Patents

Literature

796 results about "Solid solution strengthening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid solution strengthening is a type of alloying that can be used to improve the strength of a pure metal. The technique works by adding atoms of one element (the alloying element) to the crystalline lattice of another element (the base metal), forming a solid solution. The local nonuniformity in the lattice due to the alloying element makes plastic deformation more difficult by impeding dislocation motion. In contrast, alloying beyond the solubility limit can form a second phase, leading to strengthening via other mechanisms (e.g. the precipitation of intermetallic compounds).

Heat and corrosion resistant cast CF8C stainless steel with improved high temperature strength and ductility

A CF8C type stainless steel alloy and articles formed therefrom containing about 18.0 weight percent to about 22.0 weight percent chromium and 11.0 weight percent to about 14.0 weight percent nickel; from about 0.05 weight percent to about 0.15 weight percent carbon; from about 2.0 weight percent to about 10.0 weight percent manganese; and from about 0.3 weight percent to about 1.5 weight percent niobium. The present alloys further include less than 0.15 weight percent sulfur which provides high temperature strength both in the matrix and at the grain boundaries without reducing ductility due to cracking along boundaries with continuous or nearly-continuous carbides. The disclosed alloys also have increased nitrogen solubility thereby enhancing strength at all temperatures because nitride precipitates or nitrogen porosity during casting are not observed. The solubility of nitrogen is dramatically enhanced by the presence of manganese, which also retains or improves the solubility of carbon thereby providing additional solid solution strengthening due to the presence of manganese and nitrogen, and combined carbon.

Owner:UT BATTELLE LLC

Normalizing type high-strength pressure vessel steel and manufacturing method thereof

The invention provides normalizing type high-strength pressure vessel steel, which comprises the following chemical components in percentage by weight: 0.12 to 0.18 percent of C, 0.15 to 0.40 percent of Si, 1.20 to 1.70 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.015 percent of S, 0.10 to 0.40 percent of Ni, 0.01 to 0.05 percent of Nb and 0.01 to 0.03 percent of Ti, 0.015 to 0.050 percent of Als, one or both of less than or equal to 0.20 percent of V and less than or equal to 0.70 percent of Cu and the balance of Fe and inevitable impurities. In the normalizing type high-strength pressure vessel steel, the specification of the steel is controlled by utilizing a single-rolling process of a steel plate, and the uniform tissue of ferrite and pearlite is obtained by adopting normalizing heat treatment; and in the process of rolling and heat treatment, the sufficient strength and good impact properties are obtained by utilizing the effects of fine-grain strengthening, precipitation strengthening and solid solution strengthening of micro-alloying elements such as the Nb, the V, the Ti and the like. In addition, the normalizing type high-strength pressure vessel steel achieves the excellent welding performance by controlling carbon equivalent and can be welded by adopting methods of manual arc welding, hidden arc welding, gas shielded welding, electroslag welding or tungsten electrode inert gas shielded-arc welding and the like; and the normalizing type high-strength pressure vessel steel has the advantages of little used precious metals, easy control of the component of each element, simple process, low production cost and high efficiency.

Owner:武钢集团有限公司

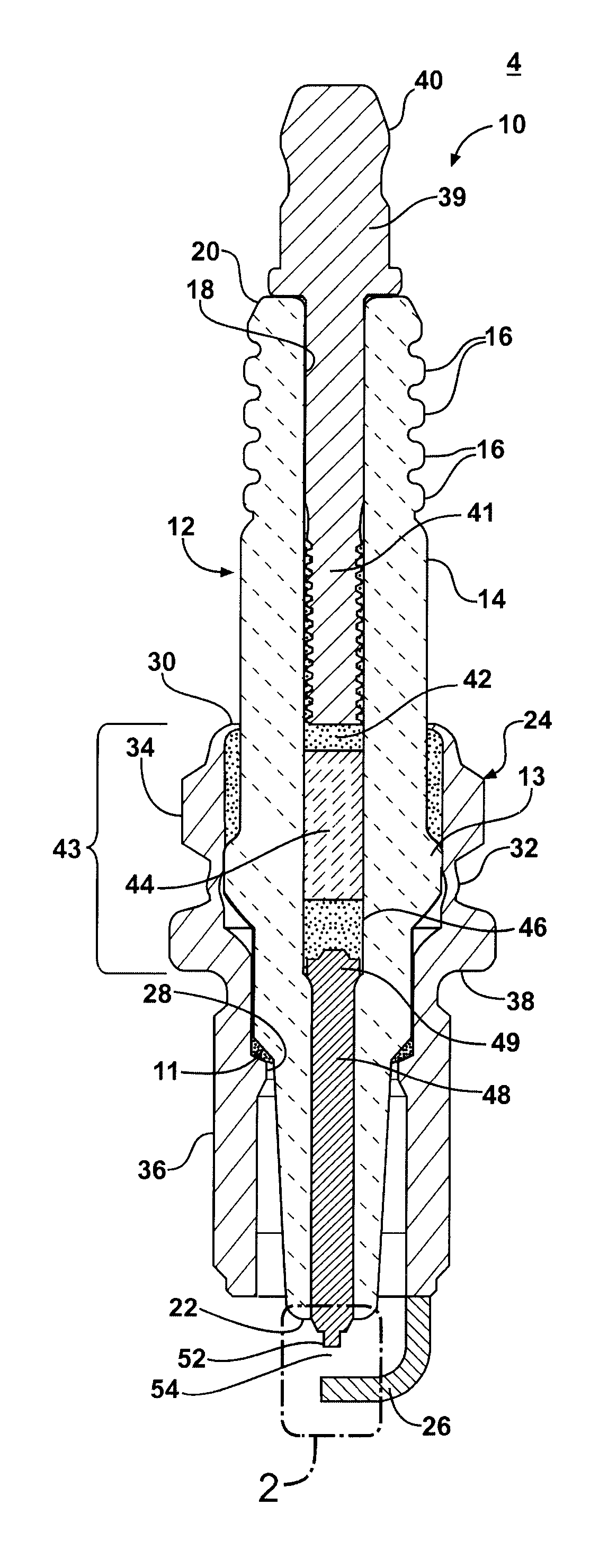

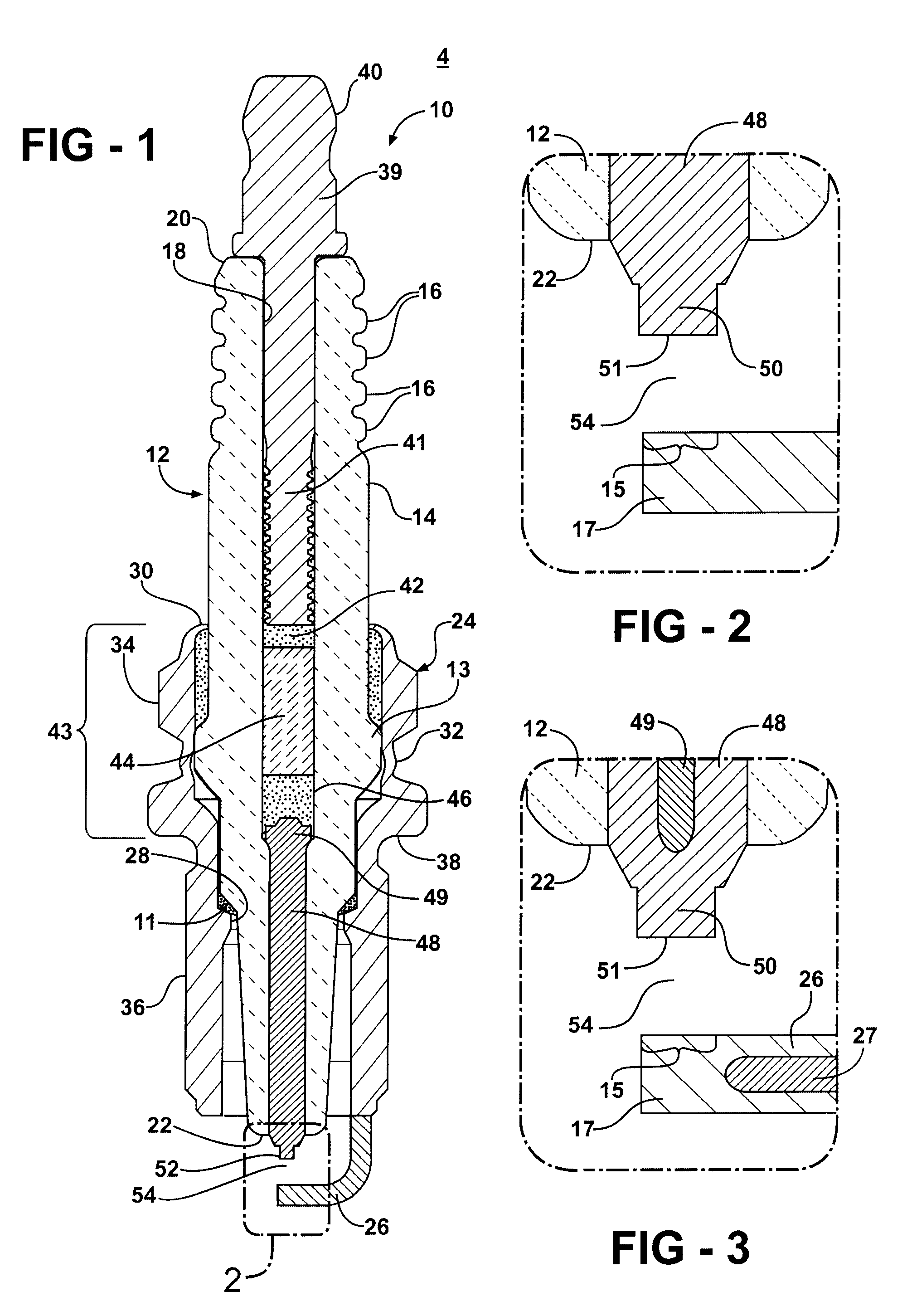

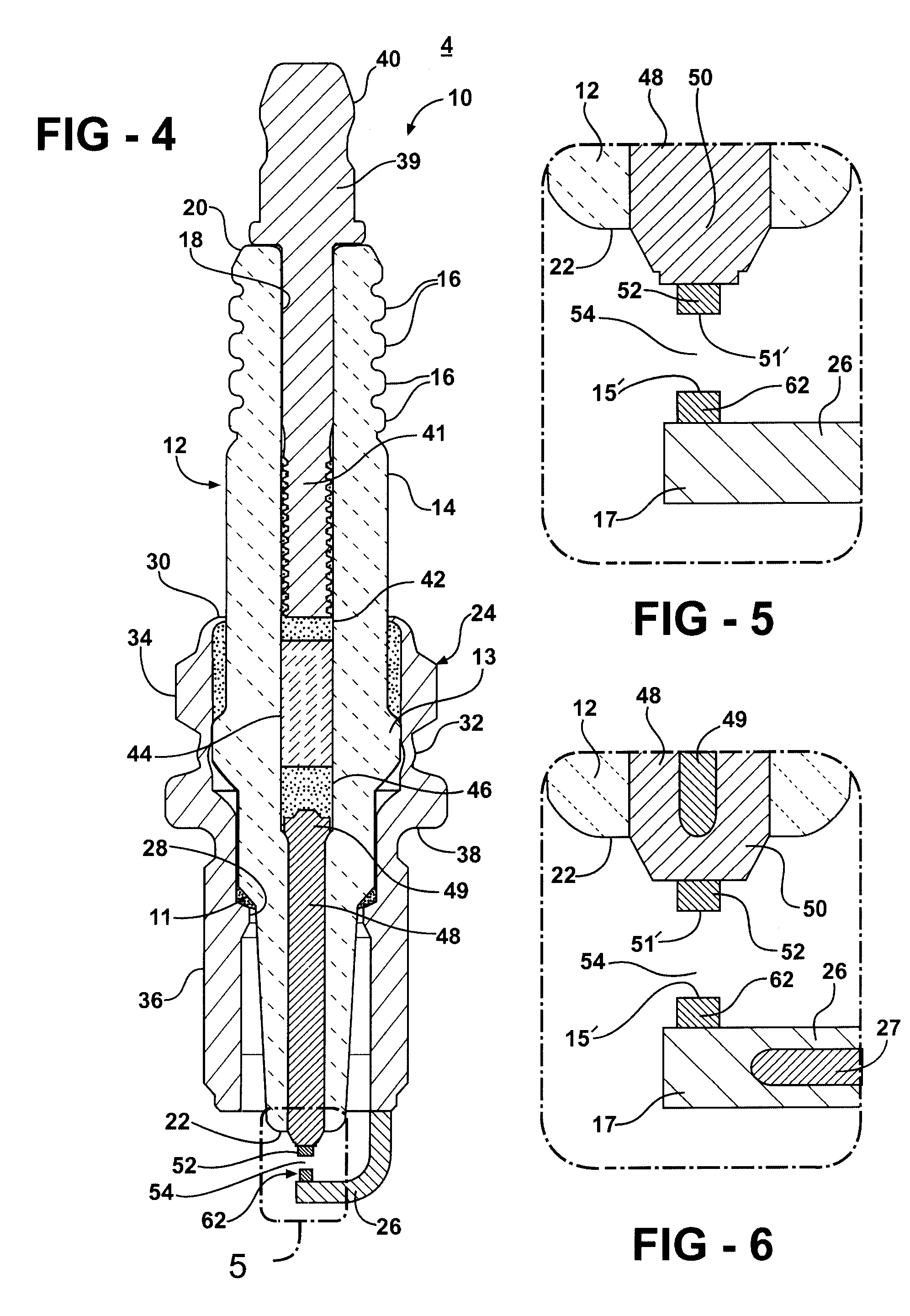

Electrode for an Ignition Device

An electrode for an ignition device is made from a Ni-based nickel-chromium-iron alloy which has improved resistance to high temperature oxidation, sulfidation, corrosive wear, deformation and fracture includes, by weight of the alloy: 14.5-25% chromium; 7-22% iron; 0.2-0.5% manganese; 0.2-0.5% silicon; 0.1-2.5% aluminum; 0.05-0.15% titanium; 0.01-0.1% total of calcium and magnesium; 0.005-0.5% zirconium; 0.001-0.01% boron, and the balance substantially Ni. It may also include at least one rare earth element selected from the group consisting of: yttrium, hafnium, lanthanum, cerium and neodymium in amounts ranging from 0.01-0.15% by weight, and incidental impurities, including cobalt, niobium, molybdenum, copper, carbon, lead, phosphorus or sulfur. These total of these impurities will typically be controlled to limits of 0.1% cobalt, 0.05% niobium, 0.05% molybdenum, 0.01% copper, 0.01% carbon, 0.005% lead, 0.005% phosphorus and 0.005% sulfur. The ignition device may be a spark plug which includes a ceramic insulator, a conductive shell, a center electrode disposed in the ceramic insulator having a terminal end and a sparking end with a center electrode sparking surface, and a ground electrode operatively attached to said shell having a ground electrode sparking surface, the center electrode sparking surface and the ground electrode sparking surface defining a spark gap therebetween. At least one of the center electrode or the ground electrode includes the solution-strengthened Ni-based nickel-chromium-iron alloy. The Ni-based nickel-chromium-iron alloy electrodes of the invention may also include a core with thermal conductivity greater than that of the Ni-based nickel-chromium-iron alloy, such as copper or silver or their alloys.

