Patents

Literature

110results about How to "Easy shape control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Double vacuum bag process for resin matrix composite manufacturing

InactiveUS20050253309A1Improve performanceImprove propertiesLaminationLamination apparatusRelative pressureResin matrix

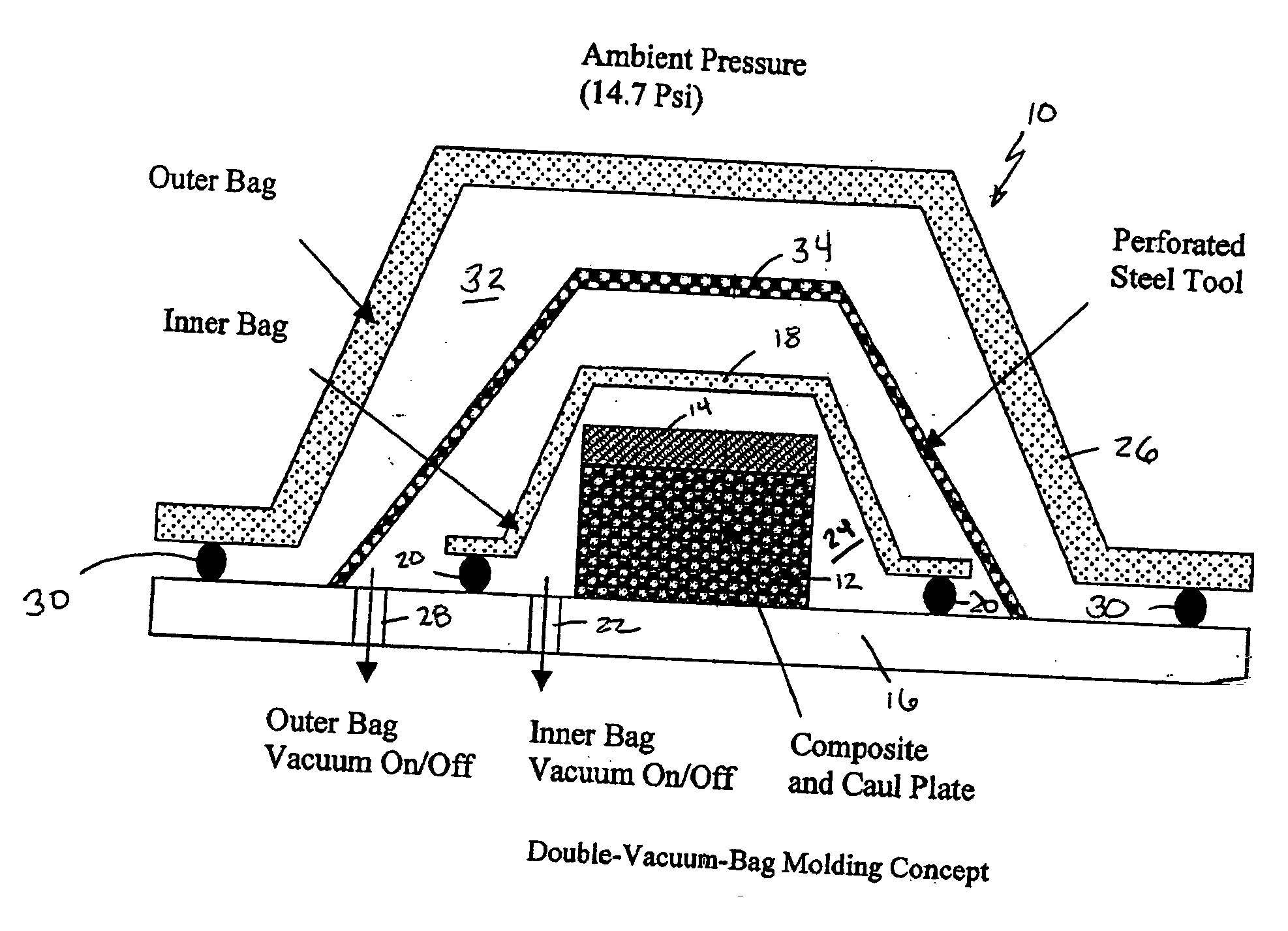

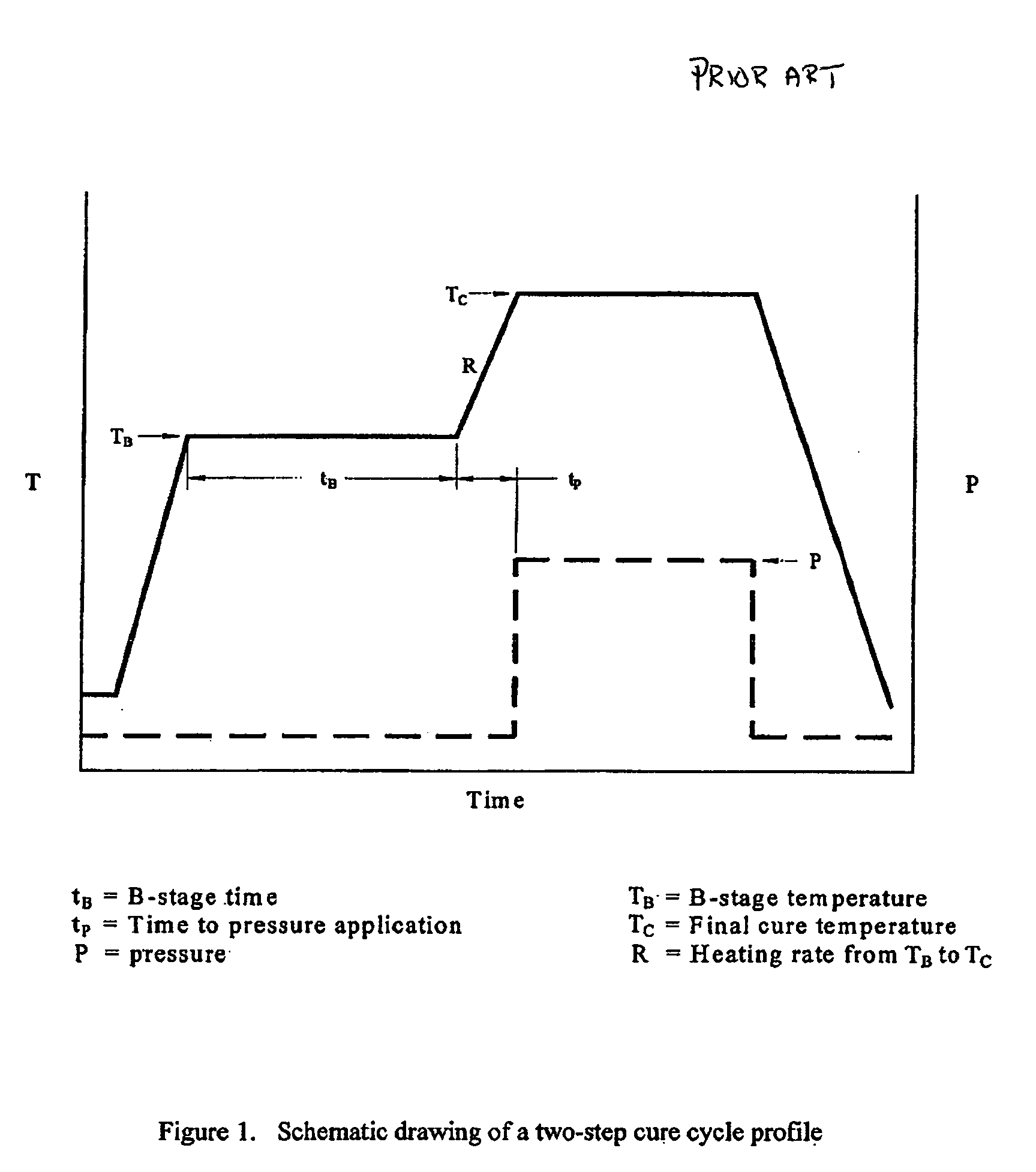

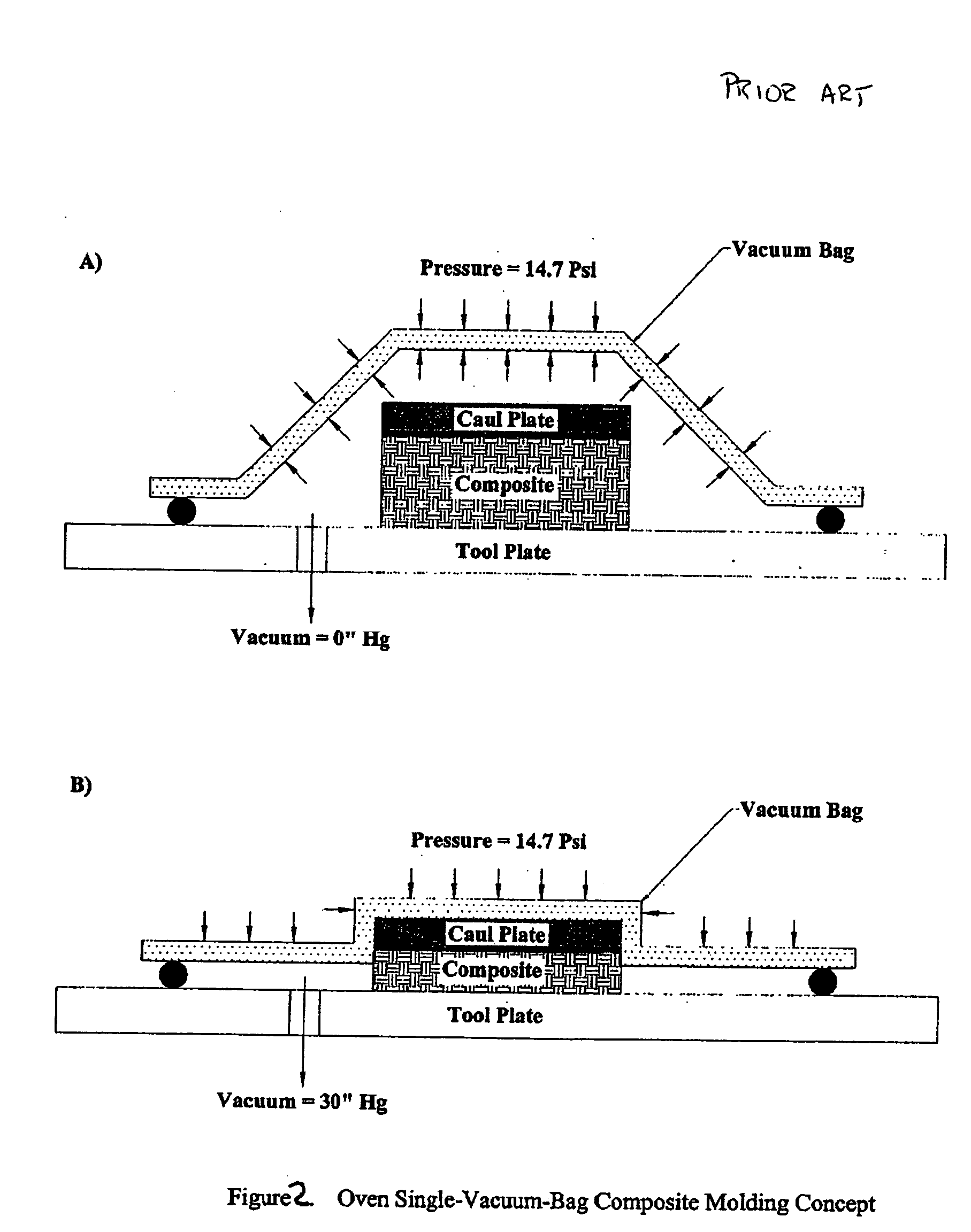

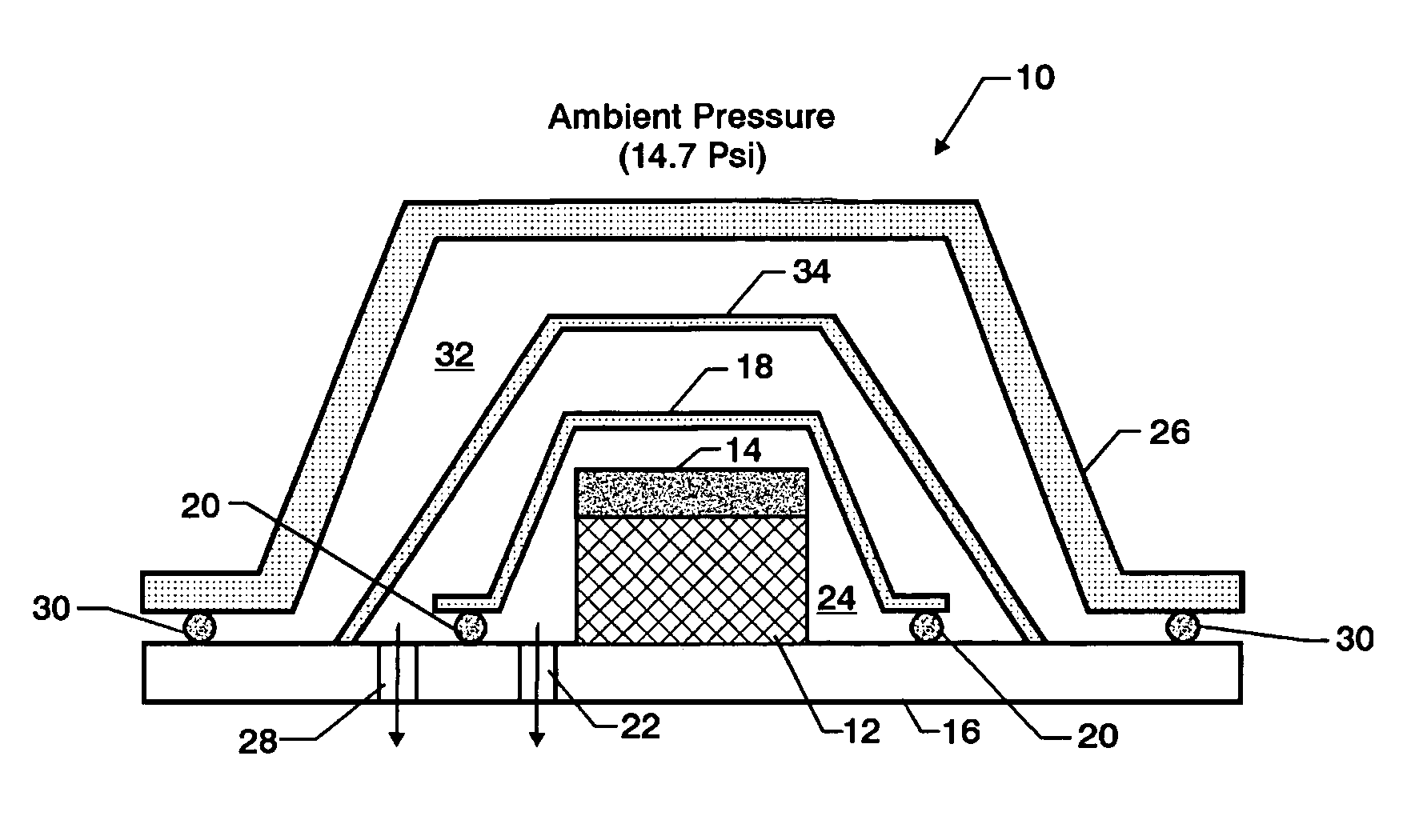

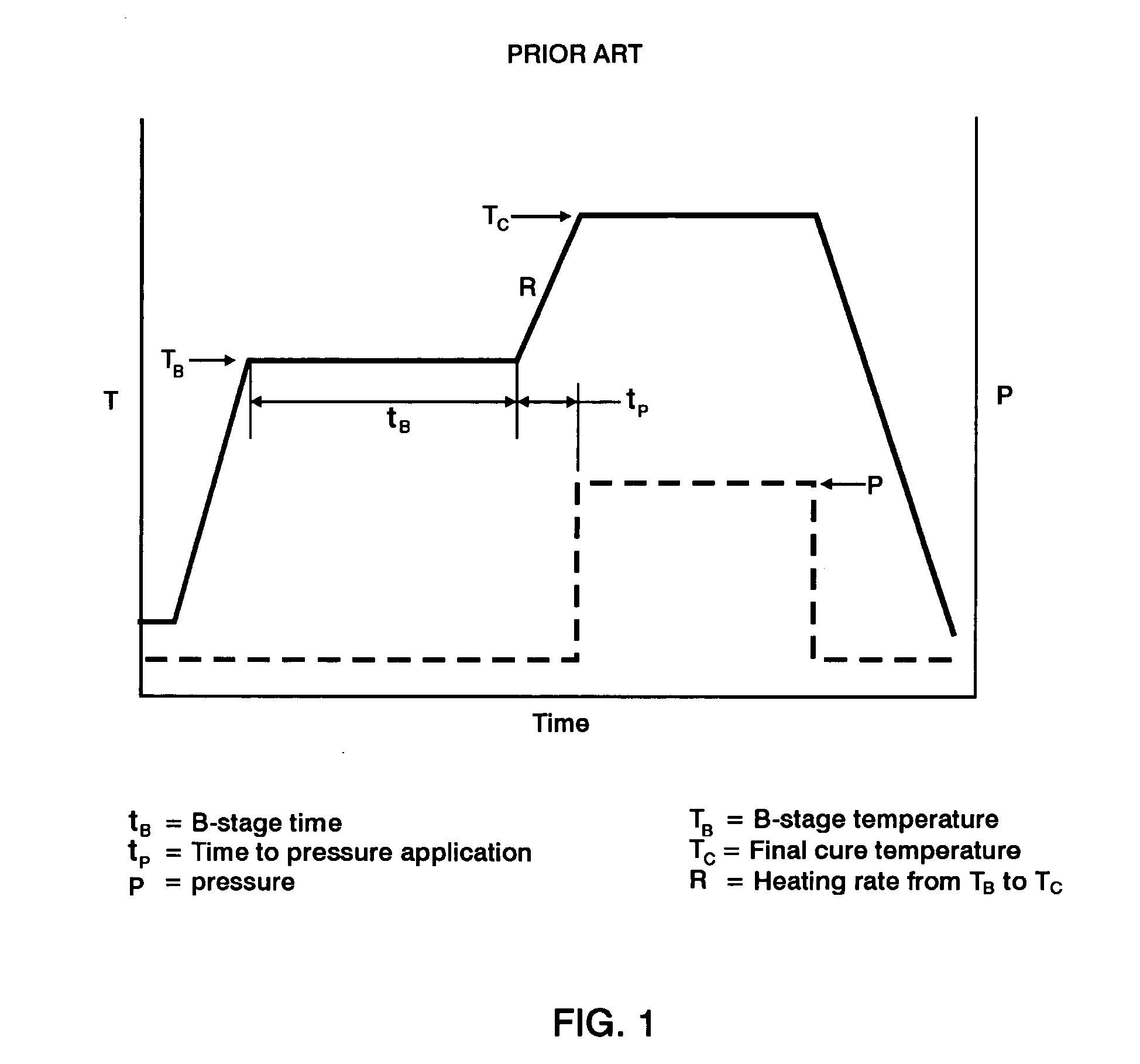

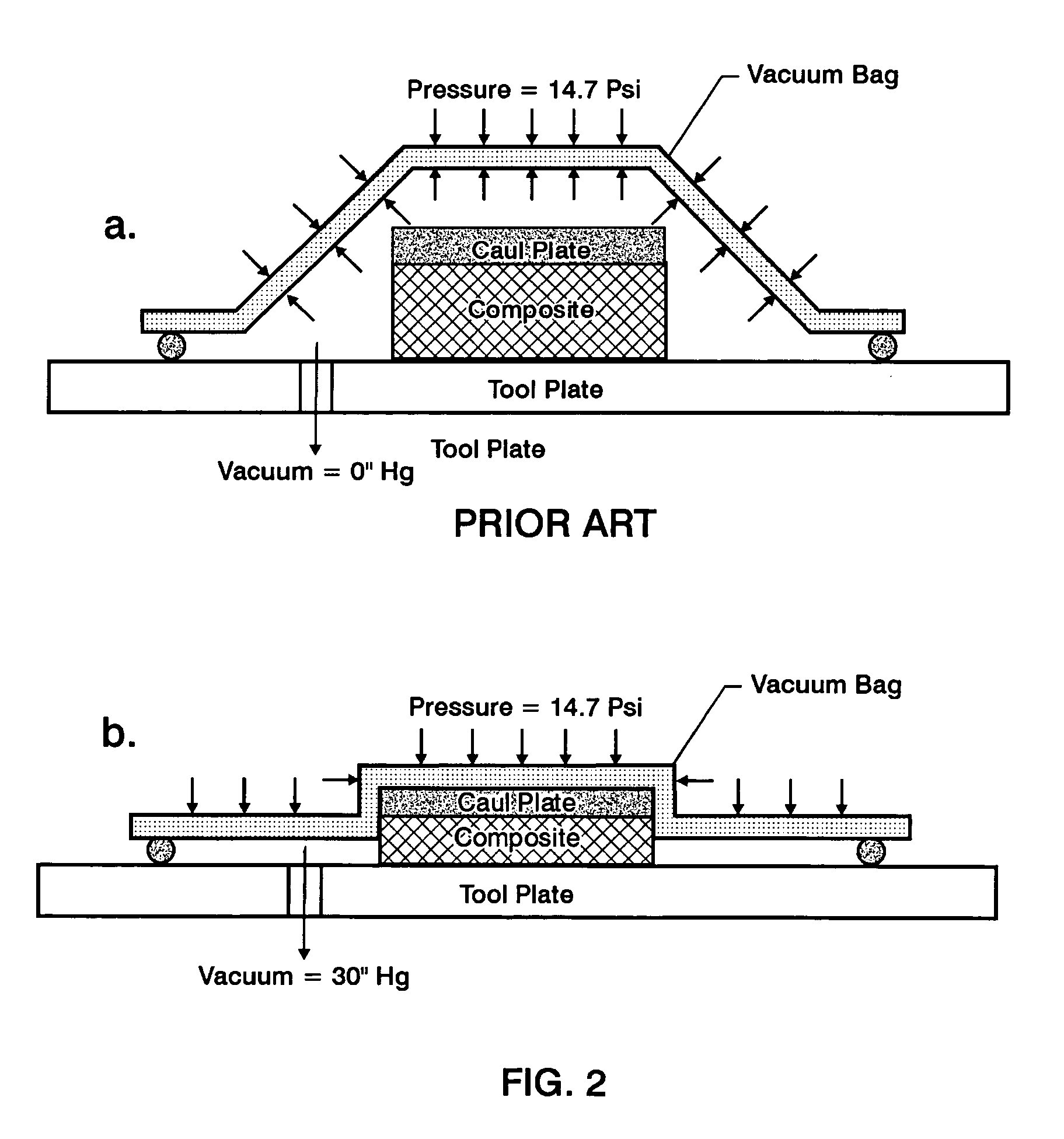

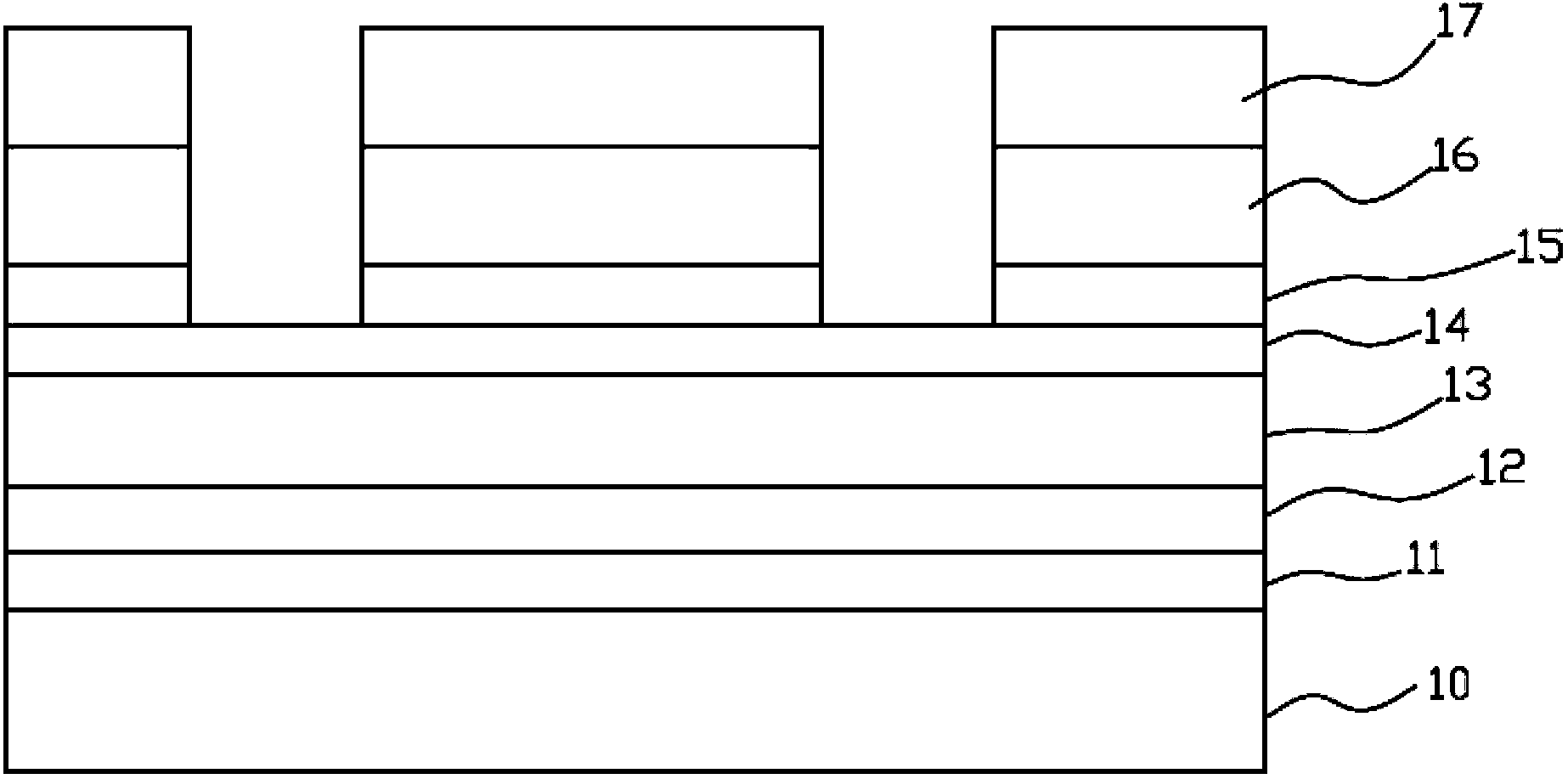

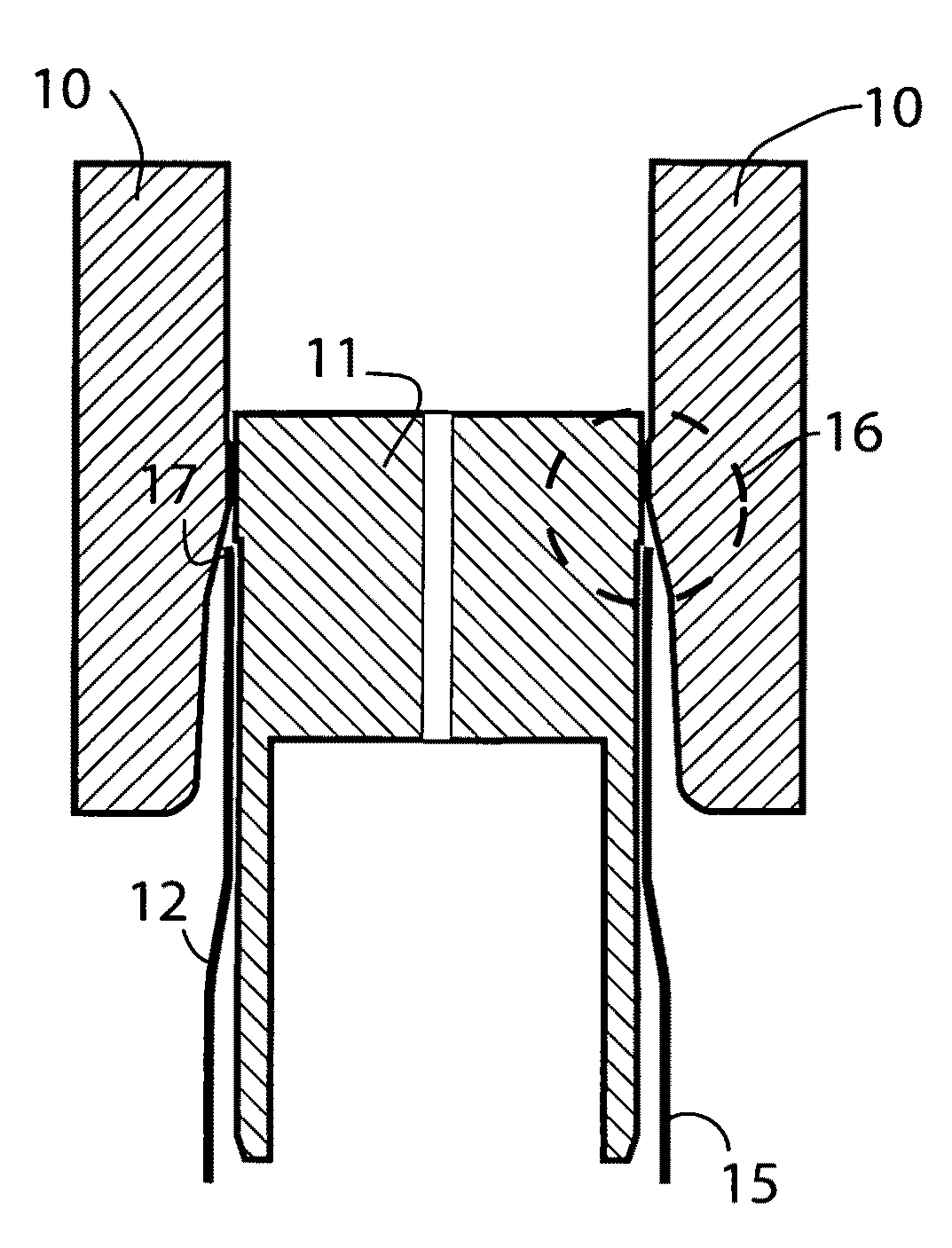

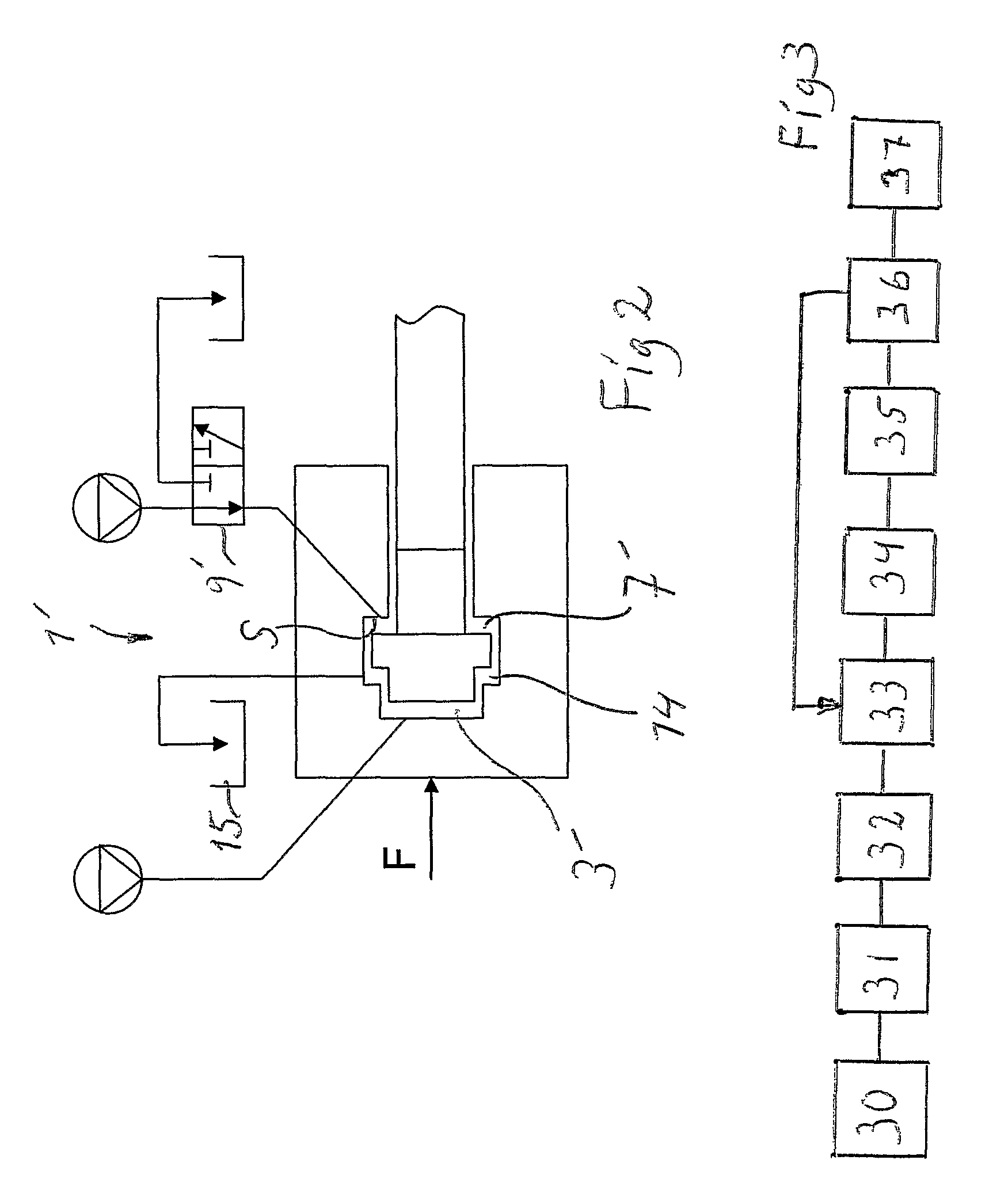

A double vacuum bag molding assembly with improved void management and laminate net shape control which provides a double vacuum environment for use in fabricating composites from prepregs containing air and / or volatiles such as reactive resin matrix composites or composites from solvent containing prepregs with non-reactive resins matrices. By using two vacuum environments during the curing process, a vacuum can be drawn during a B-stage of a two-step cycle without placing the composite under significant relative pressure. During the final cure stage, a significant pressure can be applied by releasing the vacuum in one of the two environments. Inner and outer bags are useful for creating the two vacuum environments with a perforated tool intermediate the two. The composite is placed intermediate a tool plate and a caul plate in the first environment with the inner bag and tool plate defining the first environment. The second environment is characterized by the outer bag which is placed over the inner bag and the tool plate.

Owner:NASA

Double vacuum bag process for resin matrix composite manufacturing

InactiveUS7186367B2Improve performanceImprove propertiesLaminationLamination apparatusRelative pressureResin matrix

A double vacuum bag molding assembly with improved void management and laminate net shape control which provides a double vacuum environment for use in fabricating composites from prepregs containing air and / or volatiles such as reactive resin matrix composites or composites from solvent containing prepregs with non-reactive resins matrices. By using two vacuum environments during the curing process, a vacuum can be drawn during a B-stage of a two-step cycle without placing the composite under significant relative pressure. During the final cure stage, a significant pressure can be applied by releasing the vacuum in one of the two environments. Inner and outer bags are useful for creating the two vacuum environments with a perforated tool intermediate the two. The composite is placed intermediate a tool plate and a caul plate in the first environment with the inner bag and tool plate defining the first environment. The second environment is characterized by the outer bag which is placed over the inner bag and the tool plate.

Owner:NASA

Epoxy microcapsule with polyurea as wall material and preparation method thereof

