Patents

Literature

439results about How to "Improve solid solubility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

7000 series aluminum alloy material and preparation method thereof

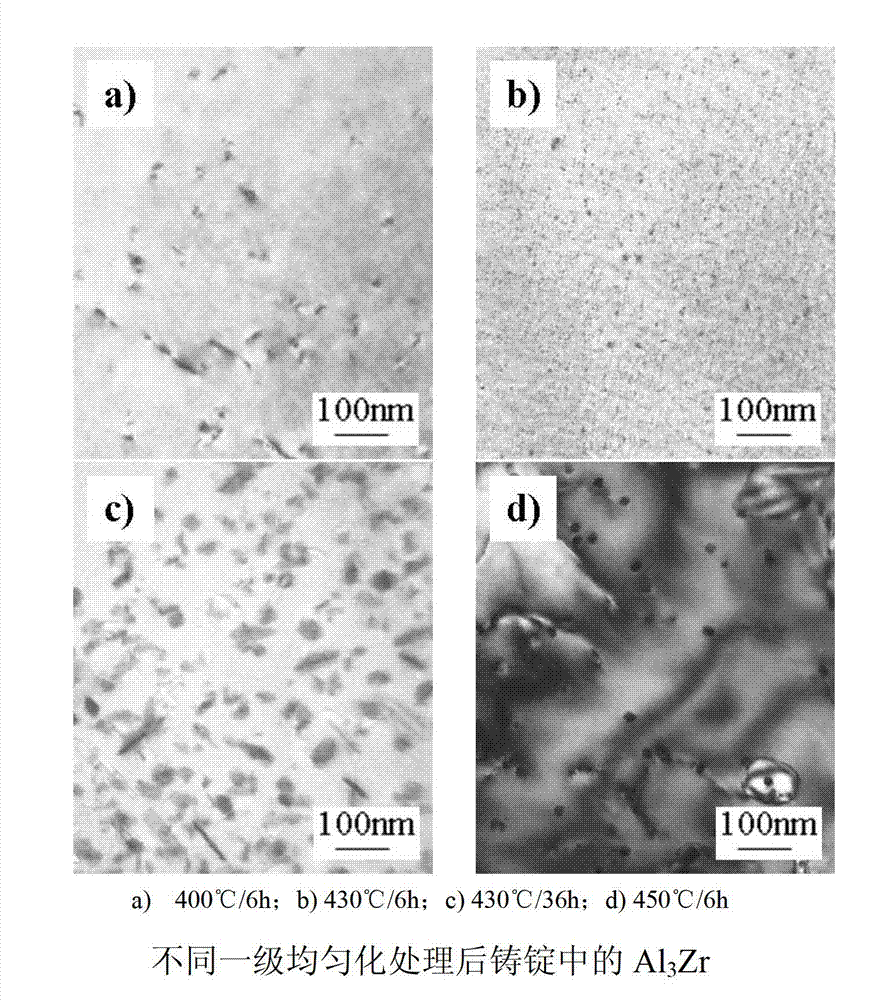

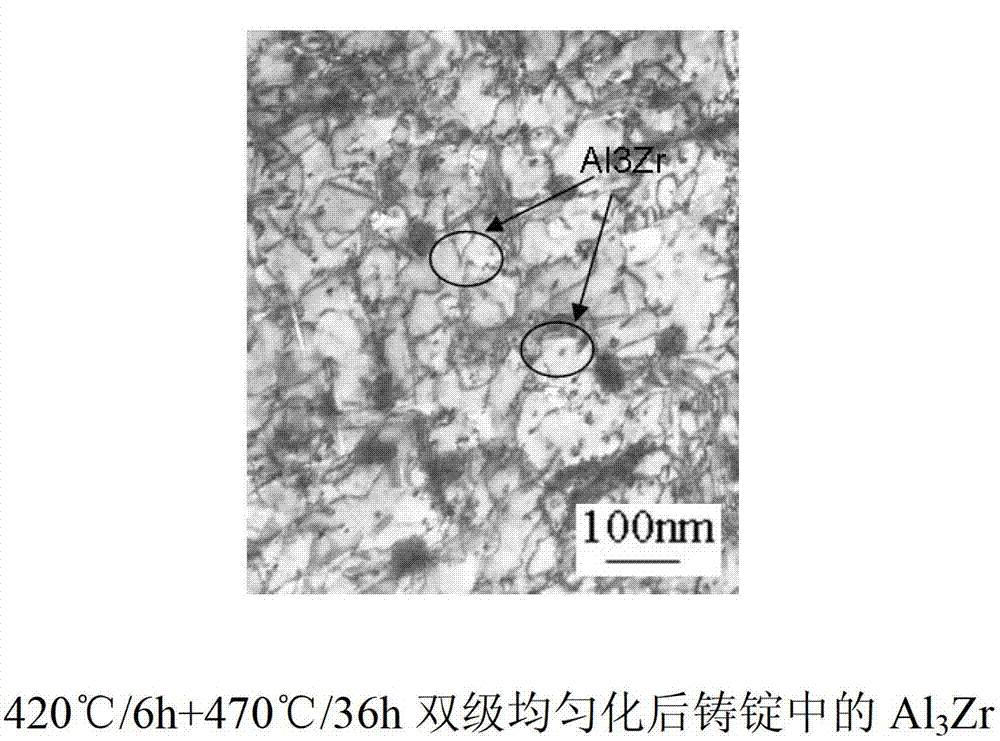

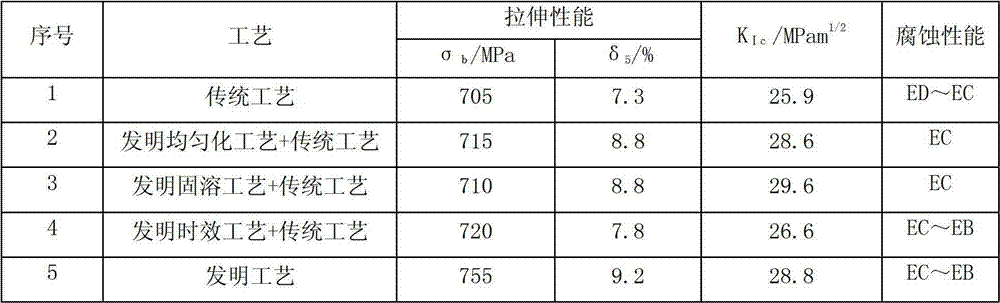

The invention relates to a 7000 series aluminum alloy material and a preparation method thereof. The aluminum alloy material has alloy components of, by weight: 7.6-11.0% of Zn, 1.2-3.0% of Mg, 1.3-2.6% of Cu, 0.04-0.30% of Zr, 0.10-0.60% of Cr, no more than 0.08% of Si, no more than 0.10% of Fe, no more than 0.10% of Ti, no more than 0.15% of total other impurities (wherein the content of single other impurity is no more than 0.05%), and balance of Al. The alloy elements Zr and Cr can be added optionally or simultaneously. The materials are prepared according to the alloy composition; the raw materials are molten; in-furnace refining and standing are carried out; and the material is cast into alloy ingots with required specifications. The alloy ingots are subjected to a preferable graded uniformization process, and is forged or extruded, such that the alloy ingots are molded; the molded materials are subjected to graded solid solution treatment, and are quenched; and artificial forced aging is carried out, such that the material can be processed into parts. The microstructures of the material are uniform, and the property of the material is stable. The ultimate tensile strength of the material can be more than 750MPa. The extensibility of the material is higher than 10%. The T-L direction KIc of the material reaches 28MPam1 / 2.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Lyophilized solid taxane composition, a process for preparing said solid composition, a pharmaceutical formulation and a kit for said formulation

InactiveUS20090215882A1High level of chemical degradationImprove solid solubilityOrganic active ingredientsBiocideDocetaxel-PNPDocetaxel

A lyophilized solid composition of taxane (preferably docetaxel and paclitaxel), is suitable to prepare a pharmaceutical formulation to be administered to mammals, particularly humans, comprising a taxane, a tensoactive, a lyophilizing excipient, and acid; also essentially free from organic solvents. The solid composition is free from polysorbate 80 and polyoxyethylated castor oil; it is sterile; it is soluble in aqueous solutions in the absence of organic solvent and it has an apparent density from 0.05 g / ml to 0.45 g / ml. A procedure of double lyophilization obtains a solid composition of taxane. A pharmaceutical formulation of a taxane comprises a solid composition of lyophilized taxane and a solubilizing composition. A kit comprises the compositions and a syringe.

