Patents

Literature

92results about How to "Increase yield point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

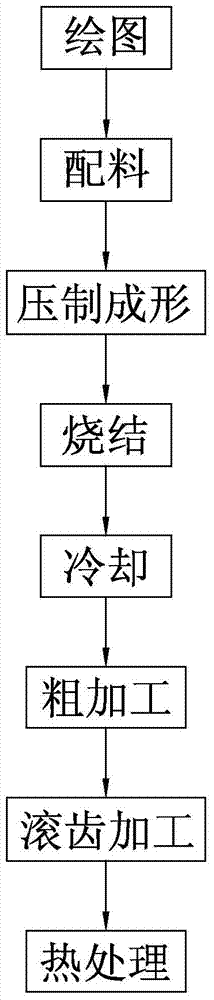

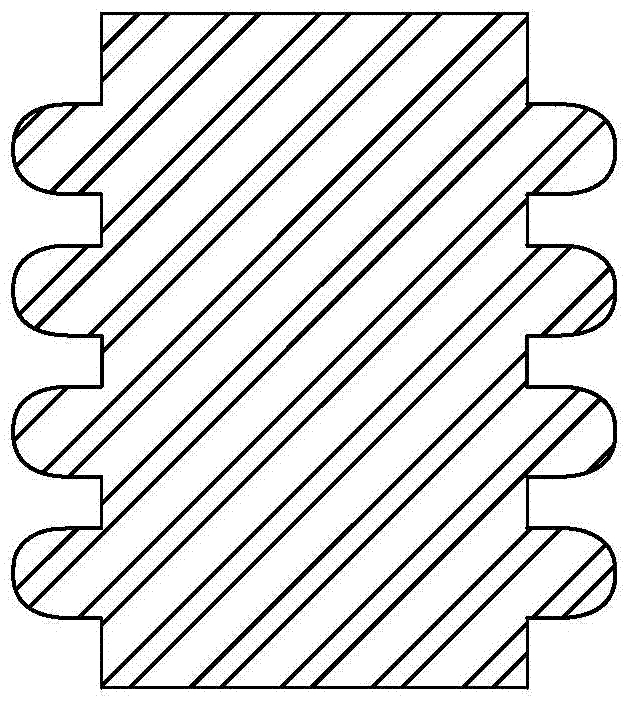

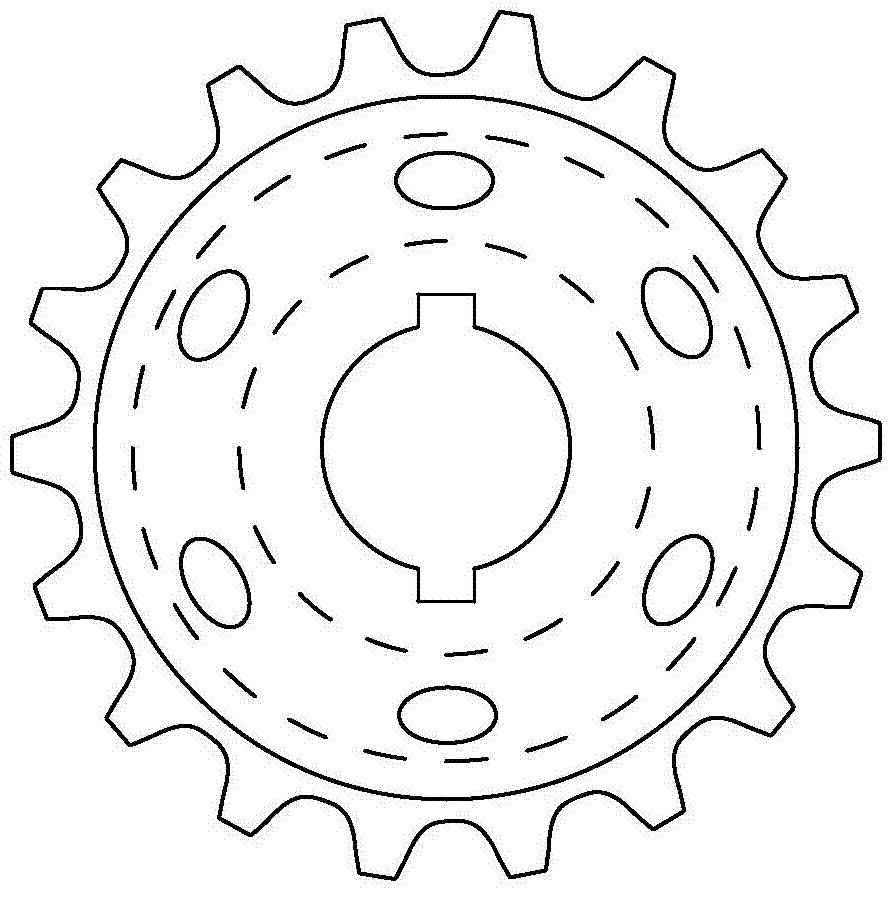

Mechanically actuated chain wheel material, and manufacturing method thereof

ActiveCN103757551AImproved mechanical properties and hardnessUniform hardness distributionAutomotive engineeringSprocket

The invention discloses a mechanically actuated chain wheel material, and a manufacturing method thereof. The mechanically actuated chain wheel material comprises following ingredients: 0.2 to 0.35 part of C, 0.35 to 0.55 part of Si, 0.6 to 0.9 part of Mn, Ni<=0.25 part, Cr<=0.20 part, S<=0.02 part, Al<=0.05 part, P<=0.03 part, Cu<=0.40 part, Mo<=0.05 part, V<=0.03 part, Nb<=0.01 part, Ti<=0.01 part, and the balance Fe. The manufacturing method comprises steps of (a) drawing; (b) material preparaing; (c) compacting and shaping; (d) sintering; (e) cooling; (f) rough machining; (g) gear hobbing processing; and (h) heat processing. According to the manufacturing method, the ingredients above are selected so as to obtain chain wheels with uniform strength. In preparation processes, the ingredients are delivered into a mould; a chain wheel blank material is obtained via upsetting extruding, and is subjected to sintering and cooling, so that the internal part of the mechanically actuated chain wheel material is compact, is high in strength, and is not easily fractured; gear hobbing processing is adopted, so that cost is reduced, and processing cycle is shortened; and phenolic aldehyde cloth base laminates are used, so that wear resistance and corrosion resistance of the chain wheels are increased.

Owner:中山舜人机械制造有限公司

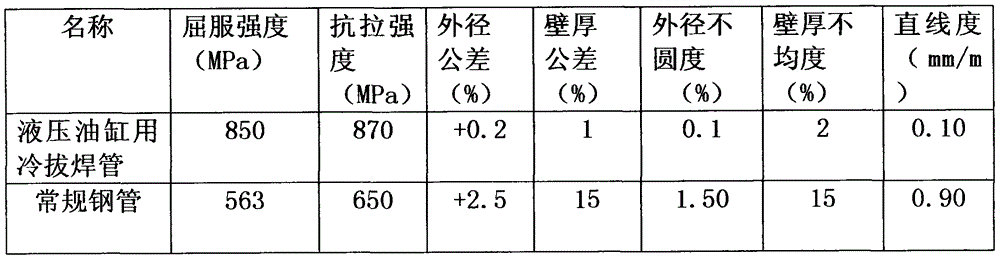

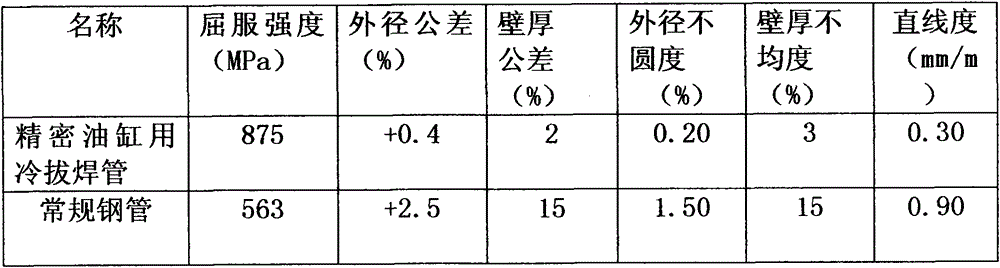

Manufacturing method for cold drawn welded pipe used for hydraulic oil cylinders

InactiveCN104646449AReduce processing difficultyImprove deburring speedWelding jointMagnetic leakage

The invention relates to a manufacturing method for a cold drawn welded pipe used for hydraulic oil cylinders. The manufacturing method includes the steps of: longitudinal shearing, roll bending formation, high-frequency welding, weld joint treatment, sizing, online eddy current flow detection, stress relief annealing, pre-straightening treatment, pipe cutting, normalizing air cooling treatment, pinching, pickling treatment, phosphating treatment, saponification treatment, cold-drawing, induction furnace quenching treatment, box type furnace tempering treatment, straightening treatment, fine boring rolling, magnetic leakage flaw detection, and pipe cutting measurement. The product obtained by the method provided by the invention has the advantages of high yield strength, high tensile strength, precise size, smooth surface, fast machine shaping speed, high yield, and remarkably improved manufacturing precision. The cold drawn welded pipe has good surface smoothness and low roughness, the follow-up gold processing amount is reduced, the steel utilization is improved, the manufacturing cost is lowered, and energy saving and environmental protection are promoted.

