Patents

Literature

4448results about "Gas flame welding apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

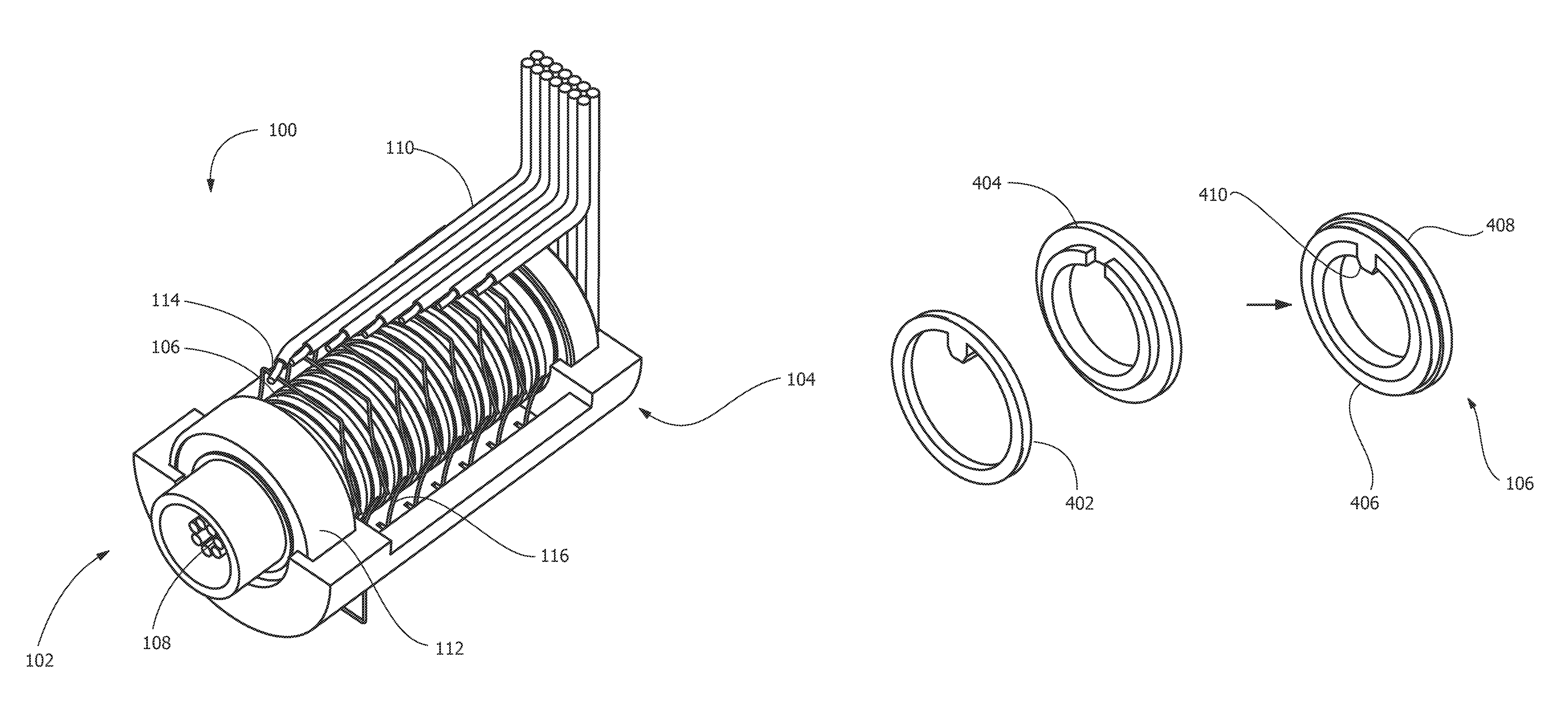

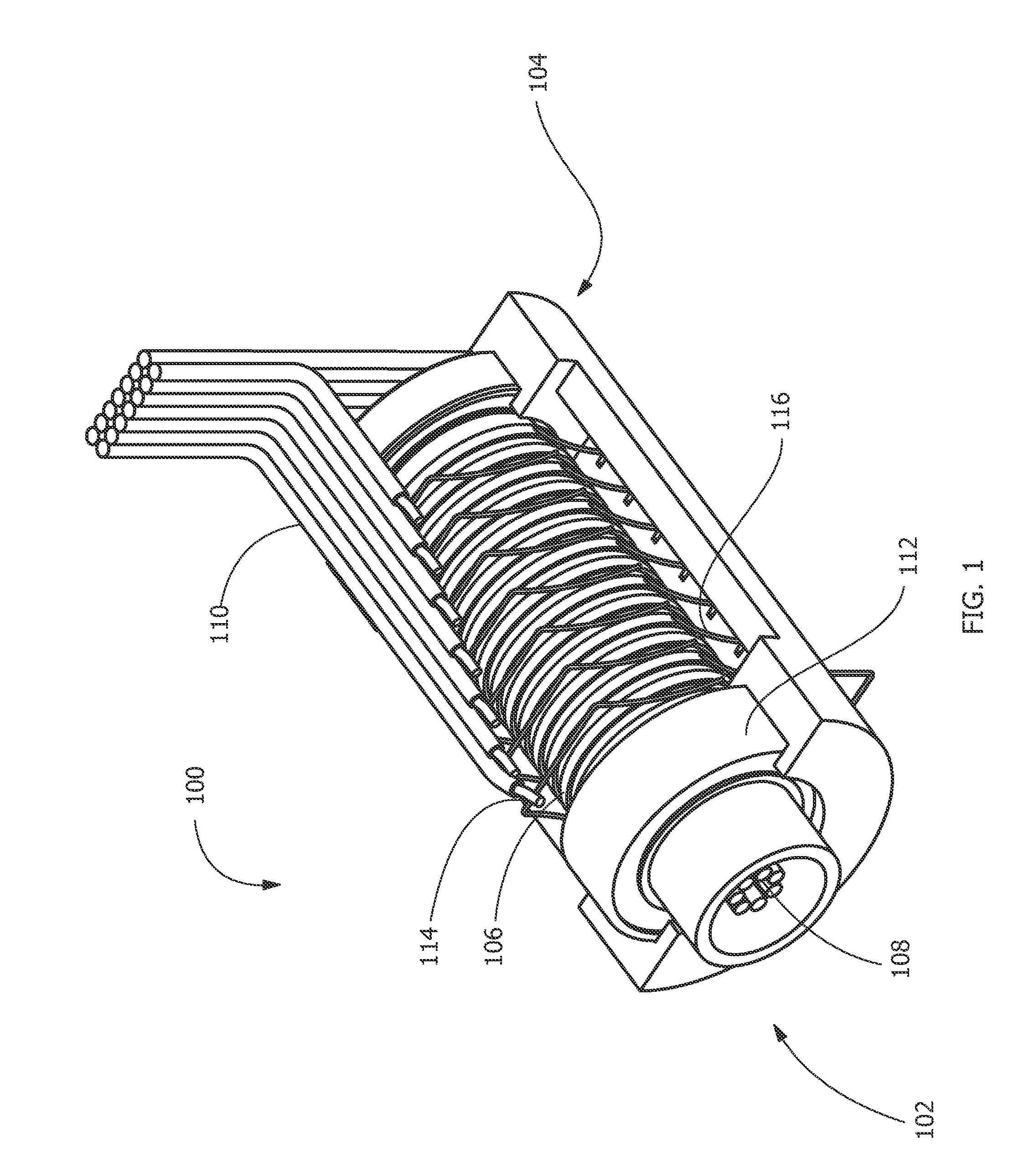

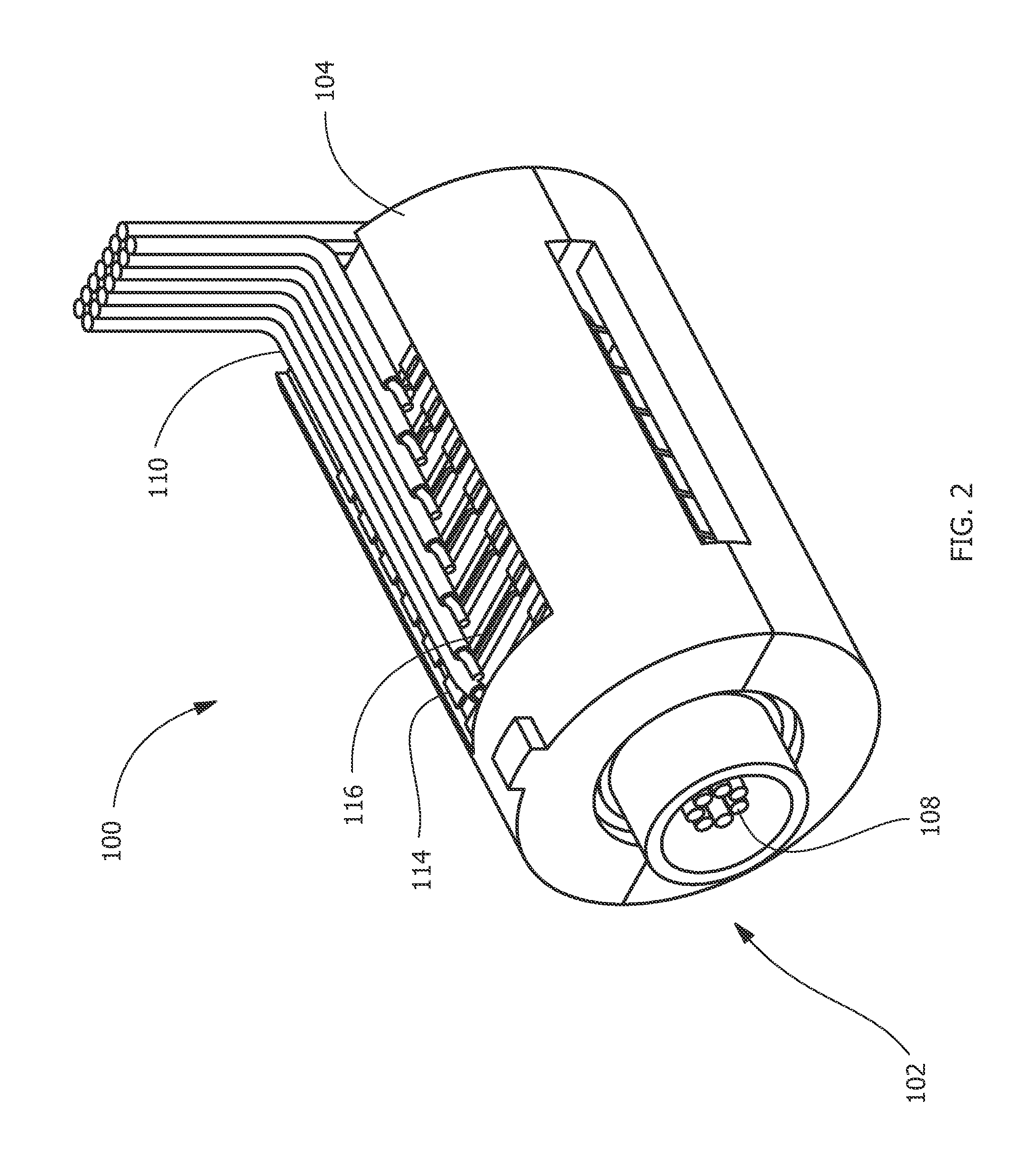

Method of fabricating a slip ring component

A process of fabricating a slip ring component, a slip ring component, and a slip ring assembly are disclosed. The process includes forming a first shot, forming a second shot, and immersion bathing the first shot and the second shot. The immersion bathing applies an electrically conductive plating to exposed surfaces of the second shot.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

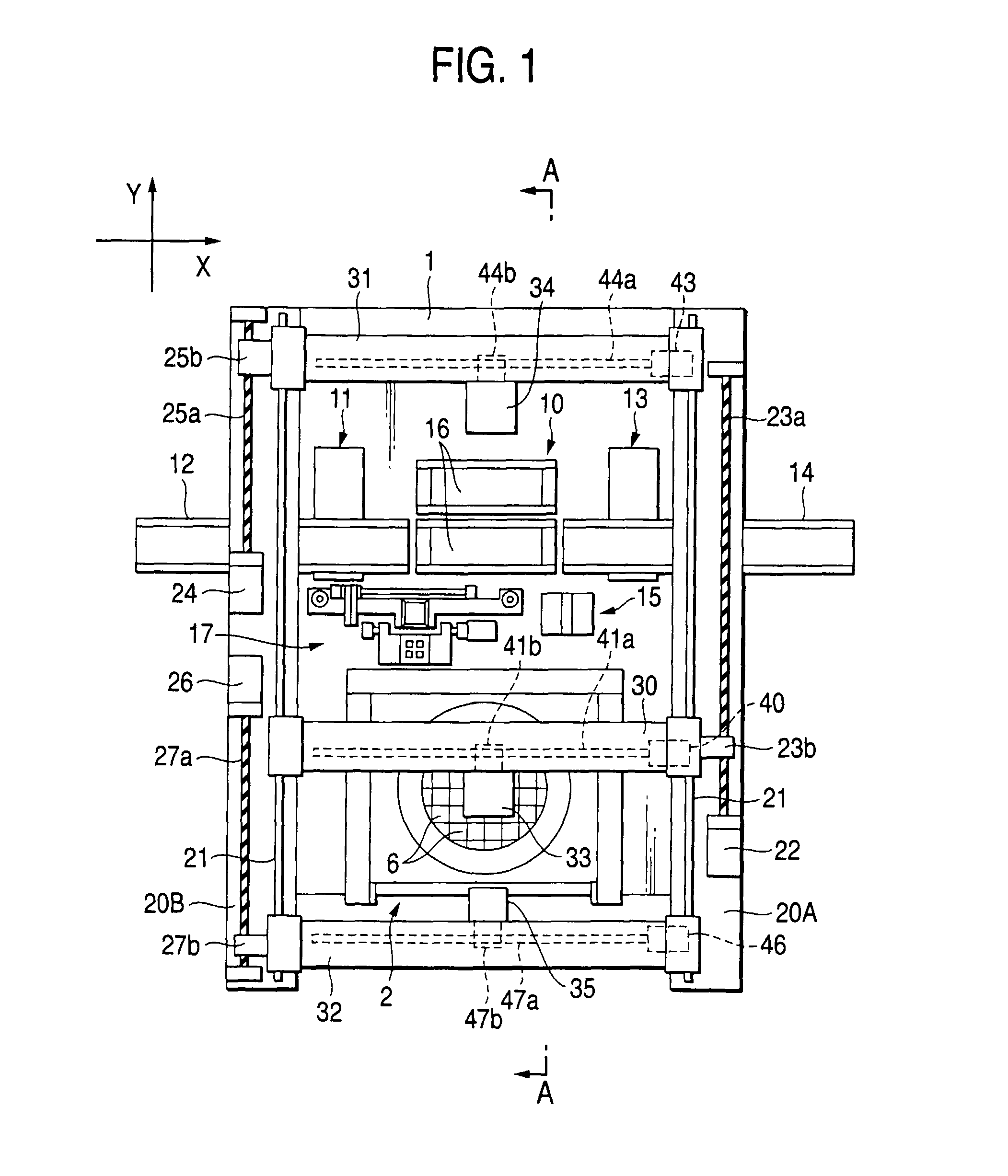

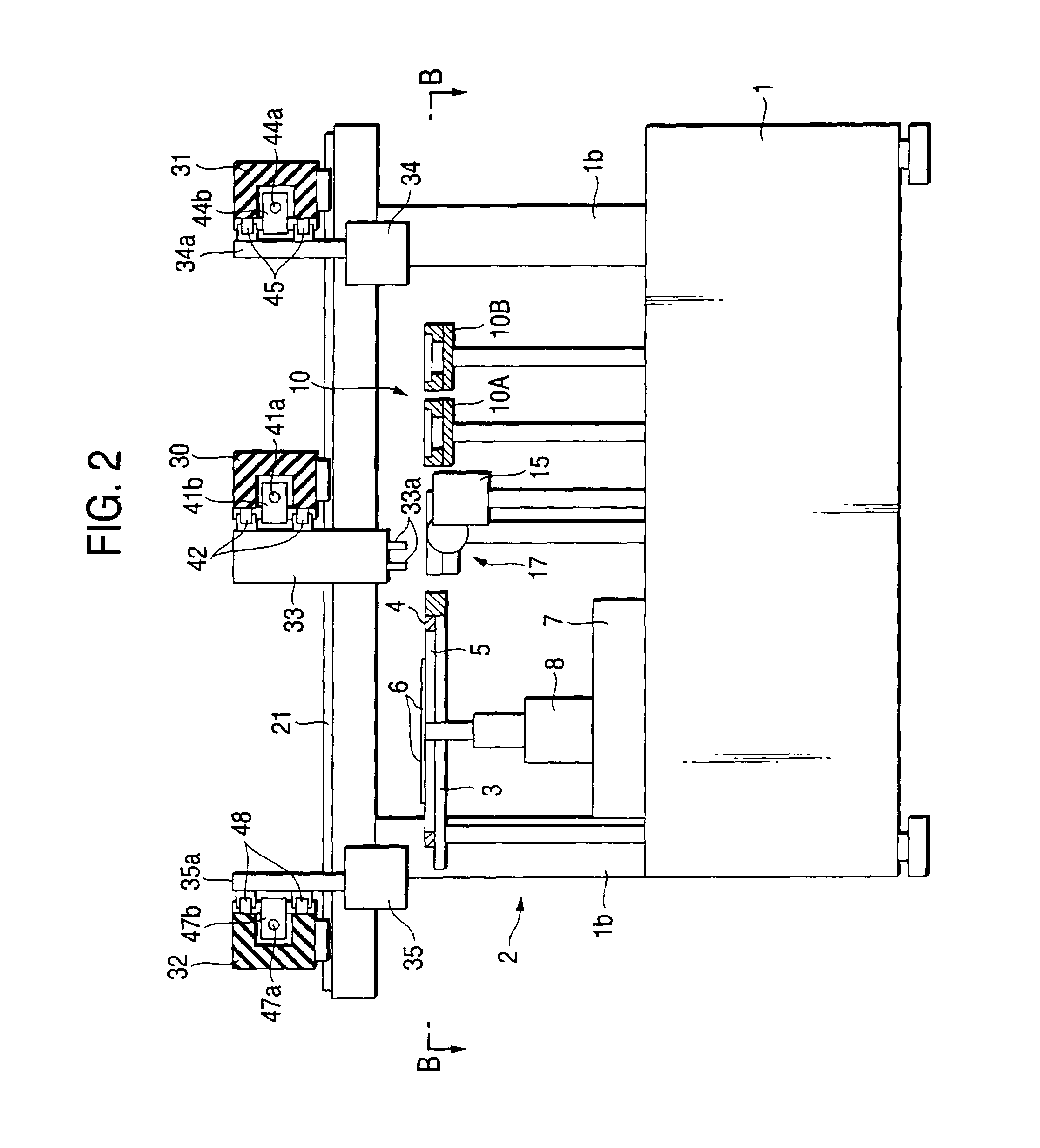

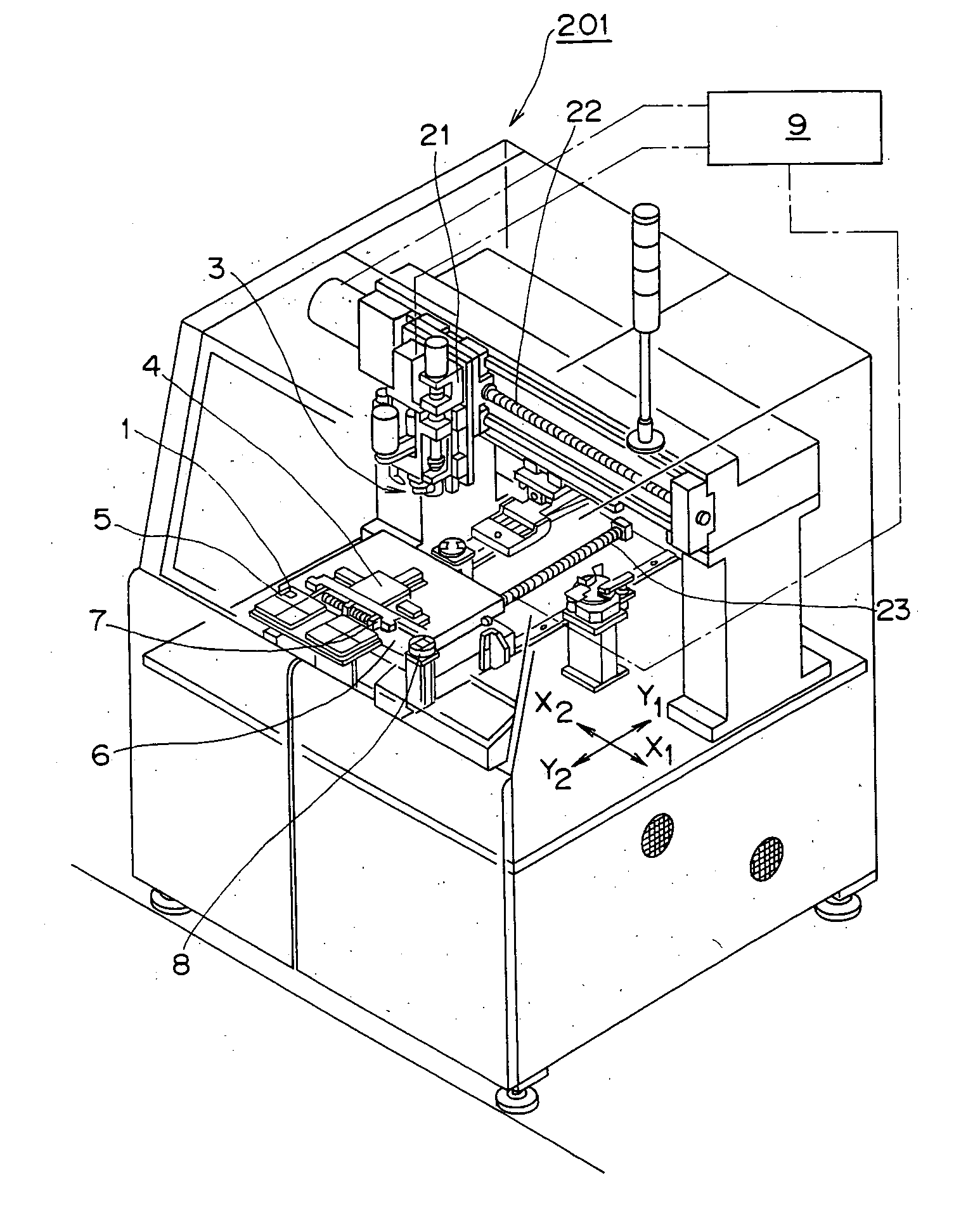

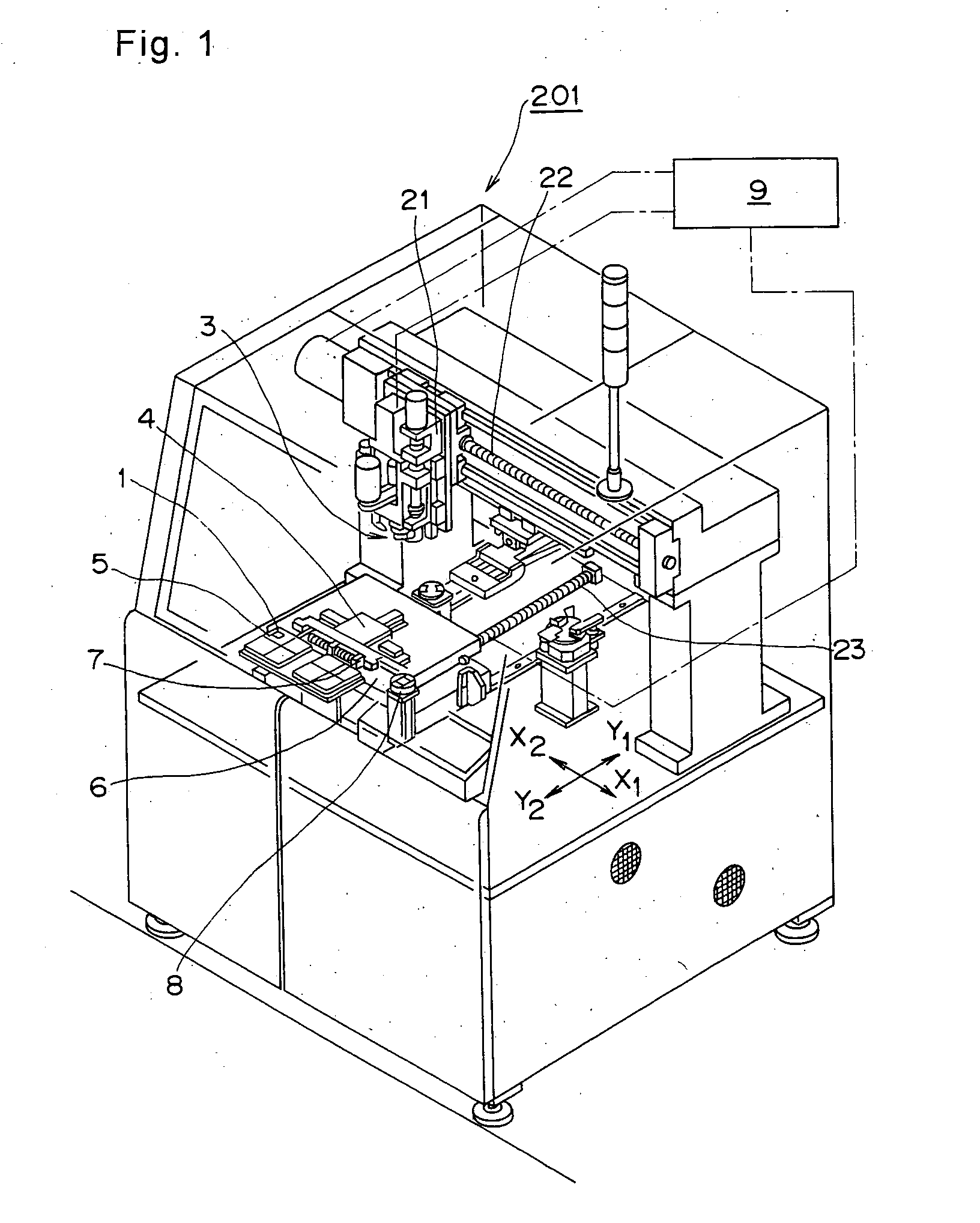

Electronic component mounting apparatus and electronic component mounting method

InactiveUS7033842B2Eliminate processingImprove efficiencySolid-state devicesSoldering apparatusElectronic componentCoating

The present invention provides an electronic component mounting apparatus, wherein a high speed operation can be provided by simplifying the structure of a mounting head and wherein the working efficiency can be improved by eliminating the use of the mounting head for a coating process. In the electronic component mounting apparatus, a flux is coated on chips supplied to an electronic component feeding unit while bump formation faces are directed upward. The chips are mounted on a substrate. A holding head receives the chips extracted from an adhesive sheet by a mounting head and is inverted relative to a stage on which a flux is spread. As a result, the bumps of the chips are covered with the flux and are flattened, and after the holding head is returned to the original stage, the chips on the stage are extracted and mounted on the substrate by the mounting head.

Owner:PANASONIC CORP

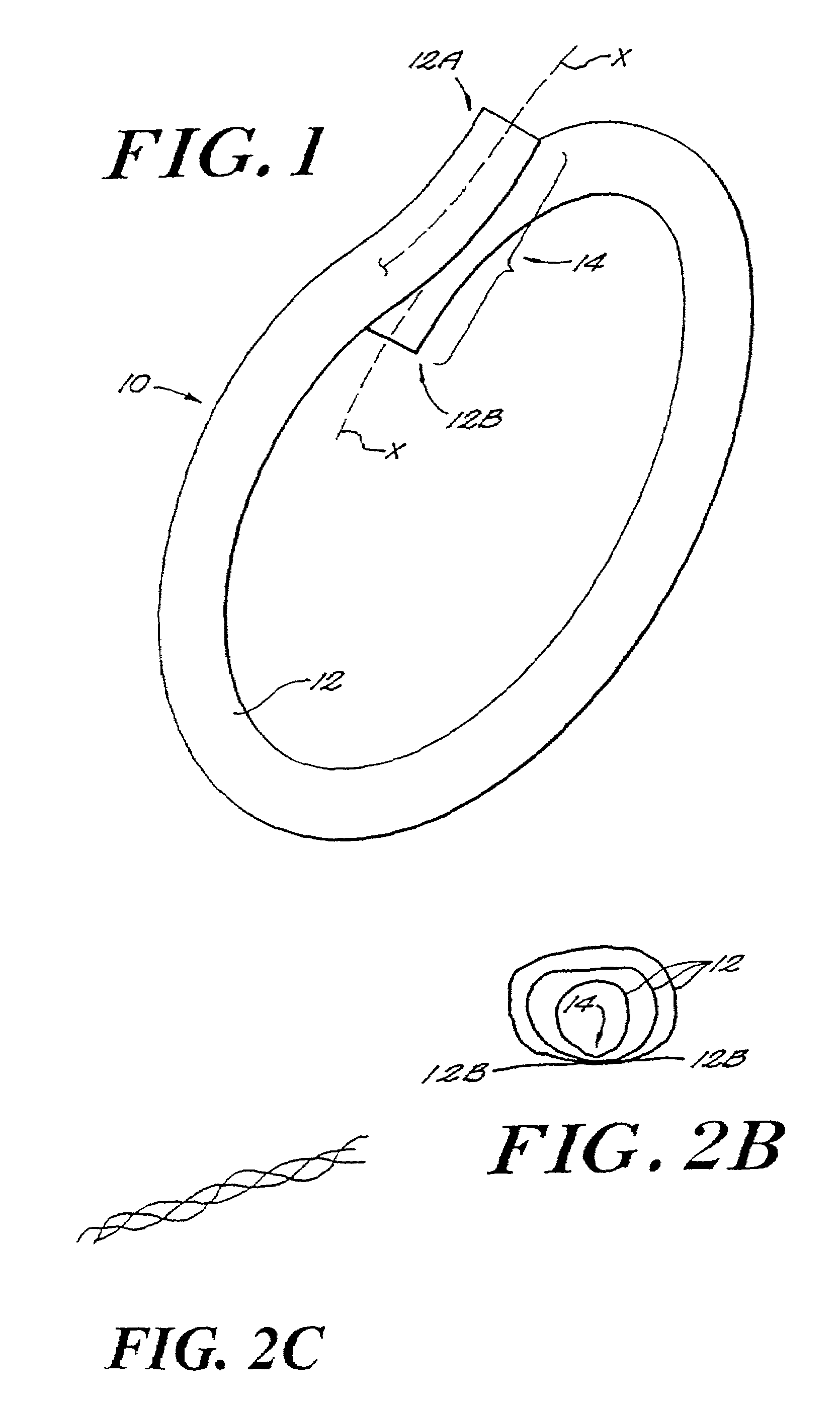

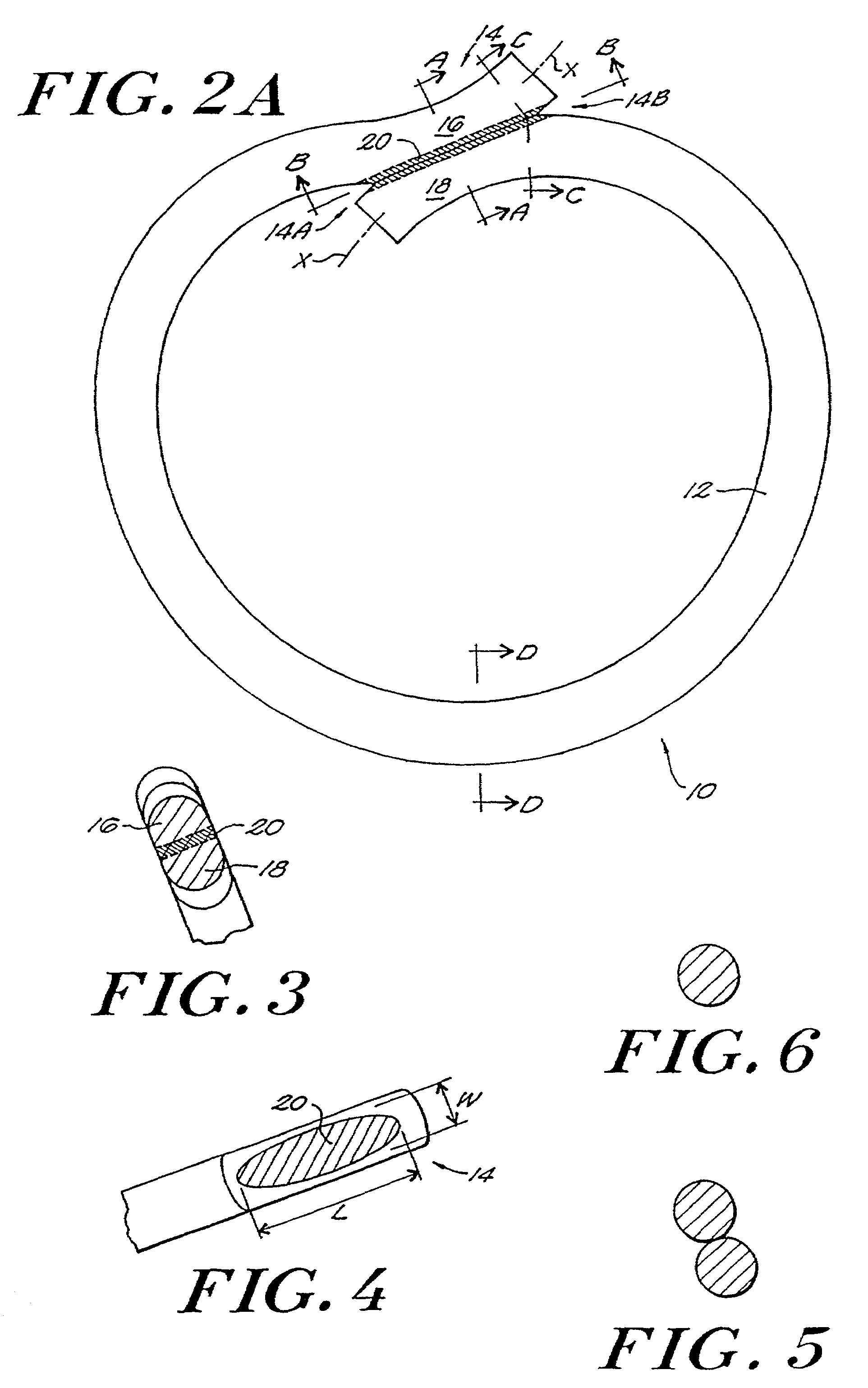

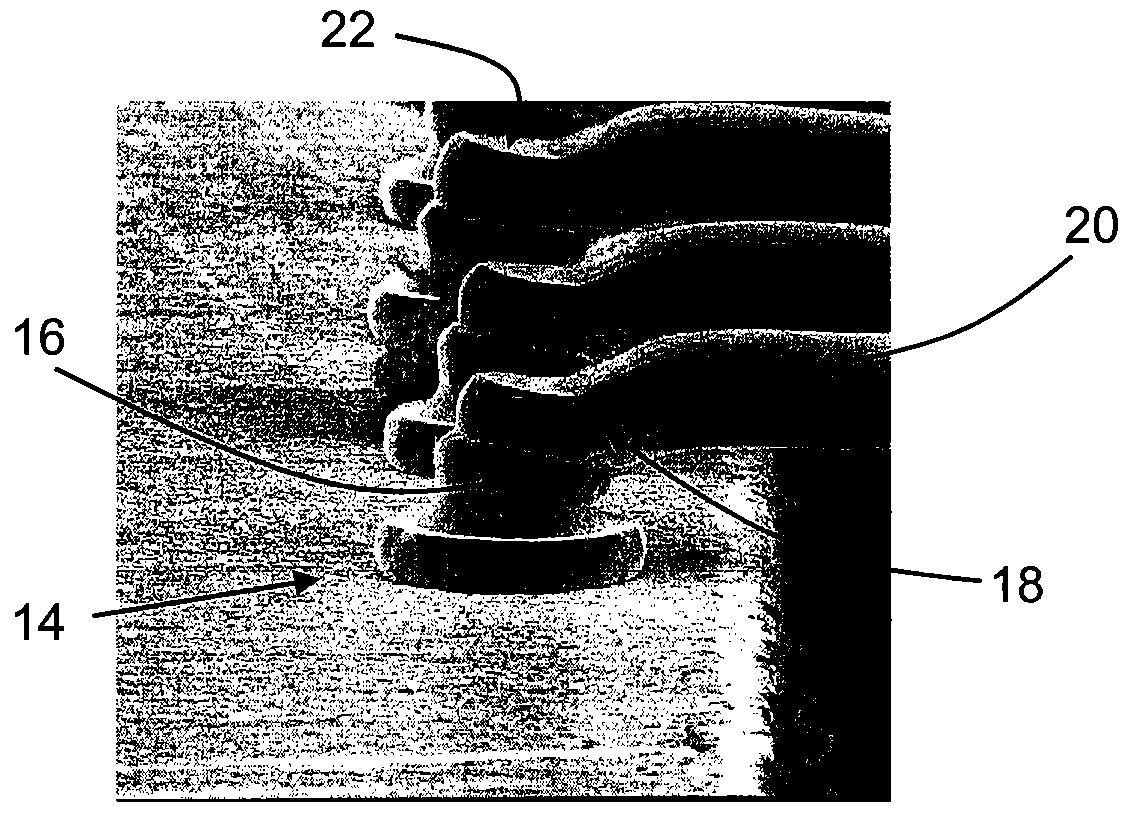

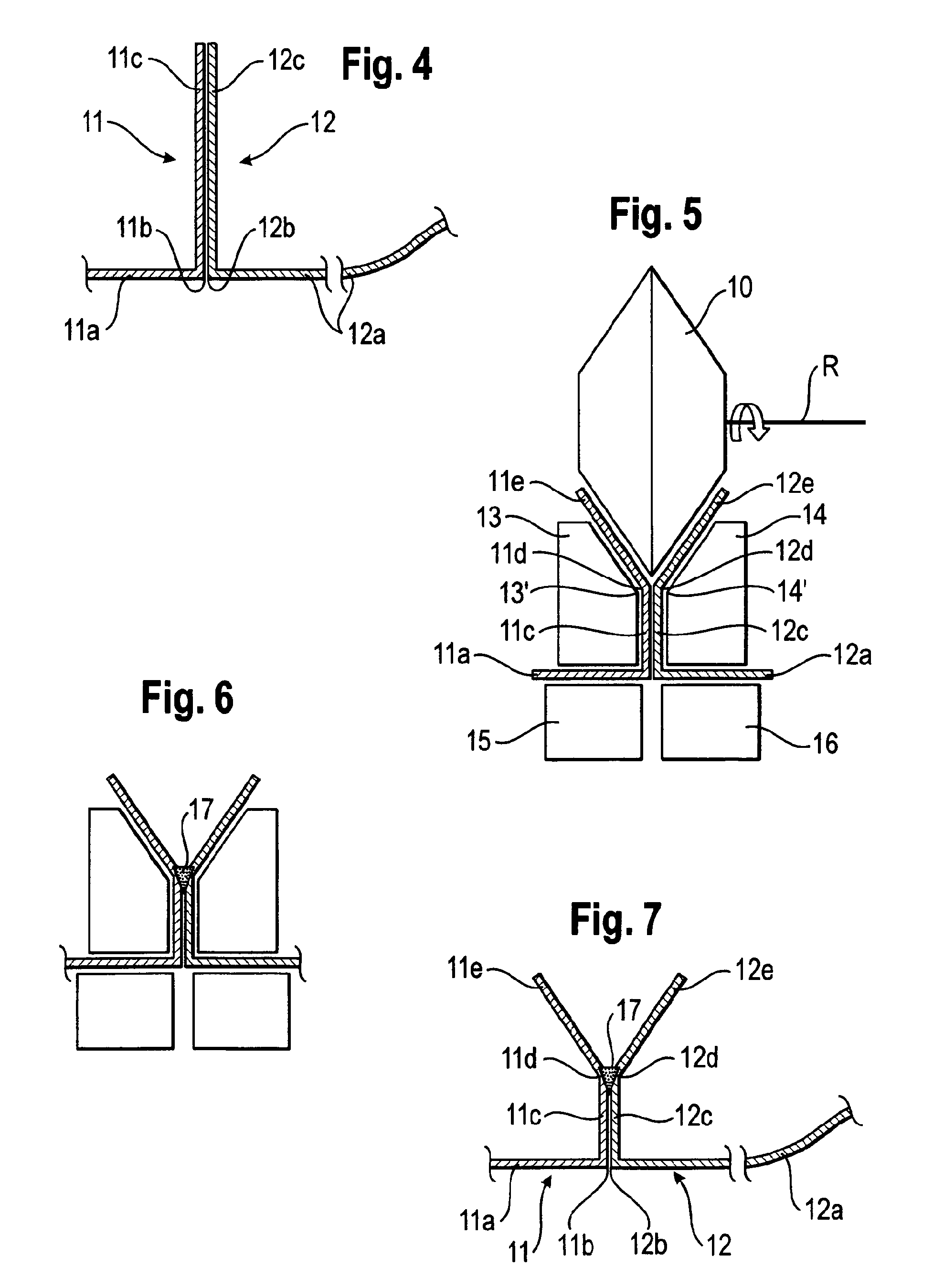

Fused loop of filamentous material and apparatus for making same

InactiveUS7090111B2Maximize joint strengthSuture equipmentsSurgical needlesSurface patternUltrasonic welding

A welding apparatus that includes a first member having a first suture-contacting surface, a second member having a second suture-contacting surface, and a device for moving the first member relative to the second member to define a gap between the respective suture-contacting surfaces. The first member is capable of vibrating and delivering mechanical energy at ultrasonic frequencies. The second member is stationary relative to the first member. A fixture element is adapted to receive and maintain two or more segments of a material to be welded in a predetermined alignment in the gap between the first and second surfaces of the first and second members during a welding operation. According to another aspect of the invention, an ultrasonic welding apparatus includes first and second members with patterned first and second suture-contacting surfaces. The patterned surfaces can be complementary or non-complementary and the surface patterns on each member may vary in either a periodic or a non-periodic manner.