Owner:ERIOCHEM SA

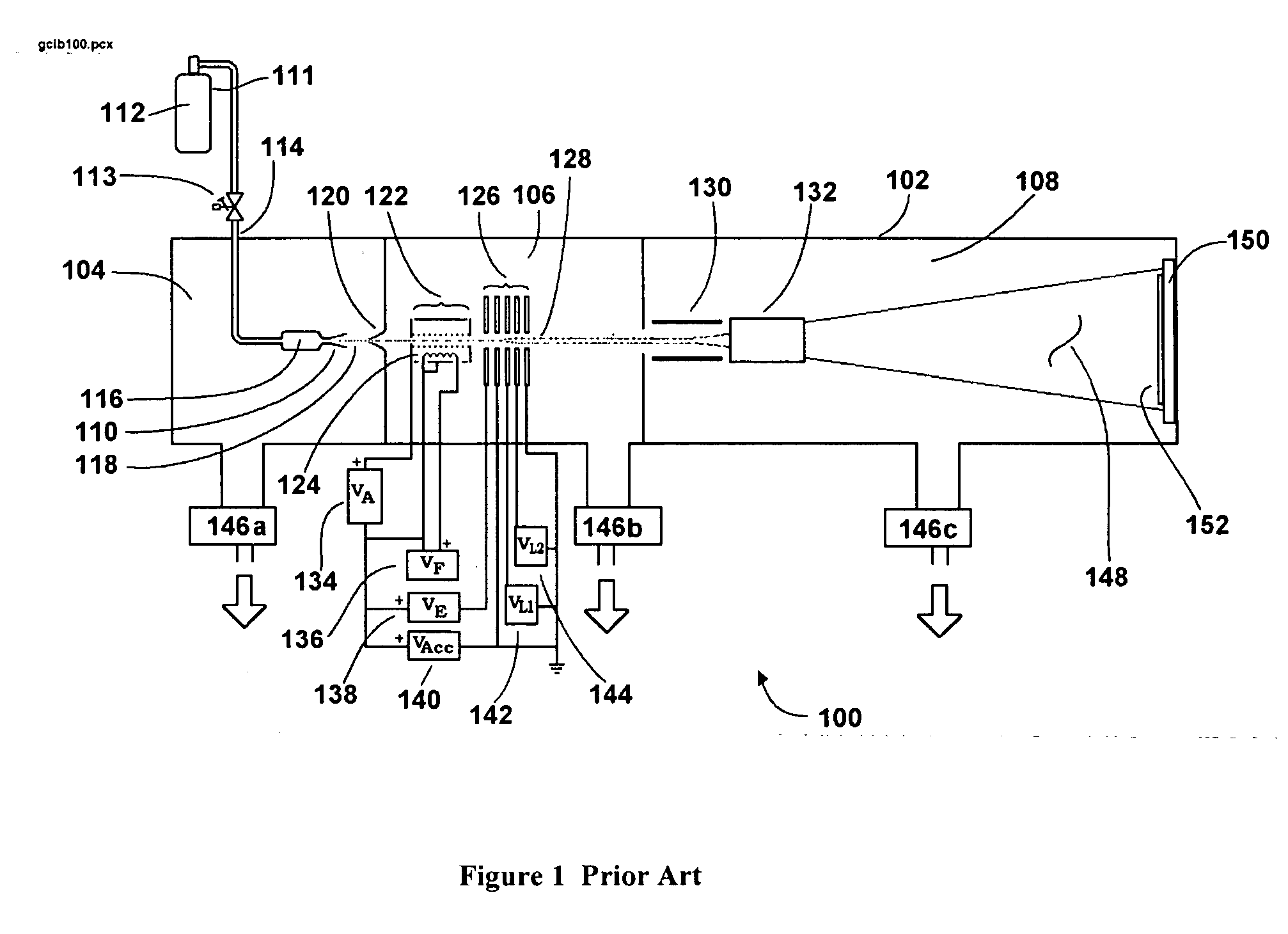

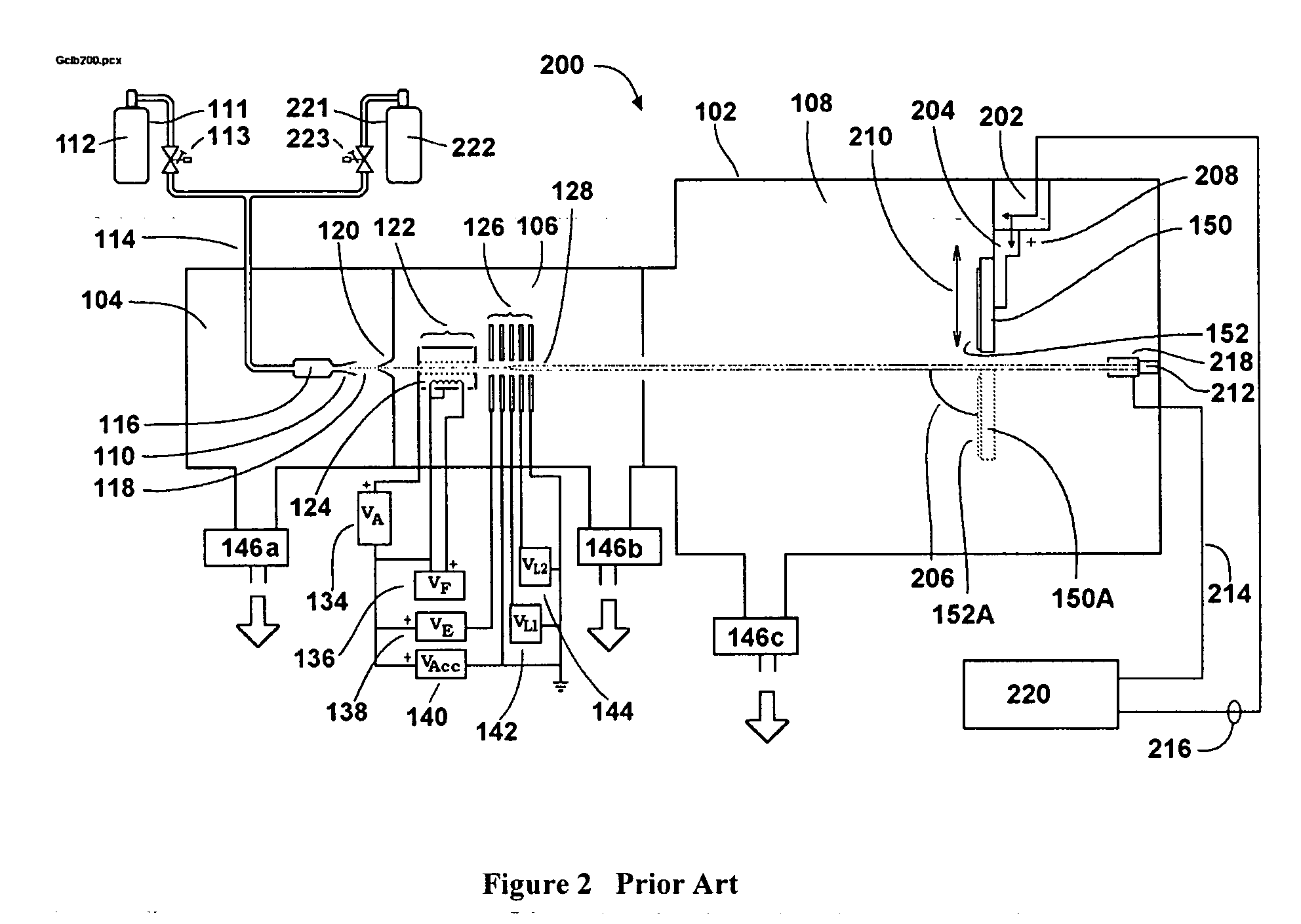

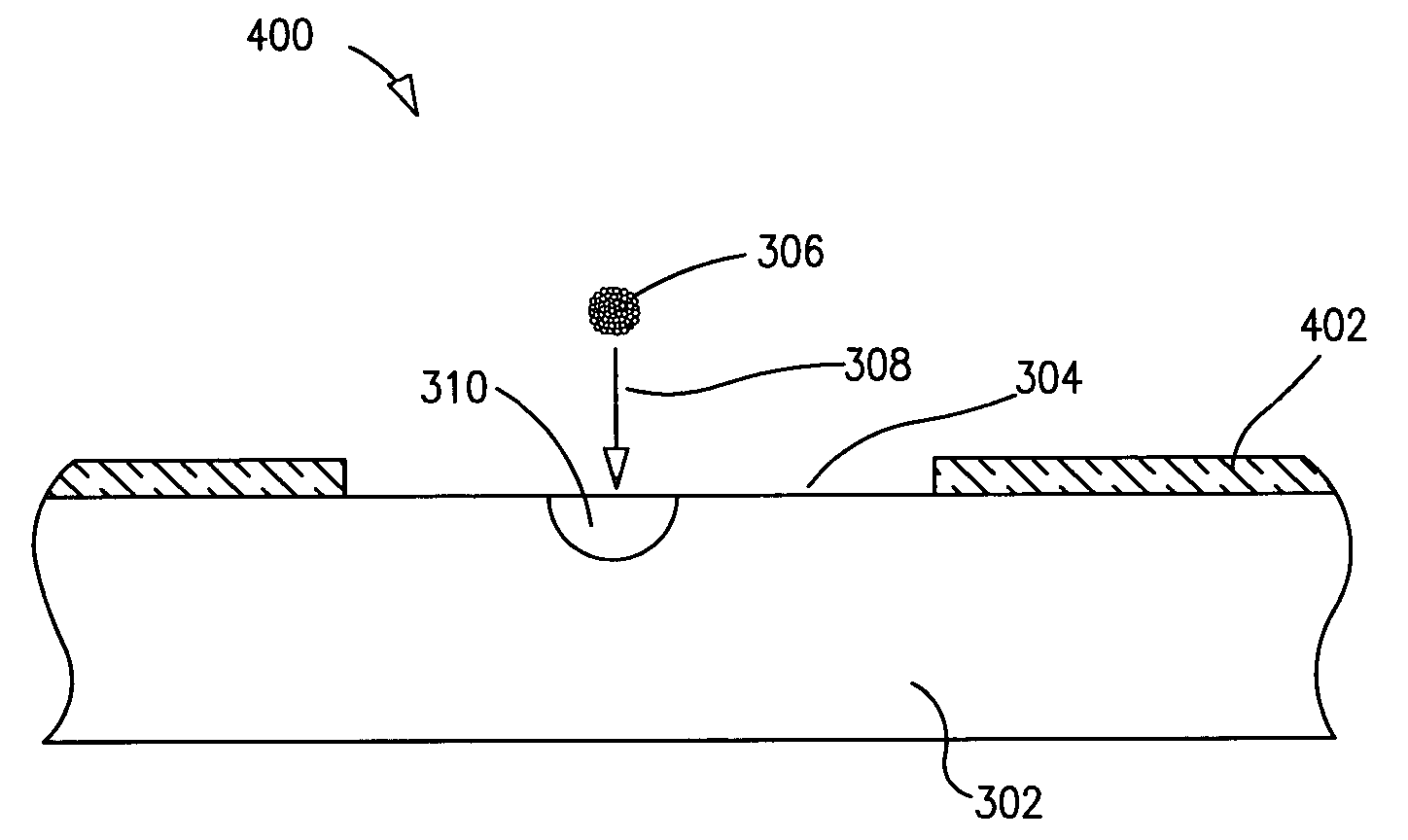

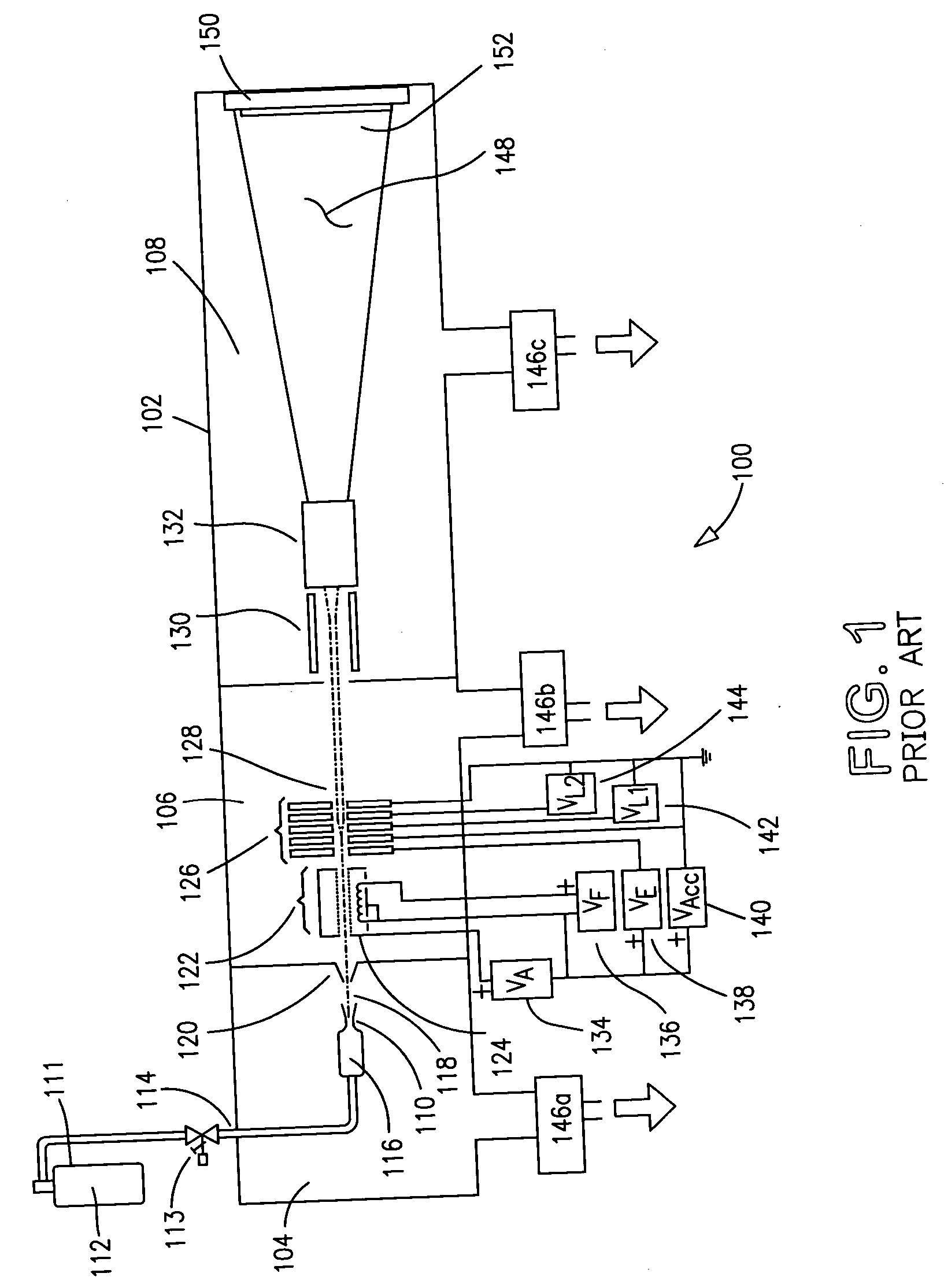

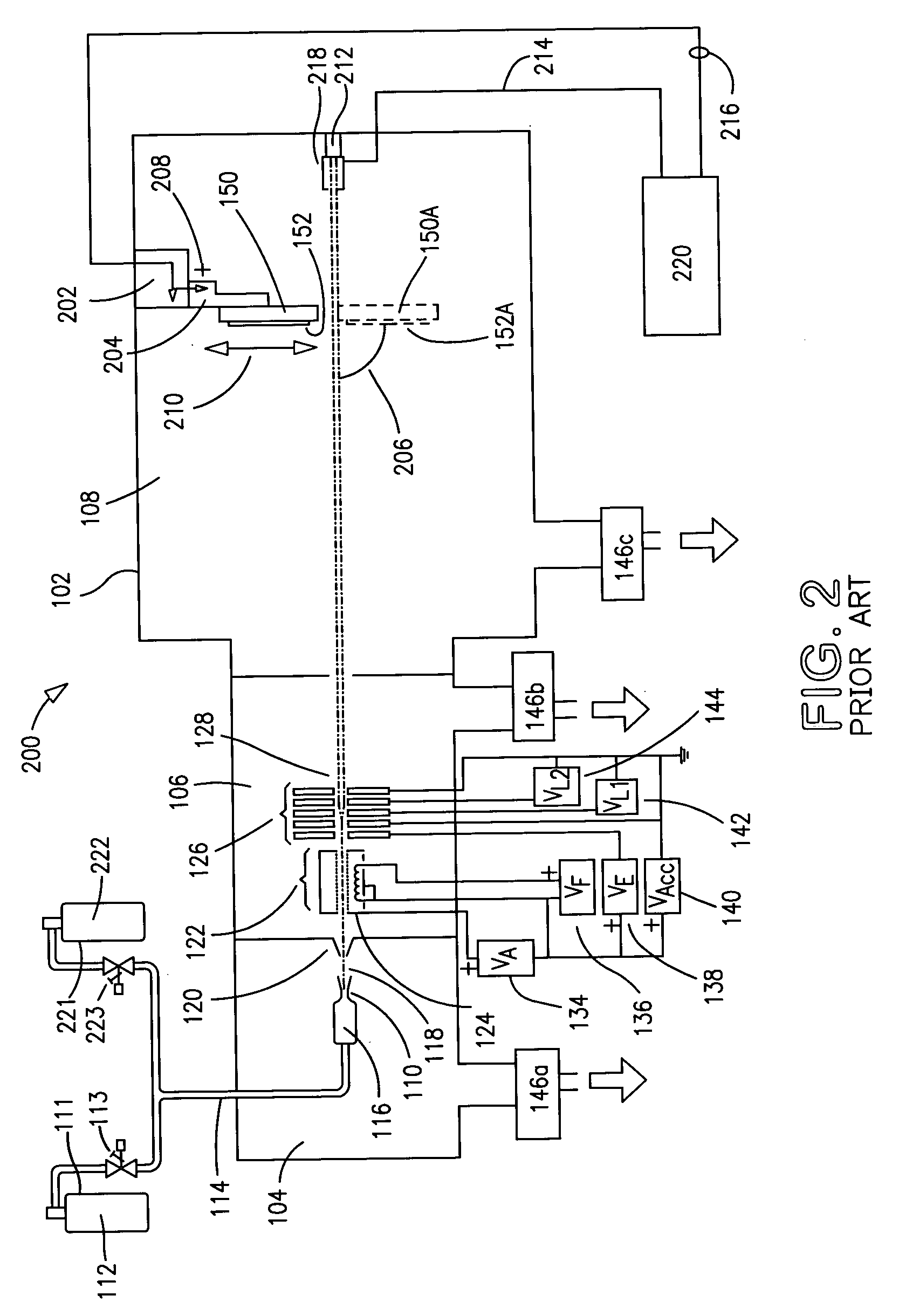

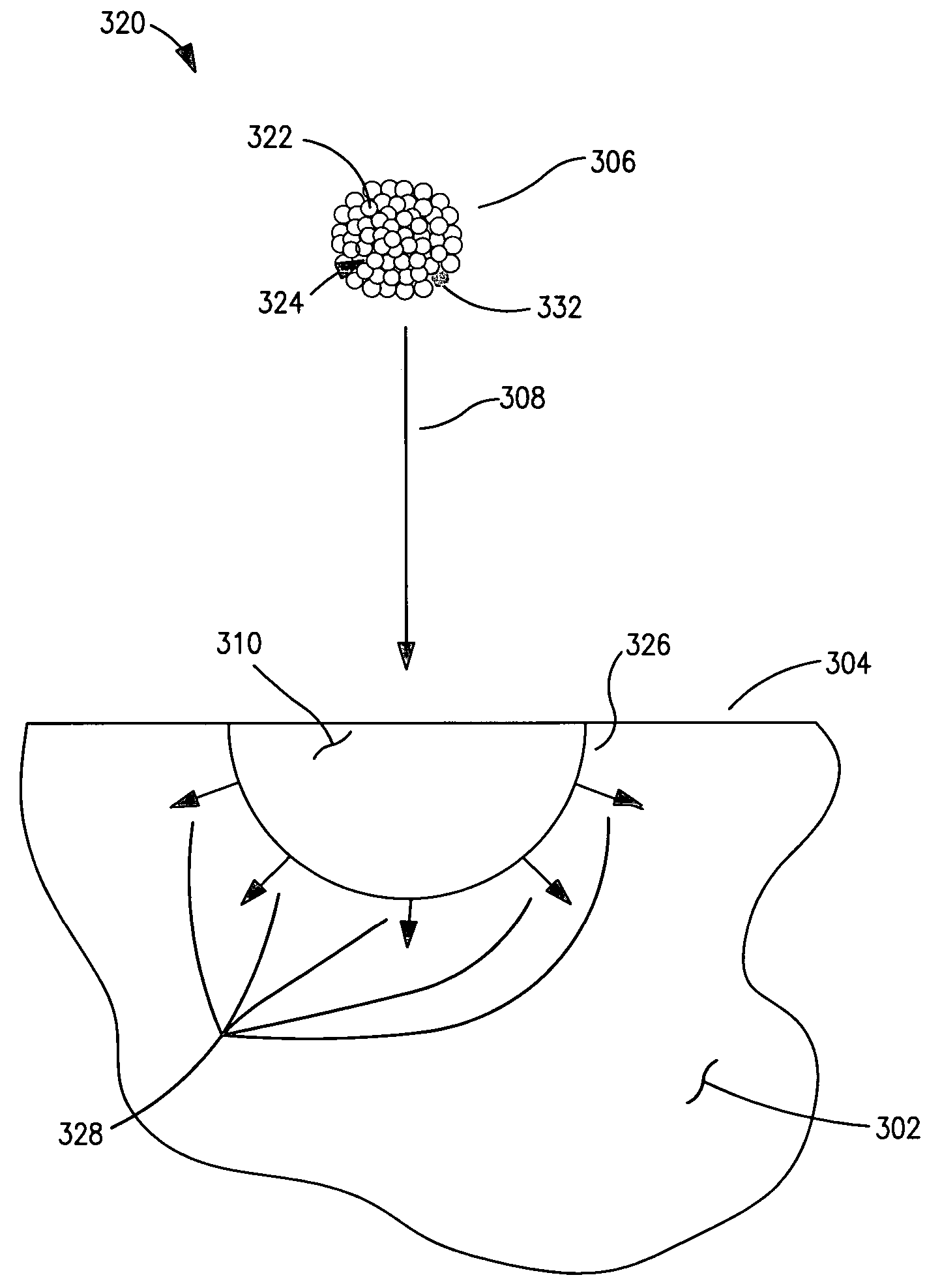

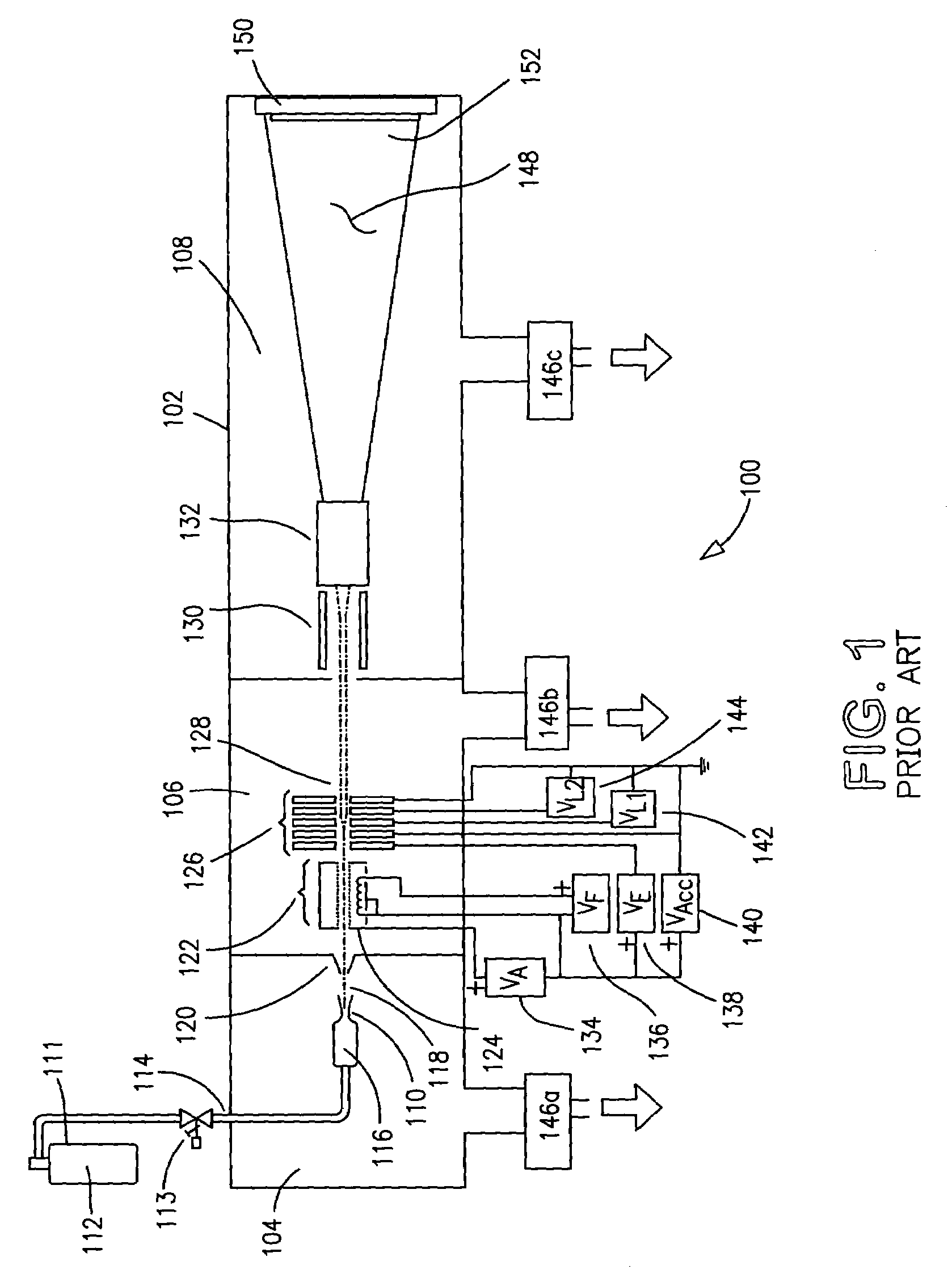

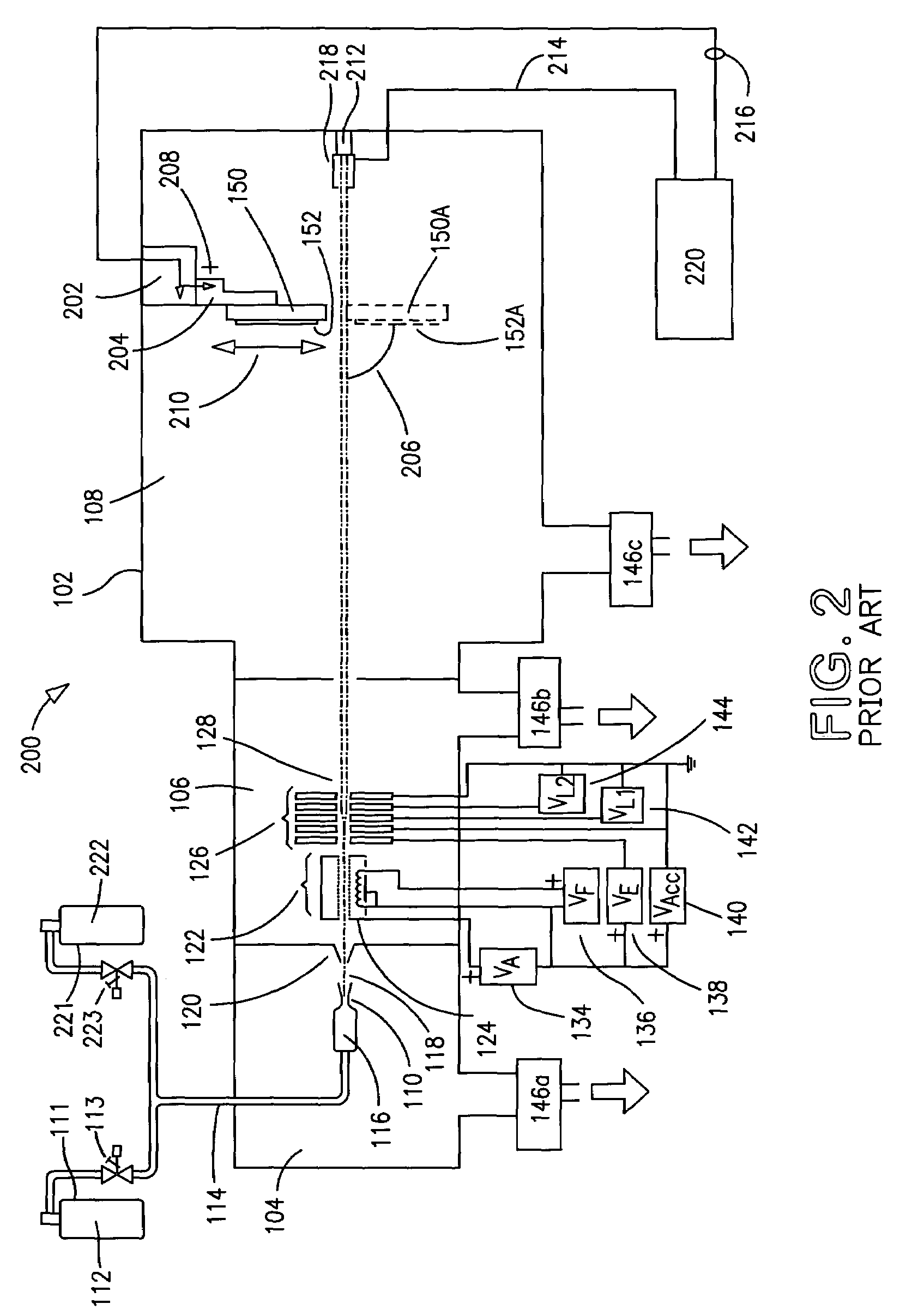

Formation of doped regions and/or ultra-shallow junctions in semiconductor materials by gas-cluster ion irradiation

ActiveUS20050277246A1Improve solid solubilityImprove efficiencyElectric discharge tubesVacuum evaporation coatingSemiconductor materialsGas cluster ion beam

Method of forming one or more doped regions in a semiconductor substrate and semiconductor junctions formed thereby, using gas cluster ion beams.

Owner:TEL EPION

Formation of ultra-shallow junctions by gas-cluster ion irradiation

ActiveUS20050202657A1Improve solid solubilityImprove efficiencyElectric discharge tubesSemiconductor/solid-state device manufacturingGas cluster ion beamIrradiation

Method of forming one or more doped regions in a semiconductor substrate and semiconductor junctions formed thereby, using gas cluster ion beams.

