Patents

Literature

84results about How to "Inner dense" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

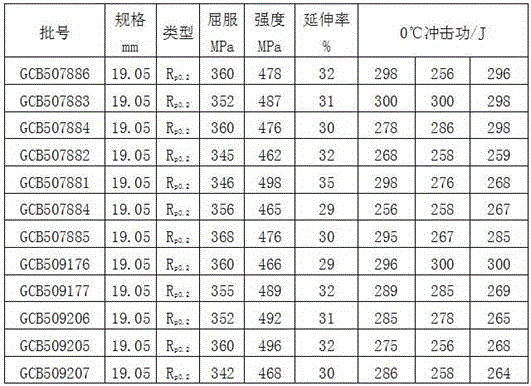

High strength steel plate for big thickness tall building structure and production method thereof

InactiveCN101323929AIncrease thickness specificationLow yield ratioMolten metal pouring equipmentsRoll mill control devicesSheet steelChemical composition

The invention relates to a steel plate with high intensity and used in construction structures of high buildings with large thickness and a production method thereof. The steel plate of the invention consists of the following components according to weight percentage: less than or equal to 0.20 percent of C, less than or equal to 0.55 percent of Si, 1.00 to 1.70 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, less than or equal to 0.70 percent of Ni, less than or equal to 0.70 percent of Cr, less than or equal to 0.20 percent of V, more than or equal to 0.015 percent of Nb, less than or equal to 0.20 percent of Ti, 0.020 to 0.060 percent of Al, and the rest is Fe and inevitable impurity. The produced Q460E-Z35 steel plate with a thickness of 100 to 110 mm is capable of meeting the requirement of high intensity steel of large-thickness construction structure (Ceq is less than or equal to 0.50 percent); the steel plate of the invention can be applied to constructing the structure of high building, has good performance of welding and anti-layer tearing, can meet the requirement of on-site key stress points, has simple production process and is capable of realizing bulk production. The high intensity steel plate of the invention has the following advantages that (1) the steel quality of the invention is purer with less than or equal to 0.025 percent of P and less than or equal to 0.010 percent of S; (2) yield ratio of the invention is relatively low and less than 0.78 actually; (3) the anti-layer tearing performance is good, and Z is larger than or equal to 35 percent in whole thickness direction; (4) low-temperature toughness at the temperature of minus 40 DEG C is good; (5) maximum thickness of the steel plate can reach 110mm.

Owner:WUYANG IRON & STEEL

High-tensile quenched and tempered steel plate for large-thickness structures and production method thereof

InactiveCN102080185AGood lamellar tear resistanceImprove low temperature toughnessRoll force/gap control deviceTemperature control deviceChemical compositionSheet steel

The invention discloses a high-tensile quenched and tempered steel plate for large-thickness structures and a production method thereof, wherein the high-tensile quenched and tempered steel plate comprises the following chemical compositions in percentage by weight: less than or equal to 0.19% of C, less than or equal to 0.50% of Si, 1.00-1.60% of Mn, less than or equal to 0.015% of P, less than or equal to 0.003% of S, less than or equal to 0.20% of microalloying elements (Nb+V+Ti+Ni), less than or equal to 0.050% of Als, and the balance of Fe and residual elements. By reasonably taking a chemical composition design on composite multicomponent microalloying elements and adopting an LF+VD (ladle refining + vacuum degassing)process, the purity of the steel plate is ensured, and the sum of levels of various inclusions is not more than 3.0; and by utilizing a thermo mechanical control process and adopting normalizing treatment, the grain fineness number of the steel plate reaches level 9.0-10.0; by means of the effective implementation of the measures, the extra-thick steel plates (thickness: greater than or equal to 100mm) for high-rise buildings with guaranteed flaw detection and mechanical properties are produced successfully.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

Large thickness steel plate for hydrogenation reaction chamber reeling equipment and production method thereof

InactiveCN101713054AImprove purityUniform compositionProcess efficiency improvementElectric furnaceSheet steelHydrogenation reaction

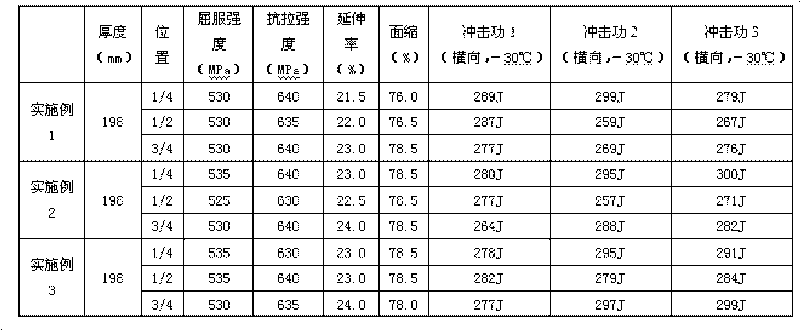

The invention discloses a large thickness steel plate for hydrogenation reaction chamber reeling equipment and a production method thereof. The steel plate takes Cr-Mo steel as the base, an amount of alloying elements, such as Ni, Cu, Al, Nb, Mn, Cr and the like are added, the contents of harmful elements, such as Sn, Sb, As, P, S and the like are controlled, and the finished large thickness steel is prepared by adopting the processes of electric furnace smelting, LF refining furnace refining, throwing down line stacking for slow-cooling, electroslag remelting, rolling and product forming, diffusion hydrogen annealing, normalizing and tempering heat treatment and the like. The thickness of the steel plate reaches 198 mm, the weight of single steel plate reaches 25 tons, the high temperature tensile strength and yield strength of the steel plate are good, the lower temperature toughness at minus 30 DEG C is good, the steel plate has good tempering embrittlement sensitivity coefficient, and the purity of the produced steel plate is high, the component is uniform, the inner part is compact, and the mechanical property is uniform. The steel plate can meet the operation requirement of hydrogenation reaction chamber reeling equipment, and is suitable for the production of the main structural parts of all hydrogenation reaction chamber reeling equipment.

Owner:WUYANG IRON & STEEL +1

High-capacity ratio rate carbon-based composite material, preparation method thereof and application thereof in lithium ion battery

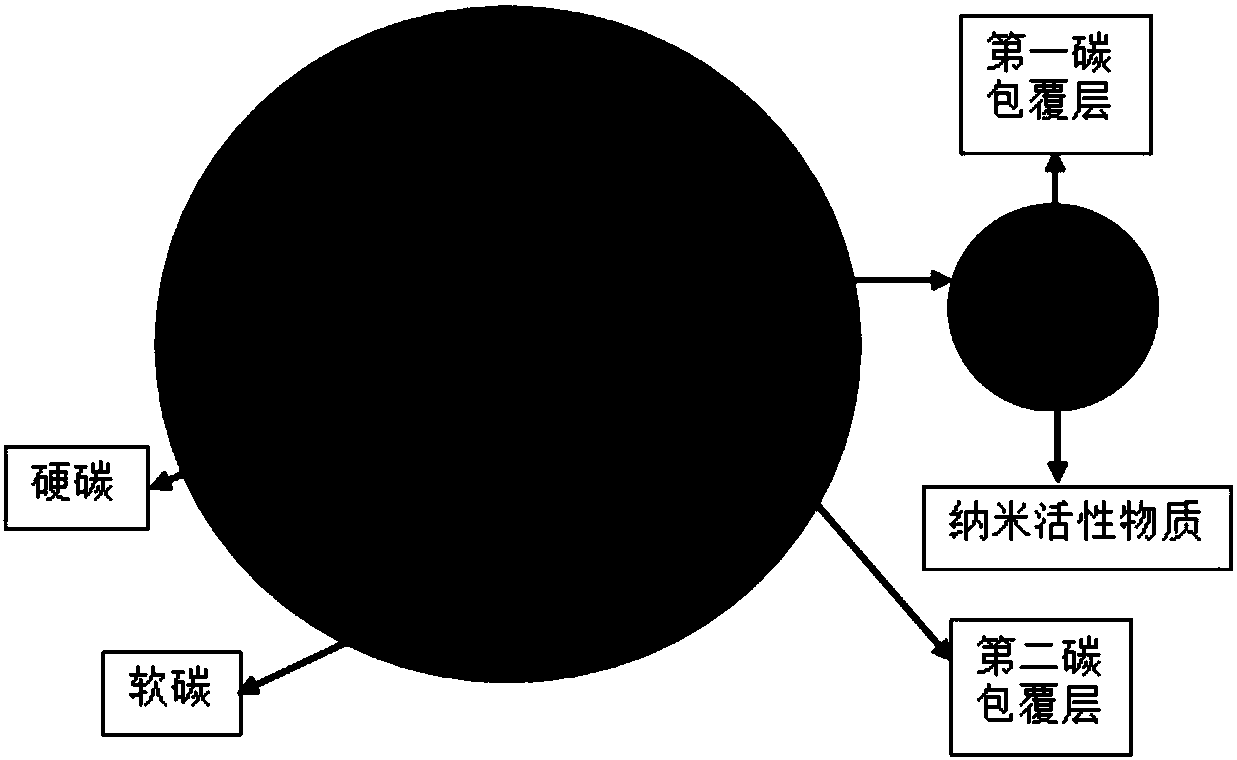

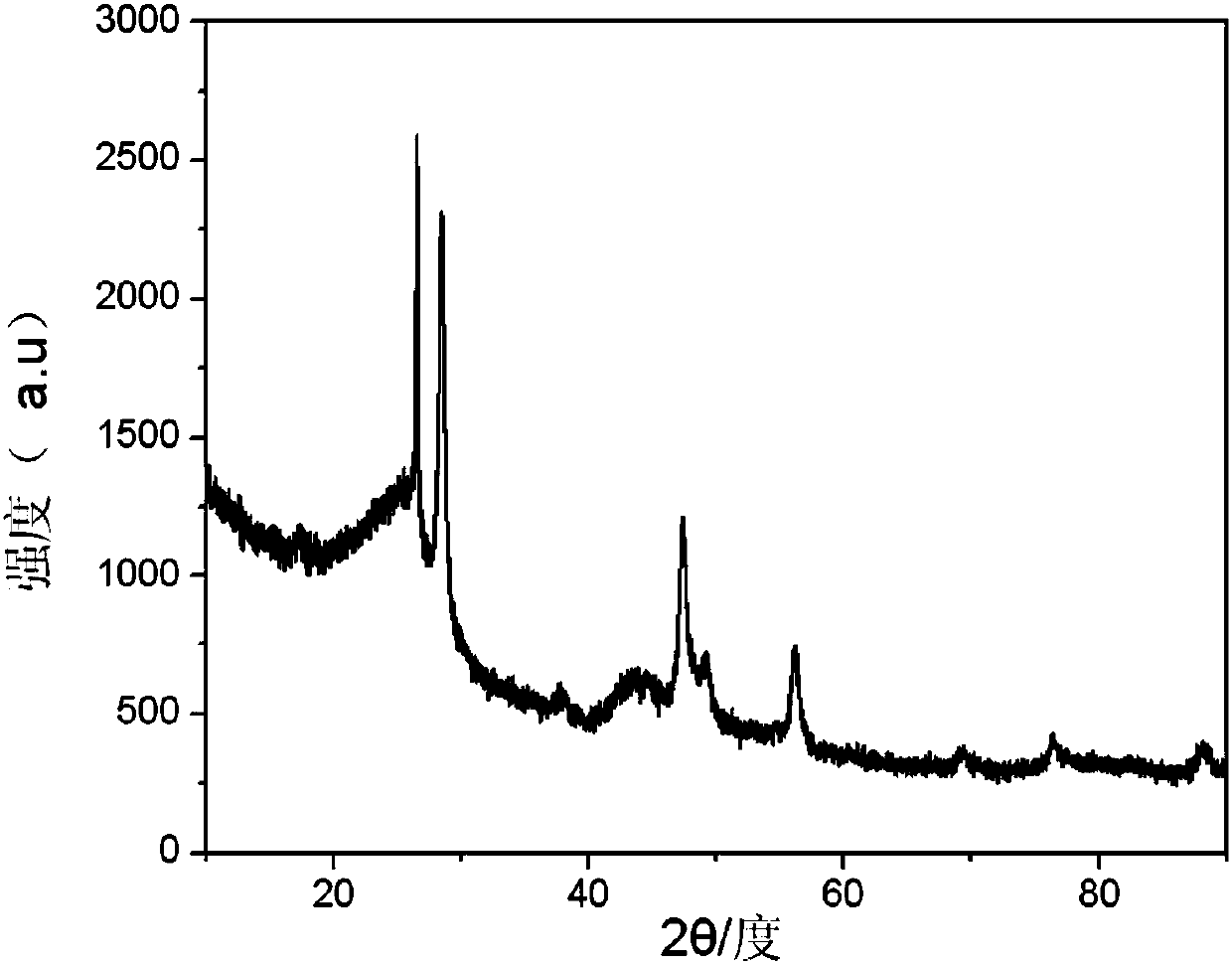

ActiveCN107768626AImprove Capacitive PerformanceImproved magnification performanceSiliconElectrode thermal treatmentCarbon coatingOrganic matter

The invention discloses a carbon-based composite material, a preparation method thereof and application thereof. The carbon-based composite material comprises micron-order soft carbon, micron-order hard carbon, a nano-active material, a first carbon coating layer and a second carbon coating layer, wherein the first carbon coating layer is coated on the surface of the nano-active material to form composite particles; the composite particles are dispersed on the surfaces of the soft carbon and the hard carbon and in the second carbon coating layer; the second carbon coating layer coats the softand hard carbon and the composite particles. The method disclosed by the invention comprises the following steps: 1) performing carbon coating on the nano-active material to form composite particles;2) dispersing the composite particles on the surface of the soft carbon and the hard carbon to form a first precursor; 3) performing coating modification by using an organic matter; 4) performing VC heating mixing or mixed kneading and molding; 5) sintering at a high temperature, thereby obtaining the composite material. The composite material disclosed by the invention is very suitable to serve as a negative electrode active material of the lithium ion battery, has high capacity and first charge and discharge efficiency and is excellent in rate capability.

