Patents

Literature

60 results about "Ceric sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rare-earth modified Ti-Zr chemical passivation solution for surface treatment of aluminium profiles and using method of rare-earth modified Ti-Zr chemical passivation solution

ActiveCN103103512AImprove compactnessImprove performanceMetallic material coating processesCerium nitratePotassium fluoride

The invention discloses a rare-earth modified Ti-Zr chemical passivation solution for surface treatment of aluminium profiles and a using method of the rare-earth modified Ti-Zr chemical passivation solution. The rare-earth modified Ti-Zr chemical passivation solution is characterized in that the passivation solution is a main salt for auxiliary film-formation, which takes rare-earth compounds as a Ti-Zr passivation treatment solution, and a passivation film is light yellow in appearance and has field judgement property on the quality of a formed film. A formula of the rare-earth modified Ti-Zr chemical passivation solution is as follows: each litre of solution contains 0.5g.L<-1>-10g.L<-1> of potassium fluotitanate (hexafluorotitanic acid), 0.5g.L<-1>-10g.L<-1> of potassium fluozirconate (fluozirconic acid), 0.5g.L<-1>-5g.L<-1> of cerium nitrate (ceric sulfate and ammonium ceric nitrate), 2g.L<-1>-10g.L<-1> of potassium nitrate, 0.5g.L<-1>-3g.L<-1> of sodium fluoride (potassium fluoride), 0.5g.L<-1>-1g.L<-1> of sodium dodecyl benzene sulfonate or OP-10, 0.2mL-5mL.L<-1> of nitric acid and 1g.L<-1>-5g.L<-1> of boric acid. The using method of the rare-earth modified Ti-Zr chemical passivation solution comprises the following steps of: (1) clearing dirt, such as dirt attached to an aluminium alloy; (2) pretreating the surface of the aluminium alloy; (3) carrying out passivating treatment on the surface of the aluminium alloy by using the rare-earth modified Ti-Zr chemical passivation solution; and (4) washing the aluminium alloy by using water and drying the aluminium alloy. The rare-earth modified Ti-Zr chemical passivation solution disclosed by the invention has the advantages of light yellow appearance, high film formation speed, simple process, uniformity in film layer, strong corrosion resistance, low environment pollution and the like.

Owner:GUANGDONG XINGFA ALUMINUM

Polishing solution used for amorphous alloy and polishing method of amorphous alloy

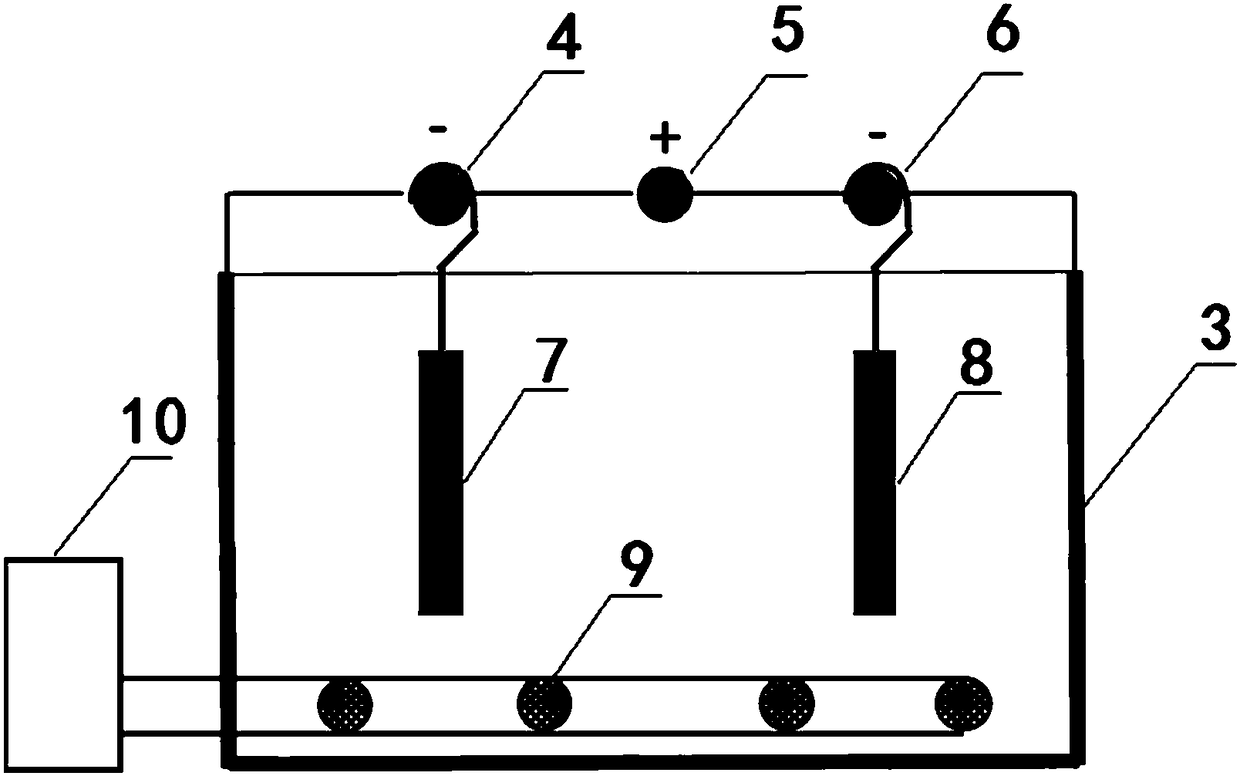

The invention provides a polishing solution used for an amorphous alloy and a polishing method of an amorphous alloy. The polishing solution comprises: a sodium salt, an ammonium salt and a brightener, i.e. ceric sulfate. The polishing method includes plasma polishing to an amorphous alloy. And the plasma polishing method consists of: connecting the amorphous alloy to a positive electrode, and immersing the amorphous alloy into an electrolytic cell containing the polishing solution, and taking the electrolytic cell body as a negative electrode for plasma polishing. The amorphous alloy prepared with the polishing solution provided in the invention and by the plasma polishing method of the invention has a smooth surface and high surface reflectivity.

Owner:BYD CO LTD

Film forming solution for magnesium alloy chemical composition coating and preparation thereof

InactiveCN101469421AStrong paint film adhesionAccelerated corrosionMetallic material coating processesChemical compositionCeric sulfate

The invention provides a magnesium alloy chemical conversion film forming solution, wherein the film forming solution is a water solution containing ceric sulfate, sulphuric acid, phytic acid, an inhibiter and a buffering agent and has a pH value between 2 and 6. The invention further provides a method for preparing the magnesium alloy chemical conversion film. The chemical conversion film obtained by the film forming solution and the method for preparing the magnesium alloy chemical conversion film has high adhesive attraction of the paint film, good corrosion resistance and wearing resistance, good compactability of the film and low electric resistance.

Owner:深圳市新合富力科技有限公司

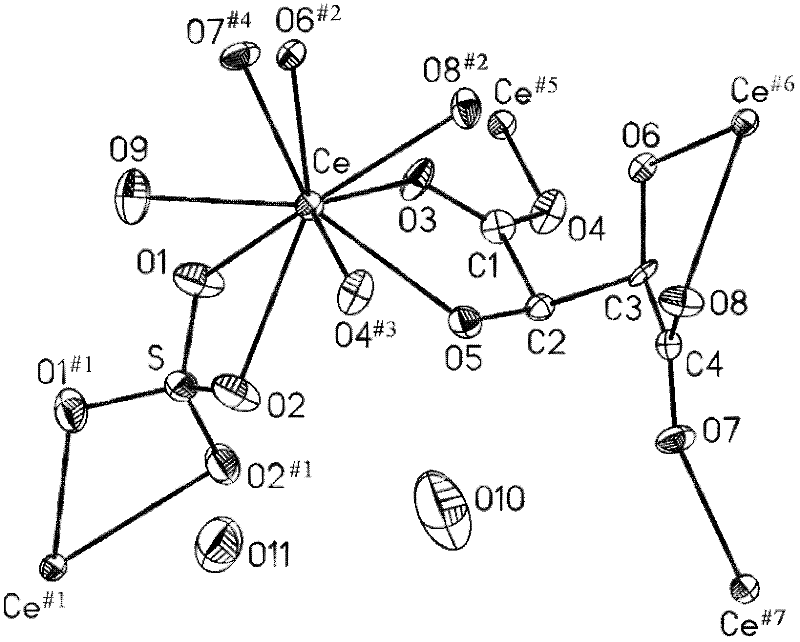

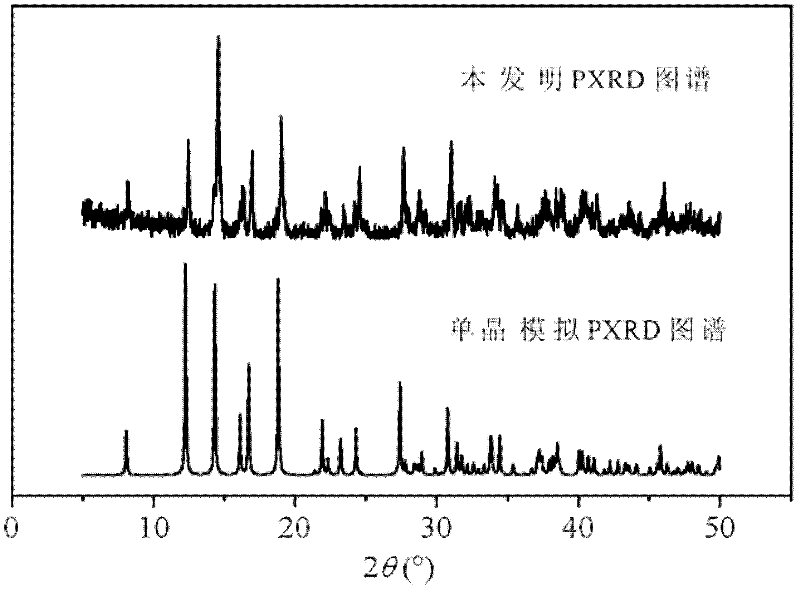

L-tartaric acid ceric sulfate ferroelectric functional material and preparation method thereof

InactiveCN102330153ASignificant features of ferroelectric functionLow costPolycrystalline material growthFrom normal temperature solutionsSpace groupCeric sulfate

The invention discloses an L-tartaric acid ceric sulfate ferroelectric functional material. The molecular formula of the ferroelectric functional material is [[Ce2(H2O)2(L-(+)-tar)2(SO4)].4H2O]. The ferroelectric functional material can pass through a sieve with 100 meshes, is white monoclinic system powder and has a C2 space group structure. The 2Pr value of a ferroelectric hysteresis of the ferroelectric functional material is 0.316muC / cm<2>, the 2Ec value is 54.1kV / cm, the Ps value is 0.335muC / cm<2> and the saturated intensity of polarization of the ferroelectric functional material is 1.34 times of that of polarization of rochelle salt. The ferroelectric functional characteristics are remarkable. The preparation method of the ferroelectric functional material comprises the following steps of: uniformly mixing cerium dioxide, L-(+)-tartaric acid and sulphuric acid; adding deionized water for a hydro-thermal reaction; after reaction, filtering to obtain an L-tartaric acid ceric sulfate tabular crystal; and grinding and sieving to obtain the colorless L-tartaric acid ceric sulfate monoclinic system powder ferroelectric functional material. The preparation method has the advantages of simple and feasible process, low requirement on equipment, low cost of raw material, high yield, no pollution and the like.

