Patents

Literature

790results about How to "Improve fatigue performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Implantable vascular device

Owner:COOK BIOTECH +2

Process for preparing nanocomposite, composition and article thereof

InactiveUS6759464B2Good dispersionImprove fatigue performancePigmenting treatmentMaterial nanotechnologyParticulatesElastomer

This invention relates to nanocomposites comprised of a functionalized elastomeric polymer, including oligomers which are elastomeric, which contains a particulate dispersion therein of an intercalated, and at least partially exfoliated, swellable clay, such as for example montmorillonite clay. Said clay may be pre-intercalated and thereafter blended with, or intercalated and at least partially exfoliated in situ within, a functionalized elastomer in an aqueous medium, wherein said functionalized elastomer contains at least one functional group selected from acid, acid-salt, anhydride, and protonated amine-modified epoxy groups. The invention further relates to articles of manufacture, including industrial belts and tires, having at least one component comprised of such nanocomposite where such component may be a coating thereon or other integral component. Such tire component may be, for example, a tire tread, tire sidewall and / or tire innerliner.

Owner:THE GOODYEAR TIRE & RUBBER CO

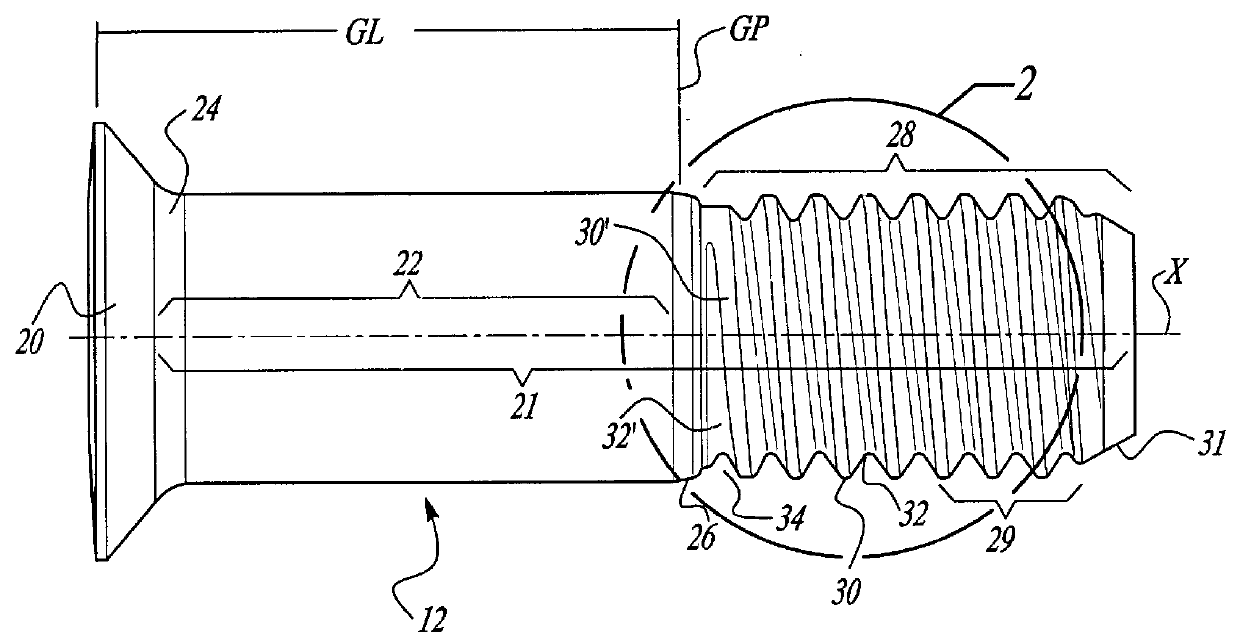

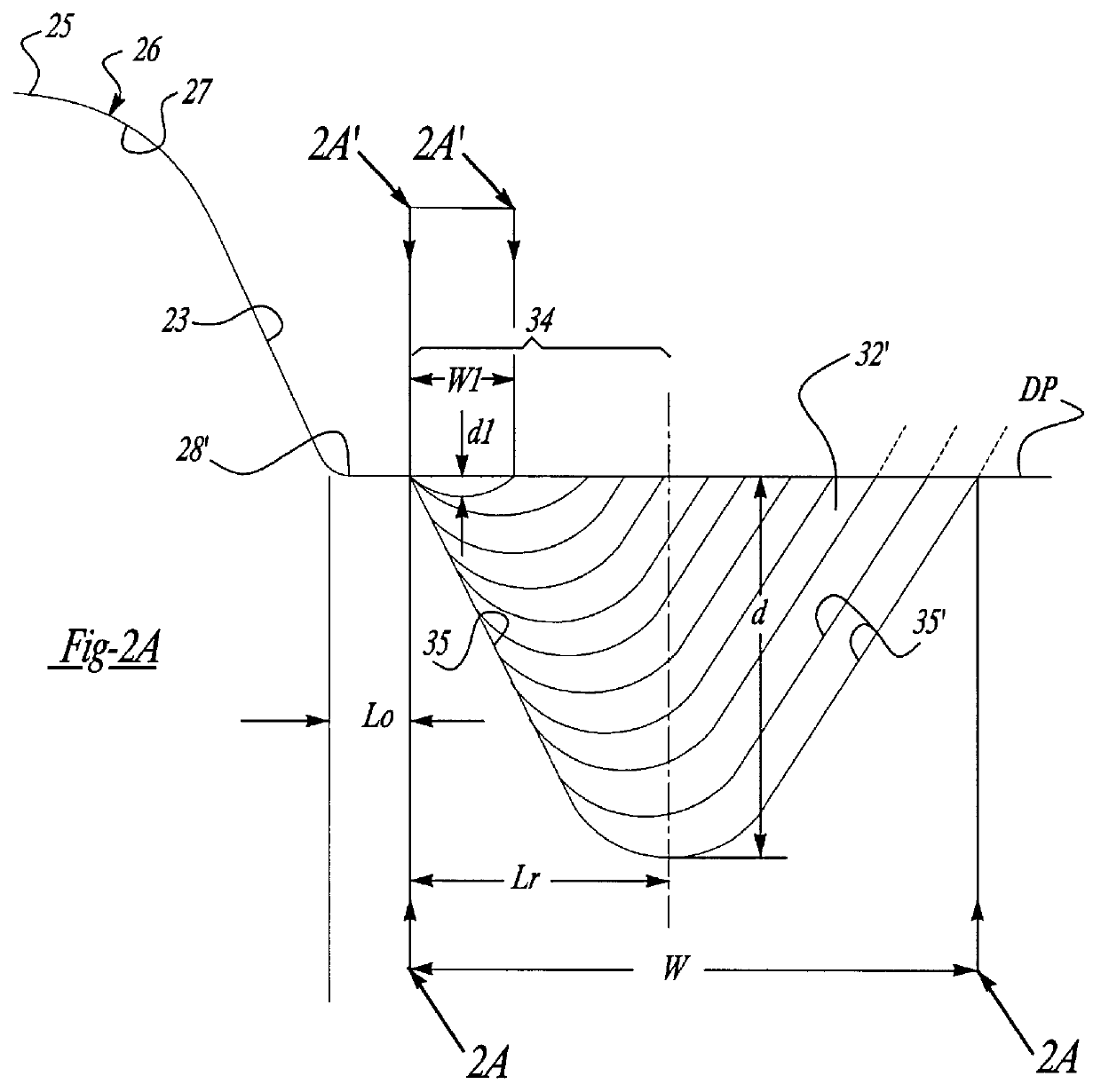

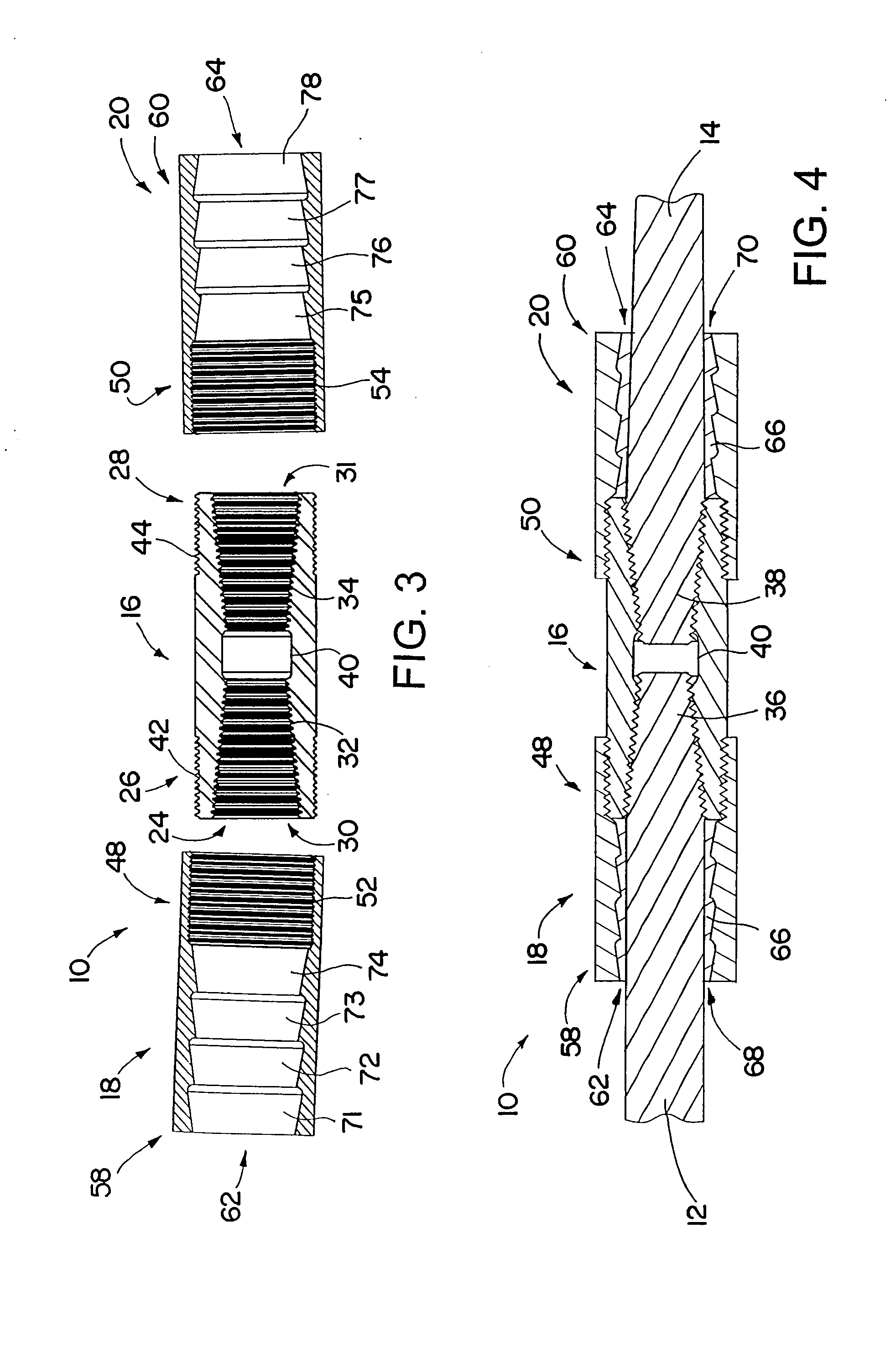

Lightweight threaded fastener and thread rolling die

InactiveUS6149363AImprove fatigue performanceImprove wear resistanceNutsBoltsEngineeringScrew thread

The present invention is to a lightweight threaded bolt type fastener having a shank with a large diameter portion and small diameter portion connected by a transition portion; a thread is roll formed on the small diameter portion and terminates in a run-out section where the thread gradually decreases in root depth and width and with the run-out section being of minimal axial length and being located closely adjacent the transition portion to produce a run-out zone of minimal axial length. A rolling die for forming the thread with minimal thread run-out having ridge segments with tapered end surfaces for providing the run-out thread with an end wall parallel to the transition portion and a method of making the bolt type fastener.