Owner:FEDERAL MOGUL WORLD WIDE LLC

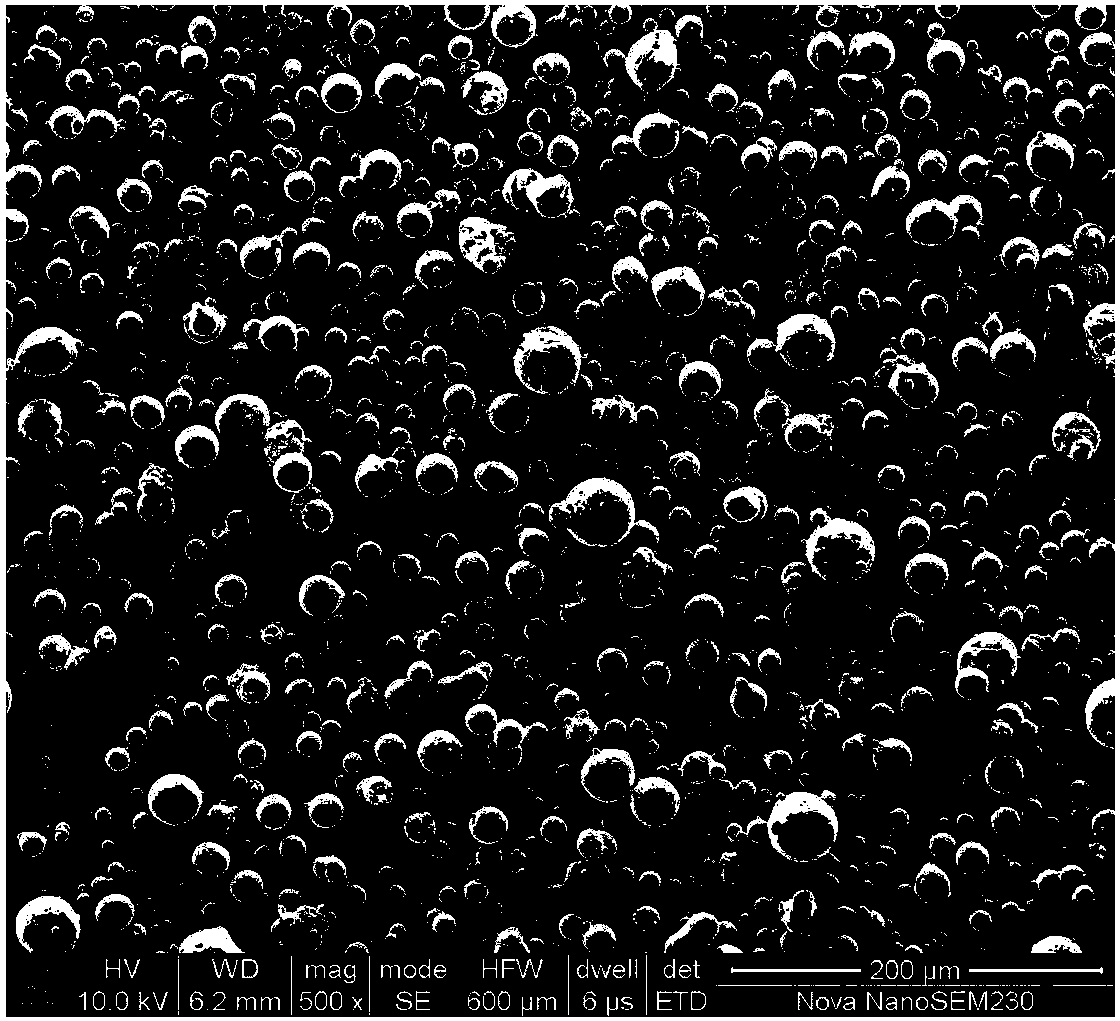

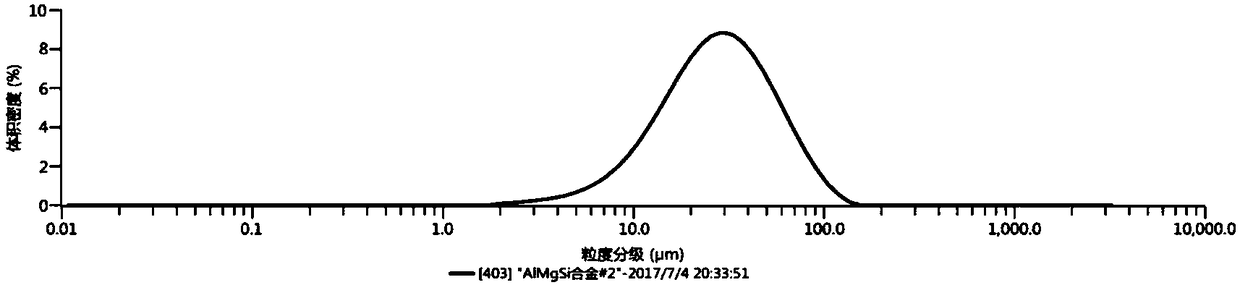

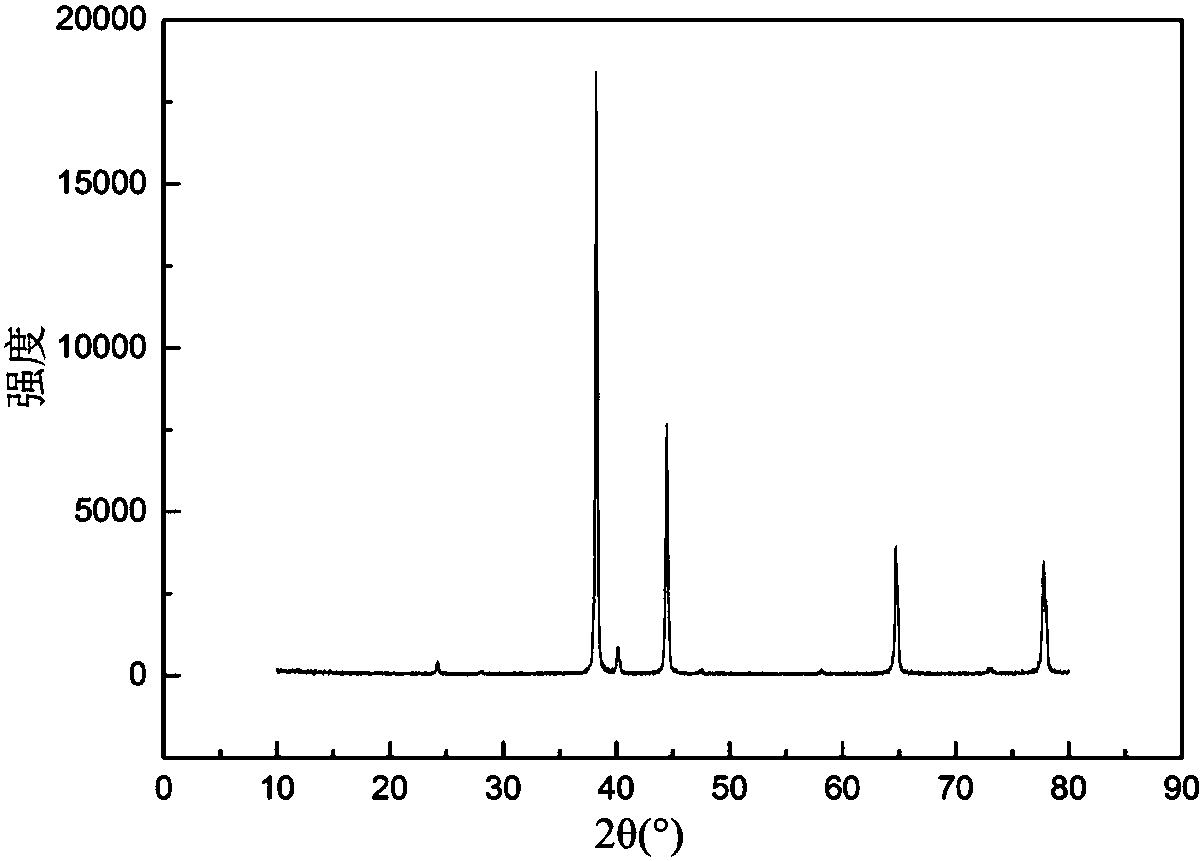

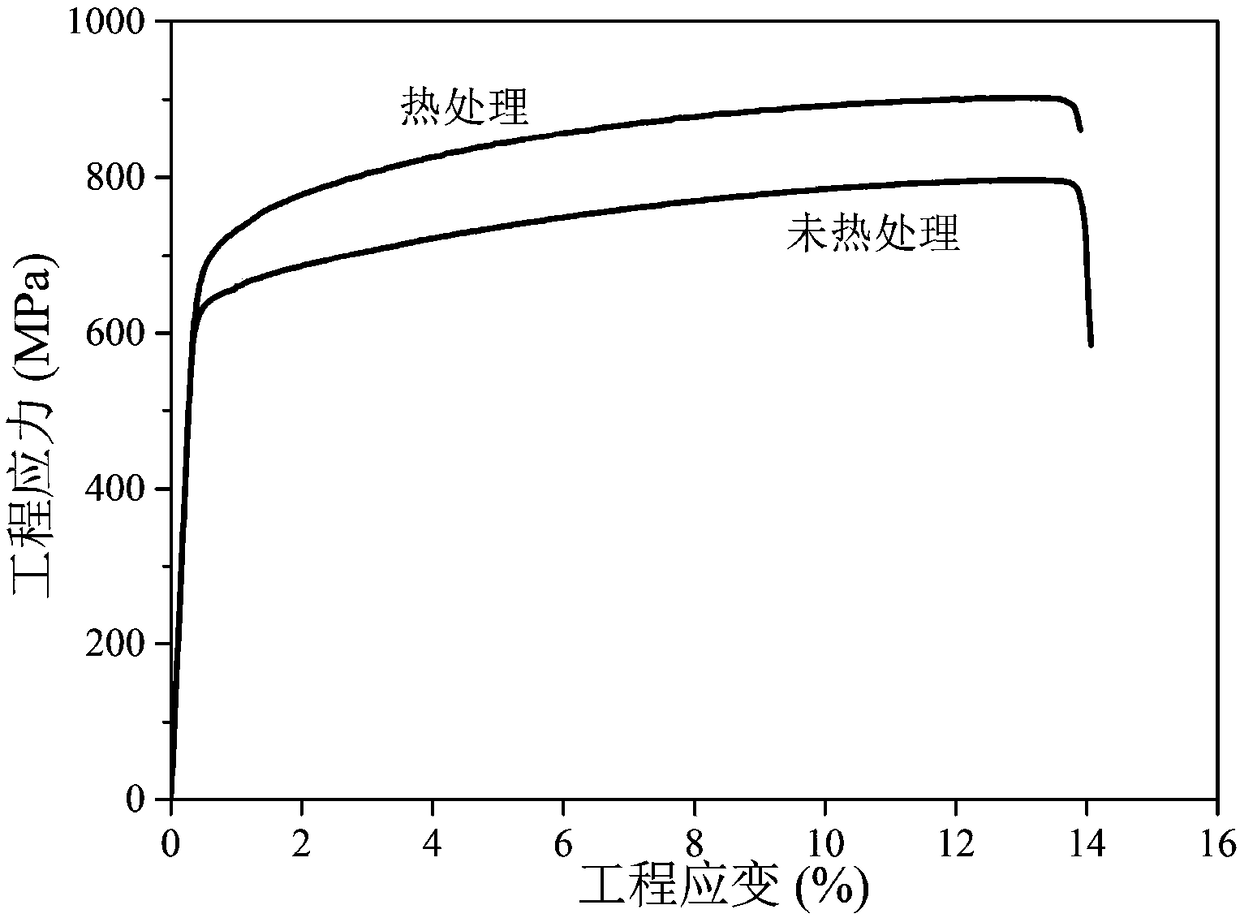

Al-Mg-Sc-Zr series aluminum alloy composition for selective laser melting technology and preparation method for molding part

ActiveCN108486433AImprove performanceIncrease contentAdditive manufacturing apparatusIncreasing energy efficiencySolubilitySelective laser melting

The invention discloses an Al-Mg-Sc-Zr series aluminum alloy composition for selective laser melting technology and a preparation method for a molding part. The composition comprises, by mass, 6-15% of Mg, 0.5-4% of Sc, 0.7-3% of Zr, 0.5-2% of Mn and the balance aluminum. An aluminum alloy molding part are prepared by smelting of master alloy, preparation of metal powder, preparation of aluminum alloy molding parts and heat treatment processes. According to the elective laser melting technology, the solubility of Mg, Sc and Zr alloy elements in aluminum matrix is greatly improved, the concentration of solid solution strengthening elements and dispersion strengthening particles in the aluminum alloy is increased, and the mechanical property of the aluminum alloy is improved. According to the aluminum alloy obtained by preparation of the selective laser melting technology, the highest density is 99.8%, the highest extension strength sigma b reaches 550 MPa, the yield strength sigma0.2 reaches 520 MPa, the plastic deformation rate of about 12 % is maintained, and the Al-Mg-Sc-Zr series aluminum alloy composition for the ctive laser melting technology and the preparation method for themolding part is applied to complicated structural parts with higher mechanical properties.

