Patents

Literature

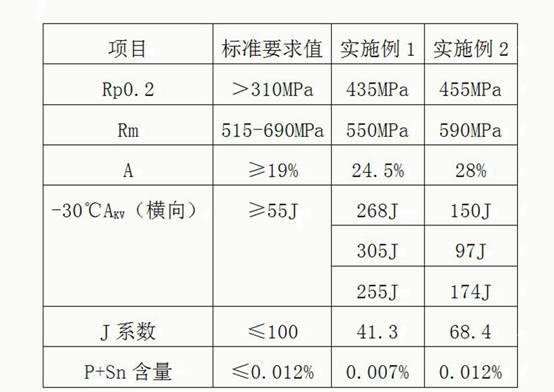

255results about How to "Good toughness match" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High strength steel plate for big thickness tall building structure and production method thereof

InactiveCN101323929AIncrease thickness specificationLow yield ratioMolten metal pouring equipmentsRoll mill control devicesSheet steelChemical composition

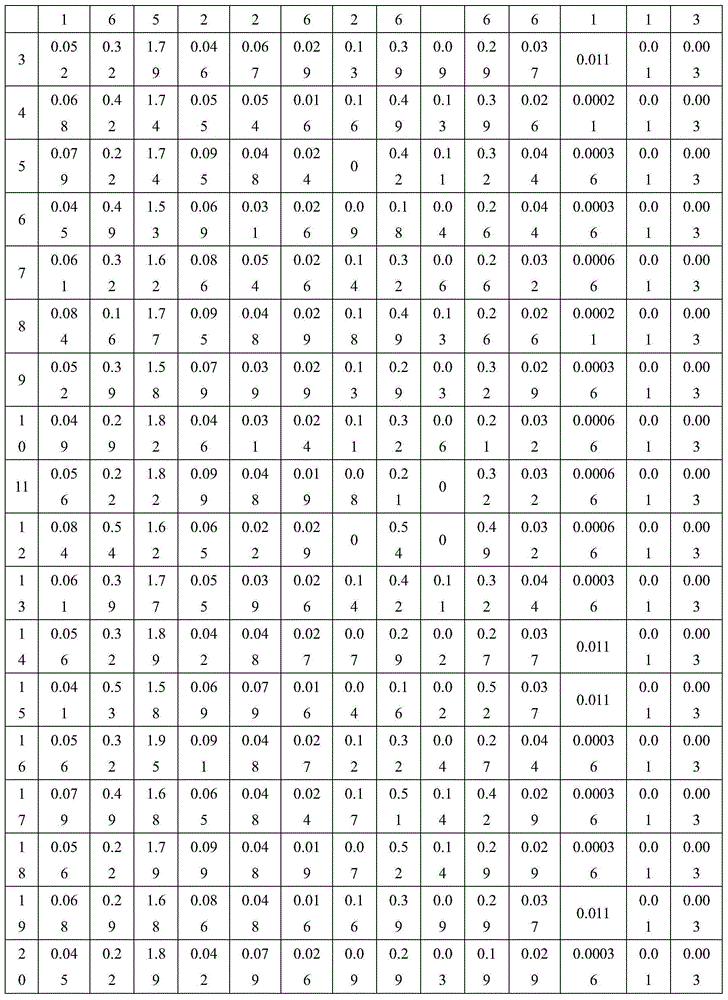

The invention relates to a steel plate with high intensity and used in construction structures of high buildings with large thickness and a production method thereof. The steel plate of the invention consists of the following components according to weight percentage: less than or equal to 0.20 percent of C, less than or equal to 0.55 percent of Si, 1.00 to 1.70 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, less than or equal to 0.70 percent of Ni, less than or equal to 0.70 percent of Cr, less than or equal to 0.20 percent of V, more than or equal to 0.015 percent of Nb, less than or equal to 0.20 percent of Ti, 0.020 to 0.060 percent of Al, and the rest is Fe and inevitable impurity. The produced Q460E-Z35 steel plate with a thickness of 100 to 110 mm is capable of meeting the requirement of high intensity steel of large-thickness construction structure (Ceq is less than or equal to 0.50 percent); the steel plate of the invention can be applied to constructing the structure of high building, has good performance of welding and anti-layer tearing, can meet the requirement of on-site key stress points, has simple production process and is capable of realizing bulk production. The high intensity steel plate of the invention has the following advantages that (1) the steel quality of the invention is purer with less than or equal to 0.025 percent of P and less than or equal to 0.010 percent of S; (2) yield ratio of the invention is relatively low and less than 0.78 actually; (3) the anti-layer tearing performance is good, and Z is larger than or equal to 35 percent in whole thickness direction; (4) low-temperature toughness at the temperature of minus 40 DEG C is good; (5) maximum thickness of the steel plate can reach 110mm.

Owner:WUYANG IRON & STEEL

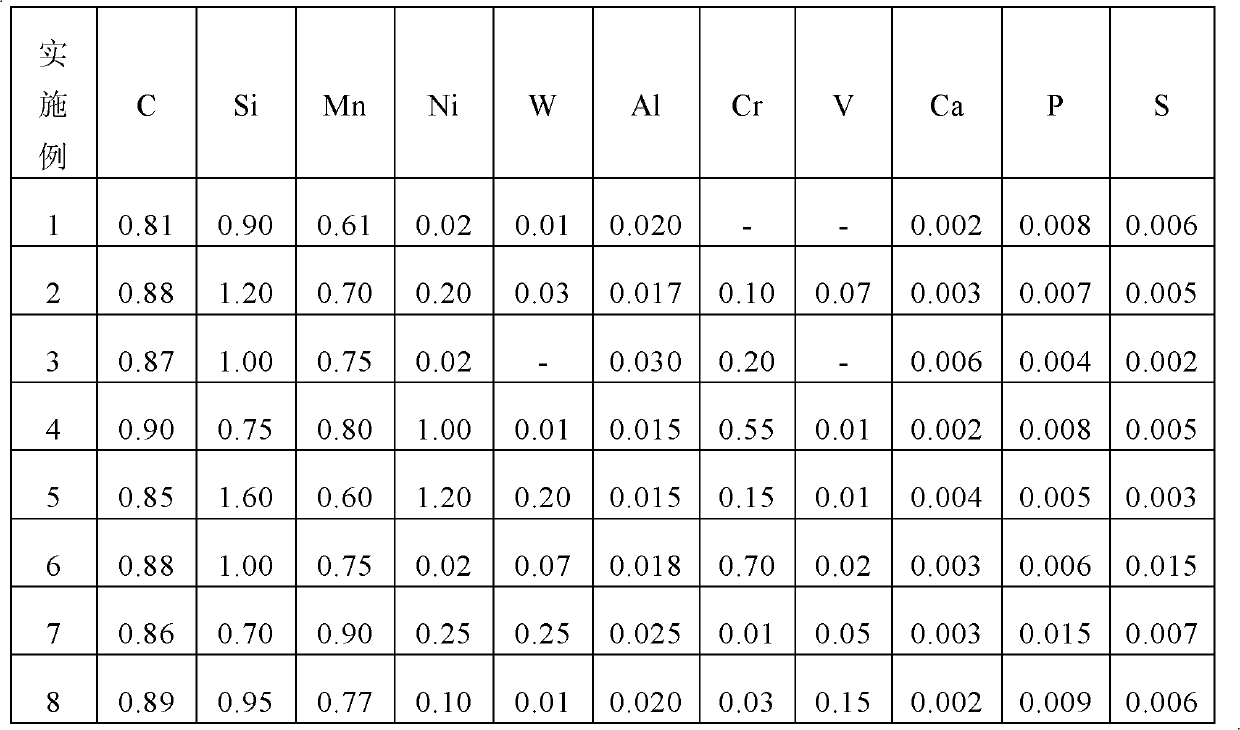

Steel wire rod for 1860MPa-level bridge cable galvanized steel wire and manufacturing method thereof

The invention relates to a steel wire rod for an 1860MPa-level bridge cable galvanized steel wire and a manufacturing method of the steel wire rod. The steel wire rod for the 1860MPa-level bridge cable galvanized steel wire comprises the following raw materials by weight percent: 0.81-0.90% of C, 0.70-1.60% of Si, 0.60-0.90% of Mn, 0.02-1.20% of Ni, 0.00-0.25% of W, 0.015-0.030 of Al, 0.00-0.70% of Cr, 0.00-0.15% of V, 0.002-0.006% of Ca, less than or equal to 0.015% of P, less than or equal to 0.015% of S and the balance of Fe and inevitable impurities, wherein the total quantity of the impurity elements is lower than 0.05%. For the steel wire rod and the preparation method of the steel wire rod, the steel wire rod is not required for salt bath processing, and can be produced by adopting conventional drawing technique, the finished steel wire after being drawn and galvanized has the strength higher than 1860MPa, has 14 times of torsion values, and can be applicable to the need for construction of extra big span bridge.

Owner:BAOSHAN IRON & STEEL CO LTD

High-strength high ductility gas protecting welding stick

InactiveCN101234457ASimple welding processStable welding wire qualityWelding/cutting media/materialsSoldering mediaChemical compositionUltra fine

The invention relates to a gas shielded welding wire with high strength and high toughness, which solves the defects that the existing strength grade in the technical field is unsuitable for market demand and is of high cost. The technical scheme of the invention is that the components of the welding wire (according to the weight percentage) are as follows: 0.04 to 0.10 of C, 0.30 to 0.80 of Si, 1.30 to 2.0 of Mn, 0.40 to 0.89 of Ni, 0.20 to 0.50 of Cr, 0.20 to 0.60 of Mo, 0.56 to 0.80 of Cu, 0.05 to 0.20 of Ti, 0.002 to 0.010 of B, less than 0.020 of P, less than 0.015 of S, less than 0.03 of Als and the rest of Fe and inevitable impurities. The welding wire of the invention has stable quality. The mechanical property of a deposited metal is that Rel is equal to 810MPa; Rm is equal to 840MPa; A is equal to 16 percent and Z is equal to 66 percent. The average impact power AKV in minus 20 DEG C is 141J; and the average impact power AKV in minus 40 DEG C is 128J; and the average impact power AKV in minus 60 DEG C is 70J. The welding wire is suitable for gas shielded welding of 800MPa grade of ultra-fine steel; as the content of Ni is reduced, the cost of the welding wire is reduced dramatically and the implementation is easy.