Owner:TEL EPION

Pharmaceutical formulation comprising taxane, a solid composition of taxane, a process for preparing said solid composition of taxane, a solubilizing composition of said solid composition of taxane, and a kit for the injectable formulation of taxane

InactiveUS20090215883A1Improve solubilityReduce usageBiocideOrganic active ingredientsSolubilityOrganic solvent

A pharmaceutical formulation of taxane intended to be administered to mammals, preferably humans, comprises two compositions combined prior to being administered, forming a transparent solution free from precipitates, in which the compositions comprise a solid composition of lyophilized taxane, free from tensoactives, oils, polymers, solubility enhancers, preservatives and excipients; and a solubilizing composition of the lyophilized taxane solid composition that comprises at least one tensoactive. This formulation is free from polysorbate 80 and polyoxyethylated castor oil. A procedure is provided for the preparation of the solid composition by means of the lyophilization of taxane in a lyophilizing organic solvent. A kit for the injectable formulation of taxane comprises a prefilled syringe. Also a pharmaceutical taxane solution for perfusion, free from organic solvent, is provided.

Owner:ERIOCHEM SA

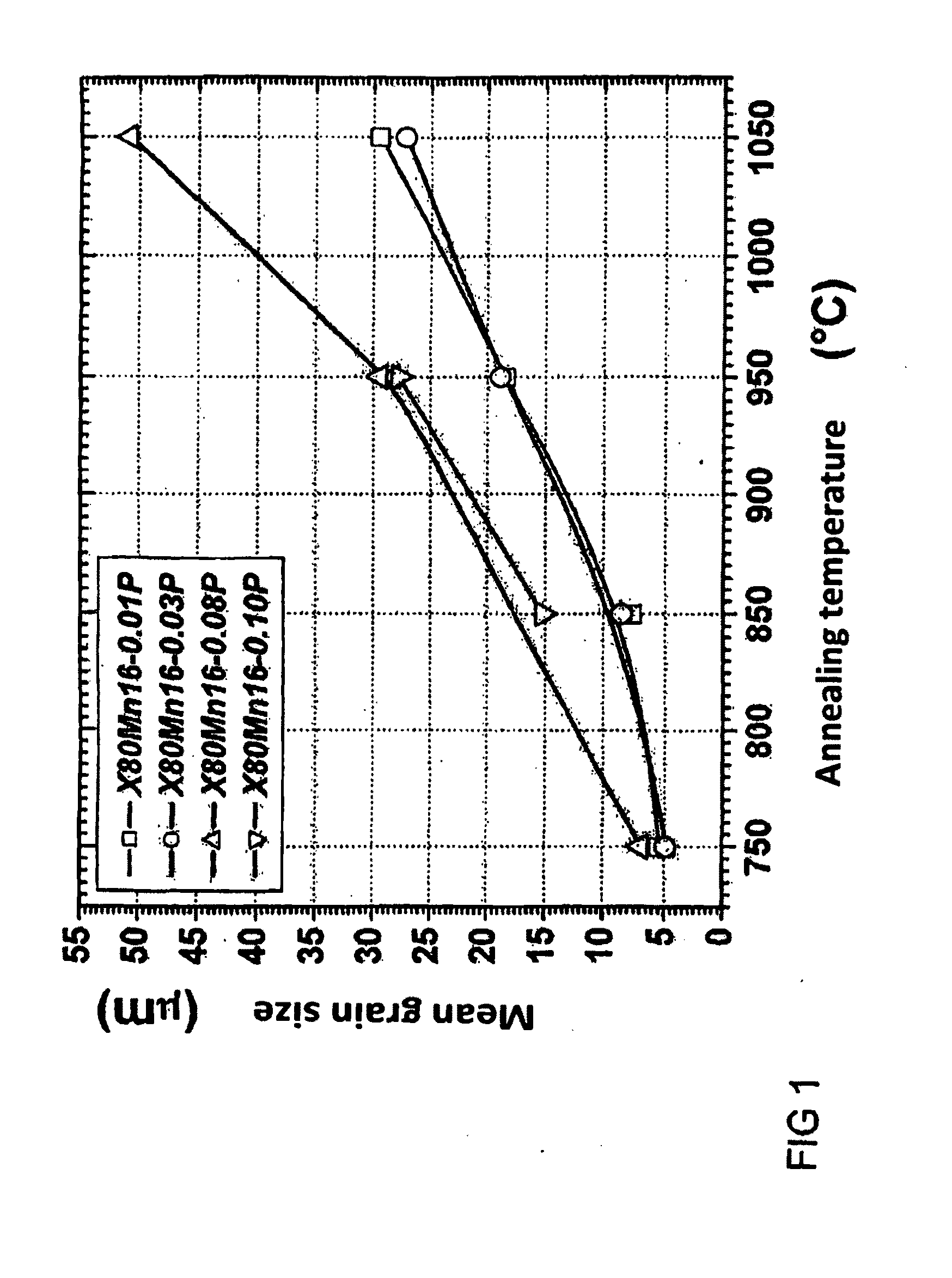

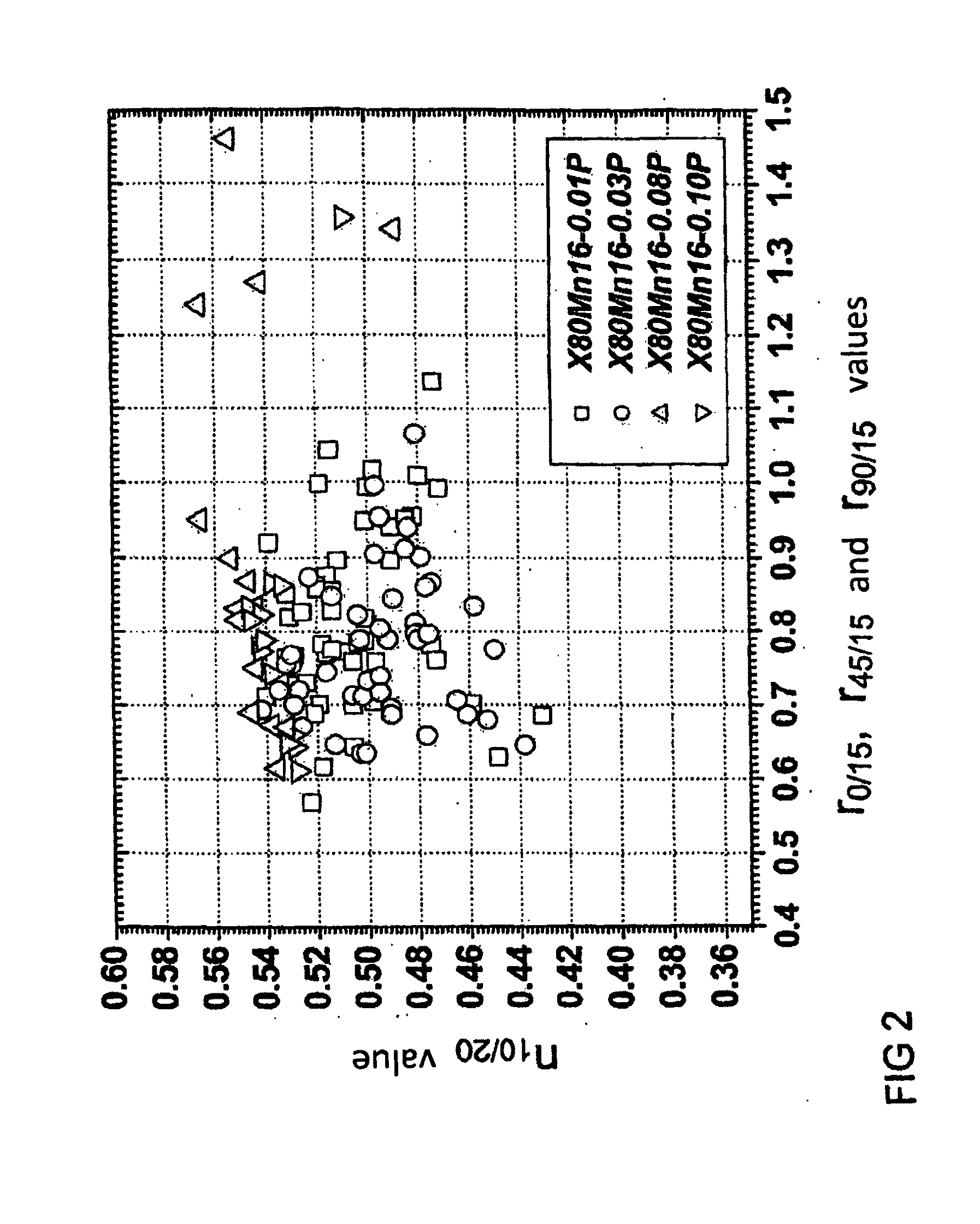

Manganese steel strip having an increased phosphorous content and process for producing the same

InactiveUS20110308673A1Improve solid solubilityImprove solubilityFurnace typesHeat treatment furnacesChemical compositionManganese

A hot-rolled austenitic manganese steel strip having a chemical composition in percent by weight of 0.4%≦C≦1.2%, 12.0%≦Mn≦25.0%, P≧0.01% and Al≦0.05% has a product of elongation at break in % and tensile strength in MPa of above 65,000 MPa %, in particular above 70,000 MPa %. A cold-rolled austenitic manganese steel strip having the same chemical composition achieves a product of elongation at break in % and tensile strength in MPa of above 75,000 MPa %, in particular above 80,000 MPa %.

Owner:VOESTALPINE STAHL GMBH

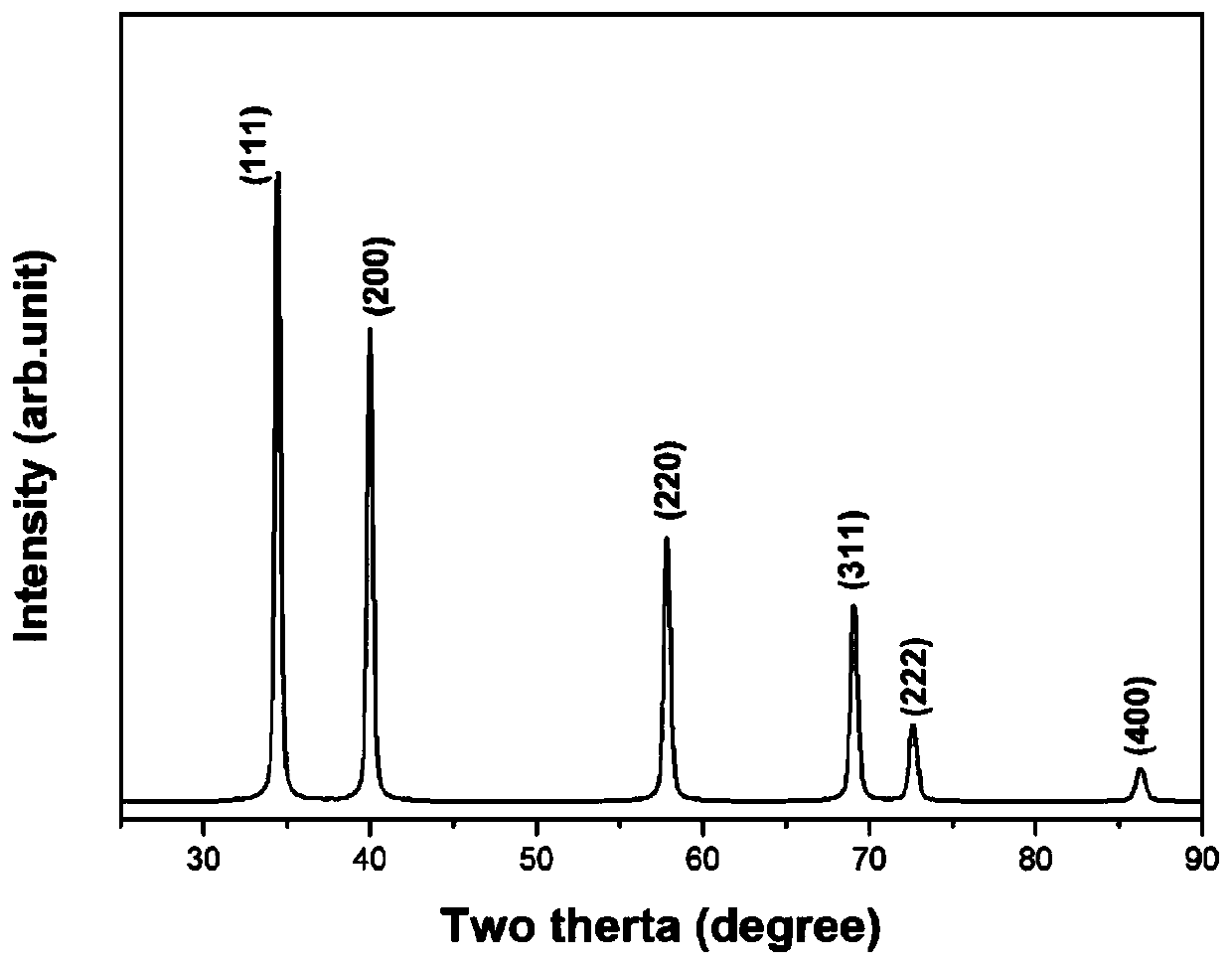

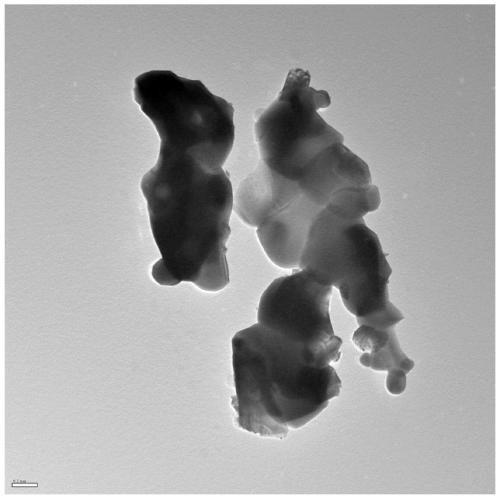

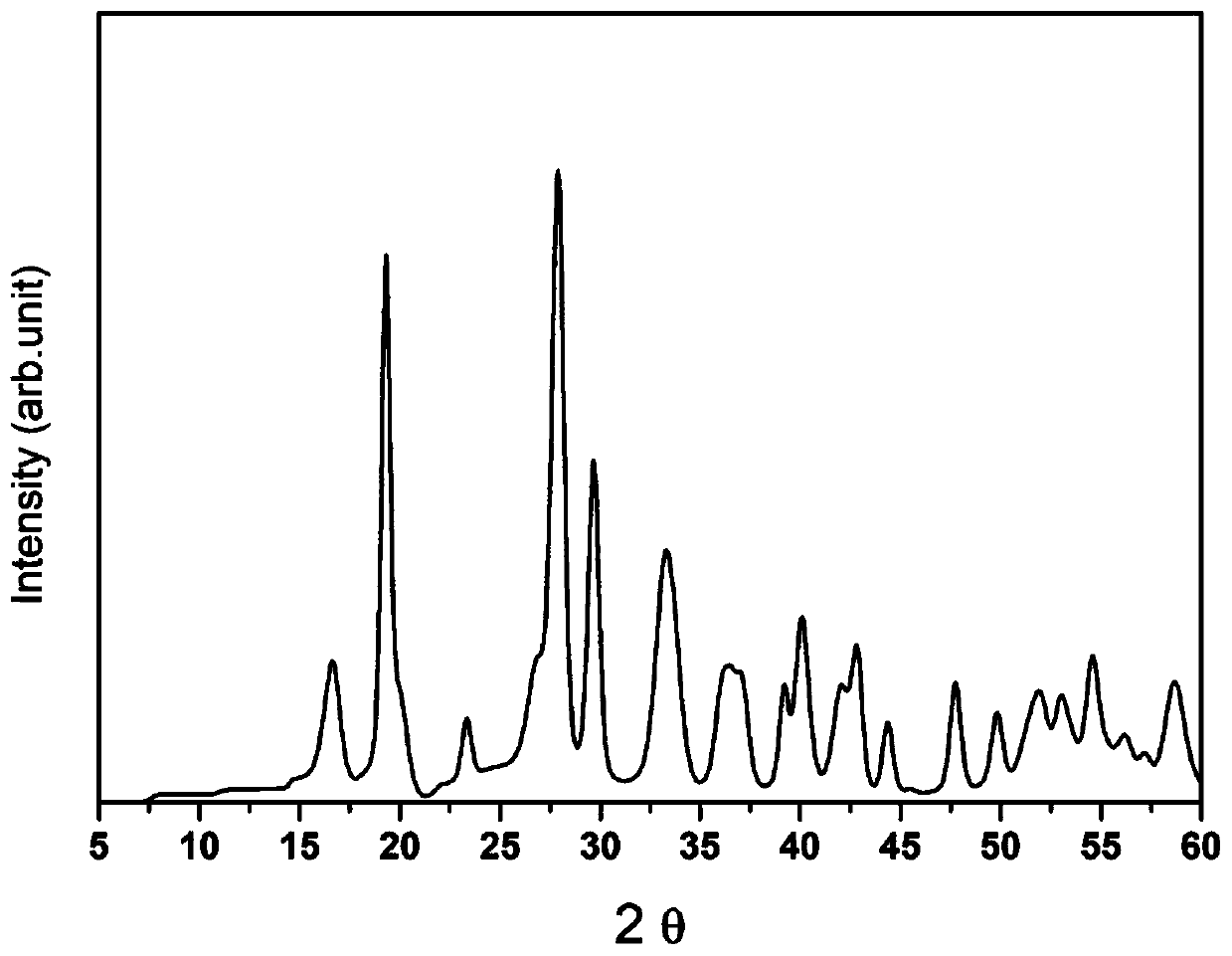

Ultrahigh-temperature high-entropy carbide powder and preparation method thereof

The invention relates to the technical field of ultrahigh-temperature ceramic powder, in particular to ultrahigh-temperature high-entropy carbide powder and a preparation method thereof. The ultrahigh-temperature high-entropy carbide powder adopts a chemical formula as follows: (Ti0.2Zr0.2Hf0.2Nb0.1W0.1Ta0.2) C, and is prepared from TiO2, ZrO2, HfO2, Nb2O5, WO3, Ta2O5 and carbon black as raw materials through wet mixing and a high-temperature carbothermal reduction reaction. The ultrahigh-temperature high-entropy carbide powder is small in grain size, low in heat conductivity and good in hightemperature stability, and is suitable to be used as a base material of an ultrahigh-temperature heat-resistant coating material, an ultrahigh-temperature heat-insulating material and an ultrahigh-temperature composite material; by the preparation method, a technology is simple, the raw material cost is low, and the high-purity ultrahigh-temperature high-entropy carbide powder can be obtained through once heating at relatively low temperature.

