Patents

Literature

1186results about How to "Increase cooling rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

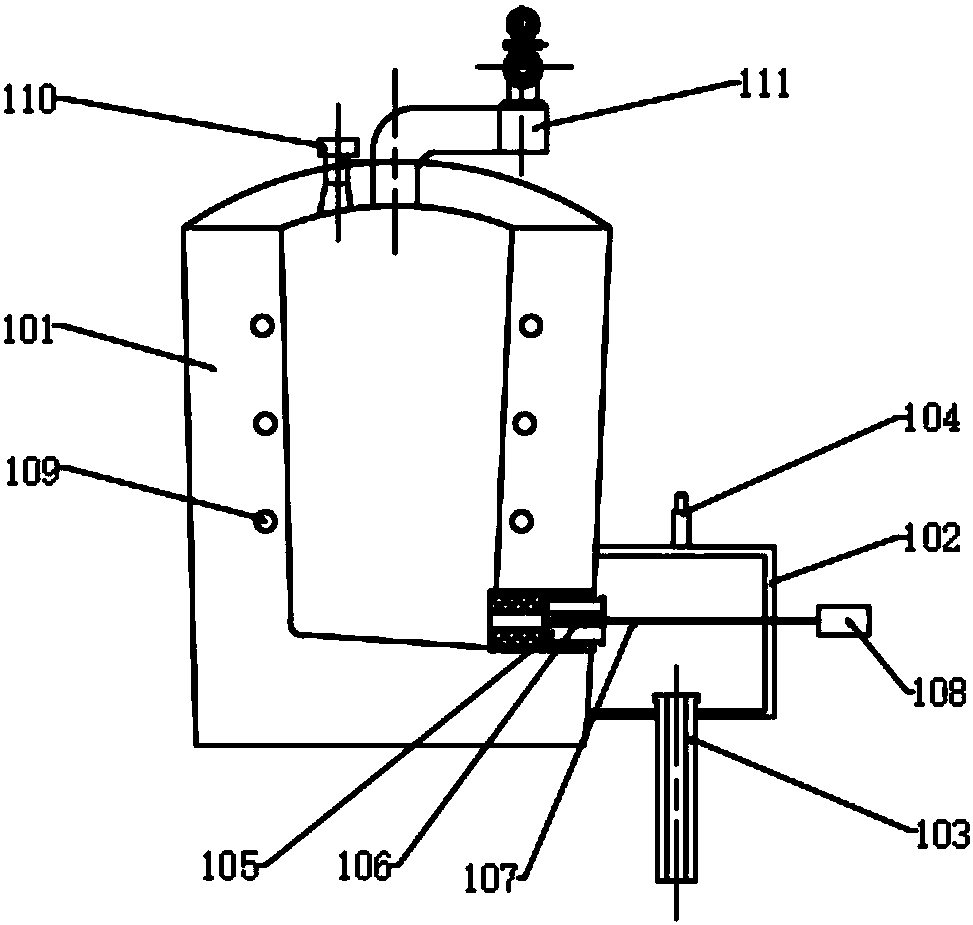

Melting furnace slag quenching dry type granulation and sensible heat recovery generating system and method using same

ActiveCN102433401AReduce cooling air volumeReduce power consumptionIncreasing energy efficiencyRecycling and recovery technologiesSlagHigh pressure water

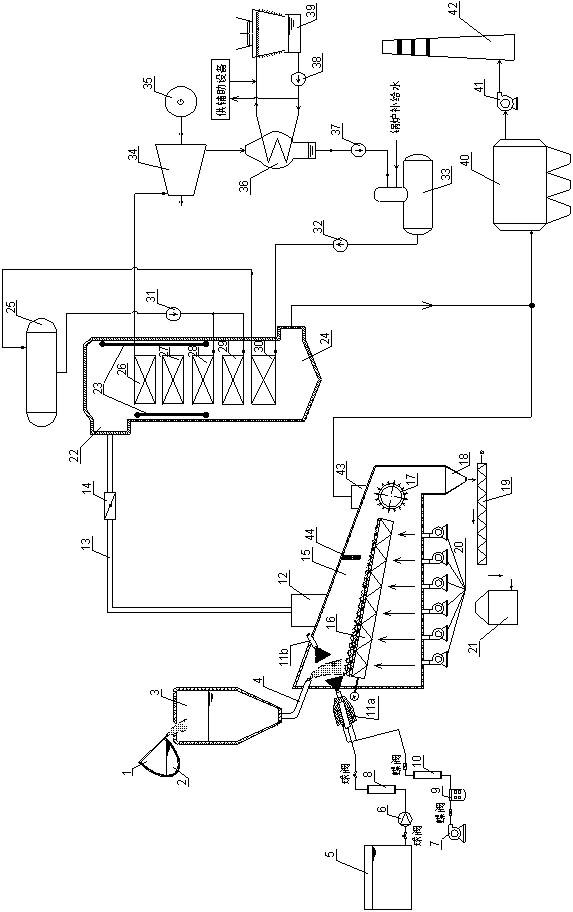

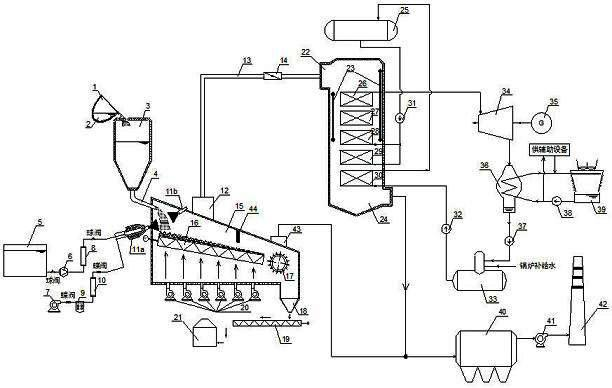

The invention provides a melting furnace slag quenching dry type granulation and sensible heat recovery generating system and a method using the same and belongs to the technical field of steel metallurgy furnace slag treatment and complementary energy recovery. The melting furnace slag quenching dry type granulation and sensible heat recovery generating system provided by the invention comprisesa slag-receiving device, a high-pressure water-air pulverization furnace slag quenching and granulating device, a furnace slag slow-cooling device, a sensible heat recovery generating device and a waste gas purification treatment device. According to the invention, the melting furnace slag is quenched and granulated by utilizing the high-pressure water-air pulverization device, so that the melting furnace slag is rapidly cooled to be in a glassy state; and then through a water-cooled type vibration grid plate, the melting furnace slag in the glassy state is further subjected to heat exchange with cold air so as to facilitate the subsequent recovery of the sensible heat. By the system provided by the invention, the melting furnace slag is quenched and granulated, and the high-temperature sensible heat resource of the furnace slag is sufficiently recovered and is used for generation on the basis that the water activity quality of the furnace slag is not influenced.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

Continuous casting technique for aluminum alloy thin belt blank

InactiveCN101269406AImprove organizationComprehensive mechanical properties of high thin stripIngotMaterials science

The invention discloses a continuous casting process of an aluminum thin billet, which is characterized in that the following steps are included: aluminum alloy ingots are preheated and are melted in a melting furnace in the role of a flux; before casting, a side closure system is preheated to 400-450 DEG C, when the temperature of a melting body ranges from 650 DEG C to 680 DEG C, the aluminum alloy ingots are arranged into a tundish for 15 to 30 minutes in the role of the flux, then through a flux distributing device, the aluminum alloy ingots flow into an equant vertical twin-roll thin strip billet continuous caster, with a left forging seam gap being 0 mm and maintaining the height of a melting pool between 90 mm and 340 mm, the casting is carried out in a sinking way; when in casting, the casting speed of the casting machine ranges from 20 to 120m / min, the thin strip blank is sent into a pinch roll after leaving a casting roller, and the forged aluminum alloy thin strip has a thickness between 1.0 mm and 3.5 mm. The continuous casting process can directly make aluminum alloy thin strip blank from the liquid aluminum alloy, the forged thin strip blank has good quality on the surface, and the internal organizational structure is uniform, thereby being conducive to succeeding rolling processes. The continuous casting process for an aluminum thin blank has short process and low cost.

Owner:CHONGQING UNIV

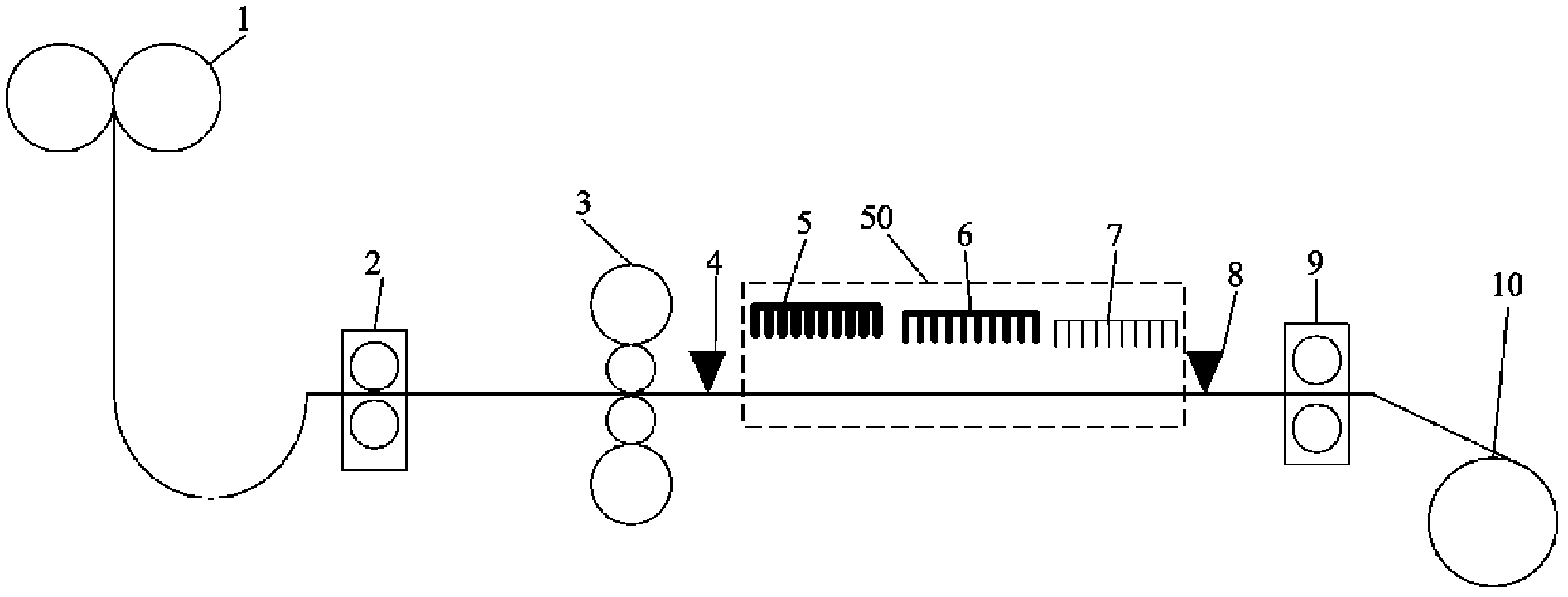

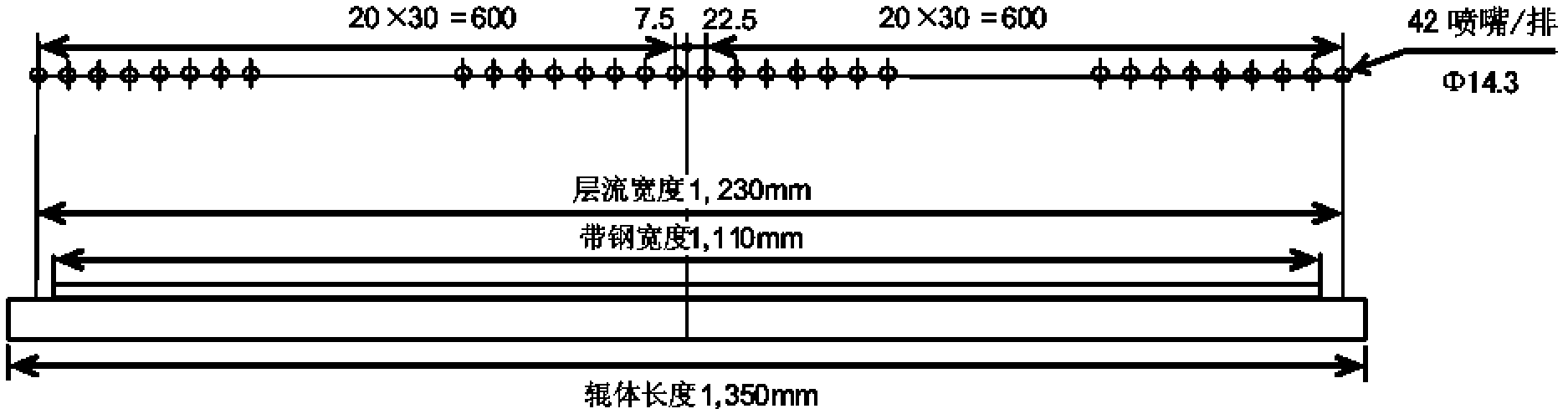

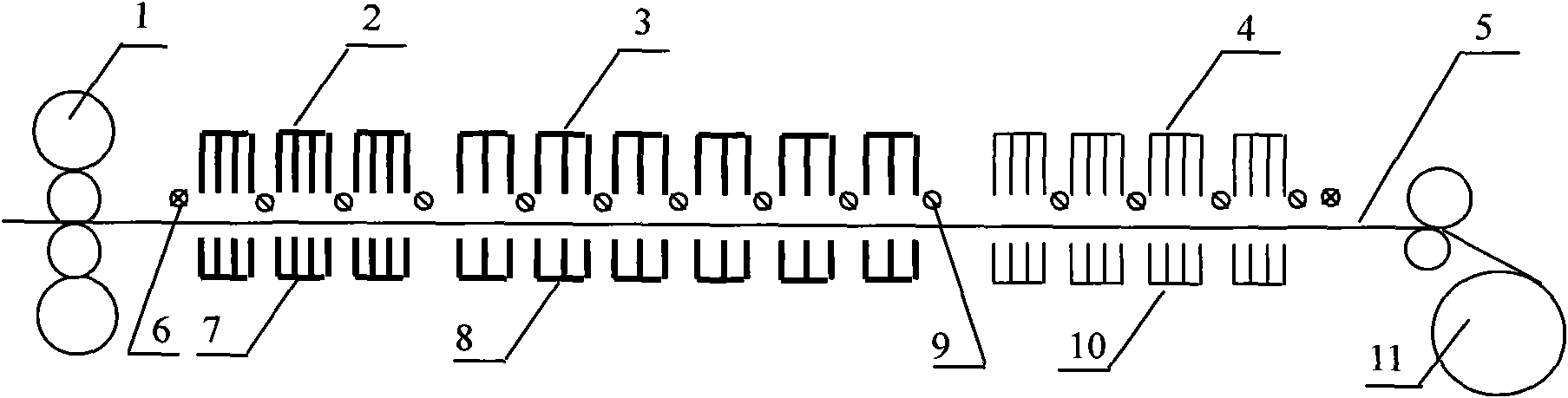

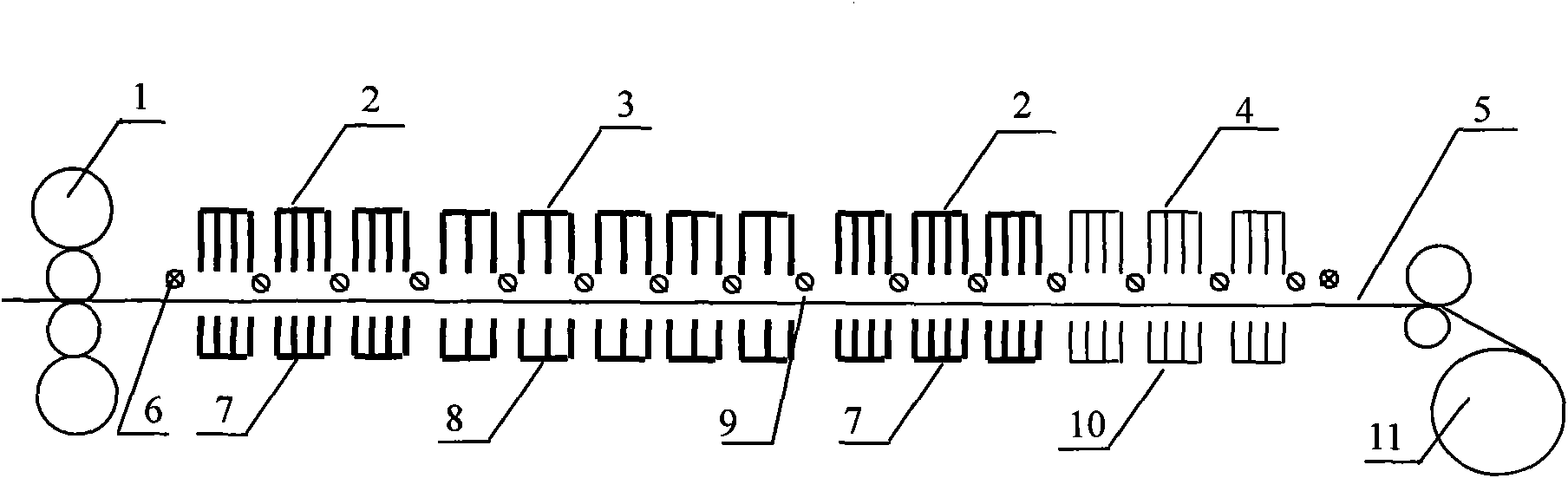

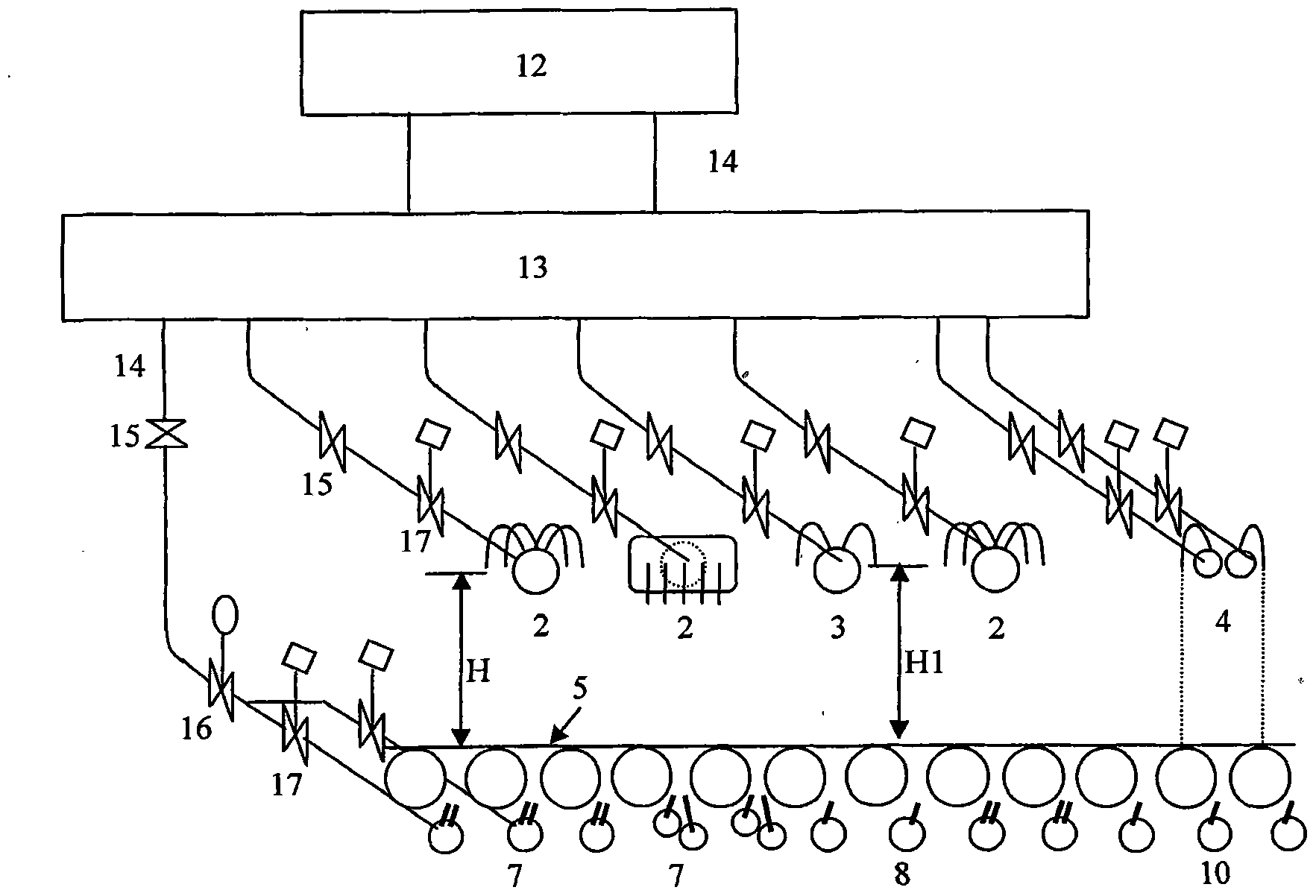

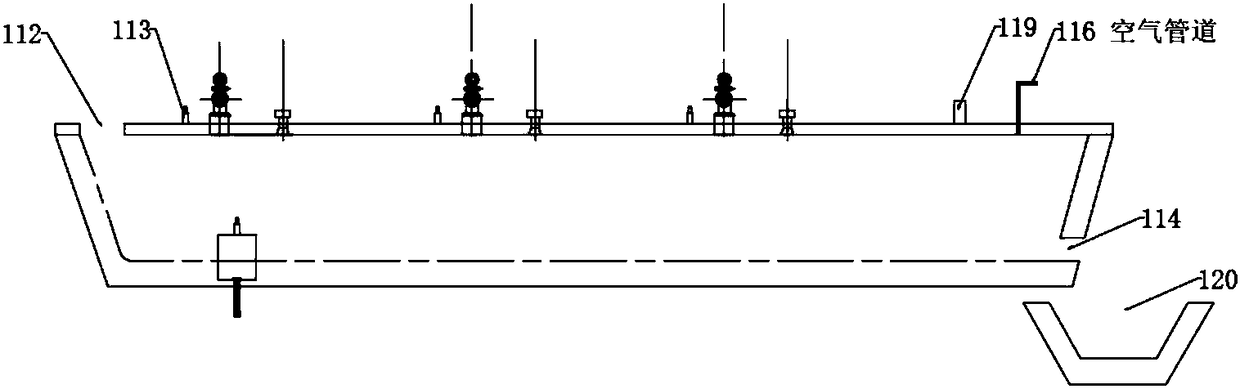

Cooling system for rolled stripe continuously-casting production line and control method thereof

ActiveCN102553950AMeet the temperature dropFulfil requirementsTemperature control deviceWork treatment devicesAdaptive learningLow speed

The invention relates to control devices or methods specially for metal rolling machines and manufacturing products of the metal rolling machines and discloses a cooling system for a rolled stripe continuously-casting production line and a control method of the cooling system. The system comprises a segmented laminar flow cooling device and a cooling control system which are arranged behind an online hot rolling machine, wherein the segmented laminar flow cooling device comprises at least two segmented laminar flow cooling collecting pipe areas, wherein one of the at least two segmented laminar flow cooling pipe collecting areas adopts a nozzle cooling collecting pipe with small pipe diameter, the cooling control system is an online double-closed-loop control system and comprises a double-closed-loop control circuit, the double-closed-loop control circuit comprises a feedforward control module, a precomputation module, a feedback control module, a coiling-ahead temperature measuring module and a self-adaption learning module, the double-closed-loop control circuit selects at least one collecting pipe area of the segmented laminar flow cooling device, the number of open collecting pipes in the selected collecting pipe area can be adjusted by a group of control valves, and the requirements on the accuracy of coiling temperature of steel stripes rolled at a low speed during the variation of speed and thickness in a limited cooling area can be met by the nozzle cooling collecting pipe with the small pipe diameter and the online double-closed-loop control system.

Owner:BAOSHAN IRON & STEEL CO LTD

High-entropy alloy powder for 3D (three-dimensional) printing and method for preparing high-entropy alloy coating by using high-entropy alloy powder

ActiveCN104841930AImprove performanceScientifically optimize the ratioIncreasing energy efficiencySelective laser sinteringHigh entropy alloys

The invention provides high-entropy alloy powder for 3D (three-dimensional) printing and a method for preparing a high-entropy alloy coating by using the high-entropy alloy powder, and belongs to the technical field of coating preparation. By the high-entropy alloy powder, the wear resistance of the existing powder materials for 3D printing is improved. The high-entropy alloy powder is prepared by using the following ingredients in atomic percentage by weight: 16%-25% of Ni, 16%-25% of Co, 16%-25% of Cr, 16%-25% of Ti and 16%-25% of V. The preparation method comprises the following steps of (1) performing ball-mill mixing on raw materials to obtain mixed powder; (2) grinding and cleaning a matrix; and (3) placing the mixed powder in a powder feeder of 3D printing equipment and sintering the mixed powder on the surface of the matrix to form the high-entropy alloy coating by using selective laser. The NiCoCrTiV coating is prepared by selective laser sintering and has the advantages of high hardness, wear resistance, corrosion resistance and the like. The high-entropy alloy powder for 3D printing and the method for preparing the high-entropy alloy coating by using the high-entropy alloy powder can be widely used in the field of 3D printing.