Owner:NINGBO UNIV

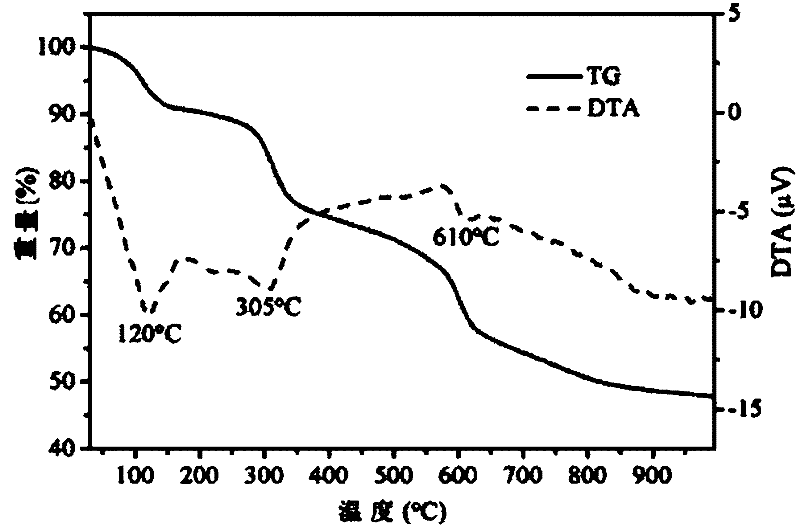

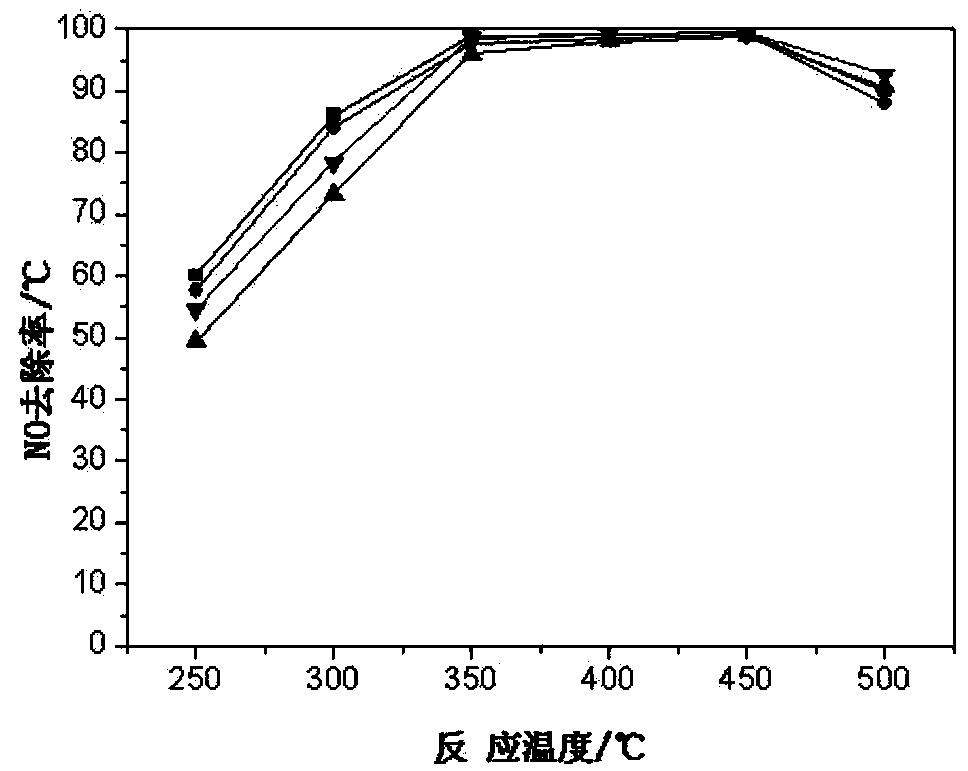

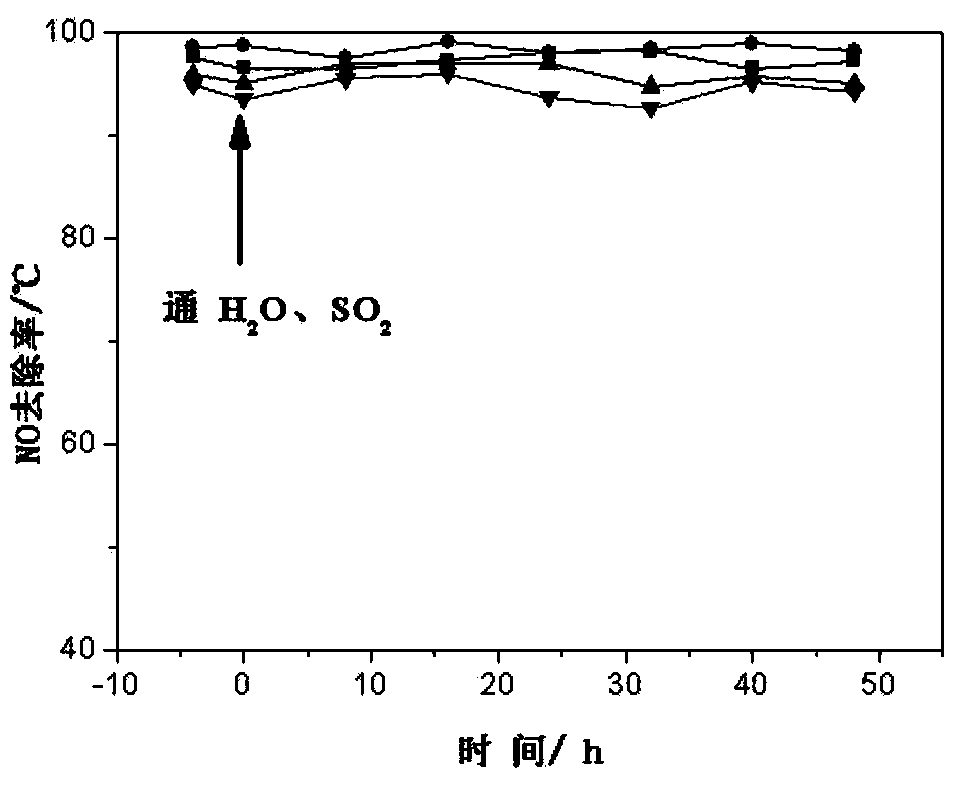

A composite metal sulfate system flue-gas-denitration catalyst and a preparation method thereof

ActiveCN103638939AStrong resistance to sulfur poisoningDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeric sulfateWater vapor

The invention relates to a composite metal sulfate system flue-gas-denitration catalyst and a preparation method thereof, and belongs to the technical fields of environmental-friendly catalytic materials and atmospheric pollution control. The catalyst and the preparation method thereof are characterized in that titanium dioxide is used as a carrier, ceric sulfate is used as an active component, and a transition-metal sulfate is used as a cocatalyst; the weight percent of the active component of the catalyst is 1-25% based on the weight of the carrier; and the weight ratio of the active component to the auxiliary is 1: (0.1-0.9). The catalyst is prepared by utilization of a direct sulfate-dipping method. Compared with technical performances of selective catalytic reduction (SCR) denitration catalysts at present, the catalyst provided by the invention broadens the middle / high-temperature denitration active temperature window, and enhances vapor-poison tolerance and sulfur dioxide poison tolerance of the catalyst significantly. The preparation technology of the catalyst is simple, environmental friendly, cheap, and free of secondary pollution.

Owner:NANJING UNIV OF TECH

Method for rapidly detecting synthetic phenol antioxidant in edible oil and fat and oil and fat food

InactiveCN102323256AAccurate detectionThe instrument is simpleMaterial analysis by observing effect on chemical indicatorBiotechnologyBenzthiazuron

The invention discloses a method for rapidly detecting the content of a synthetic phenol antioxidant, particularly the content of BHA (Butyl Hydroxy Anisol), TBHQ (Tert-Butyl Hydroquinone) and PG (Propyl Gallate), in edible oil and fat and oil and fat food. The method comprises the following steps of: by using an organic solvent as an extracting agent, uniformly mixing the extracting agent and a sample to be detected; carrying out oscillating extraction; taking extraction liquid; adding 3-methyl-2-benzothiazolinonehydrazone hydrochloride and ammonium ceric sulfate which are used as color development reagents into the extraction liquid; shaking the mixture well; standing; and rapidly detecting the content of the synthetic phenol antioxidant by a spectrophotometry. In the method, large-scale expensive equipment such as an HPLC (High Performance Liquid Chromatography), a GC (Gas Chromatograph) and the like are not required. An instrument required by the method is simple. The method is simple and convenient to operate, can be completed by non professional staffs, has low cost, high accuracy and reproducibility, is time-saving and labor-saving and has wide market application prospect.

