Patents

Literature

773results about How to "Prevent spontaneous combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

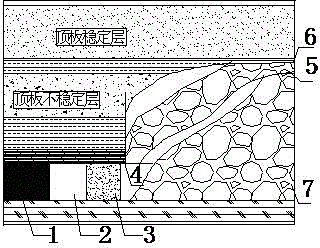

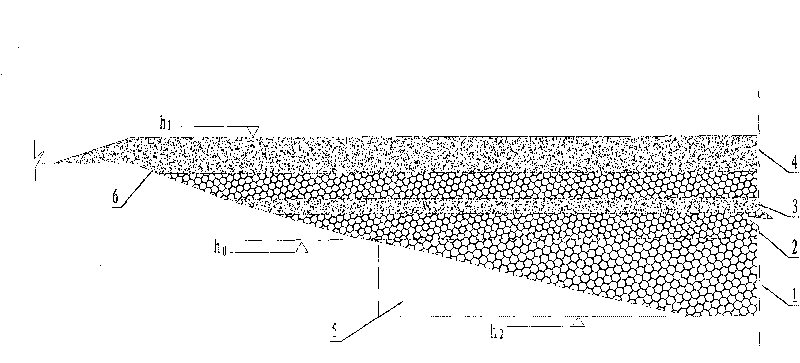

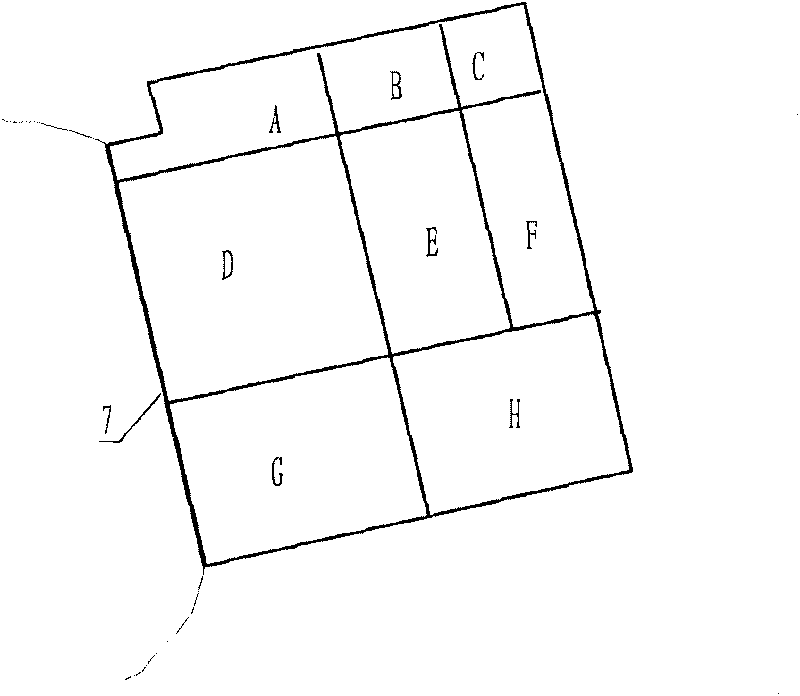

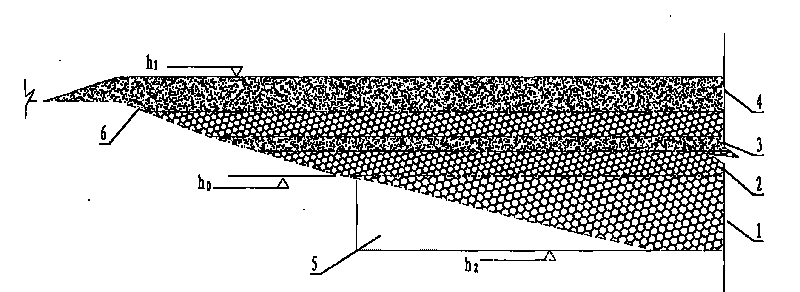

The roof caving and tunnel protecting method

InactiveCN101509395AHighlight substantiveReduce widthUnderground chambersMaterial fill-upMining engineeringFissure

The invention relates to a method for controlling caving and lane-guarding. The method is characterized in that in a working surface roadway, drilling, blasting or cracking are carried out on a roof of a coal seam of complete hard strata with large thickness of a hanging arch in a goaf; bursting or cutting off are carried out on a complete hard roof strata with large thickness to facilitate the hanging arch in the goaf to collapse at the back of a force piece; collapsed waste rock fills the goaf, supports superincumbent stratum in a fissure zone and releases high bearing stress passed into the coal body adjacent to the goaf from weight of the large-thickness complete hard strata of the hanging arch in the goaf and the superincumbent stratum in the fissure zone thereof, so that the bearing stress in the coal body adjacent to the goaf is reduced and laneways in the space are protected. The method of the invention fundamentally improves stability of surrounding rock of laneways adjacent to the goaf and increases coal mining rate of ends of thick coal seam caving coal working surface.

Owner:TAIYUAN UNIV OF TECH

Wet-lay flame barrier

InactiveUS20060068675A1Increase speedExtension of timeDomestic upholsteryLayered productsFiberGlass fiber

Nonwoven wet-lay flame barrier of the invention comprises a blend of water dispersible fibers, that are inherently fire resistant and nonshrinking to direct flame, along with water dispersible fibers extruded from polymers made with halogenated monomers and optionally including fiberglass and wood pulp, being together thermally bonded with a binder resin in a wet-lay manufacturing process to provide a relatively thin, but dense, durable flame barrier with excellent tensile, and durability properties in the end use application. The wet-lay flame barrier of this invention also allows for the manufacture of open flame resistant composite articles, while also permitting the continued use of conventional non-flame retardant dress cover fabrics, conventional non-flame retardant fiberfills and conventional non-flame retardant polyurethane foams.

Owner:HANDERMANN ALAN C +3

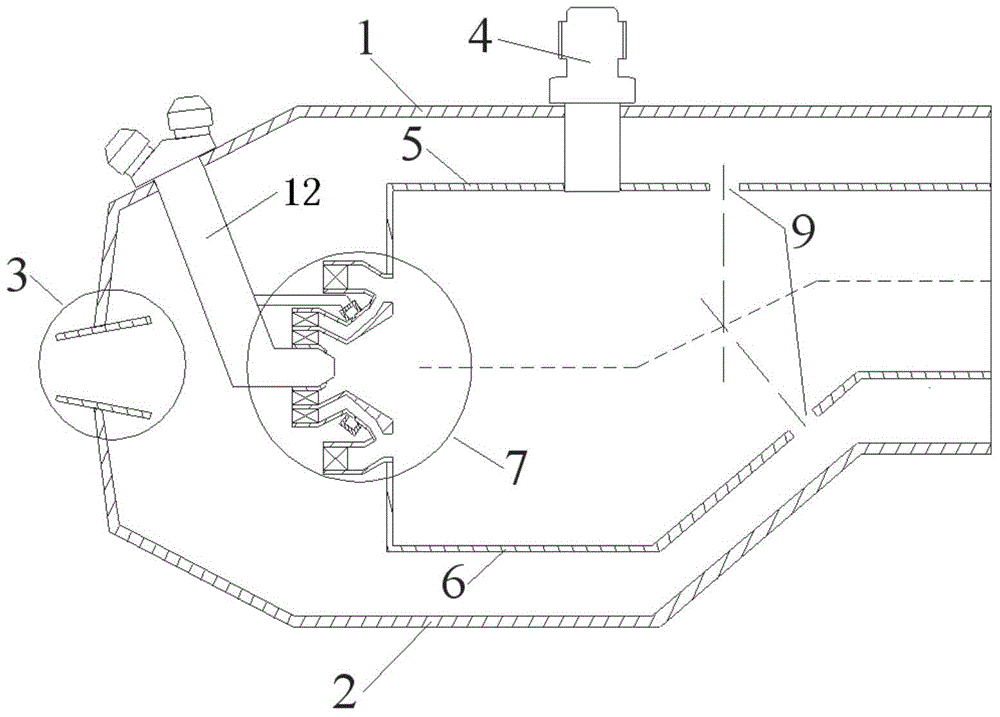

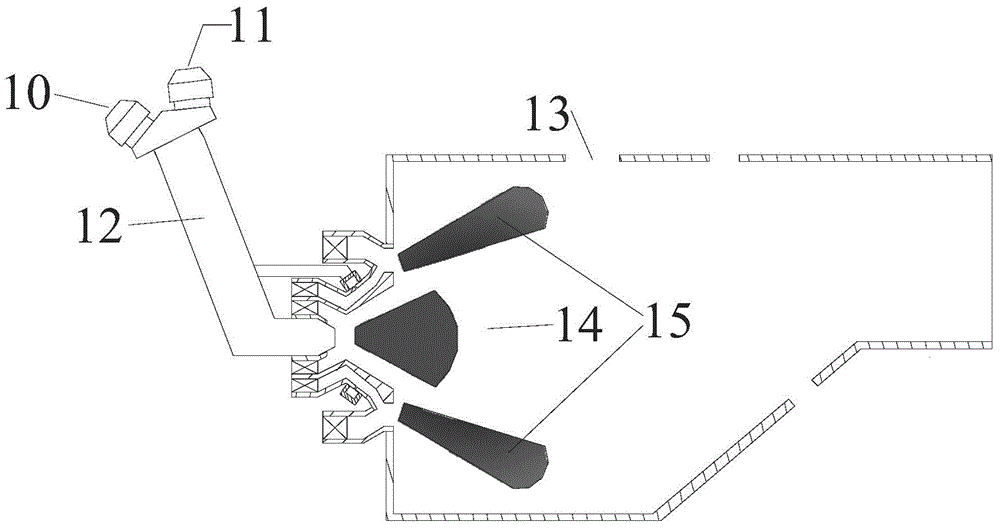

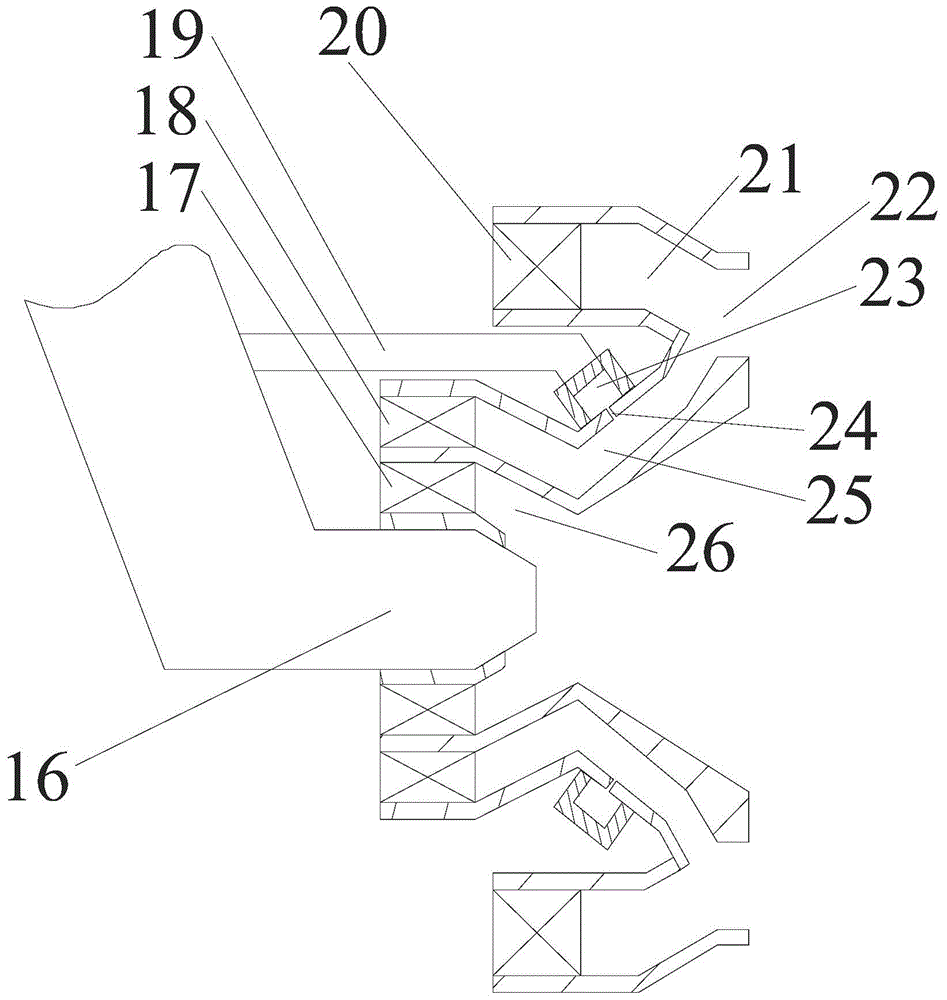

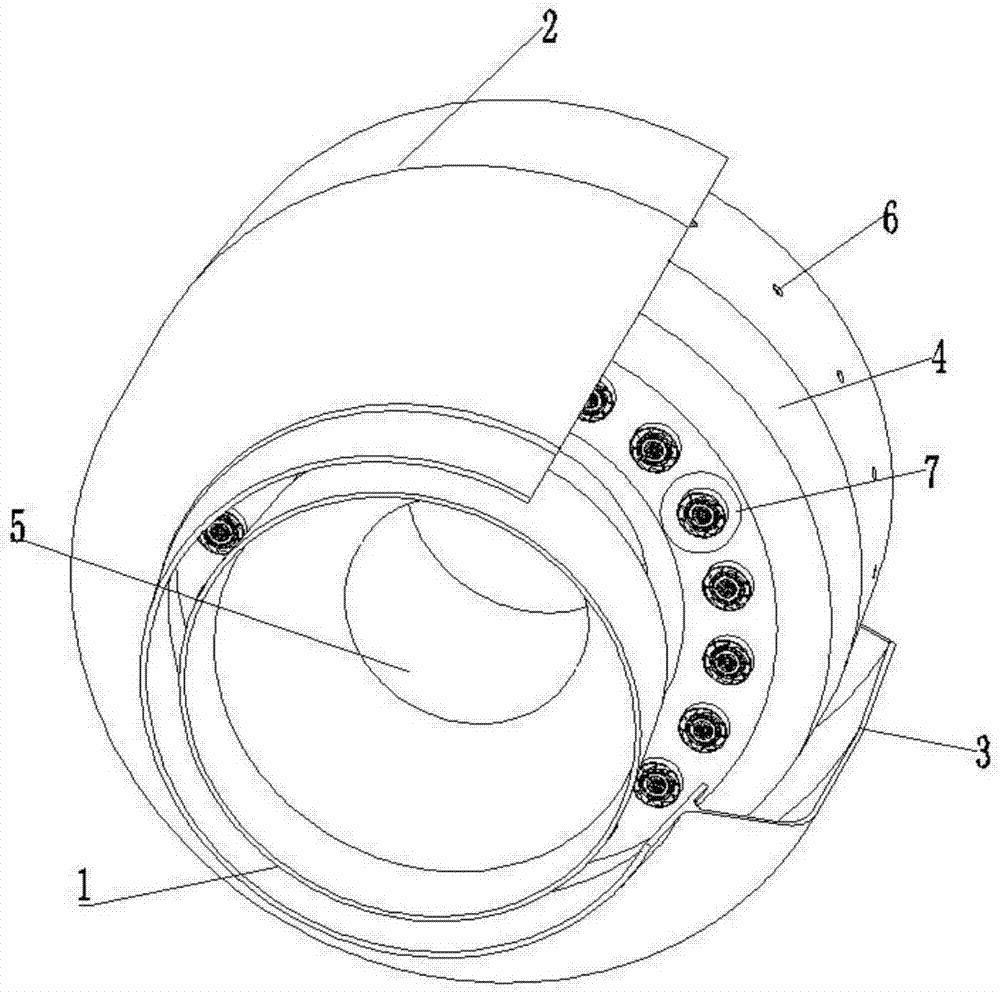

Layered part premixing low-pollution combustor of main combustion level lean oil premixing

ActiveCN104456628AImprove uniformityExtended service lifeContinuous combustion chamberCombustion chamberCoupling

The invention discloses a layered part premixing low-pollution combustor of main combustion level premixing and pre-evaporation. The layered part premixing low-pollution combustor has a pre-heating function. Fuel oil is divided into a main combustion level and an on-duty level. Diffusive combustion is adopted by the on-duty level, lean oil premixed combustion is adopted by the main combustion level, and the premixed combustion of a layered part is achieved through coupling of the diffusive combustion and the lean oil premixed combustion. The on-duty level is composed of a centrifugal atomizing nozzle and first level rotational flow air. The fuel oil of the main combustion level is supplied through multi-point direct-injection type nozzles, and oil and air mixing is enhanced through preheating of second level rotational flow air by combination of transverse jet air and on-duty level flame. The on-duty level is used in part-load conditions such as starting and slow operation, a stable combustion range can be broadened, combustion efficiency can be improved, and emission of CO and UHC is lowered; the on-duty level and the main combustion level work at the same time in the heavy load working condition, the on-duty level provides stable ignition sources for the main combustion level, a main combustion area is in a lean oil state, the temperature is far lower than the adiabatic flame temperature, and emission of NOx of high-load conditions can be reduced remarkably.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Slickened or siliconized flame resistant fiber blends

InactiveUS20060160454A1Extinguish any residual flameMinimal shrinkageDomestic upholsteryFibre treatmentFiberPolymer science

The invention relates to slickened or siliconized flame resistant fiber blends that are well suited for use in mattresses, boxsprings, upholstered furniture, fiber-filled bed clothing, transportation seating or any end use application where a soft materials are desired for flame resistant (FR) purposes. Some of the fibers in the blend are slickened. The FR fibers incorporated into these blends include both char forming FR fibers and oxygen depleting FR fibers. FR char-forming fibers are those which exhibit little shrinkage when exposed to direct flame and are not spun from polymers manufactured with halogenated monomers. Oxygen depleting FR fibers are spun from polymers manufactured with halogenated monomers.

