Patents

Literature

229results about How to "Easy descaling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

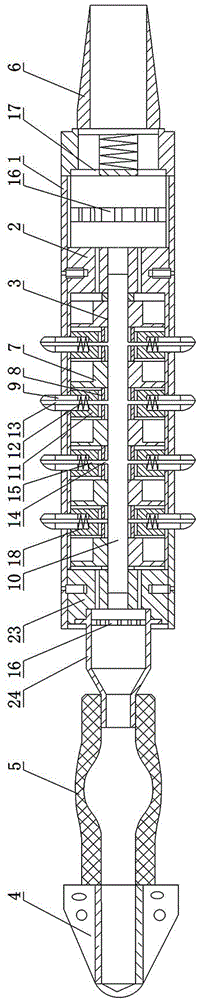

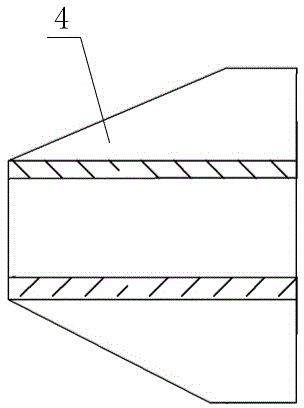

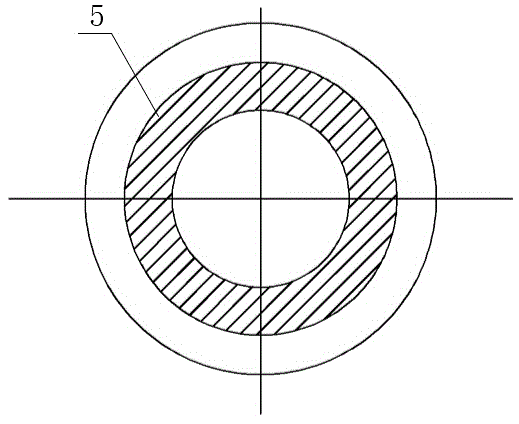

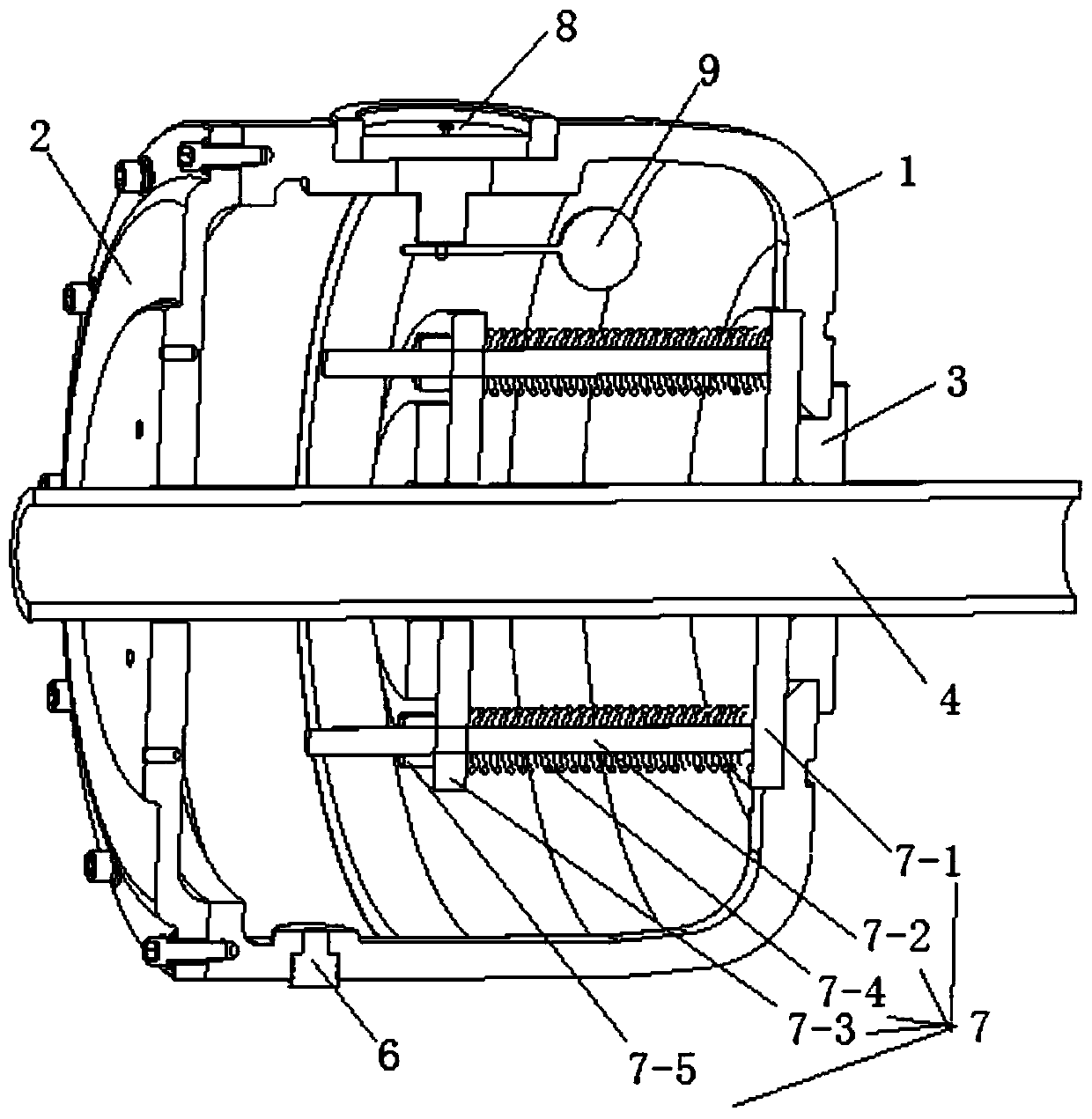

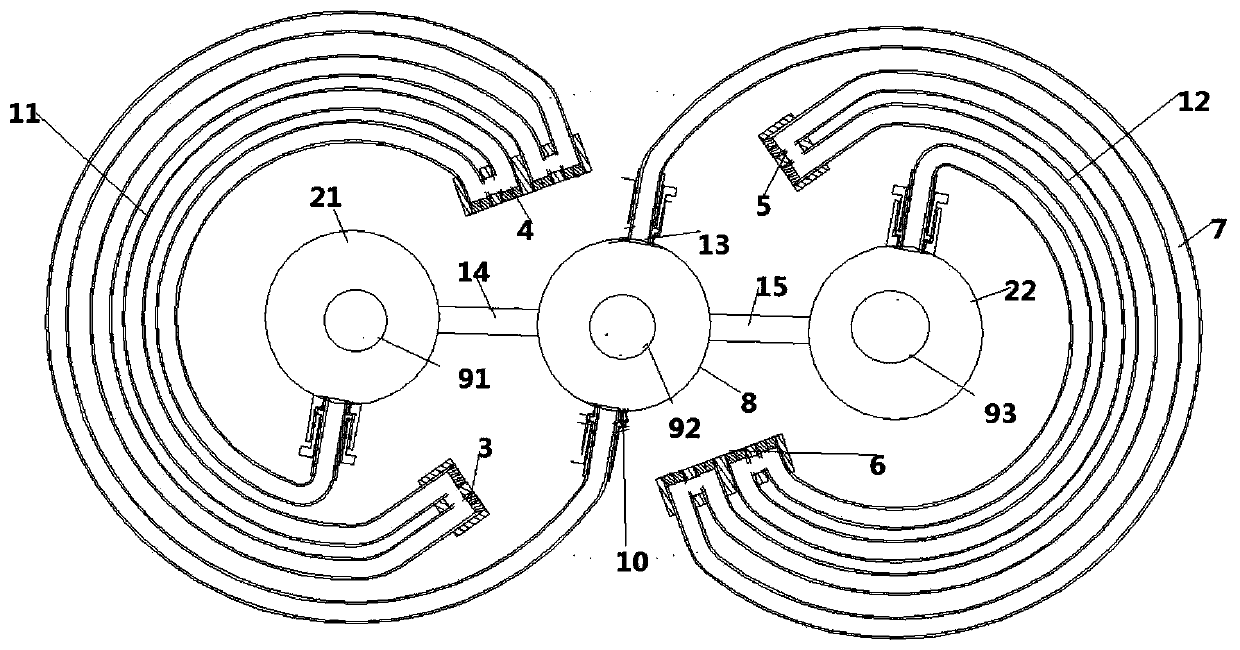

Automatic descaling device and method for shafts

ActiveCN104100231AReduce card rotationEnhanced descaling abilityCleaning apparatusImpellerEngineering

