Patents

Literature

3768 results about "Modified carbon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Conformal coatings comprising carbon nanotubes

InactiveUS7118693B2Material nanotechnologyMagnetic/electric field screeningModified carbonElectromagnetic interference

Owner:EIKOS

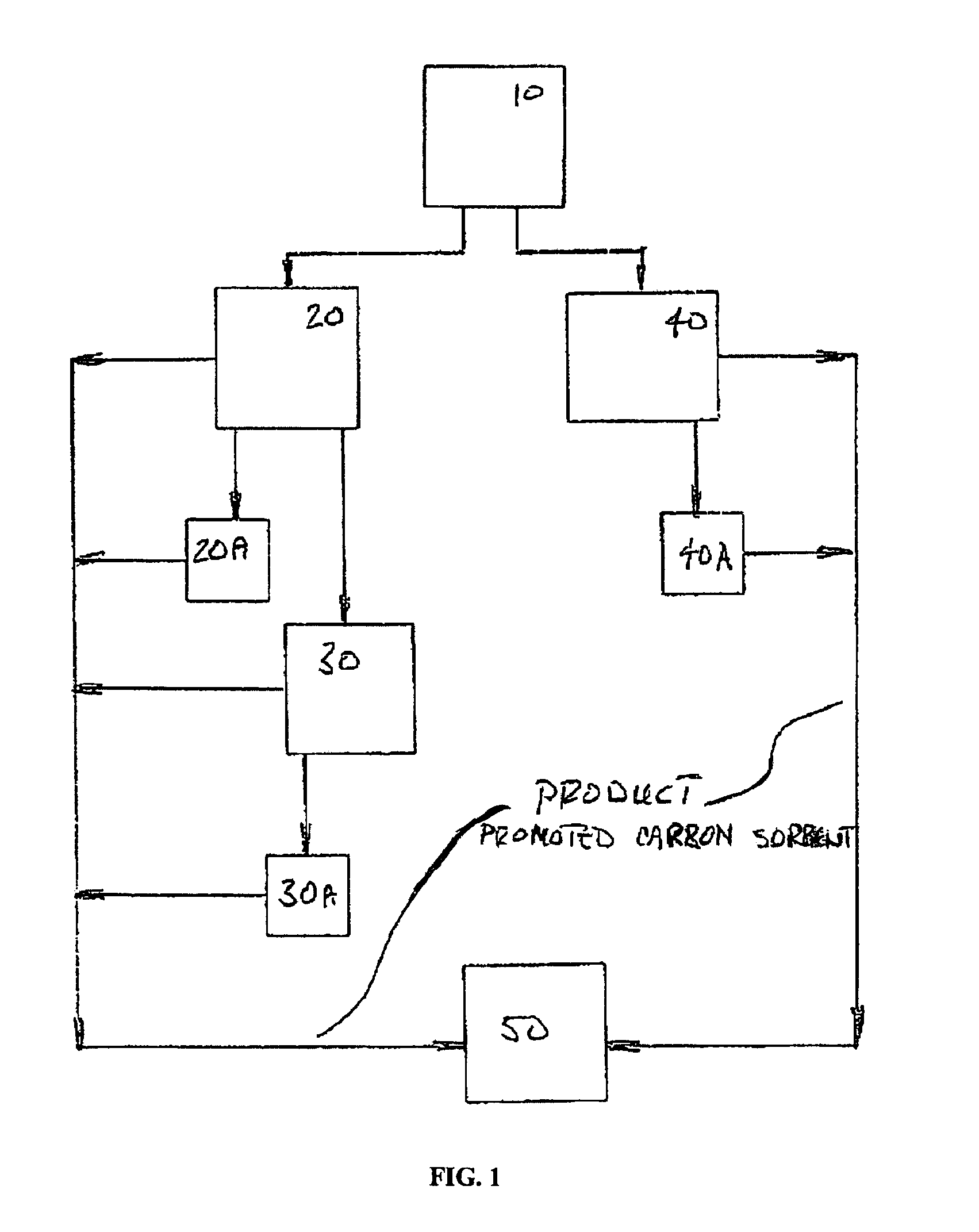

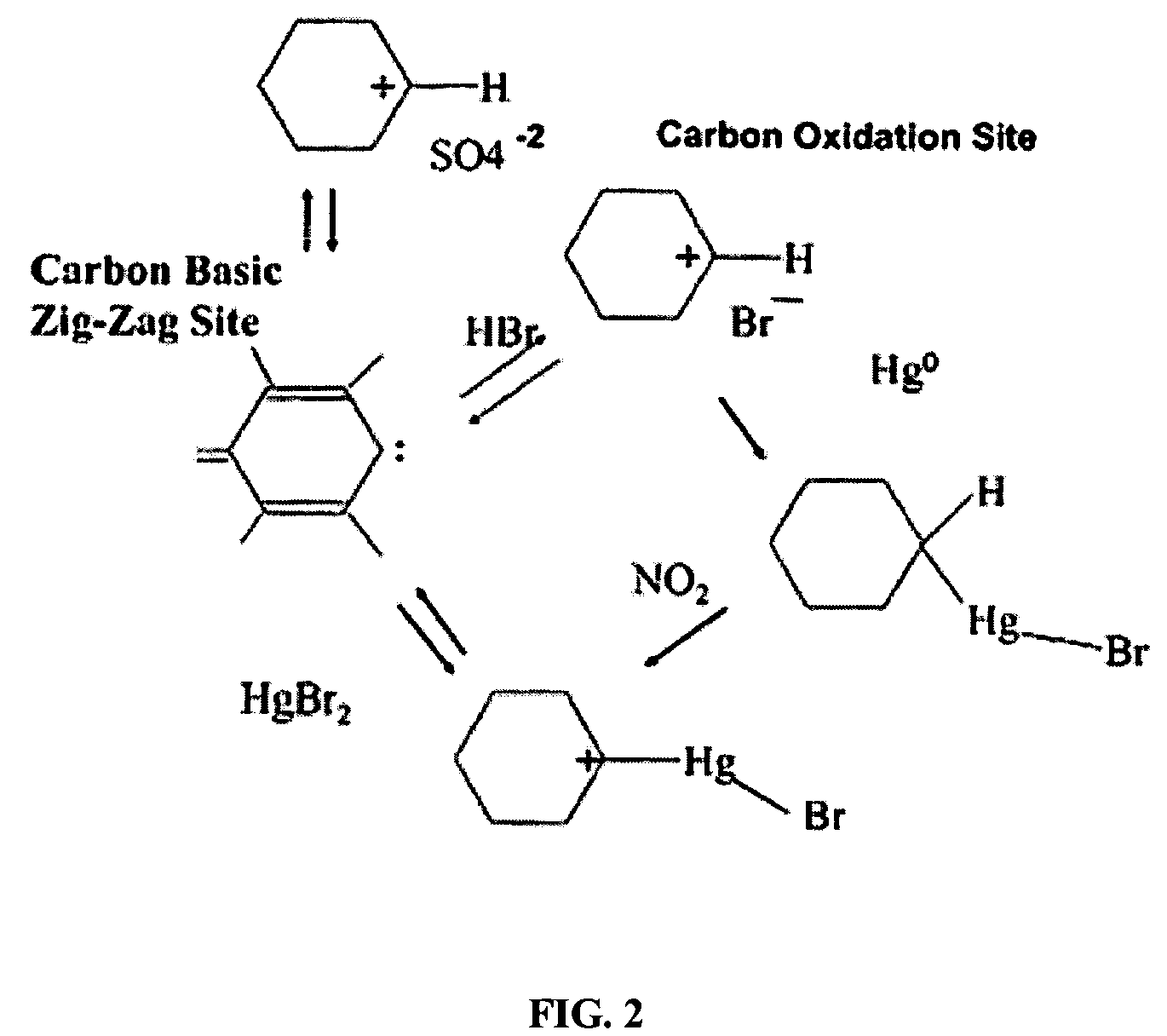

Sorbents for the oxidation and removal of mercury

ActiveUS20060048646A1Reduce the amount requiredHigh activityGas treatmentUsing liquid separation agentActivated carbonHalogen

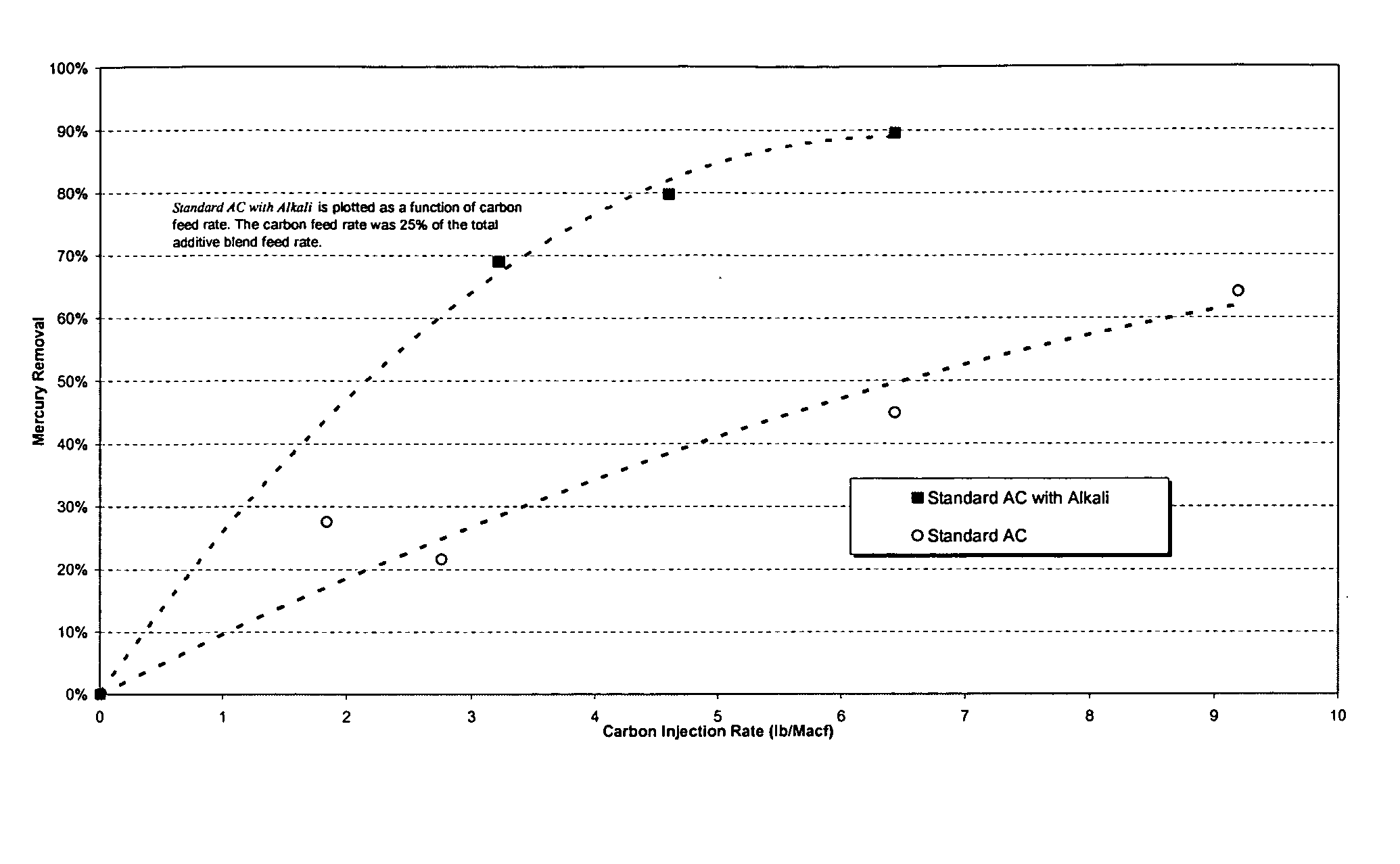

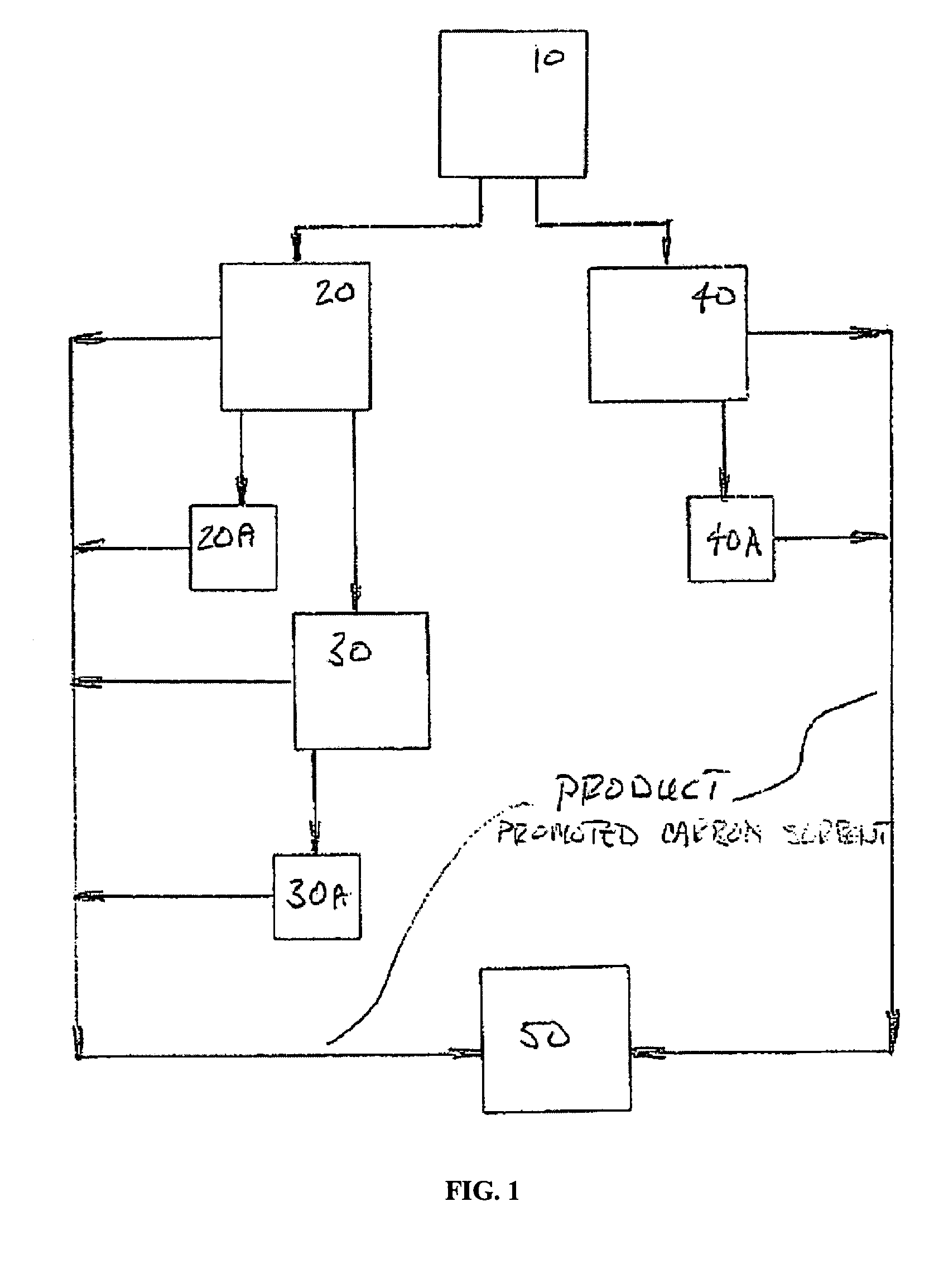

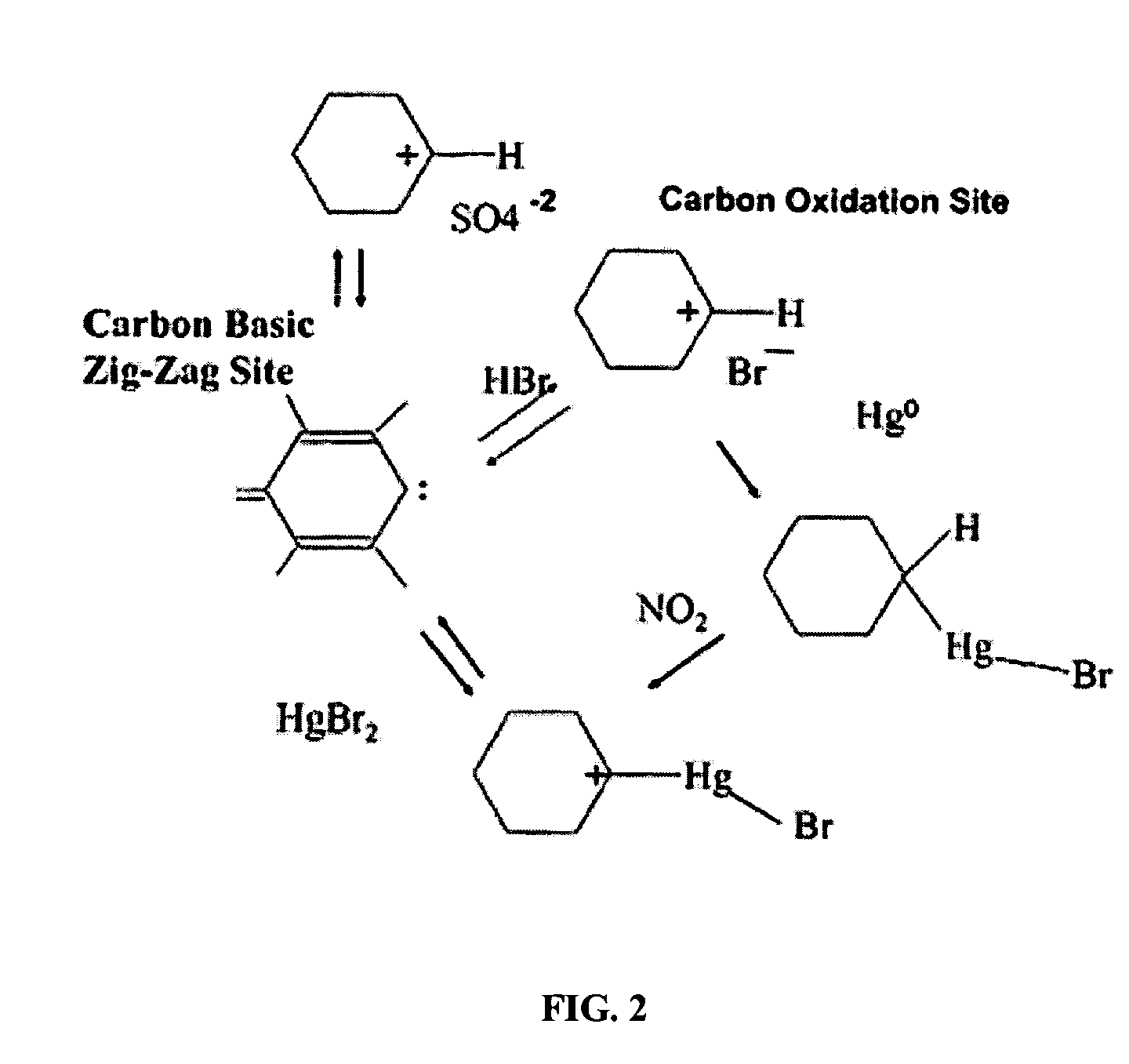

A promoted activated carbon sorbent is described that is highly effective for the removal of mercury from flue gas streams. The sorbent comprises a new modified carbon form containing reactive forms of halogen and halides. Optional components may be added to increase reactivity and mercury capacity. These may be added directly with the sorbent, or to the flue gas to enhance sorbent performance and / or mercury capture. Mercury removal efficiencies obtained exceed conventional methods. The sorbent can be regenerated and reused. Sorbent treatment and preparation methods are also described. New methods for in-flight preparation, introduction, and control of the active sorbent into the mercury contaminated gas stream are described.

Owner:MIDWEST ENERGY EMISSIONS CORP

Sorbents for the oxidation and removal of mercury

ActiveUS7435286B2Efficient use ofEasy to controlGas treatmentUsing liquid separation agentActivated carbonHalogen

A promoted activated carbon sorbent is described that is highly effective for the removal of mercury from flue gas streams. The sorbent comprises a new modified carbon form containing reactive forms of halogen and halides. Optional components may be added to increase reactivity and mercury capacity. These may be added directly with the sorbent, or to the flue gas to enhance sorbent performance and / or mercury capture. Mercury removal efficiencies obtained exceed conventional methods. The sorbent can be regenerated and reused. Sorbent treatment and preparation methods are also described. New methods for in-flight preparation, introduction, and control of the active sorbent into the mercury contaminated gas stream are described.