Owner:BTR NEW MATERIAL GRP CO LTD

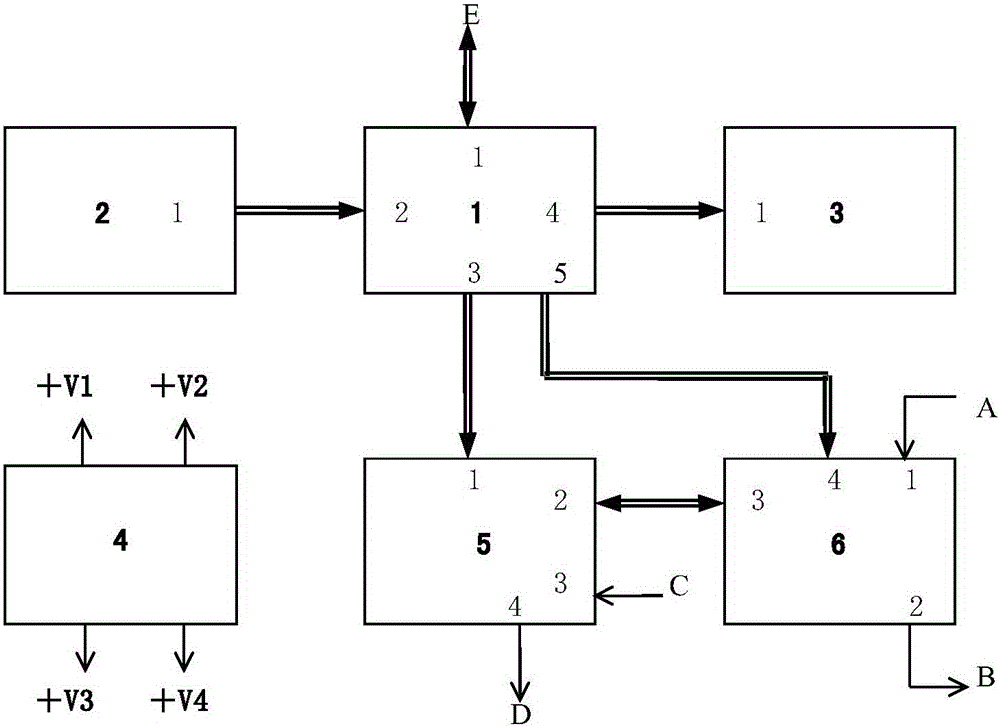

Optical fiber multi-domain sensing system and demodulation method

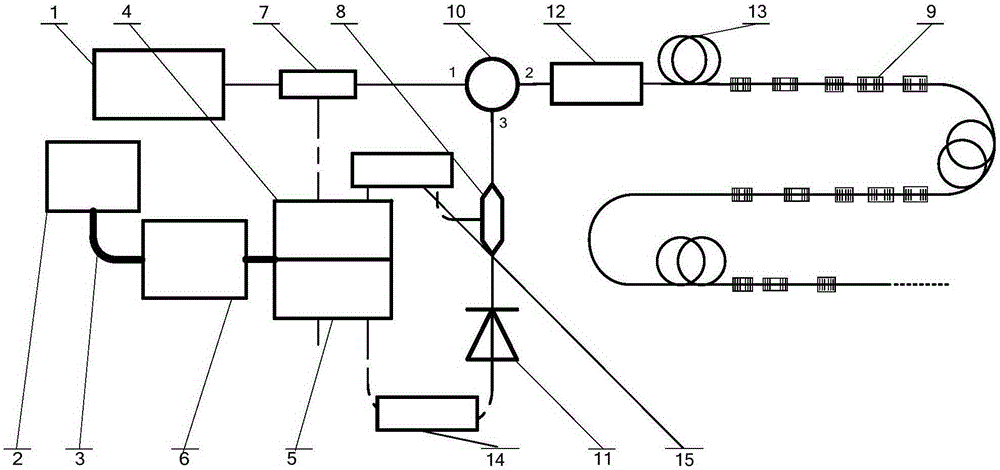

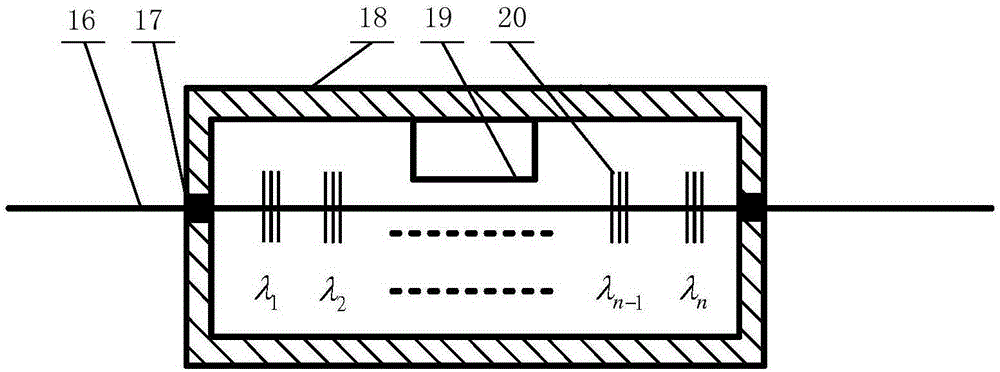

InactiveCN105203137AOvercome limitationsVoltage Jitter EliminationConverting sensor output opticallyVIT signalsMicrostructure

The invention relates to an optical fiber multi-domain sensing system and a demodulation method. The system comprises a sensing system light path which is mainly composed of a broadband light source, a light pulse modulation module, an adjustable FP filter, distributed microstructure sensing optical fibers, a circulator, a spectral calibration device and a time-delay optical fiber; a sensing system signal generation and data acquisition unit which is composed of a DA module, an AD module, an FPGA module, a detector, a receiving circuit and a driving circuit; and a data transmission processing unit which is composed of a data processing module and an I / O transmission bus. High-speed, high-precision and broadband demodulation of wavelength domain, frequency domain, time domain and other multi-domain information of light sensing signals can be realized so that the optical fiber multi-domain sensing system has advantages of small size, compact and stable structure and high reliability.

Owner:HUAZHONG UNIV OF SCI & TECH

High-strength martensite stainless steel plate and production method thereof

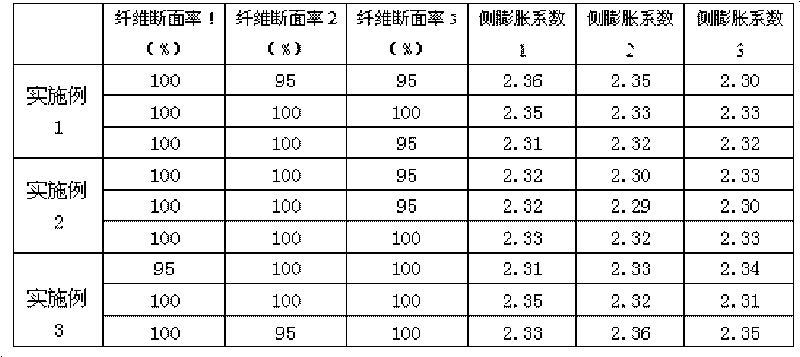

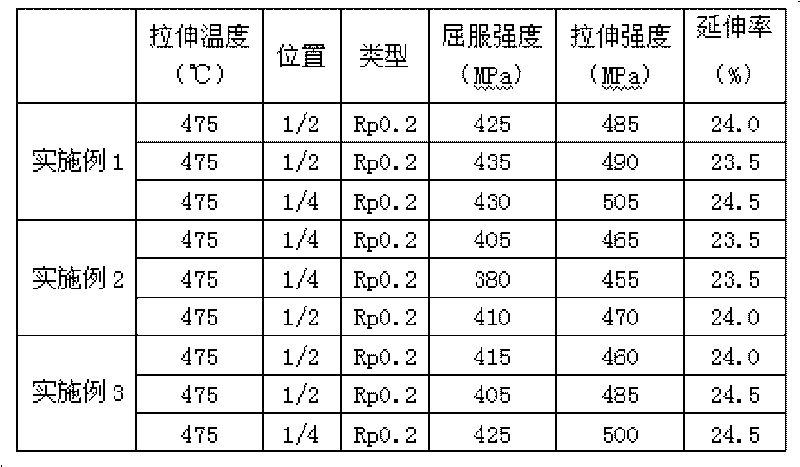

ActiveCN105132820AGuaranteed straightnessImprove surface qualityMartensitic stainless steelSlow cooling

The invention discloses a high-strength martensite stainless steel plate and a production method thereof. The production method comprises a cogging process, a rolling process and a thermal treatment process. The steel plate consists of the following chemical components in percentage by mass: less than or equal to 0.06% of C, less than or equal to 1.00% of Si, less than or equal to 1.00% of Mn, less than or equal to 0.030% of P, less than or equal to 0.015% of S, 15.00%-17.00% of Cr, 4.50%-5.50% of Ni, 0.80%-1.20% of Mo, less than or equal to 0.00025% of H, greater than or equal to 0.020% of N, and the balance of Fe and inevitable impurities. The rolling process adopts whole-process water-avoiding quick rolling without extruding by use of a vertical stick; after being cogged, steel ingot is introduced into a slow cooling pit to carry out slow cooling; the rolling process adopts multi-pass heating quick rolling with small rolling reduction; and the thermal treatment process adopts a quenching and tempering process. The steel plate is good in plate form and stable in performance, good in room-temperature tensile strength and yield strength, good in low-temperature impact toughness at a temperature of (-)40 DEG C and good in ductility.

Owner:WUYANG IRON & STEEL

Large-thickness rolled steel plate instead of case one for large-sized ball mill and production method thereof

InactiveCN101956130AGood toughness indexIncrease thickness specificationTemperature control deviceMetal rolling arrangementsMolten steelHydrogen treatment

The invention discloses a large-thickness rolled steel plate instead of a cast one for a large-sized ball mill and a production method thereof. The steel plate is formed by smelting the following components by weight percent: 0.160-0.190% of C, less than or equal to 0.45% of Si, 1.300-1.500% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.020-0.050% of Als, 0.015-0.025% of Nb and the balance Fe and inevitable impurities. The method comprises the following steps: smelting molten steel in an electric furnace; refining in an LF refining furnace; performing vacuum treatment in a vacuum degassing furnace; and casting, electroslag remelting, heating, rolling to finished product, cooling, performing hydrogen expanding treatment and normalizing and the like to prepare into the finished product thick steel plate. The invention has the following advantages: 1) the strength and toughness are matched favorably, the yield strength Re is more than or equal to 265 MPa, Rm is 430-600 MPa, the longitudinal impact power is more than or equal to 34J at the temperature of 0 DEG C, and A is more than or equal to 17%; 2) the lamellar tearing resistance is good, and Z is more than or equal to 35%; 3) the steel of the invention is purer, P is less than or equal to 0.015%, and S is less than or equal to 0.005%: 4) the internal quality is more compact, and can satisfy the requirement of the A578C class detection standard; and 5) the maximum thickness of the steel plate can achieve 288mm.

Owner:WUYANG IRON & STEEL +1

690 MPa-grade hydrogen sulfide corrosion resisting steel plate and production method thereof

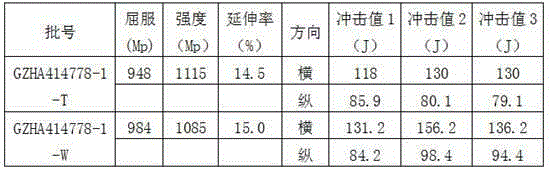

The invention discloses a 690 MPa-grade hydrogen sulfide corrosion resisting steel plate. The steel plate comprises the following chemical components in percentage by mass: 0.14-0.16% of C, 0.20-0.40% of Si, 1.05-1.10% of Mn, 0.40-0.45% of Ni, P not more than 0.012%, S not more than 0.003%, 0.020-0.040% of Al, 0.020-0.030% of Nb, 0.035-0.040% of V, 0.01-0.02% of Ti, 0.30-0.35% of Cr, 0.25-0.30% of Mo, 0.0015-0.0020% of B, N not more than 0.010%, Cu not more than 0.20%, and the balance of Fe and inevitable impurities. A production method of the 690 MPa-grade hydrogen sulfide corrosion resisting steel plate comprises the procedures of heating, rolling and heat treatment. The 690 MPa-grade hydrogen sulfide corrosion resisting steel plate has such characteristics as high compactness, higher strength grade, excellent low-temperature impact toughness, excellent lamellar tearing resistance and excellent hydrogen sulfide corrosion resistance, can satisfy the requirements of hydrogen sulfide corrosion resisting steel for ship storage tanks, is excellent in comprehensive performance and welding performance, and is lower in cost.

