Environmental protection water-solubility quenching liquid

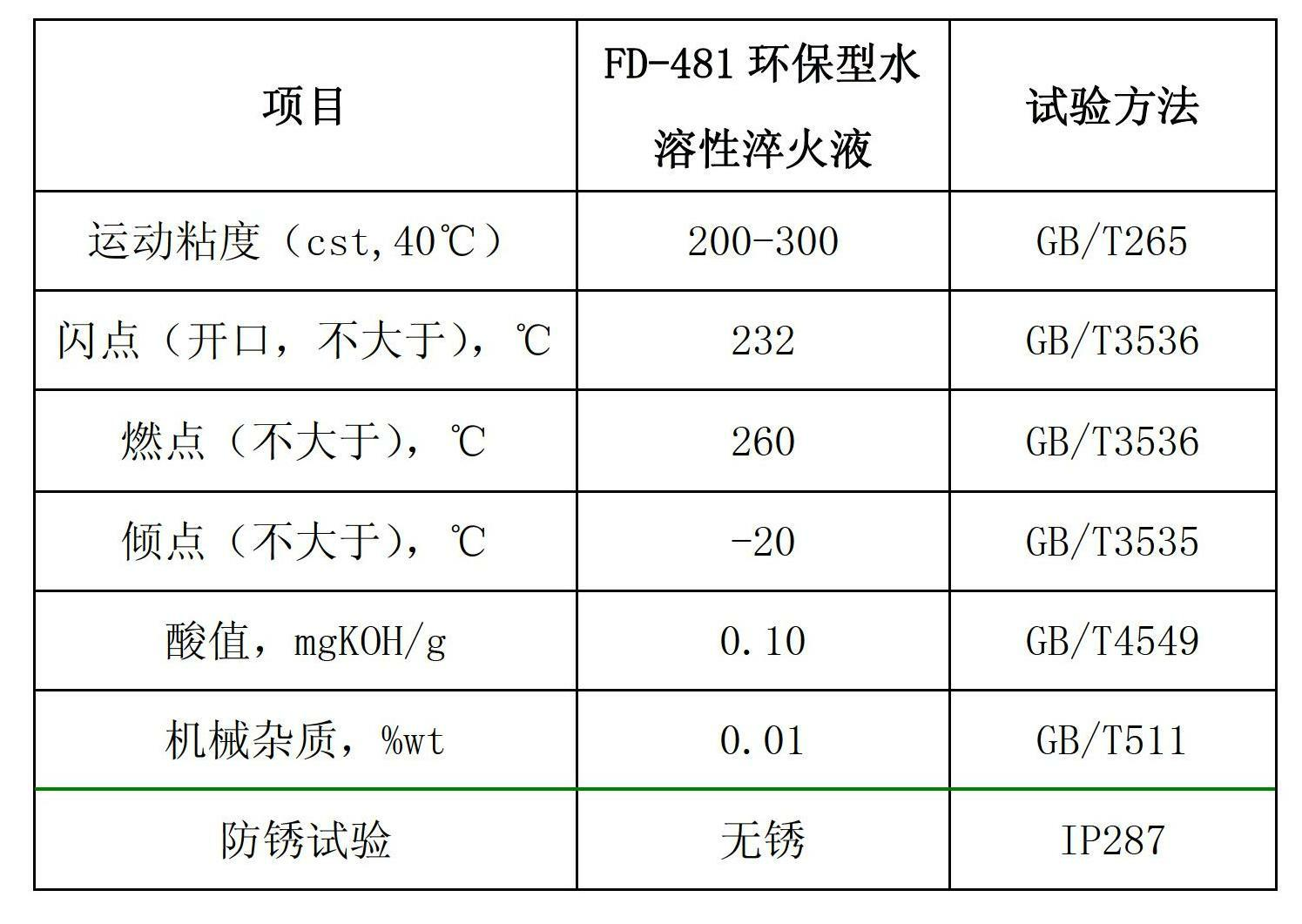

A water-soluble, quenching liquid technology, used in quenching agents, heat treatment equipment, manufacturing tools, etc., to save production costs, meet anti-rust requirements, and improve processing accuracy and surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