Owner:HUCK INT INC

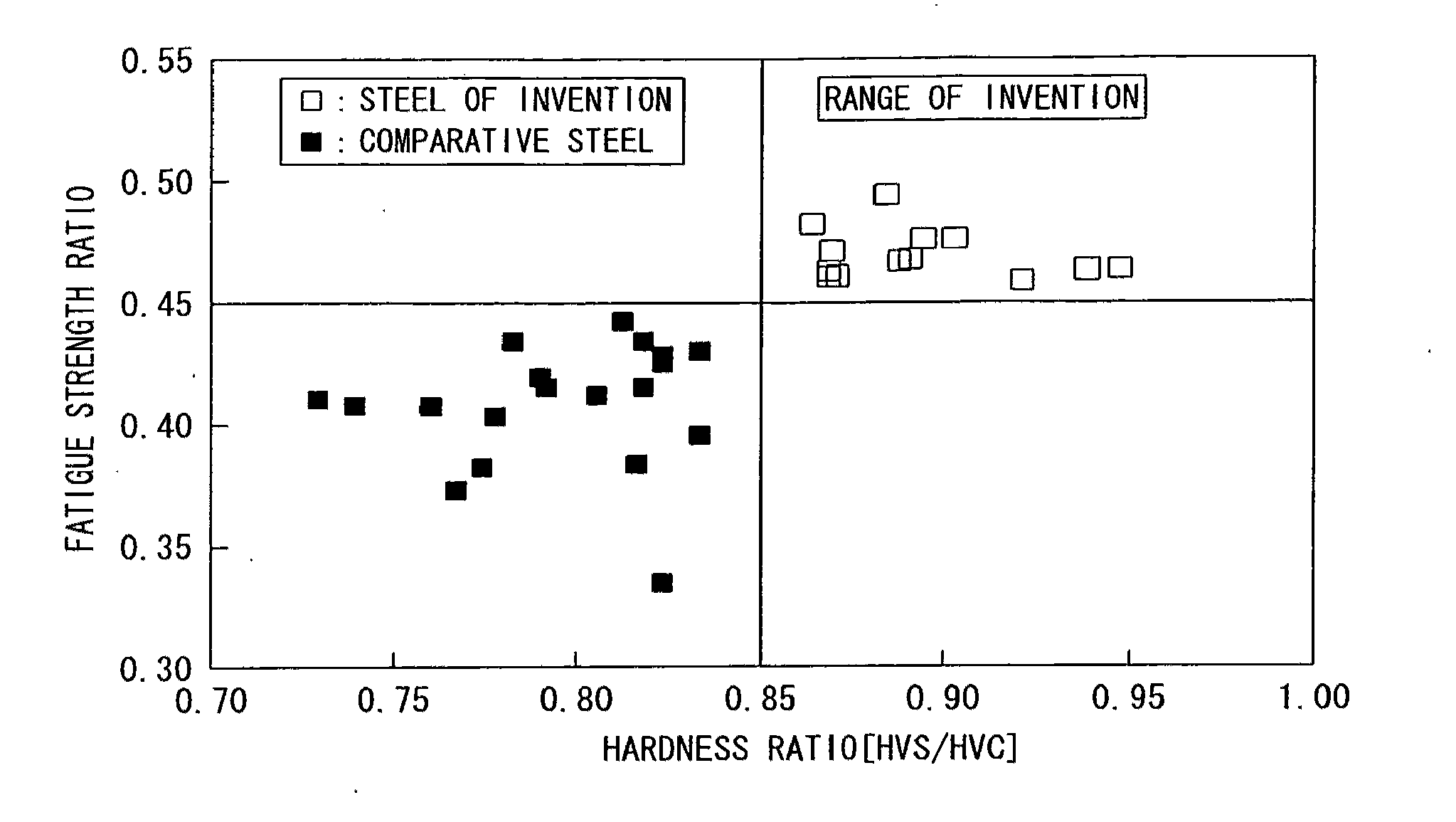

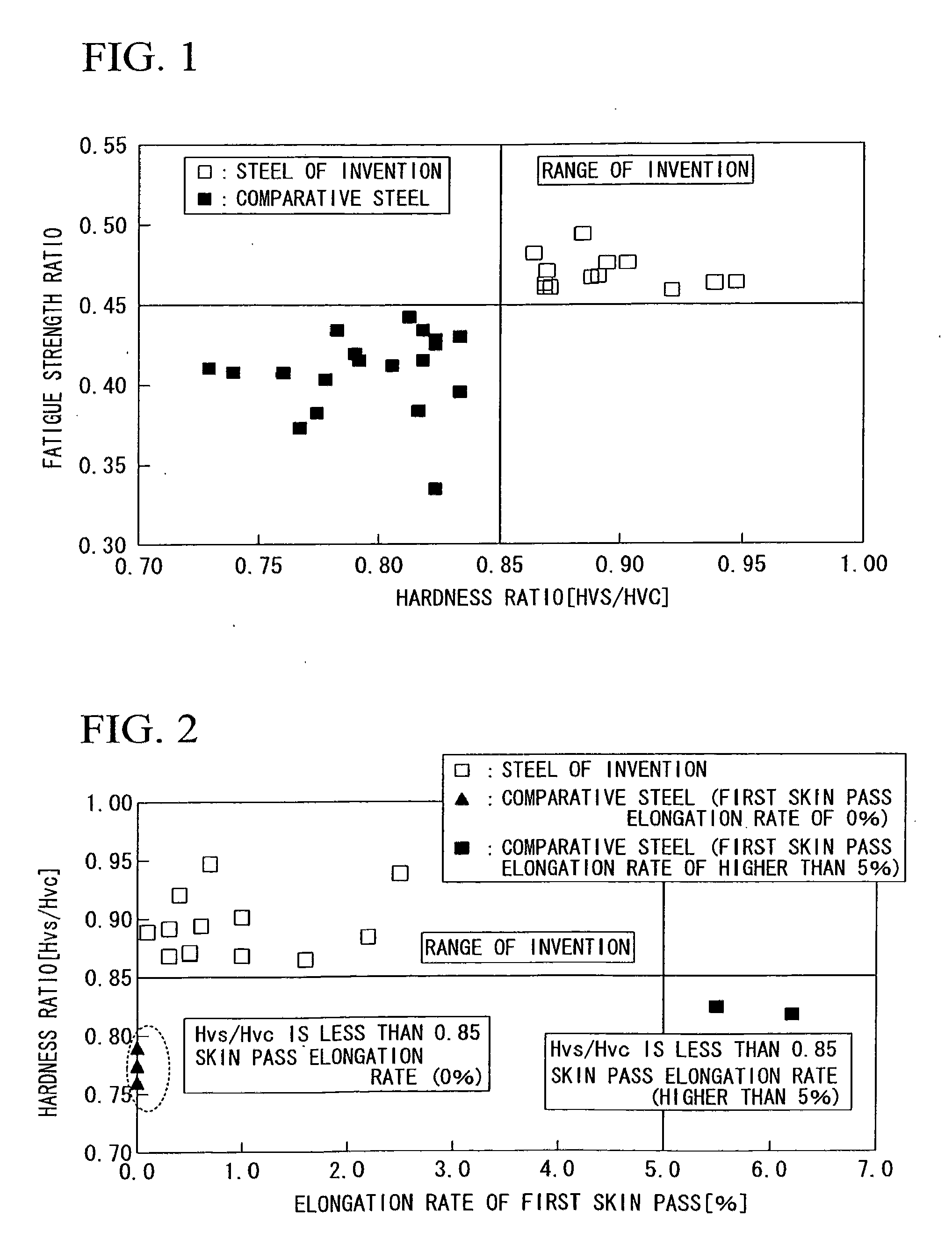

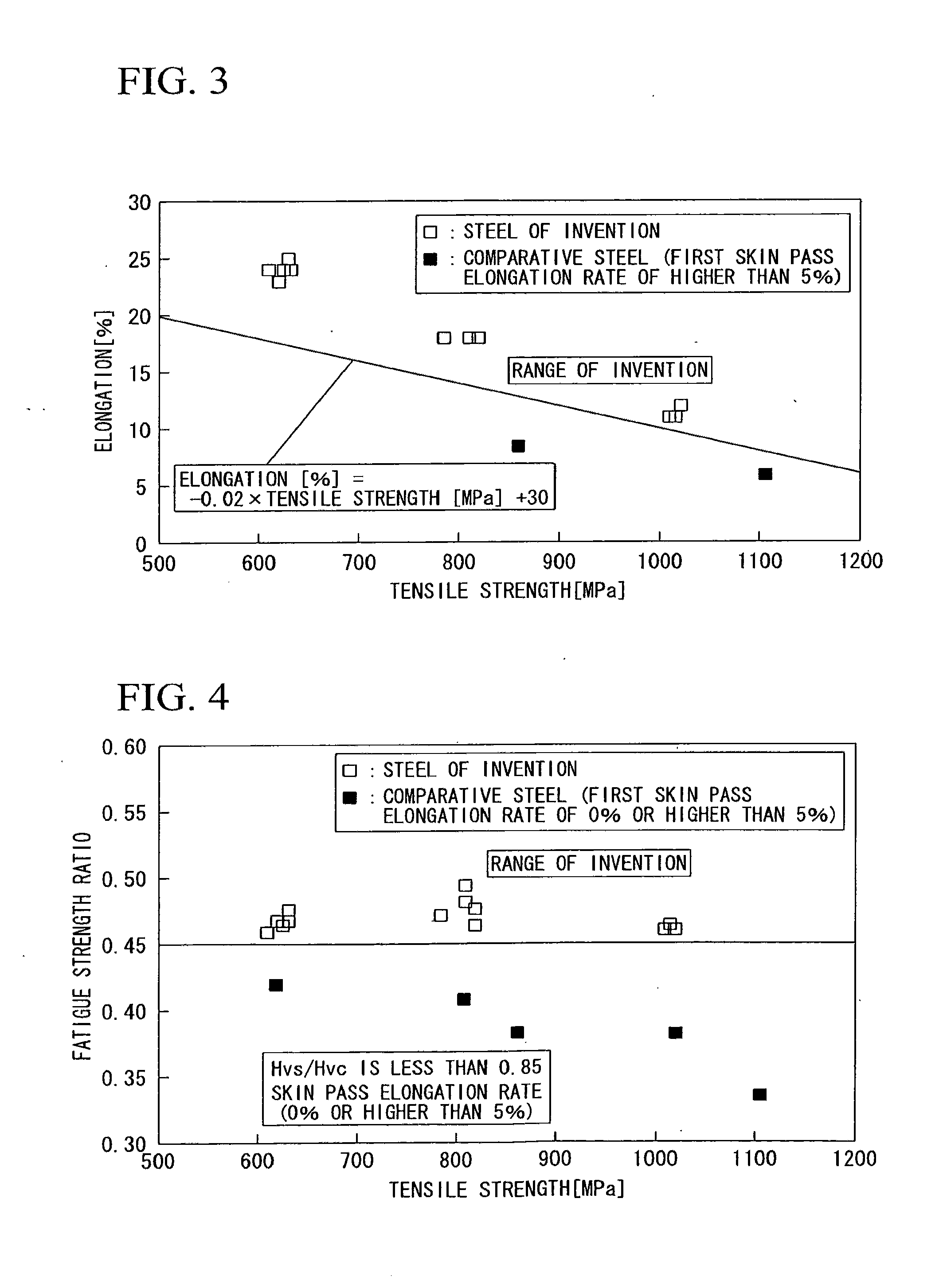

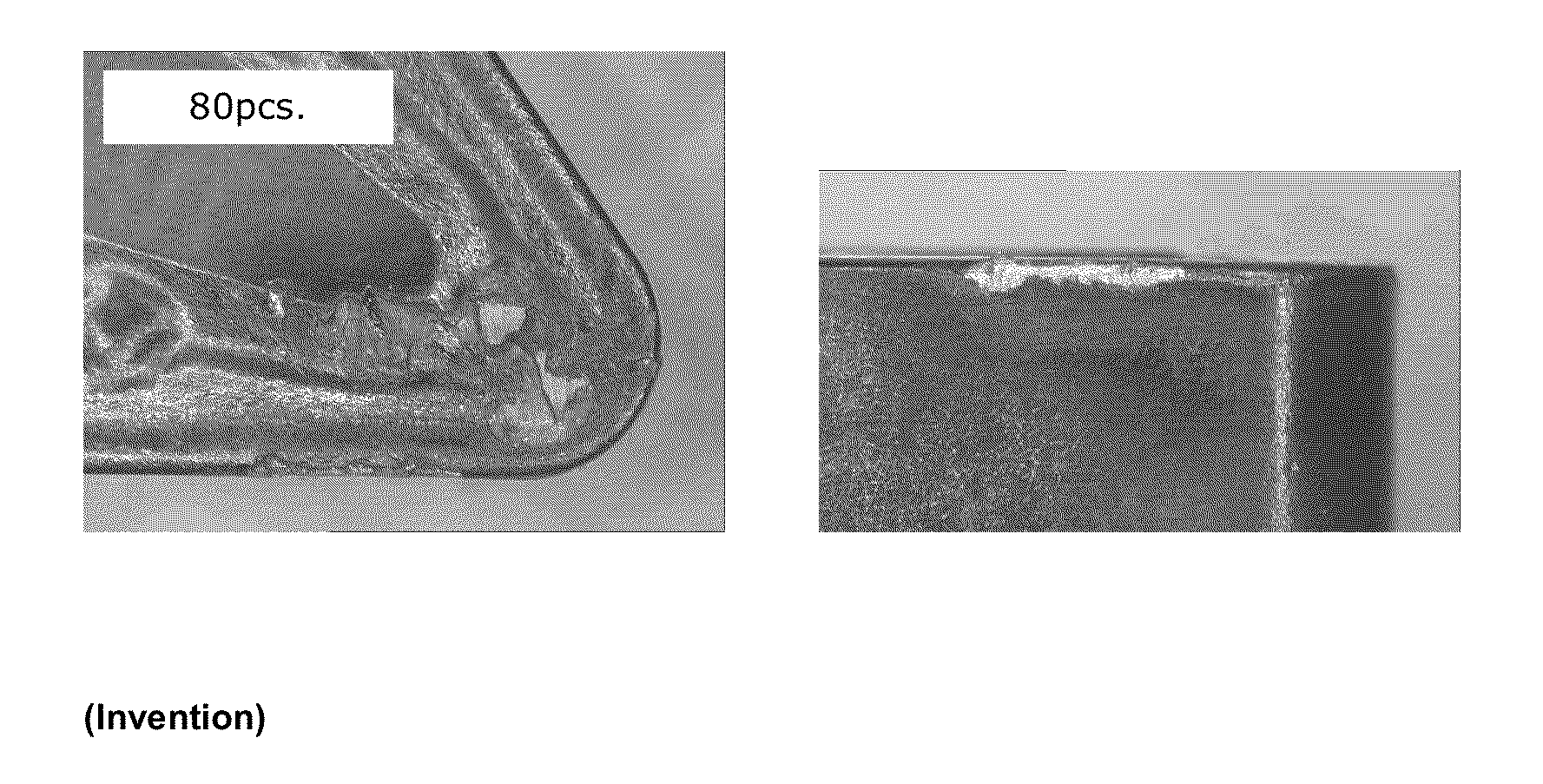

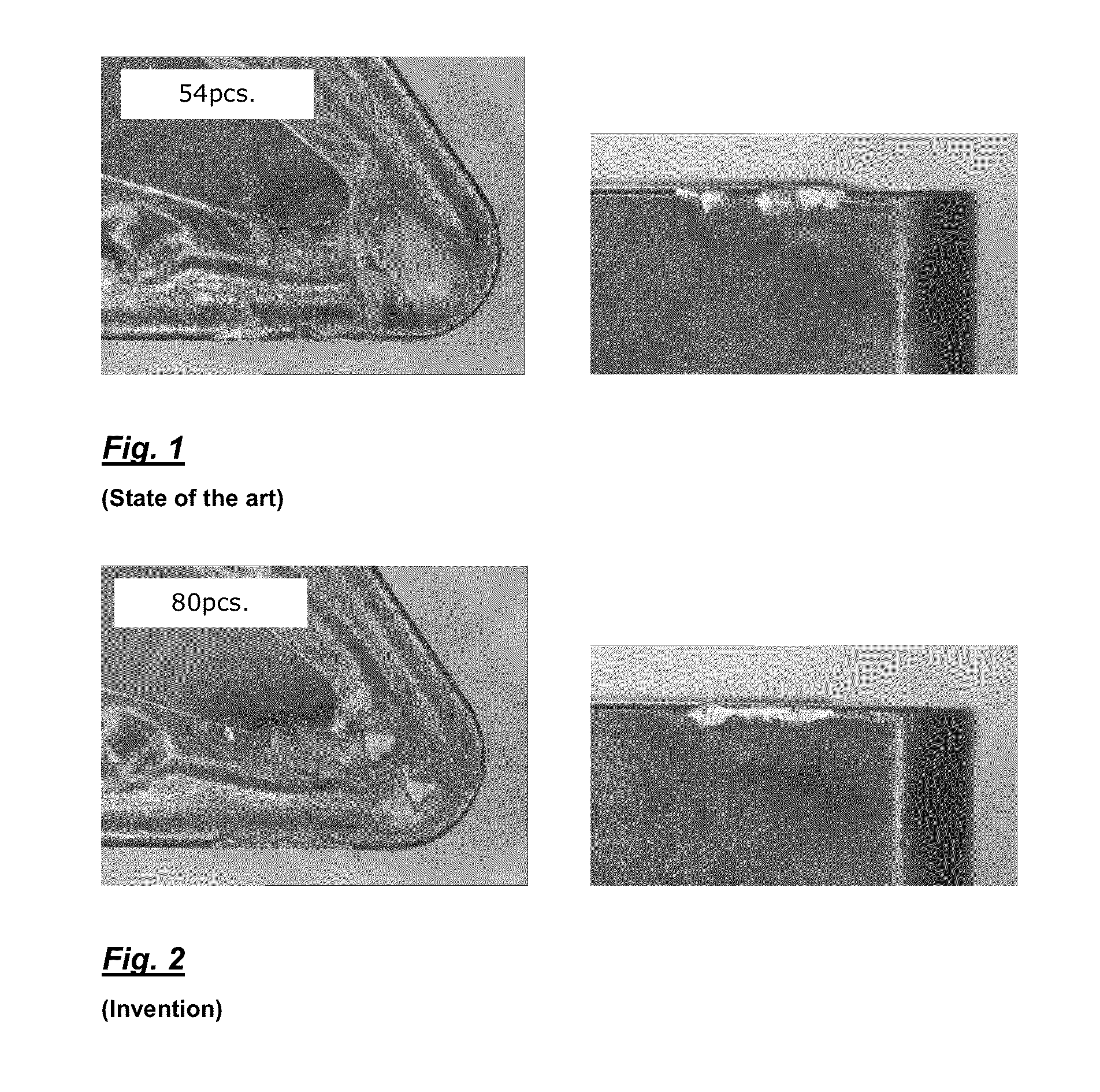

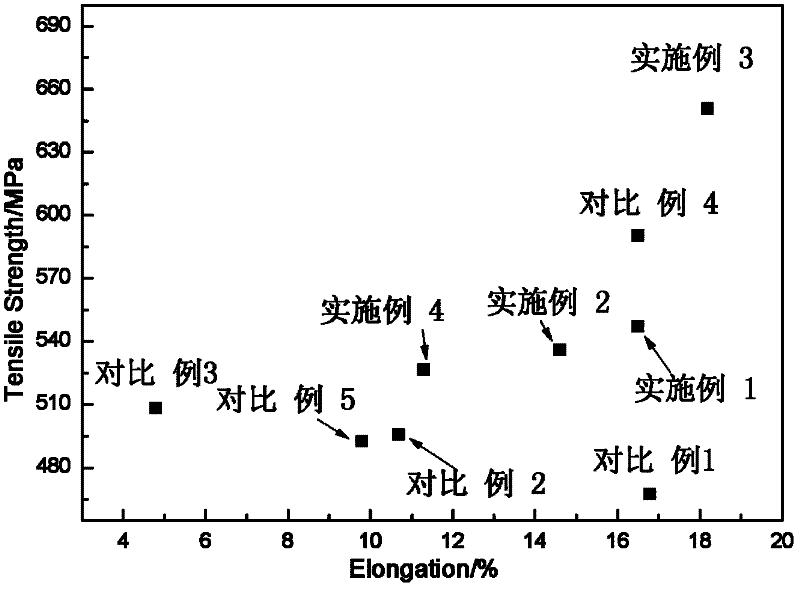

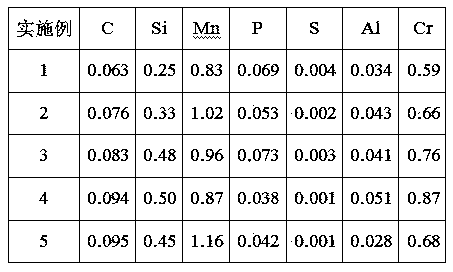

High-strength steel sheet, hot-dipped steel sheet, and alloy hot-dipped steel sheet that have excellent fatigue, elongation, and collision characteristics, and manufacturing method for said steel sheets

ActiveUS20120031528A1Improve crash performanceHigh yield stressHot-dipping/immersion processesFurnace typesUltimate tensile strengthImpurity

This high-strength steel sheet includes: in terms of percent by mass, 0.03 to 0.10% of C; 0.01 to 1.5% of Si; 1.0 to 2.5% of Mn; 0.1% or less of P; 0.02% or less of S; 0.01 to 1.2% of Al; 0.06 to 0.15% of Ti; and 0.01% or less of N; and contains as the balance, iron and inevitable impurities, wherein a tensile strength is in a range of 590 MPa or more, and a ratio between the tensile strength and a yield strength is in a range of 0.80 or more, a microstructure includes bainite at an area ratio of 40% or more and the balance being either one or both of ferrite and martensite, a density of Ti(C,N) precipitates having sizes of 10 nm or smaller is in a range of 1010 precipitates / mm3 or more, and a ratio (Hvs / Hvc) of a hardness (Hvs) at a depth of 10 μm from a surface to a hardness (Hvc) at a center of a sheet thickness is in a range of 0.85 or more.

Owner:NIPPON STEEL CORP

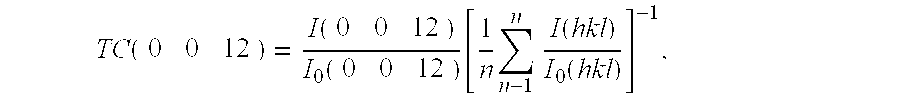

Cutting Insert and Method for Production Thereof

ActiveUS20140193624A1Advantageous or disadvantageous effects on the wear resistance of the cutting insertFatigue propertyPolycrystalline material growthLayered productsHard metalLayer thickness

Cutting insert made of hard metal, cermet or ceramic substrate body with multi-layer coating applied thereto by CVD methods. The coating has a total thickness of 5 to 40 μm and, starting from the substrate surface, has one or more hard material layers, an alpha aluminium oxide (α-Al2O3) layer of a layer thickness of 1 to 20 μm and optionally at least portion-wise over the α-Al2O3 layer one or more further hard material layers as decorative or wear recognition layers. The α-Al2O3 layer has a crystallographic preferential orientation characterised by a texture coefficient TC (0 0 12)≧5 for the (0 0 12) growth direction.The α-Al2O3 layer has an inherent stress in the region of 0 to +300 MPas, and the substrate within a region of 0 to 10 μm from the substrate surface has an inherent stress minimum in the region of −2000 to −400 MPas.

