Patents

Literature

31results about How to "Moderate cooling rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

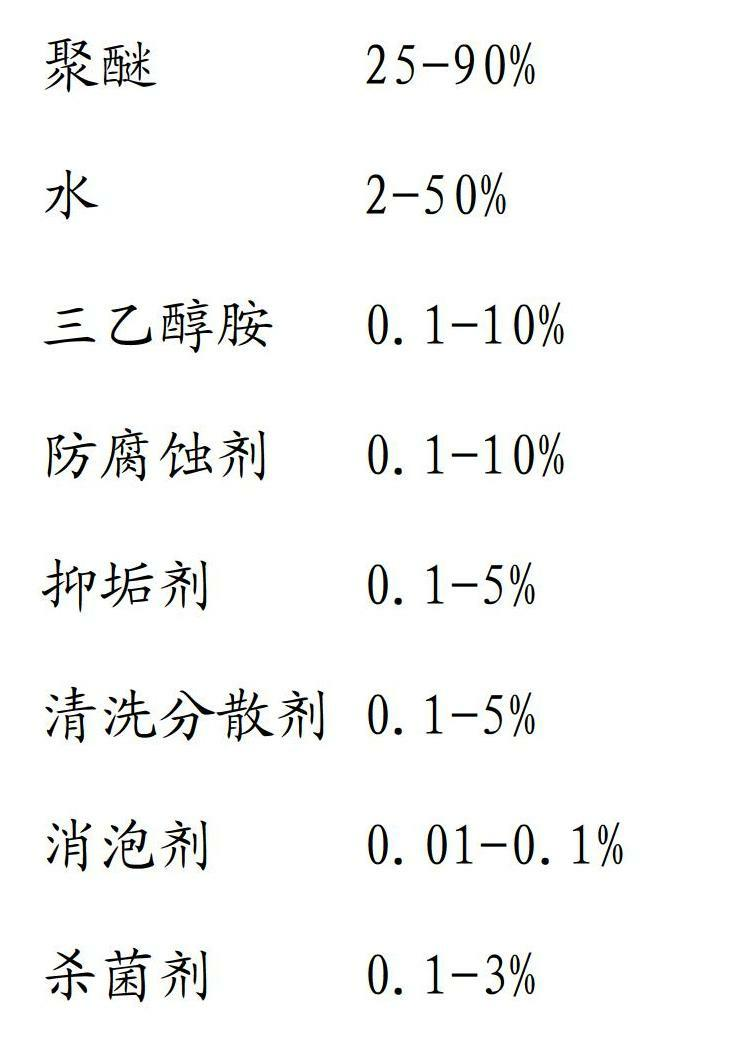

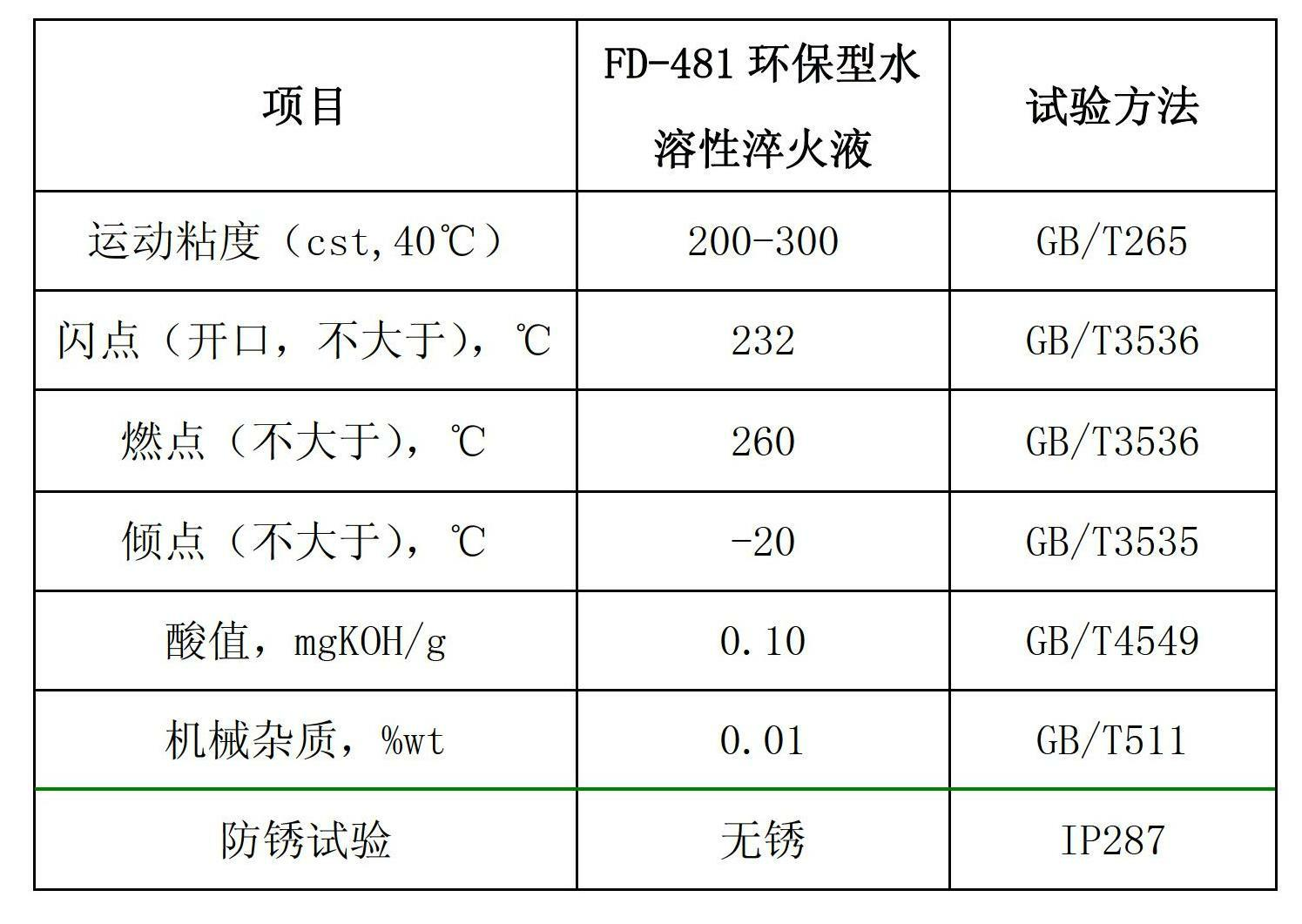

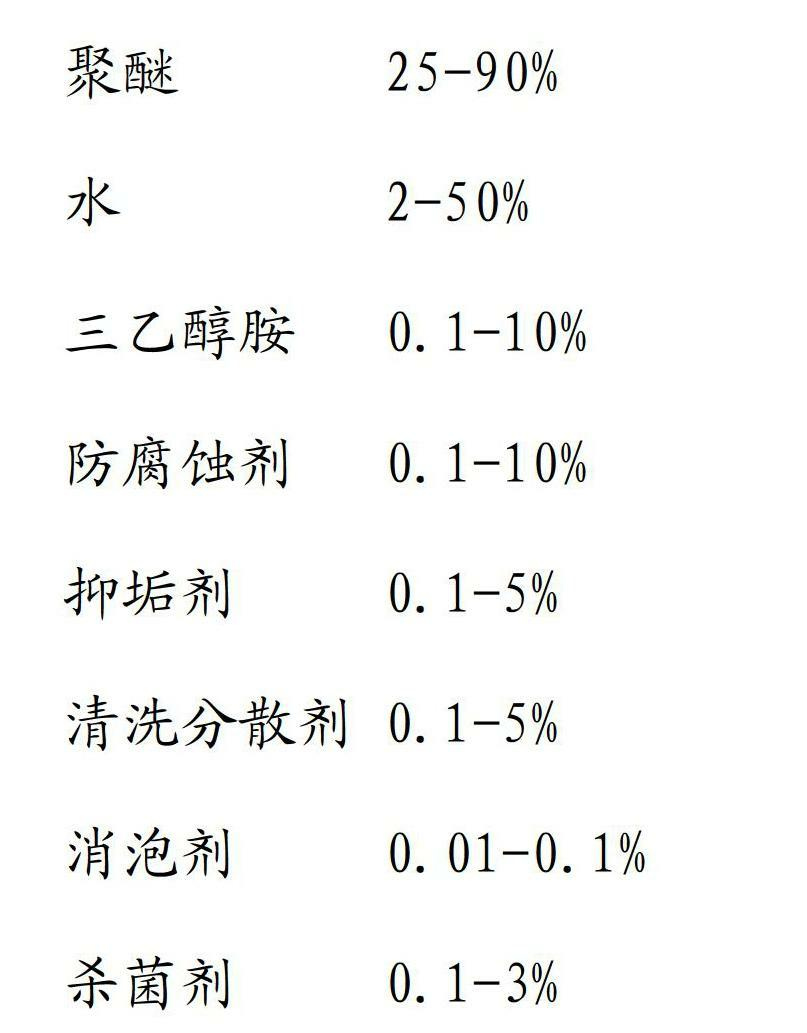

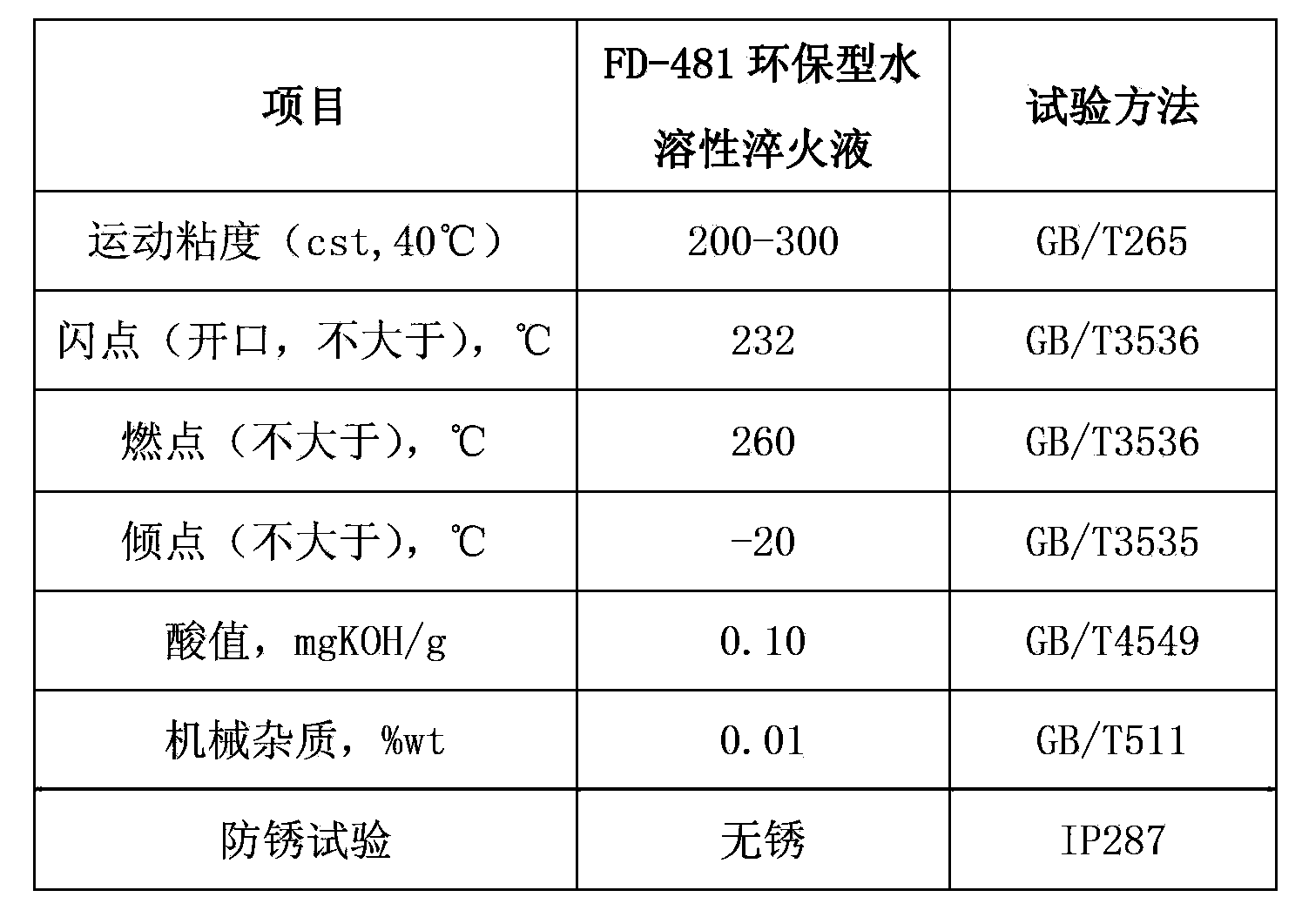

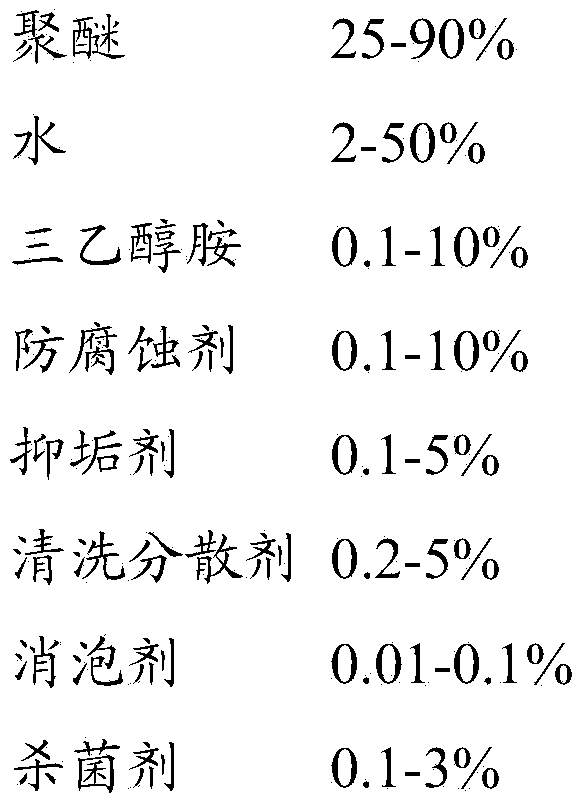

Environmental protection water-solubility quenching liquid

ActiveCN102643963AImprove final performanceImprove machining accuracyQuenching agentsSolubilitySurface cleaning

