Patents

Literature

288 results about "Ball bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ball bonding is a type of wire bonding, and is the most common way to make the electrical interconnections between a chip and the outside world as part of semiconductor device fabrication. Gold or copper wire can be used, though gold is more common because its oxide is not as problematic in making a weld. If copper wire is used, nitrogen must be used as a cover gas to prevent the copper oxides from forming during the wire bonding process. Copper is also harder than gold, which makes damage to the surface of the chip more likely. However copper is cheaper than gold and has superior electrical properties, and so remains a compelling choice.

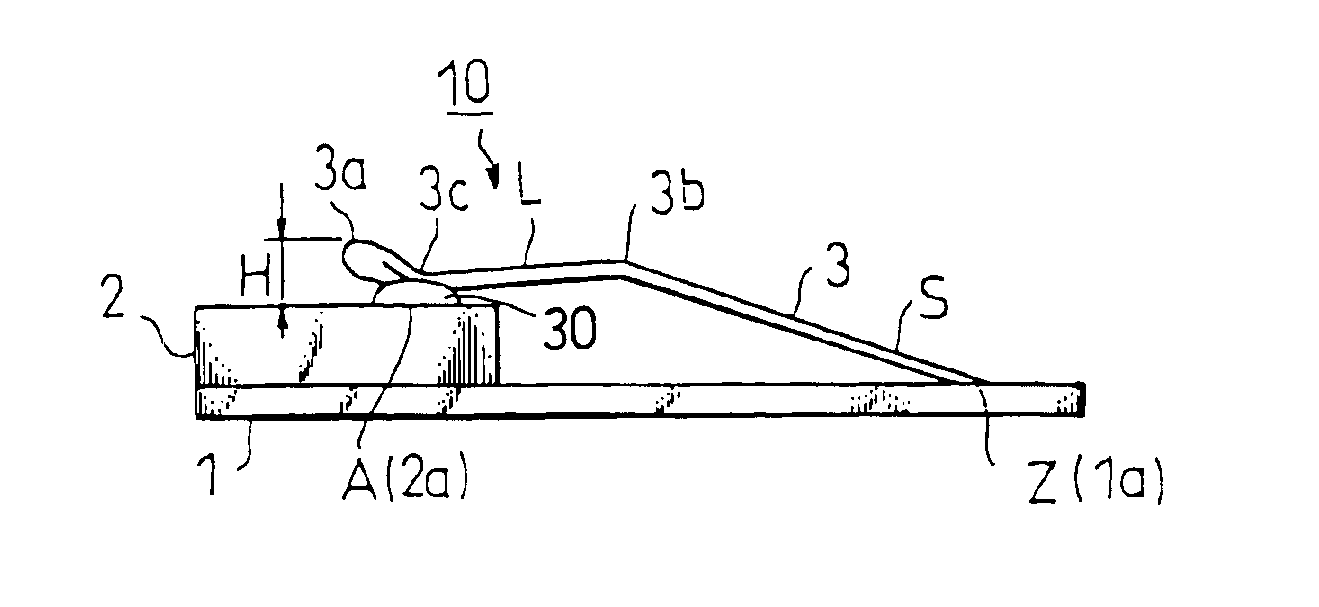

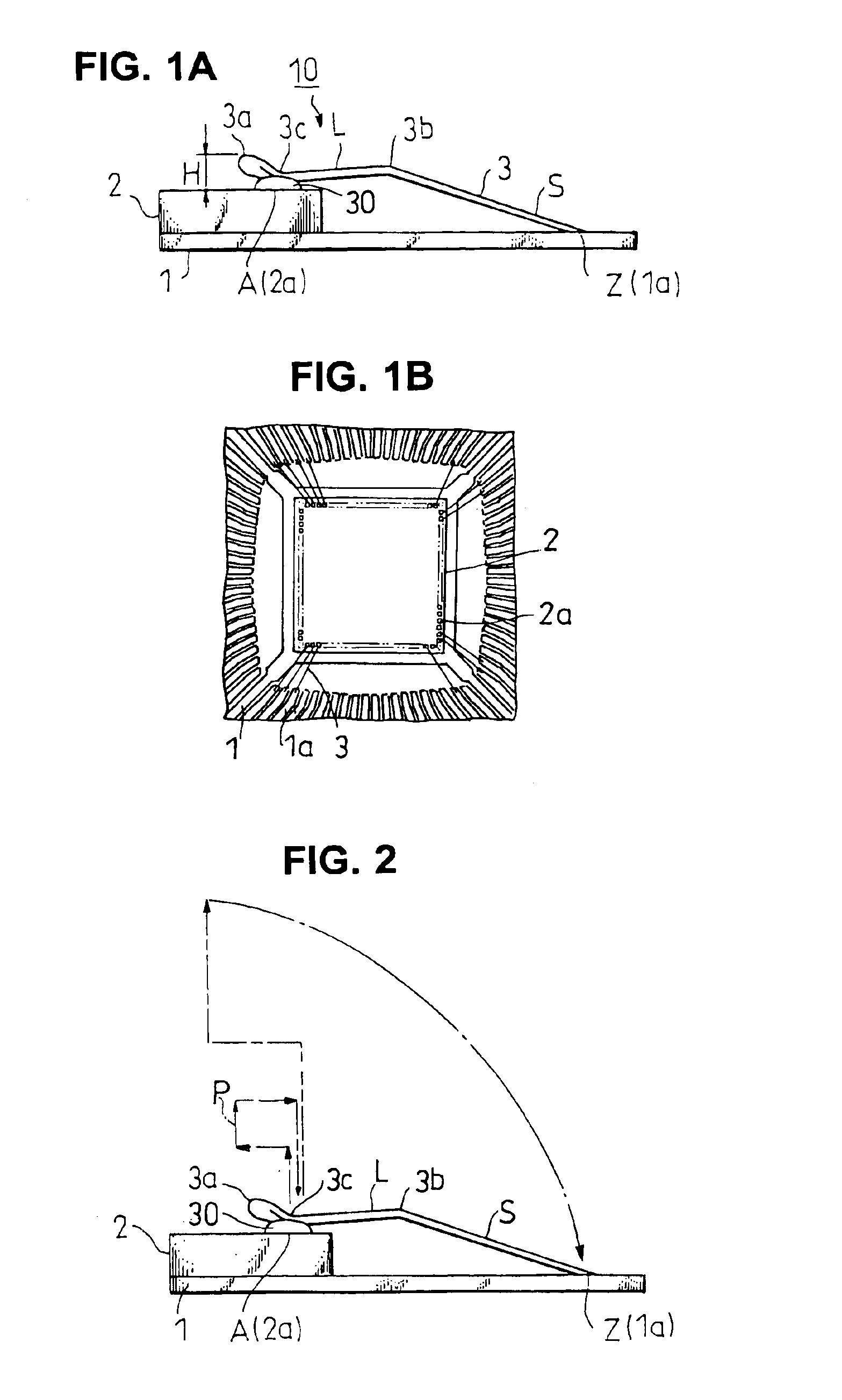