Owner:WALTER AG

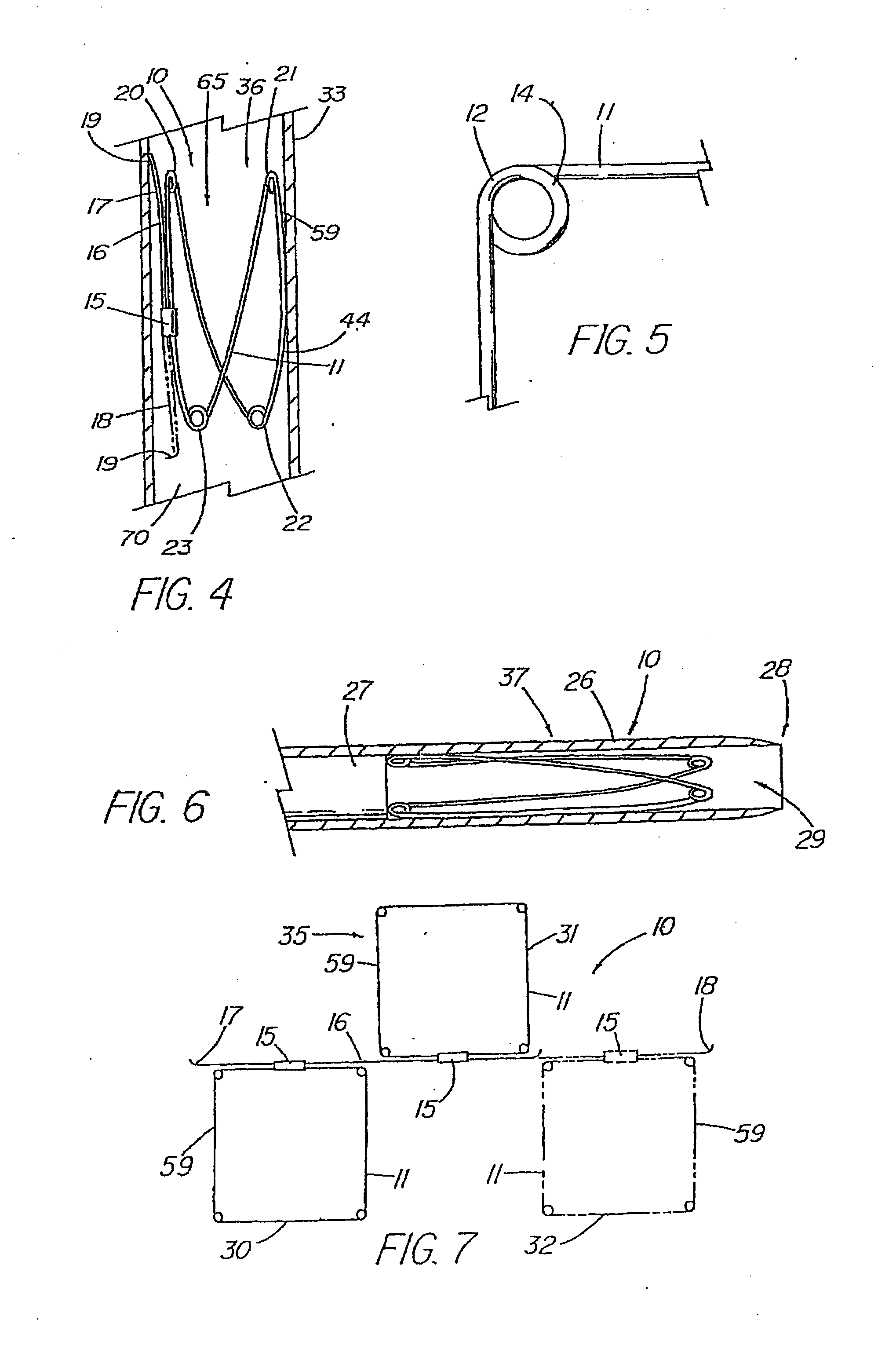

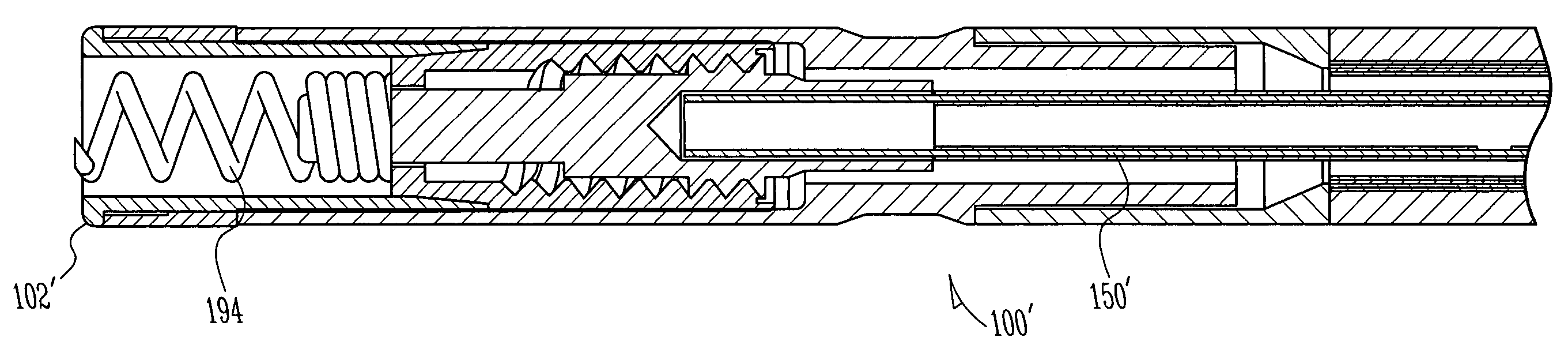

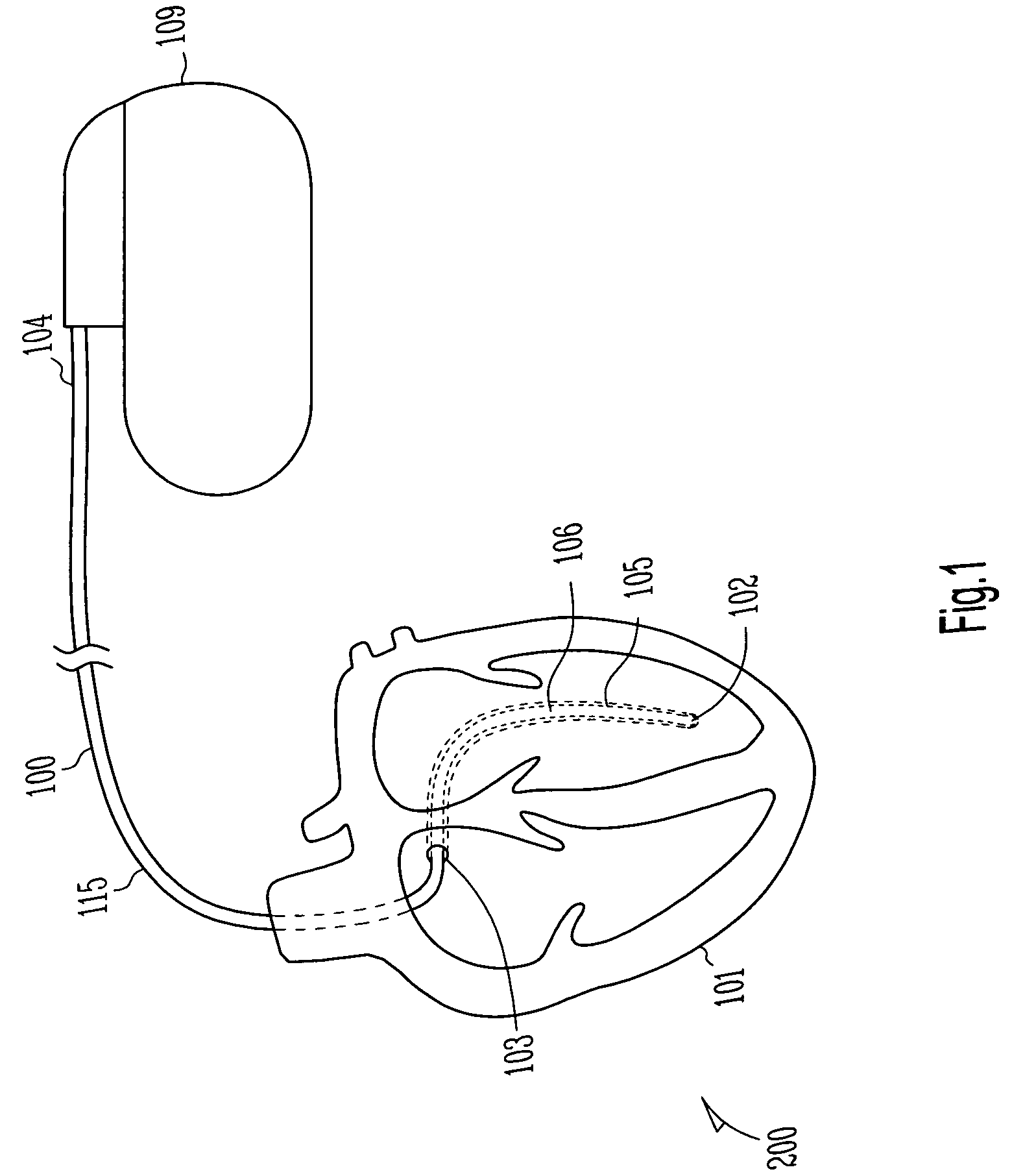

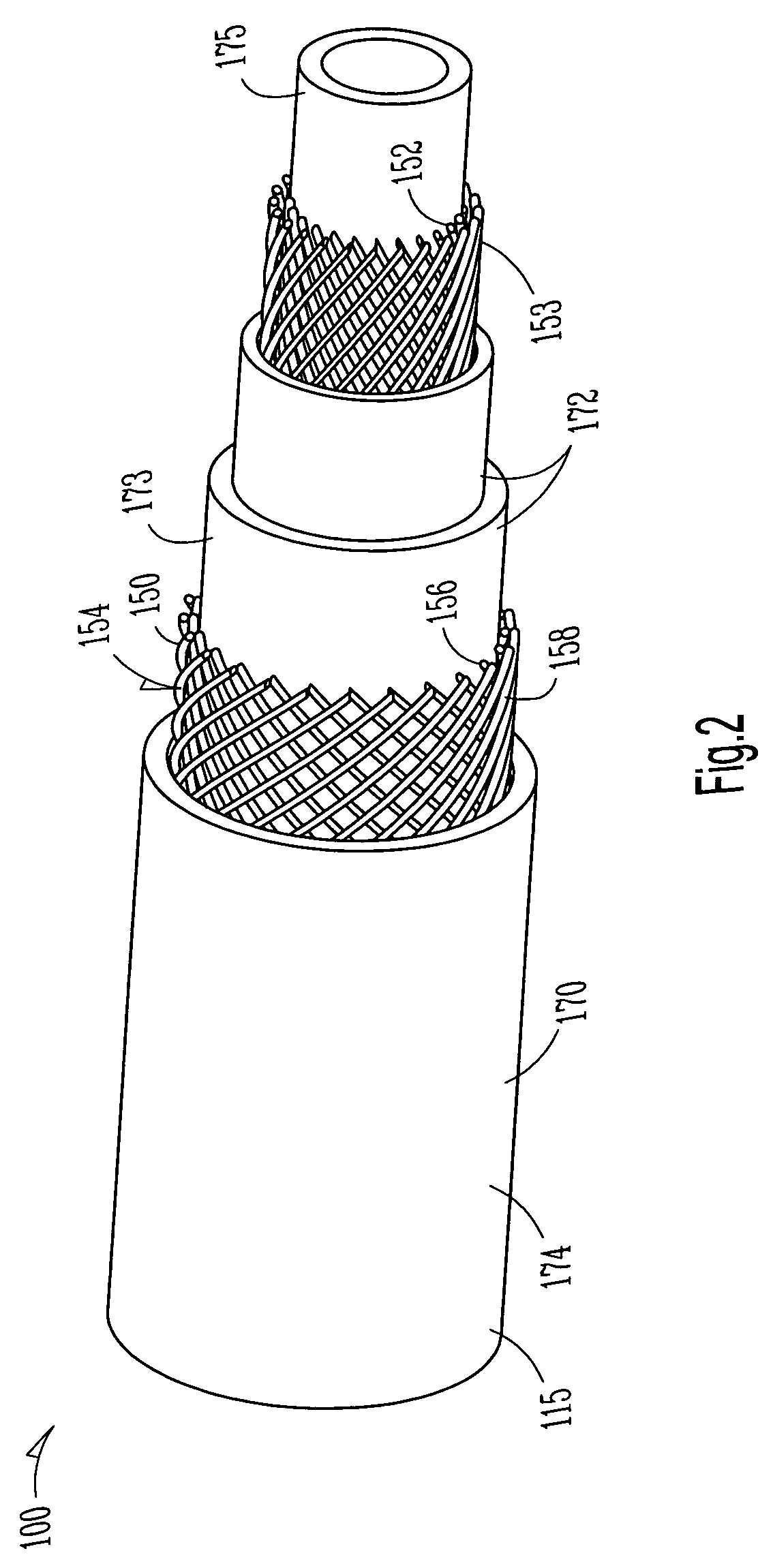

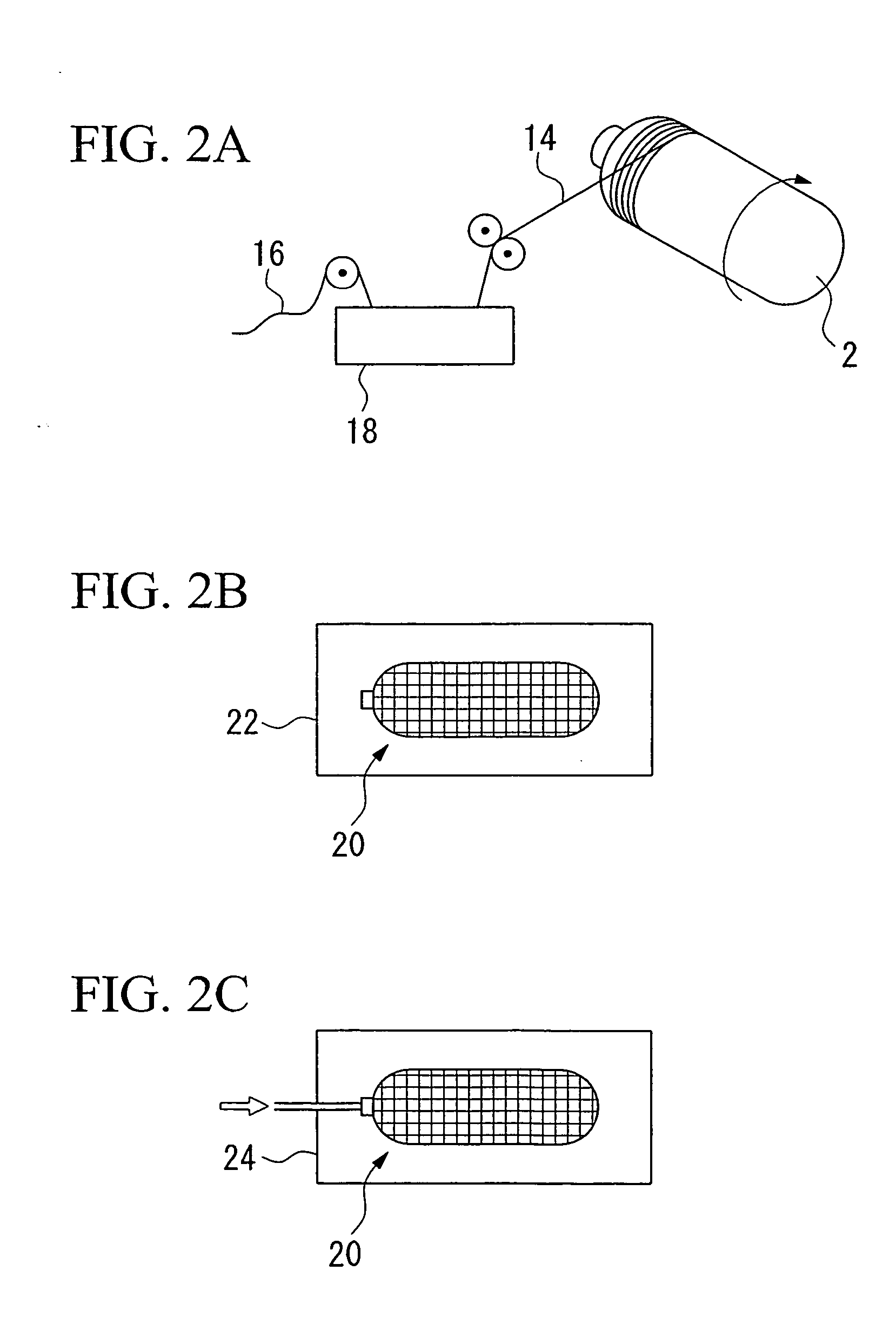

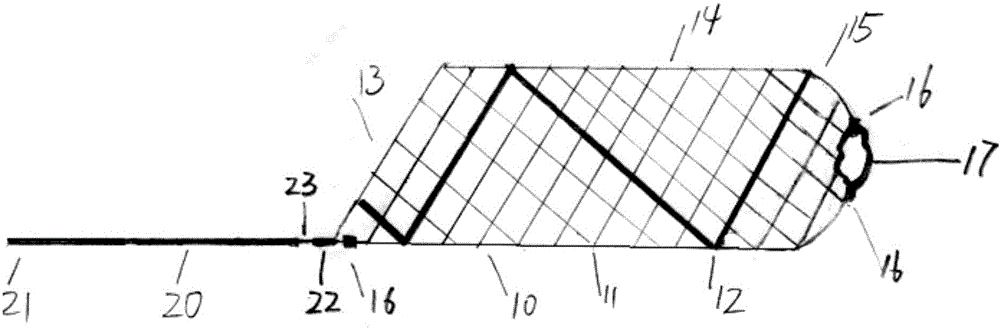

Lead having composite tubing

InactiveUS7337009B2Improve fatigue performanceSmall diameterTransvascular endocardial electrodesExternal electrodesElectrical conductorEngineering

Owner:CARDIAC PACEMAKERS INC

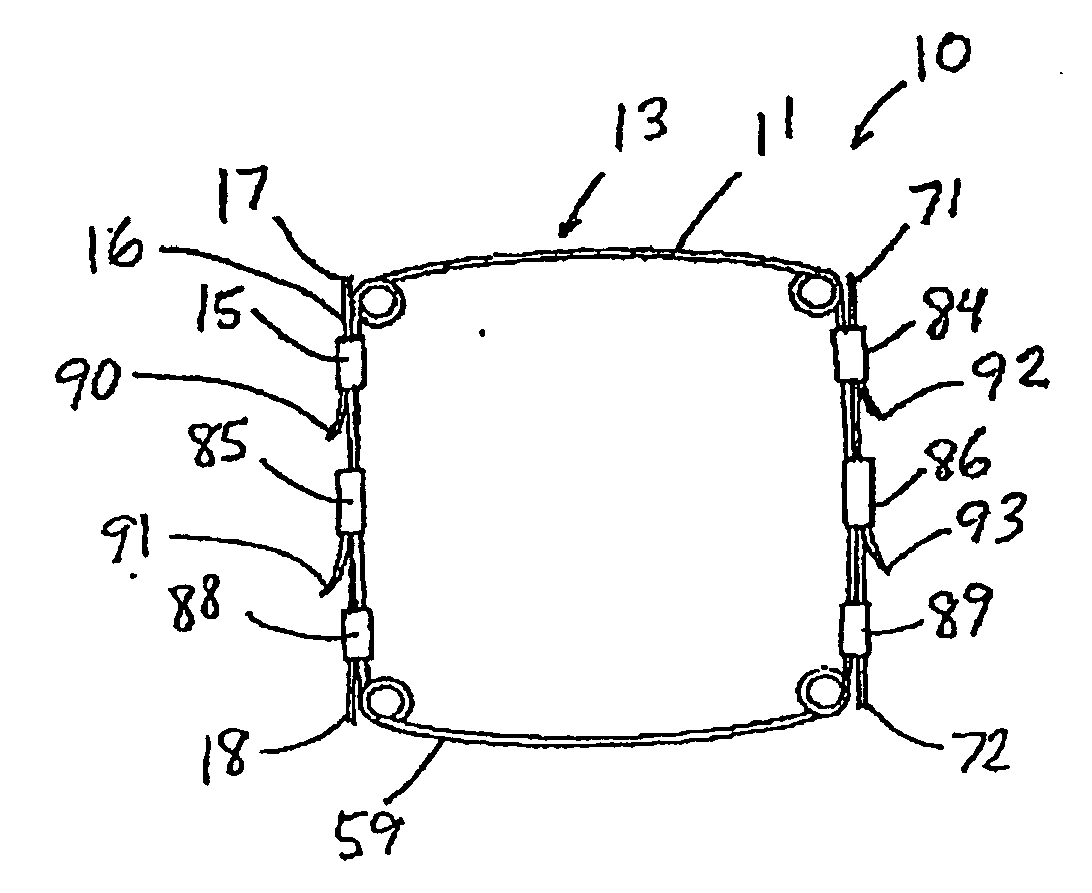

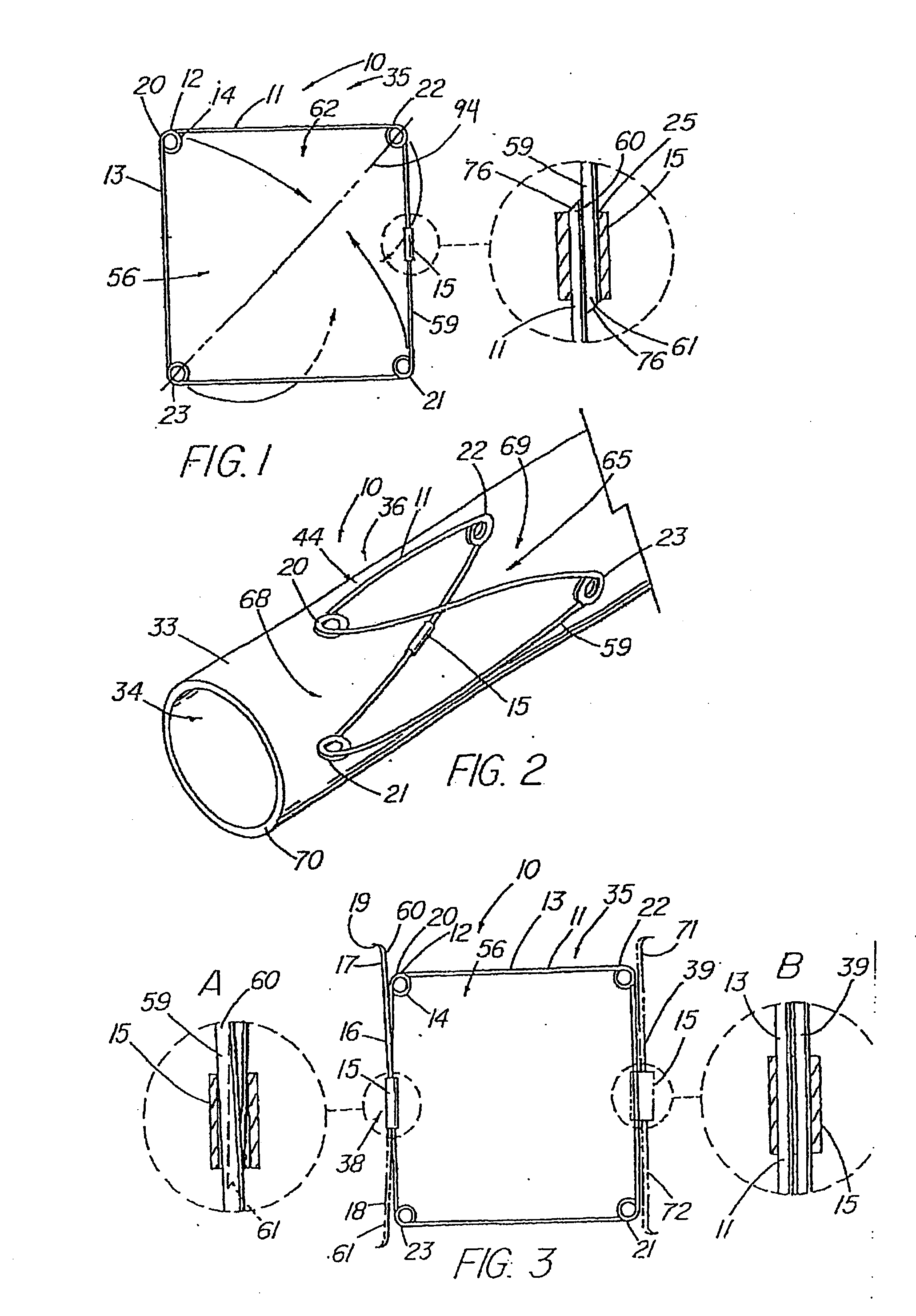

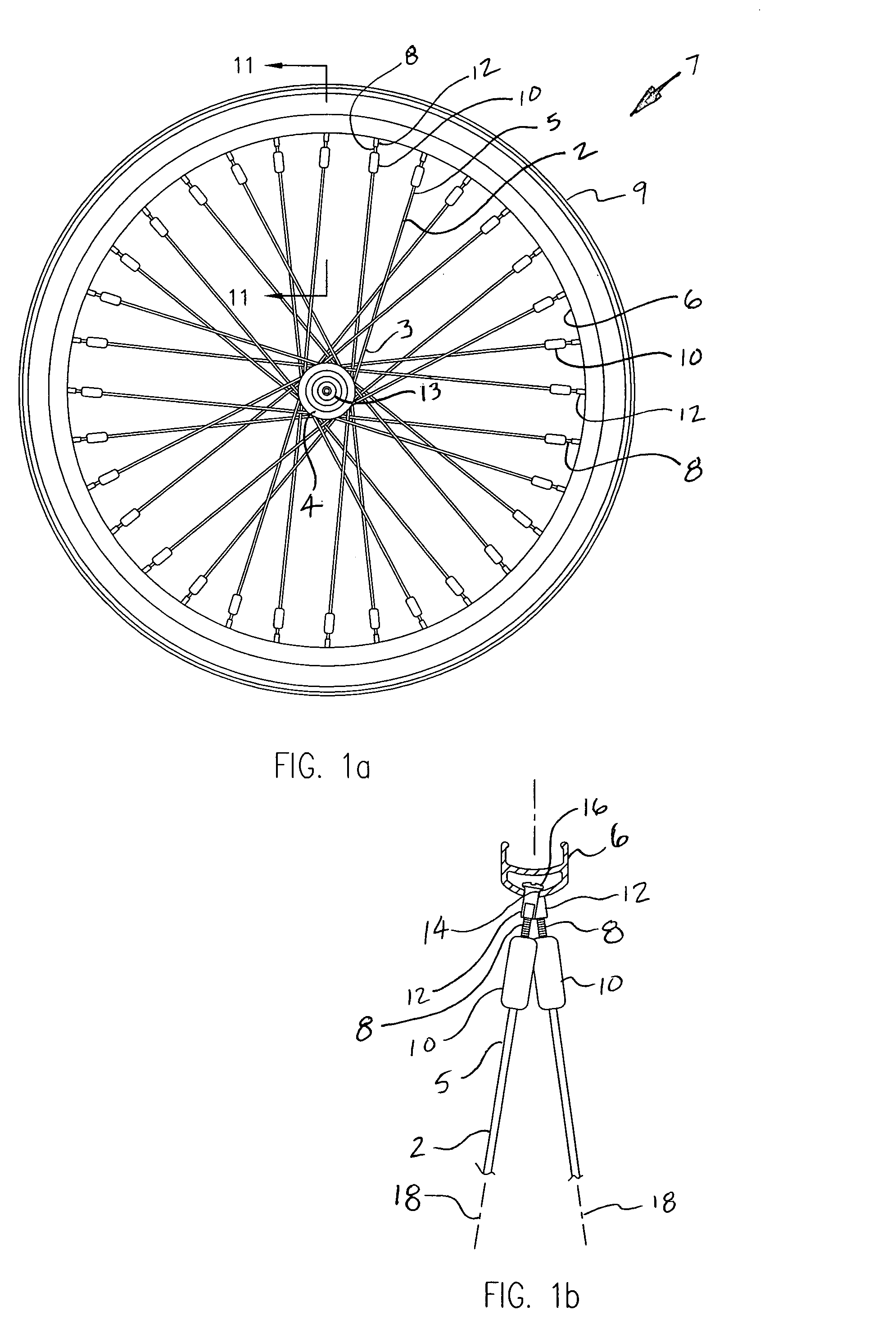

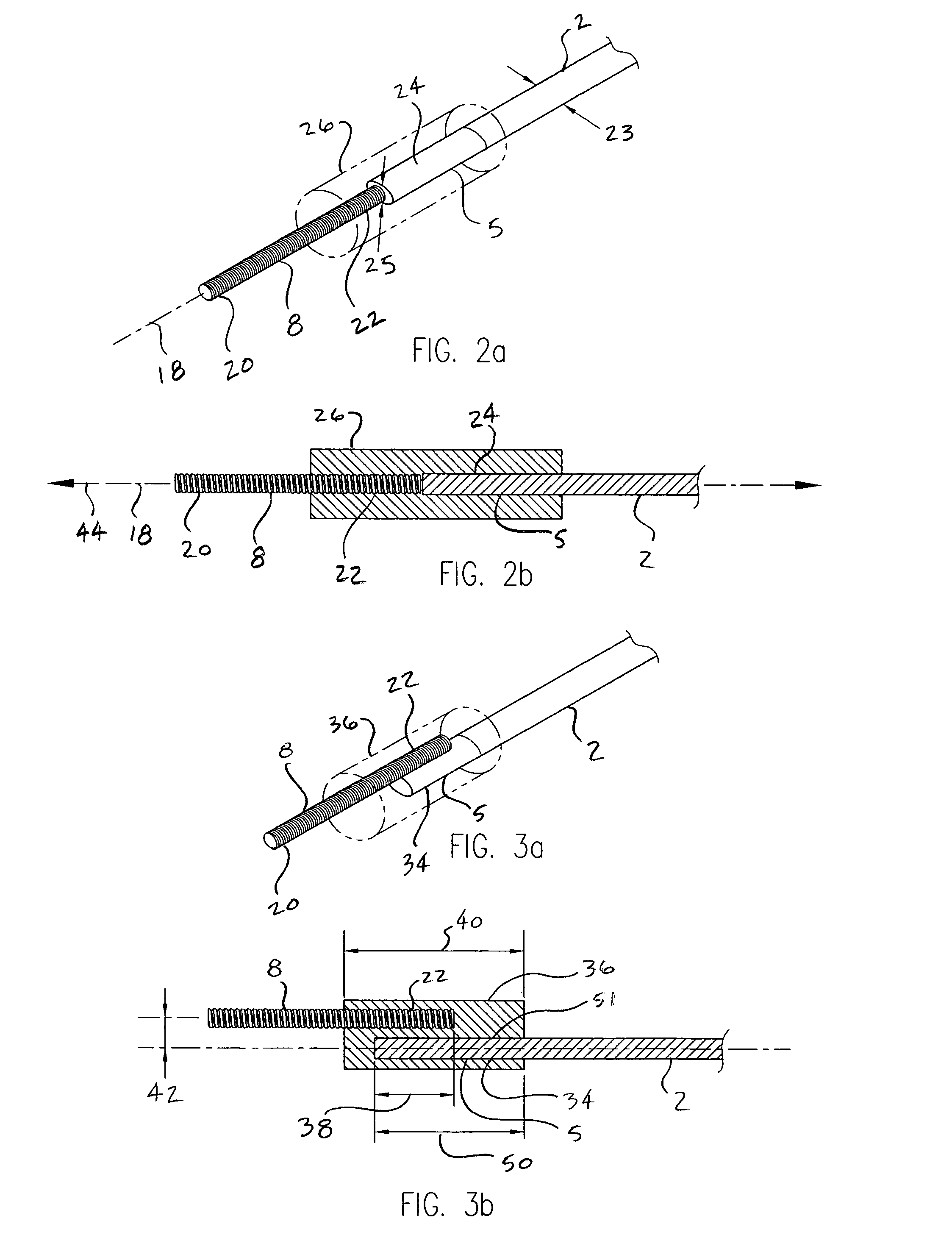

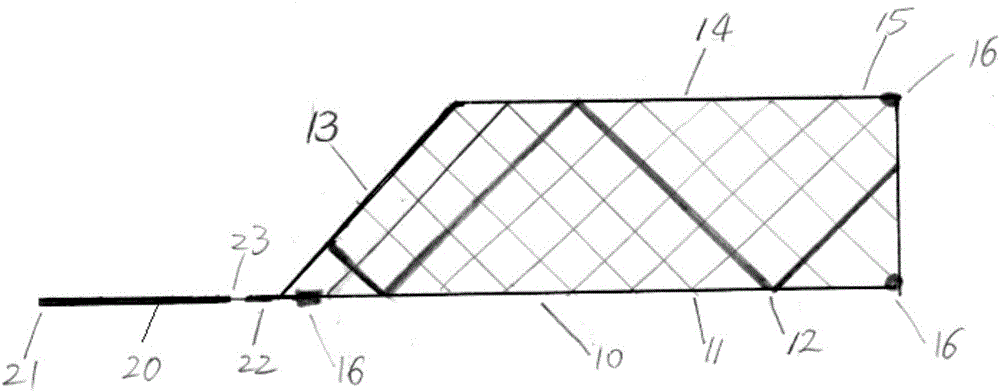

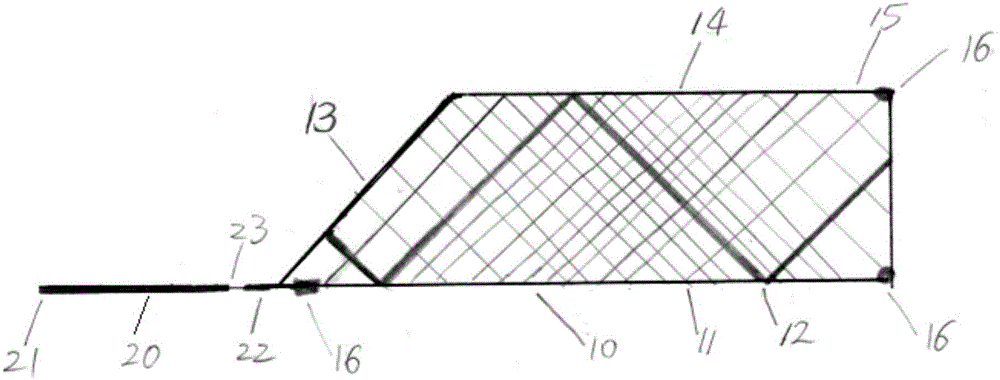

Connecting system for tensile elements

An improved connecting system for tensile elements, including a longitudinal tensile element having an end portion and a cross-section thereof, a deformable connecting element; a bracing element, and a tensile axis of applied tensile load along said longitudinal tensile element. The deformable connecting element surrounds the cross section of the longitudinal tensile element and the deformable connecting element is joined to the longitudinal tensile element by means of plastic deformation of said deformable connecting element. The deformable connecting element is connected to the bracing element.