Owner:淄博星澳新材料研究院有限公司

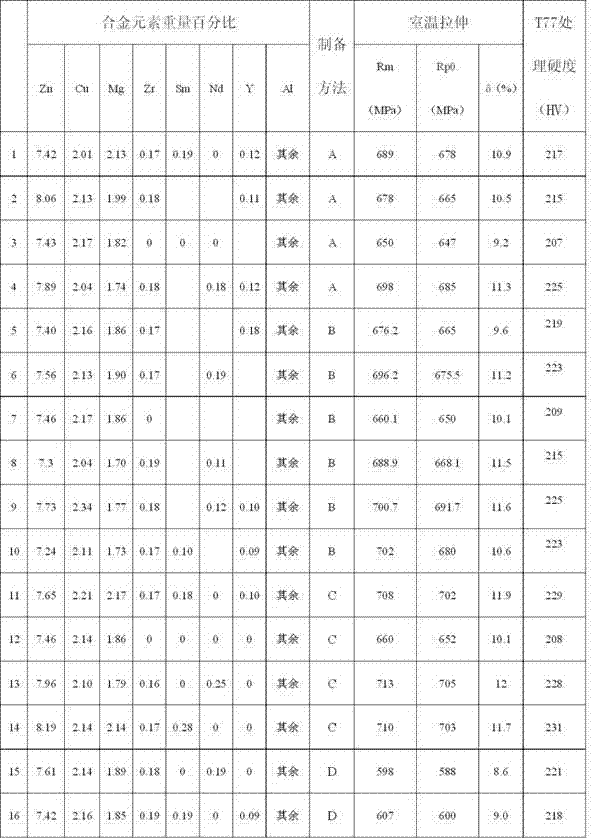

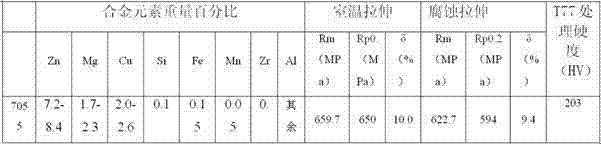

Ultra-strong strength, high-toughness and anticorrosive aluminum alloy and preparation method for same

ActiveCN103667825AImprove corrosion resistanceImprove solid solubilityRare-earth elementElectromagnetic casting

The invention relates to an ultra-strong strength, high-toughness and anticorrosive aluminum alloy and a preparation method for the same. A trace amount of specially-reinforced rare earth elements Sm, Nd and Y are added on the basis of an Al-Zn-Mg-Cu-Zr alloy, an electromagnetic casting mode is adopted for improving the solid solubility of the alloy, homogenizing the structure and reducing segregation, and the proportion of main alloy elements is optimized to make a breakthrough in the strength of the alloy. The aluminum alloy has ultra-strong strength, higher plasticity and high anticorrosive performance; in addition, the high-abundance rare earth element such as Sm and Y serving as one of raw materials is excessively overstocked in the market, and is low in cost, so that not only can be the cost of the alloy remarkably lowered, but also the problem of application unbalance of the rare earth elements can be relieved; the strength of a material prepared from the alloy is stronger than 700MPa after the material is subjected to T77 treatment, and is remarkably stronger than that of a material prepared from a 7055 alloy, and the comprehensive performance of the material is remarkably higher than that of a material prepared from an Al-Zn-Cu-Mg aluminum alloy currently with the highest comprehensive performance.

Owner:华峰铝业有限公司

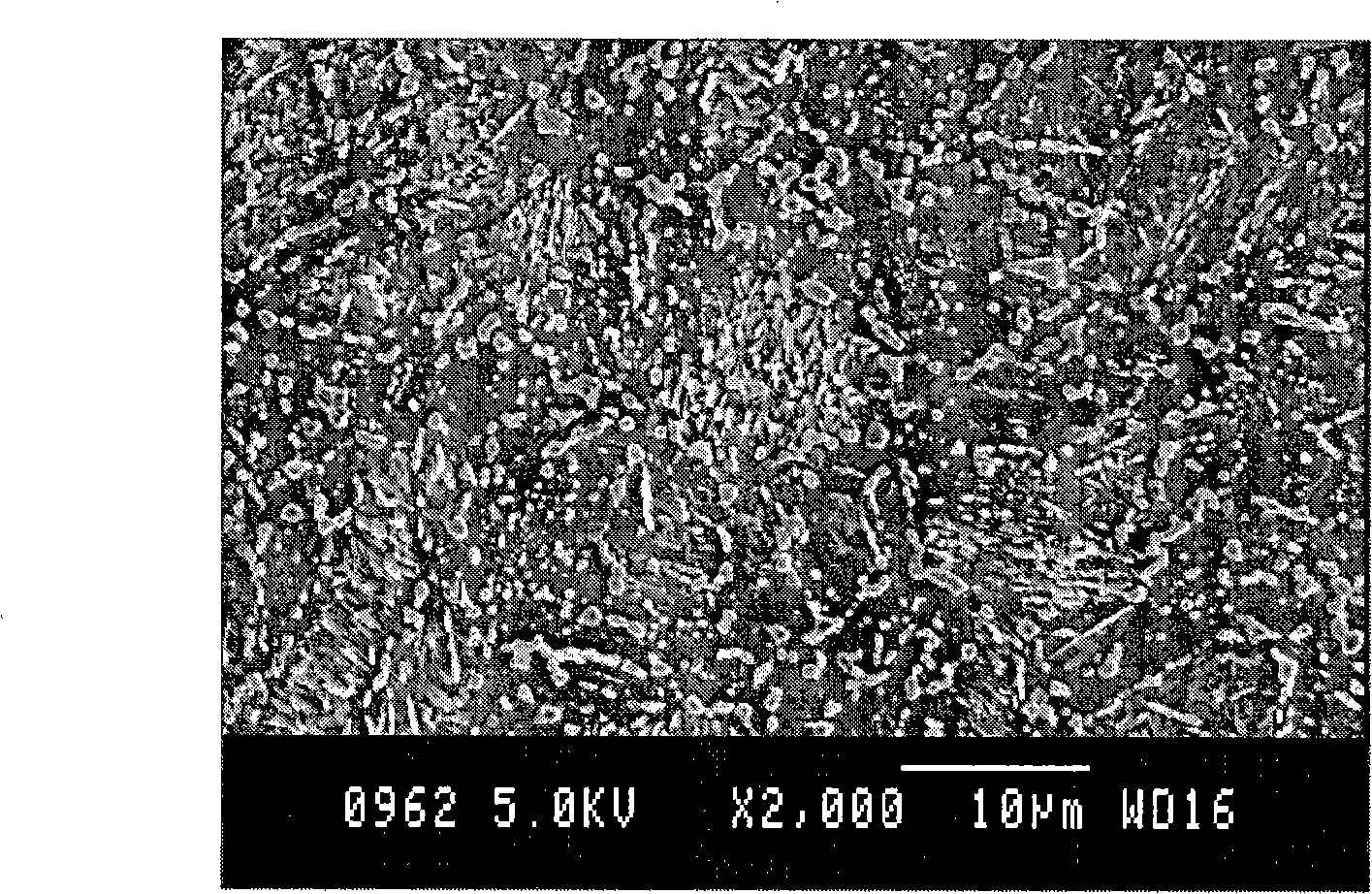

Method for preparing nano-structured nitrogen silicon zirconium coating on surface of hard alloy substrate

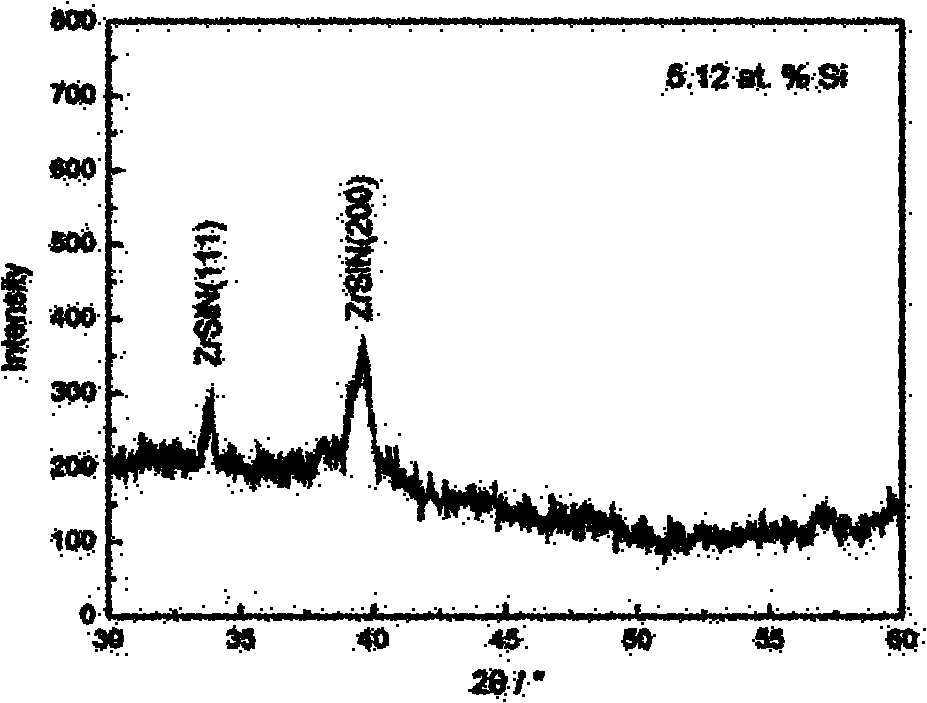

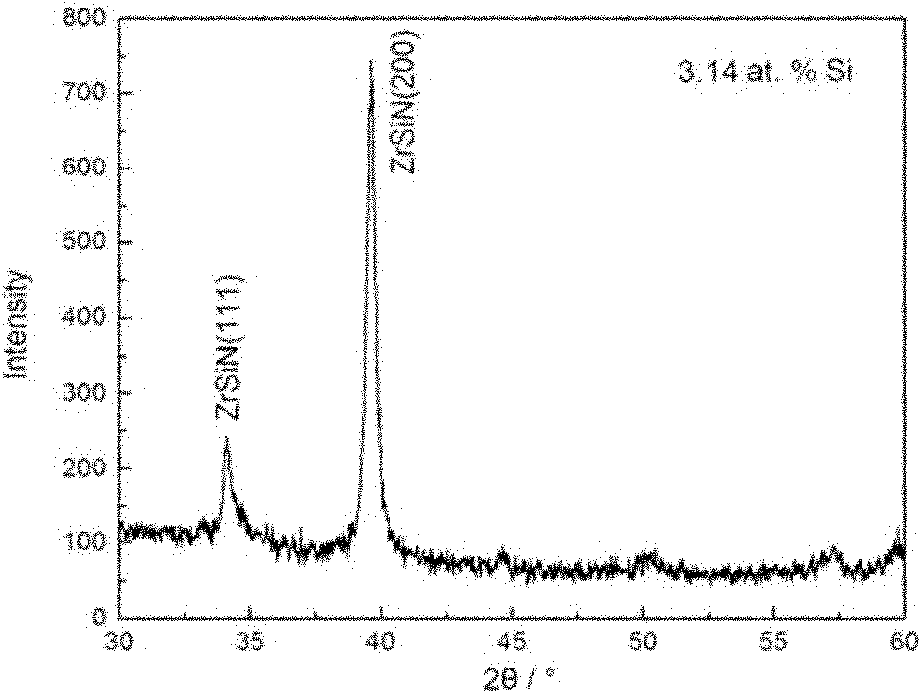

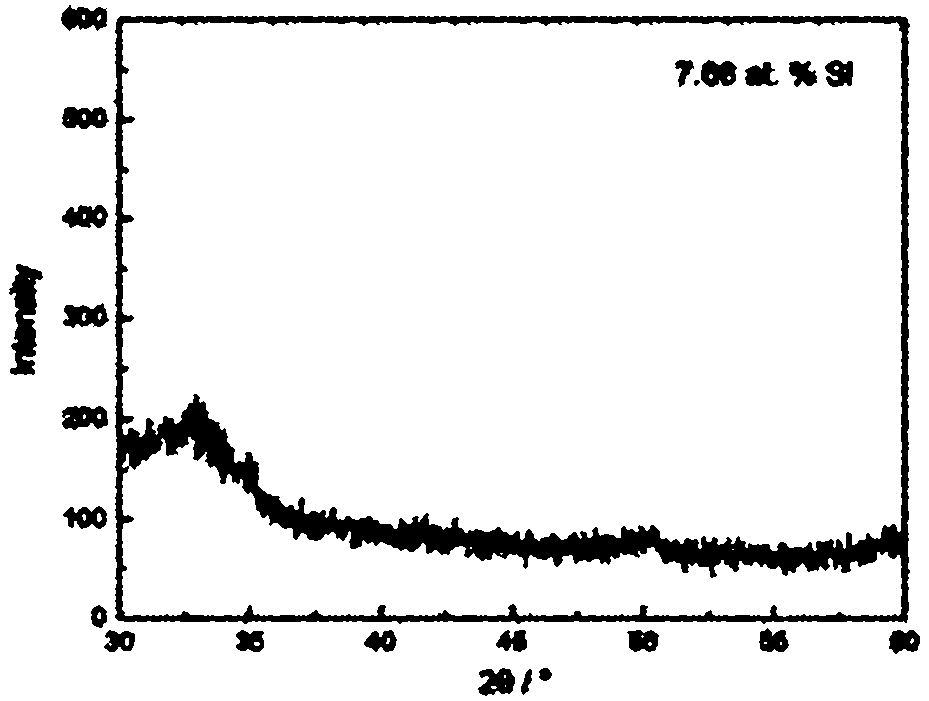

InactiveCN101921982AHigh hardnessGrowth inhibitionVacuum evaporation coatingSputtering coatingNano structuringAlloy substrate

The invention provides a method for preparing a nano-structured nitrogen silicon zirconium coating on the surface of a hard alloy substrate, relating to a hard alloy. A direct-current and radio frequency reaction co-sputtering method is used to prepare the nano-structured nitrogen silicon zirconium coating through controlling the power of a Si target. When the content of Si in a ZrSiN coating is reduced, the Si atoms in the coating exist in the mode of replacing Zr atoms, the ZrSiN coating with low content of Si is solid solution, and the cross section of the ZrSiN coating is in a column structure. The solid solubility and the hardness of the ZrSiN coating are increased with the increment of the content of Si. When the content of Si in the coating reaches a definite amount, excessive element of Si can form amorphous Si3N4 at crystal boundary with element of N. When the content of Si in the coating is further increased, a great amount of amorphous Si3N4 is generated, thus seriously inhabiting the growth of ZrN crystal particles and influencing the degree of crystallization of the coating, in addition, the coating is changed to be in an amorphous state and is in a non-column equiaxial structure.

Owner:XIAMEN UNIV

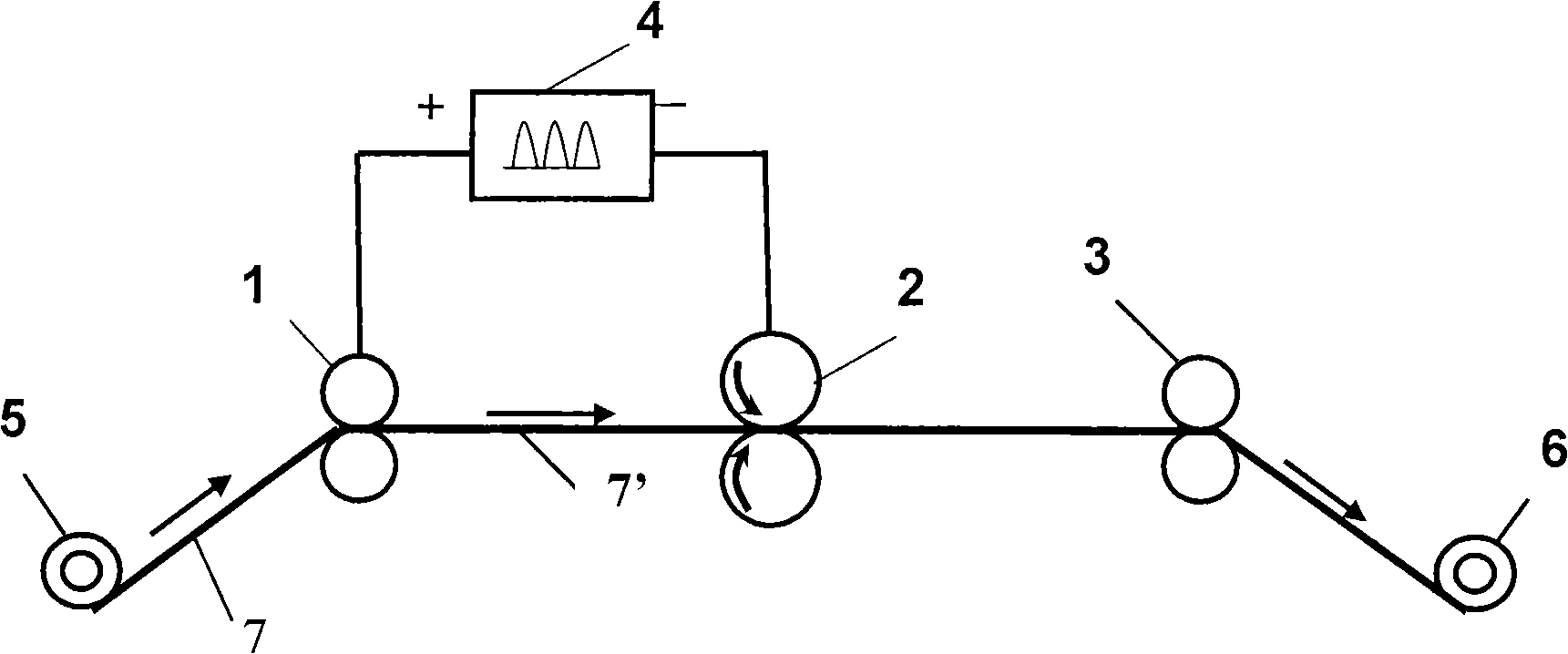

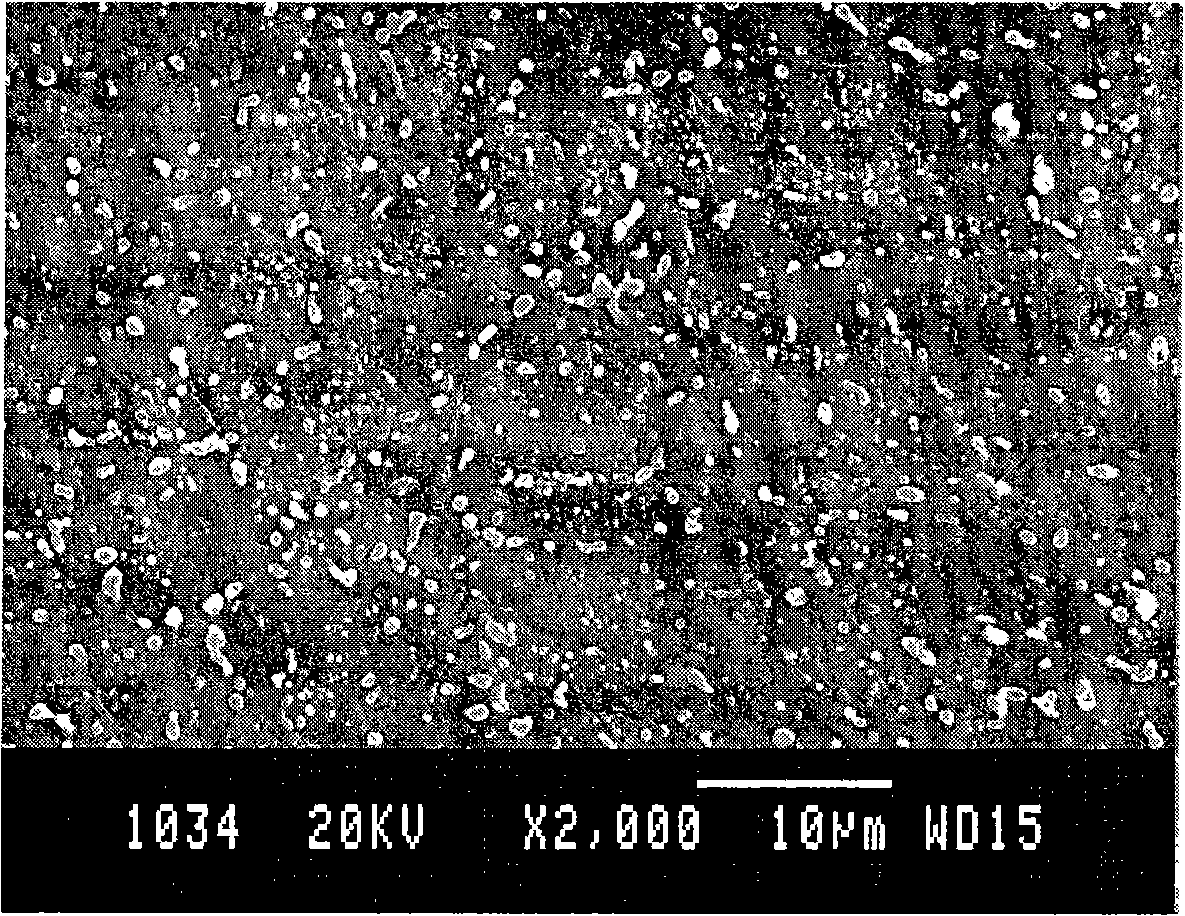

High-strength high-toughness AZ91 magnesium alloy strip eletrotoughening process method and system