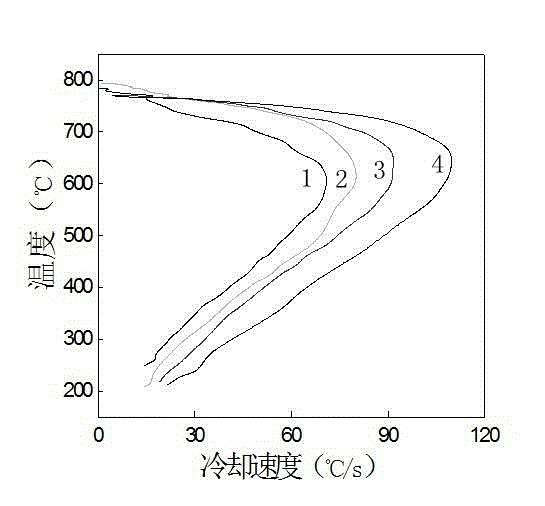

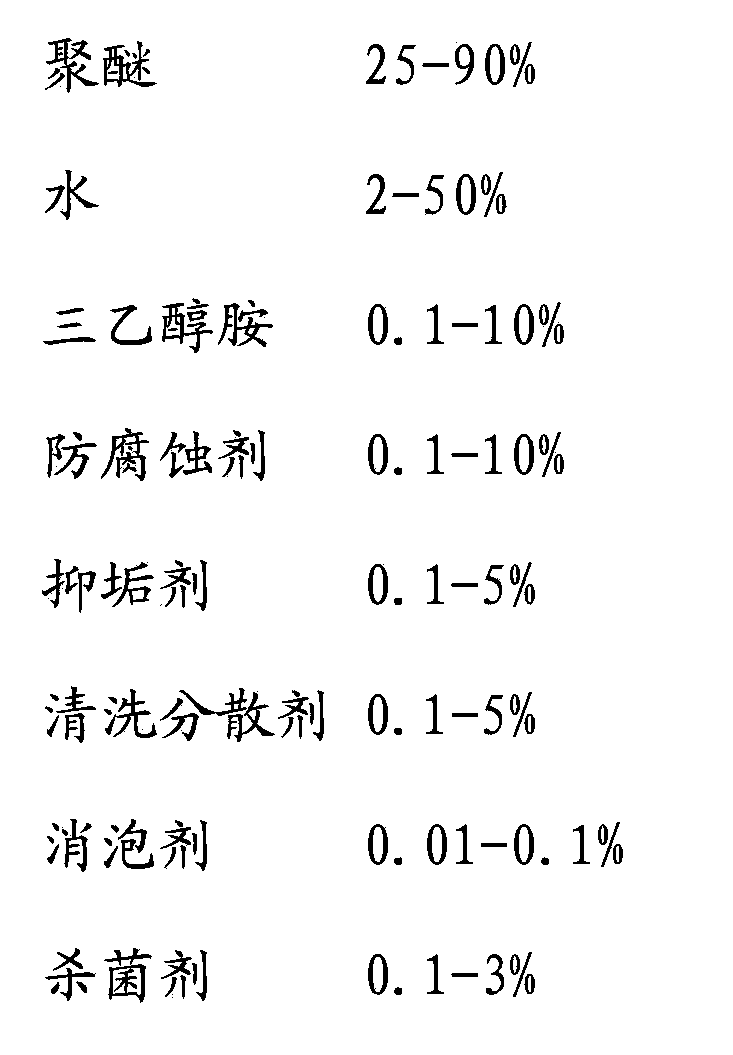

The invention discloses environmental protection water-solubility quenching liquid, which, by weight, comprises components of 25-90% of polyether, 2-50% of water, 0.1-10% of triethanolamine, 0.1-10% of anticorrosive agent, 0.1-5% of dirty restrain agent, 0.1-5% of washing dispersing agent, 0.01-0.1% of antifoaming agent and 0.1-3% of fungicide. The polyether molecular weight is 30000-50000. The water-solubility quenching liquid is compounded with balanced rust-inhibiting additive and the washing dispersing agent, has great cooling speed in a high-temperature cooling stage, can refine grains, has moderate cooling speed in a low-temperature cooling stage, effectively solves cracking and deformation problems in a workpiece cooling process, and improves surface quality of a workpiece. Excellent rust-proof performance effectively protects the quenched workpiece, and rust-proof requirements between working procedures are completely met. The environmental protection water-solubility quenching liquid has prominent surface cleaning performance, scale cinder is avoided, output quantity is small, production efficiency is improved, and production cost is saved.

Owner:上海福岛新材料科技有限公司

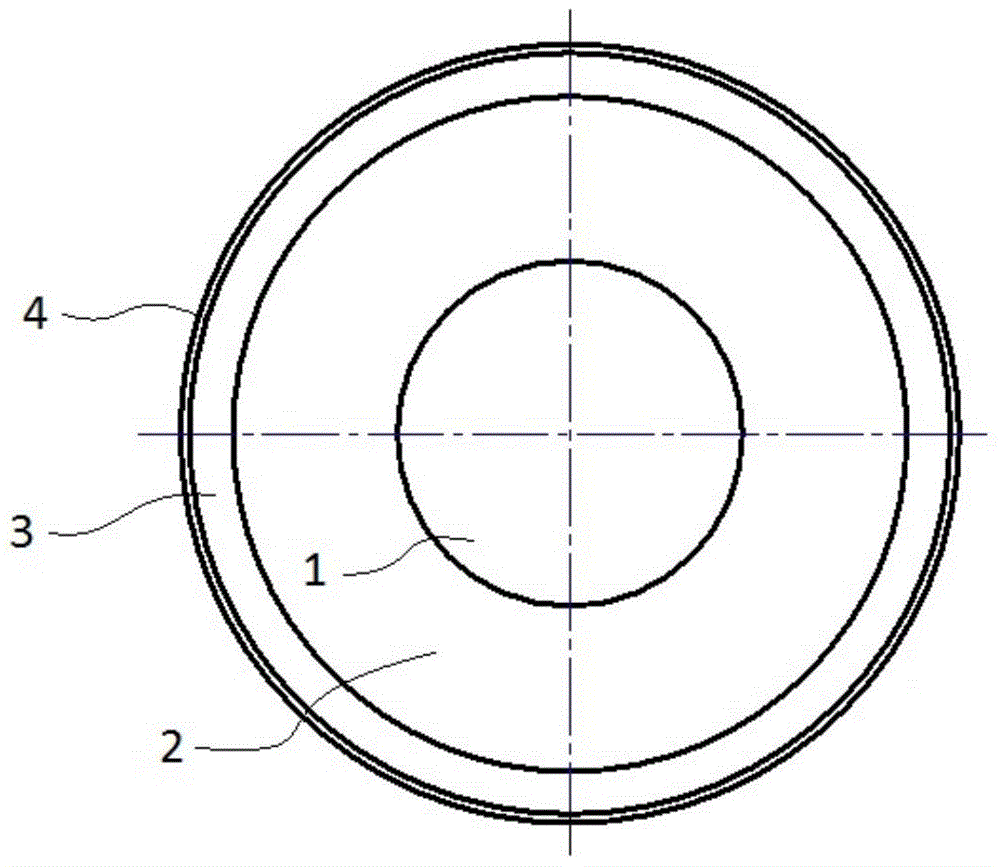

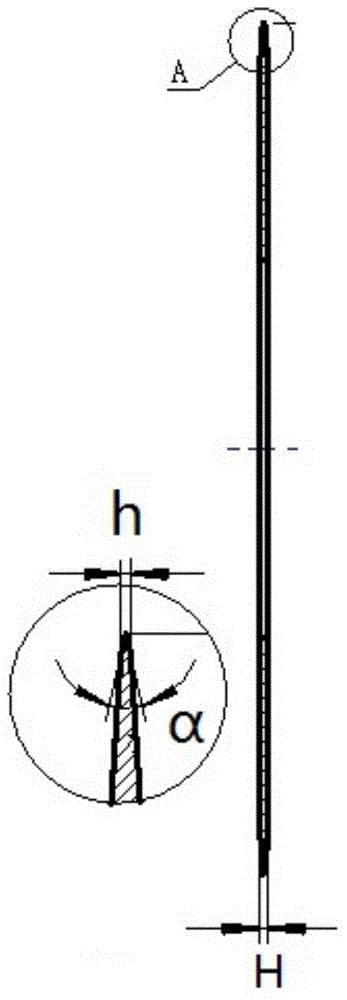

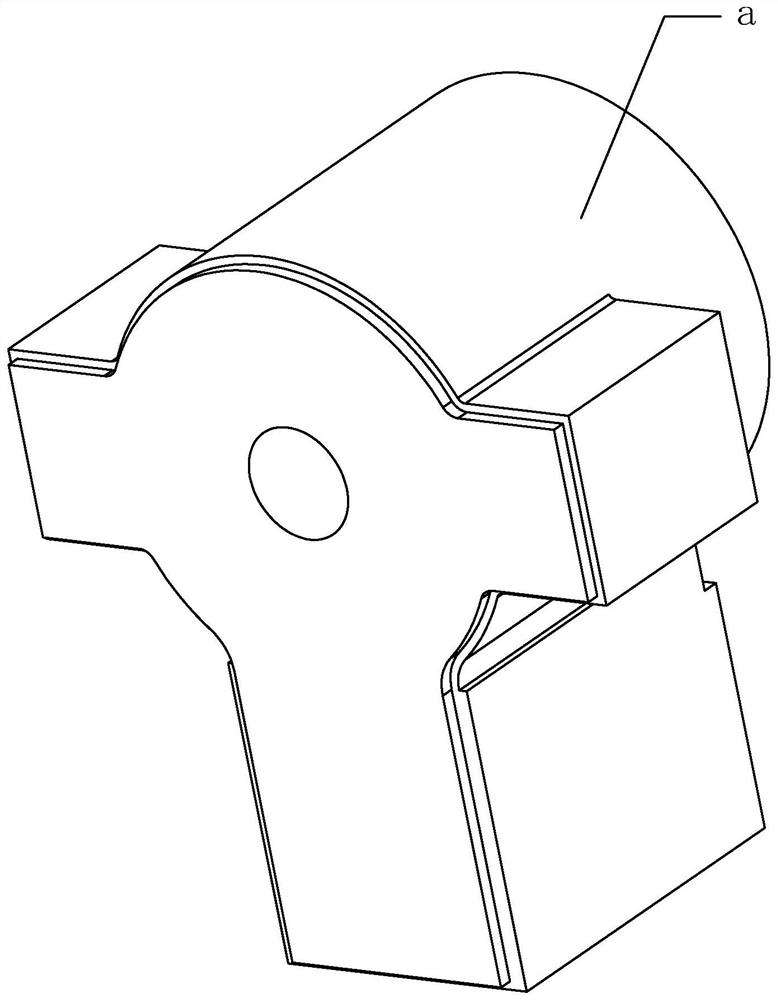

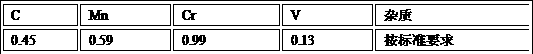

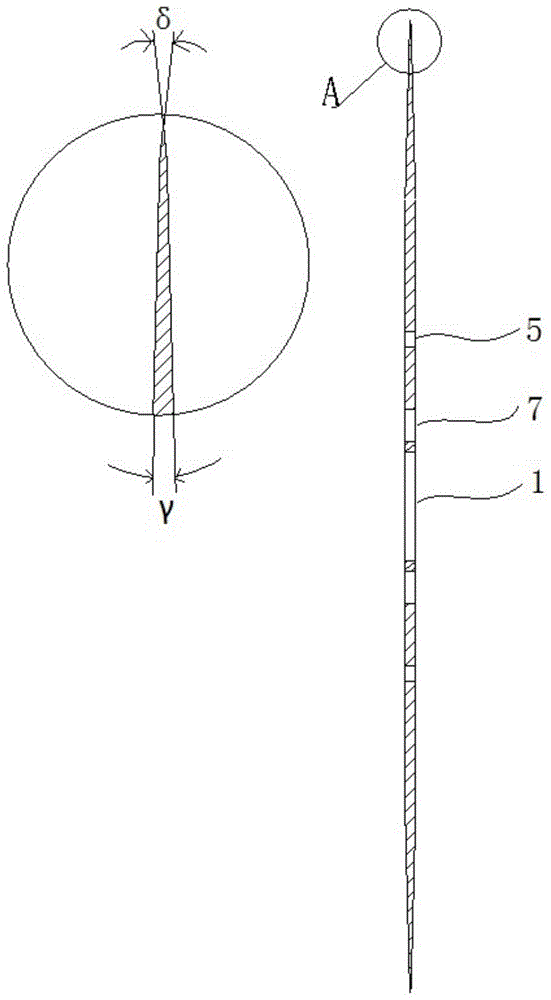

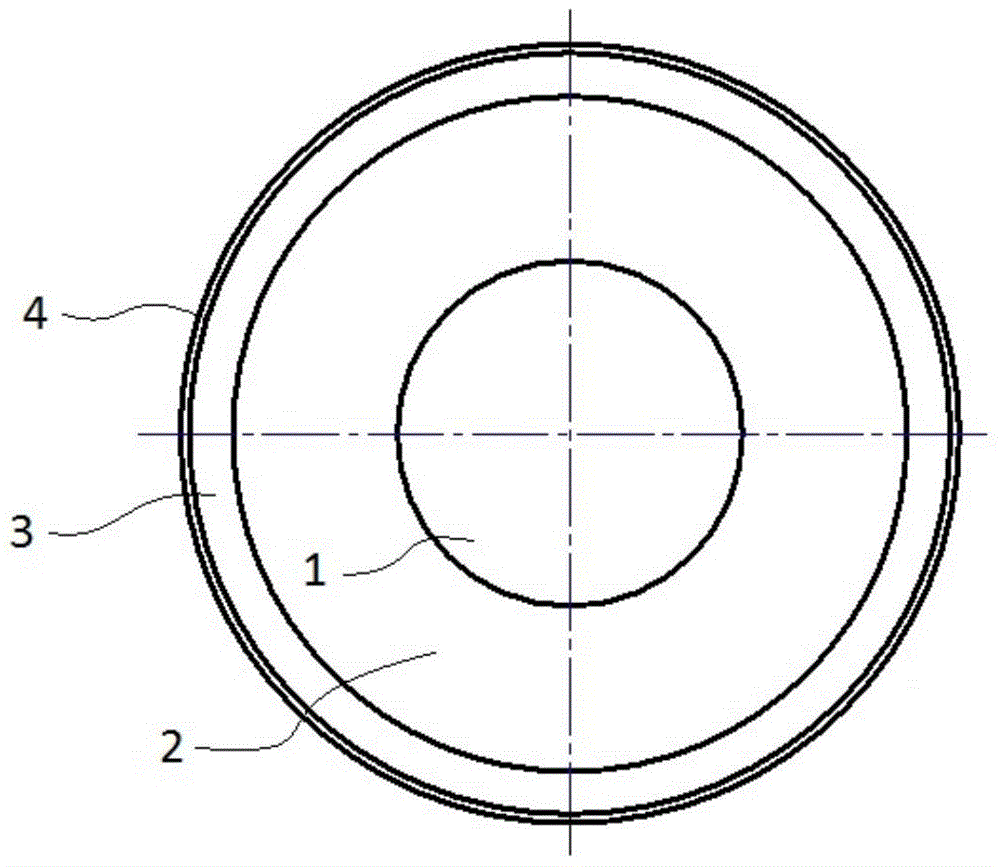

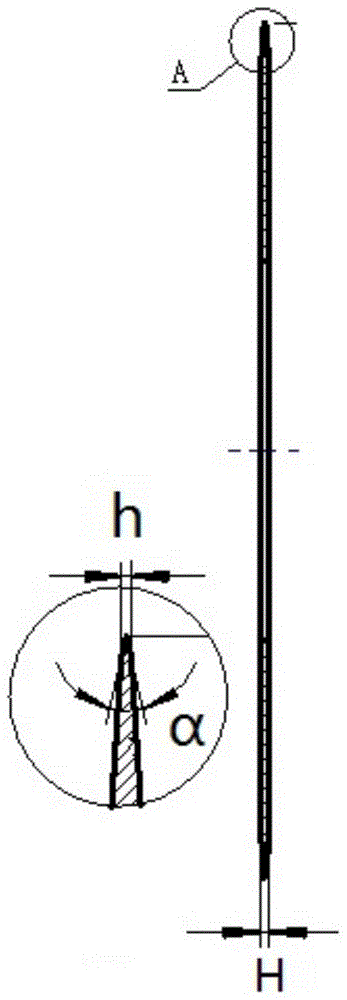

Slitting cutting disc and preparation method thereof

The invention discloses a slitting cutting disc and a preparation method thereof, which belong to the process field of cutters. The slitting cutting disc is of a circle blade, and comprises a center hole, a cutter disc and a blade, wherein the center hole is arranged in the center of the cutter disc, the blade is arranged on an outer ring of the cutter disc, a blade opening is arranged on an outer ring of the blade, and the opening angle delta ( ) of blade opening is 23-27 degrees. The opening thickness h of the blade opening is 0.24-0.26mm. The materials which are made into the slitting cutting disc comprise components with percentage by weight: carbon (C) 1.15-1.33%, nitrogen (N) 0.2-0.4%, manganese (Mn) 0.30-0.40%, silicon (Si) 0.52-1.20%, chromium (Cr) 8.50-10.50%, tungsten (W) 1.50-2.50%, vanadium (V) 0.35-0.50%, molybdenum (Mo) 0.25-0.4%, nickel (Ni) 0.30-0.40%, copper (Cu) <=0.30%, sulphur (S)<=0.020% and phosphorus (P)<=0.027%, and the allowance is ferrum (Fe). The slitting cutting disc has the advantages that the slitting cutting disc is excellent in abrasive resistance and is not easy to deform, and the blade opening resists abrasion, not easy to crack, long in service life and easy to make.

