Patents

Literature

321results about How to "Well organized" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

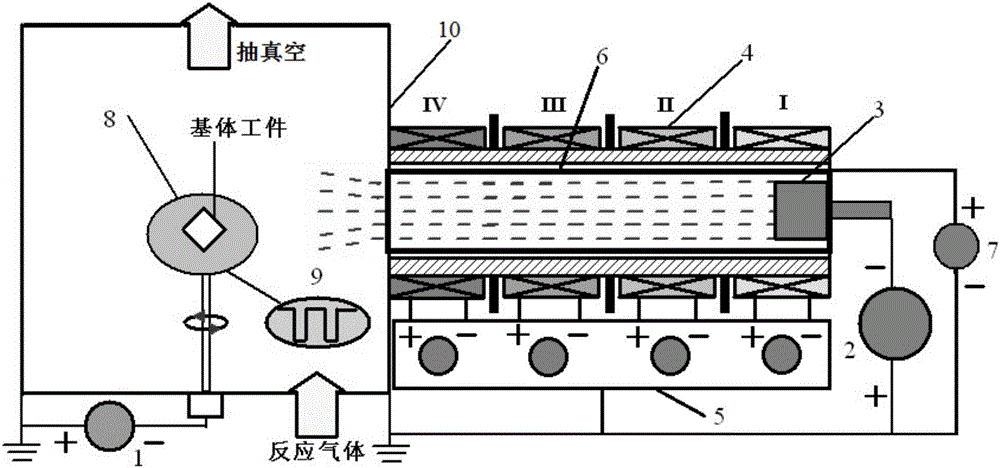

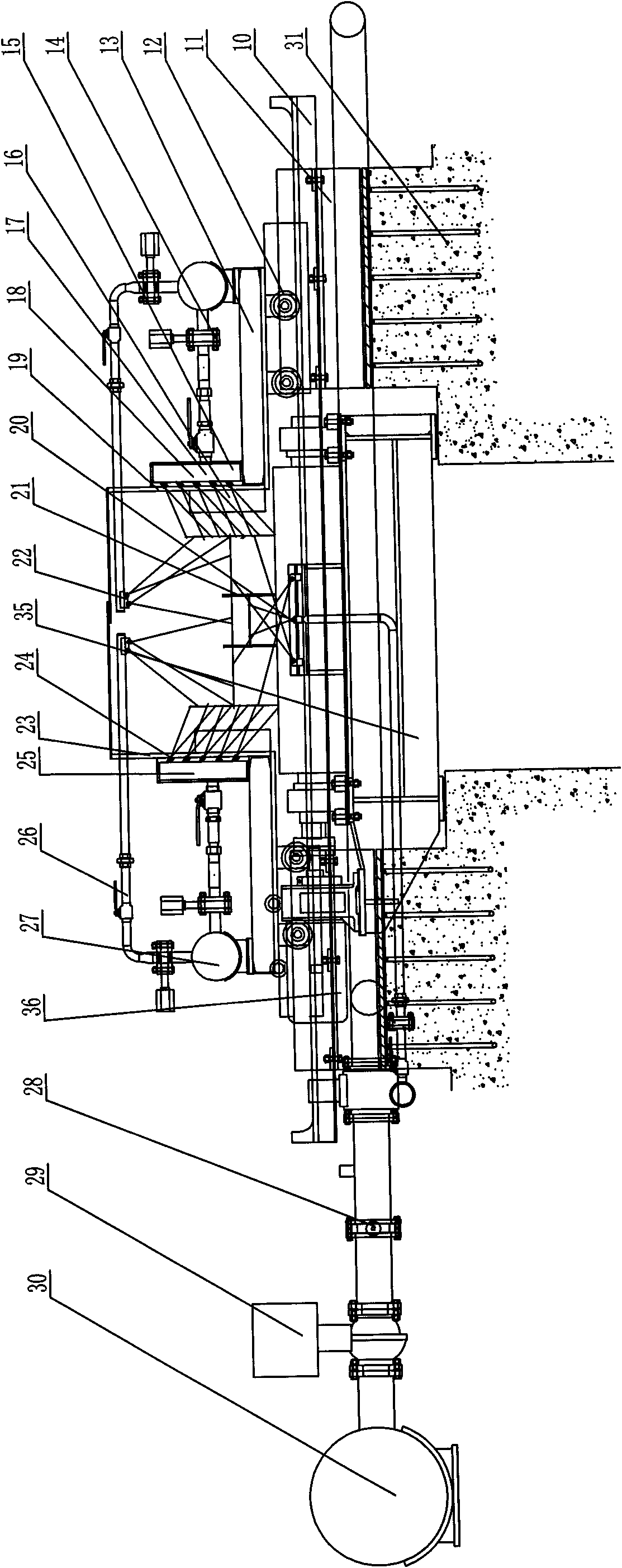

Multi-stage magnetic field arc ion plating method for lining positive bias straight pipe

InactiveCN105925940AReduce lossImprove transmission efficiencyVacuum evaporation coatingSputtering coatingPhysicsElectric arc

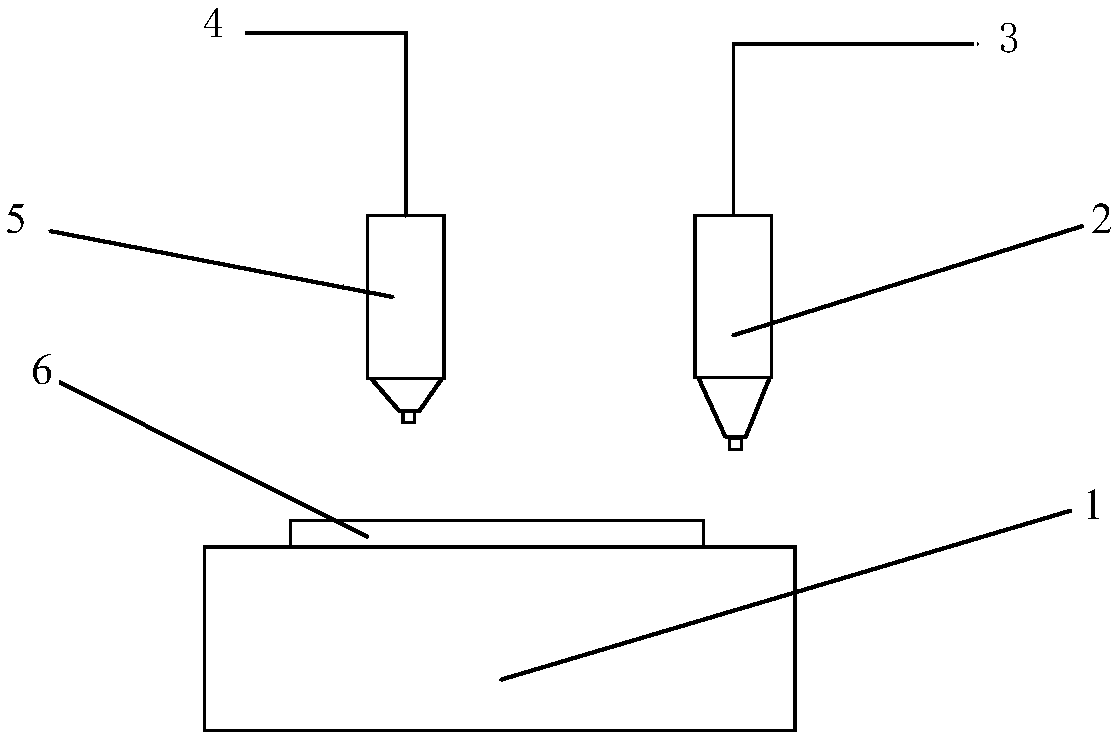

The invention discloses a multi-stage magnetic field arc ion plating method for a lining positive bias straight pipe, and belongs to the technical field of material surface treatment. The problems that in a multi-stage magnetic field filtering device, pollution to the inner wall of a pipeline due to macroparticles needs to be removed, and losses are caused in the plasma transmitting process need to be solved. The method comprises the steps that firstly, a workpiece to be coated is arranged on a sample table in a vacuum chamber, and a related power source is powered on; and secondly, film deposition is conducted, when the vacuum degree in the vacuum chamber is smaller than 10-4Pa, work gas is guided in, the air pressure is adjusted, a coating power source is started, meanwhile, energy of plasmas is adjusted through a grid bias power supply, the macroparticle defect is further eliminated through a lining positive bias straight pipe device, the transmission efficiency of the arc plasmas is guaranteed through the lining positive bias straight pipe device, needed technology parameters are set, and film deposition is conducted.

Owner:魏永强

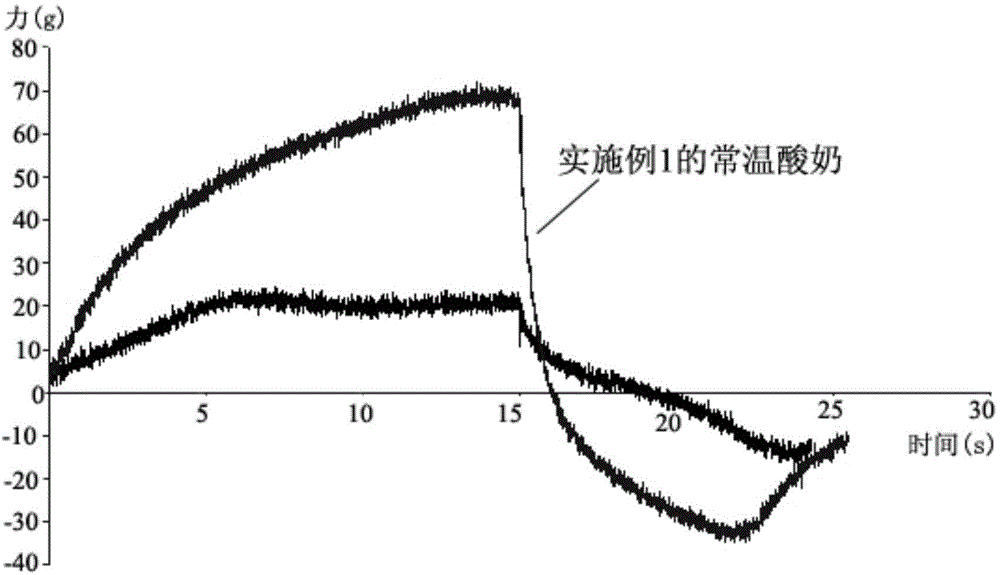

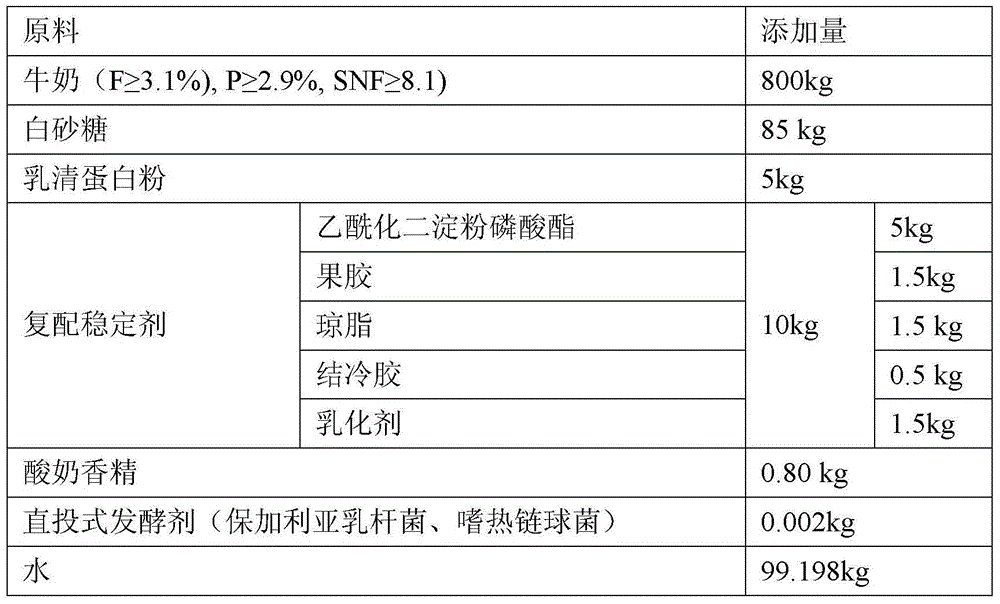

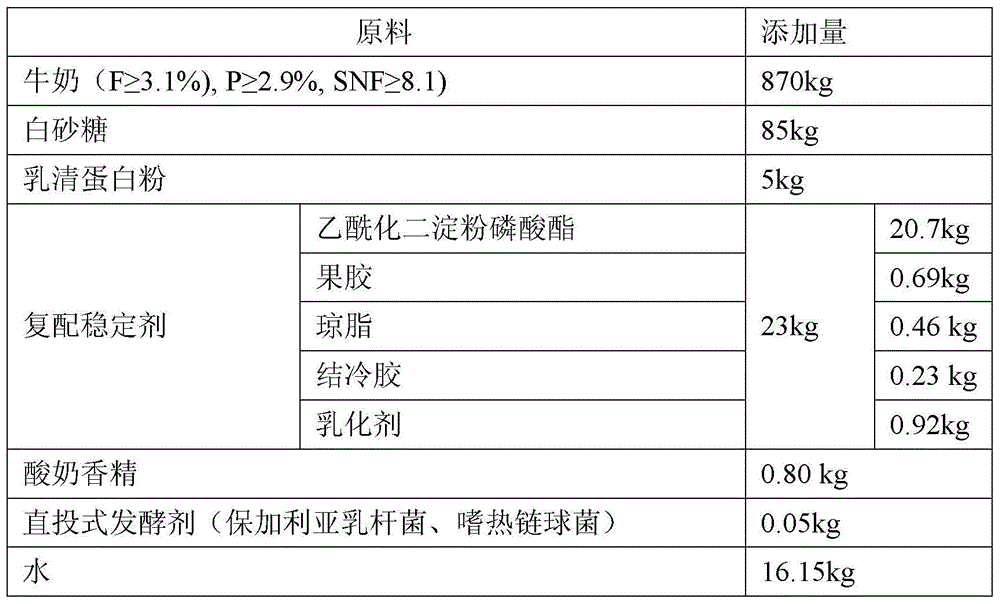

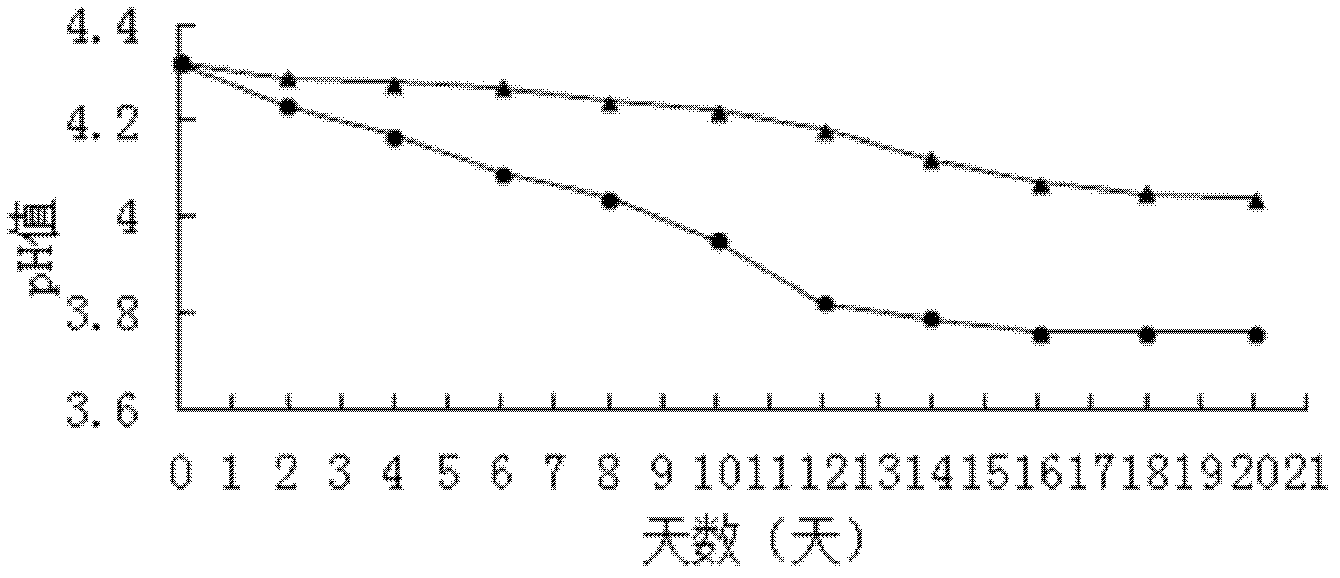

Compounded stabilizer, normal temperature yoghurt containing compounded stabilizer, and preparation method of yogurt

