Patents

Literature

30 results about "ZK60 magnesium alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

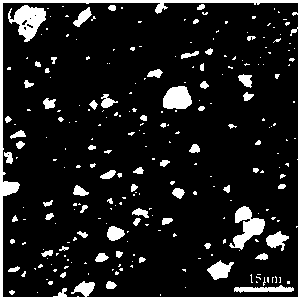

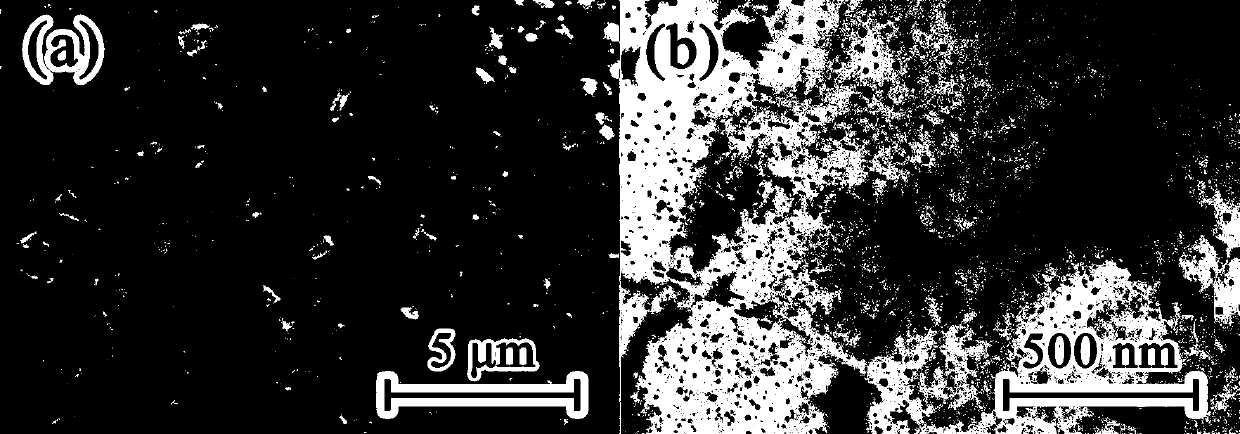

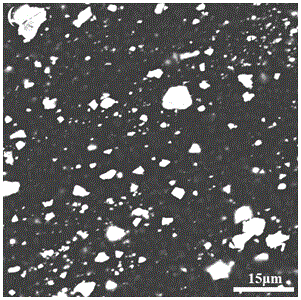

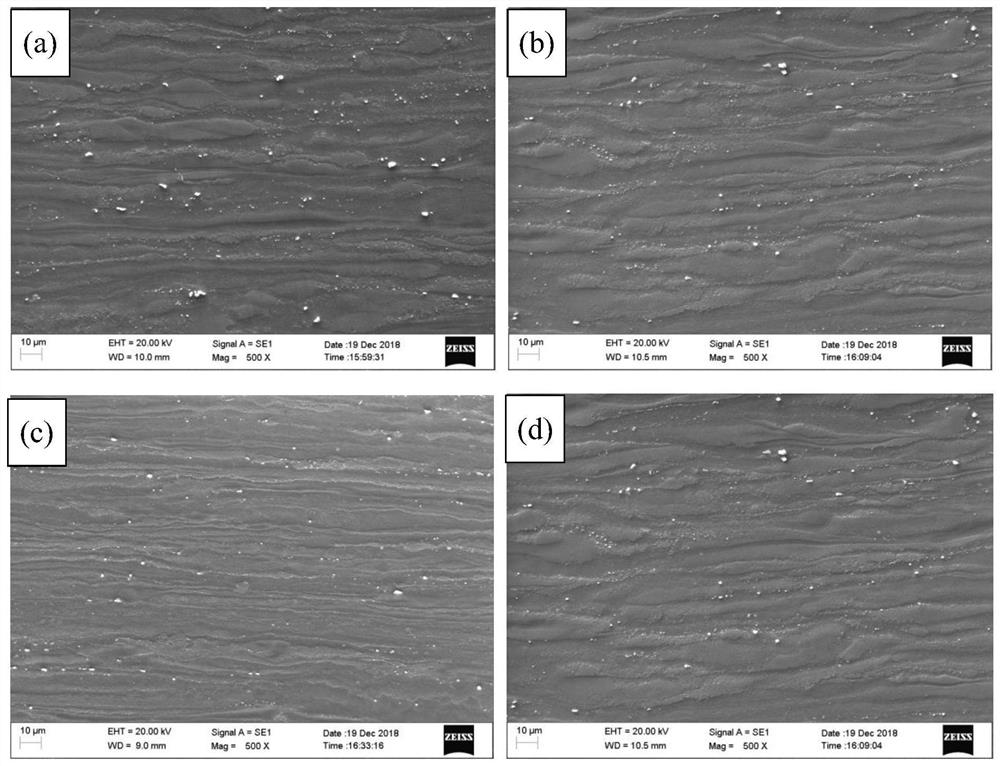

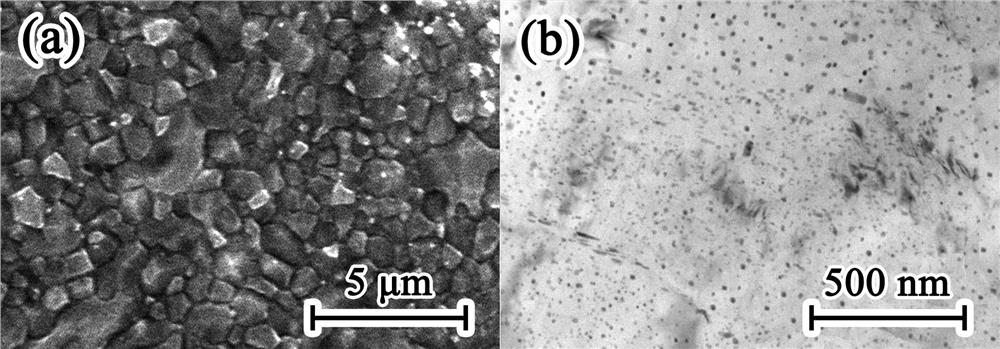

An extruded ZK60 magnesium alloy with an initial grain size of ∼9.4 μm was processed by high pressure torsion (HPT) for up to 5 revolutions and microstructural observations were carried out using optical and scanning electron microscopy.

Magnesium alloy of high intensity and high yield ratio and preparation method thereof

The invention provides a magnesium alloy material of high intensity and high yield ratio. The alloy comprises the following components by mass: 5.0-9.0% of Zn; 0.5-1.5% of Mn; 1-10% of Sn; less than 0.15% of inevitable impurities; and the balance magnesium. By means of plastic forming and a choice of reasonable technological conditions for heat treatment after forming, the magnesium alloy material of the invention can be of high intensity and high yield ratio, and is higher than the high-strength wrought magnesium alloy ZK60 in terms of yield strength and tensile strength. With low cost, good extrudability and formability at a low temperature, the magnesium alloy material provided in the invention boasts substantial application potential, thus being able to partly replace the magnesium alloy material ZK60.

