Patents

Literature

5150 results about "SODIUM DODECYL BENZENE SULFONATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

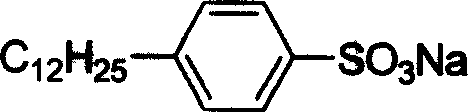

Sodium Dodecyl Benzene Sulphonate (SDBS, LAS) is a kind of efficient additive which can improve the quality of organic and inorganic chemical products that are easy to absorb moisture and agglomerate.

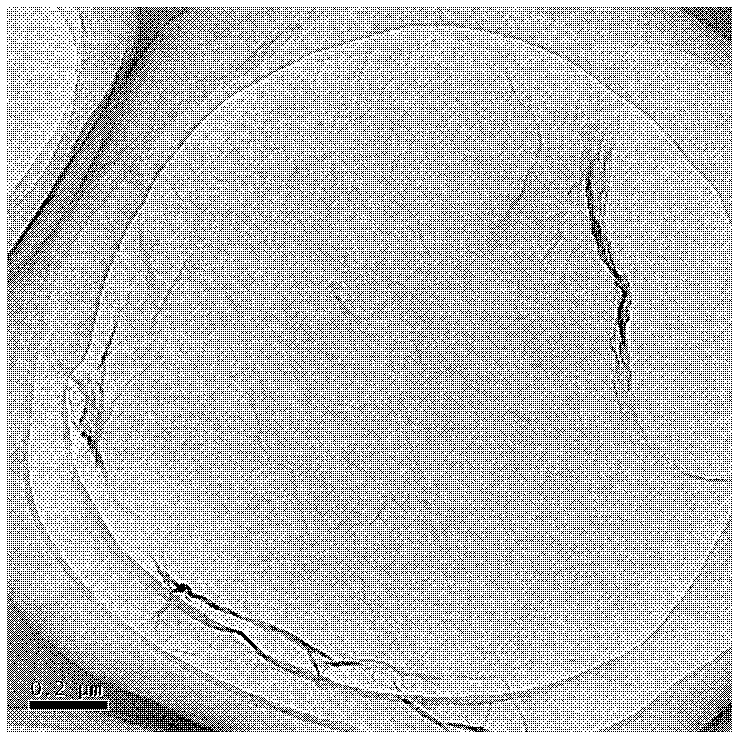

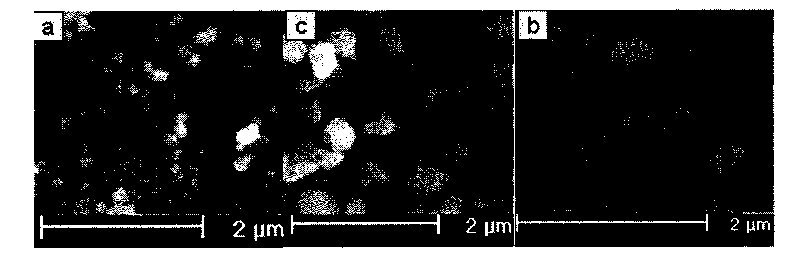

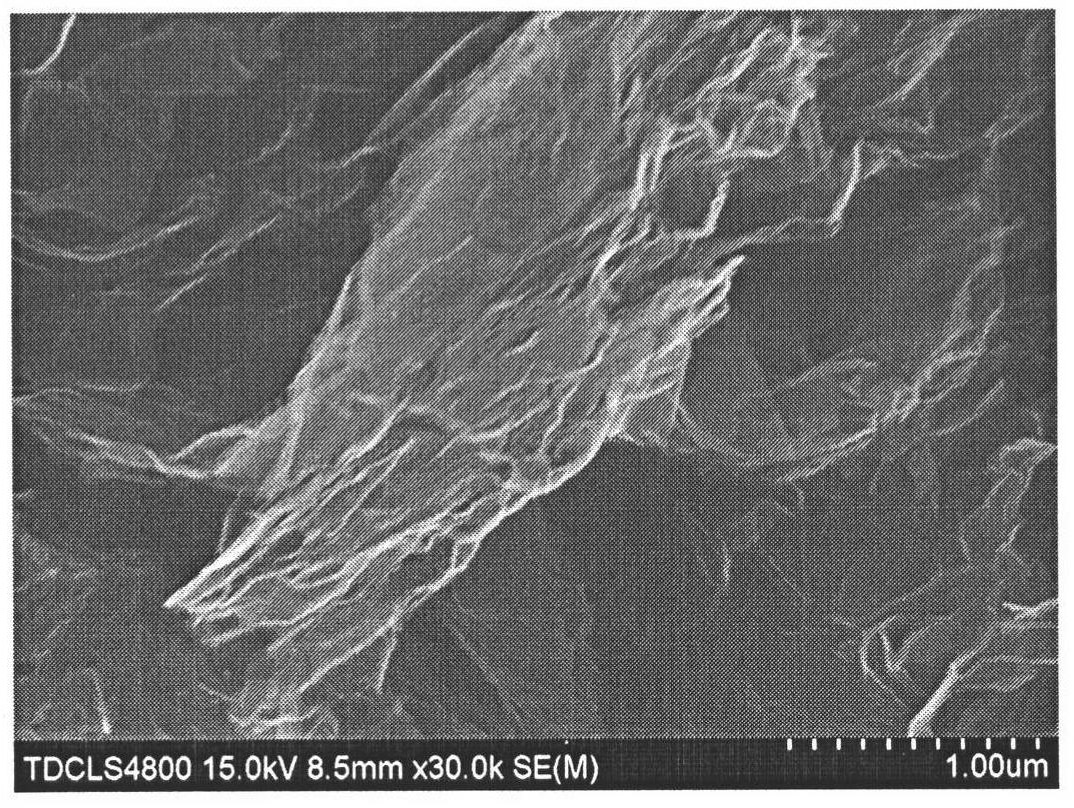

Preparation method of graphene-carbon nanotube compound film based on three-dimensional network appearance

InactiveCN102417176AImprove uniformityReduce surface resistanceNanotechnologyPolyethylene terephthalate glycolMeth-

The invention discloses a preparation method of a graphene-carbon nanotube compound film based on a three-dimensional network appearance. The method comprises the step of: transferring and stamping graphene and a carbon nanotube onto glass, a tantalum sheet, a silicon chip, a stainless steel plate or a polyethylene glycol terephthalate substrate in the mass ratio (1-10):1 through spraying deposition or vacuum suction filtration, wherein the grapheme is graphene oxide prepared by using an improved Hummers method; and a preparation method of a carbon nanotube solution comprises the following steps of: mixing acids; dispersing surfactants such as sodium lauryl sulfate, sodium dodecyl benzene sulfonate and hexadecyl trimethyl ammonium bromide in an auxiliary way, and the like. The graphene-carbon nanotube compound film prepared by adopting the method has the advantages of adjustable transmission and surface resistance, high uniformity, high stability, simple preparation method process and the like, and can be loaded on a rigid substrate as well as a flexible substrate.

Owner:TIANJIN UNIV

Surface activating agent for oil-field thick-oil well

InactiveCN101024764AGood viscosity reduction effectImprove performanceTransportation and packagingMixingPhenolOleic Acid Triglyceride

The invention discloses a surface activator used in oil field thick oil well that is made up from water 1500kg, sheet alkali 330kg, alcohol 450kg, oleic acid 275kg, alkyl phenol polyoxyethylene (15) ether 200kg, sodium dodecyl benzene sulfonate 150kg. The invention could decrease interface tension, and under the emulsion effecting, the o / w or w / o would form flow state in normal state to be convenient to convey and pump. The invention has low cost and high effect.

Owner:图们市科兴石化技术开发有限公司

Coal slime flotation collector and preparation method thereof

The invention discloses a coal slime flotation collector and a preparation method thereof. The coal slime flotation collector comprises the following matters in percentage by weight: 20-50 percent of kerosene and / or light diesel oil, 1-5 percent of primary emulsion, 0.006-0.015 percent of auxiliary emulsion and the balance of water; wherein the primary emulsion is a mixture of polyoxyethylene sorbitan fatty acid ester and dehydrated sorbitol fatty acid ester, and the hydrophile-lipophile balance (HLB) value of the primary emulsion is within 12.8-14.3; the auxiliary emulsion is selected from the following (1) or (2), wherein the (1) is sodium dodecyl benzene sulfonate, and the (2) is a mixture obtained by mixing fatty alcohol polyoxyethylene ether sulfate and the sodium dodecyl benzene sulfonate according to the mass ratio of 1: 0.5-2. The coal slime flotation collector has good stability, simple preparation process and 40-60 percent of the oil-saving ratio on the premise of improving the float yield and the tail coal ash proportion. The collector is beneficial to saving the energy, reducing the emission and improving the economical benefit when being used for floating the coal slime.

Owner:SHANXI MEDICAL UNIV

Completely fused paper soap and its making process

InactiveCN1357613AImprove solubilityImprove decontamination abilityDetergent materialsPhenolFatty alcohol

The component of the paper soap include carboxymethyl cellulose sodium, fatty alcohol polyioxymethyl ethyleneethere sodium sulfate, sodium dodecyl benzene sulfonate, lauryl sodium sulfate, cocinin diethanolamide, nonly phenol polyoxyethyleneether, glycerine, quaternary ammonium salt and citric acid. Its preparation includes preparing carboxymethyl cellulose sodium mother liquor, adding the mixed solution of other components to prepare solution through stirring, spraying the prepared solution of PVC plate and drying in a sealed room and moisture extract at 35-40 deg.c to form film.