Owner:HARBIN ENG UNIV

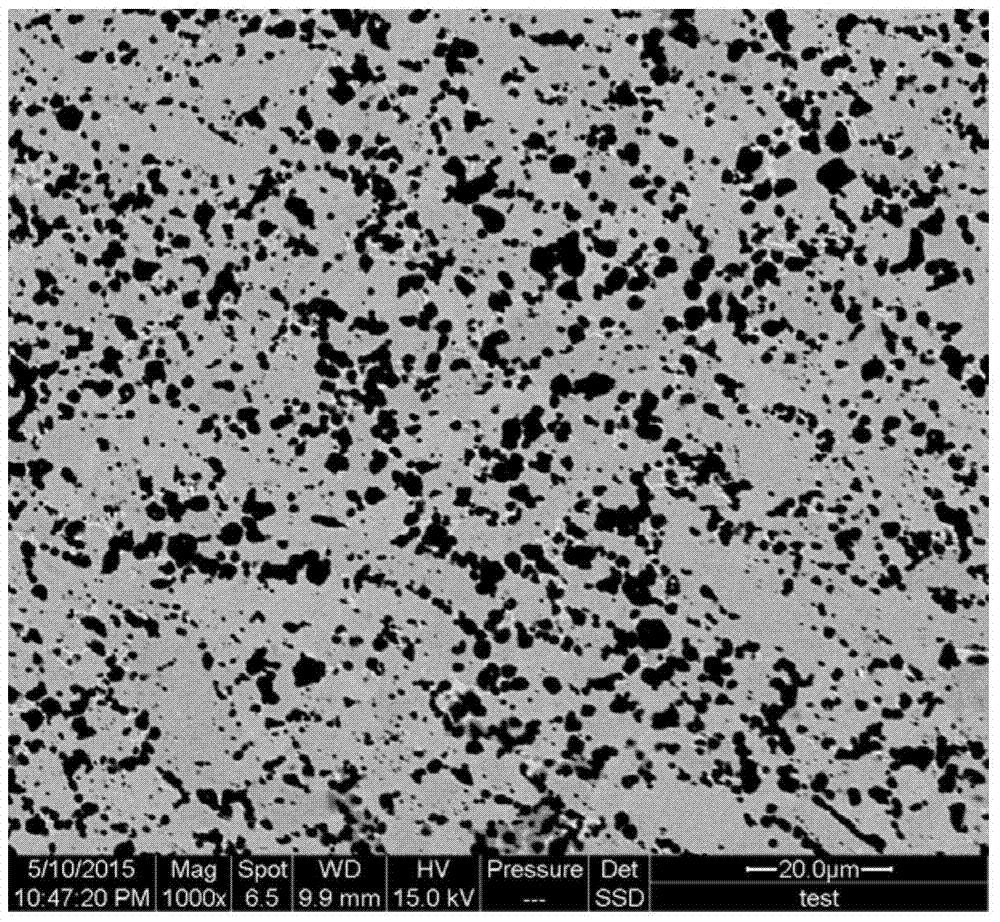

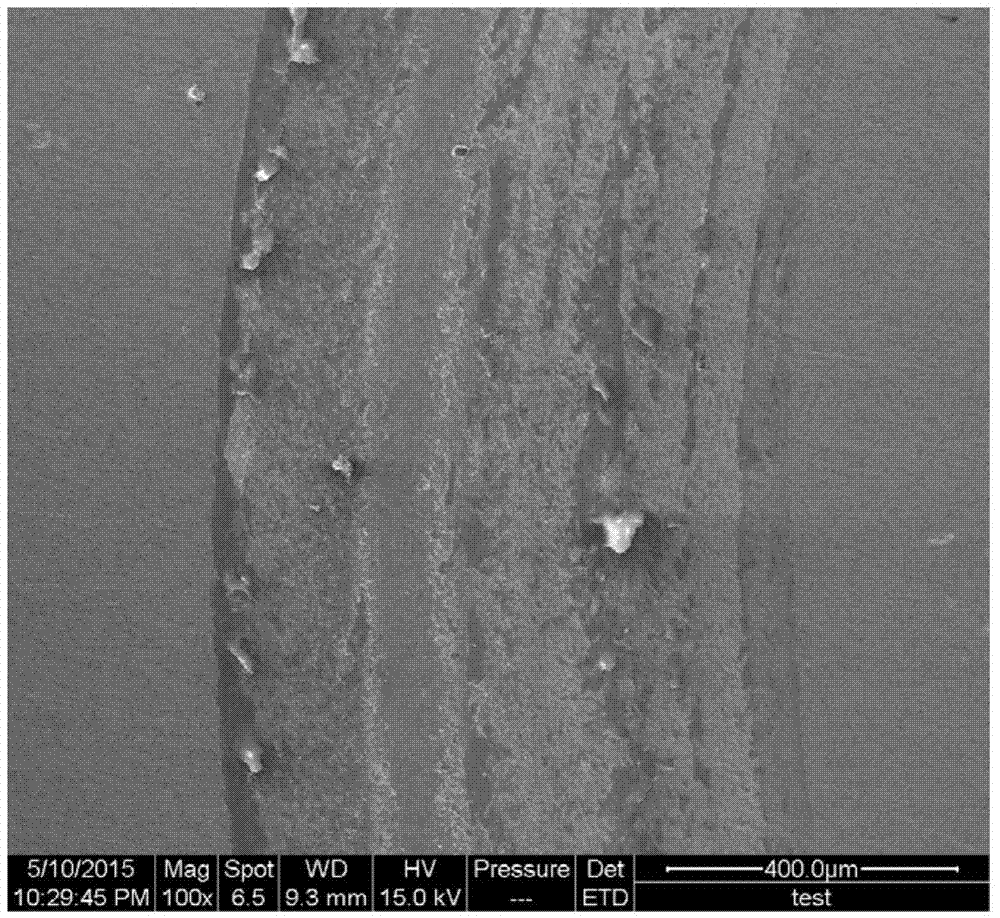

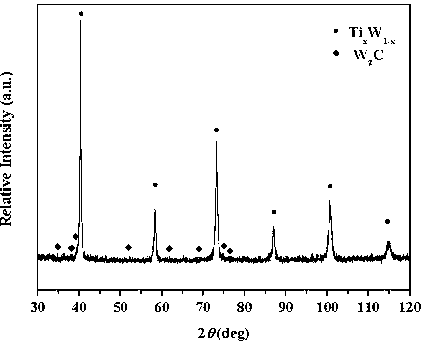

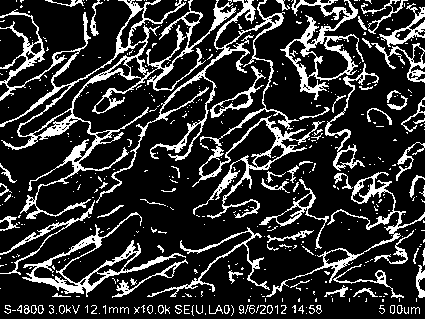

Method for preparing solid solution toughened wolfram-base composite material through laser rapid forming

InactiveCN103074532AImprove microstructureImprove performanceIncreasing energy efficiencySelective laser meltingHigh energy

The invention belongs to the technical field of laser rapid forming, and particularly relates to preparation of a solid solution toughened wolfram-base composite material. A preparation method of the solid solution toughened wolfram-base composite material is as follows: original mixed powder comprises W (wolfram) powder and TiC powder, wherein the TiC powder is 1-1.5wt percent of the total content; and the mixed powder is ball-milled in a high-energy mechanical ball mill for 30-45 h, and then the TiC / W composite material is formed by using a selective laser melting process. The parameters of the adopted laser process are as follows: the powder-bed depth is 50-60 Mum, the laser spot diameter is 200-210 Mum, the laser power is 120-140 W, the laser scanning rate is 100-300 mm / s, and the laser scanning interval is 120-140 Mum. According to the invention, the solid solution toughened wolfram-base composite material is successfully prepared through the method that combines high-energy mechanical ball milling and the selective laser melting process, and the fragility of W material is effectively improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

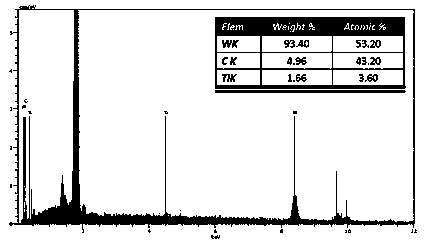

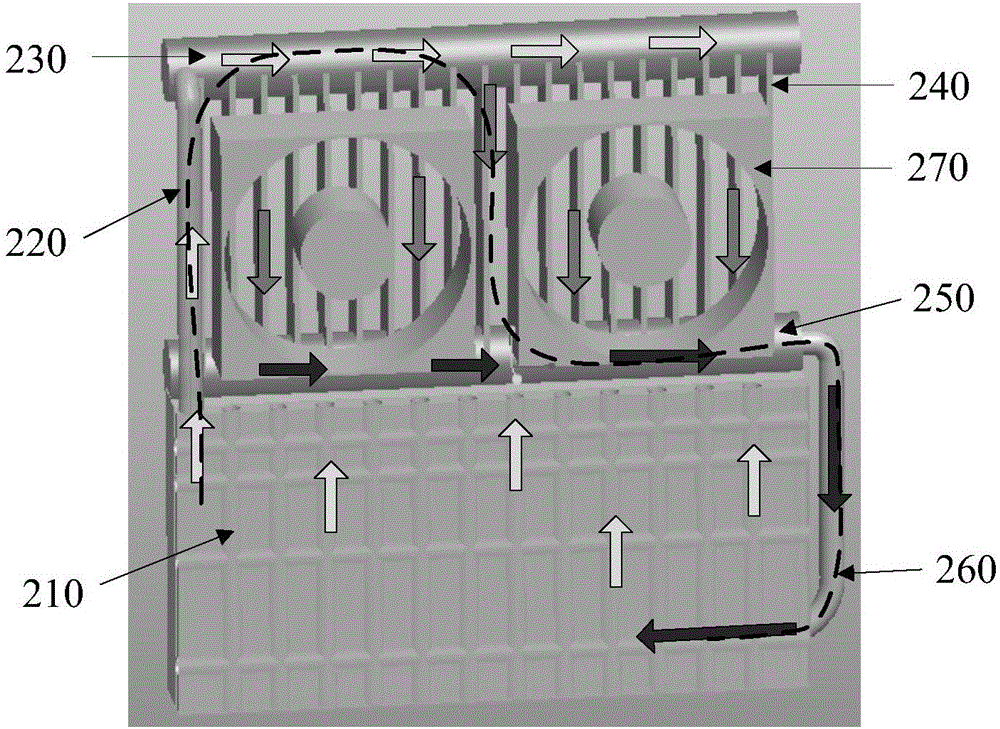

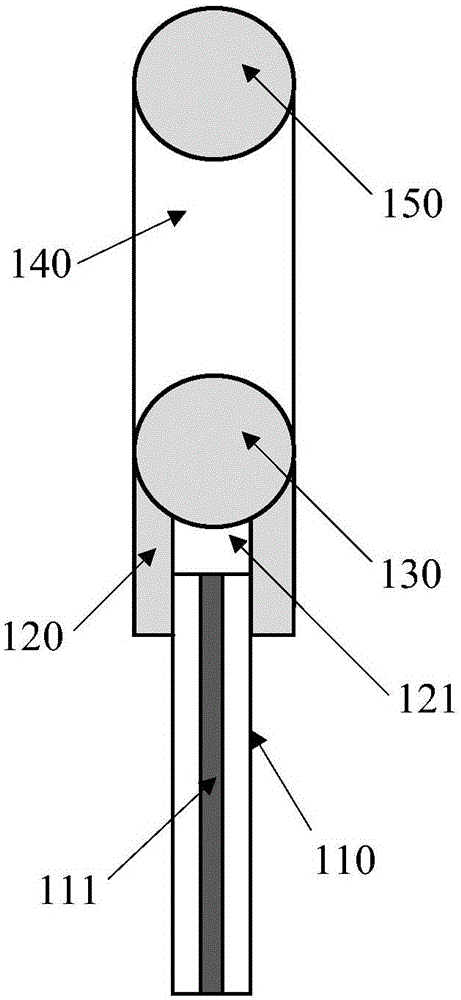

Radiating equipment

ActiveCN105682423AMiniaturizationAchieve lightweightModifications using liquid coolingPulp and paper industryEvaporator

An embodiment of the invention discloses radiating equipment. The weight of the radiating equipment can be lowered and the radiating efficiency of the radiating equipment can be improved. The radiating equipment comprises an evaporator (110), a first-stage pressure balancer (120), a collecting pipe (130), a condenser (140) and a second-stage pressure balancer (150), wherein multiple steam pipelines (111) are arranged in the evaporator (110); working mediums are added in the multiple steam pipelines (111); the upper side of the evaporator (110) is communicated with the lower side of the first-stage pressure balancer (120) through the multiple steam pipelines (111); the upper side of the first-stage pressure balancer (120) is communicated with the lower side of the collecting pipe (130); the upper side of the collecting pipe (130) is communicated with the lower side of the condenser (140); and the upper side of the condenser (140) is communicated with the lower side of the second-stage pressure balancer (150).

Owner:HUAWEI TECH CO LTD

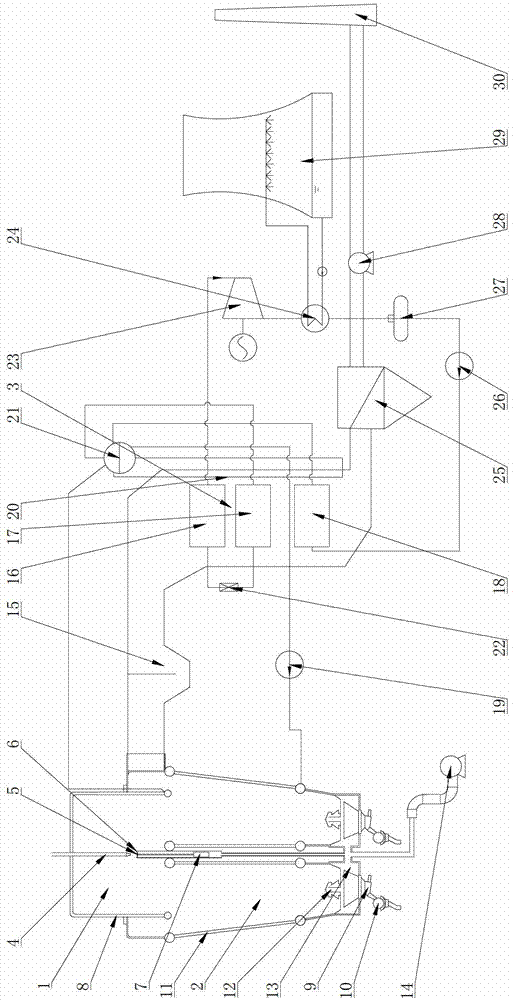

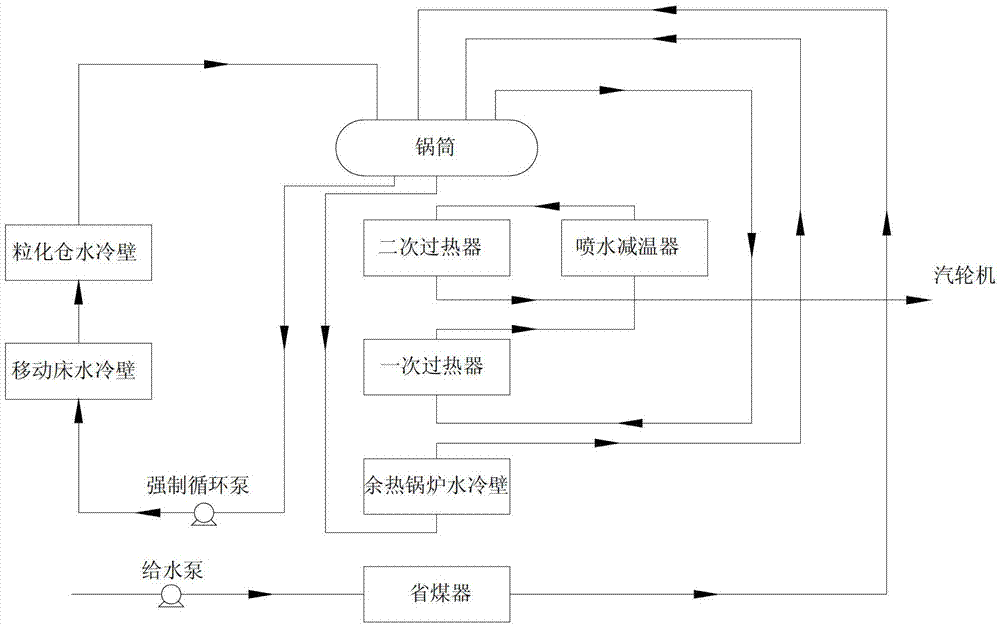

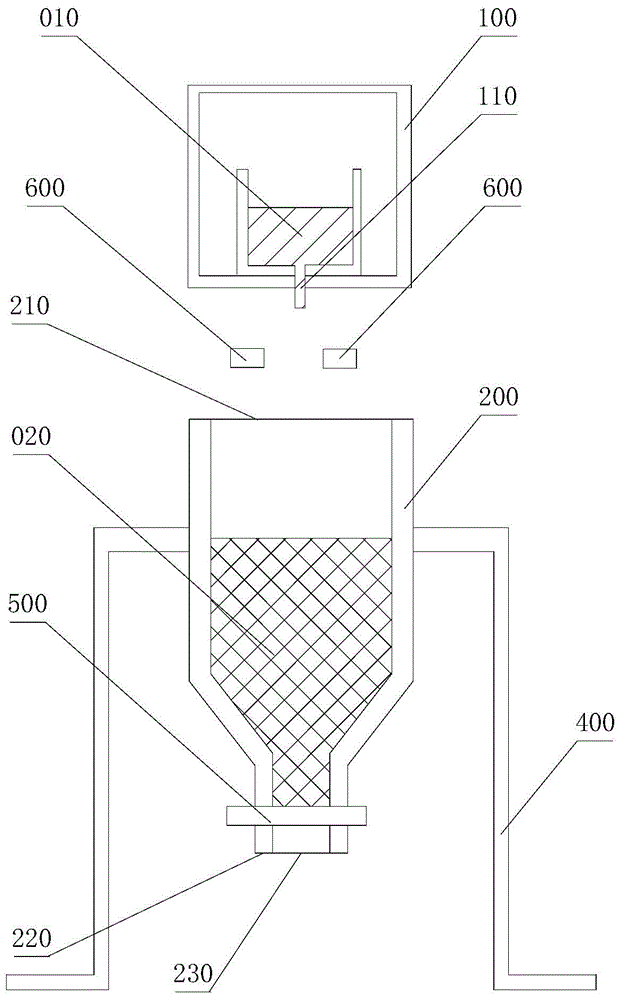

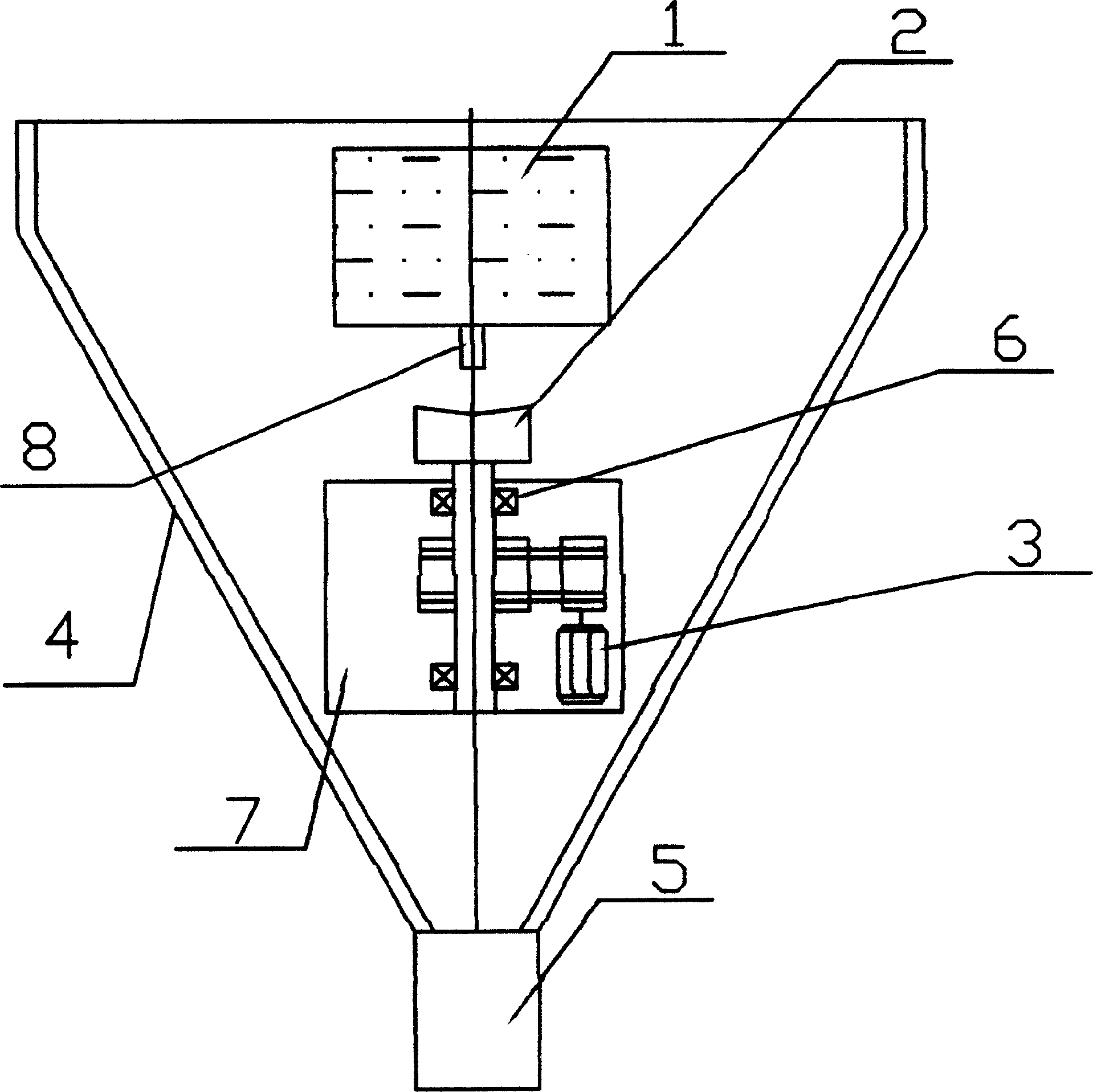

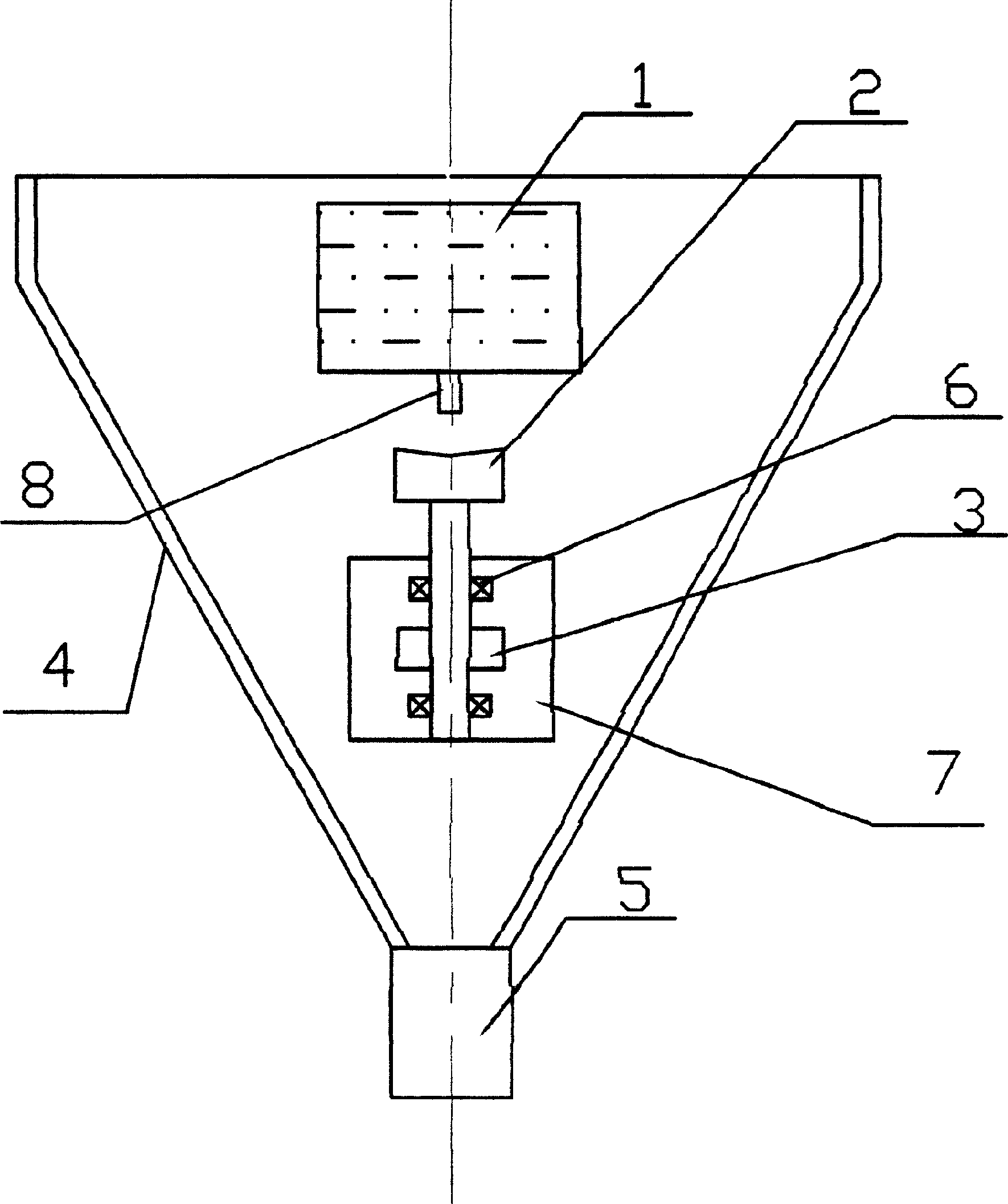

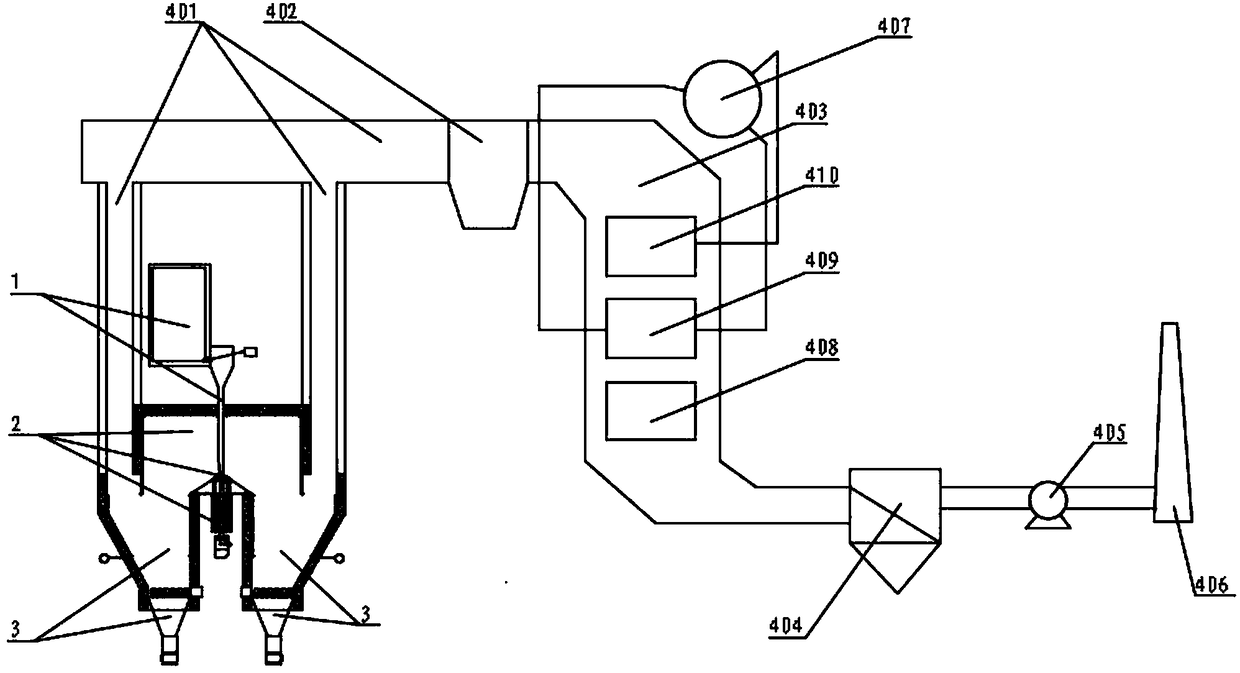

Afterheat recovery system and method of dry granulating liquid slag

ActiveCN102827969AEasy to diluteImprove granulation effectIncreasing energy efficiencyRecycling and recovery technologiesRecovery methodLiquid slag