InactiveCN103331133AIncrease the degree of cross-linkingGood brittlenessMicroballoon preparationMicrocapsule preparationIsocyanatePolyurea

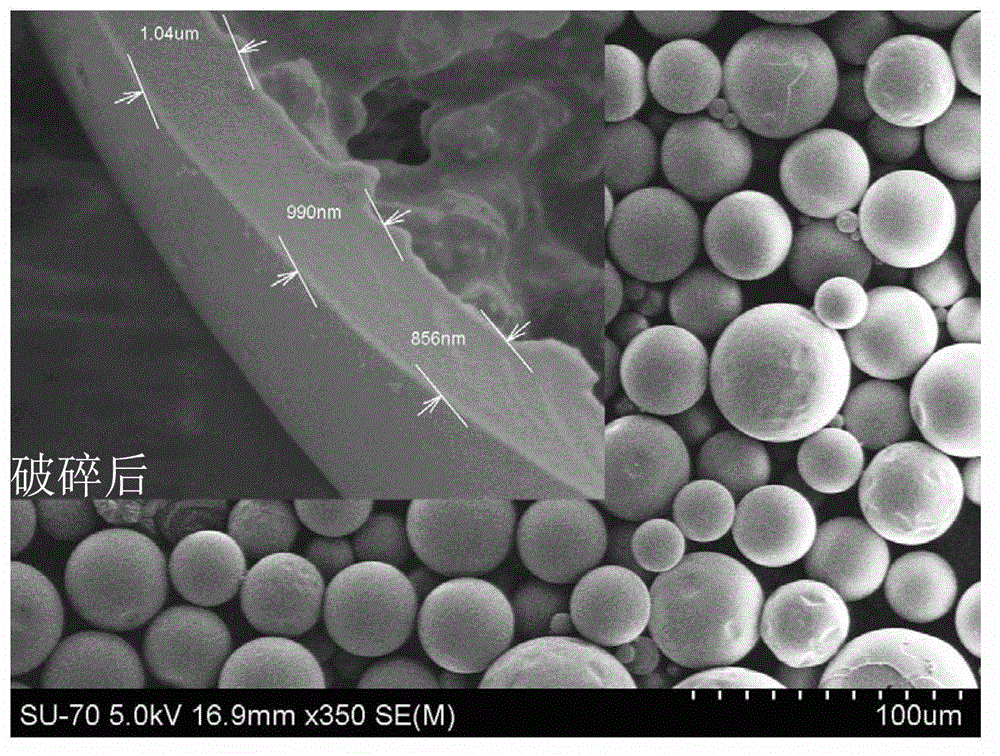

The invention relates to the technical field of self repair materials and provides an epoxy microcapsule with polyurea as a wall material. The core material of the microcapsule comprises liquid epoxy resin, the wall material of the microcapsule is crosslinked polyurea prepared by carrying out an interface reaction on polyisocyanate and water, and the polyisocyanate comprises polyisocyanate containing three elements or more than three elements. The invention also provides a preparation method of the epoxy microcapsule with polyurea as the wall material. The preparation method of the epoxy microcapsule with polyurea as the wall material comprises the following steps of: dispersing polyisocyanate and liquid epoxy resin into water containing a surface active agent to obtain a mixed solution, stirring the mixed solution for 0.5-5 hours at the temperature of 25-90 DEG C, filtering, washing, and drying, so that the epoxy microcapsule with polyurea as the wall material is obtained. The preparation method of the epoxy microcapsule with polyurea as the wall material is simple and practicable and is applicable to industrial production.

Owner:SHENZHEN UNIV

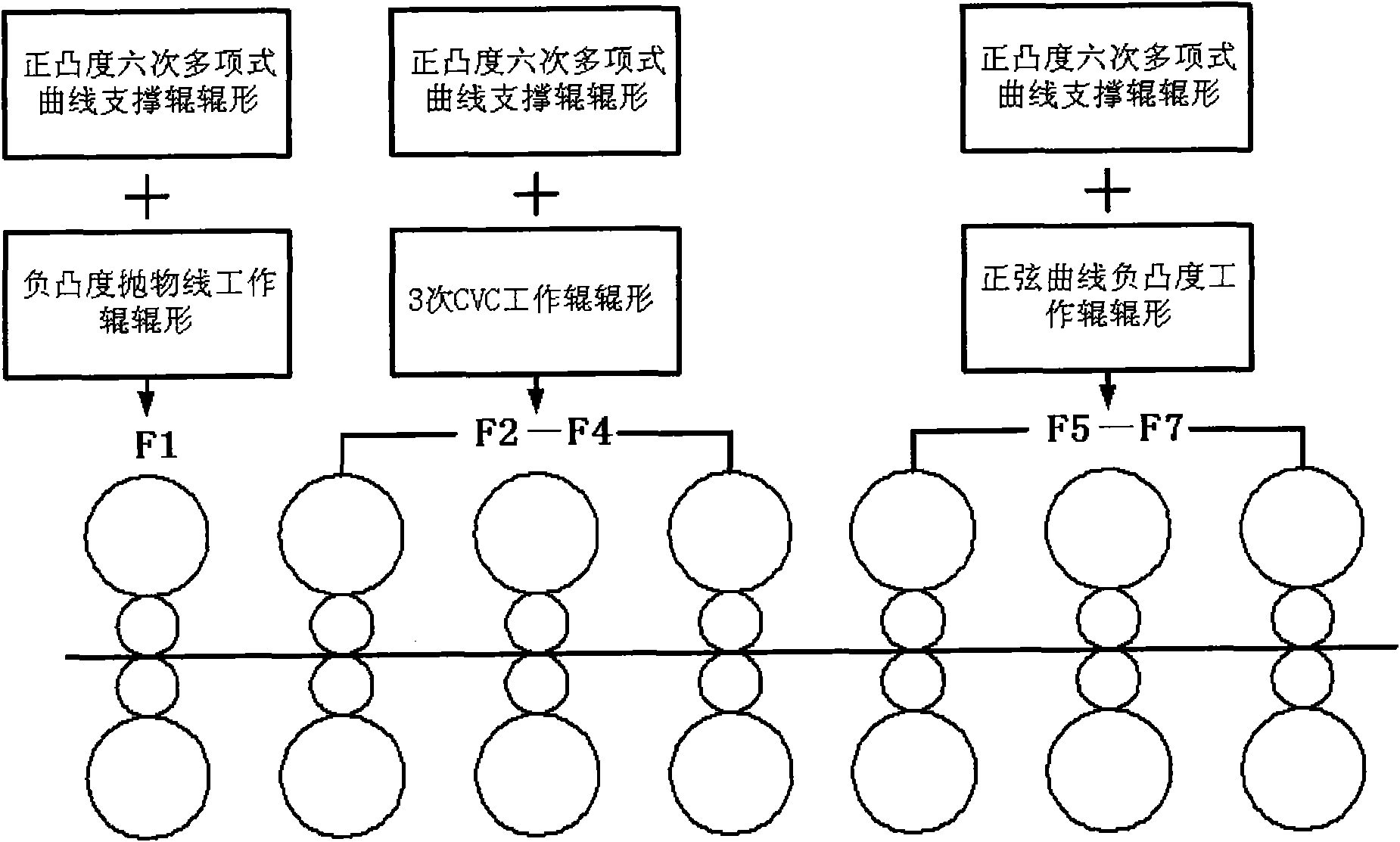

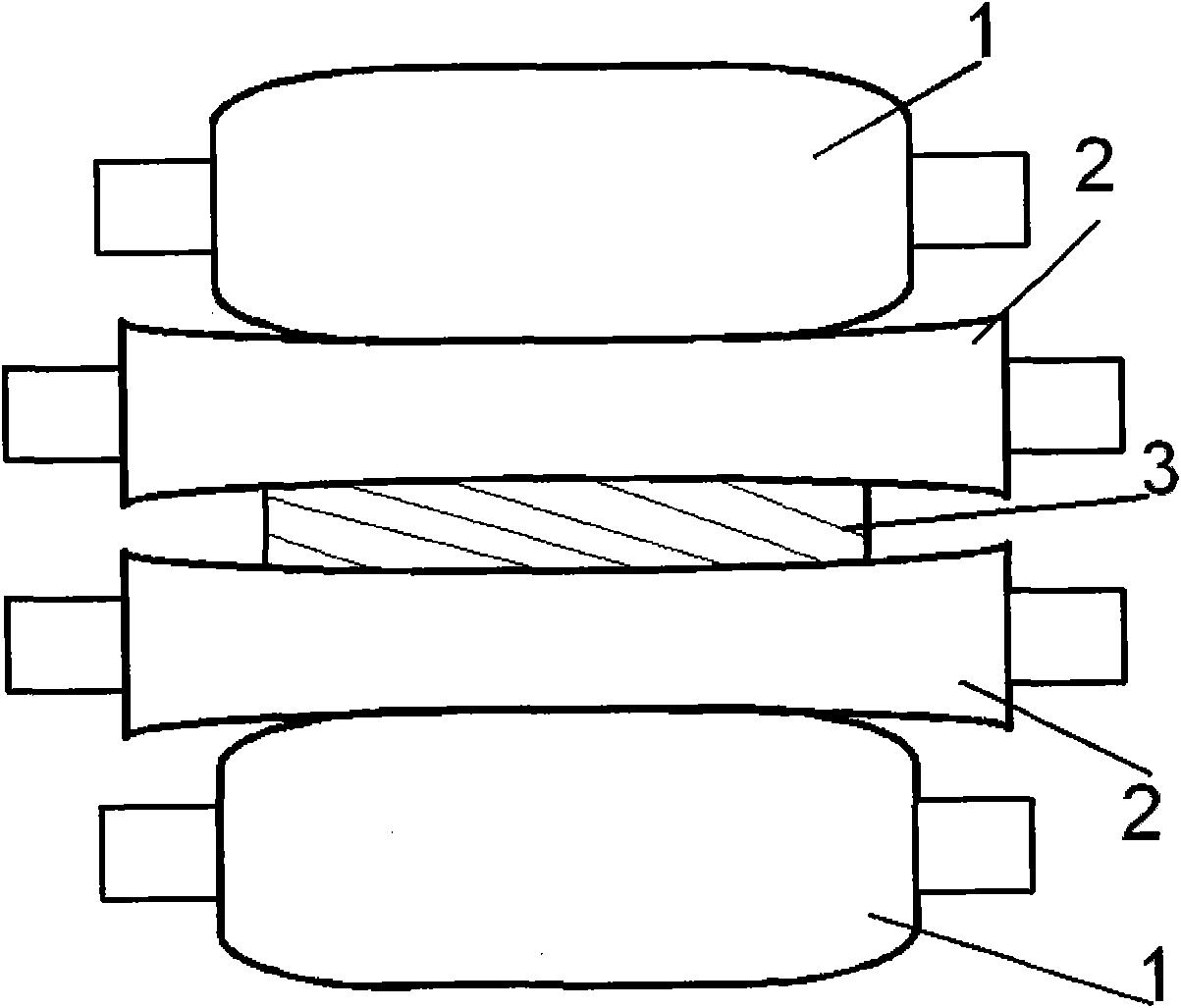

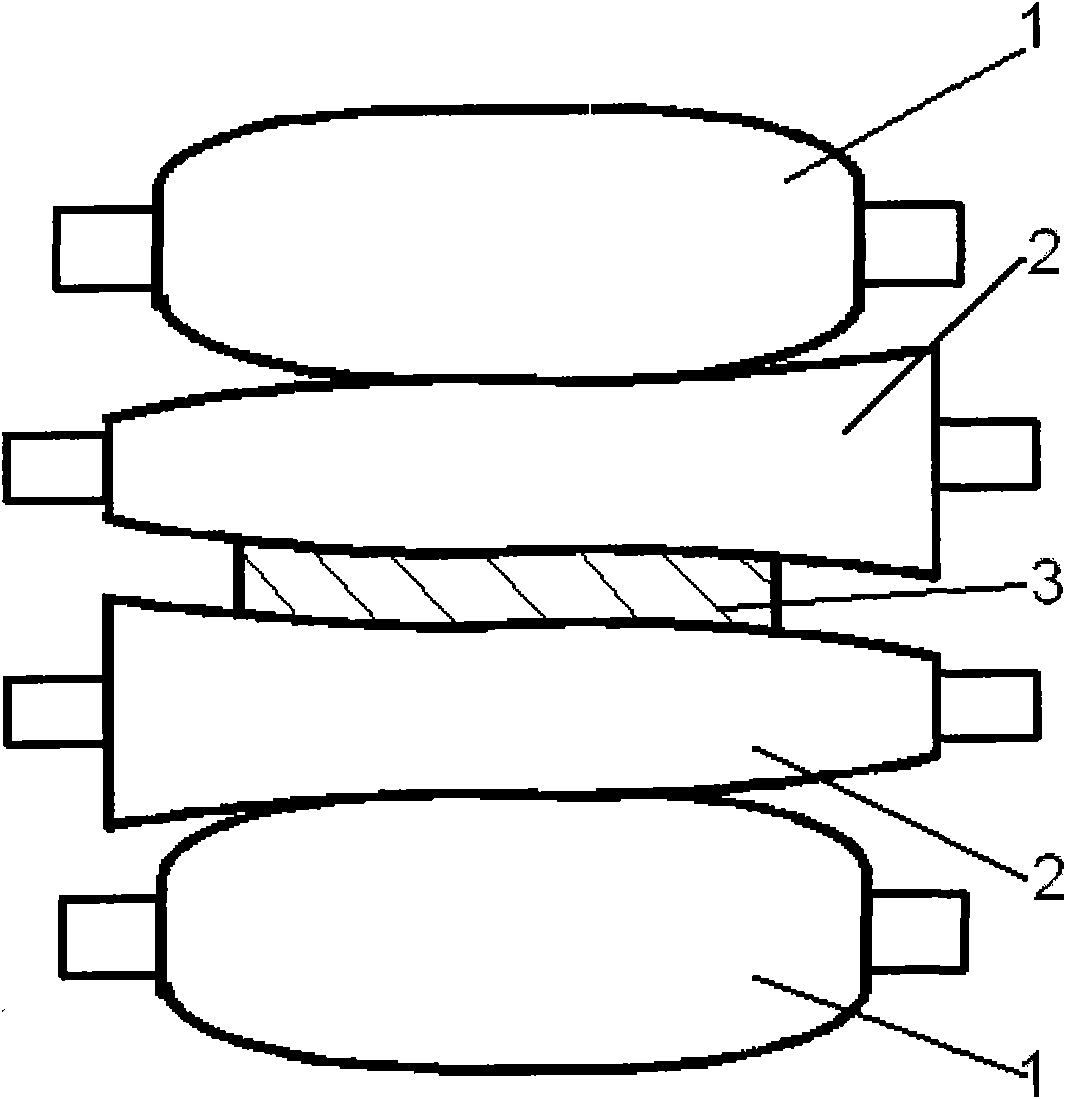

Complete roll forming configuring method for wide flat steel hot rolling finish mill set

ActiveCN101890429AReasonable configurationHigh precisionRollsMetal rolling arrangementsWork rollRoll forming

The invention relates to a complete roll forming configuring method for a wide flat steel hot rolling finish mill set. According to the characteristics that an upstream machine frame controls the convexity and a downstream machine frame controls the flatness in the seven-machine frame and four-roll hot rolling wide flat steel finish mill, a finish rolling inlet machine frame F1 adopts negative convexity working roll forming, a machine frame F2, a machine frame F3 and a machine frame F4 adopt cubic CVC working roll forming, and a machine frame F5, a machine frame F6, and a machine frame F7 adopt negative convexity working roll forming of sine curves and are matched with periodic roll shifting of the working roll with long stroke. The supporting rolls of all the machine frames of the finish mill set adopt positive convexity roll forming of sextic polynomes. The method improves the transverse rigidity of the machine frames of the finish mill, improves regulation and control efficiency of roll bending force of the working roll, and reduces flexibility deformation of the roll. The roll forming configuring method for the finish mill set improves stability of the wide flat steel rolling, reduces the deflection amount of the wide flat steel, prolongs the planned length for rolling and greatly improves profile shape control precision of the wide flat steel.