Owner:QINGHAI SUNGLOW MAGNESIUM

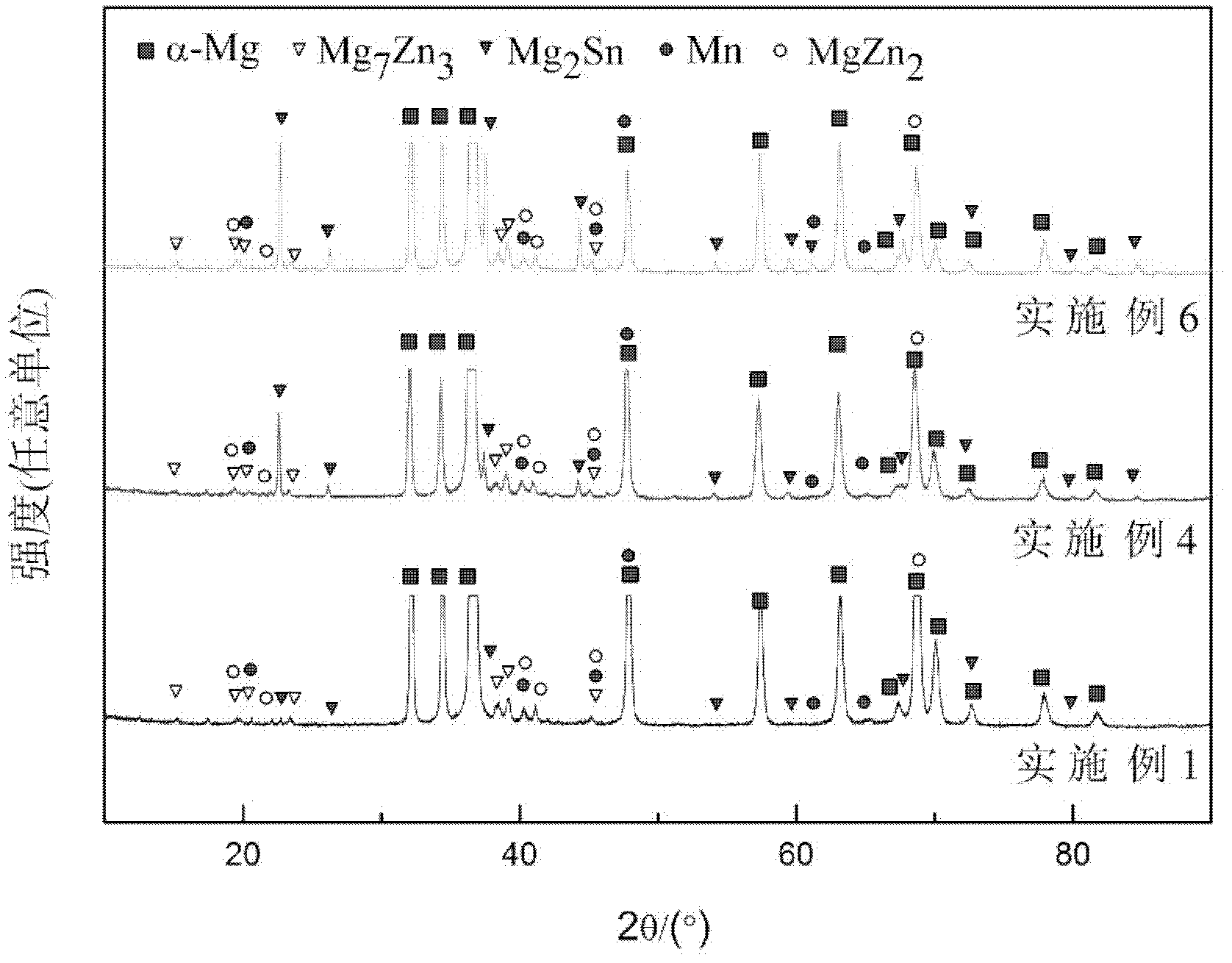

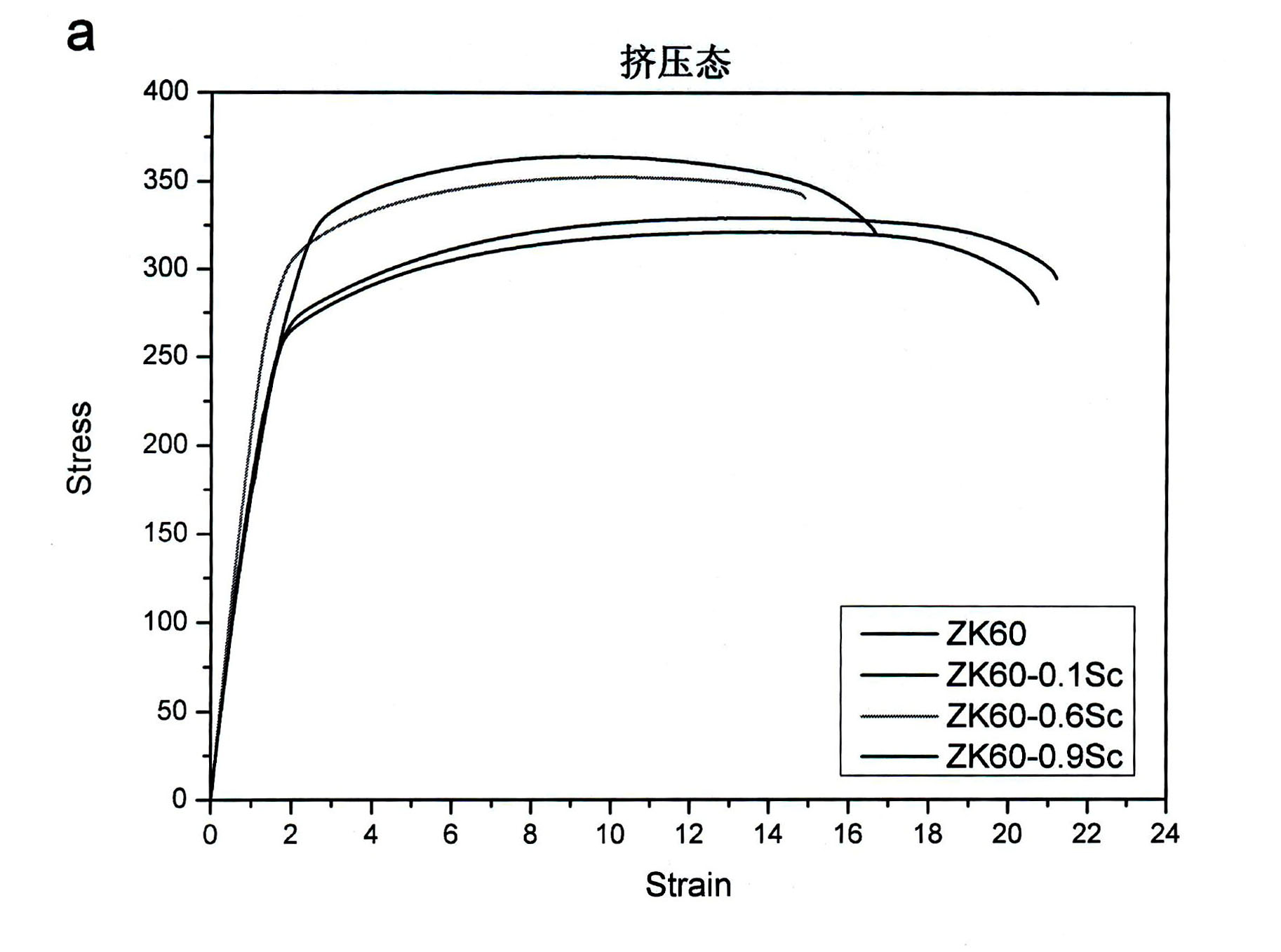

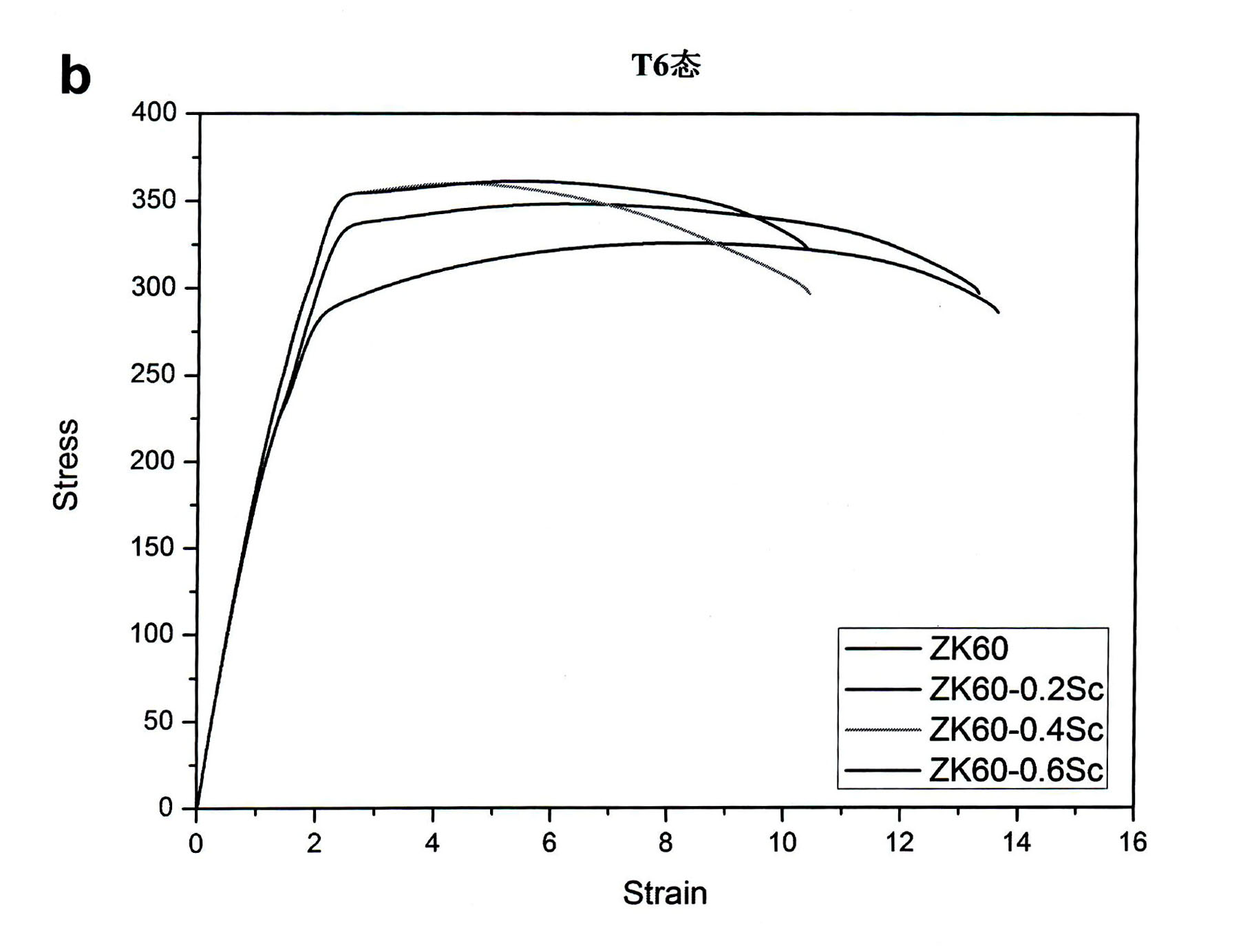

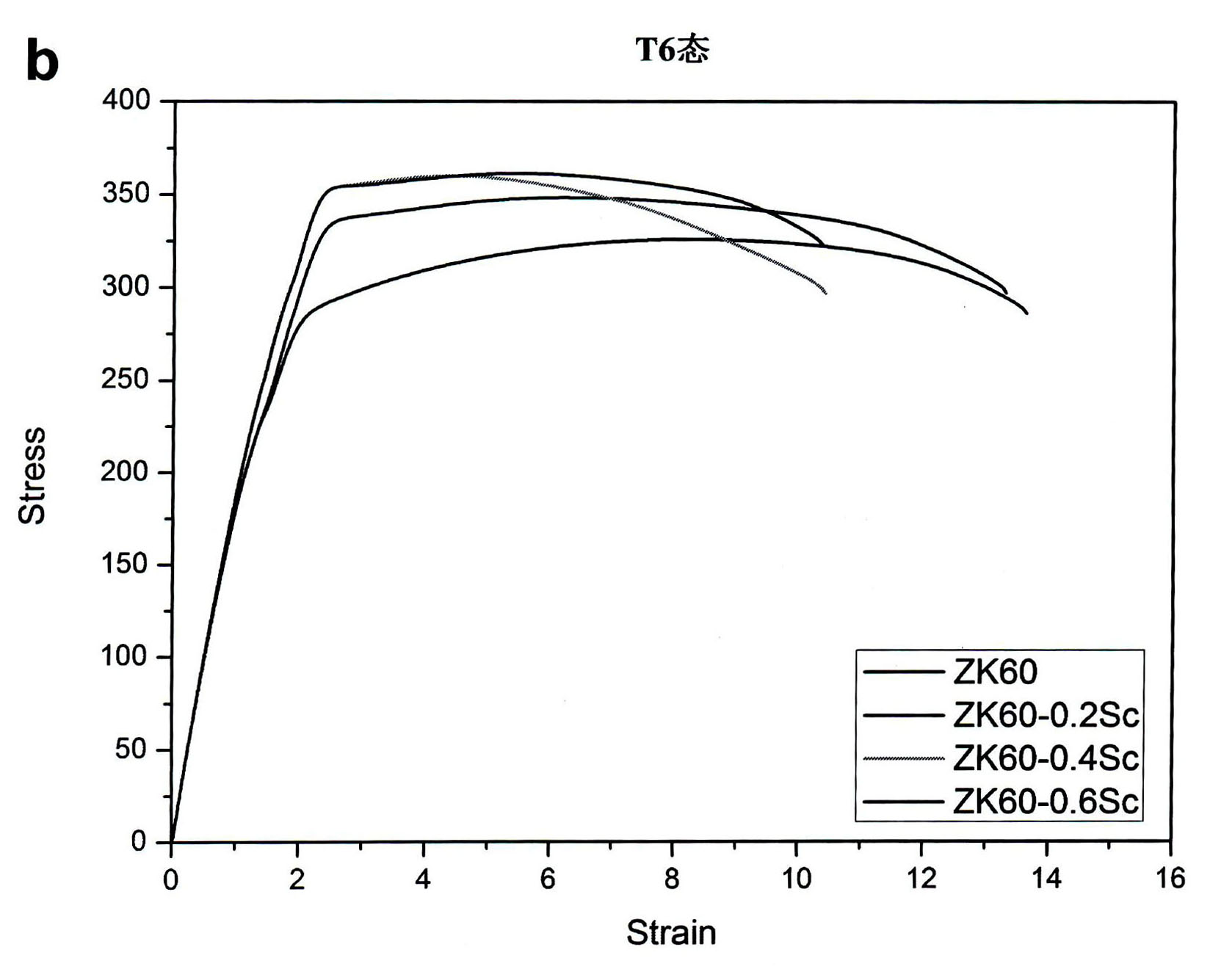

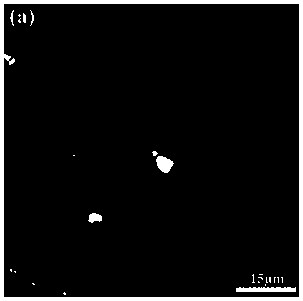

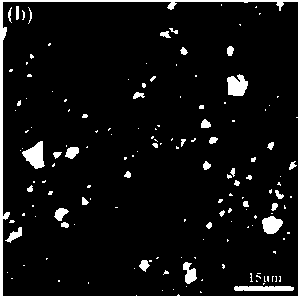

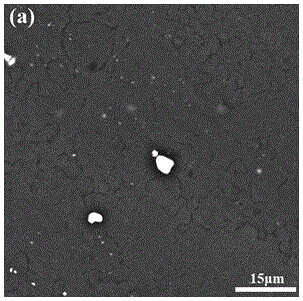

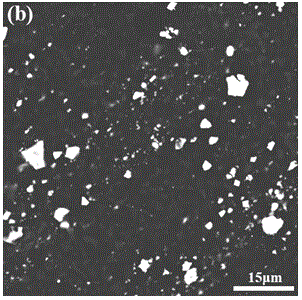

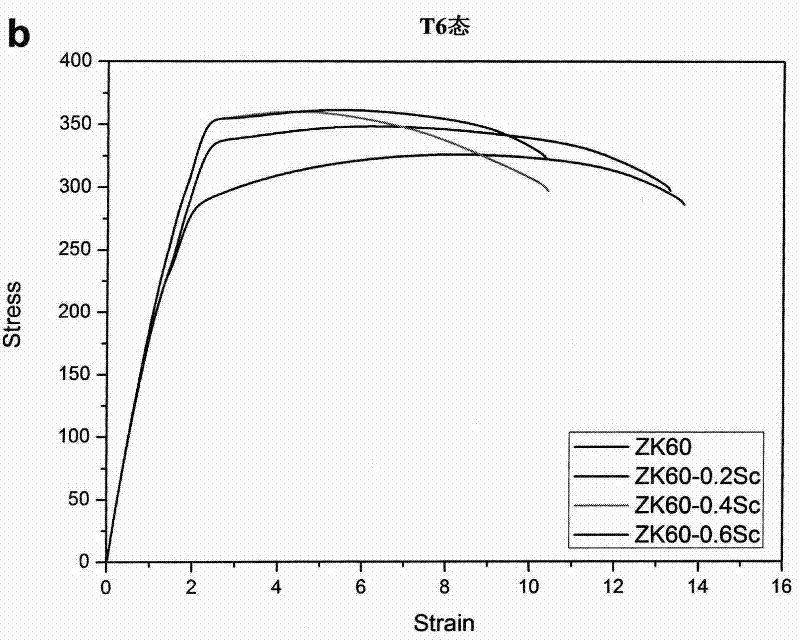

Method for reinforcing ZK60 magnesium alloy by adding Sc

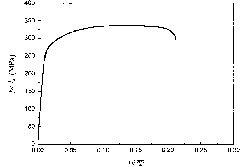

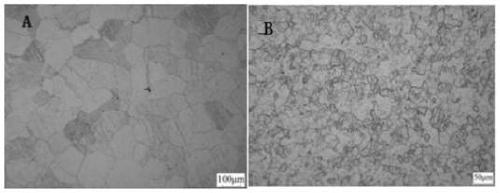

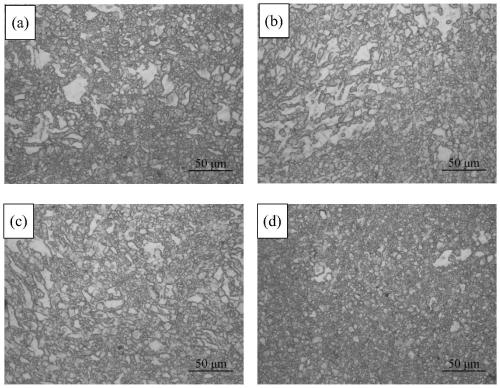

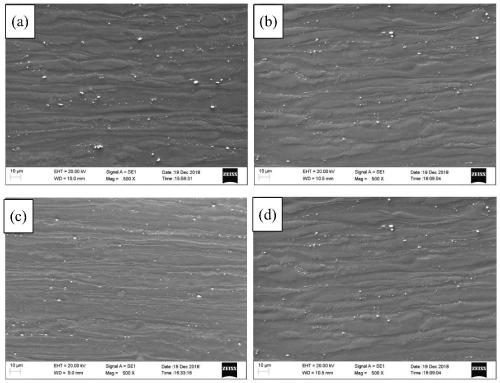

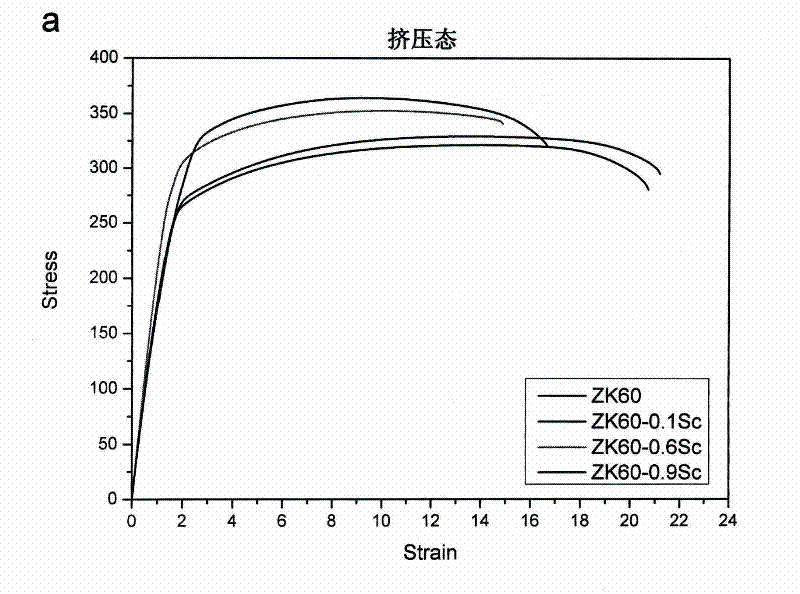

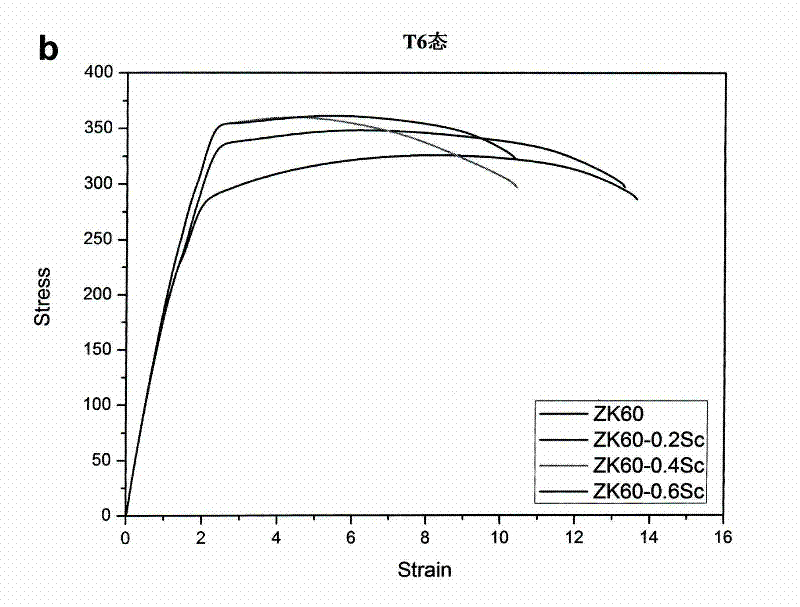

The invention discloses a method for reinforcing a ZK60 magnesium alloy by adding Sc, which is realized by adding a rare-earth element Sc into the ZK60 magnesium alloy. The method comprises the following concrete steps of: smelting and ingot making, homogenizing, hot-extruding, heat treatment and the like. Because of the addition of the Sc, crystalline grains of the ZK60 magnesium alloy is effectively refined, intergranular reticular precipitated phases become thin with uniform distribution, and thin and diffused particle-shaped precipitated phases are formed at a crystal boundary, and after the intergranular reticular precipitated phases and thin and diffused particle-shaped precipitated phases are subjected to homogenization, extrusion and heat treatment, the tensile strength of the alloy can reach 364MPa, the yield strength can reach 352MPa and the yield ratio is close to 1. Compared with the common ZK60 alloy, a product in the method has the tensile strength and the yield strength which are respectively improved by 39MPa and 67MPa, and thus, the tensile strength and the yield strength of the ZK60 magnesium alloy are obviously improved and the industrial application range of the ZK60 magnesium alloy is widened.

Owner:CHONGQING UNIV

Wrought magnesium alloy containing rare earth cerium and yttrium and having high yield ratio

ActiveCN103952613AInhibit growthFully tap the potential of useMechanical componentsThermal deformation

The invention provides a wrought magnesium alloy containing rare earth cerium and yttrium and having high yield ratio. The alloy comprises the following components in percentage by mass: 4.90-5.20wt.% of Zn, 0.50-0.80wt.% of Zr, 0.50-0.70wt.% of Ce, 0.10-1.50wt.% of Y, less than 0.12wt.% of inevitable impurities and the balance of Mg. A certain amount of cerium and yttrium are added into the ZK60 magnesium alloy to effectively refine grains, and cerium and yttrium as well as magnesium and zinc in the alloy can form fine and dispersed strengthening phases to effectively hinder growth of recrystallized grains in the thermal deformation process and strengthen the matrix, so that the high yield ratio can be obtained, and the yield strength exceeds 300MPa which is remarkably higher than that of the magnesium alloy ZK60. Meanwhile, good plasticity is guaranteed. The material provided by the invention can enhance the reliability of mechanical parts, the product quality is improved and the utilization ratio of the material is improved, so that the using potential of the magnesium alloy material is fully explored.