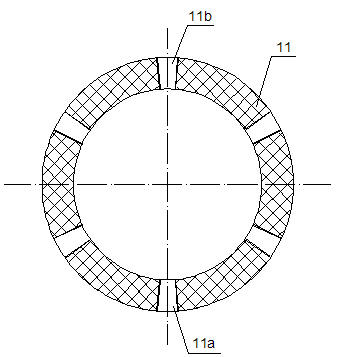

The invention discloses an afterheat recovery system and an afterheat recovery method of dry granulating liquid slag. The system comprises a granulating cabin, a moving bed and an afterheat recovery system, the inner surface of the granulating cabin is provided with a granulating cabin water cooling wall, the center of the top of the granulating cabin is provided with a slag pipe, the slag pipe extends into the granulating cabin, the lower part of the tail end of the slag pipe is provided with a centrifugal granulator, the centrifugal granulator is connected with a motor arranged at the lower part of the centrifugal granulator, the lateral side of the centrifugal granulator is provided with an air supply pipeline, an annular air opening is formed between the centrifugal granulator and the air supply pipeline, the lower part of the granulating cabin is provided with the moving bed, the inner surface of the moving bed is provided with a moving bed water cooling wall, the top of the moving bed is provided with an air outlet, the bottom of the moving bed is provided with a slag discharge device, an air inlet device is arranged above the slag discharge device, the afterheat recovery system comprises a primary dust remover, an afterheat boiler, a secondary dust remover, an exhaust fan and a chimney which are connected in sequence, and the primary dust remover is connected with the air outlet arranged at the top of the moving bed. The system and the method effectively solve the problems of heat recovery and furnace slag granulation of equipment such as a blast furnace.

Owner:XI AN JIAOTONG UNIV +1

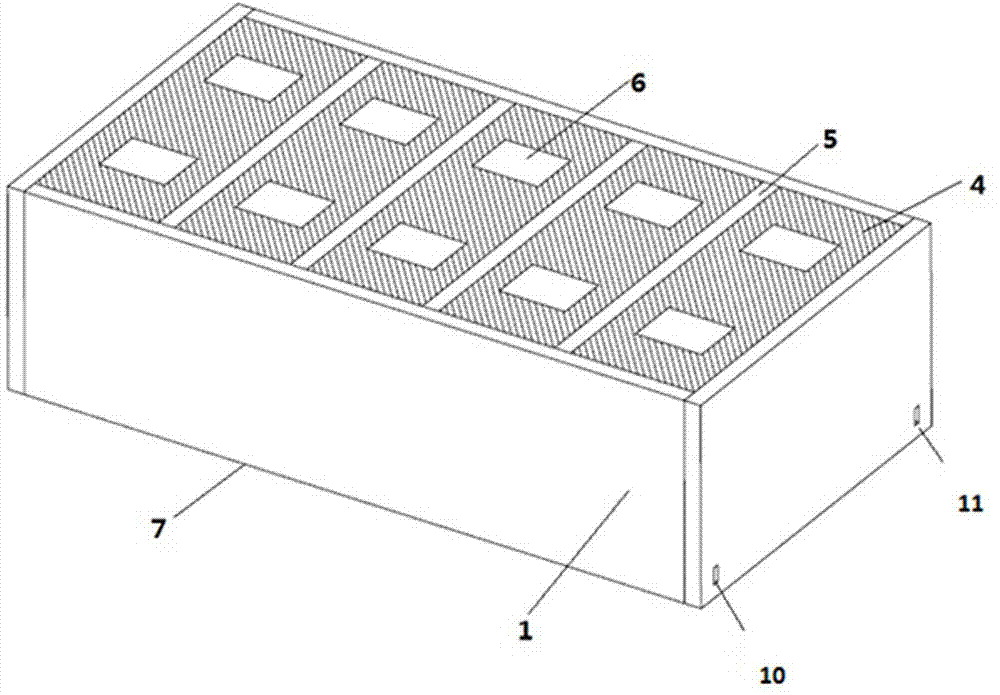

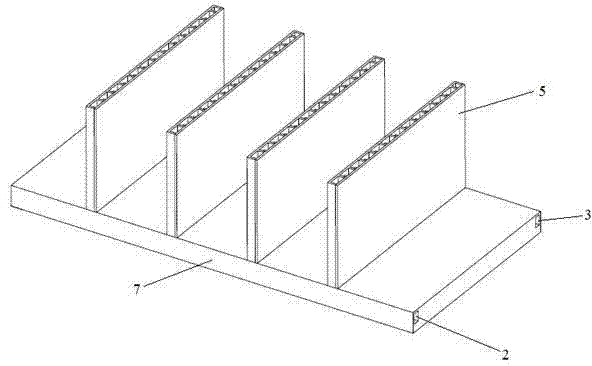

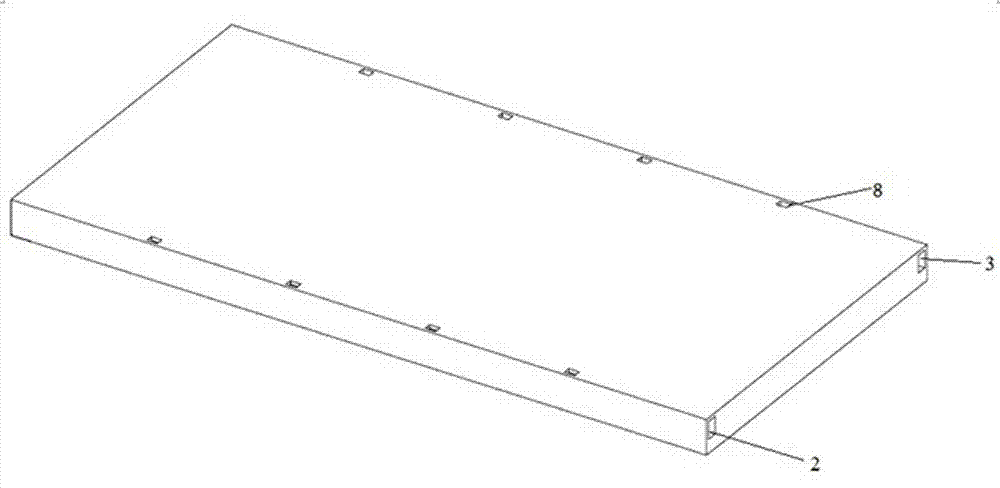

Water cooling and composite phase change material combined power battery heat dissipating device

ActiveCN104241729AImprove thermal conductivityIncrease heat storageSecondary cellsBatteriesPower batteryProcess engineering

The invention discloses a water cooling and composite phase change material combined power battery heat dissipating device which comprises a box body and a base plate arranged at the bottom of the box body, wherein a water inflow channel and a water outflow channel which are used for accommodating cooling water are respectively arranged inside the base plate and along two long edges, aperture passages communicated with the water inflow channel and the water outflow channel respectively are arranged on the upper surface of the base plate and along the two long edges, tabular micro-channel heat exchangers are arranged on the base plate at certain intervals in the length direction, micropore flow passages are arranged inside the tabular micro-channel heat exchangers, the two end ports of each micropore flow passage are respectively connected with an aperture passage I communicated with the water inflow channel and an aperture passage II communicated with the water outflow channel, and spaces formed by the tabular micro-channel heat exchangers, the base plate and the box body are filled with a composite phase change material. The water cooling and composite phase change material combined power battery heat dissipating device provided by the invention has the advantages of high heat accumulation and heat dissipation rates, convenience in operation and maintenance, low cost and the like, can be used for heat dissipation of high-power and quick charge-discharge power batteries, and can improve the working performance and the reliability of batteries.

Owner:SOUTH CHINA UNIV OF TECH

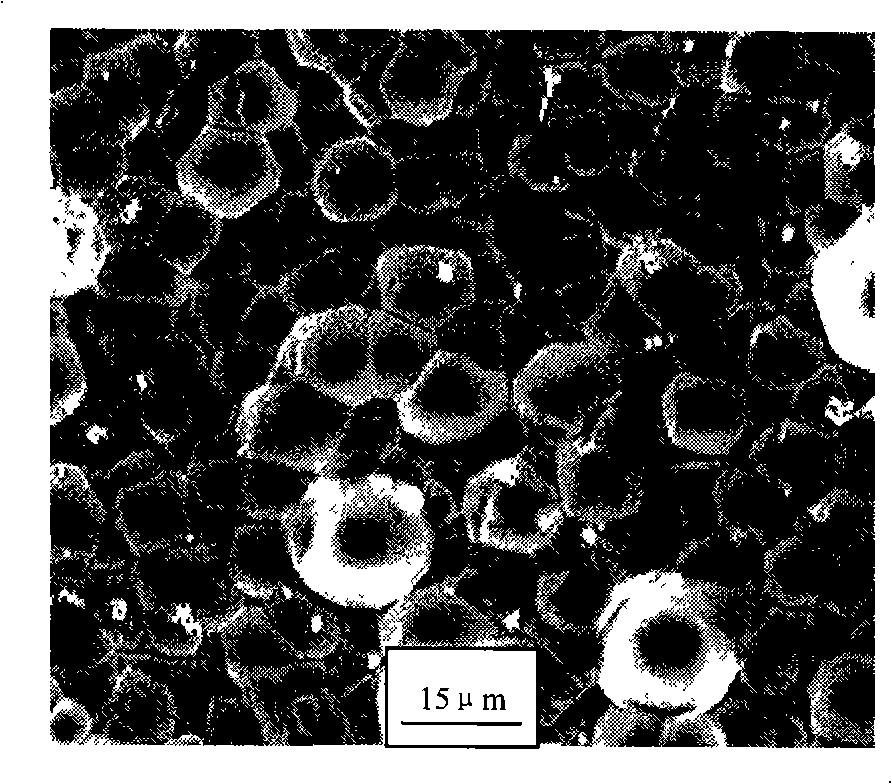

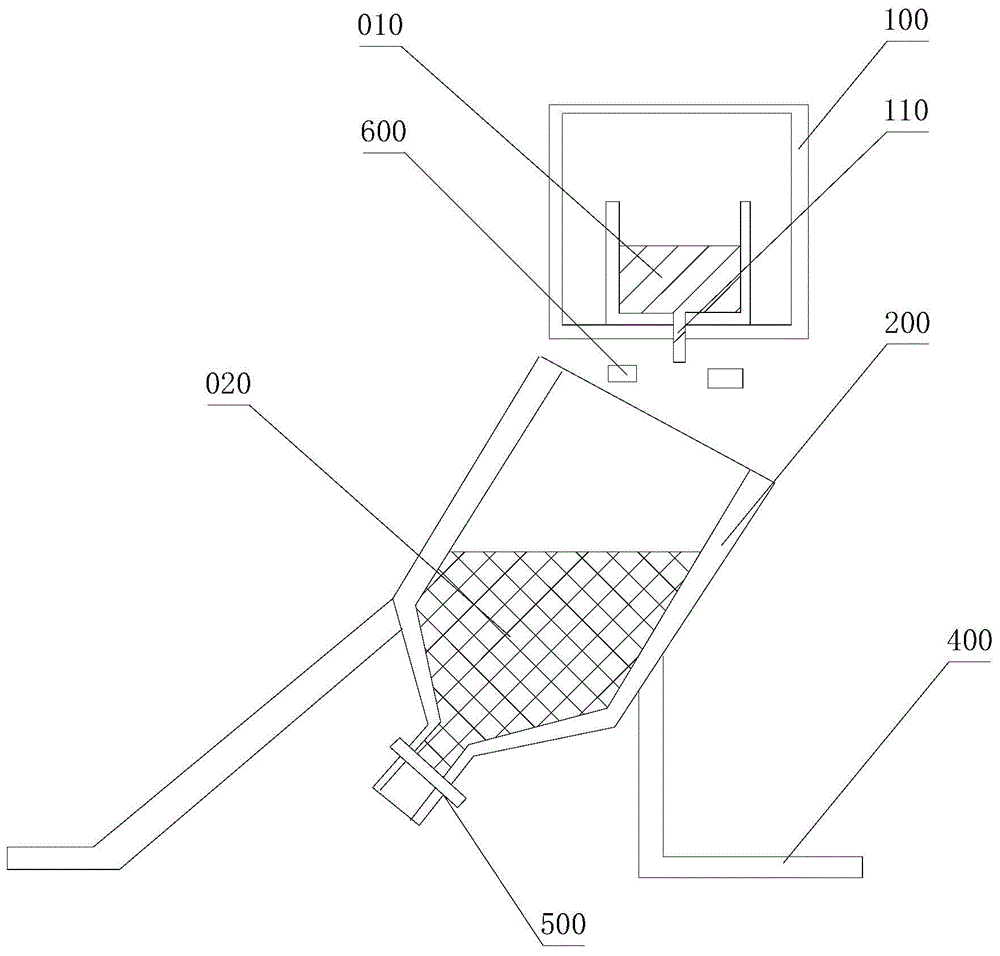

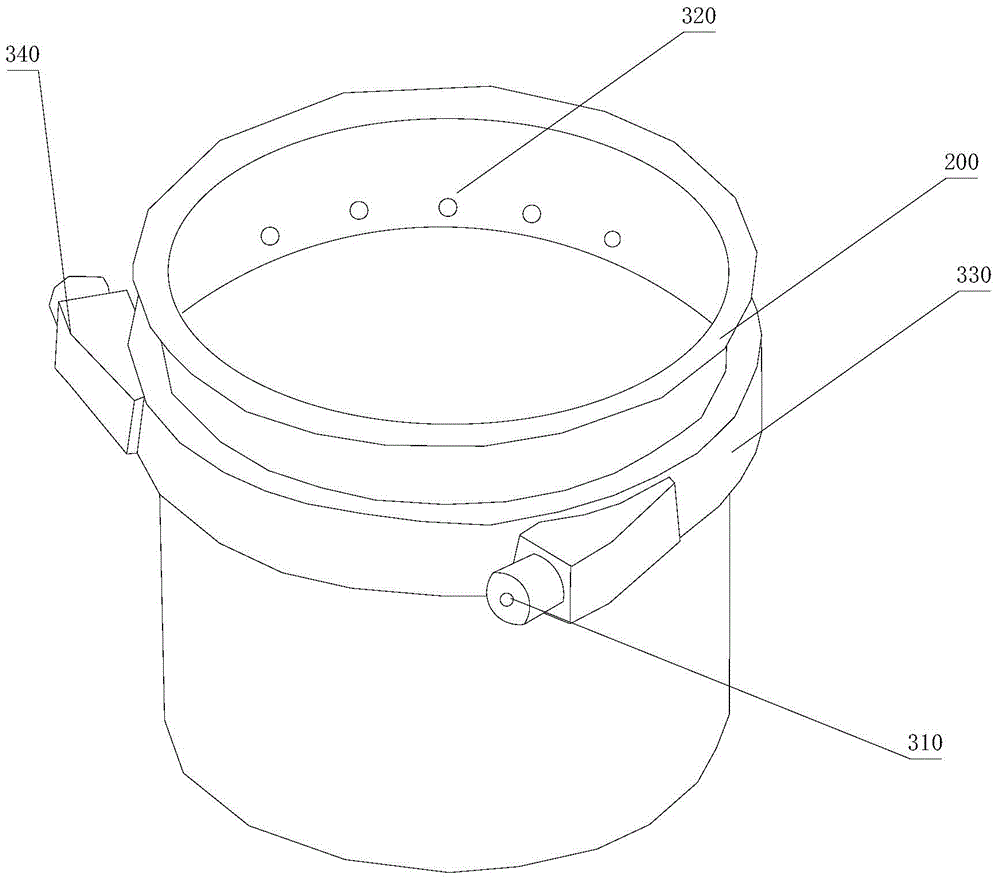

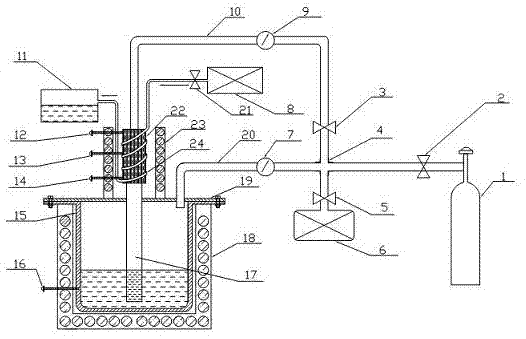

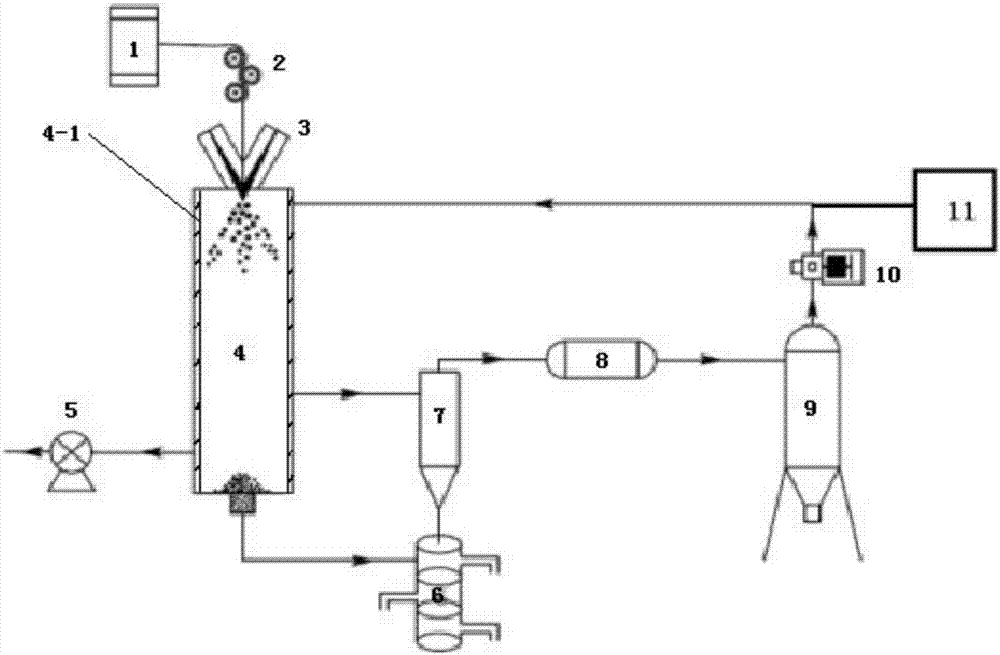

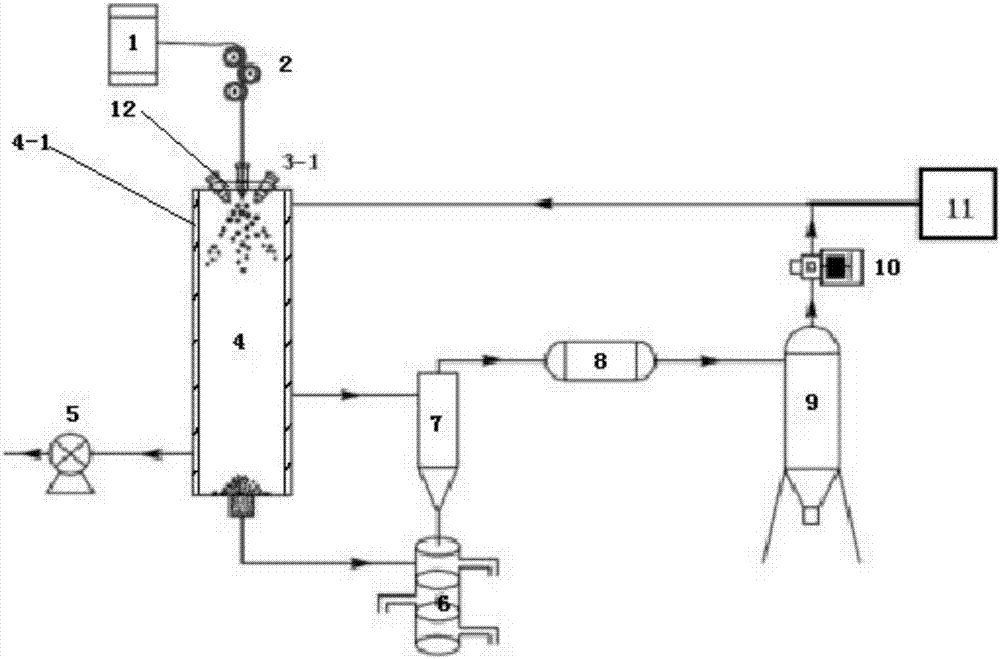

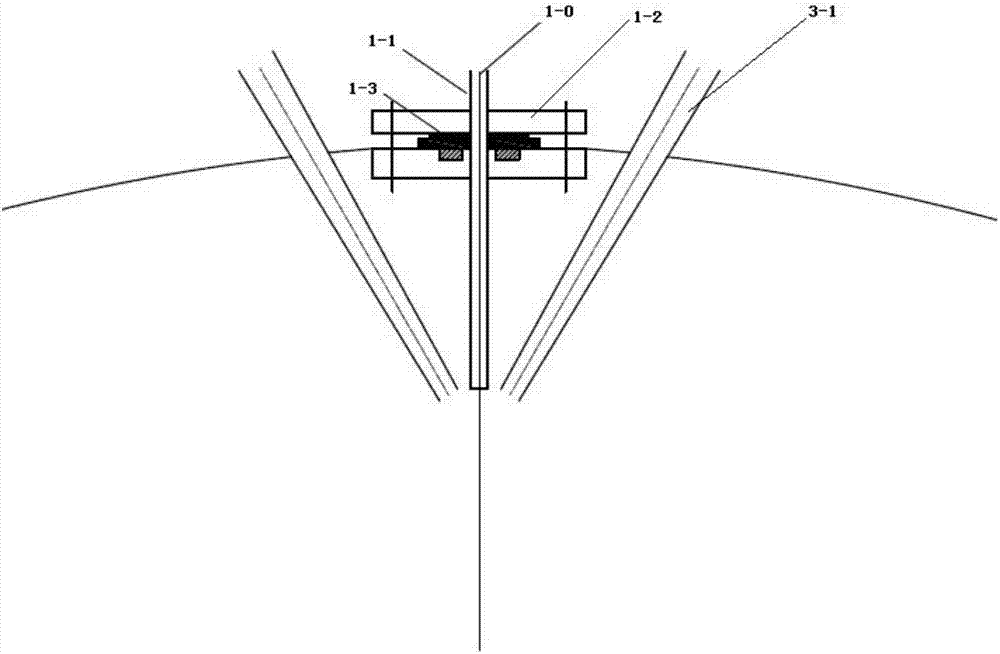

Method and device for manufacturing amorphous powder

The invention provides a method and device for manufacturing amorphous powder. The method for manufacturing the amorphous powder comprises the following steps that raw materials are fused to obtain fusion liquid; in the flowing-out and falling process, the fusion liquid interacts with atomized gas to be broken into droplets; the droplets move in the water at the high speed for a certain time to obtain first fluid; the first fluid is collected and separated to obtain the amorphous powder. The method for manufacturing the amorphous powder comprises a fusion device, a gas atomization device, a rotating water system and a discharge collection device. The gas atomization mode is adopted to enable the fusion liquid to be broken into the droplets, the final oxygen content of the power can be reduced, high-speed water flowing can break through a water steam film generated on the surface by droplet solidification in the water, the cooling rate is improved, and therefore the complete amorphous alloy powder with the larger grain diameter can be obtained.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

