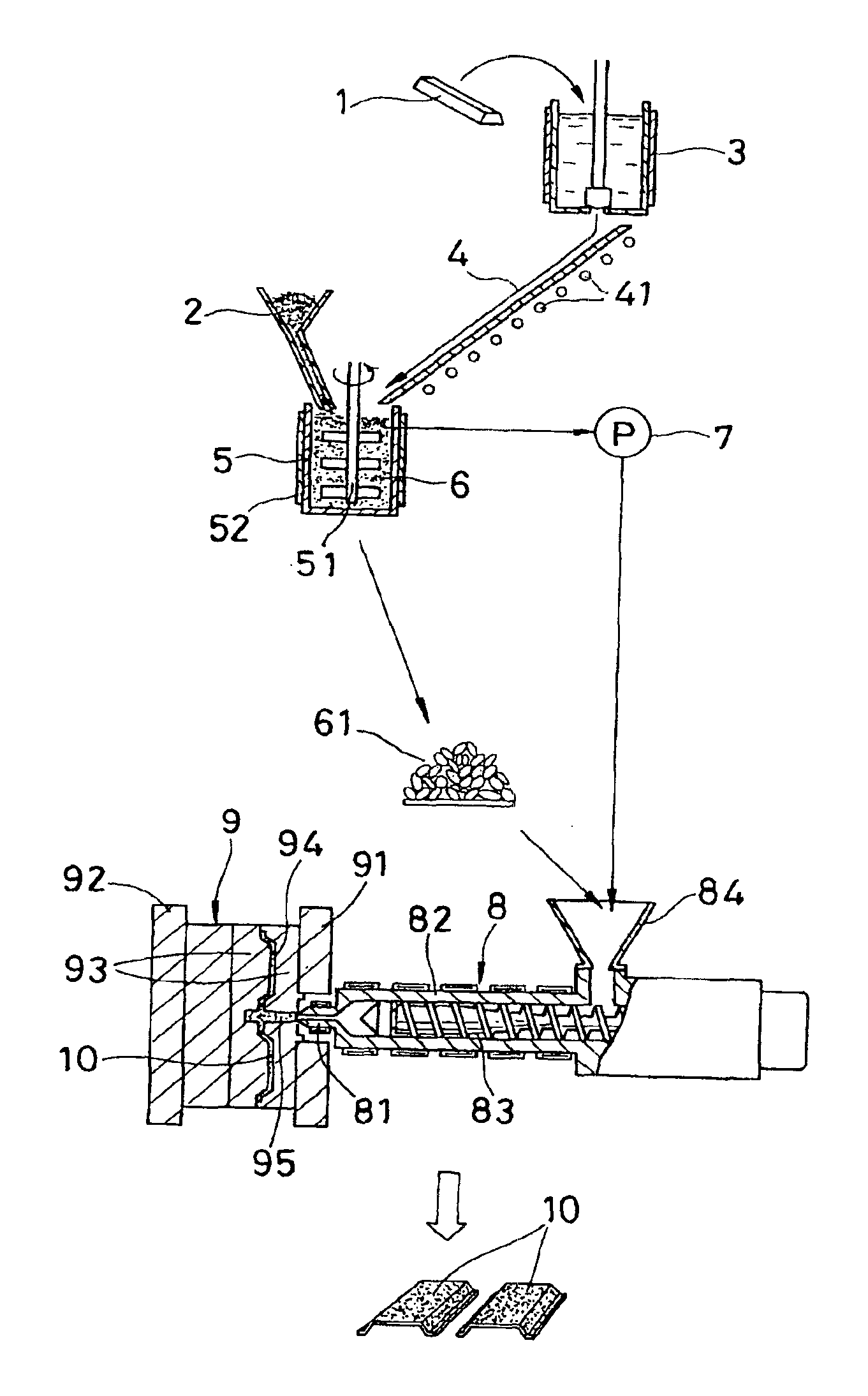

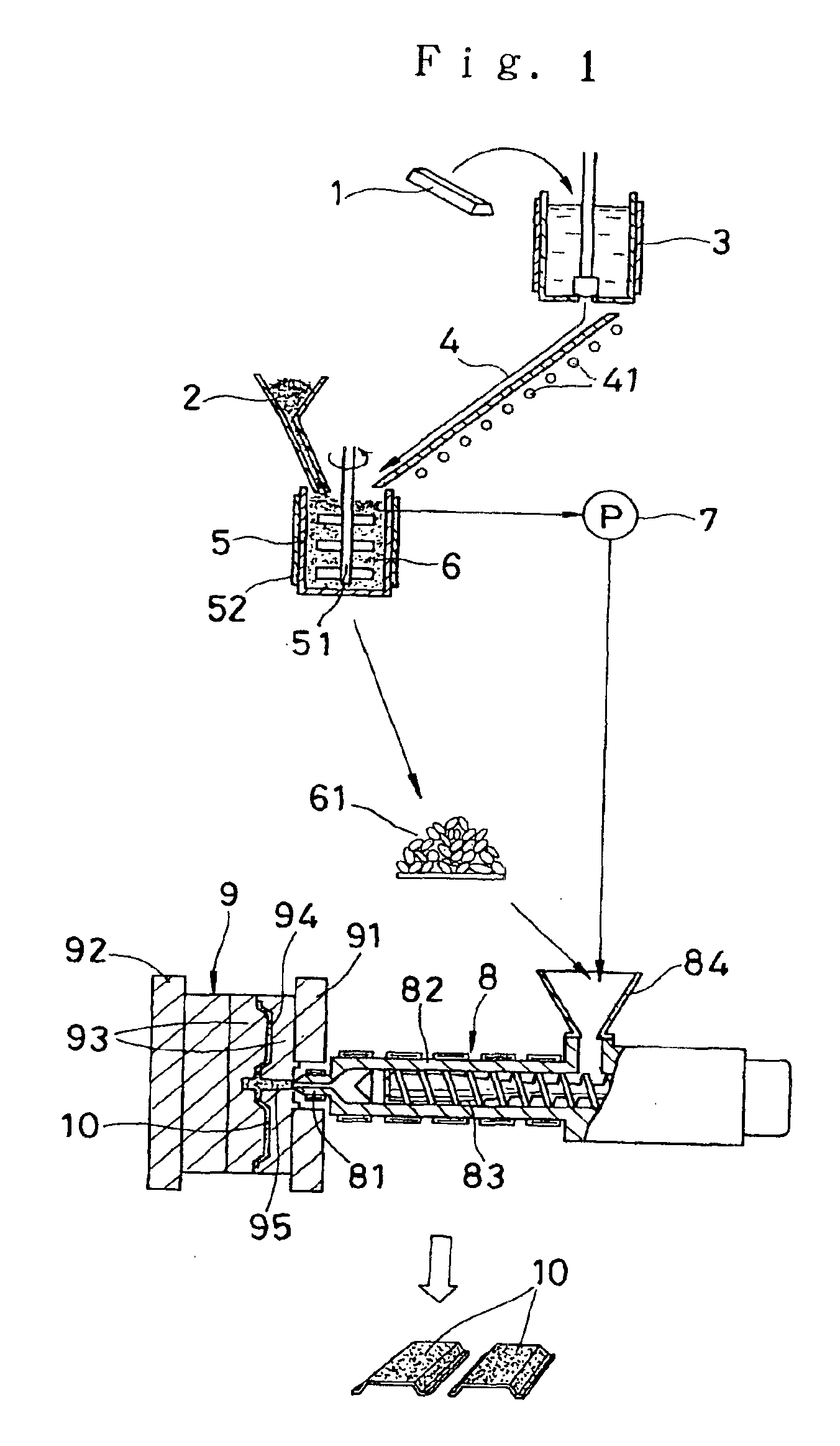

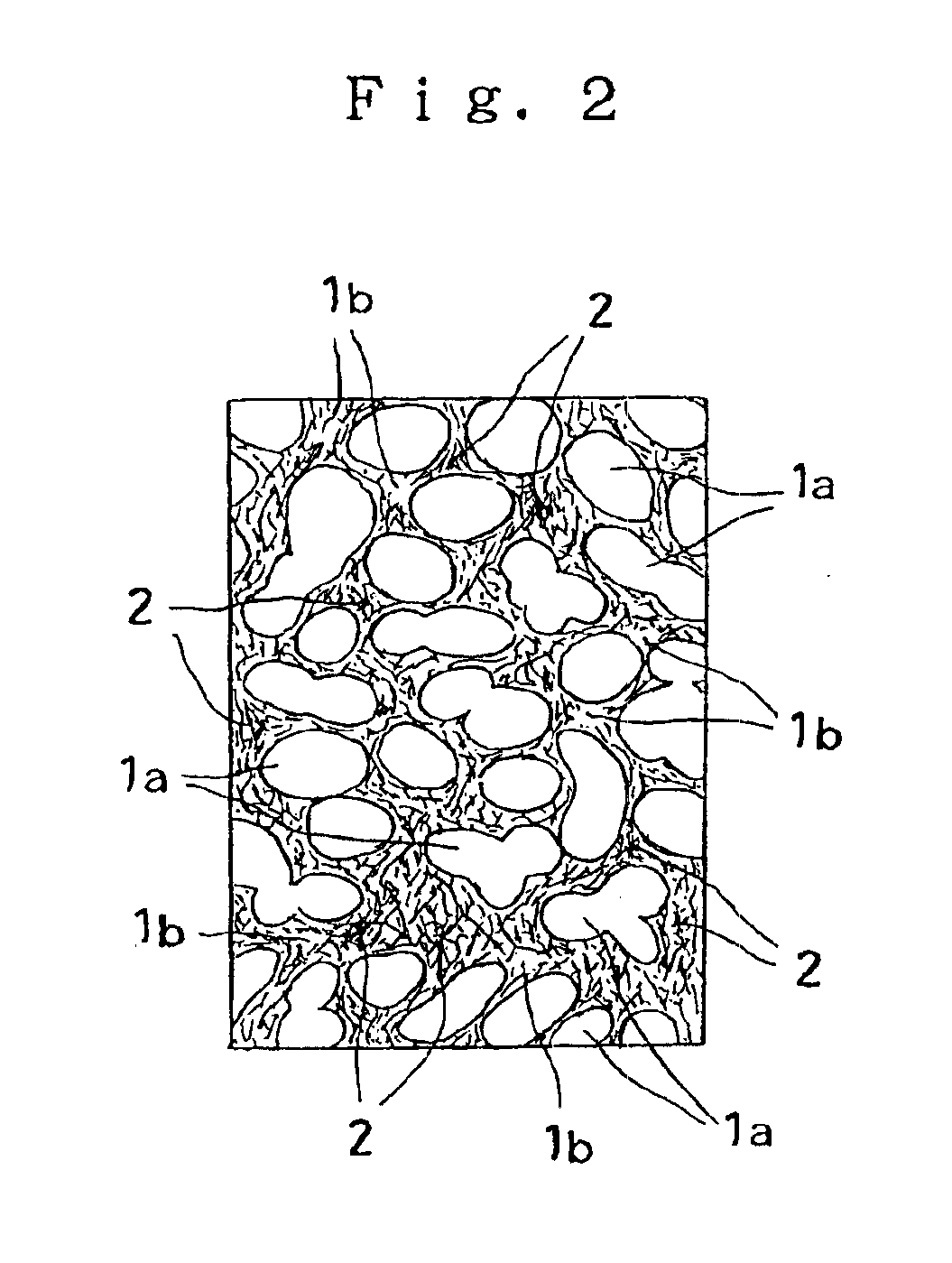

Method for producing a composite metal product

A low melting point metal material is made to a thixotropic state in which liquid phases and solid phases coexists. In the thixotropic state of the low melting point metal material, a carbon nano material is kneaded with the low melting point metal material and forms a composite material. Thus obtained composite material is supplied to a metal molding machine and injected into a mold in a thixotropic state or a completely molten state of the metal so that the composite material fills the mold, thereby the composite material is molded to a composite metal product. With the above process, it is possible to injection mold the composite metal product to which the characteristics of the carbon nano material are applied.

Owner:NISSEI PLASTIC IND CO LTD

Preparation method of high-specific-surface-area porous nitrogen-doped graphitizing carbon nanomaterial