Owner:WUYANG IRON & STEEL

An incoherent spread spectrum communication apparatus with variable data rate

ActiveCN108988906AQuick captureFast demodulationRadio transmissionHigh level techniquesData transmissionSignal-to-noise ratio (imaging)

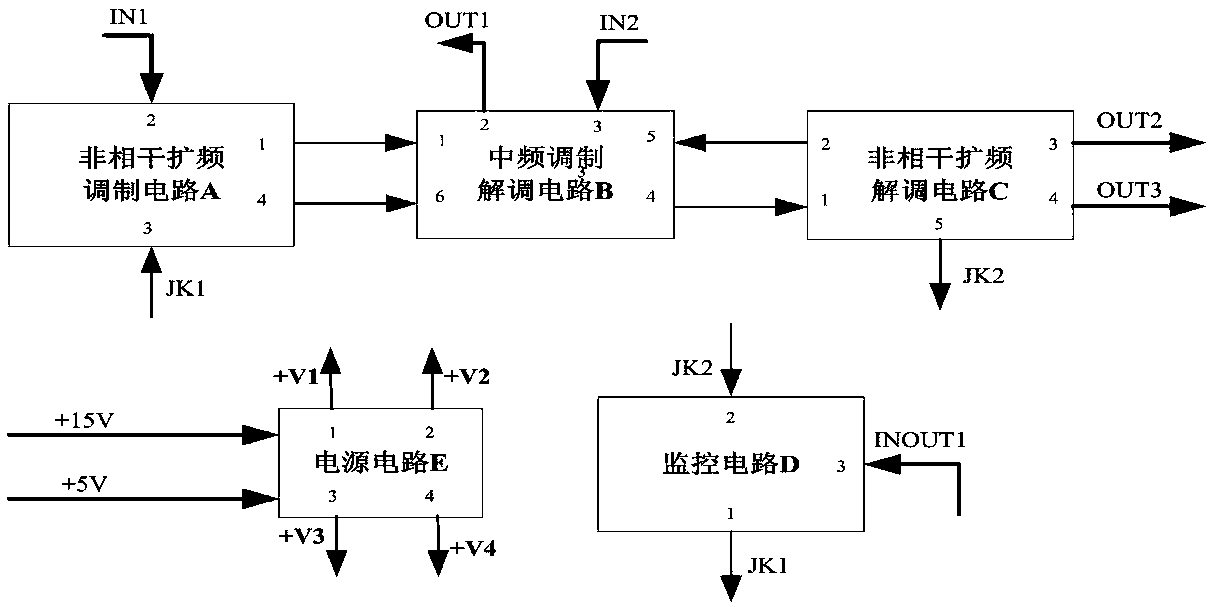

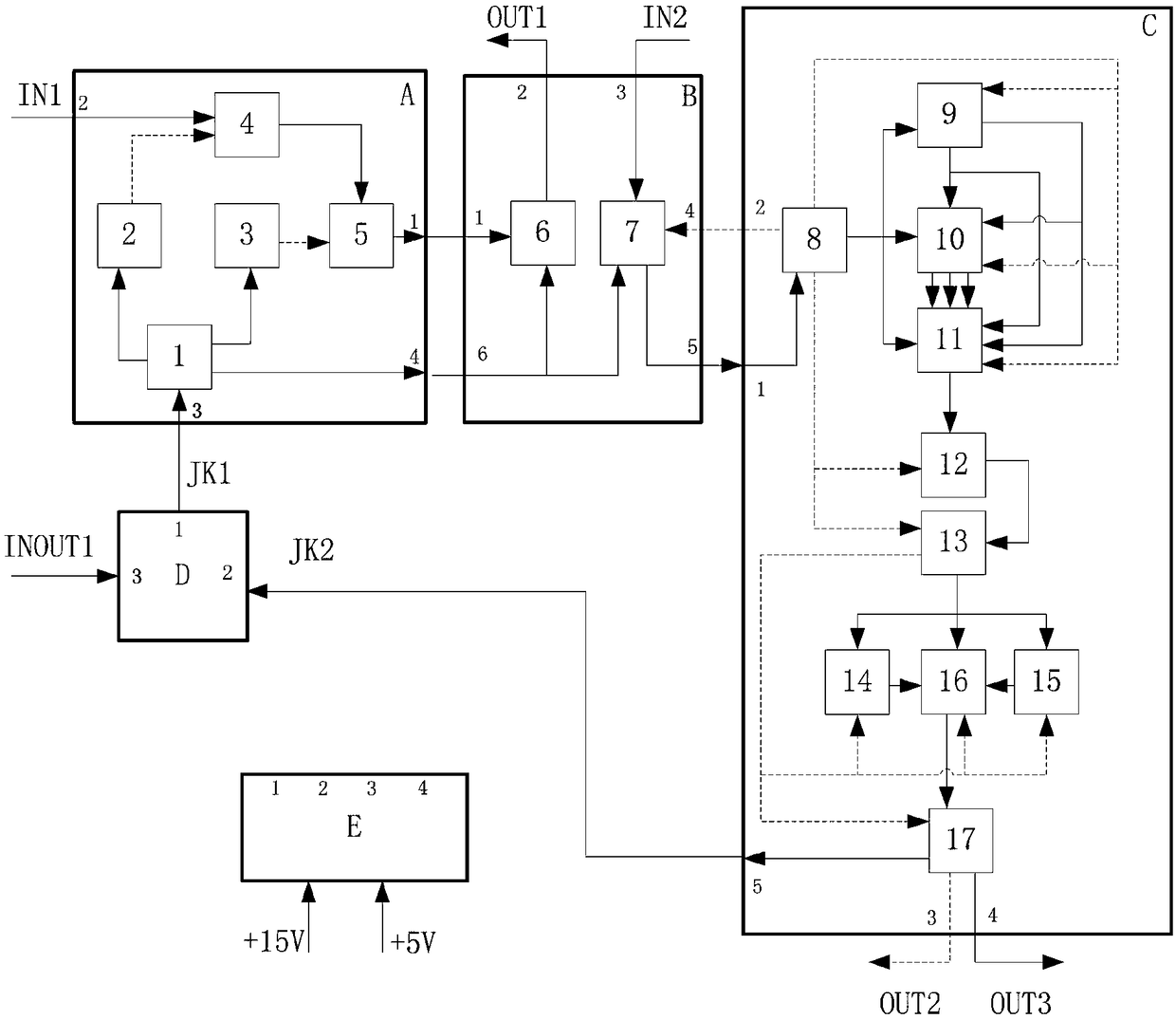

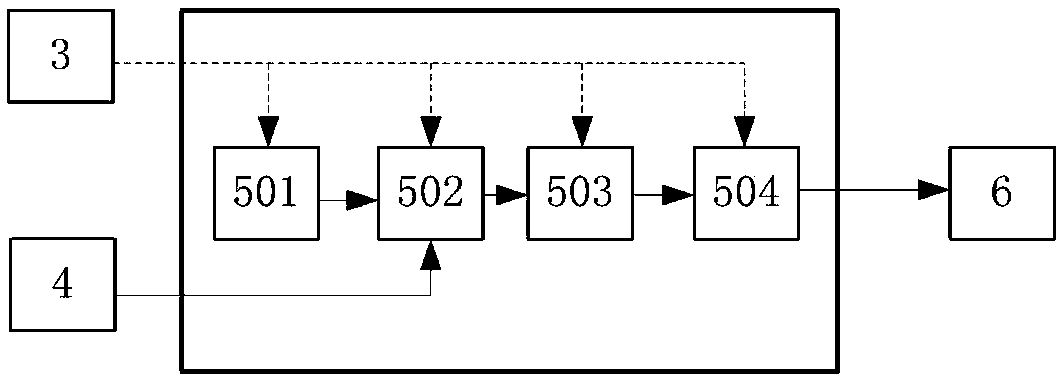

The invention discloses a non-coherent spread spectrum communication device with variable data rate, which relates to realizing non-coherent spread spectrum modulation and demodulation data transmission with variable data rate bit by bit, configurable spread spectrum code rate, strong anti-Doppler performance and fast synchronization speed under the condition of low signal-to-noise ratio. Frequency sweep, parallel partial coherence and incoherent accumulation are used to realize the fast acquisition of incoherent spread spectrum signals with large frequency offset range, and digital average filter and square filter are used to achieve symbol timing synchronization of incoherent spread spectrum signals. The invention has high integration degree, strong portability, light weight and low power consumption, small commissioning workload of the whole machine, simple and flexible interface, easiness in expanding, and stable and reliable performance, the circuit is integrated in a 292mm long,185mm wide and 28mm high square terminal, weighing 0.6 kg, which is especially suitable for the application of non-coherent spread spectrum modulation and demodulation channel transmission terminal inairborne satellite communication system with limited volume and weight.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

SA387Gr11Cl1 steel plate for petrochemical pipelines and production method thereof

The invention discloses an SA387Gr11Cl1 steel plate for petrochemical pipelines and a production method thereof. The SA387Gr11Cl1 steel plate is composed of the following components in percentage by weight: 0.08-0.11% of C, 0.50-0.65% of Si, 0.40-0.50% of Mn, less than or equal to 0.010% of P, less than or equal to 0.008% of S, 1.10-1.30% of Cr, 0.45-0.55% of Mo, 0.10-0.14% of Ni, less than or equal to 0.20% of Cu, 0.025-0.045% of Al, less than or equal to 0.003% of Sb, less than or equal to 0.010% of Sn, less than or equal to 0.010% of As and balance of Fe and inevitable impurities. According to the steel plate disclosed by the invention, the composition proportion of the SA387Gr11Cl1 steel plate in ASTM A387 is optimistically improved, and the contents of impurity elements such as P and S are strictly controlled; and the steel plate has the advantages of good tensile property, superior low temperature impact toughness, superior high temperature creep resistance, excellent corrosion resistance, higher compression strength, higher low temperature toughness and superior welding performance, and is suitable for high temperature and high pressure severe working conditions of petrochemical equipment.