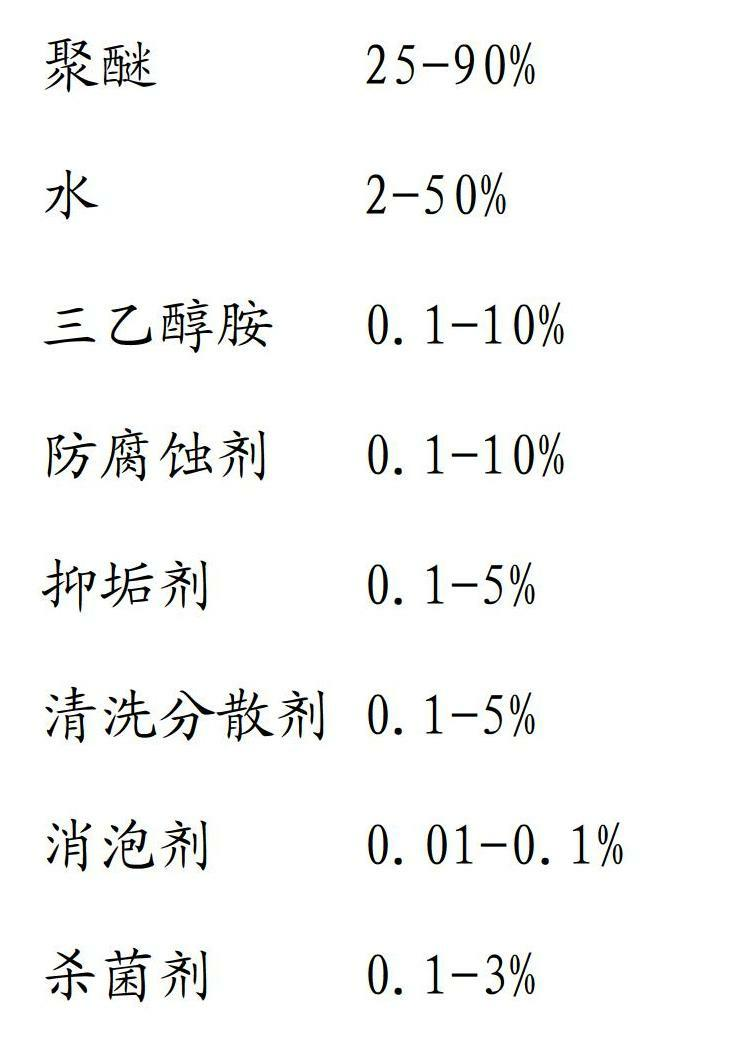

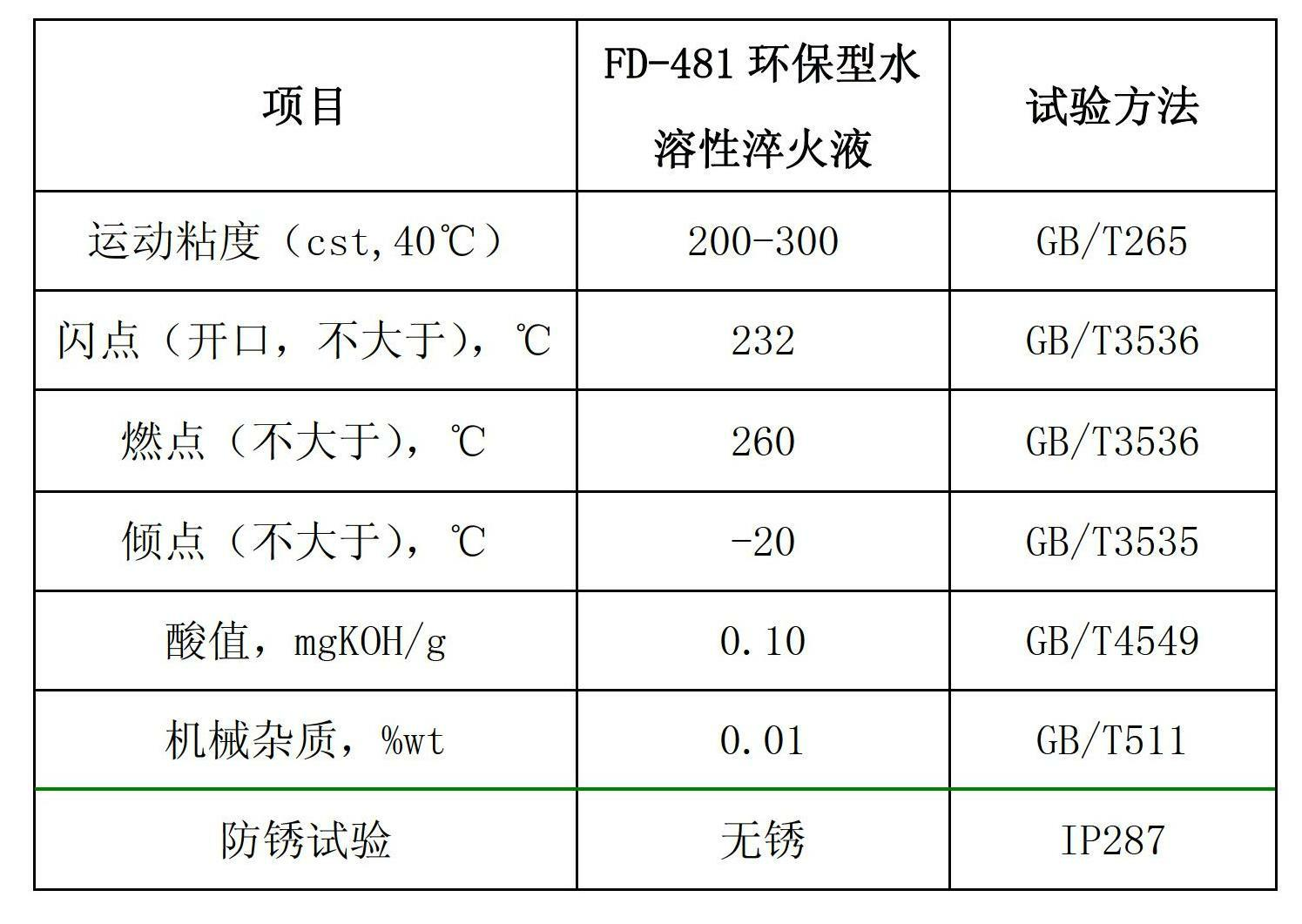

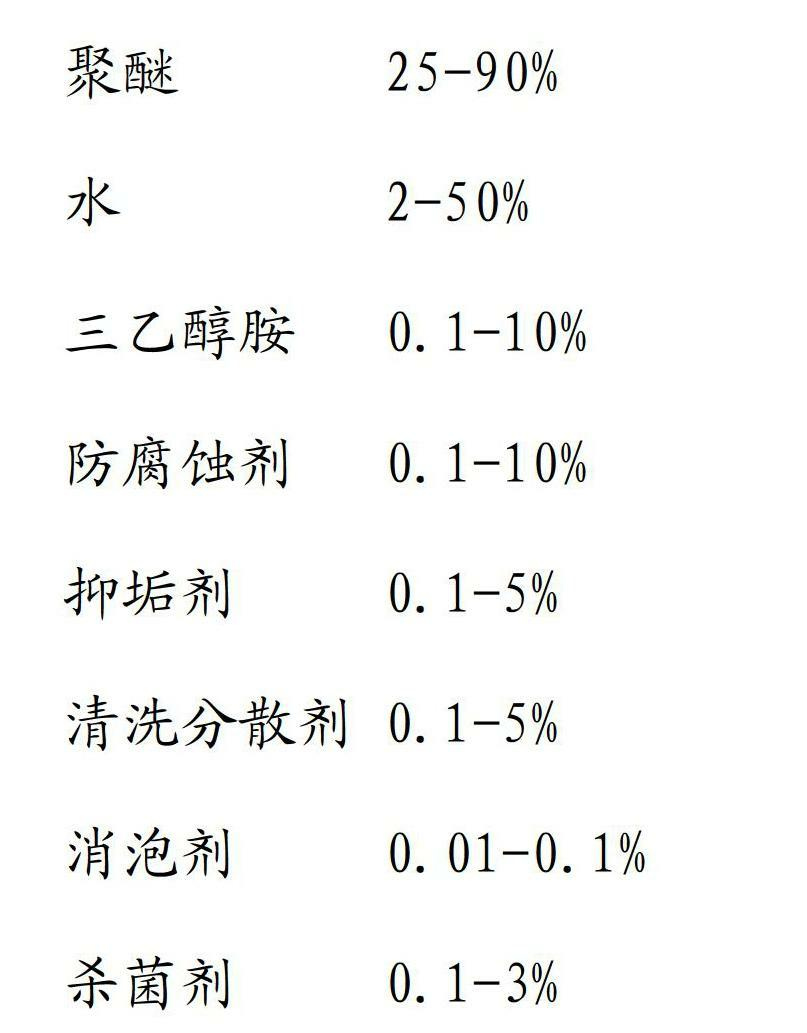

Environmental protection water-solubility quenching liquid

ActiveCN102643963AImprove final performanceImprove machining accuracyQuenching agentsSolubilitySurface cleaning

The invention discloses environmental protection water-solubility quenching liquid, which, by weight, comprises components of 25-90% of polyether, 2-50% of water, 0.1-10% of triethanolamine, 0.1-10% of anticorrosive agent, 0.1-5% of dirty restrain agent, 0.1-5% of washing dispersing agent, 0.01-0.1% of antifoaming agent and 0.1-3% of fungicide. The polyether molecular weight is 30000-50000. The water-solubility quenching liquid is compounded with balanced rust-inhibiting additive and the washing dispersing agent, has great cooling speed in a high-temperature cooling stage, can refine grains, has moderate cooling speed in a low-temperature cooling stage, effectively solves cracking and deformation problems in a workpiece cooling process, and improves surface quality of a workpiece. Excellent rust-proof performance effectively protects the quenched workpiece, and rust-proof requirements between working procedures are completely met. The environmental protection water-solubility quenching liquid has prominent surface cleaning performance, scale cinder is avoided, output quantity is small, production efficiency is improved, and production cost is saved.

Owner:上海福岛新材料科技有限公司

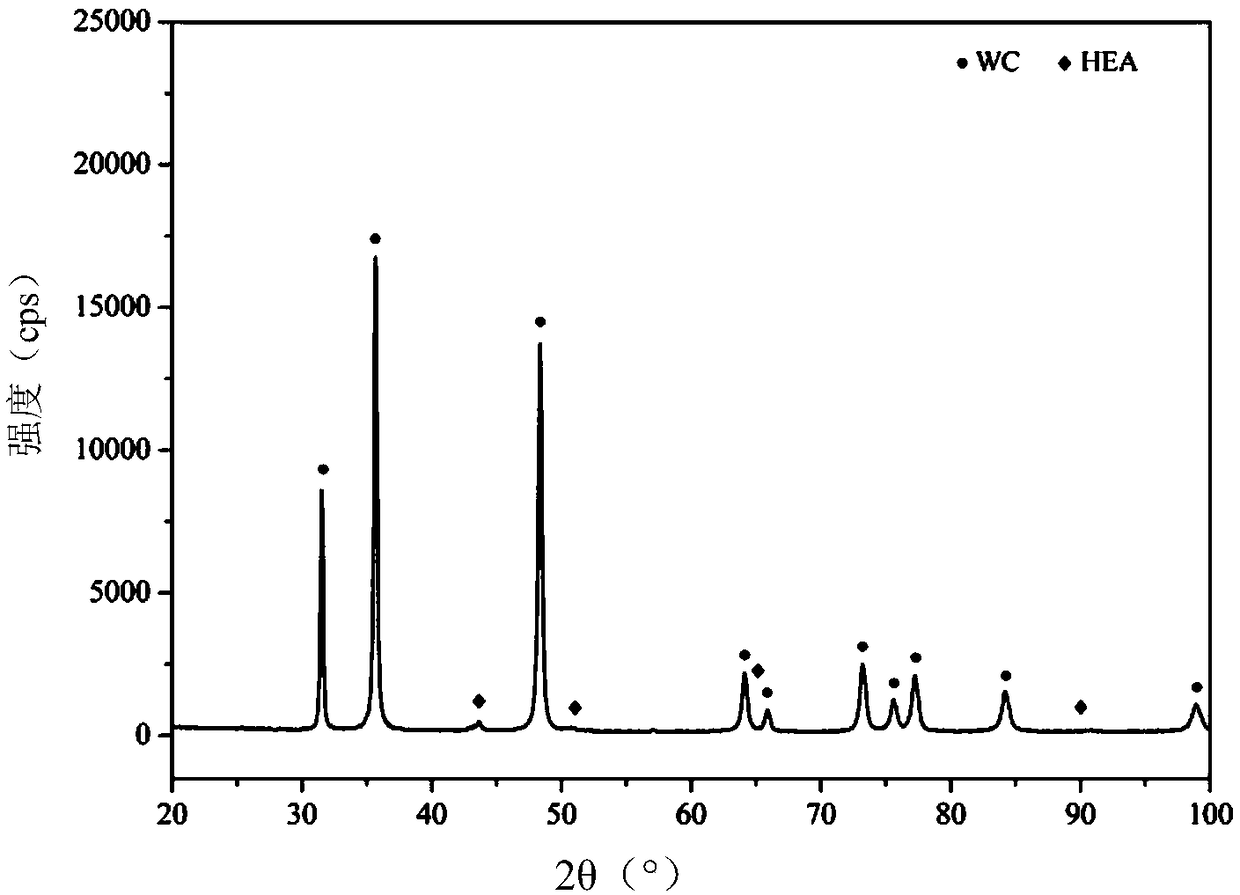

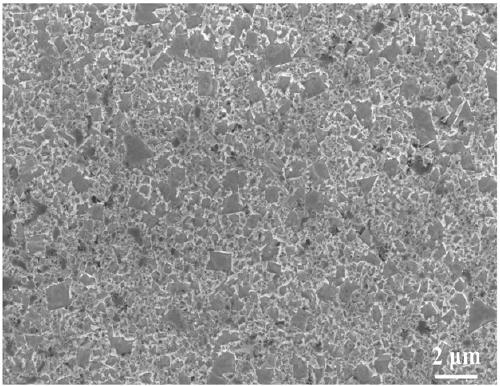

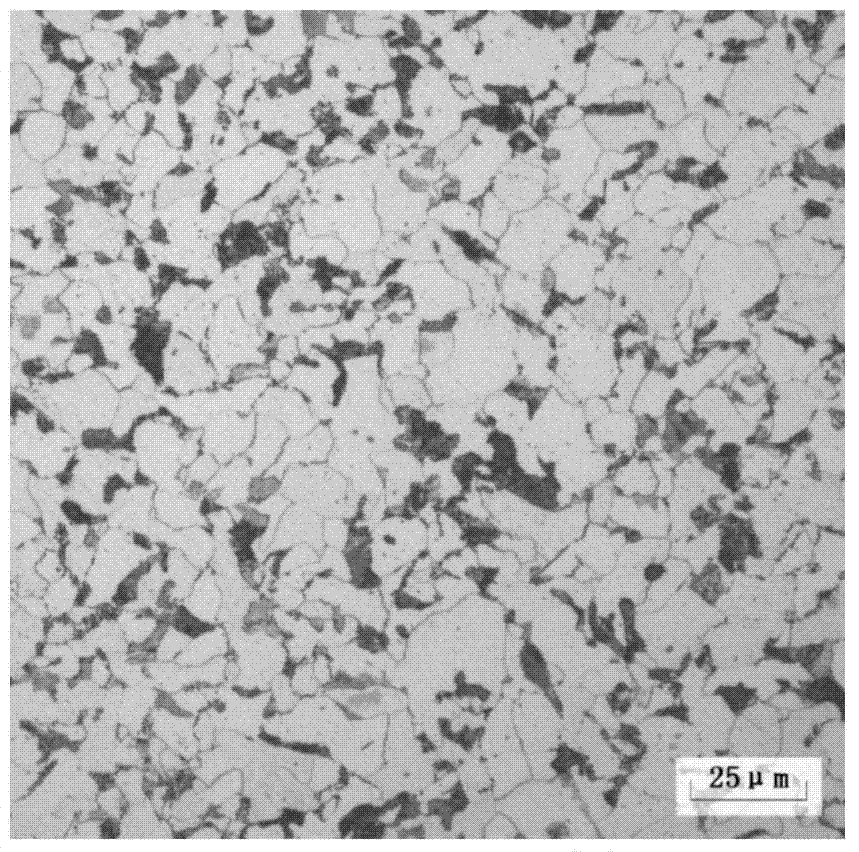

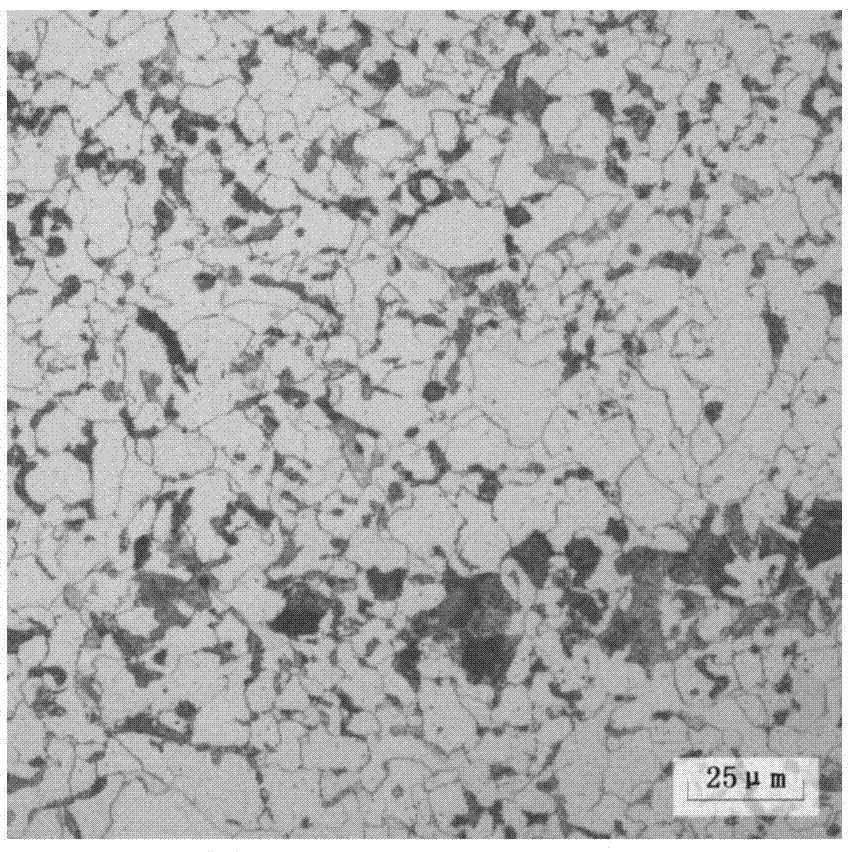

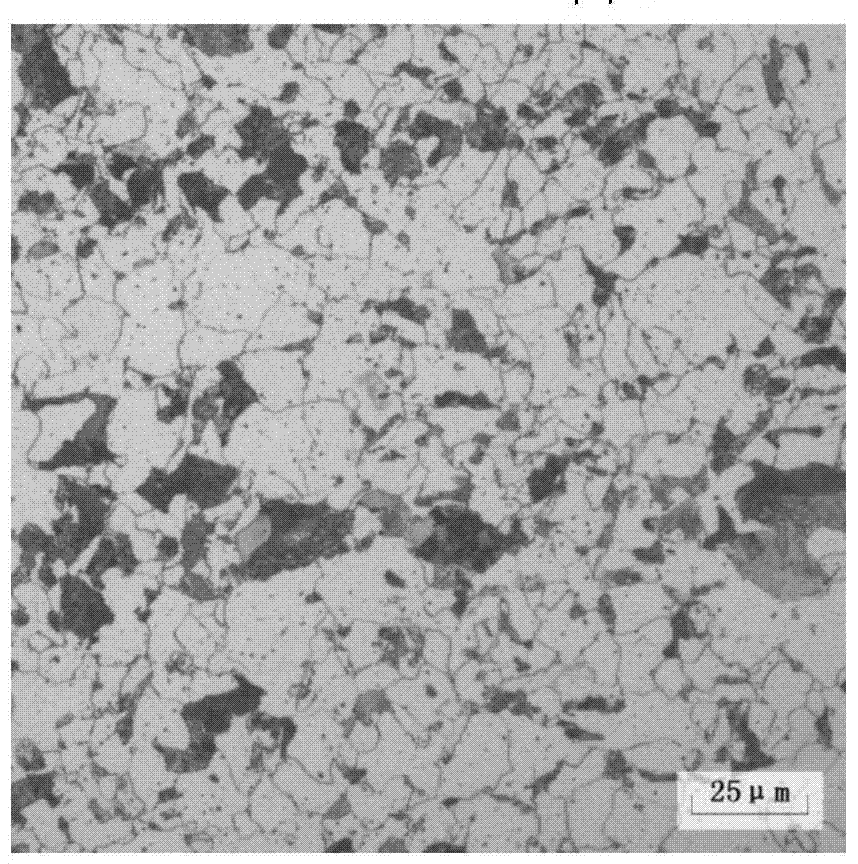

High-entropy alloy binding phase ultrafine tungsten carbide hard alloy and preparation method thereof

The invention belongs to the technical field of hard alloy, and discloses high-entropy alloy binding phase ultrafine tungsten carbide hard alloy and a preparation method thereof. According to the high-entropy alloy binding phase ultrafine tungsten carbide hard alloy, high-entropy alloy is used as a binding phase, and tungsten carbide is used as a hard phase; the high-entropy alloy is prepared fromthe components of five or more of Al, Co, Cr, Cu, Fe and Ni, and an atomic percentage of each element is 5-35%. The method comprises the steps that after high-entropy alloy powder and WC powder are mixed, spark plasma sintering forming is conducted to obtain the high-entropy alloy binding phase ultrafine tungsten carbide hard alloy. The tungsten carbide hard alloy is fine and small in crystal grain, and is good in comprehensive mechanical performance; adding a crystal growth inhibitor is not needed; consumption of the Co is significantly reduced, so that the raw material cost is reduced.

Owner:SOUTH CHINA UNIV OF TECH

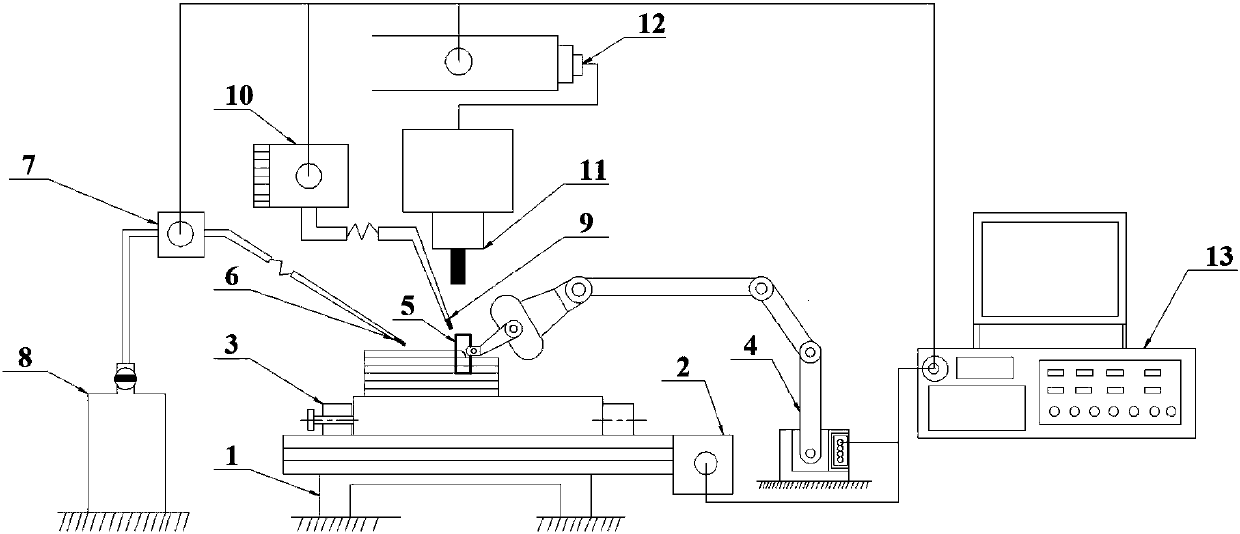

Method and device for improving forming quality of laser additive manufacturing thin-wall parts

ActiveCN107685149AStable jobOvercoming flow problemsAdditive manufacturing apparatusIncreasing energy efficiencyForming processesMetal

The invention provides a method and device for improving the forming quality of laser additive manufacturing thin-wall parts. The device comprises a movable platform system, a laser metal deposition system, an auxiliary forming system, an active cooling system and a central control system. According to the forming method, when the laser metal deposition system conducts cladding forming on the thin-wall parts, the auxiliary forming system controls the thin-wall thicknesses and the forming directions in real time; when the multiple layers of the thin-wall parts are deposited, the problem of molten pool flowing caused by interlayer stacking can be solved, and the problem that the surface roughness in the thin-wall forming process is excessively large due to interlayer stacking is solved, andthe thickness-changeable thin wall, the flat thin wall and the curved thin wall are machined; and meanwhile, the active cooling system cools deposited layers in real time. The problems that the quality of the laser cladding formed surfaces is low; during continuous multiplayer depositing, the temperature is increased, therefore, thermal stress of the deposited layers is accumulated, consequently the deposited layers are cracked, and microstructures of the deposited layers are coarse; and the forming efficiency is low due to slow cooling are solved, and high-quality and efficient forming of thecomplex thin-wall parts is achieved.