Owner:BEIJING CARINAE MATERIAL TECH CO LTD

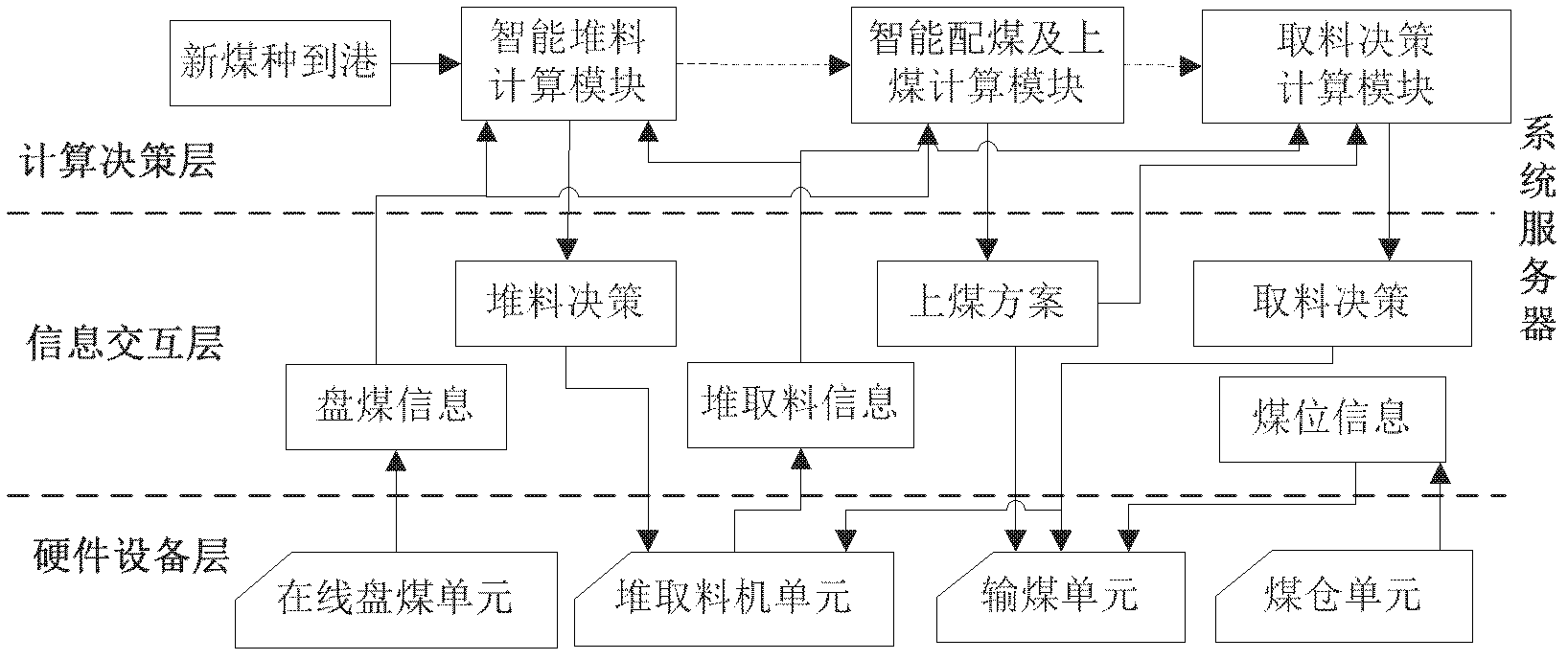

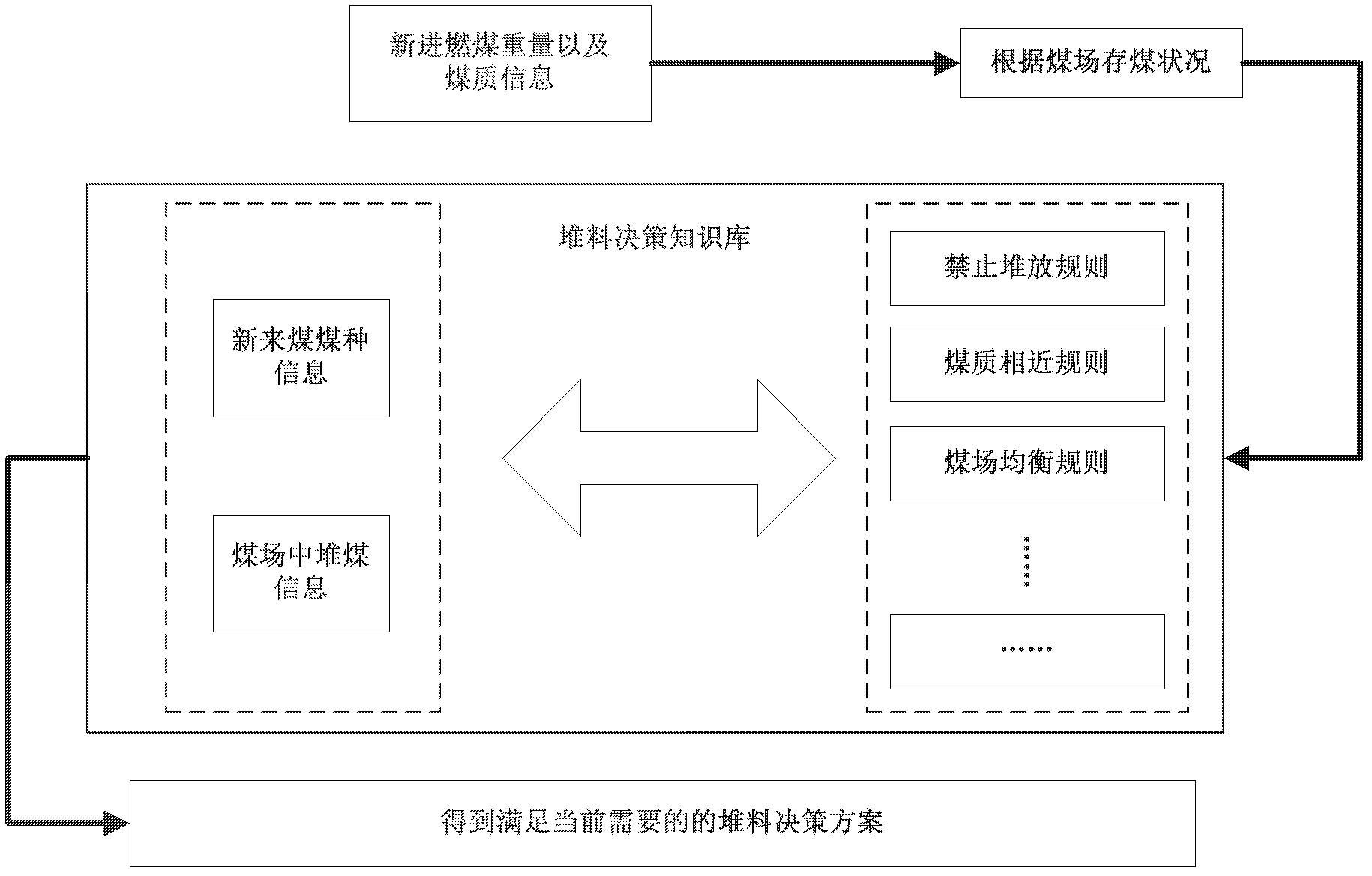

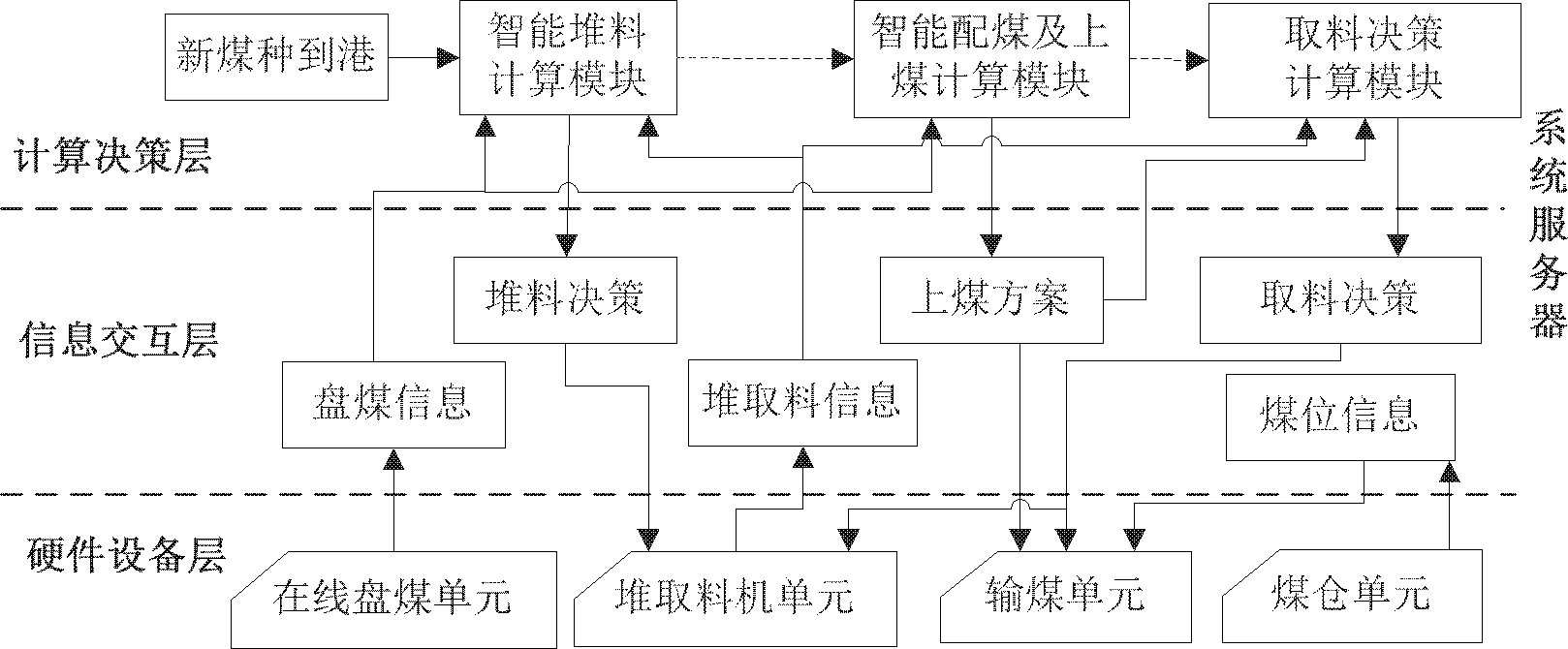

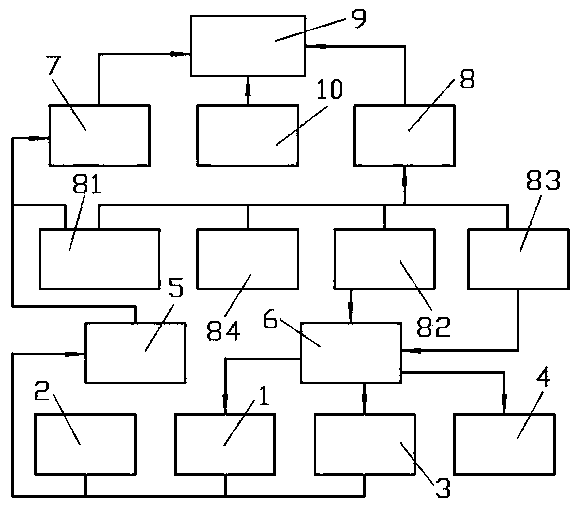

Intelligent fire coal scheduling system for thermal power plant

ActiveCN102541036AEnsure safetyPrevent spontaneous combustionTotal factory controlProgramme total factory controlProcess engineeringCoal

The invention provides an intelligent fire coal scheduling system for a thermal power plant. The system comprises an on-line coal inventory unit, a material piling and taking machine unit, a coal conveying unit, a coal bin unit and a system server, wherein the system server comprises an intelligent material piling calculation module, an intelligent coal distributing and feeding calculation module, and a material taking decision module; the intelligent material piling calculation module determines the optimal coal piling position to guide the material piling and taking machine unit to complete coal piling; the intelligent coal distributing and feeding calculation module is used for receiving coal inventory information of the on-line coal inventory unit and the real-time state of a boiler unit, determining a coal distribution scheme according to the coal inventory information and the real-time state of the boiler unit and further determining a coal feeding scheme according to boiler characteristics and the coal distribution scheme; and the material taking decision module determines a material taking path according to the coal inventory information and the coal feeding scheme to guide the material piling and taking machine unit and the coal conveying unit to cooperatively complete material taking. The fire coal of the thermal power plant is subjected to full-life cycle management and intelligent scheduling, and the boiler unit is ensured to have high safety, economy and environment friendliness under the condition of co-combustion.

Owner:HUAZHONG UNIV OF SCI & TECH

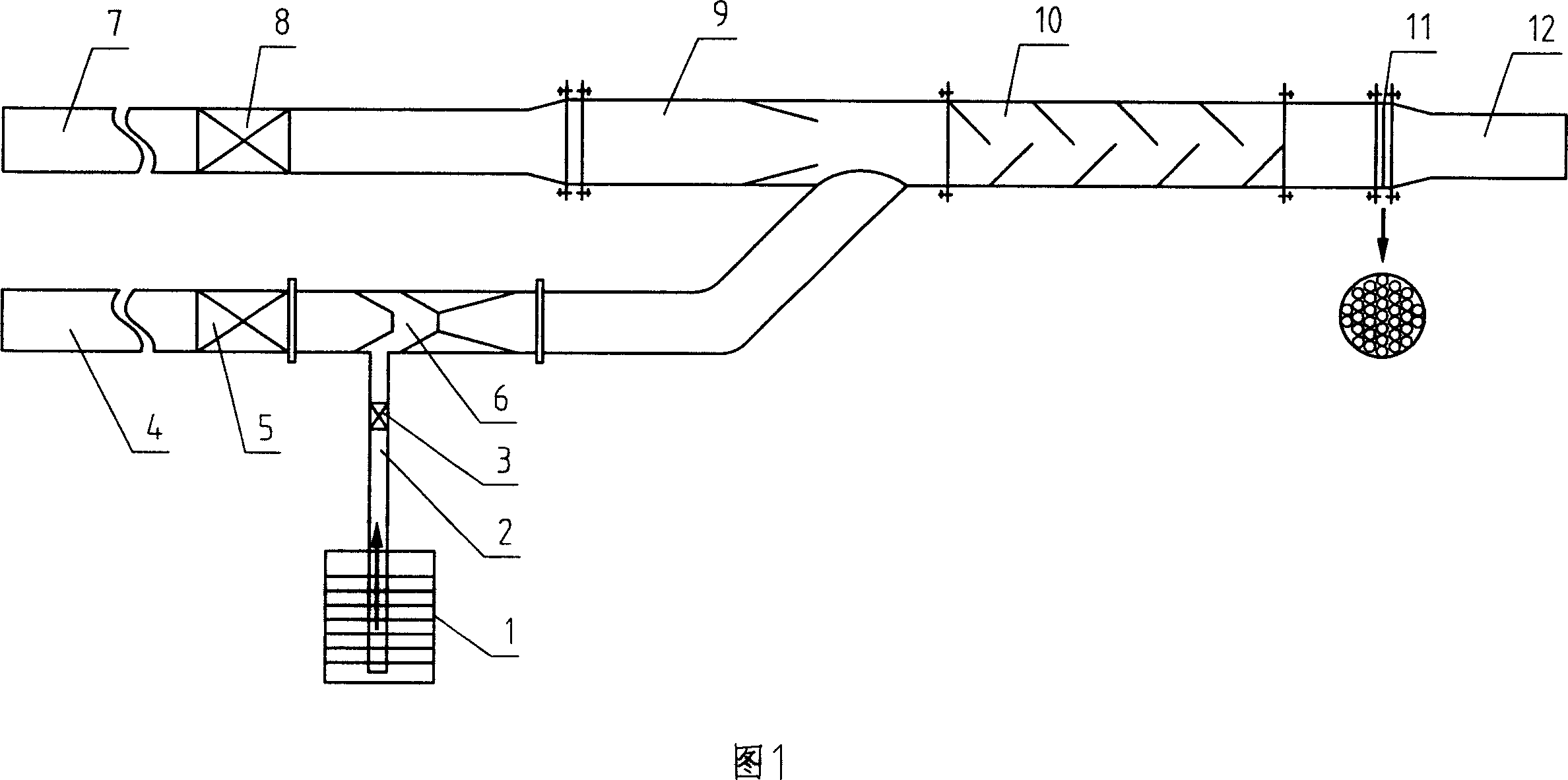

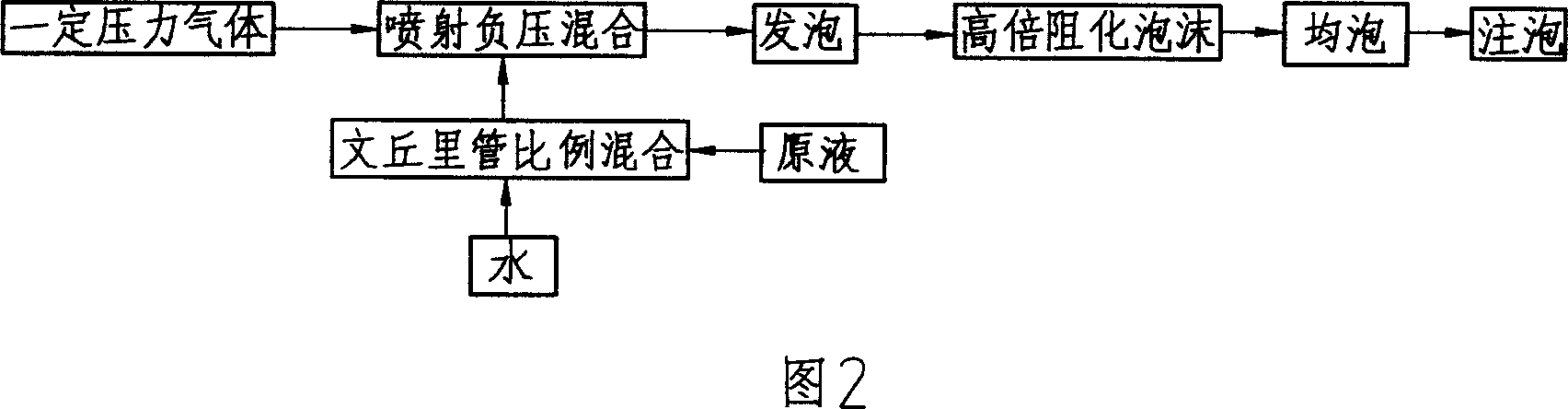

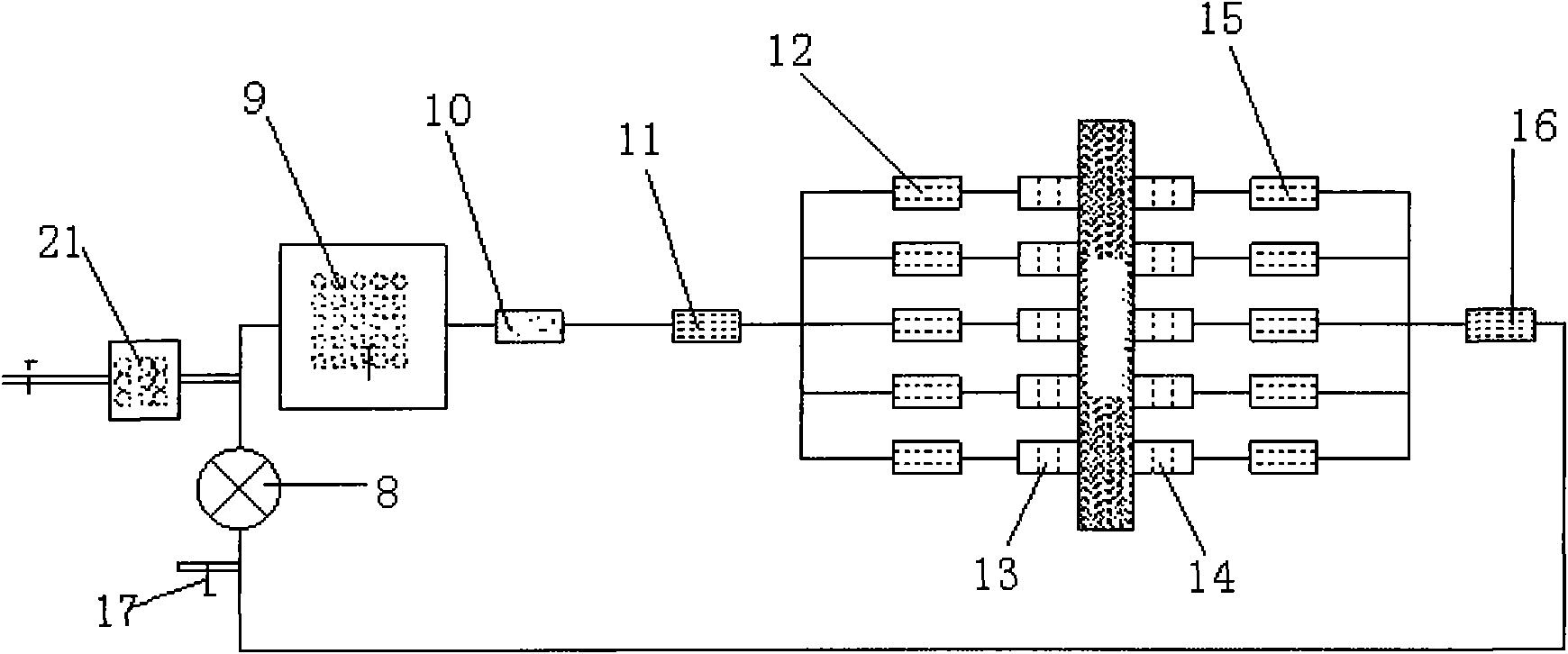

High power inhibition foam for preventing and controlling coal self-ignition and generating device thereof

The present invention provides a high power inhibition foam capable of preventing and controlling coal self-combustion and its generation equipment. It is characterized by that the pressure water flow is mixed with high power inhibition foam raw liquor according to a certain ratio, then their mixture is fed into a spray mixer under the action of negative pressure formed by water pressure and gas with a certain pressure in sprayer, and the gas, water and high power inhibition foam raw liquor can be fed into a foaming device by means of spraying mode under the gas pressure so as to make foam formation. Said foam can be used for covering coal body, and can be used for preventing coal self-combustion.