Owner:WUHAN IRON & STEEL (GROUP) CORP

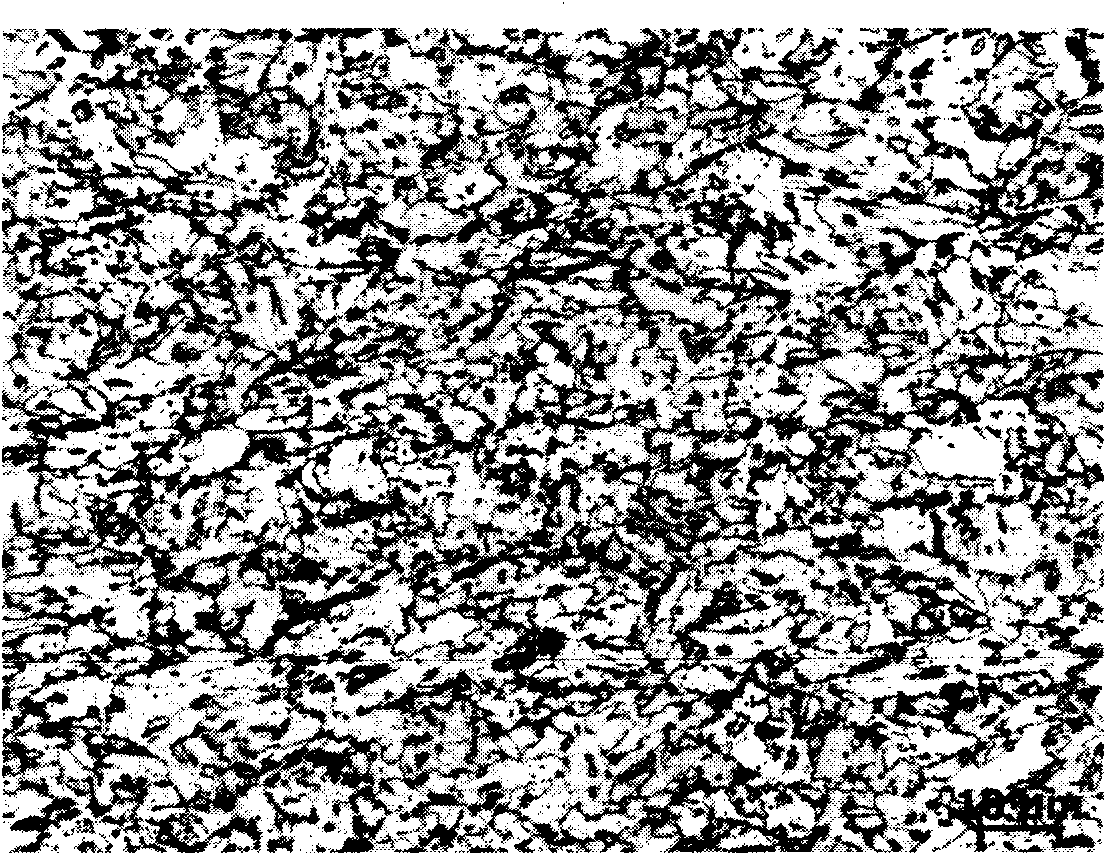

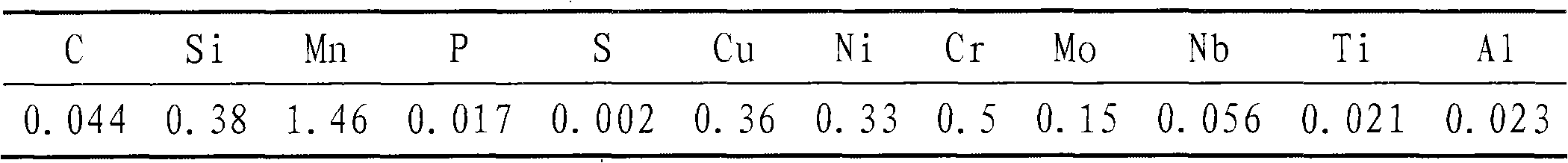

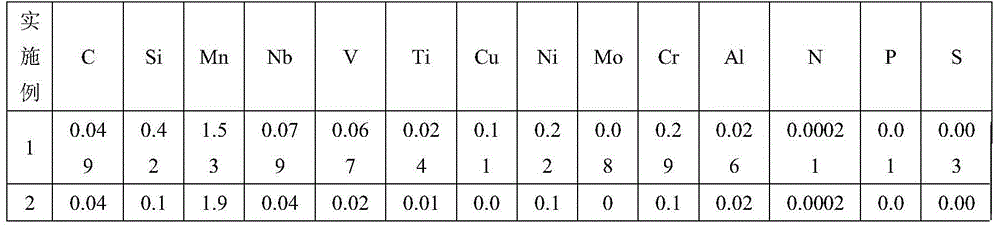

Non-quenched acicular structure high strength low yield ratio weathering resistant steel and production method thereof

InactiveCN101660108AThe ingredients are designed to be simpleObvious effectManufacturing convertersSimple componentHigh intensity

The invention relates to a non-quenched acicular structure high strength low yield ratio weathering resistant steel and a production method thereof. The steel comprises components by weight percent: basic components: 0.03-0.08% of C, 0.30-0.60% of Si, 1.30-1.80% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.30-0.60% of Cu, 0.20-0.50% of Ni, 0.40-0.80% of Cr, 0.10-0.40% of Mo, 0.030-0.080% of Nb and less than or equal to 0.04% of Ti; optional components are two or more in less than or equal to 0.04% of AlS and less than or equal to 0.40kg / t steel of RE or less than or equal to 0.005% of Ca; and the rest of Fe and impurities. Welding cold crack is low in susceptibility coefficient and high in corrosion resisting index. The steel has simple components as wellas excellent moldability, weatherability, weldability and low temperature toughness; meanwhile, the preparation technique is simple, heat treatment is not needed, the production period is short, and the production cost is low.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Ultrahigh strength abrasion resistant steel and method of preparing the same

InactiveCN101250673AHigh yield strengthImprove impact toughnessTemperature control deviceFurnace typesChemical compositionWear resistant

The invention discloses a superhigh intensity wear-resistant steel and the manufacturing method, which belongs to the manufacturing field of low alloying steels, according to percentage by weight, the chemical components of the steel are that C 0.10-0.17%, Si 0.25-0.50%, Mn 1.20-1.50%, P<=0.018%, S<=0.008%, Cr 0.20-0.05%, Ni0.25-0.50%, Mo 0.10-0.40%, Als 0.02-0.06%, B<=0.005%, RE<=150g / t, and the allowance is Fe and unavoidable impurities, and the content of carbon is Ceq(%)<=0.60, Ceq(5)=C+Mn / 6+(Mo+Cr+V) / 5+(Ni+Cu) / 15. The specific method for producing the steel comprises the following steps: smelting ultra-pure steel, desulfurizing molten iron, compounding and converting the top and the bottom of a converter, doing vacuum treatment, feeding rare earth (RE) silk through a crystallizer, casting into bar plates, heating the bar plates, roughing, planishing, air cooling or feeding middle pressure, water cooling, quenching and tempering steel plates. V does not contain in the chemical components of the steel, inner stress of steel is low, steel welding property is improved, and steel has excellent abrasion resistance and ultra-high strength and toughness properties, which is beneficial for popularization and application.

Owner:武钢集团有限公司

High strength low yield ratio welding structure steel and production method thereof

The invention belongs to welded structural steel with high strength and low yield ratio and a production method thereof, aiming at solving the defects that a steel plate or a steel coil with the specification smaller than 25mm can only be produced, the process is long, and the like. The invention adopts the measures that the welded structural steel contains chemical components by weight that: 0.04-0.10 percent of C, 0.60-2.00 percent of Si, 1.50-2.50 percent of Mn, less than or equal to 0.030 percent of P, less than or equal to 0.010 percent of S, 0.20-0.50 percent of Cu, 0.40-0.80 percent of Cr, 0.35-0.80 percent of Ni, 0.0008-0.0030 percent of B, and at least three of the following components: less than or equal to 0.60 percent of Mo, 0.015-0.060 percent of Nb, 0.030-0.120 percent of V, less than or equal to 0.030 percent of Ti, less than or equal to 0.040 percent of Als and less than or equal to 0.010 percent of Zr, and the rest is Fe and unavoidable impurities; and meanwhile, Mn and Cr also need to satisfy the condition that Mn and Cr are equal to 2.20-2.80 percent, and the welding cold crack sensitivity coefficient Pcm is equal to C plus Si / 30 plus (Mn plus Cu plus Cr) / 20 plus Mo / 15 plus Ni / 60 plus V / 10 plus 5B and is less than or equal to 0.30 percent; the production method comprises the following steps of heating a steel billet, rough rolling, finishing rolling, relaxing and laminar cooling, and the laminar cooling comprises the following steps of slow cooling, quick cooling and natural cooling to room temperature.

Owner:武钢集团有限公司

Refractory anti-seismic construction steel for high-toughness welding structures, and production method thereof

InactiveCN101691643AImprove fire resistanceImprove seismic performanceChemical compositionRefractory

The invention discloses refractory anti-seismic construction steel for high-toughness welding structures, and a production method thereof, and solves the problem that the traditional construction steel is high in Mo that is a noble alloying element, high in producing-processing cost, low in refractory property and poor in anti-seismic performance. Based on the chemical composition of steel in percentage by weight, the steel comprises 0.05 to 0.13 percent of C, 0.10 to 0.60 percent of Si, 0.80 to 1.80 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.010 percent of S, 0.15 to 0.50 percent of Mo, 0.15 to 0.50 percent of Cr, 0.015 to 0.050 percent of Nb, and 0.010 to 0.050 percent of Als, at least one of 0.01 to 0.10 percent of V, 0.005 to 0.020 percent of Ti, 0.05 to 0.50 percent of Ni, 0.0010 to 0.020 percent of RE and 0.0010 to 0.010 percent of Ca, and the balance of Fe and inevitable impurities. The steel has the advantages of low content of Mo that is a noble alloying element, short production process and cycle, excellent refractory and anti-seismic performance, good cold-hot machining performance and excellent low-temperature toughness and welding performance.