Owner:SCHLANGER RAPHAEL

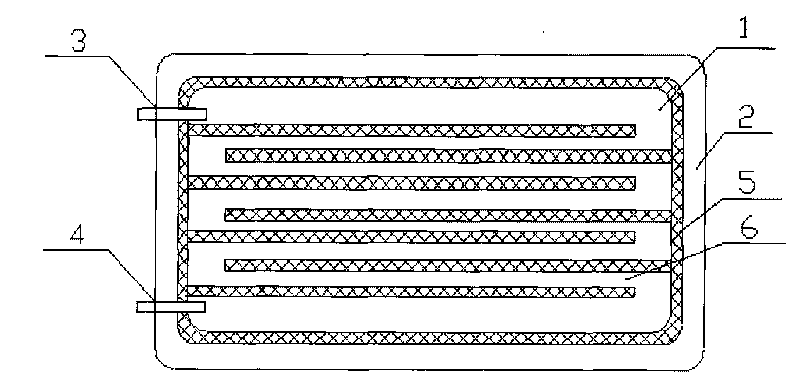

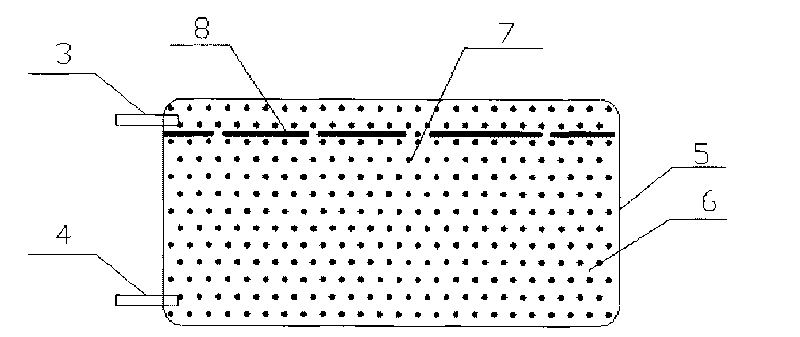

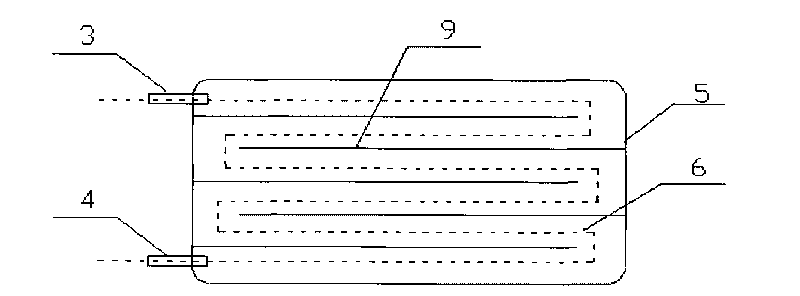

Stainless steel plate type heat exchanger and processing molding method thereof

InactiveCN101691961AUniform refrigerant flow pathLow flow resistanceShaping toolsEvaporators/condensersSteel platesHoneycomb

The invention discloses a stainless steel plate type heat exchanger and a processing molding method thereof. The plate type heat exchanger comprises a snakelike flow channel type and honeycomb flow channel type evaporation plate or a cold plate. The plate type heat exchanger adopts a stainless steel plate and consists of a stainless steel upper plate, a stainless steel lower plate, an inlet pipe and an outlet pipe, wherein the two stainless steel plates are overlapped and connected by a special welding method; the inlet pipe and the outlet pipe are inserted in the upper end and the lower end between the two stainless steel plates and are connected with the stainless steel plate type heat exchanger body by using an electric arc welding method; and then the plate type heat exchanger is finally molded through a mould and high-pressure bulging technology.

Owner:CHONGQING UNIV

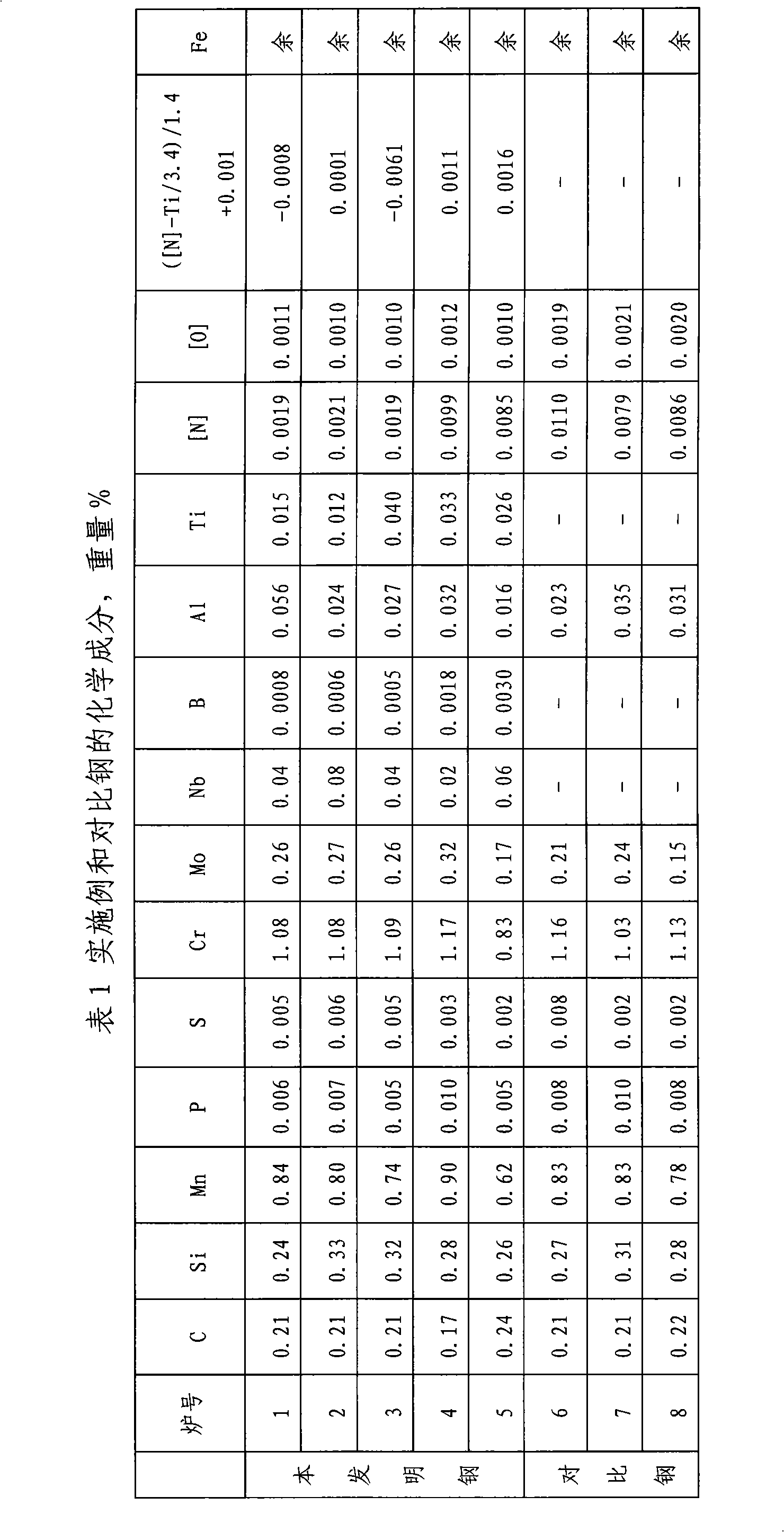

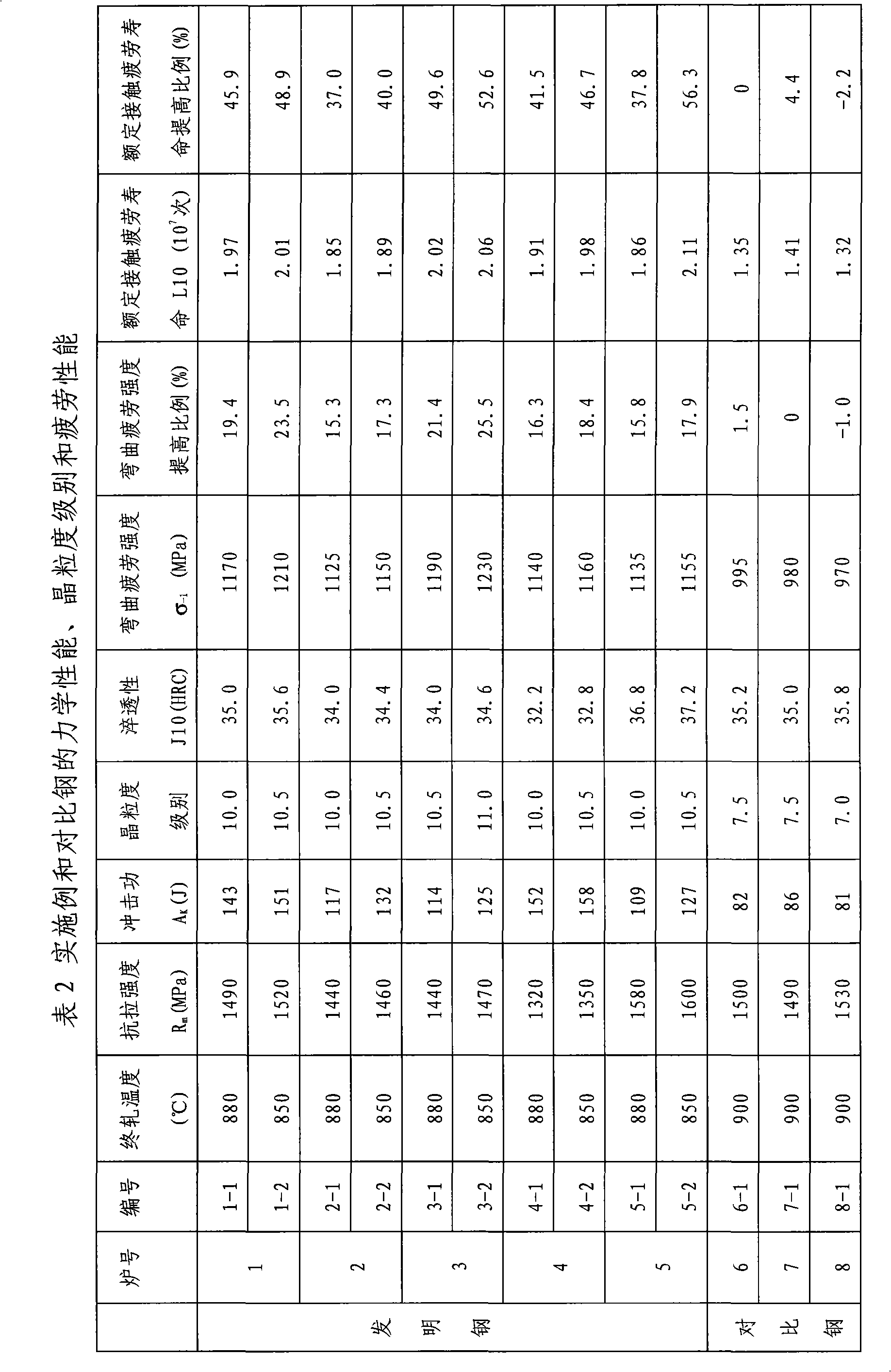

Steel for fine grain carburizing gear and method of manufacturing the same

The invention belongs to the alloy steel field, particularly relating to steel for a fine grain carburization gear and a preparation method thereof. The steel comprises the following chemical compositions in weight percentage: 0.15 to 0.25 percent of C, less than or equal to 0.35 percent of Si, 0.60 to 0.90 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.010 percent of S, 0.80 to 1.20 percent of Cr, 0.15 to 0.35 percent of Mo, 0.02 to 0.08 percent of Nb, 0.0005 to 0.0035 percent of B, 0.02 to 0.06 percent of Al, 0.01 to 0.04 percent of Ti, less than or equal to 0.015 percent of [N], less than or equal to 0.0015 percent of [O], the balance being Fe and inevitable impurities. Meanwhile, Ti is more than or equal to 2[N] and B is more than or equal to ([N] minus Ti / 3.4) / 1.4 plus 0.001; and the rolling production process with the finish-to-gage temperature below 900 DEG C is adopted. Compared with the prior carburization gear steel 20CrMoH, the grain size of the steel after carburizing and quenching exceeds ten grade, the bending fatigue resistance(sigama-1) is improved by more than 15 percent and the contact fatigue life(L10) is improved by more than 30 percent.

Owner:CENT IRON & STEEL RES INST

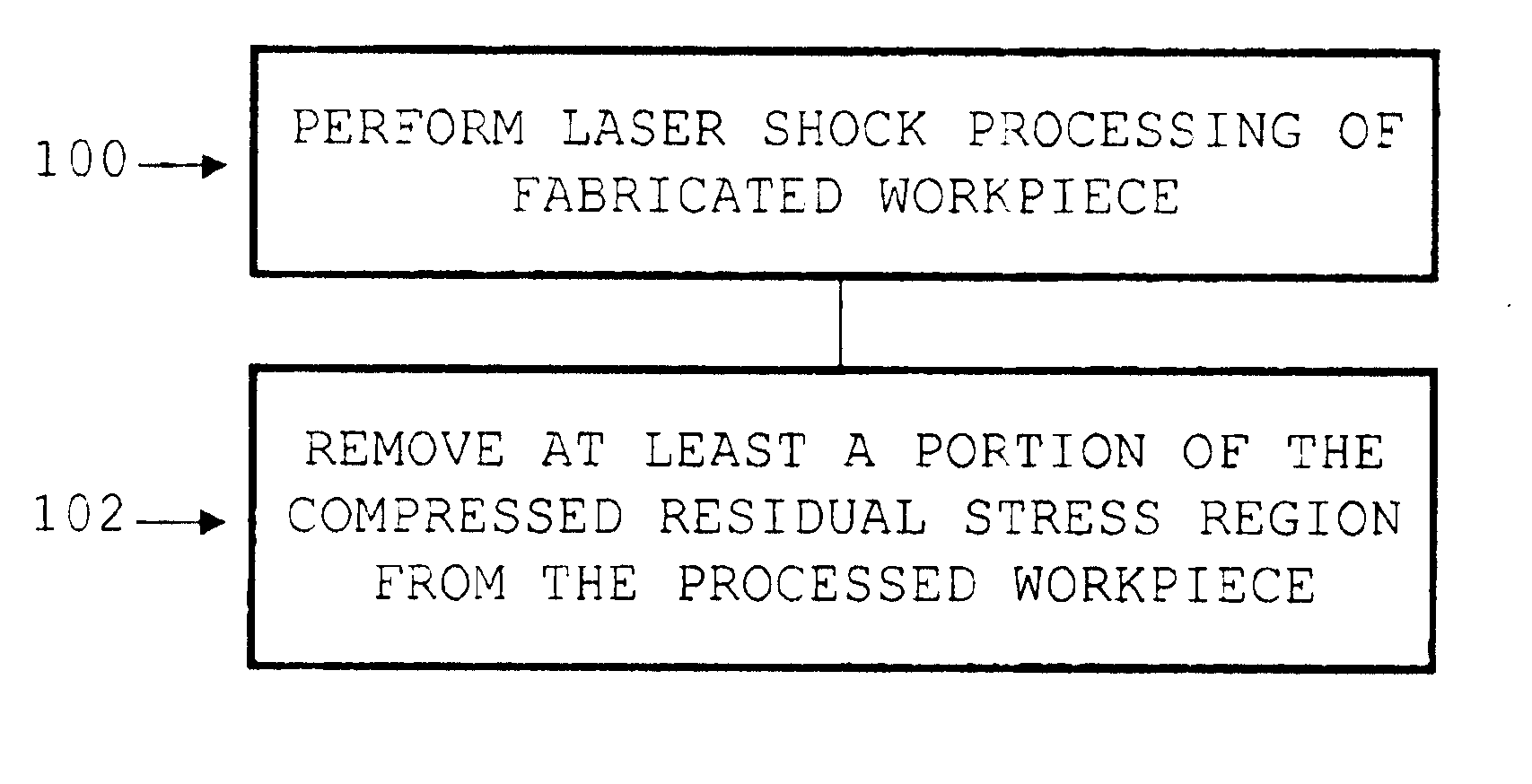

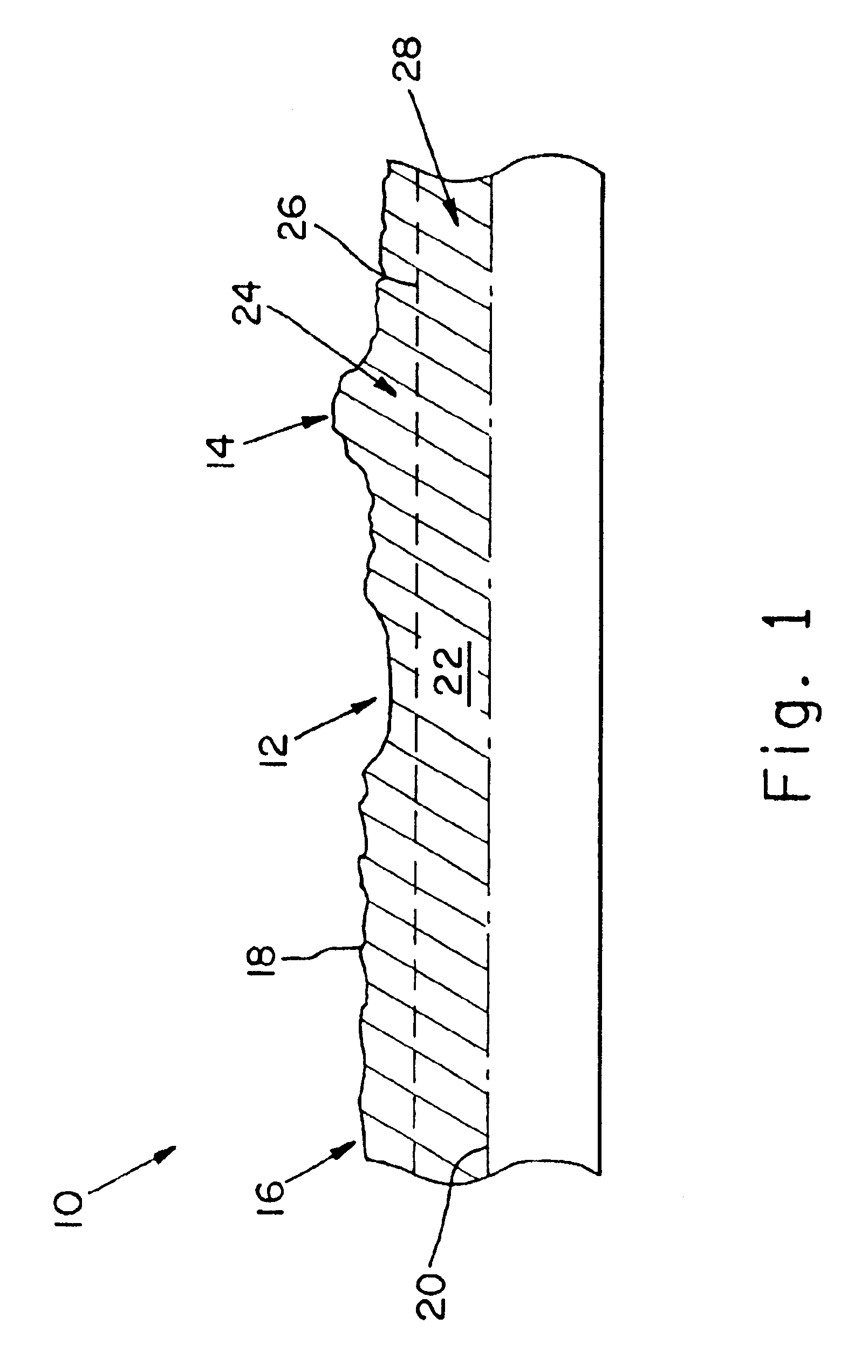

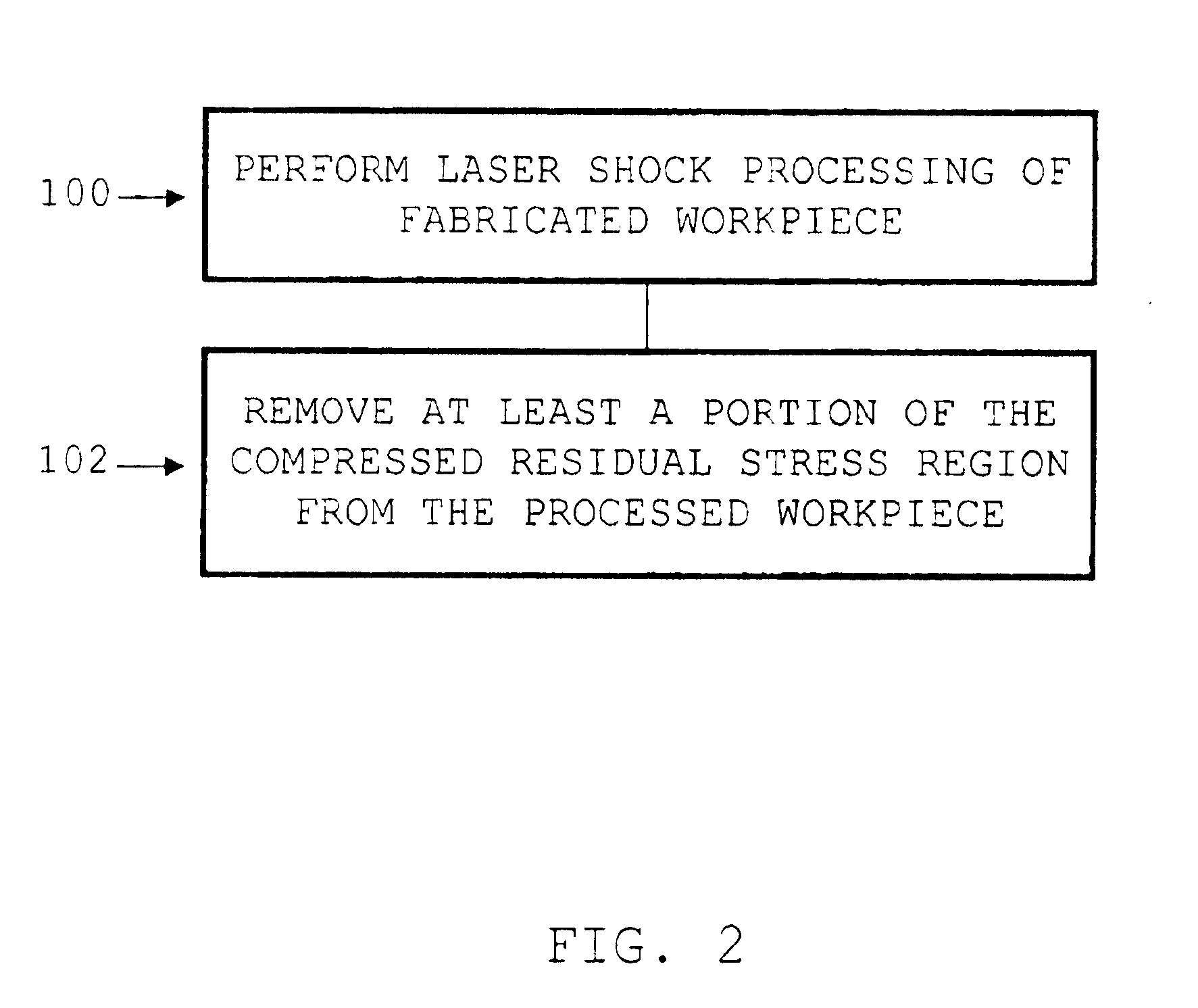

Method of modifying a workpiece following laser shock processing

InactiveUS6852179B1Improve fatigue performanceThin material handlingLaser beam welding apparatusMaterial removalHigh intensity

A method of manufacturing a workpiece involves performing any one of various post-processing part modification steps on a workpiece that has been previously subjected to laser shock processing. In one step, material is removed from the compressive residual stress region of the processed workpiece. Alternately, the workpiece may be provided with oversized dimensions such that the removal process removes an amount of material sufficient to generate a processed workpiece having dimensions substantially conforming to design specifications. Alternately, the material removal process is adapted to establish a penetration depth for material removal that coincides with the depth at which the workpiece exhibits maximum compressive residual stress. Alternately, a first high-intensity laser shock processing treatment is performed on the workpiece, followed by the removal of material from the compressive residual stress region, and then a second low-intensity laser shock processing treatment is performed on the workpiece. Material may be removed from the compressive residual stress region through a workpiece surface different from the laser shock processed surface. Material may also be deposited onto the laser shock processed surface.