Owner:JIANGSU UNIV OF SCI & TECH

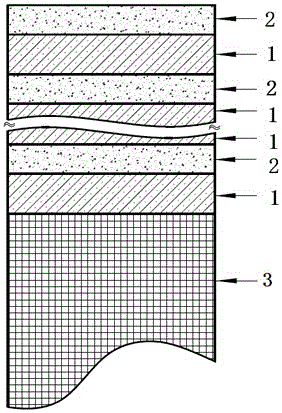

Preparation process of TiCN multilayer composite coating layer on slotting cutter surface of steam turbine rotor

ActiveCN105154880AImprove performanceExtend your lifeVacuum evaporation coatingSputtering coatingMilling cutterHardness

The invention relates to a preparation process of a TiCN multilayer composite coating layer on a slotting cutter surface of a steam turbine rotor; and the preparation process comprises surface pretreatment of a cutter basal body, cleaning, cutter clamping and loading, preparation of the multilayer composite coating layer, cooling and discharge, and aftertreatment. The multilayer structure formed by the coating layer preparation process uses TiN and TiCN as alternating coating layers to prepare 50 TiN and TiCN alternating coating layers on the slotting cutter surface; TiN is the backing layer; and TiCN is the outermost layer. The coating layer prepared by the method relieves the residual stress of the coating layer and the cutter basal body, so that the bonding force of the basal body and the coating layer is larger, the bonding degree of the coating layer is higher, and the coating layer is not easy to be stripped off. In addition, C atoms are introduced based on TiN to cause the lattice distortion and the solid solution strengthening effect, so that the surface hardness of the cutter basal body can reach HV3500, the cutter wear resistance is improved, the cutter service life is prolonged, the machining quality of the steam turbine rotor is guaranteed, and the production cost is reduced.

Owner:SHANGHAI INST OF TECH +1

High strength Al-Mg-Sc alloy powder, preparation method thereof, application in 3D printer and 3D printing method of high strength Al-Mg-Sc alloy powder

ActiveCN108465807AHigh strengthImprove plasticityAdditive manufacturing apparatusIncreasing energy efficiencyRare earthHigh intensity

The invention discloses high strength Al-Mg-Sc alloy powder, and a preparation method, application and 3D printing method thereof. The specific combination of the alloy powder has multiple strengthening mechanisms of nanometer precipitation strengthening, fine grain strengthening, solid solution strengthening and the like, and high strength and plasticity are achieved. The rare earth high strengthAl-Mg-Sc alloy powder is subjected to 3D printing, parts are free of cracks, the compactness degree is high, the tensile strength and the elongation percentage are far higher than those of AL-12Si and AlSi10Mg alloys for traditional 3D printing, and the problems that a traditional aluminum alloy is low in 3D printing strength and poor in elongation percentage, and the stretching performance and the elongation percentage cannot be improved at the same time are solved. The tensile strength of the parts formed by printing the high strength Al-Mg-Sc alloy powder can reach 523 MPa or above, and the elongation percentage can exceed 13%.

Owner:CENT SOUTH UNIV +1

Microalloy HRB500E steel bar containing chrome and nitrogen and production method thereof

The invention discloses a microalloy HRB500E steel bar containing chrome and nitrogen and a production method thereof. By fully utilizing the strengthening effect and the corrosion-proof effect of chrome on the steel bar, solid solution strengthening elements, namely manganese and silicon, are partially substituted, and a microalloy element, namely vanadium or columbium is partially or fully substituted; a cheap nitrogen element is used for performing microalloy treatment on the steel bar, so that the micro nitrogen separating strengthening effect is achieved; by the production method, the HRB500E steel bar can be produced; Rel of the steel bar is 520 to 580MPa, Rm of the steel bar is 640 to 730 MPa, A is 22 to 32 percent, Rm / Rel is 1.30 to 1.40, the cold bending qualified rate is 100 percent, the welding carbon equivalent weight is less than or equal to 0.50, and the comprehensive cost of one ton of steel bar is 40-100 yuan lower than that of one ton of the steel bar produced by the conventional method; during aging of three months, the fluctuation values of the Rm value and the Rel value are less than 10MPa; and the steel bar has excellent welding performance and good corrosion-proof property.

Owner:长沙东鑫环保材料有限责任公司

Alloy vermicular cast iron glass mold material and preparation method thereof

The invention relates to an alloy vermicular cast iron glass mold material and a preparation method thereof, and belongs to the field of glass mold manufacturing. The alloy vermicular cast iron glass mold material comprises the following chemical elements in percentage by mass: 3.5-3.6% of carbon, 2.9-3.0% of silicon, 0.4-0.5% of manganese, 0.4-0.5% of molybdenum, less than 0.15% of vanadium, less than 0.10% of titanium, 0.3-0.4% of chromium, 0.4-0.5% of nickel, less than 0.05% of phosphorus, less than 0.03% of sulfur and the balance of iron. The invention has the following advantages: the reasonable selection of the metal elements and the mass percents thereof is beneficial to saving noble metal materials and reducing the variety of the used noble metal elements; the selected alloy elements have a favorable solution strengthening effect, thereby being beneficial to enhancing the strength of the iron element under a high-temperature environment and then prolonging the service life of the glass mold; and the preparation method provided by the invention is beneficial to the dispersion and distribution of second-phase carbides in grain boundaries, so that the grain boundaries can be strengthened, and the creep strength can be improved.

Owner:ORI MOLD TECH SUZHOU

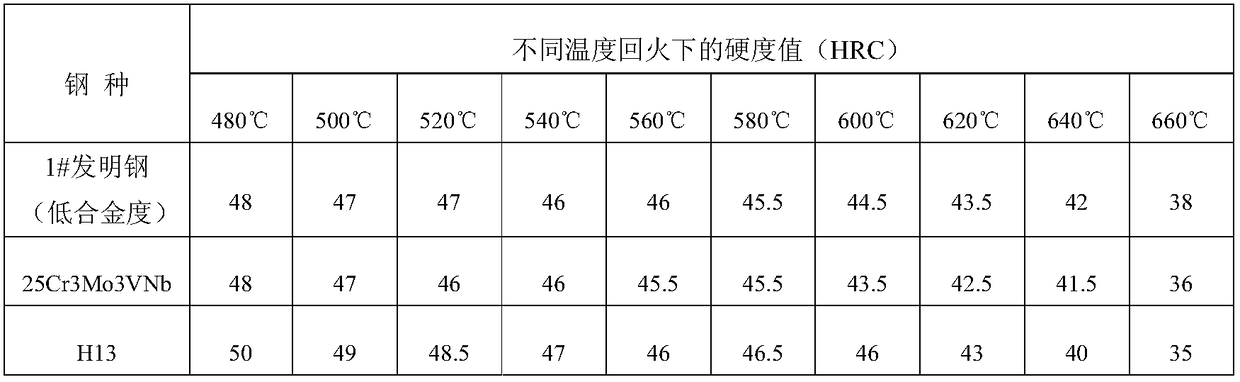

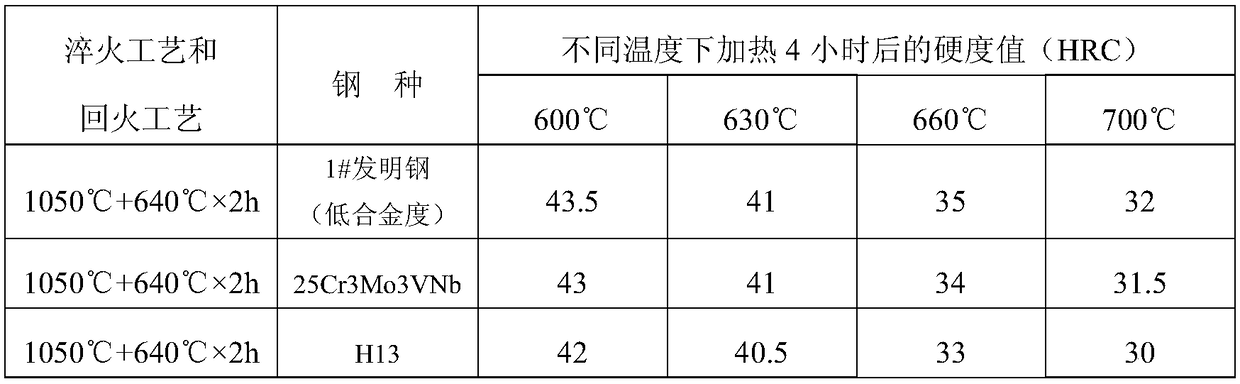

High-temperature, high-strength and low-carbon hot work die steel and preparation method thereof

The invention discloses hot work die steel capable of being used for a long term at the working condition of 600-700 DEG C and belongs to the field of material and preparation. The hot work die steelcomprises the following components in percentage by mass: 0.12-0.30 of C, equal to or less than 0.5 of Si, equal to or less than 0.5 of Mn, 1.0-3.0 of Cr, 1.5-2.5 of Mo, 0.3-1.2 of W, 0.5-1.6 of Ni, 0.2-1.0 of V, 0.03-0.15% of Nb, equal to or less than 0.05 of N, equal to or less than 0.03 of S, equal to or less than 0.03 of P, equal to or less than 3.5 of (Mo+W), equal to or less than 1.0 of (Nb+V) and the balance of Fe and unavoidable impurity elements. According to the hot work die steel, low carbon is adopted to form lath martensite so as to obtain high tenacity at room temperature and lowtemperature; through alloying of Cr, W, Mo, V, Nb and the like and the thermal deformation optimization and thermal treatment technology, solution strengthening is improved and MC and M2C type carbide still keeping stability at 600-700 DEG C is formed so as to obtain high temperature strength and thermal stability of the material. Compared with the commonly used hot work die steel at present including H13, 25Cr3Mo3NiNbZr and the like, the high temperature strength at 700 DEG C of the hot work die steel is improved by 50-100%, the tempering thermal stability is improved by 50-100%, the problemabout hot work die steel used at 600-700 DEG C is better solved, and the hot work die steel has longer service life at 600 DEG C and below.