Owner:TORNIER INC

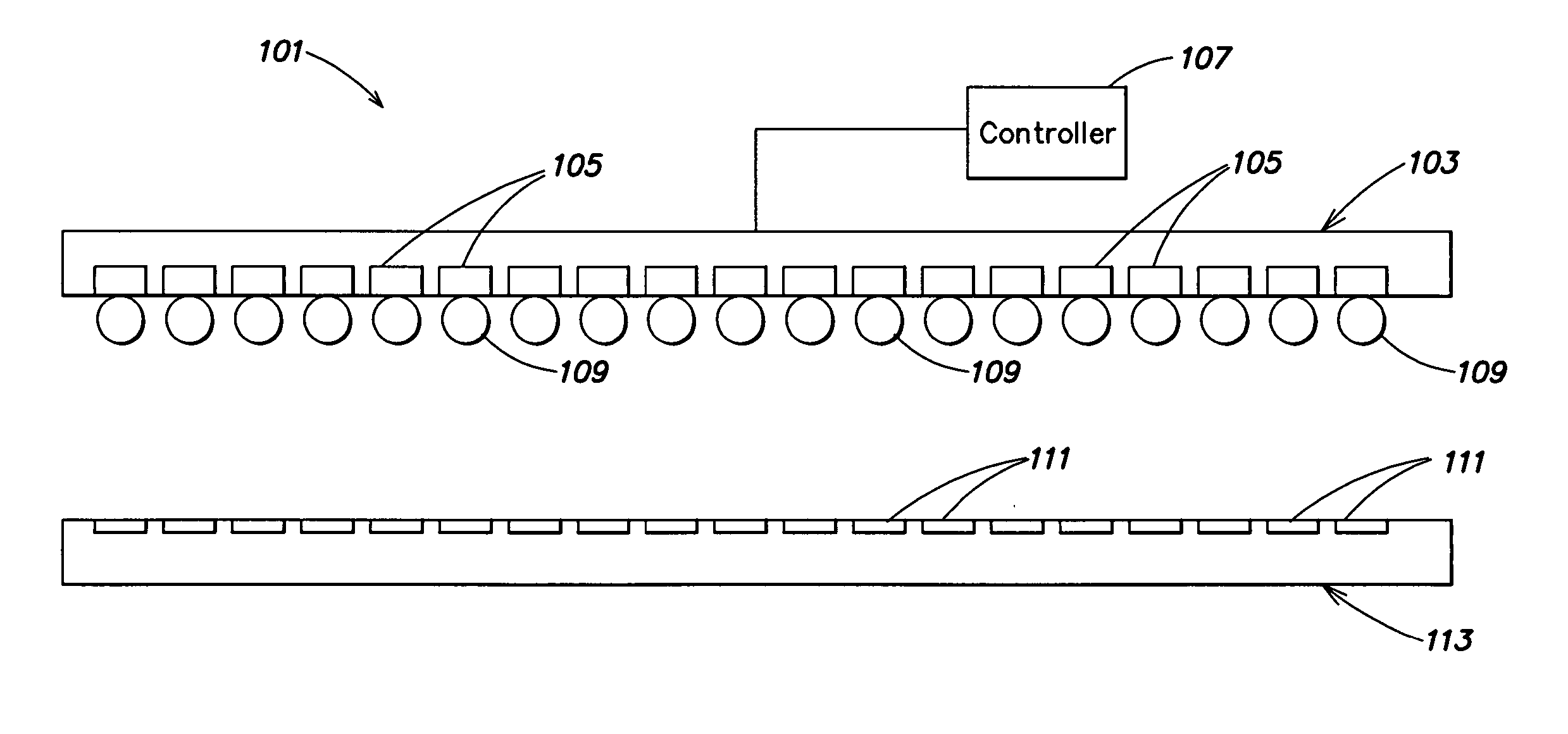

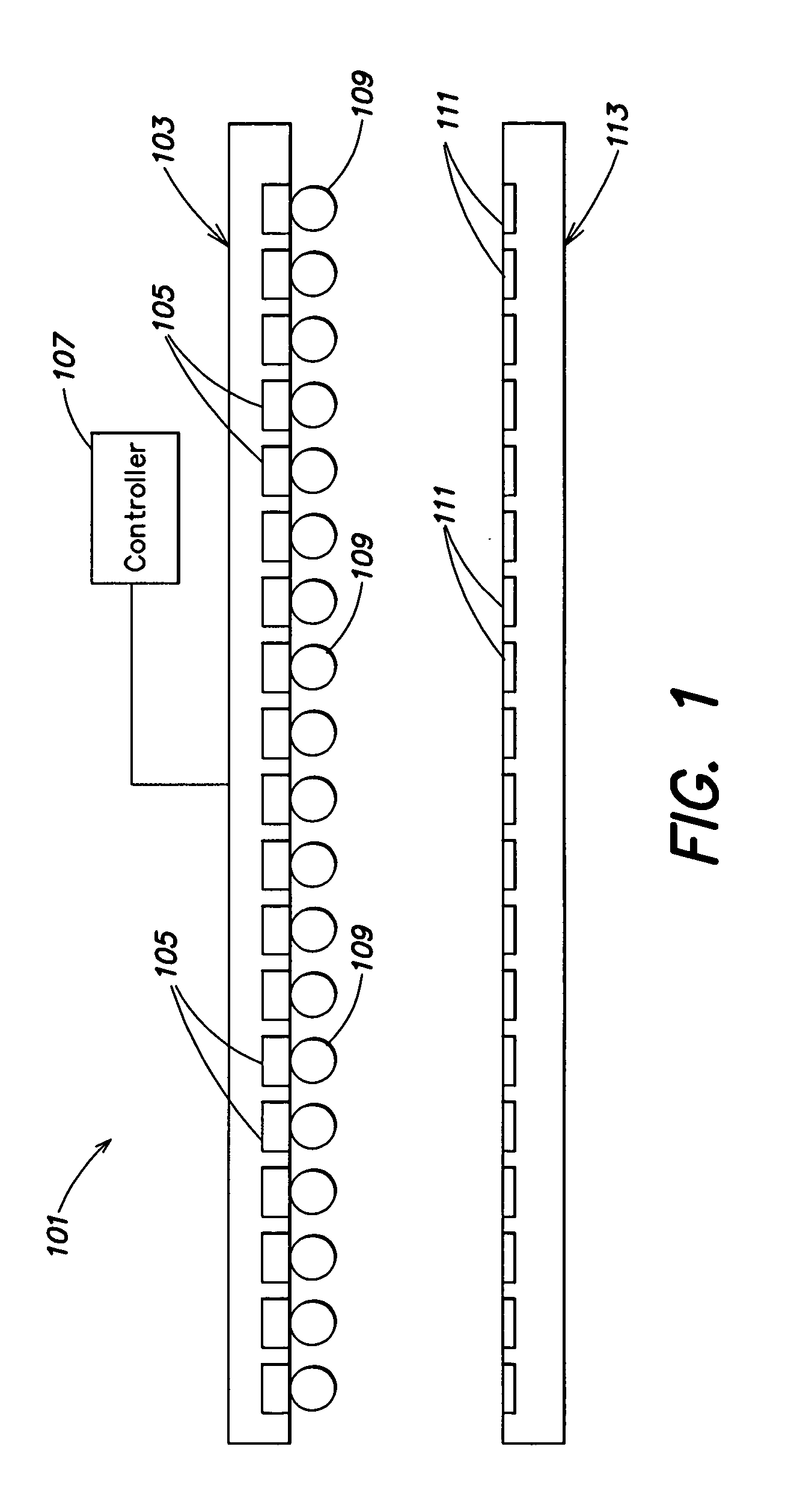

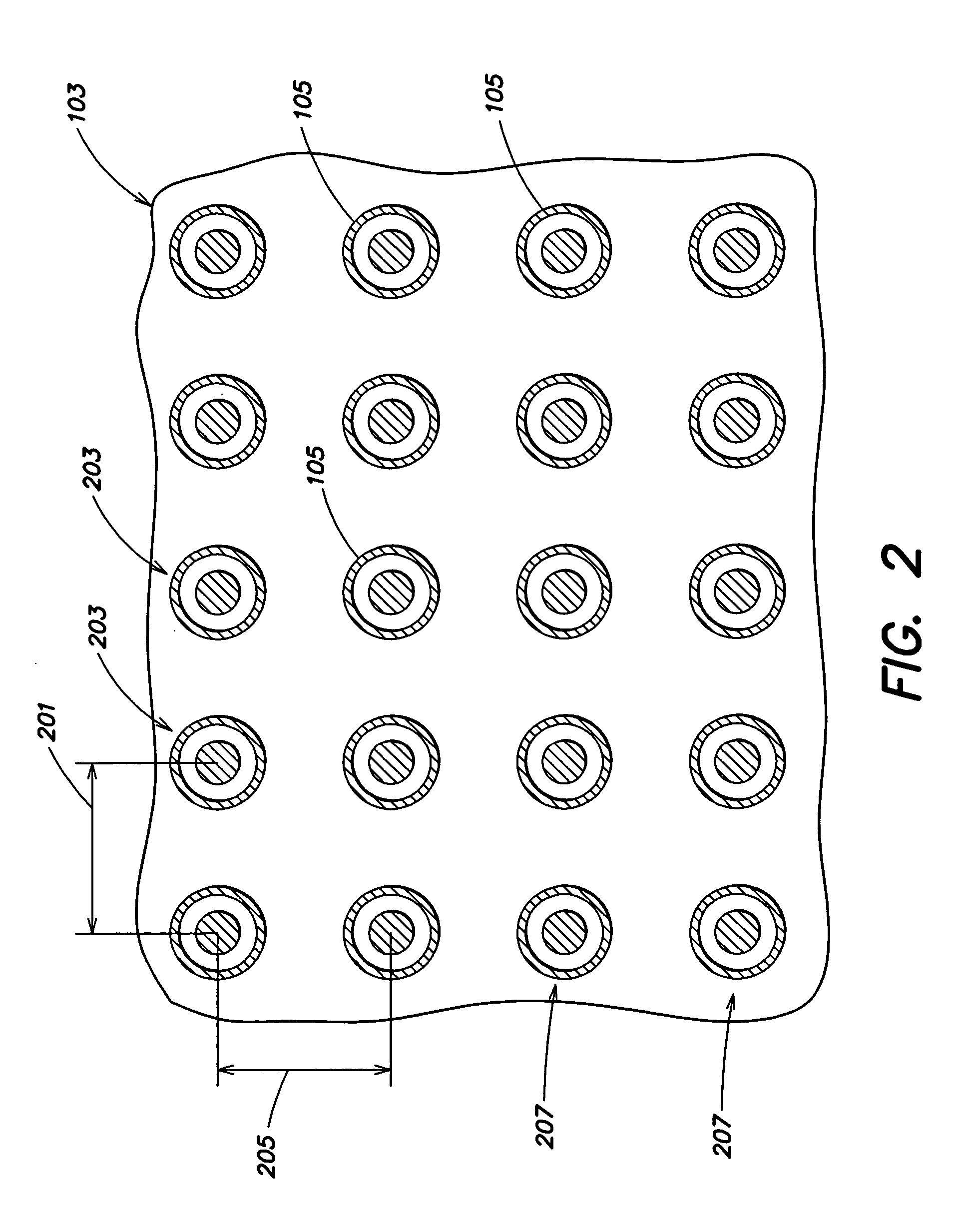

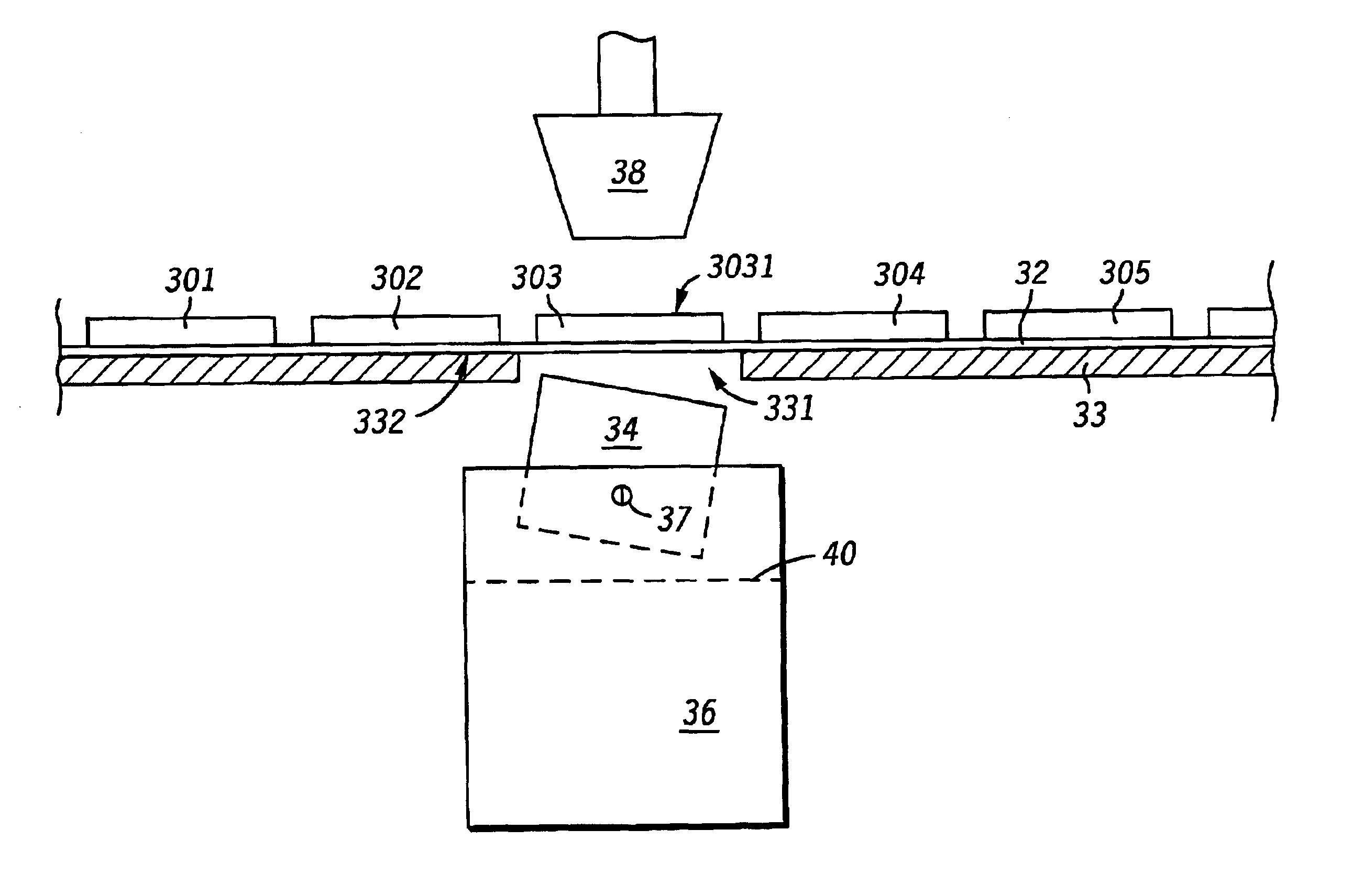

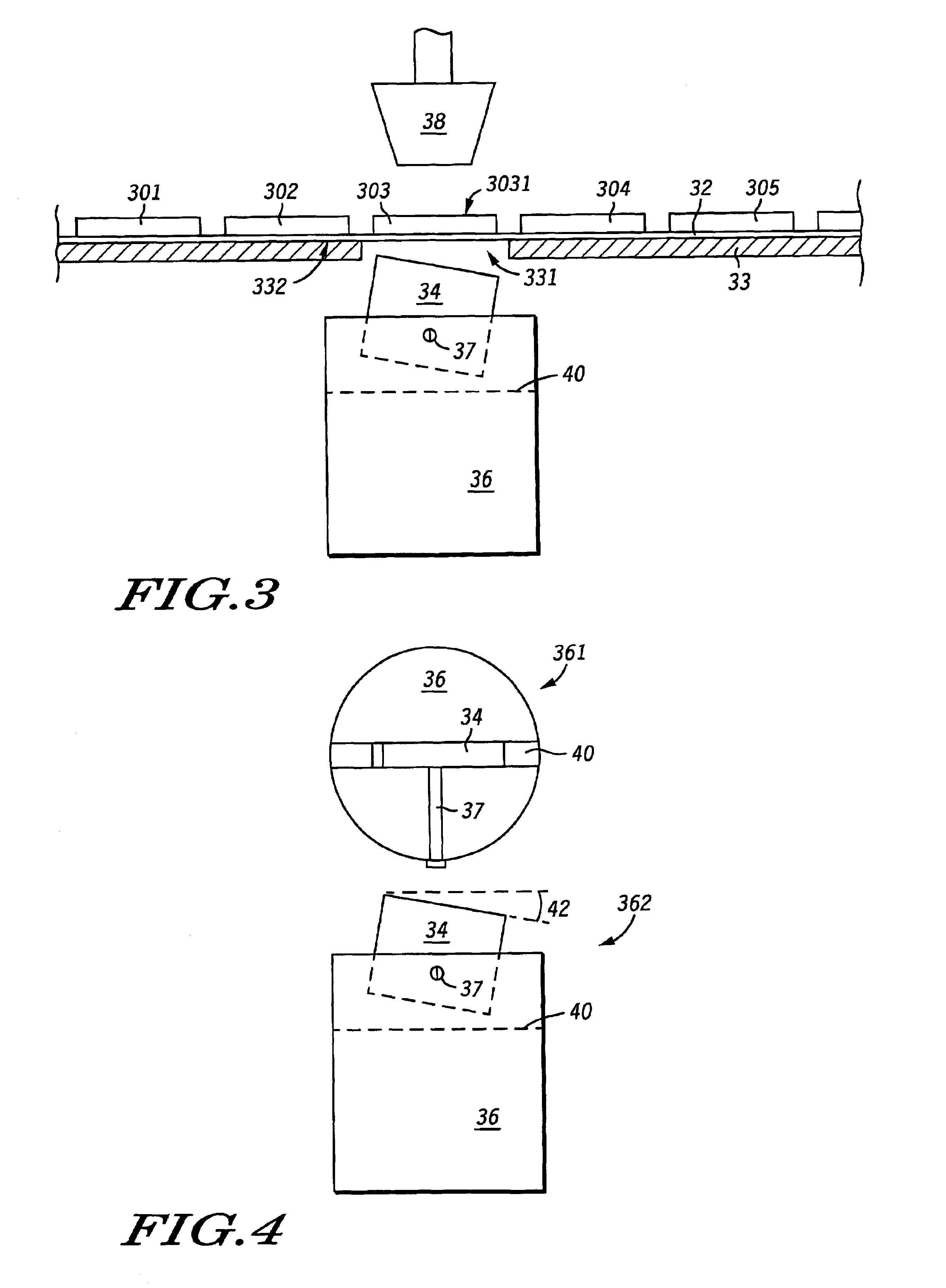

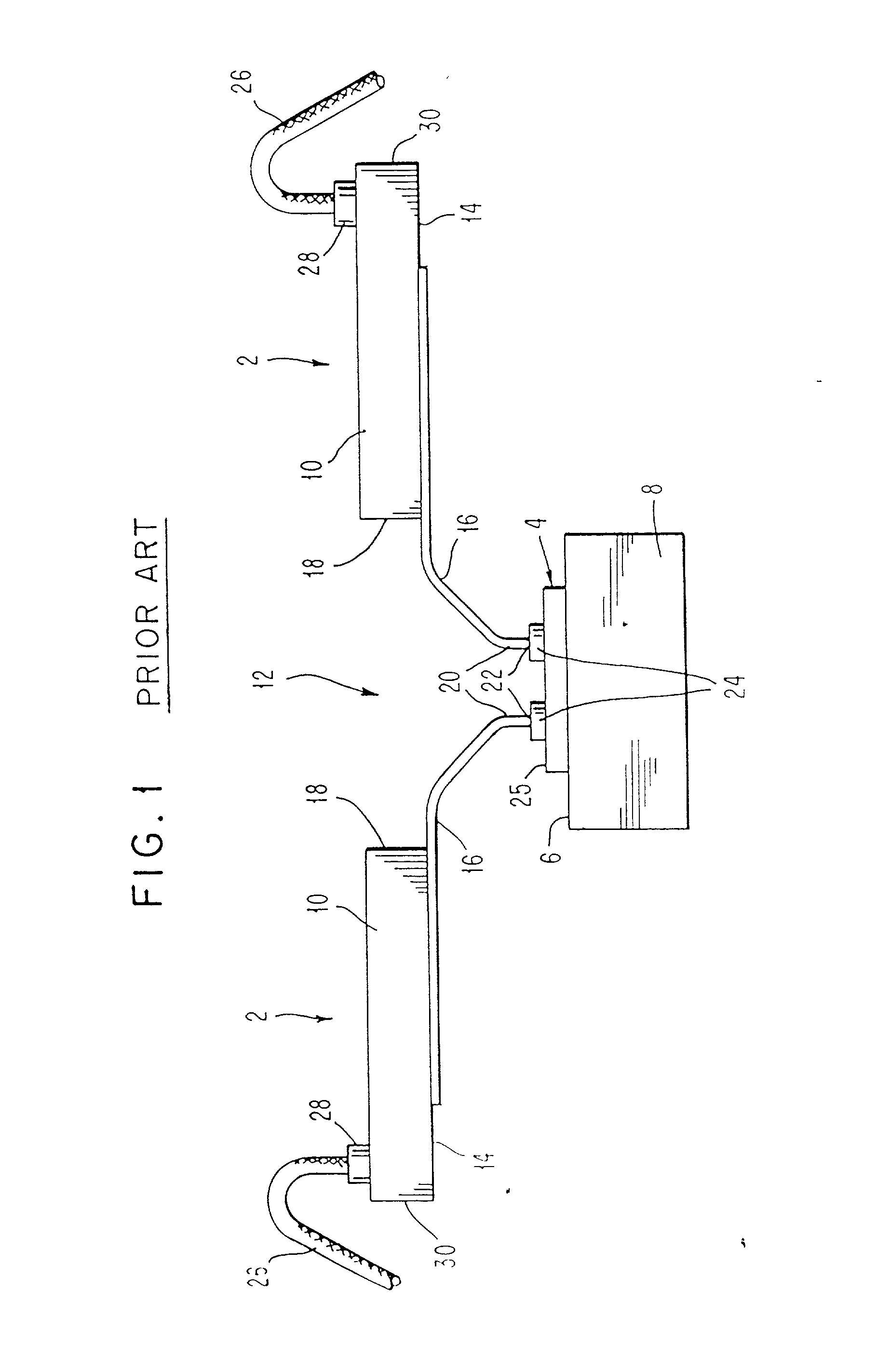

Methods and apparatus for transferring conductive pieces during semiconductor device fabrication

InactiveUS20050232728A1Semiconductor/solid-state device detailsSolid-state devicesSemiconductorSemiconductor device fabrication

In a first aspect, a programmable transfer device is provided for transferring conductive pieces to electrode pads of a target substrate. The programmable transfer device includes (1) a transfer substrate; and (2) a plurality of individually addressable electrodes formed on the transfer substrate. Each electrode is adapted to selectively attract and hold a conductive piece during transfer of the conductive piece to an electrode pad of a target substrate. Numerous other aspects are provided.

Owner:APPLIED MATERIALS INC

Process for disengaging semiconductor die from an adhesive film

Owner:NXP USA INC

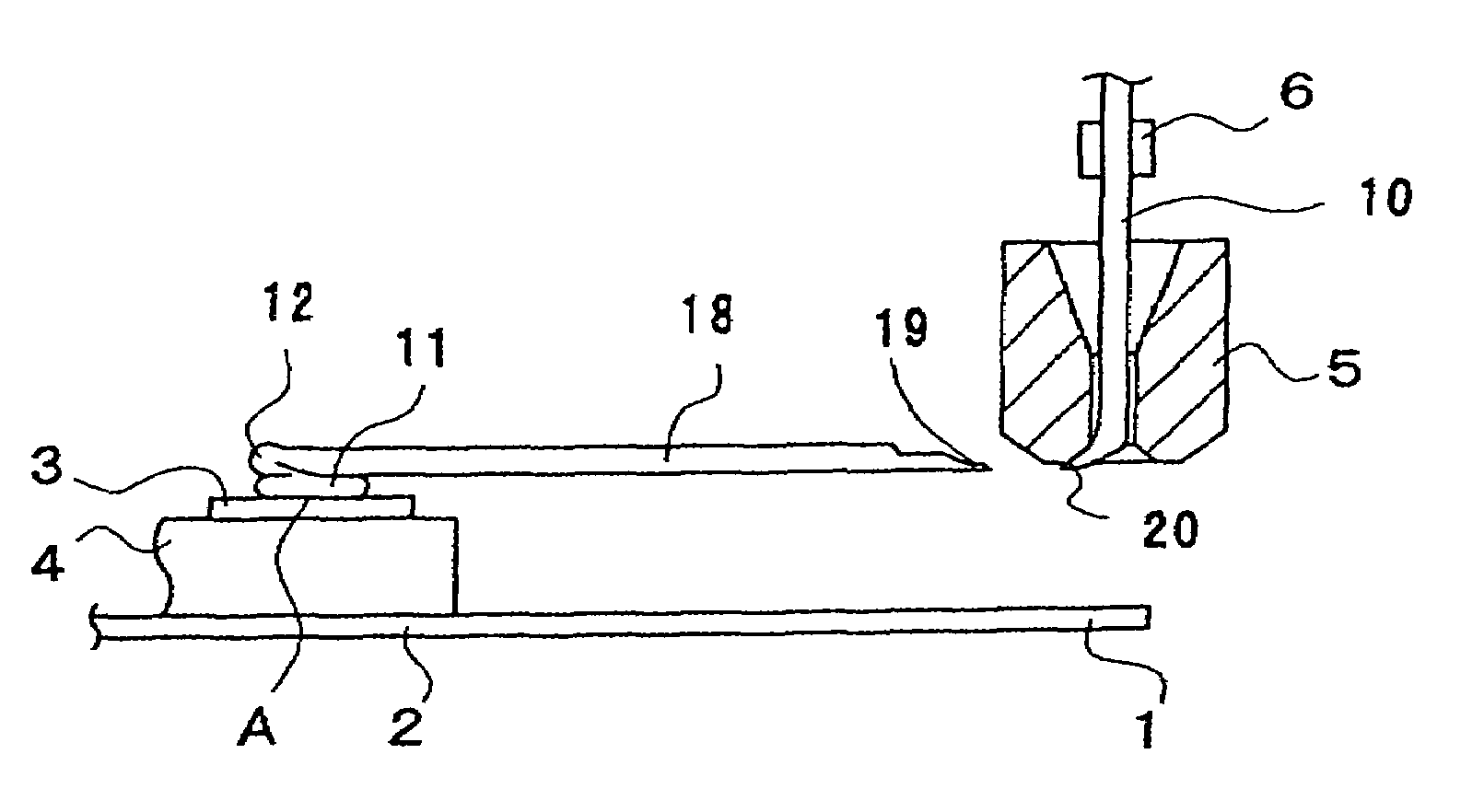

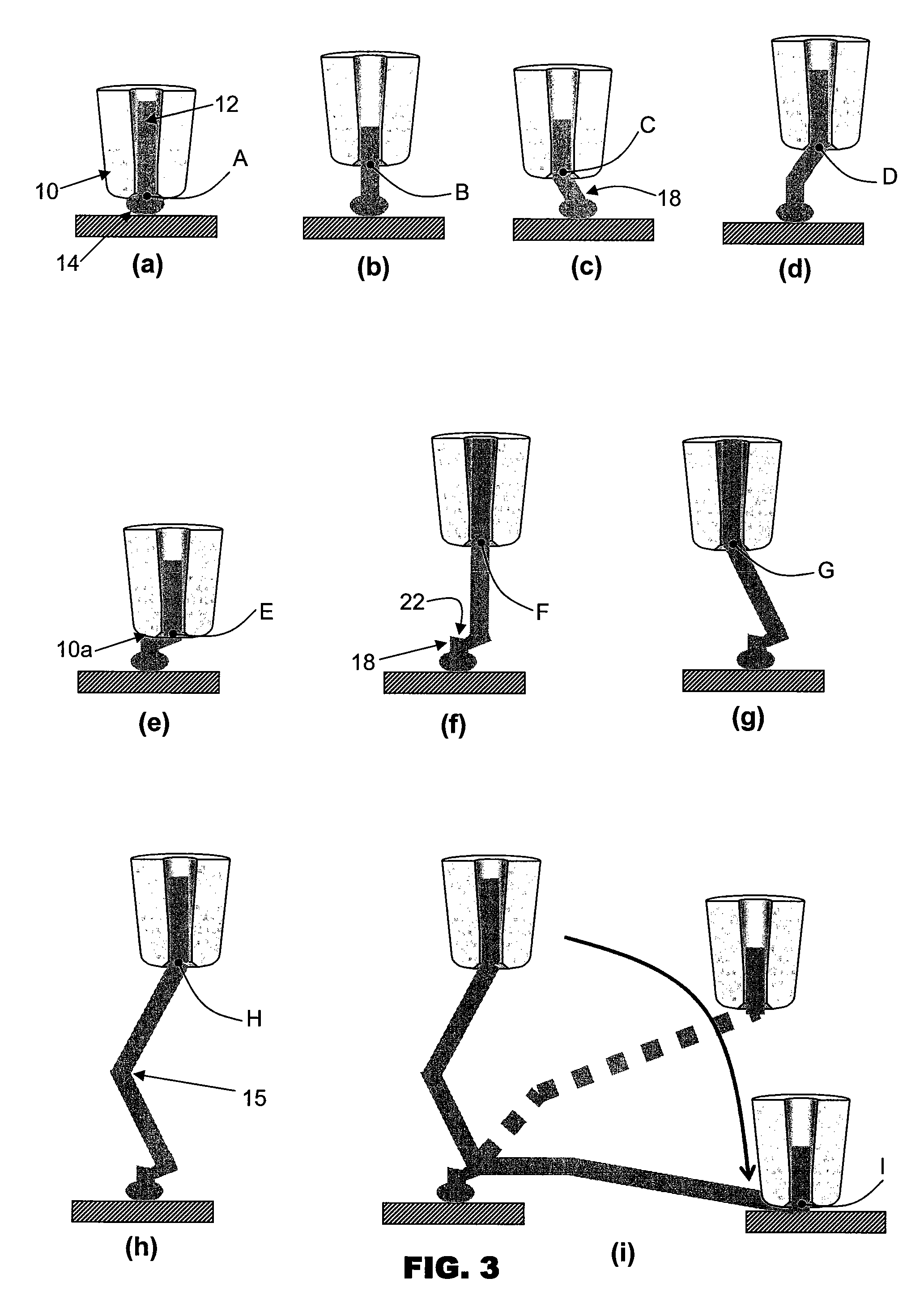

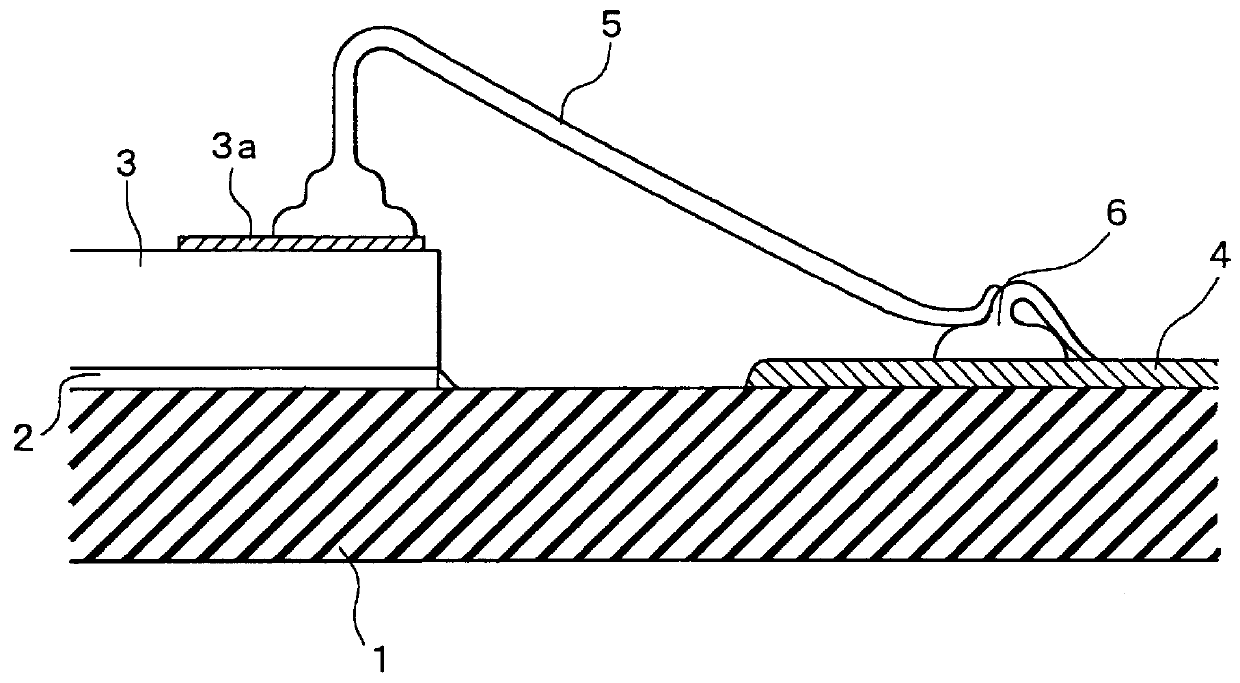

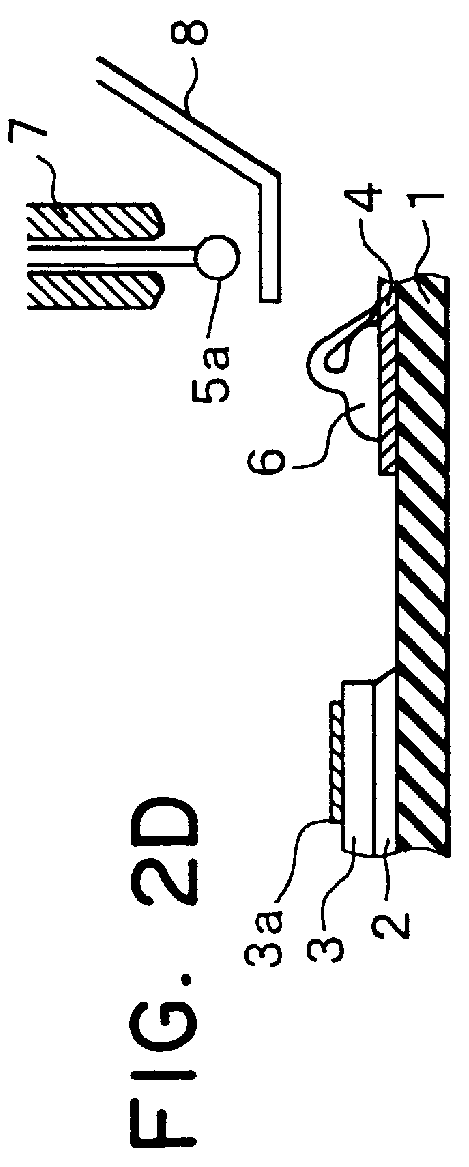

Wire bonding method

InactiveUS7621436B2Inhibit swellingImprove straightnessSolid-state devicesWelding/cutting auxillary devicesEngineeringWire bonding

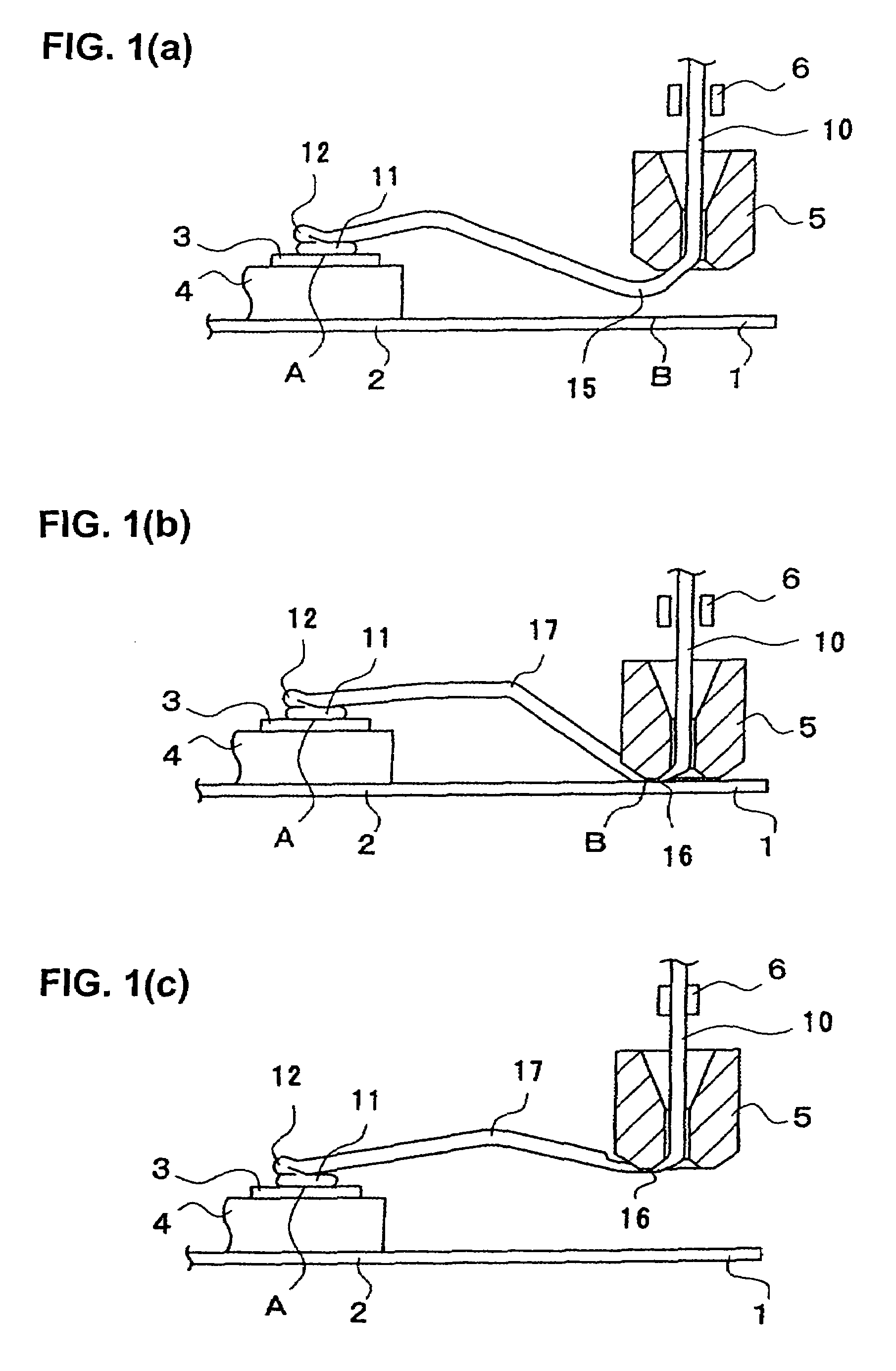

A wire bonding method including the steps of: descending a capillary 5 from above an external lead 1 to press a wire 10 to such an extent that the wire is not completely connected to the external lead 1, thus forming a thin part 16 in the wire; next ascending the capillary 5 and the thin part 16 to substantially the same height as a first bonding point A, then moving the capillary 5 in a direction away from the first bonding point A, thus making a linear wire portion 18 and then cutting the wire at the thin part 16; then connecting the end 19 (thin part) of the linear wire portion 18 and the wire tip end 20 at the lower end of the capillary 5 are connected to the external lead 1; and then separating the wire tip end 20 from the external lead 1.