Owner:安徽华天机械股份有限公司

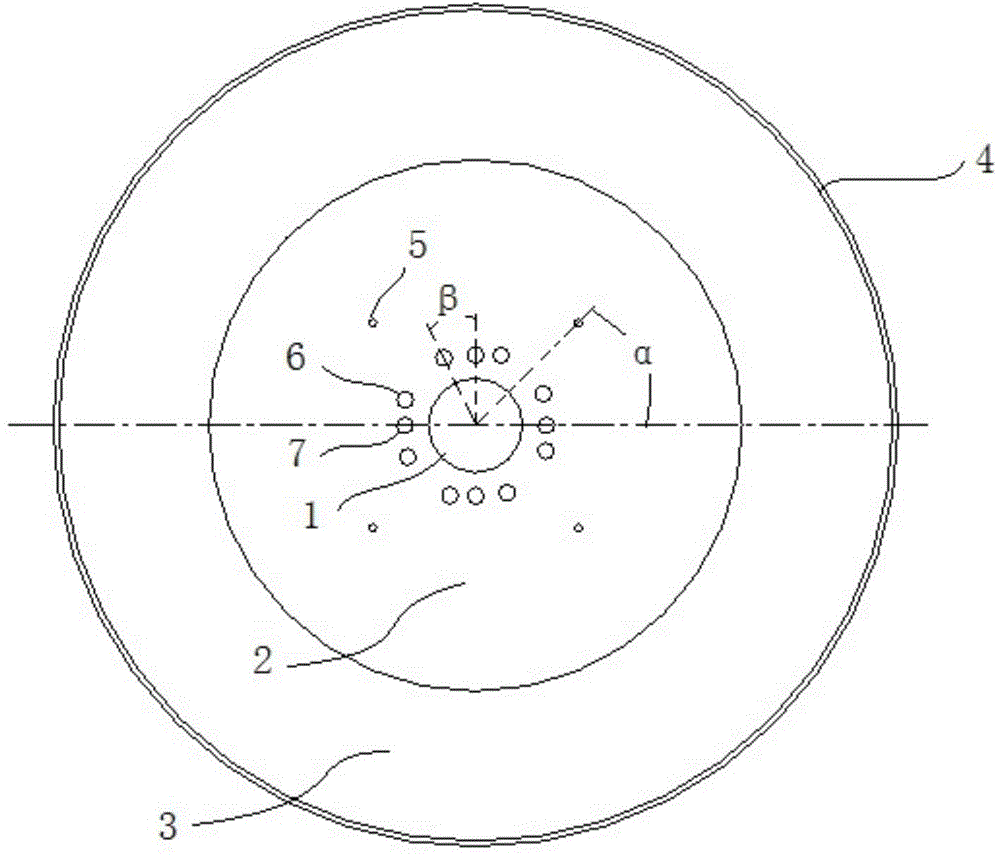

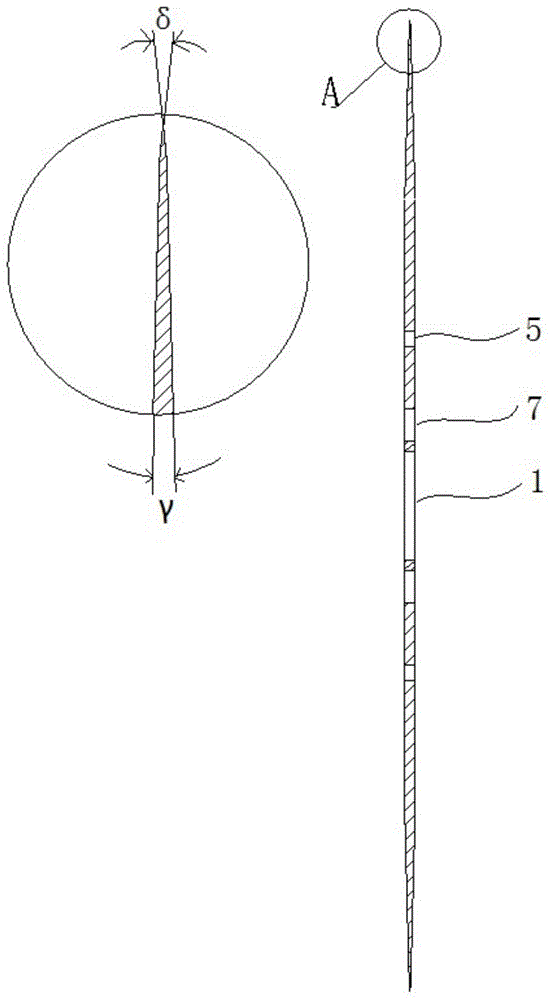

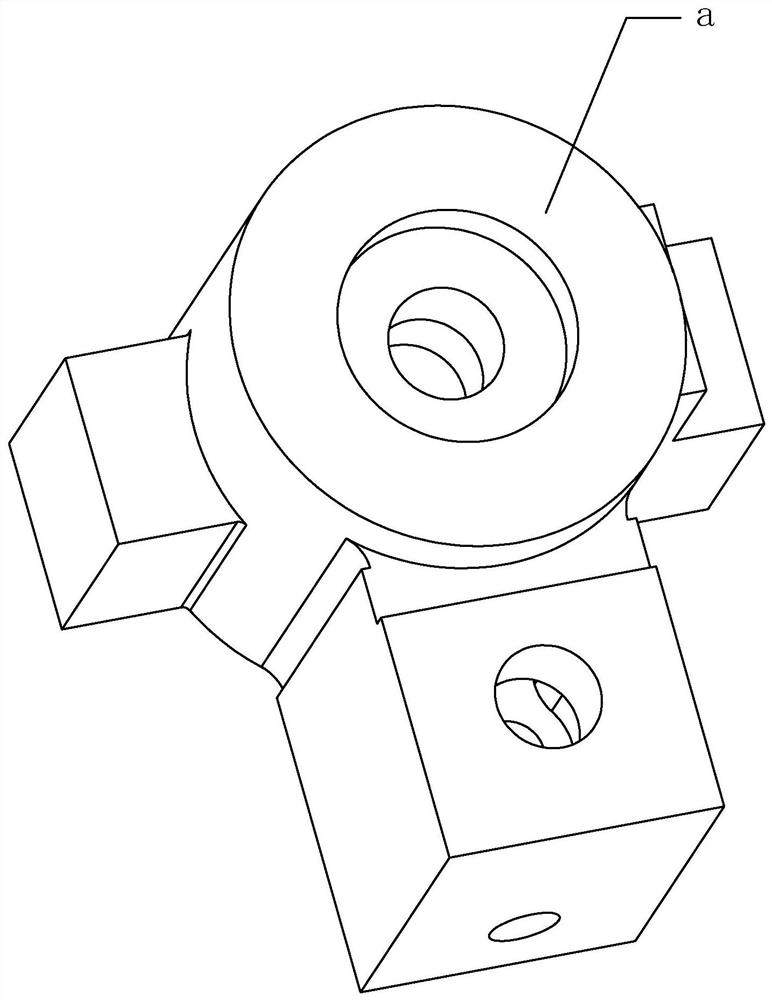

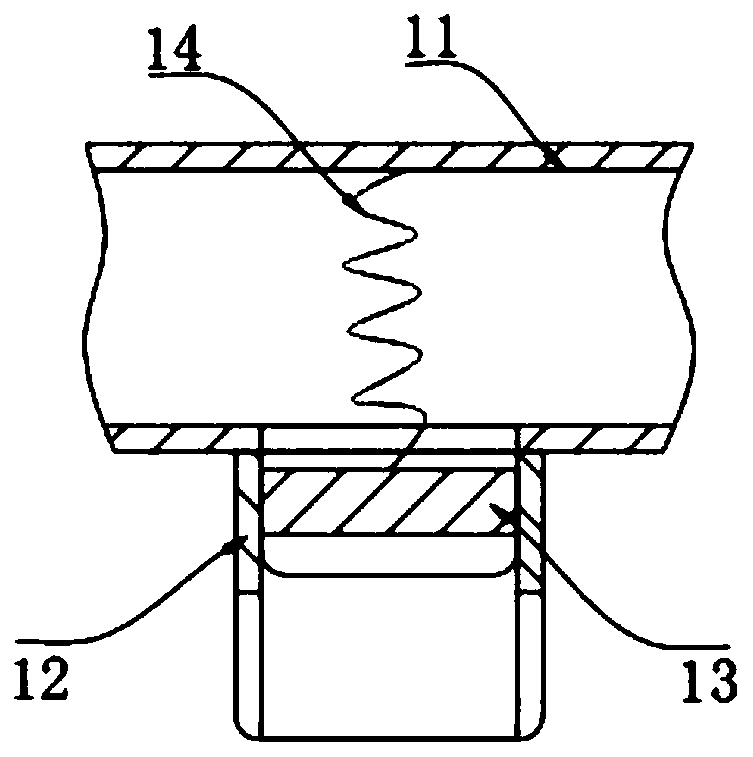

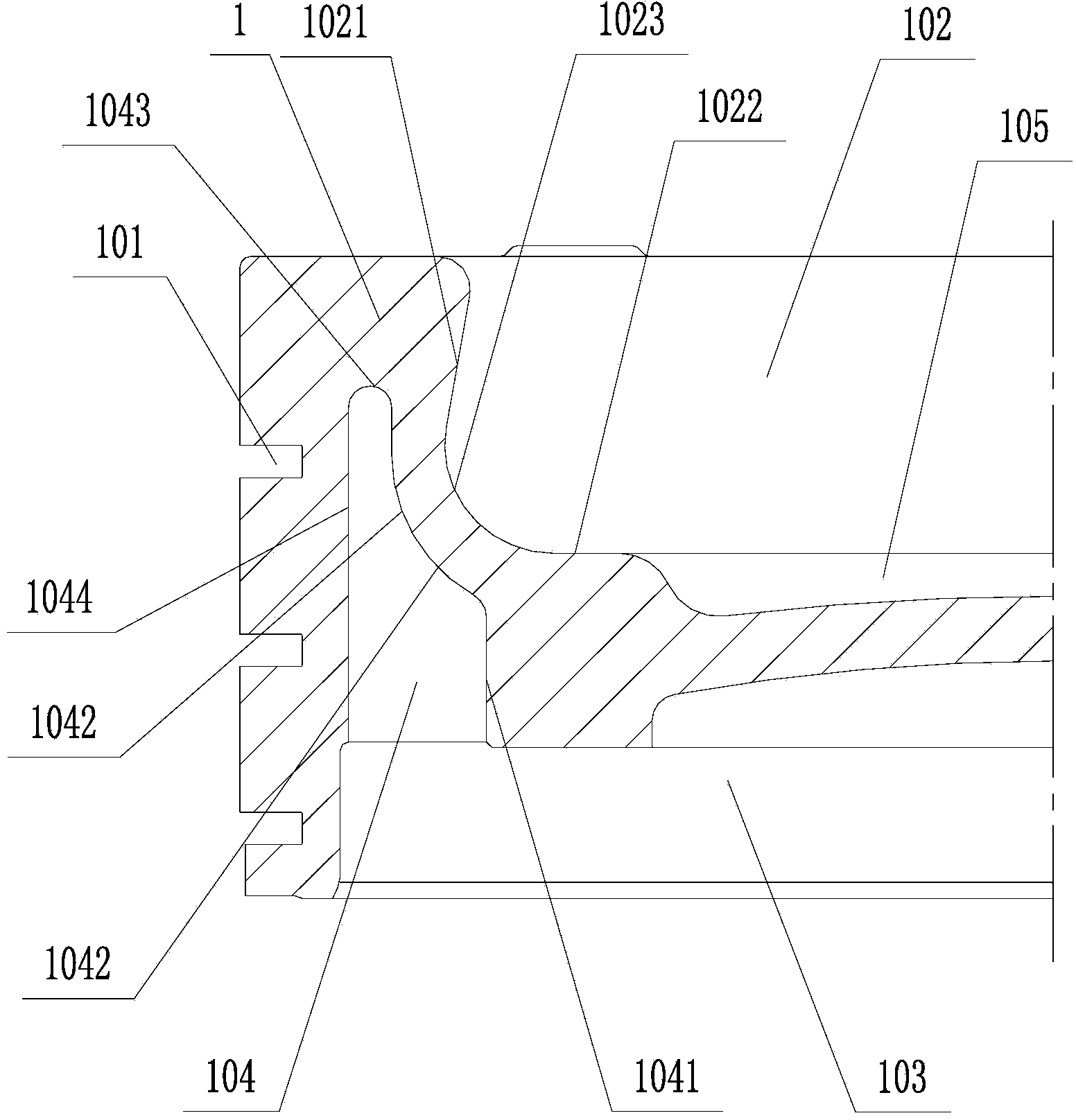

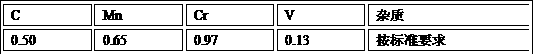

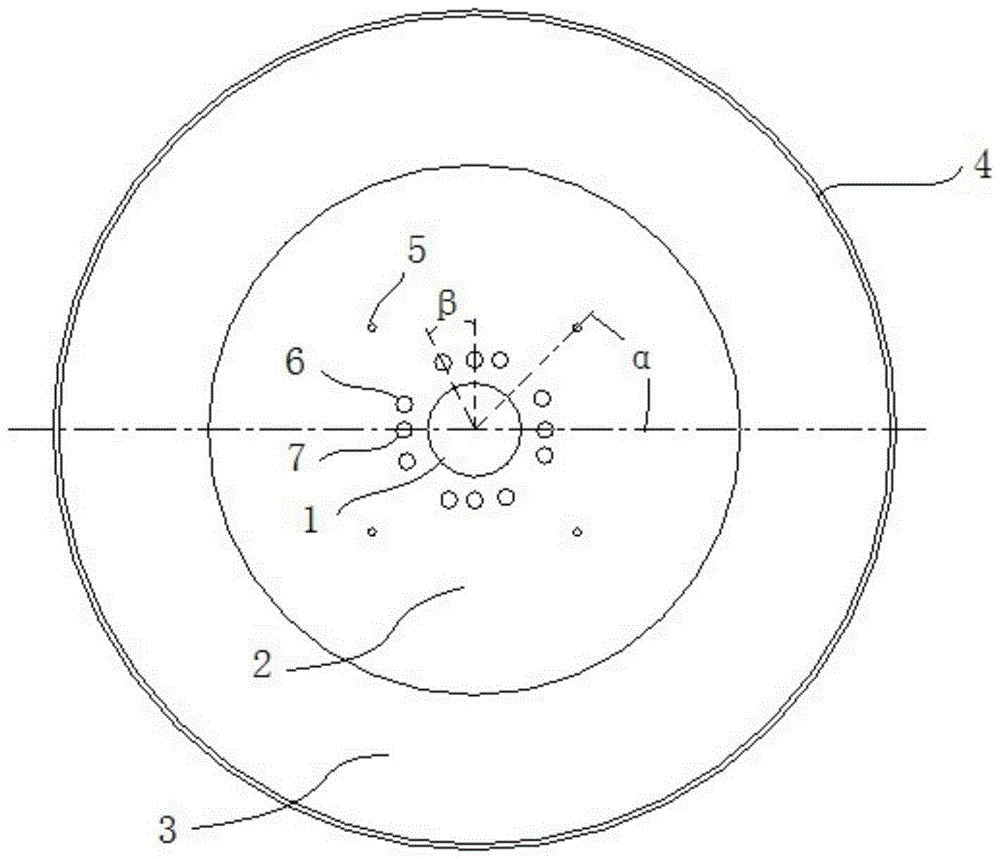

Flat and round cutter and manufacturing method thereof

ActiveCN104942879AIncrease sharpnessImprove securityFurnace typesMetal working apparatusEngineeringAlloy

The invention discloses a flat and round cutter and a manufacturing method thereof and belongs to the field of machining of cutters. The flat and round cutter comprises a center hole, a cutter head and a blade, wherein the center hole is located in the center of the cutter head, the blade is located on the outer ring of the cutter head, a cutting edge is arranged on the outer ring of the blade, the cutting edge angle delta of the cutting edge is in a range of 13-18 degrees, and threaded holes and mounting holes are formed in the cutter head. The flat and round cutter is manufactured from an alloy material comprising special elements under strictly controlled technological conditions through steps such as blank forging, isothermal spheroidizing, preliminary processing, heat treatment, rough grinding, leveling, tempering, deep processing and the like, the cutter has very high abrasion resistance while meeting the requirement for the sharpness, the service life is long, and the cutting edge is low in abrasion loss and free of cracking after long-term usage.

