Patents

Literature

390 results about "Al element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

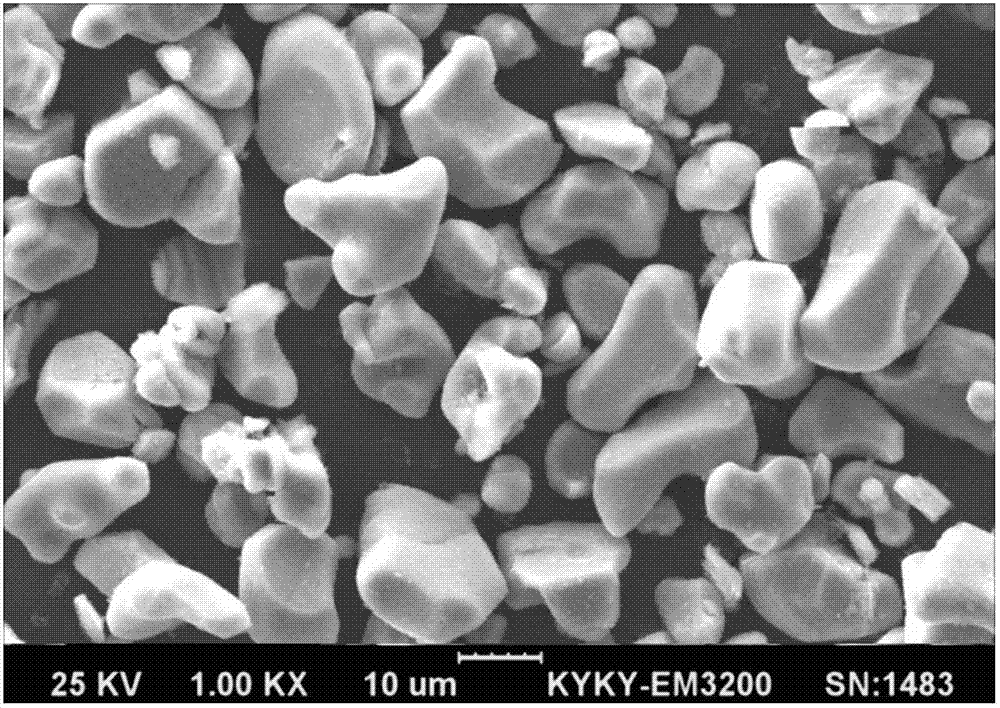

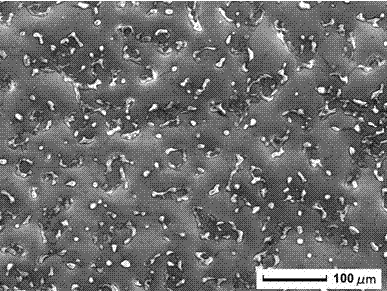

Preparation method of Co3O4 with large grain size and uniformly doped with aluminum

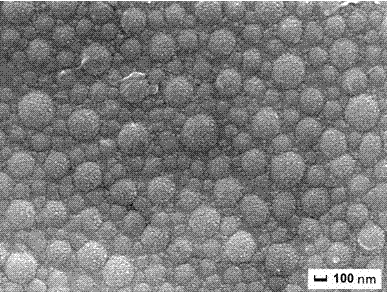

ActiveCN108011101AEvenly distributedUniform particle size distributionCell electrodesCobalt oxides/hydroxidesCobalt(II,III) oxideMicrometer

The invention relates to a preparation method of Co3O4 with large grain size and uniformly doped with aluminum. The invention provides the preparation method of the Co3O4 which is uniformly doped withaluminum and is large in grain size and uniform in particle distribution, and the obtained Co3O4 with the large grain size and uniformly doped with aluminum can completely conform to the requirementof preparation of 4.45V high-voltage lithium cobalt oxide. According to the method, the large-grain size and aluminum-doped cobalt carbonate is synthesized by a wet method, and the problems of difficulty in enlargement of cobalt hydroxide (or hydroxyl cobalt) system grain size and non-uniform particle distribution are solved; with the regard to the problem of uniform aluminum doping of a cobalt carbonate system, a parameter is set from principle, an aluminum compound is prevented from being independently separated out and gathered, the doped Al element can be uniformly distributed in the Co3O4, the grain size reaches 15 micrometers or above, and the particle distribution is uniform; and the lithium cobalt oxide prepared from the aluminum-doped Co3O4 has high specific capacity and excellentcycle property under 4.45V.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드

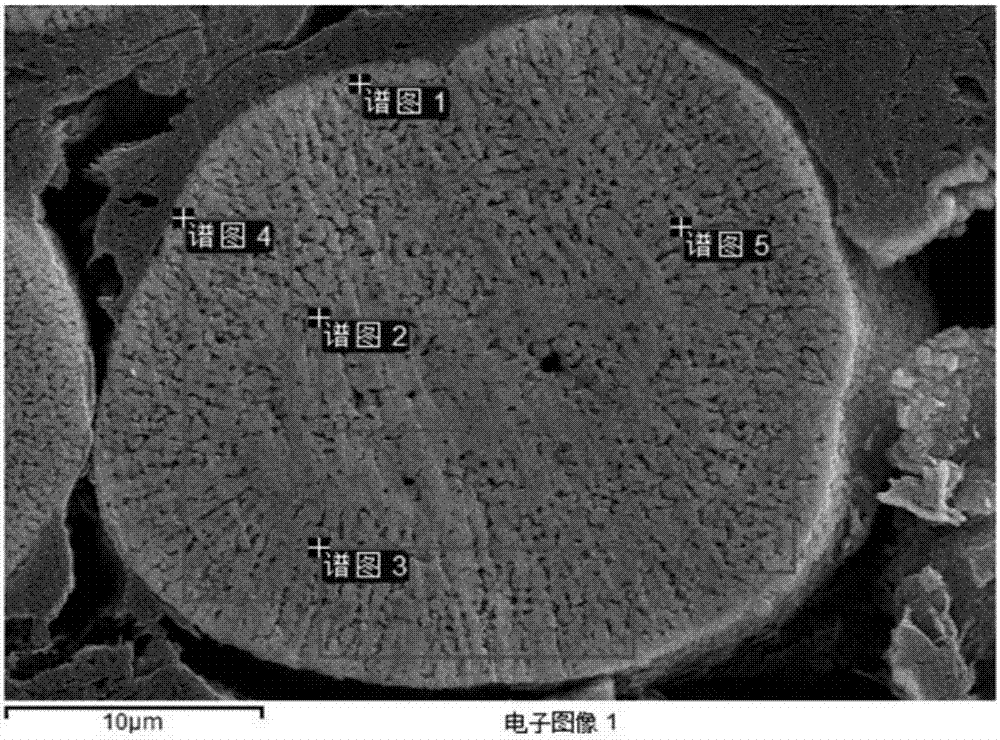

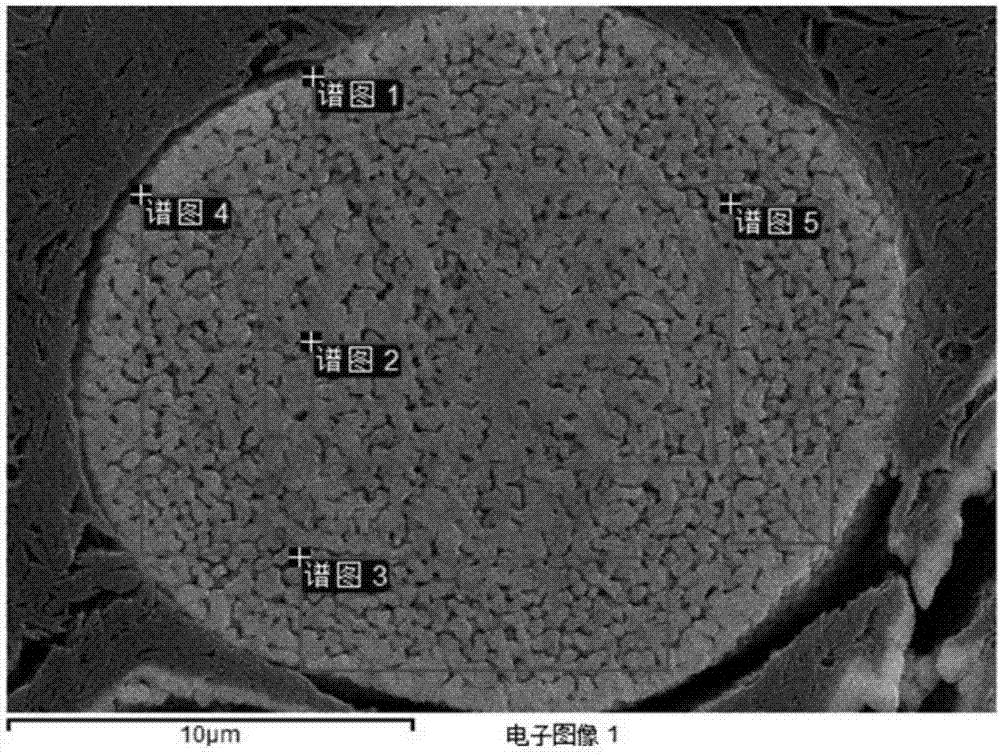

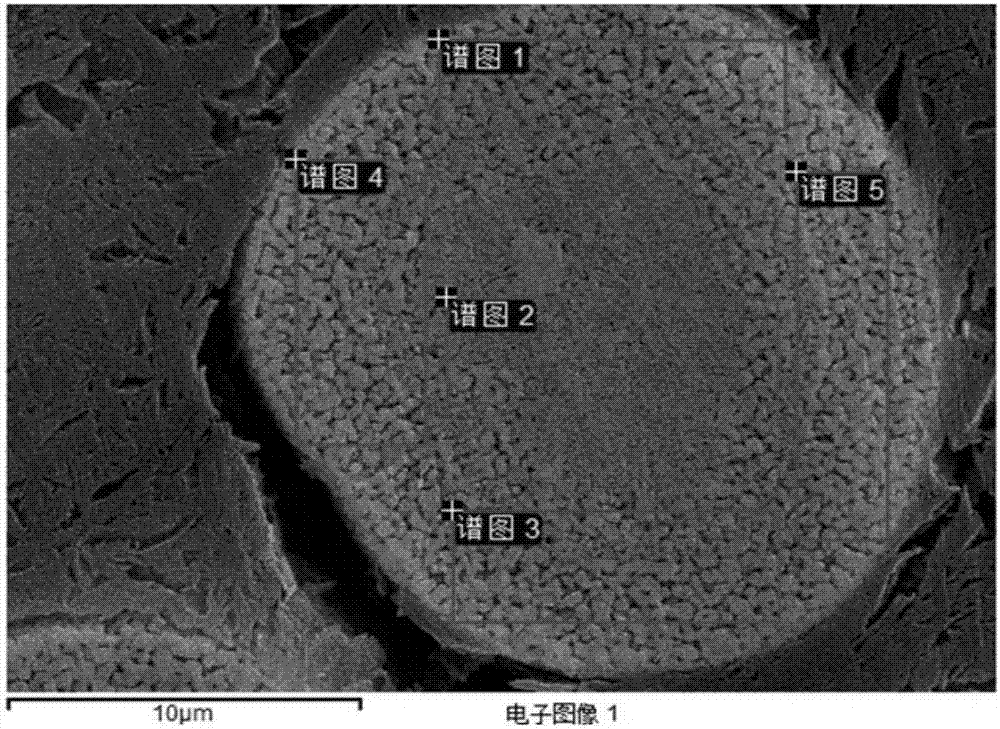

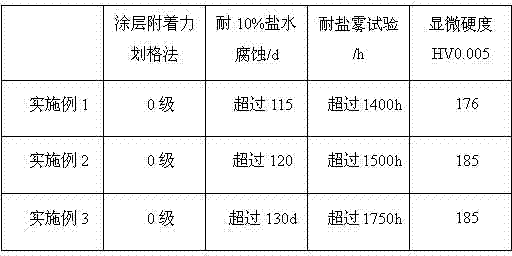

High-corrosion-resistant water soluble zinc aluminium multielement alloy-based nano anticorrosion paint as well as preparation method and application thereof

InactiveCN103242686AOvercome the Difficulty of ScatteringEvenly distributedPretreated surfacesAnti-corrosive paintsSurface-active agentsDefoaming Agents

The invention discloses a high-corrosion-resistant water soluble zinc aluminium multielement alloy-based nano anticorrosion paint as well as a preparation method and application thereof and belongs to the technical field of metal surface anticorrosion paints. The high-corrosion-resistant water soluble zinc aluminium multielement alloy-based nano anticorrosion paint comprises the following components in percentage by weight: 15-30wt% of Zn-Al-based multielement alloy powder, 0.5-2wt% of modified nano powder, 2.5-20wt% of methyl alcohol, 6-12wt% of sintering protective agent, 0.5-1.5wt% of titanate coupling agent, 1.8-3.6wt% of non-ionic surface active agent, 0.9-1.8wt% of corrosion inhibitor, 1-3wt% of adhesive force enhancer, 0.4-0.65wt% of thickener, 0.05-0.1wt% of defoaming agent and the balance of deionized water, wherein the Zn-Al-based multielement alloy powder is in a scale shape, the scale diameter is less than 20 micrometers, and length-diameter ratio is more than 30. The high-corrosion-resistant water soluble zinc aluminium multielement alloy-based nano anticorrosion paint is more uniform in Zn-Al element distribution in micro scale and has high corrosion resistance, wear resistance and erosion resistance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

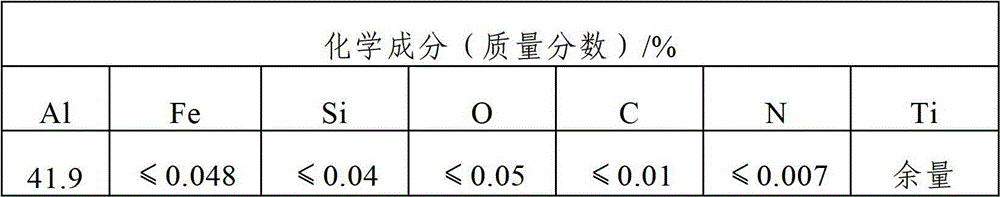

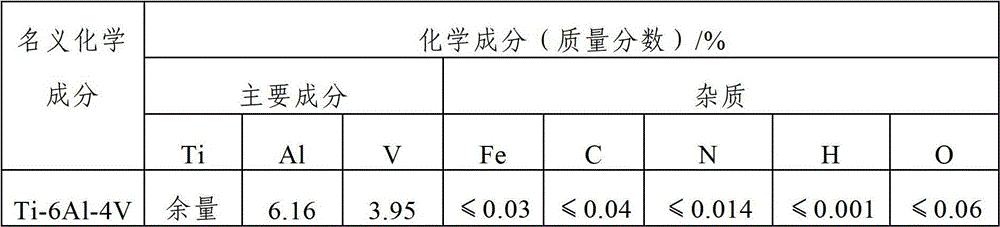

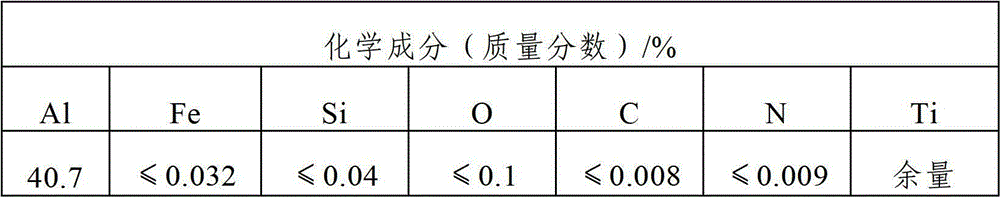

Method for preparing TC4 titanium alloy ingot casting through electron beam cold bed hearth smelting

The invention discloses a method for preparing TC4 titanium alloy ingot casting through electron beam cold bed hearth smelting. The method comprises steps as follows: 1, uniformly mixing sponge titanium and aluminum shot, pressing to obtain electrode slabs, and welding to obtain an electrode, then transferring into a vacuum consumable electro-arc furnace to smelt once to obtain Ti-Al intermediate alloy; 2, crushing the Ti-Al intermediate alloy to obtain Ti-Al intermediate alloy particles; and 3, uniformly mixing the sponge titanium, the Al-V intermediate alloy and the Ti-Al intermediate alloy particles, pressing to obtain electrode slabs, and splicing the electrode slabs to obtain the electrode, and then transferring into an electron beam cold bed hearth to smelt once to obtain the TC4 titanium alloy ingot casting. According to the method, the Ti-Al intermediate alloy is used for replacing the aluminum shot, so that volatilization of an Al element is reduced, utilization rates of raw materials are improved, and service efficiency of the electron beam cold bed hearth is improved; the method has stronger advantages of reducing processing cost of a titanium material and improving production efficiency, because the electron beam cold bed hearth is adopted for one-time smelting; and cleanliness of the titanium alloy ingot casting can be improved, so that a high-quality ingot casting can be obtained.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

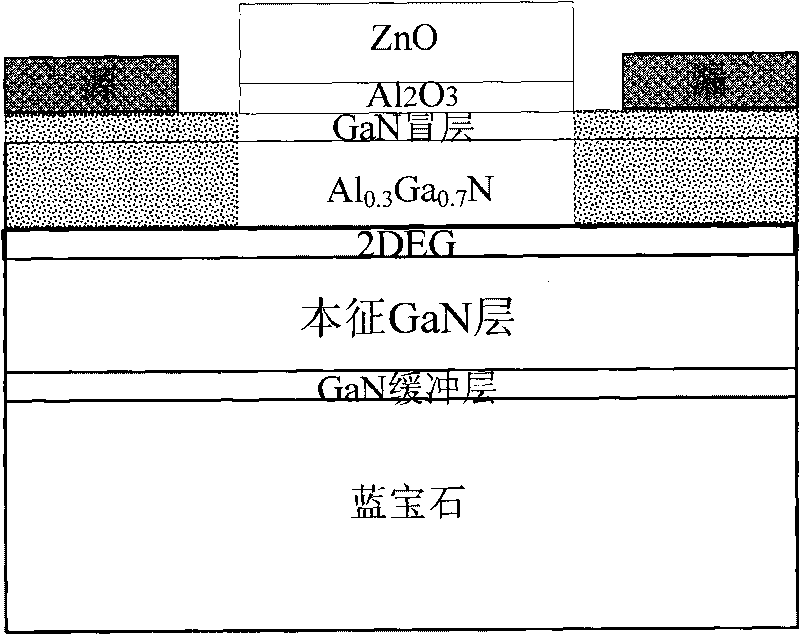

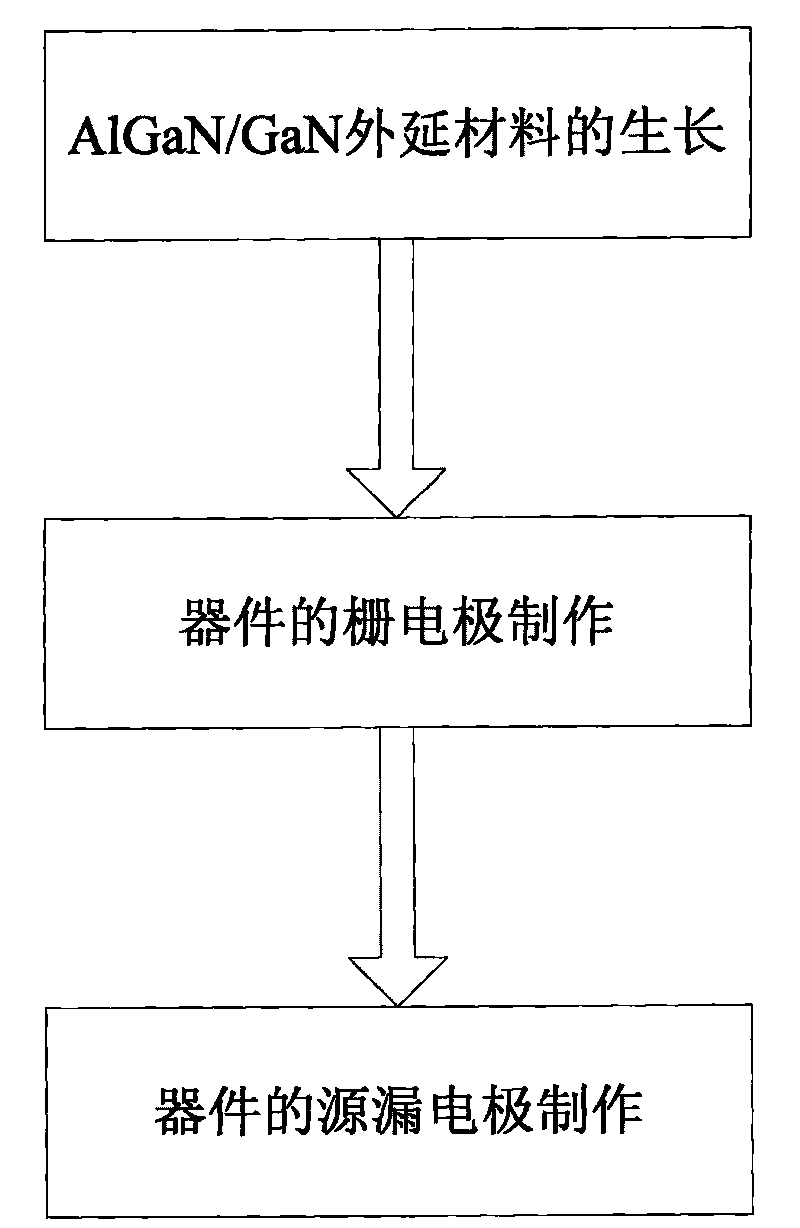

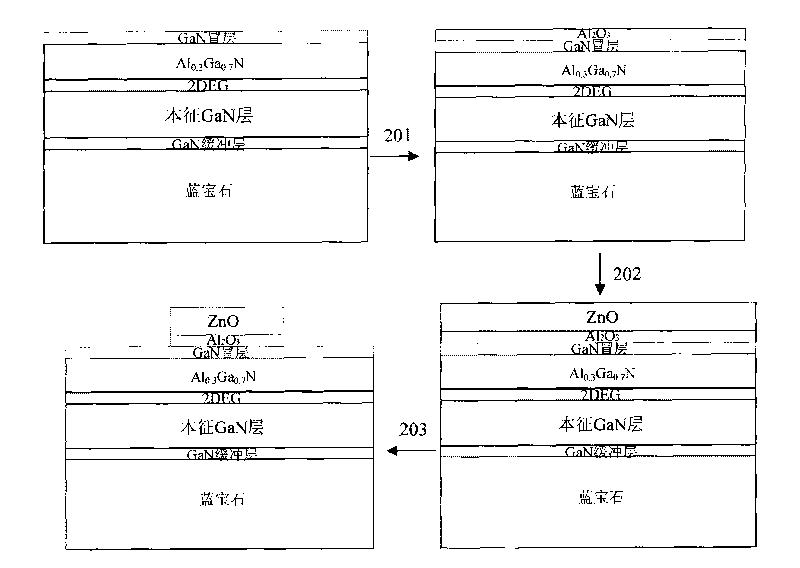

AlGaN/GaN insulated gate high electron mobility transistor (HEMT) and manufacturing method thereof

ActiveCN101710590AAchieve short channelImprove frequency characteristicsSemiconductor/solid-state device manufacturingSemiconductor devicesElectronAl element

The invention discloses an AlGaN / GaN insulated gate high electron mobility transistor (HEMT) device and a manufacturing method thereof, relating to the field of microelectronic technique and mainly solving the problems of low frequency and poor radiation resistance of the device. The device comprises a GaN buffer layer, an intrinsic GaN layer, an AlO.3GaO.7N layer, a GaN coating layer, a gate oxide layer, a gate electrode, a source electrode and a drain electrode, wherein Al2O3 is used as the gate oxide layer, and transparent ZnO is used as the gate electrode. The Al element is doped in the ZnO gate electrode, and the length of the ZnO gate electrode is equal to the distance between the source electrode and the drain electrode. The manufacturing method of the device sequentially comprises the steps of: firstly, carrying out epitaxial material growth, then manufacturing the Al2O3 gate oxide layer and the ZnO gate electrode, and finally, manufacturing the source electrode and the drain electrode at two sides of the ZnO gate electrode by using a self-aligned method. The device has the advantages of good frequency characteristics, good radiation resistance, simple processes, good repeatability and high reliability, thereby being used as an electronic component in a high frequency circuit or a high speed circuit.