Owner:CHINA COAL TECH ENG GRP CHONGQING RES INST

Coal-fired power plant coal yard refined management system and control method thereof

ActiveCN103455901AFast and accurate deliveryAccurate accessSystems intergating technologiesLogisticsInformatizationData acquisition

The invention relates to a coal-fired power plant coal yard refined management system and a control method of the coal-fired power plant coal yard refined management system. The coal-fired power plant coal yard refined management system is characterized by comprising a laser disc coal instrument, an intelligent temperature monitoring meter, a metering device, a stacker-reclaimer, a data acquisition unit, a controller, a data server, an application server and a computer client side. The application server comprises a coal database management module, a real-time stock management module, a coal storage management module and a heat loss evaluation and control module. The control method is characterized by including the following steps that coal pile outline data points and digital signs in a coal yard field are acquired according to the laser disc coal instrument, and three-dimensional reconstruction of coal piles is completed based on a VC++ and OpenGL platform; when coal is transported to a factory, information is input to the coal database management module through an input port in the computer client side. According to the coal-fired power plant coal yard refined management system and the control method, the informatization and intelligentization method is adopted, information is quickly and accurately transmitted, and coal heat loss is reduced.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

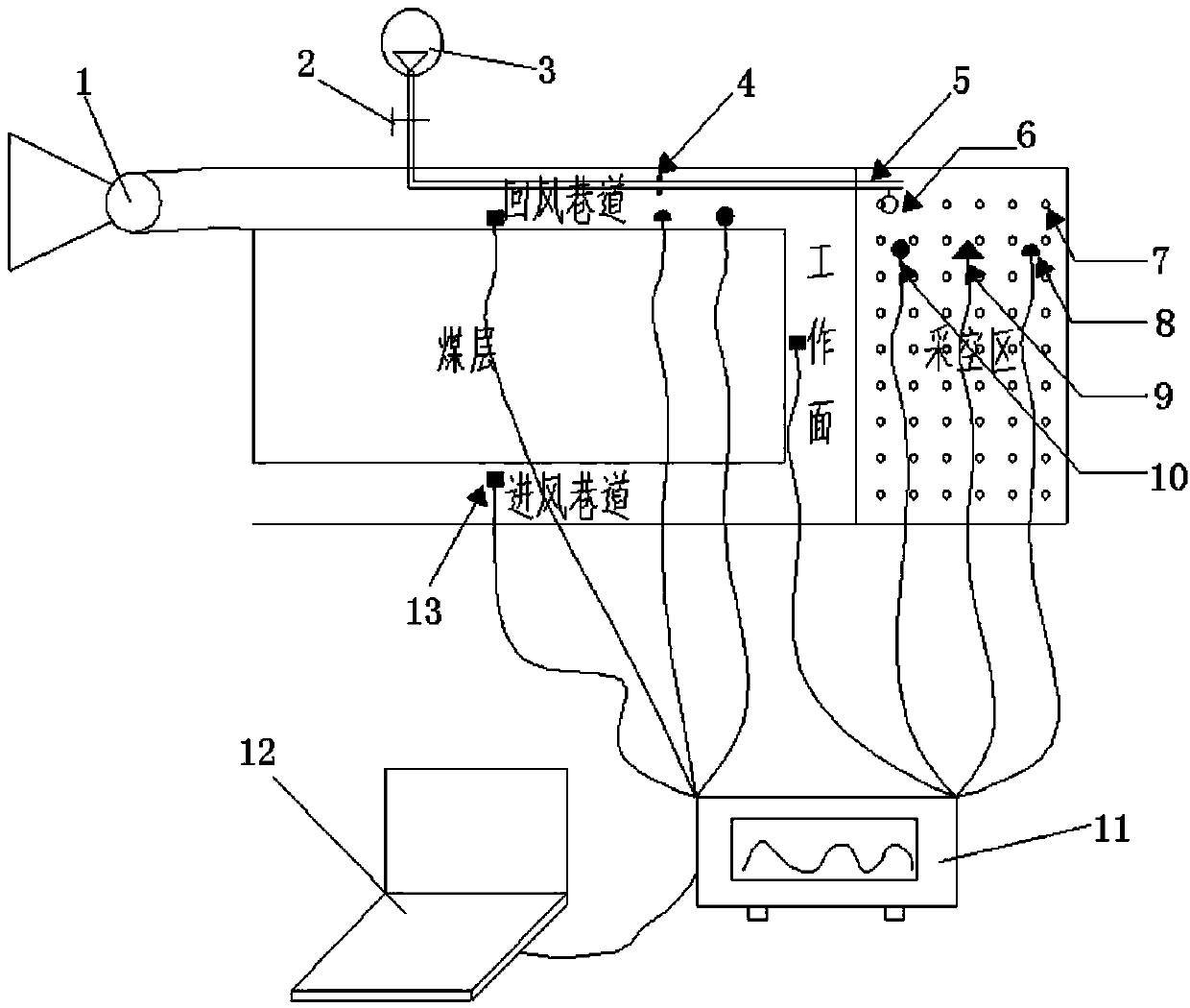

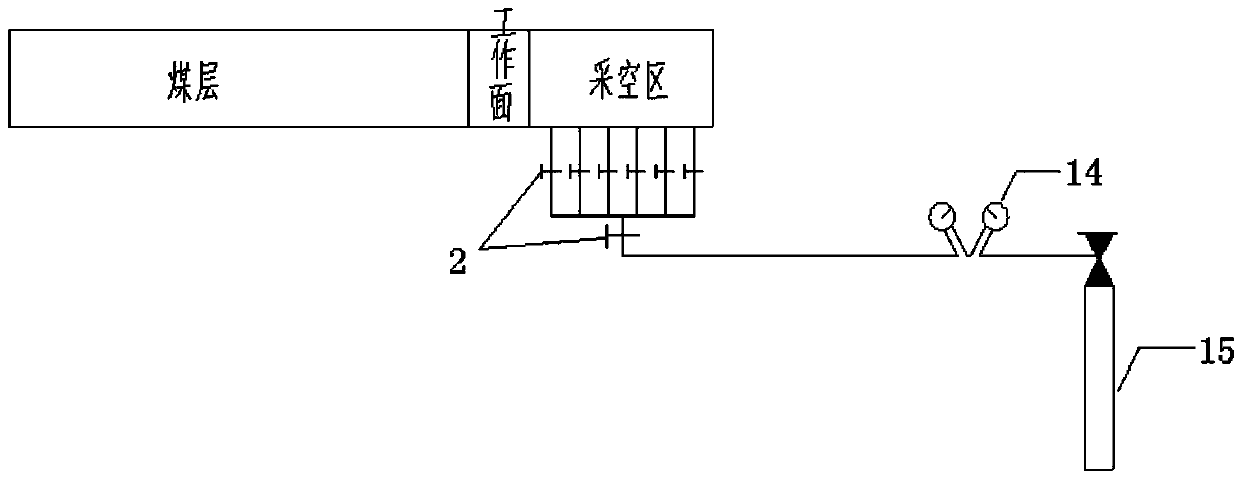

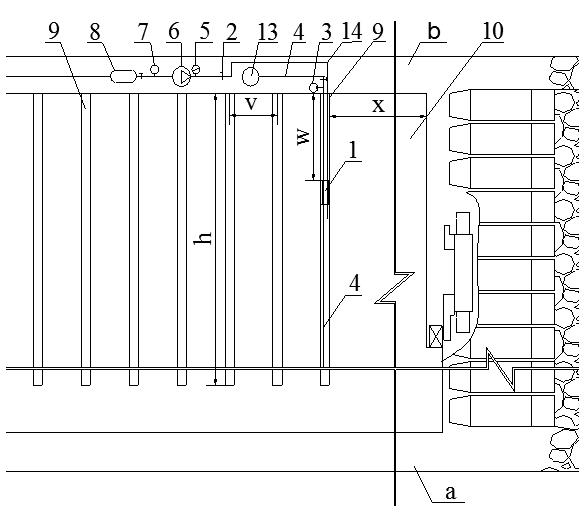

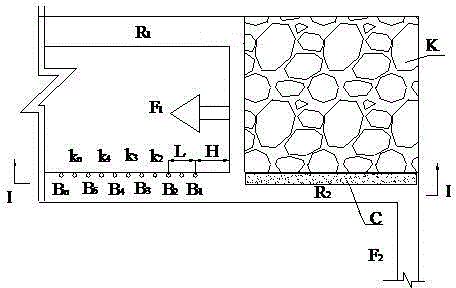

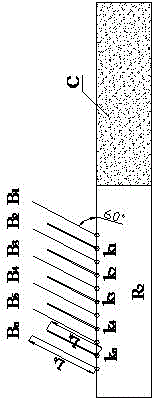

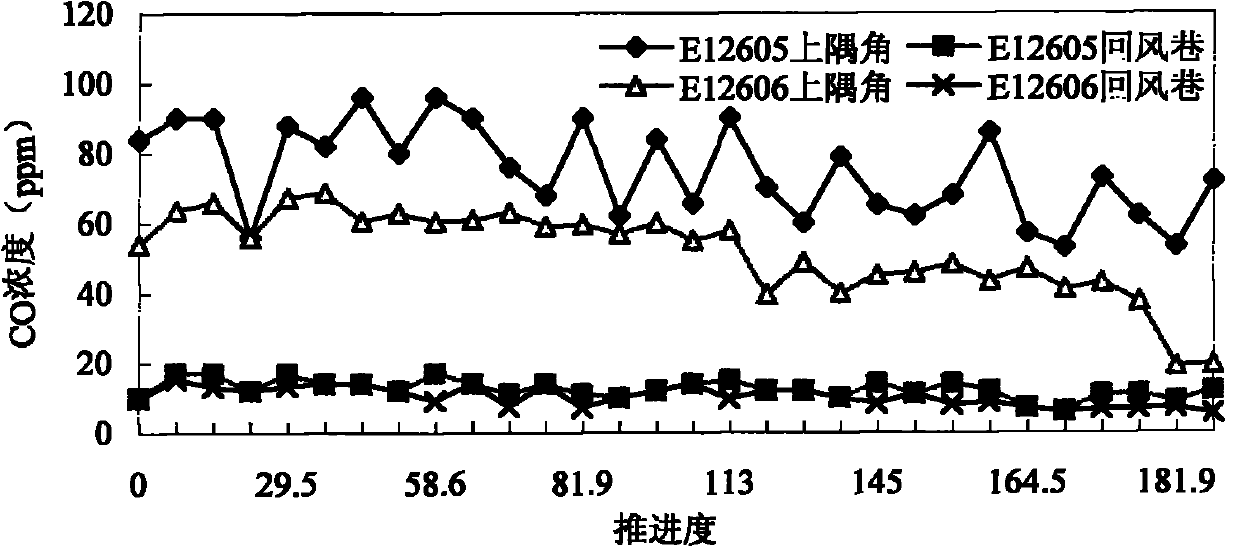

Simulation experiment device of gas extraction and coal spontaneous combustion of spontaneous combustion-prone and high gas concentration coal seam goaf

InactiveCN103775122APrevent spontaneous combustionPrevent gas overrun problemTunnel/mines ventillationGas removalProcess engineeringData acquisition module

The invention discloses a simulation experiment device of gas extraction and coal spontaneous combustion of a spontaneous combustion-prone and high gas concentration coal seam goaf. The simulation experiment device of the gas extraction and the coal spontaneous combustion of the spontaneous combustion-prone and high gas concentration coal seam goaf comprises a U-shaped working surface coal mining system, a ventilation system, a gas system, an extraction system, a data test and acquisition system. The U-shaped working surface coal mining system comprises an air inlet roadway, an air return roadway, a working surface and a goaf. The ventilation system comprises an exhaust ventilator and an accessory of the exhaust ventilator. The gas system comprises a gas bottle, a valve, a pressure gauge and a gas feeding pipe. The extraction system comprises a gas drainage pump, a gas drainage pipe, a valve, a flowmeter and a negative pressure sensor. The data test and acquisition system comprises an air velocity sensor, a gas concentration sensor, a temperature sensor, a co sensor, a data acquisition module, an IPC (Industrial Personal Computer) and the like. The simulation experiment device of the gas extraction and the coal spontaneous combustion of the spontaneous combustion-prone and high gas concentration coal seam goaf can truly simulate the relation between the gas extraction and the coal spontaneous combustion of the spontaneous combustion-prone and high gas concentration coal seam goaf to achieve the simultaneous testing of gas drainage and coal spontaneous combustion.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

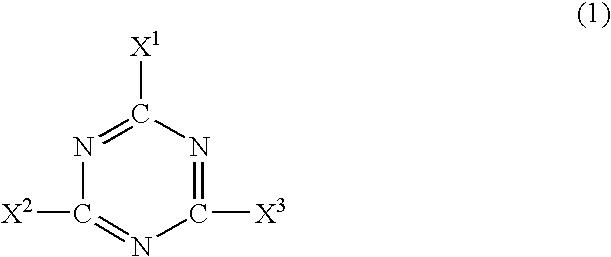

Chemical fire retartant for preventing controlling coil mineral well coal self-igniting

ActiveCN100999996AReduced propensity to spontaneous combustionPrevent spontaneous combustionDust removalFire preventionPolymer resinCombustion

The present invention discloses one kind of chemical inhibitor for preventing and controlling the self combination of coal in coal mine. The chemical inhibitor is water solution of pH 3-5 and comprising surfactant in 0.5-1 wt%, polymer resin in 0.1 wt% and oxidant in certain concentration. During coal mining, water is injected to the coal bed, and the chemical inhibitor is spread to the residual coal and other easy-to-fire areas alone or after being mixed to other fire extinguishing material. The chemical inhibitor makes the different active structural radicals in coal body oxidized irreversibly to lose low temperature oxidation activity and lower the self combustion tendency of coal to avoid self combustion of coal completely. The present invention is simple, low in cost and suitable for coal mine operation.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

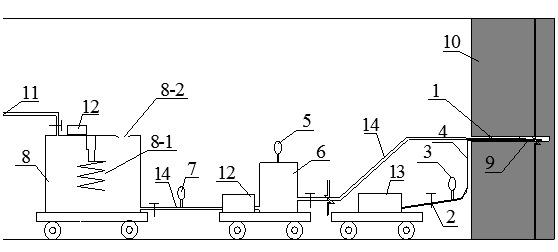

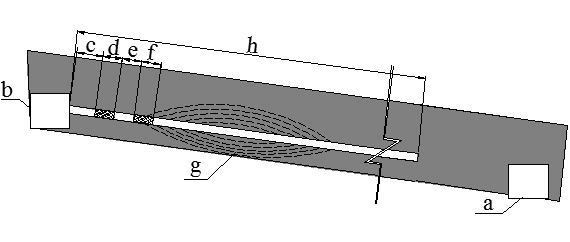

Hydrofracturing-based method and equipment for diminishing dust and eliminating outburst of coal bed

The invention discloses a hydrofracturing-based method and hydrofracturing-based equipment for diminishing dust and eliminating outburst of a coal bed. The method comprises the following steps of: firstly, drilling a long hole towards a working surface in a return airway of the coal-excavating working surface, sealing the hole with a hole sealer for hydrofracturing and forming a hydrofractured seam in the coal rock body; secondly, adding sand into a sand mixer and conveying the mixed fluid of water and sand into the hydrofractured seam by using a mud sand pump, wherein thin sand is added first and then thick sand is added; thirdly, connecting a mash gas extracting pipeline to the hydrofractured hole, draining water through negative pressure and extracting mash gas; and finally, removing the mash gas extracting pipeline from the hole sealer, and connecting a static-pressure water-injecting pipeline for performing static-pressure water injection into the coal bed after the hydrofracturing and the mash gas extraction and stopping water injection till the water flows to the position 3 to 5m ahead of the coal wall of the working surface. By employing the expansion of the main hydrofractured seam of the coal bed, the expansion of wing-shaped branched seams and the soaking effect of the absorbed water, the structure of the coal bed is changed, the strength of the coal bed is weakened and the permeability of the coal bed is improved, so the aims of weakening the strength of the coal bed, increasing the permeability of the coal bed, eliminating the outburst and diminishing the dust are achieved.

Owner:CHINA UNIV OF MINING & TECH

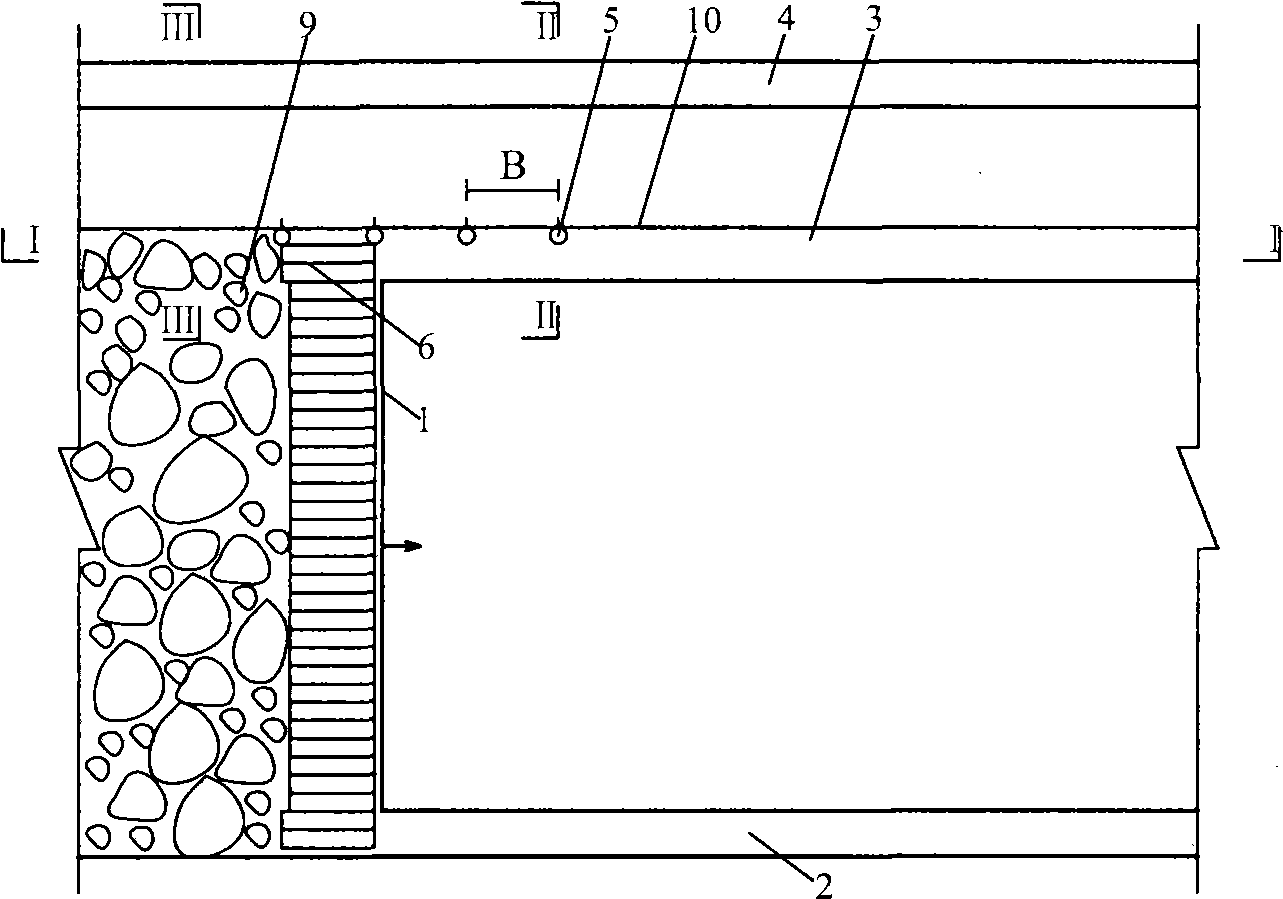

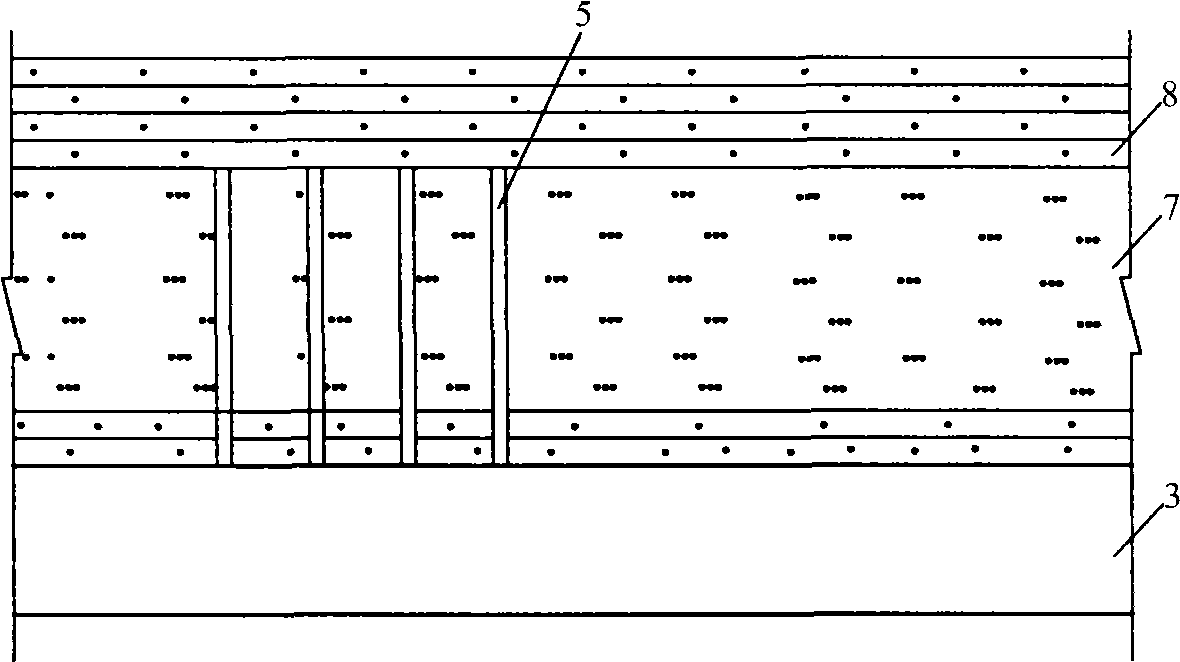

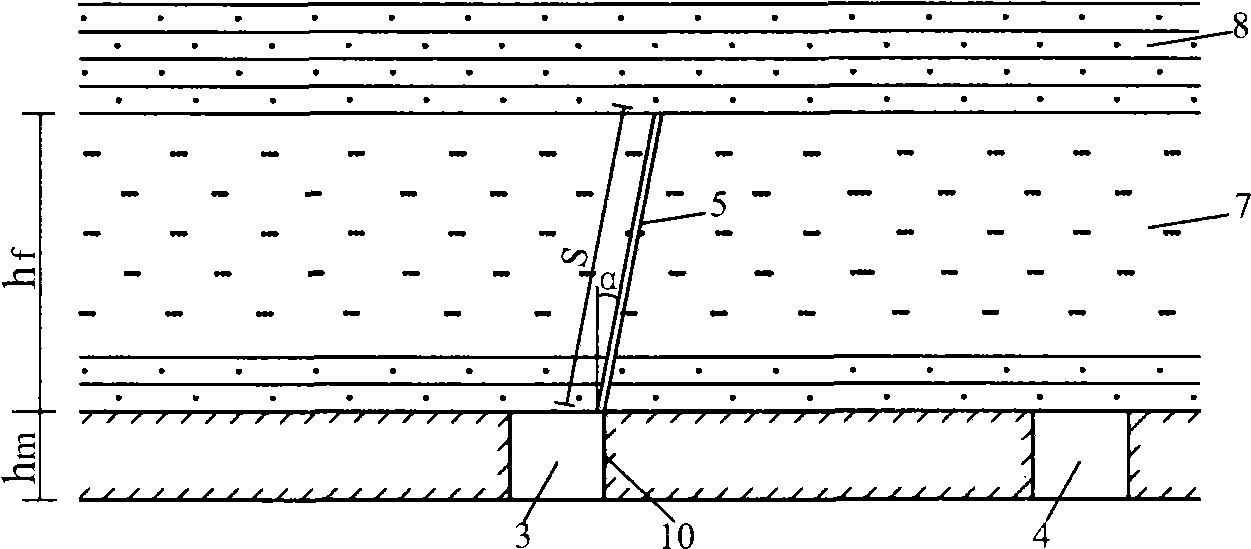

Roadside packing gob-side entry retaining top-cutting explosion pressure relief method

InactiveCN104790954ARelieve pressureEliminate problems such as support difficultiesUnderground miningSurface miningStructural engineeringDeep hole

The invention discloses a roadside packing gob-side entry retaining top-cutting explosion pressure relief method which comprises the following four steps: I, confirming a top-cutting method, the drilling construction time and a drilling construction site; II, confirming top-cutting pressure relief explosion drilling parameters; III, drilling deep-hole explosion holes and explosive filling and sealing holes; IV, performing explosion top-cutting pressure relief. The roadside packing gob-side entry retaining top-cutting explosion pressure relief method is applied to roadside packing gob-side entry retaining top-cutting explosion pressure relief.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Filling-reclaiming method for building land in coal mining subsidence areas

InactiveCN101713291AEase the growing tensionSave the occupied landUnderground miningSurface miningSpontaneous combustionPorosity

The invention provides a filling-reclaiming method for building land in coal mining subsidence areas, which belongs to the technical field of mining and is used to solve the problem of developing and utilizing coal gangue. The invention adopts a technical scheme that the method is implemented according to the following steps: a, draining accumulated water in reclamation areas and clearing silt; b, striping and stockpiling surface soil; c, determining the thickness and density of coal gangue for hierarchical backfilling through a vibration pressure test; and d, performing hierarchical backfilling compaction on the coal gangue and soil. The method has the following main advantages that: 1, the ways of utilizing the coal gangue are expanded, and environmental pollution caused by stockpiling the coal gangue on ground is reduced; 2, the situation that building land is increasingly short is alleviated by reclaiming subsidence land to be the building land; and 3, the treatment for coal gangue for large-area hierarchical backfilling by a hierarchical vibration-compaction method is economical, reasonable and ideal in compaction effect, can improve the compactness and bearing capacity of coal gangue layers, and can prevent the spontaneous combustion or efflorescence of coal gangue foundations and the separation of harmful substances from polluting local environment because hierarchical compaction greatly reduces porosity and isolates air.