Owner:LSP TECH INC

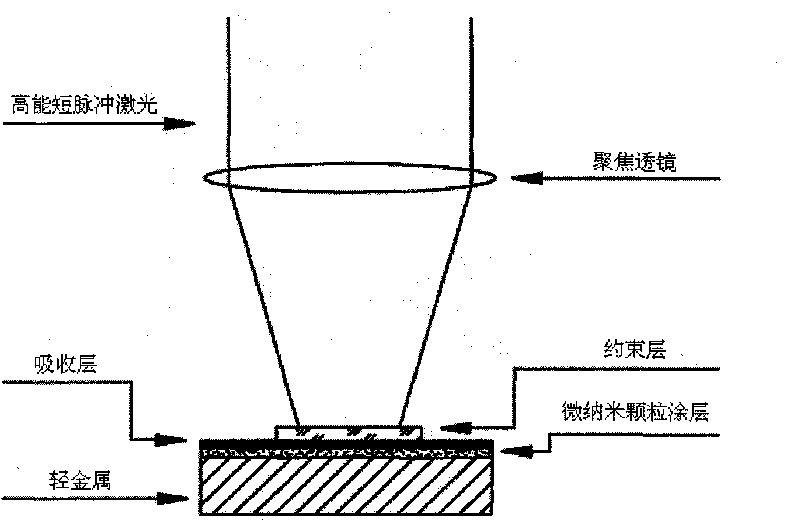

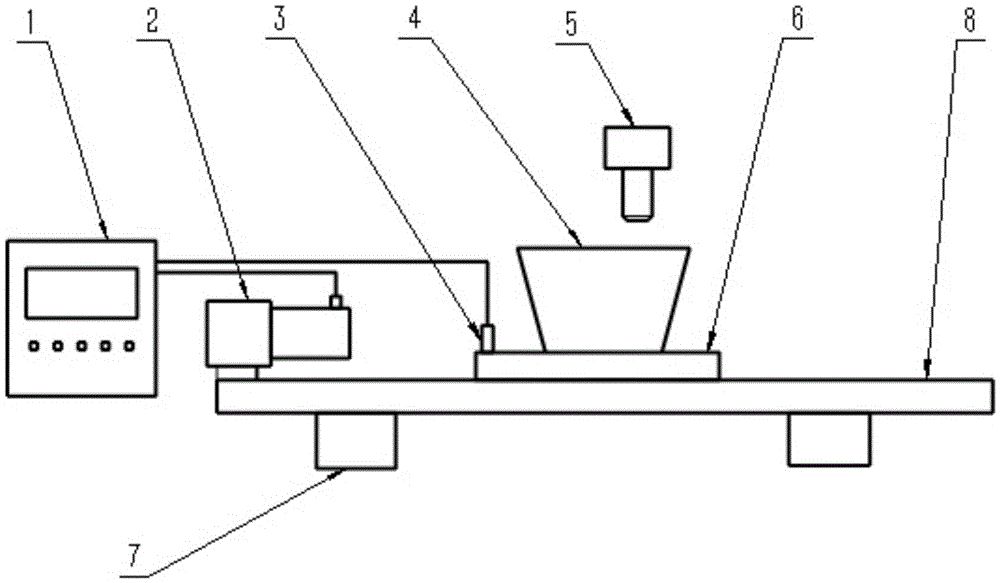

Light metal surface laser impact micronano particle injection reinforcing method

The invention relates to a light metal surface laser impact micronano particles injection reinforcing method, comprising the following steps: 1) removing the oxide layer probably existing on the surface of the light metal by a mechanical polishing or chemical corrosion method, then grinding and polishing with sand paper, and finally cleaning the surface of the light metal alloy with acetone or alcohol; 2) precoating the micronano particles on the surface of the light metal with inorganic bonding agent, recoating a layer of black paint on the surface of the micronano particle coating layer to serve as the absorption layer of laser impact after drying, and drying naturally; 3) impacting the absorption layer and the micronano particle layer with high-energy short pulse laser, and utilizing K9 glass or running water as a restriction layer during laser impact; and 4) soaking the micronano particle coating layer processed by acetone, and then removing the absorption layer through washing with running water or ultrasonic washing to obtain the micronano particle injection reinforcing layer. The invention integrates the actions of laser impact reinforcement, nano particle reinforcement and nano particle reinforcement, can dramatically improve hardness, abrasion resistance and fatigue resistance property of light metal surface layer, and has wide application prospect.

Owner:TSINGHUA UNIV

Heat treatment technology for markedly raising comprehensive performance of aluminium alloy

InactiveCN102242325AMeet the requirements of large structural partsPractical application value of large industry5005 aluminium alloySolid solution

A heat treatment technology for markedly raising comprehensive performance of aluminium alloy is accomplished by the adoption of the following scheme: carrying out a solid solution treatment on the aluminium alloy, taking the aluminium alloy out of a furnace and carrying out water quenching, and carrying out a pre-aging treatment, cold deformation and a secondary aging treatment. Nanometer-level aging precipitation strengthening phase is formed by the pre-aging treatment, and dislocation configuration generated from the subsequent cold deformation can be changed, so as to improve the strength, ductility and toughness of the alloy; during the cold deformation, nanometer-level atomic clusters will precipitate out from solute atoms precipitated during the pre-aging treatment, or ''pinning'' air mass is formed around the dislocation structure, thus further raising the strength of the alloy. The precipitated precipitation strengthening phase is nanometer level, thus raising the ductility and toughness of the alloy and markedly enhancing the strength of the alloy on the basis of guaranteeing good plasticity. The technological process provided by the invention is simple, is convenient to operate, can be adopted to markedly raise comprehensive performance such as the strength and plasticity of the aluminium alloy and improve the corrosion resistant performance and fatigue resistant performance of the aluminium alloy, and is suitable for industrial application.

Owner:CENT SOUTH UNIV

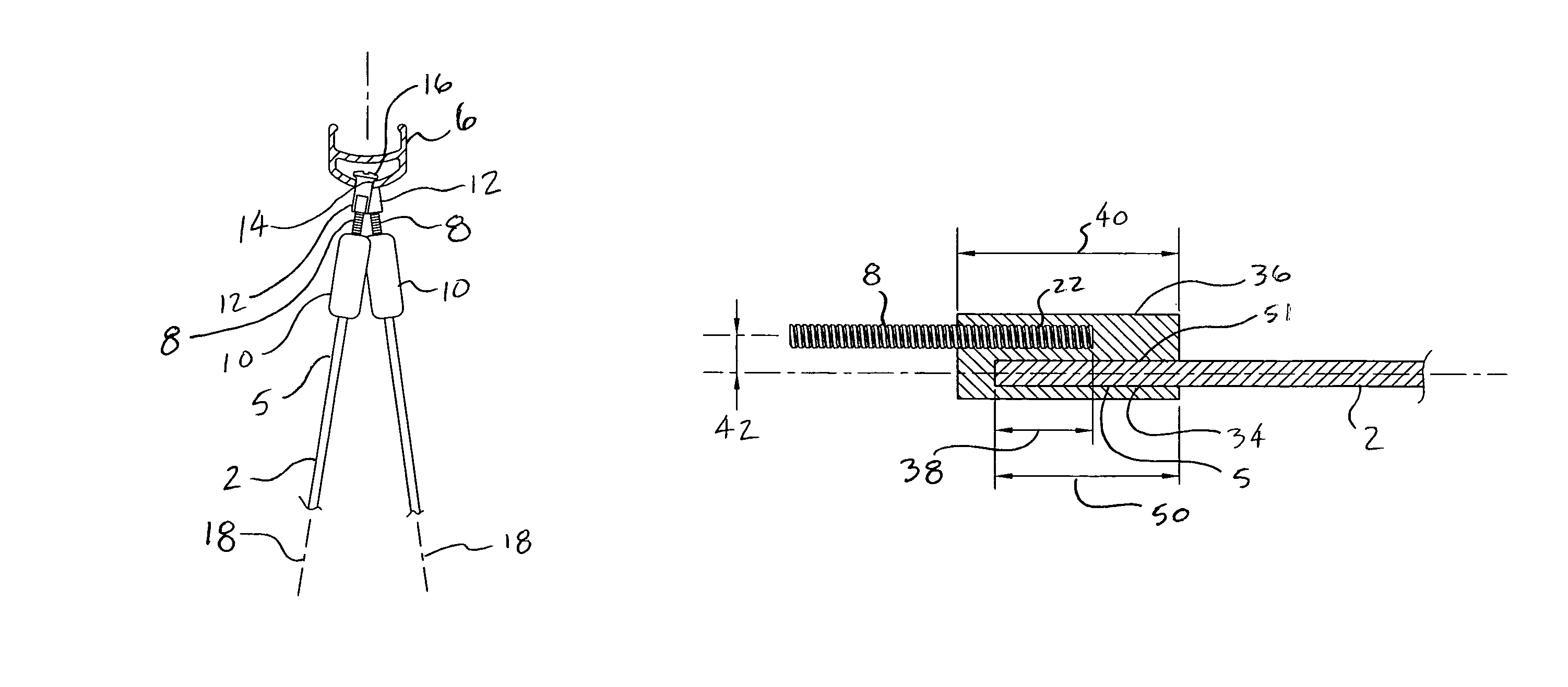

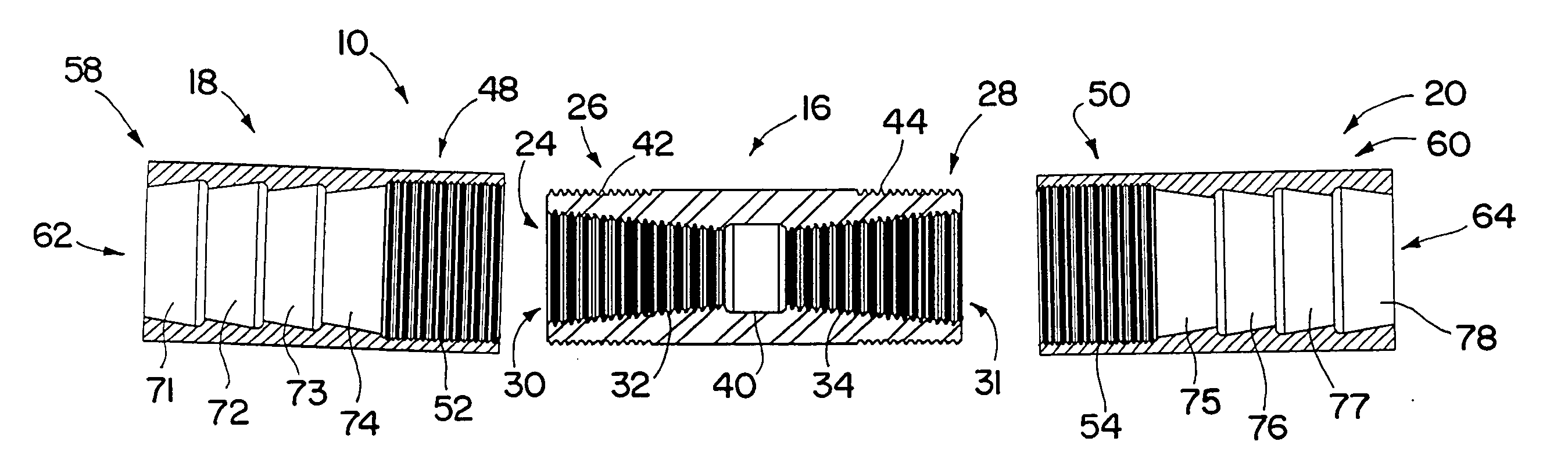

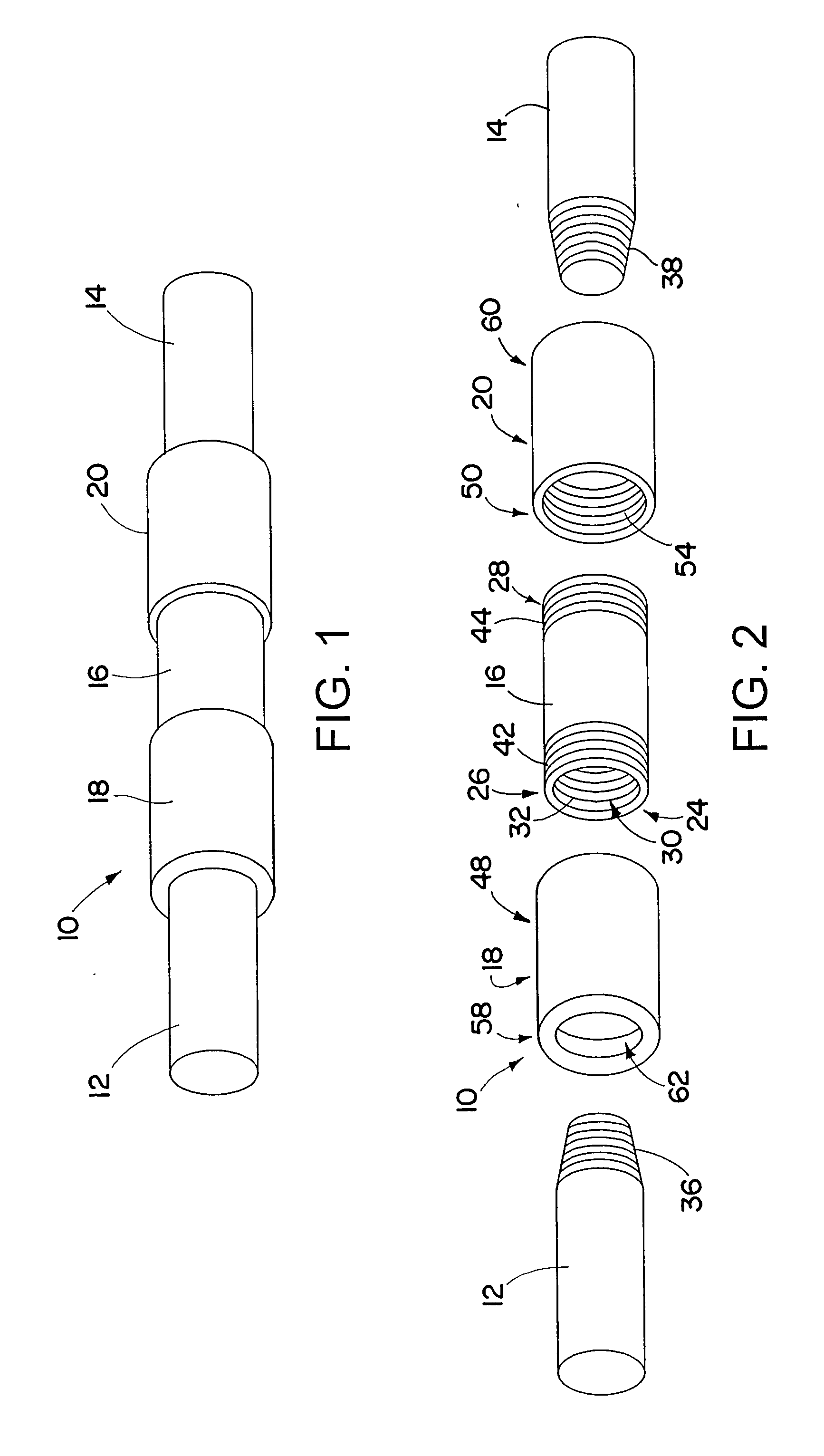

Reinforcing bar splice with threaded collars

InactiveUS20070175167A1Increase holdingsThread stress concentrationStrutsDrilling rodsFilling materialsEngineering

A reinforcing bar splice secures together reinforcing bar ends by utilizing, at both ends, both tapered-thread coupling and coupling involving a filler, such as a grout or an epoxy. The splice may include a central tapered-thread central sleeve or coupler, and a pair of collars that are screwed onto externally-threaded ends of the central sleeve. The central sleeve has a channel therethrough with tapered internal threads at both ends, and a center internal relief. The internal relief is an increased radius center portion that ensures full thread contact between the tapered internal threads and external threaded sections of the rebar ends. The sleeve has externally-threaded ends that are engaged by internally-threaded ends of a pair of collars. Distal to their internally-threaded ends, the collars have filler-material-receiving channels. The channels include plural sloped surfaces for aiding in securing filler material between the collars and the rebar ends.

Owner:ERICO INT

Added material manufacturing method under vibration condition

ActiveCN105458264AImprove manufacturing precisionGrain refinementAdditive manufacturing apparatusIncreasing energy efficiencyLean manufacturingMetal

The invention proposes an added material manufacturing method under a vibration condition. In an arc wire feeding added material manufacturing or laser powder feeding melting added material manufacturing process, mechanical vibration with a certain frequency is synchronously introduced, so that parts are located in a micro vibrating state; and the mechanical vibration acts on a micro liquid-state molten bath formed in the added material manufacturing process to refine grains, so that the structure becomes more uniform, and such phenomenon as air holes, inclusions and incomplete fusion is reduced or even eliminated. Meanwhile, the vibration acts on metal just condensed, so that the stress generated by vibration and residual stress generated in the added material manufacturing process are superposed to generate local plastic deformation to achieve the purpose of reducing residual stress and deformation of added material manufacturing parts, and the added material manufacturing parts under vibration condition are more excellent in performances.

Owner:HUAZHONG UNIV OF SCI & TECH

55Si2MnVNbN spring steel and production process thereof

InactiveCN101717893AHigh strengthHigh tensile strengthTemperature control deviceMetal rolling arrangementsWorking environmentSpring steel

The invention relates to spring steel and a production process thereof, in particular to 55Si2MnVNbN spring steel and a production process thereof. The 55Si2MnVNbN spring steel comprises the following components in percentage by weight: 0.52 to 0.60 percent of C, 1.60 to 1.90 percent of Si, 0.60 to 0.80 percent of Mn, 0.15 to 0.35 percent of Cr, 0.06 to 0.12 percent of V, 0.015 to 0.025 percent of Nb, 0.80 to 1.50 percent of N, less than or equal to 0.0035 of P, less than or equal to 0.0035 percent of S and the balance of Fe and inevitable impurities. The process comprises electric furnace electrosmelting, LF refining, VD furnace vacuum degassing, continuous casting and rolling. The spring steel can meet the requirements of springs on various severe working environments, high strength and long service life and has high tensile strength, high delayed fracture resistance, high corrosion resistance, high fatigue resistance and high elasticity attenuation resistance.