Owner:XIAN CETC XIDIAN UNIV RADAR TECH COLLABORATIVE INNOVATION INST CO LTD

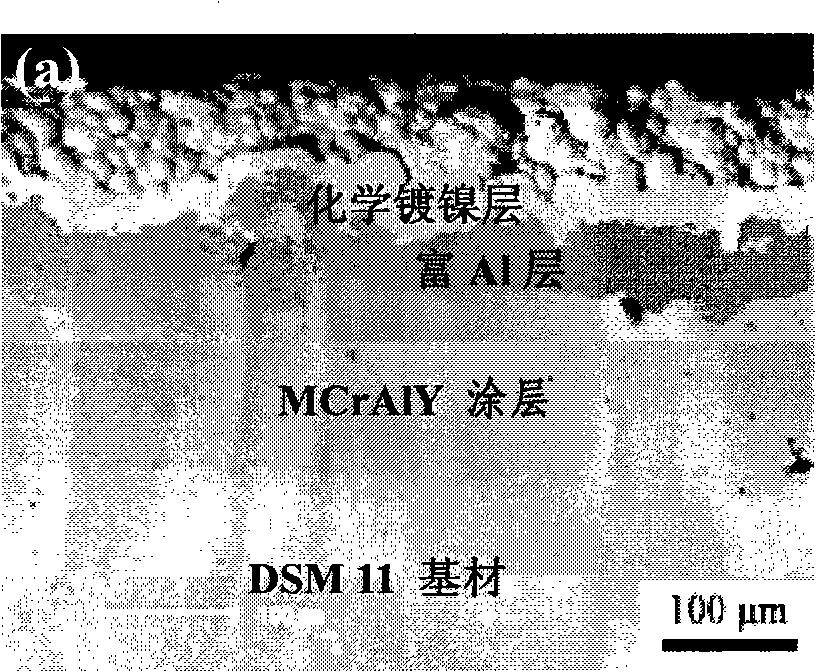

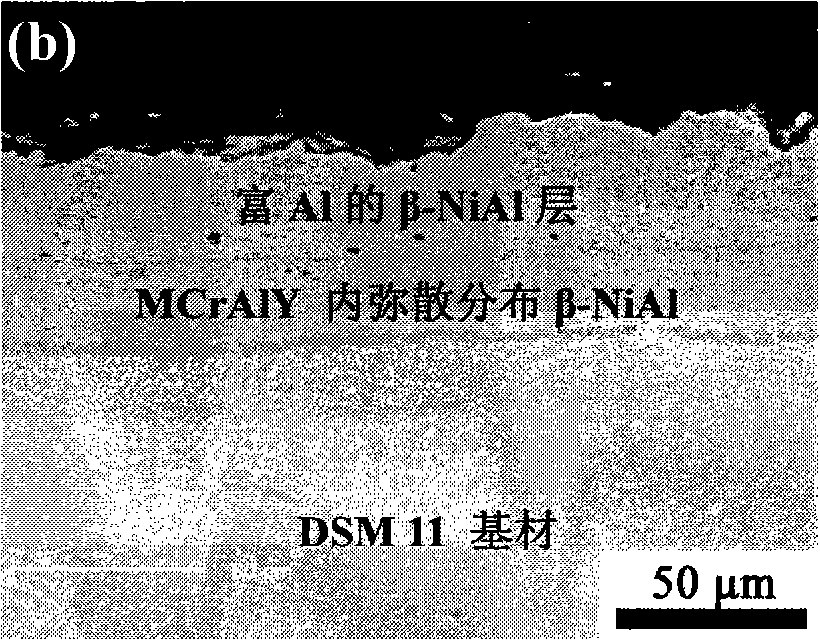

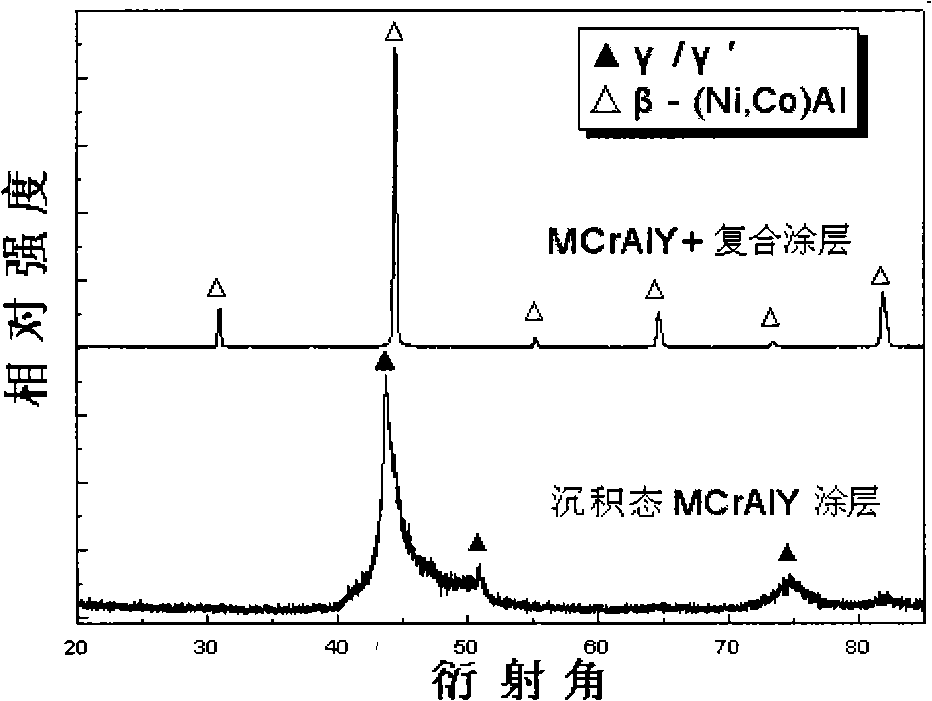

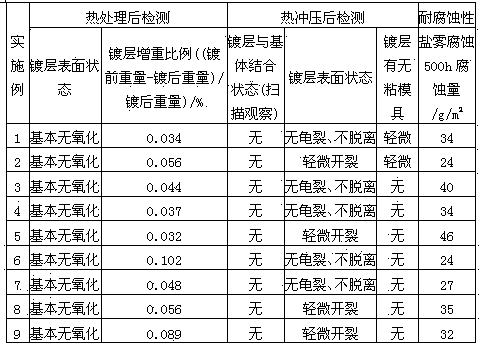

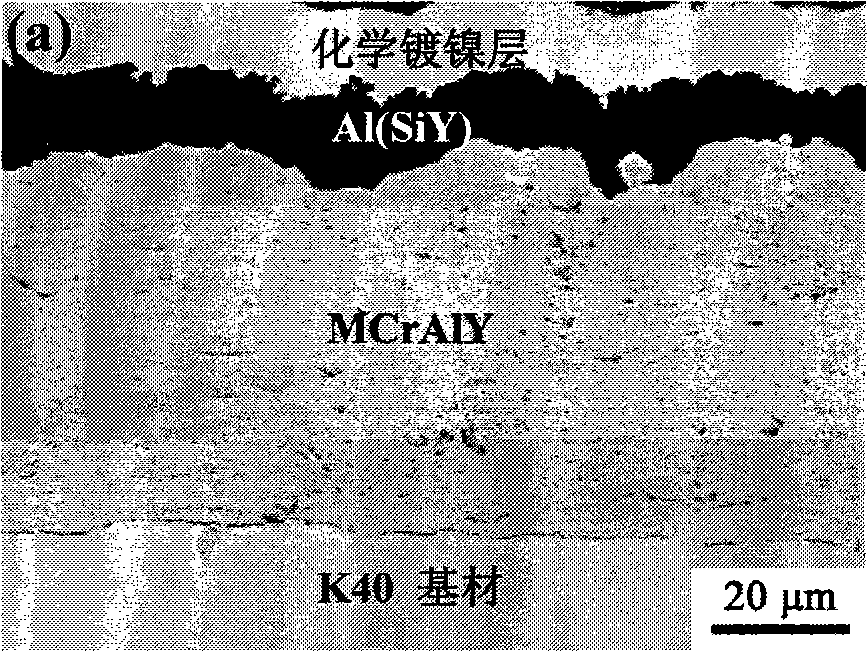

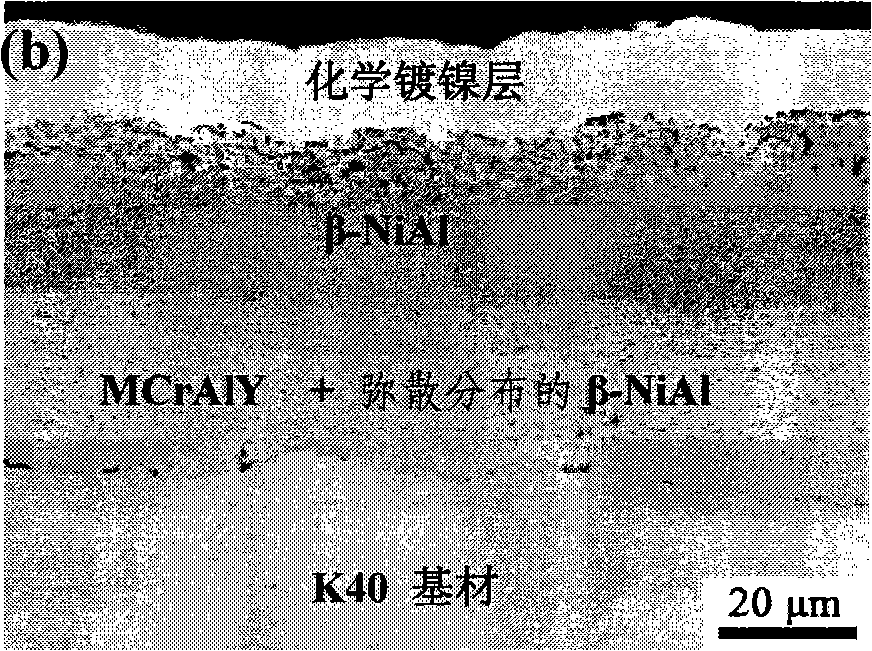

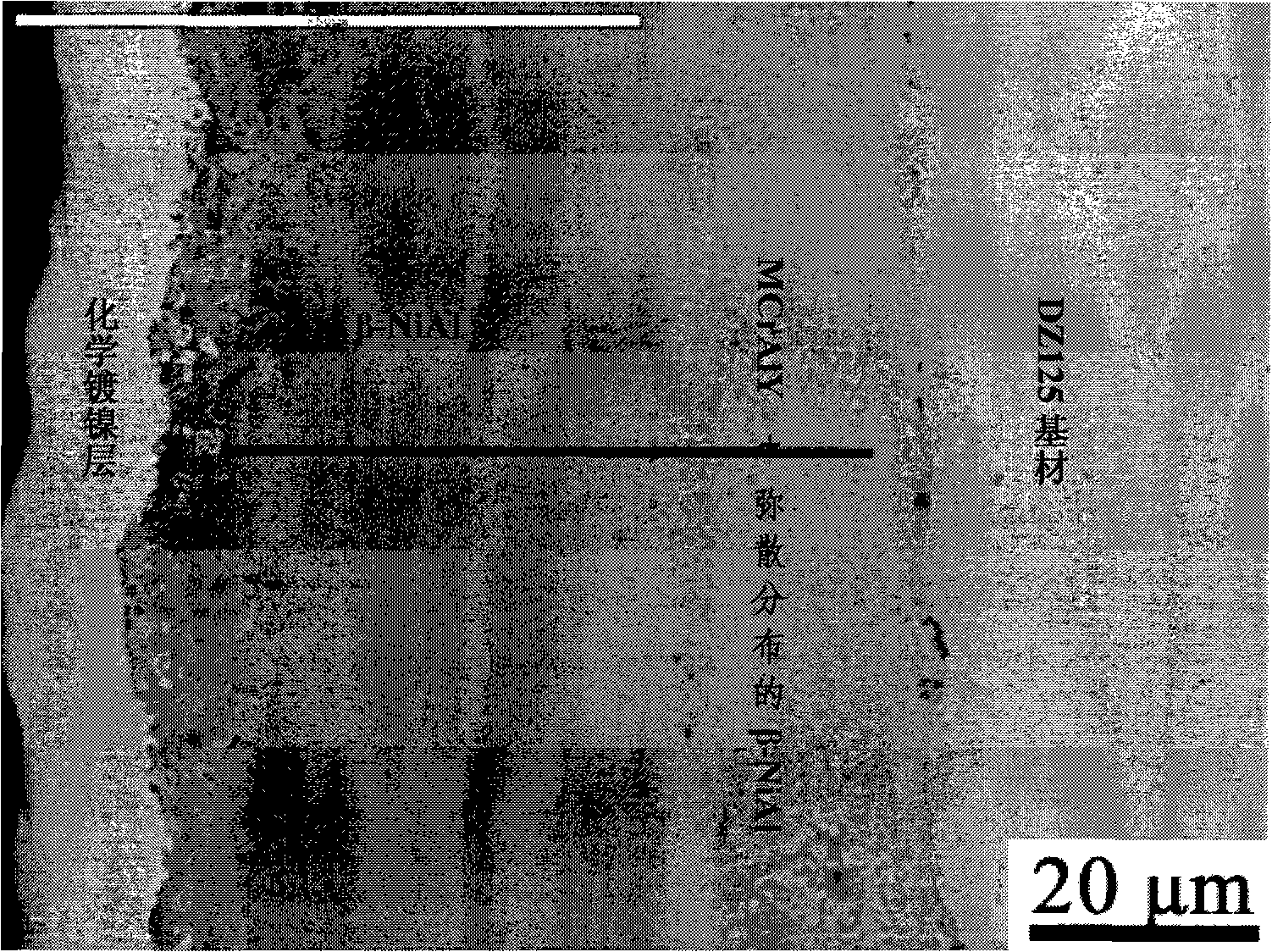

Ni-base superalloy complex gradient coating and preparation technique thereof

InactiveCN101310971ADoes not bring strippingImprove scoreLayered productsVacuum evaporation coatingSuperalloyDepth direction

The invention mainly relates to the coating technique, in particular to a gradient MCrAlY coating used for protecting high-temperature alloy and a preparation method thereof. The invention prepares an MCrAlY composite gradient coating by adopting the method combining the arc ion plating (AIP) and the diffusion aluminizing. The thickness of an aluminum-rich layer on the surface of the MCrAlY composite coating can be controlled by setting the aluminizing temperature and the period of heat preservation and the Al elements are distributed in a gradient way along the depth direction; in addition, the chemical vapor deposition method used for the aluminizing has the advantages of good uniformity on the aluminum-rich layer and being not affected by the size and shape of a sample. Since the method of direct diffusion is adopted without introducing a weak interface, the MCrAlY high-temperature protective coating can increase the content of Al memory phase to the utmost extent under the condition that the mechanical property of the coating is guaranteed, so as to improve the high-temperature oxidization resistance and the heat corrosion resistance of the coating, and can effectively prolong the service life of the coating. The MCrAlY composite gradient coating and the preparation method of the invention can be applied to the protection of Ni-based and Co-based high-temperature alloys.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

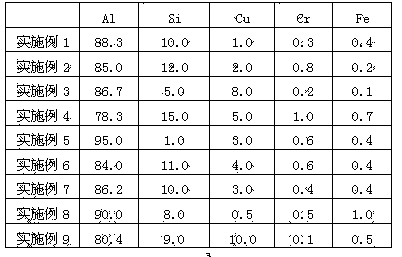

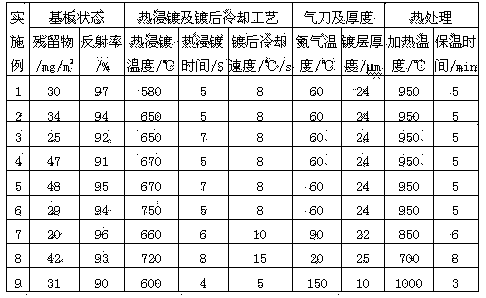

High-temperature oxidation resistant plating layer material and hot dipping method for hot stamping formed steel

ActiveCN104233149AImprove high temperature oxidation resistanceImprove corrosion resistanceHot-dipping/immersion processesHot stampingSheet steel

The invention discloses a high-temperature oxidation resistant plating layer material and a hot dipping method for hot stamping formed steel. A hot stamping formed steel plate enters a plating solution for hot dipping and then is subjected to cooling and heat treatment so that a hot dipping steel plate can be obtained, wherein the plating solution comprises the following components in percentage by mass: 1.0%-15.0% of Si, 0.5%-10.0% of Cu, 0.1%-1.0% of Cr, less than or equal to 1.0% of Fe and the balance of Al and inevitable impurities. According to the method, the Cu element and Al element which are contained in a plating layer form a high-melting point intermetallic compound in a cooling process after the hot dipping, and Cr is gathered on the surface of the plating layer to form a compact oxidation film, so that the high-temperature oxidation resistant property of the plating layer is greatly enhanced; the Cu element is enriched on the surface of the plating layer, so that the corrosion-resisting property of the plating layer is greatly enhanced. The high-temperature oxidation resistance and the high-temperature corrosion resistance of the plating layer are enhanced by utilizing the intermetallic compounds formed among Al, Si, Cr, Cu and Fe; and the obtained plating layer has the advantages of reasonability in structure, tight combination with a substrate and good high-temperature oxidation resistance and corrosion-resisting property.