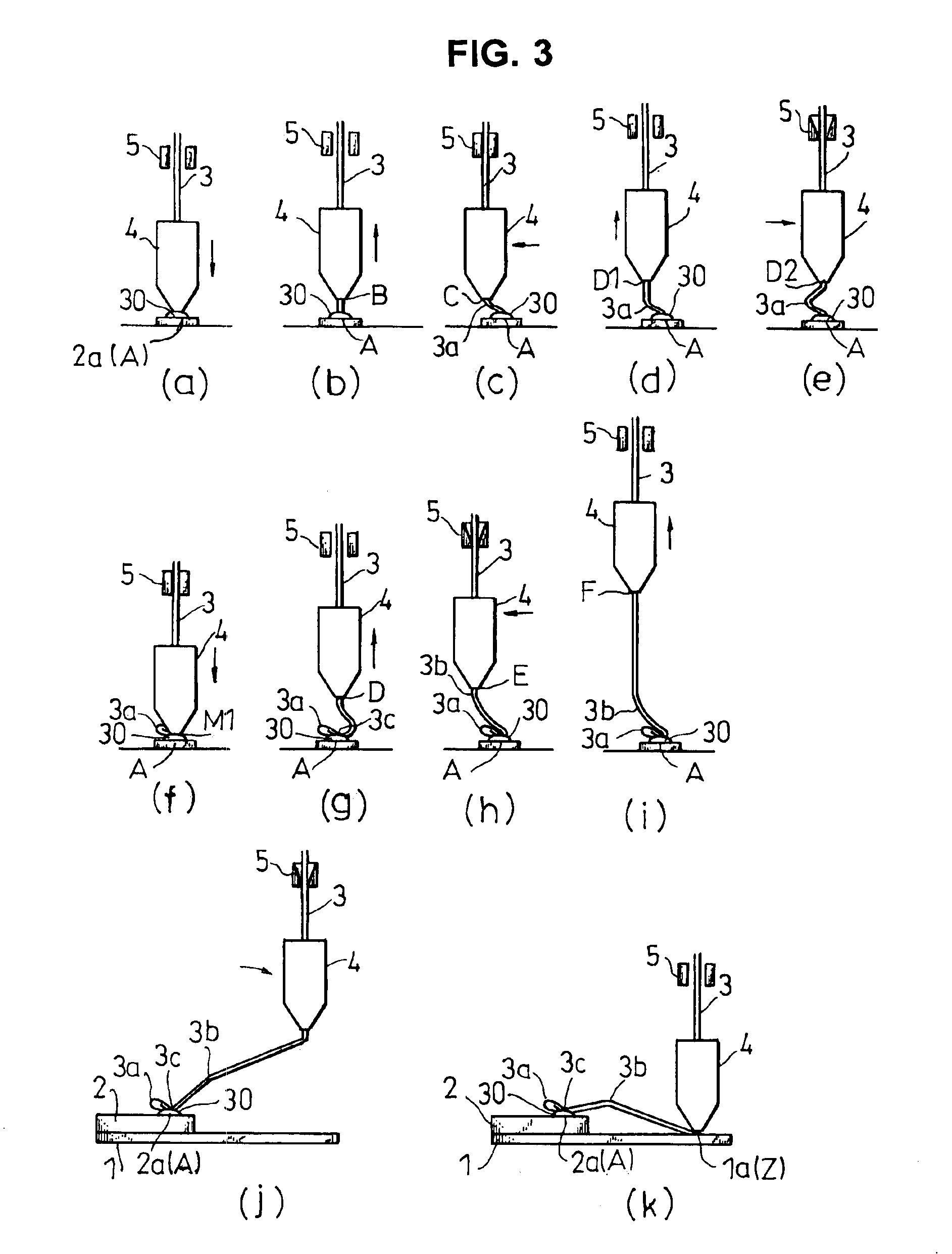

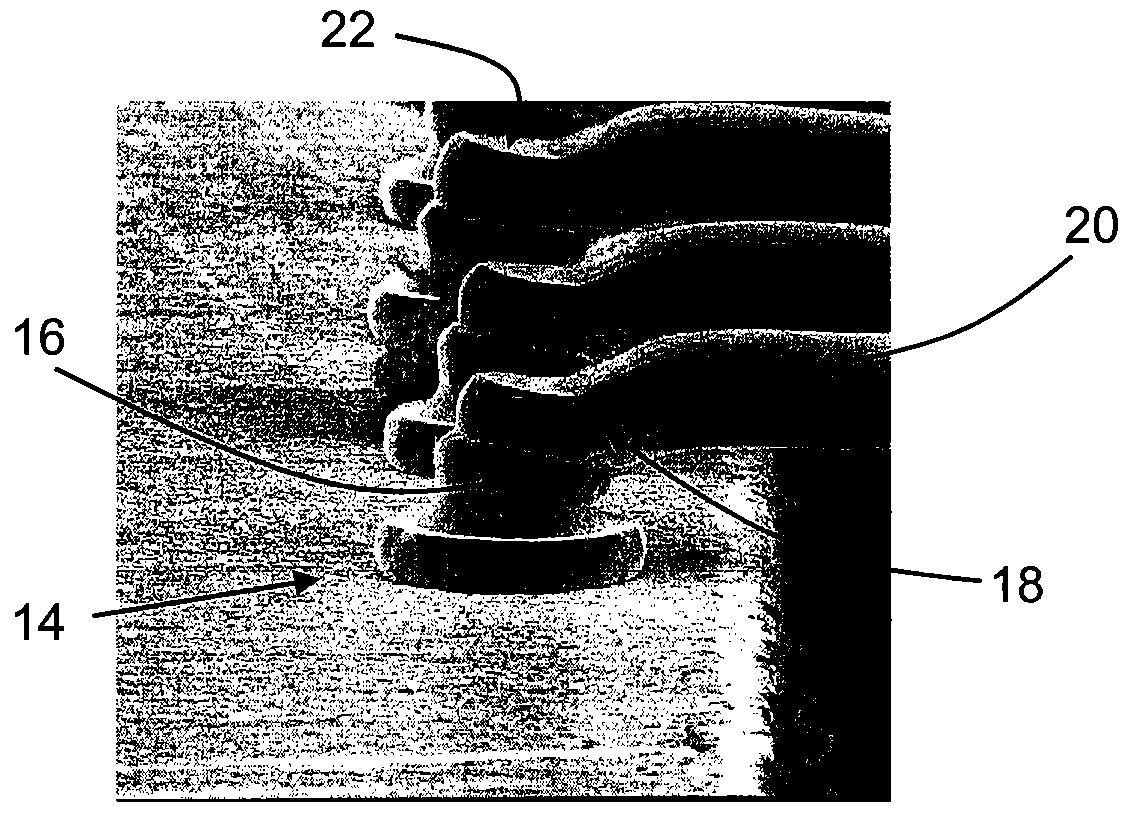

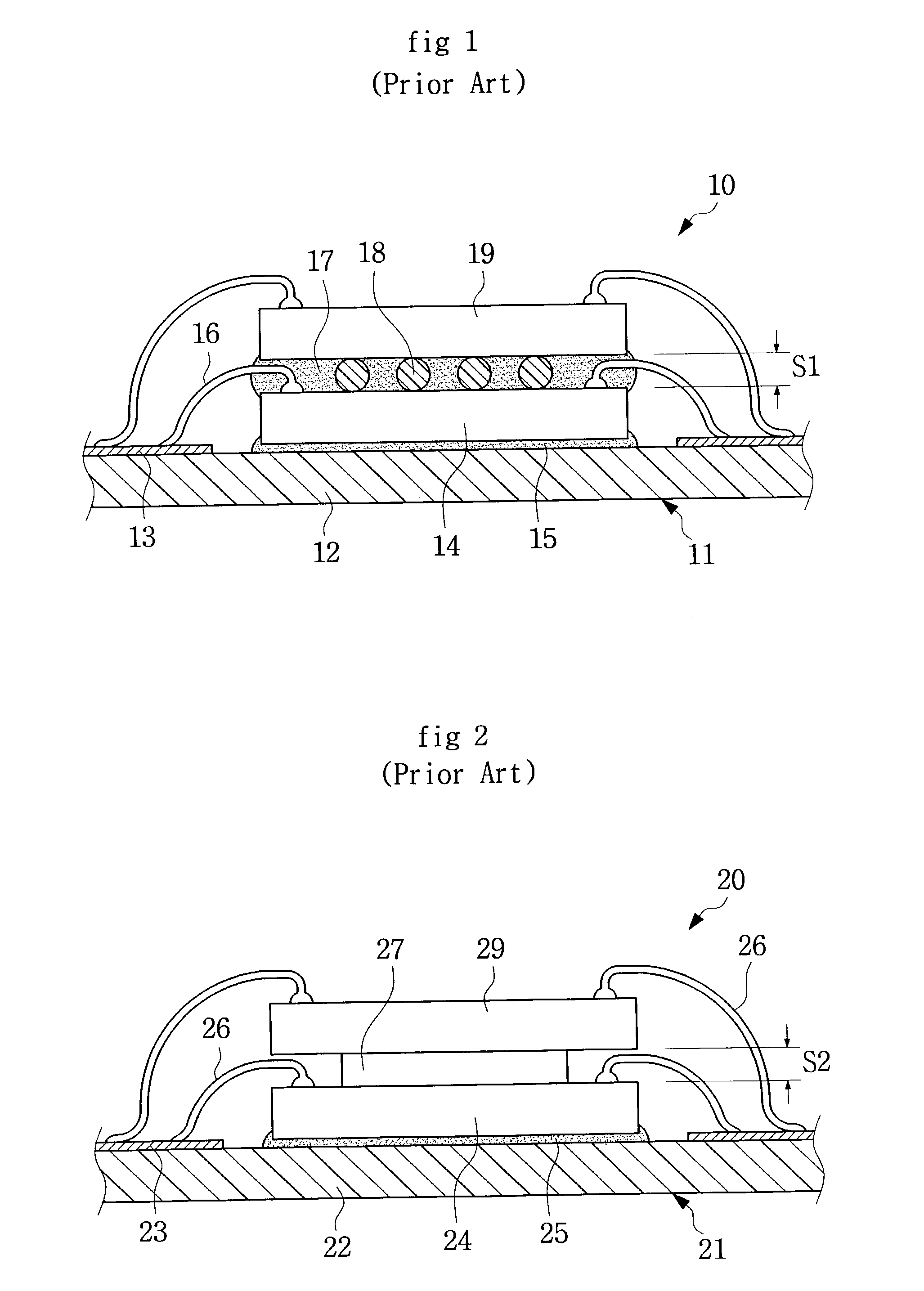

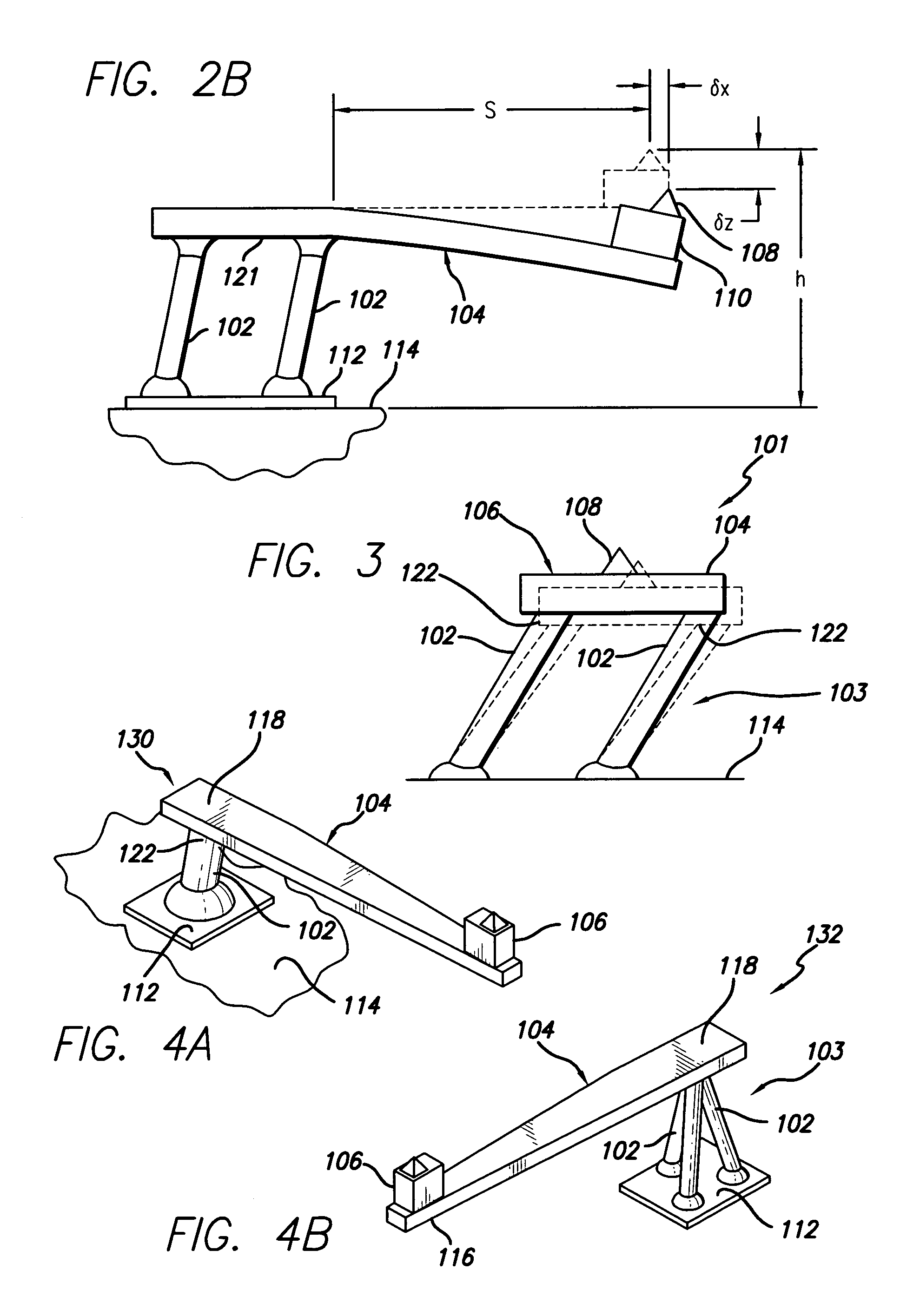

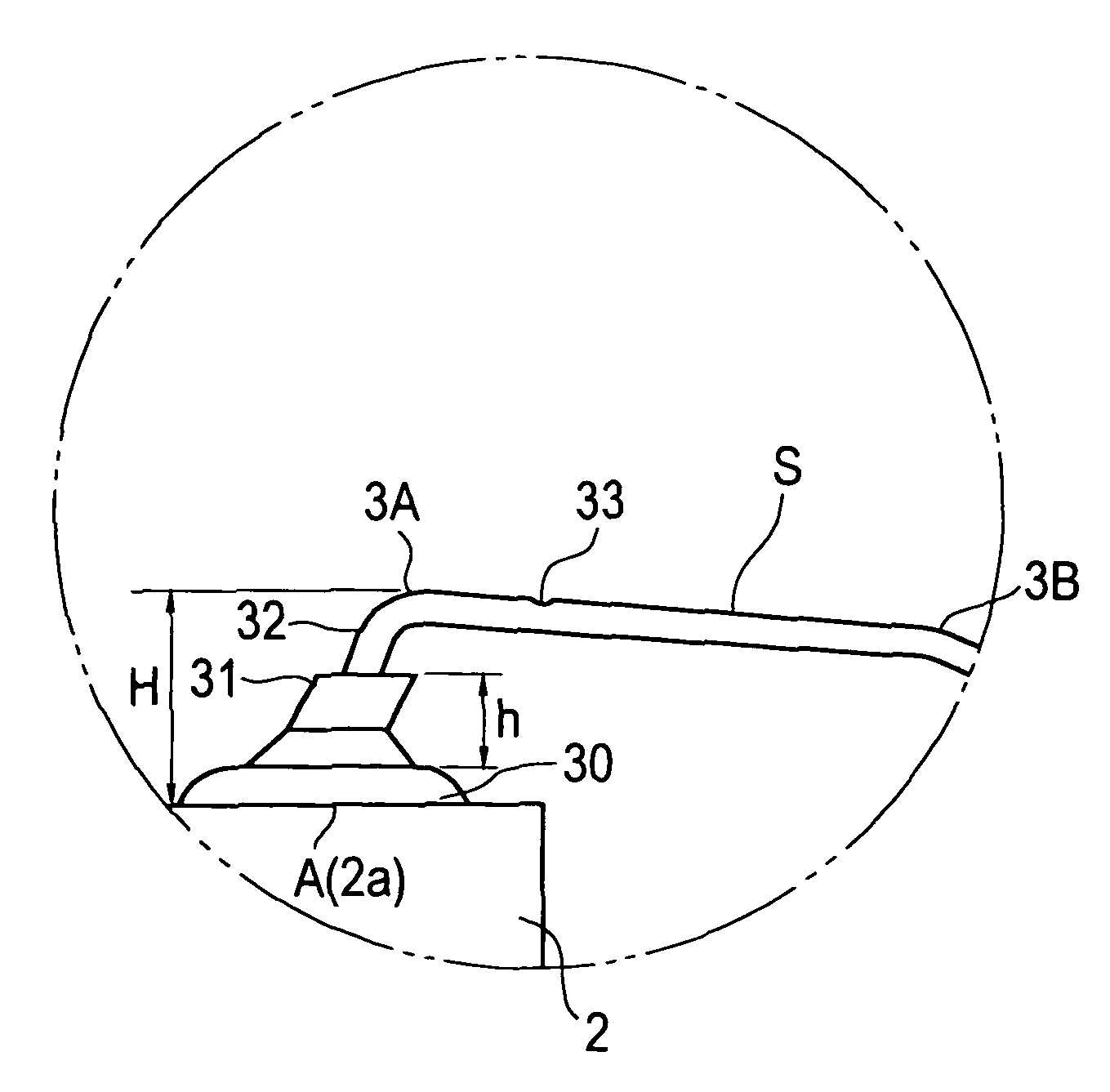

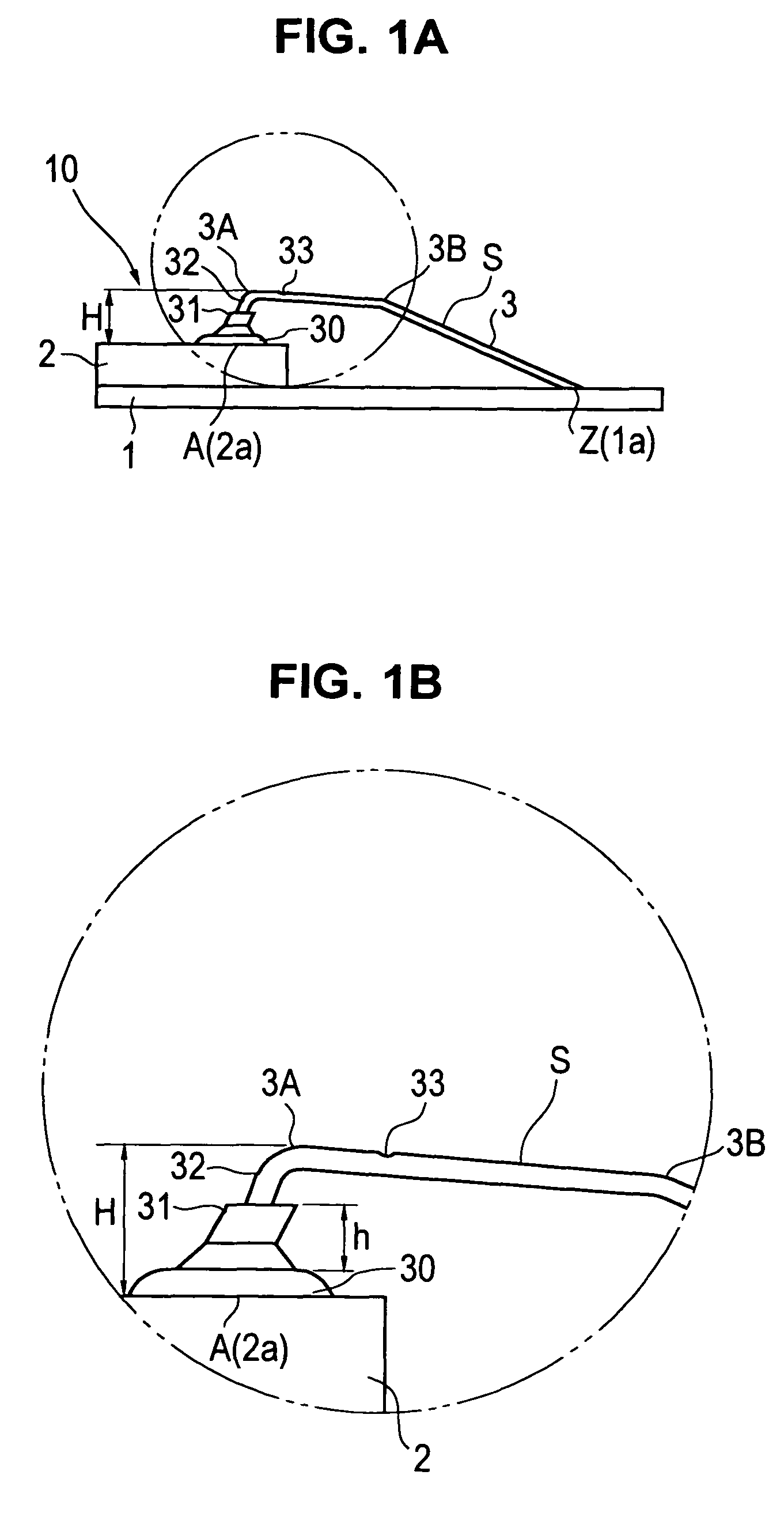

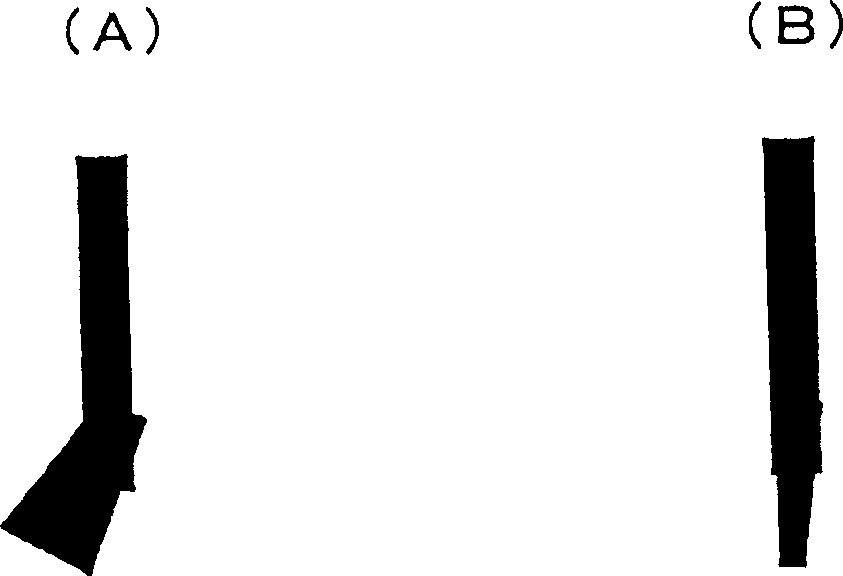

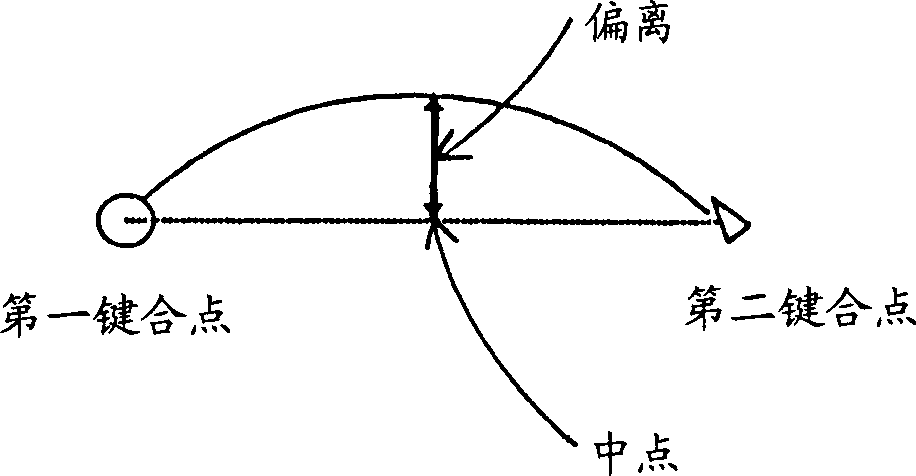

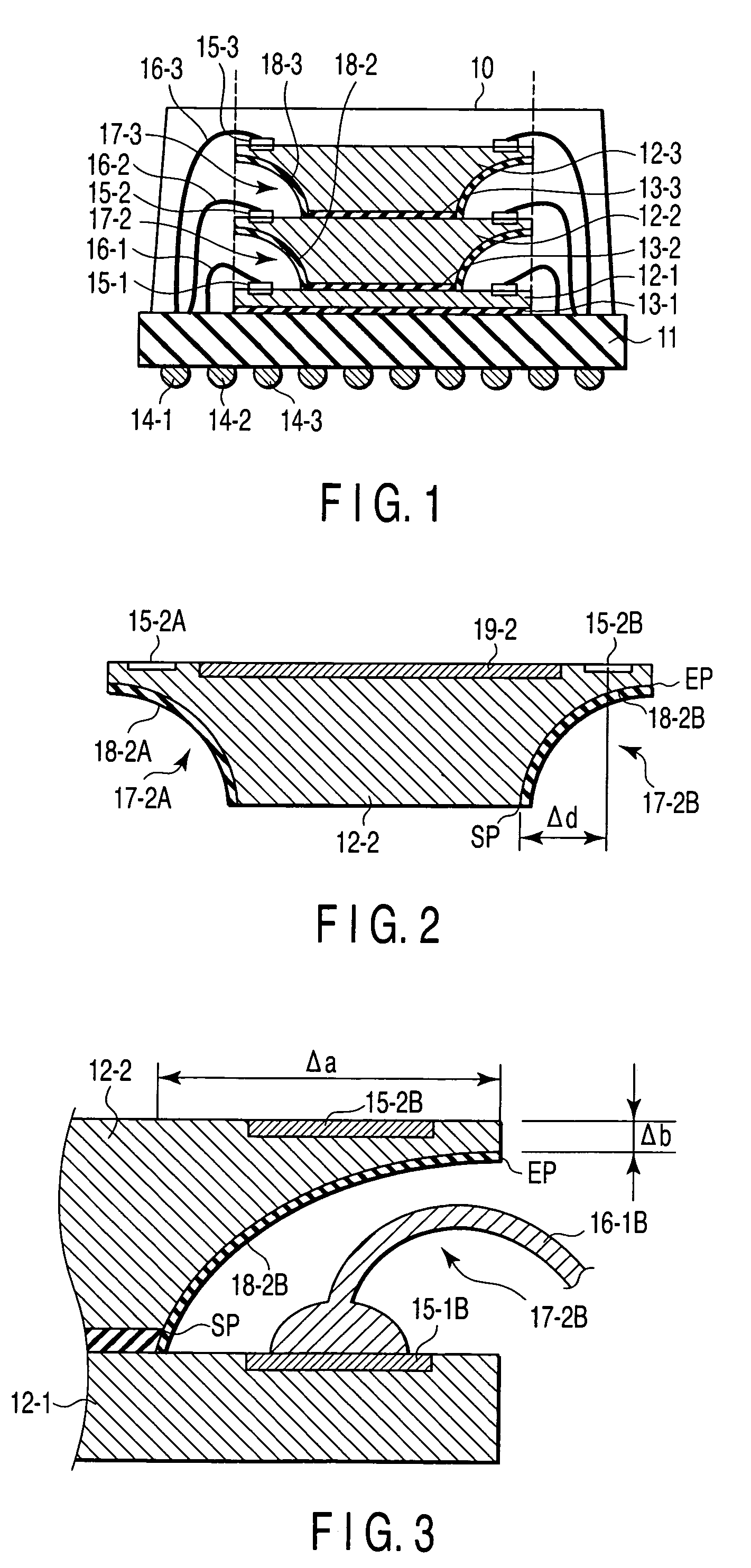

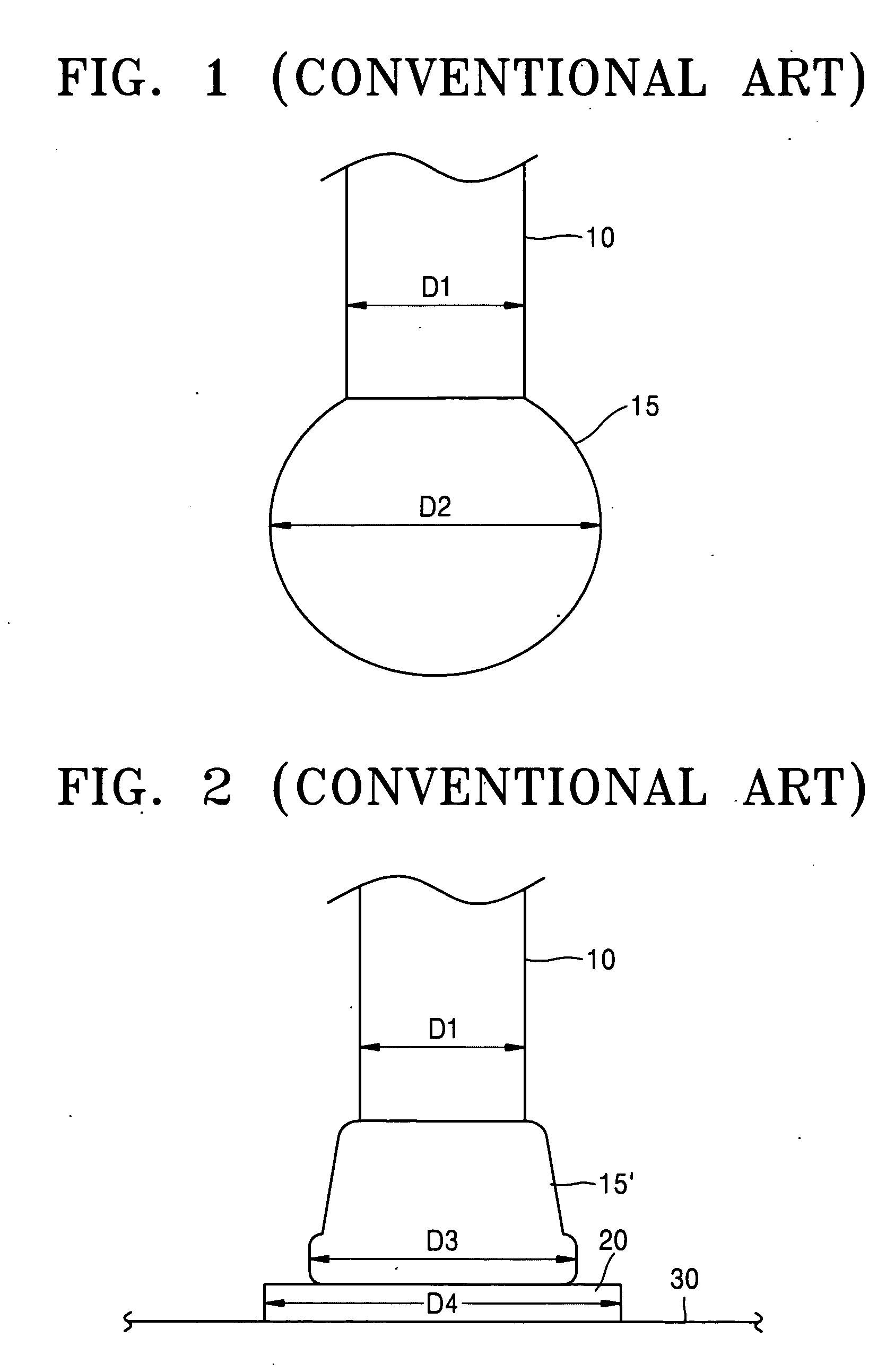

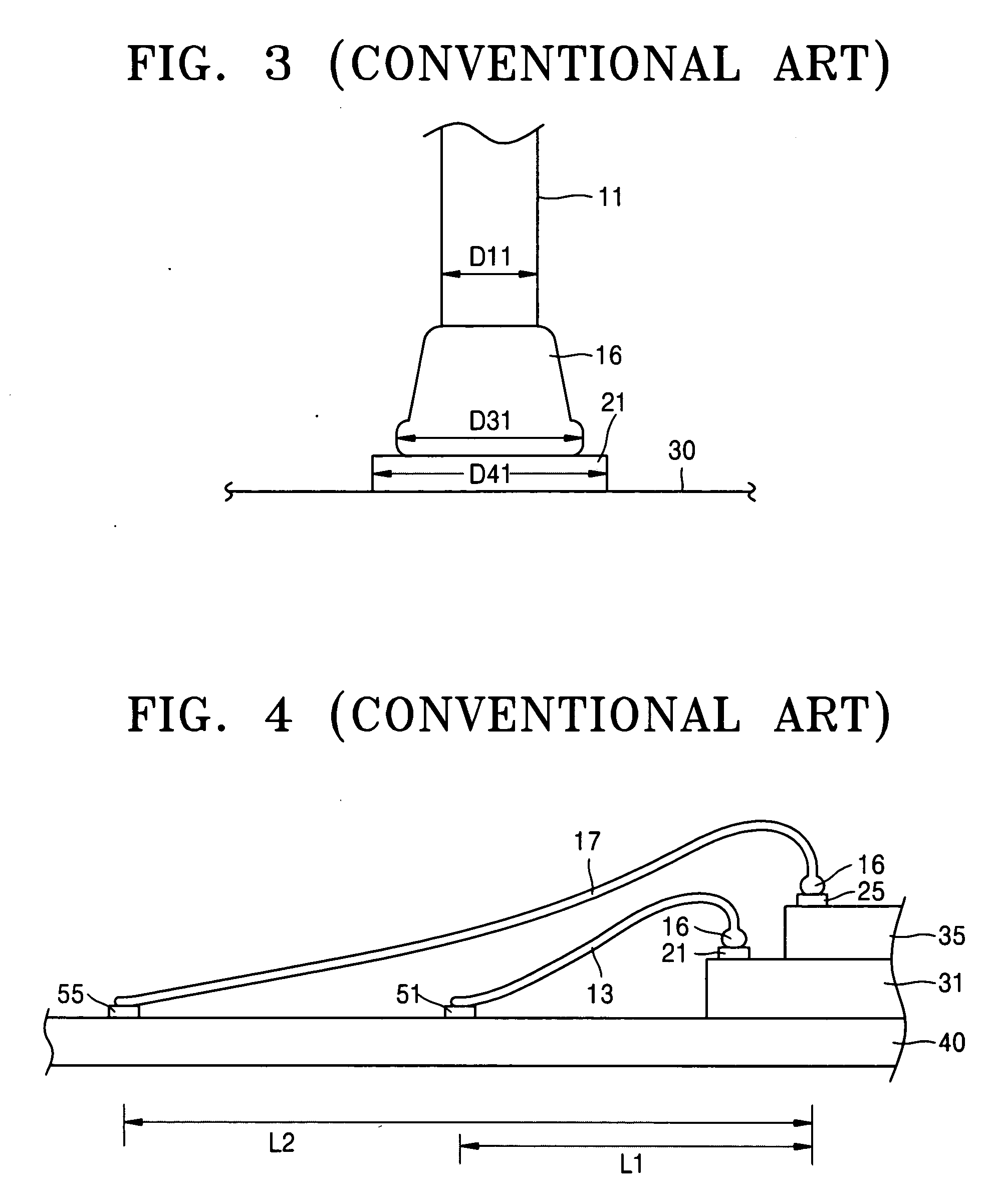

Wire loop, semiconductor device having same, wire bonding method and wire bonding apparatus

InactiveUS6933608B2Low profileNot easy to damageSemiconductor/solid-state device detailsSolid-state devicesWire rodLoop control

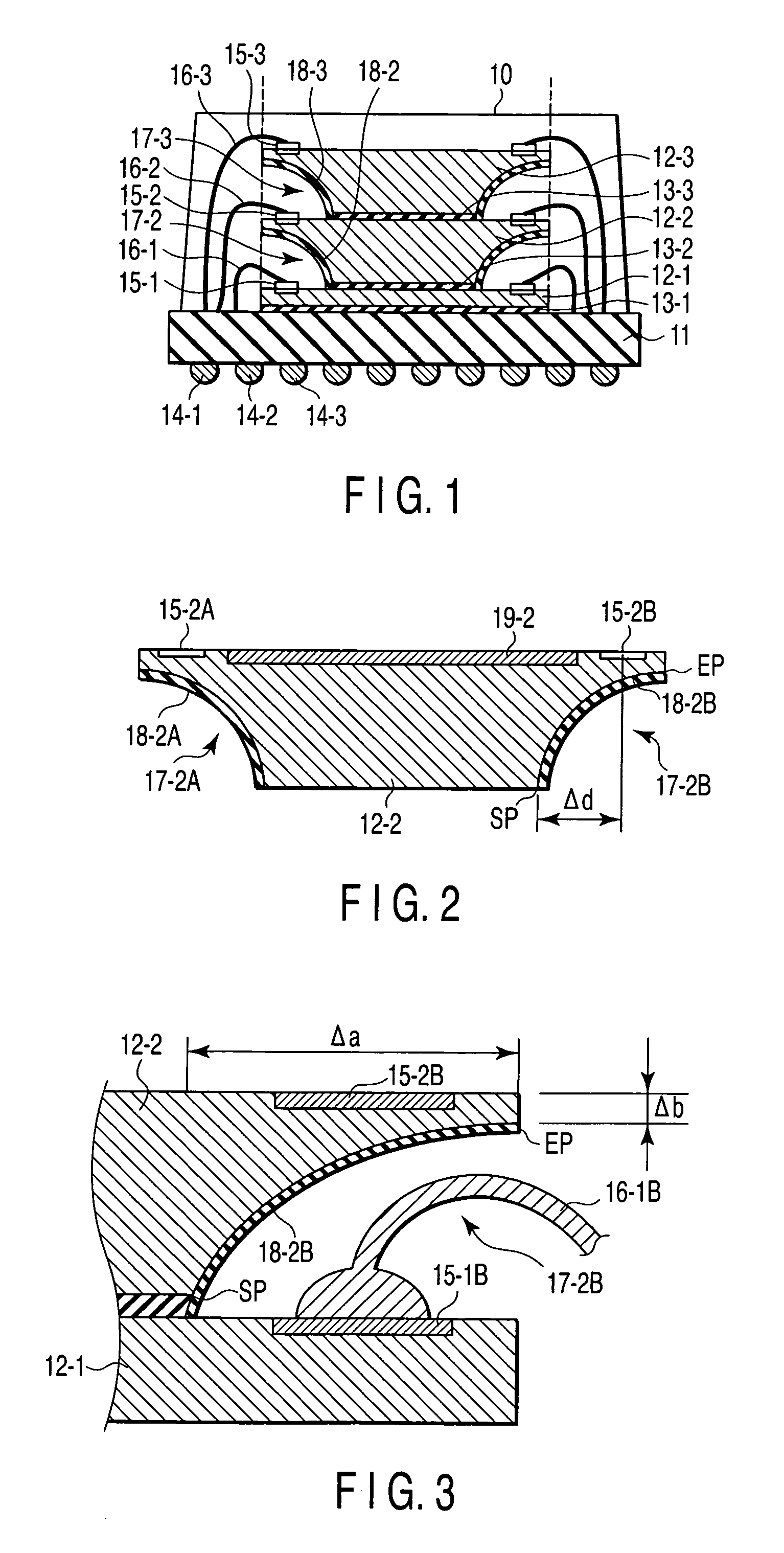

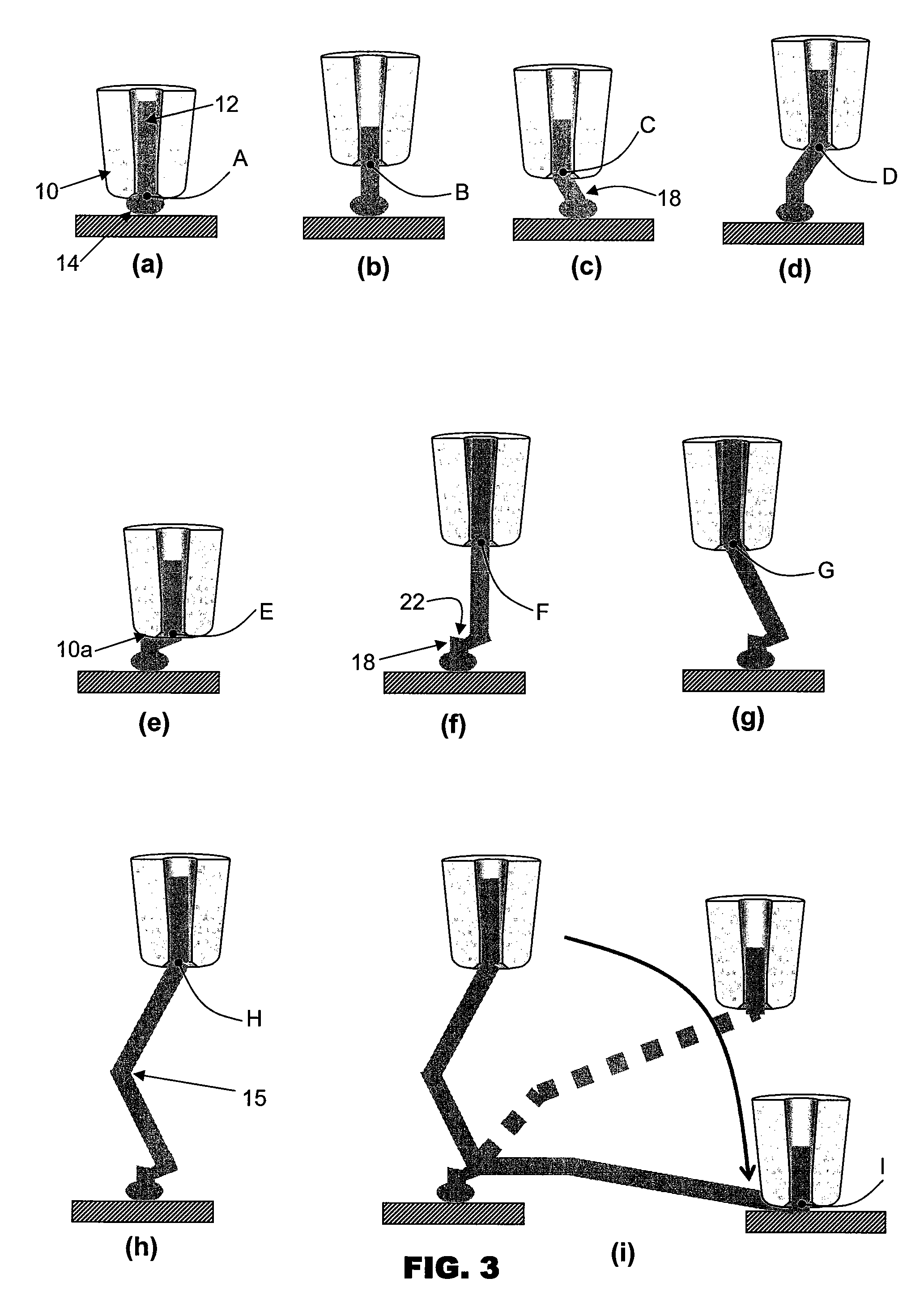

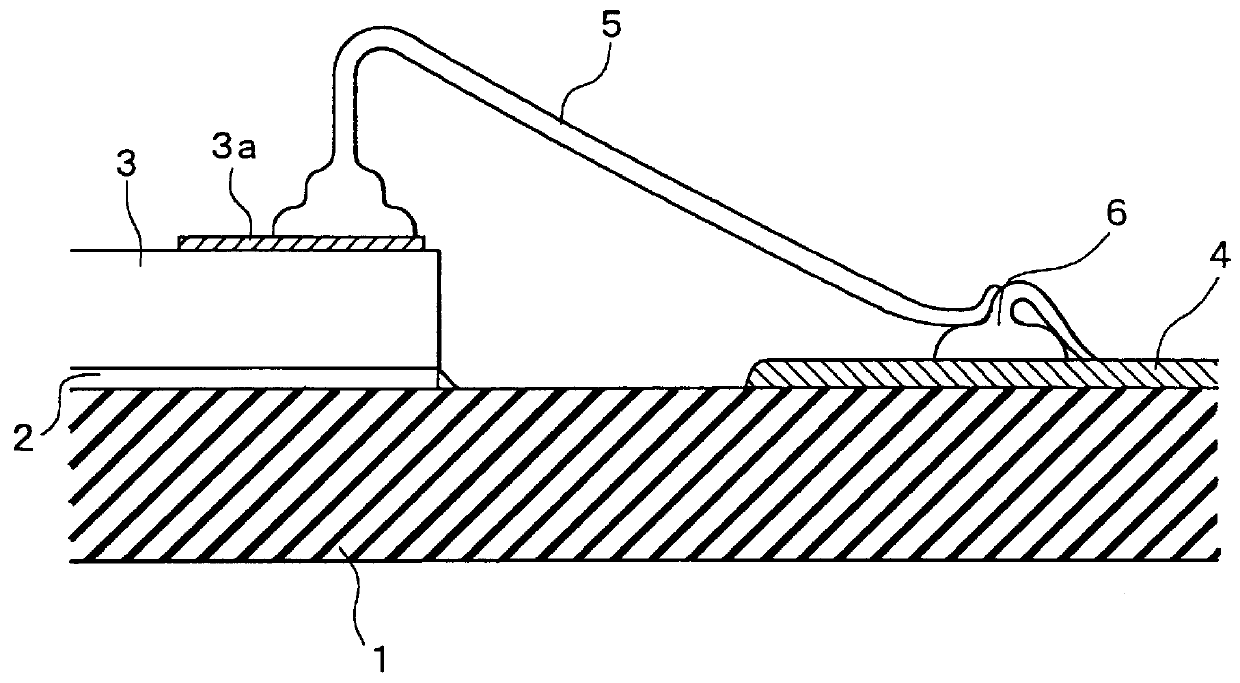