Owner:云南健牛环境监测有限公司 +1

Preparation method of anhydrous ceric sulfate

InactiveCN101633514AGood water solubilityMeet quality requirementsRare earth metal compoundsSolubilityCeric sulfate

The invention discloses a preparation method of anhydrous ceric sulfate, taking high-purity cerium hydroxide as a raw material, and comprising the following steps: using industrial concentrated sulfuric acid to carry out acid dissolution on cerium hydroxide, controlling the (H<+>) mol / L of spent acid of the acid solution, the Ce<4+> dissolved concentration (g / L) of the acid solution and the dissolving temperature to fully dissolve the cerium hydroxide, then carrying out concentrated crystallization, cooling and filtering to obtain crystallized ceric sulfate which is put into a crucible and dehydrated and dried in a drying box, and then obtaining the product, namely anhydrous ceric sulfate. The anhydrous ceric sulfate prepared by the method has high product purity, good water solubility, short process flow and convenient operation, and is easy for scale production; in addition, the mother liquor can be reused, thereby playing a role of energy saving and emission elimination.

Owner:甘肃稀土新材料股份有限公司

Catalyst used for producing promoter N-cyclohexyl benzothiazole sulfonamide and its preparation method

InactiveCN102380404AEasy to prepareEasy to industrializeOrganic chemistryMolecular sieve catalystsCerium nitrateCeric sulfate

The invention relates to a catalyst used for producing promoter N-cyclohexyl benzothiazole sulfonamide and its preparation method. The catalyst is selected from one or more of metal salts of copper acetate, copper sulphate, cupric nitrate, cobaltous acetate, cobaltous sulphate, cabaltous nitrate, cerium acetate, ceric sulfate, cerium nitrate, manganese acetate, manganese sulfate, manganese nitrate and the like. A carrier of the catalyst is selected from one or more of active carbon, SiO2, Al2O3, TiO2, mesoporous material molecular sieve, microporous material molecular sieve and the like. The prepared catalyst is used in a reaction for synthesizing CBS by oxygen through an oxidation process, the reaction is used for representing the performance of the catalyst. The catalyst amount is 0.01-0.1% of weight of a reactant. The catalyst has reasonable formula, contains active ingredients and carriers, the usage amount is less, and the catalysis effect is good. The catalyst is capable of increasing the dispersion area of the active ingredients so as to increase the contact area of the active ingredients and the reactant, raising the reaction speed and simultaneously reducing the amount of the catalyst. The CBS yield can reach more than 98% by optimizing the reaction condition.

Owner:KEMAI CHEM

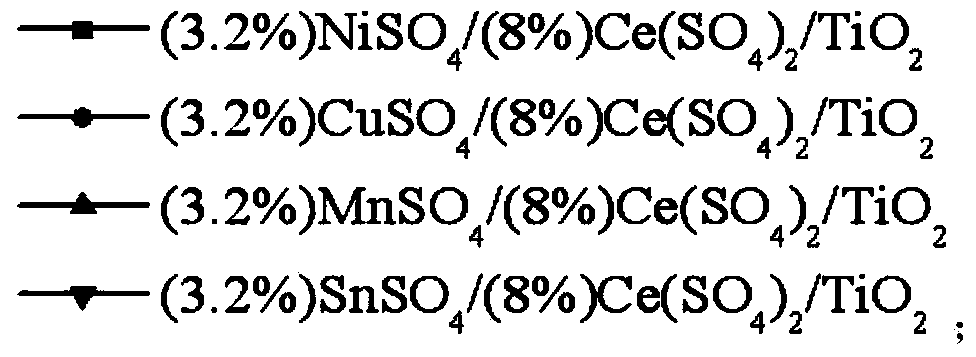

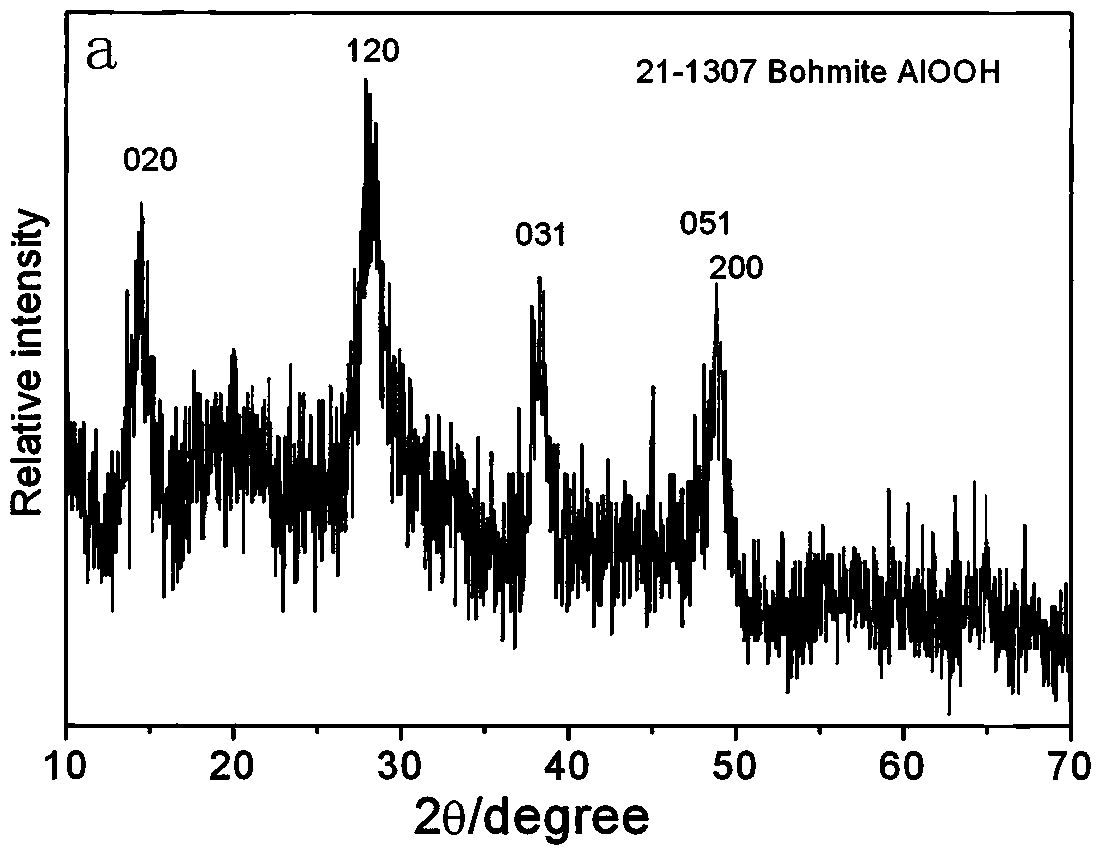

Preparation method of CeO2/gamma-Al2O3 multi-level structure composite microspheres

InactiveCN103433018ACatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsNano structuringLevel structure

The invention discloses a preparation method of CeO2 / gamma-Al2O3 multi-level structure composite microspheres, which comprises the following steps: firstly reacting under a hydrothermal condition by taking water as a reaction medium, KAl(SO4)2.12H2O as an aluminum source, ceric sulfate as a cerium source and urea as a precipitating agent; performing centrifugal washing on the product and drying to obtain precursor CeO2 / gamma-AlOOH microspheres with regular and controllable appearance; then putting the dried precursor CeO2 / gamma-AlOOH multi-level structure microspheres in a muffle furnace; heating at a certain heating speed to 600-800 DEG C; preserving heat for 1-4 hours to decompose the gamma-AlOOH; and performing phase transformation to obtain the CeO2 / gamma-Al2O3 multi-level structure composite microspheres. By adopting the method disclosed by the invention, the prepared CeO2 / gamma-Al2O3 multi-level structure composite microspheres are of hollow structures and are formed by sheet nanocrystallines. The CeO2 / gamma-Al2O3 multi-level structure composite microspheres have the features of a nano structure as well as the advantages of a micron structure, and are of great significance to the development of a novel catalyst.

Owner:嘉善华阳木业植绒有限公司

Method of plugging leak of medium-depth well via cross-linked polymer gel plugging agent

ActiveCN105114032AAvoid stickingEnsure anaerobicDrilling compositionSealing/packingCross-linkCeric sulfate

The invention relates to a method of plugging a leak of a medium-depth well via cross-linked polymer gel plugging agent. Raw materials include, by weight, 120 parts of refined cotton sodium salt solution, 75-85 parts of acrylamide, 13-17 parts of ammonium persulfate, 2-5 parts of ceric sulfate, 4 parts of beta-D-mannuronic acid (M), 1-1.5 parts of ammonium dihydrogen phosphate, 100 parts of composite Portland cement mortar, 150-200 parts of mixed microfiber. A water-cement ratio of the composite Portland cement mortar is 0.44. The plugging agent is obtained by adding the acrylamide, ammonium persulfate granules, ceric sulfate granules, the beta-D-mannuronic acid (M), the composite Portland cement mortar, the mixed microfiber and the ammonium dihydrogen phosphate in order into the refined cotton sodium salt solution and mixing them well; the plugging agent is delivered to a leak layer; a pressure test is run after mud replacement is performed in a drill pipe; if bottom hole pressure rises, borehole mud replacement is performed after standing and pressure holding; after standing and pressure holding for 12 hours, a leak plugging pressure-bearing test is run; if pump pressure is normal, drilling is continued. The method allows reliable leak plugging and resistance to high temperature and pressure.