Owner:UNIV OF SCI & TECH BEIJING

High strength alloy round aluminium rod and production method thereof

ActiveCN101956103AChange the way of beingChange speedMetal rolling arrangementsNitrogenHigh intensity

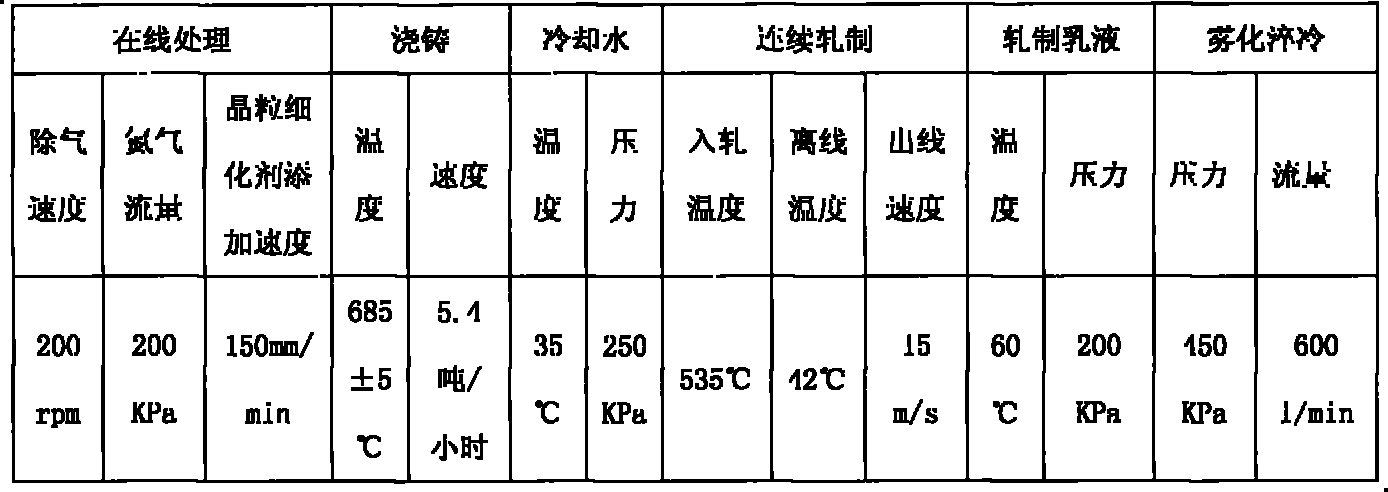

The invention provides a high strength alloy round aluminium rod and a production method thereof. Liquid aluminium with the content of more than 99.5% is added into a smelting furnace, the temperature is controlled to be 760-800 DEG C; silicon and magnesium and iron chelating agent are added, wherein the content of Si is controlled to be less than or equal to 0.6%, the content of Mg is controlled to be 0.3-0.9%, and the content of Fe is controlled to be less than or equal to 0.3%; aluminium melt is prepared, nitrogen is utilized to blow powder refining agent into the solution for refining, the usage amount of refining agent is 1.2kg / ton, and the pressure of nitrogen which is led in is 0.05-0.4MPa, thus obtaining aluminium melt with higher purity; and continuous casting and tandem rolling are carried out on aluminium melt subject to standing, before casting, Al-Ti-B rod is added in a chute at the speed of 150mm / min, so as to carry out online grain refinement treatment on the aluminium melt; and the rolled wire is subject to solid solution strengthening by virtue of an atomization quenching channel. Compared with common pure aluminium electrician round aluminium rod, the Al-Si-Mg alloy round aluminium rod of the invention has the advantages that: tensile strength is improved by 56.5%, the maximum can reach 64.6%; corresponding elongation is increased by 200%, the maximum can reach 228%; and resistivity is increased by only 28%.

Owner:YUNNAN ALUMINUM

Corrosion resistant niobium-titanium alloy, and method for manufacturing plates and pipes with the same

InactiveCN102703757AImprove corrosion resistanceExpand the range of corrosion resistanceSolid solution strengtheningTitanium alloy

The invention relates to a corrosion resistant niobium-titanium alloy, and a method for manufacturing plates and pipes with the corrosion resistant niobium-titanium alloy, wherein the corrosion resistant niobium-titanium alloy contains the following components by weight: 0.1-4.9% o Nb, not more than 0.08% of C, not more than 0.03% of N, not more than 0.012% of H, not more than 0.1% of O, not morethan 0.1% of Fe, and the balance of Ti. In Ti-(0.8-6%) Nb alloy pipes disclosed by the invention, titanium is as a matrix; little niobium is added; mechanical property of the niobium is improved by asolid-solution strengthening way; shearing strength and tensile strength of the alloy are higher than pure titanium; the tensile strength is increased by 10-20%; good plasticity and formability are kept; cold working performance is excellent; the niobium is added to further increase corrosion resistance of titanium and enlarge corrosion resistant range of titanium, so that the corrosion resistantniobium-titanium alloy is a good easily-formed corrosion resistant material.

Owner:NINGXIA ORIENT TANTALUM IND

High-temperature alloy cast tube material for 700 DEG C level ultra-supercritical thermal power generating unit reheater and preparation method of high-temperature alloy cast tube material

ActiveCN103556073AReduced tendency to increase brittlenessImprove high temperature mechanical propertiesSolid solution strengtheningSuperalloy

The invention belongs to the field of materials, and in particular relates to a high-temperature alloy cast tube for a 700 DEG C level ultra-supercritical thermal power generating unit reheater and a preparation method of the high-temperature alloy cast tube, aiming to obtain good high-temperature mechanical properties and simplify a processing technology. The adopted technical scheme is as follows: the high-temperature alloy cast tube comprises the following components in percentage by mass: 0.05-0.21% of C, 20-25% of Cr, 30-39% of Ni, less than or equal to 0.7% of Mn, less than or equal to 0.3% of Si, less than or equal to 1.6% of Nb, less than or equal to 2.5% of Mo, 1.0-3.5% of W, less than or equal to 0.3% of Ti, less than or equal to 1.0% of Al, less than or equal to 0.10% of N, less than or equal to 0.005% of B, less than or equal to 0.15% of Re and the balance of Fe. The preparation method comprises the steps of preparing raw materials, smelting, casting, and performing surface treatment and heat treatment. The alloy material disclosed by the invention reduces the brittleness increasing tendency of alloy during the service time, and the high-temperature mechanical properties of the alloy are improved through solid solution strengthening.

Owner:XIAN THERMAL POWER RES INST CO LTD

Super-hard five-component transition metal carbide single-phase high-entropy ceramic material and preparation method thereof

ActiveCN110194667ARegulating the densification processCalcination temperature is lowOxygenMechanical property

The invention discloses a super-hard five-component transition metal carbide single-phase high-entropy ceramic material and a preparation method thereof, belongs to the technical field of super-hard ceramic materials, and particularly relates to a super-hard single-phase high-entropy ceramic material and a preparation method thereof. In the prior art, the existing multi-component carbide preparation method can cause oxygen pollution, and the density is difficultly increased. A purpose of the present invention is to solve the problems in the prior art. According to the present invention, the super-hard five-component transition metal carbide single-phase high-entropy ceramic material has a chemical formula of (Tix1Zrx2Nbx3Tax4Mx5)C; the preparation method comprises: 1, weighing, 2, mixing,3, calcining, 4, high temperature sintering, and 5, demolding; and with the method, the density and the mechanical properties of the carbide are improved, the significant solid solution strengtheningeffect and the high density significantly improve the hardness of the material, and the super-hard five-component transition metal carbide single-phase high-entropy ceramic material can be obtained.

Owner:HARBIN INST OF TECH

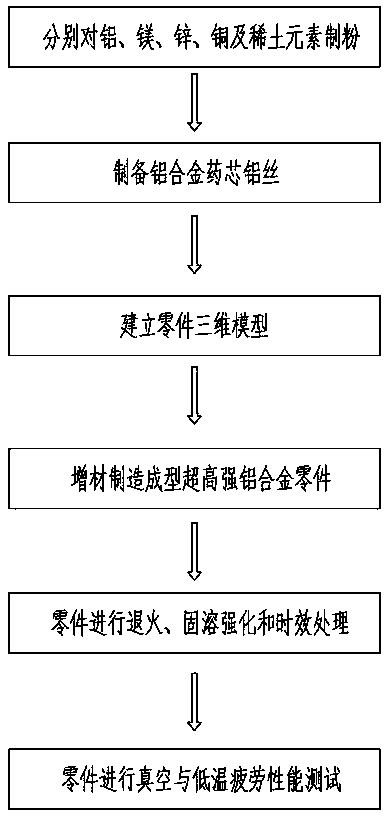

Method for preparing complex high strength aluminum alloy by adopting laser-induced electric arc additive manufacturing technology

ActiveCN107803503AMake up for evaporationMake up for the lossAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing technologyMuffle furnace

The invention relates to a method for preparing a complex high strength aluminum alloy by adopting a laser-induce electric arc additive manufacturing technology. The method comprises the following steps of (1) adopting an atomization pulverization process for powdering aluminum, magnesium, zinc, copper, zirconium and scandium respectively; (2) mixing the powder according to the proportion, rollinga high strength aluminum alloy into a tubular shape, and filling the powder into a tube core of the tubular high strength aluminum alloy so as to obtain an aluminum alloy flux core aluminum wire; (3)building a part three-dimensional model, and guiding into a laser-induce electric arc additive manufacturing and forming device; (4) guiding the aluminum alloy flux core aluminum wire into a weldinggun, melting the aluminum alloy flux core aluminum wire under a laser-induce electric arc, and forming the complex high strength aluminum alloy on a base plate according to a hierarchical path track through a robot; (5) separating a parts from the base plate, and putting the parts into a muffle furnace so as to be subjected to annealing, solution strengthening and aging treatment. The method provided by the invention can be used for forming the high strength aluminum alloy parts with complex structure and shape through additives, and has the advantages of quickness, accuracy in manufacturing,short manufacturing period, and low cost.

Owner:HUBEI POLYTECHNIC UNIV

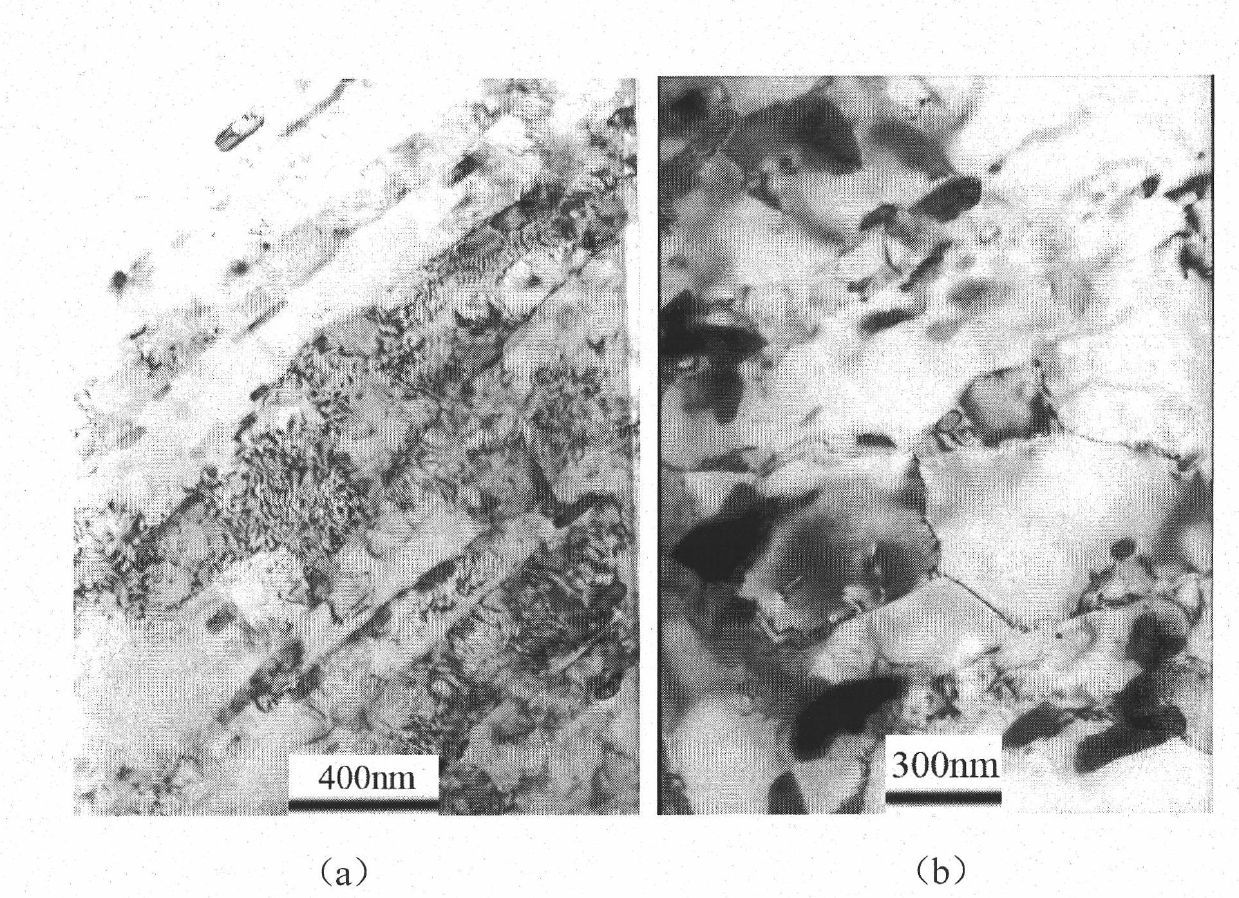

Endogenous ductile phase reinforced ti-based amorphous composite material and preparation method thereof