Owner:SHINKAWA CO LTD

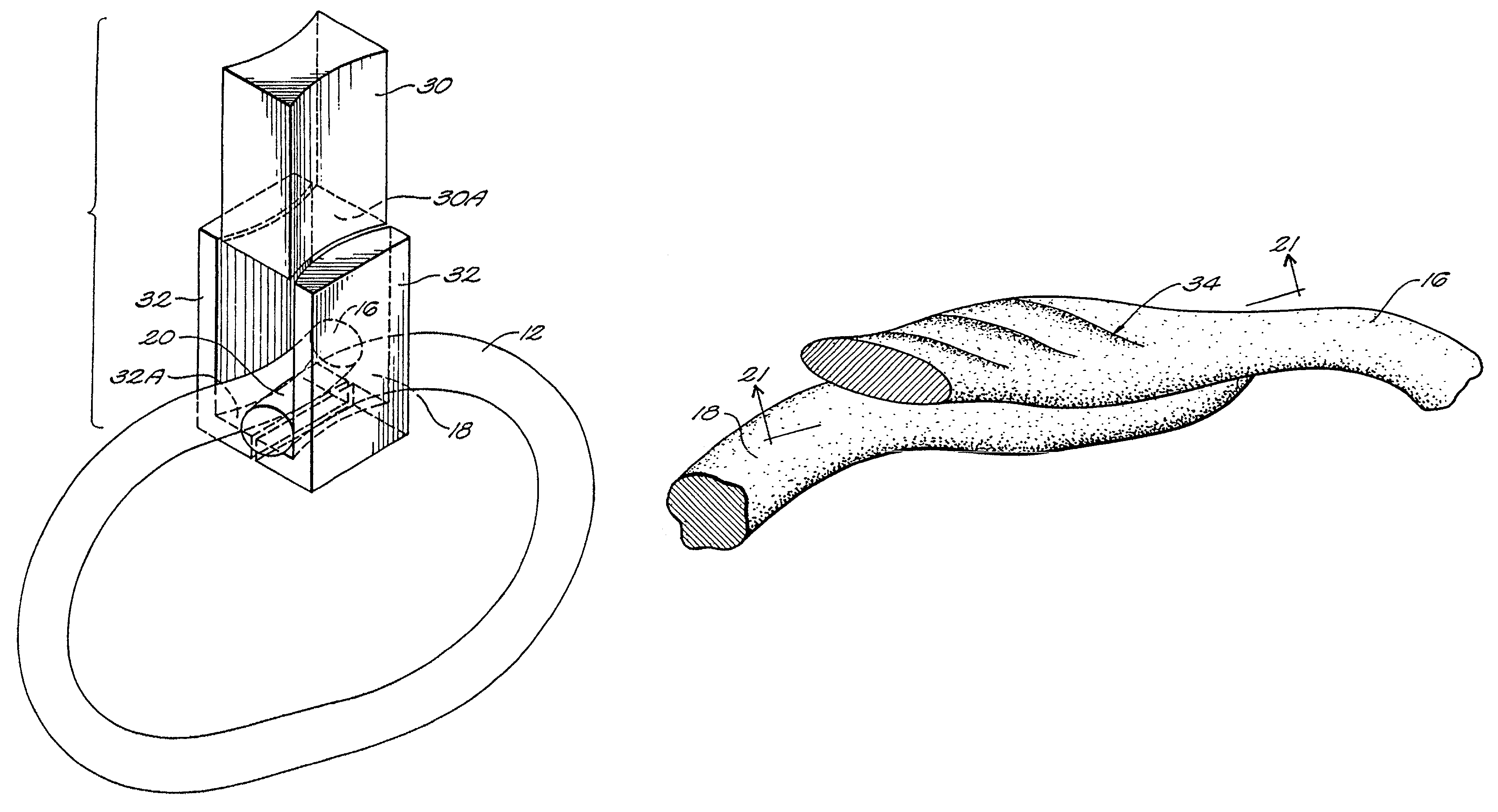

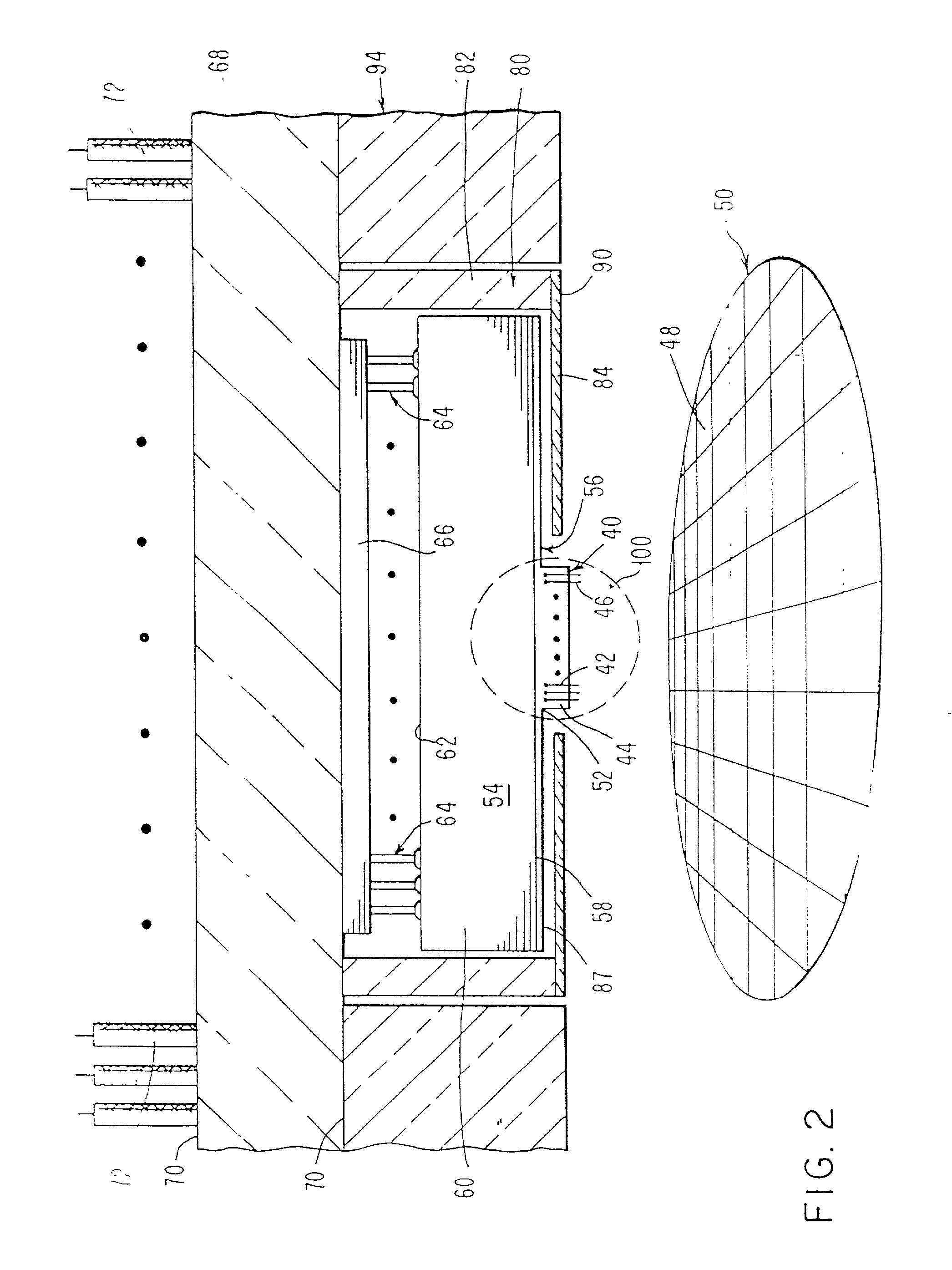

High density integrated circuit apparatus, test probe and methods of use thereof

InactiveUS20070271781A9High performance functional testingHigh-temperature burnElectrically conductive connectionsElectronic circuit testingElastomerElectricity

The present invention is directed to a high density test probe which provides a means for testing a high density and high performance integrated circuits in wafer form or as discrete chips. The test probe is formed from a dense array of elongated electrical conductors which are embedded in an compliant or high modulus elastomeric material. A standard packaging substrate, such as a ceramic integrated circuit chip packaging substrate is used to provide a space transformer. Wires are bonded to an array of contact pads on the surface of the space transformer. The space transformer formed from a multilayer integrated circuit chip packaging substrate. The wires are as dense as the contact location array. A mold is disposed surrounding the array of outwardly projecting wires. A liquid elastomer is disposed ion the mold to fill the spaces between the wires. The elastomer is cured and the mold is removed, leaving an array of wires disposed in the elastomer and in electrical contact with the space transformer The space transformer can have an array of pins which are on the opposite surface of the space transformer opposite to that on which the elongated conductors are bonded. The pins are inserted into a socket on a second space transformer, such as a printed circuit board to form a probe assembly. Alternatively, an interposer electrical connector can be disposed between the first and second space transformer.

Owner:GLOBALFOUNDRIES INC

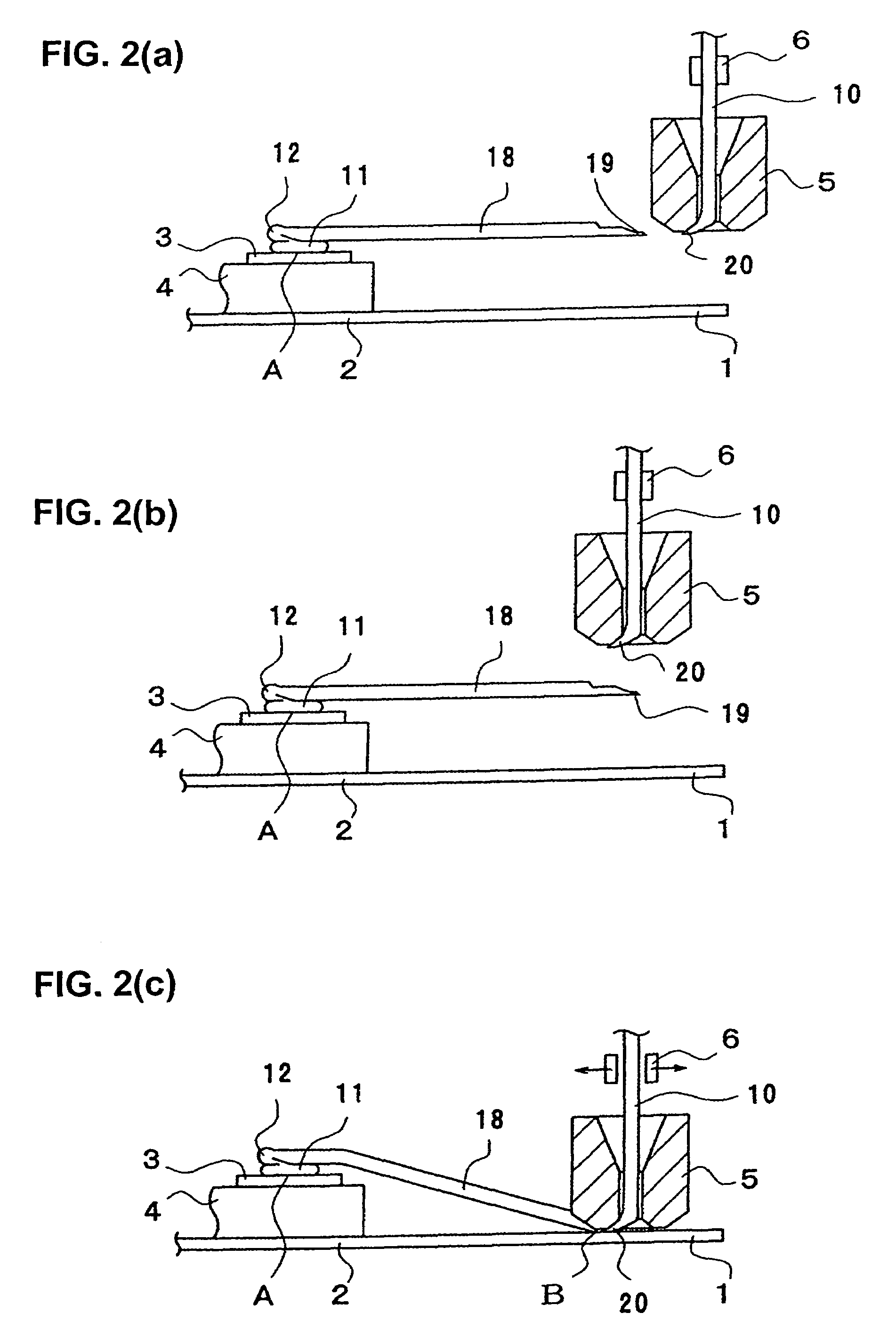

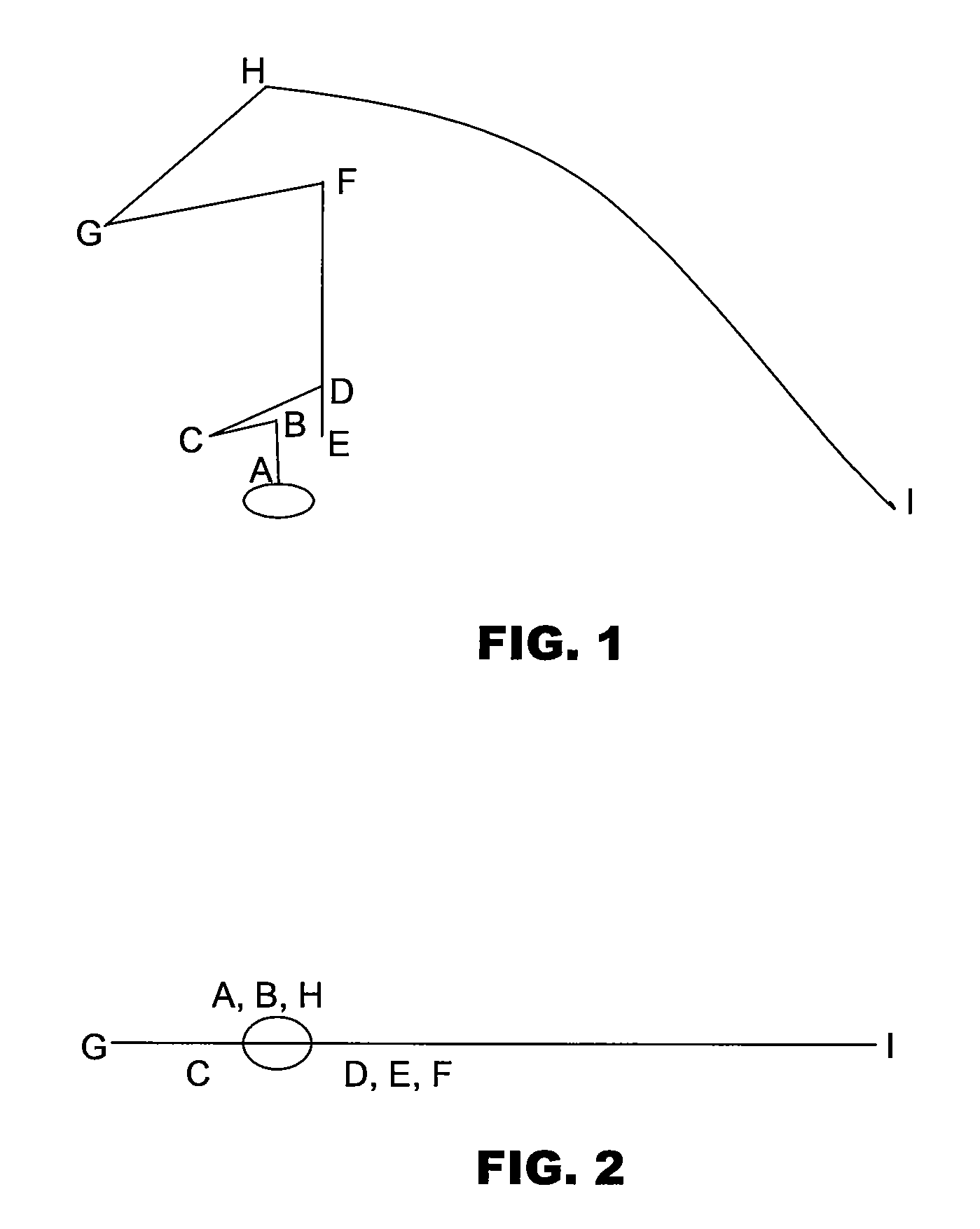

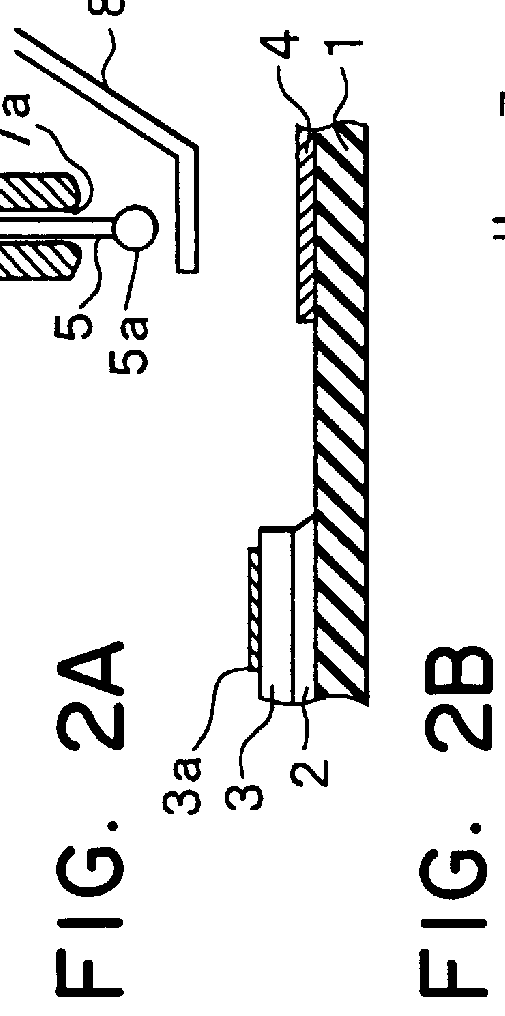

Wire bonding method for forming low-loop profiles

ActiveUS7780064B2Reduce the overall heightAvoid disadvantagesCooking-vessel materialsSemiconductor/solid-state device detailsLead bondingEngineering

Owner:ASM TECH SINGAPORE PTE LTD

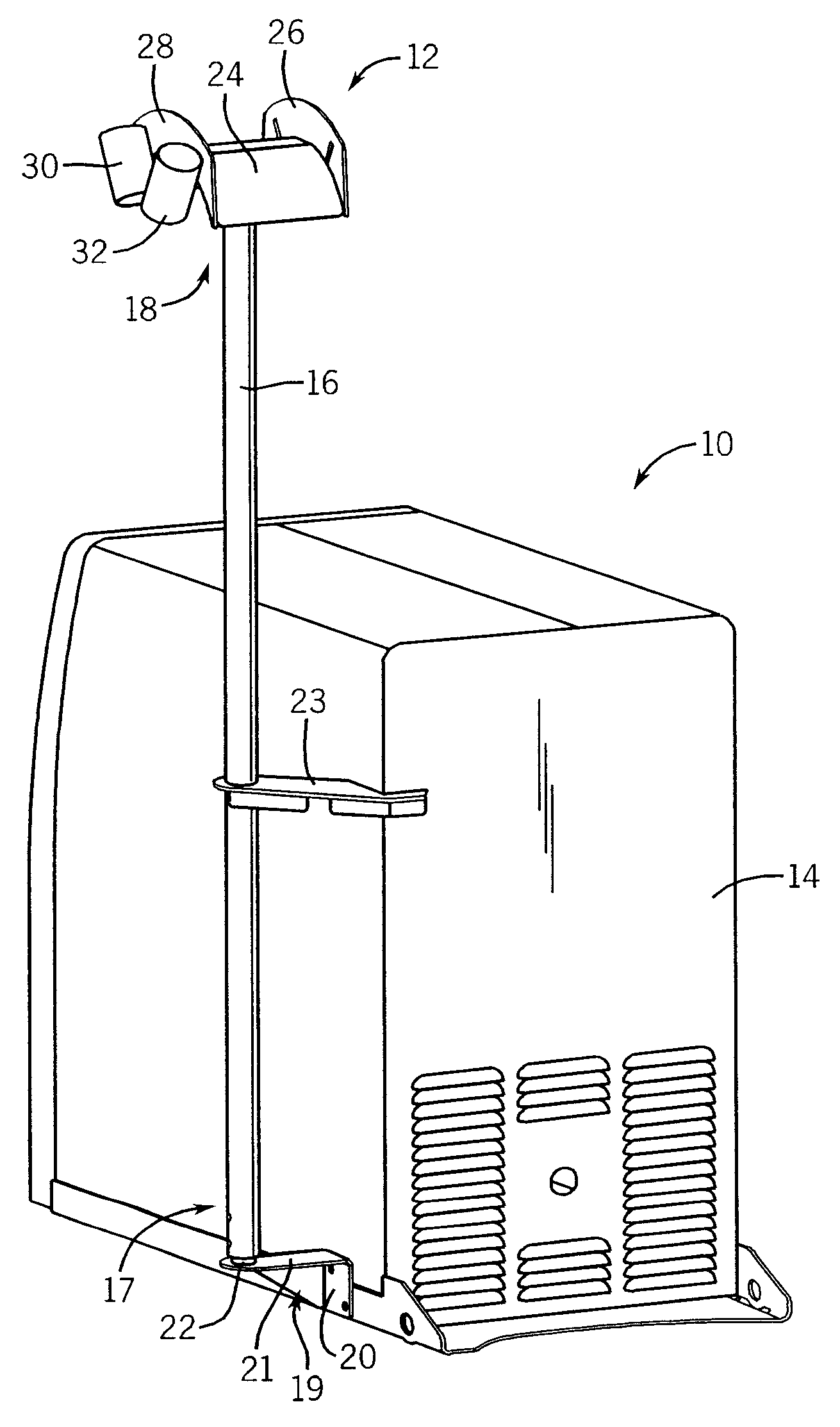

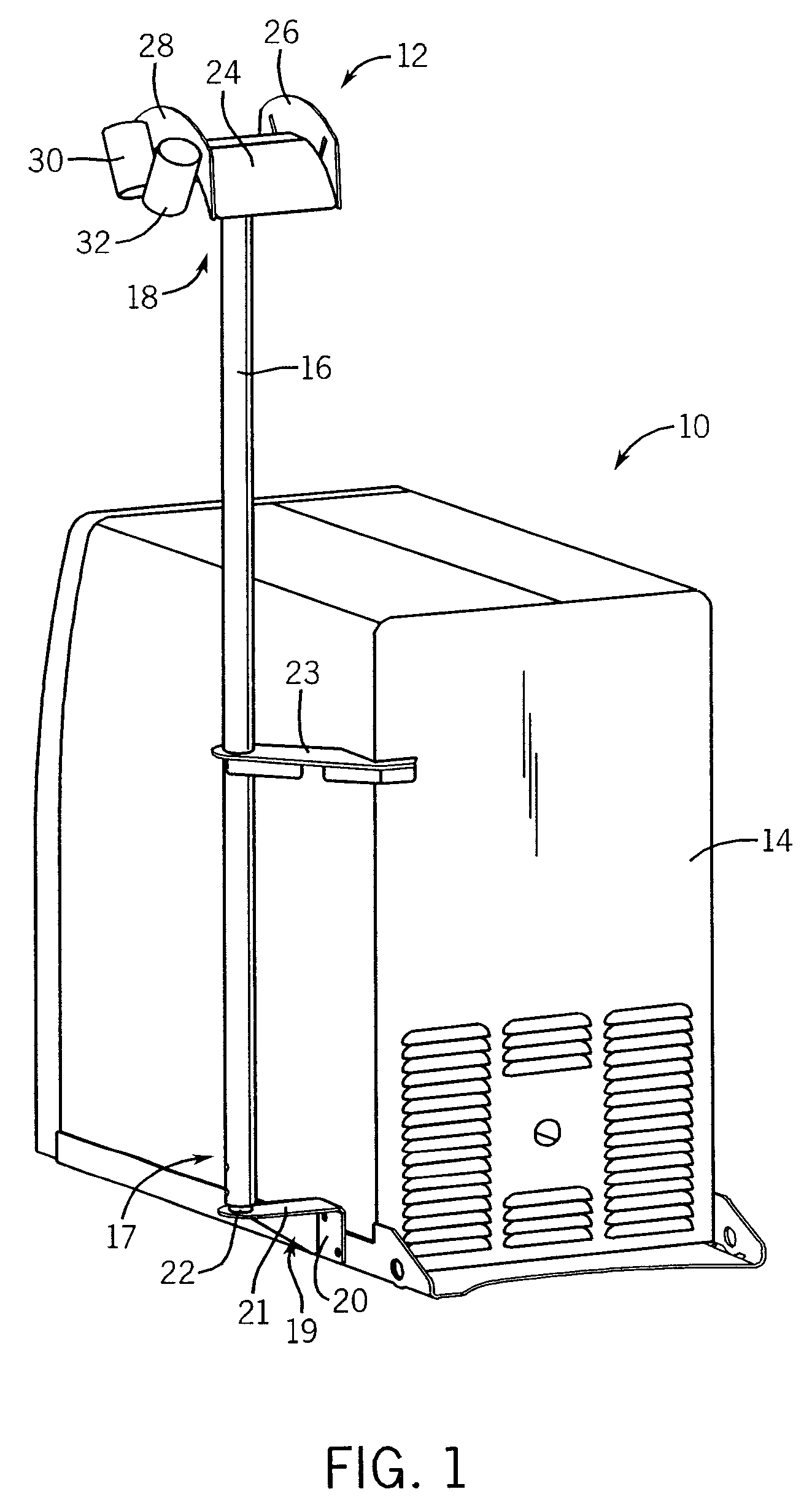

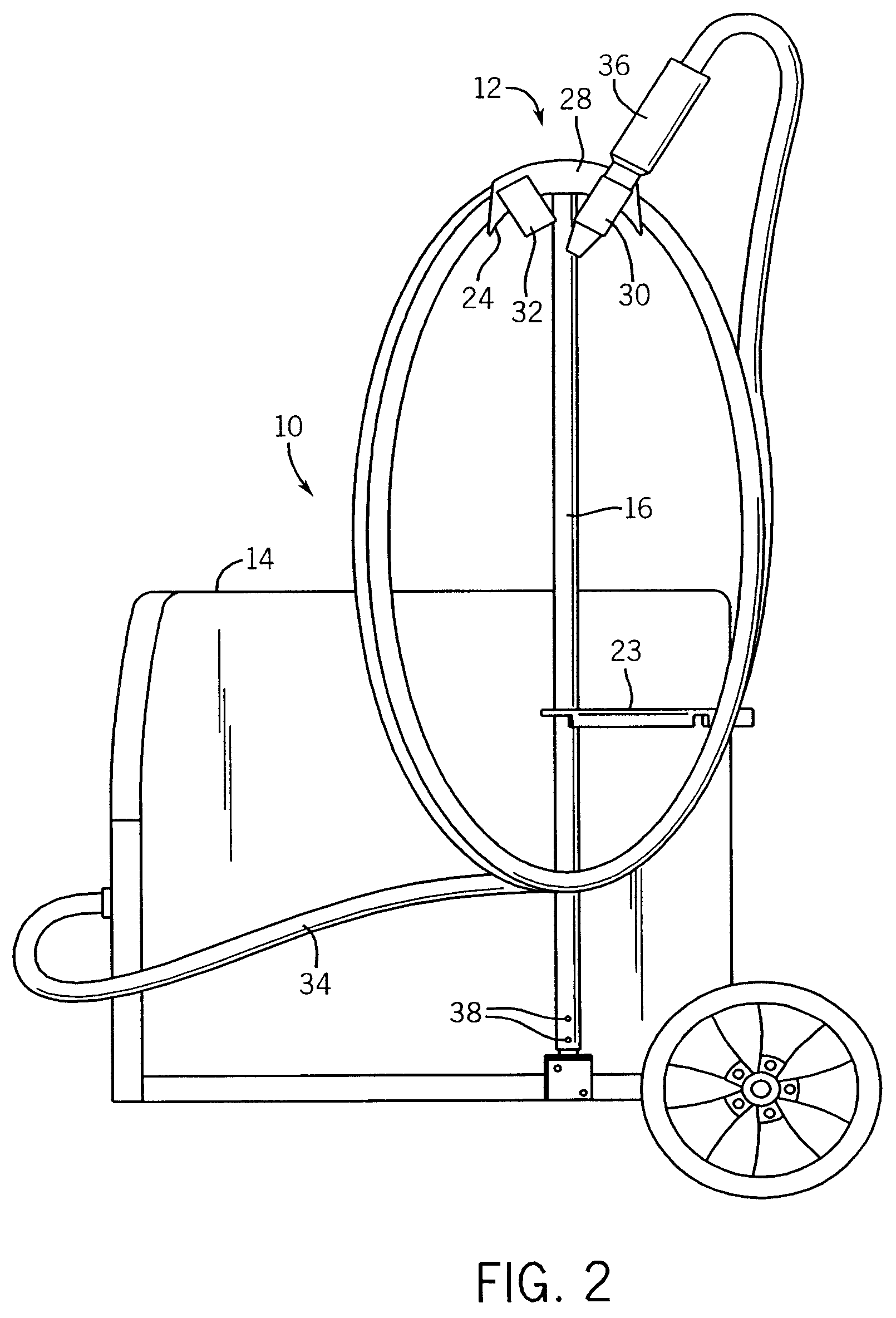

Elevated welding-type cable support system

ActiveUS20080135533A1Easy to storeWeld torches cleaningWelding/cutting auxillary devicesSupporting systemEngineering

A cable management system for a welding-type system includes a support column extending in a first direction from a first end supported by a welding-type device to a second end arranged above the welding-type device. The cable management system also includes a cable support arranged on the second end of the support column that extends in a second direction substantially transverse to the first direction. Accordingly, a portion of the cable support extends away from the welding-type device to allow a cable supported thereon to extend below the cable support and proximate to the welding-type device.