Owner:SHOUGANG CORPORATION

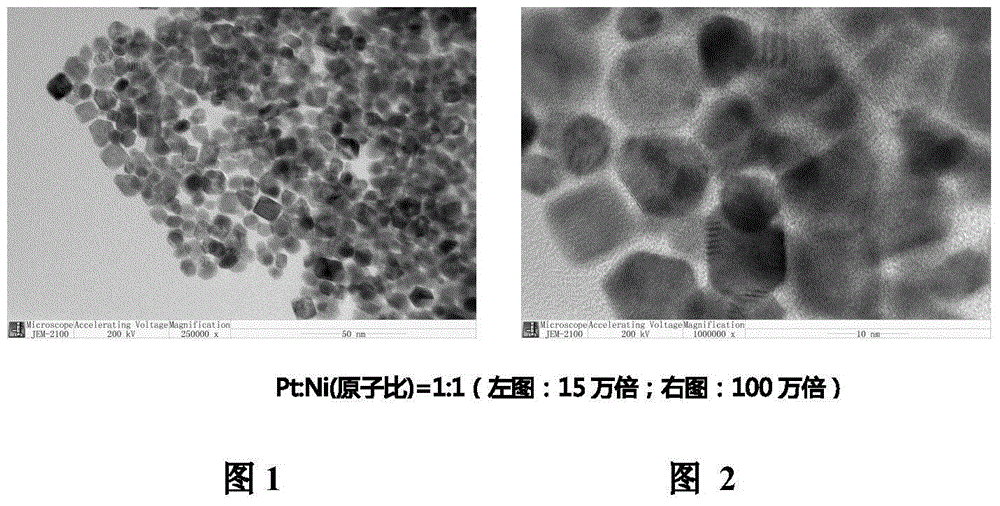

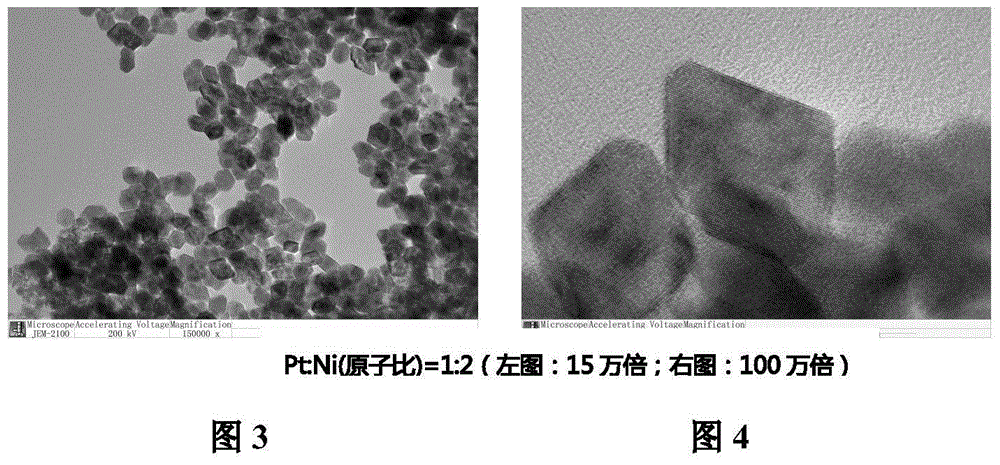

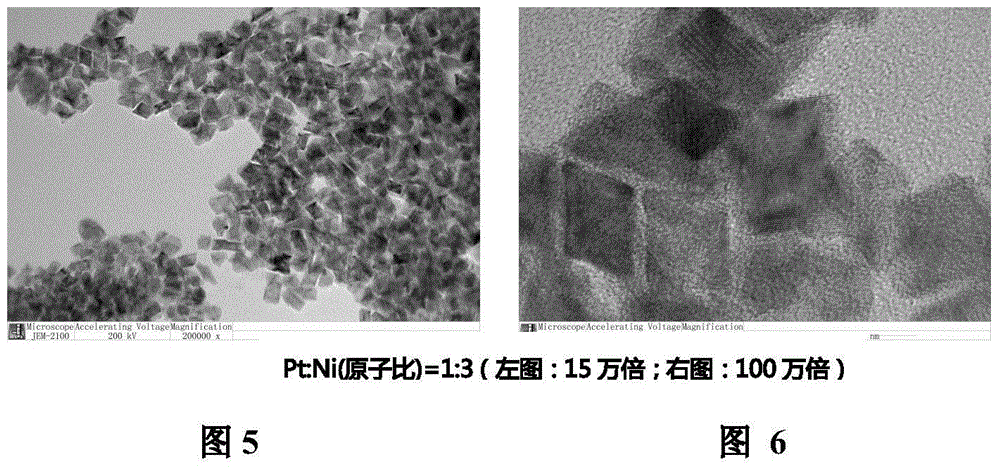

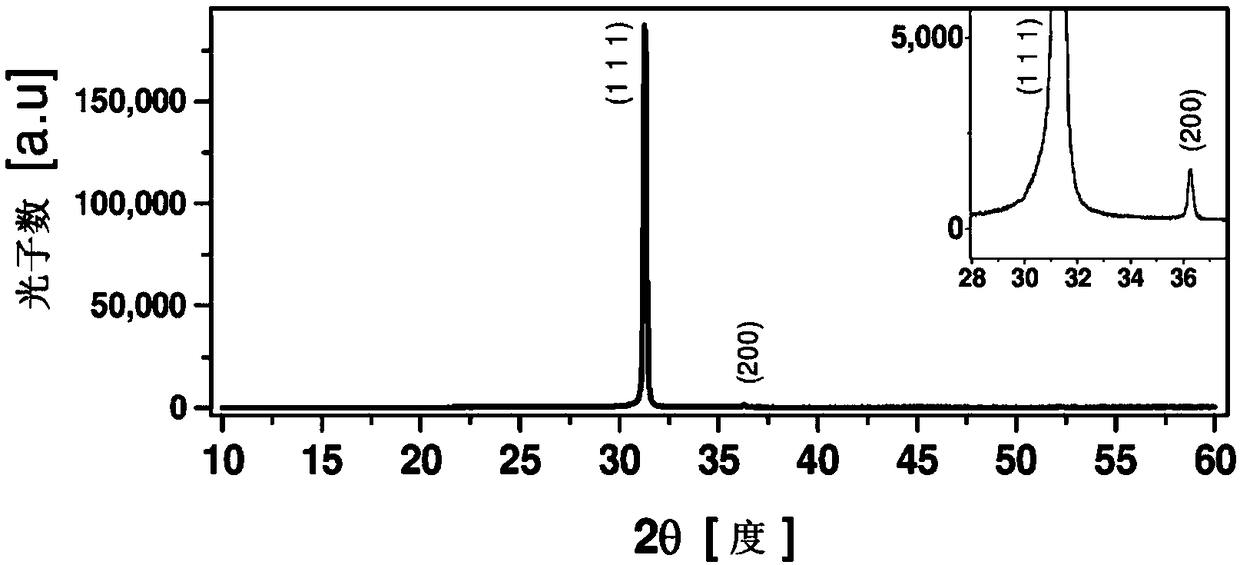

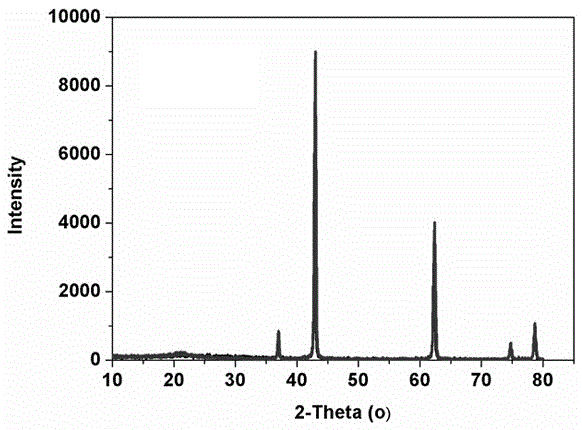

Method for preparing proton-exchange membrane fuel cell oxygen reduction catalyst based on PtNi (111) octahedral single crystal nanoparticles

InactiveCN104998658AHigh catalytic activity for oxygen reductionPt content decreasedCell electrodesMetal/metal-oxides/metal-hydroxide catalystsN dimethylformamideSingle crystal

Owner:昆明贵研催化剂有限责任公司

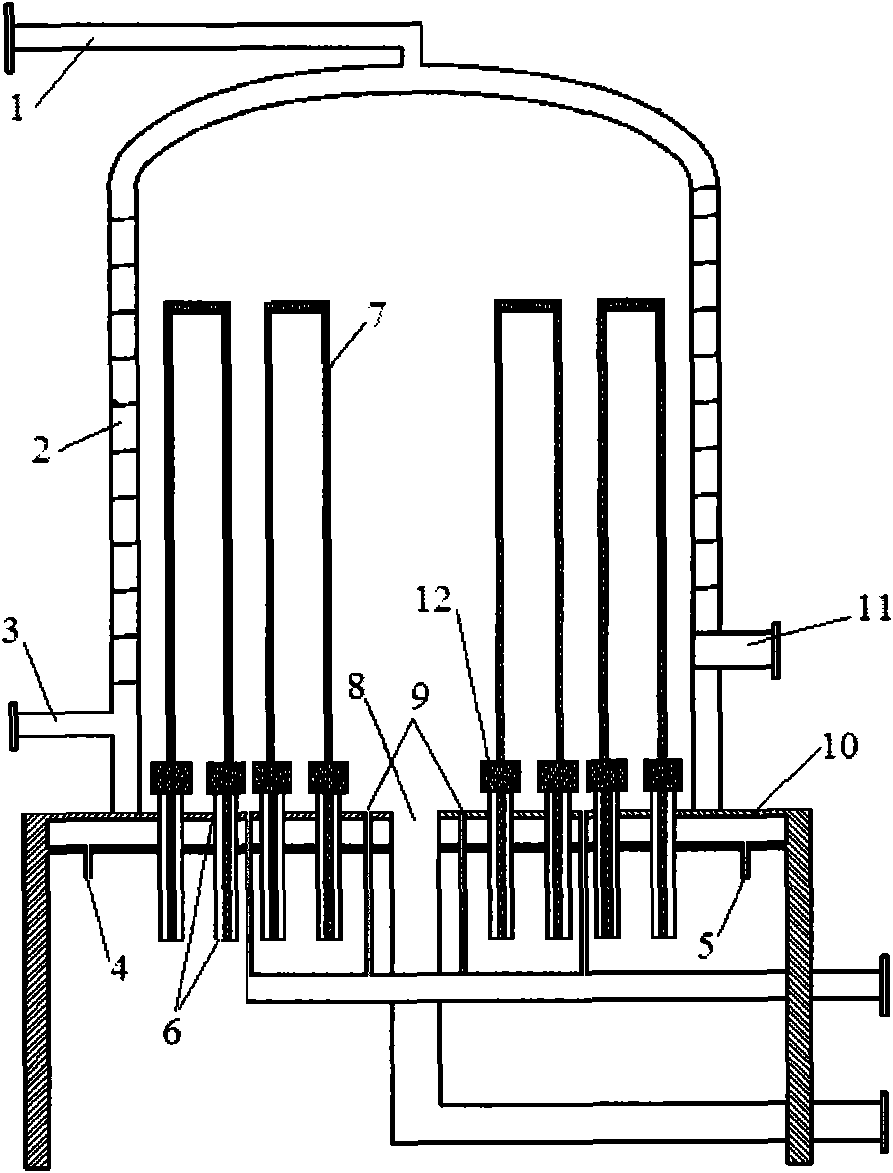

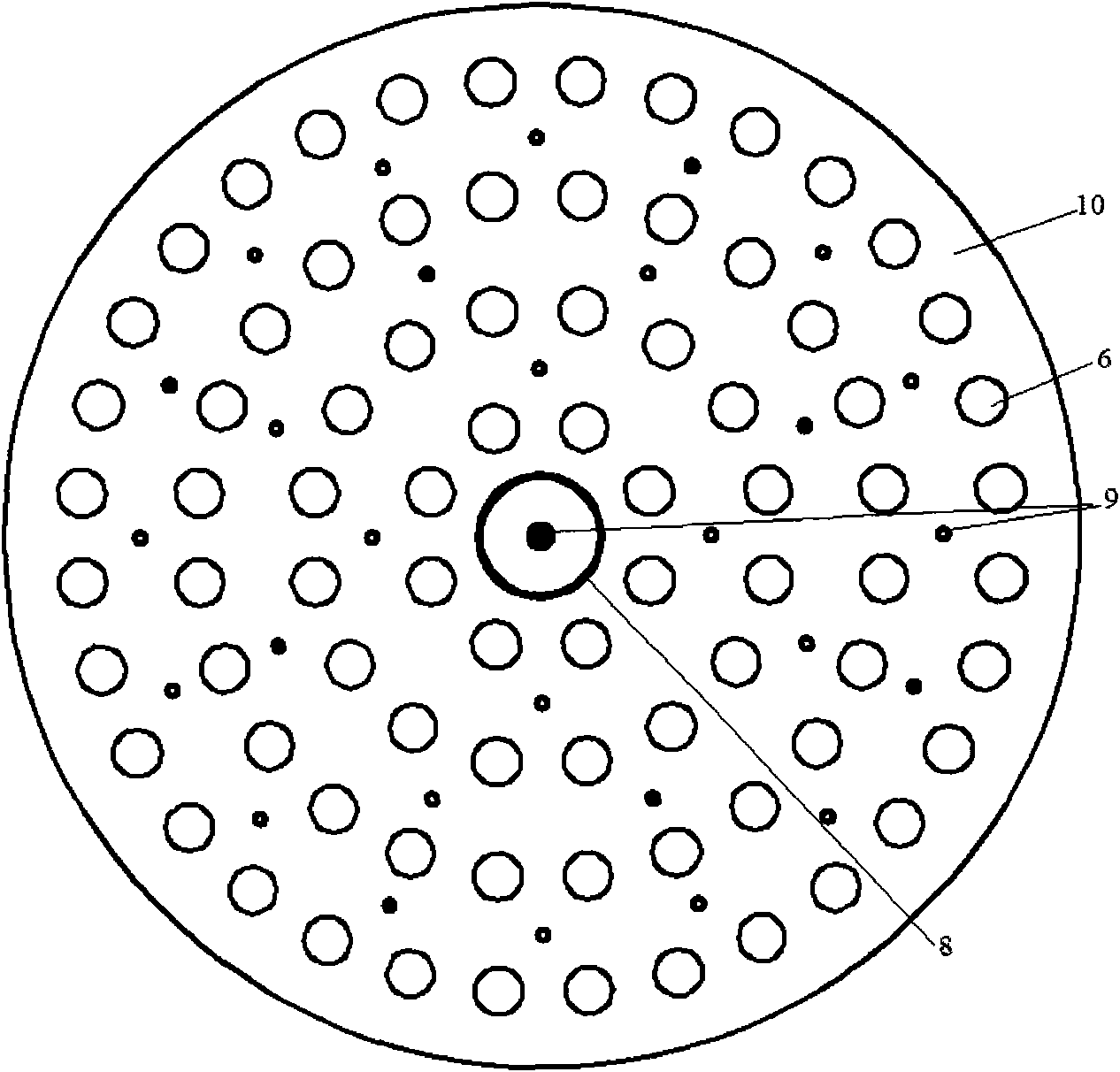

High-efficiency large polycrystalline silicon reducing furnace

InactiveCN101870471AEfficient use ofPromote growthPolycrystalline material growthSiliconMetallurgyHeat energy

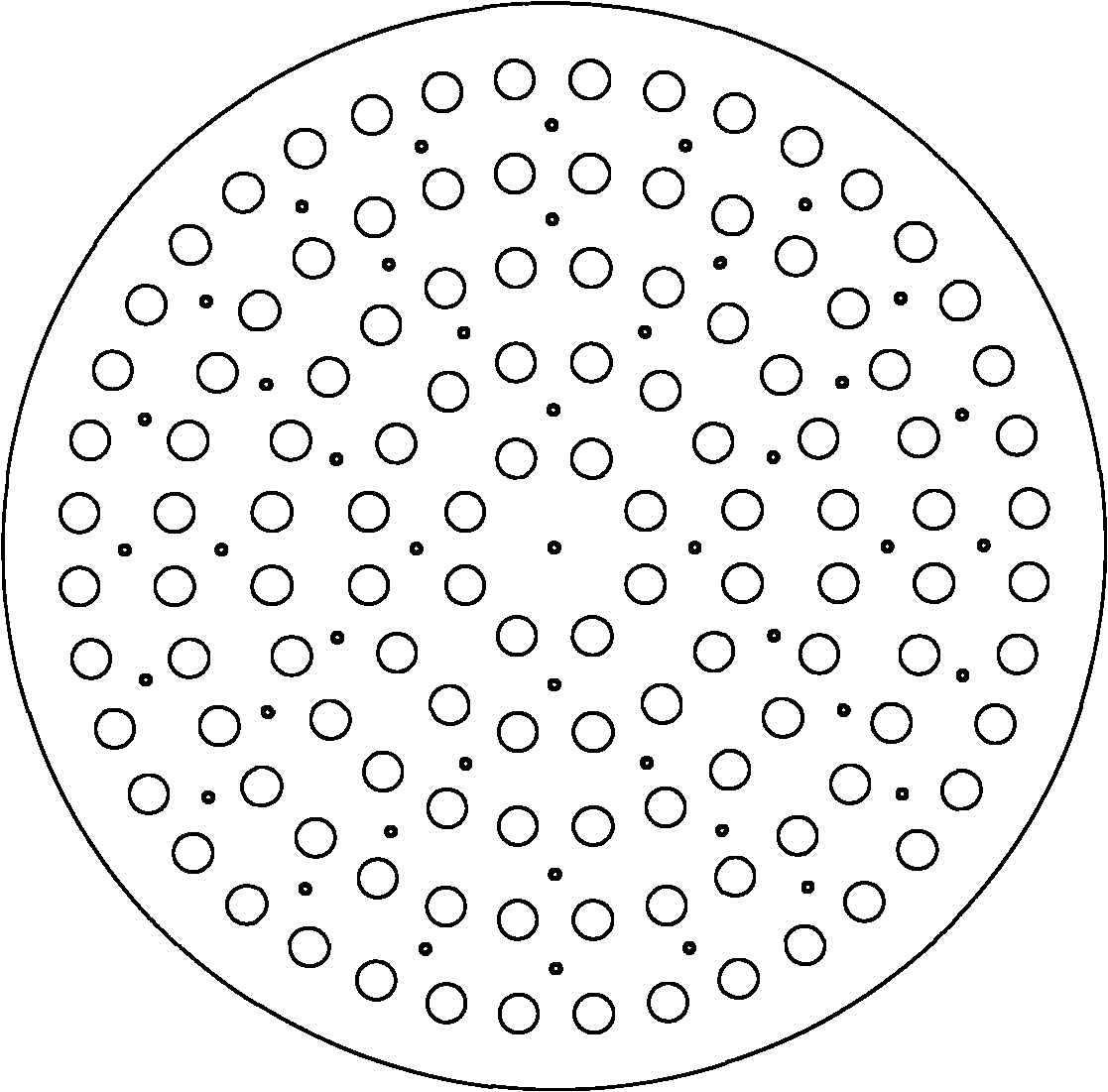

The invention discloses a high-efficiency large polycrystalline silicon reducing furnace which comprises a chassis and a bell type furnace barrel, wherein the bell type furnace barrel covers the chassis, and a plurality of pairs of electrodes, at least one air inlet and at least one exhaust port are closely arranged on the chassis. The high-efficiency large polycrystalline silicon reducing furnace is characterized in that the pair number of the electrodes is 2n(n+1), wherein n is the distributed layer number of the electrodes and is not less than 4, and the 2n(n+1) pairs of electrodes are arranged in n layers and regularly arranged according to 4n pairs, such as 4 pairs, 8 pairs, 12 pairs and the like in each layer. The more dense and regular electrode arrangement is realized by a reactor, the utilization ratio of the heat energy in the reducing furnace is improved, and more uniform flow field distribution is realized, thereby improving the polycrystalline silicon yield of each furnace, improving the product surface quality and reducing the energy consumption.