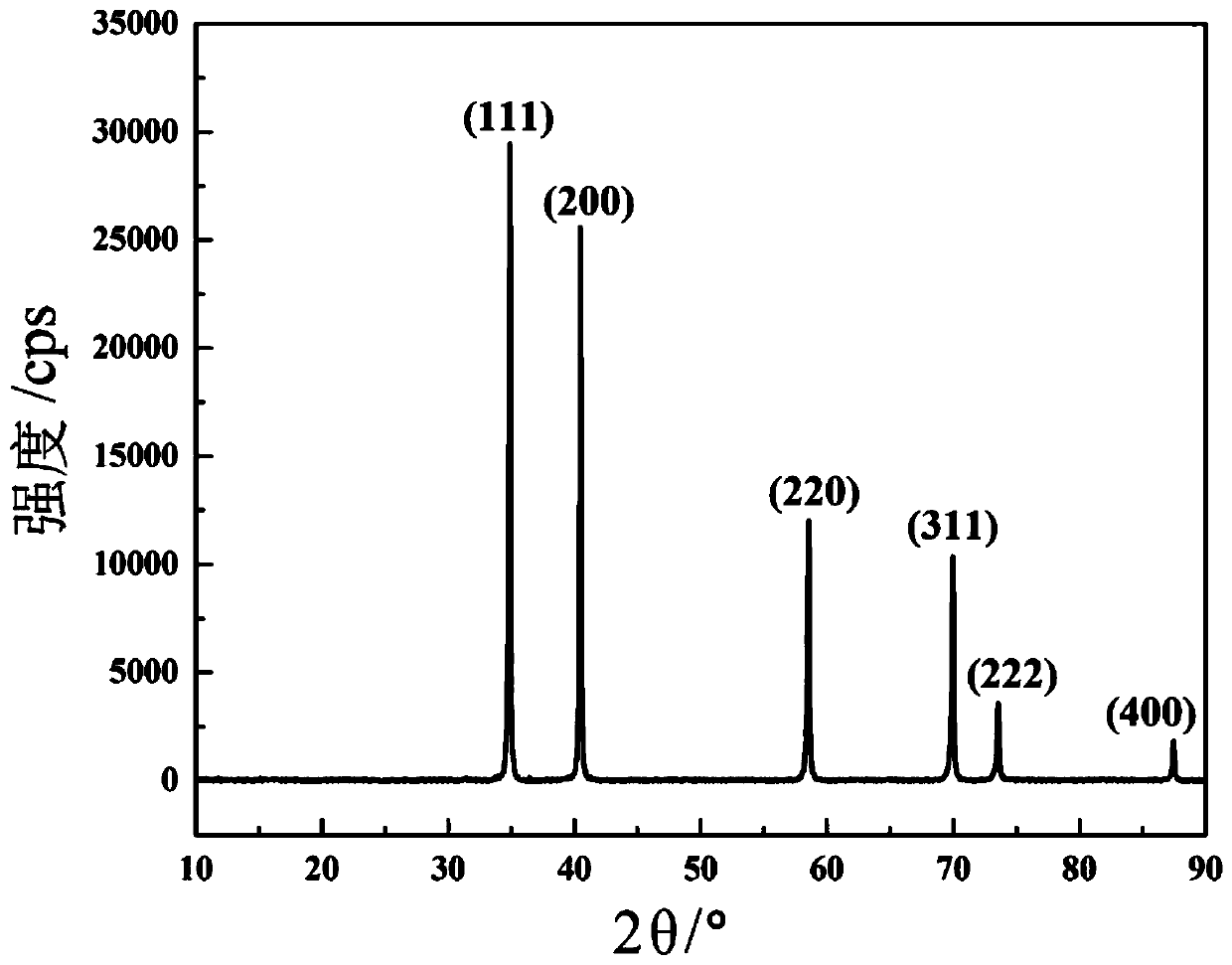

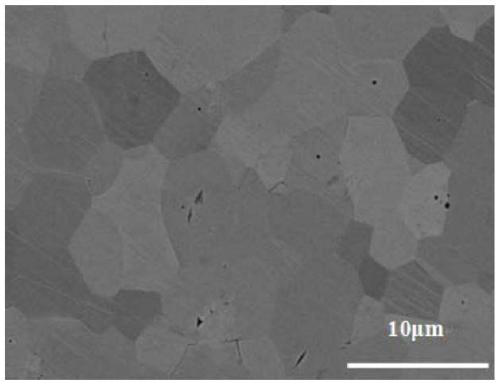

ActiveCN102296253AStable manufacturingNo post-treatment process requiredTensile strainSolid solution strengthening