Owner:MIDWEST ENERGY EMISSIONS CORP

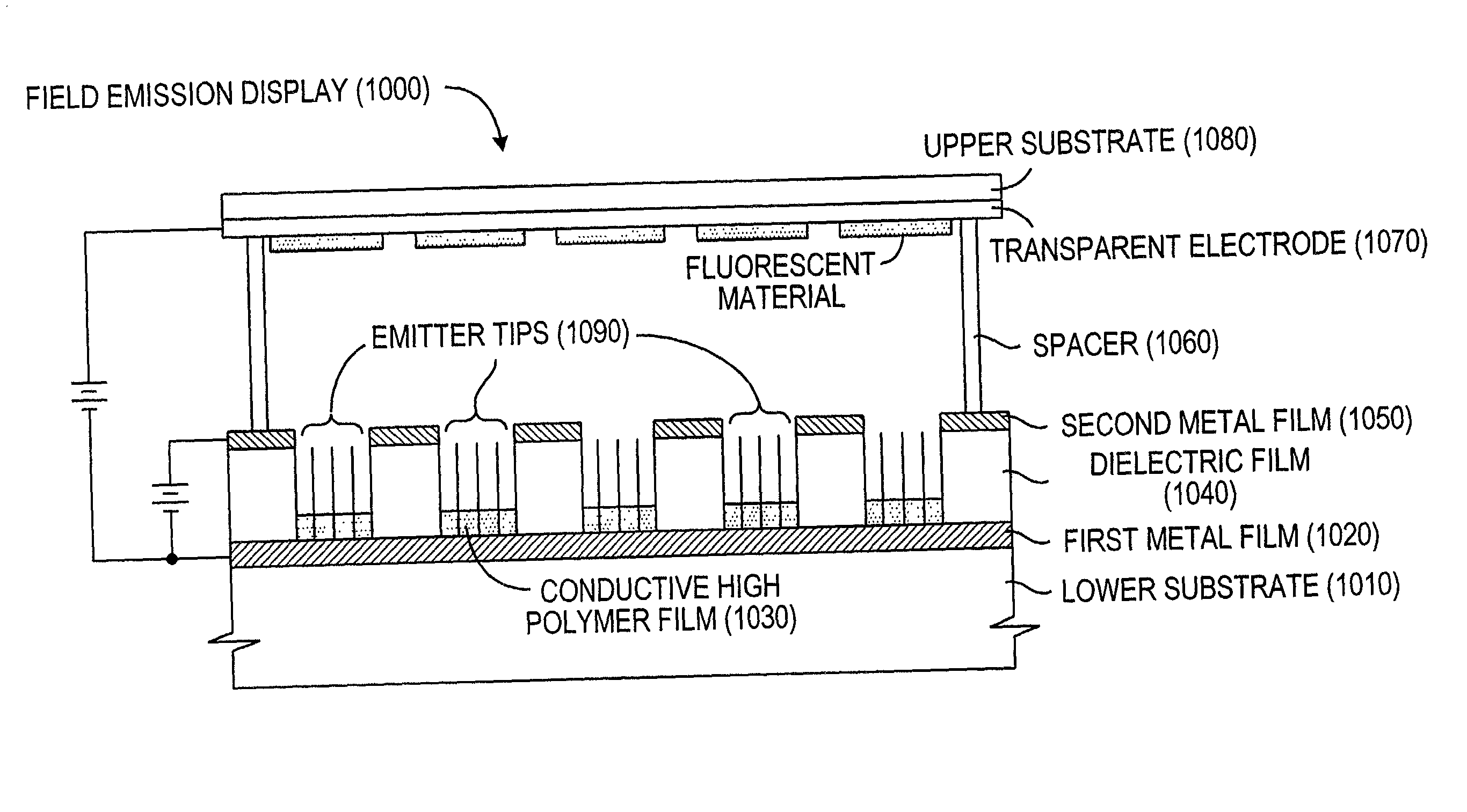

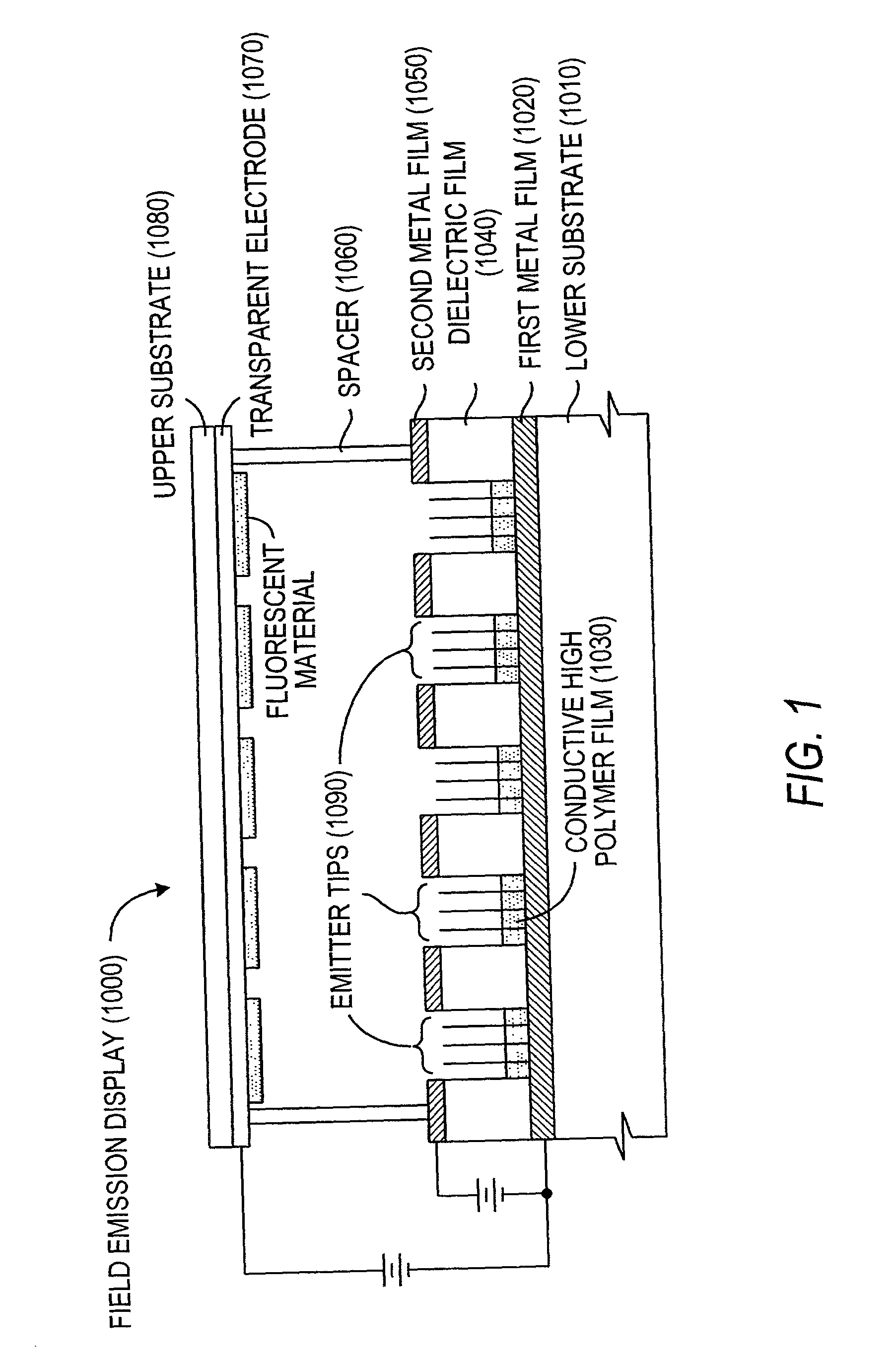

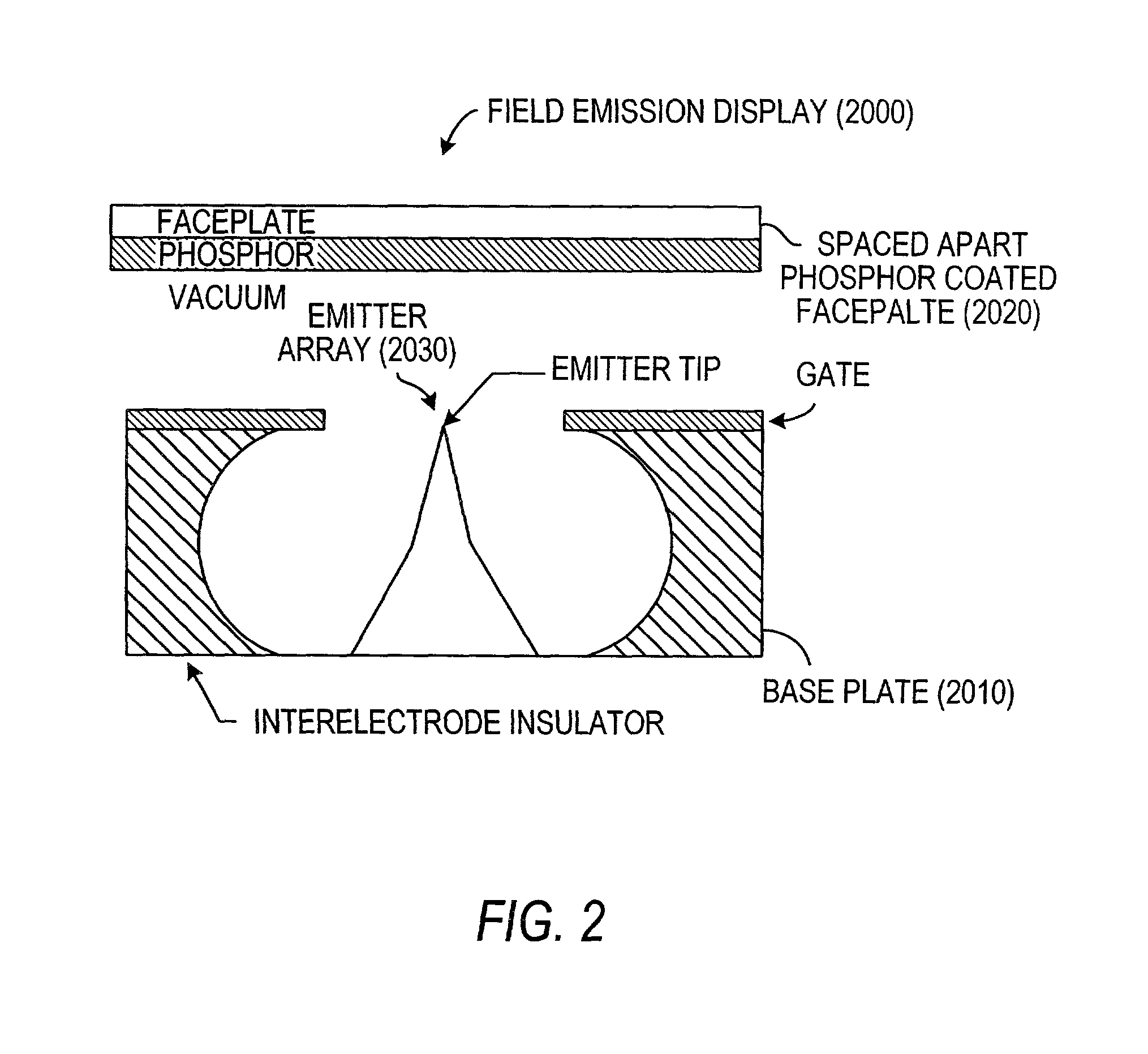

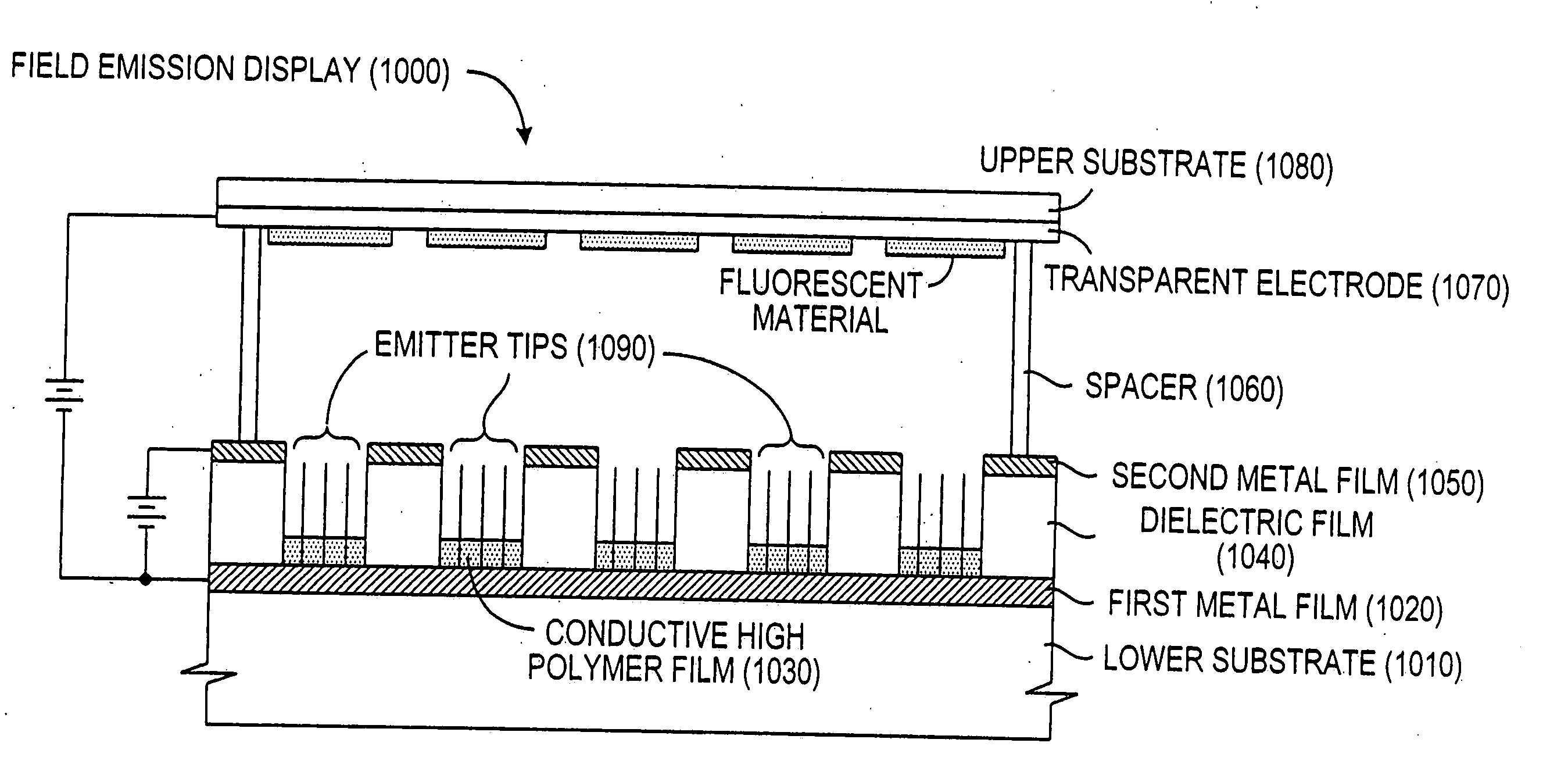

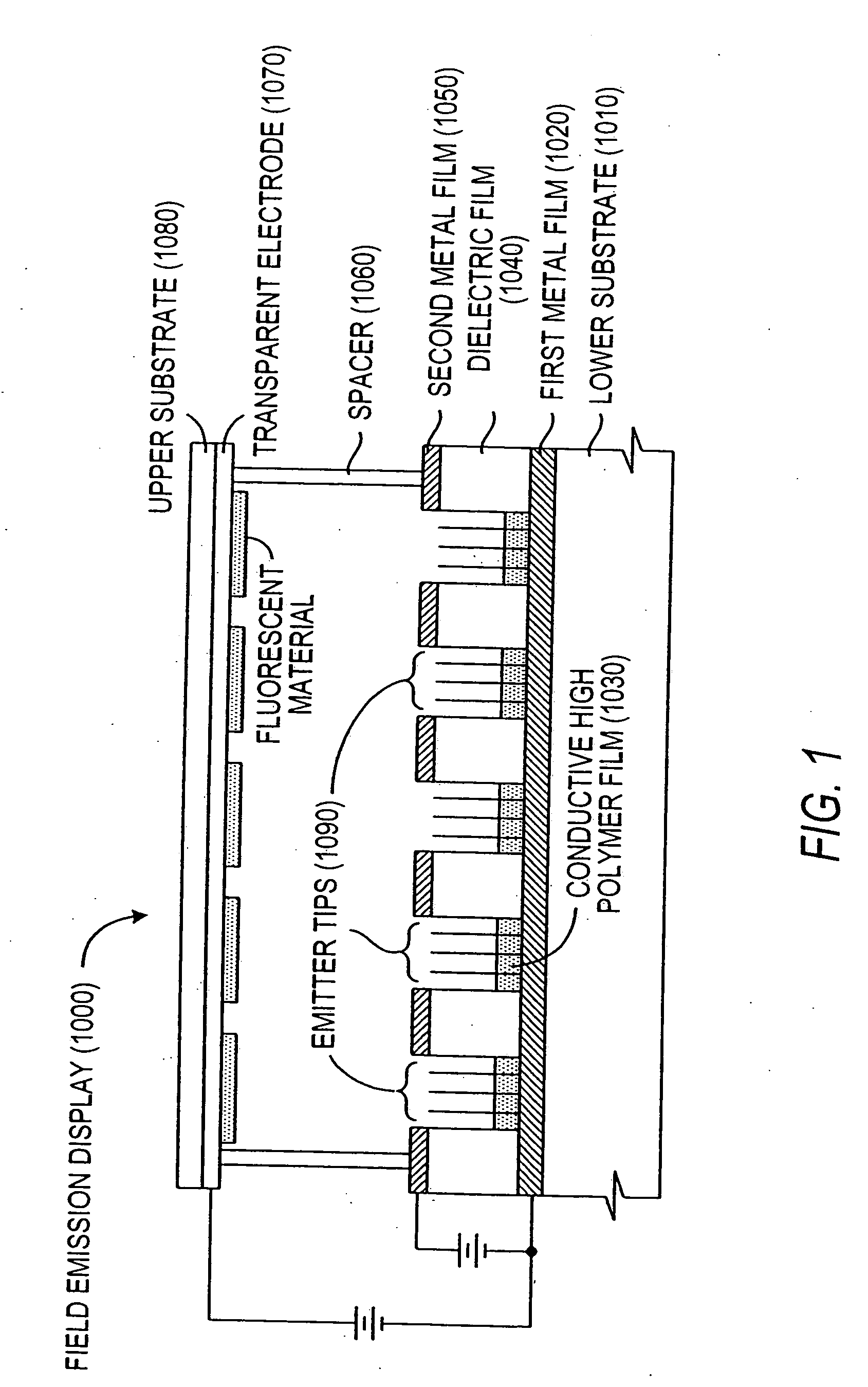

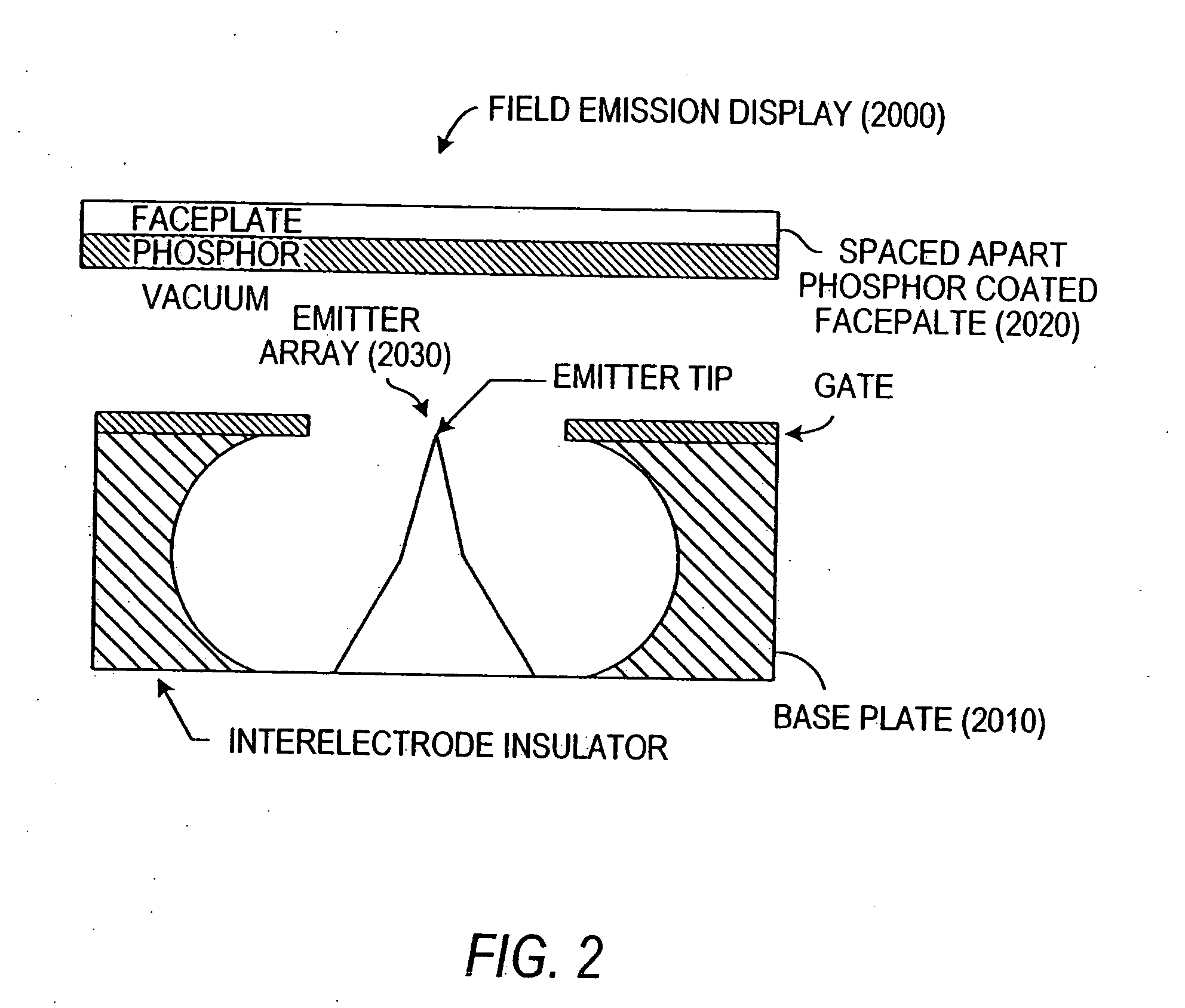

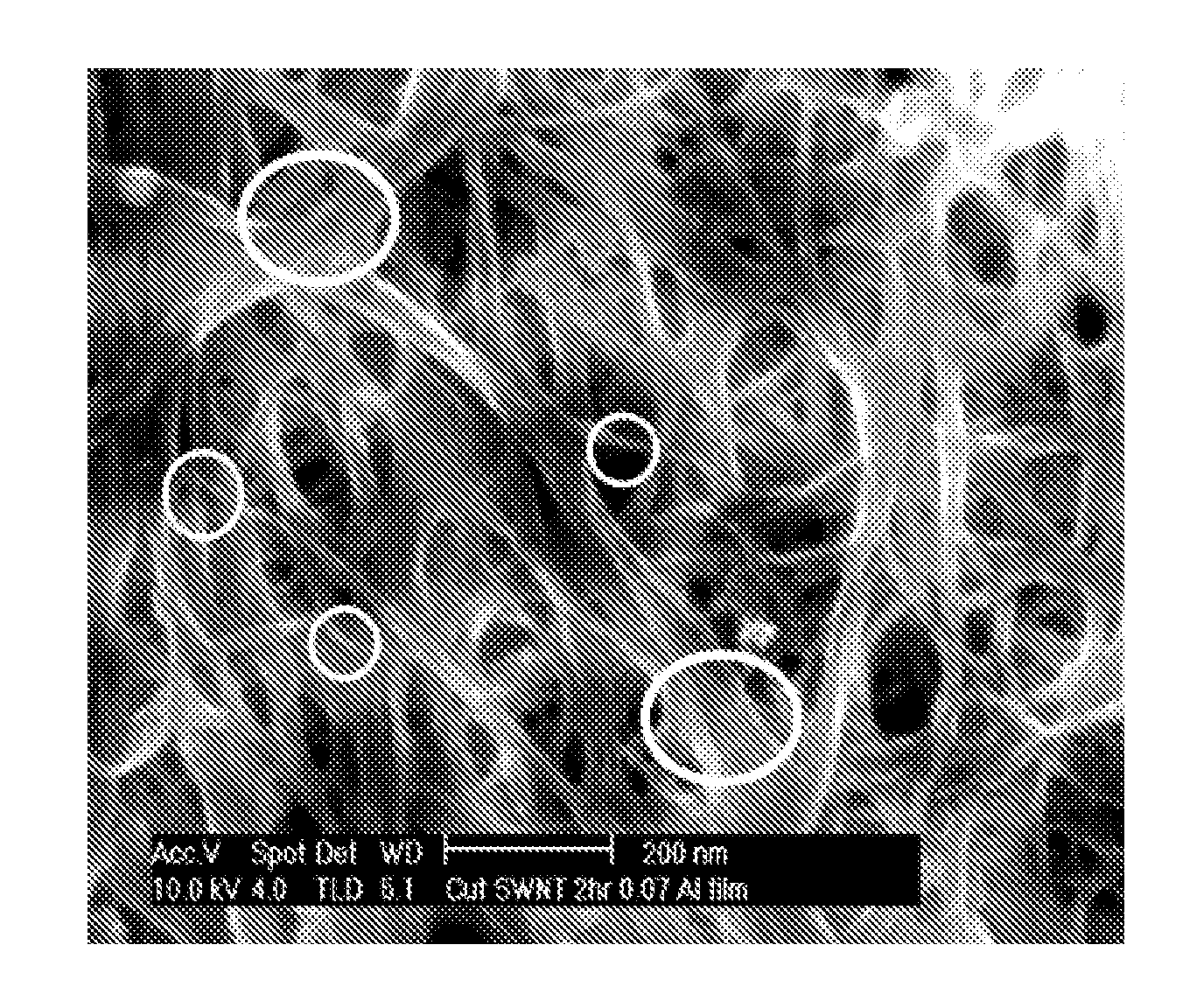

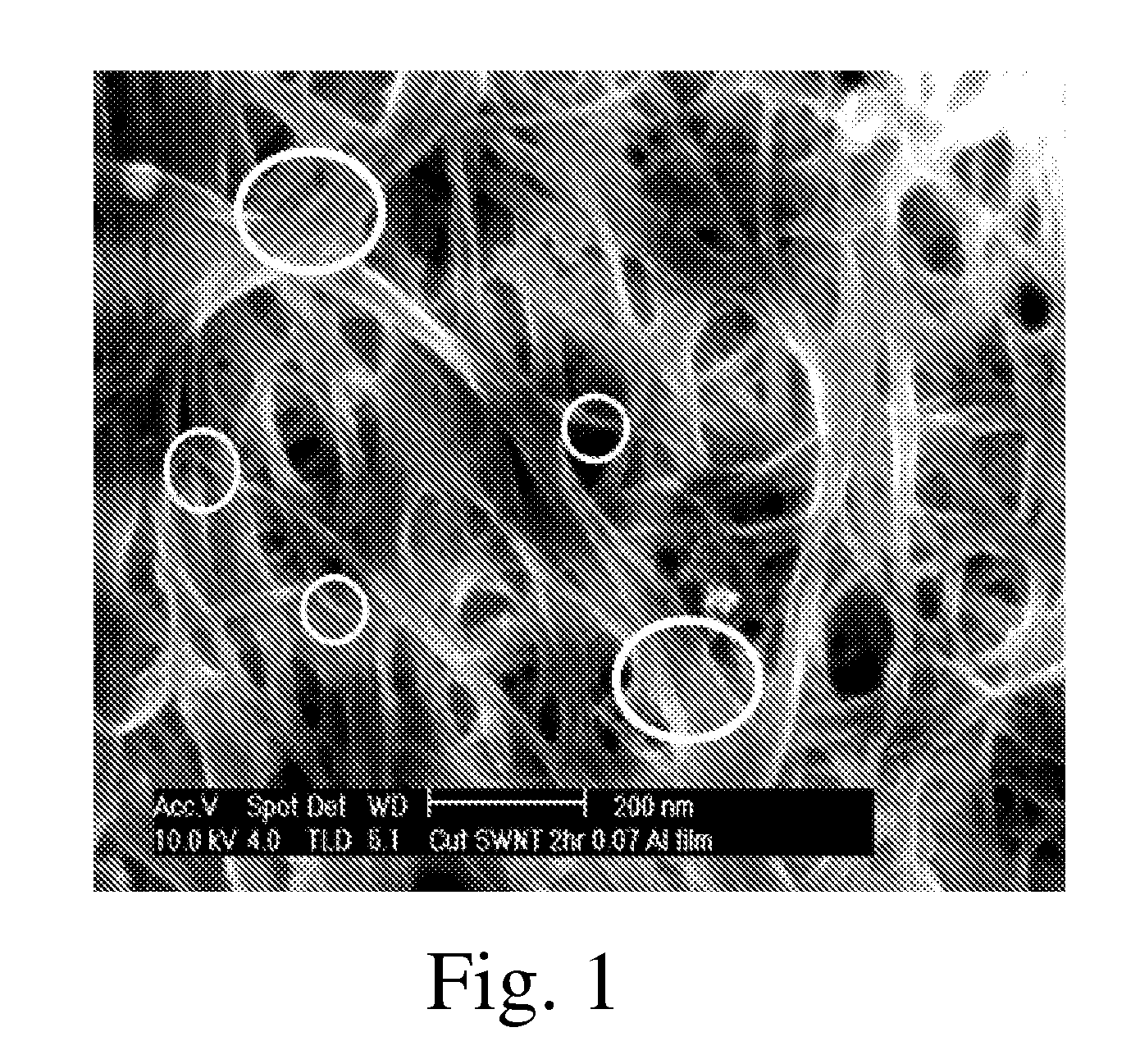

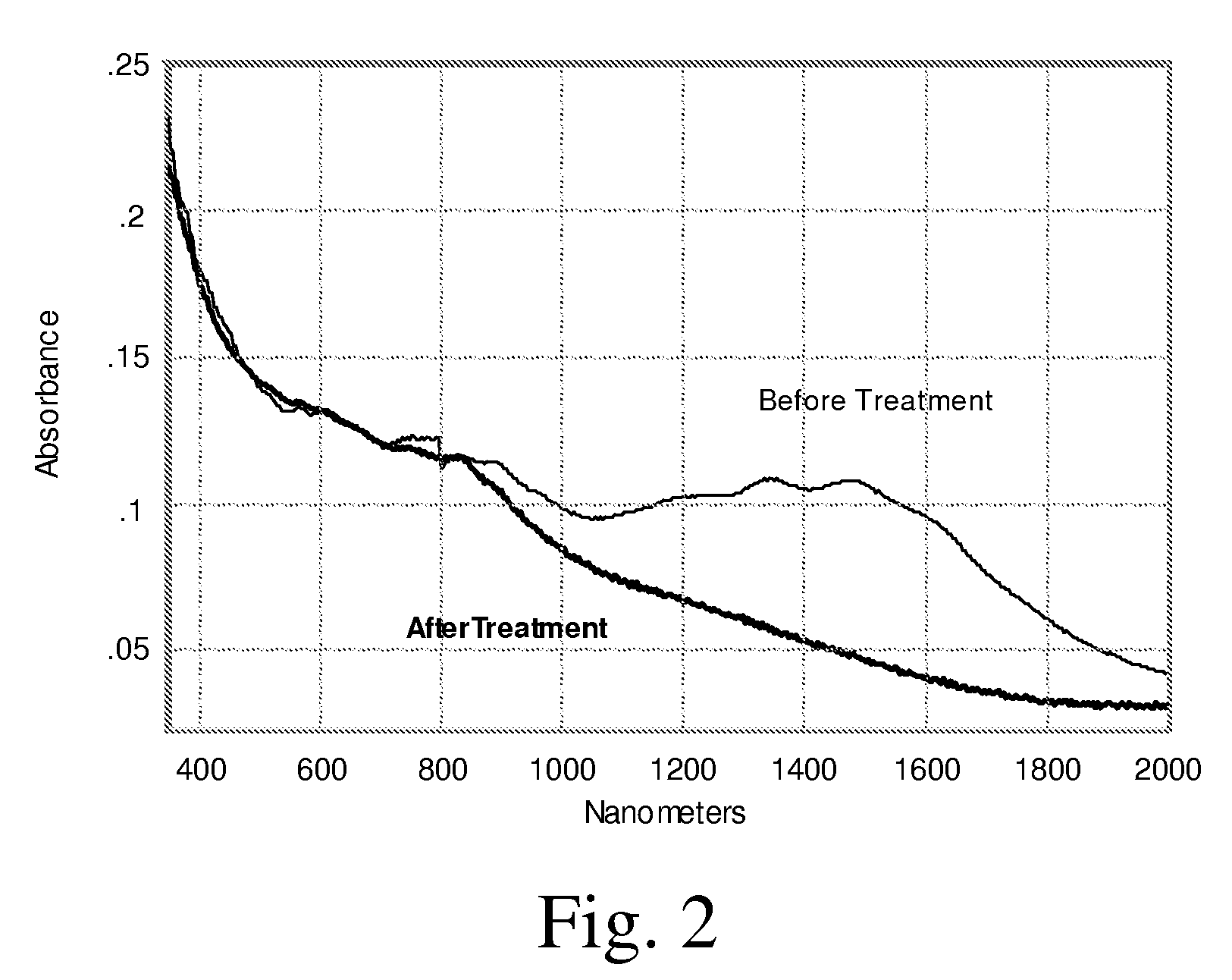

Field emission devices using modified carbon nanotubes

InactiveUS20030090190A1Accelerate emissionsReduce voltageNanostructure manufactureNanoinformaticsField emission deviceModified carbon

The present invention relates to a field emission device comprising an anode and a cathode, wherein said cathode includes carbon nanotubes nanotubes which have been subjected to energy, plasma, chemical, or mechanical treatment. The present invention also relates to a field emission cathode comprising carbon nanotubes which have been subject to such treatment. A method for treating the carbon nanotubes and for creating a field emission cathode is also disclosed. A field emission display device containing carbon nanotube which have been subject to such treatment is further disclosed.