Owner:煤炭科学研究总院唐山研究院

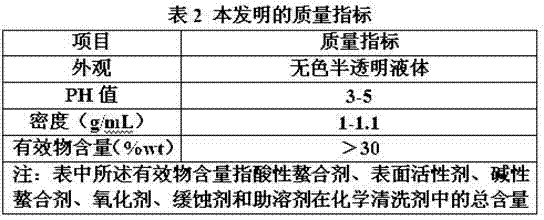

Chemical cleaning agent for clearing impurities such as ferrous sulfide

InactiveCN102345136AEasy to cleanPrevent spontaneous combustionNon toxicitySODIUM DODECYL BENZENE SULFONATE

The invention relates to a chemical cleaning agent for clearing impurities such as ferrous sulfide, which is made of the following raw materials in percentage by weight: 1-15% of acidic chelating agent, 0.05-5% of surfactant, 1-20% of alkaline chelating agent, 5-30% of oxidant, 0.1-1% of corrosion inhibitor, 0.1-2% of cosolvent and the balance of water; the acidic chelating agent is preferably selected from citric acid; the surfactant is preferably selected from sodium dodecyl benzene sulfonate; the alkaline chelating agent is preferably selected from ammonia or disodium ethylene diaminetetraacetate; the oxidant is preferably selected from hydrogen peroxide; the corrosion inhibitor is preferably selected from polybasic phosphate (A ester); and the cosolvent is preferably selected from benzoic acid or sodium benzoate. The invention has the beneficial effects of effectively clearing dirt such as ferrous sulfide in devices at normal temperatures and avoiding the spontaneous combustion of the ferrous sulfide and has the characteristics of low cost, large dirt clearing amount, good dirt clearing effect, non-toxicity, safety, simple and convenient operation, and the like.

Owner:NINGBO ZHONGYI PETROCHEM TECH

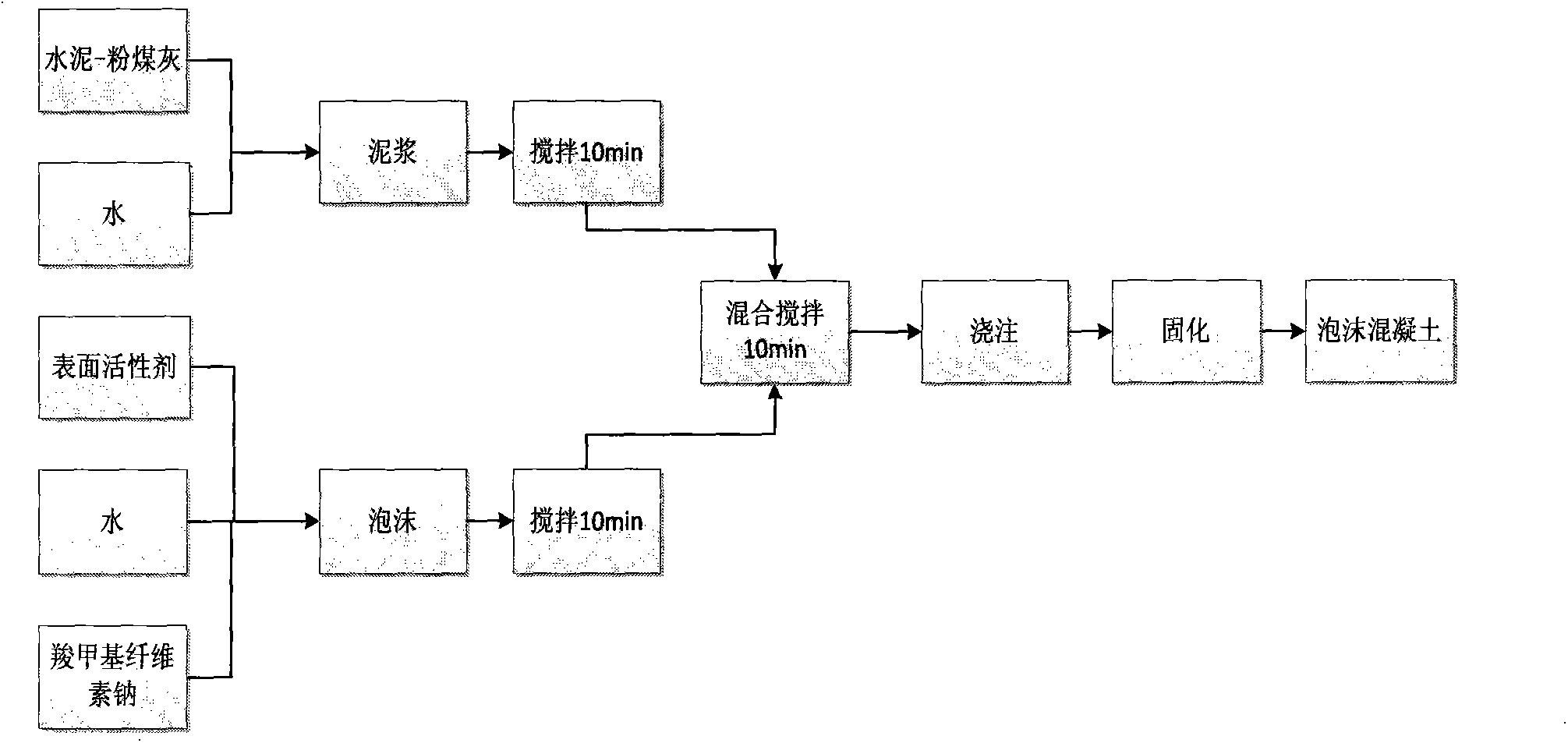

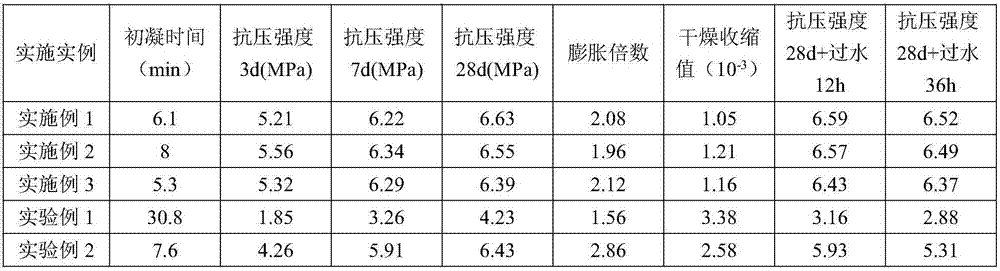

Pulverized fuel ash-cement foam material for controlling spontaneous combustion of coal and preparation method of pulverized fuel ash-cement foam material

ActiveCN103964766APrevent spontaneous combustionLow costCeramicwareSpontaneous combustionPulverized fuel ash

The invention discloses a pulverized fuel ash-cement foam material for controlling the spontaneous combustion of coal and a preparation method of the pulverized fuel ash-cement foam material. The pulverized fuel ash-cement foam material is prepared from the following components by weight: 10-40 % of sulfoaluminate superfine cement, 10-40 % of pulverized fuel ash, 0.5-0.9 % of carboxymethyl cellulose, 0.1-0.6 % of sodium fluoride, 0.2-0.6 % of melamine, 0.1-0.4 % of aluminum sulfate, 0.3-0.6 % of lauryl sodium sulfate, 0.4-0.6 % of sodium dodecyl benzene sulfonate, 0.5-0.8 % of saponin and the balance of water. The foam material is high in expansion rate of foam, long in stabilizing time, low in rate of water loss, good in plugging performance, and very suitable for extinguishment underground a coal mine. The pulverized fuel ash-cement foam material has the advantages of being low in cost, good in plugging performance, high in strength, simple to construct and the like.

Owner:胡相明

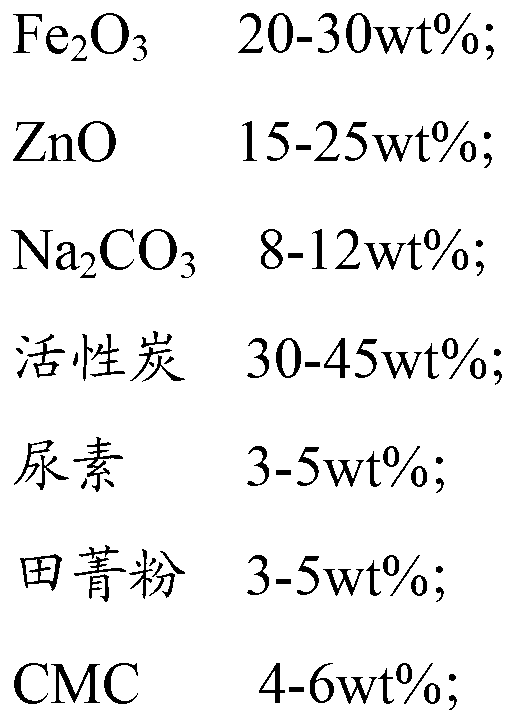

Inorganic salt type inhibitor for preventing and controlling spontaneous combustion of residual coal in goaf of coal mine

InactiveCN101766877AAvoid contactStop spontaneous combustionDust removalFire preventionSpontaneous combustionSodium bicarbonate

The invention discloses an inorganic salt type inhibitor for preventing and controlling spontaneous combustion of residual coal in a goaf of a coal mine, which belongs to the field of fire prevention and extinguishment in the goaf of the coal mine. The inorganic salt type inhibitor consists of sodium bicarbonate, calcium bicarbonate, calcium chloride, magnesium chloride, sodium chloride and zinc chloride according to a certain proportion by weight. The average inhibiting rate of the inorganic salt type inhibitor can achieve 85%, and the inhibiting effect is ideal. When in use, the inhibitor is covered on the surface of the residual coal in the goaf, thereby achieving the effects of preventing and controlling the spontaneous combustion of a coal layer in the region for a long time. The dusting method of the inorganic salt type inhibitor for fire prevention and extinguishment is safe and stable, the process flow is simple, the operation is convenient, the initial investment is low, and the using cost is relatively low. The fire prevention and extinguishment technology of the inorganic salt type inhibitor which has thermal instability and can release inert gas carbon dioxide has broad application prospects in the work of preventing and controlling the spontaneous combustion fire disasters of the coal layers. The inorganic salt type inhibitor is applicable to the fire prevention and extinguishment in the goaf of the coal mine.