Owner:HEBEI IRON AND STEEL

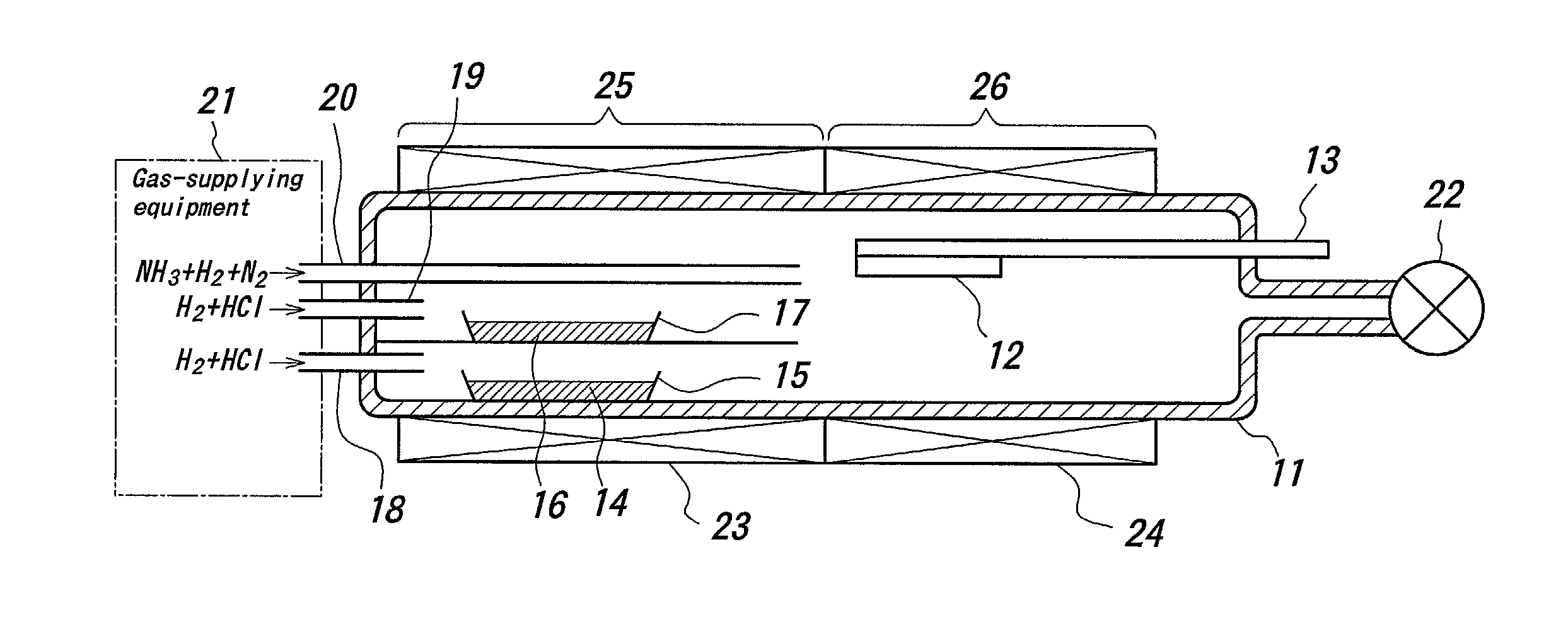

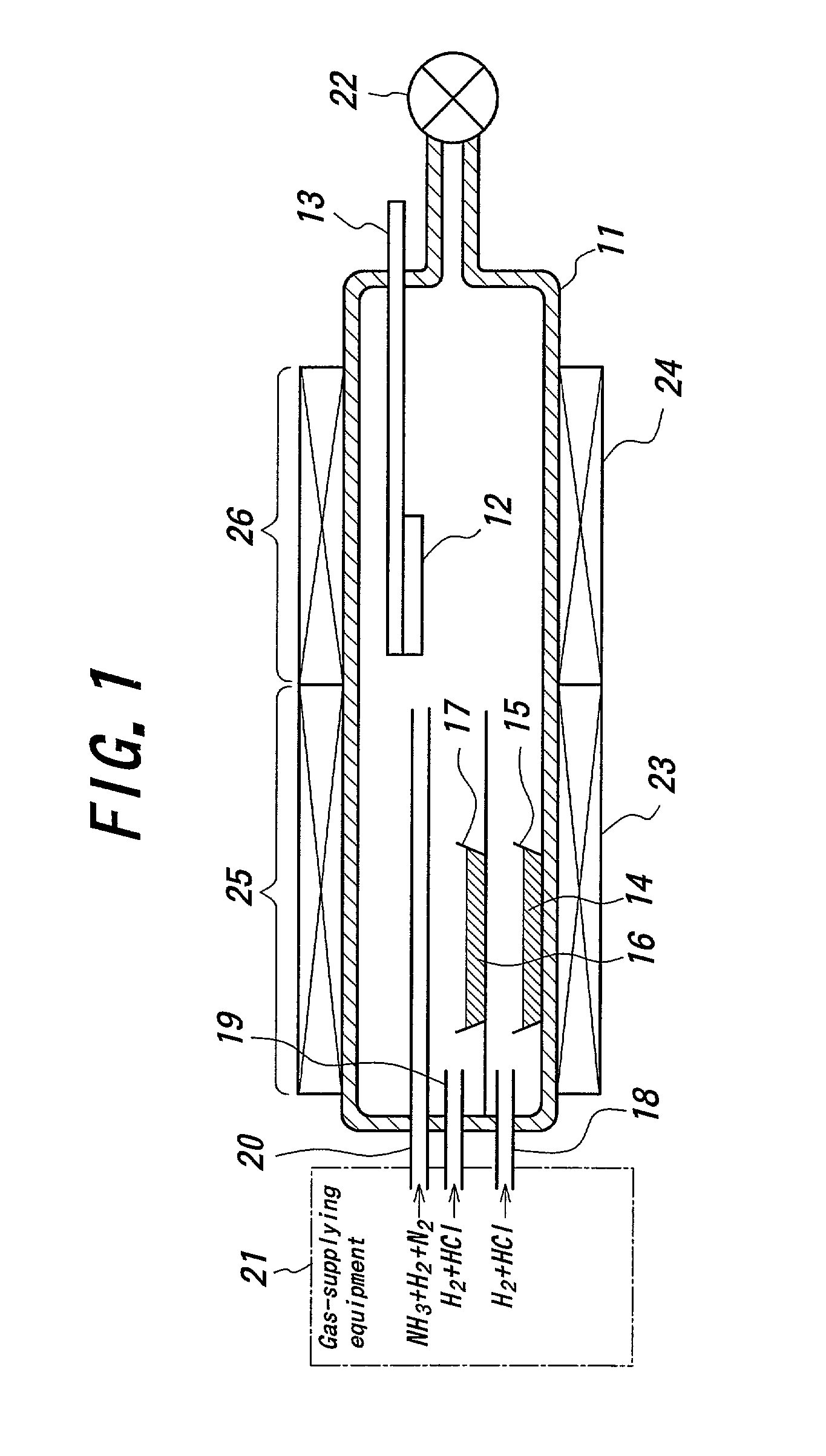

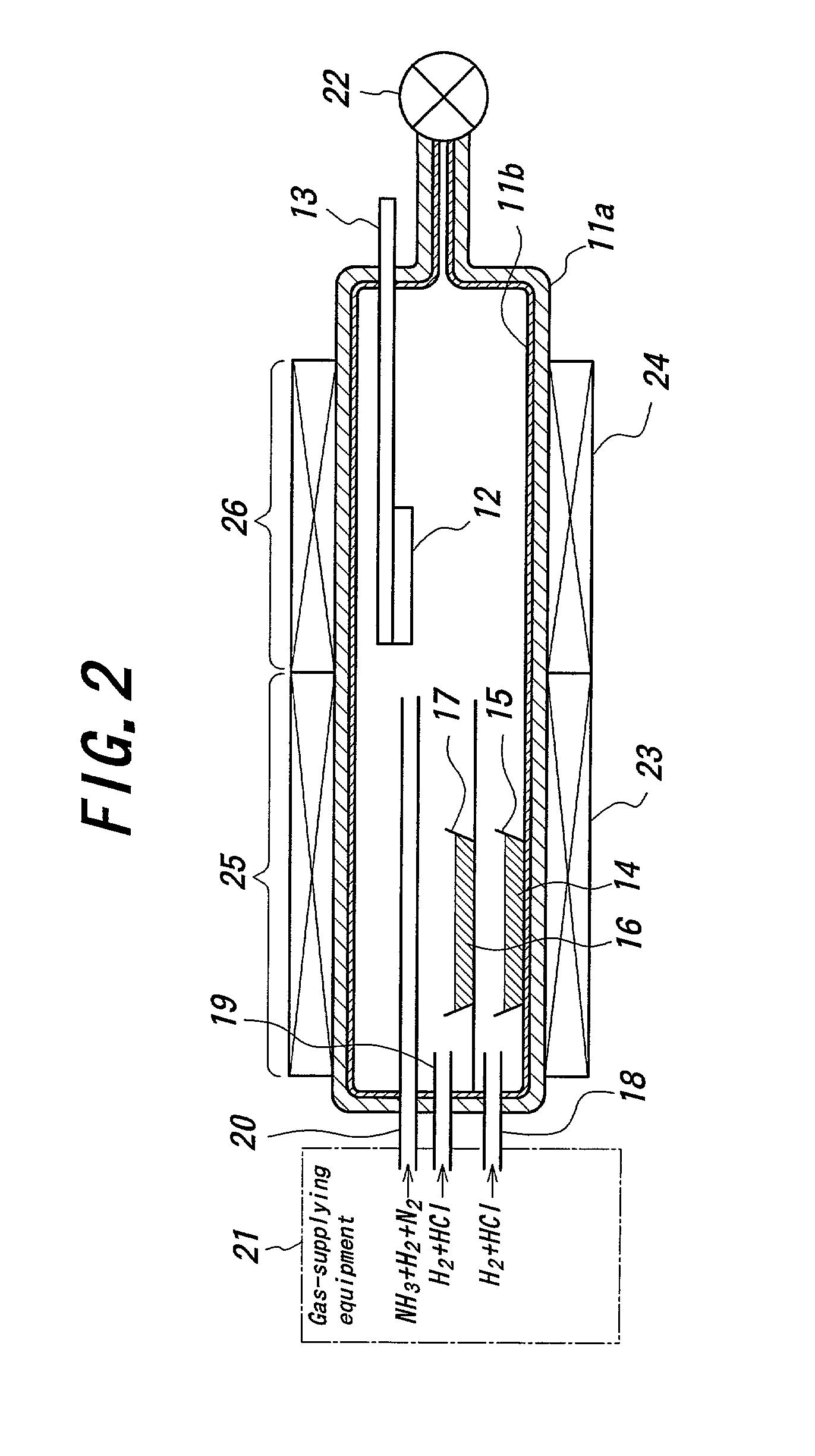

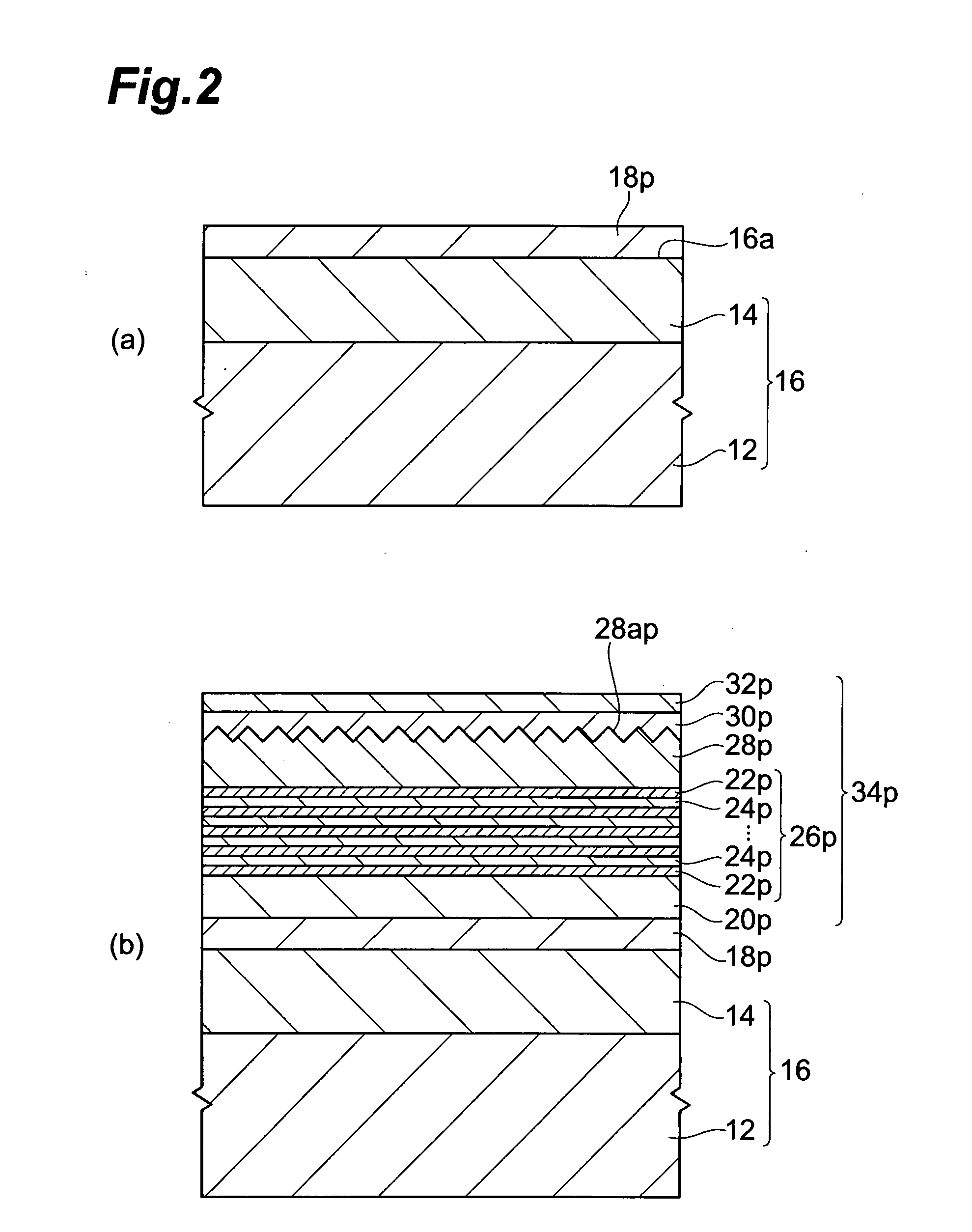

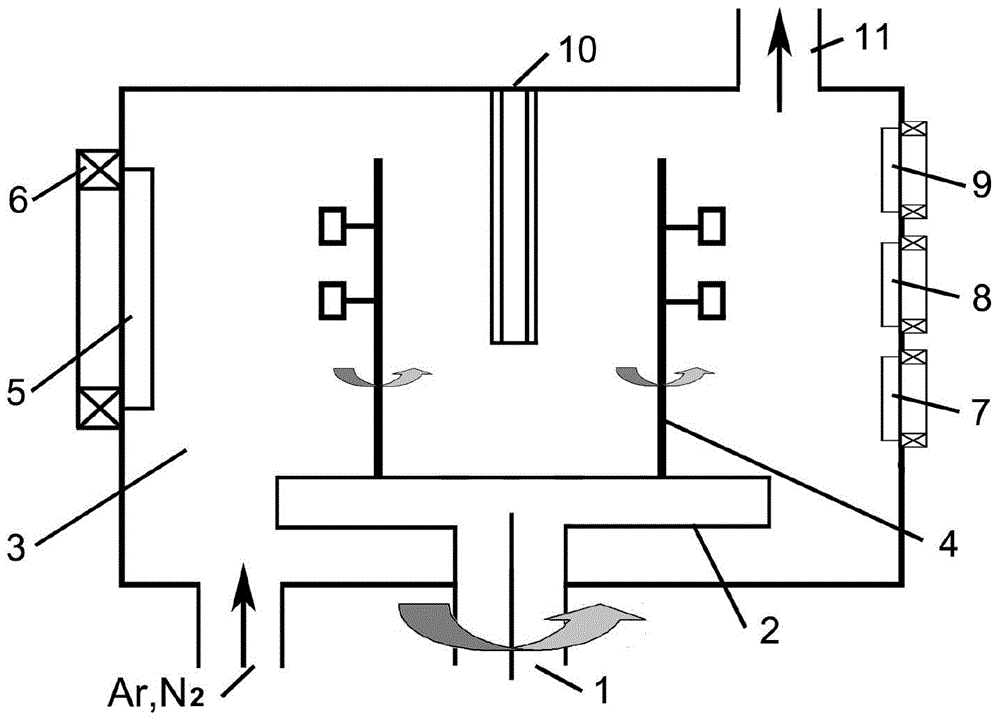

Apparatus for fabricating a III-V nitride film and a method for fabricating the same

InactiveUS7033439B2Easy to processFabrication can be reducedAfter-treatment apparatusPolycrystalline material growthAluminium chlorideHydrogen

A hydrogen chloride gas and an ammonia gas are introduced with a carrier gas into a reactor in which a substrate and at least an aluminum metallic material through conduits. Then, the hydrogen gas and the ammonia gas are heated by heaters, and thus, a III–V nitride film including at least Al element is epitaxially grown on the substrate by using a Hydride Vapor Phase Epitaxy method.The whole of the reactor is made of an aluminum nitride material which does not suffer from the corrosion of an aluminum chloride gas generated by the reaction of an aluminum metallic material with a hydrogen chloride gas.

Owner:NGK INSULATORS LTD

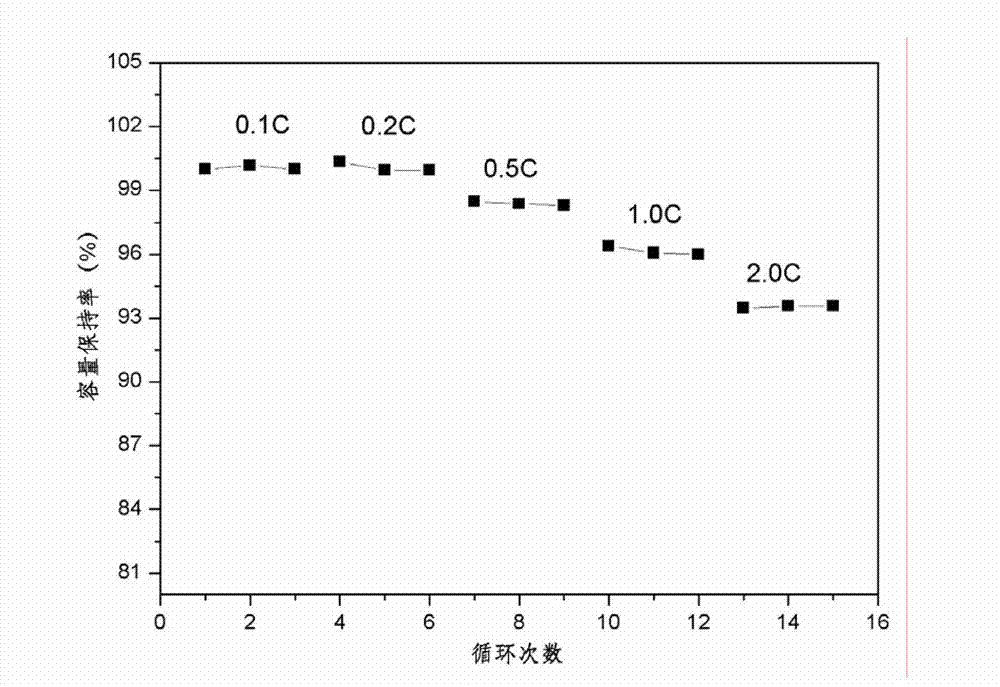

Surface composite coated anode material, preparation method thereof and lithium ion battery

ActiveCN102956895AExcellent rate performanceExcellent high temperature cycle performanceCell electrodesSecondary cellsPhosphateMass ratio

The invention provides a surface composite coated lithium ion battery anode material, a preparation method thereof and a lithium ion battery. The anode material comprises a lithium intercalation compound basal body and an Al2O3-AlPO4 composite layer which is coated on the basal body. The mass ratio of Al elements to lithium intercalation compounds is 0.04-0.15 percent. The mass percent of Al2O3 in the composite layer is 10-90 percent. The preparation method comprises the following steps of: dissolving easily soluble aluminum salt in solvent to form solution A; dissolving easily soluble alkaline substances and easily soluble phosphate in solvent to form solution B; dispersing the lithium intercalation compounds in a dispersing medium to obtain a dispersion system M; enabling the solution B and the solution A to form sol substances, adding the sol substances into the dispersion system M and enabling sol particles to be evenly adsorbed on the surfaces of the lithium intercalation compounds; and finally conducting solid-liquid separation and subsequent treatment. By adopting the technical scheme, the defects of sole coating can be effectively overcome, and the lithium ion battery with excellent rate capability and high-temperature circulating performance can be prepared.

Owner:QINGHAI TAIFENG XIANXING LITHIUM ENERGY TECH CO LTD

Zirconium cladding surface resistant to high temperature and oxidation ZrCrFe/AlCrFeTiZr composite gradient coating preparing technology

ActiveCN107513694AImprove the interface binding forceHigh strengthVacuum evaporation coatingSputtering coatingHigh entropy alloysAlloy coating

The invention discloses a zirconium cladding surface resistant to high temperature and oxidation ZrCrFe / AlCrFeTiZr composite gradient coating preparing technology. Ultrahigh vacuum multitarget co-sputtering technique is adopted, a ZrCrFe / AlCrFeTiZr composite gradient alloy resistant to high temperature and oxidation protecting coating is prepared on the surface of a zirconium alloy base body, and the zirconium cladding surface resistant to high temperature and oxidation ZrCrFe / AlCrFeTiZr composite gradient coating preparing technology comprises the steps of predepositional treatment, bias voltage anti-splash washing and ZrCrFe / AlCrFeTiZr composite gradient alloy coating deposition. The preparing process of the composite coating is divided into two steps, the first step is to prepare ZrCrFe gradient transition layer coating, in a deposited ZrCrFe transition layer, the atomic percentage content of Zr element is changed from the gradient of 100 at%-35 at% in the thickness direction, the atomic percentage content of Cr element is changed from the gradient of 0 at%-33 at% in the thickness direction, and the atomic percentage content of Fe element is changed from the gradient of 0 at%-33 at% in the thickness direction; the second step is to prepare a AlCrFeTiZr high-entropy alloy coating, in a deposited AlCrFeTiZr high-entropy alloy coating, the atomic percentage content of Al element is controlled in 0.5 at%-1.0at %, and the atomic percentage of other elements is between 10 at%-35 at%. Bonding force of the coating prepared by the technology is excellent, the surface is dense and uniform, and the coating has excellent performance such as high strength, resistance to high temperature and oxidation and irradiation resistance.

Owner:田雨

Codeposition gradient Ni-base superalloy coating and preparation technique thereof

InactiveCN101310972AReduce degradationExtended service lifeVacuum evaporation coatingSputtering coatingDepth directionSuperalloy

The invention mainly relates to the coating technique, in particular to a gradient MCrAlY coating used for protecting high-temperature alloy and a preparation method thereof. The invention adopts a method combining the arc ion plating (AIP) co-deposition and the vacuum diffusion annealing to prepare an MCrAlY coating with the Al element concentration distributed along the depth direction in a gradient way. Compared with the existing conventional MCrAlY high-temperature protective coating, the gradient MCrAlY coating of the invention effectively increases the content of Al memory phase in the coating, so as to improve the high-temperature oxidization resistance and the heat corrosion resistance of the coating, and can effectively prolong the service life of the coating. The MCrAlY gradient coating and the preparation method of the invention can be applied to the protection of Ni-based and Co-based high-temperature alloys.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

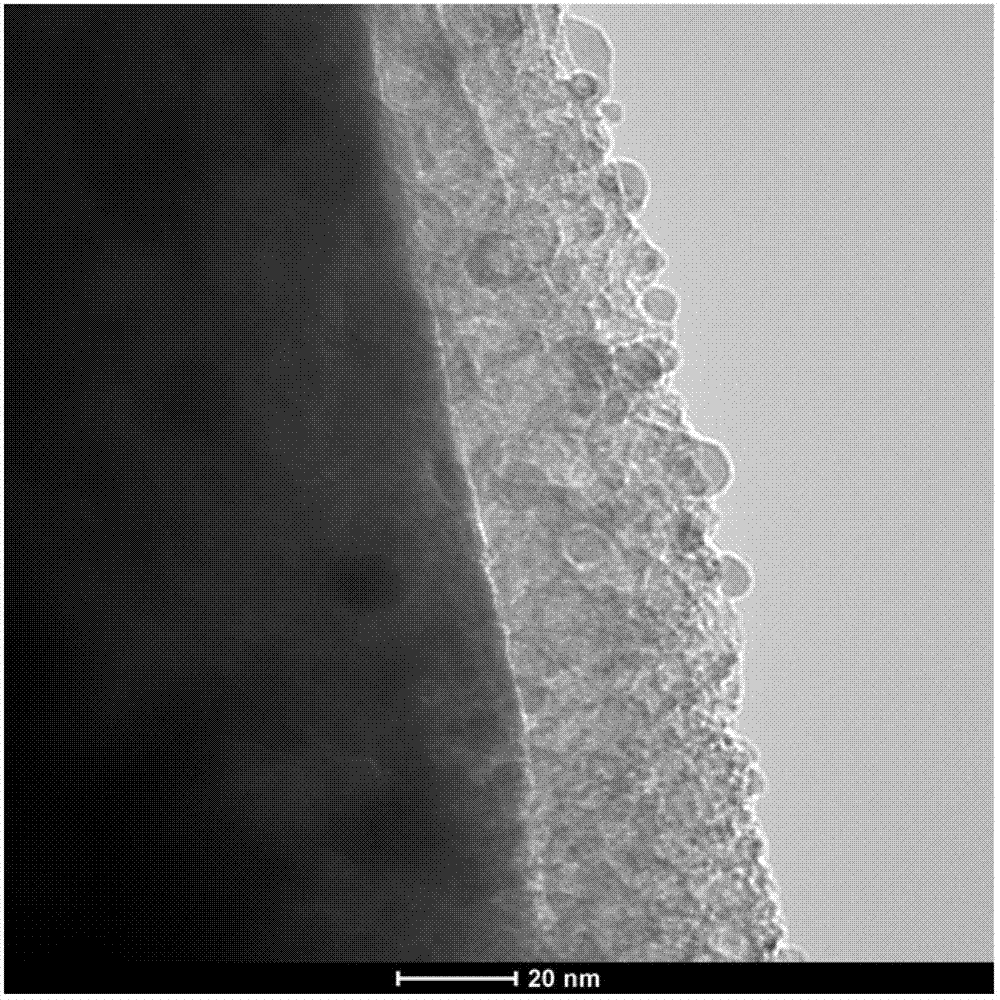

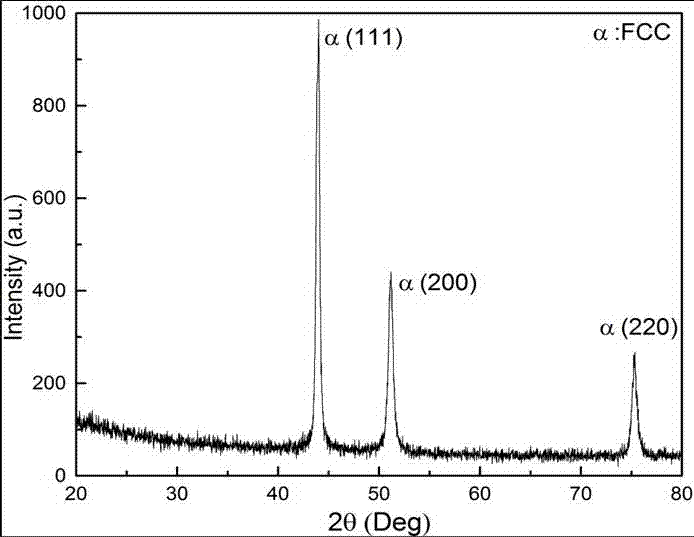

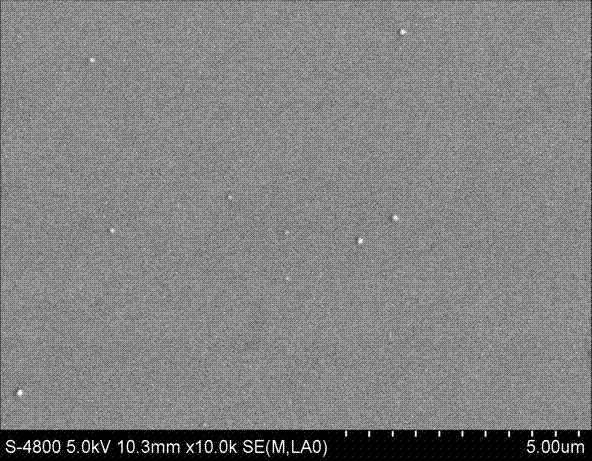

Method for preparing core-shell type nano-porous platinum alloy catalyst

InactiveCN103055895ASmall sizeControl ingredientMetal/metal-oxides/metal-hydroxide catalystsAl powderFuel cells

The invention belongs to the technical field of nanometallic materials, and relates to a method for preparing a core-shell type nano-porous platinum alloy catalyst. The method comprises the following steps of: weighing pure Al powder, pure Pt powder and pure X element powder according to an alloy composition proportion of Al-Pt-X (X is at least one of Ni, Co, Cu, Fe or Ti), and mechanically alloying the weighed pure Al powder, pure Pt powder and pure X element powder in a ball grinding mill to obtain Al-Pt-X alloy powder; and de-alloying the Al-Pt-X alloy powder in an alkaline solution and an acid solution sequentially, selectively removing Al element and partial X element, thus obtaining the core-shell type nano-porous platinum alloy catalyst. A mechanical alloying method is adopted to prepare a precursor alloy, the technology is simple, the production efficiency is greatly increased, the obtained nano-porous platinum-base alloy is small in size and of a core-shell type nano-porous structure, and the catalyst has a high specific surface area and can serve as a fuel cell catalyst.