Owner:WUYANG IRON & STEEL

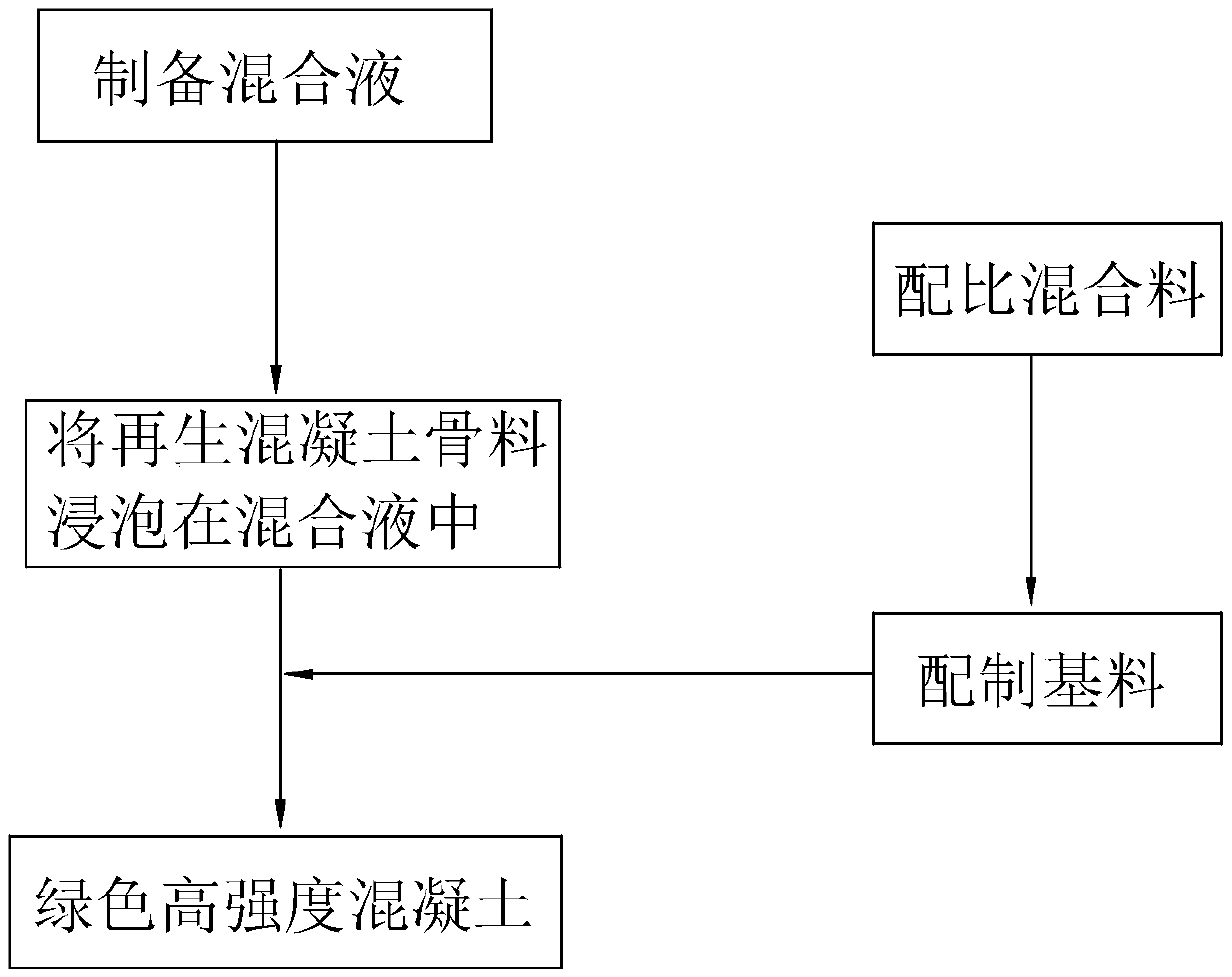

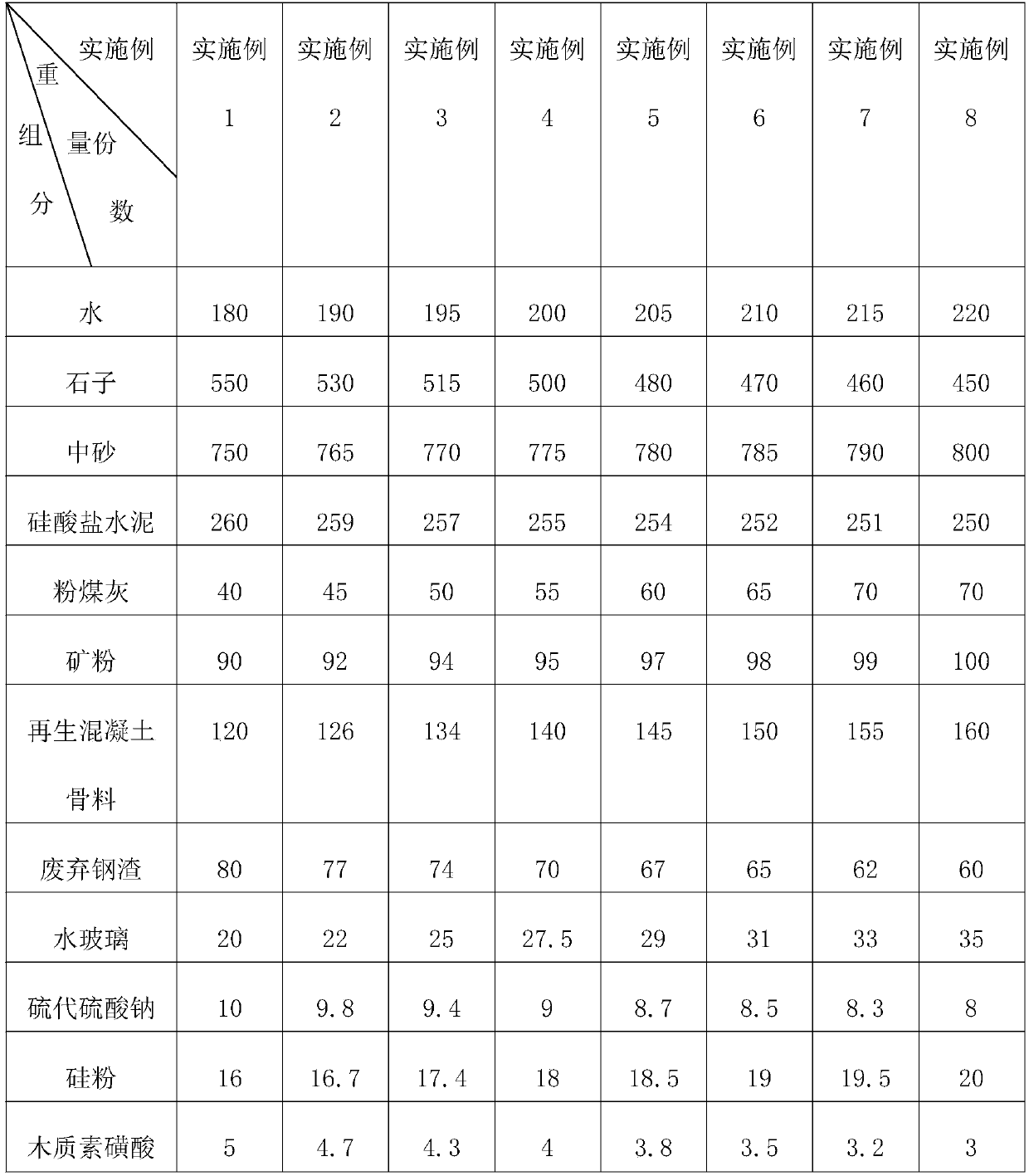

Green high-strength concrete and preparation technology thereof

InactiveCN109608152AFine surfaceInner denseSolid waste managementHigh strength concreteEnvironmental resistance

The invention discloses green high-strength concrete and a preparation technology thereof, and relates to the technical field of concrete production. The problems are solved that since recycled concrete aggregate in concrete is poor in stability, the overall structural strength of the concrete is not uniform, and the stability is poor. The green high-strength concrete includes, by weight, 180-220parts of water, 450-550 parts of cobbles, 751-800 parts of medium sand, 250-260 parts of Portland cement, 40-70 parts of pulverized fuel ash, 90-100 parts of mineral powder, 120-160 parts of recycledconcrete aggregate, 61-80 parts of abandoned steel slag, 20-35 parts of water glass, 8-10 parts of sodium thiosulfate, 16-20 parts of intensifying filling and 3-5 parts of a water reducing agent. Thegreen high-strength concrete has good stability and structural strength, and is uniform in overall structural strength, realizes greening in production, and has good applicability.

Owner:杭州申华混凝土有限公司

Large-thickness high-performance SA302GrC steel plate and production method thereof

The invention relates to a large-thickness high-performance SA302GrC steel plate and a production method thereof, belonging to the technical field of steel smelting processes. According to the technical scheme, the production method comprises procedures of smelting, casting, heating, rolling, cooling after rolling, normalizing, accelerated cooling and tempering; and the steel plate is prepared from the following chemical ingredients in percentage by mass: 0.10-0.18% of C, 0.15-0.40% of Si, 1.20-1.45% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.40-0.55% of Ni, 0.45-0.60% of Mo, and the balance of Fe and inevitable impurities. The steel plate has the following advantages that the obdurability matching is good, the yield strength Re is greater than or equal to 345Mpa, the transverse Charpy impact in the position which is 1 / 4 of the plate thickness at minus 10 DEG C is less than 41J, the steel quality is purer, the lamellar tearing resisting property is good, the through thickness direction Z is greater than or equal to 35%, the welding property is good, and the thickness of the steel plate is 135mm. The steel plate which is produced by using the production method provided by the invention has the characteristics of high purity, uniformity in component and internal compactness, and has good obdurability matching.

Owner:WUYANG IRON & STEEL +1

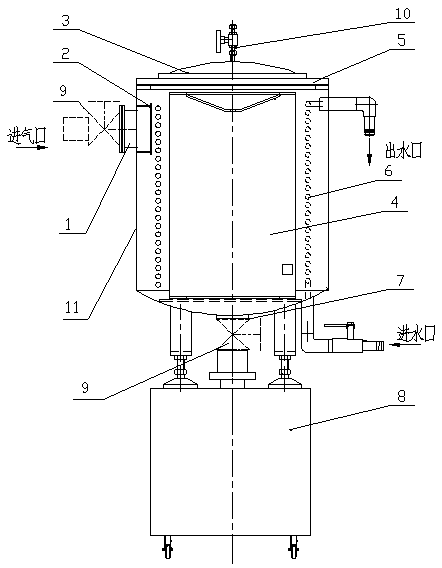

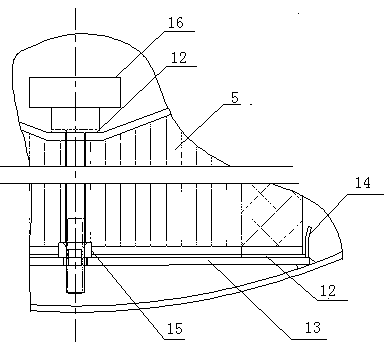

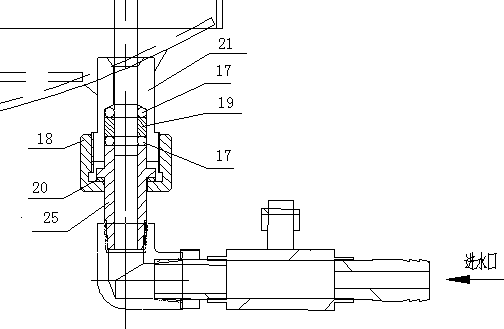

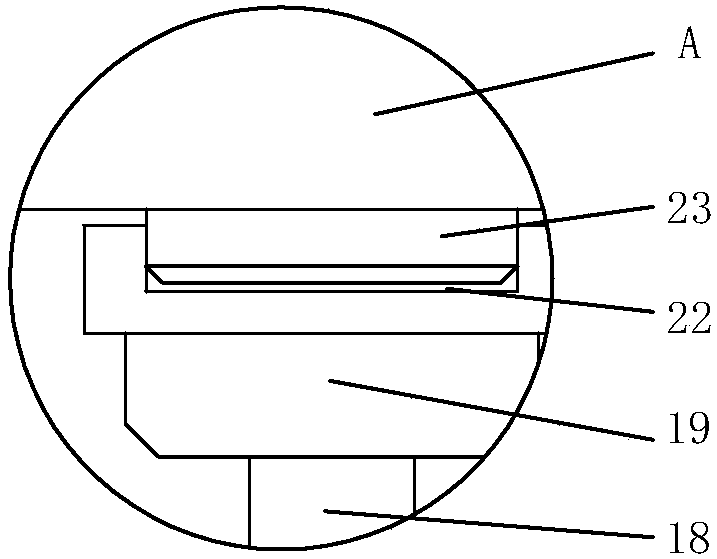

Vacuum filter

InactiveCN105498380AOptimize the installation structureQuick and easy installationHuman health protectionDispersed particle filtrationFiltrationUpstream downstream

The invention discloses a vacuum filter, and belongs to the field of filtration, which is used for solving the problems of cooling and dedusting of high-temperature and dust-contained gas in a vacuum working system. The vacuum filter comprises a cavity body, a diffuser and a filter element, wherein the cavity body is provided with a gas inlet connected with a specific gas pipeline and a gas outlet connected with a vacuum pump; the top end of the cavity body is provided with a top cover connected with the cavity body in a sealed mode; the cavity body is internally provided with the diffuser at the gas inlet; the filter element is installed at the center in the cavity body; the side wall of the filter element is provided with filter holes; the bottom surface of the filter element is provided with an opening leading to the gas outlet of the cavity body, thereby preventing the vacuum pump and an upstream-downstream system from being damaged by high-temperature, corrosive and dangerous dust particles, and solving the problem of too complex and frequent maintaining frequency of the vacuum pump of the vacuum filtration system. From the aspect of environment protection, gas in pipelines can be further cooled down and purified, and air pollution can be reduced.