Owner:JIANGSU ZHONGNENG POLYSILICON TECH DEV

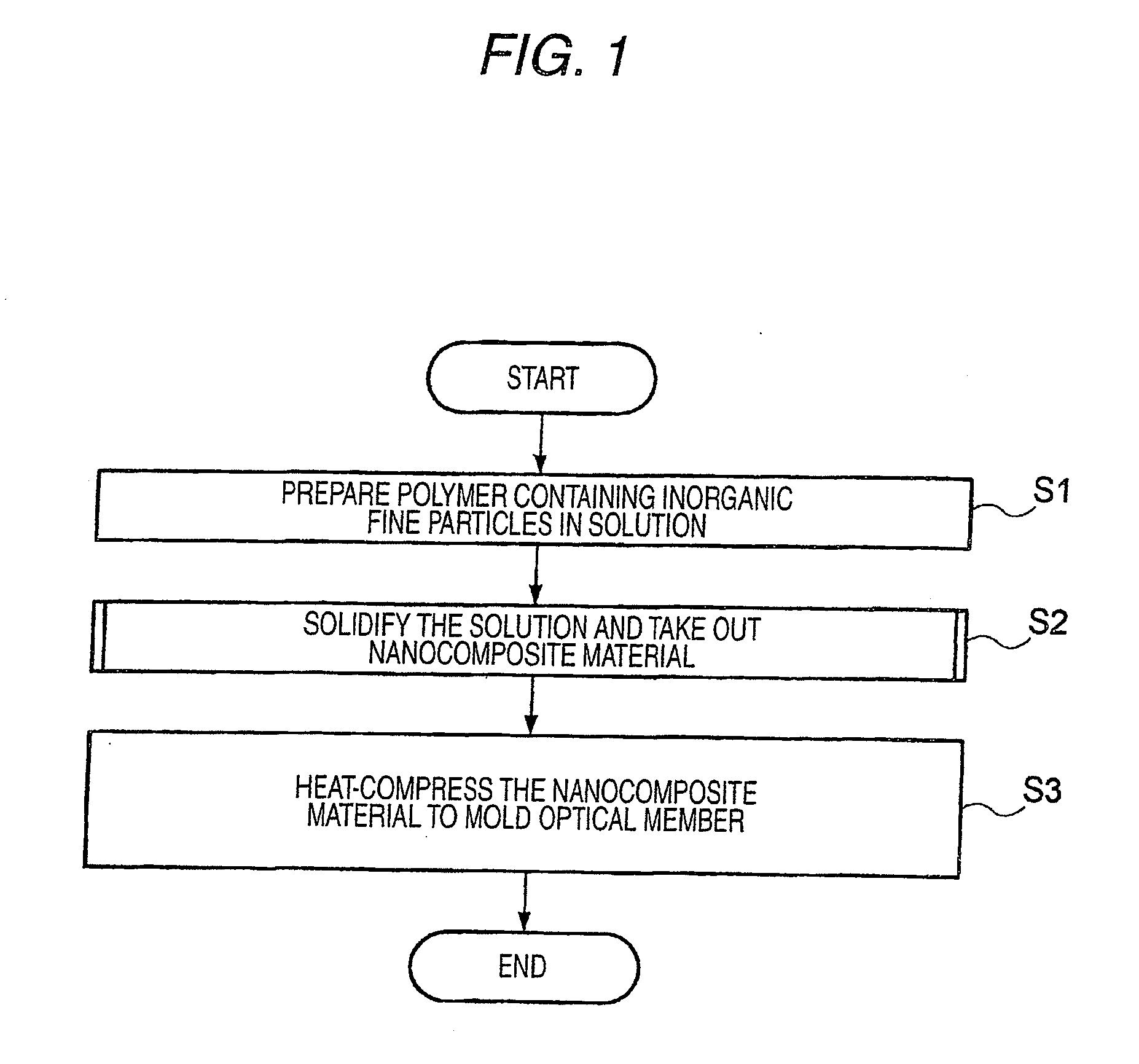

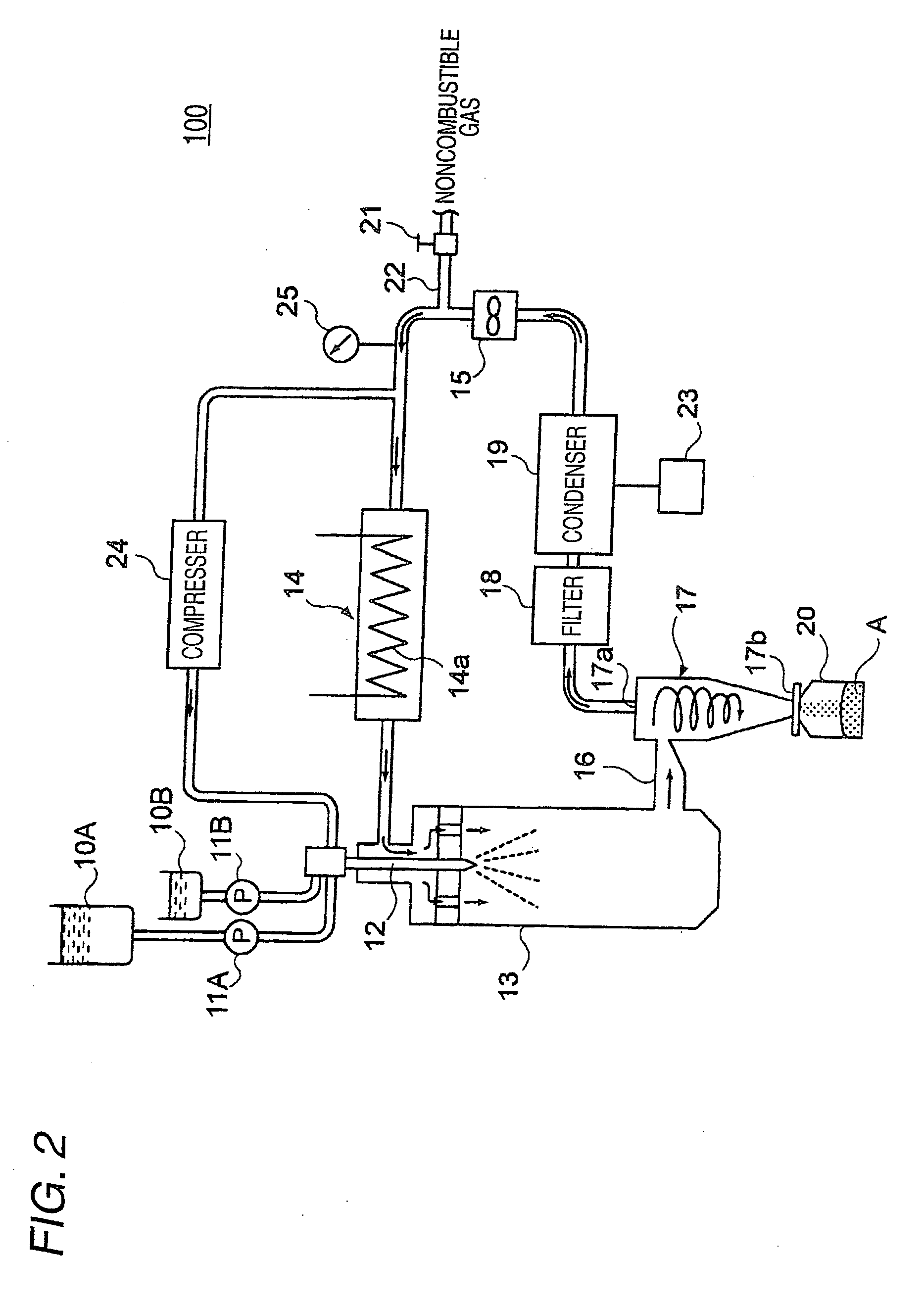

Method for producing optical member and optical member formed by the production process

InactiveUS20100225013A1Easy shape controlDownsizingMaterial nanotechnologyOptical articlesNanometrePolymer chemistry

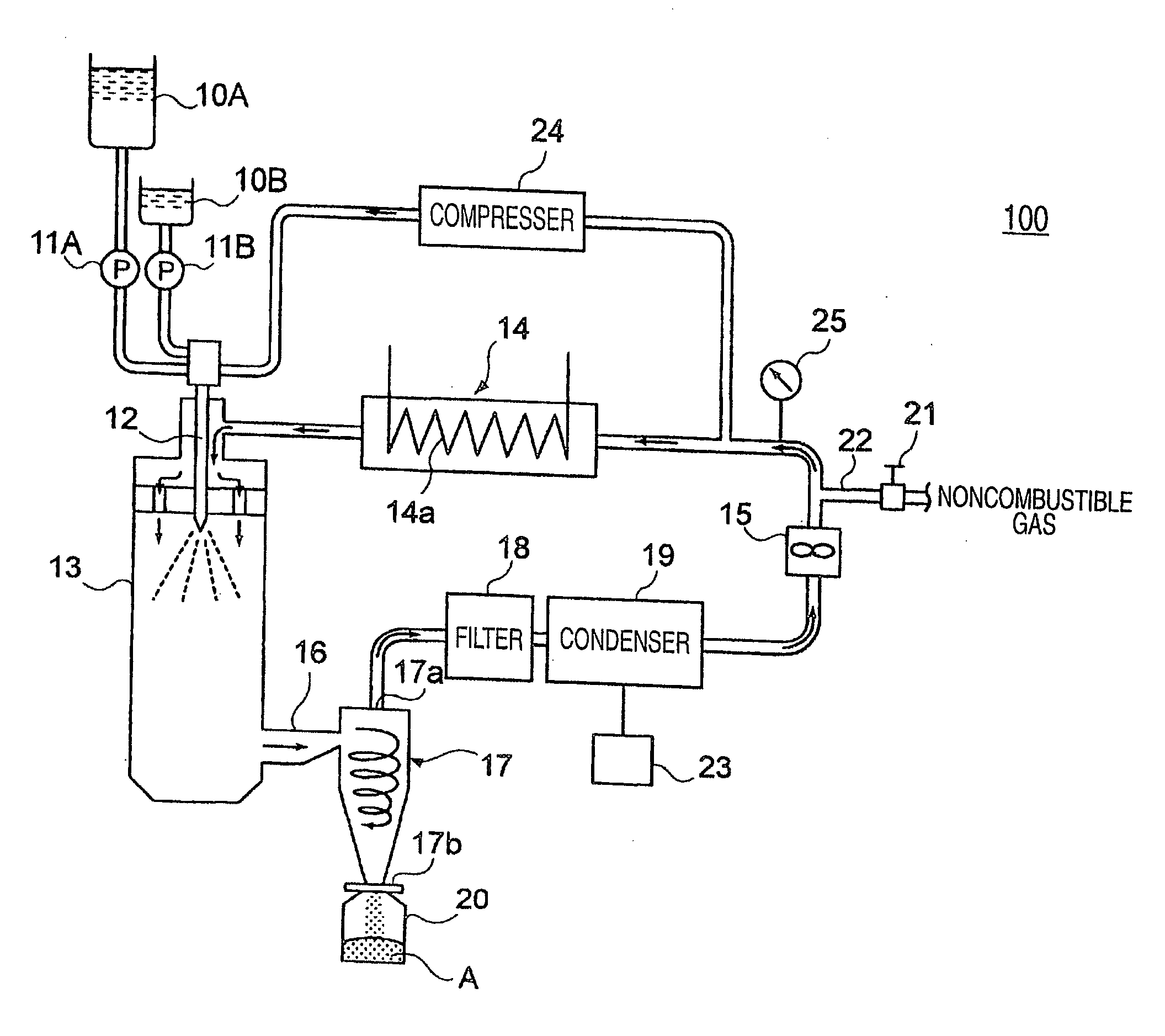

A method for producing an optical member from a nanocomposite material which includes a thermoplastic resin containing inorganic fine particles is provided. The method includes:a first step of preparing in a solution the thermoplastic resin containing the inorganic fine particles;a second step of drying and solidifying the solution containing the prepared thermoplastic resin to produce the nanocomposite material having a specific surface area (surface area / volume) of 15 mm−1 or more; anda third step of heat-compressing the produced nanocomposite material to form the optical member in a desired shape.

Owner:FUJIFILM CORP

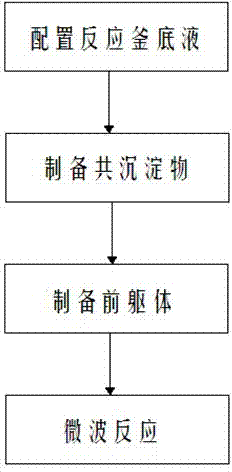

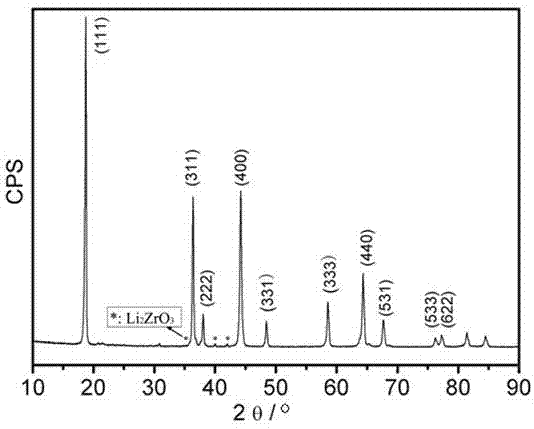

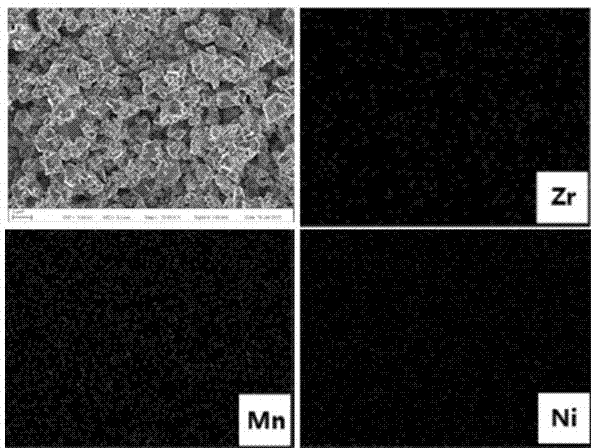

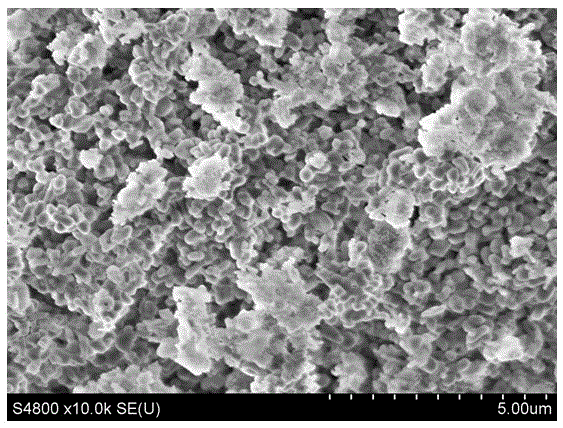

Preparation method of surface covered nickel lithium manganate positive electrode material

ActiveCN103794777AShorten microwave firing timeImprove cycle performanceCell electrodesSecondary cellsMicrowaveReaction temperature

The invention discloses a preparation method of a surface covered nickel lithium manganate positive electrode material. The preparation method comprises the following steps: a, preparing a reaction kettle bottom solution; b, preparing a coprecipitate; c, preparing a precursor; and d, performing a microwave reaction. The preparation method of the surface covered nickel lithium manganate positive electrode material provided by the invention has the advantages that as a microwave sensitized material, zirconia, is added in a precursor preparation process, a reaction material is urged to effectively absorb microwave to rapidly warm to the reaction temperature 700-950 DEG C, and the microwave firing time of the product is remarkably shortened to 1-10 minutes; when the nickel lithium manganate material is burnt at high temperature, the zirconia and a Li source can react at a nickel lithium manganate surface to generate a lithium ion conductor Li2ZrO3 coating layer, and thus the cycle property and the rate property of the product are remarkably improved.

Owner:威海区域创新中心有限责任公司

A heat treatment method for high-strength wear-resistant steel plate

The invention relates to a heat treatment method for high-strength wear-resistant steel plates, which comprises the following steps in turn: I, controlling an original plate shape, wherein a hot-rolled steel plate is subjected to a hot rolling process and is subjected to 5-7-pass straightening by a straightener, so that the plate shape waviness of the steel plate is 2-4mm / 2m; II, performing surface treatment, namely performing shot blasting on the upper and lower surfaces of the steel plate by using a shot blasting machine; II, quenching, namely heating the steel plate in a roller hearth normalizing furnace together with the furnace to a critical point Ac3, namely 10-50DEG C, keeping the temperature at a rate of 1.5-2.0min / mm according to the thickness of the steel plate, discharging the steel plate at a rate of 0.10-0.50m / s into a quenching machine, and quenching to room temperature; and IV, tempering, namely performing low temperature tempering treatment on the roller hearth normalizing furnace at the temperature of between 350 and 380DEG C, and controlling the temperature keeping time at a rate of 3min / mm according to the thickness. In the heat treatment method for the high-strength wear-resistant steel plates, the roller hearth normalizing furnace and a common quenching machine are adopted, and the waviness of finished products is 3-6mm / 2m.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Process for the preparation of halide perovskite and perovskite-related materials

InactiveCN109312464AEasy shape controlLow toxicityFrom normal temperature solutionsVacuum evaporation coatingMetal alloyElectrical battery

This invention is related to a method for the preparation of halide perovskite or perovskite-related materials on a substrate and to optoelectronic devices and photovoltaic cells comprising the perovskites prepared by the methods of this invention. The method for the preparation of the perovskite includes a direct conversion of elemental metal or metal alloy to halide perovskite or perovskite-related materials.

Owner:YEDA RES & DEV CO LTD

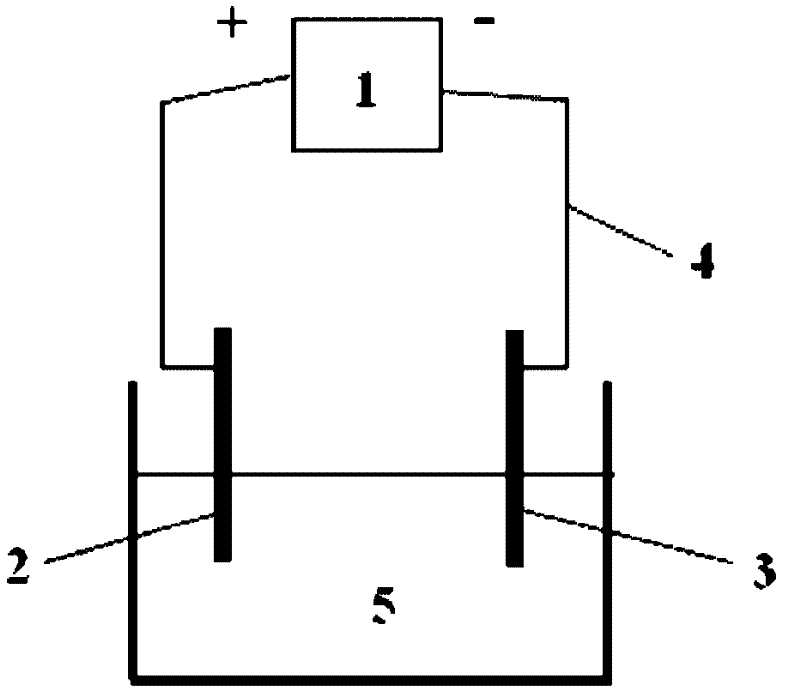

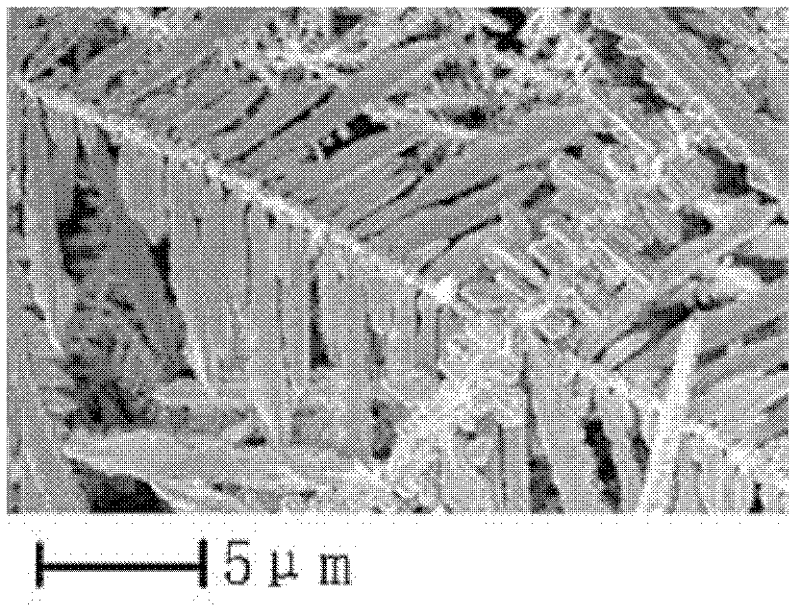

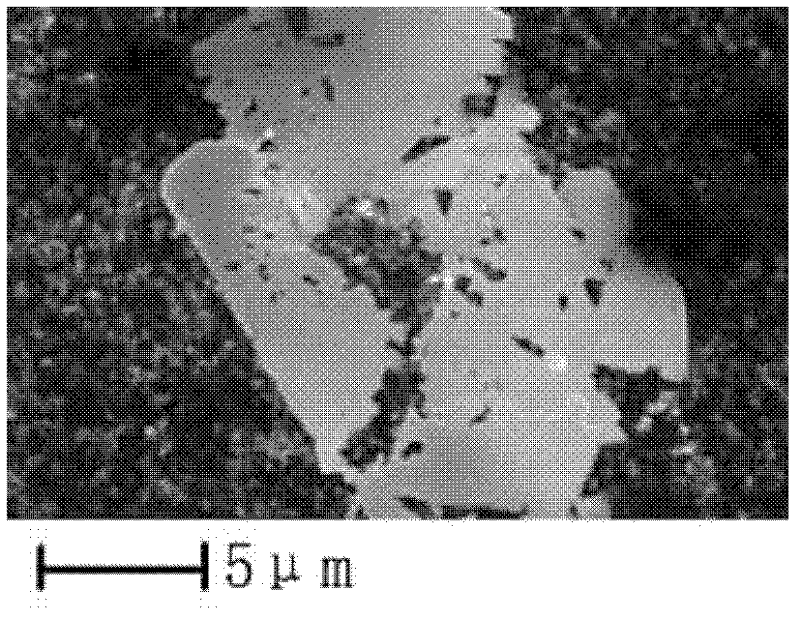

Method for electrochemically aided preparation of silver powder with special form

InactiveCN102418118ASimple preparation processLow costMaterial nanotechnologyElectrochemical responseMetallic electrode

The invention provides a method for electrochemically aided preparation of silver powder with a special form. According to the invention, carbonic or metallic electrodes are used as a working electrode and a counter electrode; after cleaning with ultrasonic wave, the working electrode and the counter electrode are immersed into a solution or sol containing silver ions prepared by using ultra pure deionized water; the working electrode is used as a cathode, the counter electrode is used as an anode, and an electrochemical reaction is carried out under an air-tight condition and the condition of a constant current; after the reaction, a resultant is separated and dried to obtain nanometer silver powder. Through control of the variety of electrodes, the amount of current flowing and the variety of electrolytes, dendritic nanometer silver powder, flake nanometer silver powder, laminated flake nanometer silver powder, fibrous nanometer silver powder, cubic cage nanometer silver powder and tetrahedron cubic cage nanometer silver powder can be prepared. The method provided in the invention enables form control and continuous preparation of nanometer silver particles to be realized without addition of any other chemical reagents; the method has the advantages of a simple process, a widely applicable product, high yield of the powder, greenness, environmental protection and feasibility in industrial production.