Owner:SHANDONG UNIV

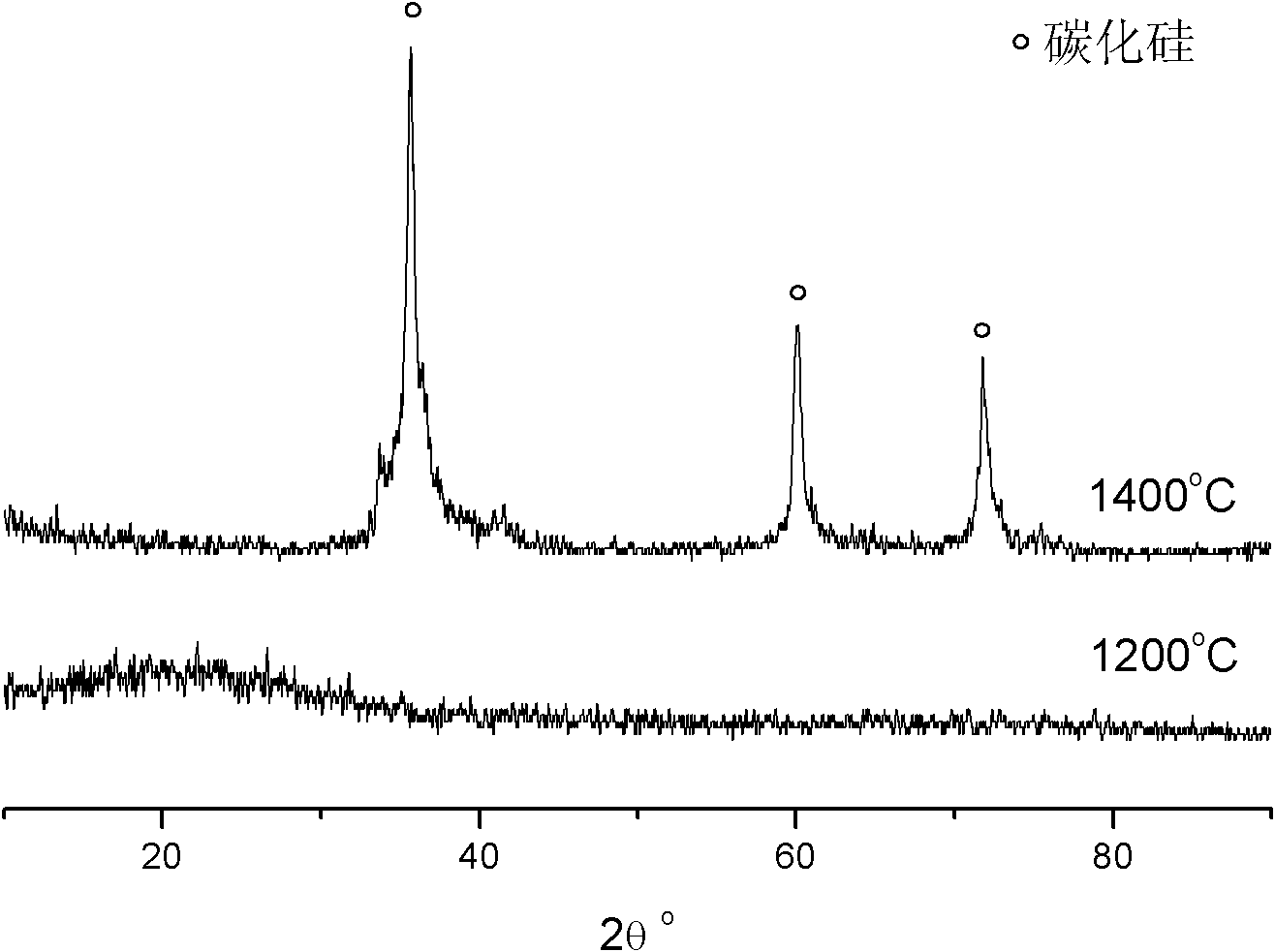

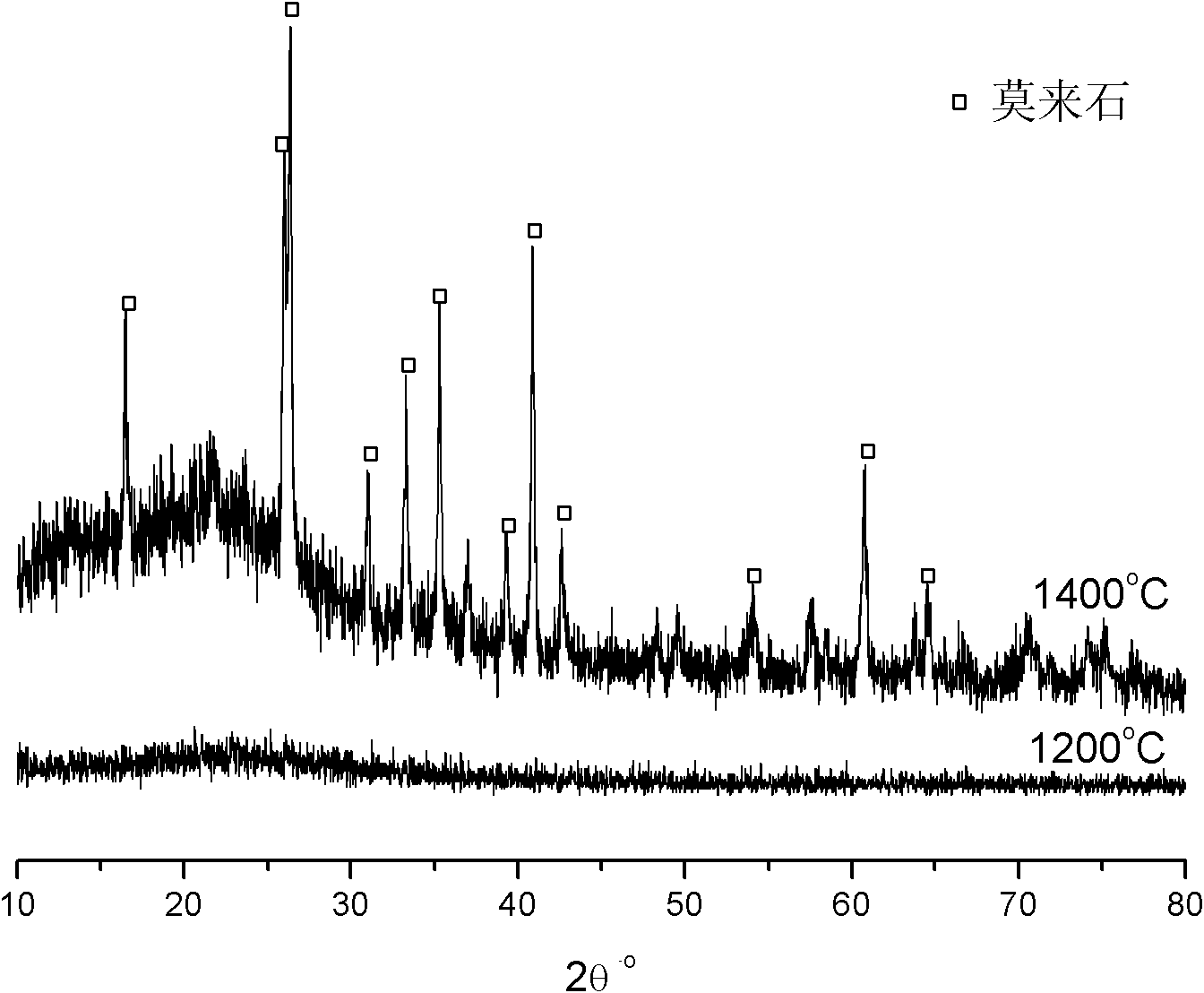

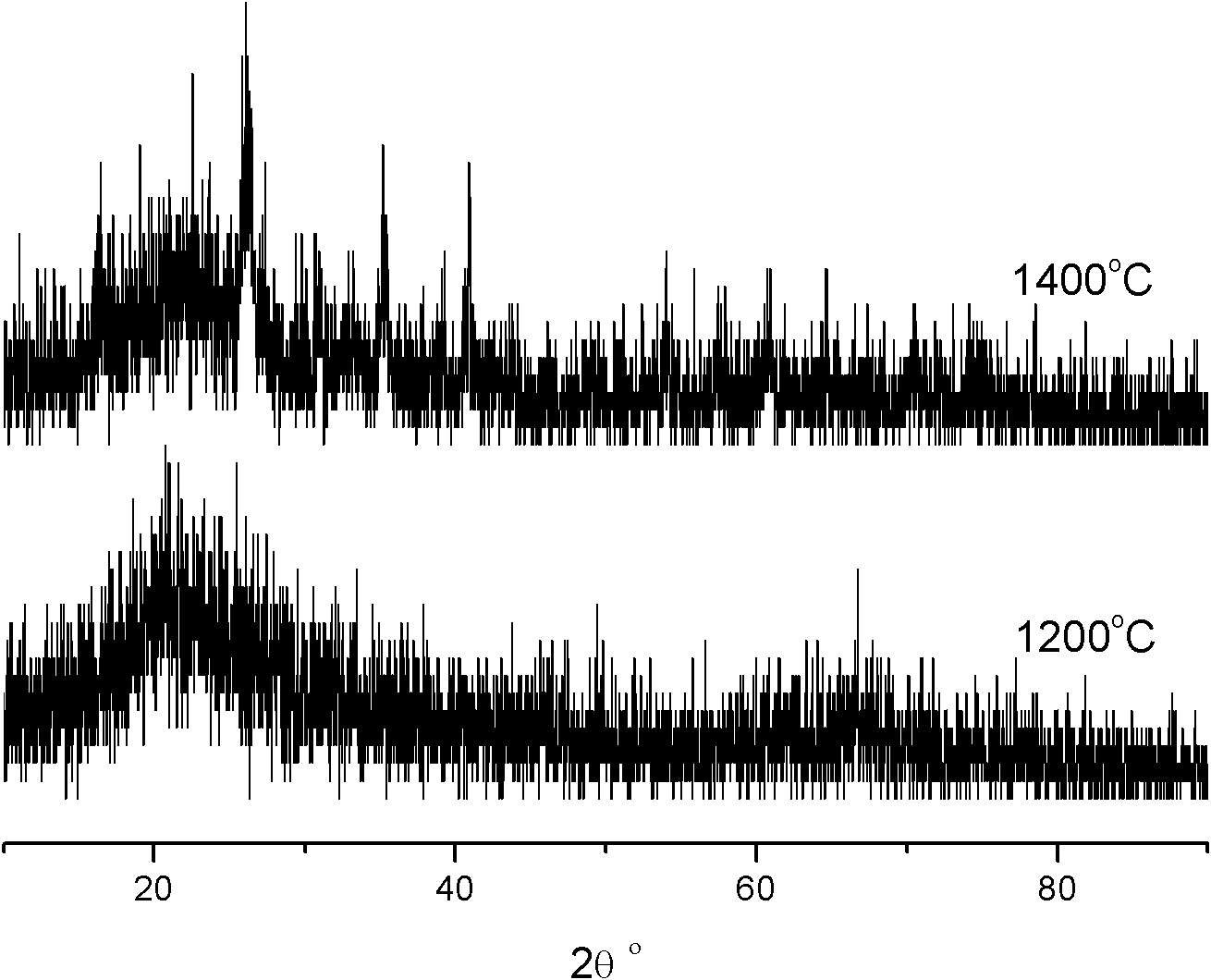

Si-Al-O-C ceramic material and preparation method thereof

The invention belongs to the field of high temperature resistant ceramic materials and preparation methods thereof and discloses an Si-Al-O-C ceramic material and a preparation method thereof. The Si-Al-O-C ceramic material contains the following elements in percentage by mass: 27-32 percent of Si element, 20-24 percent of O element, 25-30 percent of C element and 14-28 percent of Al element. The preparation method of the Si-Al-O-C ceramic material comprises the steps of aluminum sol preparation, gel preparation, precursor preparation, Si-Al-O-C ceramic material preparation and the like. The invention has the advantages of low cost, good heat stability, simple preparation process, low equipment requirements, and the like.

Owner:NAT UNIV OF DEFENSE TECH

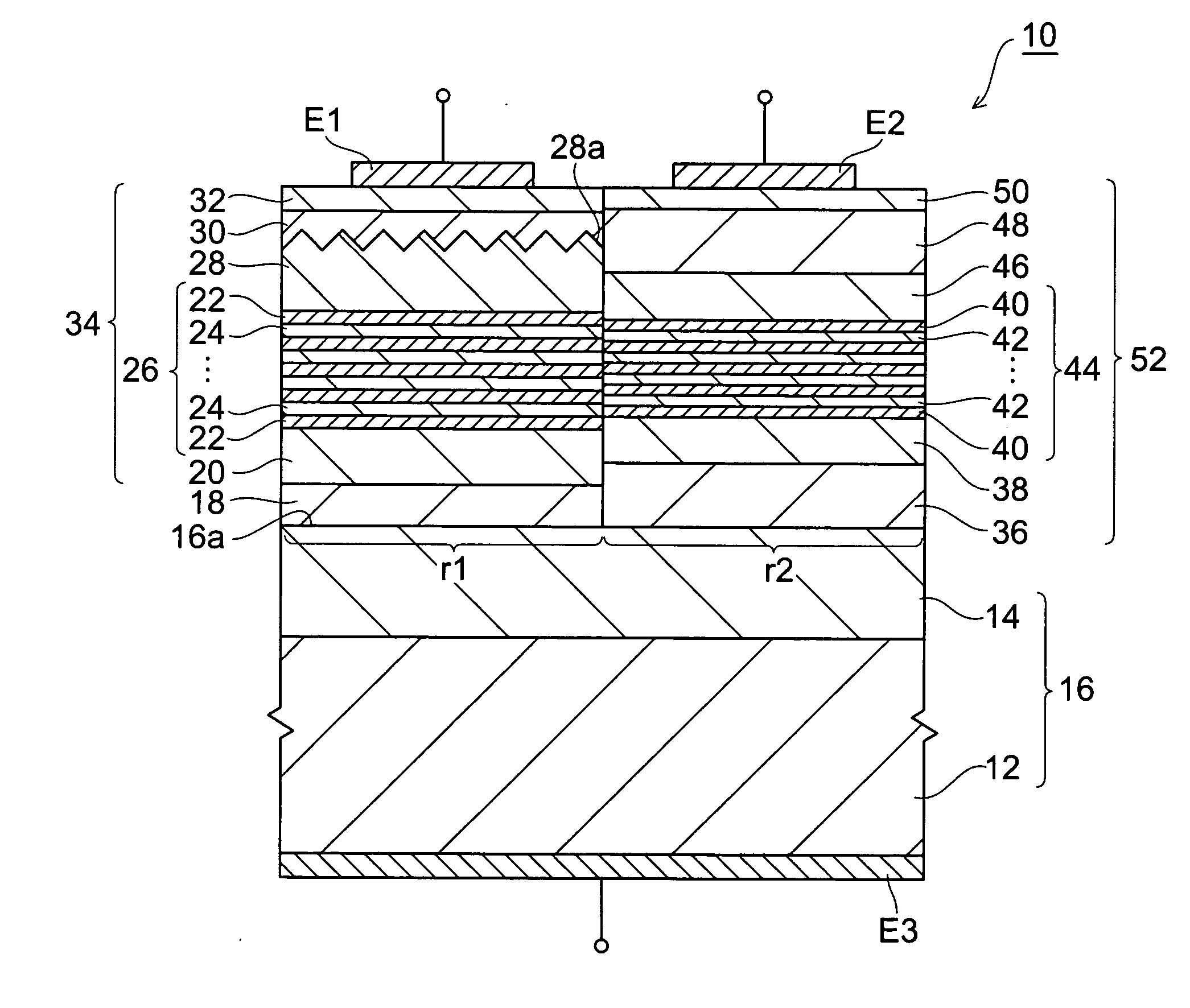

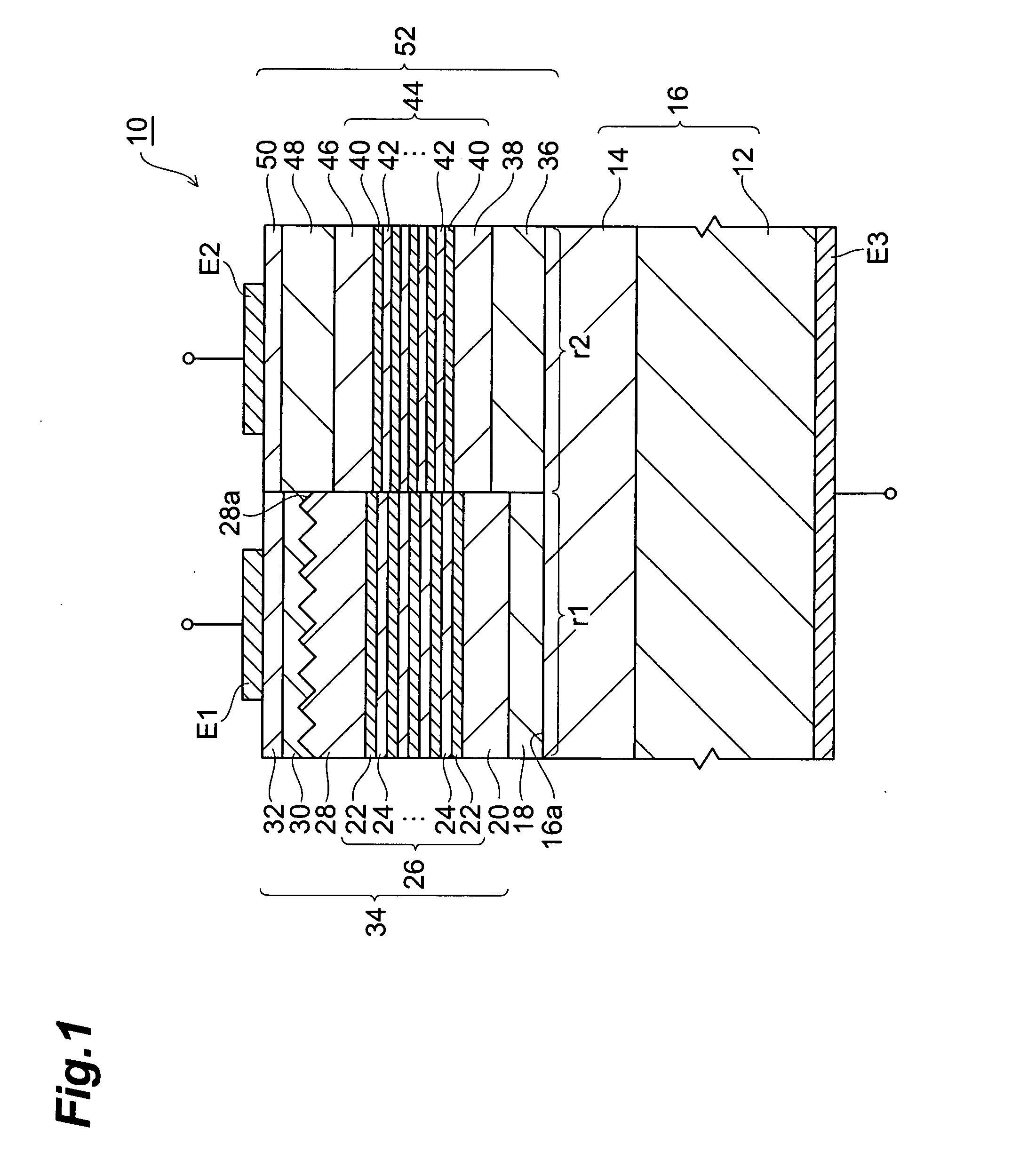

Integrated optical device and fabrication method thereof

InactiveUS20080003704A1Inhibition of abnormal growthEnhanced couplingLaser optical resonator constructionSemiconductor/solid-state device testing/measurementOptical couplingDry etching

An integrated optical device comprising a first semiconductor optical element provided on a first region of the main face of a substrate and a second semiconductor optical element provided on a second region and optically coupled to the first semiconductor optical element is fabricated. A first III-V compound semiconductor layer containing Al element is formed on the main face. A second III-V compound semiconductor layer for forming the first semiconductor optical element is then formed on the first III-V compound semiconductor layer. An etching mask M is formed on the first region. The end point of the dry etching is detected by using the etching mask M to dry-etch the second III-V compound semiconductor layer while detecting Al element. The first semiconductor optical element is thus formed. The second semiconductor optical element is formed on the second region.