Owner:武钢集团有限公司

High-performance weather-resisting anti-seismic steel for building and production method thereof

The invention relates to low alloyed steel used for building and a production method thereof, aiming at solving the defects that the prior building steel has atmospheric corrosion resisting property and does not consider the shock resistance problem. The invention adopts the measures that the low alloyed steel contains components by weight of 0.05-0.16 percent of C, 0.10-0.50 percent of Si, 0.60-1.50 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.010 percent of S, 0.15-0.60 percent of Cu, 0.25-0.80 percent of Cr, 0.10-0.50 percent of Ni, 0.01-0.10 percent of V, 0.005-0.030 percent of Ti at least one component of 0.010-0.040 percent of Nb, 0.010-0.050 percent of Als, 0.0010-0.0060 percent of Ca and 0.0010-0.020 percent of RE, and the rest of Fe and unavoidable impurities; and the production method comprises the following steps of molten iron desulphurizing and RH degassing, heating to 1150-1310 DEG C, rough rolling with the temperature being controlled at 1100-1200 DEG C and finishing rolling, wherein the beginning temperature of the finishing rolling is 880-980 DEG C, the rolling reduction ratio of each step is 15-30 percent, the final temperature of the finishing rolling is 800-900 DEG C, and the accumulated rolling reduction ratio of three steps of 35-50 DEG C.

Owner:WUHAN IRON & STEEL (GROUP) CORP

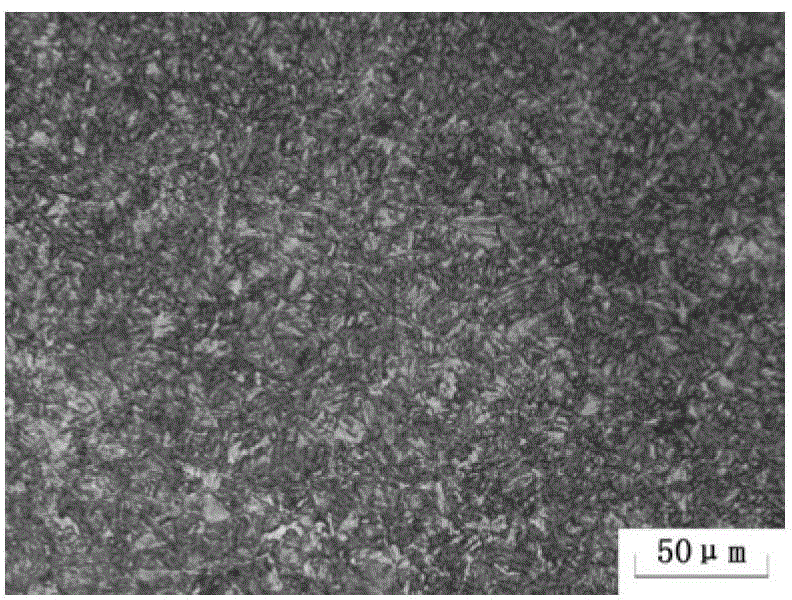

Titanium alloy with matched high strength and toughness and preparation process of titanium alloy

ActiveCN106591625AOptimizing plastic rheological propertiesHigh strengthHigh intensityTitanium alloy

The invention relates to a titanium alloy and the field of forming processes, in particular to titanium alloy with matched high strength and toughness and a preparation process of the titanium alloy. The alloy comprises the following components in percentages by weight: 5.5-6.5% of Al, 1.5-2.5% of Sn, 1.5-2.5% of Zr, 2.5-3.5% of Mo, 0.5-1.5% of Cr, 0.5-1.5% of V, 0.1-0.3% of Fe, 0.1-0.2% of O and the balance of Ti and inevitable impurities. The preparation process of the alloy comprises the following steps: step one, carrying out one-heating-number forging in a beta single-phase region at the temperature of 20-50 DEG C above an alloy phase transformation point, wherein forging deformation is about 40%-80%; step two, forging and forming in an alpha+ beta two-phase region at the temperature of 20-50 DEG C below the alloy phase transformation point, wherein the heating number of forging of the two-phase region is controlled to be 1-3, and the accumulative deformation does not exceed 20%; and step three, carrying out heat treatment in a temperature range of 500-600 DEG C. The titanium alloy can be used for manufacturing various types of products such as rods and wires, plates and forge pieces of high-strength and high-toughness titanium alloy, and is applied to the fields of aviation, aerospace, ships and warships and the like with requirements on structure weight reduction and corrosion resistance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

