Chemical cleaning agent for clearing impurities such as ferrous sulfide

A ferrous sulfide and cleaning agent technology, which is applied in the chemical industry, can solve problems such as threatening the life safety of construction workers, difficulty in waste liquid treatment, and side effects, so as to improve the quality of maintenance, prevent stress corrosion cracking, and prevent local The effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

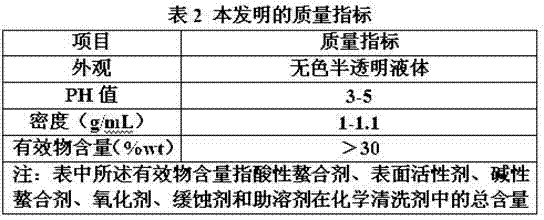

[0022] Dissolve 10g of citric acid in 20g of water, add 1g of sodium dodecylbenzene sulfonate, stir well, add 30g of 10% ammonia solution, control the pH between 3-5, and then add 2.5g of 1% polyphosphate A ester And 0.5g of benzoic acid, stir to dissolve, then add 36g of 27% hydrogen peroxide. Dilute 5 mL of the prepared solution to 50 mL, and conduct a scale dissolution test of ferrous sulfide. The results are shown in Table 1.

Embodiment 2

[0024] Dissolve 12g of citric acid in 20g of water, add 1g of sodium dodecylbenzene sulfonate, stir well, add 6g of ethylenediamine, control the pH between 3-5, then add 3g of 1% polyphosphate A ester and 1g Sodium benzoate, stir to dissolve, then add 37g of 27% hydrogen peroxide. Dilute 5 mL of the prepared solution to 50 mL, and conduct a scale dissolution test of ferrous sulfide. The results are shown in Table 1.

Embodiment 3

[0026] Dissolve 15g of EDTA disodium in 30g of water, add 0.5g of sodium dodecylbenzene sulfonate, stir well, add 10g of concentrated ammonia water, control the pH at 3-5, then add 1g of 1% polyphosphate A ester and 0.5g of benzene After stirring the sodium formate to dissolve, add 43g of 27% hydrogen peroxide. Dilute 5 mL of the prepared solution to 50 mL, and carry out the ferrous sulfide scaling test. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com