Patents

Literature

889 results about "Spark gap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A spark gap consists of an arrangement of two conducting electrodes separated by a gap usually filled with a gas such as air, designed to allow an electric spark to pass between the conductors. When the potential difference between the conductors exceeds the breakdown voltage of the gas within the gap, a spark forms, ionizing the gas and drastically reducing its electrical resistance. An electric current then flows until the path of ionized gas is broken or the current reduces below a minimum value called the "holding current". This usually happens when the voltage drops, but in some cases occurs when the heated gas rises, stretching out and then breaking the filament of ionized gas. Usually, the action of ionizing the gas is violent and disruptive, often leading to sound (ranging from a snap for a spark plug to thunder for a lightning discharge), light and heat.

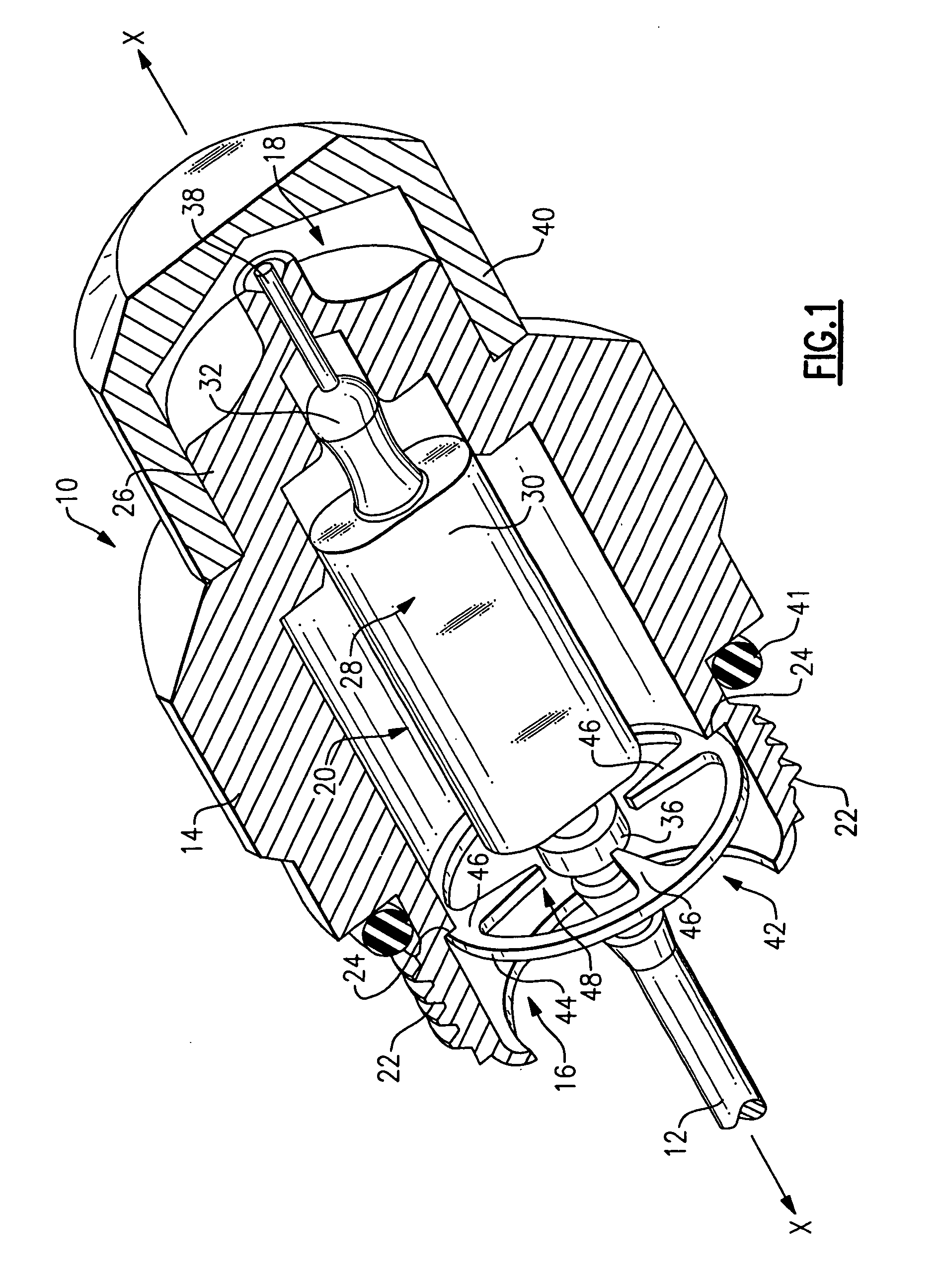

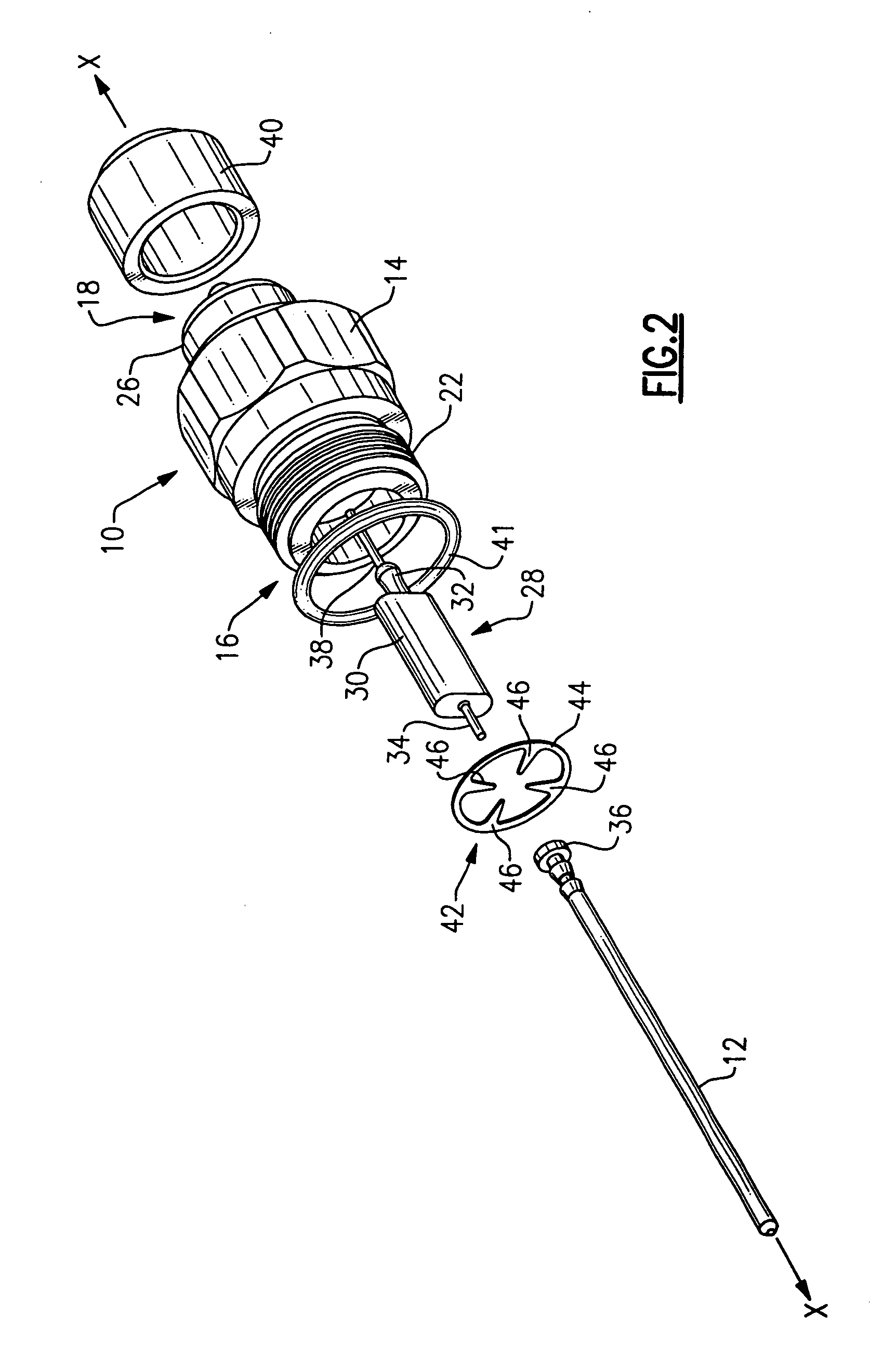

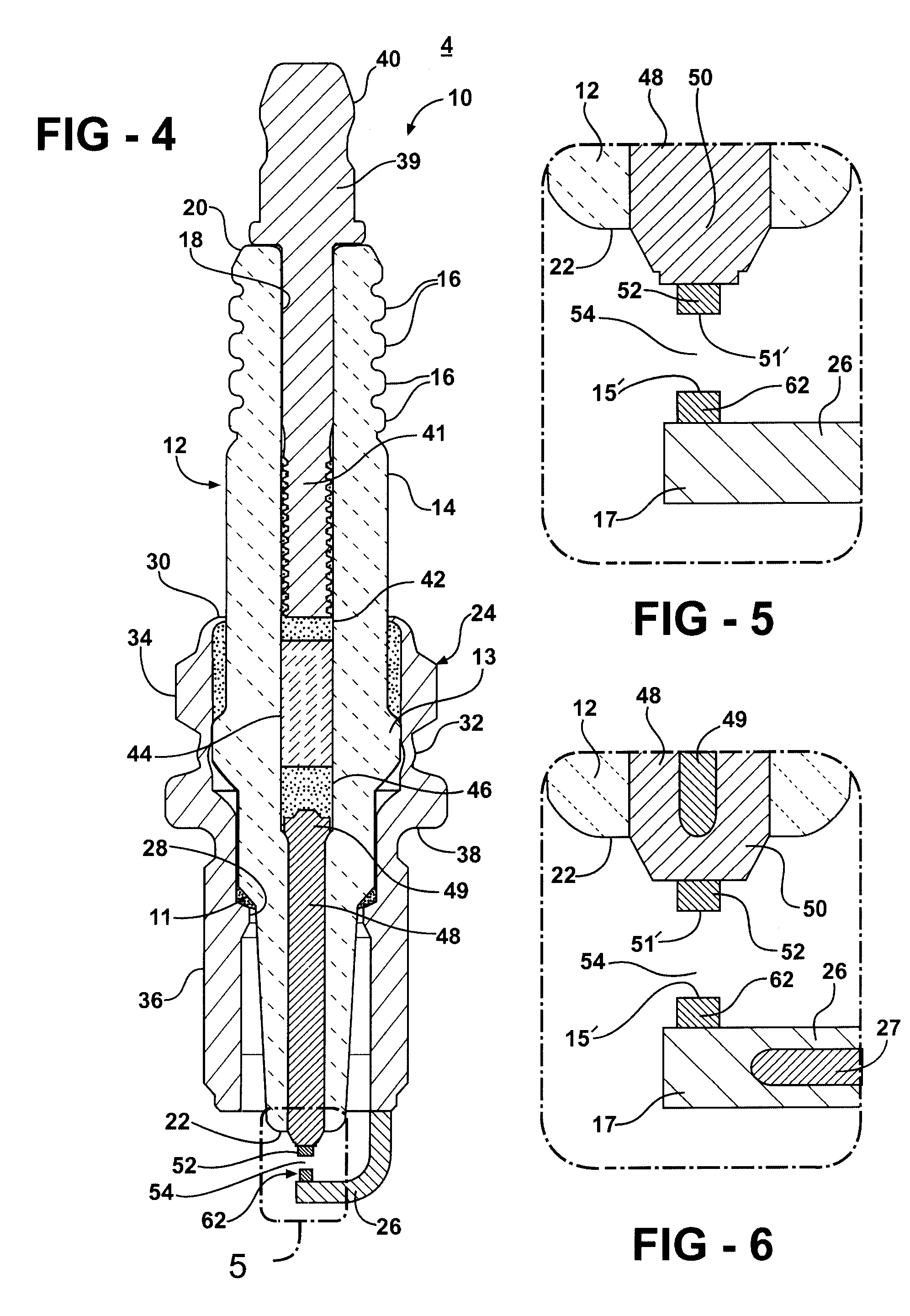

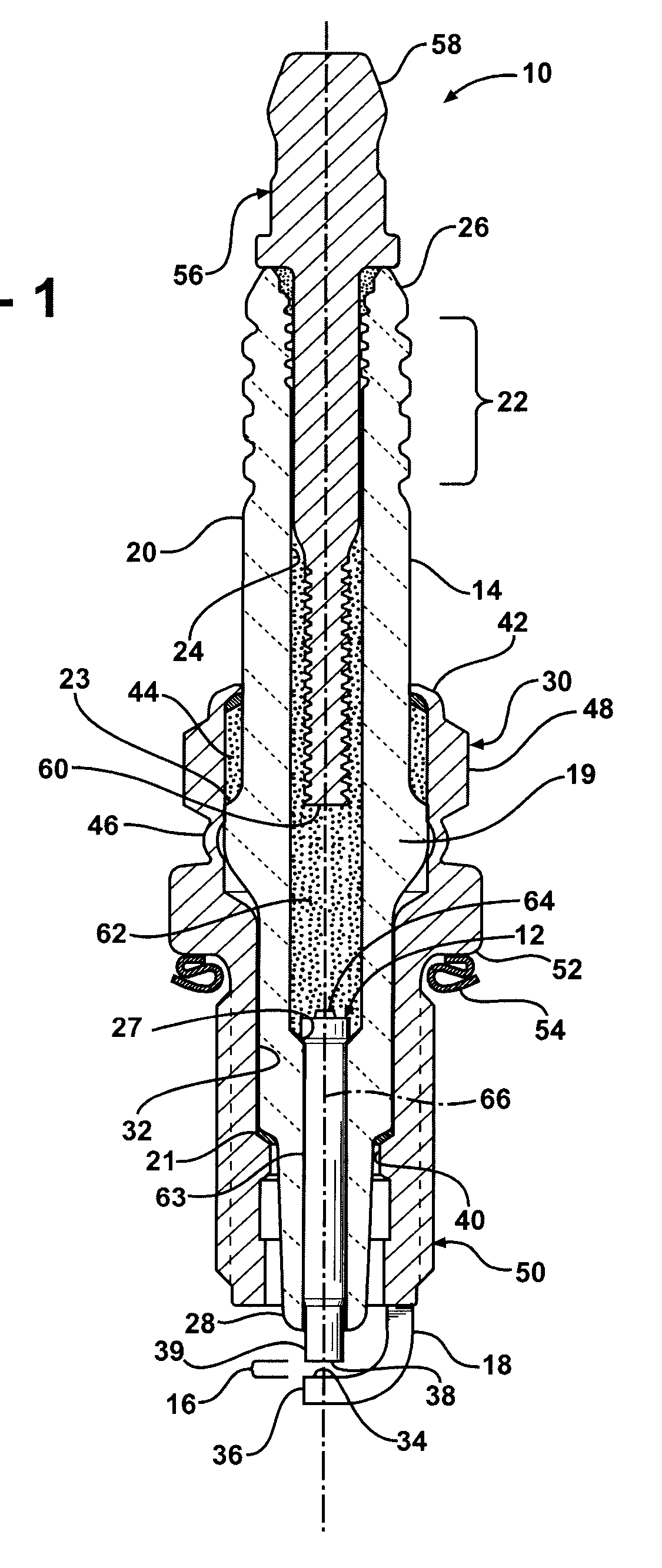

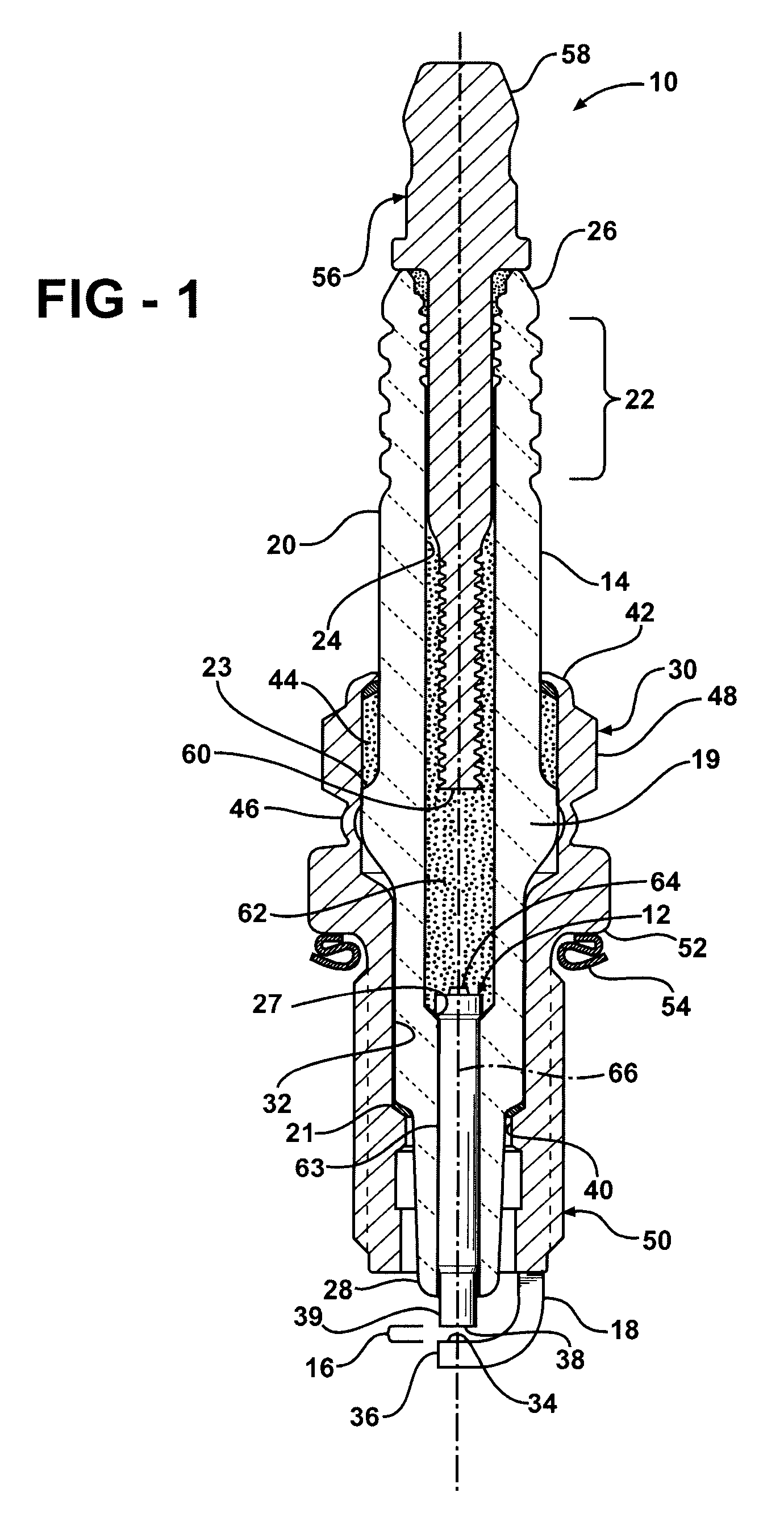

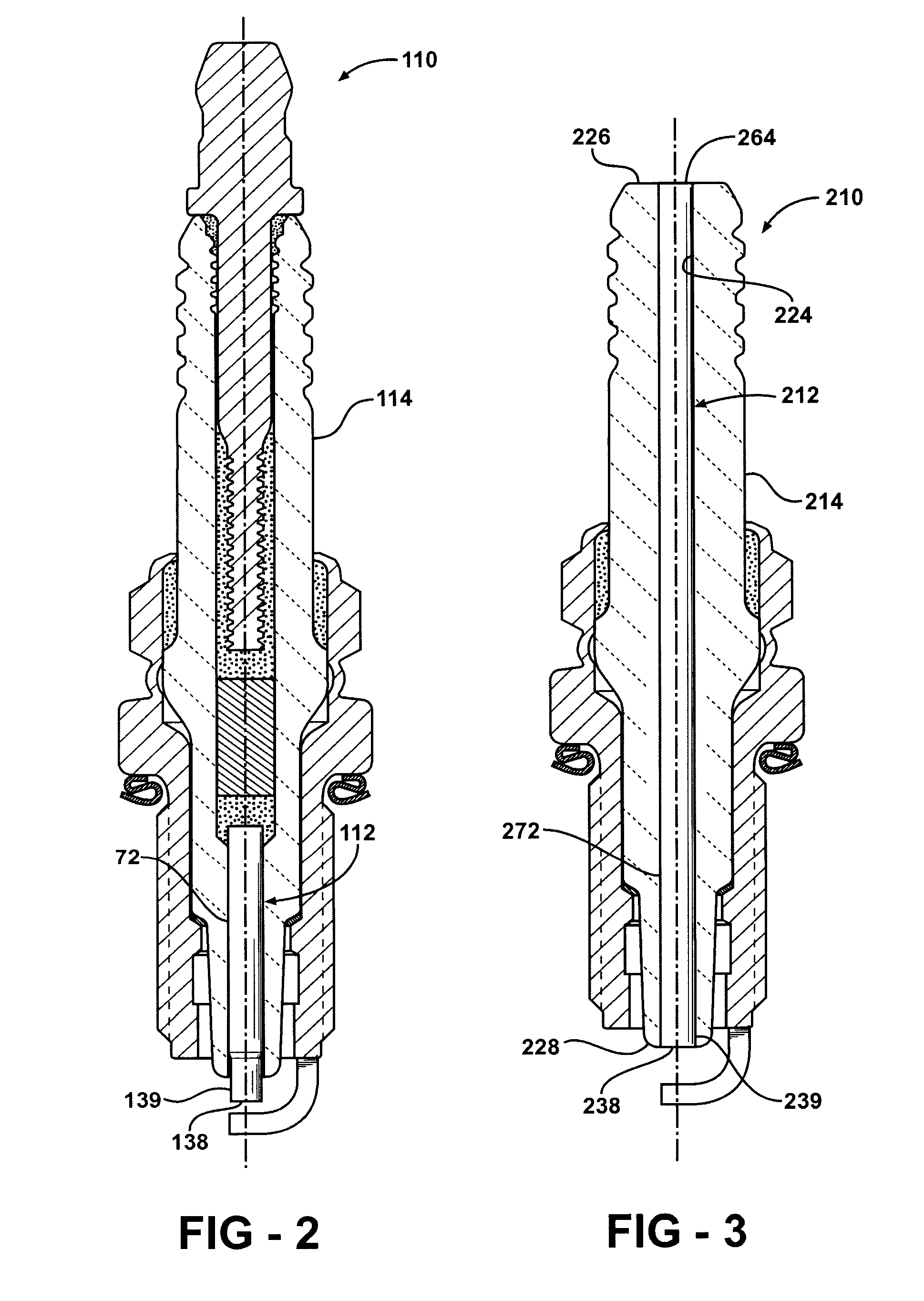

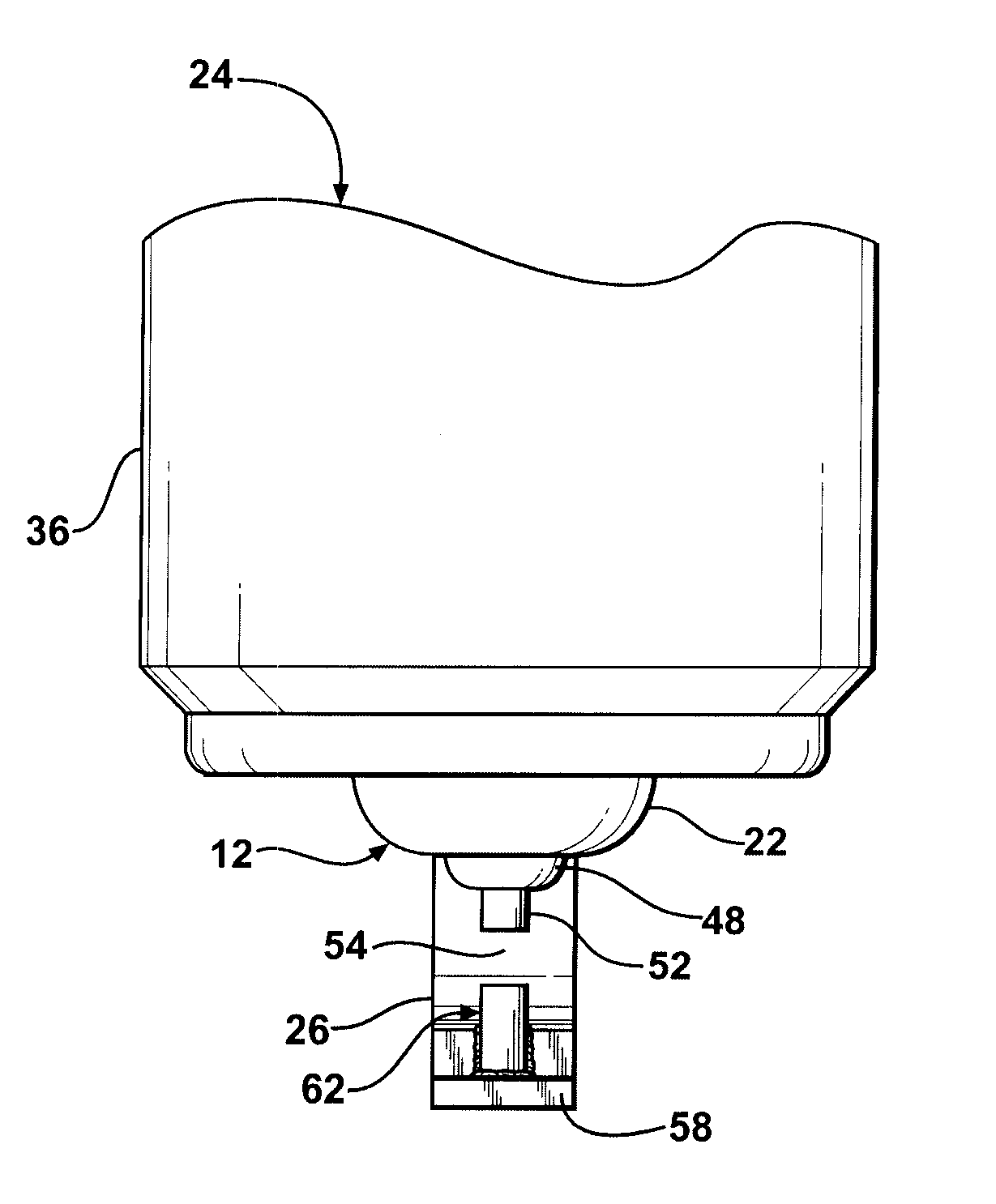

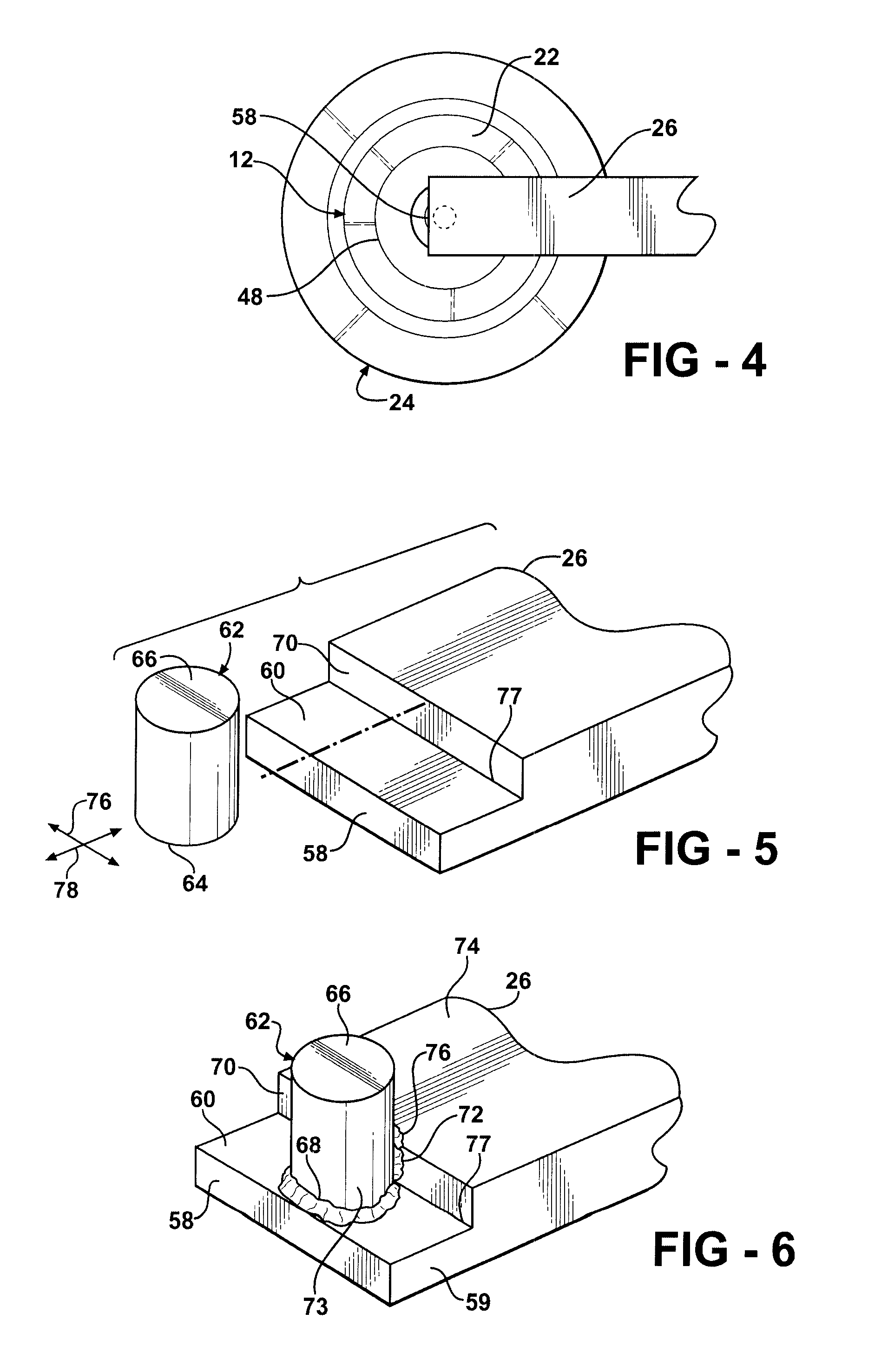

Adjustable electrode and related method

InactiveUS6217531B1Broad spectrumEasy to replaceChiropractic devicesEye exercisersElectricityElectrical conductor

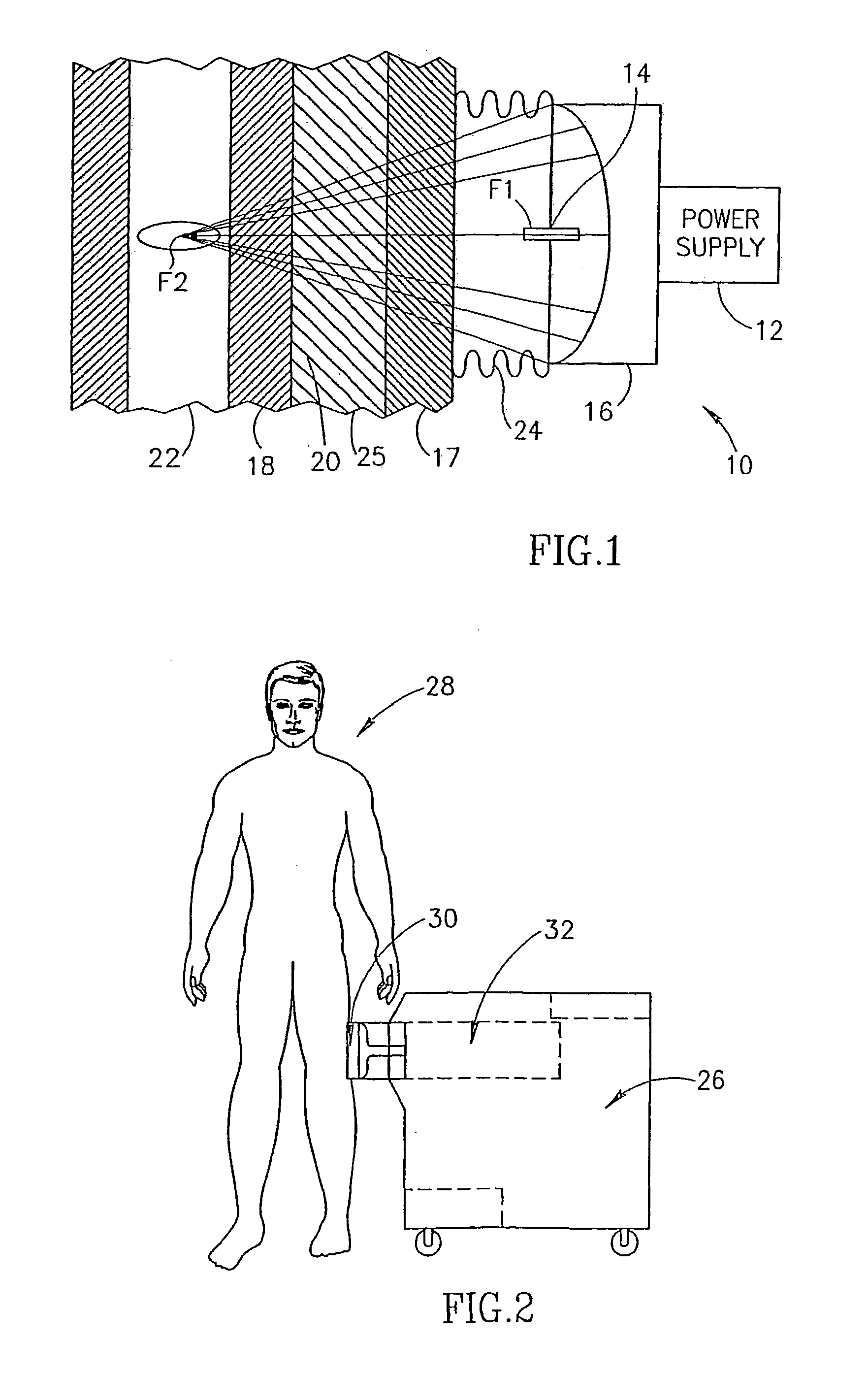

The present invention relates to a electrode assembly and related method that includes a insulator assembly, an electrode assembly, a charging system, a mechanism for measuring electrical voltages, a mechanism for adjusting the distance between inner and outer electrode tips, and a controller. The insulator assembly includes an insulator body having a hollow central portion with a threaded inner wall. The insulator assembly includes inner and outer conductors that are electrically connected to the charging system and are physically connected to inner and outer electrodes, respectively. The electrodes are positioned such that their longitudinal axes are aligned and the tips of the electrodes are in relatively close physical proximity. The distance between the tips is defined as the spark gap. The charging system charges a capacitor that discharges and forms a spark across the spark gap. The electrical measuring mechanism measures the discharge voltage of the capacitor and the controller compares it to a reference voltage, issuing a correction signal to the adjusting mechanism that repositions the electrodes, thus optimizing the spark gap. An alternate embodiment analyzes the charge and discharge characteristics of an electrode assembly that utilizes a second capacitor and an inductor to adjust the spark gap.

Owner:MTS MEDICAL TECH & SERVICES

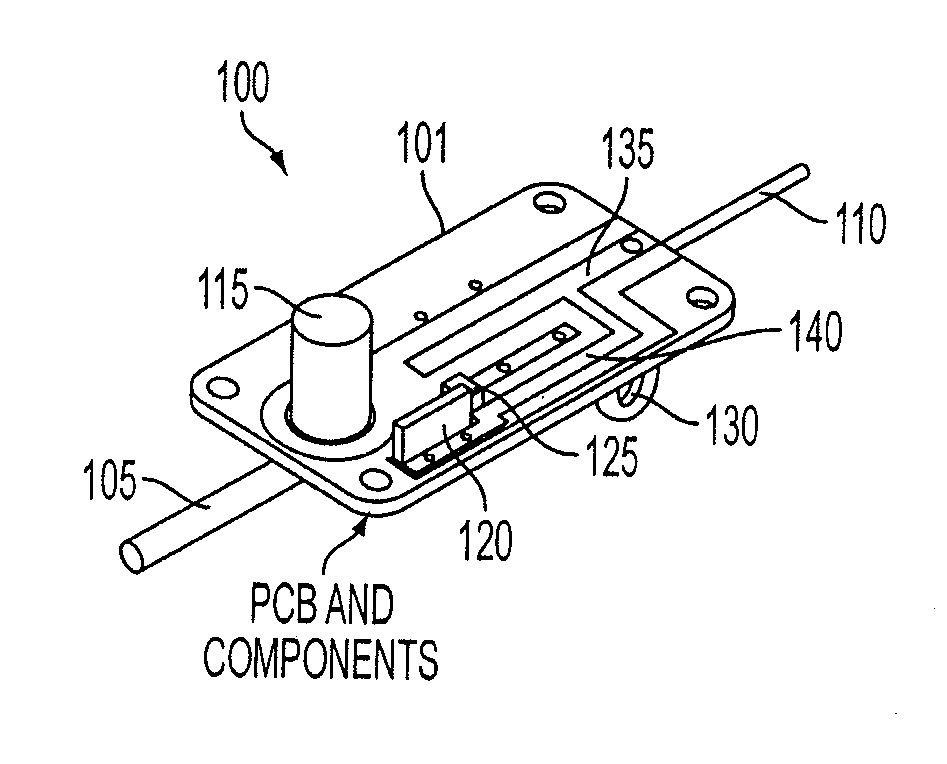

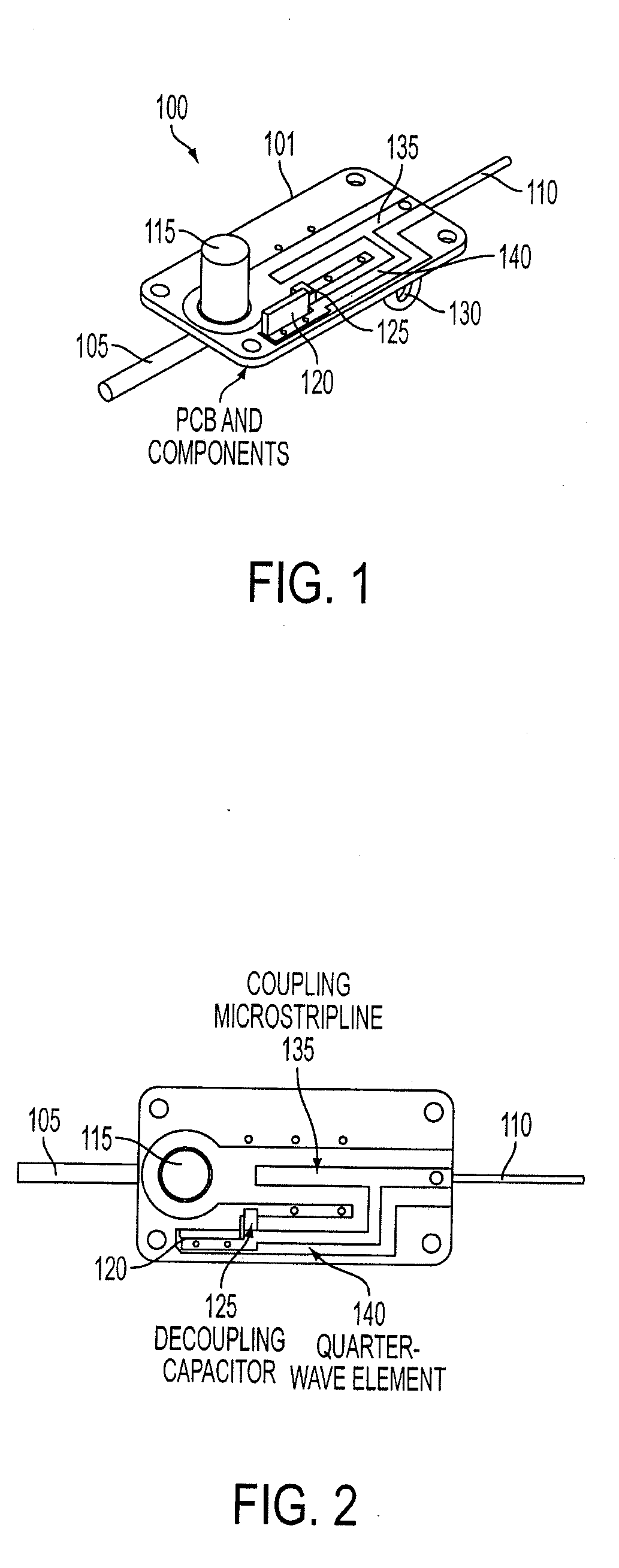

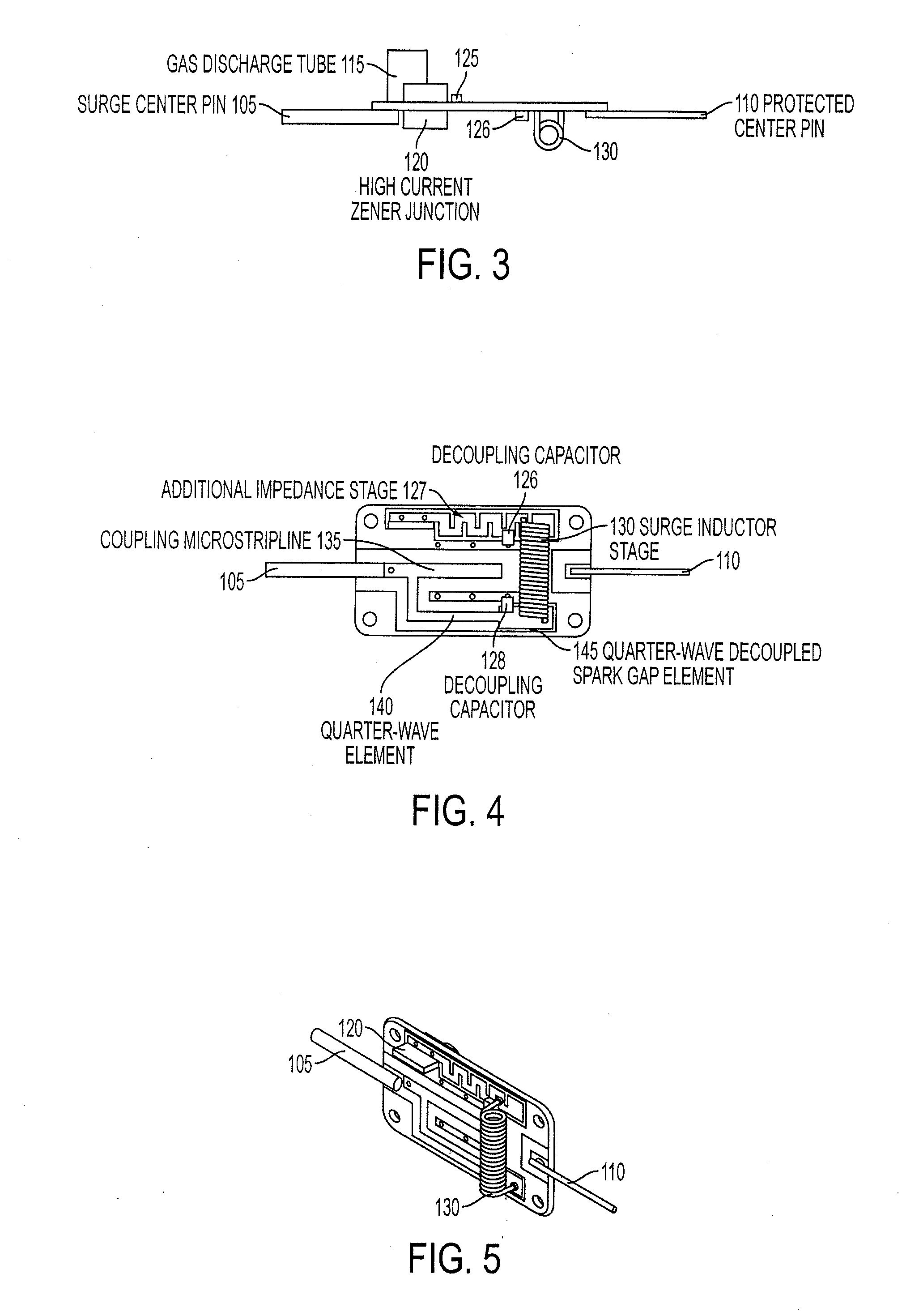

Apparatus for high surge voltage protection

InactiveUS7161785B2Emergency protective arrangement detailsOvervoltage protection resistorsElectricityCoaxial cable

A surge protection element for a conventional cable connector includes a printed circuit board preferably shaped as two concentric rings connected by two spokes. The outer ring is electrically connected to the grounded portion of the cable connector body. A printed circuit trace on one of the spokes is separated from a printed circuit trace on the inner ring by a spark gap. If a high voltage surge is carried by the coaxial cable transmission line, a spark is formed in the gap. As a consequence, the high voltage surge is transferred to the surge protection element which in turn conducts the electricity to the grounded body of the connector.