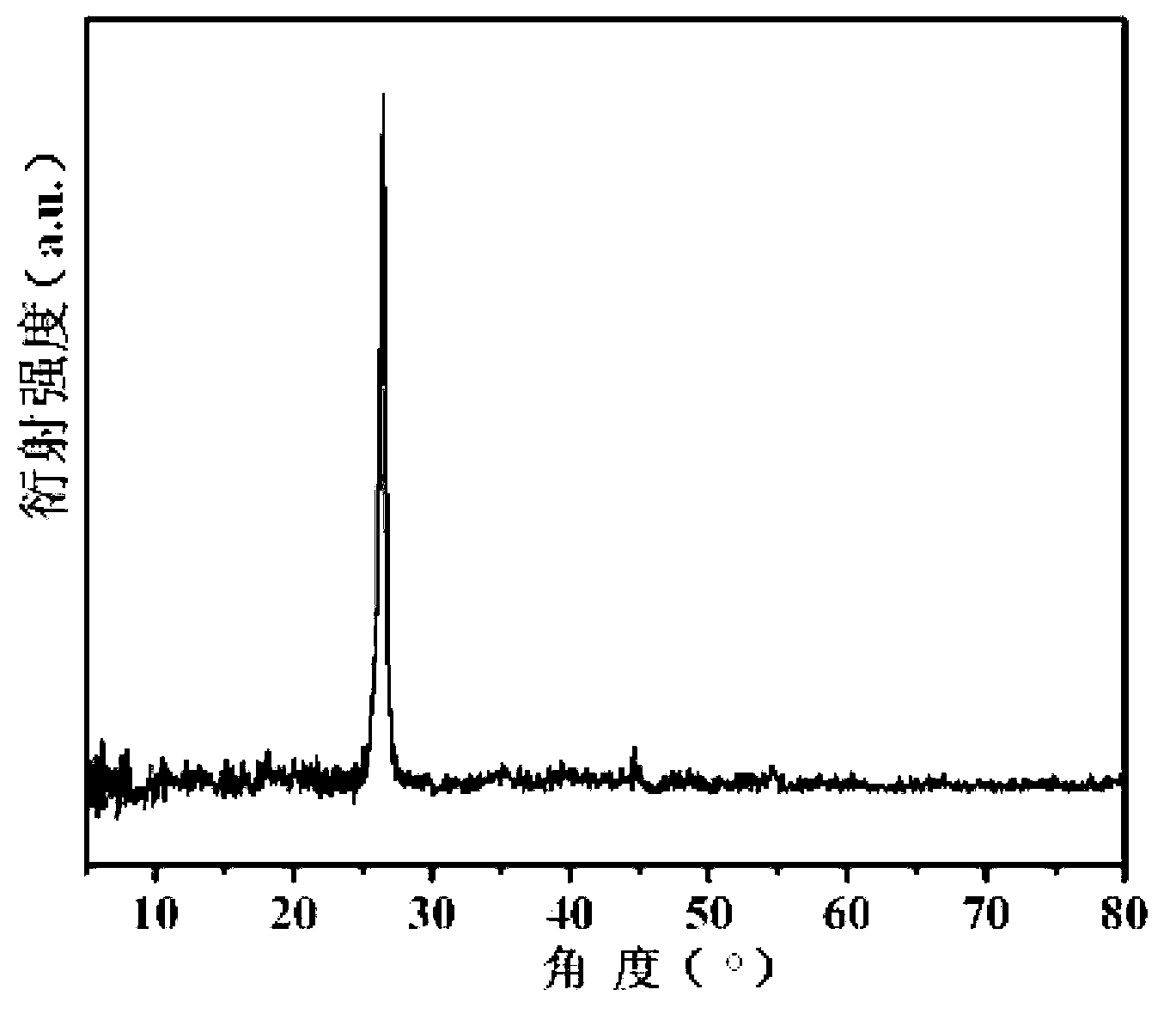

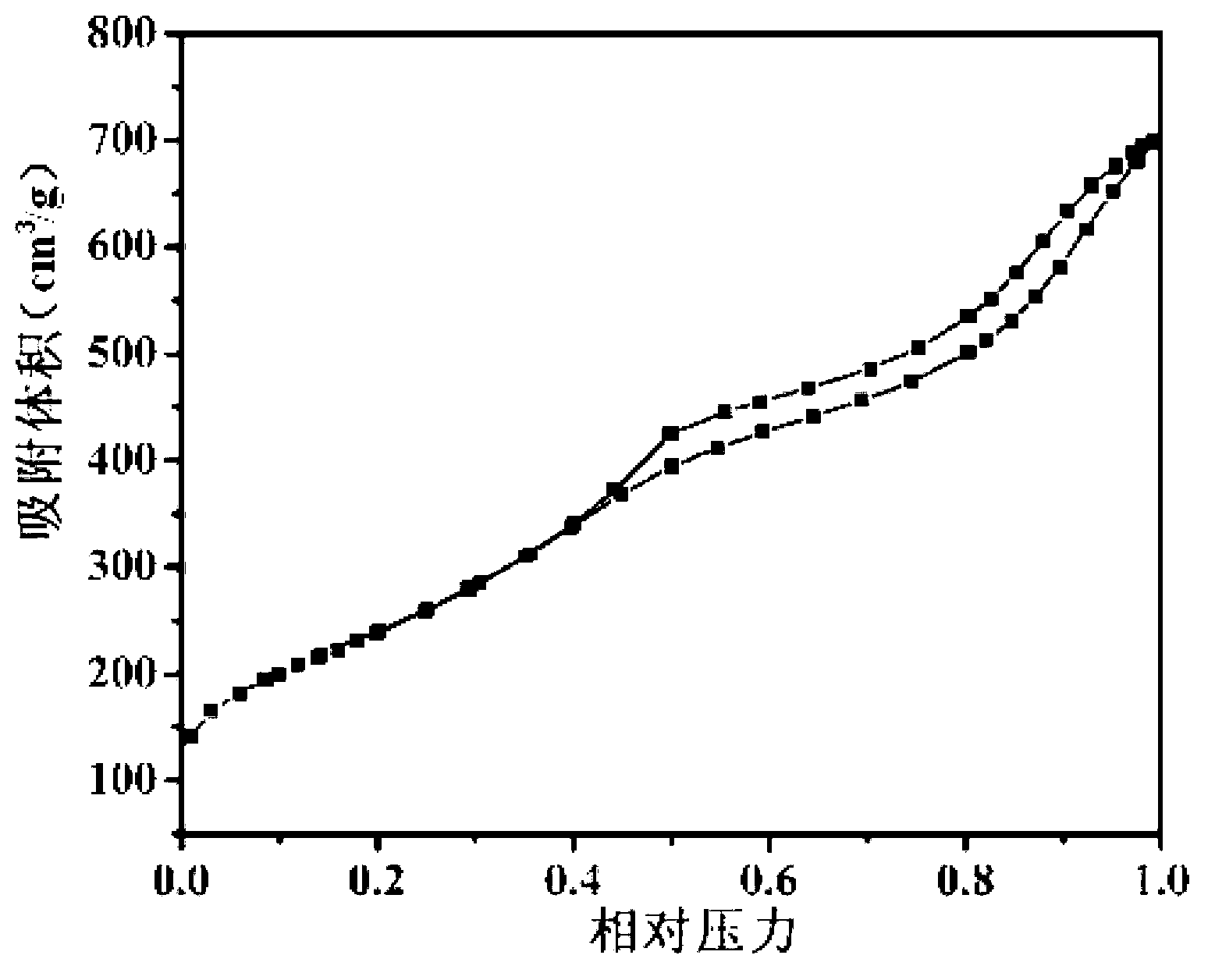

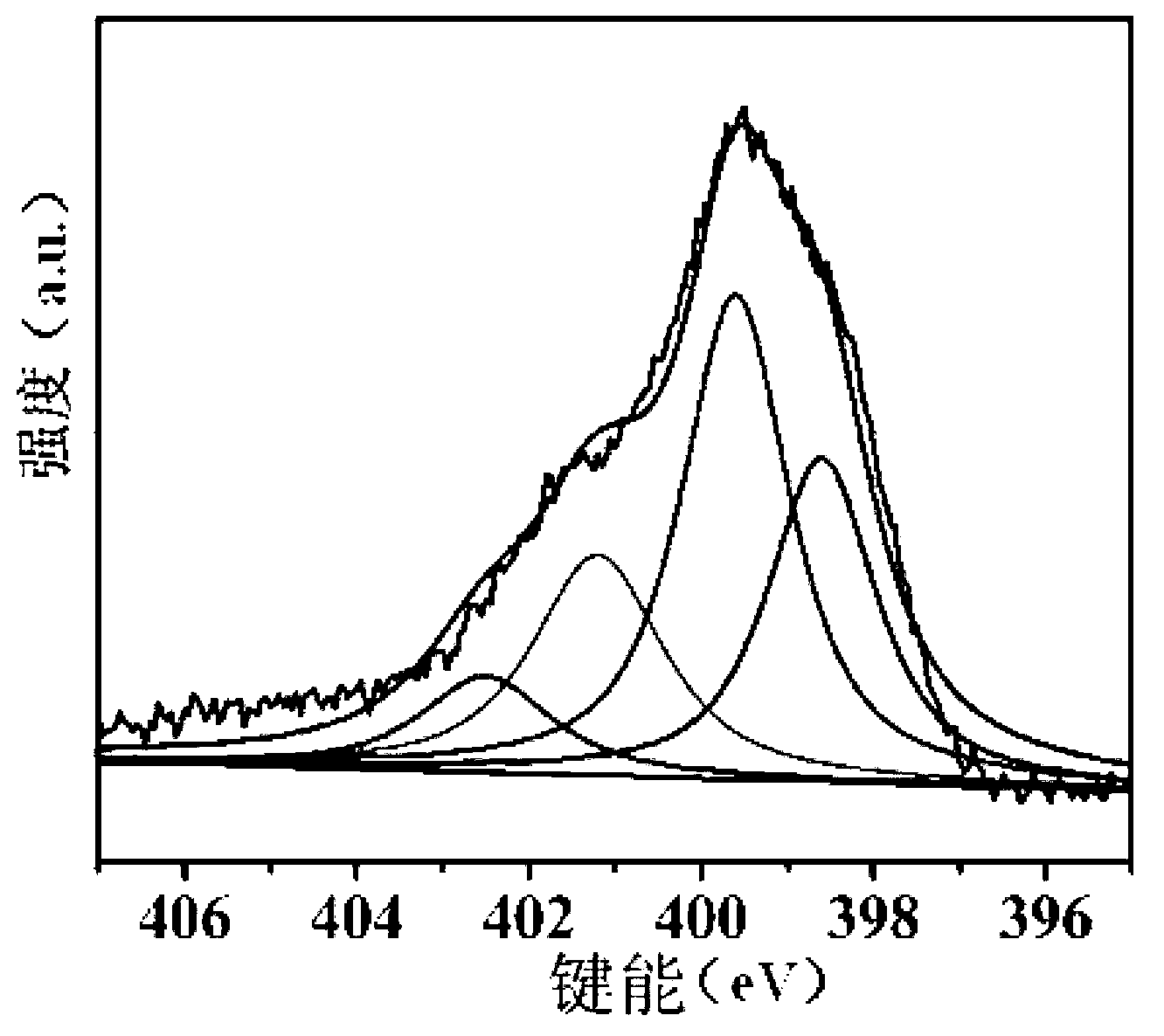

ActiveCN103303912AAchieve preparationHigh degree of graphitizationMaterial nanotechnologyNano-carbonLow nitrogenPore diameter

The invention discloses a preparation method of a high-specific-surface-area porous nitrogen-doped graphitizing carbon nanomaterial, relating to a preparation method of a carbon material and aiming at solving the problems of small specific surface area, low nitrogen content, low productivity, poor graphitizing degree and high cost of the nitrogen-doped graphitizing carbon nanomaterial prepared by the prior art. The preparation method comprises the steps of: I. preparing a complex; II. curing and carbonizing the complex; and III. carrying out acid leaching method treatment, and drying. Compared with an existing nitrogen-doped graphitizing carbon nanomaterial, the prepared high-specific-surface-area porous nitrogen-doped graphitizing carbon nanomaterial has the advantages that the graphitizing degree is improved, the nitrogen content is increased, and the specific surface area is obviously increased, and the high-specific-surface-area porous nitrogen-doped graphitizing carbon nanomaterial has obvious pore diameter distribution. The preparation method is used for preparing the high-specific-surface-area porous nitrogen-doped graphitizing carbon nanomaterial.

Owner:HEILONGJIANG UNIV

Carbon nano material/metal nano material composite nano ink

InactiveCN102993820AReduce manufacturing costLow costConductive layers on insulating-supportsInksCyclohexanoneKetone

The invention provides a carbon nano material / metal nano material composite nano ink which comprises solvent, an additive, a carbon nano material and a metal nano material. The carbon nano material / metal nano material composite nano ink is characterized in that the solvent can comprise water, alcohol organic solvent (ethanol(alcohol), isopropanol, n-butanol and the like), ester organic solvent (ethyl acetate, butyl acetate, ethylene-propylene acetate and the like), benzene organic solvent (methylbenzene, dimethylbenzene and the like) and ketone organic solvent (cyclohexanone, acetone, methylethylketone, butanone and the like); the additive comprises surfactant, pH value stabilizer, defoaming agent, diluter, reinforcer and the like; the carbon nano material comprises a single-layer carbon nanotube, a double-layer carbon nanotube, a multi-layer carbon nanotube and graphene; the metal (copper, silver, gold, platinum, nickel and the like, also including an alloy nano material, an ITO metal composite nano material and the like) nano material further comprises a metal nanoparticle, a metal nanowire or a metal nanotube; the components of the nano ink must include one carbon nano component and one metal nano component, such as a single-layer carbon nanotube and copper nanowire composite ink, a double-layer carbon nanotube and silver nanowire composite ink, a single-layer carbon nanotube and silver nanoparticle composite ink or any other possible combination; the components can be regulated according to specific applications; and a composite nano conductive film can be formed on different bases through different electronic printing processes. The ink can be used in the printing of a flexible base material and can be conveniently prepared into a flexible conductive film.