Owner:HYPERION CATALYSIS INT

Modification of nanotubes oxidation with peroxygen compounds

InactiveUS20030039604A1Easy to shapeEasy to measureMaterial nanotechnologyNanostructure manufactureCompound aNanotube

A method of chemically modifying carbon nanotubes having a diameter less than one micron comprising: contacting the nanotubes with a peroxygen compound selected from the group consisting of organic peroxyacids, inorganic peroxoacids and organic hydroperoxides, or a salt thereof, under oxidation conditions and thereby producing modified carbon nanotubes. Oxidation of the nanotubes increases the degree of dispersion of aggregates of nanotubes and aids in the disassembling of such aggregates. The dispersed nanotubes are used to prepare rigid structures and can be used in electrodes and capacitors.

Owner:HYPERION CATALYSIS INT

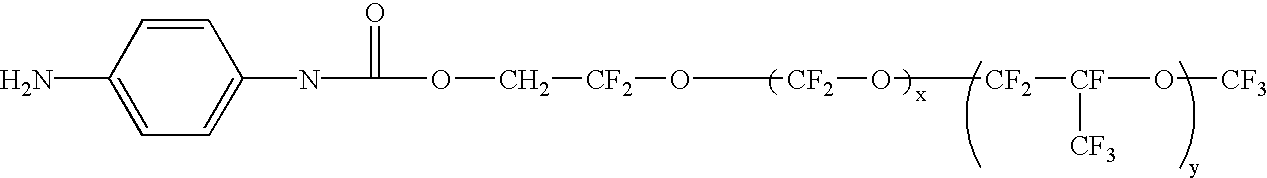

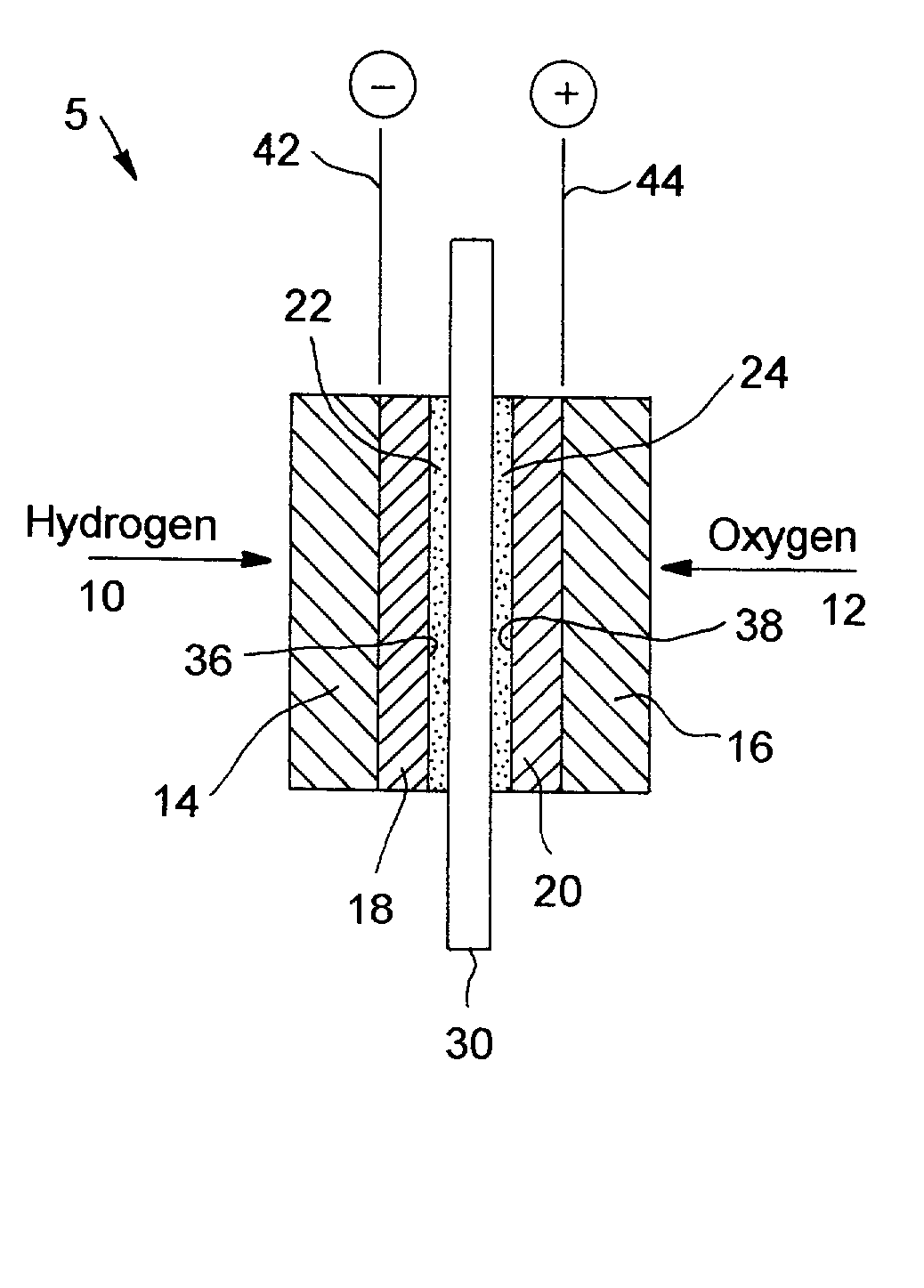

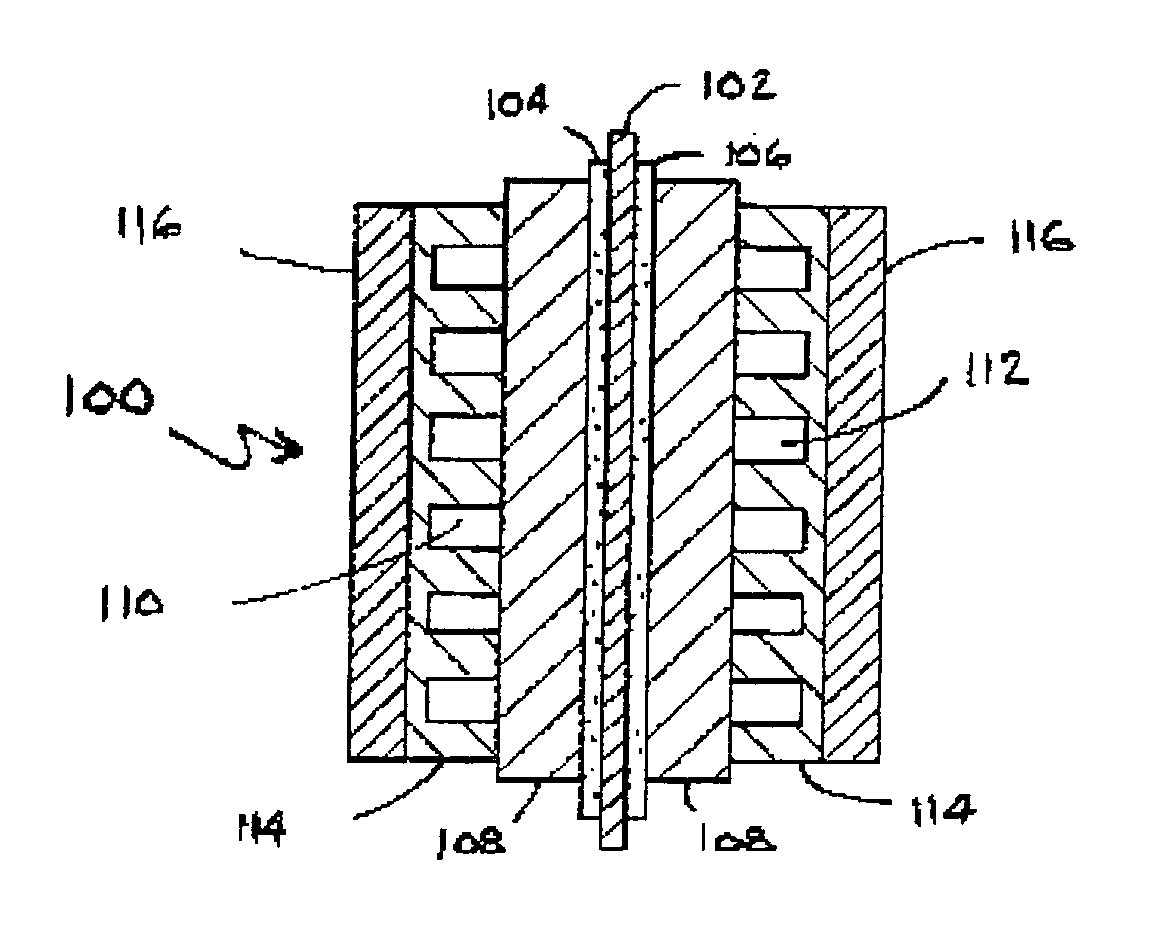

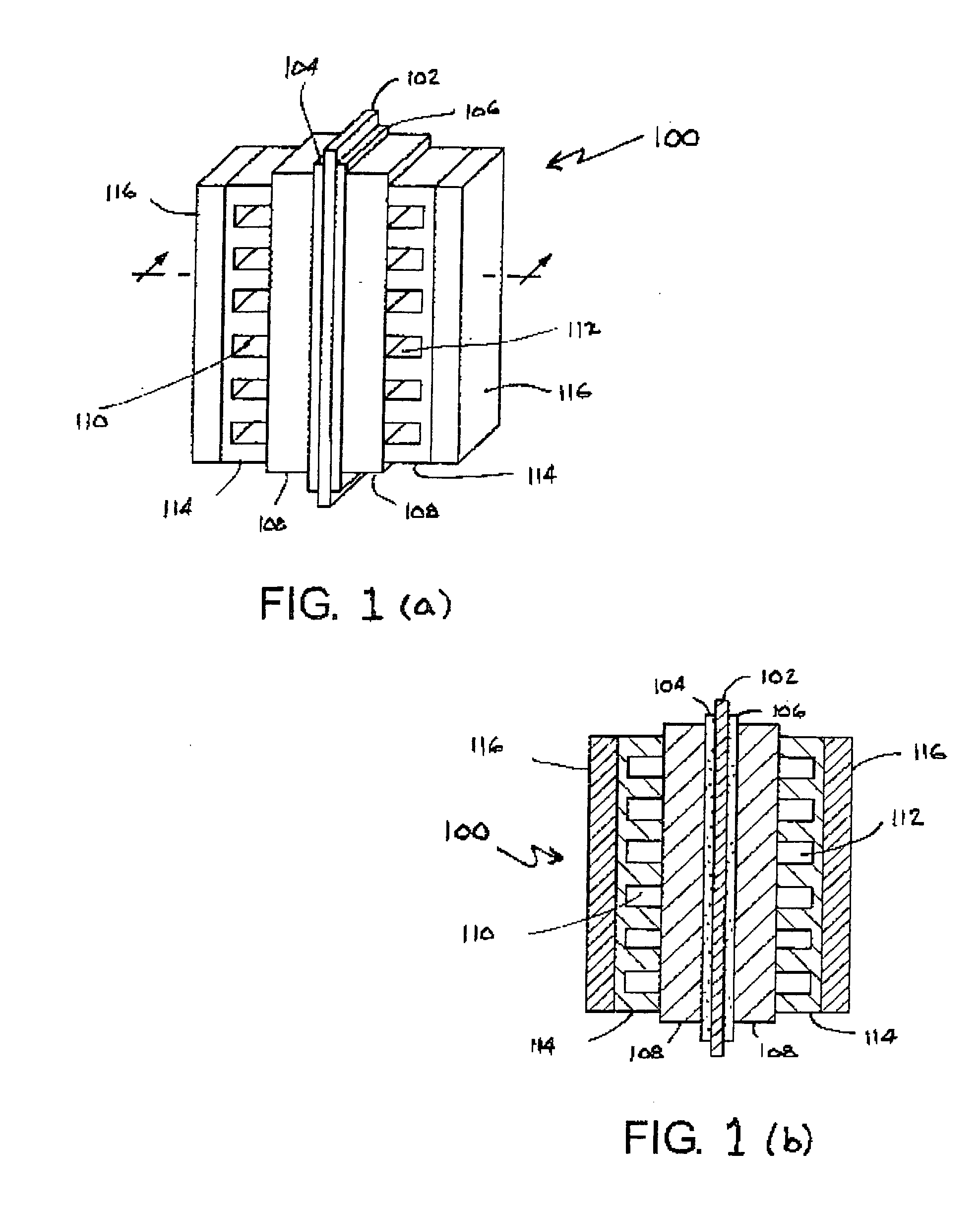

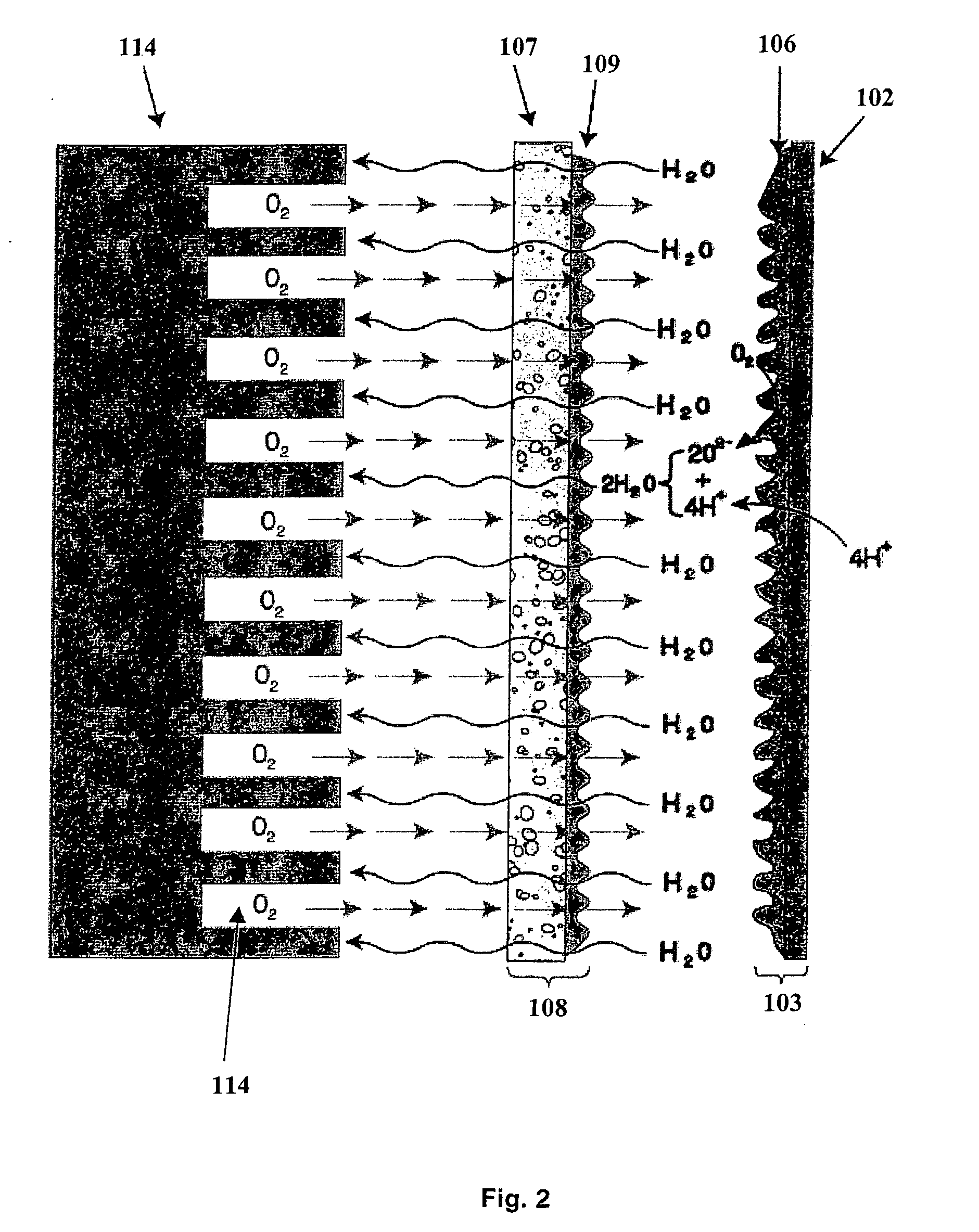

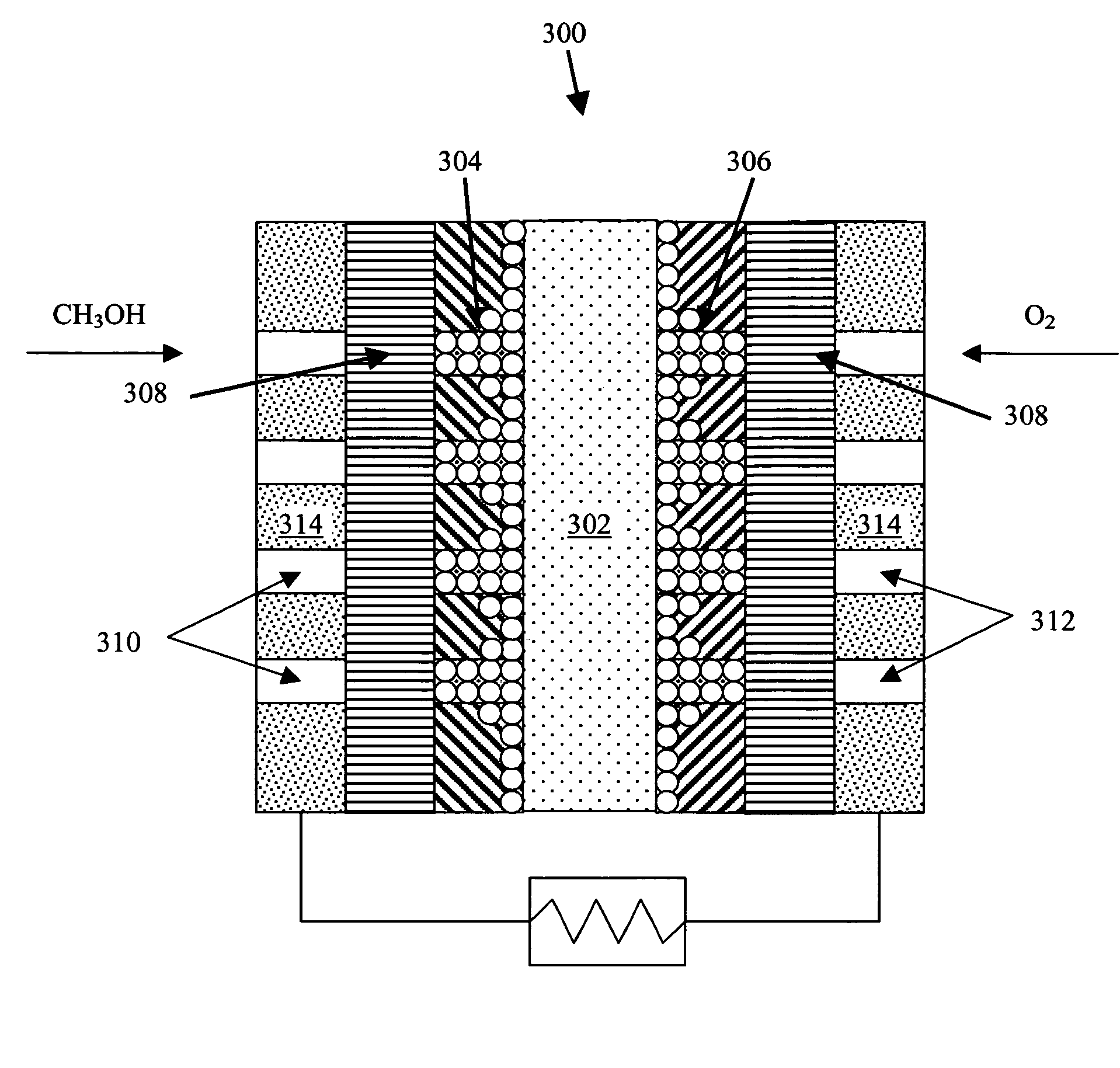

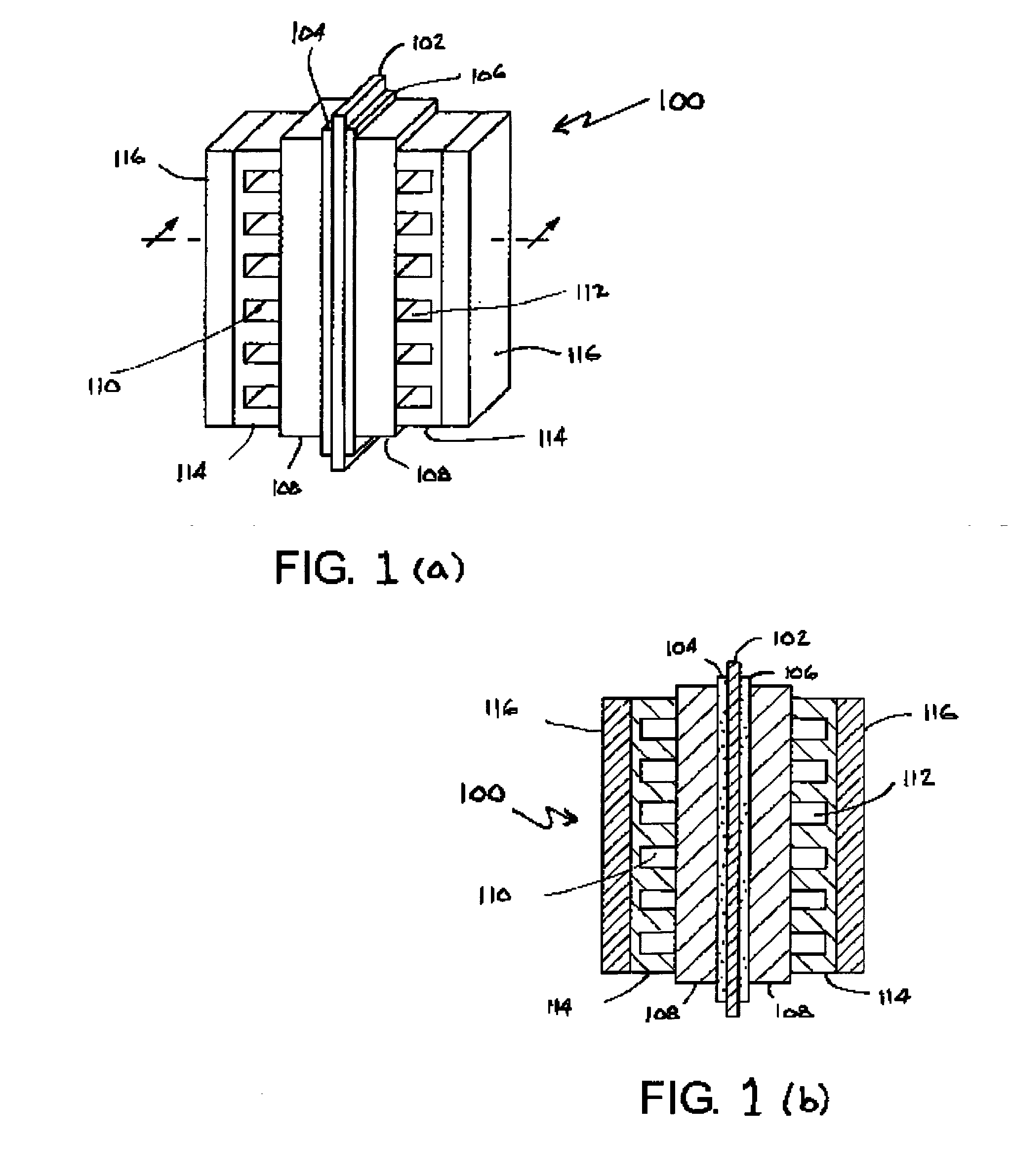

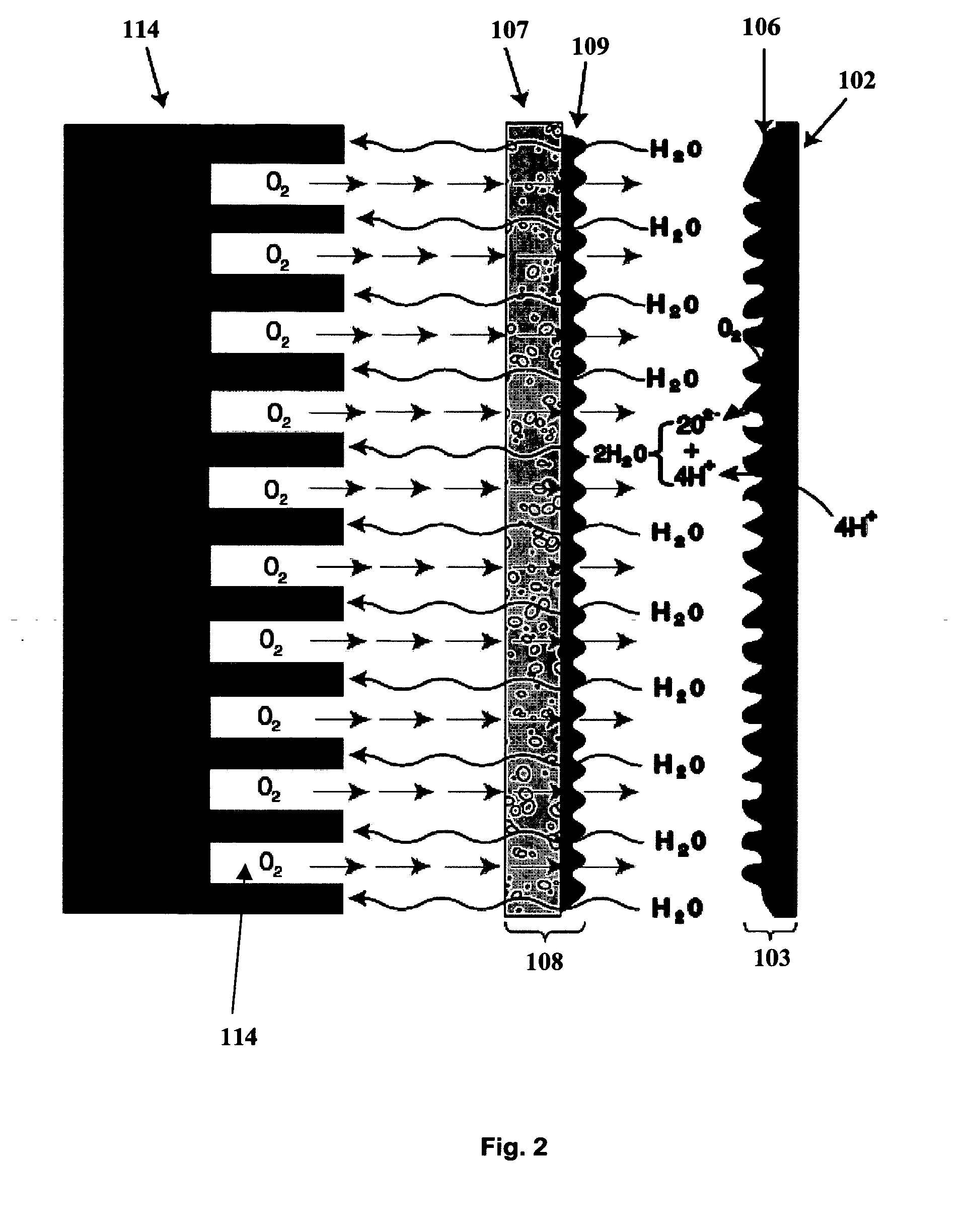

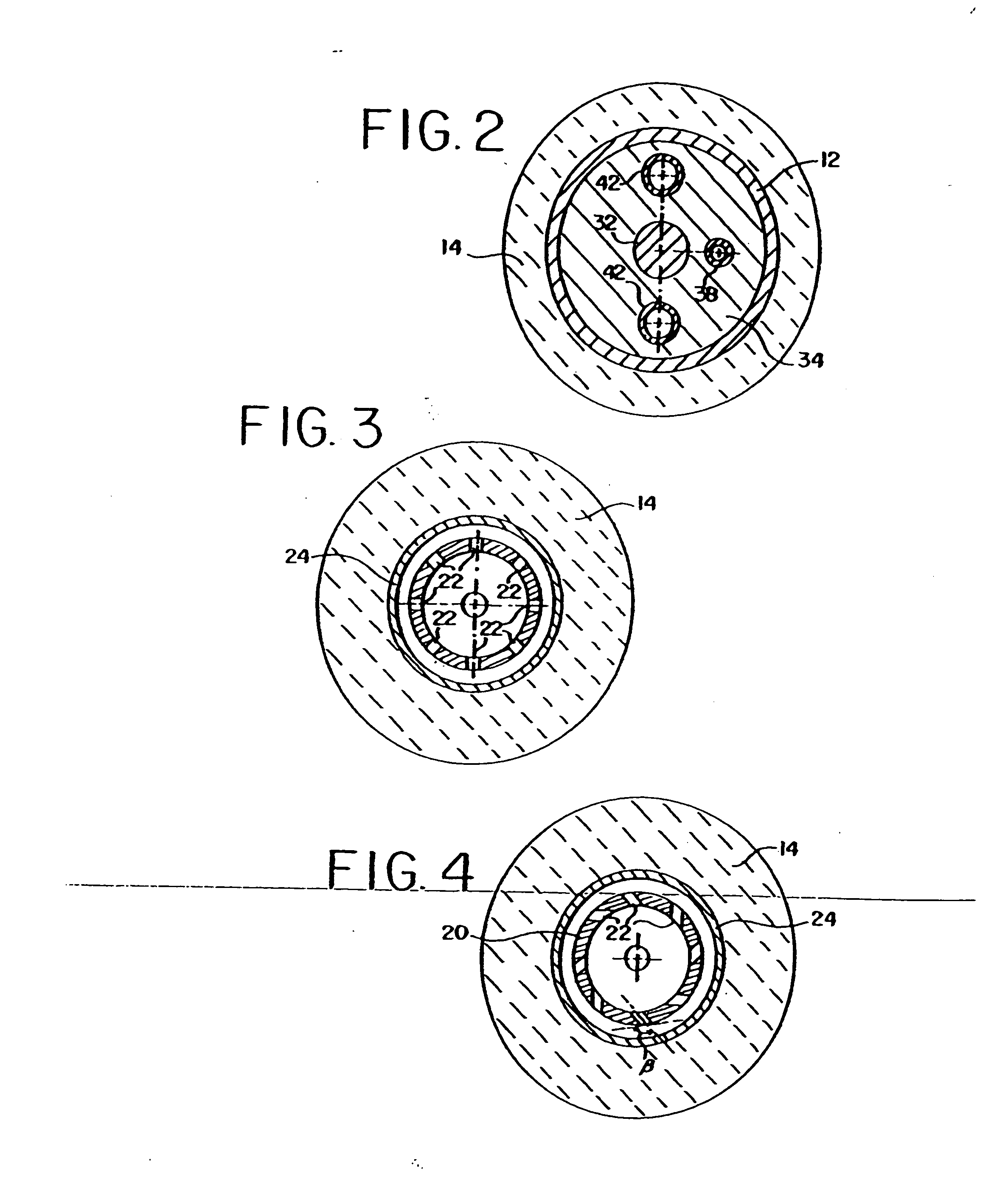

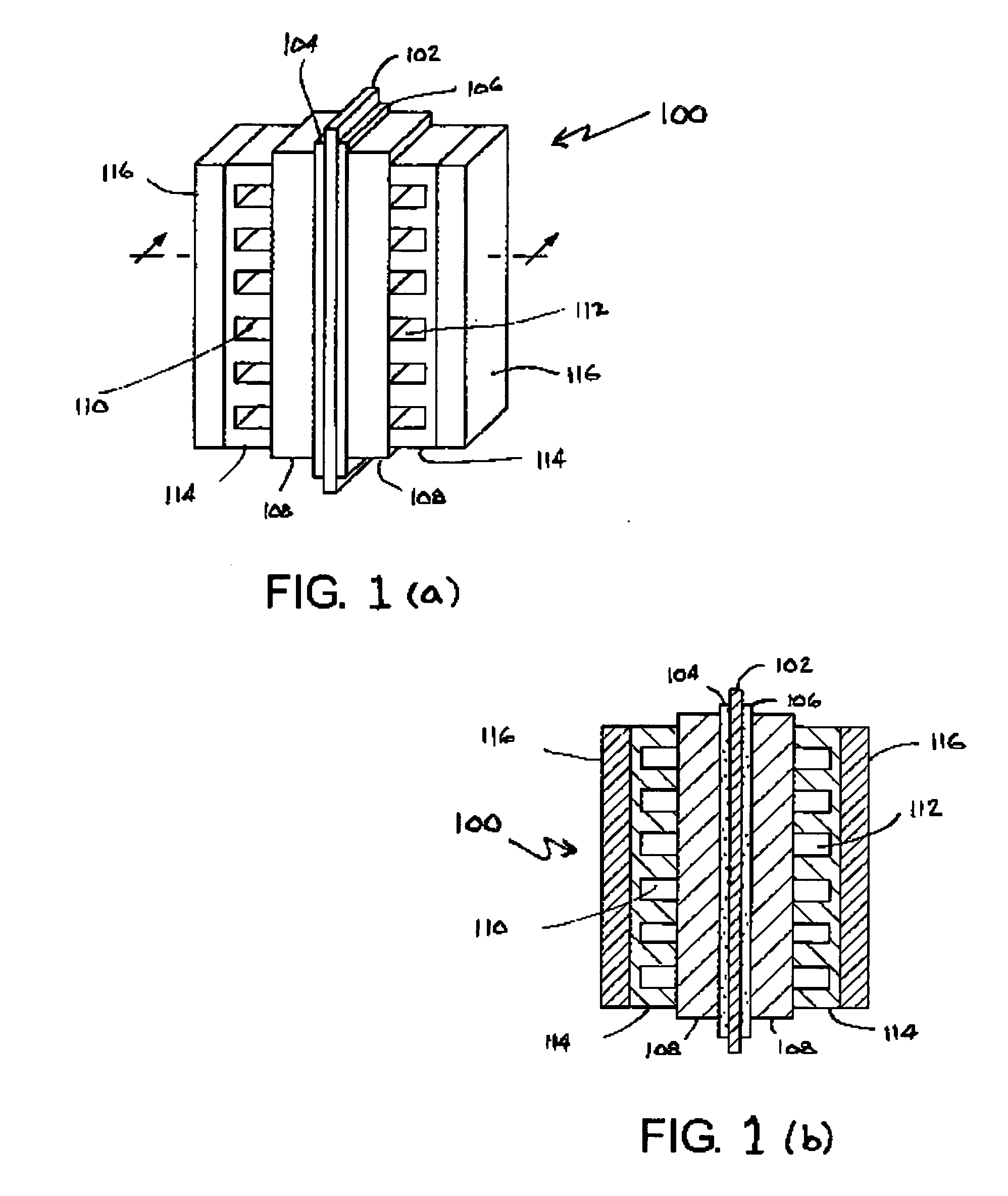

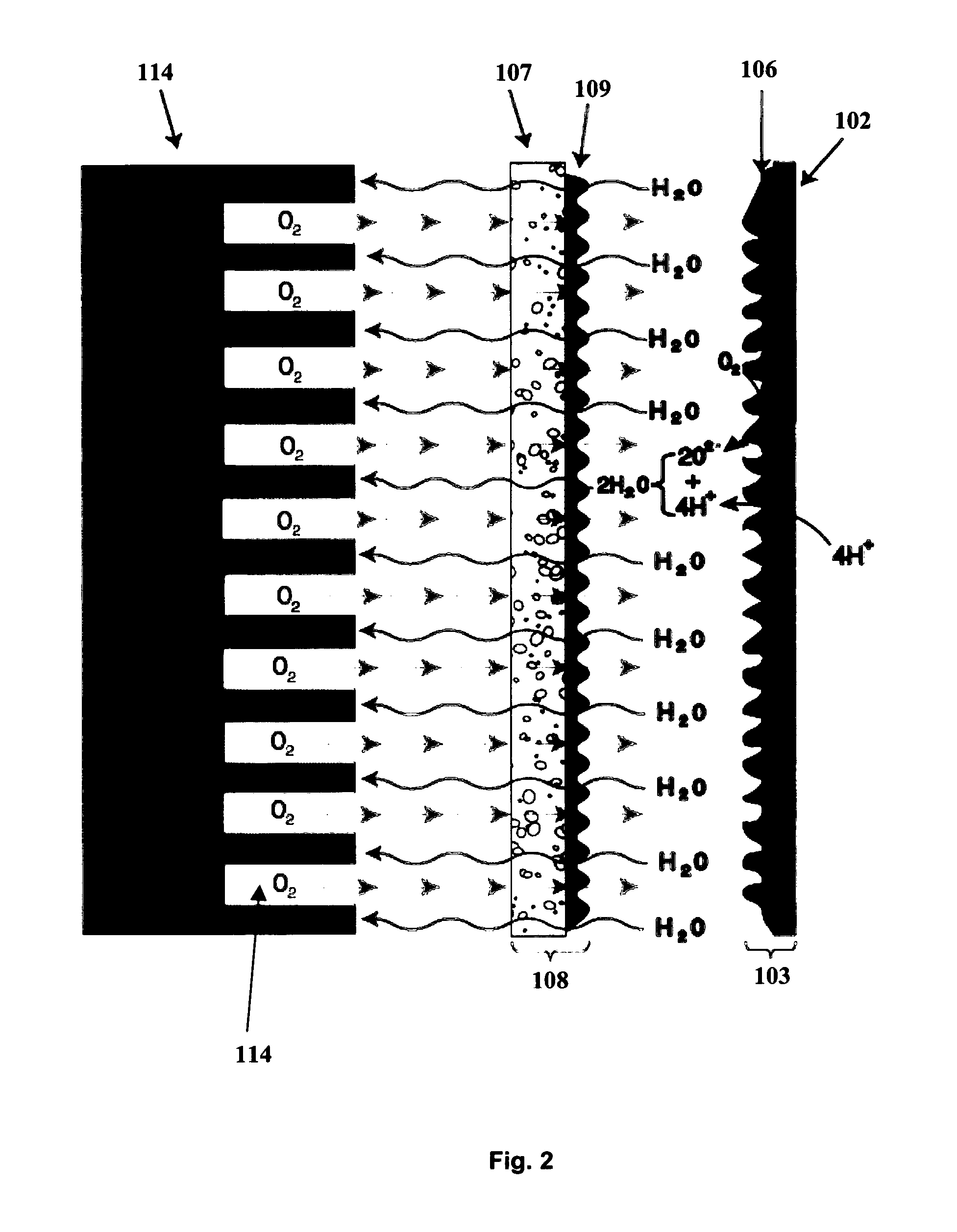

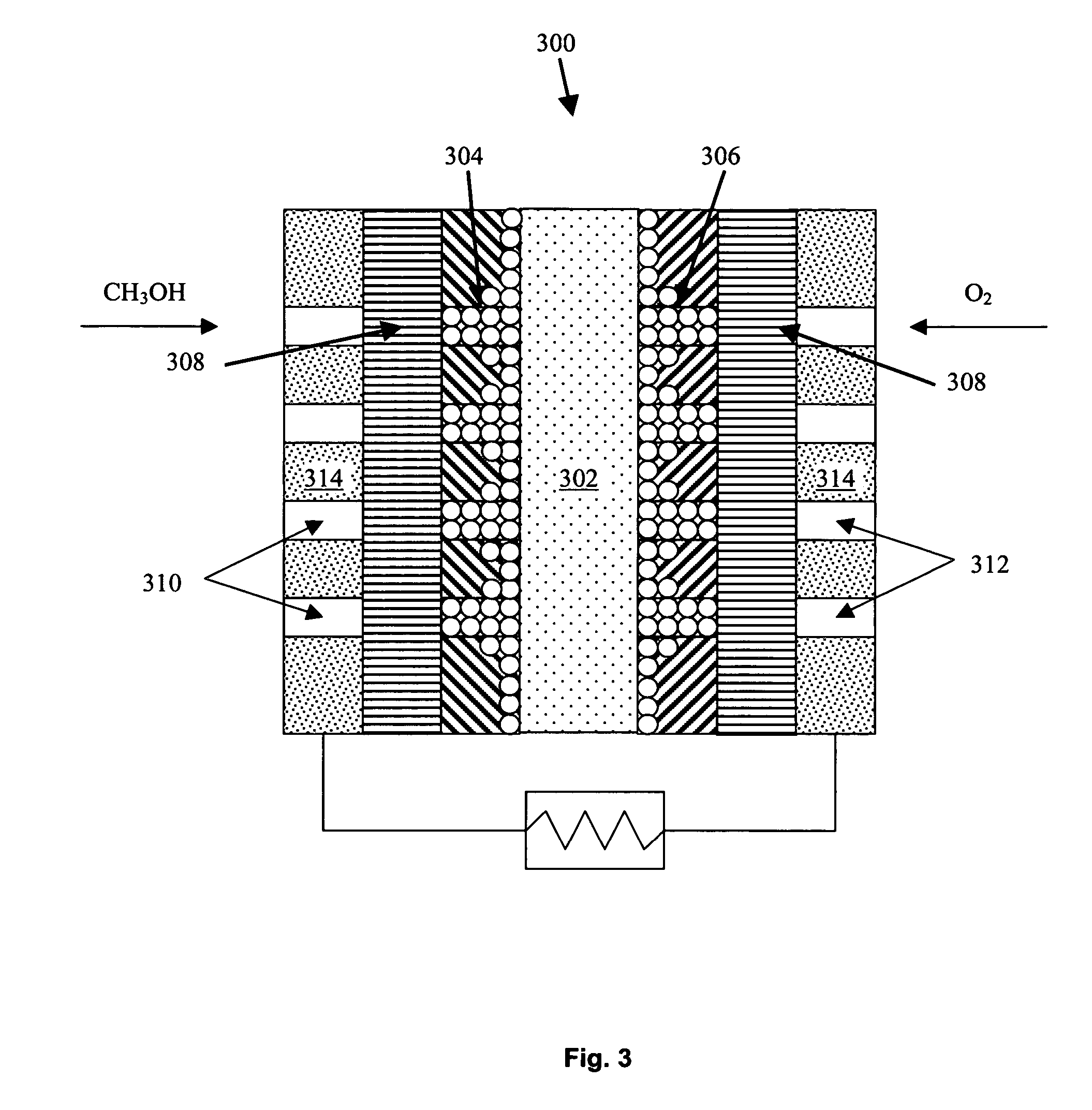

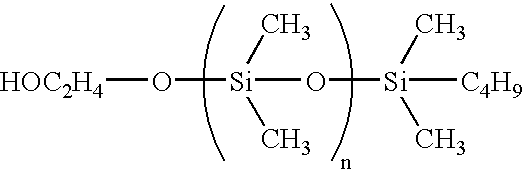

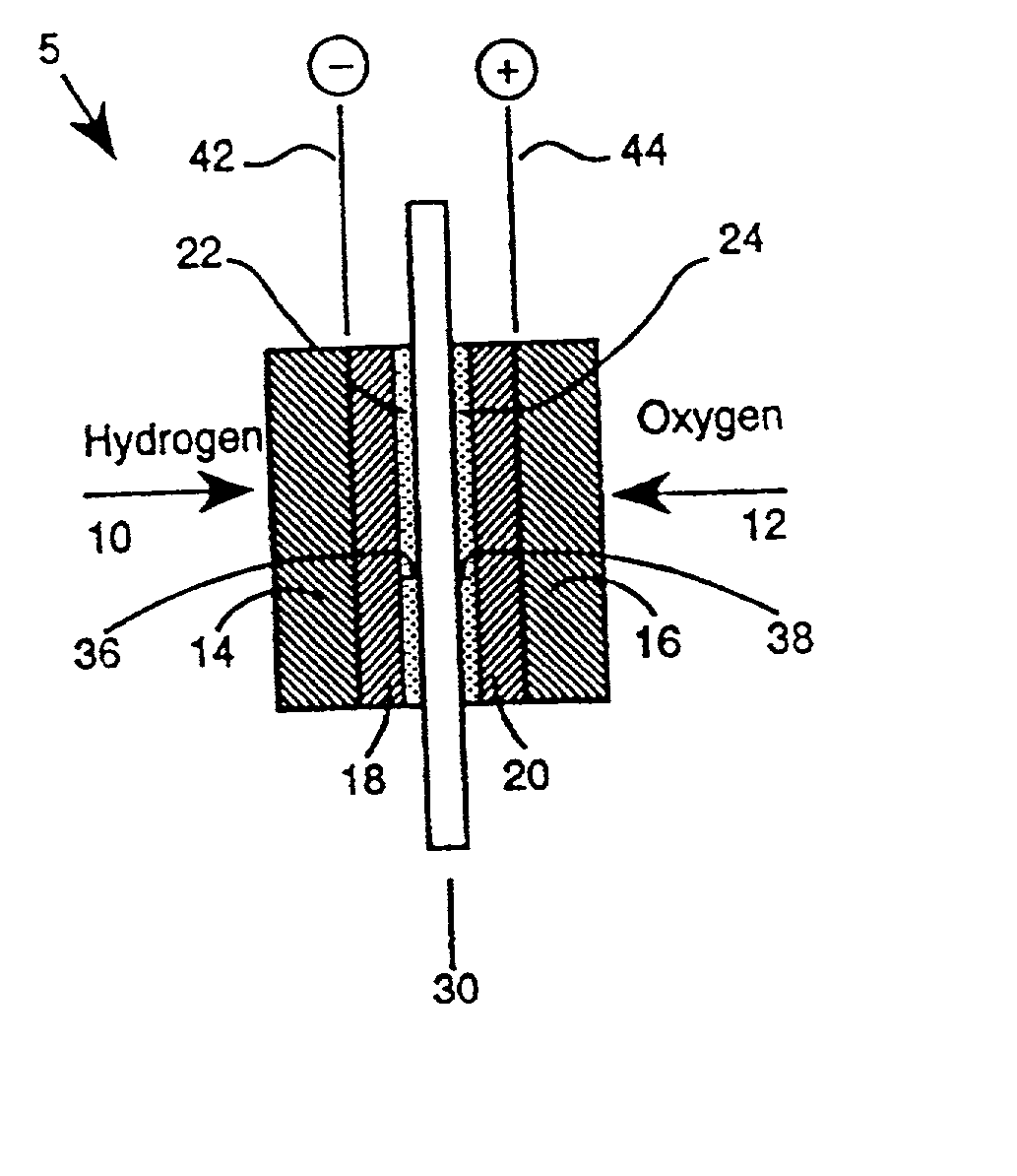

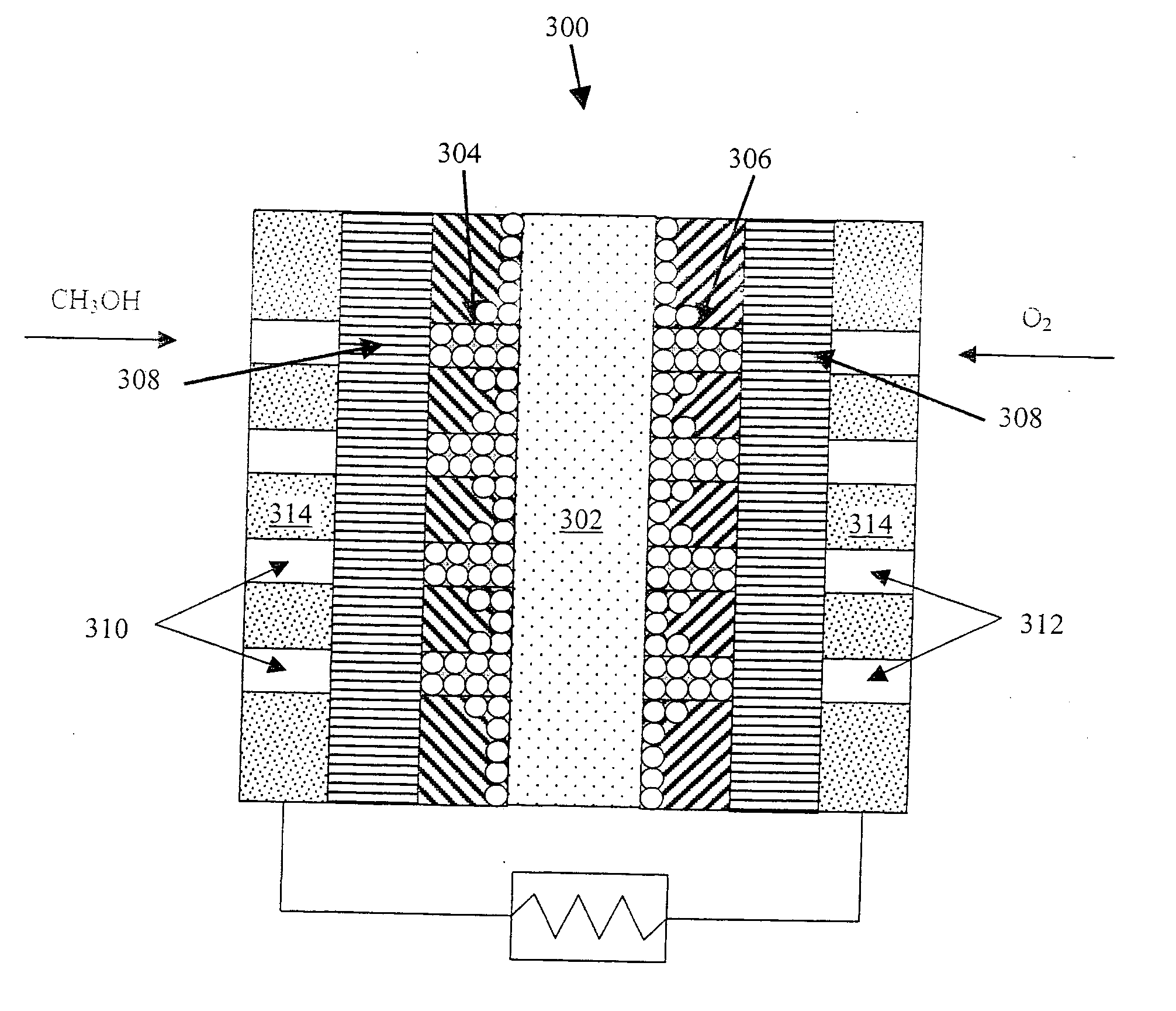

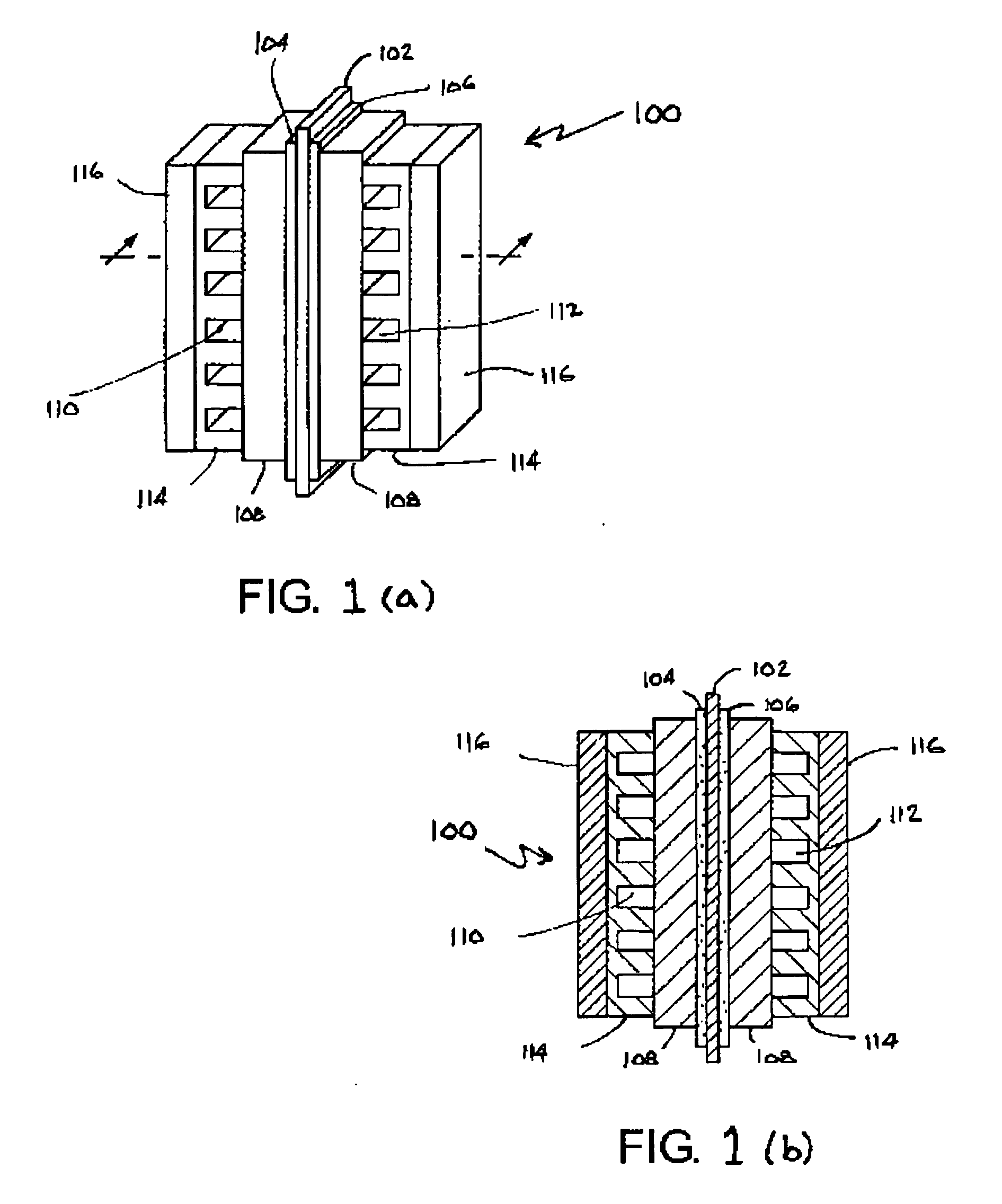

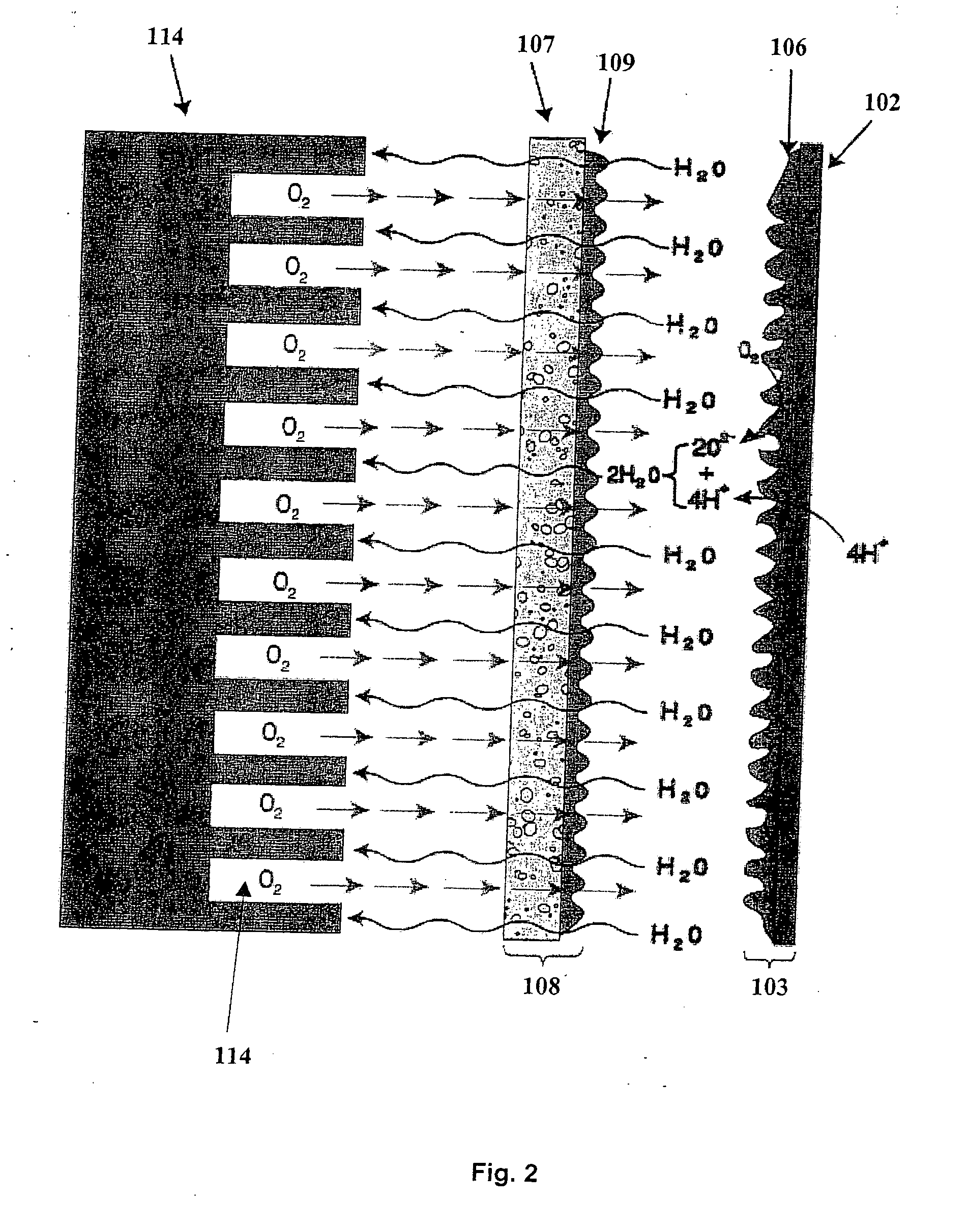

Fuel cells and other products containing modified carbon products

InactiveUS20030017379A1Decrease electrode performanceReduction of gas mass transport efficiencyOrganic diaphragmsAlkali metal halidesFuel cellsModified carbon

Fuel cells are described and contain a gas diffusion electrode, a gas diffusion counter-electrode, an electrolyte membrane located between the electrode and counter-electrode. The electrode or counter-electrode or both contain at least one modified carbon product. The electrolyte membrane can also or alternatively contain modified carbon products as well. The modified carbon product is a carbon product having attached at least one organic group. Preferably the organic group is a proton conducting group and / or an electron conducting group. The present invention preferably permits the elimination of fluoropolymer binder in the active or catalyst layer and further preferably leads to a thinner active layer and / or a thinner electrolyte membrane. Other uses and advantages are also described.

Owner:CABOT CORP

Modified carbon products, their use in electrocatalysts and electrode layers and similar devices and methods relating to the same

Electrodes and electrocatalyst layers incorporating modified carbon products. The modified carbon products may advantageously enhance the properties of an electrode or electrode layer, leading to more efficiency within the a fuel cell or similar device.

Owner:CABOT CORP

Modified carbon products, their use in fluid/gas diffusion layers and similar devices and methods relating to the same

Gas / Fluid diffusion layers incorporating modified carbon products. The modified carbon products advantageously enhance the properties of gas / fluid diffusion layers, leading to more efficiency within a fuel cell or similar device incorporating the gas / fluid diffusion layer.

Owner:CABOT CORP

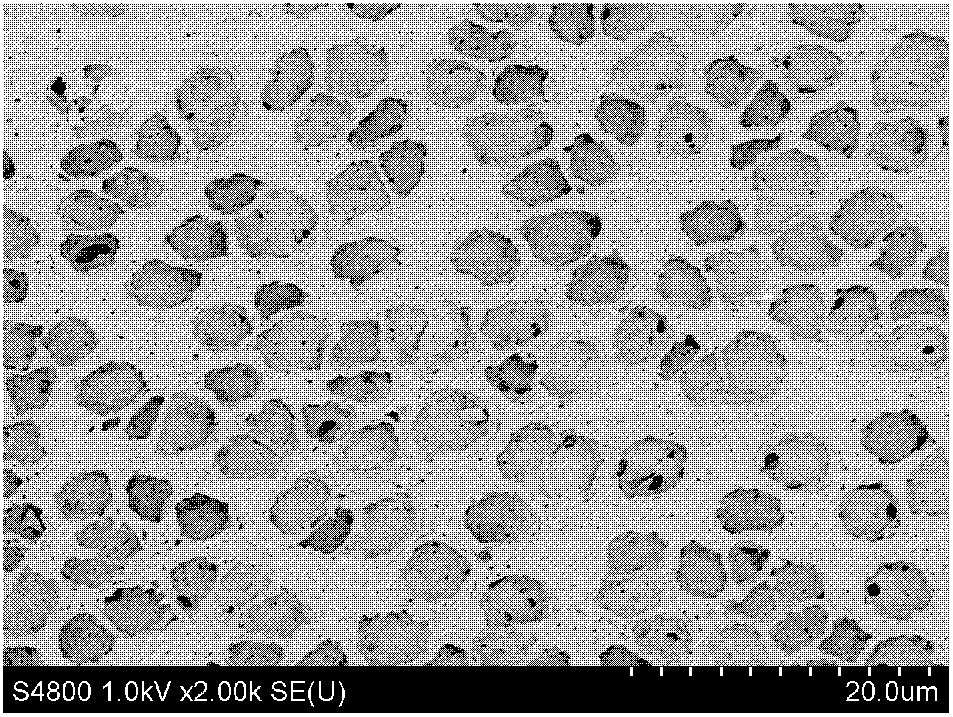

Graphene modified carbon fiber emulsion sizing agent and preparation method thereof