Owner:青岛赛瑞达电子科技有限公司

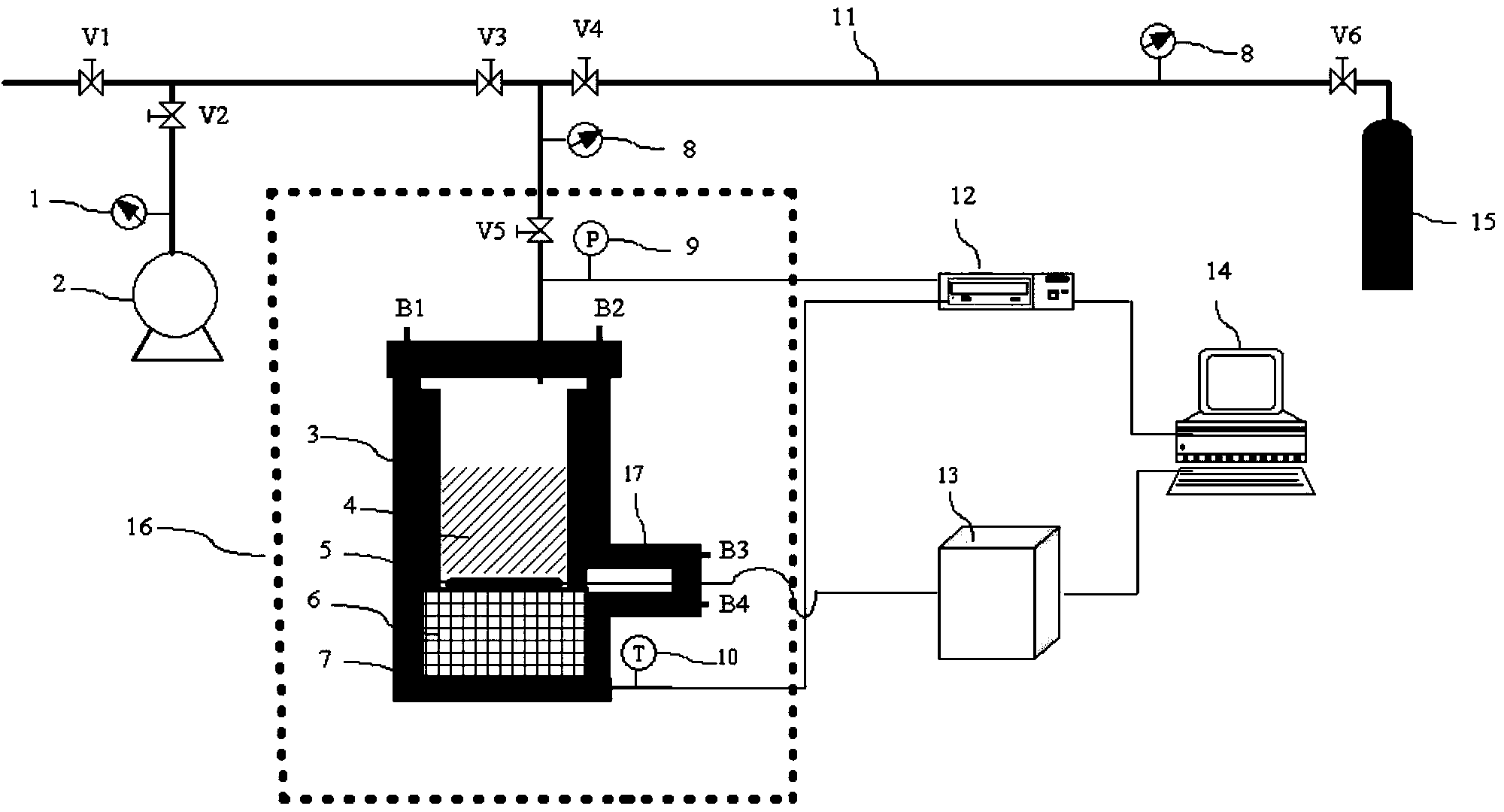

In-situ heat conductivity coefficient testing device and method for gas hydrate

The invention provides an in-situ heat conductivity coefficient testing device and method for a gas hydrate. The inner wall of a reaction kettle is lined with fluorine plastic material; before production of a gas hydrate, gas is highly dissolved; the super-cooling degree is adopted in the production process; the gas hydrate is generated under a gas-liquid interface in the reaction kettle; the obtained hydrate sample is flat in surface, compact in the interior and high in gas content; the hydrate sample is in full contact with a heat conduction probe arranged at the bottom of the reaction kettle, and high-pressure compaction is not needed; a heat conduction testing device comprises a set of thermophysical property analysis tester based on a transient plane thermal source method; the heat conduction probe is adhered to the surface of a background material layer; the background material layer is arranged flat at the bottom of the reaction kettle; the background material layer is adhered to a cylinder cured by a high-strength structural adhesive; the heat conduction probe is adhered to the background material layer by the same high-strength structural adhesive. The hydrate synthesized by the device and the method is high in quality; the heat conductivity coefficient test is simple in operation, convenient in data acquisition and accurate and reliable in test value.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Rice dumpling capable of reducing rice on reed leaf and preparation method of rice dumpling

InactiveCN104012849ALess sticky rice or even no sticky riceCombined compactFood thermal treatmentFood preparationCalcium bicarbonateSodium diacetate

The invention relates to a food and a preparation method thereof, and in particular relates to a rice dumpling capable of reducing rice on reed leaf and a preparation method of the rice dumpling. The method comprises the following steps: previously preparing raw materials: water, sticky rice, sodium carbonate, sesame oil, corn powder, sodium diacetate and calcium bicarbonate, cooking reed leaves, making rice dumpling, and soaking the rice dumpling. The invention aims at effectively reducing the rice on the reed leaf.

Owner:徐旭波

Hydrogen sulfide corrosion resistant hardened and tempered high-strength steel plate for offshore drilling platform and producing method for hydrogen sulfide corrosion resistant hardened and tempered high-strength steel plate

The invention discloses a hydrogen sulfide corrosion resistant hardened and tempered high-strength steel plate for an offshore drilling platform. The steel plate consists of the following chemical components in percentage by weight: 0.13%-0.15% of C, 0.15%-0.35% of Si, 1.10%-1.30% of Mn, 1.20%-1.25% of Ni, less than or equal to 0.012% of P, less than or equal to 0.003% of S, 0.020%-0.050% of Al, 0.020%-0.030% of Nb, 0.030%-0.040% of V, 0.015%-0.02% of Ti, 1.00%-1.10% of Cr, 0.40%-0.50% of Mo, 0.0005%-0.0015% of B, less than or equal to 0.25% of Cu, and the balance Fe and inevitable impurities. A production method comprises the processes of heating, rolling and thermal treatment. The steel plate produced by the production method has the characteristics of being uniform in component and internally compact, has a good structure, good comprehensive properties, good hydrogen sulfide corrosion resistance and good welding performance, and the performances of the steel plate completely meet operating requirements of the hydrogen sulfide corrosion resistant hardened and tempered high-strength steel plate for the offshore drilling platform.

Owner:WUYANG IRON & STEEL

Preparing method of environment-friendly antibacterial and mildew-proof composite fiber panel

InactiveCN109227867AAchieve reuseInner densePressure impregnationFlat articlesFiberManufacturing technology

The invention relates to the technical field of panel manufacturing, in particular to a preparing method of an environment-friendly antibacterial and mildew-proof composite fiber panel. The method includes the steps of preparing basic fiber, preparing enhancing fiber, preparing a binder, preparing a flame-retardant enhancer, preparing a curing agent, mixing the materials and preparing the panel. By means of the method, wastes are recycled, and the prepared panel is environmentally friendly, high in mechanical strength, excellent in mildew-proof and flame-retardant performance, free of harmfulgas releasing, controllable in production process, free of toxin and harm and suitable for batch production and has high practical value and good application prospects.

Owner:HEFEI SHANGHAN DECORATION ENG CO LTD

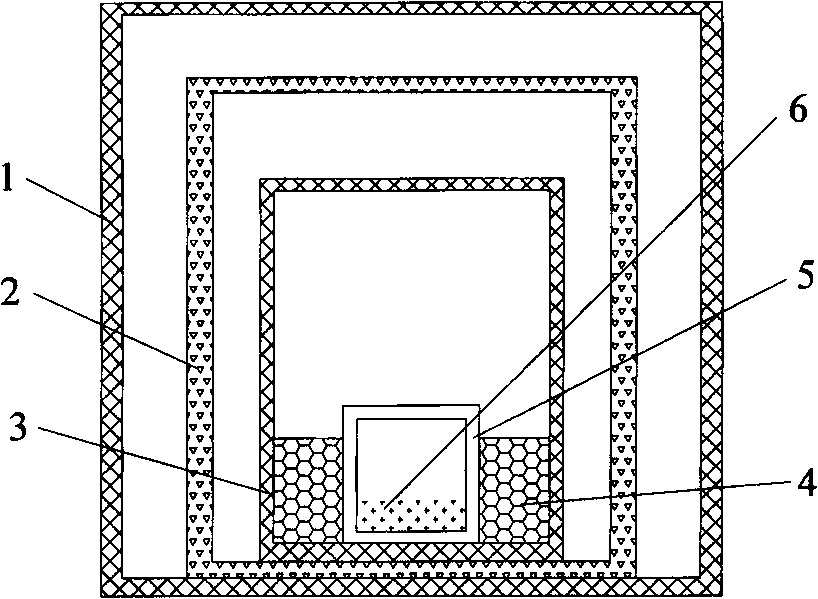

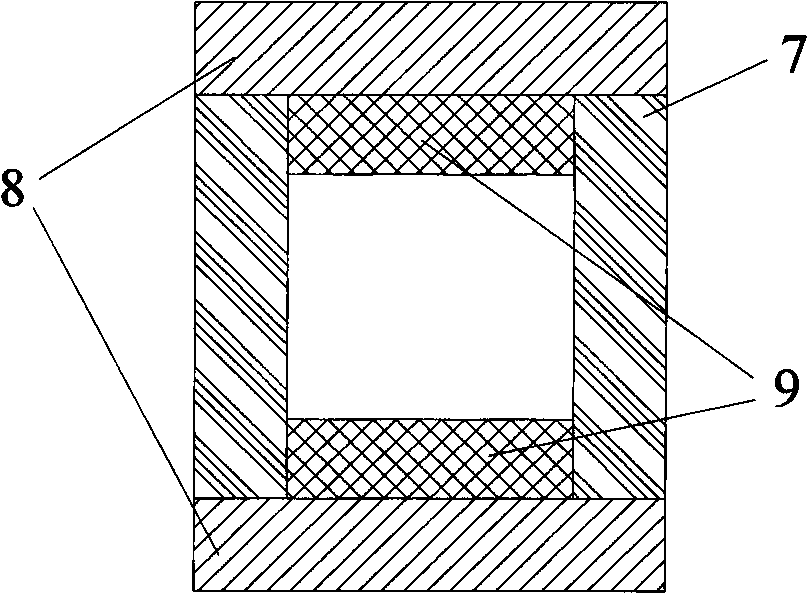

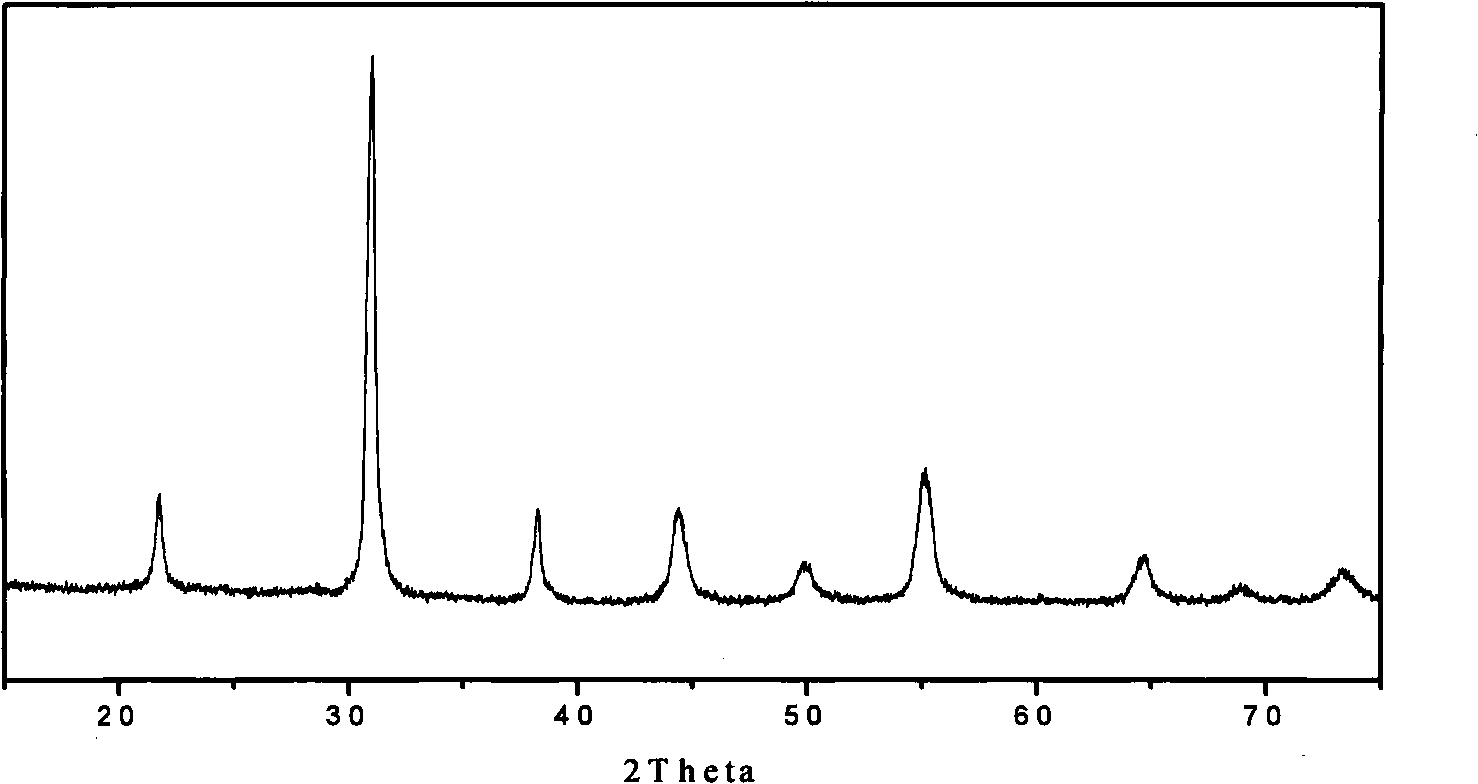

Microwave auxiliary thermal treatment method for ceramic fibre and thermal insulation body structure

The invention provides a microwave auxiliary heat treatment method for ceramic fiber, and a heat insulator structure thereof, and relates to a ceramic fiber. The invention provides the microwave auxiliary heat treatment method for ceramic fiber, and the heat insulator structure thereof. The prepared fiber has a single-phase structure, has the length-diameter ratio more than 200, is compact in inside, and can be used for 1-3 type piezoelectric composite materials. The ceramic fiber is obtained by putting gel fiber into a crucible, putting the crucible with the gel fiber into a heat insulator, presintering the whole heat insulator in a microwave oven and then subjecting the presentered fiber to heat treatment in a muffle furnace. The heat insulator structure thereof is provided with an outer-layer heat insulator, a secondary-outer-layer Al2O3 heat insulator and an inner-layer crucible, and a microwave auxiliary absorbing medium is arranged between the secondary-outer-layer Al2O3 heat insulator and the inner-layer crucible.