The invention relates to a compounded stabilizer, normal temperature yoghurt containing the compounded stabilizer, and a preparation method of the yogurt. The compounded stabilizer comprises, by mass, 50-90% of esterified modified starch, 3-15% of pectin, 2-15% of agar, 4-15% of an emulsifier and 1-5% of gellan gum. The invention also provides normal temperature yoghurt containing the compounded stabilizer, and a preparation method of the yogurt. The compounded stabilizer has good process tolerance, improves the viscosity stability of a technology processed normal temperature yoghurt system and the viscosity recovery stability of a subsequent product, and allows the viscosity of yogurt at normal temperature of 20-40DEG C to be similar or greater than the viscosity of yogurt refrigerated at normal temperature of 3500-5000cp. The normal temperature yogurt prepared in the invention can be stored at normal temperature of 20-40DEG C for 4-6 months, and allows high quality yogurt to be drunk in remote cold chain lacking places.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Aluminum alloy workpiece additive manufacturing method implemented through friction stir welding

InactiveCN109108505AImprove mechanical propertiesElimination of internal tissue for refinementWelding/soldering/cutting articlesNon-electric welding apparatusFriction weldingVolumetric Mass Density

The invention discloses an aluminum alloy workpiece additive manufacturing method implemented through friction stir welding. On the basis of an existing electric arc additive manufacturing aluminum alloy workpiece, the characteristic that aluminum alloy is soft in property is combined, after an aluminum alloy workpiece is manufactured from electric arc additives layer by layer, friction stir welding intensification treatment is conducted on each layer, and therefore, defects such as pass gaps, interlayer incomplete fusion, air holes and the like can be eliminated through friction stir weldingwhen each layer is manufactured. Compared with the pure electric arc additive manufacturing aluminum alloy workpiece, by means of the method, the structural state of the aluminum alloy workpiece obtained through additive manufacturing can be improved; the grains can be finer; second-phase grains are finer and are distributed more uniformly; and the dislocation density achieved in the aluminum alloy additive manufacturing workpiece is increased. Compared with existing friction stir welding intensification, grain refining and defect elimination are conducted on each layer of the workpiece so that the strength of the whole workpiece can be improved rather than only surface modification, namely surface intensification, is conducted.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

Ultra supercritical heat-resistant steel welding rod and production method thereof

InactiveCN103737199AGood workmanshipGood mechanicalWelding/cutting media/materialsSoldering mediaFerrosiliconManganese

The invention discloses an ultra supercritical heat-resistant steel welding rod which is composed of an H08A core wire and coating wrapping the surface of the core wire, wherein contents of sulfur, phosphorus, arsenic, aluminum and the like in the H08A core wire are low, and the coating comprises components of 30%-39% of marbles, 22%-30% of fluorites, 6%-9% of rutiles, 7.5%-8.6% of ferromolybdenum, 29%-31% of chromium metal, 5%-9% of silica powder, 2%-5% of ferrosilicon, 1%-1.8% of ferrovanadium, 0.4%-0.8% of ferroniobium, 1.8%-2.8% of nickel powder, 0.4%-0.8% of sodium carbonate, 0.4%-0.8% of carboxyl methyl cellulose (CMC), 0.2%-0.6% of amorphous graphite, 0.6%-1.5% of nitrogen-bearing ferrochromium, 1.6%-3% of electrolytic manganese, 3%-3.8% of cobalt powder and 4%-5% of ferroboron.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

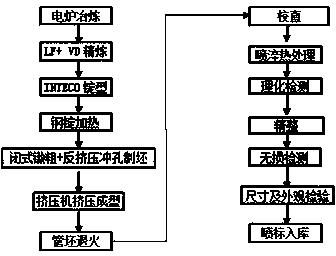

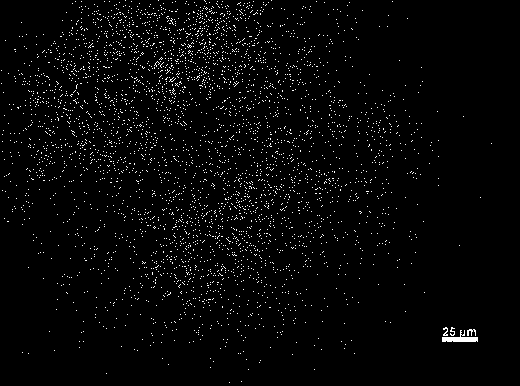

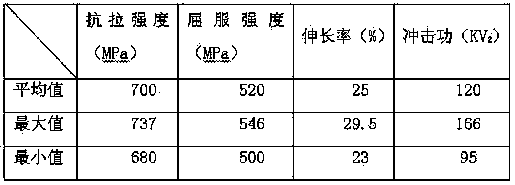

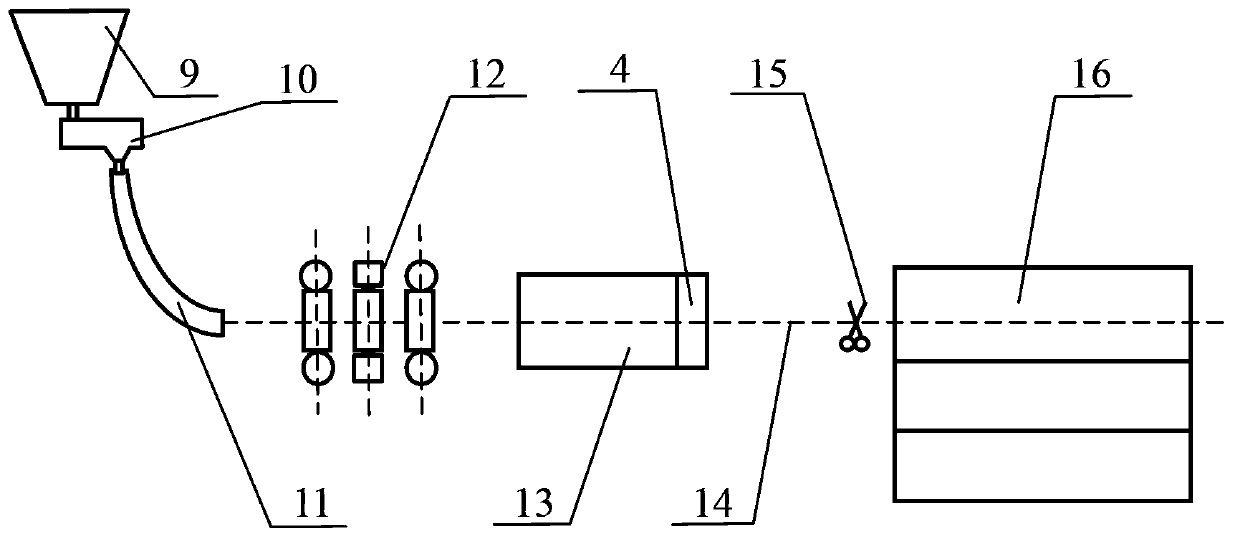

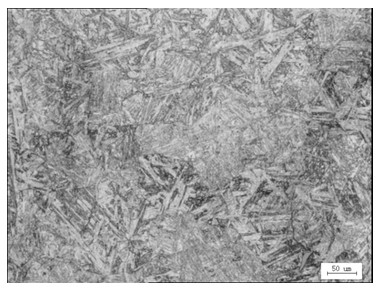

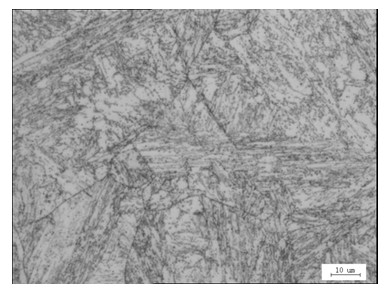

Manufacturing method of high-quality P92 large-aperture thick-wall seamless steel pipe of ultra-supercritical unit

The invention relates to a manufacturing method of a high-quality P92 large-aperture thick-wall seamless steel pipe of an ultra-supercritical unit and belongs to the field of heat-resistant steel tubing manufacture. The manufacturing method realizes dynamic combination of internal control of steel chemical components, improvement of steel purity, steel ingot casting, enclosed upsetting, reverse extrusion punching, extrusion molding and spraying quenching, the steel tube obtained by the manufacturing method satisfies ASMESA335, EN10216-2 and GB5310 standard requirements, the microstructure of the steel tube is completely tempered martensite and satisfies the requirement of clear martensite lath orientation in the 400x view field, delta-ferrite content is less than or equal to 1% and less than or equal to 3% in the most serious field, and comprehensive performance indexes satisfy the international advanced level. The manufacturing method can produce different specifications of P92 large-aperture thick-wall seamless steel pipes having the external diameter of 325-1200mm, wall thickness of 20-180mm and length less than or equal to 12500mm, and can be used in different fields of an ultra-supercritical boiler and power-station four-pipes. The manufacturing method can effectively guarantee product quality and the high-quality P92 large-aperture thick-wall seamless steel pipe obtained by the manufacturing method can replace an imported product.

Owner:INNER MONGOLIA NORTH HEAVY INDS GROUP

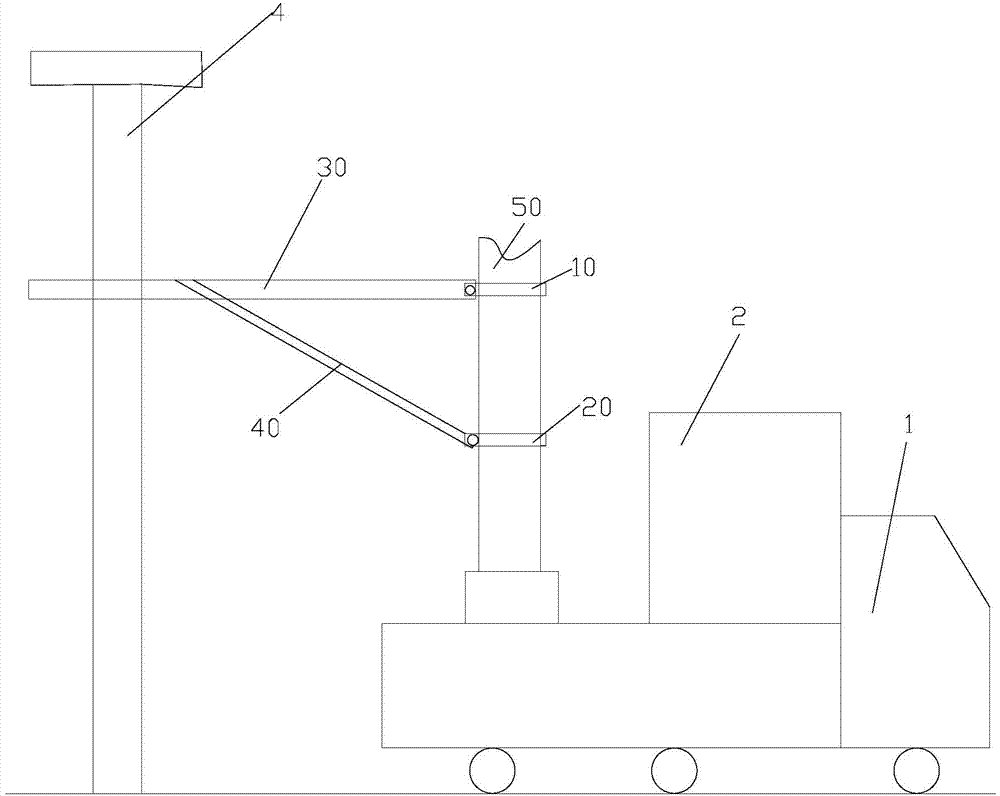

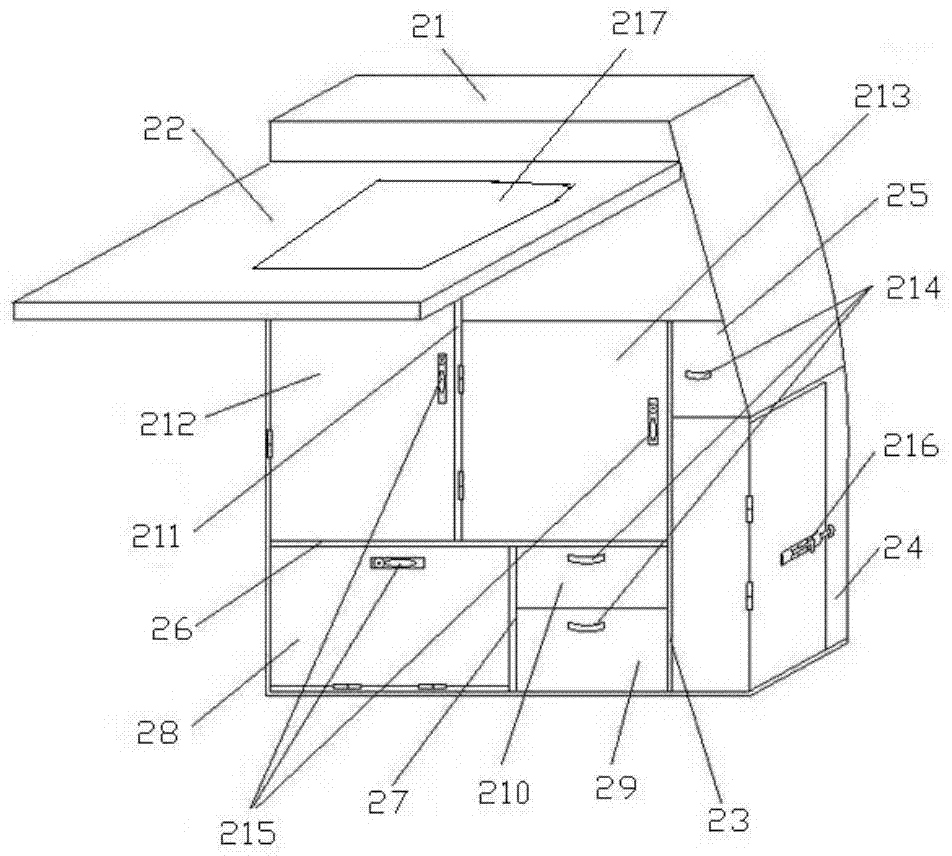

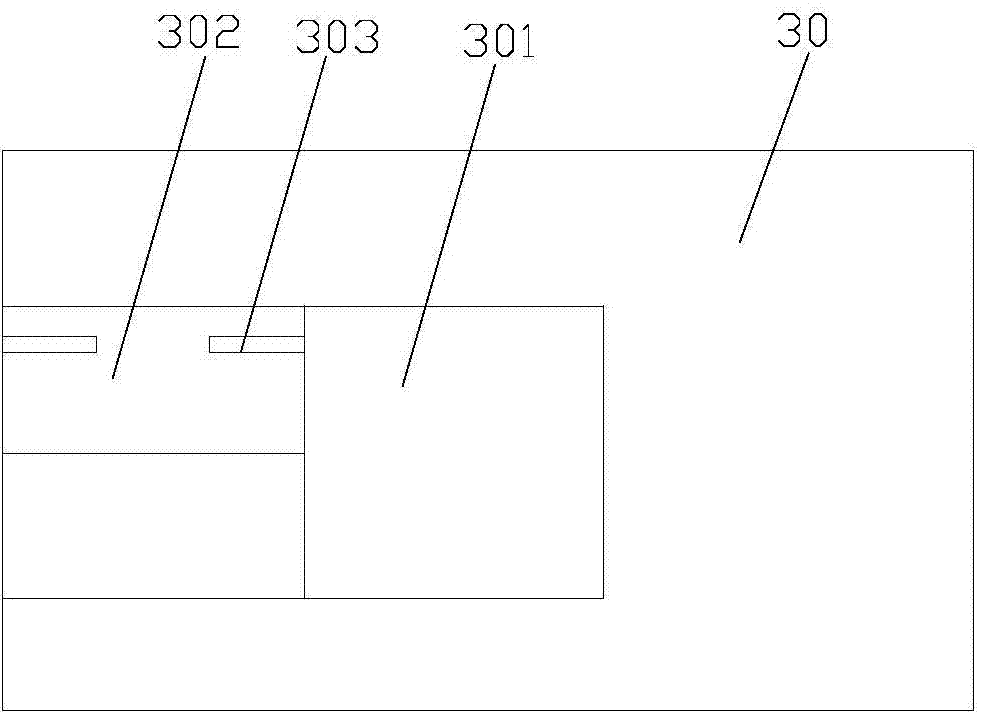

Vehicular power maintenance system with maintenance tool box

ActiveCN104773680AEasy to maintainImprove efficiencyLifting devicesVehicle componentsEmbedded systemMaintenance system

The invention discloses a vehicular power maintenance system with a maintenance tool box. The vehicular power maintenance system with the maintenance tool box comprises a vehicle main body, a lifting device and a maintenance bracket, wherein the lifting device is arranged on the vehicle main body; the maintenance bracket is arranged in a hoisting device; the ends of a lifting platform are provided with movable plates which can be opened; the movable plates are arranged adjacent to a working opening; the movable plates form a maintenance muzzle bell which is communicated with the working opening after being opened; the vehicle main body is also provided with the maintenance tool box; the maintenance tool box comprises a box body; one side of the box body is provided with a cabinet door; a plurality of compartments and drawers, which are formed by baffle plates, are arranged in the box body; cameras are arranged in the compartments and the drawers; the cabinet door is provided with a door panel; the baffle plates are also provided with rotary display screen assemblies connected with the cameras.