Owner:ILLINOIS TOOL WORKS INC

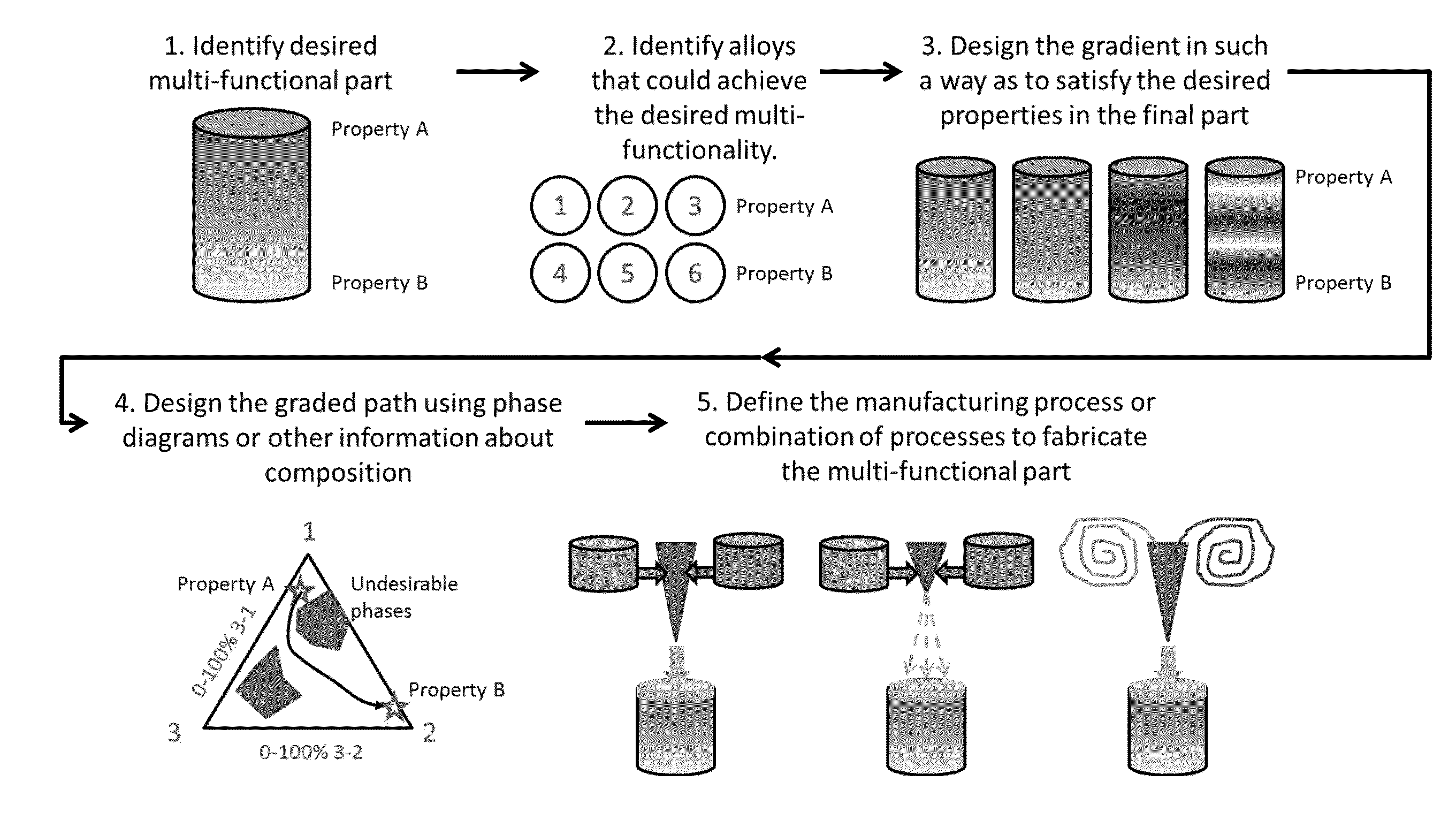

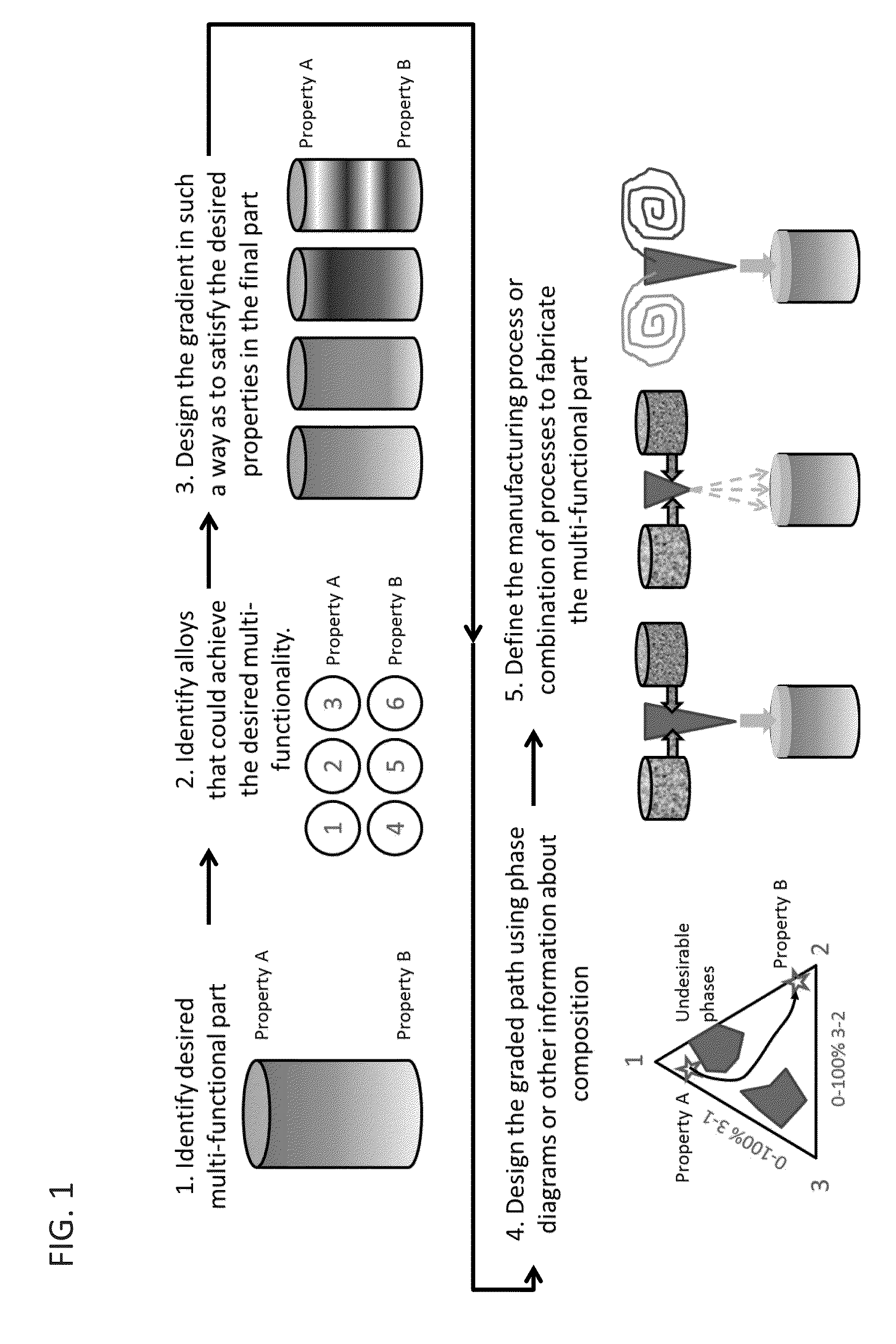

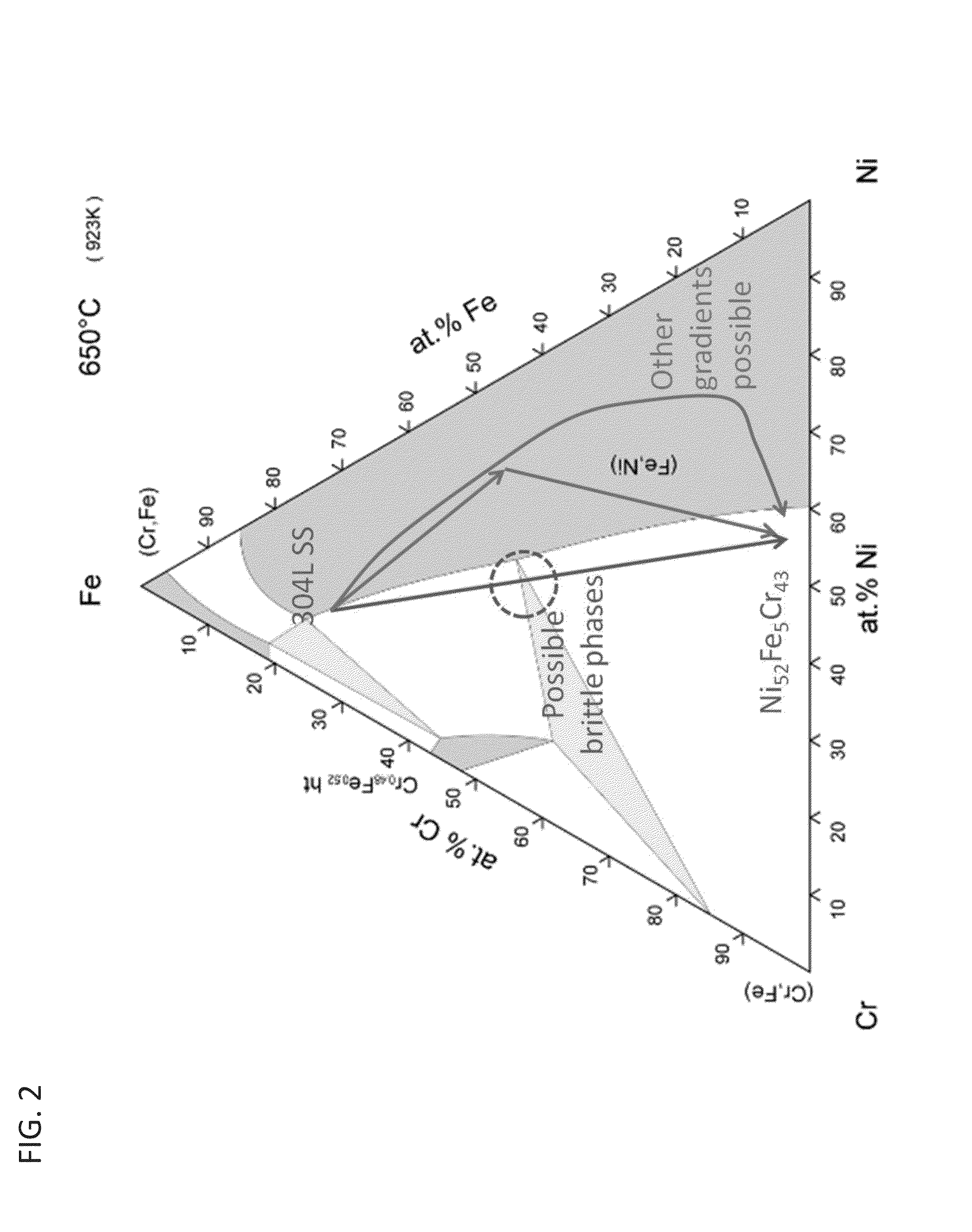

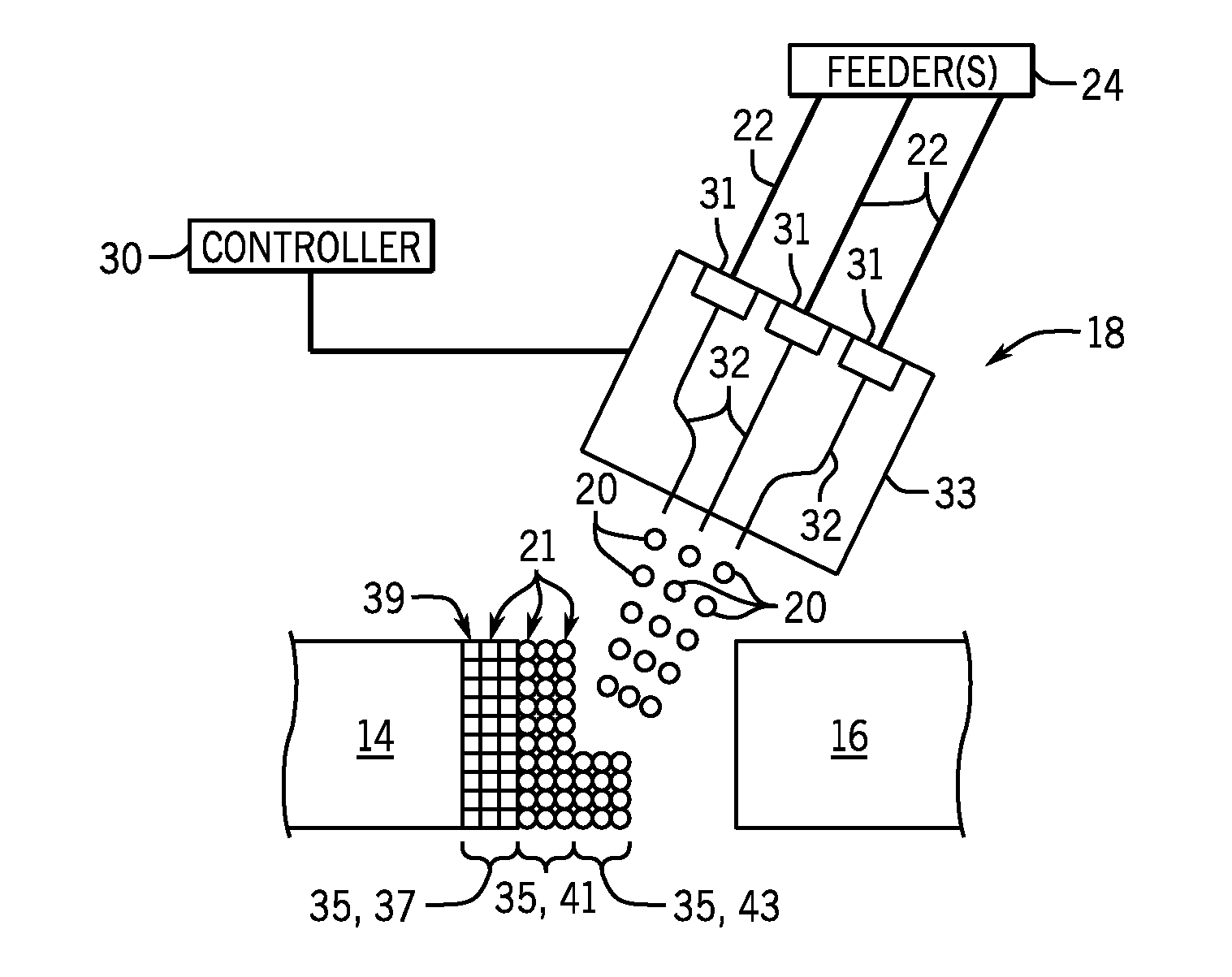

Methods for fabricating gradient alloy articles with multi-functional properties

ActiveUS20150044084A1High speedSufficient cooling rateAdditive manufacturingMolten spray coatingMetal alloyGradient material

Systems and methods for fabricating multi-functional articles comprised of additively formed gradient materials are provided. The fabrication of multi-functional articles using the additive deposition of gradient alloys represents a paradigm shift from the traditional way that metal alloys and metal / metal alloy parts are fabricated. Since a gradient alloy that transitions from one metal to a different metal cannot be fabricated through any conventional metallurgy techniques, the technique presents many applications. Moreover, the embodiments described identify a broad range of properties and applications.

Owner:CALIFORNIA INST OF TECH

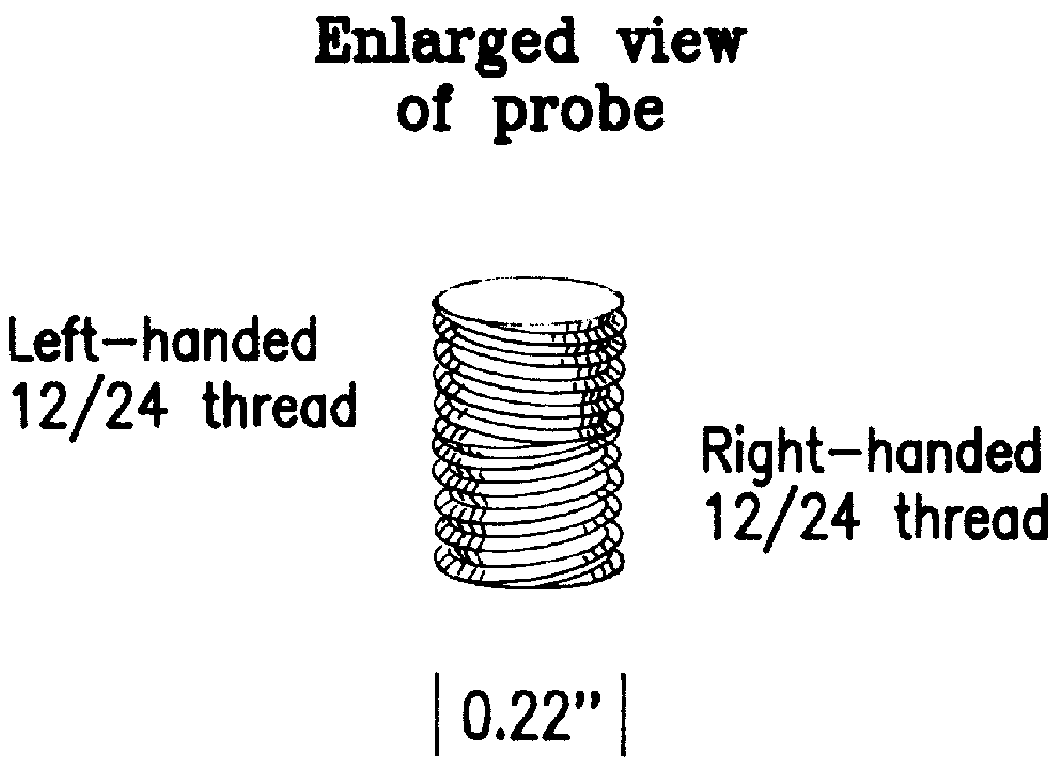

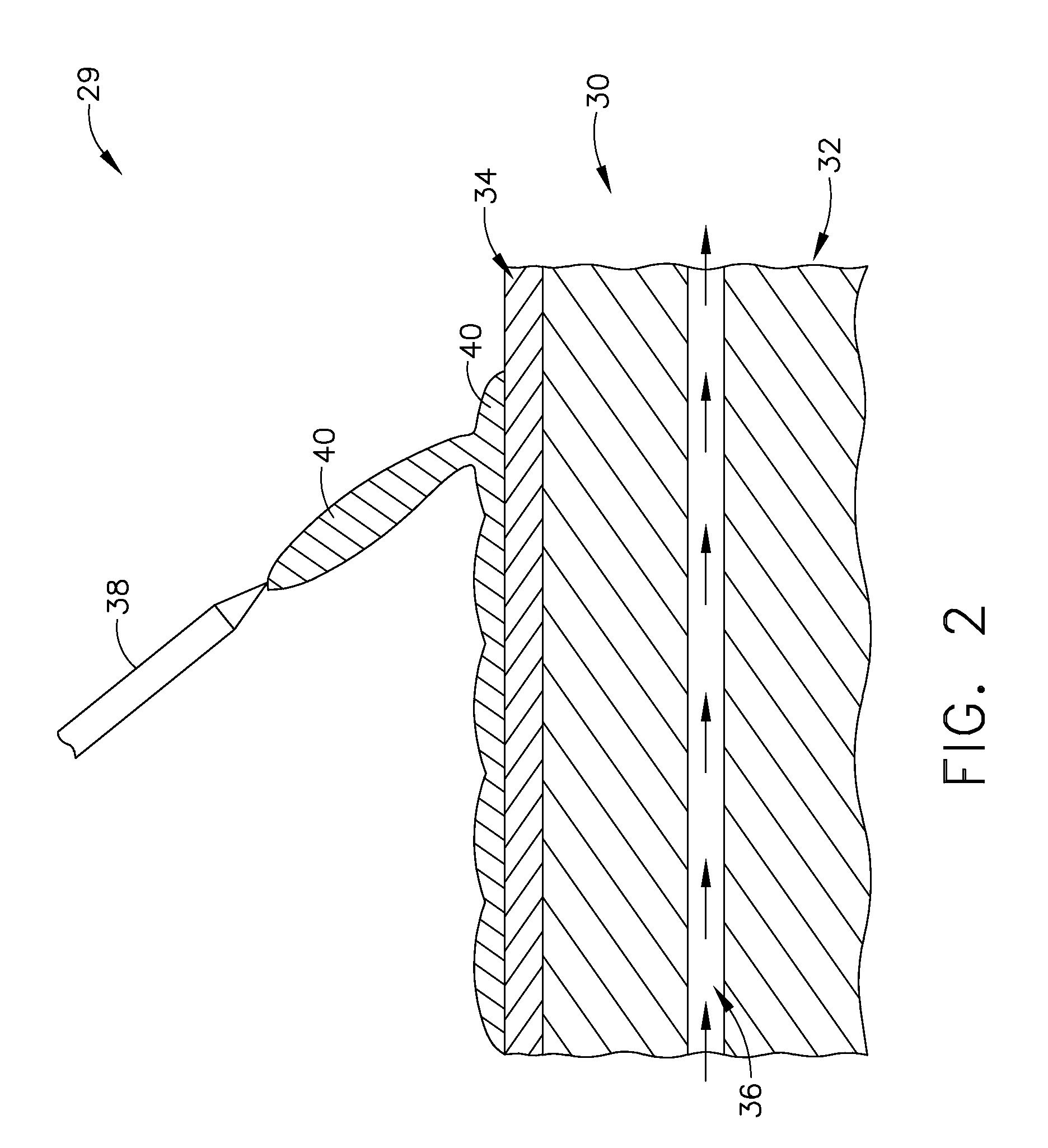

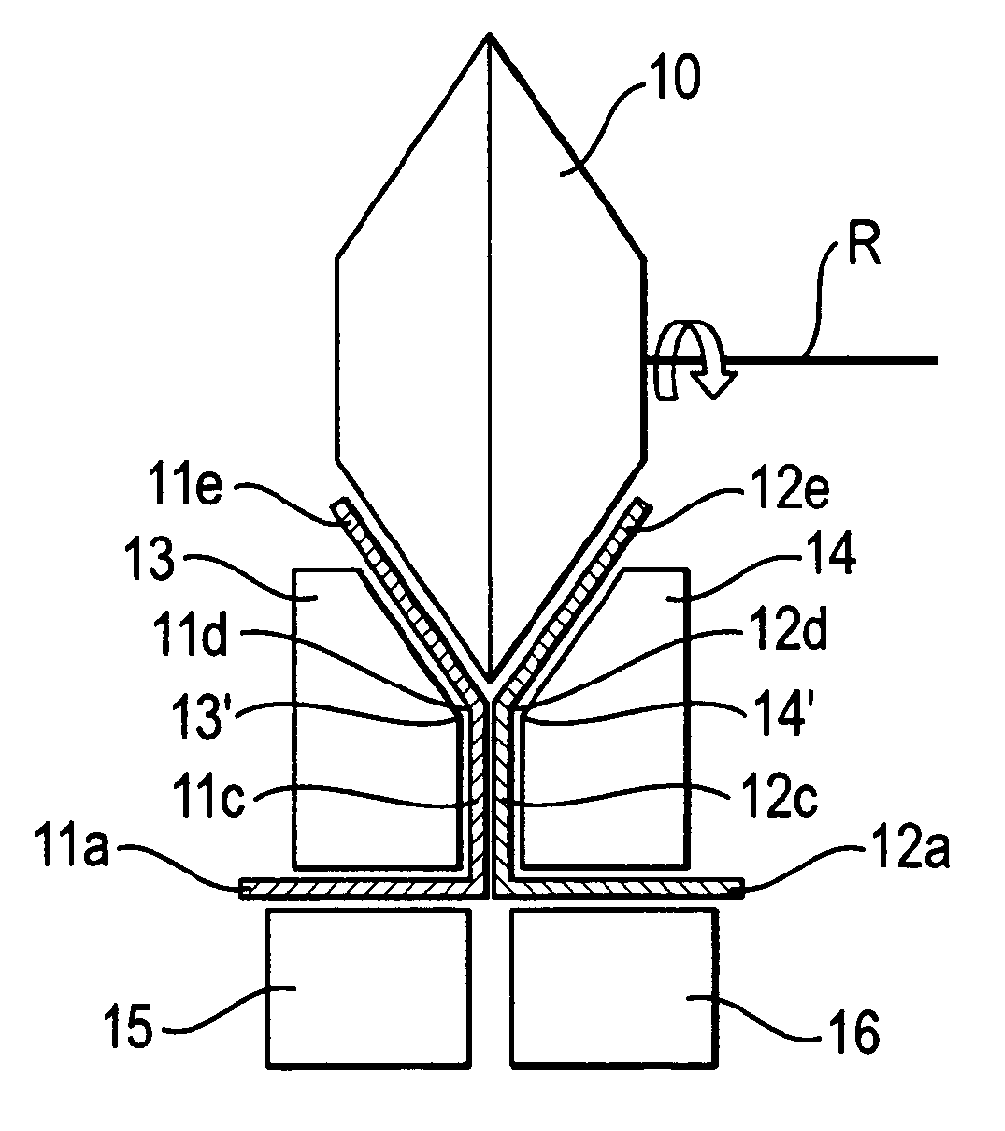

Enantiomorphic friction-stir welding probe

InactiveUS6029879AHigh strengthImproved friction-stirWelding/cutting auxillary devicesSemiconductor/solid-state device manufacturingShoulder regionEngineering

A friction-stir welding probe tip is disclosed which has right-handed threads on one portion of the probe and left-handed threads on another portion of the probe such that weld material is drawn to the middle of the weld as the friction-stir welding probe is rotated and passed along the joint region of the pieces to be joined. This probe tip is also fitted with a shoulder region for gripping by a rotation means.

Owner:C INNOVATIONS

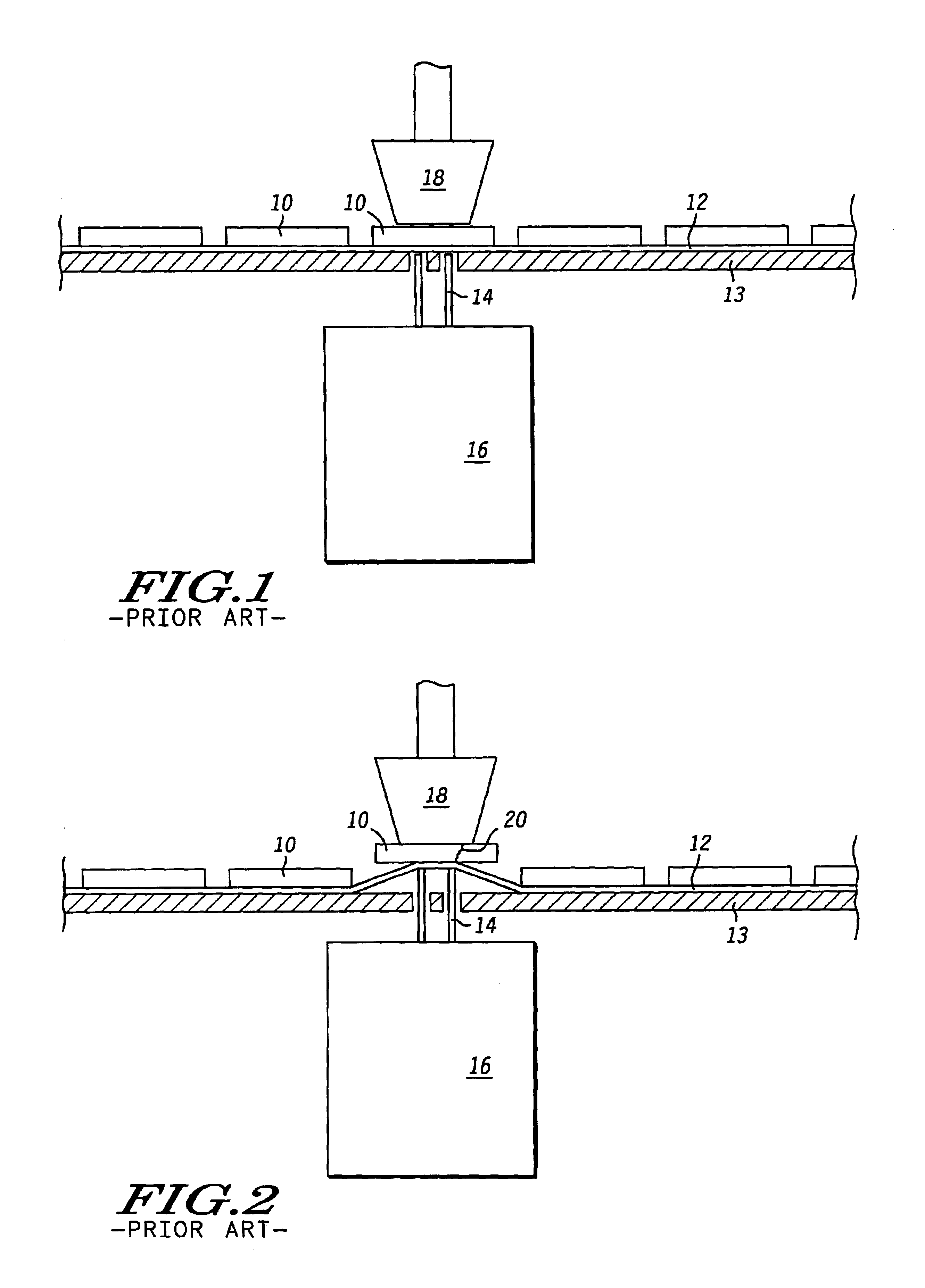

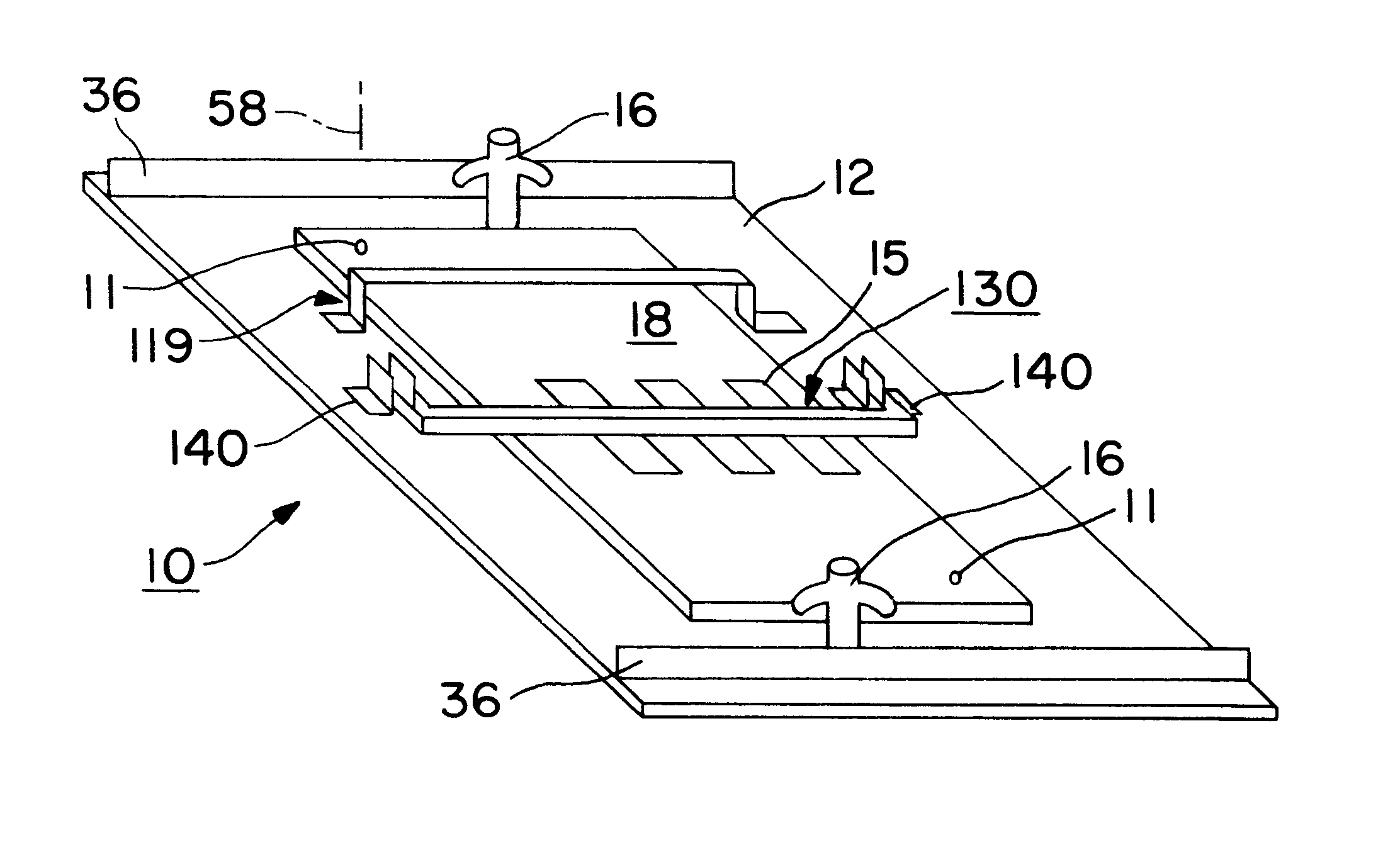

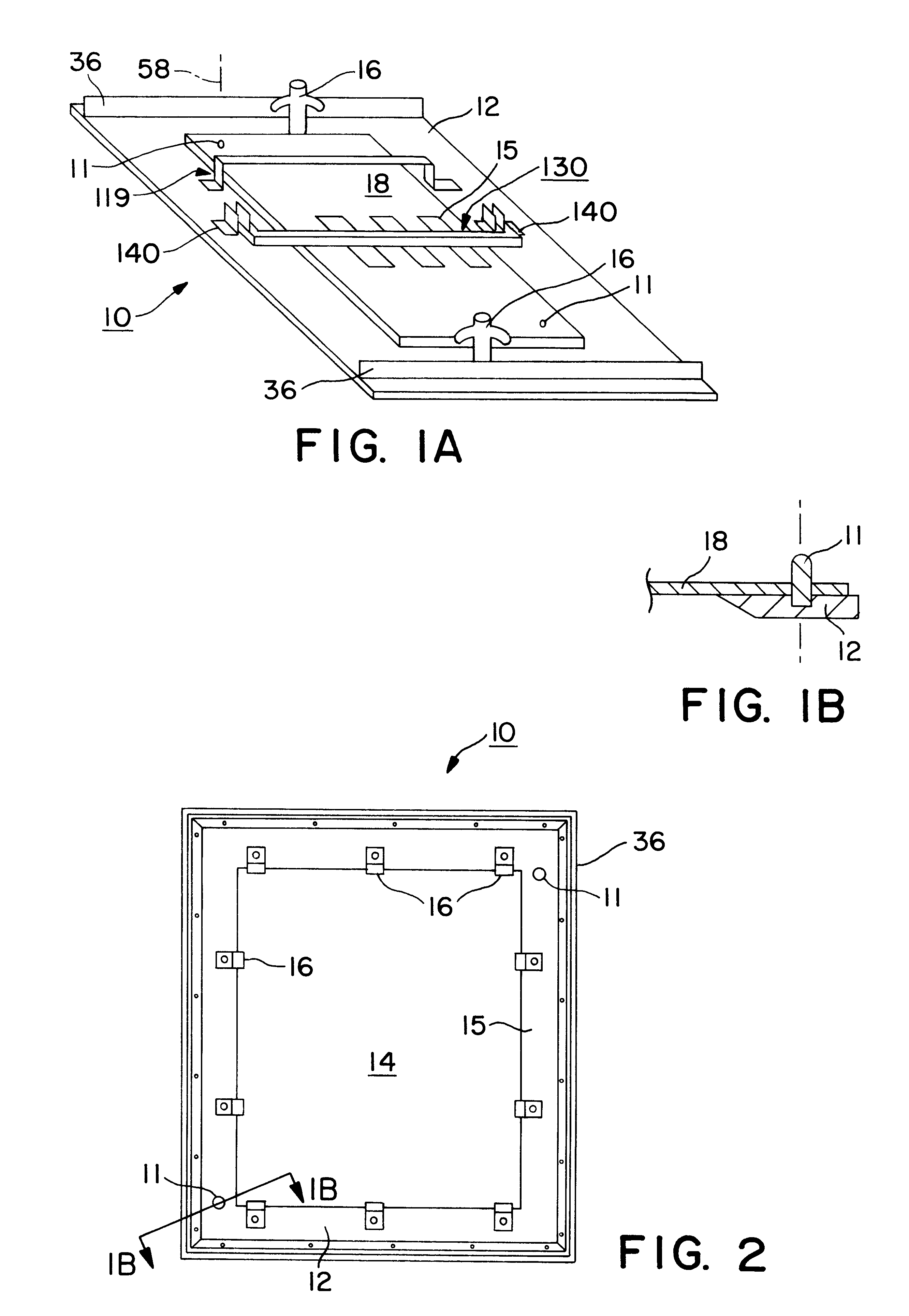

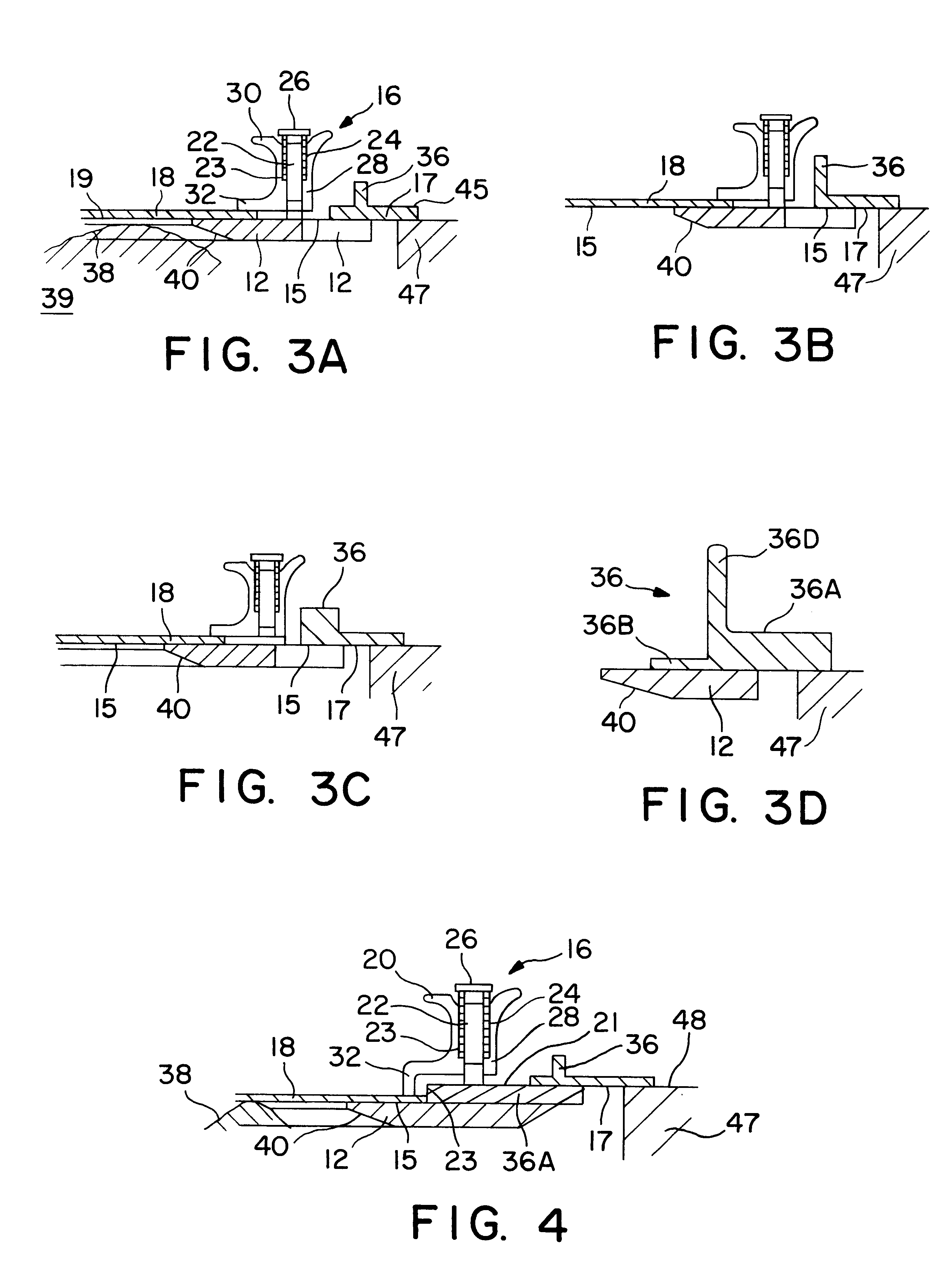

Wave soldering fixture

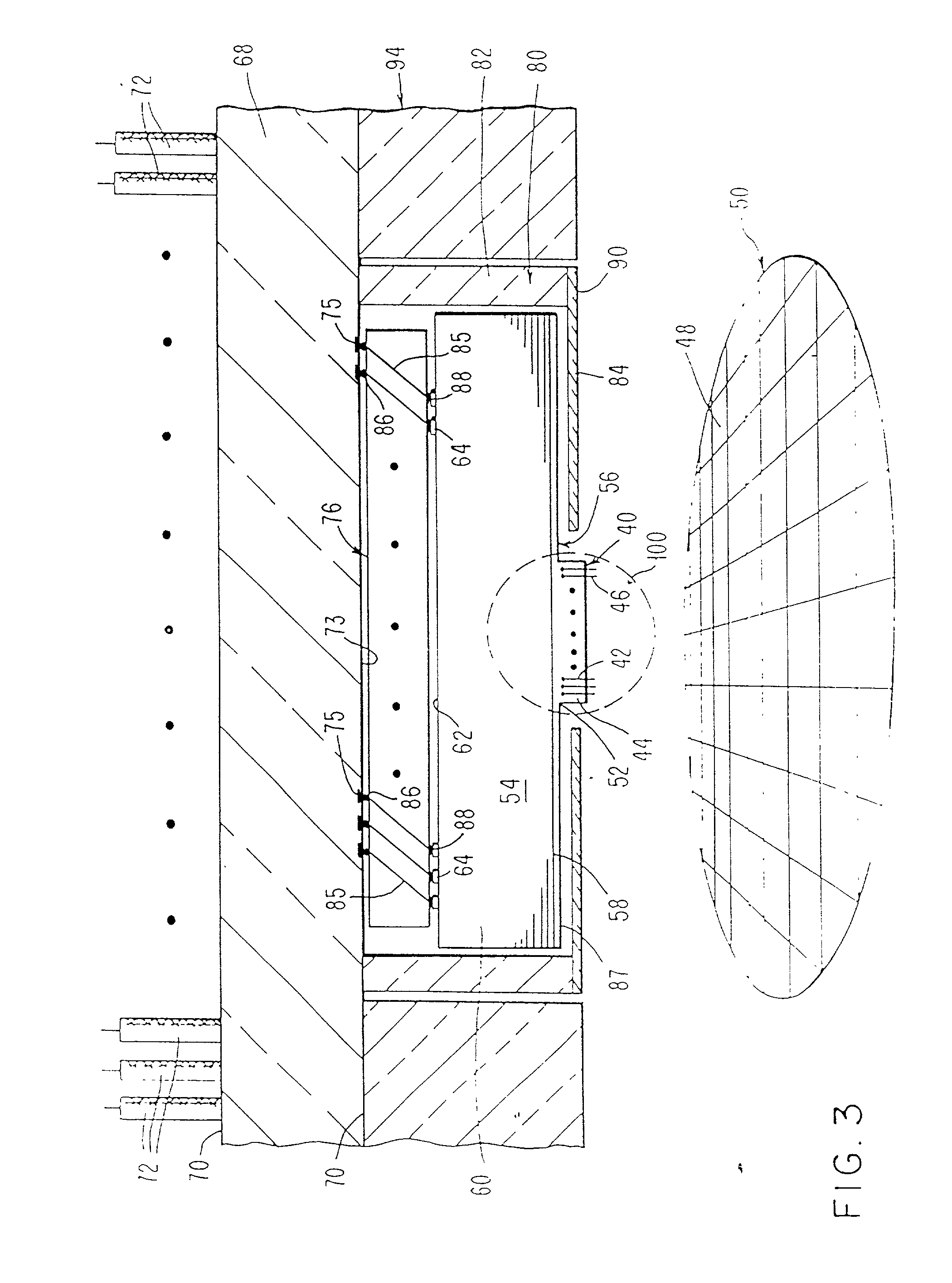

InactiveUS6237832B1Minimizing conductionMinimizing warpage/bowingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAluminum extrusion

An apparatus used in a process for supporting a printed circuit board during a wave soldering operation including a frame with a frame opening in which a surface of the frame supports the board and also serves as a reference surface for vertically positioning the board above the solder pool. The board is secured against the reference surface with spring loaded clamps. Stiffeners preferably being an aluminum extrusion having a Tee or angle cross section is mounted along the outside edge of the reference surface of the frame and has a second reference surface facing in a direction opposite the reference surface of the frame. The second reference surface on the extrusion is accessible for support by a slide rail so that the height of the reference surface of the frame above the surface of the pool is independent of the thickness of the board or frame. A board support bar for minimizing warpage of the board from heat is disclosed as well as a hold down bar that secures components on the board so that they do not float away when contacted by the solder wave.