The invention relates to a graphene modified carbon fiber emulsion sizing agent and a preparation method thereof. The conventional solvent sizing agent is not environment-friendly. The sizing agent is a mixed system consisting of organic resin, an emulsifying agent, a lubricating agent, graphene, an organic solvent and deionized water, wherein the emulsifying agent, the lubricating agent, the graphene and the organic solvent are respectively 2 to 14 percent, 0.5 to 2 percent, 0.05 to 1 percent and 30 to 200 percent based on the mass of the organic resin; and the solid content of the mixed system is 0.1 to 5 percent. The preparation method of the sizing agent comprises the following steps of: dissolving the organic resin in the organic solvent to form organic resin solution, adding the emulsifying agent, the lubricating agent and the deionized water into the organic resin solution, and stirring until the mixed system is subjected to phase transfer; adding the deionized water until the solid content is 30 to 50 percent to obtain organic resin emulsion; and adding the graphene into the organic resin emulsion, and adding the deionized water to dilute the mixed system until the solid content is 0.1 to 5 percent so as to obtain the graphene modified sizing agent. The method is simple and reliable, and the prepared graphene modified sizing agent can well protect carbon fibers and effectively improve the interface property of the carbon fibers and matrix resin.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Modification of nanotubes oxidation with peroxygen compounds

InactiveUS20030086858A1Easy to measureGood dispersionMaterial nanotechnologyNanostructure manufactureCompound aNanotube

Owner:HYPERION CATALYSIS INT

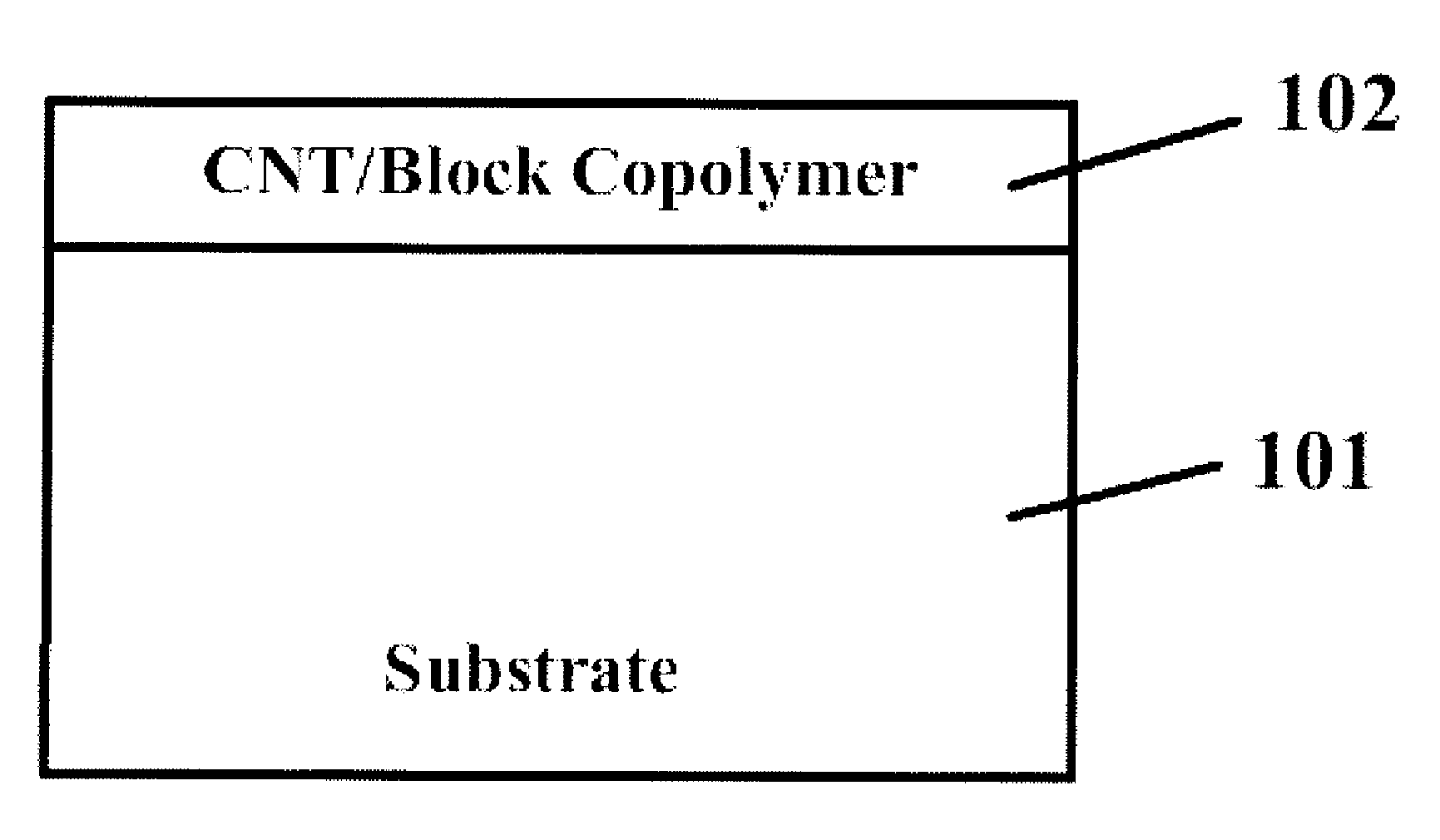

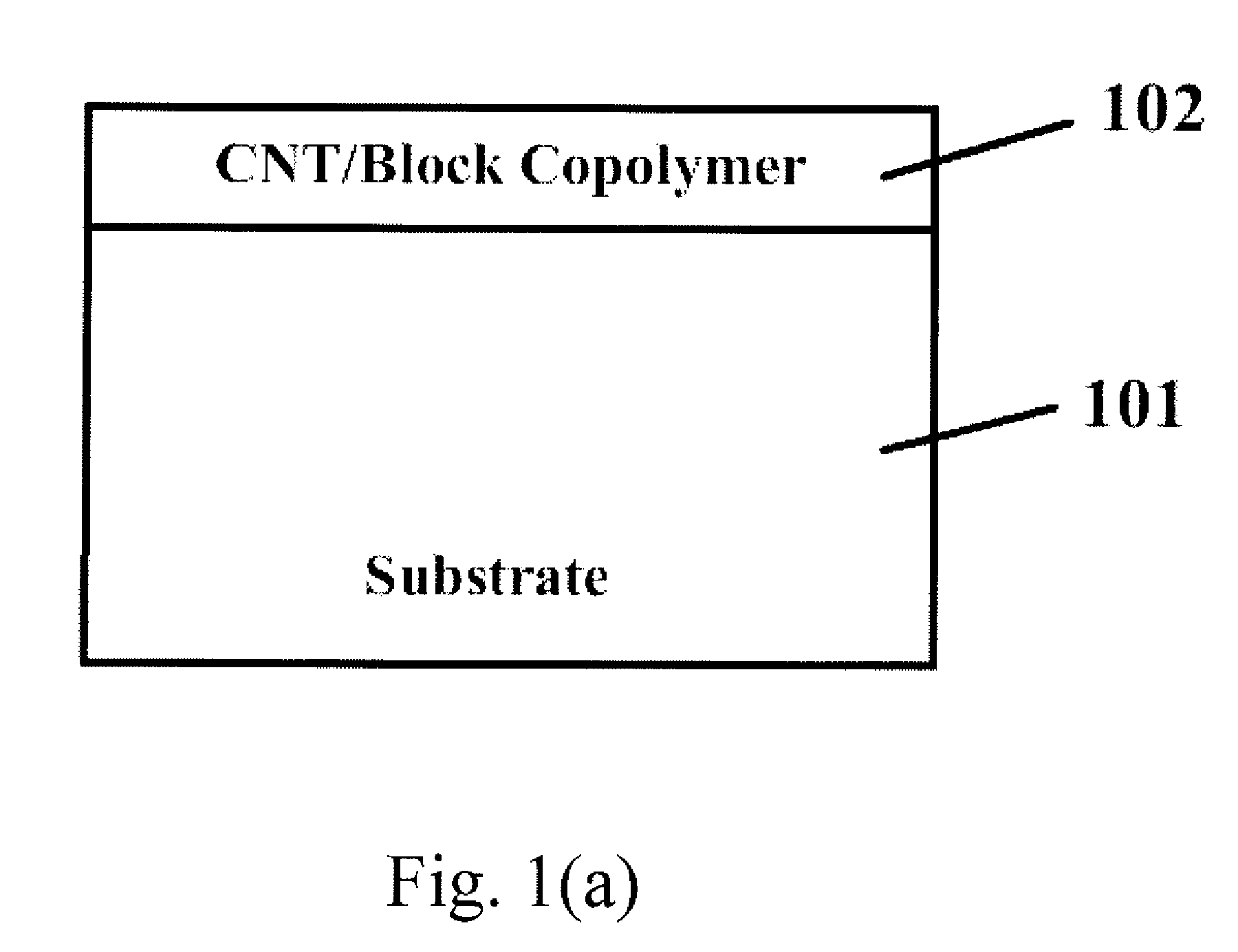

Dispersions of carbon nanotubes in copolymer solutions and functional composite materials and coatings therefrom

A dispersion includes a plurality of non-chemically modified carbon nanotubes, a soluble block copolymer providing at least one block of a conjugated polymer and at least one block of a non-conjugated polymer, and at least one solvent. At 25° C. exclusive of any mechanical force and after one hour, at least 90% of the plurality of carbon nanotubes exist in the dispersion as isolated carbon nanotubes. The components of the dispersion can be combined with a polymer miscible with the block copolymer to form a carbon nanotube polymer composite upon removal of the solvent. The dispersion can be cast on a substrate and then dried to form a coating, including forming a superhydrophobic coating on the substrate. The non-conjugated polymer of the block copolymer or another miscible conjugated polymer including a copolymer can include functionalities that non-covalently attach to the carbon nanotube surface, such as for manipulating carbon nanotube properties including for enhanced solubility or enhanced biocompatibility.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

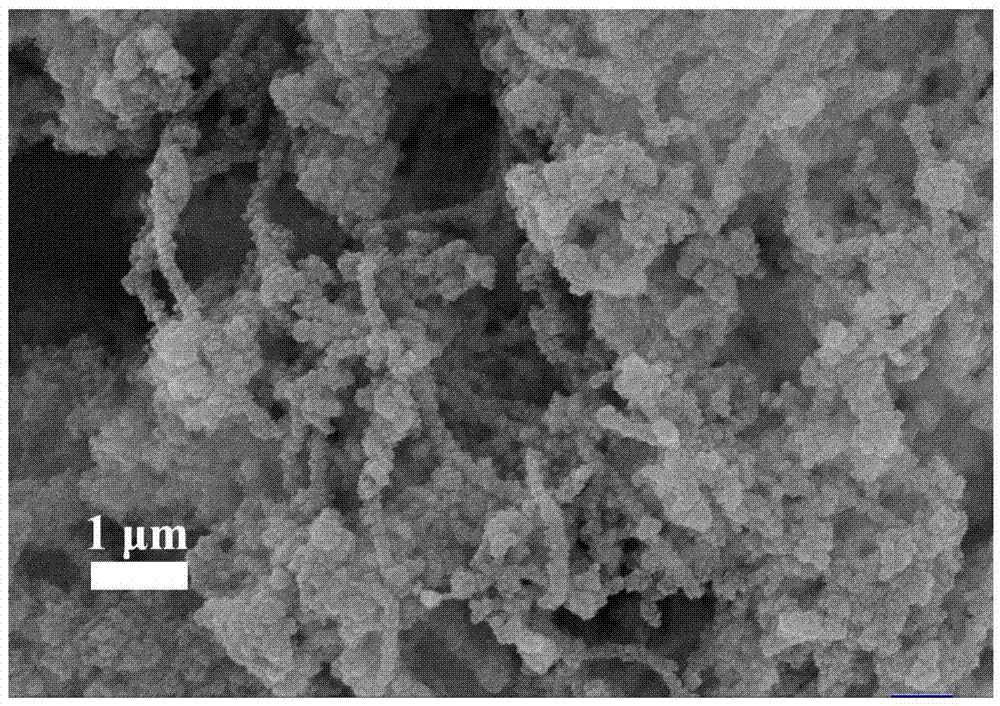

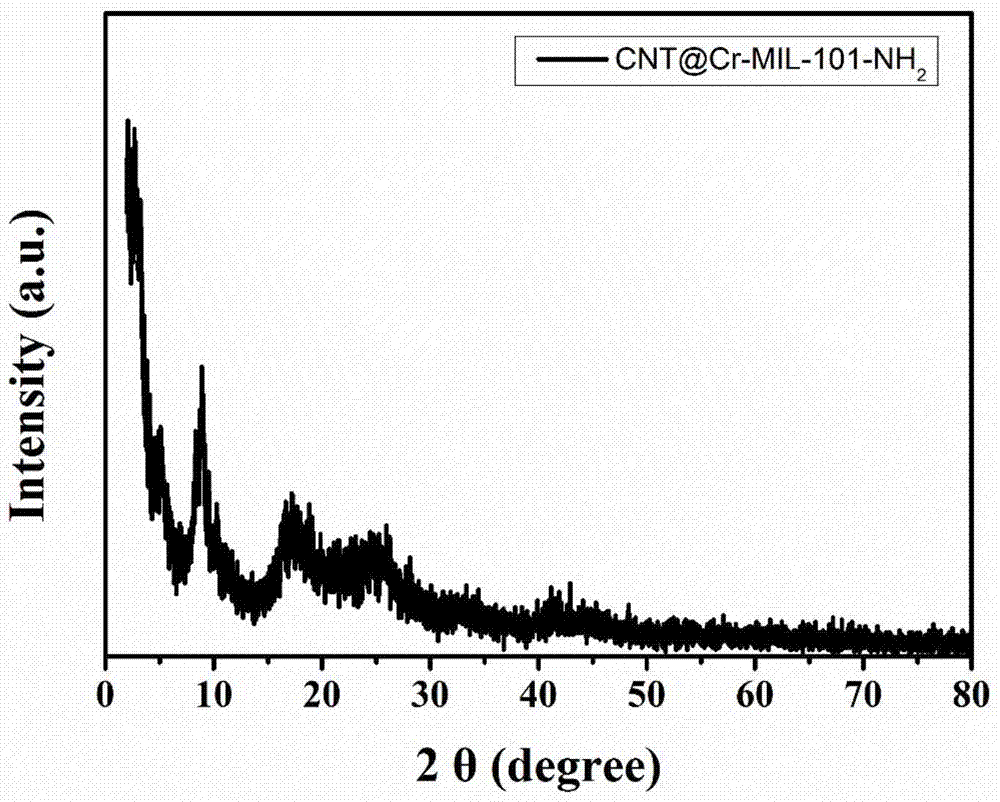

Preparation method for carbon-containing material metal organic framework-based composite phase change material

InactiveCN104745149AImprove heat transfer performanceImprove cycle stabilityHeat-exchange elementsModified carbonMetal-organic framework

The invention discloses a preparation method for a carbon-containing material metal organic framework-based composite phase change material and belongs to the field of nano composite materials and composite phase change materials. The preparation method comprises the following steps: carrying out in-situ growth of MOFs particles on a polyvinylpyrrolidone (PVP)-modified carbon material surface by adopting a hydrothermal method to prepare a carbon-containing material metal organic framework-based porous carrier material; then, dispersing a carbon material @MOFs porous carrier material into a prepared solution containing a phase change core material by adopting a solution dipping