InactiveCN101298653AOxidation does not occurToughening treatment is widely applicableHigh energyRoom temperature

The invention discloses an electro-strengthening and toughening processing method of a belt material of AZ91 magnesium alloy and a system thereof. The electro-strengthening and toughening processing method comprises following steps: when the belt material of magnesium alloy is transmitted at a certain speed which is driven by a roller on an electro plastic rolling machine, high-energy impulse current that is output by an impulse power source through an electrode is input into an electriferous region section of the moving belt material of magnesium alloy, and the Joule heating effect and the non-heating effect are generated in the electriferous region section, thus causing the phase transition of internal microscopic constitution from bulky lath-shaped Beta-Mg17Al12 that are gathering and agglomerating in an initial state to Beta-Mg17Al12 particles that are evenly distributed and approximately sphere-shaped, or causing the solid solution effect that leads Beta-Mg17Al12 to be dissolved in a substrate; the processed belt material can be naturally air cooled at room temperature. The electro-strengthening and toughening processing method of the belt material of AZ91 magnesium alloy has short processing time and high production efficiency, and simultaneously avoids the high-temperature oxidation of the magnesium alloy. After the electro-strengthening and toughening processing, the microscopic constitution of the belt material of magnesium alloy can be remarkably improved, the unit extension of the microscopic constitution is increased from 11.8 percent in the initial aging state to over 20 percent, and the tensile strength of the microscopic constitution is not dramatically lowered.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

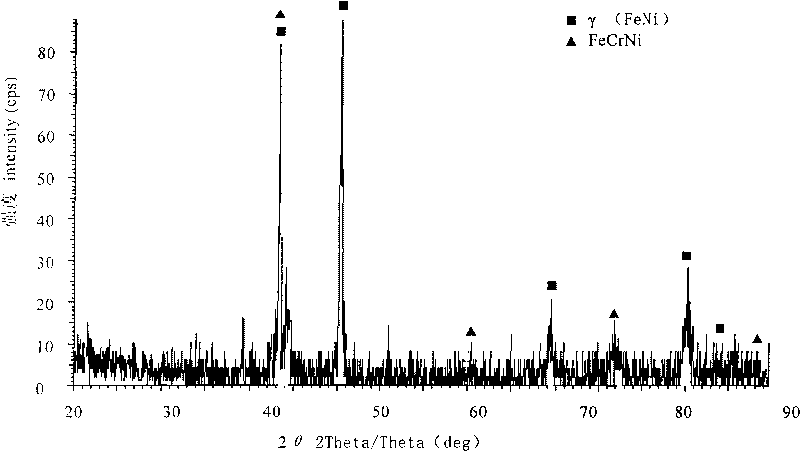

Iron-based alloy powder material for plasma cladding quick forming

InactiveCN101709469AImprove toughnessModerate hardnessMetallic material coating processesHardnessWear resistance

The invention discloses an iron-based alloy powder material for plasma cladding quick forming, which comprises the following alloy components in percentage by weight: 0.05-0.15 percent of C, 4-8 percent of Ni,10-15 percent of Cr, 0.1-1 percent of B, 0.8-1.2 percent of Si, 0.8-1.2 percent of Mo, 0.25-0.70 percent of Nb, 0.25-3.5 percent of mixed RE(containing 47 percent of Ce, 26 percent of La,18 percent of Nd and 5 percent of Pr in percentage by mass) and the balance of Fe. The iron-based alloy powder with the components is especially suitable for plasma cladding quick forming, and a cladding layer has medium hardness and wear-resistance. The iron-based alloy powder has little tendency to crack and other cladding defects under the condition of multi-layer cladding, and the cladding process is excellent with low powder cost. The powder can be also used for restoring work-piece size or used as a bottom layer before a functional cladding layer is formed during plasma single-layer cladding repair, and can be applied to wider application needs.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Degradable magnesium alloy bio-implantation material and preparation method thereof

ActiveCN104498790ANo toxicityImprove corrosion resistanceProsthesisCardiovascular stentInsertion stent

The invention relates to a degradable magnesium alloy bio-implantation material which is characterized by consisting of the following components in percentage by mass: 0-12% of Zn, 0-10.5% of Ca and the balance of Mg and unavoidable impurities carried by the raw materials, wherein the total content of Zn and Ca is higher than or equal to 1.0%; the total content of unavoidable impurities is higher than or equal to 0.005%; in the unavoidable impurities, the content of Fe is lower than or equal to 0.0005%, the content of Ni is lower than or equal to 0.0005%, and the content of Cu is lower than or equal to 0.001%; and the invention also relates to a preparation method of the degradable magnesium alloy bio-implantation material. The degradable magnesium alloy bio-implantation material provided by the invention is non-toxic to a human body, has good corrosion resistance and good strength, and is suitable to be used for preparing magnesium alloy bio-implantation devices such as bone nails, bone plates and cardiovascular stents.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

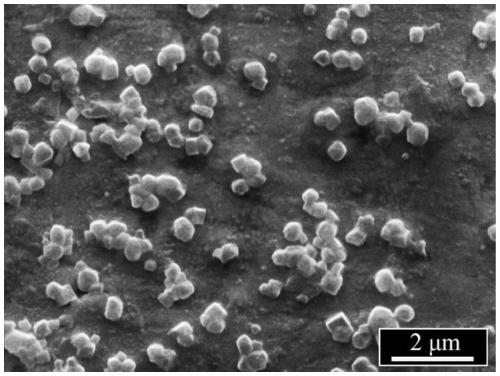

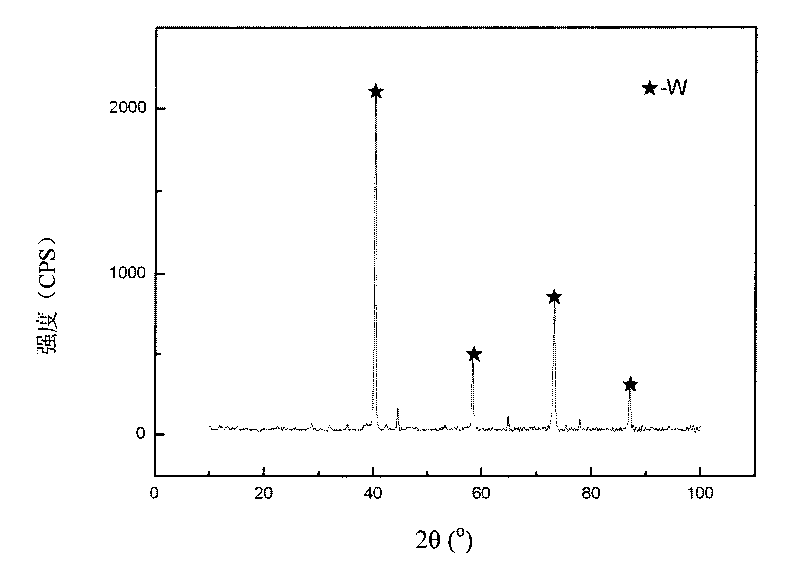

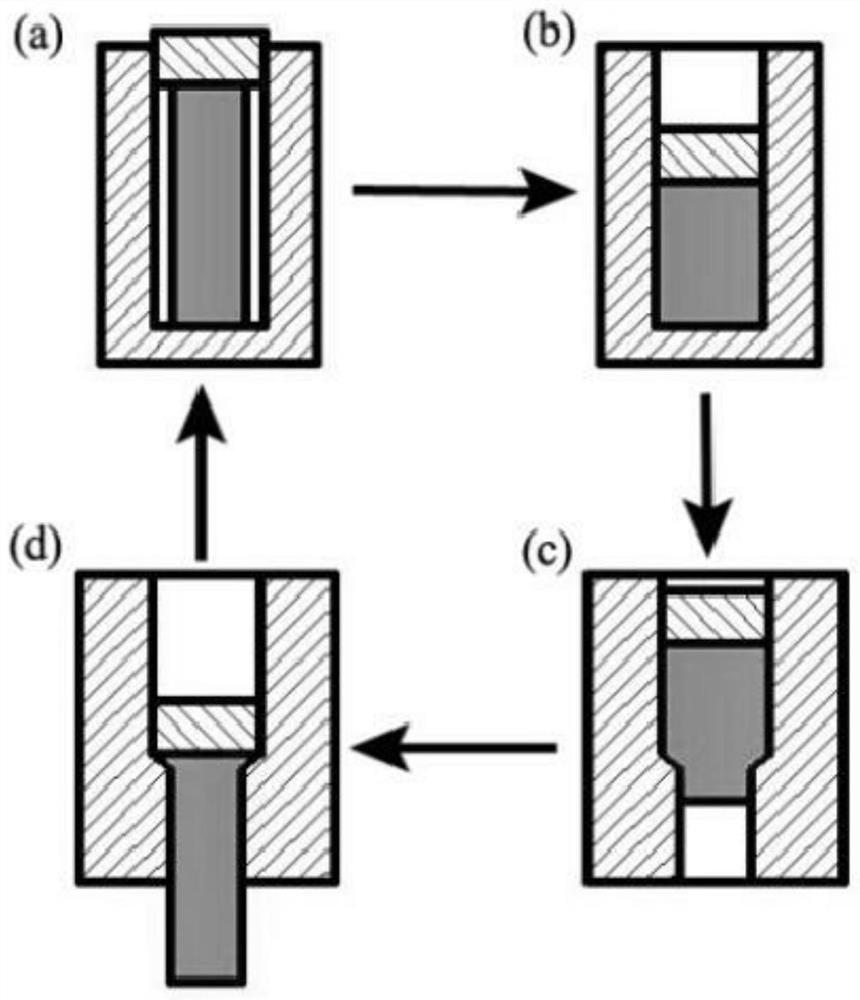

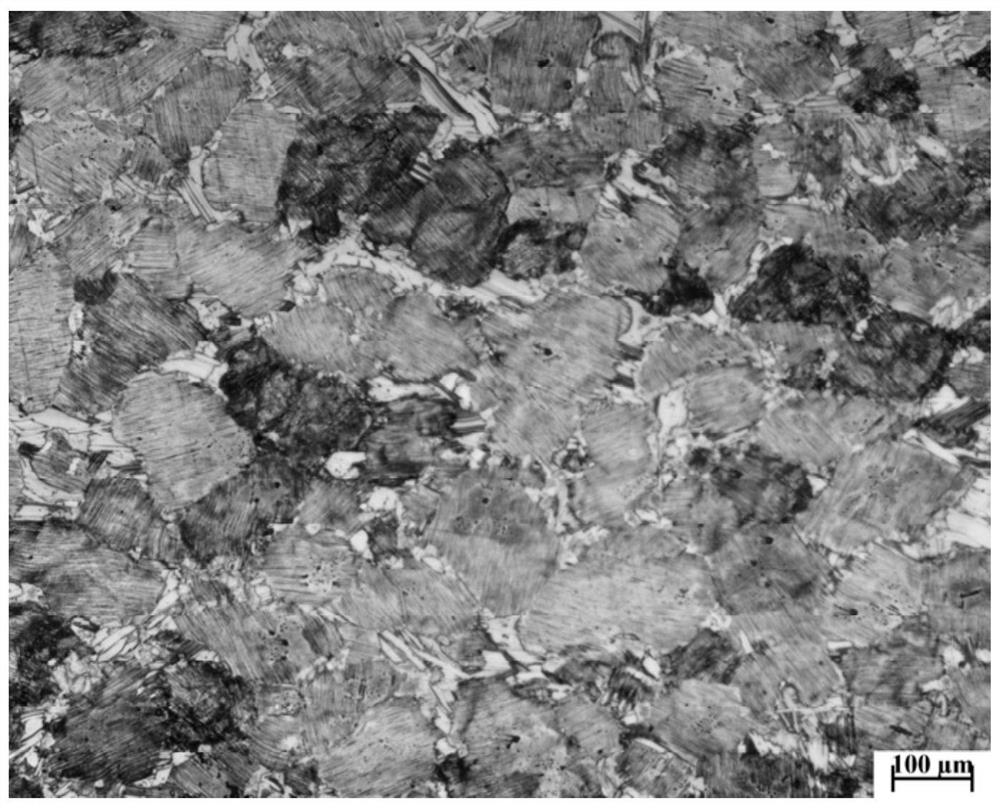

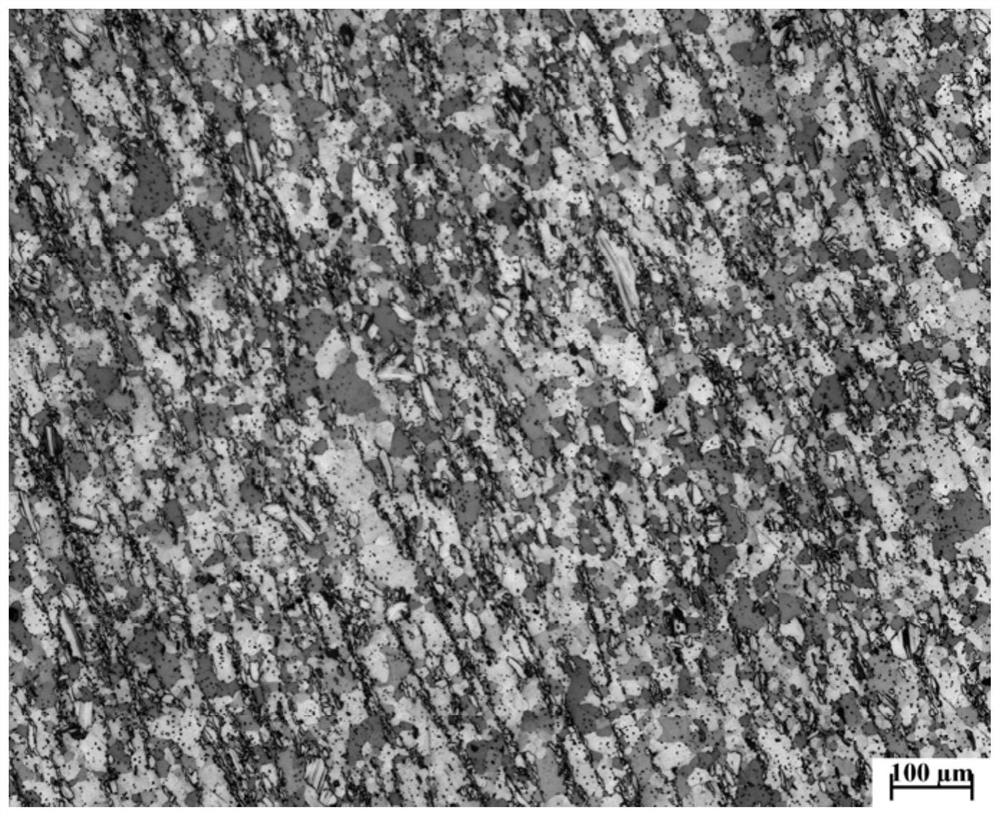

Nanocrystalline tungsten-based alloy block body material and preparation method thereof

The invention relates to a plastic forming technique and a powder metallurgical technique, in particular to a nano crystal tungsten based alloy block material and a method for preparing the same. The block material comprises the following components in weight percentage: 86 to 88 percent of W, 6.5 to 7.5 percent of Ni, 2.5 to 3.5 percent of Fe, 2 to 4 percent of Mo and 1 to 2 percent of Co. The preparation method comprises the following steps: Fe-Co-Ni and W-Mo after dry mixing are ball milled in advance respectively until the Fe, Co and Ni completely form solid solution, and tungsten phase crystal grain is thinned to below 100nm; the Fe-Co-Ni and W-Mo are subjected to high energy ball milling until the Fe-Co-Ni is evenly distributed around the W-Mo crystal grain; and the discharge plasma rapid sintering is adopted. The nano crystal tungsten based alloy block material has the advantages of reasonable formula, even and thin microstructure, nearly full compact, higher hardness and tensile strength and good specific elongation, and the method for preparing the block material effectively improves the mechanical performances of the sintering material.