Owner:杨阳

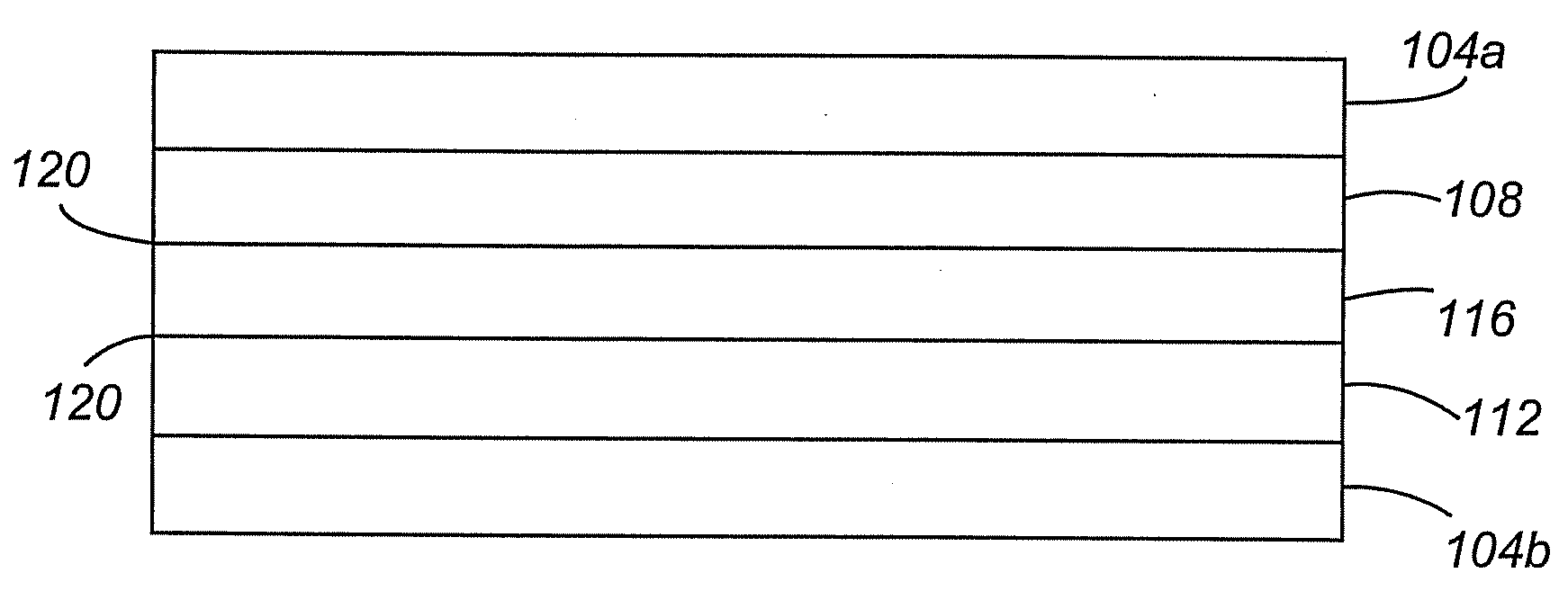

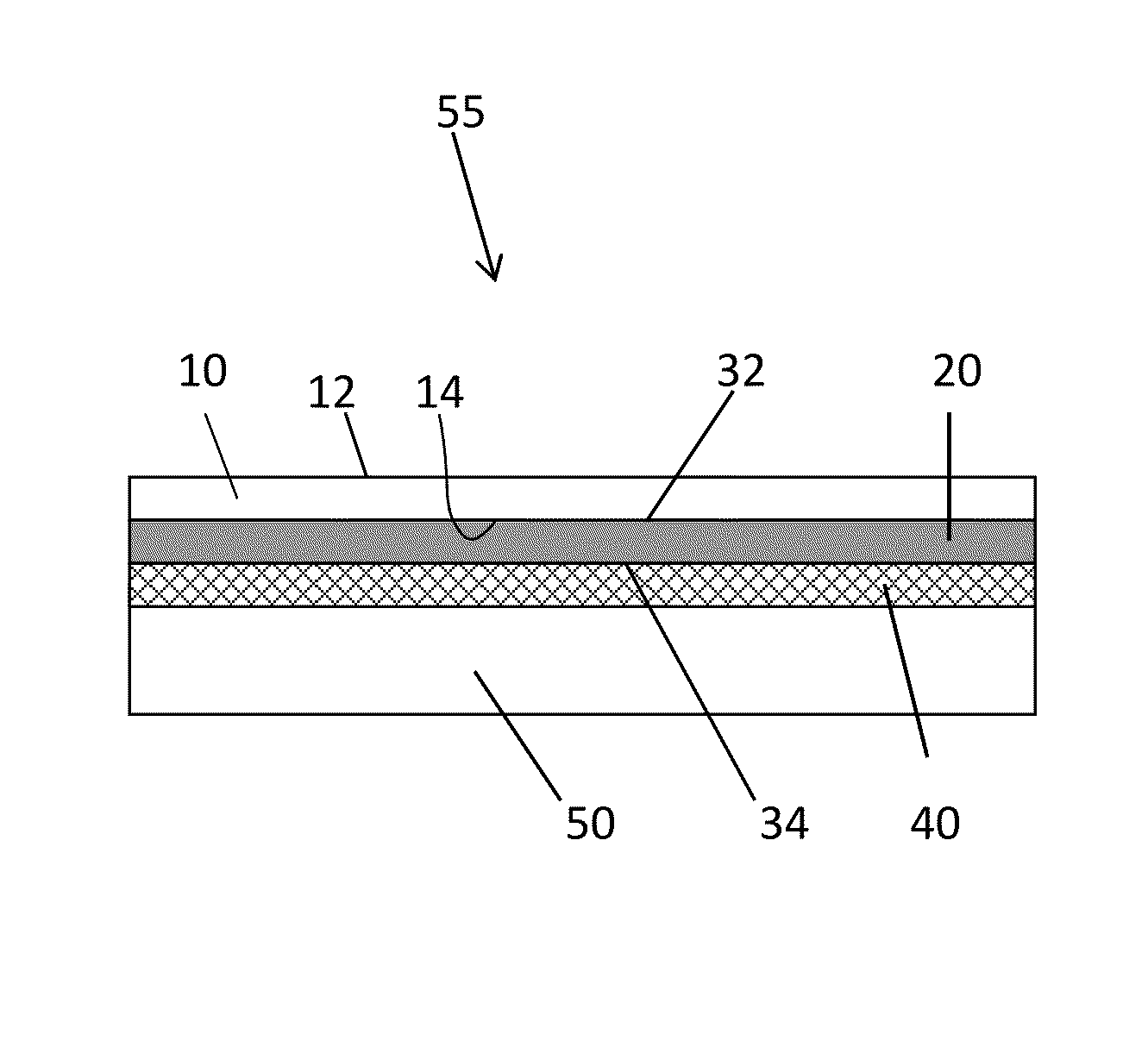

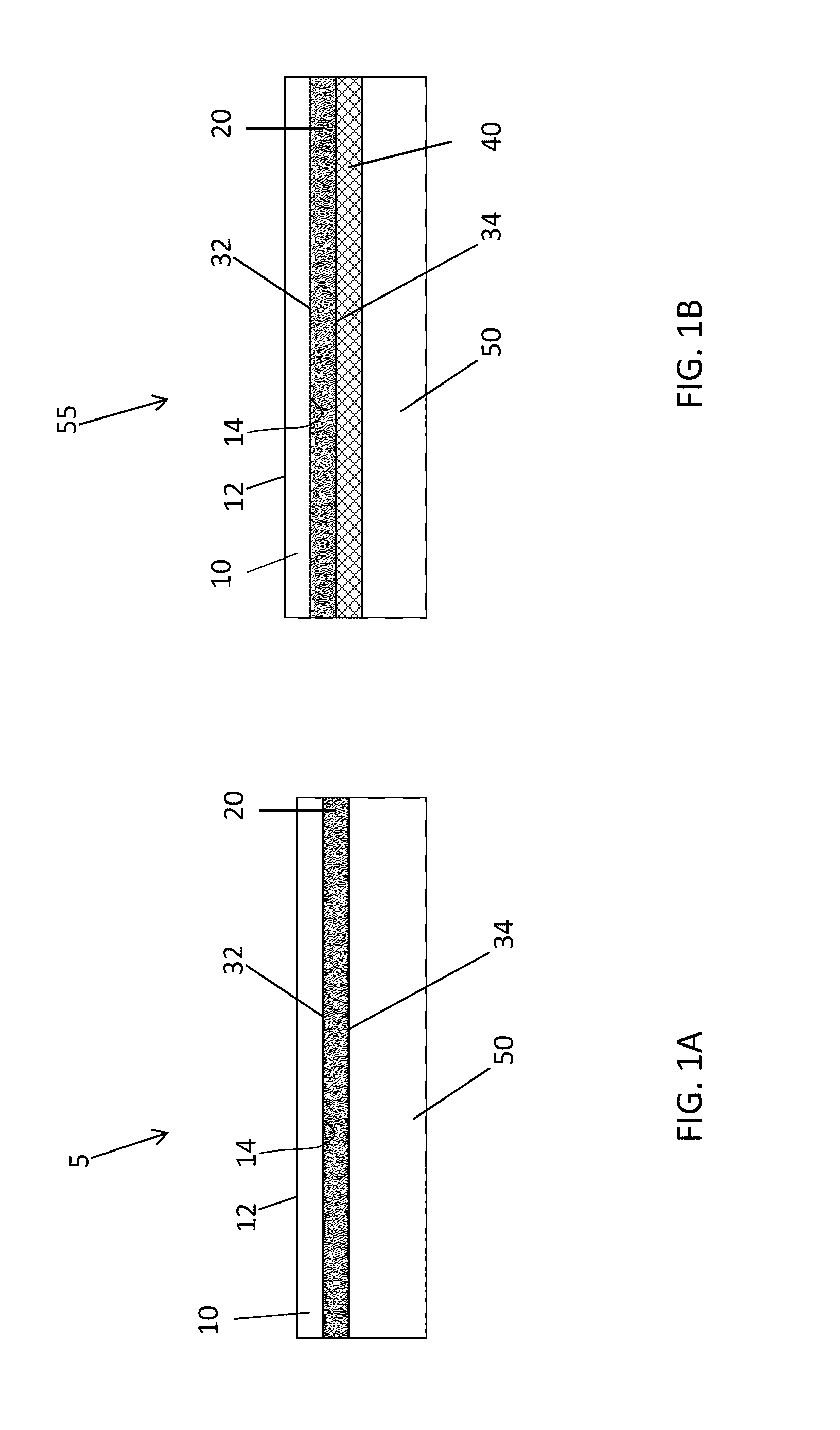

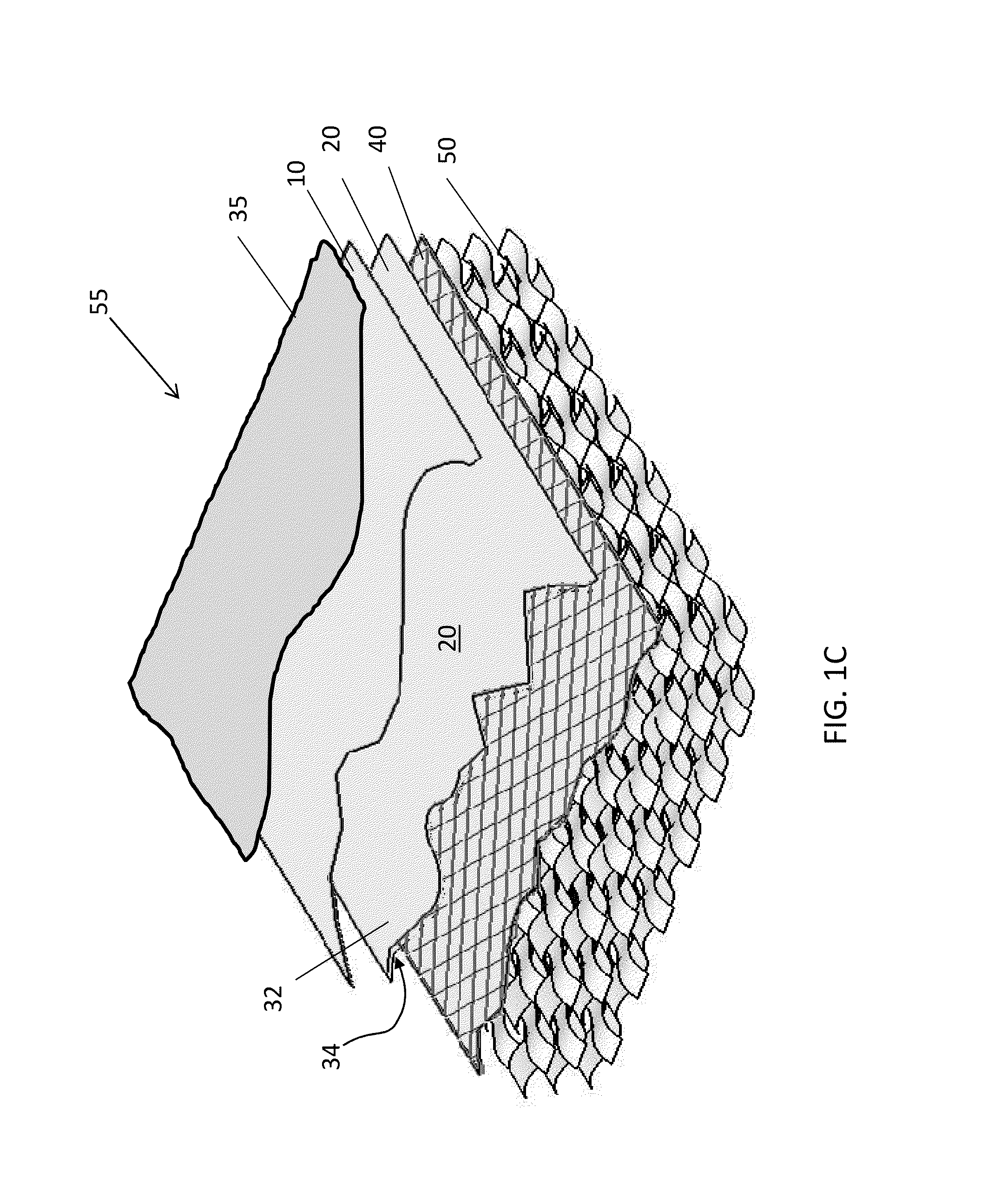

Nanoreinforced films and laminates for aerospace structures

ActiveUS20140011414A1Improved ultraviolet resistance and resistance to microcrackingMaterial nanotechnologyWarp knittingPolymer resinNanofiber

A composite laminate for use on an external part of an aerospace vehicle has improved ultraviolet resistance and resistance to microcracking from thermal cycling. The laminate comprises a nanoreinforcement film, a support veil, and a composite layer. The laminate also can have a lightning strike protection layer and an external paint and primer. The nanoreinforcement film can comprise carbon nanomaterial and a polymer resin, and the composite layer has one or more layers of a reinforcement and a polymer resin. The carbon nanomaterial can be carbon nanofibers, and the nanoreinforcement film can have an areal weight of less than about 100 g / m2. The carbon nanomaterial can also comprise carbon nanofibers and carbon nanotubes.

Owner:ROHR INC +1

Enhancing thermal conductivity of fluids with graphite nanoparticles and carbon nanotube

InactiveUS7348298B2Improve thermal conductivityGood enhancement of thermal characteristicMaterial nanotechnologyAdditivesNanoparticleGraphite

A fluid media such as oil or water, and a selected effective amount of carbon nanomaterials necessary to enhance the thermal conductivity of the fluid. One of the preferred carbon nanomaterials is a high thermal conductivity graphite, exceeding that of the neat fluid to be dispersed therein in thermal conductivity, and ground, milled, or naturally prepared with mean particle size less than 500 nm, and preferably less than 200 nm, and most preferably less than 100 nm. The graphite is dispersed in the fluid by one or more of various methods, including ultrasonication, milling, and chemical dispersion. Carbon nanotubes with graphitic structure is another preferred source of carbon nanomaterial, although other carbon nanomaterials are acceptable. To confer long term stability, the use of one or more chemical dispersants is preferred. The thermal conductivity enhancement, compared to the fluid without carbon nanomaterial, is proportional to the amount of carbon nanomaterials (carbon nanotubes and / or graphite) added.

Owner:ASHLAND OIL INC +1

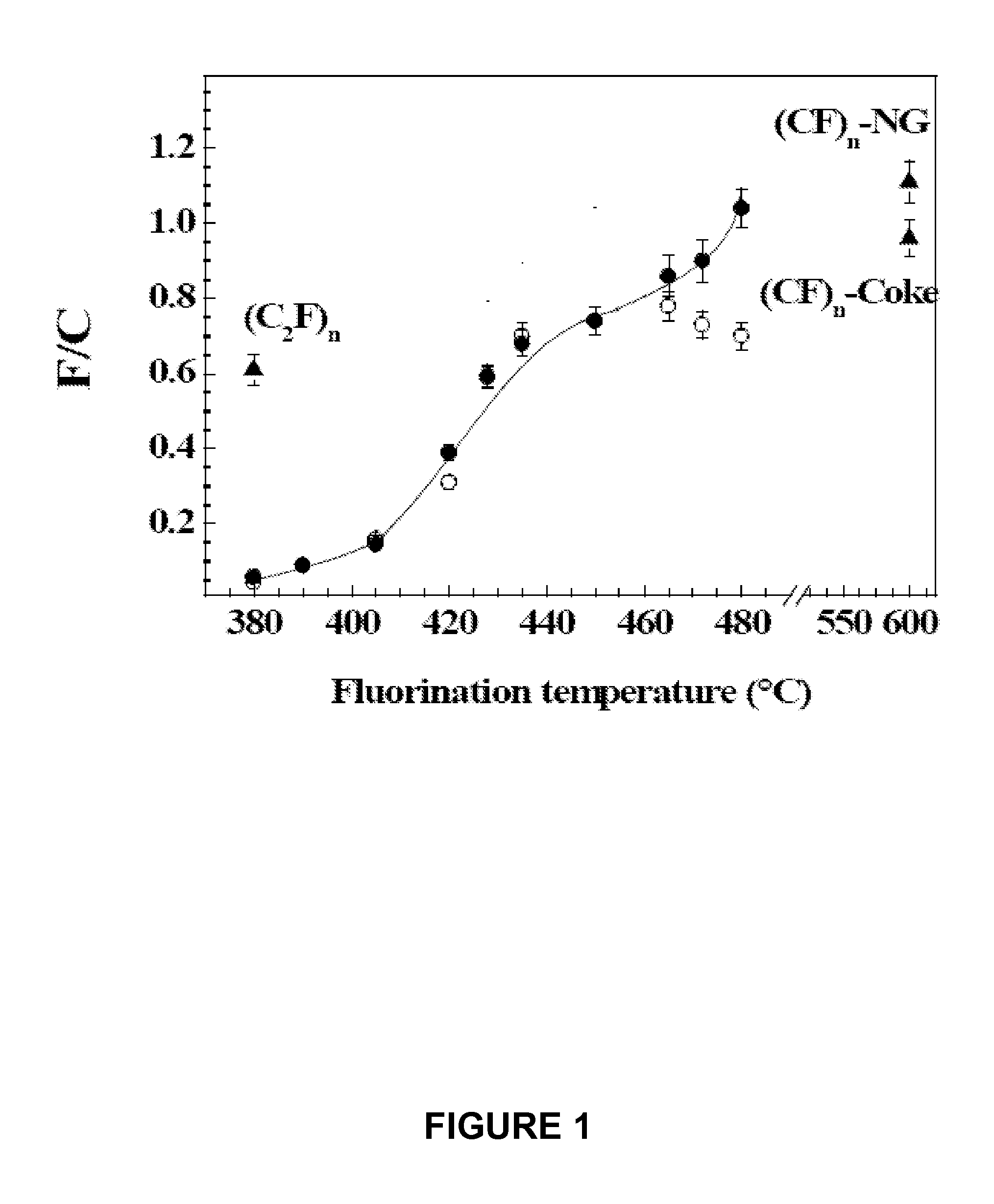

Fluorination of multi-layered carbon nanomaterials

ActiveUS20070231696A1Improve battery performanceHigh discharge rateMaterial nanotechnologyPigmenting treatmentLithiumElectrochemistry

The invention provides fluorinated multi-layered carbon nanomaterials and methods for their production. In one aspect of the invention, the carbon nanomaterials are partially fluorinated and retain some unreacted carbon. The invention also provides electrodes and electrochemical devices incorporating the fluorinated carbon nanomaterials of the invention. In one aspect of the invention, the electrochemical has a first electrode including the at least partially fluorinated carbon materials of the invention and a second electrode including a source of lithium ions