method; adsorbing a phase change core material by utilizing an oversized specific surface area of the metal organic framework material and a nao duct structure; and drying at a temperature higher than the phase change material to obtain the carbon-containing material metal organic framework-based composite phase change material. The material can be used for improving the heat transfer performances of the composite phase-change material, effectively preventing core material leakage, and has the advantages of wide core material selection range. The composite phase change material prepared by the method provided by the invention is excellent in heat transfer performance, good in circulating stability, simple in process and suitable for large-scale production.

Owner:UNIV OF SCI & TECH BEIJING

Preparing method of nanometer particle carbon nanotube compound catalyst

InactiveCN101224434AEasy to operateGood catalyticOrganic-compounds/hydrides/coordination-complexes catalystsModified carbonElectrostatic interaction

The invention relates to a preparation method of a nano particle carbon nanotube compound catalyst. The carbon nanotube with electric charges on surface is obtained from the materials which can generate non-covalent action with the carbon nanotube. Then nano particle with opposite electric charges on surface to that of the non-covalent modified carbon nanotube is added and completely mixed, and excess nano particle is removed to finally obtain the nano particle carbon nanotube catalyst compound. A plurality of nano particle carbon nanotube catalyst compounds can be prepared by the invention, all of which represent very good catalytic activities. The invention adopts the method of non-covalent modified carbon nanotube to obtain carbon nanotube with perfect surface. Meanwhile, the invention provides the nano particle, in particular, the morphology controllable nano particle on the load of carbon nanotube with an effective way by utilizing the electrostatic interaction of carbon nanotube and namo particle, thus extending the applications of morphology controllable nano particle in catalytic field.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Process for preparing nano SiO2 modified carbon fiber emulsion pasting agent

ActiveCN1632217AImprove protectionHigh strengthFibre treatmentFibre chemical featuresCarbon fibersEmulsion

A preparation method of a nano-SiO2 modified carbon fiber emulsion sizing agent, which uses nano-SiO2 as a sizing resin modification material, and the modified material, sizing resin, emulsifier, dispersant, organic solvent and particle-free water are prepared in a certain weight ratio Carbon fiber-forming functional emulsion sizing agent. After the carbon fiber is impregnated with a certain concentration of modified sizing agent for an appropriate time, the strength of the carbon fiber increases by up to 8.7%; the interfacial shear strength (IFSS) of the single fiber composite material can reach up to 43.67MPa; ILSS) up to 98.7MPa.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Thermally modified carbon blacks for various type applications and a process for producing same

InactiveUS20050063893A1Improve thermal conductivityImprove fatigue performancePigmenting treatmentMaterial nanotechnologyModified carbonFood contact

Owner:COLUMBIAN CHEM CO +1

Modified carbon products, their use in bipolar plates and similar devices and methods relating to same

InactiveUS20050221139A1Improve hydrophobicityReduce hydrophobicityElectrolyte holding meansFuel cells groupingFuel cellsModified carbon

Bipolar plates incorporating modified carbon products. The modified carbon products advantageously enhance the properties of the bipolar plates, leading to more efficiency within a fuel cell or a similar device.