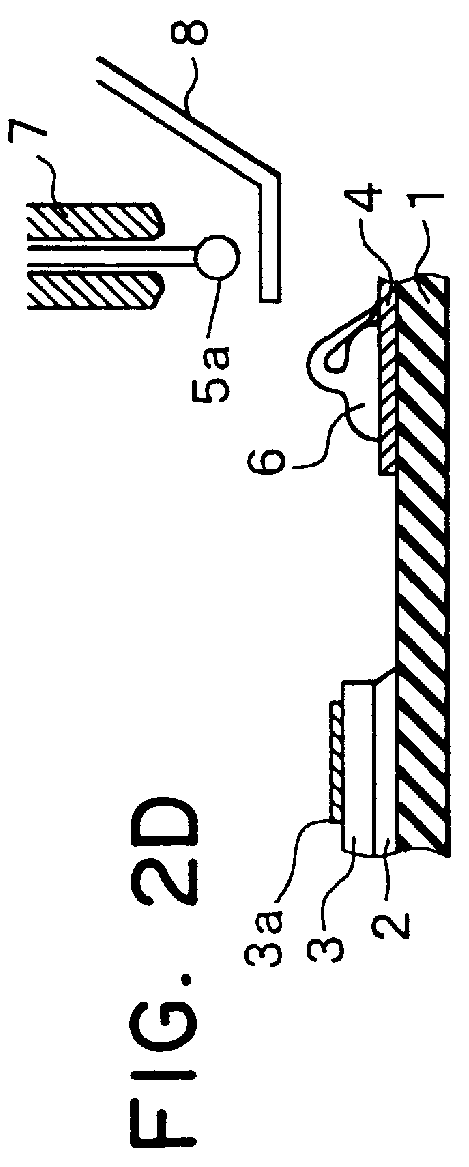

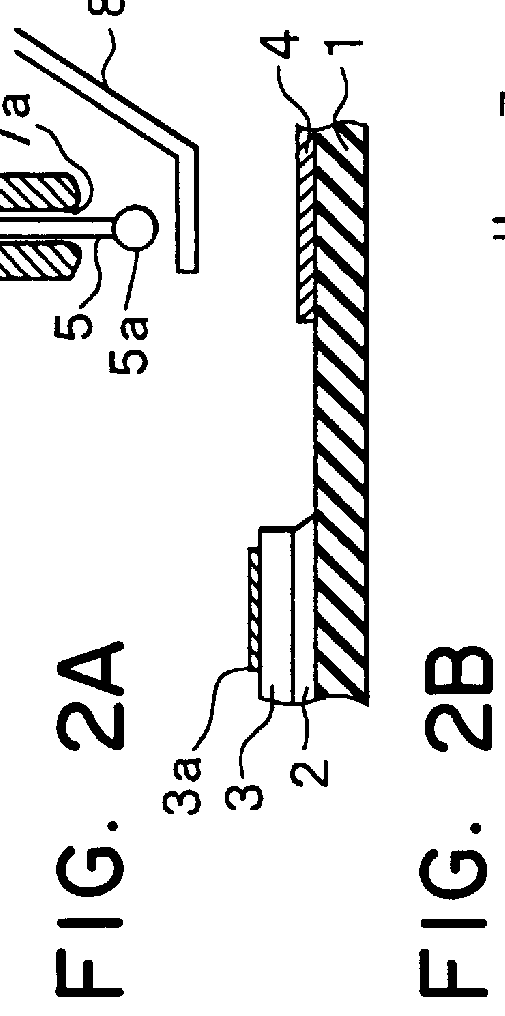

A wire loop comprises a wire connecting a first bonding point and a second bonding point therethrough, wherein the wire has a crushed part formed therein by crushing the part of the wire and a top of a ball bonded to the first bonding point with a capillary. The wire loop is formed by a wire bonding method which includes: bonding the wire to the first bonding point; moving the capillary horizontally and vertically while carrying out loop control; bonding the wire to the vicinity of the top of the ball bonded to the first bonding point; and thereafter, moving the capillary horizontally and vertically to the second bonding point while delivering the wire and carrying out loop control, and then bonding the wire to the second bonding point.