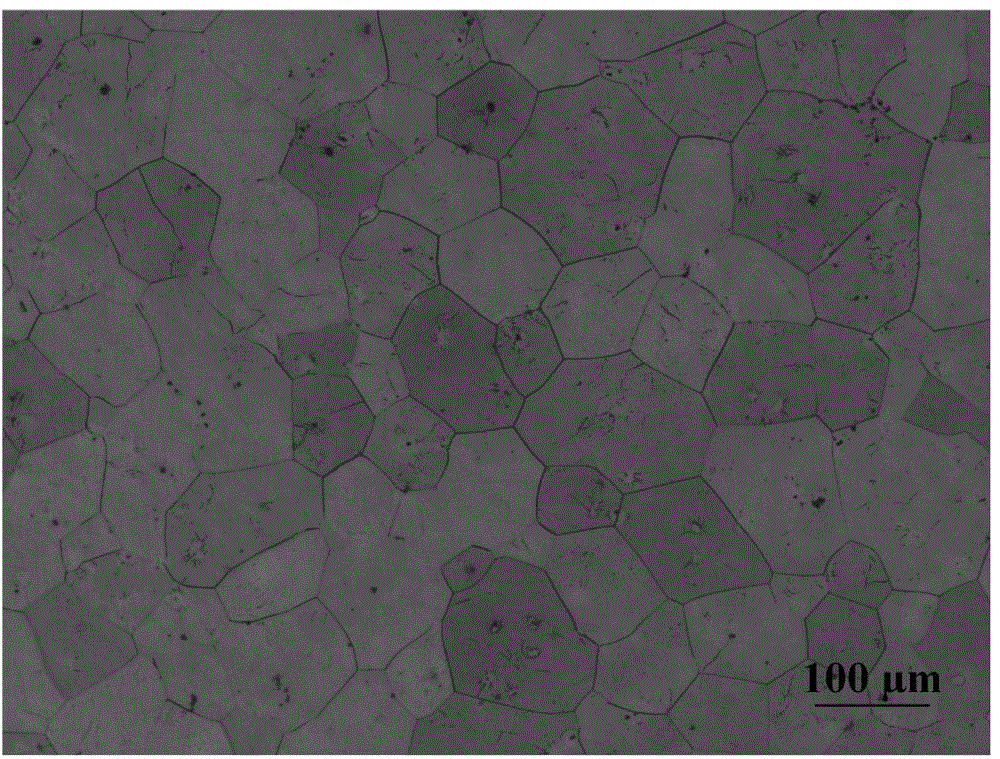

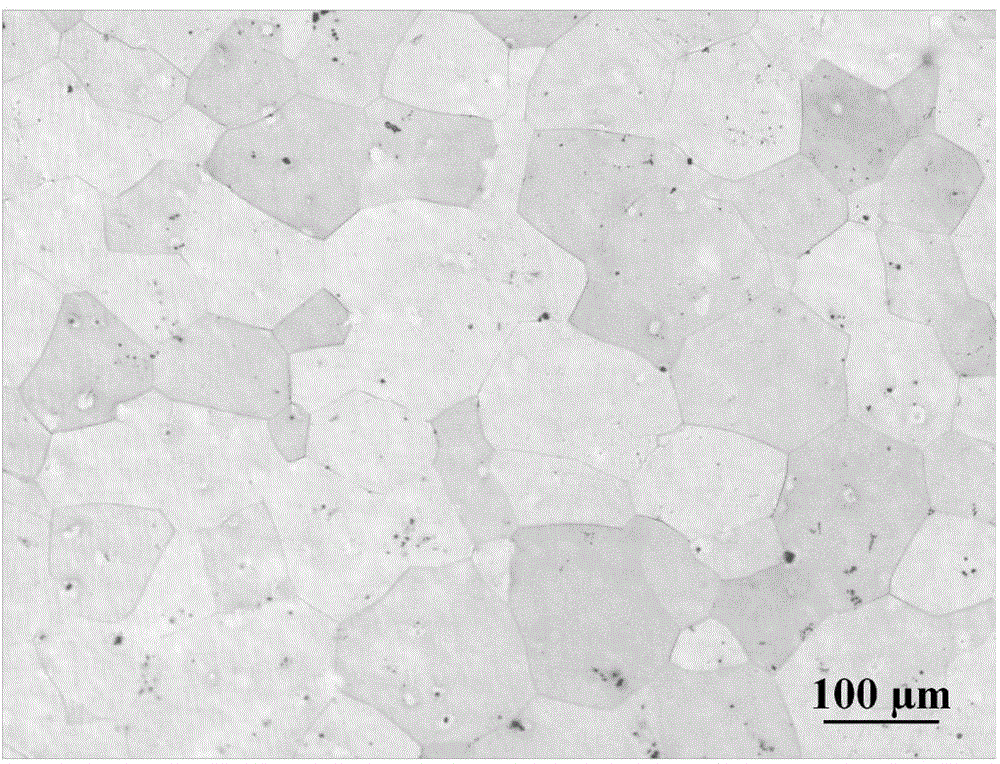

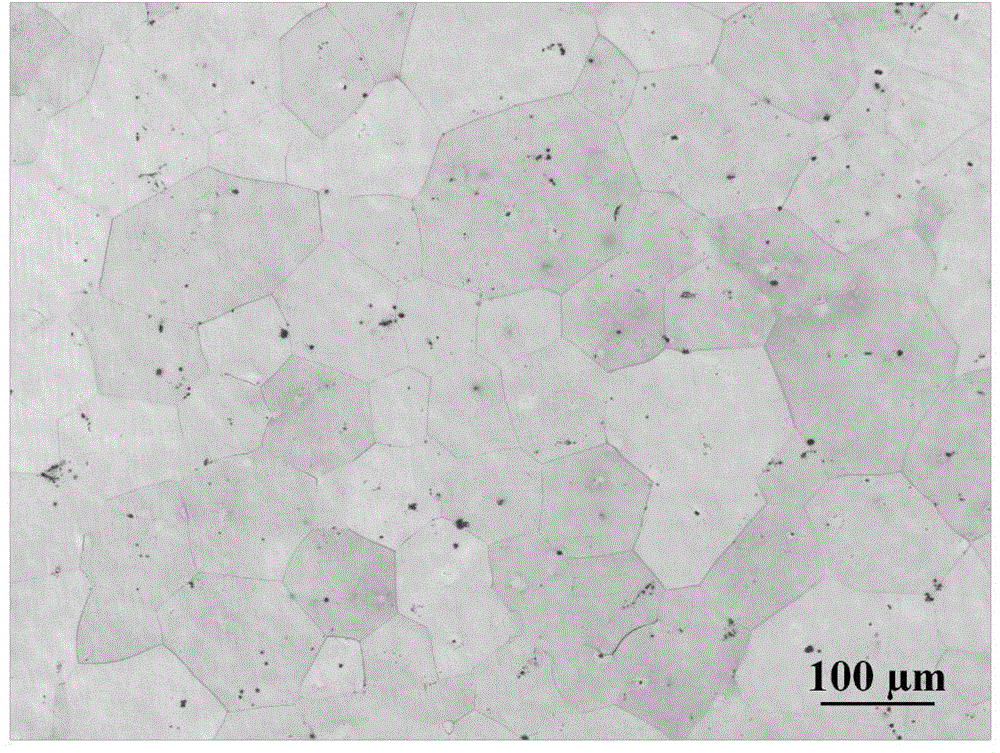

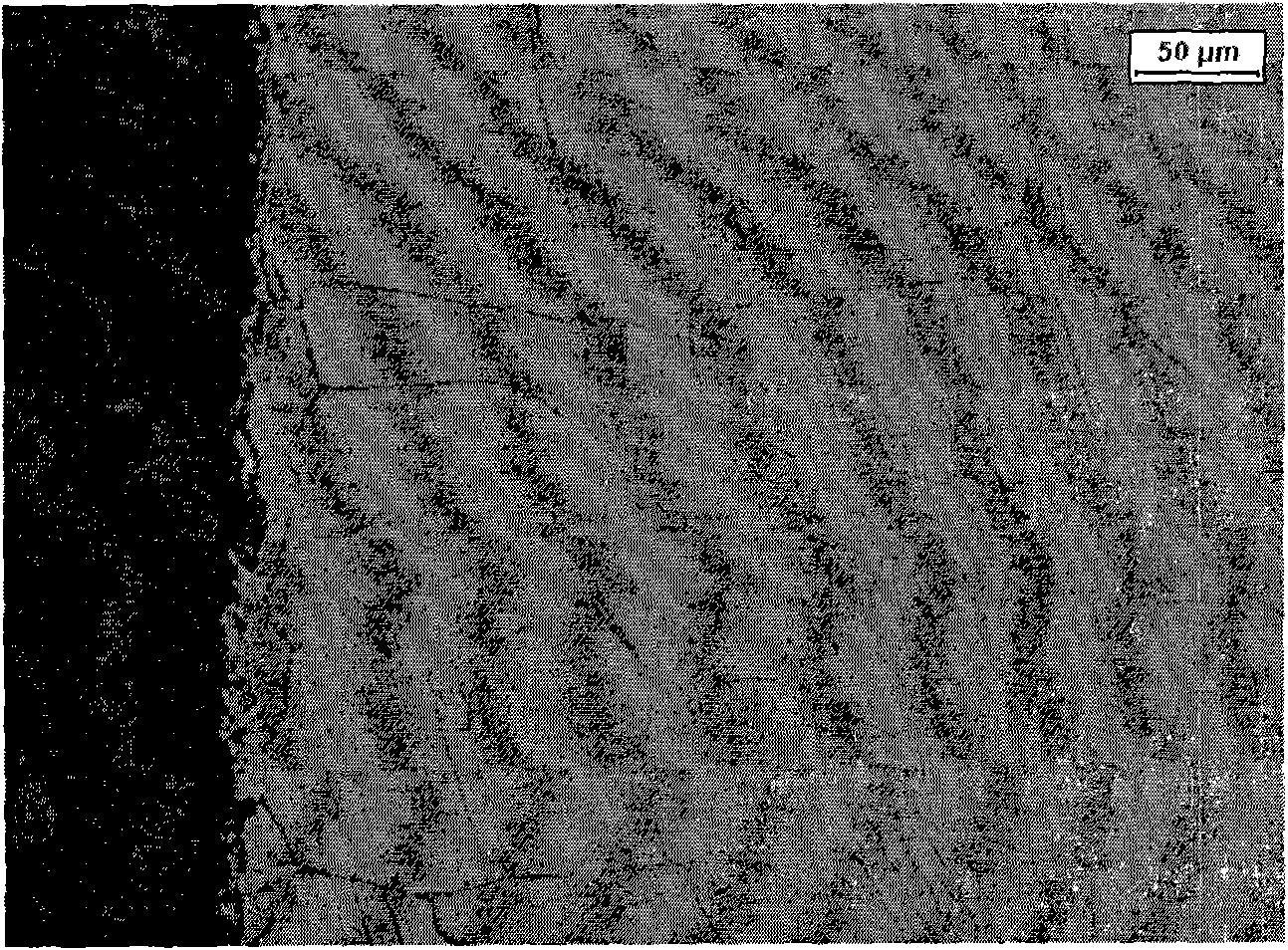

The invention relates to the field of Ti-based amorphous composite materials, in particular to the design and preparation method of endogenous toughness β-Ti solid solution reinforced Ti-based amorphous composite materials. The composition of the composite material is (atomic percentage) TiaAbBcBed, wherein: A is one or several elements of Zr, Nb, Ta, Mo, V, and W, and B is one or several elements of Cu, Ni, Fe, and Co. species, a=30-65; b=26-38; c=1-25; d=0-25. The toughness β-Ti solid solution reinforced Ti-based amorphous composite material with different volume fractions is obtained by adjusting the alloy composition, the size of the β-Ti solid solution is 1-200 μm, and the volume fraction is 0-100. The composite material exhibits excellent comprehensive mechanical properties, and has a certain degree of plastic deformation behavior while having high strength. The compressive yield strength is 1000-1900MPa, the compressive breaking strength is 1200-2300MPa, and the compressive strain is 2-20%; the tensile yield strength of the composite material is 1000-1900MPa, the tensile breaking strength is 1200-2000MPa, and the tensile strain is 2 -20%. It plays an important role in the application of Ti-based amorphous composite materials.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Microalloy HRB400E steel bar containing chrome and nitrogen and production method thereof

The invention discloses a microalloy HRB400E steel bar containing chrome and nitrogen and a production method thereof. By fully utilizing the strengthening effect and the corrosion-proof effect of chrome on the steel bar, solid solution strengthening elements, namely manganese and silicon, are partially substituted, and a microalloy element, namely vanadium or columbium is partially or fully substituted; a cheap nitrogen element is used for performing microalloy treatment on the steel bar, so that the micro nitrogen separating strengthening effect is achieved; by the production method, the HRB400E steel bar can be produced; Rel of the steel bar is 430 to 490MPa, Rm of the steel bar is 570 to 650 MPa, A is 24 to 35 percent, Rm / Rel is 1.30 to 1.40, the cold bending qualified rate is 100 percent, the welding carbon equivalent weight is less than or equal to 0.45, and the comprehensive cost of one ton of the steel bar is 20 to 80 yuan lower than that of one ton the steel bar produced by the conventional method; during aging of three months, the fluctuations of the Rm value and the Rel value are less than 10MPa; the welding performance is excellent; and the steel bar has good corrosion-proof property.

Owner:长沙东鑫环保材料有限责任公司

Al-Mg-Er welding wire and preparation process thereof

ActiveCN101716704AThe smelting process is stableEasy to implementWelding/cutting media/materialsSoldering mediaAluminum substrateMixing ratio

The invention discloses an Al-Mg-Er welding wire and a preparation process thereof. The Al-Mg-Er welding wire mainly comprises the following chemical components in percentage by mass: 4.3 to 6.5 percent of Mg, 0.4 to1.2 percent of Mn, 0.05 to 1.3 percent of Zr, 0.1 to 0.6 percent of Er and the balance of Al and other inevitable impurities. The preparation method comprises: preparing pure aluminum ingots, pure magnesium ingots, Al-Mn(10.0) preliminary alloy, Al-Er (0.6) preliminary alloy and Al-Zr (4.5) preliminary alloy; melting the alloys in a mixing ratio in a medium frequency induction electric resistance furnace and performing casting to make a cast ingot; subjecting the homogenized cast ingot to end cutting and face milling and hot extrusion; and after intermediate annealing, performing wire drawing in a wire drawing machine while performing pass annealing, subjecting the wire drawn to surface treatment, and coiling the wire to obtain the Al-Mg-Er welding wire of the invention. The welding wire of the invention has the advantages that: the smelting process is stable and easy to implement and the drawing performance of the welding wire is high; the obvious refining molding performance of the structure of the welding wire is high, the strength of weld joint metal is guaranteed and that the plasticity of weld joint metal is equal to that of a parent metal is guaranteed; and the impurity content of the Al-Mg-Er welding wire is low, the toughness is improved, the solution strengthening of an aluminum substrate is promoted, and the strength of the weld joint metal is improved effectively.

Owner:BEIJING UNIV OF TECH

Aluminum alloy and alloy sheet thereof as well as preparation method of alloy sheet

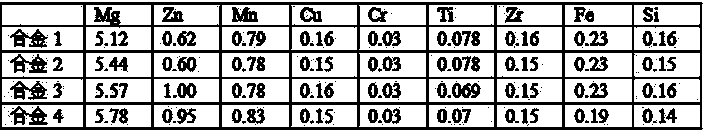

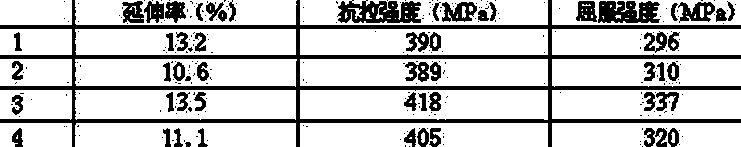

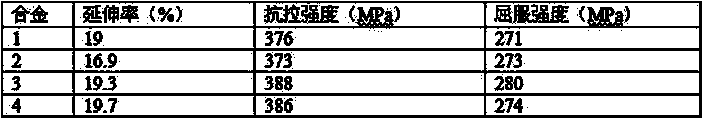

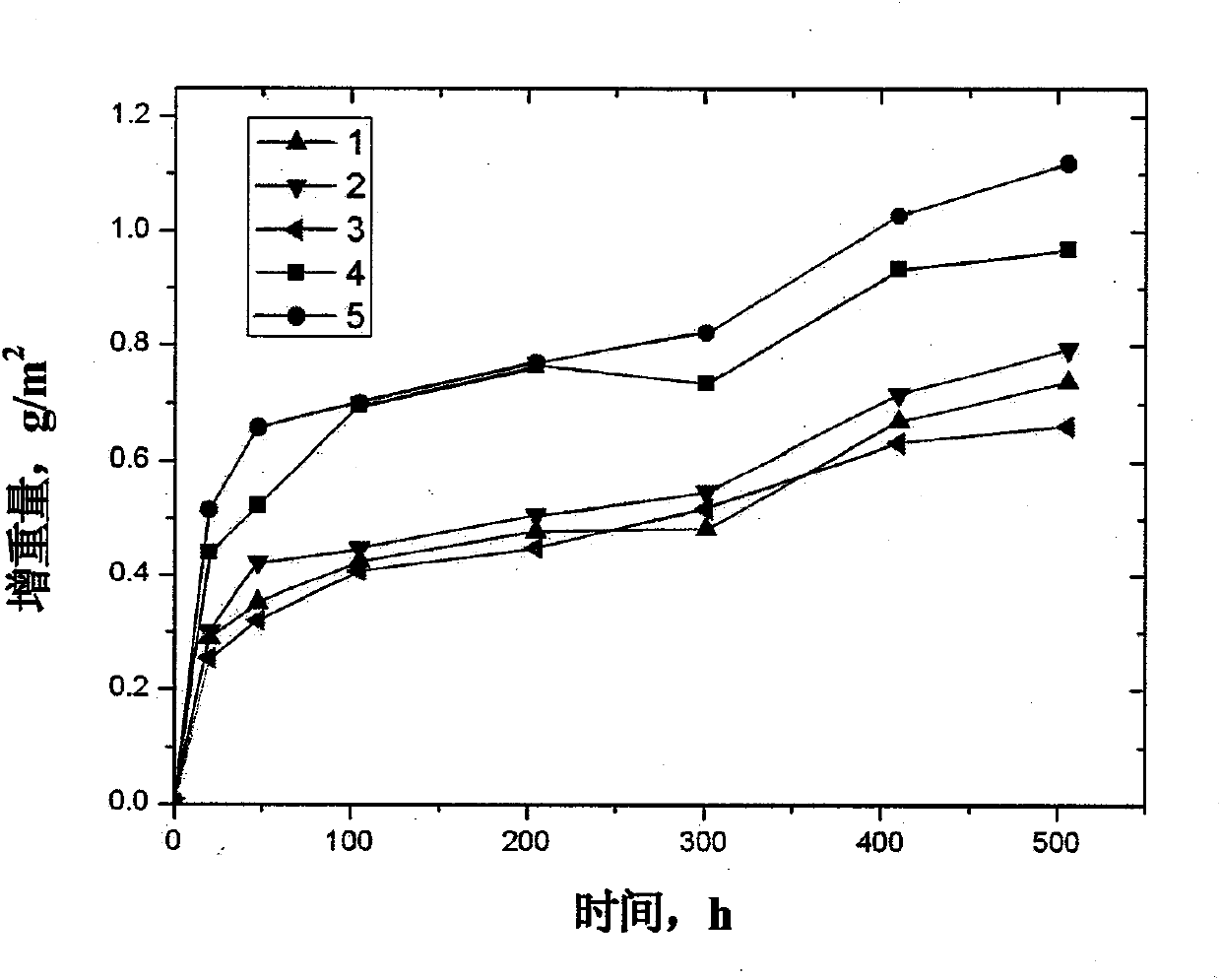

The invention relates to an aluminum alloy and an alloy sheet thereof as well as a preparation method of the alloy sheet, belonging to the field of non-ferrous metal and preparation thereof. The aluminum alloy comprises the compositions in percentage by mass: 5.5-6.0% of Mg, 0.6-1.2% of Zn, 0.1-0.2% of Cu, 0.6-1.0% of Mn, 0-0.1% of Cr, 0-0.15% of Ti, 0.05-0.25% of Zr, 0-0.25% of Fe, 0-0.2% of Si, and the balance of Al. The stable-state or work hardening-state aluminum alloy sheet can be obtained by performing preheating or homogenization treatment to an alloy ingot prepared by the compositions, then carrying out corresponding hot rolling, cold rolling, annealing, prestretching and the like. Through the sheet, the continuous precipitation capability of Al3Mg2 in crystal boundary can be greatly reduced while the solid solution strengthening action of the Mg element can be ensured, and the sheet has excellent mechanical performance and anti-corrosion property compared with the traditional AA5059-H321 and AA5059-H131.

Owner:UNIV OF SCI & TECH BEIJING +1

Hot galvanizing steel plate with yield strength more than or equal to 550MPa, and manufacturing method thereof

ActiveCN102796949AHigh yield strengthHigh strengthHot-dipping/immersion processesReduction rateSheet steel

The invention discloses a hot galvanizing steel plate with yield strength more than or equal to 550MPa, and a manufacturing method of the hot galvanizing steel plate; the hot galvanizing steel plate with the yield strength more than or equal to 550MPa comprises the following components by mass percent: 0.05-0.12% of C, less than or equal to 0.08% of Si, 0.3-0.9% of Mn, 0.020-0.060% of Als, less than or equal to 0.03% of P, less than or equal to 0.03% of S and the balance of Fe and unavoidable impurities; the manufacturing method of the hot galvanizing steel plate with the yield strength more than or equal to 550MPa comprises the steps of cast steel plate (CSP) continuous casting and rolling, steel plate pickling cold rolling and steel plate continuous zinc coating; according to the invention, the chemical components of the hot galvanizing steel plate are designed in an optimal way, alloying elements with high price are not added into the hot galvanizing steel plate, the strength of products can be improved by structure strengthening and solution strengthening of C and Mn, and the production cost is greatly reduced; the grain size is reduced, and the product strength is improved by reducing the CSP rolling temperature; the product strength is improved by controlling the acid rolling reduction rate; and the yield strength of the products can be guaranteed by controlling the galvanized annealing temperature and speed as well as the hydrogen content.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Laser nanometer cermet alloying process for surface of metallurgic hot roller

InactiveCN1932079AImprove thermal stabilityHigh strengthRollsMetallic material coating processesCeramic coatingCo2 laser

The laser nanometer cermet alloying process for surface of metallurgical hot roller includes the following steps: 1. machining the roller to eliminate surface fatigue layer to obtain required size and shape, grinding the surface to be laser treated, eliminate dirt and cleaning properly; 2. mixing phenolic resin adhesive and nanometer carbide ceramic paint homogeneously and coating the mixture to the surface of the roller in the thickness of 0.01-0.05 mm before air drying; and 3. scanning the nanometer ceramic coating on the surface of the roller fast with high power CO2 laser in the technological parameters of laser power 1,000-10,000 W, scanning speed of 1.5-20 m / min, lapping rate of 15-35 % and light spot diameter of 0.6-5 mm. The present invention has optimized technological parameters, and can result in solid solution reinforcing and dispersion reinforcing effect, raise the heat stability of the alloy layer, and raise the strength, plasticity and toughness of the alloy layer.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