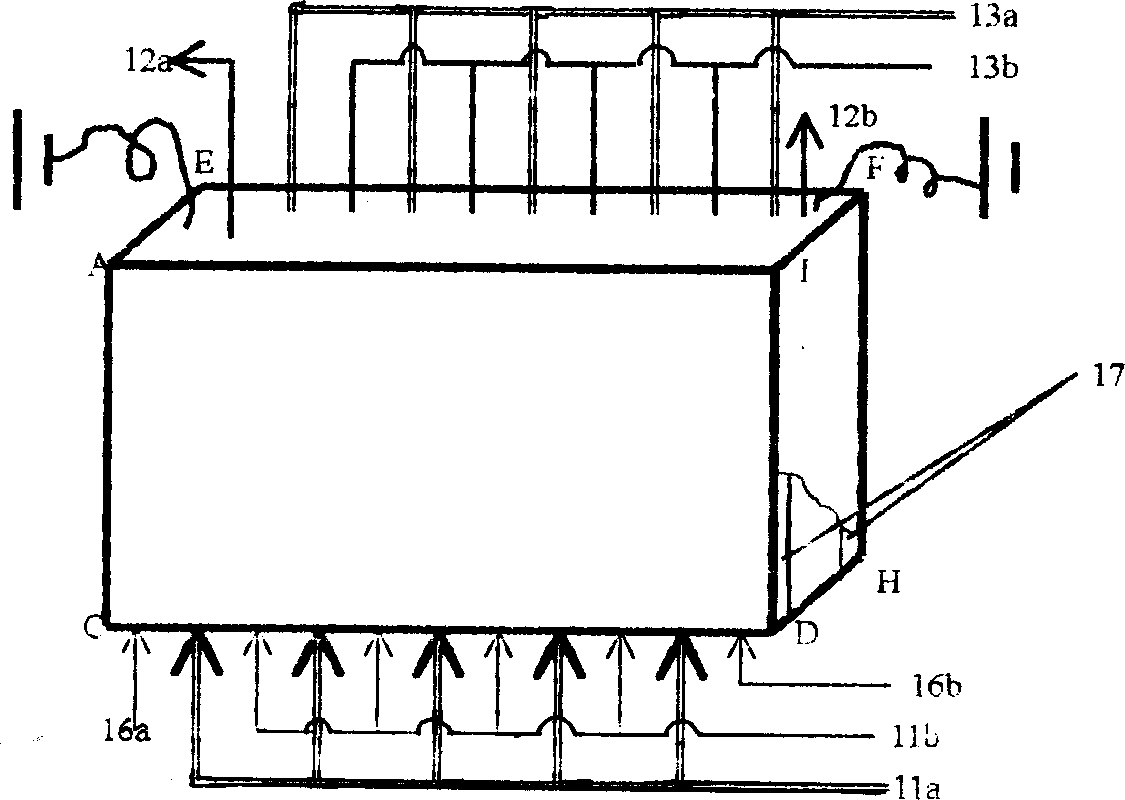

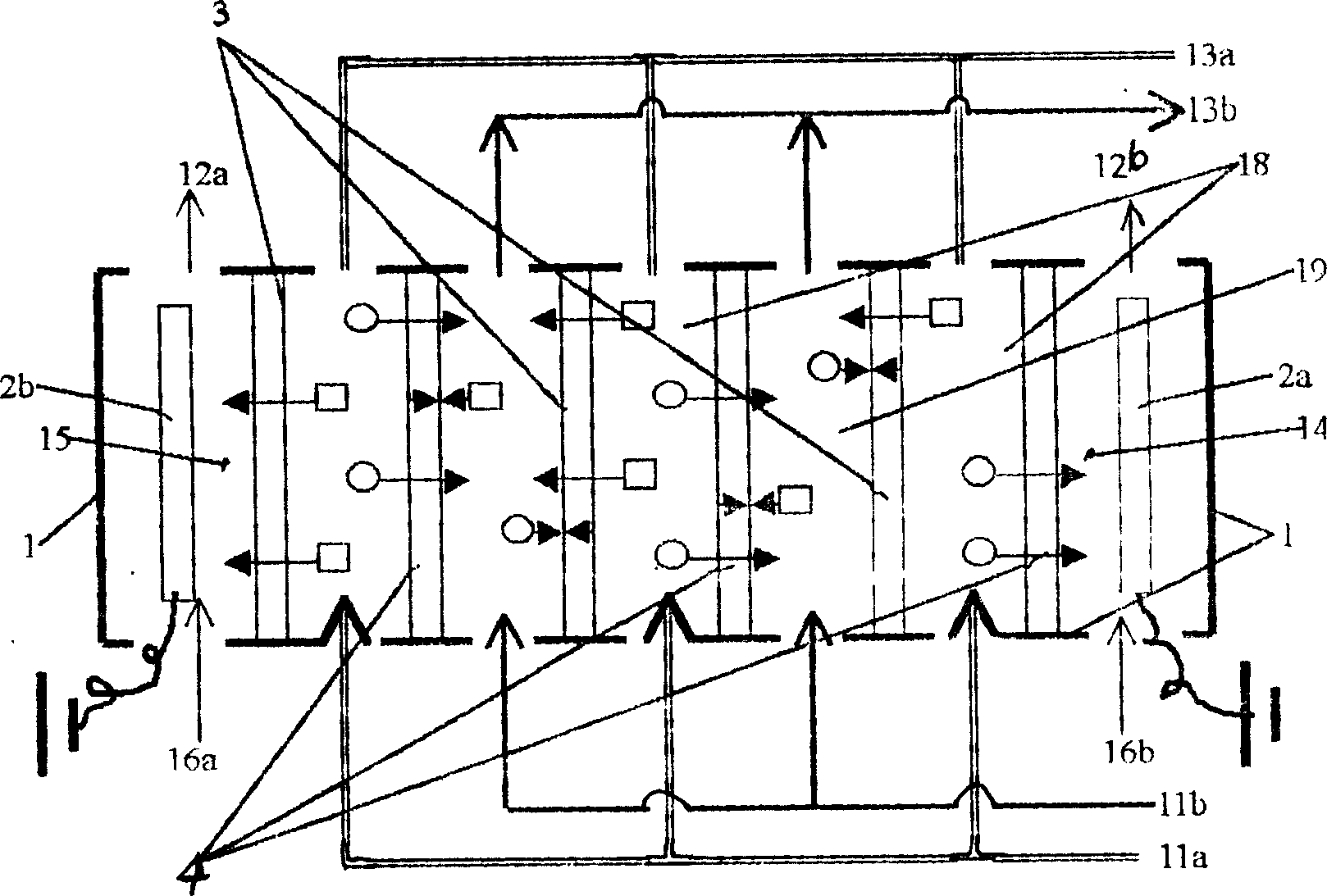

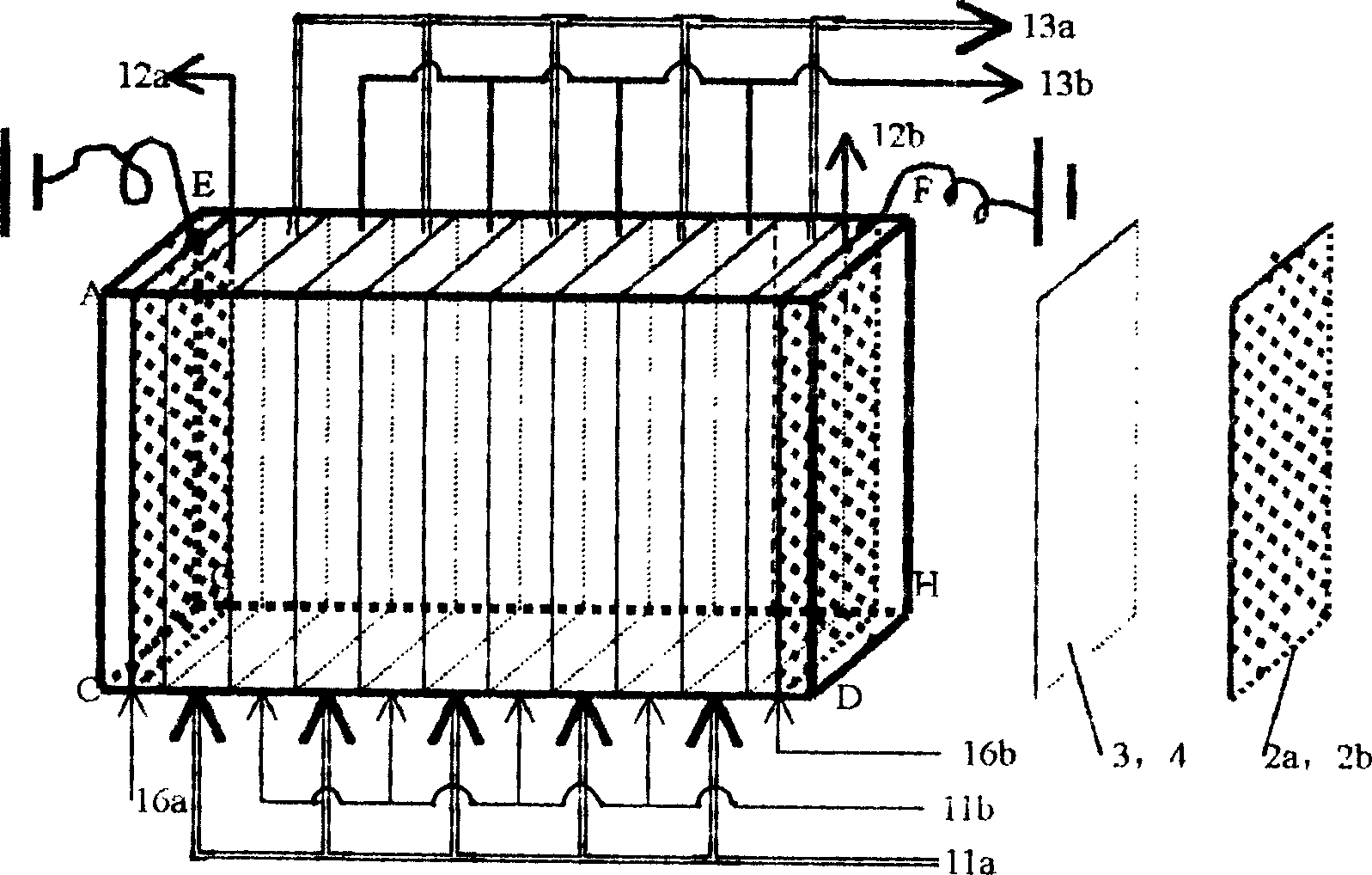

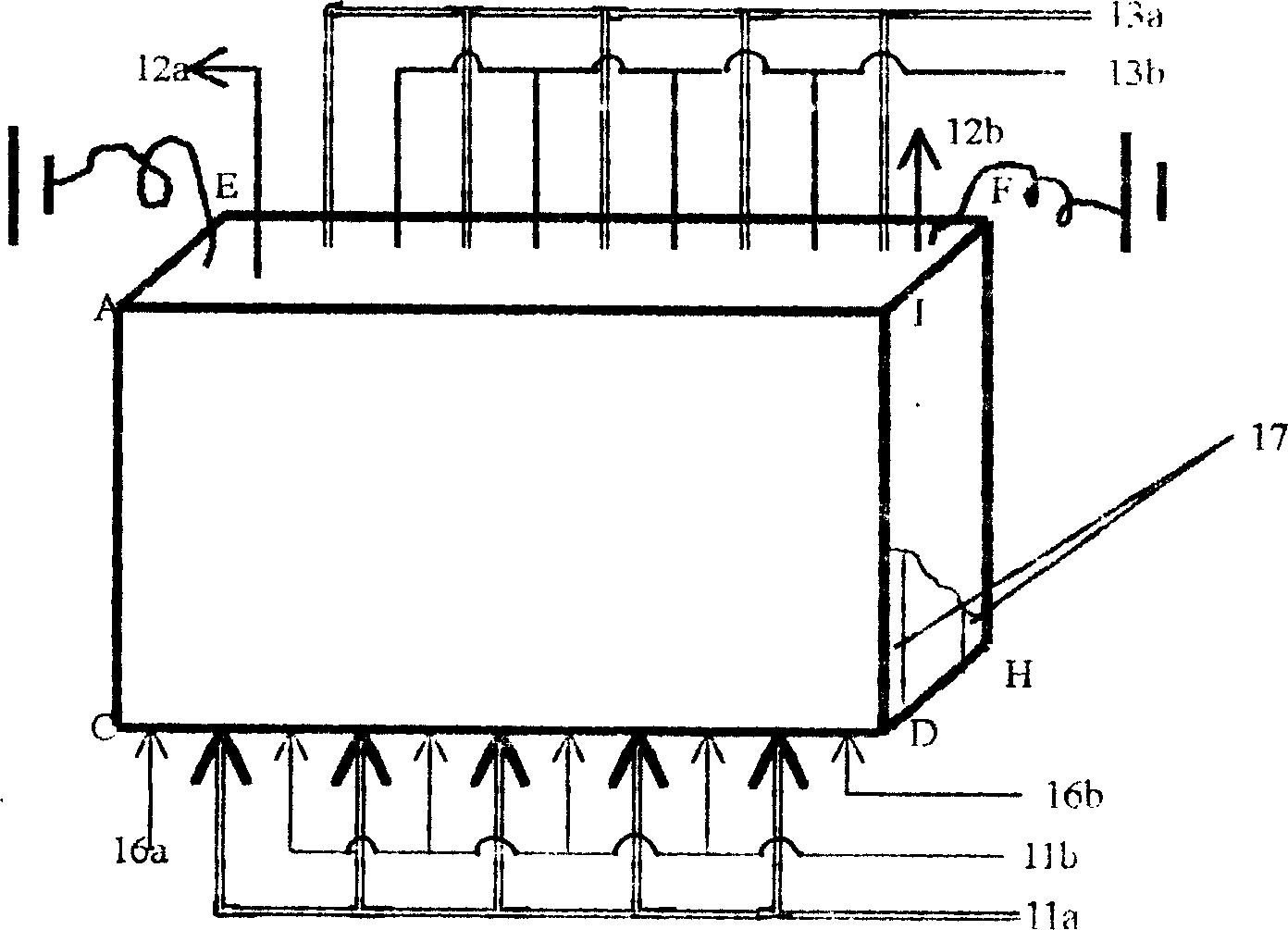

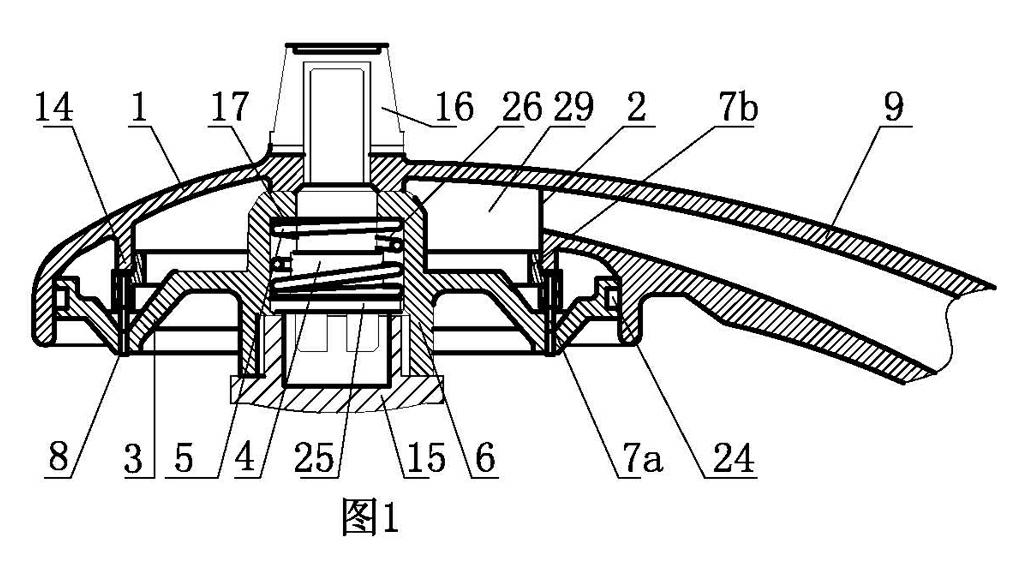

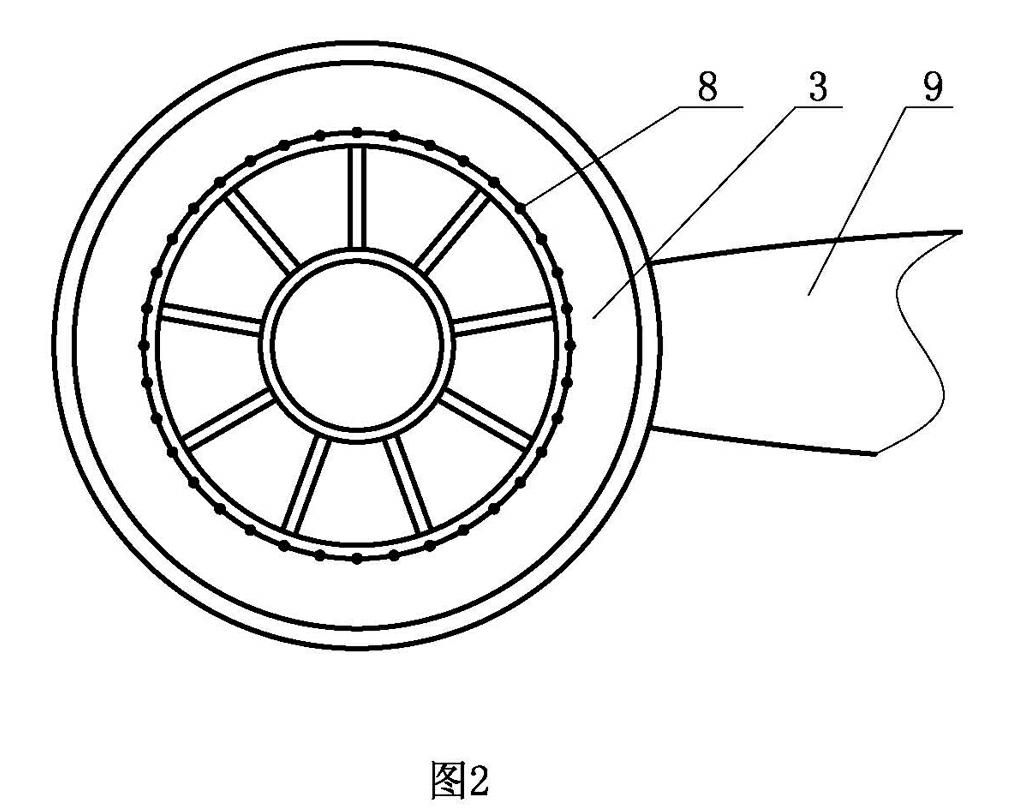

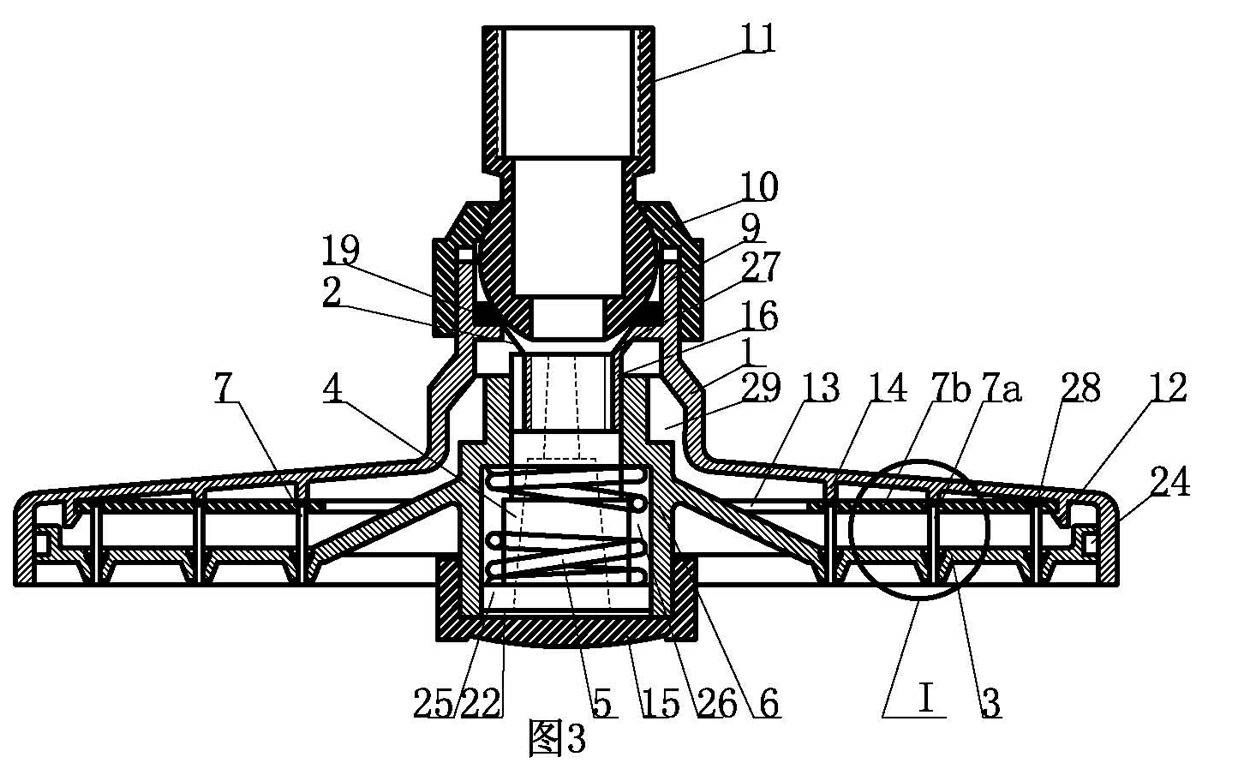

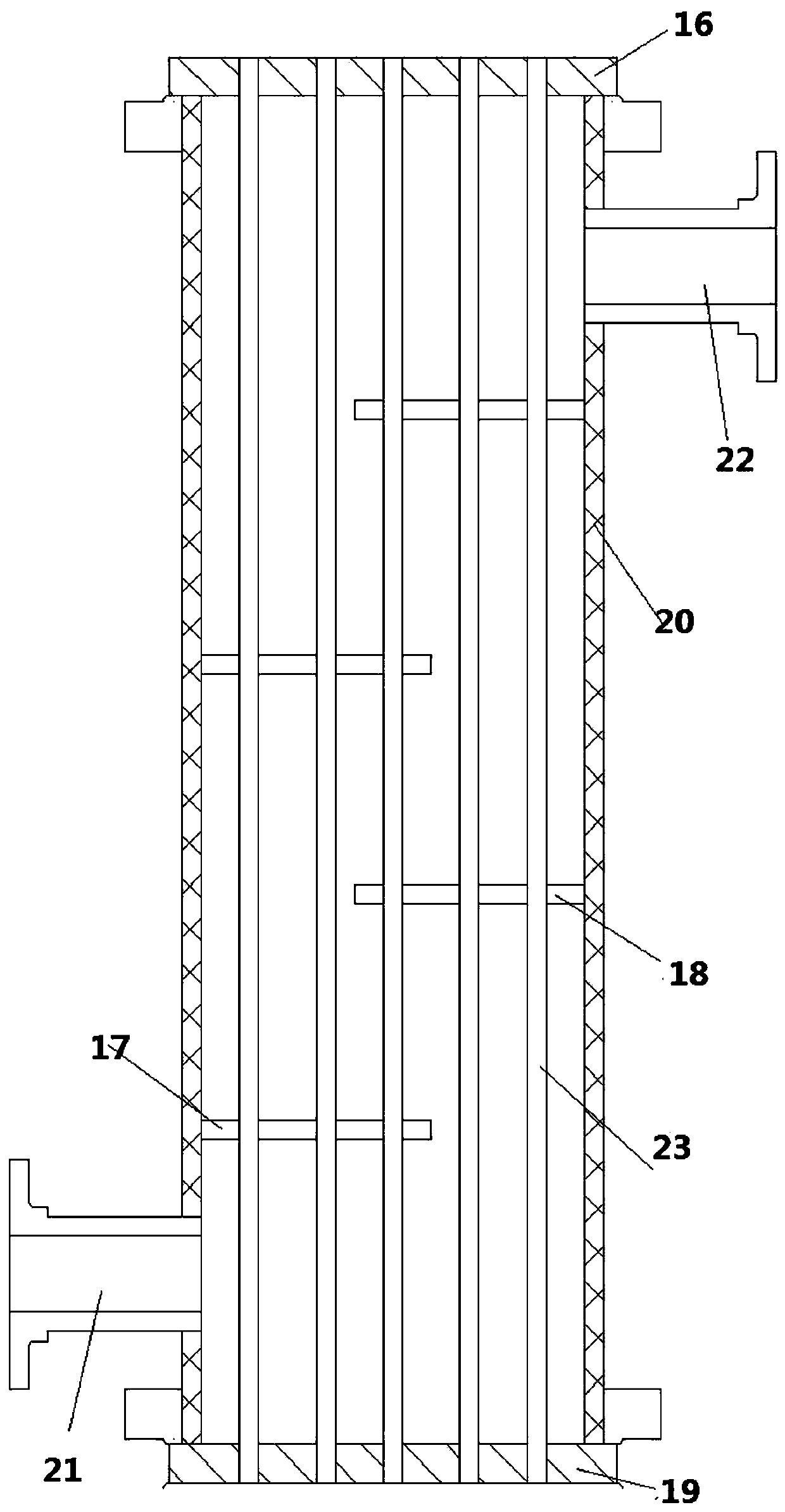

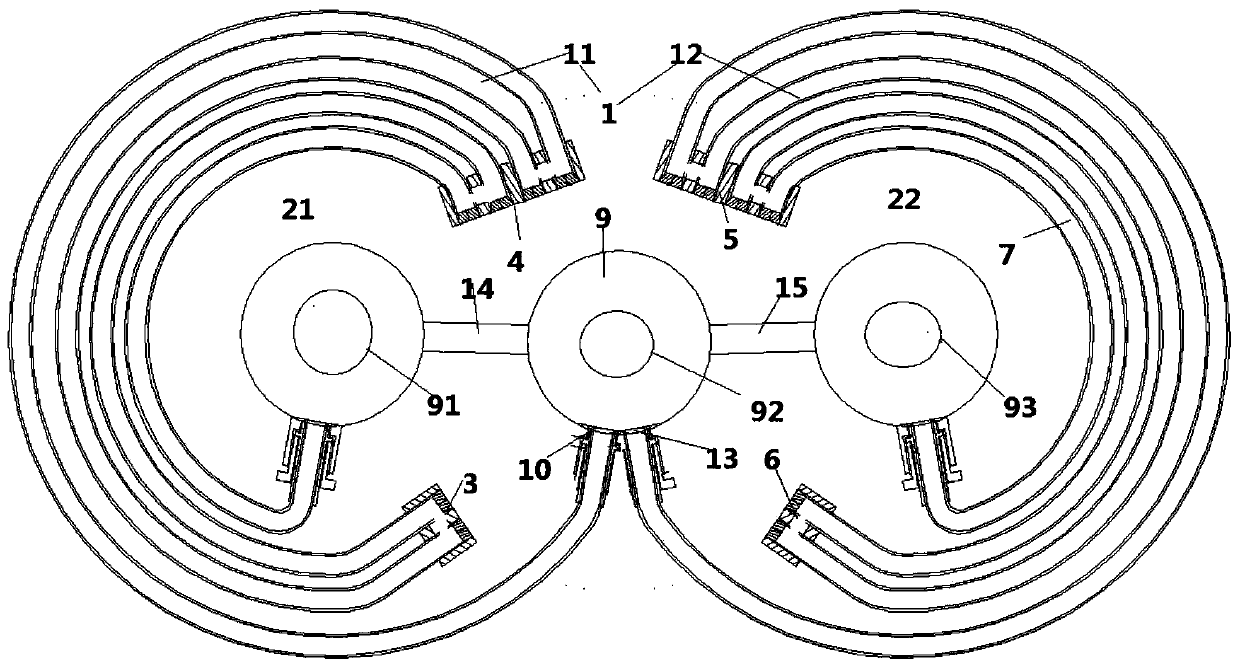

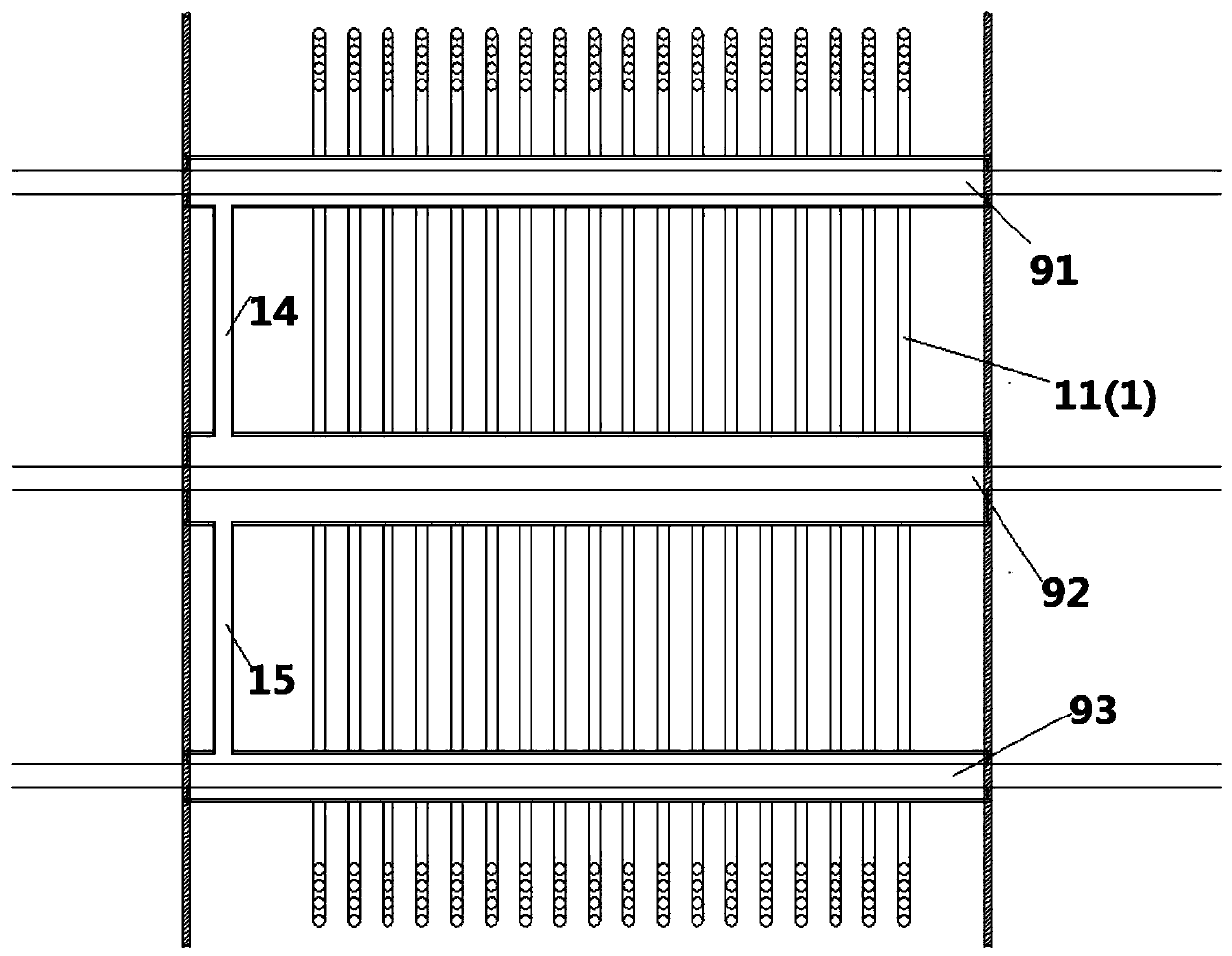

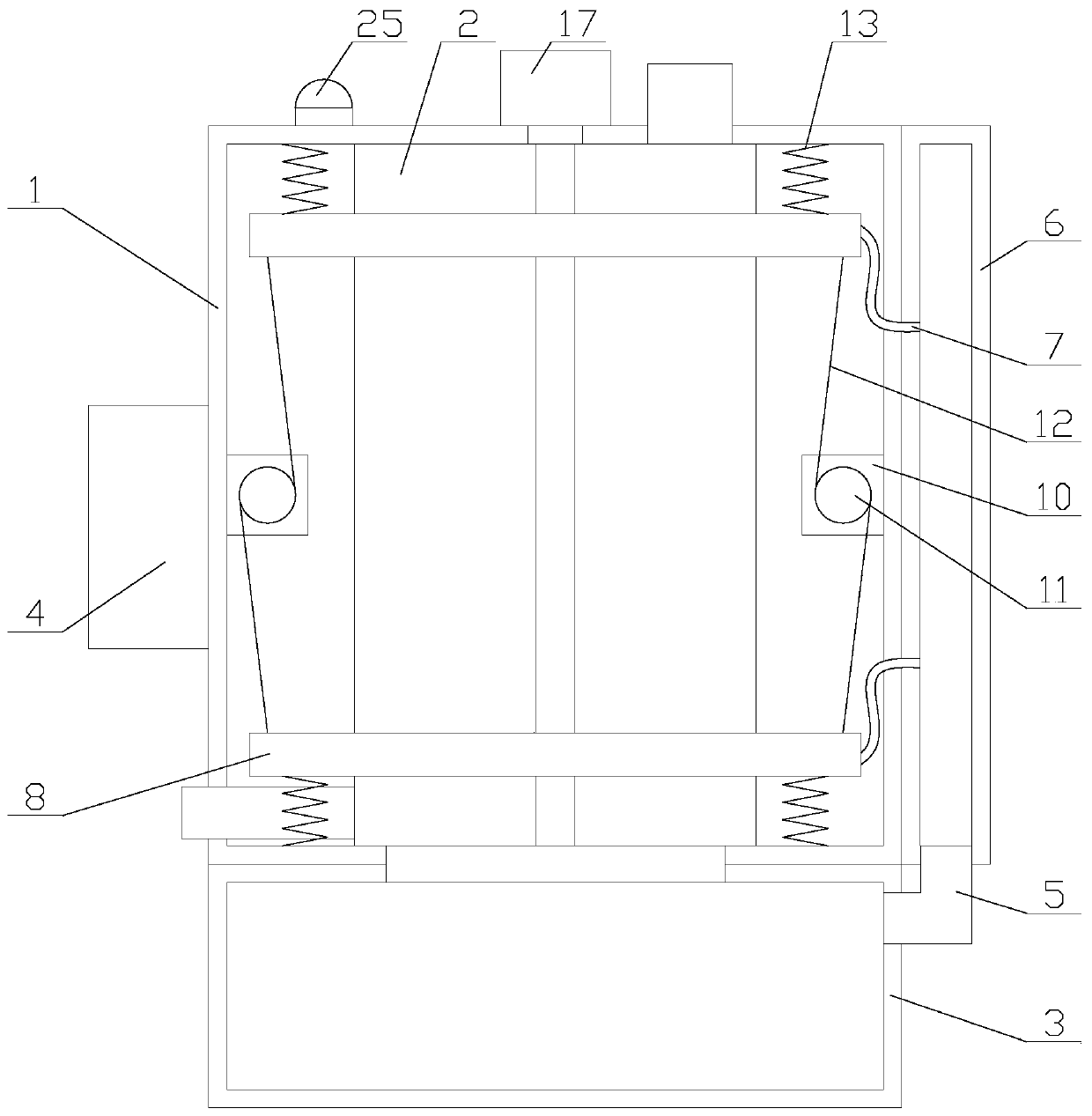

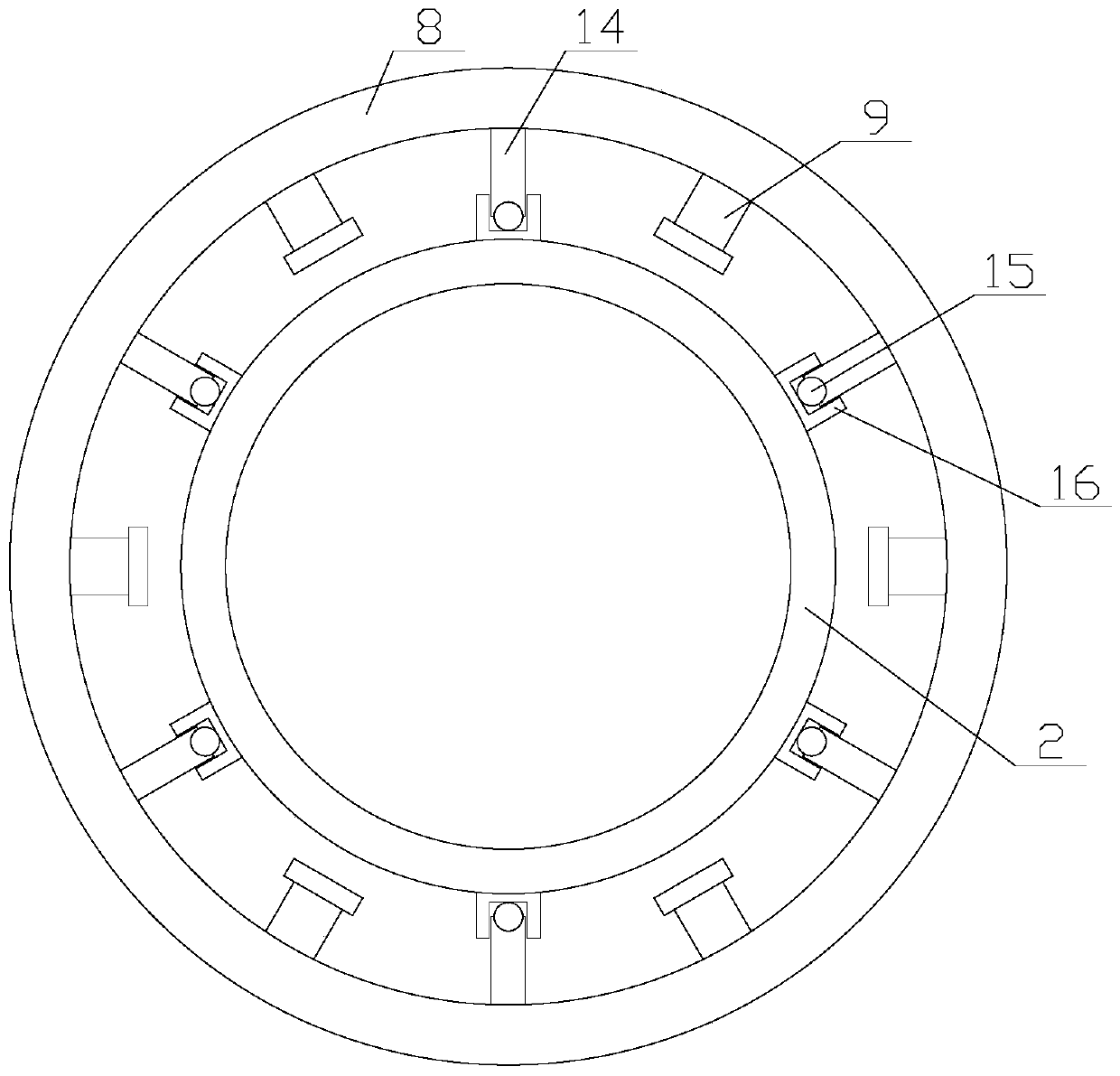

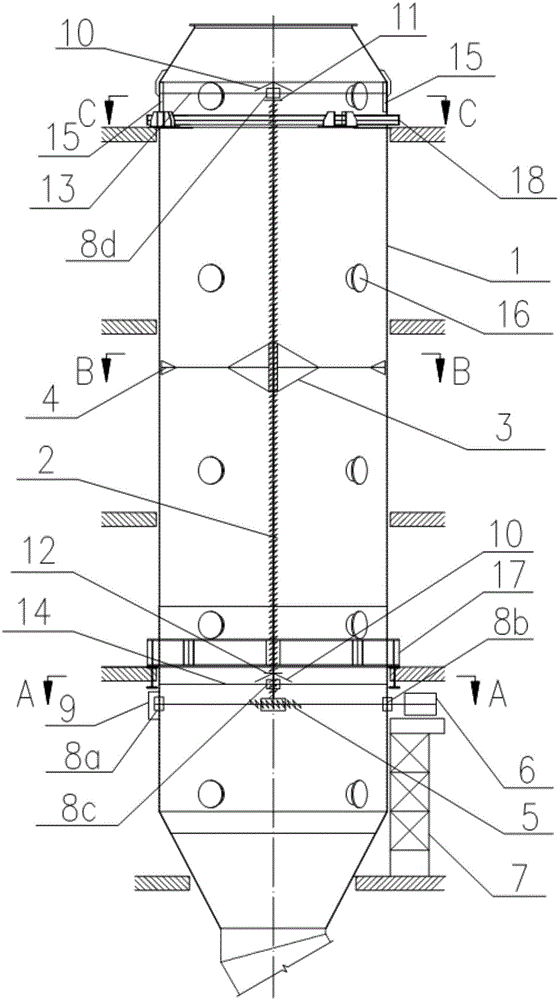

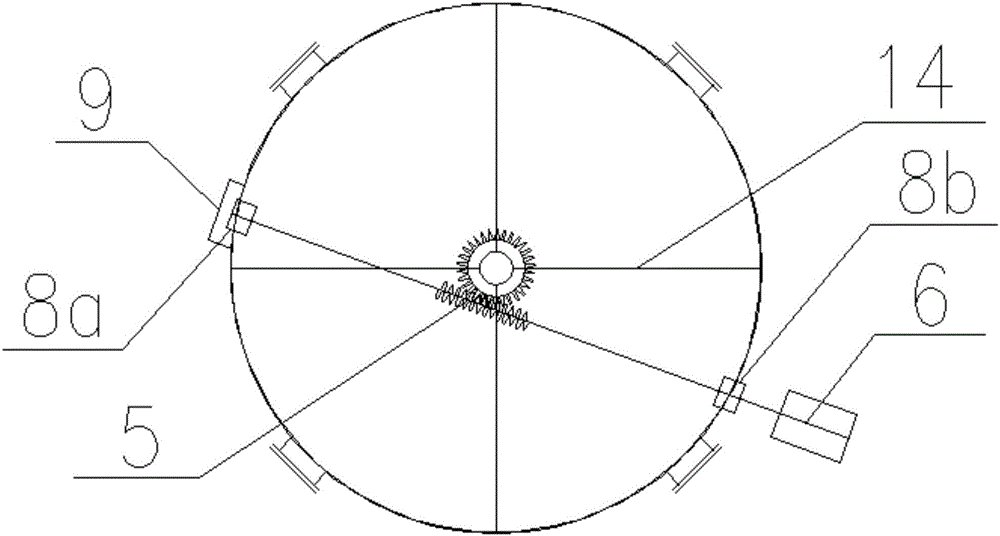

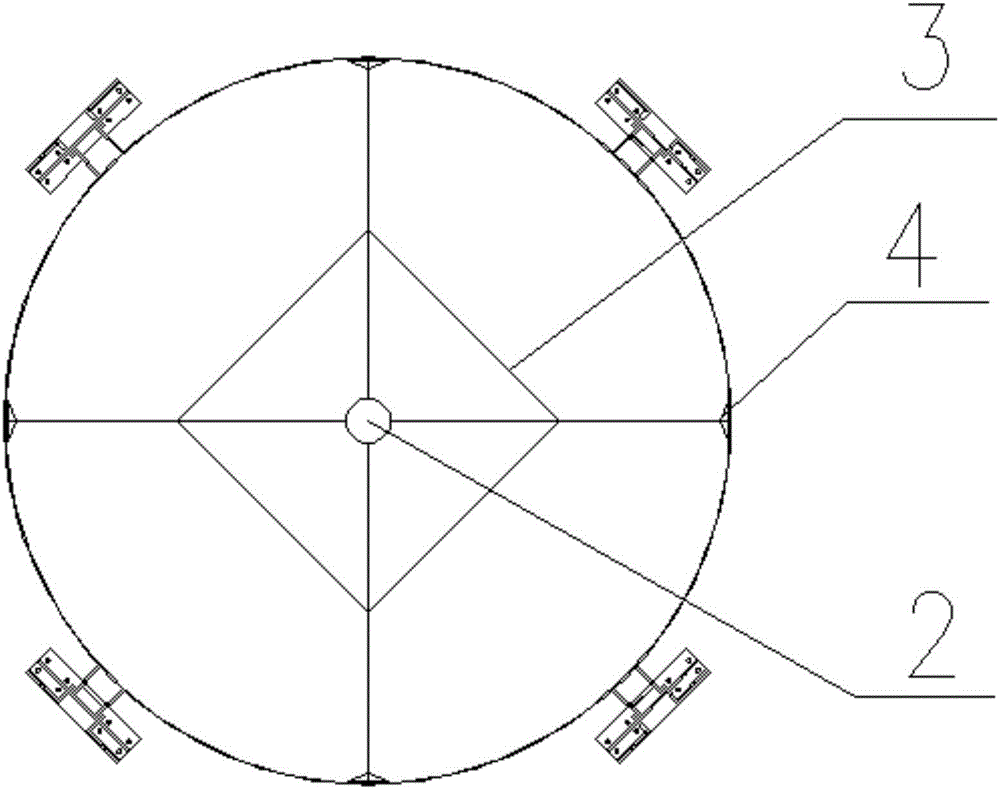

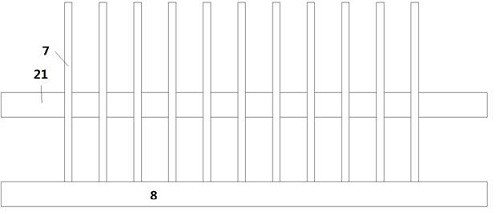

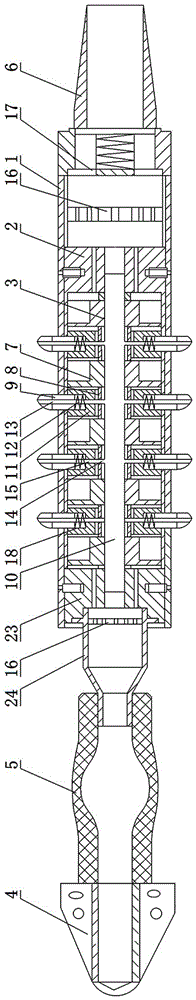

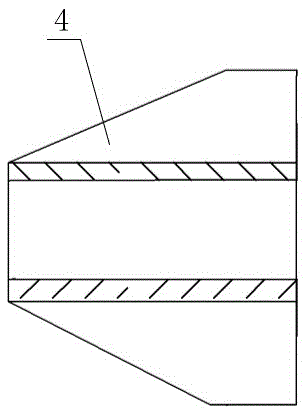

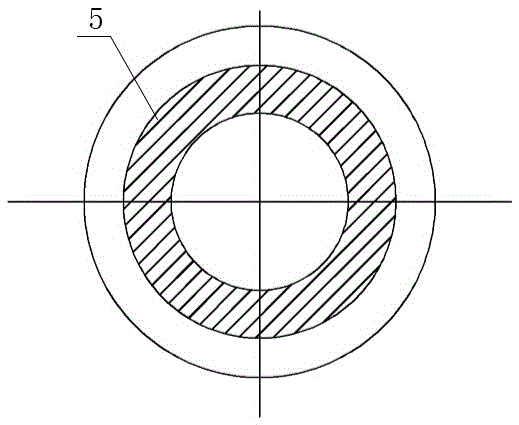

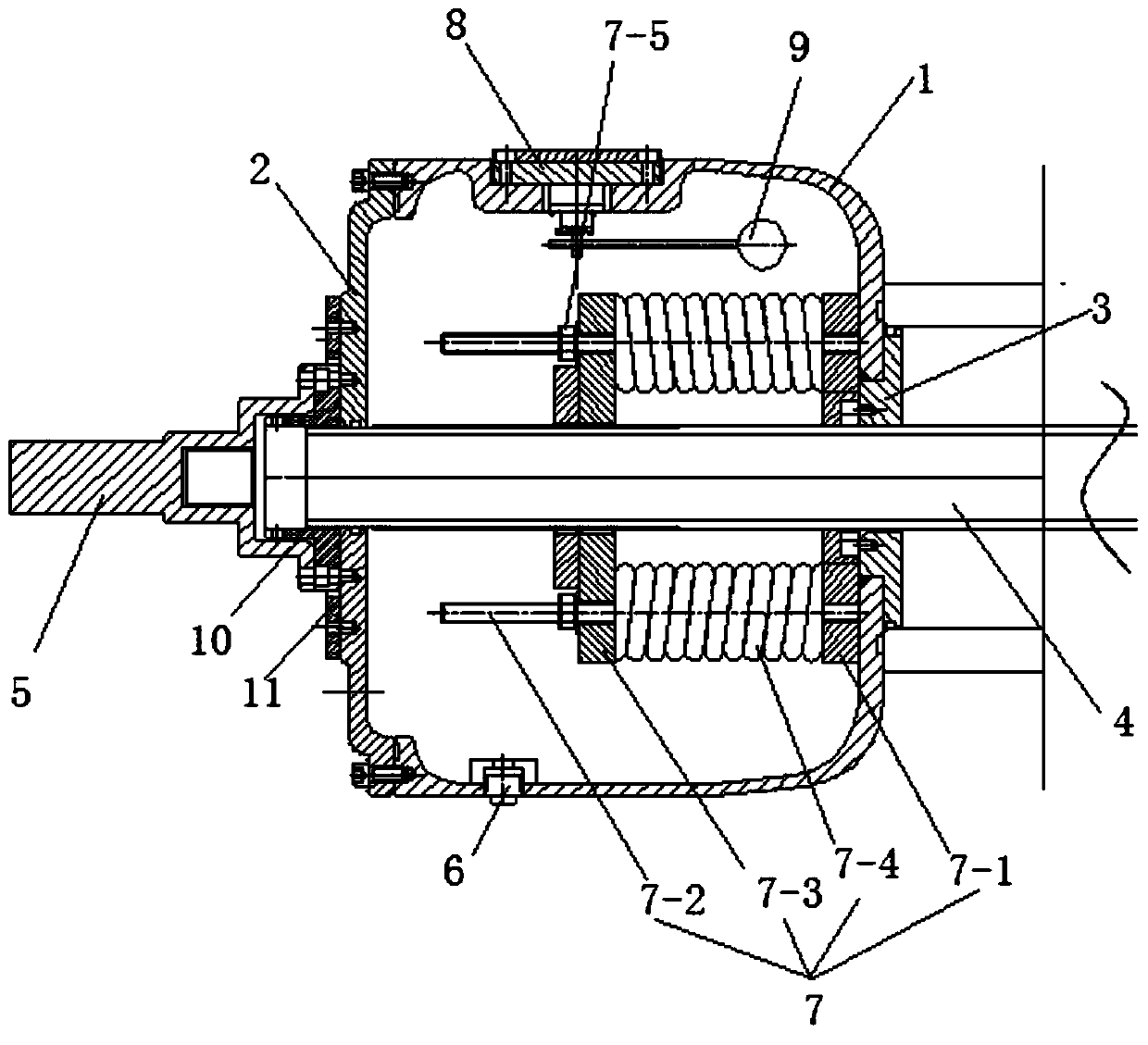

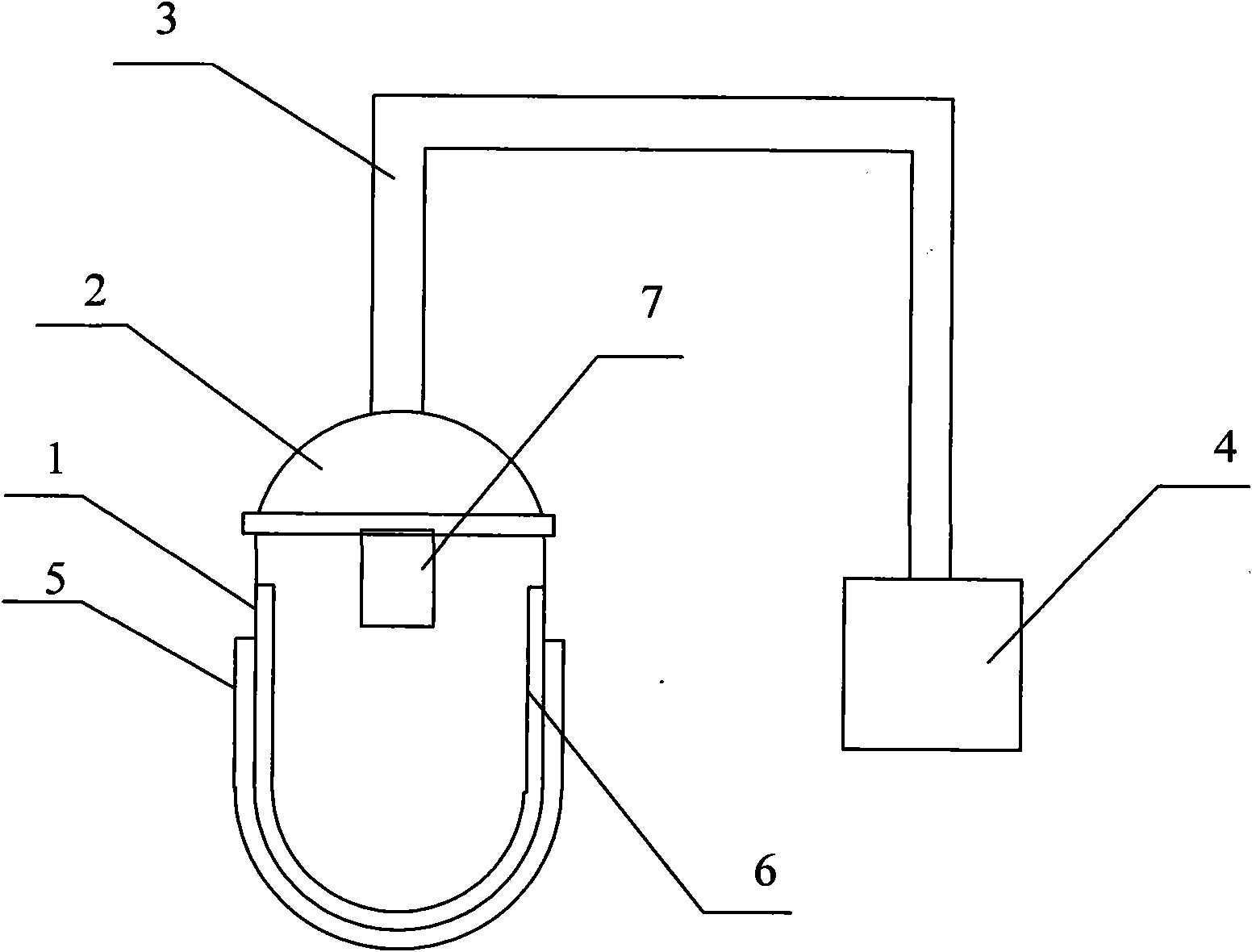

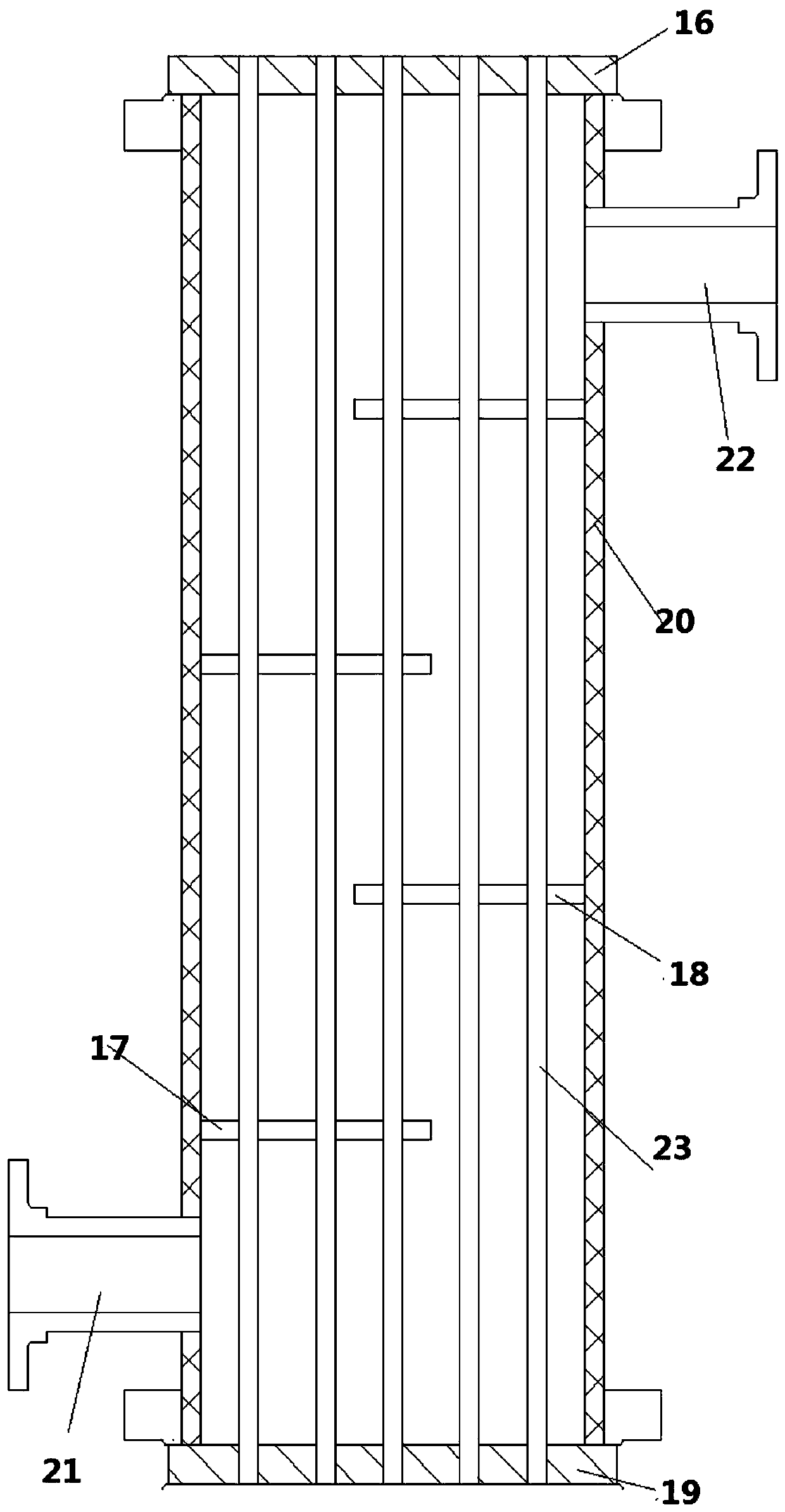

The invention discloses an automatic descaling device for shafts. The automatic descaling device comprises a pump shell (1), a pump body, a mandrel (3), an inflow head (4), a rubber sleeve (5), a connector (6), impellers (7) and scraper devices. The mandrel (3) is fixedly connected with the pump body. The impellers (7) and blade wheels (11) are mounted on the mandrel (3) at intervals. The scraper devices are mounted on the outer peripheries of the blade wheels (11). The inflow head (4) and the rubber sleeve (5) are communicated with the water inlet end of the mandrel (3). The water outlet end of the pump shell (1) is sequentially connected with a pressure control valve (17) and the connector (6). The invention further discloses a descaling method. The automatic descaling device and method has the advantages that downhole gas-liquid kinetic energy is converted into operation mechanical energy of the descaling device so as to achieve automatic descaling, descaling time is shortened, and combination of high-speed gas-liquid descaling and mechanical descaling is achieved.

Owner:SOUTHWEST PETROLEUM UNIV

Oxide scale control method for improving corrosion resistance of hot rolled medium plate

ActiveCN103962386AImprove corrosion resistanceReduce contentTemperature control deviceWork treatment devicesScale structureMechanical property

The invention provides an oxide scale control method for improving the corrosion resistance of a hot rolled medium plate and belongs to the technical field of metallurgy. The control method comprises the steps that smelting molten steel is made into a plate billet in a continuous casting mode, and the plate billet is heated, subjected to heat preservation and then roughly descaled, wherein the rough descaling pressure is larger than or equal to 16 MPa, and the rough descaling time is 4-10 seconds; the plate billet is subjected to rough rolling and then finish rolling, and finish descaling is conducted before an odd number of secondary finish rolling stages, wherein the finish descaling pressure is larger than or equal to 16 MPa, and the finish descaling time is 4-10 seconds; after being subjected to finish rolling, the plate billet is placed onto a cooling bed and cooled to the room temperature at the speed of 10-25 DEG C per second. According to the control method, a hot rolling