Owner:UNIV OF SCI & TECH BEIJING

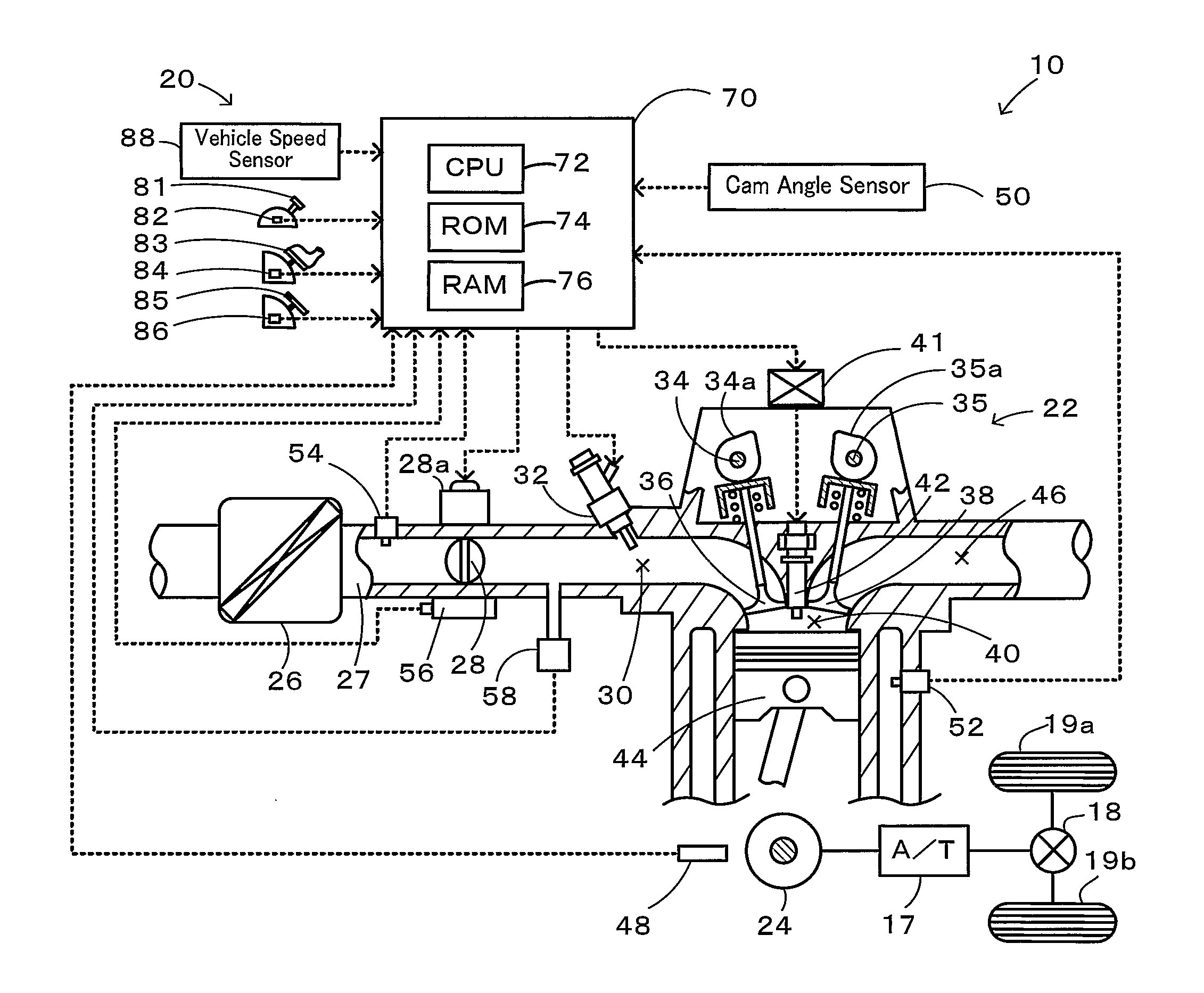

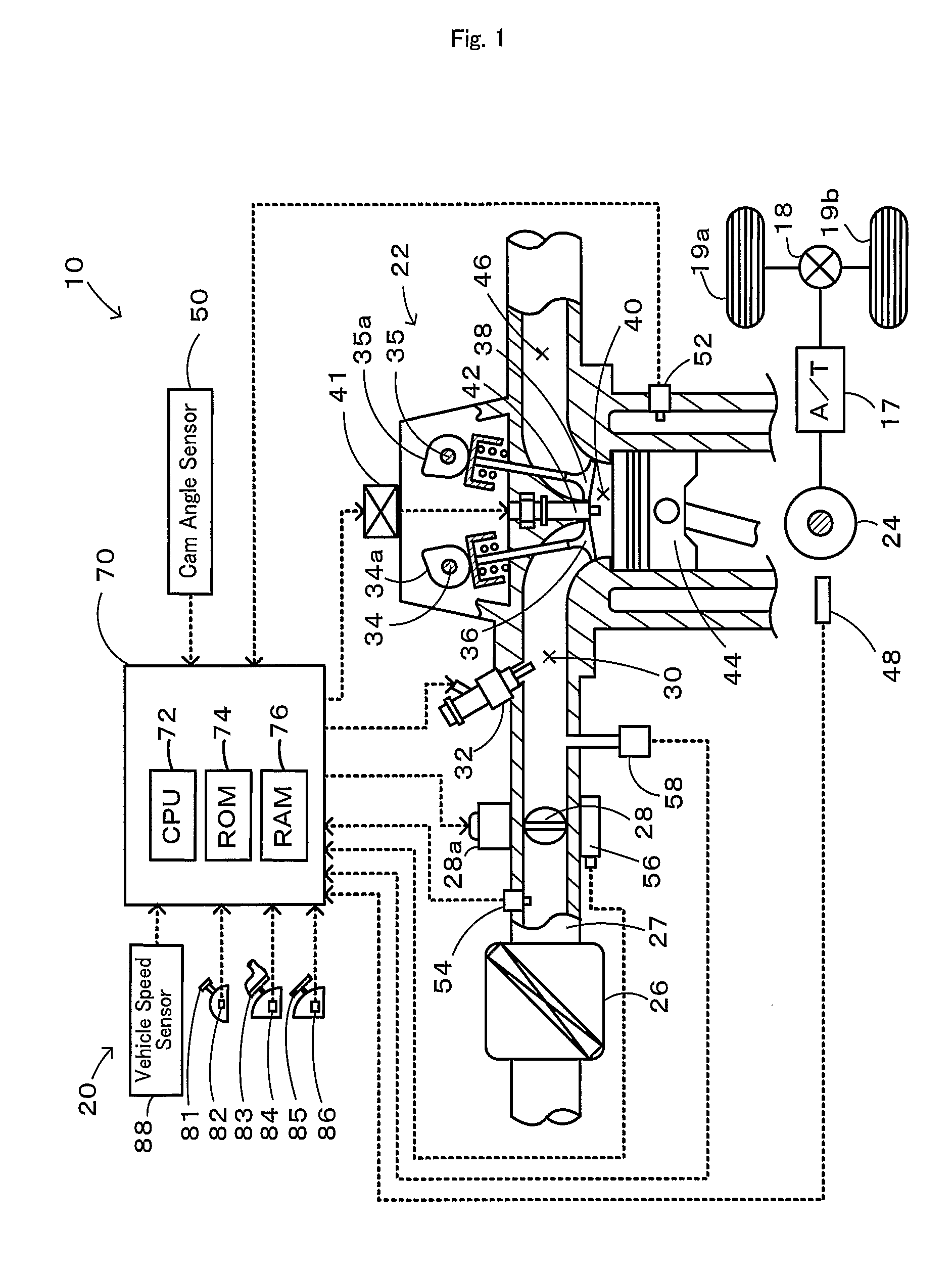

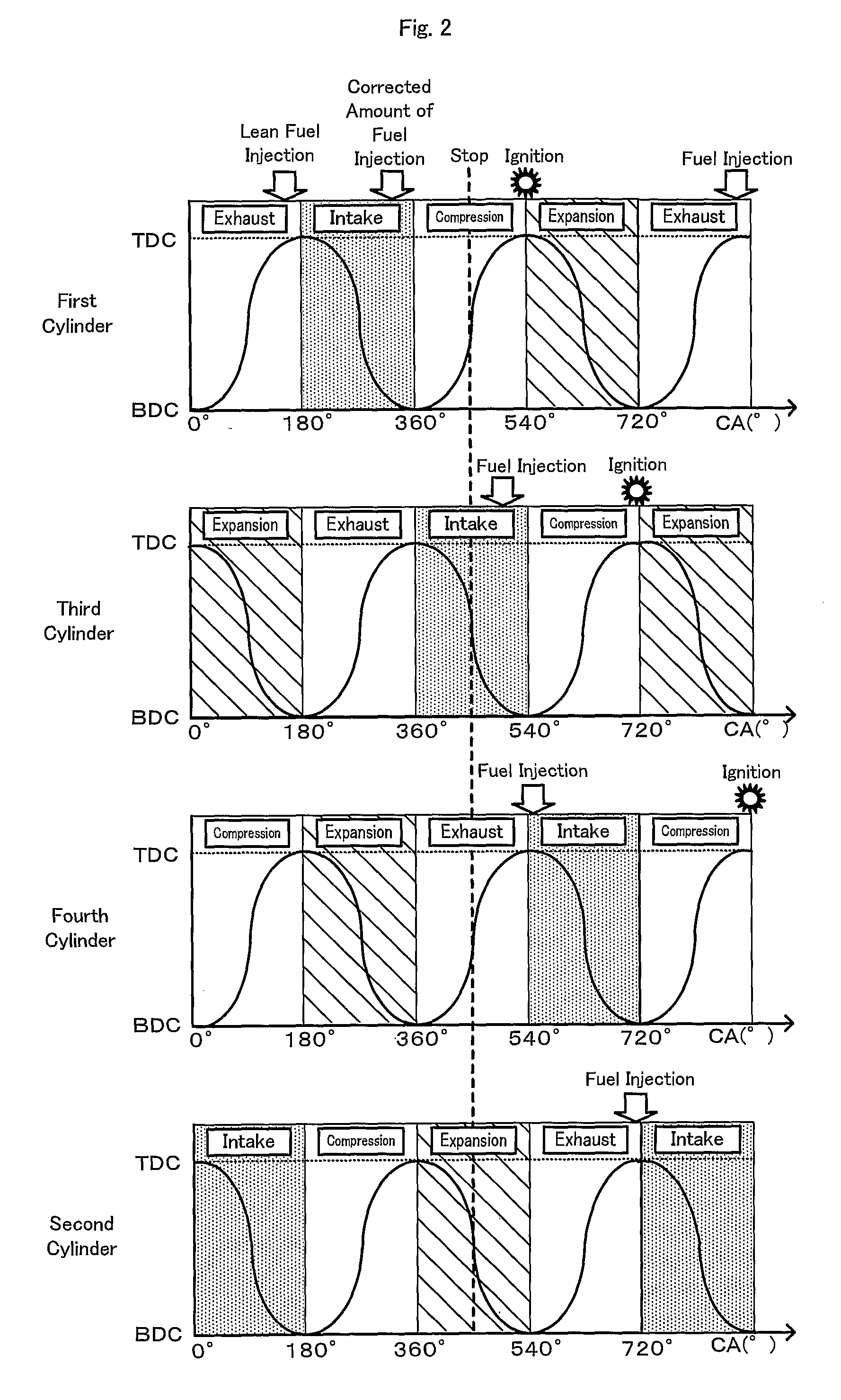

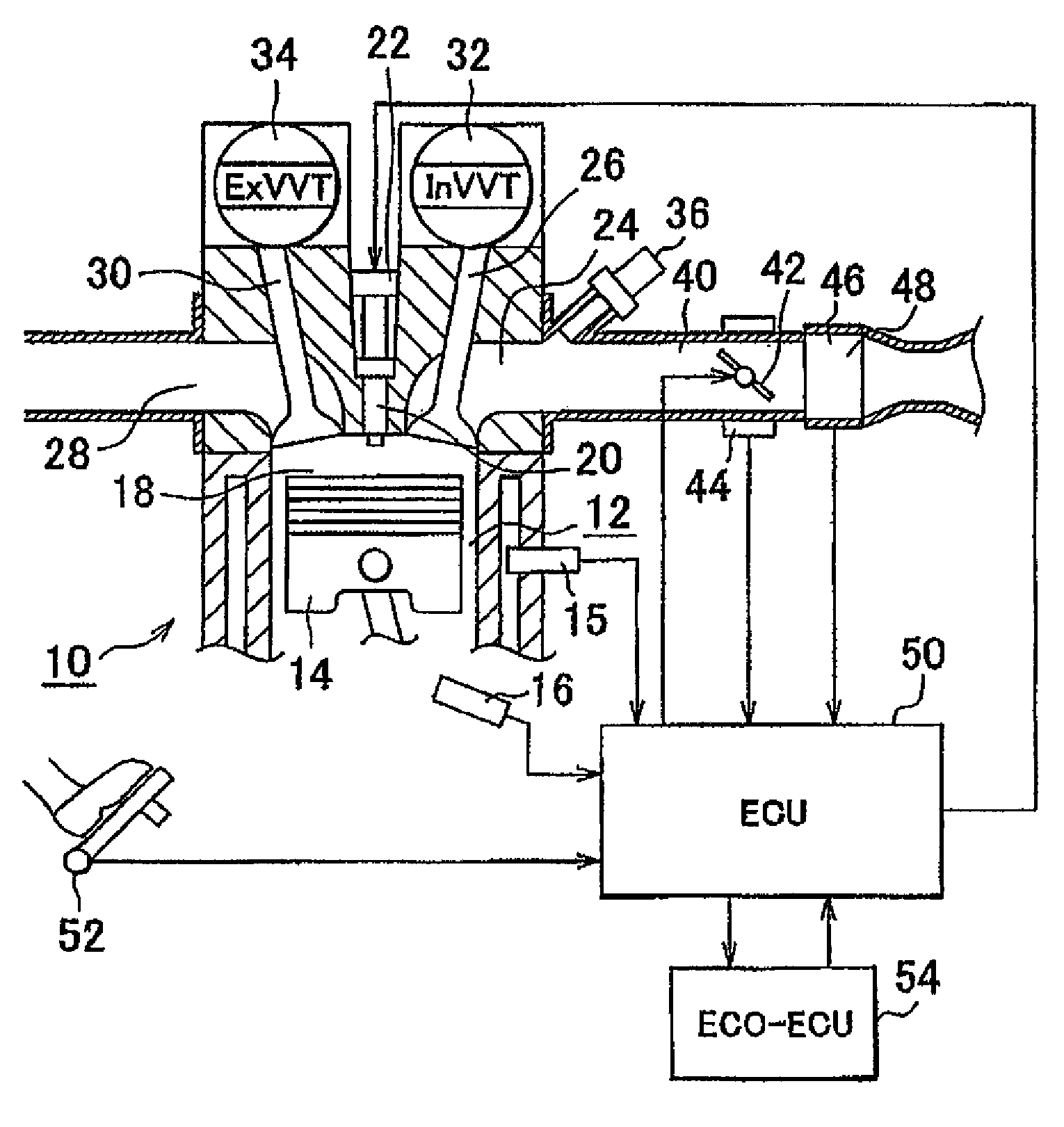

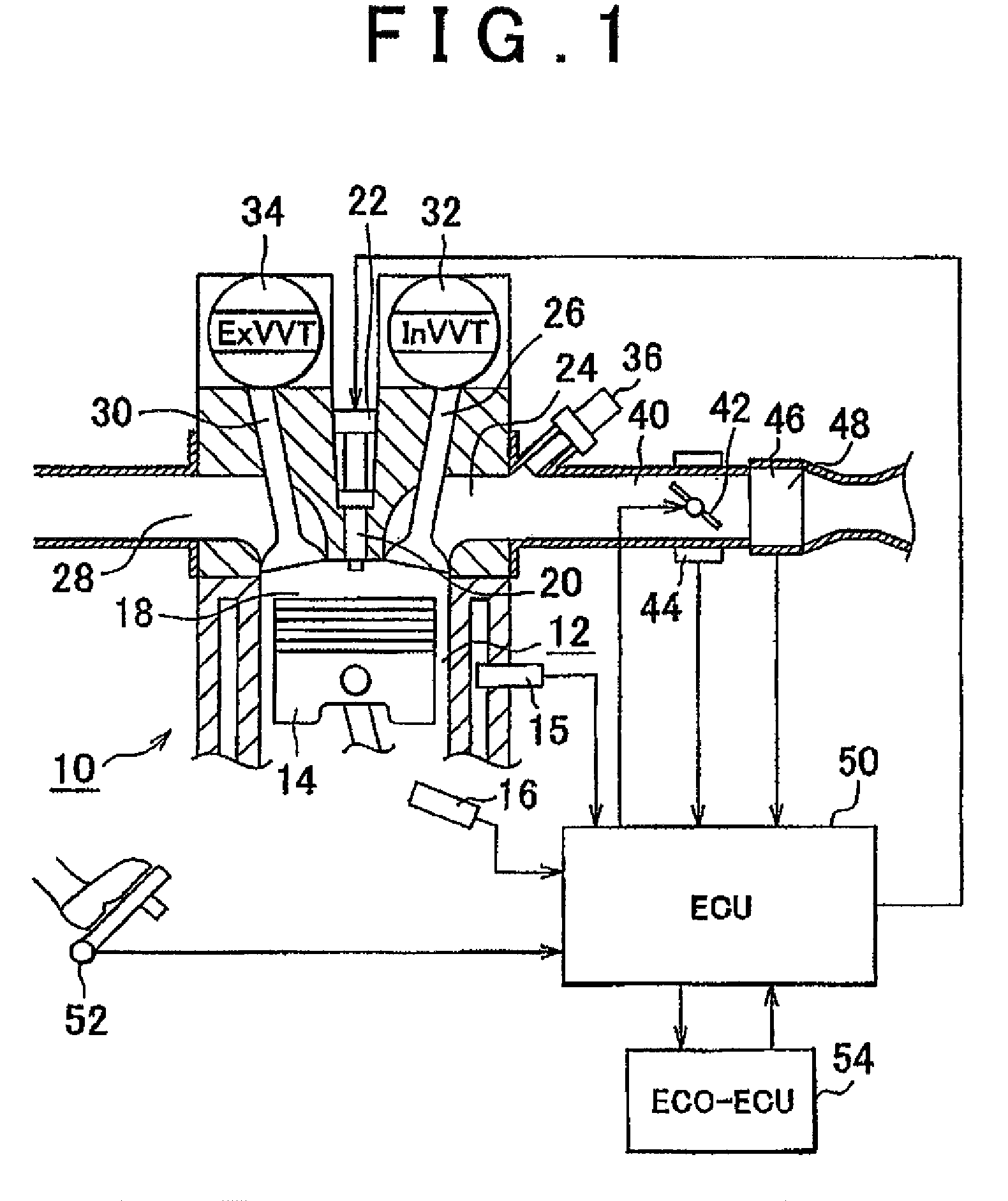

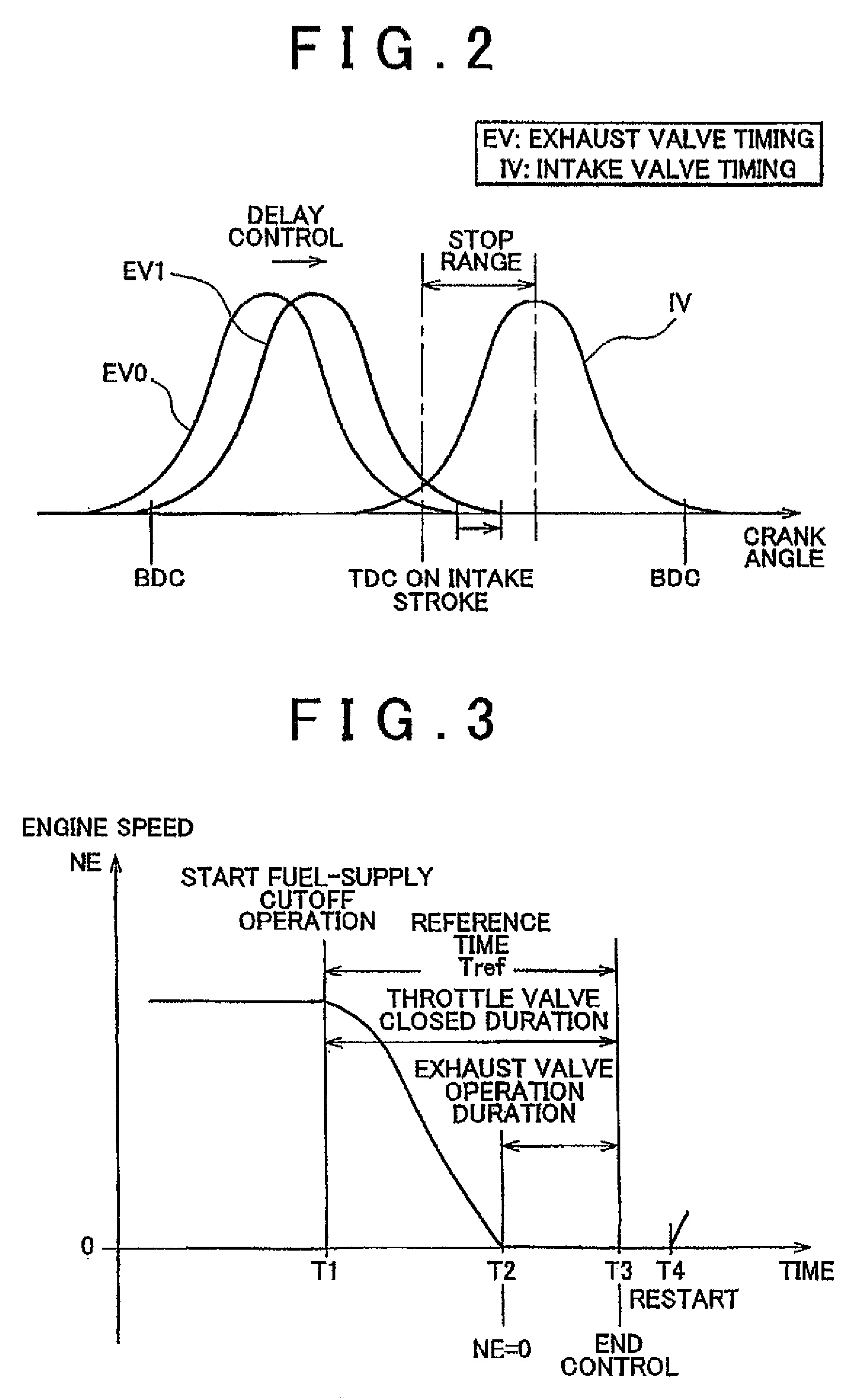

Internal Combustion Engine System and Internal Combustion Engine Control Method

ActiveUS20080091328A1Avoid vibrationStart fastAnalogue computers for vehiclesPower operated startersCombustionTop dead center

The internal combustion engine control technique of the invention computes a TDC pass rotation speed Ntdc, which represents the rotation speed of an engine when one of multiple cylinders of the engine passes over a top dead center TDC (step S110). The control technique estimates an engine stop crank angle CAs from a map that is experimentally or otherwise obtained to represent a variation in TDC pass rotation speed Ntdc against the stop position of the engine (step S120), and specifies a fuel injection cylinder that stops in a preset cycle range including part of a compression stroke at a stop of the engine (step S130). The specified fuel injection cylinder receives lean fuel injection at a specific fuel injection timing (step S170). When the specified fuel injection cylinder is later presumed not to pass over a top dead center TDC of the compression stroke, a corrected amount of fuel is injected into the specified fuel injection cylinder (step S240). When the specified fuel injection cylinder is later presumed to pass over the top dead center TDC of the compression stroke, on the other hand, the control technique ignites an air-fuel mixture of the intake air and the injected fuel for combustion in the compression stroke, synchronously with fuel injection into a next cylinder that goes into the compression stroke after the specified fuel injection cylinder (step S270).

Owner:TOYOTA JIDOSHA KK

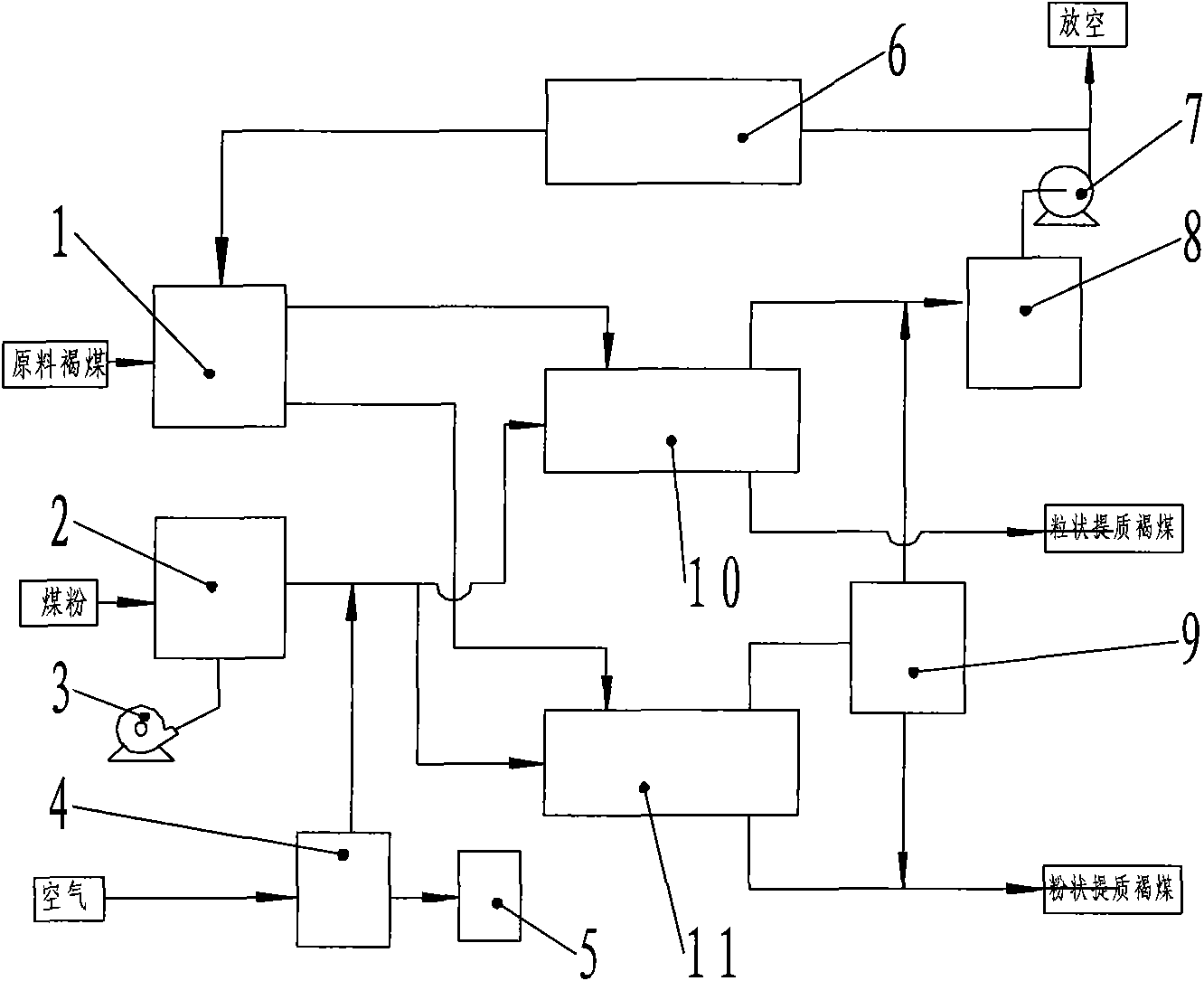

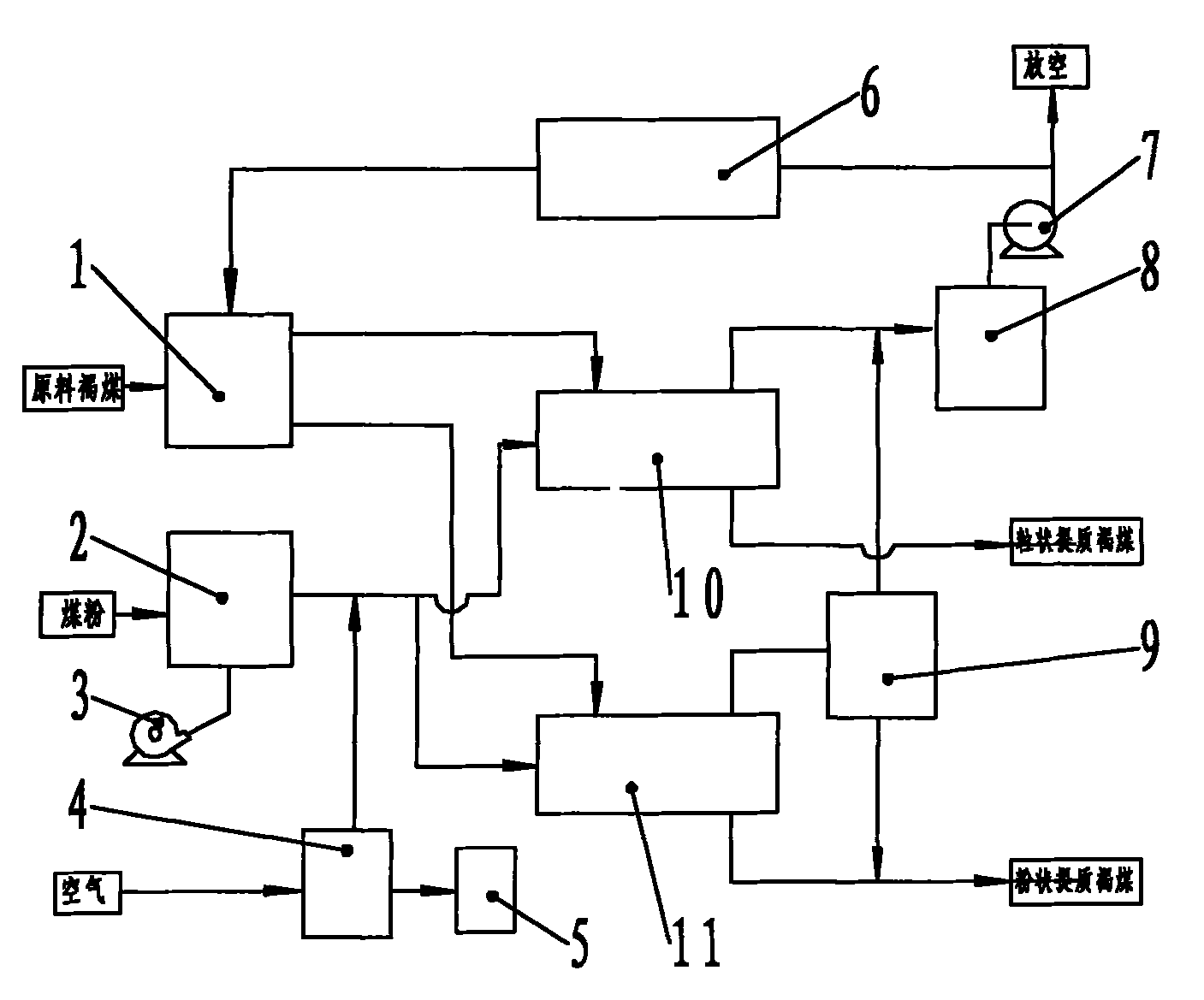

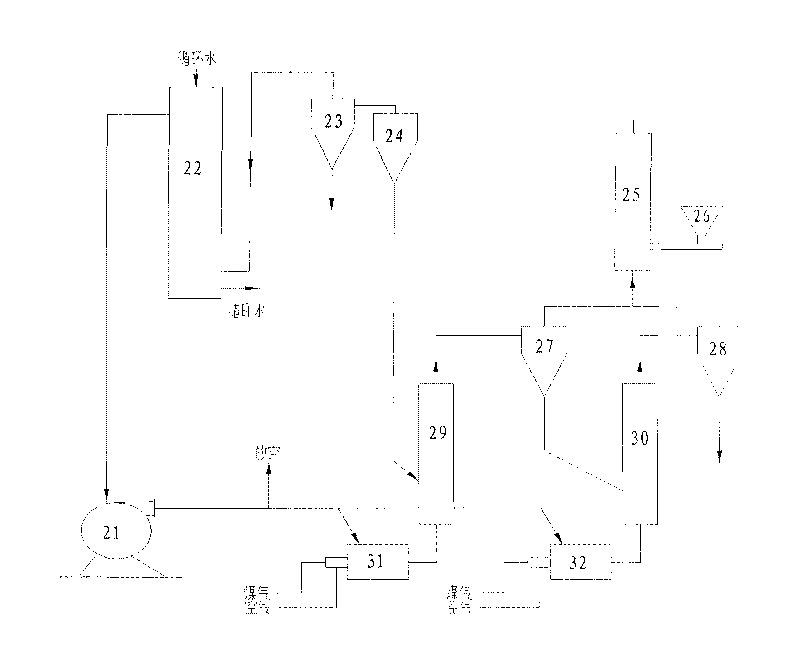

Method and device for drying and quality enhancement of lignite

InactiveCN101776370AImprove qualityIncrease useDrying solid materials with heatDrying machine combinationsLow oxygenCoal