Owner:SOUTH CHINA UNIV OF TECH

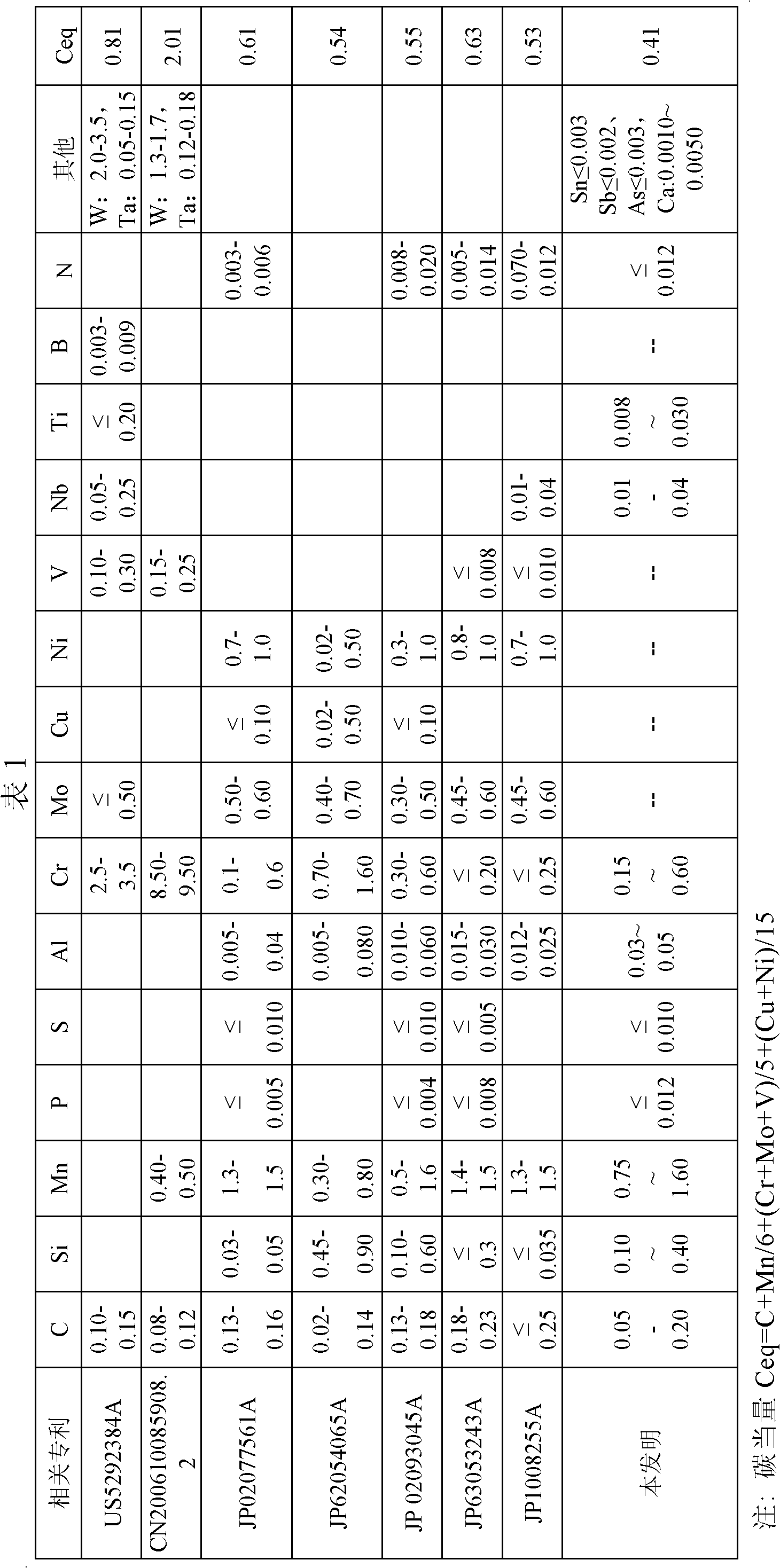

Steel for nuclear pressure vessels and manufacturing method thereof

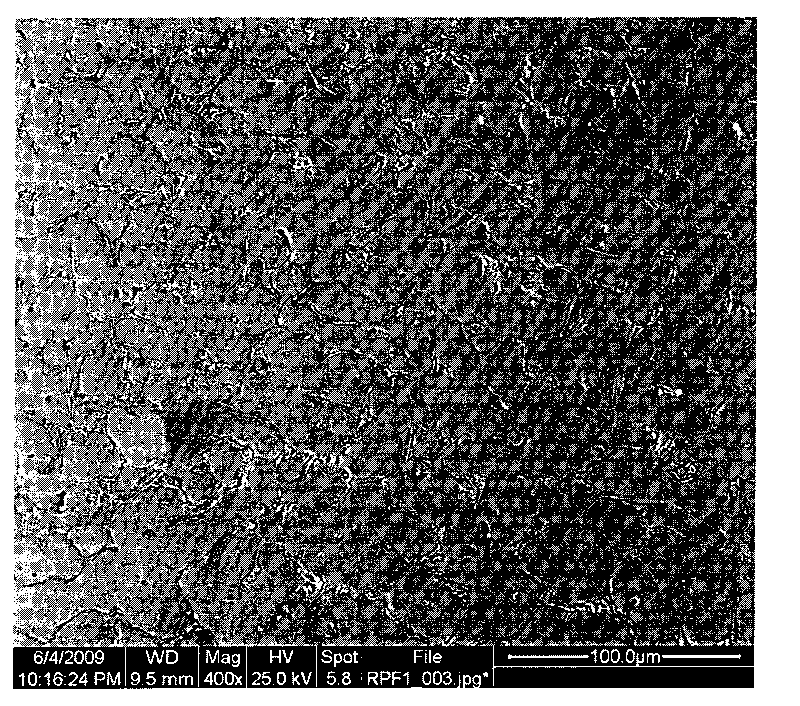

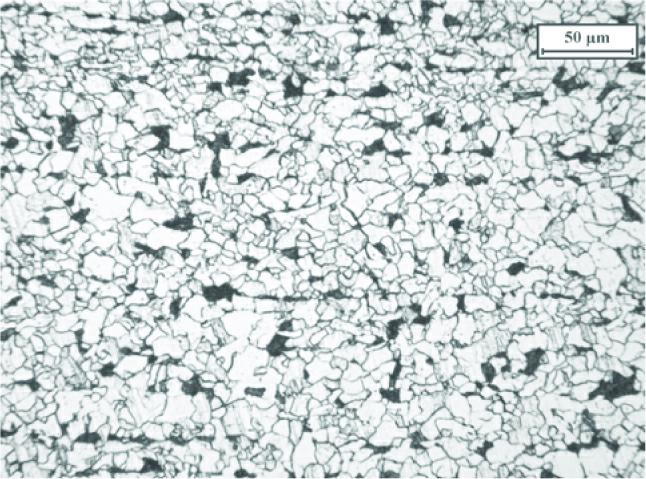

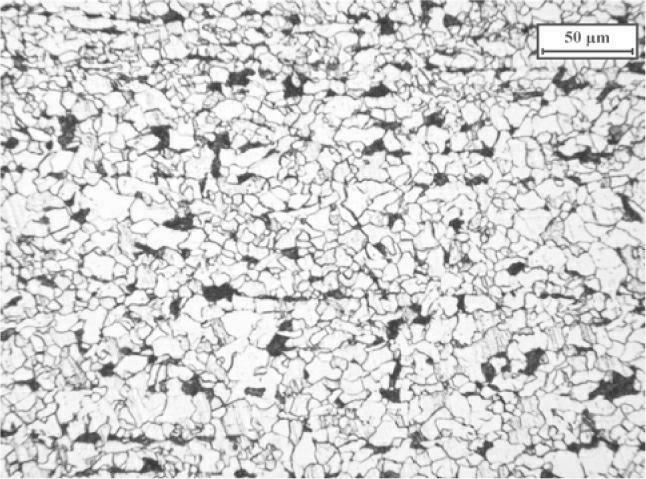

The invention discloses a kind of steel for nuclear pressure vessels and a manufacturing method thereof. The manufacturing method comprises the following steps of: 1) smelting and plate blank casting, wherein the steel comprises the following components in percentage by weight: 0.05-0.20% of C, 0.10-0.40% of Si, 0.75-1.6% of Mn, 0.15-0.6% of Cr, 0.010-0.04% of Nb, 0.008-0.03% of Ti, 0.030-0.050% of Alt, 0.0010-0.0050% of Ca, 0.003-0.012% of N, less than or equal to 0.010% of S, less than or equal to 0.012% of P, less than or equal to 0.003 wt. % of Sn, less than or equal to 0.002% of Sb, less than or equal to 0.003% of As, and the balance of Fe and inevitable impurities, wherein Alt / N is greater than or equal to 2; 2) hot rolling, wherein the heating temperature of a plate blank is 1100-1250 DEG C, the first-stage rolling temperature is 950-1020 DEG C, the first-stage reduction ratio is greater than or equal to 80%, the second-stage rolling temperature is 780-900 DEG C, and the second-stage reduction ratio is greater than or equal to 60%; and 3) cooling and coiling, wherein the cooling speed is 4.0-15 DEG C / s, and the coiling temperature is 590-680 DEG C; and through a controlled rolling and cooling process, the microscopic structure of the obtained steel for nuclear pressure vessels is a fine ferritic and pearlitic structure.

Owner:BAOSHAN IRON & STEEL CO LTD

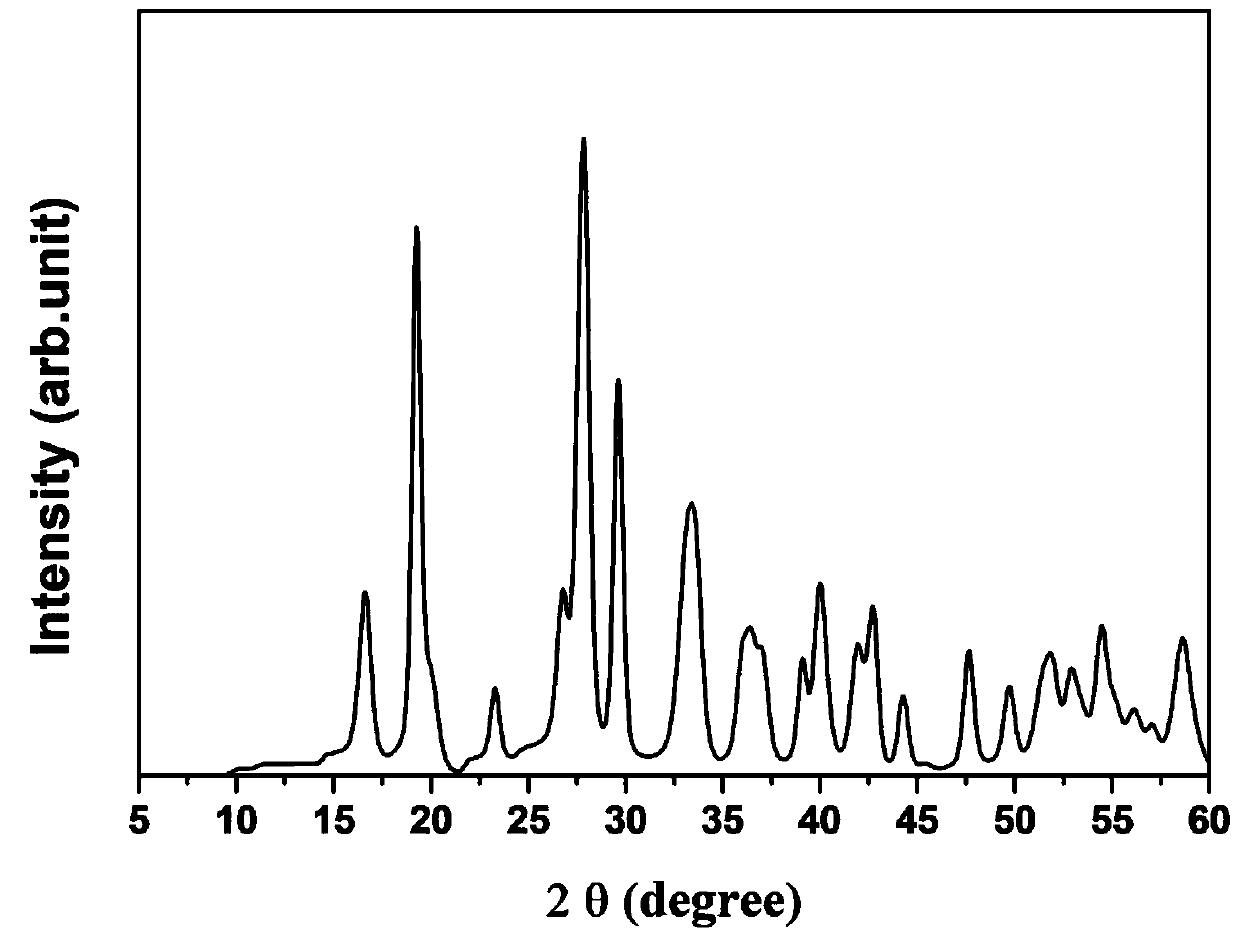

Polybasic solid solution rare earth silicate ceramic powder and preparation method thereof

The invention relates to the technical field of ultrahigh temperature ceramic powder, in particular to polybasic solid solution rare earth silicate ceramic powder and a preparation method thereof. Thechemical formula of the polybasic solid solution rare earth silicate ceramic powder is (Y0.2Yb0.2Re'0.2Re'0.2La0.2)2Si2O7, wherein Re' and Re' are selected from any two of Nd, Ce, Sm, Er and Eu. Thepreparation method comprises the following steps: mixing raw materials by adopting a wet-mixing method, and drying; then placing the mixture in a high-temperature reaction furnace for reacting; performing wet milling and spray drying granulation to obtain the polybasic solid solution rare earth silicate ceramic powder. The polybasic solid solution rare earth silicate ceramic powder has high solidsolubility, excellent high temperature resistance, no decomposition at a high temperature and low thermal conductivity. The preparation method is simple and feasible.

Owner:淄博星澳新材料研究院有限公司

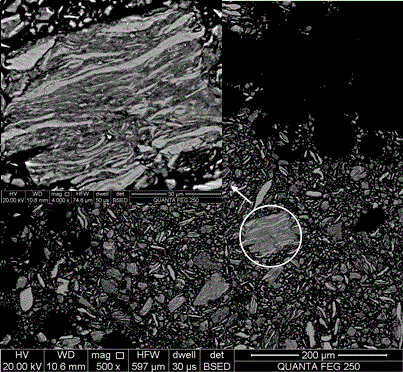

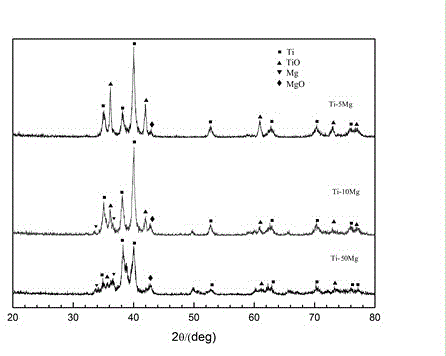

A Ti-Mg alloy material, a preparing method thereof and applications of the alloy material

The invention discloses a Ti-Mg alloy material applied as human tissue bone repair materials and a preparing method thereof. Phase composition of the alloy comprises Ti, Mg, TiO and MgO. The alloy comprises 70-80% of the Ti, 0-10% of the Mg, 8-20% of the TiO and 2-5% of the MgO. The Ti-Mg alloy is prepared by utilization of mechanical alloying and spark plasma sintering. The porosity of the alloy is smaller than 1%, the Vickers hardness of the alloy is HV400-HV500, the compressive strength of the alloy is 1600-1700 MPa, the elasticity modulus of the alloy is 12-13 GPa, the self-corrosion potential of the alloy ranges from -900 mV to -800 mV, the self-corrosion current density is 50-90 [mu]A / cm<2>. The alloy has characteristics of uniform structure, high compactness, good mechanical compatibility, capability of being biodegradable, and good corrosion resistance.

Owner:CENT SOUTH UNIV

Production technology of high-strength 7-series aluminum alloy pipe

ActiveCN109355538AHigh strengthIncreased resistance to stress corrosion susceptibilityFurnace typesHeat treatment furnacesIngot castingMechanical property

The invention belongs to the technical field of heat treatment of aluminum alloy, and relates to a production technology of a high-strength 7-series aluminum alloy pipe. An aluminum alloy ingot casting is prepared from the following raw materials according to the mass percentage: 7.5-8.5% of Zn, 1.0-3.5% of Mg, 0.10-0.20% of Cu, 0.05-0.3% of Zr, 0.1-1.5% of Mn, 0.05-0.3% of Cr, 0 .05% of Ti, 0.05%of B, less than or equal to 0.05% of single impurity, less than or equal to 0.15% of impurities in total and the balance Al. The two-stage homogenizing treatment and the two-stage aging heat treatment are adopted in the production technology of the aluminum alloy pipe, wherein according to the two-stage homogenizing system, the heat preservation is carried out for 24 hours at the temperature of 470 DEG C, and the heat preservation is carried out for 10 hours at the temperature of 480 DEG C; and according to the two-stage aging system, the heat preservation is carried out for 7 hours at the temperature of 110 DEG C to 130 DEG C, and the heat preservation is carried out for 10 hours at the temperature of 165 DEG C to 170 DEG C. The overall mechanical property of the high-strength 7-series aluminum alloy pipe is effectively improved.

Owner:CHINA ZHONGWANG

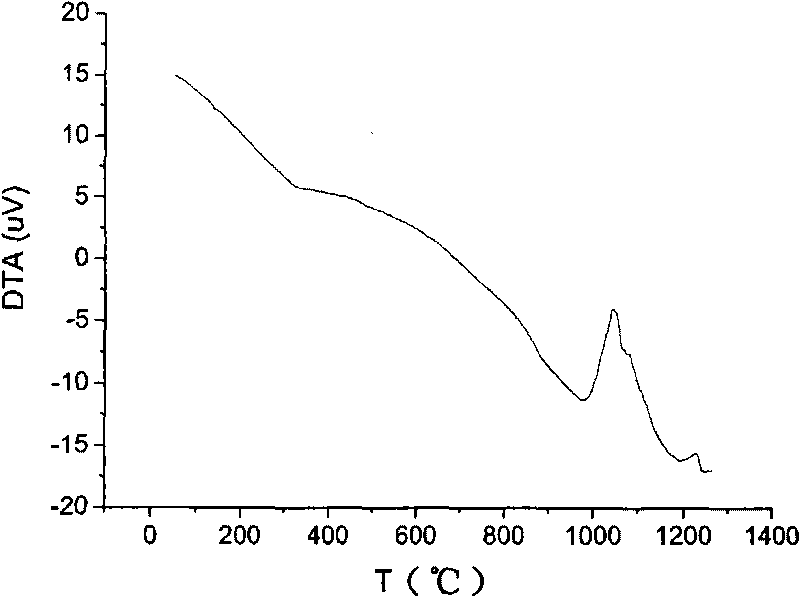

Ca and heavy rare earth Gd-containing die-casting heat resisting magnesium alloy and preparation thereof

The invention relates to a die-casting heat resistant magnesium alloy containing Ca and heavy rare earth element Gd and a preparation method thereof, pertaining to the metal material technical field. The components and weight percentage thereof of the alloy are: 3.0 to 8.0 percent of Al, 0.1 to 3.0 percent of Ca, 0.1 to 3.0 percent of Gd, 0 to 0.5 percent of Mn, lower than 0.02 percent of impurity elements and the rest is Mg. The preparation method of the alloy comprises the following steps: the materials are weighed, and industrial pure Mg is heated under the protection of the mixed gas of N2 and 0.2 percent of SF6; after Mg is wholly melted, industrial pure Al, industrial pure Ca and Al-Mn interalloy are added at the temperature of 650 to 680 DEG C, Mg-Gd interalloy is added at the temperature of 660 to 680 DEG C, the temperature is increased to 740 to 760 DEG C, and when the Mg liquid is cooled to 670 to 690 DEG C, the mixture carries out die casting. The preparation method of the invention has the advantages of low cost and high production efficiency, obviously increases the tensile strength, the yield strength, the elongation percentage and the creep resistance of the alloy at room temperature, and has excellent die-casting performance.

Owner:SHANGHAI JIAO TONG UNIV

Nickel-based high-temperature alloy bar and preparation method thereof

The invention provides a nickel-based high-temperature alloy bar and a preparation method thereof. The nickel-based high-temperature alloy bar comprises the following steps of S1, vacuum smelting; S2,forging; S3, hot rolling; S4, solid solution treatment; and S5, machining. On a basis of optimizing alloying element components, a relationship between strength and toughness of an alloy is coordinated, so that high strength and high toughness of the nickel-based high-temperature alloy are achieved. By adopting advanced vacuum smelting process and electroslag remelting process, the obtained alloycomponents are uniform in tissue, and a high purity precision alloy ingot is obtained. The alloy bar which is relatively high in thermoplasticity is prepared by way of hot forging, hot rolling and solid solution treatment. Compared with a conventional 718 high-temperature alloy bar, the nickel-based high-temperature alloy bar is more excellent in mechanical property, and hardness and wear resistance of the bar are improved well.