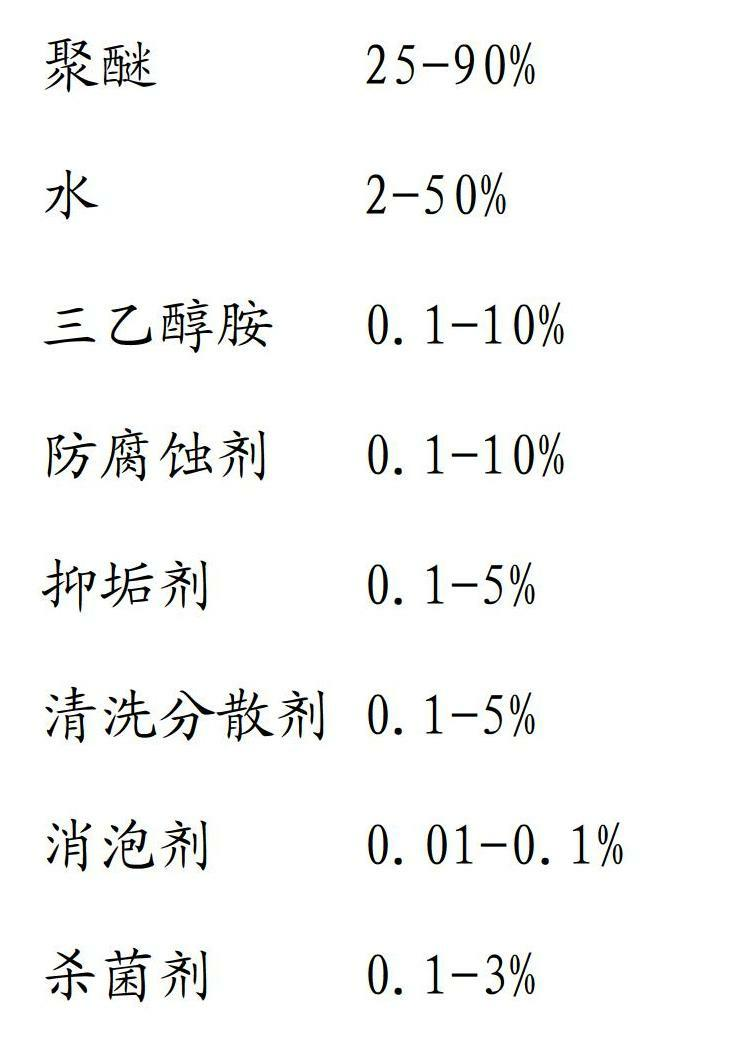

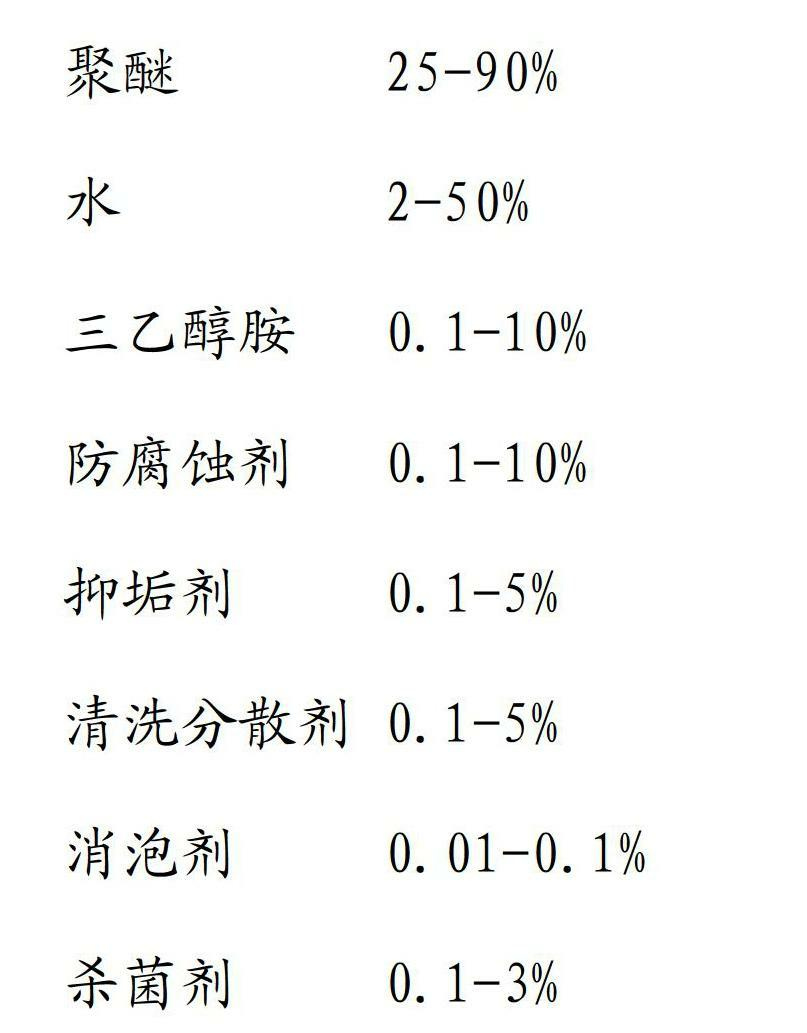

[0017] The environment-friendly water-soluble quenching liquid of the present invention is formed by selecting the following ingredients in proportion, and the weight components are as follows: polyether 3800025%, triethanolamine 8%, sodium benzoate 5.2%, benzotriazole 4.8%, phosphoryl carboxylic acid 4% , polyoxyethylene ether 1.3%, polyethylene glycol 60000.1%, fungicide MIT (isothiazolinone derivatives) 1.6%, and the balance is water.

[0018] The preparation method and steps are as follows:

[0019] According to the process requirements, water, triethanolamine, sodium benzoate, benzotriazole, phosphoryl carboxylic acid, polyoxyethylene ether, polyethylene glycol 6000 and bactericide MIT are weighed in proportion and added to the mixing device and heating function. In the stainless steel blending kettle, adjust the temperature to 30-45°C and stir for 2 hours, slowly add polyether 38000 to dissolve and disperse according to the regulations, and mix and disperse fully. Filte...

Embodiment 2

[0021] The environment-friendly water-soluble quenching liquid of the present invention is formed by selecting the following ingredients in proportion, and the weight components are as follows: polyether 40000 45%, triethanolamine 10%, sodium benzoate 3%, benzotriazole 1.8%, phosphoryl carboxylic acid 0.1 %, polyoxyethylene ether 2%, polyethylene glycol 6000 0.05%, fungicide MIT (isothiazolinone derivatives) 0.1%, and the balance is water.

[0022] The preparation method and steps are as follows:

[0023] According to the process requirements, water, triethanolamine, sodium benzoate, benzotriazole, phosphoryl carboxylic acid, polyoxyethylene ether, polyethylene glycol 6000 and bactericide MIT are weighed in proportion and added to the mixing device and heating function. In the stainless steel blending kettle, adjust the temperature to 30-45°C and stir for 2 hours, slowly add polyether 40000 to dissolve and disperse according to the regulations, and mix and disperse fully. Fil...

Embodiment 3

[0025] The environment-friendly water-soluble quenching liquid of the present invention is formed by selecting the following ingredients in proportion, and the weight components are as follows: polyether 42000 53%, triethanolamine 4%, adipic acid 2.2%, tricarboxylic acid 1.7%, hydroxyethylene phosphoric acid 2%, polyoxyethylene ether 0.1%, polyethylene glycol 0.01%, fungicide MBM (morpholine derivatives) 2.3%, and the balance is water.

[0026] The preparation method and steps are as follows:

[0027] According to the process requirements, water, triethanolamine, adipic acid, tricarboxylic acid, hydroxyethylene phosphoric acid, polyoxyethylene ether, polyethylene glycol and bactericide MBM are weighed in proportion and added to the stainless steel tank with stirring device and heating function. In the blending kettle, adjust the temperature to 30-45°C and stir for 2.5 hours, slowly add polyether 42000 to dissolve and disperse according to the regulations, and mix and disperse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com