Owner:JOHN MEZZALINGUA ASSOC INC

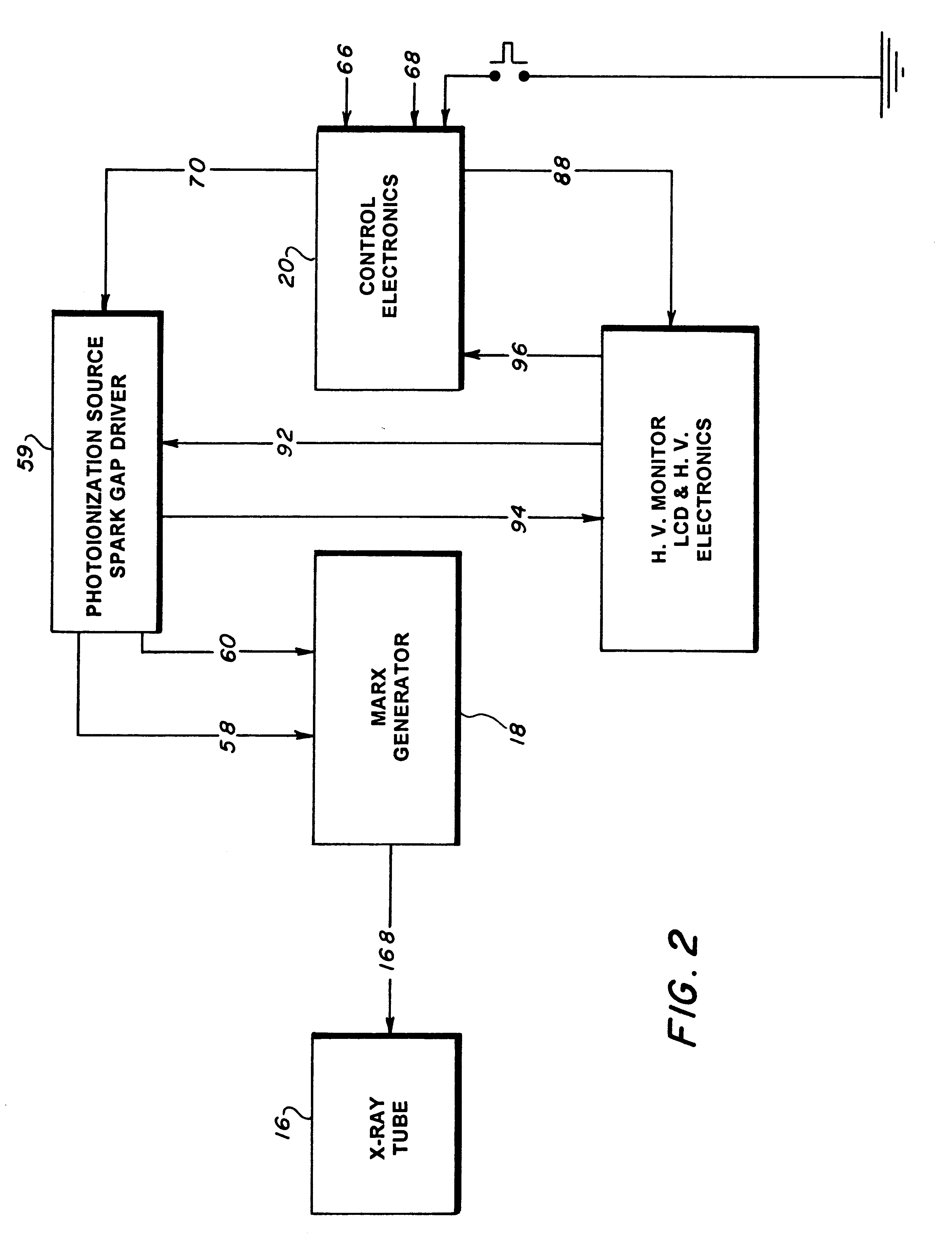

Mobile X-ray unit

A portable X-ray unit, of a relatively light-weight, occoping a volume of less then one-half a cubic foot containing an x-ray head assembly, a unique Marx generator, a plurality of spark-gap switches and control electronics is disclosed. The Marx generator allows for the development of a relatively high voltage in excess of 100 kV, yet allows for the discharge thereof within the nanosecond range. The Marx generator is enclosed by an acrylic insulator that cooperates with an aluminum enclosure, which functions as a return current path for the capacitors in the Marx generator and also as a shield against the escape of electromagnetic radiation from the pulsed x-ray unit. The Marx generator and spark-gap switches are confined within the pressurized chamber that may contain nitrogen gas to reduce the separation of the gap in the spark-gap switches.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

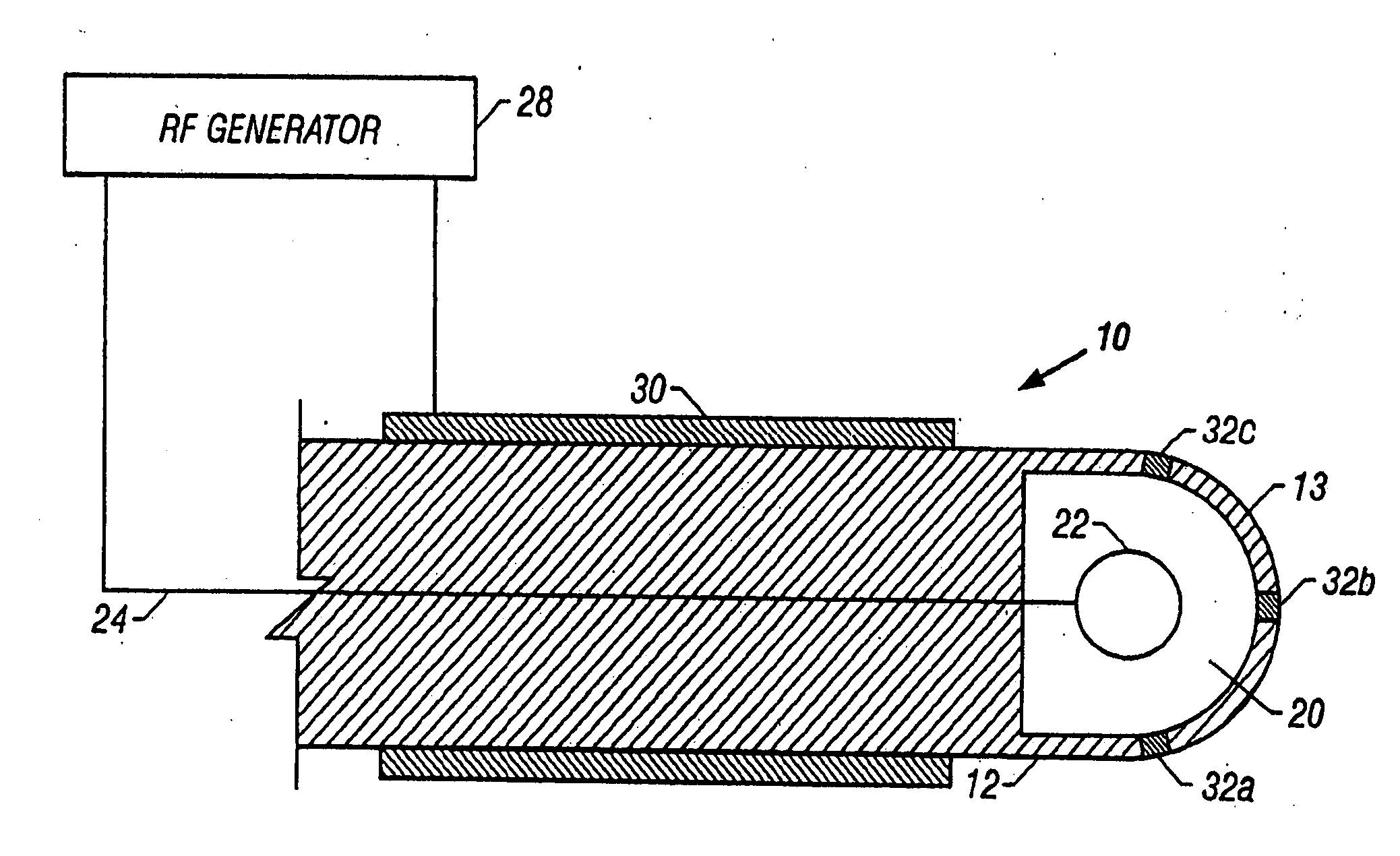

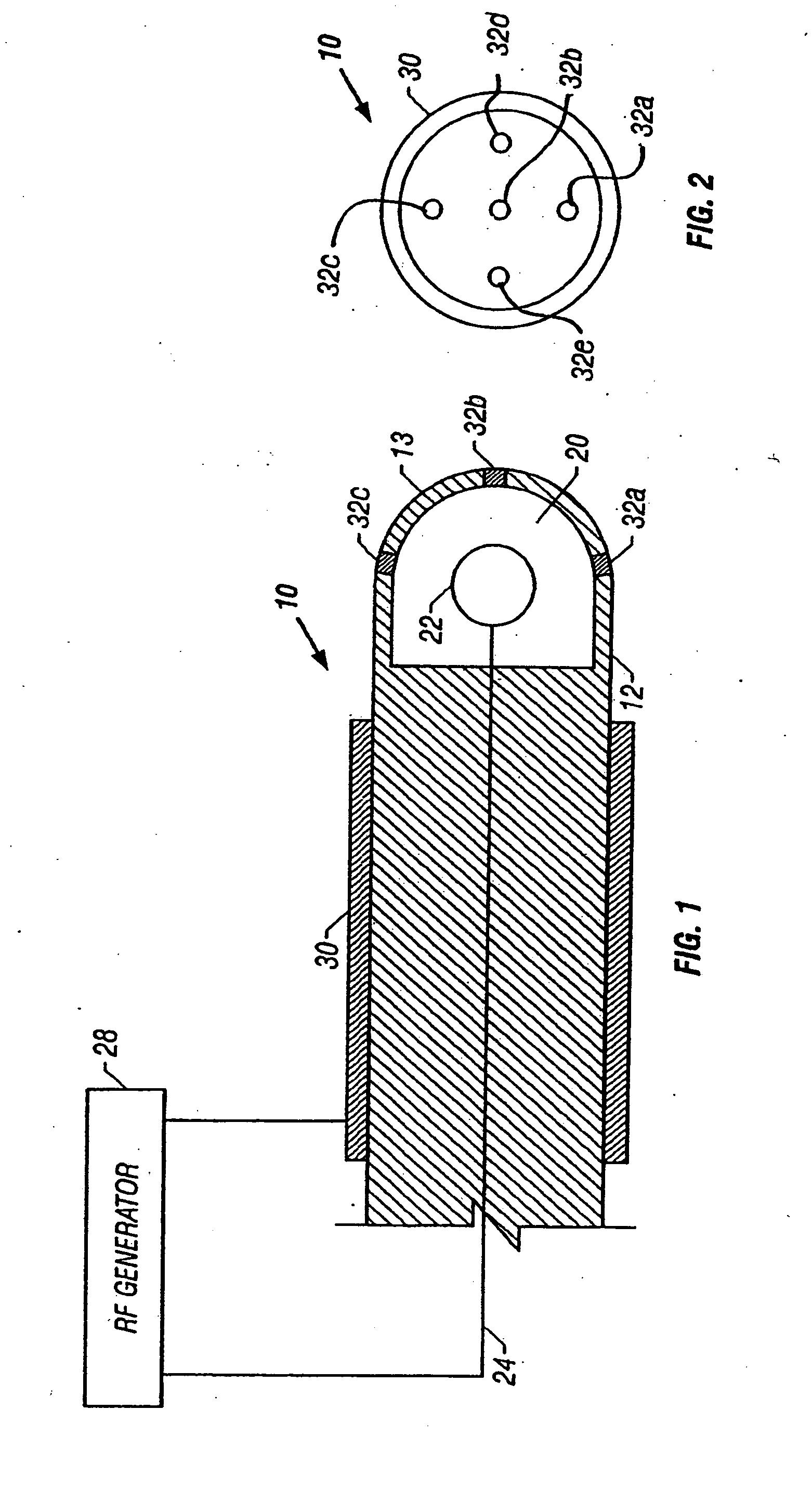

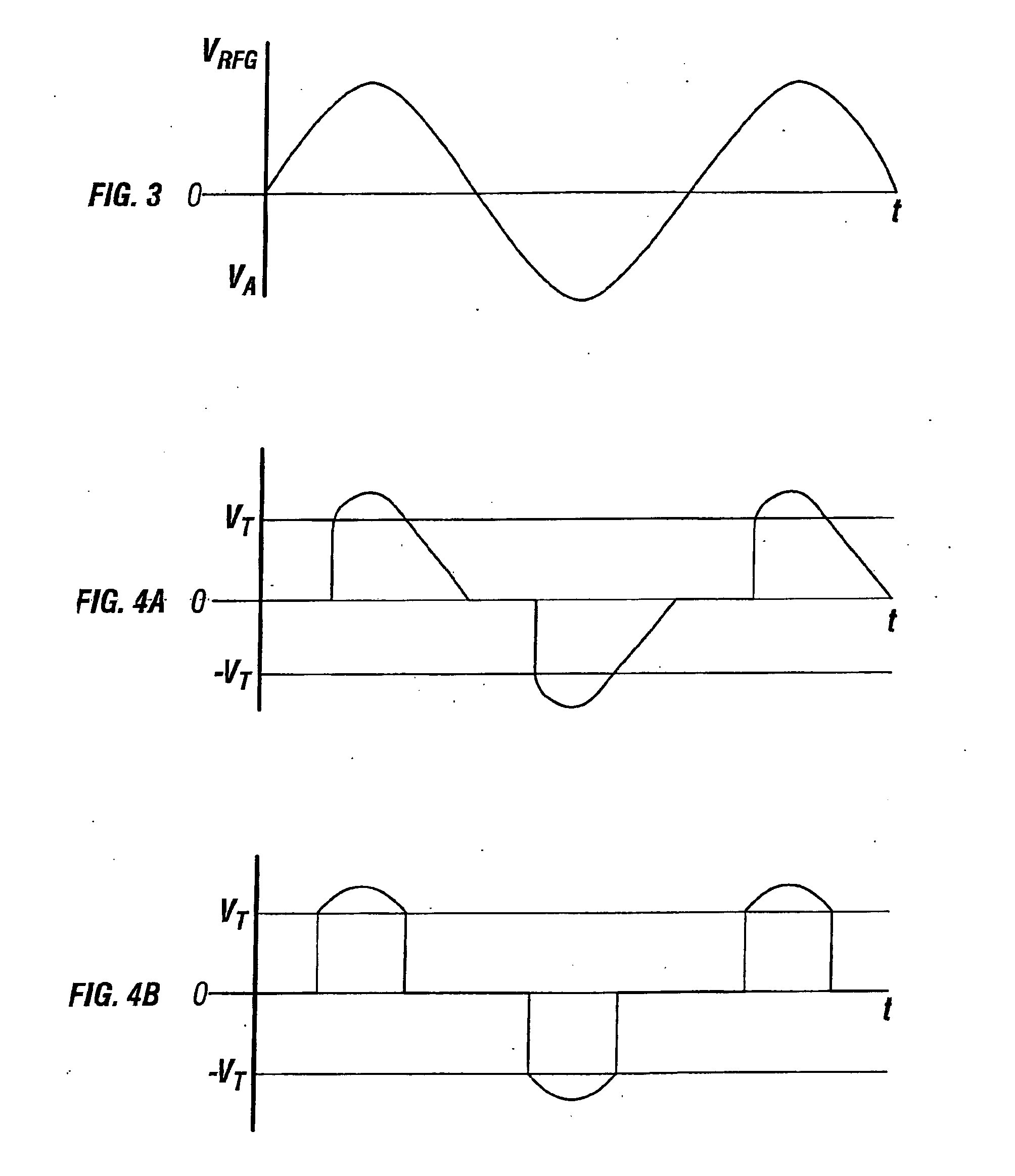

Voltage threshold ablation apparatus

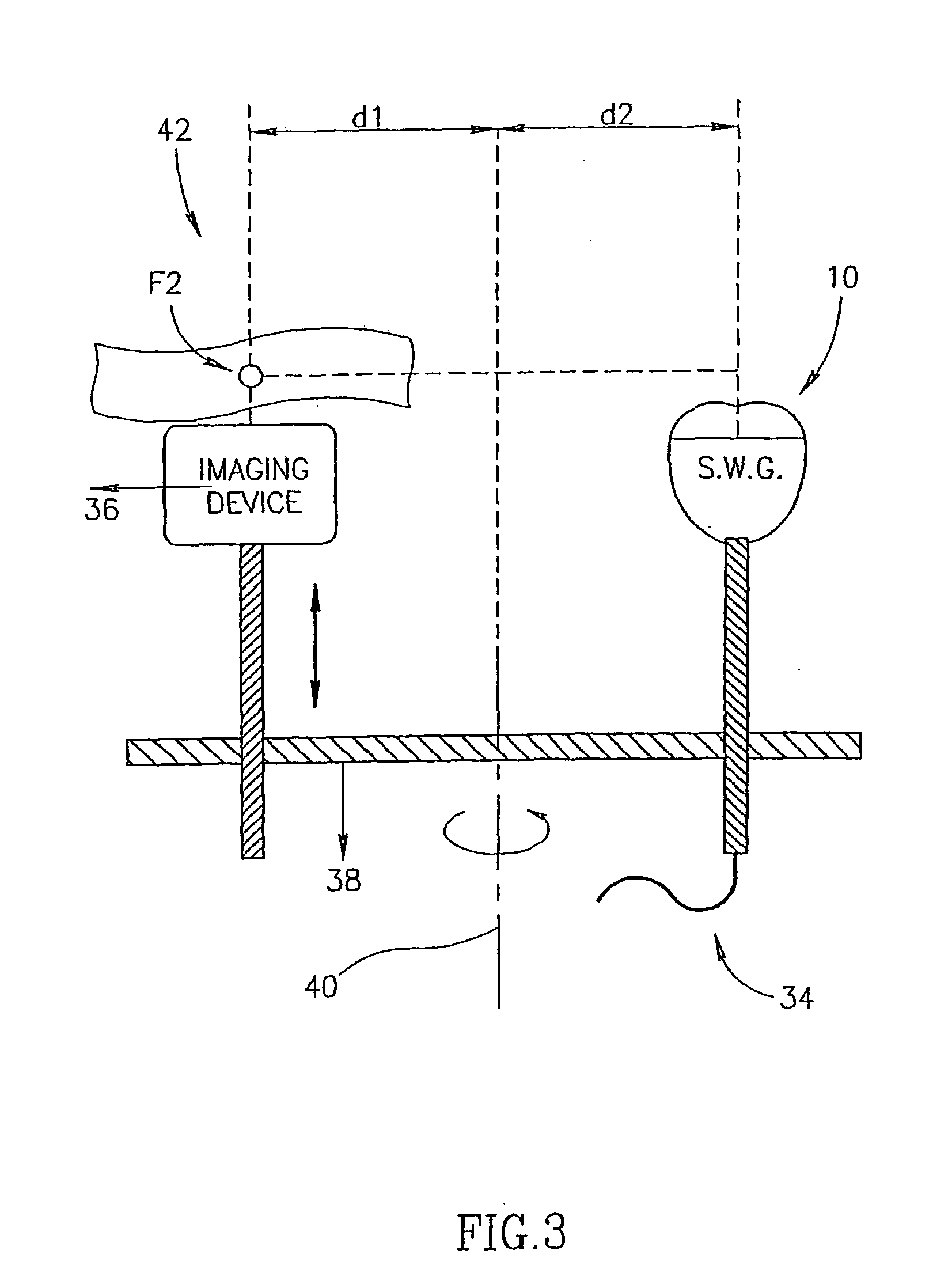

A method and apparatus for treating tissue using an electrosurgical system. The system includes an electrosurgical system having an RF generator, a treatment electrode electrically coupled to the RF generator and positioned in contact with target tissue to be treated, and a spark gap switch positioned between the RF generator and the target tissue. The spark gap includes a threshold voltage and is configured to prevent conduction of current from the RF generator to the tissue until the voltage across the spark gap reaches the threshold voltage. The method includes the steps of using the RF generator to apply a voltage across the spark gap switch, the spark gap switch causing conduction of current from the RF generator to the target tissue once the voltage across the spark gap reaches the threshold voltage.