process adjustment scheme is proposed according to an oxide scale structure of the hot rolled medium plate; the cooling speed of the plate billet on the cooling bed is controlled, the oxide scale structure is controlled reasonably by controlling the eutectoid reaction degree of FeO, and therefore the corrosion resistance of the surface of the hot rolled medium plate is improved; since existing equipment and process conditions in a steel mill are utilized, investment cost and production cost are not increased, and the corrosion resistance of the hot rolled medium plate is improved on the basis of guaranteeing the mechanical properties of the hot rolled medium plate.

Owner:NORTHEASTERN UNIV

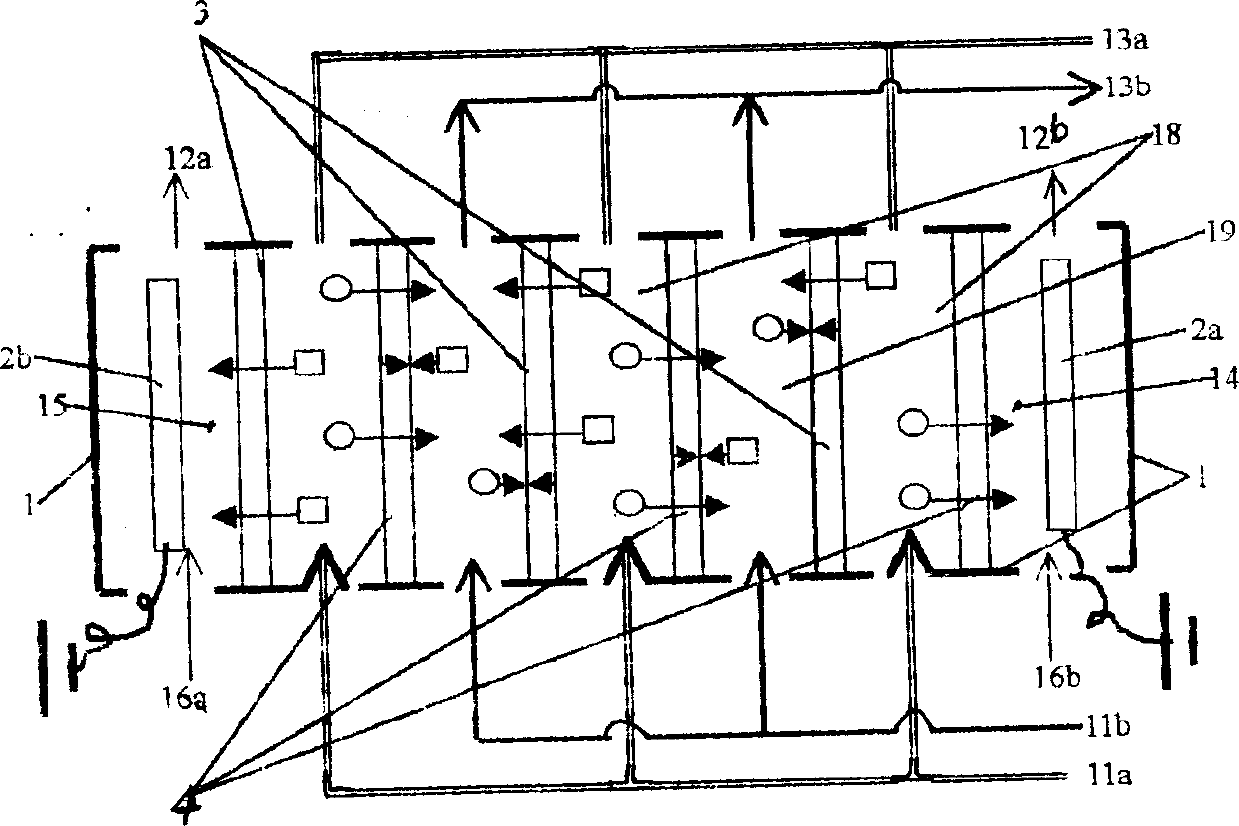

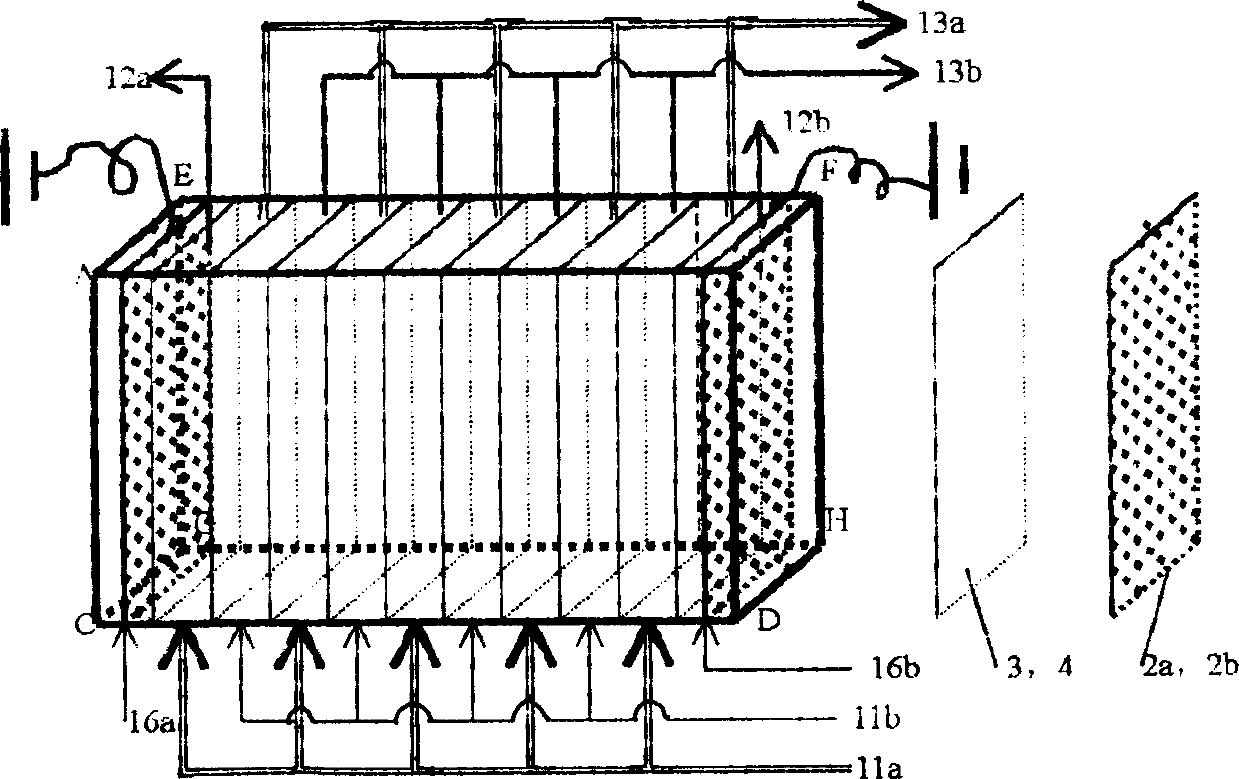

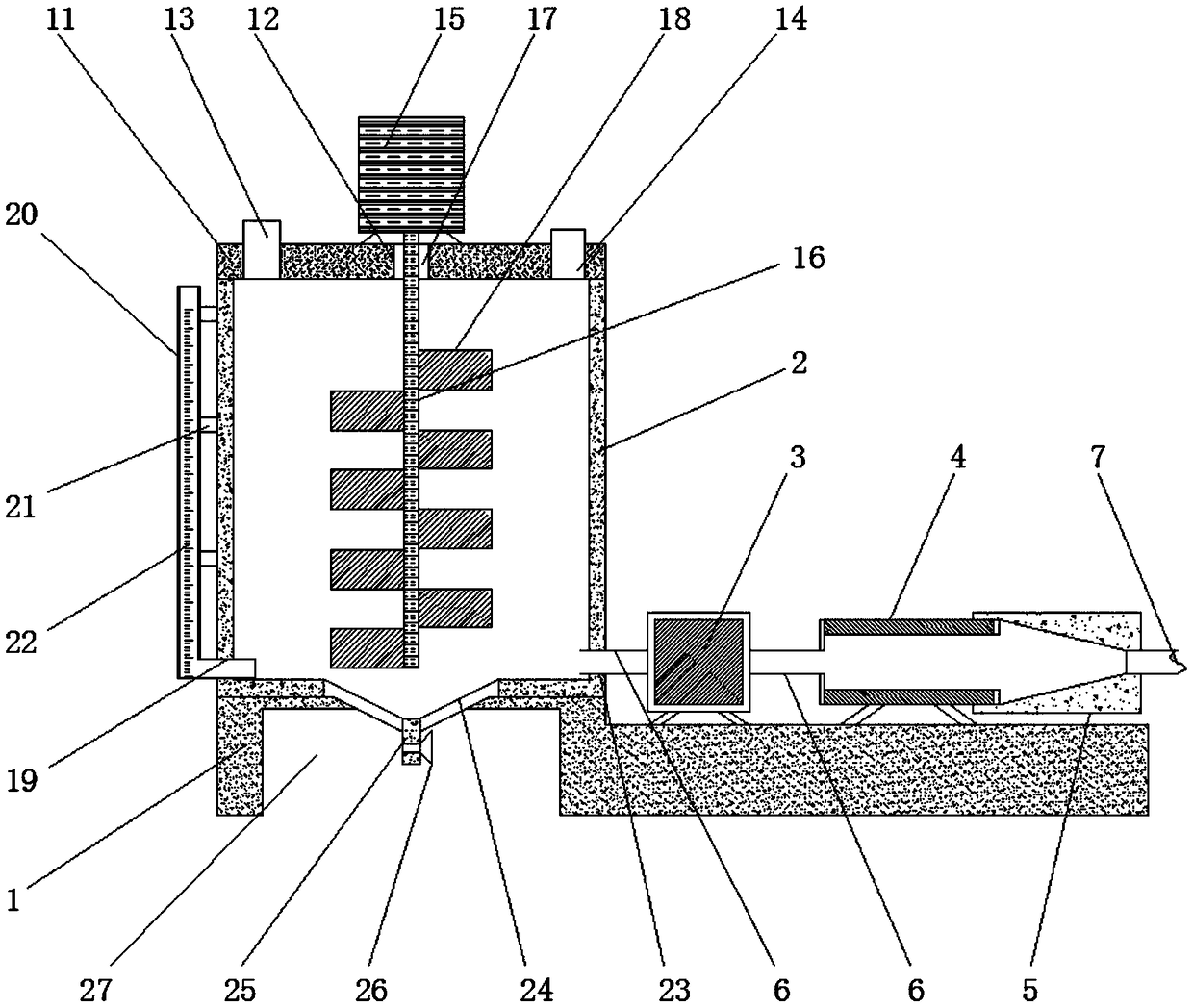

Process and apparatus for treating water by magneto-electric dialysis

InactiveCN1359857AImprove processing efficiencyIncrease directional forceGeneral water supply conservationDispersed particle separationMagnetic tension forceElectric consumption

A magneto-electric dialysis process for desalinating seawater, preparing salt from seawater and desalting industrial water is characterized by that on the basis is existing electric dialysis equipment, a static magnetic field is additionally used to directionally shift the cations and anions in flowing solution. Its apparatus is composed of a casing with different water inlets and outlets and electrodes, a group of cationic exchange membranes and anionic exchange membranes, which are alternatively arranged between anode and cathode, and a permanent magnet attached to each wall of the casing. Its advantages are high throughput, less electric consumption and not scaling.

Owner:陈树庆 +1

Water treating magnetoelectric dialysis process

InactiveCN1526654AEasy to handleImprove processing efficiencyGeneral water supply conservationDispersed particle separationWater desalinationSeawater

The water treating magnetoelectric dialysis process may be used in sea water desalting, salted water desalting, sea water concentration to produce salt, desalting industrial water, etc. Ion exchange membrane with selective penetration is utilized in establishing a water processing electric dialysis space, where electrolyte ion is made to migrate directionally in the DC electric field. The present invention features that in the electric dialysis space, one static magnetic field is applied, which has magnetic force line direction perpendicular to the water flow direction and the current direction to strengthen the directional migration of anion and cation in the flowing solution. The present invention is superior to available electric dialyser with small water processing amount, great power consumption, easy scaling and other demerits. The present invention is realized simply through applying two permanent magnets onto two opposite walls of the electric dialyser casing.

Owner:陈树庆 +1

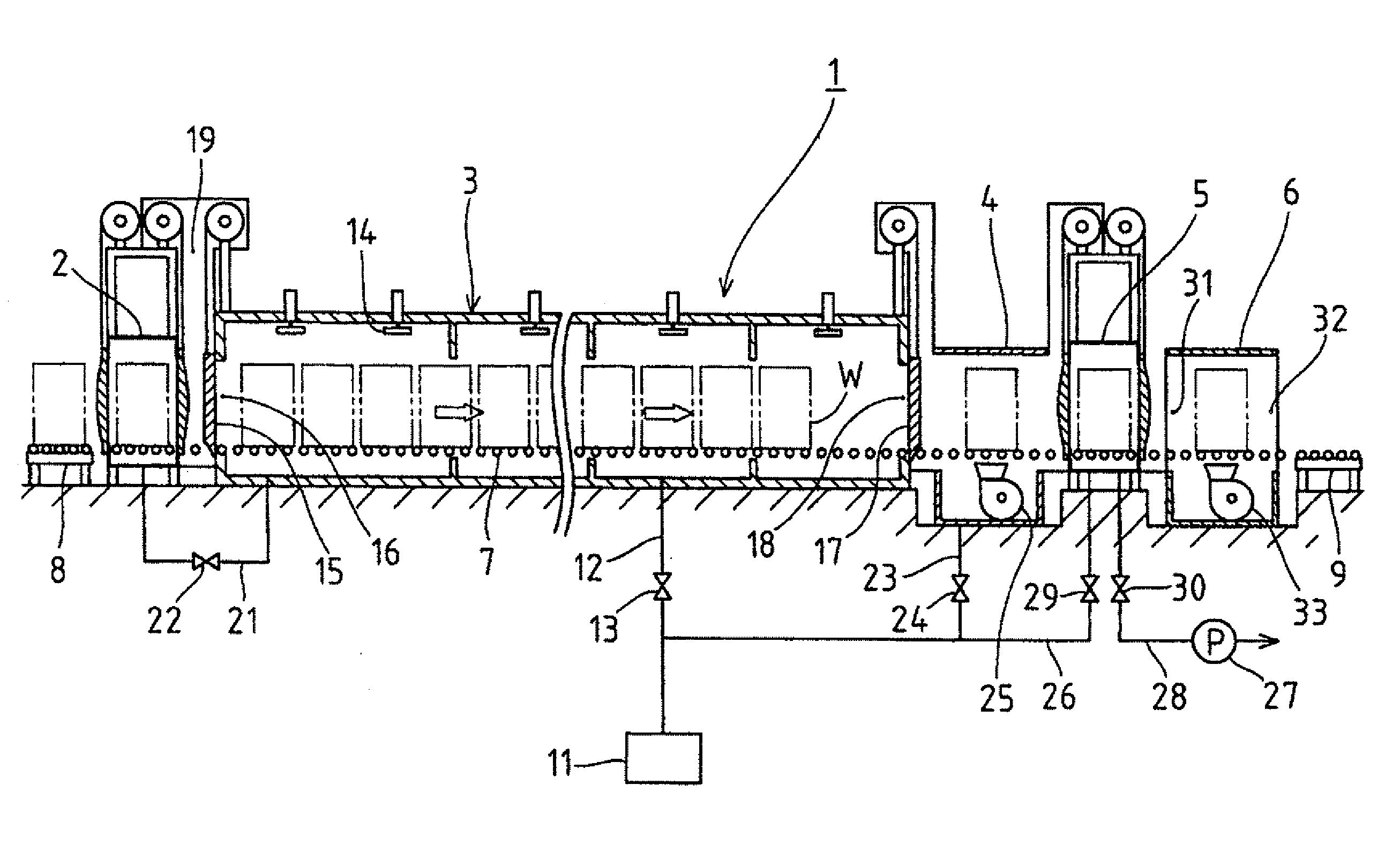

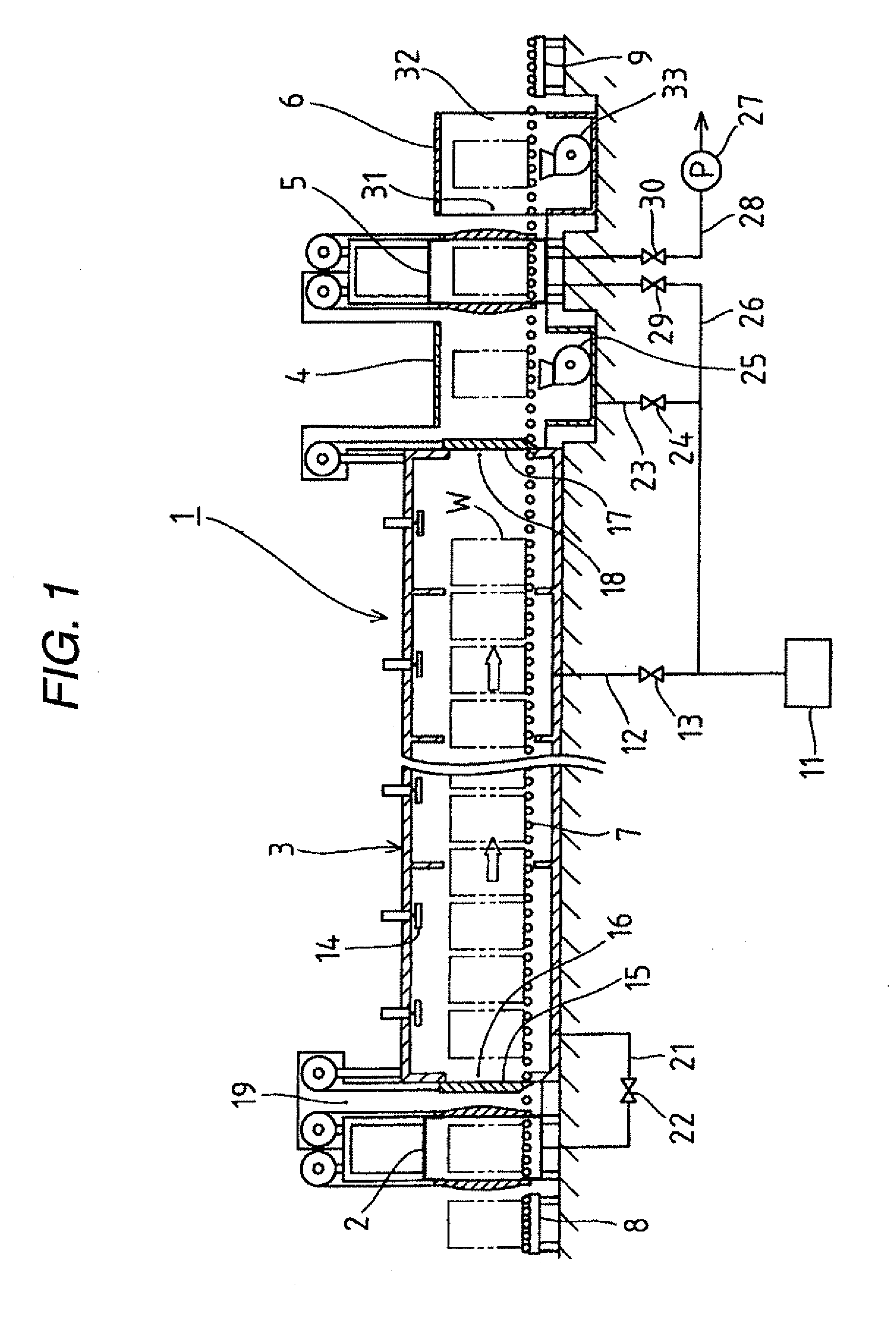

Continuous heat treatment furnace

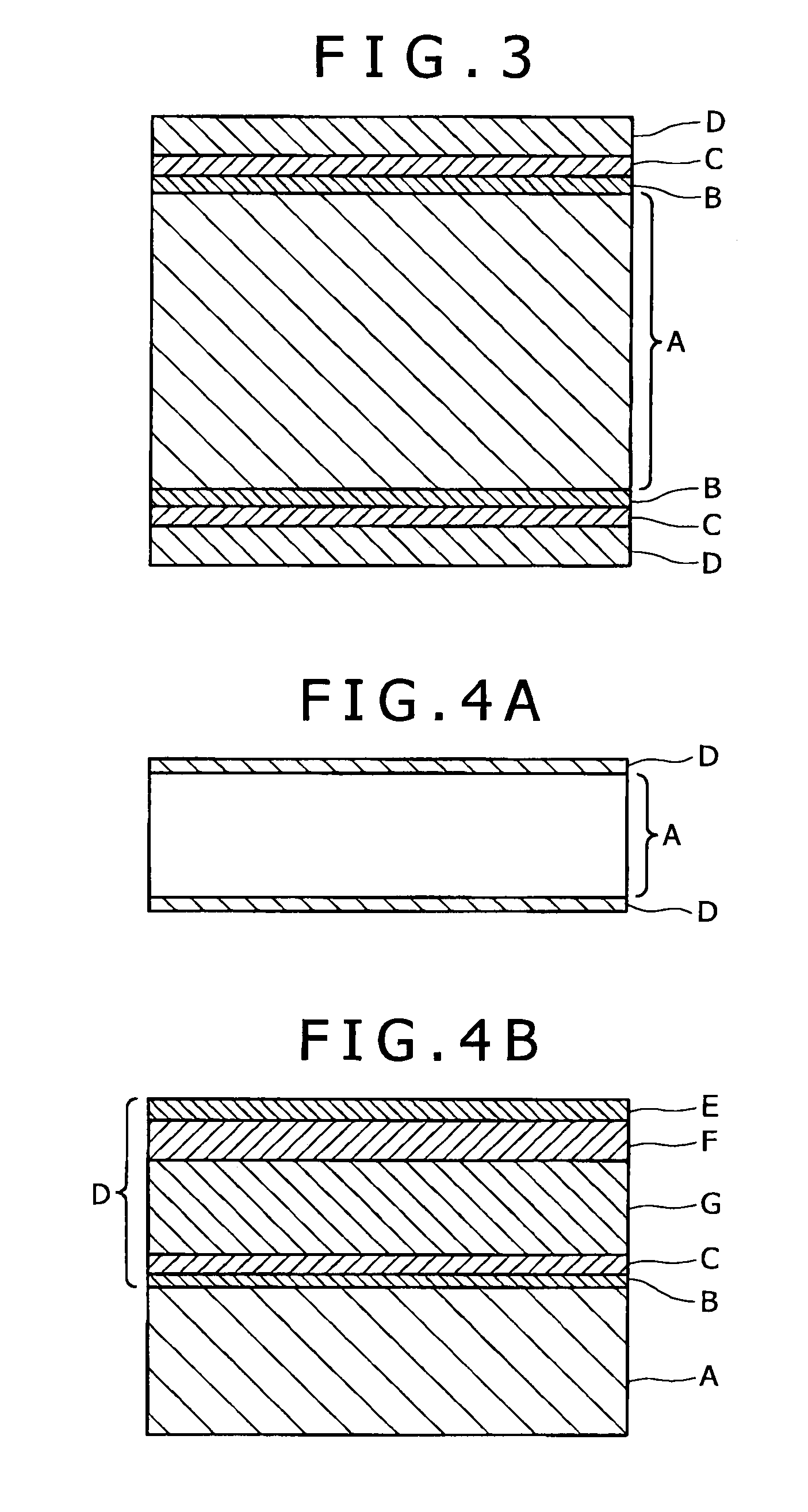

InactiveUS20100068669A1Poor pickling property is preventedReduce the temperatureFurnace typesHandling discharged materialMetallurgyCooling chamber