Owner:成都洁利康实业发展有限公司

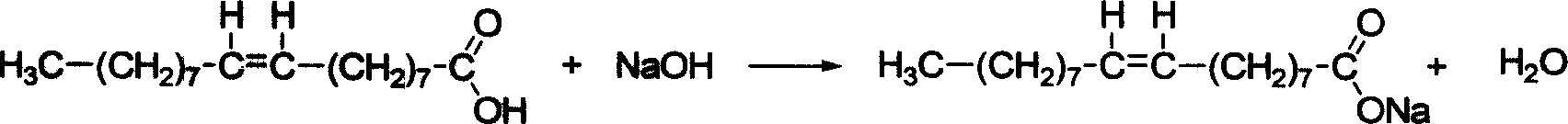

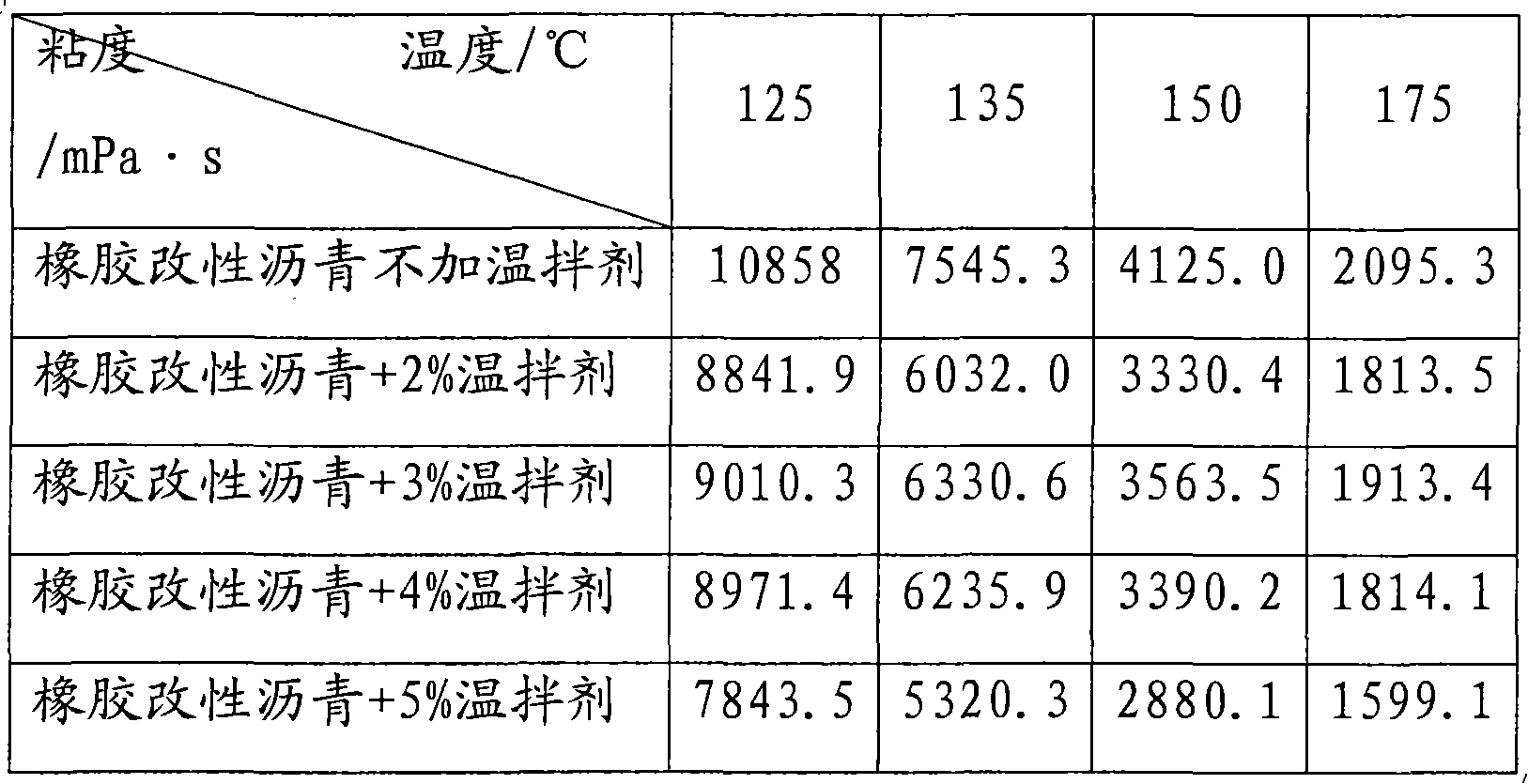

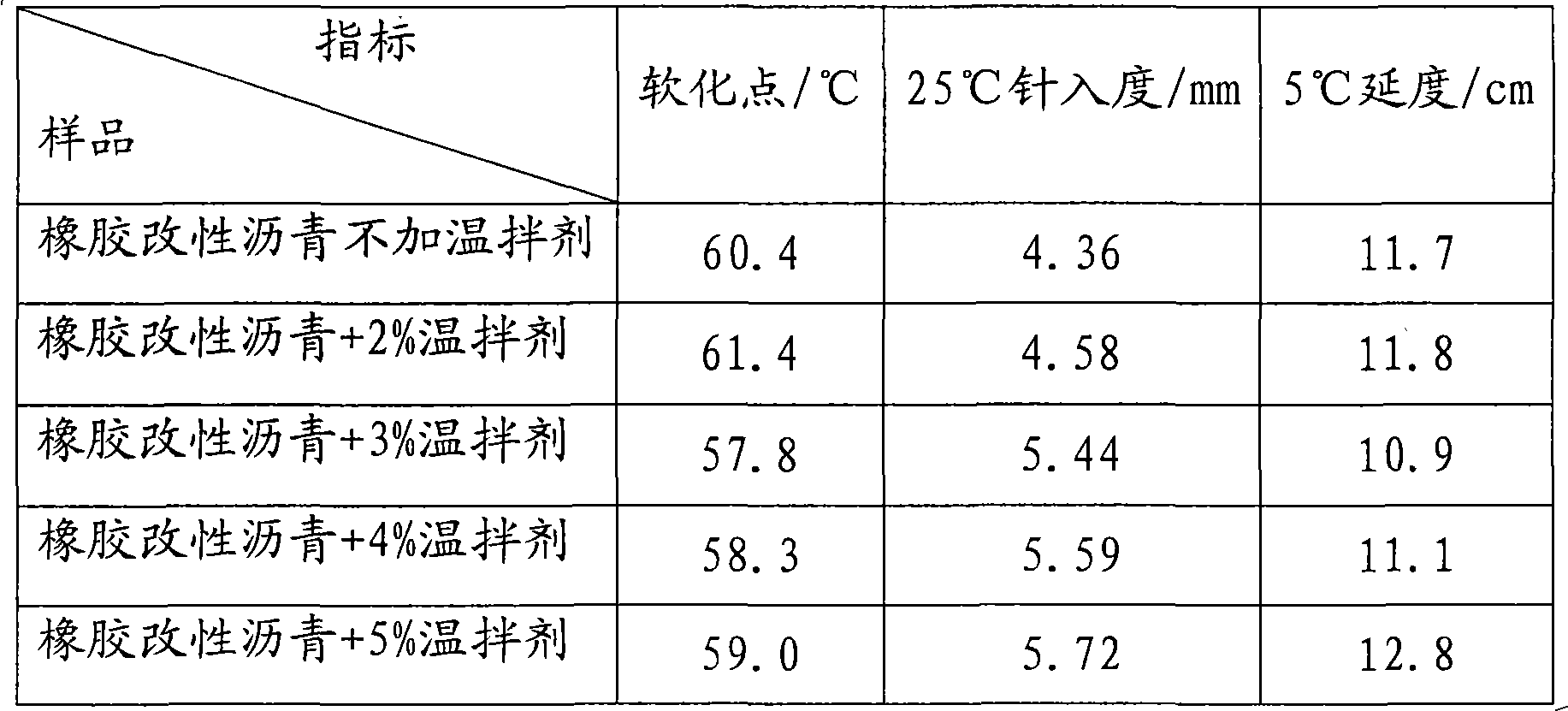

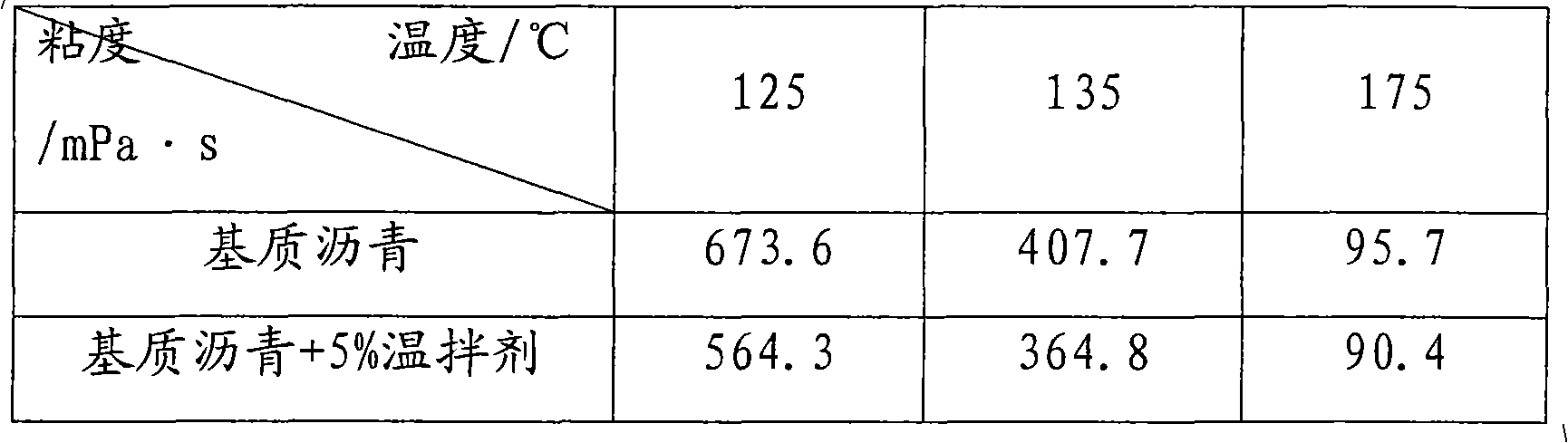

Rubber modified asphalt warm-mixing agent, preparation method and application

InactiveCN101831187ALow viscosityLow softening pointClimate change adaptationBuilding insulationsSurface-active agentsFatty alcohol

The invention discloses a rubber modified asphalt warm-mixing agent, a preparation method and application thereof. The warm-mixing agent comprises the following components in parts by weight: 100 parts of water, 5-30 parts of fatty alcohol sodium sulfate, 15-30 parts of palmitic acid, 5-30 parts of oleic acid, 1-20 parts of sodium dodecyl benzene sulfonate, 1-15 parts of cetyltrimethylammonium chloride and 10-30 parts of imidazoline-type cationic surface active agent ODD. The preparation method comprises the following steps of: adding the water in a container at the temperature of 65 DEG C, and then adding the following substances under the condition of stirring: the fatty alcohol sodium sulfate, the palmitic acid, the oleic acid, the sodium dodecyl benzene sulfonate, the cetyltrimethylammonium chloride and the imidazoline-type cationic surface active agent ODD, and stirring for 15 min to obtain the warm-mixing agent. The warm-mixing agent is directly applied to rubber asphalt or matrix asphalt to reduce the viscosity of the asphalt. The kinematic viscosity of the rubber powder asphalt added with the warm-mixing agent at the temperature of 150 DEG C can reach less than 3.0Pa.s of the kinematic viscosity at the temperature of 180 DEG C, and the production temperature can be reduced by about 30 DEG C, thereby not only preventing the rubber asphalt from being aged but also saving energy and reducing equipment loss.

Owner:BEIJING UNIV OF CHEM TECH

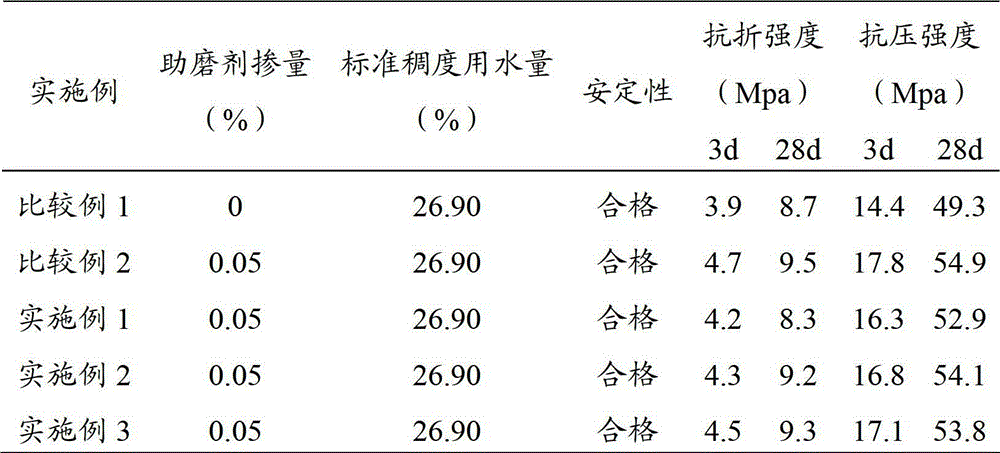

Grinding aid for slag cement

The invention provides a grinding aid for slag cement. The grinding aid provided by the invention comprises the following components by weight percent: 5-20wt% of alcohol amine compound, 0.1-5wt% of hydroxypropyl methyl cellulose, 5-30wt% of polyhydric alcohol compound, 0.5-10wt% of sodium hexametaphosphate, 1-10wt% of soluble sulfate, 1-8wt% of sodium dodecyl benzene sulfonate and the balance of water. In the grinding agent provided by the invention, the hydroxypropyl methyl cellulose is beneficial for stimulating the activity of the slag, forming stable hydrous products in the reaction process, improving the property of the cement, improving the strength of the cement and improving the stability of the liquid grinding aid at the same time. Experimental result shows that the grinding aid is capable of increasing the breaking strength of the cement to 9.5MPa and increasing the compressive strength to about 55MPa.