Owner:WUXI DAJIN HIGH PRECISION COLD DRAWN STEEL TUBE

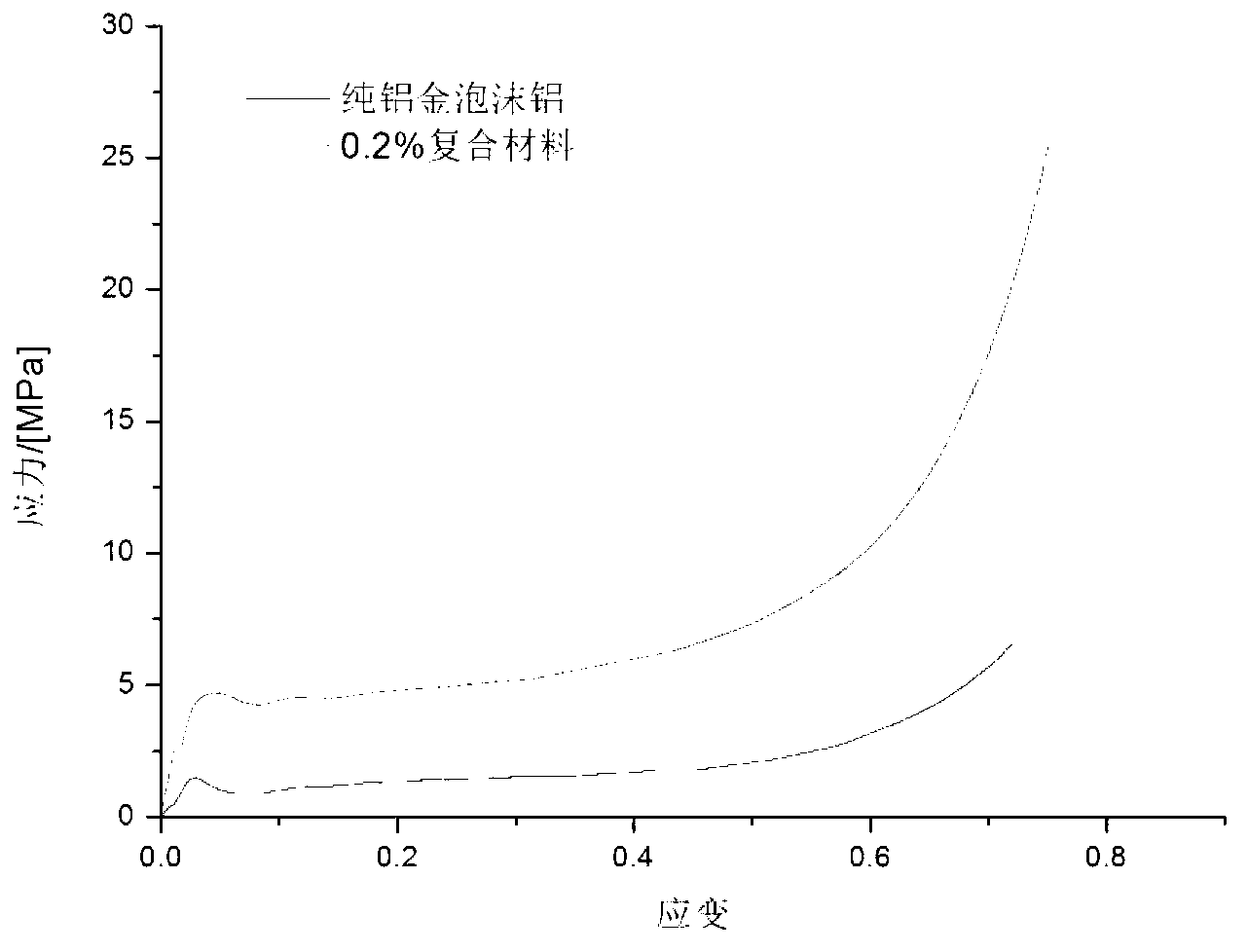

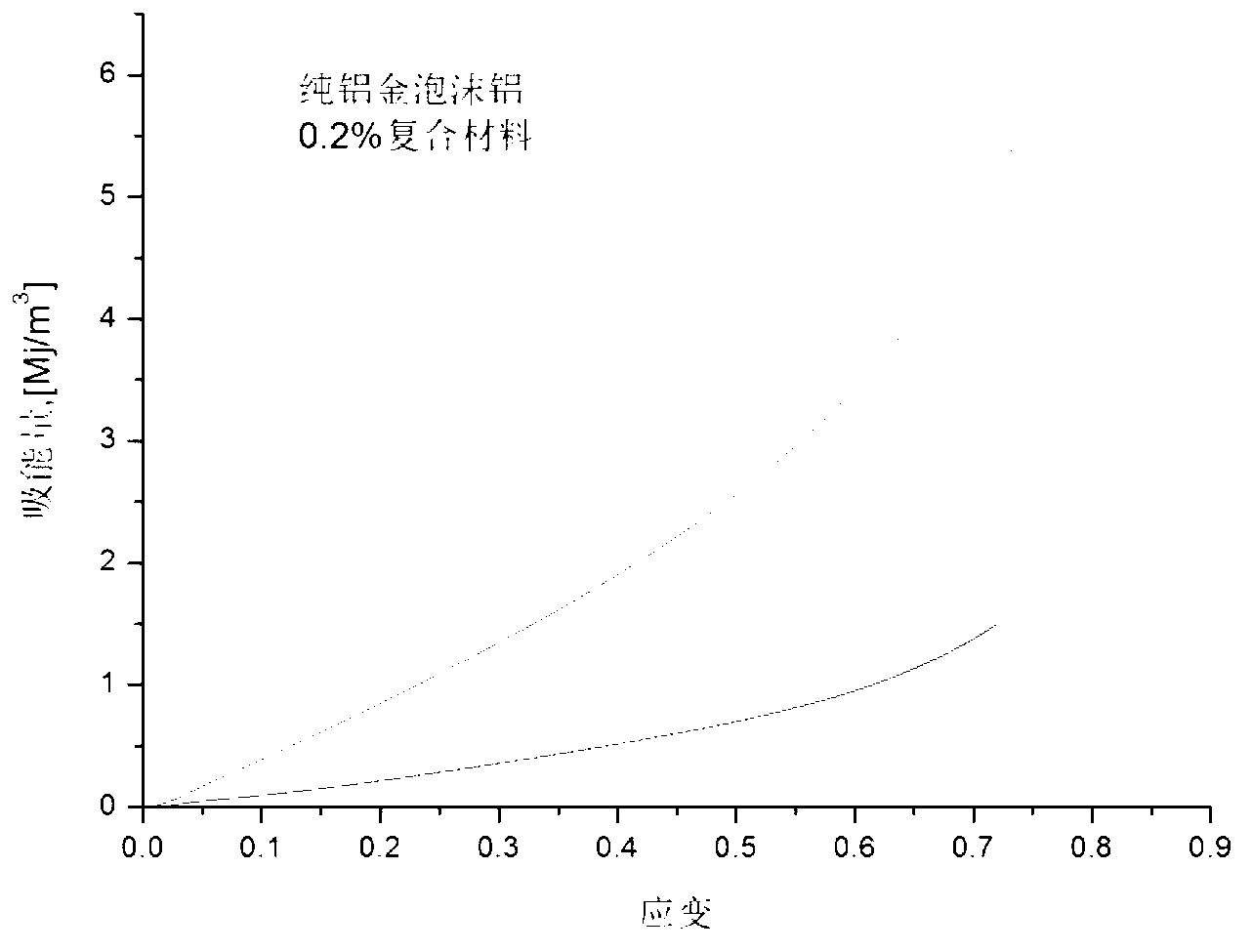

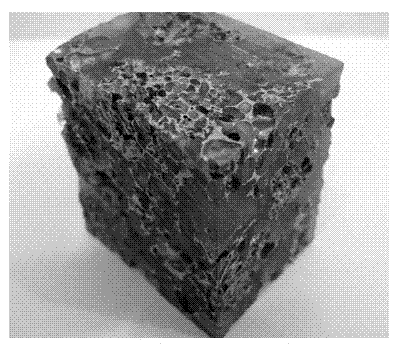

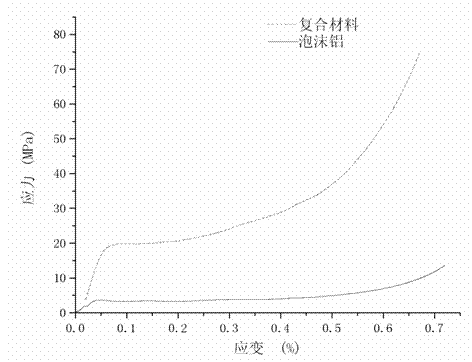

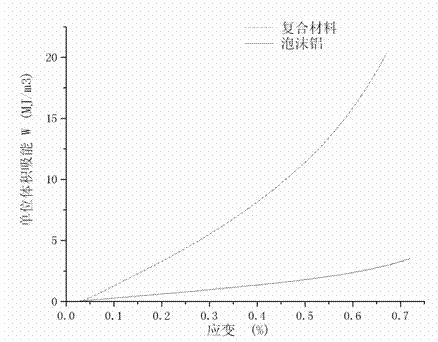

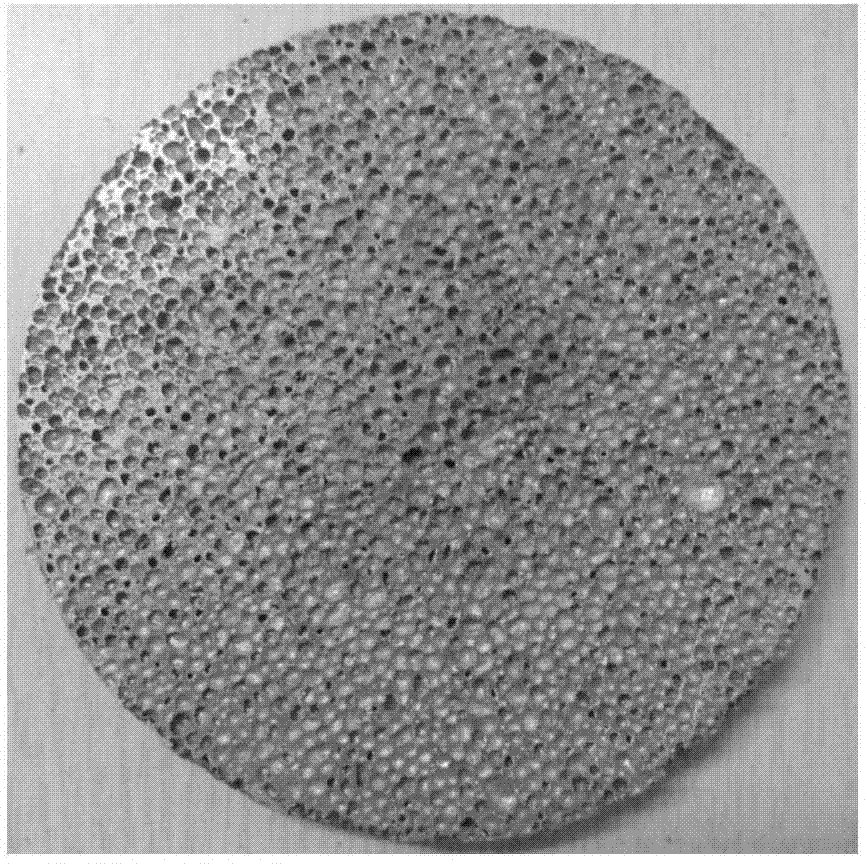

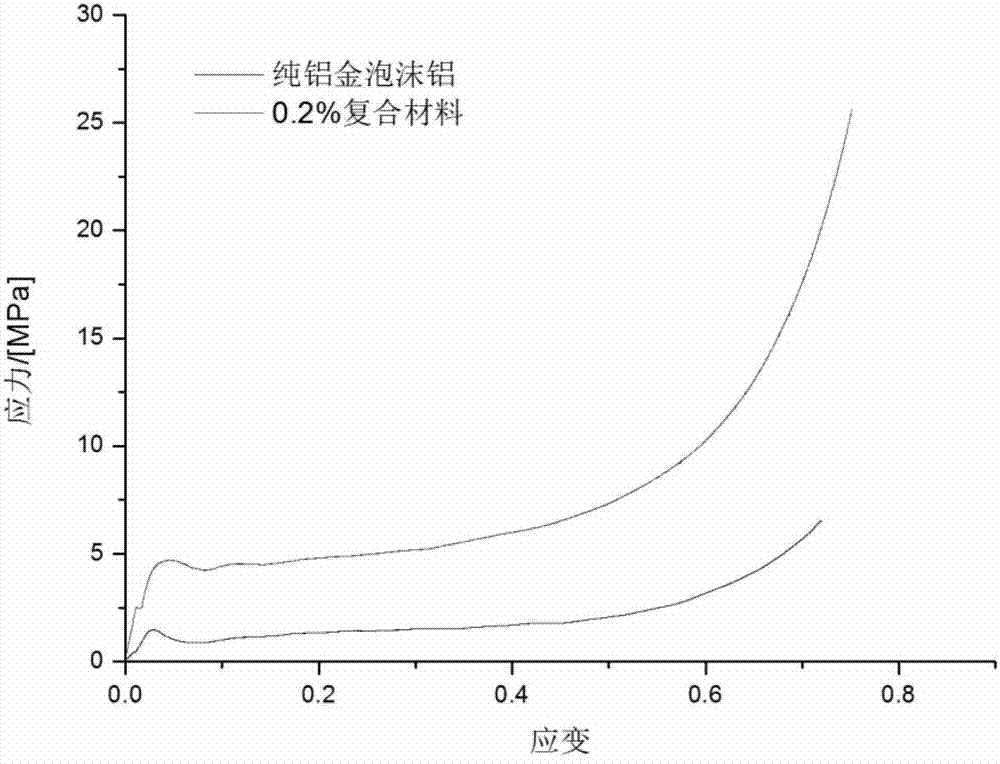

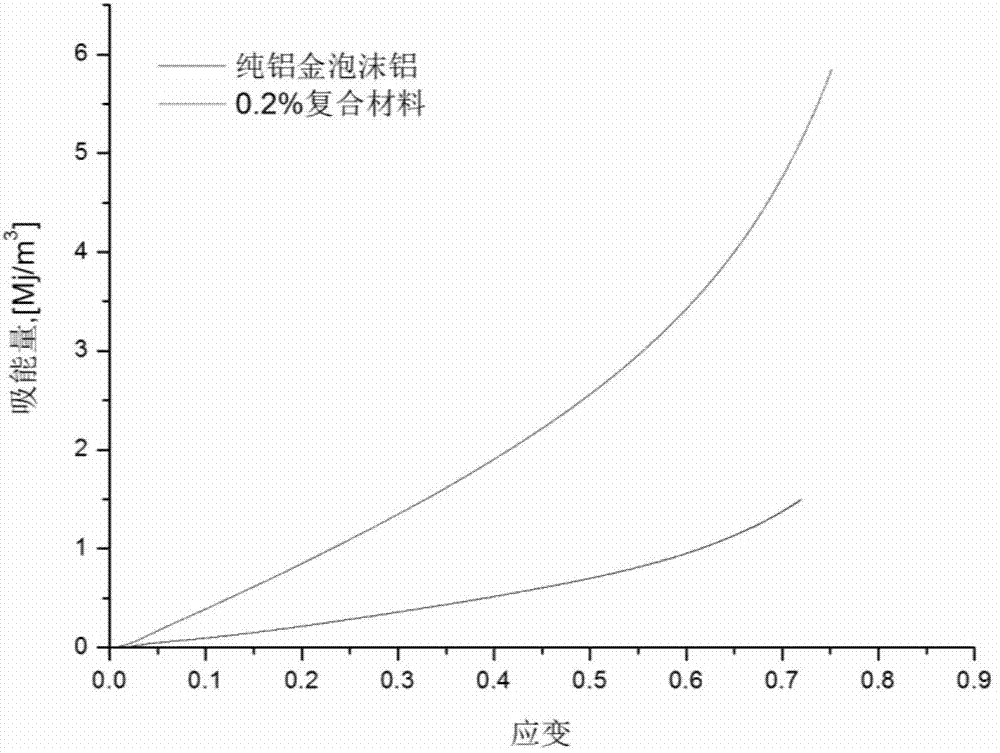

Method for preparing foamed aluminum composite material

The invention provides a method for preparing a foamed aluminum composite material, relates to the manufacturing of alloy with open or closed pores, and specifically relates to a method for compounding dispersed embedded manganese particles and closed-pore foamed alumium. The method comprises the following steps of: smelting commercially pure alumium into alumium melt and preserving heat, tackifying the alumium melt, adding manganese particles, foaming the alumium melt with manganese and preserving heat, cooling in air so that the foamed alumium is solidified and formed, and then cooling by wind, thereby obtaining the closed-pore foamed alumium composite material high in compression strength, and high in porosity and ductile fracture finally. The method provided by the invention overcomes the shortcomings of low compression strength of the commercially pure alumium-based foamed alumium composite material prepared by the prior art and easy brittle fracture in the compression process.