The invention provides a method and a device for the drying and the quality enhancement of lignite. The device comprises a drying / sieving device, a preheating and drying / sieving device, a hot blast heater, a drying drum, a vibration fluidized bed, a cyclone separator, a defogger and a dust remover. The hot blast heater is respectively connected to the drying drum and the vibration fluidized bed, and an outlet of the preheating and drying / sieving device is respectively connected with the drying drum and the vibration fluidized bed. The preheating and drying / sieving device divides the lignite into two stages of big particle diameter and small particle diameter, high-temperature flue gas generated by the hot blast heater is used as a heating medium, the temperature of the flue gas is regulated by the residual low-oxygen gas after oxygen gas is separated by using an air separation system, the drying drum and the vibration fluidized bed are used for producing the quality-enhanced lignite with the big particle diameter and the small particle diameter, different production requirements are met, and part of exhausted tail gas is circularly used for preheating the raw materials of the lignite after being defogged. The invention respectively carries out drying and quality enhancement on the lignite according to the sizes of the particle diameters by grading equipment, eliminates the problem of uneven drying caused by different particle diameters, realizes the effective quality enhancement and the comprehensive utilization of coal resources, and is used for the large-scale process of drying and quality enhancement of the lignite.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

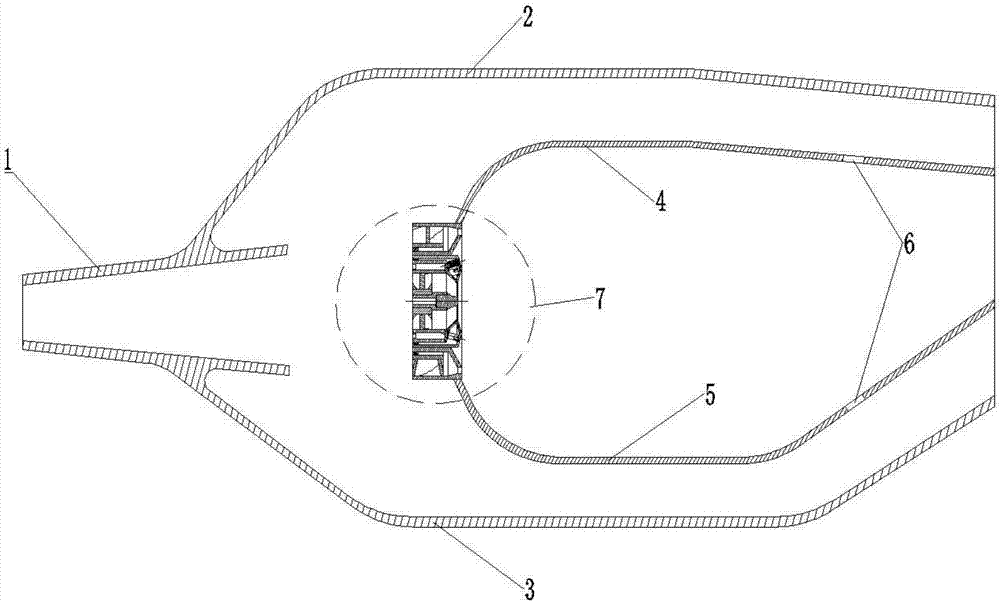

Lean oil direct injection and mixing low-pollution combustion chamber

ActiveCN107543201AGuarantee job stabilityReduce the temperatureContinuous combustion chamberSpontaneous combustionGasoline direct injection

The invention relates to a lean oil direct injection and mixing low-pollution combustion chamber. The lean oil direct injection and mixing low-pollution combustion chamber is composed of a diffuser, acombustion chamber outer case, a combustion chamber inner case, a combustion chamber head, a flame tube outer wall and a flame tube inner wall, wherein combustion air all enters a flame tube from thecombustion chamber head; the combustion chamber head is divided into an on-duty grade and a main combustion grade through a grading and partitioning combustion strategy; the on-duty grade and the main combustion grade both adopt a direct injection and mixing combustion method, the phenomena of spontaneous combustion and tempering are effectively avoided, and the risk of occurrence of oscillationcombustion is lowered; the lean oil direct injection and mixing low-pollution combustion chamber only works in an on-duty grade mode under an idling rating state, the designed partial equivalence ratio is higher, and the work stability of the combustion chamber is guaranteed; and with the increase of the work state of the combustion chamber, the main combustion grade is opened gradually, the maincombustion grade and the on-duty grade work simultaneously under a large state, the designed combustion area average equivalence ratio is lower, the average temperature of the combustion area is effectively lowered, and therefore the generation quantity of pollutants is lowered.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

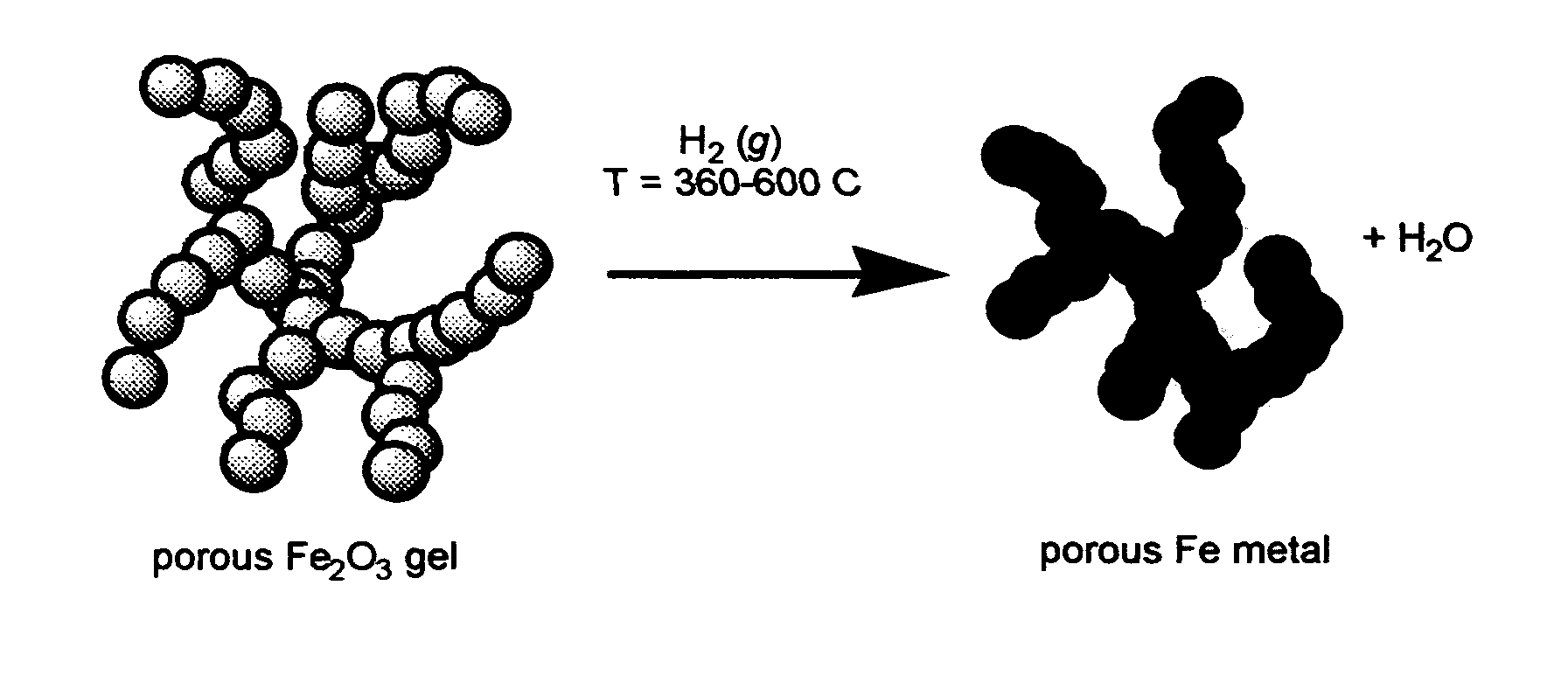

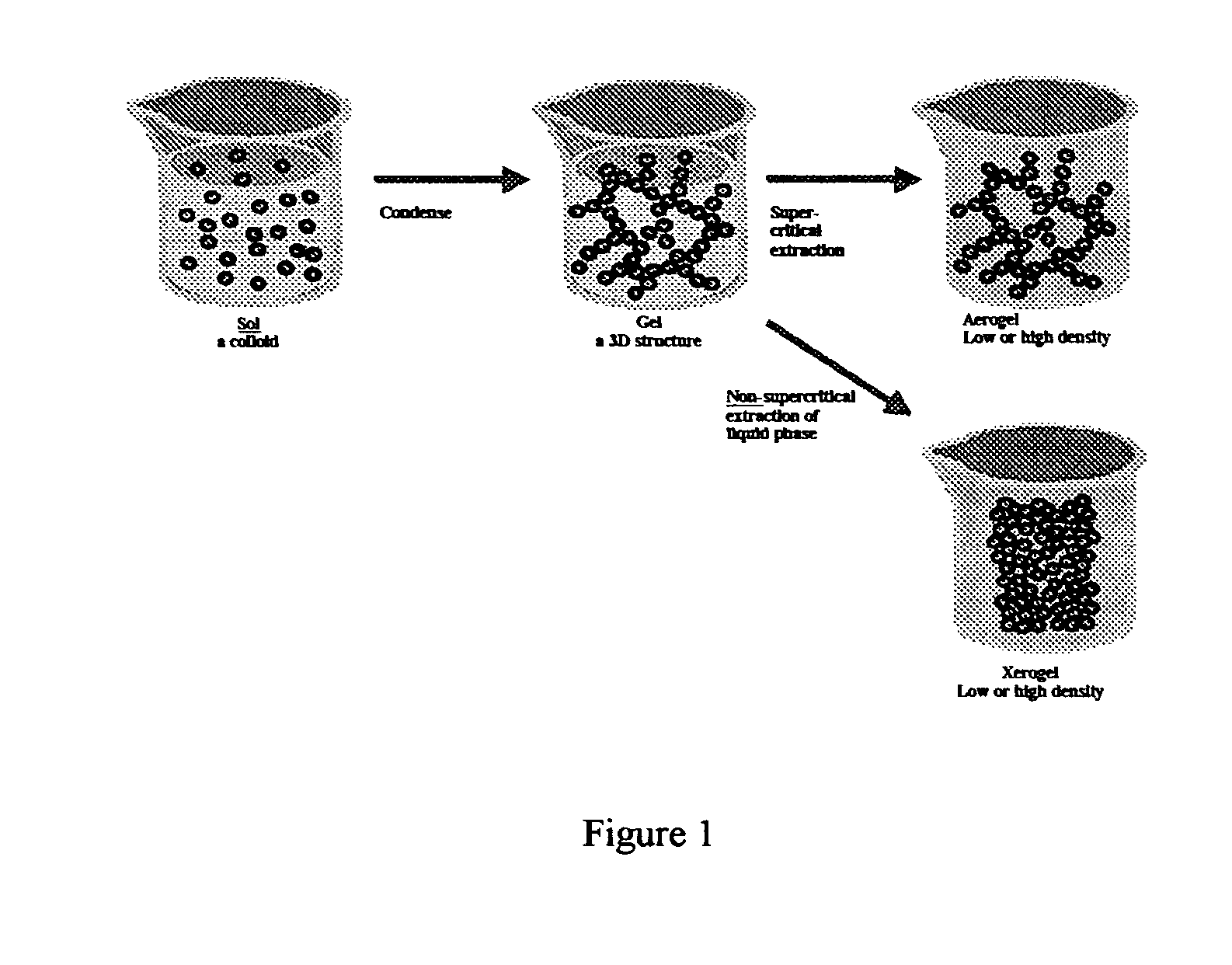

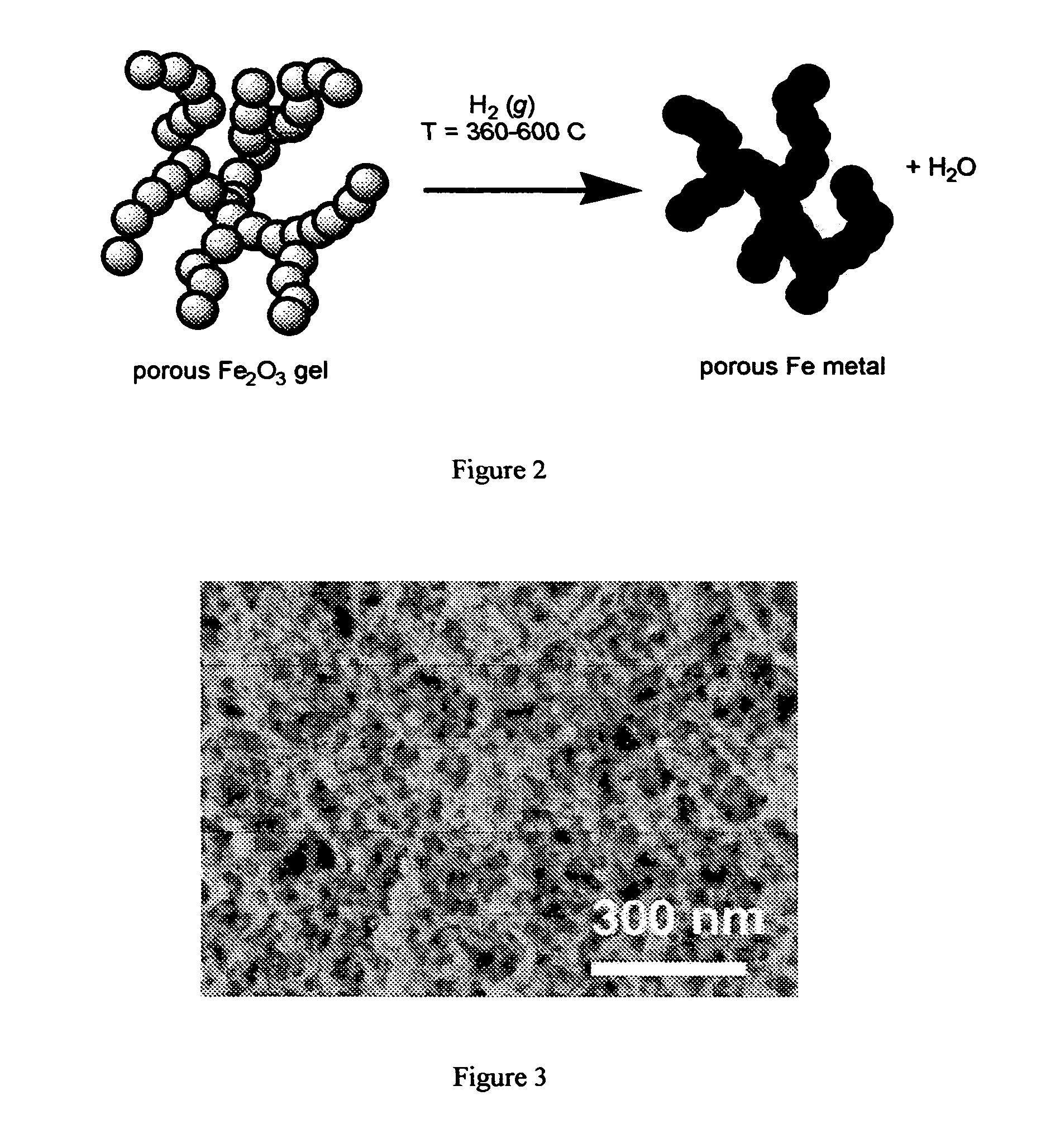

Preparation of porous pyrophoric iron using sol-gel methods

InactiveUS20060042417A1Easy to oxidizePrevent spontaneous combustionHigh surface areaChemical reduction

New sol-gel methods can be employed to generate high surface area porous iron (III) oxide-based solids. Chemical reduction of such porous solids at low temperatures allows the preparation of high surface area porous iron with little sintering, with the only byproduct being water. The material is readily pyrophoric and has utility in new decoy flares. The material, prepared by this synthetic route, eliminates the use of hot caustic leaching solutions. It does not require the incorporation of any hazardous materials or processes that are not already used in current production methods.

Owner:RGT UNIV OF CALIFORNIA

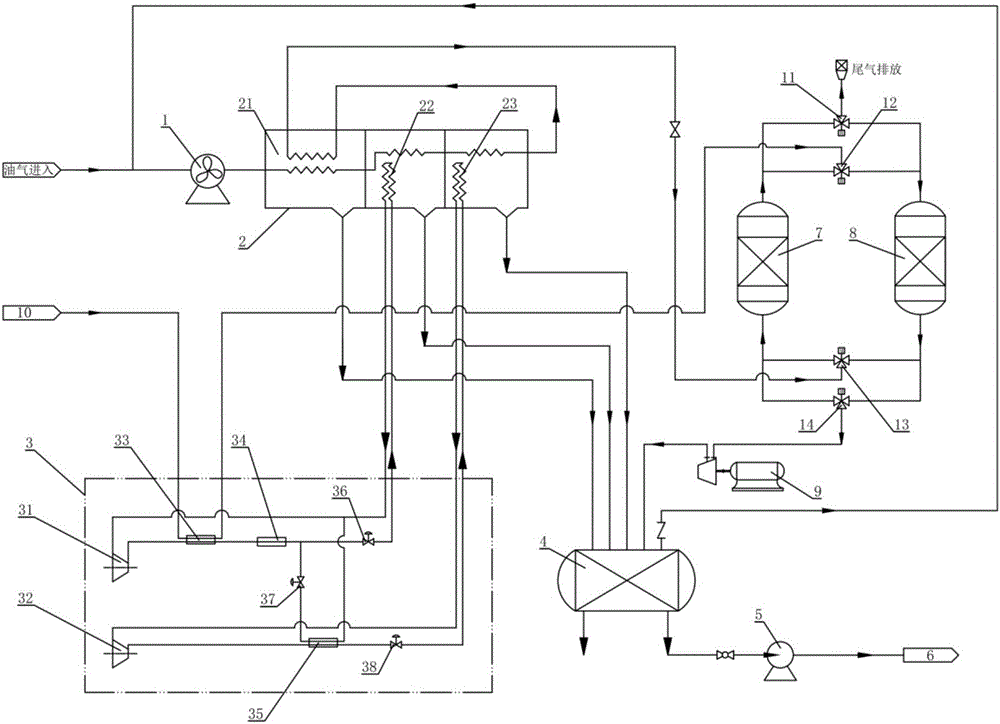

Oil gas recovery device and method

InactiveCN106166399AReduce energy consumptionEliminate potential safety hazardsGas treatmentMultiple-effect/fractional condensationAutomatic controlDesorption

The invention relates to an oil gas recovery device, comprising an anti-exposure centrifugal fan, a cold box, a refrigeration unit, a liquid storage tank, a liquid return pump, an oil storage tank, a first adsorption tank, a second adsorption tank, a vacuum pump, a nitrogen making unit, and Including the PLC automatic control system; the oil and gas are first transported into the cold box by the anti-exposure centrifugal fan, and the liquid oil condensed by the pre-cooling part, the first-level condensing part and the second-level condensing part of the cold box is sent to the liquid storage tank, and then returned to the storage tank. The liquid pump is sent to the oil storage tank for recovery; the oil and gas from the secondary condensing part are sent to the first adsorption tank after the heat is raised by the pre-cooling part, and the first adsorption tank and the second adsorption tank are cycled for adsorption and desorption. When the first adsorption tank or the second adsorption tank enters the desorption stage, the vacuum pump is turned on, and when the vacuum degree of the adsorption tank reaches the set value, the hot nitrogen gas is turned on to desorb the oil and gas with the hot nitrogen gas. By utilizing the advantages of the condensation method and the adsorption method to optimize the combination, the purpose of reducing energy consumption and eliminating potential safety hazards is achieved.