Owner:XIAMEN UNIV

Method for preparing glass fiber cement felt

ActiveCN105948620AImproves carbonation resistanceImprove wear resistanceGlass fiberWeather resistance

The invention provides a method for preparing glass fiber cement felt. The method comprises the preparing steps sequentially: preparing composite cement paste, and carrying out anisobaric baking molding on the composite cement paste and glass fiber felt, wherein an anisobaric baking molding process for the composite cement paste and the glass fiber felt comprises the steps of carrying out paste lifting and cavity filling, carrying out pressure-maintaining baking and carrying out depressurizing releasing. According to the method, the prepared composite cement paste is introduced into a mold and is subjected to anisobaric baking molding together with the glass fiber felt, so that the method is more efficient; the glass fiber cement felt prepared by the method provided by the invention has excellent weather resistance and various physical properties; and meanwhile, the interior is tight, and the surface is smooth, so that the accuracy of preparing of the glass fiber cement felt can be guaranteed, and meanwhile, the service effect and service life of the prepared product are guaranteed.

Owner:安徽瑞联节能科技股份有限公司

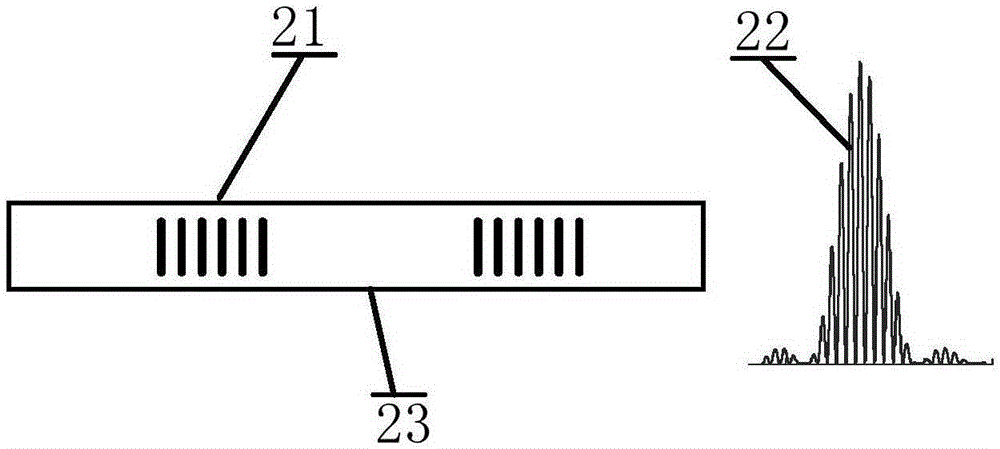

Modem based disperse pilots

ActiveCN106027442AImprove communication efficiencyImprove demodulation performanceMulti-frequency code systemsMultiple carrier systemsModem deviceCommunications system

The invention discloses a modem based disperse pilots, and relates to the modem technology of a communication system applying high-order modulation in the communication field. According to the modem, a frame format is improved on the basic structure of the communication system. Through addition of the disperse pilots, the carrier recovery complexity is reduced, and the carrier recovery performance of the modem is improved. The realization process of the modem is simple and effective. The modem is very suitable for the communication system applying a high-order modulation mode.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

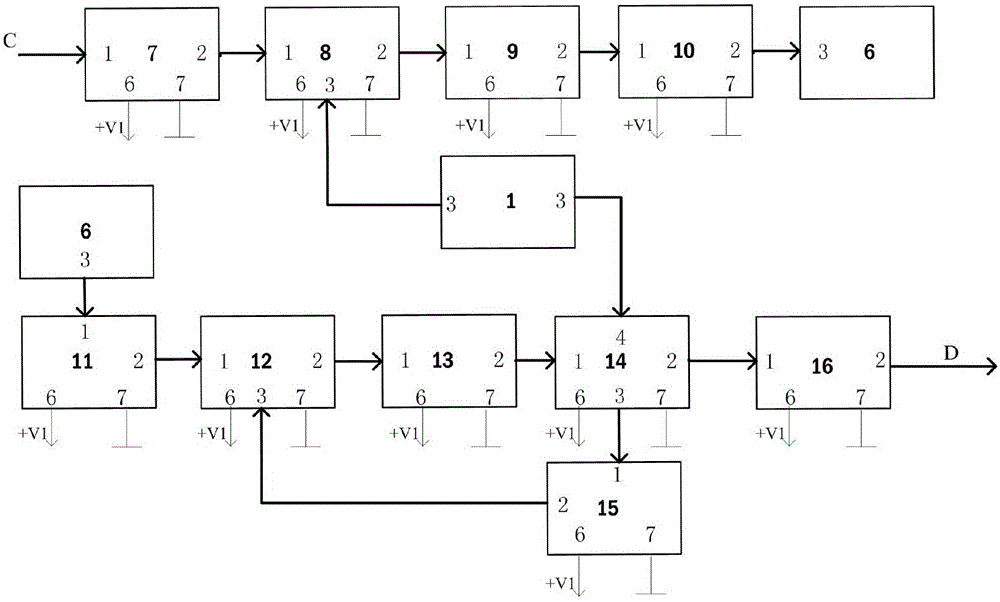

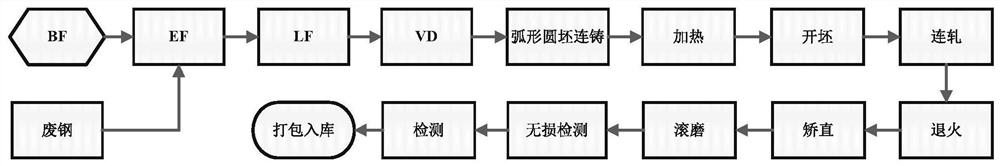

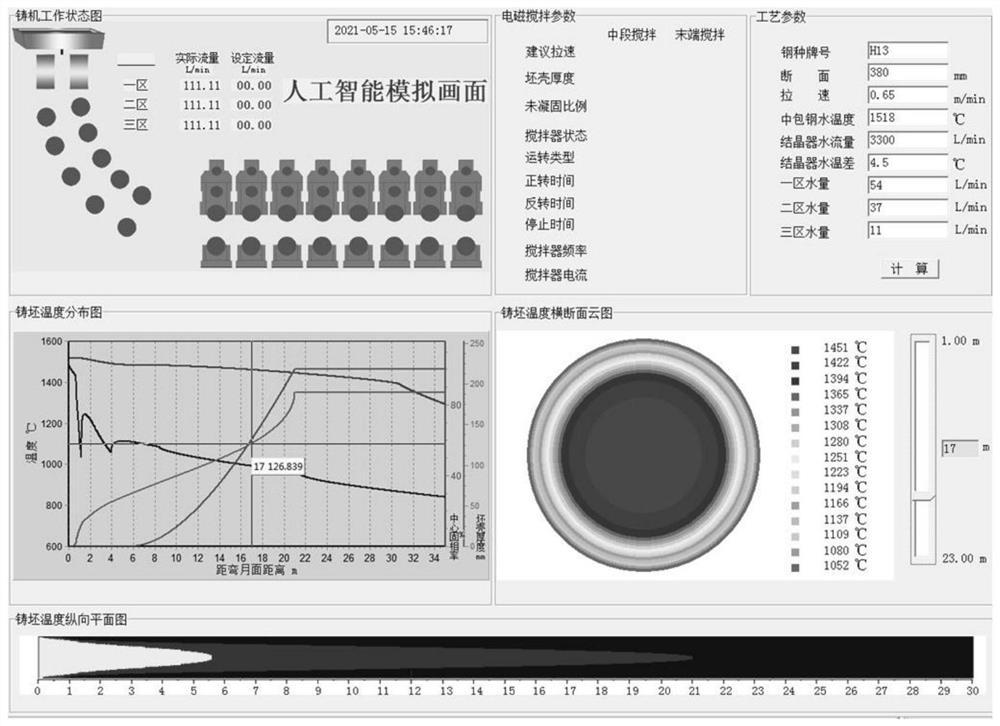

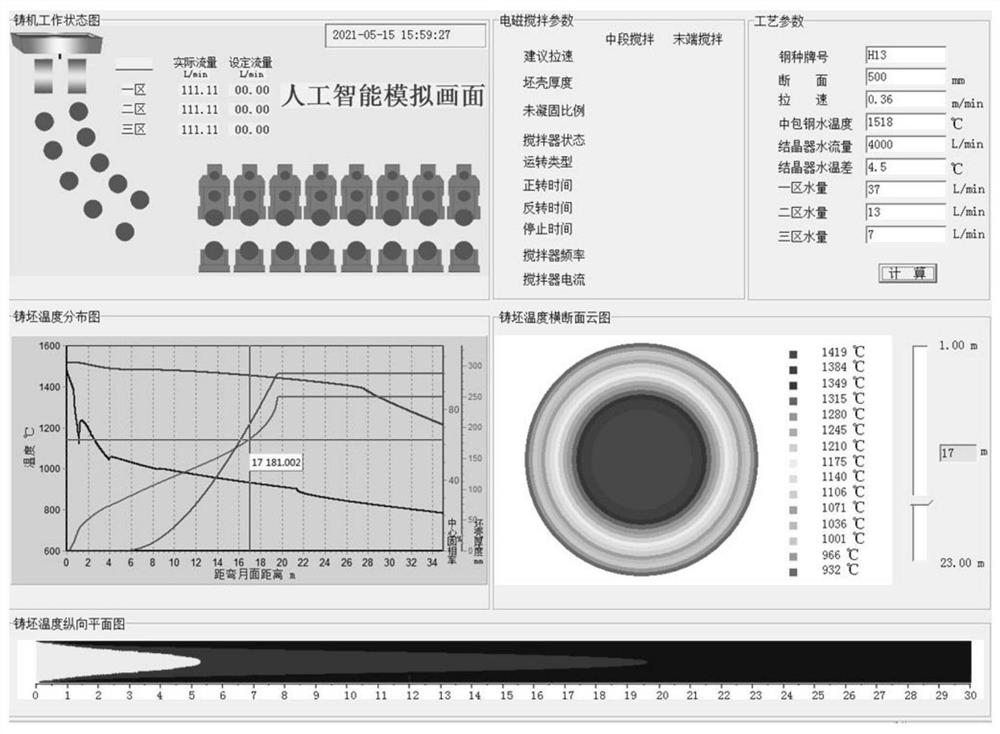

Hot work die steel H13 and continuous casting and rolling manufacturing process thereof

The invention discloses a hot work die steel H13 and a continuous casting and rolling manufacturing process thereof. The continuous casting and rolling manufacturing process comprises the steps of molten steel smelting, LF refining, VD vacuum treatment, continuous casting and steel rolling, wherein the molten iron is produced through blast furnace smelting, so that the molten iron with a low content of harmful elements can be obtained, after the obtained molten steel is subjected to refining and VD vacuum treatment, molten steel containing a low content of harmful elements such as P, S, Cu, Ni, As, Sb and Sn is obtained, a continuous casting round billet with good internal quality is obtained by adopting three-stage electromagnetic stirring and setting the reasonable degree of superheat, casting speed and cooling process, a steel rod obtained through rolling is heated through four temperature sections, and then the steel rod with the compact interior and the good surface quality is obtained. Besides, the flaw detection qualification rate is greatly increased.

Owner:JIANGSU LIANFENG ENERGY EQUIP

Preparing method of mould-proof environment-friendly artificial boards

InactiveCN109333745AAchieve reuseInner denseWood treatment detailsPressure impregnationBatch productionAdhesive

The invention relates to the technical field of board manufacturing, in particular to a preparing method of mould-proof environment-friendly artificial boards. The preparing method comprises the stepsof preparing basic fibers, preparing reinforced fibers, preparing adhesives, preparing a flame-retardant enhancer, preparing a curing agent, mixing the materials and preparing the boards. By means ofthe preparing method of the boards, waste is recycled and environment friendliness is achieved; and the prepared boards have good mechanical strength, excellent mould-proof and flame-retardant properties, free of emission of harmful gas, controllable in the production process, nontoxic and harmless, area suitable for batch production and have high practical value and good application prospects.