Owner:HEBEI UNIV OF TECH

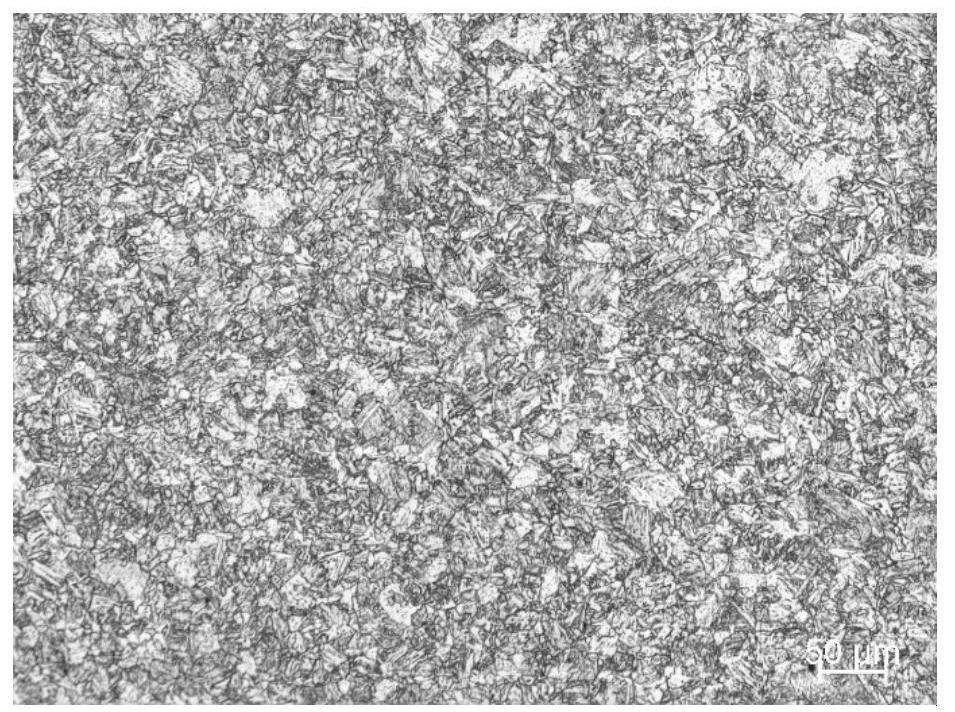

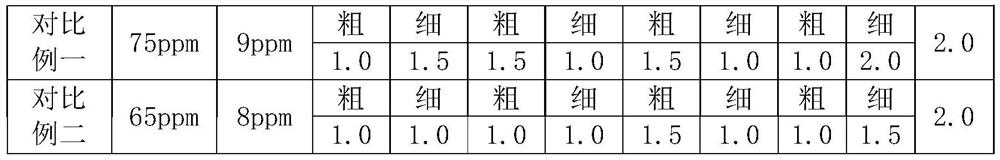

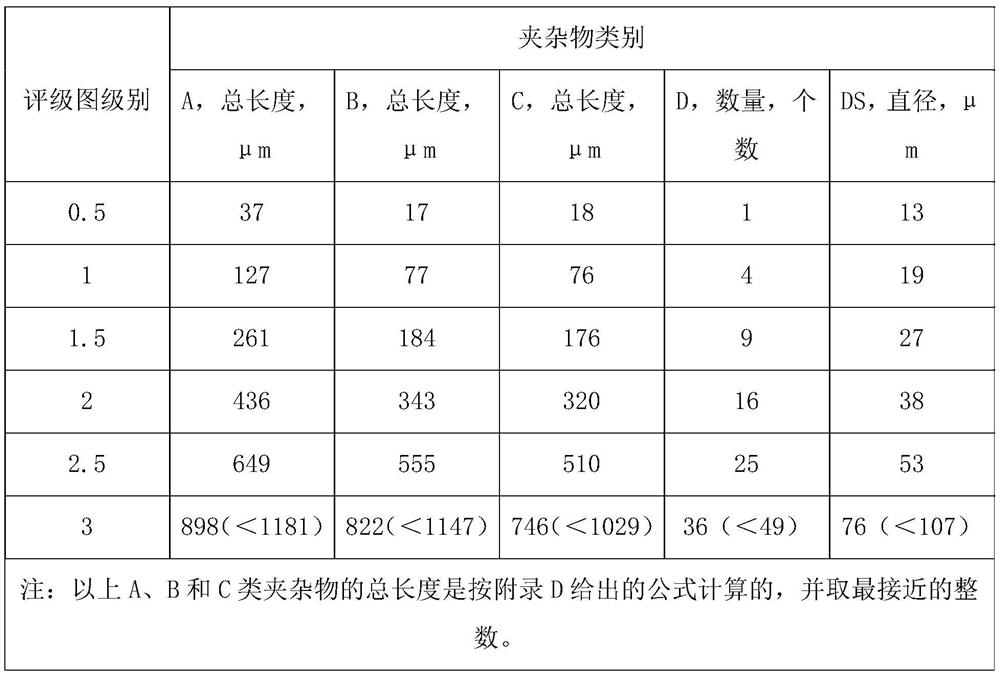

Textile fuzzing flexible card clothing steel wire rod and manufacturing method thereof

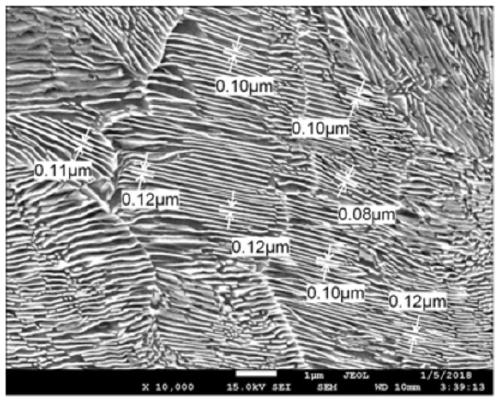

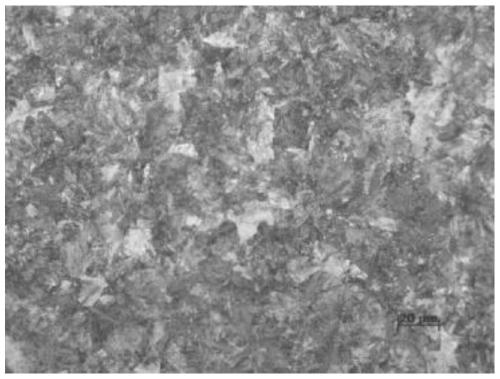

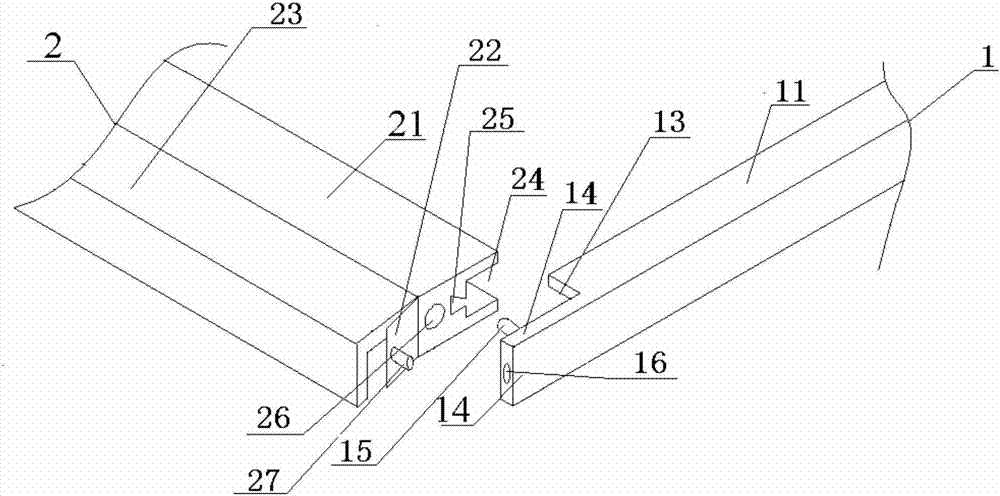

The invention relates to a textile fuzzing flexible card clothing steel wire rod and belongs to the technical field of the special steel wire rods. The wire rod meets the conditions that the tensile strength is 1000-1200 Mpa, and the reduction of area is greater than 45%; a microstructure of the steel wire rod meeting the tensile property comprises 85% or more of the sorbite content and the balance ferrite; the sorbite interlamellar spacing is uniformly controlled, wherein the interlamellar spacing is stable at 0.08-0.20 [mu]m; nonmetallic inclusions in the wire rod are evaluated according toGB / T10561; Ds type inclusions are stable at 0.5 level or less, and the deep drawing of the wire rod can be met; and the wire rod with the diameter of 5.5 mm can be drawn into a thin steel wire with the diameter of 0.2 mm, and then quenched and tempered into a flexible card clothing.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD +1