Owner:SHANGHAI JIAO TONG UNIV +1

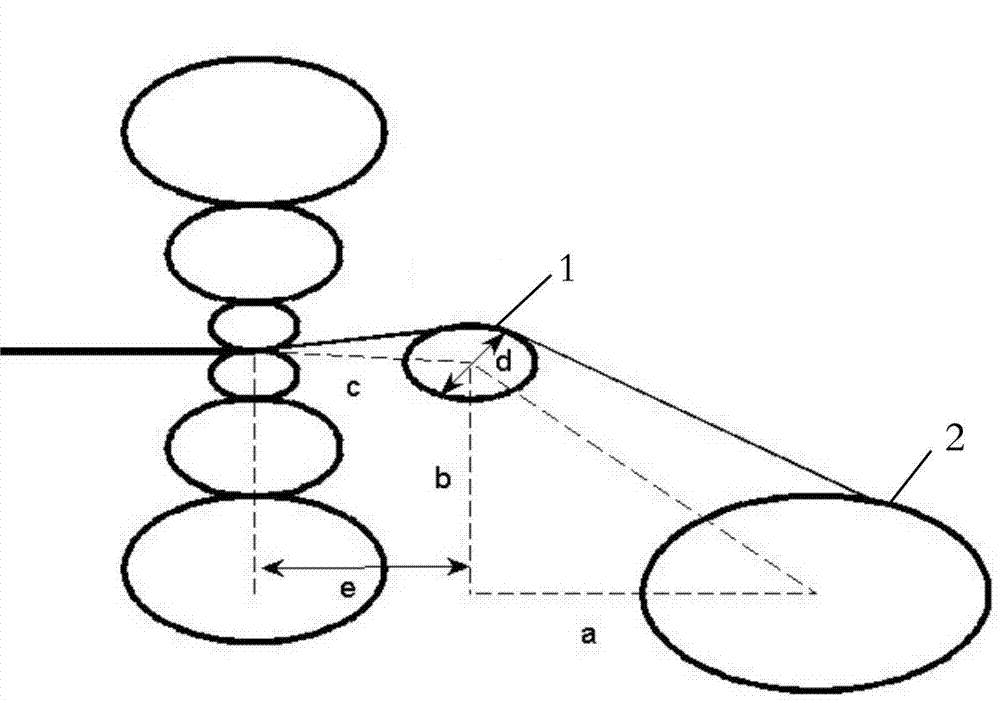

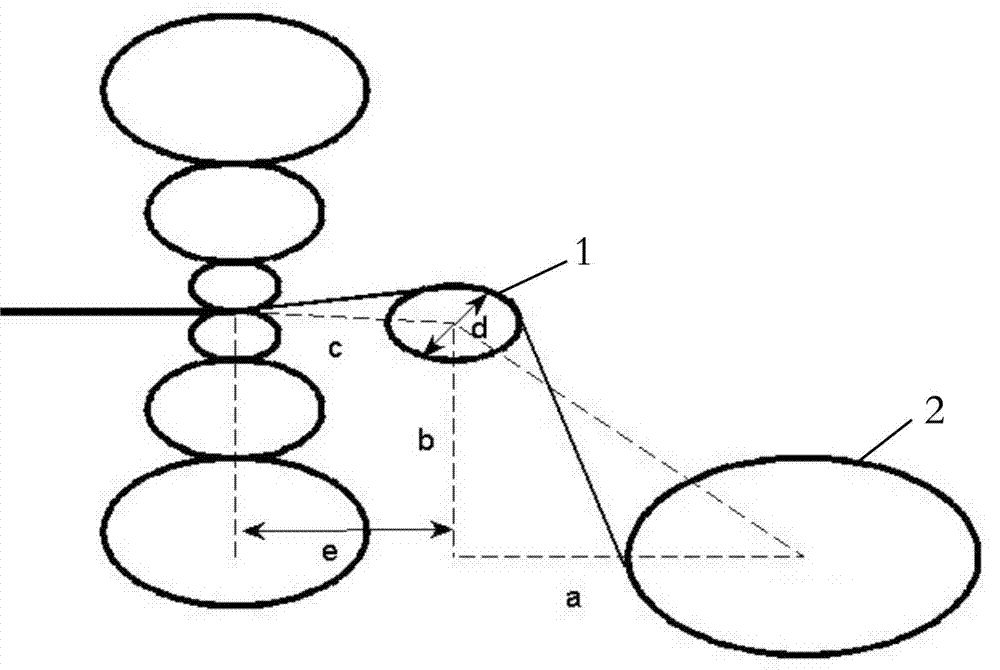

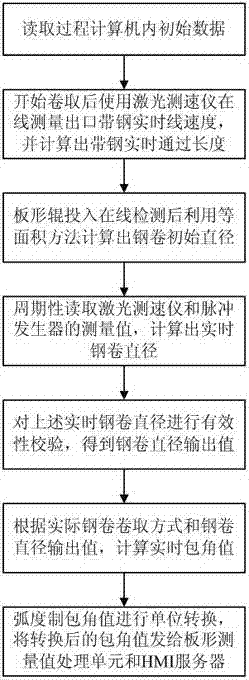

Online calculating method for wrap angle of cold-rolled strip steel plate shape roll

InactiveCN102806235AGuaranteed reasonablenessFit specific circumstancesProfile control deviceControl systemStrip steel

The invention provides an online calculating method for a wrap angle of a cold-rolled strip steel plate shape roll. The method comprises the following steps: 1) after beginning winding, measuring real-time linear velocity of an outlet strip steel online by using a laser velocimeter, and calculating a real-time passing length of the strip steel; 2) after the plate shape roll is put into online detection, figuring out an initial diameter of a steel coil by using an equal-area method; 3) periodically reading measured values of the laser velocimeter and a pulse generator, and figuring out a real-time steel coil diameter; 4) checking validity of the real-time steel coil diameter so as to obtain a steel coil diameter output value; and 5) calculating a real-time wrap angle value according to an actual steel coil winding method and the steel coil diameter output value. According to the invention, extended functions of the exiting hardware equipment of a cold rolled plate shape control system are sufficiently performed; a high-accuracy and real-time continuous strip steel winding diameter is indirectly figured out by effectively utilizing a direct physical relation between the linear velocity of the strip steel and rotation speed of a winder; moreover, an online checking link of a strip steel winding diameter calculated value is provided, so that the reasonability of the calculated value is guaranteed.

Owner:WISDRI ENG & RES INC LTD

New cleaning method, apparatus and use

ActiveUS20170267949A1High densityInert and hydrolytically stableInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsChemistryPolyamide

A method for cleaning a substrate which is or comprises a textile, the method comprising agitating the substrate in the presence of a cleaning composition comprising: i. cleaning particles comprising a thermoplastic polyamide and a particulate inorganic filler having a density of at least 2.5 g / cm3, said cleaning particles having an average particle size of from 1 to 100 mm, wherein the cleaning particles have an average density of at least 1.65 g / cm3 and / or the particulate inorganic filler has a D50 particle size of at least 10 microns and / or a D90 particle size of at least 40 microns; and ii. a liquid medium.

Owner:XEROS LTD

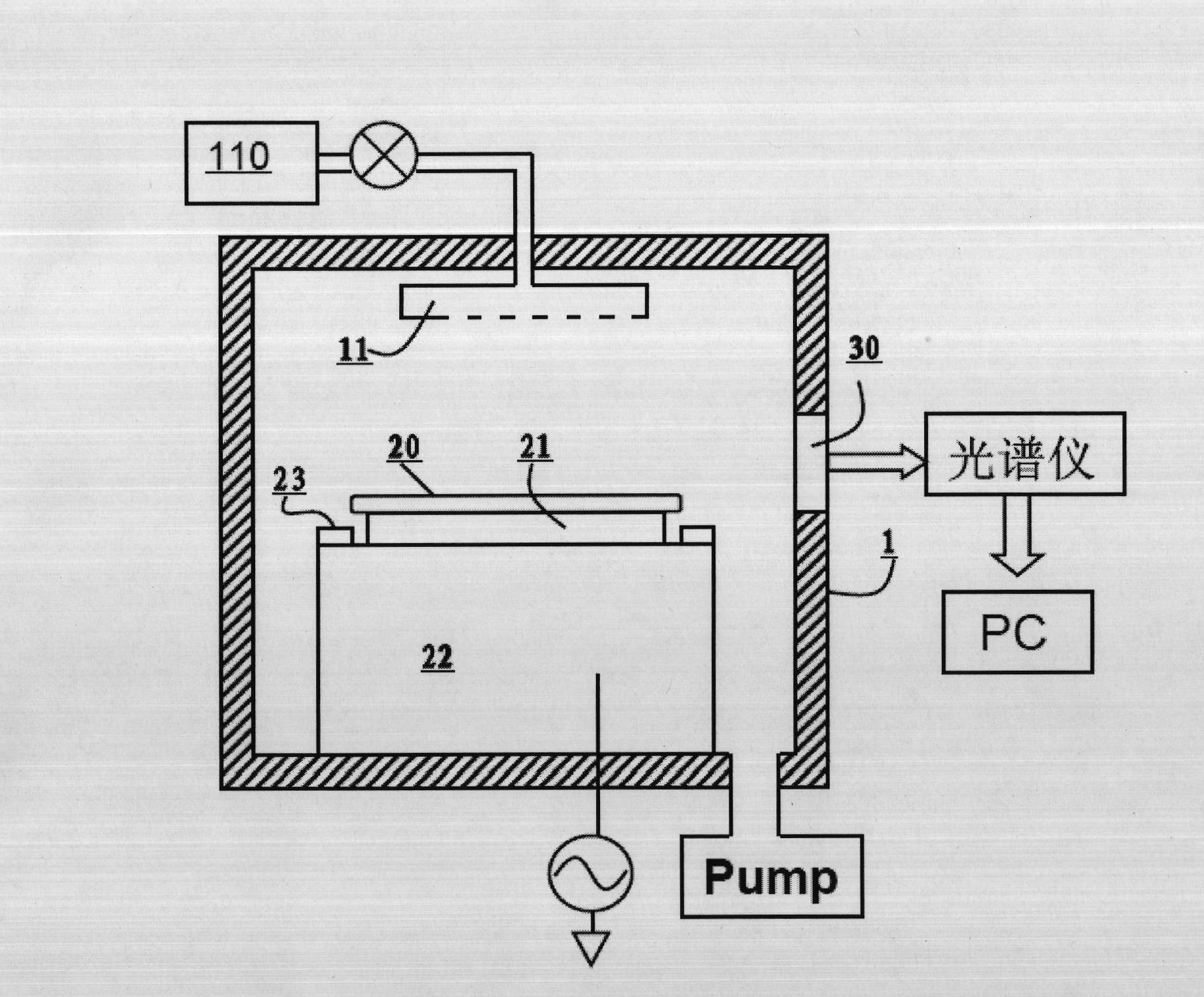

Air leakage detecting method for reaction cavity and control method for vacuum reactor

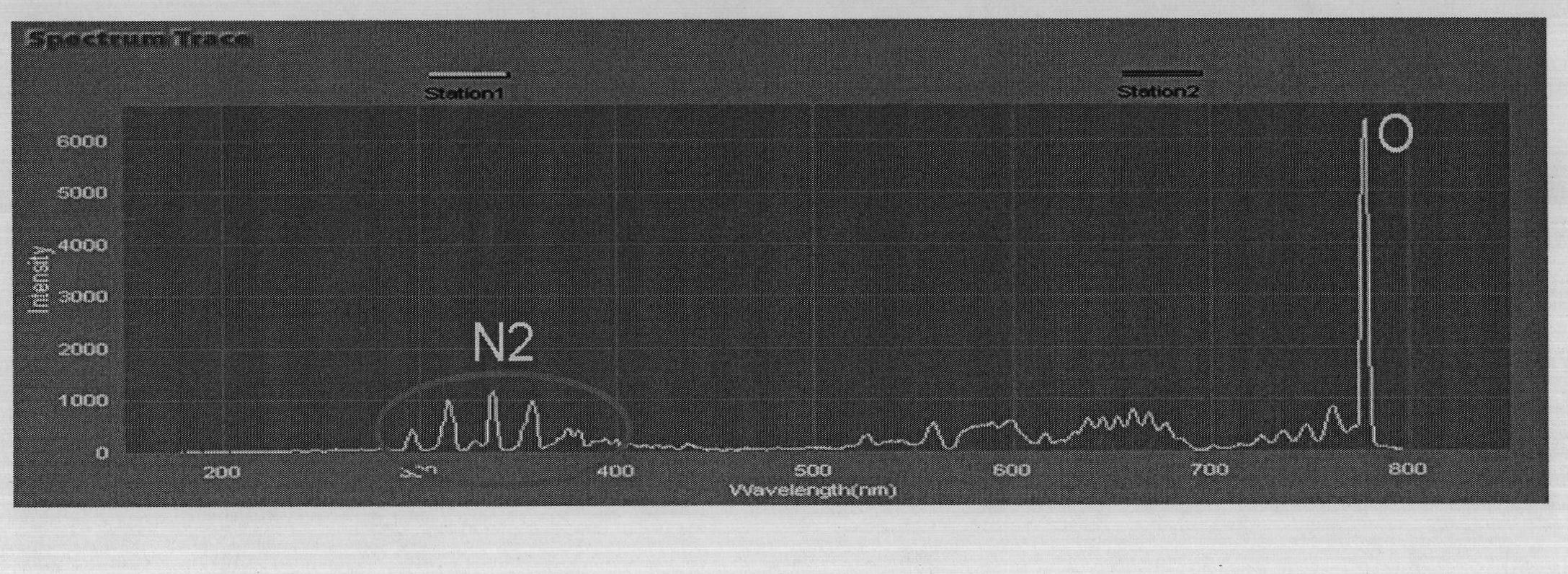

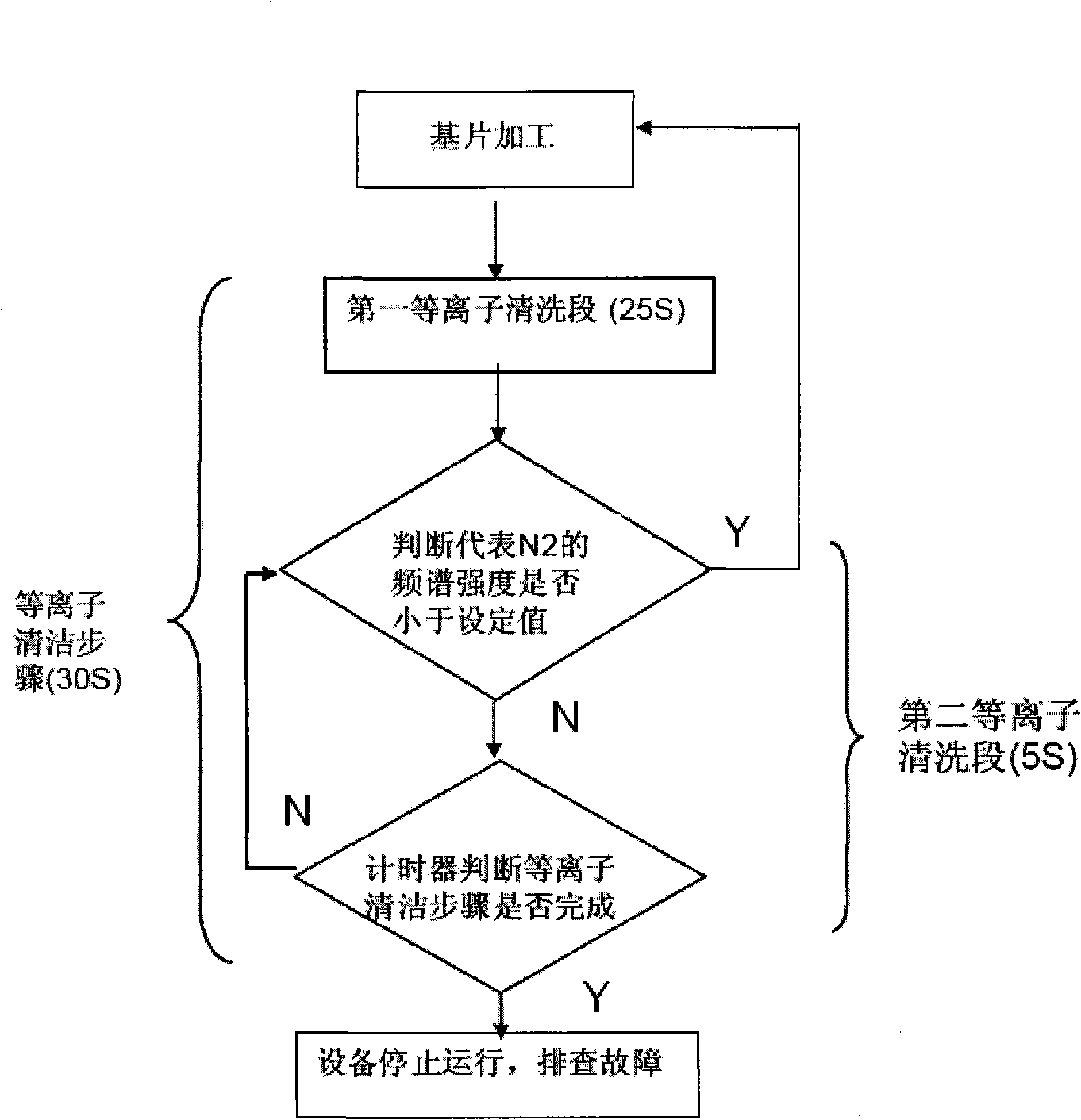

ActiveCN102403191AEasy shape controlHigh precisionSpectrum investigationSemiconductor/solid-state device manufacturingFrequency spectrumNitrogen

The invention discloses an air leakage detecting method for a reaction cavity and a control method for a vacuum reactor, which can realize accurate air leakage condition detection of the reaction cavity of the vacuum reactor in real time while the capacity is unaffected by detection steps. The air leakage detecting method includes steps of processing a substrate to be processed in the reaction cavity, removing the substrate to be processed and proceeding to a cleaning procedure, igniting plasmas by feeding oxygen in the cleaning procedure, and analyzing whether a spectrum generated by the oxygen plasmas contains a frequency spectrum representing nitrogen or not by the aid of an optical observation device. The reaction cavity leaks if the intensity of the spectrum representing nitrogen is larger than the set value, and the vacuum reactor needs to be stopped operating. A next processing procedure can be performed if the detection shows that the spectrum representing nitrogen is not larger than the set value. Air leakage can be detected in real time by the air leakage detecting method by the aid of existing processing procedures and equipment, and thereby capacity is guaranteed.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

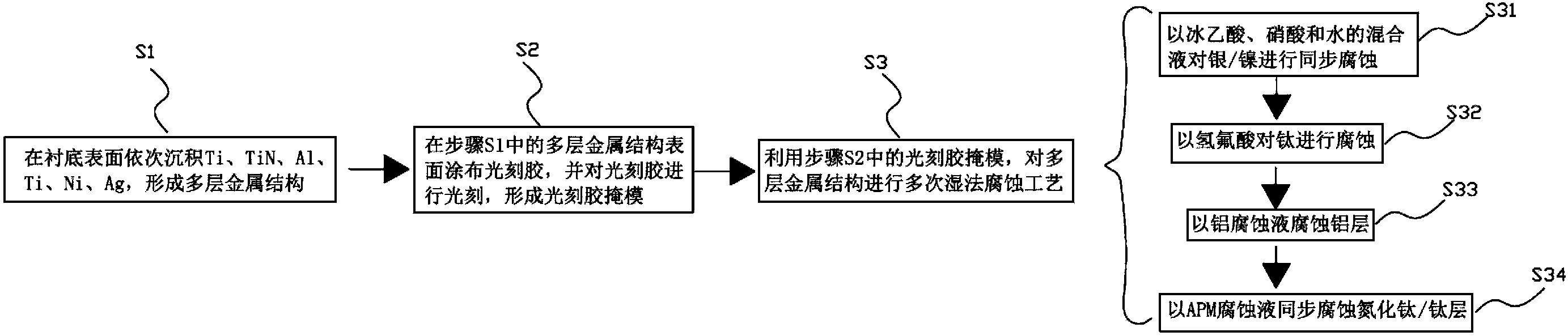

Wet etching method in multilayer metal patterning process

ActiveCN103681277ALow costEasy shape controlSemiconductor/solid-state device manufacturingSemiconductor devicesHydrofluoric acidAcetic acid

The invention provides a wet etching method in the multilayer metal patterning process. According to the method, etching is performed on Ag and Ni by utilizing the mixed liquor of glacial acetic acid (CH3COOH), nitric acid (HNO3) and water, etching is performed on Ti by utilizing diluted hydrofluoric acid, etching is performed on Al by utilizing an Al etching solution, and finally, etching is performed on TiN and Ti by utilizing an APM solution. According to the invention, the photoetching process needs only once, so the cost is greatly reduced, and the advantage of good etching window morphology control can be realized in all wet etching steps, so the quality of the patterning process can be improved, and Ag, Ni, Al as well as TiN and Ti are etched in one step separately, so the flow of the wet etching process can be simplified, and the efficiency of the process can be improved.

Owner:CSMC TECH FAB2 CO LTD

Preparation method of nano-coated composite powder

ActiveCN109175396AAvoid the disadvantage of coarse particle sizeSuppress merge growthMaterial nanotechnologyTransportation and packagingMaterials preparationAlloy

The invention discloses a preparation method of nano-coated composite powder, and belongs to the technical field of material preparation. According to the preparation method of the nano-coated composite powder, in the preparation process, a precipitant is added into an organic solution containing powder particles and metal compounds, a nano-precursor wrapping the surfaces of the powder particles is obtained, the nano-coated composite powder of a nucleus-shell structure is obtained through reduction, through a solvation effect of the metal compounds in the organic solution and the weak electrolyte property of the precipitant in the organic solution, the defects of too high local concentration, too long reaction time and large particle size of reaction products during the precipitation reaction are overcome, the average particle size of the prepared metal precursor is smaller than 200 nm, the metal precursor wraps the surfaces of the powder particles in a colloidal state, after low temperature reduction, nano metal or alloy particles adhere to the surfaces of the powder particles, and a nano-coating layer with highly uniform phase distribution is formed.

Owner:CENT SOUTH UNIV

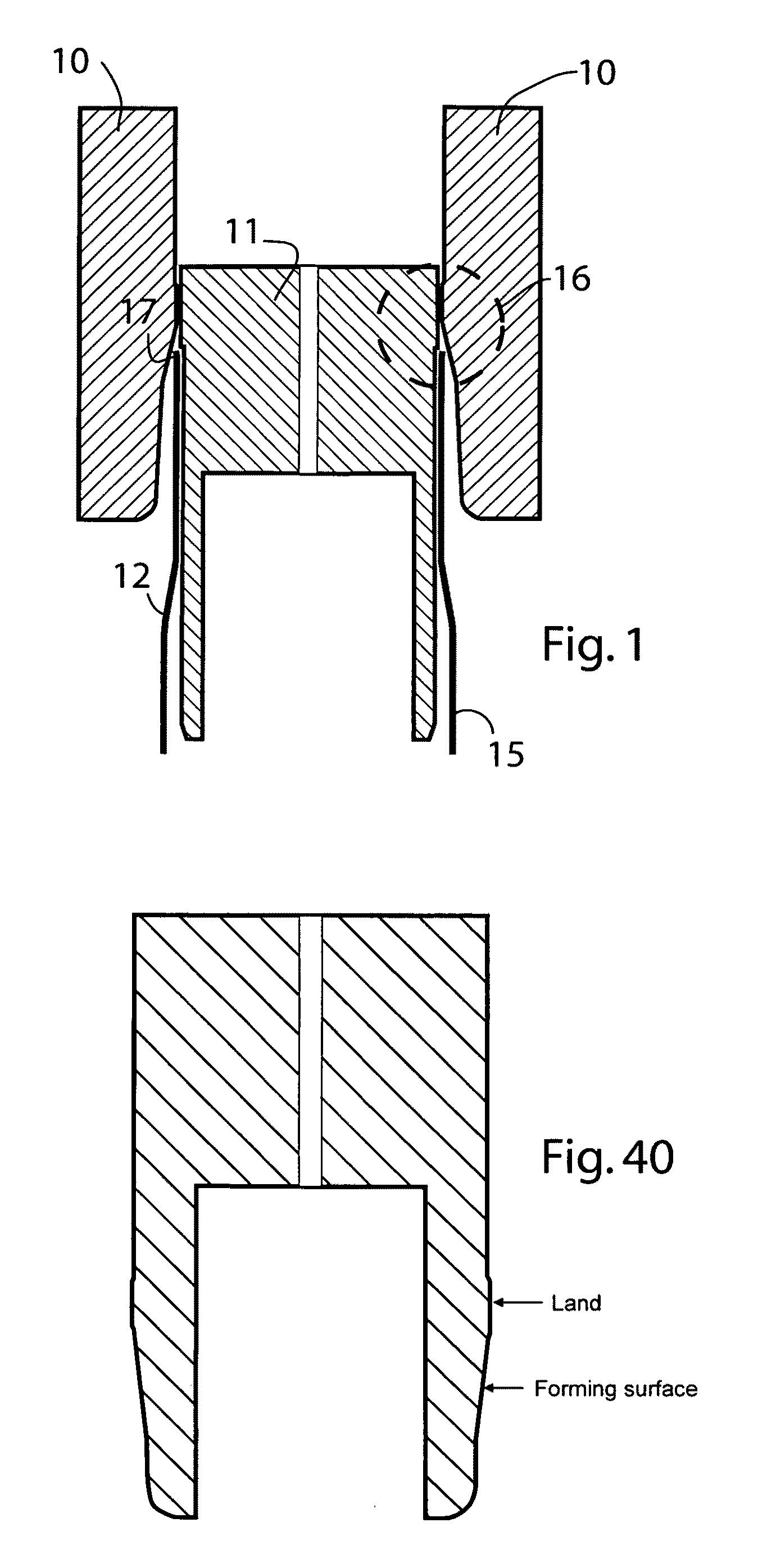

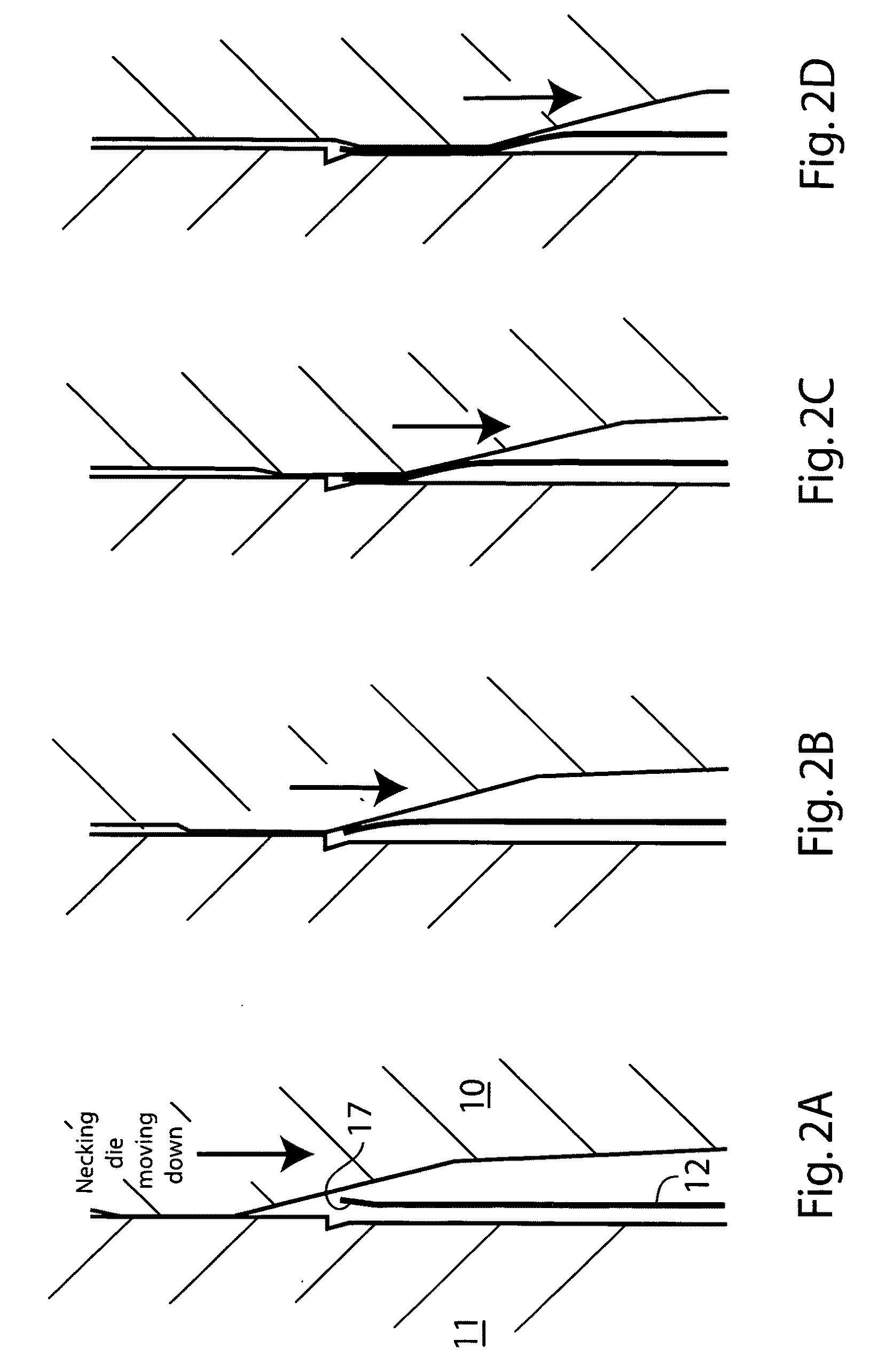

Minimizing circumferential transition lines during container shaping operations

InactiveUS20090193866A1Easy to shapeSimple designShaping toolsCutting toolsTransition lineEngineering