Owner:中石化石油工程技术服务有限公司 +1

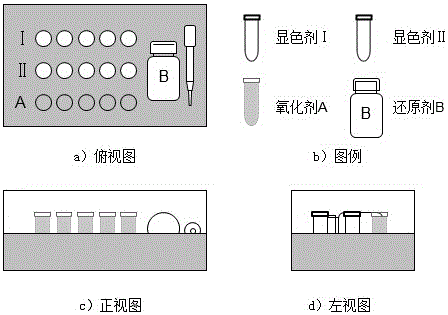

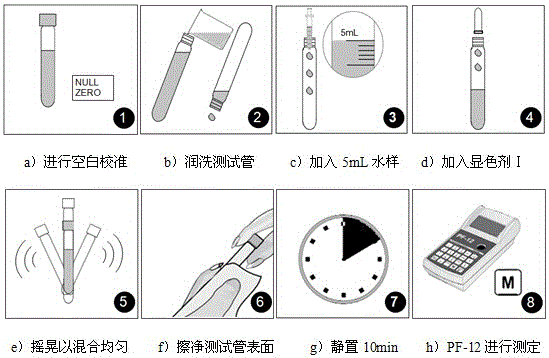

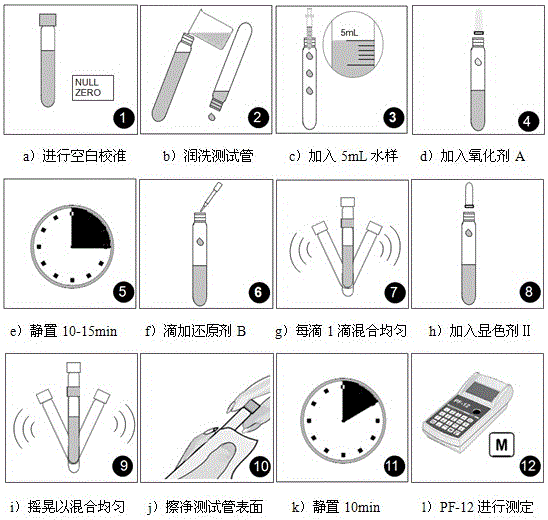

On-site emergency detection reagent for chromium in water and use method thereof

ActiveCN105823745AEasy to operateEasy to carryColor/spectral properties measurementsCeric sulfateSodium azide

The invention discloses an on-site emergency detection reagent for chromium in water and a use method thereof. Chromium (VI) and diphenylcarbazide (DPC) have chromogenic reaction under acidic conditions to prepare a color developing agent, ceric sulfate and chromium oxide (III) have oxidation reaction under acidic conditions to prepare oxidant, and sodium azide is selected as a reduction agent. The use method includes the following steps that firstly, when the concentration of chromium (VI) in a water sample is measured, a color developing agent I is added into a 5 mL to-be-detected water sample and dissolved till the volume is 10 mL, the mixture stands still for 10 min and is measured by a portable spectrophotometer, and the concentration of chromium (VI) in the to-be-detected water sample is obtained; secondly, when the total chromium concentration in the water sample is measured, the oxidant A is added into a 5 mL to-be-detected water sample, the water sample is light yellow, the mixture stands still for 10-15 min, then 1-2 drops of reduction agent B is added till light yellow fades, a color developing agent II is added till the volume is 10 mL, the mixture stands still for 10 min and is measured by the spectrophotometer, and the total chromium concentration in the to-be-detected water sample is obtained. The reagent has the advantages of being high in sensitivity, good in accuracy, high in timeliness, convenient to carry and the like.

Owner:HARBIN INST OF TECH

Polishing solution used for amorphous alloy and polishing method of amorphous alloy

The invention provides a polishing solution used for an amorphous alloy and a polishing method of an amorphous alloy. The polishing solution comprises: a sodium salt, an ammonium salt and a brightener, i.e. ceric sulfate. The polishing method includes plasma polishing to an amorphous alloy. And the plasma polishing method consists of: connecting the amorphous alloy to a positive electrode, and immersing the amorphous alloy into an electrolytic cell containing the polishing solution, and taking the electrolytic cell body as a negative electrode for plasma polishing. The amorphous alloy prepared with the polishing solution provided in the invention and by the plasma polishing method of the invention has a smooth surface and high surface reflectivity.

Owner:BYD CO LTD

A chemical silvering solution and a silvering method

ActiveCN104342645AWith metallic lusterAchieve improvementLiquid/solution decomposition chemical coatingChemical platingCeric sulfate

A chemical silvering solution is provided. The chemical silvering solution comprises a silver salt, a complexing agent, a pH conditioner, a surfactant and additives. The additives comprise lanthanum oxide and ceric sulfate. The weight ratio of the lanthanum oxide to the ceric sulfate is 2-5:1. The pH of the chemical silvering solution is 8.3-9.8. A chemical silvering method using the chemical silvering solution is also provided by the invention. Products obtained by using the chemical silvering solution are compact and uniform in appearance, while products obtained by using silvering solutions of the same kind in the market have appearances with protruding and nonuniform particles and even have skip plating in local parts. The chemical silvering solution has a longer time for starting decomposition than the silvering solutions of the same kind in the market and is more stable.

Owner:BYD CO LTD

Electrolyte for anodizing of surface of pure aluminum part and method for anodizing of surface of pure aluminum part

The invention relates to an electrolyte for anodizing of the surface of a pure aluminum part and a method for anodizing of the surface of the pure aluminum part, and belongs to the technical field ofanodizing of aluminum. The electrolyte for anodizing of the surface of the pure aluminum part is a mixed solution of sulfuric acid, glycerin and ceric sulfate, the mass concentration of sulfuric acidis 155-165 g / L, the volume concentration of glycerin is 4-8 ml / L, and the mass concentration of ceric sulfate is 2-4 g / L. By the adoption of the electrolyte for anodizing of the surface of the pure aluminum part, sulfuric acid serves as a main component, a proper amount of glycerin and a proper amount of ceric sulfate are added into the electrolyte, a high-hardness Al2O3 film can be formed on thesurface of the pure aluminum part, the thickness of the Al2O3 film is only 15-30 micrometers, and the Vickers hardness can reach 420-500 HV.

Owner:HENAN PINGZHI HIGH VOLTAGE SWITCHGEAR +2

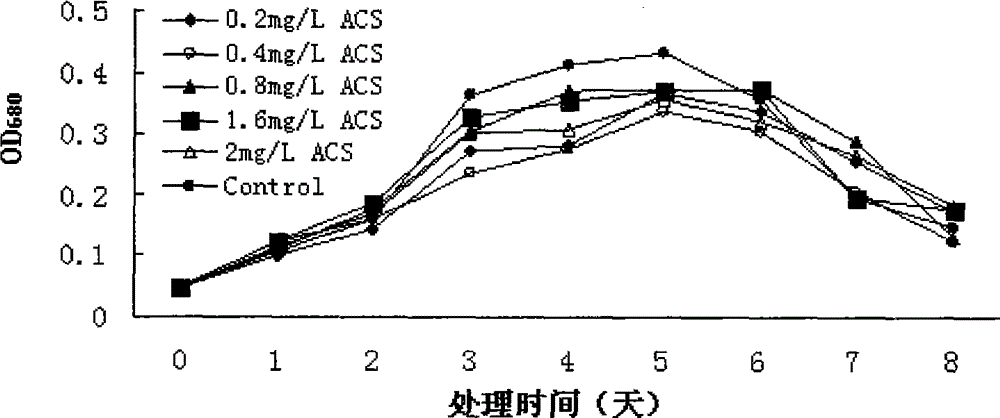

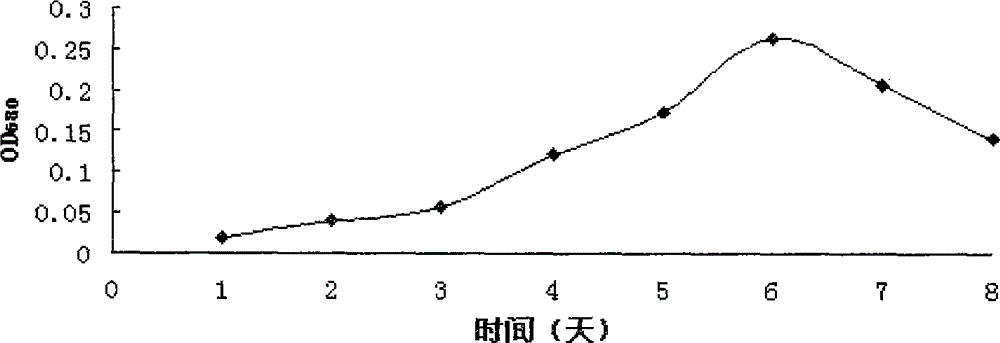

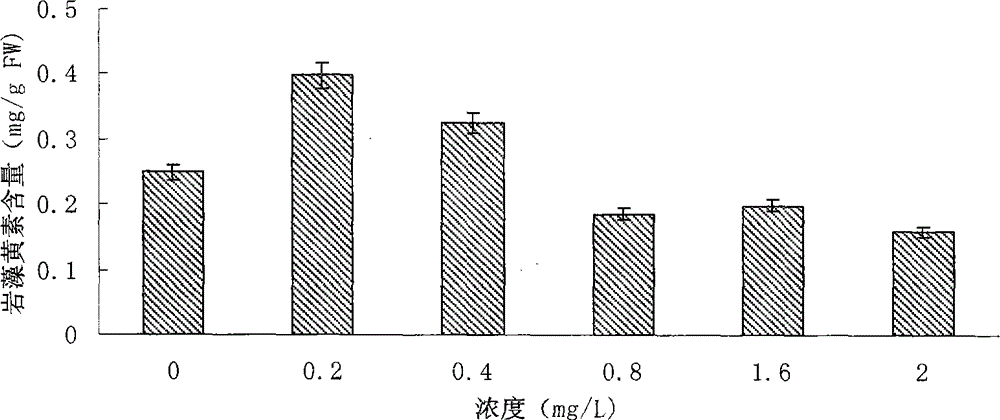

Method for increasing fucoxanthin content of Phaeodactylum tricornutum by using ammonium ceric sulfate

InactiveCN104531602AIncrease contentEasy to operateUnicellular algaeMicroorganism based processesCeric sulfateFreeze-drying

The present invention discloses a method for increasing the fucoxanthin content of Phaeodactylum tricornutum by using ammonium ceric sulfate. The method comprises: mixing sterilized seawater and an MAD mother liquor to obtain a nutrition liquid, adding a Phaeodactylum tricornutum mother liquor to the nutrition liquid to culture, culturing for 2 days, adding ammonium ceric sulfate, continuously culturing for 6 days, collecting the algae liquid, carrying out centrifugal separation, removing the supernatant, collecting the algae, carrying out a freeze-drying treatment on the algae for 2 days, grinding for spare, dissolving the grinded algae with dehydrated alcohol, standing for 1 h at a temperature of 4 DEG C, and centrifugating for 10 min at a temperature of 4 DEG C at a speed of 13000 rpm to obtain the supernatant. According to the present invention, the operations are simple and convenient, the cost is low, the production cycle is short, and the method is suitable for batch production and industrial production.