Owner:CHONGQING UNIV

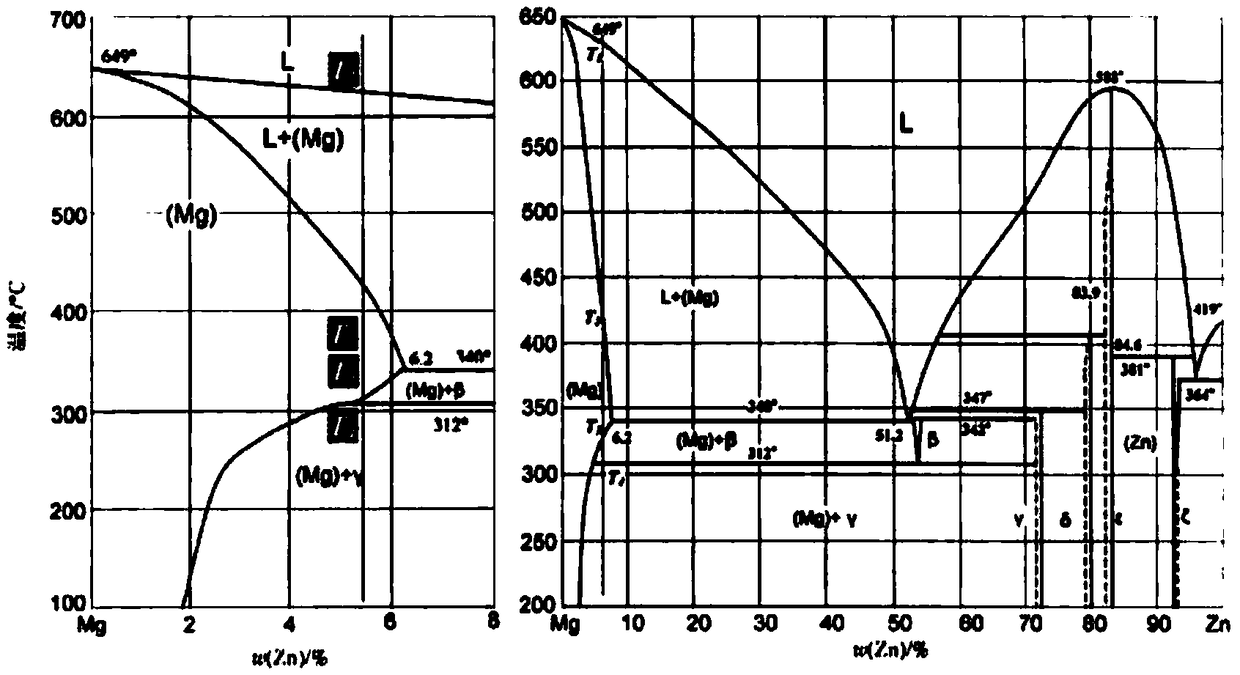

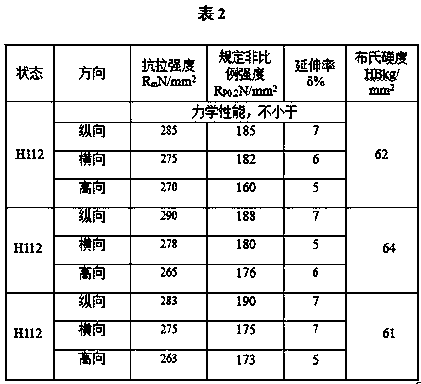

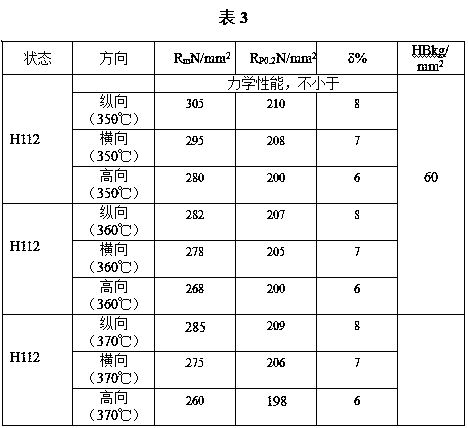

High-performance wrought magnesium alloy material

The invention relates to a high-purity high-performance magnesium alloy material, which consists of the following components in percentage by mass: 6.2 to 6.4 percent of Zn, 0.5 to 0.6 percent of Zr, 0.007 to 0.011 percent of inevitable Fe, Si, Cu, Ni and other impurities, and the balance magnesium. The material is prepared by the following steps: selecting raw magnesium with higher purity as a raw material; melting the raw magnesium by using the semicontinuous casting technology; properly increasing the melt standing time to ensure that compound particles containing Fe, Si and other impurity elements can be sufficiently deposited and a high-purity alloy cast blank can be prepared; and preparing the Mg-Zn-Zr wrought magnesium alloy by adopting the conventional extruding technology. The wrought magnesium alloy can maintain the high strength of traditional commercial ZK60 magnesium alloy to ensure that the plasticity and forming performance of the alloy can be greatly improved and the application potential of the material is sufficiently developed. Furthermore, the technical equipment used in the invention is conventional universal equipment, and the preparation process is simple.

Owner:CHONGQING UNIV

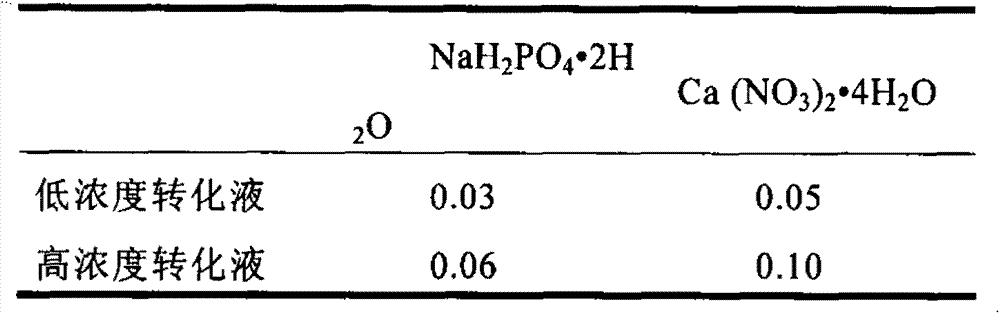

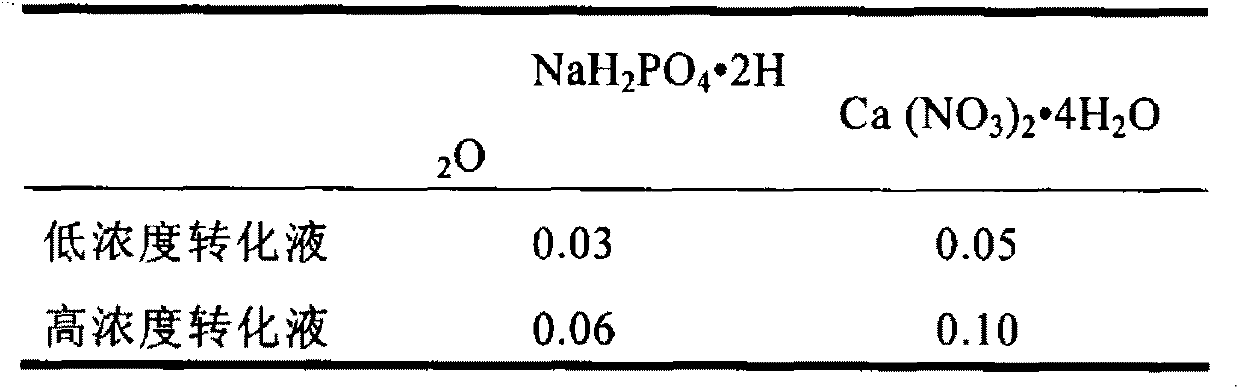

Preparation method of biodegradable magnesium alloy/calcium phosphate coating composite material

InactiveCN103484845AImprove corrosion resistanceConvenient researchMetallic material coating processesCalcium biphosphateCalcium phosphate coating

The invention relates to a preparation method of a biodegradable magnesium alloy / calcium phosphate coating composite material. The preparation method comprises the steps of pre-treating a matrix, preparing a conversion liquid, and preparing a bionic calcium phosphate coating to obtain the biodegradable magnesium alloy / calcium phosphate coating composite material. Compared with the prior art, the preparation method has the advantages that the prepared ZK60 magnesium alloy / calcium phosphate coating composite material can be used for remarkably improving the corrosion resistance of a ZK60 magnesium alloy, greatly reducing the degradation rate of the ZK60 magnesium alloy in a bionic body liquid and promoting the research and application of the ZK60 magnesium alloy in the medical field.