Owner:STATE GRID CORP OF CHINA +1

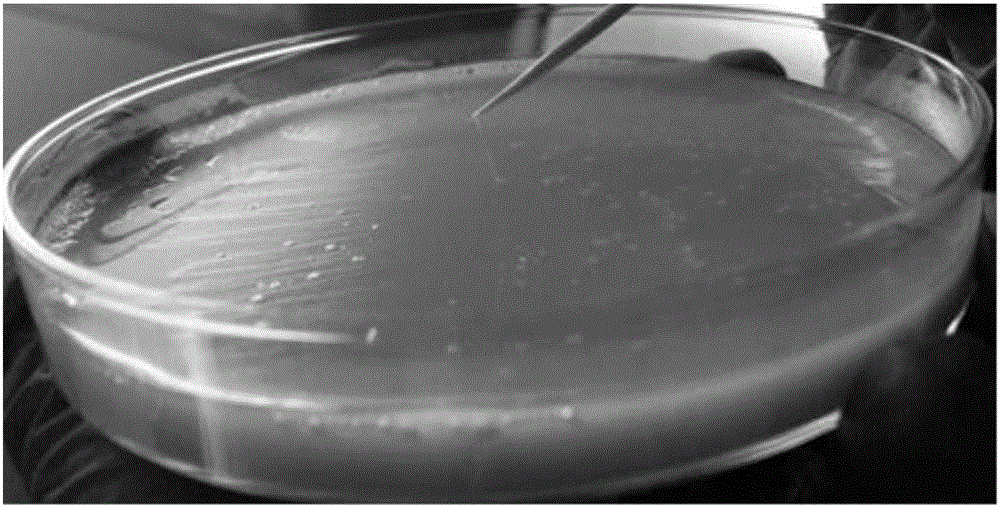

Streptococcus thermophilus and application thereof

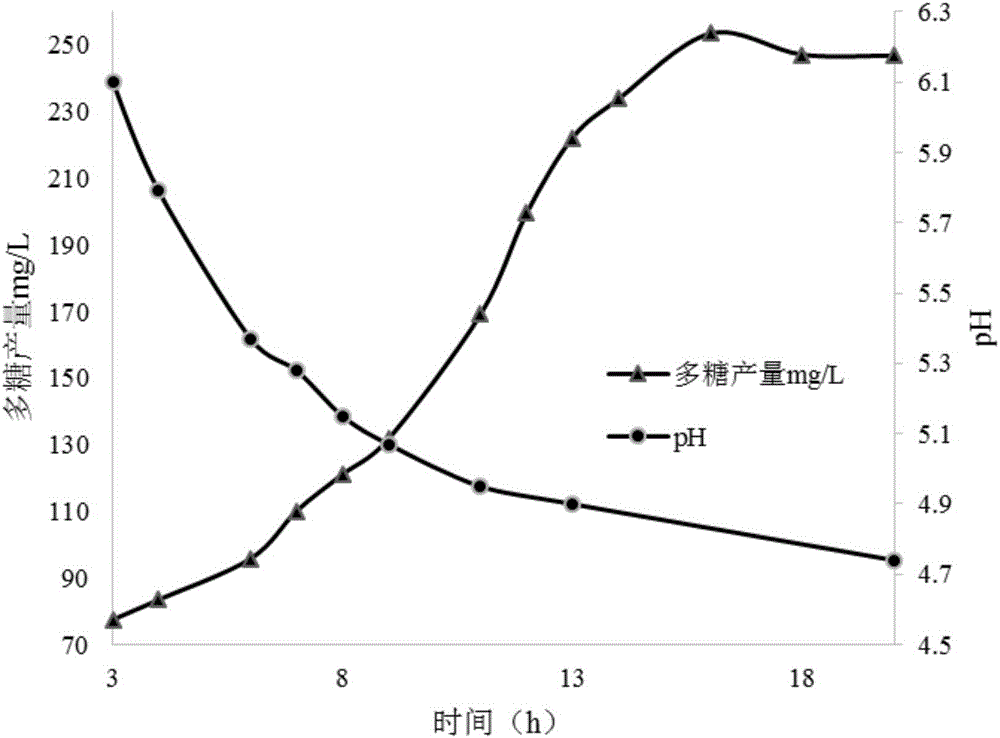

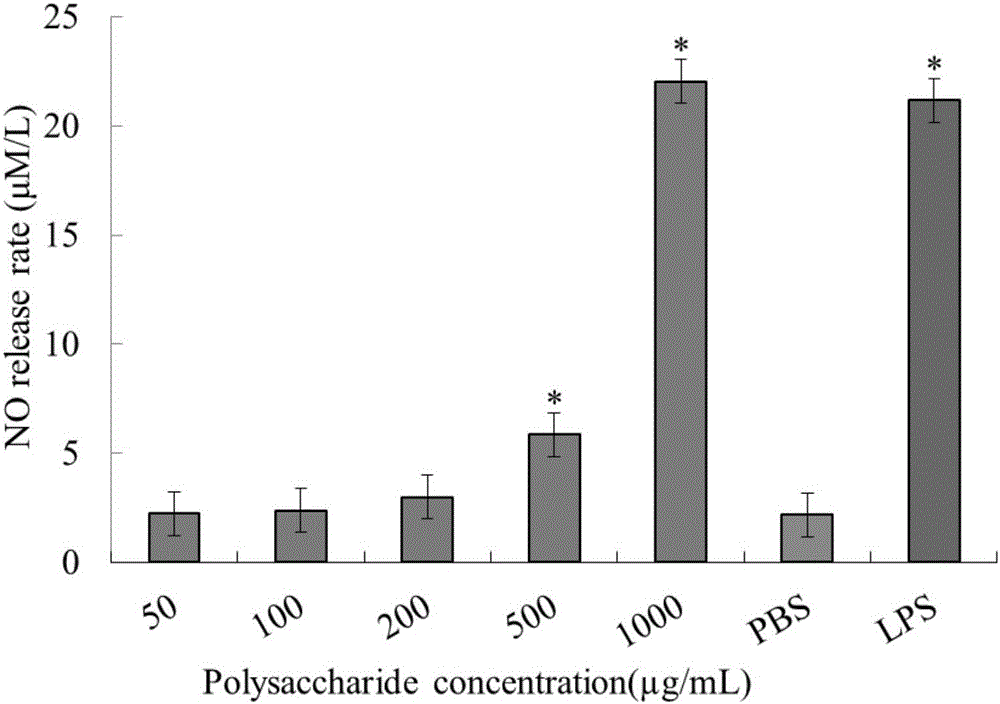

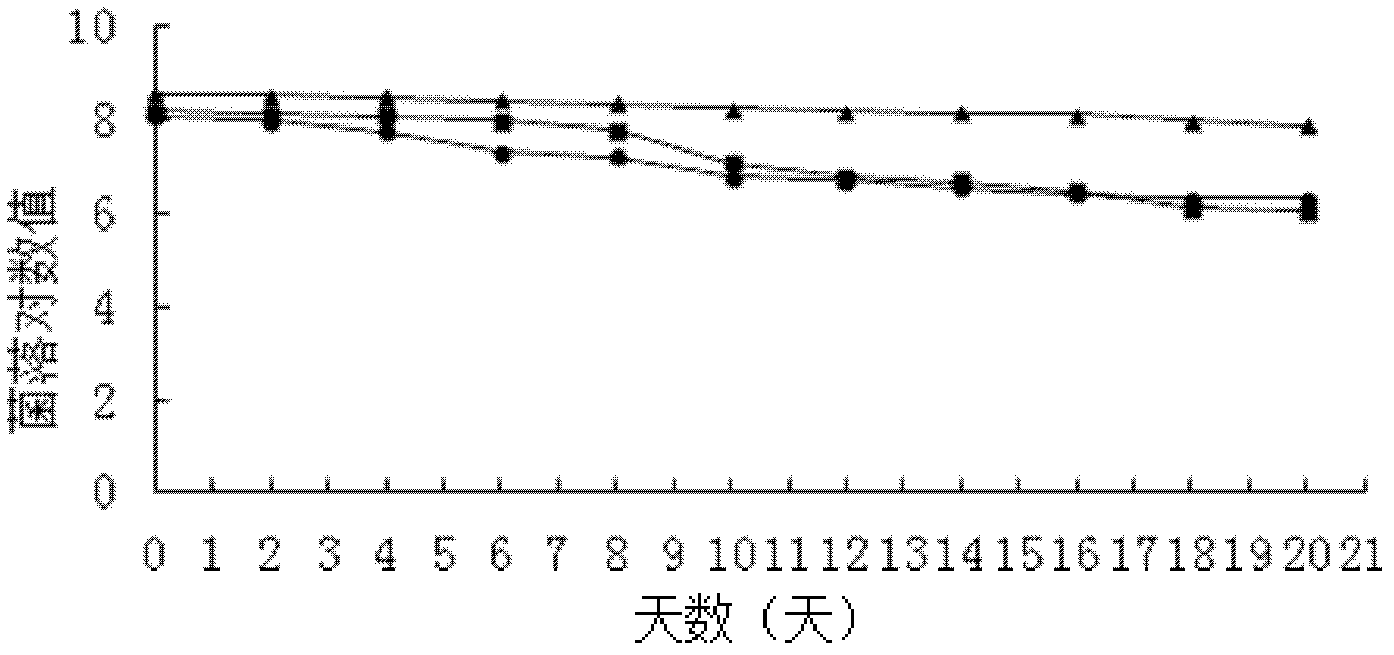

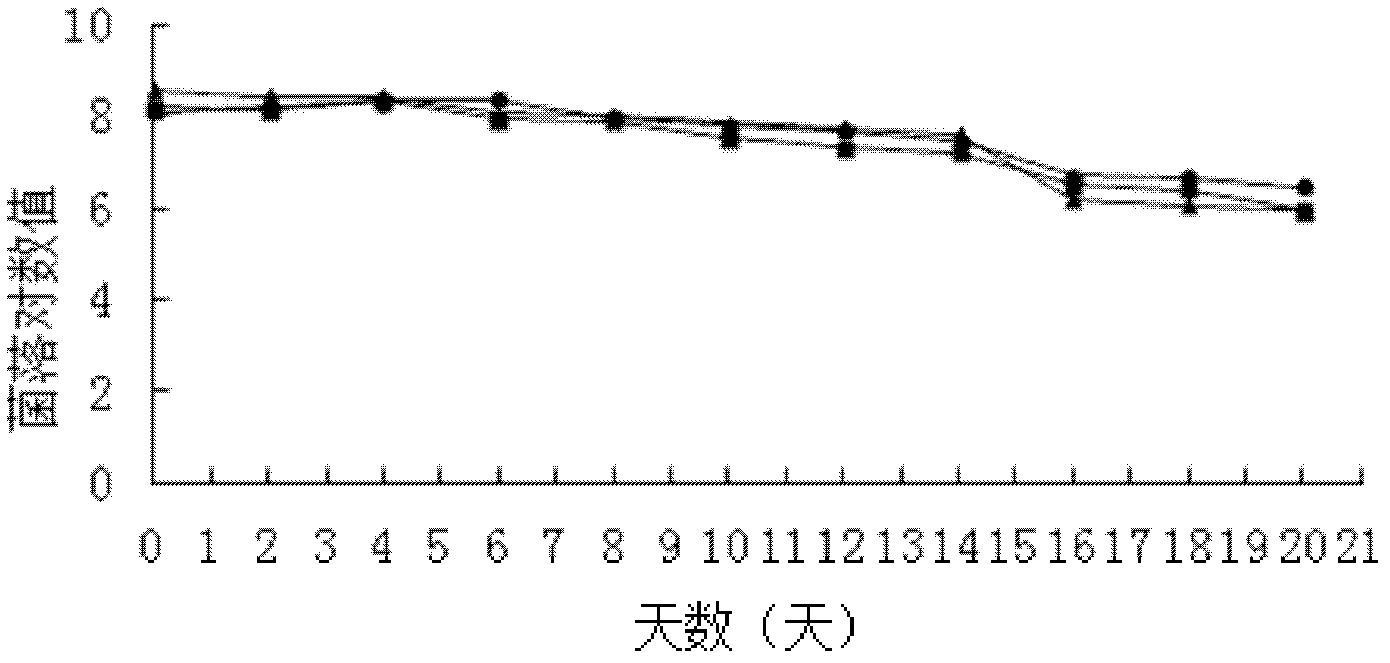

InactiveCN105886434AWell organizedImprove textural properties such as tissue stateMilk preparationBacteriaFlavorImmunologic Competence

The invention provides a streptococcus thermophilus AR-333 strain and application thereof. The streptococcus thermophilus AR-333 strain is obtained through being separated from naturally fermented milk, and the collection number of the strain is CGMCC 10262. The streptococcus thermophilus AR-333 is fermented for 16h under the condition of 40 DEG C by skimmed milk; the yield of extracellular mucopolysaccharide reaches 256.97 mg / L; meanwhile, the streptococcus thermophilus is used as a yoghourt fermenting agent; the viscosity of yoghourt can be obviously improved; the tissue state of the yoghourt can be improved; good flavor is realized; the generated extracellular mucopolysaccharide has an immunologic competence regulating function; macrophages RAW264.7 can be simulated to release NO.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Method for preparing yoghourt rich in gamma-aminobutyric acid (GABA)

ActiveCN102550670AHas nutritional valueImprove securityMilk preparationNutritive valuesBiotechnology

A method for preparing yoghourt rich in gamma-aminobutyric acid (GABA) relates to a method for preparing yoghourt and comprises the steps of resuscitating, purifying and activating lactobacillus plantarum NDC75017, lactobacillus bulgaricus 11057 and streptococcus thermophilus CICC 20379, respectively enlarging culture solutions and then mixing to obtain a leavening agent, and inoculating the leavening agent to sterilized milk to ferment. The GABA content in the yoghourt rich in GABA is 151.51mg / 100g. High-yield GABA bacterial strains and existing commonly-used bacterial strains are compoundedand then fermented to prepare the yoghourt rich in GABA, all the bacterial strains are food-grade lactic acid bacteria, and the safety is high. In addition, products have double effects, and the yoghourt rich in GABA integrates physiological efficacy of the GABA and health-care effect of yoghourt, namely the yoghourt rich in GABA is provided with special physiological efficacy of the GABA and thehealth-care effect of the yoghourt and is novel health-care yoghourt.