Owner:JIANGSU UNIV

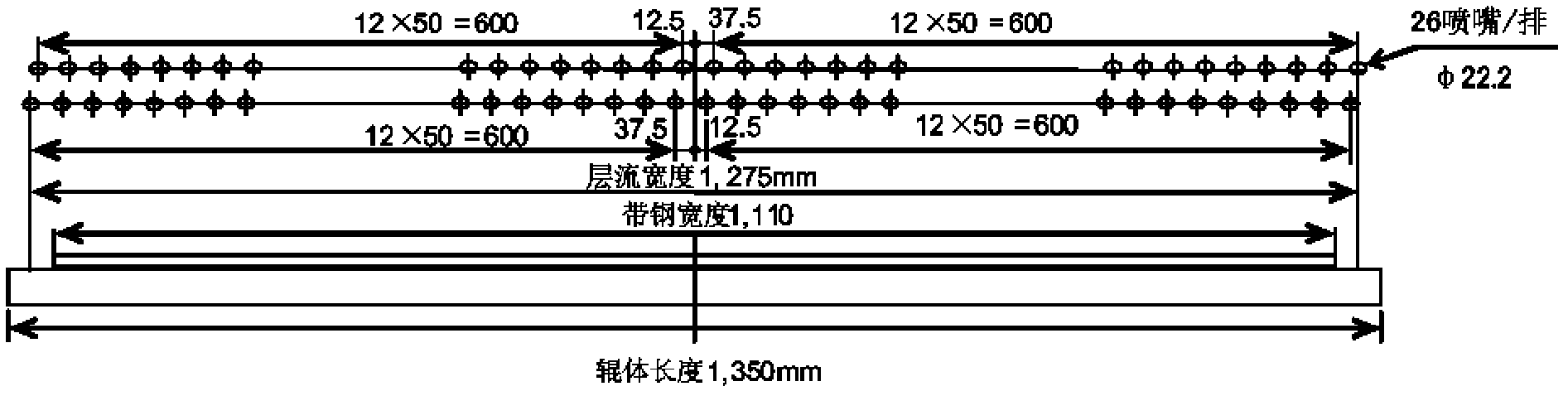

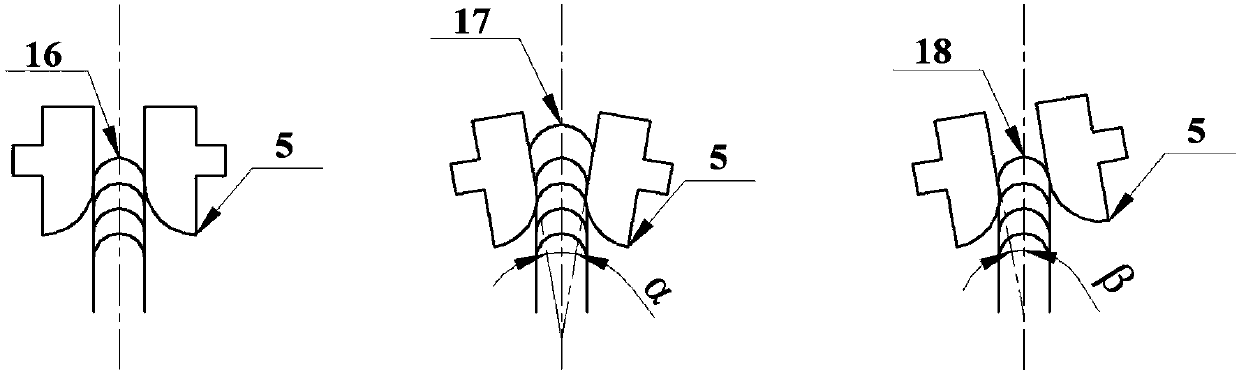

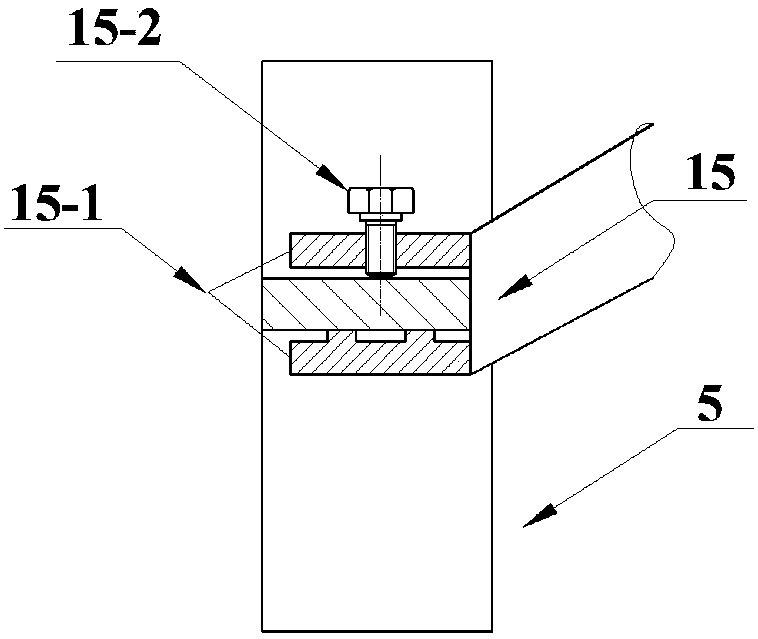

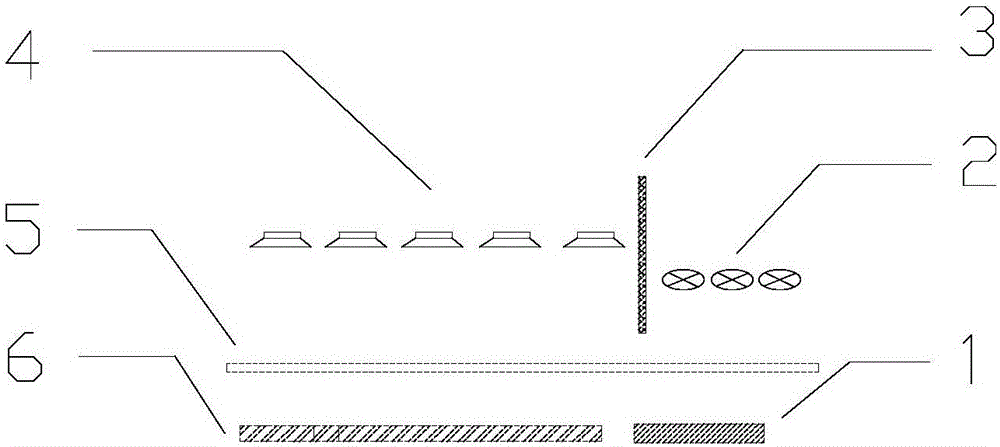

Hot rolled strip laminar cooling device capable of controlling cooled strip shape

InactiveCN101879531AIncrease cooling rateEasy to adjustWork treatment devicesMetal rolling arrangementsHigh densityLaminar cooling

The invention provides a hot rolled strip laminar cooling device capable of controlling cooled strip shape. The device is arranged between a finishing mill and a coiling machine and is formed by a cooling area which is formed by a water distributor, a high-density upper header, an upper coarse adjustment header, an upper fine adjustment header, a high-density lower head, a lower coarse adjustment header, a lower fine adjustment header and a high-level water tank, wherein the water distributor is connected with the high-density upper header, the upper coarse adjustment header, the upper fine adjustment header, the high-density lower head, the lower coarse adjustment header and the lower fine adjustment header respectively through a pipeline, a hand valve, a flow regulating valve and a pneumatic on-off valve. The hot rolled strip laminar cooling device capable of controlling cooled strip shape is formed by a plurality of cooling sections which consist of one or two forced cooling sections Q, one coarse cooling section C and a fine cooling section J, wherein the forced cooling section Q is formed by a plurality of high-density upper header groups and high-density lower header groups; the coarse cooling section C is formed by an upper coarse adjustment header group and a lower coarse adjustment header group; and the fine cooling section J is formed by an upper fine adjustment header group and a lower fine adjustment header group. The invention has the advantages that the ultrafast cooling and the shape-controllable even cooling can be realized and the production needs of all kinds of commercial hot rolled strips and cold rolled base materials can be satisfied.

Owner:UNIV OF SCI & TECH BEIJING

Method and apparatus for preparing sheet-type metal pwoder by atomized drop deformation

The present invention relates to a method for preparing flake metal powder by means of atomizing liquid drop deformation. Said method includes the following steps: heating and melting metal raw material, then making the molten metal be passed through the discharge spout of crucible bottom portion according to stable flow rate of 3-30g / sec. And be poured onto the center of disk rotated at high speed, the rotating speed of the disk is 1000-5000 rpm, under the action of centrifugal force atomizing and forming so as to obtain the invented product. Said equipment comprises, smelting crucible, rotating disk atomizer, drive motor, atomizing chamber, bearing and water-cooling chamber.

Owner:UNIV OF SCI & TECH BEIJING

Multiphase nano ceramic particle reinforced Al-based composite material and laser 3D printing forming method thereof

The invention discloses a multiphase nano ceramic particle reinforced Al-based composite material and a laser 3D printing forming method thereof. AlSiMg powder with a purity of 99.9% and above and a particle size of 15-30 mu m is selected as a composite material base of the Al-based composite material; a powder composition with a purity of 99.9% or above and a particle size of 10-100 mu m is selected as a reinforced phase of the Al-based composite material, and the powder composition comprises Al2O3, SiO2, TiN and TiC, ZnO and Y2O3; after the two kinds of powder are mixed, the obtained mixture is sequentially subjected to high-temperature calcining synthesis, ball-milling and 3D printing forming, so that a required 3D block can be processed. The Al-based composite material obtained according to the invention has uniformly refined microscopic structures and excellent mechanical properties, and in comparison with the performance levels of traditional casting or powder metallurgy products of corresponding materials, the comprehensive mechanical properties of the Al-based composite material are increased by 25% or above.

Owner:JIANGSU SILAIMU INTELLIGENT TECH CO LTD

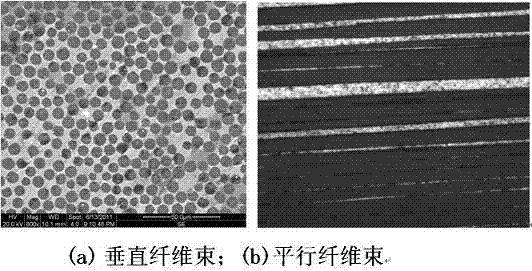

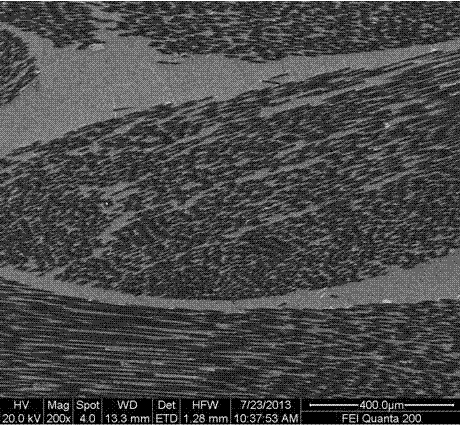

Liquid-state near-net forming method and device for continuous carbon fiber enhanced aluminum-based composite material

InactiveCN103540873ARealize hypoxic temperature control preheatingAchieve cooling rate controlFiberCarbon fibers

The invention discloses a liquid-state near-net forming method and device for a continuous carbon fiber enhanced aluminum-based composite material, namely a vacuum-assisted pressure-adjusting and infiltration casting method and device. The method comprises four procedures of smelting an alloy and pre-heating fibers, carrying out vacuum-assisted pressure-adjusting and infiltration, condensing at a high pressure and cooling rapidly. The device is composed of an alloy smelting device, a vacuum-assisted pressure-adjusting and infiltration device and a casting rapid cooling device. The liquid-state near-net forming method and device have the characteristics that (1) low-oxygen and temperature-controllable pre-heating of nickel-plated carbon fibers is realized; (2) low-pressure infiltration and high-pressure condensation of the aluminum-based composite material are realized; (3) the control of a cooling speed in the condensation of a composite material casting is realized. According to the liquid-state near-net forming method and device for the continuous carbon fiber enhanced aluminum-based composite material, oxidization and burning loss caused by pre-heating the carbon fibers, prefabricated body deformation in the infiltration process and interface reaction problems in the condensation process of the composite material are solved. The liquid-state near-net forming of the continuous carbon fiber enhanced aluminum-based composite material can be realized and the prepared composite material has the advantages of dense tissues, few interface reactions, high mechanical properties and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

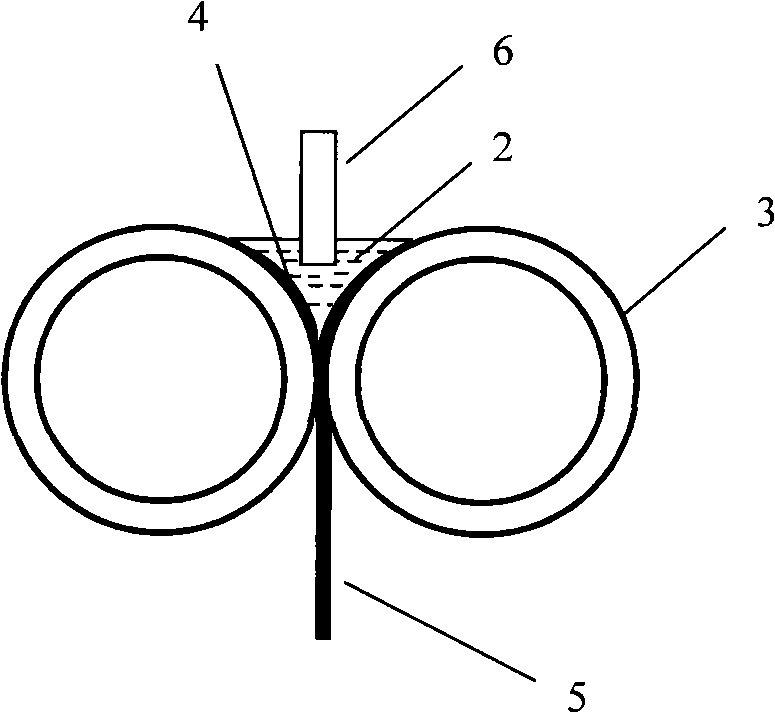

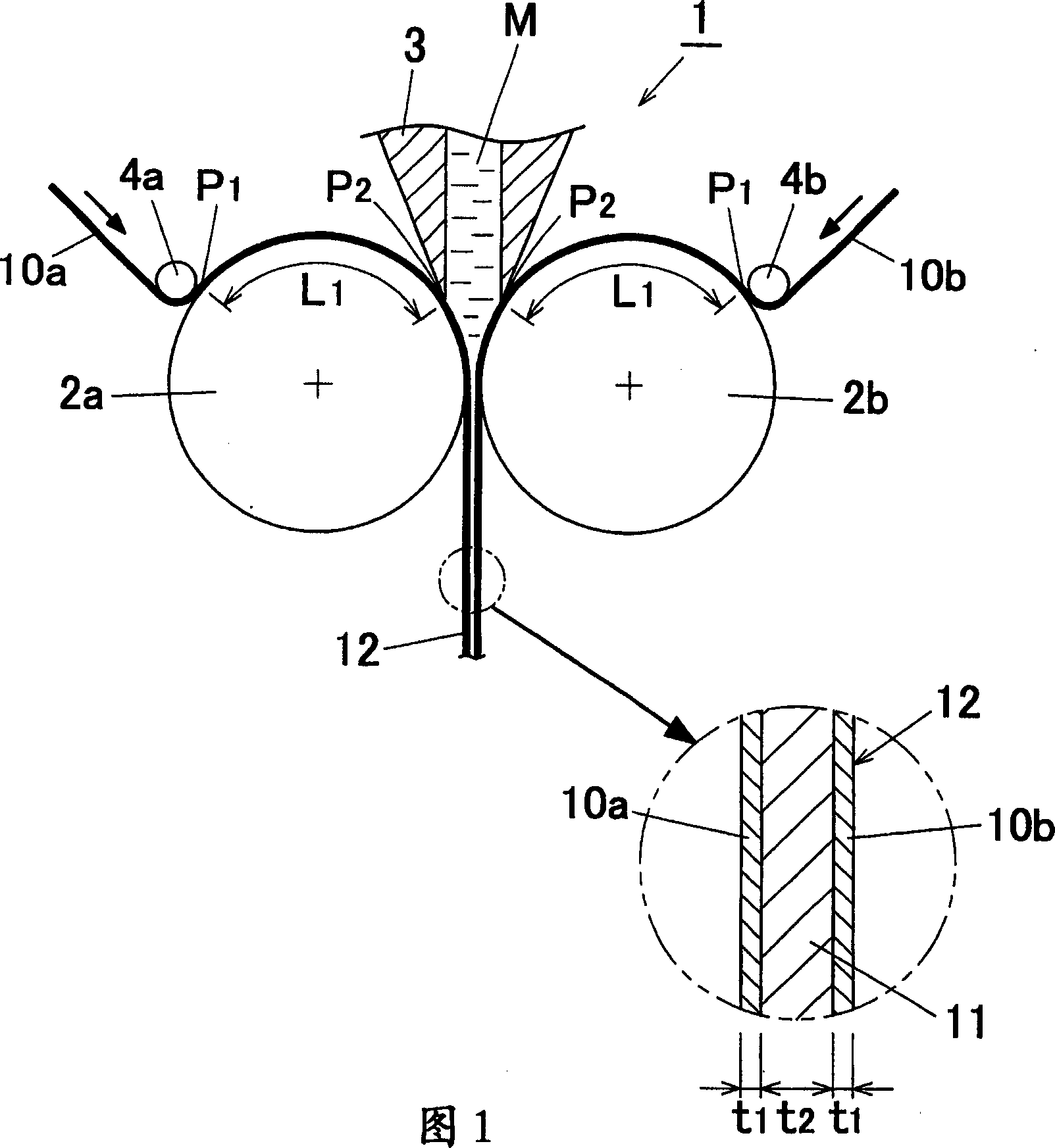

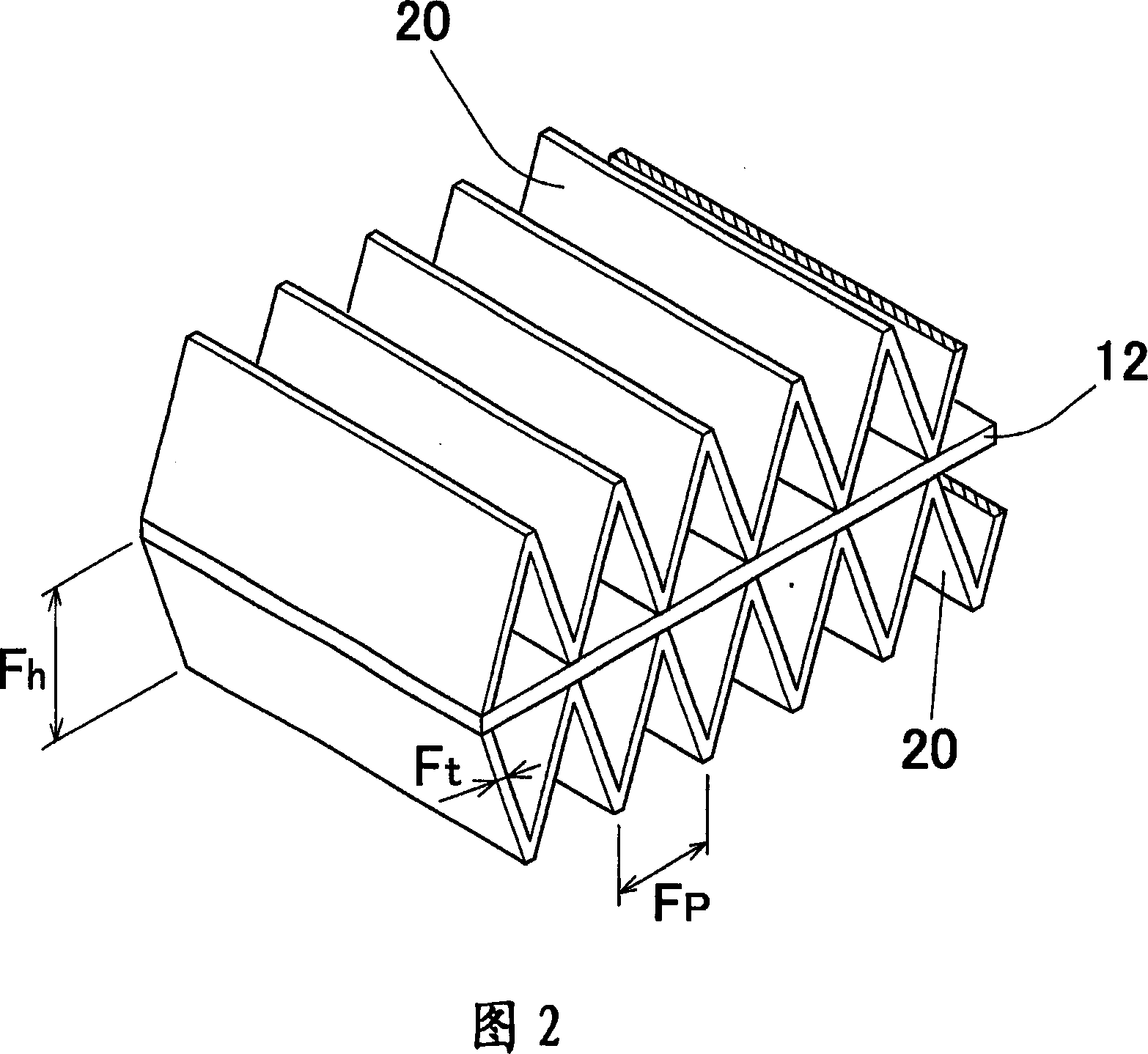

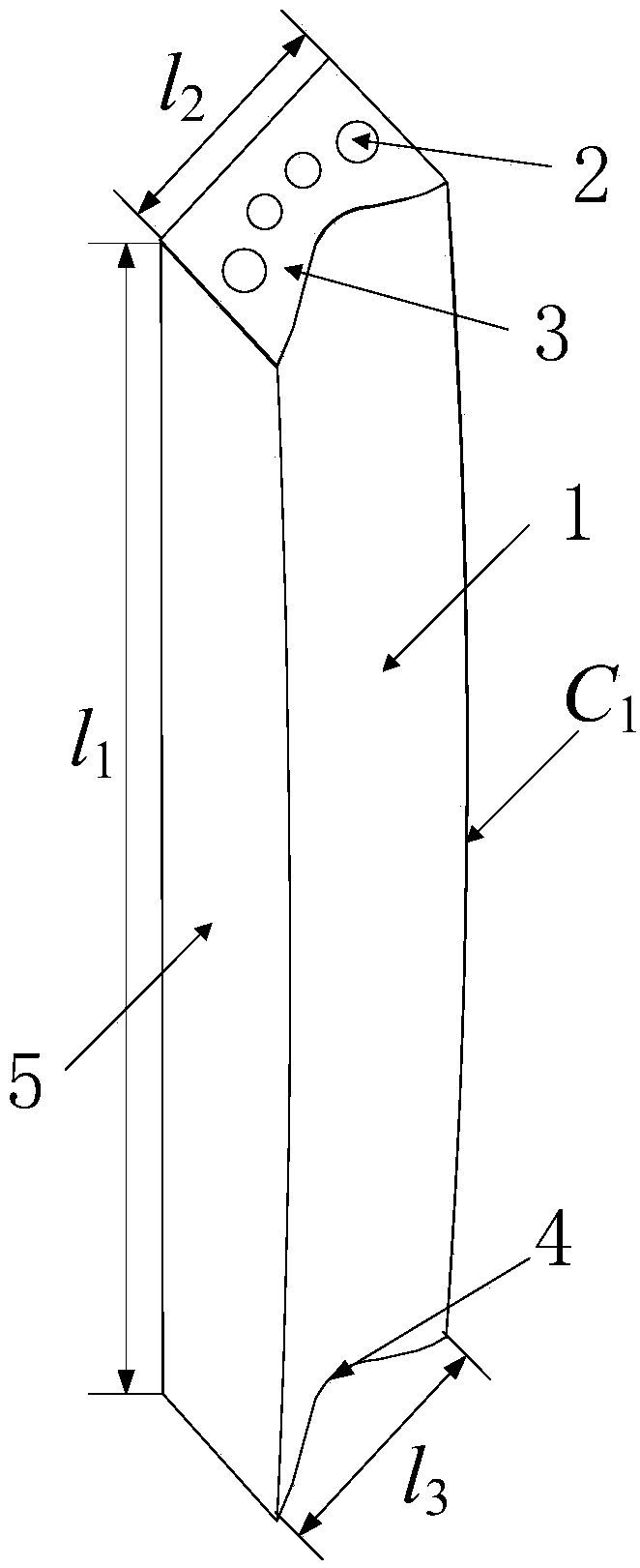

Clad material, method for manufacturing said clad material, and apparatus for manufacturing said clad material

InactiveCN1933928AControl tensionIncrease cooling rateHeat exchange apparatusMetal rolling arrangementsMeeting placeMolten metal

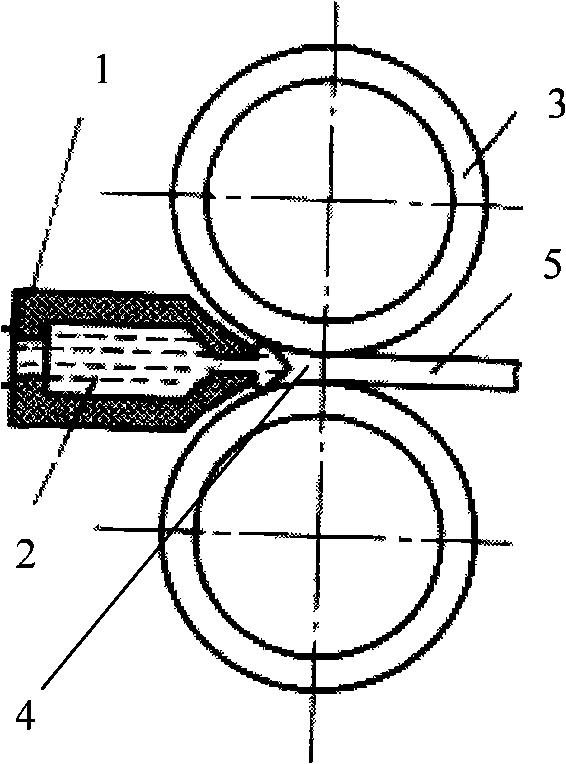

A method for manufacturing a clad material in which a core material is cast and skin materials are pressure-bonded thereon aims to prevent deterioration of adhesiveness of the core material and the skin materials while keeping sufficient cooling rate of the core material, prevent thickness variation and / or breakage of the skin materials during the manufacturing process, and keep the surface property of the cooling rolls constant. The method for manufacturing a clad material (11) includes the steps of continuously supplying molten metal (M) into a gap between a pair of cooling rollers (2a) (2b) to cast a core material, and cladding skin materials (10a) (10b) on both surfaces of the core material with hot rolling by continuously supplying the skin materials on peripheral surfaces of the cooling rollers so that the skin materials prevent direct contact between the cooling rollers and the molten metal, wherein the skin materials are supplied so as to come into contact with the peripheral surfaces of the cooling rollers, and wherein a contact distance (L1) from a contact starting point (P1) where the skin material begins to come into contact with the cooling roller to a meeting point (P2) where the skin material begins to come into contact with the molten metal is set to 100 times or more of a thickness (t1) of the skin material.