Owner:NINGBO UNIV

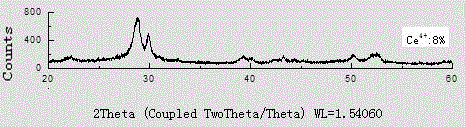

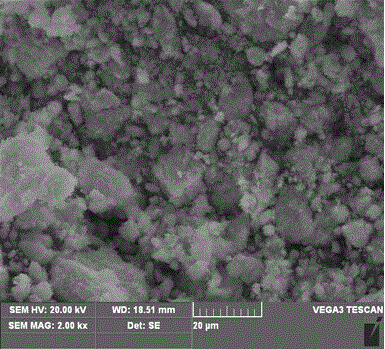

Ultraviolet visual light absorbent and application thereof

ActiveCN105040408APromote absorptionReduce harmCosmetic preparationsToilet preparationsTungstateCeric sulfate

The invention discloses an ultraviolet visual light absorbent and application thereof. The ultraviolet visual light absorbent is obtained with lanthanum sulfate, ammonium tungstate and ceroussulfate serving as raw materials through a coprecipitation method. The structural formula of the ultraviolet visual light absorbent is La2 (WO4)3:Ce4+. Ce4+ accounts for 4% to 8% of the La2 (WO4)3:Ce4+. The ultraviolet visual light absorbent can absorb ultraviolet light to serve as application on the aspect of an ultraviolet absorber. The prepared La2 (WO4)3:Ce4+ has maximum absorption at the wavelength of 240 nm, the absorbing ability of the ultraviolet region is far higher than the adsorbing ability of the visual region, and the ultraviolet visual light absorbent has the advantages of being wide in absorption wavelength range, high in absorption capacity, high in efficiency and capable of absorbing ultraviolet light. The La2 (WO4)3:Ce4+ is easy to prepare, stable in property and high in safety and has good generalizability and market prospects.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

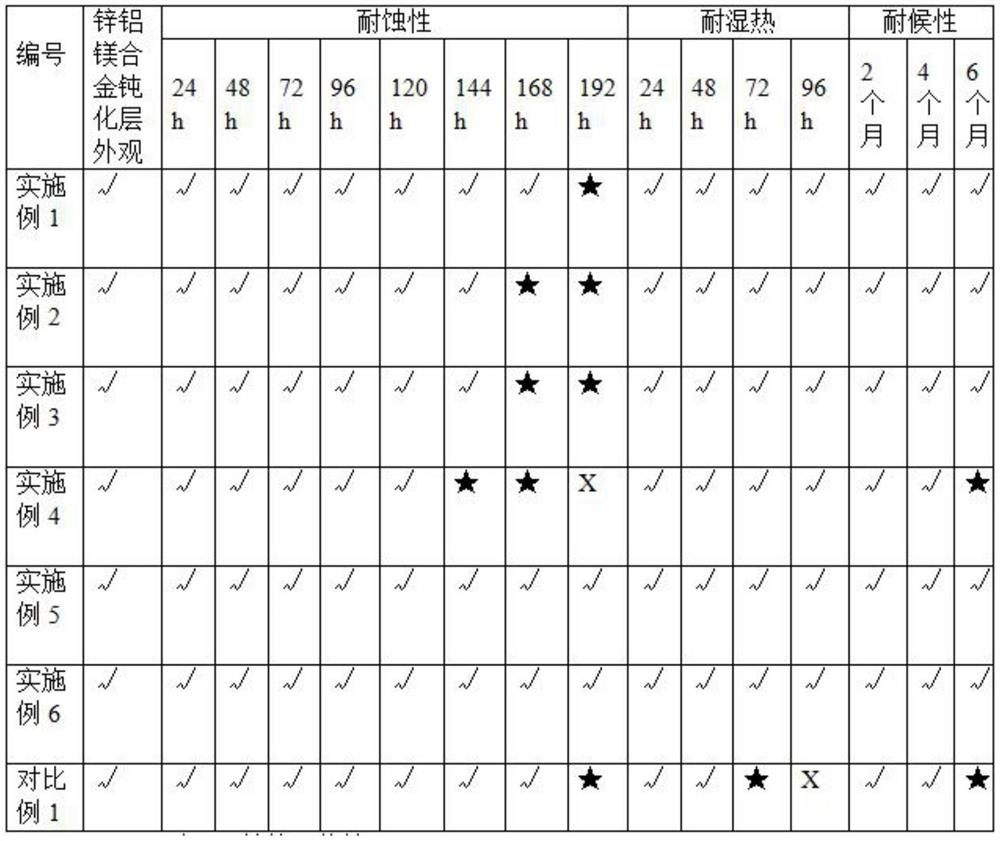

Zinc-aluminum-magnesium alloy self-repairing chromium-free passivator as well as preparation method and application thereof

PendingCN112962090AGuaranteed corrosion resistanceGuaranteed resistance to heat and humidityMetallic material coating processesEpoxyChromium free

The invention relates to the technical field of metal surface treatment chemicals, and provides a zinc-aluminum-magnesium alloy self-repairing chromium-free passivator as well as a preparation method and application thereof. The chromium-free passivator comprises 10-15 parts of anionic acrylic acid modified epoxy resin, 5-30 parts of modified alkaline silica sol, 3-5 parts of nanoscale hydroxyl graphene sol, 5-10 parts of silicate, 3-5 parts of zinc nitrate, 5-10 parts of sodium tungstate, 0.05-2 parts of soluble aluminum salt, 1-3 parts of ceric sulfate, 20-40 parts of a film forming accelerant, 2-8 parts of a stabilizer, 4-8 parts of a pH regulator, 2-6 parts of an oxidizing agent, and the balance water. A zinc-aluminum-magnesium alloy treated by the chromium-free passivator has bright appearance, and the passivated zinc-aluminum-magnesium alloy has excellent corrosion resistance, humidity and heat resistance and weather resistance; and the prepared chromium-free passivator is environmentally friendly, can replace a traditional hexavalent chromium passivator, is expected to be widely applied to the zinc-aluminum-magnesium industry, and has great industrial value and social value.

Owner:合肥华清方兴表面技术有限公司

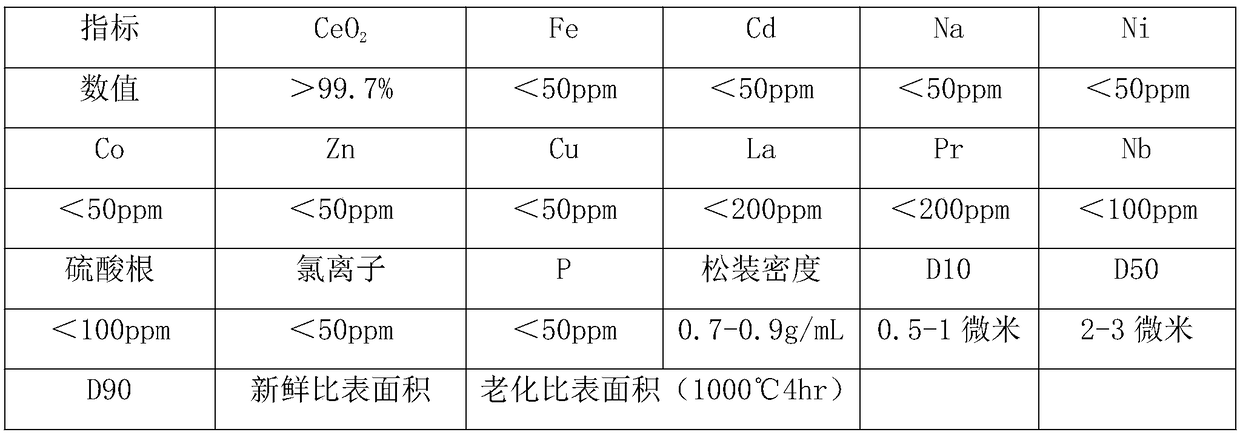

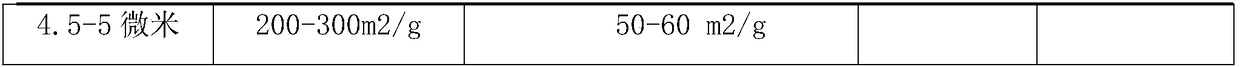

Preparation method of cerium oxide with large specific surface area

ActiveCN108178180ALarge poresLarge specific surface areaRare earth metal oxides/hydroxidesMetal/metal-oxides/metal-hydroxide catalystsOxalateCeric sulfate

The invention discloses a preparation method of cerium oxide with large specific surface area. The preparation method comprises the following steps: preparing liquid: preparing ceric sulfate, ammoniumcarbonate and oxalic acid into a solution and putting the prepared oxalic acid solution into a reaction still, adding an ammonium carbonate solution the volume of which is 0.1 to 0.12 time that of the oxalic acid solution; then adding a ceric sulfate solution and the ammonium carbonate solution into a base solution and cooling the temperature at constant speed in the reaction still; after material adding is finished, stopping cooling the temperature of the reaction still; keeping the temperature and carrying out stirring reaction for 1 to 1.5 hours; then carrying out solid-liquid separation to obtain first filtrate and first residues; adding the first residues into pure water for washing; then drying, crushing and sieving to obtain a sieved material; calcining the sieved material in a rotary kiln, and crushing and screening to obtain the cerium oxide with the large specific surface area. The preparation method of the cerium oxide with the large specific surface area, disclosed by theinvention, has the advantages of simple preparation process, larger specific surface area at normal temperature and high temperature and high catalytic activity.

Owner:蒋央芳

Preparation method of 1,4-naphthoquinone

InactiveCN109400456AIncrease surface tensionLower surface energyQuinone preparation by oxidationQuinone separation/purificationLiquid wasteElectrolysis

The invention discloses a preparation method of 1,4-naphthoquinone. The preparation method comprises the following steps: taking ceric sulfate as an oxidizing agent, and dissolving the ceric sulfate into a sulfuric acid solution, thus forming a water phase; dissolving naphthalene into an organic solvent, thus forming an oil phase; mixing the water phase with the oil phase, adding an emulsifying agent, and carrying out oxidation reaction under the conditions of carrying out heat preservation and stirring; after completing the reaction, integrally cooling the water phase and the oil phase untilafter-filtration is carried out on all cerous sulfate, thus obtaining solid 1,4-naphthoquinone; separating the water phase from the oil phase, recycling the oil phase, and recycling the water phase after carrying out electrolytic regeneration on the water phase. According to the preparation method disclosed by the invention, the reaction speed is increased, and byproducts are reduced; an extraction phase of an old technology is omitted, and meanwhile, the recovery rate of naphthoquinone is increased; meanwhile, the water phase and the oil phase are both completely recycled and reused, zero emission of liquid waste is realized, the environment is not polluted, and a production method of the 1,4-naphthoquinone is economical and environment-friendly.