Owner:安徽华天机械股份有限公司

Water-soluble polyether hardening agent

ActiveCN102719629AEliminate soft spotsReduce internal stressQuenching agentsCooling effectSebacic acid

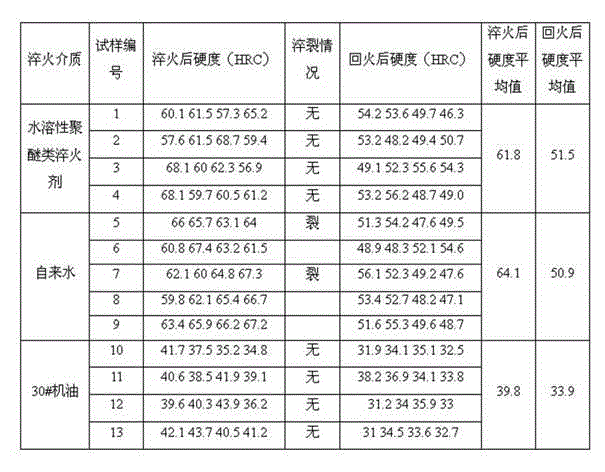

The invention belongs to the field of heat treatment of metals, and particularly relates to a water-soluble polyether hardening agent. According to weight ratio, the formula of the water-soluble polyether hardening agent is as follows: water-soluble polyether : glycol : sebacic acid : monoethanolamine : sodium nitrate : sodium chloride is equal to 45:15:8:8:8:16. When in use, the water-soluble polyether hardening agent needs to be diluted with water to form solution which contains 3 to 12 percent of water-soluble polyether, 1 to 4 percent of glycol, 0.53 to 2.13 percent of sebacic acid, 0.53 to 2.13 percent of sodium nitrate and 1.06 to 4.26 percent of sodium chloride, and simultaneously antirust agent accounting for 0 to 1 percent of the weight of the solution and preservative agent accounting for 0 to 1 percent of the weight of the solution are added. The water-soluble polyether hardening agent has a unique cooling effect, the cooling speed can be regulated, and the hardenability is good and uniform. Meanwhile, the water-soluble polyether hardening agent has the advantages of abundant material sources, low production cost, economy, practicability, no pollution, no toxicity, aging resistance, nonflammability, appropriate cooling speed in the martensitic range and the like.