Owner:SUMITOMO ELECTRIC IND LTD

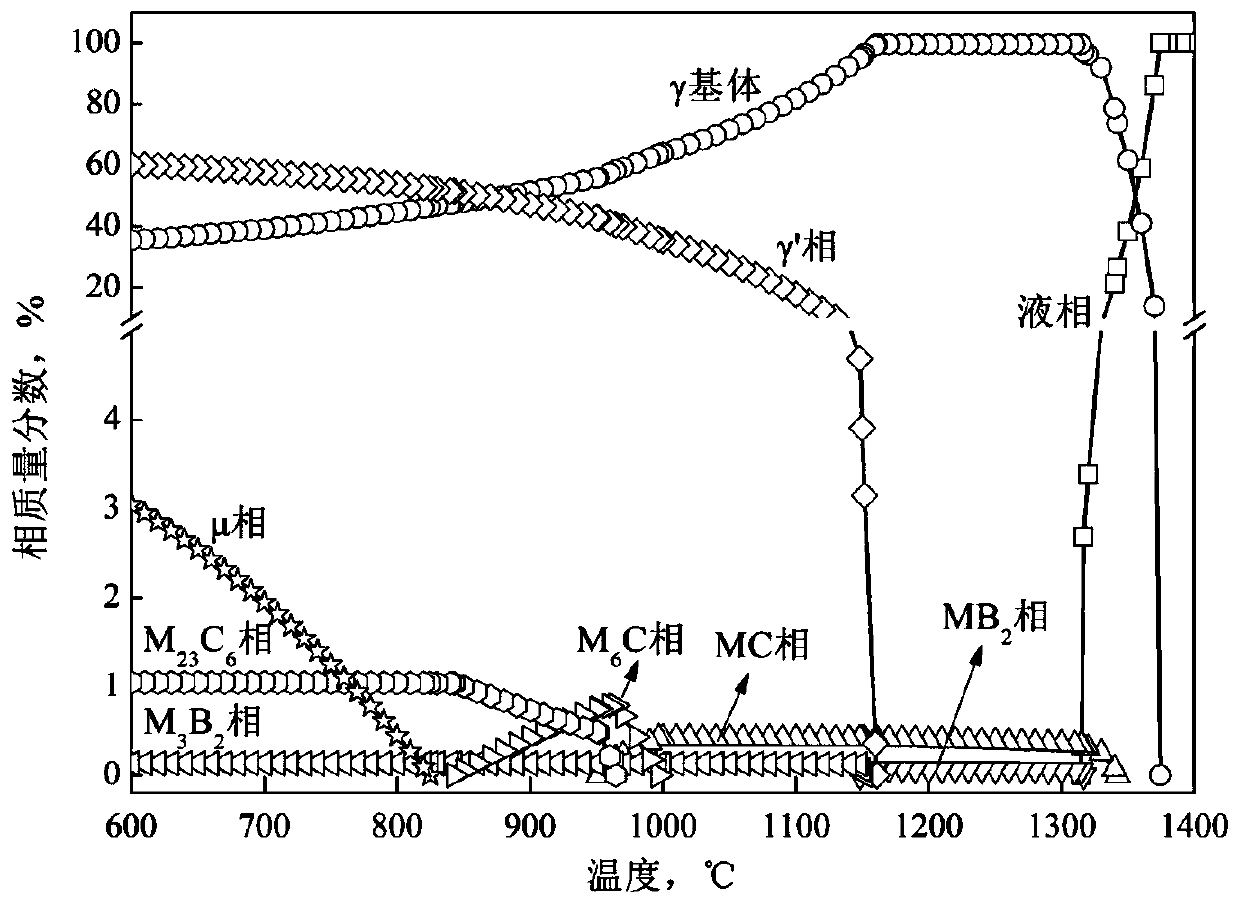

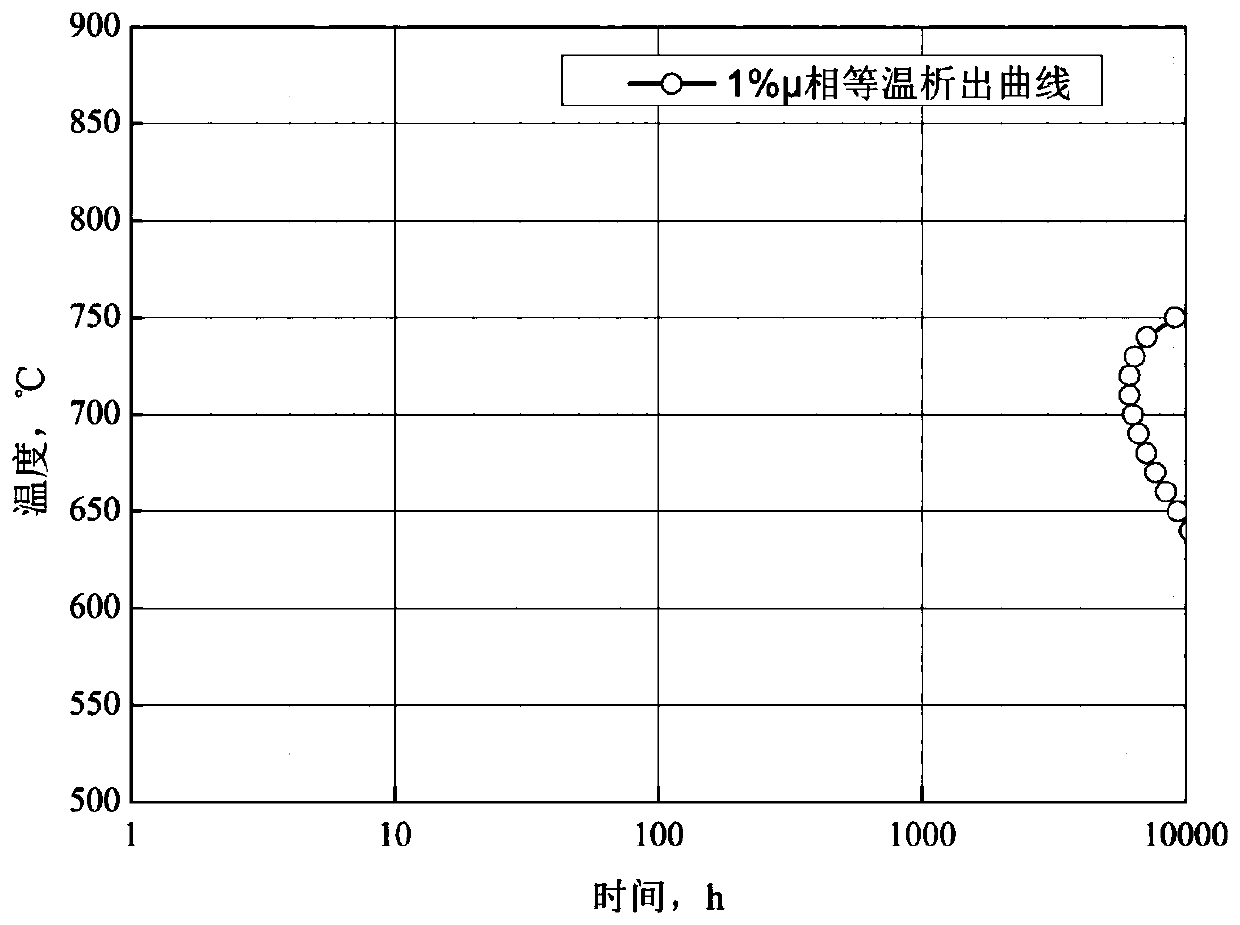

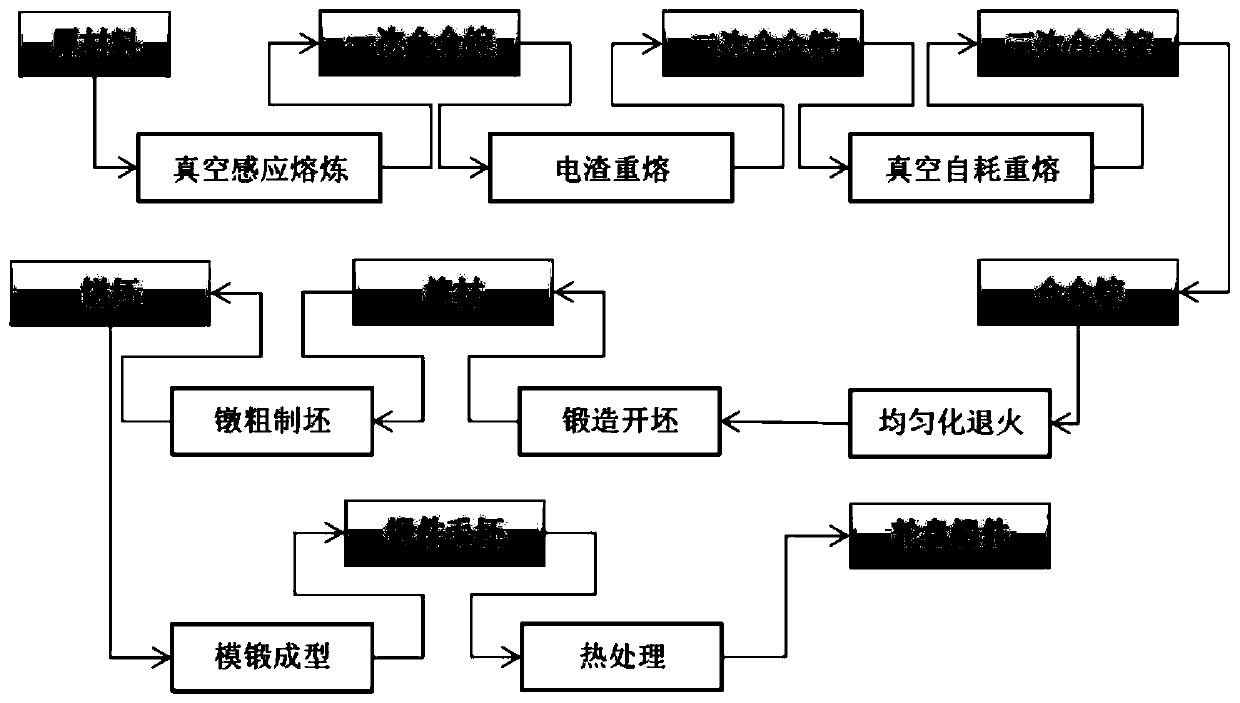

Nickel-based deformed superalloy with high aluminum content and preparation method thereof

ActiveCN111187946AGood mechanical propertiesSatisfied with service stabilityMetal-working apparatusSolid solution strengtheningSuperalloy

The invention provides a nickel-based deformed superalloy with high aluminum content and a preparation method thereof. A traditional Ni-Co-Cr component serves as a matrix element, the content of the alloy element is increased, particularly, the content of a solid solution strengthening phase gamma'phase forming element Al is increased, the content of a strengthening phase gamma'phase is increasedto 55%-65%, and the temperature bearing capacity of the alloy is effectively improved. A proper amount of Nb element is added into the alloy, so that the stability of a gamma'phase can be improved, the casting-forging process performance is further improved, the long-time structure stability of the alloy at 850 DEG C can be improved by reducing the addition of Cr element, and the surface stabilityloss caused by the reduction of the Cr element can be compensated by the high-content Al element. Meanwhile, a duplex technology or a triple technology is adopted for preparing and machining an alloyraw material, the obtained nickel-based deformed superalloy solves the problem that no high-performance wheel disc forge piece material capable of being used at 850 DEG C for a long time exists at present, and the nickel-based deformed superalloy particularly has excellent tensile strength and yield strength and long service life at 850 DEG C.

Owner:BEIJING CISRI GAONA TECH +1

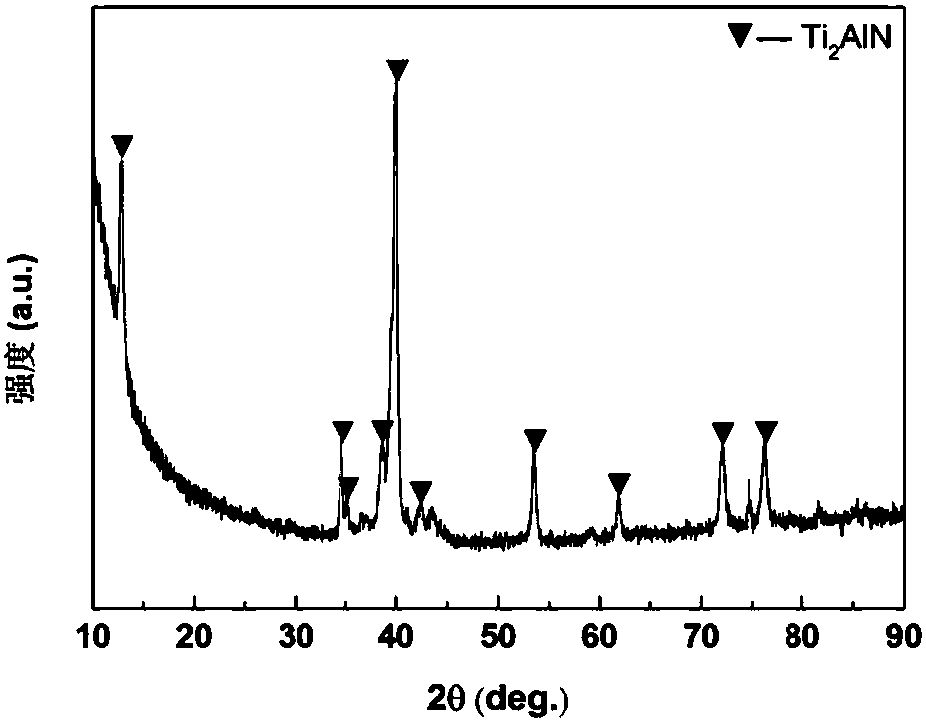

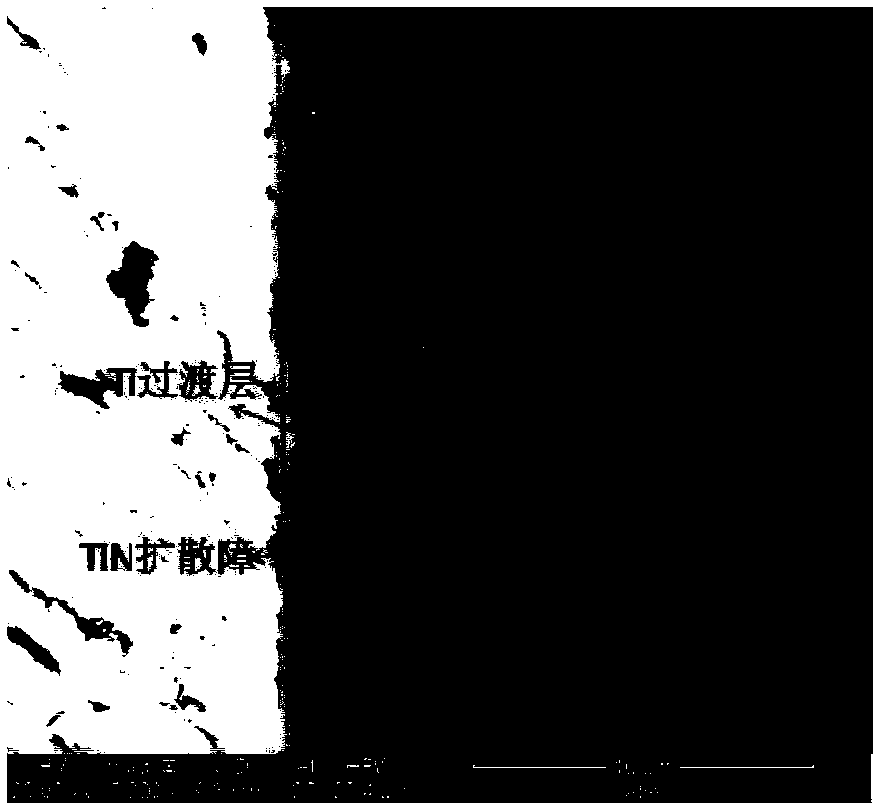

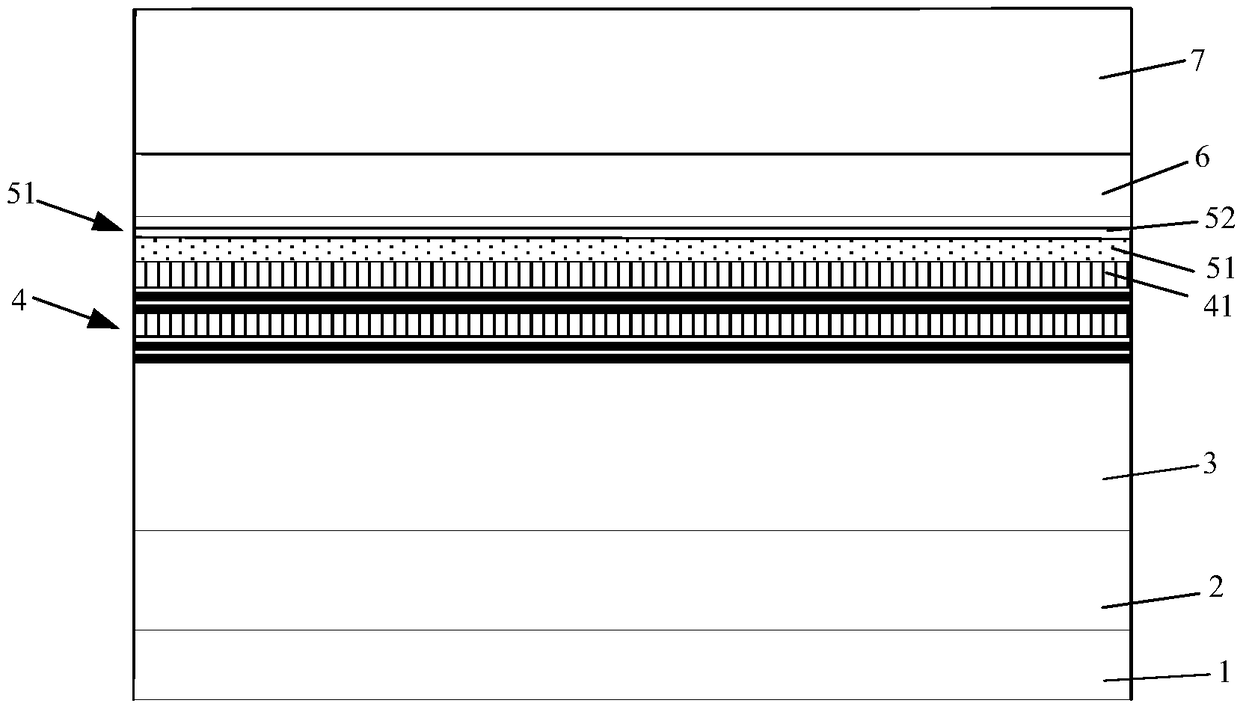

Preparation method for high-purity high-density MAX phase coating

ActiveCN107620033AEasy to controlEasy to homogenize large area depositionVacuum evaporation coatingSputtering coatingHigh densityNitrogen

The invention provides a preparation method for a high-purity high-density MAX phase coating. According to the method, an arc ion plating technology is combined with a magnetron sputtering technology,an M-position element is provided for the arc, an A-position Al element is provided for magnetron, nitrogen or hydrocarbon as reaction gas is introduced for deposition, then thermal treatment is adopted, and the high-purity high-density MAX phase coating is prepared. The prepared MAX phase coating is high in purity, good in compactness, free of a microdefect, high in preparation efficiency, low in cost and capable of overcoming the defects that large particles on the surface of a MAX phase coating prepared through a single arc method are excessive, the density is low, the efficiency is low bymeans of a magnetron sputtering method, and the defects are obvious and has the wide application prospects on the aspects of high-temperature protection, corrosion-resistant application and the like,and the industrial production of the MAX phase coating can be achieved easily.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

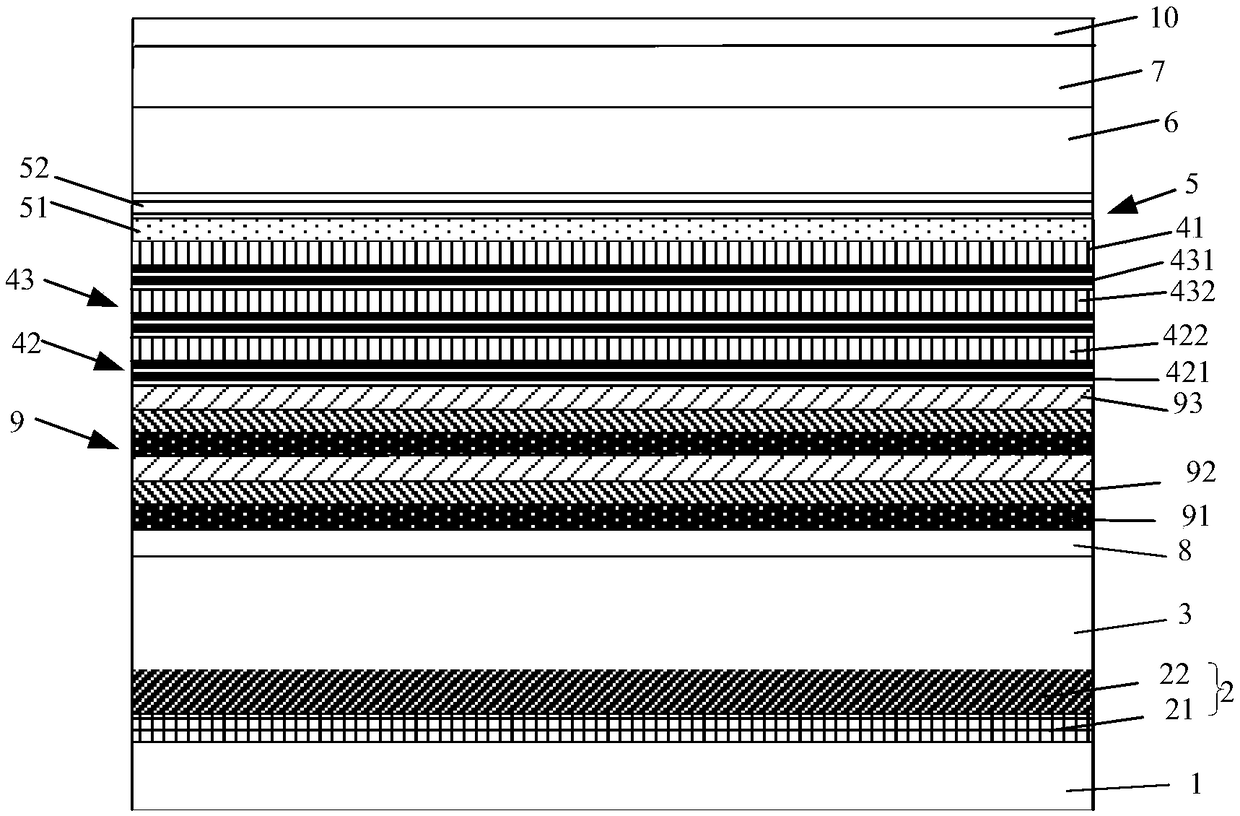

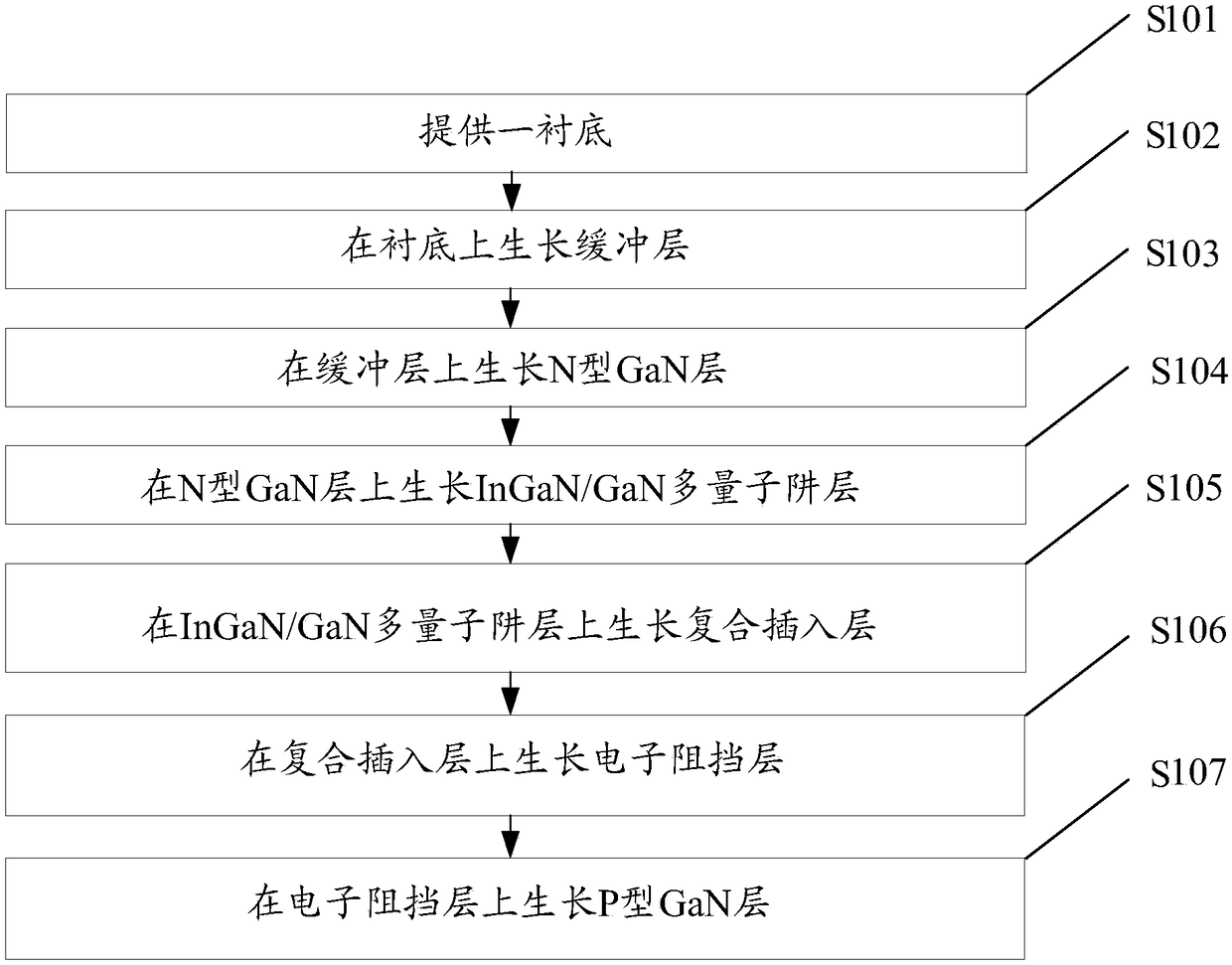

Epitaxial wafer of light emitting diode and preparation method thereof

InactiveCN109360876AImprove compound efficiencyImprove luminous efficiencySemiconductor devicesQuantum wellElectron blocking layer