High-impact-toughness steel rail and production method thereof

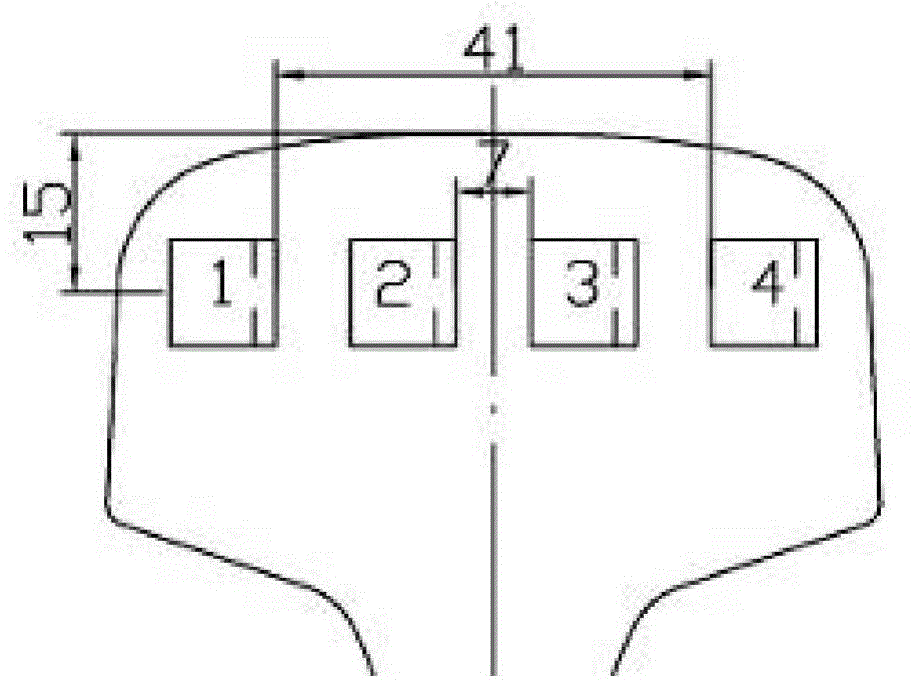

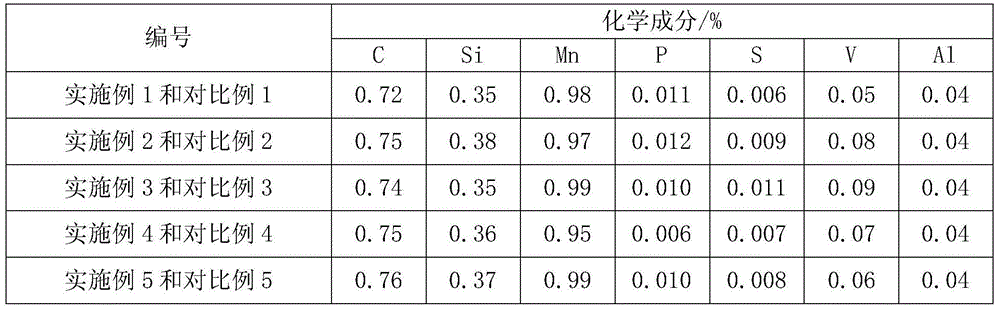

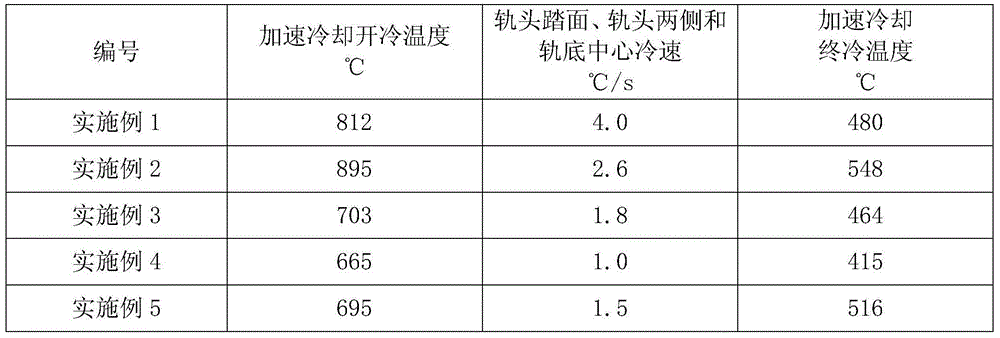

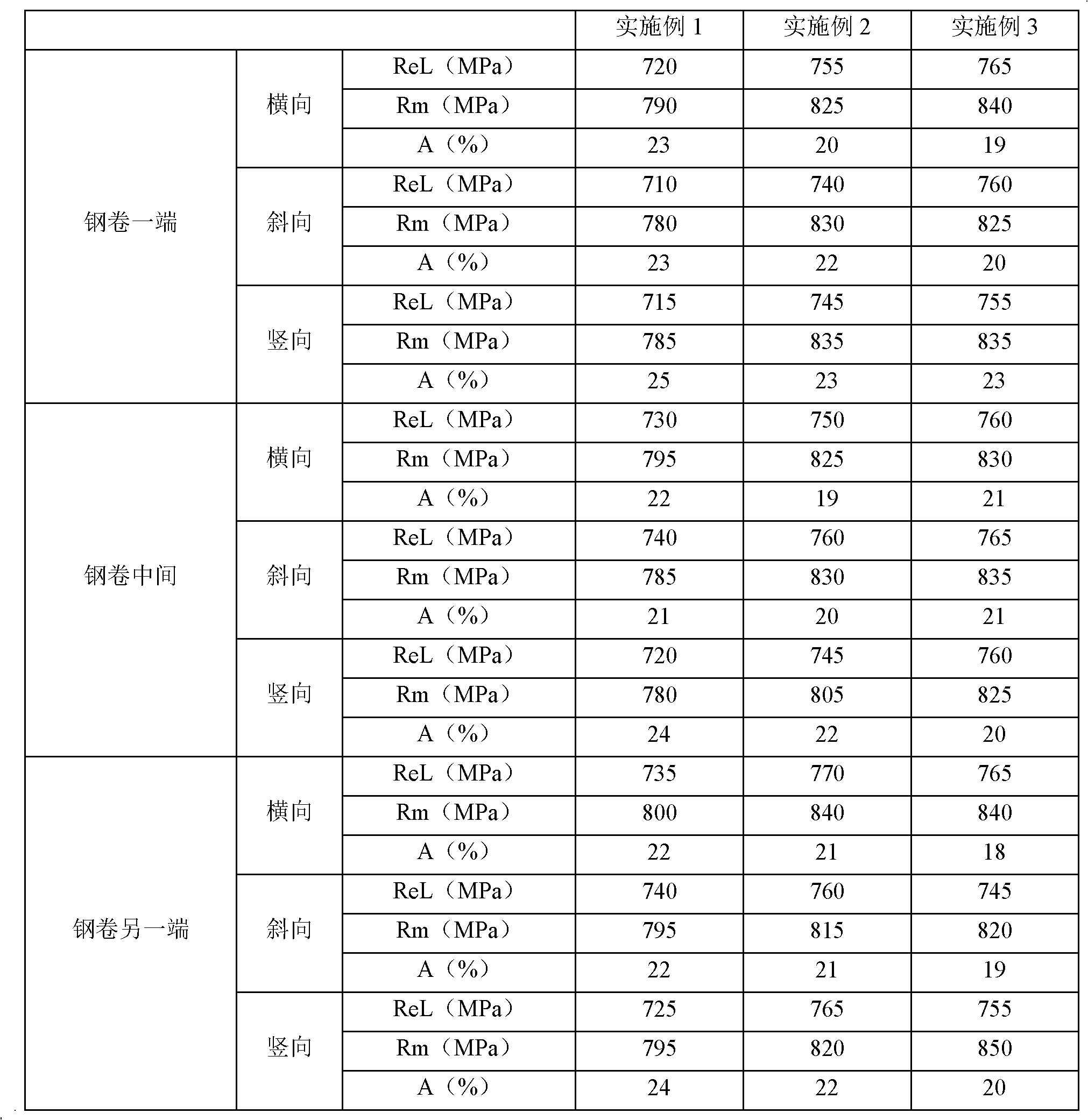

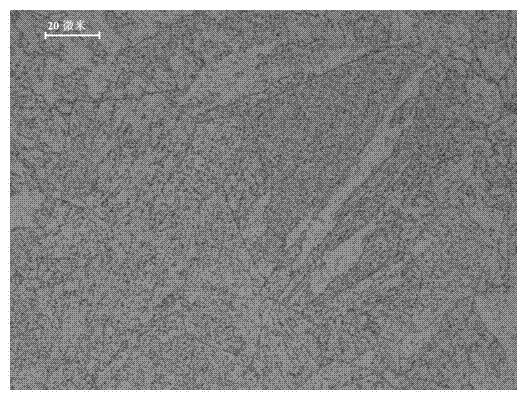

ActiveCN104480390AGood toughness matchImprove fatigue performanceFurnace typesQuenching agentsChemical compositionRolling contact fatigue

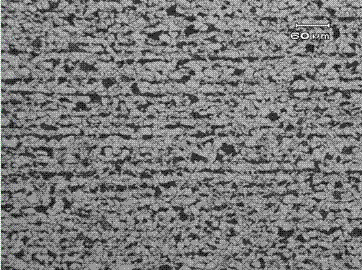

The invention relates to a high-impact-toughness steel rail and a production method of the high-impact-toughness steel rail, and belongs to the field of steel rail material production technologies. The technical aim of providing the high-impact-toughness steel rail is achieved. The high-impact-toughness steel rail is a pearlite steel rail, the interlamellar spacing ranges from 0.05 micron to 0.09 micron, and normal temperature ballistic work ranges from 30 J to 35 J. The steel rail comprises the chemical components: 0.71-0.82 percent of C, 0.25-0.45 percent of Si, 0.75-1.05 percent of Mn, 0.03-0.15 percent of V, no more than 0.030 percent of P, no more than 0.035 percent of S, no more than 0.020 percent of Al and the balance Fe and unavoidable impurities. The rail head U-type impact toughness of the steel rail manufactured through the method can be more than 30 J, tensile strength is larger than 1.300 MPa, the steel rail has good strength and toughness matching, the rolling contact fatigue property and wear-resisting property in the use process are good, and the high-impact-toughness steel rail is suitable for being used as steel rails for railways in high and cold areas.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

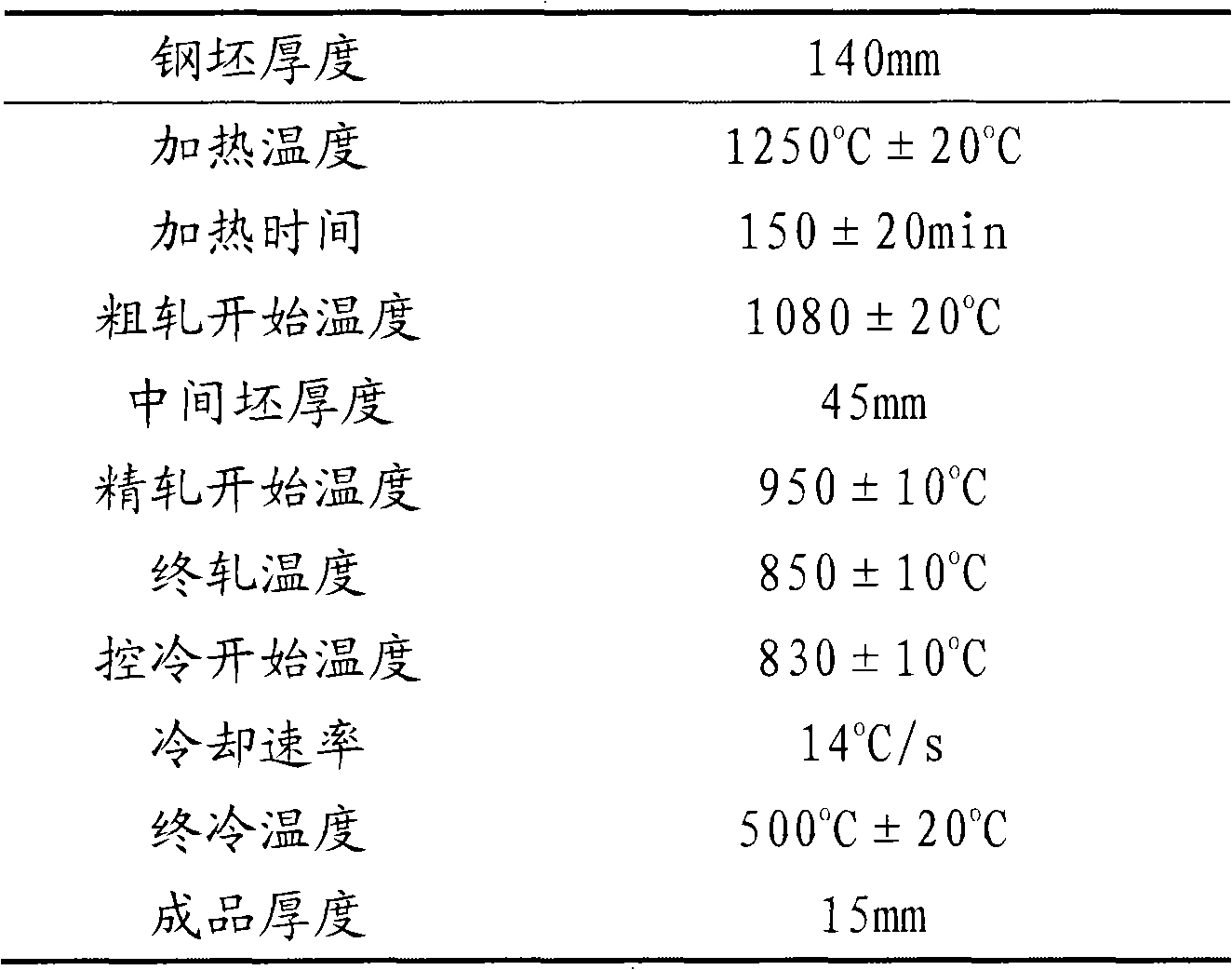

Hot rolling steel plate for automobile girder, and manufacturing method thereof

The present invention provides a manufacturing method of a hot rolling steel plate for an automobile girder. The production method comprises a steelmaking step, a continuous casting step, a heating step, a hot continuous rolling step and a coiling step, and is characterized in that components of the molten steel after steelmaking comprise 0.05-0.1 wt% of C, 0.15-0.35 wt% of Si, 1-2 wt% of Mn, 0.01-0.1 wt% of Nb, 0.03-0.12 wt% of Ti, less than or equal to 0.025 wt% of P, less than or equal to 0.01 wt% of S, and the balance of Fe and unavoidable impurities, a finish rolling temperature in the hot continuous rolling step is 830-900 DEG C, and a coiling temperature is 600-700 DEG C. The present invention further provides the hot rolling steel plate prepared by using the method and provided for the automobile girder. With the manufacturing method, production cost is reduced, and rolling process control is simple. With the hot rolling steel plate for the automobile girder, hot rolling product structures are substantially enriched and improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

A kind of high plasticity high tenacity super high strength steel plate and its production method

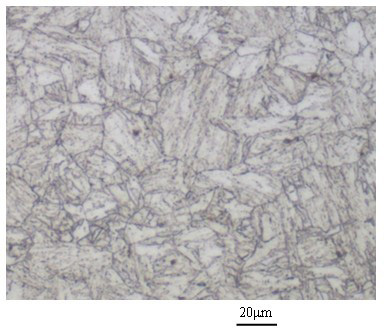

InactiveCN102286695AUniform tissueFully exert the strengthening effectTemperature control deviceHeat treatment process controlTemperingImpurity

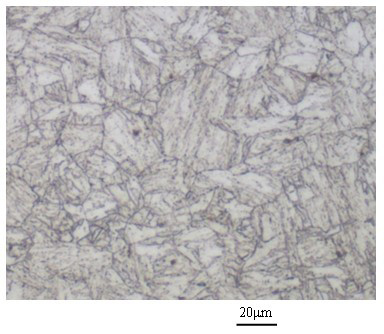

The invention discloses a high-plasticity, high-toughness, ultra-high-strength steel plate and a manufacturing method thereof. The chemical composition of the high-strength steel plate is calculated by weight percentage, C: 0.14-0.18%, Si: 0.10-0.30%, Mn: 0.80-1.30%, P : ≤0.015%, S: ≤0.005%, Nb: 0.010~0.050%, Ti: 0.006~0.020%, V: 0.020~0.060%, Cr: 0.30~0.60%, Mo: 0.20~0.80%, the balance is Fe and unavoidable impurities. Manufacturing method: Smelting in a converter. Through the TMCP process, followed by quenching and tempering treatment. The microstructure of the high ductility, high toughness and ultra-high strength steel plate obtained is tempered sorbite, the lamellar spacing is fine, and the original austenite grains are uniform and fine. It has the characteristics of stable production process, strong operability, low cost and high performance.

