Zinc-aluminum-magnesium alloy self-repairing chromium-free passivator as well as preparation method and application thereof

A chromium-free passivation agent, zinc-aluminum-magnesium technology, applied in the direction of metal material coating process, can solve the problems of environmental and human harm, and achieve the effect of improving corrosion resistance, excellent corrosion resistance and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

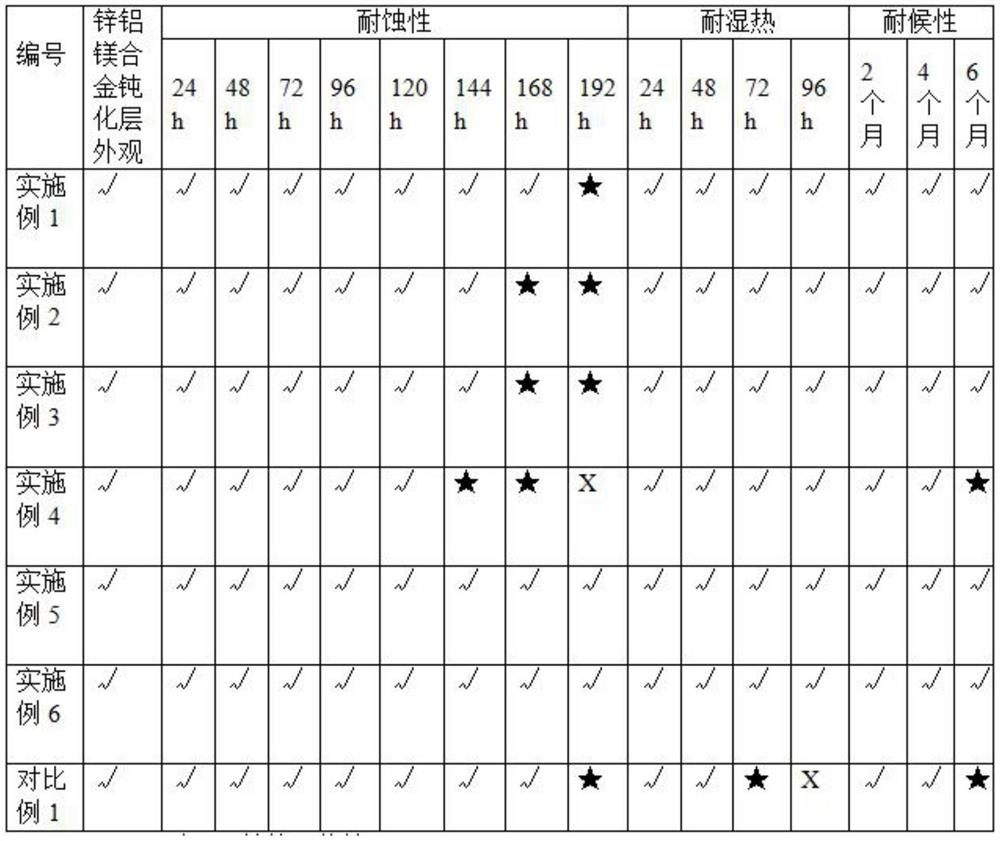

Examples

Embodiment 1

[0045]10 parts of anionic acrylic modified epoxy resin, 5 parts of modified alkaline silica sol, 3 parts of nano-scale hydroxyl graphene sol, 5 parts of silicate, 3 parts of zinc nitrate, 5 parts of sodium tungstate, 0.05 part of soluble aluminum salt , 1 part of cerium sulfate, 20 parts of alcohol ester twelve, 2 parts of benzotriazole, 2 parts of sodium ferrate, and the rest is water;

[0046] The pH value of the chromium-free conversion agent is 8.0-9.0.

Embodiment 2

[0048] 10 parts of anionic acrylic modified epoxy resin, 5 parts of modified alkaline silica sol, 5 parts of silicate, 3 parts of zinc nitrate, 5 parts of sodium tungstate, 0.05 parts of soluble aluminum salt, 1 part of ceric sulfate, alcohol ester 20 parts of twelve, 2 parts of benzotriazole, 2 parts of sodium ferrate, and the rest is water;

[0049] The pH value of the chromium-free conversion agent is 8.0-9.0.

Embodiment 3

[0051] 10 parts of anionic acrylic modified epoxy resin, 5 parts of modified alkaline silica sol, 3 parts of nano-scale hydroxyl graphene sol, 5 parts of silicate, 3 parts of zinc nitrate, 5 parts of sodium tungstate, 0.05 part of soluble aluminum salt , 20 parts of alcohol ester twelve, 2 parts of benzotriazole, 2 parts of sodium ferrate, and the rest is water;

[0052] The pH value of the chromium-free conversion agent is 8.0-9.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com