Anticorrosion magnesium alloy

A magnesium alloy and corrosion-resistant technology, applied in the field of corrosion-resistant magnesium alloys, can solve the problems of low mechanical properties, poor room temperature plasticity, and no corrosion resistance, and achieve the effects of large solid solubility, improved corrosion resistance, and reduced hazard.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: Mg+Cd (Cd=0.9%) alloy

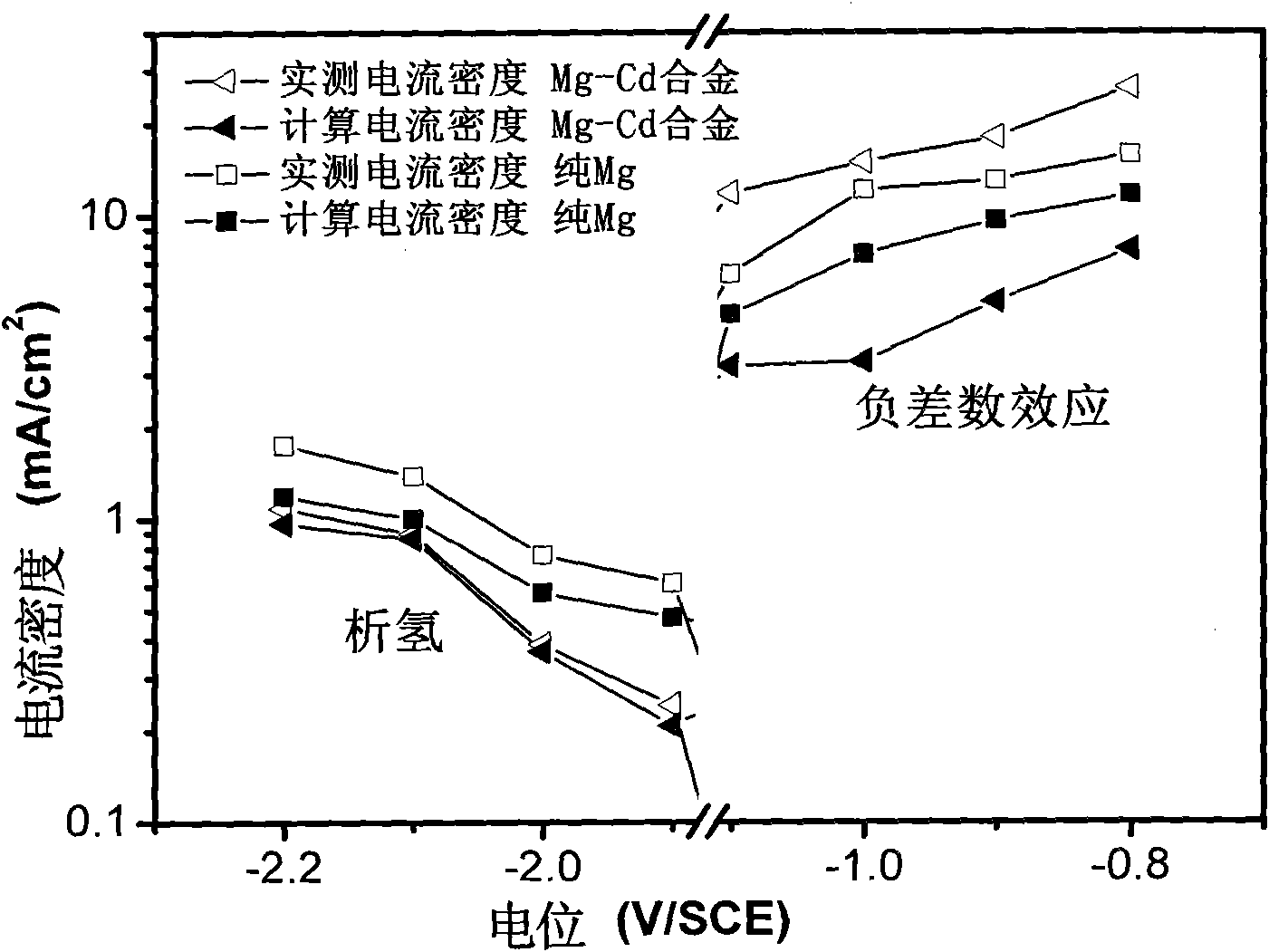

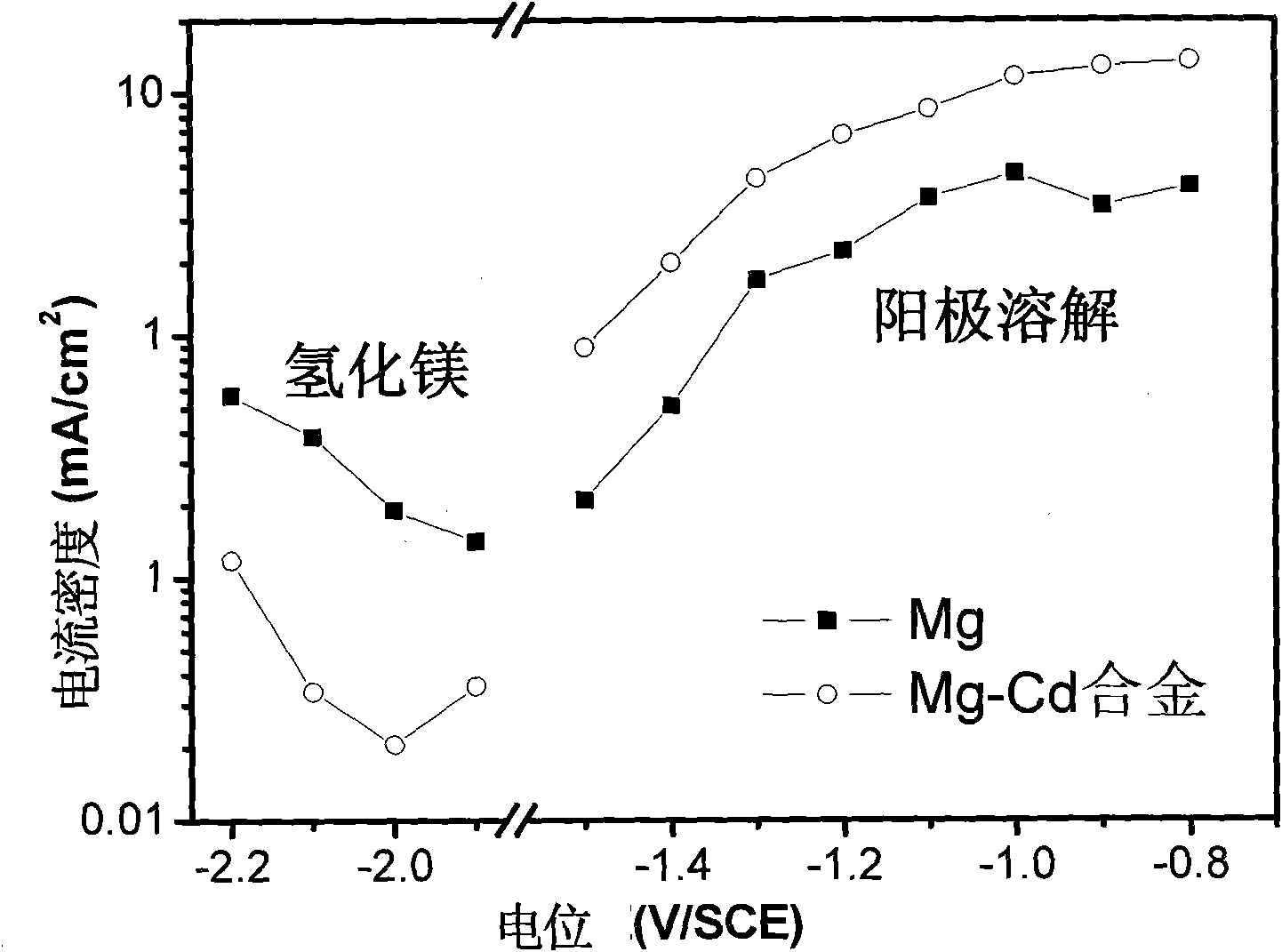

[0021] In the present embodiment, the composition and mass percent of the corrosion-resistant magnesium alloy containing cadmium are: Cd 0.9%, impurity element Fe 0.015%, Cu 0.0015%, Si 0.008%, Ni 0.0015%, Mg surplus; select magnesium ingot ( purity 99.995wt%) and cadmium ingot (purity 99.995wt%); the corrosion properties of the alloy are shown in Table 1, the mechanical properties are shown in Table 2, and the effects of inhibiting hydrides and negative differential numbers are shown in Figure 1.

[0022] Weigh the material according to the ratio, preheat the pure magnesium to 200°C, put it into a low-carbon steel crucible with a preheating temperature of 300°C, and put it into SF 6 -CO 2 Shielding gas (SF 6 :CO 2 The volume ratio is 1:100), when the magnesium alloy is completely melted and the melt temperature reaches 730-740°C, add cadmium ingots, which are preheated to 200°C; then continue to stir, and pass into SF 6 -CO 2 ...

Embodiment 2

[0023] Embodiment 2: Mg+Cd (Cd=1.7%) alloy