Owner:NORTHEASTERN UNIV

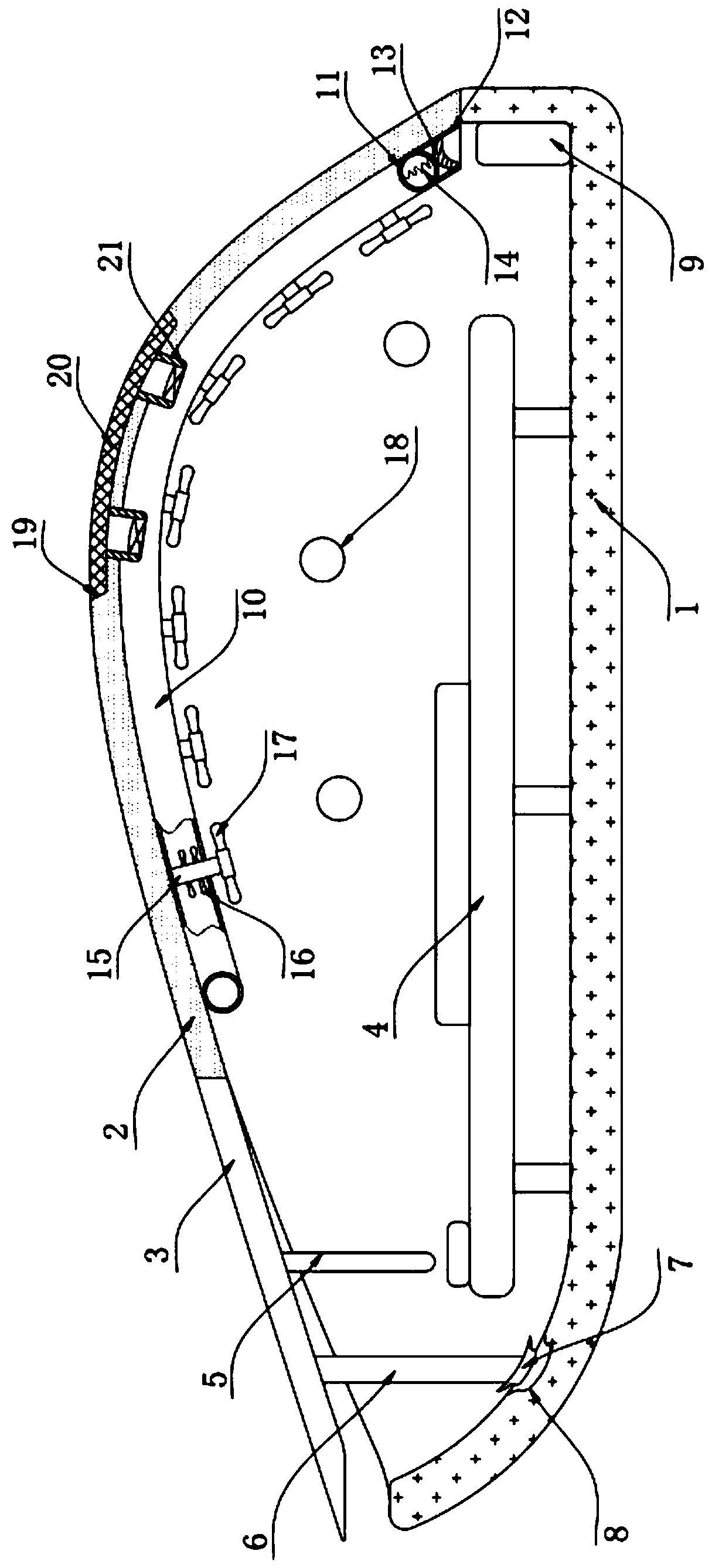

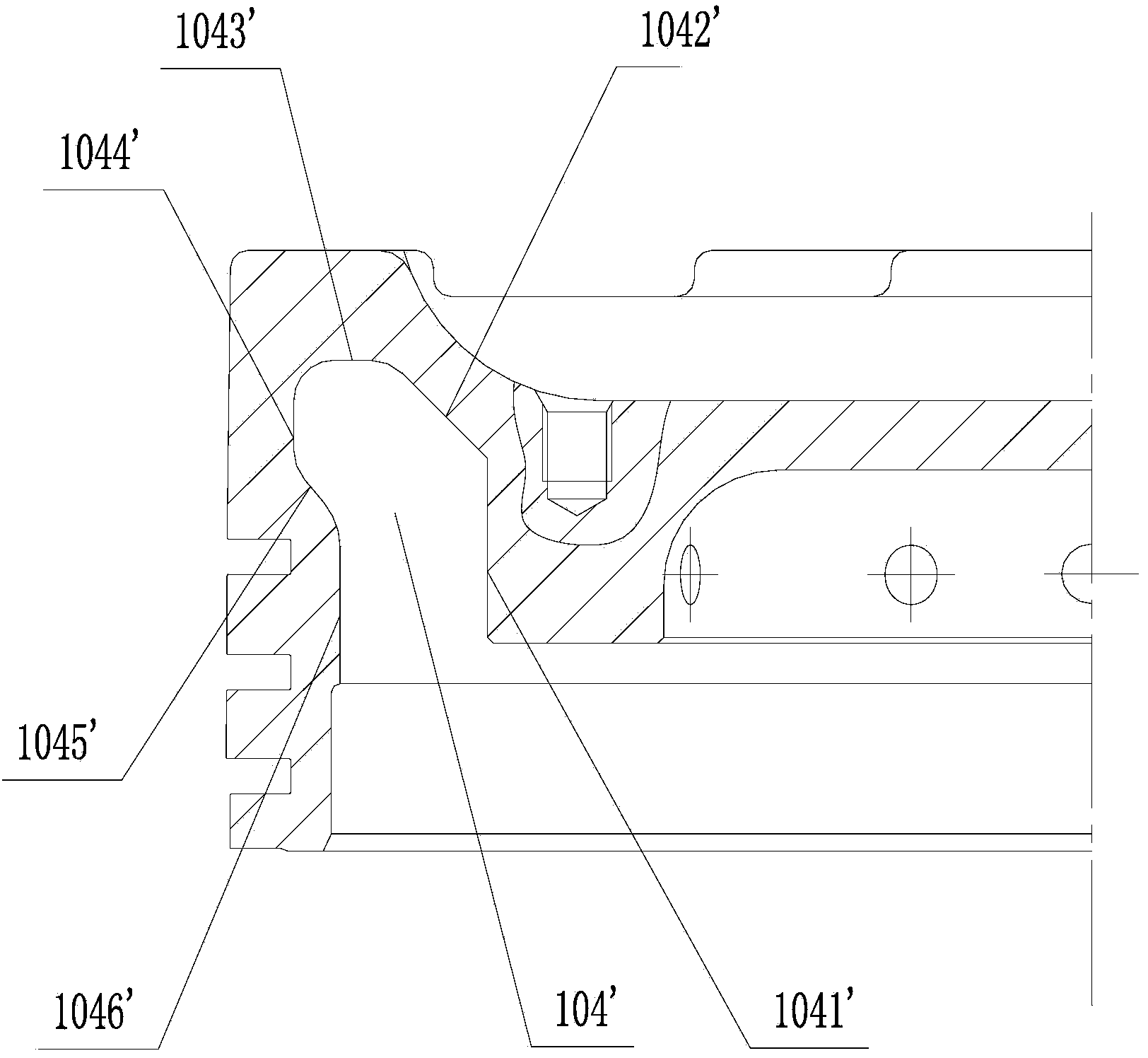

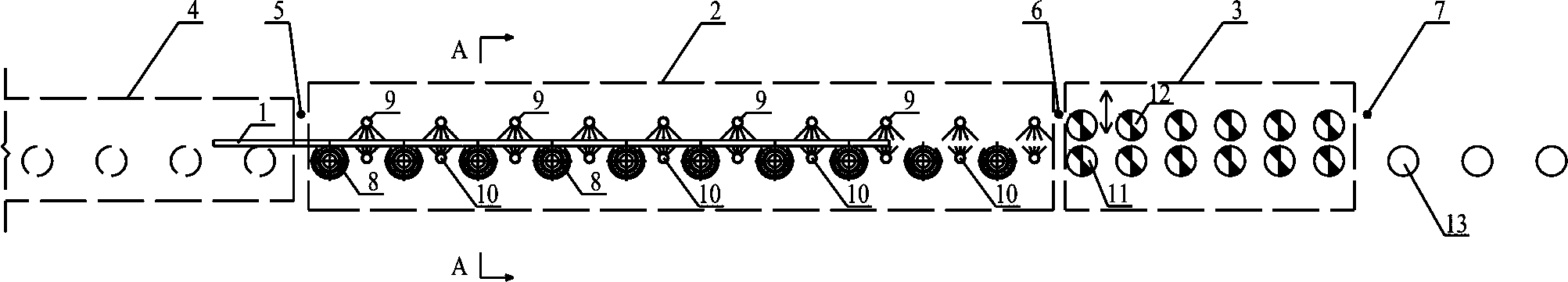

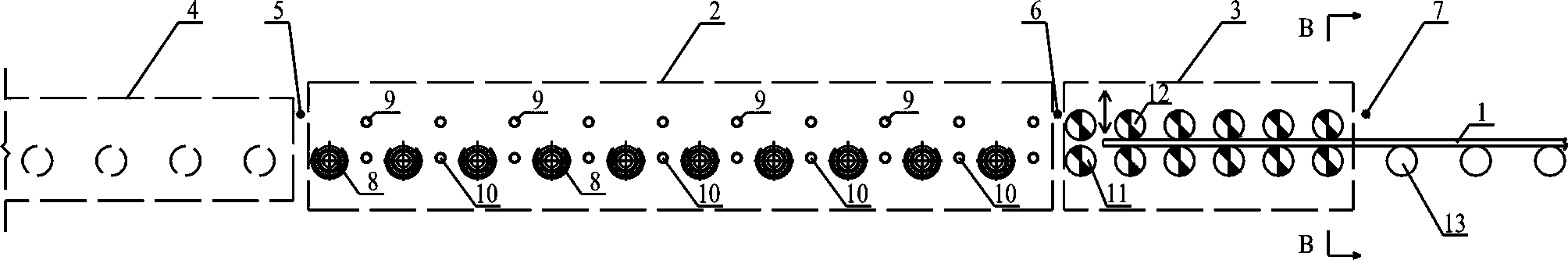

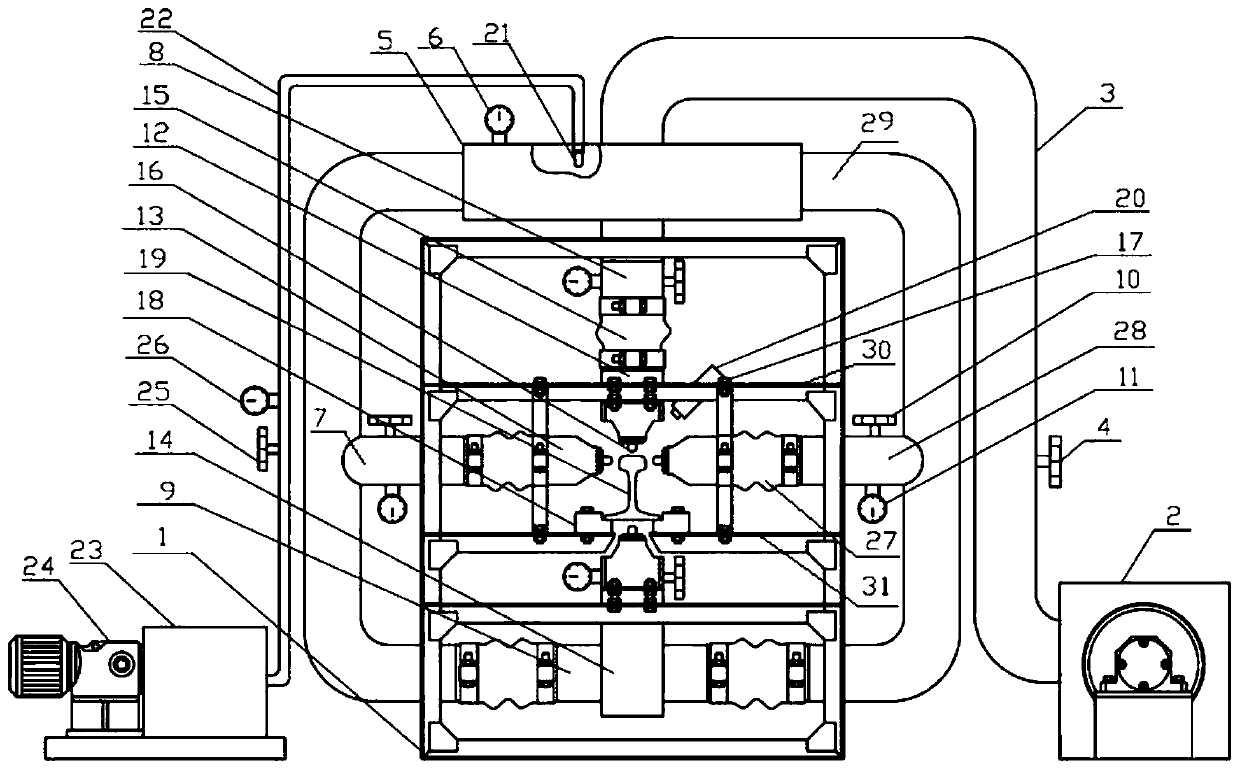

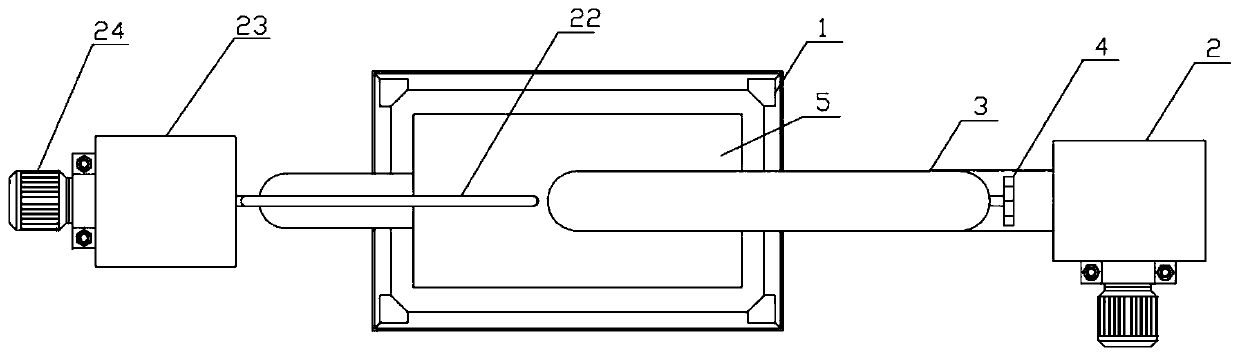

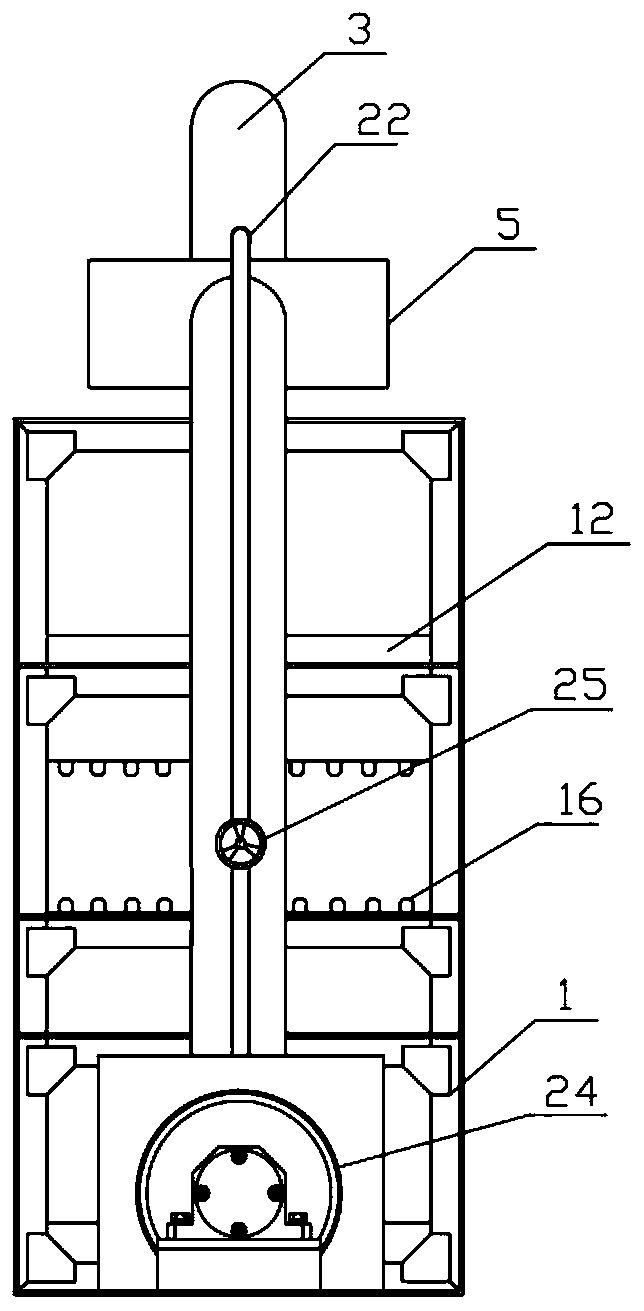

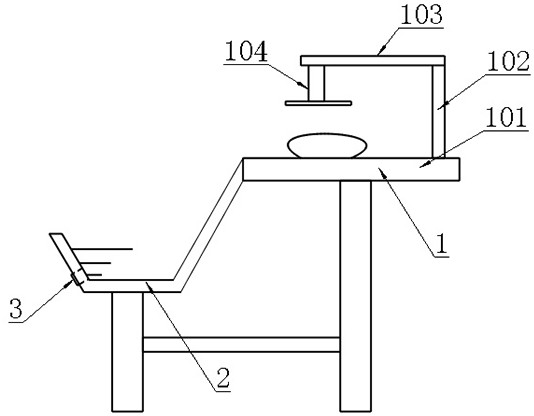

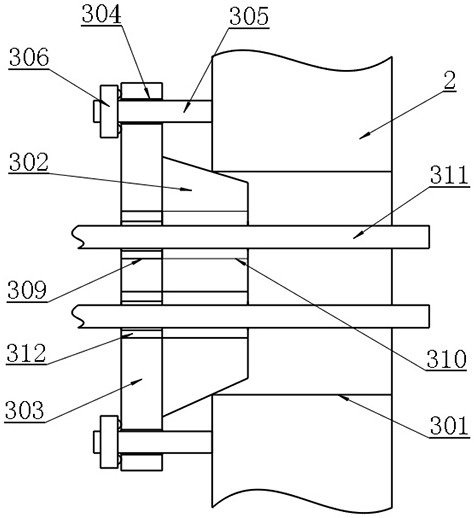

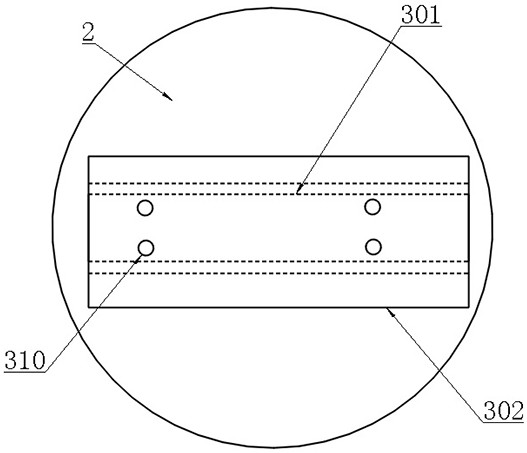

Steel rail heat treatment device and heat treatment method

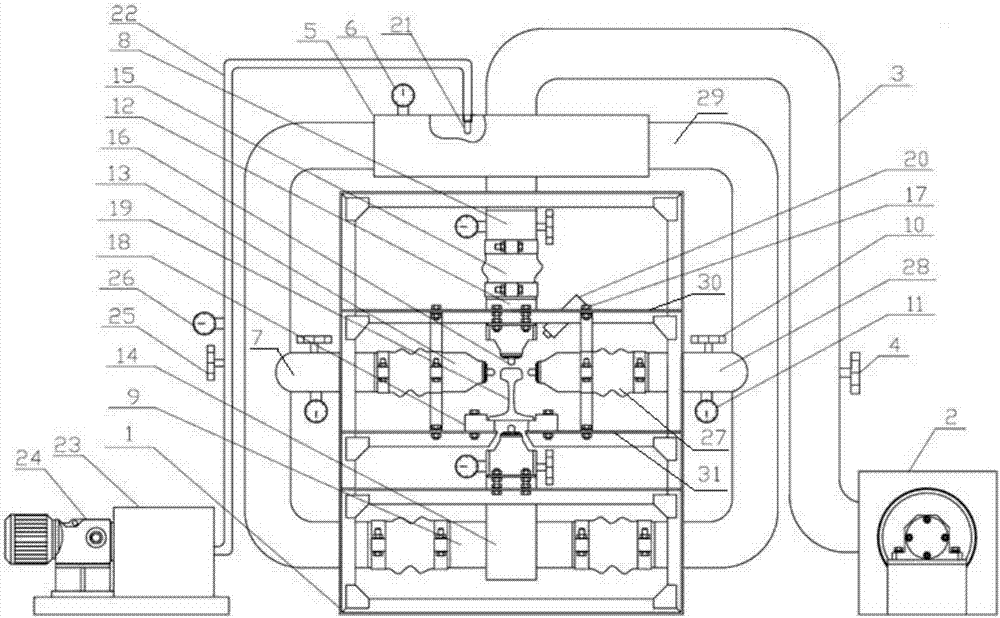

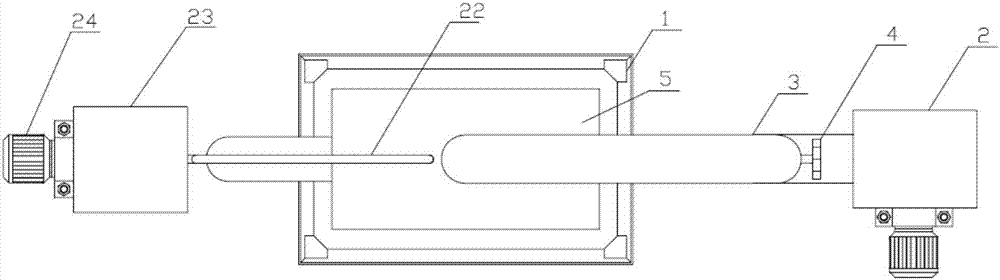

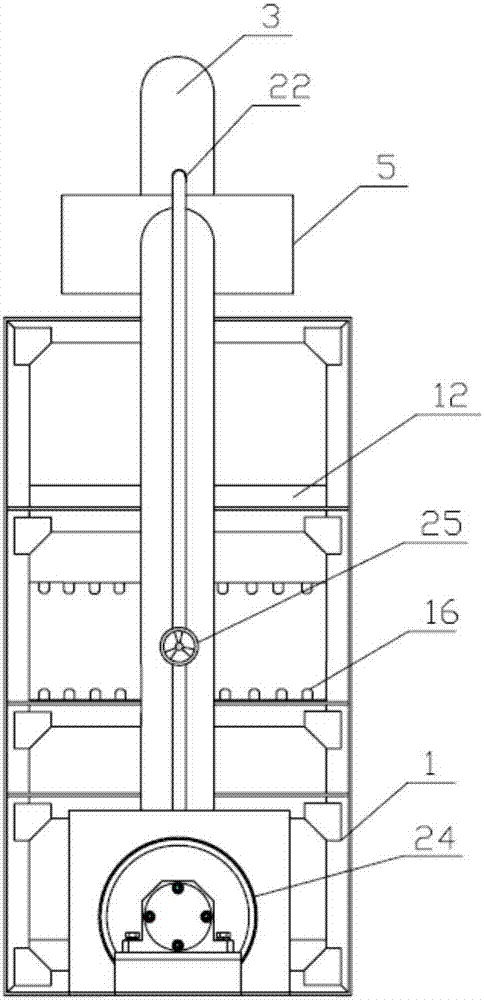

ActiveCN107130098AWell mixedStable controlFurnace typesHeat treatment furnacesTherapeutic effectEngineering

The invention discloses a steel rail heat treatment device. The steel rail heat treatment device comprises a heat treatment mechanism, a water supply mechanism, a gas supply mechanism, a main frame and a steel rail holding mechanism for holding a steel rail. The heat treatment mechanism comprises a pressure-stabilized air bellow, the pressure-stabilized air bellow is connected with an upper air bellow, a lower air bellow, a left air bellow and a right air bellow through a small vent pipe correspondingly, and first nozzles are arranged on the upper air bellow, the lower air bellow, the left air bellow and the right air bellow correspondingly; the first nozzle of the upper air bellow is arranged over the steel rail, the first nozzle of the lower air bellow is arranged under the steel rail, and the central axes of the first nozzle of the upper air bellow and the first nozzle of the lower air bellow coincide with the central axis of the steel rail; the first nozzle of the left air bellow and the first nozzle of the right air bellow are symmetrically arranged on the two sides of the steel rail; the water supply mechanism and the gas supply mechanism are connected with the pressure-stabilized air bellow correspondingly, and the steel rail holding mechanism is arranged in the main frame. The invention further provides a steel rail heat treatment method. The steel rail heat treatment device and the heat treatment method are easy, the operation is convenient, and the heat treatment effect of the steel rail can be ensured.

Owner:武汉钢铁有限公司

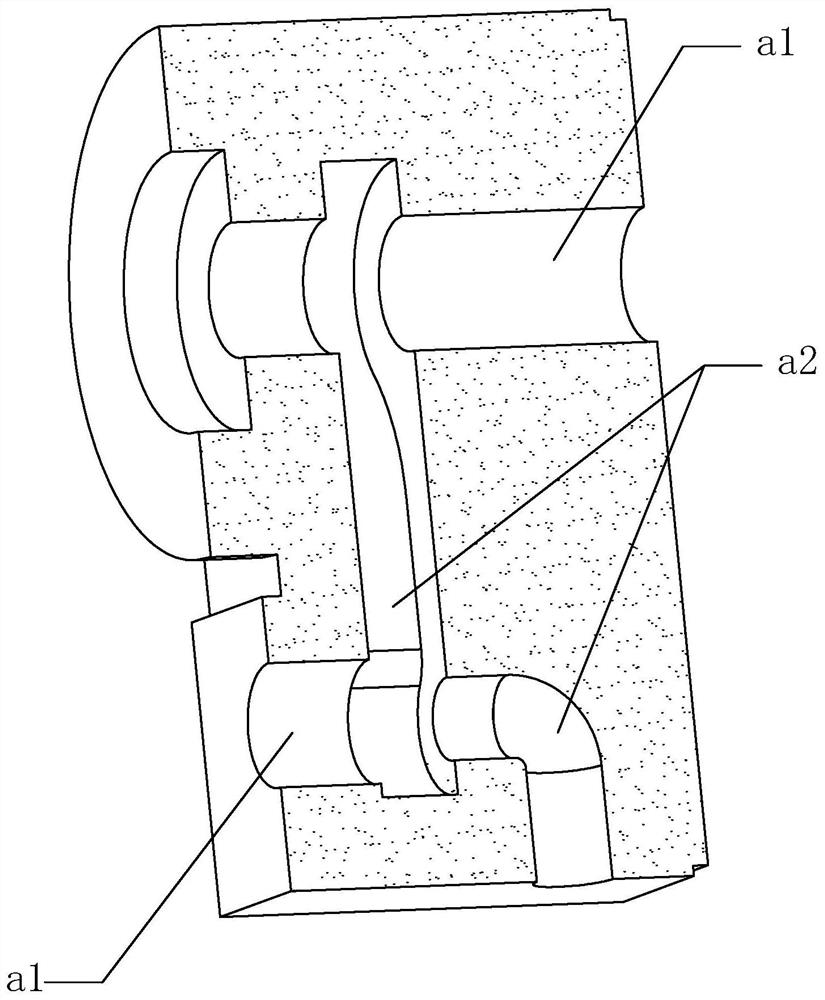

Casting method of hydraulic casting

PendingCN113967722ALow gas productionModerate cooling rateFoundry mouldsFoundry coresSmelting processSilicon

A casting method of a hydraulic casting comprises the steps that (1) sand mold manufacturing is conducted, specifically, a casting system of the hydraulic casting is cast through molding sand, the casting system comprises a casting cavity and a pouring system, and a sand core is arranged in the casting cavity to form a hydraulic cavity of the casting and a valve body mounting hole; (2) a burdening process is carried out; (3) a smelting process is carried out; (4) a spheroidizing process is carried out; (5) an inoculation process is carried out; and (6) a pouring process is carried out, specifically, when the temperature is reduced to 1280-1330 DEG C, molten iron is poured into the casting system to form the casting; metal-stream inoculation is conducted through inoculation powder while pouring is conducted, the adding amount is 0.08%-0.10% of the total amount of the original molten iron, the inoculation powder is a silicon-barium inoculant, and the silicon-barium inoculant comprises, by mass, 69%-74% of Si, 0.5%-2.0% of Ca, 1.5%-2.5% of Ba, 2%-2.5% of Al, smaller than or equal to 0.02% of S and the balance iron; and after the casting is cooled, the hydraulic casting is obtained. The scheme provided by the invention has the advantages that the defects of ring gas and slag inclusions of the hydraulic casting can be effectively improved, and the phenomena such as sand falling of a surface structure cannot occur in the pouring process.

Owner:宁波拓铁机械有限公司

Heat dissipation mouse

InactiveCN111221425ARealize handlingModerate temperature to stay comfortableDigital data processing detailsInput/output processes for data processingEngineeringCold area

The invention discloses a heat dissipation mouse. The mouse comprises a bottom shell, an upper cover is fixed at the upper end of the bottom shell; and the upper cover is composed of an end cover andan elastic piece. The mouse is characterized in that a mainboard is fixed to the inner bottom of the bottom shell, a T-shaped trigger groove is formed in the inner bottom of the bottom shell, an electromagnet is fixed to the end, away from a trigger groove, of the bottom shell, a contact rod and an opening and closing rod are fixed to the lower end of the elastic piece, the T-shaped trigger blockis fixed to the bottom of the opening and closing rod, and a cooling pipe is fixed to the lower side wall of the end cover. The mouse has the advantages that the on-off frequency of the electromagnetdirectly determines the flowing speed of liquid, namely the cooling speed, in a cold area in a cold taking pipe, the on-off frequency of the electromagnet is directly determined by the click frequencyof the mouse, and the palm of a user sweats more easily when the click frequency of the mouse is high, so that the cooling efficiency is directly related to the click frequency, the proper cooling speed can be guaranteed, and the operation hand feeling of the mouse is kept comfortable.