The invention discloses an epitaxial wafer of a light emitting diode and a preparation method thereof, and belongs to the field of the light emitting diode manufacture. A combined inserting layer installed between an electron blocking layer and an InGaN / GaN multi-quantum well layer can be cooperated with the last one GaN quantum barrier layer doped with an Al element in the InGaN / GaN multi-quantumwell layer. The last one GaN quantum barrier layer doped with the Al element can play a partial effect of blocking an electron, the electron is blocked in the InGaN / GaN multi-quantum well layer, andan AlN layer and an InGaN layer with higher potential barriers in the combined inserting layer can also play the effect of blocking the electron. In addition, because a magnesium element is doped in the AlN layer and the InGaN layer, the AlN layer and the InGaN layer can be used as a hole source, the electron can be blocked in the InGaN / GaN multi-quantum well layer, and more holes can enter the InGaN / GaN multi-quantum well layer and are combined with the electrons so as to illuminate, and combination efficiency of the electrons and holes in the InGaN / GaN multi-quantum well layer is improved, so luminous efficiency of the light emitting diode is improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

Method for reinforcing surface of hot-extrusion die through cementation compounding

InactiveCN104911552AReduce hardnessMake up for the lack of performanceVacuum evaporation coatingSputtering coatingAl elementPower flow

The invention discloses a method for reinforcing a surface of a hot-extrusion die through cementation compounding. The method comprises the following steps: polishing and cleaning the surface of a die subjected to nitriding treatment, and performing CrAlN coating processing in arc ion plating equipment; with a rectangular Ti target as a Ti source of a bottom layer and a transition layer, controlling the sputtering rate of the rectangular Ti target through the current of the arc power of the rectangular target; with a circular CrAl target as the Cr and Al element source of a CrAlN coating, controlling the sputtering rate of the circular CrAl target through the current of the arc power of the circular CrAl target; ionizing high-purity Ar and N2 so as to be combined with Cr and Al elements, and depositing on the nitriding layer of the die to form the CrAlN coating. The method disclosed by the invention is applicable to the field of hot-extrusion dies in high-temperature and heavy-load harsh service conditions.

Owner:XI AN JIAOTONG UNIV

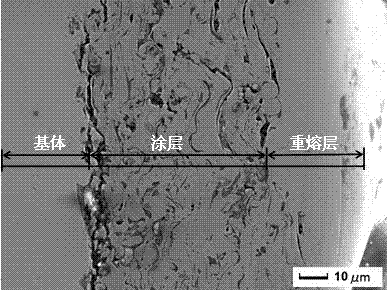

Anti-oxidation MCrAlY fine-grain protective coating material and preparation method thereof

InactiveCN103789713AImprove antioxidant capacityRefining the coating structureMolten spray coatingSuperalloyPlasma sprayed

The invention relates to the technical field of coatings, and particularly relates to an anti-oxidation MCrAlY fine-grain protective coating material and a preparation method thereof. The anti-oxidation MCrAlY fine-grain protective coating material comprises a high-temperature alloy matrix, an MCrAlY protective coating, and a super-fine grain remelting layer. The invention further discloses a preparation method of the anti-oxidant MCrAlY fine-grain protective coating material, namely, an MCrAlY protective coating with a super-fine grain structure is prepared by adopting an air plasma spraying (APS) and high current pulsed electron beam (HCPEB) compounding technology. The MCrAlY protective coating with the super-fine grain structure, prepared by adopting the compounding technology, is capable of accelerating selective oxidation of an Al element, and promoting the coating to rapidly form a continuous and compact oxidation film within a short time, thereby reducing the consumption of an oxidation film generating element in the oxidation process, and further improving the anti-oxidation capacity of the coating.

Owner:JIANGSU UNIV

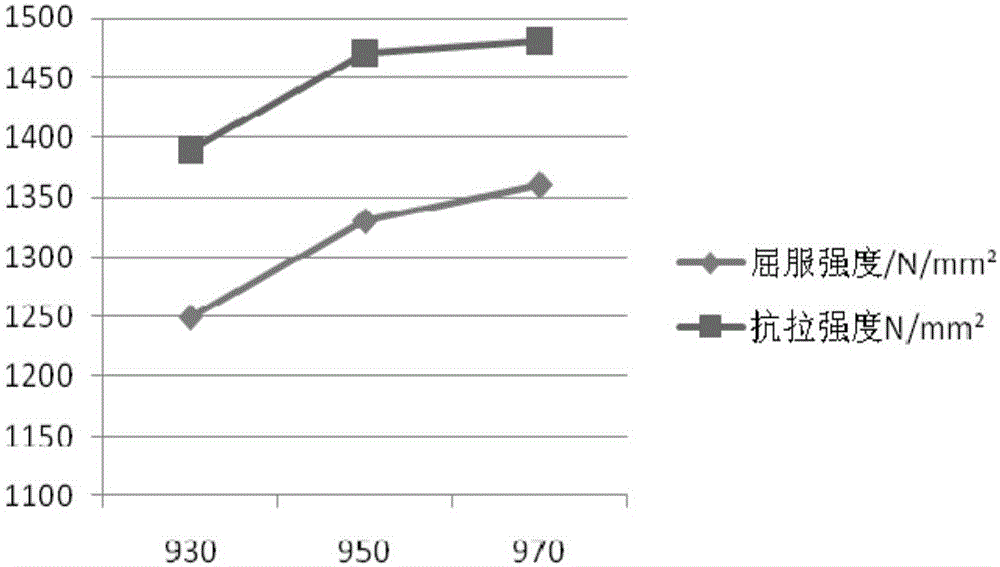

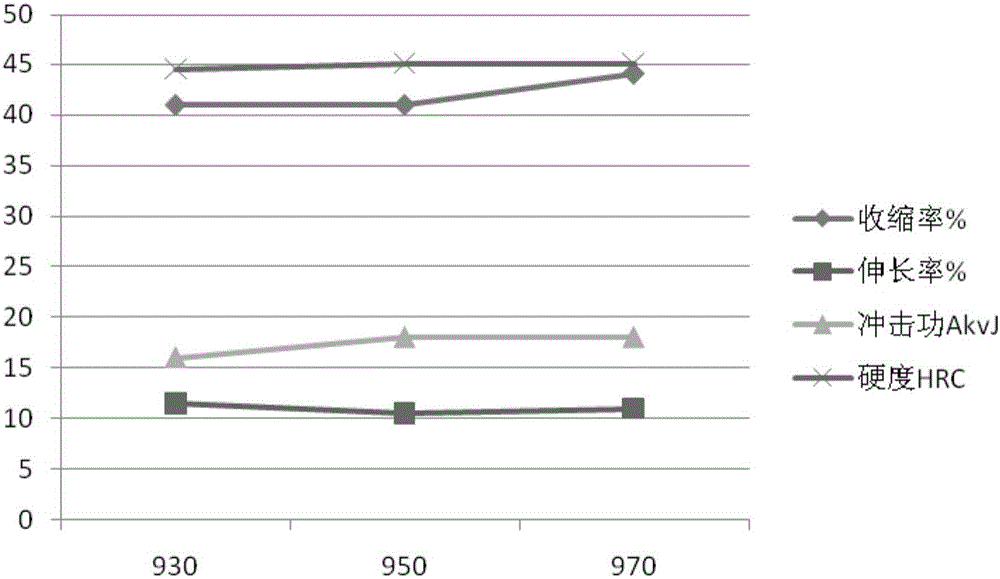

Cr3 series hot work die steel and heat treatment method thereof

The invention provides a Cr3 series hot work die steel. The hot work die steel comprises, by weight percentage, 0.38%-0.50% of C, 0.15%-0.70% of Si, 0.30%-0.90% of Mn, smaller than or equal to 0.020% of P, smaller than or equal to 0.010% of S, 2.80%-3.50% of Cr, 1.40%-2.00% of Ni, 1.80%-2.60% of Mo, 0.10%-0.50% of V, 0.020%-0.10% of Al, 0.02%-0.20% of Nb and the balance Fe. According to the chemical component formula of the Cr3 series hot work die steel (remembered as YD3 series die steel), compared with existing Cr3Mo3(4Cr3Mo3SiV, H10) series hot work die steel, C, Mn and Cr of the YD3 series die steel are equivalent in content, the content of Mo, V and Si is reduced, the Ni element is added, the Nb element is added, the Al element is added, and therefore toughness is improved.

Owner:YINGKOU SPECIAL STEEL FORGING

AlCoCrFeMn high-entropy alloy with non-equal atomic ratio and preparation method of AlCoCrFeMn high-entropy alloy

ActiveCN111235454AHigh strengthGood thermal stability at high temperatureHigh entropy alloysAl element

The invention discloses an AlCoCrFeMn high-entropy alloy with a non-equal atomic ratio and a preparation method of the AlCoCrFeMn high-entropy alloy. The atomic ratio of all elements of Al to Co to Crto Fe to Mn in the high-entropy alloy is equal to (0.3-0.7): to 2 to 1 to 1 to 1. The preparation method comprises the following steps that (1) a raw material is taken in proportion, and cleaning anddrying are conducted; (2) the raw material is put into a non-consumable arc melting furnace, vacuumizing is conducted and protective gas is added; (3) Ti which is arranged in the furnace in advance is firstly smelted, then the raw material is smelted, and suction casting is conducted by using a copper mold to form an alloy ingot; (4) the alloy ingot is subjected to solid solution, water quenchingand rolling deformation; and (5) the deformed alloy ingot is annealed to obtain the AlCoCrFeMn high-entropy alloy with the unequal atomic ratio. According to the AlCoCrFeMn high-entropy alloy with the non-equal atomic ratio and the preparation method of the AlCoCrFeMn high-entropy alloy, by adding a certain amount of Co element, the strength of the high-entropy alloy is improved, the content of the Co element is increased, and the alloy has good thermal stability; and the plasticity of the high-entropy alloy is adjusted by adding a certain amount of Al element, and the prepared high-entropy alloy has good strength and plasticity.

Owner:JIANGSU UNIV OF TECH

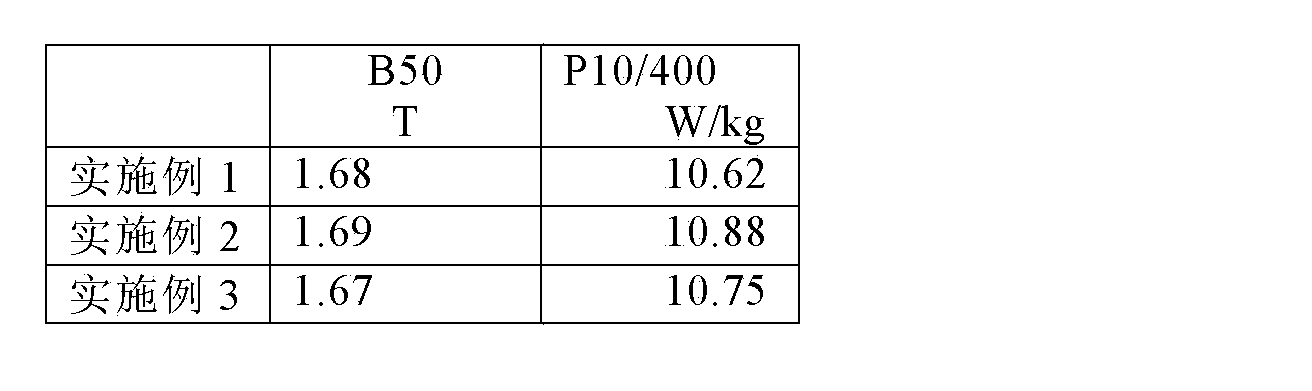

High-aluminum thin electrical steel and producing method thereof

The invention provides high-aluminum thin electrical steel and a producing method thereof. The steel comprises following chemical components by weight: not more than 0.0030% of C, 1.5-2.0% of Si, 0.10-0.30% of Mn, not more than 0.008% of P, not more than 0.0020% of S, not more than 0.0025% of N, 1.5-2.0% of Als, not more than 0.001% of Ti, not more than 0.0020% of Nb and not more than 0.0020% of V, with the balance being Fe and other unavoidable residual elements. The producing method includes smelting, continuous casting, hot rolling, normalizing, cold rolling and annealing. By high-aluminum alloying, the sensitivity of the steel in hot conditions is reduced and lattice deformation is relieved, thus facilitating stability of the product producing process. The Al element increases the specific resistance, allows the (100) component to be increased and the (111) component to be reduced, reduces the iron loss and achieves high silicon effects. The plate shape is controlled by rolling with heat and a secondary cold rolling method. The electrical steel and the producing method are suitable for producing cold-rolled non-oriented silicon steel thin strips having a thickness of 0.2-0.3 mm, and meet the technical requirements of frequency conversion.

Owner:ANGANG STEEL CO LTD

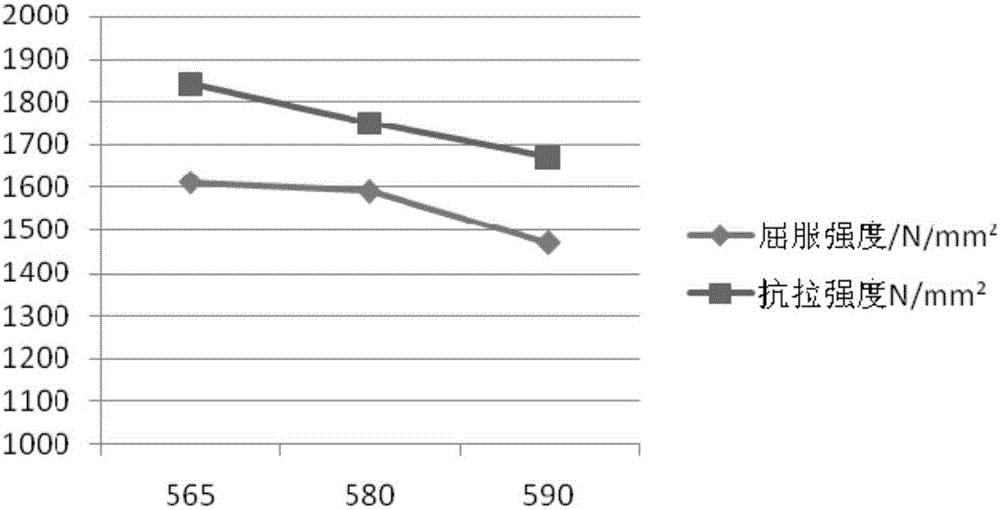

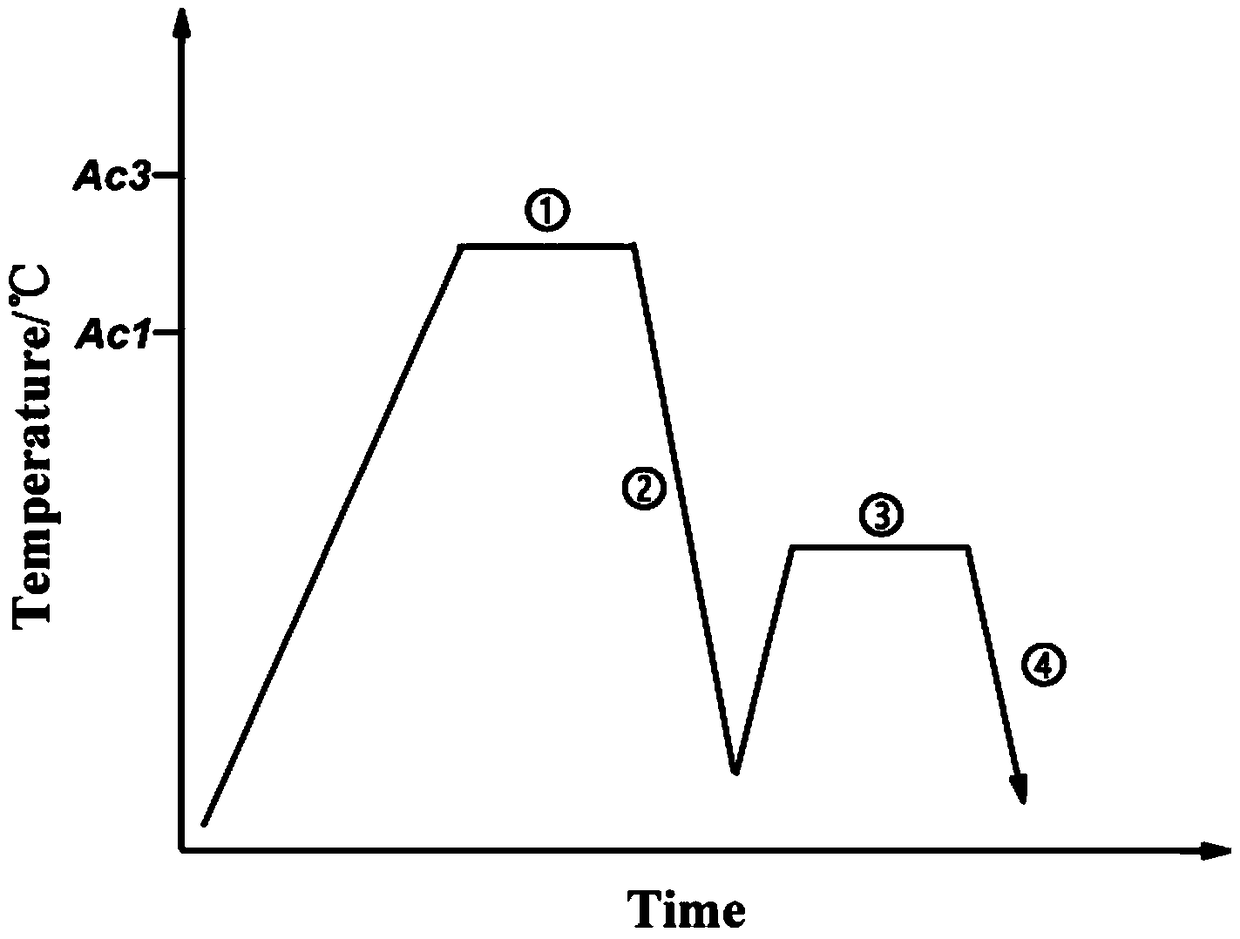

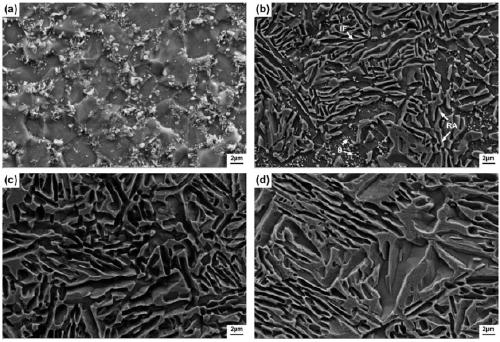

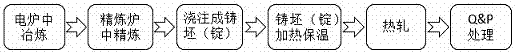

Ultrahigh-strength-toughness medium-manganese phase-change induced plasticity steel and preparation method thereof

The invention discloses an ultrahigh-strength-toughness medium-manganese phase-change induced plasticity steel and a preparation method thereof. The ultrahigh-strength-toughness medium-manganese phase-change induced plasticity steel comprises, by weight, 0.35%-0.36% of C, 4.5%-7.5% of Mn, 3.2% of Al, 0.07% of P, 0.03% of S and the balance Fe. The first preparation process comprises the following steps of smelting, forging and hot rolling, and a two-phase region annealing and low-temperature tempering process; and the second preparation process comprises the following steps of smelting and forging, hot rolling and cold rolling, and a two-phase region annealing and low-temperature tempering process, the stress can be eliminated by the low-temperature tempering process, and the austenite stability is improved. The heating treatment process which is simple and high in feasibility is utilized to obtain the high-toughness advanced steel type, product of strength and elongation can reach 75 GPa%, and the performance requirements of third-generation advanced high-strength steel are met; and meanwhile, according to the preparation method, the content of C (close to 0.4wt.%) is properly increased, and the purposes aim at improving the austenite content at room temperature and ensuring full proceeding of the TRIP effect through element distribution ; and a small amount of Mn and Al elements are added into the components, and other precious alloy elements are not added, so that the production cost is reduced.

Owner:SOUTHWEST JIAOTONG UNIV

Component design and production method of 1500 MPa-grade low-carbon and medium-manganese copper-contained steel

The invention relates to component design and a production method of 1500 MPa-grade low-carbon and medium-manganese copper-contained steel. The 1500 MPa-grade low-carbon and medium-manganese copper-contained steel comprises the following chemical components in percentage by mass: 0.20-0.23% of C, 0.5-0.8% of Si, 3.5-4.0% of Mn, 1.2-2.0% of Al, 0.5-1.0% of Cr, 0.6-1.0% of Cu, 0.2-0.5% of Ni, 0.003-0.012% of N, 0.00051-0.003% of B, and the balance of Fe and inevitable impurities. One part of alloy elements are added based on traditional TRIP steel to largely increase the content of manganese to reach the medium-manganese range; when Al is used for replacing the Si elements, a proper amount of Si elements are retained, so that the Al and Si elements are matched for use; and a certain quantity of precipitation-hardened Cu elements are added to match with a proper amount of Ni elements for use to eliminate the hot brittle phenomenon caused by Cu in hot working. In addition, few Cr elements are added; a proper amount of N elements are added to match with the Al elements for use; through matching between hot rolling and hot partition processes, a martensite+residual austenite+separated second-phase particle structure with ultrahigh strength and excellent plasticity is obtained; and the tensile strength exceeds 1500 MPa.