Owner:湖北均瑶大健康饮品股份有限公司

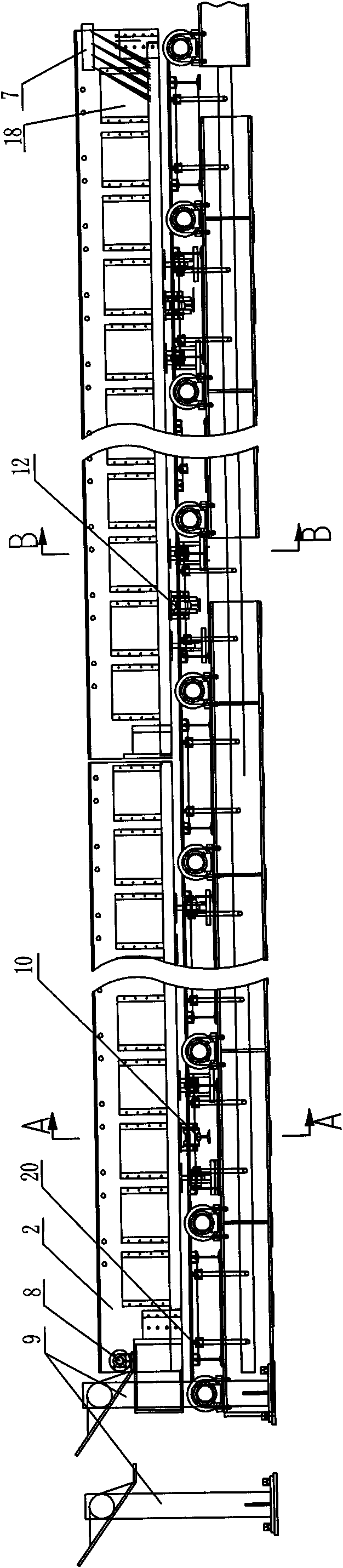

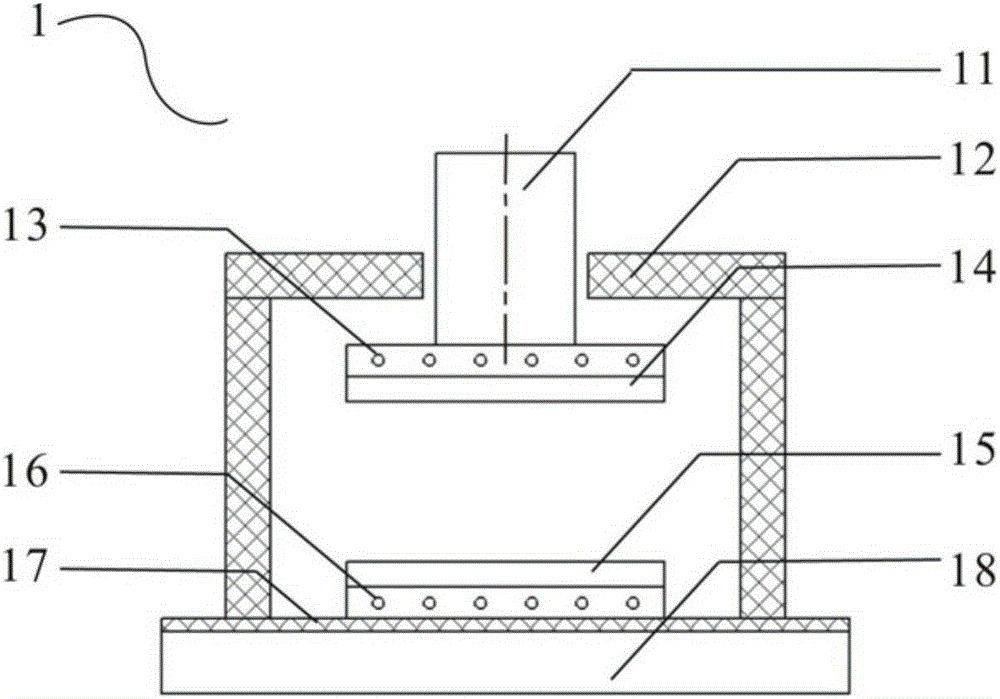

Ultrafast cooling device for large rolled H-shaped steel

ActiveCN101804422AWell organizedImprove mechanical propertiesWork treatment devicesMetal rolling arrangementsMechanical propertyMaterials science

The invention relates to an ultrafast cooling device for large rolled H-shaped steel, belonging to the technical field of production control and cooling for high-performance H-shaped steel.The invention provides a ultrafast cooling device for large rolled H-shaped steel, which can enable the H-shaped steel to obtain good texture and mechanical property.The cooling device comprises a rail support of a transverse rail, which is fixed at the upper part of the device, a cooling unit provided with a cooling rack, which is arranged on the transverse rail and a transverse roller wheel which is arranged below the cooling rack; wherein the cooling unit comprises a lateral nozzle unit, an upper nozzle unit and a side board provided with a groove; the side board is arranged on the cooling rack, a lateral nozzle tank body is fixed outside the side board; and an upper nozzle unit is arranged above the inside of the side board, a lower nozzle unit is arranged on a motor base of a conveying rail, the lower nozzle unit is connected with a water supply pipe; an electromagnetic flowmeter, a pressure sensor and a pneumatic open and close valve are respectively on the water supply pipe and thermodetectors are respectively arranged at the entrance and exit of the ultrafast cooling device.

Owner:NORTHEASTERN UNIV +1

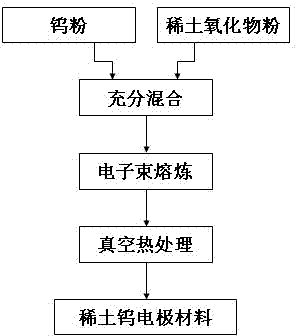

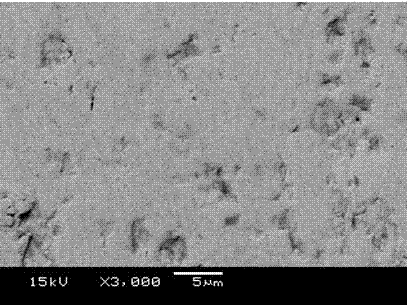

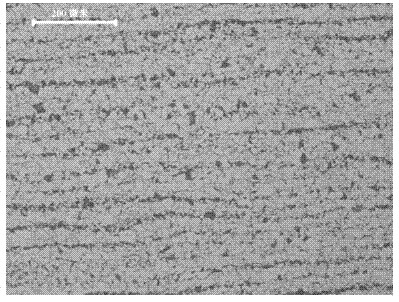

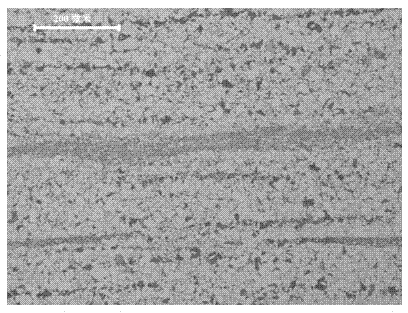

Method for preparing rare-earth-tungsten electrode material

The invention relates to the technical field of metallurgical smelting, in particular to a method for preparing a tungsten electrode material by smelting. The method comprises the following steps: firstly, sufficiently mixing tungsten powder and rare-earth oxide powder to obtain mixed powder, and processing the mixed powder through hot-press forming to obtain a tungsten-based block mixture; secondly, performing electron beam vacuum high-temperature smelting on the tungsten-based block mixture, and solidifying and cooling to obtain a rare-earth-tungsten alloy ingot; and finally, thermally processing the rare-earth-tungsten alloy ingot in vacuum to obtain the rare-earth-tungsten electrode material. Extremely high-density energy is supplied by an electron beam to smelt a rare-earth-tungsten material, so that the rare-earth-tungsten electrode material obtained after smelting is relatively high in compactness; compared with hot-press sintering, the electron beam smelting technology has an obvious advantage in preparation of a refractory metal and can obtain a more excellent structure; the performance of the electrode material can be improved by doping a certain amount of rare-earth oxide; and through an analysis on change of the microscopic hardness, improvement of the added rare-earth oxide on the hardness of the electrode to a certain extent can be determined.

Owner:DALIAN UNIV OF TECH

Phosphate-free water-retaining agent meat product and preparation method thereof

InactiveCN101756259AImproves water retention and tissue conditionImprove acid and heat resistanceFood preparationPoultry meatCalcium EDTA

The invention discloses a phosphate-free water-retaining agent meat product, which is characterized by consisting of sodium alginate, edible calcium, livestock and poultry meat, seasoning accessory food and water, which respectively account for 0.01-8.0%, 0.01-8.0%, 0.1-70% and 1.0-10% by weight percent, and the rest is water. The invention overcomes the defects that a phosphate water-retaining agent has peculiar taste and influences the balance of calcium and phosphor of an organism, sodium alginate greatly improves the water-retaining property and the tissue state of meat products, so the acid resistant and heat resistant properties, water absorbability, adhesiveness, gel property and the like of the meat products are improved, the absorption of fat and water is promoted, the water interfacial tension is reduced, the emulsive oil drop is stabilized by the protein on the surface of the product to play the role of protection so as to prevent the emulsification state from being damaged, and thereby the invention achieves the purposes of water retention and oil retention.

Owner:OCEAN UNIV OF CHINA

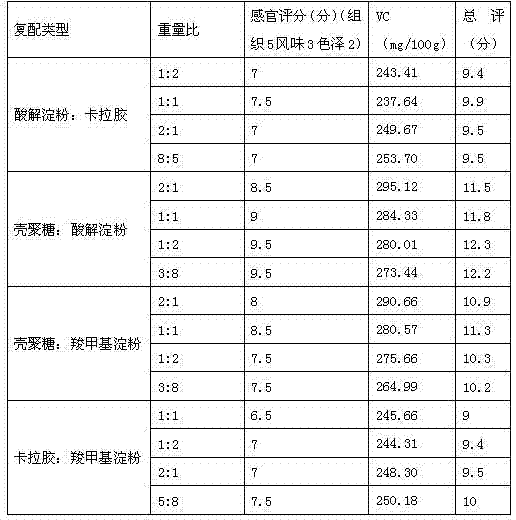

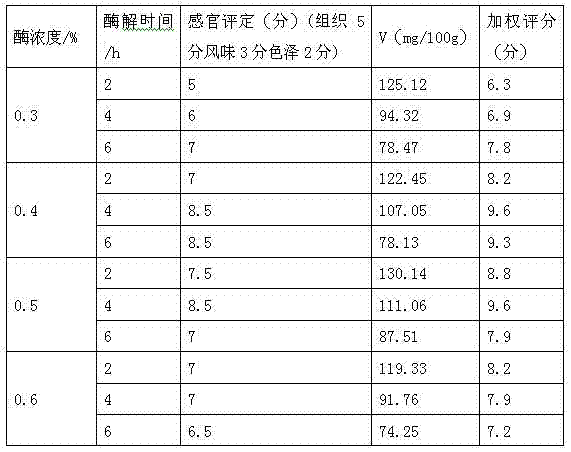

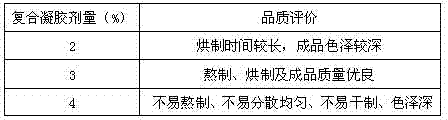

Rosa roxburghii tratt fruit cake and preparation method thereof

The invention discloses a rosa roxburghii tratt fruit cake and a preparation method thereof. The rosa roxburghii tratt fruit cake is prepared from rosa roxburghii tratt fruit residue, water, cellulase, a composite gelling agent and a flavoring agent, wherein the composite gelling agent consists of chitosan and acidolysis starch. The method not only sufficiently utilizes the byproduct to avoid resource waste, but also gives full play to the nutrition healthcare value of fruit residue, wherein the rosa roxburghii tratt fruit residue is rich in crude fibers; and through the technical scheme adopted by the invention, the prepared cake product is orange red or brownish red, has uniformly distributed tiny particles of rosa roxburghii tratt fruit residue, obtains transparency and glossiness, rich flavor and specific smell of the raw rosa roxburghii tratt fruit, is moderate in acidity and softness and appropriate in elasticity and toughness, does not have rough mouthfeel, contains rich dietary fibers, has nutritional and healthcare effects, and is a leisure nutritional food suitable for various consumers.

Owner:贵州山珍宝绿色科技开发有限公司

Health-care fish balls containing almonds and preparation method of health-care fish balls

The invention discloses health-care fish balls containing almonds. The fish balls are prepared from raw materials in parts by weight as follows: 200-220 parts of fresh silver carp flesh, 6-7 parts of egg white, 4-5 parts of potato starch, 30-33 parts of Chinese yams, 7-8 parts of pork fat, 3-4 parts of honey, 7-8 parts of fresh bayberries, 3-4 parts of sweet almonds, 1-1.2 parts of Lindernia ruellioides, 0.7-0.8 parts of immature orange fruits, 1.1-1.3 parts of Zinnia elegans, 0.8-1.0 part of saccharose, 0.5-0.6 parts of carrageenan, 0.4-0.5 parts of ginger, 4-5 parts of spices and proper amounts of table salt and water. According to the fish balls, adopted auxiliary materials such as the sweet almonds and the like have functions of moistening lung dryness and relaxing bowels, and adopted Chinese herbal medicines such as the Zinnia elegans and the like has functions of clearing heat and realizing diuresis.

Owner:王龙云

Maximum-thickness S355G10+N steel plate for ocean platform and production method of steel plate

The invention discloses a maximum-thickness S355G10+N steel plate for an ocean platform and a production method of the maximum-thickness S355G10+N steel plate. The production method of the maximum-thickness S355G10+N steel plate comprises smelting, casting, heating, rolling, cooling and heat treatment processes. The maximum-thickness S355G10+N steel plate comprises the following chemical ingredients in percentage by weight: 0.08-0.12% of C, 0.15-0.50% of Si, 1.40-1.65% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.040-0.060% of V, 0.020-0.030% of Nb, 0.020-0.050% of Al, less than or equal to 0.43% of Cea, less than or equal to 0.22% of Pcm and the balance of Fe and inevitable impurities. The maximum-thickness S355G10+N steel plate has the advantages that low-carbon and high-microalloying design thought is adopted in composition design, the problem of segregation of carbon and manganese is solved, and the requirements such as high strength, high impact toughness and wide cold bending performance are met; hardenability of the maximum-thickness S355G10+N steel plate is guaranteed under the low-carbon and low-equivalent carbon content conditions, and the maximum-thickness S355G10+N steel plate has good structure and overall performance and welding performance; and the maximum-thickness S355G10+N steel plate has good mechanical properties, welding performance and processability and can meet requirements of construction technological conditions of an ocean engineering equipment manufacturing plant.

Owner:WUYANG IRON & STEEL

Crystal pork aspic and production process thereof

ActiveCN102415573AHigh melting temperatureOvercoming short shelf lifeFood preparationChemistryFlavor

The invention belongs to the technical field of meat product deep processing, and relates to crystal pork aspic and a production process thereof. The crystal pork aspic is mainly prepared by the following steps of: performing salting, cooking, stewing and forming procedures and the like on fine pork shoulders and pigskin serving as main raw materials to obtain an instant pot-stewed meat product. The product prepared by the method is low in production cost and suitable for industrial production. The crystal pork aspic produced by the process overcomes the defect that the traditional crystal pork aspic has low melting temperature and cannot be secondarily sterilized, potassium chloride replaces partial sodium chloride, the content of table salt is reduced, dietary nutrition is balanced, andthe crystal pork aspic has good flavor and mouthfeel and is an ideal leisure food.

Owner:NANJING AGRICULTURAL UNIVERSITY

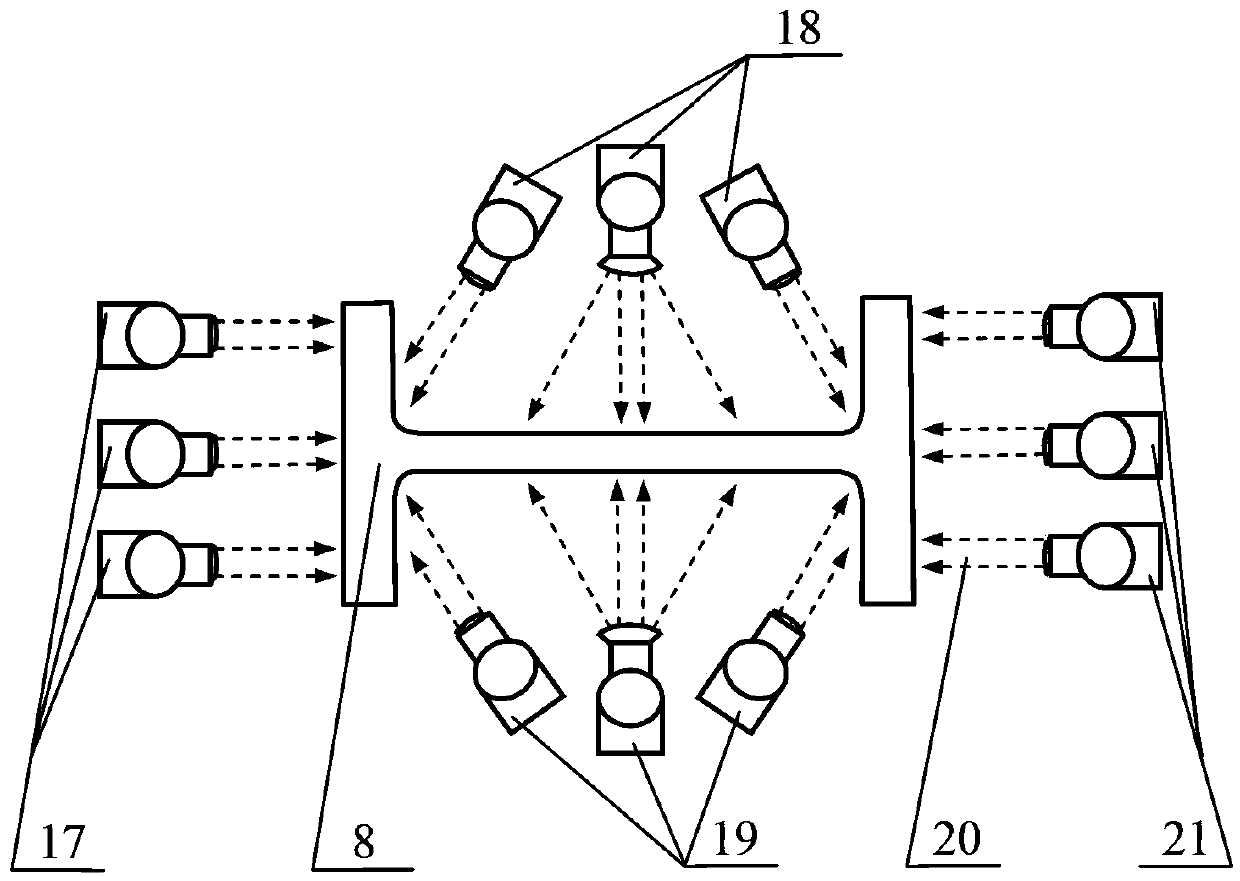

Cast rolling H-shaped steel cooling device

ActiveCN103357678AGood comprehensive mechanical propertiesWell organizedWork treatment devicesMetal rolling arrangementsSpray nozzleMechanical property

The invention provides a cast rolling H-shaped steel section cooling device. The cast rolling H-shaped steel section cooling device comprises a shell, three sets of upper spraying nozzles, an upper spraying pipe, three sets of lower spraying nozzles, a lower spraying pipe, three sets of left spraying nozzles, a left spraying pipe, three sets of right spraying nozzles and a right spraying pipe. The shell is of a box-shaped structure, the three sets of upper spraying nozzles are arranged in the shell and are used for being respectively aligned with two R portions of the upper side of the H-shaped steel section and the center of a web perpendicularly, the upper spraying pipe is arranged in the shell and is connected with the three sets of the upper spraying nozzle, the lower spraying pipe is arranged in the shell and is connected with the three sets of the lower spraying nozzles, the three sets of the left spraying nozzles are arranged in the shell and are sequentially arranged from top to bottom and are used for being aligned to the left side face of the H steel section to enable cooling water to be evenly sprayed to the left side face of the H steel section, the left spraying pipe is arranged in the shell and is connected with the three sets of left spraying nozzles, and the right spraying pipe is arranged in the shell and is connected with the three sets of right spraying nozzles. Cooling water sprayed by each set of spraying nozzles does not interfere with each other. The cast rolling H steel section cooling device enables the H steel section to be good in organization state, and therefore better comprehensive mechanical property is obtained.