Owner:DFINE INC

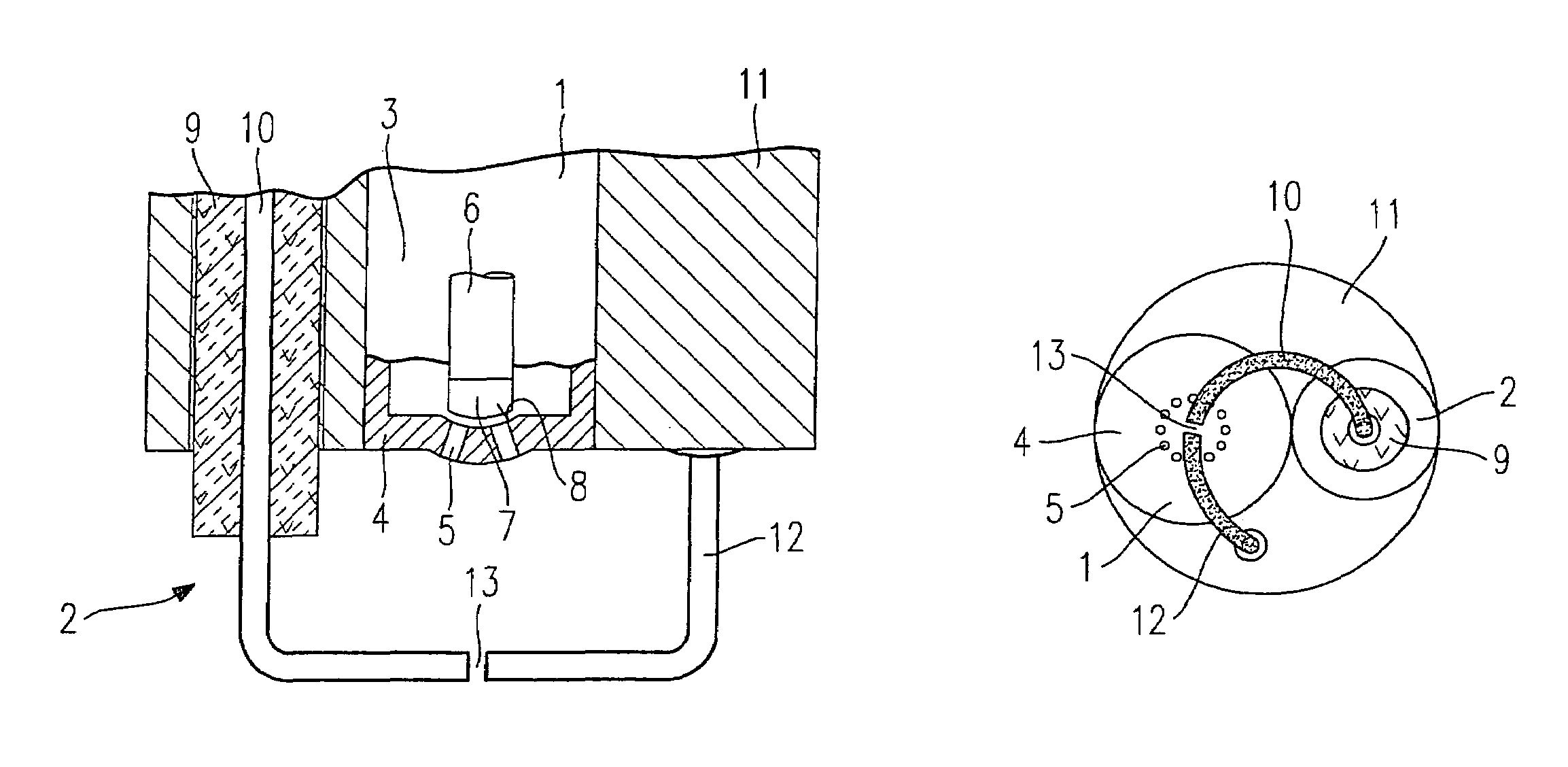

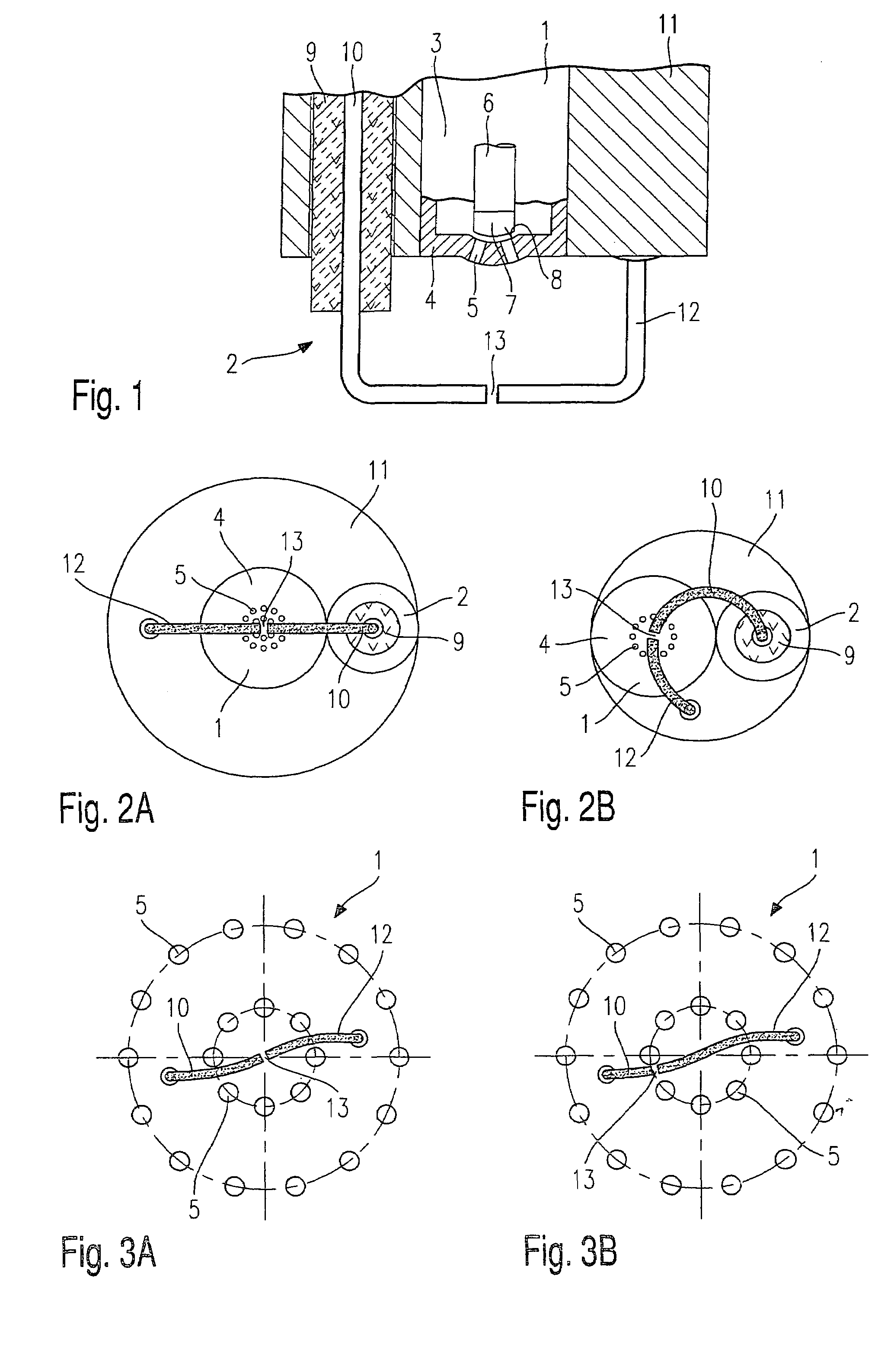

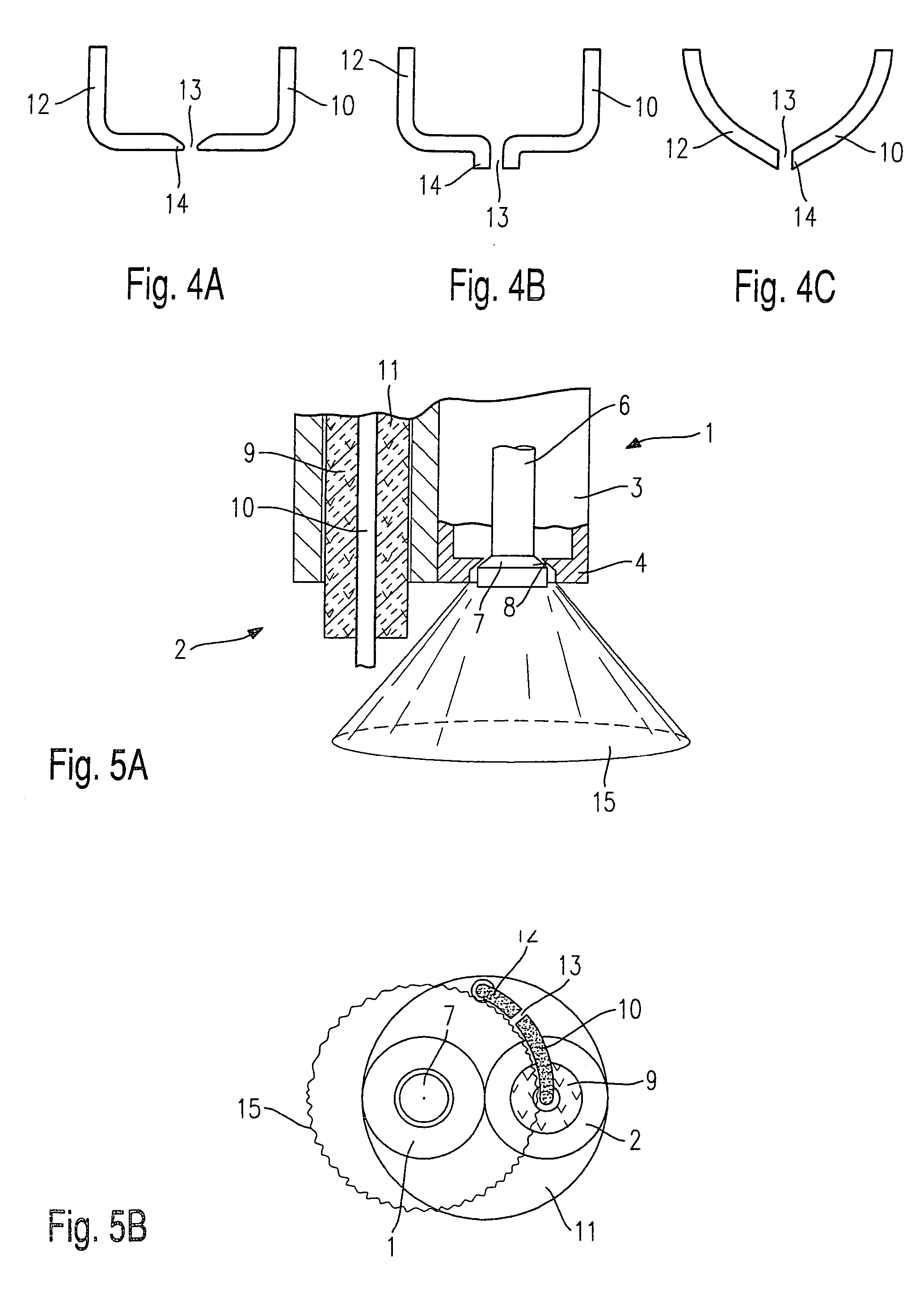

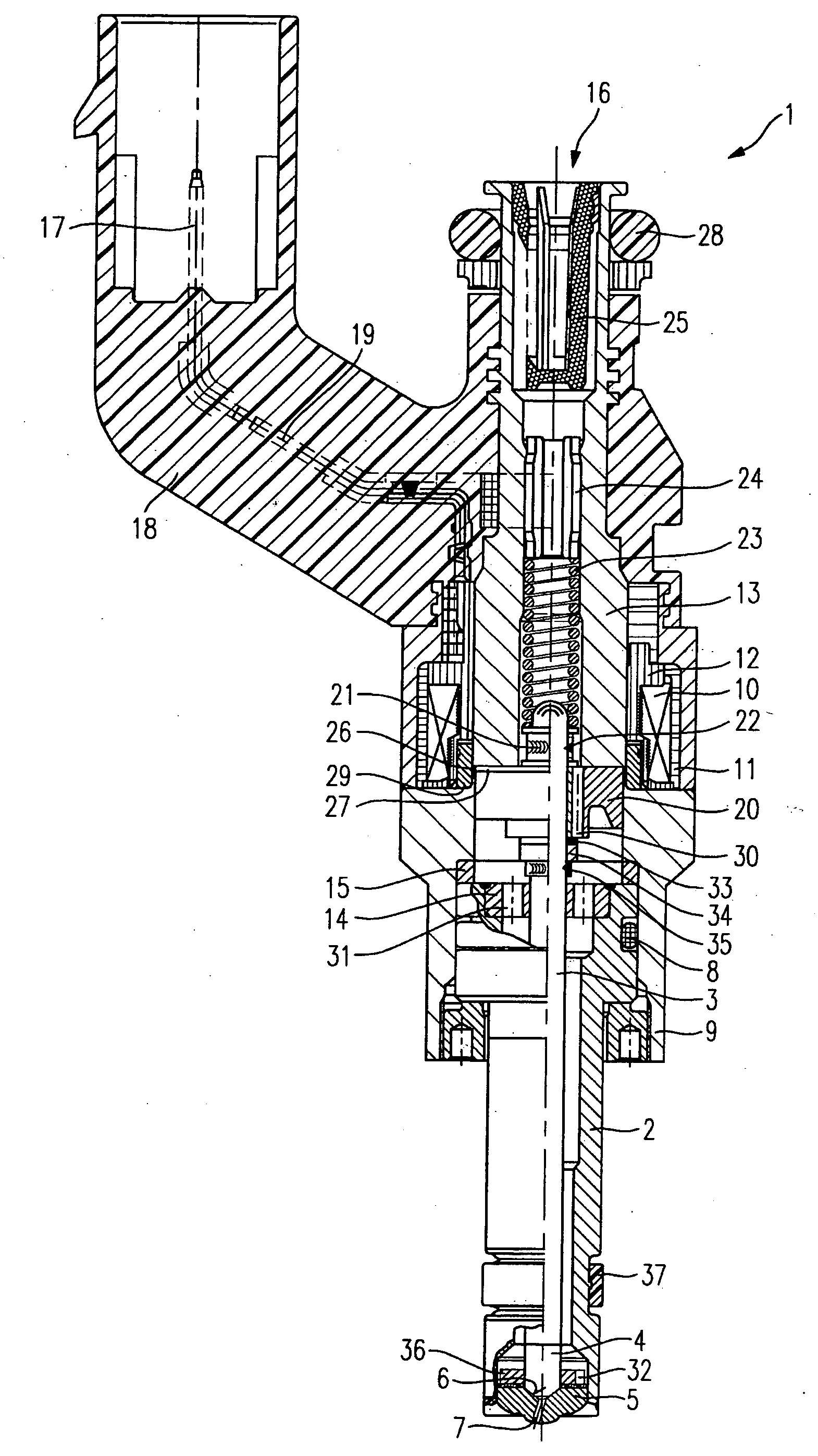

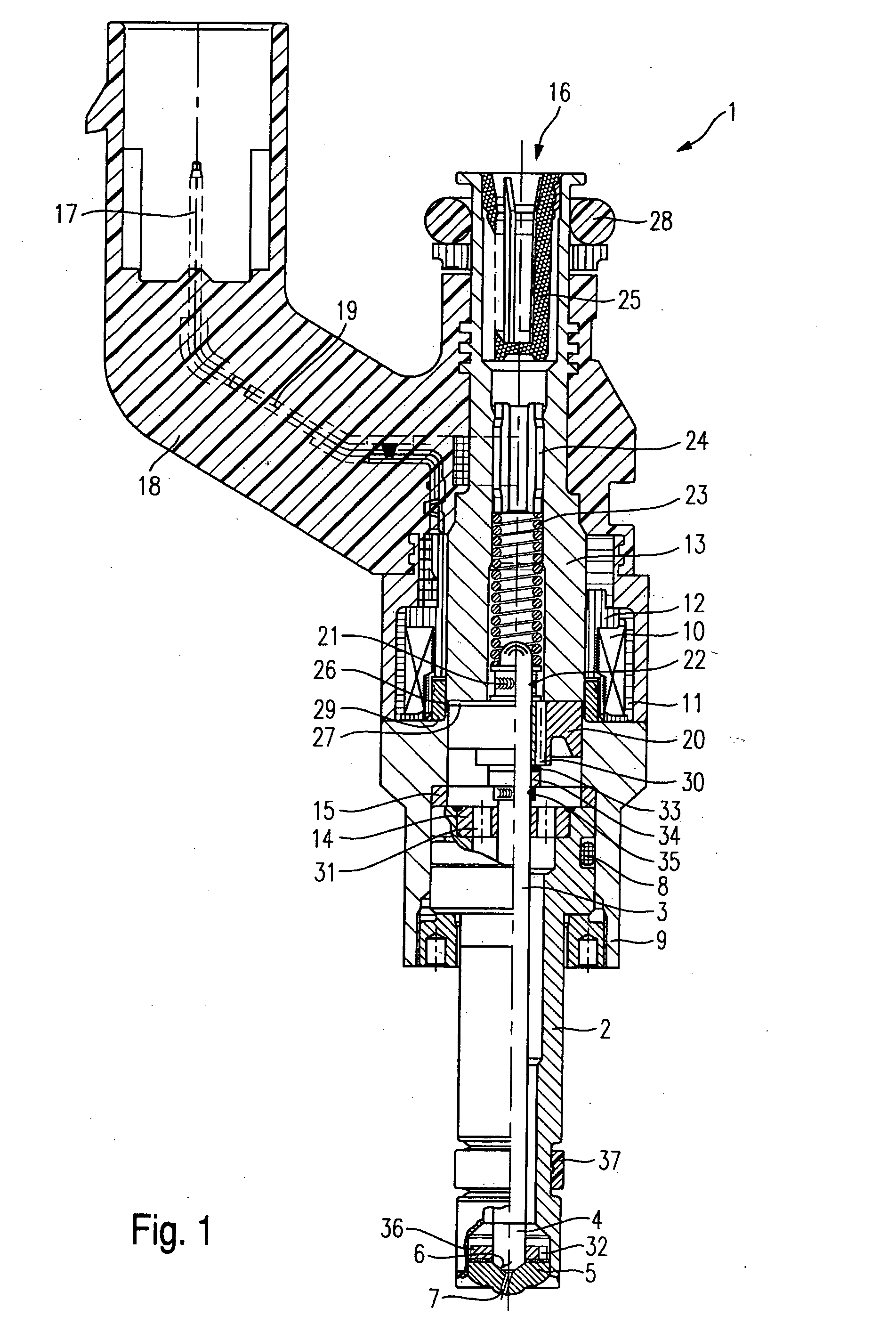

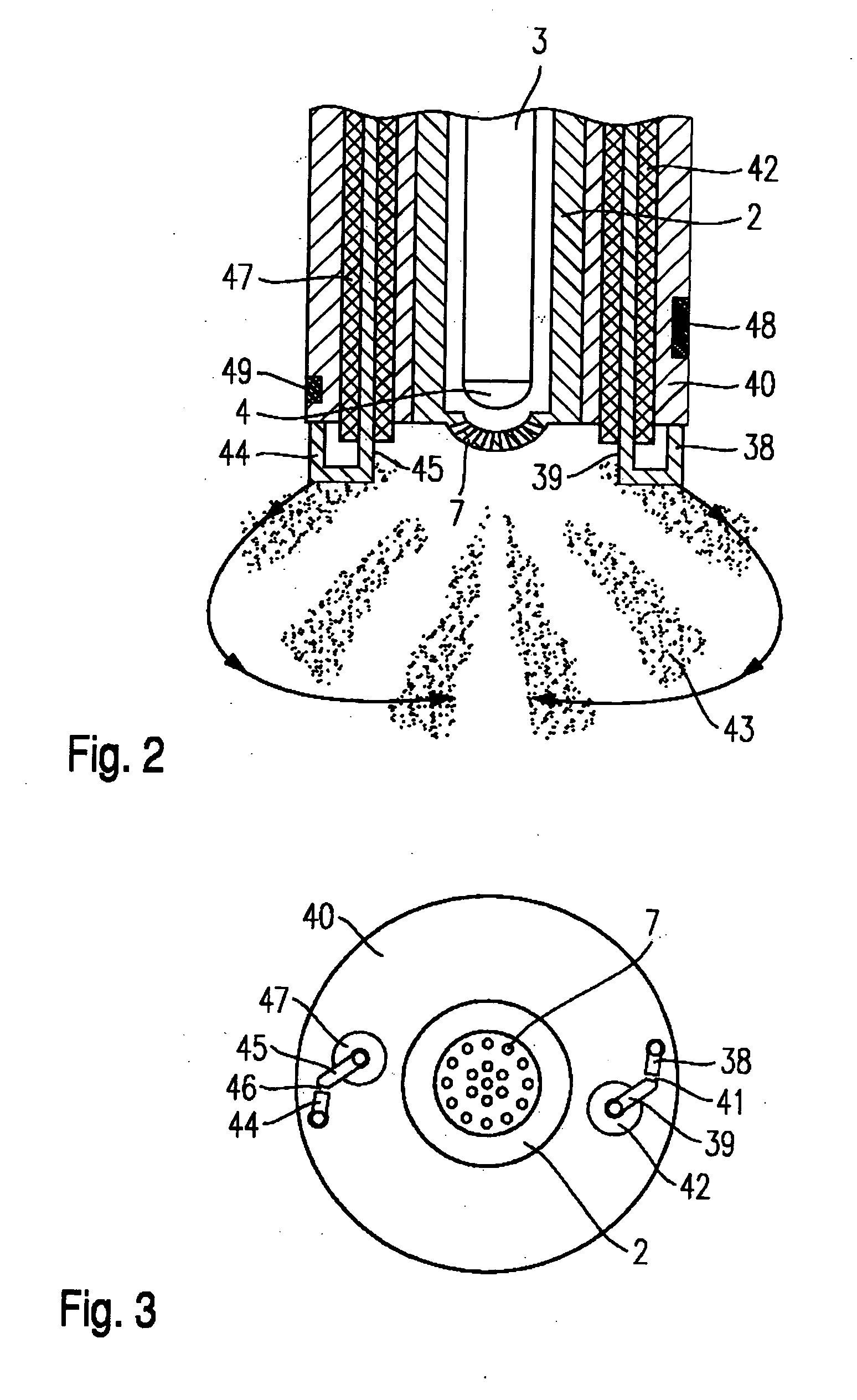

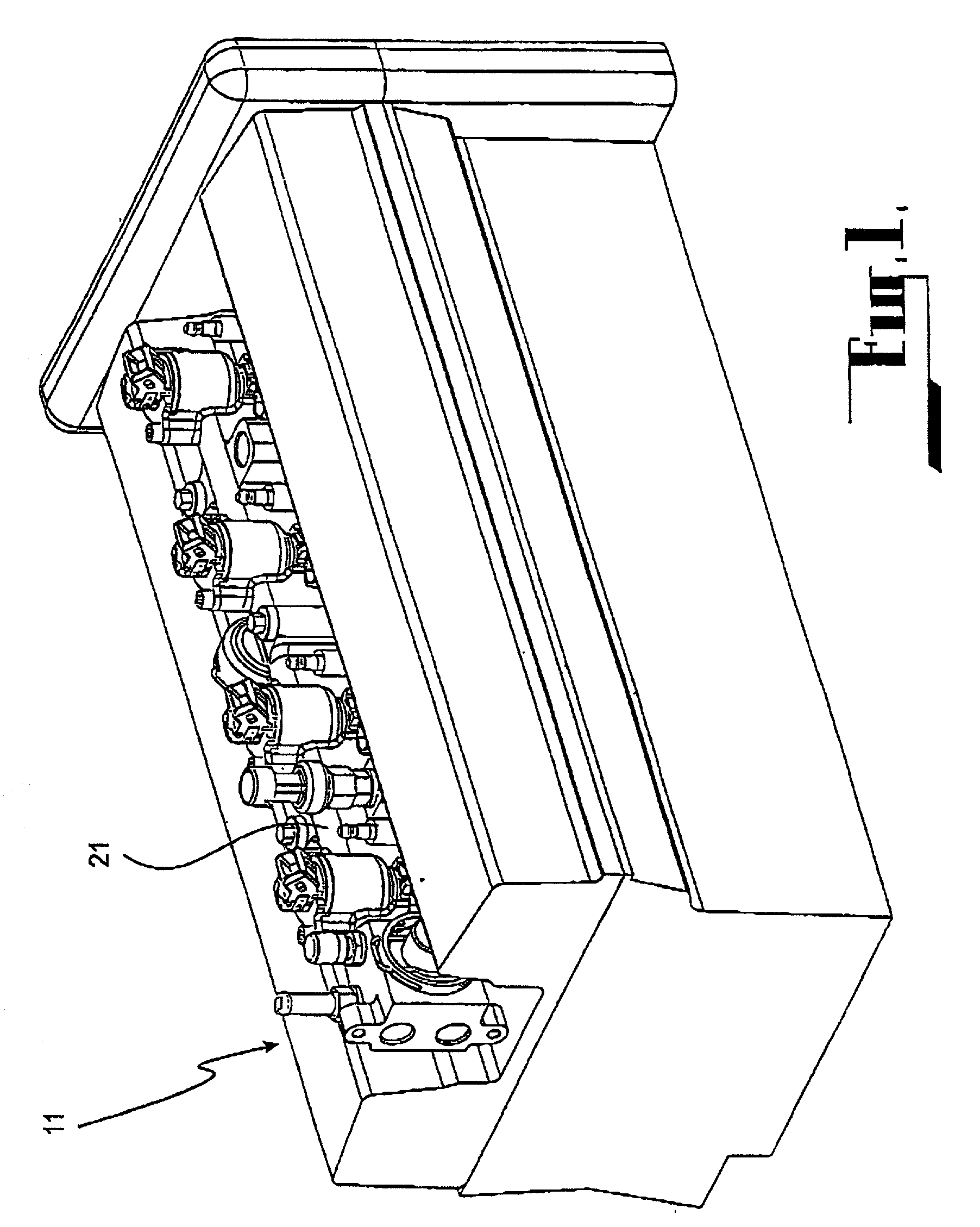

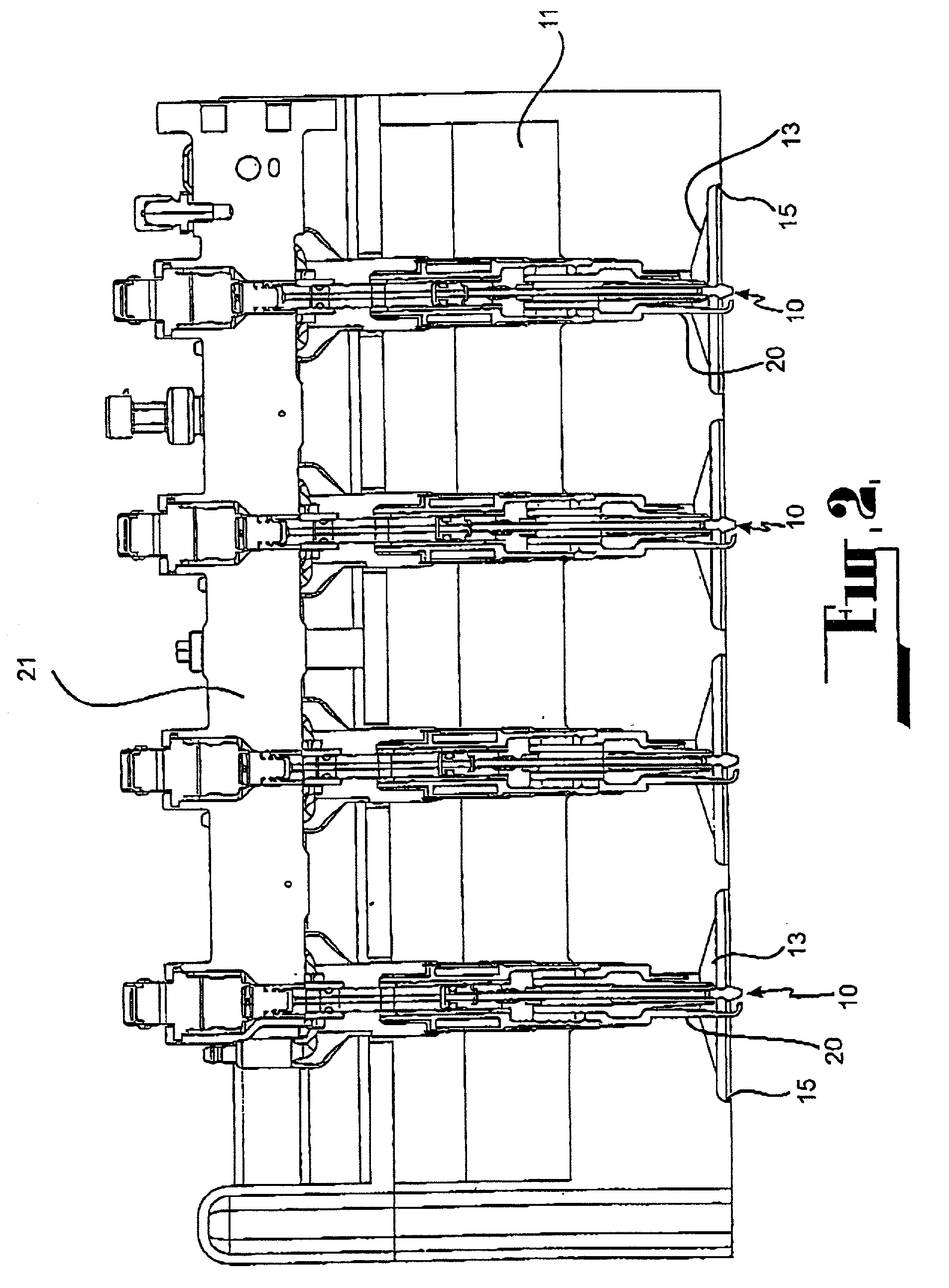

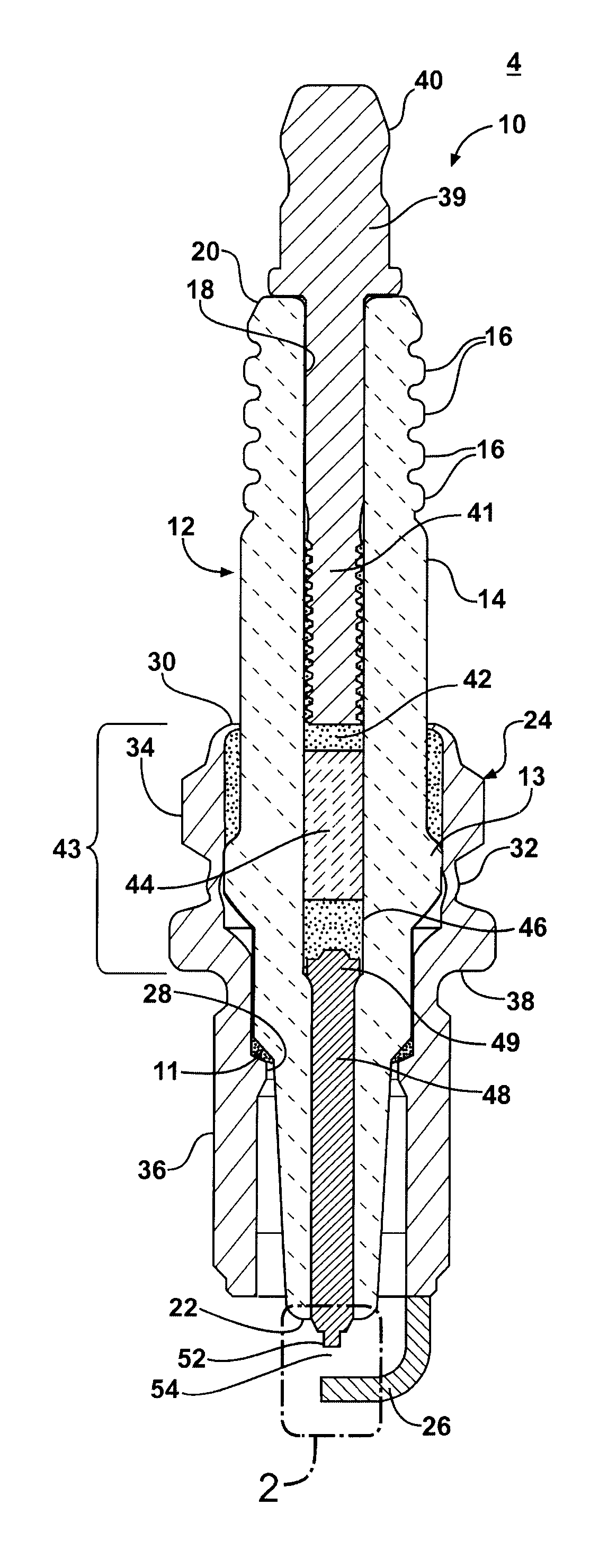

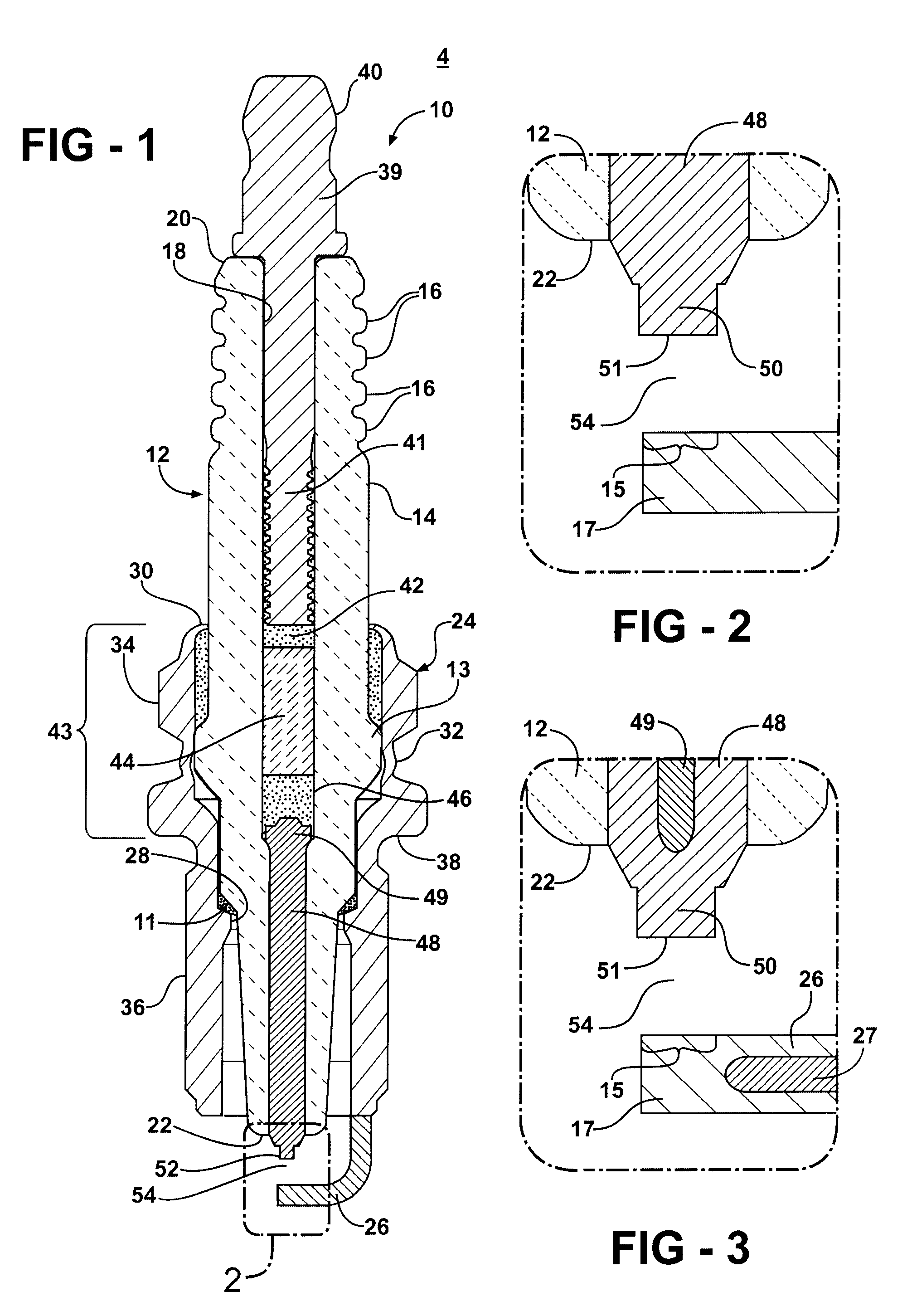

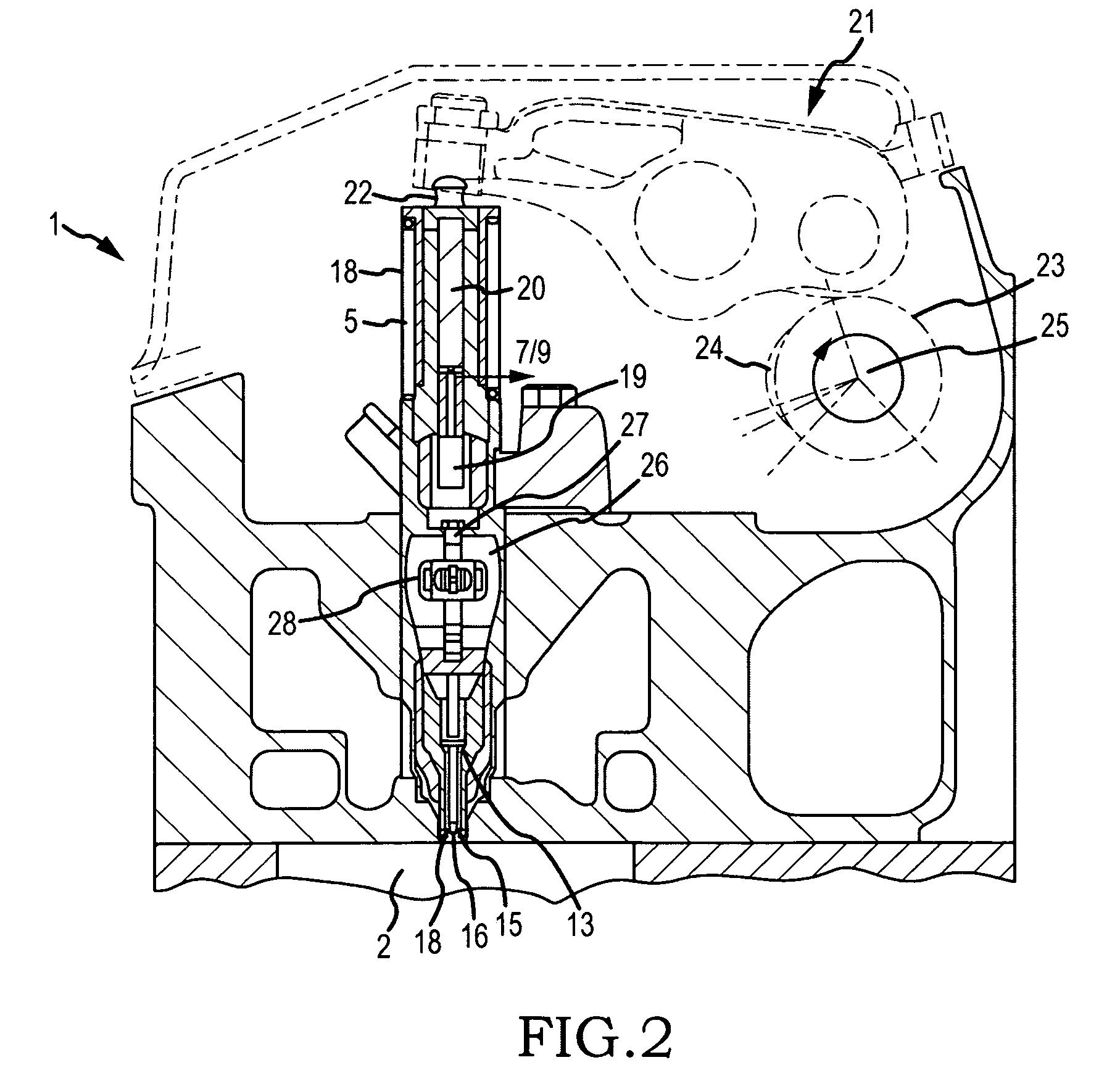

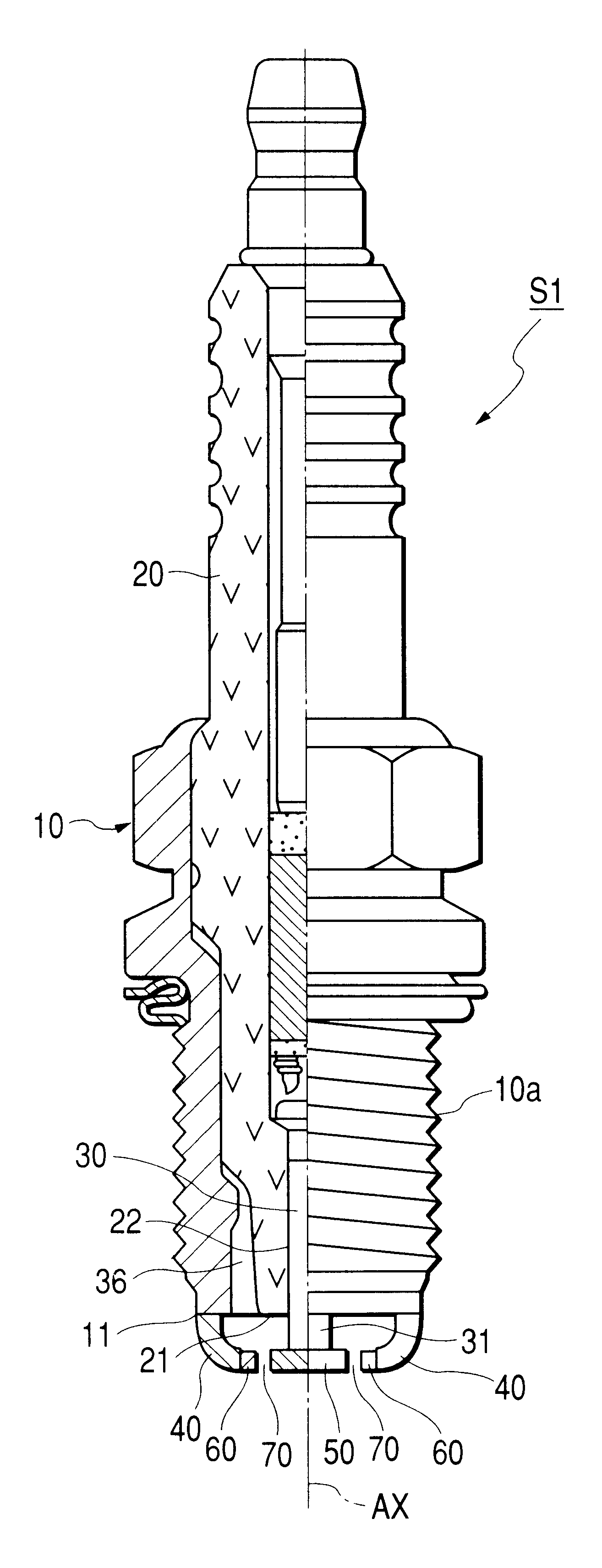

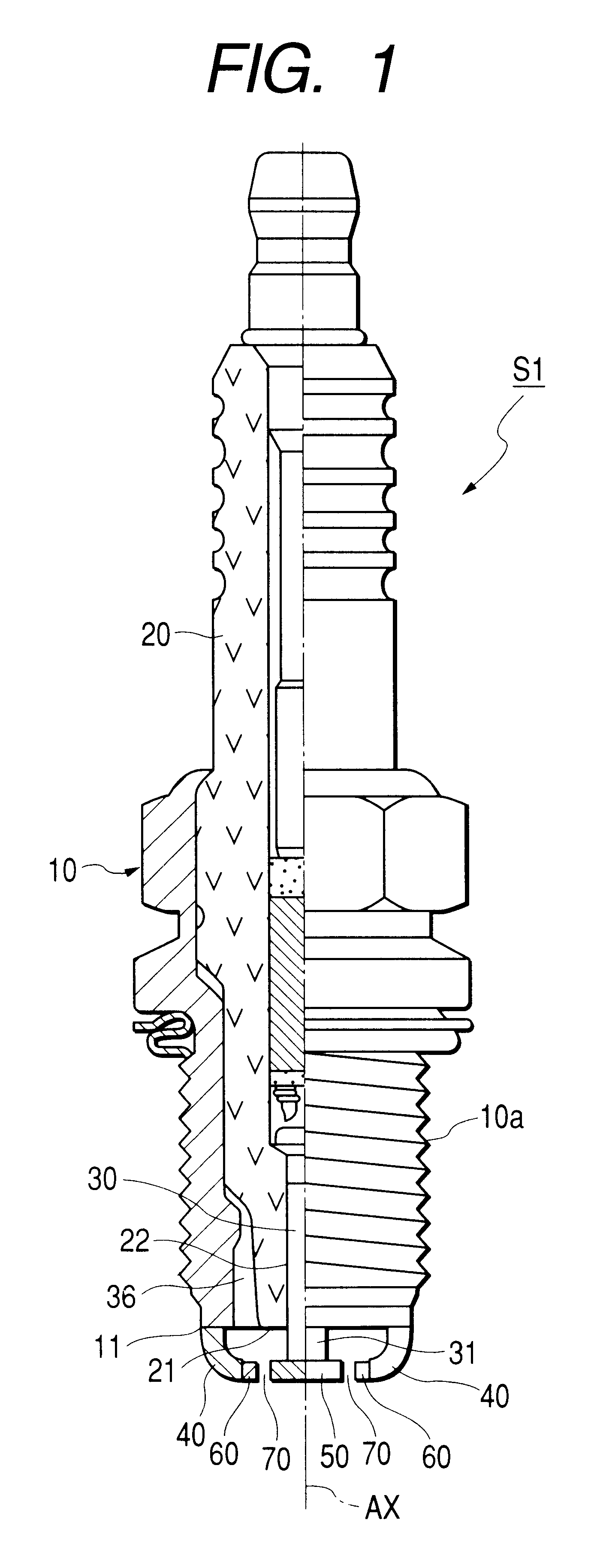

Combined fuel injection valve-ignition plug

InactiveUS7077100B2Sparking plugsFuel injection apparatusCombustion chamberInternal combustion engine

A fuel injector having an integrated spark plug is provided, the fuel injector providing direct injection of fuel into a combustion chamber of an internal combustion engine, and the spark plug for igniting the fuel injected into the combustion chamber. Also provided is a spark-plug insulator that insulates a first electrode and a second electrode which is set apart from the first electrode by a spark gap, the fuel injector and the spark-plug insulator of the spark plug being arranged in a shared housing. The spark gap has a width of 50 to 300 μm and is disposed in front of the fuel injector at a distance of 3 to 10 mm.