Owner:TONGJI UNIV

Aging strengthening type magnesium alloy and heat treatment process thereof

The invention provides an aging strengthening type magnesium alloy and a heat treatment process thereof. The alloy comprises, by weight, 6.8-8.0% of zinc, 0.8-1.5% of copper and 0.8-1.5% of manganese, with the balance being magnesium and inevitable impurities. According to the heat treatment process, an alloy ingot is subjected to two-stage homogenization treatment under the condition of (330-360) DEG C * (4-8)h+(400-420) DEG C * (16-20)h and is subjected to thermal forming at the temperature of 360-400 DEG C, a finished product is subjected to solution treatment at the temperature of 400-430 DEG C for 2-4 hours, and two-stage aging is performed under the condition of (80-100) DEG C * (3-5)h+(175-190) DEG C * (15-18)h after water cooling, so that an aging strengthening effect much better than that of a commercial high-strength ZK60 alloy can be achieved, and alloy strength can be improved obviously. The alloy does not contain heavy metal and is low in cost; the limitation that aging strengthening of conventional commercial magnesium alloys is achieved through MgZn2 phases is broken through; through proper heat treatment process, precipitated phases in the alloy can be precipitated in a small dispersed mode and the ageing strengthening potential of the alloy can be developed to the greatest extent.

Owner:CHONGQING UNIV

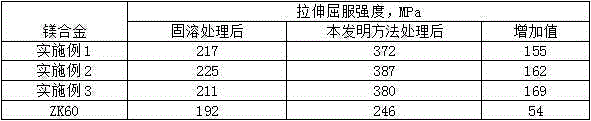

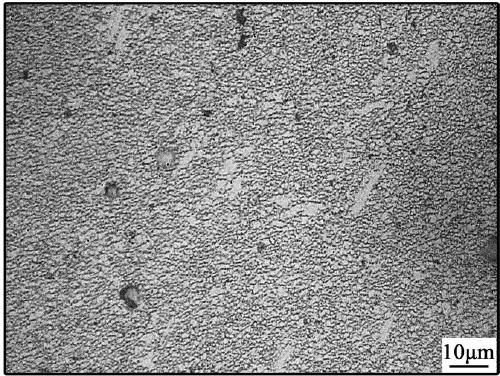

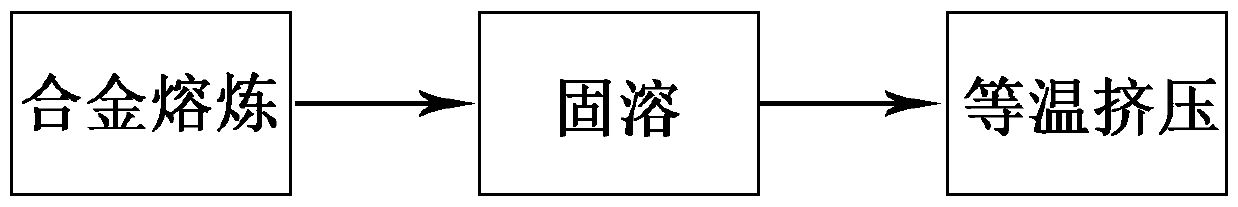

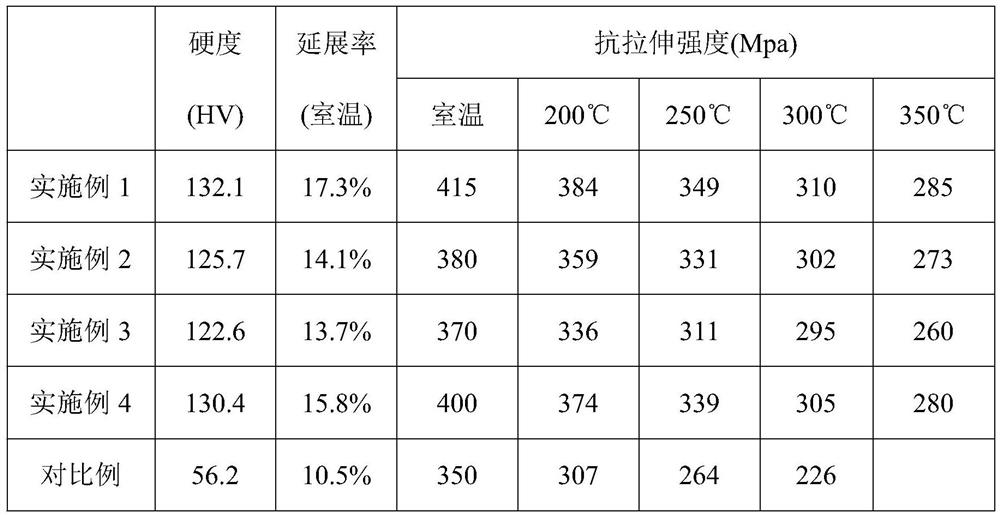

Low-cost preparation method of ultrafine-grained high-strength plastic rare earth magnesium alloy

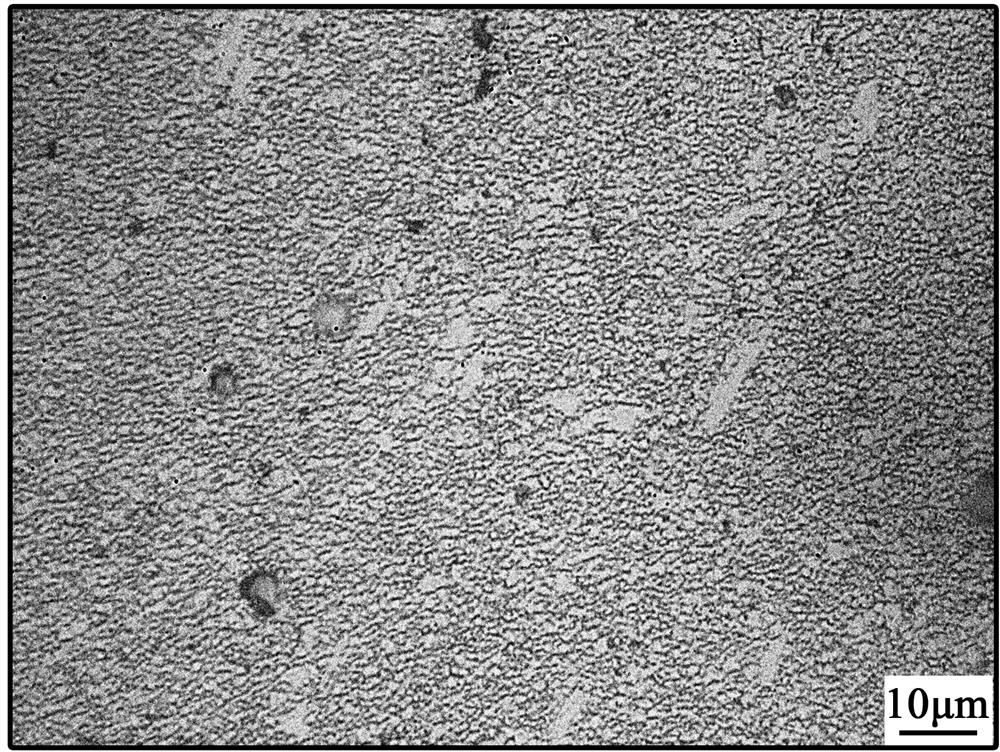

The invention discloses a low-cost preparation method of an ultrafine-grained high-strength plastic rare earth magnesium alloy. The low-cost preparation method comprises the steps of alloy smelting, solution treatment and isothermal extrusion, specifically, firstly a ZK60 magnesium alloy containing a rare earth element ytterbium (Yb) with a mass percentage of 0.8-1.5% is smelted according to the composition, then rapidly condensed into an ingot and then subjected to the solution treatment at 400 DEG C for 48 h, and finally the isothermal extrusion is performed at 330-350 DEG C with a strain rate of 0.1-1.0 s<-1> and an extrusion ratio of 10-30 to obtain an ultrafine-grained high-strength plastic magnesium alloy block with an average grain size of less than 1 [mu]m, the tensile strength ofmore than 400 MPa and the elongation of more than 15%. According to the low-cost preparation method of the ultrafine-grained high-strength plastic rare earth magnesium alloy, conventional low extrusion ratio deformation is utilized to obtain an ultrafine-grained structure which is difficult to obtain in a conventional magnesium alloy system, the addition amount of the rare earth element is combined to control the strength and plasticity of the alloy, and finally a magnesium alloy block material which is refined in structure and has high strength and plasticity is obtained. The cost is low, theprocess is short, the efficiency is high, and good industrial application prospects are achieved.

Owner:SOUTHWEST UNIVERSITY

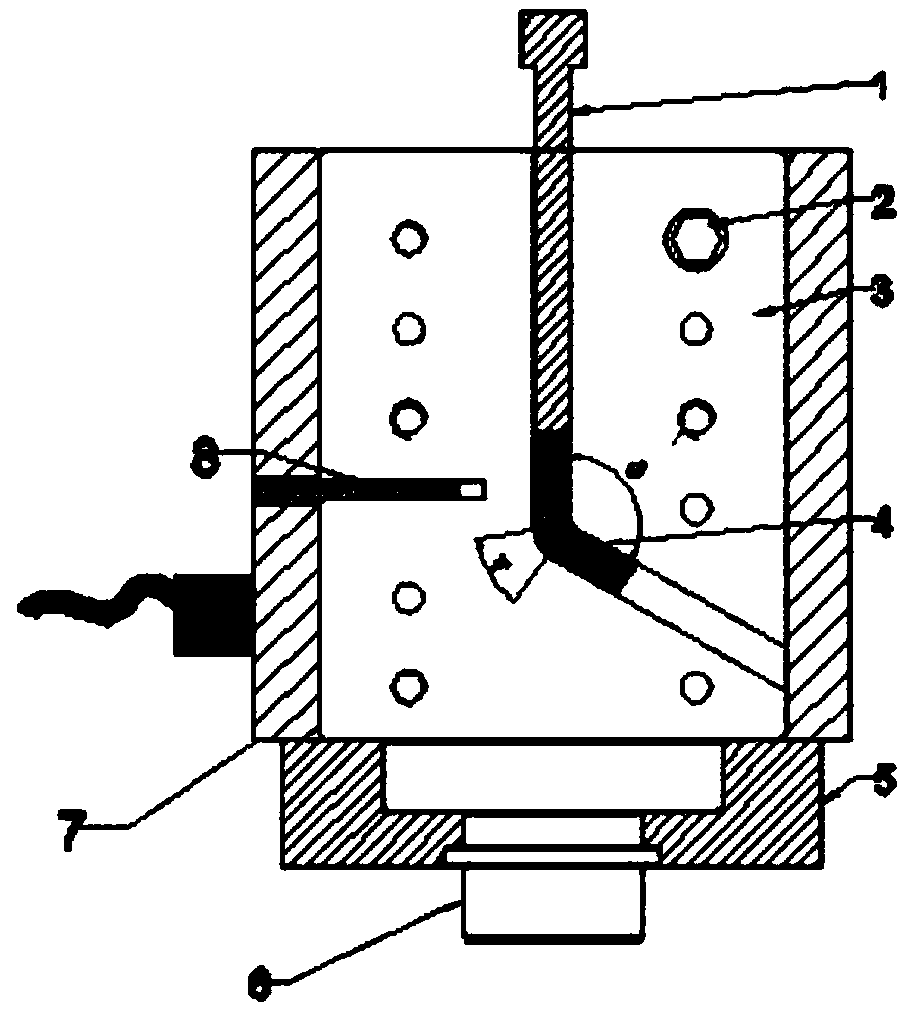

Fast extrusion method of ZK60 magnesium alloy profile

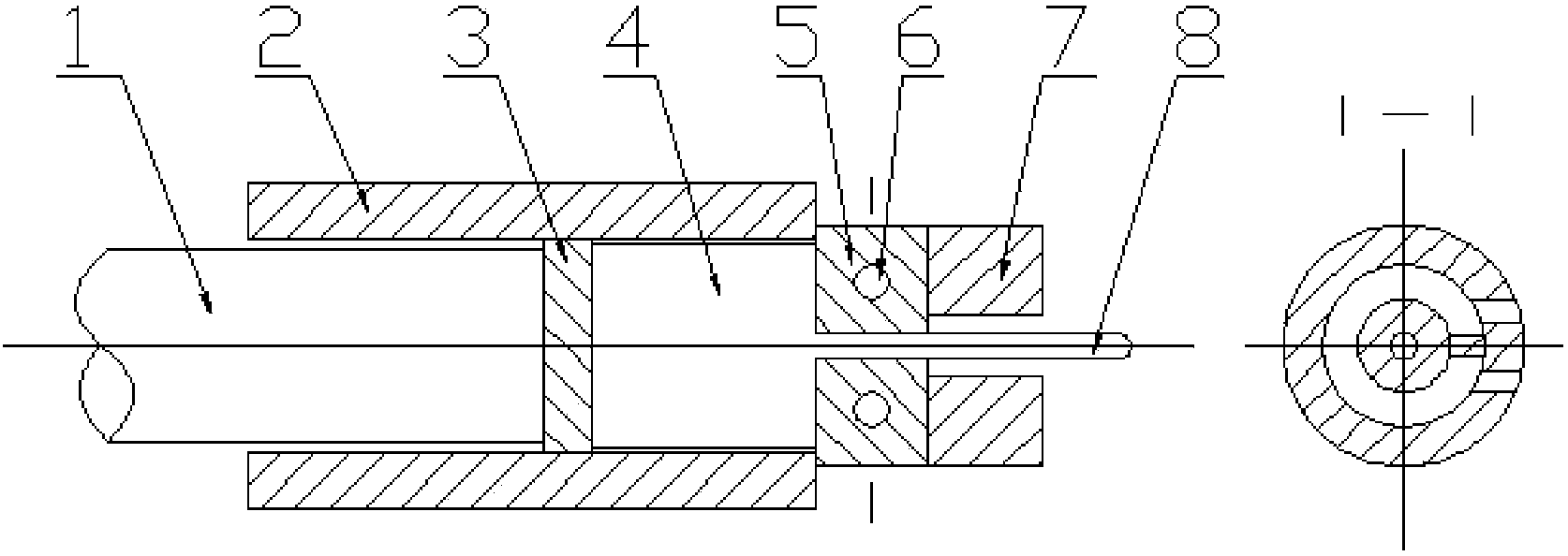

InactiveCN104259232AQuality improvementAvoid breakingExtrusion control devicesZK60 magnesium alloyThermocouple