Owner:SHANDONG JIANZHU UNIV

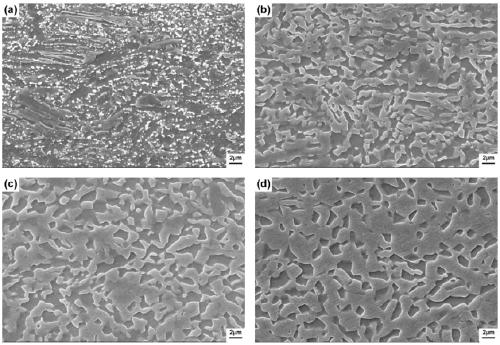

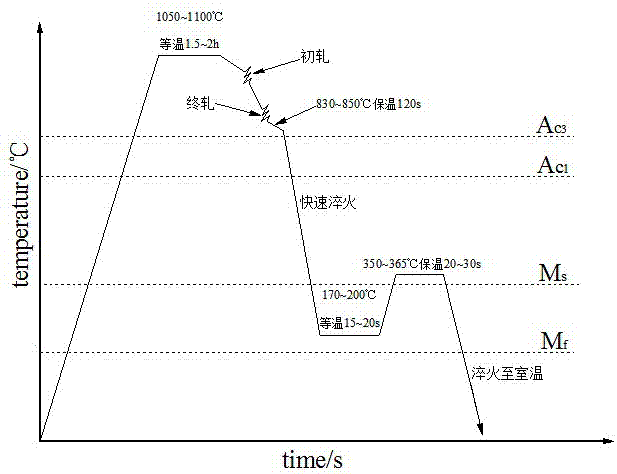

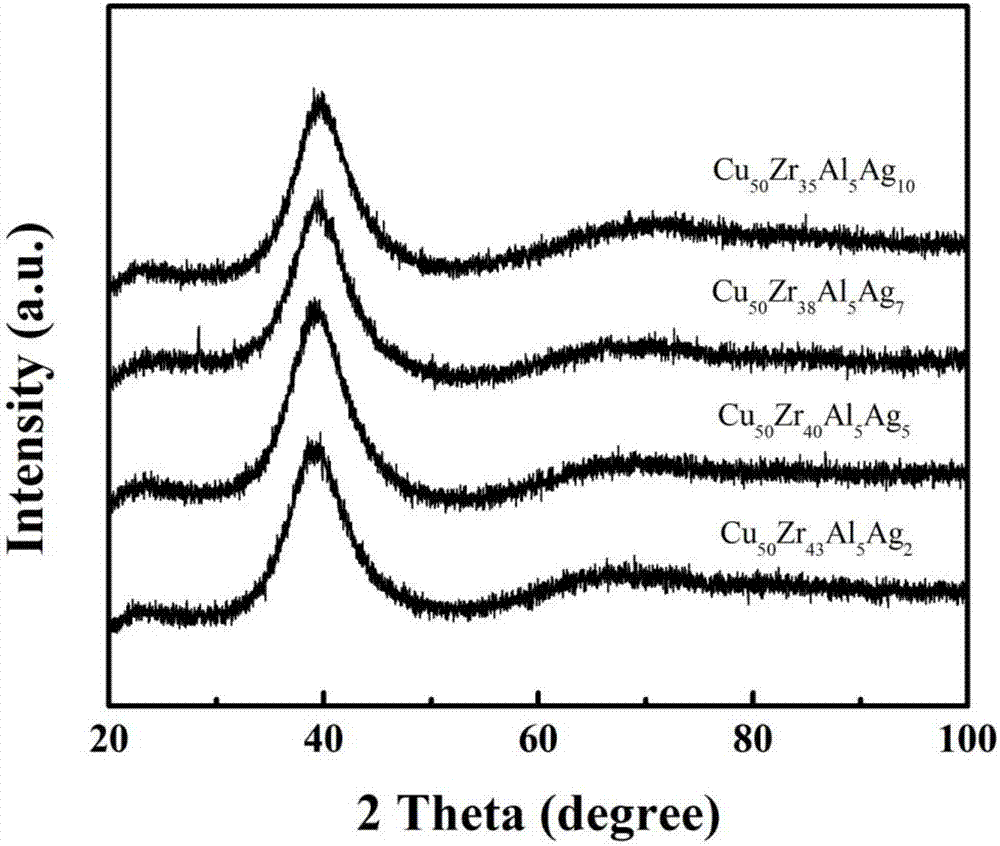

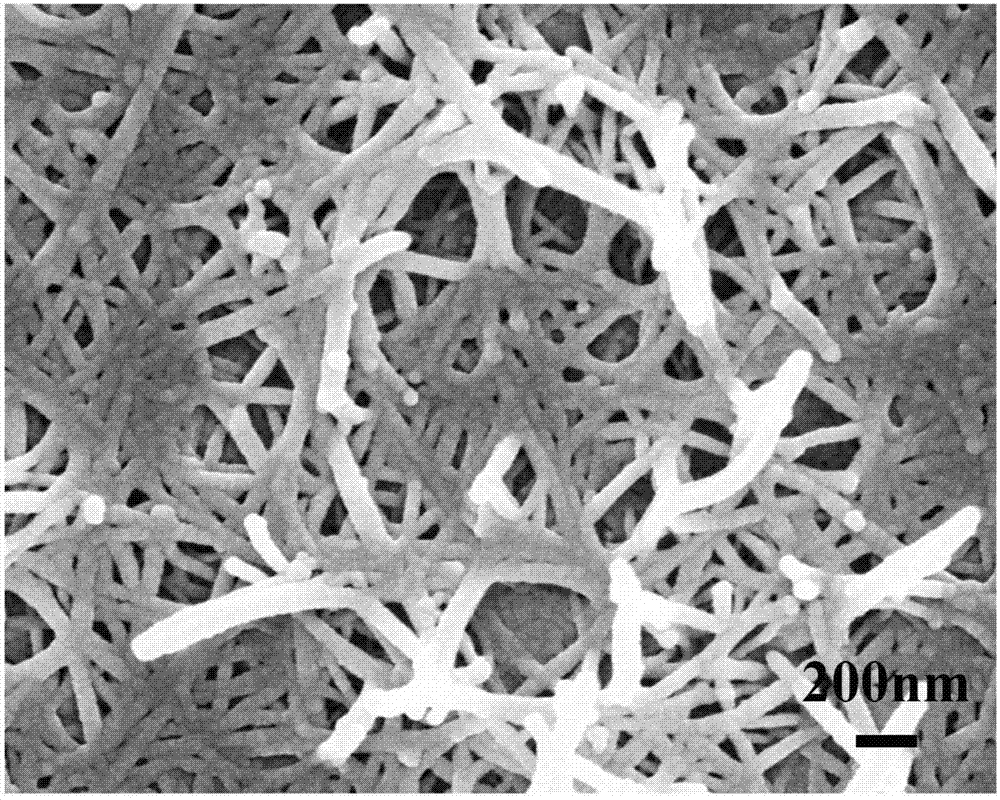

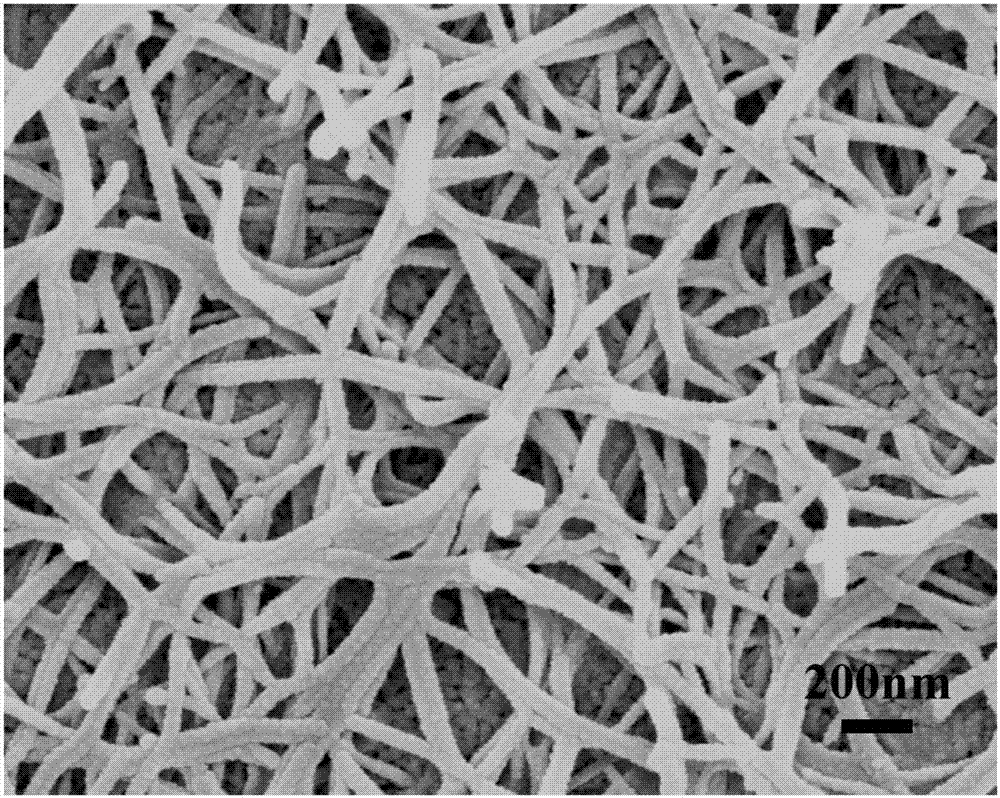

Preparation method for precious metal and transition metal nanowires and nano reticular material

ActiveCN107326209AEasy to prepareNothing producedVacuum evaporation coatingSputtering coatingNanowireQuenching

The invention discloses a preparation method for precious metal and transition metal nanowires and a nano reticular material, and belongs to the field of nanomaterial preparation. The preparation method comprises the following steps that firstly, a Cu-Zr-Al-Ag non-crystal alloy thin belt is prepared by adopting a solution fast quenching method; then a suitable corrosive liquid is selected, chemical de-alloying processing is conducted, Zr and Al elements are removed, and a nanoporous copper silver composite material is obtained; after the end of the corrosion process, the nanoporous copper silver composite material is washed repeatedly through distilled water and absolute ethyl alcohol, after the nanoporous copper silver composite material is dried by air, precious metal or transition metal atom clusters are sputtered onto the surface of the nanoporous copper silver composite material through ion sputtering equipment, the precious metal or transition metal nanowires grow out, the diameter of the nanowires is 10-100 nm, and the nanowires grow continuously in a staggered mode to form the nano reticular material. The preparation method is simple and convenient in technology, economical and controllable in process, a prepared precious metal nanonet shows the good performance such as surface enhanced raman scattering (SERS), the broad application prospects in optics, electricity, catalysis, biology and other areas are achieved.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing filter membrane of palladium-base alloy/aperture gradient Ti-Al intermetallic compound homogeneous support body for hydrogen separation

InactiveCN1640527AImprove antioxidant capacityImprove corrosion resistanceSemi-permeable membranesGas phaseOxidation resistant

The present invention relates to production of semipermeable membrane, and relates to a special preparation method of semipermeable membrane for separation process. It utilizes die pressing or isostatic cool pressing process to make Ti and Al element powder be directly combined with Ti foil or Al foil and formed into sheet blank or tubular blank, or first utilizes die pressing or isostatic cool pressing processto make Ti and Al element powder be formed into sheet blank or tubular blank, then utilizes Al liquid surface melt-dipping mode to obtani composite formed blank; then utilizes low-temperature preparation and high-temperature short-term reaction two-stage vacuum sintering synthesizing method to prepare TiAl intermetallic compound pore diameter gradient homogeneous supporting body, then adopts CVD or PVD mode to uniformly plate a layer of palladium-based alloy membrane whose thickness is 5-50 micrometers on its surface.

Owner:CENT SOUTH UNIV

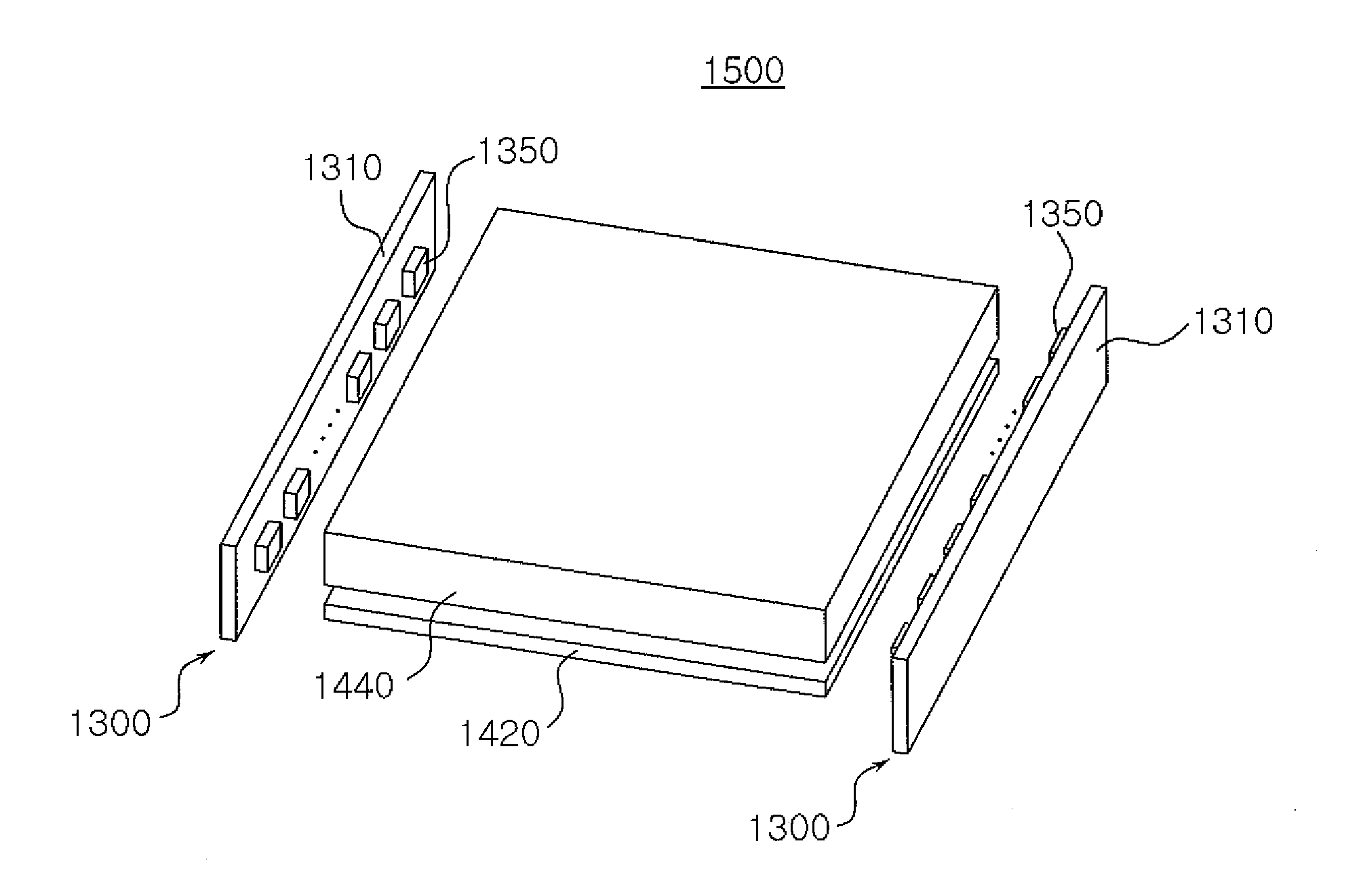

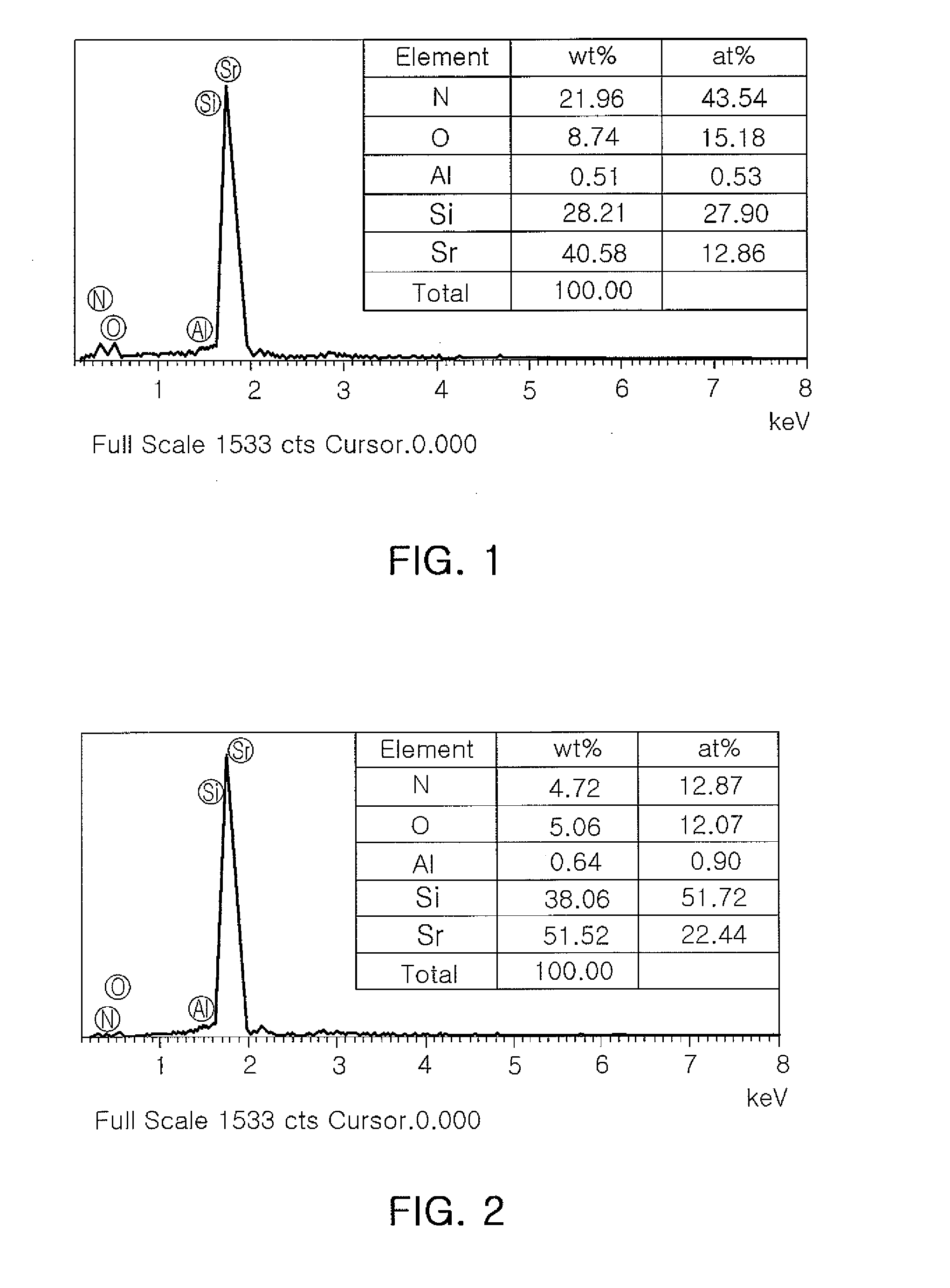

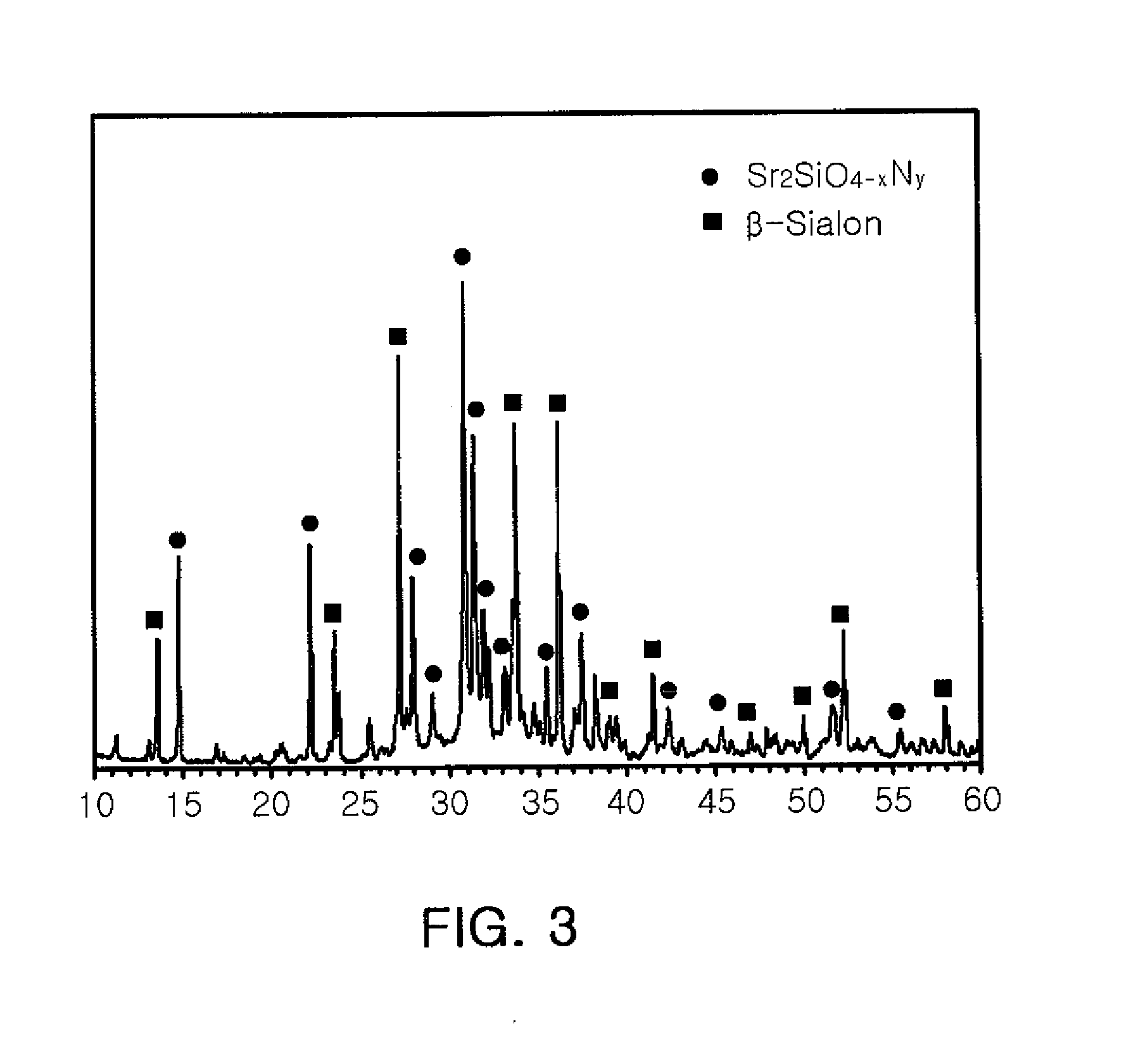

Complex Crystal Phosphor, Light Emitting Device, Surface Light Source Apparatus, Display Apparatus, and Lighting Device

ActiveUS20110234118A1Good chemical stabilityImprove thermal stabilityElectric light circuit arrangementLuminescent compositionsOxygenLight emitting device

A complex crystal phosphor is an inorganic composition containing at least an M element, an Al element, silicon, oxygen, and nitrogen. The inorganic composition has particles having at least two types of crystal phase, and the at least two types of crystal phase include a first crystal phase which is the same as a M2SiO4 crystal and a second crystal phase as a β-sialon crystal. Here, M is at least one element selected from the group consisting of (Mg), calcium (Ca), strontium (Sr), and barium (Ba).