Owner:ROBERT BOSCH GMBH

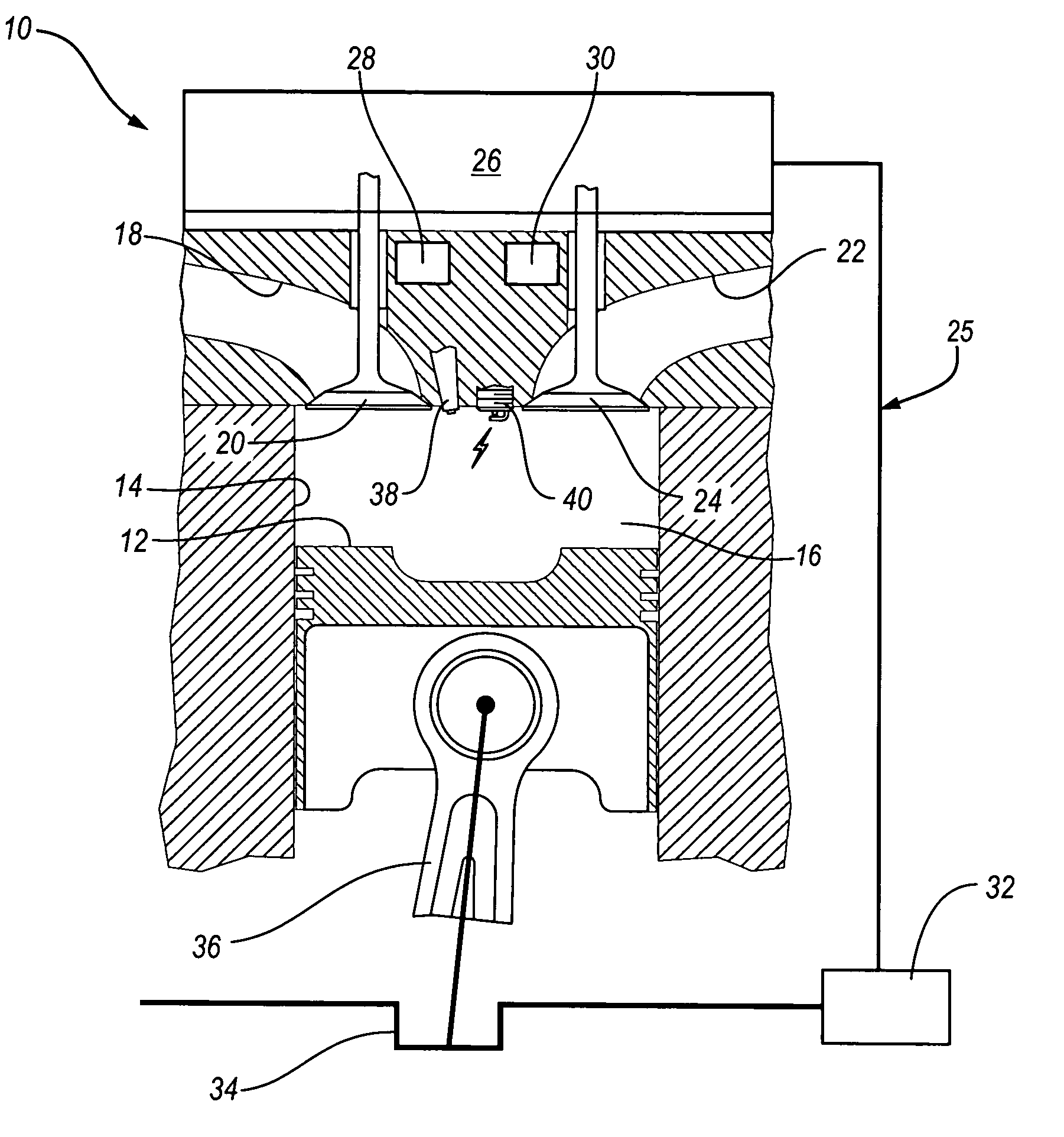

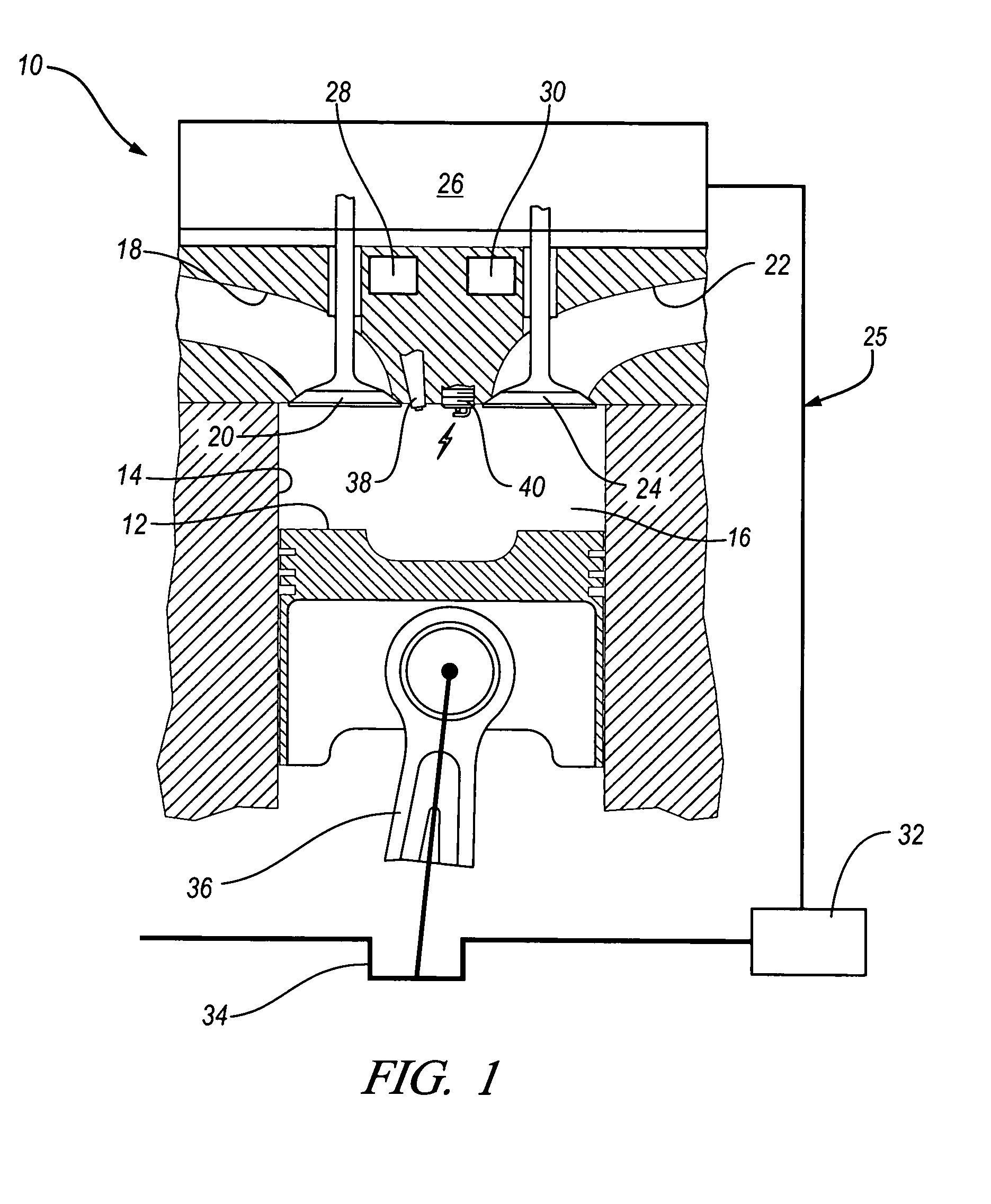

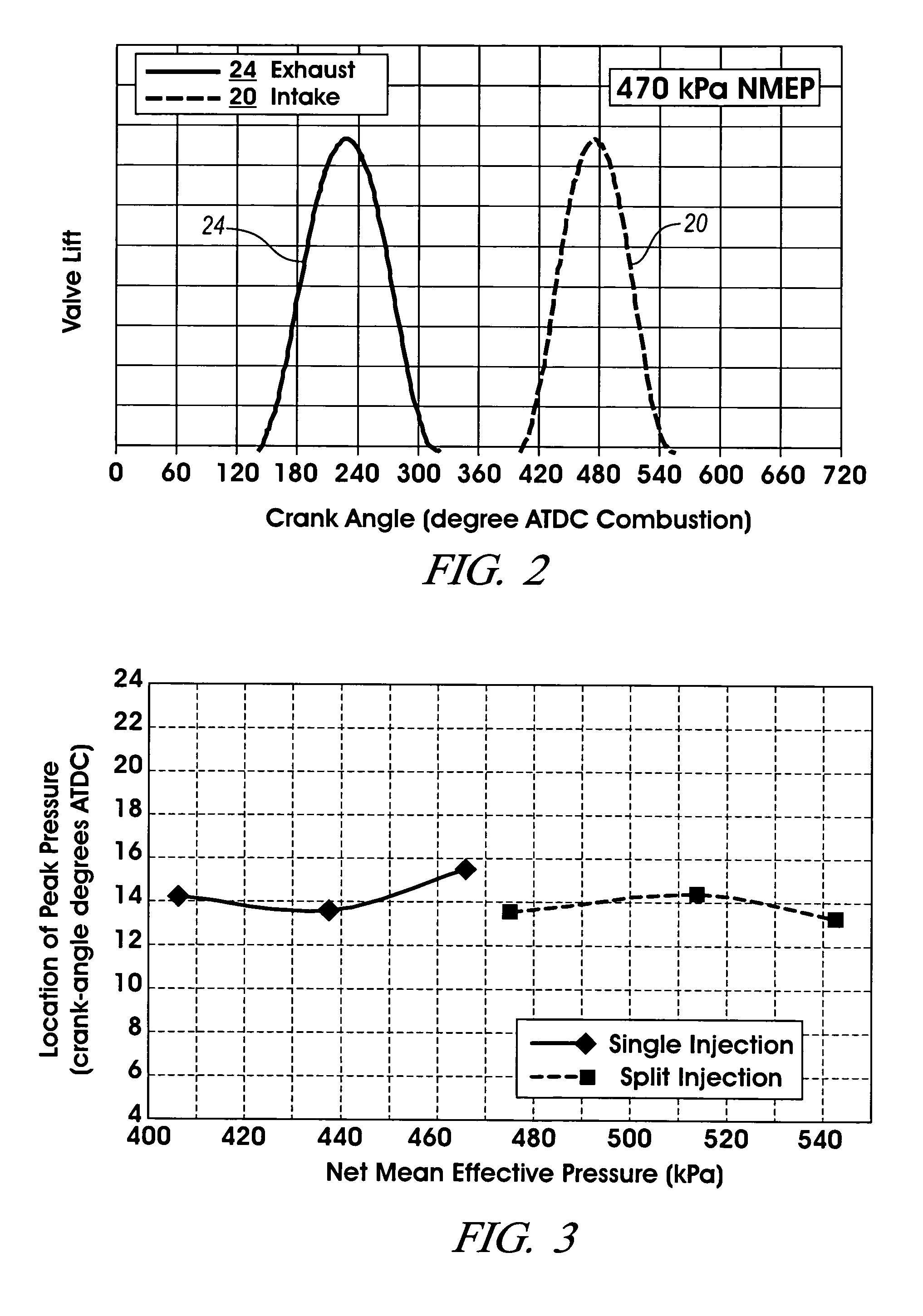

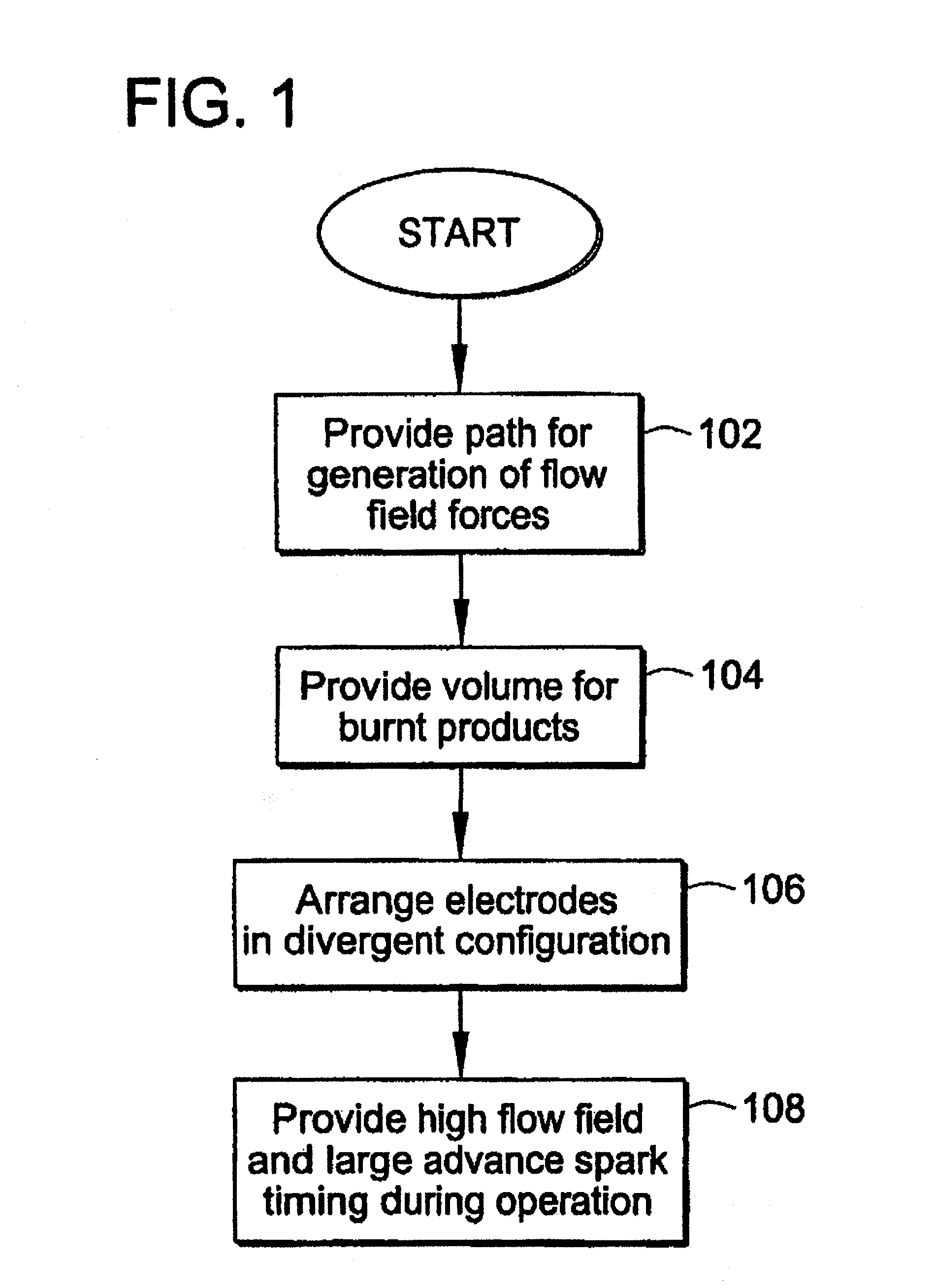

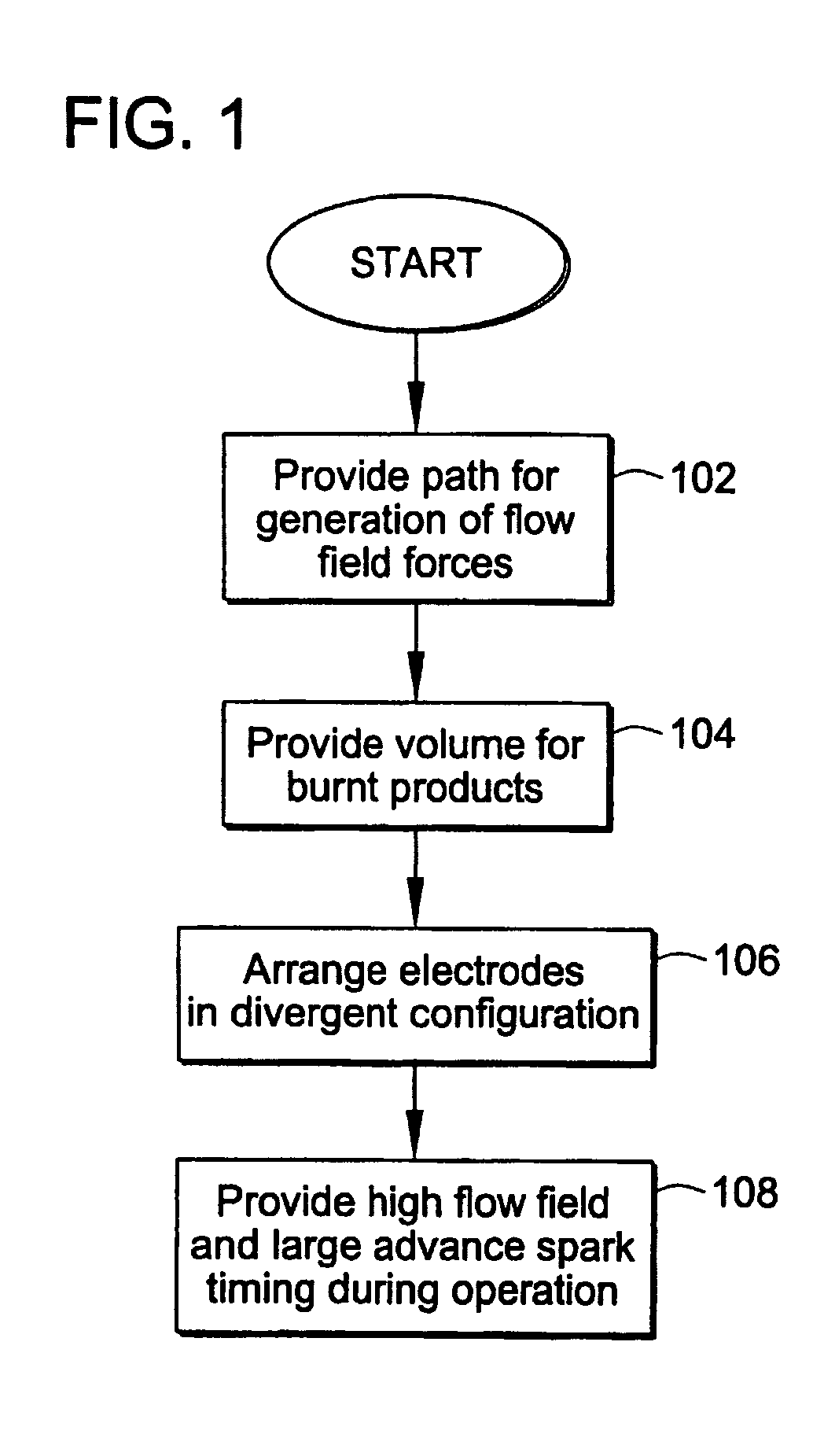

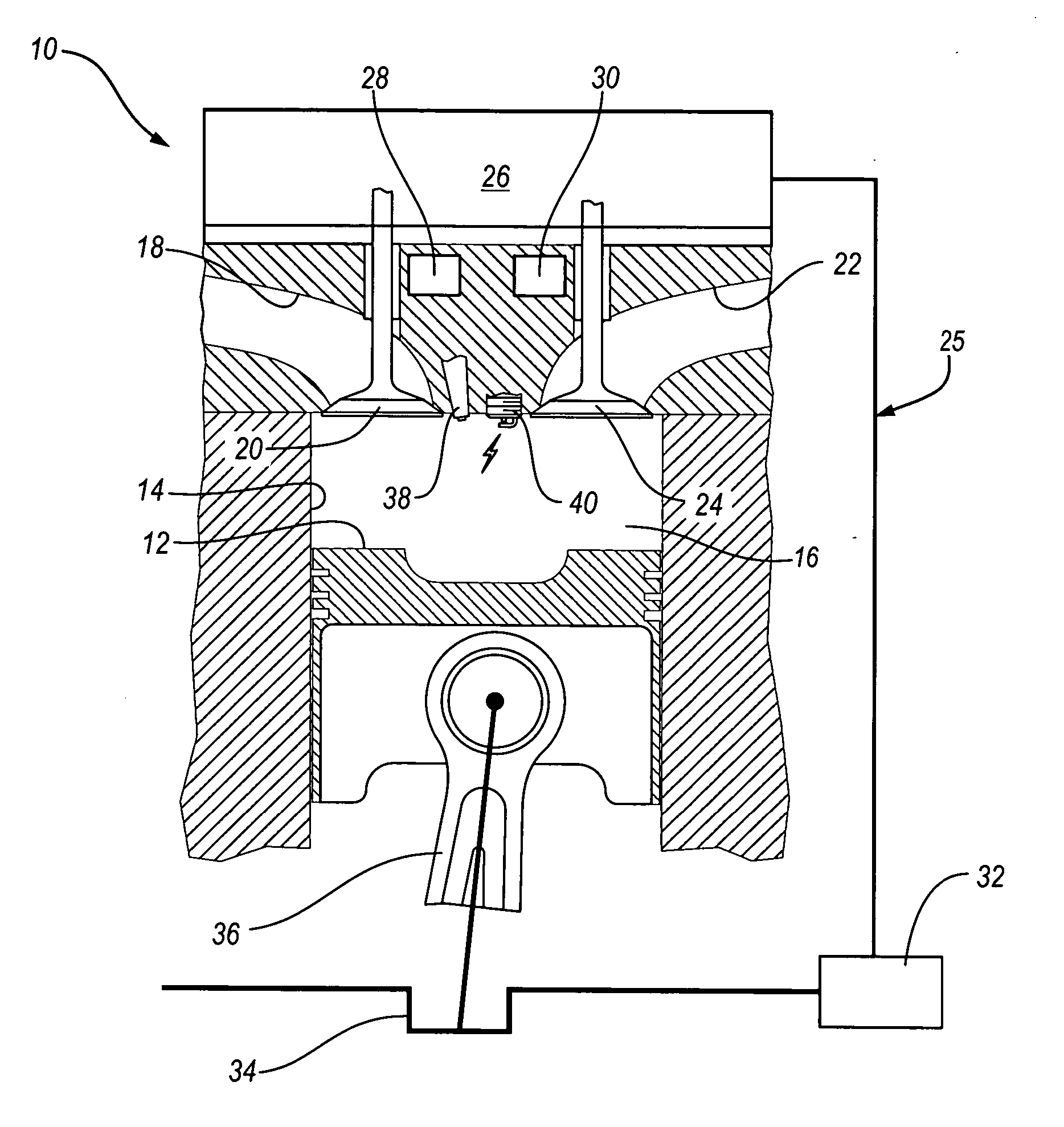

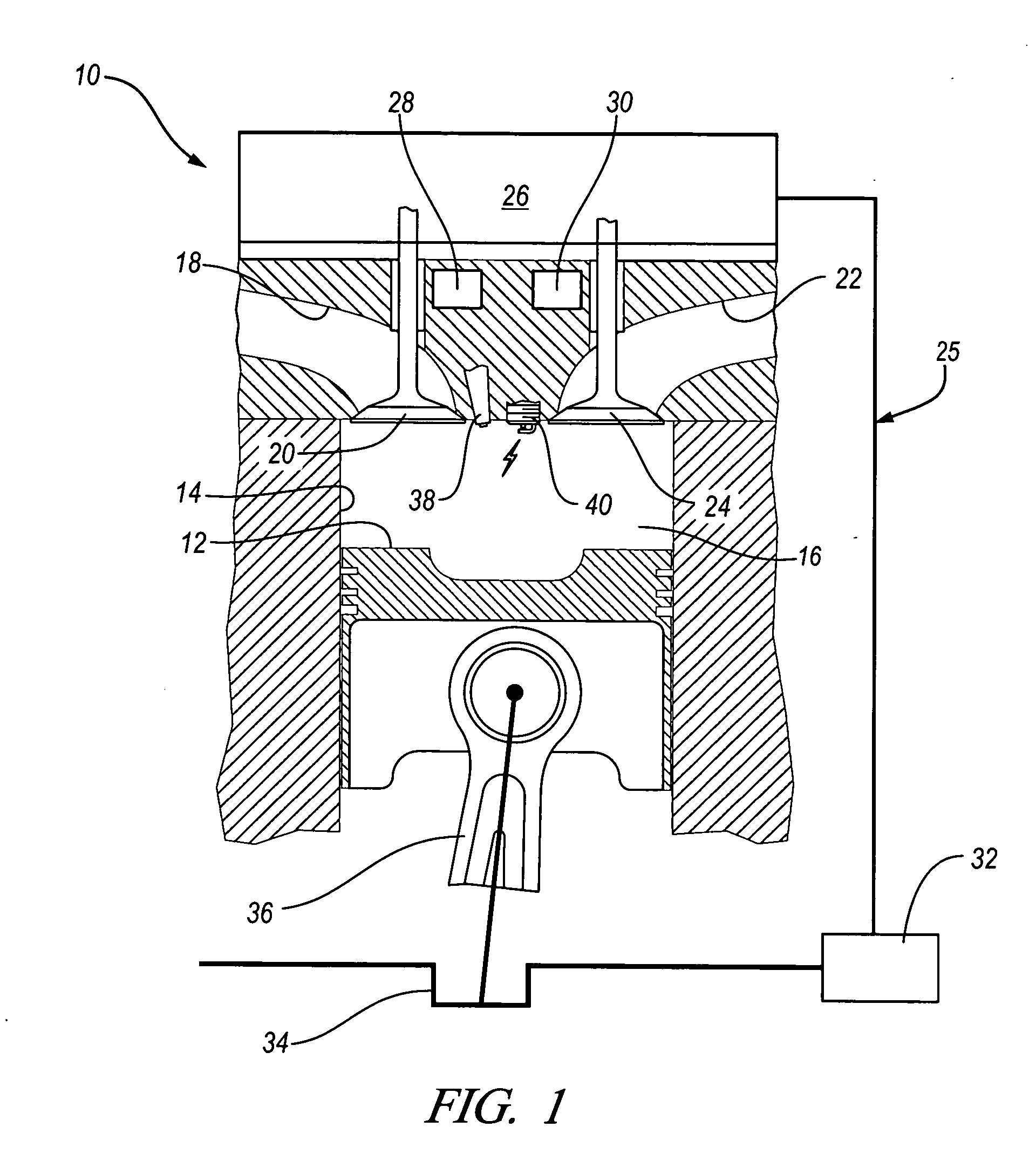

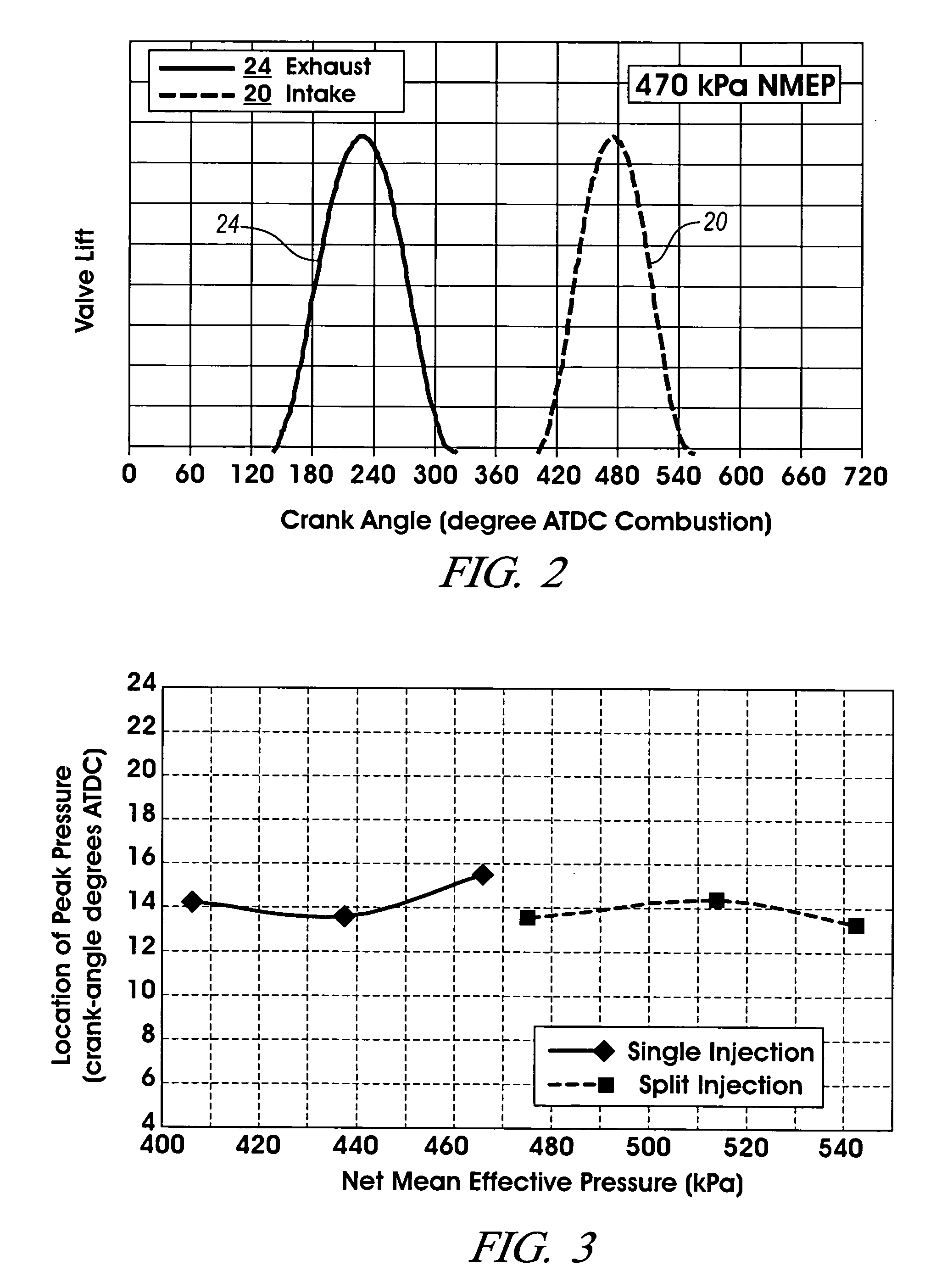

Method for mid load operation of auto-ignition combustion

ActiveUS6994072B2Electrical controlNon-fuel substance addition to fuelPressure riseMultiple injection

A method is disclosed for expanding the mid load operation limit in a four-stroke gasoline direct-injection controlled auto-ignition combustion engine. A system is employed for variably actuating the intake and exhaust valves and for operating the valves with an exhaust re-compression or exhaust re-breathing valve strategy. A spark plug is provided. A fuel injector having multiple injection capability is employed. A first fuel charge is injected into the combustion chamber to form a lean air-fuel mixture. A second fuel charge is injected into the combustion chamber to form a stratified air-fuel mixture having an ignitable mixture located near the spark plug. The ignitable mixture is ignited at the spark gap, thereby causing spark-ignition combustion that causes a sufficient increase in chamber pressure and temperature to trigger auto-ignition of the lean air-fuel mixture, resulting in the obtaining of a higher engine load before a pressure rise rate in the combustion chamber exceeds a prescribed threshold value.

Owner:GM GLOBAL TECH OPERATIONS LLC

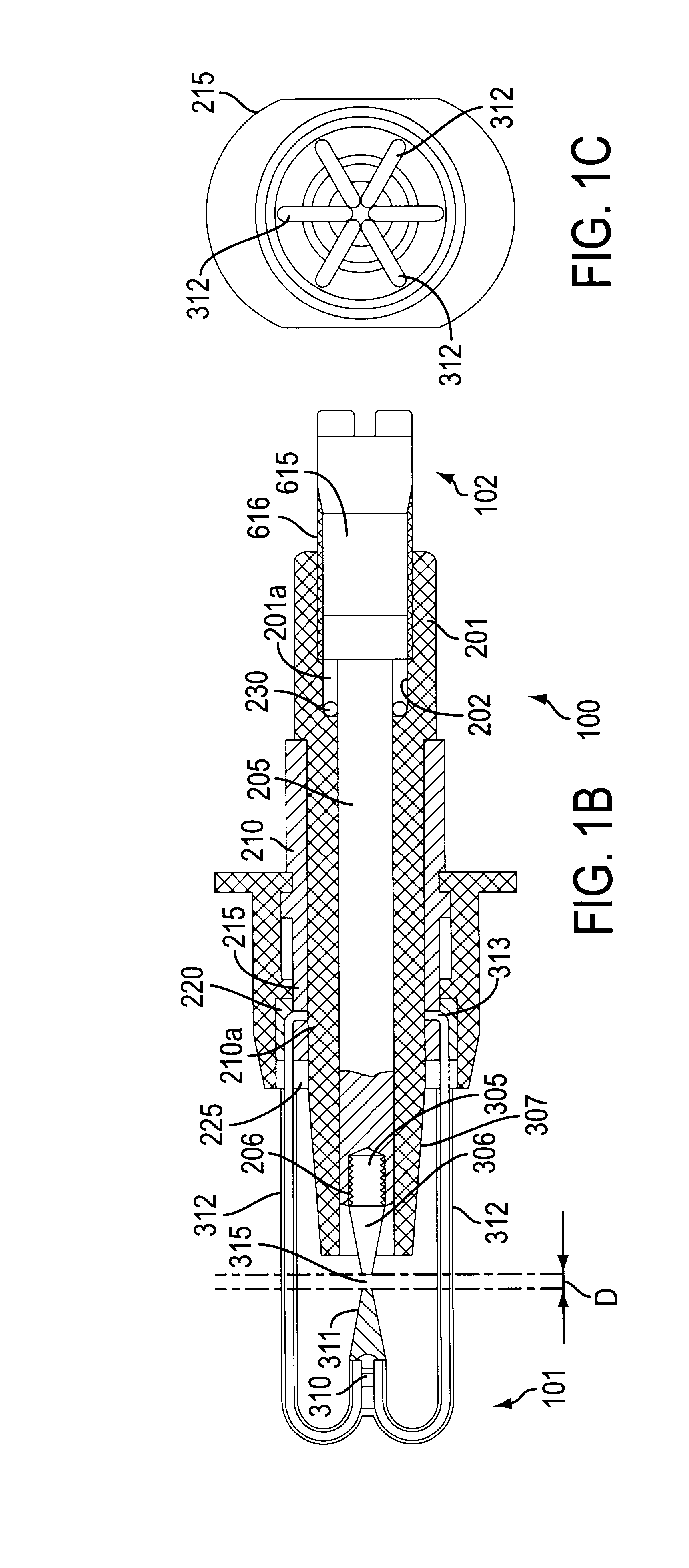

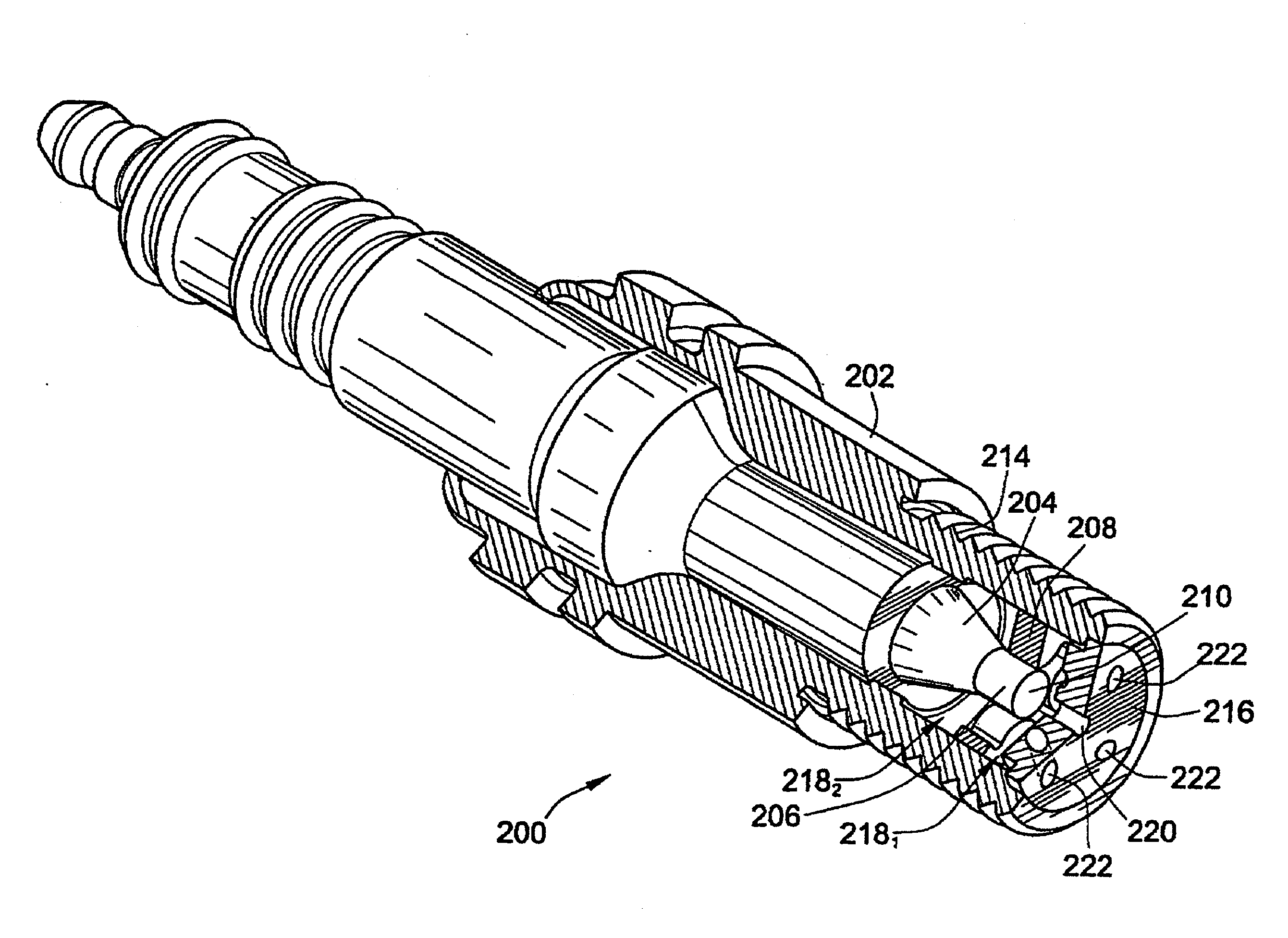

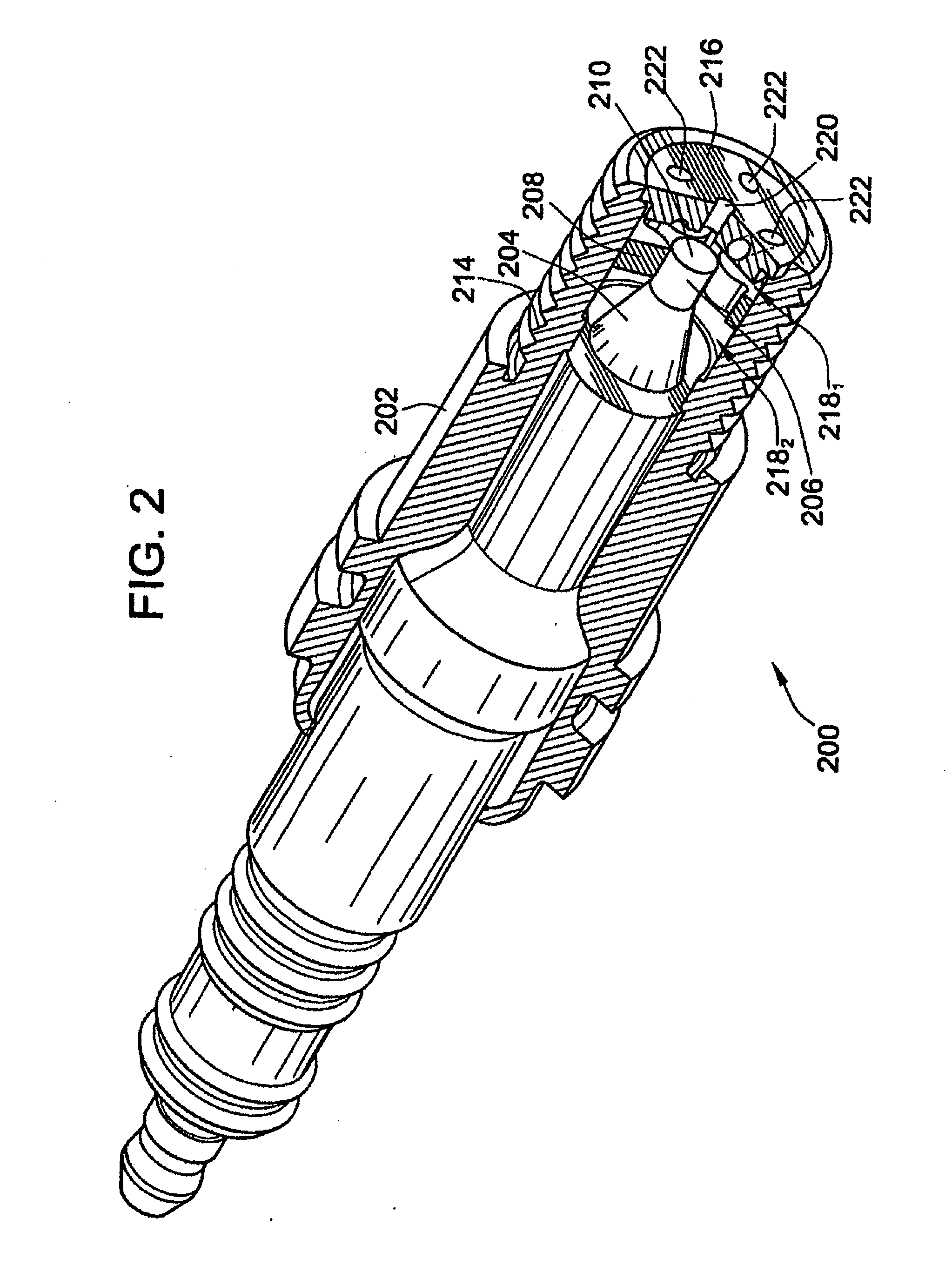

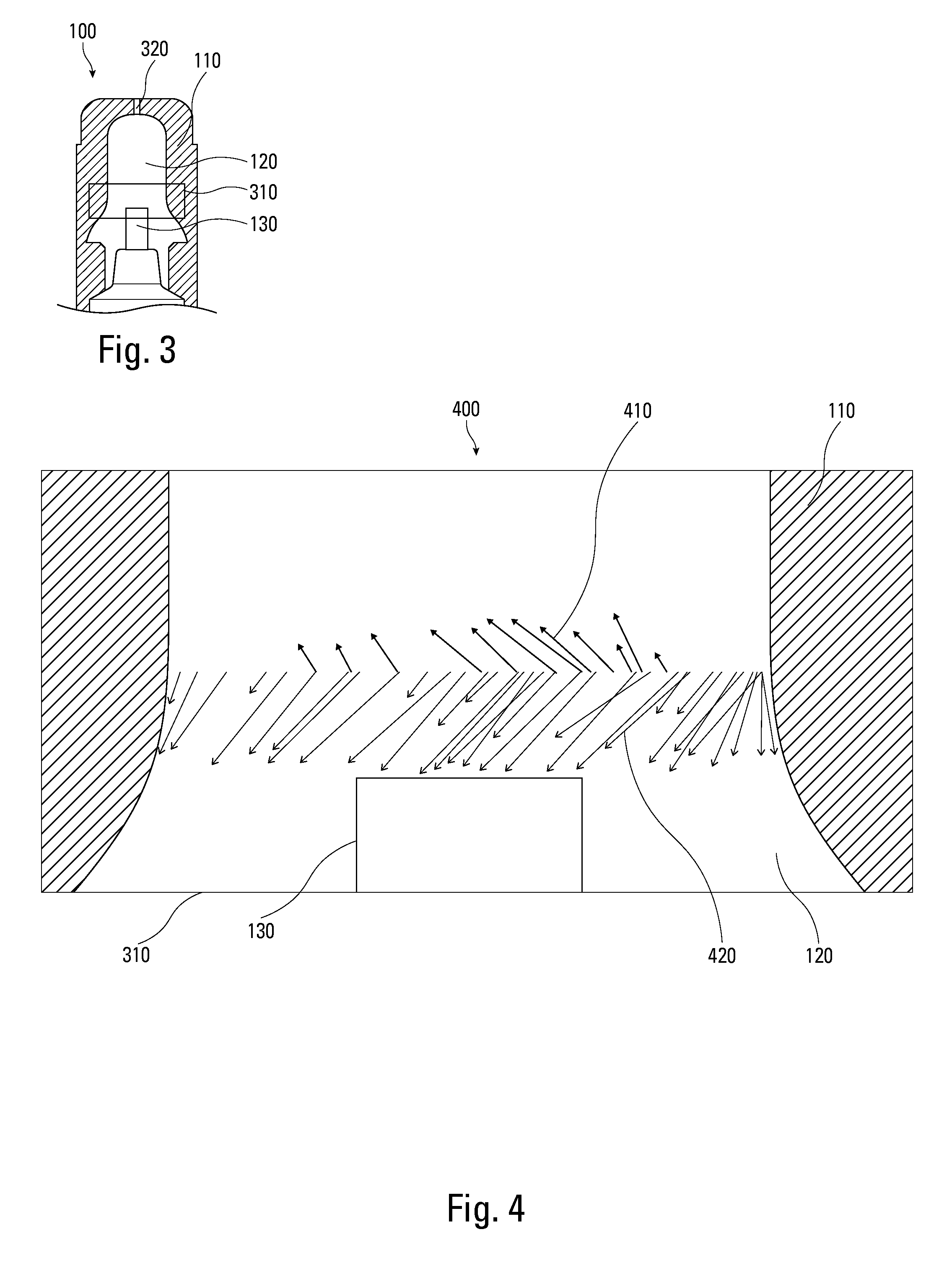

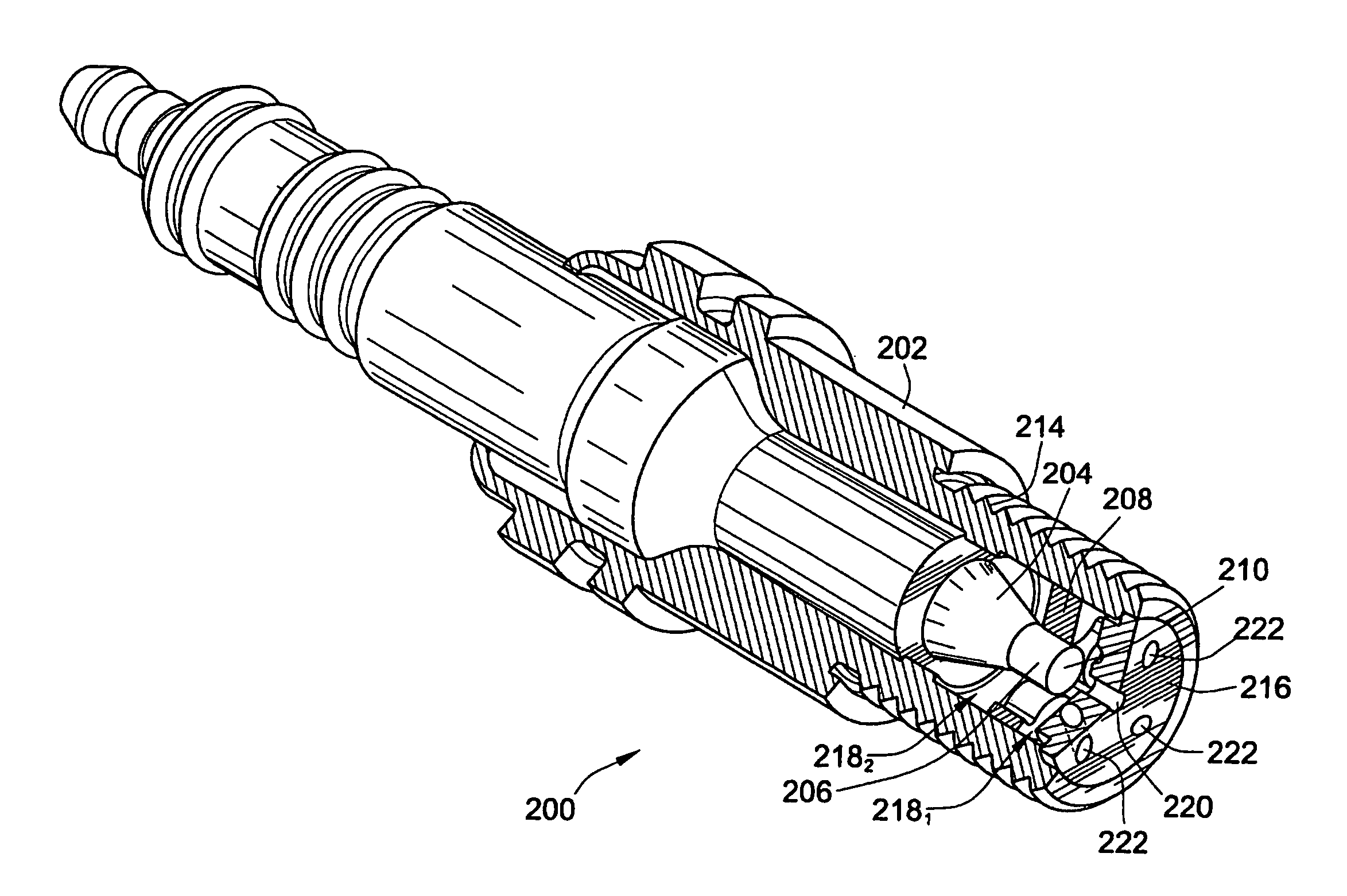

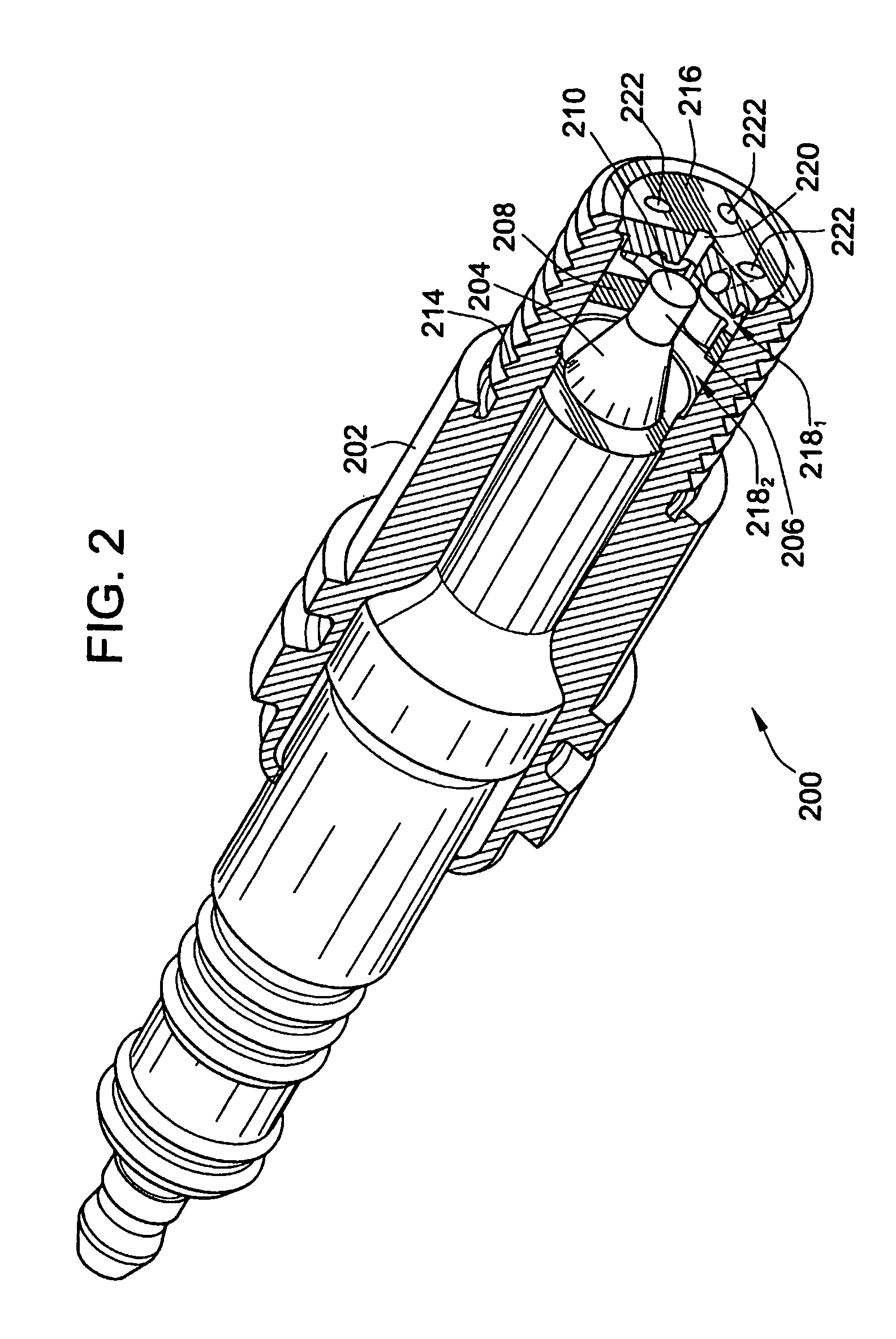

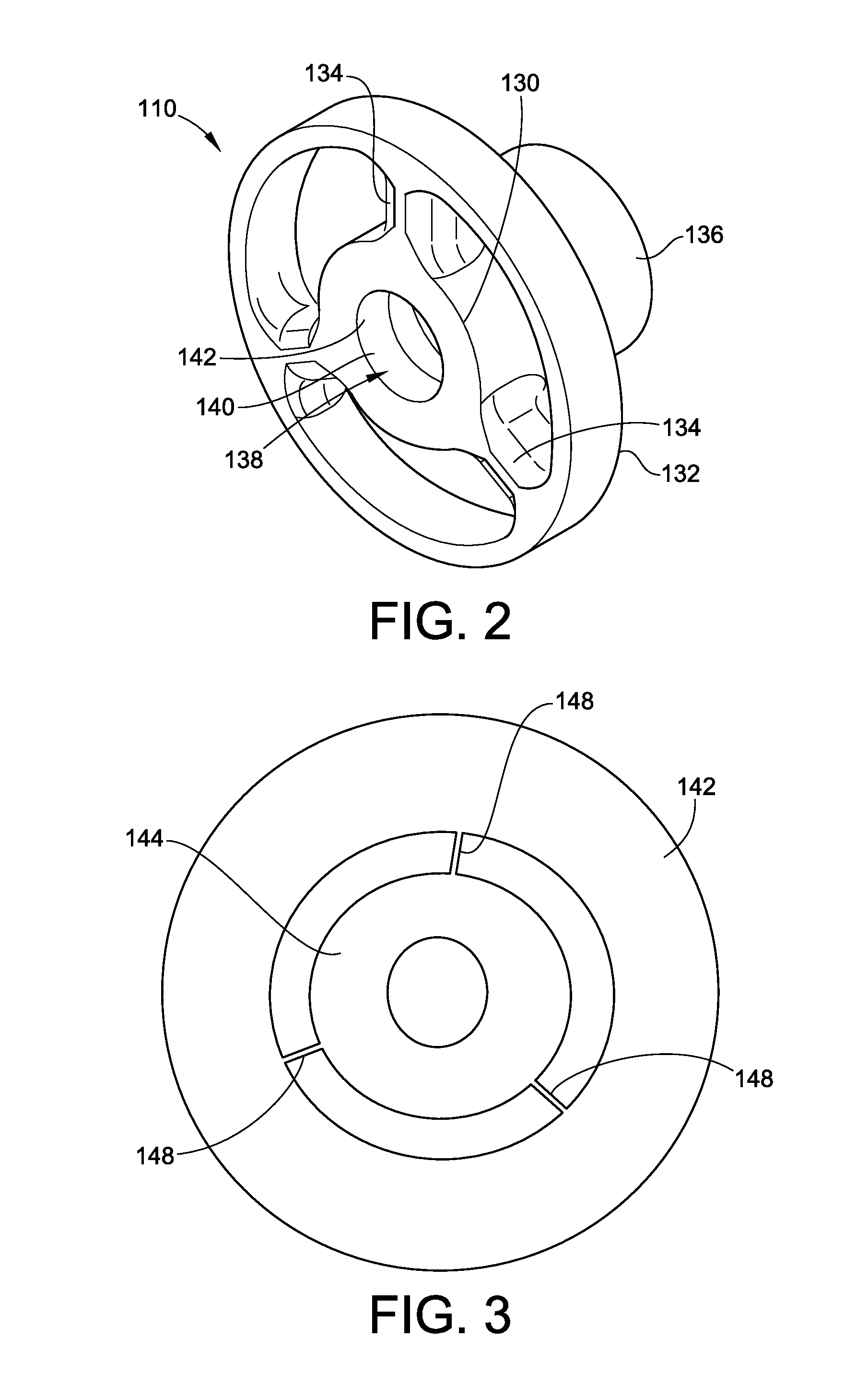

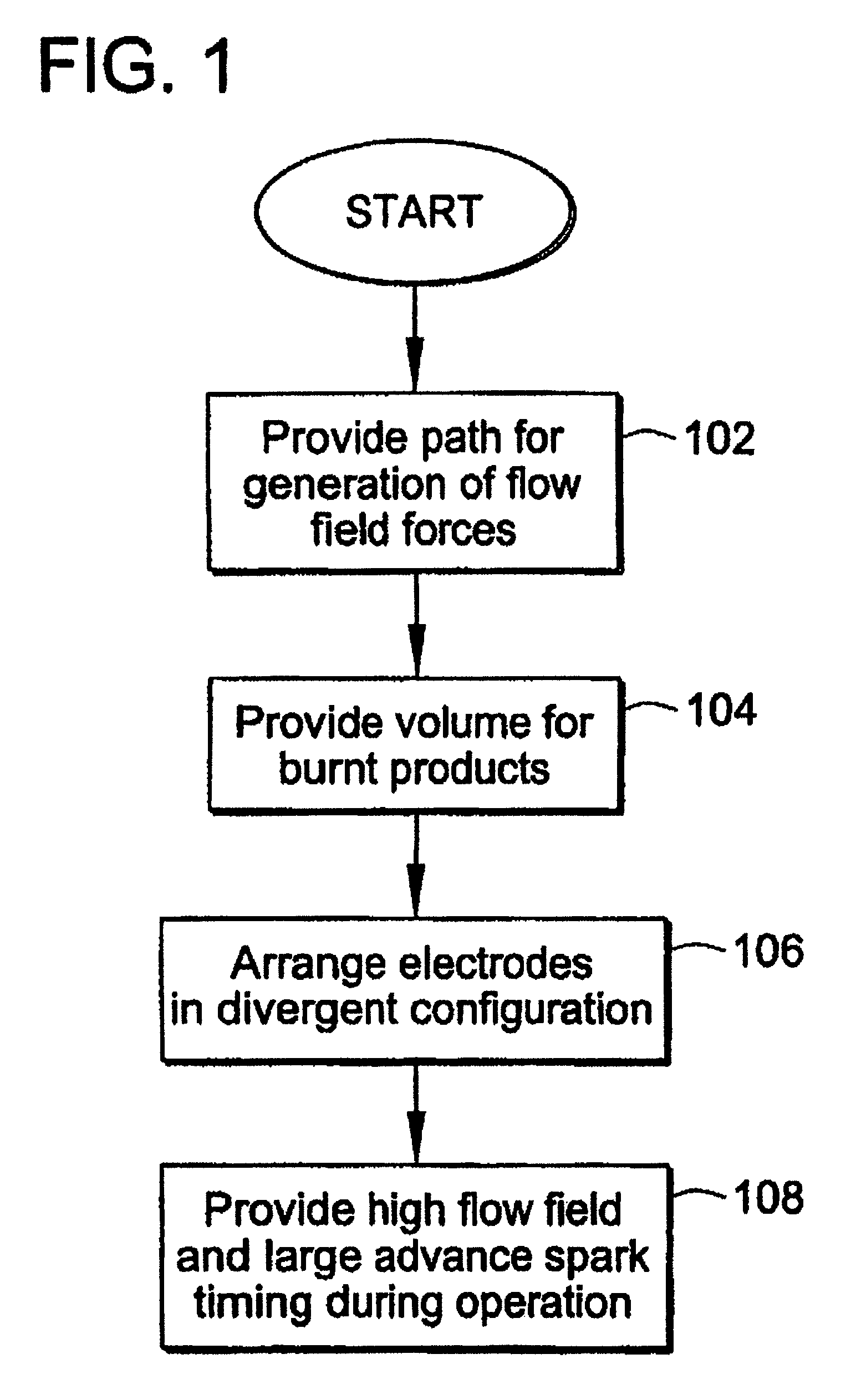

Controlled Spark Ignited Flame Kernel Flow in Fuel-Fed Prechambers

ActiveUS20120125287A1Improve flowHigh trafficSparking plugsInternal combustion piston enginesAlloyEngineering

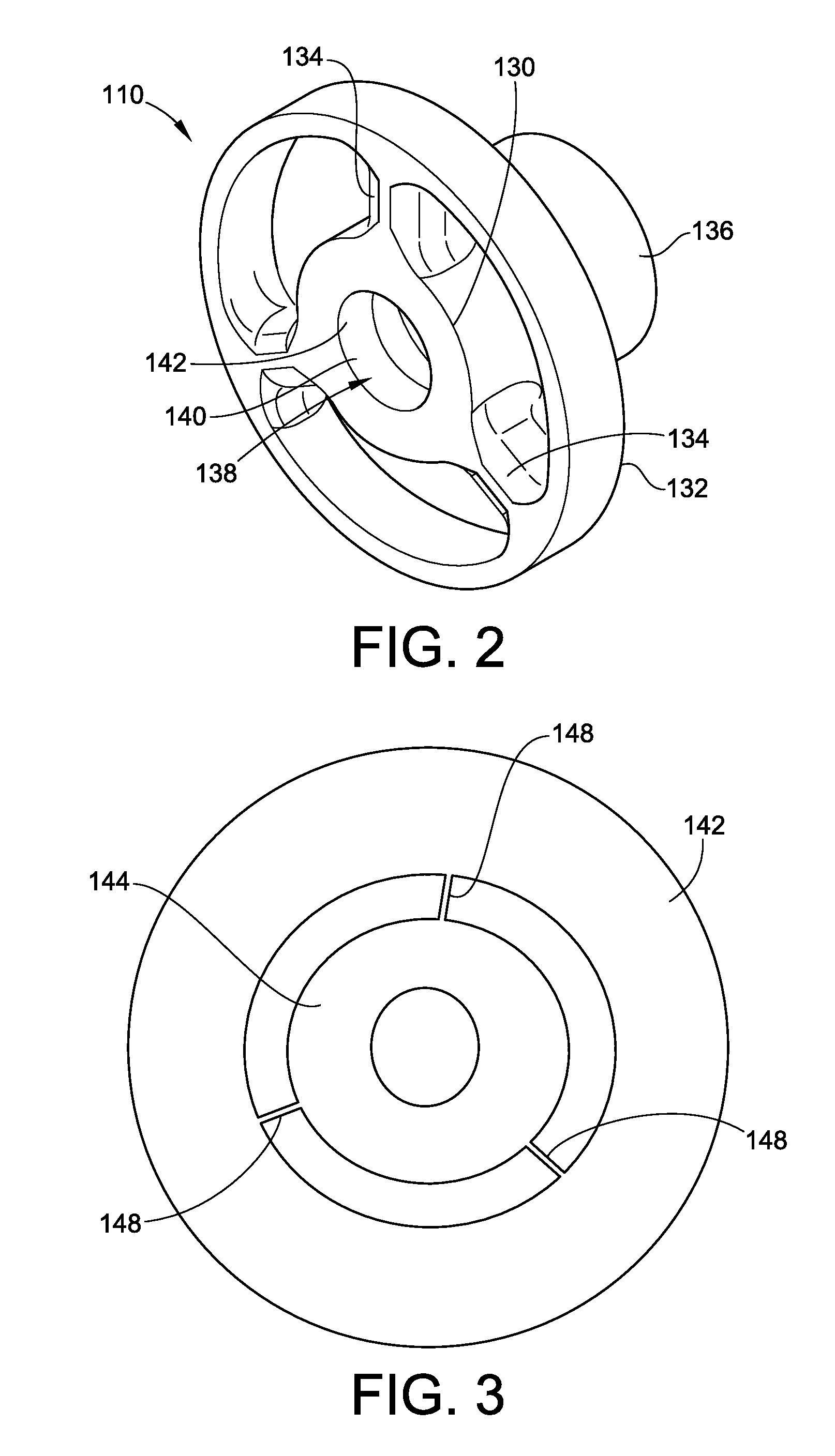

A pre-chamber spark plug that includes a shell. Additionally, the pre-chamber spark plug includes an insulator disposed within the shell. In a particular embodiment, a center electrode has a first portion surrounded by the insulator, and a second portion that extends from the insulator into a pre-chamber. The pre-chamber defined by the shell. In a further embodiment, a ground electrode is attached to the insulator. In particular embodiments, the ground electrode is tubular in shape and includes an inner spark surface ring spaced in surrounding relation to the center electrode to create a spark gap, an outer ring attached to the shell, and a plurality of rounded spokes connecting the inner and outer rings. In a particular embodiment, the ground and center electrodes accommodate attachment of precious metal alloys to increase electrode surface life. In another embodiment the ground electrode and insulator is coaxial to the center electrode.