Owner:LAIWU IRON & STEEL GRP

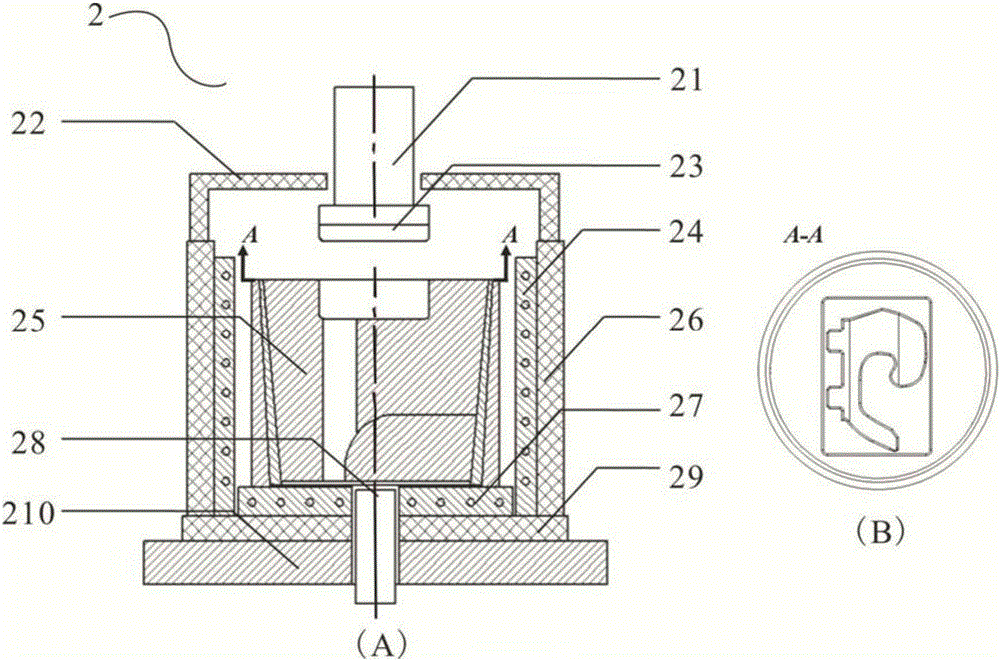

3D super-plasticizing treatment method and superplasticity precision shaping method for magnesium alloy

The invention discloses a 3D super-plasticizing treatment method and superplasticity precision shaping method for magnesium alloy. Within the superplastic deformation temperature range of the magnesium alloy, a non-hollow magnesium alloy casting obtained after forging pretreatment passes through at least two cycles to obtain a forging stock of the set size, and 3D super-plasticizing treatment is finished, wherein the non-hollow magnesium alloy casting passes through the axis Z, the axis X and the axis Y in sequence to press down the stock to achieve a cycle. By means of 3D super-plasticizing forging treatment, through large plastic deformation in all directions, homogenizing, grain refining and structure densifying of materials are fully achieved, refined grains are averagely smaller than 20 microns, the equiaxial grain refining effect is remarkable, and the strength performance of the casting can be greatly improved. Through the superplasticity precision shaping method for the magnesium alloy based on 3D super-plasticizing treatment, a light magnesium alloy transition car coupler with high strength is prepared out; and compared with an existing transition car coupler, the weight is reduced by about 75%, the strength is above 350 MPa, and the requirement for the service life of the transition car coupler of this type can be met.

Owner:崇州天智轻量化制造有限公司

Method for performing high-moisture organization by using wheat vital wheat gluten plasmogen

PendingCN105410329ASolve the difficulty of extrusion aloneGood formabilityVegetable proteins working-upWheat glutenMoisture

The invention discloses a method for preparing high-moisture organized protein by using wheat vital wheat gluten plasmogen. According to the method, extrusion treatment is performed on the wheat vital wheat gluten plasmogen by using a twin-screw extruder with a cooling die head, and high-moisture wheat vital wheat gluten organized protein products are prepared. The high-moisture organized protein which is prepared by using the wheat vital wheat gluten plasmogen in the method presents texture similar to that of meat and better fibrous structure characteristics; besides, the vital wheat gluten plasmogen is used as a raw material, drying the raw material is not needed, and water is not needed to be added for mixing, so that the original activity of vital wheat gluten can be maintained, energy resources are saved, pollution is reduced, products have better appearance and texture, comprehensive and balanced nutrition, low fat and low cholesterol, the products are suitable for public consumption, and the products have broad development and application prospects in the respect of replacing meat products or being used as meat simulants.

Owner:河南省邓肯生物科技有限公司 +1

Ficus carica fruit ferment and preparation method thereof

ActiveCN104336547AWell organizedAdd flavorYeast food ingredientsFood preparationAdditive ingredientFicus opposita

The invention discloses a ficus carica fruit ferment and a preparation method thereof. The preparation method comprises the following steps: taking the ficus carica fruits as a main raw material, and subjecting the material to hypertonic extraction, fermentation with compound bacterial species, after-ripening, clearing and film filtering to prepare the ficus carica fruit ferment. In the process disclosed in the invention, the nutritional ingredients in the ficus carica fruits are not lost or damaged, and after fermentation with the compound probiotic bacteria, the nutritional and health-care value of the ficus carica fruits are significantly improved. The prepared ficus carica fruit ferment product has a good organization state and flavor; the liquid is clear and transparent, is pink to dark red in color, is mellow in taste, is harmonious in acidness and sweetness, and has the characteristic fragrance of the ficus carica fruits. The ficus carica fruit ferment is suitable for the taste requirement of the public consumers. The preparation process is simple, and the process is controllable. The obtained ferment product is stable in quality, can be stored at normal temperature, is suitable for production in large scale and has a good market prospect.

Owner:深思来福(深圳)科技有限公司

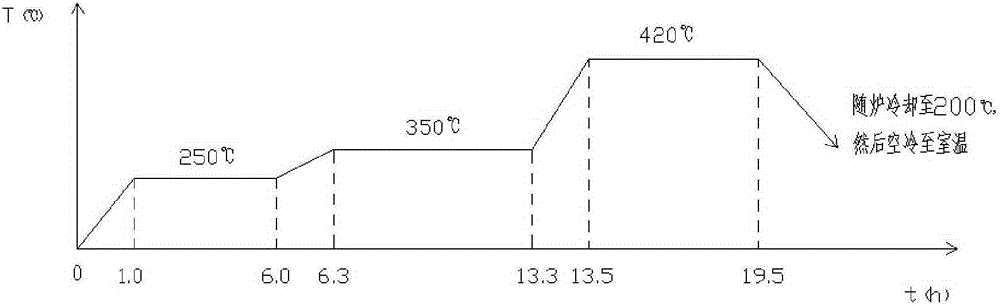

Heat treatment process of steel forging for hydraulic cylinder of deep-sea oil recovery equipment

The invention relates to a heat treatment process of a steel forging for a hydraulic cylinder of deep-sea oil recovery equipment, and the heat treatment process comprises the following steps: (1) selecting martensitic precipitation hardening stainless steel as a steel forging material of a 15-5PH hydraulic cylinder, wherein the martensitic precipitation hardening stainless steel comprises the following elements in percentage by weight: 0.04-0.07% of carbon, 0.001-0.60% of silicon, 0.80-1.00% of manganese, 14.00-14.50% of chromium, 5.00-5.50% of Ni, 2.50-4.00% of copper,0.15-0.25% of niobium, not more than 0.035% of phosphorus and not more than 0.025% of S, the chromium equivalent is 14.08-15.52% and the Ni equivalent is 6.60-8.10%; (2) heating the forging to 1060+ / -5 DEG C, carrying out heat preservation for 180 minutes, taking out the forging, and carrying out oil cooling on the forging until the temperature is lower than 32 DEG C; (3) heating the forging to 620+ / -5 DEG C, carrying out heat preservation for 360 minutes, taking out the forging, and air-cooling the forging to room temperature; (4) heating the treated forging processed in the step (3) of the hydraulic cylinder to 1040+ / -5 DEG C, carrying out heat preservation for 140 minutes, taking out the forging and carrying out oil cooling on the forging until the temperature of the forging is lower than 32 DEG C; and (5) heating the forging to 580+ / -5 DEG C, carrying out heat preservation for 360 minutes, taking out the forging and air-cooling the forging to room temperature.

Owner:NANJING DEV ADVANCED MFG

Traditional Chinese medicine ultrasonic atomization agent for treating xerophthalmia and preparation method thereof

InactiveCN102824547ATargetedWell organizedSenses disorderAerosol deliveryOcular ConjunctivaSaposhnikovia divaricata

The invention discloses a traditional Chinese medicine ultrasonic atomization agent for treating xerophthalmia and a preparation method thereof. The traditional Chinese medicine ultrasonic atomization agent is prepared from the Chinese medicine raw materials in percentage by weight: 8 to 25 percent of Chinese medicine raw materials and 75 to 92 percent of water, wherein the Chinese medicine raw materials comprise the following components in percentage by weight: 5 to 15 percent of radix ophiopogonis, 5 to 15 percent of the root of straight ladybell, 5 to 15 percent of radix bupleuri, 5 to 15 percent of angelica root, 5 to 15 percent of chrysanthemum, 5 to 15 percent of barbary wolfberry fruit, 5 to 15 percent of dendrobe, 5 to 15 percent of mulberry leaf, 5 to 15 percent of divaricate saposhnikovia root, 5 to 15 percent of fructus viticis and 2 to 12 percent of mint. The traditional Chinese medicine combination is dialectically screened, and the traditional Chinese medicine ultrasonic atomization agent is high in preparation purity, high in clarity and suitable for an ultrasonic atomization instrument for xerophthalmia, the liquid medicine reaches the eye conjunctiva and surrounding skin of the eyes to realize blood circulation, the absorption and availability is high, and the liquid medicine is easily accepted by a patient. Compared with the methods for treating xerophthalmia, such as single eye drops for dropping the eyes, traditional Chinese medicine for oral administration and traditional Chinese medicinal fuming and washing external treatment, the ultrasonic atomization agent has the advantages of accurate curative effect and no toxic or side effect, and a novel effective and non-toxic treatment medicine and method can be increased for the common diseases and frequently-occurring diseases in ophthalmology. The ultrasonic atomization agent has the advantages of simple manufacture, convenience, safety, good curative effect, low cost and no toxic and side effect.

Owner:于耀光 +1

690 MPa-grade hydrogen sulfide corrosion resisting steel plate and production method thereof

The invention discloses a 690 MPa-grade hydrogen sulfide corrosion resisting steel plate. The steel plate comprises the following chemical components in percentage by mass: 0.14-0.16% of C, 0.20-0.40% of Si, 1.05-1.10% of Mn, 0.40-0.45% of Ni, P not more than 0.012%, S not more than 0.003%, 0.020-0.040% of Al, 0.020-0.030% of Nb, 0.035-0.040% of V, 0.01-0.02% of Ti, 0.30-0.35% of Cr, 0.25-0.30% of Mo, 0.0015-0.0020% of B, N not more than 0.010%, Cu not more than 0.20%, and the balance of Fe and inevitable impurities. A production method of the 690 MPa-grade hydrogen sulfide corrosion resisting steel plate comprises the procedures of heating, rolling and heat treatment. The 690 MPa-grade hydrogen sulfide corrosion resisting steel plate has such characteristics as high compactness, higher strength grade, excellent low-temperature impact toughness, excellent lamellar tearing resistance and excellent hydrogen sulfide corrosion resistance, can satisfy the requirements of hydrogen sulfide corrosion resisting steel for ship storage tanks, is excellent in comprehensive performance and welding performance, and is lower in cost.