Owner:CHUNG HENRY

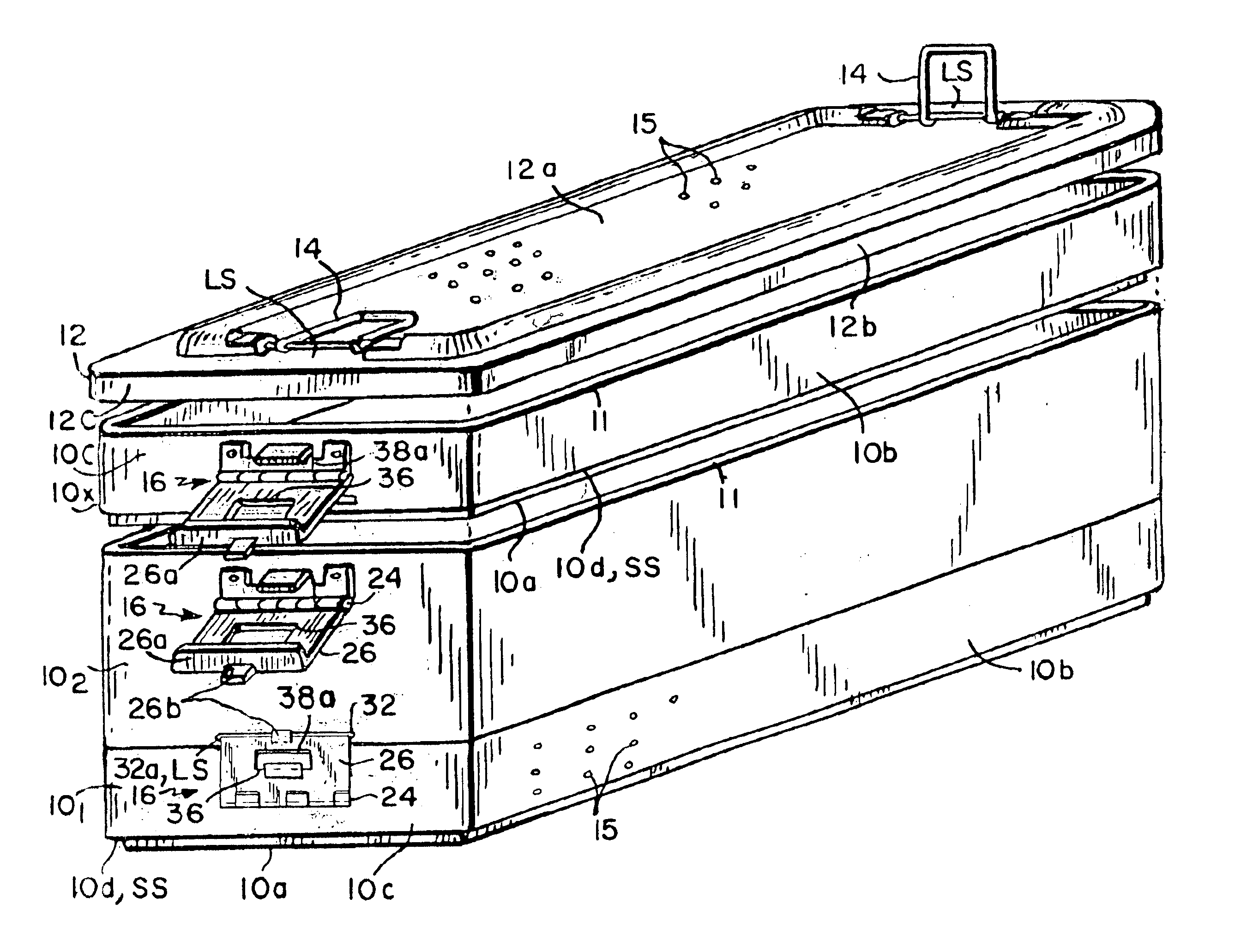

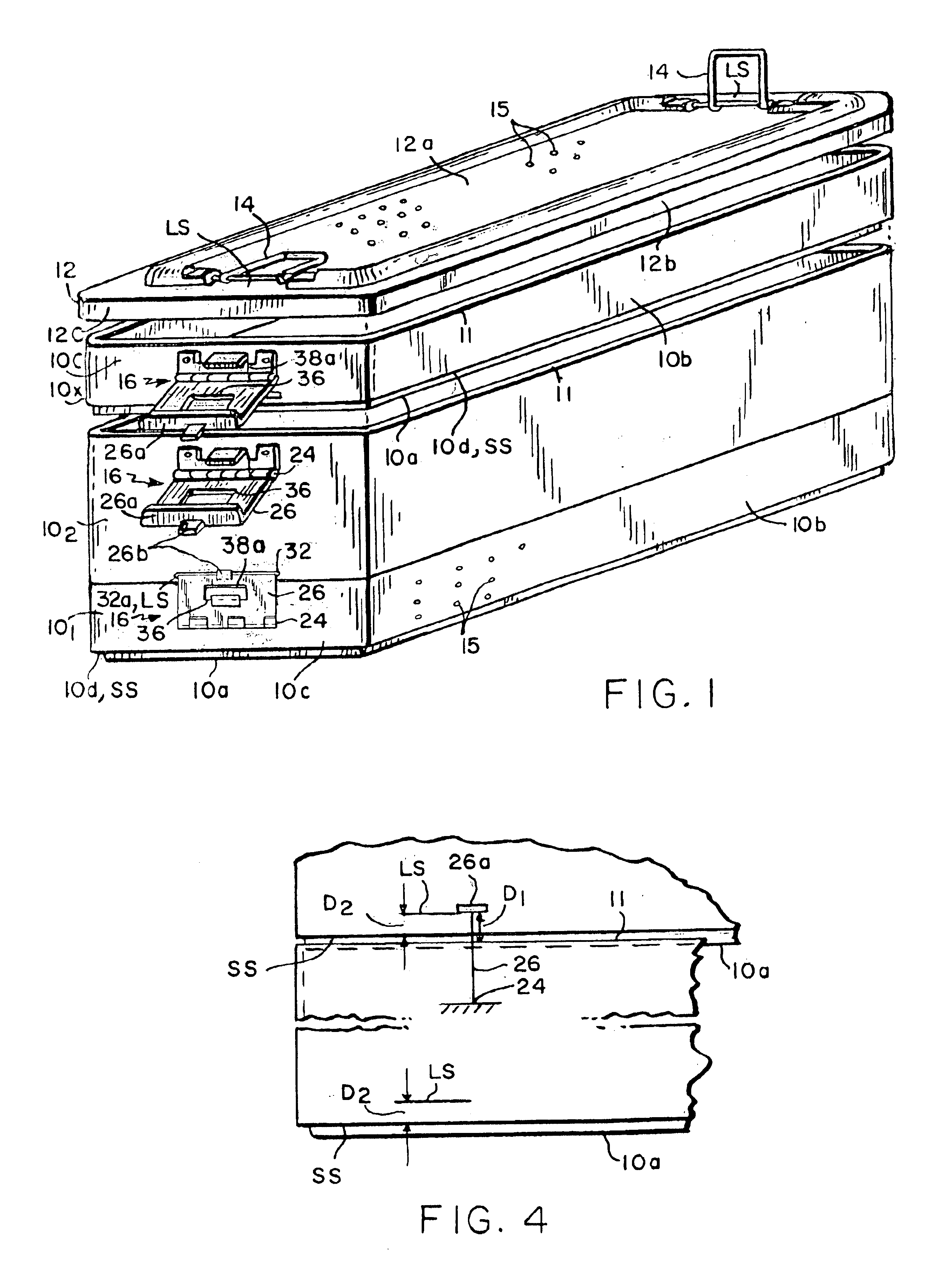

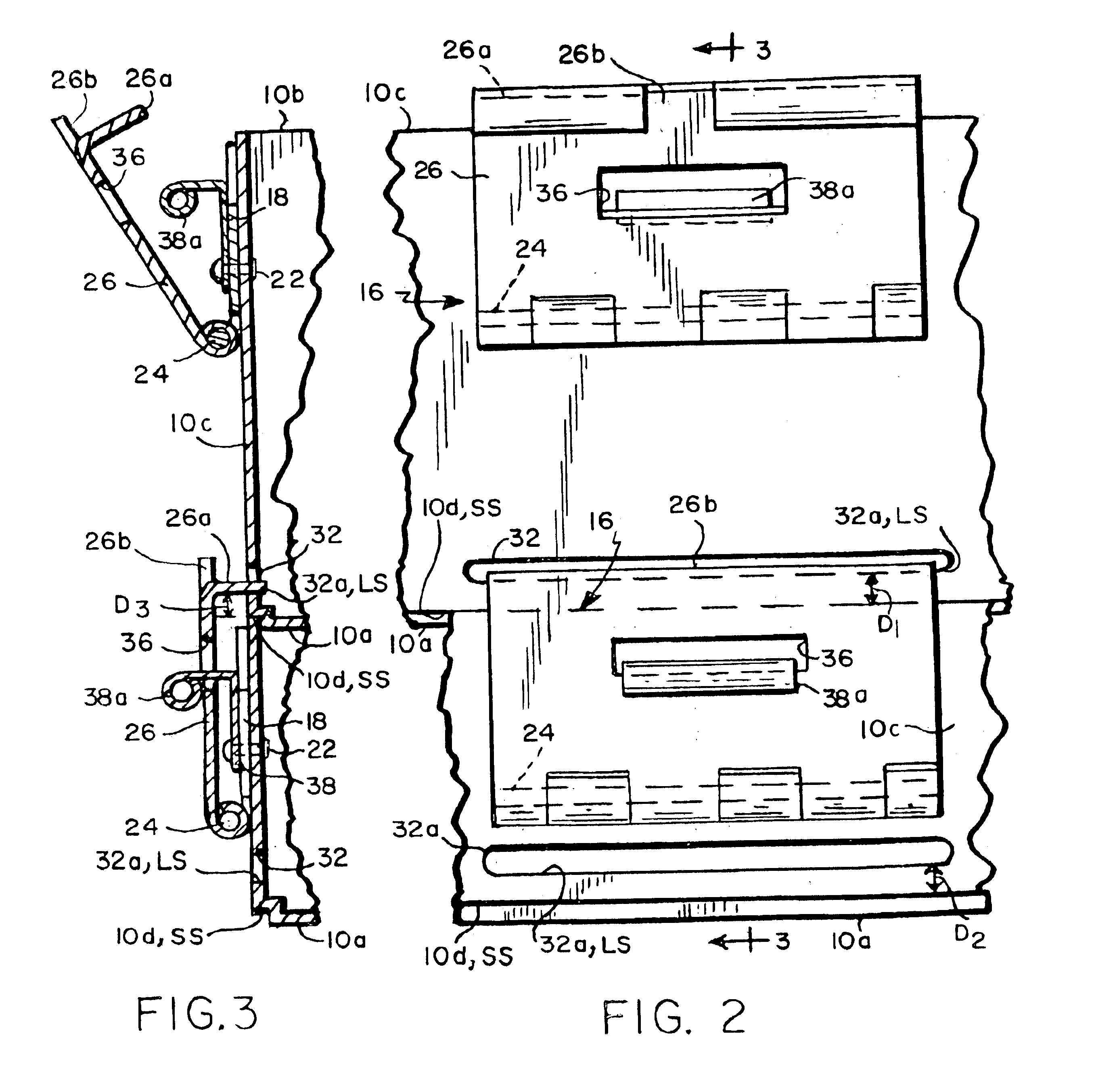

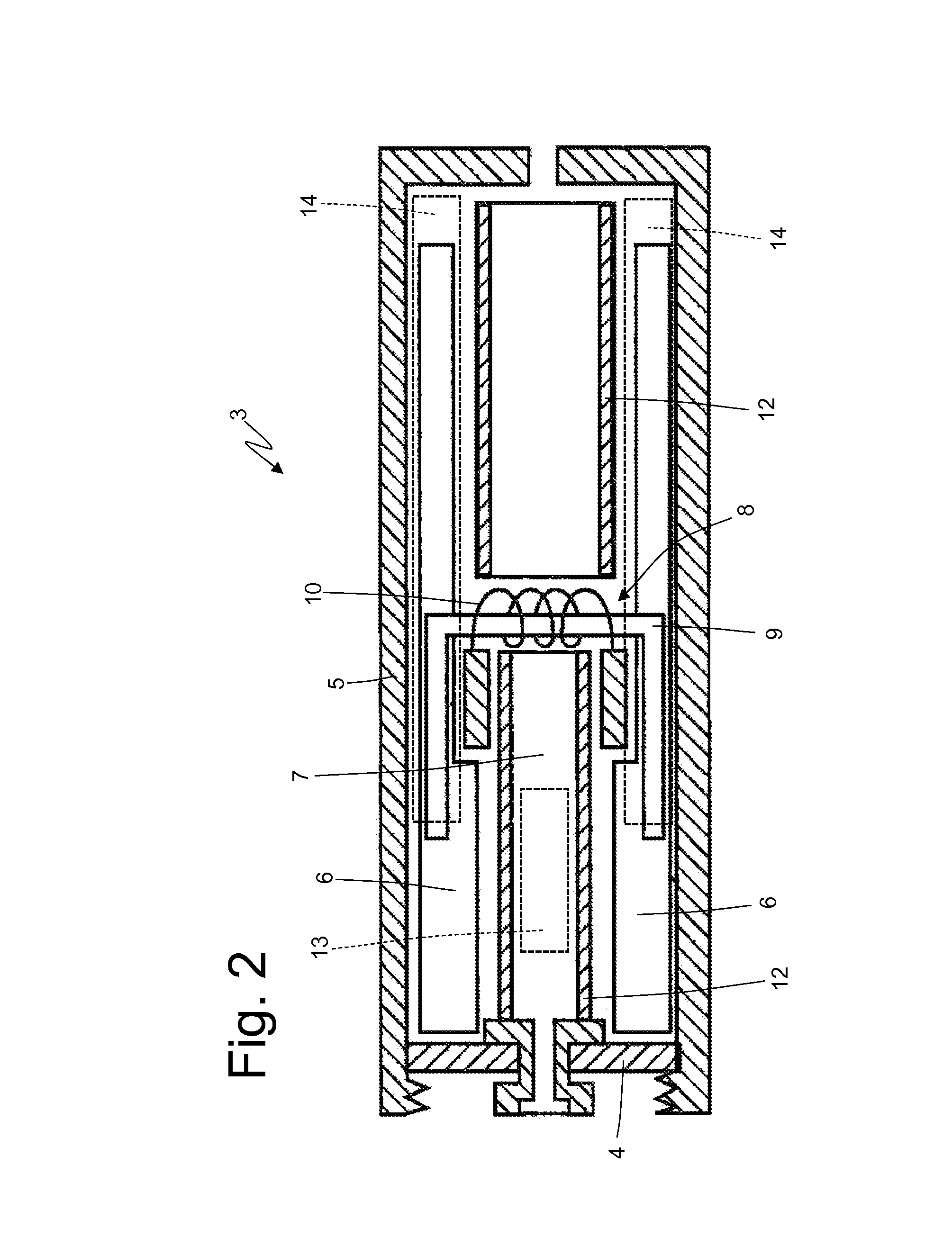

Variably stackable sterilization tray system

InactiveUS6874634B2Easy to transportMinimizing size and costSurgical furnitureDispensing apparatusSurgical siteEngineering

A tray system composed of a vertical stack of trays especially adapted to contain, and protect surgical instruments being carried from a sterilizer to an operating site. The trays may have various heights and be arranged in any order in the stack. Each tray includes a plurality of latches, each latch having an arm swingably mounted to the tray and terminated by a projection spaced a selected distance D1 above the tray rim or top when the latch is swung to its latching position. Each tray also includes a corresponding plurality of latching surfaces located under the latches on that tray. The distance D2 between the seating surfaces and latching surfaces of each tray corresponds substantially to the distance D1 of that tray. This enables the latch arms of each tray to be latched to the latching surfaces of an overlying tray in the stack or to a cover so as to form a closed compact transportable package. Different latch embodiments for securing the trays together are also disclosed.

Owner:SYMMETRY MEDICAL MFG INC

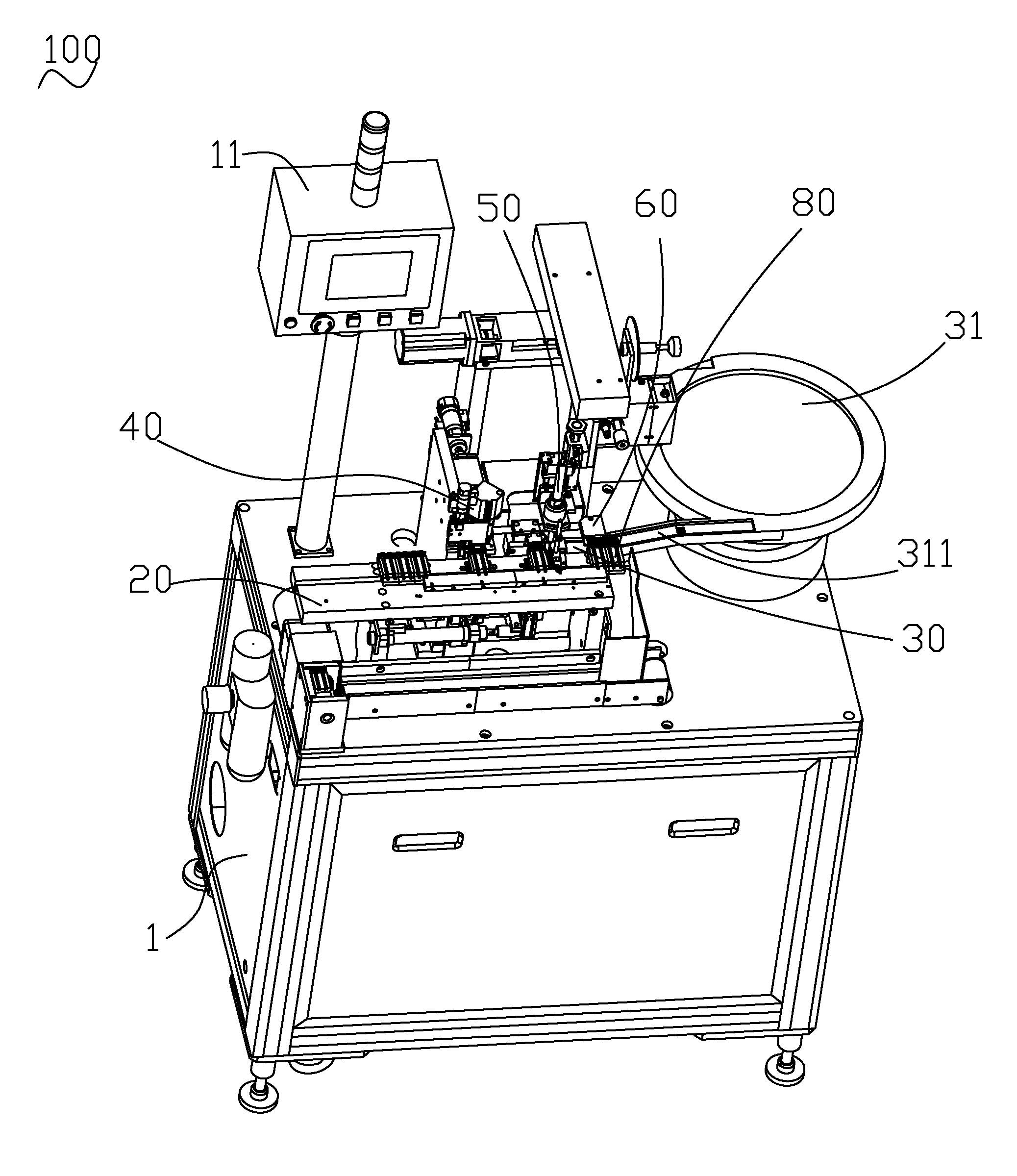

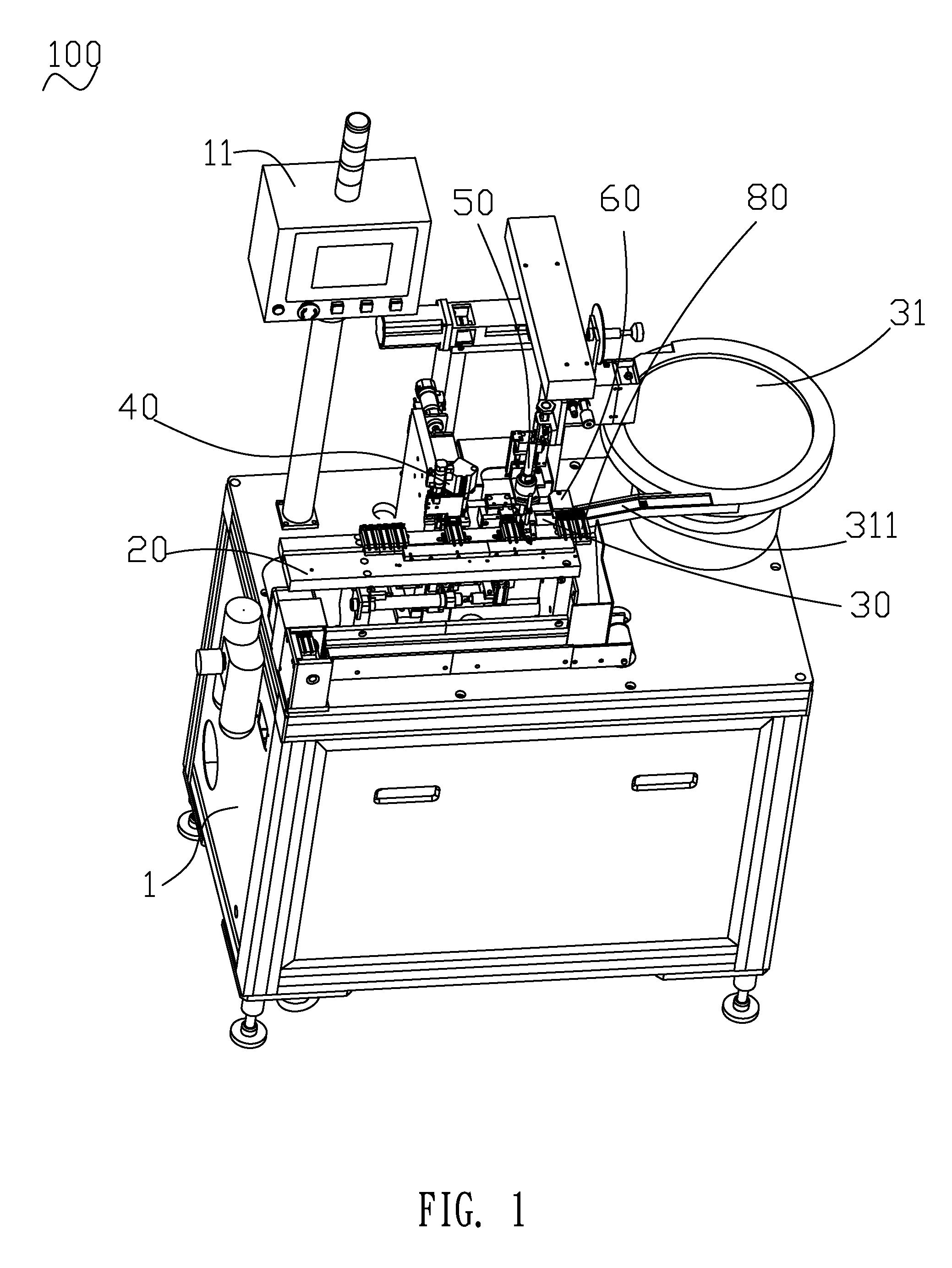

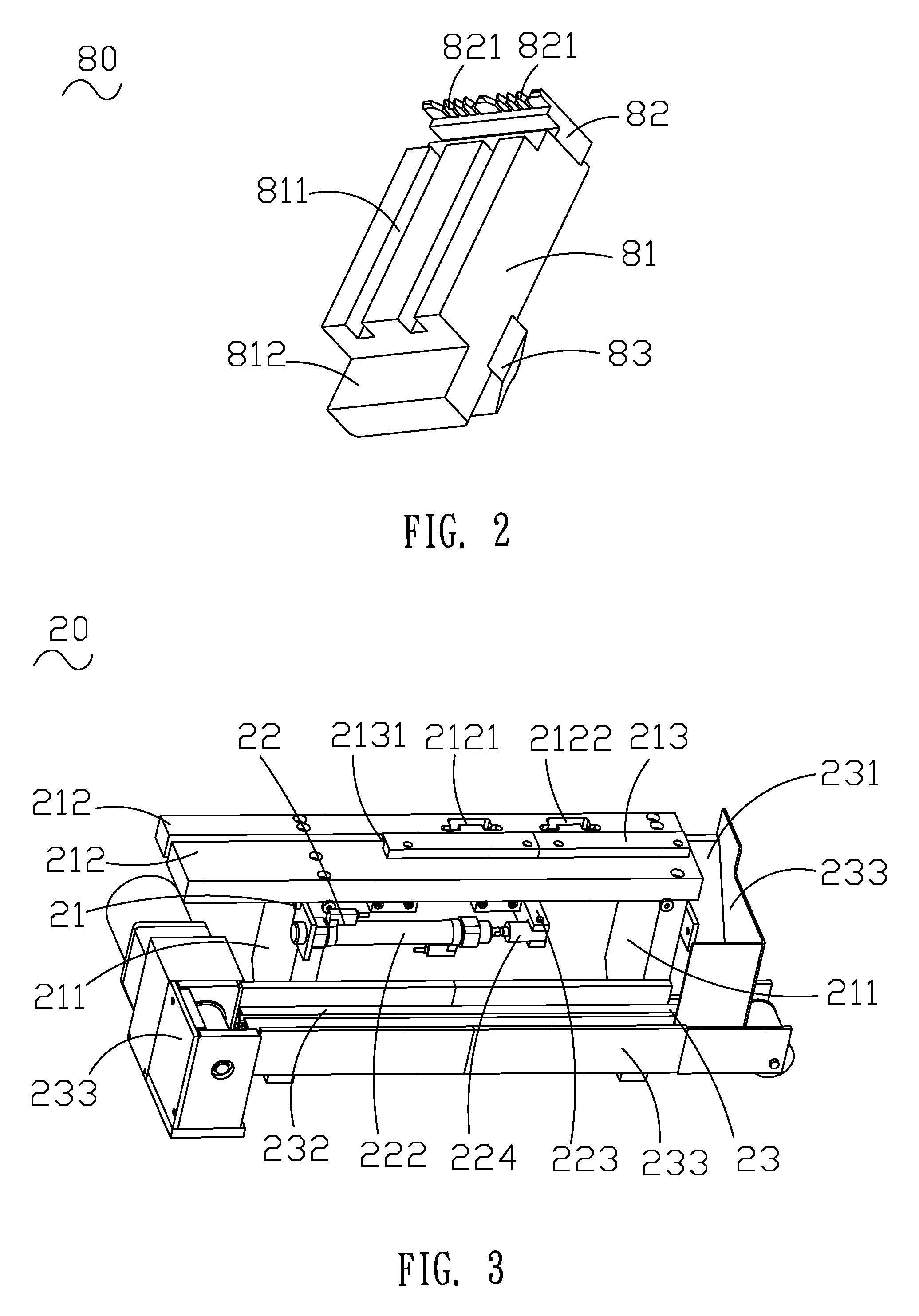

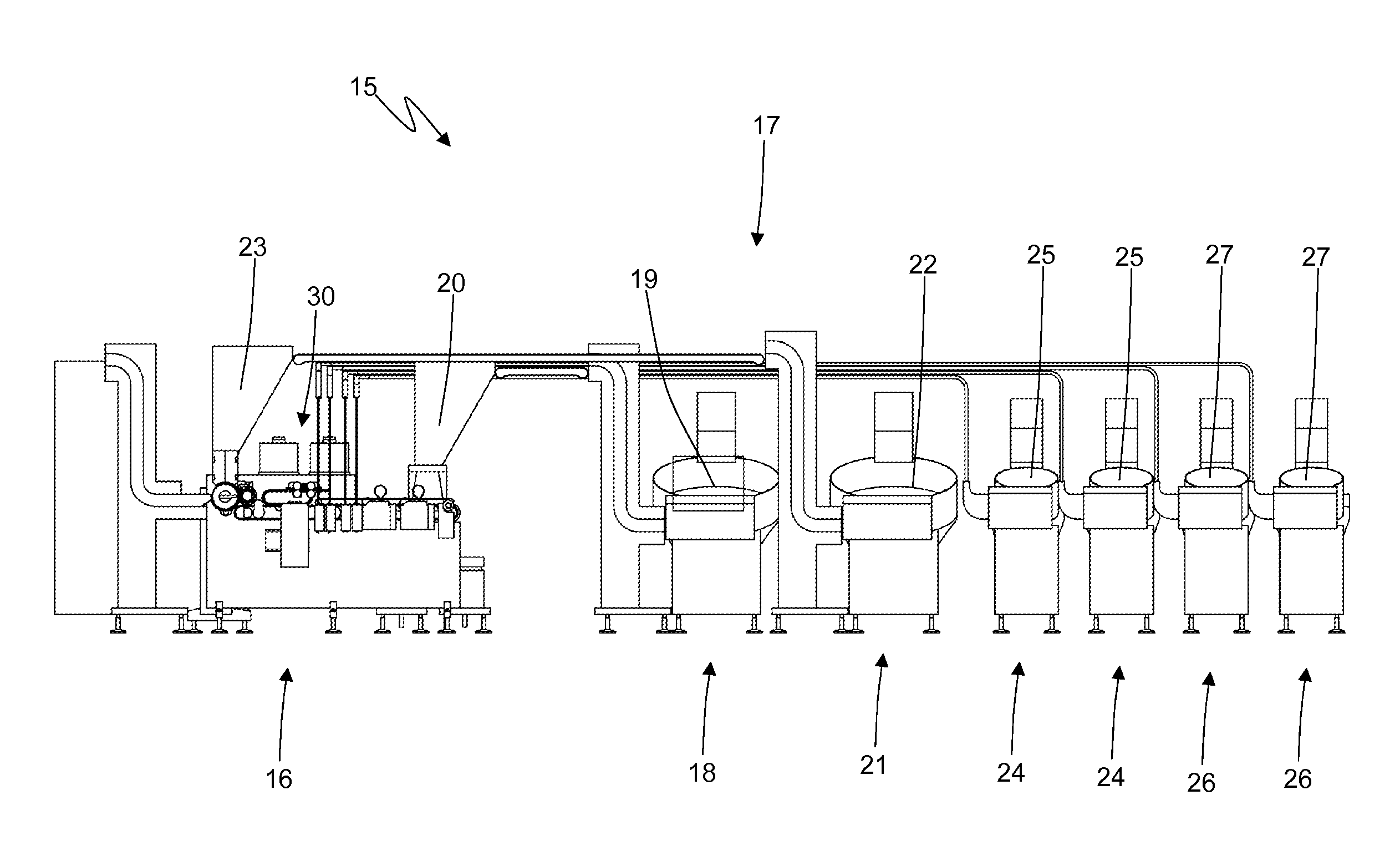

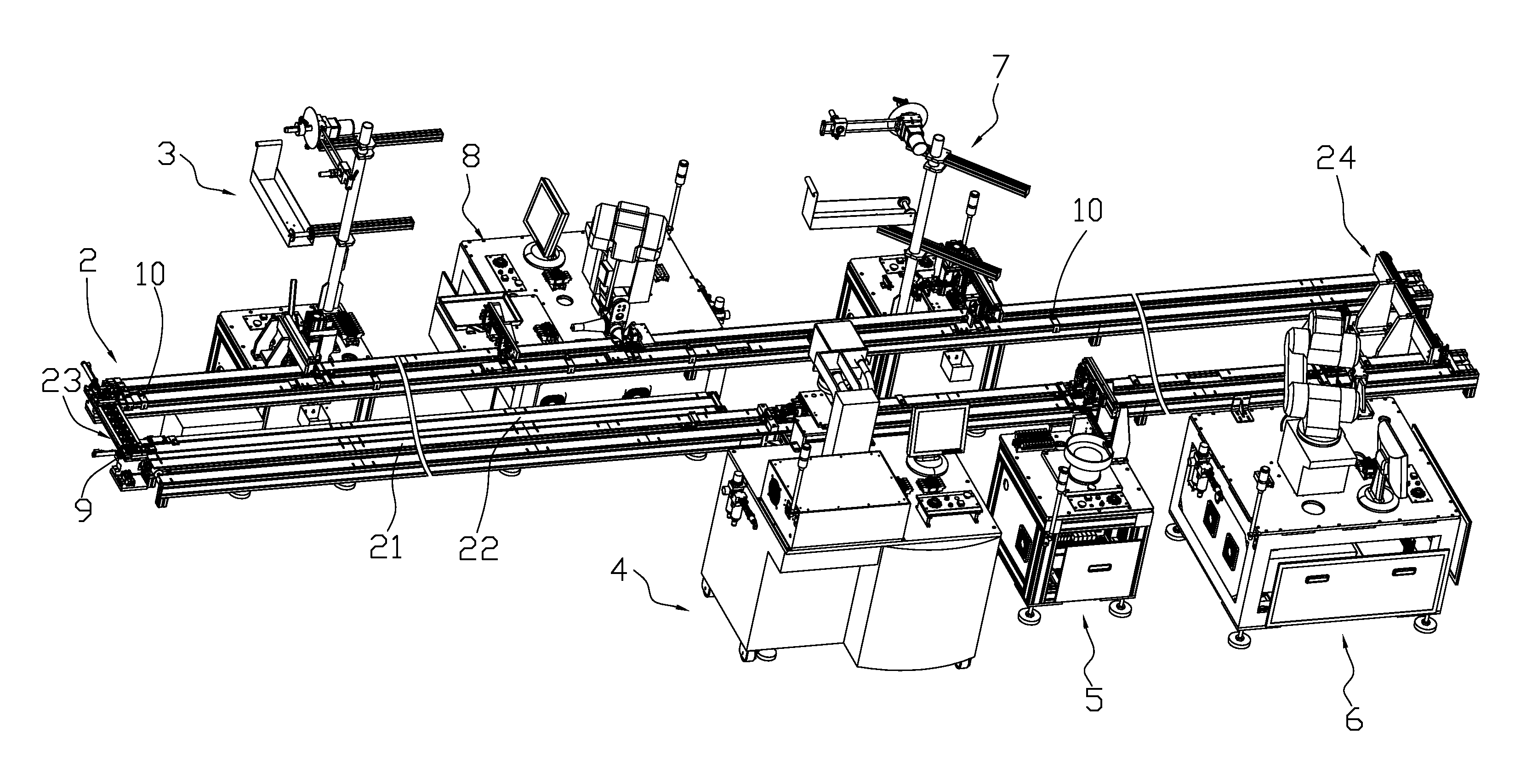

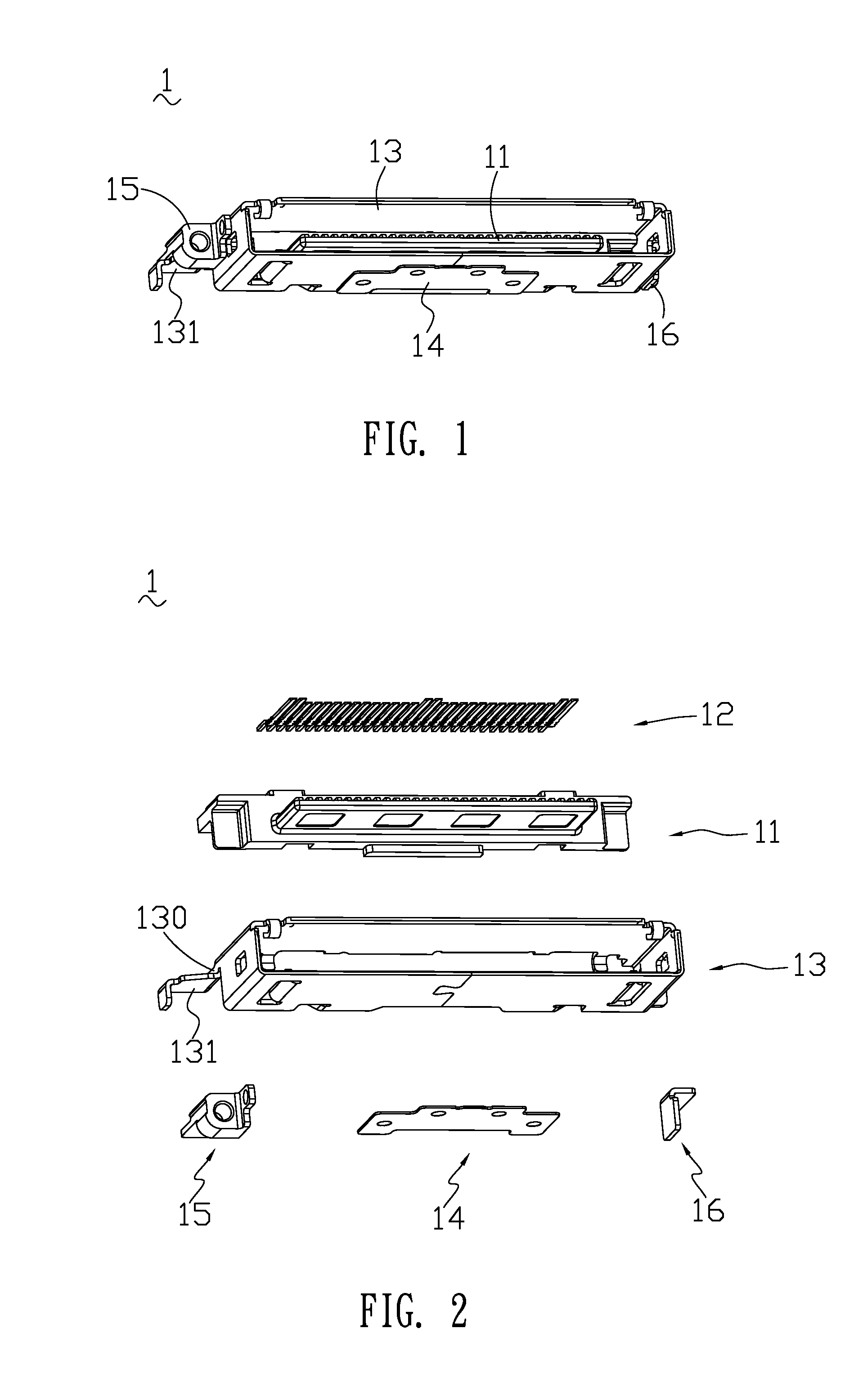

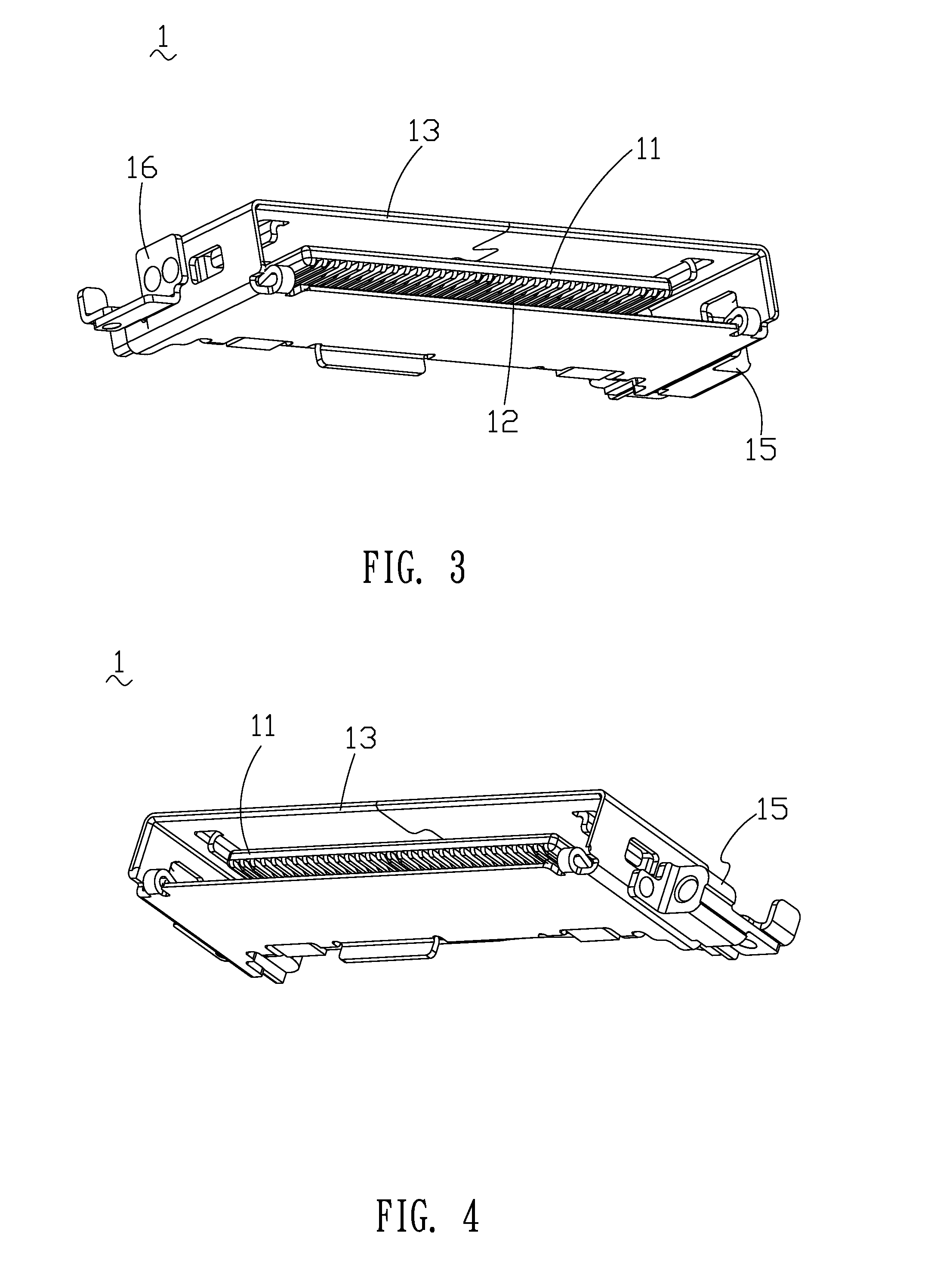

Automatic soldering machine

InactiveUS8011557B1High production efficacyImprove product qualityWelding/cutting auxillary devicesFeeding apparatusControl systemEngineering

An automatic soldering machine for soldering wires, each exposing at least one core wire and electronic components with at least one soldering portion respectively is disclosed. The automatic soldering machine comprises an equipment, a delivery mechanism, a plurality of clamps, a feeding mechanism, an insulation removing mechanism, a soldering mechanism, an unloading mechanism and a programmable control system. The delivery mechanism delivers the wires. The clamps locate the wires. The feeding mechanism conveys the electronic components. The insulation removing mechanism cuts the core wires and strips insulations at tops of the core wires. The soldering mechanism solders the core wires and the soldering portions of the electronic components. The unloading mechanism separates the soldered electronic components and core wires off from the clamps. The programmable control system is connect to the aforesaid mechanisms and controls thereof with high production efficacy and stable production quality.