Owner:WOODWARD GOVERNOR CO

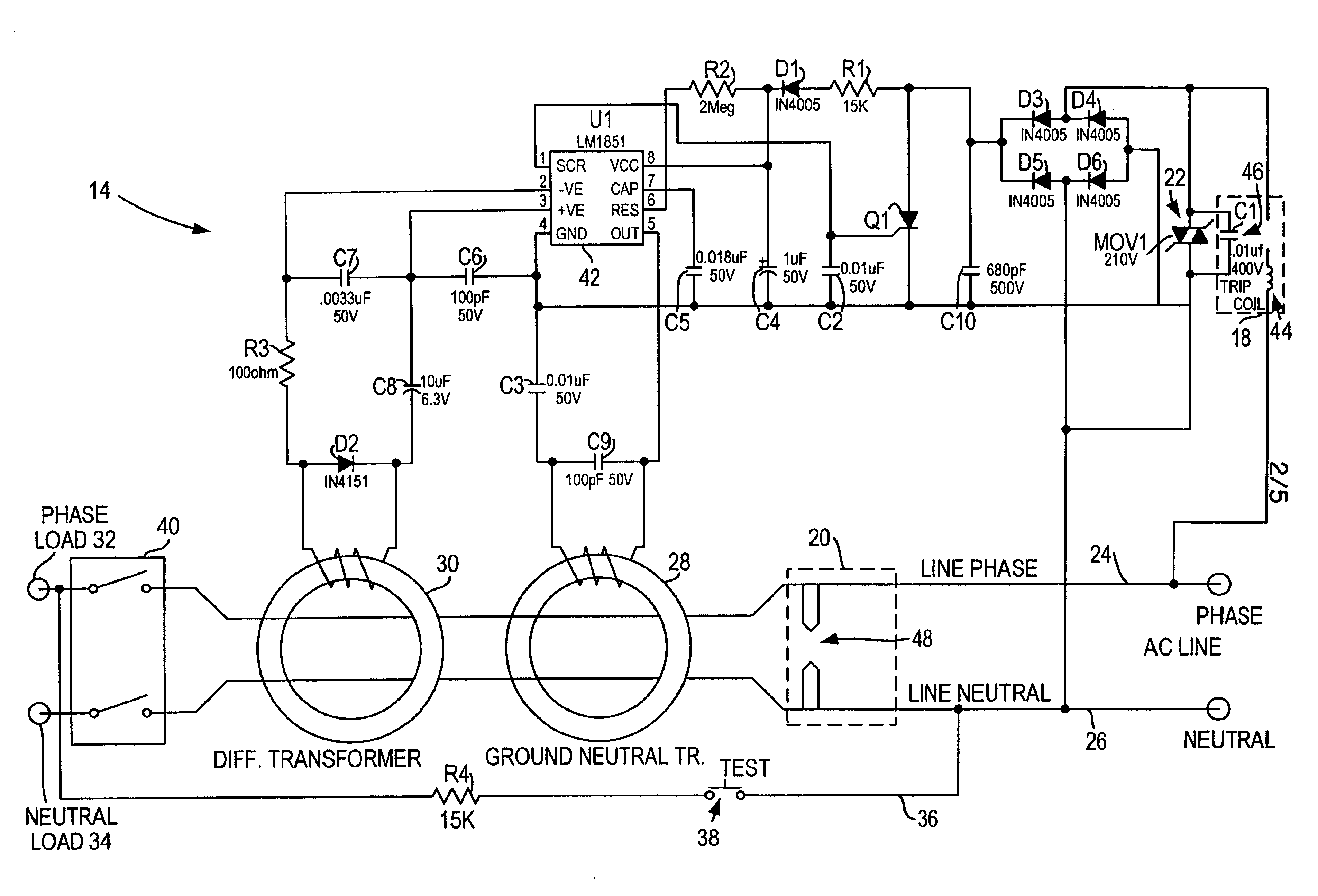

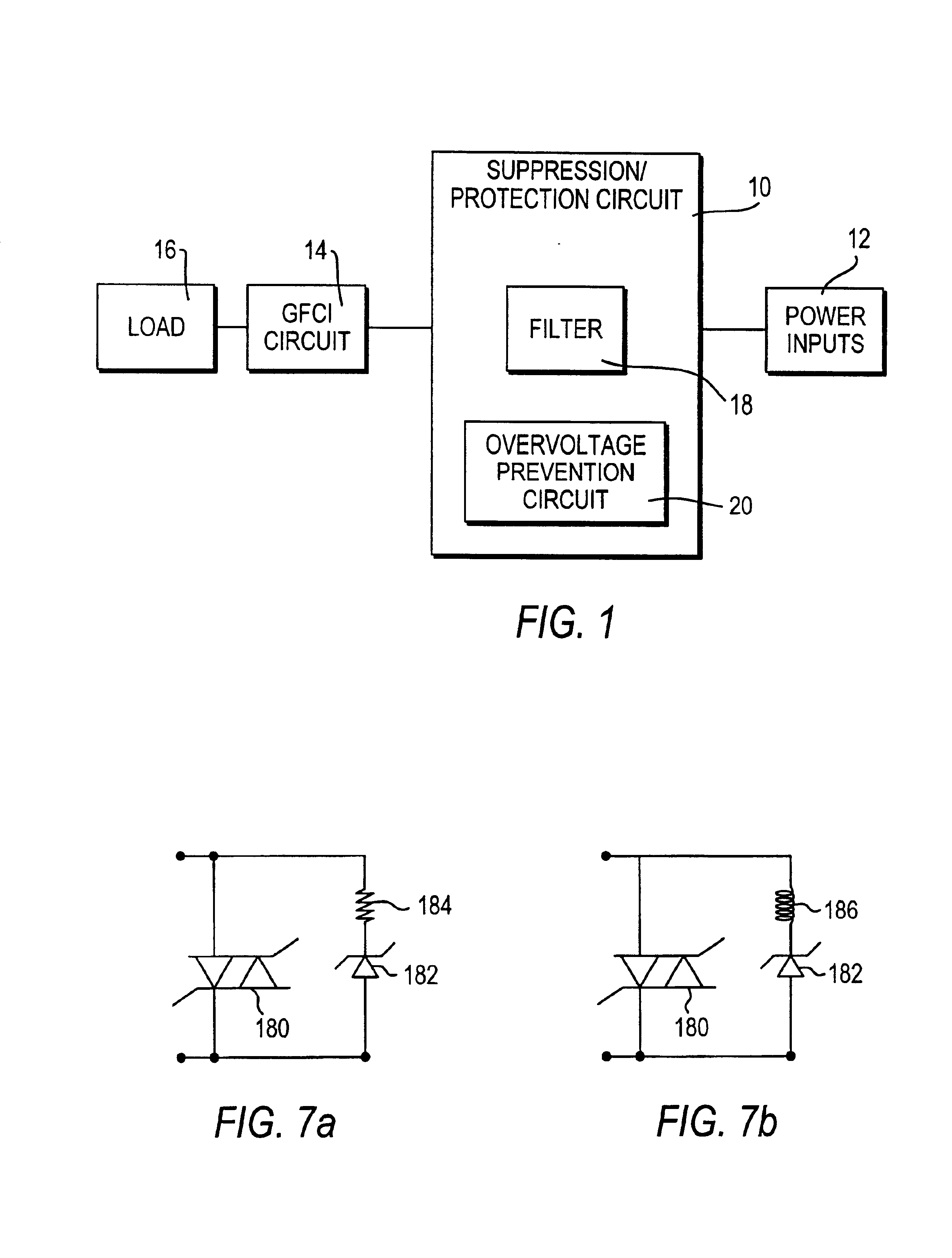

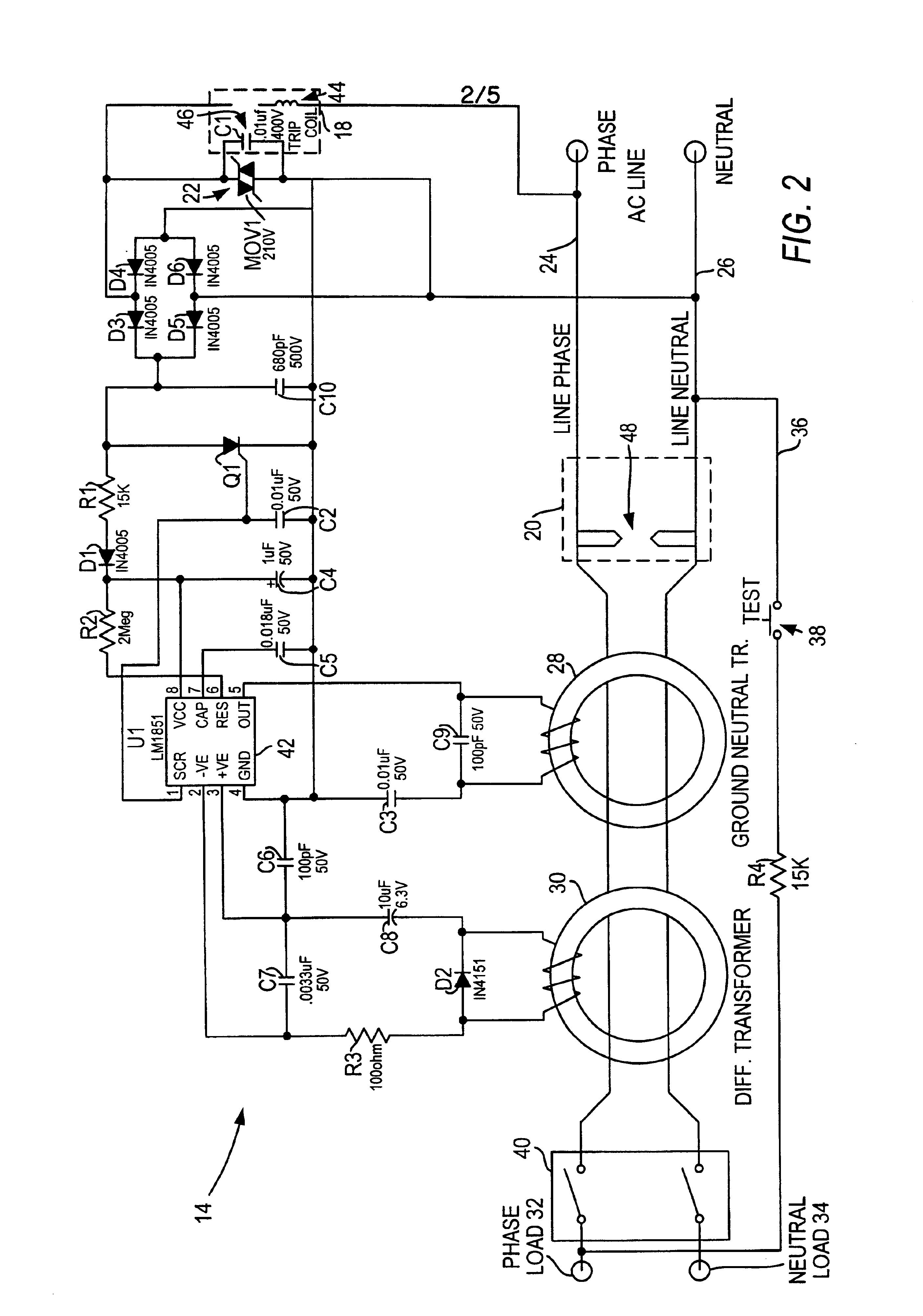

Circuit interrupter with improved surge suppression

InactiveUS6900972B1Switch operated by earth fault currentsArrangements responsive to excess currentOvervoltageLow-pass filter

A suppression and protection circuit is used in conjunction with a circuit interrupter. In one configuration, a voltage clamping device such as a metal oxide varistor is utilized in a ground fault circuit interrupter product for handling transient surges and overvoltage conditions and is placed in series with a solenoid coil. The suppression and protection circuit includes a crowbar device across the line such as a header spark gap to prevent overvoltages, and a low pass filter such as an LC filter for suppressing transient surges.

Owner:LEVITON MFG

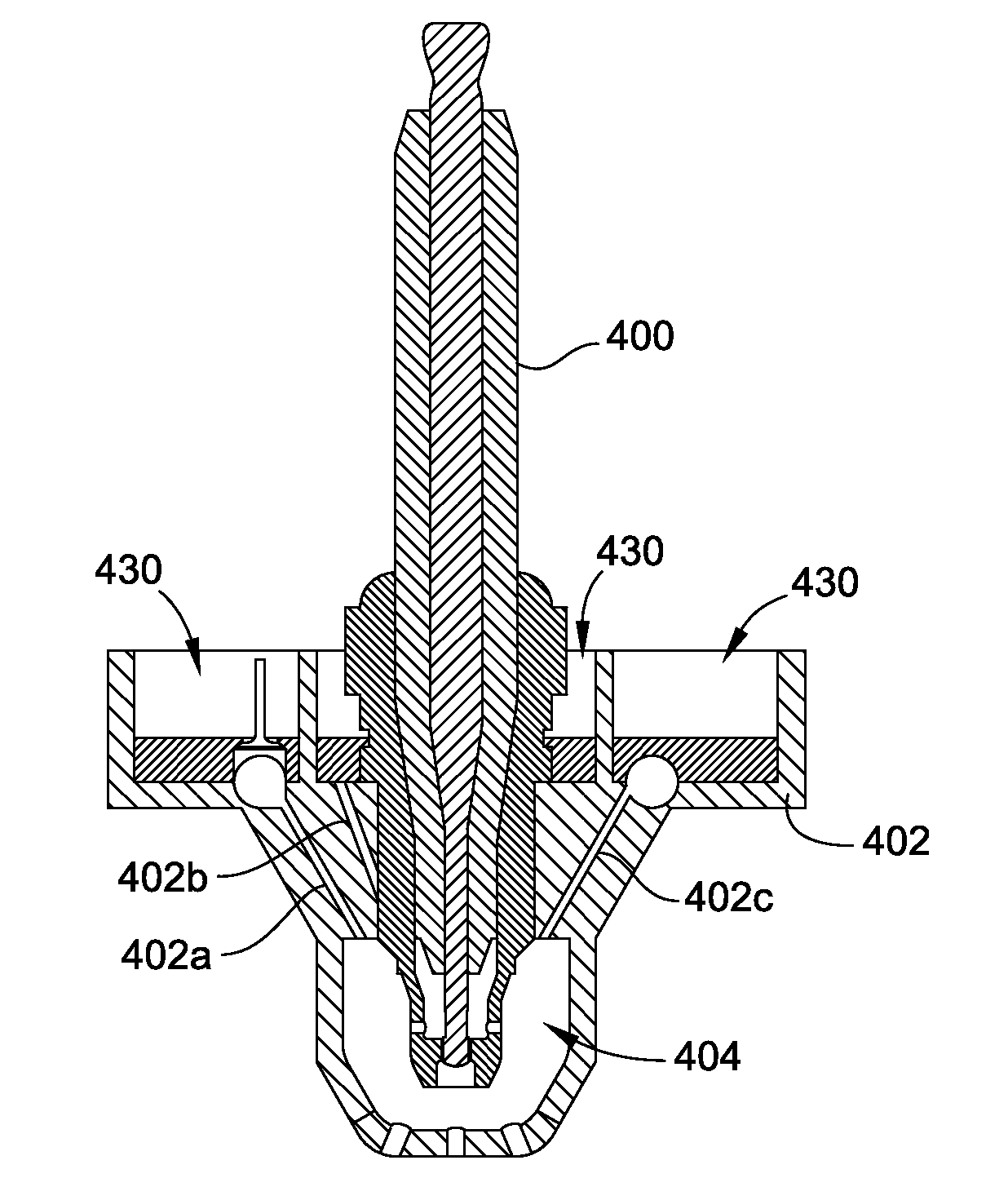

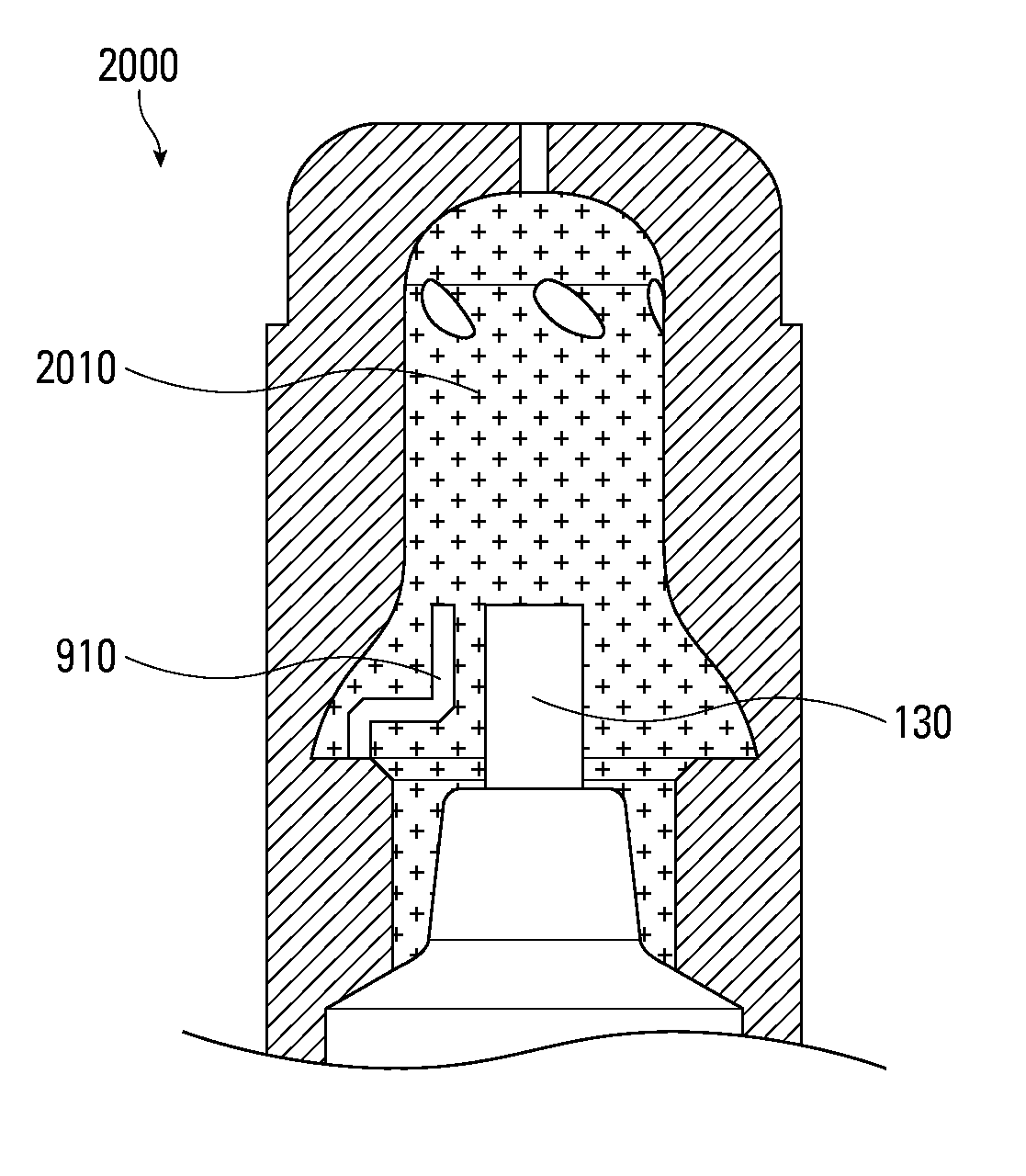

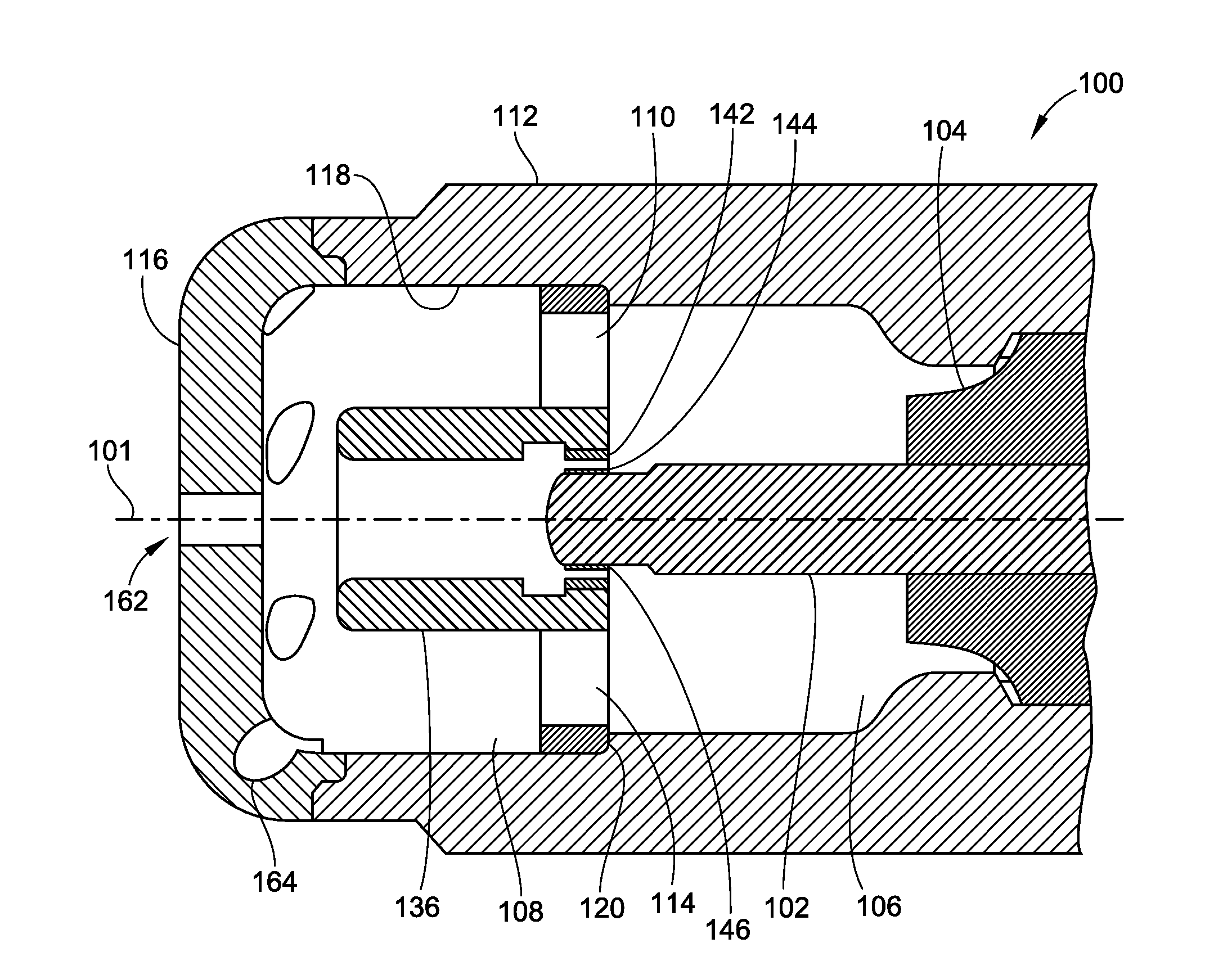

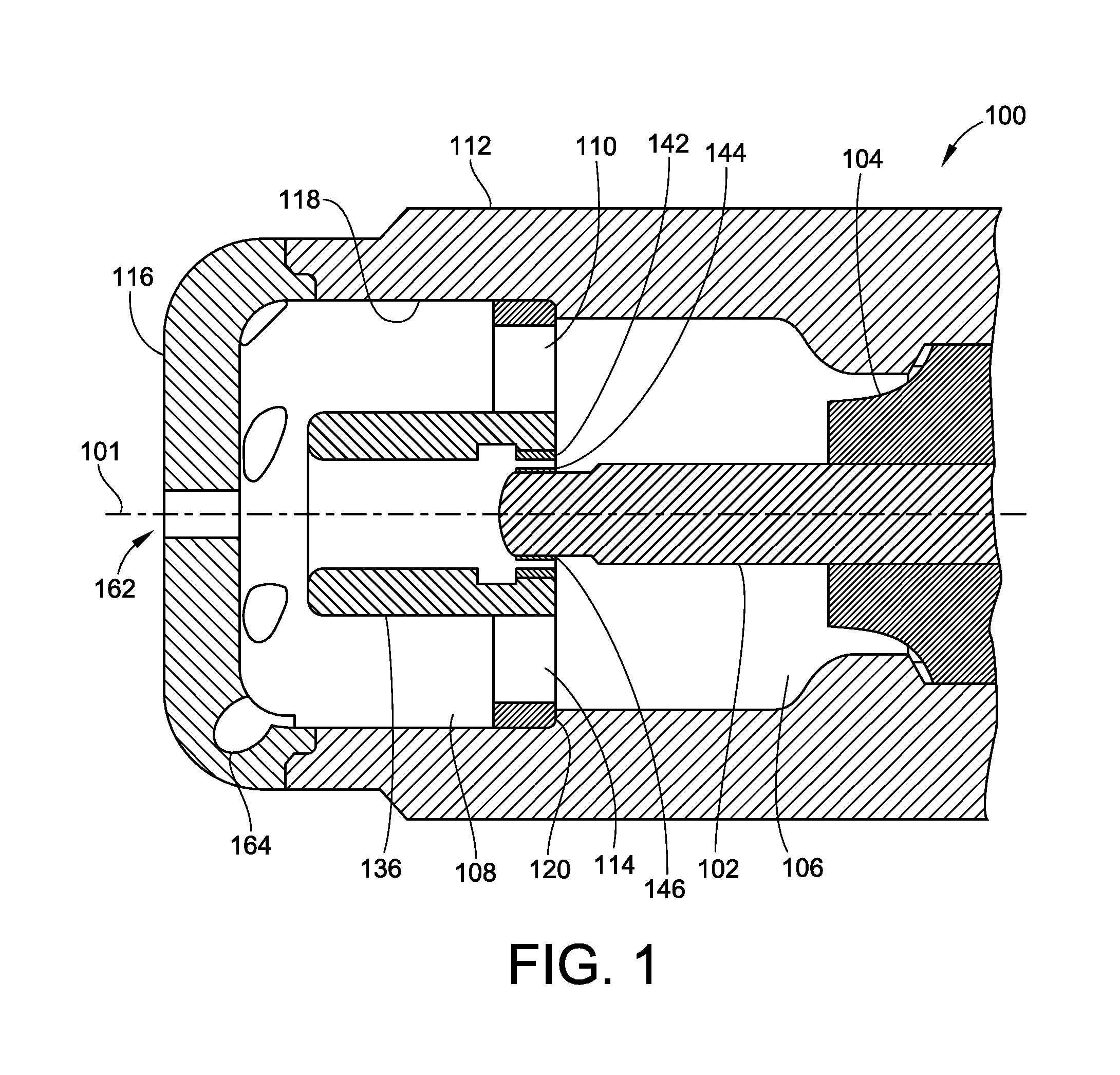

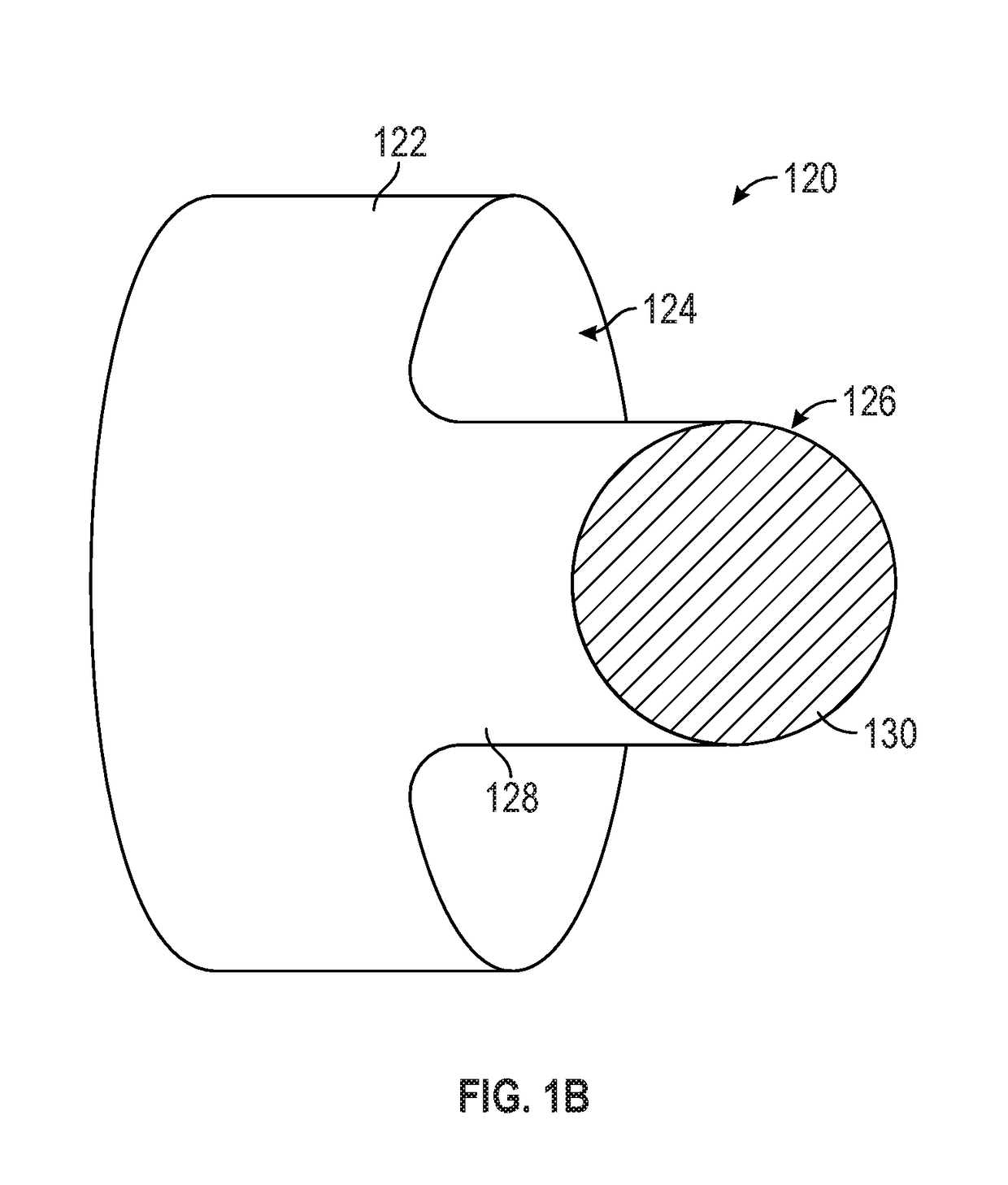

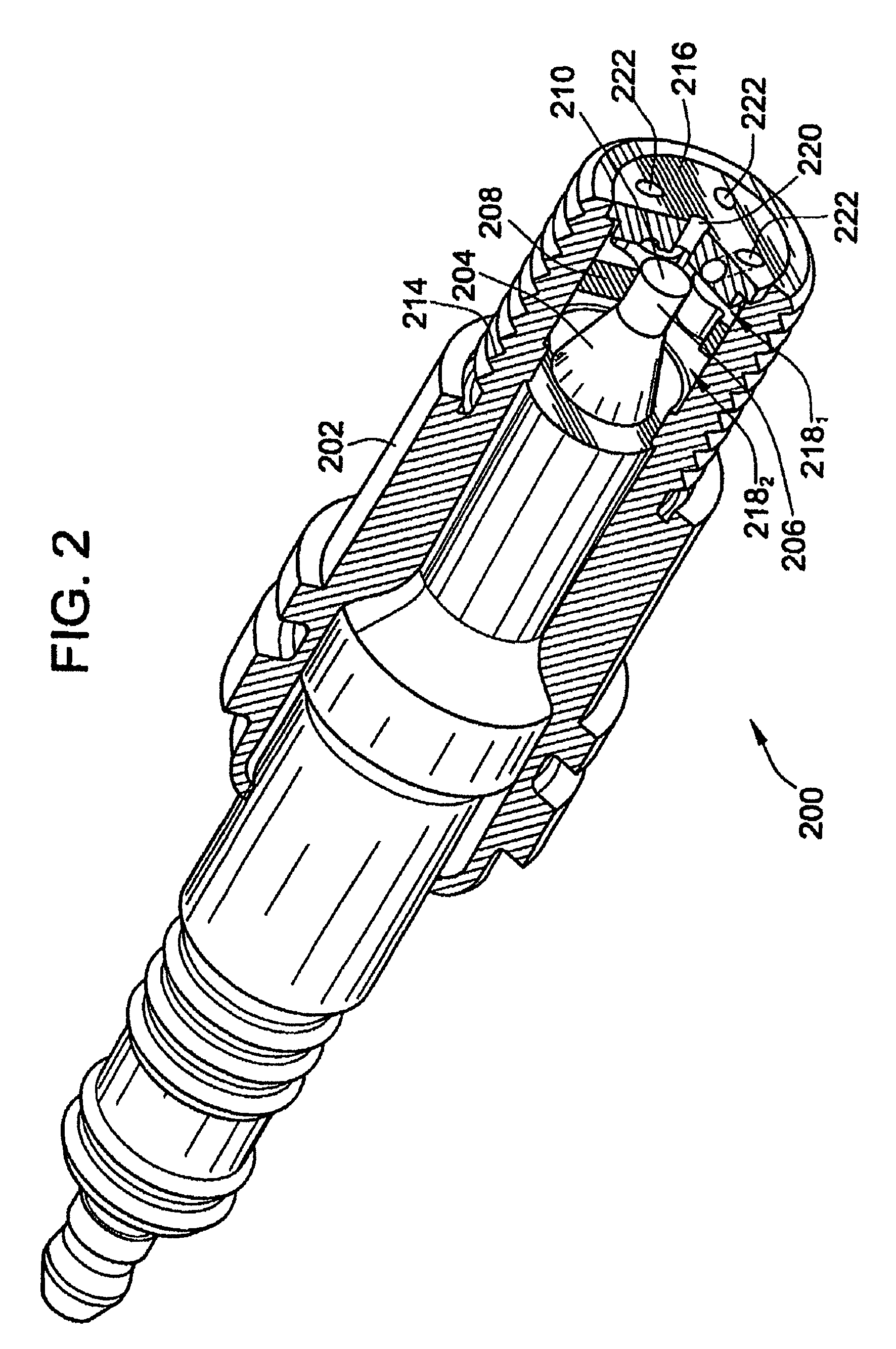

Pre-Chamber Spark Plug

ActiveUS20090309475A1Maximize spark plug lifeReduce erosionSpark gapsInternal combustion piston enginesElectricityElectrode erosion

A method and apparatus to maximize spark plug life in pre-chamber spark plugs operating with ultra-lean mixtures and / or elevated engine BMEP is presented. Electrode erosion is reduced by spreading discharge energy over a wider surface area, maintaining fuel concentration in the spark gap, controlling gas static pressure during discharge, and maintaining safe electrode temperature. Energy is spread via a swirling effect created by periphery holes in an end cap, resulting in a lower specific energy discharge at the electrodes. Divergently configured electrodes reduce the spark voltage at high operating pressures and the energy required for ignition. The flow field generated at the electrodes prevents electrical shorts due to water condensation and avoids misfire. The center electrode insulation provides an effective heat transfer path to prevent electrode overheating and pre-ignition. The volume behind the electrodes provides a volume for burnt products from previous combustion cycles and leads to more reliable ignition.

Owner:WOODWARD GOVERNOR CO

Pressure-pulse therapy device for treatment of deposits

A device, system and method for the generation of therapeutic acoustic shock waves for at least partially separating a deposit from a vascular structure. The shock waves may optionally be generated according to any mechanism which is known in the art, including but not limited to, spark gap technology, electromagnetic shock wave generation and piezoelectric technology for generating therapeutic pressure pulses. Examples of deposits which may be treated with the present invention include, but are not limited to, atherosclerotic plaques, any type of clot, and any type of thrombus or embolus. The vascular structure itself may be any such structure for conducting blood flow, including but not limited to arteries, veins and the aortic arch.

Owner:MEDISPEC LTD

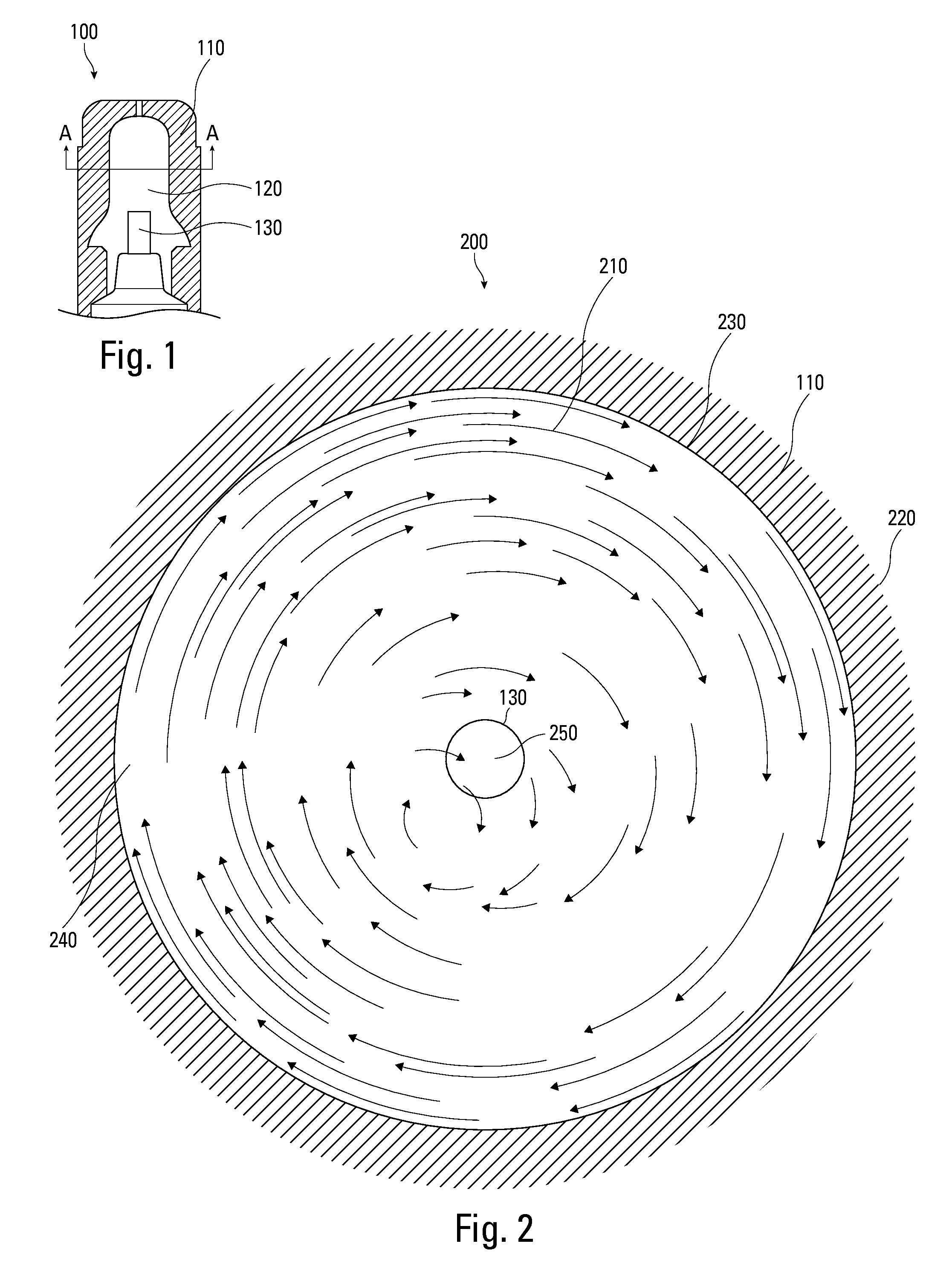

Method and apparatus for achieving high power flame jets while reducing quenching and autoignition in prechamber spark plugs for gas engines

ActiveUS20130055986A1Increase ignition delayPrevent spontaneous combustionSparking plugsInternal combustion piston enginesEngineeringQuenching

A prechamber spark plug may have a prechamber having a pre-determined aspect ratio and hole pattern to achieve particular combustion performance characteristics. The aspect ratio and hole pattern may induce a rotational flow of fuel-air in-filling streams inside the prechamber volume. The rotational flow of the fuel-air mixture may include both radial flow and axial flow characteristics based on the aspect ratio and hole pattern. Axial flow characteristics can include a first axial direction proximate the periphery of the rotational flow and a counter second axial direction approaching the center of the rotational flow. The radial and axial flow characteristics may further include radial air-fuel ratio stratification and / or axial air-fuel ratio stratification. The rotational flow, the radial flow and the axial flow may be adjusted by alteration of the aspect ratio and hole pattern to achieve particular combustion performance characteristics in relation to a wide variety of spark gap geometries.