Owner:WUYANG IRON & STEEL

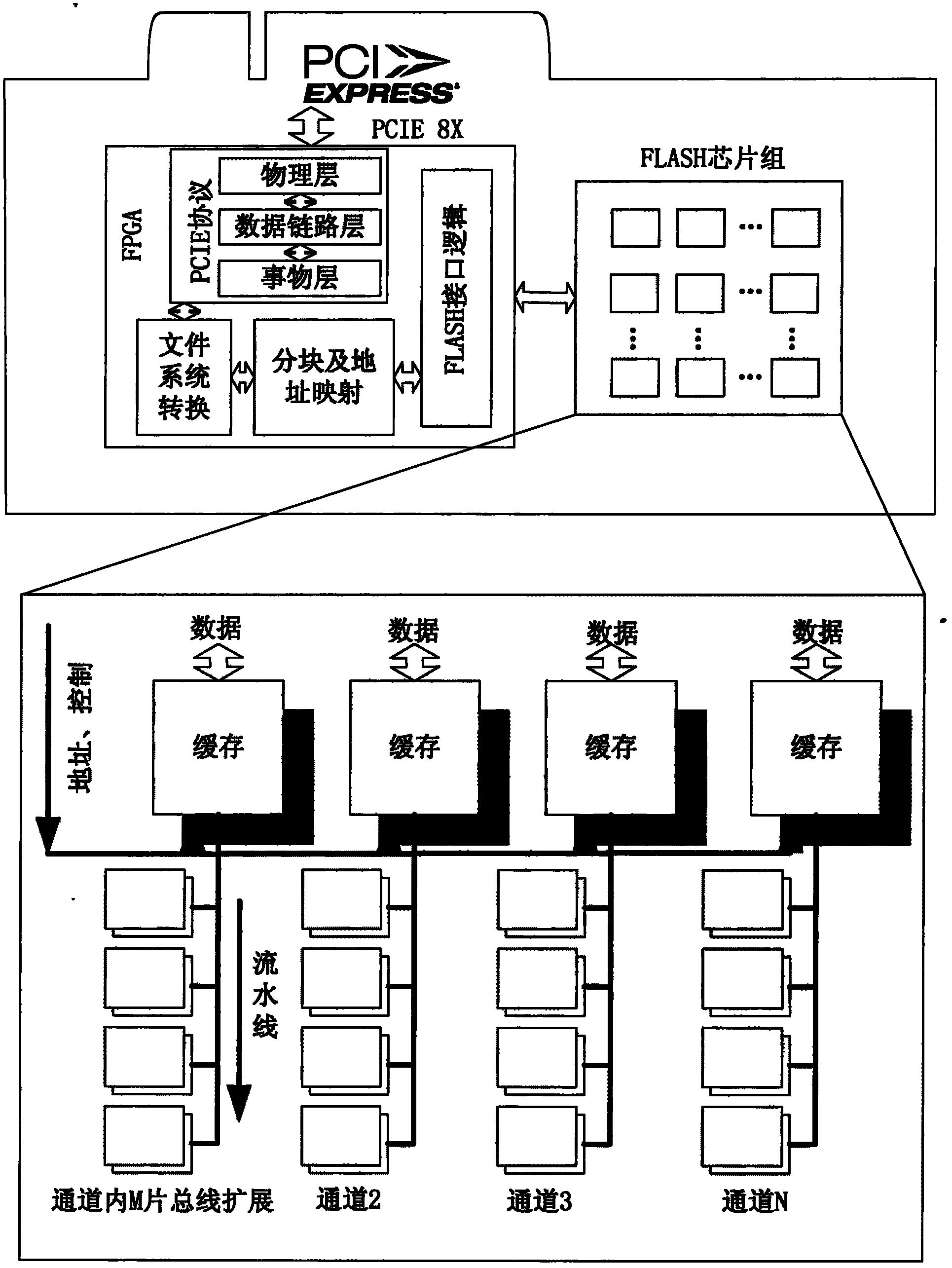

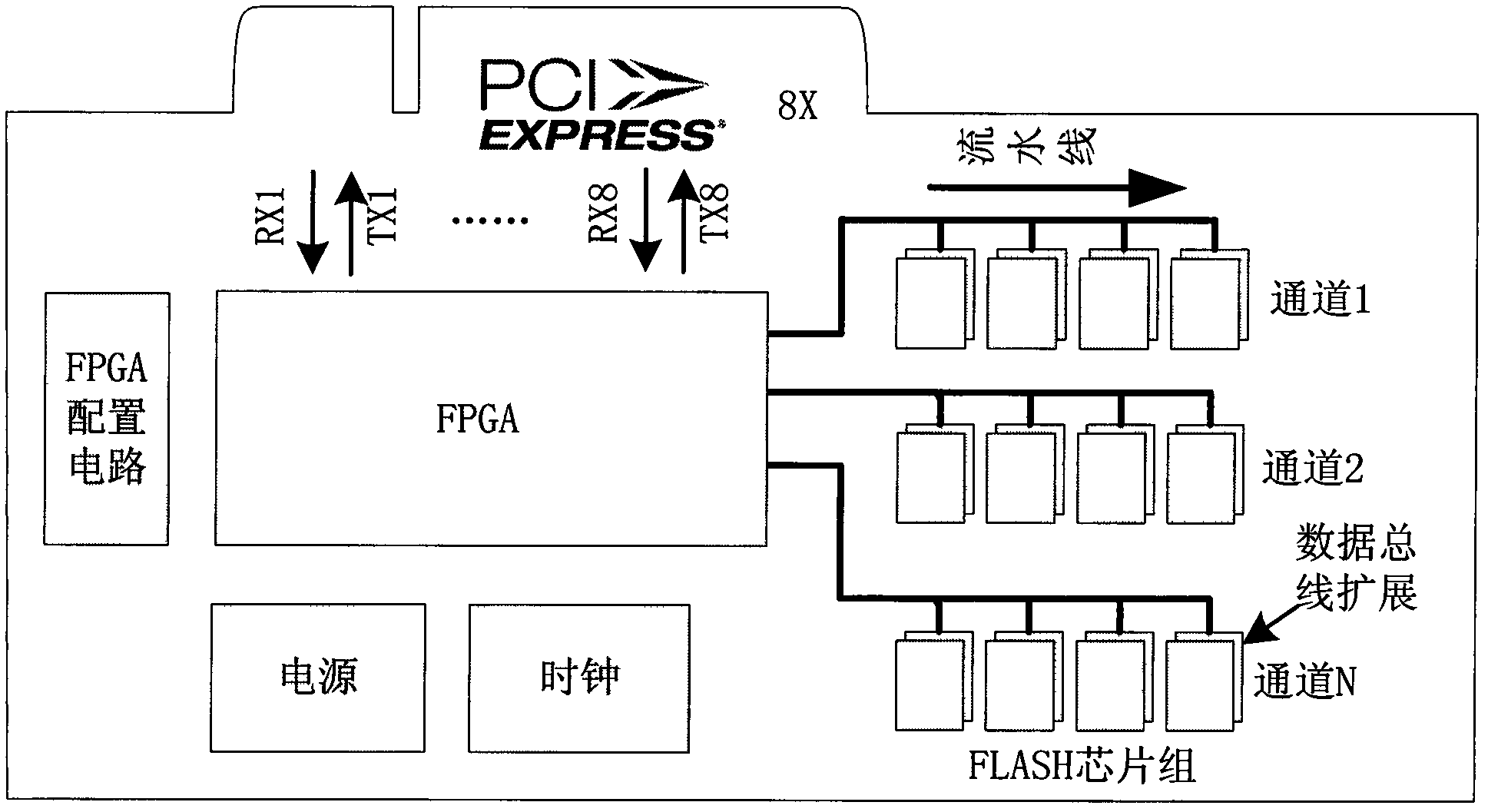

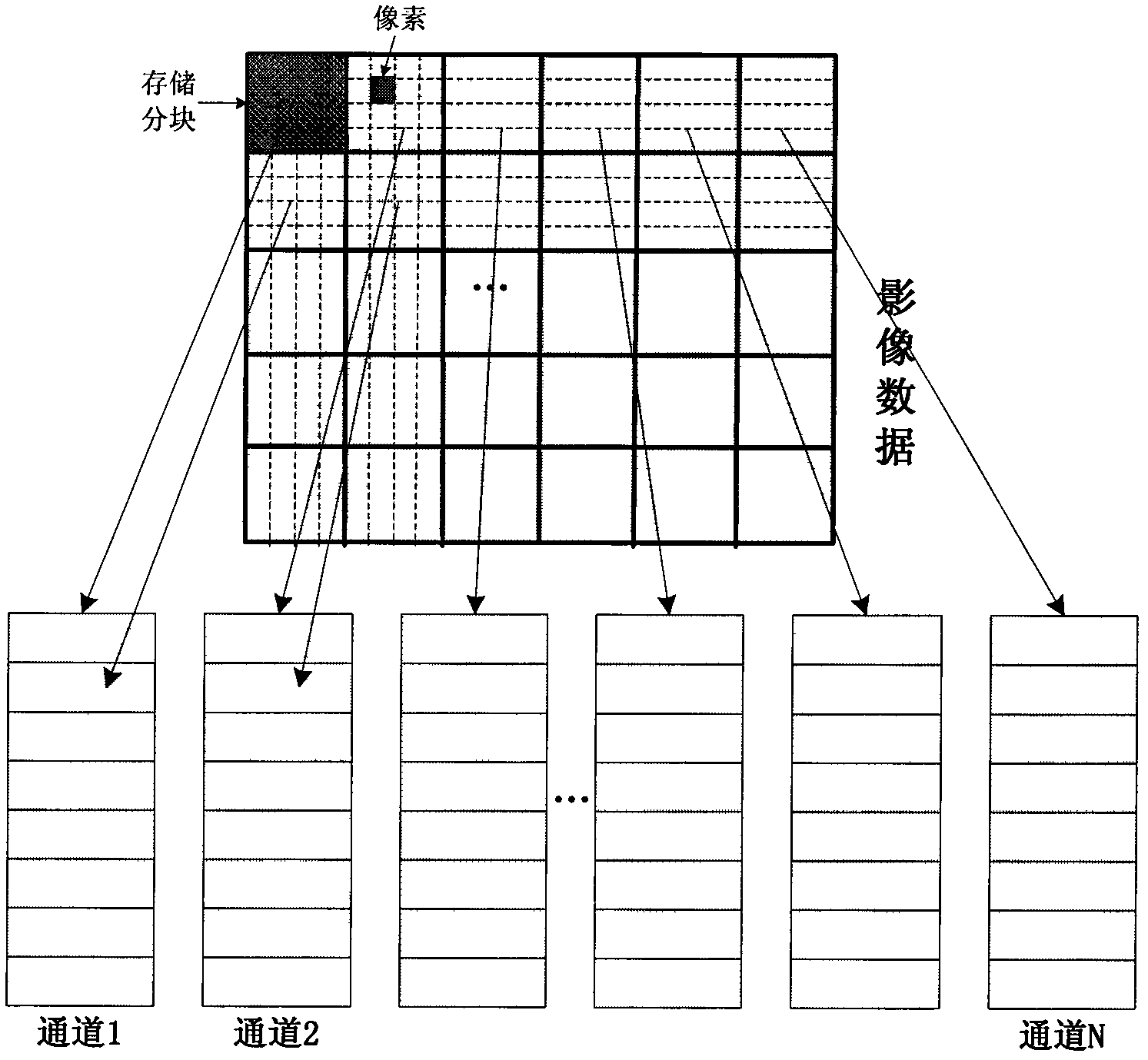

Solid state disk for rapidly storing and displaying massive image data

InactiveCN102360342AHighly integratedWell organizedMemory adressing/allocation/relocationSolid-stateAddress mapping

The invention relates to a solid state disk for rapidly storing and displaying massive image data, which comprises a hardware architecture and a software algorithm for rapidly storing and displaying the massive image data. On the hardware architecture, solid state storage medium is reasonably and efficiently organized through comprehensive utilization of a channel internal bus extension technology, a channel internal pipelining technology and a multichannel parallel technology, so that the access speed of the storage medium is improved, and the data-transfer capacity of a system is improved through utilizing a PCIE (Peripheral Component Interconnect Express) interface to transfer data; and on a software architecture, rapid storage and display of the image data is mainly realized through a blocking storage and address mapping technology of the image data. The channel internal bus extension technology, the channel internal pipelining technology and the multichannel parallel technology are comprehensively utilized aiming at the characteristics of the massive image data, so that the organization of FLASH is more reasonable and efficient.

Owner:NAT UNIV OF DEFENSE TECH

Quasi beta forging process for TC25 titanium alloy

The invention provides a forging technology. Through the adoption of the technology, the purposes that a TC25 alloy forged piece can be produced on a high power screw press, and the mechanical property, the metallographic structure and the ultrasonic wave of the forged piece can satisfy the standard requirements of a certain type of engine made of the TC25 alloy can be achieved. The technology comprises the following processing steps: firstly blanking, then manufacturing blanks, heating the manufactured blanks before forging, putting the blanks heated before forging in a die for die forging, and finally performing heat treatment on the forged piece molded through forging so as to obtain the TC25 alloy. The technology is characterized in that the high power screw press is adopted to perform die forging on the blanks heated before forging.

Owner:WUXI TURBINE BLADE

Method for preparing lacto coccus dry-powder product

The method for producing lactococcus dried powder product includes the following steps: separating out the lactococcus strain from commodity sour milk or natural fermented food, inoculating said lactococcus strain into special enrichment culture liquor, using 10%-15% of sodium hydroxide to neutralize and stabilize pH value is fermentation liquor in 6.0-6.2 making enrichment culture for 4.0-4.7 hr. at 32-43 deg.C, making the fermentation liquor undergo the process of centrifugal treatment to obtain centrifugal precipitate, making said centrifugal precipitate with thallus freeze-drying protecting agent under the sterile condition, before freeze-drying making pre-cooling treatment for 6-12 hr., finally vacuum freeze-drying and adopting nitrogen-charging package so as to obtain the invented product.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

High-performance wrought magnesium alloy material

The invention relates to a high-purity high-performance magnesium alloy material, which consists of the following components in percentage by mass: 6.2 to 6.4 percent of Zn, 0.5 to 0.6 percent of Zr, 0.007 to 0.011 percent of inevitable Fe, Si, Cu, Ni and other impurities, and the balance magnesium. The material is prepared by the following steps: selecting raw magnesium with higher purity as a raw material; melting the raw magnesium by using the semicontinuous casting technology; properly increasing the melt standing time to ensure that compound particles containing Fe, Si and other impurity elements can be sufficiently deposited and a high-purity alloy cast blank can be prepared; and preparing the Mg-Zn-Zr wrought magnesium alloy by adopting the conventional extruding technology. The wrought magnesium alloy can maintain the high strength of traditional commercial ZK60 magnesium alloy to ensure that the plasticity and forming performance of the alloy can be greatly improved and the application potential of the material is sufficiently developed. Furthermore, the technical equipment used in the invention is conventional universal equipment, and the preparation process is simple.

