Oxide scale control method for improving corrosion resistance of hot rolled medium plate

A technology of iron oxide scale and control method, which is applied in the field of metallurgy to achieve the effects of improving compactness, ensuring surface quality and corrosion resistance, and increasing investment and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

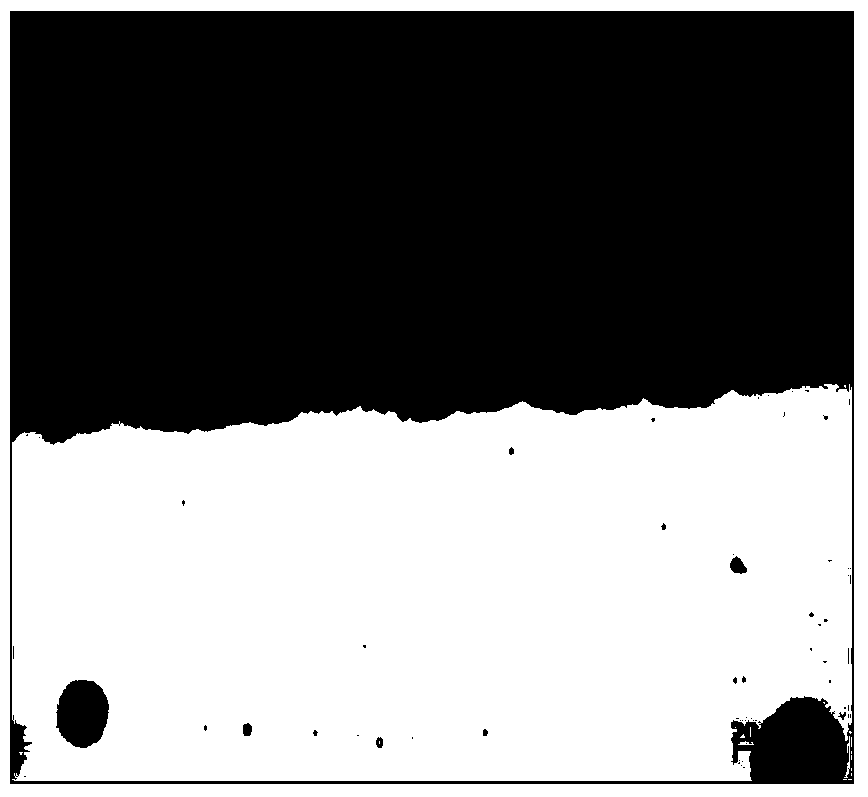

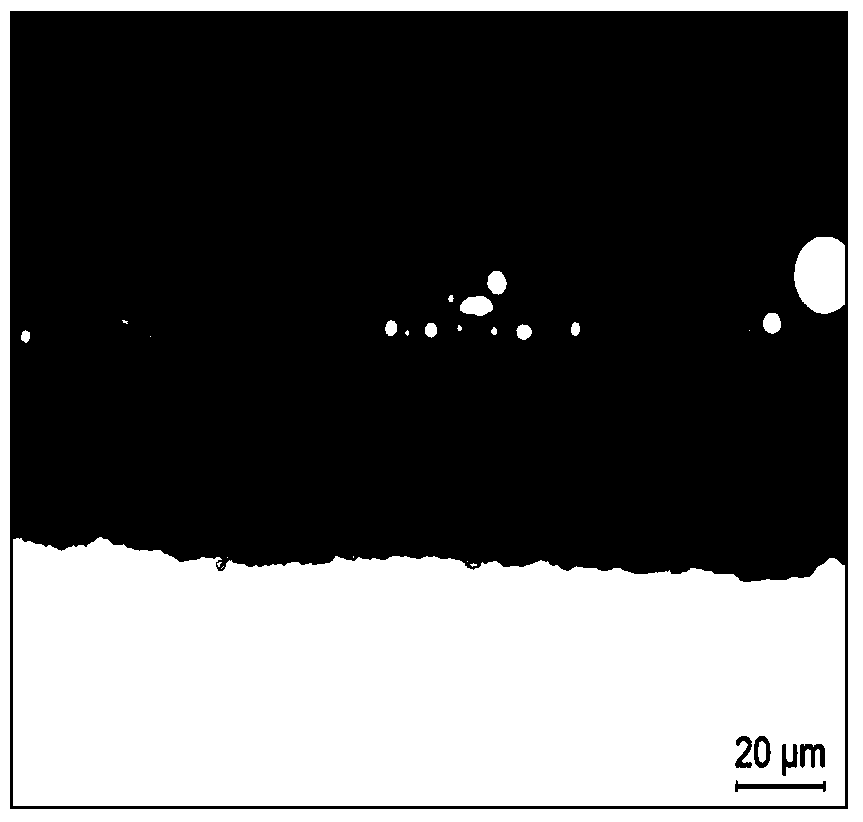

Image

Examples

Embodiment 1

[0024] Step 1: Smelting molten steel and casting into slab, the slab composition is C: 0.11%, Si: 0.15%, Mn: 1.05%, P: 0.007%, S: 0.004%, Al: 0.012%, Nb: 0.034%, V: 0.04%, the balance is iron;

[0025] Step 2: Heat the slab to 1250°C for 210min; then use high-pressure water for rough descaling, the rough descaling temperature is 1200°C, the rough descaling water pressure is 16MPa, and the rough descaling time is 5s, so that the surface of the steel plate has no surface. Iron oxide scale and mold slag, to achieve no residue;

[0026] Step 3: The slab after rough descaling enters the rough rolling stage, the start rolling temperature is 1150°C, the final rolling temperature is 1120°C, and the cumulative reduction is 85%;

[0027] Step 4: The slab after rough rolling enters the finishing rolling stage. Before the odd-numbered finishing rolling stage, the fine descaling is carried out. The fine descaling water pressure is 18MPa, and the fine descaling time is 6s. Descale 3 times...

Embodiment 2

[0036] Step 1: Smelting molten steel and casting into slab, the slab composition is C: 0.09%, Si: 0.35%, Mn: 1.18%, P: 0.006%, S: 0.002%, Al: 0.023%, Nb: 0.04%, V: 0.036%, the balance is iron;

