Nickel-based deformed superalloy with high aluminum content and preparation method thereof

A deformed superalloy, nickel-based technology, applied in the direction of metal processing equipment, etc., can solve the problems of large element segregation tendency, easy formation of metallurgical defects, poor plasticity, etc., and achieve good mechanical properties and satisfactory service stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Example 1. A preparation method for a nickel-based deformed superalloy disc forging that can be used at 850°C for a long time

[0058] In this example, a nickel-based deformed superalloy disc forging (with a diameter of 200 mm) that can be used at 850°C for a long time is prepared. The alloy composition is shown in the part of Example 1 in Table 1.

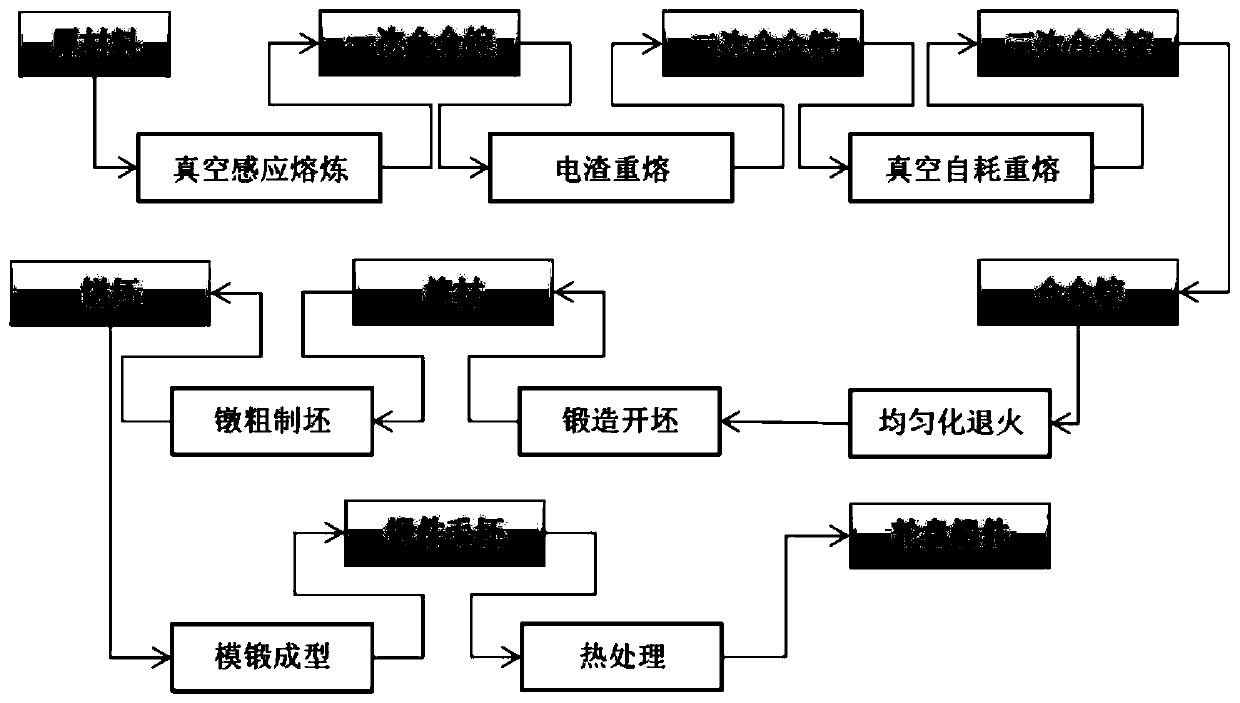

[0059] The preparation process of the alloy wheel disc forging is as follows:

[0060] The smelting adopts a dual process (ie, vacuum induction melting and vacuum consumable remelting). The diameter of the primary alloy ingot obtained by vacuum induction melting is 250mm, and the diameter of the alloy ingot obtained by vacuum consumable remelting is 305mm. Vacuum induction smelting includes the following steps: weighing raw materials according to the alloy element ratio, and performing vacuum induction smelting. The vacuum induction melting process includes several steps such as evacuation, smelting period, refining and ta...

Embodiment 2

[0065] Example 2. A preparation method for a nickel-based deformed superalloy disc forging with a diameter of 550mm that can be used at 850°C for a long time

[0066] In this example, a nickel-based deformed superalloy disc forging with a diameter of 550mm is prepared for long-term use at 850°C. The alloy composition is shown in Example 2 of Table 1.

[0067] The preparation process of the alloy wheel disc forging is as follows:

[0068] The smelting adopts dual process, vacuum induction melting + vacuum consumable remelting, the diameter of the alloy ingot for vacuum induction melting is 370mm, and the diameter of vacuum consumable remelting alloy ingot is 460mm. Vacuum induction smelting includes the following steps: weighing raw materials according to the alloy element ratio, and performing vacuum induction smelting. The vacuum induction melting process includes several steps such as evacuation, smelting, refining and tapping. The vacuum degree in the evacuation stage is 7...

Embodiment 3

[0073] Example 3. A nickel-based deformed superalloy wheel disk forging with a diameter of 900mm that can be used at 850°C for a long time

[0074] In this example, a nickel-based deformed superalloy disc forging with a diameter of 900mm is prepared for long-term use at 850°C. The alloy composition is shown in Example 3 in Table 1.

[0075] The preparation process of the alloy wheel disc forging is as follows:

[0076] The smelting adopts a triple process, vacuum induction melting + electroslag remelting + vacuum consumable remelting, the diameter of the vacuum induction melting alloy ingot is 355mm, the diameter of the electroslag remelting alloy ingot is 423mm, and the diameter of the vacuum consumable remelting alloy ingot is 508mm . Vacuum induction smelting includes the following steps: weighing raw materials according to the alloy element ratio, and performing vacuum induction smelting. The vacuum induction melting process includes several steps such as evacuation, sme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com