The present invention provides a continuous heat treatment furnace including: a heating chamber heating a treatment object in an inert gas atmosphere; a front chamber provided at one end of the heating chamber; and a first cooling chamber cooling the treatment object in an inert gas atmosphere, a vacuum purge chamber, and a second cooling chamber cooling the treatment object in an oxidizing gas atmosphere, which are connected in this order to the other end of the heating chamber, in which the treatment object transferred from the front chamber to the heating chamber is subjected to the heating in the heating chamber, and then subjected to one cooling selected from the cooling in the inert gas atmosphere in the first cooling chamber and the cooling in the oxidizing gas atmosphere in the second cooling chamber depending on a type of the treatment object.

Owner:DAIDO STEEL CO LTD

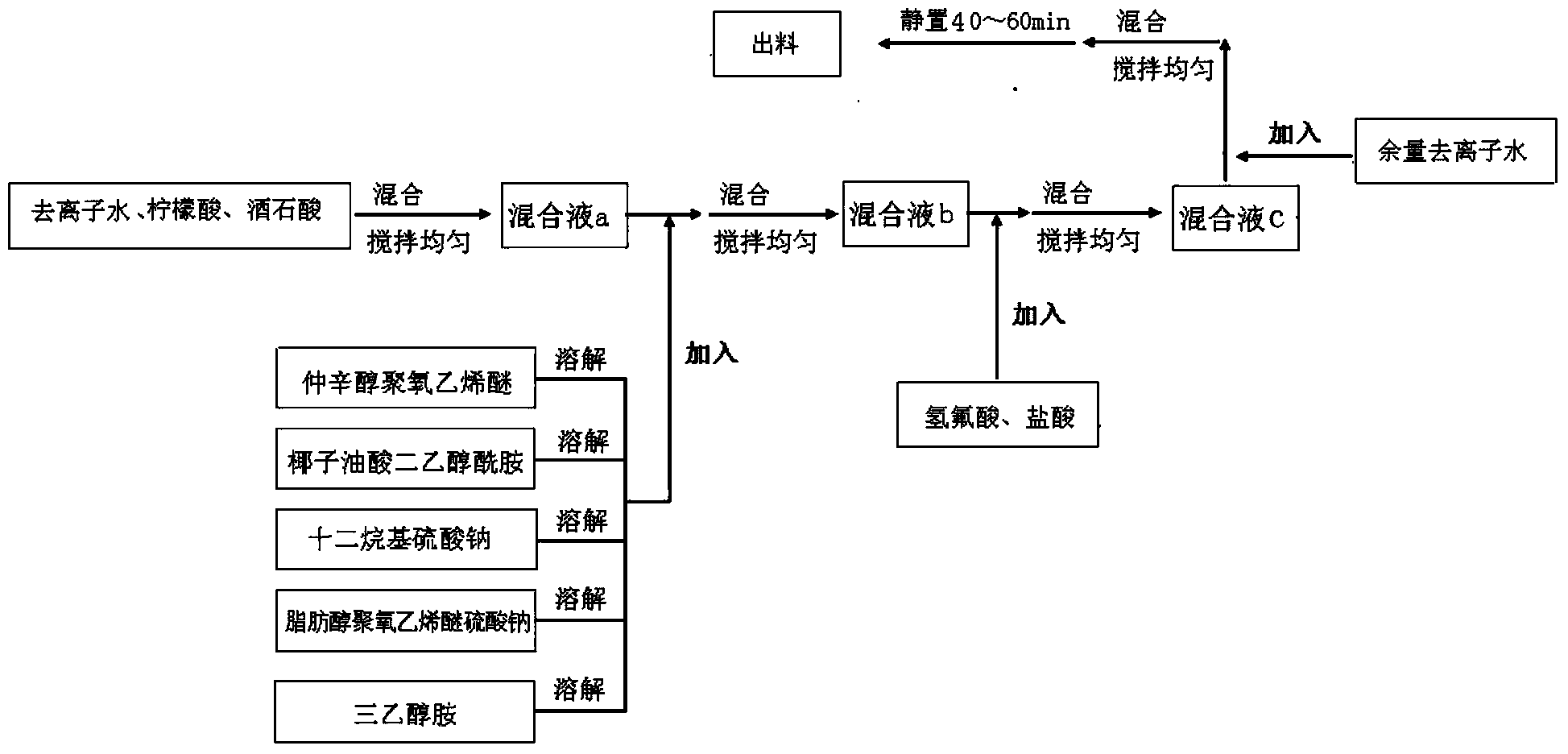

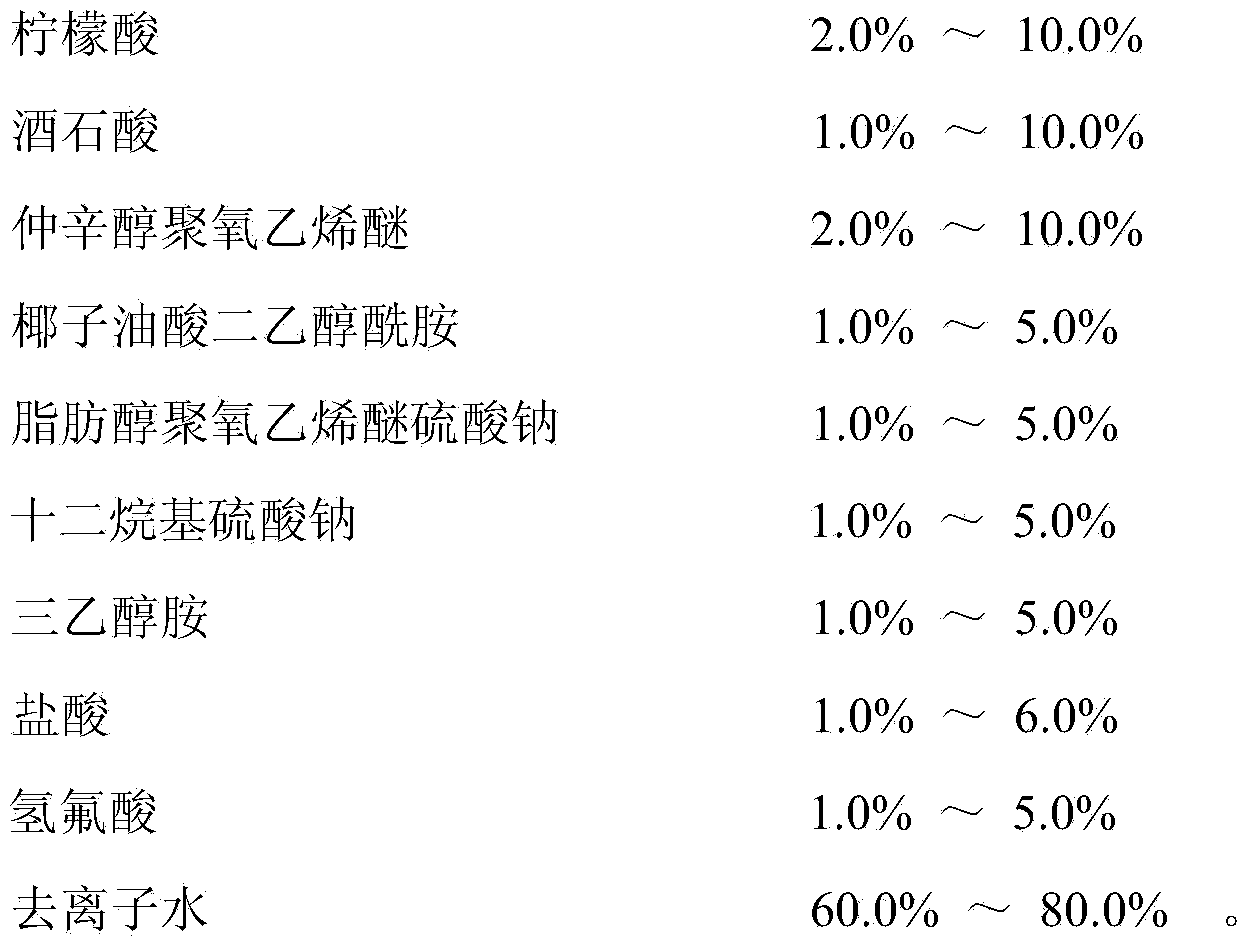

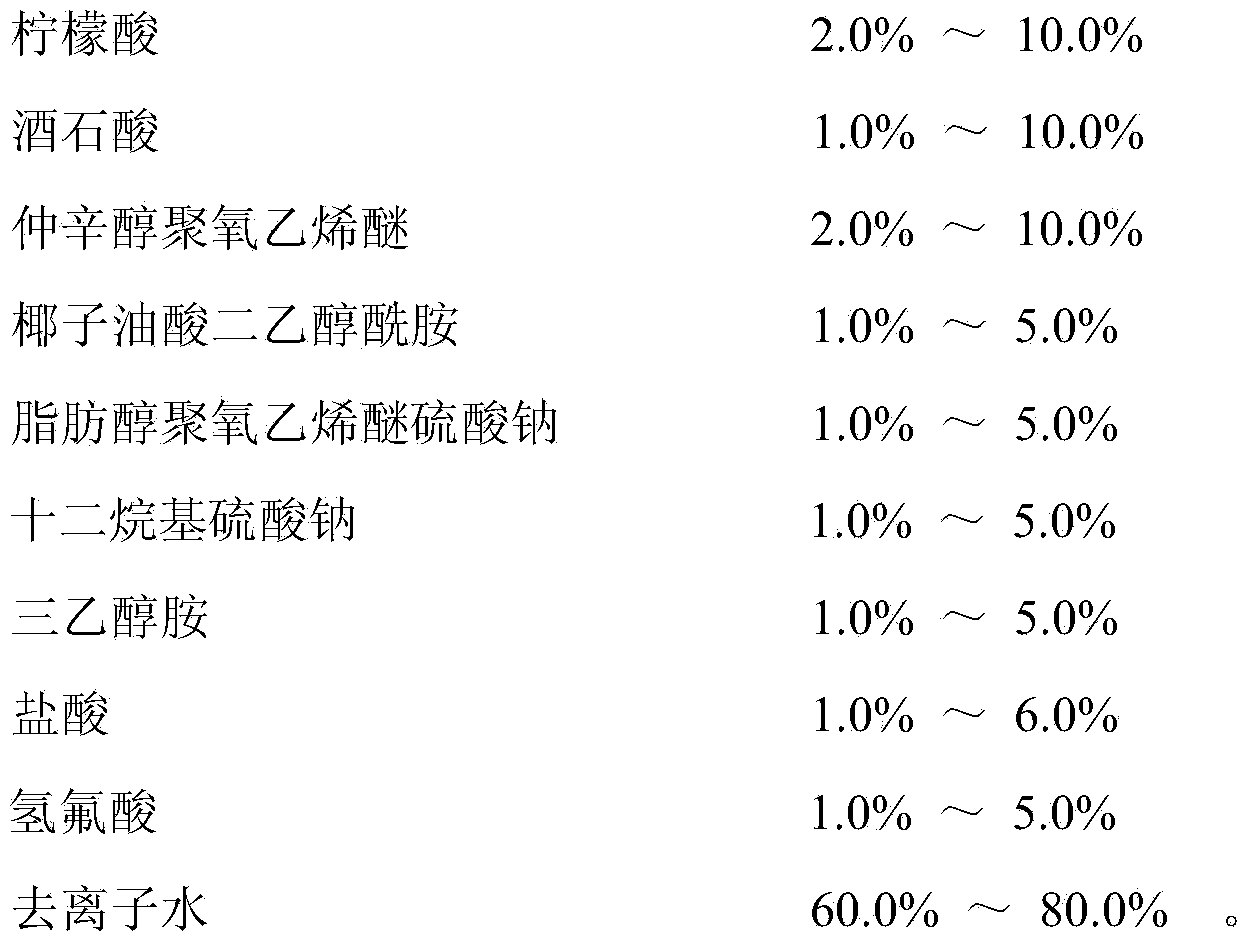

Treating agent for aluminum case of controller of electric bicycle and preparation method of treating agent

The invention discloses a treating agent for an aluminum case of a controller of an electric bicycle and a preparation method of the treating agent, and belongs to the technical field of chemical descaling. The treating agent consists of citric acid, tartaric acid, octanol polyoxyethylene ether, coconut oil diethanoamine, sodium sulfate fatty alcohol-polyoxyethylene ether, lauryl sodium sulfate, lauryl sodium sulfate, triethanolamine, hydrochloric acid, hydrofluoric acid and deionized water. The components are mixed and uniformly stirred to obtain the treating agent. The treating agent is a cleaning agent which is good in descaling effect, strong in cleaning force, convenient to use, environment-friendly, high in biodegradation rate and green and environment-friendly. In addition, the treating agent is extremely low in corrosion rate to equipment.

Owner:江苏省轻工业科学研究设计院有限公司

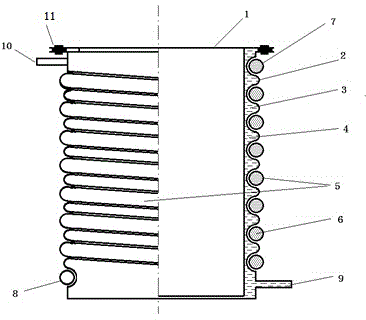

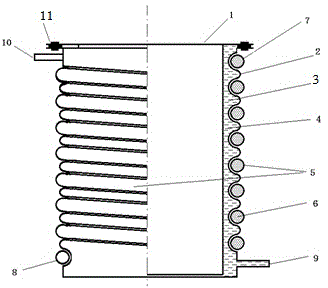

Heat exchanger of heating pump for heating water

InactiveCN104019680AImprove heat transfer efficiencyEnsure Hygienic StandardsStationary tubular conduit assembliesWater flowEngineering

The invention discloses a heat exchanger of a heating pump for heating water. The heat exchanger comprises an inner bucket and an outer bucket, wherein the inner bucket is embedded in the outer bucket; a water flow channel for water flow is formed between the inner and outer buckets; a water flow inlet is formed in the bottom of the outer bucket; a water flow outlet is formed in the top of the outer bucket; the water flow inlet and the water flow outlet are distributed at two sides of the outer bucket; a spiral groove is pressed in the outer peripheral wall of the outer bucket; and a heat exchange structure in which a heating work medium flows is arranged in the spiral groove. The heat exchanger of the heating pump for heating water has the beneficial effect that heated water and the work medium of the heating pump flow in a complete counter-current manner and the flow speeds are relatively high; the heat exchange efficiency of the heat exchanger is greatly improved; the scale formation speed is reduced; the heat exchanger adopts an open type structure, the inner and outer buckets can be detached and the washing and descaling operations can be conveniently realized, so that the heat exchange efficiency and the sanitary standard of high-temperature hot water are guaranteed, an effective solution for large scale application of a water heater of a high-temperature heating pump is provided and the energy-saving effect is remarkable.

Owner:江苏乐普四方科技有限公司

Automatic scale-cleaning shower head

The invention discloses an automatic scale-cleaning shower head, which comprises a shell body, wherein a water inlet is arranged on the shell body, and a water chamber is arranged in the shell body. The water inlet is communicated with the water chamber, and a guide post is fixedly installed in the water chamber. The guide post is fixedly connected with the shell body, and a sliding sleeve is movably installed at the periphery of the guide post.. The periphery of the sliding sleeve is provided with a moving plate, and the periphery of the moving plate is matched with the shell body. A plurality of water outlets are arranged on the moving plate, and a plurality of descaling needles are fixedly installed in the shell body, correspond to the water outlets, and are matched and sealed with the water outlets one to one. A limiting piece is installed on the shell body or the guide post, and the limiting piece is used for limiting the moving-down limiting position of the sliding sleeve or the moving plate. As the automatic scale-cleaning shower head is provided with the descaling needles and the sliding sleeve which can move up and down, the sliding sleeve can do a reciprocating motion up and down, so that the water outlets and the descaling needles mutually rub, scales adhered to the inner surfaces of the water outlets are thoroughly removed, and the normal water spraying of a water injection nozzle is ensured. Therefore, the service life of the shower head can be prolonged, the descaling difficulty is reduced, and the descaling efficiency is increased. The shower head can realize descaling through switching of a water valve.

Owner:修昌珉

Method for controlling three-valve heat exchanger by temperature difference

InactiveCN111412773AAchieve vibrationThe result is accurateIndirect heat exchangersVibration cleaningData connectionEngineering

The invention provides a method for controlling a three-valve heat exchanger by the temperature difference. A first valve, a second valve and a third valve are arranged at inlets of a first heat exchange pipe, a second heat exchange pipe and a third heat exchange pipe, a first temperature sensor, a second temperature sensor and a third temperature sensor are respectively arranged in a left side pipe, a center pipe and a right side pipe and are used for detecting the temperature in the left side pipe, the center pipe and the right side pipe, the first temperature sensor, the second temperatureand the third temperature sensor are in data connection with a controller, the controller extracts the temperature data of the left side pipe, the right side pipe and the center pipe according to thetime sequence, and obtains the temperature difference or the accumulation of the temperature difference change through the comparison of the temperature data of adjacent time periods, and when the temperature difference is lower than a threshold value, the controller controls the opening and closing of the first valve, the second valve and the third valve so as to control whether first fluid, third fluid and second fluid are subjected to heat exchange or not. According to the method, the new fluid is started to carry out alternate heat exchange by detecting the detection temperature differenceor the accumulated temperature difference change, so that the vibration of an elastic tube bundle is continuously driven, and the heat exchange efficiency and the descaling operation can be further realized.

Owner:QINGDAO UNIV OF SCI & TECH

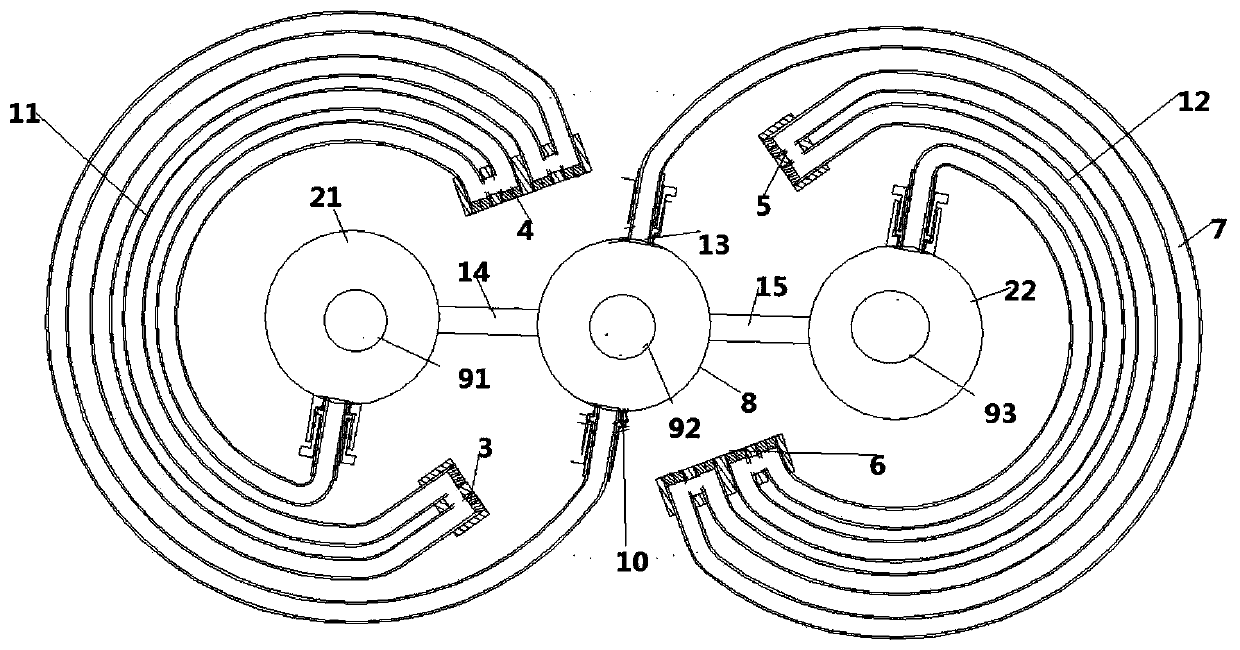

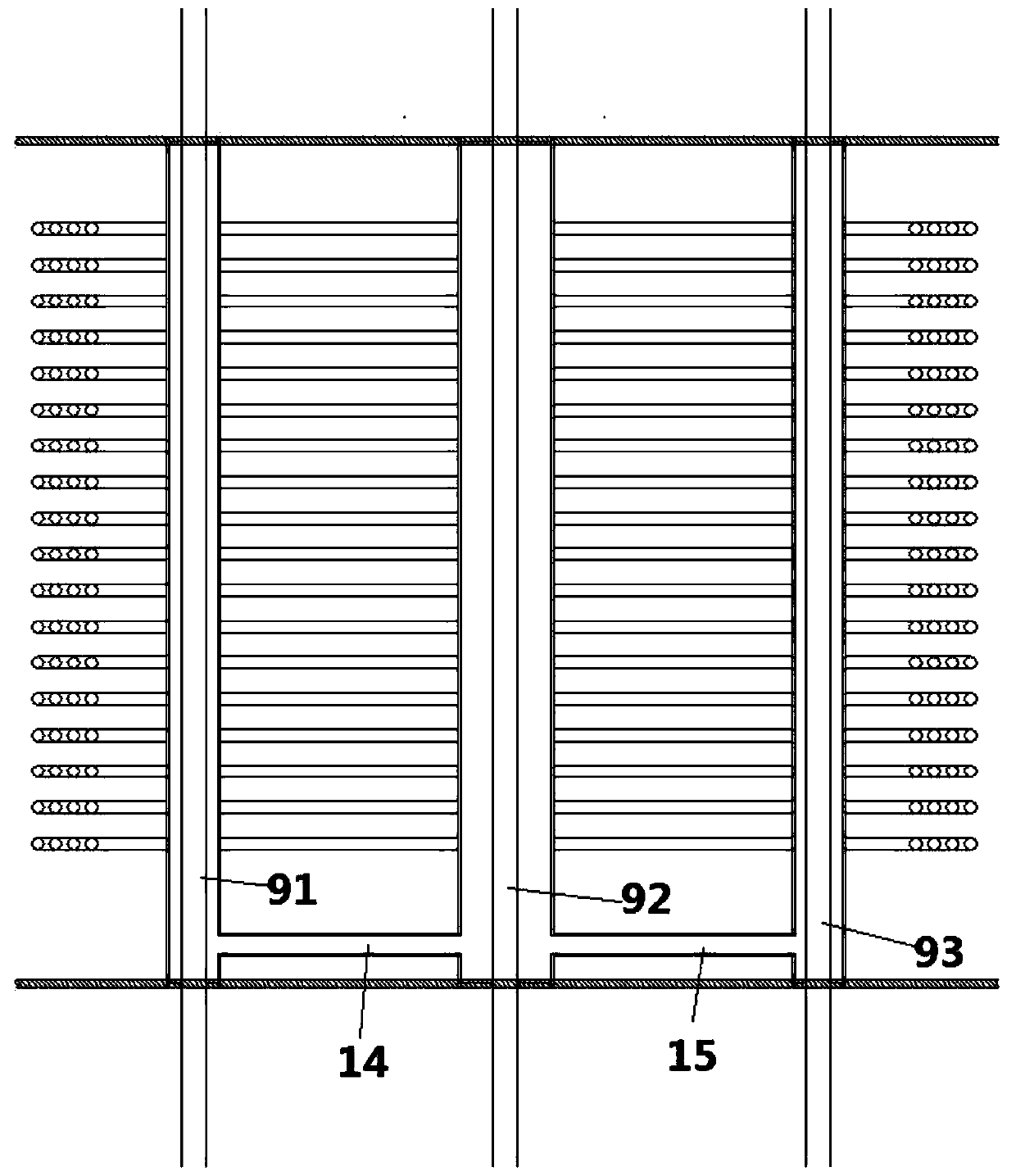

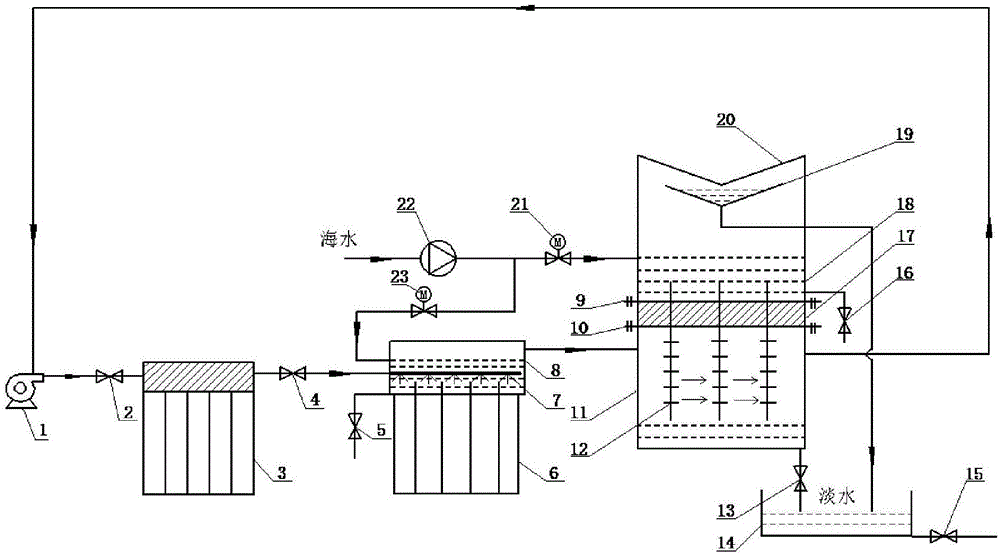

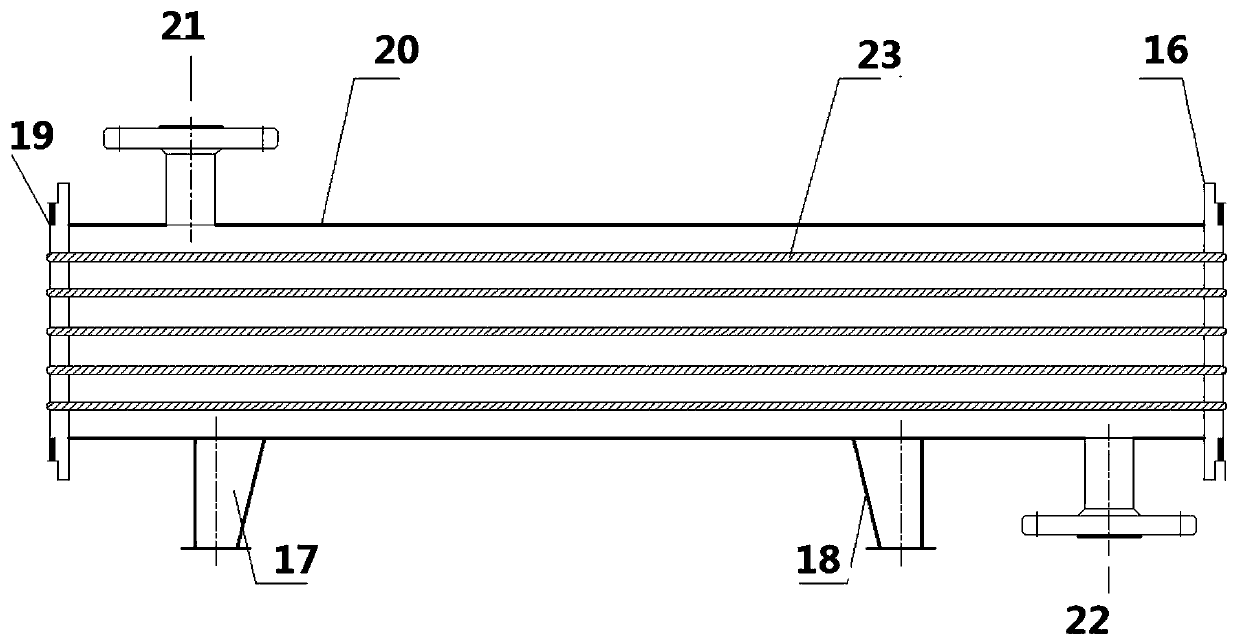

Heat accumulating type humidification and dehumidification solar seawater desalination system and technological method thereof