Owner:CENT NAT DE LA RECHERCHE SCI +2

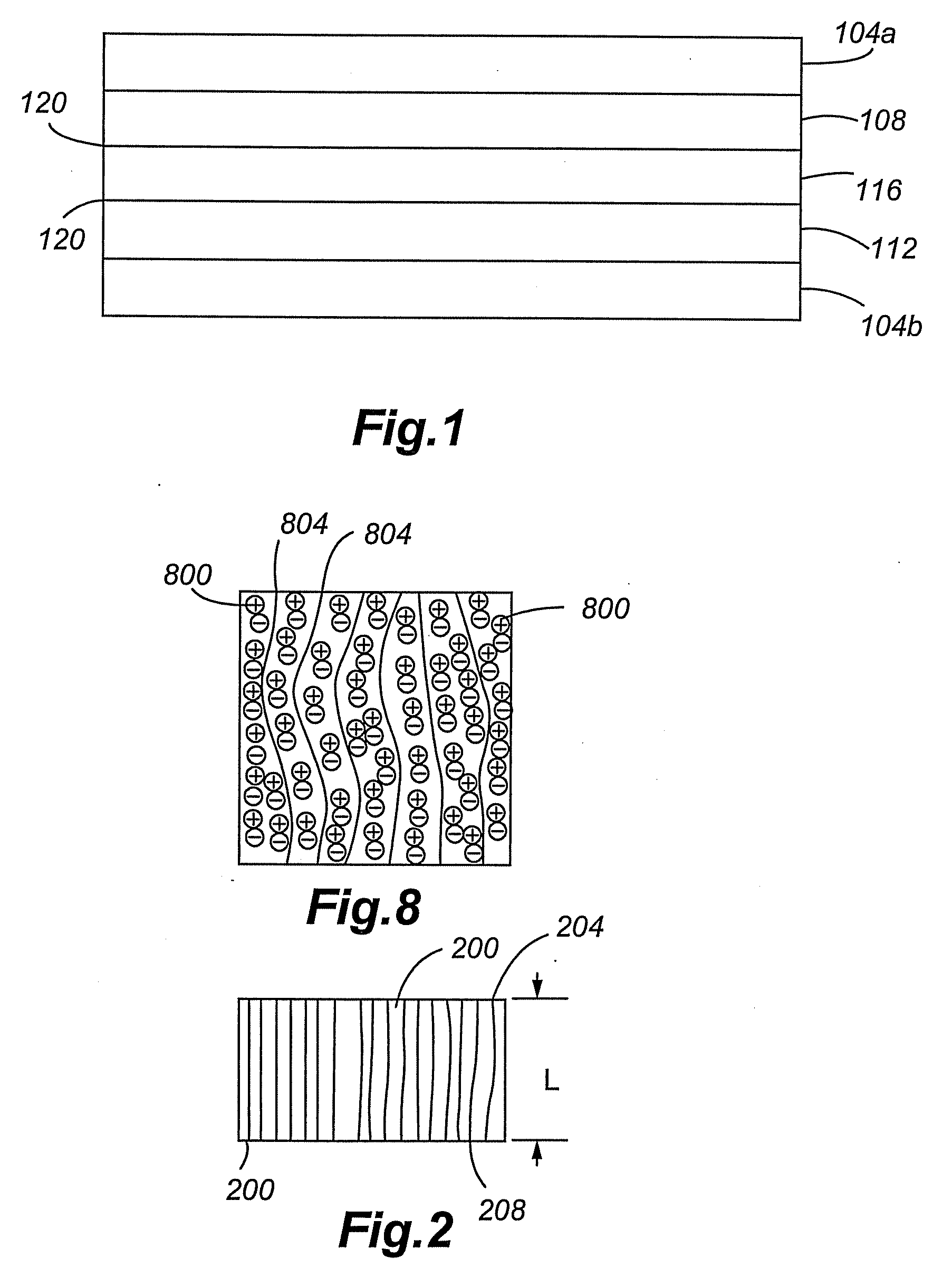

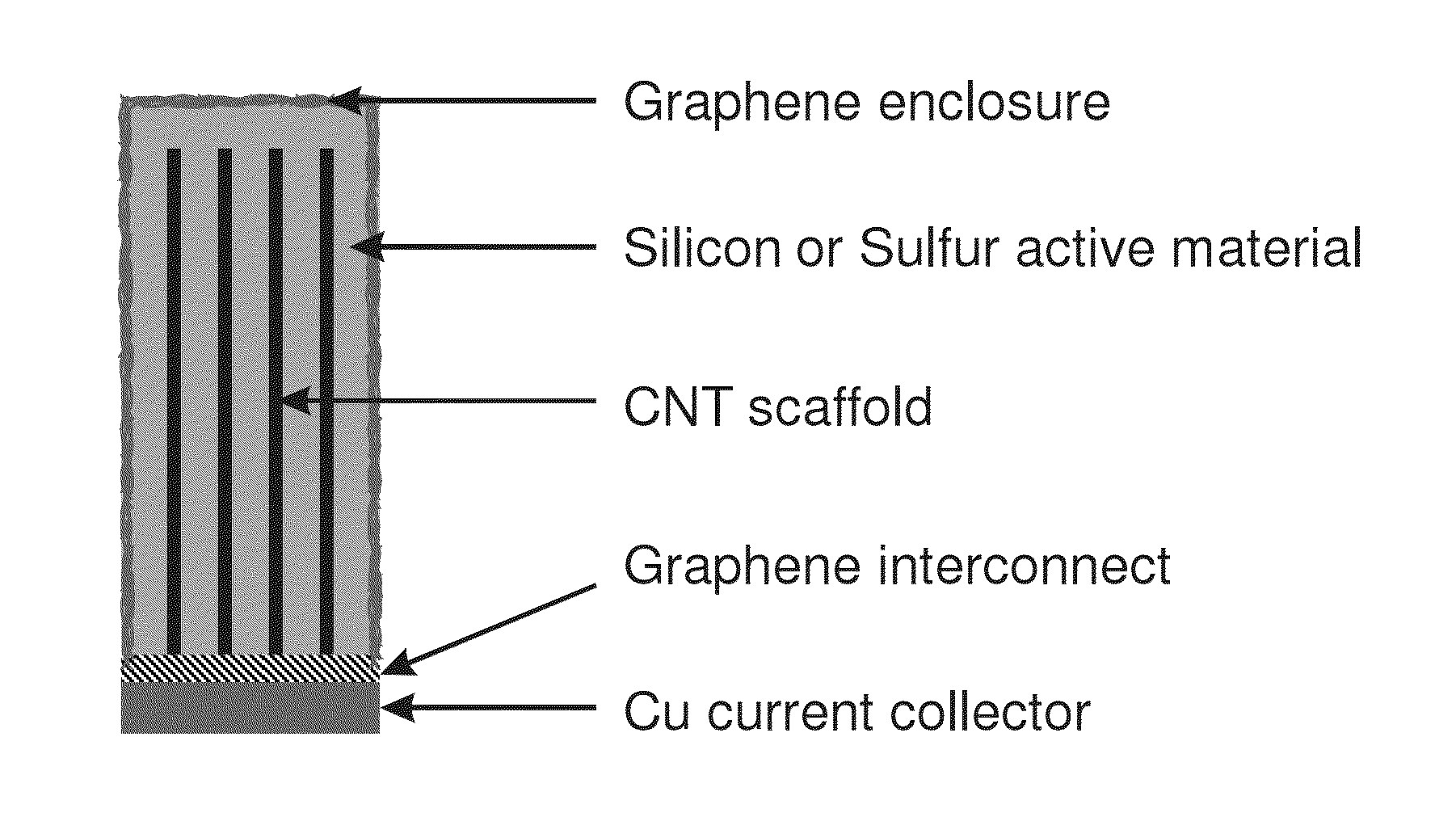

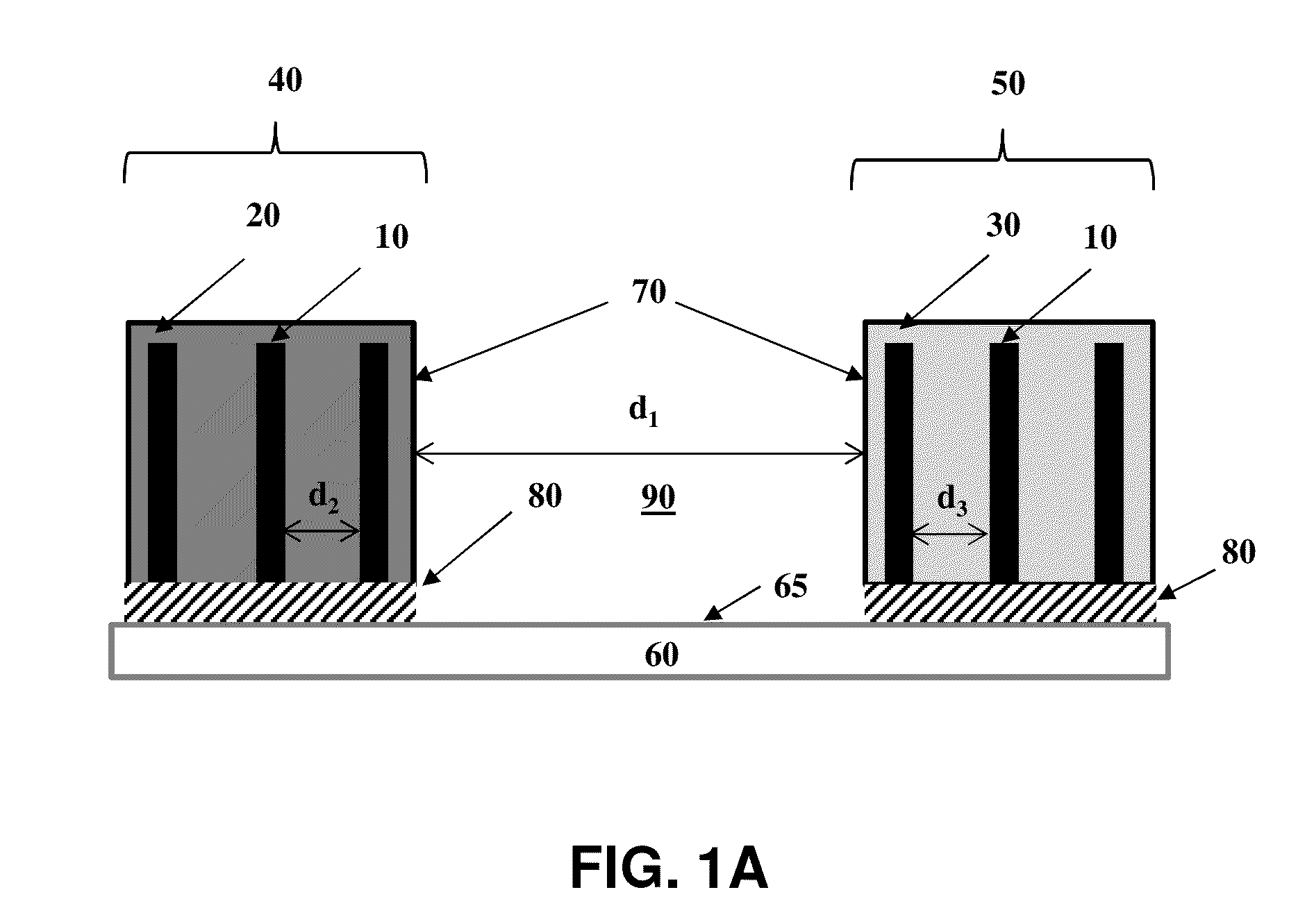

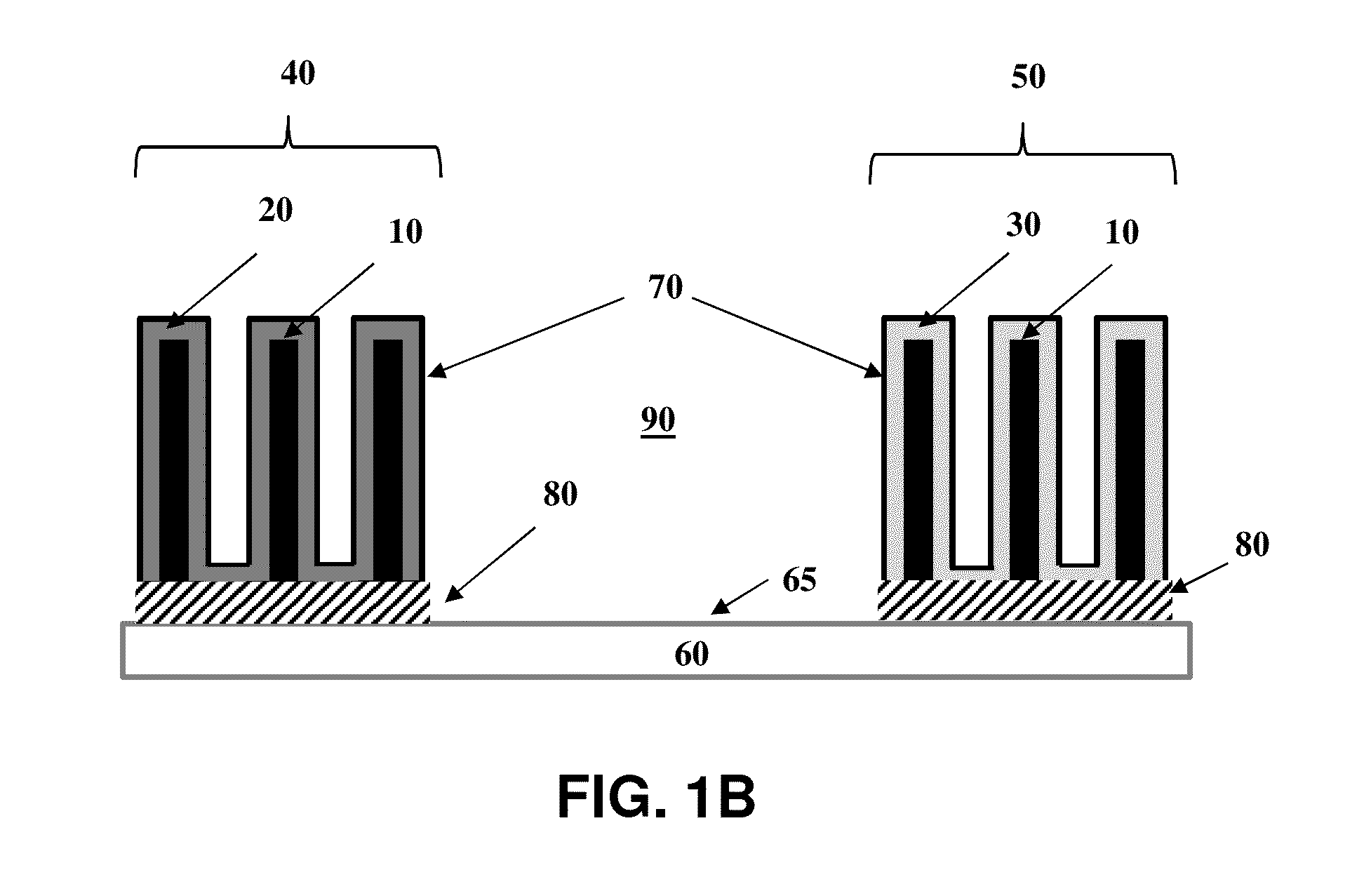

Carbon Nanotubes - Graphene Hybrid Structures for Separator Free Silicon - Sulfur Batteries

ActiveUS20150010788A1Improve power performanceImprove cycle lifeMaterial nanotechnologyFinal product manufactureMetallic lithiumDischarge rate

Provided herein are electrochemical systems and related methods of making and using electrochemical systems. Electrochemical systems of the invention implement novel cell geometries and composite carbon nanomaterials based design strategies useful for achieving enhanced electrical power source performance, particularly high specific energies, useful discharge rate capabilities and good cycle life. Electrochemical systems of the invention are versatile and include secondary lithium ion cells, such as silicon-sulfur lithium ion batteries, useful for a range of important applications including use in portable electronic devices. Electrochemical cells of the present invention also exhibit enhanced safety and stability relative to conventional state of the art lithium ion secondary batteries by using prelithiated active materials to eliminate the use of metallic lithium and incorporating carbon nanotube and / or graphene, composite electrode structures to manage residual stress and mechanical strain arising from expansion and contraction of active materials during charge and discharge.

Owner:CALIFORNIA INST OF TECH

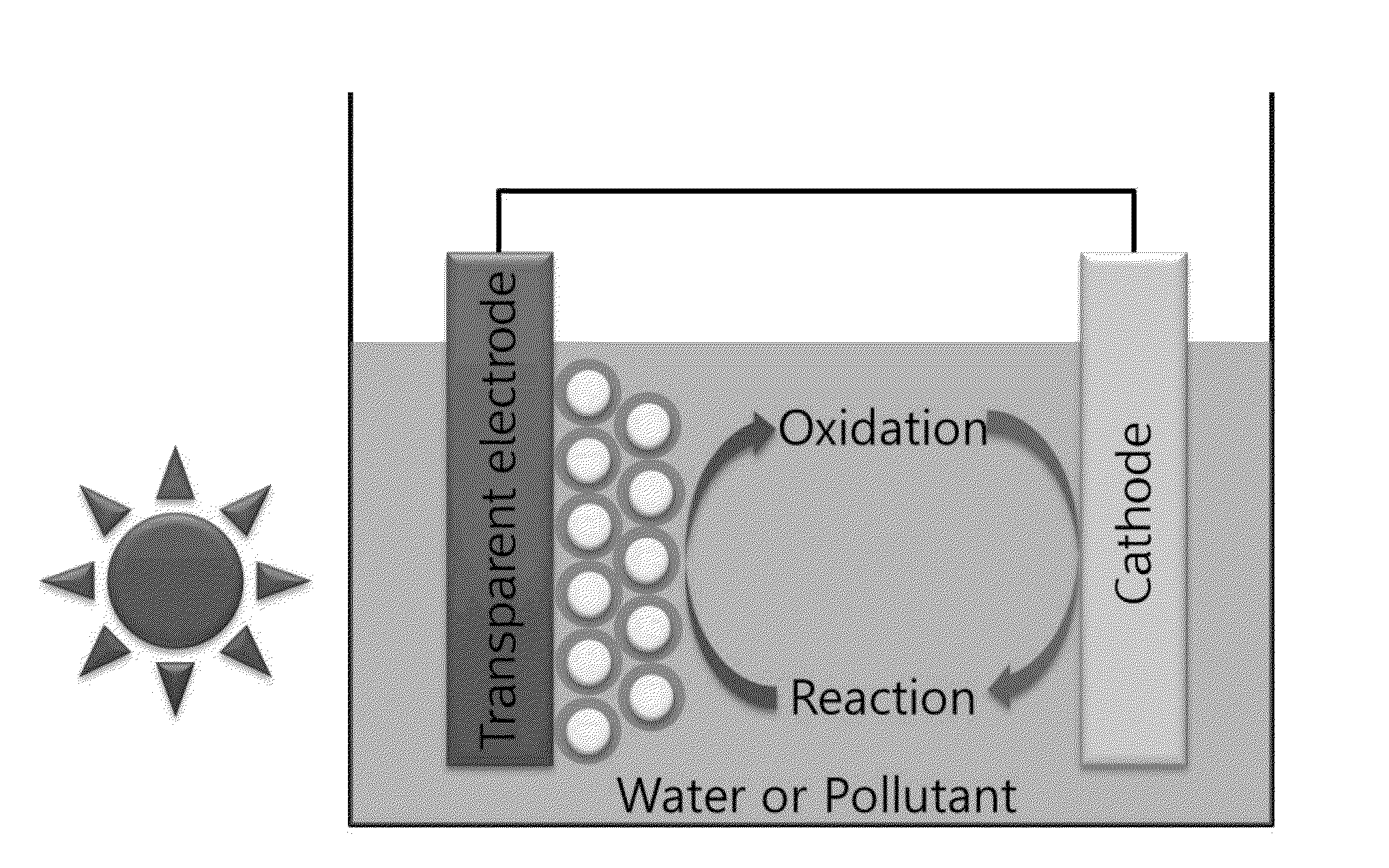

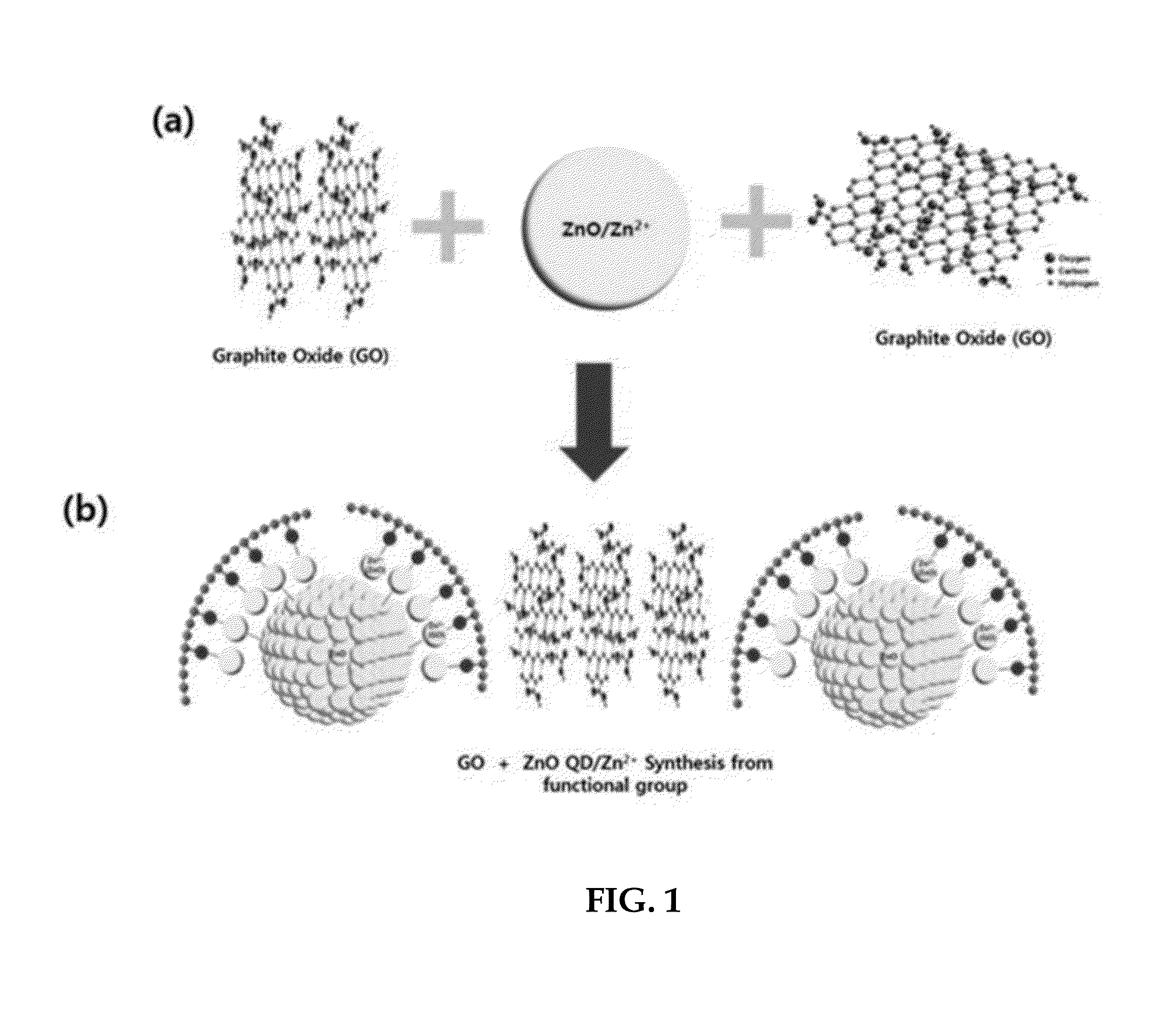

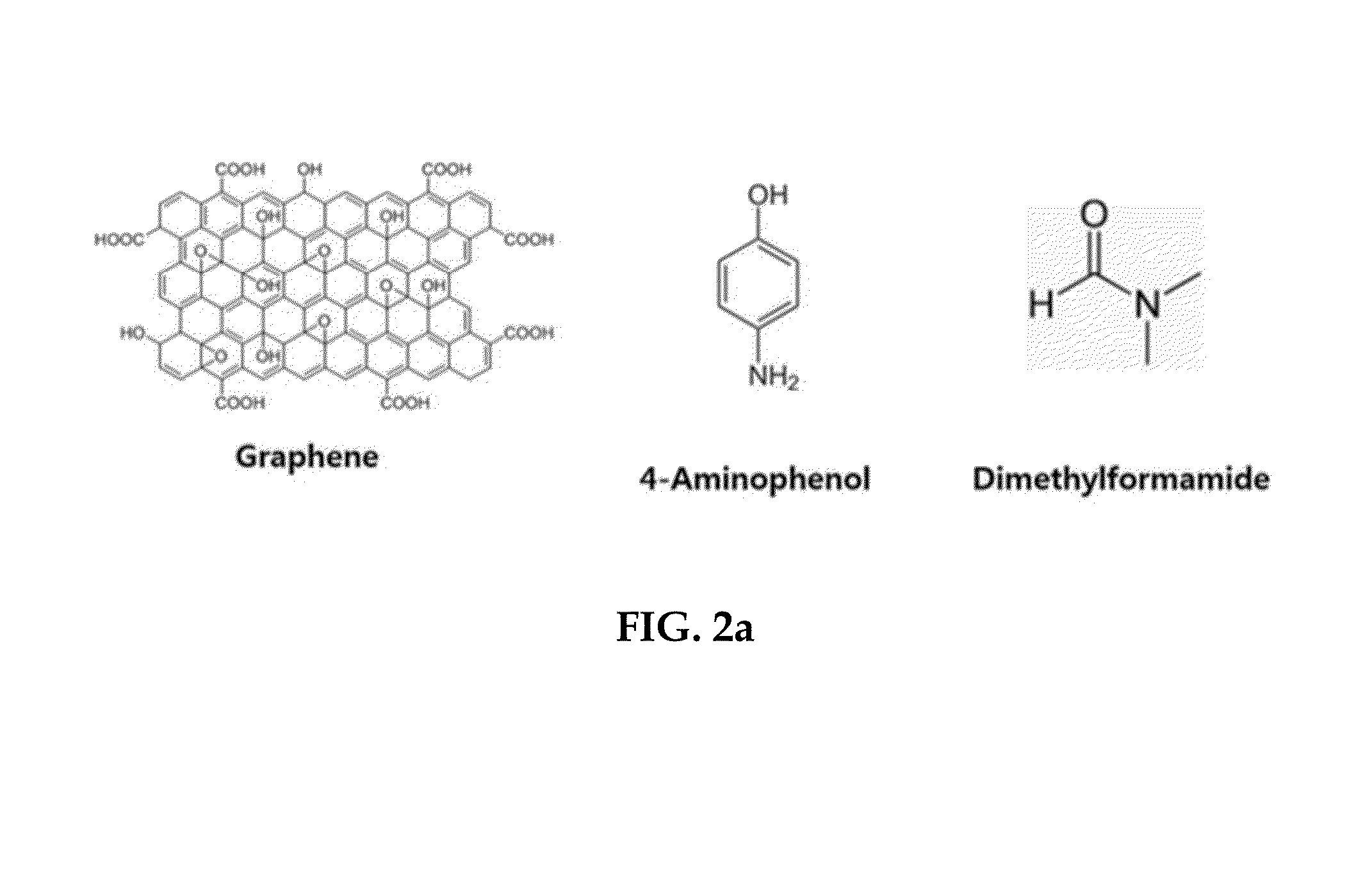

Photocatalyst using semiconductor-carbon nanomaterial core-shell composite quantum dot and method for preparing the same

ActiveUS20160144348A1Improve photocatalytic performanceImprove solubilityCellsLight-sensitive devicesQuantum dotMicroparticle

The present invention relates to a photocatalyst using a semiconductor-carbon nanomaterial core-shell composite quantum dot and a method for preparing the same, more particularly to a microparticle in which a semiconductor-carbon nanomaterial core-shell composite quantum dot is self-assembled using 4-aminophenol, capable of improving photoelectochemical response and photoconversion efficiency when used as a photocatalyst or a photoelectrode of a photoelectochemical device, a photoelectochemical device using the same and a method for preparing the same.