Owner:SHANDONG HONGYI TECH +1

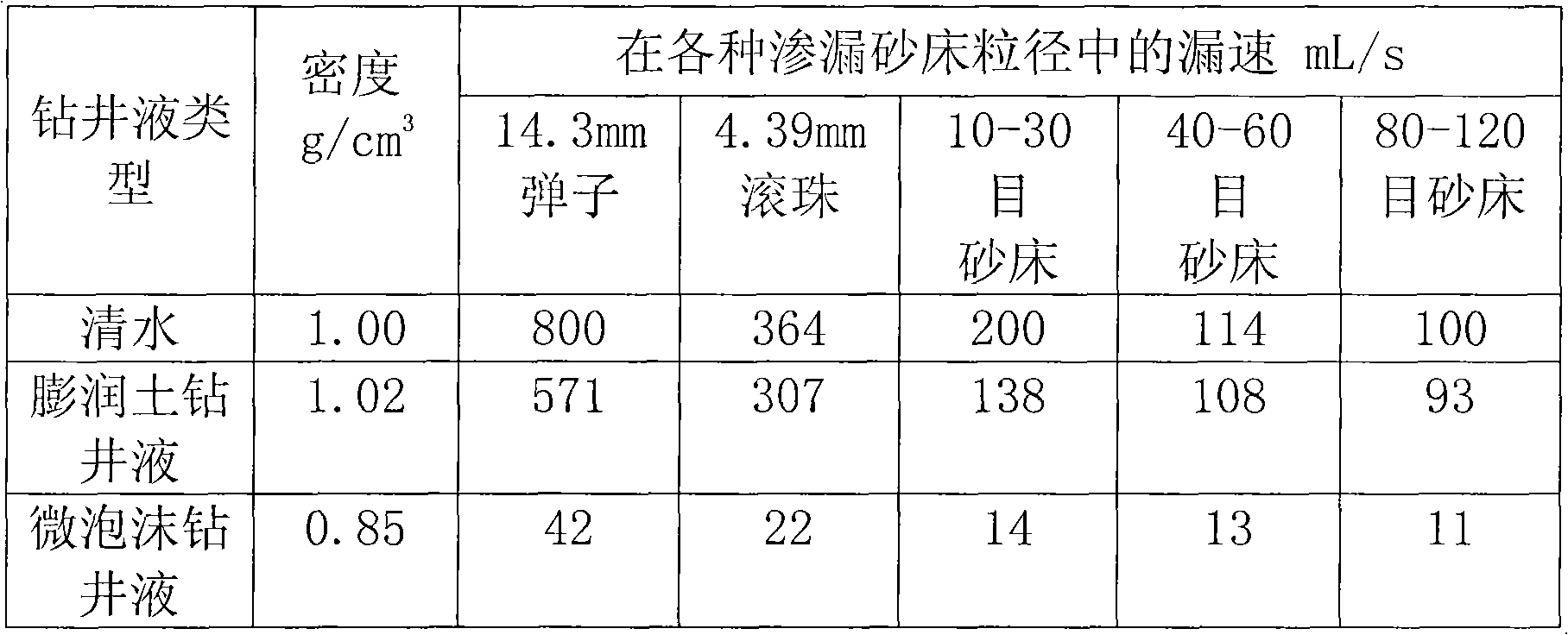

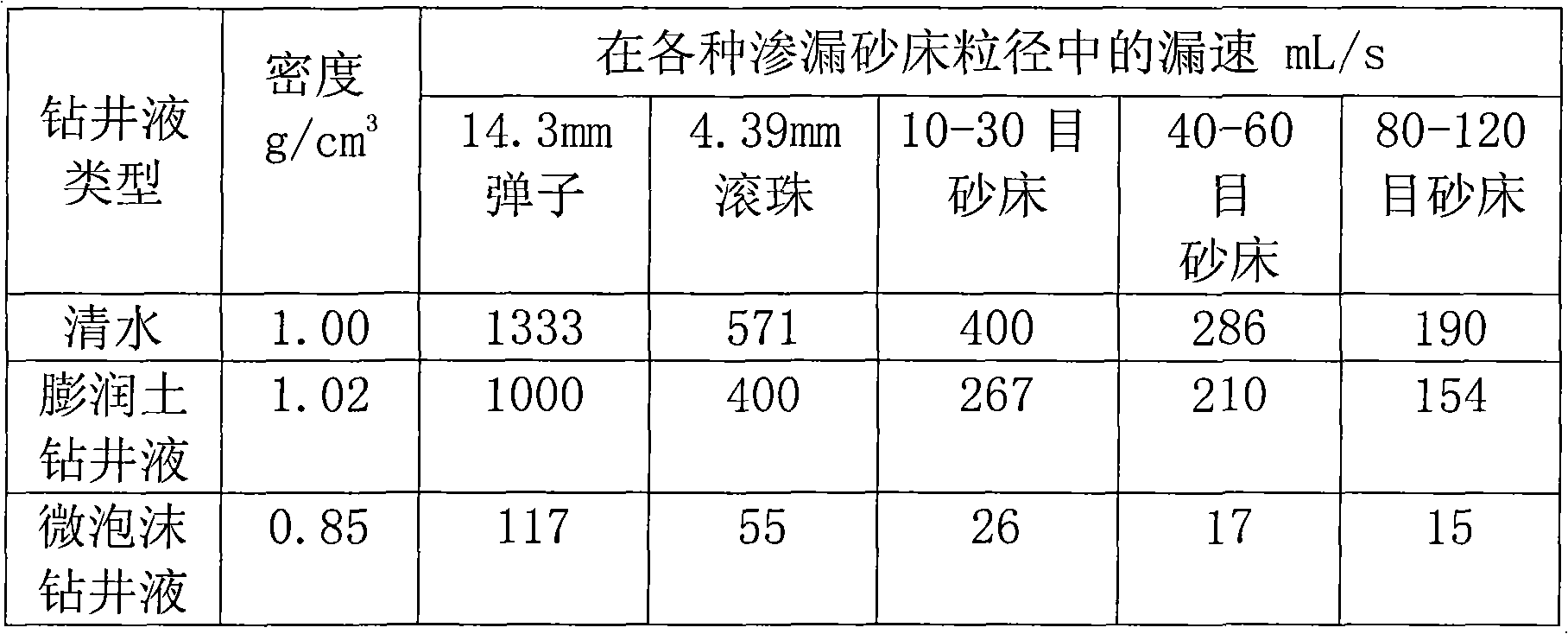

Micro-foam drilling fluid

The invention discloses a micro-foam drilling fluid. The micro-foam drilling fluid comprises the following compositions: 40 to 50 grams of bentonite, 3 to 5 grams of composite foaming agent, 2 grams of xanthan, 3 grams of high-viscosity carboxymethyl cellulose, 3 grams of sodium carbonate, 2 to 3 grams of strong zwitterionic coating agent, 5 grams of partially-hydrolyzed polyacrylonitrile ammonium salt, 5 grams of organic silicon humic acid kalium, 5 grams of lignite resin and 1 grams of viscosity reducer for the drilling fluid in each liter of the drilling fluid, wherein the composite foaming agent consists of lauryl sodium sulfate and sodium dodecyl benzene sulfonate according to mass ratio of 7:3. The drilling fluid has low density, good shielding effect and remarkable anti-leaking effect of a low-pressure easy-to-leak layer and can effectively improve the quality of well cementation.

Owner:DAQING PETROLEUM ADMINISTRATION +1

Boiler coal combustion-improving desulfurizing and denitrifying agent composition and preparation method thereof

The invention provides a boiler coal combustion-improving desulfurizing and denitrifying agent composition. The composition comprises the following raw materials in parts by weight: 2-7 parts of sodium carbonate, 1-3 parts of alumina, 2-8 parts of aluminium hydroxide, 2-5 parts of ferric trichloride, 2-6 parts of ferric oxide, 3-10 parts of potassium permanganate, 3-10 parts of potassium chlorate, 10-35 parts of activated attapulgite clay, 15-30 parts of urea, 2-4 parts of ammonium formate, 2-4 parts of ammonium chloride, 6-23 parts of ammonium acetate, 3-9 parts of manganese oxide, 9-12 parts of copper chloride, 1-3 parts of copper oxide, 2-4 parts of zinc sulfate, 1-3 parts of zinc nitrate, 7-18 parts of potassium dichromate, 1.0-1.5 parts of titanium dioxide, 0.5-1.0 part of barium molybdate, 0.5-1.5 parts of cobalt sulfate, 0.5-1.5 parts of vanadium pentoxide, 0.3-0.7 part of cerium oxide, 0.1-0.2 part of sodium dodecyl benzene sulfonate and 0.1-0.2 part of alkyl glyceryl ether. The composition is convenient to use, has stable properties, plays roles of combustion improving, desulfurization and denitrification, has coal saving rate of 8-25% and can remove fixed sulfur by 50-70%.

Owner:兰州熙瑞化工科技有限公司

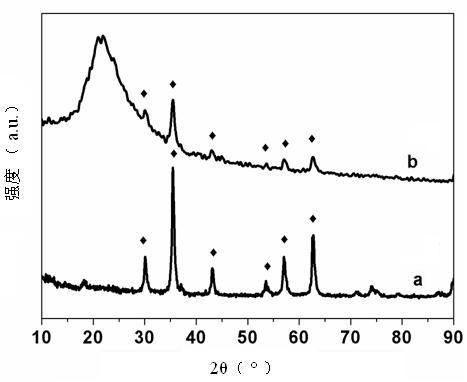

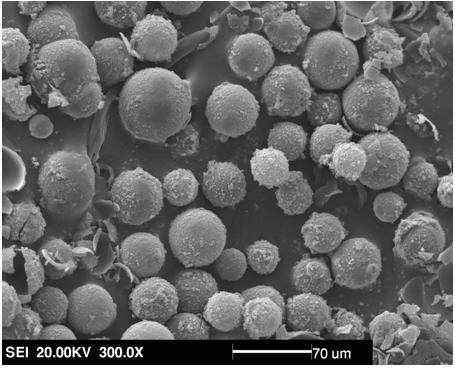

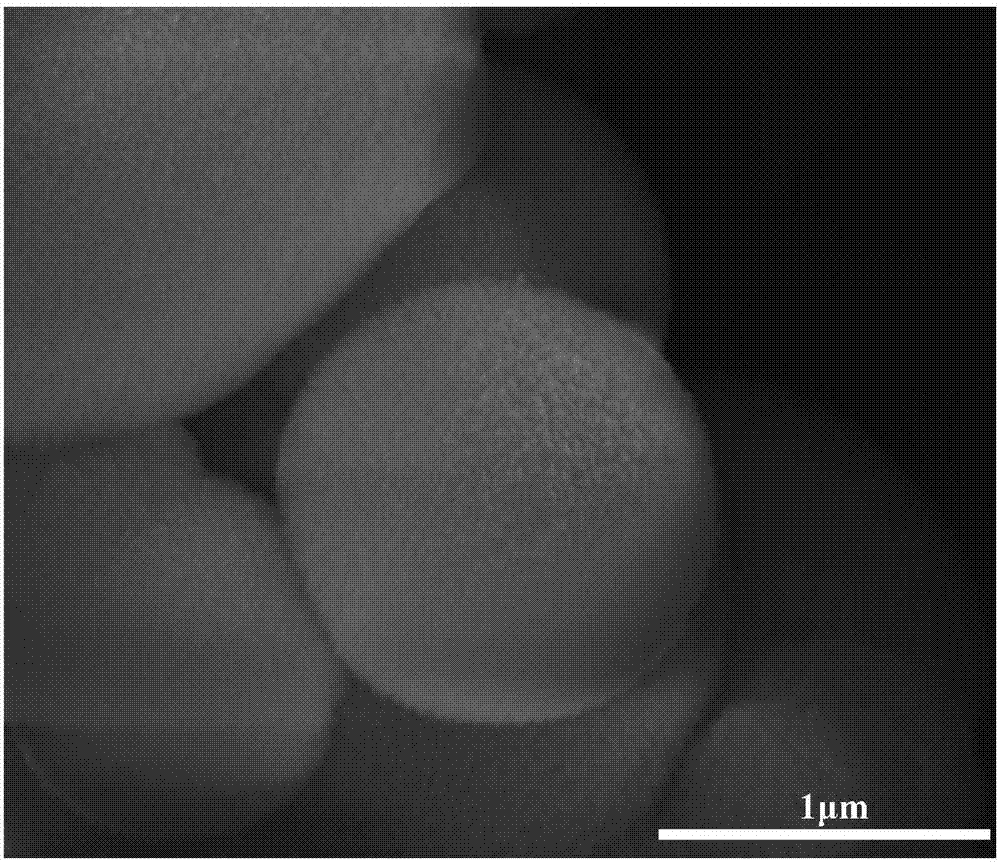

Method for preparing magnetic ferroferric oxide/conductive polyaniline light-weight composite hollow microspheres

InactiveCN101885915AGood dispersionNot easy to reuniteMicroballoon preparationMicrocapsule preparationConductive polymer compositeMicrosphere

The invention provides a method for preparing magnetic ferroferric oxide / conductive polyaniline light-weight composite hollow microspheres, which relates to a method for preparing a magnetic ferroferric oxide / conductive polyaniline composite material. The invention solves the problems of high density and easy agglomeration of the traditional magnetic nanometer particle / conductive polymer composite material. The method comprises the following steps of: regulating ferrous chloride and ferric chloride solutions to be alkaline, adding sodium dodecyl benzene sulfonate and reacting to obtain ferroferric oxide; and modifying hollow glass microspheres by using poly(diallyldimethylammonium chloride) solutions after alkaline cleaning, then reacting the hollow glass microspheres with the ferroferric oxide, sequentially immersing obtained solid particles by using the poly(diallyldimethylammonium chloride) solutions and polystyrene sulfonic acid solutions, then adding the solid particles to aniline solutions, initiating polymerization by using ammonium persulfate, and washing and drying the solid particles to obtain the composite hollow microspheres. The composite hollow microspheres have both conductivity and magnetism, the density is 0.78-0.8g / cm<3>, and the composite hollow microspheres are not easy to agglomerate and are used for fields of military equipment stealth technology and civil anti-electromagnetic radiation.