Owner:KAIJOO KK

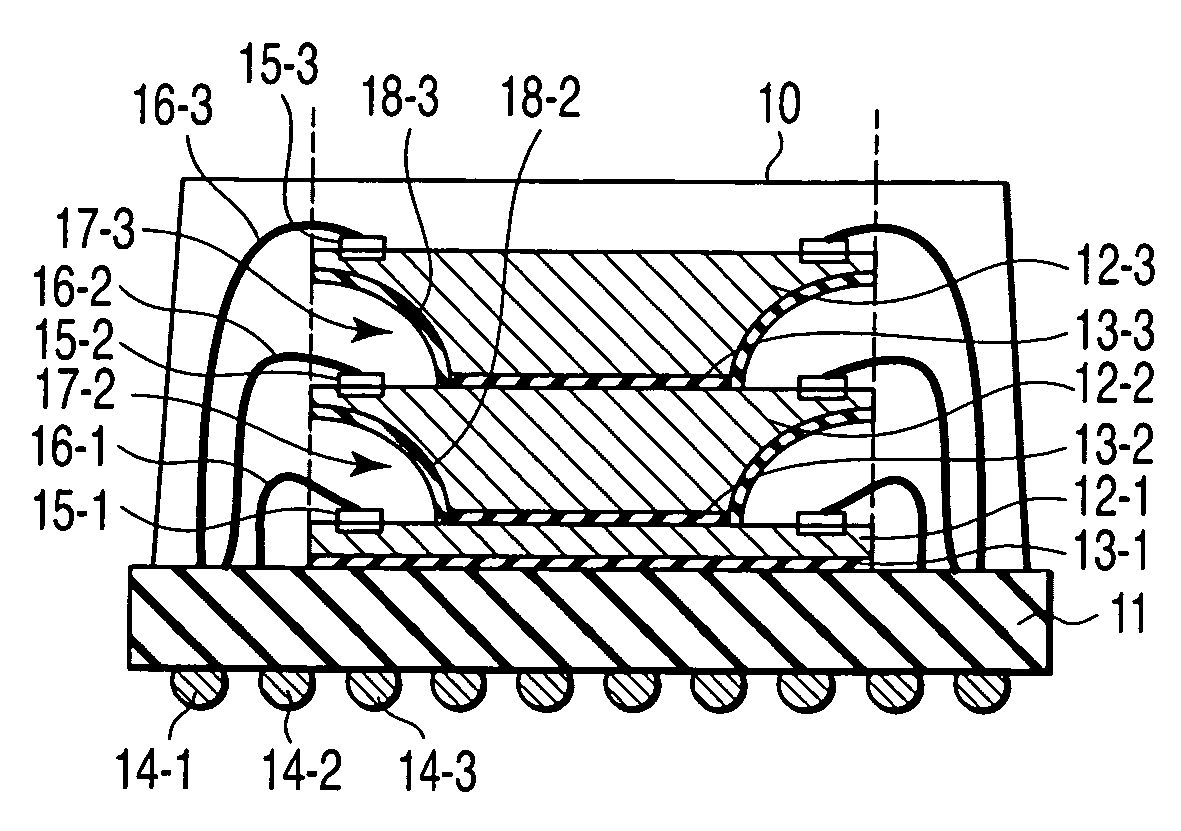

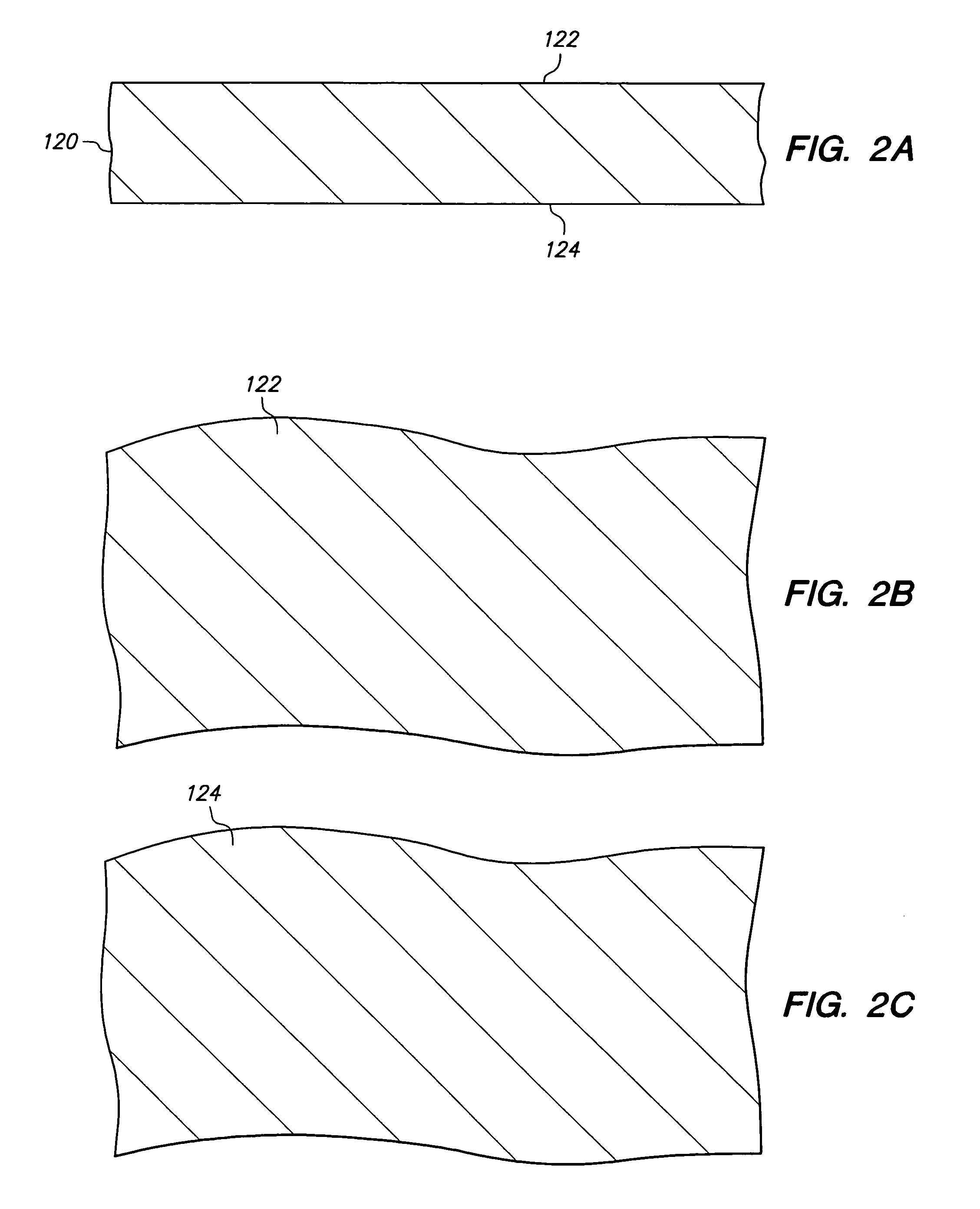

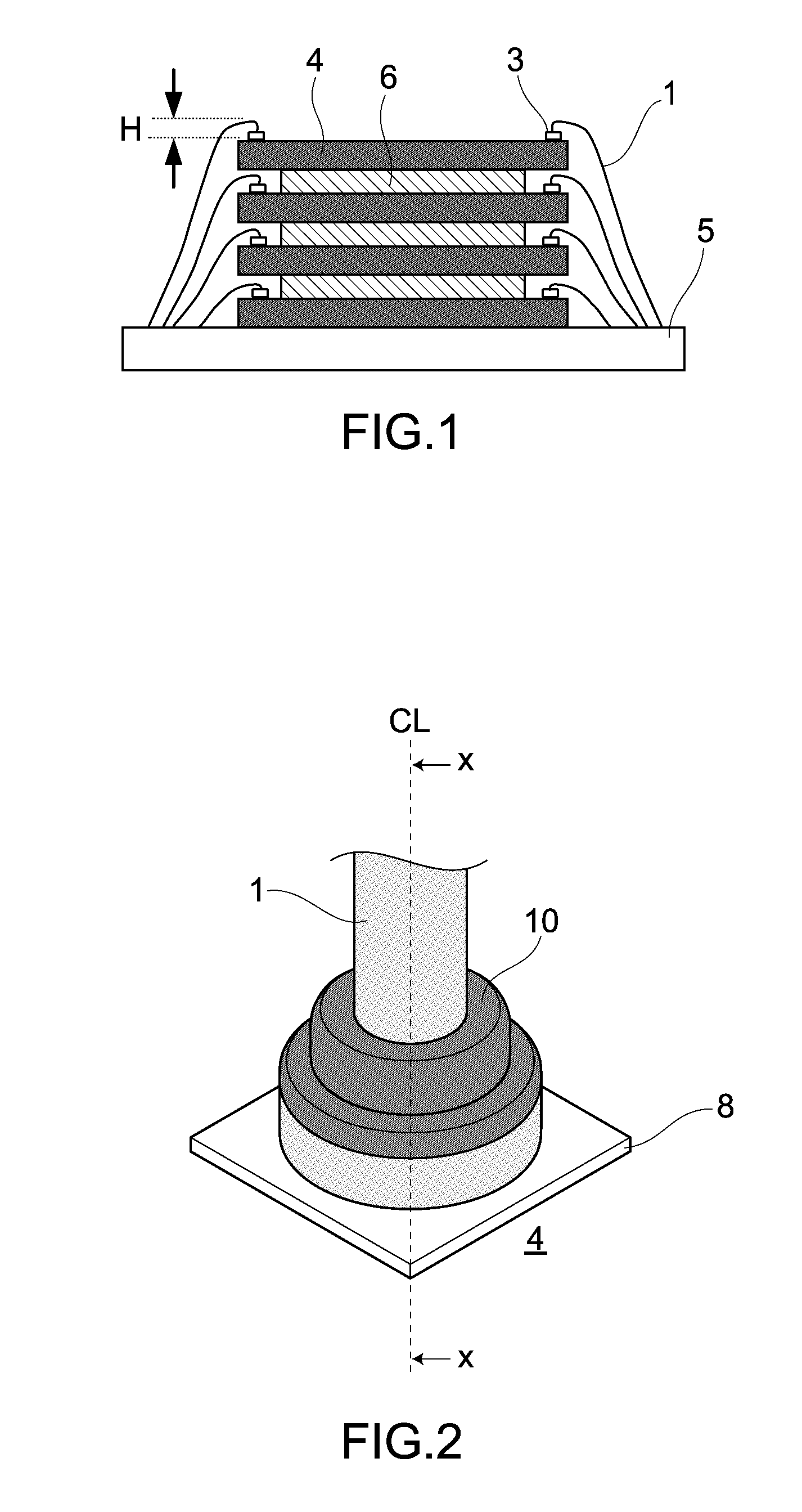

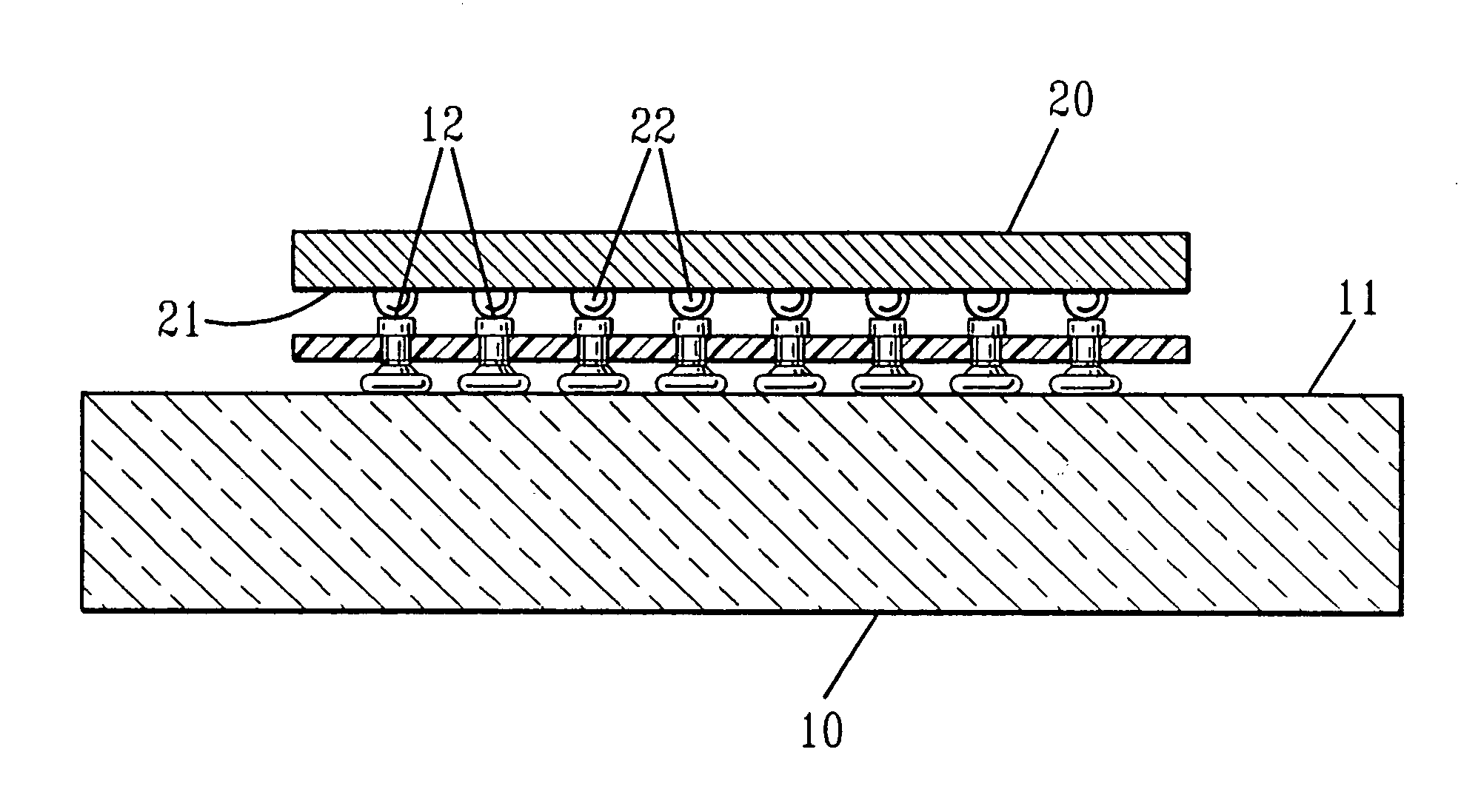

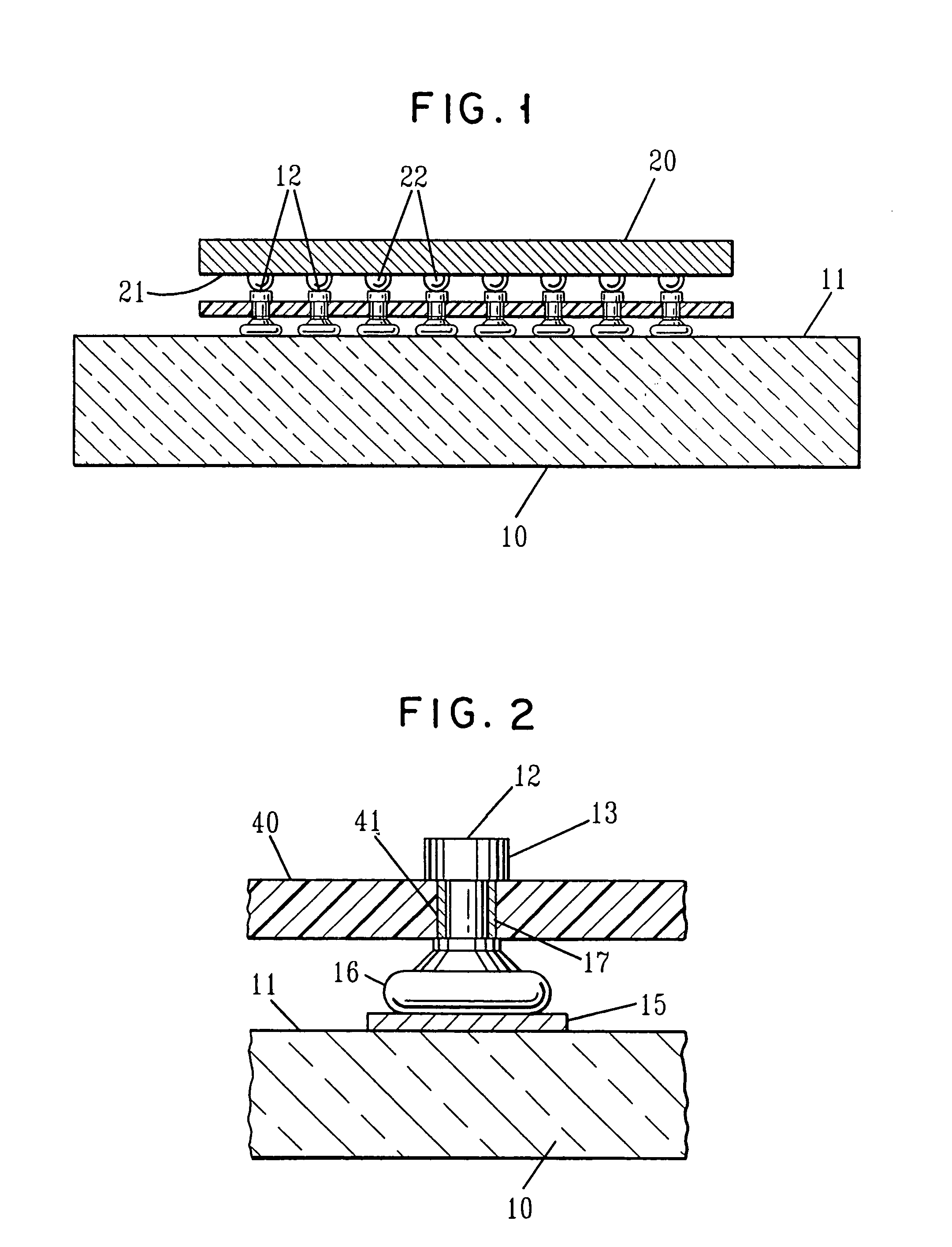

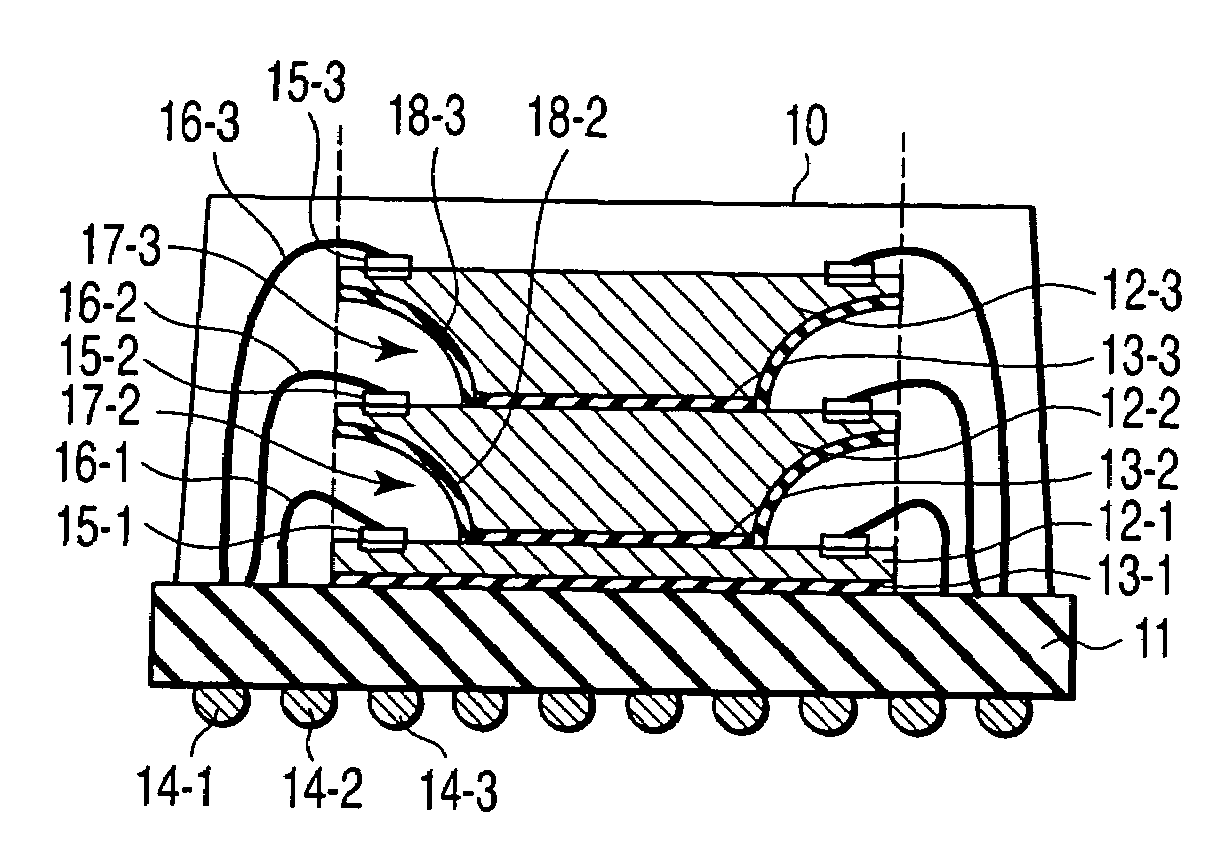

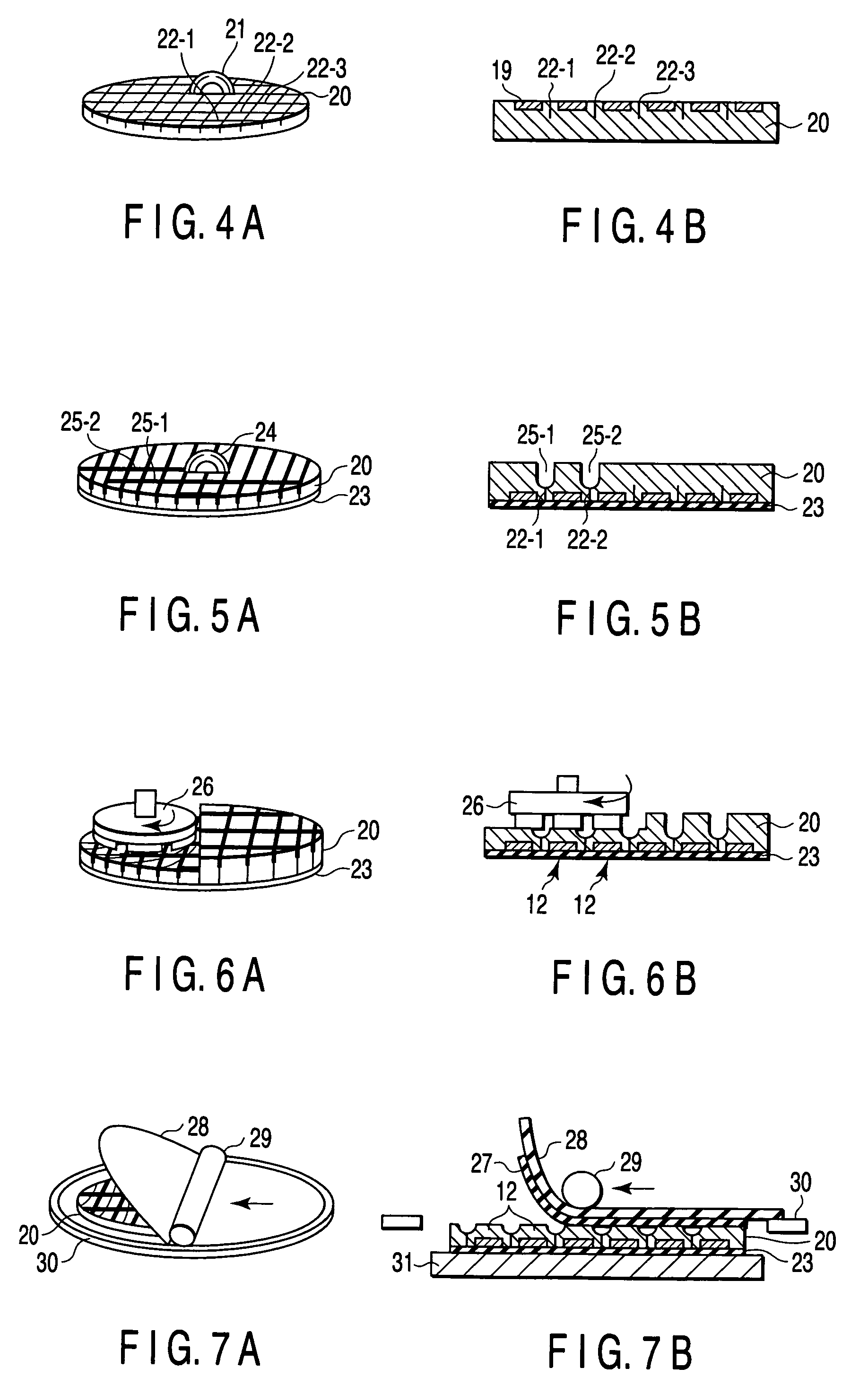

Semiconductor device having semiconductor chips stacked and mounted thereon and manufacturing method thereof

ActiveUS20060175697A1Semiconductor/solid-state device detailsSolid-state devicesLead bondingSemiconductor chip

Chips are stacked and mounted on a circuit board having external connection electrodes and mounted thereon by wire bonding. At least one of the chips stacked on the chip includes overhung portions each of which has a start point inside bonding pads, is made thinner in a direction towards the outer periphery to an end point reaching the side wall and forms a space used to accommodate ball bonding portions between the overhung portion and the main surface of the chip arranged in the lower stage on a backside corresponding in position to the bonding pads, and insulating members formed to cover the overhung portions and prevent bonding wires of the chip arranged in the lower stage from being brought into contact with the upper-stage chip.

Owner:KIOXIA CORP

Control of size and heat affected zone for fine pitch wire bonding

InactiveUS6180891B1Electrically conductive connectionsSemiconductor/solid-state device detailsHeat-affected zoneLead bonding

The amount of melting of the bonding wire is closely regulated, and reduction of size and improvement of uniformity of the free air ball is obtained for ball bonding at pitches of less than ninety mils even when bonding wire of reduced diameter is employed. Quenching of the bonding wire adjacent to the free air ball also limits the temperature rise in the bonding wire and the extent of a heat affected zone having less tensile strength and stiffness to less than one micron and with reduced grain enlargement. The present invention provides such a bond for electronic packaging of increased reliability, potential functionality, increased manufacturing yield and reduced process complexity.