Owner:NANJING IRON & STEEL CO LTD

Superlarge thickness hydrogen chromium molybdenum steel plate for hydrogenation equipment and manufacture method thereof

The invention relates to a superlarge thickness hydrogen chromium molybdenum steel plate for hydrogenation equipment and a manufacture method thereof, and belongs to the technical field of ferrous metallurgy. A technical scheme is as below: the steel plate comprises the following components by weight: no more than 0.15% of C, no more than 0.10% of Si, 0.300.60% of Mn, no more than 0.007% of P, no more than 0.005% of S, 2.00-2.50% Cr, 0.90-1.10% of Mo, no more than 0.02% of Nb, no more than 0.20% of Cu, no more than 0.20% of Ni, no more than 0.003% of Sb, no more than 0.005% of Sn, no more than 0.016% of As, no more than 0.003% of O, N no more than 0.008%, no more than 0.0002% of H, no more than 0.03 of Ti and the balance of Fe and unavoidable impurities; a round steel ingot with piece weight of 80 tons is produced by electric arc furnace smelting and casting; and the steel ingot is subjected to forging cogging, rolling and a heat treatment process including normalizing, accelerated cooling and tempering to prepare the superlarge thickness chromium molybdenum steel plate with a maximum thickness of 256mm for hydrogenation equipment. A finished steel plate has maximum single weight reaching 60 tons, good cold bending property, no cracking during material manufacture and good resilience. The method provided by the invention reduces labor intensity, saves time and improves the utilization rate of materials.

Owner:WUYANG IRON & STEEL +1

Petroleum case pipe with high strength and toughness and producing method thereof

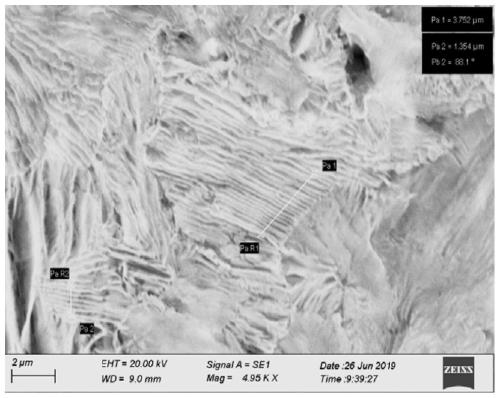

InactiveCN101285151AImprove toughnessGrain refinementDrilling rodsTemperature control deviceAlloyUltra fine

The invention discloses a petroleum casing pipe with high obdurability and a method for making the same. The invention aims to provide a petroleum casing pipe with high obdurability which can meet the mining conditions of deep wells or ultra-deep wells in the oil field and a method for making the same. The compositions in percentage by weight of the petroleum casing pipe are: 0.22 to 0.35 percent of C, 0.17 to 0.30 percent of Si, 0.45 to 0.60 percent of Mn, 0.80 to 1.10 percent of Cr, 0.70 to 1.10 percent of Mo, 0.015 to 0.040 percent of Al , less than 0.20 percent of Ni, less than 0.20 percent of Cu, 0.070 to 0.100 percent of V, less than 0.050 percent of Nb, less than 0.0015 percent of Ca, less than 0.010 percent of P, less than 0.003 percent of S, the balance being Fe. The petroleum casing pipe of the invention adopts a quenched and tempered steel of Cr-Ni-Mo-V alloy system. An ultra-fine lath is obtained after the steel is heat-treated. A certain amount of austenitic toughness phases are distributed dispersedly on a martensite matrix, which improves the obdurability of the steel so as to adapt to bear the outside squeezing load and the axial load brought by the deep wells or the ultra-deep wells.

Owner:TIANJIN UNIV OF COMMERCE

Thick chromium-molybdenum steel plate for hydrogenation equipment and production method thereof

InactiveCN102181806AImprove toughnessDoes not reduce weldabilityRoll mill control devicesMetal rolling arrangementsSheet steelIngot

The invention discloses a thick chromium-molybdenum steel plate for hydrogenation equipment, and also discloses a production method of a steel plate. The steel plate comprises the following components by weight percent: 0.12%-0.15% of C, 0.02%-0.07% of Si, 0.50%-0.60% of Mn, less than or equal to 0.007% of P, less than or equal to 0.005% of S, 2.35%-2.50% of Cr, 0.95%-1.10% of Mo, 0.012%-0.02% ofNb, less than or equal to 0.20% of Cu, less than or equal to 0.20% of Ni, less than or equal to 0.003% of Sb, less than or equal to 0.005% of Sn, less than or equal to 0.016% of As, less than or equal to 0.003% of O, less than or equal to 0.008% of N and less or equal to 0.0002% of H, the balance of Fe and inevitable impurities. For the steel plate, an electroslag remelting technology is adopted,electroslag ingot with the maximum piece weight being 50t is melted, and the maximum thickness of the produced thick chromium-molybdenum steel plate for the hydrogenation equipment can achieve 198mm,and the maximum piece weight of the single-piece finished steel plate can achieve 37.2t by a heating-rolling technology and thermal-processing production equipment of normalizing plus accelerated cooling plus tempering.

Owner:WUYANG IRON & STEEL +1

Large-thickness structural steel plate for high-rise building and production method thereof

The invention relates to a large-thickness structural steel plate for a high-rise building and further relates to a production method of the steel plate at the same time. The steel plate is formed by melting the following component percentages by weight: 0.16-0.19% of C, not more than 0.55% of Si, 1.40-1.55% of Mn, not more than 0.012% of P, not more than 0.003% of S, 0.020-0.050% of TAl (total aluminum), 0.020-0.30% of Nb, 0.035-0.050% of V, not more than 0.30% of Ni, not more than 0.30% of Cr, not more than 0.05% of Ti, and the balance of Fe and inevitable impurities. The production method comprises the steps as follows: smelting; refining; continuously casting; stacking; heating; rolling; stacking and slowly cooling; detecting defects; normalizing; and obtaining the finished steel plate. The shop sign of the steel plate is Q390GJC / Z35, the delivery state of the steel plate is normalization, continuous casting blanks with cross sections of 330 mm * 2400 mm are adopted to form the steel plate, the maximum thickness of the steel plate is 120 mm, and the requirements of the level II in the JB / T4730.3-2005 detection standard are met; and the steel plate has the characteristics of capability of being formed by the continuous casting blanks, larger thickness, higher strength and toughness, good lamellar tearing resistance and the like, and is suitable for manufacturing structural members for the high-rise building.

Owner:WUYANG IRON & STEEL +1

Spring steel wire rod with cryogenic drawing performance, spring steel wire, spring and manufacturing method thereof

ActiveCN111041372AImprove mechanical propertiesReduce depthProcess efficiency improvementWire rodTempering

The embodiment of the invention provides a spring steel wire rod with cryogenic drawing performance, a spring steel wire, a spring and a manufacturing method thereof, and relates to the field of wirerods. The spring steel wire rod with cryogenic drawing performance comprises the following chemical components in percentage by mass: 0.32%-0.40% of Si and 0.016%-0.030% of Als. The manufacturing method of the spring steel wire comprises the steps that the spring steel wire rod is directly subjected to cold drawing, and the maximum reduction rate of drawing reaches 95%; the drawn steel wire is subjected to low-temperature stress relief annealing treatment, the percentage reduction of area is greater than or equal to 35% and the bending fatigue life is greater than or equal to 20 times. The low-alloy spring steel wire rod with good comprehensive mechanical properties is developed, the wire rod can be directly cold-drawn to produce a thin spring steel wire with large deformation without intermediate annealing, the cold-drawn steel wire can be directly wound into the spring without oil quenching and tempering treatment, the requirement for bending fatigue resistance of the steel wire canalso be met and the production cost is greatly reduced.

Owner:SGIS SONGSHAN CO LTD

High-strength high-toughness X100 pipeline steel hot-rolled steel strip and manufacturing method thereof

ActiveCN102560284AEasy to changeHigh strengthMetal rolling arrangementsChemical elementSimple component

The invention discloses a high-strength high-toughness X100 pipeline steel hot-rolled steel strip. The steel strip comprises the following chemical elements in percentage by mass: 0.015 to 0.090 percent of C, 0.1 to 0.5 percent of Si, 1.50 to 1.79 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.003 percent of S, 0.10 to 0.40 percent of Cr, 0.03 to 0.10 percent of Nb, 0.001 to 0.100 percent of Zr, 0.01 to 0.035 percent of Ti, 0.31 to 0.60 percent of Mo, 0.10 to 0.40 percent of Cu, 0.10 to 0.50 percent of Ni, 0.0010 to 0.0050 percent of Ca, 0.02 to 0.045 percent of Al, less than or equal to 0.010 percent of N, less than or equal to 0.008 percent of O and the balance of Fe and other inevitable impurities. Correspondingly, the invention also discloses a method for manufacturing the steel strip. The hot-rolled steel strip has high comprehensive mechanical properties and manufacturability and comprises simple components.

Owner:BAOSHAN IRON & STEEL CO LTD

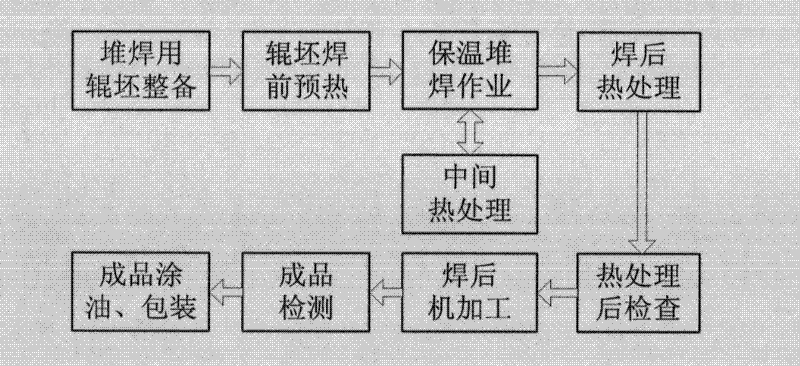

Overlaying-combining-remanufacturing substrate material for Cr4 and Cr5 series of hot rolling work rolls and back-up rolls

InactiveCN102528222AImprove the ability to prevent crack propagationOptimize ingredients and contentArc welding apparatusWelding/cutting media/materialsMetallurgyChemical property

The invention relates to an overlaying-combining-remanufacturing substrate material for Cr4 and Cr5 series of hot rolling work rolls and back-up rolls. The material comprises the following ingredients by proportioning: 0.02-0.10% of C, 0.8-1.8% of Mn, 0.2-0.5% of Si, 4.0-8.0% of Ni, 0.4-1.4% of Ti, 0.1-0.2% of V and the balance of Fe. The substrate material can be well combined with a roll surface and has excellent physical and chemical properties, and can effectively overcome the defects of small cracks and shedding caused by lamellar tearing in the using process of original rolls and overlaying materials.