ActiveCN106800320AImprove heat utilizationIncreased freshwater productionWater treatment parameter controlGeneral water supply conservationWater vaporEngineering

The invention discloses a heat accumulating type humidification and dehumidification solar seawater desalination system and a technological method thereof. A heat tube-vacuum tube type solar thermal collector is used for directly heating the air and the seawater in a bubbler; a porous bubbling discharge pipe is dipped into the seawater so as to enable the air to bubble and humidify adding in the seawater in a spraying way; a humidifier is simple in structure, and easy to processing, disassembly and descaling. The condensation latent heat of vapor is recovered by the lower part of a fin inorganic heat tube in a dehumidifier and is then transmitted to a phase-change material and the seawater; part of the heat is used for heating and humidifying the air above a seawater desalter by means of the seawater desalter so as to generate fresh water, and the other part of heat is stored in a solid-liquid form and is released out at night; therefore, the condensation latent heat utilization rate and the fresh water yield are higher. The phase-change material is used for storing heat, so that the temperature at a heat exchange cold end of the heat tube is constant, and the heat exchange effect is good. A power grid or an independent photovoltaic power generation system is used for supplying power for the seawater desalination system, so that the seawater desalination system is flexible in scale and wide in application range, and can be used for desalting the coastal and island seawater and desalting the bitter salt water in inland remote and border areas.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

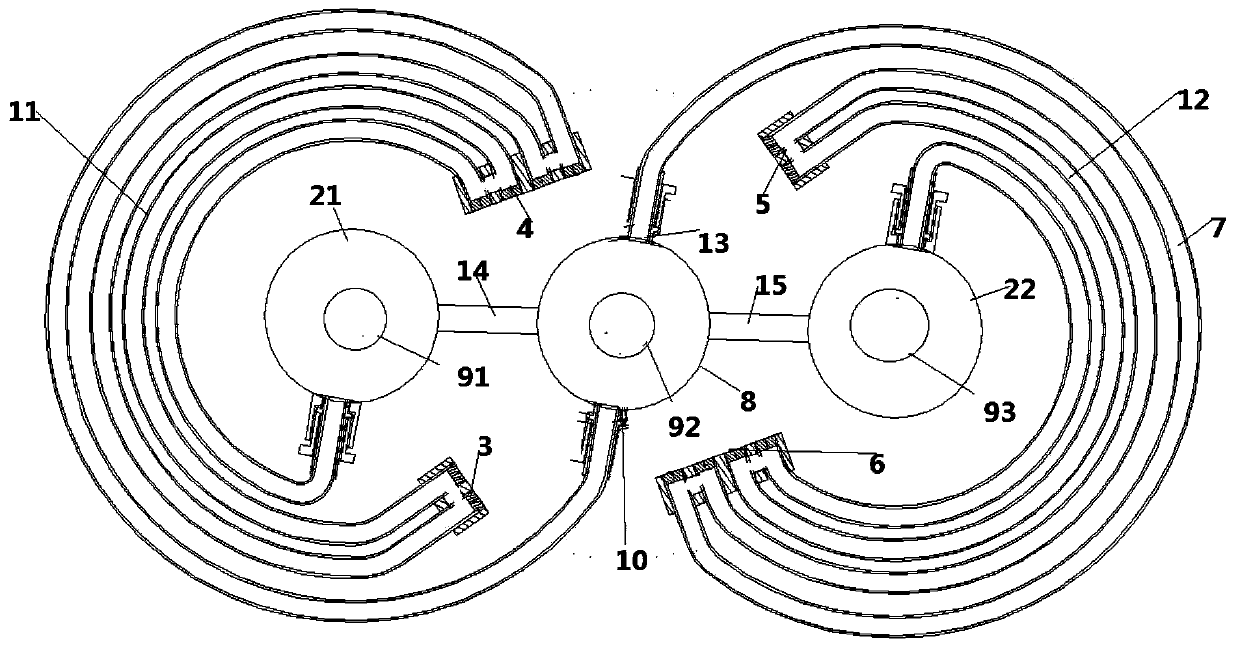

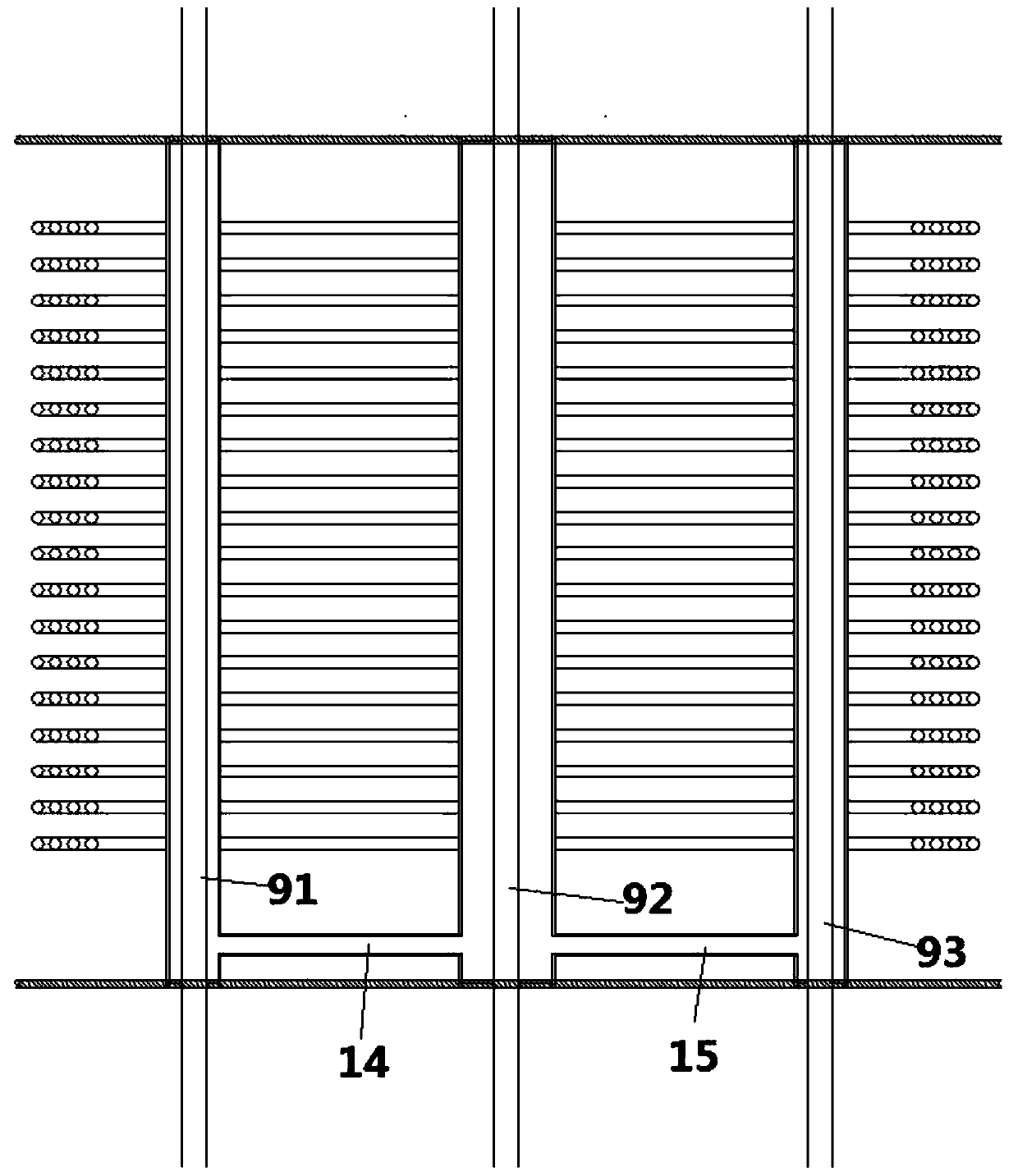

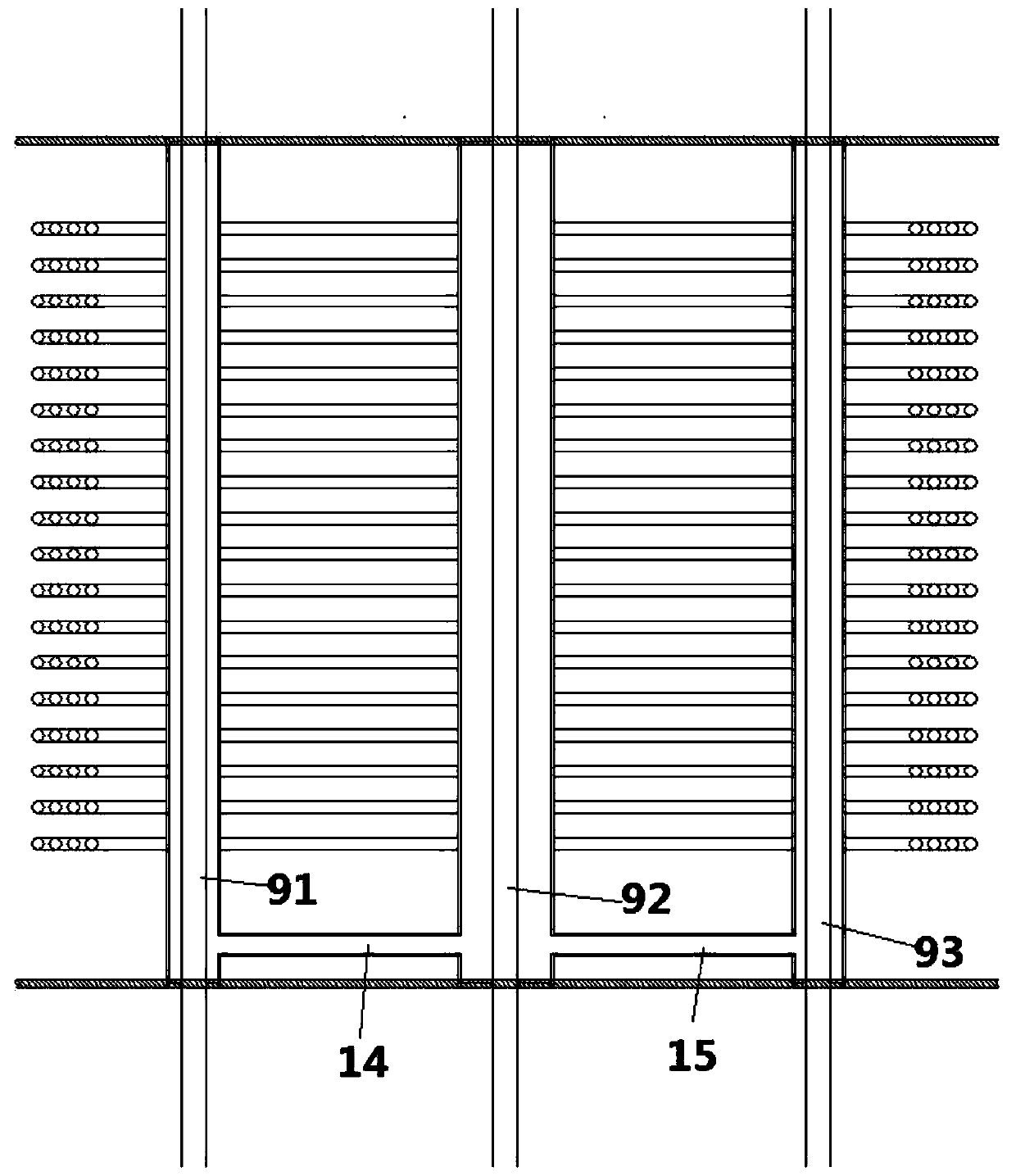

Heat exchanger achieving liquid level heat exchange control of four kinds of fluid

PendingCN111288823AImprove heat transfer efficiencyEasy descalingVibration cleaningHeat exchanger casingsLiquid level sensorMechanics

The invention provides a heat exchanger achieving liquid level heat exchange control of four kinds of fluid. A first valve, a second valve and a third valve are arranged on an inlet of a first heat exchange pipe, an inlet of a second heat exchange pipe and an inlet of a third heat exchange pipe correspondingly. A first liquid level sensor, a second liquid level sensor and a third liquid level sensor are arranged in a left side pipe, a center pipe and a right side pipe correspondingly. A controller controls the first valve, a second valve and a third valve to be opened and closed according to the detected liquid levels of the left side pipe, the right side pipe and the center pipe, and therefore the first fluid, the second fluid and the third fluid are controlled to carry out heat exchangeor not. According to the heat exchanger, the first valve, the second valve and the third valve are controlled to be opened and closed according to liquid level detection; on one hand, constant heat exchange is carried out on a shell side in the process; and on the other hand, an elastic heat exchange pipe can periodically and frequently vibrate, and therefore a very good descaling and heat exchange effect is achieved.

Owner:QINGDAO UNIV OF SCI & TECH

Energy-saving type coal-fired boiler with water scale removal function

InactiveCN110319588AAffects heat transfer efficiencyAvoid wastingCombustion technology mitigationWater heatersSpray nozzleEngineering

The invention relates to an energy-saving type coal-fired boiler with a water scale removal function. The energy-saving type coal-fired boiler with the water scale removal function comprises a main body, a water tank and a heating chamber, and further comprises a waste heat recovery mechanism and a descaling mechanism, wherein the descaling mechanism comprises a first motor, a screw rod, a slidingblock, a scraping plate and two connecting rods, the waste heat recovery mechanism comprises an air storage chamber and an air injection assembly, the air injection assembly comprises two driving units and two air injection units, and each air injection unit comprises a connecting box, a hose and six nozzles. According to the energy-saving coal-fired boiler with the water scale removal function,through descaling work, the descaling work can be carried out on the inner wall of the water tank, the situation that the water scale adhere to the inner wall of the water tank is avoided, and the heat conduction efficiency of the water tank is influenced; and through the waste heat recovery mechanism, high-temperature waste gas generated when the water tank in the heating chamber is heated can beguided into the nozzles to carry out heating and heat insulation work on the water tank, the situation that the high-temperature waste gas is directly discharged into the atmosphere is avoided, the energy is wasted, and the energy-saving property of the equipment is improved.

Owner:GUANGZHOU OUSHU ENVIRONMENTAL PROTECTION TECH CO LTD

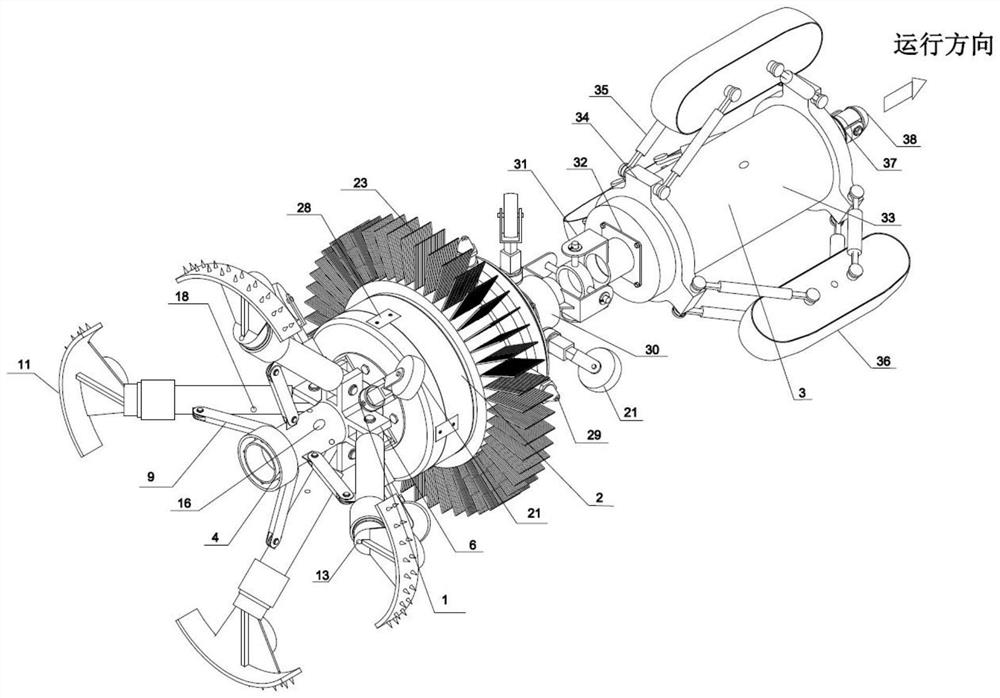

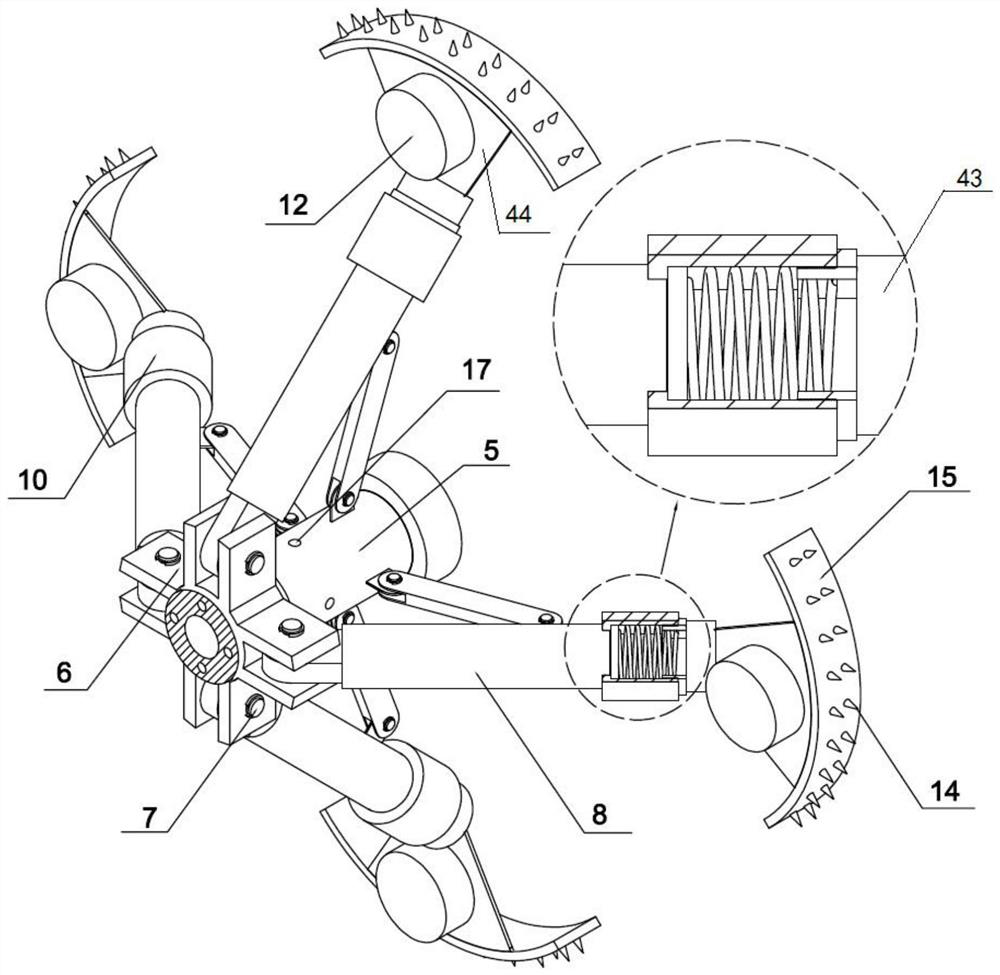

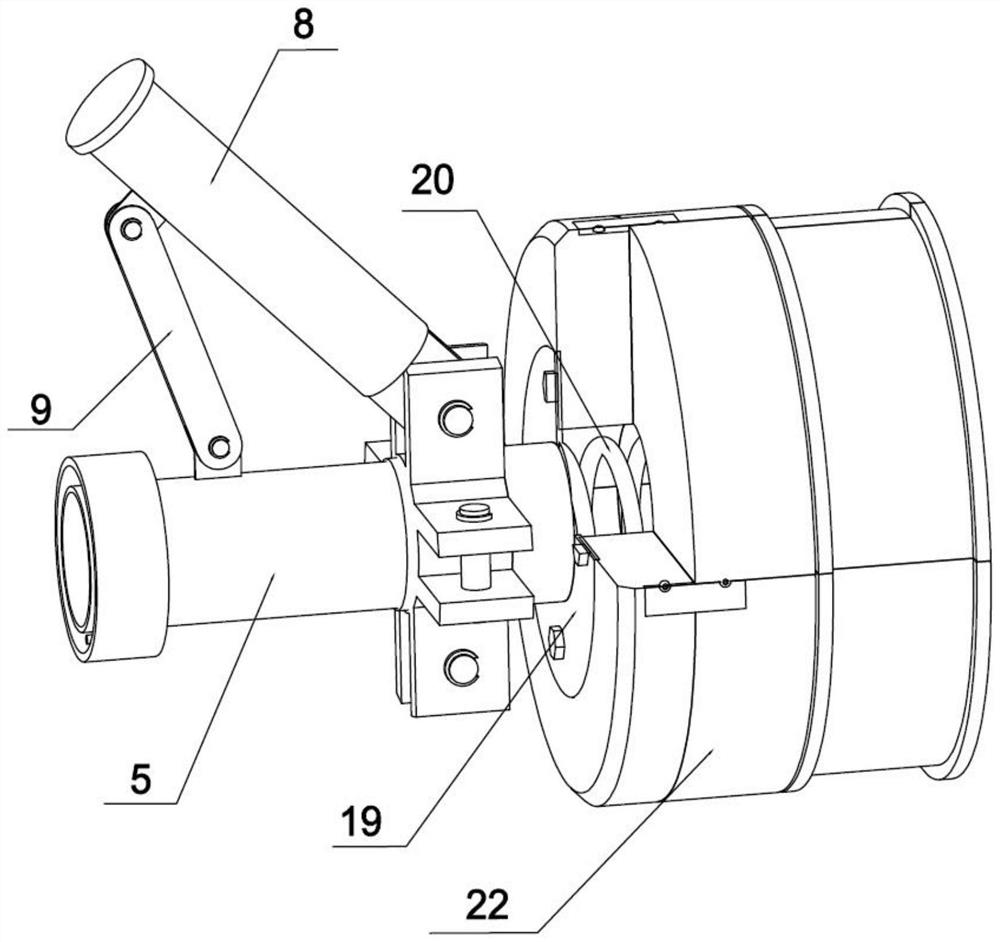

In-pipe combined type visual automatic descaling device and descaling method

ActiveCN112893346AChanges in scale structureGuaranteed efficiencyHollow article cleaningCleaning using liquidsElectric machineryJet flow

The invention discloses an in-pipe combined type visual automatic descaling device which comprises an ultrasonic descaling assembly, a mechanical descaling assembly and a power assembly. The ultrasonic descaling assembly comprises an inner shaft, a four-way connector, a claw head arm rod, an arm rod supporting rod and an ultrasonic descaling claw head. The mechanical descaling assembly comprises a connecting ring, a supporting wheel, a device cavity, a wheel brush, an outer rotor motor, a jet flow component and a connecting disc. The power assembly is fixedly installed at the side, away from the jet flow component, of the connecting disc, and an infrared camera is installed at the other end of the power assembly. The invention further discloses an in-pipe combined type visual automatic descaling method. According to the in-pipe combined type visual automatic descaling device and the descaling method provided by the invention, pipelines with different sizes and in various scaling forms can be cleaned stably and efficiently on the premise that the pipelines are not damaged, and the descaling effect is visualized.