Owner:SAMSUNG ELECTRONICS CO LTD

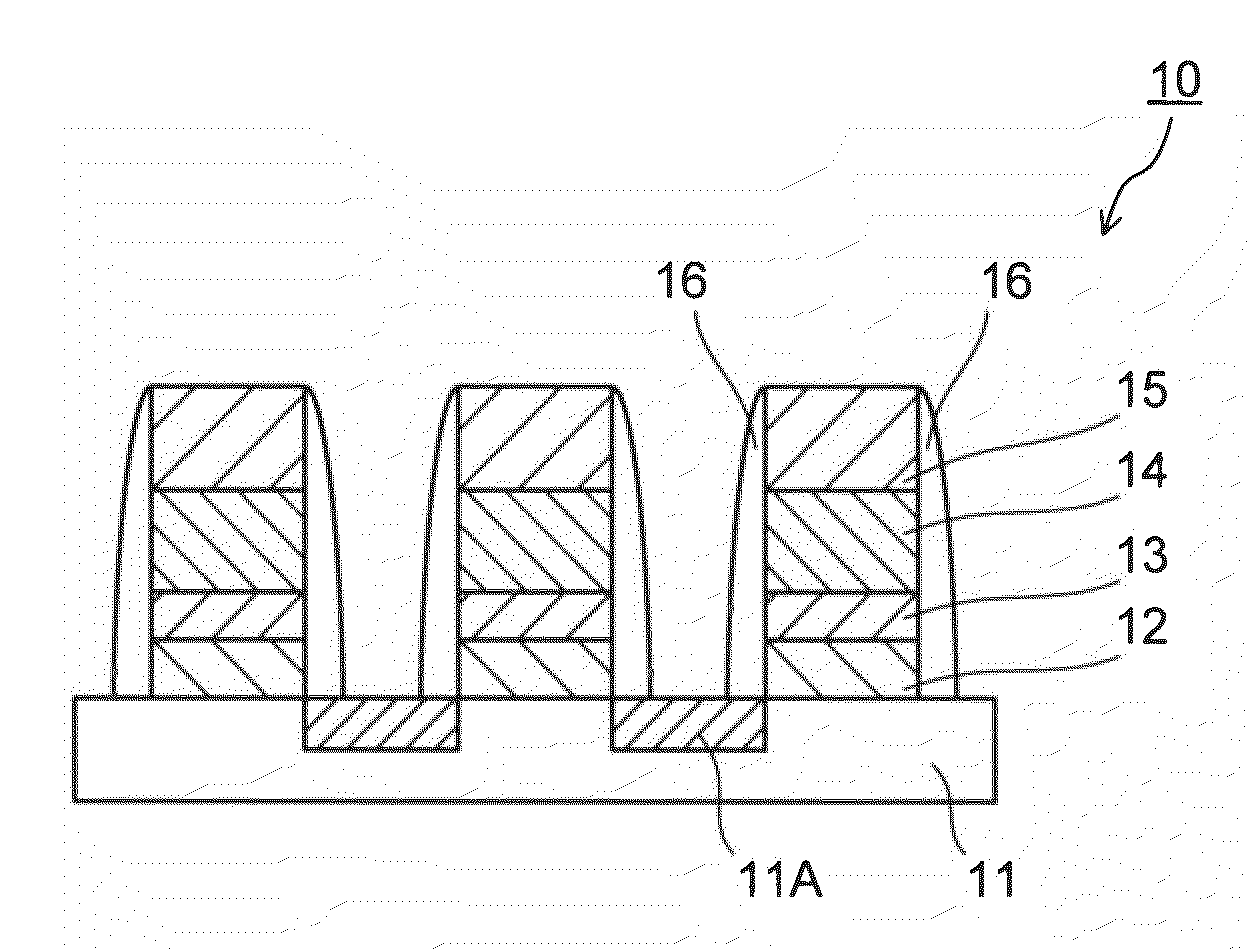

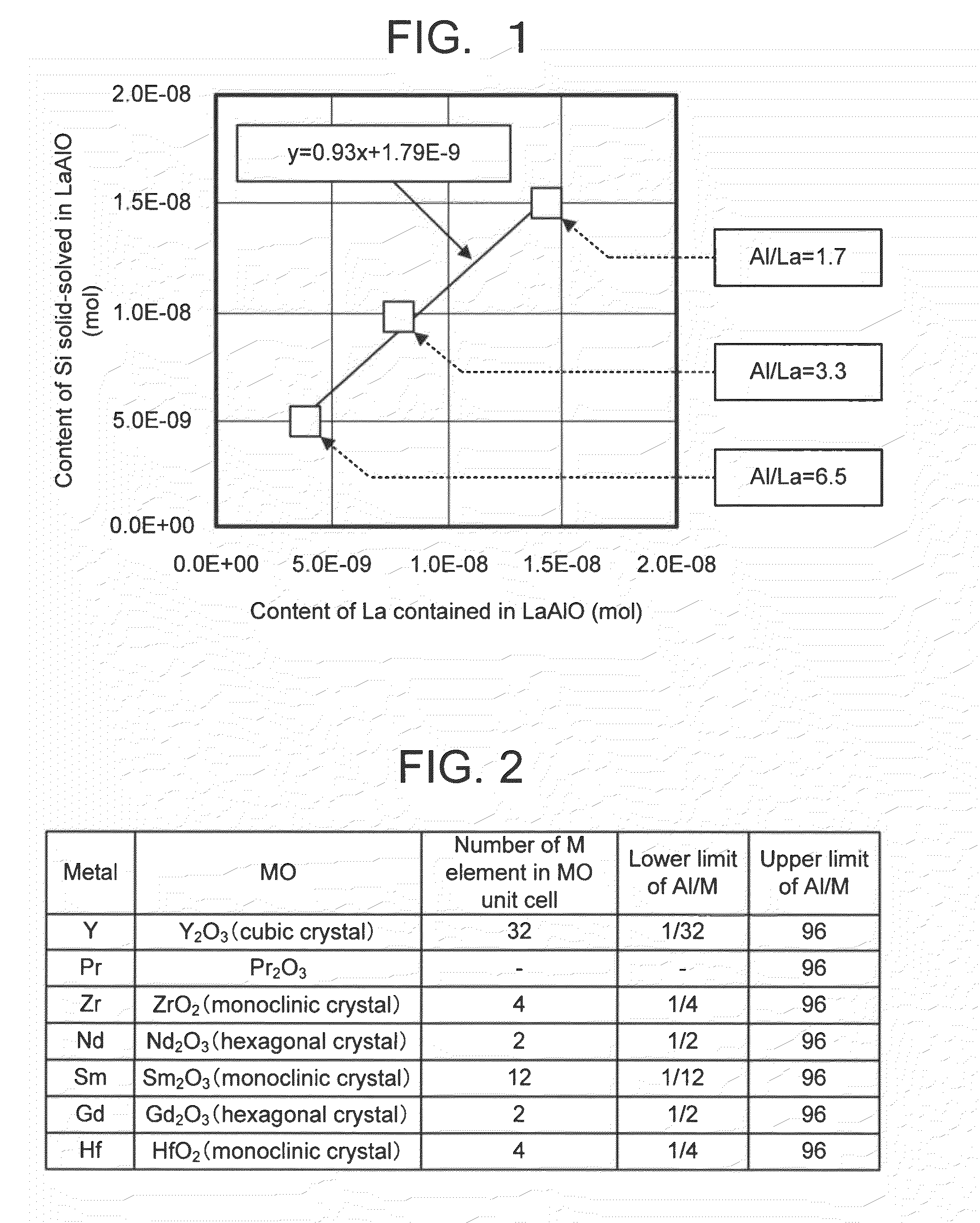

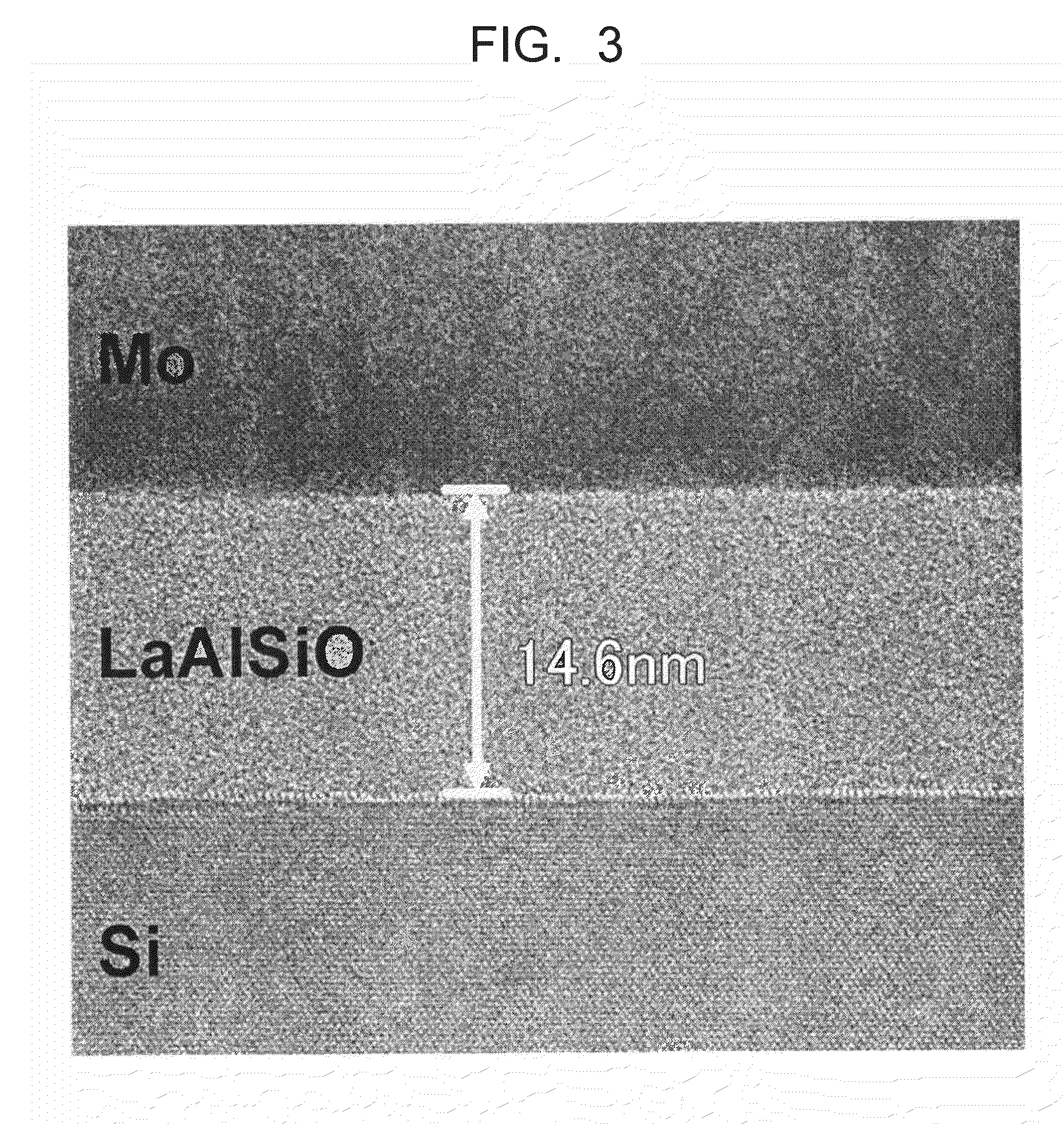

Semiconductor device and method for manufacturing a semiconductor device

InactiveUS20090242963A1Semiconductor/solid-state device manufacturingSemiconductor devicesDielectricComposite oxide

In a semiconductor device, the side walls are made of SiO2, SiN or SiON, and the top insulating film or gate insulating film is made of an oxide including Al, Si, and metal element M so that the number ratio Si / M is set to no less than a number ratio Si / M at a solid solubility limit of SiO2 composition in a composite oxide including metal element M and Al and set to no more than a number ratio Si / M at the condition that the dielectric constant is equal to the dielectric constant of Al2O3 and so that the number ratio Al / M is set to no less than a number ratio Al / M where the crystallization of an oxide of said metal element M is suppressed due to the Al element and set to no more than a number ratio Al / M where the crystallization of the Al2O3 is suppressed due to the metal element M.

Owner:KIOXIA CORP

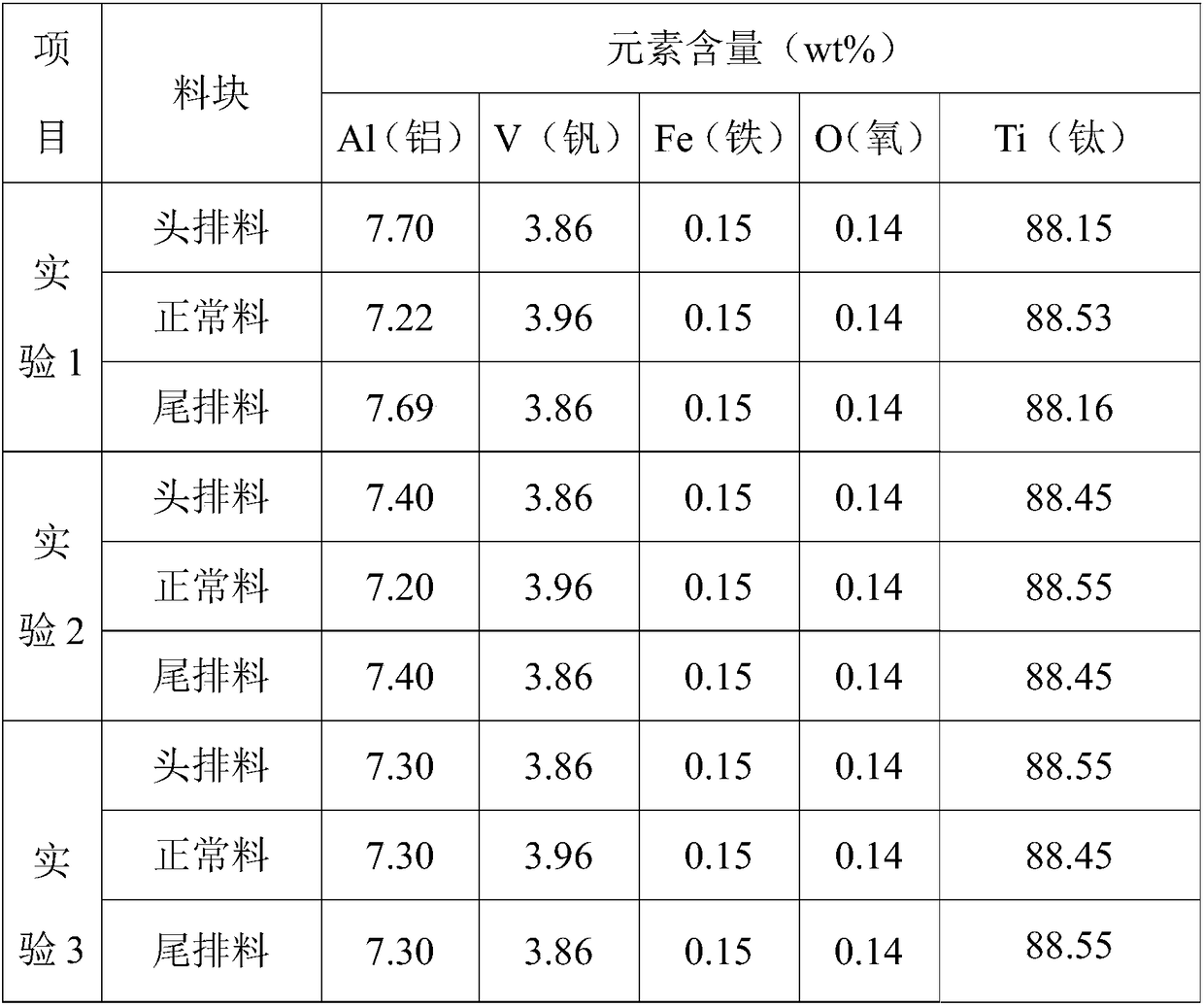

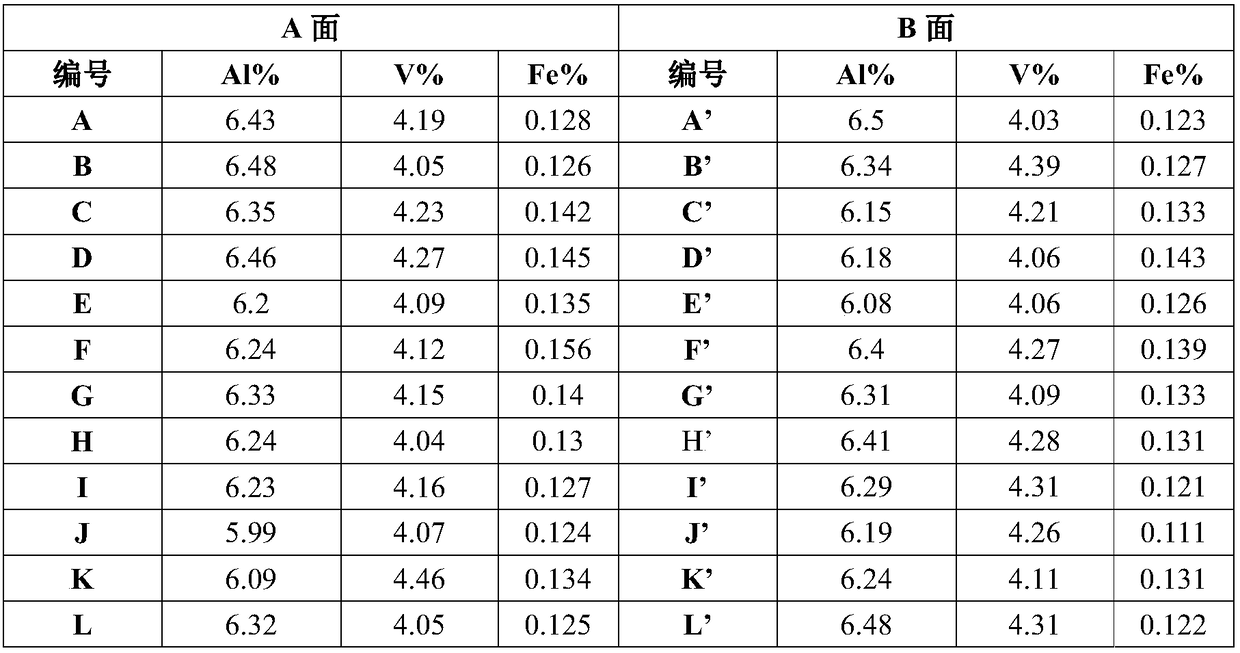

Method for improving uniformity of Al element in TC4 titanium alloy

The invention relates to a method for improving the uniformity of the Al element in TC4 titanium alloy. The method comprises the following steps: (1) preparing materials, namely preparing raw materials containing Ti, Al and V metel elements, including primary discharge materials, normal materials and tailed discharge materials; (2) sequentially feeding the primary discharge materials, normal materials and tailed discharge materials into electron beam cold hearth melting, and melting, wherein the content of Al element in the primary discharge materials is higher than 0.3-0.7% which is the content of Al element in normal materials; and the content of Al element in the normal materials is 7.00-7.40%. The method can be used for remarkably improving the uniformity of chemical ingredients of head and tail parts of ingots, reducing the cutting amount of head and tail parts of the ingots, and integrally improving the uniformity and / or yield of TC4 titanium alloy.

Owner:QINGHAI JUNENG TITANIUM IND CO LTD

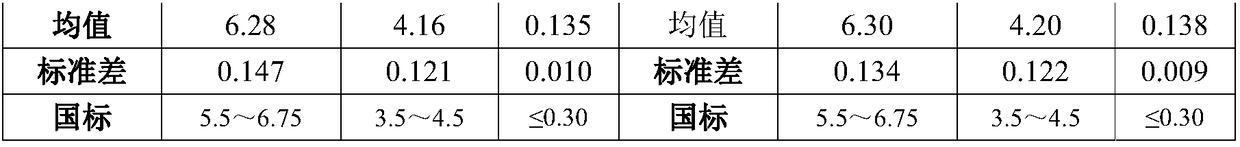

Layered positive electrode material for lithium-ion battery and preparation method of layered positive electrode material

ActiveCN107994212AStable crystal structureReduce surface residual alkali contentSecondary cellsPositive electrodesManganeseCobalt

The invention discloses a layered positive electrode material for a lithium-ion battery. The layered positive electrode material comprises a body and a B2O3 coating layer, wherein a chemical formula of the body is Li<x>(NiCoMn<c>)<1-y>M<y>O<2>, wherein x is smaller than or equal to 1.04 and greater than or equal to 0.96, y is smaller than or equal to 0.06 and greater than or equal to 0.01, ais smaller than or equal to 0.9 and greater than or equal to 0.8, a+b+c is equal to 1, and M is selected from at least one of an Al element, a Mg element, a Ti element and a Zr element. The inventionfurther discloses a preparation method of the layered positive electrode material for the lithium-ion battery. The method comprises the following steps of mixing a nickel-cobalt manganese hydroxide,a lithium source and a nano oxide additive evenly and carrying out first sintering to obtain unmodified powder; stirring the unmodified powder and water, carrying out centrifugal separation to obtaina solid material, drying and crushing to obtain washing powder; adding LIBOB to an organic solvent for dissolving, adding the washing powder for mixing, stirring, evaporating and carrying out second sintering to obtain the layered positive electrode material for the lithium-ion battery.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Gas-shielded high-toughness solid welding wire and use method and application thereof

InactiveCN105880871AImprove toughnessHave a strong deoxidizing effectArc welding apparatusWelding/cutting media/materialsWeld lineImpurity

The invention provides a gas-shielded high-toughness solid welding wire which is prepared from the following chemical components by mass percentage: 0.10-0.12% of C, 0.40-0.50% of Si, 0.60-0.70% of Mn, less than or equal to 0.010% of S, less than or equal to 0.015% of P, 1.2-1.5% of Cr, 0.50-0.60% of Mo, less than or equal to 0.02% of Ni, less than or equal to 0.03% of Cu, 0.030-0.080% of Al, less than or equal to 0.0040% of Sb, less than or equal to 0.0050% of Sn, less than or equal to 0.0050% of As, and the balance Fe. According to the invention, welding line metal with low impurity content is obtained by adopting welding wires with low S, P, Sb, Sn and As contents, and the content and proportion of Si and Mn are adjusted, thus playing a good deoxidization role and being favorable for uniform texture of the wielding line; by adding Al element, a strong deoxidizing effect can be achieved, the grains can be refined, and the low-temperature impact toughness of the welding line metal can be remarkably improved; and the gas-shielded high-toughness solid welding wire is excellent in technological performances, steady in welding arc, little in welding smoke and splashing and attractive in formed welding lines.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com