Owner:KOREA INST OF SCI & TECH

Conductive yarn and production method thereof

InactiveCN103820909AAdjustable resistanceHas bactericidal propertiesYarnNanowireCarbon nanomaterials

The invention relates to a conductive yarn, made by wrapping a yarn with a metal nano-wire and carbon nanomaterial, and a production method thereof. The method includes: soaking a yarn in metal nano-wire solution and evaporating and drying, or repeating the step, to obtain the metal nano-wire wrapped conductive yarn; or soaking the metal nano-wire wrapped yarn in carbon nanomaterial solution and evaporating and drying, or repeating the step several times, to obtain the conductive yarn wrapped with the metal nano-wire and the carbon nanomaterial material; or soaking a yarn in metal nano-wire and carbon nanomaterial mixed solution and evaporating and drying, or repeating the step several times, to obtain the conductive yarn wrapped with the carbon nanomaterial and the metal nano-wire. The production method is very simple, easy for industrialized production and applicable to production of textile electronic devise, and has very promising application prospect.

Owner:NANJING UNIV OF POSTS & TELECOMM

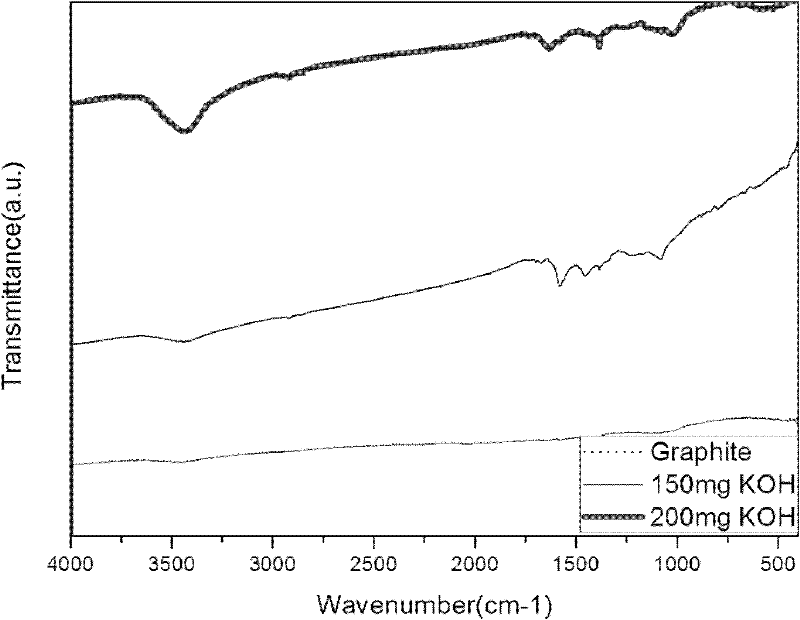

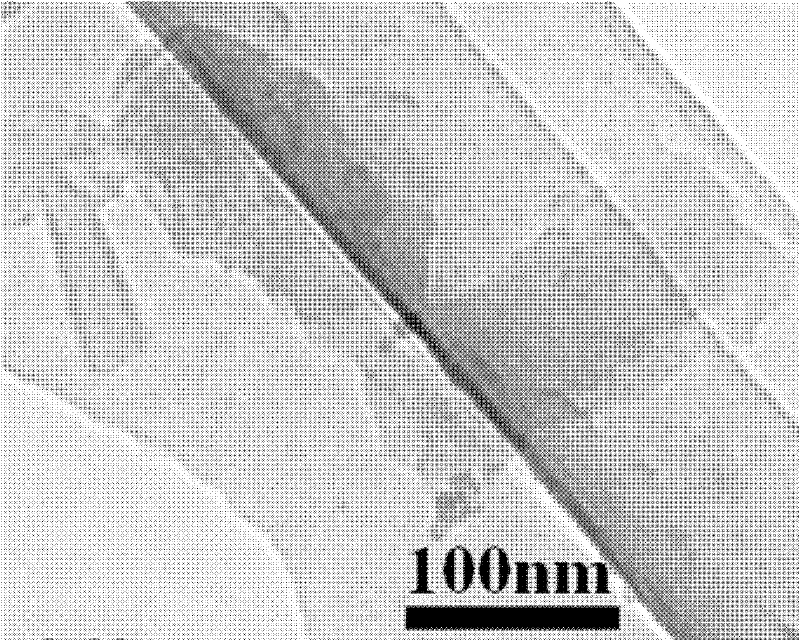

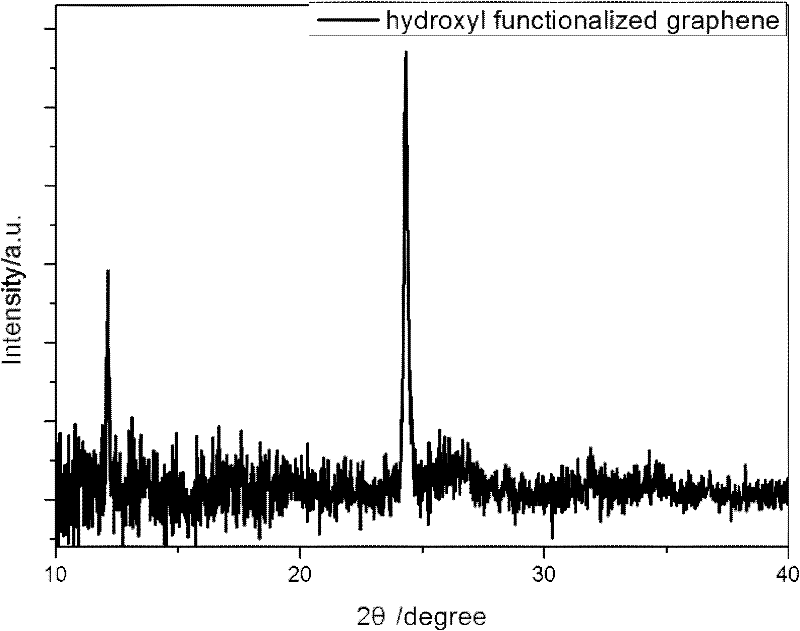

Low-temperature preparation method of hydroxy-functionalized graphene

InactiveCN102225759AThe internal structure is intactHigh degree of crystallinityNanotechnologyPotassium hydroxideEngineering

The invention relates to a novel and simple low-temperature preparation method of hydroxy-functionalized grapheme, belonging to the field of novel carbon nanomaterials. The preparation method provided by the invention comprises the following steps of: adding graphite powder and potassium hydroxide solid to a ball milling tank, then adding milling balls to the ball milling tank, placing the ball milling tank in a ball mill, continuously ball-milling under air blast and room temperature conditions at a speed of 200-400 r / min for 10-16 hours, transferring the ball-mill product to a sample bottle by deionized water, and then removing unreacted potassium hydroxide by deionized water until the solution was neutral. By using the preparation method provided by the invention, hydroxy-functionalized grapheme can be prepared at room temperature, and the hydroxy-functionalized grapheme has a lamellar structure, contains a large number of hydroxyl groups on the surface, well remained internal structure and a high crystallinity.