[0037] Step 2: Heat the slab to 1150°C for 300min; then use high-pressure water for rough descaling, the rough descaling temperature is 1100°C, the rough descaling water pressure is 18MPa, and the rough descaling time is 6s, so that the surface of the steel plate has no surface. Iron oxide scale and mold slag, to achieve no residue;

[0038] Step 3: The slab after rough descaling enters the rough rolling stage, the starting rolling temperature is 1100°C, the final rolling temperature is 1000°C, and the cumulative reduction is 70%;

[0039] Step 4: The slab after rough rolling enters the finishing rolling stage. Before the odd-numbered finishing rolling stage, the fine descaling is carried out. The fine descaling water pressure is 20MPa, and the fine descaling time is 5s. Descale twice;...

Embodiment 3

[0043] Step 1: Smelting molten steel and casting into slab, the slab composition is C: 0.07%, Si: 0.24%, Mn: 1.2%, P: 0.008%, S: 0.004%, Al: 0.04%, Nb: 0.034%, V: 0.038%, the balance is iron;

[0044] Step 2: Heat the slab to 1220°C for 260min; then use high-pressure water for rough descaling, the rough descaling temperature is 1180°C, the rough descaling water pressure is 16MPa, and the rough descaling time is 5s, so that the surface of the steel plate has no surface. Iron oxide scale and mold slag, to achieve no residue;

[0045] Step 3: The slab after rough descaling enters the rough rolling stage, the starting rolling temperature is 1130°C, the final rolling temperature is 1110°C, and the cumulative reduction is 78%;

[0046] Step 4: The slab after rough rolling enters the finishing rolling stage. Before the odd-numbered finishing rolling stage, the fine descaling is carried out. The fine descaling water pressure is 20MPa, and the fine descaling time is 4s. Descale 3 tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com