Owner:PROMETHEUS APPLIED TECH

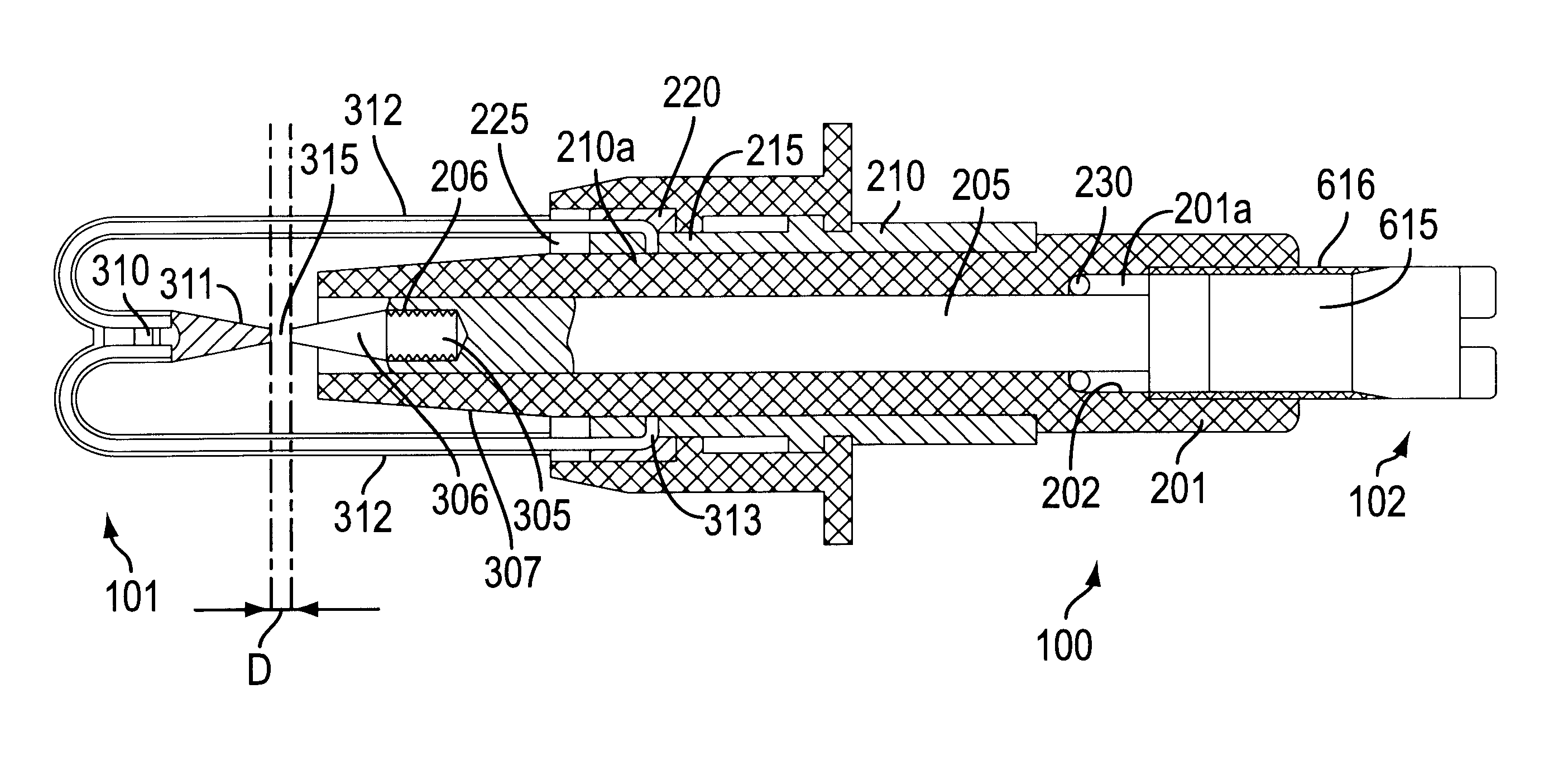

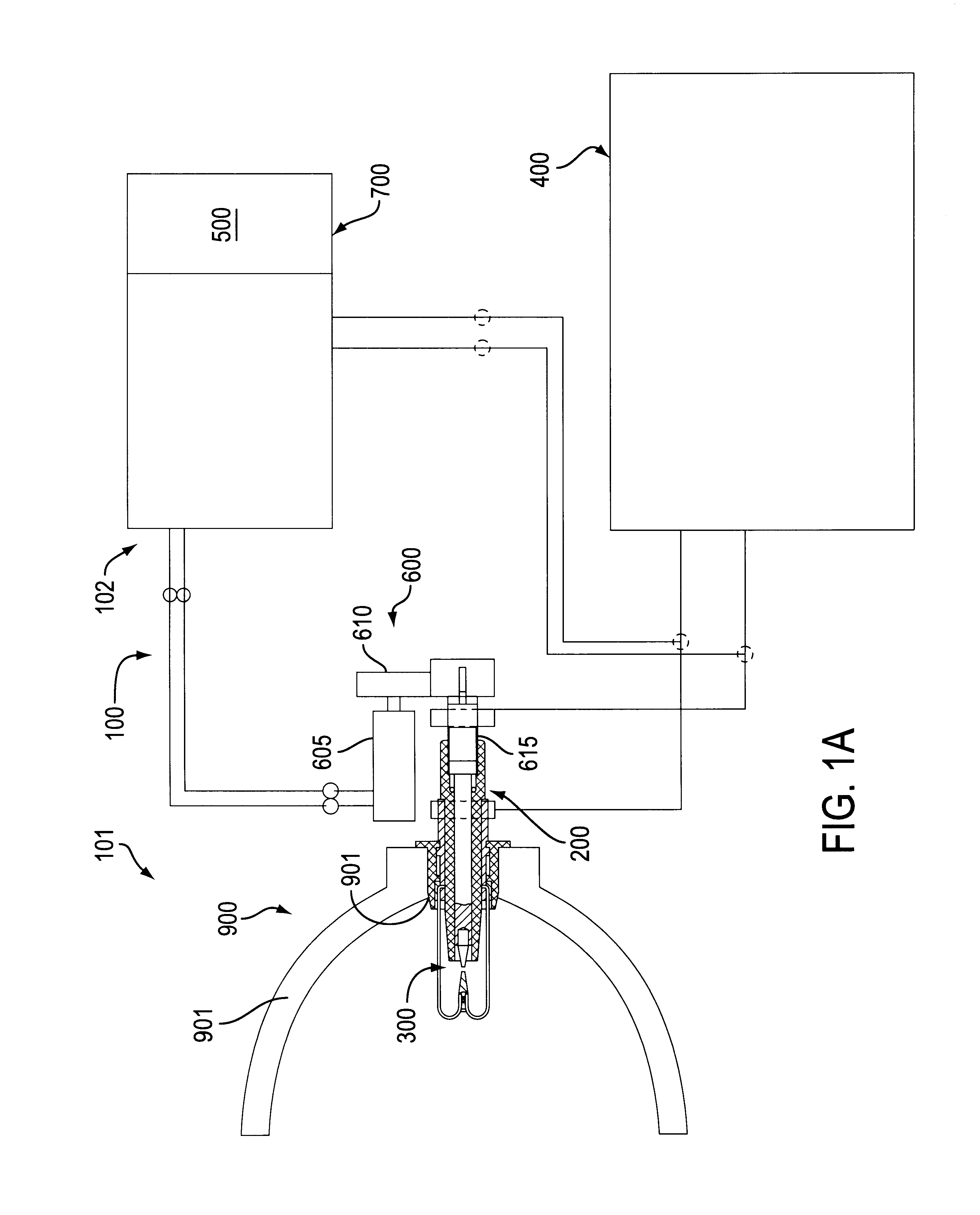

Fuel Injector Having an Integrated Ignition Device

InactiveUS20080072871A1Reduce thicknessEasy to monitorMachines/enginesFuel injection with sensorsCombustion chamberElectrode pair

A fuel injector having an integrated ignition device includes a first electrode pair for igniting fuel which is injected directly into a combustion chamber of an internal combustion chamber through spray-discharge orifices of the fuel injector. The first electrode pair is made up of a ground electrode and a center electrode which are set apart by a spark gap. The fuel injector and the ignition device are situated in a shared housing. The ignition device has at least one additional spark gap and / or an additional electrode pair.

Owner:ROBERT BOSCH GMBH

Pre-chamber spark plug

ActiveUS7659655B2Life maximizationReduce erosionSparking plugsInternal combustion piston enginesElectricityElectrode erosion

Owner:WOODWARD GOVERNOR CO

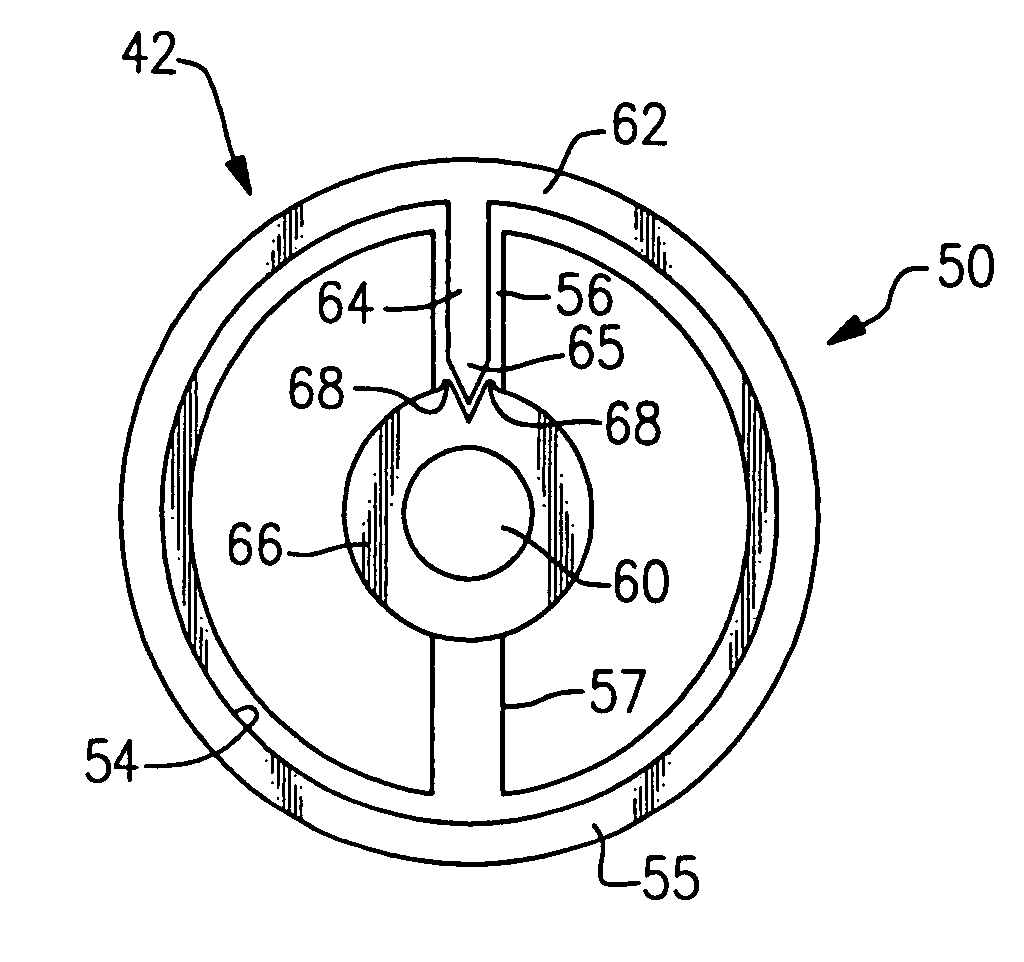

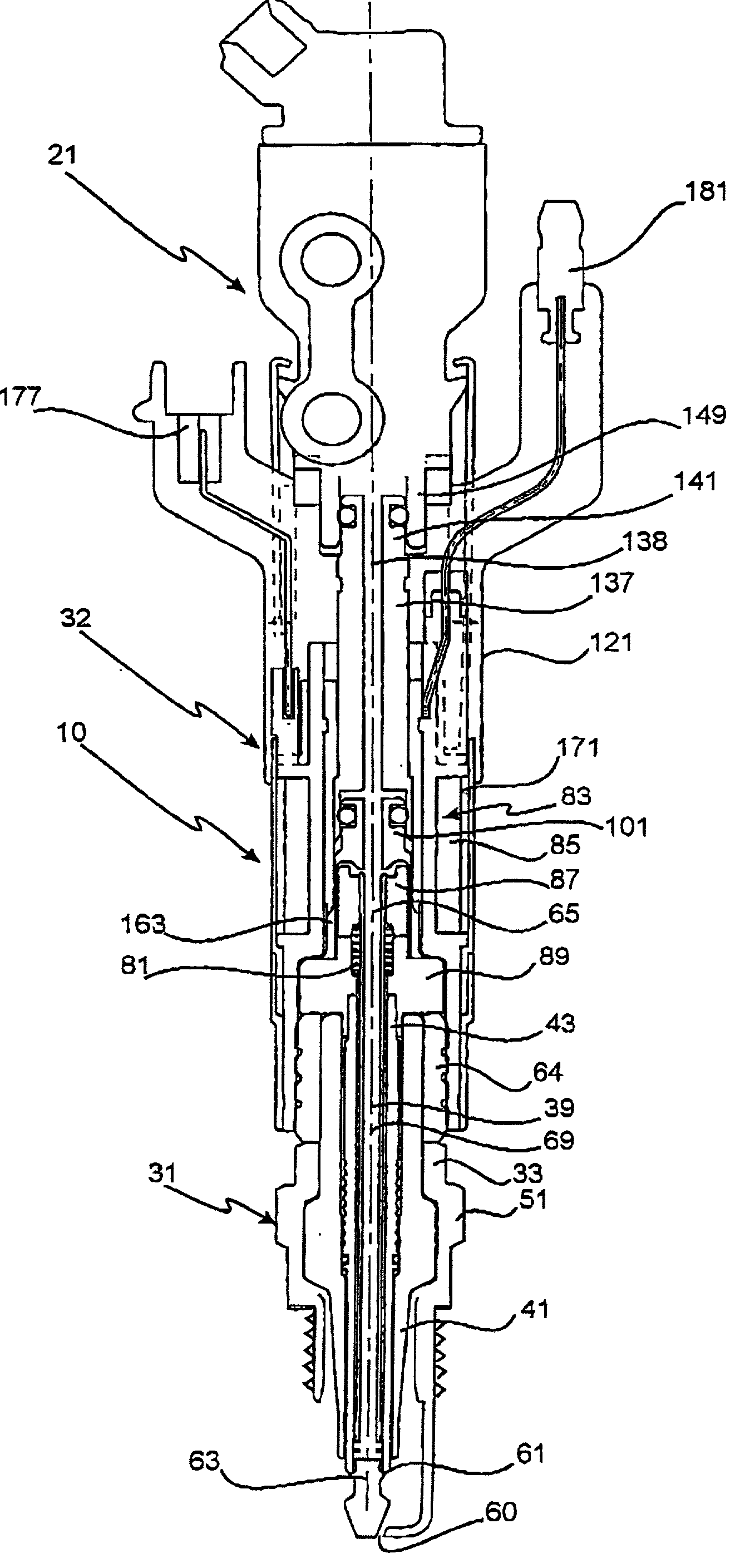

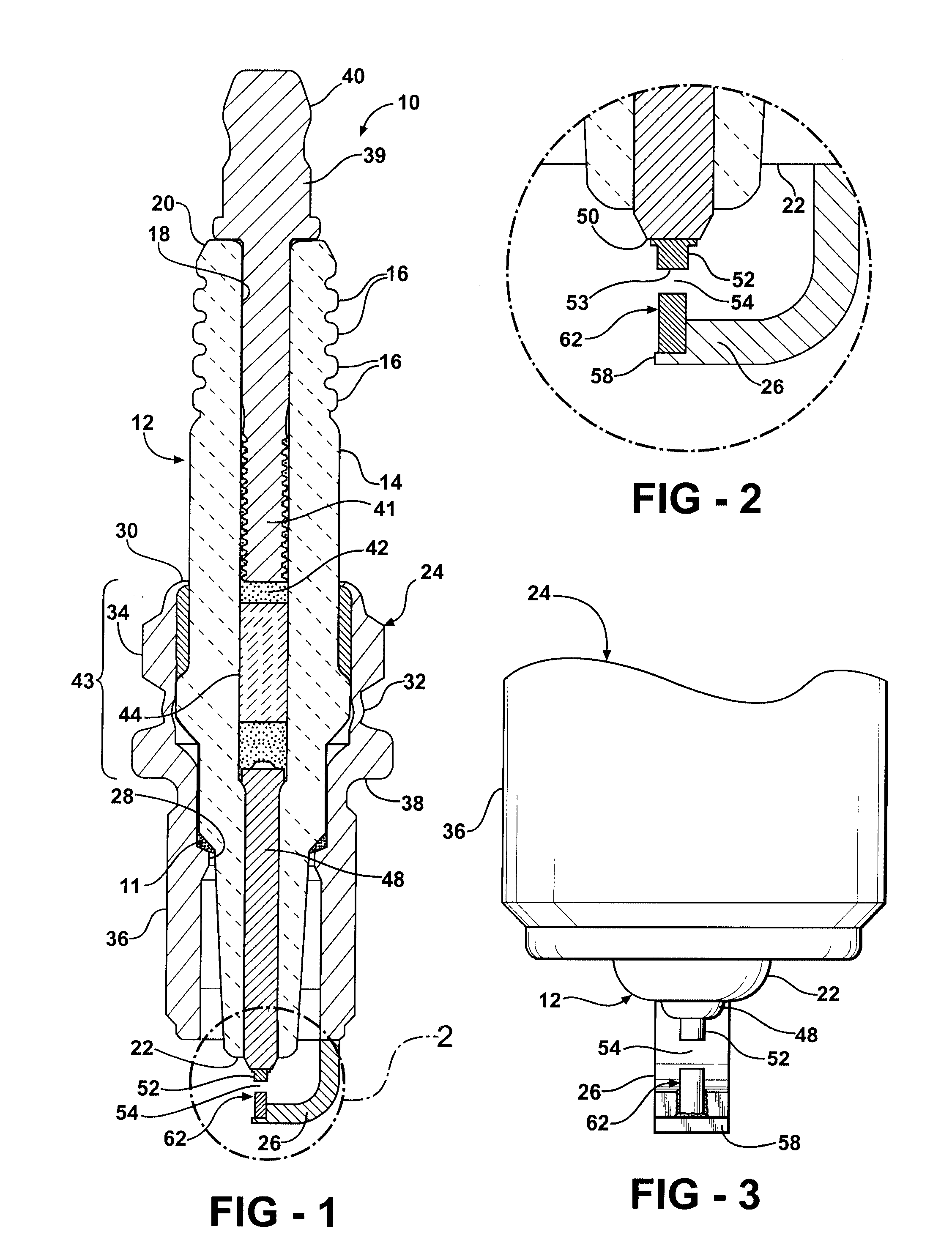

Direct injection of fuels in internal combustion engines

InactiveUS20050045146A1Maintain integritySparking plugsHigh pressure gas fuel injectionCombustionEngineering

A fuel delivery injector for an internal combustion engine. The fuel injector forms pan of a device (10) which provides a combined injection and ignition means for the engine. The fuel delivery injector comprises a first portion (31) and a second portion (32) adapted to be detachably connected together. The first portion has a delivery port (37) defined between a valve seat (61) and a valve member (63) movable with respect to the valve seat (61) for opening and closing the delivery port (37). An actuating member (87) is provided in the first portion (31) and is operatively connected to the valve member (63). An actuating means (85) is provided in the second portion (32). When the first and second portions (31, 32) are connected together, the actuating mean (85) is operably associated with the actuating member (87) to provide an actuating assembly (83). Typically, the actuating assembly (83) comprises an electromagnetic means in which the actuating member (87) comprises a solenoid armature and the actuating means (85) comprises a solenoid oil, whereby connection of the first and second portions (31, 32) together completes assembly of the electromagnetic means. Where the device (10) provides a combined fuel injector and ignition me the device (10) is provided with a primary electrode (58) which cooperates with a secondary electrode (57) to define a spark gap (60). A popper projection (62) provided on the valve member (63) is utilized to define the primary electrode (58), as well as to provide spray guidance effects on the fuel spray issuing from the delivery port (37). The device (10) providing the combined fuel injection and ignition means is also described and claimed.

Owner:ORBITAL ENGINE CO PTY LTD

Electrode for an Ignition Device

An electrode for an ignition device is made from a Ni-based nickel-chromium-iron alloy which has improved resistance to high temperature oxidation, sulfidation, corrosive wear, deformation and fracture includes, by weight of the alloy: 14.5-25% chromium; 7-22% iron; 0.2-0.5% manganese; 0.2-0.5% silicon; 0.1-2.5% aluminum; 0.05-0.15% titanium; 0.01-0.1% total of calcium and magnesium; 0.005-0.5% zirconium; 0.001-0.01% boron, and the balance substantially Ni. It may also include at least one rare earth element selected from the group consisting of: yttrium, hafnium, lanthanum, cerium and neodymium in amounts ranging from 0.01-0.15% by weight, and incidental impurities, including cobalt, niobium, molybdenum, copper, carbon, lead, phosphorus or sulfur. These total of these impurities will typically be controlled to limits of 0.1% cobalt, 0.05% niobium, 0.05% molybdenum, 0.01% copper, 0.01% carbon, 0.005% lead, 0.005% phosphorus and 0.005% sulfur. The ignition device may be a spark plug which includes a ceramic insulator, a conductive shell, a center electrode disposed in the ceramic insulator having a terminal end and a sparking end with a center electrode sparking surface, and a ground electrode operatively attached to said shell having a ground electrode sparking surface, the center electrode sparking surface and the ground electrode sparking surface defining a spark gap therebetween. At least one of the center electrode or the ground electrode includes the solution-strengthened Ni-based nickel-chromium-iron alloy. The Ni-based nickel-chromium-iron alloy electrodes of the invention may also include a core with thermal conductivity greater than that of the Ni-based nickel-chromium-iron alloy, such as copper or silver or their alloys.

Owner:FEDERAL MOGUL WORLD WIDE LLC

Pre-chamber spark plug with tubular electrode and method of manufacturing same

ActiveUS20120125279A1Improve flowHigh trafficSpark gapsInternal combustion piston enginesEngineeringAlloy

A pre-chamber spark plug that includes a shell, and an end cap attached to the shell. Additionally, the pre-chamber spark plug includes an insulator disposed within the shell. In a particular embodiment, a center electrode has a first portion surrounded by the insulator, and a second portion that extends from the insulator into a pre-chamber. The pre-chamber defined by the shell and end cap. In a further embodiment, a ground electrode is attached to the shell. In particular embodiments, the ground electrode is tubular in shape and includes an inner spark surface ring spaced in surrounding relation to the center electrode to create a spark gap, an outer ring attached to the shell, and a plurality of rounded spokes connecting the inner and outer rings. In a particular embodiment, the ground and center electrodes accommodate attachment of precious metal alloys to increase electrode surface life.

Owner:WOODWARD GOVERNOR CO

Surge protection circuit for passing DC and RF signals

A surge protection circuit may include a tuned circuit board with traces designed to provide a surge protected and RF isolated DC path while propagating RF signals through the PCB dielectric with microstrip lines. The surge protection circuit utilizes high impedance RF decoupling devices such as quarterwave traces or inductors which isolate the multistage DC protection scheme which may include a gas discharge tube, serial surge impeding devices such as inductors and / or resistors, a decoupled air / spark gap device and a Zener diode junction.

Owner:INFINITE ELECTRONICS INT INC

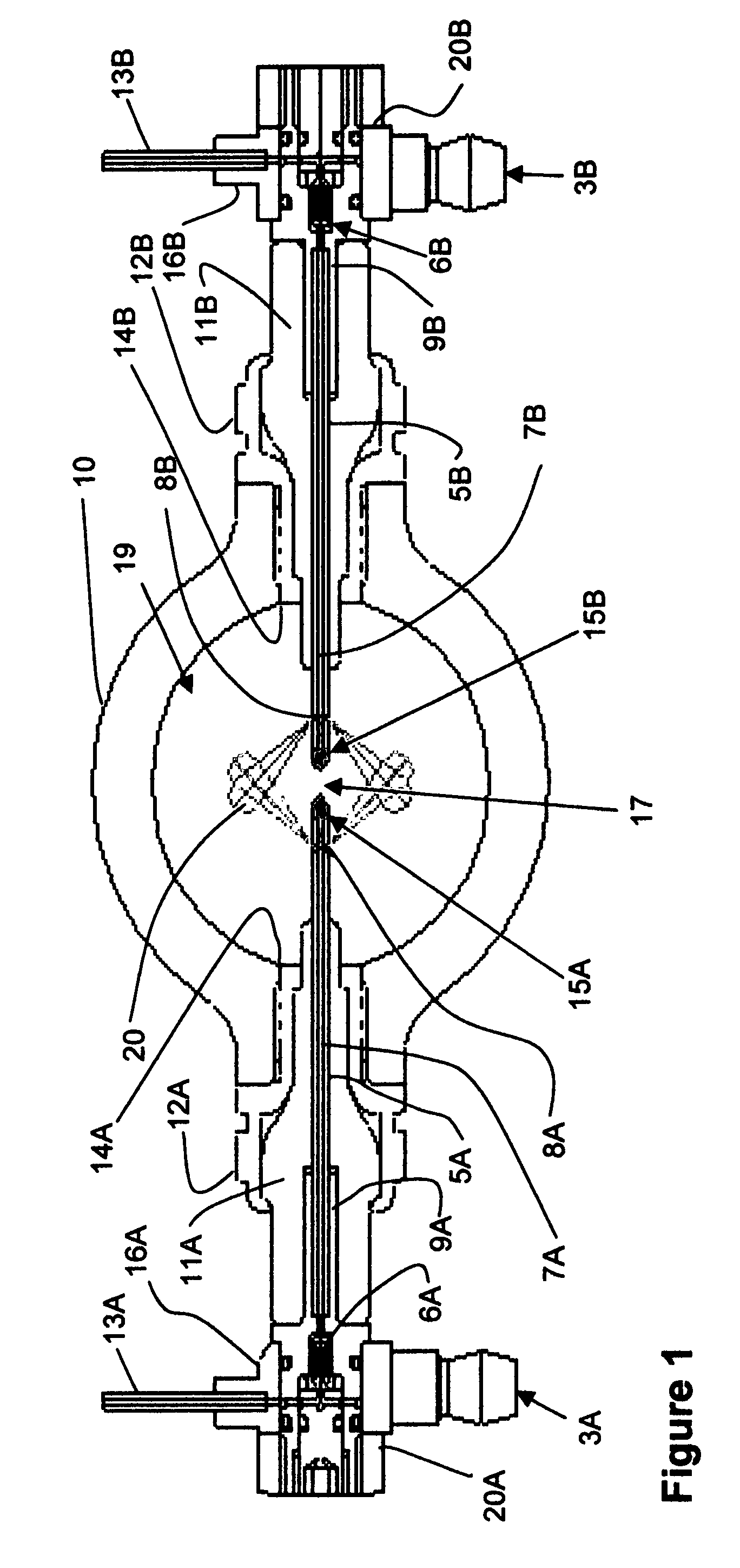

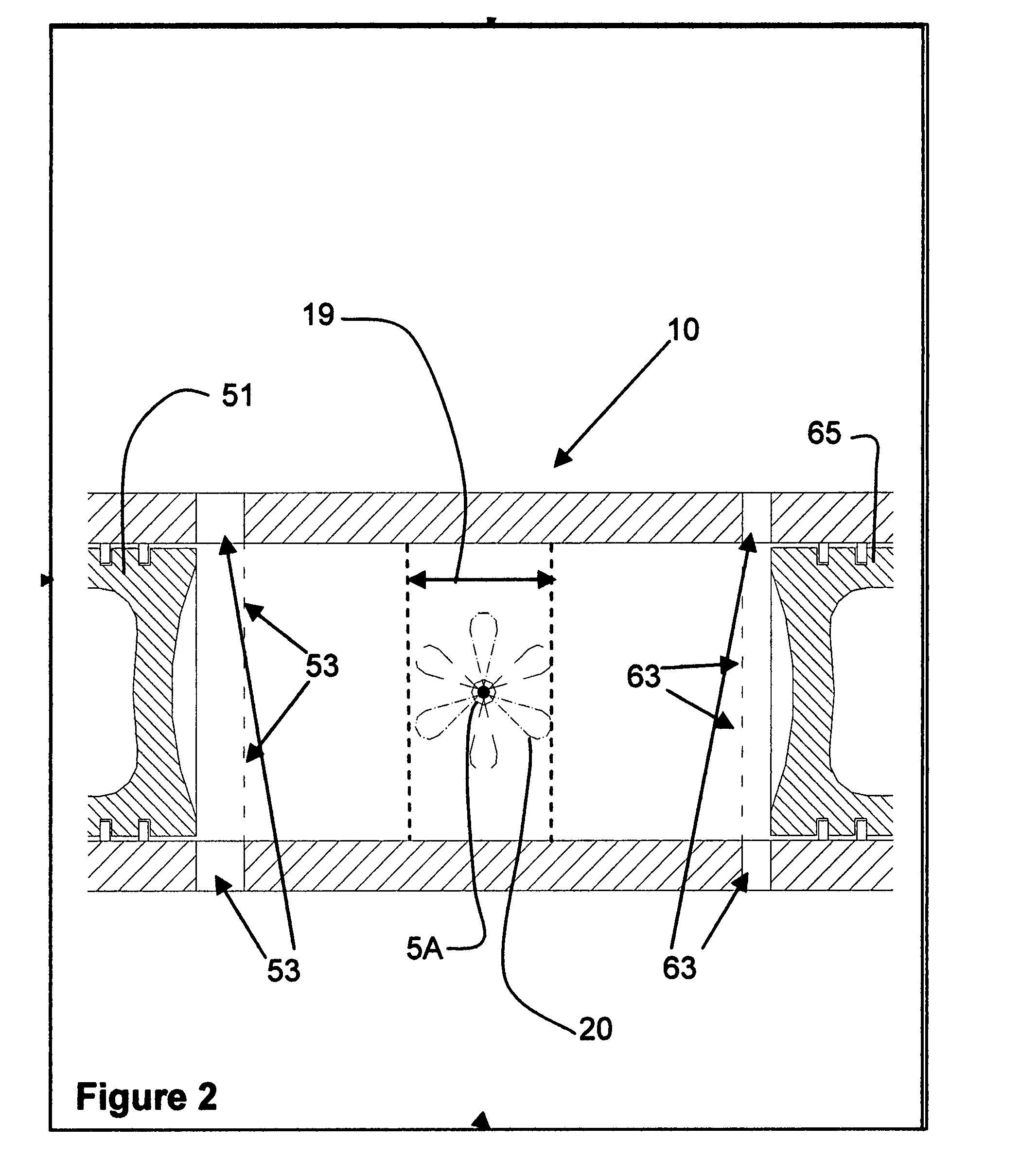

Spark ignition and fuel injector system for an internal combustion engine

InactiveUS7650873B2Avoid excessive heat buildupImprove engine efficiencyCombustion enginesFuel injection apparatusCombustion chamberCapillary channel

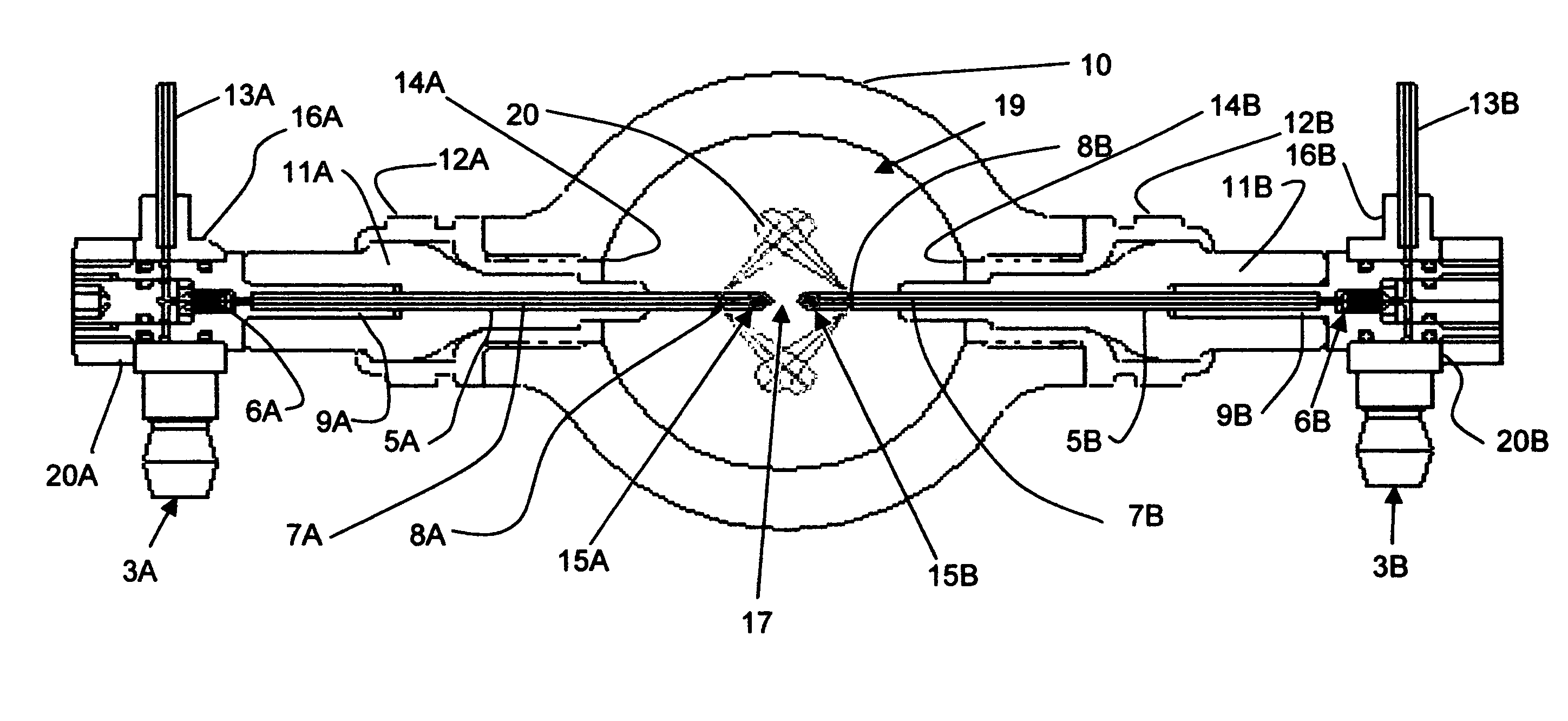

An improved spark ignition system for an internal combustion engine that includes a pair of electrodes disposed to extend from opposite sides and into a combustion chamber to form a spark gap between them that is central to the combustion chamber. Each electrode is integral with a conductive fuel delivery tube that contains a capillary passage and fuel outlet ports adjacent the electrode. The heat from combustion conducted into the electrodes and fuel delivery tubes is used to vaporize the fuel within the capillary passages before it exits the outlet ports as an atomized fog into the combustion chamber adjacent the spark gap. The vaporization of the fuel flowing in the capillary passages absorbs energy from the electrodes and thus performs a cooling effect on the electrodes. The spacing of the electrodes from opposite sides of the cylinder also allows a design that can utilize and increased spark gap to produce a larger spark across the gap.

Owner:ADVANCED PROPULSION TECH

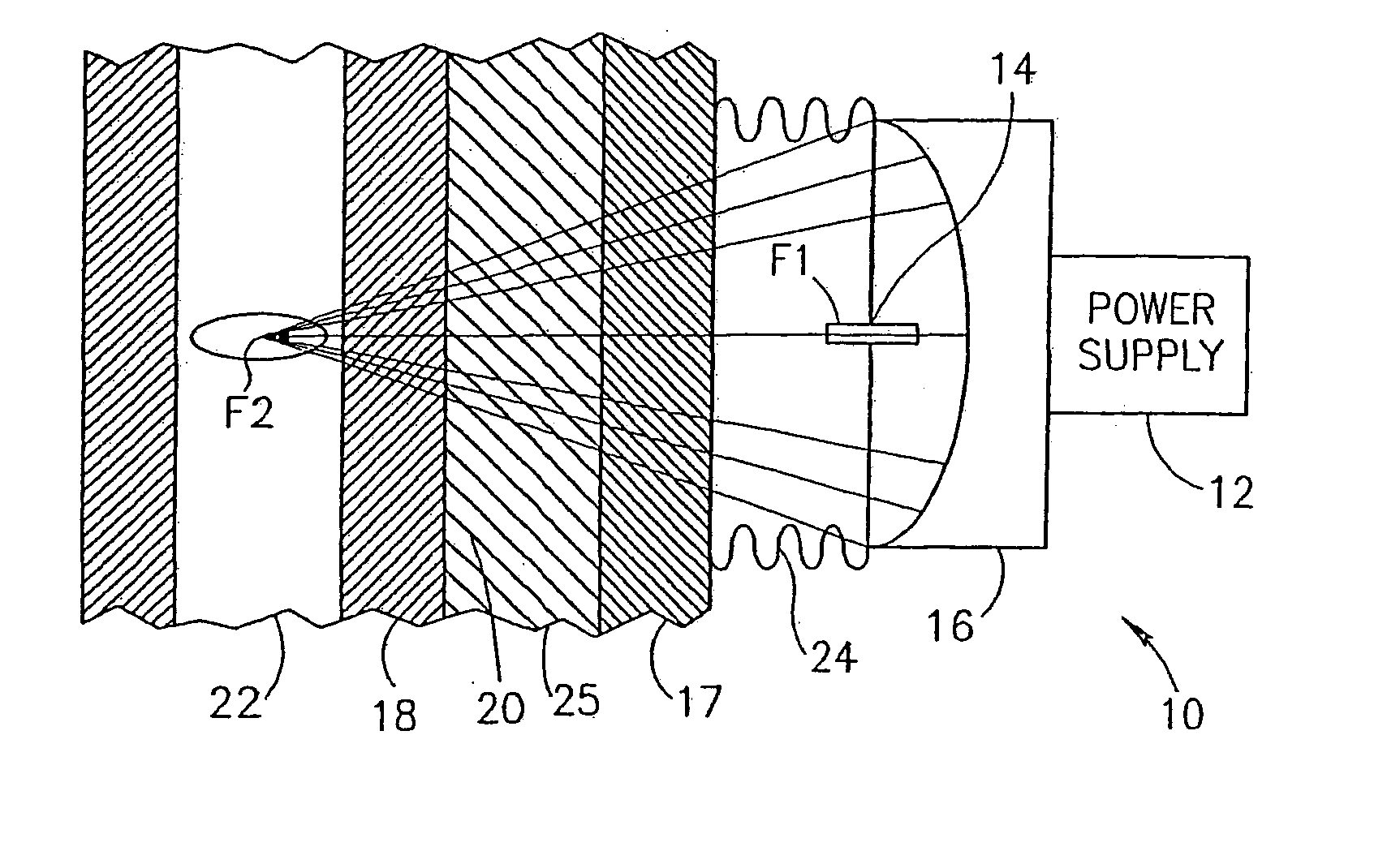

Shock wave electrodes

Disclosed herein shock wave catheters comprising one or more shock wave electrodes for cracking calcifications located within blood vessels. In some variations, a shock wave catheter has first and second shock wave electrodes each circumferentially disposed over the outer surface of the catheter. In certain variations, the first electrode has a recess and the second electrode has a protrusion that is received by the recess and a spark gap is located along the separation between the recess and the protrusion. The second electrode can also have a recess that receives a protrusion from a third shock wave electrode, where the separation between the second and third electrodes along the separation between the recess and the protrusion forms a second spark gap. A shock wave can be initiated across these spark gaps when a voltage is applied over the electrodes.