Owner:HEFEI SHANGHAN DECORATION ENG CO LTD

Weather-resistance bridge high-strength steel plate and production method thereof

InactiveCN101876032BIncrease thickness specificationExcellent performance indexWeather resistanceUltimate tensile strength

Owner:WUYANG IRON & STEEL +1

Flexible packing former for concrete face rockfill dam face

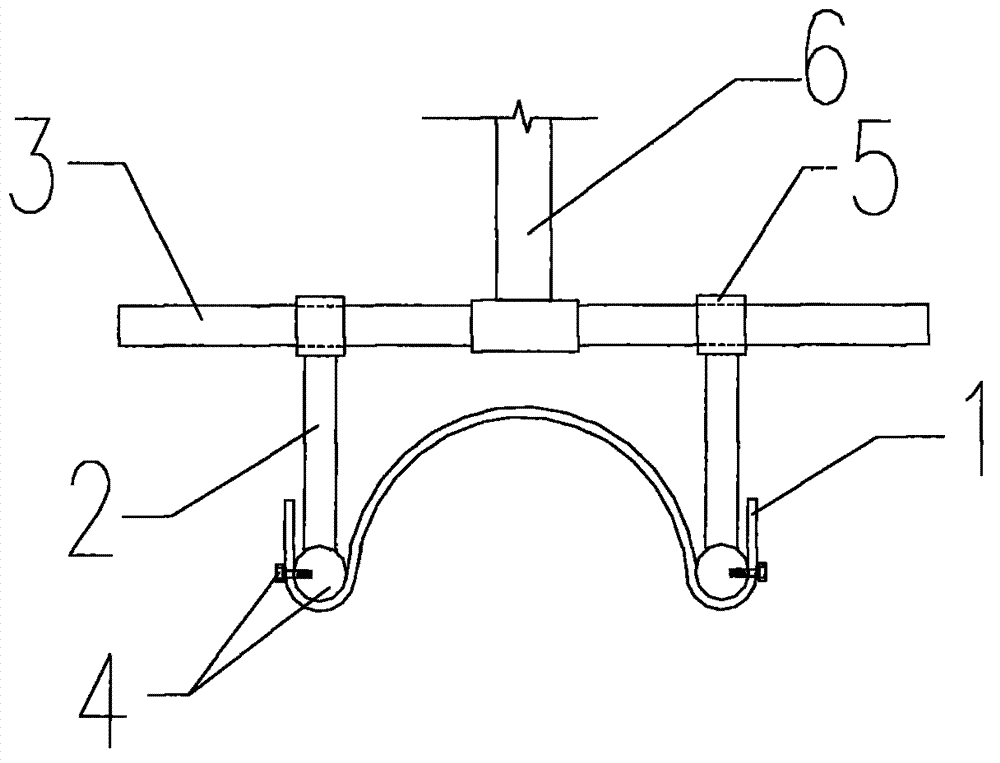

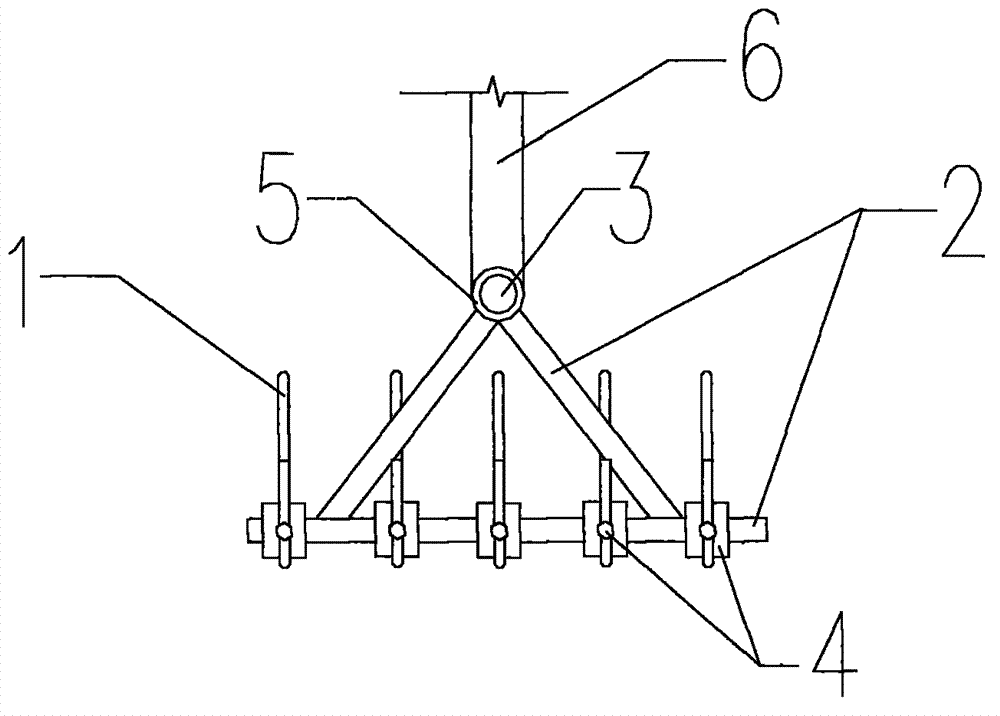

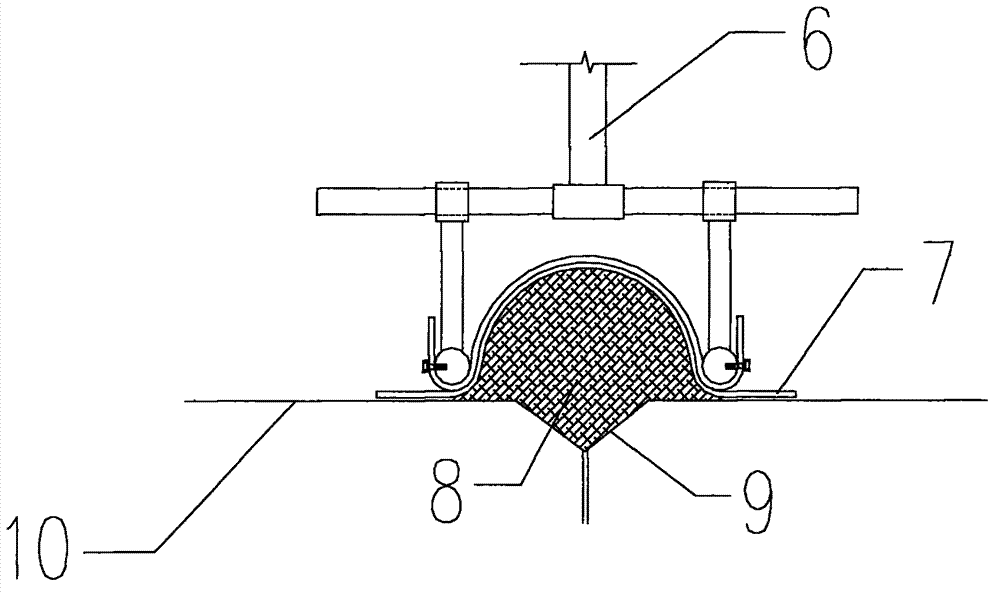

The invention provides a flexible packing former for a concrete face rockfill dam face. The flexible packing former is characterized by comprising a machine body, wherein the machine body comprises forming belts for clamping and pressing flexible packing, fixing parts for fixing the two ends of each forming belt and connecting parts for connecting the fixing parts; slot surfaces for clamping and pressing the flexible packing are formed in the forming belts; the slot surfaces are matched with the outer profile of the cross section of the flexible packing to be embedded and filled or matched with the decomposed cross section of the flexible packing to be embedded and filled in shape; the number of the forming belts is no less than 2; the forming belts are made from materials which are easy to deform and good in tensile strength; such materials which are easy to deform and good in tensile strength are nonmetal materials, such as rubber, leather, plastic and the like, or metal materials, such as copper, aluminum, iron and the like; the connecting parts can be used for adjusting the spacing among the fixing parts; and the fixing parts are provided with fixtures capable of clamping the forming belts. According to the flexible packing former, the problems of low efficiency and low quality in embedding and filling joint materials in jointing and caulking construction of the concrete face rockfill dam face can be effectively solved.

Owner:朱博程 +1

Preparation method of environment-friendly plate

The invention relates to the technical field of plate manufacturing, in particular to a preparation method of an environment-friendly plate. The preparation method comprises the steps of basic fiber preparation, reinforced fiber preparation, bonder preparation, preparation of an inflaming retarding reinforcing agent, preparation of a curing agent, material mixing and plate preparation. According to the preparation method of the plate, waste is utilized repeatedly; the preparation method is green and environment-friendly; the prepared plate is good in mechanical strength and has excellent mouldresistance and inflaming retarding performance; no harmful gas is released; the production process is controllable; the plate is poisonless and harmless and is suitable for batch production; and highpractical value and good application prospects are achieved.

Owner:HEFEI SHANGHAN DECORATION ENG CO LTD

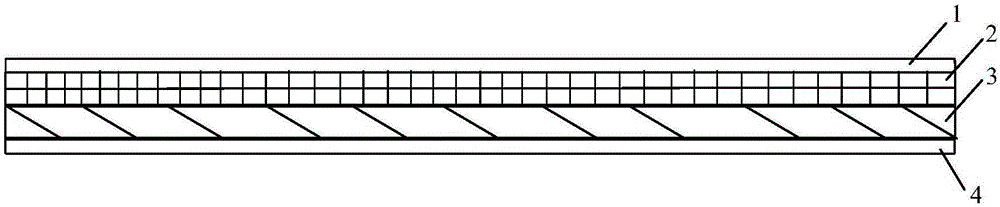

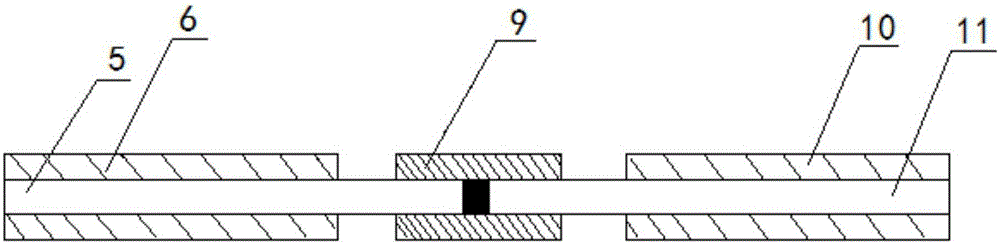

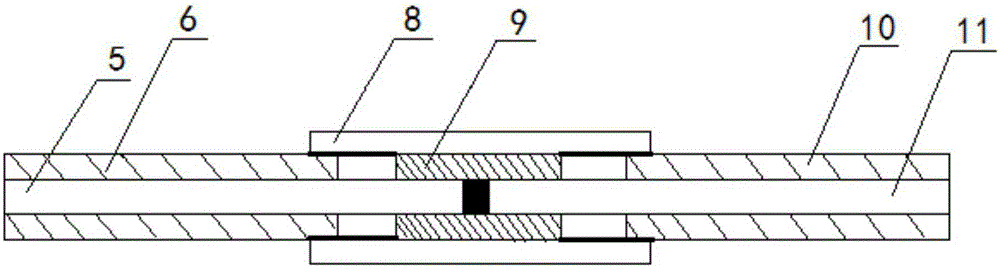

Four-in-one mica tape and insulating method for applying same to motor leading-out wire connection part

ActiveCN105245049AGood flexibilityHigh tensile strengthWindings insulation shape/form/constructionSynthetic resin layered productsFiberAdhesive

The invention discloses a four-in-one mica tape, which comprises a first polymer thin film, a reinforced fiber cloth, mica paper and a second polymer thin film, wherein the layers of materials are adhered by using a high temperature resistant adhesive. The invention further discloses an insulating method for applying the four-in-one mica tape to a motor leading-out wire connection part. The four-in-one mica tape provided by the invention replaces ordinary mica tapes and serves as wrapping insulation materials for the leading-out wire connection part, has excellent flexibility, is tightly attached to the leading-out wire connection part of a high-voltage motor, is high in tensile strength, and is not prone to crumple; further, the internal structure of the four-in-one mica tape is even, compact and voidless, is not prone to be layered, and has good moisture-proof effect. By adopting the insulating method provided by the invention, the insulation structure of the leading-out wire connection part is fully sealed and insulated integrally, the interior of the insulation structure is compact and voidless, and partial discharge cannot be produced.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