Owner:CHONGQING UNIV

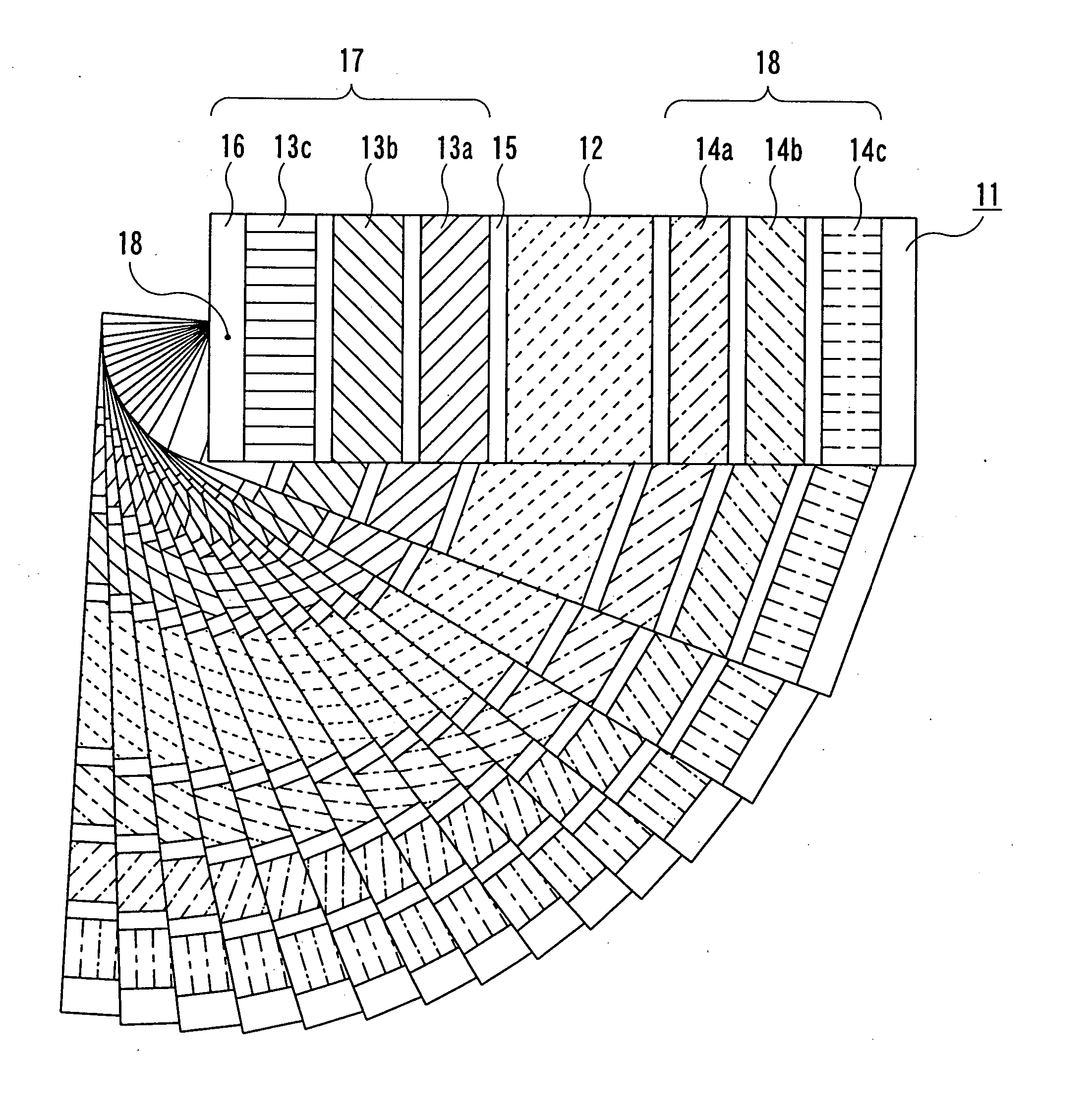

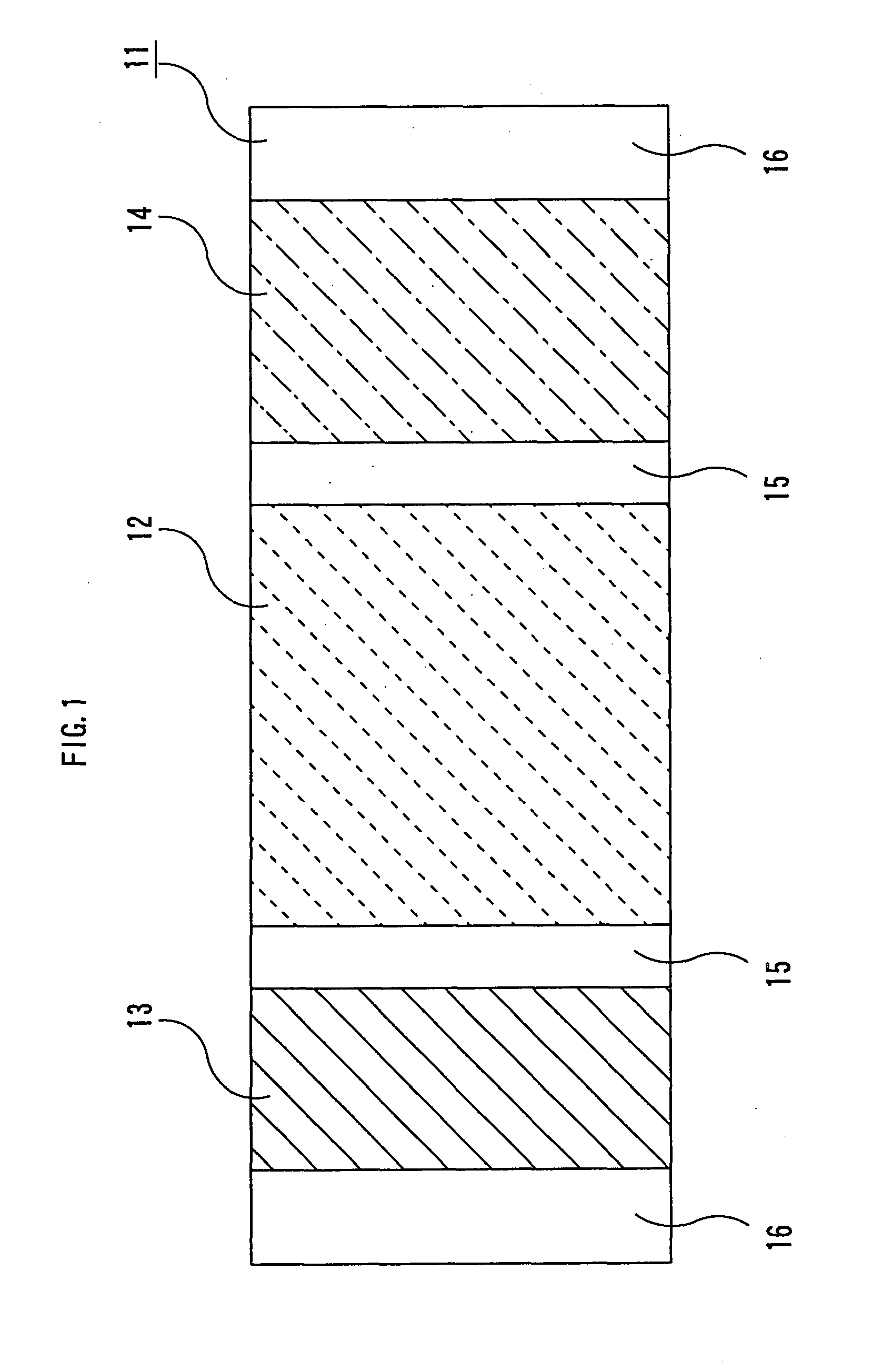

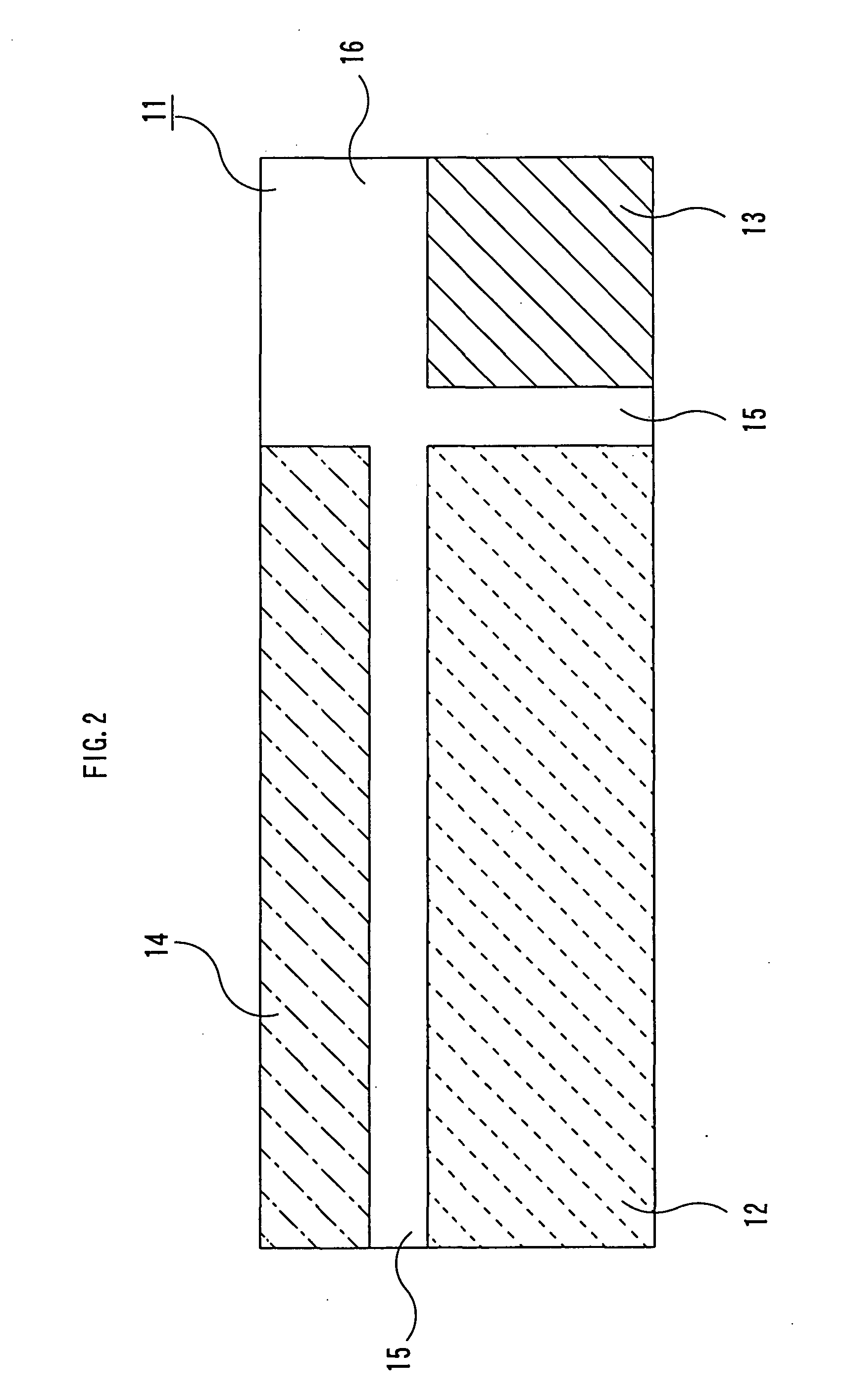

Color card, color book comprising the same, and color card with picture sample

InactiveUS20040004719A1Avoid difficult choicesWell-organizedRadiation pyrometryPattern printingColor chartColor tone

A color card showing at least three color samples is provided. Among the color samples, a light color sample expressing a light color tone occupies a larger space than samples expressing the other color tones. A deep color sample expressing a deep color tone in the color card is arranged on one side of the light color sample, and a neutral color sample expressing a neutral color tone which stands between the light and deep color tones is arranged on the other side. Use of such a color card allows the user to roughly select a color card showing a color tone suited for being applied to an object to be painted from a plurality of color cards based on their light color samples, and then select one of color tones shown in the selected color card.

Owner:KIKUSUI CHEM IND CO LTD

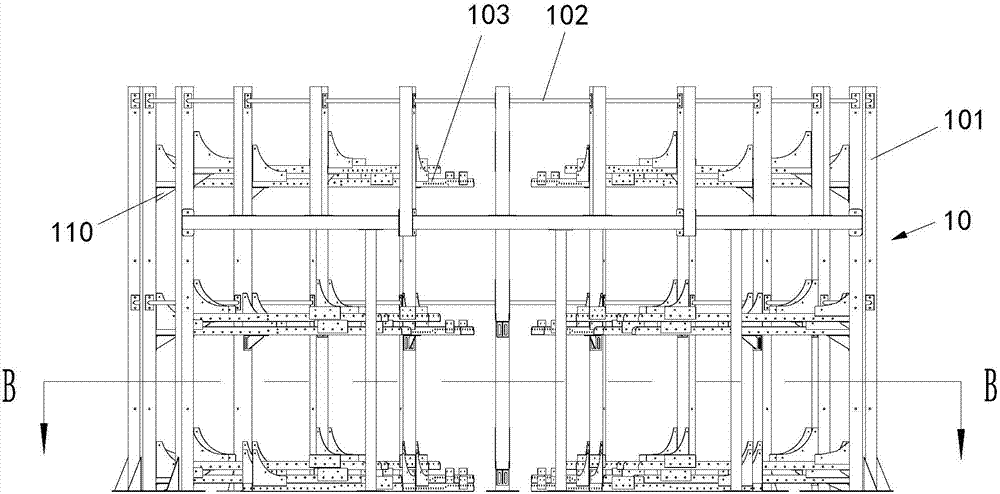

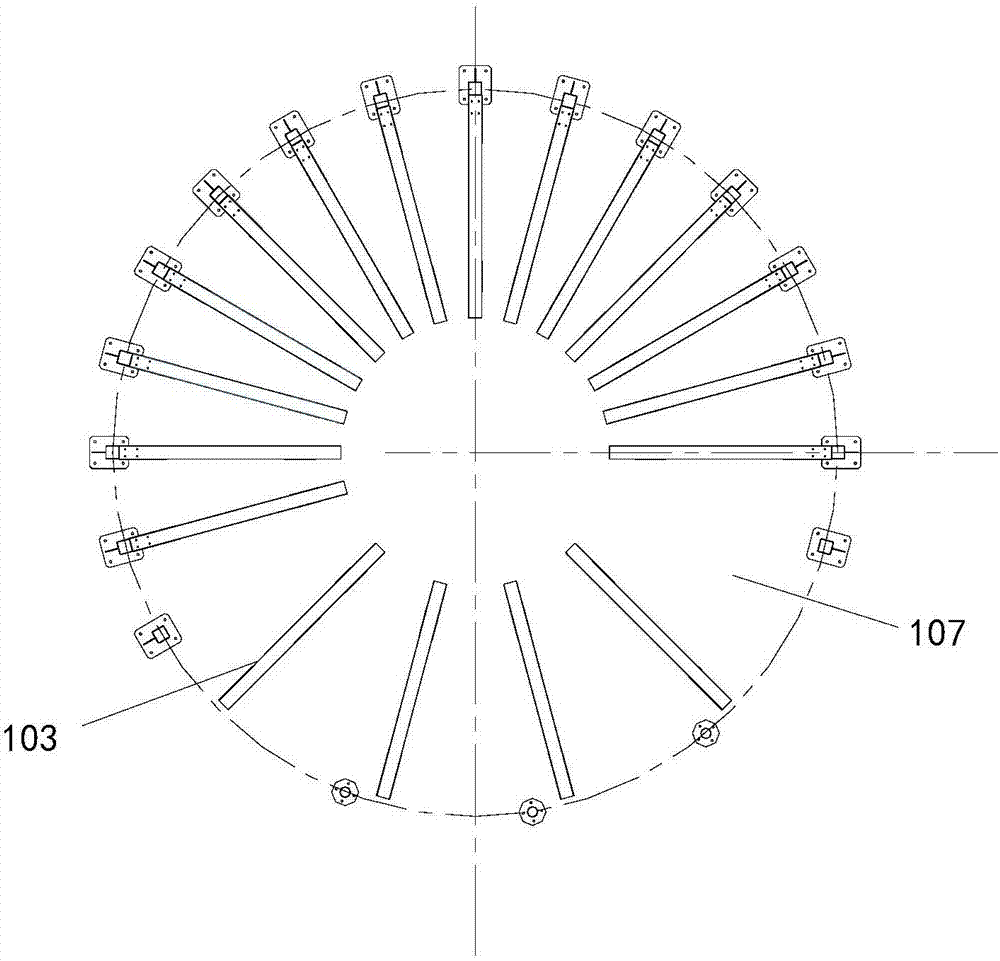

Intelligent bicycle garage

PendingCN107542294AWith electromagnetic locking functionEnsure safetyParkingsStructural engineeringControl theory

The invention discloses an intelligent bicycle garage comprising a peripheral support, a rotating lifting device and a push-and-pull mechanism. The peripheral support is used for storing bicycles in astereoscopically-stacked manner. The rotating lifting device is located at the center axis in the peripheral support and used for conveying the bicycles to each bicycle storage stall in the peripheral support. The push-and-pull mechanism is located between the peripheral support and the rotating lifting device and is used for pushing the bicycles on the rotating lifting device into the bicycle storage stalls on the peripheral support and pulling the bicycles on the bicycle storage stall on the peripheral support into the rotating lifting device. The bicycle in a lifting frame is lifted by a rotating mechanism and a lifting mechanism to the closest bicycle storage stall on the peripheral support, then the bicycle is parked in the bicycle garbage through the push-and-pull mechanism, and thebicycle storage efficiency is high; then, an empty lifting frame falls to the entrance and exit position of the peripheral support under the action of the rotating mechanism and the lifting mechanism, the procedure is executed in cycles, and the bicycles are parked in the bicycle garage in the stereoscopically-stacked manner. The intelligent bicycle garage can reduce the occupied area of the bicycles and improve the space utilization rate.