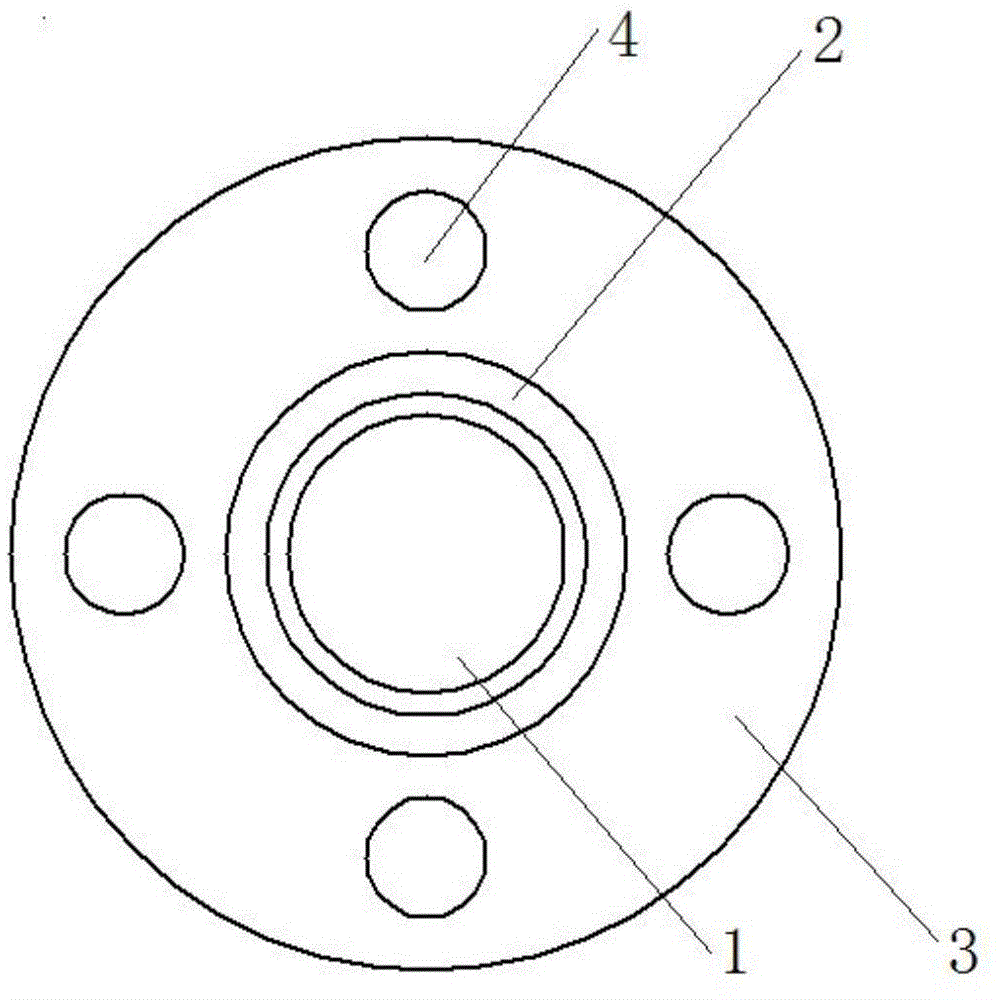

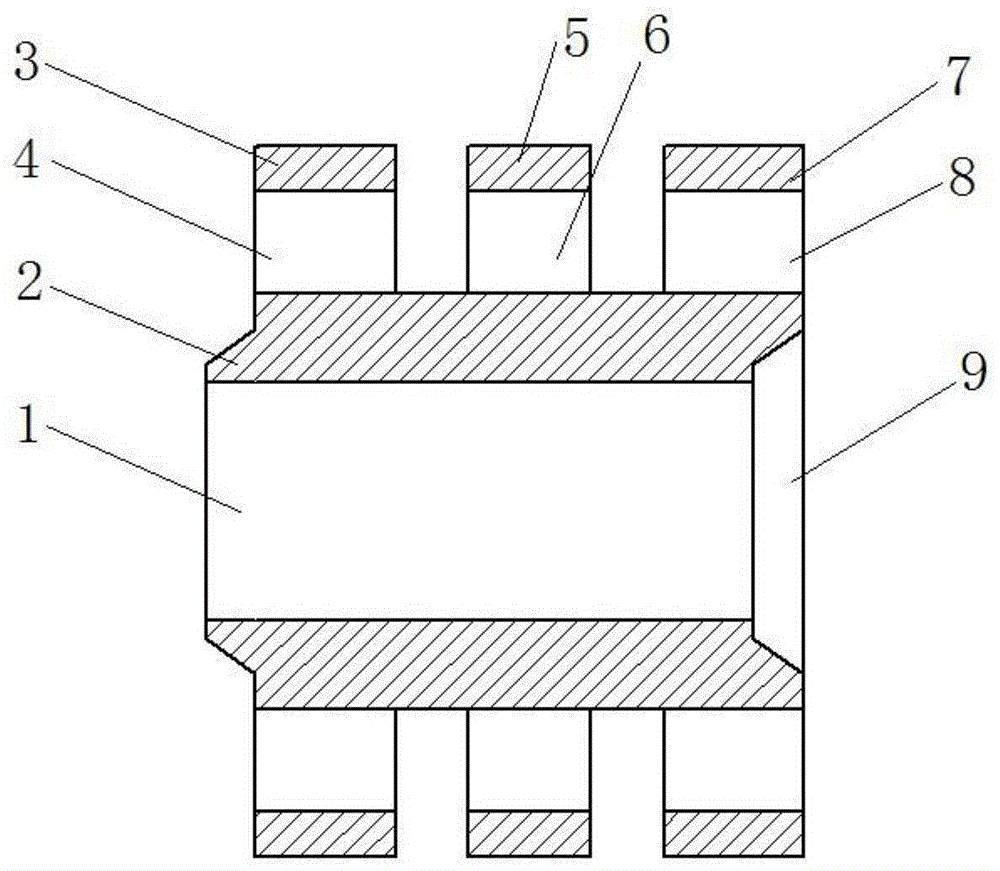

F304/F304L double-standard stainless steel flange and production process thereof

ActiveCN104791562AReasonable structureExquisite designFlanged jointsCircular discSS - Stainless steel

The invention discloses an F304 / F304L double-standard stainless steel flange. The F304 / F304L double-standard stainless steel flange comprises a through hole and a flange plate. The flange plate is of a disc structure, the through hole is formed perpendicular to the flange plate with the center axis of the flange plate serving as the center line, and the edges of the two ends of the through hole are provided with a boss and a groove respectively. The flange plate comprises a front flange plate body, a middle flange plate body and a rear flange plate body which are sequentially arranged in parallel, the diameters of the front flange plate body, the middle flange plate body and the rear flange plate body are equal, the thicknesses of the front flange plate body and the rear flange plate body are equal, at least four fixing holes are evenly formed in each flange plate body, the hole diameters of the front fixing holes, the middle fixing holes and the rear fixing holes are equal, and the positions of the front fixing holes, the middle fixing holes and the rear fixing holes correspond. The invention further discloses a production process of the F304 / F304L double-standard stainless steel flange. The F304 / F304L double-standard stainless steel flange is high in rigidity and strength, resistant to corrosion, ingenious in structural design, high in practicality and long in service life.

Owner:WUXI HUAERTAI MACHINERY MFG

Preparation method of composite material of epoxy resin and closed-cell foamed aluminum

InactiveCN103113715AGood energy absorptionGood mechanical propertiesAluminum matrix compositesAluminum composites

The invention discloses a preparation method of a composite material of epoxy resin and closed-cell foamed aluminum, and relates to a composite material which is formed by a high polymer material and a foamed metal material. The preparation method comprises the following steps of: degreasing and decontaminating closed-cell foamed aluminum pieces by using 0.1mol / L of sodium hydroxide alkali liquid; neutralizing the alkali liquid on the closed-cell foamed aluminum pieces by using 0.01mol / L of hydrochloric acid; mixing the epoxy resin E-44 and a curing agent according to a mass ratio of 1:1; proportioning the closed-cell foamed aluminum pieces and the epoxy resin with the curing agent in a mold in a water bath at 70 DEG C according to a volume ratio of 1:1 or 3:1; after bubbles float up, taking out the mold from the water bath; standing for one week at normal temperature so as to obtain a dispersed embedded type epoxy resin and closed-cell foamed aluminum material. By utilizing the method, the defects that the conventional foamed aluminum-based composite material is low in yield strength, resource and energy are wasted in production, the cost is high and the environment can be polluted, are solved.

Owner:TANGSHAN HAODONG PRECISION MACHINERY

Manufacturing method of cold drawn welded pipe for precision oil cylinder

The invention relates to a manufacturing method of a cold drawn welded pipe for a precision oil cylinder. The manufacturing method comprises the following steps: longitudinal shearing, rolling forming, high-frequency welding, tensioning, online eddy current inspection, stress relief annealing, normalizing air cooling treatment, pre-straightening treatment, pipe cutting, pinching, acid washing treatment, phosphating treatment, saponification treatment, cold drawing, induction furnace quenching treatment, tempering treatment in a box type furnace, straightening treatment, honing, magnetic leakage inspection and pipe cutting measurement. A product obtained by the method has the advantages of high yield strength, high tensile strength, precise size, smooth surface, high processing and forming speed, high yield, obviously improved manufacturing precision, good surface smoothness of the cold drawn welded pipe, low roughness, reduced subsequent gold processing, improved utilization rate of steel, reduced manufacturing cost and capability of promoting energy conservation and environmental protection.