Owner:SHOCKWAVE MEDICAL

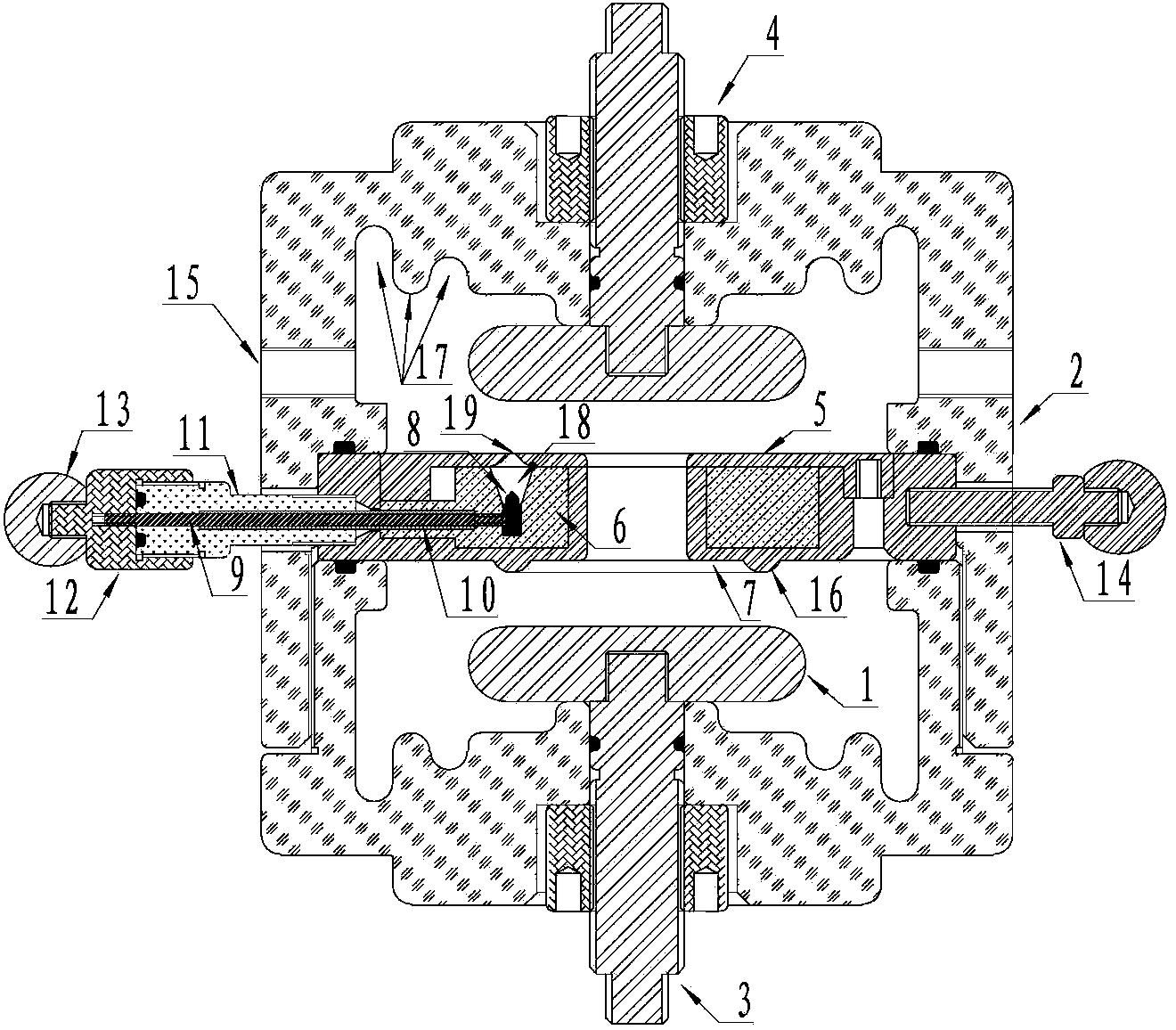

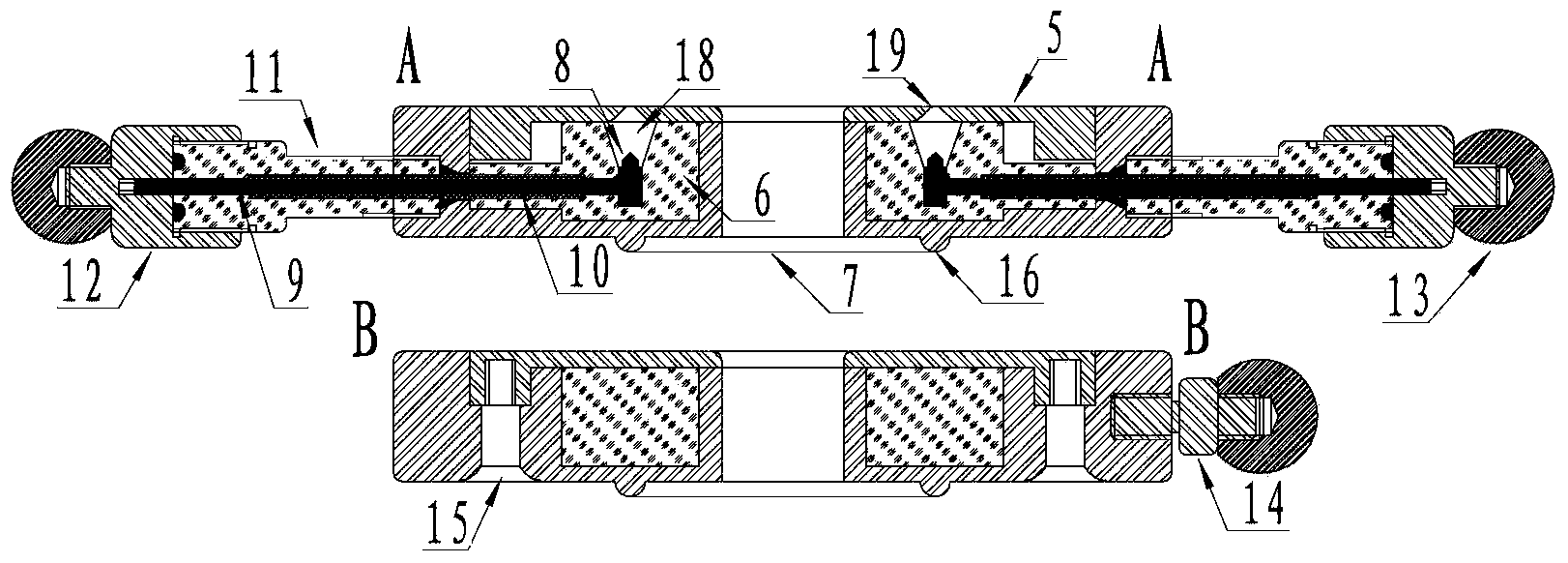

Multichannel gas spark switch applying plasma synthesis jet trigger technology

ActiveCN103441427AReduce ablationReduced gas dielectric strengthSpark gaps with auxillary triggeringEngineeringOrganic glass

The invention discloses a multichannel gas spark switch applying a plasma synthesis jet trigger technology. The multichannel gas spark switch is characterized in that the spark gap of an air switch is divided by a middle trigger electrode into two equal parts; the trigger electrode is composed of three portions, i.e., an upper electrode disc, a lower electrode disc and an insulation ring; more than one excitation cavities and jet orifices are embedded into the insulation ring for generating at one side of the trigger electrode multichannel plasma injection; and the surface of an electrode portion at the other side is provided with an annular metal protrusion for forming multichannel discharge in the relative spark gap. A switch housing is made of organic glass or other insulation materials, so that when a trigger pulse reaches the trigger electrode, a higher field distortion coefficient is formed at the side of the annular electrode portion, and at the same time the multichannel plasma injection is formed at the other side, thus the spark inductance of the air switch is reduced, the electrode ablation is minimized, and the service life of the switch is prolonged.

Owner:XI AN JIAOTONG UNIV

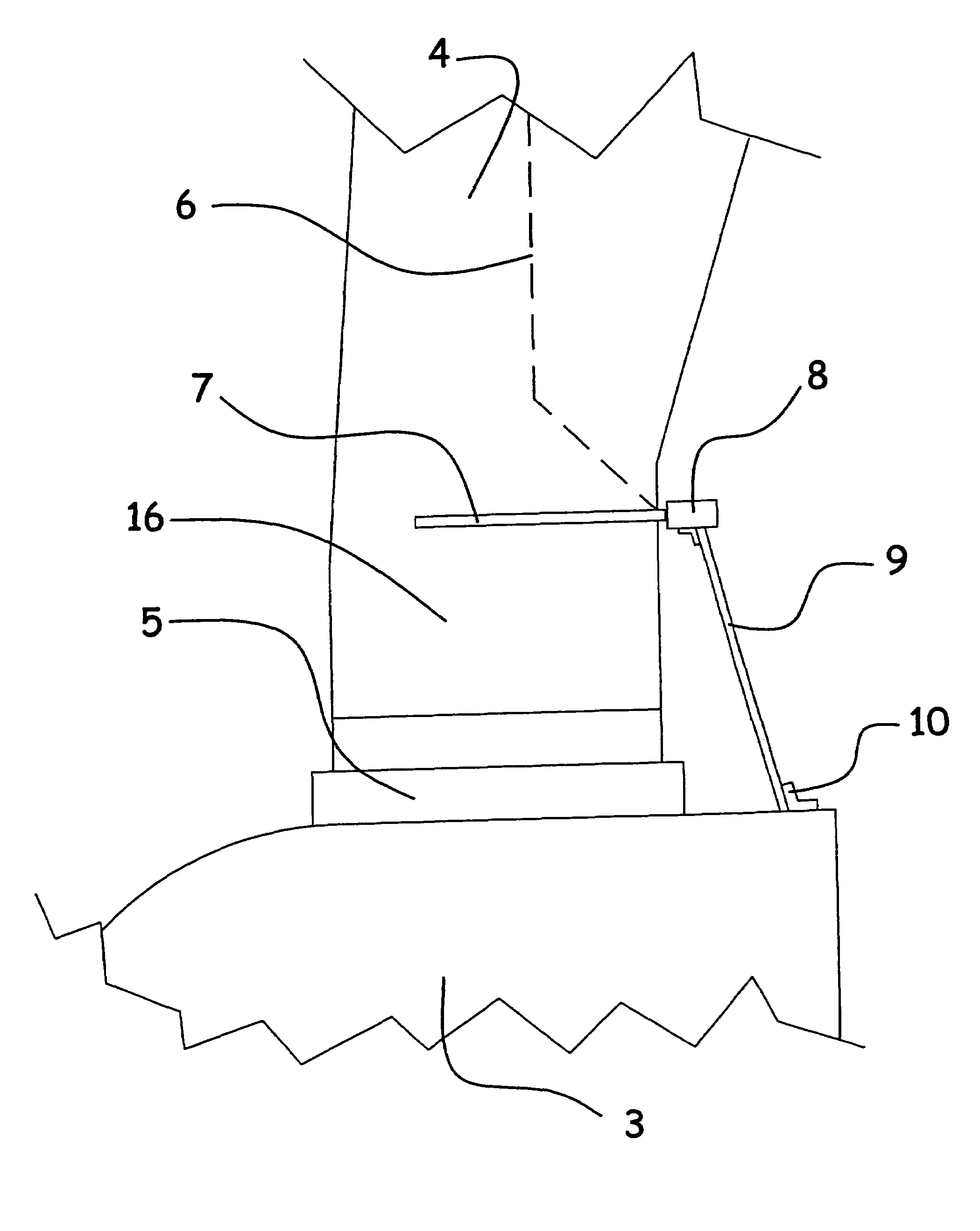

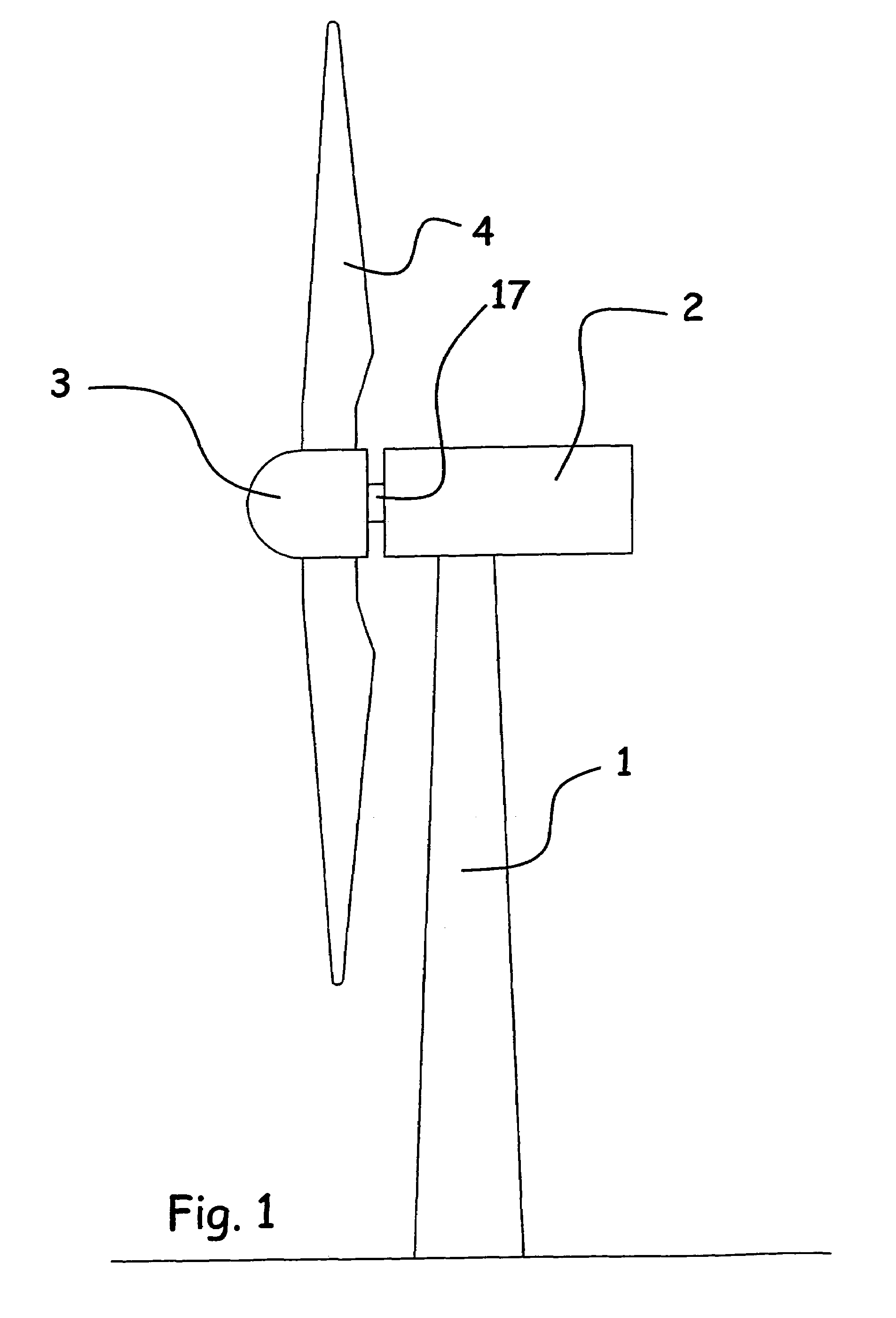

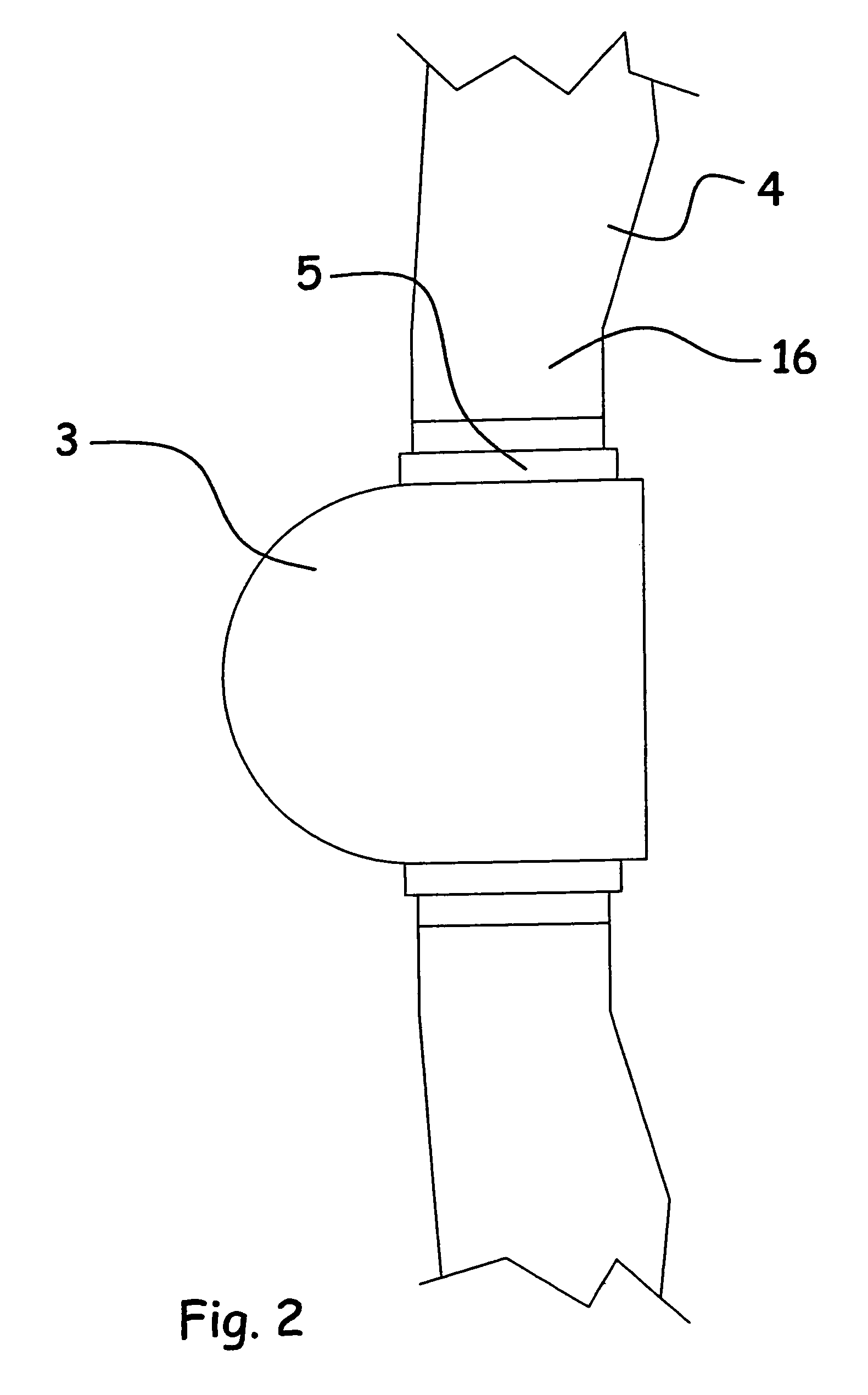

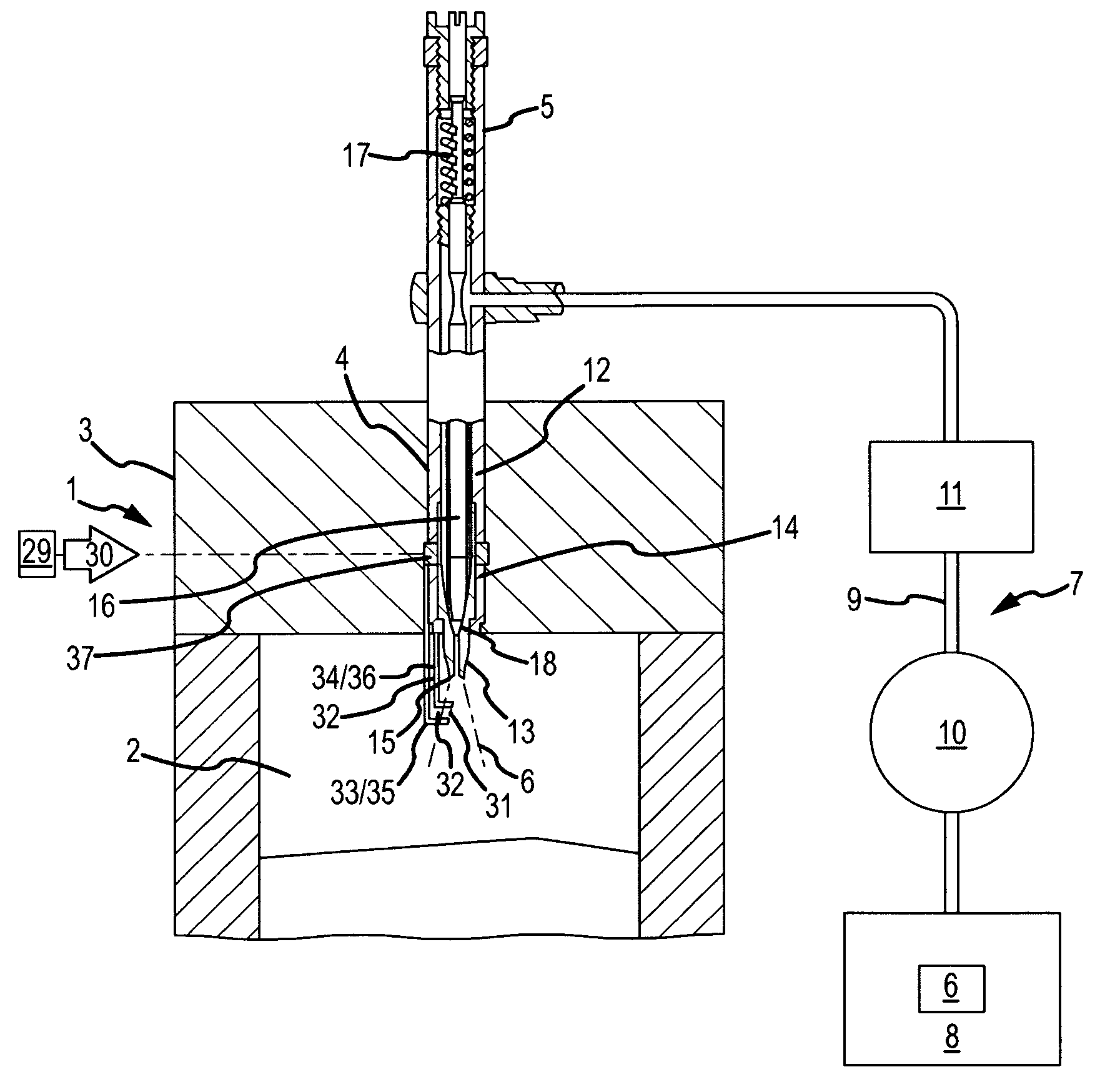

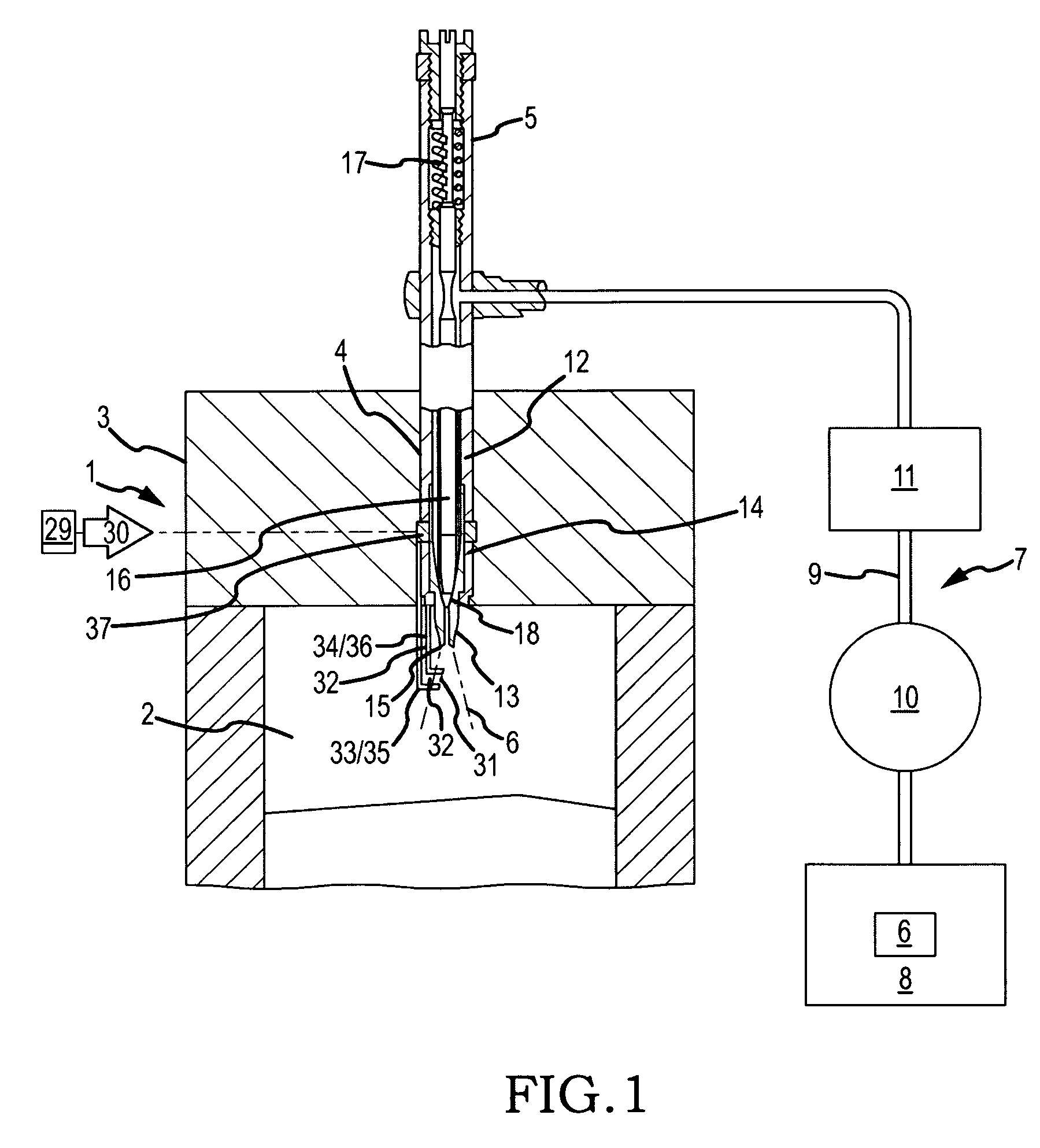

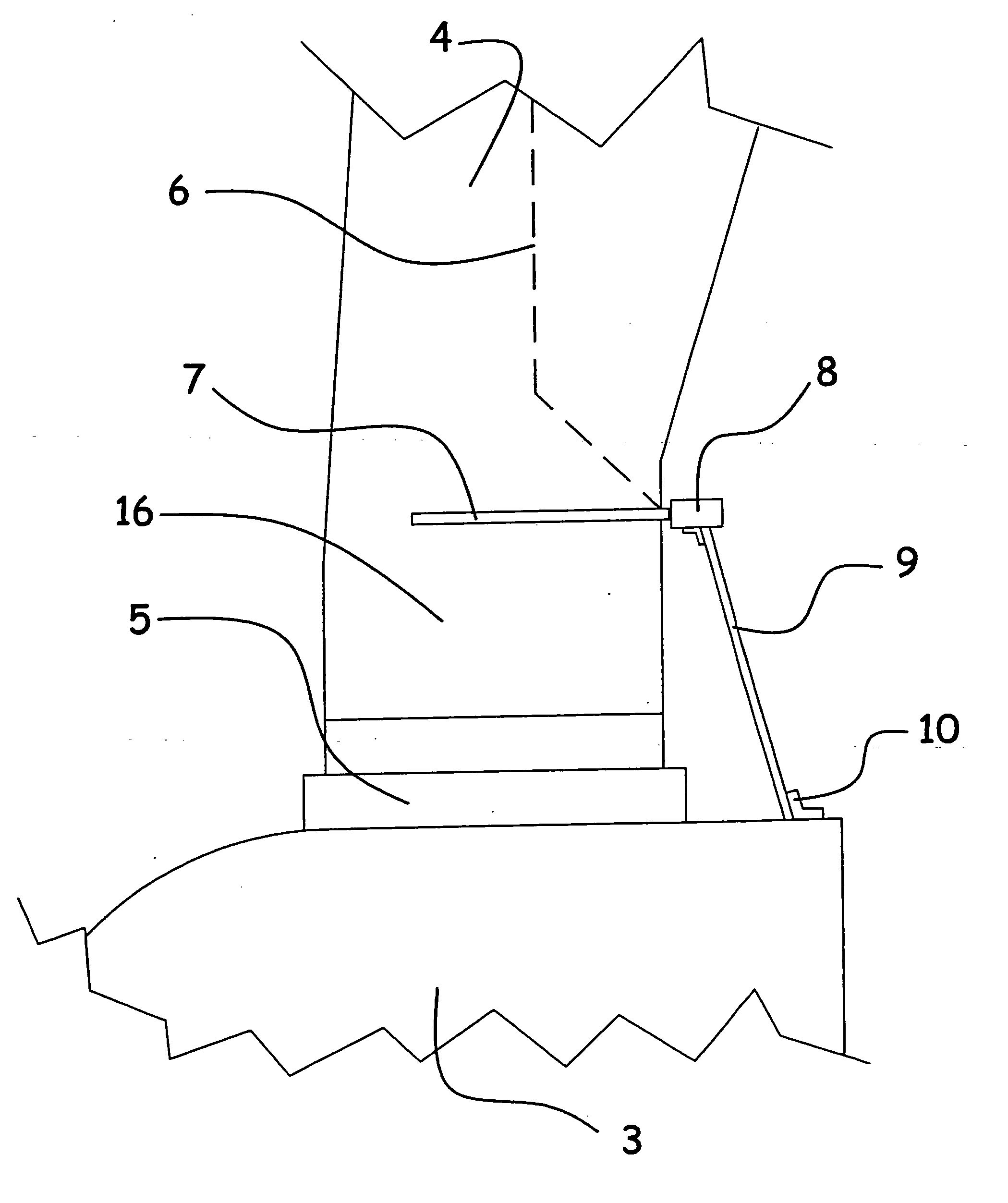

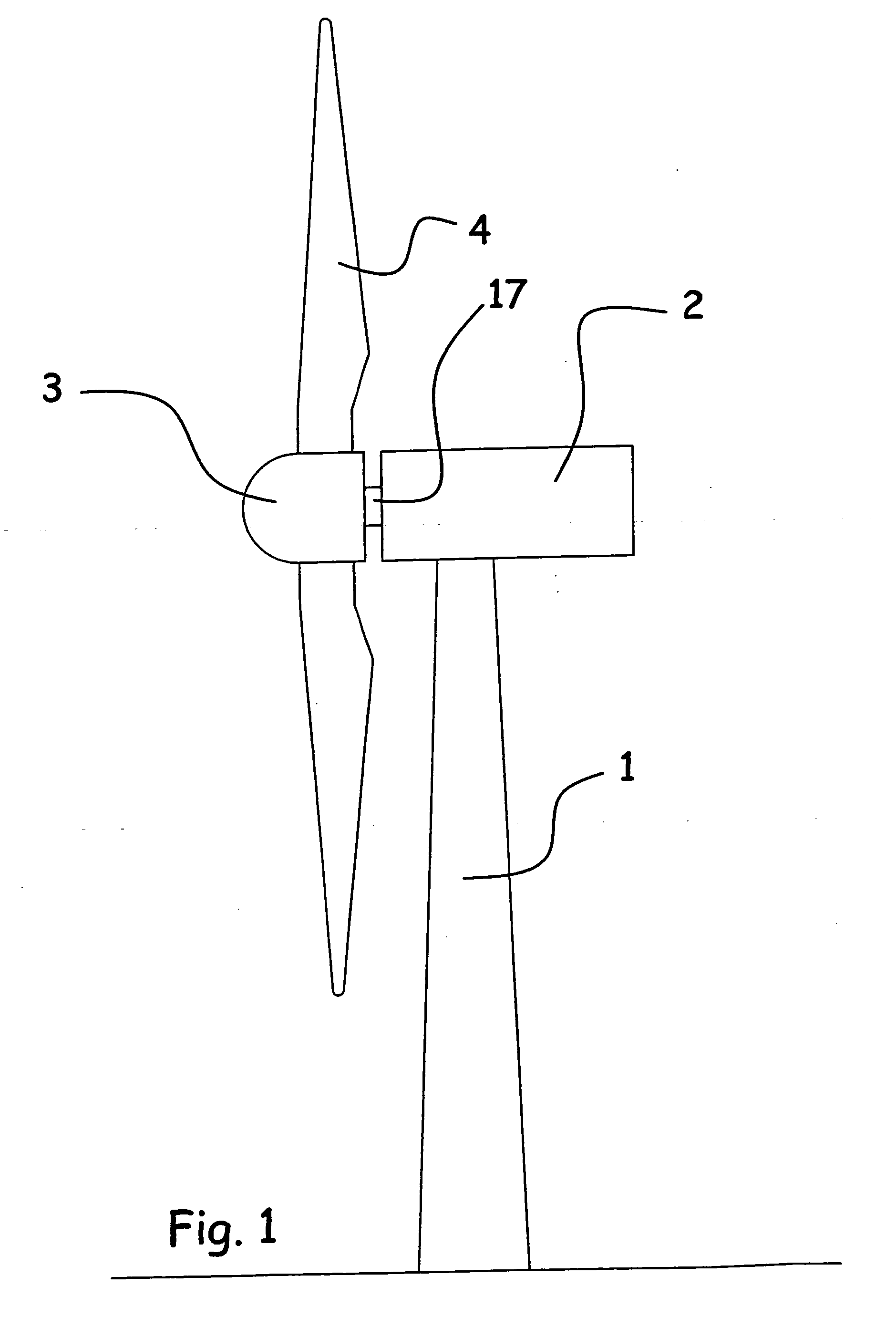

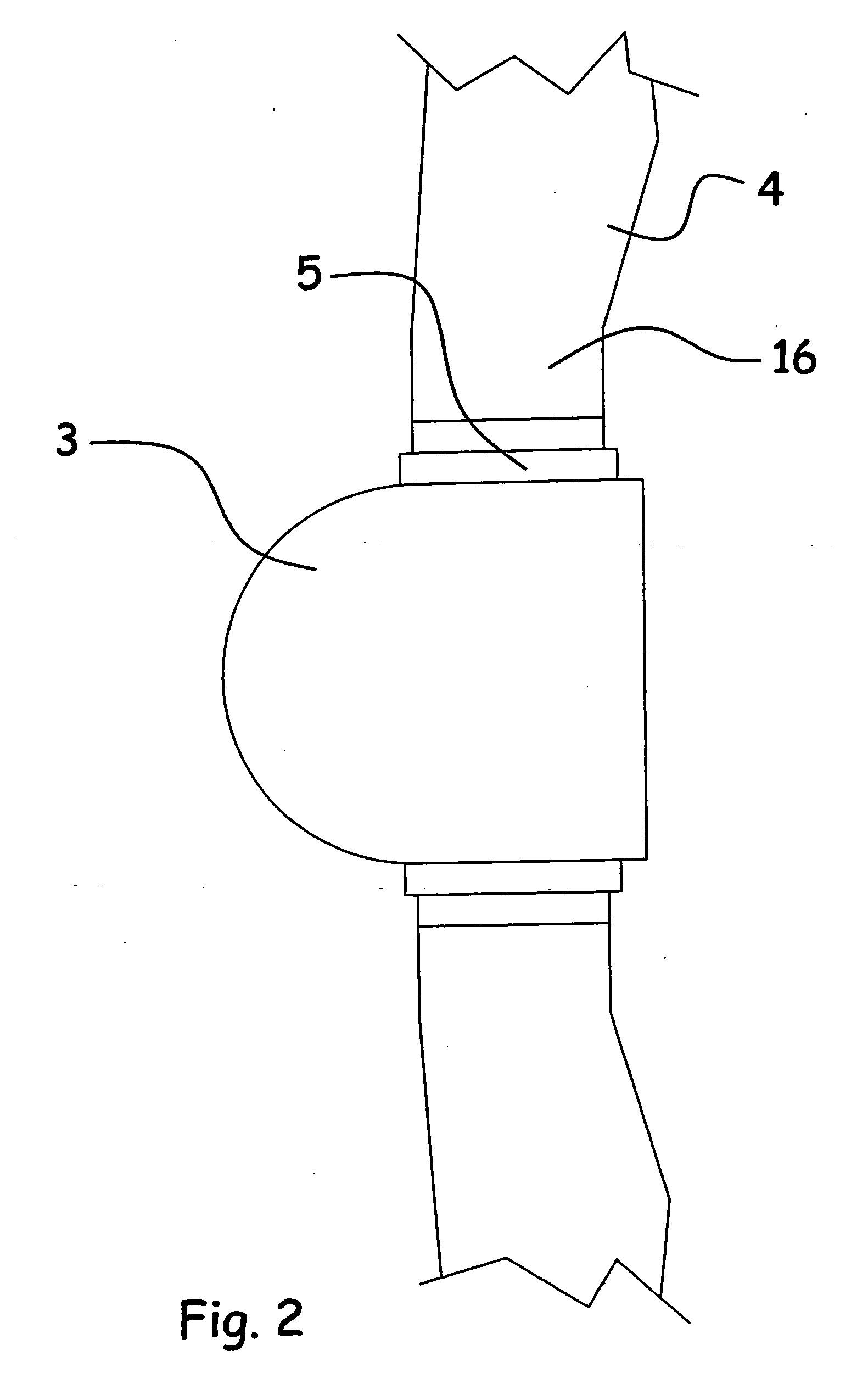

Lightning protection of a pitch-controlled wind turbine blade

ActiveUS7390169B2Current protectionReduce resistancePropellersPump componentsTurbine bladeBlade pitch

A wind turbine rotor including a rotor hub (3) and a plurality of blades (4), and where each blade root (16) is connected to said rotor hub through a pitch bearing (5) in such a manner that the pitch angle of the blade is adjustable by a turning of the blade about its longitudinal axis relative to the rotor hub. The blade is provided with at least one electrically conducting lightening down-conductor (6) extending in the longitudinal direction of the blade to the blade root and being electrically isolated from the pitch bearing (5). A spark gap (15) is provided between the lightning down-conductor and the rotor hub, said spark gap (15) being adapted to conduct a lightning current passing through the lightning down-conductor. A sliding contact connection (7, 12) is provided parallel to the spark gap (15) between the lightning down-conductor (6) and the rotor hub (3), said sliding contact connection ensuring electrical contact between said lightening down-conductor (6) and said rotor hub (3) irrespective of the pitch angle of the blade. The invention also relates to a wind turbine including such a rotor.