The invention discloses a fast extrusion method of a ZK60 magnesium alloy profile, and aims to increase an extrusion speed of the commercial ZK60 magnesium alloy profile and prevent common extrusion cracks from being generated on the profile surface during hot extrusion simultaneously. The hot extrusion method is adopted for producing the ZK60 magnesium alloy profile, a cooling channel is arranged on an extrusion die, and a cooling medium passes through the extrusion die to cool the extrusion die in the extrusion process; and meanwhile, thermoelectric couples are arranged on the extrusion die for temperature measurement, and a flow control valve is adopted to regulate the flow of the cooling medium online, so that the temperature change range of the die in the extrusion process is plus or minus 5 DEG C, mass accumulation of deformation heat in the extrusion process is prevented, defects of profile breakage, periodic extrusion cracks or oxidation and the like due to local overheating are overcome, the extrusion speed of the profile is increased to 1 m / min-5 m / min, and the fast extrusion method is suitable for magnesium alloy profiles of extruders at various tonnages.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

Method for preparing degradable magnesium alloy and modified polylactic acid coating composite material

InactiveCN103934184AImprove corrosion resistanceConvenient researchPretreated surfacesCoatingsZK60 magnesium alloyPre treatment

The invention relates to a method for preparing a degradable magnesium alloy and modified polylactic acid coating composite material. The method includes the following steps that a magnesium alloy matrix is polished so that a surface oxidization layer is removed; acid etching pre-treatment and neutralizing treatment are carried out on the magnesium alloy matrix; polylactic acid is dissolved in a chloroform solution and a polylactic acid solution is prepared; the magnesium alloy matrix is immersed in the polylactic acid solution, and the surface of the magnesium alloy matrix is wrapped with a polylactic acid coating in a solution immersing and coating method; the obtained magnesium alloy material wrapped with the polylactic acid is stored for 2-3 days in a ventilated place, so that chloroform in the polylactic acid solution is volatilized completely, and the degradable magnesium alloy and modified polylactic acid coating composite material is obtained. Compared with the prior art, the anti-corrosion performance of ZK60 magnesium alloy can be improved obviously through the obtained magnesium alloy and modified polylactic acid coating composite material, the degradation rate of the ZK60 magnesium alloy in an organism can be greatly reduced, and researching and application of the ZK60 magnesium alloy in the medical field are promoted.

Owner:TONGJI UNIV

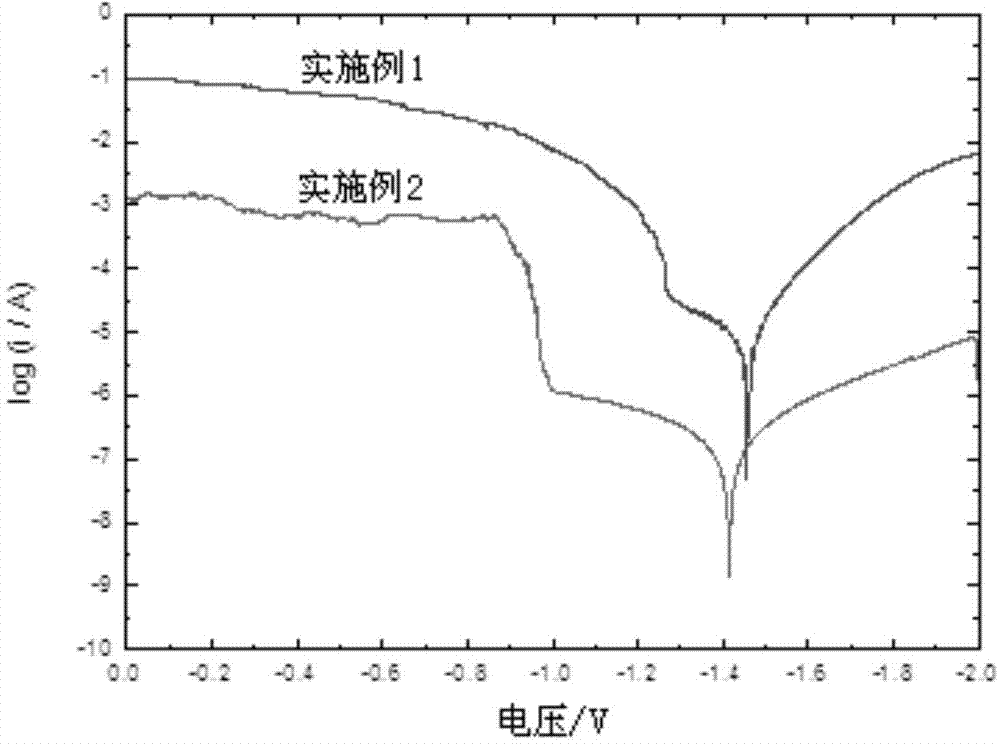

Corrosion-resistant high-performance wrought magnesium alloy and preparation method thereof

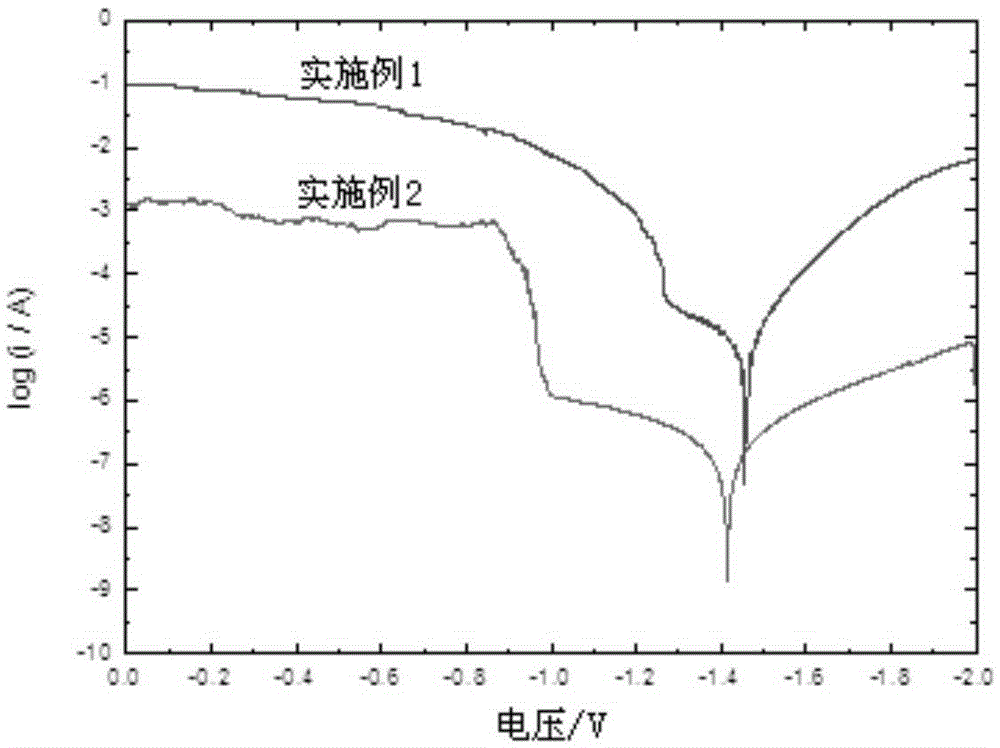

The invention discloses a corrosion-resistant high-performance wrought magnesium alloy and a preparation method thereof. The preparation method comprises the steps of alloy smelting, solid solution and hot extrusion. Firstly, a ZK60 magnesium alloy containing a rare earth element ytterbium (Yb) with the mass percent of 1.8% to 2.1% is smelted according to ingredients, then solid solution treatmentis carried out on the ZK60 magnesium alloy for 450 DEG C*24 h in protection gas, and hot extrusion is carried out at the temperature of 250 DEG C to 320 DEG C with the strain rate of 0.005 s<-1> to 0.01 s<-1> and the extrusion ratio of 32-40. The tensile strength of the finally obtained ZK60 alloy is 400-450 MPa, the ductility ranges from 10% to 20%, and compared with a commercialized ZK60 alloy,the corrosion current density can be reduced by 1-2 magnitudes orders. According to the corrosion-resistant high-performance wrought magnesium alloy and the preparation method thereof, a wrought magnesium alloy material prepared through a conventional process is utilized, high strength and high plasticity are achieved, excellent corrosion resistance is achieved, and the corrosion-resistant high-performance wrought magnesium alloy can be adopted as a ideal alternative to aerospace, weapon, 3C and biomedical materials.

Owner:SOUTHWEST UNIVERSITY

ZK60 magnesium alloy and preparation method thereof

The invention discloses ZK60 magnesium alloy, characterized by comprising, by mass, 2.5-3% of Al, 0.8-1.2% of Zn, 0.15-0.2% of Mn, 0.06% of Si, 0.03% of Cu, 0.02% of Ni, 0.01% of Fe, and the balance of Mg. A preparation method of the ZK60 magnesium alloy includes the steps of (1) selecting each material according to a mass ratio, preheating the selected materials, mixing pure magnesium, magnesium-silicon intermediate alloy and magnesium-calcium intermediate alloy, heating to allow melting in a protective atmosphere to form a melt at 760-850 DEG C, and holding the temperature to obtain alloy liquid; (2) lowering the temperature of the alloy liquid introducing high-purity argon to carry out refining, holding the temperature, and allowing standing to obtain refined alloy liquid, pouring the refined alloy liquid into a mold, and cooling and condensing to obtain finished magnesium alloy. The finished magnesium alloy is prepared by extruding with a magnesium alloy channel corner hot extrusion mold.

Owner:GUIZHOU UNIV

Preparation method of biodegradable magnesium alloy/calcium phosphorus coating composite material

InactiveCN103484845BImprove corrosion resistanceConvenient researchMetallic material coating processesCalcium biphosphateCalcium phosphate coating

The invention relates to a preparation method of a biodegradable magnesium alloy / calcium phosphate coating composite material. The preparation method comprises the steps of pre-treating a matrix, preparing a conversion liquid, and preparing a bionic calcium phosphate coating to obtain the biodegradable magnesium alloy / calcium phosphate coating composite material. Compared with the prior art, the preparation method has the advantages that the prepared ZK60 magnesium alloy / calcium phosphate coating composite material can be used for remarkably improving the corrosion resistance of a ZK60 magnesium alloy, greatly reducing the degradation rate of the ZK60 magnesium alloy in a bionic body liquid and promoting the research and application of the ZK60 magnesium alloy in the medical field.