Owner:WUXI DAJIN HIGH PRECISION COLD DRAWN STEEL TUBE

Gas-shielded flux-cored wire for welding of SUS316L austenitic stainless steel deep-cooling low-temperature storage and transportation container and device

ActiveCN107971657AAdjust the melting pointAdjustable viscosityArc welding apparatusWelding/cutting media/materialsManganeseSodium titanate

The invention discloses a gas-shielded flux-cored wire for welding of a SUS316L austenitic stainless steel deep-cooling low-temperature storage and transportation container and device and the preparation method thereof. The as-shielded flux-cored wire comprises a steel strip and a flux core wrapped in the steel strip, and the flux core comprises the following components of, by weight, 4.25-5.85 parts of natural rutile, 0.8-1.9 parts of quartz sand, 0.7-1.8 parts of sodium titanate, 0.25-0.3 part of sodium fluoride, 0.125-0.275 part of calcined alpha alumina, 0. 27wt% of calcined alpha aluminaand 0.025-0.15 part of nitrogen-containing ferrochromium, 0.085-0.05 part of spray silicon iron, 1.05-1.45 parts of electrolytic manganese, 3.6-4.85 parts of metal chromium, 6.42-6.85 parts of atomized iron powder, 1. 9-2.5 parts of nickel powder, and 1.0-1.35 parts of molybdenum. The gas-shielded flux-cored wire has the advantages that efficient semi-automatic and automatic welding technologies are achieved, the welding efficiency is high, splashing is low, the appearance is attractive, the welding current is wide, and the voltage adaptability strong.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

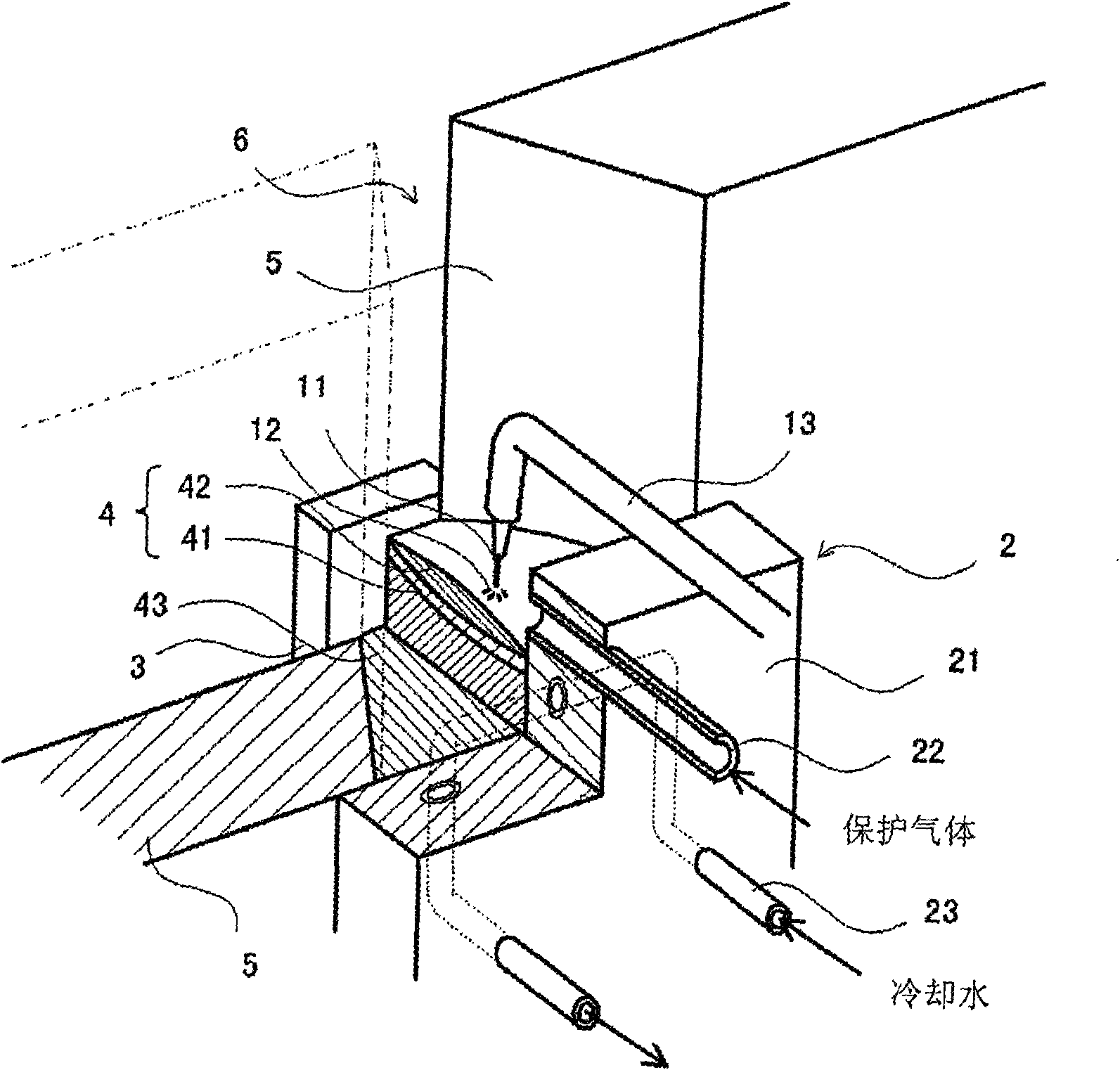

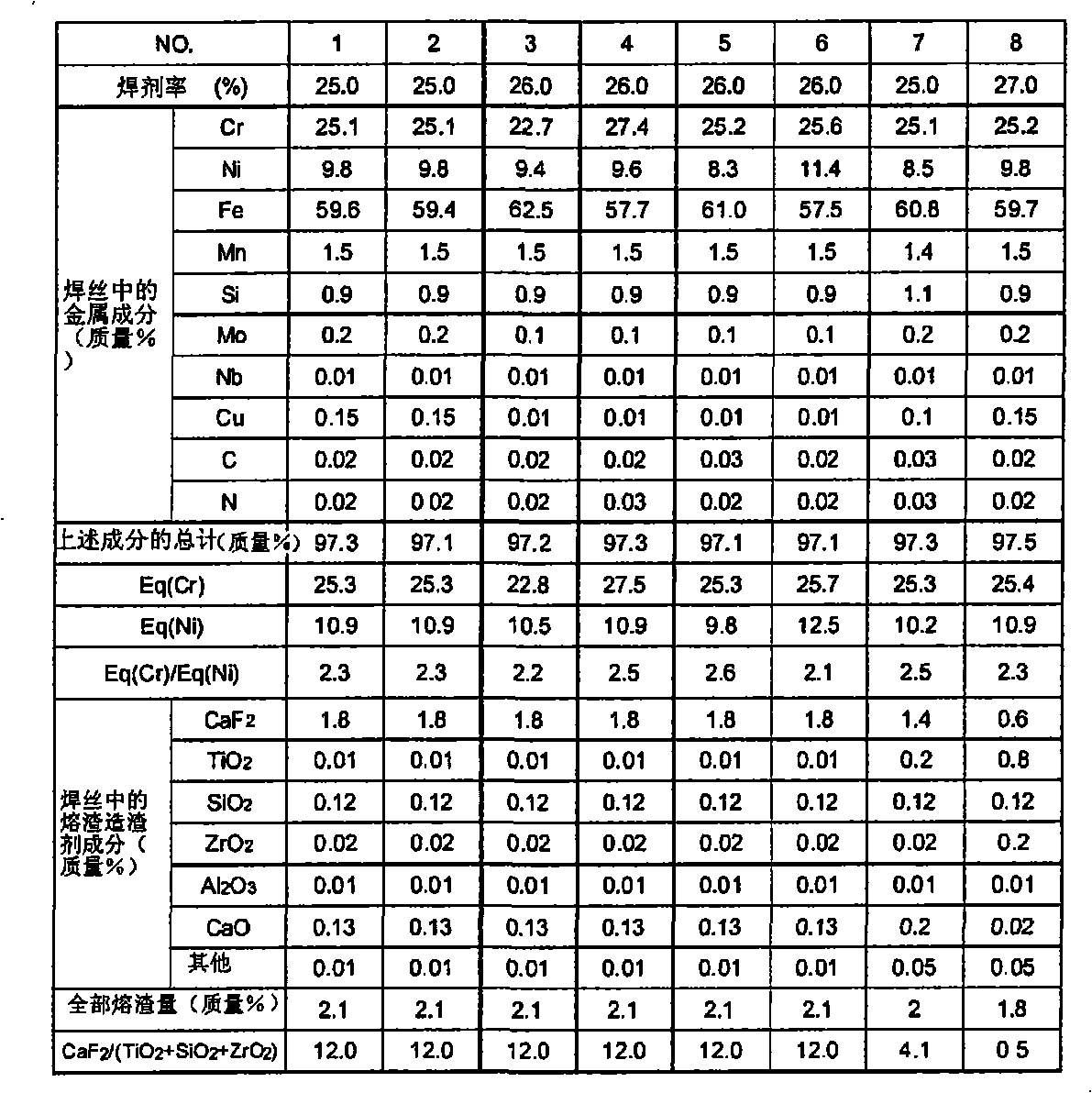

Flux-cored wire for stainless steel

InactiveCN101596655AExcellent mechanical propertiesReduce toughnessArc welding apparatusWelding/cutting media/materialsSheet steelHigh intensity

The present invention relates to a flux-cored wire for stainless steel, which is characterized by filling welding flux into an outer skin composed of stainless steel, wherein relative to the total mass of the welding flux, the welding flux comprises 22-28 wt% of Cr, 8-12 wt% of Ni, and 55-70 wt% of Fe, the content of C is less than 6 wt%, the content of N is less than 5 wt%, when setting the content of Cr as [Cr], the content Mo as [Mo], the content of Ni as [Ni], the content C as [c], and the content of N as [N], the ratio Eq(Cr) / Eq(Ni) between the equivalent of Cr Eq(Cr) and the equivalent of Ni Eq(Ni) is 2.0 to 2.6, which is calculated by following formula. Eq(Cr)= [Cr] + [Mo], Eq (Ni) = [Ni] + 35 X [C] + 20 X [N]. Incomplete fusion and under cut can not occur, even if when welding very thick stainless steel plate according to the composing, thereby high toughness welding metal can be obtained under high intensity and very low temperature.

Owner:KOBE STEEL LTD

Supporting hanger for grooved cable bridge and preparation process of supporting hanger

ActiveCN104862608AHigh elastic limitIncrease yield pointSolid state diffusion coatingCable trayElectric cables

The invention discloses a supporting hanger for a grooved cable bridge. The supporting hanger comprises the following constituents: C, Cr, B, Ni, N, Mo, Cu, Al, V, W, Si, Mn, Nb, Ti, S, P, and the balance of Fe and inevitable impurities. The invention further provides a preparation process of the supporting hanger for the grooved cable bridge. The preparation process is simple and feasible, low in manufacture cost and pollution-free in the manufacture process, and the prepared supporting hanger is abrasion-proof, corrosion resistant, high in strength and long in service life.