Owner:WENZHOU MEDICAL UNIV

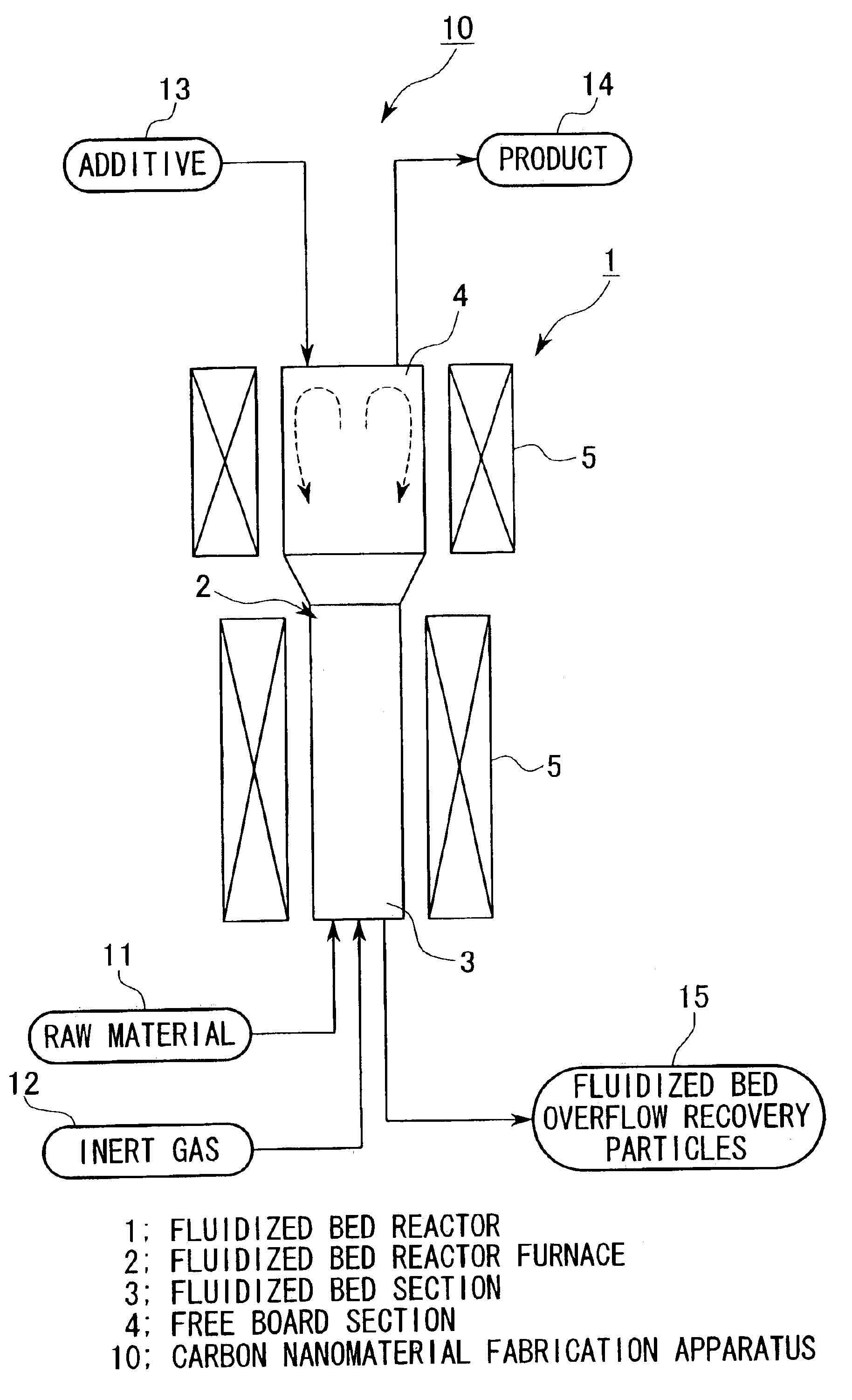

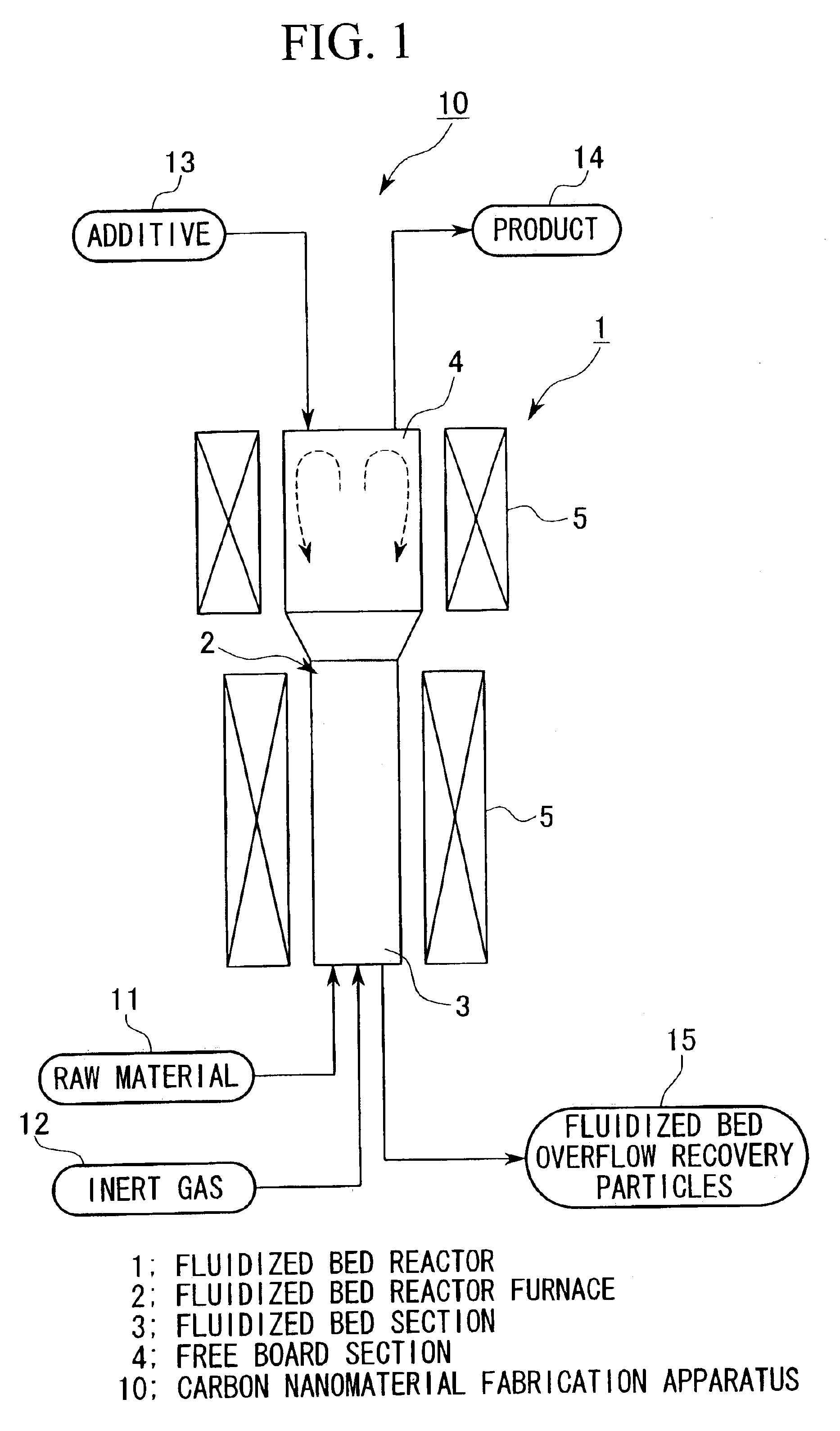

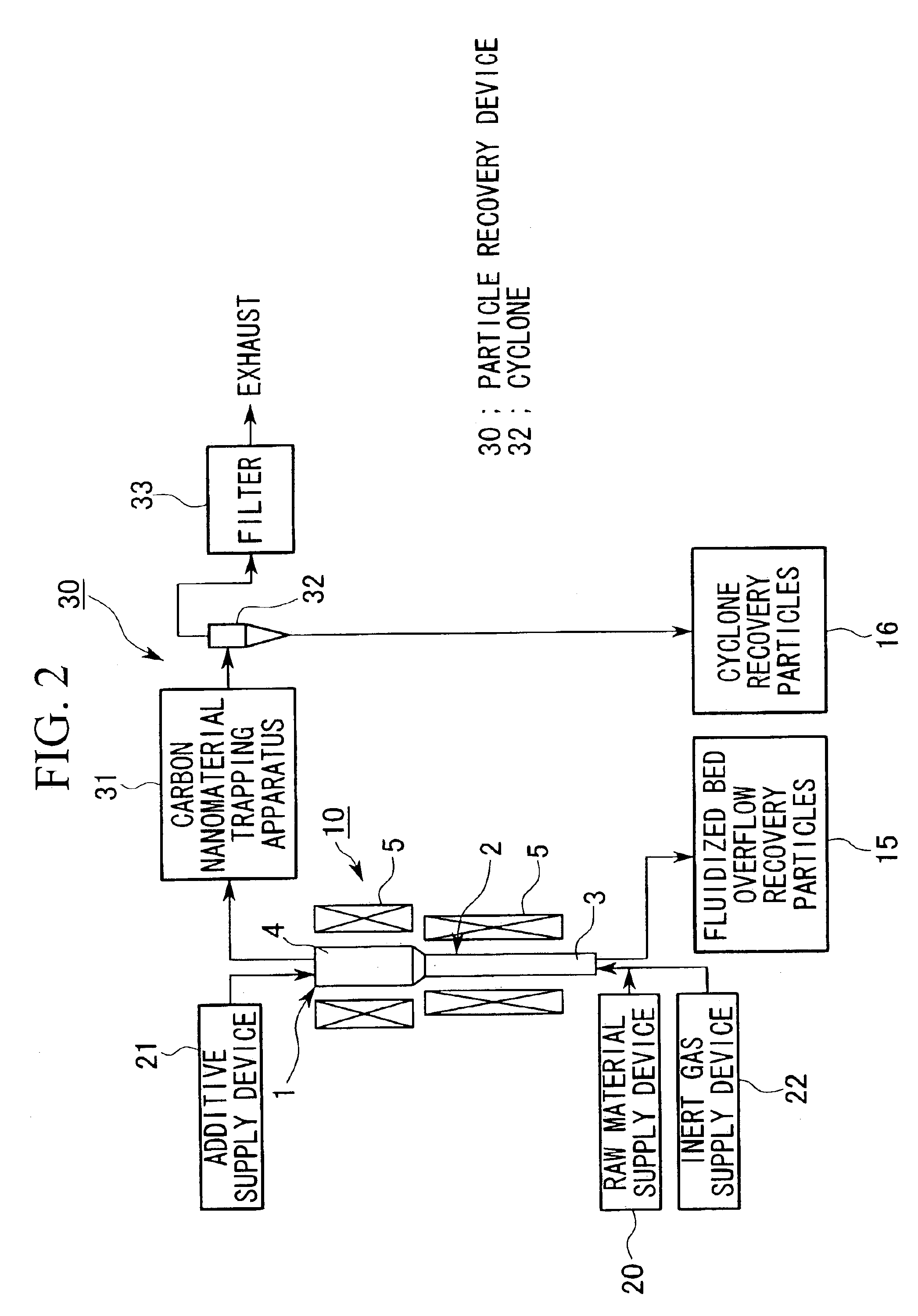

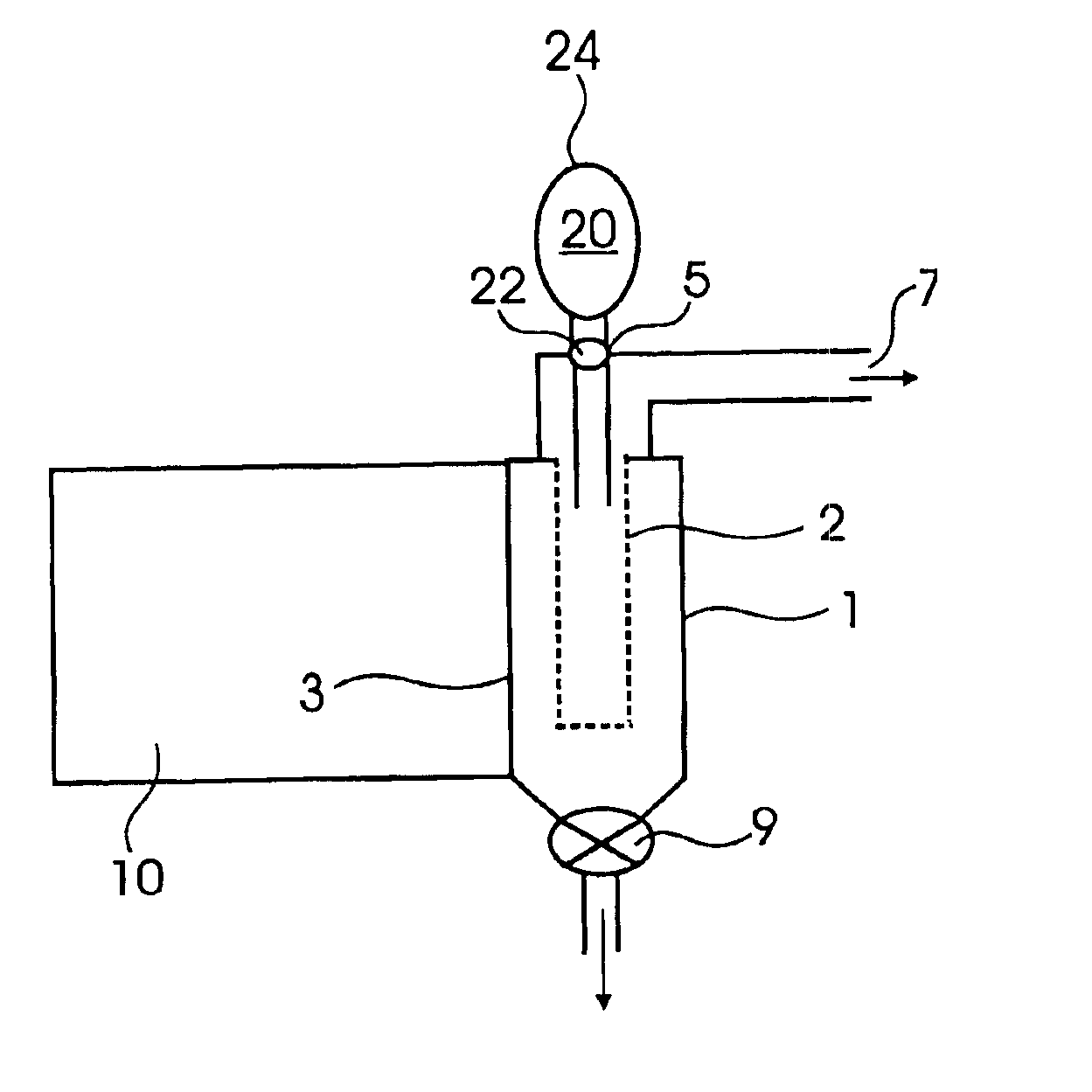

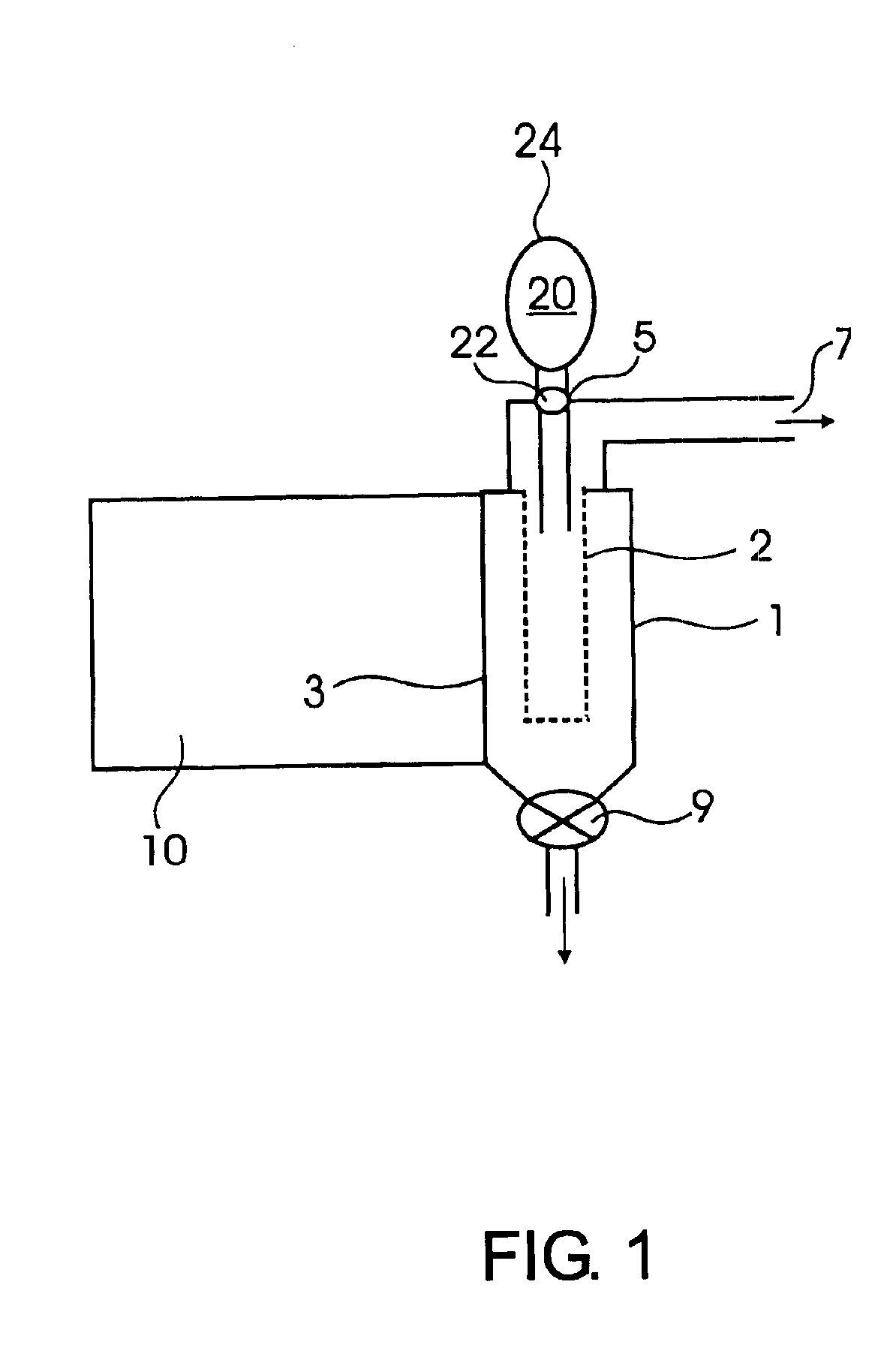

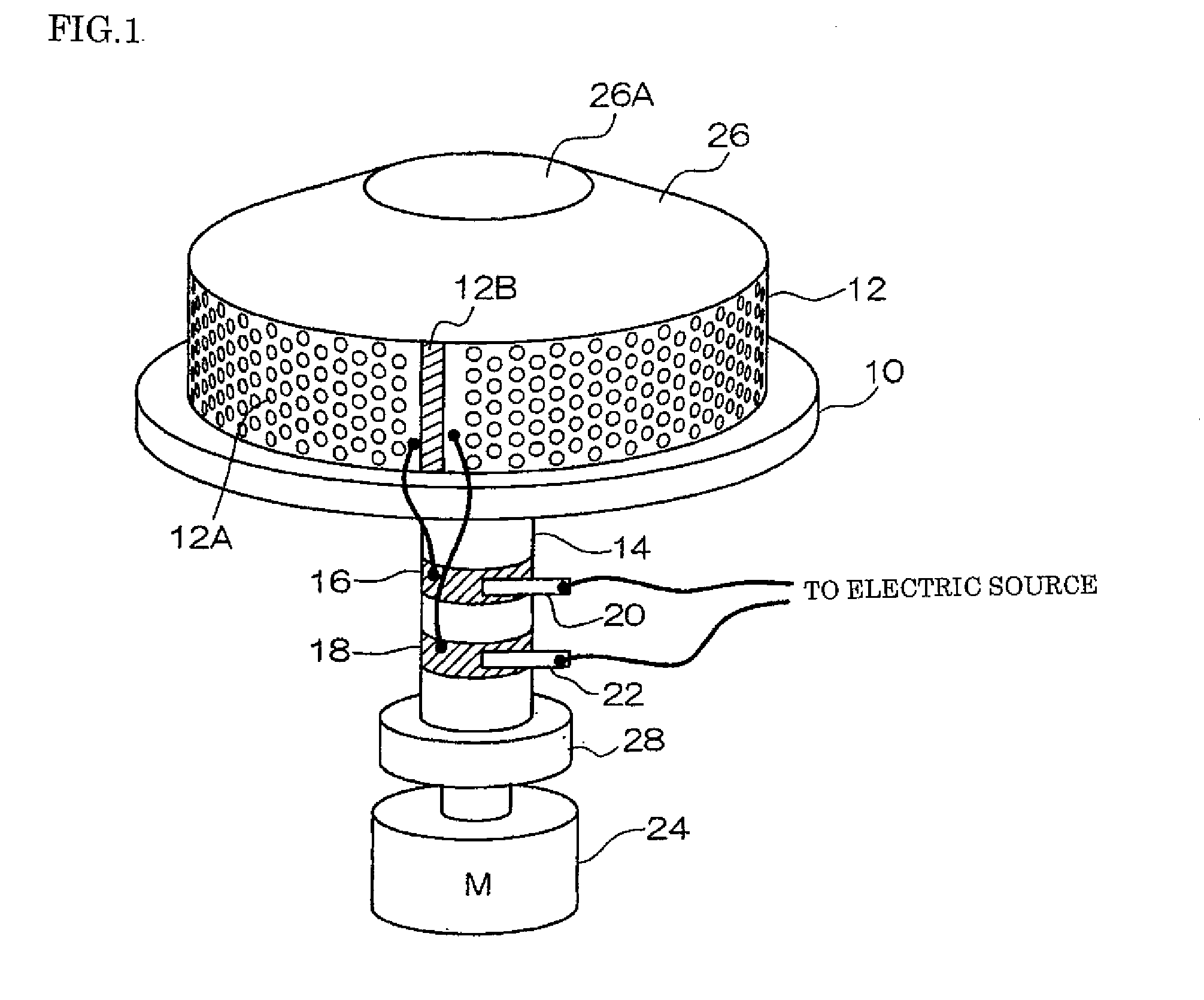

Manufacturing method for a carbon nanomaterial, a manufacturing apparatus for a carbon nanomaterial, and manufacturing facility for a carbon nanomaterial

InactiveUS6905544B2Effective recoveryImprove efficiencyMaterial nanotechnologyNanostructure manufactureFiberFluidized bed

The invention has as an object proving a carbon nanomaterial fabrication method that can continuously mass-produce a high purity carbon a nanomaterial. The tube-shaped or fiber-shaped carbon nanomaterial having carbon as the main constituent is fabricated with a compound that includes carbon (raw material) and an additive that includes a metal by using a fluidized bed reactor.

Owner:MITSUBISHI HEAVY IND LTD

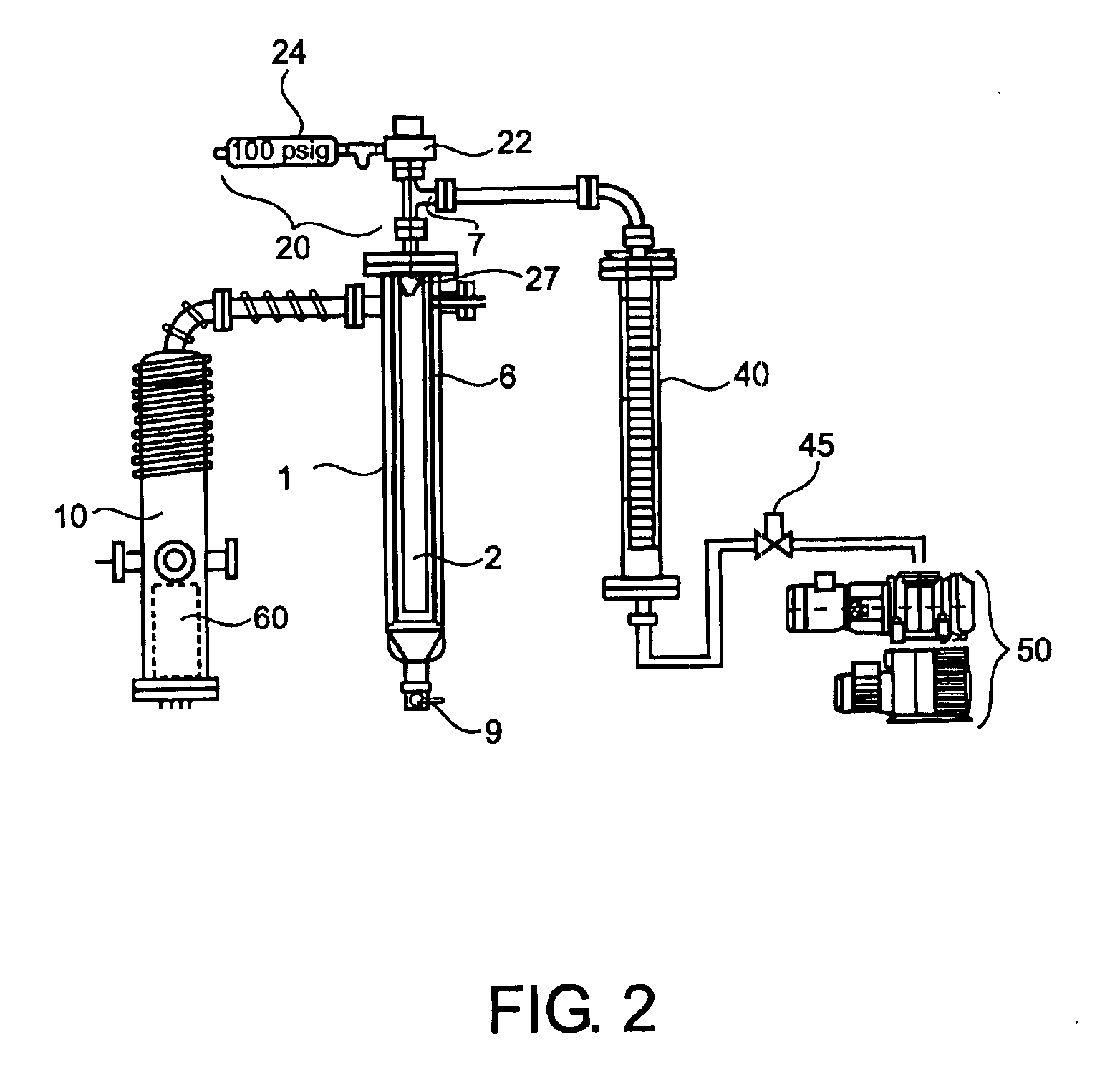

Filter devices and methods for carbon nanomaterial collection

InactiveUS6887291B2Facilitate continuous synthesisEasy to disassembleMaterial nanotechnologyCombination devicesReactor systemCombustion

Filter devices and methods for collection of carbon nanomaterials, including fullerenes, produced in gas phase reactors are provided. The filter devices provide for in situ cleaning of filters to release captured product for collection. Product can be released and removed from the reactor without disrupting continuous synthesis of carbon nanomaterials. The filter devices facilitate increased reactor operation and larger scale production of carbon nanomaterials. The filters are cleaned by application of a motive force and / or a gas flow to the filter. In a specific embodiment filters are cleaned by a reverse flow of gas pulses to the filter provided. The invention also provides reactor systems for gas phase synthesis of carbon nanomaterials that can be operated continuously employing the filter device of this invention. Preferred reactor systems are those which synthesize carbon nanomaterials by combustion. Methods for continuous production of carbon nanomaterials using the filtering devices and methods of this invention are also provided.