Owner:HARBIN INST OF TECH

High-temperature water-in-oil drilling fluid

InactiveCN102031095AOvercoming the problem of insufficient temperature resistanceMeet the requirements of temperature resistanceDrilling compositionMineral oilSODIUM DODECYL BENZENE SULFONATE

The invention relates to a high-temperature water-in-oil drilling fluid which is composed of the following components in parts by weight: 70-90 parts of base oil, 3-7 parts of organic bentonite, 2-5 parts of oxidized asphalt, 2-5 parts of sulfonated gilsonite, 20-60 parts of CaCl2 aqueous solution of which the mass concentration is 20%, 6-10 parts of calcium oxide, 1.5-5.5 parts of UZEMUL-S, 2-5 parts of ABS (acrylonitrile butadiene styrene) and barite, wherein the base oil is non-blooming mineral oil with low aromatic hydrocarbon; the UZEMUL-S is a main emulsifier, the HLB (hydrophile-lipophile balance) value is 2.5, and the UZEMUL-S is formed by synthetizing an organic acid and an organic acid amide; and the ABS auxiliary emulsifier is sodium dodecyl benzene sulfonate, and the HLB value is 10. The invention resists temperature of 240 DEG C, can overcome the difficulty of insufficient heat-resistant capability of the existing drilling fluid and is favourable for satisfying the requirement of drilling fluid heat-resistant capability for deep wells and ultra deep wells.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

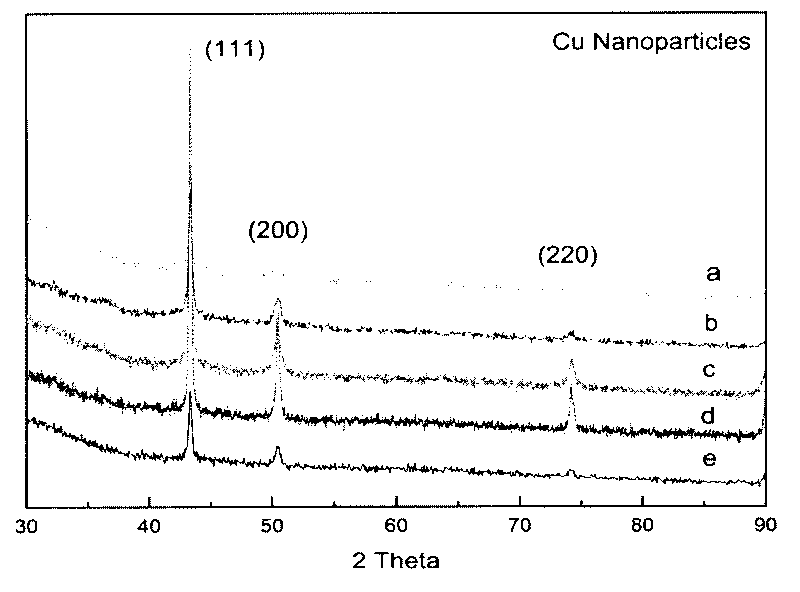

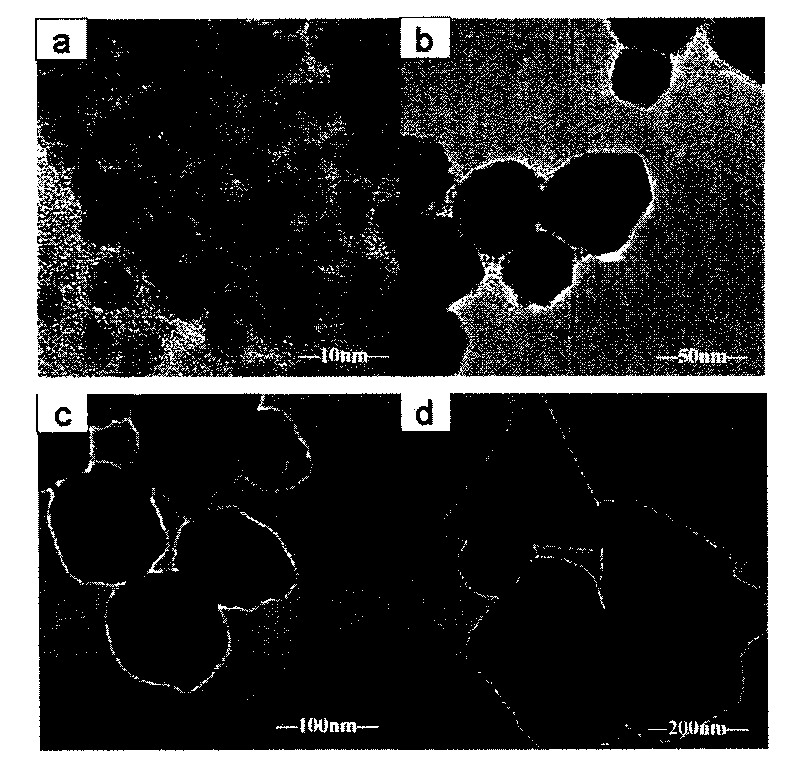

Preparation method of copper nanoparticles with different particle diameters

The invention discloses a preparation method of copper nanoparticles with different particle diameters and relates to a metal nanoparticle. The invention provides a preparation method of copper nanoparticles with different particle diameters, which has simple, economic, environment-friendly process. The preparation method comprises the following steps: adding metal salt of copper chloride or copper acetate, a solvent, a protective agent, a complexing agent and a surfactant in a vessel in sequence, and stirring to obtain a mixture, wherein the protective agent is polyvinylpyrrolidone, polyvinyl alcohol, polyacrylic acid, or the like, the complexing agent is oleic acid, hexadecylamine, oleamide, or the like, and the surfactant is hexadecyl dimethyl ammonium bromide, sodium dodecyl benzene sulfonate or the like; adding a reducing agent in the mixture for reacting, wherein the reducing agent is ascorbic acid, sodium formaldehyde sulphoxylate, sodium borohydride, or the like; cooling the reactant till the temperature is below 40 DEG C, then adding a precipitating agent, mixing, and centrifugally separating; then washing with the organic solvent, centrifugating, and extracting the precipitate; and then drying the precipitate to obtain red powder copper nanoparticles with different particle diameters.

Owner:XIAMEN UNIV

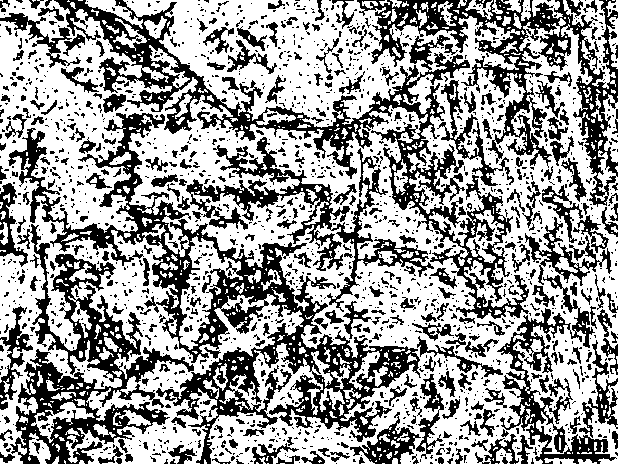

Metallographic etched process for displaying G Cr15 original austenite grain border

InactiveCN101187606AShorten the timeGood reproducibilitySurface/boundary effectPreparing sample for investigationAlcoholMetallography

A metallographic corrosion method for displaying a GCr15 original austenitic grain boundary comprises adding picric acid 5g into distilled water100ml and mixing continuously, then adding sodium dodecyl benzene sulfonate 5ml 50% and mixing, finally adding ferric chloride 2g, and using after placing for 24 hours. A sample is grinded roughly, grinded finely, polished, cleared, dried, immersed into caustic erodent for 2-5 minutes according to normal method under a quenching tempering condition until etched surface is changed into silver grey, cleaned up through flowing water, cleaned with alcohol 95%, and dried. If the sample is over-corroded, polishing paste W0.5-1.0 or metallographic polishing egent0.5-1.0 is added on silk polishing cloth, the sample is polished slightly with hands, then cleaned with alcohol 95%, and dried. According to practical condition, grain granularity measurement can adopt methods of picture contrast, grid, intercept, quantitative metallography, and the like, to assess according to relevant standards.

Owner:LUOYANG BEARING SCI & TECH CO LTD

Chemical etching liquid for metals and etching method

The invention provides a chemical etching liquid for metals. The chemical etching liquid comprises ferric chloride, hydrochloric acid, phosphoric acid, hydrogen nitrate, a corrosion inhibitor and a surface active agent. The corrosion inhibitor is at least one of hexamethylene tetramine, ethidene diamine, triethanolamine and heptadecane amide; and the surface active agent is one or two of sodium lauryl benzenesulfate and dodecyl alcohol amine. The invention further discloses a chemical etching method for metals; with the method, the metals are etched through spraying the etching liquid; and the etching liquid is provided by the invention. The etching liquid provided by the invention can be applied to surface etching of various metals, particularly stainless steel, copper and aluminum alloy; and since the metals can be etched with the same etching liquid, the consumption of equipment is reduced.

Owner:南通麦特隆新材料科技有限公司

Composite fertilizer special for dragon fruits

The invention relates to a composite fertilizer special for dragon fruits. The composite fertilizer consists of urea, ammonium nitrate, monoammonium phosphate, potassium sulfate, humic acid salt, chitosan, borax, zinc chloride, sodium molybdate, manganese sulfate, ferrous sulfate, magnesium sulfate, copper sulfate, salicylic acid, sodium dodecyl benzene sulfonate, dimethyl sulfoxide, monosodium glutamate waste liquor, an EM (effective microorganism) liquid and the like. The composite fertilizer disclosed by the invention is used for overcoming the defects that the specially applied fertilizer is lack in the current dragon fruit cultivation production, the fertilizer use amount is high and organic nutrition components are few.

Owner:蚌埠行时知识产权运营有限公司

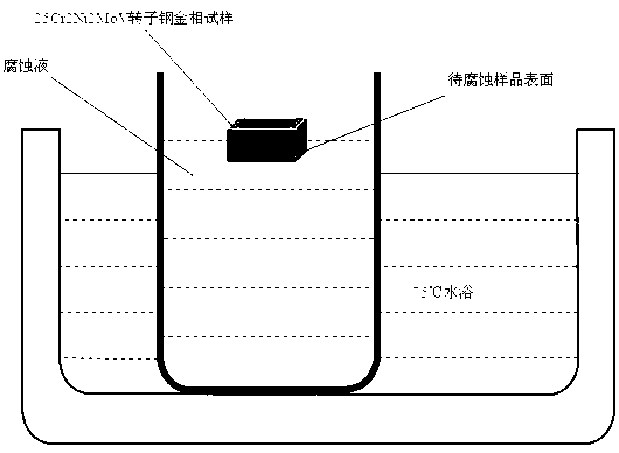

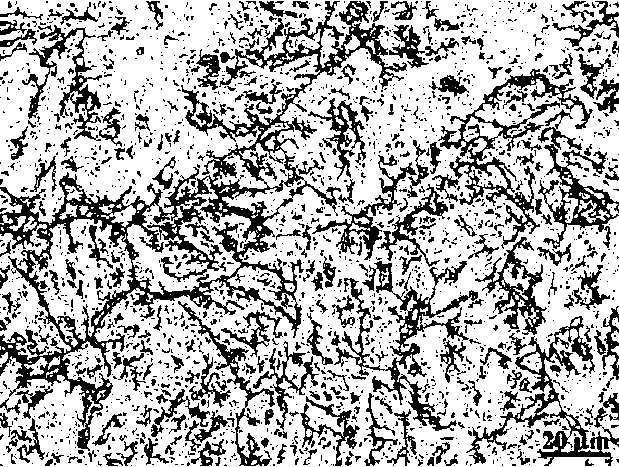

Metallographic corrosion method for clearly displaying original austenite grain boundary of NiCrMoV type rotor steel

The invention relates to a metallographic corrosion method for clearly displaying the original austenite grain boundary of a NiCrMoV type rotor steel, and belongs to the field of metallographic sample preparation. The method comprises the steps of: coarse grinding, fine grinding, polishing and corroding; putting a polished sample into a corrosive liquid of 75 DEG C, wherein the formula of the corrosive liquid comprises 200ml of distilled water, 5g of picric acid, 2ml of 5% diluted hydrochloric acid and 4g of sodium dodecyl benzene sulfonate; etching for 2minutes, taking the sample out, cleaning the sample with flowing water, cleaning the sample with alcohol and drying; and observing the clear original austenite grain boundary through an optical microscope. The method has the advantages that a difficult displaying problem of the original austenite grains of the NiCrMoV type rotor steel is solved, the original austenite grain boundary can be very clearly displayed, and the method is simple and practicable.

Owner:SHANGHAI UNIV +1

Cement grinding aid and preparation method thereof

InactiveCN101125742AImprove grinding efficiencyReduce grinding power consumptionCement grindingTriisopropanolamine

The invention discloses a cement grinding aid and a preparation method thereof. Raw materials of the cement grinding aid consists of 10-30 percent of triethanolamine, 12-30 percent of tirisopropanolamine, 5-20 percent of ethylene glycol, 3-10 percent of propanediol, 15-40 percent of water, 1-5 percent of sodium dodecyl benzene sulfonate, 3-10 percent of lignin and 2-5 percent of anhydrous sodium sulfate; water is poured into a reactor and heated to 40-50 DEG C to be reserved; the sodium dodecyl benzene sulfonate is added to be stirred for 15min; the anhydrous sodium sulfate is added and stirred for 10min, then the lignin is added and stirred for 30min; materials in the reactor are filtered by a 150 mesh screen; the ethylene glycol and the propanediol are added and stirred for 20min; the triethanolamine and the tirisopropanolamine are added and stirred for 30min and the grinding aid products are obtained. The cement grinding aid can improve grinding efficiency and early and later strength of cement and reduce cement cost.