Owner:QUANZHOU TIANLONG ENVIRONMENTAL ENG

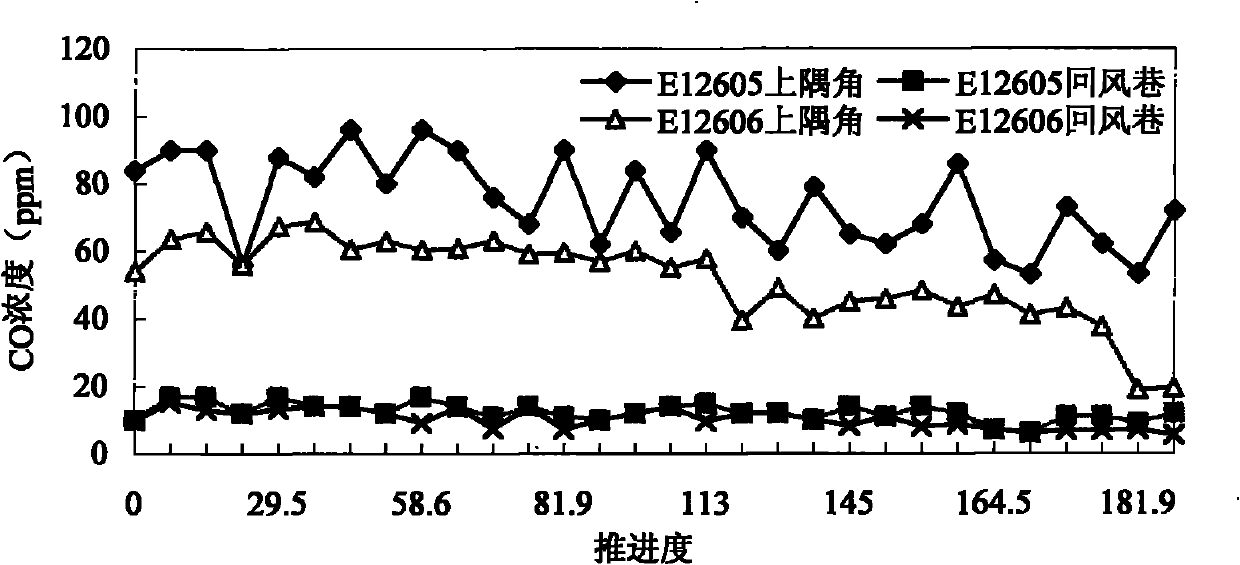

Light filling material for mines

ActiveCN107337412AGood expansion performanceImprove stress resistanceCeramicwareSpontaneous combustionUltrasound attenuation

The invention discloses a light filling material for mines. The filling material is prepared from components in parts by mass as follows: 65-85 parts of a base material, 10-15 parts of a coagulant, 1-5 parts of an excitant, 1-10 parts of an adjusting admixture, 0.1-1 part of a foaming agent and 0.1-1 part of a foam stabilizer. To meet the demands for upper corner filling and airtight wall construction, the light filling material has the characteristics of being light in weight, non-ignitable, small in density, adjustable in strength and setting time, excellent in expansibility and crushing resistance, free of obvious attenuation of water passing strength, environment-friendly, low in cost and the like and has remarkable effects on filling in a drilling site and upper corners of the mine, and the problems of gas accumulation and spontaneous combustion of coal can be effectively solved.

Owner:SHANDONG ANSHI GREEN MINING TECH DEV

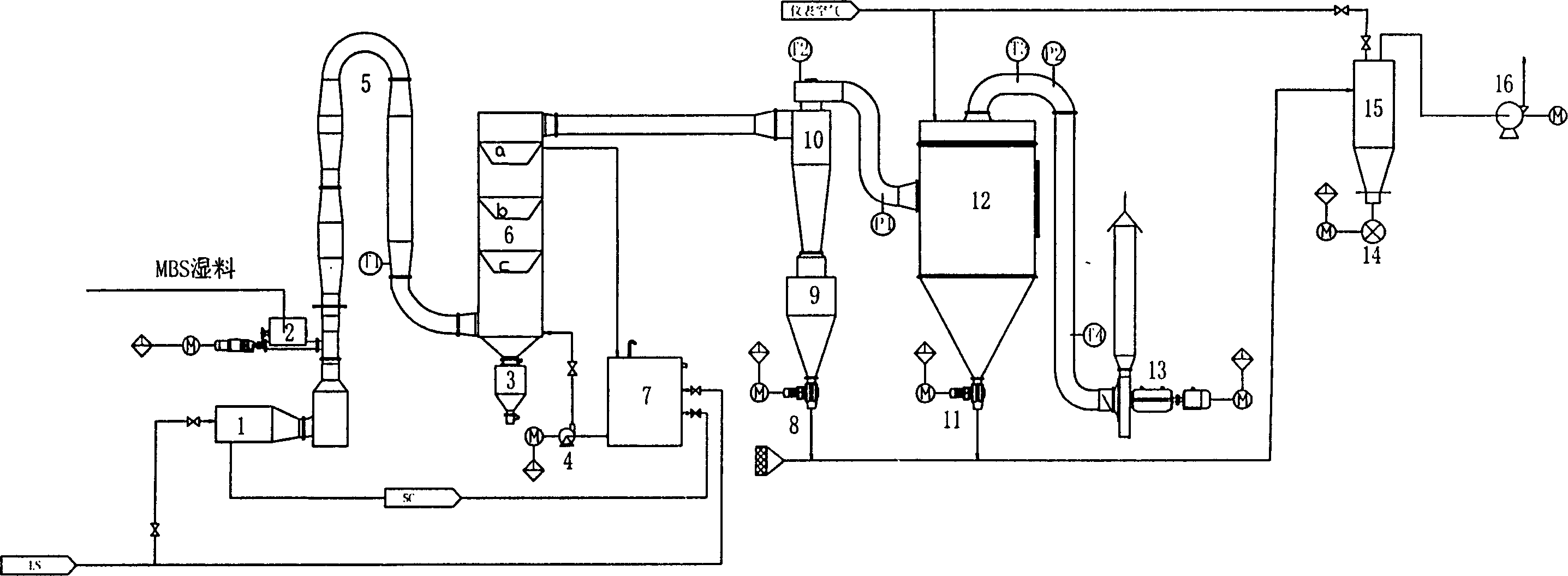

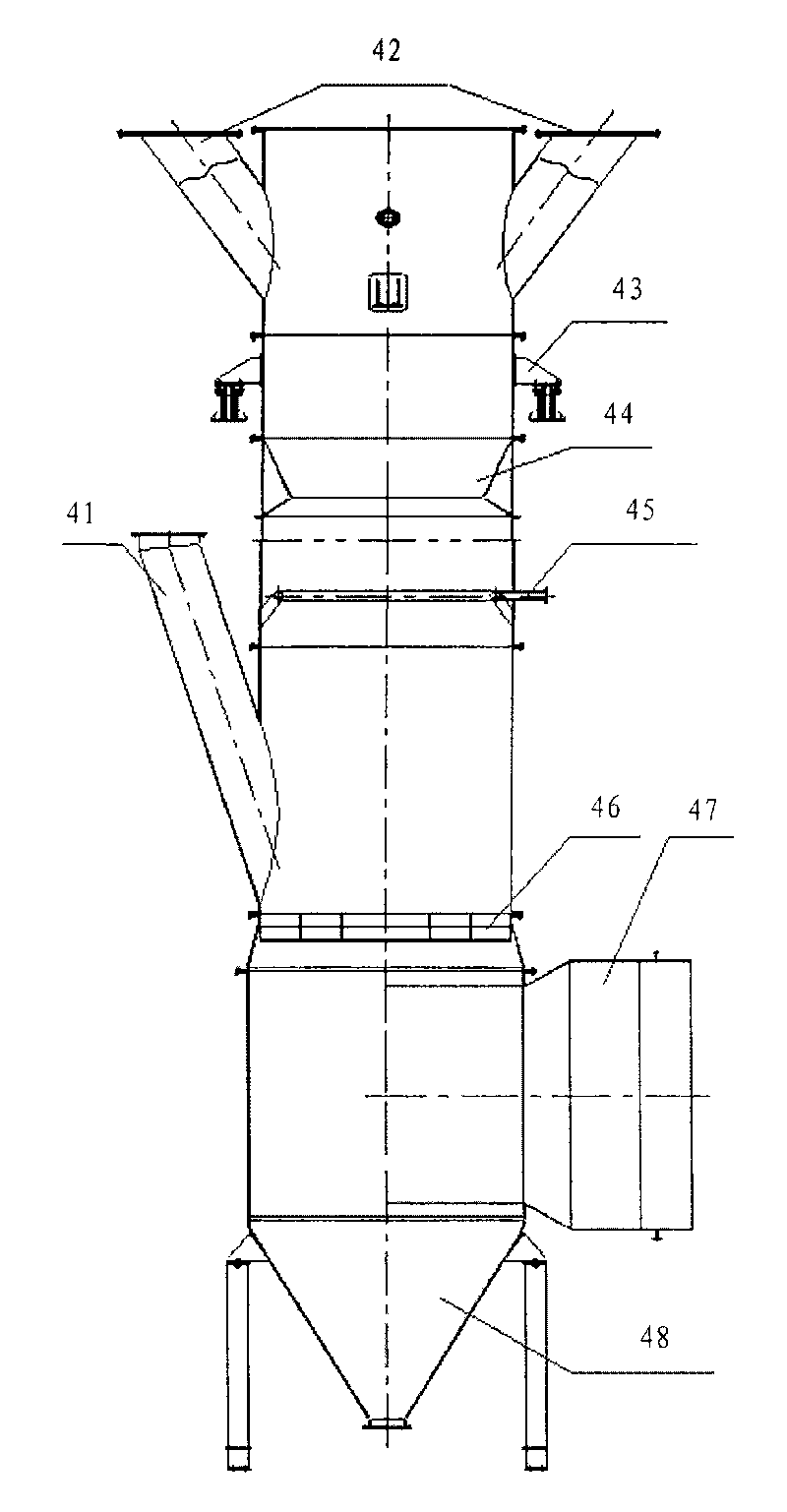

Method and apparatus for drying copolymer of methyl methacrylate-styrene-butadiene

InactiveCN1731057APrevent leakageReduce pollutionDrying solid materials with heatHearth type furnacesEngineeringMethacrylate methyl

The combined continuous airflow-cyclone MBS drying process includes drying wet MBS with hot air in a pulse drier to reduce water content to 10-15 %, making MBS enter to the cyclonic drier tangently in eddy flow mode to delay dry with hot water as heat source to water content of 0.5 %, and further processing in cyclonic separator and bag type dust collector. The operation conditions include air temperature of 125-130 deg.c, water temperature of 70-80 deg.c, average material residence time of 15-25 min, negative pressure operation and temperature in the cyclonic drier of 55-60 deg.c. The apparatus includes mainly screw conveyer, steam heat radiator to heat air, pulse drier, cyclonic drier, cyclonic separator, antistatic bag type dust collector, hot water tank, induced draft fan, etc. The present invention has high drying efficiency, low power consumption, and other advantages.

Owner:CNPC JILIN CHEM GROUP CORP

Preparation method for high-strength and high-hardness nanocrystalline tungstate-cobalt hard alloy

InactiveCN102994792ASlow down irregular growthPrevents oxidation and spontaneous combustionCemented carbideDoping

The invention discloses a preparation method for a high-strength and high-hardness nanocrystalline tungstate-cobalt hard alloy, which is finished by adopting eight process flows of reinforced grinding machining, proportioning, wet-grinding, drying, forming agent doping, granulating, press-forming and pressure-sintering for the conventional raw material, namely, sub-fine WC (tungstate-cobalt) powder; in the method, common sub-fine-grain WC powder having a Fsss (furnace safeguard supervisory system) granularity of 0.6-0.8 mum, and metal Co powder having a granularity of 0.2-0.4 mum; and the granularity and the granularity distribution of the sub-fine WC are changed by the added working procedure of reinforced grinding treatment, so that the advantage granularity of WC in the obtained super-coarse-grain hard alloy achieves 0.2-0.4 mum, and the hard alloy is high in toughness, complete in crystallization, few in defects, small in microstrain, uniform in sub-fine grains, high in microhardness, and greatly improves the wear resistance and impact toughness.

Owner:HUNAN CENTURY SPECIAL ALLOY

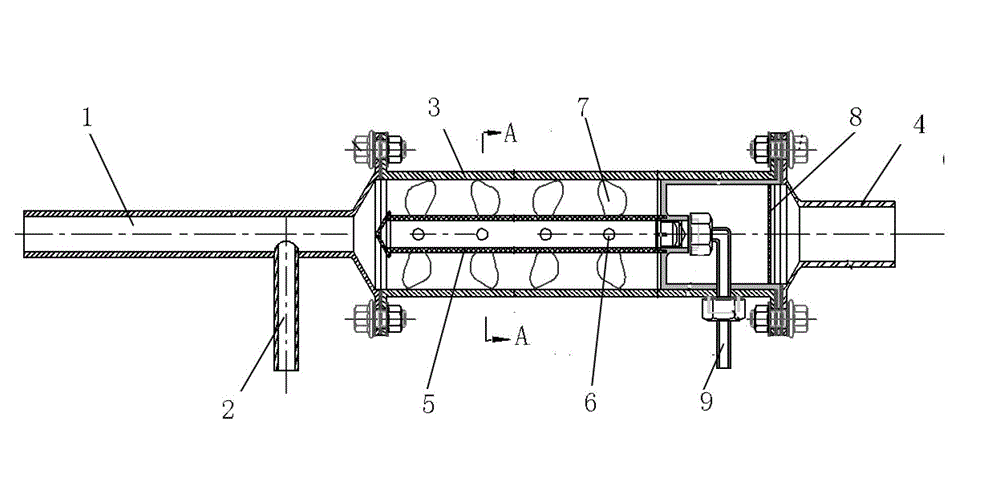

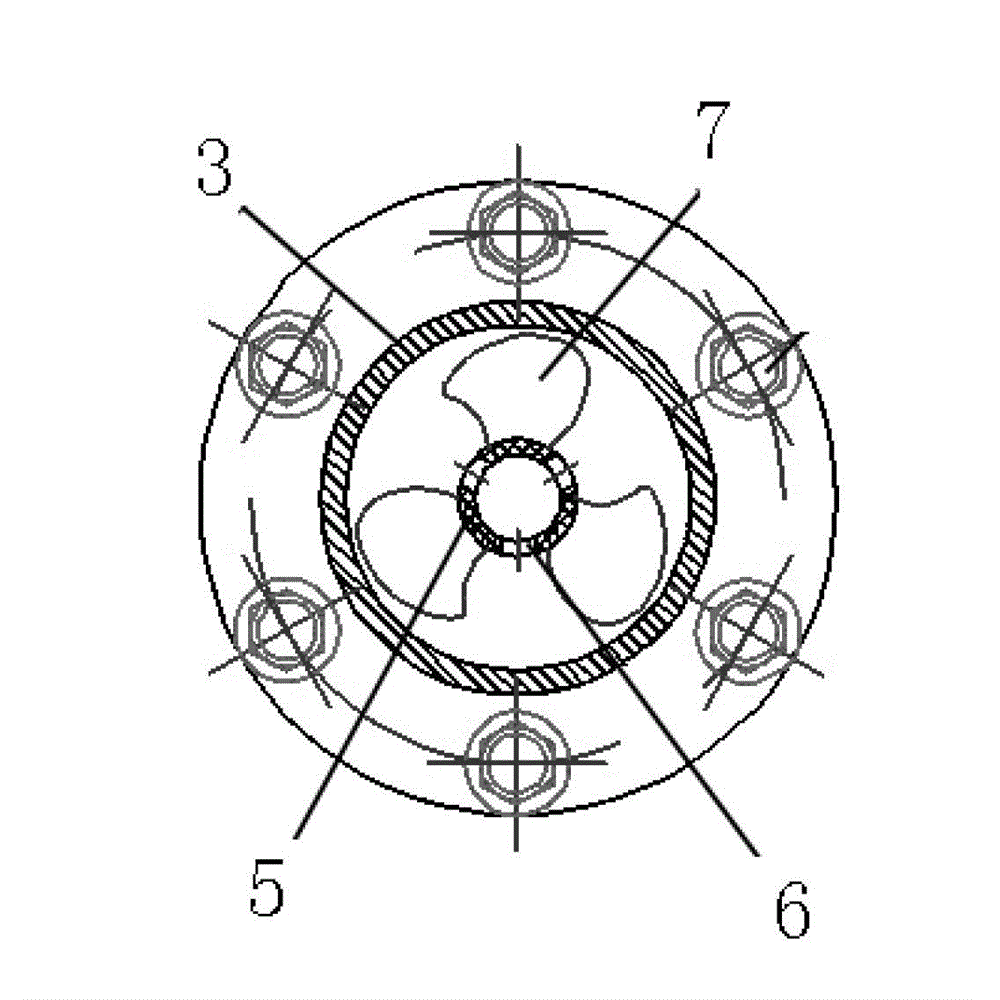

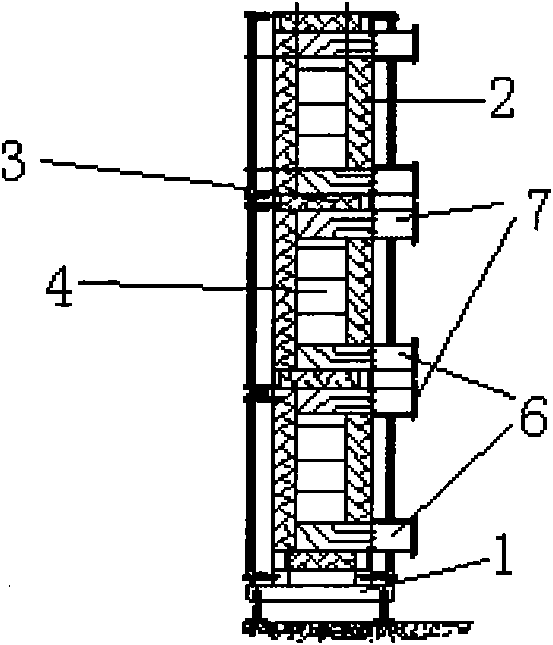

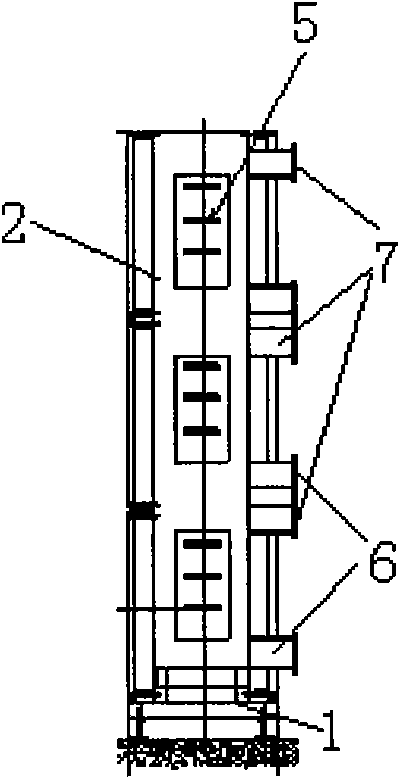

Device for preventing coal from burning spontaneously and rapidly extinguishing under coal mine and working method thereof

InactiveCN102979552APrevent spontaneous combustionAchieve fire extinguishingMixing methodsDust removalSpiral bladeEngineering

The invention discloses a device for preventing coal from burning spontaneously and rapidly extinguishing under a coal mine and a working method thereof. The device comprises a cylindrical foamed shell of which the two ends contract, wherein one end of the foamed shell is connected with a compressed air line; one side of the compressed air line is provided with a foam stock solution inlet; the other end of the foamed shell is connected with a foam output pipeline; 6-8 groups of spiral blades are arranged on a hollow shaft of an axis in the foamed shell at certain intervals; air outlet holes are formed among the spiral blades; included angles between the turning directions of the spiral blades and the axial direction of the hollow shaft are 45-60 degrees; each group of spiral blades has the same turning direction; and two adjacent groups of spiral blades have opposite turning directions. A mixture is foamed twice, so that the foaming times are raised to 50-150 times rapidly within a short period of time, and the aims of preventing and controlling spontaneous turning of coal and rapidly extinguishing are fulfilled.