Owner:SOUTHWEST PETROLEUM UNIV +2

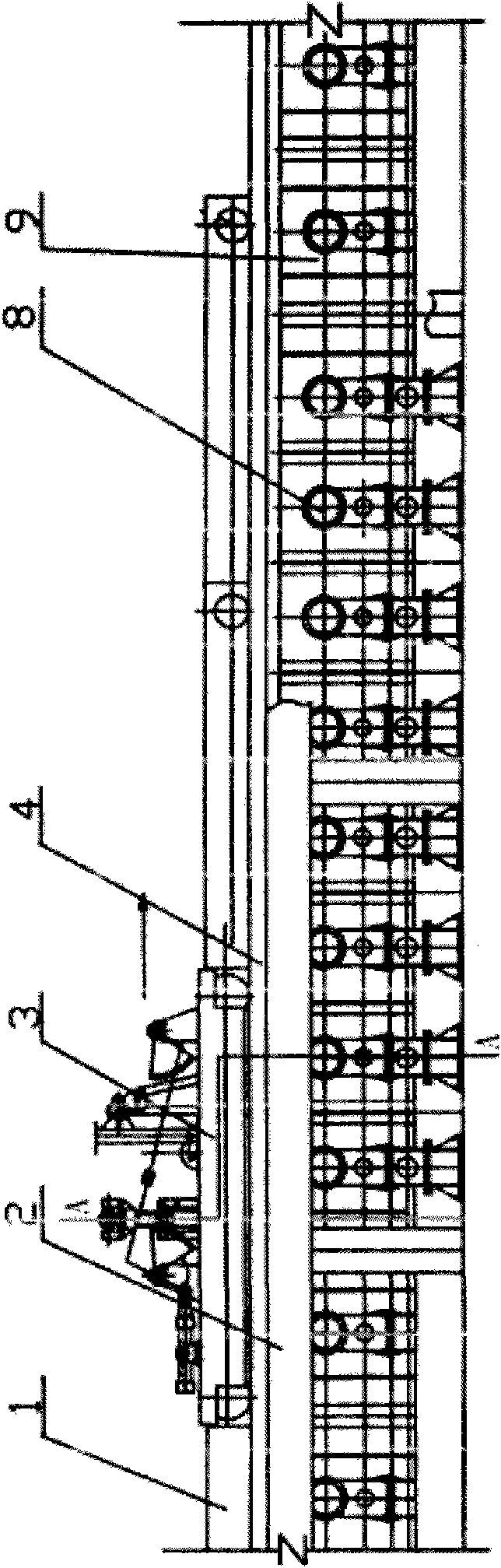

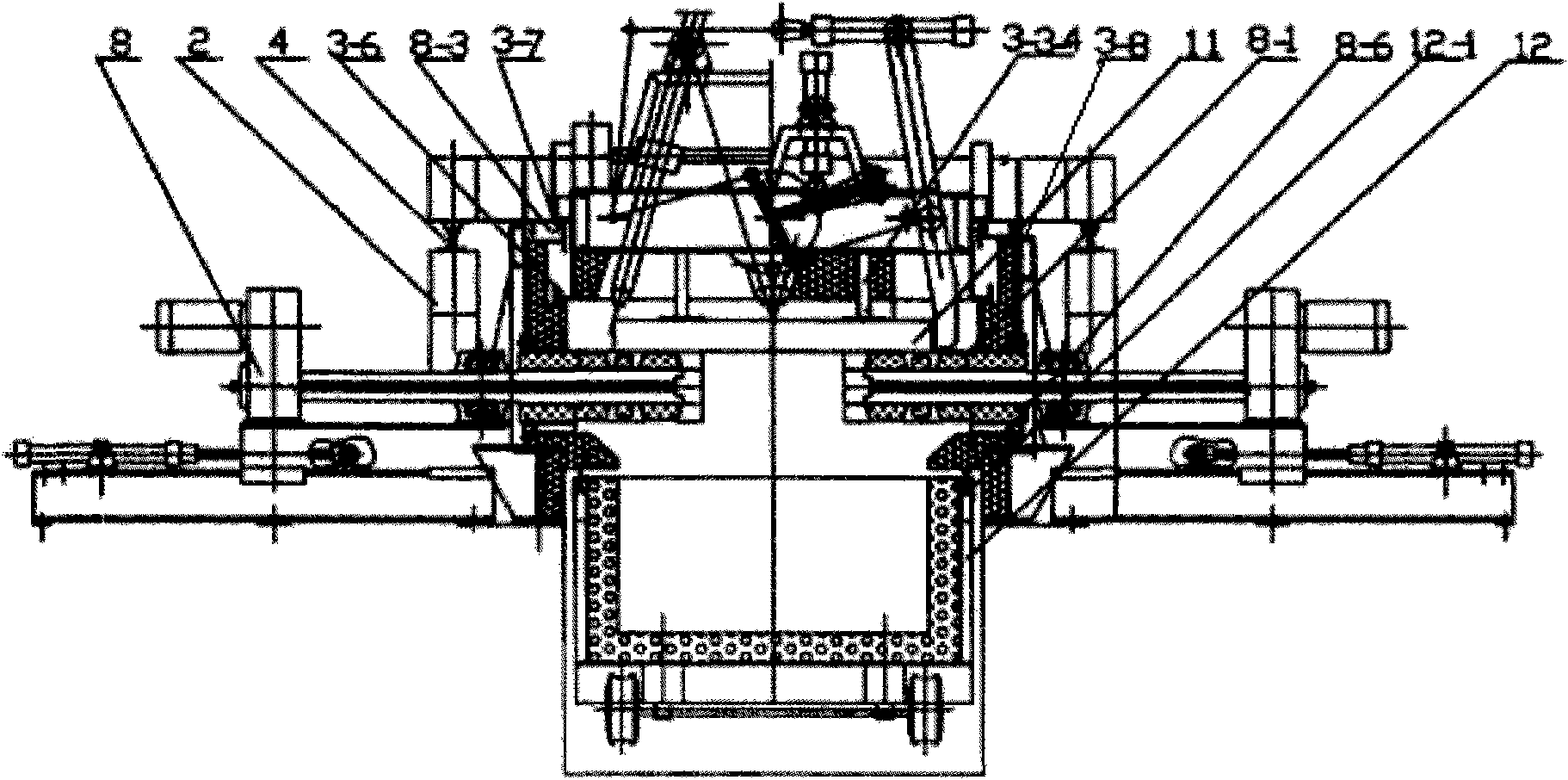

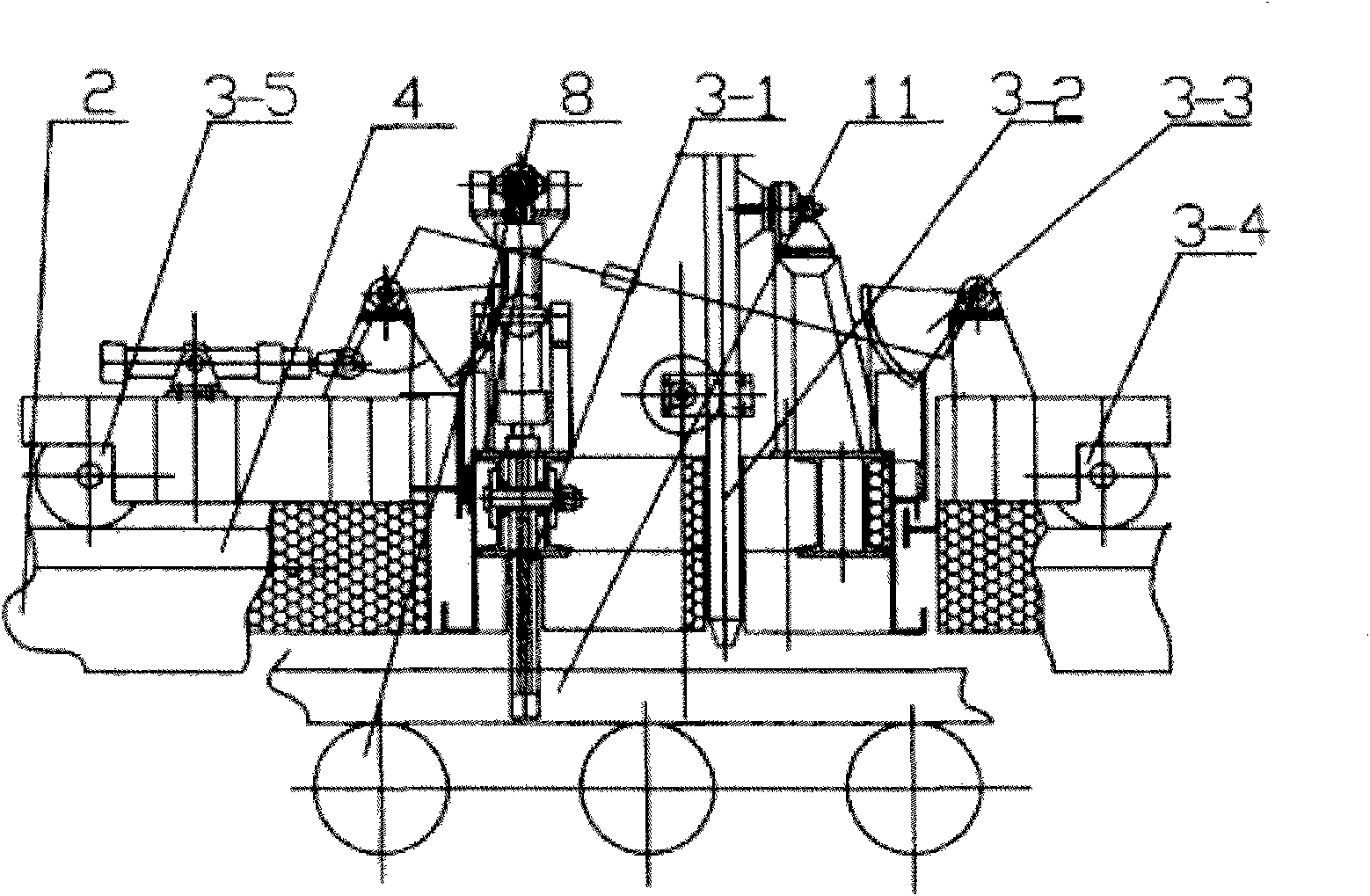

Flame cutting system with insulation device for flame cutting zone of billet

InactiveCN101862877ASolve the connection relationshipSolve the cooling problemGas flame welding apparatusEngineeringFlame cutting

The invention provides a flame cutting system with an insulation device for a flame cutting zone of billets, which comprises track beams arranged on both sides. The top parts of the track beams are respectively provided with a heavy track, a flame cutting trolley slides back and forth on the heavy tracks, the front end and the rear end of the flame cutting trolley are respectively connected with at least one mobile insulation cover, the mobile insulation covers are connected with each other and slide back and forth on the heavy tracks along with the flame cutting trolley, a row of internal water cooling billet-conveying rollers with an insulation device are arranged between the two track beams, billet cantilever rollers penetrate through the internal water cooling billet-conveying rollers, and billets arranged below the flame cutting trolley slide back and forth on the billet cantilever rollers. The invention has the advantages of minimizing the heat dissipation of the billets, preventing the air leakage of the joint surface, effectively solving the problem of sealing the shaft end, efficiently preventing heat dissipation, ensuring the performance and strength of the roller rings, and reducing the consumption of cooling water.

Owner:何学才

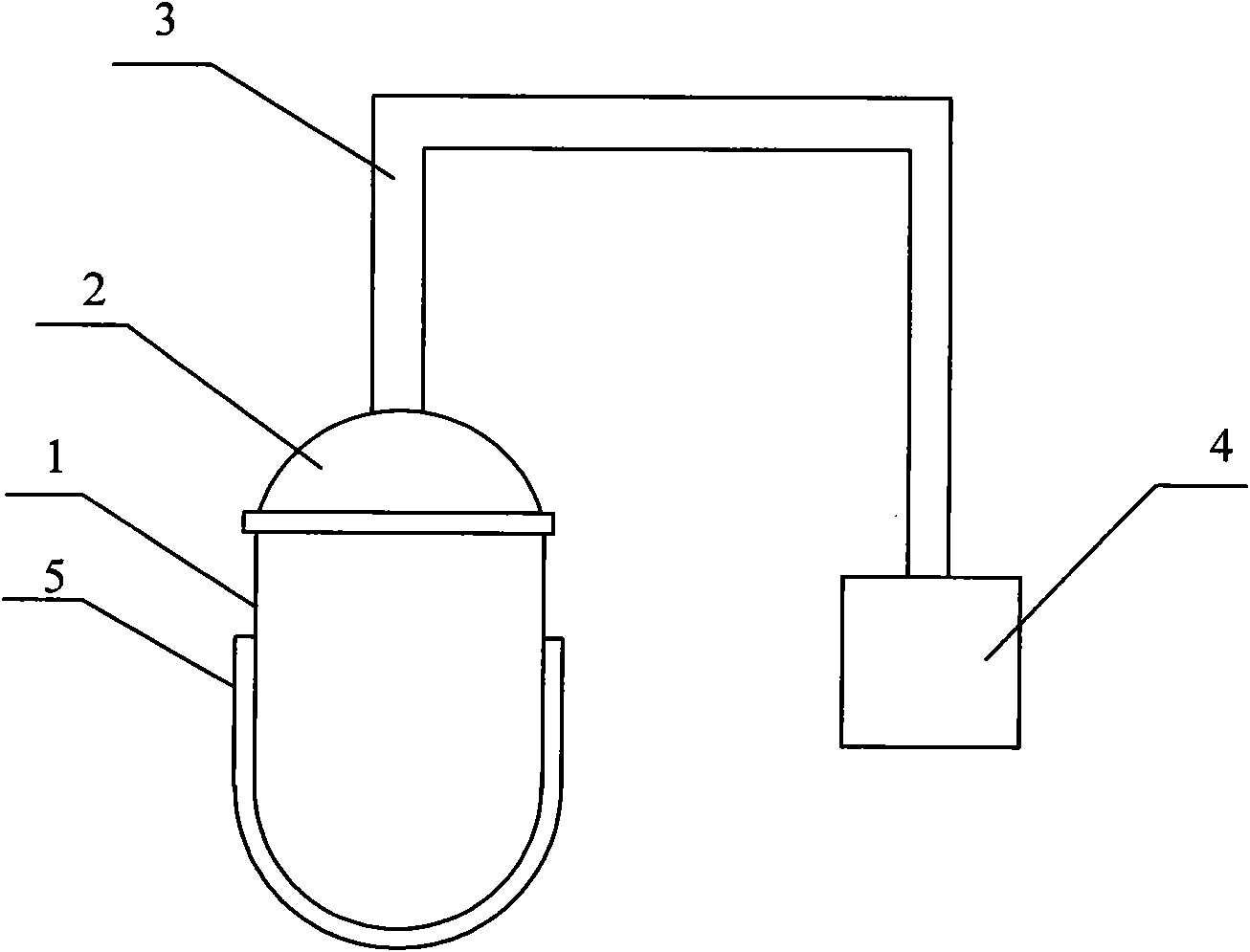

Water treater capable of eliminating positive ions by electricity

PendingCN109399764ADepolarization of cationsTo achieve a permanent cureSpecific water treatment objectivesWater/sewage treatment by electrochemical methodsExisting TreatmentHigh-voltage direct current

The invention relates to an water treater capable of eliminating positive ions by electricity. The water treater comprises a power box, a rod, a negative ring and a high voltage generator. An indicating lamp is arranged on the surface of the power box, a wire inlet port and a wire outlet port are arranged on a power box body, the high voltage generator is arranged in the power box, and two wire inlet connectors connected with the alternating current are arranged on the high voltage generator; a positive connector and a negative connector are arranged on the high voltage generator, the positiveconnector is connected with the rod through a wire, the negative connector is connected with the negative ring through a wire, the rod is inserted into a water treatment tank or a water delivery pipe, and the high voltage generator outputs high-voltage direct currents after the power box is energized. The treatment method of the water treater is green, environmentally friendly, safe and free frompollution, and has better anti-scaling, descaling, sterilizing and corrosion-inhibiting effects than other existing treatment methods, so that syndromes and root causes are treated, the engineering investment and operating costs are low, management is facilitated, and the water treater can be widely applied to positive ion depolarization, anti-scaling, descaling, sterilization and corrosion inhibition of industrial water.

Owner:HAINAN HAIJIAHUI TECH CO LTD

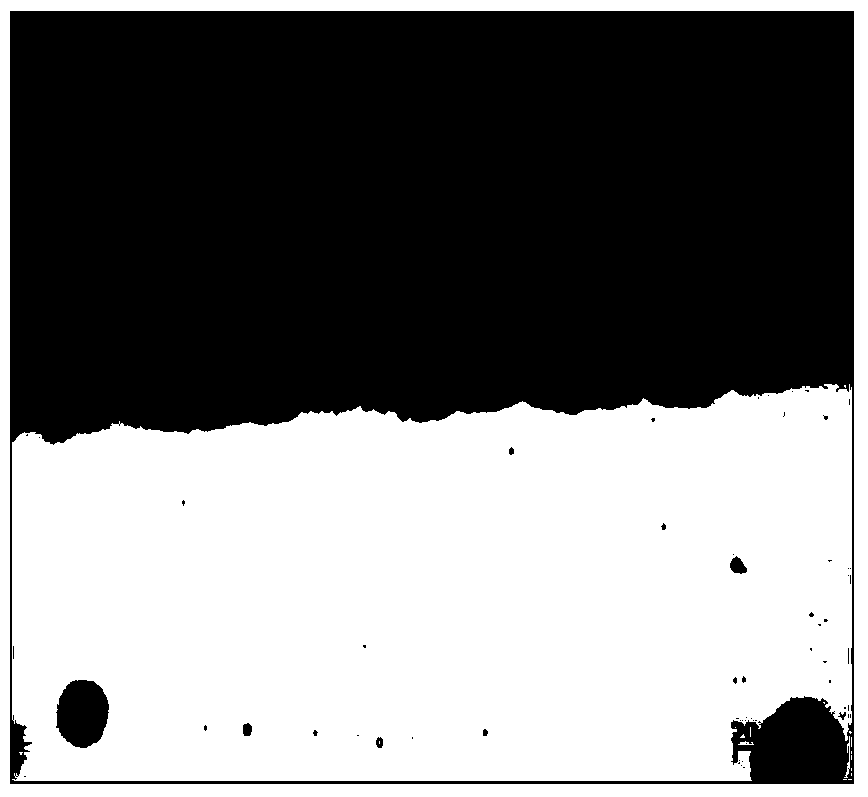

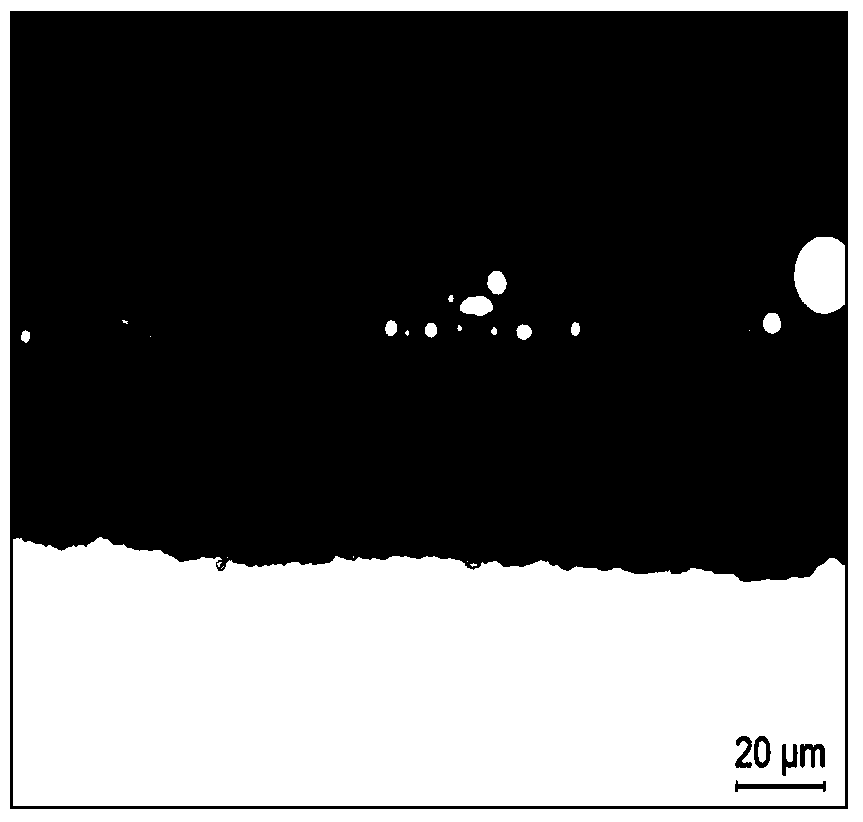

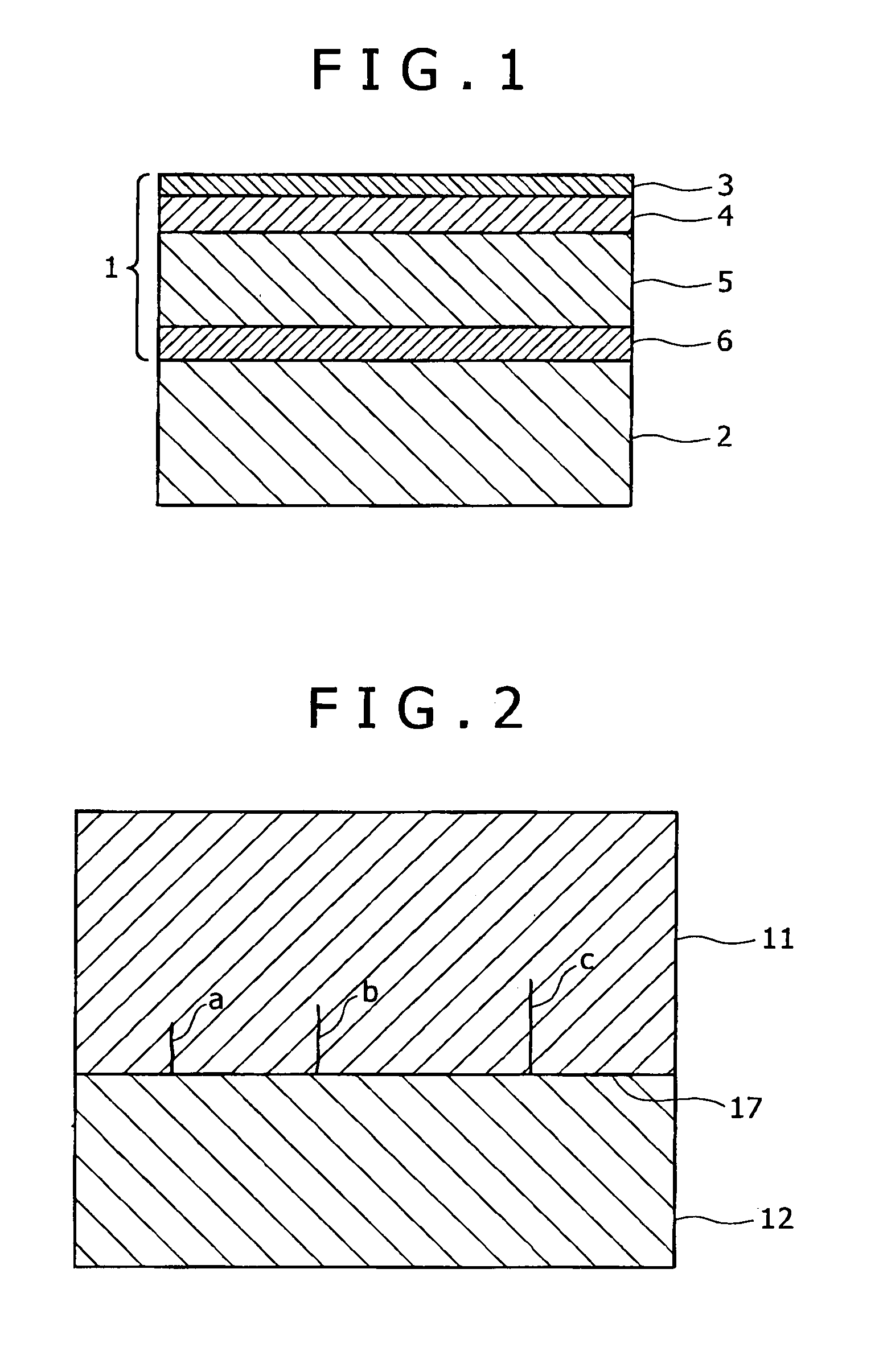

Method for production of steel material having excellent scale detachment property, and steel wire material having excellent scale detachment property

ActiveUS20090229710A1Easy descalingIncrease volumeWork treatment devicesSolid state diffusion coatingSurface oxidationHot rolled

The present invention aims at providing a method for production of a steel product which surely retains scale during cooling, storage, and transportation and permits scale to scale off easily at the time of mechanical descaling and pickling that precede the secondary fabrication.The steel product is produced by heating and hot rolling a steel billet and spraying the hot-rolled steel product with steam and / or water mist having a particle diameter no larger than 100 μm, for surface oxidation.

Owner:KOBE STEEL LTD

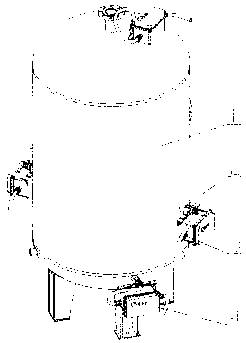

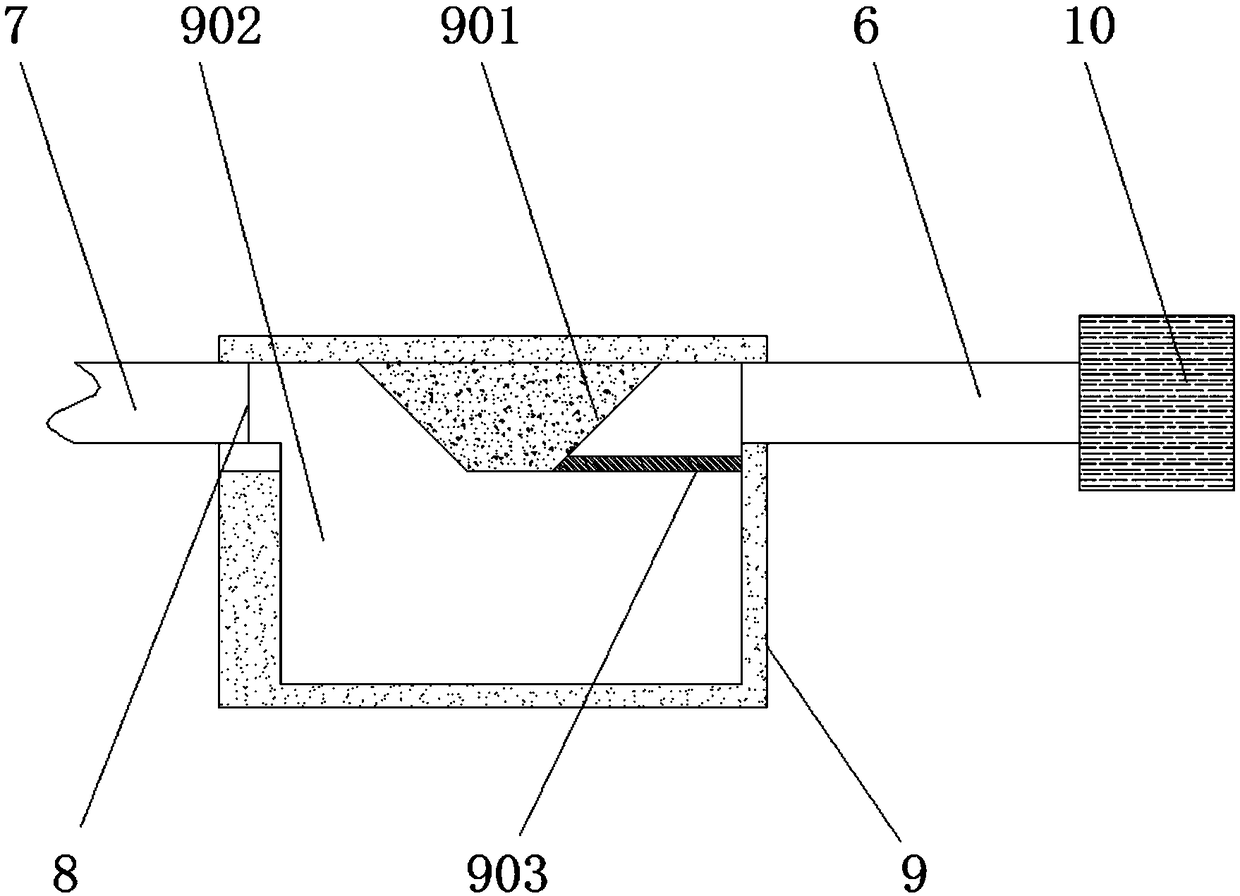

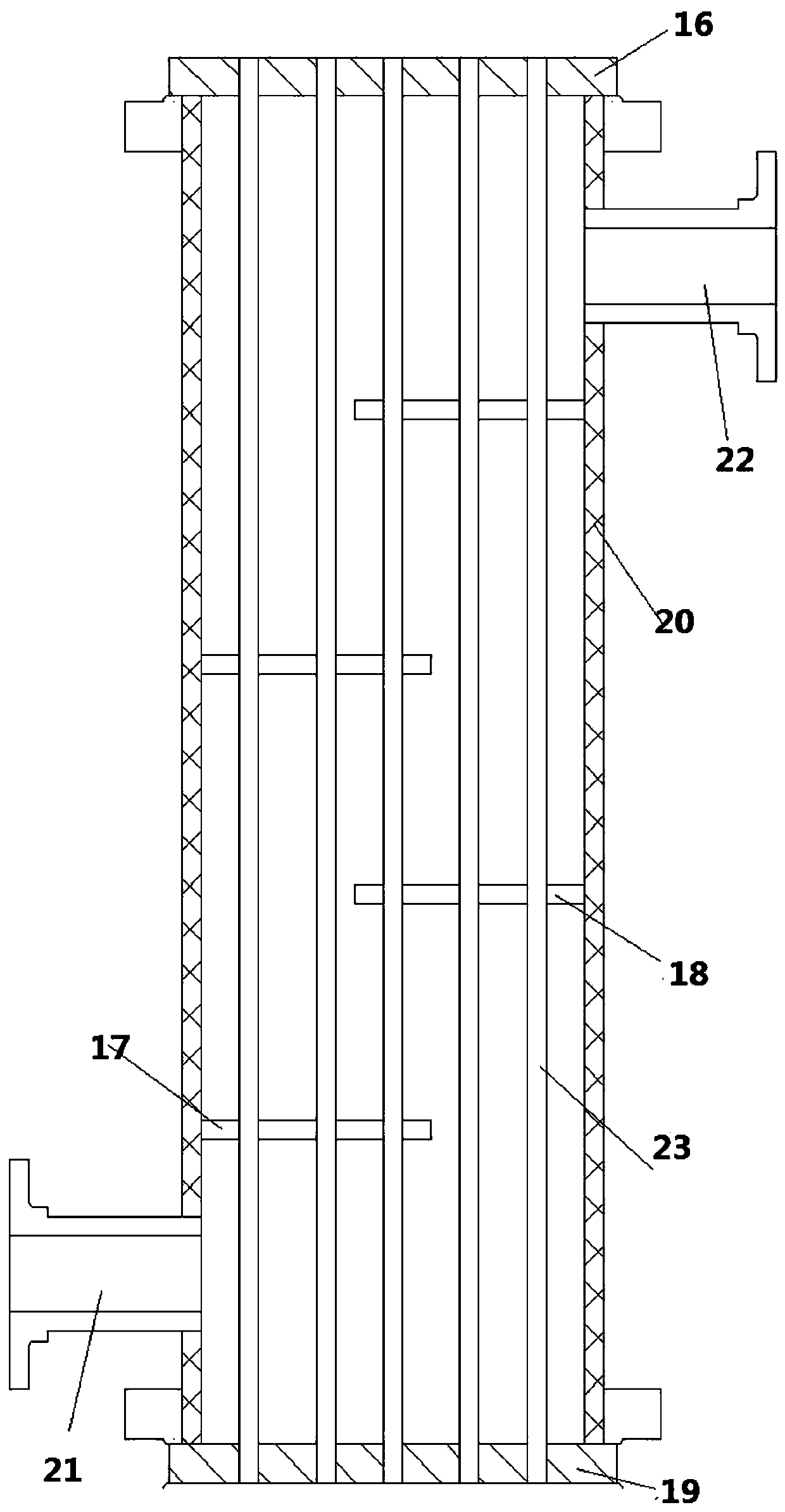

Passive descaling type evaporative cooler

The invention relates to the field of environmental protection equipment, in particular to a passive descaling type evaporative cooler. The passive descaling type evaporative cooler is used for descaling of the inner walls of evaporative coolers or easy-to-scale barrels in converter gas purification and recovery systems in the metallurgical industry. The passive descaling type evaporative cooler comprises an evaporative cooling barrel, and further comprises a drive mechanism, a descaling device and a supporting mechanism used for mounting of the descaling device. The descaling device is arranged in the evaporative cooling barrel. The drive mechanism drives the descaling device through the supporting mechanism to move in the axial direction and / or the circumferential direction of the evaporative cooling barrel to carry out descaling on the inner wall of the evaporative cooling barrel. The passive descaling type evaporative cooler has the beneficial effects that descaling of the interior of the evaporative cooling barrel is achieved through the descaling device; the structure is simple; operation is stable; the service life of equipment is prolonged; descaling is simple and convenient; dirt recycling is facilitated; pollution and waste are reduced; and energy saving and environment protection are achieved.