Owner:洛阳万顺建材有限公司

Rare-earth modified Ti-Zr chemical passivation solution for surface treatment of aluminium profiles and using method of rare-earth modified Ti-Zr chemical passivation solution

ActiveCN103103512AImprove compactnessImprove performanceMetallic material coating processesCerium nitratePotassium fluoride

The invention discloses a rare-earth modified Ti-Zr chemical passivation solution for surface treatment of aluminium profiles and a using method of the rare-earth modified Ti-Zr chemical passivation solution. The rare-earth modified Ti-Zr chemical passivation solution is characterized in that the passivation solution is a main salt for auxiliary film-formation, which takes rare-earth compounds as a Ti-Zr passivation treatment solution, and a passivation film is light yellow in appearance and has field judgement property on the quality of a formed film. A formula of the rare-earth modified Ti-Zr chemical passivation solution is as follows: each litre of solution contains 0.5g.L<-1>-10g.L<-1> of potassium fluotitanate (hexafluorotitanic acid), 0.5g.L<-1>-10g.L<-1> of potassium fluozirconate (fluozirconic acid), 0.5g.L<-1>-5g.L<-1> of cerium nitrate (ceric sulfate and ammonium ceric nitrate), 2g.L<-1>-10g.L<-1> of potassium nitrate, 0.5g.L<-1>-3g.L<-1> of sodium fluoride (potassium fluoride), 0.5g.L<-1>-1g.L<-1> of sodium dodecyl benzene sulfonate or OP-10, 0.2mL-5mL.L<-1> of nitric acid and 1g.L<-1>-5g.L<-1> of boric acid. The using method of the rare-earth modified Ti-Zr chemical passivation solution comprises the following steps of: (1) clearing dirt, such as dirt attached to an aluminium alloy; (2) pretreating the surface of the aluminium alloy; (3) carrying out passivating treatment on the surface of the aluminium alloy by using the rare-earth modified Ti-Zr chemical passivation solution; and (4) washing the aluminium alloy by using water and drying the aluminium alloy. The rare-earth modified Ti-Zr chemical passivation solution disclosed by the invention has the advantages of light yellow appearance, high film formation speed, simple process, uniformity in film layer, strong corrosion resistance, low environment pollution and the like.

Owner:GUANGDONG XINGFA ALUMINUM

Paraffin wax phase change energy storage material and preparation method thereof

InactiveCN102127395ALow priceImprove surface propertiesSolid waste managementHeat storage plantsParaffin waxFilm coating

The invention provides a paraffin wax phase change energy storage material and a preparation method thereof. The paraffin wax phase change energy storage material comprises 48 to 56.7 percent of paraffin wax, 14.2 to 32 percent of high-density polyethylene, 4 to 5.7 percent of sodium dodecyl benzene sulfonate serving as a surfactant, 10.4 to 15.6 percent of sodium alginate serving as a film forming material and 5.6 to 7.8 percent of anhydrous calcium chloride serving as a crosslinking agent. The method for preparing paraffin wax phase change energy storage material comprises the following steps: preparing a microcapsule phase change material by using paraffin wax as a core material and high-density polyethylene as supporting material and by using a melting method; and preparing millimetercapsule phase change material by using a thin film coating technique. In the invention, the technical problems of low paraffin wax mixing amount, low storage performance, leakage, low stability and the like of the conventional microcapsule phase change material are solved.

Owner:SOUTHEAST UNIV

Preparation method of highly filled polyethylene synthetic paper

The invention relates to a preparation method of highly filled polyethylene synthetic paper. The preparation method is characterized in that: high density polyethylene, heavy calcium carbonate, waterless calcium chloride, sodium dodecyl benzene sulfonate and an antioxidant 1076 are added to a banbury mixer, and a temperature reaches 150 to 180 DEG C through banburying; materials after banburying are sent to an extruder, and melts from the extruder are sent to a calender by a T-shaped die head and then calendered into sheets at the temperature of 140 to 160 DEG C; the sheets from the calender are cooled to below 50 DEG C by air with a relative humidity of 50 % to 100%; and the sheets are sent to a multi-roller stretcher, preheated in the stretcher to 110 to 130 DEG C, and stretched by group 2 to 5 stretching rollers to obtain the needed synthetic paper. The purity of the highly filled polyethylene synthetic paper prepared through the method provided by the present invention is 0.9 to 1.5 g / cm<3>.

Owner:EAST CHINA UNIV OF SCI & TECH +1

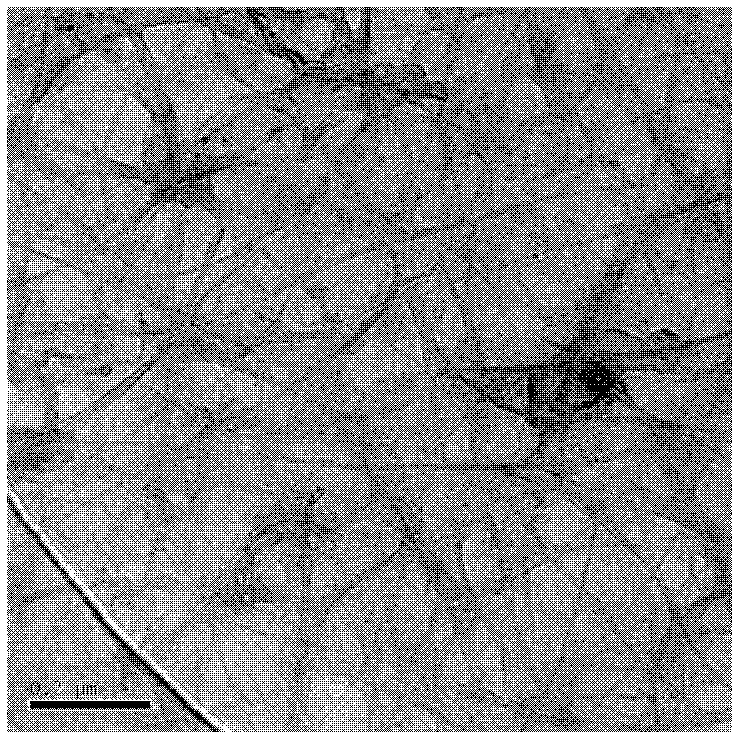

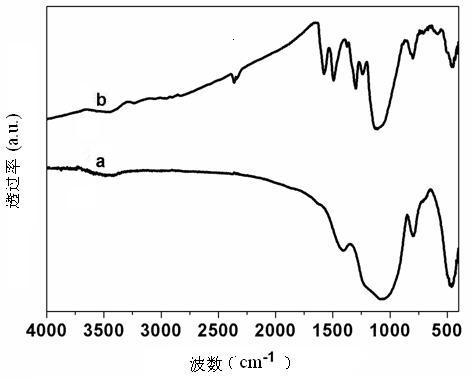

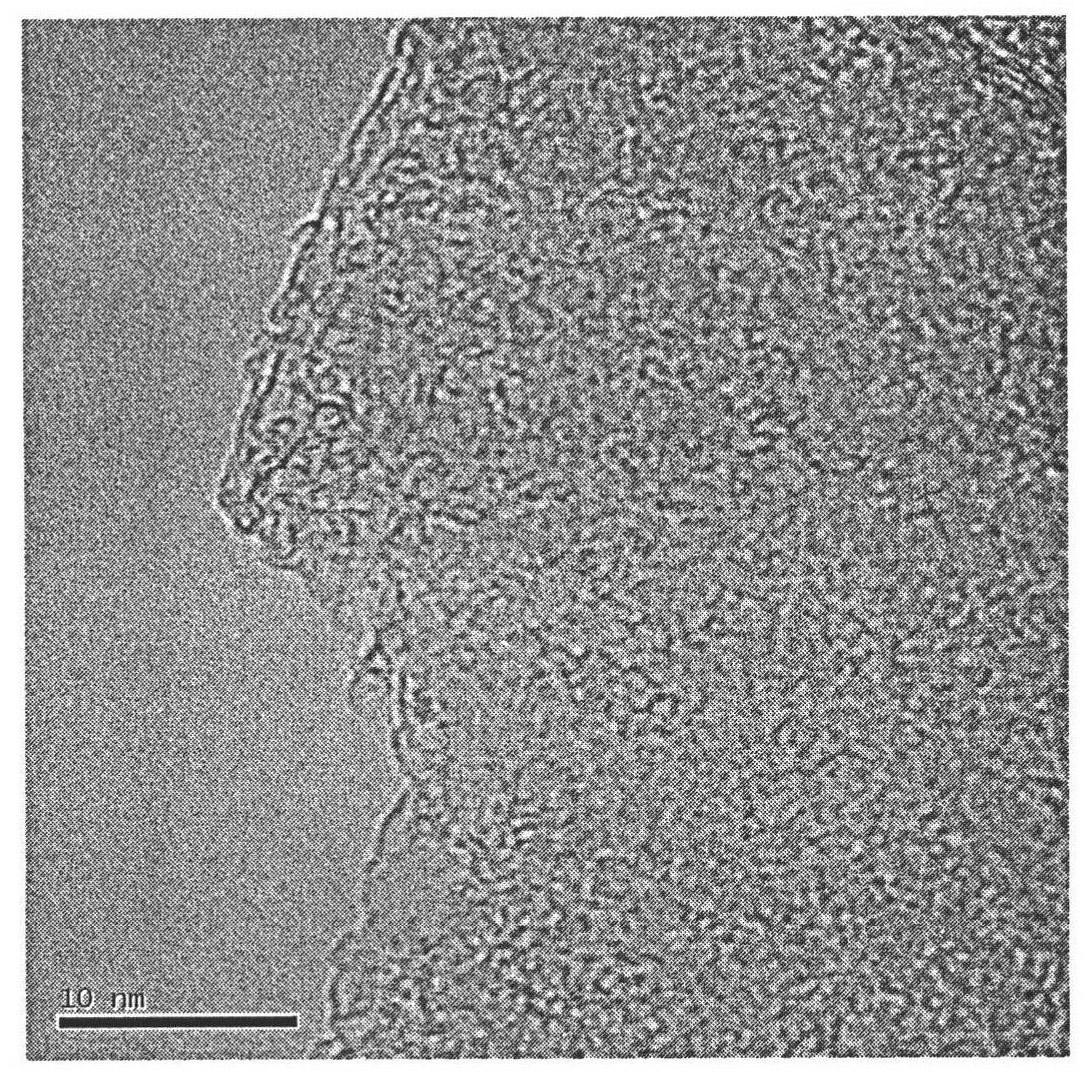

Preparation method of graphene loaded with anatase type nano titanium dioxide and application thereof

InactiveCN102324505ASmall sizeEvenly dispersedAlkaline accumulator electrodesNanotechnologyFlake graphiteSODIUM DODECYL BENZENE SULFONATE

The invention discloses a preparation method of graphene loaded with anatase type nano titanium dioxide and an application thereof. The preparation method comprises the following steps: preparing graphite oxide from crystalline flake graphite; carrying out reduction reaction on the graphite oxide to obtain graphene by taking hydrazine hydrate as a reducing agent and sodium dodecyl benzene sulfonate as a dispersing agent; preparing titanium hydroxide colloidal solution by taking tetrabutyl titanate as a titanium source; mixing the ethanol solution of graphene and the titanium hydroxide colloidal solution, stirring and calcining to prepare the graphene loaded with anatase type nano titanium dioxide. The graphene loaded with anatase type nano titanium dioxide prepared by the method can be mixed with copper powder to prepare the negative electrode of a nickel-hydride secondary battery. The method provided by the invention has the advantages of simple preparation process and low cost and is easy to operate. When the prepared graphene loaded with anatase type nano titanium dioxide is used as the active material of the cathode of the secondary battery, the effects of high discharge specific capacity and good circulation stability are achieved.