Owner:CHINA JINGYE ENG +1

X70 large deformation resisting pipeline steel and manufacturing method

The invention discloses an X70 large deformation resisting pipeline steel and a manufacturing method. The steel comprises chemical components including, by mass percent, 0.04%-0.09% of C, 0.15%-0.55% of Si, 1.45%-1.75% of Mn, 0.04%-0.10% of Nb, 0.02%-0.08% of V, 0.01%-0.03% of Ti, 0%-0.20% of Cu, 0.15%-0.55% of Ni, 0%-0.15% of Mo, 0.15%-0.45% of Cr, 0.025%-0.045% of Al, 0.0002%-0.011% of N, smaller than or equal to 0.015% of P, smaller than or equal to 0.005% of S, and the balance Fe and other inevitable impurity elements. Production of the X70 large deformation resisting pipeline steel comprises the following process routes of material preparing, converter or electric furnace smelting, furnace exterior refining, casting, slab reheating, controlled rolling and controlled cooling, and after two-phase region quenching, tempering is conducted or the tempering technology is not adopted. Compared with the prior art, the X70 large deformation resisting pipeline steel and the manufacturing method have the beneficial effects that the yield ratio is lower, the uniform ductility is higher, tenacity matching is better, the steel plate and copper plate performance difference is small, the structure uniformity in the thickness direction is high, and the strip-shaped level is low.

Owner:ANGANG STEEL CO LTD

Thermally-formed steel plate with high fatigue strength for axle housing of heavy truck, and manufacturing method thereof

Owner:JIGANG GRP

Low-compression ratio super-strength steel plate for ocean engineering and manufacturing method thereof

InactiveCN102691018AHigh strengthImprove plasticityHeat treatment process controlSolderabilityUltimate tensile strength

The invention discloses a low-compression ratio super-strength steel plate for ocean engineering and a manufacturing method thereof. The super-strength steel plate for ocean engineering comprises the following chemical components in percentage by weight: 0.04-0.07% of C, 0.10-0.30% of Si, 1.60-1.80% of Mn, less than or equal to 0.010% of P, less than or equal to 0.0080% of S, 0.030-0.050% of Nb, 0.020-0.060% of V, 0.006-0.015% of Ti, 0.90-1.30% of Ni, 0.30-0.60% of Cr, 0.20-0.40% of Cu, 0.40-0.60% of Mo, and the balance of Fe and inevitable impurities. The laboratory smelting, trial rolling on a rolling mill, TMCP (thermal mechanical control processing) technology and thermal refining are sequentially performed, thus the super strength, high toughness, weldability and manufacturability of the super-strength steel plate for ocean engineering are realized.

Owner:NANJING IRON & STEEL CO LTD

High-strength steel plate for ocean engineering and production method thereof

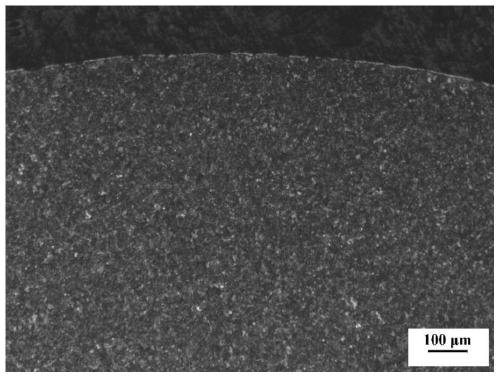

InactiveCN105586537APlay a role in diffusion strengtheningImprove low temperature toughnessQuenchingMechanical property

The invention discloses a high-strength steel plate for ocean engineering and a production method thereof. The production method comprises the working procedures of smelting, continuous casting, heating, rolling, heat stacking and heat treatment, wherein the molten steel obtained in the smelting procedure comprises the following chemical ingredients with contents in percentage by mass: 0.05-0.09% of C, 0.10-0.30% of Si, 1.1-1.35% of Mn, not greater than 0.010% of P, not greater than 0.003% of S, 0.15-0.4% of Ni, 0.15-0.35% of Cr, 0.10-0.30% of Mo, 0.020-0.050% of Nb, 0.03-0.05% of V, 0.020-0.050% of TAl, and balance Fe and inevitable impurities; a quenching and tempering process is adopted in the heat treatment procedure; during the quenching process, a heating temperature is 880-910 DEG C, and a total heating time is PLC +(20-40) minutes; and during the tempering process, a heating temperature is 580-620 DEG C, a total heating time is 1.5-2 minutes per millimetre, and air cooling is carried out after discharge. According to the method disclosed by the invention, through adjustment and optimization for the proportion of alloy elements in the steel plate, and quenching and low-temperature short-time tempering, good mechanical properties of the steel plate can be guaranteed under a low-carbon-equivalent condition, and the steel plate is enabled to have good structure, comprehensive property and welding property.

Owner:WUYANG IRON & STEEL

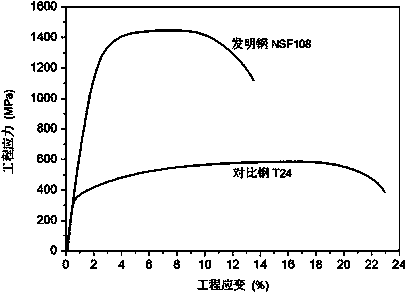

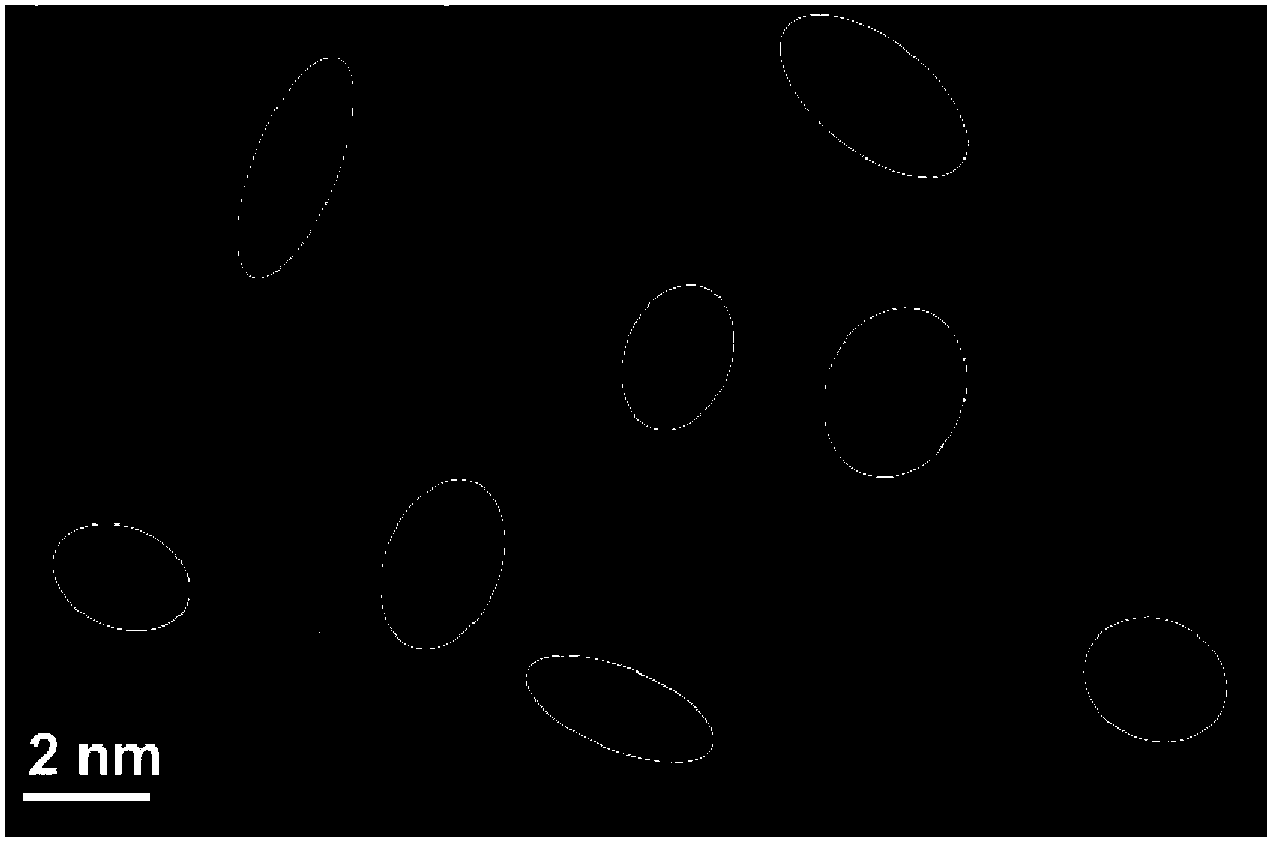

Cu-rich nanocluster reinforced ultra-high strength ferrite steel and manufacturing method thereof

An ultrahigh strength ferritic steel strengthened by using Cu-rich nanoclusters, and a manufacturing thereof. Components of the steel in weight percentage are as following: C (0 to 0.2%), Cu ( 0.5 to 5%), Ni (0.01 to 4%), Mn (0.01 to 4%), Al (0.001 to 2%), Cr (0 to 12%), Mo (0 to 3%), W (0 to 3%), Mo+W (not lower than 0.05%), V (0 to 0.5%), Ti (0 to 0.5%), Nb (0 to 0.5%), V+Ti+Nb (not lower than 0.01%), Si (0 to 1%), B (0.0005 to 0.05%), P (not higher than 0.04%), S (not higher than 0.04%), N (not higher than 0.04%), O (not higher than 0.05%), and the remaining are Fe and unavoidable impurities. Melting, casting, forging and rolling, and ageing treatment are performed to obtain a ferritic steel which mainly comprises nanoclusters and combined with cryptomere, and receives solid solution and dislocations strengthening treatment, thereby obtaining outstanding toughness, weldability and corrosion resistance.