Owner:CISDI ENG CO LTD +1

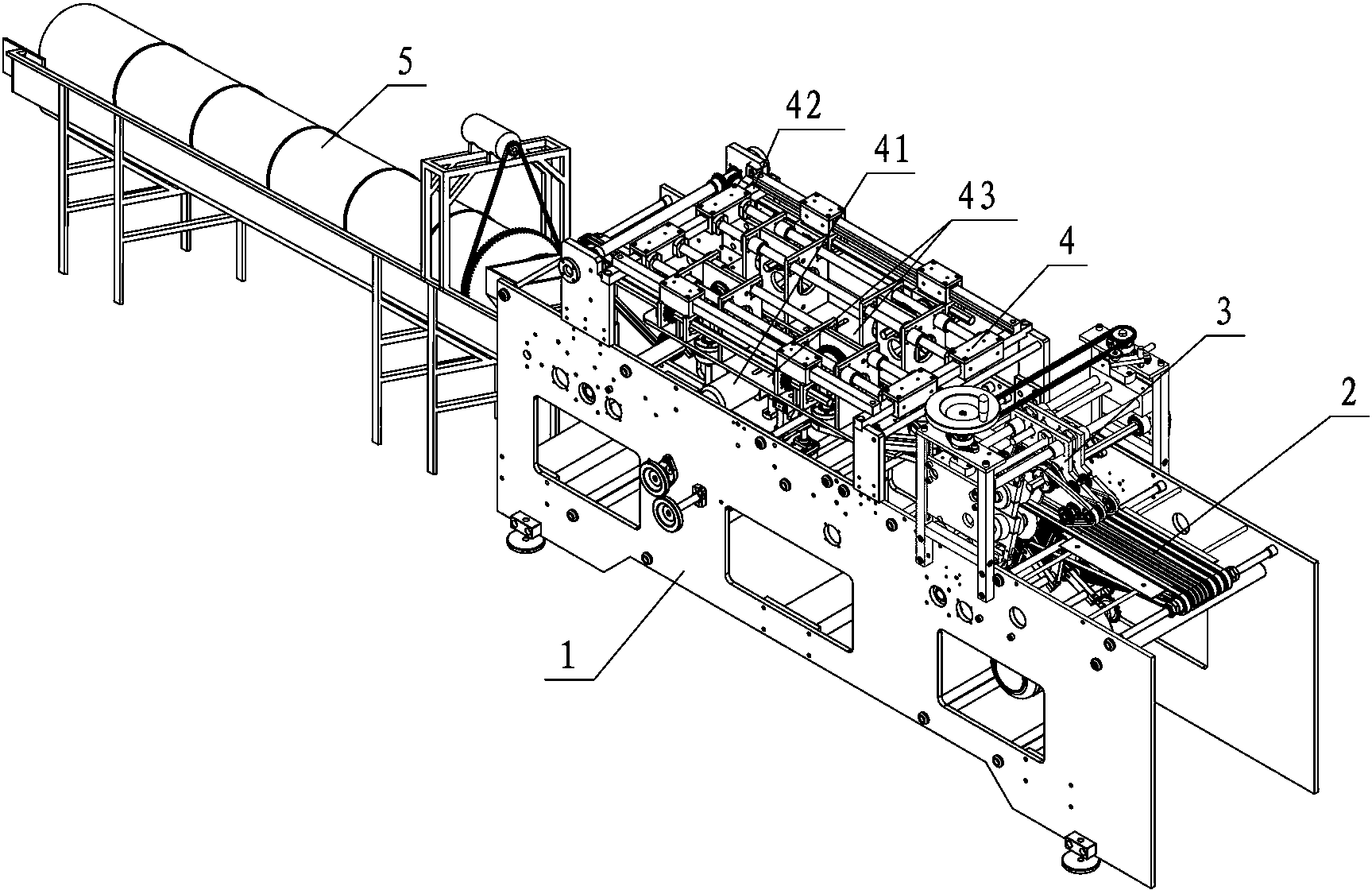

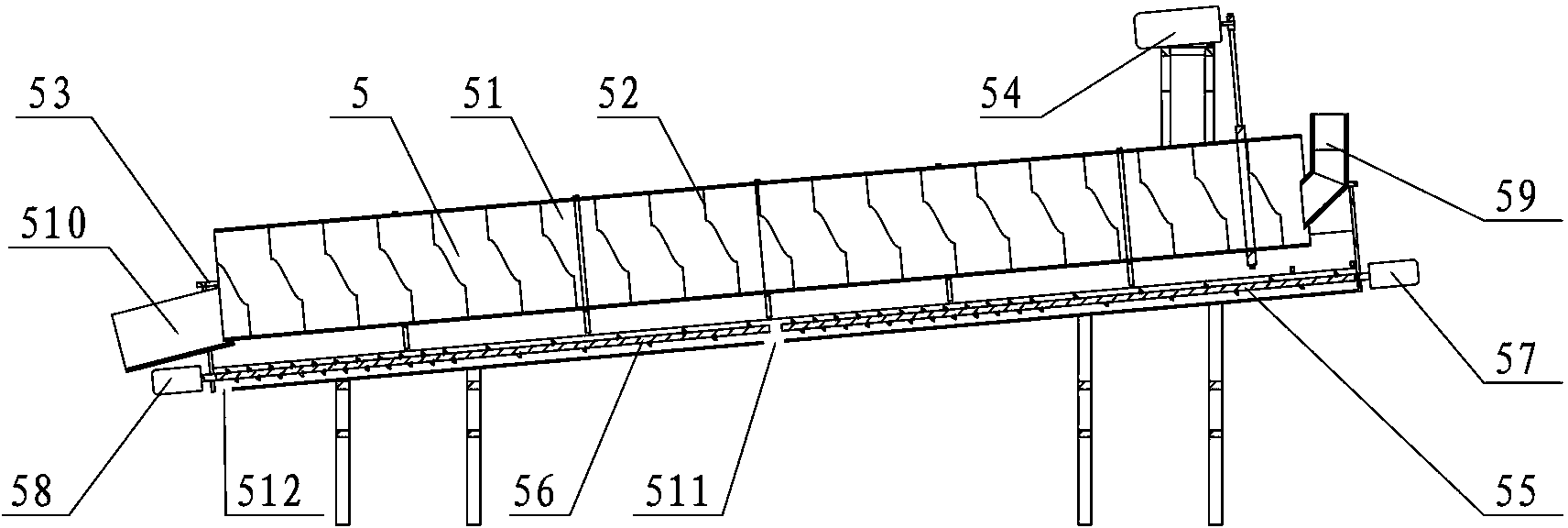

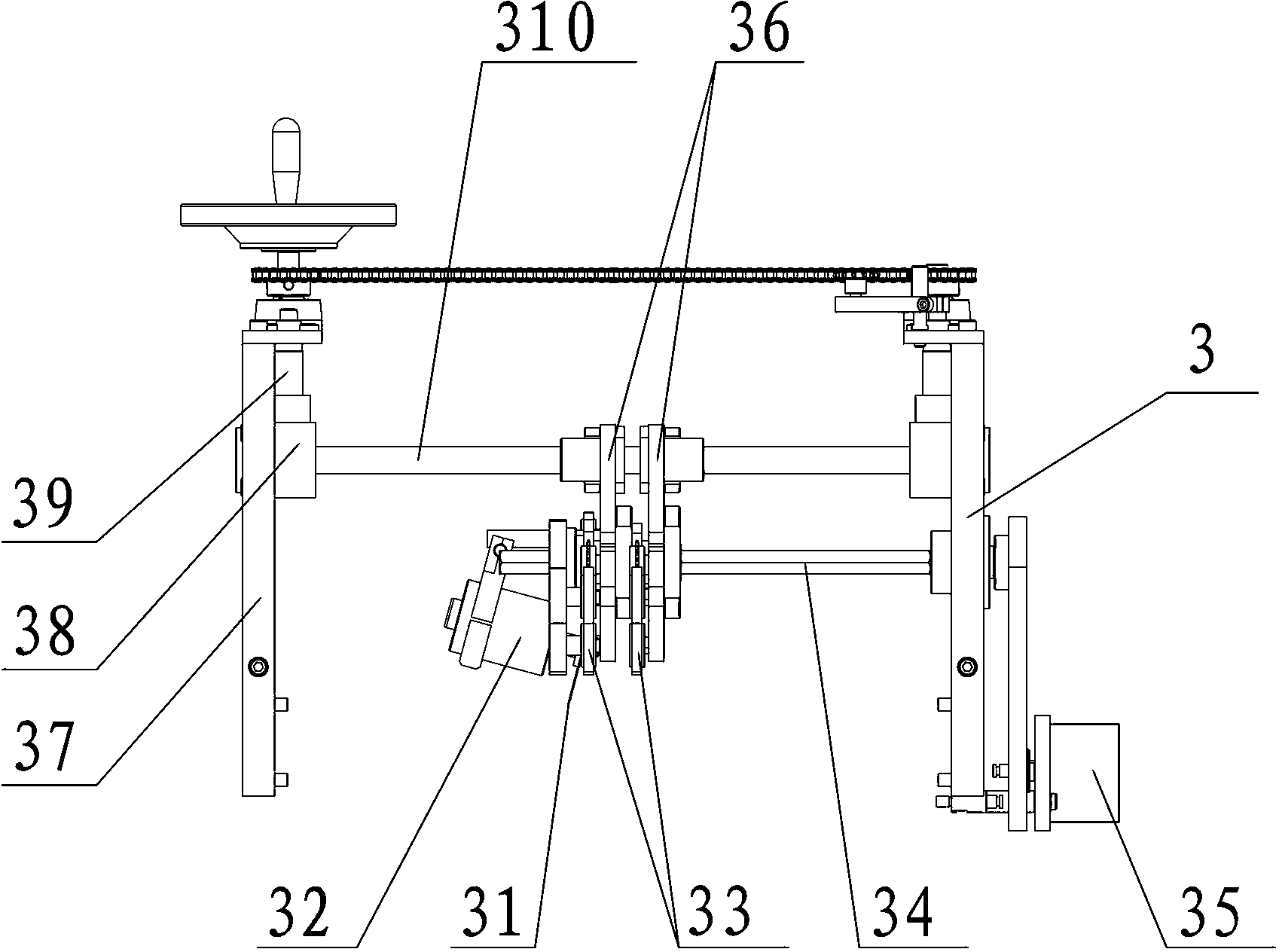

Automatic fish killing and washing device

InactiveCN103380808AEffectively drainActive connectionFish washing/descalingFish processingEngineering

The invention discloses an automatic fish killing and washing device, and relates to fish processing and washing equipment. The automatic fish killing and washing device comprises a frame, a conveying belt, a fish head cutting device, a fish belly cutting device and a fish washing device, wherein the fish head cutting device and the fish belly cutting device are sequentially arranged on the frame and positioned above the conveying belt, and the fish washing device is arranged at an output end of the conveying belt. A fish is placed at an input end of the conveying belt, a fish head is cut off by the fish head cutting device, a fish belly is cut open by the fish belly cutting device, and the fish enters the fish washing device from the output end of the conveying belt and is washed by the fish washing device. A plurality of fish processing procedures are effectively connected from front to back, the fish washing device is provided with a rotating cylinder and blades, the fish rubs with a cylinder wall in a rotating mode, fish scales can be scraped by a netted structure on the cylinder wall, the rotating cylinder is inclined, the rotating fish is conveyed at a certain speed in the rotating cylinder along the blades, and the fish scales are more effectively and completely removed and can be effectively discharged by two screw rods arranged on the lower portion of the rotating cylinder, so that accumulation of the fish scales is avoided.

Owner:苍南县汤记码头水产品有限公司

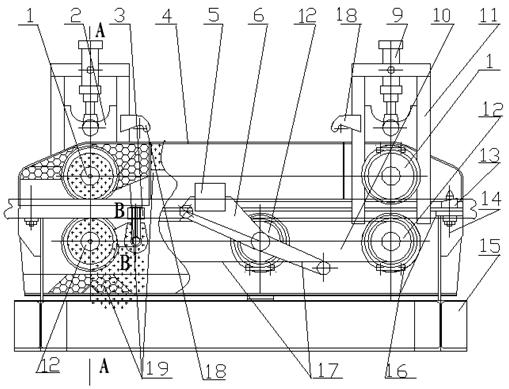

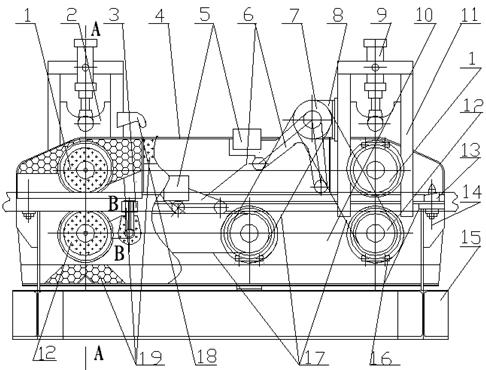

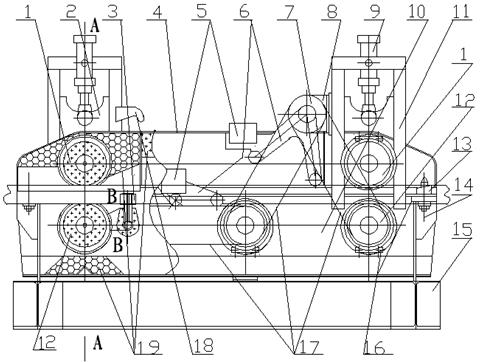

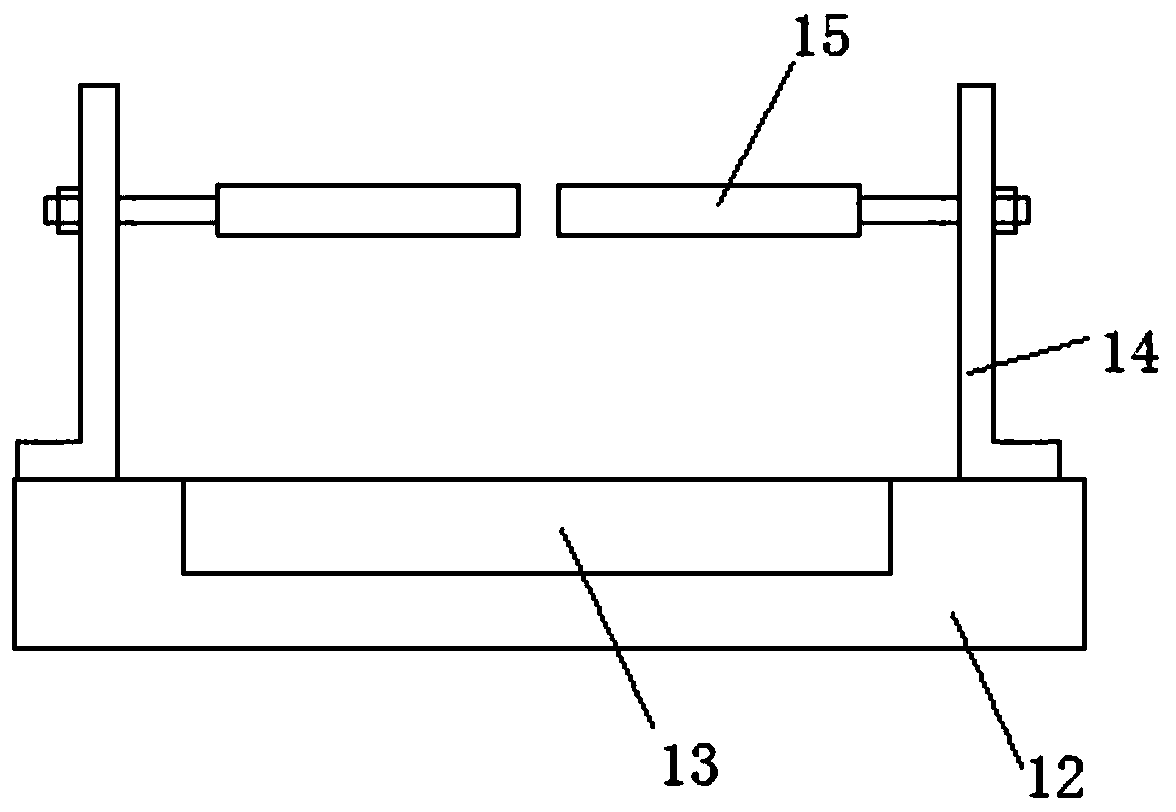

Underdriving progressive withdrawal and straightening machine with heat insulation device

The invention provides a progressive underdriving five-roller straightening and withdrawal machine with a heat insulation device. The withdrawal and straightening machine comprises a pair of withdrawal rollers and a pair of straightening rollers which are arranged inside a heat insulation cover, and a lower roller. Three underdriving rollers are arranged on a withdrawal and straightening machine base with a refractory castable material and transmitted by a chain wheel and are connected with a speed reducer with a variable frequency speed-regulating motor outside a production line through a coupler and a universal-joint spindle; and two upper driven rollers are arranged on a lifting guide cover pulled by a hydraulic cylinder and provided with a refractory fiber. A cantilever vertical roller is arranged on the withdrawal and straightening machine base; the diameter of the roller can be changed along with the width of casting blank; all the rollers are communicated with water to be cooled; and a plurality of withdrawal and straightening machines are arranged on an overhead base shared by the withdrawal and straightening machines through a tapered wedge. The progressive underdriving five-roller withdrawal and straightening machine has the advantages of preventing billet steel from heat dissipation and oxidation to the greatest degree, improving operating conditions of electromechanical equipment, moving the electromechanical equipment outside the production line so as to facilitate maintenance and management, preventing air leakage on a joint surface by adopting sand seal, and effectively realizing the sealing and cooling of an axial end by adopting an air knife structure.

Owner:何学才

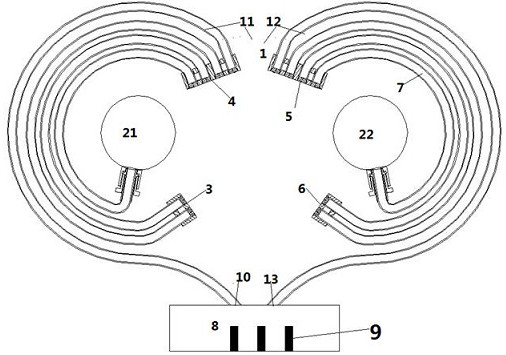

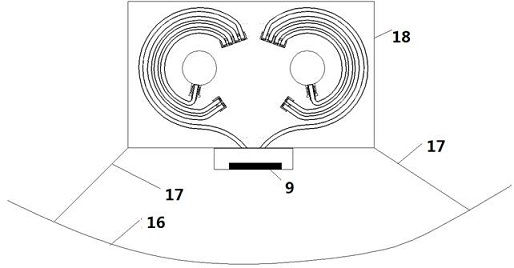

Solar heat collection device for descaling at night

ActiveCN112212522AAchieve vibrationEasy descalingSolar heating energySolar heat collector detailsThermodynamicsEngineering

The invention provides a solar heat collection device for descaling at night. The solar heat collection device for descaling at night comprises a heat collection pipe box, a left upper pipe, a right upper pipe and a heat release pipe group, the heat collection pipe box comprises a first pipe opening and a second pipe opening, the first pipe opening is connected with an inlet of a left heat releasepipe group, the second pipe opening is connected with an inlet of a right heat release pipe group, an outlet of the left heat release pipe group is connected with the left upper pipe, an outlet of the right heat release pipe group is connected with the right upper pipe, a first outlet and a second outlet are formed in one side of the heat collection pipe box, an electric heater is arranged in theheat collection tube box, the electric heater operates at night, and the electric heater adopts an intermittent heating mode, namely, heating is carried out for a period of time firstly, then heatingis stopped for a period of time, and then heating is carried out again, and circulation is carried out ceaselessly. According to the solar heat collection device for descaling at night, on one hand,the solar heat collection device is assisted in heating at night, and on the other hand, through the operation of the electric heater, a heat collecting pipe continuously vibrates so that the descaling work can be carried out.

Owner:东营海能石油装备有限责任公司

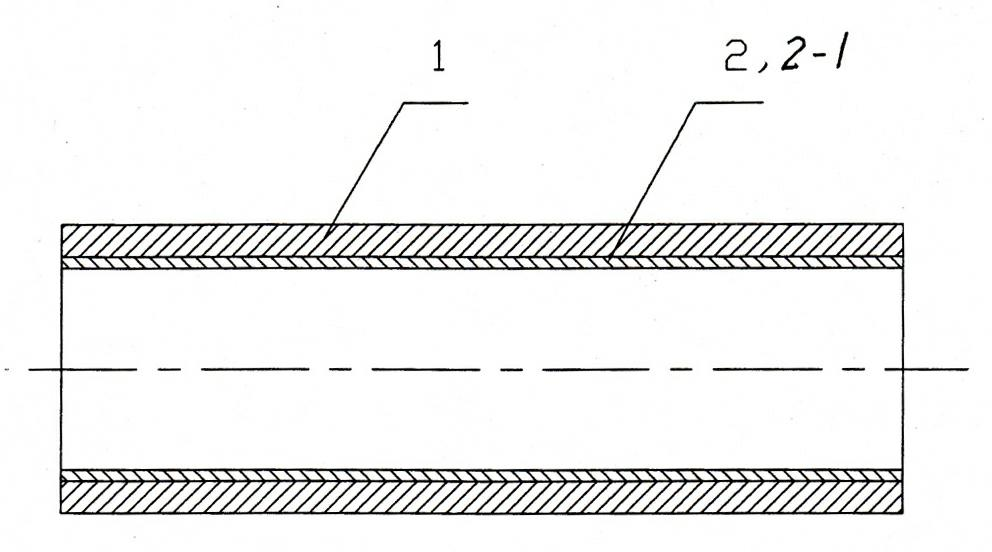

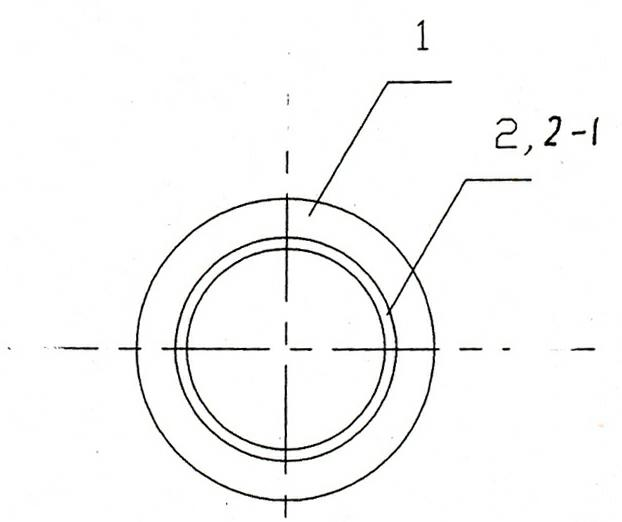

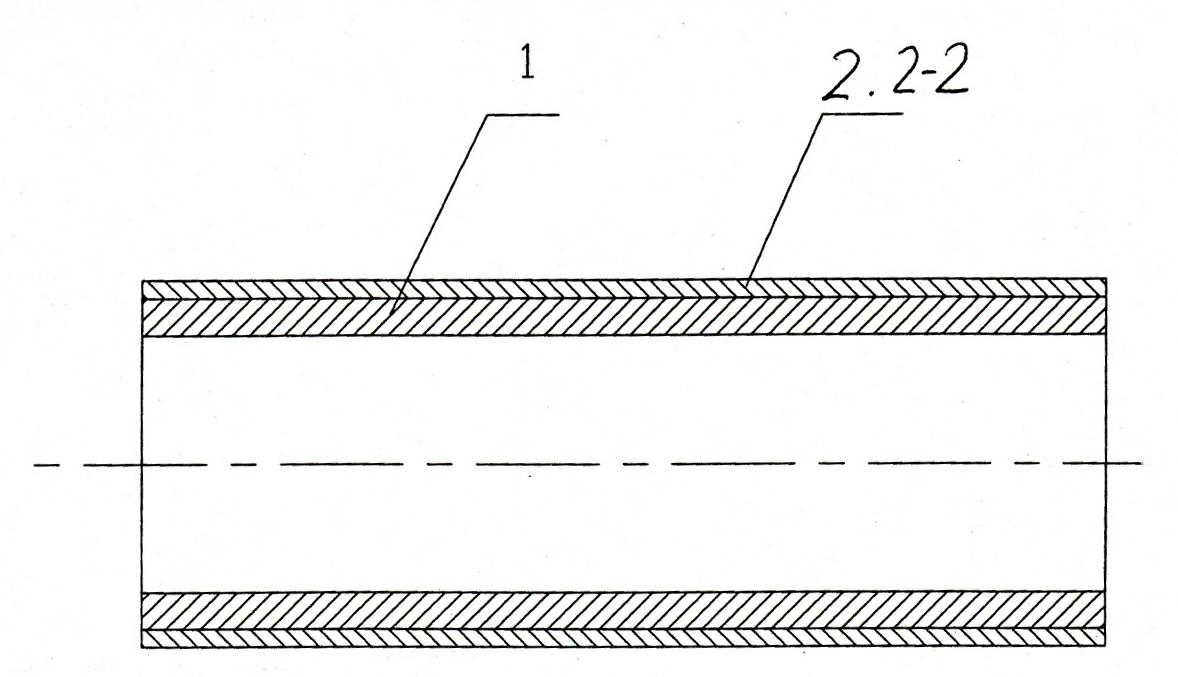

Heat exchanger tube

InactiveCN102128553AImprove work efficiencySimple structureCoatingsTubular elementsShape-memory alloyAlloy

The invention discloses a heat exchanger tube which comprises a tube body (1). The heat exchanger tube is mainly characterized in that the tube body (1) is coated with a shape memory alloy thin film (2). The heat exchanger tube disclosed by the invention has the characteristics of simple structure and convenience in descaling, and the like. The heat exchanger tube is also suitable for many aspects such as fluid material delivery pipelines and the like.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

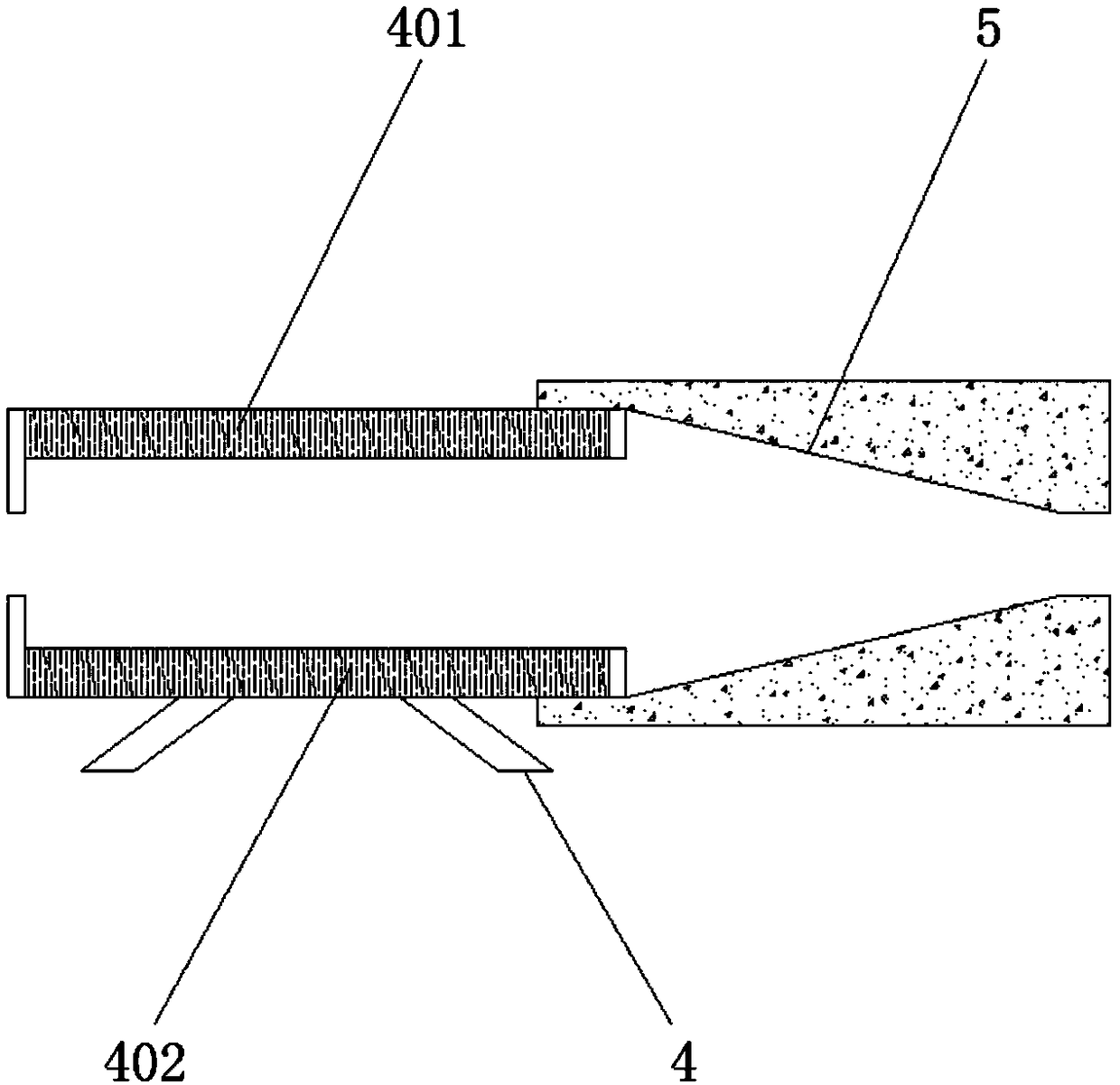

Well bore automatic descaling device and descaling method thereof

ActiveCN104100231BOvercome the easy-to-stuck problemReduced flow areaCleaning apparatusImpellerMechanical energy

The invention discloses an automatic descaling device for a shaft, which comprises a pump casing (1), a pump body, a mandrel (3), a fluid inlet head (4), a rubber cartridge (5), a joint (6), an impeller (7) and The scraper device, the mandrel (3) is fixedly connected with the pump body, the impeller (7) and the blade wheel (11) are installed at intervals on the mandrel (3), the scraper device is installed on the outer circumference of the blade wheel (11), and the fluid enters The head (4) and the rubber cartridge (5) are connected to the water inlet end of the mandrel (3), and the water outlet end of the pump casing (1) is sequentially connected to the pressure control valve (17) and the joint (6); the descaling method is also disclosed . The beneficial effects of the present invention are: realize the utilization of downhole gas-liquid kinetic energy into the working mechanical energy of the descaling device, achieve automatic descaling effect, shorten the descaling time; realize two descaling methods of high-speed gas-liquid descaling and mechanical descaling combination.