The invention provides a method of designing shaping tools for metal containers (such as metal bottles) to minimize the formation of visible transition lines or ripples conventionally produced in such procedures as die necking and outward flaring. The method involves carefully measuring differences between an actual shape produced and a design shape resulting from an original set of shaping tools. The tools are then refined in design to take into account metal spring back and the effect of one shaping stage on the results of previous stages. The redesign goes through several iterations to ensure that each change produces an improvement of the formed container. In this way, the formation of transition lines can be minimized because the actual shape of the container more closely resembles the smooth design shape. Dies designed in this way are then used for commercial shaping operations.

Owner:NOVELIS INC

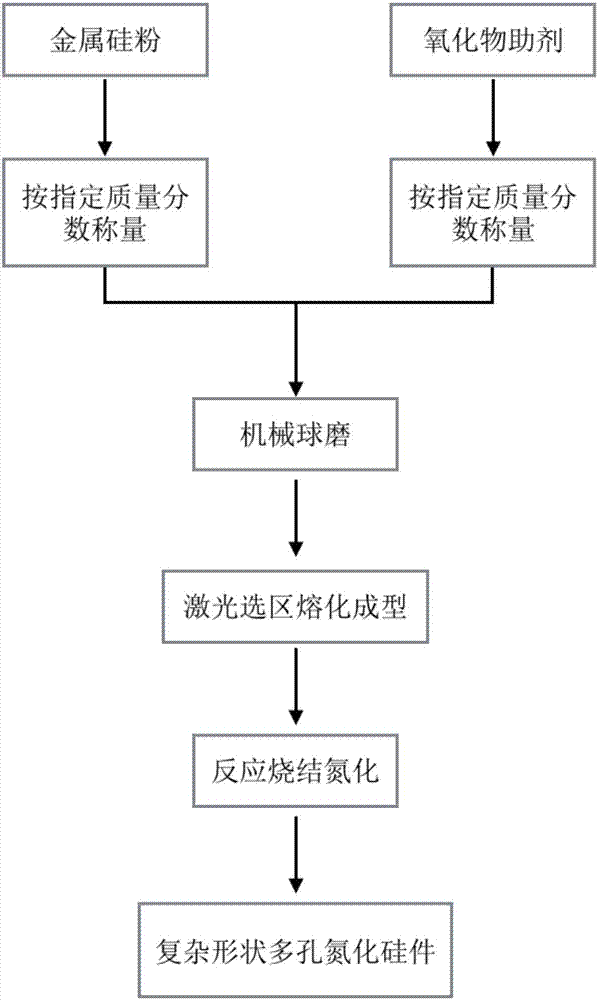

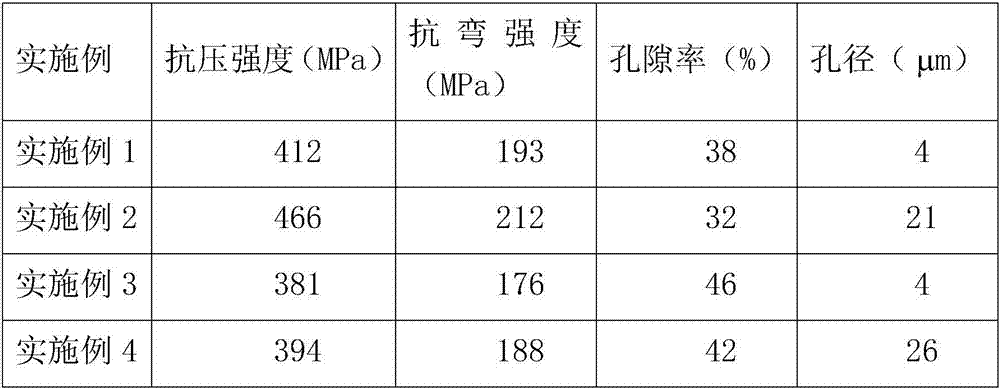

Preparation method of porous silicon nitride part with complicated shape

ActiveCN108002842AImprove manufacturing efficiency and shape control abilityGood flexibilityAdditive manufacturing apparatusCeramicwareSilica fumeManufacturing efficiency

The invention belongs to the technical field of material molding, and discloses a preparation method of a porous silicon nitride part with a complicated shape. The method combines a metal selective laser melting process with a silicon nitride reaction sintering process, and provides a novel idea for preparing the porous silicon nitride part with a large size and complicated shape; and the method specifically comprises the following steps: (1) providing metal silicon powder and an oxide sintering auxiliary agent according to predetermined mass parts to be used as raw materials; (2) performing micro-area partial sintering on the raw materials by adopting the selective laser melting process to preform a porous silicon green body; and (3) performing reaction sintering on the porous silicon green body, and performing nitriding to obtain the porous silicon nitride part with the complicated shape. According to the preparation method provided by the invention, shape and performance control tothe porous silicon nitride part is easy to realize, the production efficiency can be improved, the flexibility is higher, and a polymer binder is not needed.

Owner:HUAZHONG UNIV OF SCI & TECH

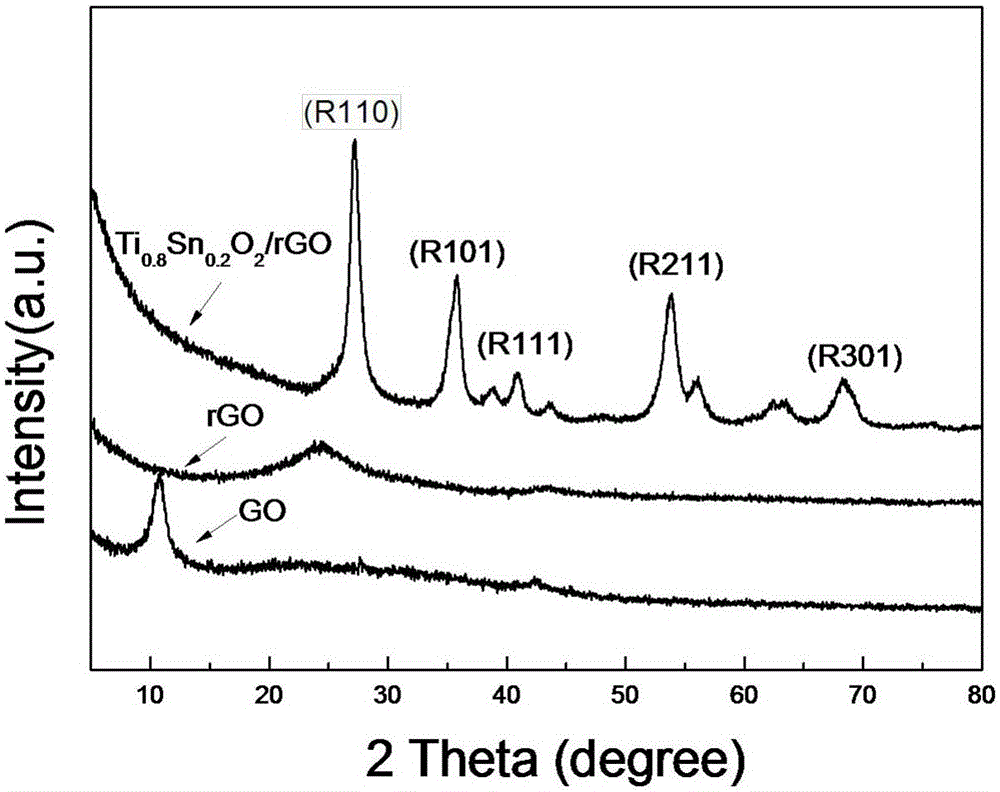

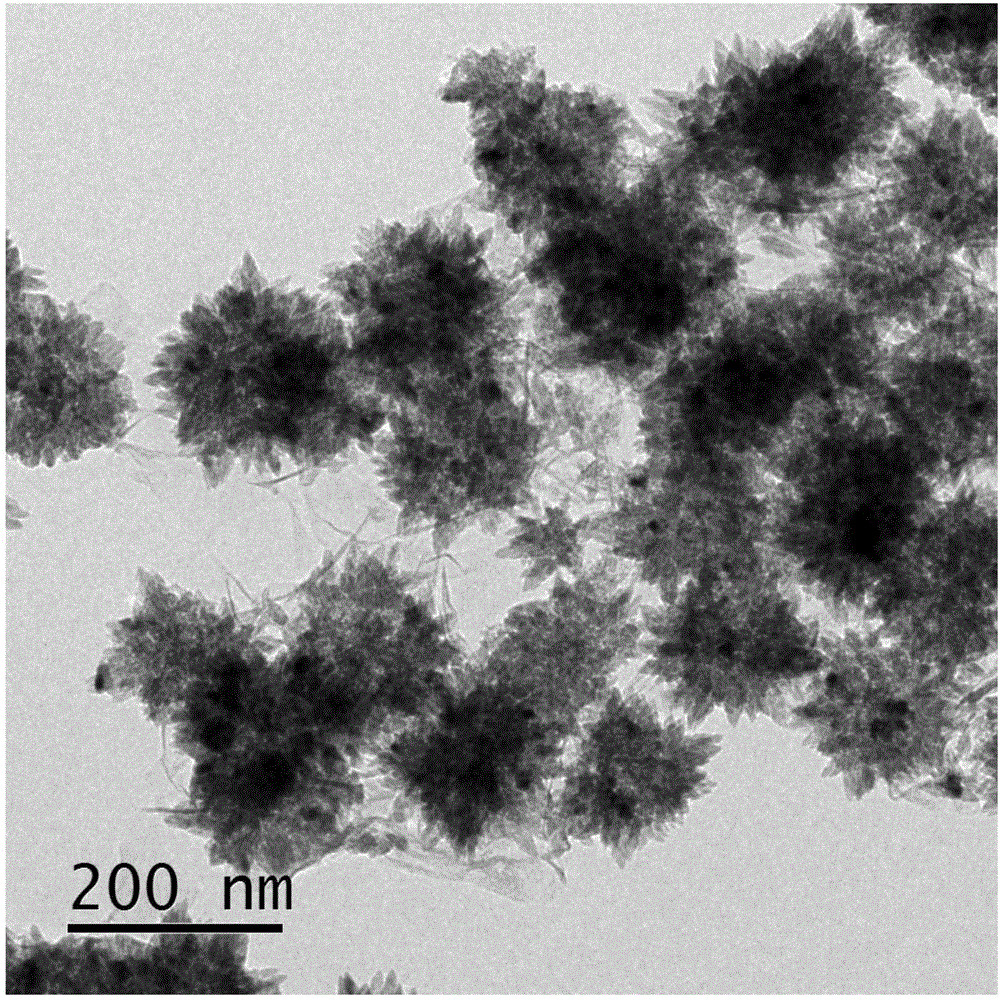

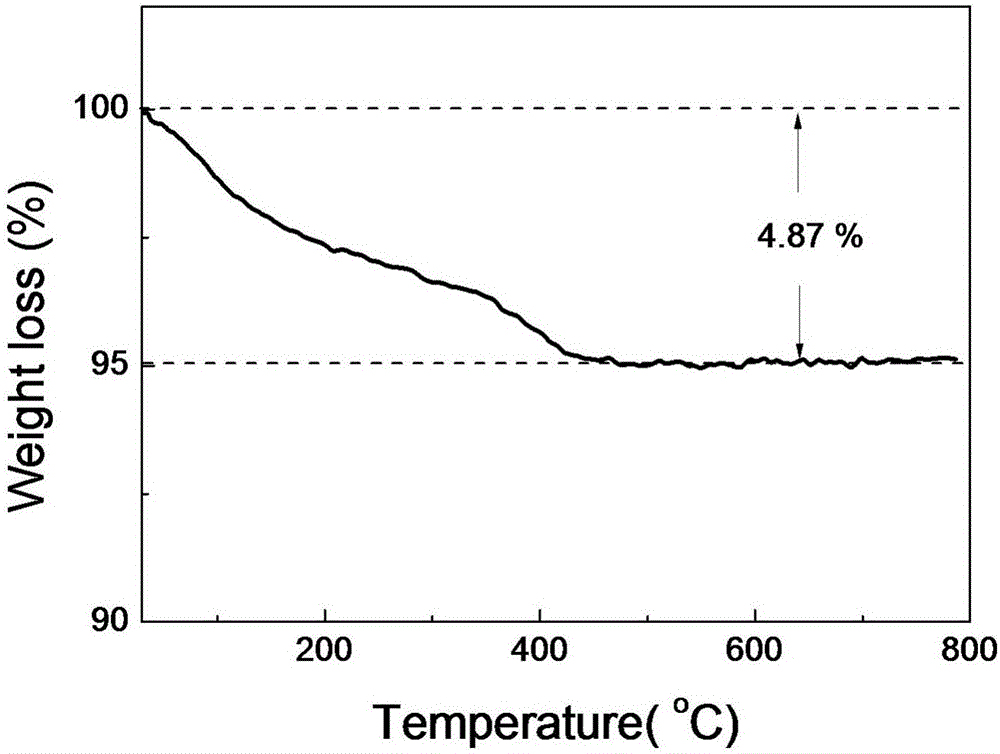

Method for producing urchin-like nano TixSn1-xO2/graphene three-dimensional composite material and application of composite material on negative electrode of lithium ion battery

InactiveCN106252607AThe principle is simpleEasy to operateNon-aqueous electrolyte accumulator electrodesElectronLithium electrode

The invention discloses a method for producing an urchin-like nano TixSn1-xO2 / graphene three-dimensional composite material and an application of the composite material on a negative electrode of a lithium ion battery. The urchin-like nano TixSn1-xO2 / graphene three-dimensional composite material is produced by a one-step hydro-thermal synthesis technology through self-assembly by using a coordination principle and a molecule self-assembly method. The method comprises the following steps: 1) preparing oxidized graphene, 2) preparing a graphite oxide sol with surface having negative electricity; and 3) producing the urchin-like nano TixSn1-xO2 / graphene three-dimensional composite material through reduction. The reaction process is carried out in an aqueous solution, other reagents are not required, and the method has the advantages of simple process, low cost, energy saving, environmental protection, and easy industrial batch production. As the negative electrode material of lithium ion battery, the three-dimensional composite structure of the material is in favor of diffusion of an electrolyte in the composite material as well as transmission of electron and ion in the material, and performances such as charge and discharge capacity, cycle life and multiplying power of the composite material can be effectively increased.

Owner:ZHENGZHOU UNIV

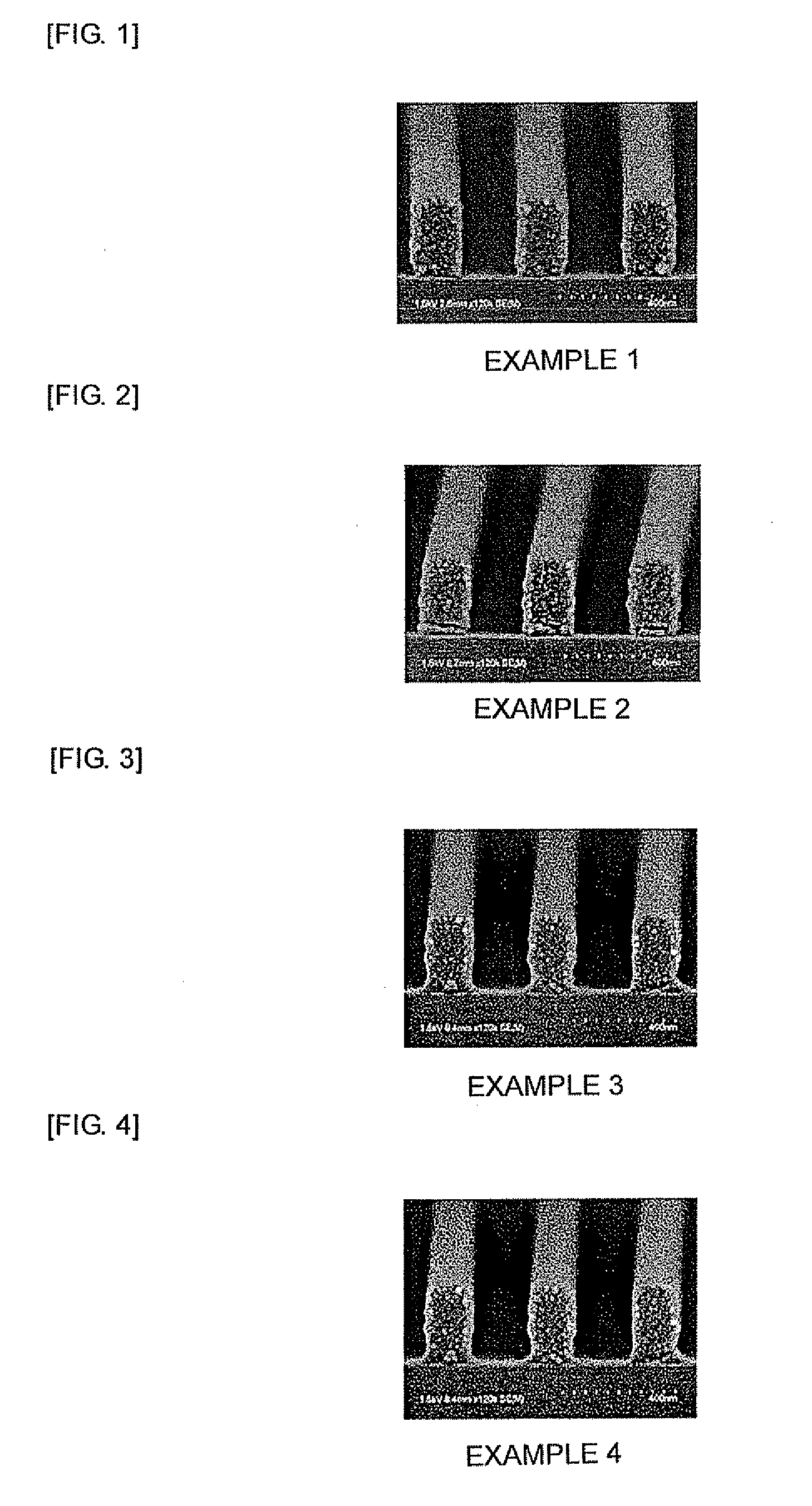

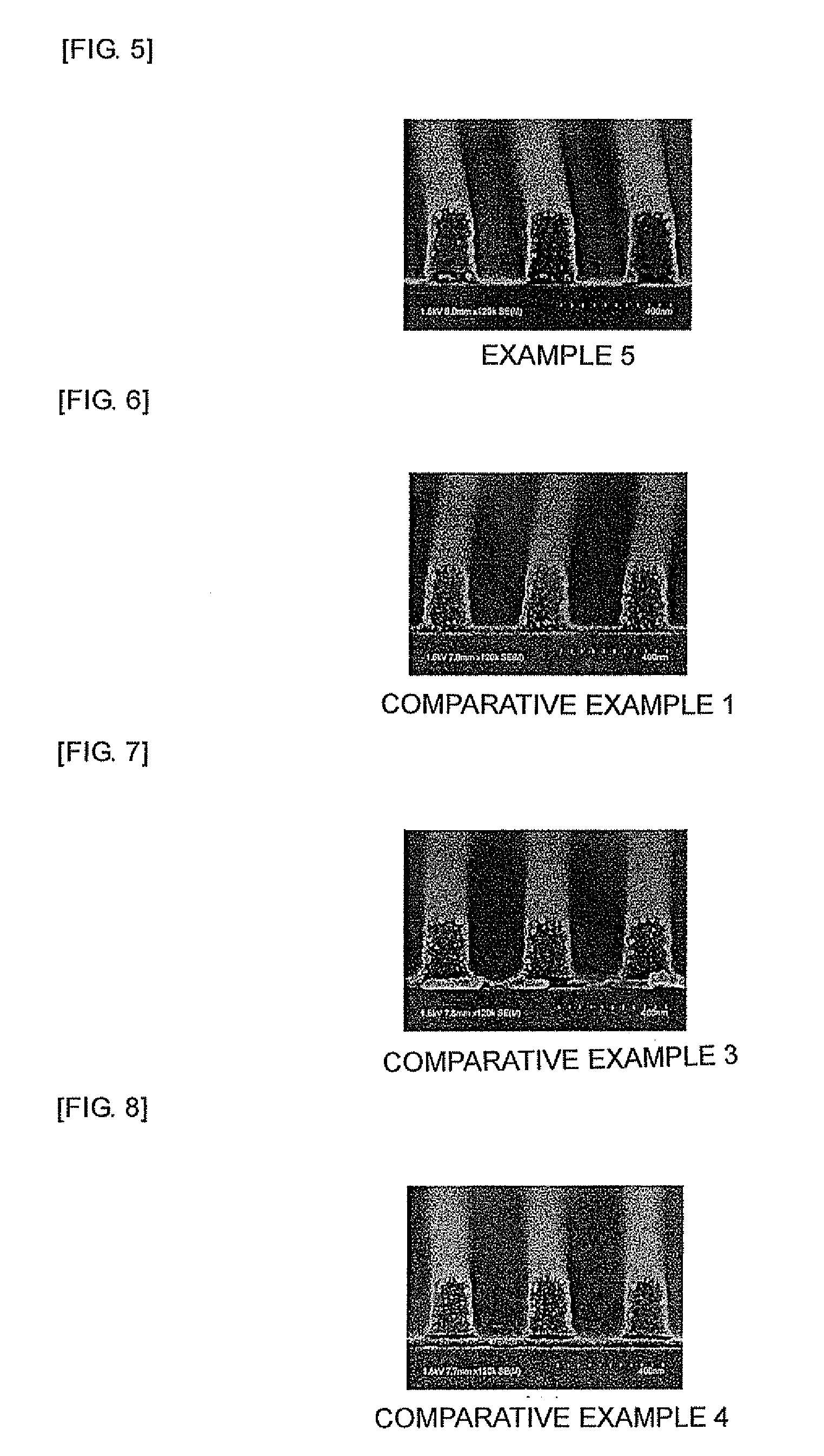

Composition for formation of photosensitive resist underlayer film and method for formation of resist pattern

InactiveUS20120288795A1Reduce generationEasy shape controlPhotosensitive materialsSemiconductor/solid-state device manufacturingResistVinyl ether

A composition for forming a photosensitive resist underlayer film and a method for forming a resist pattern. The composition for forming a photosensitive resist underlayer film includes a polymer having a structural unit of Formula (1), a compound having at least two vinyl ether groups, a photo-acid generator; and a solvent:where R1 is a hydrogen atom or a methyl group, R2 is a C1-4 alkyl group, and i is an integer of 0 to 4.