Owner:TIANJIN UNIV

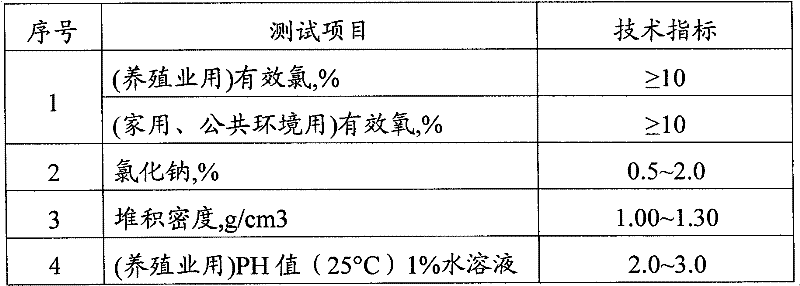

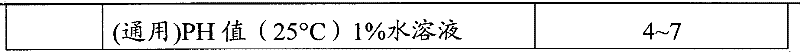

Composite potassium hydrogen persulfate disinfectant and its manufacturing process

ActiveCN102265904AMeet needsWith low toxicity and ultra-low toxicityBiocideFungicidesPotassium persulfateDisinfectant

The invention relates to a compound potassium hydrogen persulfate disinfectant and a manufacturing process thereof. The compound potassium hydrogen persulfate disinfectant comprises the following components in percentage by weight: 60-65% of potassium hydrogen persulfate complex, 0-1.8% of sodium chloride, 2-10% of aminosulfonic acid, 0-2% of sodium dodecyl benzene sulfonate, 0-10% of sodium hexametaphosphate, 0-25% of sodium citrate, 0-25% of sodium tartrate, 0-0.2% of flavoring agent and 0-0.12% of pigment. In the compound potassium hydrogen persulfate disinfectant provided by the invention, the different disinfection requirements of medical, family and livestock and poultry breeding industries are sufficiently considered and the contents of the components in the formula are adjusted according to different users, so that the compound potassium hydrogen persulfate disinfectant can meet the needs of different users; the compound potassium hydrogen persulfate disinfectant has good killing effects on almost all zoonotic bacteria, fungi and viruses, and simultaneously has the characteristics of low toxicity and ultra-low toxicity; and the wide application ranges and good stability and security are perfectly combined.

Owner:上海泰缘生物科技股份有限公司

Water-solubility printing ink washing agent

InactiveCN101638532ASimple recipeEasy to manufactureChemical paints/ink removersSolubilityAlkylphenol

A water-solubility printing ink washing agent comprises A component, B component and solvent according to weight ratio of 1: (1.5-2.5): (0.04-0.08), wherein raw materials of the A component are as follows according to weight parts: 12-15 parts of fatty alcohol-polyoxyethylene ether, 0.5-1 part of alkylphenol polyoxyethylene, 8-10 parts of aviation kerosene, 2-4 parts of dibutyl phthalate, 1-3 parts of butyl cellosolve, 1-2 parts of benzyl alcohol and 1-3 parts of butyl acetate; raw materials of the B component are as follows according to weight parts: 5-8 parts of sodium dodecyl benzene sulfonate, 1-2 parts of ethanolamine, 1-3 parts of diethanolamide, 0.5-1 part of urea, 0.5-1 part of sodium carbonate, 0.3-0.5 part of sodium silicate, and 45-55 parts of water. The preparation of the invention is simple, has simple and convenient manufacture, stable performance, safe usage, does not easily burn, does not corrode device and does not pollute the environment. The washing agent has good washing effect, is safe and non-toxic, has easily obtained and stored raw materials, has high stability, can be repeatedly used, and has wide market prospect.