Owner:KINGSHORE NEW RESOURCES ELECTRIC JIANGSU

Heat treatment technology for stainless steel workpieces

The invention provides a heat treatment technology for stainless steel workpieces. The heat treatment technology comprises the following steps: quenching, heating a stainless steel workpiece to 930-960 DEG C, keeping the temperature for 2.5-3.5 h, oil-cooling the stainless steel workpiece, and taking out the stainless steel workpiece when surface temperature of the stainless steel workpiece is less than or equal to 110 DEG C; carrying out medium-temperature tempering, putting the quenched stainless steel workpiece into a heating furnace and heating to 400-450 DEG C, keeping the temperature for 8-10 h, taking out the stainless steel workpiece and air-cooling the workpiece to room temperature. According to the stainless steel heat-treatment technology, oil quenching is carried out after heating so as to reduce stress generated during the cooling and avoid deformation and simultaneously enhance surface hardness of the stainless steel workpiece. Through medium-temperature tempering, a tempered troostite is obtained, and high elasticity and yield point and proper toughness are achieved.

Owner:宁波市鄞州兴达旅游用品厂

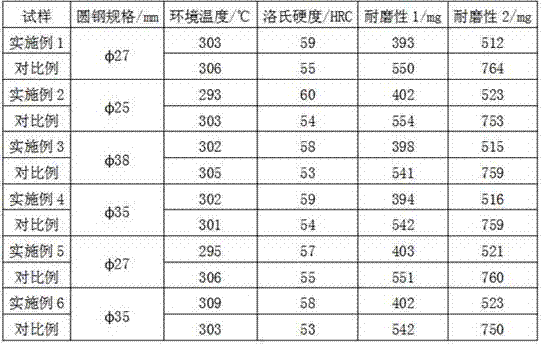

Steel for heavy-duty loader tire protecting chain and production method thereof

ActiveCN106967924AIncrease yield pointHigh tensile strengthTemperature control deviceDecompositionHeavy duty

The invention discloses steel for a heavy-duty loader tire protecting chain and a production method thereof. The steel is composed of, by mass, 0.35-0.42% of C, 0.70-1.10% of Si, 0.85-1.20% of Mn, 0.035% P or less, 0.035% of S or less, 0.40-0.60% of Cr, 0.008-0.015% of Tal and the balance Fe and inevitable impurities. The protecting chain utilizes Si element to significantly improve the steel yield point, tensile strength, the quenching temperature, the hardenability, the corrosion resistance and antioxidant capacity through combining with Cr element; Mn element is utilized to improve the hardenability and refine a pearlite; Cr element is utilized to slow down the decomposition speed of an austenite, improve the hardenability, promote formation of a passive film on the surface of steel and improve the corrosion resistance of the steel; and Al element is utilized to reduce the sensitivity of the steel to a gap, refine the natural steel grain and increase the temperature of grain coarsening. According to the steel for the heavy-duty loader tire protecting chain and the production method thereof, the Rockwell hardness reaches to 55 or more, wear resistance is good, a converter and continuous casting production can be used, adding of precious metal elements is not needed, and cost is low.

Owner:河北张宣高科科技有限公司

High-strength impact-resistance type steel used for shelf beam and welding technology thereof

InactiveCN104762558ALow wear resistanceGuaranteed flexibilitySuperimposed coating processElectroplatingImpurity

The invention discloses a high-strength impact-resistance type steel used for shelf beam, which comprises the following chemical components by weight percentage: 0.13-0.28% of C, 0.20-0.30% of Si, 0.20-0.46% of Mn, 0.85-0.95% of Cr, 0.28-0.32% of Ti, 0.16-0.22% of Mo, 0.24-0.36% of Nb, 0.05-0.07% of Cu, 0.18-0.36% of V, 0.59-0.79% of Al, 0.25-0.32% of rare earth trace element and the balance of Fe and impurity; the rare earth trace element comprises the following chemical components by mass percentage: 2-4% of Nd, 4-8% of Ce, 3-5% of Er, 2-6% of Pr, 1-4% of Pm, 0-5% of Dy, and the balance of La; the total content of impurity is less than or equal to 0.2, wherein, P is less than or equal to 0.005%, S is less than or equal to 0.007%, H is less than or equal to 0.004%, N is less than or equal to 0.006%, and O is less than or equal to 45ppm. The steel processing technology comprises the following steps: feeding, electroplating, drawing, annealing, insulating, pickling, drying and warehousing. The invention also designs a processing technology of the high-strength impact-resistance type steel used for shelf beam. The high-strength impact-resistance type steel used for shelf beam can obviously increase the wear-resistant compact-resistant capability of the steel, and has the advantages of simple operation technology, energy saving and environmental protection.

Owner:SUZHOU KESHENG STORAGE & LOGISTICS EQUIP

Explosion-proof type fixed ammonia gas detection probe and manufacturing method thereof

InactiveCN105039787AHigh elastic limitIncrease yield pointMaterial analysisRare-earth elementPhysical chemistry

The invention discloses an explosion-proof type fixed ammonia gas detection probe used on an ammonia gas detector. The explosion-proof type fixed ammonia gas detection probe comprises a displayer and a probe tube extending out of the displayer. The probe tube comprises the following components of C, Mn, P, S, Mo, Ni, Cu, Si, Ti, Cr, Mn, Fe, Pb, Nb, V, rare earth elements and the balance Al. The rare earth elements comprise La, Y, Sc, Gd, Sm, Ho, Tb and the balance lanthanide. The invention further provides a manufacturing method for the explosion-proof type fixed ammonia gas detection probe. The manufacturing method is simple and easy to implement, manufacturing cost is low, pollutants cannot be generated in the manufacturing process, the corrosion resistance of the manufactured fixed ammonia gas detection probe is good, the explosion-proof performance is good, service life is prolonged, and cost is reduced.

Owner:JIANGSU JINDI ELECTRONICS TECH

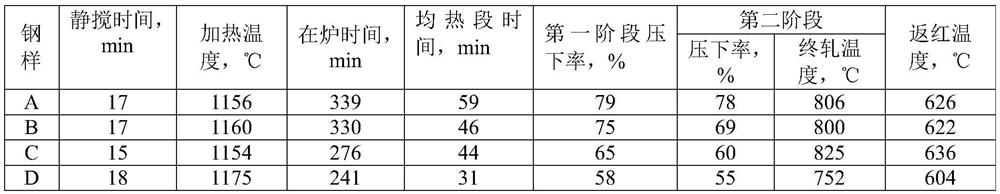

High-strength container plate with excellent low-temperature toughness and manufacturing method

The invention discloses a high-strength container plate with excellent low-temperature toughness and a manufacturing method, and relates to the technical field of iron and steel production. The high-strength container plate is prepared from the chemical composition in percentage by mass: 0.07% to 0.11% of C, 0.10% to 0.30% of Si, 1.30% to 1.60% of Mn, 0.40% to 0.80% of Ni, 0.05% to 0.12% of Mo, 0.02% to 0.05% of V, 0.02% to 0.05% of Alt, less than or equal to 0.008% of P, less than or equal to 0.002% of S and the balance of Fe and avoidable impurities. The material strength is upgraded by adding a small amount of alloy, the alloy cost is low, accurate control is easily achieved, the use temperature is lower, the strength is further significantly improved, and the material consumption of tank construction can be reduced.

Owner:NANJING IRON & STEEL CO LTD

Low-alloy heat-resistant high-strength steel and steel member and preparation methods thereof

The invention relates to low-alloy heat-resistant high-strength steel and a steel member and preparation methods thereof. The low-alloy heat-resistant high-strength steel comprises the following components in percentage by weight: 0.04-0.06% of C, 0.06-0.2% of Si, 0.06-0.35% of Mn, 1.3-1.5% of Cr, 0.35-0.45% of Pd, less than or equal to 0.009% of P, less than or equal to 0.006 of S, 0.2-0.4% of Ni, 0.01-0.08% of Cu, 0.3-0.4% of V, 0.1-0.2% of Nb, 0.2-0.5% of W, 0.005-0.02% of Ti and the balance of Fe and unavoidable impurities. The low-alloy heat-resistant high-strength steel member prepared from the low-alloy heat-resistant high-strength steel has the advantages of higher room temperature tensile strength, yield point and surface hardness.

Owner:上海闵轩钢结构工程有限公司

Combined photovoltaic module aluminium frame and production process thereof

PendingCN107196591AImprove performancePlay the effect of purifying castingsPhotovoltaicsPhotovoltaic energy generationEngineeringPhotovoltaics

The invention discloses a combined solar photovoltaic module frame. The combined solar photovoltaic module frame comprises a main body frame; the main body frame is composed of a long frame, a short frame and a U-shaped fixing block; the long frame and the short frame are matched; the short frame is composed of a first concave profile, fixing edges and a first connection block; the fixing edges are arranged at two ends of the first concave profile; the first connection block is formed by extension from one side of the first concave profile; a first groove and a glue injecting groove are also arranged at the notch of the first concave profile; locating holes are also arranged at two ends of the first concave profile; a fixing block is also arranged on the fixing edge; the long frame mainly comprises a second concave profile; a second groove is arranged at the notch of the second concave profile; extension plates extend from two ends of the second concave profile; a locating column is arranged on the extension plate; and a fixing hole is also formed on the side surface of the extension plate. The invention further designs a production process of the combined solar photovoltaic module frame. The aluminium frame is simple in structure, good in protection performance, low in cost and convenient to disassemble and install; furthermore, the aluminium frame can be individually used; and furthermore, multiple aluminium frames can be used in a combined manner.

Owner:镇江神飞新能源科技有限公司

Production method for smelting F55 dual-phase steel in intermediate frequency furnace

The invention provides a production method for smelting F55 dual-phase steel in an intermediate frequency furnace. The production method comprises the following steps that S1, molten steel is prepared in the intermediate frequency furnace according to the following ingredients in percentage by mass: less than or equal to 0.03% of C, less than or equal to 1.00% of Si, less than or equal to 1.00% of Mn, less than or equal to 0.02% of P, less than or equal to 0.015% of S, 24.0%-26.0% of Cr, 6.0%-8.0% of Ni, 3.0%-4.0% of Mo, 0.2%-0.3% of N and the balance of Fe; S2, abottom slag accounting for 2% of the weight of the molten steel is added into the intermediate frequency furnace, and melting is conducted; S3, after melting down, a Si-Ca wire is added for deoxidation; S4, slagging off is conducted after adding Si-Ca wires for 10 minutes, and high-aluminum refractory brick fragments and CaF2 are added to make new slag; S5, a deoxidizing agent is added into the slag layer in batches for first diffusion deoxidation; S6, components in front of the furnace are sampled and analyzed, FeCrNi alloy and alloy elements of Si, Mn, Mo and N are supplemented, and then diffusion deoxidation for the second time is conducted; and S7, the slag amount is adjusted, and tapping is conducted after white slag is kept for 15 minutes. Compared with the prior art, the oxygen content and the inclusion content in the intermediat requency smelting duplex stainless steel are reduced through reasonable intermediate frequency smelting burdening, deoxidation and slagging processes.