Owner:TONGJI UNIV

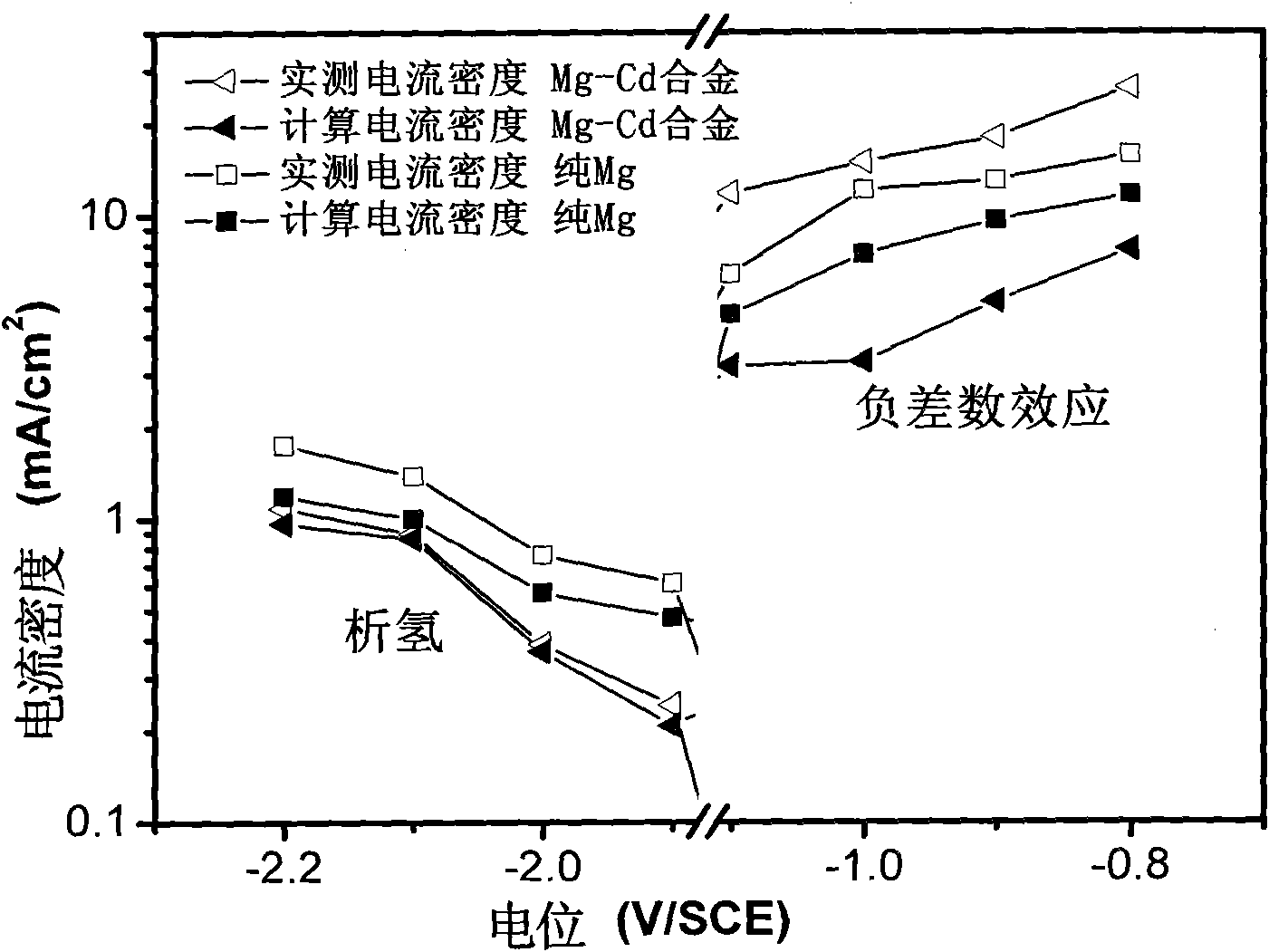

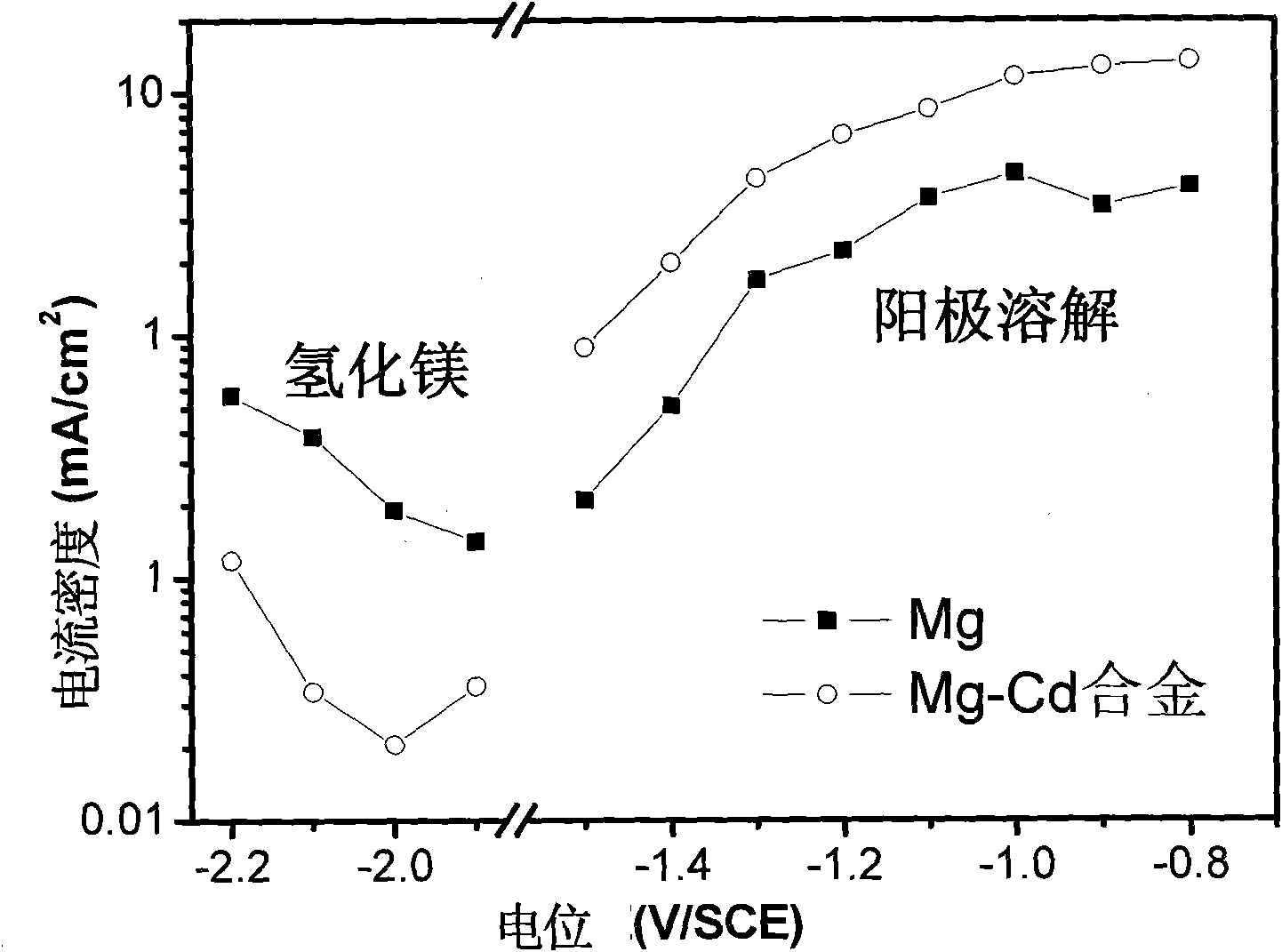

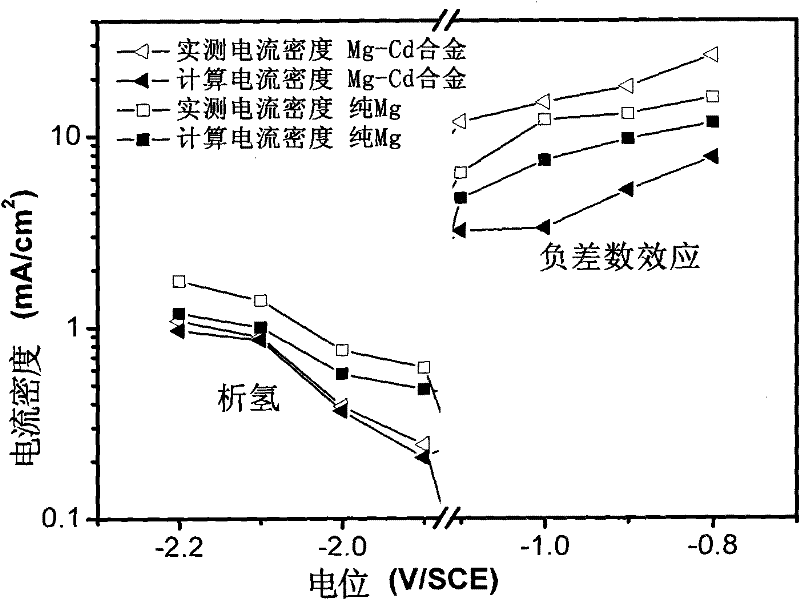

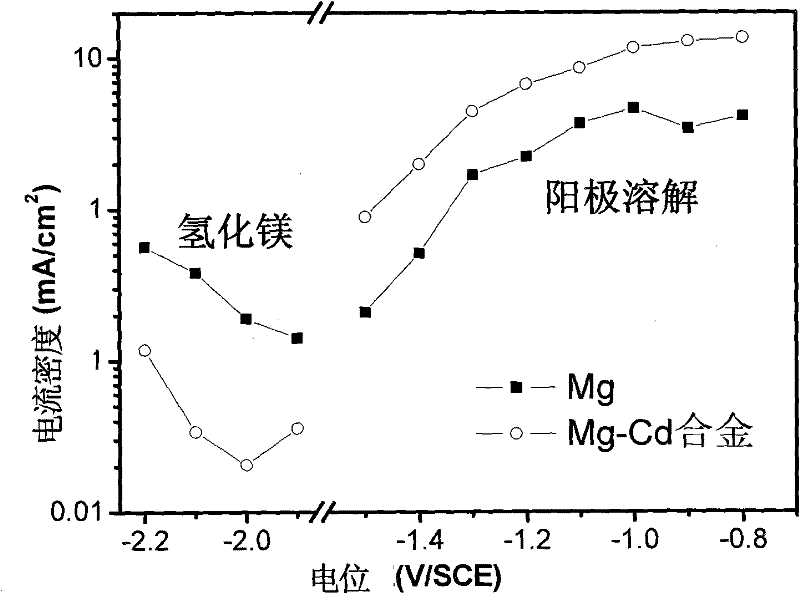

Anticorrosion magnesium alloy

The invention relates to an anticorrosion magnesium alloy, belonging to the field of metal materials. The magnesium alloy comprises the following components by mass: 0.3-3% of Cd, not more than 0.02% of Fe, not more than 0.002% of Cu, not more than 0.01% of Si, not more than 0.002% of Ni and the balance of magnesium, wherein Fe, Cu, Si and Ni are impurity elements. The alloy has the following beneficial effects: the element cadmium is added to the alloy, thus obviously lowering the cost of the alloy and avoiding the rare earth resources from being wasted; and the mechanical performance and the anticorrosion performance of the alloy are superior to the mechanical performance and the anticorrosion performance of pure magnesium, thus solving the problems of easy combustion, poor room temperature plasticity, lower mechanical performance, incapability of being against corrosion and the like during smelting in the prior art.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

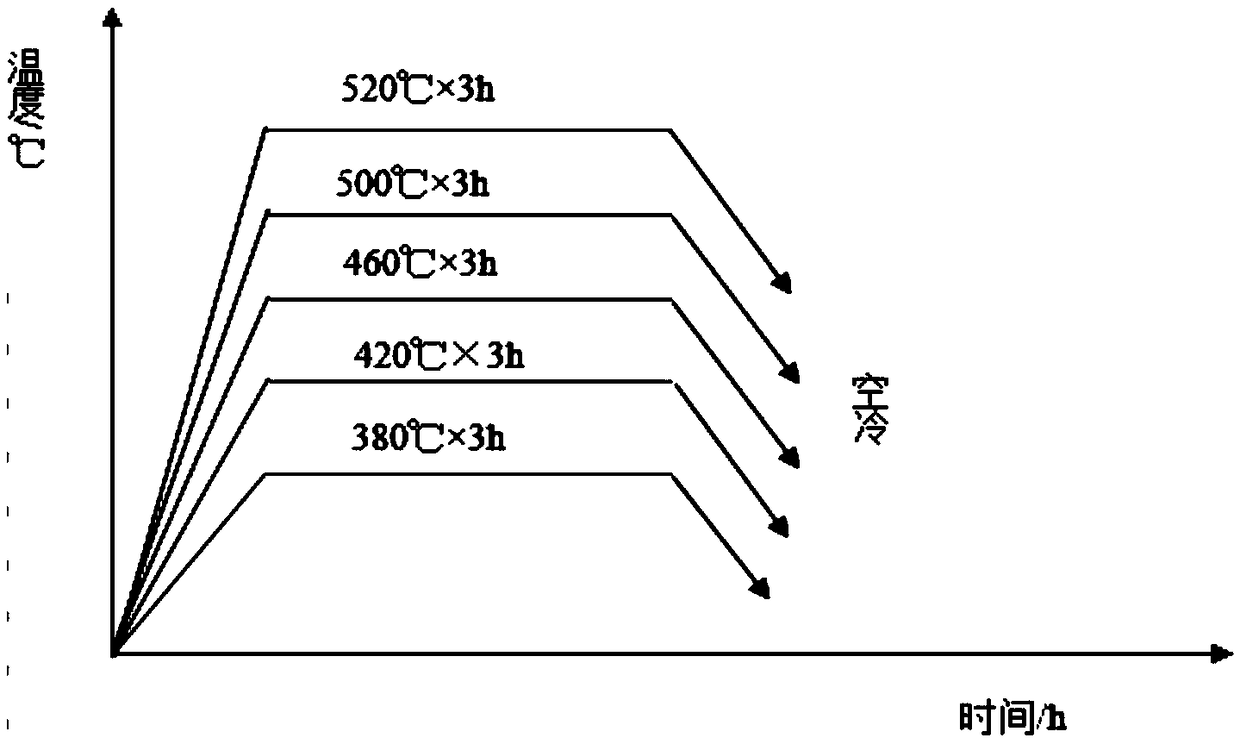

ZK60 magnesium alloy heat treatment process and performance study thereof,

The invention discloses a ZK60 magnesium alloy heat treatment process and a performance study thereof, and belongs to the field of magnesium alloy machining. The ZK60 magnesium alloy heat treatment process studies the heat treatment process of a high-strength deformed magnesium alloy ZK60 and the influence of the heat treatment process on the structure and performance of the alloy from a heat treatment method combining solid solution treatment with aging treatment. The optimal solid solution treatment process of the ZK60 magnesium alloy is that thermal insulation is performed at 500 DEG C for3 hours, and the optimal aging treatment process is that thermal insulation is performed at 180 DEG C for 12 hours. The ZK60 magnesium alloy heat treatment process has the advantages that the development of the magnesium alloy gets rid of the current situation that a cast magnesium alloy is the main component for a long time, the application of the deformed magnesium alloy in industrial products is increased, the industrialization process of the magnesium alloy is promoted, and the rapid development of the whole deformed magnesium alloy field is promoted.

Owner:安徽恒利增材制造科技有限公司

A high yield-strength ratio wrought magnesium alloy containing rare earth cerium and yttrium

The invention provides a high yield ratio deformed magnesium alloy containing rare earth cerium and yttrium. The composition of the alloy includes Mg, Zn, Zr, Ce, and Y, and the mass percentage of each component is: Zn: 4.90~5.20wt .%; Zr: 0.50~0.80wt.%; Ce: 0.50~0.70wt.%; Y: 0.10~1.50wt.%; unavoidable impurities <0.12wt.%; the balance is Mg. Adding a certain amount of cerium and yttrium to the ZK60 magnesium alloy can effectively refine the grains. The cerium, yttrium and magnesium and zinc in the alloy form a fine and dispersed strengthening phase, which can effectively prevent the growth of recrystallized grains during thermal deformation. Large and strengthened matrix, high yield ratio can be obtained, the yield strength exceeds 300MPa, which is significantly higher than the high-strength wrought magnesium alloy ZK60, while ensuring good plasticity. The material of the invention can increase the reliability of mechanical parts, improve product quality, increase material utilization rate, and fully tap the use potential of magnesium alloy materials.