Owner:IBM CORP

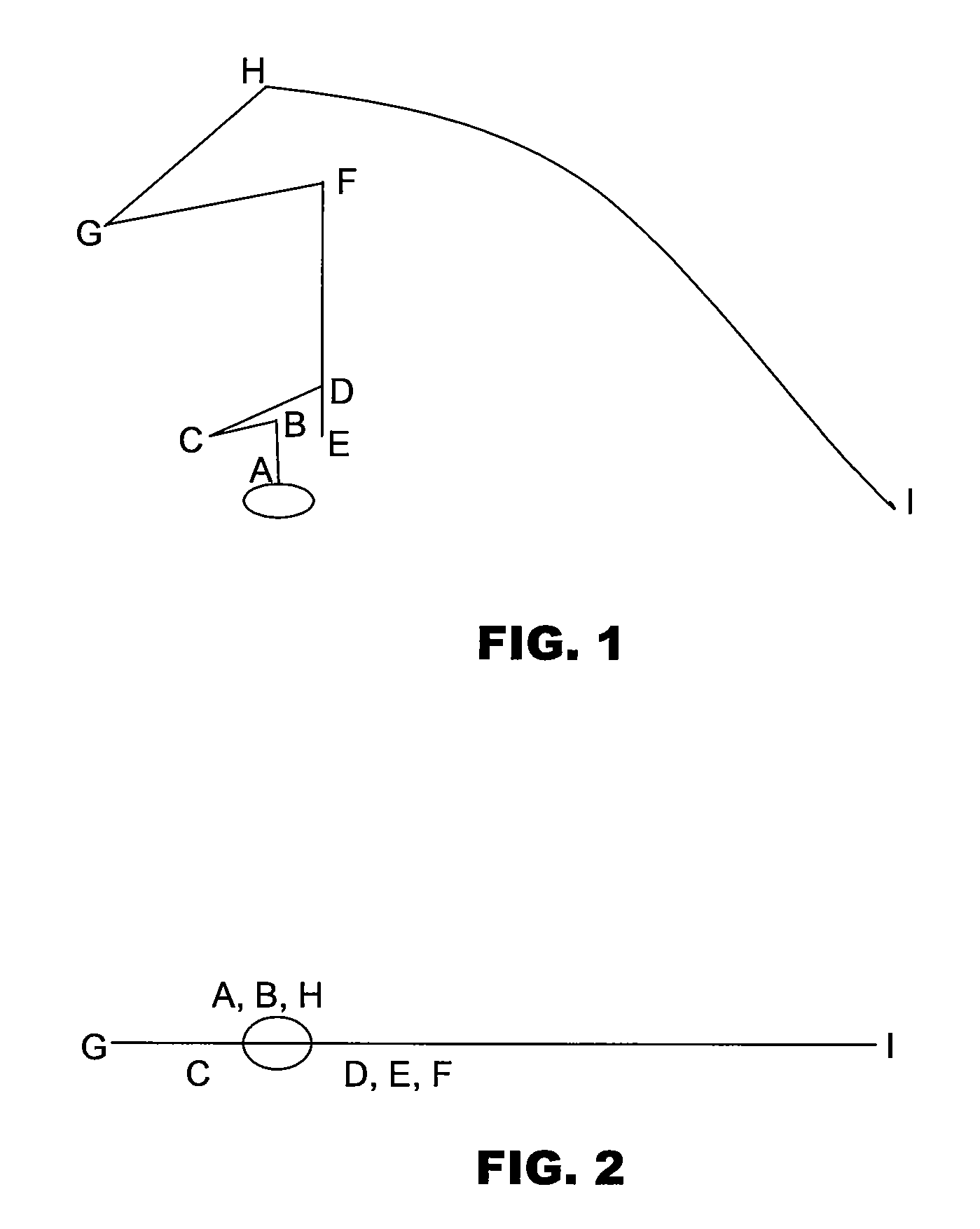

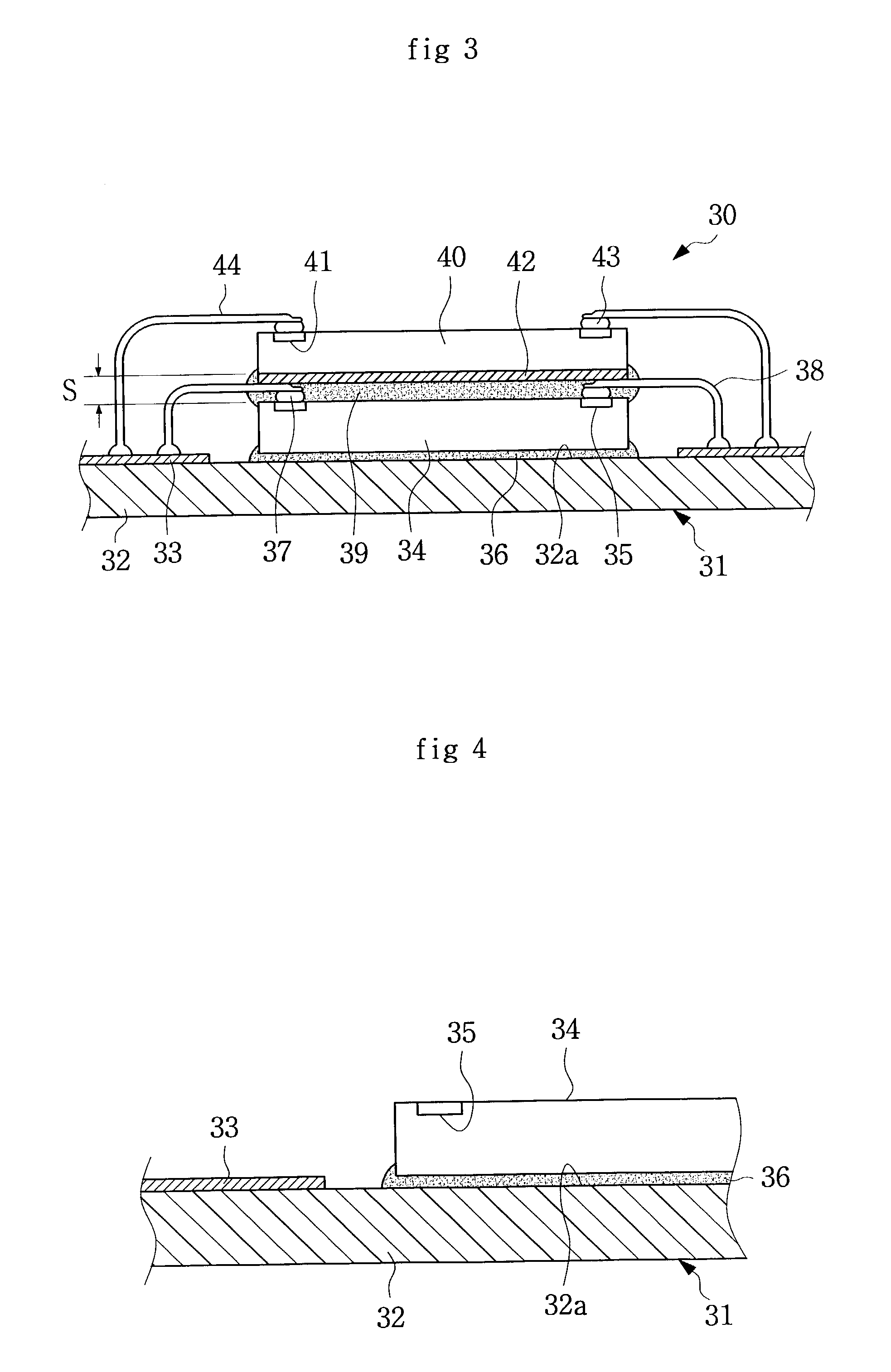

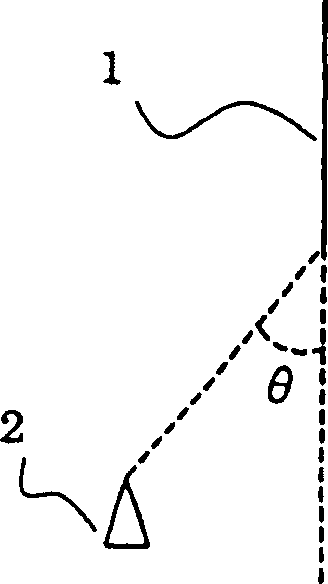

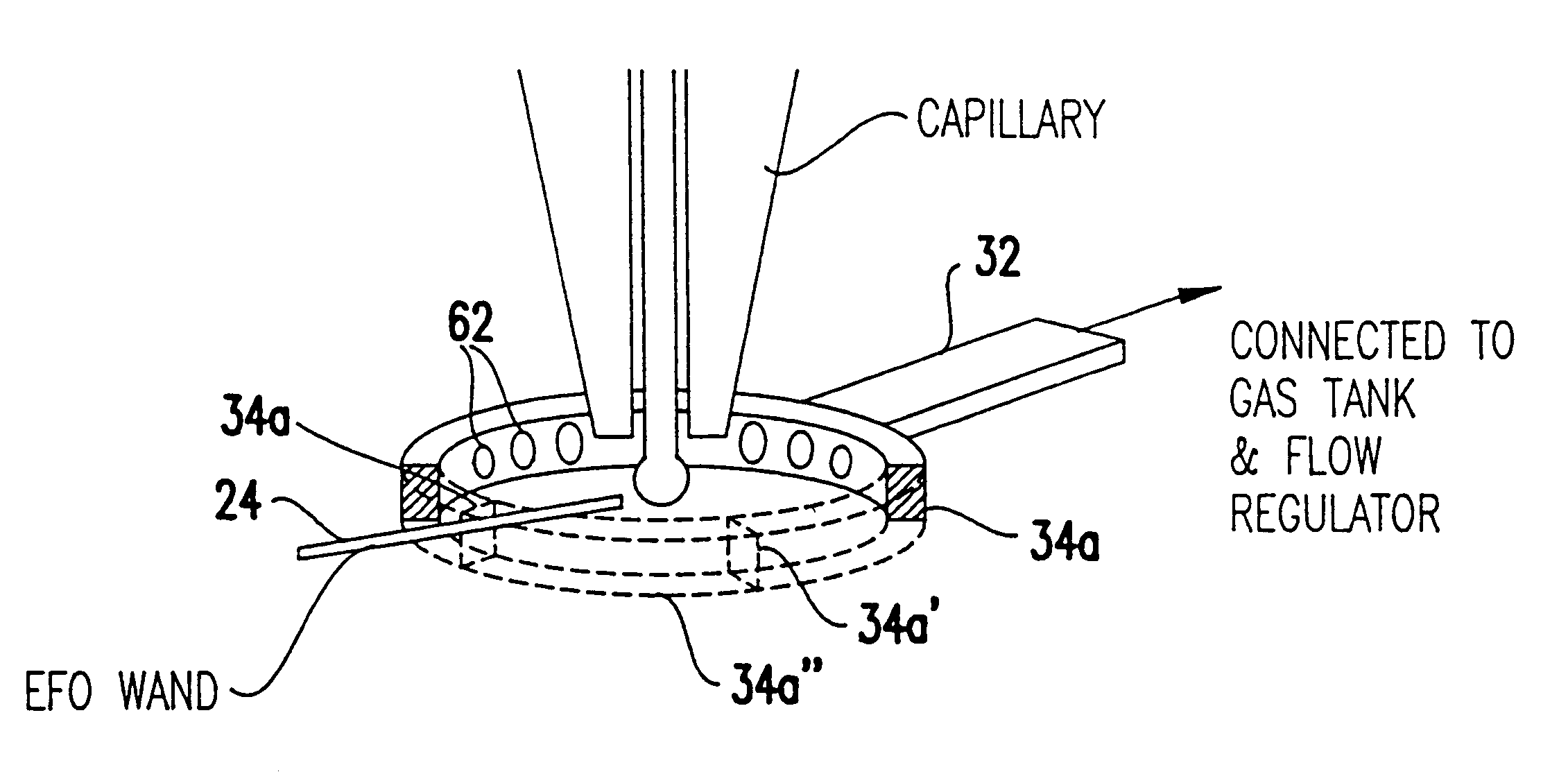

Wire bonding method for forming low-loop profiles

ActiveUS7780064B2Reduce the overall heightAvoid disadvantagesCooking-vessel materialsSemiconductor/solid-state device detailsLead bondingEngineering