Owner:SHANDONG UNIV OF SCI & TECH

Pre-oxidation furnace

The invention discloses a pre-oxidation furnace, which comprises a furnace frame on which a furnace body is fixed; the inside of the furnace body is fixed with horizontally arranged clapboards which divide a furnace retort in the furnace body into a plurality of layers of mutually independent furnace chambers; a front end face and a rear end face which are opposite on each layer of furnace chamberare respectively provided with a yarn inlet and a yarn outlet; opposite side walls of each layer of the furnace chamber are provided with an air inlet and an air outlet; the pre-oxidation furnace comprises a fan; and an air outlet of the fan is communicated with the air inlet of each layer of the furnace chamber through an air intake system, while an air inlet is communicated with the air outletof each layer of the furnace chamber through an air outlet system. The pre-oxidation furnace has simple structure, and solves the problems of the prior pre-oxidation equipment in aspects of temperature uniformity, an oxygen content control system and a spontaneous precursor combustion phenomenon, and an effective space of a hearth is fully utilized, so equipment and production cost is saved, and the economic production of carbon fibers is feasible.

Owner:HEFEI RISINE HEATEK

Novel dust-inhibiting and fire-retarding covering agent for coal, and preparation method thereof

InactiveCN102464971ALow costEasy to produceOther chemical processesSpontaneous combustionSocial benefits

The invention discloses a novel dust-inhibiting and fire-retarding covering agent for coal, and a preparation method thereof. The dust-inhibiting and fire-retarding covering agent comprises components of, by mass: 4-5% of a film forming agent, 10-12% of a curing agent, 2-3% of a film forming auxiliary agent, 1-3% of a penetrant, 1-3% of a fire retardant, and 74-82% of water. The preparation method of the dust-inhibiting and fire-retarding covering agent comprises steps that: the film forming agent is added and dissolved in water under a certain temperature; the temperature is controlled; the solution is continuously stirred, and the curing agent, the film forming auxiliary agent, the penetrant, and the fire retardant are orderly added to the solution while stirring; the mixture is stirred, until a reaction is sufficiently carried out. The novel dust-inhibiting and fire-retarding covering agent is sprayed onto the surface of coal under a normal temperature, and other equipments and conditions are not required. Within a short time, a flexible and compact continuous high-molecular covering membrane is formed, such that phenomena of dust emission and spontaneous combustion during transportation and stacking processes can be avoided. Therefore, coal economic loss and environmental pollution can be effectively reduced; and great economic benefits and social benefits of environmental protection are provided.

Owner:SHANDONG UNIV OF SCI & TECH

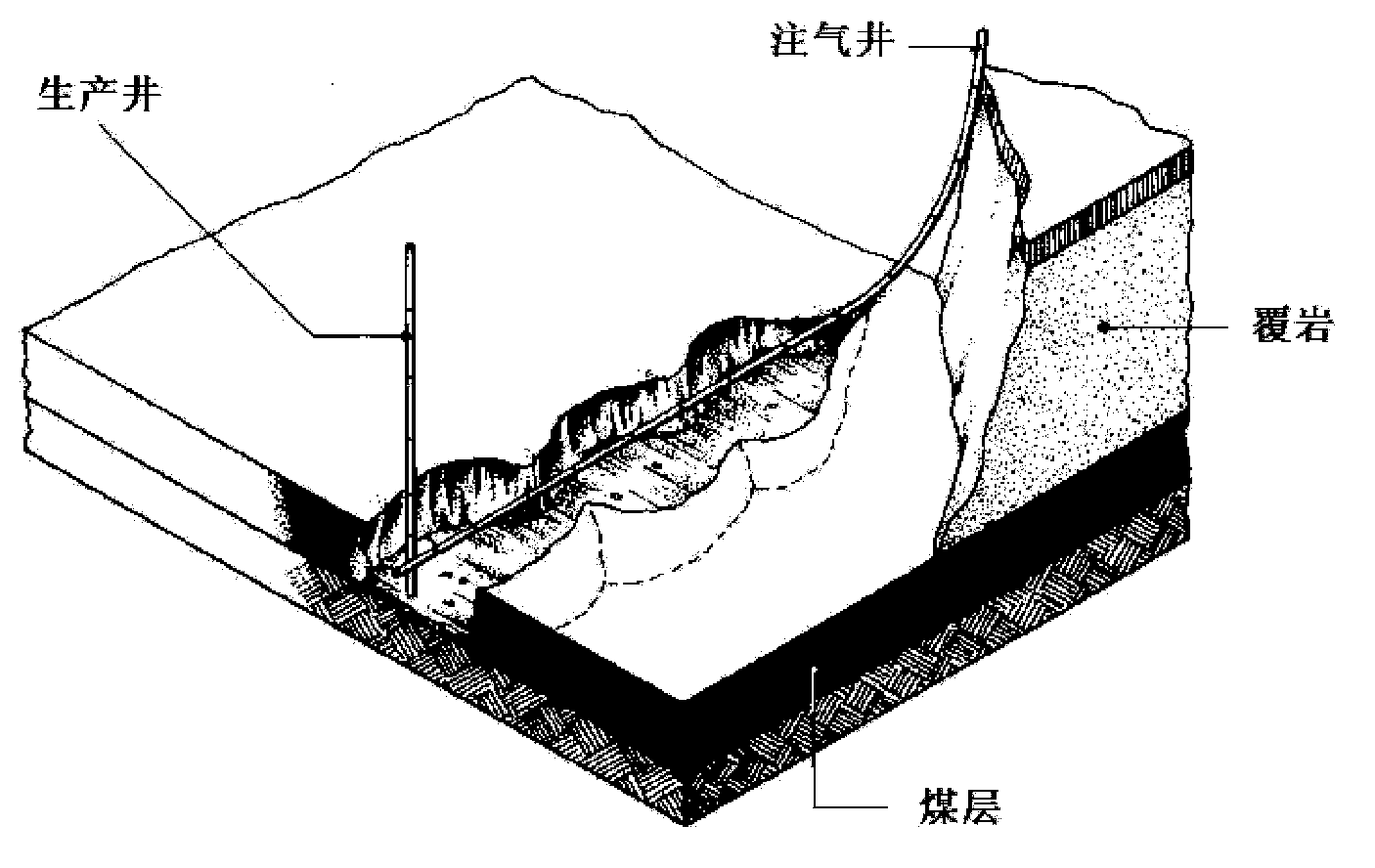

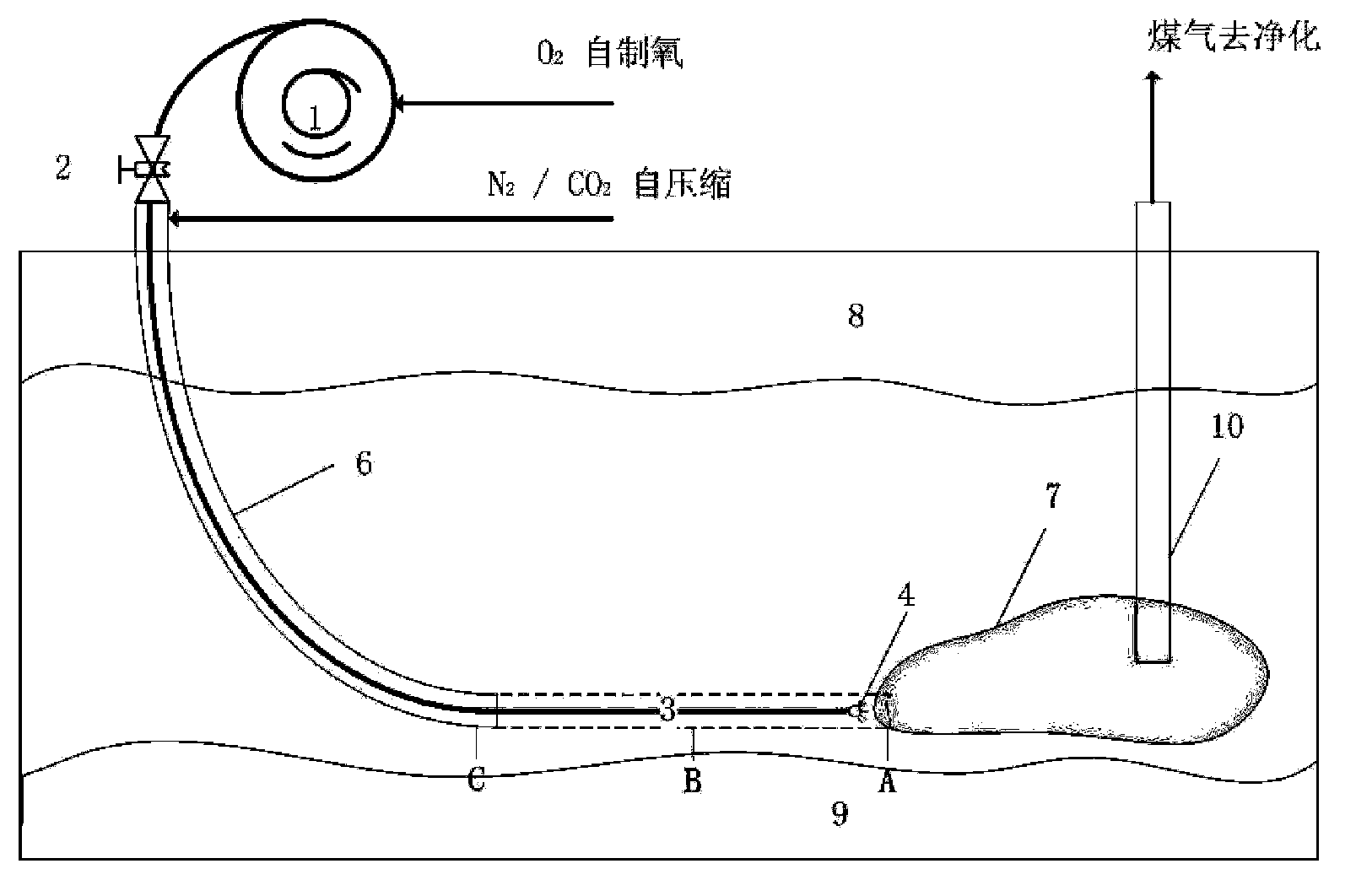

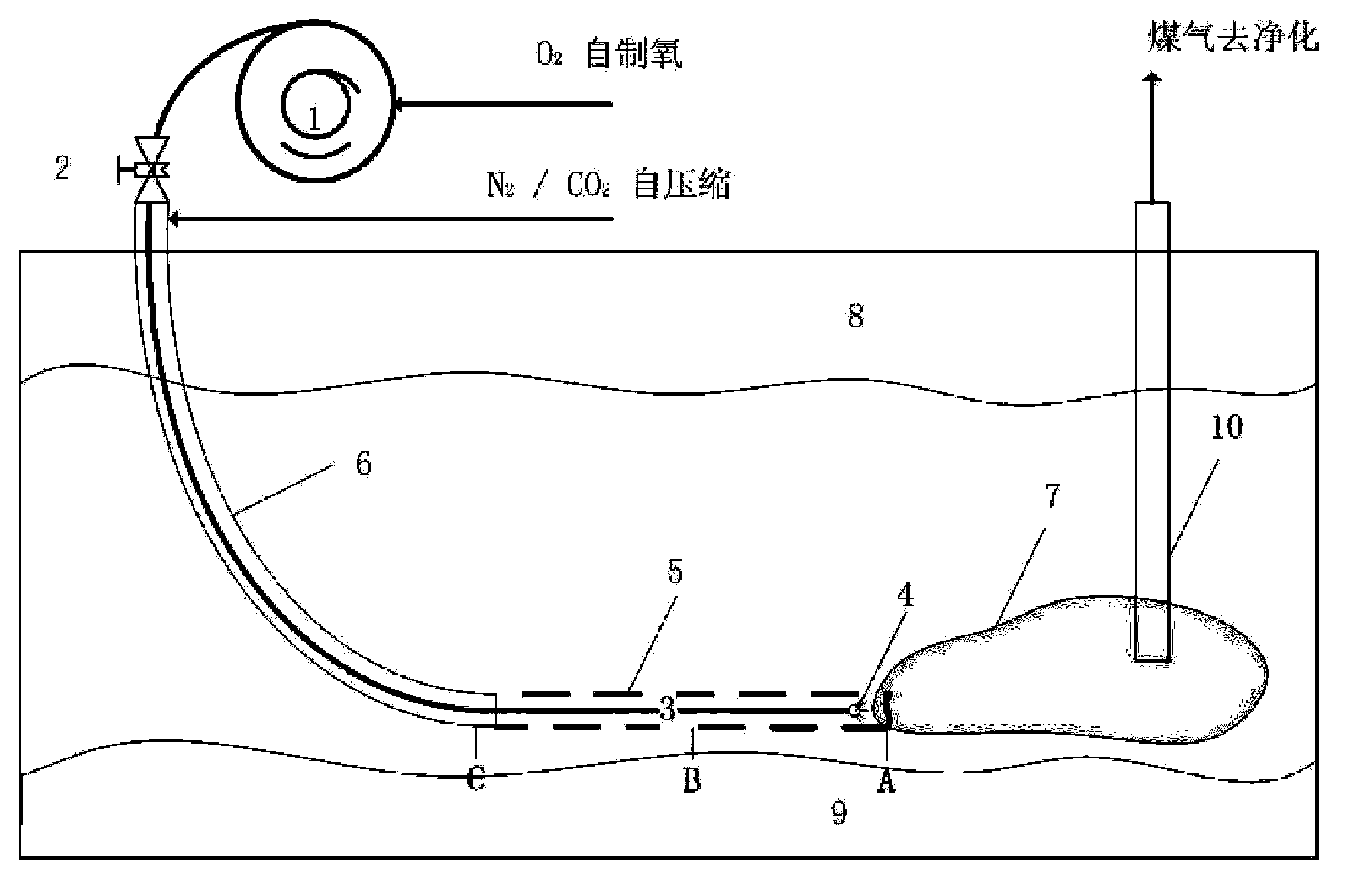

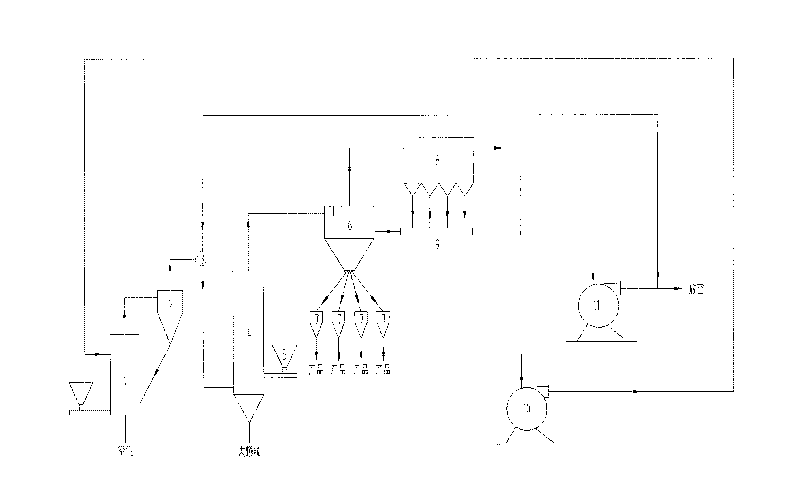

Controllable gas injection point gas injection device, gas injection technology and gasification method

ActiveCN104251133AReduce gasification combustion dead zoneImprove gasification recovery rateConstructionsFluid removalCombustionDirectional well

The invention relates to a controllable gas injection point gas injection device, a gas injection technology and a gasification method. The gas injection device comprises a directional well channel. A continuous oil pipe is arranged in the directional well channel and is communicated with an oxygen / oxygen-enriched gas pipeline; an annular space between the continuous oil pipe and the directional well channel is communicated with an auxiliary gasification agent pipeline and a steam pipeline; and a gas injection well head is arranged at the starting end of the continuous oil pipe, and a nozzle is arranged at the tail end of the continuous oil pipe. On the basis of the directional drilling and continuous oil pipe technology, the directional drilling and continuous oil pipe matched mode is utilized for achieving moving of a gas injection point, and on the principle of adjusting gasification agent injection parameters and controlling reverse combustion at the same time, the aims of adjusting and controlling the position movement and combustion speed of a flame working face and carrying out reverse combustion ignition and gasification of an underground coal seam can be achieved.

Owner:ENN SCI & TECH DEV

Smoke semi-closed circulating lignite straight pipe type airflow drying method

ActiveCN101726167AGood dispersionImprove dry strengthDrying solid materials with heatDrying gas arrangementsAir volumeDirect combustion

The invention relates to a smoke semi-closed circulating lignite straight pipe type airflow drying method, which ensures the safety and reliability of a device and makes the maximization of the device possible through direct combustion of lignite to generate smoke, once drying of a straight pipe type airflow dryer to meet the moisture requirement of a product, large-grain inertia setting, collection of a fine grain bag type dust collector, even blending of large grains and fine grains through a blending device, emptying and air quantity control through a mixed temperature fan and a booster fan.

Owner:CHNA ENERGY INVESTMENT CORP LTD +3

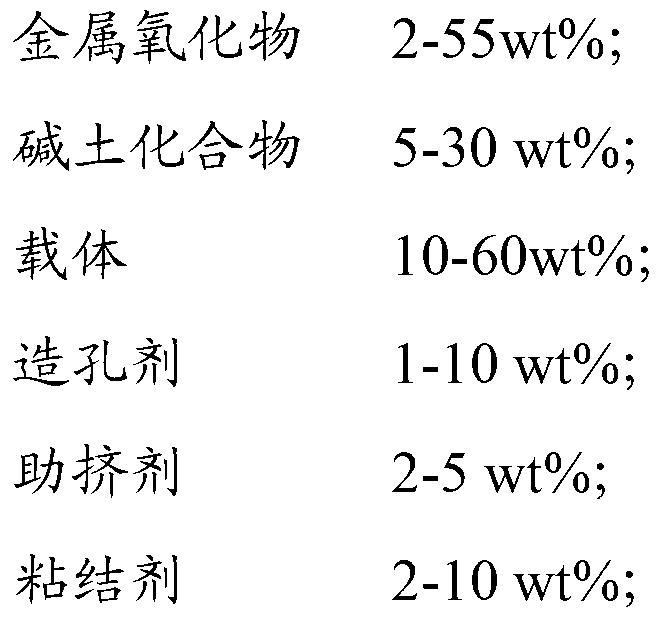

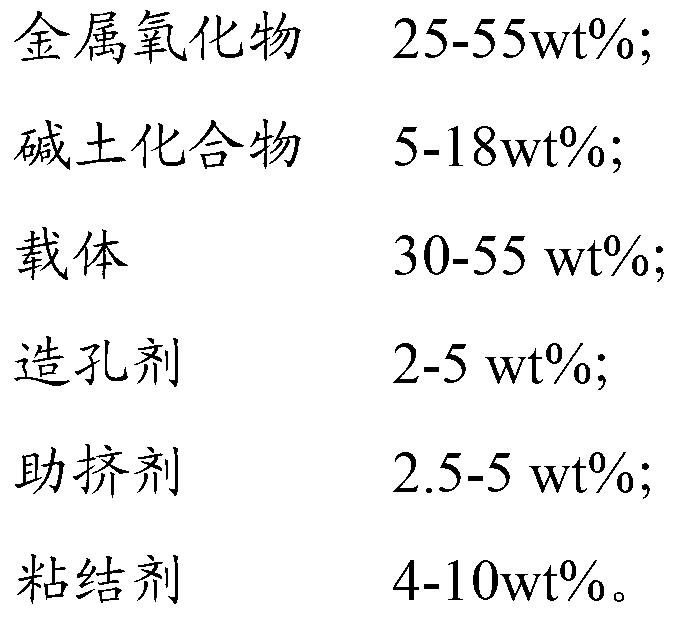

Deodorant and preparation method and application thereof

ActiveCN103341317ALarge specific surface areaGood purificationDispersed particle separationThioetherLarge pore

The invention discloses a deodorant and a preparation method and application thereof. The deodorant is prepared from the following components: 2-55wt% of metallic oxide, 5-30wt% of alkaline earth compound, 10-60wt% of carrier, 1-10wt% of pore forming substance, 2-5wt% of extrusion assisting agent, and 2-10wt% of binder, the preparation method comprises the following steps of mixing all the materials, adding appropriate water, putting into a banded extruder for extruding into strip shape through disorderly pinching, drying at 50-200 DEG C, roasting at 150-450 DEG C, and obtaining the deodorant The deodorant can be used under the condition of 10-100 DEG C, 0.1-10Mpa, and 100-10000h<-1> of airspeed. The deodorant has large pore volume and specific surface area, and high sulfur capacity, one-way sulfur capacity of the deodorant is more than 30wt%, the removal efficiency of COS, mercaptan, thioether, dimethyl dithio is more than 90%, and benzene series and low carbon hydrocarbon substances are removed at the same time; the preparation method is simple, and has no pollution and low cost.

Owner:康健科技(山东)有限公司

Control apparatus and method for internal combustion engine

InactiveUS8141533B2Prevent spontaneous combustionStartability is improvedAnalogue computers for vehiclesValve arrangementsExhaust valveEngineering

A control apparatus includes a detection unit that detects a stop request to an engine, a throttle closing control unit that, when the stop request is detected, adjusts an opening amount of a throttle valve to an engine-stop throttle valve opening amount smaller than a current opening amount an engine stop detection unit that detects a stop of the engine, an engine-stop exhaust valve control unit that adjusts an opening / closing characteristic of an exhaust valve of a cylinder that will be placed initially in an intake stroke when the engine is restarted so that, when the opening amount of the throttle valve is adjusted to the engine-stop throttle valve opening amount and a stop of the engine is detected, the exhaust valve has an engine-stop exhaust valve opening / closing characteristic by which a closing timing of the exhaust valve is more delayed than a current closing timing of the exhaust valve.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com