Owner:四川锐华科技有限公司

Method for measuring low-content antimony in gangue sample

InactiveCN110646563AFast analysisHigh precisionChemical analysis using titrationCeric sulfateMethyl orange

The invention provides a method for measuring low-content antimony in a gangue sample. The method comprises the following steps: 1) configuring and calibrating a ceric sulfate standard solution; 2) sample preparation: dissolving the gangue sample in a mixed solution of sulfuric acid and hydrochloric acid; and 3) titration: continuing to heat the solution in the step 2) to 80-90 DEG C, immediatelyadding 0.2% methyl orange-methylene blue solution, titrating the ceric sulfate standard solution under constant oscillating, and heating the solution to 80-90 DEG C in the vicinity of the end point, and continuing to titrate until green appears. The method provided by the invention is an improvement based on a ceric sulfate capacity method and is consistent with the reagents used in the traditional ceric sulfate capacity method, so no special ceric sulfate needs to be purchased; no toxic reagent is used neither; the method provided by the invention has a high analysis speed; the precision andthe accuracy of the method are relatively high; the method can be easily mastered by the operation personnel, and the operation personnel does not need to be additionally trained; and satisfactory results can be obtained for the analysis of gangue samples with antimony contents of 0.05-50.50% antimony.

Owner:湖南新龙矿业有限责任公司

Floating-bead-contained mica powder modified quartz-based lost foam paint and preparation method thereof

InactiveCN106009795AImprove dispersion stabilityImprove adhesionFoundry mouldsFoundry coresSodium BentoniteCeric sulfate

Owner:MAANSHAN XINGLONG FOUNDRY CO LTD

Preparing method for beta-menadione

ActiveCN109265333ANo peroxidationThe production process is economical and environmentally friendlyQuinone preparation by oxidationBulk chemical productionElectrolysisOrganic solvent

The invention discloses a preparing method for beta-menadione. The preparing method includes the following steps that 1, ceric sulfate is dissolved in a sulfuric acid solution, a ceric sulfate solution is obtained, the beta-methylnaphthalene is dissolved in an organic solvent, and a beta-methylnaphthalene organic solution is obtained; 2, the ceric sulfate solution and the beta-methylnaphthalene organic solution are simultaneously added into a reaction kettle, the mixture is stirred and reacted at the constant temperature, the reaction is ended, cooling crystallization is carried out, and the finished-product beta-menadione is obtained through filtering; 3, the filtered cerous sulfate solution in a liquid phase is separated from the organic solvent, the organic solution is distilled and recycled to be reused, and the cerous sulfate solution is subjected to electrolytic oxidation through a diaphragm to be reused. Chromium oxidation is thoroughly replaced with the preparing method for thebeta-menadione, hexavalent chromium does not exist in the product, the beta-methylnaphthalene is dissolved in an organic phase and reacted, the contact area of the material is larger, the reaction rate is higher, peroxidation of the beta-menadione can be avoided, and the product purity is high.

Owner:SICHUAN YINHE CHEM

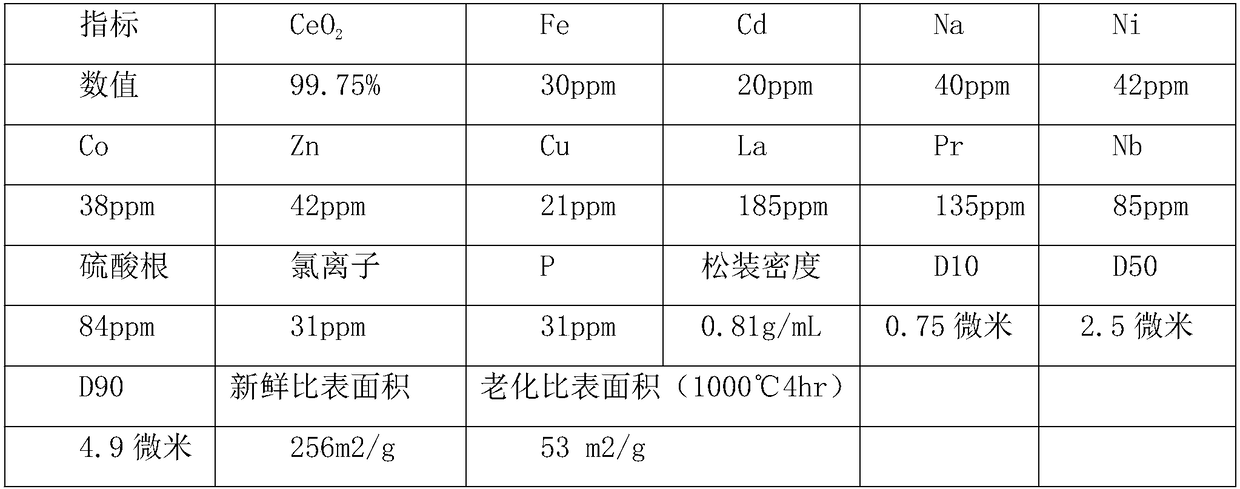

Preparation method and product of modified corn starch chelating agent

InactiveCN106117426AHigh grafting rateImprove the effect of graftingOther chemical processesGlycidyl methacrylateCeric sulfate

The invention discloses a preparation method and a product of a modified corn starch chelating agent. The preparation method comprises the following steps: corn starch is subjected to a reaction with a certain amount of an ammonium ceric sulfate-nitric acid solution and glycidyl methacrylate at a lower temperature, glycidyl methacrylate grafted corn starch with a higher grafting ratio is obtained firstly, then the grafting product is subjected to an amination reaction with diethylenetriamine, and a target product, namely, the modified corn starch chelating agent is obtained finally. The production energy consumption and the production cost are reduced effectively by means of the preparation method; due to the higher grafting ratio, the modified corn starch chelating agent has better grafting effect, is more stable and has higher chelating capacity, thereby having broad application prospect and market potential.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Method for preparing azelaic acid by catalytic oxidation of oleic acid

ActiveCN101811954ALow priceEasy to separateOrganic compound preparationCarboxylic compound preparationCeric sulfateCatalytic oxidation

The invention relates to a method for preparing azelaic acid by catalytic oxidation of oleic acid, which comprises the following steps of: adding raw material oleic acid and a catalyst ceric sulfate into a four-opening bottle which is provided with a blender, a reflux condenser and a thermometer; adding hydrogen peroxide, and stirring in the ozone atmosphere at the concentration of 2 to 6 percent; controlling the reaction temperature to between 35 and 55 DEG C under normal pressure, and reacting for 1 to 3 hours; stirring and raising the temperature to 65-105 DEG C, continuing to introducing ozone, reacting for 6 to 10 hours, standing, and separating an oil layer from a water layer; washing the oil layer for three times by using deionized water with the temperature of between 90 and 100 DEG C and merging with the water layer; slowly cooling to 5 DEG C, crystallizing, and separating to obtain coarse azelaic acid crystallization; and recrystallizing for three times by using the deionized water with the temperature of between 90 and 100 DEG C to prepare the azelaic acid. The method has high reaction yield, simple technology, and easily separated reaction system, effective reduction of the production cost, and environmental protection.

Owner:ZHEJIANG HUANUO CHEM IND

Treating solution for preparing Al-Mo-Mn-Re quaternary composite passivation film on aluminum profile surface and its application method

ActiveCN102732870BImprove compactnessImprove performanceMetallic material coating processesCerium nitrateCeric sulfate

The invention discloses a treating solution for preparing a corrosion resistant Al-Mo-Mn-Re quaternary composite passivation film on an aluminum alloy surface and its application method. The passivation solution is characterized by being a passivation treatment solution which is used for preparing a passivation film on an aluminum alloy surface by utilizing a molybdate, a rare earth salt and a permanganate oxidant. Per liter of the treating solution consists of: 8g.L<-1>-25g.L<-1> of sodium molybdate (or ammonium molybdate), 5g.L<-1>-10g.L<-1> of potassium permanganate, 0.5g.L<-1>-3g.L<-1> of sodium fluoride (or potassium fluoride), 0.5g.L<-1>-5g.L<-1> of cerium nitrate (or ceric sulfate, lanthanum nitrate), 1g.L<-1>-5g.L<-1> of acetic acid, 0.5g.L<-1>-1g.L<-1> of sodium dodecyl benzene sulfonate (or OP-10) . The application method includes: (1) removing adhered dust and other dirt from the aluminum alloy; (2) then conducting pretreatment on the aluminum alloy surface; (3) using the treating solution for passivation treatment; and (4) carrying out water washing and drying. The treating solution of the invention has the advantages of fast film formation speed, simple process, uniform film, strong corrosion resistance, and less environmental pollution, etc.