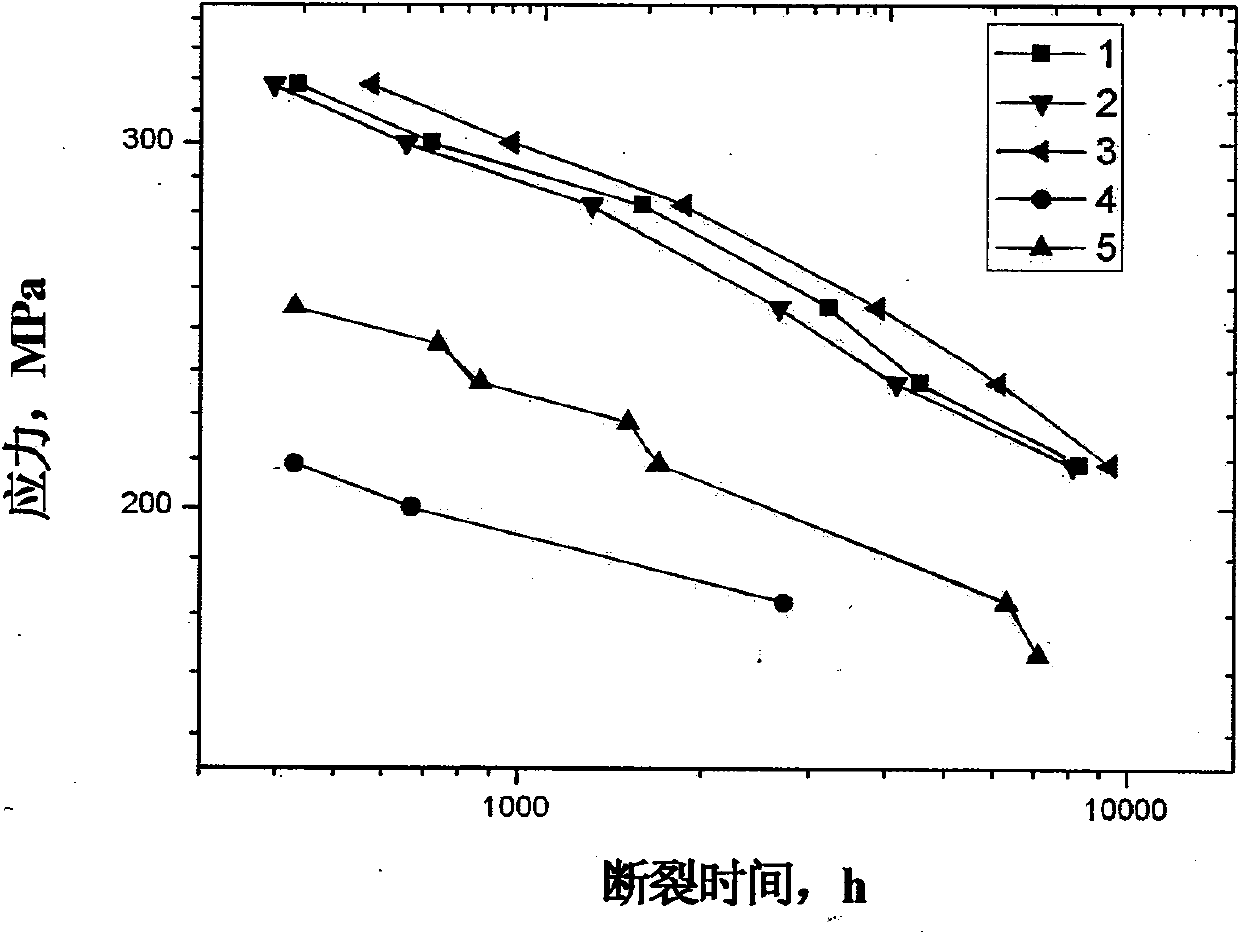

High-chromium martensitic heat-resistant steel and manufacturing method thereof

InactiveCN102086494AHigh strengthImprove antioxidant capacityOxidation resistantSolid solution strengthening

The invention belongs to the technical field of heat-resistant alloys, and particularly relates to high-chromium martensitic heat-resistant steel with high oxidation resistance and high creep resistance at a high temperature. The high-chromium martensitic heat-resistant steel is a novel structural material mainly applied to the manufacturing of high-pressure steam pipelines for super (ultra super)-critical thermal power stations. The steel comprises the following components in percentage by weight: 0.07 to 0.10 percent of C, 10.0 to 11.0 percent of Cr, 0.3 to 0.5 percent of Mo, 2.0 to 3.0 percent of W, 2.0 to 3.0 percent of Co (the content ratio of Co to W is more than or equal to 0.8 and is less than or equal to 1.2), 0.3 to 0.5 percent of Mn, 0.2 to 0.4 percent of Si, less than 0.5 percent of Ni, 0.001 to 0.006 percent of B, and the balance of Fe. In the high-chromium martensitic heat-resistant steel, by compoundly adding low molybdenum, high tungsten and high cobalt when the chromium content is increased and keeping the content ratio of cobalt to tungsten within a certain range, the coarsening of M23C6 which plays a role in precipitation strengthening in a microstructure can be inhibited, the content of delta-ferrite in the microstructure is effectively controlled to be lower than 5 percent (volume fraction), and the solid solution strengthening effect is greatly improved, so that the high-chromium martensitic heat-resistant steel which has both high oxidation resistance and high creep resistance at a high temperature and is used for thermal power stations is obtained.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for preparing nitrogen-contained ODS (oxide dispersion strengthened) nickel-free austenite alloy by mechanical alloying process

The invention discloses a method for preparing nitrogen-contained ODS (oxide dispersion strengthened) nickel-free austenite alloy by a mechanical alloying process, which comprises the following steps of: mixing pure metal element powder of Fe, Cr, Mn, W, Ti and Al and nanometer Y2O3 powder in the following mass ratio: 17-20% of Cr, 18-22% of Mn, 1.5-2.5% of W, 2-4% of Al, 0.5-1.0% of Ti, 0.3-0.6% of Y2O3 and the balance of Fe; loading into a ball-milling tank of a horizontal planetary high-energy ball mill; after the is vacuumized, filling the ball-milling tank with high-purity nitrogen; controlling the pressure at 0.1-1atm; carrying out ball milling for 30-90 hours, wherein the ball mill is shut down for 1 hour in every five hours of ball milling; obtaining the ODS nickel-free austenite alloy powder of which the nitrogen content is 0.1-0.8%; and sintering to obtain the ODS nickel-free austenite alloy. According to the nickel-free austenite alloy, the solid solution strengthening of nitrogen and oxide dispersion strengthening can be simultaneously realized, and the service capability of the nickel-free austenite stainless steel under the high-temperature environment can be improved to a great extent.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of carbon-containing high-entropy alloy composite material

ActiveCN108213422AHigh yield strengthGuaranteed plasticityAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingHigh density

The invention discloses a preparation method of a carbon-containing high-entropy alloy composite material. The method comprises the steps of (1) preparing high-entropy pre-alloyed powder, wherein thehigh-entropy pre-alloyed powder comprises at least four of metal elements of Fe, Co, Cr, Ni and Ni, and a C element; and (2) performing selective laser melting molding on the high-entropy pre-alloyedpowder; and performing following thermal treatment on the molded part to obtain the carbon-containing high-entropy alloy. According to the method, high-entropy alloys with outstanding plasticity, suchas Fe, Co, Cr and Ni, are used for preparing a substrate, so that the high plasticity remains after the selective laser melting molding; and meanwhile, an interstitial element C is introduced and issubjected to solid solution reinforcing, so that the yield intensity and the ultimate strength of the substrate can be obviously improved; the supercooling degree in the selective laser melting process is high, the interstitial element C can be uniformly dissolved into the substrate in a solid solution manner, and coarse and big carbide are not segregated and separated out, so that the plasticityof the material is ensured; a high-density (more than 99%) product is prepared through the selective laser melting mode.

Owner:CENT SOUTH UNIV

Gd-doped magnesium lithium alloy

The invention provides a Gd-doped magnesium-lithium alloy, which comprises the following components in weight percent: 6 to 9 percent of Li, 2 to 5 percent of Al, 0.5 to 2 percent of Zn, 0.2 to 1.5 percent of Gd, and the balance being Mg. The rare earth GD is introduced into the magnesium-lithium alloy on the basis of the addition of common magnesium-lithium alloy strengthening elements Al and Zn. Al is the main strengthening element of the alloy, while Zn is also the strengthening element of the alloy and changes the plasticity of the alloy simultaneously; and the Gd can generate solution strengthening action to improve the microstructure of the alloy and refine crystal grains. At the same time, the improvement of Li content allows the alloy to be positioned in an alpha+beta two-phase region, thereby improving the plasticity of the alloy and reducing density of the alloy simultaneously.

Owner:HARBIN ENG UNIV

Heat-resistant magnesium alloy and preparation method thereof

InactiveCN104046871AImprove mechanical propertiesImprove creep resistanceRare-earth elementSolid solution strengthening

The invention provides a heat-resistant magnesium alloy. The magnesium alloy comprises the following components: 3.5wt%-4.5wt% of Al, 2.5wt%-3.5wt% of La, 1.5wt%-3.0wt% of Sm, 0.2wt%-0.4wt% of Mn, impurity elements of which the total amount is less than 0.03wt% and the balance of magnesium. The invention provides a preparation method of the magnesium alloy. The preparation method comprises the steps of smelting a magnesium source, an aluminum source, a lanthanum source, a samarium source and a manganese sources to obtain an alloy liquid; carrying out press casting on the alloy liquid to obtain the heat-resistant magnesium alloy. Since the heat-resistant magnesium alloy provided by the invention contains rare earth elements, namely, La and Sm, La and Sm inhibit the generation of Mg17Al12 phase, and Sm can have a better solution strengthening effect, and thus the heat-resistant magnesium alloy provided by the invention has the advantages of good mechanical properties and creep resistance at high temperature.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

High-strength heat-resisting magnesium alloy suitable for sand casting and preparation method thereof

The invention discloses high-strength heat-resisting magnesium alloy suitable for sand casting and a preparation method thereof. The high-strength heat-resisting magnesium alloy suitable for sand casting comprises, by mass, 7-11% of Gd, 1-4% of Y, 0.5-2.5% of Ag, 0.2-0.6% of Zr, 0.1-0.3% of B, lower than 0.02% of impurity elements and the balance Mg, wherein the impurity elements include Si, Fe, Cu and Ni. The preparation method comprises the steps of smelting and heat treatment. The Gd and the Y are used as main alloy elements of the high-strength heat-resisting magnesium alloy, the Ag is added into the alloy to improve the solid solution strengthening effect of rare earth alloy and refine a precipitated phase, a K2ZrF6 salt mixture and B2O3 are added to inhibit grain growth of the alloy in sand casting and follow-up solid solution process, reduce segregation of the elements Zr and B, improve the yield of the elements Zr and B and reduce the production cost of the magnesium alloy.

Owner:SHANGHAI JIAO TONG UNIV +1

High-strength and high-elasticity-modulus casting Mg alloy and preparation method thereof

The invention provides a high-strength and high-elasticity-modulus casting Mg alloy and a preparation method thereof. The Mg alloy comprises 6-12wt% of Gd, 1-5wt% of Li, 1-5wt% of Y, 2-6wt% of Al, the balance of Mg and inevitable impurities, wherein the total content of Si, Fe, Cu and Ni in the impurities is smaller than 0.03wt%. The preparation method of the Mg alloy includes the sequential steps of vacuum melting and heat treatment. Compared with the prior art, the preparation method has the advantages that by adopting a vacuum induction melting furnace for melting, inclusions generated in the melting process are reduced, and the retention time of a melt at a high temperature is substantially shortened; the effects of solution strengthening and age hardening of the Mg alloy can be fully exerted under the optimized heat treatment process.