Owner:JIANGXI BAOSHUNCHANG SPECIAL ALLOY CO LTD

Novel automobile body structural member die-casting die steel and preparation process thereof

InactiveCN110241358AImprove hardenabilityImprove red hardnessProcess efficiency improvementThermal fatigueDie casting

The invention provides novel automobile body structural member die-casting die steel and a preparation process thereof. The die steel comprises the following components of, by mass, 0.25%-0.35% of C, 0.20%-0.40% of Si, 0.20%-0.60% of Mn, less than or equal to 0.002% of P, less than or equal to 0.001% of S, 7%-9% of Cr, 2.5%-3.5% of Mo, 0.30%-0.50% of V, 0.40%-0.60% of W, 0.10%-0.30% of Nb, 0.005%-0.10% of N, 0.05%-0.20% of Ti and the balance Fe and inevitable impurities. Therefore, the novel automobile body structural member die-casting die steel has good hardenability, wear resistance and thermal fatigue resistance.

Owner:NINGBO HELI TECH CO LTD

Method for preparing foamed aluminum composite material

Owner:HEBEI UNIV OF TECH

Machining technology of cold rolled alloy flat steel

The invention discloses a machining technology of cold rolled alloy flat steel. The machining technology of cold rolled alloy flat steel comprises the process steps of heat treatment, shot blasting, cold rolling, phosphorus saponification treatment, cold drawing, secondary heat treatment, secondary cold drawing, packaging and the like, wherein the carbon content of a raw material is 1.5-2.3%; thecold rolled alloy flat steel has high forming speed and high yield, does not damage a coating, and can be made into various cross-sectional forms to meet the requirements of using conditions; and coldrolling can cause large plastic deformation of the steel, so that the yield point of the steel is improved.

Owner:黄石市龙飞精密金属加工有限公司

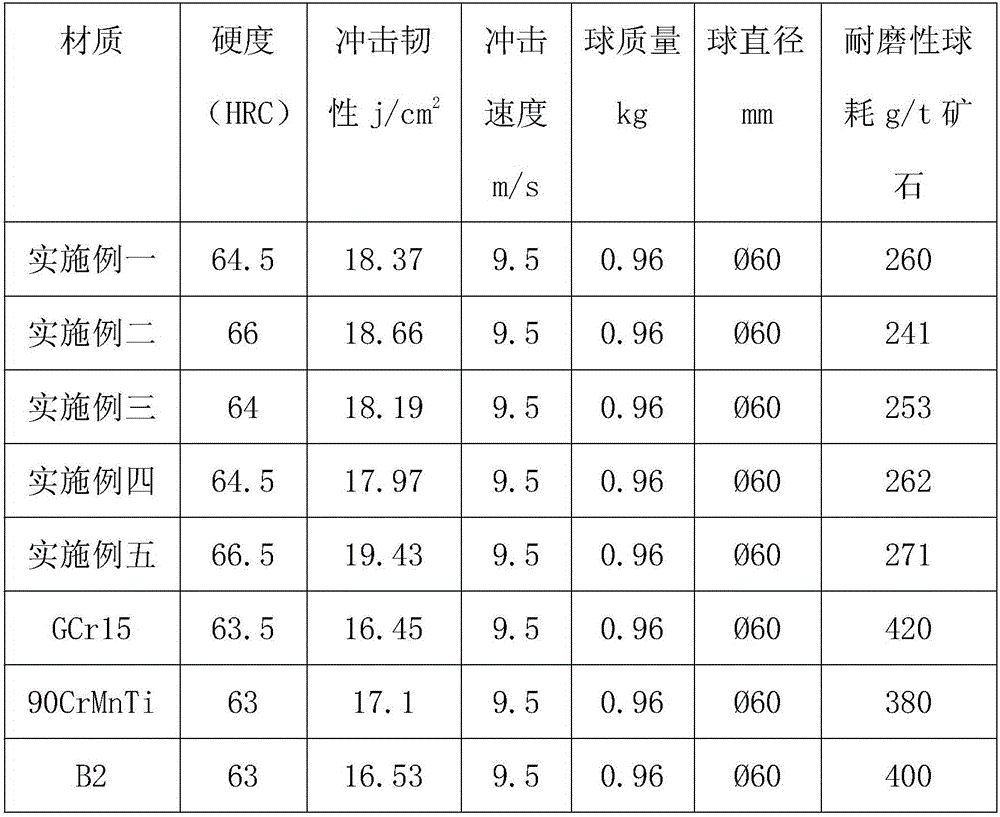

Steel for high-strength wear-resisting type ball grinder steel balls and preparation method thereof

The invention discloses steel for high-strength wear-resisting type ball grinder steel balls. The steel comprises, by weight, 0.9%-1.0% of C, 0.2%-0.4% of Si, 0.8%-1.2% of Mn, 1.0%-1.3% of Cr, 0.15%-0.23% of W, 0.04%-0.10% of Ti, 0-0.03% of P, 0-0.03% of S, and the balance Fe and a small number of impurities. The preparation method includes the steps that S1, smelting is performed, the W, Fe, Cr and Ti are smelted at first, and smelted molten steel is obtained; S2, refining is conducted, the smelted molten steel is transferred into a refining furnace, the C, Si, Mn, P and S and a refining agent are added for primary refining, and then the vacuum degassing and desulfuration procedures are carried out, so that refined liquid is obtained; and S3, the refined liquid is placed into a continuous casting machine, a casting blank is obtained by forming, cooling and cutting, and then the casting blank is subjected to rough rolling and finish rolling procedures so that the steel for the high-strength wear-resisting type ball grinder steel balls can be obtained. According to the steel, strength and hardness are high, the wear-resisting property is also high, and the service life is long; and purity is high, the degassing and desulfuration speed is also high, and the effect is good.

Owner:DENGFENG RONGTAI MACHINERY PARTS CO LTD

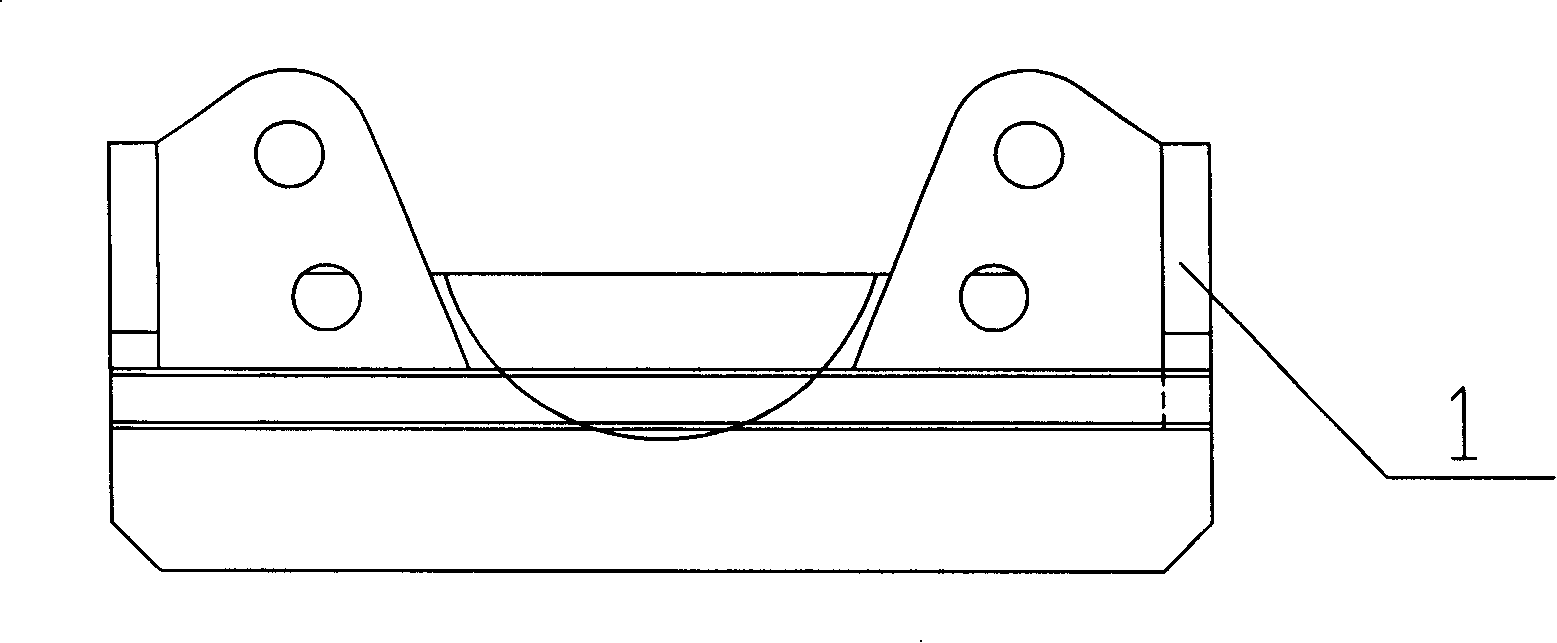

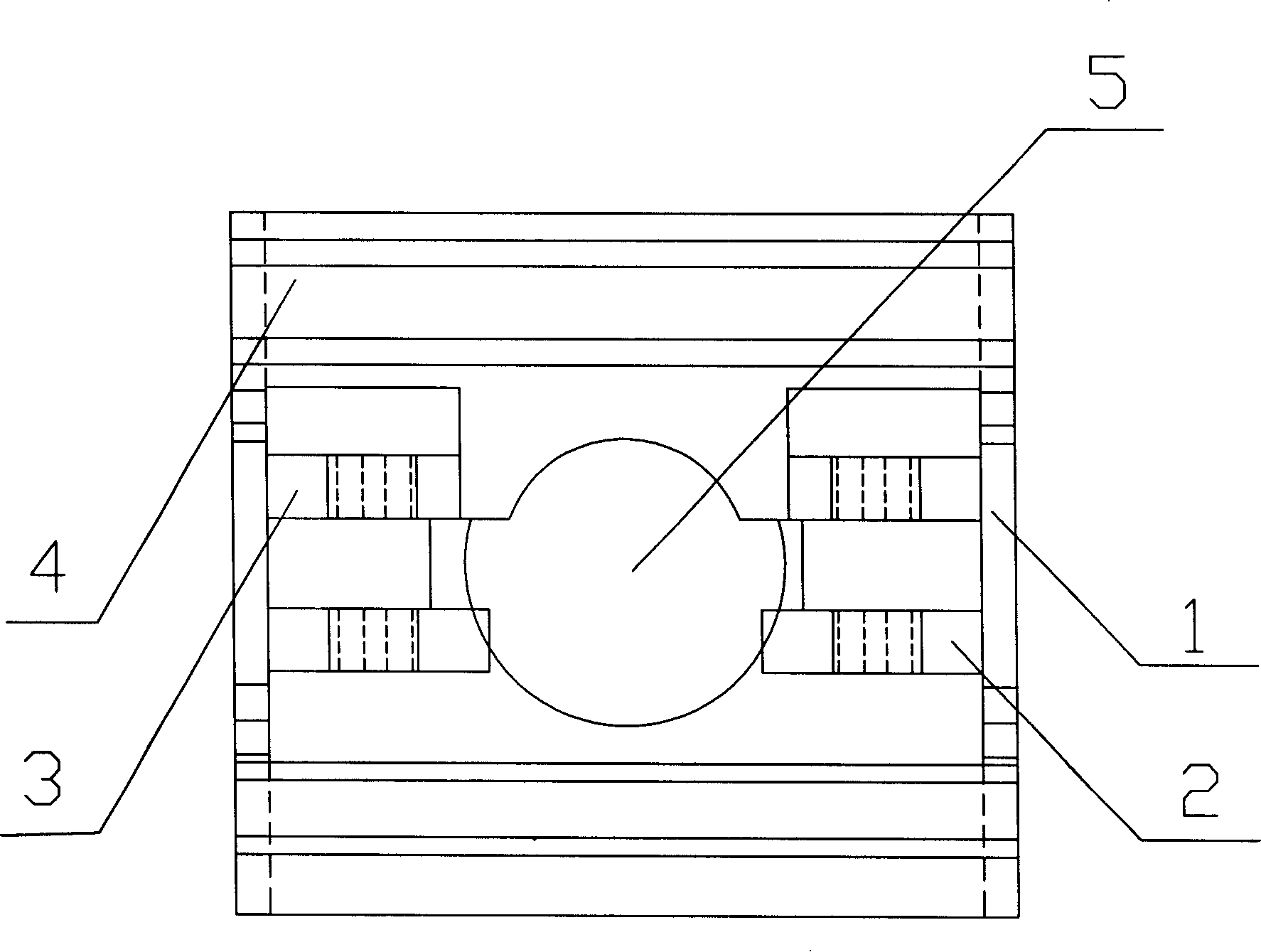

Hydraulic support cap

InactiveCN101196120AMeet the conditions of useImproved stress structureMine roof supportsProps/chocksEngineeringAlloy