Owner:CHONGQING UNIV

Novel flux for ZK60 magnesium alloy, and preparation method and usage method thereof

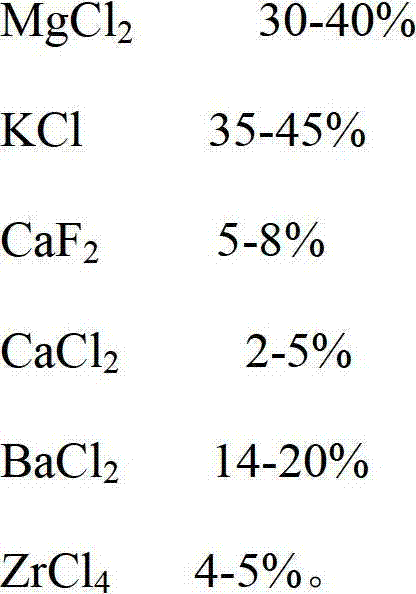

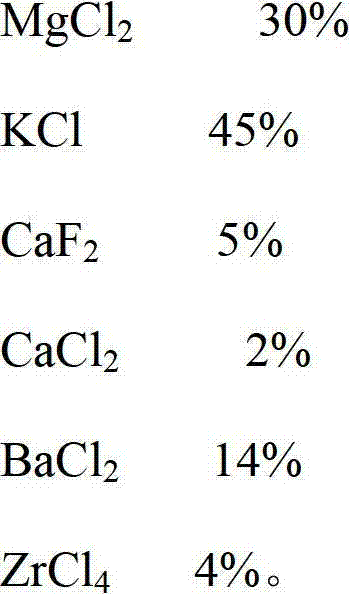

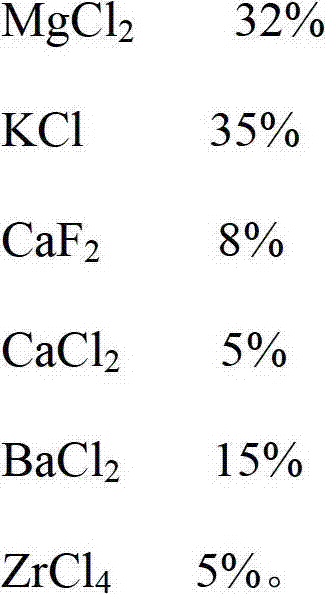

The invention relates to a novel flux for ZK60 magnesium alloy, and a preparation method and a usage method thereof, and belongs to the smelting field. The novel flux is characterized by comprising the following raw materials, by weight: 30-40% of MgCl2, 35-45% of KCl, 5-8% of CaF2, 2-5% of CaCl2, 18-20% of BaCl2, and 4-5% of ZrCl4. The novel flux provided by the invention enables the yield of the Zr element in the magnesium alloy increases to 70-75%, so as to effectively control smelting cost and save the zirconium resource, and has a breakthrough significance in the research of the field.

Owner:山东宏泰科技有限公司

Strong-plasticity magnesium alloy and preparation method thereof

InactiveCN112048688AImprove strong plasticityGood mechanical propertiesZK60 magnesium alloyUltimate tensile strength

The invention provides a preparation method of a strong-plasticity magnesium alloy. The method comprises the following steps of rolling a solid solution magnesium alloy to obtain a rolled magnesium alloy; and carrying out ultrasonic surface rolling processing on the rolled magnesium alloy to obtain the strong-plasticity magnesium alloy. According to the method, material grains are refined by rolling the solid solution magnesium alloy, so that the magnesium alloy reaches a good state in the mechanical property, then the rolled magnesium alloy is further subjected to surface modification throughultrasonic surface rolling processing (USRP), and a gradient nanostructure is prepared in the alloy; and rapid reduction of plasticity of the material when the strength is improved is delayed, so that the magnesium alloy has excellent strength and plasticity. Experimental results show that the product of strength and elongation of the prepared ZK60 magnesium alloy is increased from 4106.7 MPa.% to 5313.2 MPa.%; and the product of strength and elongation of the prepared AZ31 magnesium alloy is increased to 1854 MPa.% from 1408 MPa.%.

Owner:GUIZHOU UNIV

Magnesium alloy of high intensity and high yield ratio and preparation method thereof

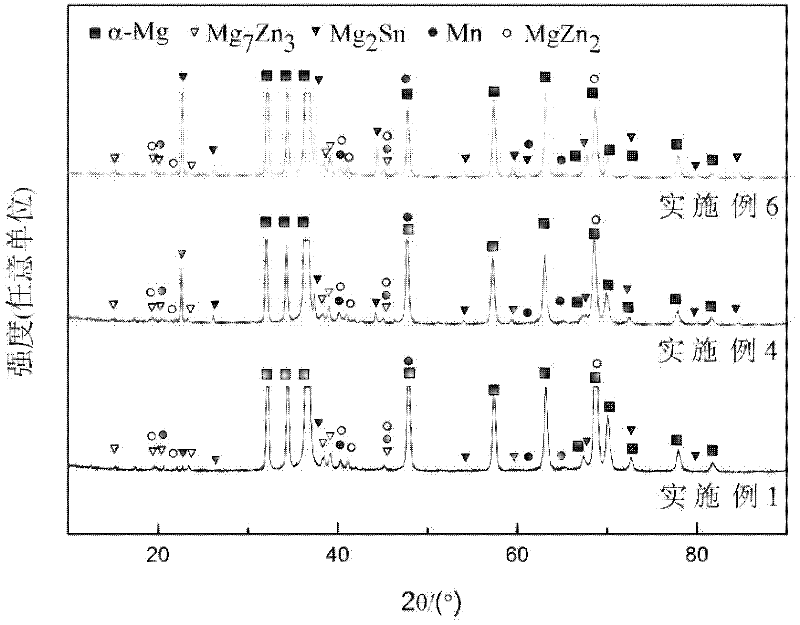

InactiveCN102230118BImprove the effect of solid solution strengtheningDispersionHigh intensityZK60 magnesium alloy

The invention provides a magnesium alloy material of high intensity and high yield ratio. The alloy comprises the following components by mass: 5.0-9.0% of Zn; 0.5-1.5% of Mn; 1-10% of Sn; less than 0.15% of inevitable impurities; and the balance magnesium. By means of plastic forming and a choice of reasonable technological conditions for heat treatment after forming, the magnesium alloy material of the invention can be of high intensity and high yield ratio, and is higher than the high-strength wrought magnesium alloy ZK60 in terms of yield strength and tensile strength. With low cost, goodextrudability and formability at a low temperature, the magnesium alloy material provided in the invention boasts substantial application potential, thus being able to partly replace the magnesium alloy material ZK60.

Owner:QINGHAI SUNGLOW MAGNESIUM

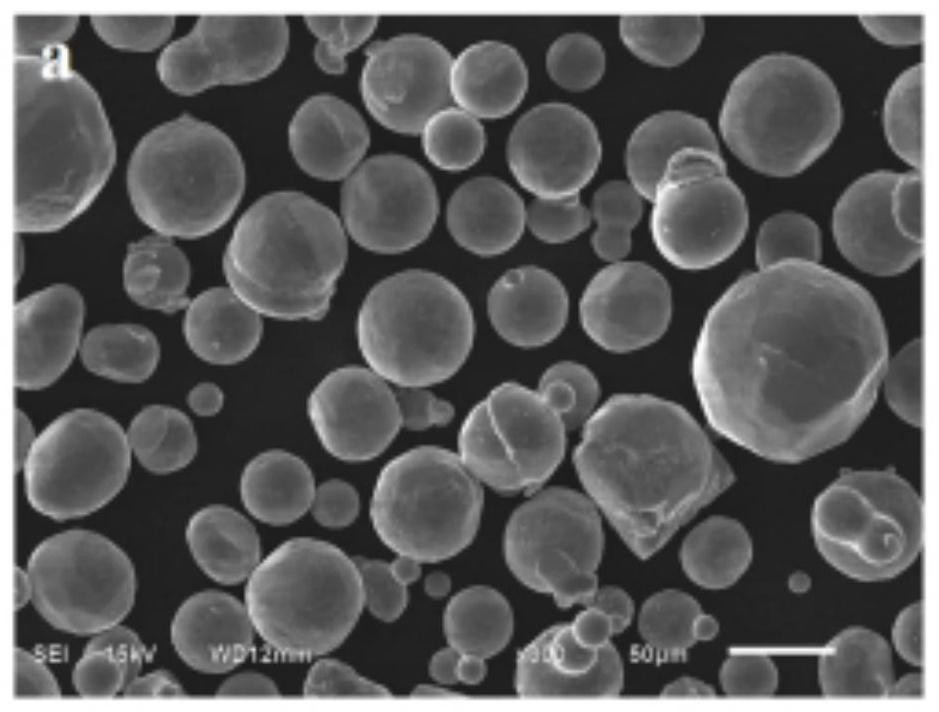

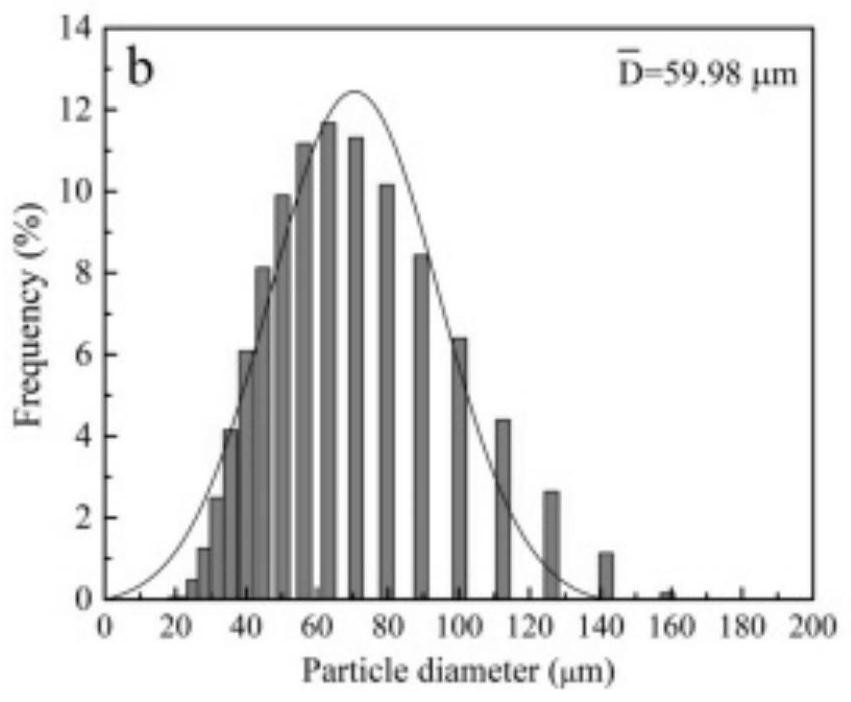

ZK60 magnesium alloy preparation method based on SPS technology

In order to solve the technical problems that an existing ZK60 magnesium alloy preparation method is uneven in structure and poor in compactness, the invention provides a ZK60 magnesium alloy preparation method based on the SPS technology. The method comprises the following steps that S1, ZK60 magnesium alloy powder is poured into a stainless steel ball milling tank, and absolute ethyl alcohol is added for ball milling; S2, vacuum drying is conducted on powder obtained after ball grinding; and S3, the powder obtained after vacuum drying is placed in a grinding tool and sintered in discharge plasma sintering equipment, and a sintered ZK60 magnesium alloy material is obtained. Compared with a traditional method for conducting sintering by using a vacuum hot-pressing sintering furnace, the method has the advantages that the sintering period of raw materials is greatly shortened and the environmental protection is improved while better strength and plasticity are ensured. The preparation method is simple, good in safety and high in economic value, and has a great popularization space.

Owner:QINGHAI UNIVERSITY

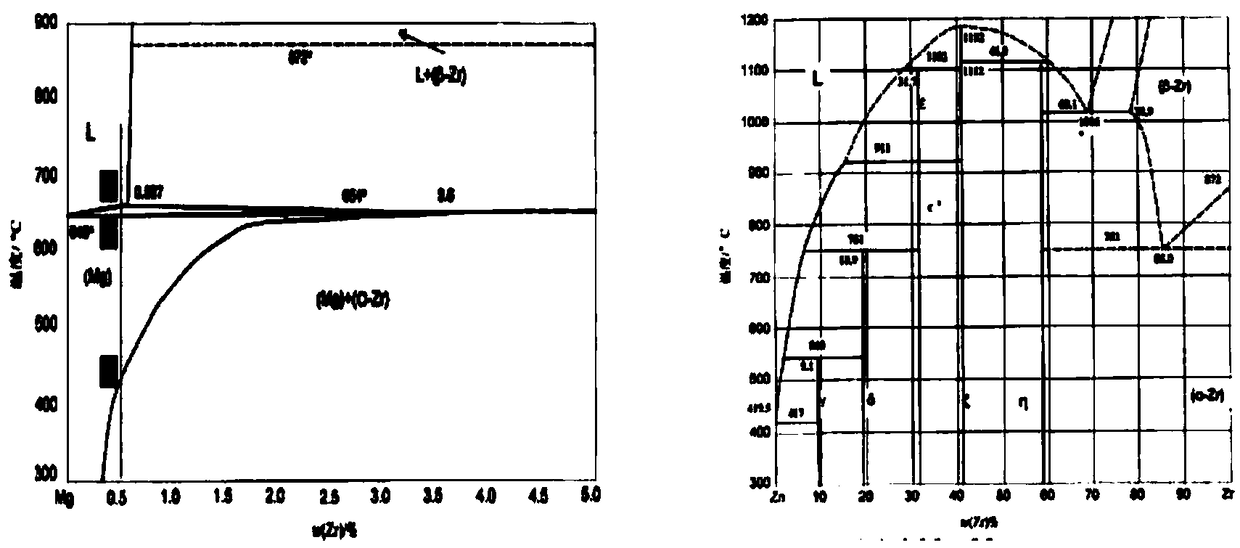

ZK6IM wrought magnesium alloy casting technology

The invention discloses a ZK6IM wrought magnesium alloy casting technology. According to the ZK6IM wrought magnesium alloy casting technology, Zr is controlled at medium upper limit, and w(Zr) is 0.6-0.8%; Zn is controlled at lower limit, and (Zn) is 5.3%-5.5%; ZK61Mmagnesium alloy melts are prevented from being over hot, and the casting speed is controlled within 36mm / min-40mm / min; the casting temperature is low as much as possible and is controlled in a range of 6950-7050 DEG C; an original crystallizer is improved, the secondary water cooling strength is reduced under the condition that primary cooling strength is not changed, and the tensile stress is reduced; and during homogenization treatment on cast ingots, the cast ingots stay in an environment at the temperature of 3900 DEG C for 12 hours. The ZK6IM wrought magnesium alloy casting technology has the advantages that the microsegregation force is eliminated, the hardness is greatly reduced, and the machining and forming property is improved effectively.