Owner:李帅

Composite heat treatment process

The invention relates to a composite heat treatment process, which belongs to the technical field of metal heat treatment. The composite heat treatment process includes the following steps: (1) primary heating, (2) air cooling, (3) air cooling, (4) primary tempering, (5) secondary heating, (6) water cooling, (7) secondary tempering, (8) quenching, (9) take out the workpiece for cleaning, drying, compounding The heat treatment is completed; the composite heat treatment process of the present invention adds a heating step before each tempering, which can well release the residual stress in the workpiece and prolong the service life, and the composite heat treatment process of the present invention uses mist Advanced quenching liquid cooling and water tank water cooling, through two rapid cooling methods, the quenching effect of the workpiece is improved.

Owner:JIANGSU FENGDONG HEAT TREATMENT & SURFACE MODIFICATION ENG & TECH RES CO LTD

Quenching oil dedicated to small module gears and preparation method of quenching oil

The invention discloses quenching oil dedicated to small module gears and a preparation method of quenching oil, and belongs to the technical field of metal heat treatment. The quenching oil comprises the following components in parts by mass: 35 to 40 parts of refined base oil, 2 to 3 parts of a cooling compound agent, 0.5 to 0.8 part of a blackening compound agent, 0.3 to 0.7 part of a brightening agent, 0.6 to 0.8 part of a surfactant and 0.04 to 0.06 part of an antioxidant. The quenching oil is specially developed for the small module gears of which the module is 1 mm or below, the optimal utilization temperature is 100 to 110 DEG C, the fluidity of the quenching oil is good in the temperature range, the cooling velocity for the small module gears is moderate, protective films are formed on the surfaces of the gears through automatic blackening during quenching, the secondary coating antirust treatment on the surfaces after heat treatment is reduced, the resources are saved, the procedure is reduced, and the efficiency is improved.

Owner:马鞍山金泉工业介质科技有限公司

Low-consumption environment-friendly spring steel water-soluble quenching liquid and quenching process

The invention discloses low-consumption environment-friendly spring steel water-soluble quenching liquid and a quenching process and belongs to the technical field of common spring steel heat treatment quenching liquid and processes. The quenching liquid is characterized in that the quenching liquid is composed of, by mass, an antioxidant, an anti-rust agent, a preservative, a defoaming agent and the balance methoxy polyethylene glycol. According to the low-consumption environment-friendly spring steel water-soluble quenching liquid and the quenching process, all the components are organically combined together, and the quenching performance of the quenching liquid can be played to the limit with the synergistic effect, namely, the defects of the quenching liquid are overcome through other functional components while the requirements for the good solubilizing performance and solubility inversing performance of basic solvent are met. When rapid oil or diesel oil quenching is replaced by the low-consumption environment-friendly spring steel water-soluble quenching liquid, the production cost is reduced and the production environment and natural resources are protected while resources are saved.