Owner:CHENG UEI PRECISION IND CO LTD

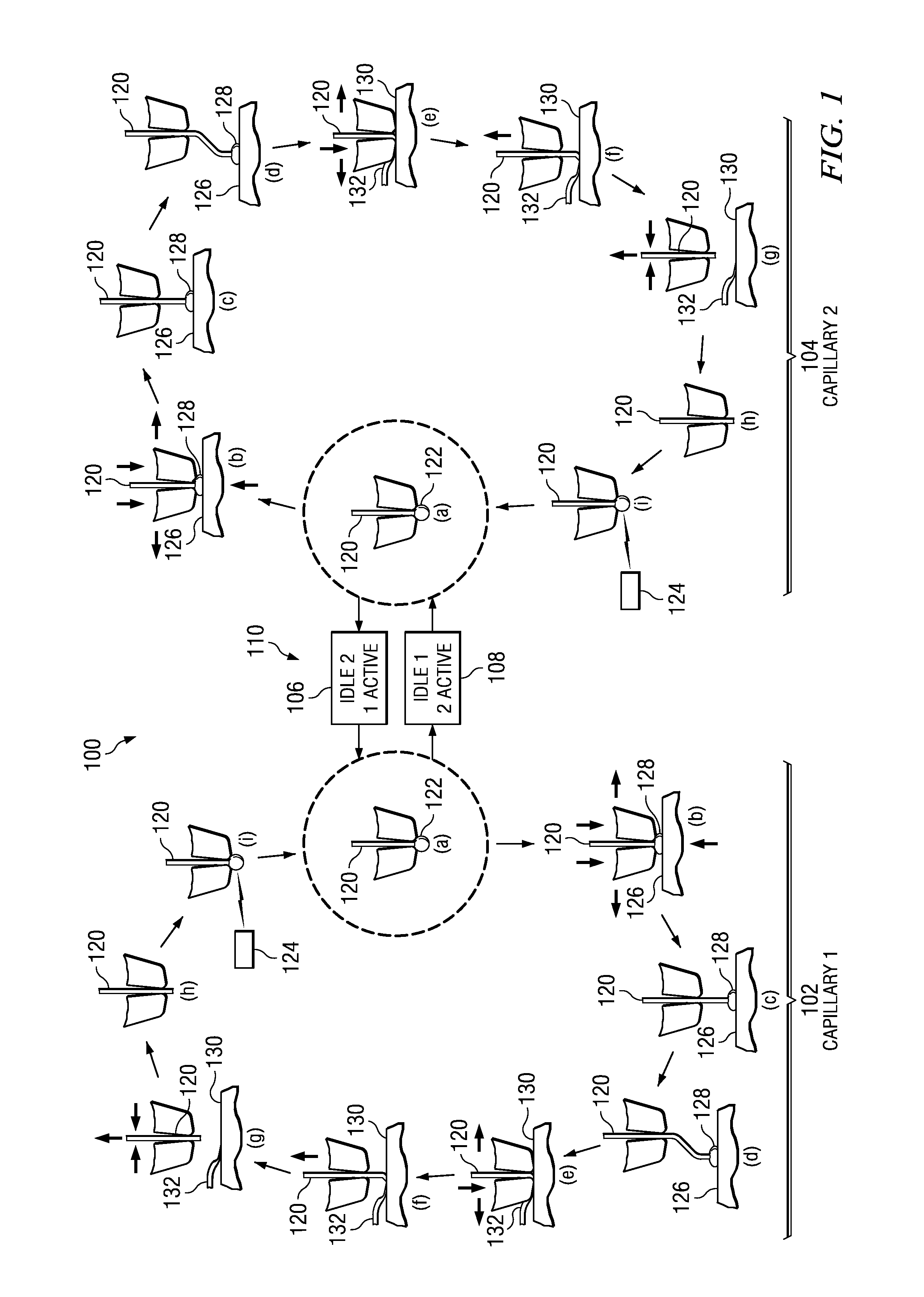

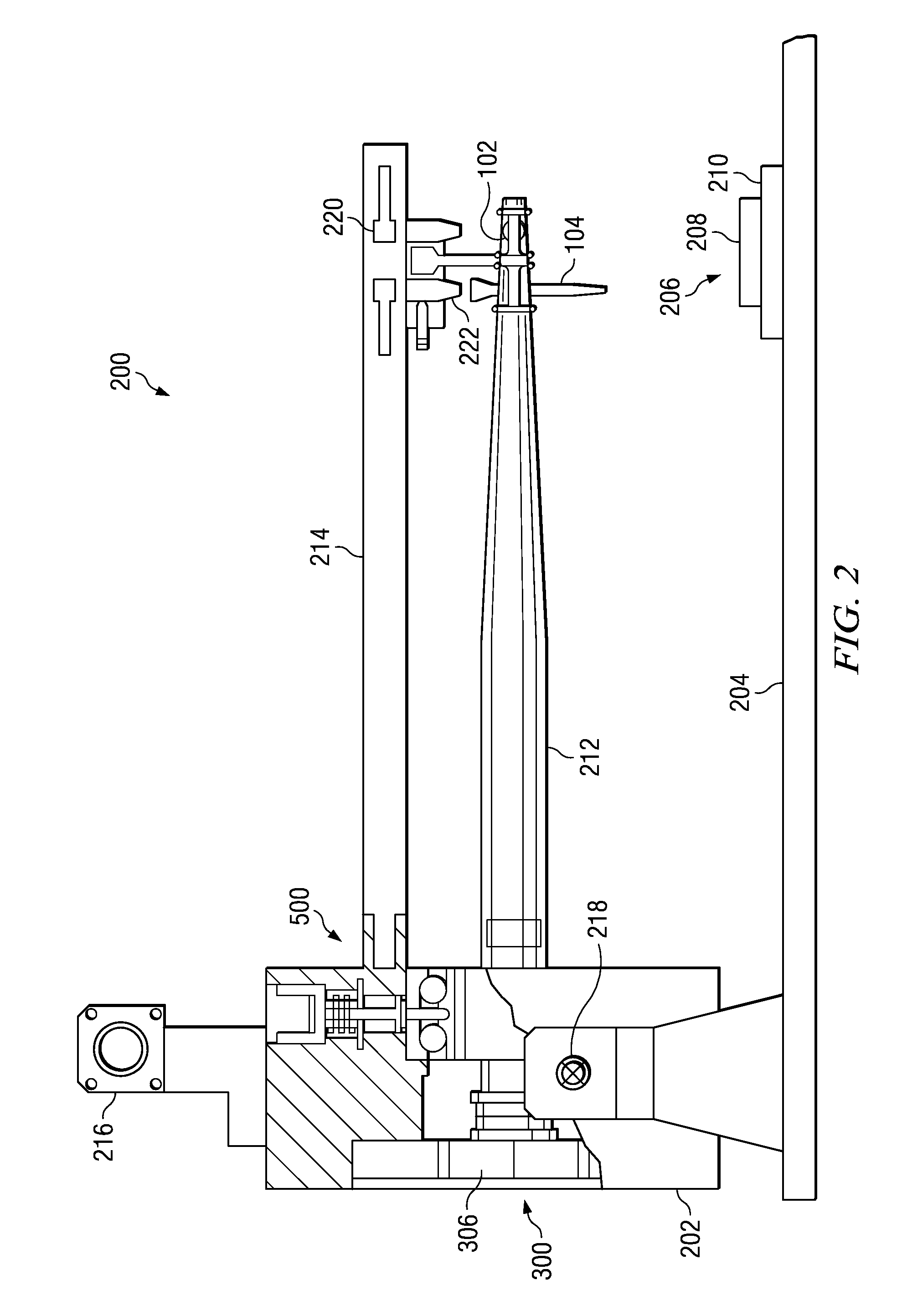

Dual Capillary IC Wirebonding

ActiveUS20110272449A1Add equipmentImprove processing throughputSemiconductor/solid-state device detailsSolid-state devicesEngineeringIntegrated circuit

The invention discloses apparatus and methods for the formation of bond wires in integrated circuit assemblies by attaching two separate wires using a dual capillary bond head. The separate wires are preferably non-identical, for example, being of different gauges and / or material composition. According to a preferred embodiment of the invention, dual capillary bond head apparatus includes a rotatable ultrasonic horn with a pair of capillaries for selectably dispensing separate strands of bond wire and for forming bonds on bond targets. According to another aspect of the invention, a method is provided for dual capillary IC wirebonding including steps for using two dual capillary bond heads for contemporaneously attaching non-identical bond wires to selected bond targets on one or more IC package assemblies.

Owner:TEXAS INSTR INC

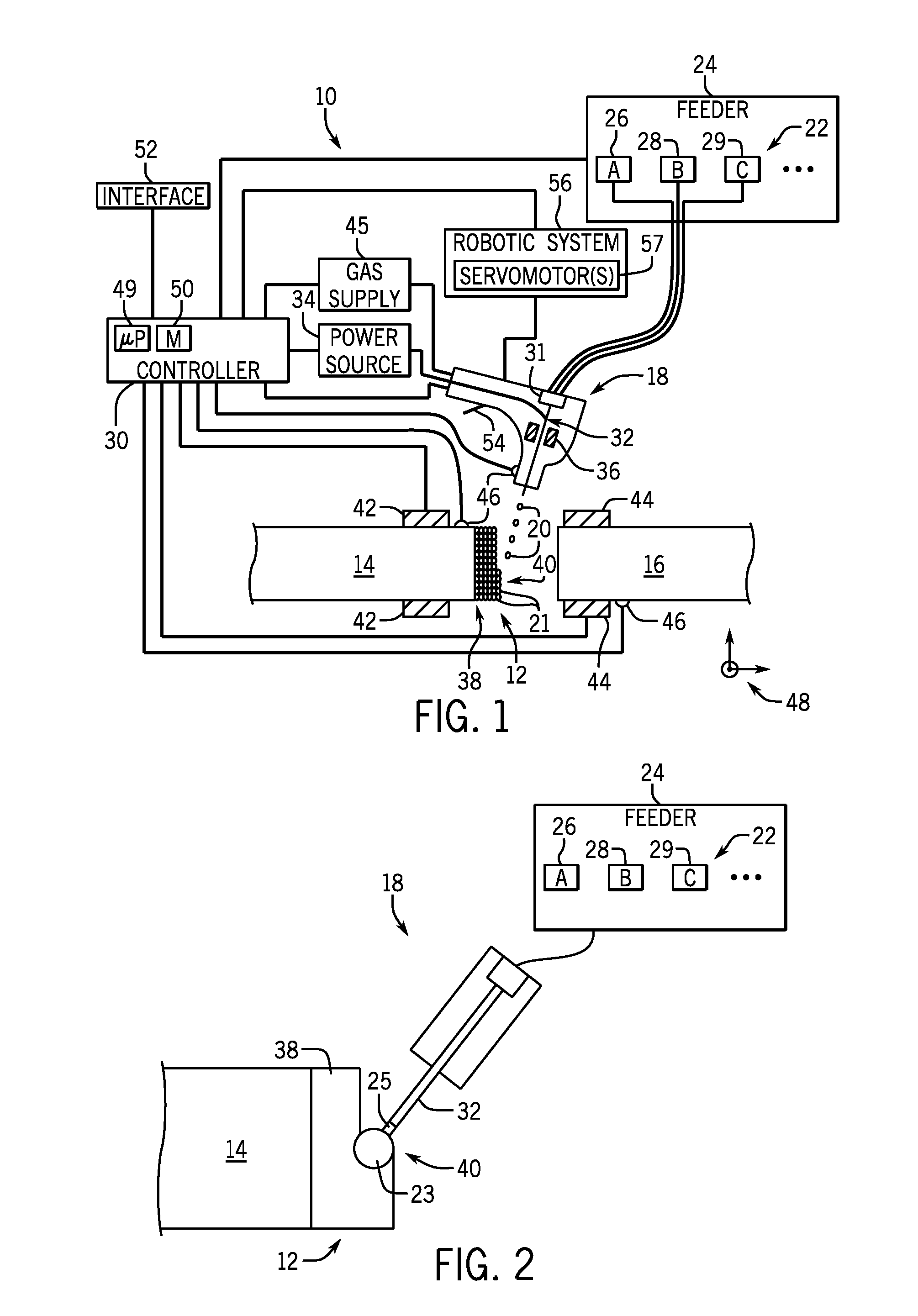

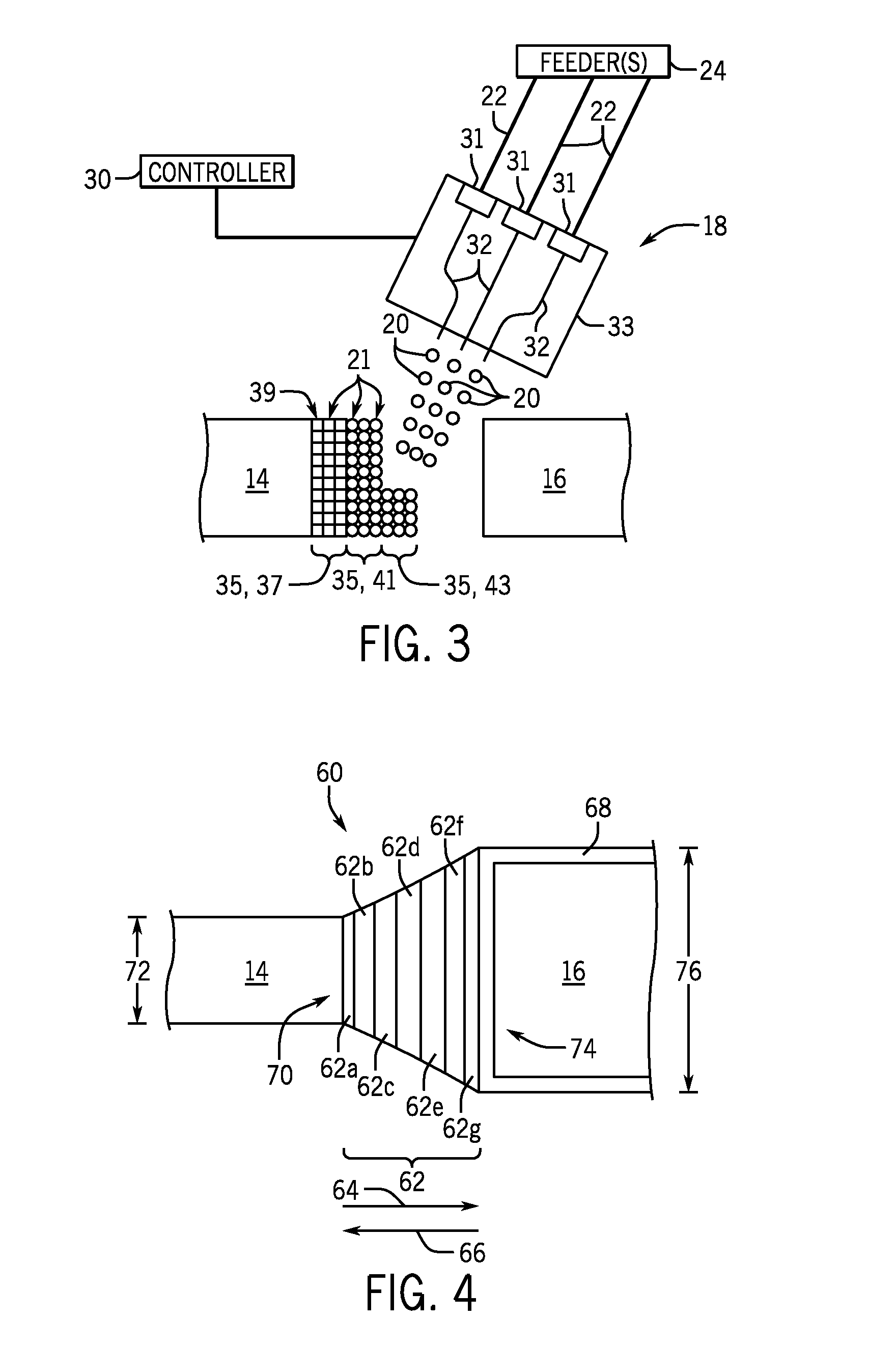

Additive manufacturing system for joining and surface overlay

An additive manufacturing system includes an additive manufacturing tool configured to receive a plurality of metallic anchoring materials and to supply a plurality of droplets to a part, and a controller configured to independently control the composition, formation, and application of each droplet to the plurality of droplets to the part. The plurality of droplets is configured to build up the part. Each droplet of the plurality of droplets includes at least one metallic anchoring material of the plurality of metallic anchoring materials.

Owner:ILLINOIS TOOL WORKS INC

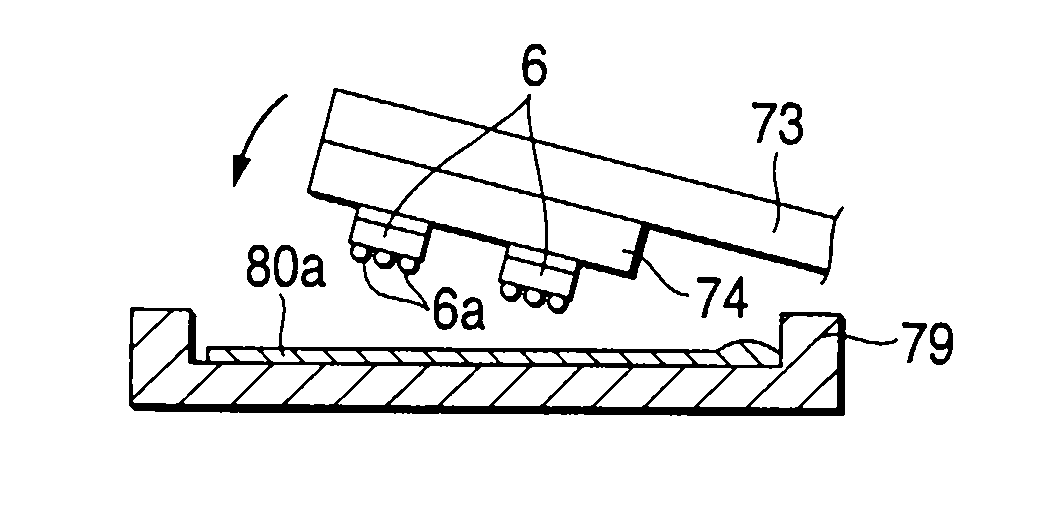

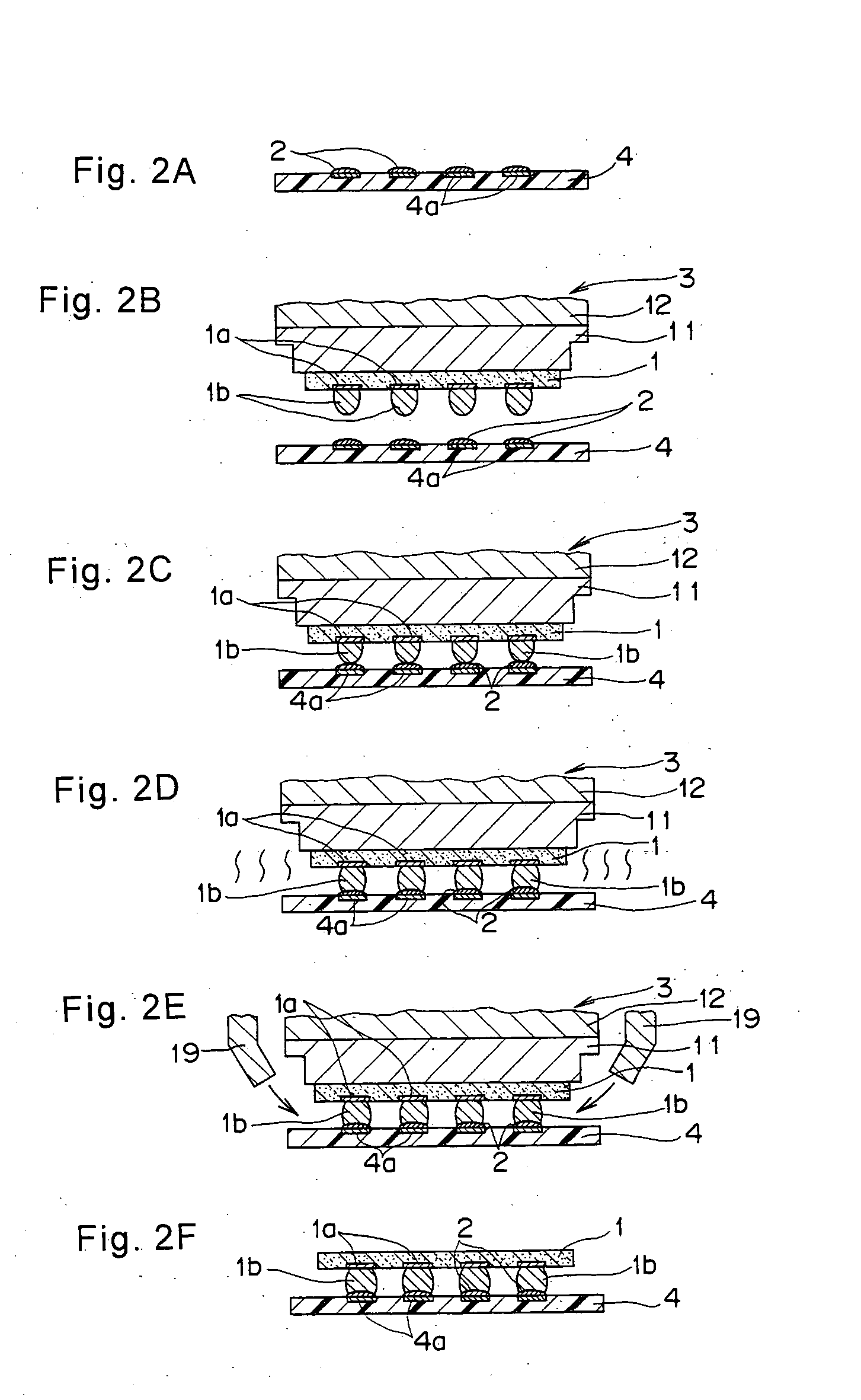

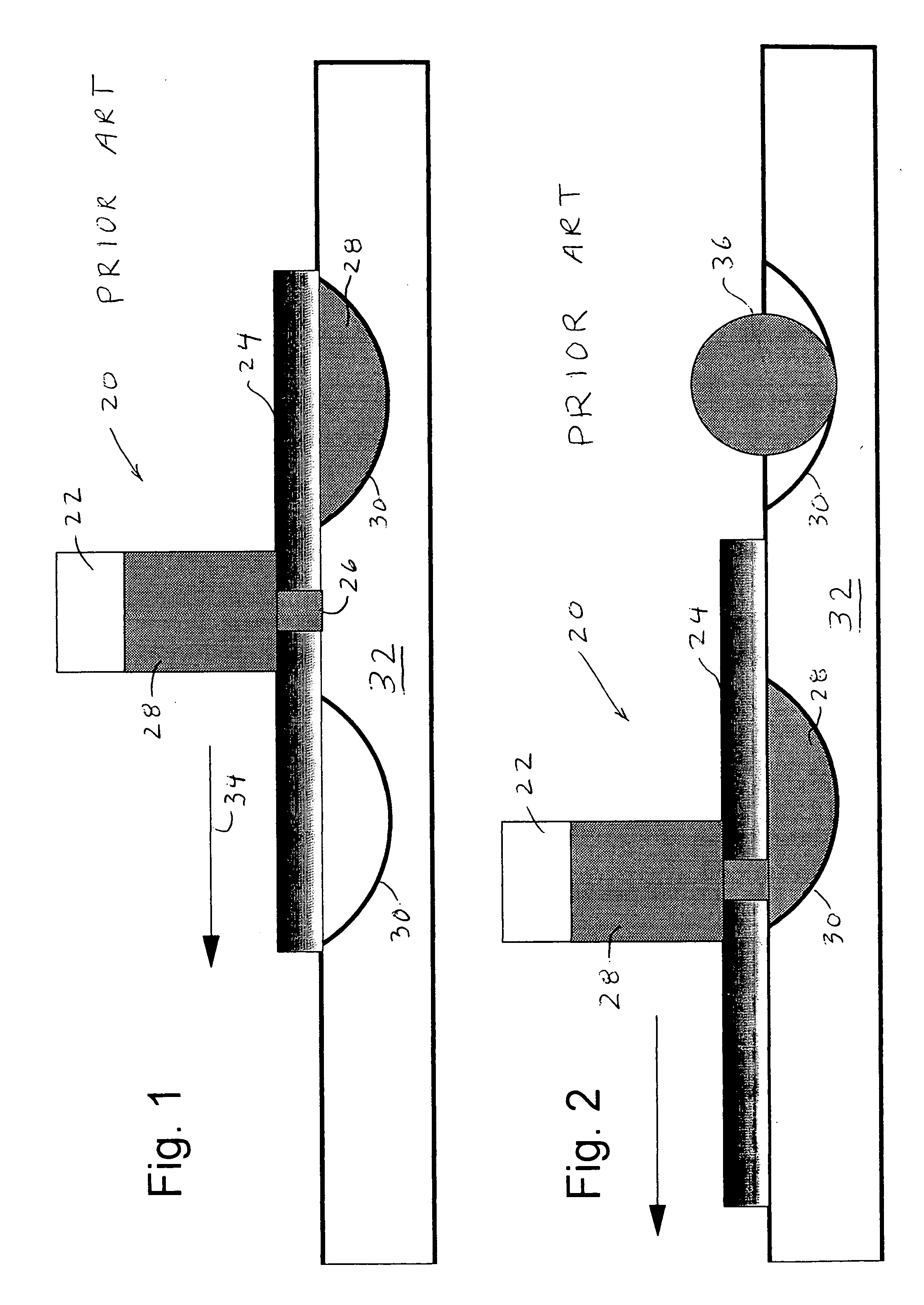

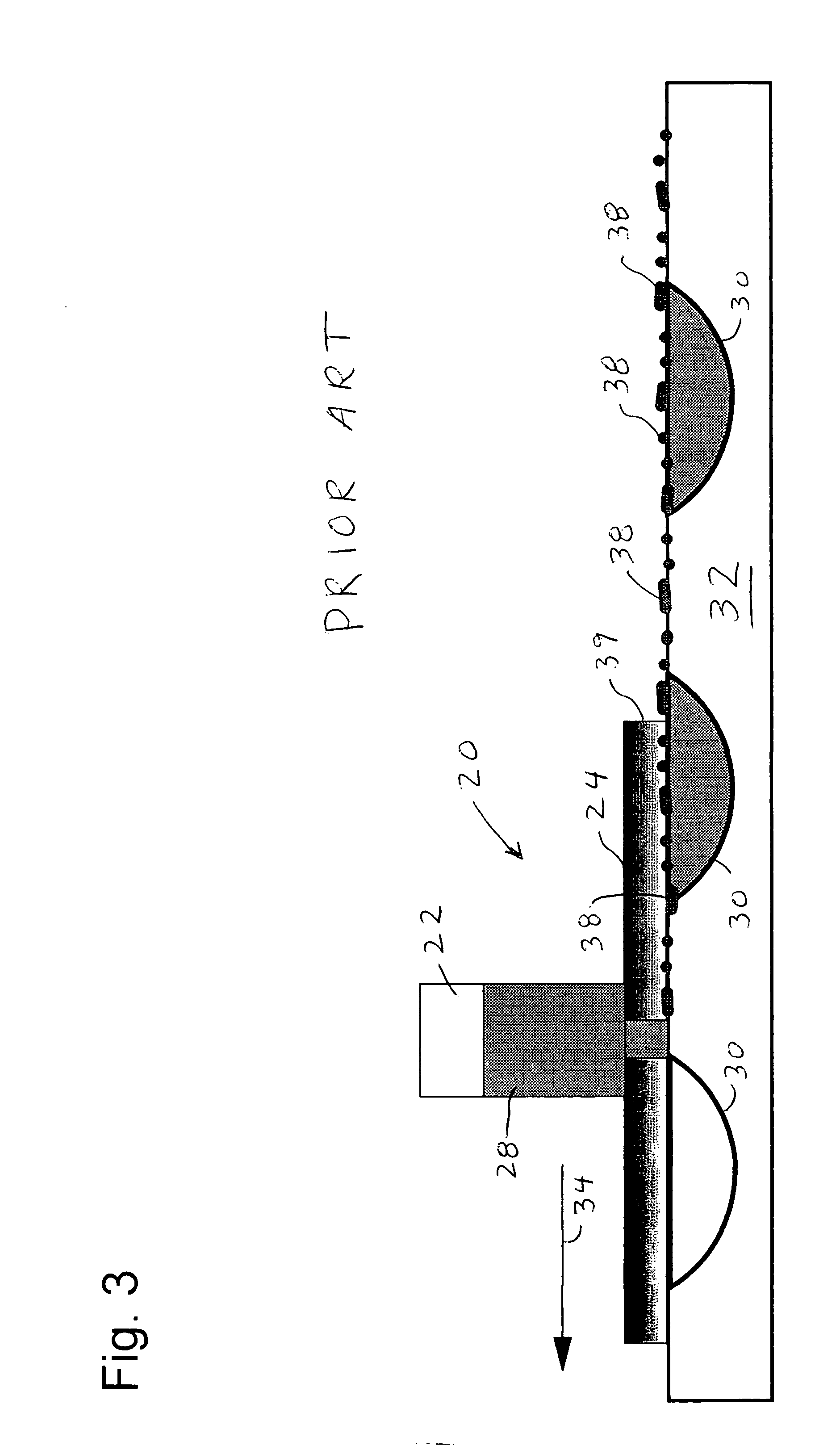

Apparatus and method for mounting electronic components

InactiveUS20050098610A1Final product manufactureWelding/cutting auxillary devicesEngineeringElectronic component

After detection of contact between respective solder bumps of an electronic component, sucked and held by a suction nozzle of a head tool, and respective solder portions of a circuit board, the solder bumps and the solder portions are melted by heating. Releasing of the electronic component from suction and holding by the suction nozzle of the head tool is performed, not at a time during solder melting, but at a time after the solder is melted, cooled and solidified. Thus, an electronic component mounting method and apparatus capable of mounting high-end electronic components having narrow-pitched bumps are provided.

Owner:PANASONIC CORP

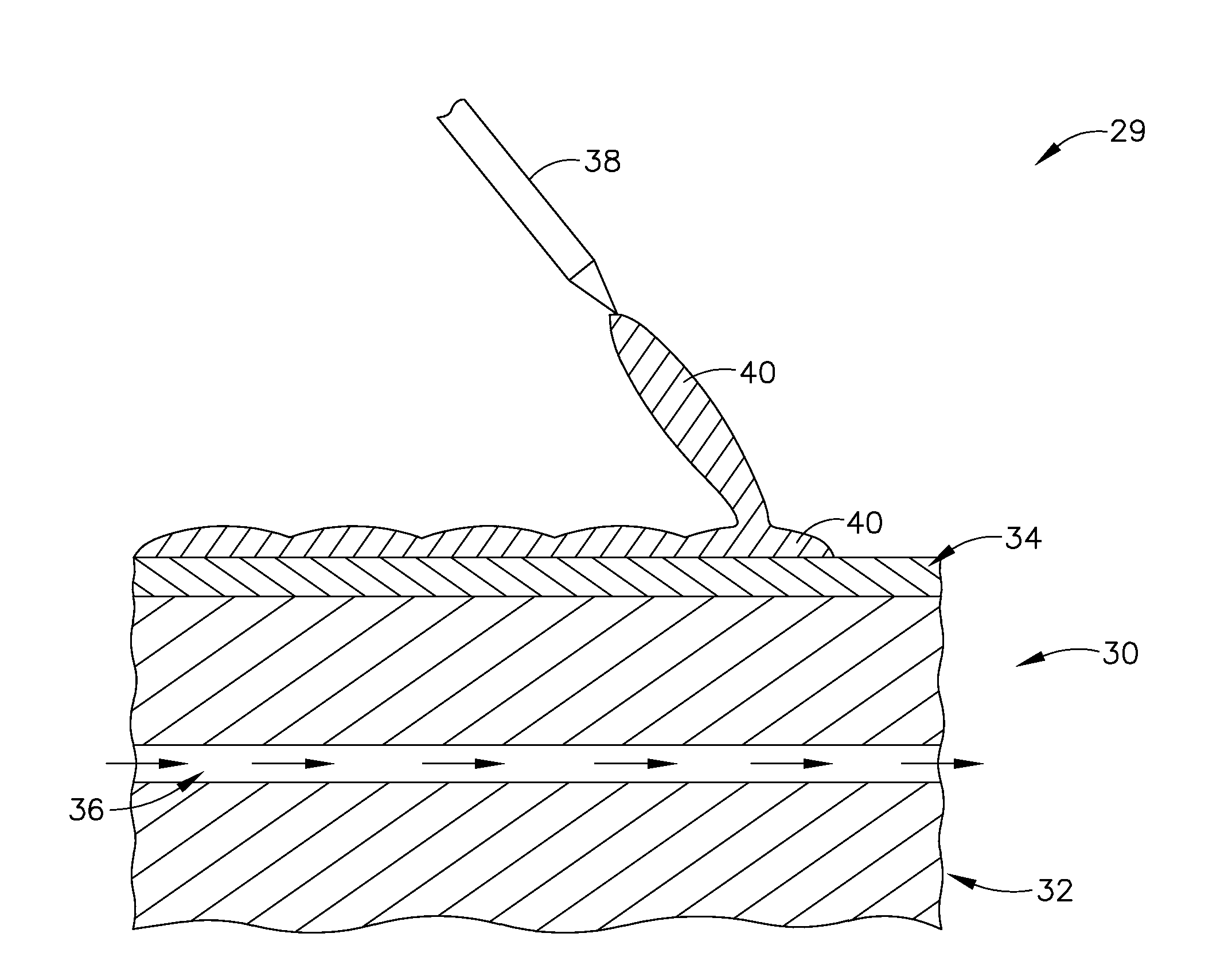

High temperature additive manufacturing systems for making near net shape airfoils leading edge protection, and tooling systems therewith

InactiveUS20100242843A1Reduce pollutionMolten spray coatingVacuum evaporation coatingLeading edgeNear net shape

Tooling systems including a mandrel for receiving, and providing shape to, a metallic deposit applied using a high temperature additive manufacturing device; a metallic cladding applied to the mandrel for reducing contamination of the metallic deposit; and at least one cooling channel associated with the mandrel for removing heat from the system.

Owner:GENERAL ELECTRIC CO

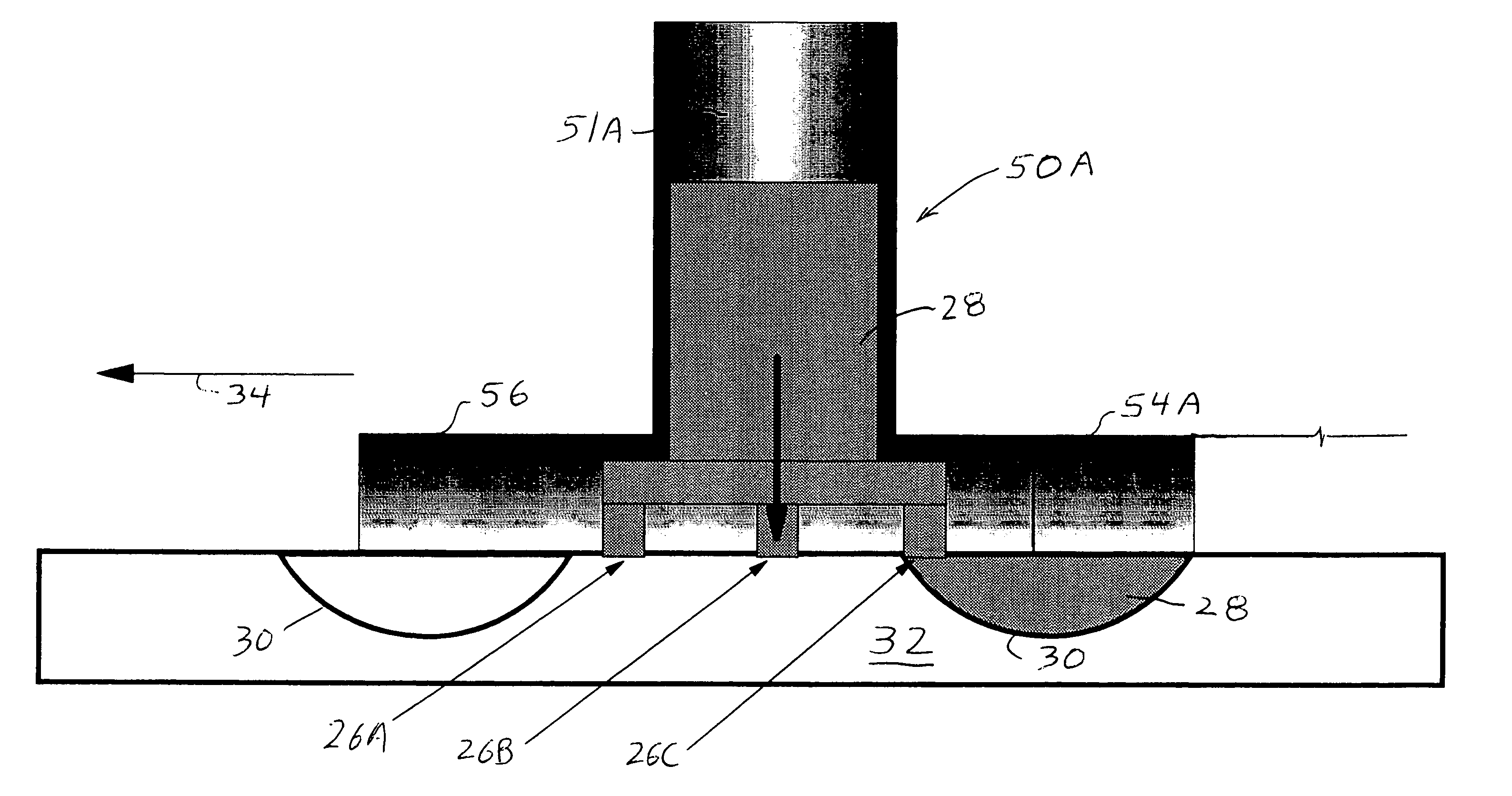

Injection molded continuously solidified solder method and apparatus

InactiveUS20050263571A1Accurate storageAccurately and completely fill the cavitiesPrinted circuit assemblingWelding/cutting media/materialsMetallurgyMaterials science

A method and apparatus for forming solder bumps by molten solder deposition into cavity arrays in a substrate immediately followed by solidification of molten solder such that precise replication of cavity volumes is consistently achieved in formed solder bump arrays. Various solder filling problems, such as those caused by surface tension and oxidation effects, are overcome by a combination of narrow molten Solder dispense slots and solidification of dispensed molten solder.