Owner:QINGDAO HEDELONG MACHINERY

Anticorrosion magnesium alloy

The invention relates to an anticorrosion magnesium alloy, belonging to the field of metal materials. The magnesium alloy comprises the following components by mass: 0.3-3% of Cd, not more than 0.02% of Fe, not more than 0.002% of Cu, not more than 0.01% of Si, not more than 0.002% of Ni and the balance of magnesium, wherein Fe, Cu, Si and Ni are impurity elements. The alloy has the following beneficial effects: the element cadmium is added to the alloy, thus obviously lowering the cost of the alloy and avoiding the rare earth resources from being wasted; and the mechanical performance and the anticorrosion performance of the alloy are superior to the mechanical performance and the anticorrosion performance of pure magnesium, thus solving the problems of easy combustion, poor room temperature plasticity, lower mechanical performance, incapability of being against corrosion and the like during smelting in the prior art.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Magnesium-based composite material and preparation method thereof

The invention provides a magnesium-based composite material and a preparation method thereof. An Al18B4O33 whisker preform is mixed into a ZK60 magnesium alloy matrix, reaction conditions are controlled to enable the Al18B4O33 whisker preform to grow in situ in the ZK60 magnesium alloy matrix to form an Al18B4O33 whisker, the Al18B4O33 whisker is uniformly distributed in the ZK60 magnesium alloy, the defect of poor mechanical property of the magnesium alloy is overcome, and the obtained magnesium-based composite material is high in hardness and good in wear resistance.

Owner:郑承盛

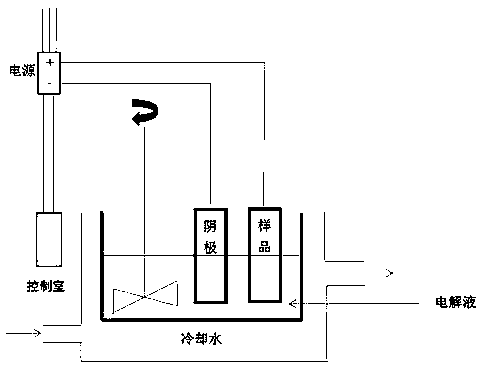

Method for improving biomedical magnesium alloy corrosion resistance through micro-arc oxidation

InactiveCN108754578AReduce the difficulty of operationLow costAnodisationProsthesisMicro arc oxidationPlasma electrolytic oxidation

The invention relates to a method for improving biomedical magnesium alloy corrosion resistance through micro-arc oxidation. The method comprises the specific steps that S1, abrasive paper is used forpolishing the surface of a ZK60 magnesium alloy product; S2, the polished magnesium alloy product is placed into an ethanol solution to be subjected to ultrasonic cleaning and drying; S3, a preparedsolution is poured into an electrolytic cell; S4, the magnesium alloy product is fixed to a support through a stainless steel wire to be soaked into an electrolyte; S5, a micro-arc oxidation power source is started, working parameters with the positive voltage being 250 V, the negative voltage being 20 V, the working frequency being 600 Hz, the positive vacuum ratio being 30%, the negative duty ratio being 70% and the positive and negative pulse number being 1 are used for conducting micro-arc oxidation processing on the magnesium alloy product for 15 min; and S6, absorbent paper is used for drying, and natural drying is then carried out after the magnesium alloy product is subjected to deionized water ultrasonic cleaning. By means of the method, toxic substances are not contained, and themethod is environment-friendly and convenient, and the prepared micro-arc oxidation magnesium alloy product has the good corrosion resistance.

Owner:徐琛沣

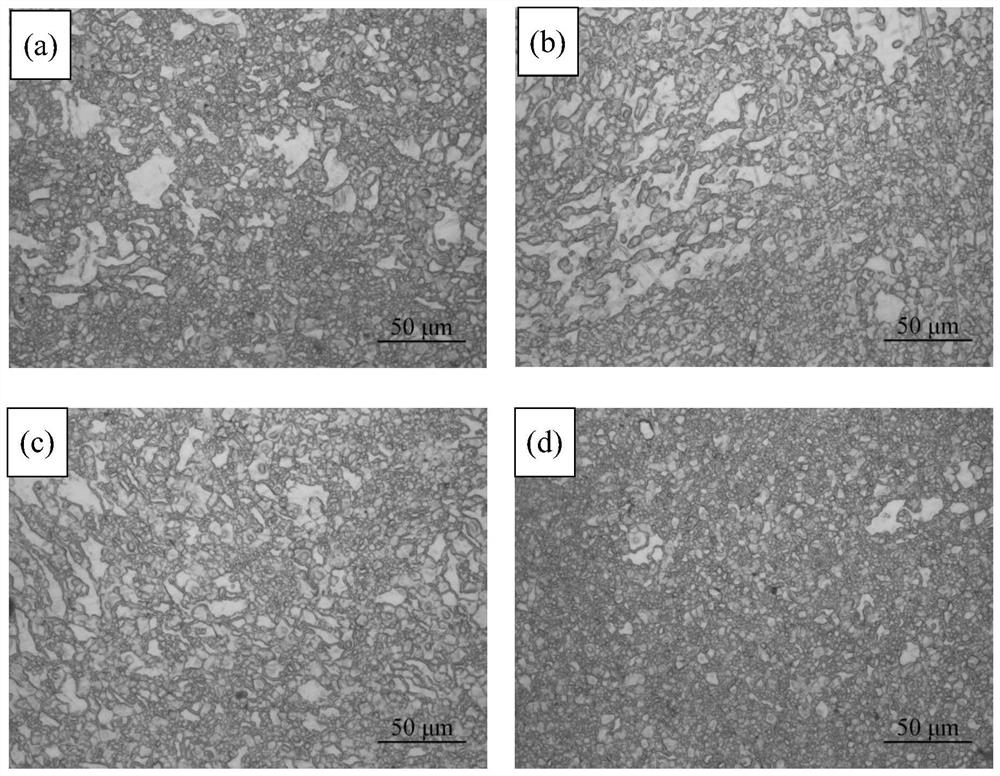

Methods of regulating grain structure and improving properties of zk60 wrought magnesium alloy

The invention relates to the technical field of wrought magnesium alloys, and specifically provides a method for regulating and improving the grain structure of ZK60 wrought magnesium alloys. The method of the invention comprises that after the ZK60 wrought magnesium alloy to be treated is subjected to solid solution treatment, the stepwise heating and pre-aging treatment is carried out, and then the extrusion treatment is carried out. This method can effectively control the grain size of ZK60 magnesium alloy by adding stepped pre-aging treatment, significantly improve the strength and plasticity of the material, fully exploit the advantages of low density and high specific strength of ZK60, and realize the promotion and application of ZK60 magnesium alloy in new energy buses. And the core problem of the lightweight goal of automobiles, laying the foundation for the promotion and application of ZK60 magnesium alloy in new energy buses.

Owner:QILU UNIV OF TECH +1

A corrosion-resistant high-performance deformed magnesium alloy and its preparation method

The invention discloses a method for preparing a corrosion-resistant high-performance deformed magnesium alloy. The steps include alloy smelting→solid solution→hot extrusion; firstly, ZK60 magnesium alloy containing 1.8-2.1% rare earth element ytterbium (Yb) is smelted according to the composition , followed by solid solution treatment at 450℃×24h in protective gas, and then at 250~320℃ for 0.005~0.01s ‑1 The strain rate and the extrusion ratio of 32-40 were hot-extruded. The tensile strength of the finally obtained wrought magnesium alloy is 400-450MPa, the elongation is 10-20%, and the corrosion current density can be reduced by 1-2 orders of magnitude compared with the commercialized ZK60 alloy. The deformed magnesium alloy material prepared by the conventional process in the present invention has high strength plasticity and excellent corrosion resistance, and can be used as an ideal candidate for aerospace, weapon, 3C and biomedical materials.

Owner:SOUTHWEST UNIV

Preparation method of degradable magnesium alloy/modified polylactic acid coating composite material

InactiveCN103934184BImprove corrosion resistanceConvenient researchPretreated surfacesCoatingsAcid etchingPre treatment

The invention relates to a method for preparing a degradable magnesium alloy and modified polylactic acid coating composite material. The method includes the following steps that a magnesium alloy matrix is polished so that a surface oxidization layer is removed; acid etching pre-treatment and neutralizing treatment are carried out on the magnesium alloy matrix; polylactic acid is dissolved in a chloroform solution and a polylactic acid solution is prepared; the magnesium alloy matrix is immersed in the polylactic acid solution, and the surface of the magnesium alloy matrix is wrapped with a polylactic acid coating in a solution immersing and coating method; the obtained magnesium alloy material wrapped with the polylactic acid is stored for 2-3 days in a ventilated place, so that chloroform in the polylactic acid solution is volatilized completely, and the degradable magnesium alloy and modified polylactic acid coating composite material is obtained. Compared with the prior art, the anti-corrosion performance of ZK60 magnesium alloy can be improved obviously through the obtained magnesium alloy and modified polylactic acid coating composite material, the degradation rate of the ZK60 magnesium alloy in an organism can be greatly reduced, and researching and application of the ZK60 magnesium alloy in the medical field are promoted.

Owner:TONGJI UNIV

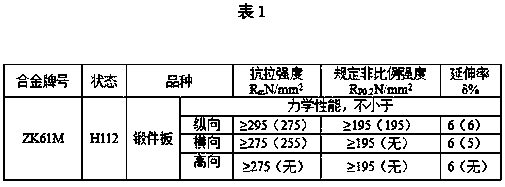

ZK61M magnesium alloy for aerospace

The invention discloses a ZK61M magnesium alloy for aerospace. The ZK61M magnesium alloy for aerospace is prepared by the following steps of (1) performing forging. specifically, a ZK61M round ingot conforming to the standard of a YS / T 627-2013 wrought magnesium and magnesium alloy round ingot is heated and forged, and is subjected to the forging in the three directions of length, width and height; (2) performing hot rolling, specifically, a forged sheet obtained in the step (1) is subjected to steer rolling, and then to the small machining rate multi-pass rolling at a temperature of 345-355 DEG C, so that a hot-rolled sheet with a total power of 26-27% is finally obtained; and (3) performing aging. specifically, the hot-rolled sheet obtained in the step (2) is subjected to aging treatmentat 170-180 DEG C for 22-26 hours to obtain the ZK61M magnesium alloy for aerospace. According to the ZK61M magnesium alloy for aerospace obtained by forging, hot rolling and aging treatment, the magnesium alloy three-way performance exceeds the requirement for aerospace materials, and the ZK61M magnesium alloy can be well applied to the aerospace military industry.

Owner:洛阳迈格镁业有限公司

A low-cost preparation method of ultrafine-grained high-strength plastic rare earth magnesium alloy

Owner:SOUTHWEST UNIV

Method for regulating and controlling grain structure of ZK60 wrought magnesium alloy and improving performance of ZK60 wrought magnesium alloy

The invention relates to the technical field of wrought magnesium alloys, and particularly provides a method for regulating and controlling the grain structure of a ZK60 wrought magnesium alloy and improving the performance of the ZK60 wrought magnesium alloy. The method comprises the steps of carrying out solution treatment on the ZK60 wrought magnesium alloy to be treated, carrying out stepped heating pre-aging treatment, and then carrying out extrusion treatment. According to the method, the stepped pre-aging treatment is added, the grain size of the ZK60 magnesium alloy can be effectivelyregulated and controlled, the strength and plasticity of a material are remarkably improved, the advantages of low density and high specific strength of the ZK60 wrought magnesium alloy are fully explored, the core problems of application and popularization of the ZK60 magnesium alloy in new energy buses and automobile lightening targets can be solved, and a foundation is laid for application andpopularization of the ZK60 magnesium alloy in new energy buses.

Owner:QILU UNIV OF TECH +1

Method for reinforcing ZK60 magnesium alloy by adding Sc

The invention discloses a method for reinforcing a ZK60 magnesium alloy by adding Sc, which is realized by adding a rare-earth element Sc into the ZK60 magnesium alloy. The method comprises the following concrete steps of: smelting and ingot making, homogenizing, hot-extruding, heat treatment and the like. Because of the addition of the Sc, crystalline grains of the ZK60 magnesium alloy is effectively refined, intergranular reticular precipitated phases become thin with uniform distribution, and thin and diffused particle-shaped precipitated phases are formed at a crystal boundary, and after the intergranular reticular precipitated phases and thin and diffused particle-shaped precipitated phases are subjected to homogenization, extrusion and heat treatment, the tensile strength of the alloy can reach 364MPa, the yield strength can reach 352MPa and the yield ratio is close to 1. Compared with the common ZK60 alloy, a product in the method has the tensile strength and the yield strengthwhich are respectively improved by 39MPa and 67MPa, and thus, the tensile strength and the yield strength of the ZK60 magnesium alloy are obviously improved and the industrial application range of the ZK60 magnesium alloy is widened.

Owner:CHONGQING UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com