Owner:ASM TECH SINGAPORE PTE LTD

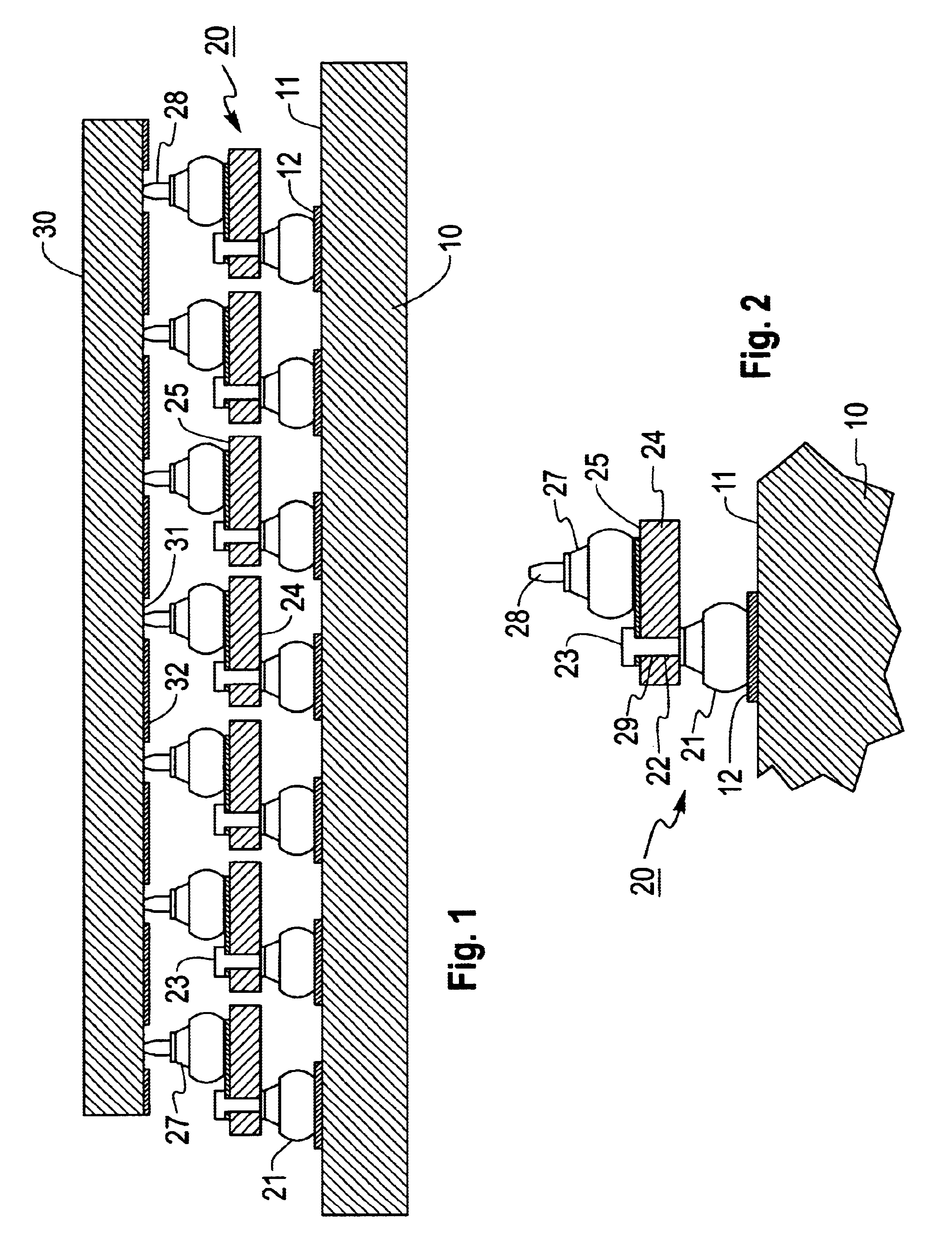

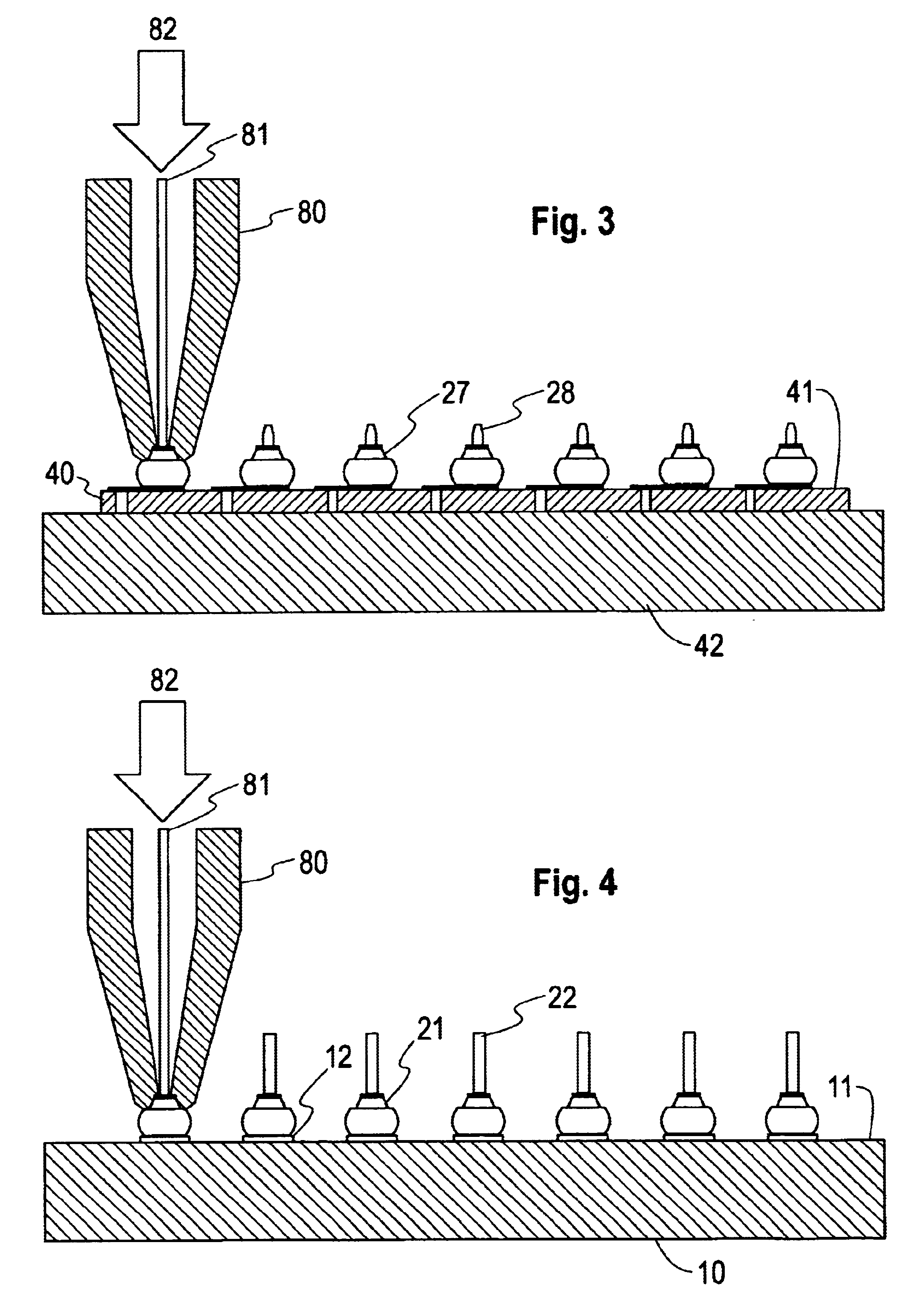

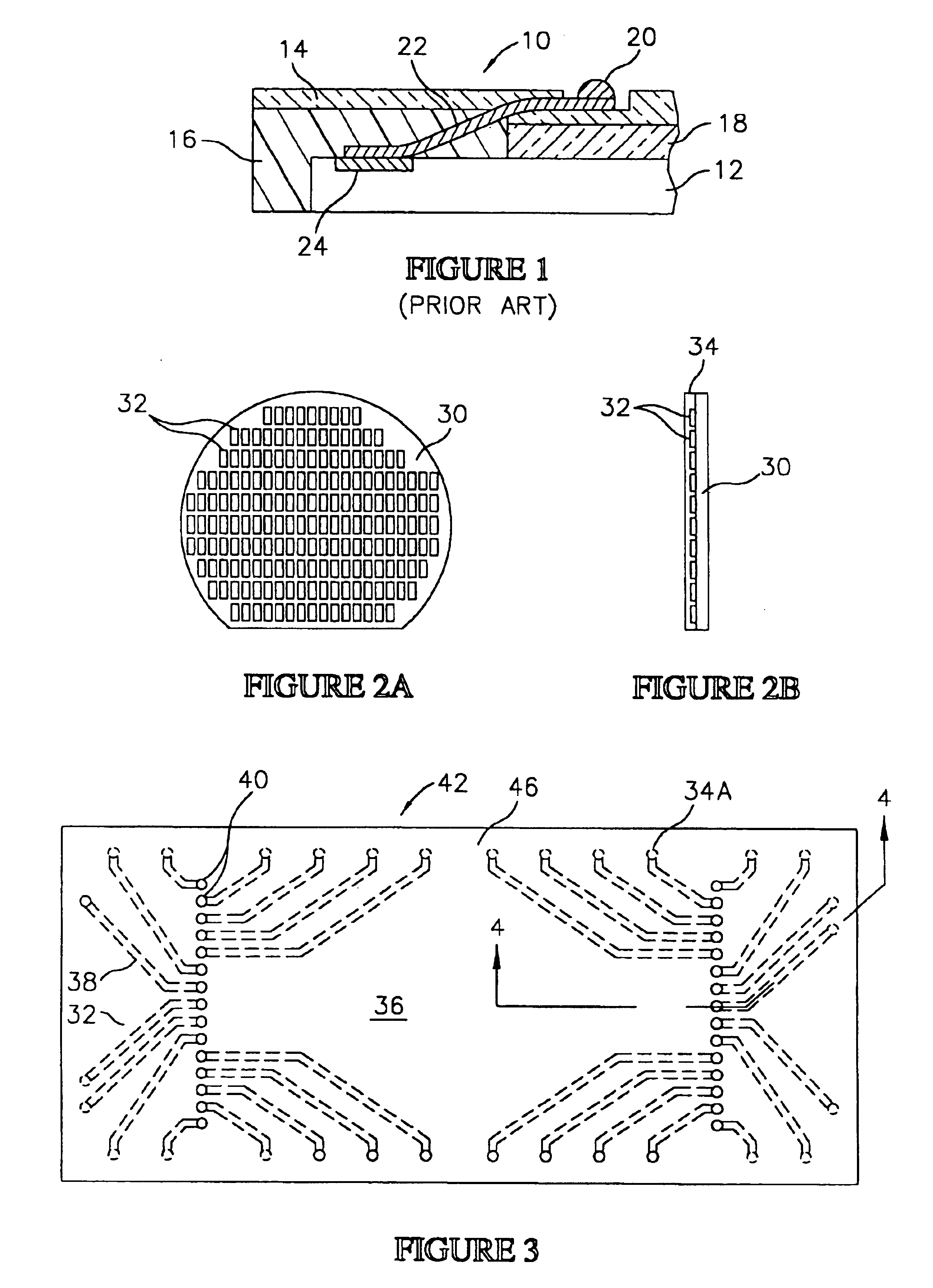

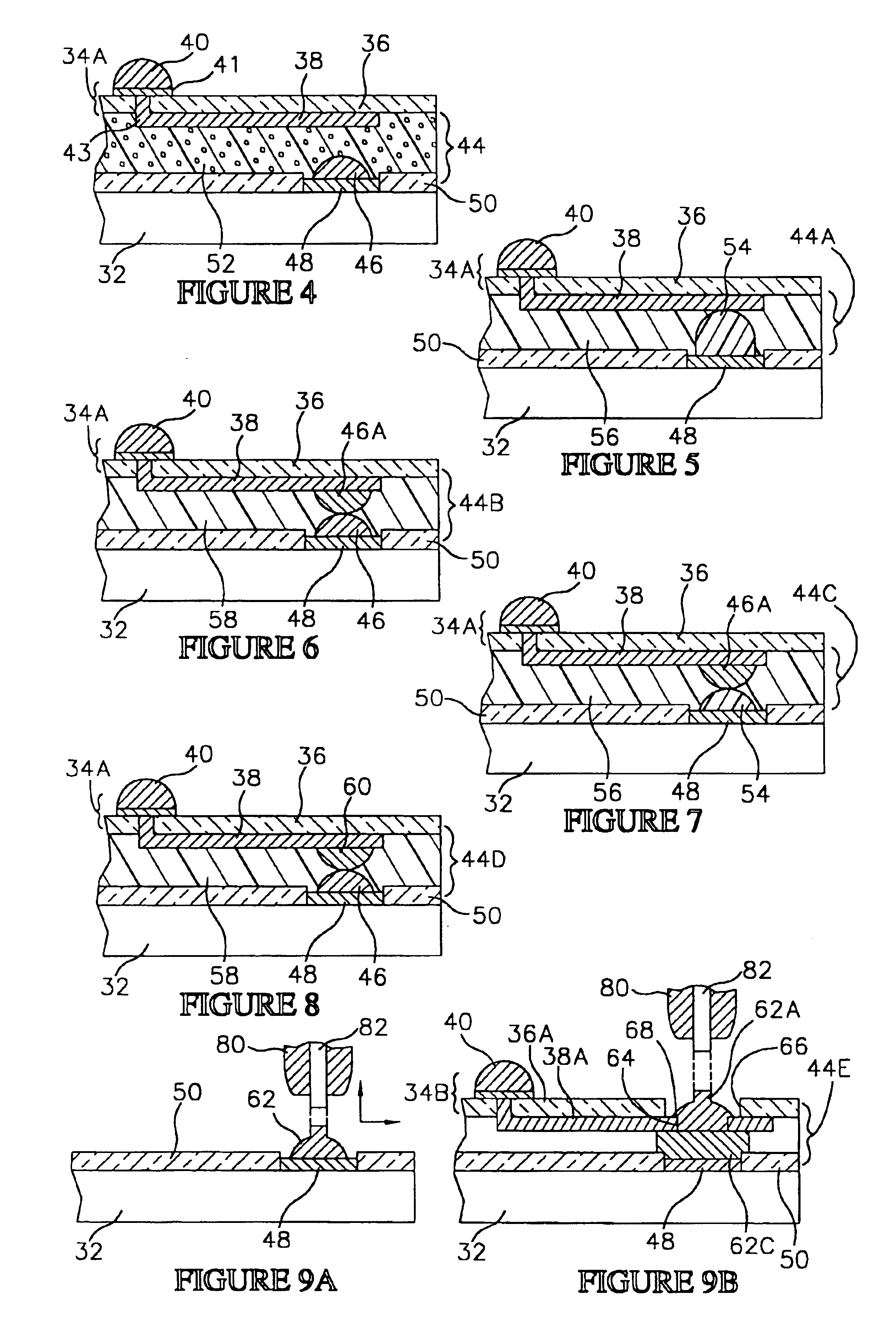

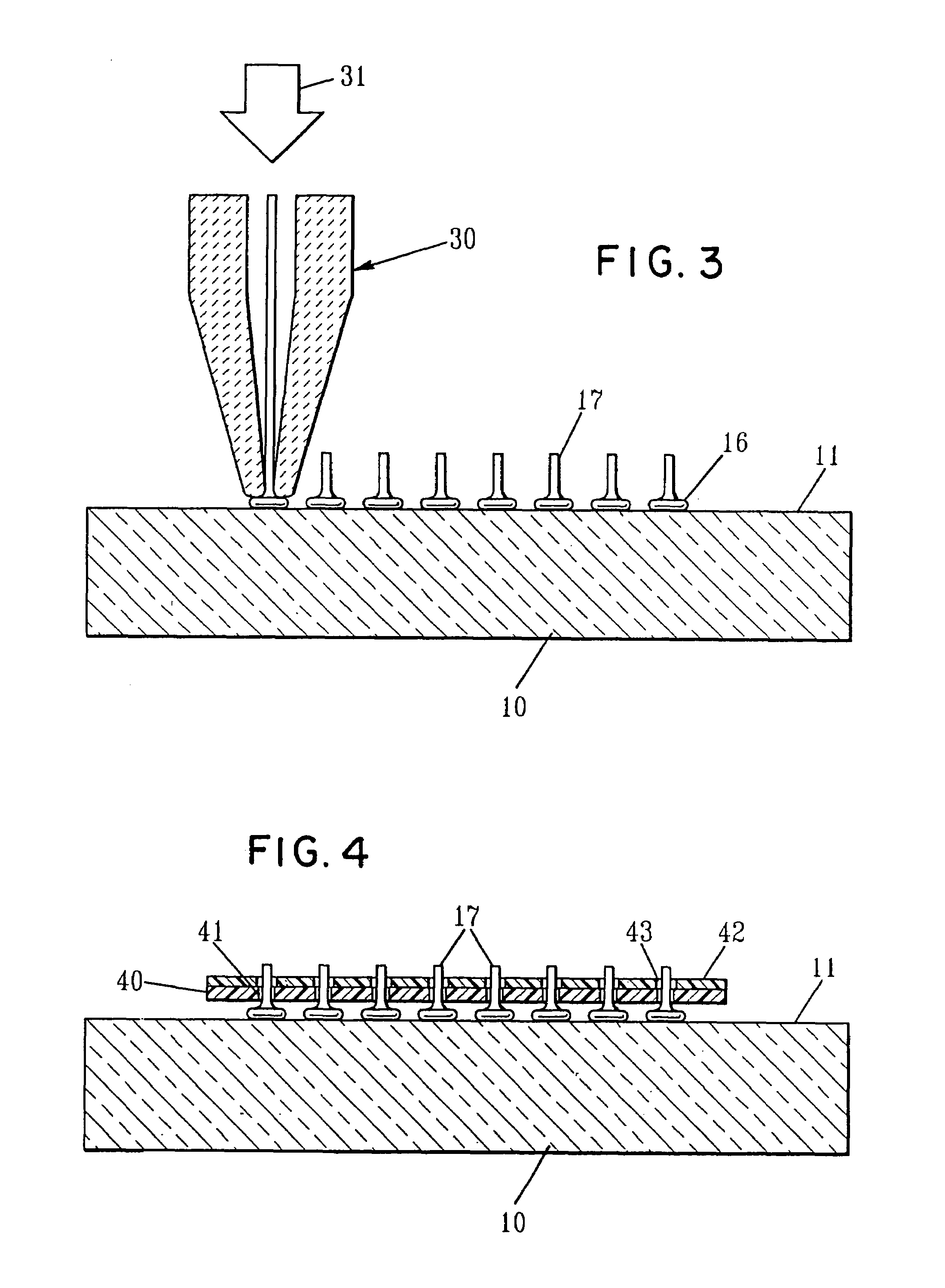

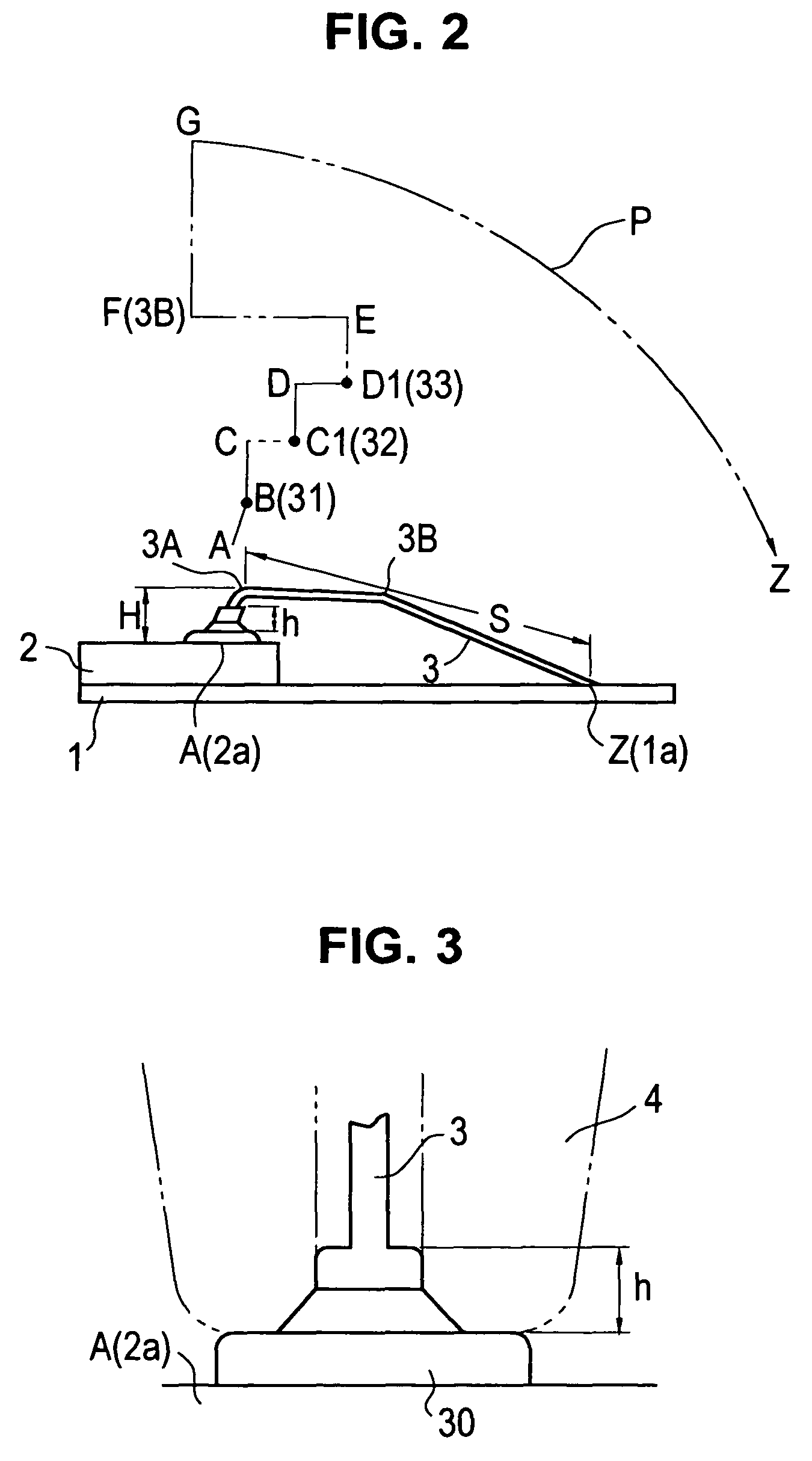

High density cantilevered probe for electronic devices

InactiveUS6329827B1Minimizes potential for damagingHigh densityPrinted circuit assemblingElectrical measurement instrument detailsContact padHigh density

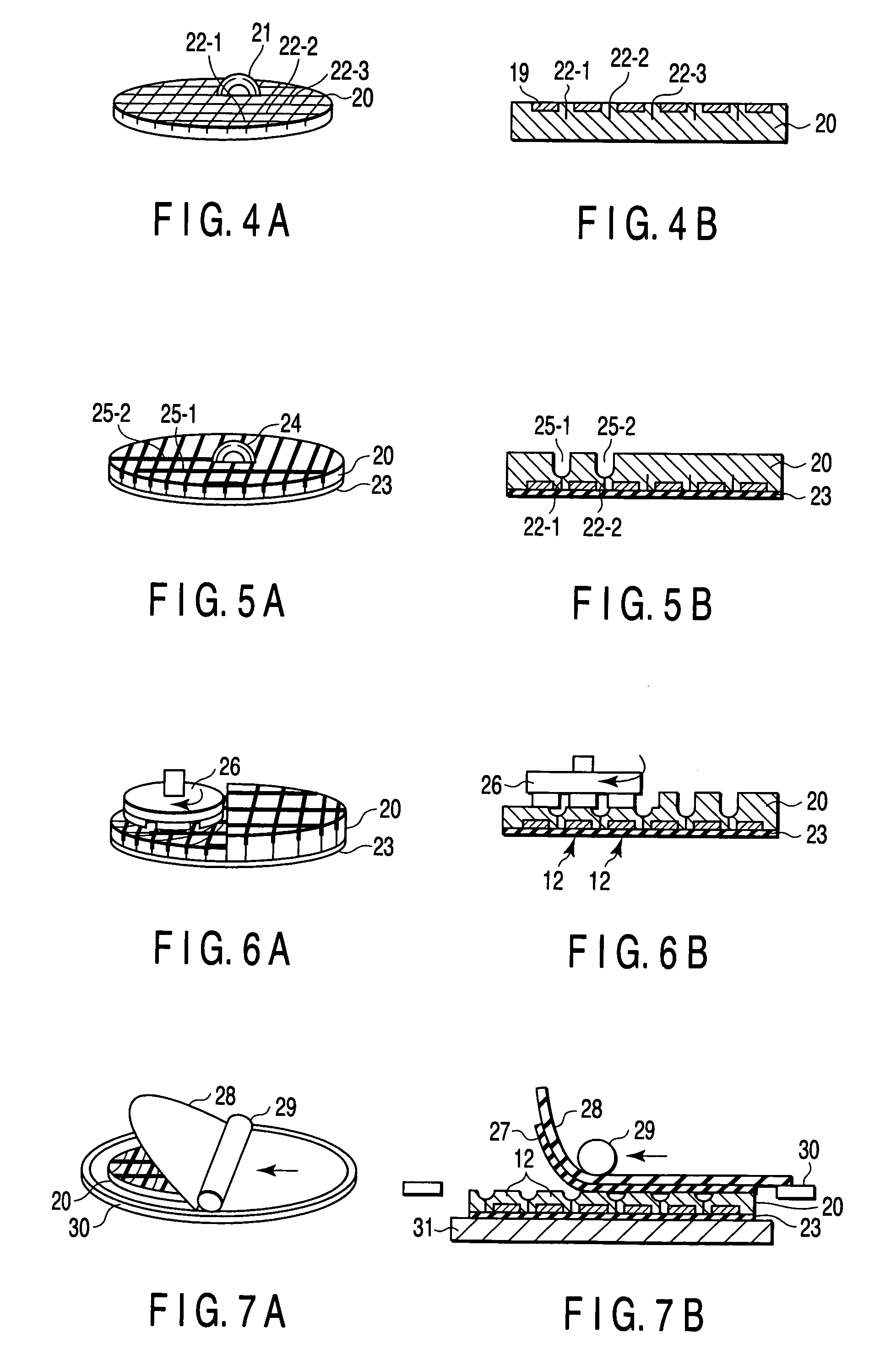

Connectors for electronic devices are described. The connector is formed by ball bonding a plurality of wires to contact locations on a fan out substrate surface. The wires are cut off leaving stubs. A patterned polymer sheet having electrical conductor patterns therein is disposed over the stubs which extend through holes in the sheet. The ends of the wires are flattened to remit the polymer sheet in place. The wire is connected to an electrical conductor on the polymer sheet which is converted to a contact pad on the polymer sheet. A second wire is ball bonded to the pad on the polymer sheet and cut to leave a second stub. The polymer sheet is laser cut so that each second stub is free to move independently of the other second studs. The ends of the second stubs are disposed against contact locations of an electronic device, such as an FC chip, to test the electronic device.