Owner:SOUTHWEST PETROLEUM UNIV

Drip irrigation system for increasing uniformity of drip irrigation

InactiveCN108934388AImprove the uniformity of drip irrigationBalanced ratioTransportation and packagingRotary stirring mixersDrip irrigationEngineering

The invention discloses a drip irrigation system for increasing the uniformity of drip irrigation. The drip irrigation system comprises a base; a dosing tank, a water pump, an ultrasonic wave pipe anda pressurizing pipe are successively arranged on the top of the base from left to right; a water inlet end of the water pump is fixedly connected with the dosing tank through a connecting pipe; a water outlet end of the water pump is fixedly connected with the ultrasonic wave pipe through the connecting pipe; one end of the ultrasonic wave pipe away from the water pump is in threaded connection with the pressurizing pipe. In the drip irrigation system for increasing the uniformity of drip irrigation, the dosing tank is arranged; water and fertilizer or drugs are respectively added into the dosing tank from a water inlet pipe and a feeding pipe; an L-shaped water level pipe with scales is arranged on the bottom of the dosing tank; a defined amount of fertilize or drugs can be added by observing the scales and acquiring the amount of added water, so that the purpose of uniformly blending can be achieved; a motor is arranged; the liquid in the dosing tank is stirred by a stirring fan blade under the rotating effect of the motor, so that the phenomena of crystallization, sedimentation, and the like, can be prevented, and the purposes of uniformly stirring and preventing scaling can beachieved.

Owner:安徽瓦大现代农业科技有限公司

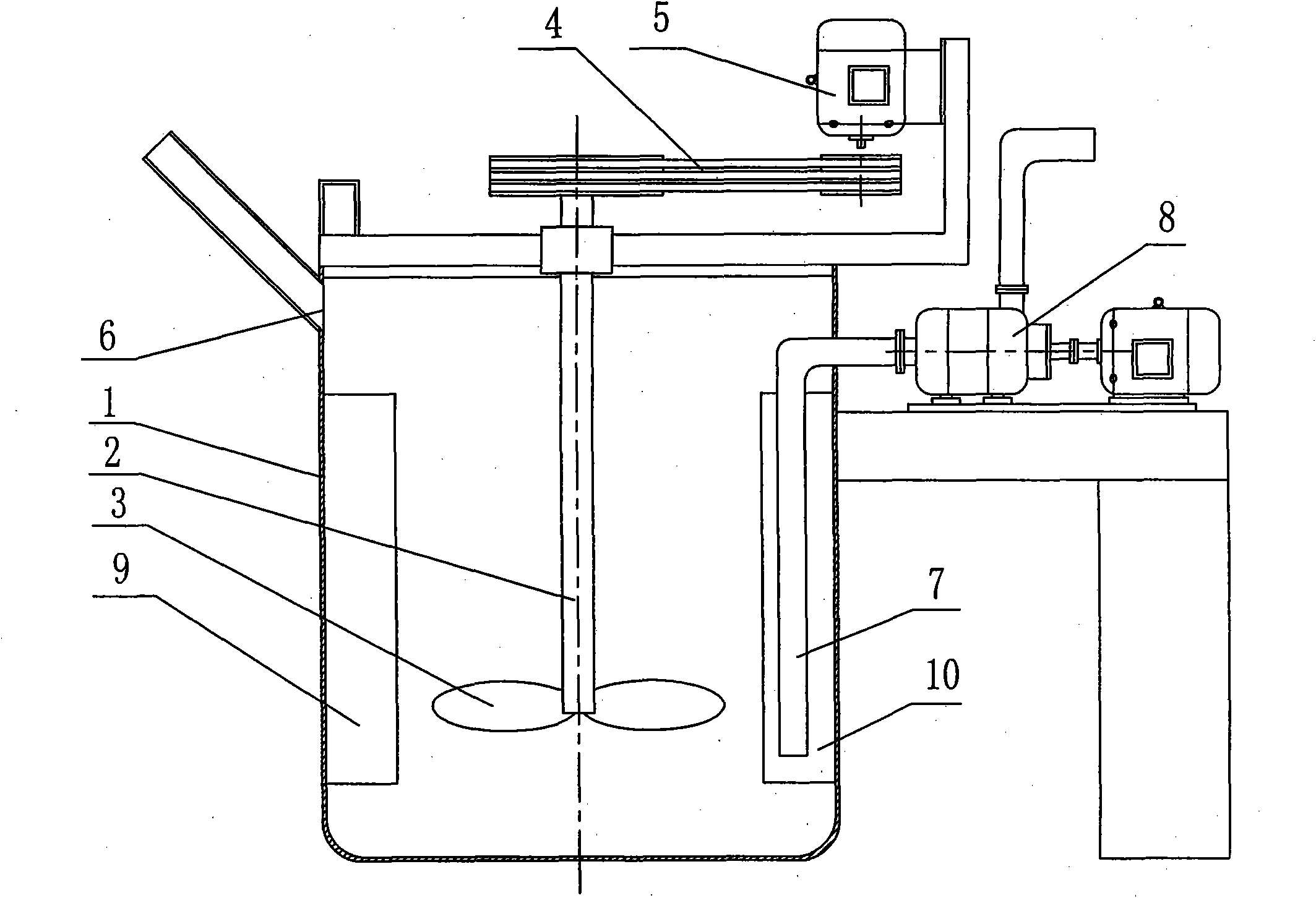

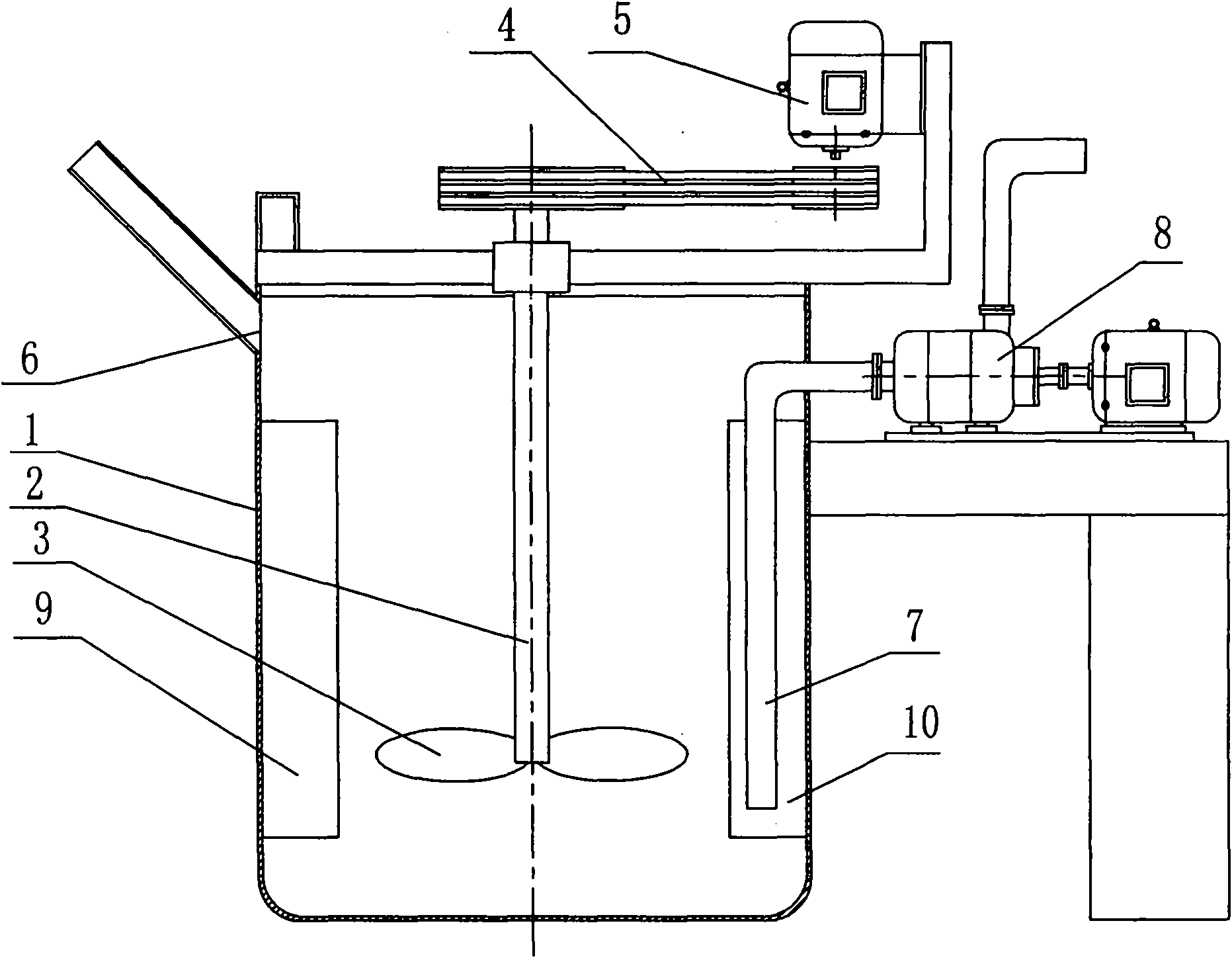

Mixing agitator for materials

InactiveCN101934206AEvenly dispersedReduce energy consumptionTransportation and packagingMixing methodsSlurryEngineering

The invention discloses a mixing agitator for materials and relates to the technical field of material mixers. A blade is connected at the lower end of an agitating shaft in a barrel; the agitating shaft is connected with a motor arranged outside the barrel body through a transmission speed-reducing mechanism; a feed port is formed at the upper end of the barrel body; a suction tube is arranged inside the barrel body; the upper end of the suction tube is connected with an inlet end of a water pump arranged outside the barrel body; two vertical guide plates are symmetrically and fixedly connected to an inner wall of the barrel body; the lower ends of the vertical guide plates are positioned below the horizontal plane of the blade; and an inlet end of the suction tube is arranged between the lower ends of the vertical guide plates and the horizontal plane of the blade. Slurry can generate omega-shaped and circumferential convective motion in the barrel body, fluid circumferentially shears convective circulation up and down, and the slurry is uniformly dispersed. The mixing agitator for materials has the characteristics of low energy consumption, uniform dispersion, strong agitation, long service life of an agitating wheel, no solid-phase settlement and the like, capacity of improving mixing uniformity of scale removing sand and water, and contribution to scale removal for steel pipes.

Owner:江苏诚德钢管股份有限公司

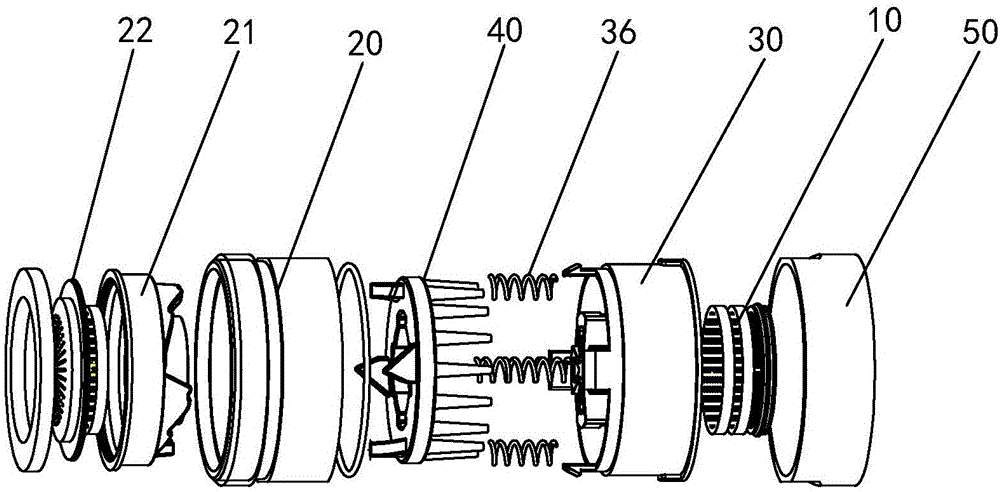

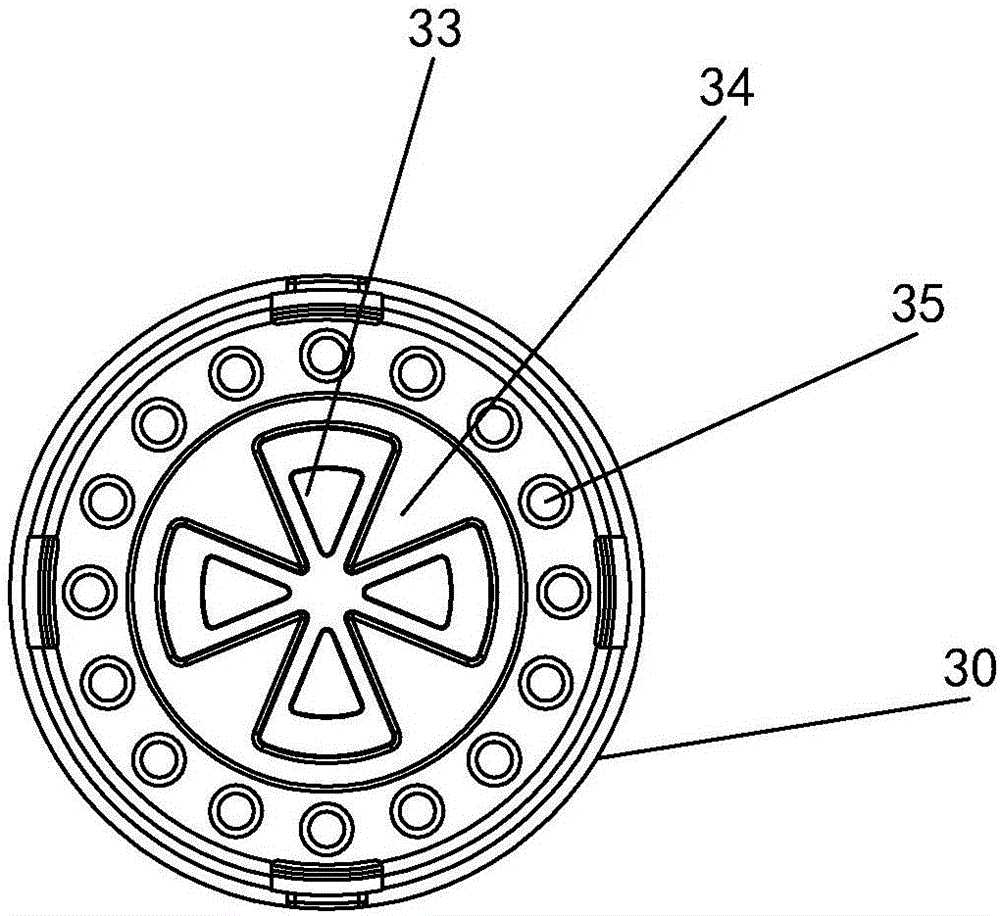

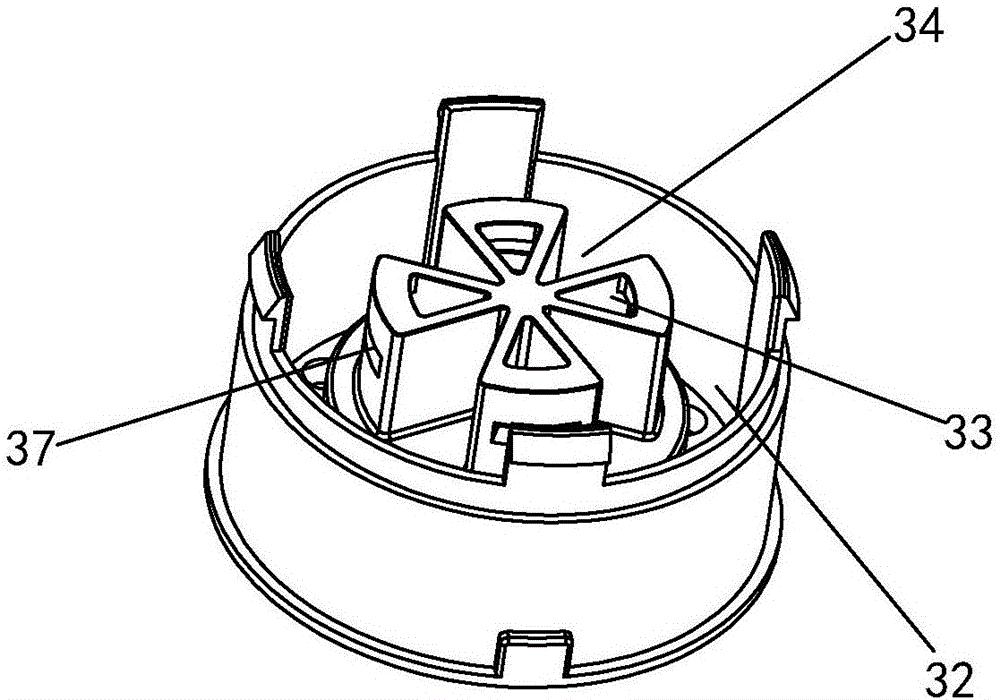

Switching type descaling bubbler and faucet

The invention relates to a switching type descaling bubbler and a faucet. The switching type descaling bubbler comprises an aeration assembly, a fixed sleeve, a movable inner core and a descaling part, wherein the fixed sleeve is provided with a plurality of water inlets; the movable inner core is provided with a first water outlet passage and a second water outlet passage, is sheathed on a fixed base, and is operated to rotationally engage the water inlet and the first water outlet passage or the second water outlet passage; the bubbler assembly is arranged in the first water outlet passage; the descaling part is arranged in the second water outlet passage, and is provided with a plurality of ejector pins; a pushing structure is arranged between the descaling part and the fixed sleeve, so as to push the ejector pins to move between the water outlets of the second water outlet passage in an inserting or disengaging way. The switching type descaling aerator has the advantages that the operation is simple, the water drain modes are diversified, the blocking possibility of the bubbler is reduced, and the service life is prolonged.

Owner:JOMOO KITCHEN & BATHROOM

Oil conservator for sleeve and processing technology of oil conservator

ActiveCN111599574AReasonable structural designImprove stabilityTransformers/inductances coolingTransformers/inductances casingsEngineeringMaterials science

The invention discloses an oil conservator for a sleeve and a processing technology of the oil conservator. The oil conservator comprises an oil conservator main body, wherein an oil conservator coverplate is mounted at one end of the oil conservator main body, a rear end sealing plate is mounted at the other end of the oil conservator main body, mounting holes are respectively formed in the middle of the rear end sealing plate and the middle of the oil conservator cover plate, a copper pipe for electric conduction is mounted in the mounting hole, the front end part of the copper pipe extendsout of the end of the oil conservator cover plate, a conductive head matched with the copper pipe is mounted on the oil conservator cover plate, the rear end of the copper pipe and the oil conservator main body are pressed and sealed through a rear end sealing plate, a spring pressing mechanism assisting in pressing and sealing is mounted on the copper pipe located in the oil conservator main body, an oil meter is mounted at the upper end of the oil conservator main body, and a connecting rod floating ball extending into the oil conservator main body is mounted at the lower end of the oil meter. According to the invention, a cylindrical transverse and straight placement mode is adopted, detection, oiling and scale discharging can be better facilitated, the rear end sealing plate is pressed and sealed through the counter-acting force of the spring, the sealing performance of the rear end sealing plate is guaranteed, the stability is good, and damage is not likely to happen.

Owner:JIANGSU ZHIDA ELECTRIC

Heat exchanger cleaning agent

InactiveCN109385341ALess corrosiveEasy descalingOrganic detergent compounding agentsPolymeric surface-active compoundsOrganic acidActive agent

The invention discloses a heat exchanger cleaning agent. The cleaning agent is characterized in that the component substances of the cleaning agent include, by mass, 5-8 parts of an organic acid, 0.1-0.5 part of a sustained-release agent, 0.5-1 part of a penetrant, 1-3 parts of a dispersing agent, 1-2 parts of a stripping agent, and 0.5-1 part of an active agent, with the balance being water. Thebeneficial effects of the cleaning agent are that the production efficiency of cheese can be enhanced, the expiration date of the cheese can be prolonged, and the convenient production and storage ofthe cheese can be realized; the cleaning agent is non-flammable, non-explosive and non-toxic; the corrosivity of the cleaning agent on equipment and human bodies is small; good descaling and rust removal effects can be realized; the cleaning rate of the cleaning agent for general dirt and rust products is greater than 99%; descaling, rust removal and passivated pre-filming can be integrated; the cleaning time can be shortened for 1 / 2 - 2 / 3; and the cleaning agent can be used under normal temperature, so that convenient usage can be achieved.

Owner:李万秋

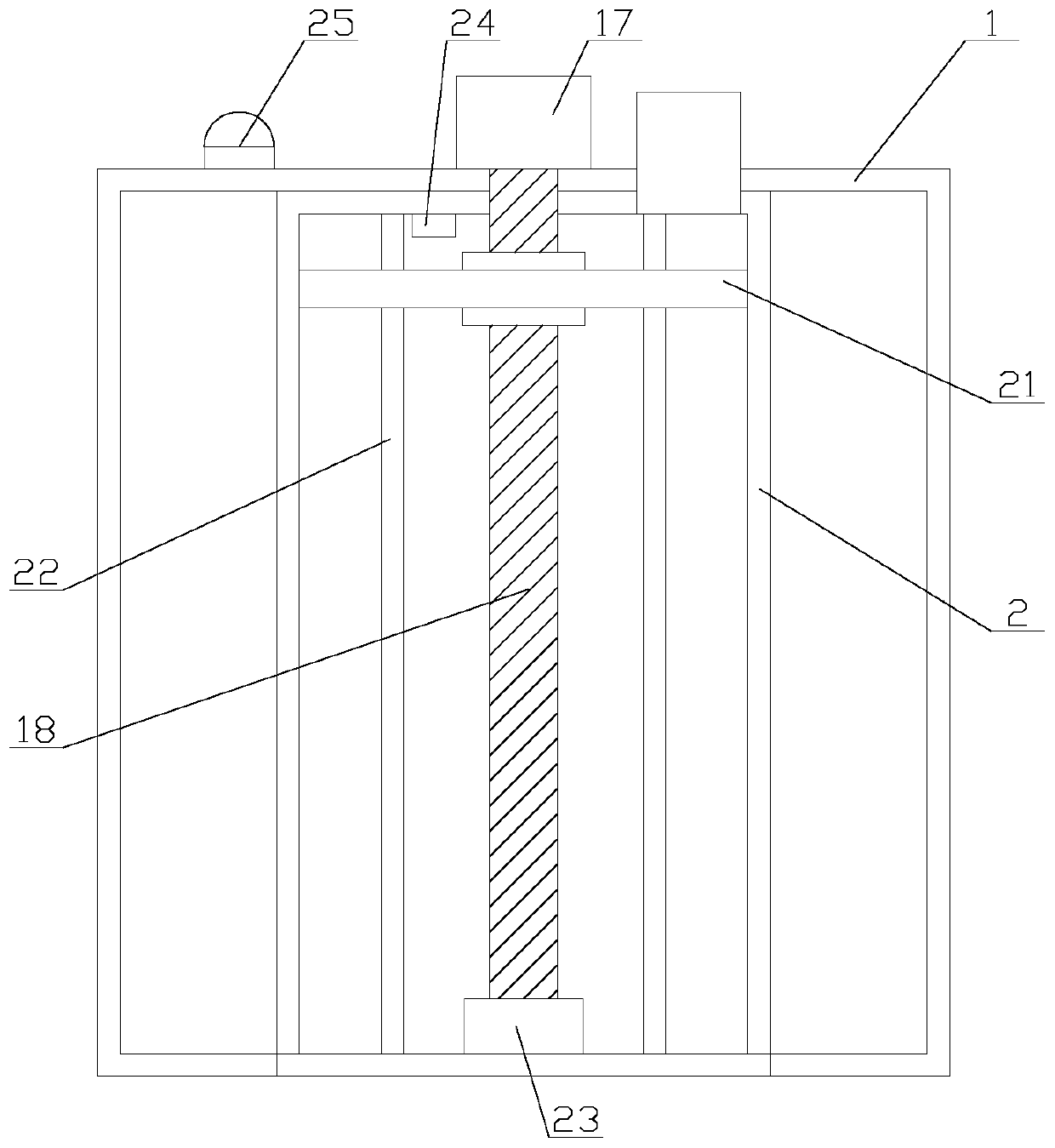

Distillation tank

The invention relates to a distillation device, in particular to a distillation tank. The distillation tank comprises a tank body and a tank cover, wherein the tank cover is arranged on the tank body; the bottom of the tank body is a hollow heating interlayer; heating medium heat transfer oil is filled into the hollow heating interlayer; and a distillate inside the tank body is indirectly heated by heating the heating medium heat transfer oil. The inner wall of the bottom of the tank body of the distillation tank is adhered with a layer of heat resisting thin film, the heat resisting thin film is required to be replaced regularly, and the tank body does not need cleaning. The distillation device comprises the design key point that: the bottom of the tank body adopts the hollow heating interlayer, so the distillation tank can be cleaned conveniently without disassembling equipment units. In addition, the distillation device can avoid non-cleaned dead angles, conveniently and easily cleans scales by using the heat resisting thin film and can conveniently remove dirt without a cleaning liquid.

Owner:爱阔特(上海)清洗设备制造有限公司

Temperature control method for opening and closing of three valves of four-fluid heat exchanger

InactiveCN111256498AImprove heat transfer effectGood descaling effectVibration cleaningStationary tubular conduit assembliesTemperature controlEngineering

The invention provides a temperature control method for opening and closing of three valves of a four-fluid heat exchanger. A first valve, a second valve and a third valve are arranged at inlets of afirst heat exchange pipe, a second heat exchange pipe and a third heat exchange pipe, a first temperature sensor, a second temperature sensor and a third temperature sensor are arranged in a left sidepipe, a center pipe and a right side pipe respectively and used for detecting temperatures in the left side pipe, the center pipe and the right side pipe, and a controller controls opening and closing of the first valve, the second valve and the third valve according to the detected temperatures of the left side pipe, the right side pipe and the center pipe, thereby controlling whether heat change is performed on first, third and second fluids or not. The new fluid is started to perform alternate heat exchange by detecting temperature change in the left side pipe, the right side pipe and thecenter pipe, so that elastic pipe bundles are continuously driven to vibrate and heat exchange efficiency and descaling operation can be further realized.

Owner:QINGDAO UNIV OF SCI & TECH

Method for controlling three-valve heat exchanger through flow speed difference

InactiveCN111412766AAchieve vibrationThe result is accurateVibration cleaningHeat exchanger casingsData connectionEngineering

The invention provides a method for controlling a three-valve heat exchanger through the flow speed difference. A first valve, a second valve and a third valve are arranged at inlets of a first heat exchange pipe, a second heat exchange pipe and a third heat exchange pipe correspondingly. A speed induction element is arranged in the free end of a pipe bundle and is used for detecting the flow speed of fluid in the free end of the pipe bundle. A flow speed sensor is in data connection with a controller. The controller extracts flow speed data according to the time sequence. Due to comparison offlow speed data of adjacent time sections, the flow speed difference or the accumulation of the flow speed difference changes of the heat exchanger is obtained, when the flow speed difference or theaccumulation of the flow speed difference changes is smaller than the threshold value, the first valve, the second valve and the third valve are controlled by the controller to be opened and closed,and whether first fluid, third fluid and second fluid conduct heat exchange or not is controlled. By means of the method, due to the fact that the speed difference or the accumulated flow speed difference changes are detected, new fluid is started to conduct alternate heat exchange, and therefore the elastic pipe bundle can be constantly driven to vibrate, and the heat exchange efficiency and thedescaling operation can be further achieved.

Owner:QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com