Owner:陕西雷帕得悬架系统有限公司

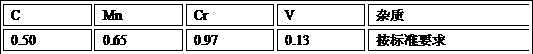

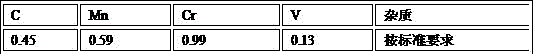

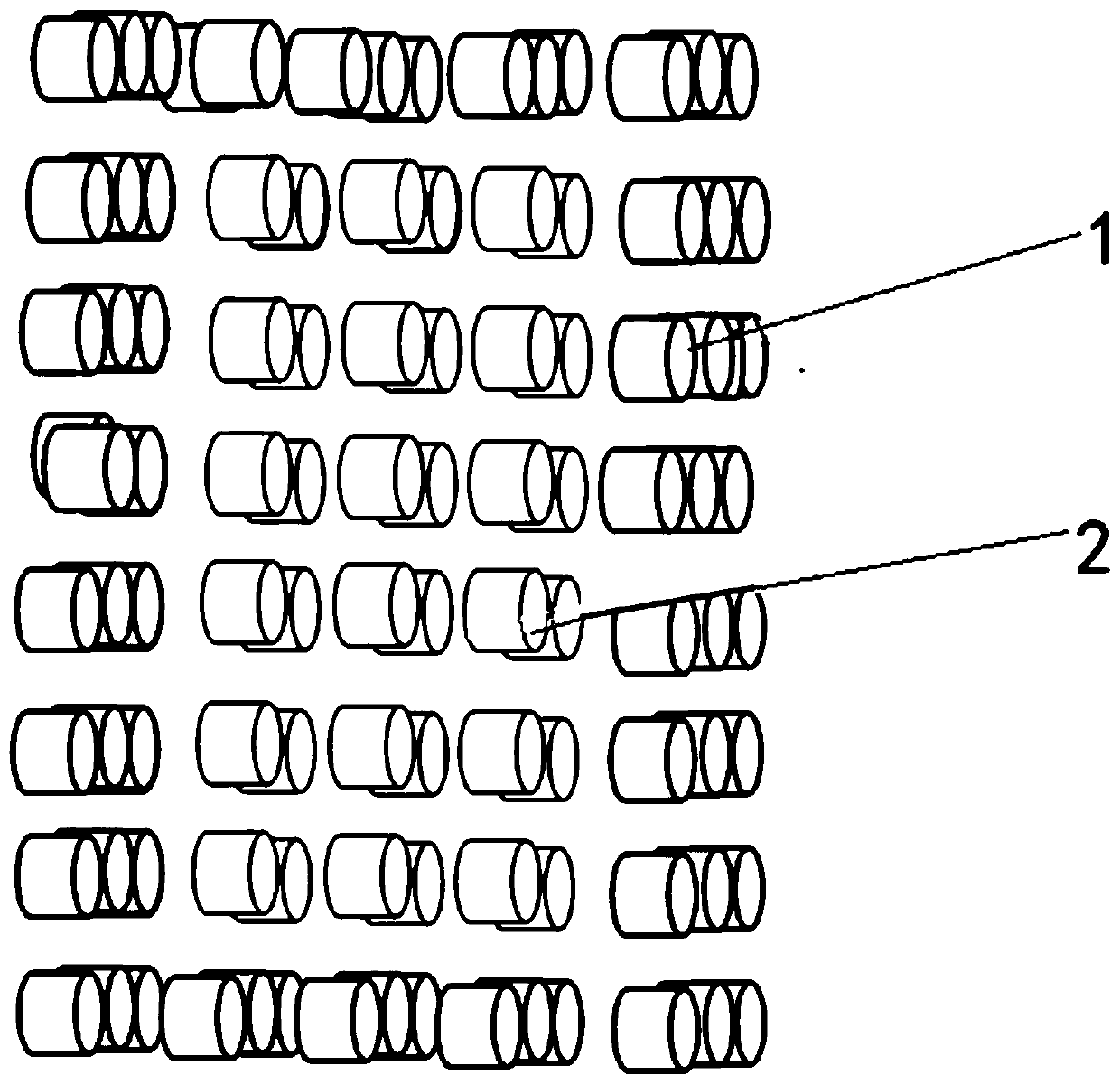

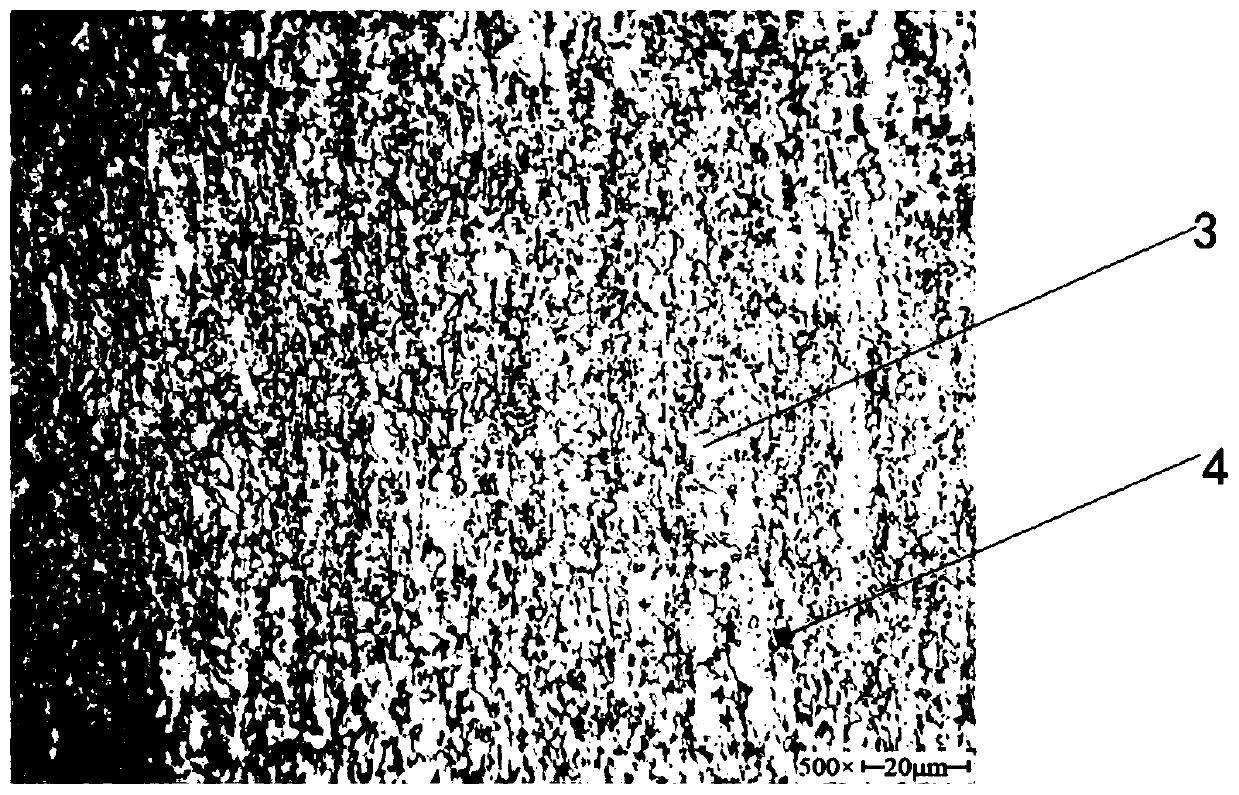

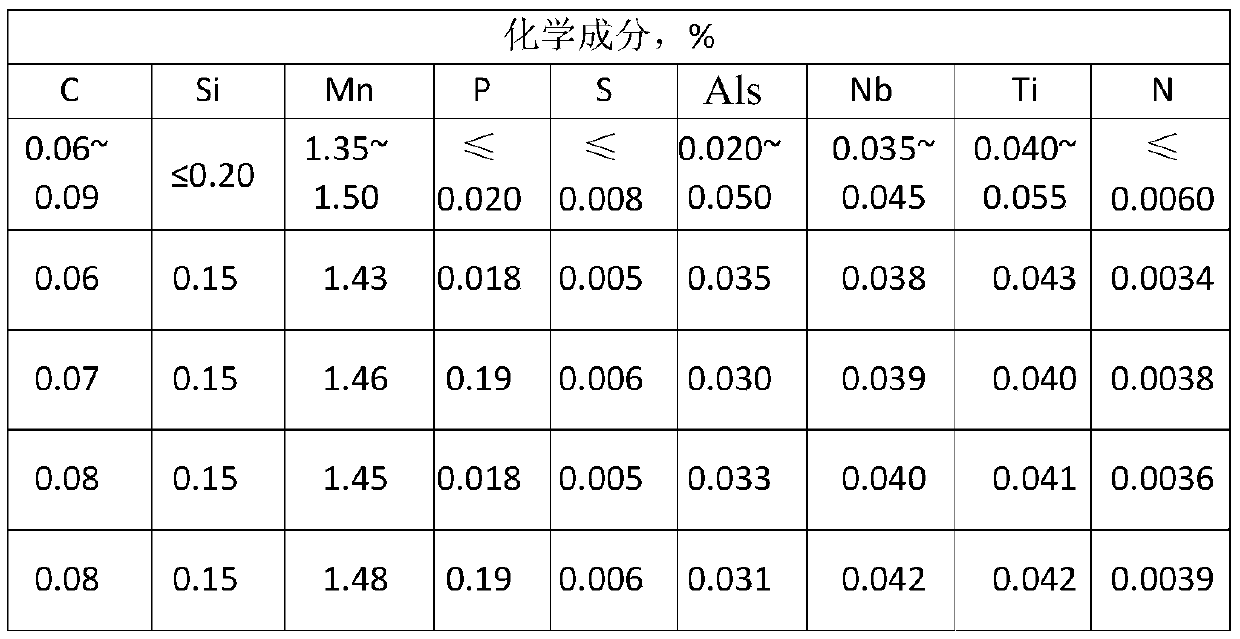

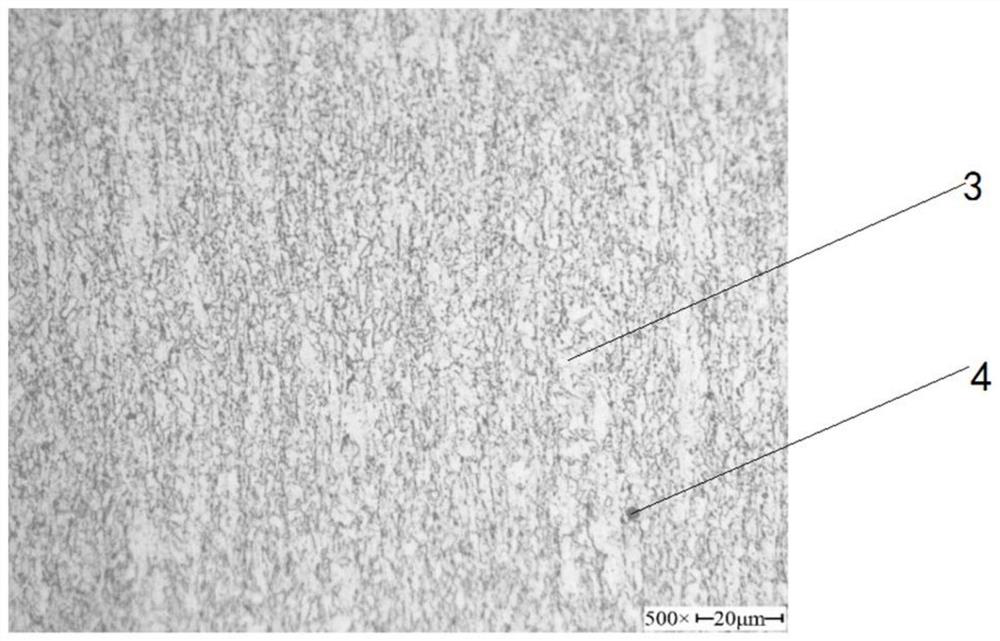

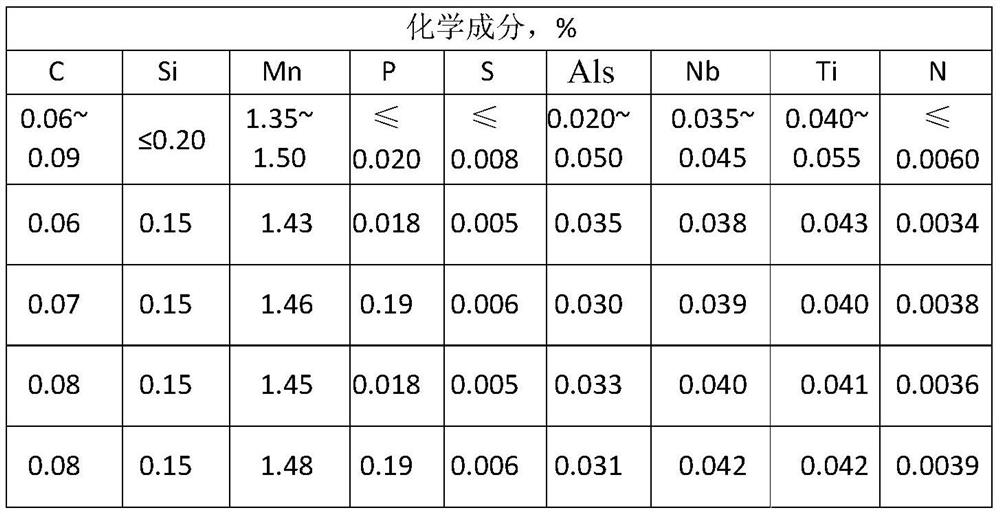

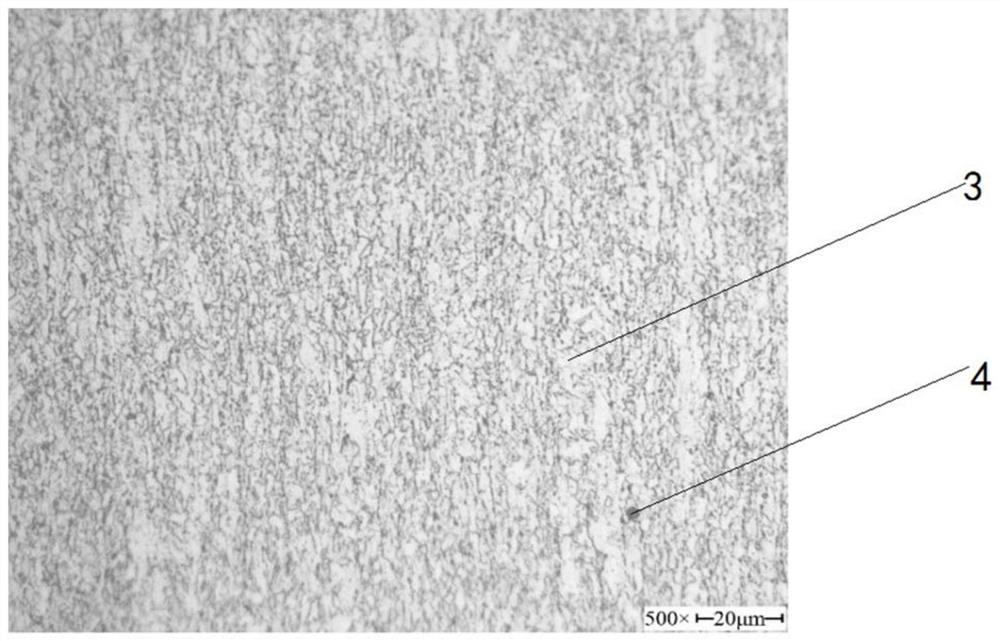

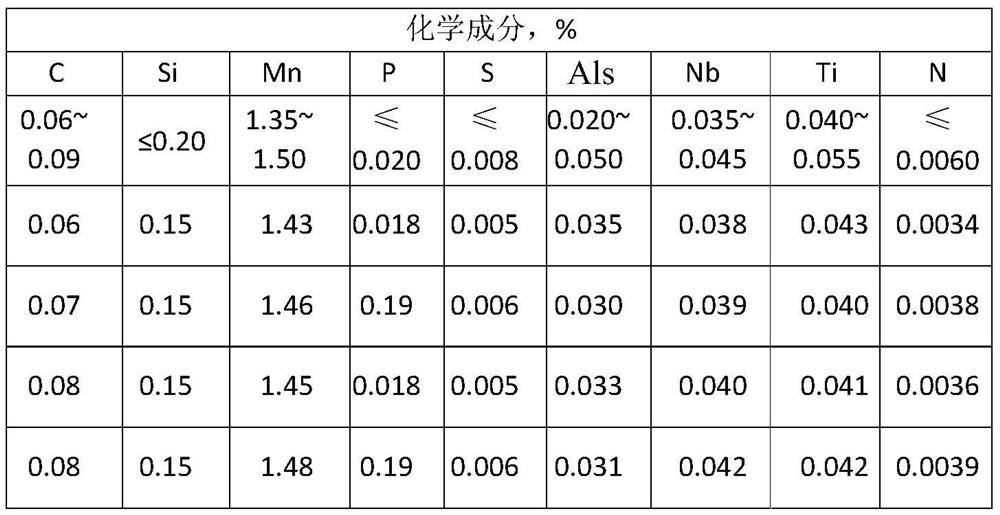

Production method for hot-rolled steel strips for 610 MPa-grade automotive frame

The embodiment of the invention provides a production method for hot-rolled steel strips for a 610 MPa-grade automotive frame. Production technological steps of the hot-rolled steel strips for the 610MPa-grade automotive frame comprise rotary furnace smelting, LF furnace refining, continuous casting, rolling plan arrangement, plate blank heating, rough rolling, high-pressure water scale removing,fine rolling, laminar cooling, reeling and pile cooling. Chemical components of the hot-rolled steel strips for the 610 MPa-grade automotive frame comprise, by weight, 0.060-0.090% of C, 0.10-0.20% of Si, 1.35-1.50% of Mn, smaller than or equal to 0.020% of P, smaller than or equal to 0.008% of S, 0.015-0.050% of Al, 0.035-0.045% of Nb, 0.035-0.045% of Ti, smaller than or equal to 0.0045% of N and the balance Fe and inevitable impurities.

Owner:LIUZHOU IRON & STEEL +1

Sand casting copper anode mold technique

ActiveCN100586609CModerate cooling rateControl cooling rateFoundry mouldsFoundry coresSoluble glassGraphite

The invention relates to a sand mold casting copper anode mould technique which is characterized in that the following steps are included: a. the modeling materials according to the parts by weight: 1part of 70-140 meshes of refined quartz sand, 0.05-0.1 part of kaolin, 0.01-0.005 part of graphite powder, 0.05-0.08 part of 2.4-2.6m of soluble glass, 0.005 part of 20-30 percent of sodium hydroxidesolution, a proper amount of 98 percent of ethanol and colophony which are evenly mixed, sanded, modeled, modified and hardened by CO2; b. the processes of demoulding, drying, painting the coating and mould assembling are carried out; c. the anode molten copper which is smelted to be eligible in an anode smelting furnace is casted into a box for temperature preservation for 20-40 hours and is demoulded; d. the finished product can be obtained after desanding and polishing. The invention leads the traditional sand mold casting technique to be used for the casting of the copper anode mould andutilizes the handpicked modeling materials so as to ensure that the shortages of air holes, gas pockets, cold shut, and the like, of the casted copper anode mould are avoided basically, the manufacture cost is low and the quality of the anode copper can be improved.

Owner:DAYE NONFERROUS METALS +1

Quenching oil capable of making fastener become black by itself after quenching and application method of quenching oil

ActiveCN105969957ASmall surface hardnessSmall deformation rateFurnace typesMetallic material coating processesAntioxidantSurface-active agents

The invention discloses quenching oil capable of making a fastener become black by itself after quenching and an application method of the quenching oil, and belongs to the technical field of metal heat treatment. The quenching oil comprises, by mass, 35-40 parts of refined base oil, 7-10 parts of composite cooling accelerant, 0.5-0.7 part of a composite blacking agent, 0.4-0.8 part of a brightening agent, 0.5-0.8 part of a surface active agent and 0.02-0.04 part of antioxidant. The composite cooling accelerant is the mixture of polyisobutene, dimethyl naphthalene and mahogany petroleum sulfonate. The composite blacking agent is the mixture of short oil alkyd resin, a coloring agent and a wetting agent. The brightening agent is the mixture of imidazoline oleate and methyl terpene resin. The coloring agent is disperse black 9. The wetting agent is fatty alcohol-polyoxyethylene ether. The surface active agent is span-80. The optimal using temperature of the quenching oil ranges from 70 DEG C to 75 DEG C, the speed for cooling the fastener is moderate, a protection film is formed on the surface in a self-blacking manner during quenching, and efficiency is improved.

Owner:马鞍山金泉工业介质科技有限公司

Water-soluble quenching agent

The invention provides a water-soluble quenching agent. The water-soluble quenching agent is prepared from the following raw materials of, by weight, 5-8 parts of a surfactant, 42-45 parts of polyether, 0.1-0.3 part of a defoamer, 0.2-0.5 part of a sterilizing agent, 35.7-47.5 parts of water, and 5-10 parts of sodium benzoate. Compared with the prior art, the water-soluble quenching agent has thefollowing beneficial effects that the quenching degree of materials can be met and controlled so as to avoid cracks of the materials; environment-friendly water-based quenching liquid with the high-quality polyether as a base is composited with the balanced surfactant, defoamer and sterilizing agent, thus the extremely large cooling rate is achieved at the high-temperature cooling stage, grains can be refined, and the final performance of a quenched workpiece is improved; and at the low-temperature cooling stage, the moderate cooling rate is achieved, so that the problems of cracking, deforming and the like in the workpiece cooling process are effectively solved, and the machining accuracy and surface quality of the workpiece are improved.

Owner:山东思科工业介质有限公司

Alloy valve and heat treatment process thereof

The invention relates to an alloy valve and a heat treatment process thereof. The alloy valve is prepared from, by mass part, 0.52% to 0.56% of C, 1.56% to 1.63% of Mg, 1.23% to 1.73% of Ni, 1.12% to1.35% of Mo, 0.08% to 0.12% of Ag, 0.010% to 0.015% of P, 0.031% to 0.35% of Zr, 0.45% to 0.47% of Cu, 3.23% to 3.54% of Al, 0.48% to 0.53% of Co, 1.12% to 1.35% of Mn, 0.010% to 0.015% of V, 0.85% to0.93% of Zn, 0.02% to 0.03% of W, 0.17% to 0.22% of Pt, 5.6% to 7.2% of Fe, 2.3% to 3.5% of Sn, 0.28% to 0.31% of filler and the balance Ti and inevitable impurities.

Owner:张剑

Quenching oil capable of enabling screw to blacken automatically after quenched and quenching method thereof

ActiveCN105925770AGuaranteed surface hardnessGuaranteed internal metallographic structureFurnace typesMetallic material coating processesAntioxidantFatty alcohol

The invention discloses quenching oil capable of enabling an screw to blacken automatically after quenched and a quenching method thereof. The invention belongs to the field of metal heat treatment technology. The quenching oil comprises the following components, by weight, 35-40 parts of refined base oil, 6-10 parts of cooling catalyzed composite agent, 0.4-0.6 parts of blackening composite agent, 0.3-0.7 parts of brightening agent, 0.4-0.7 parts of surface activating agent and 0.02-0.04 parts of antioxidant. The cooling catalyzed composite agent is a mixture of dialkyl naphthalene and petroleum sulfonate; the blackening composite agent the mixture of short oil alkyd resin, colouring agent and wetting agent; the brightening agent is the mixture of imidazoline oleate and methyl terpene resin; the surface activating agent is span-80. The colouring agent is disperse black 9; the wetting agent is fatty alcohol-polyoxyethylene ether. The best using temperature of the quenching oil is between 75 DEG C and 80 DEG C. Between 75 DEG C and 80 DEG C, the cooling speed of the quenching oil for the screw is moderate, the surface can be blackened automatically and a protective film can be formed while the quenching, so that the processes can be reduced and the efficiency can be improved.

Owner:马鞍山金泉工业介质科技有限公司

Novel piston top of gas engine

The invention provides a novel piston top of a gas engine. The piston top comprises a cylindrical piston top body, wherein annular grooves are distributed in the side wall of the piston top body; the upper end surface of the piston top body is concave inwards to form a first cavity body, and the lower end surface of the piston top body is concave inwards to form a second cavity body; the outer edge of the second cavity body is continuously concave inwards to form a cooling cavity which consists of an inner ring bearing surface, a connecting surface, an upper bottom surface and an outer ring bearing surface which are successively connected, the inner ring bearing surface and the outer ring bearing surface are parallel to the axis of the piston top body, the connecting surface is arc-shaped, and the center of a circle of the connecting surface is positioned on one side of the inner ring bearing surface. Due to the adoption of the piston top of the gas engine disclosed by the invention, the volume of the cooling cavity is reduced, so that the cooling speed of a piston is moderate, too high or too low cooling speed is avoided, and the heat loss is small, so that the oil consumption rate is reduced; at the same time, after the volume of the cooling cavity is reduced, the oil mass of cooling oil is reduced, the consumed power of a lubricating oil pump is reduced, and the cost is reduced; the structure of the piston top is simple, the processing is facilitated, and the processing cost is reduced.

Owner:DALIAN BINCHENG PISTON MFG

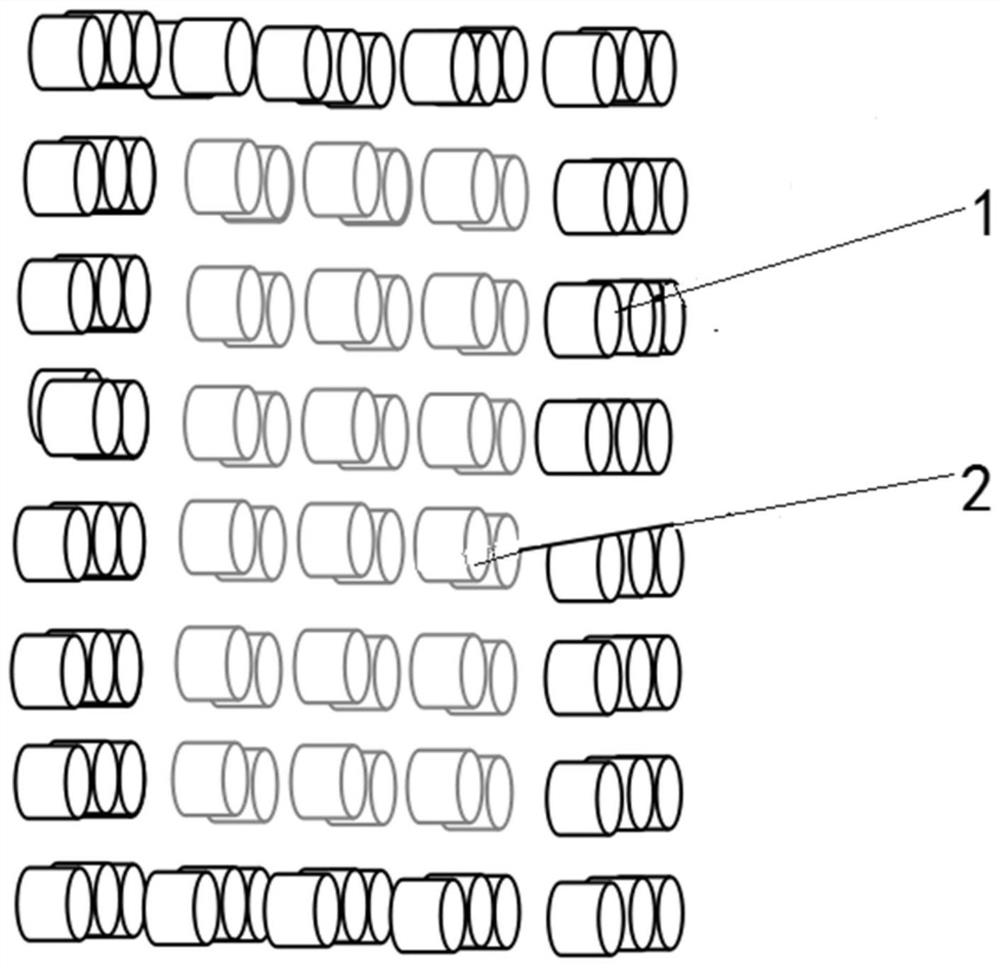

Rapid cooling method and device after medium and thick plate heat treatment furnace

ActiveCN102586565BAchieve coolingLow costFurnace typesHandling discharged materialThick plateMetallurgy

The invention provides a rapid cooling method after a medium and thick plate heat treatment furnace. The method comprises the following steps of: in the conveying process of steel plates treated by using a heat treatment furnace, preliminarily reducing the temperature of the steel plates in a gas blowing mode, and further reducing the temperature of the steel plates in a contact cooling mode. A rapid cooling device after the medium and thick plate heat treatment furnace comprises an air cooling mechanism and a roller cooling mechanism which are sequentially arranged behind the heat treatment furnace, wherein the air cooling mechanism comprises a roller way for conveying the steel plates, and a cooling spray pipe for spraying cooling gas to the steel plates in the conveying process; and the roller cooling mechanism comprises a plurality of water-cooled conveying rollers which are used for exchanging heat with the steel plates in the conveying process. Compared with cooling bed equipment and other cooling modes, the rapid cooling device and the rapid cooling method have the advantages that: auxiliary equipment and processes such as loading and unloading are not required, and the steel plates are cooled in the conveying process, so that the equipment cost is reduced, and the cooling efficiency is also improved.