Owner:CABOT CORP

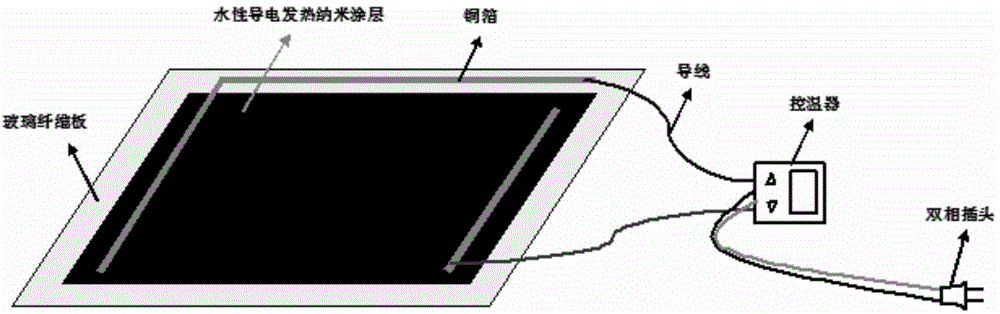

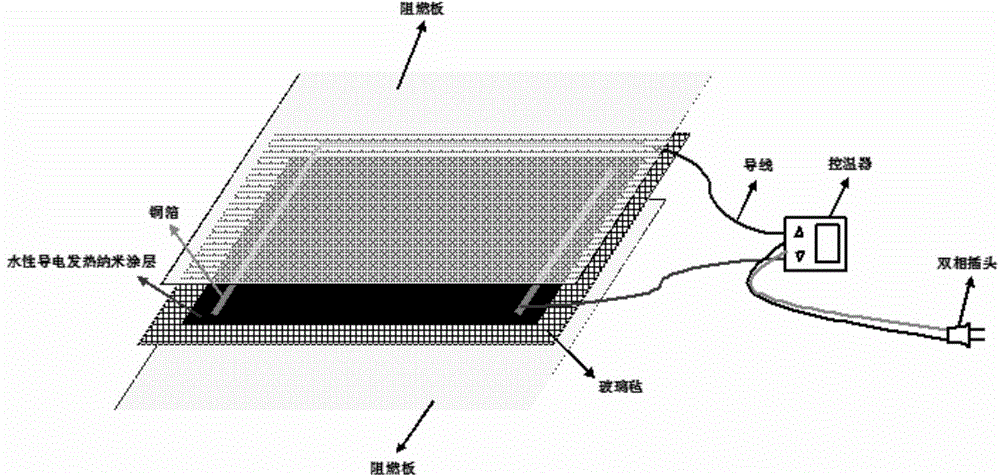

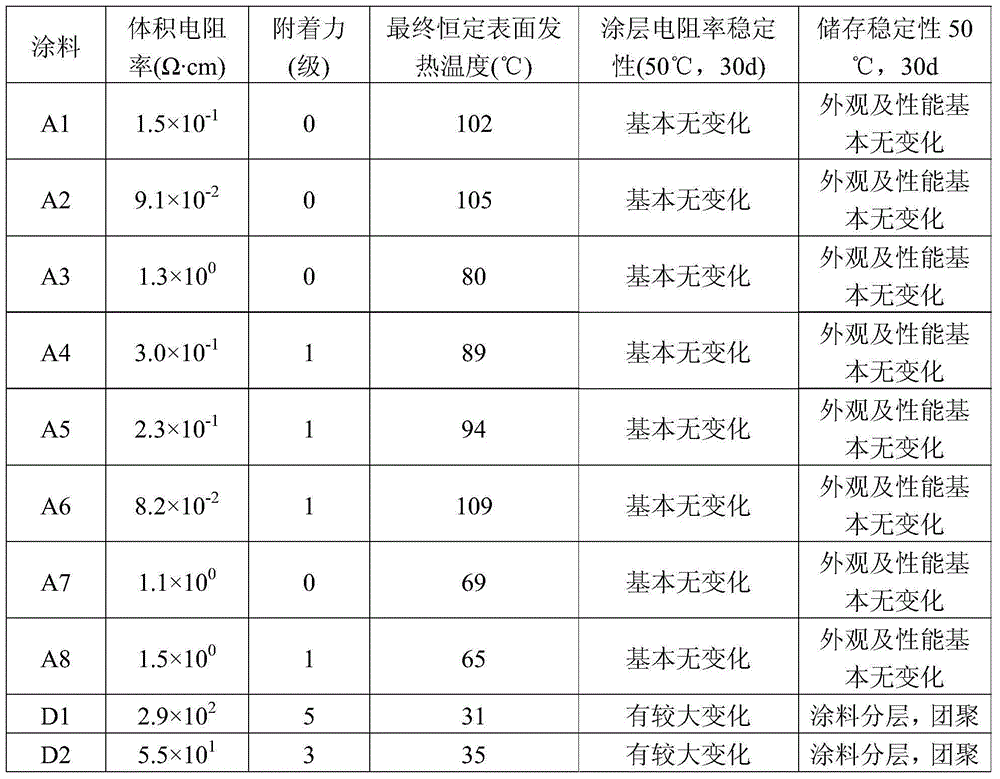

Composition for water-based electric heating nano paint, water-based electric heating nano paint as well as preparation method and application of water-based electric heating nano paint

ActiveCN105017831AAddress unfavorable defectsGood compatibilityPolyurea/polyurethane coatingsEpoxy resin coatingsWater basedOrganic solvent

The invention discloses a composition for water-based electric heating nano paint. The composition comprises water-based resin and a water dispersion containing conductive nano particles; the water dispersion containing the conductive nano particles is a water dispersion containing hydroxyl modified carbon nanotube or a water dispersion containing graphene, or the water dispersion containing the conductive nano particles comprises a water dispersion containing the hydroxyl modified carbon nanotube and a water dispersion containing graphene. The invention also discloses water-based electric heating nano paint as well as a preparation method and application thereof. The water-based conductive heat-conduction nano paint can be used for solving the defects in the prior art that the oil organic resin is used as a bonding agent and the organic solvent serving as the solvent is harmful to the environment; meanwhile, the adhesive force is better, the resistance rate is lower, the heating is faster, the heating amount is higher, and the heating performance is more stable.

Owner:MATERIAL & IND TECH RES INST BEIJING +1

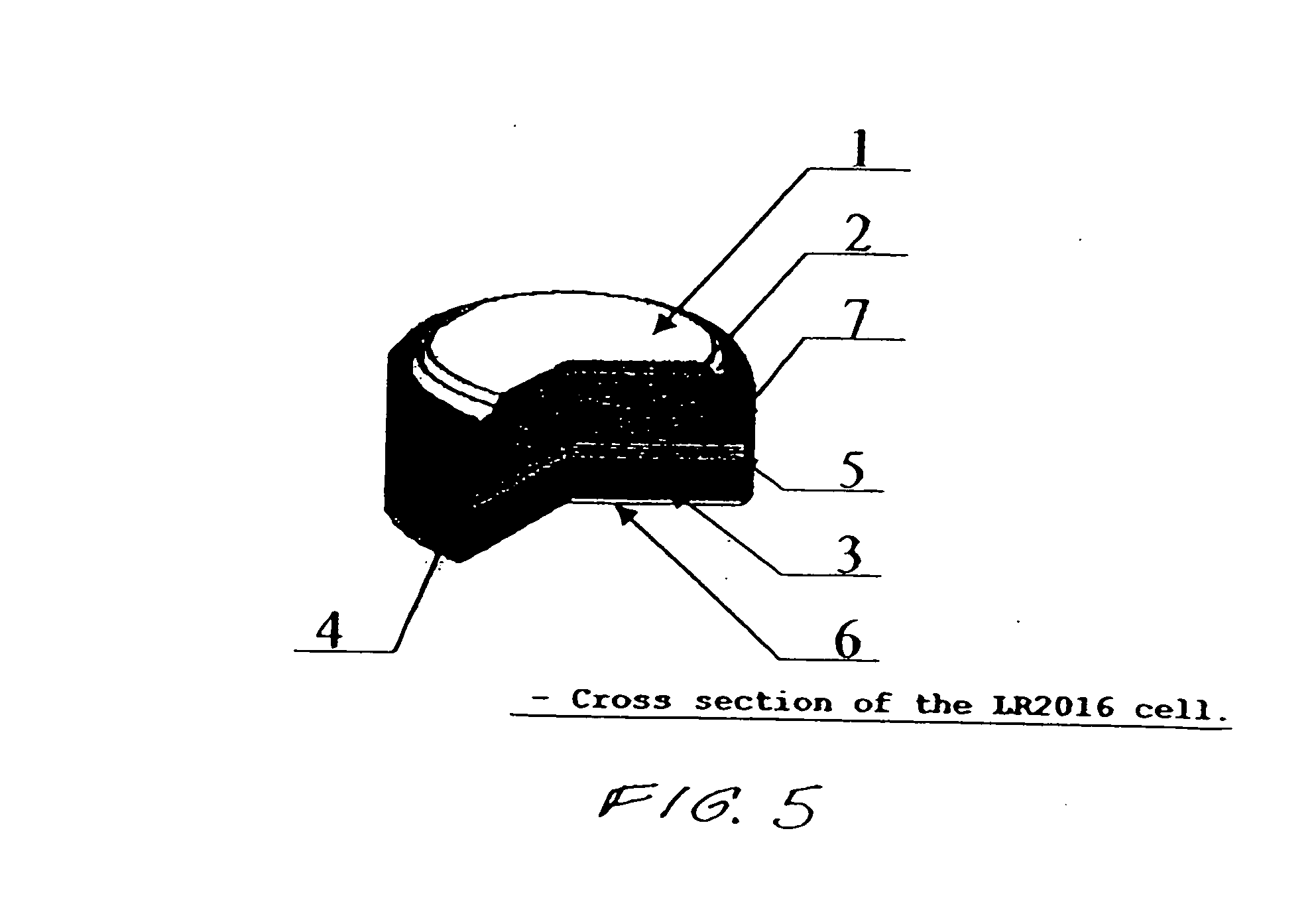

Thermally modified carbon blacks for various type applications and a process for producing same

InactiveUS20050063892A1Oxidation resistance can be improvedReduced metal and ash contentPigmenting treatmentMaterial nanotechnologyModified carbonOxidation resistant

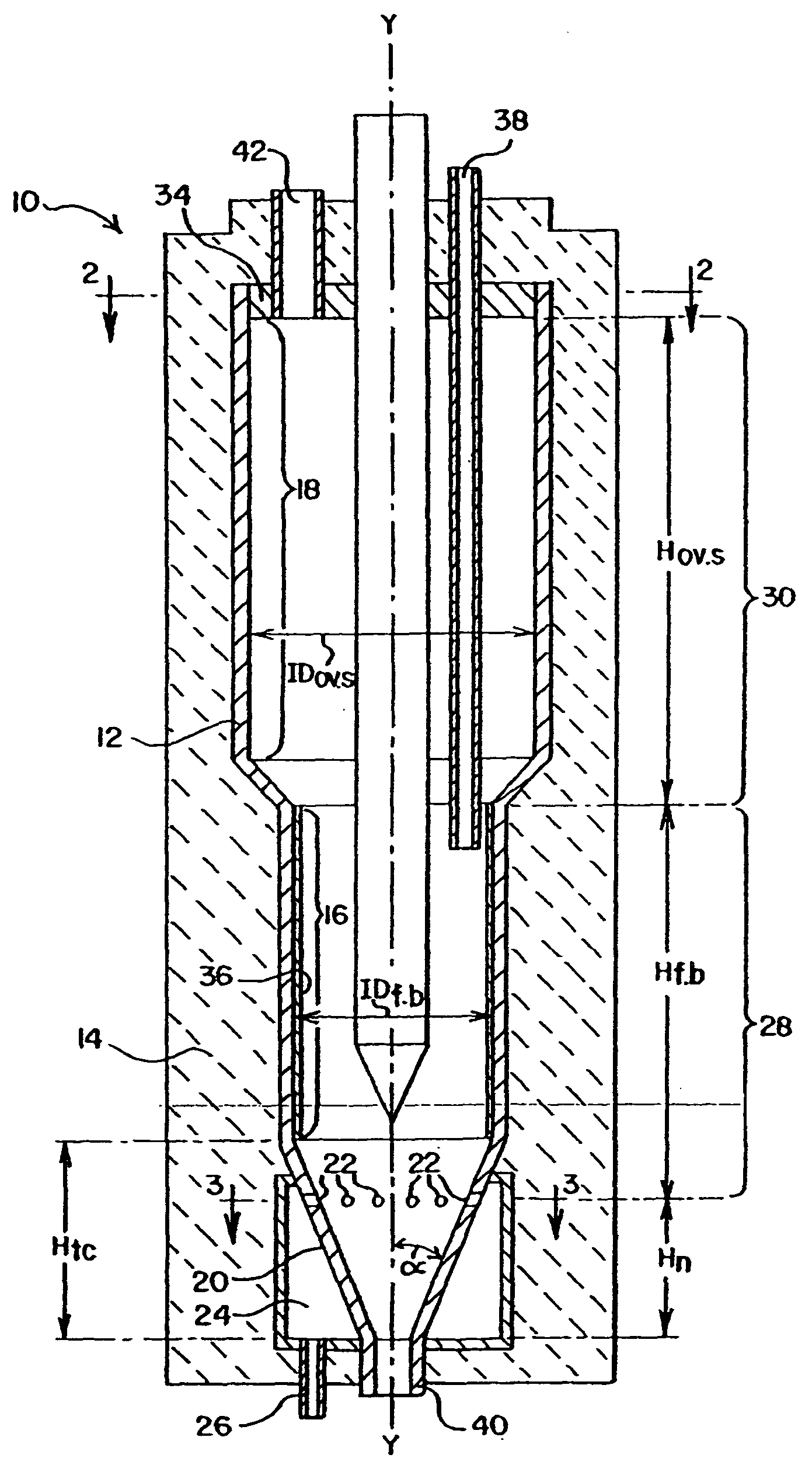

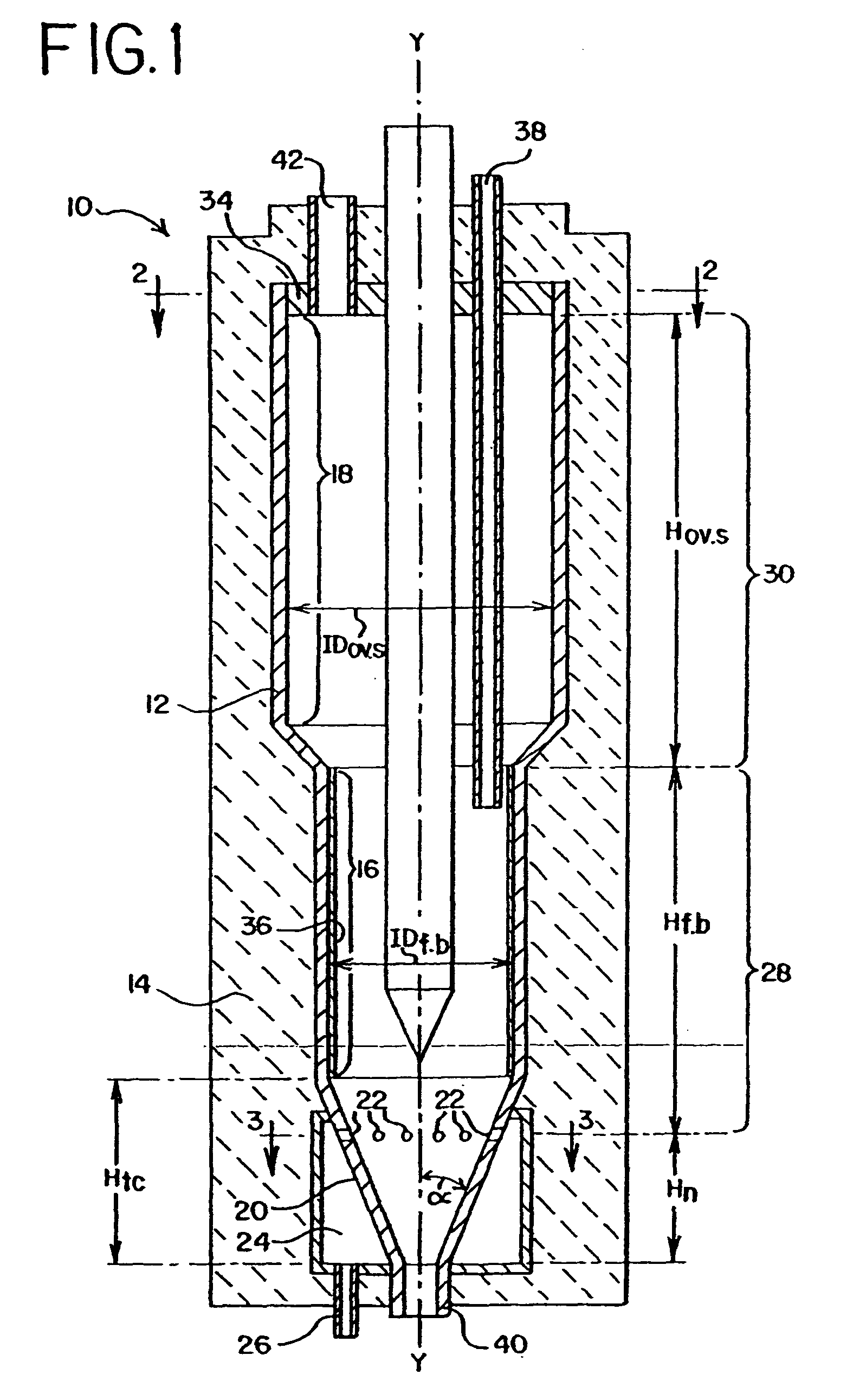

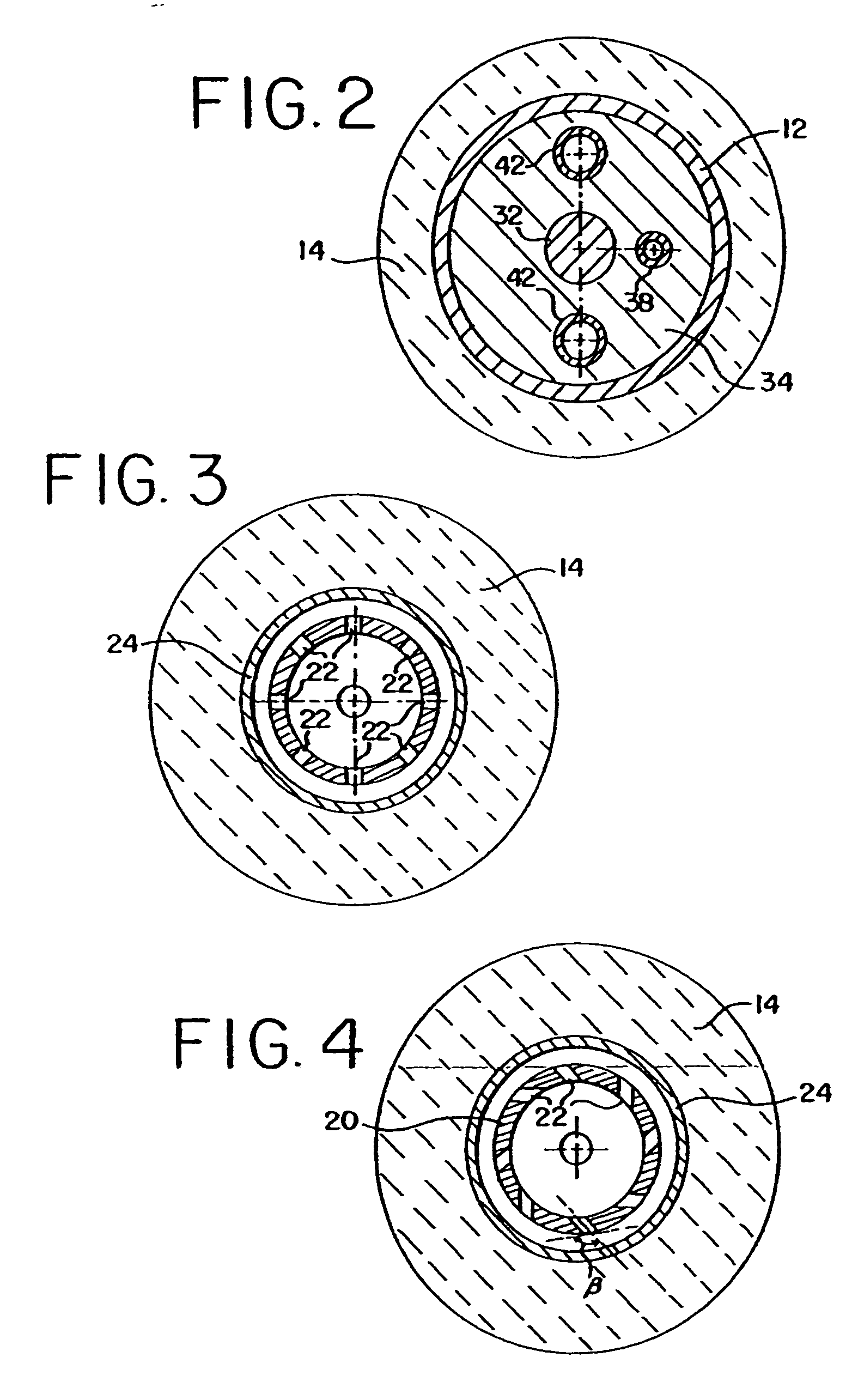

An electro thermal fluidized bed furnace is adapted to be used in a process for continuously heat treating of fine particulate matter, such as carbon black material, by continuously introducing a non-reactive fluidizing gas through the nozzles of the furnace at a pre-determined rate, continuously introducing untreated carbon black material through the feed pipe of the furnace at a predetermined rate so that it forms a fluidized bed, energizing the electrode so as to heat the fluidized bed, and continuously collecting the treated carbon black from the discharge pipe. The carbon black collected from the discharge pipe exhibits properties of having the PAHs and sulfur removed, the carbon black has been graphitized, the moisture pick-up by the carbon black has been eliminated and the carbon black is more oxidation resistant, Furthermore, the resultant furnace carbon backs have a particle size of 7-100 nm and an oil absorption number of 50-300 ml / 100 g., while the thermal blacks have a particle size of 200-500 nm and an oil absorption number of less than 50 ml / 100 g. All of these properties result in thermally modified carbon blacks having such properties and of such purity so as to provide improved performance properties in food contact type applications, moisture cured polymer systems, zinc-carbon dry cell battery applications, and semi-conductive wire and cable applications.

Owner:COLUMBIAN CHEM CO +1

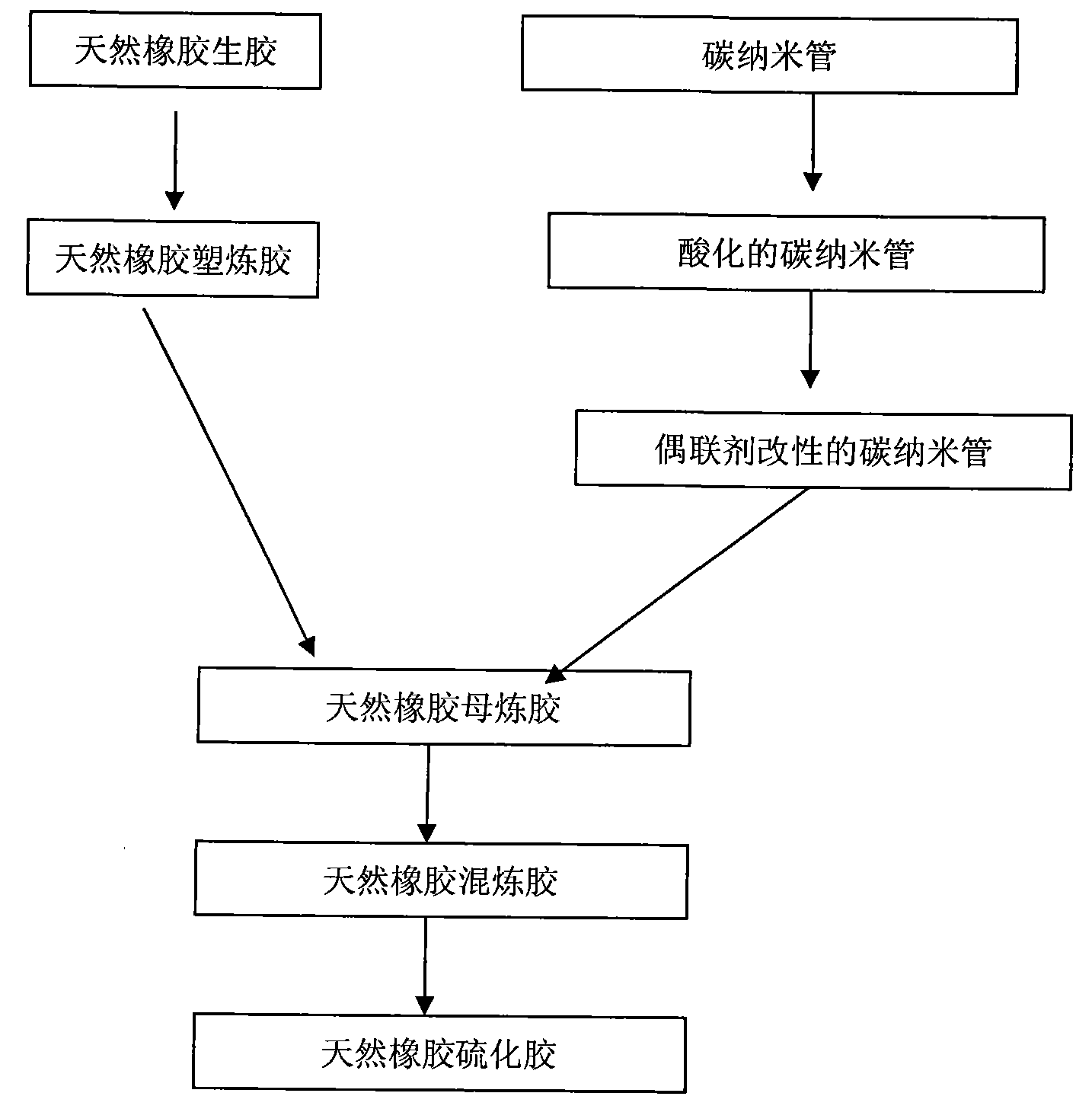

High-performance natural rubber vulcanized rubber of carbon-containing nano-tube, and preparation method thereof

InactiveCN101831090AImprove mechanical propertiesImprove high temperature resistancePigment treatment with organosilicon compoundsPolymer scienceHeat conducting

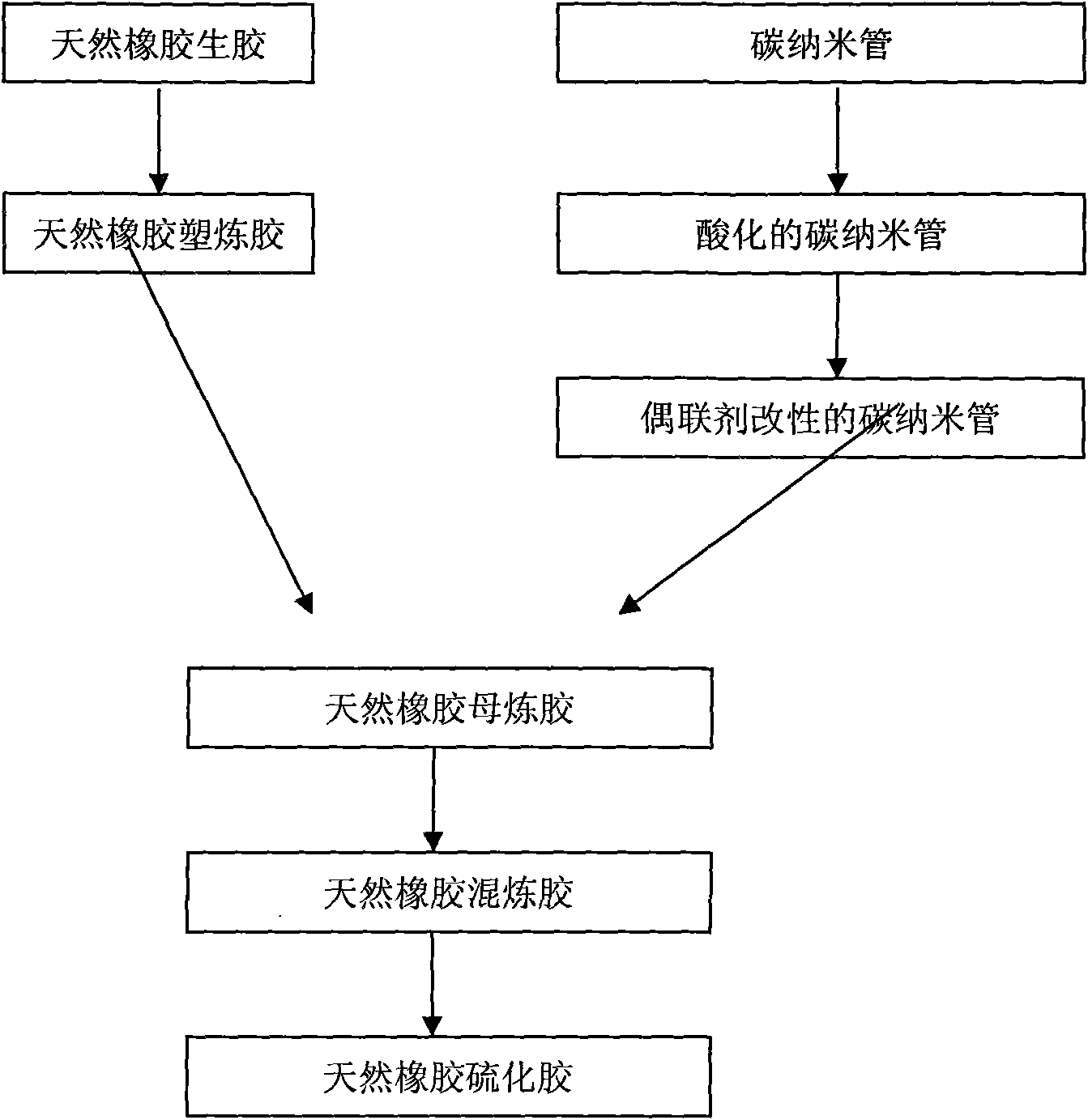

The invention relates to a high-performance natural rubber vulcanized rubber of a carbon-containing nano-tube, which is prepared by a method comprising the steps of: plasticating the carbon-containing nano-tube with a modified surface and natural rubber together to prepare master batch; adding crude rubber, carbon black, zinc oxide, vulcanized agent and accelerating agent into the master batch, processing the obtained mixture by an open mill or an internal mixer, and obtaining natural rubber mixer modified by the carbon-containing nano-tube; and carrying out vulcanizing processing, and obtaining the modified natural rubber vulcanized rubber. By adding the modified carbon-containing nano-tube into the natural rubber material, the invention leads the comprehensive performances such as wear-resisting property, mechanism strength, anti-aging performance, heat-conducting property, anti-fatigue performance and the like of the natural rubber to be remarkably improved, thus improving the using performance of the natural rubber vulcanized rubber, reducing the using quantity of carbon black, and expanding the application scope of the natural rubber vulcanized rubber.