Owner:CITY UNIVERSITY OF HONG KONG

Ultra-large linear energy input welding high-strength steel and production method thereof

InactiveCN101818304AImprove mechanical propertiesImprove toughnessRoll mill control devicesMetal rolling arrangementsSheet steelChemical composition

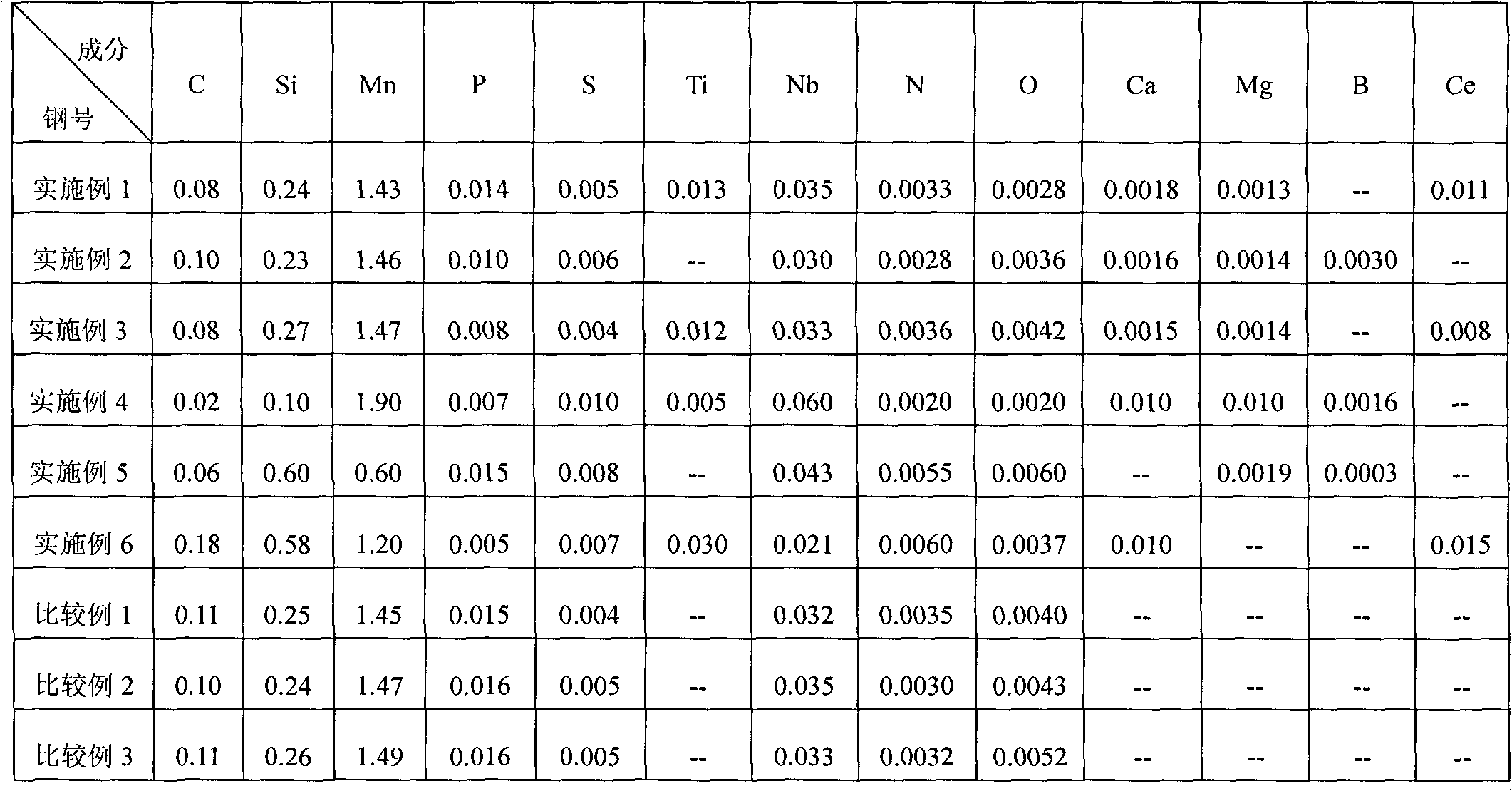

The invention discloses ultra-large linear energy input welding high-strength steel and a production method thereof, and solves the problems of high alloying cost, poor welding performance of steel plates and low HAZ impact toughness of the conventional large linear energy input welding high-strength steel. The steel comprises the following chemical compositions in percentage by weight: 0.02 to 0.18 percent of C, 0.10 to 0.60 percent of Si, 0.60 to 1.90 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.010 percent of S, less than or equal to 0.060 percent of Nb, 0.0020 to 0.0060 percent of N, 0.0020 to 0.0060 percent of O, and at least two of 0.005 to 0.030 percent of Ti, less than or equal to 0.010 percent of Ca, less than or equal to 0.010 percent of Mg, 0.0003 to 0.003 percent of B, and 0.008 to 0.015 percent of Ce, and the balance of Fe and inevitable impurities. In addition, the chemical compositions meet the following conditions: (1) 4.0C+Mn is less than or equal to 2.1; (2) the carbon equivalent CE is equal to C+Si / 24+Mn / 6+Ni / 40+Cr / 5+Mo / 4+V / 14 and is less than or equal to 0.39. A casting blank with the compositions is prepared through hot metal desulphurization, converter top and bottom blowing, vacuum deep treatment and fine adjustment of the compositions, the casting blank subjected to controlled rolling is air-cooled to room temperature, and the high-strength strong-toughness and excellent-match steel is obtained. The steel has the advantages of high strength, excellent low temperature toughness, and high Z-direction performance, and can bear ultra-large linear energy input (more than or equal to 500kJ / cm) welding.