Owner:MAOMING COLLEGE

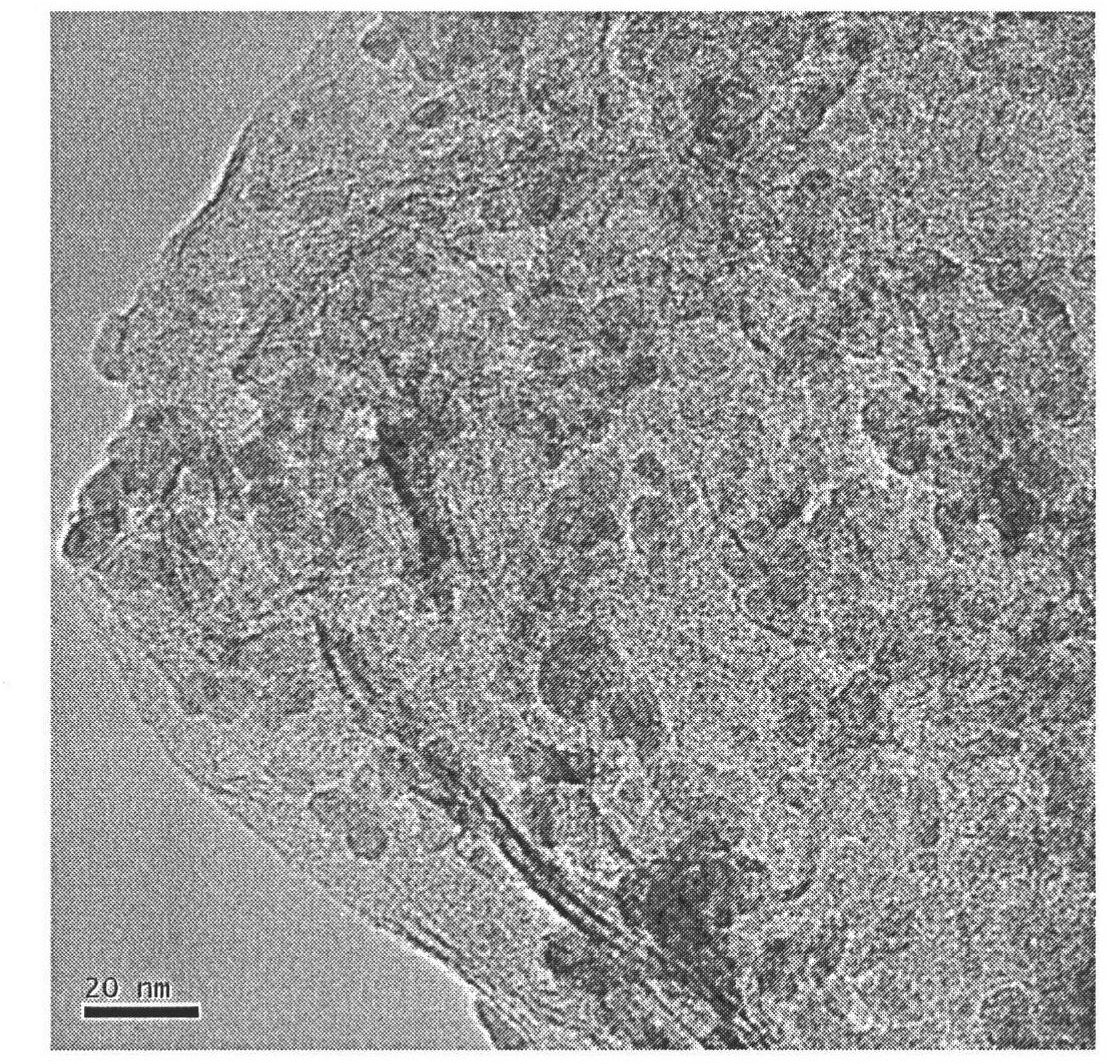

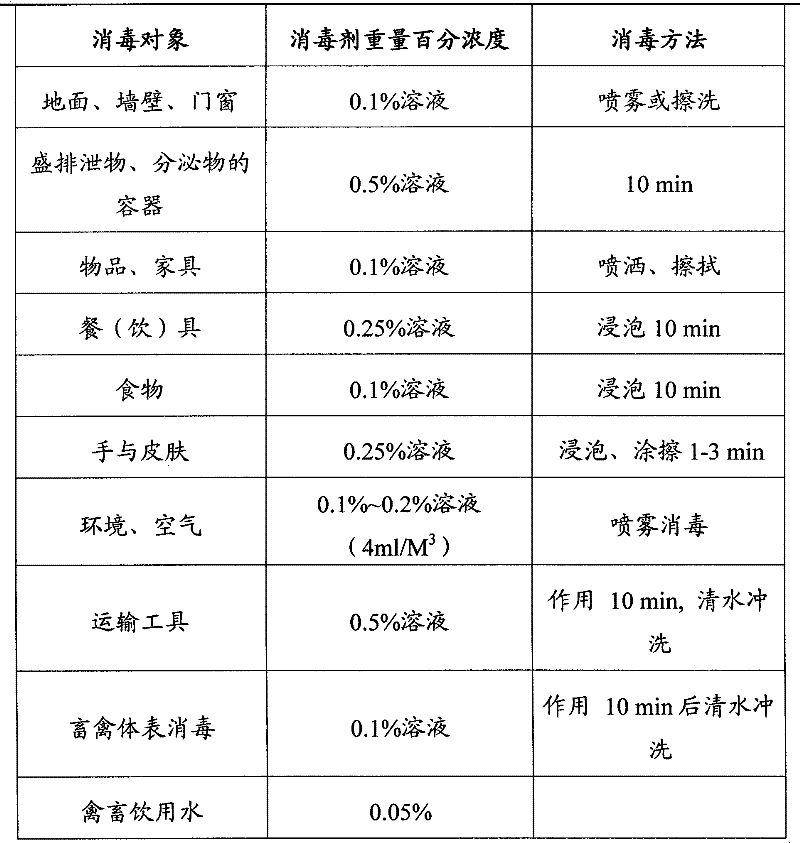

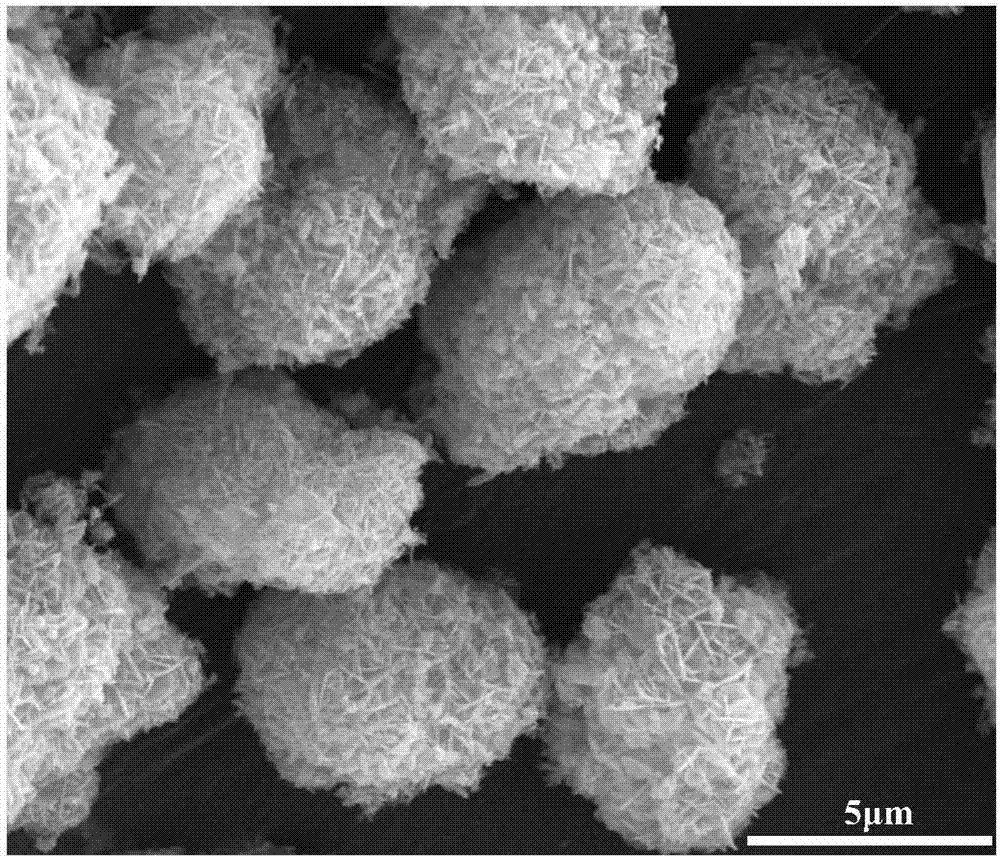

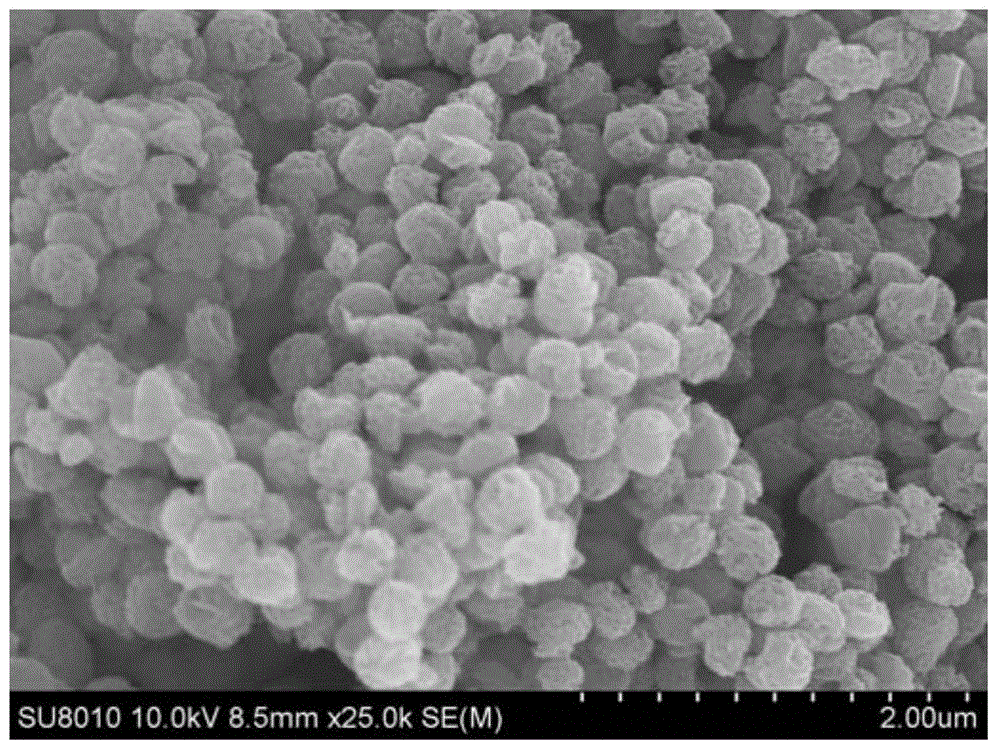

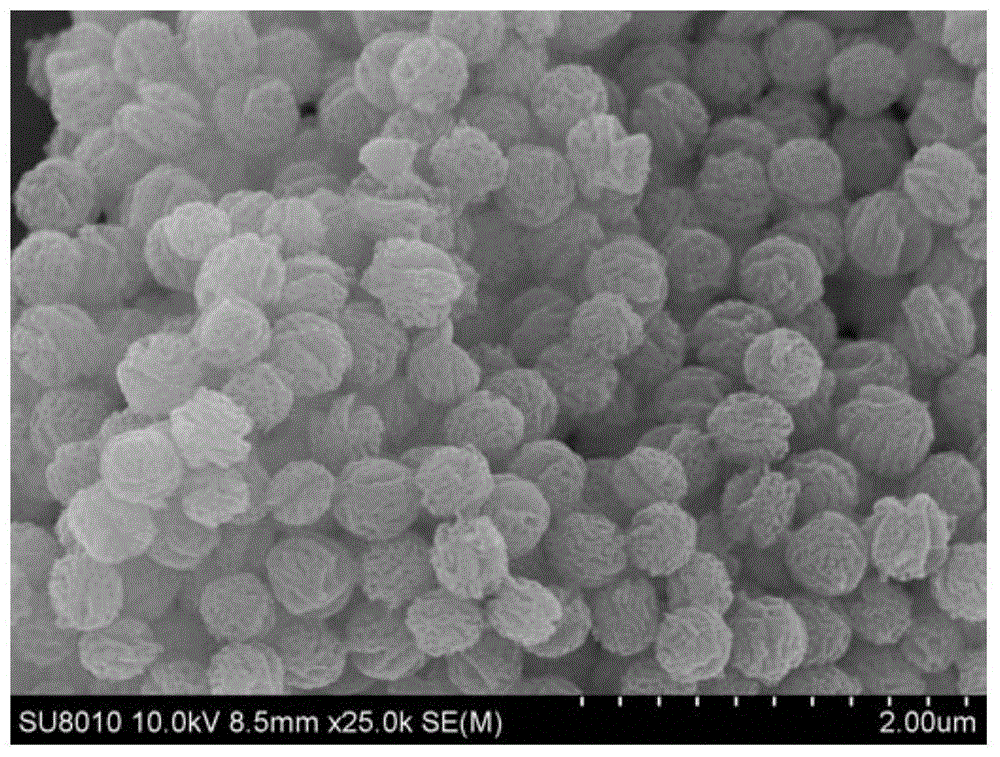

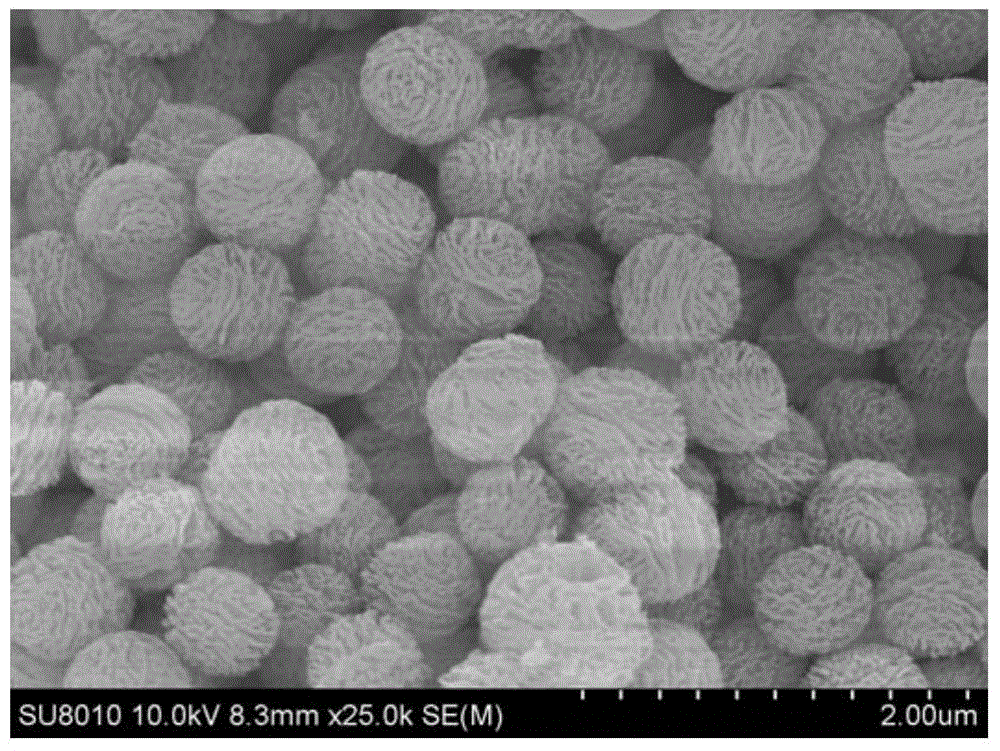

Method of preparation of ternary anode material precursor

The invention relates to a method of preparation of a ternary anode material precursor and belongs to the field of chemical energy storage batteries. The preparation method comprises the steps that a precursor of a nickel-cobalt-manganese ternary material is prepared by adopting a hydroxide coprecipitation method, and primary particle crystal face growth is controlled by utilizing the synergistic effect of a surfactant compounded system and ammonia water. Specifically, sodium dodecyl benzene sulfonate and the sulfo-betaine 12 surfactant compounded system are added in alkali liquor, the synthesis condition of the precursor is adjusted in the preparation process to control a crystal structure of the material, and the nickel-cobalt-manganese ternary anode material precursor different in primary particle morphology is obtained. The nickel-cobalt-manganese ternary material precursor prepared by adopting the method has different primary particle morphology and distribution, has different influences on migration and diffusion of corresponding anode material Li<+>after lithium-mixed calcination and thus shows different electrochemical properties.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

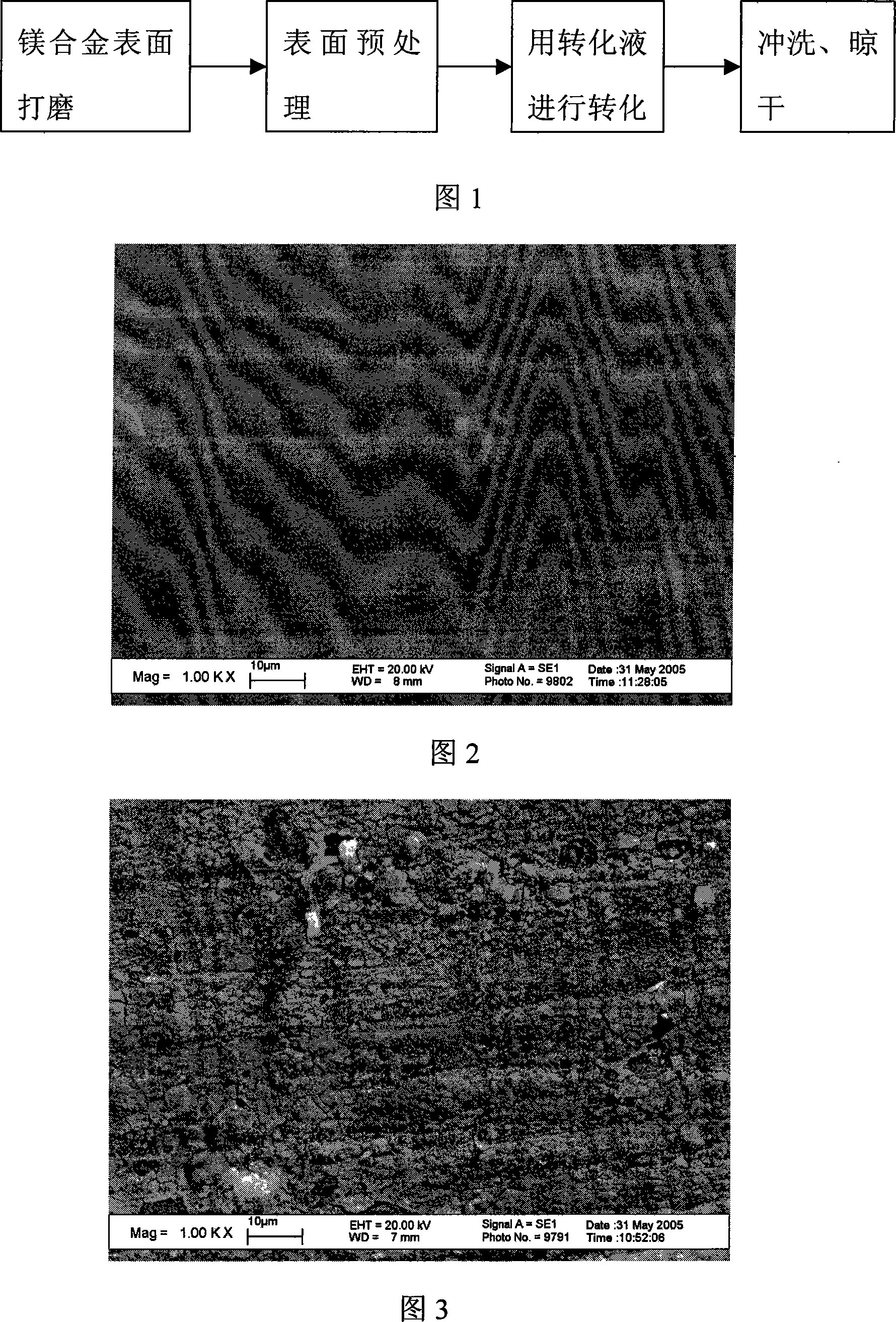

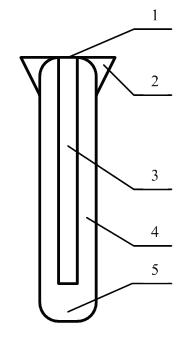

Non-chromium treatment fluid for preparation of corrosion-resistant oxidation film on magnesium alloy surface and method of use thereof

InactiveCN101225517AImprove corrosion resistanceGood adhesionMetallic material coating processesPersulfatePhytic acid

The invention discloses a preparation and application method for conversion liquid of a corrosion resistant oxide film on magnesium alloy surface, which is characterized in that: the conversion liquid adopts rare-earth-containing salt, permanganate, persulphate, nitrate and perchlorate as composite oxidant, zirconium salt, vanadic salt and strontium salt as film forming promoter, boric acid, aminoacetic acid-hydrochloric acid solution as pH buffer regulator, pyridine, thiourea and derivatives, tannins, phytic acid and the salt compound as corrosion inhibitor, sodium dodecyl benzene sulfonate and dodecyl phenol polyoxyethlene ether (OP-10) as wetting agent; the conversion liquid is free from hexavalent chromium and environment-friendly; heating is not required for chemical conversion treatment, and the treatment time is 1 to 5min; composite oxide film with good corrosion resistance performance comprising rare-earth composite oxide, magnesia and manganese oxide can be rapidly prepared at on magnesium alloy surface at ambient temperature. The preparation method for conversion liquid of a corrosion resistant oxide film on magnesium alloy surface has the advantages of fast film forming, simple process, uniform film, strong corrosion resistance and less environmental pollution.

Owner:广州市宏盈机械设备有限公司

Foam drainage gas recovery method for natural gas horizontal well

InactiveCN102587865AThe effect of drainage and gas recovery is obviousSimple and safe operationFluid removalDrilling compositionRecovery methodPolyethylene glycol

The invention relates to a foam drainage gas recovery method used for a natural gas horizontal well. The method is capable of injecting a foam scrubbing agent into the bottommost end of a gas well shaft, so that the whole shaft is filled with foam fluid and optimal drainage gas recovery effect is achieved. The technical scheme of the method comprises the following steps: firstly, manufacturing a dynamical underground foam scrubbing bar which consists of a gas nozzle, a tail wing, a boosting agent, a shell and a protection head sleeve, wherein the material for manufacturing the tail wing, the shell and the protection head sleeve is the solid foam scrubbing agent which consists of polyoxyethylene alkyl ethers, polyethylene glycol, urea, imidazoline, sodium dodecyl benzene sulfonate and saturated alcohol sulfate; and the boosting agent is one of dry ice, sodium hydride or potassium oxide; and secondly, throwing the dynamical underground foam scrubbing bar to the bottom of the well, wherein the boosting agent is in contact with water to generate a large amount of gas, so that the foam scrubbing bar is pushed to the bottommost end; and as the foam scrubbing agent is dissolved, a large amount of foam is formed to achieve the optimal effect of drainage gas recovery. The method disclosed by the invention has a wide application range without any wellhead equipment and energy, is simpleand safe in operation, low in cost and has no pollution to the environment.