Owner:FRONTIER CARBON CORP

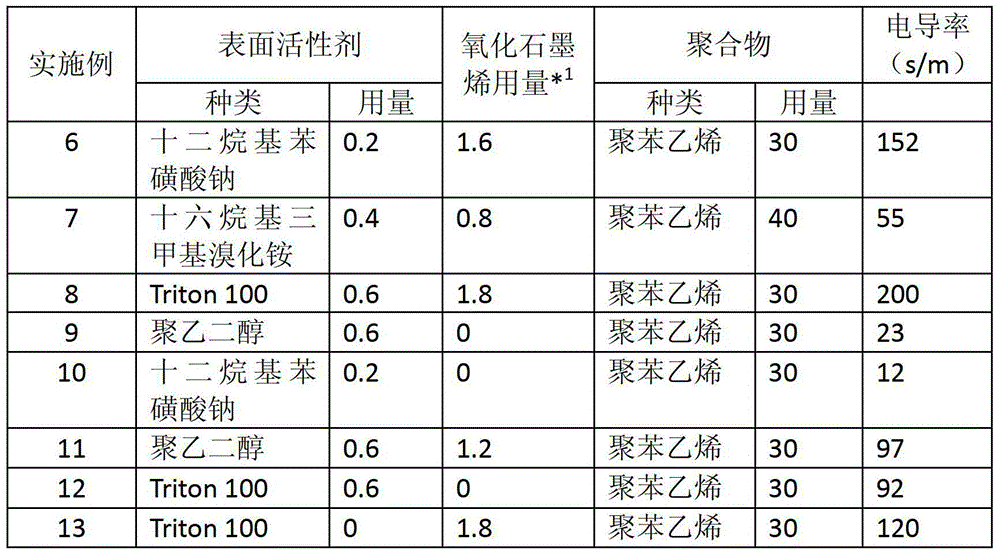

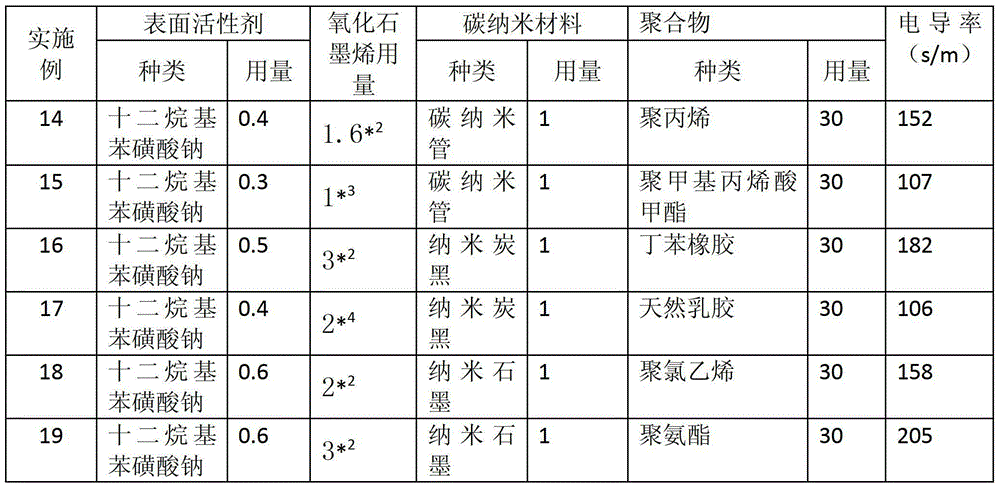

Compound dispersing agent of carbon nanomaterial and method for preparing electric conduction polymeric composite thereof

ActiveCN103333368AGood dispersionReduce contact resistance increasePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsModified carbonConductive coating

The invention discloses a compound dispersing agent of a carbon nanomaterial and a method for preparing an electric conduction polymeric composite thereof. The compound dispersing agent comprises a surface active agent and graphene oxide, wherein the mass ratio of the surface active agent to graphene oxide ranges from 0.1:1 to 9:1. The compound dispersing agent modified carbon nanomaterial is compounded with a nano-polymer, so that the polymer-carbon nanomaterial electric conduction composite with high electric conductivity can be obtained. The compound dispersing agent has a good dispersing effect on the carbon nanomaterial and can effectively reduce contact resistance of the modified carbon nanomaterial; the preparation process is easy to operate, the environment is protected, the compound dispersing agent can be widely applied to fields of preparation of various coatings such as antistatic coatings, electromagnetic shielding coatings and conductive coating and the like.

Owner:CHENGDU SCI & TECH DEV CENT CHINA ACAD OF ENG PHYSICS

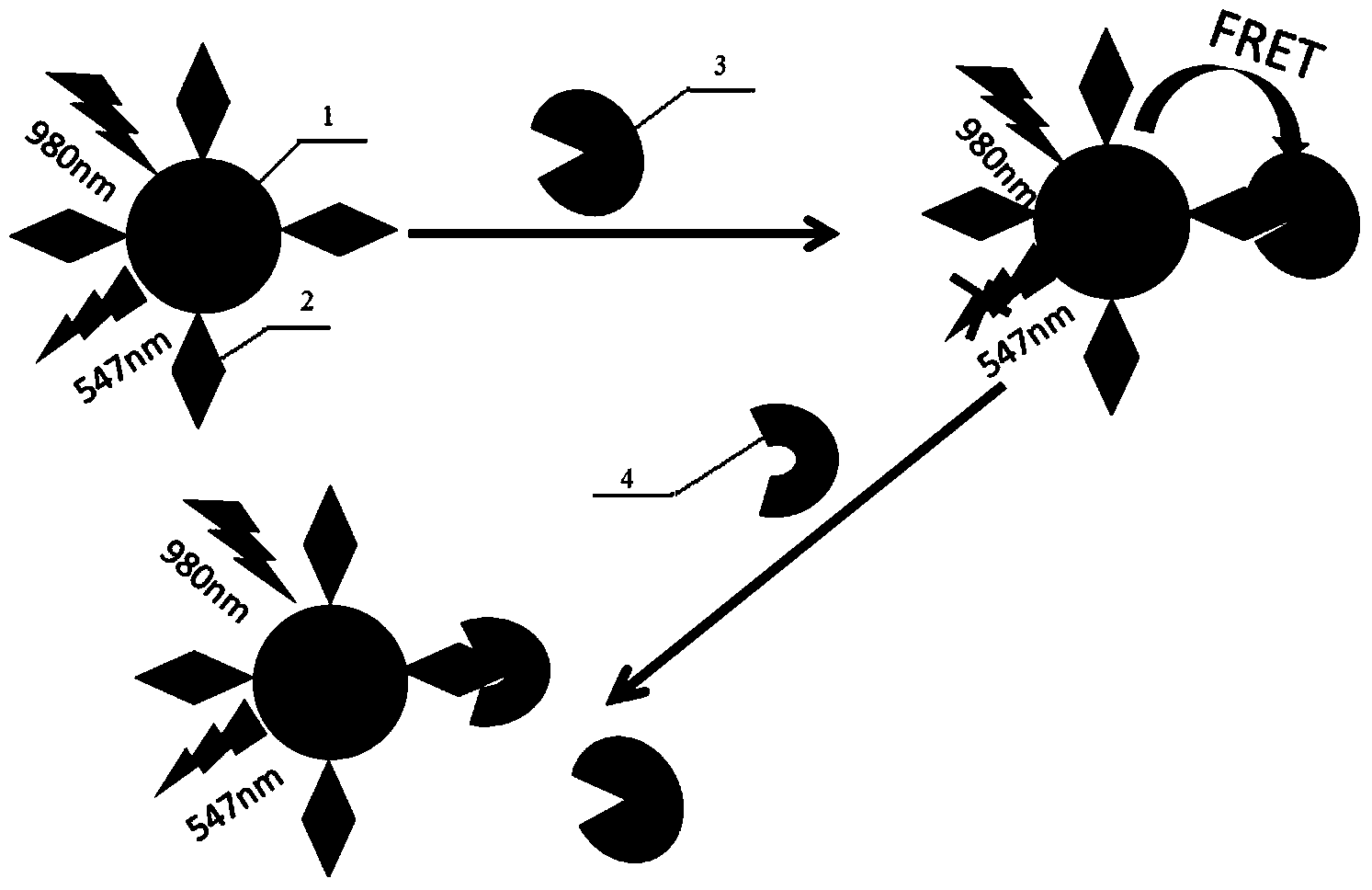

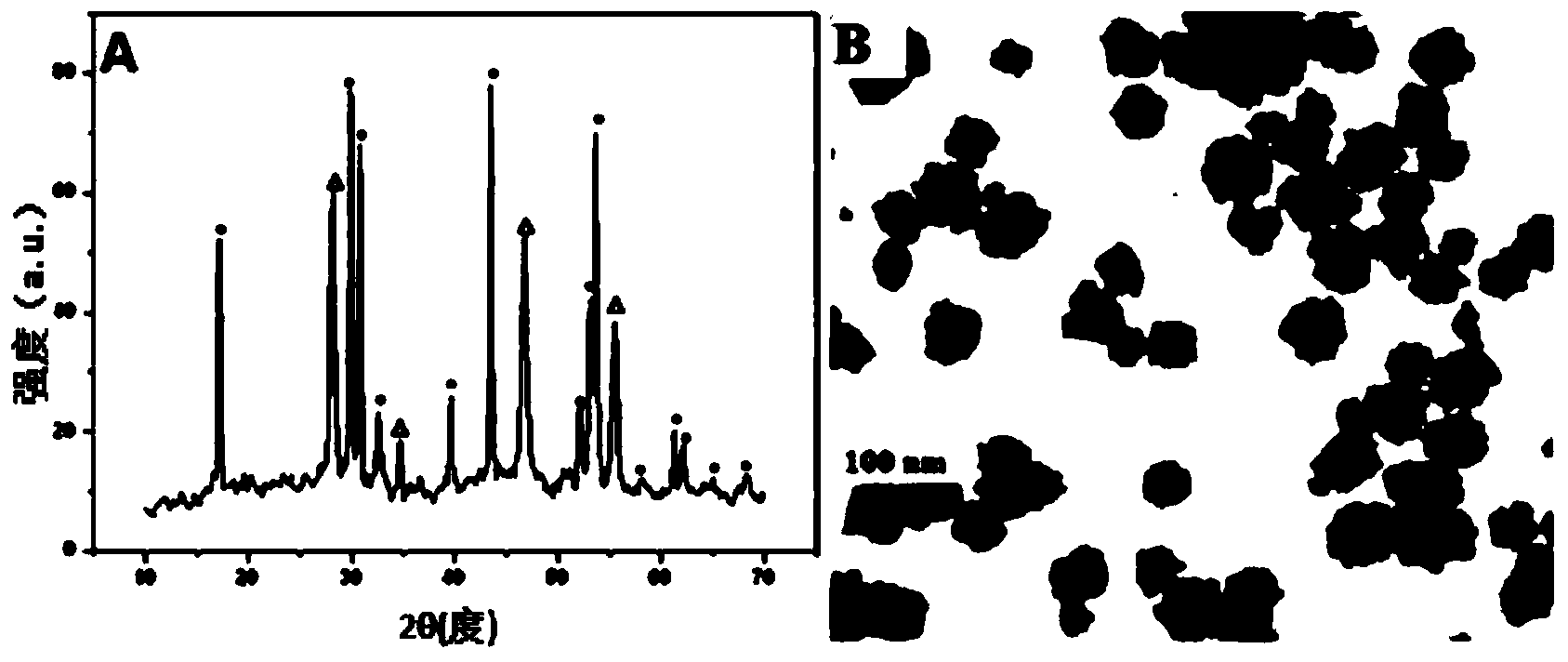

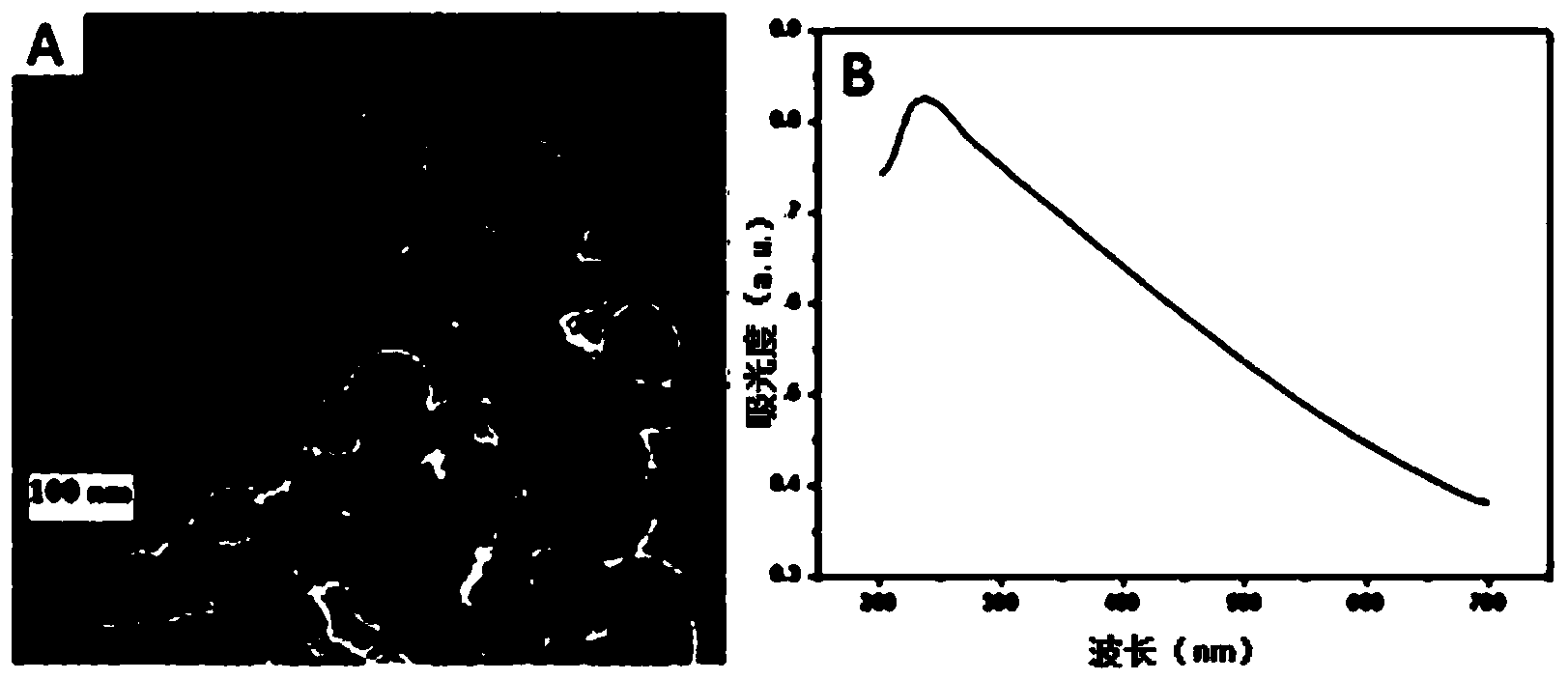

Method for detecting upconversion fluorescence resonance energy transfer by using carbon nanomaterial as receptor

InactiveCN103487418ACarbon source is easy to getEasy to prepareFluorescence/phosphorescenceLuminescent compositionsSurface markerQuenching

The invention discloses a method for detecting fluorescence resonance energy transfer by using a water-soluble upconversion fluorescence nanomaterial as a fluorescence donor and using a carbon nanomaterial as a fluorescence receptor. The method comprises the following specific steps: (1) preparing the water-soluble upconversion fluorescence nanomaterial and performing surface marker to obtain a fluorescence donor solution; (2) preparing the carbon nanomaterial to obtain a fluorescence receptor solution; (3) mixing the fluorescence donor solution and the fluorescence receptor solution for incubation and measuring the fluorescence intensity to obtain a fluorescence quenching curve; (4) mixing certain-concentration fluorescence donor solution and certain-concentration fluorescence receptor solution for incubation, adding a target object with different concentrations for continuous incubation, measuring the fluorescence intensity and drawing a standard curve; (5) calculating the concentration of the target object in an actual sample according to the standard curve. According to the method, interference of the background fluorescence of a biological sample can be avoided, detection to serum or the target object in a whole blood sample can be directly realized, the washing and separation processes are not needed, the detection speed is high, and the cost is low.

Owner:GUANGZHOU IMPROVE MEDICAL TECH CO LTD

Carbon dots with high fluorescent quantum yield, and application thereof in fluorescent color development

InactiveCN103395771AHigh fluorescence quantum yieldMaterial nanotechnologyNano-carbonEthylenediamineQuantum yield

The invention relates to carbon dots with high fluorescent quantum yield, and an application thereof in fluorescent color development, and belongs to the application field of fluorescent carbon nanomaterials. Specifically, the invention relates to the carbon dots with the high fluorescent quantum yield which are synthesized by using citric acid and ethene diamine as raw materials as a fluorescent ink for writing or fluorescent printing, and further broadens the application thereof in fluorescent electrospining, fluorescent micro arrays and fluorescent composites. The carbon dots with the high fluorescent quantum yield are obtained by blending 1-100 mmol of citric acid and 1-100 mmol of ethene diamine in 5-100 mL of deionized water and transferring the mixture into a reaction kettle; carrying out a hydrothermal reaction for 2-10 hours at a temperature of 100-500 DEG C; cooling the reaction kettle to a room temperature after the reaction is finished to obtain a water solution of the carbon dots with the high fluorescent quantum yield; pouring the water solution of the carbon dots in a dialysis bag with a molecular weight of 3,500; dialyzing for 48-60 h; spin drying a dialysis outer solution and vacuum drying.