Owner:武钢集团有限公司

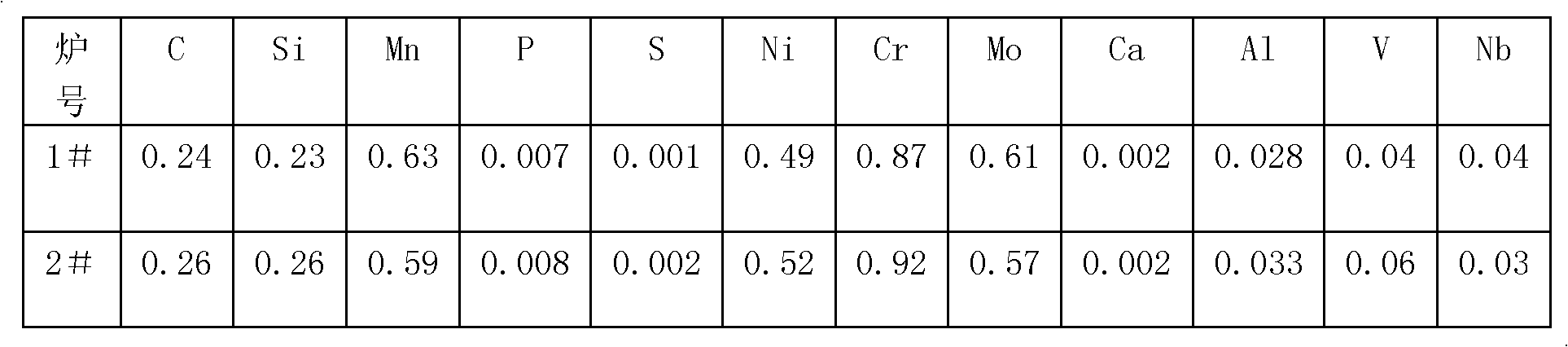

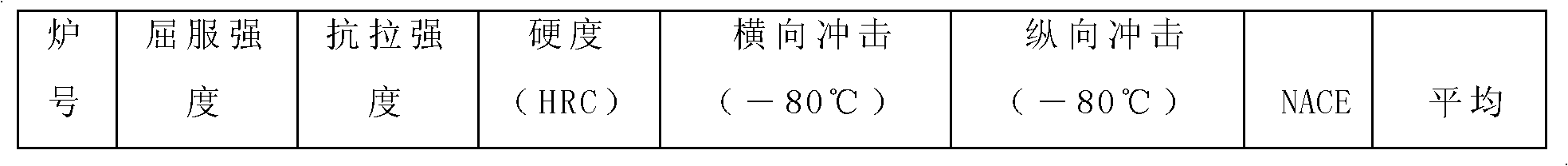

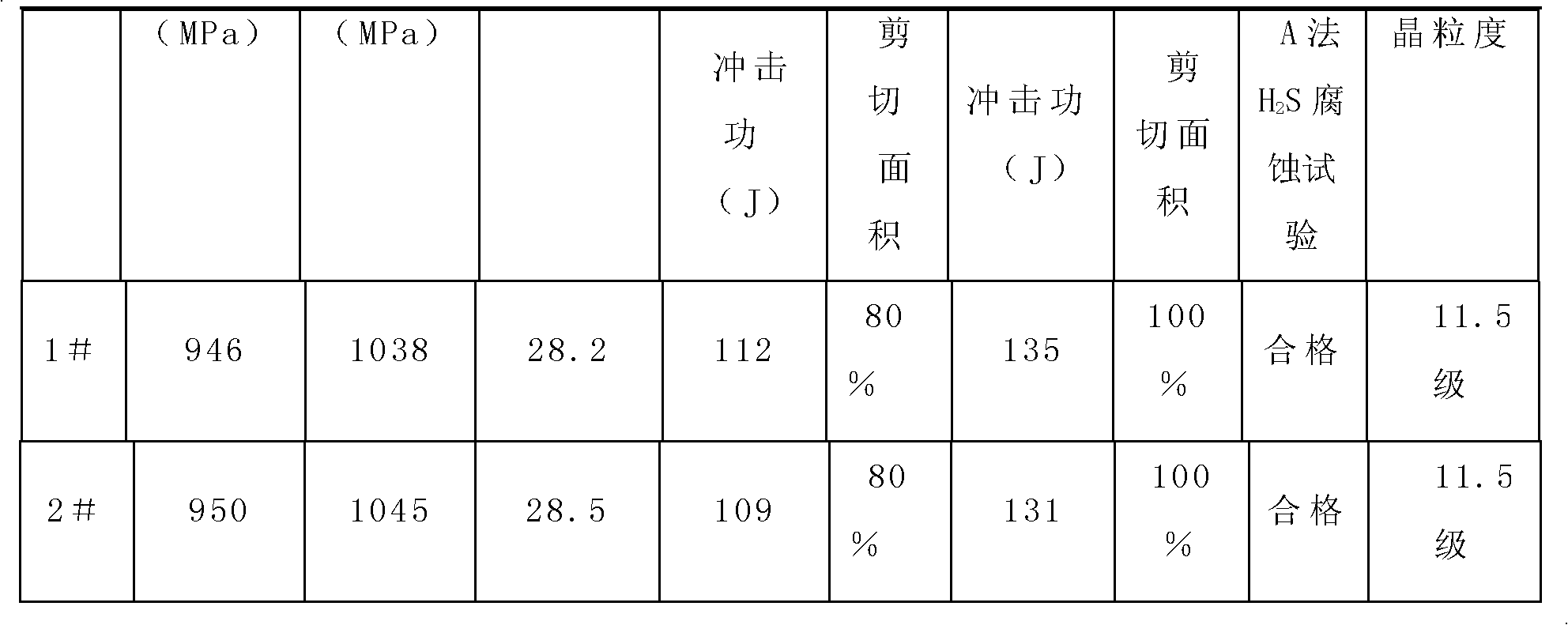

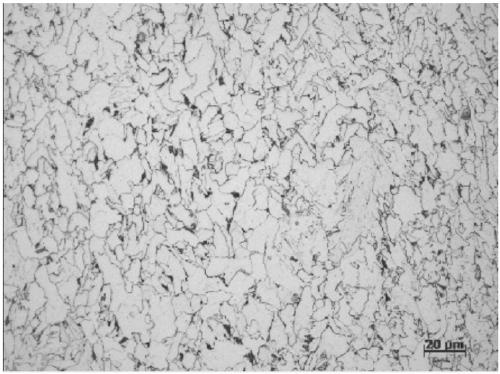

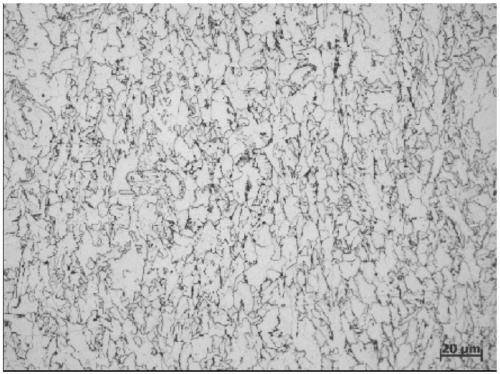

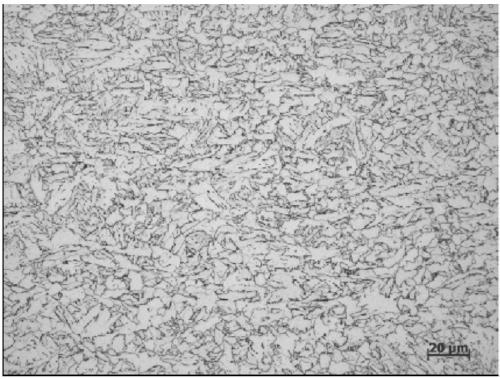

130ksi steel-grade low-temperature drill rod with high toughness and corrosion resistance and manufacturing method thereof

ActiveCN101935808AHigh strengthGood toughness matchFurnace typesMetal rolling arrangementsThermal treatmentImpurity

The invention provides a 130ksi steel-grade low-temperature drill rod with high toughness and corrosion resistance, comprising the following components in weight by percentage: 0.20%-0.30% of C, 0.15%-0.40% of Si, 0.25%-0.85% of Mn, 0.45%-1.25% of Cr, 0.25%-0.85% of Mo, 0.35%-0.85% of Ni, 0.03%-0.10% of V, 0.01%-0.06% of Nb, 0.008%-0.050% of Al, 0.0015%-0.0050% of Ca and the balance of ferrum and a trace of impurity elements. Meanwhile, the invention provides a manufacturing method of the 130ksi steel-grade low-temperature drill rod with high toughness and H2S corrosion resistance. The drill rod has the advantages that by adopting reasonable raw material components, the drill rod ensures impact toughness, favorable H2S corrosion-resistant capacity and material strength; the purity of steel is improved in a steel making process; in a rolling process, the production rhythm is improved, and the quality of the inner surface and the outer surface and the size precision of a steel tube are improved; the impact toughness and the corrosion-resistant capacity of the steel are improved by thermal treatment, and the toughness of the steel tube is improved, which is important for improving the corrosion resistance of the steel tube.

Owner:TIANJIN PIPE GROUP CORP

Steel plate for guide blades of large hydropower generating units and production method thereof

InactiveCN101948982AExcellent toughness indexIncrease thickness specificationUltimate tensile strengthToughness

The invention discloses a steel plate for guide blades of large hydropower generating units, which is smelted by the following components by weight: 0.18-0.21% of C, 0.60-0.80% of Si, 1.10-1.25% of Mn, not more than 0.020% of P, not more than 0.005% of S, not more than 0.15% of Cu, 0.020-0.050% of Alt and the balance Fe and inevitable impurities. The steel plate has the following advantages: (1) the steel plate has good strength and toughness matching, yield strength not less than 275MPa, Rm not less than 490MPa, 0-DEG C longitudinal impact energy not less than 27J, A50 not less than 14%, psi not less than 30% and HB not less than 145; (2) the steel plate is purer and has P not more than 0.020% and S not more than 0.005%; (3) the steel plate has denser internal quality and can meet the requirement of the JB / T1271-2002 forging detection standard; and (4) the maximum thickness of the steel plate can reach 226mm.

Owner:WUYANG IRON & STEEL +1

F grade steel used for series of ships and ocean engineering and flexibility production method thereof

The invention relates to F grade steel used for a series of ships and ocean engineering. The steel is prepared from the chemical components of, in percentage by mass, 0.05-0.09% of C, 0.15-0.50% of Si, 0.80-1.30% of Mn, less than or equal to 0.0070% of P, less than or equal to 0.0030% of S, 0.10-0.30% of Ni, 0.008-0.020% of Ti, 0.0030-0.0060% of N, 0.020-0.050% of Nb, 0.020-0.050% of Al and the balance Fe and inevitable impurity elements. According to a production technology process, by conducting hot metal pretreatment, converter steel-making, LF refining, RH vacuum degassing, Ca treatment, continuous casting, casting blank dehydrogenation treatment, heating, rolling, cooling (strip temperature straightening) in combination with reasonable component designing, control of tissues and crystal grain dimensions of different steel plates is conducted, multi-strength grade flexibility production of four steel grades of 235 MPa, 315 MPa, 355 MPa and 400 MPa is completed, the low-temperatureimpact toughness is excellent, the ductility is excellent, and is higher than or equal to 25%, a high cooling speed and a thin plate shape are guaranteed, the production technology is stable, and batch production is easy.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Large-thickness rolled steel plate instead of case one for large-sized ball mill and production method thereof

InactiveCN101956130AGood toughness indexIncrease thickness specificationTemperature control deviceMetal rolling arrangementsMolten steelHydrogen treatment

The invention discloses a large-thickness rolled steel plate instead of a cast one for a large-sized ball mill and a production method thereof. The steel plate is formed by smelting the following components by weight percent: 0.160-0.190% of C, less than or equal to 0.45% of Si, 1.300-1.500% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.020-0.050% of Als, 0.015-0.025% of Nb and the balance Fe and inevitable impurities. The method comprises the following steps: smelting molten steel in an electric furnace; refining in an LF refining furnace; performing vacuum treatment in a vacuum degassing furnace; and casting, electroslag remelting, heating, rolling to finished product, cooling, performing hydrogen expanding treatment and normalizing and the like to prepare into the finished product thick steel plate. The invention has the following advantages: 1) the strength and toughness are matched favorably, the yield strength Re is more than or equal to 265 MPa, Rm is 430-600 MPa, the longitudinal impact power is more than or equal to 34J at the temperature of 0 DEG C, and A is more than or equal to 17%; 2) the lamellar tearing resistance is good, and Z is more than or equal to 35%; 3) the steel of the invention is purer, P is less than or equal to 0.015%, and S is less than or equal to 0.005%: 4) the internal quality is more compact, and can satisfy the requirement of the A578C class detection standard; and 5) the maximum thickness of the steel plate can achieve 288mm.

Owner:WUYANG IRON & STEEL +1

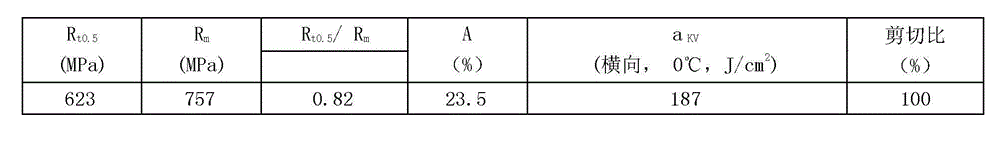

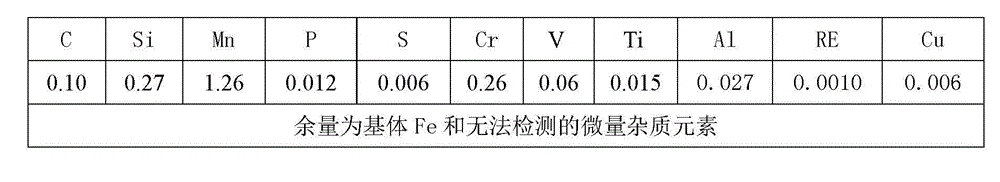

Rare earth containing, high-strength and high-toughness seamless steel pipe for L555Q pipeline and production method thereof

The invention relates to a rare earth containing, high-strength and high-toughness seamless steel pipe for the L555Q pipeline and a production method thereof. The seamless steel pipe is composed of 90 wt% of blast furnace molten iron and 10 wt% of high-quality waste steel in percentage by weight. The pipe blank comprises the following chemical components in percentage by weight: 0.06 to 0.13 wt% of C, 0.15 to 0.35 wt% of Si, 1.10 to 1.40 wt% of Mn, not more than 0.020 wt% of P, not more than 0.010 wt% of S, 0.10 to 0.30 wt% of Cr, 0.03 to 0.09 wt% of V, 0.01 to 0.03 wt% of Ti, 0.01 to 0.04 wt% of Al, 0.0005 to 0.0100 wt% of rare earth (RE), not more than 0.10 wt% of Cu, and the balance being substrate Fe and undetectable trace impurity elements. The mechanical properties of the seamless steel pipe are as follows: the yield strength is 600 to 680 MPa, the residual stress is smaller than or equal to 30 MPa, the impact value is more than or equal to 160 J / cm<2>, and the grain size is more than or equal to 8.5 grade. The technology process can be simplified as the following steps: molten iron pre-treating, smelting in a top-bottom combined blowing converter, refining in a LE furnace, VD vacuum processing, round continuous casting, cutting, heating the pipe blank, perforating, continuous rolling, sizing (stretch reducing), cooling, sawing, heat treating, straightening, flaw detecting, and chamfering. The product has the advantages of low impurity element content, high roughness matching degree, uniform and fine tissue, and good welding performance.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com