Owner:SOUTHWEST PETROLEUM UNIV

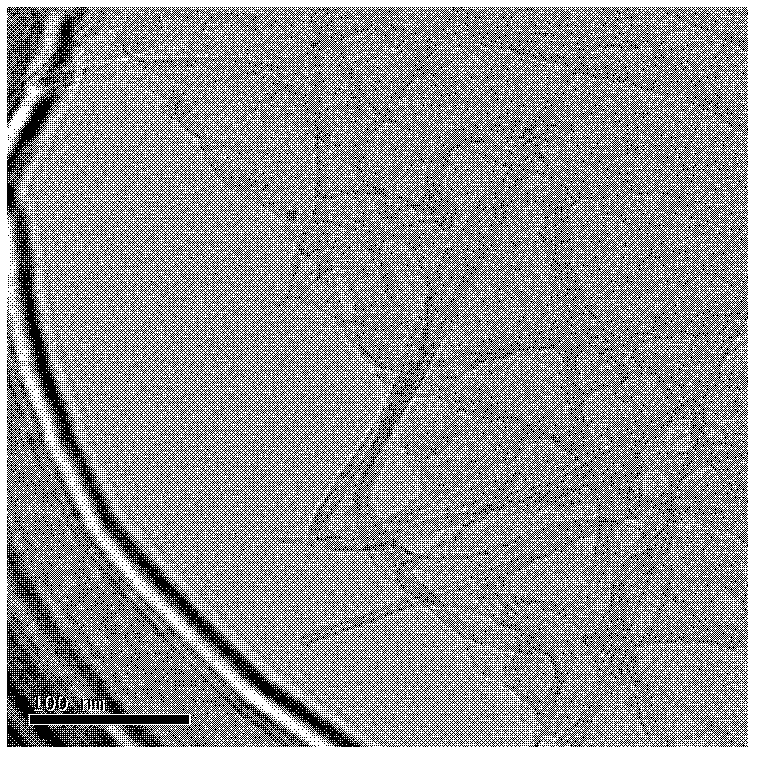

Preparation method for mesoporous silica material

InactiveCN104787768AEasy to prepareMild operating conditionsMaterial nanotechnologySilicaMesoporous silicaSilicon dioxide

The invention belongs to the technical field of mesoporous nanomaterial preparation, and discloses a preparation method for a size-controllable mesoporous silica material. According to the preparation method, micelles formed by two surfactants of hexadecyl trimethyl ammonium bromide and sodium dodecyl benzene sulfonate are taken as templates, ethyl orthosilicate is taken as a silicon source, ethanol and ether are taken as co-solvents, under an ammonia water-water system, the size-controllable mesoporous silica material is synthesized, and finally, the templates are removed by baking. The preparation method is simple to operate and mild in condition; the morphology and the specific surface area are controlled by adjusting the concentration and proportion of the surfactants and the ratio of the two co-solvents, and the prepared silica nanomaterial is regular in morphology, uniform in particle size and stable in structure; the prepared silica nanomaterial having different morphologies and pore sizes can be widely applied to adsorption, catalysis, carriers, drug slow release and other fields.

Owner:SOUTH CHINA UNIV OF TECH

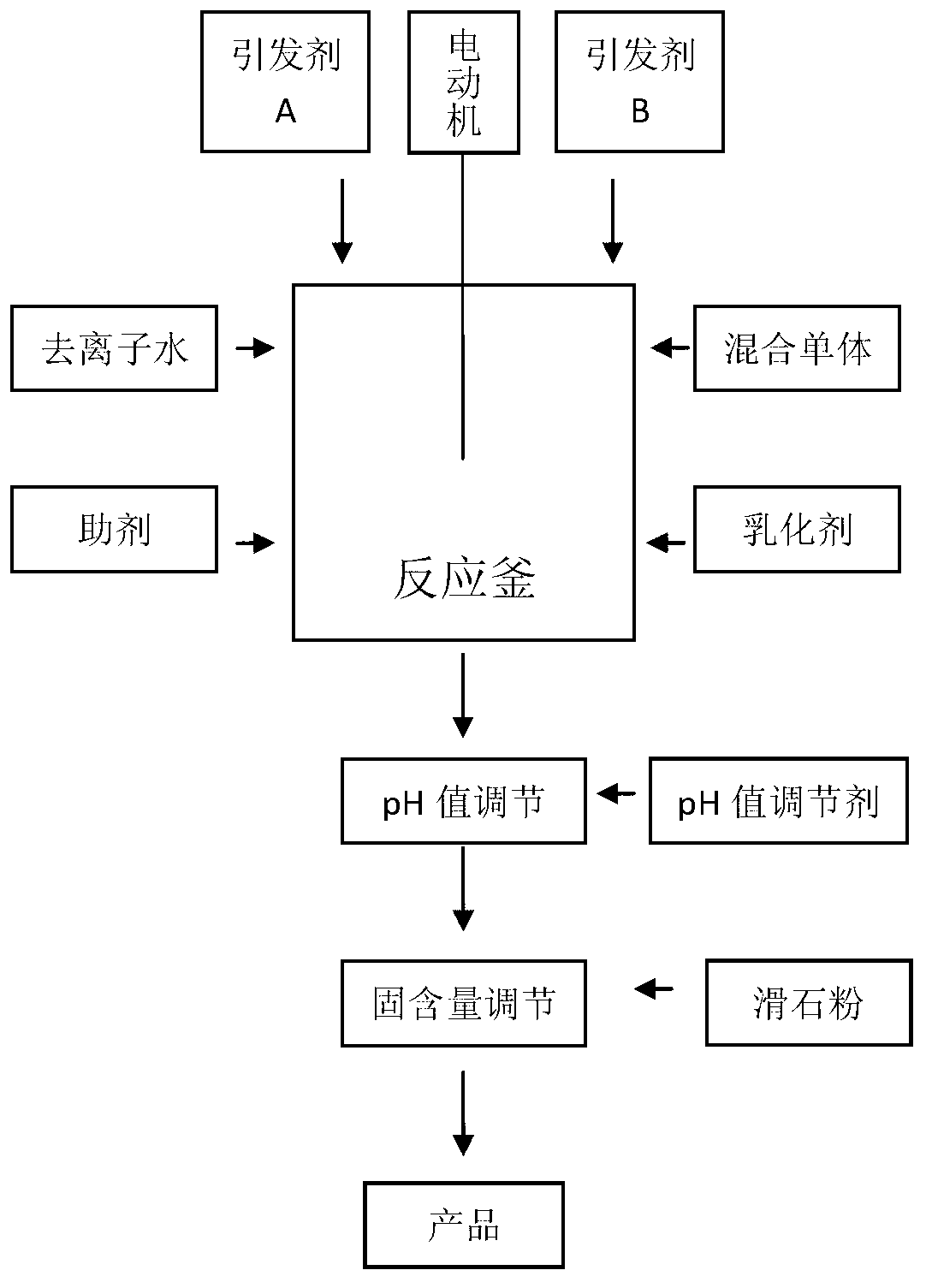

Polyvinyl dichloride (PVDC) latex used for interior and exterior wall coating materials and preparation method thereof and application thereof

The invention discloses a polyvinyl dichloride (PVDC) latex used for interior and exterior wall coating materials and a preparation method thereof and application thereof. The PVDC latex is obtained by a mixed monomer, an auxiliary, an initiating agent and an emulsifying agent through a once polymerization method, wherein the mixed monomer contains a certain amount of vinylidene chloride, vinyl chloride and acrylic ester, and the emulsifying agent contains sodium dodecyl benzene sulfonate and OP-10 or OP-4. The PVDC latex enables a system to be stable, and is free of emulsification breaking and sediment after placed for 24 months under temperature of 30 DEG C and relative humidity (RH) of 70%, and free of damage by calcium and magnesium in use. The interior and exterior wall coating materials obtained by the PVDC latex have the advantages of being environment-friendly, waterproof, damp proof (mildew resistant), coincident with the V-0 grade of the underwriters laboratories (UL) 94 standard in fire resistance, and the like.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

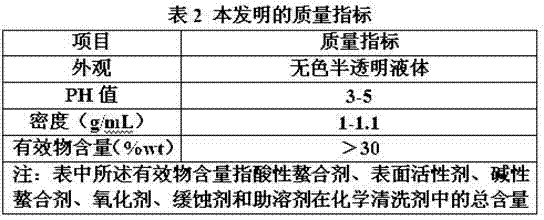

Chemical cleaning agent for clearing impurities such as ferrous sulfide

InactiveCN102345136AEasy to cleanPrevent spontaneous combustionNon toxicitySODIUM DODECYL BENZENE SULFONATE

The invention relates to a chemical cleaning agent for clearing impurities such as ferrous sulfide, which is made of the following raw materials in percentage by weight: 1-15% of acidic chelating agent, 0.05-5% of surfactant, 1-20% of alkaline chelating agent, 5-30% of oxidant, 0.1-1% of corrosion inhibitor, 0.1-2% of cosolvent and the balance of water; the acidic chelating agent is preferably selected from citric acid; the surfactant is preferably selected from sodium dodecyl benzene sulfonate; the alkaline chelating agent is preferably selected from ammonia or disodium ethylene diaminetetraacetate; the oxidant is preferably selected from hydrogen peroxide; the corrosion inhibitor is preferably selected from polybasic phosphate (A ester); and the cosolvent is preferably selected from benzoic acid or sodium benzoate. The invention has the beneficial effects of effectively clearing dirt such as ferrous sulfide in devices at normal temperatures and avoiding the spontaneous combustion of the ferrous sulfide and has the characteristics of low cost, large dirt clearing amount, good dirt clearing effect, non-toxicity, safety, simple and convenient operation, and the like.

Owner:NINGBO ZHONGYI PETROCHEM TECH

Method for recycling carbon and electrolytes from waste cathode carbon block of aluminum electrolytic cell

InactiveCN105821445AReduce dosageReduced dosage of chemicals (reduced amount of collectorElectrolysis componentsCalcium/strontium/barium fluoridesKeroseneFuel oil

The invention discloses a method for recycling carbon and electrolytes from a waste cathode carbon block of an aluminum electrolytic cell. The method comprises the following steps that 1, the cathode carbon block is crushed and grinded; 2, cathode carbon powder obtained from the cathode carbon block subjected to crushing and grinding in the step 1 is stirred and leached in alkali liquor and then filtered, so that a filter cake A1 and filtrate B1 are obtained; and a precipitating agent is added into the filtrate B1, so that a filter cake A2 and filtrate B2 are obtained after filtering is conducted; and 3, the filter cake A1, the filter cake A2, a flotation medium and flotation reagents are subjected to mixing and pulp conditioning, and thus the carbon and electrolytes are obtained through flotation and separation; the flotation reagents comprises the collecting agents, the foaming agents and the conditioning agents; the collecting agents are composed of the collecting agent C1 and the collecting agent C2 at the mass ratio of 0.65-0.75:0.25-0.35; the collecting agent C1 is selected from at least one of coal tar, heavy oil, kerosene and diesel oil; and the collecting agent C2 is selected from at least one of dodecylamine, sodium dodecyl benzene sulfonate, sodium oleate and sodium dodecyl sulfate. According to the method for recycling the carbon and the electrolytes from the waste cathode carbon block of the aluminum electrolytic cell, the carbon powder and the electrolytes are effectively separated and recycled from the waste cathode carbon block.

Owner:CENT SOUTH UNIV

Chemical cleaning method of reverse osmosis membrane

ActiveCN101721916AEffective elutionThe process is continuous and stableSemi-permeable membranesGeneral water supply conservationReverse osmosisChemical cleaning

The invention relates to a chemical cleaning method of a reverse osmosis membrane. In the method, aiming at a reverse osmosis membrane for processing PTA refining wastewater, inorganic pollutants which are formed by cobalt ions, manganese ions, hydroxide thereof and the like and are deposited and adsorbed on the surface of the membrane are dissolved and eluted by using acid rinse prepared by citric acid and sodium bisulfite; organic colloid pollutants deposited and adsorbed on the surface of the membrane are dissolved and eluted by using alkaline rinse containing sodium dodecyl benzene sulfonate and sodium hydroxide. The method can elute the pollutants on the surface effectively, restore operating flux, operating pressure and desalination rate of the reverse osmosis membrane, and ensure that the process of processing the reverse osmosis membrane for the PTA refining wastewater is stable in operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com