Owner:SHOWA DENKO KK

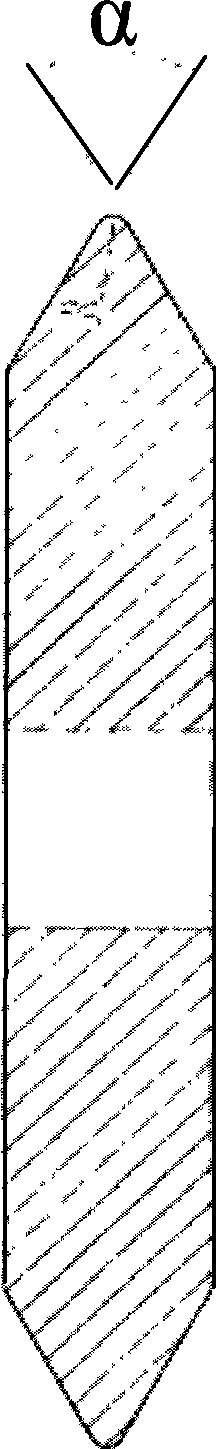

Method and device for manufacturing metal amorphous wires

The invention relates to a method and a device for manufacturing metal amorphous wires, belonging to the field of the direct forming and the approximate forming of rapid amorphous wire solidification. The device comprises a vacuum system, a smelting system, a drawing system and a master alloy feeding mechanism and is technologically characterized in that alloy well melted according to nominal compositions is made into a preformed rod with the diameter of 6mm to 10mm; a metal roller is processed into an edge-form excircle with a certain angle, and the perform rod is put into a BN crucible to be melted into a protrusion in a steamed bread shape; and a lifting device is utilized at a suitable temperature to slowly lift alloy liquid until rise to the top and contact with the metal roller so as to dip out a melting body layer with a certain thickness under the integrative actions of the momentum transfer and the alloy physical properties and round the melting body layer into wires under the actions of the gravity, the surface tension, the solidification contraction, and the like. The metal amorphous wires produced by the method and the device have the advantages of high de-crystallization degree, good roundness and evenness, and the like, are particularly suitable for production with ferromagnetic wire materials, such as a Co base, a Fe base, and the like and can also be used for the direct forming and the approximate forming of active metal wires, such as a Ti base, an Al base, and the like.

Owner:HARBIN INST OF TECH

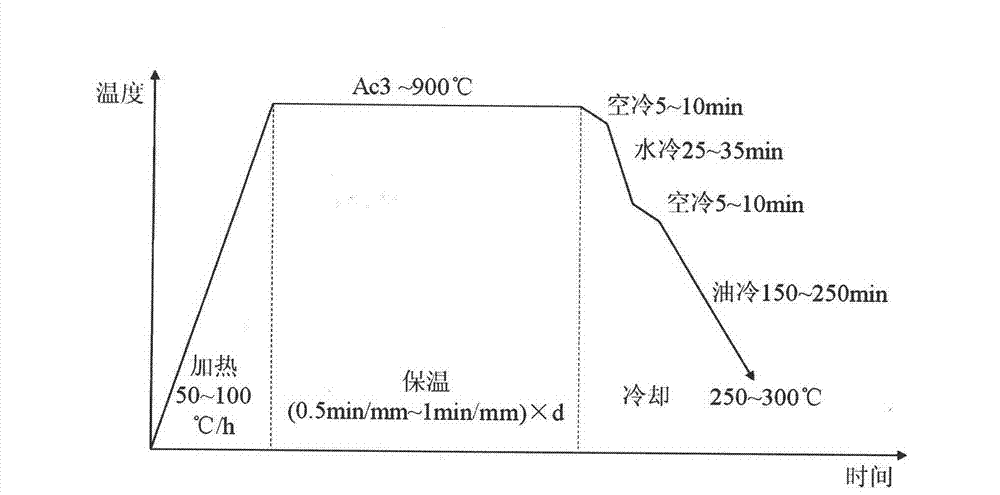

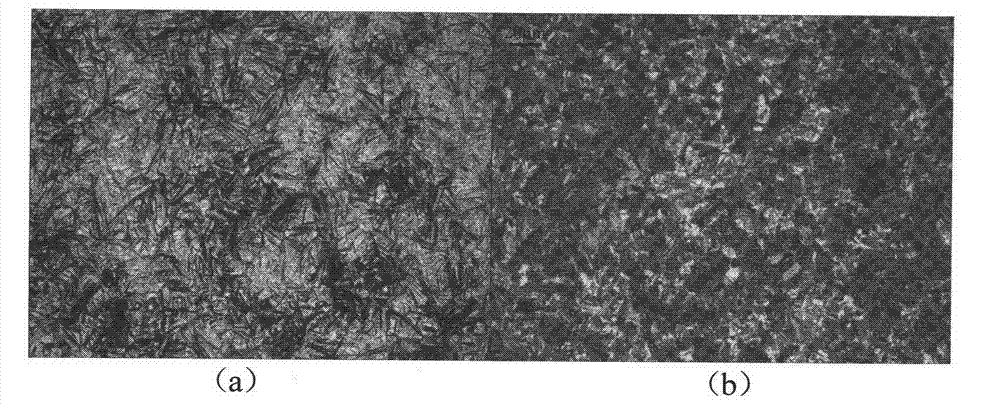

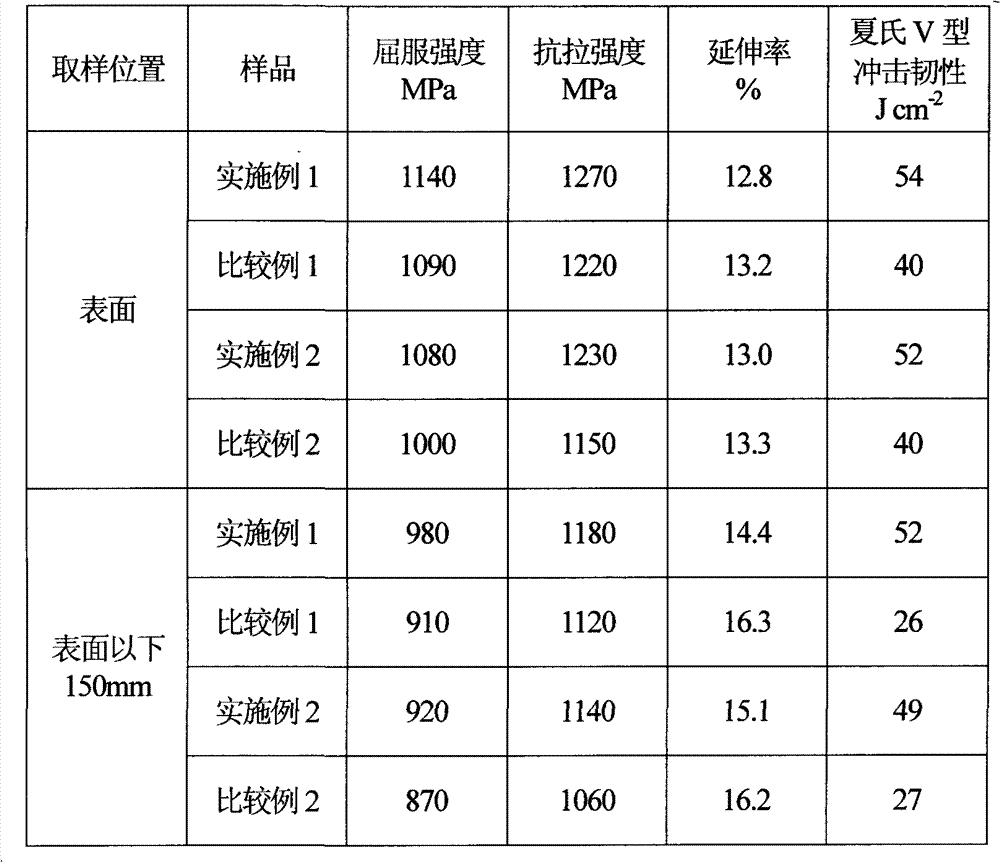

Quenching heat treatment process for hot work die steel with low heat resistance

ActiveCN102776450AAddressing poor organizational performanceAvoid it happening againForging/hammering/pressing machinesHeat resistanceAlloy

The invention relates to the field of heat treatment technology and provides a quenching heat treatment process for low-heat resistance hot work die steel which has low content of alloy and costs little in production and especially for low-heat resistance hot work die steel with a great tonnage and a great size. The process overcomes the problem that insufficient cooling capability of quenching oil causes generation of abundant upper bainite structures, which further leads to deterioration of the performance of steel. The quenching heat treatment process comprises the following steps: heatingthe low-heat resistance hot work die steel and carrying out insulation and full austenization on the low-heat resistance hot work die steel; carrying out segmented quenching heat treatment by using different cooling mediums at different temperatures; and carrying out tempering heat treatment immediately after surface temperature of the low-heat resistance hot work die steel drops to a certain range. According to the invention, a high cooling rate and low residual stress are obtained through a segmented quenching technique based on characteristics of changes of a microstructure of the low-heatresistance hot work die steel in the process of continuous cooling, and therefore, generation of abundant upper bainite structures in the low-heat resistance hot work die steel and the phenomena of deformation and cracking during quenching heat treatment are avoided and the purposes of improving comprehensive mechanical properties and prolonging a service life are achieved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

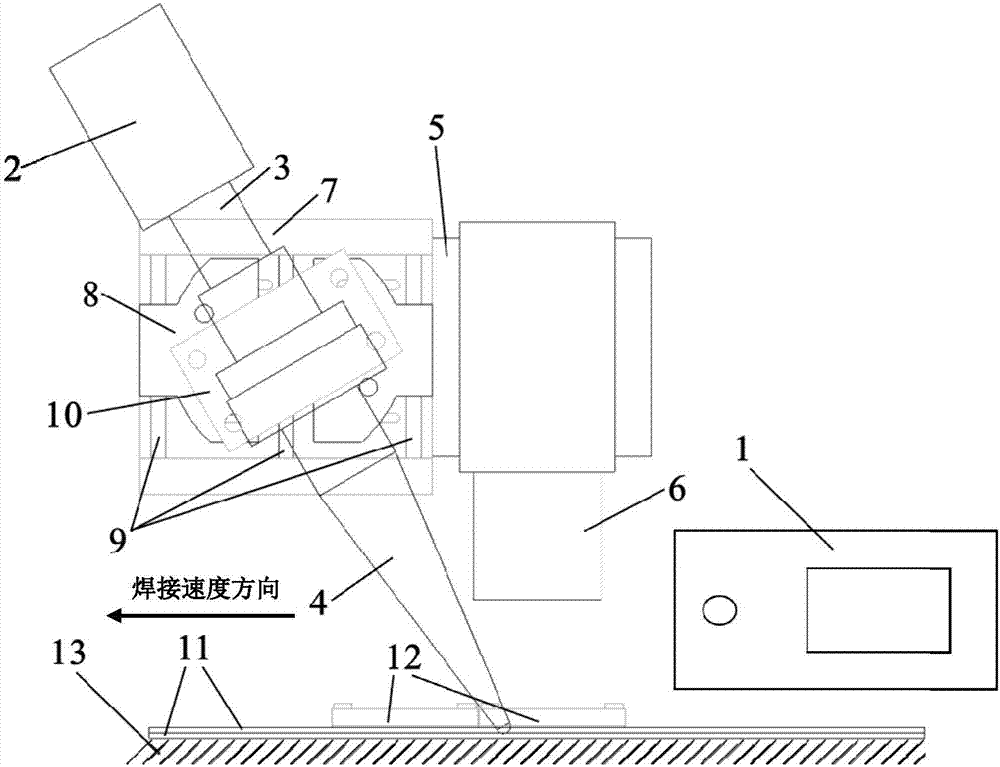

Ultrasonic vibration assisted laser welding method for heterogeneous material

ActiveCN107570872ASpeed up the flowFully dilutedLaser beam welding apparatusWeld seamAlternating current

The invention belongs to the technical field of laser welding and relates to an ultrasonic vibration assisted laser welding method for a heterogeneous material. Ultrasonic vibration is introduced intolaser welding of the heterogeneous material, specially, ultrasonic-frequency alternating current is produced by an ultrasonic generator, vibration production and amplitude magnification are implemented by an ultrasonic vibrator, and finally, the ultrasonic vibration is guided into a welding pool by the welding material. Follow-up regulation is performed on the laser welding process of the heterogeneous material by means of special effect produced through ultrasonic vibration in the welding pool. Compared with a traditional laser welding method for the heterogeneous material, designed ultrasonic vibration assisted laser welding equipment for the heterogeneous material can effectively inhibit formation of an incomplete fusion area and a brittle phase in a welding seam and homogenizes element distribution in the welding seam, so that mechanical performance and corrosion resistance of a welding joint are improved, meanwhile, a laser machining system is not required to be changed, and theapplication of the method is not limited by size of the welding material.

Owner:DALIAN UNIV OF TECH

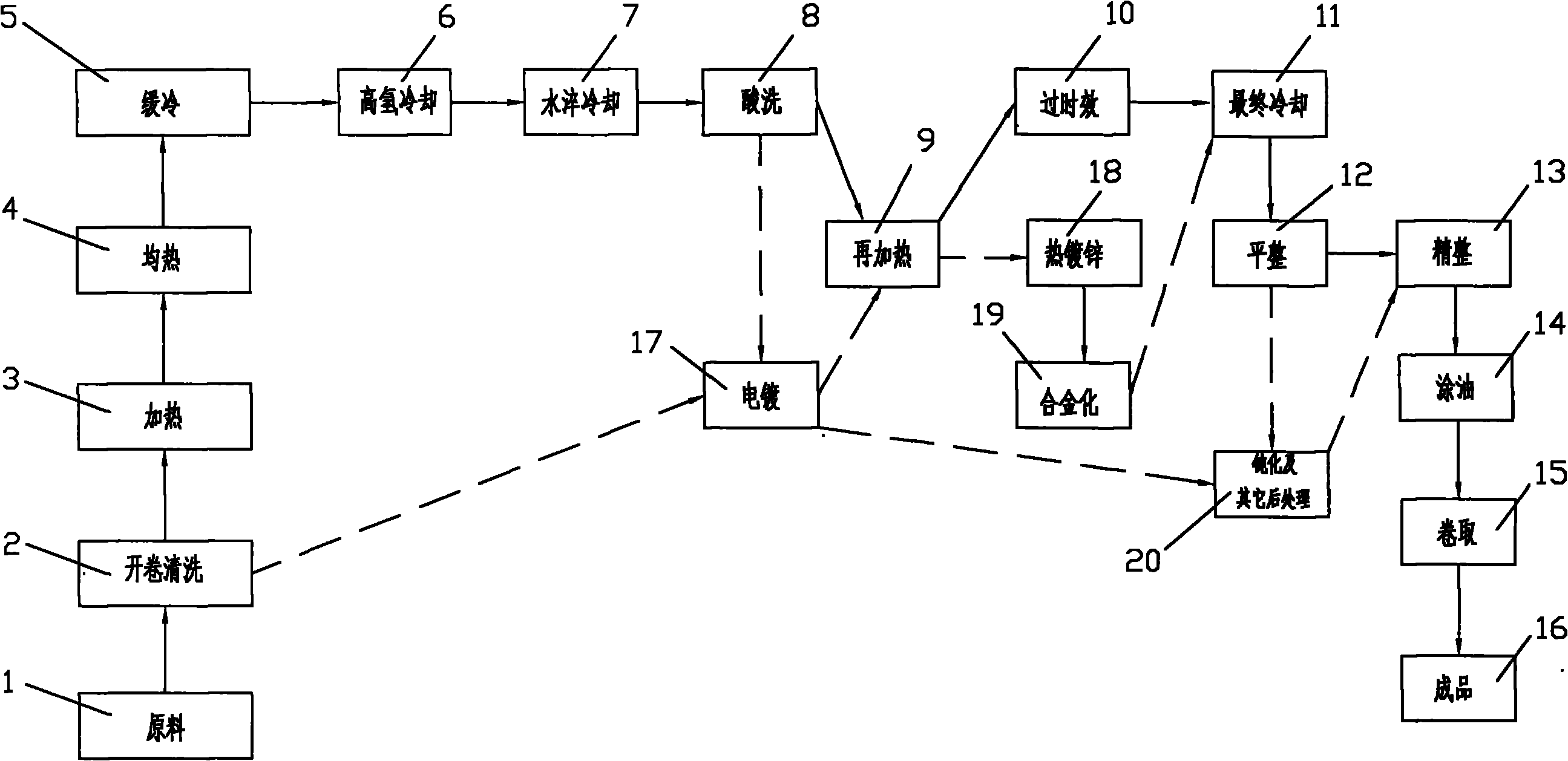

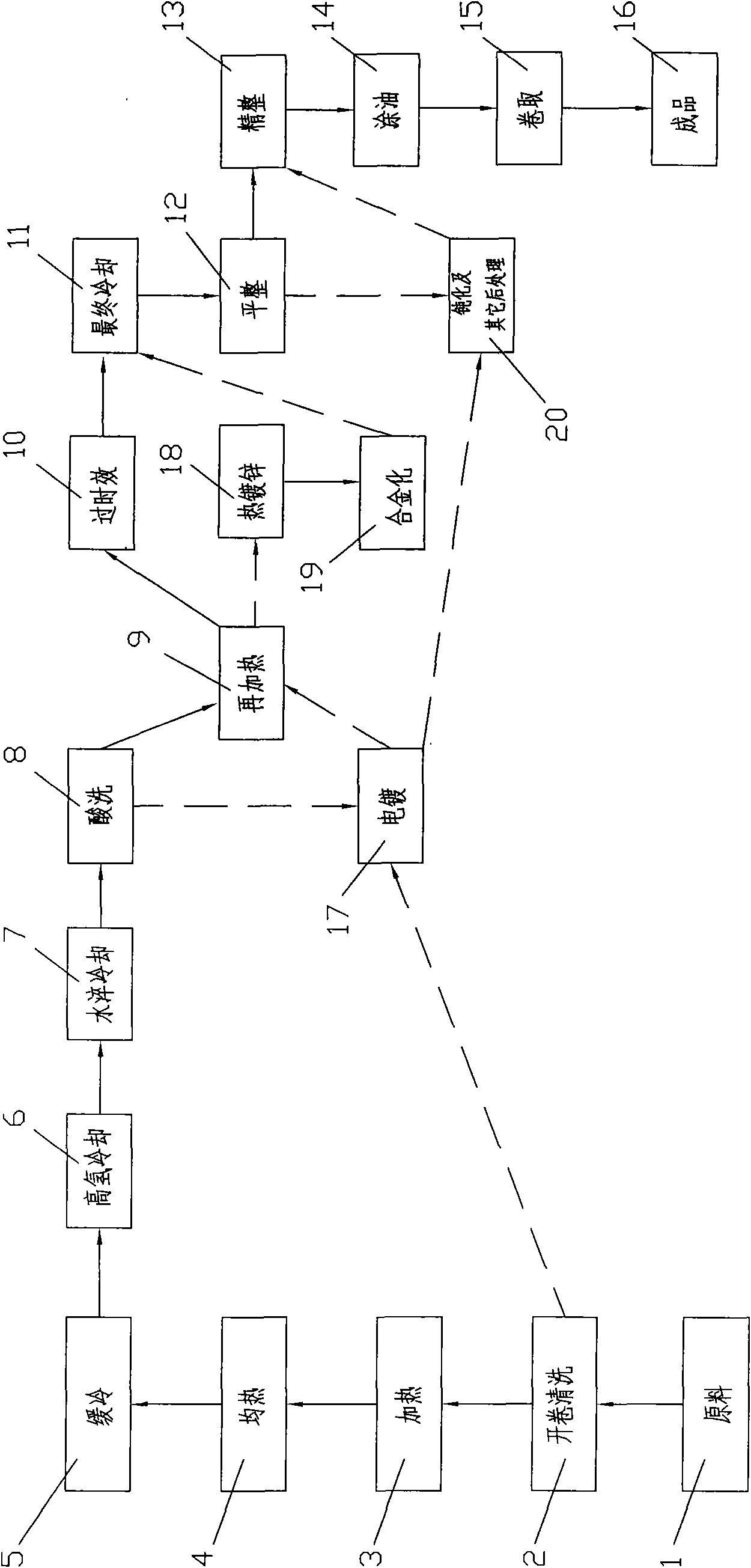

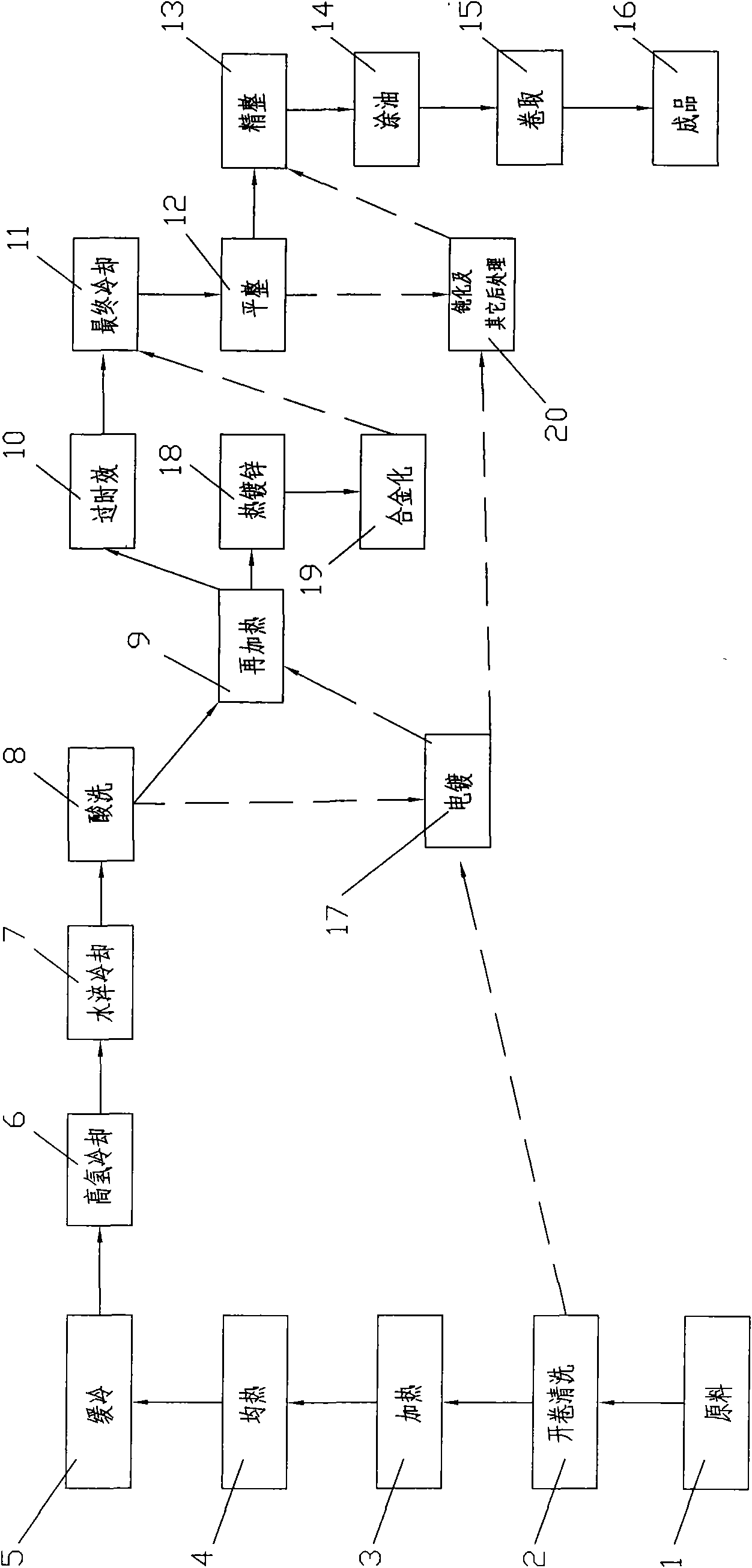

Flexible strip processing line suitable for producing various high-strength steel

ActiveCN101812578ARich product varietyReduce manufacturing costHot-dipping/immersion processesFurnace typesElectroplatingSlow cooling

The invention discloses a flexible strip processing line suitable for producing various high-strength steel, which has the following configuration: decoiling, cleaning, heating, soaking and slow cooling stations are arranged sequentially to a gas jet cooling station and a water quenching cooling station; a reheating station is arranged on the rear of the gas jet cooling station; an overaging station or hot galvanizing station and coating normalizing and annealing station are arranged on the rear of the reheating station, and a movable bypass channel is connected with the reheating and overaging stations; then, final cooling and leveling stations are arranged, and oiling or passivating and other postreatment stations are connected to a coiling station so as to obtain finished products; an acid pickling and electroplating stations are arranged corresponding to the water quenching cooling station; and a connecting channel is arranged on the rear of the electroplating station, and is correspondingly connected with the reheating or directly connected with the passivating station and other posttreatment stations. The flexible strip processing line integrates production of common cold-rolled sheets, and hot dip galvanized and coating alloying annealed sheets and electroplating of Zn and Ni sheets, particularly superstrength cold-rolled sheets, galvanized sheets and hot dip galvanized and coating alloying annealed sheets to one machine set so as to realize flexible production.