Owner:WISDRI WUHAN WIS IND FURNACE

A heat treatment process for silicon-manganese alloy spring steel

The invention discloses a heat treatment process with regard to silicon-manganese alloy spring steel, and belongs to the technical field of heat treatment processes for spring steel. According to the invention, heat treatment steps comprising heating, quenching and tempering can be carried out with regard to the silicon-manganese alloy spring steel, and the heat treatment process is scientific and reasonable in design, and capable of effectively preventing the silicon-manganese alloy spring steel from decarburization and graphitization tendencies; a quenching liquid used in the heat treatment process is safe, environment-friendly and non-toxic, capable of effectively replacing the original oil-based quenching medium with high energy consumption and high pollution, long in service life, and excellent in quenching effect; and in addition, the silicon-manganese alloy spring steel treated through the process is capable of achieving a finished product state, and provided with a layer of anti-rust film, so that additional shot-blasting and painting processes are not needed, and the heat treatment process is more economic and convenient.

Owner:陕西雷帕得悬架系统有限公司

A 610mpa grade hot-rolled steel strip for automobile girders

Owner:LIUZHOU IRON & STEEL +1

Rail heat treatment device and heat treatment method

ActiveCN107130098BWell mixedStable controlFurnace typesHeat treatment furnacesEngineeringTherapeutic effect

The invention discloses a steel rail heat treatment device. The steel rail heat treatment device comprises a heat treatment mechanism, a water supply mechanism, a gas supply mechanism, a main frame and a steel rail holding mechanism for holding a steel rail. The heat treatment mechanism comprises a pressure-stabilized air bellow, the pressure-stabilized air bellow is connected with an upper air bellow, a lower air bellow, a left air bellow and a right air bellow through a small vent pipe correspondingly, and first nozzles are arranged on the upper air bellow, the lower air bellow, the left air bellow and the right air bellow correspondingly; the first nozzle of the upper air bellow is arranged over the steel rail, the first nozzle of the lower air bellow is arranged under the steel rail, and the central axes of the first nozzle of the upper air bellow and the first nozzle of the lower air bellow coincide with the central axis of the steel rail; the first nozzle of the left air bellow and the first nozzle of the right air bellow are symmetrically arranged on the two sides of the steel rail; the water supply mechanism and the gas supply mechanism are connected with the pressure-stabilized air bellow correspondingly, and the steel rail holding mechanism is arranged in the main frame. The invention further provides a steel rail heat treatment method. The steel rail heat treatment device and the heat treatment method are easy, the operation is convenient, and the heat treatment effect of the steel rail can be ensured.

Owner:武汉钢铁有限公司

A kind of low-consumption environment-friendly spring steel water-soluble quenching liquid and quenching process

ActiveCN105543456BModerate cooling rateGood inverse solubilityQuenching agentsPhysical chemistryProcess engineering

The invention discloses low-consumption environment-friendly spring steel water-soluble quenching liquid and a quenching process and belongs to the technical field of common spring steel heat treatment quenching liquid and processes. The quenching liquid is characterized in that the quenching liquid is composed of, by mass, an antioxidant, an anti-rust agent, a preservative, a defoaming agent and the balance methoxy polyethylene glycol. According to the low-consumption environment-friendly spring steel water-soluble quenching liquid and the quenching process, all the components are organically combined together, and the quenching performance of the quenching liquid can be played to the limit with the synergistic effect, namely, the defects of the quenching liquid are overcome through other functional components while the requirements for the good solubilizing performance and solubility inversing performance of basic solvent are met. When rapid oil or diesel oil quenching is replaced by the low-consumption environment-friendly spring steel water-soluble quenching liquid, the production cost is reduced and the production environment and natural resources are protected while resources are saved.

Owner:陕西雷帕得悬架系统有限公司

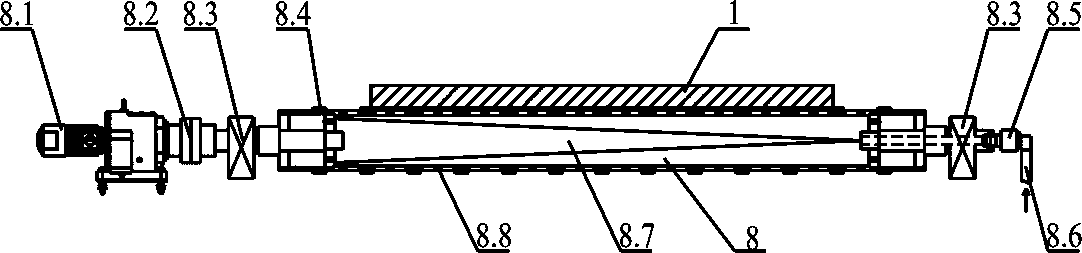

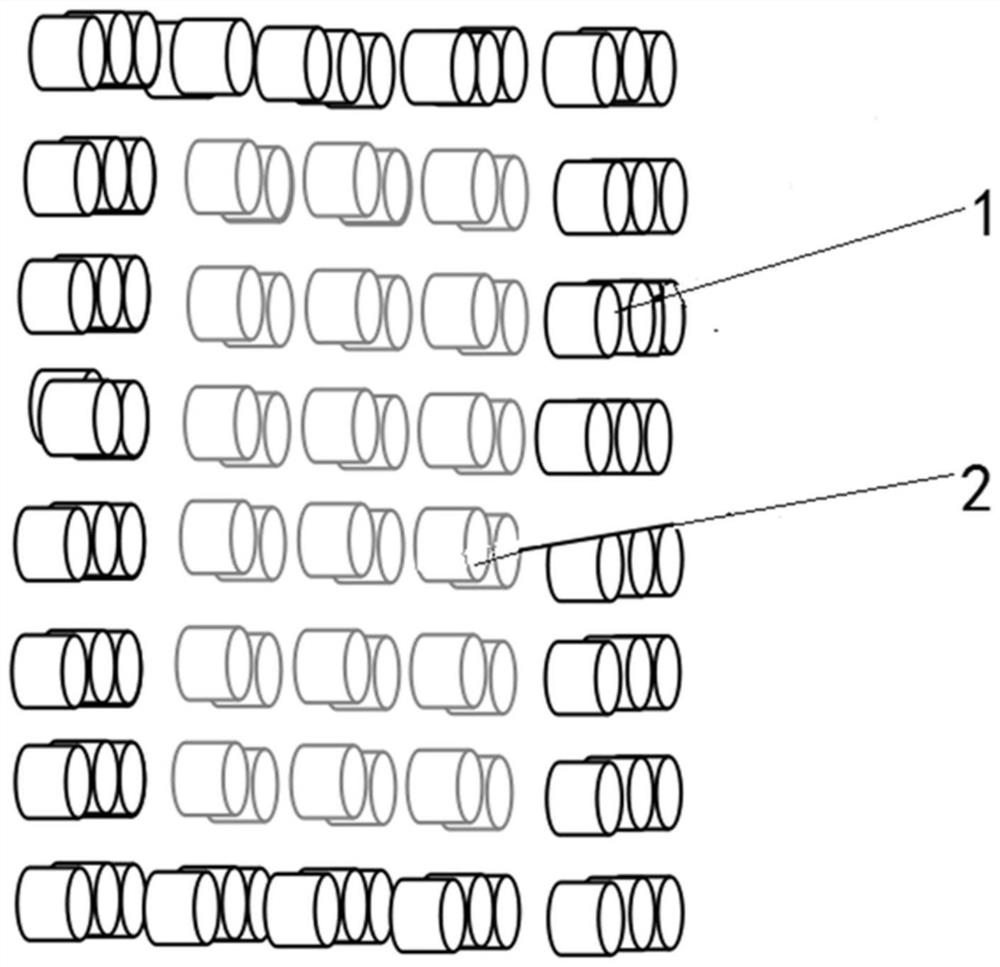

A kind of production method of high-strength graphene-enhanced polyester staple fiber

ActiveCN111155195BSimple production methodHigh strengthFilament forming substance formingArtificial thread manufacturing machinesPolyesterPolymer science

The invention belongs to the technical field of fiber structures, and in particular relates to a method for producing high-strength graphene-reinforced polyester staple fibers. The invention achieves the effect of effective production of graphene-enhanced polyester staple fibers by first melting and granulating and then melting and blending the graphene master batch of a specific component and the common polyester fiber master batch. The invention has the advantages of simple and effective production method of graphene-enhanced polyester short fibers, high strength and good wear resistance of graphene-enhanced polyester short fibers, and good combined cooling effect of composite coolers in the production process. The reinforced polyester staple fiber has the advantages of moderate cooling speed, uniform cooling range, and simple and convenient cutting action after cooling.

Owner:福建经纬新纤科技实业有限公司

A kind of production method of hot-rolled steel strip for 610mpa grade automobile frame

The embodiment of the present invention provides a method for producing a hot-rolled steel strip for a 610MPa-level automobile frame. The production process steps for the hot-rolled steel strip for a 610MPa-level automobile frame include: converter smelting, LF furnace refining, continuous casting, and rolling plan Arrangement, slab heating, rough rolling, high-pressure water descaling, finishing rolling, laminar cooling, coiling and stack cooling; the chemical composition and weight percentage of the hot-rolled steel strip for the 610MPa grade automobile frame are: carbon C: 0.060~0.090%, silicon Si: 0.10~0.20%, manganese Mn: 1.35~1.50%, phosphorus P≤0.020%, sulfur S≤0.008%, aluminum Als: 0.015~0.050%, niobium Nb: 0.035~0.045% , titanium Ti: 0.035-0.045%, nitrogen N≤0.0045%, the balance is Fe and unavoidable impurities.

Owner:LIUZHOU IRON & STEEL +1

A kind of quenching oil capable of making fasteners self-blackening after quenching and its application method

ActiveCN105969957BImprove quenching effectGood effectFurnace typesMetallic material coating processesAntioxidantSurface-active agents

The invention discloses quenching oil capable of making a fastener become black by itself after quenching and an application method of the quenching oil, and belongs to the technical field of metal heat treatment. The quenching oil comprises, by mass, 35-40 parts of refined base oil, 7-10 parts of composite cooling accelerant, 0.5-0.7 part of a composite blacking agent, 0.4-0.8 part of a brightening agent, 0.5-0.8 part of a surface active agent and 0.02-0.04 part of antioxidant. The composite cooling accelerant is the mixture of polyisobutene, dimethyl naphthalene and mahogany petroleum sulfonate. The composite blacking agent is the mixture of short oil alkyd resin, a coloring agent and a wetting agent. The brightening agent is the mixture of imidazoline oleate and methyl terpene resin. The coloring agent is disperse black 9. The wetting agent is fatty alcohol-polyoxyethylene ether. The surface active agent is span-80. The optimal using temperature of the quenching oil ranges from 70 DEG C to 75 DEG C, the speed for cooling the fastener is moderate, a protection film is formed on the surface in a self-blacking manner during quenching, and efficiency is improved.

Owner:马鞍山金泉工业介质科技有限公司

A kind of flat circular knife and its manufacturing method

ActiveCN104942879BIncrease sharpnessImprove securityFurnace typesMetal working apparatusAlloyEngineering

The invention discloses a flat and round cutter and a manufacturing method thereof and belongs to the field of machining of cutters. The flat and round cutter comprises a center hole, a cutter head and a blade, wherein the center hole is located in the center of the cutter head, the blade is located on the outer ring of the cutter head, a cutting edge is arranged on the outer ring of the blade, the cutting edge angle delta of the cutting edge is in a range of 13-18 degrees, and threaded holes and mounting holes are formed in the cutter head. The flat and round cutter is manufactured from an alloy material comprising special elements under strictly controlled technological conditions through steps such as blank forging, isothermal spheroidizing, preliminary processing, heat treatment, rough grinding, leveling, tempering, deep processing and the like, the cutter has very high abrasion resistance while meeting the requirement for the sharpness, the service life is long, and the cutting edge is low in abrasion loss and free of cracking after long-term usage.

Owner:安徽华天机械股份有限公司

A kind of quenching oil and quenching method capable of making screws self-blackening after quenching

ActiveCN105925770BAchieve mechanical strengthAchieve hardnessFurnace typesMetallic material coating processesAntioxidantFatty alcohol

The invention discloses quenching oil capable of enabling an screw to blacken automatically after quenched and a quenching method thereof. The invention belongs to the field of metal heat treatment technology. The quenching oil comprises the following components, by weight, 35-40 parts of refined base oil, 6-10 parts of cooling catalyzed composite agent, 0.4-0.6 parts of blackening composite agent, 0.3-0.7 parts of brightening agent, 0.4-0.7 parts of surface activating agent and 0.02-0.04 parts of antioxidant. The cooling catalyzed composite agent is a mixture of dialkyl naphthalene and petroleum sulfonate; the blackening composite agent the mixture of short oil alkyd resin, colouring agent and wetting agent; the brightening agent is the mixture of imidazoline oleate and methyl terpene resin; the surface activating agent is span-80. The colouring agent is disperse black 9; the wetting agent is fatty alcohol-polyoxyethylene ether. The best using temperature of the quenching oil is between 75 DEG C and 80 DEG C. Between 75 DEG C and 80 DEG C, the cooling speed of the quenching oil for the screw is moderate, the surface can be blackened automatically and a protective film can be formed while the quenching, so that the processes can be reduced and the efficiency can be improved.

Owner:马鞍山金泉工业介质科技有限公司

A special quenching oil for small modulus gears and its preparation method

ActiveCN105950844BAchieve mechanical strengthImprove quenching effectFurnace typesQuenching agentsAntioxidantBase oil

The invention discloses quenching oil dedicated to small module gears and a preparation method of quenching oil, and belongs to the technical field of metal heat treatment. The quenching oil comprises the following components in parts by mass: 35 to 40 parts of refined base oil, 2 to 3 parts of a cooling compound agent, 0.5 to 0.8 part of a blackening compound agent, 0.3 to 0.7 part of a brightening agent, 0.6 to 0.8 part of a surfactant and 0.04 to 0.06 part of an antioxidant. The quenching oil is specially developed for the small module gears of which the module is 1 mm or below, the optimal utilization temperature is 100 to 110 DEG C, the fluidity of the quenching oil is good in the temperature range, the cooling velocity for the small module gears is moderate, protective films are formed on the surfaces of the gears through automatic blackening during quenching, the secondary coating antirust treatment on the surfaces after heat treatment is reduced, the resources are saved, the procedure is reduced, and the efficiency is improved.

Owner:马鞍山金泉工业介质科技有限公司

A kind of slitting disc knife and its manufacturing method

The invention discloses a slitting cutting disc and a preparation method thereof, which belong to the process field of cutters. The slitting cutting disc is of a circle blade, and comprises a center hole, a cutter disc and a blade, wherein the center hole is arranged in the center of the cutter disc, the blade is arranged on an outer ring of the cutter disc, a blade opening is arranged on an outer ring of the blade, and the opening angle delta ( ) of blade opening is 23-27 degrees. The opening thickness h of the blade opening is 0.24-0.26mm. The materials which are made into the slitting cutting disc comprise components with percentage by weight: carbon (C) 1.15-1.33%, nitrogen (N) 0.2-0.4%, manganese (Mn) 0.30-0.40%, silicon (Si) 0.52-1.20%, chromium (Cr) 8.50-10.50%, tungsten (W) 1.50-2.50%, vanadium (V) 0.35-0.50%, molybdenum (Mo) 0.25-0.4%, nickel (Ni) 0.30-0.40%, copper (Cu) <=0.30%, sulphur (S)<=0.020% and phosphorus (P)<=0.027%, and the allowance is ferrum (Fe). The slitting cutting disc has the advantages that the slitting cutting disc is excellent in abrasive resistance and is not easy to deform, and the blade opening resists abrasion, not easy to crack, long in service life and easy to make.

Owner:安徽华天机械股份有限公司

Environmental protection water-solubility quenching liquid

ActiveCN102643963BImprove final performanceImprove machining accuracyQuenching agentsFungicideSolubility

Owner:上海福岛新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com