[0024] In the present embodiment, the composition and mass percent of the corrosion-resistant magnesium alloy containing cadmium are: Cd 1.7%, impurity element Fe 0.018%, Cu 0.0016%, Si 0.007%, Ni 0.0012%, Mg surplus; select magnesium ingot ( purity 99.995wt%) and cadmium ingot (purity 99.995wt%); the corrosion properties of the alloy are shown in Table 1, the mechanical properties are shown in Table 2, and the effects of inhibiting hydrides and negative differential numbers are shown in Figure 1.

[0025] Weigh the material according to the ratio, preheat the pure magnesium to 200°C, put it into a low-carbon steel crucible with a preheating temperature of 300°C, and put it into SF 6 -CO 2 Shielding gas (SF 6 :CO 2 The volume ratio is 1:100), when the magnesium alloy is completely melted and the melt temperature reaches 730-740°C, add cadmium ingots, which are preheated to 200°C; then continue to stir, and pass into SF 6 -CO 2 ...

Embodiment 3

[0026] Embodiment 3: Mg+Cd (Cd=2.4%) alloy

[0027] In the present embodiment, the composition and the mass percent of the corrosion-resistant magnesium alloy containing cadmium are: Cd 2.4%, impurity element Fe 0.010%, Cu 0.0013%, Si 0.01%, Ni 0.002%, Mg surplus; select magnesium ingot ( purity 99.995wt%) and cadmium ingot (purity 99.995wt%); the corrosion properties of the alloy are shown in Table 1, the mechanical properties are shown in Table 2, and the effects of inhibiting hydrides and negative differential numbers are shown in Figure 1.

[0028] Weigh the material according to the ratio, preheat the pure magnesium to 200°C, put it into a low-carbon steel crucible with a preheating temperature of 300°C, and put it into SF 6 -CO 2 Shielding gas (SF 6 :CO 2 The volume ratio is 1:100), when the magnesium alloy is completely melted and the melt temperature reaches 730-740°C, add cadmium ingots, which are preheated to 200°C; then continue to stir, and pass into SF 6 -CO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com