Owner:BAOSHAN IRON & STEEL CO LTD

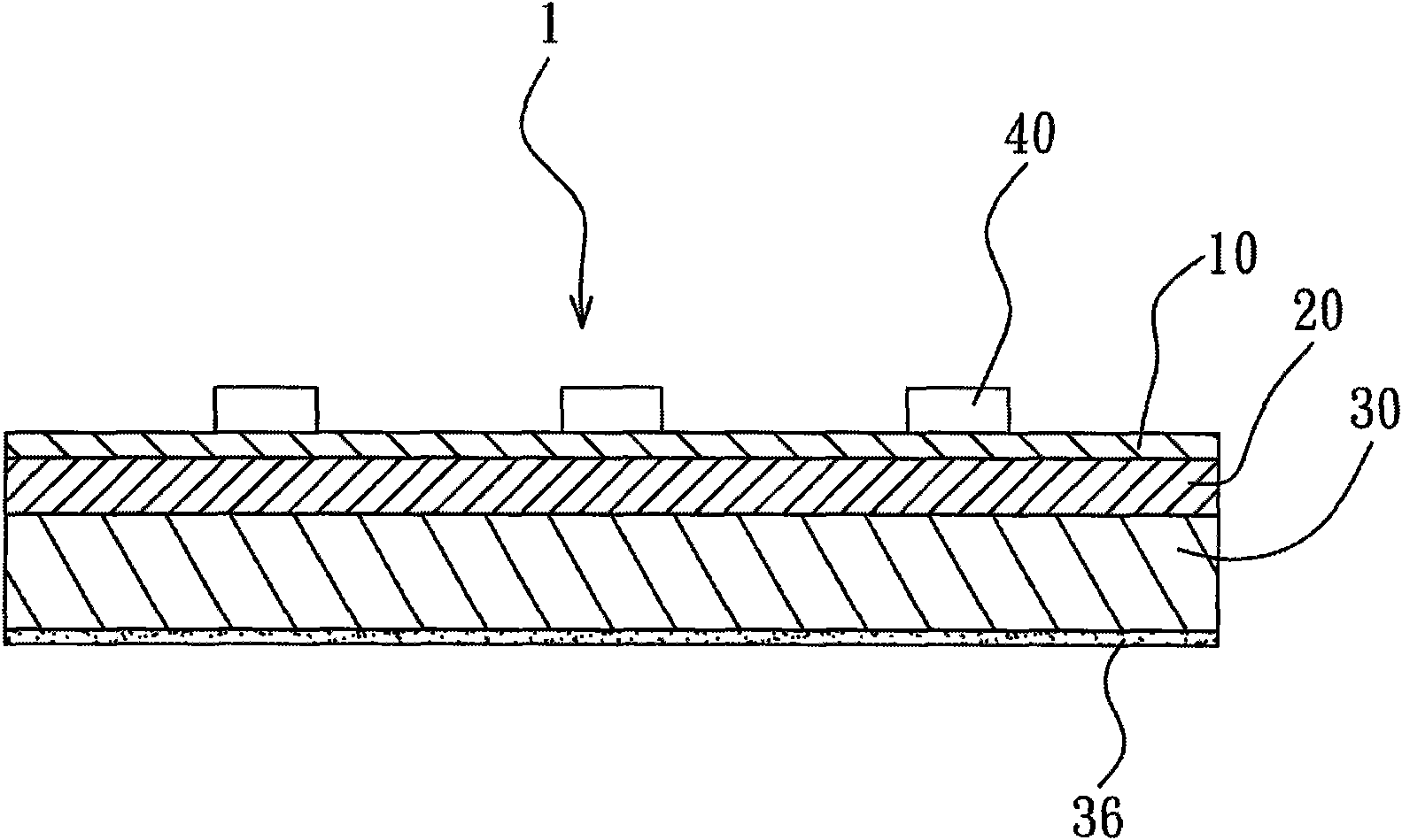

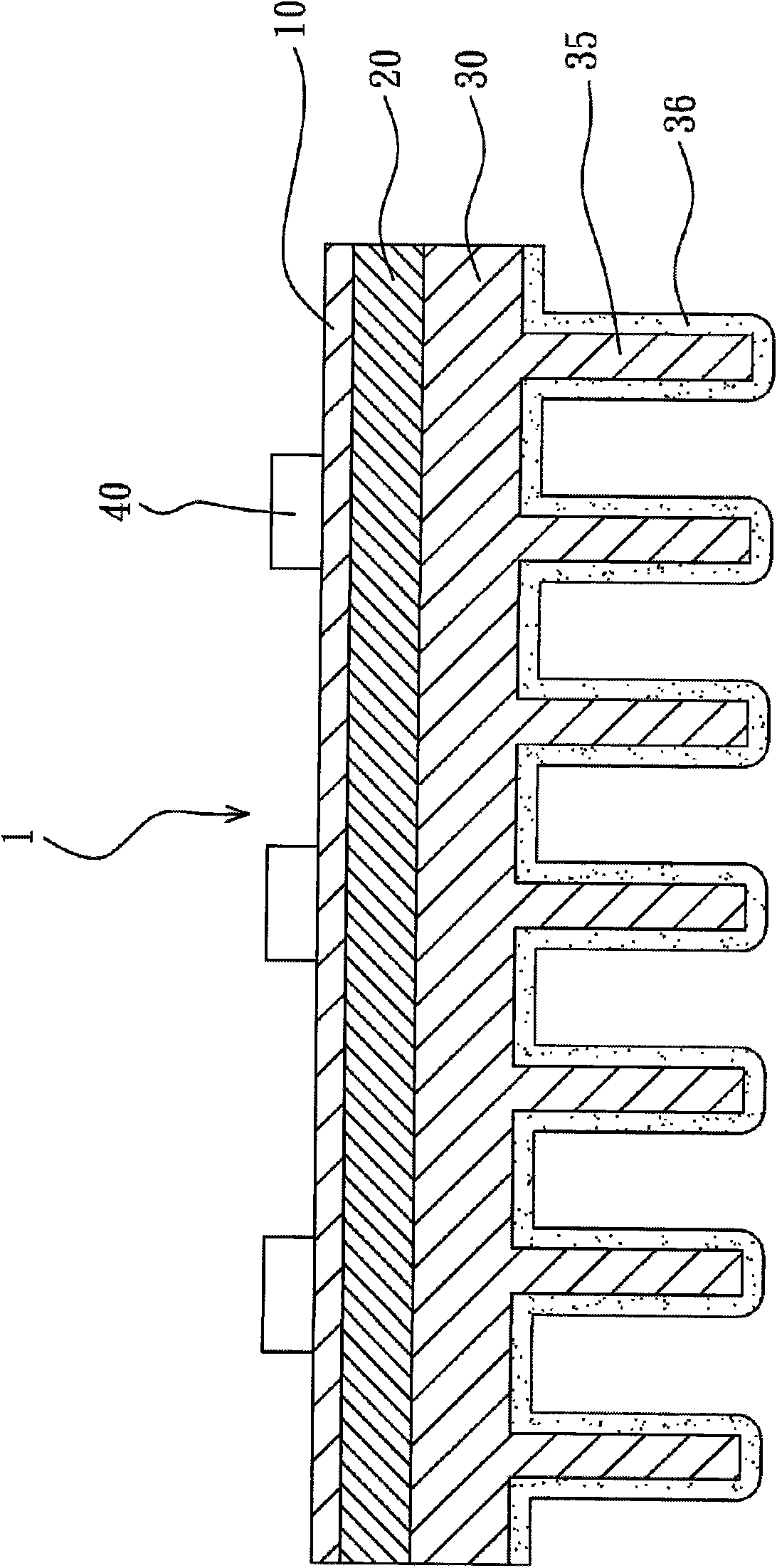

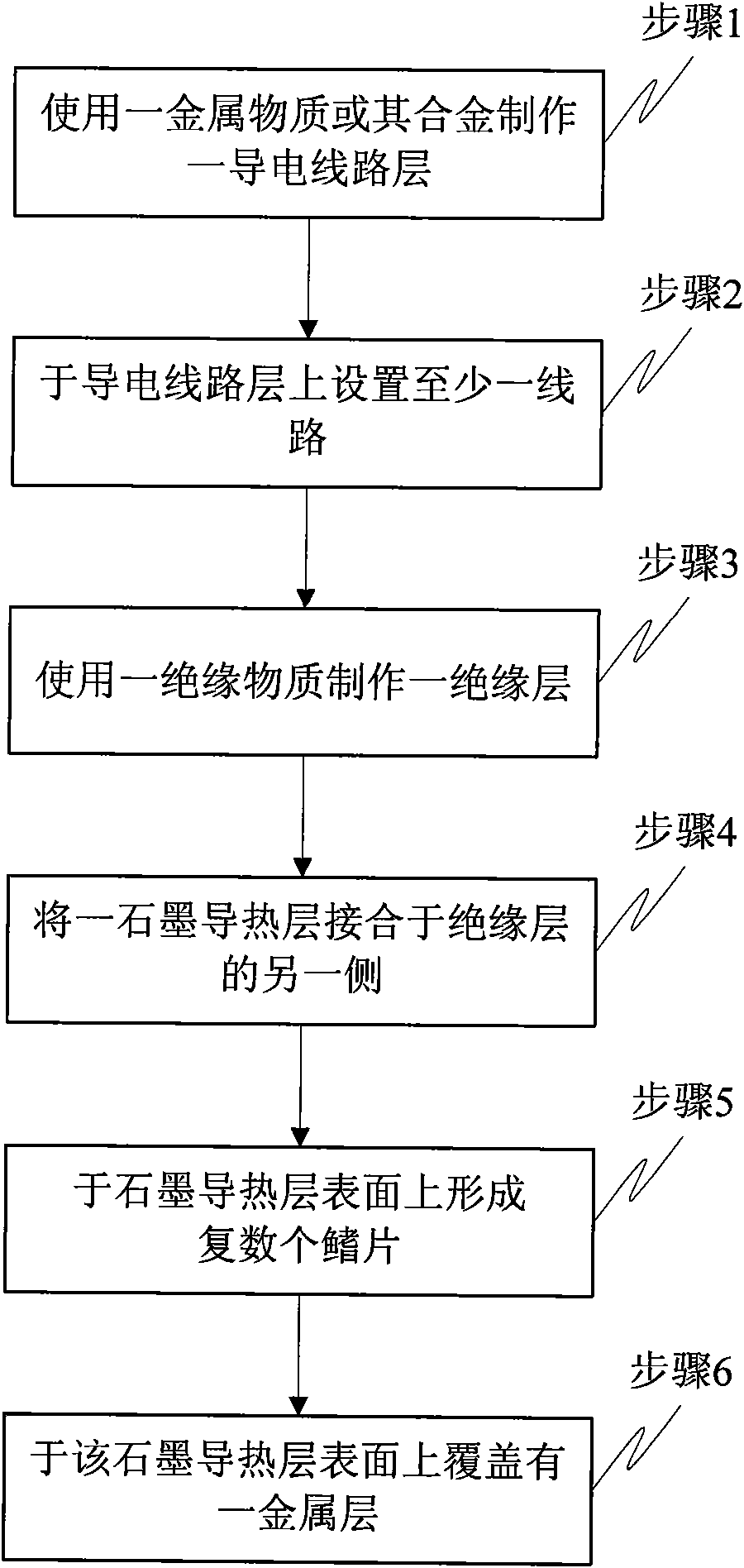

High heat radiating circuit substrate and manufacturing method thereof

InactiveCN101652020AReduce manufacturing costDiffused evenlyPrinted circuit detailsPrinted circuit manufactureManufacturing cost reductionHeat conducting

The invention relates to a high heat radiating circuit substrate and a manufacturing method thereof. The high heat radiating circuit substrate comprises a conducting wire layer, an insulating layer and a graphite heat conducting layer, wherein at least one electronic component can be arranged on the conducting wire layer, and wires are arranged on the conducting wire layer for connecting the electronic component; the insulating layer is positioned at one side of the conducting wire layer; and the graphite heat conducting layer is arranged at one side of the insulating layer and can uniformly radiate the heat generated by the electronic component. The manufacturing method of the high heat radiating circuit substrate comprises the following steps: firstly, using a metallic substance or an alloy thereof to manufacture the conducting wire layer; secondly, forming at least one wire on the conducting wire layer; thirdly, using an insulating substance to manufacture the insulating layer; andfourthly, jointing the graphite heat conducting layer to the other side of the insulating layer. Since the heat conducting layer of the high heat radiating circuit substrate and the manufacturing method thereof use the graphite material, not only the manufacturing cost can be reduced, but also the heat can be radiated uniformly to increase the heat radiating rate, and the like.

Owner:大连九久光电制造有限公司

Novel system for preparing spherical powder through plasma atomization

The invention discloses a novel system for preparing spherical powder through plasma atomization. The novel system for preparing spherical powder through plasma atomization comprises a feeding device, one or more plasma cabinets, an atomization tower, a vacuum pump and an air supply device, wherein the vacuum pump and the air supply device are both connected with the atomization tower, and the air supply device is used for supplying inert gas. The novel system for preparing spherical powder through plasma atomization further comprises a powder screening device, and a discharge outlet of the atomization tower is connected with the powder screening device. The plasma cabinets are mounted at the top of the atomization tower. The atomization tower comprises an inner wall and an outer wall, and a water-cooling interlayer is formed between the inner wall and the outer wall. The multiple plasma cabinets are arranged, raw materials in the molten state are impacted while raw materials are molten through a gathering focus point of a plurality of angled jet flows by means of the high-temperature and high-speed jet flows, and the particle size of powder is effectively reduced; and an atomization main body is cooled rapidly through the water-cooling interlayer, so that atomized materials are cooled at a high cooling speed, and the quality and sphericity of collected fine powder are increased.

Owner:JIANGSU TIANYING PLASMA TECH CO LTD +1

Method for eliminating light induced degradation of boron-doped crystalline silicon cell and device thereof

InactiveCN106711285AIncrease cooling rateReduce light-induced attenuationFinal product manufactureSemiconductor devicesOxygen compoundOptoelectronics

The invention provides a method for eliminating light induced degradation of a boron-doped crystalline silicon cell. Reduction of the cell efficiency caused by the cell boron-oxygen compound process can be eliminated through fast heating and high illumination processing, constant temperature heating and high illumination processing and fast cooling and keeping out of the sun and cooling processing so that the efficiency and the reliability of the cell can be enhanced and the production cost of the cell can be saved. Correspondingly, the invention also provides a device for eliminating light induced degradation of the boron-doped crystalline silicon cell. The structure is simple and operation is convenient.

Owner:DONGFANG HUANSHENG PHOTOVOLTAIC (JIANGSU) CO LTD

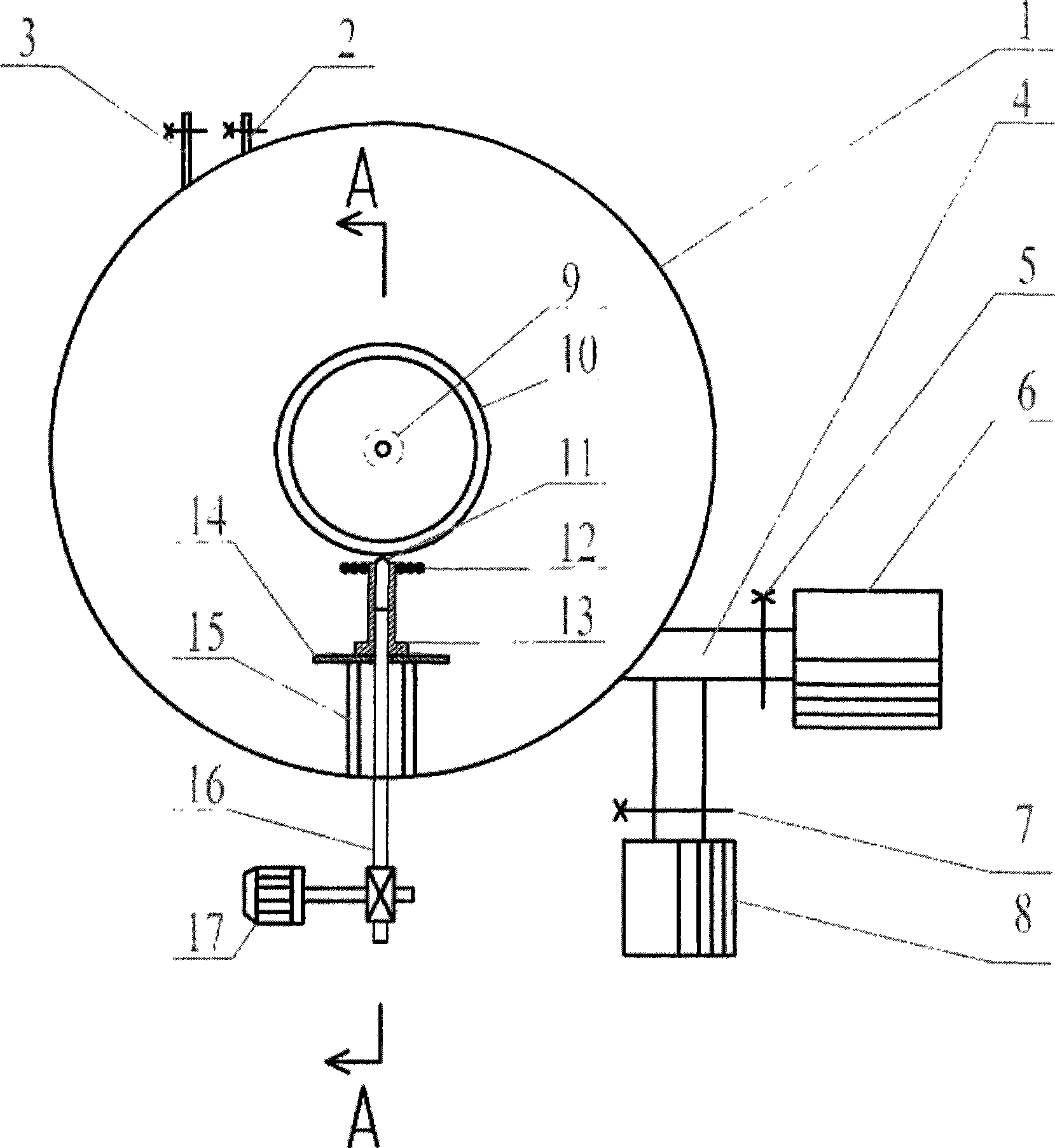

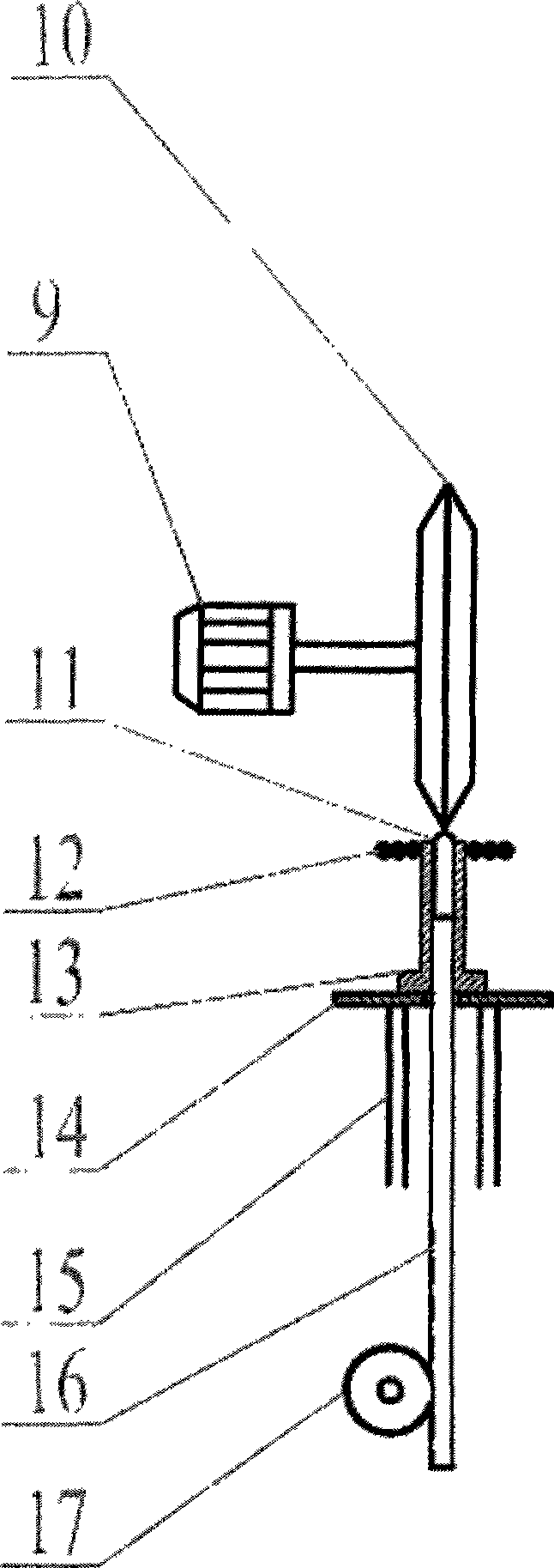

Liquid molten slag dry-type centrifugal granulation and afterheat recycle system having molten slag buffer-storage and flow control functions

ActiveCN108330233AEnsure structural stabilityGuaranteed operational safetyExhaust gas handlingRecycling and recovery technologiesMetallurgyIron industry

The invention discloses a liquid molten slag dry-type centrifugal granulation and afterheat recycle system having molten slag buffer-storage and flow control functions. The system comprises a molten slag buffer-storage and flow control unit, a granulation unit, a mobile bed unit and an afterheat utilization unit; the molten slag buffer-storage and flow control unit is arranged at the upper part ofthe granulation unit and is used for buffer-storage of the liquid molten slag and controlling the flow rate and speed of the liquid molten slag falling to the granulation unit; the granulation unit is used for granulating the falling liquid molten slag; the mobile bed unit is arranged at the lower part of the granulation unit and is used for cooling and temporarily storing the granulated molten slag; hot air inside the granulation unit and the mobile bed unit communicates with the afterheat utilization unit; and the afterheat utilization unit comprises a hot air flue, a primary dust collector, an afterheat boiler, a secondary dust collector, an exhaust fan and a chimney which are arranged in sequence. The system disclosed by the invention does not use water resources, is free of environmental pollution, can effectively recycle high-quality afterheat resources contained in the high-temperature liquid molten slag, and can meet the urgent requirements of energy conservation and emissionreduction of the present steel and iron industry.

