Compound dispersing agent of carbon nanomaterial and method for preparing electric conduction polymeric composite thereof

A carbon nanomaterial and composite dispersant technology, which is applied in the treatment of dyed low molecular organic compounds, dyed high molecular organic compounds, chemical instruments and methods, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

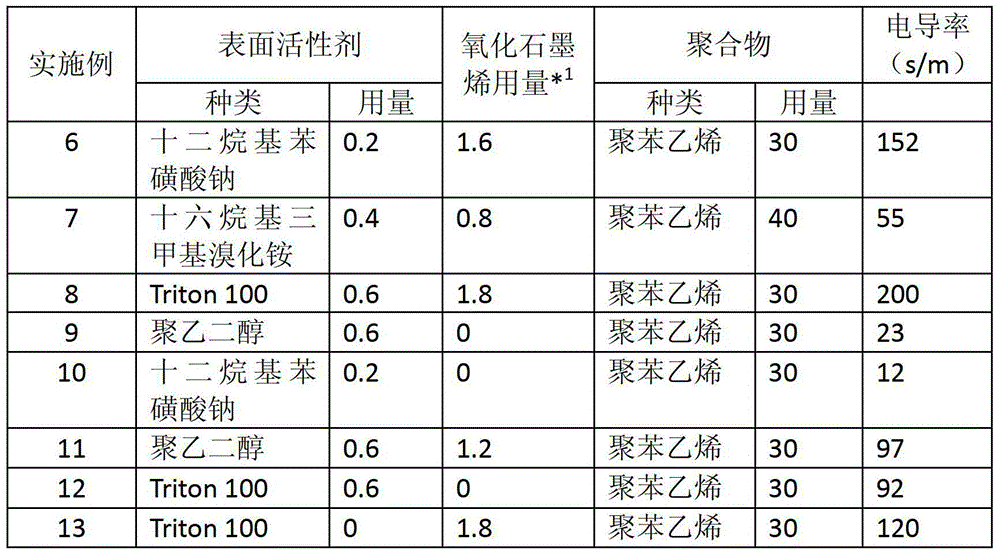

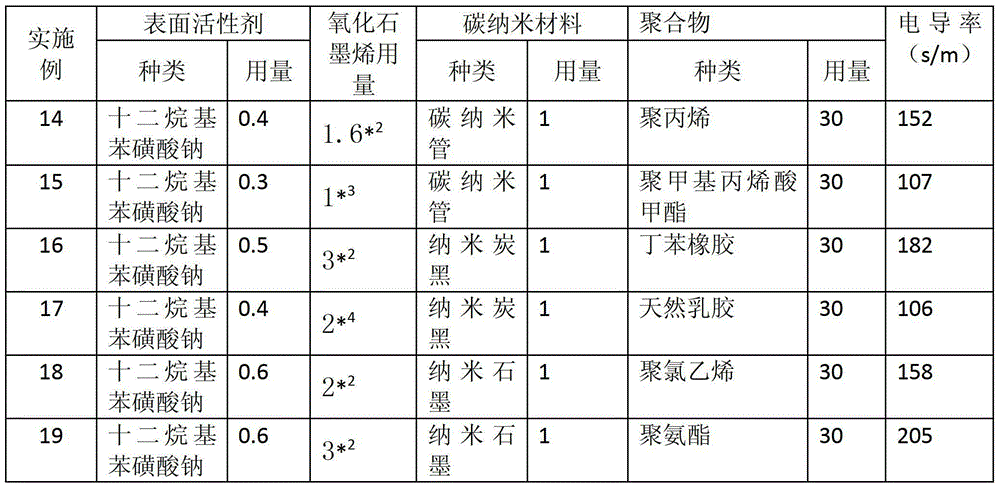

Examples

Embodiment 1

[0044] Embodiment 1: 0.1 gram of sodium lauryl sulfate and 1 gram of graphene oxide are added in 100 grams of water, after stirring for 1 hour, then ultrasonic 15 minutes, form uniform solution, this solution is mixed with 1 gram of carbon nanotubes, Ultrasound for 30 minutes to form a uniform black suspension, add 25 grams of polystyrene particles to the above suspension, stir and mix again for 1 hour, add 100 ml of 45% hydroiodic acid solution to the suspension to make graphite oxide The carbon nanotube-graphene-polystyrene particle composite powder is obtained by chemical reduction of alkene, and the water is removed. Styrene composite material with a conductivity of 150 s / m.

Embodiment 2

[0045] Embodiment 2: 0.5 gram of sodium lauryl sulfate and 1 gram of graphene oxide are added in 100 grams of water, after stirring for 1 hour, then ultrasonic 15 minutes, form uniform solution, this solution is mixed with 1 gram of carbon nanotubes, Ultrasound for 30 minutes to form a uniform black suspension, add 10 grams of polystyrene particles to the above suspension, stir and mix again for 1 hour, add 100 ml of 45% hydroiodic acid solution to the suspension to make graphite oxide The carbon nanotube-graphene-polystyrene particle composite powder is obtained by chemical reduction of alkene, and the water is removed. Styrene composite material has an electrical conductivity of 426 s / m.

Embodiment 3

[0046] Embodiment 3: 1 gram of sodium lauryl sulfate and 1 gram of graphene oxide are added in 100 grams of water, after stirring for 1 hour, then ultrasonic 15 minutes, form uniform solution, this solution is mixed with 1 gram of nano carbon black, Ultrasound for 30 minutes to form a uniform black suspension, add 10 grams of polystyrene particles to the above suspension, stir and mix again for 1 hour, add 100 ml of 45% hydroiodic acid solution to the suspension to make graphite oxide The carbon nanotube-graphene-polystyrene particle composite powder is obtained by chemical reduction of alkene, and the water is removed. Styrene composite material with a conductivity of 120 s / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com