Owner:NANJING IRON & STEEL CO LTD

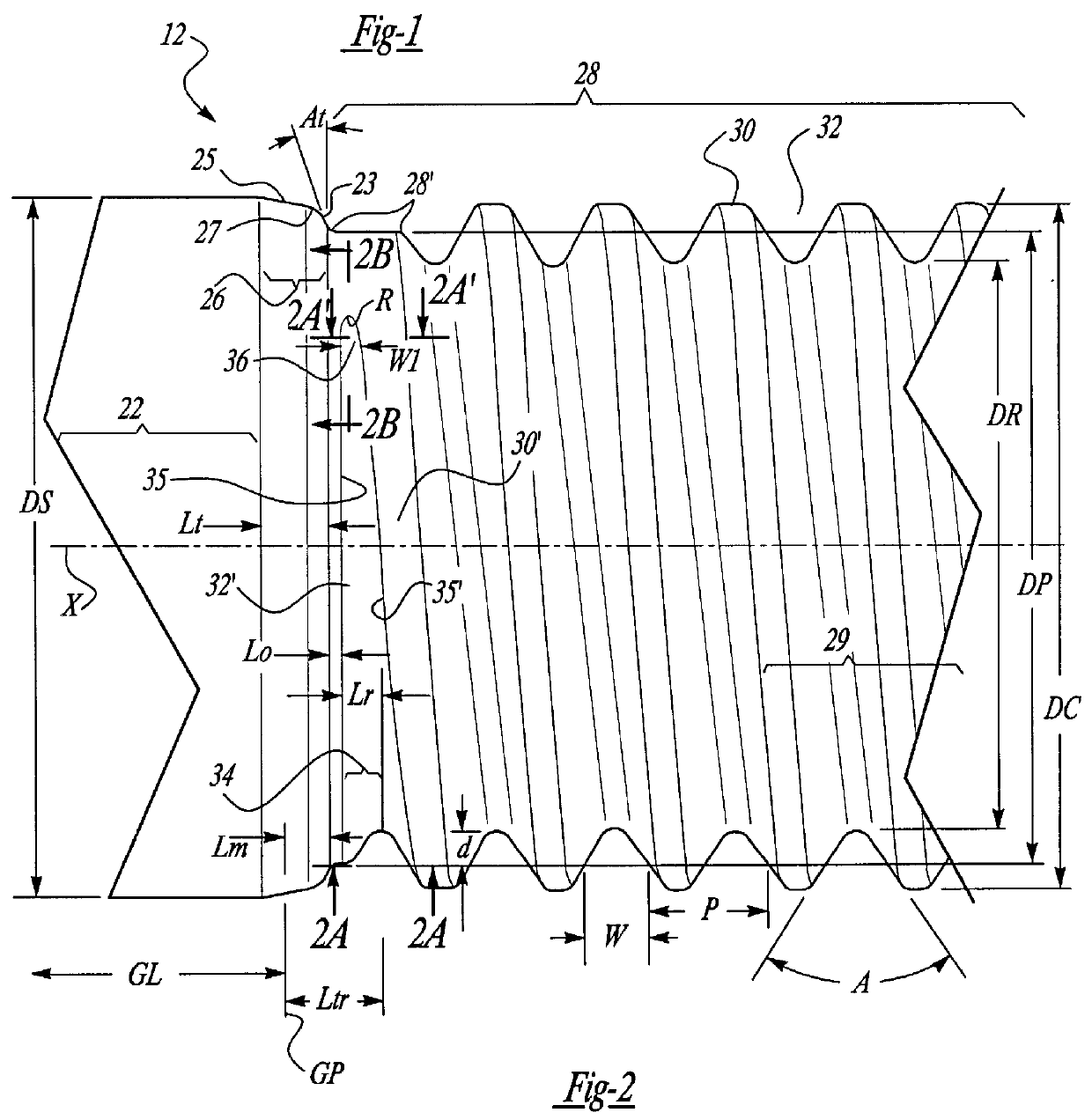

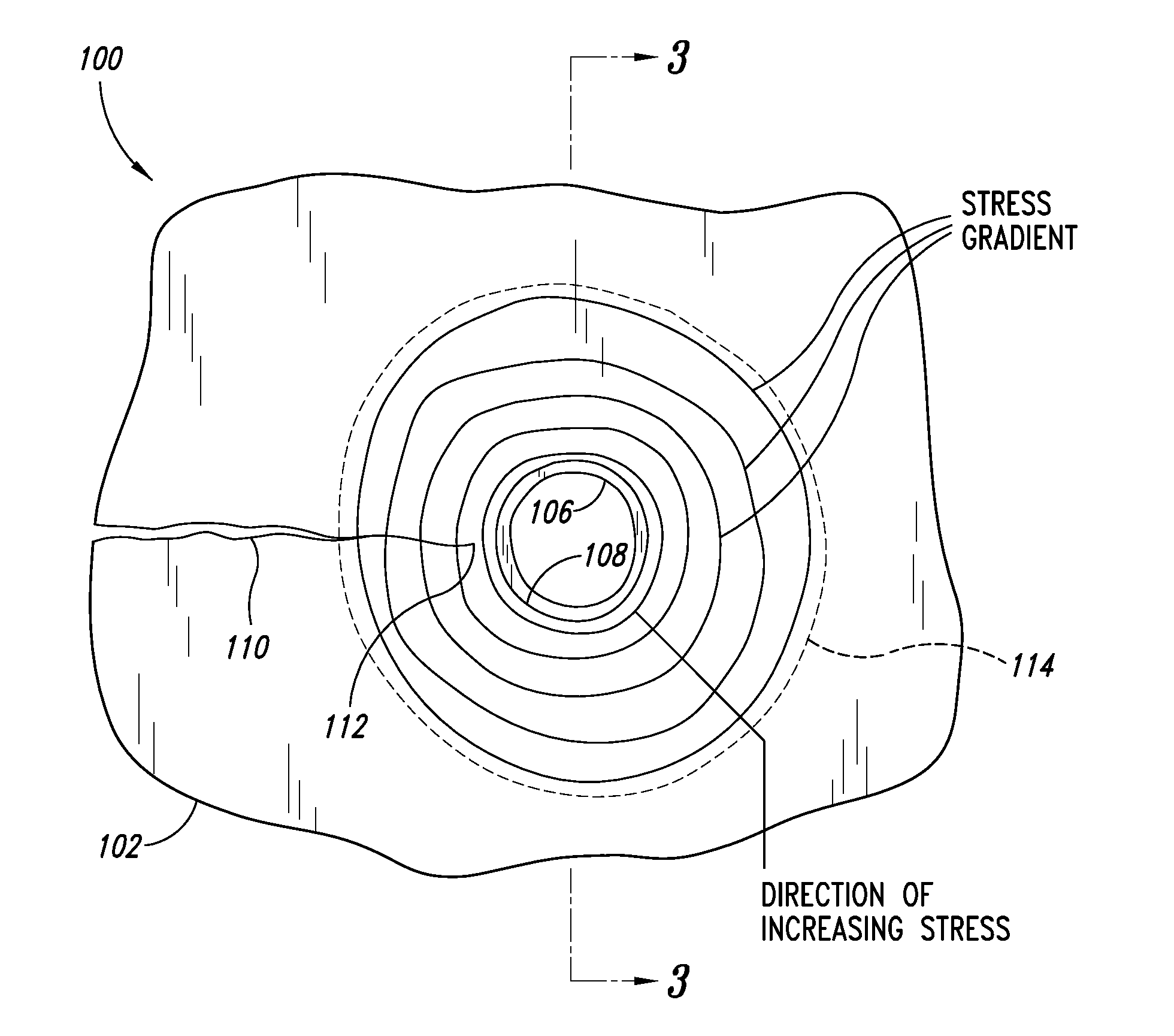

Expandable crack inhibitors and methods of using the same

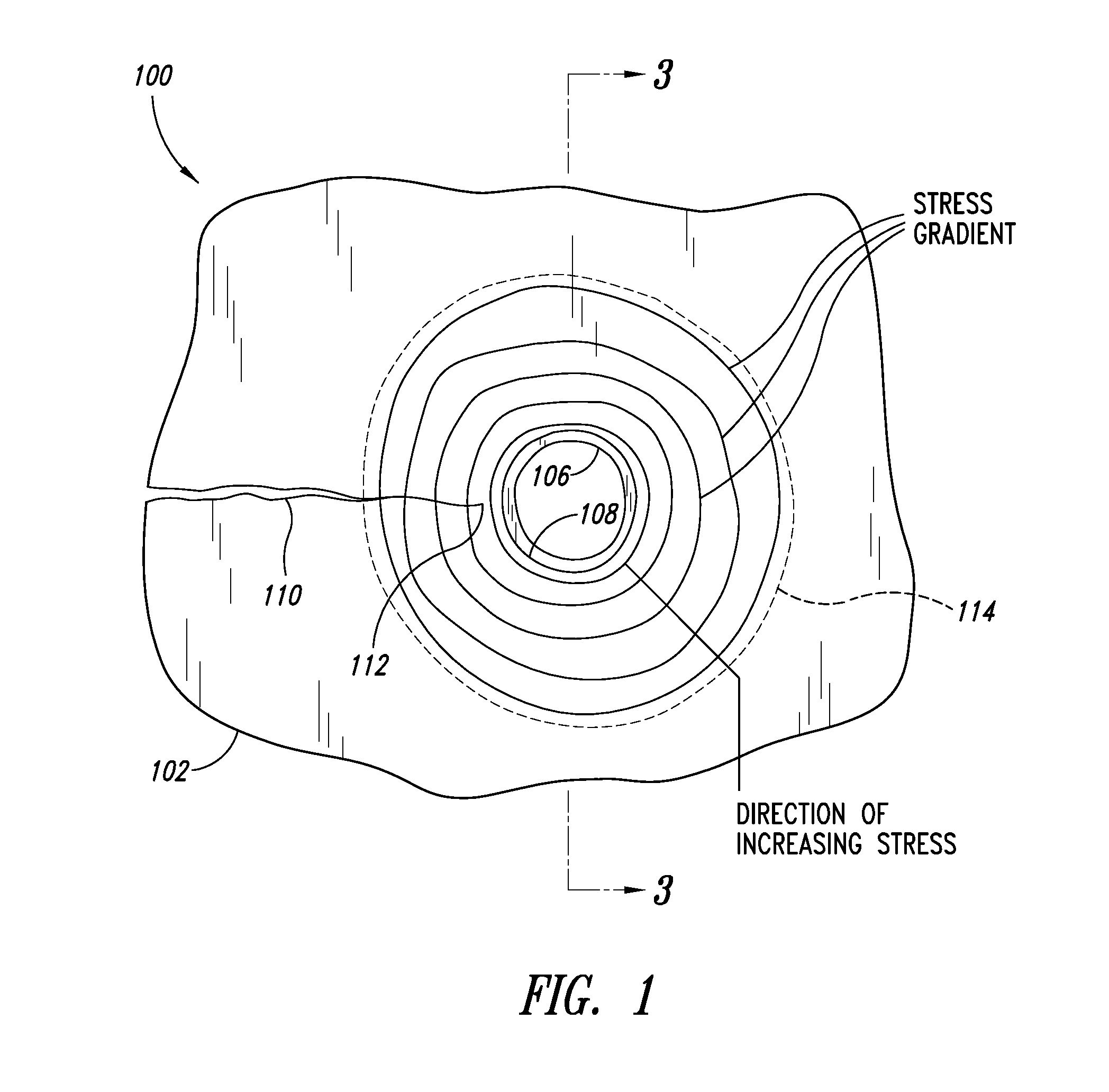

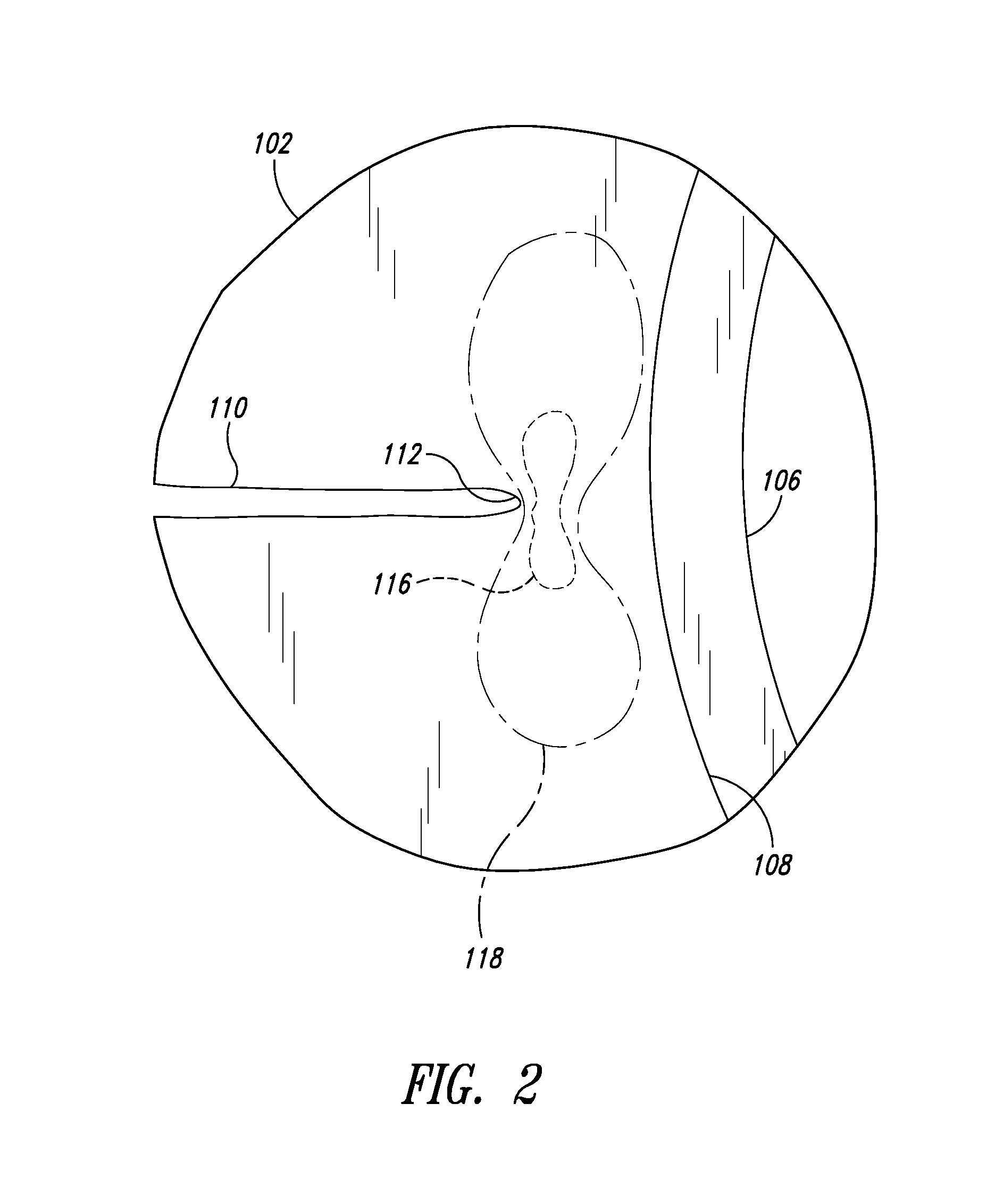

ActiveUS20120304577A1Extended service lifeImprove fatigue performanceBuilding repairsFoundation repairInterference fitEngineering

One or more crack inhibitors can be installed to improve fatigue performance by producing stress states that prevent or inhibit crack initiation. Crack inhibitors can also prevent or retard crack growth. A mandrel can be used to radially expand the crack inhibitors to both induce compressive residual stresses and to form an interference fit between the crack inhibitor and a workpiece. The mandrel can be removed from the installed crack inhibitor, which is left in the workpiece to ensure proper stress states are maintained.

Owner:FATIGUE TECH

Low rigidity, low compression permanent deformation cold tolerant butadiene nitrile rubber compositions

The invention provides a permanent deformation cold resistance nitrile-butadiene rubber composition with low hardness and low compression, which contains nitrile-butadiene rubber, peroxides and auxiliary crosslinking agents; wherein, the auxiliary crosslinking agents are selected from one or a plurality of 1, 3-(citraconic maleimide methyl) benzene, meta phenylene bis maleimide, triallyl cyanurate and triallyl isocyanurate. The nitrile-butadiene rubber which is prepared by the nitrile-butadiene rubber composition has the advantages that peroxide curing system containing the auxiliary crosslinking agents of the invention can improve the cold resistance and has small compression permanent deformation; at the same time, the tensile strength and the elongation at break are large, and the fatigability is good. The advantages are not possessed by the curing systems that singly use peroxides and the combination of the peroxide sulphur and other auxiliary crosslinking agents.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +1

Hot-rolled H-shaped steel, and application and production method thereof

The invention relates to a hot-rolled H-shaped steel, and application and a production method thereof. The hot-rolled H-shaped steel contains the following components in percentage by weight: 0.08-0.18% of C, 0.20-0.45% of Si, 1.00-1.65% of Mn, 0.005-0.035% of P, at most 0.025% of S, at most 0.10% of V, less than 0.070% of Nb, less than 0.025% of Ti, and the balance of iron and inevitable impurities. The hot-rolled H-shaped steel can be used for semitrailer girders. According to the production method of the hot-rolled H-shaped steel for semitrailer girders comprises, a selective cooling process is adopted after the hot rolling of the H-shaped steel, thereby uniformly cooling the H-shaped steel with higher temperature to a proper temperature within a short time; and the cooling process lowers the waves at the wing edge and web plate due to the nonuniform temperature of the rolled piece. According to the production method, the hot-rolled H-shaped steel with the specification of 491*146*7*11.5 and the yield strength of 345-500 MPa, which is produced under the reasonable control on the production technique, substitutes the welded H-shaped steel and enhances the all-day fatigue property and safety of the semitrailer.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

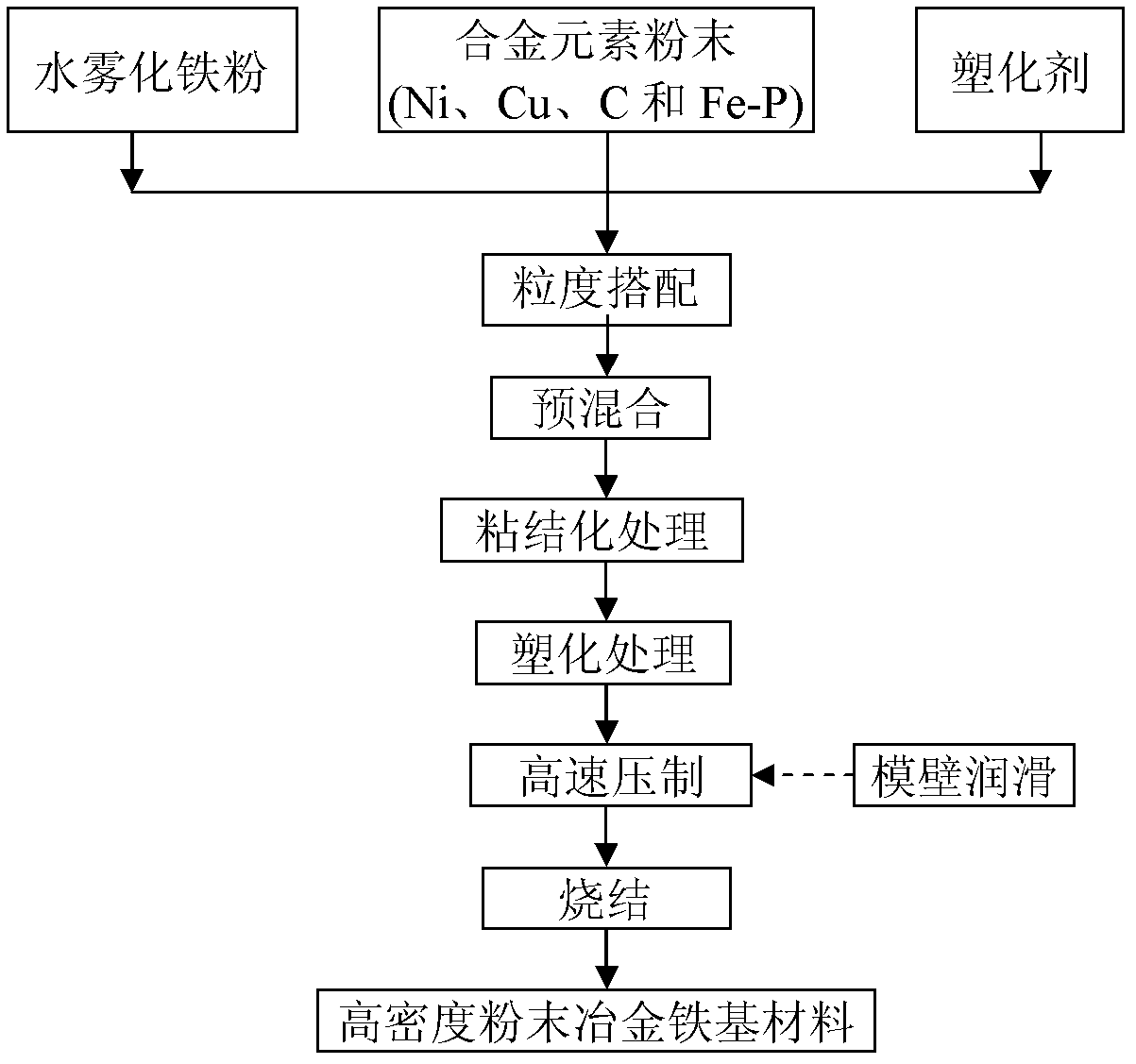

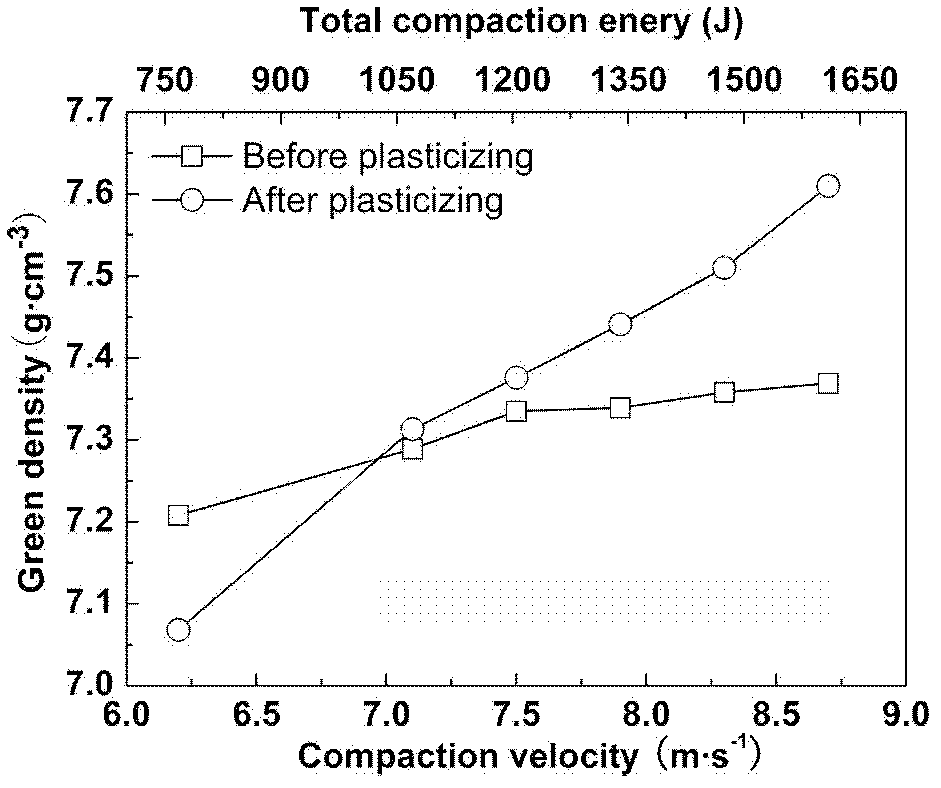

Method for forming bonded iron-based powder by high velocity compaction technology

Owner:YANGZHOUSSHINE POWDER METALLURGY

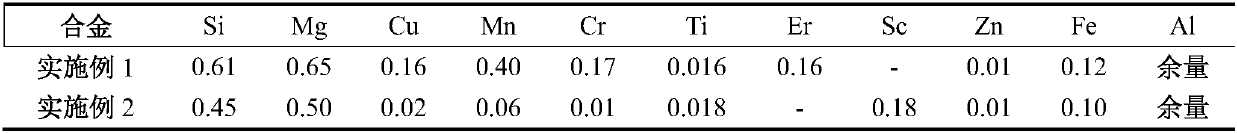

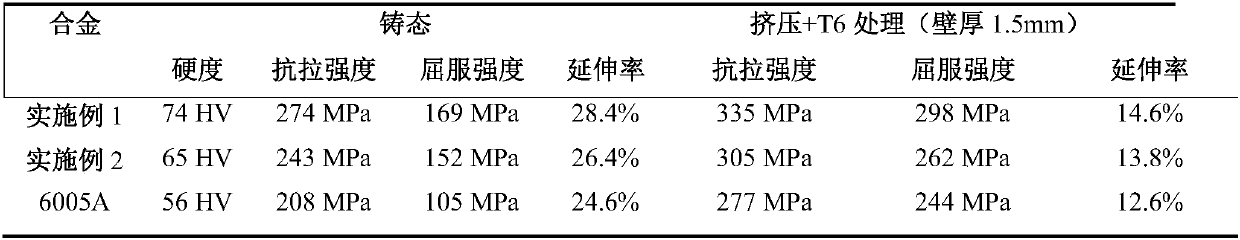

High performance Al-Mg-Si aluminum alloy extrusion material and preparation method thereof

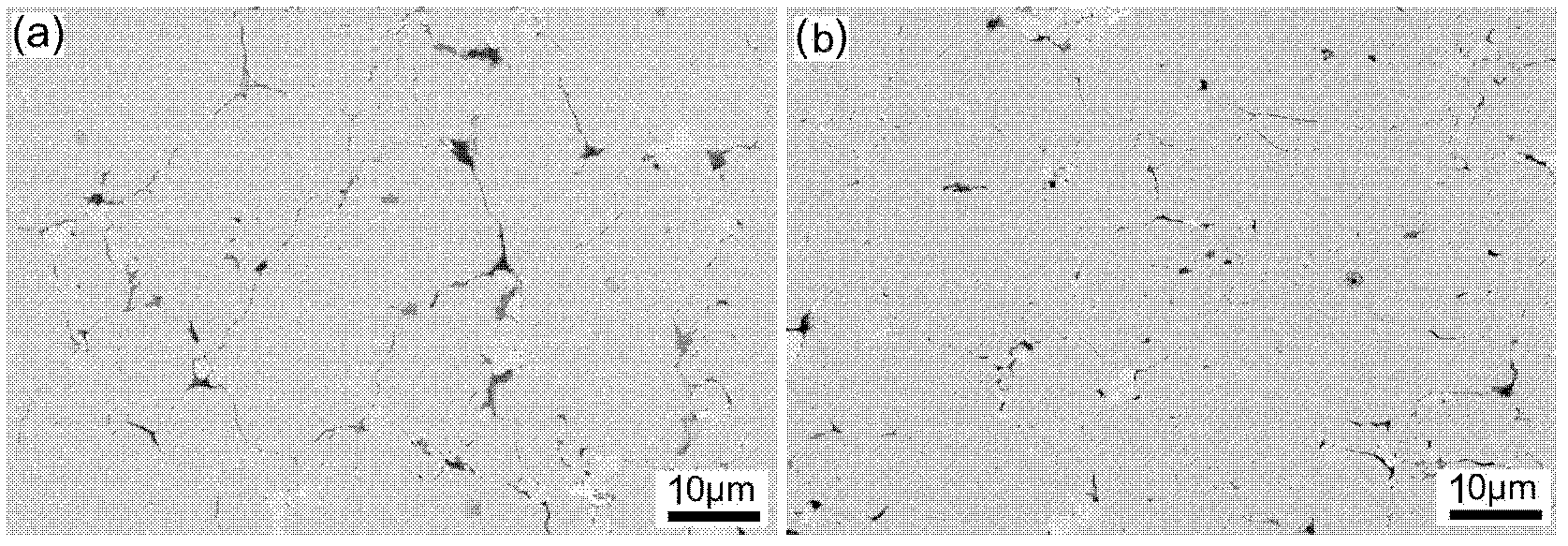

ActiveCN110669964AImprove performanceStrong precipitation strengtheningRare-earth elementSingle element

The invention belongs to the technical field of aluminum alloy materials, and relates to a high performance Al-Mg-Si aluminum alloy extrusion material and a preparation method thereof. The high performance Al-Mg-Si aluminum alloy extrusion material is prepared from the following element components in percent by weight: 0.4-0.7% of Si, 0.5-0.7% of Mg, 0.01-0.2% of Cu, 0.05-0.45% of Mn, 0.01-0.3% ofCr, 0.01-0.02% of Ti, 0.05-0.30% of rare earth elements, less than or equal to 0.1% of Zn, less than or equal to 0.15% of Fe and the balance Al, wherein the content of single elements is less than orequal to 0.05%, the total content of impurities is less than or equal to 0.15%, and any one or two of the rare earth elements Er and Sc are mixed. The preparation method can optimize the alloy components obviously, balance and refine crystal grains, purify and clean a melt, reduce the casting flaws and improve the quality of a cast ingot greatly. In addition, the surface quality of an extruded profile can be better improved, and the extrusion speed and the thermal treatment comprehensive mechanical property of the extruded profile product are improved.