Owner:GUANGDONG XINGFA ALUMINUM JIANGXI

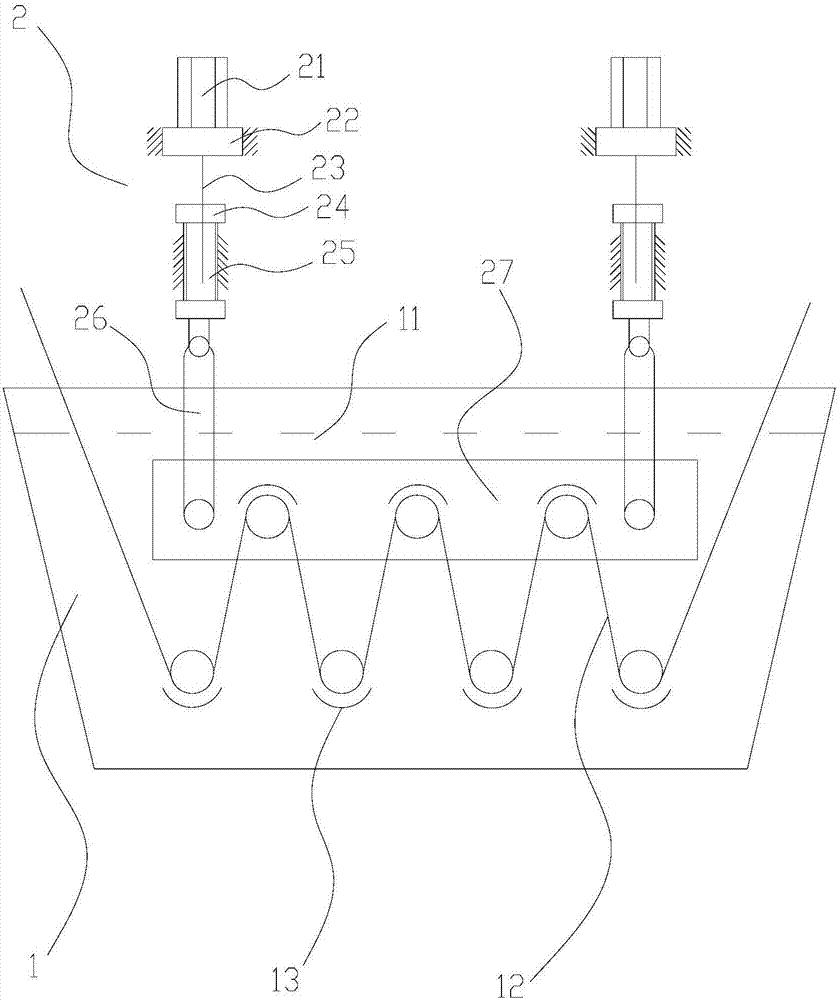

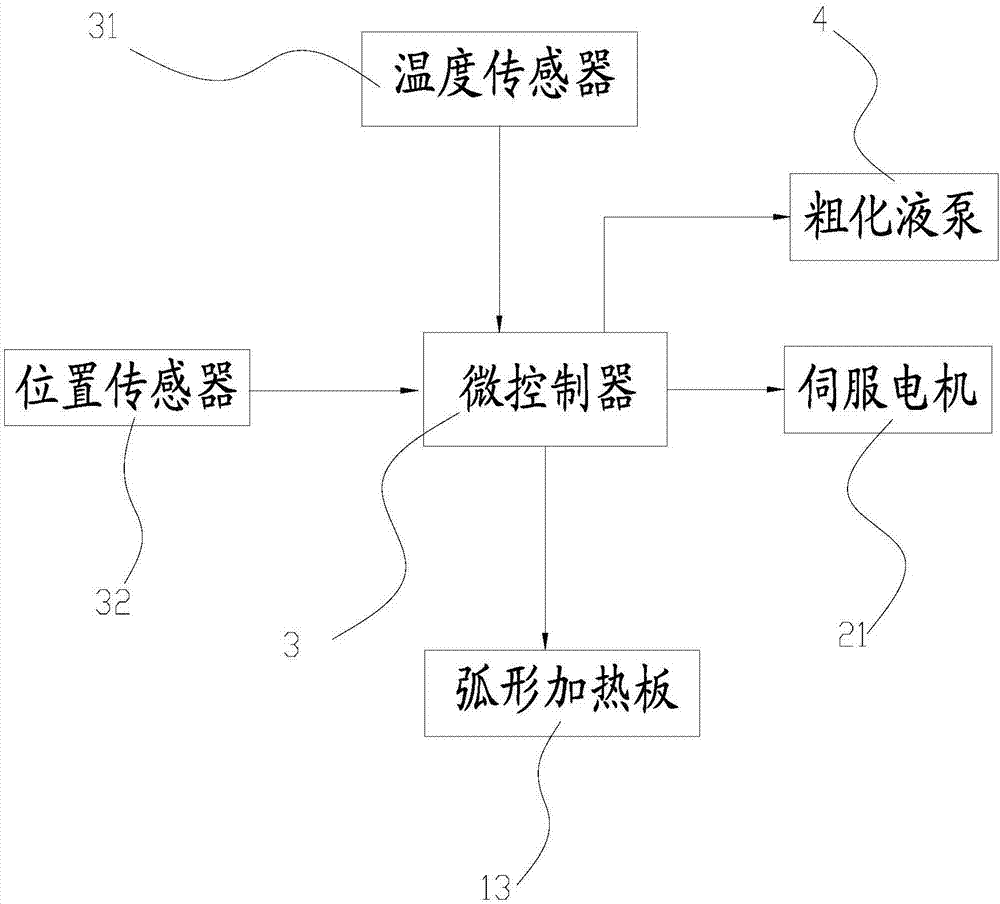

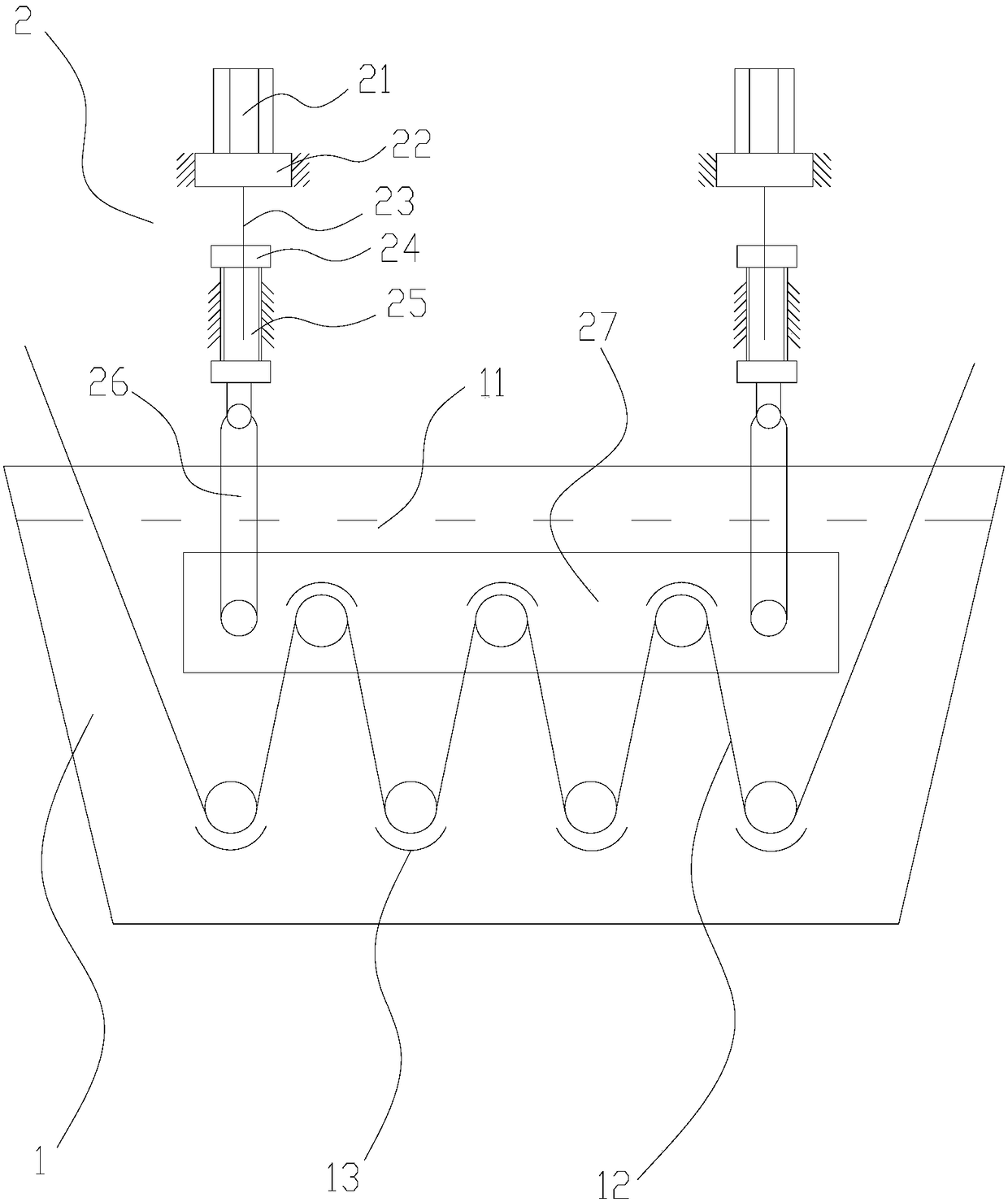

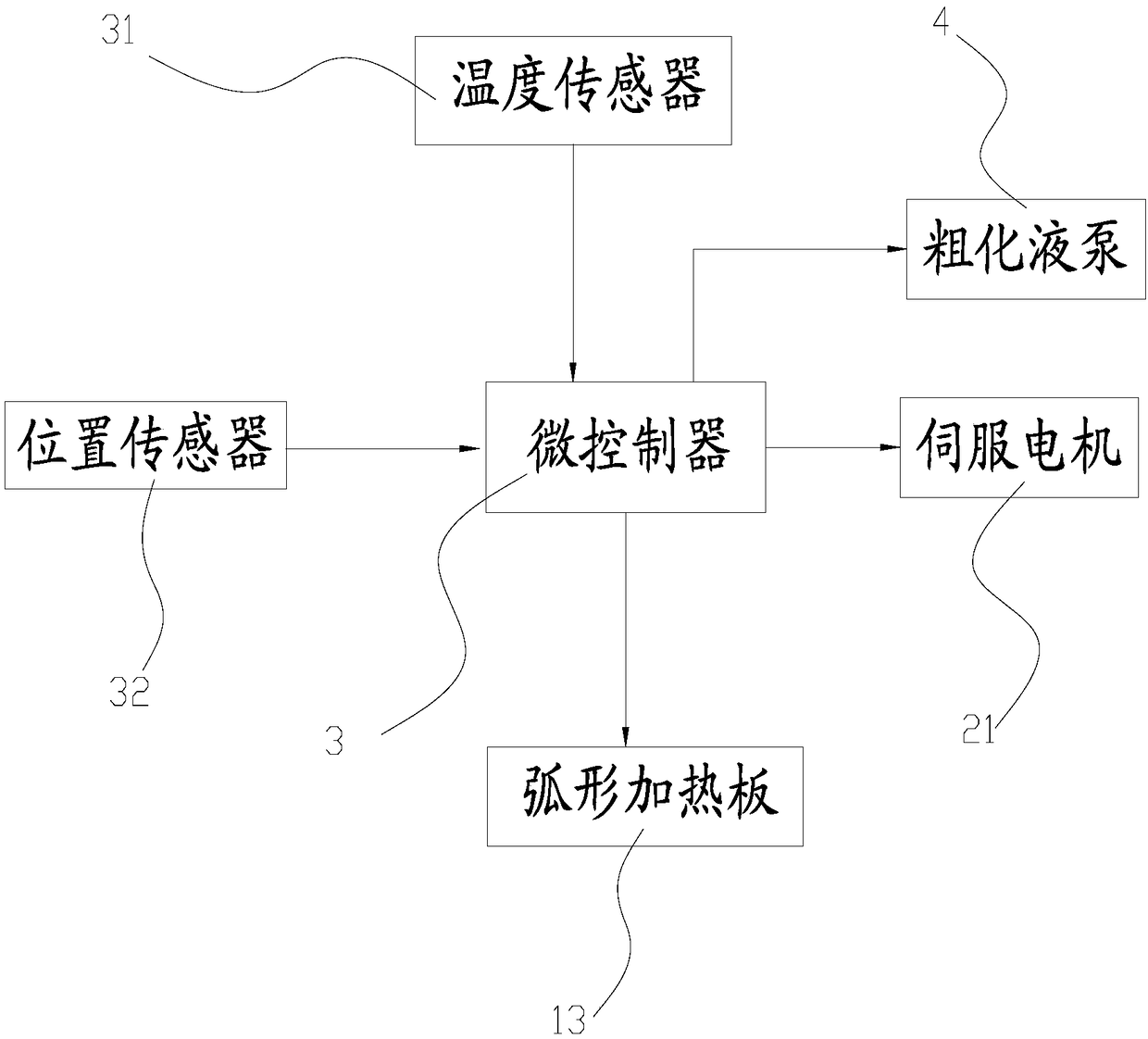

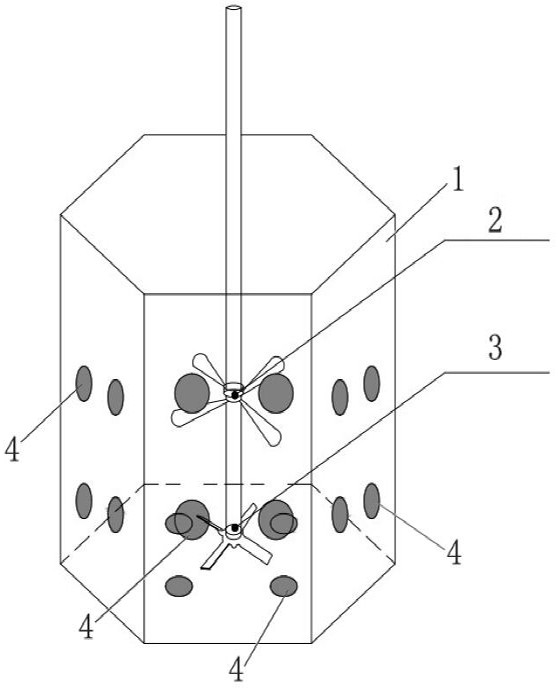

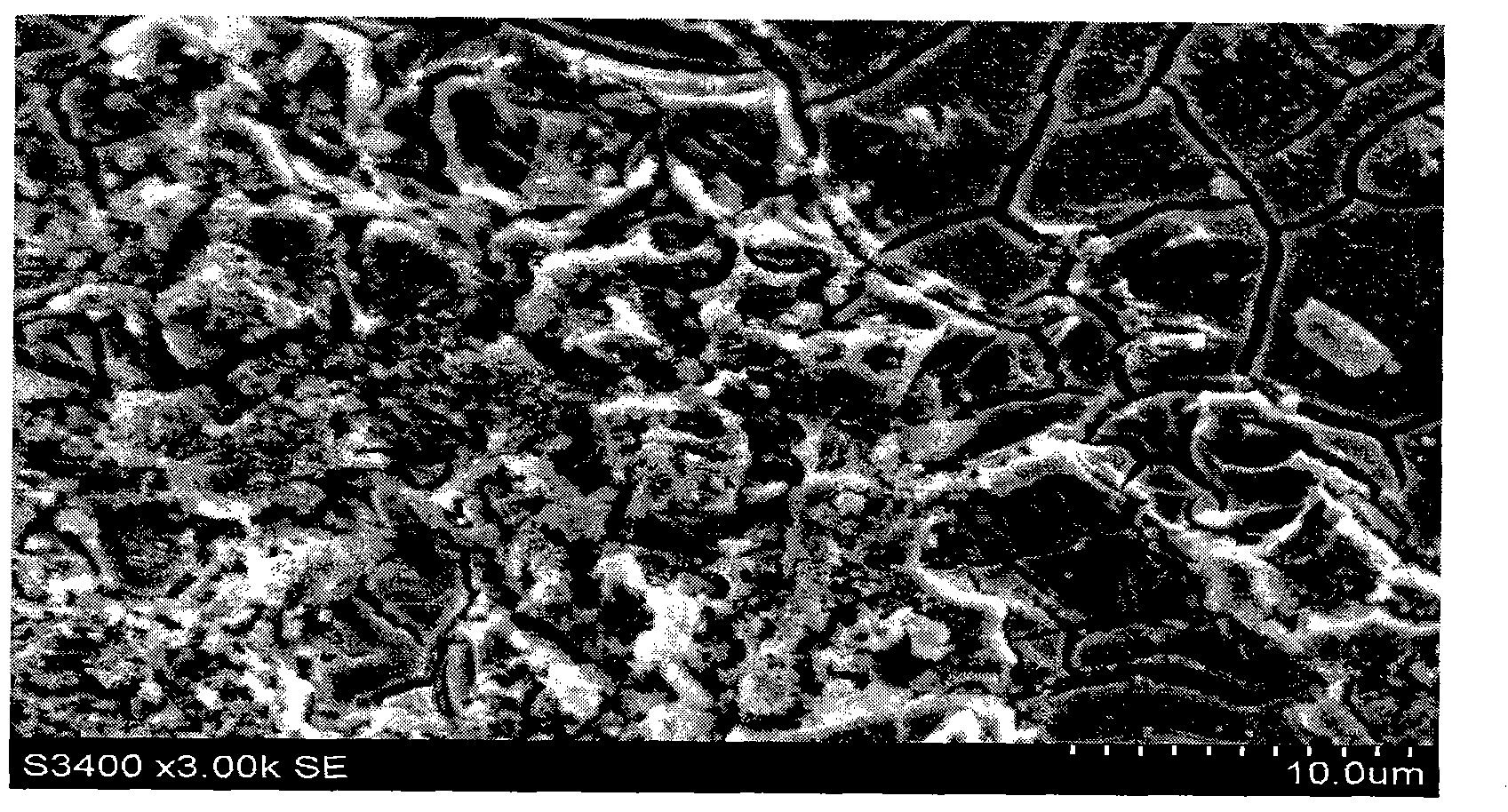

Roughening treatment process and equipment for lead-free soldering electrolytic copper foils

ActiveCN106884201AExtend or shorten the timeAvoid harmElectrolysis componentsRough surfaceSodium molybdate

The invention discloses a roughening treatment process for lead-free soldering electrolytic copper foils. According to the treatment process, a combined additive which is composed of at least three compounds of sodium tungstate, sodium molybdate, sodium nitrite, stannous sulfate, hydrochloric acid, cerous sulfate and ceric sulfate is used; the combined additive is used for replacing a high-toxic additive arsenic, and harm to the environment and human bodies is prevented; in addition, the combined additive can enable a series of isolated nodes on the copper foils to form loose tumor bodies, high-spread rough surfaces are achieved, permeability and adhesive force with base materials are higher, and appearance chroma is more uniform. In addition, the invention discloses equipment adopted by the treatment process. The equipment comprises a roughening tank used for containing a roughening treatment solution, multiple rollers used for conveying the copper foils are fixedly connected in the roughening tank, and the rollers are arranged at intervals in an up-and-down manner, so that the copper foils surround the peripheries of the rollers to form a corrugation shape, and the time of the copper foils in the roughening treatment solution can be prolonged or shortened according to practical requirements.

Owner:建滔(连州)铜箔有限公司

A roughening treatment process and equipment for lead-free soldering electrolytic copper foil

ActiveCN106884201BExtend or shorten the timeAvoid harmElectrolysis componentsRough surfaceSodium molybdate

Owner:建滔(连州)铜箔有限公司

Preparation method of silver-coated copper conductive powder

PendingCN114101665AFully dispersedFully moistenedTransportation and packagingMetal-working apparatusCeric sulfateActive agent

Owner:深圳市绚图新材科技有限公司 +1

Improved water quenching slag adsorbent and preparation method thereof

InactiveCN101879433AImprove adsorption capacityReduce manufacturing costOther chemical processesWater/sewage treatment by sorptionSlagCeric sulfate