Owner:BELANGER LUC +12

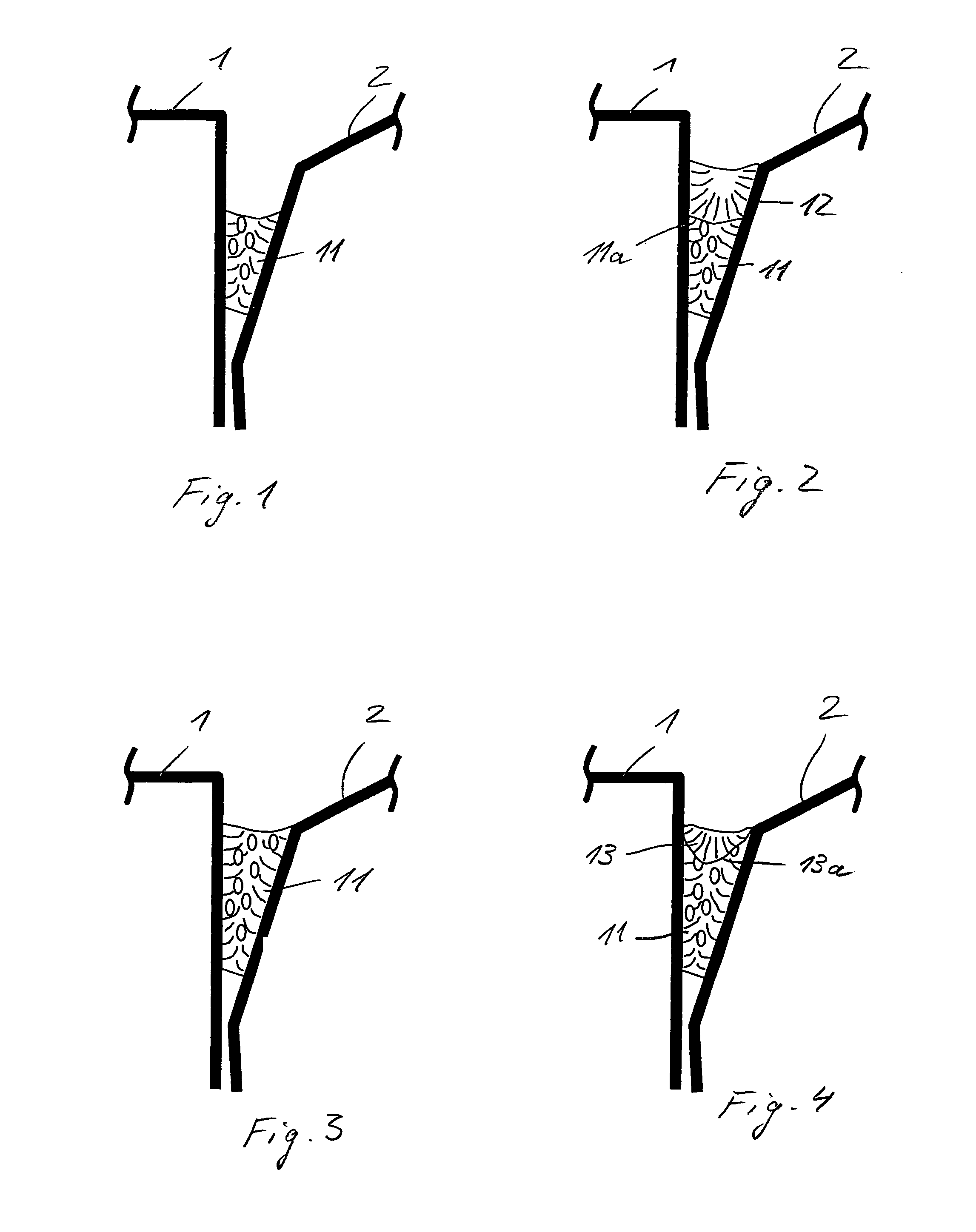

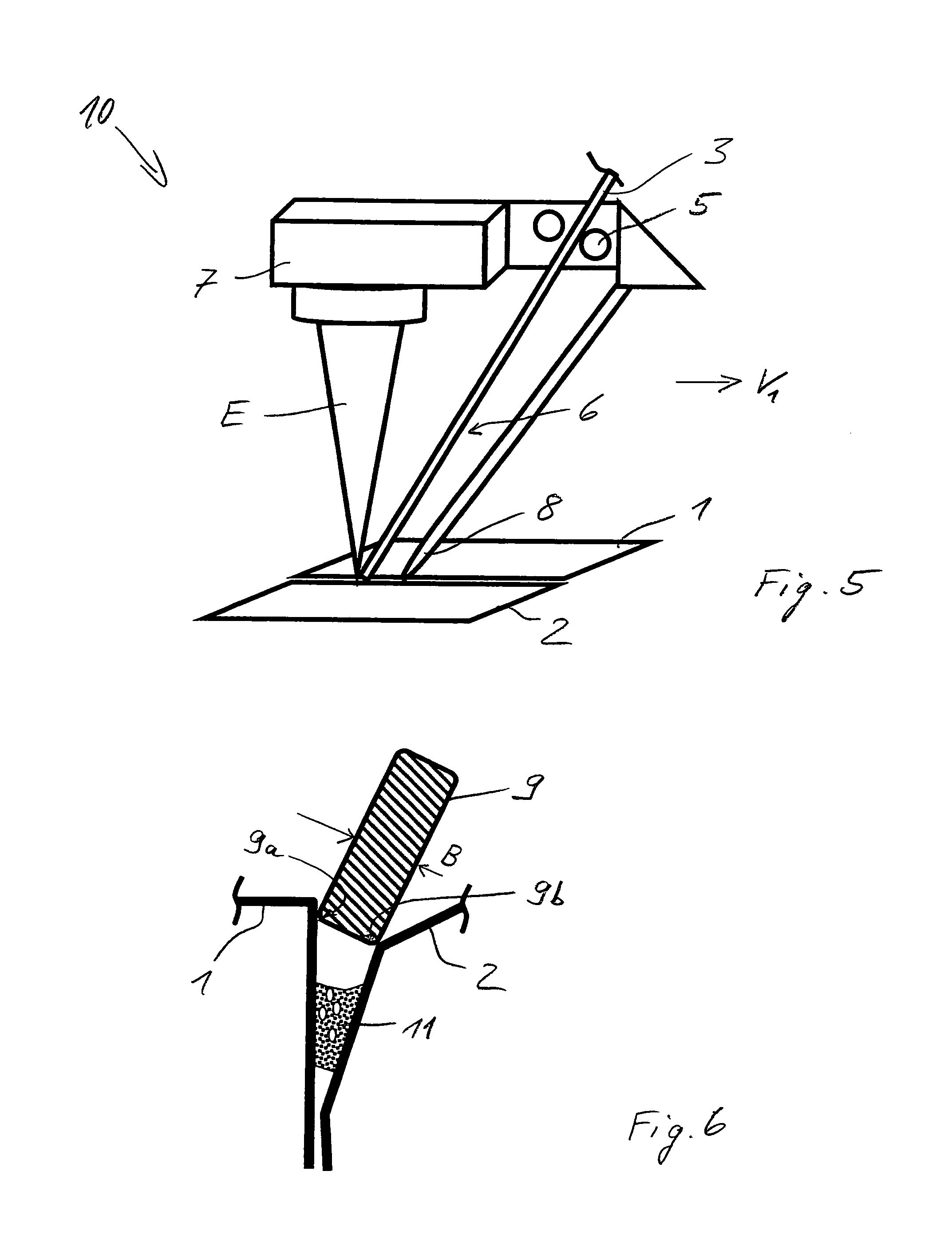

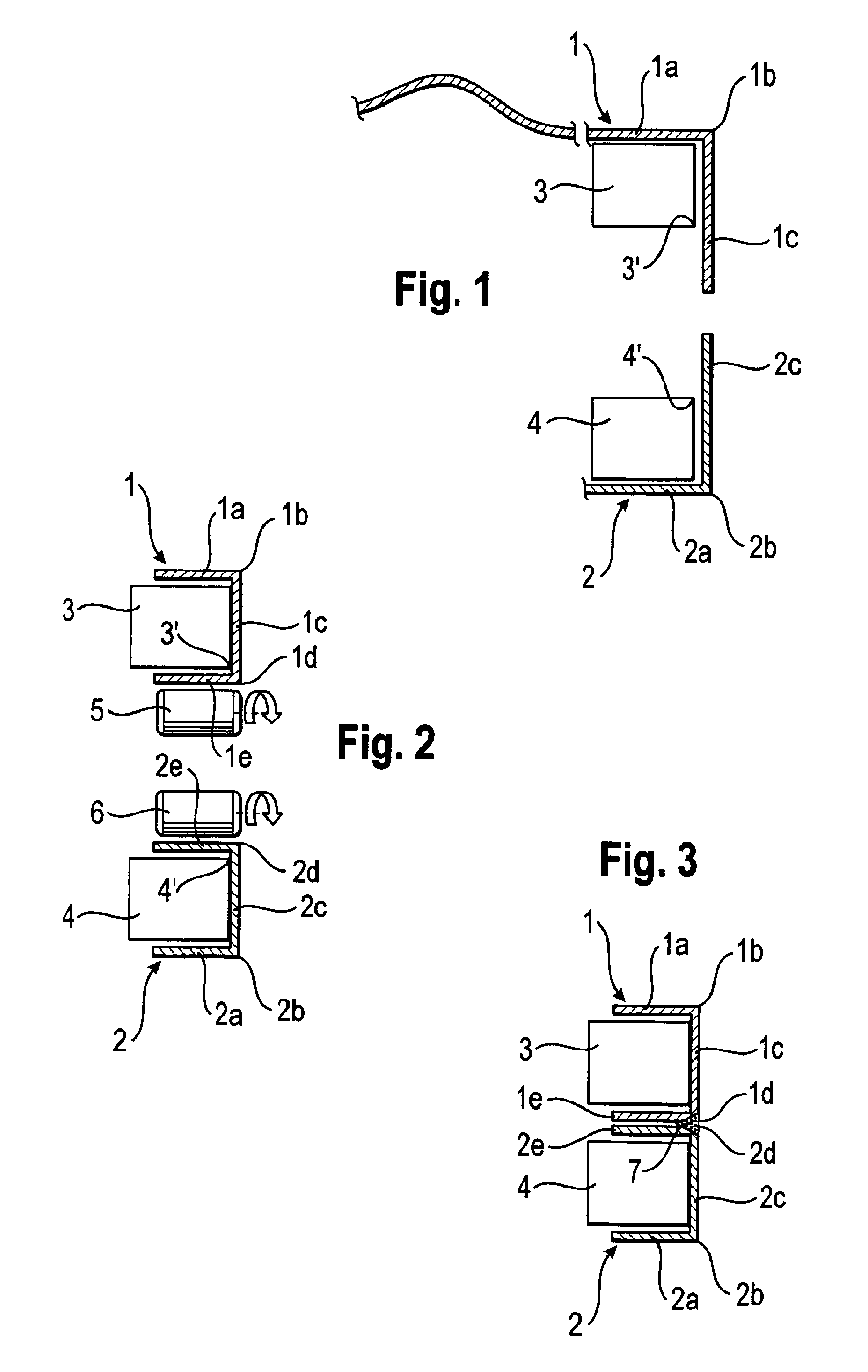

Method of soldering or welding components

ActiveUS8686314B2Increase speedIncrease production speedWelding/cutting auxillary devicesVehicle componentsEngineeringSoldering

Owner:FFT PRODIONSSYST

Composite of sheet metal parts

InactiveUS8631996B2Increase contactGood lookingWelding/cutting auxillary devicesBuilding componentsEngineeringSoldering

Owner:TOYOTA MOTOR CO LTD +1

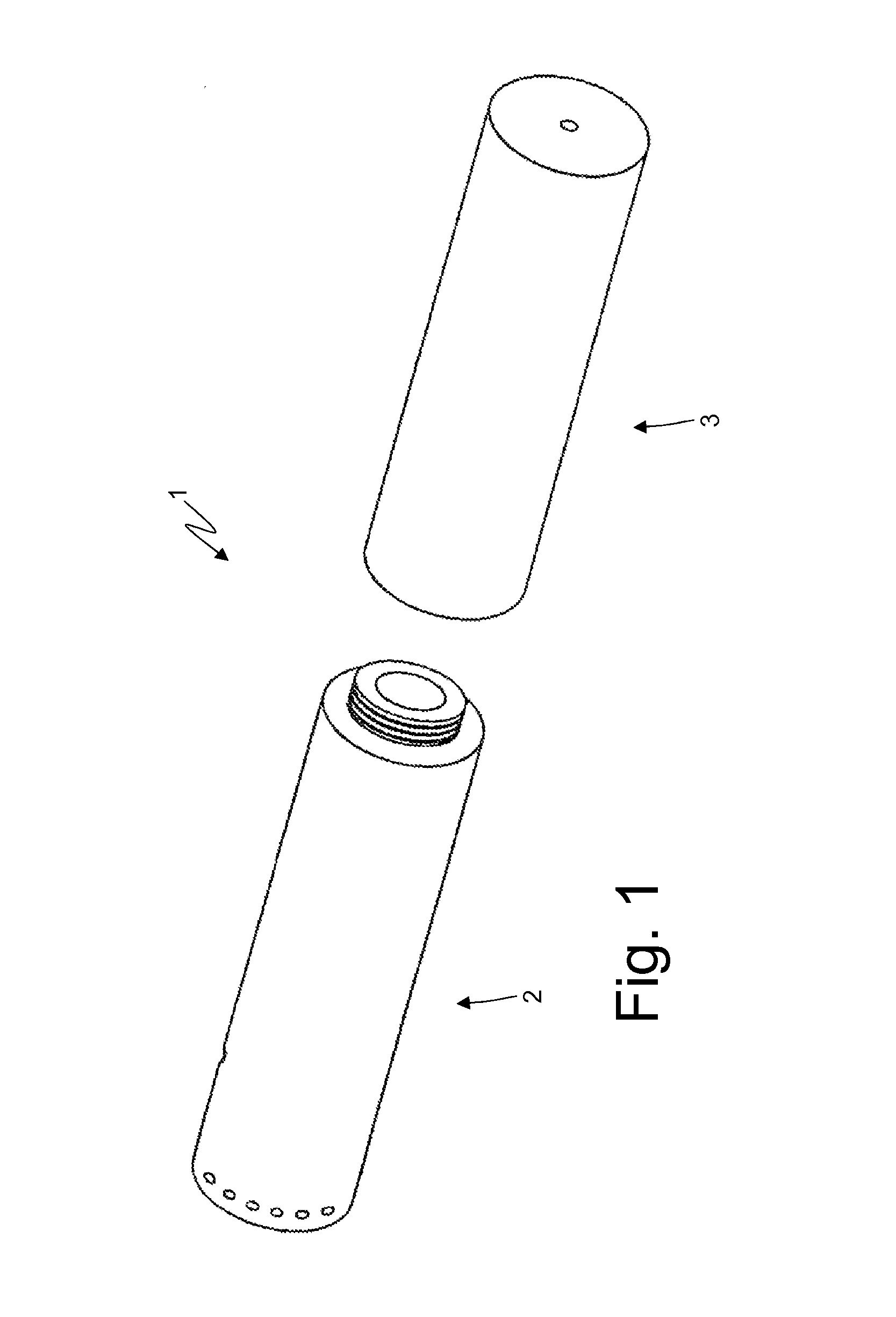

Machine and method for producing a cartridge for an electronic cigarette provided with a heat resistor

ActiveUS20160144458A1High levelEasy and inexpensive to manufactureExhaust apparatusWelding/cutting auxillary devicesElectronic cigaretteElectron

A manufacturing machine and a method for producing a cartridge for an electronic cigarette comprising a supporting base, a pair of power electrodes fitted to the supporting base, and a heating member folded into a ‘U’ around the power electrodes are disclosed: a conveyor comprising a pocket for feeding the supporting base fitted with the power electrodes along a conveying path; a connecting unit which connects the heating member to the power electrodes while the supporting base, fitted with the power electrodes, is housed inside the pocket on the conveyor; a welding device located along the conveyor to weld a pair of terminals of a heat resistor of the heating member to the corresponding power electrodes; and a folding device, which cooperates with the connecting unit and folds the heating member into a ‘U’ before the heating member is connected to the power electrodes.

Owner:GD SPA

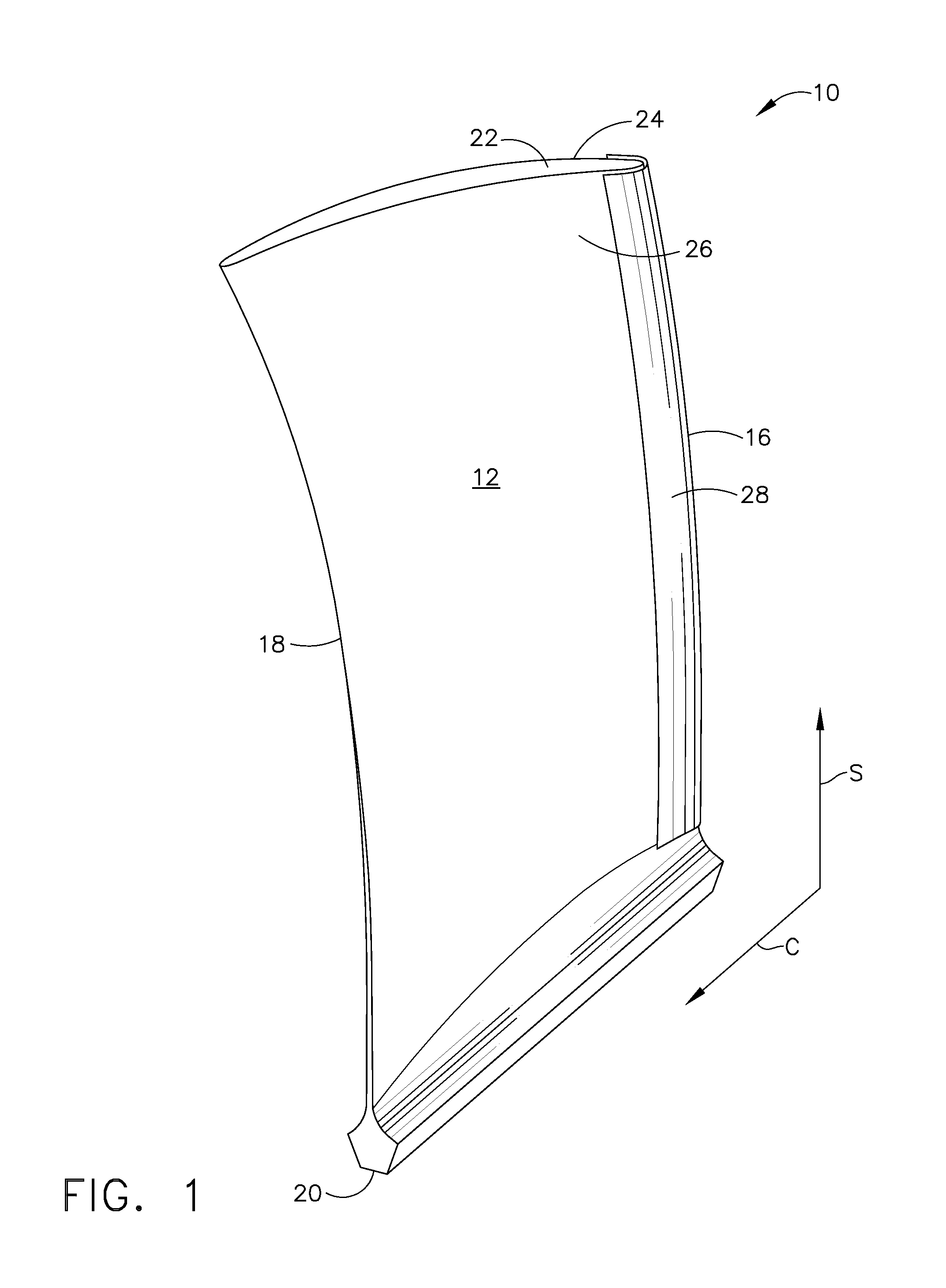

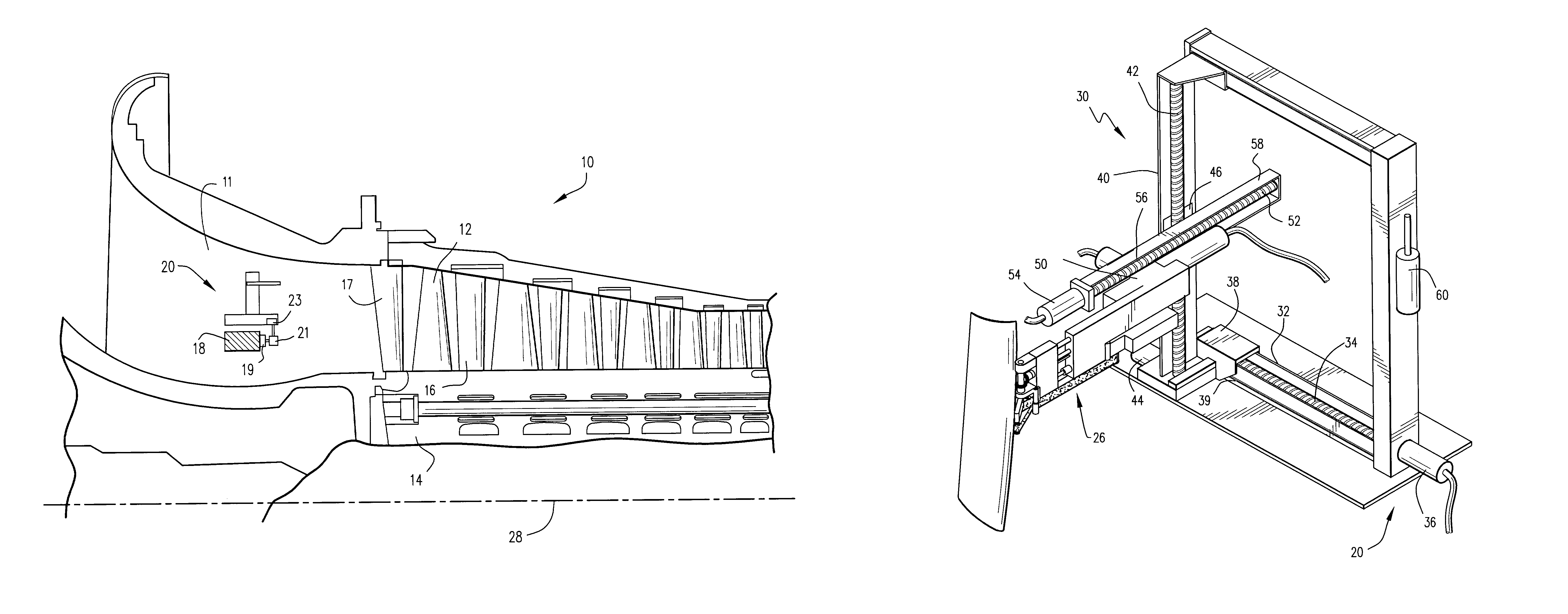

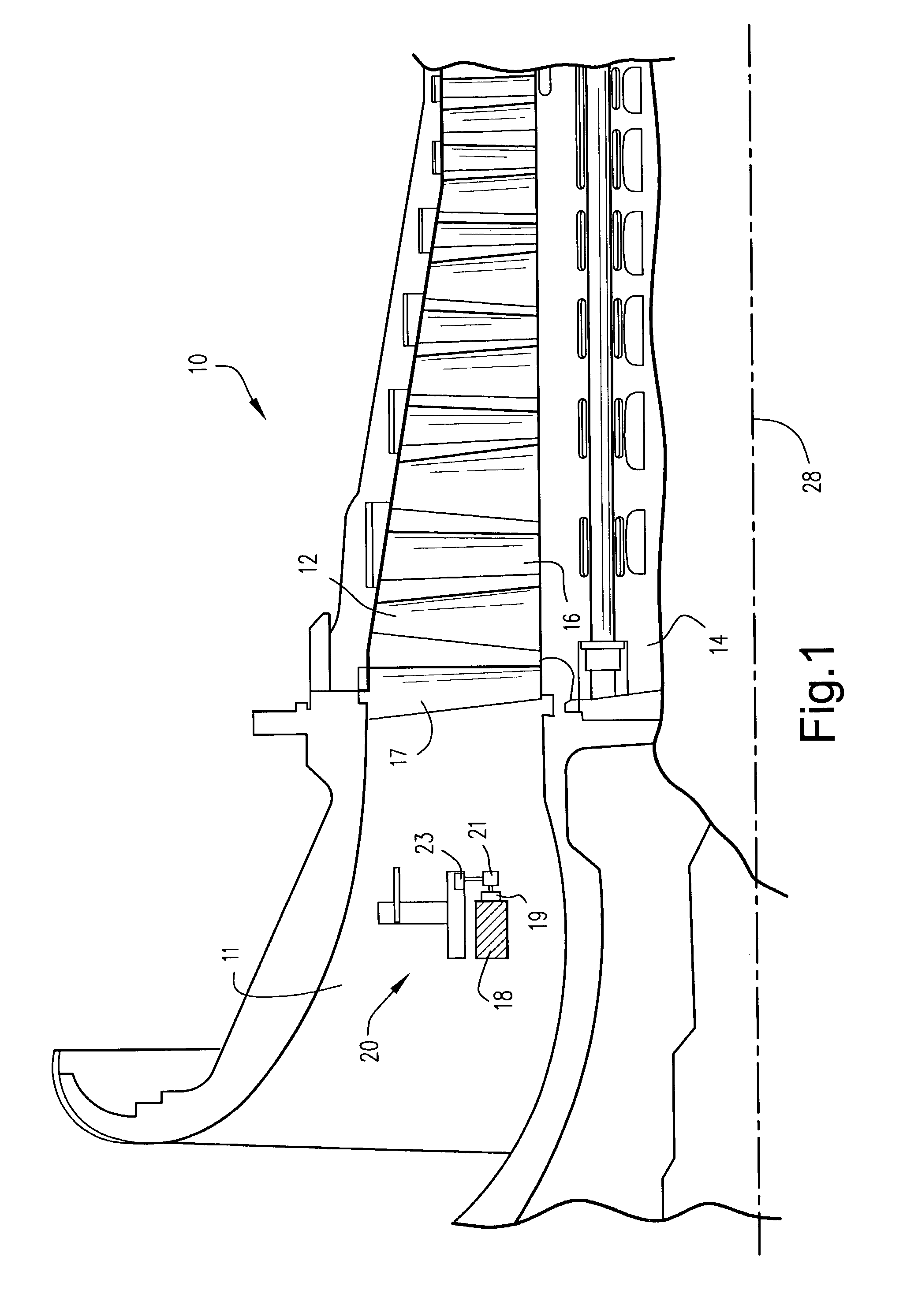

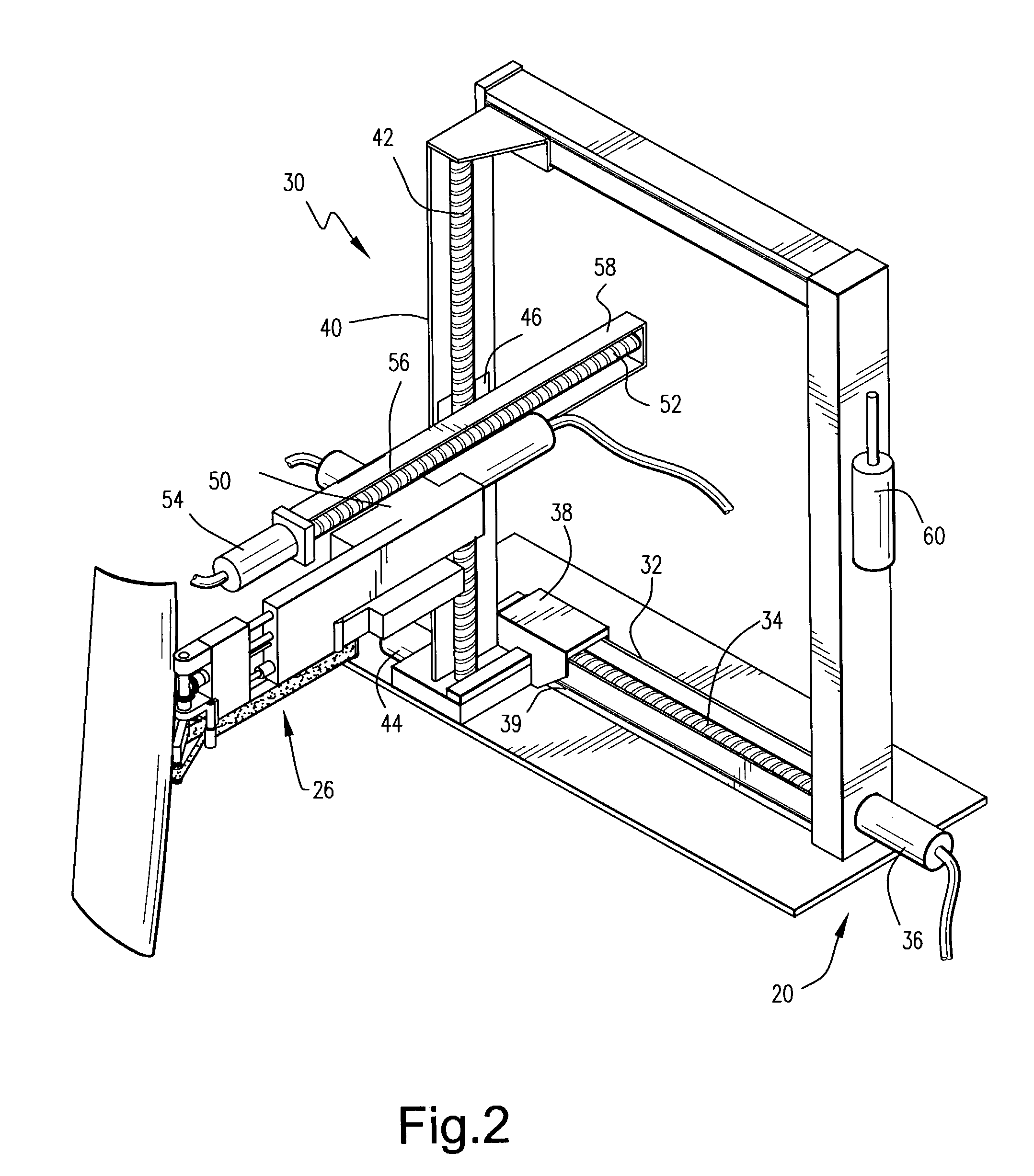

Apparatus and methods for repairing compressor airfoils in situ

InactiveUS7032279B2Maximize impactFine surfacePump componentsAssembly machinesEngineeringManipulator

The apparatus includes a track mounted in the inlet of a compressor. A manipulator is mounted for movement about the track and carries three modules, the last of which mounts a tool head for movement in a Cartesian coordinate system and about the track. A measuring head measures the location of the airfoil surface. An abrading tool mounted on the third module removes surface material from the airfoil. Subsequently, a shot-peening device, either a flapper with embedded shot or free shot is impacted against the abraded surface to strengthen the surface. Final inspection is performed by a light and camera head mounted on the third module.

Owner:GENERAL ELECTRIC CO

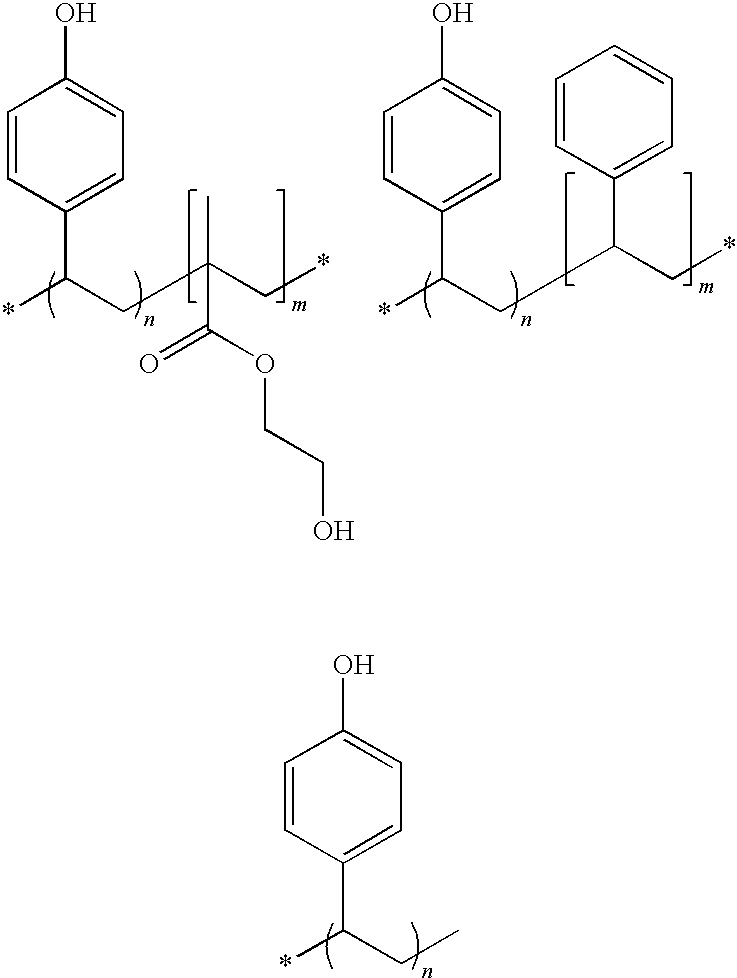

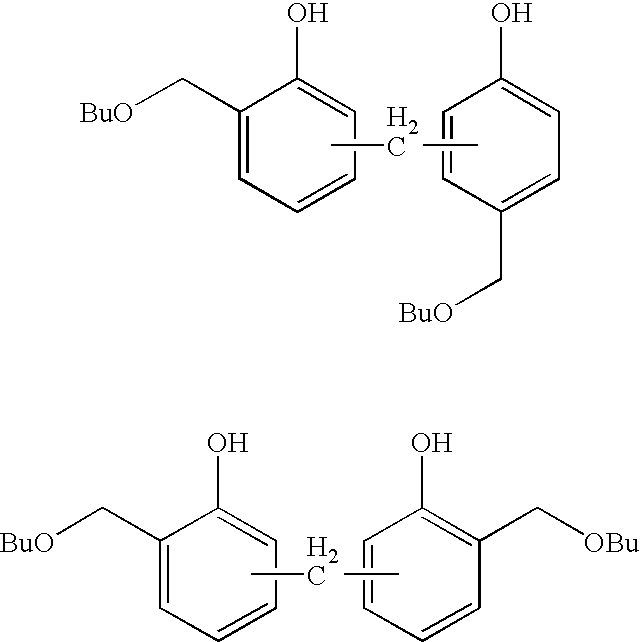

Uv curable hybridcuring ink jet ink composition and solder mask using the same

InactiveUS20090163615A1Improve adhesionImprove impact resistanceImpression capsInksCross-linkSolder mask

The present application provides a latent ink-jet ink formulation suitable as solder mask. The composition generally comprises: (a) at least one compound capable of self cross-linking (USM); (b) at least one phenolic resin; (c) at least one solvent; (d) at least one mineral filler; (e) at least one polyol; and (f) at least one photoinitiator.

Owner:CAMTEK LTD

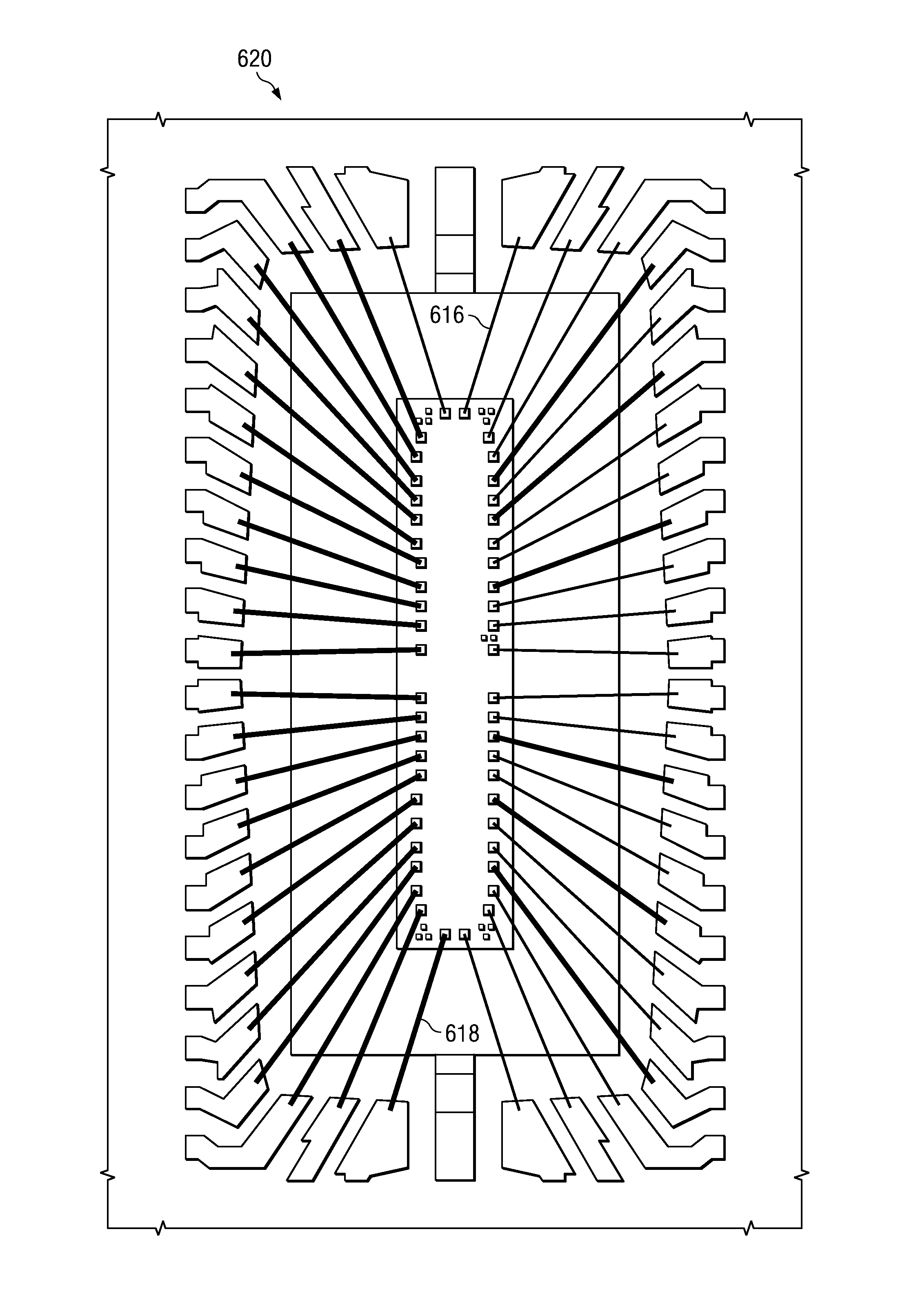

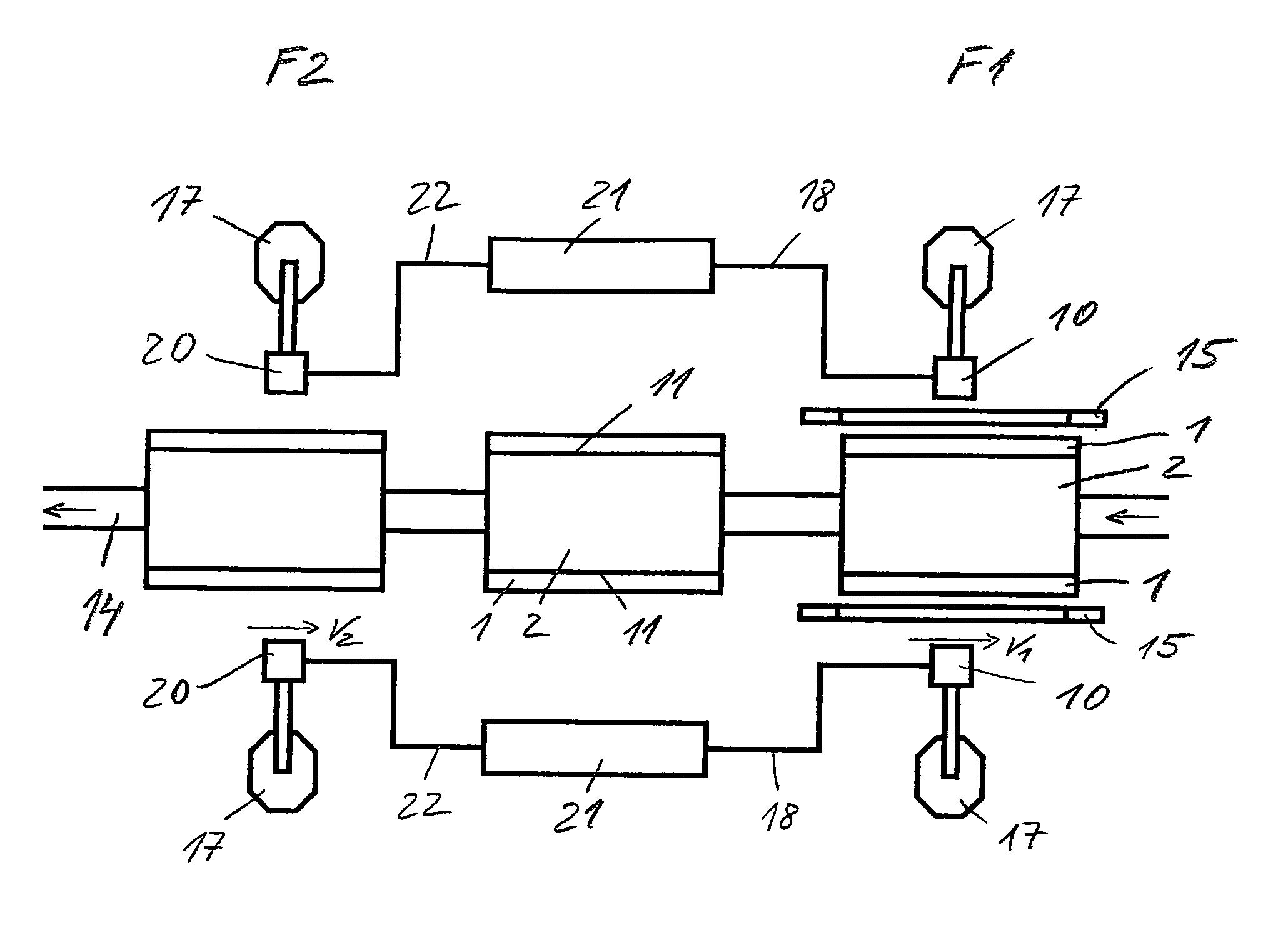

Automatic soldering system

InactiveUS20120055975A1Easy to assembleImprove pass ratePrinted circuit assemblingWelding/cutting auxillary devicesControl systemEngineering

An automatic soldering system includes a conveyance mechanism, a vehicle, a first part assembling mechanism, a first soldering mechanism, a turn-over mechanism, a second part assembling mechanism, a second soldering mechanism, and a control system. The vehicle is conveyed by the conveyor mechanism for carrying a workpiece. The first part assembling mechanism and the first soldering mechanism assemble and solder a first part to the primary workpiece carried by the vehicle. The turn-over mechanism turns the vehicle that is conveyed by the conveyor mechanism and carries the primary workpiece having the first part assembled thereto by a predetermined angle. The second part assembling mechanism and the second soldering mechanism assemble and solder and position a second part to the primary workpiece. The control system is electrically connected to and thus controls the first part and second part assembling mechanisms, the first and second soldering mechanisms, and the turn-over mechanism.