Owner:JIANGSU XINHUA ALLOY ELECTRIC

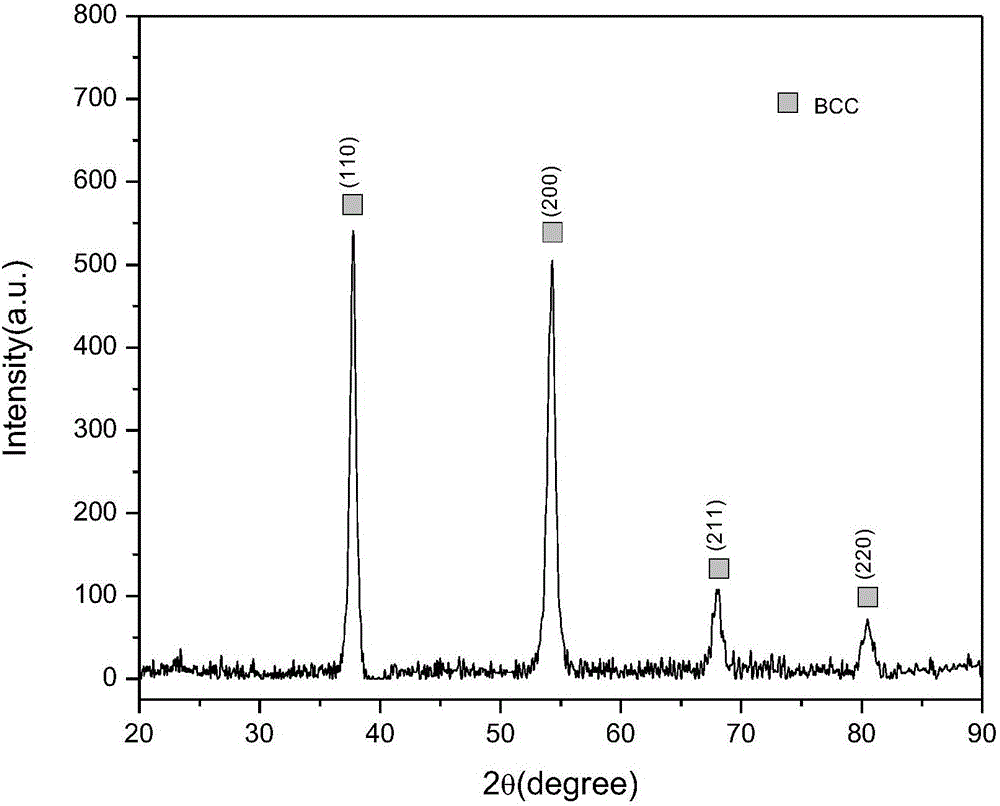

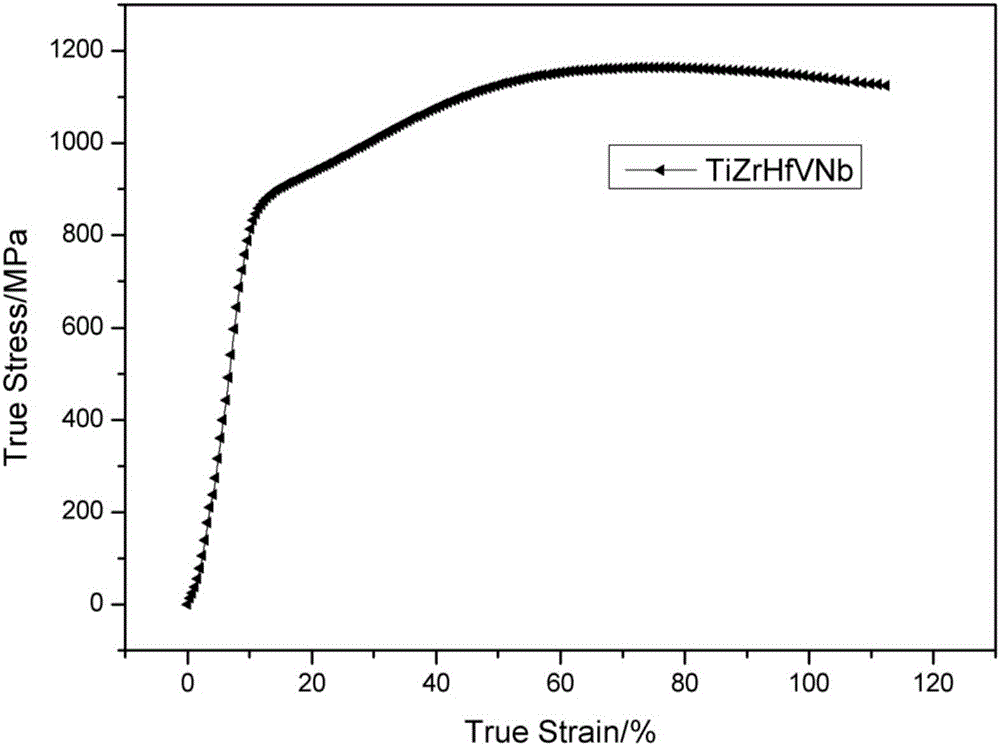

High-plasticity five-element refractory high-entropy alloy and preparation method thereof

The invention relates to high-plasticity five-element refractory high-entropy alloy and a preparation method thereof and belongs to the field of metal materials. The high-entropy alloy is prepared from zirconium, titanium, hafnium, vanadium and niobium, wherein the molar weights of the zirconium, the titanium, the hafnium, the vanadium and the niobium are equal. The preparation method of the high-plasticity five-element refractory high-entropy alloy comprises the steps that the zirconium, the titanium, the hafnium, the vanadium and the niobium are placed in a water-cooling metal crucible in a melting point progressively-decreasing sequence, the element with the lowest melting point is placed at the bottom, and the element with the highest melting point is placed at the top; and arc striking smelting is conducted in an oxygen-free environment till the five elements are fully mixed, and the high-entropy alloy is obtained. The high-entropy alloy is of a single body-centered cubic structure, the yield strength of the high-entropy alloy is higher than 800 MPa, the tensile strength is over 1100 MPa, and the plastic strain is larger than 55%; and the large solid solubility between the elements is obtained, and a simple solid-solution phase is formed. The preparation method has the advantages that the power is high, the performance is table, operation is convenient, the melting point is high, the vacuum degree is high, and the quantity of impurities is small.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

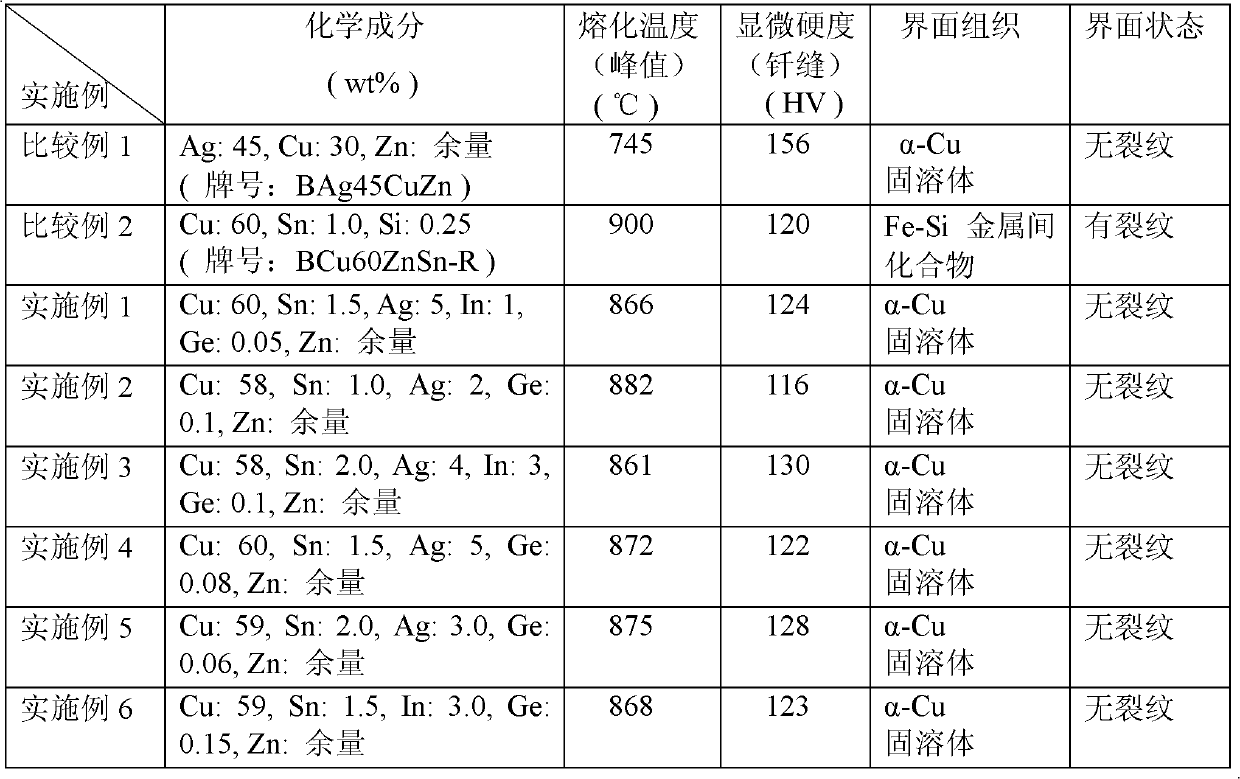

Brass brazing alloy

InactiveCN102601542AImprove reliabilityLow Ag contentWelding/cutting media/materialsSoldering mediaBraze alloyMelt temperature

The invention discloses brass brazing alloy, which comprises Cu, Zn, Sn, Ge, Ag and / or In. The brass brazing alloy consists of components including, by mass percentage, from 58 to 60% of Cu, from 0.5 to 3.0% of Sn, from 1.0 to 6.0% of Ag and / or from 1.0 to 5.0% of In, from 0.05 to 0.3% of Ge and the balance Zn. Compared with an existing brass brazing material, the brass brazing alloy has the advantages that melting temperature is low, the brass brazing alloy can replace a silver brazing material to be used for brazing steel / copper joints, and cost is low due to the fact that Ag content of the brass brazing alloy is low.

Owner:SOUTH CHINA UNIV OF TECH

High-strength high-toughness high-nitrogen austenitic stainless steel welding wire and preparation method thereof

ActiveCN108526750AIncrease contentImprove solid solubilityArc welding apparatusWelding/cutting media/materialsManganeseAustenite

The invention relates to a high-strength high-toughness high-nitrogen austenitic stainless steel welding wire and a preparation method thereof. The welding wire is prepared from the alloy components in percentage by weight: less than 0.1 percent of C, less than 0.02 percent of S, less than 0.03 percent of P, 0.1 to 0.9 percent of Si, 5 to 21 percent of Mn, 15 to 23 percent of Cr, 0 to 8 percent ofNi, 0 to 5 percent of Mo, 0.2 to 0.95 percent of N, the balance Fe, and less than 0.1 percent of other impurities. The preparation process comprises the steps of smelting through an induction furnace, electro slags remelting, hot forging, hot rolling, heat treating, and drawing of the welding wire. According to the welding wire provided by the invention, the component proportion is scientific andreasonable, the content of nitrogen elements is increased, the content of manganese elements is adjusted, and the solid solubility of the nitrogen is increased, so that the prepared welding wire is stable in welding process, less in escape amount of hydrogen elements, less in blowhole defects, good in welding processability, high in deposited metal strength, excellent in impact toughness at the temperature of minus 40 DEG C, suitable for welding high-nitrogen austenitic stainless steel, particularly suitable for welding the austenitic stainless steel with the requirement on low-temperature impact toughness, and capable of being surfacing-welded so as to be used as anti-corrosion layers for other steel and iron materials.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

Method for preparing copper-base tungsten coating through compounded process of laser and thermal spraying

ActiveCN101717910AImprove heat resistanceImprove thermal shock resistanceMolten spray coatingThermal sprayingCoating system

The invention relates to a method for preparing a copper-base tungsten coating through a compounded process of laser and thermal spraying. The method is characterized by comprising the following steps of: preparing a nickel base alloy transition bottom layer on the surface of a copper matrix by using a low pressure plasma coating system, and remelting the transition bottom layer with laser beams; and then preparing an intermediate transmission layer and the tungsten coating of a Ni-W alloy by using the low pressure plasma coating system, and then remelting with the laser beams to obtain the tungsten coating. By using a gradient coating structure, the method effectively solves the problem of thermal stress caused by mismatching of the coefficient of thermal expansion of the copper and the tungsten, and improves the cohesion strength of the tungsten coating and the matrix, the tungsten coating and the tungsten coating. The coating and the matrix can achieve metallurgical bonding by using the laser beam remelting, bonding property is also improved and the tungsten coating with compact surface is obtained. The tungsten coating prepared by the method has excellent anti-heat radiation and anti-thermal shock properties and is suitable to be used as heated end component materials in equipment, such as first wall material in a ray target, a rocket nozzle, an airplane nozzle throat and a nuclear fusion device.

Owner:GUANGDONG INST OF NEW MATERIALS

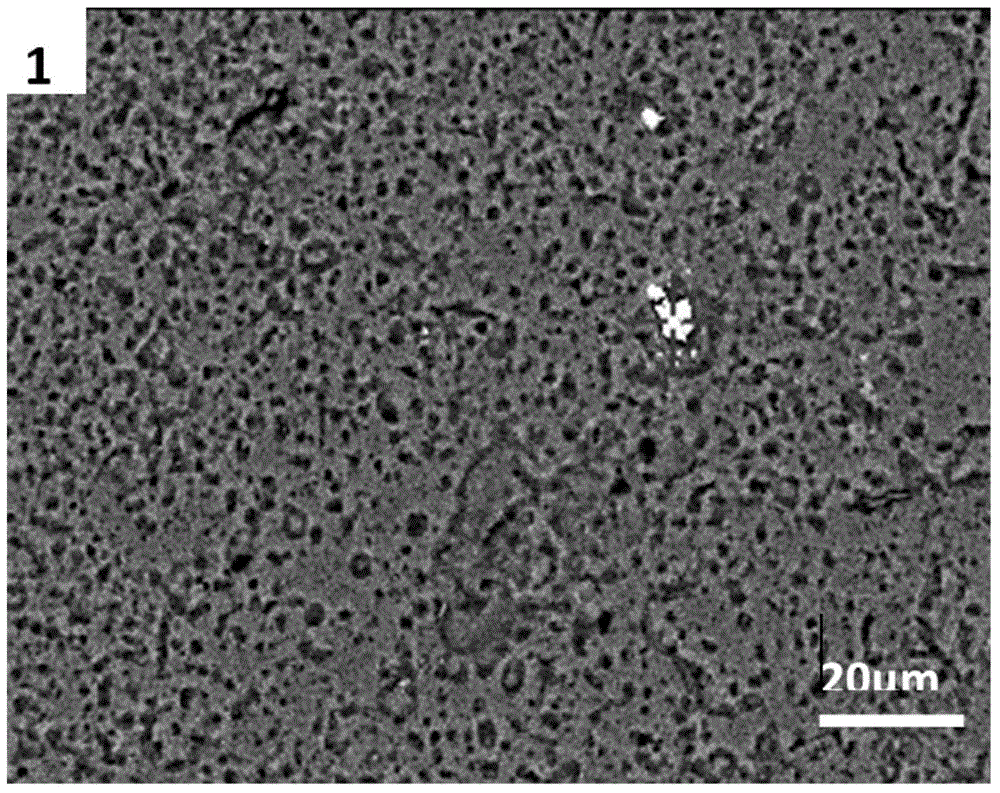

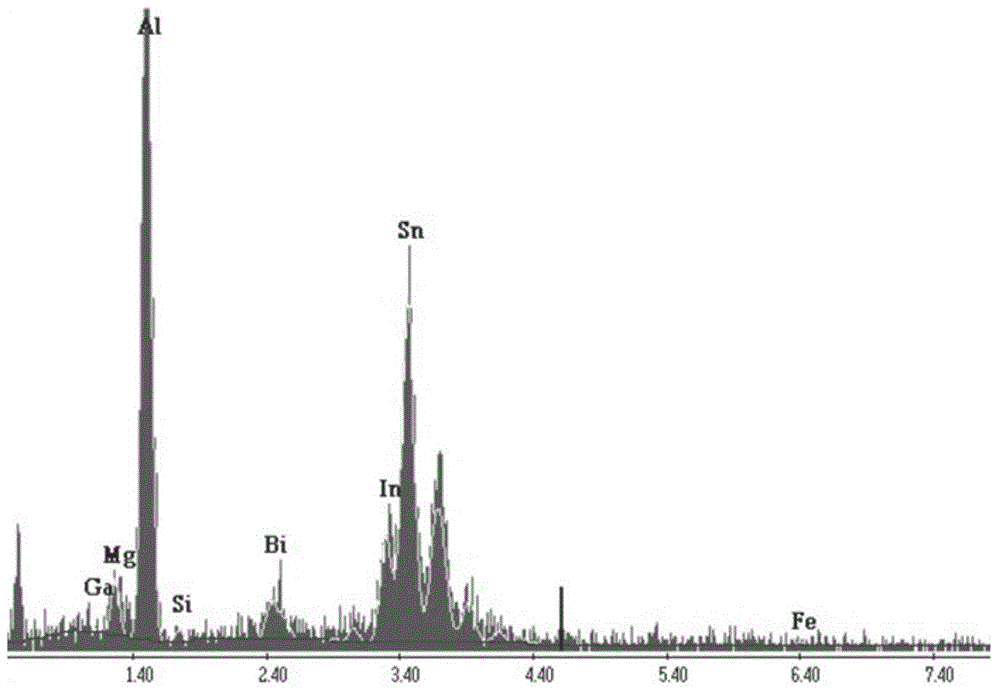

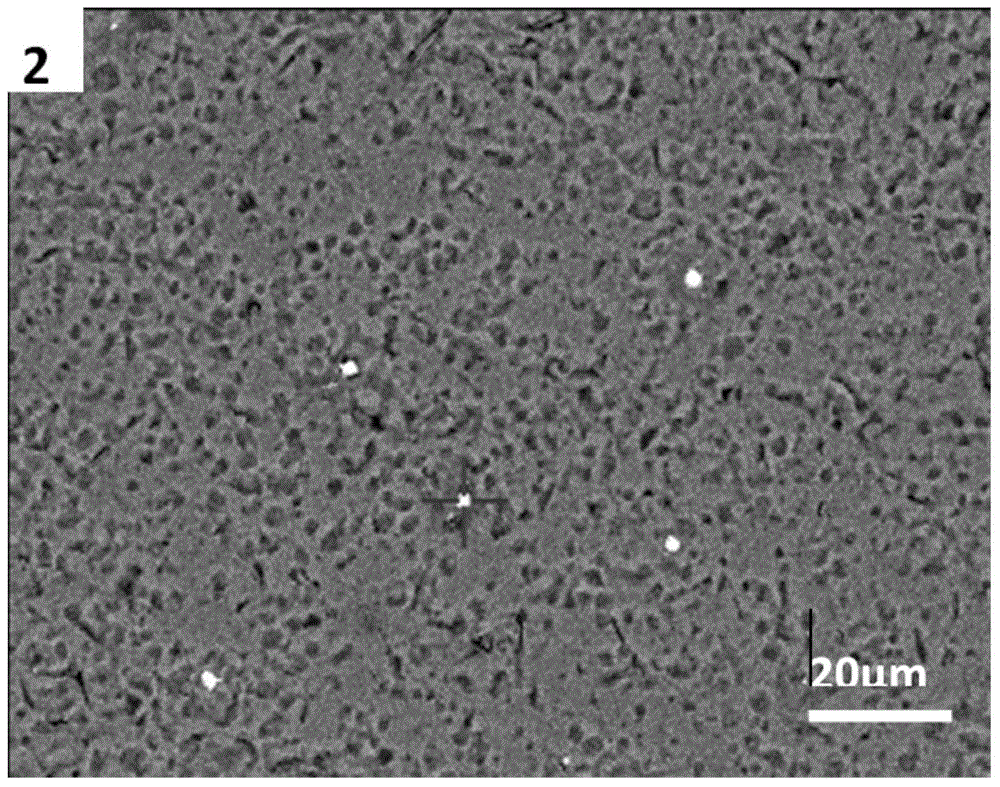

Rare-earth-modified aluminium alloy anode plate and preparation method thereof

ActiveCN104561673AReduce hydrogen evolution corrosion rateImprove solid solubilityHigh current densityCerium

The invention discloses a rare-earth-modified aluminium alloy anode plate and a preparation method thereof. The anode plate is prepared from raw materials such as an aluminium block, a magnesium block, a bismuth granule, a tin granule, a gallium granule, an indium granule, a lanthanum granule and a cerium granule in the mass ratio of (96.6-99.31):(0.5-2):(0.1-1):(0.05-0.2):(0.01-0.1):(0.01-0.05):(0.01-0.03):(0.01-0.02). Proper amounts of various alloy elements are weighed according to the formula during alloy casting and molten in a resistance furnace crucible at the temperature of 750-800 DEG C, and then alloy melt is poured into a water-cooling steel mold for use. The solid solution temperature in alloy solid solution heat treatment is in a range of 500-560 DEG C, and the solid solution time is in a range of 5-8 h. The single-pass rolling temperature in an alloy rolling machining technology is in a range of 400-450 DEG C, and the single-pass deformation is in a range of 35-45%. The rare-earth-modified aluminium alloy anode plate is low in self-corrosion speed and high in electrochemical activity during high-current-density discharging and meets performance requirements of high current efficiency, stable discharging and small hydrogen evolution amount during movement of an alkaline aluminum battery.