The invention relates to an improved water quenching slag adsorbent and a preparation method thereof, belonging to the treatment field of industrial wastewater. The improved water quenching slag adsorbent comprises the following components in weight percentage: 93.5%-96.7% of blast-furnace water quenching slag, 1.4%-2.8% of ceric sulfate and 1.9%-3.7% of ferric chloride. The preparation method comprises the following steps of: cleaning and washing the blast-furnace water quenching slag with water, drying and then sieving the grinded blast-furnace water quenching slag by using a 100-mesh sieve; mixing and uniformly stirring the processed blast-furnace water quenching slag with the ceric sulfate and the ferric chloride, wetting with water and then uniformly stirring; and drying, grinding and sieving by using the 100-mesh sieve, and then placing the sieved mixture in a muffle furnace for roasting 1-2 h at the temperature of 500 DEG C-600 DEG C to obtain the improved water quenching slag adsorbent. Due to the adoption of industrial wastes as raw materials, the improved water quenching slag adsorbent has the advantages of reduction of production cost, better processing effect and easy operation. Because the surface of the improved water quenching slag adsorbent is coated with a ferric and ceric coating, the specific surface area and the adsorbability of the improved water quenching slag adsorbent are improved, and the improved water quenching slag adsorbent can adsorb copper ions and ammonia nitrogen in water bodies at room temperature when the pH is 3-10.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Pollution-free preparation method of ceric sulfate

The invention belongs to the field of preparation of inorganic chemistry, in particular to a pollution-free preparation method of ceric sulfate. The preparation method comprises the following steps: dissolving cerium chloride crystals in deionized water; adding strong alkali into the mixture; after full reaction, carrying out aging, suction filtration and cleaning; adding the obtained filter cakesinto dilute sulfuric acid; heating the mixture to react till the filter cakes are fully dissolved; carrying out cooling, crystallizing and suction filtration; and filtering the filter cakes to obtainsaffron yellow high quality ceric sulfate.

Owner:CHANGZHOU GEOQUIN NANO NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com