Owner:LM GLASSFIBER

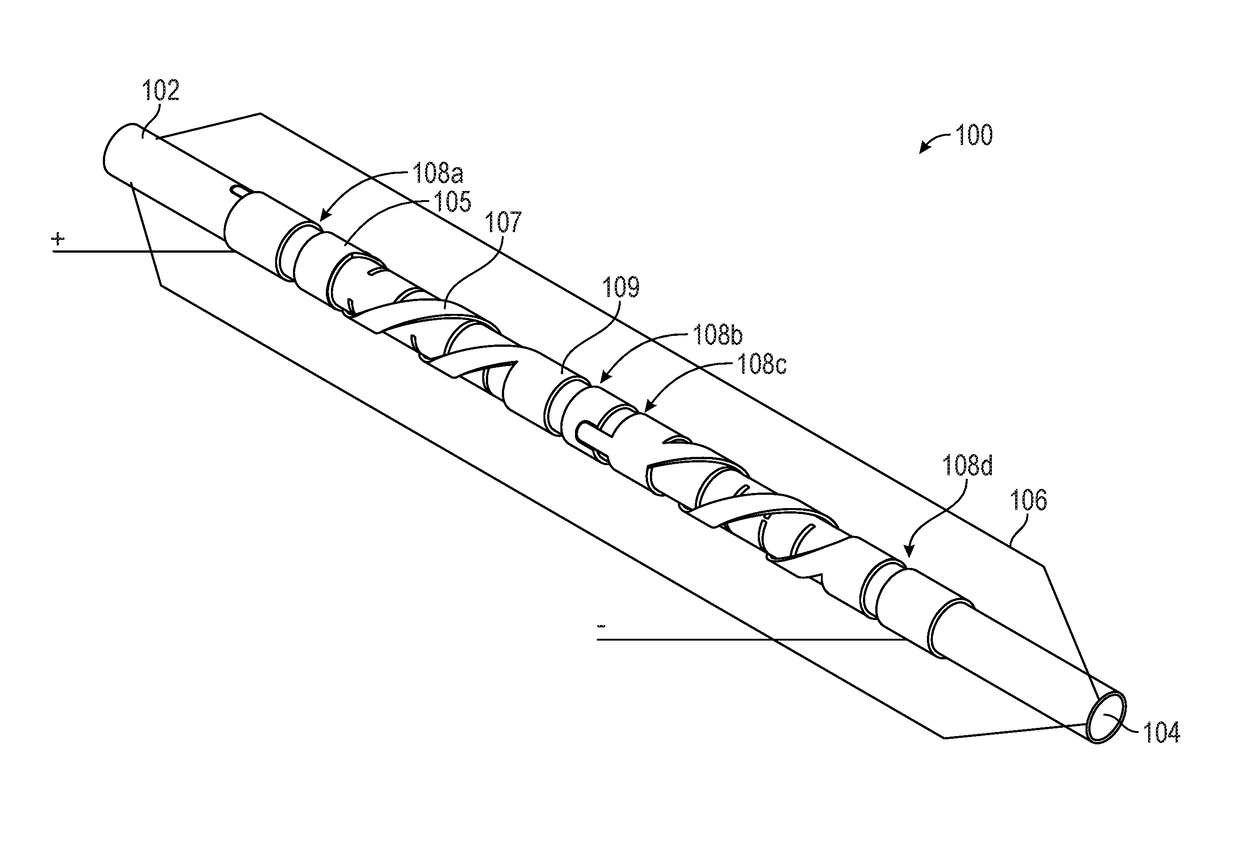

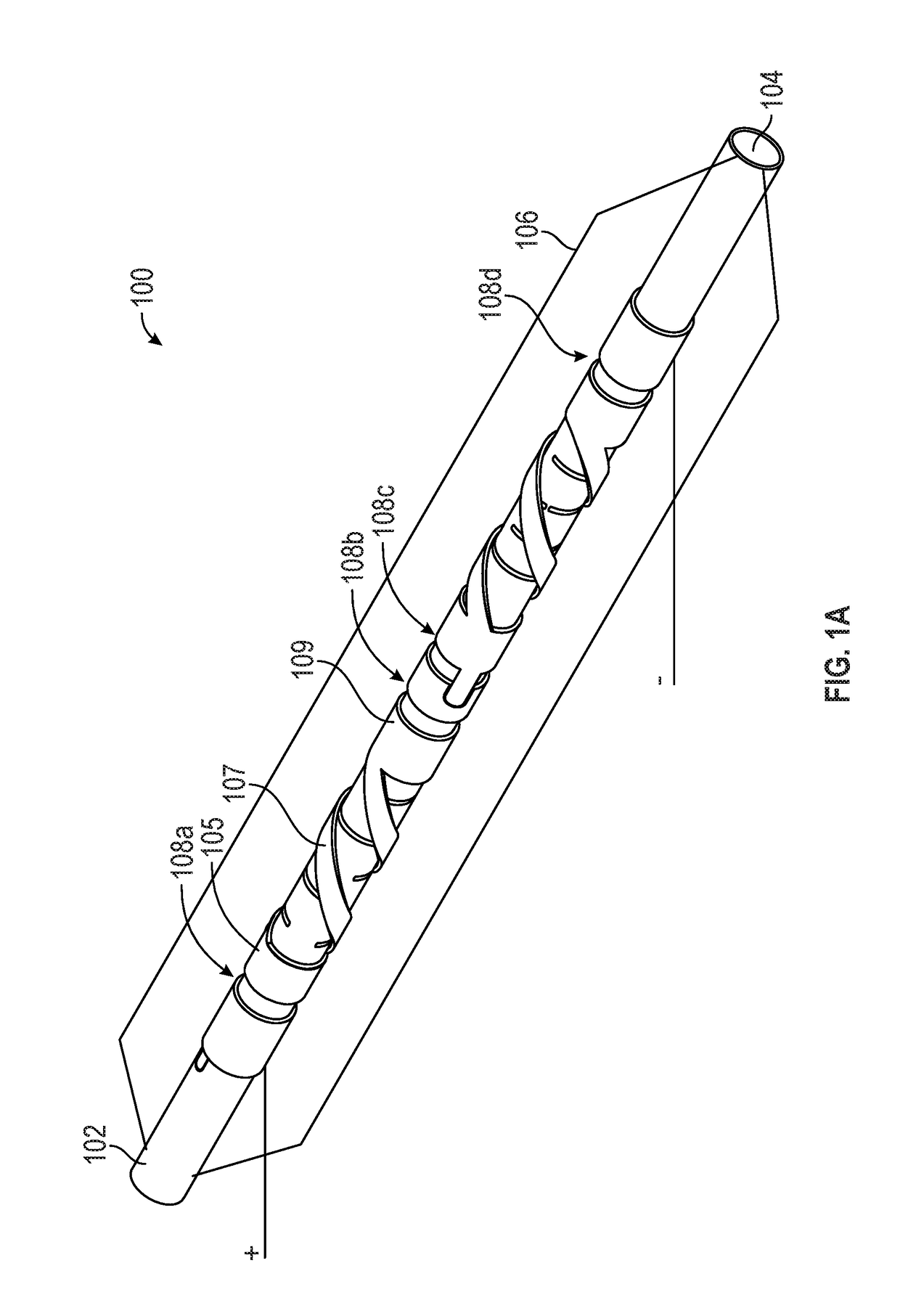

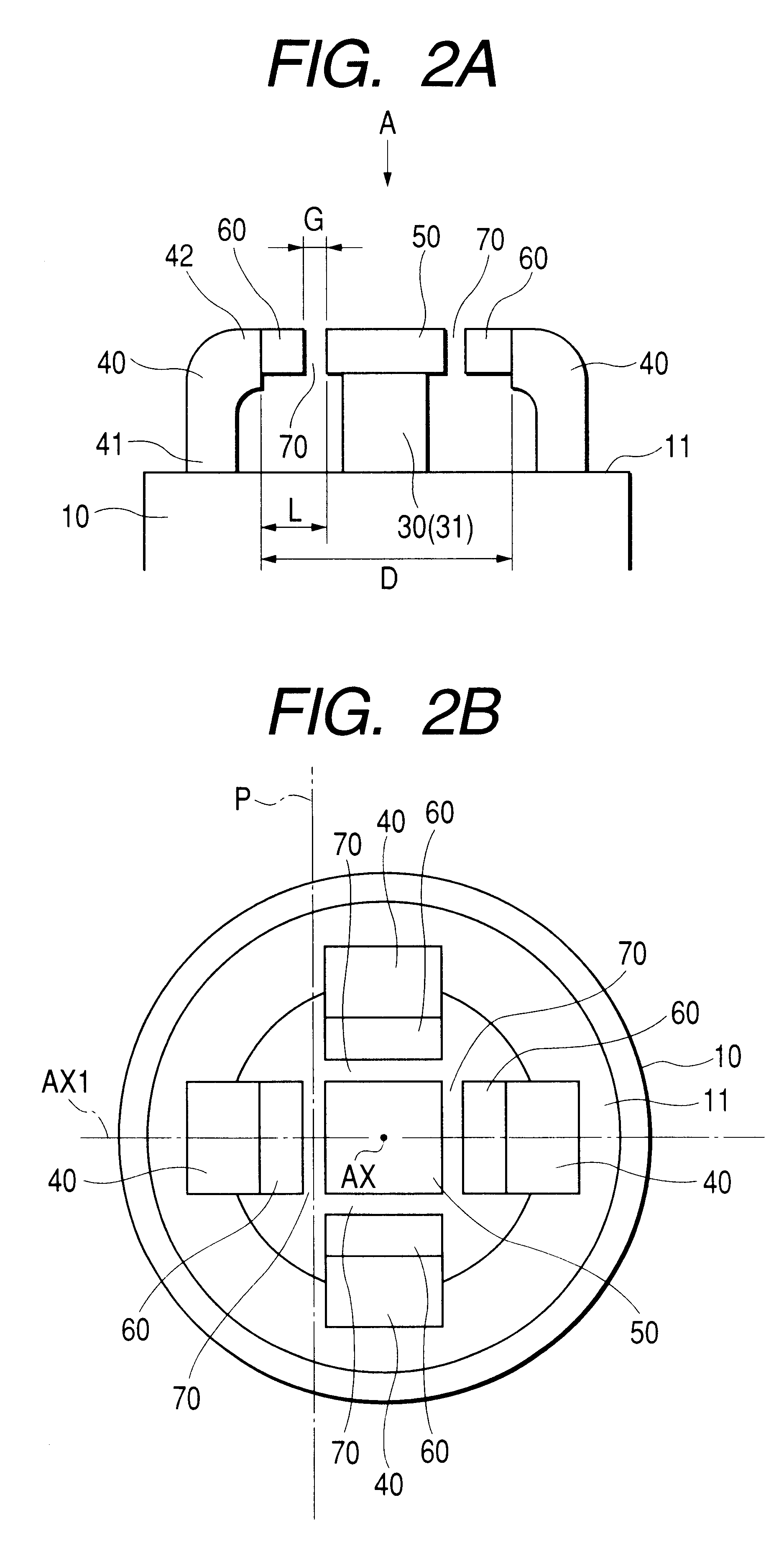

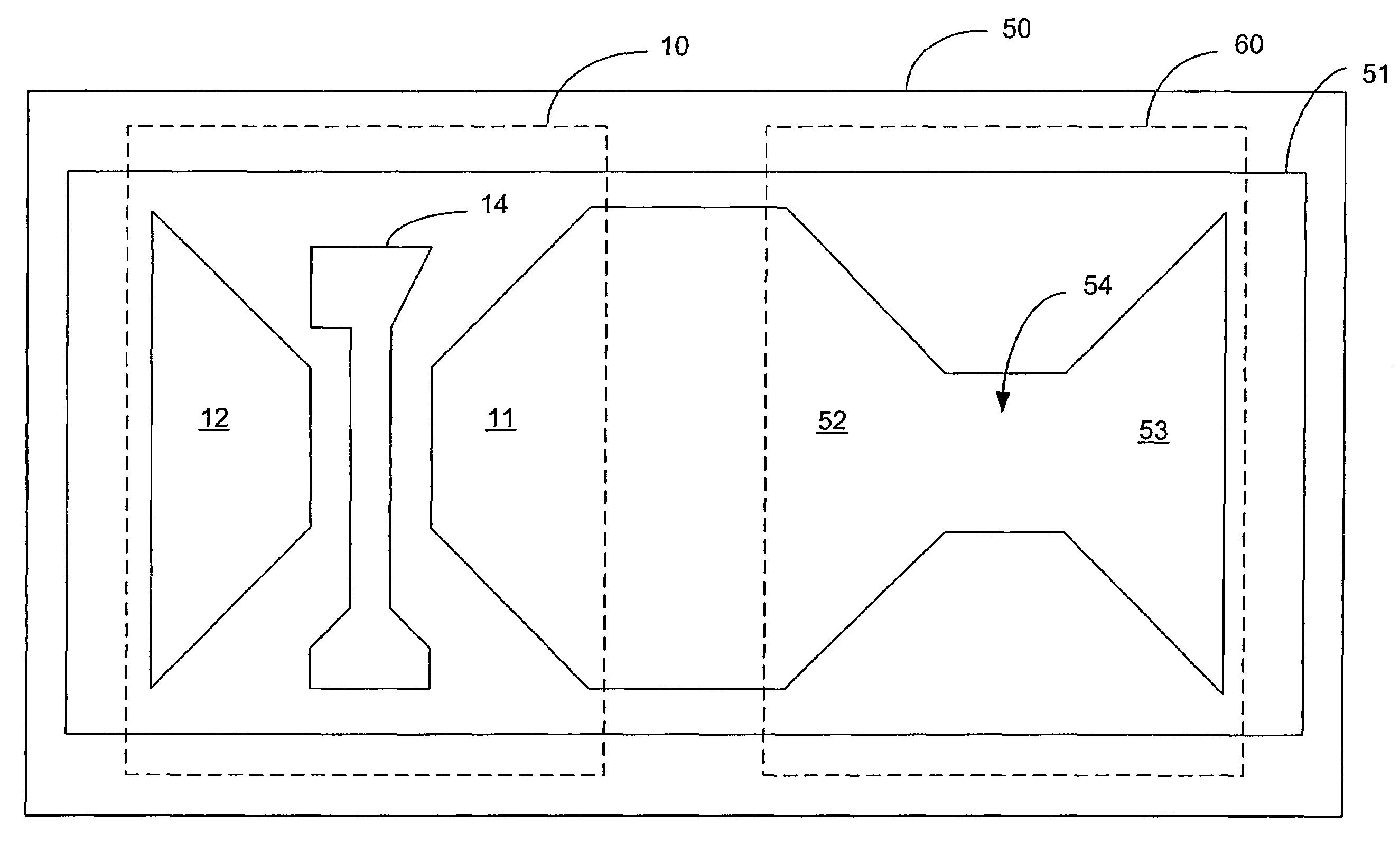

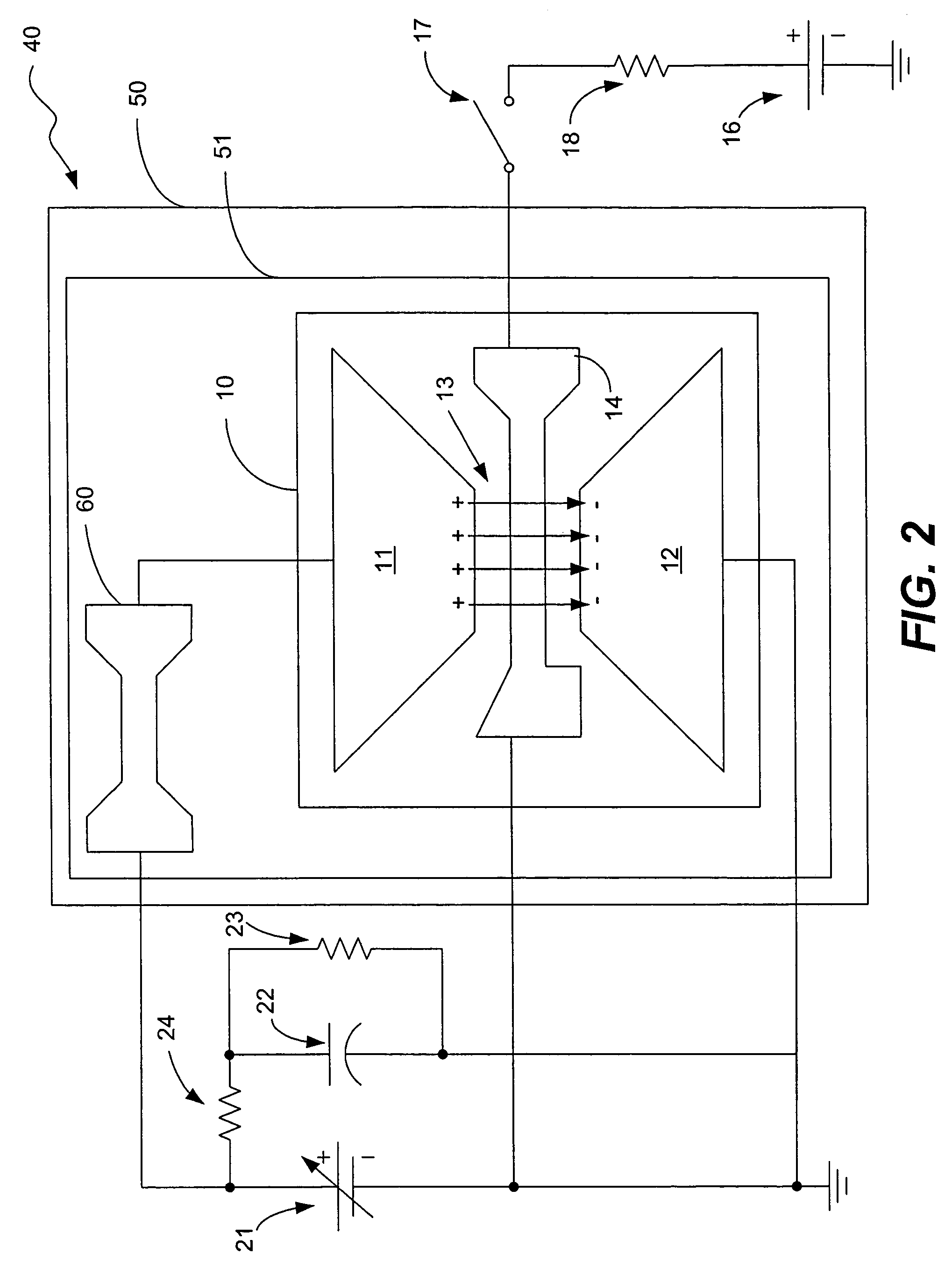

Fuel injection stream parallel opposed multiple electrode spark gap for fuel injector

ActiveUS8069836B2Improve ignition efficiencyImprove efficiencySparking plugsFuel injection apparatusElectricityCombustion

Generally, a multiple electrode spark gap fuel injector and methods of utilizing a multiple electrode spark gap fuel injector for internal combustion engines. Specifically, at least one pair of electrodes having a corresponding pair of electrode ends radially located and axially located in relation to an amount of dispersed fuel to increase efficiency of fuel combustion.

Owner:BIG CAT ENERGY CORP

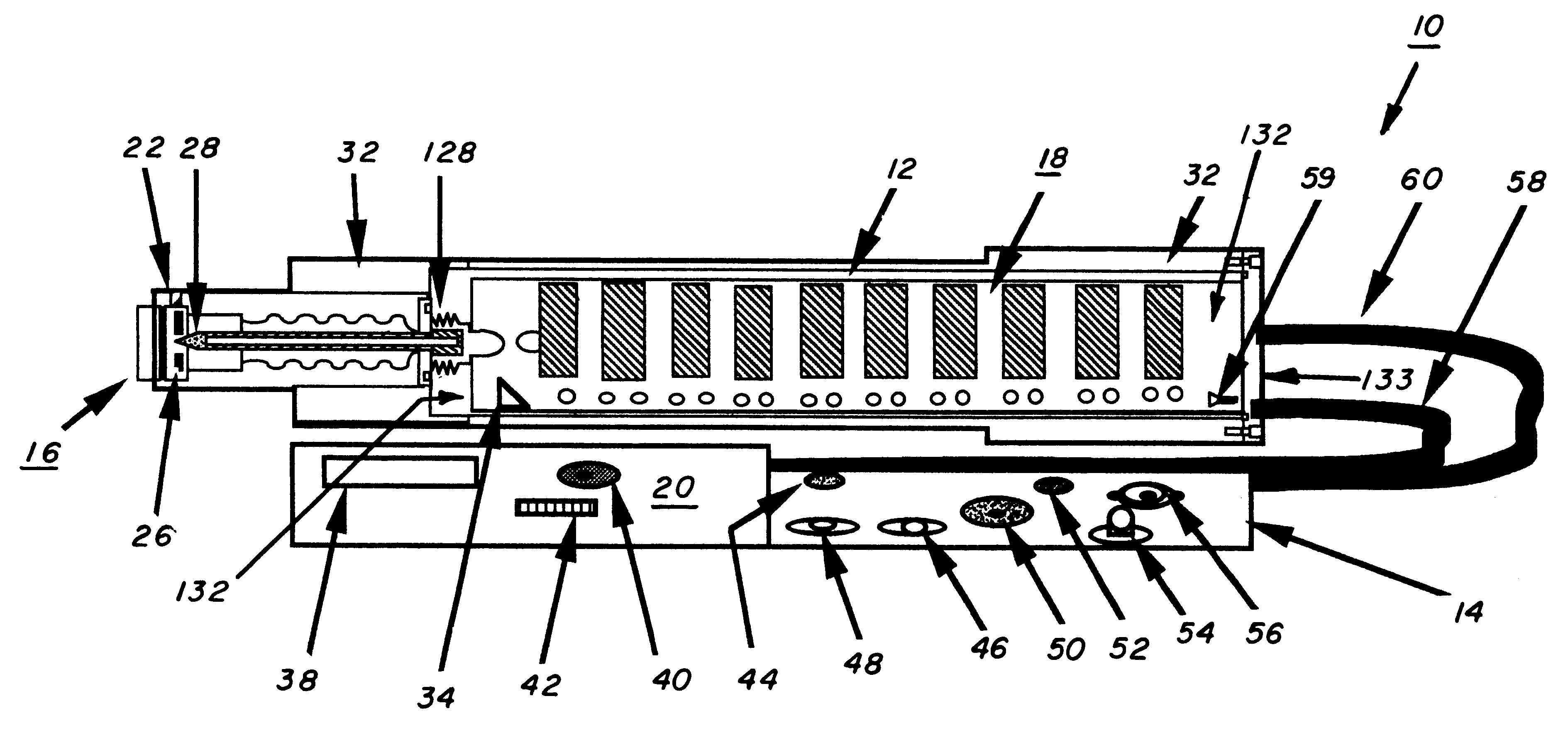

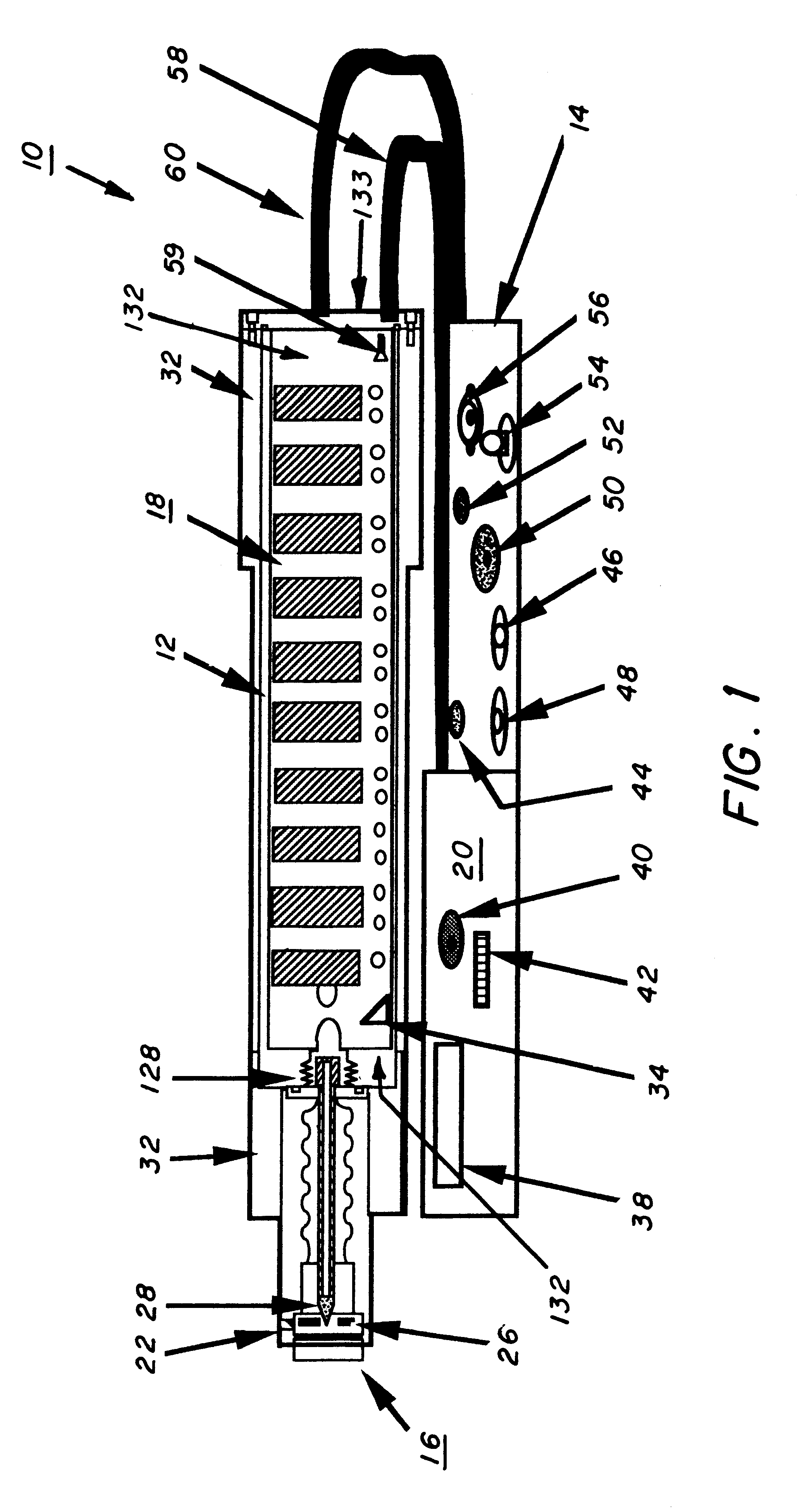

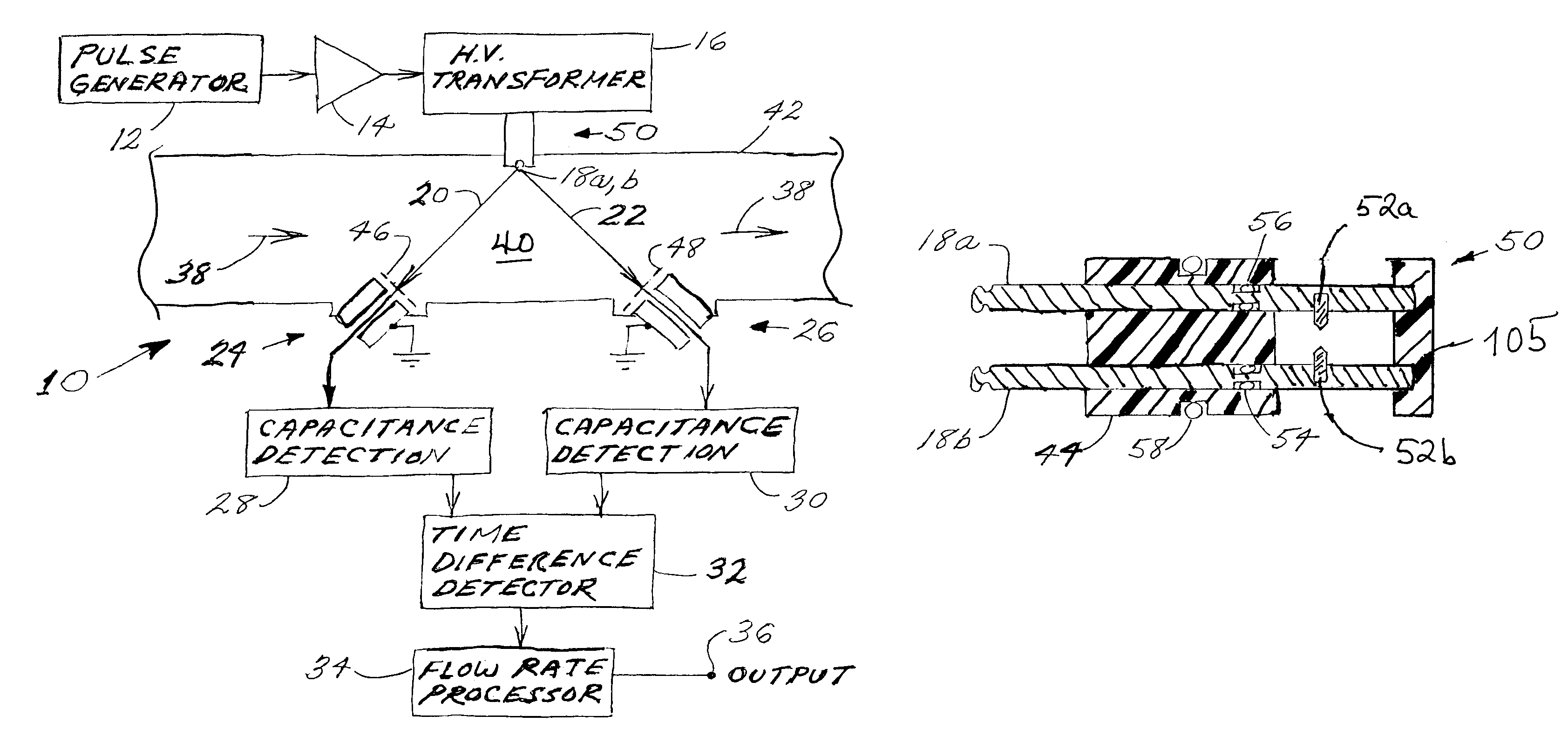

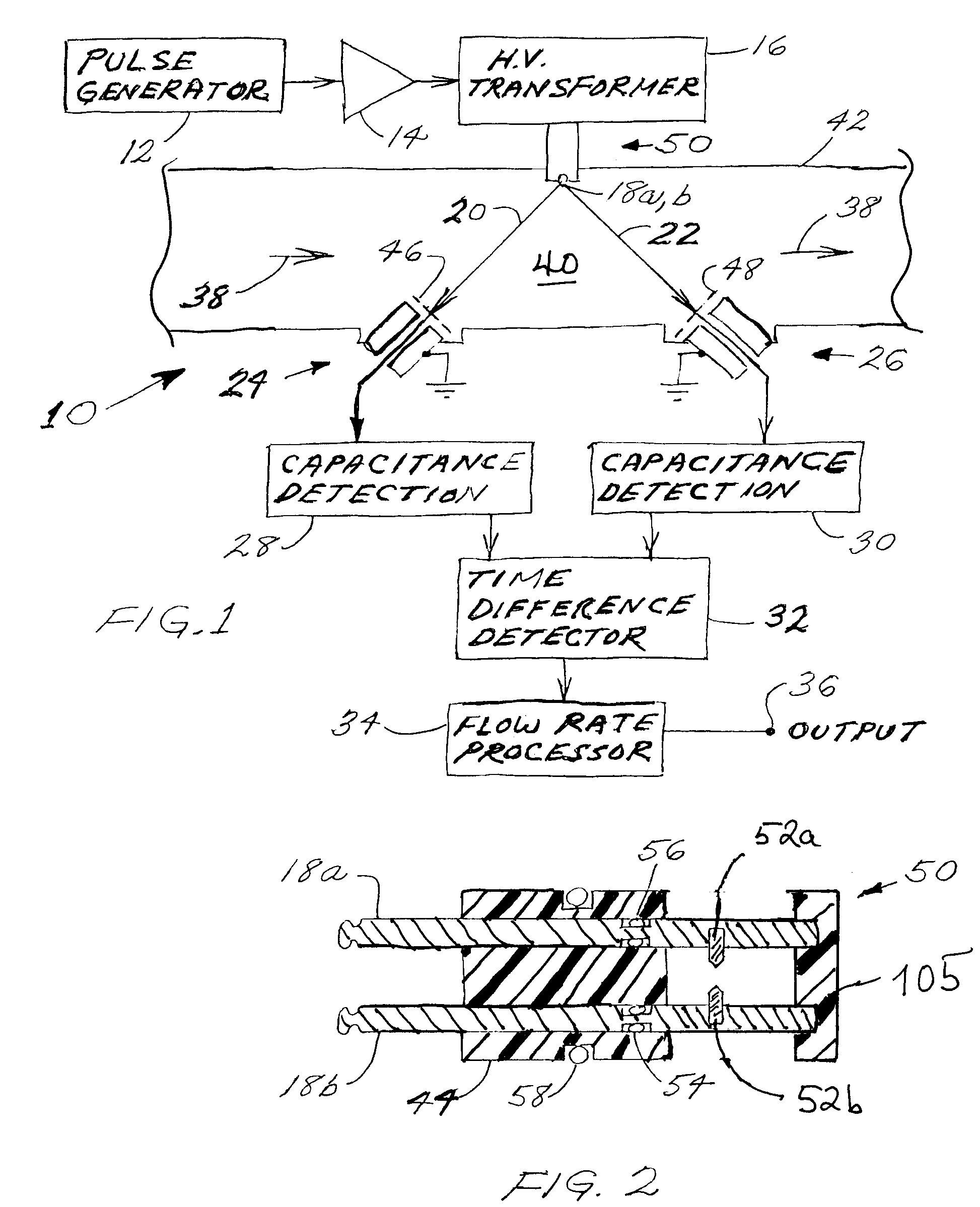

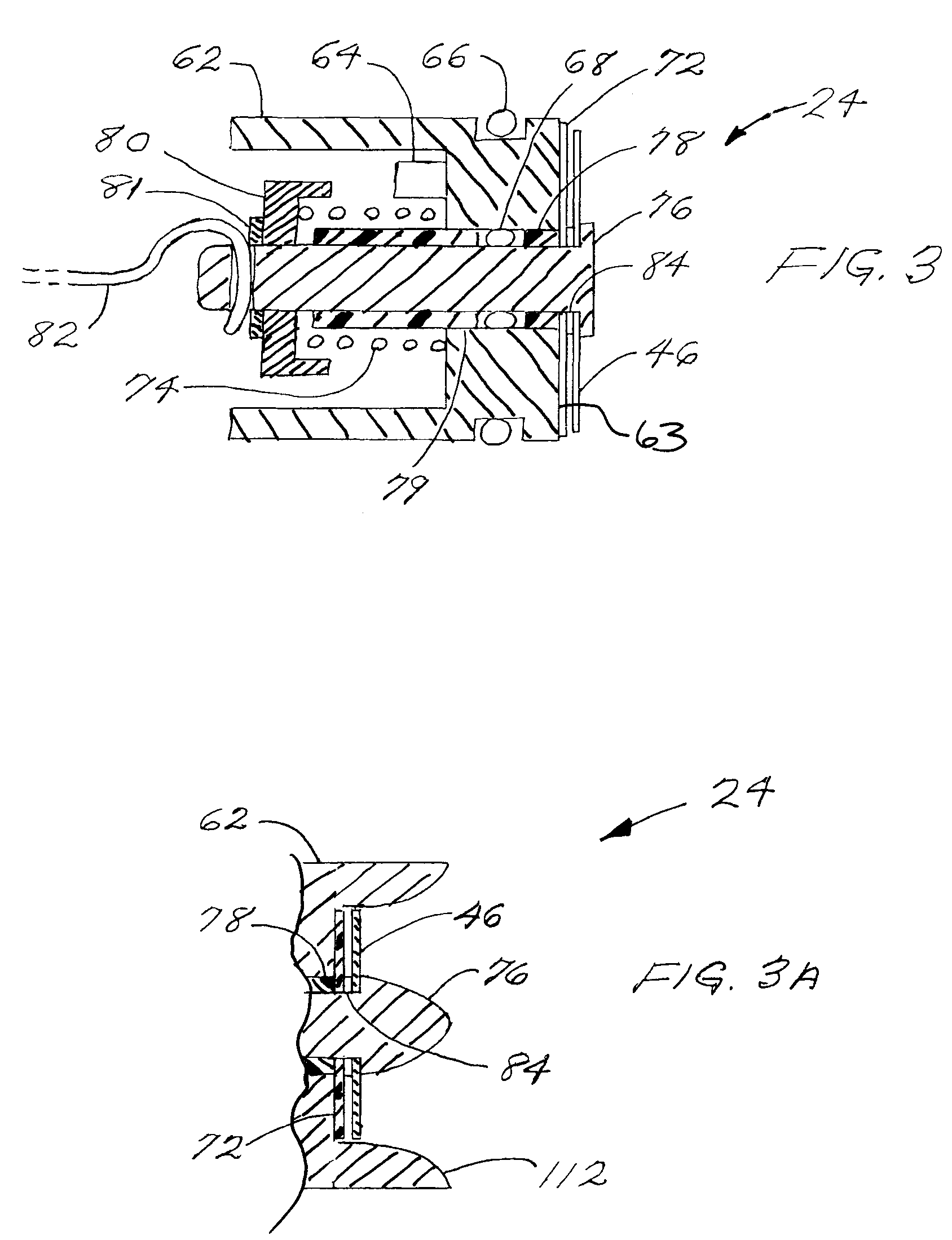

Acoustic pulse flow meter

InactiveUS7628081B1Increase sound powerOvercome Impedance MismatchVolume/mass flow measurementAcoustic energyEngineering

A time-of-flight flow meter that is particularly useful for measuring the flow of gases, such as steam, uses a spark gap periodically energized with an electrical pulse to generate an acoustic pulse. The pulse is detected by upstream and downstream acoustic detectors that may be capacitive transducers having flexible plates wetted on both sides by the fluid so that no external venting is required. The acoustic detectors may be electrically heated to avoid condensation effects. In some cases the interior of the pipe or other conduit is shaped near the source so as to define acoustic beams aimed at the detectors and so as to concentrate the received acoustic energy on the detectors.

Owner:ONICON INC

Method of producing a spark plug

In producing a spark plug including a central electrode having a first chip including noble metal and an earth electrode having a second chip including the noble metal, a spark gap being disposed between the first and second chips, a chip including the noble metal. The chip is welded to an end of the central electrode and to an end of the earth electrode. The welded chip is cut to form the first and second chips and the spark gap.

Owner:DENSO CORP

Pre-chamber spark plug

ActiveUS7922551B2Life maximizationReduce erosionSpark gap detailsInternal combustion piston enginesElectricityElectrode erosion

A method and apparatus to maximize spark plug life in pre-chamber spark plugs operating with ultra-lean mixtures and / or elevated engine BMEP is presented. Electrode erosion is reduced by spreading discharge energy over a wider surface area, maintaining fuel concentration in the spark gap, controlling gas static pressure during discharge, and maintaining safe electrode temperature. Energy is spread via a swirling effect created by periphery holes in an end cap, resulting in a lower specific energy discharge at the electrodes. Divergently configured electrodes reduce the spark voltage at high operating pressures and the energy required for ignition. The flow field generated at the electrodes prevents electrical shorts due to water condensation and avoids misfire. The center electrode insulation provides an effective heat transfer path to prevent electrode overheating and pre-ignition. The volume behind the electrodes provides a volume for burnt products from previous combustion cycles and leads to more reliable ignition.

Owner:WOODWARD GOVERNOR CO

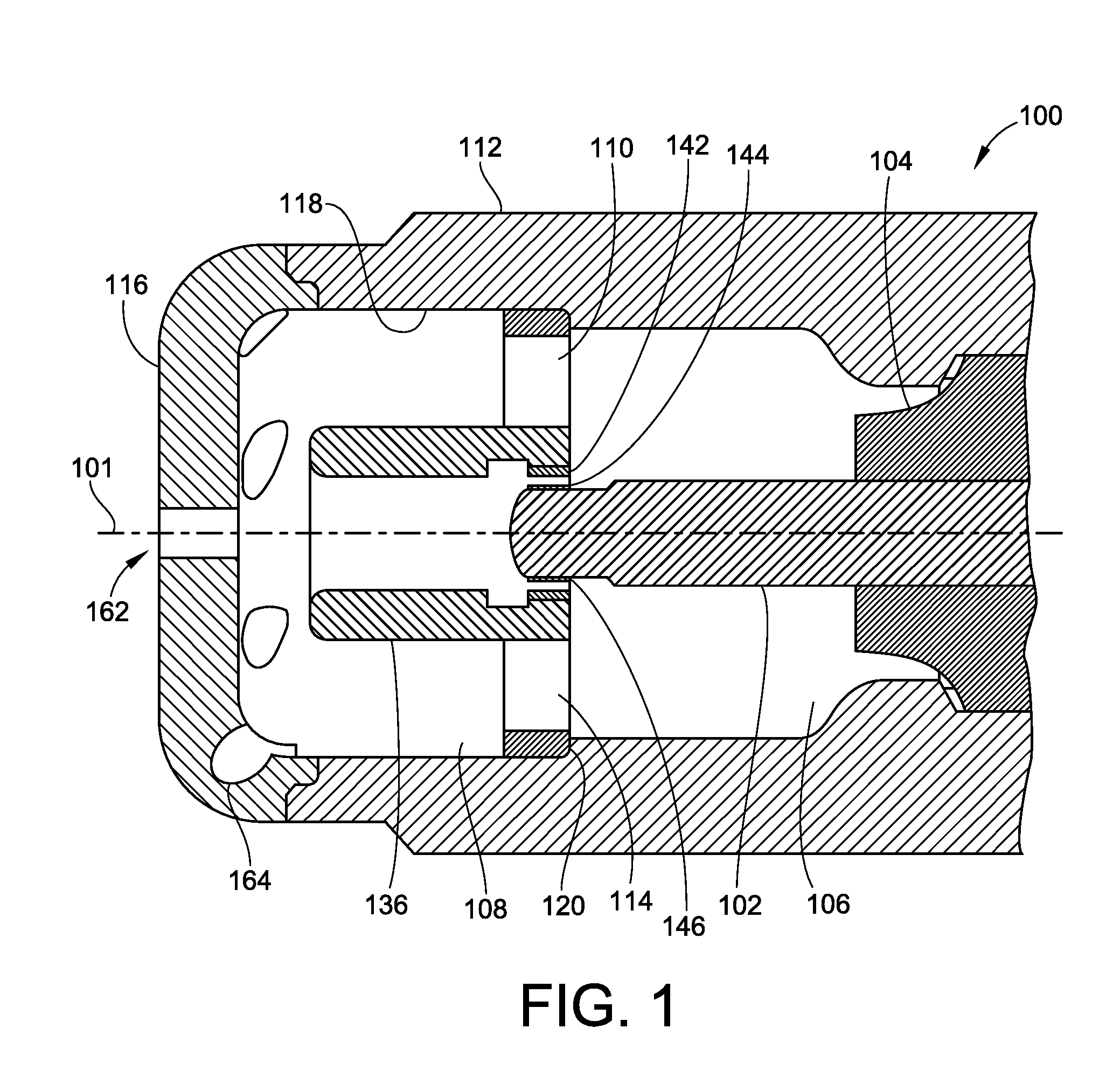

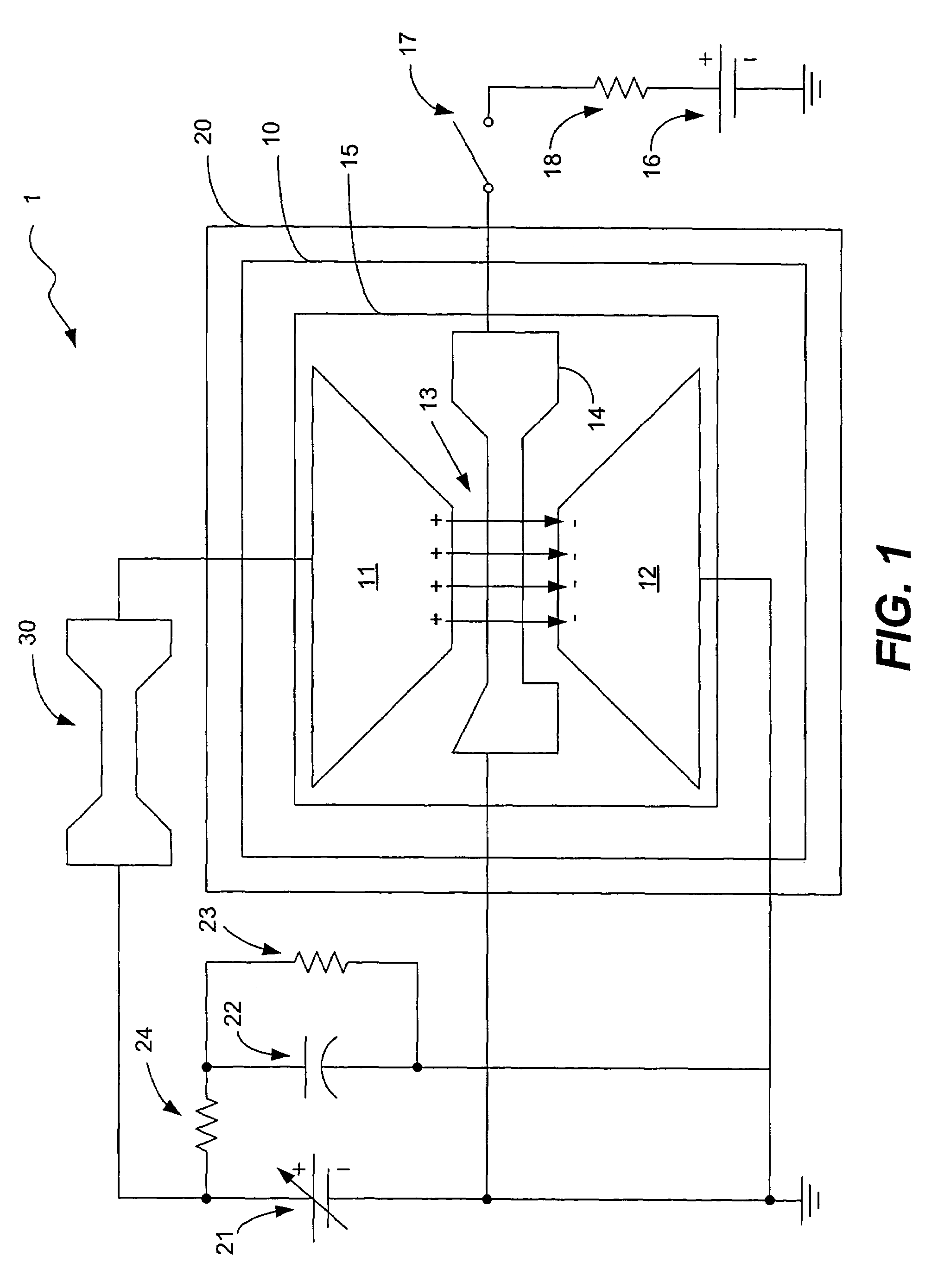

Integrated spark gap device

ActiveUS6977468B1Low costSmall sizeSpark gaps with auxillary triggeringElectric light circuit arrangementDielectric substrateEngineering

A spark gap device that is formed in an integrated circuit (IC). The IC has a dielectric substrate upon which a high-voltage switch is disposed. The switch includes an anode element and a cathode element separated from each other by a spark gap. A trigger electrode is disposed on the substrate material in the spark gap. A capacitor is electrically coupled to the trigger electrode. The cathode and anode elements and the trigger electrode preferably are at least partially covered with a dielectric material. When the capacitor is charged, the charge on the capacitor exerts a strong electric field on the cathode and anode elements that causes ions to migrate in the cathode and anode elements toward the spark gap. When the trigger electrode is excited by an electrical current, the ions arc across the gap and a conductive path is created between the cathode element and the anode element.

Owner:AUBURN UNIV

Method for mid load operation of auto-ignition combustion

ActiveUS20060005804A1Easy loadingElectrical controlNon-fuel substance addition to fuelPressure riseMultiple injection

A method is disclosed for expanding the mid load operation limit in a four-stroke gasoline direct-injection controlled auto-ignition combustion engine. A system is employed for variably actuating the intake and exhaust valves and for operating the valves with an exhaust re-compression or exhaust re-breathing valve strategy. A spark plug is provided. A fuel injector having multiple injection capability is employed. A first fuel charge is injected into the combustion chamber to form a lean air-fuel mixture. A second fuel charge is injected into the combustion chamber to form a stratified air-fuel mixture having an ignitable mixture located near the spark plug. The ignitable mixture is ignited at the spark gap, thereby causing spark-ignition combustion that causes a sufficient increase in chamber pressure and temperature to trigger auto-ignition of the lean air-fuel mixture, resulting in the obtaining of a higher engine load before a pressure rise rate in the combustion chamber exceeds a prescribed threshold value.

Owner:GM GLOBAL TECH OPERATIONS LLC

Lightning protection of a pitch-controlied wind turbine blade

A wind turbine rotor including a rotor hub (3) and a plurality of blades (4), and where each blade root (16) is connected to said rotor hub through a pitch bearing (5) in such a manner that the pitch angle of the blade is adjustable by a turning of the blade about its longitudinal axis relative to the rotor hub. The blade is provided with at least one electrically conducting lightening down-conductor (6) extending in the longitudinal direction of the blade to the blade root and being electrically isolated from the pitch bearing (5). A spark gap (15) is provided between the lightning down-conductor and the rotor hub, said spark gap (15) being adapted to conduct a lightning current passing through the lightning down-conductor. A sliding contact connection (7, 12) is provided parallel to the spark gap (15) between the lightning down-conductor (6) and the rotor hub (3), said sliding contact connection ensuring electrical contact between said lightening down-conductor (6) and said rotor hub (3) irrespective of the pitch angle of the blade. The invention also relates to a wind turbine including such a rotor.

Owner:LM GLASSFIBER

Ceramic electrode, ignition device therewith and methods of construction thereof

A spark plug, a center electrode therefore and method of construction is provided. The spark plug has a generally annular ceramic insulator extending between a terminal end and a nose end. A conductive shell surrounds at least a portion of the ceramic insulator and a ground electrode having a ground electrode sparking surface is operatively attached to the shell. An elongate center electrode has a body extending between opposite ends, wherein the body is compacted and sintered of a conductive or semi-conductive ceramic material. One of the electrode ends provides a center electrode sparking surface to provide a spark gap between the center electrode sparking surface and the ground electrode sparking surface.

Owner:FEDERAL MOGUL IGNITION

Spark Plug With Fine Wire Ground Electrode

InactiveUS20070290593A1Strong and more secure jointFacilitates various attachment mechanismSparking plugsEngineeringInternal combustion engine

A spark plug for a spark-ignited internal combustion engine includes a generally tubular ceramic insulator. A conductive shell surrounds at least a portion of the ceramic insulator and includes at least one ground electrode. A center electrode is disposed in the ceramic insulator. The center electrode has an upper terminal end and a lower sparking end in opposing relation to the ground electrode, with a spark gap defining the space therebetween. The ground electrode extends from an anchored end adjacent the shell to a distal end adjacent the spark gap. The ground electrode includes a ledge formed on its distal end having at least one inset planar surface and an inset back wall. A high-performance metallic sparking tip is attached to the distal end of the ground electrode. The sparking tip has a base end disposed in surface-to-surface contact with the inset planar surface of the ledge. A particular advantage of the invention is achieved by the inset planar surface completely covering the base end of the sparking tip and extending outwardly therefrom to provide an exposed peripheral interface whereby optional attachment methods, such as welds may be applied, if desired, about at least a portion of the exposed periphery of the base end. In addition, portions of the sparking tip may abut the inset back wall, upper surface of center electrode or both enabling attachment of the sparking tip to the points where it abuts these surfaces.

Owner:FEDERAL MOGUL WORLD WIDE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com