Owner:XI AN JIAOTONG UNIV

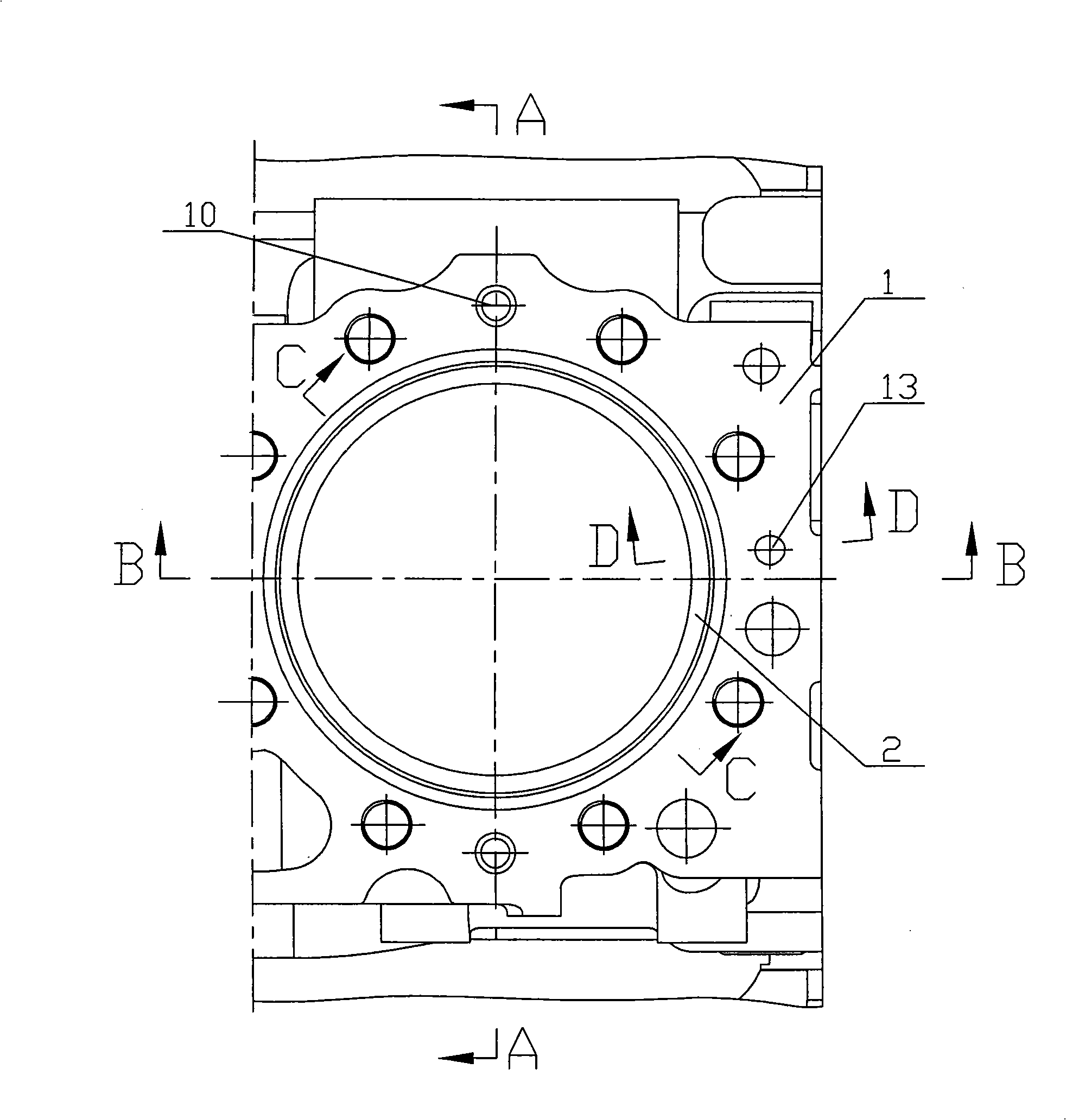

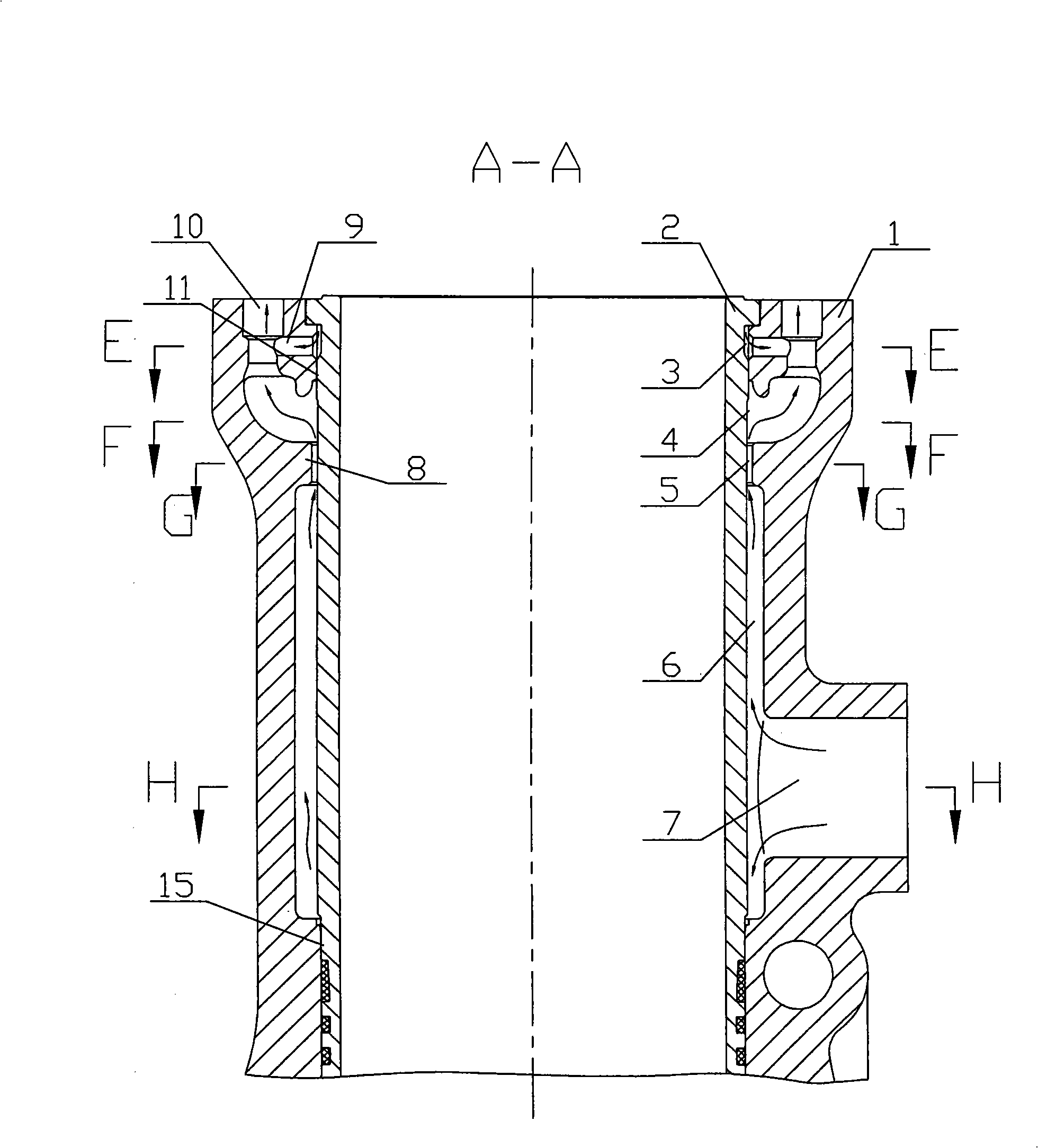

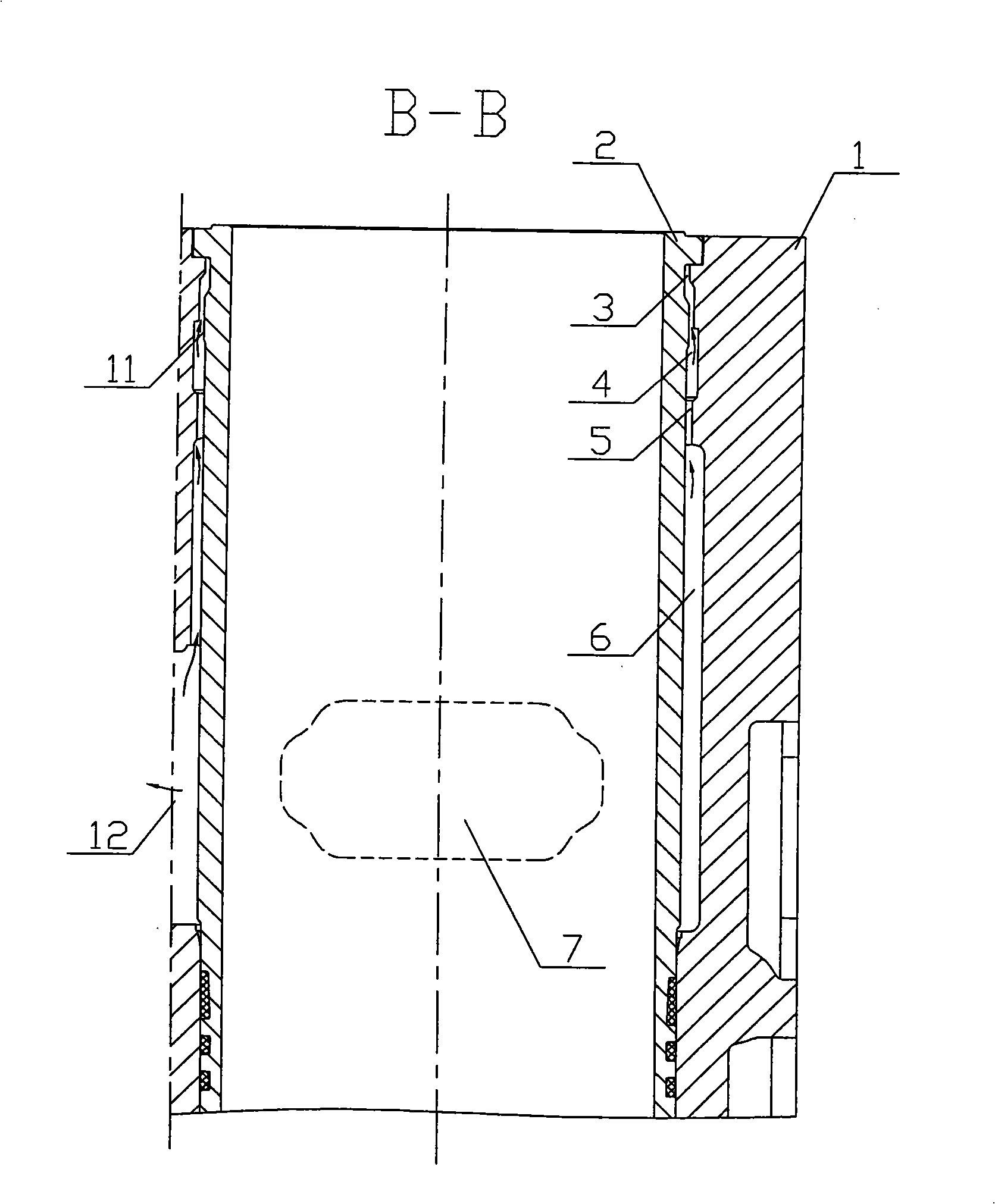

Water-cooled engine body

InactiveCN101349213AIncrease flow rateHigh trafficLiquid coolingCylinder headsCooling chamberEngineering

The invention relates to a water-cooled engine body, in particular to an air cylinder body of a wet-type cylinder liner engine. The air cylinder body comprises a cylinder body and a cylinder liner, and is characterized in that an upper positioning belt and a lower positioning belt are arranged on the cylinder liner; the inner surface of the cylinder body is provided with a convex ring; a cooling water channel formed between the lower positioning belt and the convex ring is used as a first cooling chamber; the cooling water channel formed between the convex ring and the upper positioning belt is used as a second cooling chamber; the cooling water channel formed over the upper positioning belt is used as a third cooling chamber; the cross-sectional area of the second cooling chamber is less than that of the first cooling chamber; and the cross-sectional area of the third cooling chamber is less than that of the second cooling chamber. The invention has the advantages that the air cylinder body can raise the flow velocity of cooling liquid, increase the flow rate of the cooling liquid, raise the heat dissipation rate of a high-temperature area, ensure that the whole cylinder liner is uniform in temperature, guarantee normal fit clearances among parts of the cylinder body and guarantee the normal work of the engine.

Owner:WUXI KIPOR POWER CO LTD

6008 aluminum alloy energy absorption box processing technology for automobile

InactiveCN108165841AMeet the requirements of impact energy absorption effectIncrease temperatureEnergy absorptionIngot

The invention belongs to the technical field of aluminum alloys, and relates to a 6008 aluminum alloy energy absorption box processing technology for an automobile. The 6008 aluminum alloy energy absorption box processing technology comprises, by weight, 0.50-0.9% of Si, less than or equal to 0.35% of Fe, less than or equal to 0.30% of Cu, less than or equal to 0,30% of Mn, 0.40-0.7% of Mg, less than or equal to 0.30% of Cr, less than or equal to 0.20% of Zn, less than or equal to 0.10% of Ti, 0.05-0.20% of V, less than or equal to 0.05% of single impurity, less than or equal to 0.15% of totalimpurities, and the balance A1. The heating temperature of a mold is 450-500 DEG C in the extrusion process, the heating temperature of an extrusion barrel is 400-450 DEG C, the heating temperature of a cast ingot is 510-530 DEG C, the extrusion speed is 5-7m / min, the temperature of an aluminum alloy ingot before quenching is larger than or equal to 520 DEG C, and when cooling is carried out at the temperature from 520 DEG C to 250 DEG C, the cooling speed is larger than or equal to 80 DEG C / S, and the temperature after quenching is less than 60 DEG C. According to the6008 aluminum alloy energy absorption box processing technology, the existing extrusion control parameters are adjusted, the temperature before quenching is raised, and the cooling rate is increased, the product meets the requirements of high precision, high strength and excellent collapse deformation, and the actual verification shows that the final effect of the product meets various standards.

Owner:CHINA ZHONGWANG

420MPa normalizing super-thick steel plate, and preparation method thereof

The invention discloses a 420MPa normalizing super-thick steel plate, and a preparation method thereof. The 420MPa normalizing super-thick steel plate comprises following chemical components, by mass, 0.14 to 0.16% of C, 0.30 to 0.40% of Si, 1.0 to 1.60% of Mn, 0.015 to 0.025% of Als, 0.005 to 0.025% of Nb, 0.065 to 0.10% of V, 0.010 to 0.02% of Ti, 0.2 to 0.45% of Ni, 0.05 to 0.30% of Cu, P less than 0.01% , S less than 0.005%, and the balance Fe and unavoidable impurities. The preparation method comprises following steps: continuous casting steel slab, which contains the above chemical components and possesses a thickness of 400mm, is subjected to two stages of rolling without water cooling, is discharged rapidly, and is subjected to stacking slow-cooling for 72h or more; and after steel plate shot blasting, the steel plate is obtained by normalizing plus accelerated cooling heat treatment process. The normalizing 100-120mm steel plate prepared by the preparation method possesses excellent strength and toughness; yield strength is more than 420MPa; and the normalizing 100 -120mm steel plate can be used for preparation of key force support elements of buildings, bridges and tower structures with large span frameworks.

Owner:SHOUGANG CORPORATION

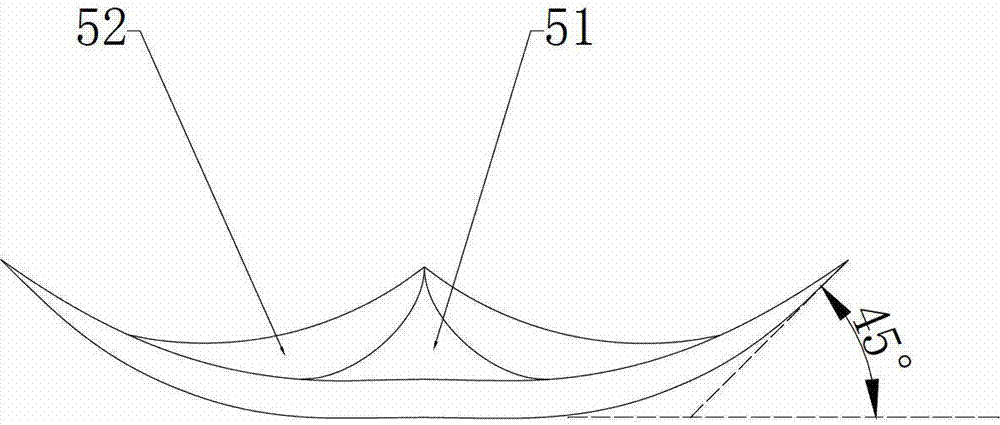

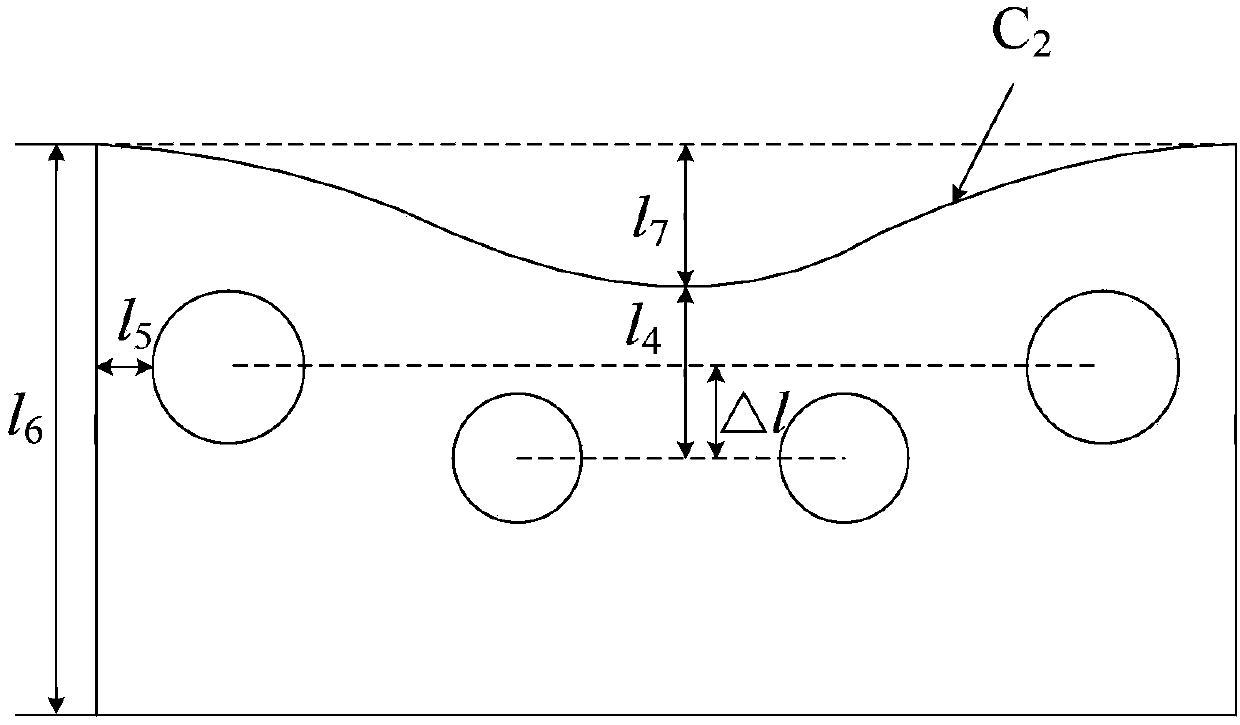

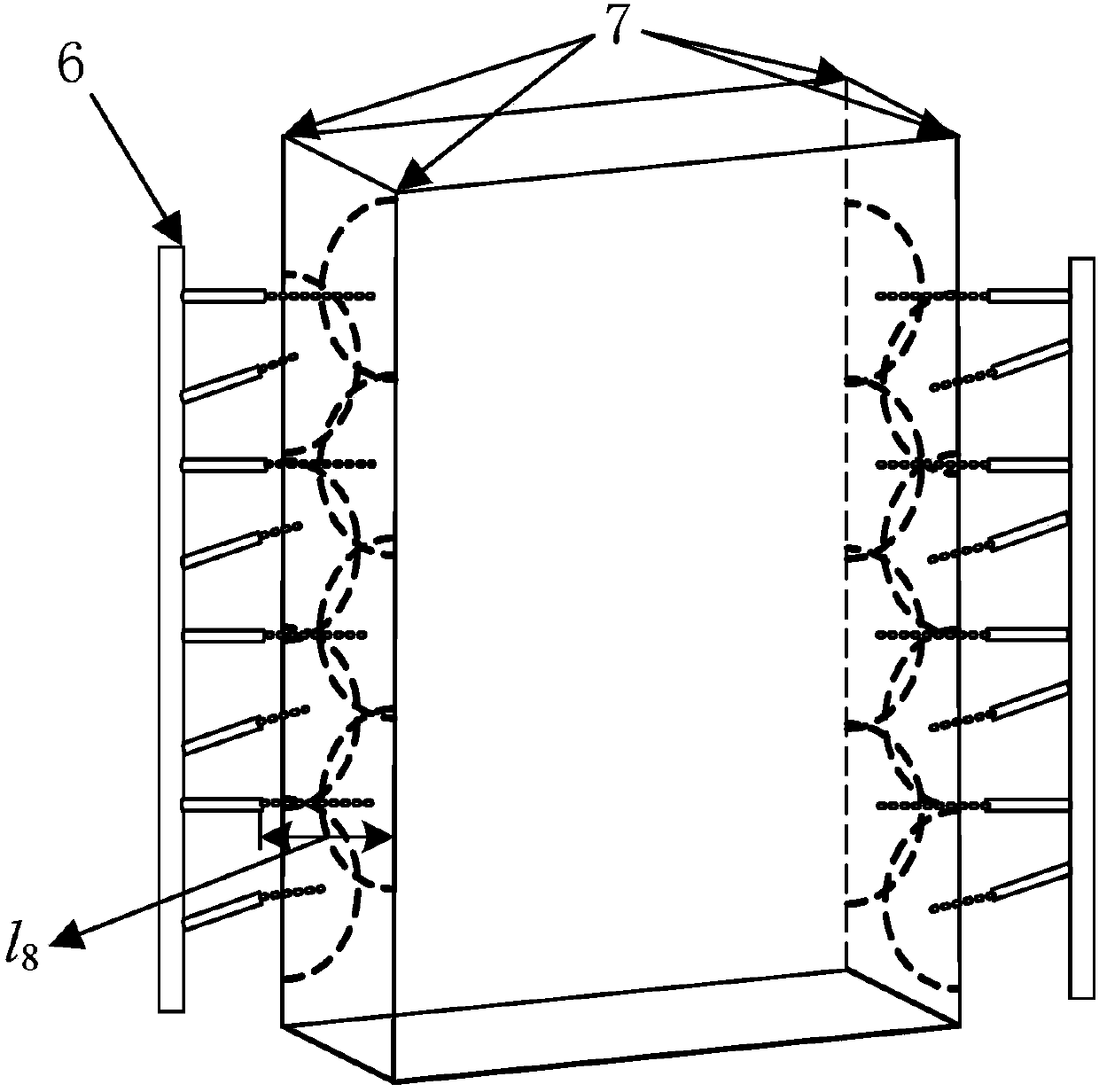

Control device and technology for corner cracks of microalloy steel sheet billet

ActiveCN108356242AIncrease cooling rateImprove tissue plasticityDistribution systemDistribution control

The invention provides a control device and technology for corner cracks of a microalloy steel sheet billet, and relates to the technical field of continuous casting and continuous rolling of steel sheet billets. The control device comprises a secondary cooling water distribution system, a corner efficient heat transfer narrow surface Gauss concave curved surface crystallizer and a crystallizer narrow surface foot roll zone new strengthened spraying system, wherein the new strengthened spraying system comprises a new water supply pipeline, a new strengthened spraying rack and a water distribution control system. In the control technology, dynamic water distribution is achieved through synergism of the corner efficient heat transfer narrow surface Gauss concave curved surface crystallizer,an integral strengthened cooling technology and a water distribution technology of the crystallizer narrow surface foot roll zone new strengthened spraying system and a wide surface integral slow cooling water distribution technology. According to the control device and the control technology, dispersion precipitation of microalloy carbonitride of corner structures of the cast billet can be stablyachieved, the corner structures of the cast billet are strengthened, narrow surface metals flow to side arcs during the large deformation pressing process of a liquid core of the cast billet, stressof the corner parts of the cast billet is reduced, and generation of the corner cracks of the microalloy steel sheet billet is radically controlled.

Owner:NORTHEASTERN UNIV

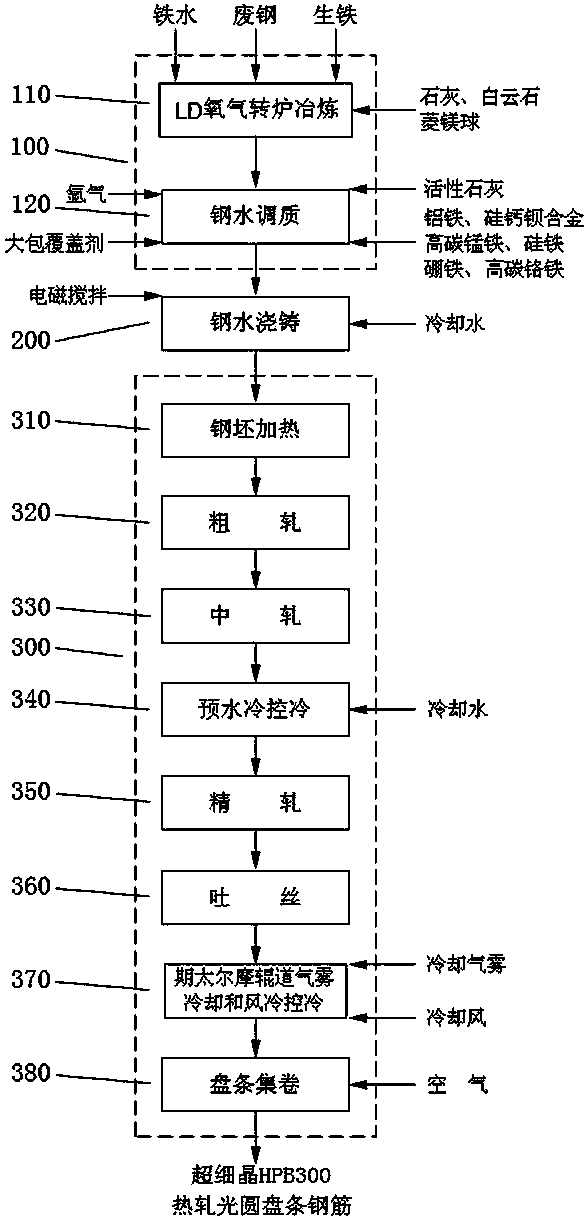

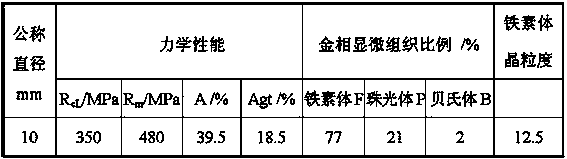

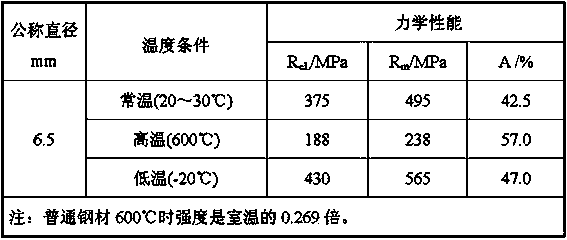

Ultra-fine grained HPB300 hot-rolling optical disc stripe reinforcing steel bar and preparation method thereof

The invention discloses an ultra-fine grained HPB300 hot-rolling optical disc stripe reinforcing steel bar and a preparation method thereof. The ultra-fine grained HPB300 hot-rolling optical disc stripe reinforcing steel bar comprises the following components in percentage by weight: 0.15-0.18% of C, 0.10-0.16% of Si, 0.16-0.28% of Mn, 0.080-0.120% of Cr, 0.0010-0.0020% of B, less than 0.030% of S, less than 0.045% of P and the balance of Fe. The reinforcing steel bar is prepared from molten iron, steel scrap and pig iron through steps of molten steel smelting, molten steel pouring and billet controlled rolling and controlled cooling. According to the reinforcing steel bar, a small amount of ferromanganese, ferroboron and high carbon ferro-chrome alloy into the steel-making step, so that the alloying cost is remarkably lowered. By adopting low-temperature controlled rolling before spinning and a stelmor roller aerial fog cooling process after spinning, the reinforcing steel bar has the advantages of low cost, good toughness, excellent high- and low-temperature performance, low stress time-validity and the like.

Owner:WUKUN STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com