Owner:西安聚束智能技术有限公司

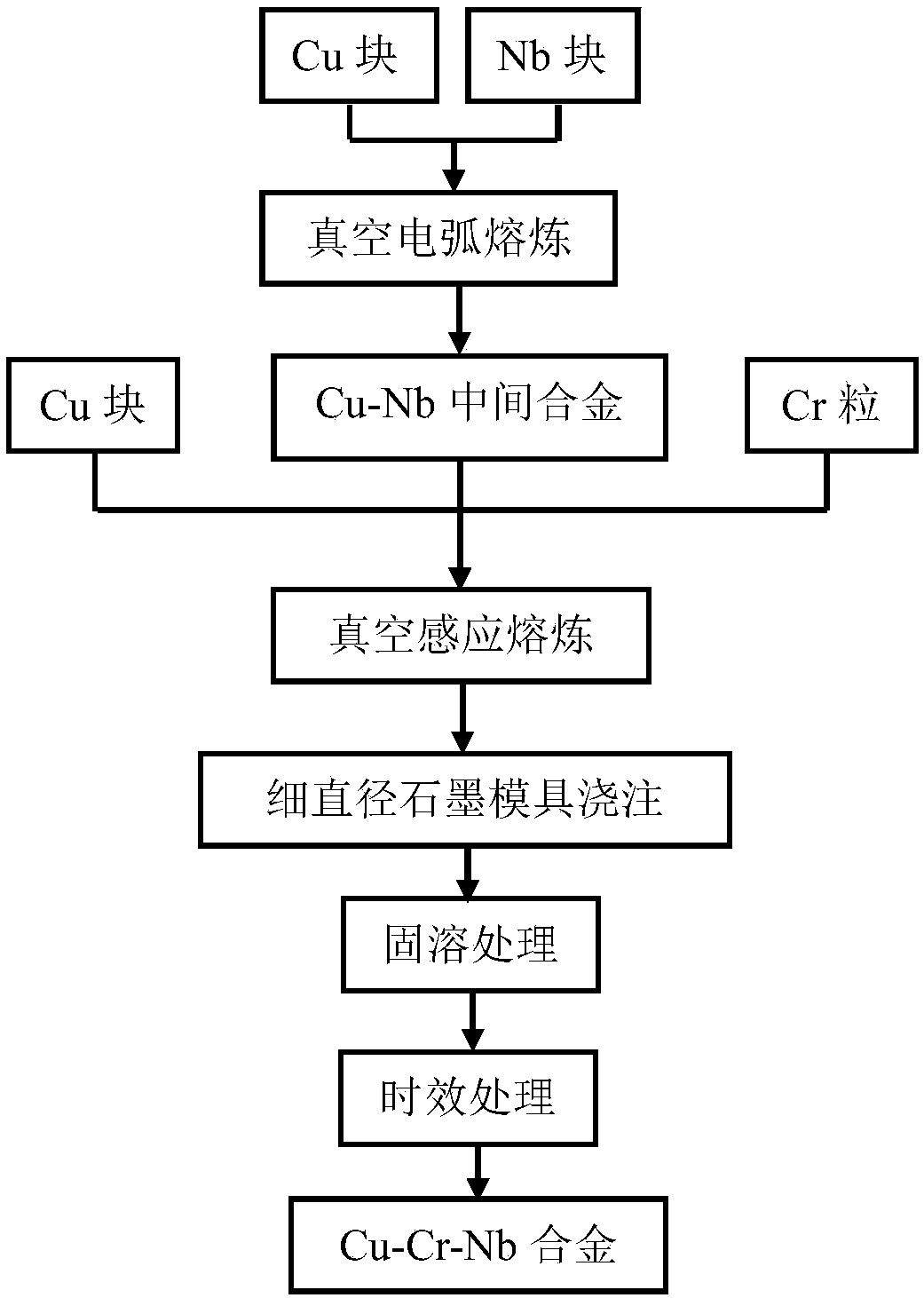

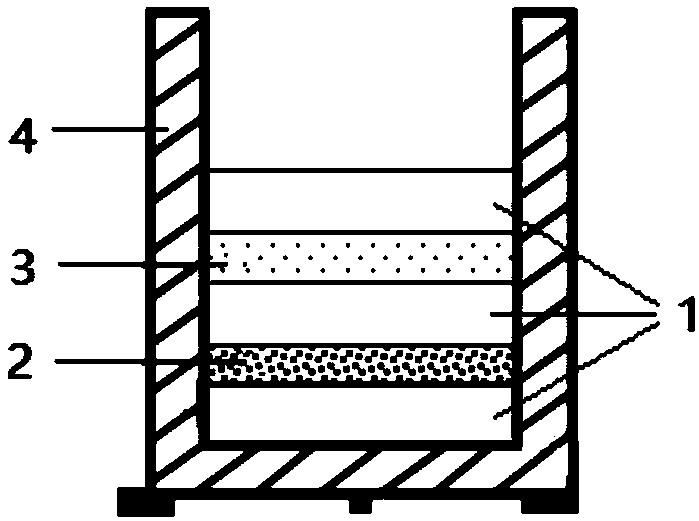

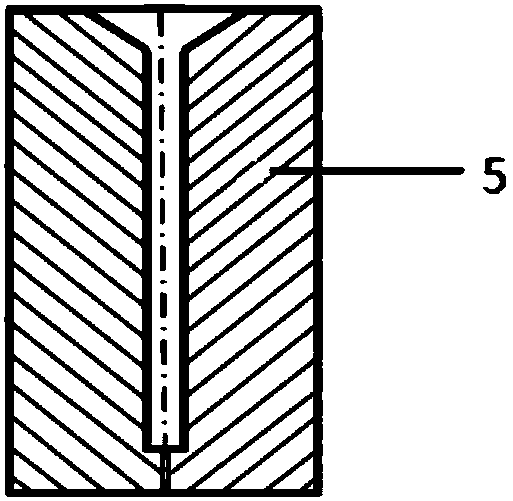

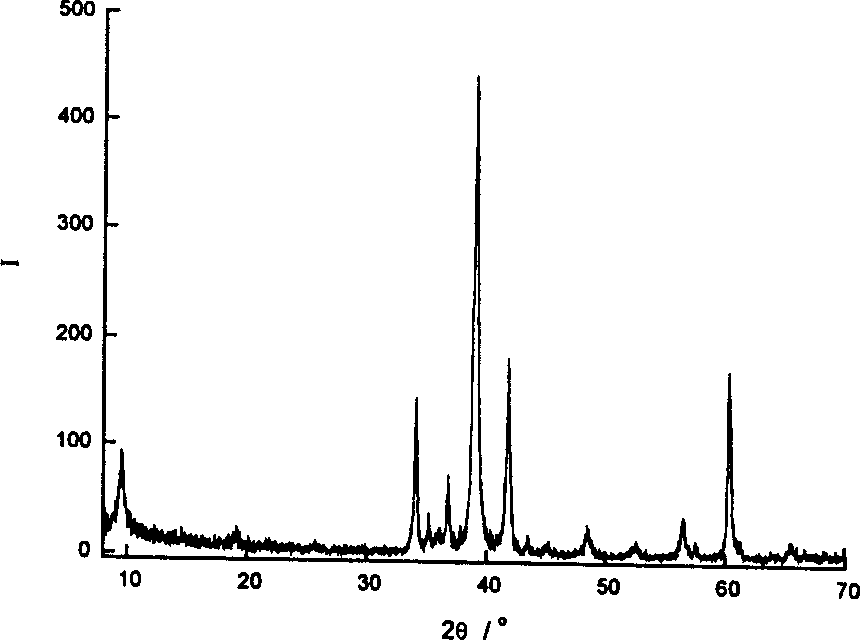

Preparation method for high-strength high-conductivity copper alloy bar

The invention discloses a preparation method for a high-strength high-conductivity copper alloy bar. The preparation method comprises the following concrete steps: placing Cu-Nb intermediate alloy, Crparticles and Cu blocks in a crucible, and carrying out melting in an induction melting furnace protected by argon so as to obtain Cu-Cr-Nb alloy liquid; subjecting the Cu-Cr-Nb alloy liquid to casting and cooling in a fine-diameter graphite mold so as to obtain a Cu-Cr-Nb alloy bar; and putting the bar into a heat treatment furnace for solutionizing and aging heat treatment, and carrying out mechanical processing so as to obtain the finished Cu-Cr-Nb alloy bar. According to the invention, the Cu-Cr-Nb alloy is prepared by using a fine-diameter graphite mold casting and cooling method, so thecooling rate of the alloy is improved, the structure of the alloy is refined, and the solid solubility of elemental Cr and Nb in a Cu substrate is greatly improved; and through the aging treatment, dispersed fine second-phase particles are precipitated from the copper substrate, so the performance of the alloy is improved.

Owner:XIAN UNIV OF TECH

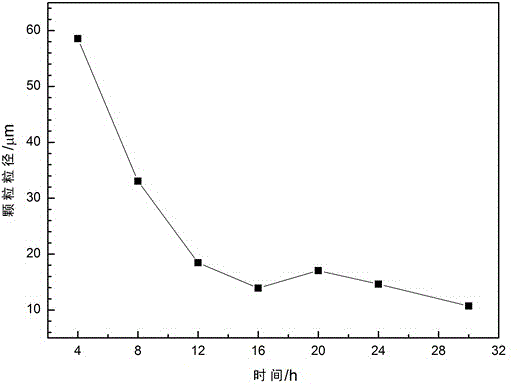

Method for preparing Ti3 AlC2 powder

A process for preparing Ti3AlC2 powder used to prepare high-performance Ti3AlC2 ceramic includes such steps as loading Ti, Al and C in the ball grinder with stainless steel balls, filling argon gas, grinding for 40-80 hr for mechanical alloying, loading the powder in crucible, annealing in argon gas, and cooling.

Owner:SHANGHAI UNIV

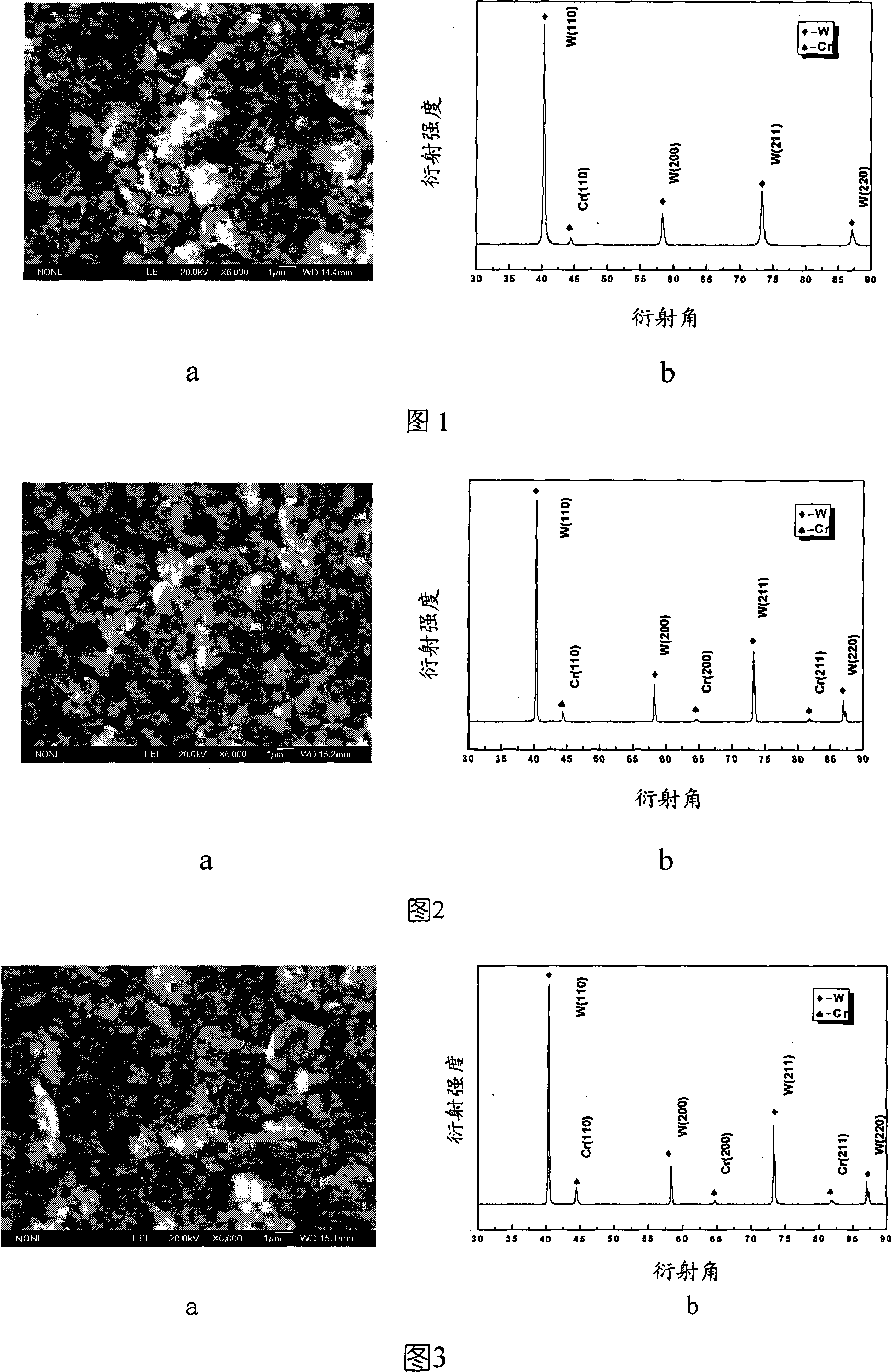

Mechanical alloyed method for manufacturing CrW alloy powder

The present invention discloses a mechanical alloying method for producing CrW alloy powders. The method includes the following steps: first, chromium powders with tungsten powders are blent at a certain proportion, and then 2 to 5 percent of process control agents and grinding balls 50 to 100 times heavier than the blended powders are added into the powders ; and finally the mixtures are put into an atmosphere-protection pot or a vacuum ball-grinding jar in a ball grinder and are grinded for 50 to 100 hours until the mixtures become solid solutions; after grinding, the ball stuff is put in static condition for a while until the ball stuff cool down fully, and then the powders are taken out. Thus, the CrW alloy powders formed by the method have tiny particles and even components, high degrees of solidification and dissolution, easy dissipation, and simple processing and easy operation.

Owner:XIAN UNIV OF TECH

High-toughness rare earth heat-resistant magnesium alloy and preparation method thereof

The invention discloses a high-toughness rare earth heat-resistant magnesium alloy. The high-toughness rare earth heat-resistant magnesium alloy comprises the following chemical components of, in percentage by mass, 8.0%-10.8% of Gd, 3.1%-4.0% of Y, 1.8%-2.2% of Zn, 0.4%-0.5% of Zr and the balance magnesium and inevitable impurity elements, the invention further discloses a preparation method of the high-toughness rare earth heat-resistant magnesium alloy, the preparation method sequentially comprises the following steps of (1) preparing a magnesium alloy casting rod; (2) homogenization of the bar, specifically, heating a magnesium alloy bar and preserving heat by adopting a grading homogenization system, then heating and reheating, preserving heat and carrying out homogenization treatment; (3) upsetting-extruding composite deformation, specifically, putting the bar into a heated upsetting-extruding composite die, and obtaining a high-toughness deformation state rare earth heat-resistant magnesium alloy material after multiple times of cyclic upsetting-extruding. (4) solid solution and aging treatment, specifically, enabling heat treatment to adopt solid solution and aging treatment and heat preservation, adopting hot water quenching after discharging, and after cooling to room temperature, conducting aging and preserving heat. The magnesium alloy prepared by the solution is good in quality, and has more obvious high tensile strength and high elongation compared with common magnesium alloys in the market.

Owner:ZHONGBEI UNIV

Formation of ultra-shallow junctions by gas-cluster ion irradiation

ActiveUS7396745B2Increasing solid solubility limitOptimize allocationElectric discharge tubesSemiconductor/solid-state device manufacturingGas cluster ion beamIrradiation

Method of forming one or more doped regions in a semiconductor substrate and semiconductor junctions formed thereby, using gas cluster ion beams.

Owner:TEL EPION

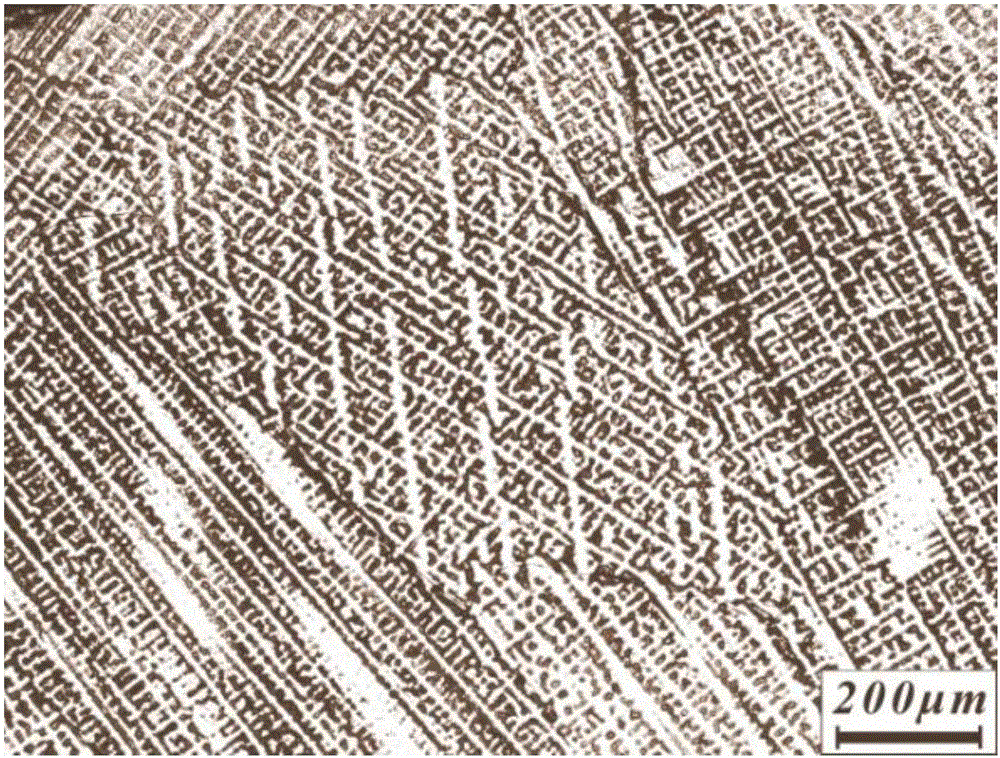

Grain-oriented pure iron manufactured through adopting single cold rolling method and method

The invention relates to grain-oriented pure iron manufactured through adopting a single cold rolling method and a method. The method comprises the steps of converter smelting, liquid steel refining through a vacuum cycle degassing process, continuous casting, slab heating, hot rolling, normalizing, cold rolling and annealing, wherein after the continuous casting step, an obtained continuous cast slab comprises the following components by mass percent: 0.01 to 0.08% of C, 0.01 to 1.0% of Si, 0.05 to 0.5% of Mn, 0.01 to 0.1% of P, 0.003 to 0.01% of S, 0.005 to 0.05% of Als, 0.005 to 0.02% of N and 0.05 to 0.8% of Cu, and the balance being Fe; in the hot rolling process, the content of gamma phases obtained during finish rolling is controlled to be 10 to 30% by mass percent; in the normalizing step, the temperature of 650 to 800 DEG C is maintained for 30 to 600 s; and the annealing step comprises decarburizing annealing and high temperature annealing. According to the method, the grain-oriented pure iron which has high saturation magnetic induction intension and sharp {110}<001> preferred orientation can be obtained through utilizing conventional production devices of conventional iron and steel enterprises, through utilizing means such as component design, reasonable cooperation of inhibitor composition and appropriate setting of rolling and thermal treatment technologies, and through utilizing a traditional thick slab production technology.

Owner:CENT IRON & STEEL RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com