Owner:NISSAN CHEM IND LTD

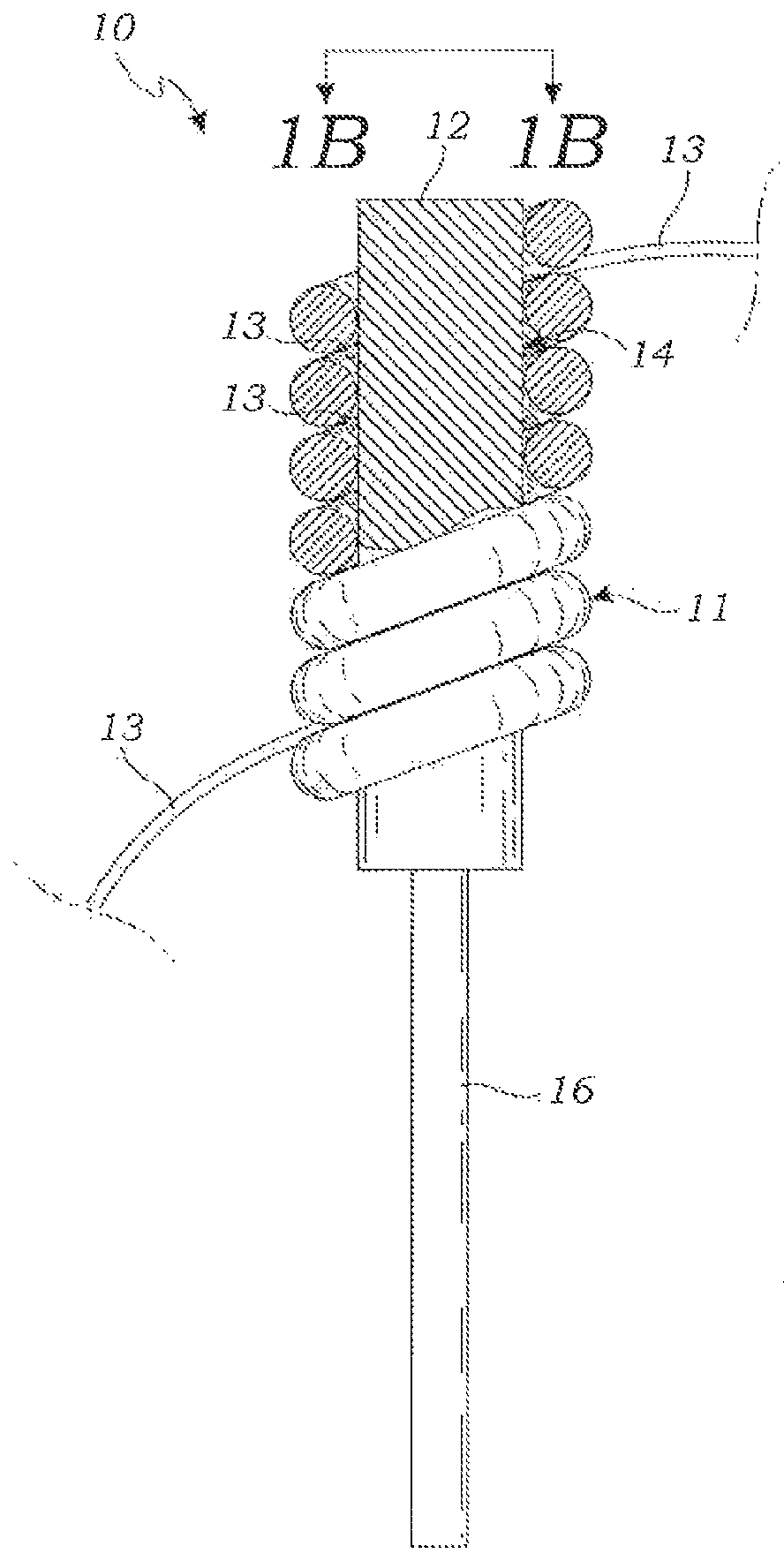

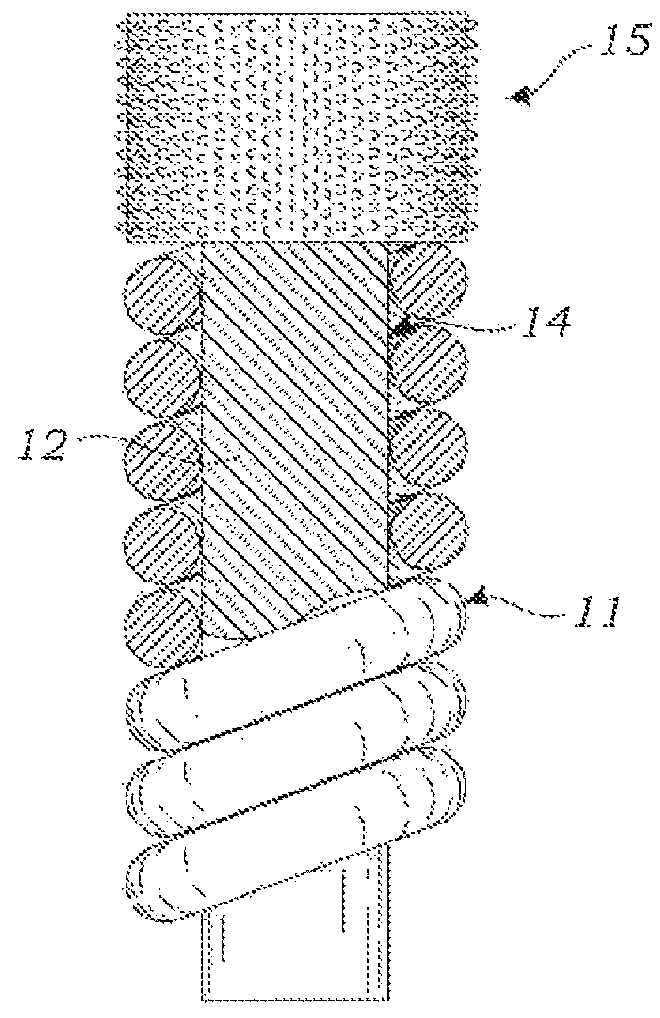

Hair styling device

A hair styling device or curler used to shape hair by capturing a tress of hair inside a continuous channel of the curler created by a wrapping element spirally wrapped around a central core element. The continuous channel captures the hair so it is self-holding and does not require additional clips or fixation elements to hold the curler in place. The curler may contain two elements or one element. The curler may be wrapped in either direction to accommodate styling both sides of the head and may be modularly connected to another curler to customize the length of the curler. The curler may be heated by a variety of means or may be left at room temperature for air drying. The curler may contain a blow dryer element, sensors or other smart technology to start or stop any function of the styling system.

Owner:BIRK JANEL

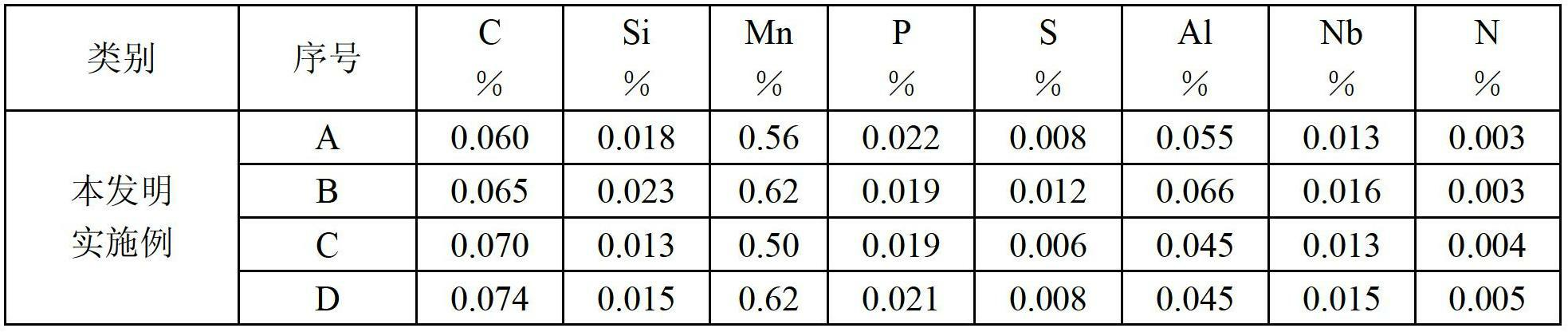

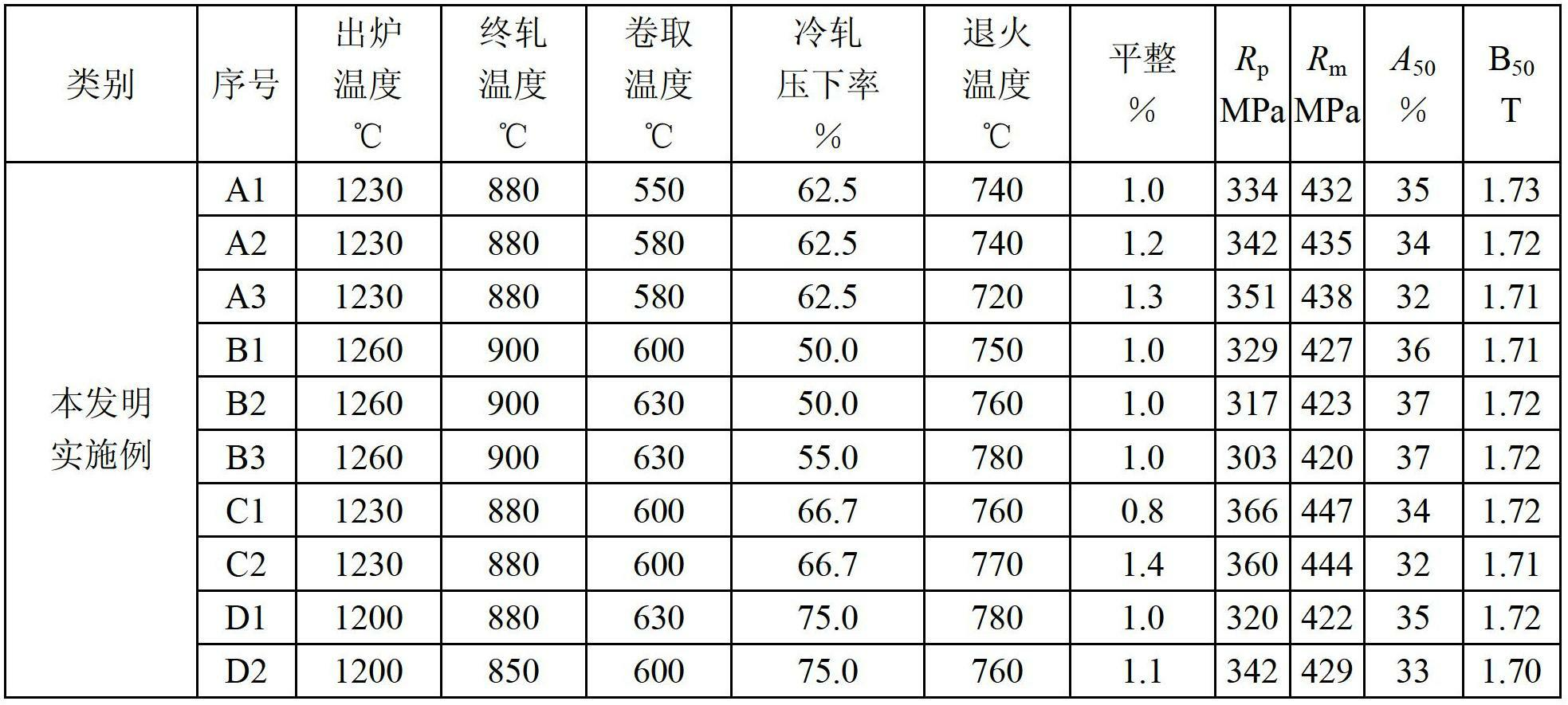

Manufacturing method for high-magnetic induction low-cost 250 MPa cold-rolled magnetic pole steel

ActiveCN102650016AFully exert the strengthening effectImprove shape qualityRoll mill control devicesMetal rolling arrangementsReduction rateHeating time

The invention discloses a manufacturing method for high-magnetic induction low-cost 250 MPa cold-rolled magnetic pole steel. The manufacturing method comprises the steps as follows: heating a plate blank to be 1200-1260 DEG C and insulating; hotly rolling, wherein the final rolling temperature is 850-900 DEG C, the coiling temperature is 550-630 DEG C and a jet water cooling way is adopted as a cooling way; cooling to be 60-80 DEG C for acid washing, wherein an air cooling way is adopted as the cooling way; coldly rolling, wherein the cold rolling reduction rate is 50-75%; continuously annealing, wherein the temperature of an uniform heating section is 720-780 DEG C and the uniform heating time is 60-200 s; and flattening by a flattening elongation rate of 0.8-1.4% to prepare the 250 MPa cold-rolled magnetic pole steel. The produced magnetic pole steel has lower yield strength ReL of more than 250 MPa and magnetic induction strength B50 of more than 1.70 T, and is suitable for manufacturing a magnetic pole iron core of a rotor body of a large water-wheel generator.

Owner:BAOSHAN IRON & STEEL CO LTD

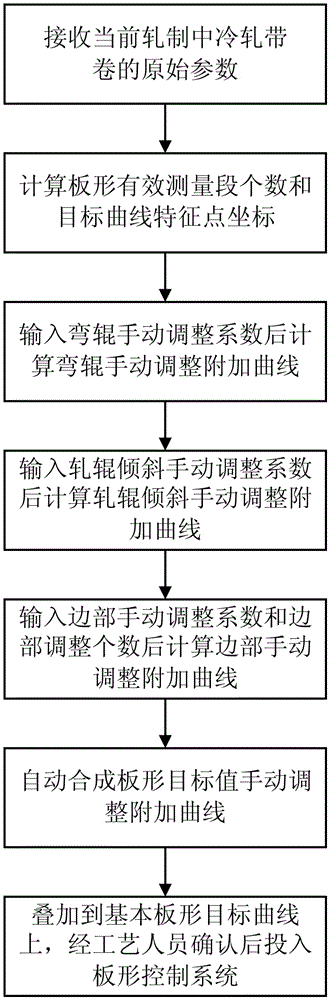

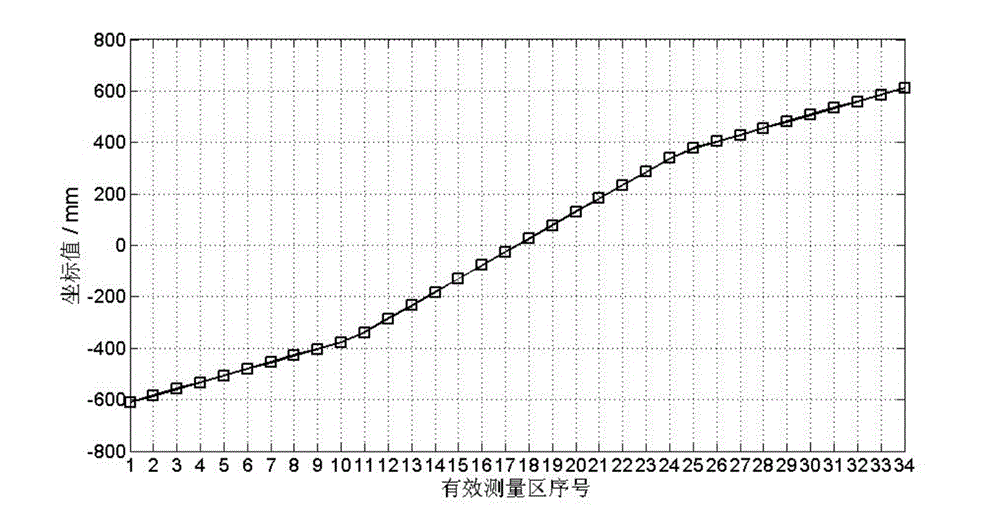

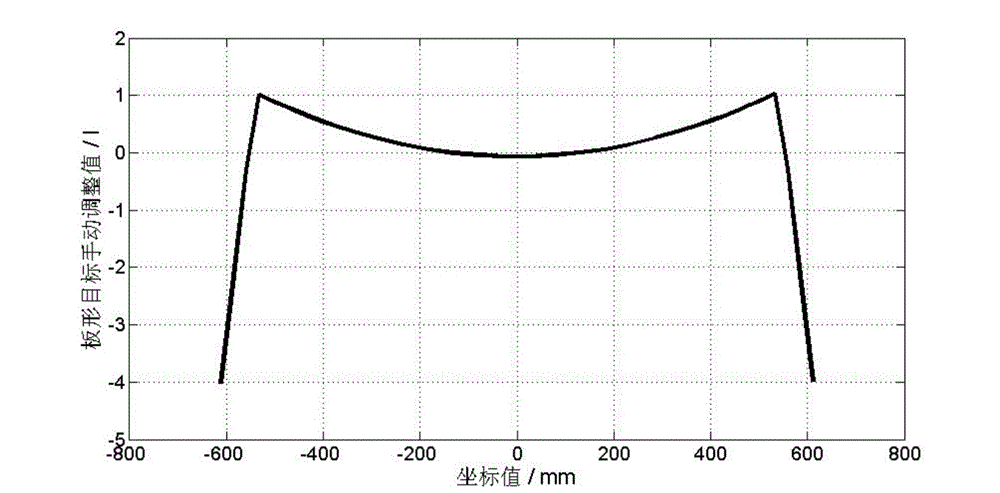

Method for manually adjusting and computing shape target curve of cold-rolled steel strip

ActiveCN102716917AFlexible implementation of control functionsGuarantee the self-equilibrium condition of internal stressProfile control devicePhase balanceComputer science

The invention provides a method for manually adjusting and computing a shape target curve of a cold-rolled steel strip. The method includes 1) receiving original parameters, which are transmitted by a process computer in real time, of a cold-rolled strip coil which is rolled currently; 2) computing the number of effective shape measurement sections and coordinates of shape target curve feature points corresponding to the effective shape measurement sections; 3) inputting manual adjustment coefficients of a bending roller and computing a manual adjustment additional curve of the bending roller; 4) inputting oblique manual adjustment coefficients of a roller and computing an oblique manual adjustment additional curve of the roller; 5) inputting manual adjustment coefficients of edges and the number of the adjusted edges and computing manual adjustment additional curves of the edges; 6) sequentially adding the additional curves obtained from the step 3), the step 4) and the step 5) according to the coordinates xi of the shape target curve feature points to obtain a shape target value manual adjustment additional curve capable of automatically meeting internal stress self-phase-balance conditions; and 7) superimposing the shape target value manual adjustment additional curve onto a basic shape target curve to obtain the shape target curve which is manually adjusted and compensated.