The invention discloses a hydraulic support stud cap, which belongs to a major stressed component on a hydraulic support for mechanical coal mining and resolves the problems of insufficient strength, easy breaking and insufficient safety and reliability performance of the existing hydraulic support stud cap. The invention comprises a side plate, a stud cap body, an ear plate 1 and a ear plate 2 positioned on the stud cap body; a ball cave is positioned at the middle section of the stud cap body; the stud cap body is an integral component forged by high-intensity alloy structure steel; the ear plate 1, ear plate 2 and the side plate are respectively welded together with the stud cap body; the reinforcement section at the peripheral of the ball cave is configured with inclined surface. Therefore, with the advantages of compact structure and greater strength, the invention, which is able to promote the production efficiency, enhance the safety performance, prolong the service life and better satisfy the usage requirement for hydraulic support, can be applied to a plurality of hydraulic support.

Owner:四川航天神坤装备有限公司

Tube shell type slide oil fresh water cooler for ship and manufacturing technology of tube shell type slide oil fresh water cooler

The invention discloses a tube shell type slide oil fresh water cooler for a ship. The tube shell type slide oil fresh water cooler comprises, by mass percentage, 0.18% to 0.20% of C, 0.84% to 0.88% of Mn, 0.13% to 0.17% of Si, 0.002% to 0.003% of P, 0.001% to 0.0015% of S, 0.09% to 0.11% of Nb, 0.02% to 0.04% of W, 0.21% to 0.23% of Ti, 0.45% to 0.65% of Al, 0.96% to 0.98% of Cu, 0.75% to 0.79% of Cr, 0.06% to 0.08% of Mo, 0.71% to 0.73% of rare earth elements, and the balanced Fe and inevitable impurities. The invention further discloses the tube shell type slide oil fresh water cooler for the ship and a manufacturing method of the tube shell type slide oil fresh water cooler. The tube shell type slide oil fresh water cooler is resistant to high temperature and acid and alkali corrosion, not prone to rusting and aging, and long in service life.

Owner:KINGSHORE NEW RESOURCES ELECTRIC JIANGSU

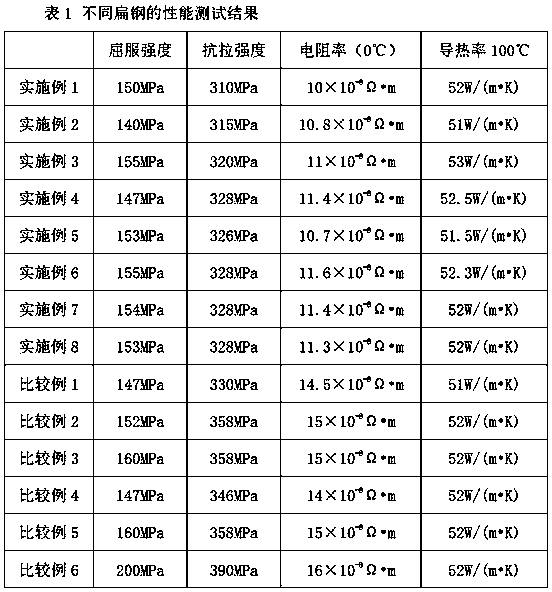

Low-cost high-conductivity electrode flat steel and smelting method thereof

The invention belongs to the field of electrode flat steel for aluminum electrolysis industry, and discloses low-cost high-conductivity electrode flat steel and a smelting method thereof. The low-costhigh-conductivity electrode flat steel contains, by weight: less than or equal 0. 005% of C, less than or equal 0.05% of Si, less than or equal 0.15% of Mn, less than or equal 0.02% of P, less than or equal 0.01% of S, and the balance Fe. The smelting method comprises the following steps: converter smelting, LF refining, RH refining of molten steel, and rolling forming. The electrode flat steel has lower cost and higher conductivity, and the resistivity delta is less than or equal to 12*10<-8> omega.m (20 DEG C). The low-cost and high-conductivity flat steel is used as a cathode material of aluminum electrolysis process, and can greatly save electric energy in the production process, greatly reduce production cost of aluminum electrolysis, and achieve the optimum combination of low cost and high performance. The smelting method can accurately control content of each component in the flat steel, and reduce crystal defects under the premise of satisfying mechanical properties and processing performance; electric resistance is reduced to the greatest extent; and electrical conductivity is improved.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Impact-resisting high-strength alloy material for partition wall of bearing warehouse and processing technique of alloy material

The invention discloses an impact-resisting high-strength alloy material for a partition wall of a bearing warehouse. The alloy material comprises the following components in percentage by mass: 0.31-0.43 percent of C, 0.29-0.35 percent of Mn, 0.11-0.13 percent of Si, 0.15-0.21 percent of Nb, 0.01-0.03 percent of W, 0.18-0.36 percent of V, 0.54-0.56 percent of Ti, 0.031-0.043 percent of Y, 2.17-3.19 percent of Al, 0.08-0.12 percent of Cu, 0.28-0.32 percent of Ni, 0.18-0.22 percent of Nb, 0.85-0.95 percent of Cr, 0.17-0.25 percent of Mo, 0.25-0.32 percent of rare-earth trace elements and the balance of Fe and unavoidable impurities, wherein the total content of the impurities is smaller than or equal to 0.2%; the content of P is smaller than or equal to 0.004%; the content of S is smaller than or equal to 0.006%; the content of H is smaller than or equal to 0.004%; the content of N is smaller than or equal to 0.006%; the content of O is smaller than or equal to 35ppm; the mass percentage of chemical components of the rear-earth trace elements is as follows: 2-4 percent of Nd, 4-8 percent of Ce, 2-6 percent of Pr, 1-4 percent of Pm, 0-5 percent of Dy and the balance of La. The invention also discloses a processing technique of the impact-resisting high-strength alloy material for the partition wall of the bearing warehouse. The alloy material disclosed by the invention is high in strength, high in toughness, excellent in processability, resistant to high temperature, resistant to corrosion, unlikely to abrade and long in service life.

Owner:SUZHOU KESHENG STORAGE & LOGISTICS EQUIP

High-strength alloy material for goods shelf bearing gird and processing process for high-strength alloy material

The invention discloses a high-strength alloy material for a goods shelf bearing grid. The alloy material is prepared from the following components in percentage by mass: 0.21-0.23% of C, 0.19-0.25% of Mn, 0.11-0.13% of Si, 0.003-0.005% of P, 0.001-0.003% of S, 0.045-0.047% of Nb, 0.01-0.03% of W, 0.54-0.56% of Ti, 0.011-0.013% of Sr, 0.17-0.19% of Al, 0.08-0.12% of Cu, 0.08-0.12% of Nb, 0.85-0.95% of Cr, 0.07-0.13% of Mo, 0.08-0.10% of lanthanum, 0.05-0.07% of neodymium, 0.01-0.03% of cerium and the balance of Fe and inevitable impurities. The invention further discloses a processing process for the high-strength alloy material for the goods shelf bearing grid. The high-strength alloy material is high in product strength, strong in toughness, excellent in processing performance, high-temperature-resistant, corrosion-resistant, less in abrasion possibility and long in service life.

Owner:SUZHOU KESHENG STORAGE & LOGISTICS EQUIP

Cold drawing welded tube manufacture process for high-accuracy hydraulic oil cylinder

The invention discloses a cold drawing welded tube manufacture process for a high-accuracy hydraulic oil cylinder, which sequentially comprises the following steps of longitudinal shearing, roll bending molding, high frequency welding, welding joint treatment, online eddy current testing, sizing cutting, normalization, pinching, surface treatment, cold drawing, annealing, straightening, defect detection and cutting for measurement. The method is quick in processing molding, high in production volume, free of damage on surfaces in cold drawing and high in manufacture accuracy. After cold drawing, bearing capacity of a welded tube is improved by about 60%, and the welded tube is high in tensile strength and good in elongation rate. Follow-up gold processing amount is reduced, utilization rate of steel materials is improved, and manufacture cost is reduced. The cold drawing welded tube can be directly applied to manufacture of high-accuracy hydraulic oil cylinders.

Owner:MARCEGAGLIA CHINA

Corrosion-resisting and high-strength aluminum alloy outer cover material used for air purifier

The invention discloses a corrosion-resisting and high-strength aluminum alloy outer cover material used for an air purifier. The corrosion-resisting and high-strength aluminum alloy outer cover material is characterized by comprising the following raw materials including, by weight, 1.25-1.29 parts of silicon, 1.76-1.78 parts of zinc, 1.42-1.46 parts of magnesium, 0.56-0.58 part of germanium, 0.14-0.16 part of chromium, 0.66-0.68 part of iron, 3.58-3.78 parts of titanium, 1.06-1.08 parts of nickel, 0.87-0.89 part of antimony, 3.87-3.97 parts of a rare earth mixture and 45-50 parts of aluminum. The corrosion-resisting and high-strength aluminum outer cover material used for the air purifier is high in strength, good in corrosion resistance, small in mass, not likely to age and deform, not likely to change colors and resistant to corrosion. Meanwhile, the invention provides a preparing method for the corrosion-resisting and high-strength aluminum alloy outer cover material used for the air purifier, the material cost is low, raw materials are easy to obtain, the technology is simple, and high practical value and good application prospects are achieved.

Owner:合肥市淑芹美装饰工程有限公司

Oil-in-water type emulsions

InactiveCN1367652AExcellent mouth meltabilityImprove stabilityEdible oils/fats ingredientsFood shapingFlavorYolk

Oil-in-water type emulsions which are excellent in emulsion stability and working properties, show stable physical properties after whipping, have a strong flavor of yolk and exhibit high meltability in the mouth. These oil-in-water type emulsions show SFC of 60% or above at 10 DEG C and 20% or above at 20 DEG C, and contain from 25 to 75% by weight of SUS triglycerides in the fat phase and from 1 to 8% by weight of enzyme-treated yolk which preferably has a protein digestion ratio of from 15 to 40%.

Owner:FUJI OIL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com