Owner:湖北聚程万丽科技有限公司

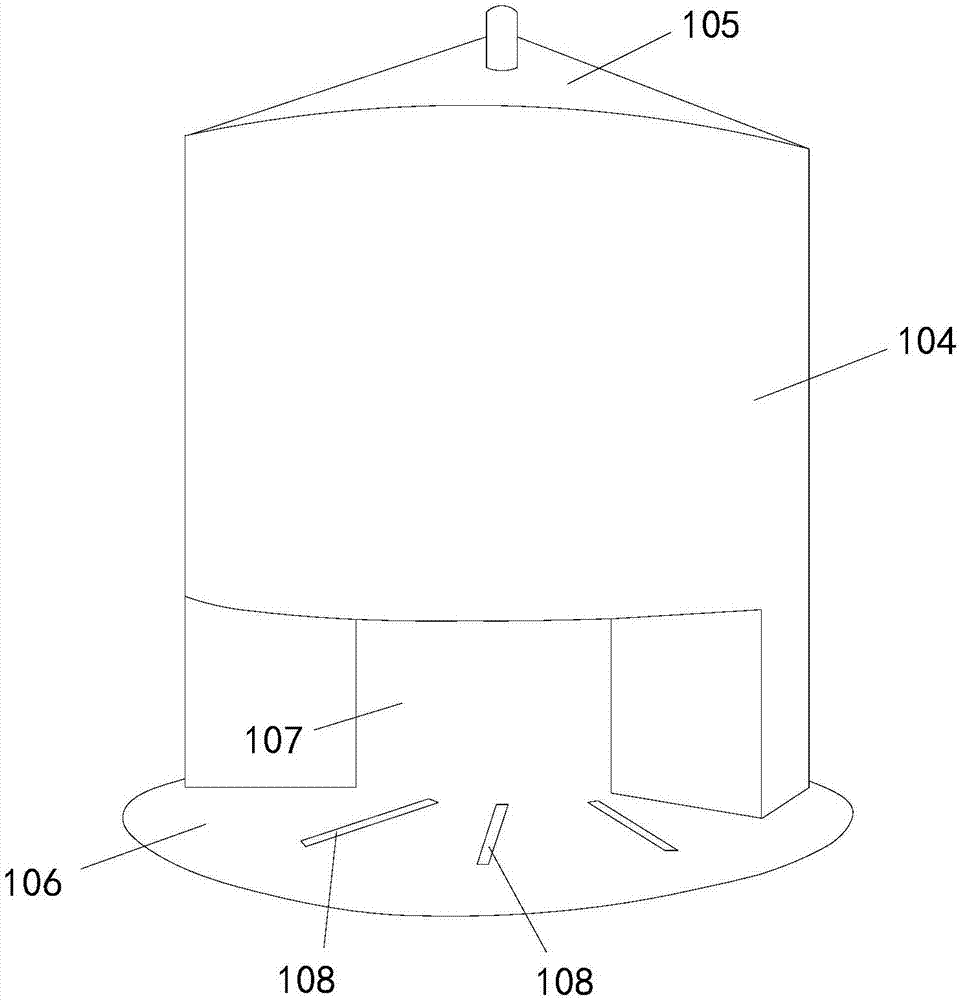

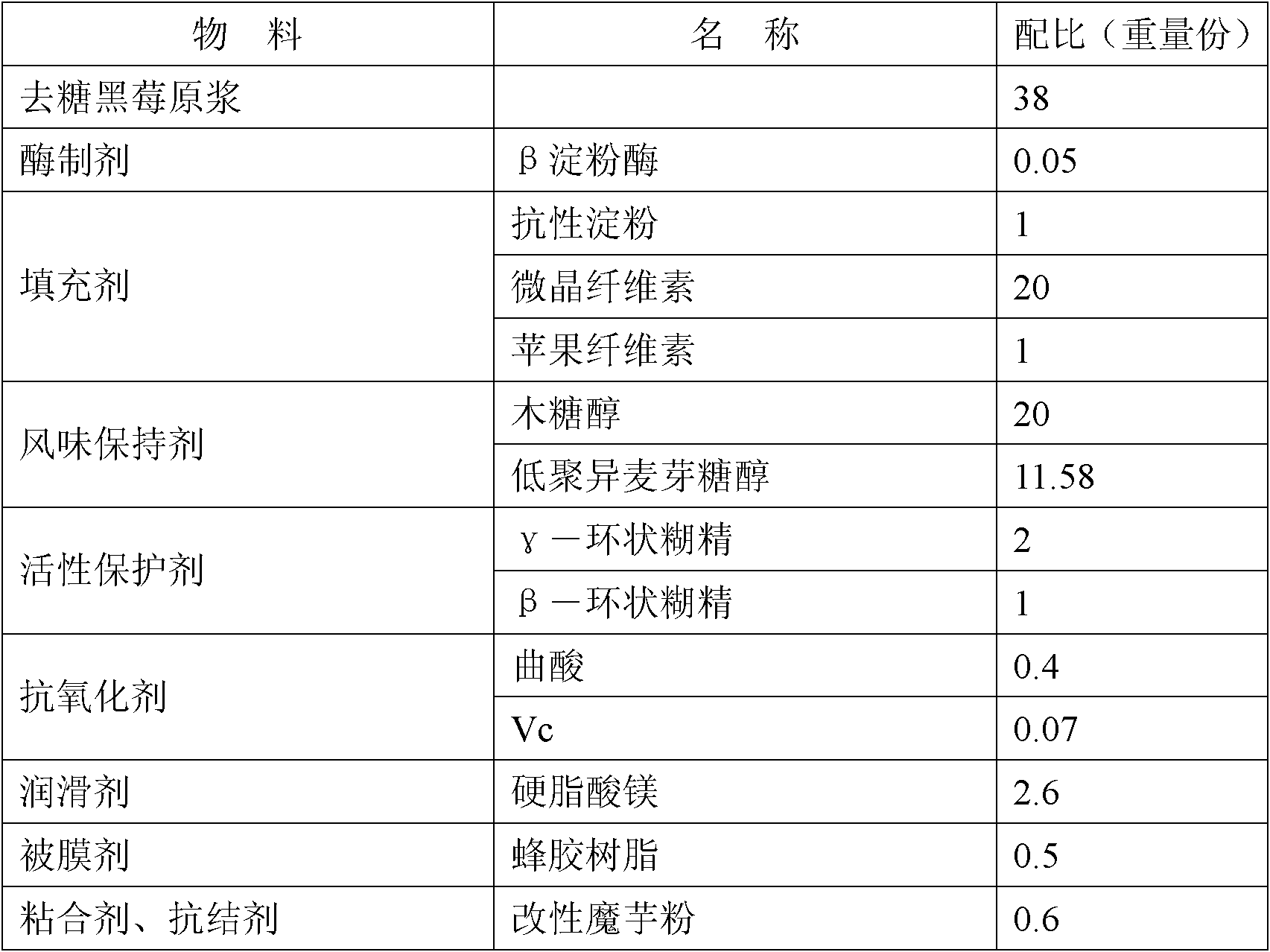

Desaccharified selenium-containing chewing tablet and preparation method thereof

The invention discloses a desaccharified selenium-containing chewing tablet which is prepared from the following components by weight: 35 to 45 parts of desaccharified blackberry raw pulp, 0.03 to 0.08 part of an enzyme preparation, 20 to 25 parts of a filler, 28 to 33 parts of a flavor conservation agent, 1 to 5 parts of an activity protection agent, 0.1 to 0.8 part of an anti-oxidant, 1 to 5 parts of a lubricant, 0.3 to 0.8 part of a coating agent and 0.3 to 0.8 part of a binder. The desaccharified selenium-containing chewing tablet provided in the invention has a good structural state and good taste and flavor and is especially applicable to diabetic patients.

Owner:文舜

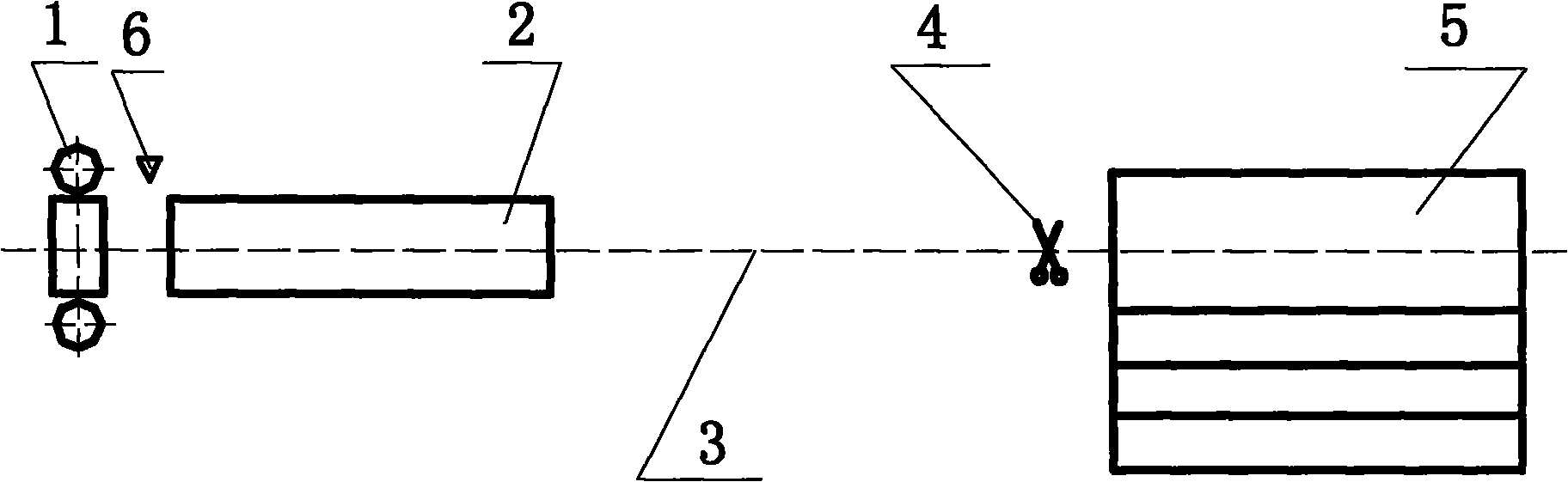

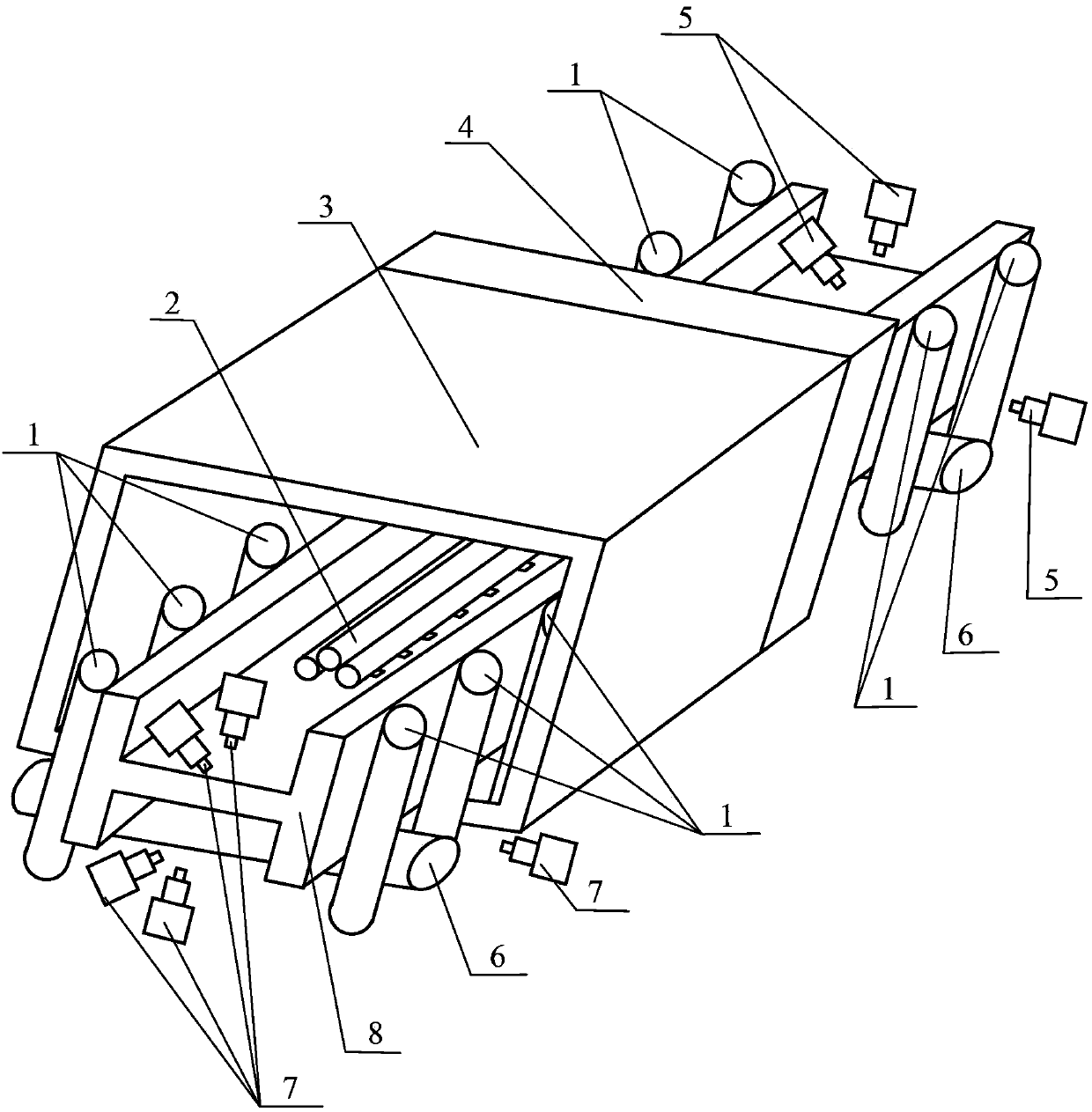

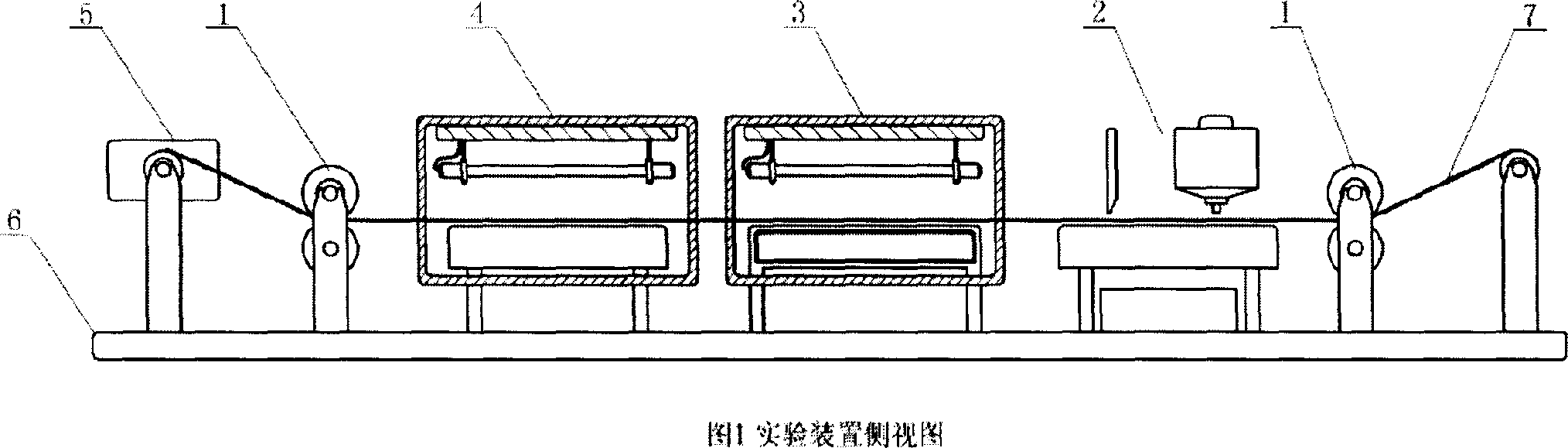

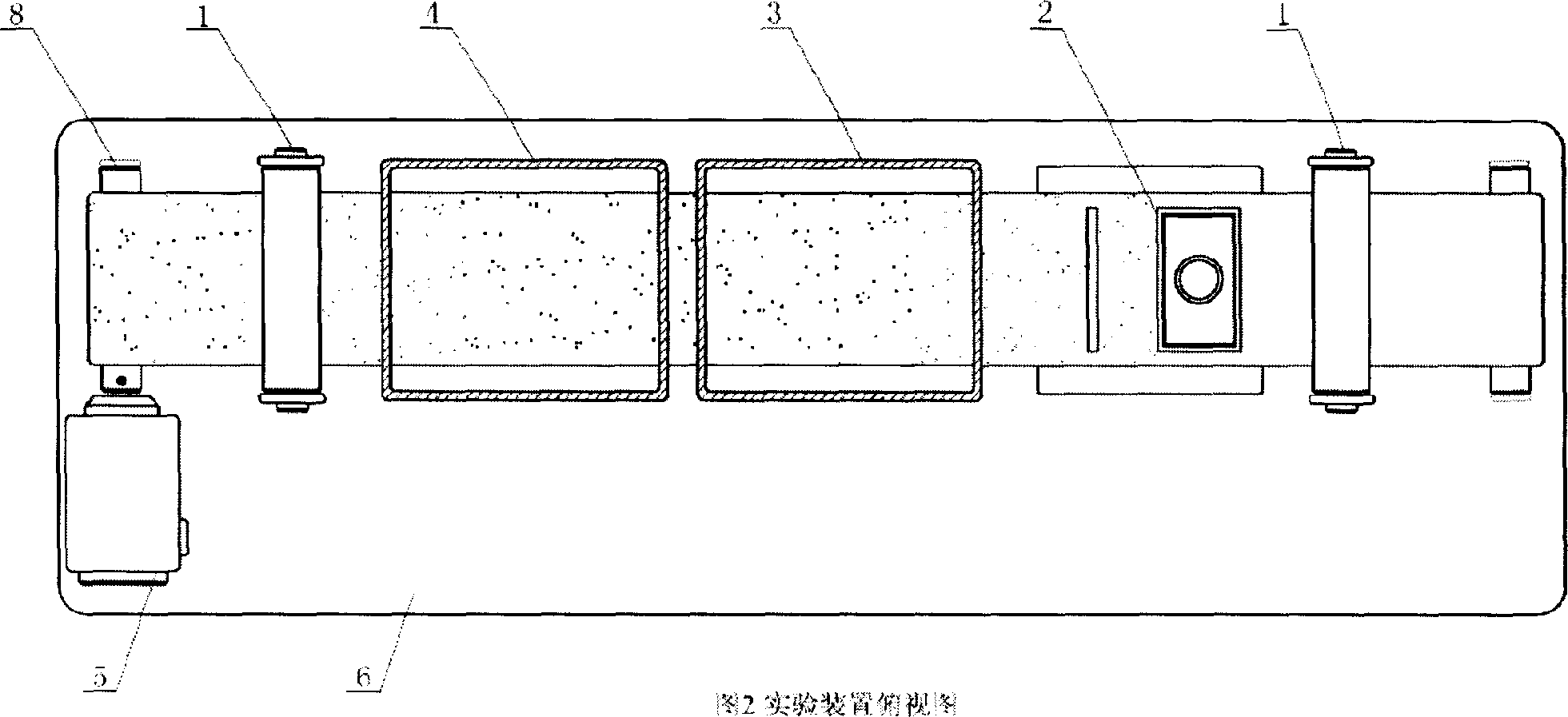

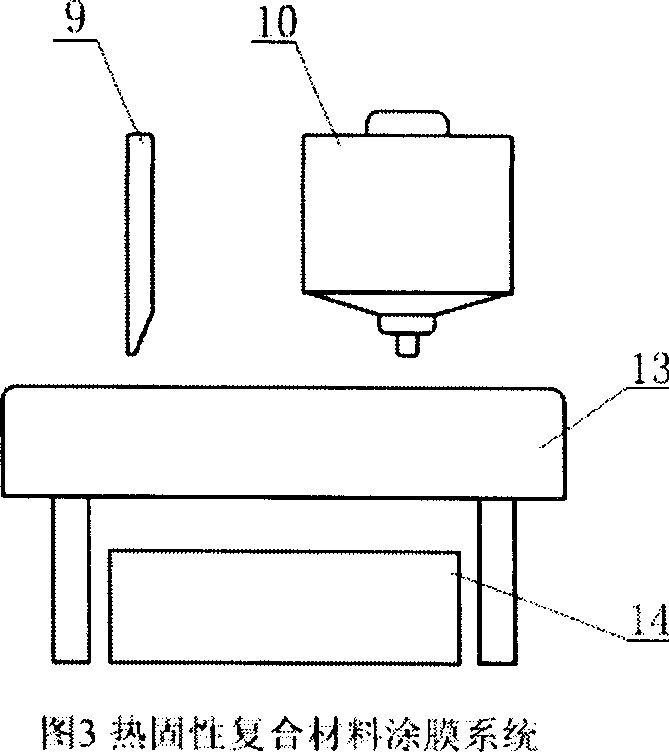

Device for preparing ordered micro structure resin base composite material film

The apparatus for preparing ordered micro structure resin base composite material film consists of a tension control system, a composite material film coating system, a magnetic field processing system, a heating treatment system, a DC servo speed regulating motor, a pedestal and other parts. All the systems are fixed successively on the pedestal. In the apparatus, ordered micro structure resin base composite material film is formed through driving the base film with the DC servo speed regulating motor, coating the resin base composite material onto the base film in the composite material film coating system, ordering the micro structure in the composite material and pre-curing in the magnetic field processing system, and final curing through heating in the heating treatment system. Compared with available technology, the present invention has the features of capacity of producing ordered micro structure composite material film in different direction, etc.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com