Owner:WISDRI ENG & RES INC LTD

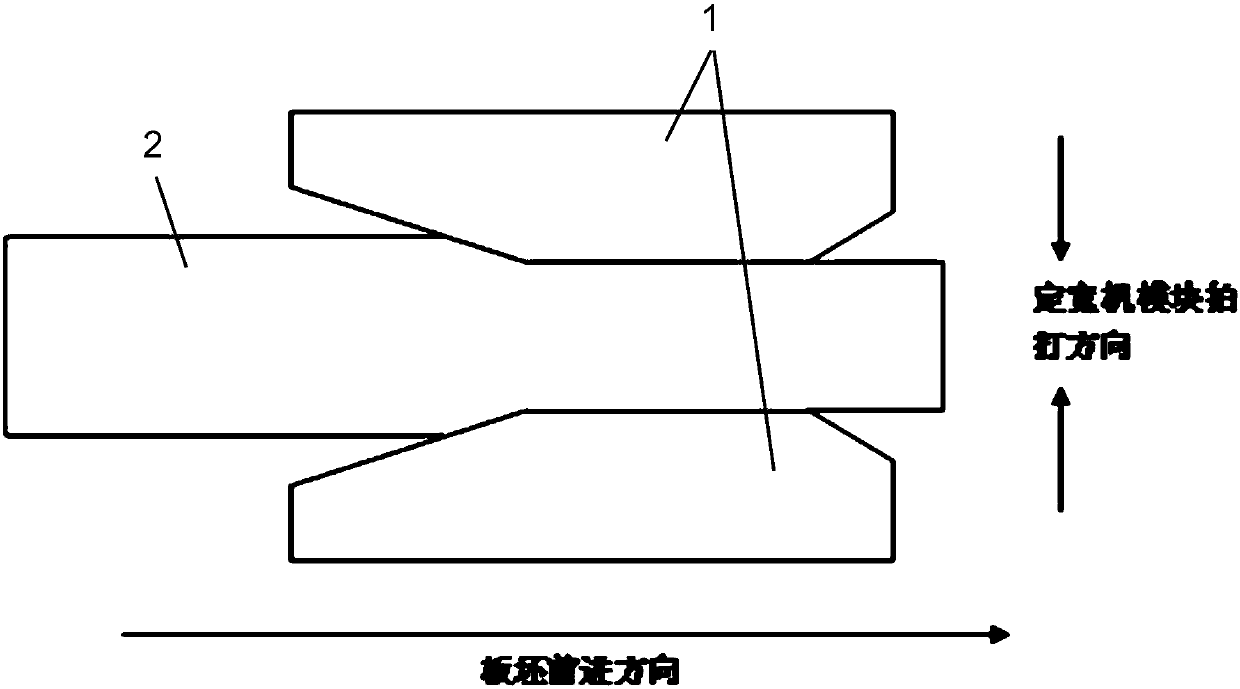

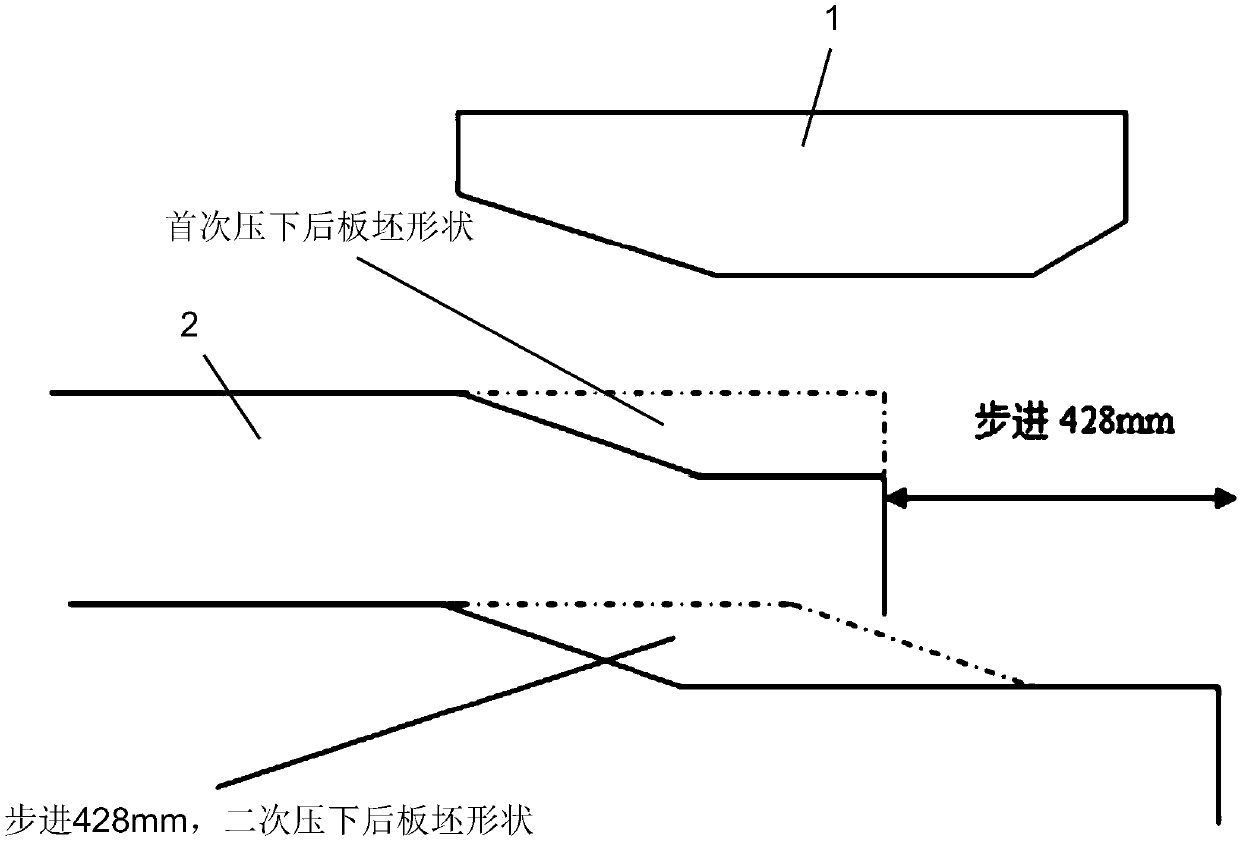

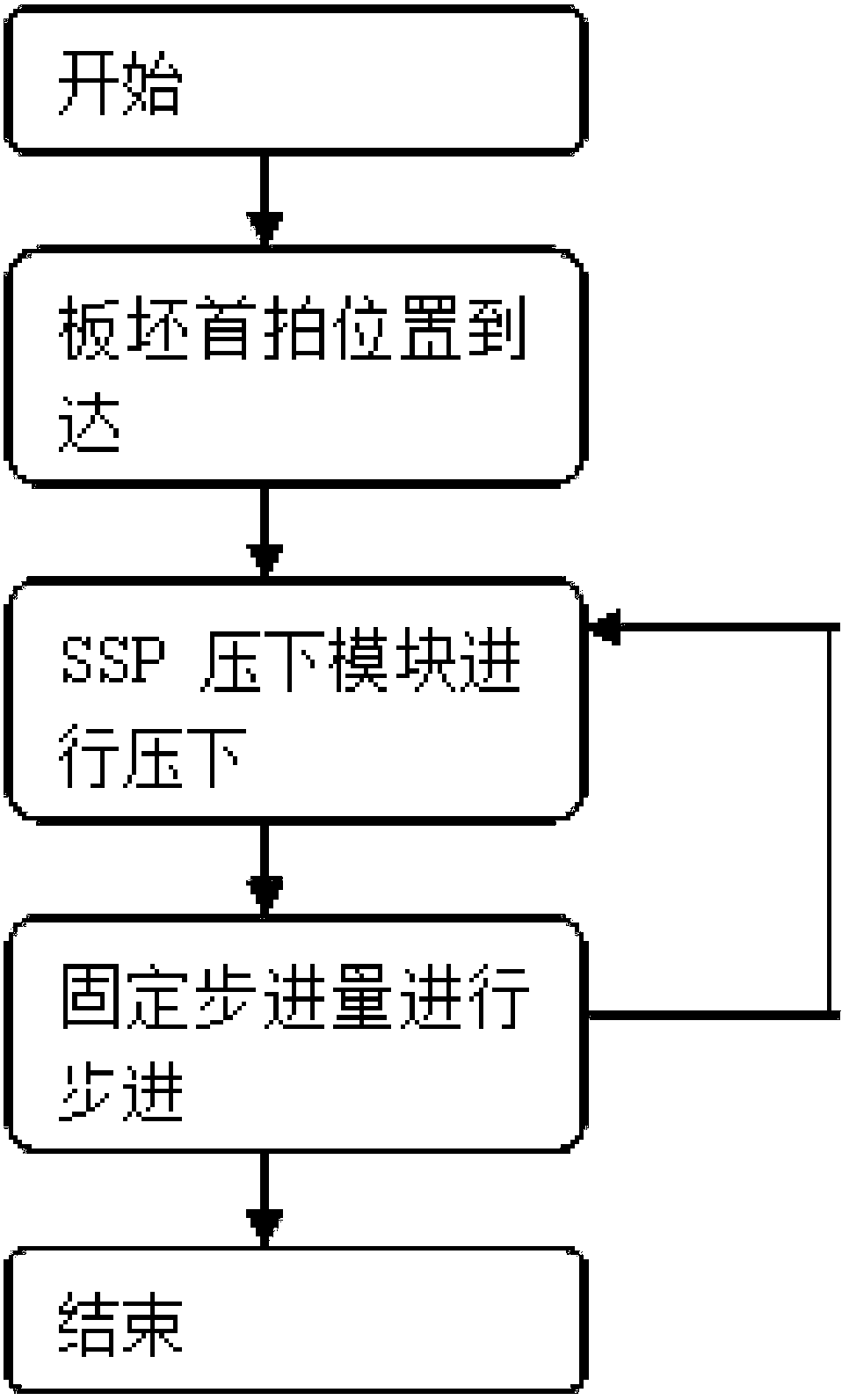

Slab head and tail width prediction-based variable step size control method for rough rolling sizing machine

InactiveCN110038905AEasy shape controlHigh yieldMetal rolling stand detailsRoll mill control devicesStrip steelPressure measurement

The invention discloses a slab head and tail width prediction-based variable step size control method for a rough rolling sizing machine. The method comprises the following steps of S1, calculating the width deviation value of a slab head part; S2, calculating the stepping length of the slab head part and a slab tail part according to the deviation obtained in S1; S3, enabling the primary beatingposition of a slab to reach a station in the pressure measuring sizing machine; S4, enabling a downward pressing module of the pressure measuring sizing machine to downwards press the slab head part for the first time; S5, carrying out stepping and downward pressing according to the calculated stepping quantity for three steps of the head part ; S6, keeping the conventional fixed stepping quantitytill the tail part; and S7, carrying out stepping and downward pressing according to the calculated tail part stepping quantity for the three times of the tail part. According to the method, different stepping lengths are set according to the head and tail width prediction under the factors of different slab widths, pressure measurement and the like, so that the head and tail control condition isoptimized, and the strip steel yield and the width control precision are improved.

Owner:BAOSHAN IRON & STEEL CO LTD

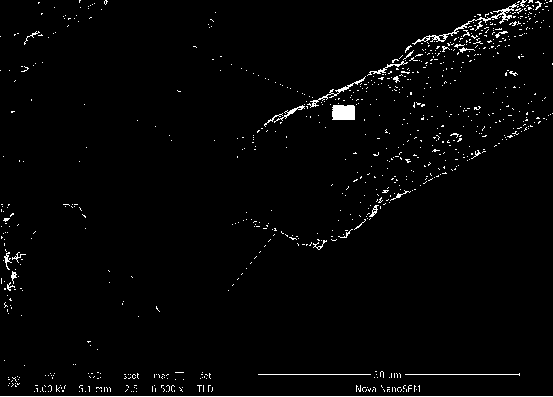

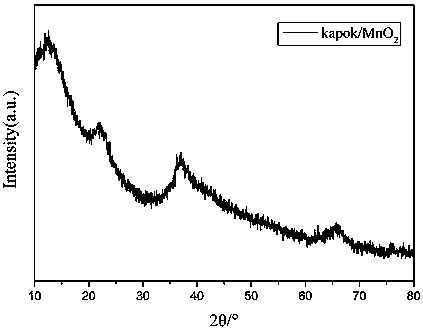

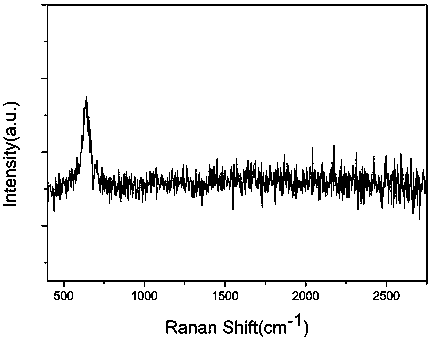

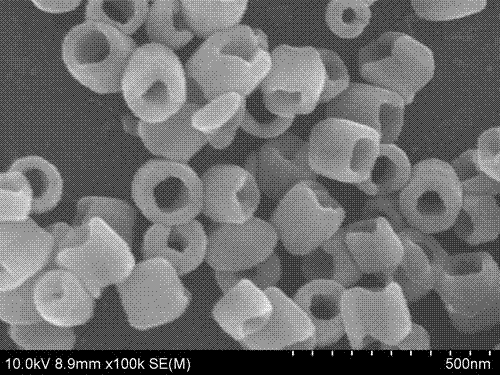

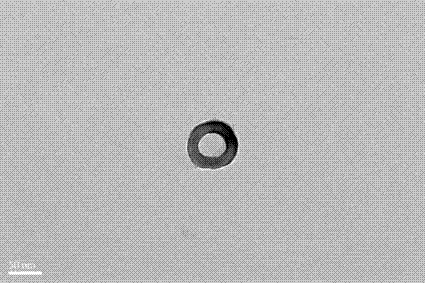

Kapok fiber/manganese dioxide structure multi-layer self-drive tubular micro-nano motor and preparing method thereof

ActiveCN109576986ALow costEnvironmental protection and easy shape controlInorganic non-active ingredientsAntineoplastic agentsNear infrared lightPotassium permanganate

The invention discloses a kapok fiber / manganese dioxide structure multi-layer self-drive tubular micro-nano motor and a preparing method thereof. With manganese dioxide adopted as the raw material andkapok fiber adopted as the template, by soaking the kapok fiber in a manganese dioxide solution, the manganese dioxide and the kapok fiber are made to have a redox reaction to generate manganese dioxide nanoparticles to be loaded on the kapok fiber, and therefore the multi-layer self-drive tubular micro-nano motor is prepared, and the motor is good in biological degradability, has carrying, conveying and releasing functions and has wide application prospects in the fields of efficient medicine loading, target cancer cell conveying, medicine near infrared light responsiveness controllable releasing, environmental control and the like.

Owner:FUJIAN UNIV OF TECH

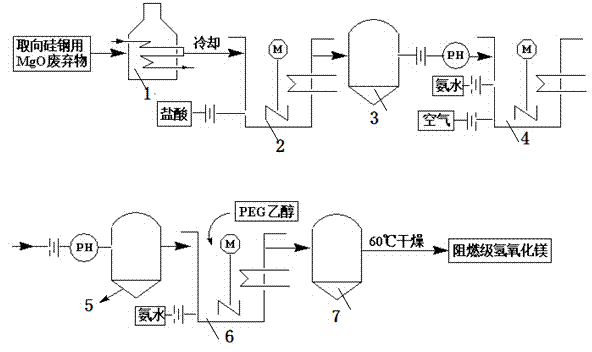

Recycling and re-preparation method of silicon-steel level magnesium oxide

InactiveCN105540622AStrong alkaline environmentHigh yieldMagnesiaFiltrationAmmonium Hydrogen Carbonate

The invention discloses a recycling and re-preparation method of silicon-steel level magnesium oxide. The method comprises the following steps: by taking magnesium oxide, a residual waste coating material after silicon steel production, as a raw material, carrying out purification treatment operations of calcination, acidolysis, iron and silicon removal, acidolysis with hydrochloric acid, and the like to obtain a high-purity magnesium chloride solution; by taking the high-purity magnesium chloride solution as a reaction solution, adding ammonium hydrogen carbonate and ammonia water as two precipitants, introducing an organic surfactant at the same time, and carrying out preparation at 40-80 DEG C to obtain a precursor, namely basic magnesium carbonate Mg2(OH)2CO3; and finally, carrying out washing, suction filtration, drying, crushing, and air blowing method calcination to prepare silicon-steel level magnesium oxide. According to the method disclosed by the invention, the wastes which are generated during production of silicon steel and contain a large amount of magnesium oxide are recycled, and high-quality silicon-steel level magnesium oxide with a high specific area and uniform particle size distribution can be prepared by virtue of the processes of purification, two-phase precipitant method precursor preparation, air blowing method calcination and the like.

Owner:SHANGHAI INST OF TECH

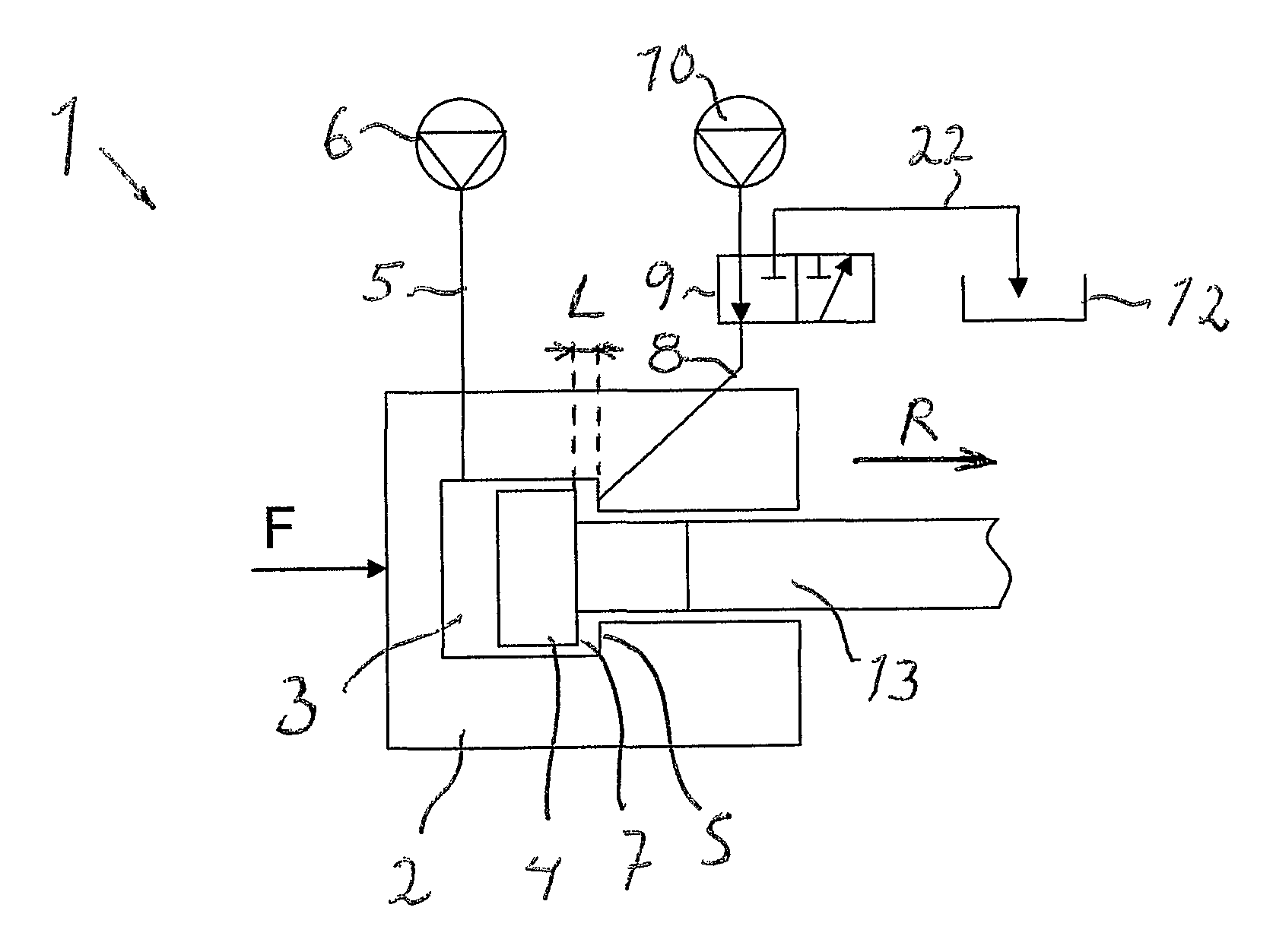

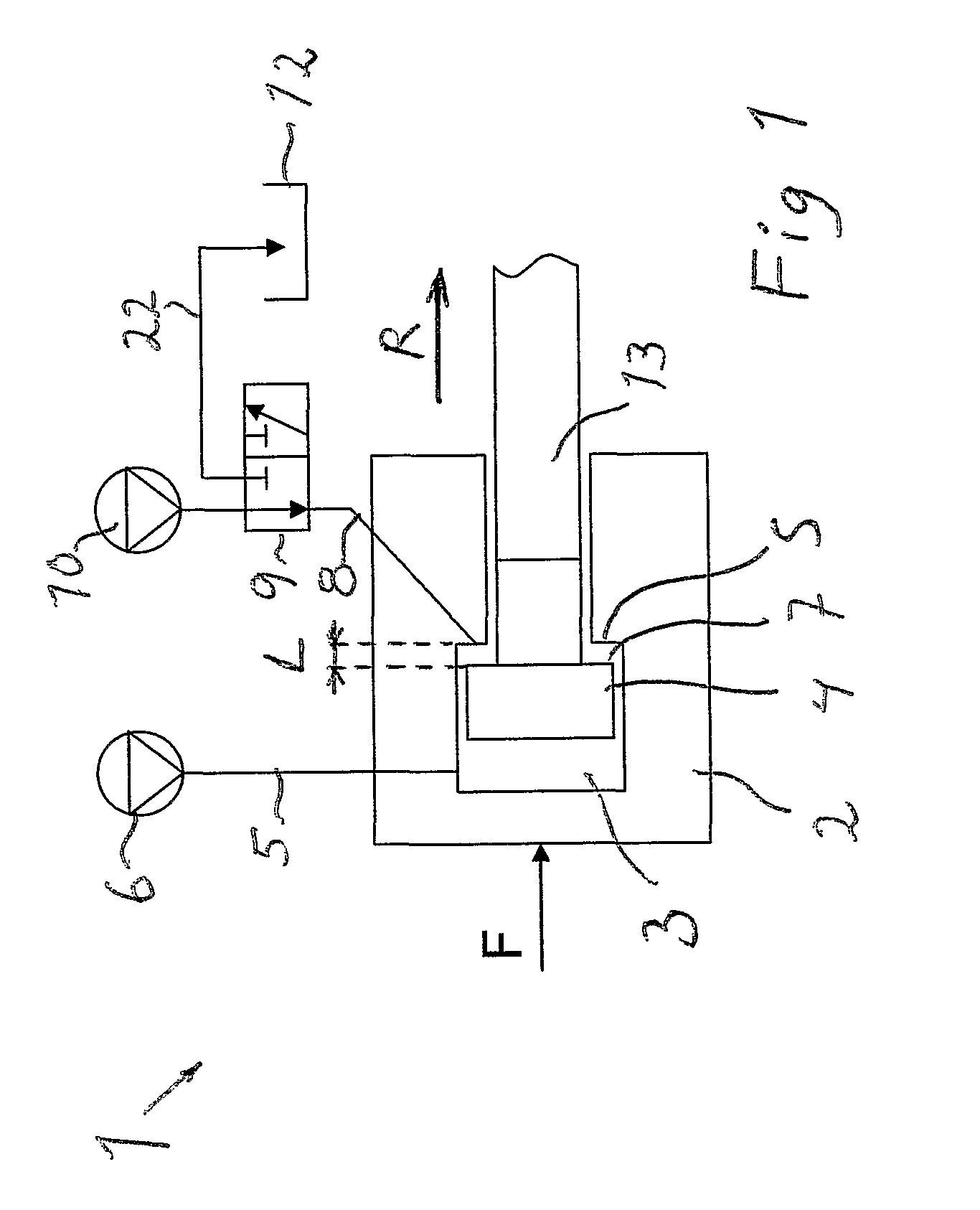

Method and device for rock drilling

InactiveUS8151899B2Easy shape controlMore effective shockwave pulsesLiquid/gas jet drillingPortable percussive toolsShock waveEngineering

A method for producing Shockwave pulses in a tool direction (R) of a pulse machine (1) having a housing (2), wherein an impulse piston (4) is arranged, wherein the impulse piston is influenced by a first force in a direction opposite to said tool direction through a first fluid pressure (Pi) in a first chamber (7), and by a second force in said tool direction, wherein 'a Shockwave pulse is produced through a rapid relief of the first fluid pressure after displacement of the impulse piston (4) relative to the housing in a direction opposite to the tool direction, is distinguished in that the length of the shock wave is controlled by the length (L) of said displacement is regulated. The invention also concerns a device, rock drilling machine and a rock drilling rig.

Owner:ATLAS COPCO ROCK DRILLS

Method for preparing flame retardant grade magnesium hydroxide

ActiveCN104743585ASolve the technical problems of recyclingRealize resource utilizationSolid waste disposalMagnesium hydroxideAmmoniaMuffle furnace

The invention provides a method for preparing flame retardant grade magnesium hydroxide. The method comprises the following steps: calcining the oriented silicon steel in a muffle furnace by use of magnesium oxide wastes, next, cooling, adding the calcined silicon steel magnesium oxide to a dissolving tank by use of the magnesium oxide wastes, dissolving by use of an acid, adding the dissolved magnesium oxide wastes to a settling tank for settling, removing the undissolved substances, guiding the solution into a reaction tank, adding ammonia water, and continuously introducing compressed air so that Fe<2+> can be transformed into Fe<3+>, controlling the pH so that the Fe<3+> is completely settled and Mg<2+> is not settled, removing Fe(OH)3 precipitate, next, adding ammonia water, ethanol and a surfactant to the solution obtained after settlement in the reaction tank, controlling the pH so that the Mg<2+> can be completely settled, and drying Mg(OH)2 to obtain the retardant grade magnesium hydroxide. The method is used for solving the problems of the technical flow of recycling the magnesium oxide waste for the silicon steel; and the waste of resources is avoided.

Owner:上海永青环保新材料有限公司

Preparation method of carbon-coated iron oxide nanotube and product and application of nanotube

ActiveCN107879379AShort processSimple methodMaterial nanotechnologyShielding materialsSucroseMechanical property

The invention provides a preparation method of a carbon-coated iron oxide nanotube and a product and application of the nanotube. The preparation method comprises the following steps: preparing a solution from a soluble iron salt, a sulfate, ammonium dihydrogen phosphate and sucrose according to a certain concentration, and magnetically stirring the solution for a certain time; and transferring the solution into a stainless steel reaction still, regulating temperature and pressure, and performing reacting for a certain time by a supercritical method to obtain the carbon-coated iron oxide nanotube. The preparation method is simple, the technological process of a carbon coating process is shortened effectively, meanwhile, the reaction time is short, the temperature is low, and the course ofthe reaction is easy to control. The carbon-coated iron oxide nanotube is prepared by the method efficiently and rapidly, has a unique core-shell structure and peculiar electrical, magnetic, optical and mechanical properties, and thus is expected to be widely applied to the fields of catalysts, battery materials, electric wave shielding materials and the like.

Owner:上海禾澜纳米科技有限公司

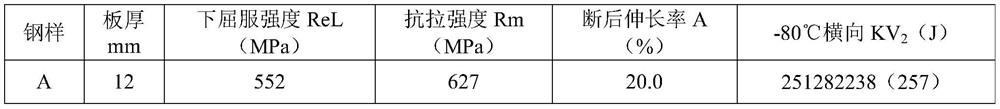

High-strength container plate with excellent low-temperature toughness and manufacturing method

The invention discloses a high-strength container plate with excellent low-temperature toughness and a manufacturing method, and relates to the technical field of iron and steel production. The high-strength container plate is prepared from the chemical composition in percentage by mass: 0.07% to 0.11% of C, 0.10% to 0.30% of Si, 1.30% to 1.60% of Mn, 0.40% to 0.80% of Ni, 0.05% to 0.12% of Mo, 0.02% to 0.05% of V, 0.02% to 0.05% of Alt, less than or equal to 0.008% of P, less than or equal to 0.002% of S and the balance of Fe and avoidable impurities. The material strength is upgraded by adding a small amount of alloy, the alloy cost is low, accurate control is easily achieved, the use temperature is lower, the strength is further significantly improved, and the material consumption of tank construction can be reduced.

Owner:NANJING IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com