Owner:NANJING UNIV OF SCI & TECH

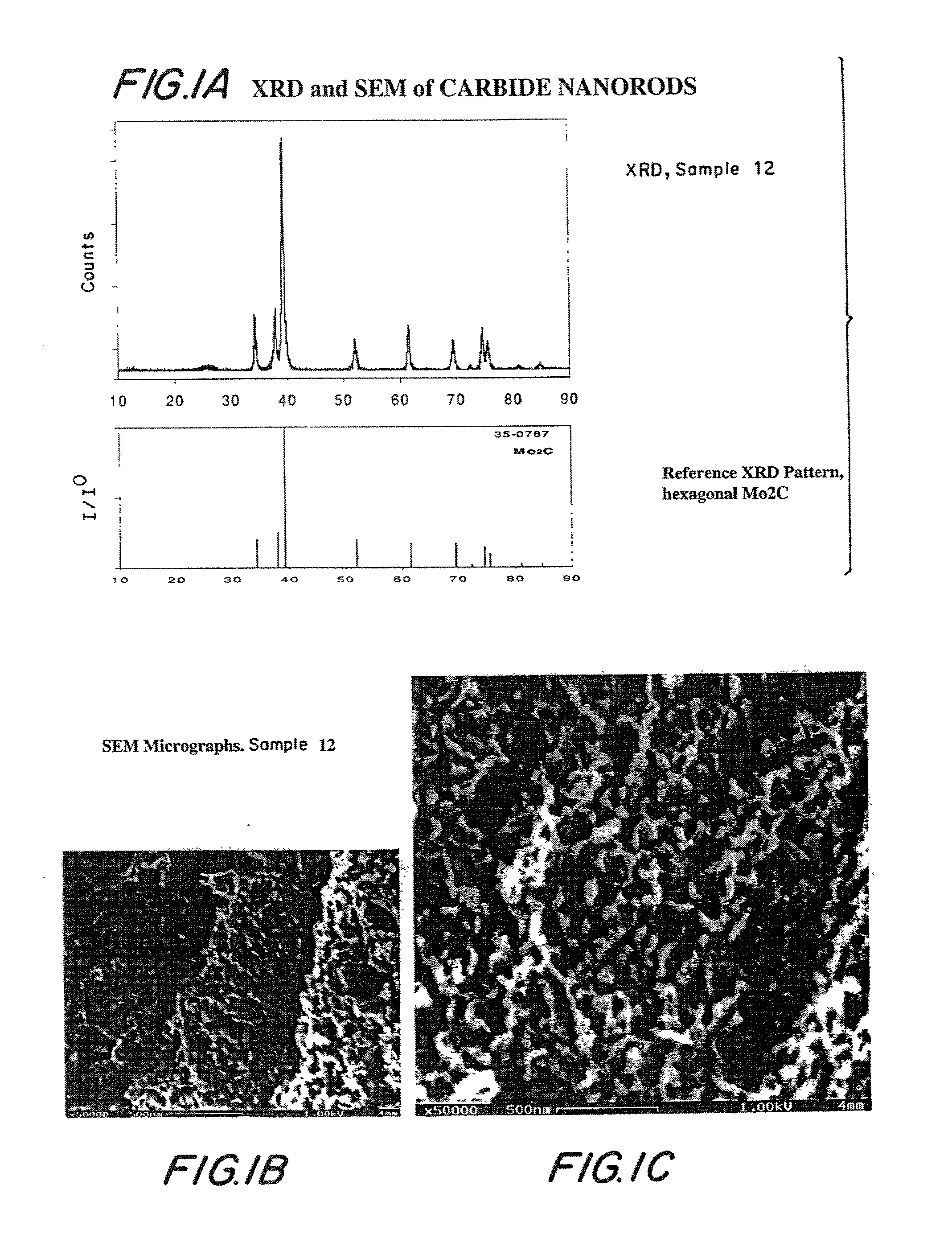

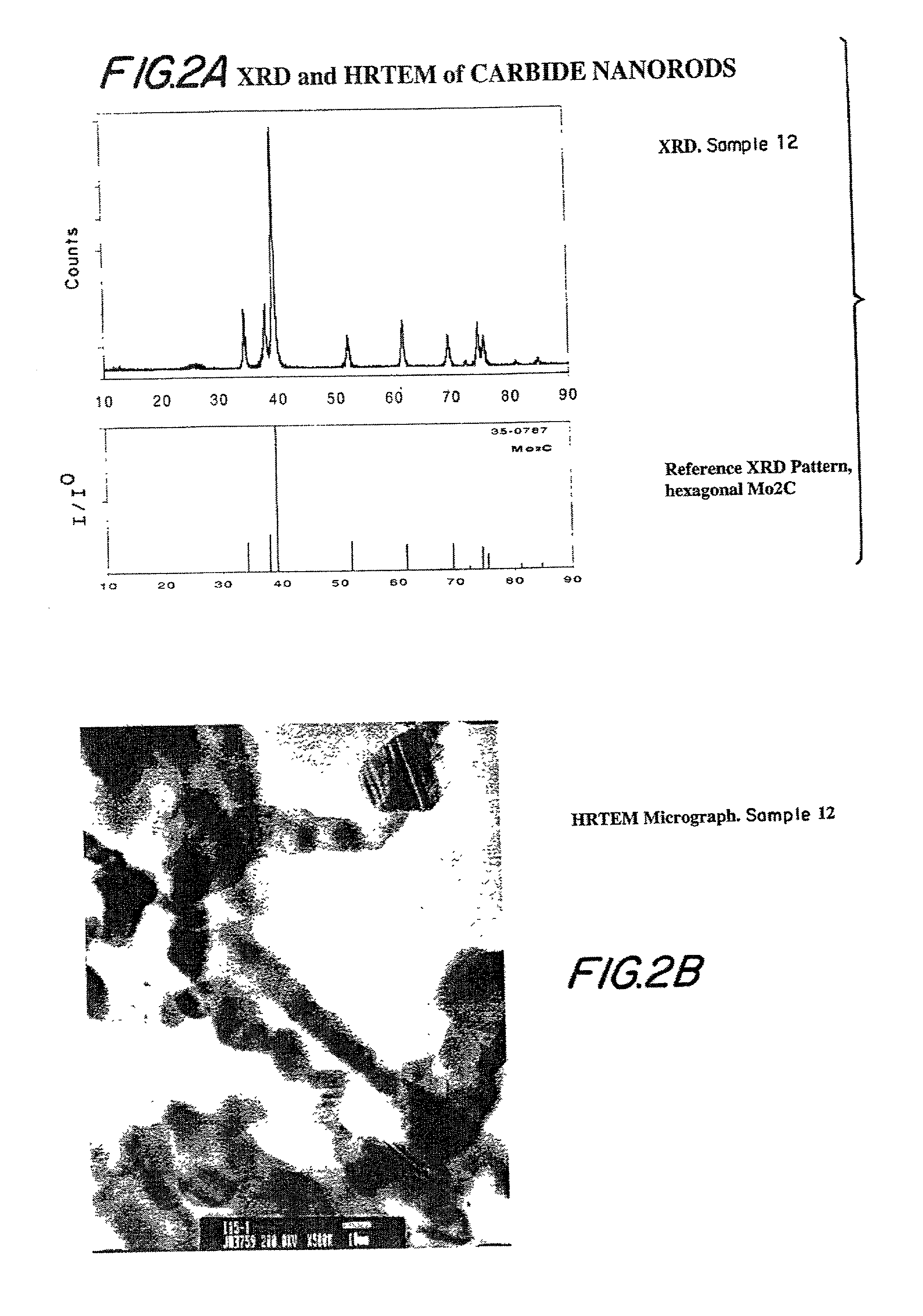

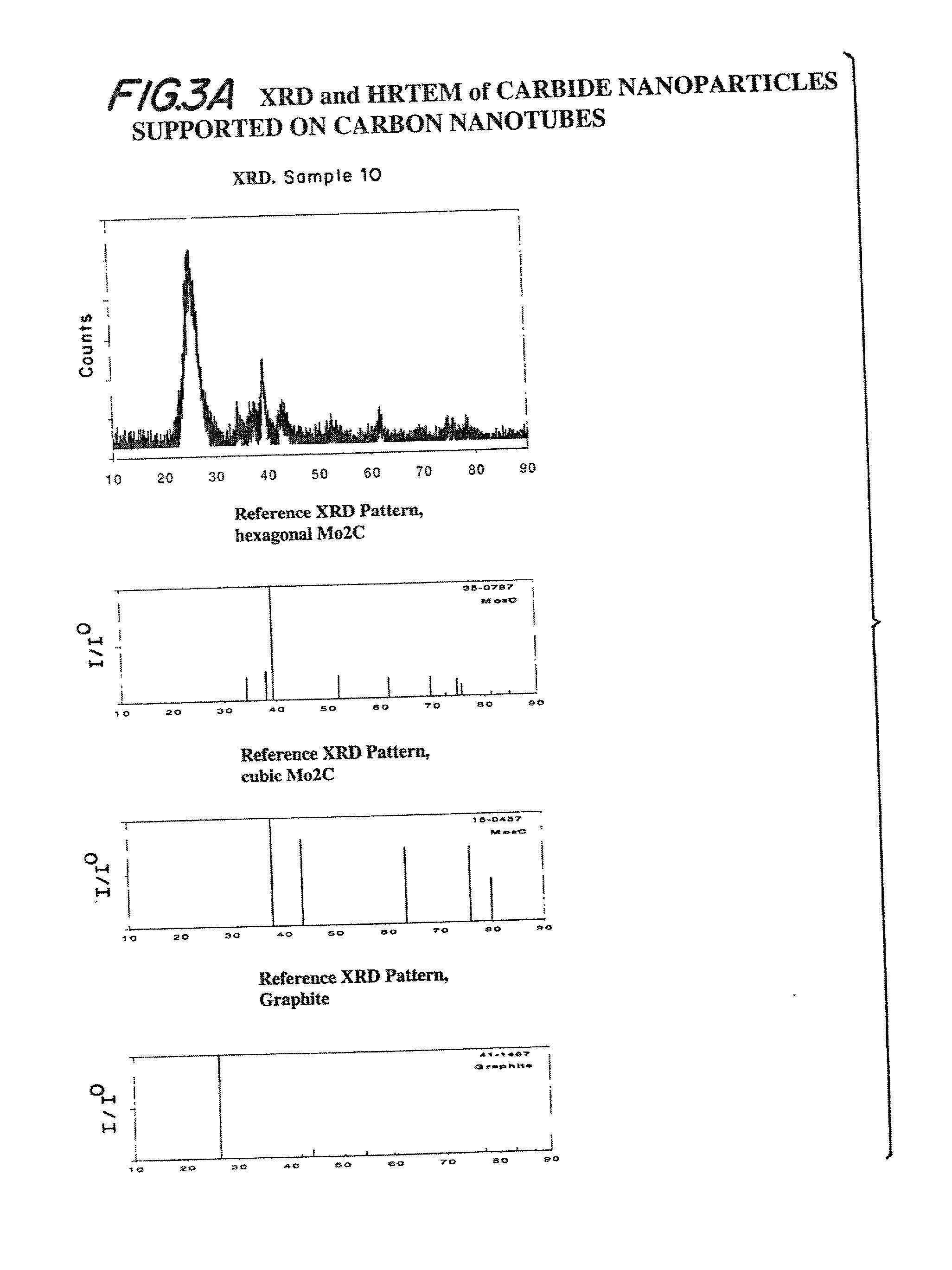

Modified carbide and oxycarbide containing catalysts and methods of making and using thereof

InactiveUS20030008772A1Improve propertiesHigh selectivityMaterial nanotechnologyHydrocarbon by isomerisationChemical reactionFluid phase

Compositions including modified carbide-containing nanorods and / or modified oxycarbide-containing nanorods and / or modified carbon nanotubes bearing carbides and oxycarbides and methods of making the same are provided. Rigid porous structures including modified oxycarbide-containing nanorods and / or modified carbide containing nanorods and / or modified carbon nanotubes bearing modified carbides and oxycarbides and methods of making the same are also provided. The compositions and rigid porous structures of the invention can be used either as catalyst and / or catalyst supports in fluid phase catalytic chemical reactions. Processes for making supported catalyst for selected fluid phase catalytic reactions are also provided.

Owner:HYPERION CATALYSIS INT

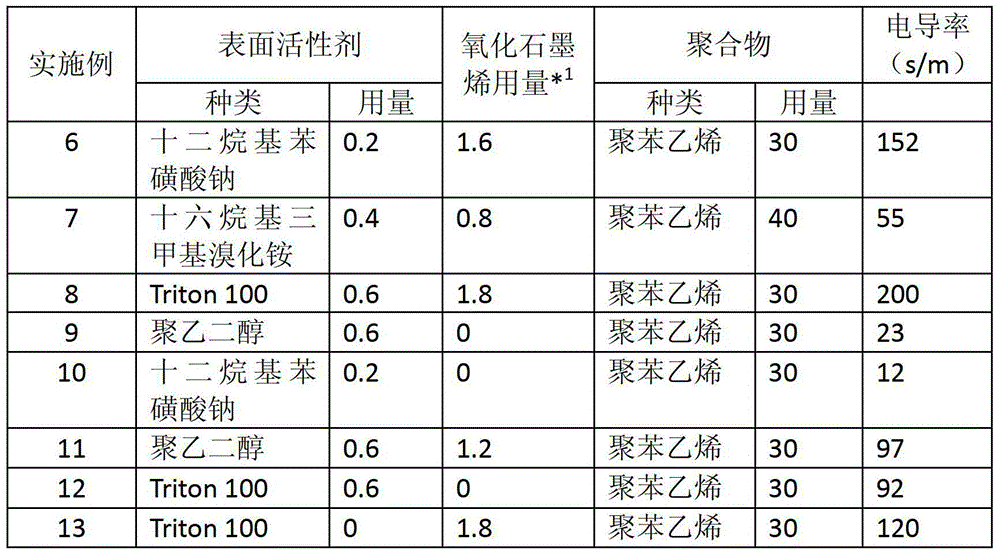

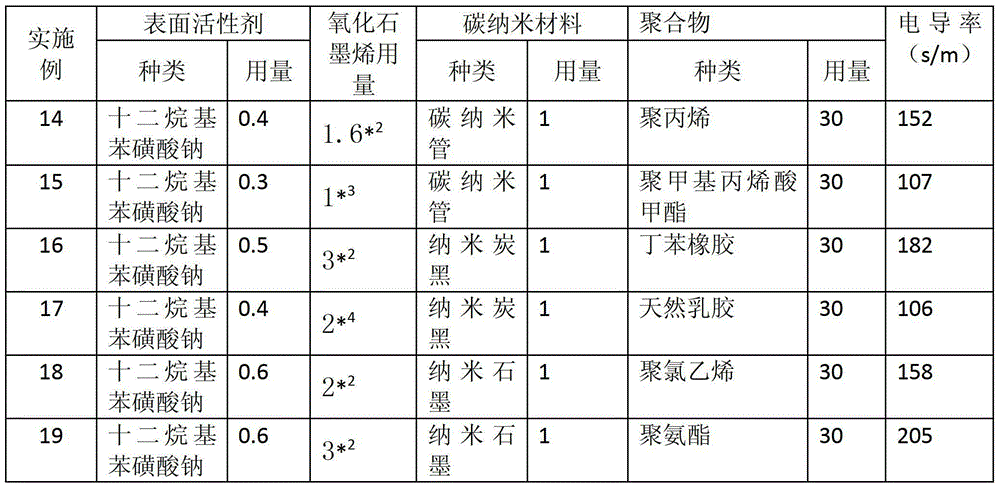

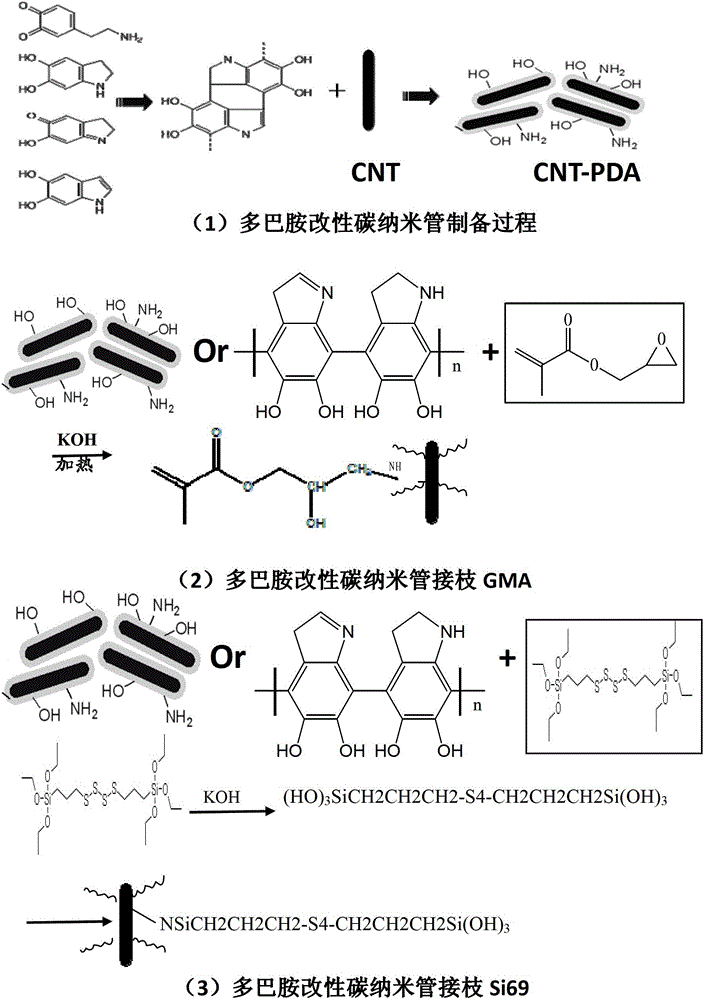

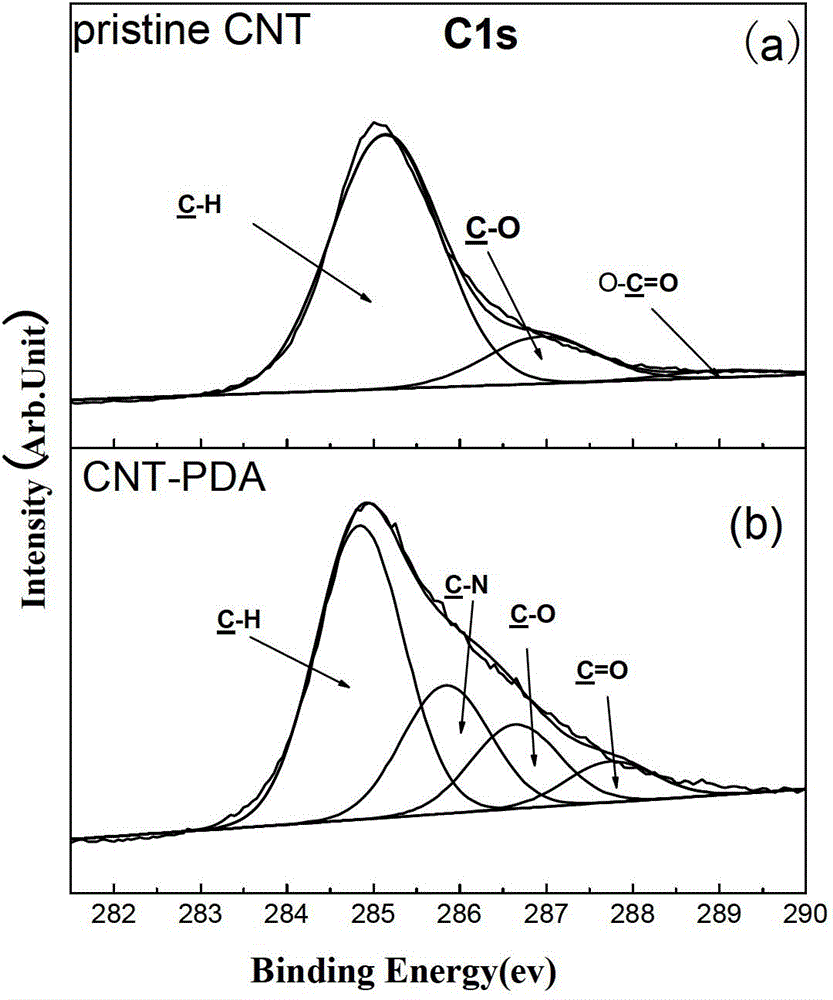

Compound dispersing agent of carbon nanomaterial and method for preparing electric conduction polymeric composite thereof

ActiveCN103333368AGood dispersionReduce contact resistance increasePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsModified carbonConductive coating

The invention discloses a compound dispersing agent of a carbon nanomaterial and a method for preparing an electric conduction polymeric composite thereof. The compound dispersing agent comprises a surface active agent and graphene oxide, wherein the mass ratio of the surface active agent to graphene oxide ranges from 0.1:1 to 9:1. The compound dispersing agent modified carbon nanomaterial is compounded with a nano-polymer, so that the polymer-carbon nanomaterial electric conduction composite with high electric conductivity can be obtained. The compound dispersing agent has a good dispersing effect on the carbon nanomaterial and can effectively reduce contact resistance of the modified carbon nanomaterial; the preparation process is easy to operate, the environment is protected, the compound dispersing agent can be widely applied to fields of preparation of various coatings such as antistatic coatings, electromagnetic shielding coatings and conductive coating and the like.

Owner:CHENGDU SCI & TECH DEV CENT CHINA ACAD OF ENG PHYSICS

Carbon nano tube surface functionalization method

Owner:BEIJING UNIV OF CHEM TECH

Surface modification method for carbon nano tube

InactiveCN102942810AGood for secondary modificationImprove thermal stabilityPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsPtru catalystModified carbon

The invention provides a surface modification method for a carbon nano tube and belongs to the field of nanotechnology. The method includes step one, uniformly mixing a carbon nano tube which is subjected to acidification by a strong oxidizing acid with a silane coupling agent and deionized water, reacting under a certain condition, filtering, washing, and drying to obtain a primary modified carbon nano tube; step two, uniformly mixing the primary modified carbon nano tube with polyhydric alcohols and a concentrated sulfuric acid, reacting under a certain condition, filtering, washing to neutral, and drying to obtain a secondary modified carbon nano tube; uniformly mixing the secondary modified carbon nano tube with an organic carboxylic acid, an esterification reaction catalyst and N,N-dimethylformamide, reacting under a certain condition by the aid of the protection of inert gases, cooling to the room temperature, filtering, washing, and drying to obtain the surface modification carbon nano tube. When the prepared modified carbon nano tube which is provided with ester groups on the surface is mixed with a polyester resin, the interface-free mixing is achieved, and the heat stability and the mechanical property of the modified polyester resin can be improved.