Owner:CHINA ZHONGWANG

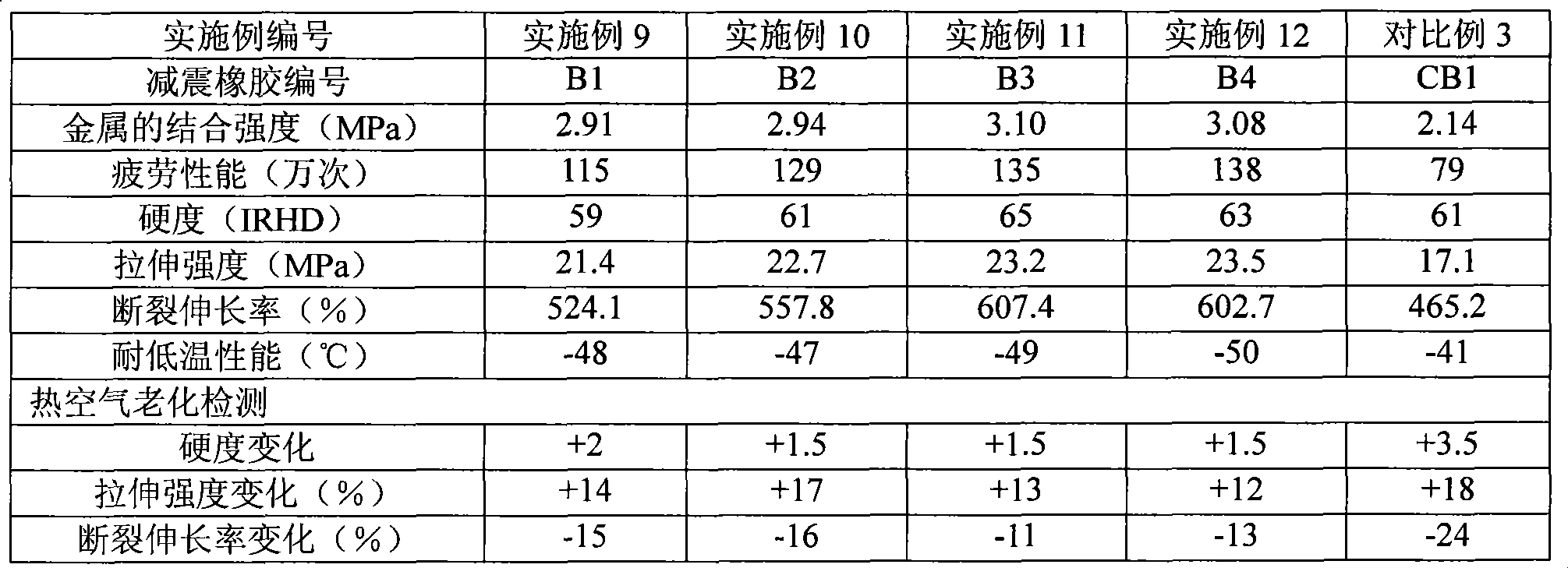

Composition for cushion rubber, preparation method thereof and cushion rubber

The invention provides a composition for damping rubber. The composition comprises rubber, a plasticizer, a vulcanizing agent, an accelerator, an antioxidant, an activating agent, a filler and a softener, wherein the rubber is natural rubber and cis-butadiene rubber; the vulcanizing agent comprises curing resin and sulfur; and the weight ratio of the curing resin to the sulfur is between 1:0.1-10. The invention also provides a method for preparing the composition for damping rubber and the damping rubber obtained through vulcanization of the composition. The composition for damping rubber can remarkably improve fatigue performance and mechanical strength of the damping rubber and can meet the requirement of vehicle damping.

Owner:BYD CO LTD

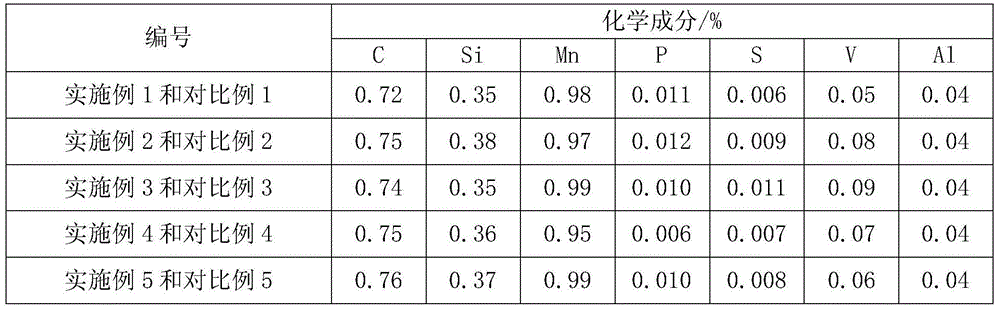

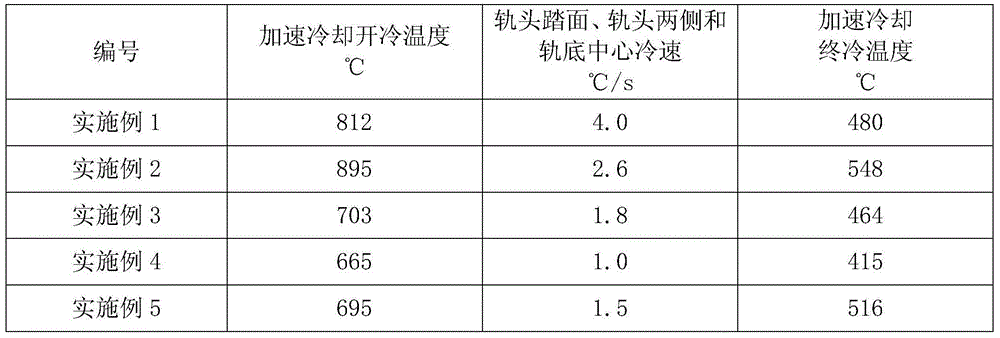

High-impact-toughness steel rail and production method thereof

ActiveCN104480390AGood toughness matchImprove fatigue performanceFurnace typesQuenching agentsChemical compositionRolling contact fatigue

The invention relates to a high-impact-toughness steel rail and a production method of the high-impact-toughness steel rail, and belongs to the field of steel rail material production technologies. The technical aim of providing the high-impact-toughness steel rail is achieved. The high-impact-toughness steel rail is a pearlite steel rail, the interlamellar spacing ranges from 0.05 micron to 0.09 micron, and normal temperature ballistic work ranges from 30 J to 35 J. The steel rail comprises the chemical components: 0.71-0.82 percent of C, 0.25-0.45 percent of Si, 0.75-1.05 percent of Mn, 0.03-0.15 percent of V, no more than 0.030 percent of P, no more than 0.035 percent of S, no more than 0.020 percent of Al and the balance Fe and unavoidable impurities. The rail head U-type impact toughness of the steel rail manufactured through the method can be more than 30 J, tensile strength is larger than 1.300 MPa, the steel rail has good strength and toughness matching, the rolling contact fatigue property and wear-resisting property in the use process are good, and the high-impact-toughness steel rail is suitable for being used as steel rails for railways in high and cold areas.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

600 MPa-level thick-specification hot rolling spoke steel and manufacturing method thereof

The invention provides 600 MPa-level thick-specification hot rolling spoke steel and a manufacturing method thereof. The spoke steel comprises the following chemical constituents in mass percent: 0.06-0.12% of C, 0.20-0.60% of Si, 0.80-1.20% of Mn, 0.02-0.06% of Alt, 0.50-1.00% of Cr, 0.03-0.08% of P, smaller than or equal to 0.005% of S, smaller than or equal to 0.006% of N, and the balance of Fe and inevitable impurities. In the manufacturing method of the spoke steel, the billet heating temperature is 1,150-1,250 DEG C, and the finish rolling temperature is 760-840 DEG C; after rolling, a conventional cooling technology is used to cool the steel at a cooling rate of 20-100 DEG C per second to 350 DEG C below, and then the steel is reeled. The steel plate is good in processability and fatigue performance, and free of Nb, V, Mo, Ni and other elements, so as to save the production cost. The steel plate provided by the invention can be widely applied to the spoke production of steel wheels of commercial vehicles.

Owner:SHANDONG IRON & STEEL CO LTD

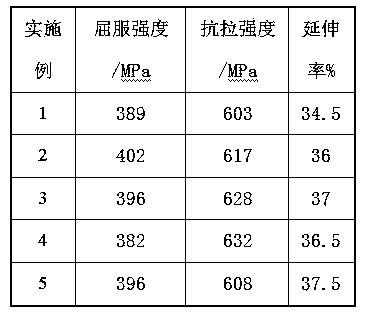

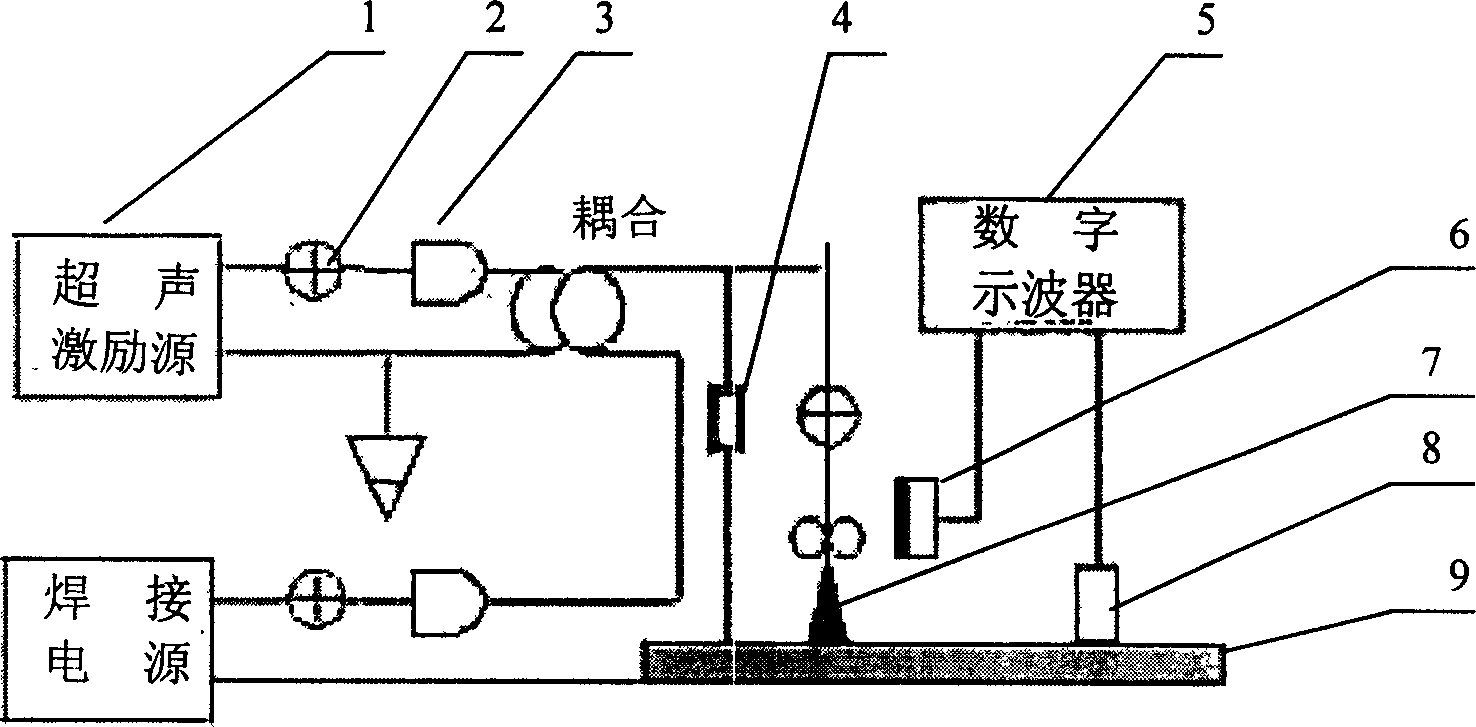

Titanium alloy welding method based on arc ultrasonic process

InactiveCN1583340APromote crystallizationGrain refinementArc welding apparatusNon-electric welding apparatusUltrasound - actionUltrasonic welding

An arc-ultrasonic welding method for Ti alloy features that an arc-ultrasonic exciting source using electric arc as heat generater and ultrasonic emitter is parallelly connected with the conventional power supply used for arc welding. The ultrasonic waves can act on the molten bath on the workpiece to be welded to improve the smelting and crystallizing procedure of Ti alloy for finer crystal grains and higher welding strength and fatigue resistance.

Owner:TSINGHUA UNIV

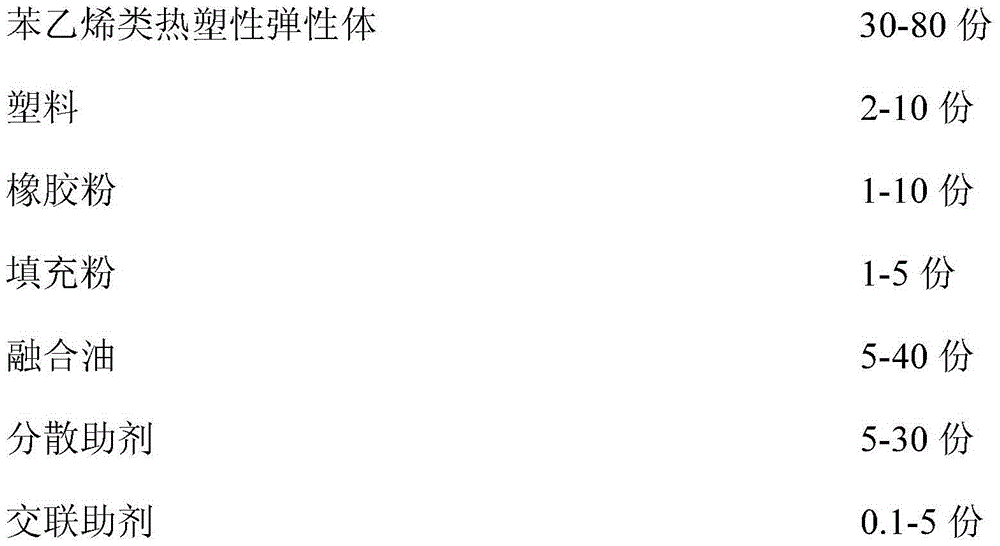

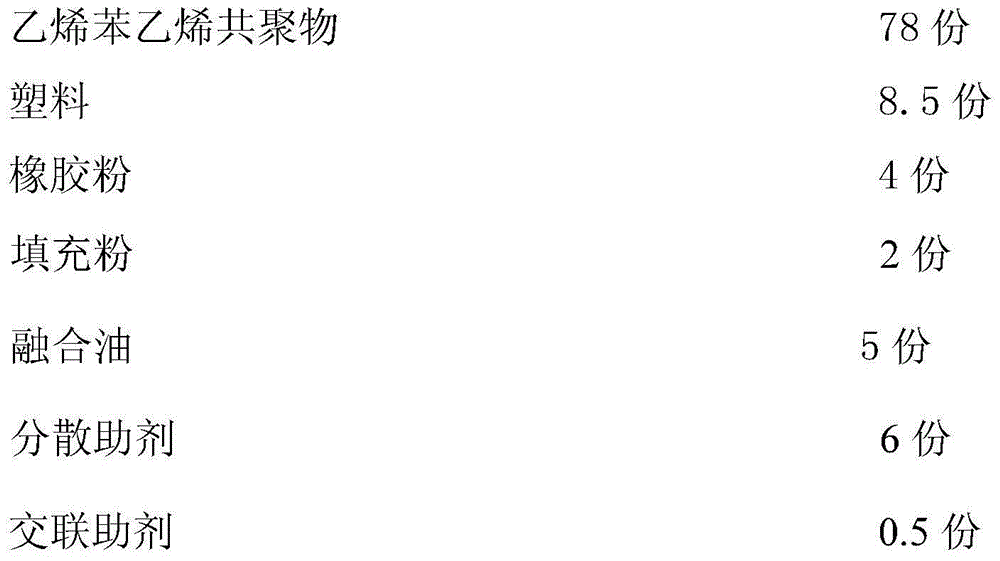

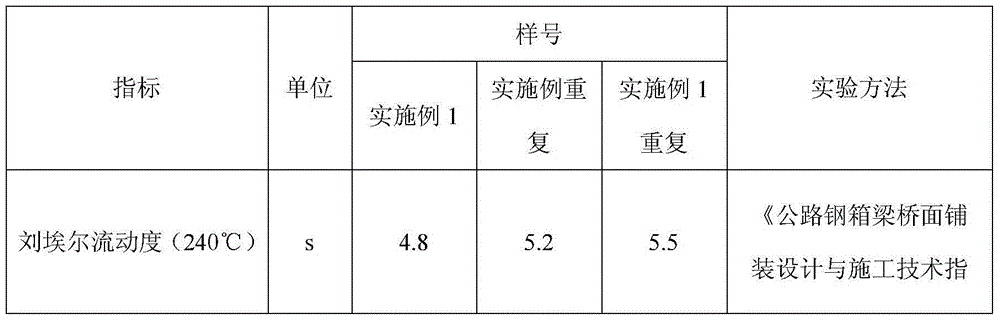

Direct vat set modifier of cast asphalt mixture and preparation method

InactiveCN103980650AImprove performanceLess production equipmentBuilding insulationsUltrasound attenuationThermoplastic elastomer

The invention discloses a direct vat set modifier of a cast asphalt mixture and is characterized in that the modifier is composed of the following components, by weight, 30-80 parts of a styrenic thermoplastic elastomer, 10-20 parts of plastic, 1-10 parts of rubber powder, 1-5 parts of a packing powder, 5-40 parts of fuser oil, 5-30 parts of a dispersing auxiliary agent and 0.1-5 parts of a crosslinking auxiliary agent. The invention also discloses a preparation method of the modifier and an asphalt mixture prepared from the modifier. The material can be directly put into a mixing plant cylinder to produce modified asphalt concrete. The produced asphalt concrete completely satisfies engineering needs. In comparison with a traditional SBS modification process, the method provided the invention has the following advantages: the step of producing modified asphalt in a traditional method is saved; production equipment of modified asphalt is save; there is no need in hot storage of modified asphalt; performance attenuation and separation of modified asphalt under hot storage condition are avoided; and positive contributions are made to low temperature and fatigue performance of the asphalt mixture.