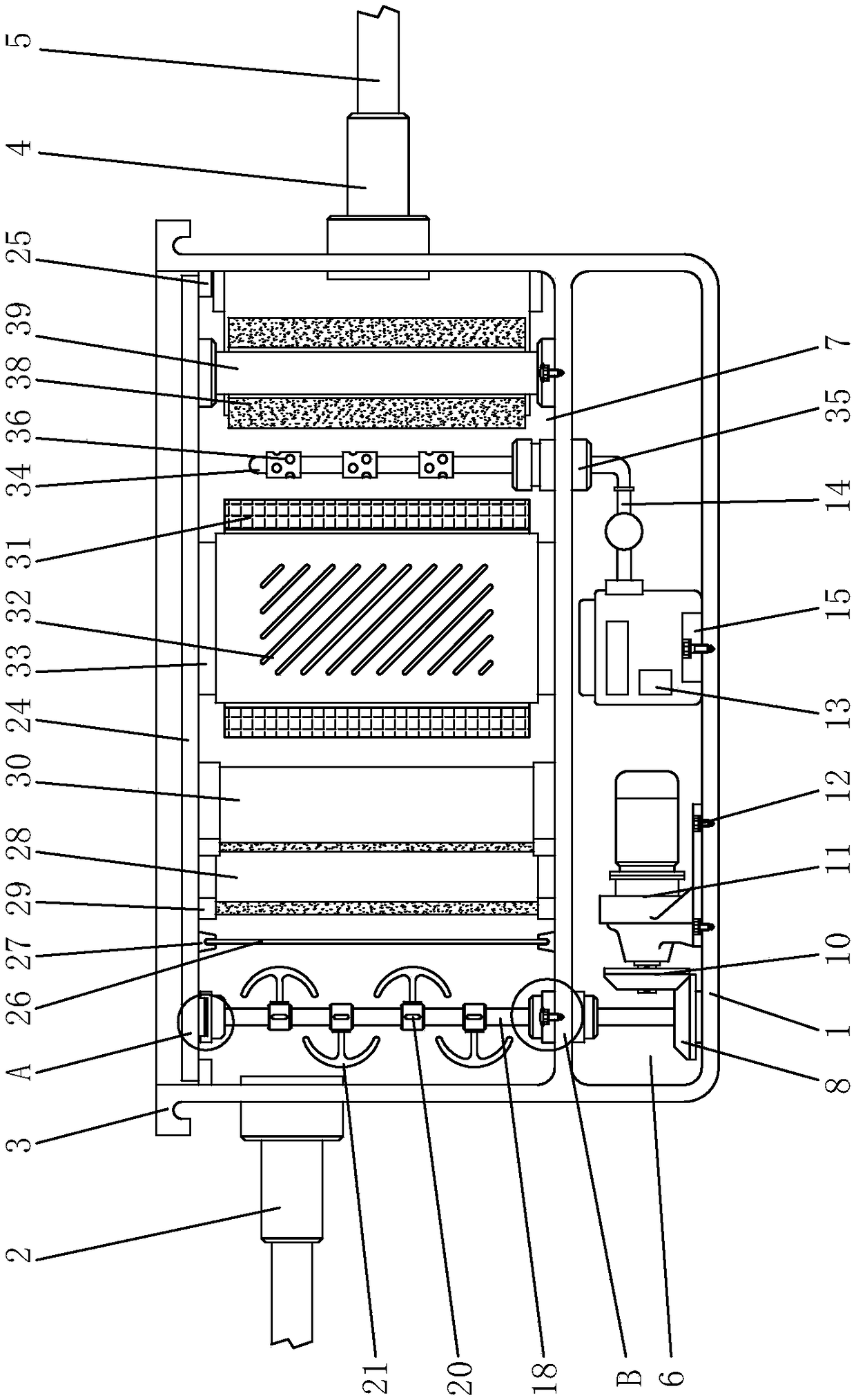

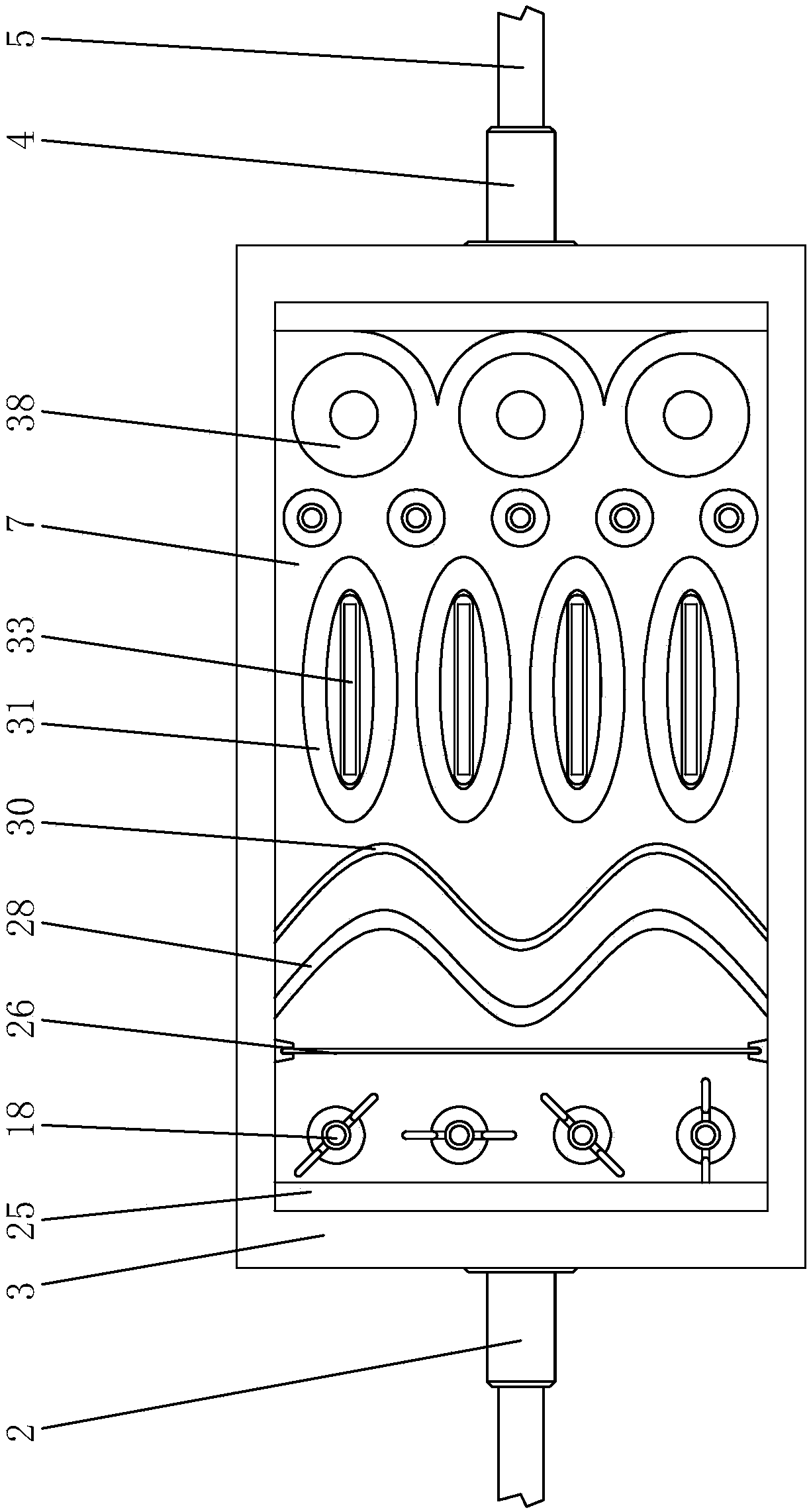

Filter system of fish pond

ActiveCN108575875AIncrease structureImprove performancePisciculture and aquariaEngineeringHigh pressure

The invention discloses a filter system of a fish pond. The filter system comprises a box body shell, a driving gear and a filter screen; the upper part of the left side of the box body shell is connected with a water inlet; an external-turning handle is arranged above the water inlet; a conversion joint is arranged on the right side of the box body shell; the right end of the conversion joint isprovided with a water outlet; a power cabin is arranged at the lower part of the inner part of the box body shell; a filter cabin is arranged above the power cabin; a transmission gear is fixed at theleft end of the inner part of the power cabin; a sealing bearing is arranged above the transmission gear; the right side of the driving gear is connected with a motor; the driving gear is positionedat the right side of the transmission gear; a connecting screw is arranged below the motor; an air compressor is arranged at the right side of the motor; a high-pressure copper pipe is connected to the right side of the air compressor; the lower end of the air compressor is fixed to an internal base; a waterproof screw is arranged in the inner part of the upper end of the sealing bearing; a waterproof cap is arranged on the waterproof screw; and rotating shafts are connected on the sealing bearing. Impurity precipitate is not formed in the filter system, and the blockage of the filter device is avoided.

Owner:日照新睿招商发展有限公司

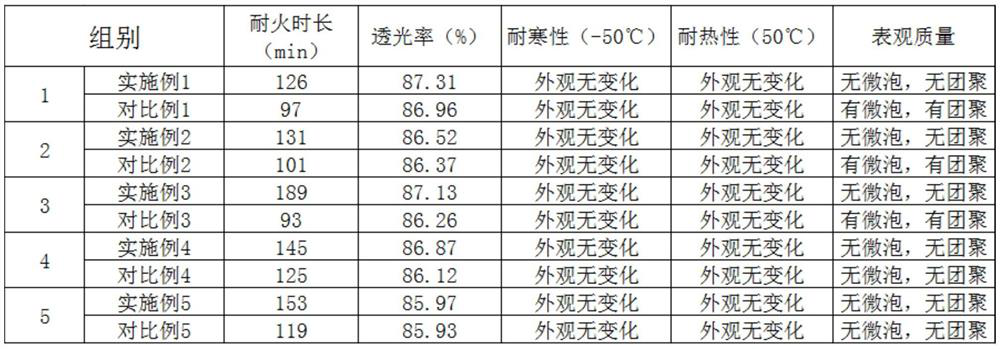

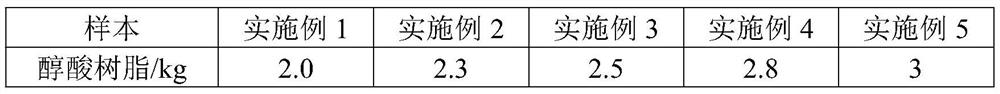

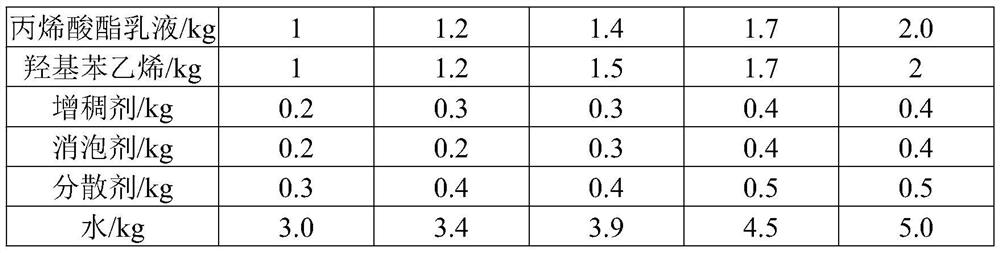

Fireproof interlayer glue, preparation method thereof and fireproof glass containing fireproof interlayer glue

The invention relates to a fireproof interlayer adhesive, which is prepared from the following raw materials in parts by weight: 45 to 50 parts of nano silicon dioxide sol, 25 to 35 parts of inorganic alkali solution, 0.8 to 1.6 parts of heat-resistant dispersant, 0.1 to 0.6 part of stabilizer, 0.2 to 0.8 part of flame retardant, 0.1 to 0.6 part of defoaming agent and 5 to 15 parts of anti-condensing agent. Wherein the stabilizer is beta-cyclodextrin; the heat-resistant dispersant is glycerol; the inorganic alkali solution is a mixed solution of potassium hydroxide and sodium hydroxide, and the molar ratio of potassium hydroxide to sodium hydroxide is (1.5-4): 1. According to the fireproof interlayer glue prepared by the preparation method disclosed by the invention, the dispersion uniformity and stability of the silica sol dispersion liquid can be effectively improved while high light transmittance of the fireproof interlayer glue is ensured, so that the fire resistance of fireproof glass is effectively improved, and the product application space is huge.

Owner:广东卫屋防火科技有限公司

Self-adhesive glue for polymer waterproof coiled material, preparation method thereof, and polymer waterproof coiled material

ActiveCN112940664AInner denseHigh hardnessNon-macromolecular adhesive additivesLayered productsAdhesive glueEmulsion

The invention relates to the field of waterproof coiled materials, and particularly discloses a self-adhesive glue for a high-molecular waterproof coiled material, a preparation method thereof, and the high-molecular waterproof coiled material. The self-adhesive glue is prepared from 10-20 parts of an acrylate emulsion, 20-30 parts of alkyd resin, 10-20 parts of hydroxystyrene, 2-4 parts of a thickening agent, 2-4 parts of a defoaming agent, 3-5 parts of a dispersing agent and 30-50 parts of water. The preparation method comprises the following steps: uniformly mixing the water, the dispersing agent and the defoaming agent, then adding the acrylate emulsion and the hydroxystyrene, uniformly mixing, then adding the acrylate emulsion and the thickening agent, and uniformly stirring to obtain the self-adhesive glue. The self-adhesive glue can be used for the bonding part of the waterproof roll and concrete, and has the advantages of high bonding strength and wet paving capability; in addition, according to the preparation method disclosed by the invention, the alkyd resin is fully reacted with the acrylate emulsion and the hydroxystyrene, so that the bonding strength of the self-adhesive glue is improved; and the waterproof coiled material prepared by the invention can adopt a construction mode of dry paving or wet paving and the like, and a concrete protection layer does not need to be arranged on the waterproof coiled material, so that green construction is realized, and energy conservation and environmental protection are realized.

Owner:吉士达建设集团有限公司

Preparation process of pressure resisting composite boards

InactiveCN109352772AInexpensive and easy to obtainInner denseRadiation/waves wood treatmentWood treatment detailsEnvironmentally friendlyFiber

The invention relates to the technical field of board manufacturing, in particular to a preparation process of pressure resisting composite boards. The process comprises the steps of preparation of basic fibers, preparation of enhanced fibers, preparation of binders, preparation of inflaming retarding reinforcing agents, preparation of curing agents, material mixing and board preparation. According to the board preparation method, waste is recycled, the process is environmentally friendly, the prepared boards are good in mechanical strength and have excellent mould proof and inflaming retarding properties, no harmful gas is released, the production process is controllable, and the boards are free of poison and harm, are suitable for volume production and have great practical value and goodapplication prospects.

Owner:合肥慧林建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com