Owner:TAIYUAN UNIV OF TECH

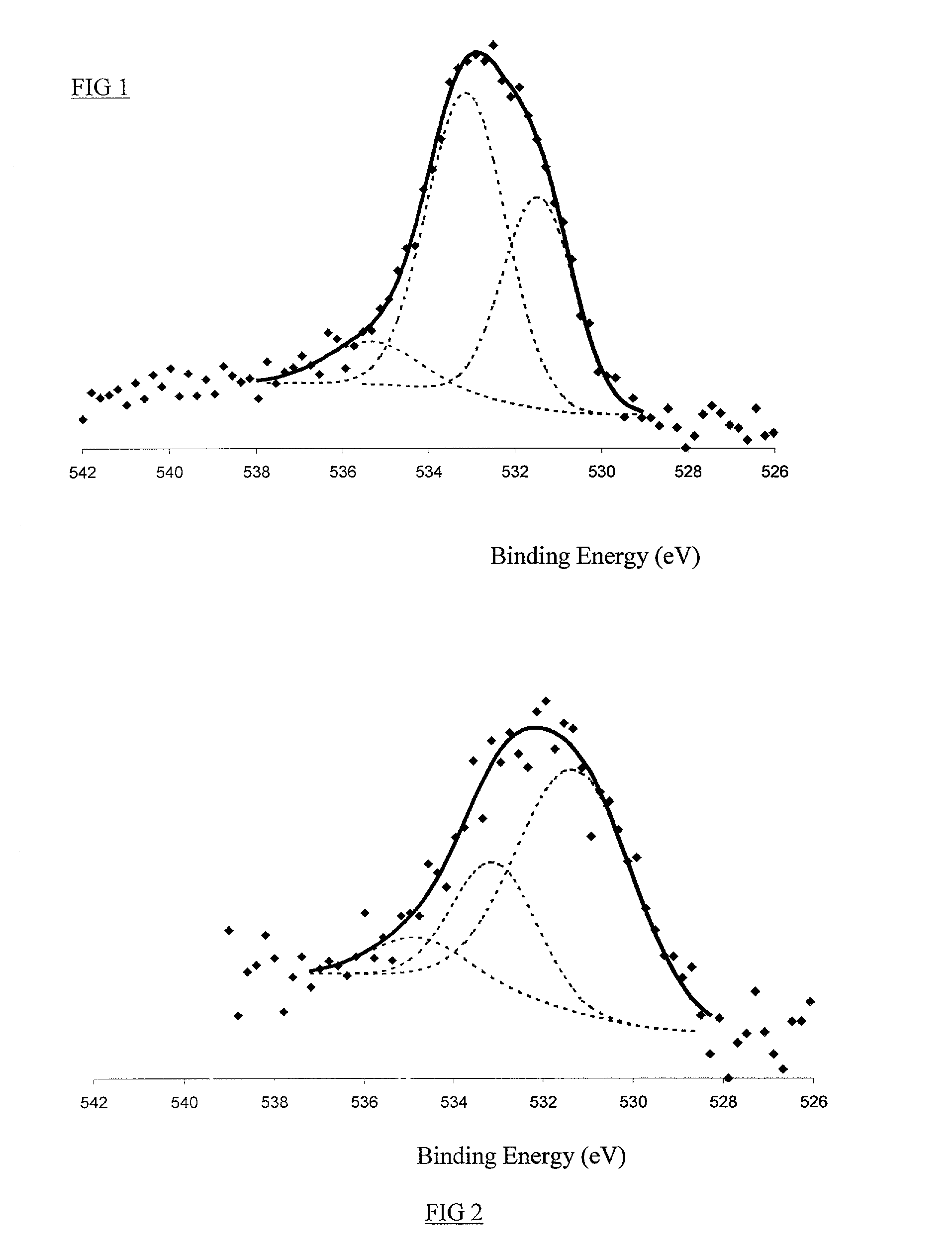

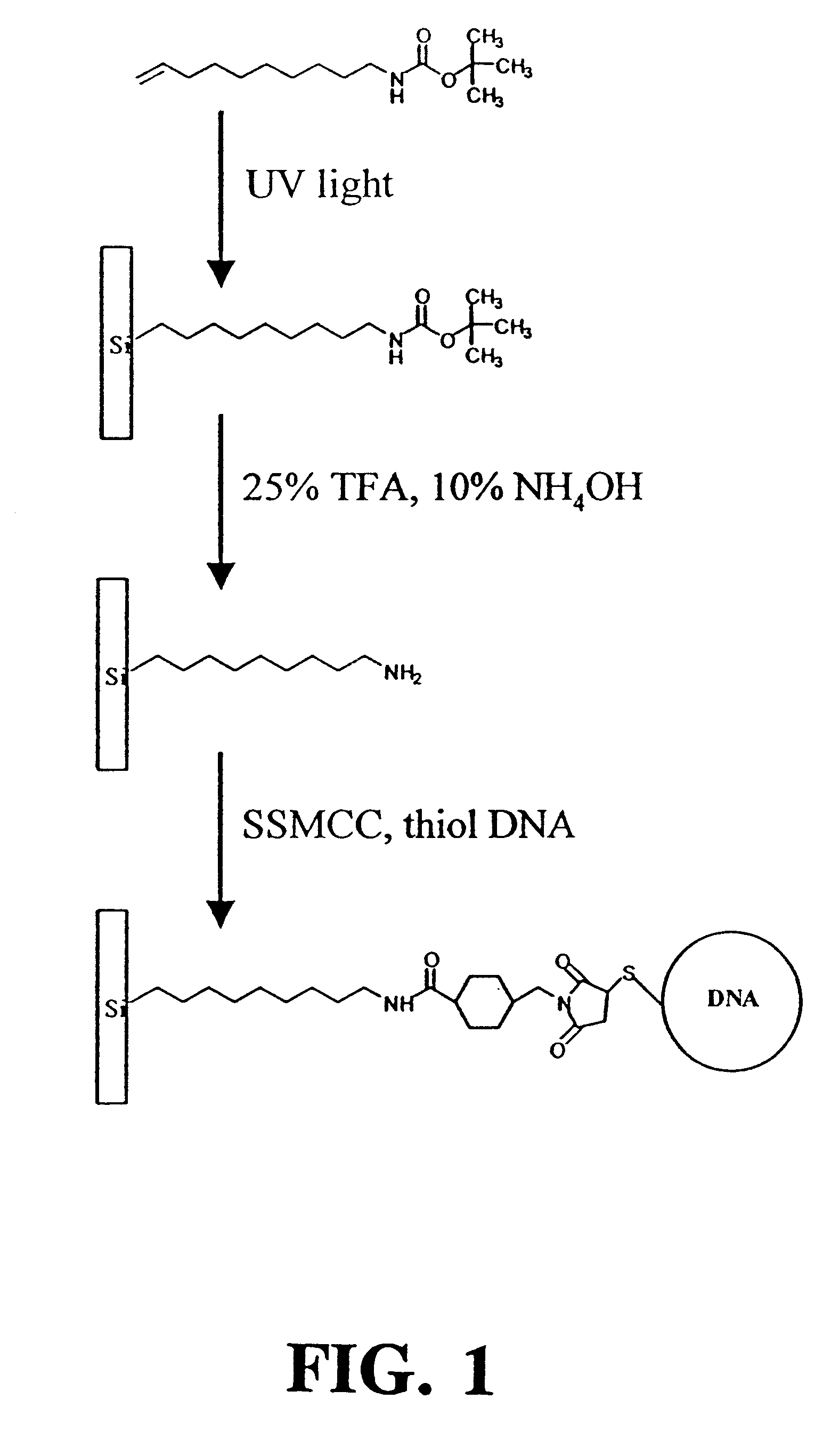

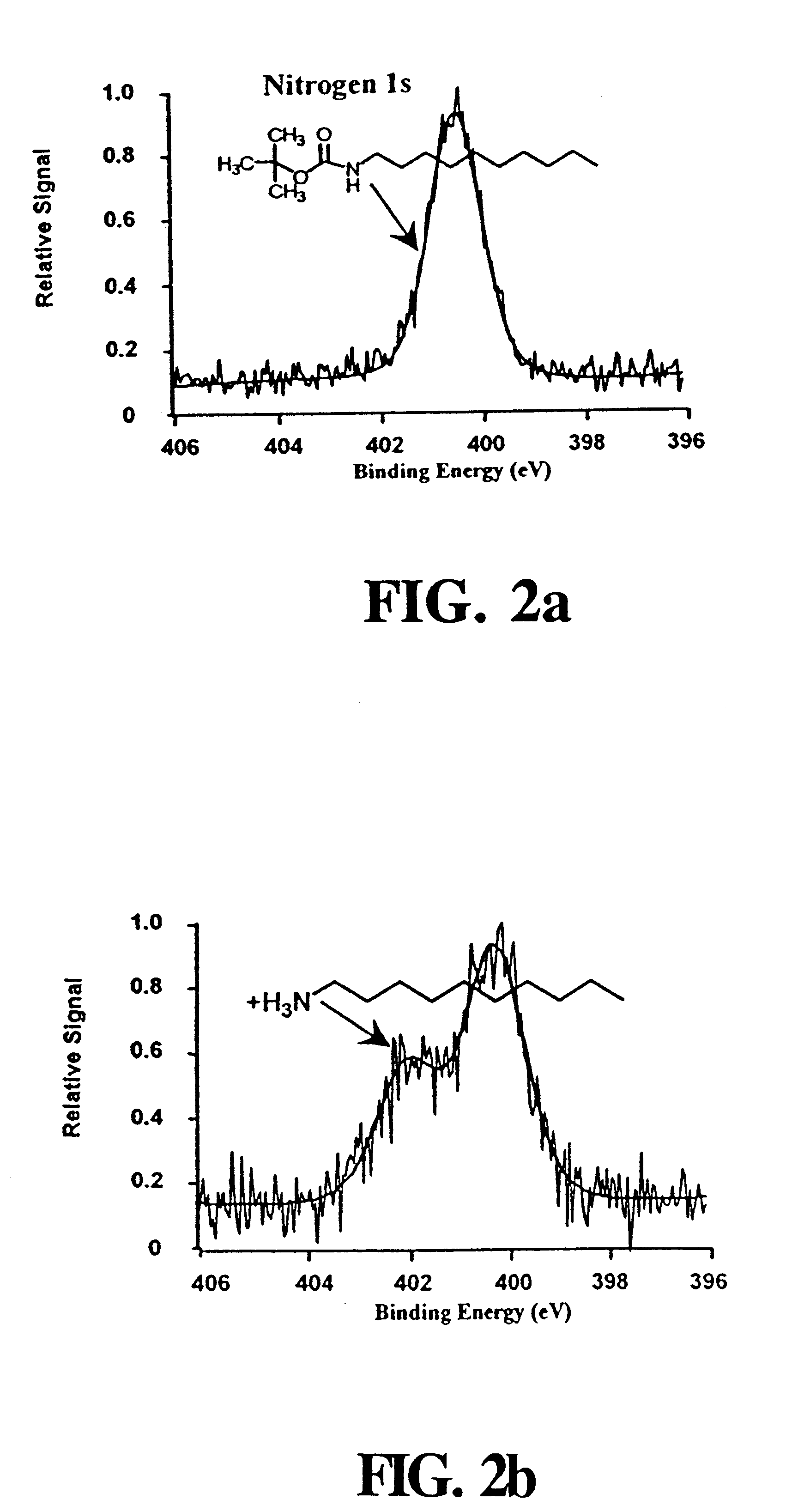

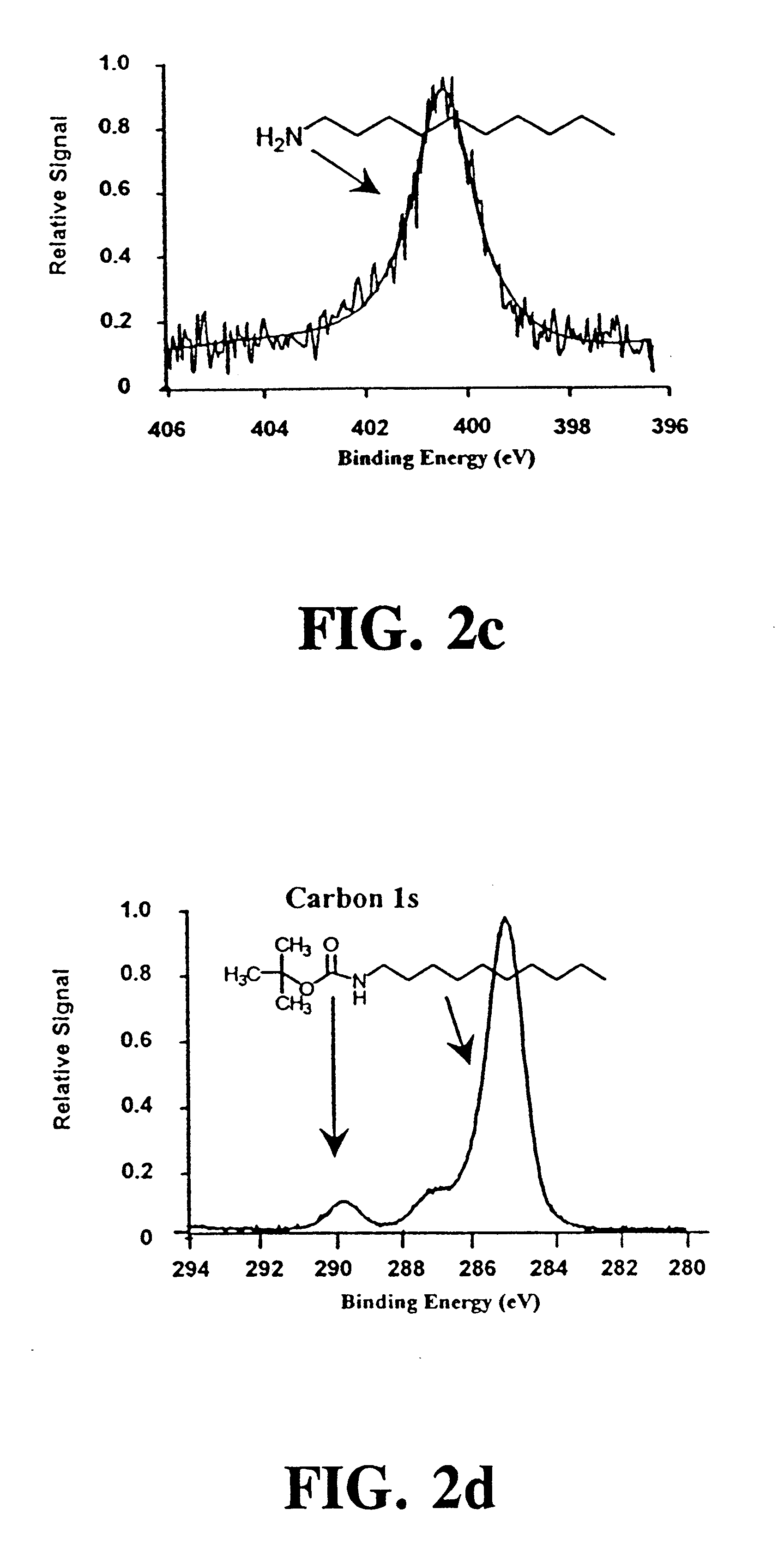

Modified carbon, silicon, & germanium surfaces

InactiveUS6569979B1Enable formationEasy to controlMaterial nanotechnologyLiquid surface applicatorsHydrogenModified carbon

Chemically-modified surfaces on unoxidized carbon, silicon, and germanium substrates are disclosed. Ultraviolet radiation mediates the reaction of protected omega-modified, alpha-unsaturated aminoalkenes (preferred) with hydrogen-terminated carbon, silicon, or germanium surfaces. Removal of the protecting group yields an aminoalkane-modified silicon surface. These amino groups can be coupled to terminal-modified oligonucleotides using a bifunctional crosslinker, thereby permitting the preparation of modified surfaces and arrays. Methods for controlling the surface density of molecules attached to the substrate are also disclosed.

Owner:WISCONSIN ALUMNI RES FOUND

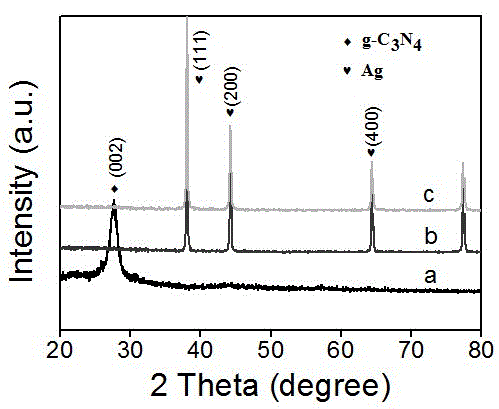

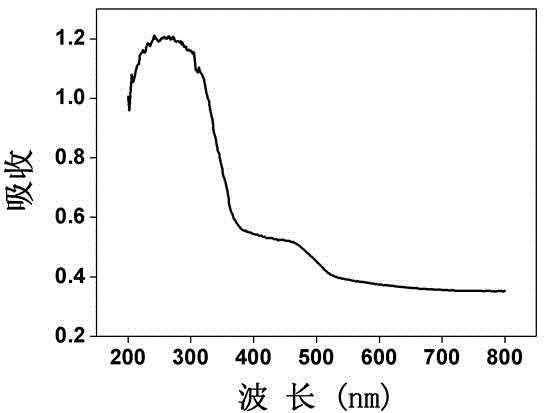

Silver-modified carbon nitride composite photocatalytic material and preparation method thereof

InactiveCN104475140AGood dispersionInhibitory complexPhysical/chemical process catalystsWater/sewage treatment by irradiationOrganic dyeModified carbon

The invention relates to a silver-modified carbon nitride composite photocatalytic material and a preparation method thereof. The preparation method comprises: dissolving dicyanodiamide or melamine in deionized water or dimethyl sulfoxide and performing ultrasonic dispersing, so as to obtain a dicyanodiamide or melamine dispersion liquid; dissolving silver nitrate in deionized water and stirring uniformly, so as to obtain a silver nitrate solution; slowly dropwise adding the silver nitrate solution into the above dicyanodiamide or melamine dispersion liquid under the condition of magnetic stirring, and continuing stirring the solution, so as to obtain a mixed precursor solution; using anhydrous ethanol and deionized water repeatedly wash the obtained mixed precursor solution for multiple times, and performing vacuum drying; and putting the obtained product in a proper crucible and covering, putting in a high-temperature furnace, and sintering for a period under the condition of nitrogen protection, so as to obtain a powdery sample. The advantages comprise that the raw material source is wide, the preparation technology is simple and practicable, and the cost is relatively low; and the prepared composite photocatalytic material has relatively good photocatalytic degradation effect on organic dye rhodamine B under irradiation of visible light.

Owner:JIANGSU UNIV

Field emission devices using modified carbon nanotubes

InactiveUS20050275331A1Reduce voltageAccelerate emissionsNanostructure manufactureNanoinformaticsField emission deviceModified carbon

The present invention relates to a field emission device comprising an anode and a cathode, wherein said cathode includes carbon nanotubes nanotubes which have been subjected to energy, plasma, chemical, or mechanical treatment. The present invention also relates to a field emission cathode comprising carbon nanotubes which have been subject to such treatment. A method for treating the carbon nanotubes and for creating a field emission cathode is also disclosed. A field emission display device containing carbon nanotube which have been subject to such treatment is further disclosed.

Owner:HYPERION CATALYSIS INT

Modified Carbon Nanotubes and Methods of Forming Carbon Nanotubes

ActiveUS20090142581A1Improved near infrared (NIR) transmittanceImprove work functionMaterial nanotechnologyLayered productsDopantModified carbon

In this invention, processes which can be used to achieve stable doped carbon nanotubes are disclosed. Preferred CNT structures and morphologies for achieving maximum doping effects are also described. Dopant formulations and methods for achieving doping of a broad distribution of tube types are also described.

Owner:BATTELLE MEMORIAL INST

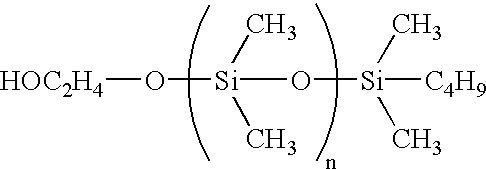

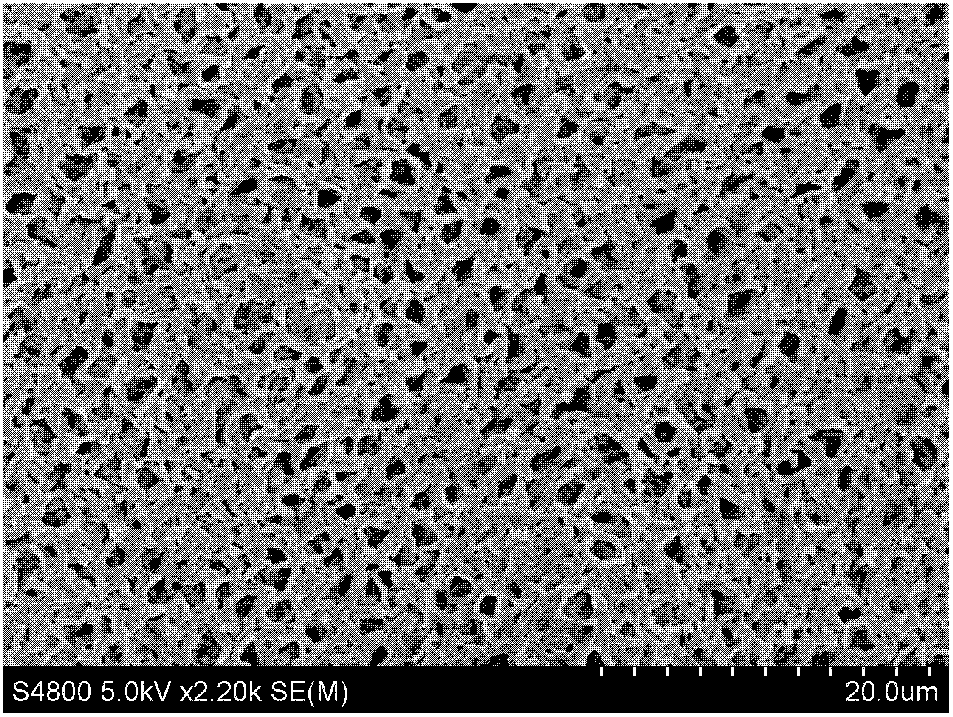

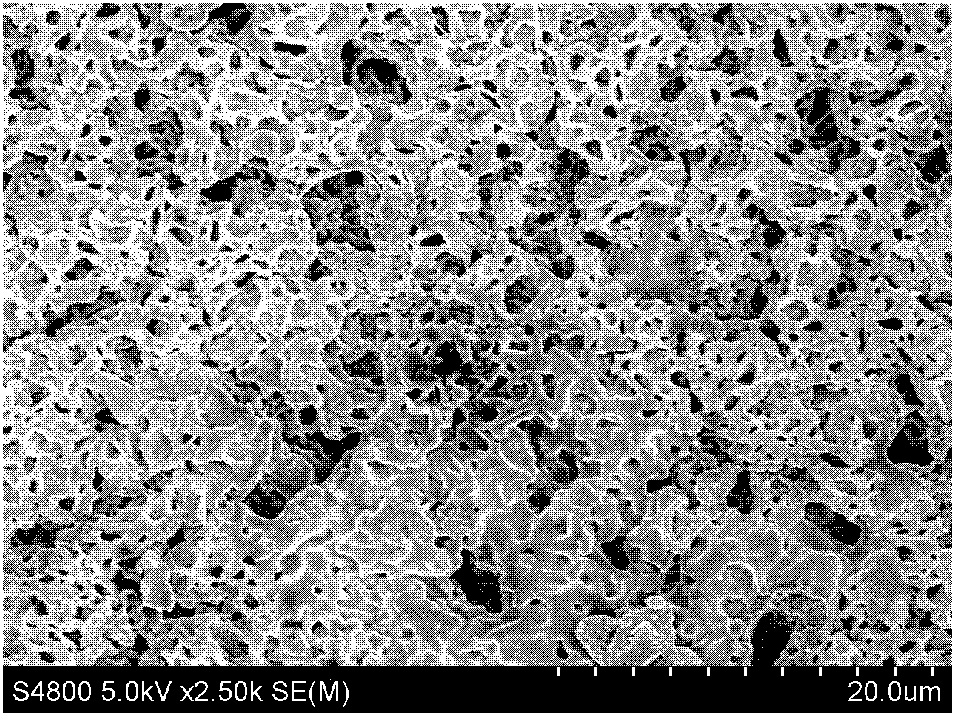

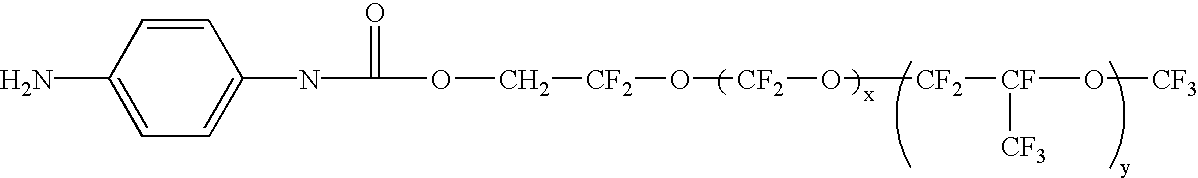

Carbon material modified porous polymer electrolyte membrane and preparation method thereof

InactiveCN102585280ASmall apertureEvenly distributedCell component detailsPolymer scienceHexafluoropropylene

The invention discloses a carbon material modified porous polymer electrolyte membrane and a preparation method thereof, and relates to the polymer electrolyte membrane and the preparation method thereof. The invention aims at solving the problems of low ionic conductivity, small lithium ion transference number and poor electrochemical stability of the conventional porous polymer electrolyte membrane. The carbon material modified porous polymer electrolyte membrane is prepared by soaking the porous polymer membrane in an electrolyte of a lithium ion battery for 1h-4h; and the porous polymer membrane is prepared from PVDF-HFP (polyvinylidene fluoride-hexafluoropropylene), a solvent, a plasticizer and a modified carbon material. The method comprises the following steps of: (1) preparing theporous polymer membrane; and (2) performing soaking treatment to get the carbon material modified porous polymer electrolyte membrane. The carbon material modified porous polymer electrolyte membranehas the advantages that the ionic conductivity achieves 10-3S / cm order of magnitude, the lithium ion transference number is 0.80-0.95, and an electrochemical stability window is 5.5V-6.0V. The preparation method disclosed by the invention is mainly used for preparing the carbon material modified porous polymer electrolyte membrane.

Owner:DAQING BRANCH OF HEILONGJIANG ACAD OF SCI

Fuel cells and other products containing modified carbon products

InactiveUS20030022055A1Improve propertiesLess-expensive to manufactureActive material electrodesSolid electrolyte fuel cellsFuel cellsModified carbon

Fuel cells are described and contain a gas diffusion electrode, a gas diffusion counter-electrode, an electrolyte membrane located between the electrode and counter-electrode. The electrode or counter-electrode or both contain at least one modified carbon product. The electrolyte membrane can also or alternatively contain modified carbon products as well. The modified carbon product is a carbon product having attached at least one organic group. Preferably the organic group is a proton conducting group and / or an electron conducting group. The present invention preferably permits the elimination of fluoropolymer binder in the active or catalyst layer and further preferably leads to a thinner active layer and / or a thinner electrolyte membrane. Other uses and advantages are also described.

Owner:CABOT CORP

Modified carbon products, their use in proton exchange membranes and similar devices and methods relating to the same

InactiveUS20050221141A1High mechanical strengthDecrease in proton conductivityElectrolyte holding meansIon-exchanger regenerationFuel cellsModified carbon

Proton exchange membranes incorporating modified carbon products. The modified carbon products advantageously enhance the properties of proton exchange membranes, leading to more efficiency within a fuel cell or similar device.

Owner:CABOT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com