Owner:CHONGQING SINO CANADA ASPHALT TECHN SERVICE

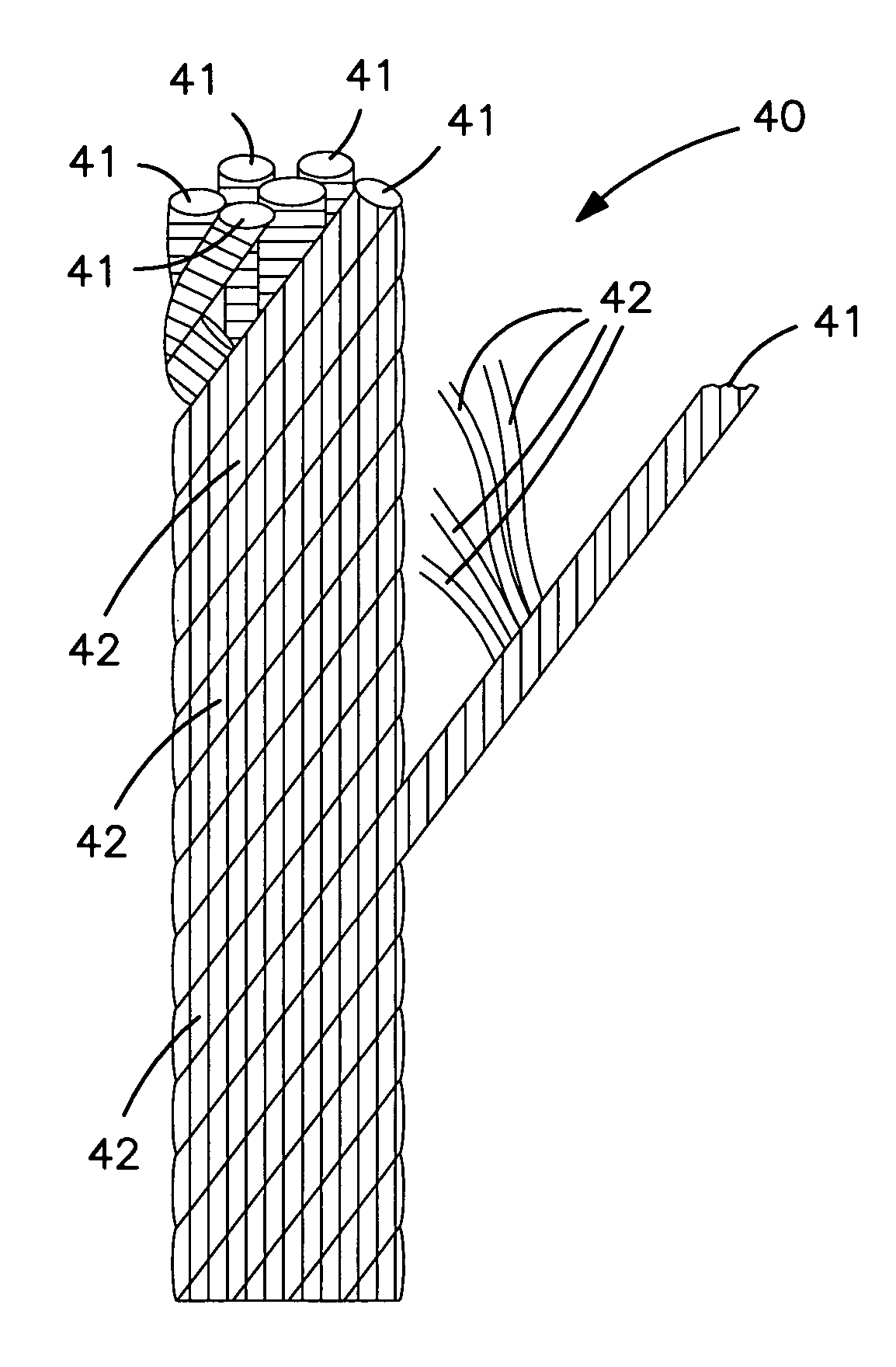

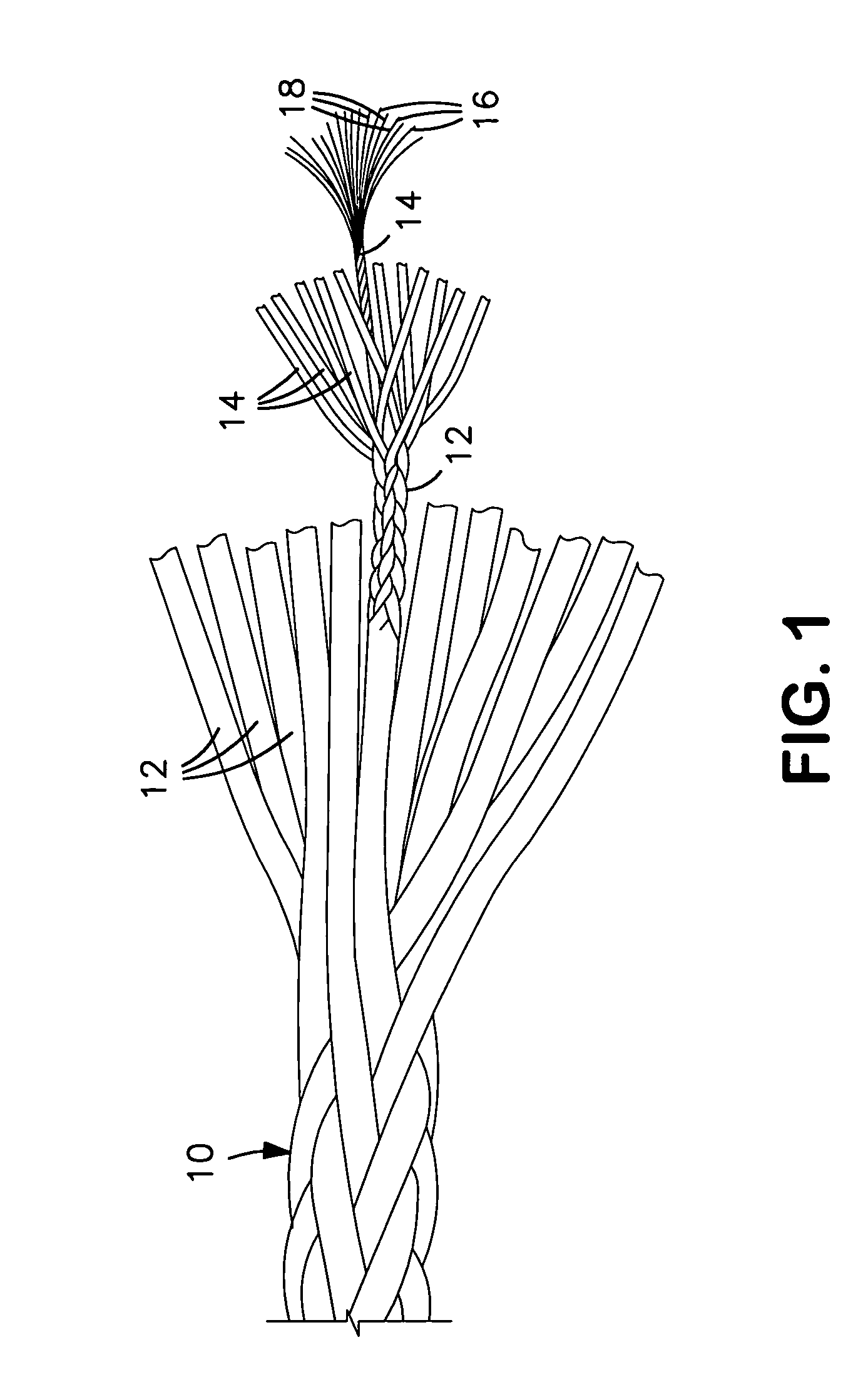

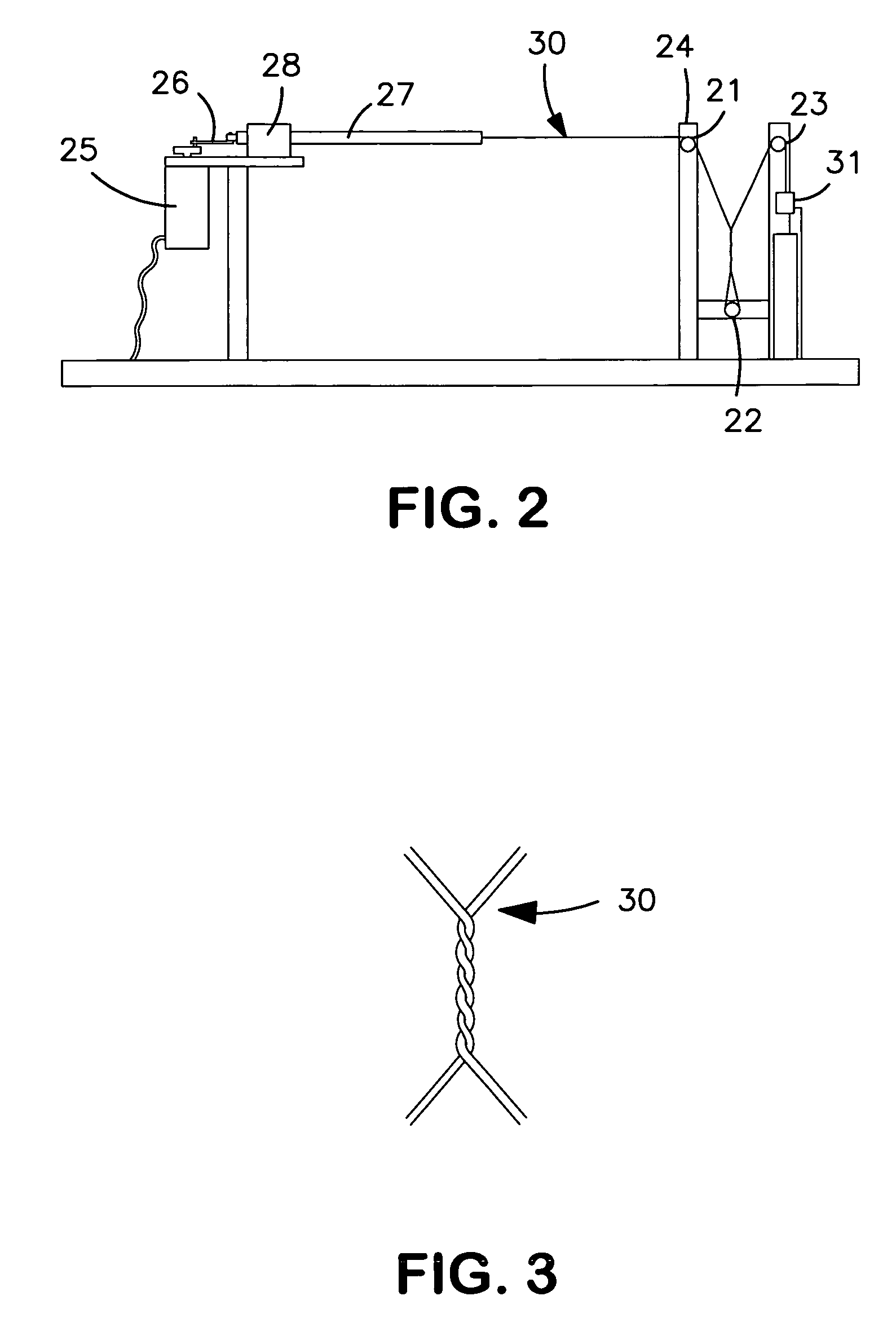

Fluoropolymer fiber composite bundle

ActiveUS7296394B2Reduce abrasionReduce wearRope making machinesWoven fabricsFiberStructural engineering

A rope comprising a plurality of bundle groups, each of said bundle groups having a periphery and comprising a plurality of high strength fibers, at least one low coefficient of friction fiber disposed around at least a portion of the periphery of at least one of the bundle groups.

Owner:WL GORE & ASSOC INC

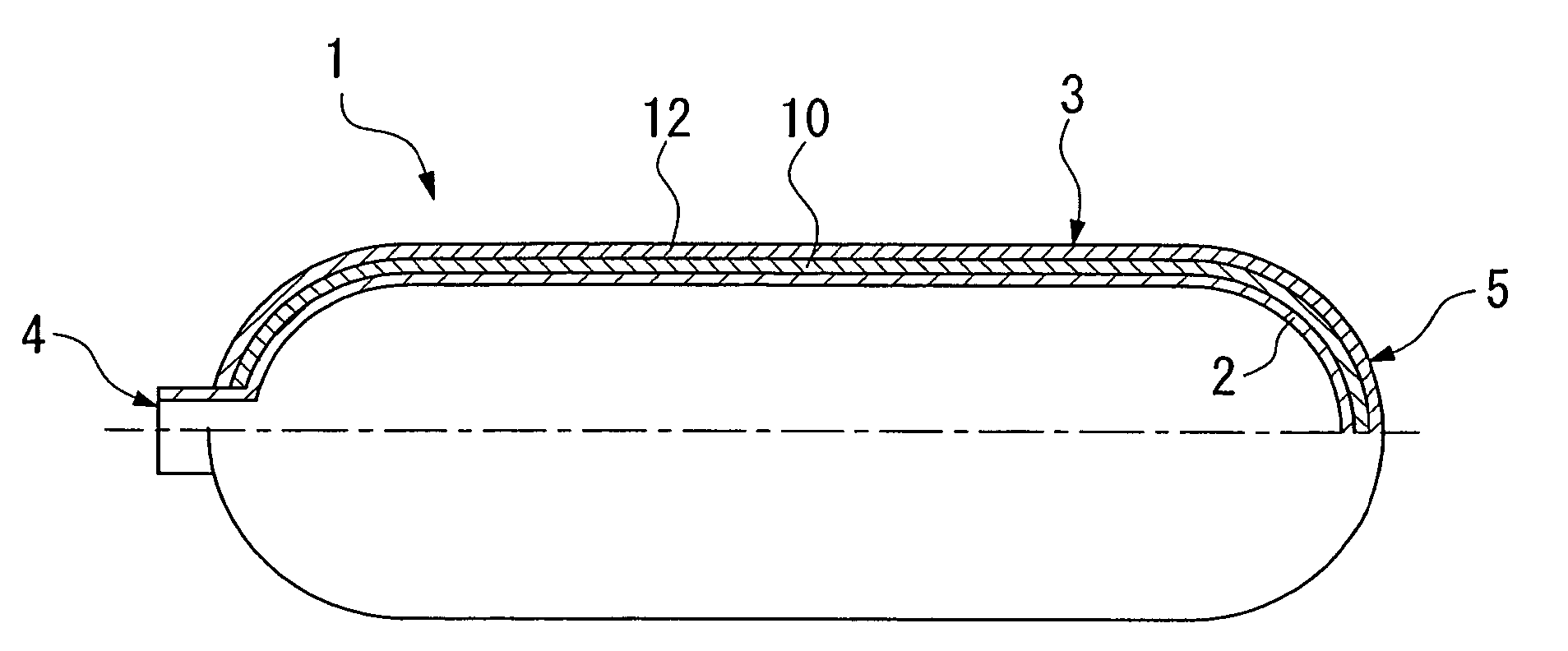

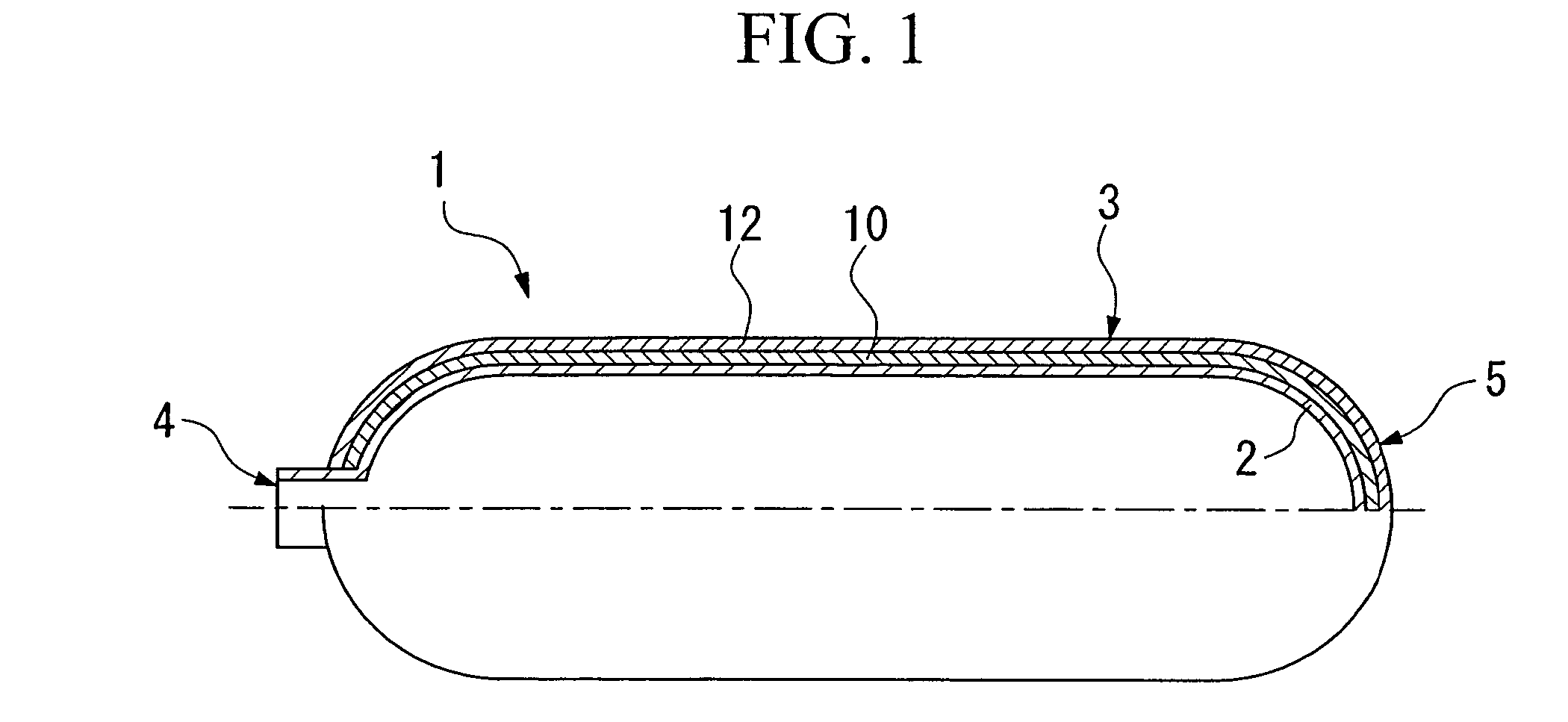

High-performance pressure vessel and carbon fiber for pressure vessel

ActiveUS20060163261A1Excellent fatigue propertyImprove fatigueLayered productsFibre chemical featuresElastic modulusFibre reinforcement

A pressure vessel includes a vessel body and a fiber reinforced plastic layer formed on the surface of the vessel body, wherein the fiber reinforced plastic layer include fiber reinforced plastic in which reinforcing fibers are impregnated with plastic, a strand elastic modulus of the reinforcing fiber is 305 GPa or higher, and a tensile elongation of the reinforcing fiber is 1.45 to 1.70%. A carbon fiber for a pressure vessel has a strand elastic modulus of 305 GPa or higher and a tensile elongation of 1.45 to 1.70%.

Owner:MITSUBISHI CHEM CORP

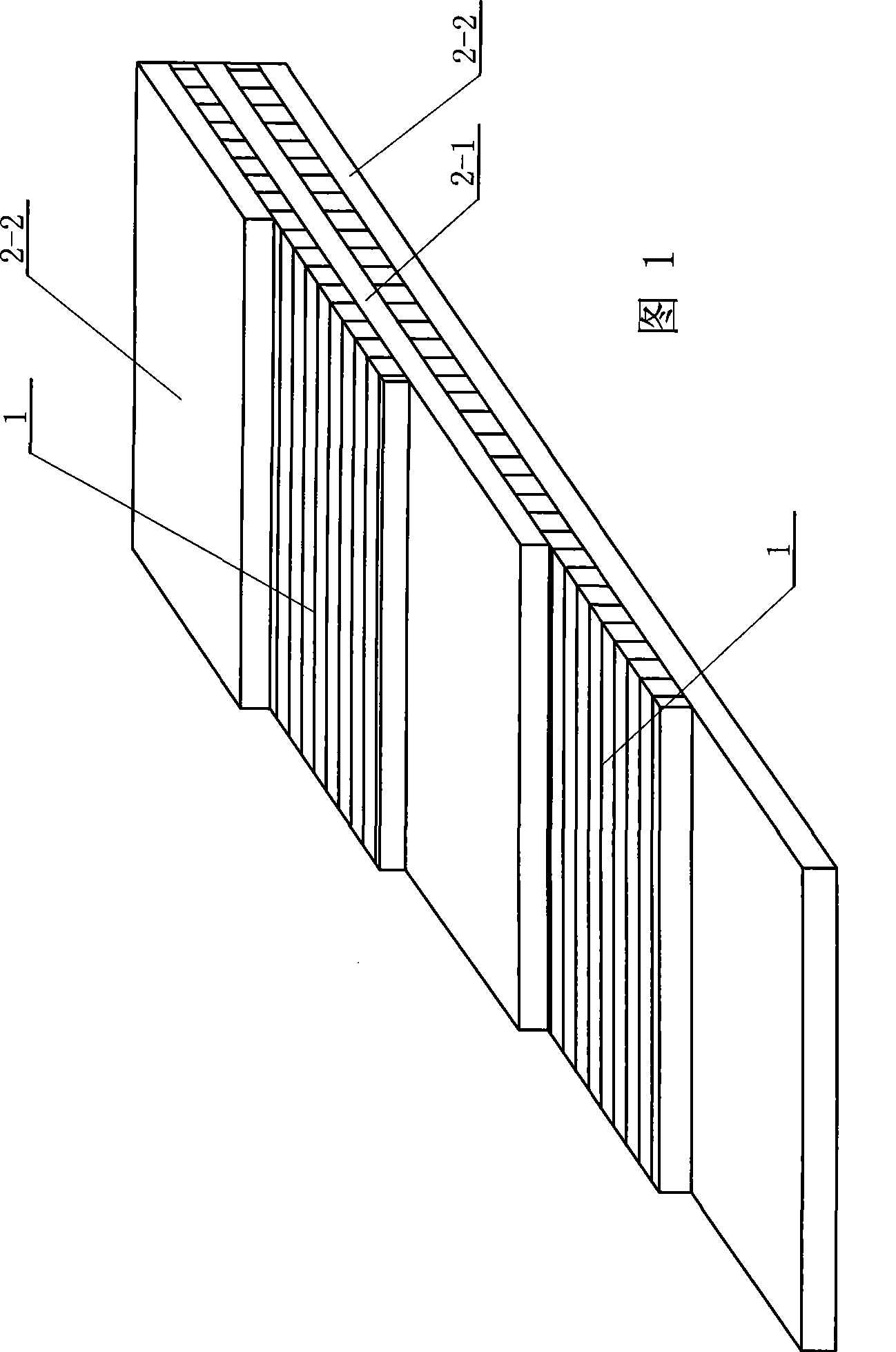

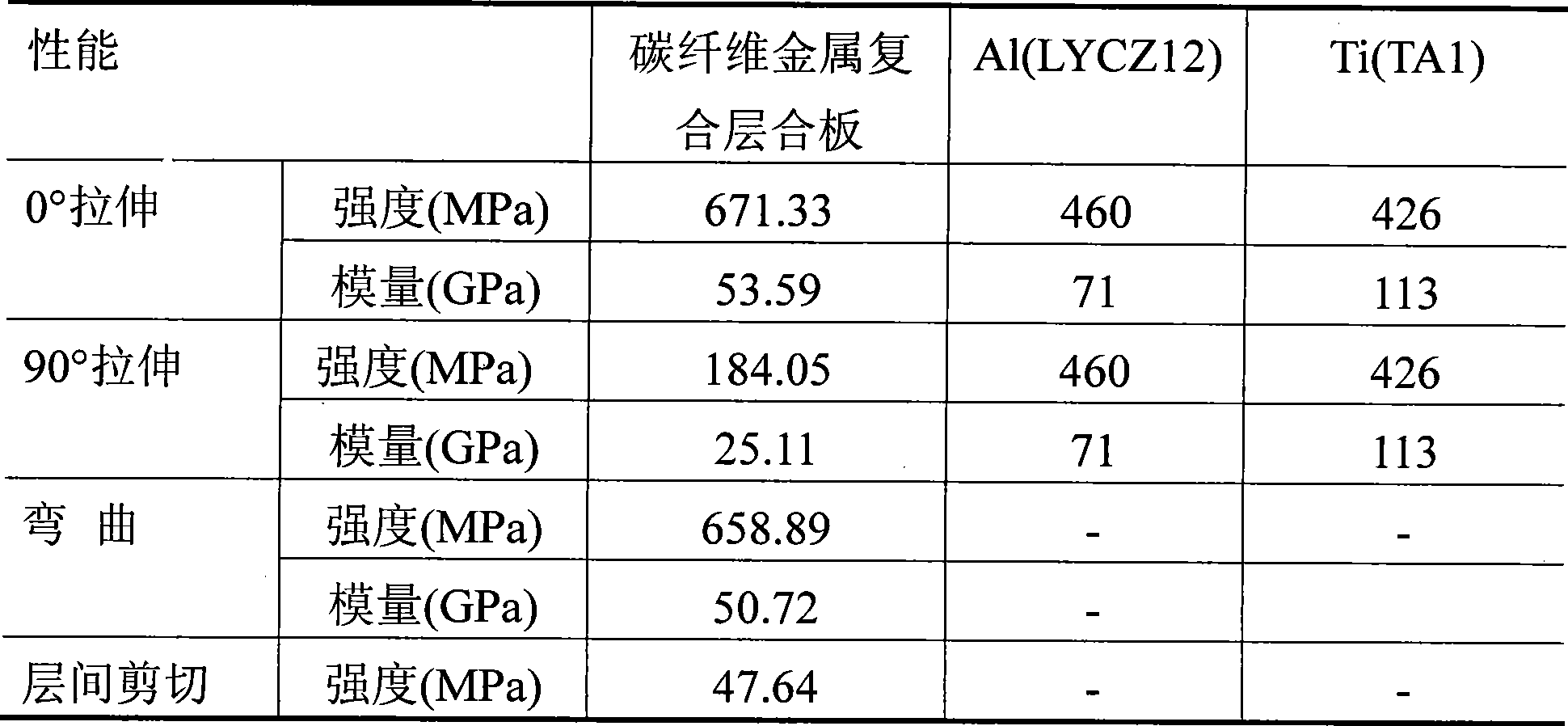

Manufacture method of carbon fiber metal composite laminated plate

InactiveCN101417524AFlame retardantImpact resistantLamination ancillary operationsLaminationFiberEpoxy

A manufacturing method of a carbon fiber metal composite laminated plate relates to a manufacturing method of a fiber metal composite laminated plate. The method aims at solving the problems that no manufacturing methods for manufacturing aircraft structural material with high specific stiffness, high specific strength, tenacity and workability exist in China. The method comprises the following steps of: carrying out surface treatment to three pieces of metal plates; winding a carbon fiber composite material layer which is soaked in liquid cement on one of the metal plates, wherein, the liquid cement is prepared by epoxy resin, a metaphenylene diamine curing agent and an anhydrous alcohol solvent according to the mass ratio of 1:0.1 to 0.18:0.15 to 0.2; fixedly arranging another two metal plates on the upper surface and the lower surface of the carbon fiber composite material layer so as to be integrally put into a mould, and then treated with mould assembling, drying, solidification by adopting the method of gradient temperature increasing, and demoulding. The manufacturing method of the invention is simple and is easy for operation. The carbon fiber metal composite laminated plate manufactured by the method of the invention has the advantages of high specific stiffness, high specific strength, also high tenacity and workability of metal material, good fatigue property, and good damage tolerance capability.

Owner:HARBIN INST OF TECH

High-performance elastic copper alloy and preparation and processing method thereof

The invention relates to high-performance elastic copper alloy and a preparation and processing method thereof. According to the weight percentage, the high-performance elastic copper alloy comprises the basic components as follows: 1 to 4 percent of Ni, 0.4 to 1 percent of Si, 0.5 to 1.5 percent of Co, and the rest percent of Cu, wherein the components in a copper alloy product need to satisfy the conditions as follows: (a) the content of Ni or Si is larger than or equal to 2.5 percent and smaller than or equal to 5 percent; (b) the content of Ni plus Si is larger than or equal to 1.4 percent and smaller than or equal to 4.0 percent; (c) the content of Ni plus Co is larger than or equal to 1.5 percent and smaller than or equal to 4 percent; and (d) the content of Ni plus Si or the content of C is larger than or equal to 1 percent and smaller than or equal to 5.0 percent. The preparation and processing method of the high-performance elastic copper alloy comprises the step: a, material burdening, material feeding, melting and casting which are conducted according to the weight percent; b, surface milling; c, hot rolling; d, solid solution treatment; e, cold processing; f, primary aging; g, cold processing; h, secondary ageing; i, pickling; and j, finished product annealing. The tensile strength Sigma b of the copper alloy is 780 to 950MPa, the plastic elongation rate Delta of the copper alloy is 4 to 10 percent, and the electric conductivity of the copper alloy is 35 to 55 percent according to an international annealed copper standard (IACS). The copper alloy has the advantages of high elasticity, high strength, high fatigability, good heat resistance and high electric conductivity.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Intravascular stent of composite structure

The invention discloses an intravascular stent of a composite structure; the intravascular stent comprises a stent main body, wherein the distal end of the stent is restrained as an adducted form by virtue of a tightening wire, and the tightening wire is degradable magnesium alloy or degradable iron alloy; one or more auxiliary wires are woven on the stent main body; when the stent is applied to blood vessel of brain, the auxiliary wire is pure platinum or alloy thereof, pure gold or alloy thereof, pure tungsten or alloy thereof, or pure tantalum or alloy thereof; and when the stent is applied to peripheral blood vessel, the auxiliary wire is cobalt-chromium alloy or stainless steel or tungsten or tantalum. The stent, when serving as a thrombus removal system for treating cerebral apoplexy, not only can be used for removing thrombus effectively for several times but also can be used for catching small thrombus flowing to distal end so as to prevent distal blood vessels from getting blocked; and the stent can be used for dilating stenosis or blocked brain blood vessel or peripheral blood vessel, so as to take an effect of dredging and reconstructing a blood flow. The stent can be repositioned and released, with high controllability; and the stent can be used for reducing operation difficulty and greatly improving an operation success rate.

Owner:魏诗荣 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com