Owner:SHANGHAI JIAO TONG UNIV +1

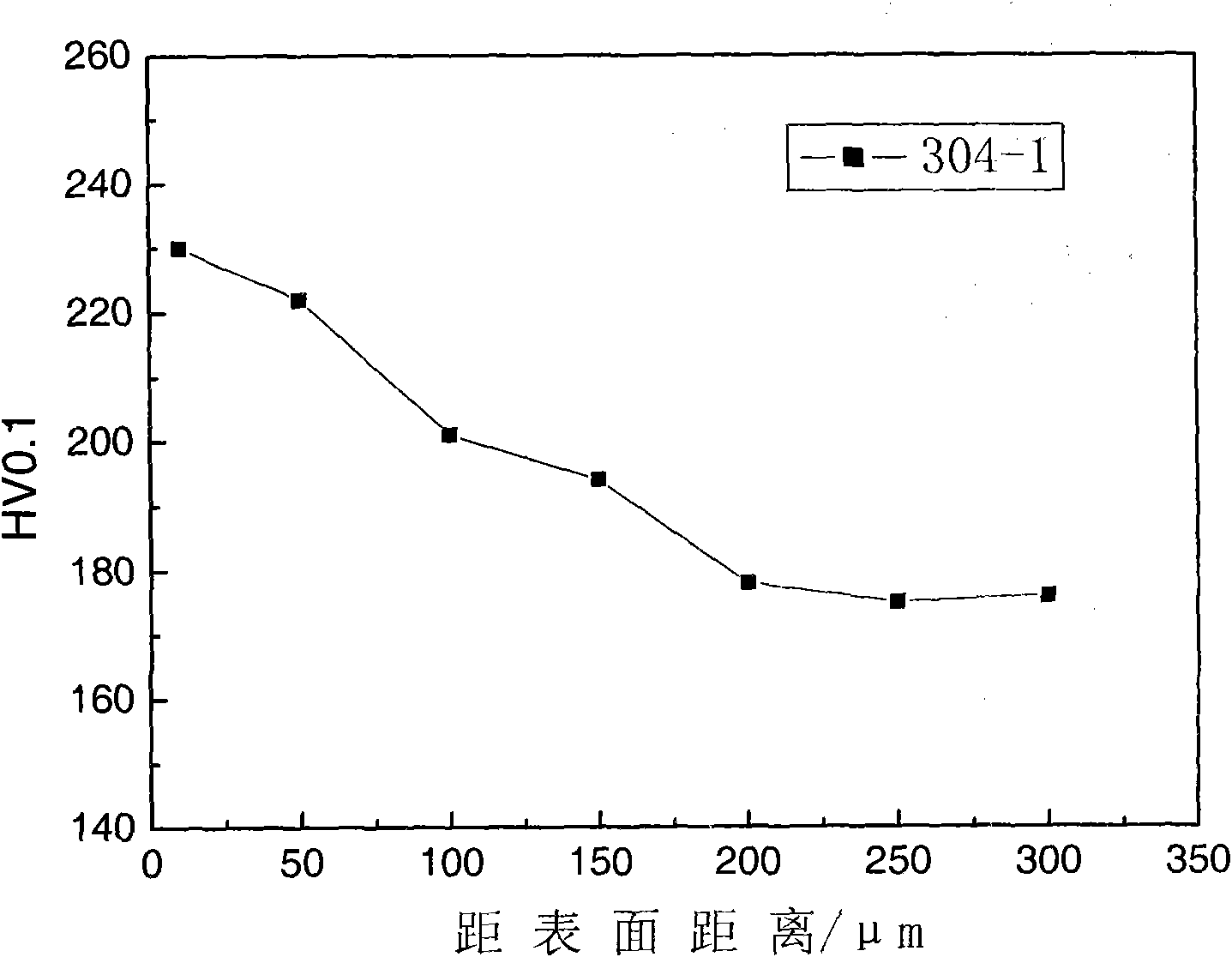

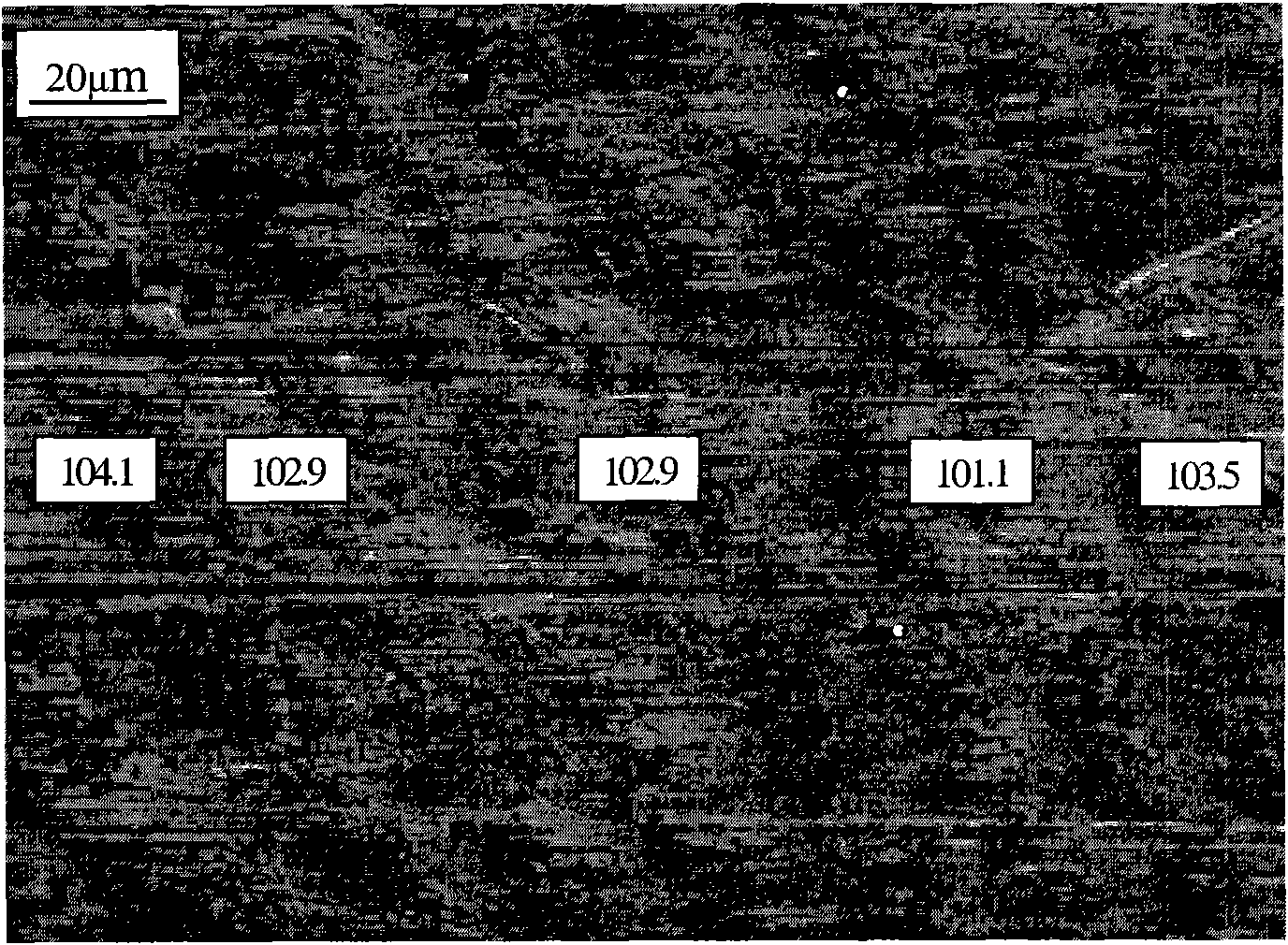

Manufacturing technique of austenitic stainless steel cold-rolled plate with good surface performance

InactiveCN101648334AHigh hardnessImprove wear resistanceSolid state diffusion coatingGrinding machinesManufacturing technologyPetrochemical

The invention provides a manufacturing technique of an austenitic stainless steel cold-rolled plate with a good surface performance. In the technique, a high-nitrogen surface layer in a solid solutionstate is formed on the austenitic stainless steel cold-rolled plate by improving the subsequent annealing atmosphere and process parameters of the austenitic stainless steel. Due to the solution strengthening function of solid solution nitrogen atoms, the hardness and the abrasive resistance of the surface of the stainless steel plate are greatly improved, and simultaneously the corrosion resistance is also improved; and each performance is improved by 10 to 50 percent, so the service life of components and parts made of the steel plate is prolonged. The austenitic stainless steel cold-rolledplate with the good surface performance is applied in the industries of petrochemical engineering, foods and medicaments and the like, and in the fields of household furniture, building decoration and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

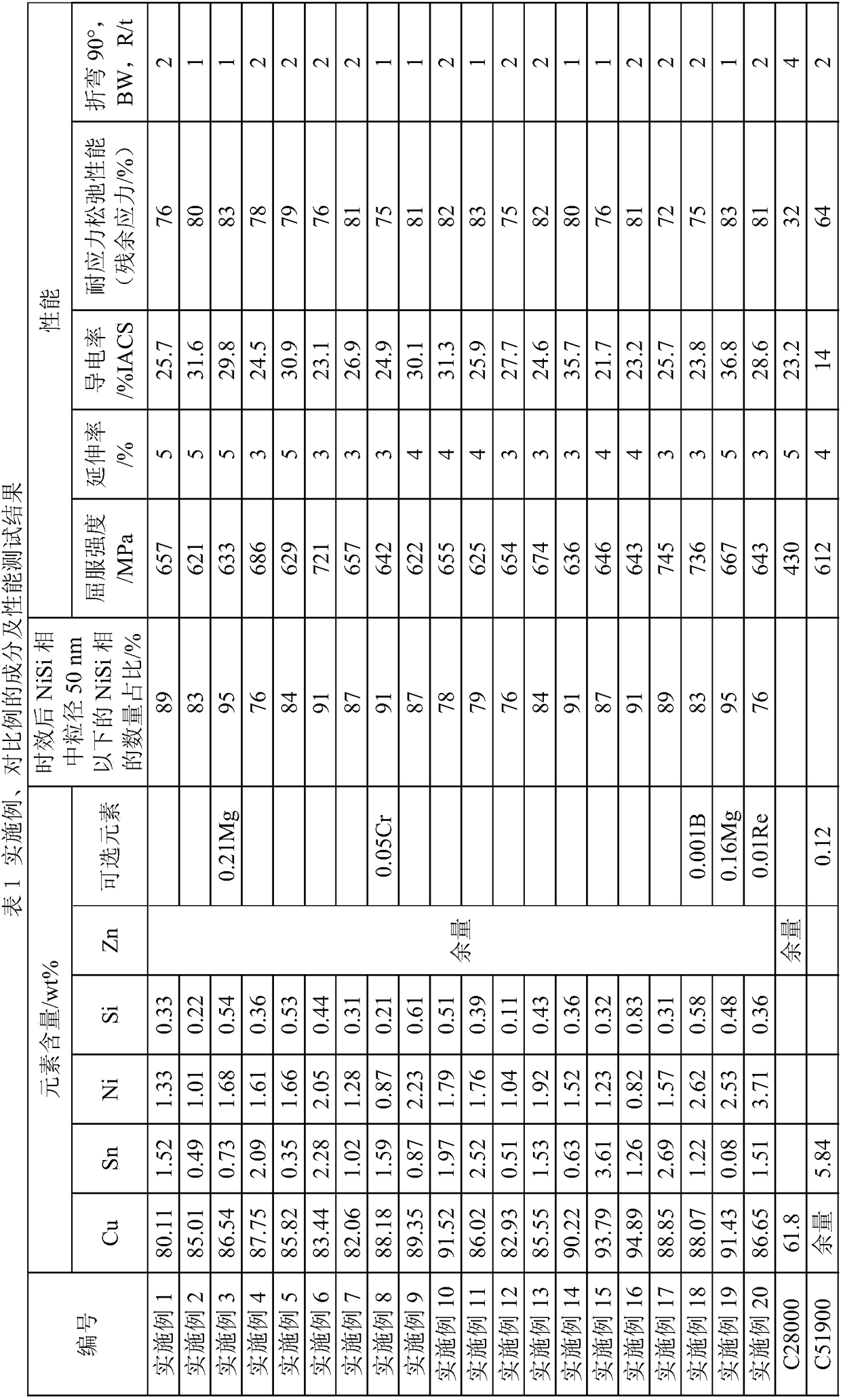

Precipitation-hardening copper alloy and application thereof

ActiveCN108285988AHigh strengthLittle effect on conductivityConductive materialMetal/alloy conductorsStress relaxationMatrix strength

The invention discloses a precipitation-hardening copper alloy which is prepared from the components in percentage by weight: 80 percent to 95 percent of Cu, 0.05 percent of to 4.0 percent of Sn, 0.01percent of to 3.0 percent of Ni, 0.01 to 1.0 percent of Si, and the balance Zn and inevitable impurities. According to the precipitation-hardening copper alloy provided by the invention, through solid solution strengthening and precipitation hardening, a combination performance of the alloy is improved, the matrix strength is improved, meanwhile, the influence on the conductivity of the alloy isless, a bending processing performance meets the requirement, and the alloy has a stress relaxation property as same as tin-phosphor bronze. The alloy provided by the invention has a better combination performance than C51900, is low in raw material cost, has remarkable advantages in welding and electroplating, can solve the utilization problem of multiple waste materials, and is widely applied toelectronic and electrical industry products such as connectors and connector assemblies.

Owner:NINGBO POWERWAY ALLOY MATERIAL

Alloy laser-cladding method for surface of helical casing in screw pump

InactiveCN102094198AExtended service lifeHigh hardnessMetallic material coating processesLaser technologyHelical scan

The invention discloses an alloy laser-cladding method for the surface of a helical casing in a screw pump. In the method, high temperature-resistant, corrosion-resistant and abrasion-resistant alloy powder is cladded on the surface of a helical casing by using the laser technology, thus forming an alloy cladding layer. The alloy powder contains elements or oxides thereof which are capable of refining, intensifying and having other effects on crystal grains of the alloy cladding layer, so the structural characteristics of the alloy cladding layer appears as refining of the crystal grains, increase of the dislocation density and uniform and compact structure, and the alloy cladding layer also has the effects on solution strengthening of the supersaturated alloy, and dispersion strengthening of superfine compounds and the like. Thus, the rigidity, wear resistance, corrosion resistance, fatigue resistance and other mechanical properties of the surface of the helical casing can be effectively improved, thereby greatly prolonging the service life of the screw pump. In addition, the method can be also used for repairing the surface of a faulted helical casing, thereby effectively lowering the production cost.

Owner:天津市汇利通金属表面技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com