Owner:JILIN UNIV

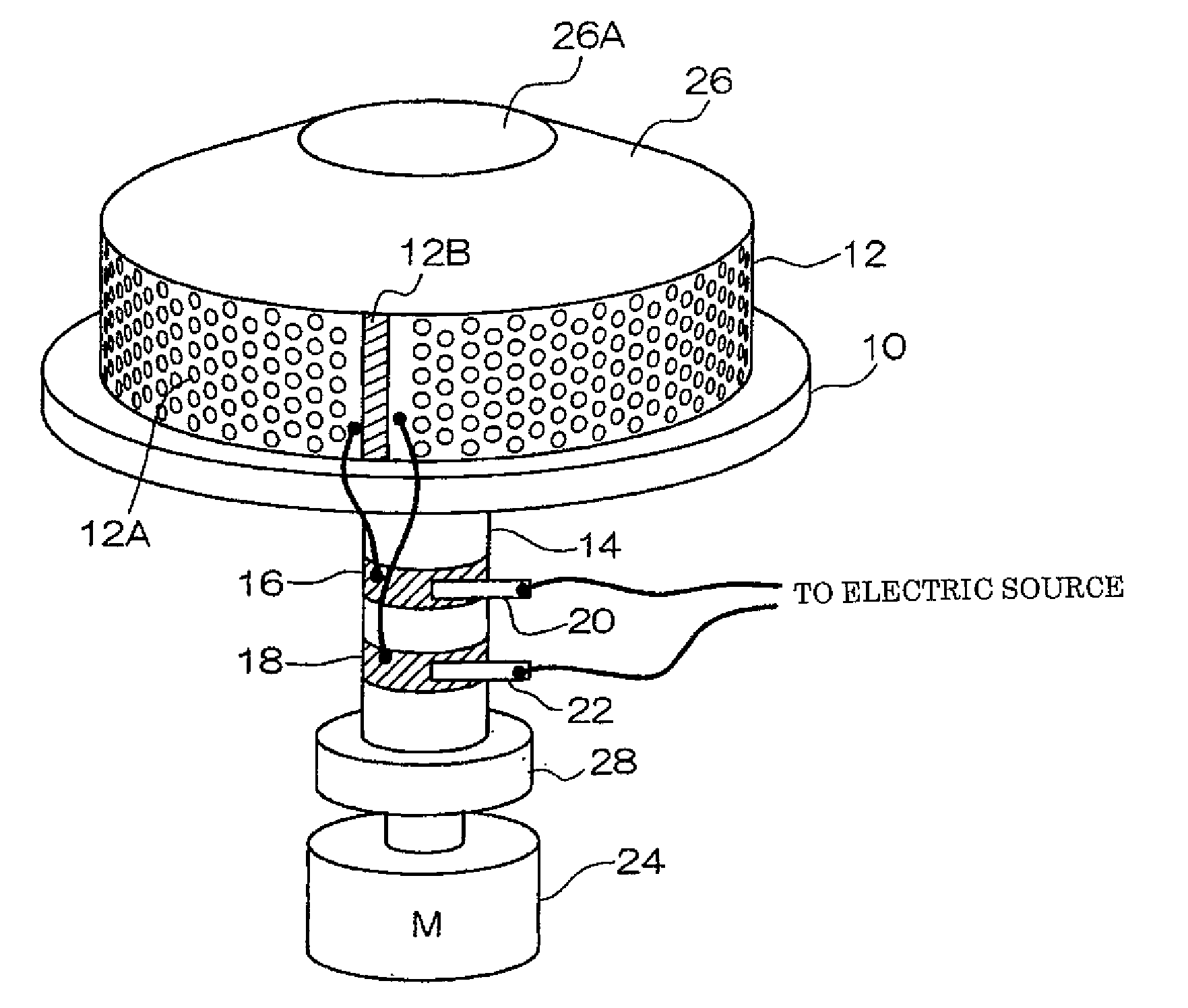

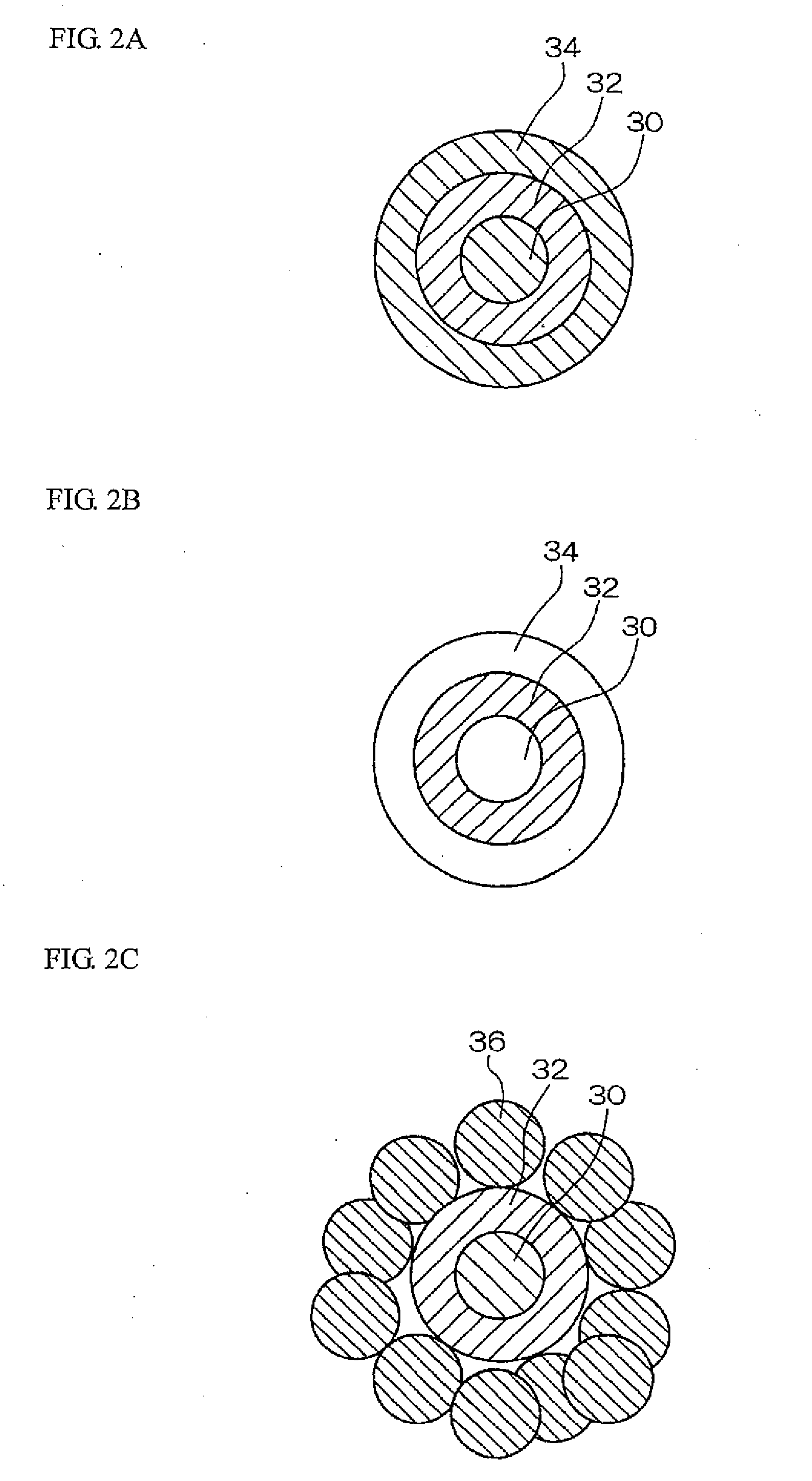

Method of Producing Carbon Nanomaterials and Centrifugal Melt Spinning Apparatus

InactiveUS20080050304A1Producing a carbon nanomaterialImprove efficiencyMaterial nanotechnologyFilament/thread formingPolymer scienceCarbonization

A carbon nanomaterial produced by: performing centrifugal melt spinning of core-shell particles that are prepared by using fine particles containing a carbon precursor polymer and a thermally decomposable polymer that disappears as a result of heat treatment, wherein the core-shell particles are heated up to a temperature at which phase separation thereof is not caused, and pressed against a plate-like heater 12 having a large number of pores 12A that penetrate therethrough in a thickness direction of the plate-like heater using centrifugal force; making the fiber obtained by the centrifugal melt spinning infusible; and performing carbonization thereof. According to this method, a carbon nanomaterial such as a carbon nanotube or a carbon nanofiber can be produced with high efficiency.

Owner:GUNMA UNIVERSITY

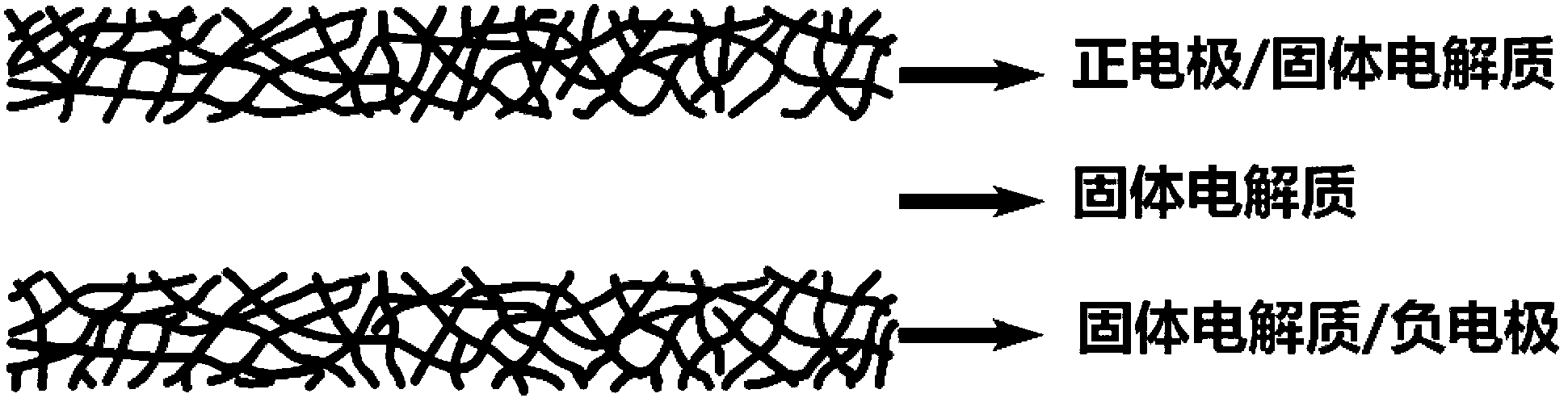

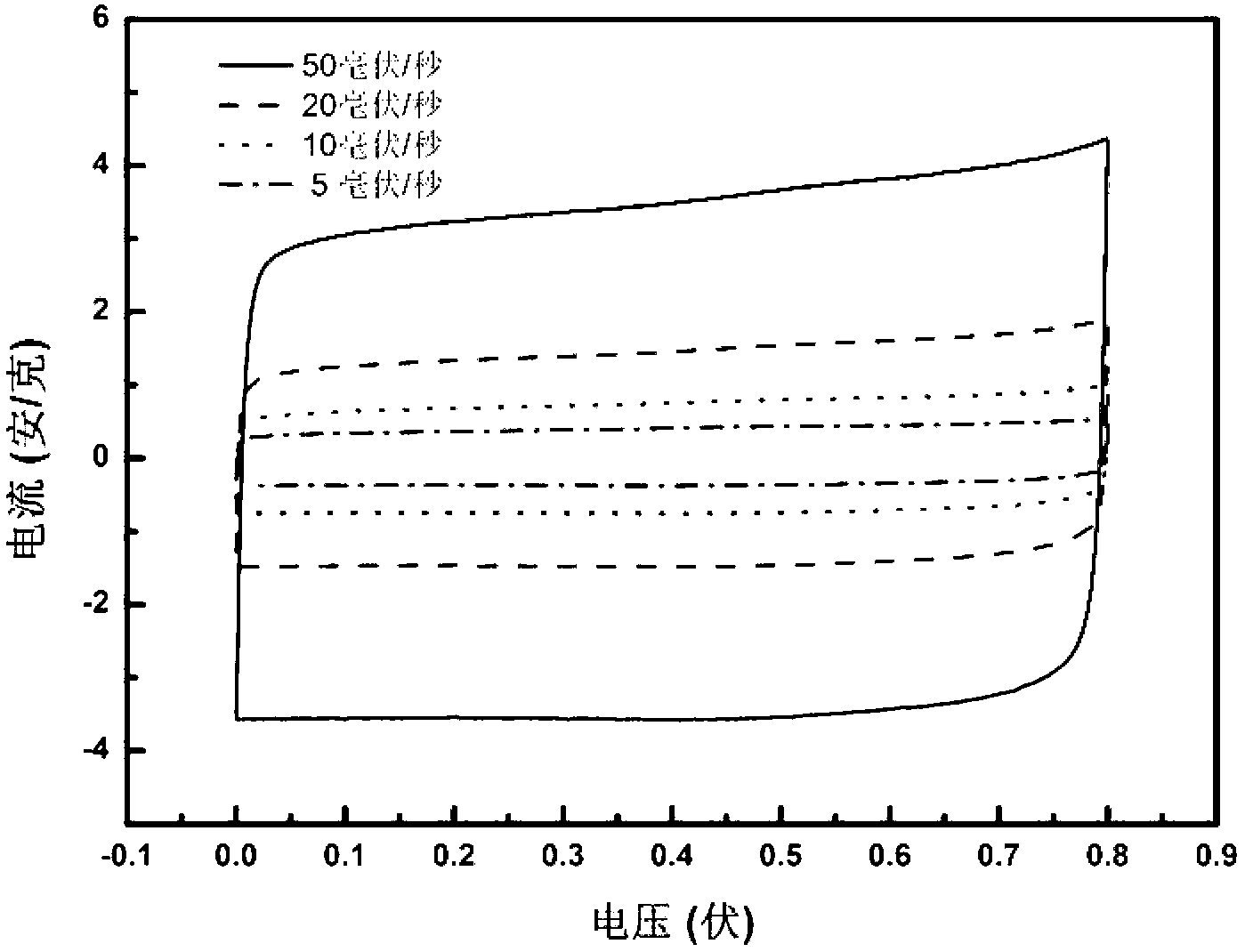

Ultra-thin, self-supporting, flexible and all-solid-state super capacitor and manufacturing method thereof

ActiveCN103219164ASmall sizeHigh specific capacitanceHybrid capacitor electrolytesHybrid capacitor electrodesCapacitanceManufacturing technology

The invention discloses an ultra-thin, self-supporting, flexible and all-solid-state super capacitor and a manufacturing method of the ultra-thin, self-supporting, flexible and all-solid-state super capacitor. The super capacitor comprises a position electrode, a solid electrolyte and a negative electrode, wherein the solid electrolyte is located between the positive electrode and the negative electrode to separate the positive electrode and the negative electrode, and the solid electrolyte evenly permeates inside a porous structure of the positive electrode and a porous structure of the negative electrode. The positive electrode and the negative electrode are made of carbon nanometer materials or carbon nanometer composite materials, and the outer side of the positive electrode and the outer side of the positive electrode are not completely embedded by the solid electrolyte and can be used for collecting currents. The thickness of the super capacitor is within the range of 10 nanometers to 10 micrometers, the inner portion of the capacitor is provided with no diaphragm, the outer portion of the capacitor needs no metal current collecting electrode or encapsulation, self-supporting can be realized, and at the same time the capacitor has high specific capacitance, high power density, high energy density, long life and high stability. The super capacitor has the advantages of being superior in performance, simple in manufacturing technology, and capable of satisfying the development demands of flexible, miniature, light electronic products at the same time, and having wide application prospects.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Conductive fiber with scabbard type structure and preparation method thereof

ActiveCN103603088AEasy to makeLow costConjugated cellulose/protein artificial filamentsFilament/thread formingFiberPolymer science

The invention discloses a conductive fiber with a scabbard type structure and a preparation method thereof. The preparation method comprises the following steps: 1) preparing a carbon nano material into a solution 1; 2) preparing the polymer into a solution 2; 3) passing the solution 1 through an inner pipe of a coaxial spinning needle head at a certain speed, at the same time, passing the solution 2 through an outer pipe of the coaxial spinning needle head at a certain speed, extruding the two into a coagulation bath, so as to form a gel fiber with scabbard type structure preliminarily; 4) transferring the gel fiber to a solution containing a reducing agent and conducting chemical reduction at a certain temperature; and 5) cleaning the gel fiber subjected to reduction in the step 4 with a solvent, drying and collecting the gel fiber to a roller, so as to obtain the conductive fiber with scabbard type structure. The invention has the advantages of simpleness, low cost and strong applicability, and is suitable for large-scale industrial production; and the produced fiber with scabbard type structure has excellent electrical and mechanical properties and can be used in the fields of power transmission, antistatic fabrics and engineering materials, etc.

Owner:杭州德烯科技集团有限公司

Preparation method for three-dimensional porous graphene doping and coating lithium titanate composite anode material

InactiveCN102646810AImprove conductivityHigh specific capacityElectrode manufacturing processesPorous grapheneCarbon layer

The invention discloses a preparation method for a three-dimensional porous graphene doping and coating lithium titanate composite anode material. The problem that a high ratio property of lithium titanate is poor can be solved by a doping vario-property of a carbon nano material to the lithium titanate, and the spinel structure of the lithium titanate can not be affected. A nano carbon layer made of the carbon nano material is doped in a carbon nano material doping lithium titanate composite material to have an effect of an electrical transmission cushion layer, so that a cyclic property of the carbon nano material doping lithium titanate composite material is improved, besides, an introduction of the carbon nano material can effectively restrain a gathering of lithium titanate particles in a heat treatment process, and simultaneously diffusion coefficients of lithium-ions in the carbon nano material doping lithium titanate composite material are increased. According to the preparation method for the three-dimensional porous graphene doping and coating lithium titanate composite anode material, the prepared three-dimensional porous grapheme has a high specific surface area, and thereby the high ratio property of the lithium titanate is further improved.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com