Owner:CHENG UEI PRECISION IND CO LTD

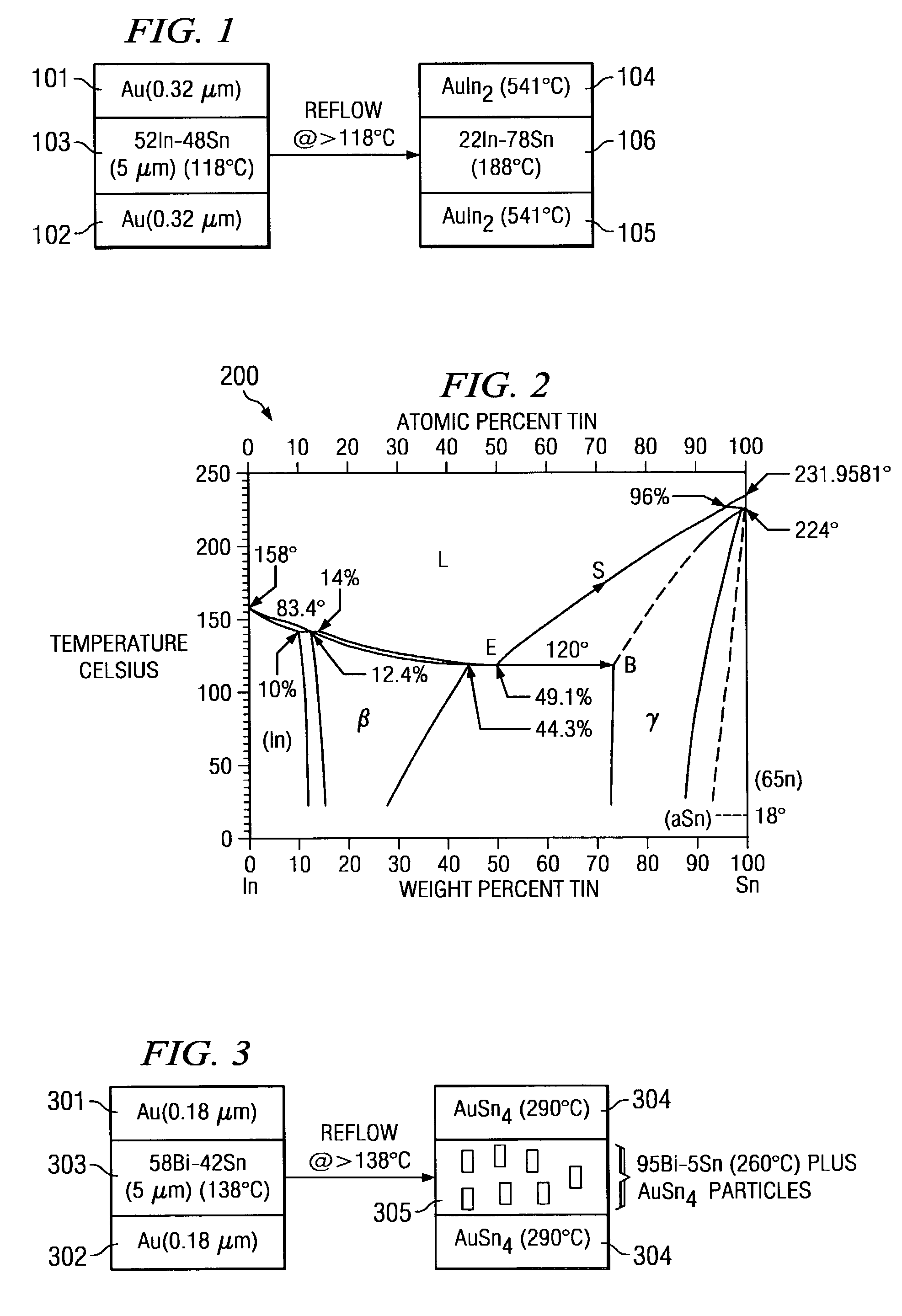

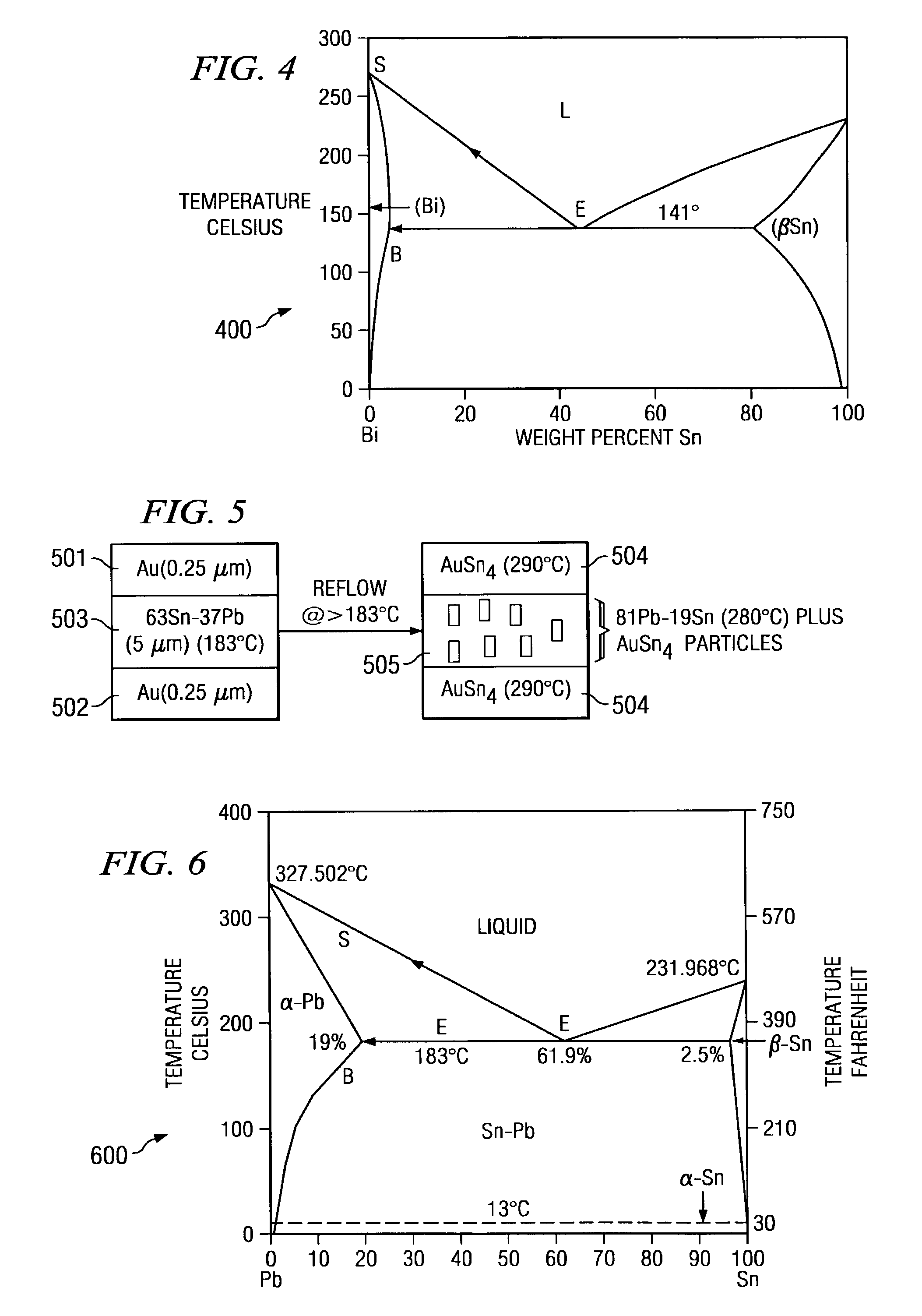

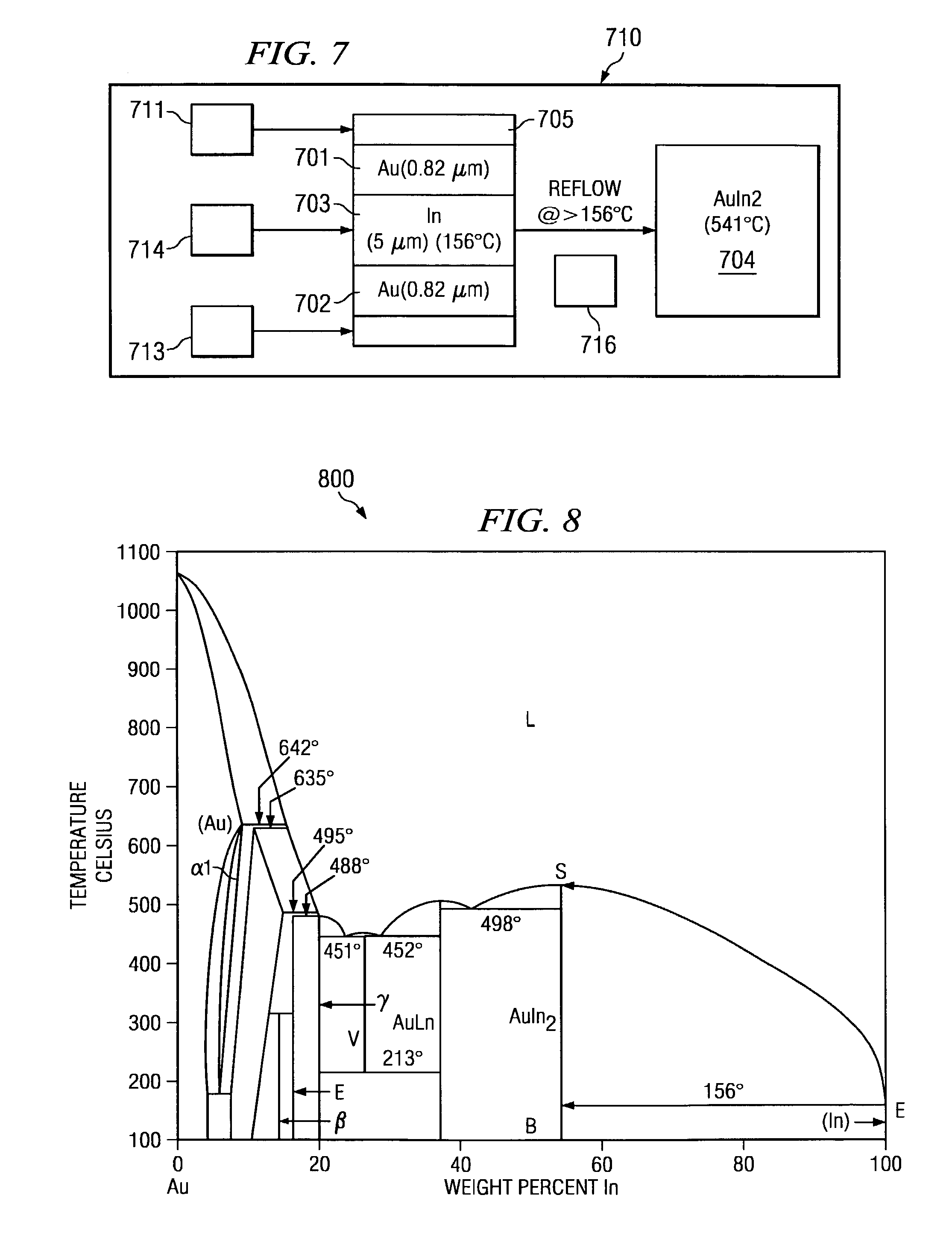

System and method for hermetic seal formation

InactiveUS7168608B2High melting temperatureMinimize thermal induced warpageEngine sealsSolid-state devicesMetallurgyHermetic seal

System and method for formation of a hermetic seal with an significantly greater melting temperature than the melting temperature of the solder employed. The hermetic seal is formed from a solder with a low melting point and a metal having a predetermined thickness that corresponds to the solder. The solder and metal combination undergoes reflow for a period of time relative to the solder thickness. The resultant seal has a melting point at a temperature significantly greater than the melting temperature of the solder.

Owner:AVAGO TECH INT SALES PTE LTD

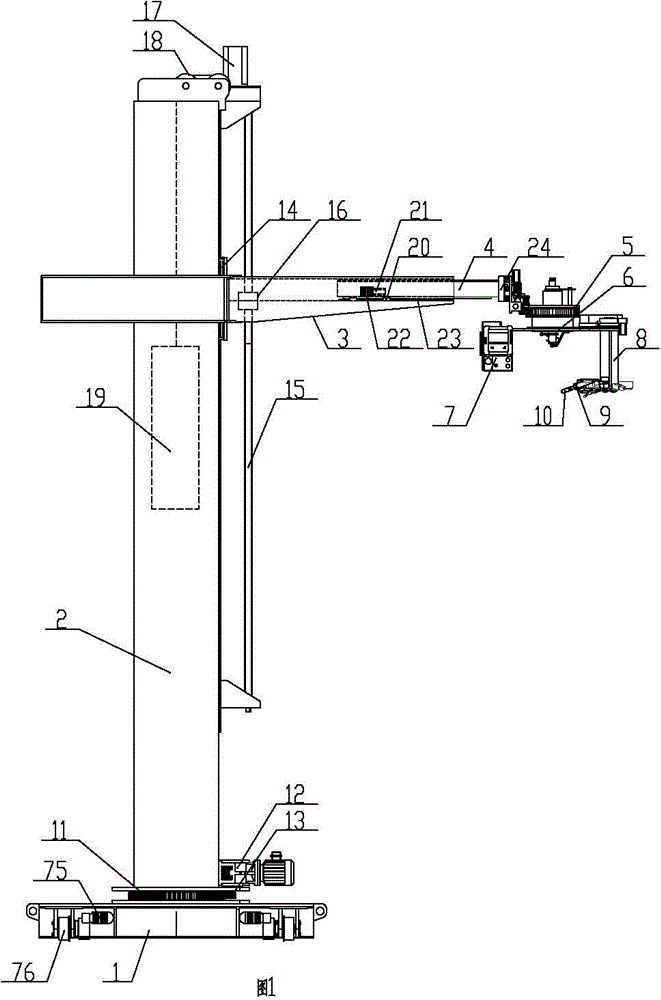

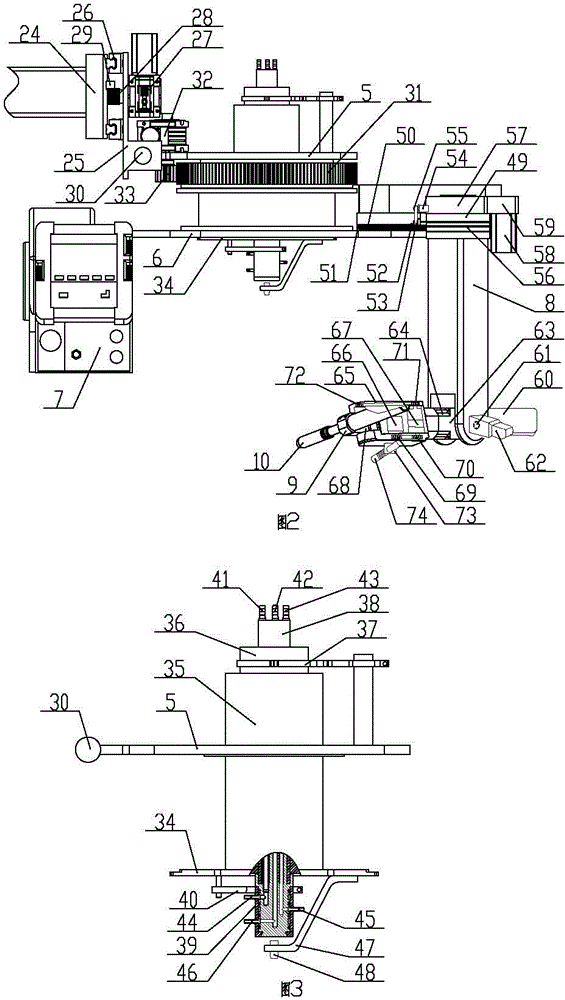

Multifunctional single-cantilever cutting and welding integrated machine

InactiveCN104308333AAvoid frequent movementReduce the number of card positioningWelding/cutting auxillary devicesAuxillary welding devicesFillet weldEngineering

The invention relates to the technical field of automated cutting and welding, and discloses a multifunctional single-cantilever cutting and welding integrated machine. The integrated machine comprises a machine frame base, a machine frame stand column, a stand column rotary device, a vertical lifting device, a machine frame transverse arm, a left-right translation device, a telescopic arm, a front-rear transverse moving device and a multi-joint machine head, wherein the machine frame stand column is mounted on the machine frame base through the stand column rotary device, and the machine frame transverse arm is mounted at the upper part of the machine frame stand column through the vertical lifting device. The integrated machine is reasonable and compact in structure and convenient to use; the welding of longitudinal, circumferential and fillet weld seams, cutting of an intersecting line hole and automatic welding of a saddle-shaped weld seam between a barrel body and a connecting pipe can be finished in a relatively fixed station through the stand column rotary device, the vertical lifting device, the left-right translation device, the front-rear transverse moving device and the multi-joint machine head, the frequent motion of a workpiece can be avoided, the clamping and positioning frequency of the workpiece is greatly reduced, the welding efficiency and quality are remarkably improved, and the labor intensity of welding workers is reduced.

Owner:新疆威奥科技股份有限公司

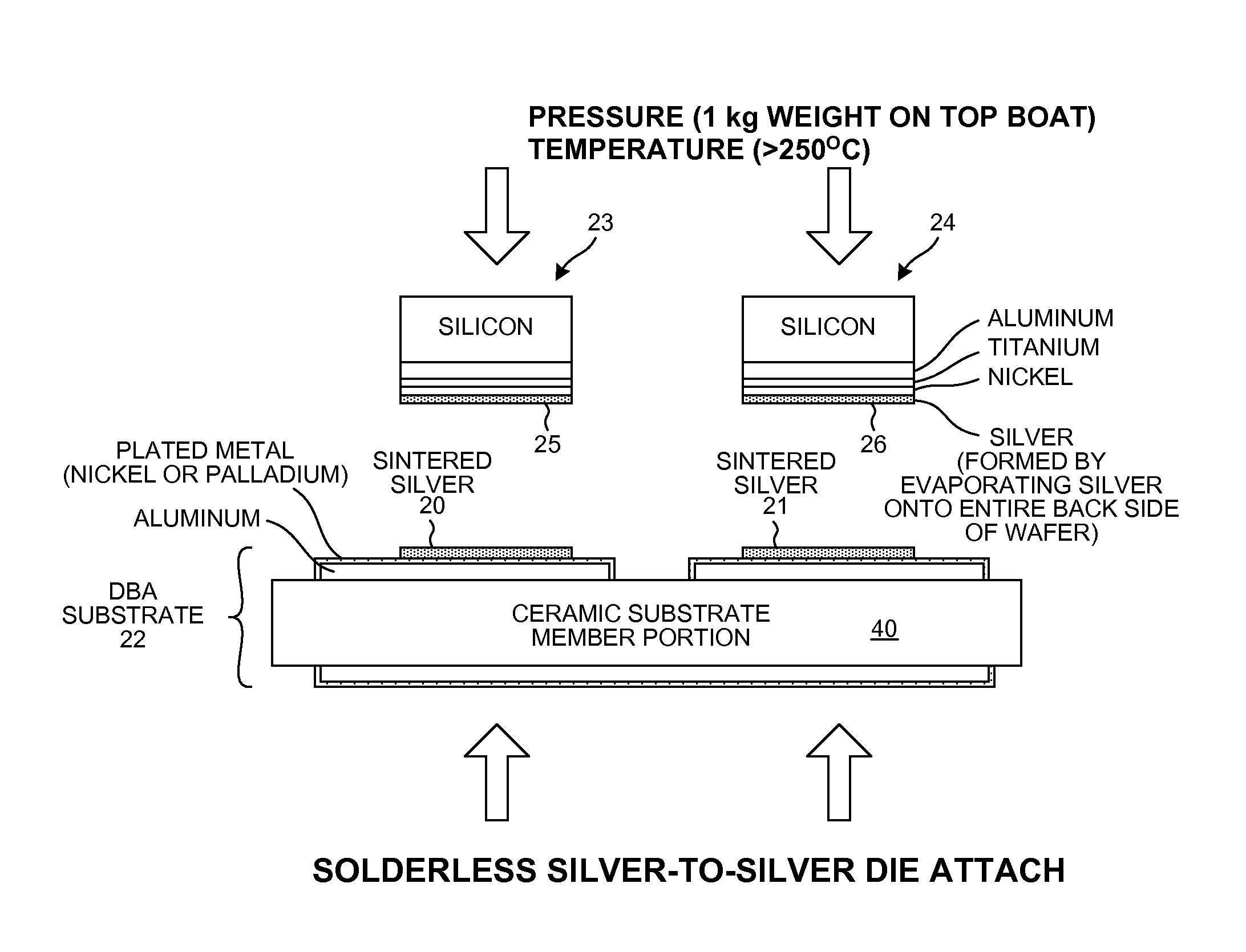

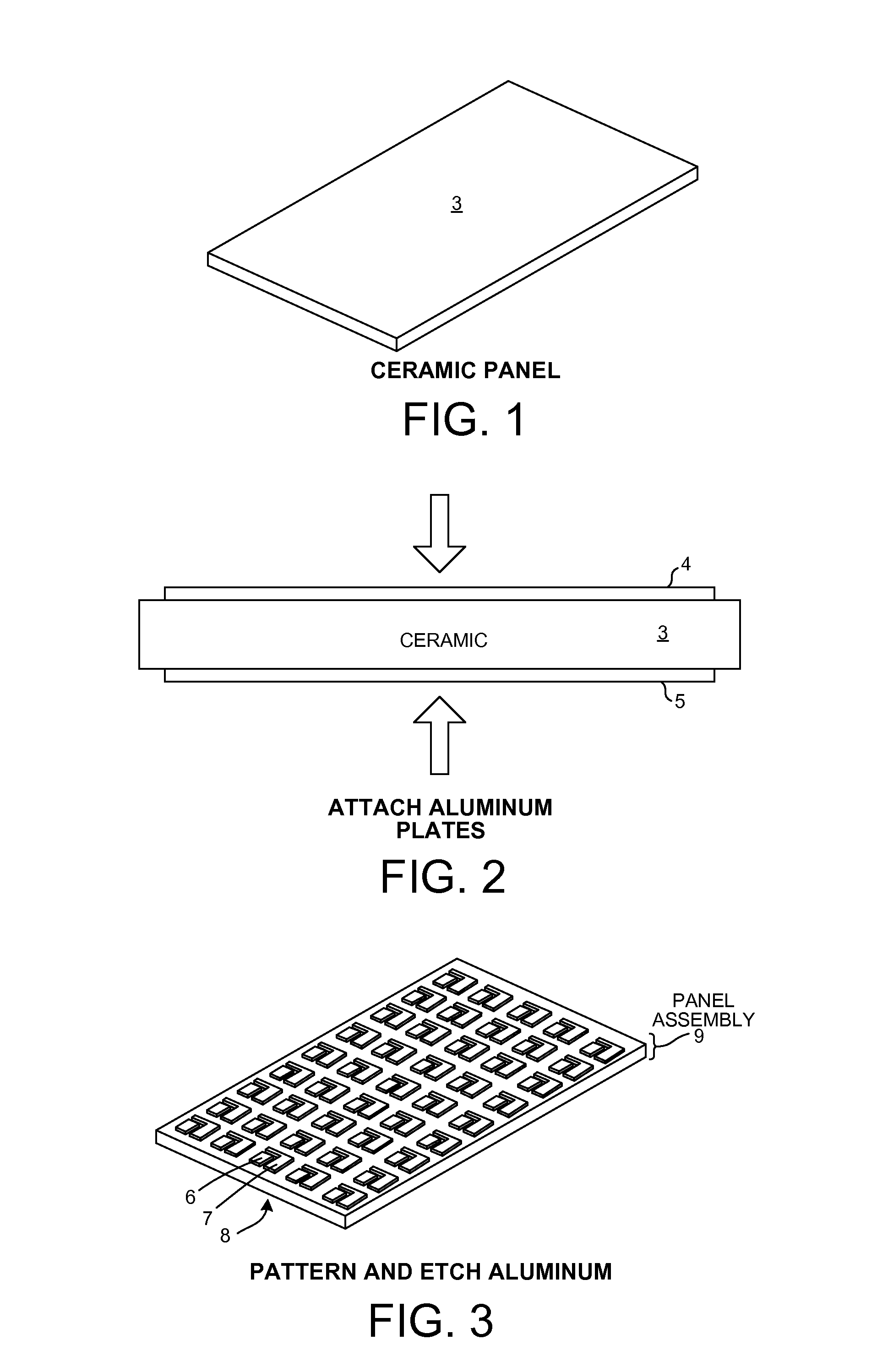

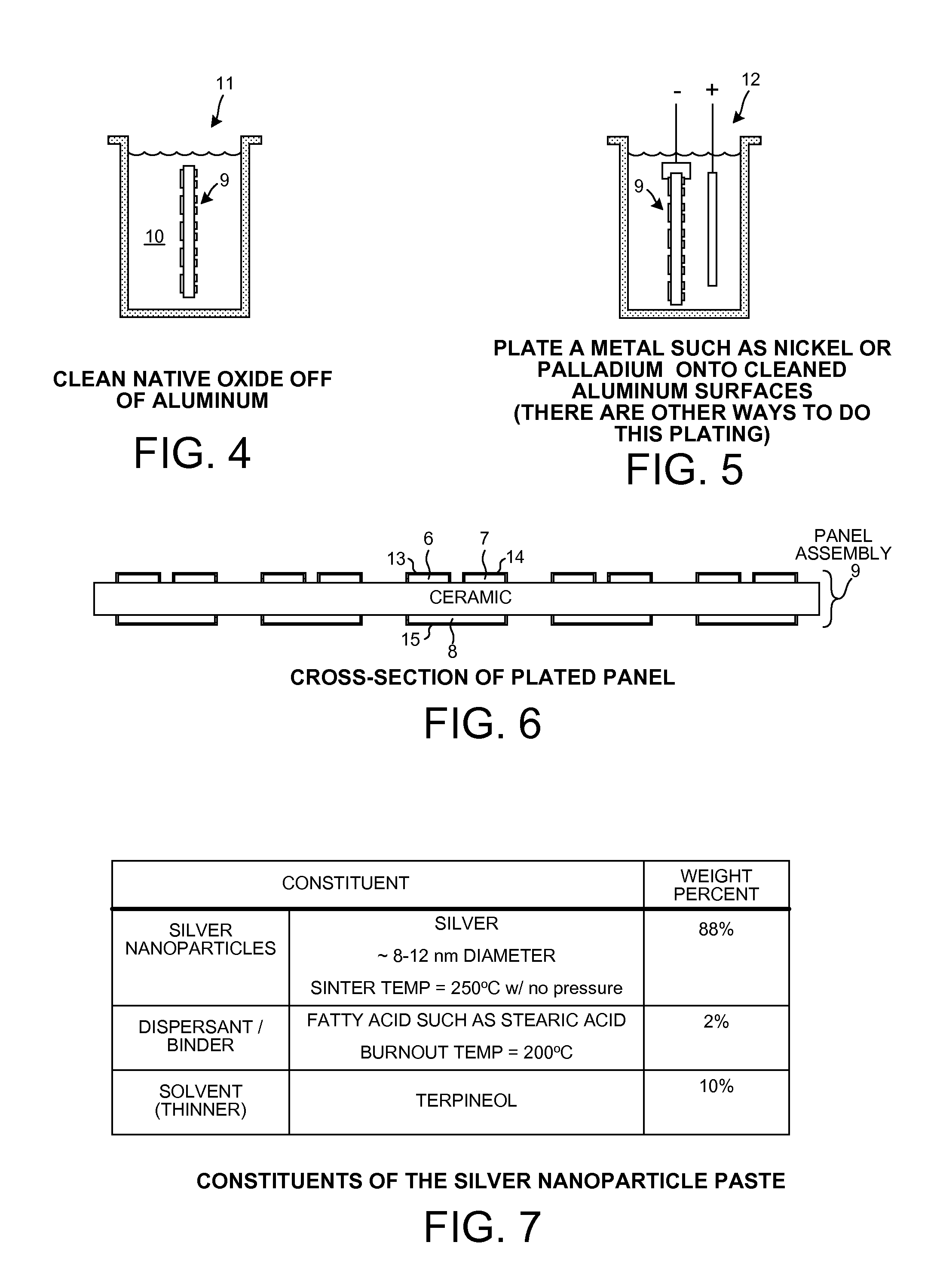

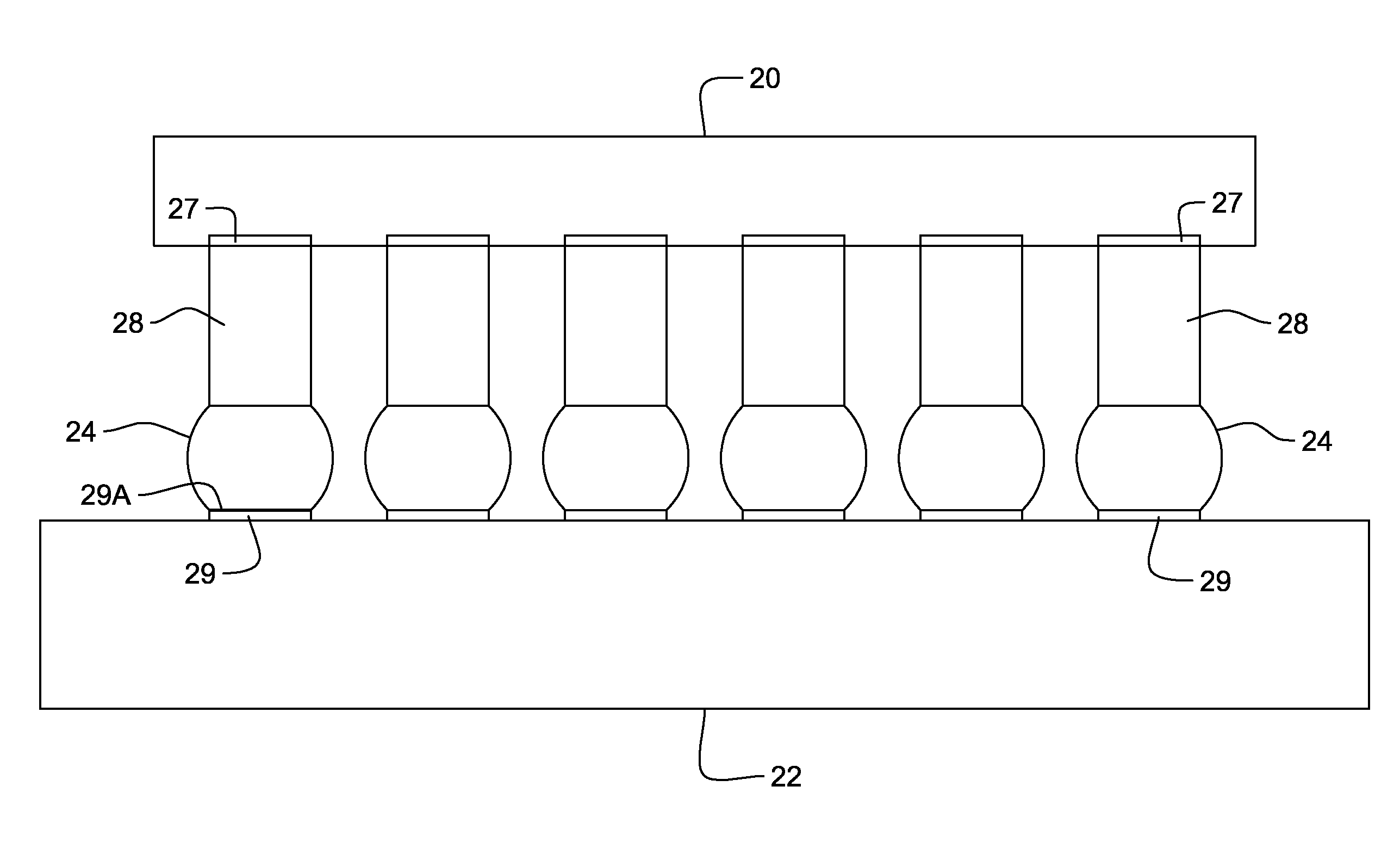

Solderless Die Attach to a Direct Bonded Aluminum Substrate

ActiveUS20130328204A1Cooking-vessel materialsSemiconductor/solid-state device detailsLead bondingLead frame

A DBA-based power device includes a DBA (Direct Bonded Aluminum) substrate. An amount of silver nanoparticle paste of a desired shape and size is deposited (for example by micro-jet deposition) onto a metal plate of the DBA. The paste is then sintered, thereby forming a sintered silver feature that is in electrical contact with an aluminum plate of the DBA. The DBA is bonded (for example, is ultrasonically welded) to a lead of a leadframe. Silver is deposited onto the wafer back side and the wafer is singulated into dice. In a solderless silver-to-silver die attach process, the silvered back side of a die is pressed down onto the sintered silver feature on the top side of the DBA. At an appropriate temperature and pressure, the silver of the die fuses to the sintered silver of the DBA. After wirebonding, encapsulation and lead trimming, the DBA-based power device is completed.

Owner:LITTELFUSE INC

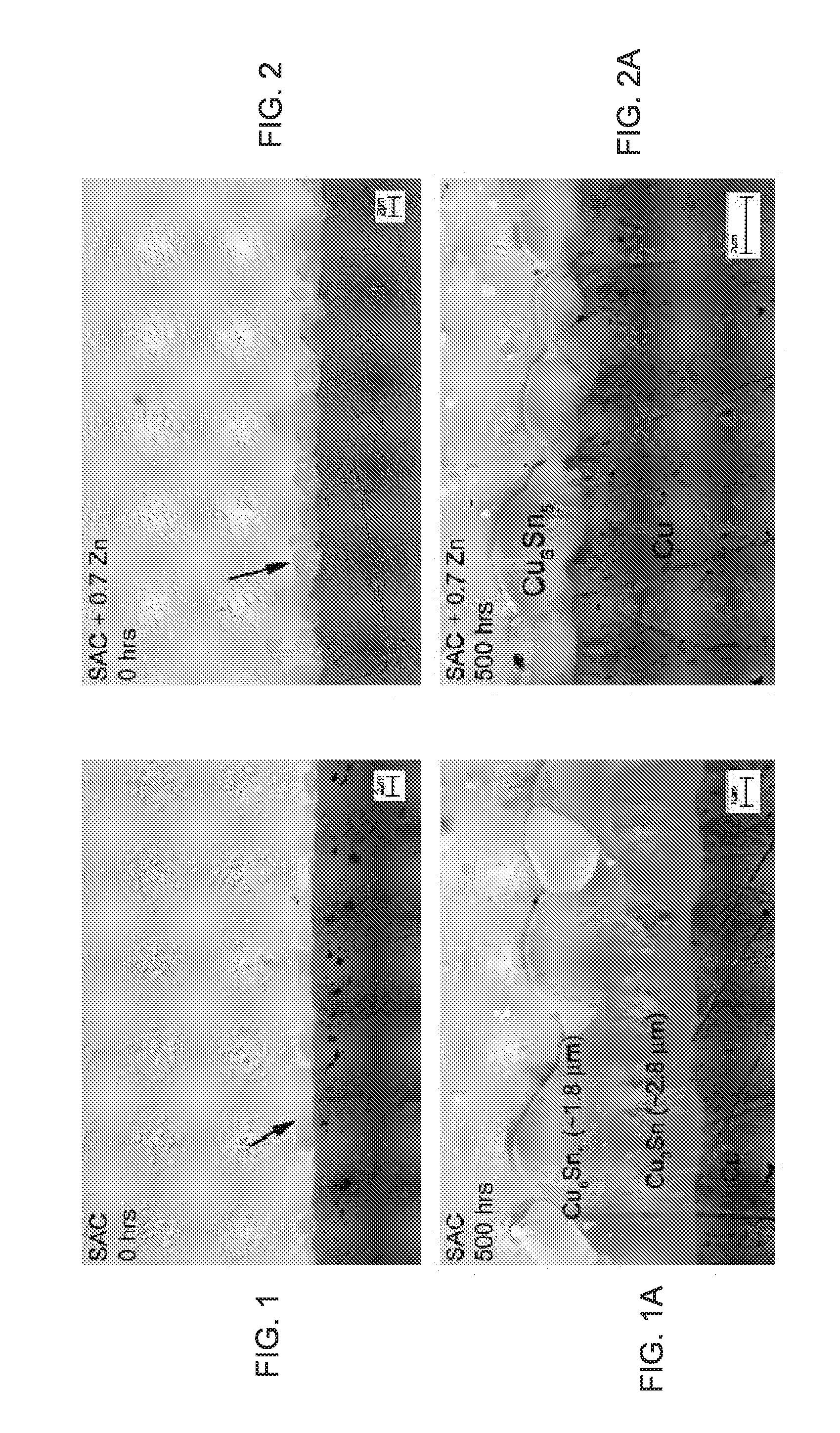

Modification of pb-free solder alloy compositions to improve interlayer dielectric delamination in silicon devices and electromigration resistance in solder joints

InactiveUS20090197114A1Good mechanical integrityImprove reliabilitySolid-state devicesPrinted circuit manufactureDielectricSilicon

A solder joint comprising a solder capture pad on a substrate having a circuit; and a lead free solder selected from the group comprising Sn—Ag—Cu solder and Sn—Ag solder adhered to the solder capture pad; the solder selected from the group comprising between 0.1 to 2.0% by weight Sb or Bi, and 0.5 to 3.0% Ag. Formation of voids at an interface between the solder and the solder capture pad is suppressed, by including Zn. Interlayer dielectric delamination is suppressed, and electromigration characteristics are greatly improved. Methods for forming solder joints using the solders.

Owner:SHIH YUAN +5

Wire bonding method

A ball is formed at the tip of a wire projecting from a capillary. The capillary is positioned above an interconnection, and ball bonding forms a bump on the interconnection. The capillary is then moved next to the bump and wedge bonding is carried out. Next, the capillary is moved upward and another ball is formed at the tip of the wire, and the wire is primary bonded to a bonding pad of a semiconductor chip. The wire is then looped and the capillary is positioned above the bump, and secondary bonding is carried out. As a result, the formation of tails on the bump is prevented.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com