Owner:TOKYO ELECTRON LTD

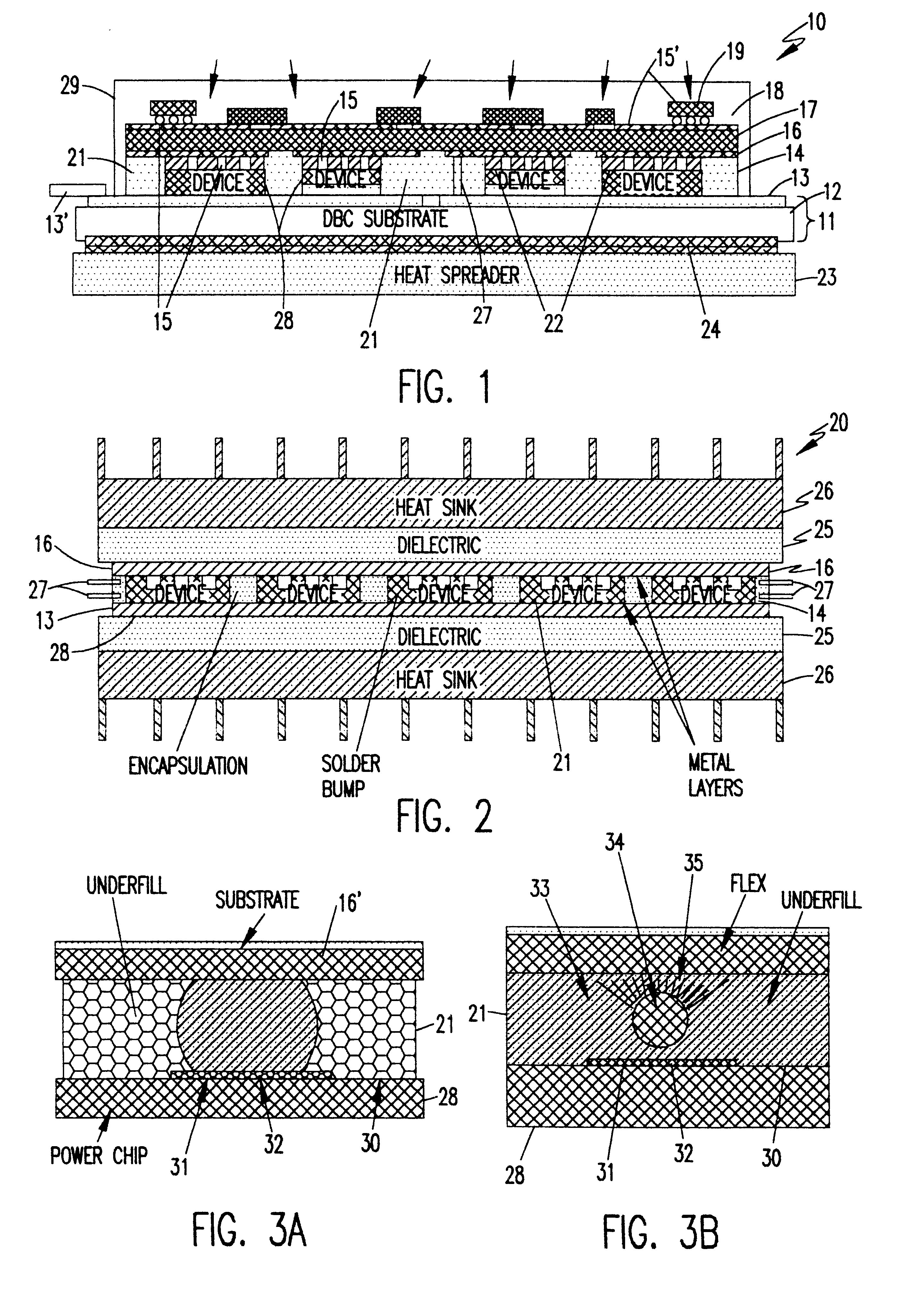

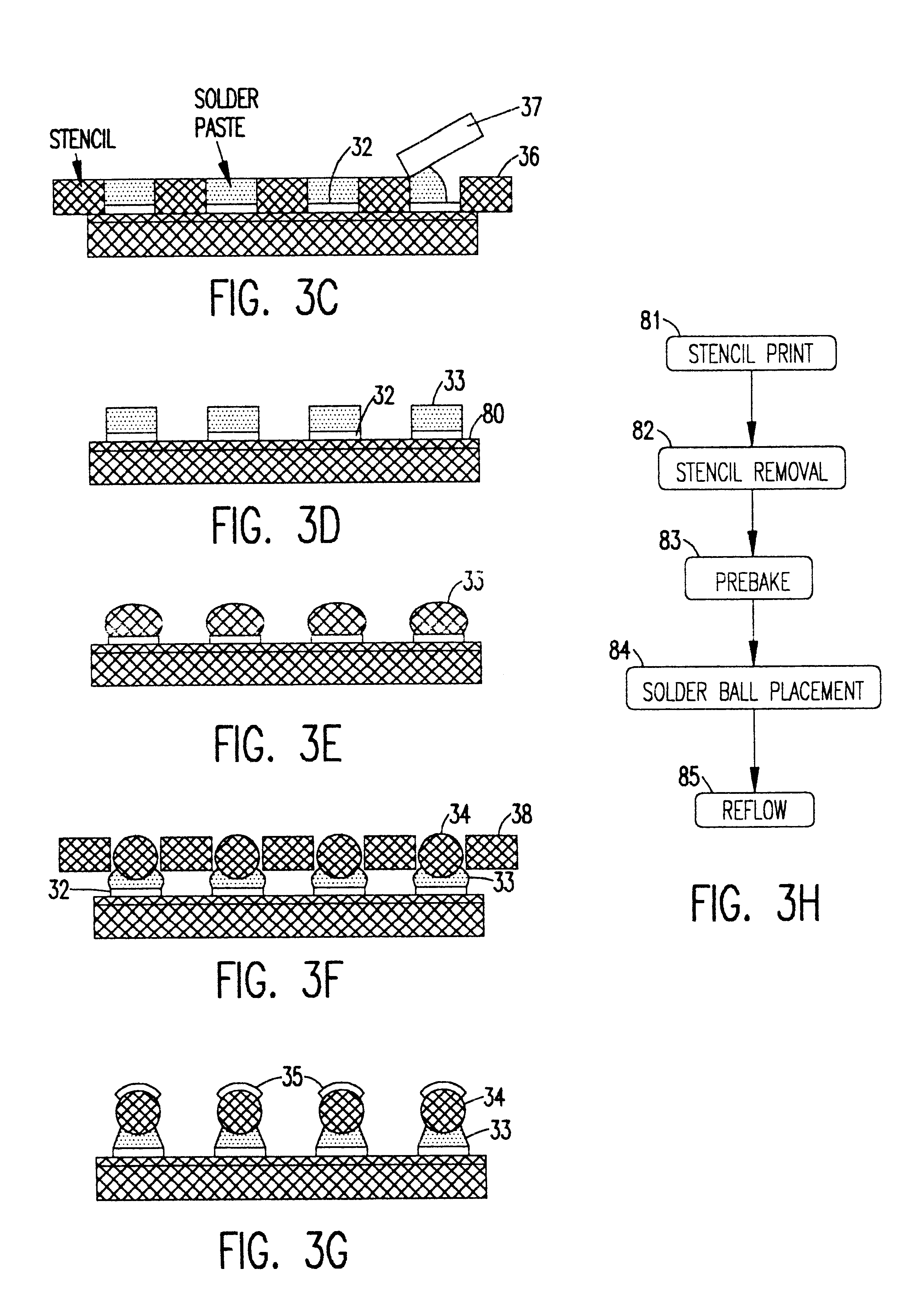

Low-cost 3D flip-chip packaging technology for integrated power electronics modules

InactiveUS6442033B1Improve performanceLow costSemiconductor/solid-state device detailsSolid-state devicesVoltage overshootLead bonding

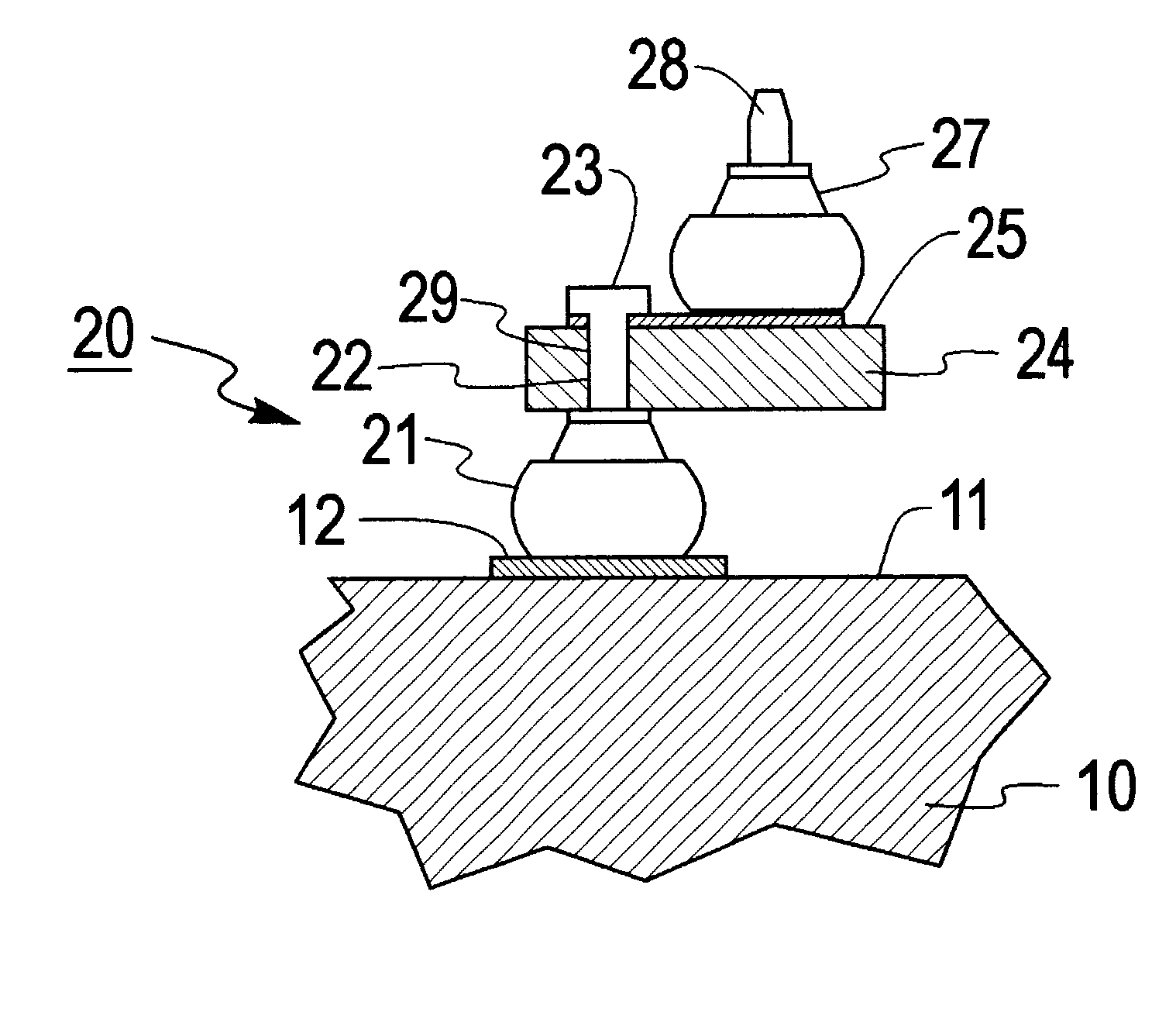

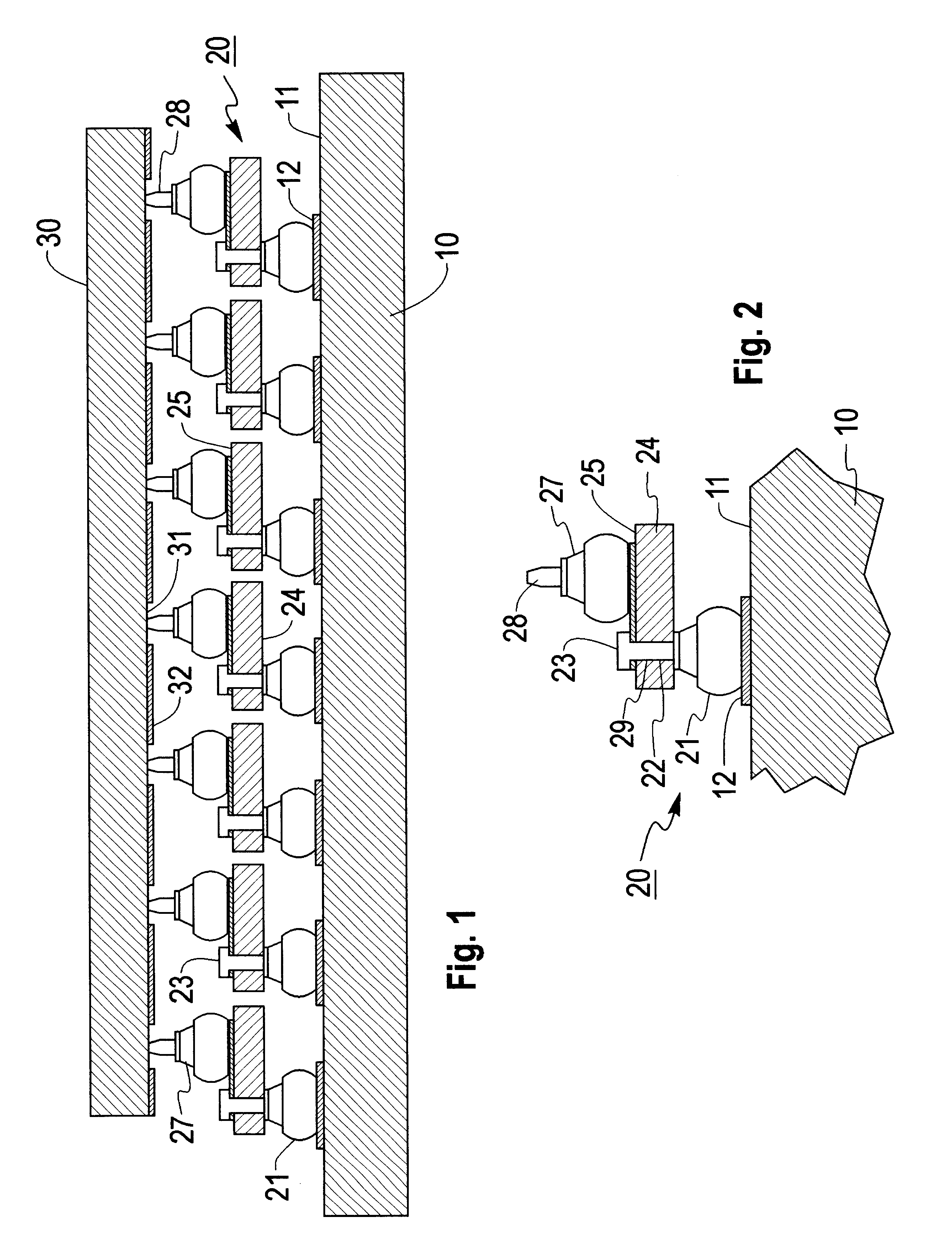

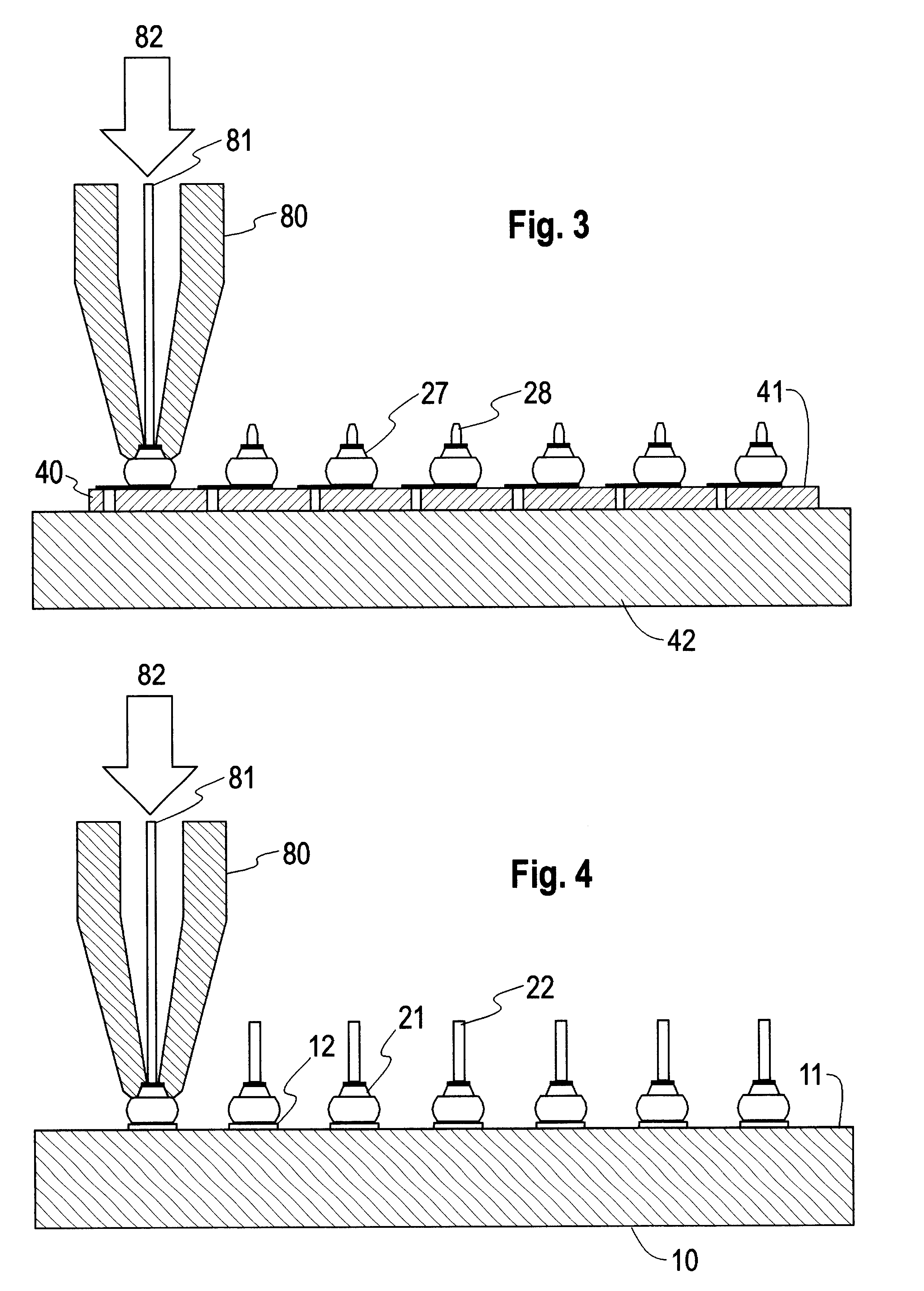

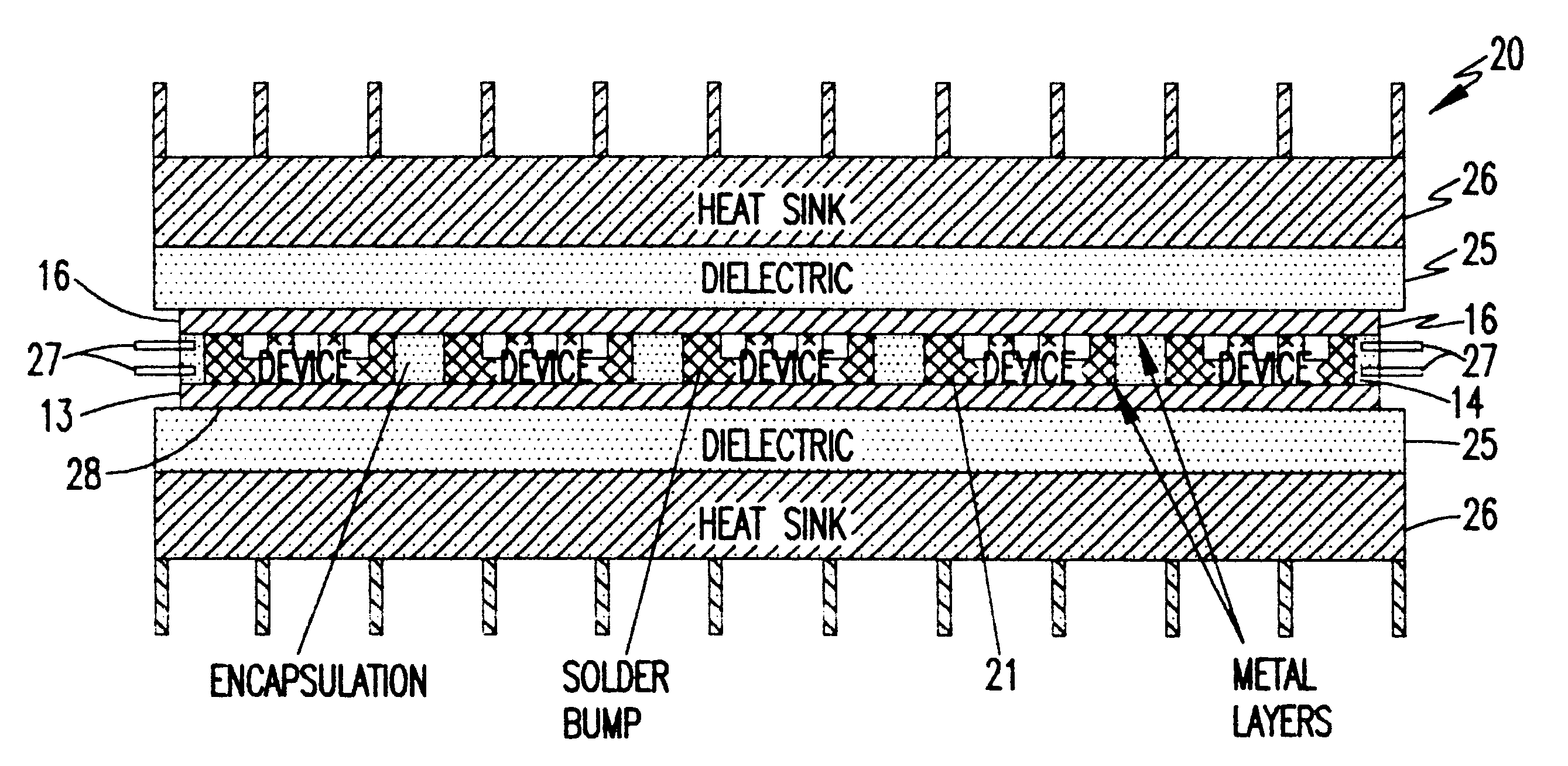

Resistance and parasitic inductance resulting from interconnection of semiconductor chips in power modules are reduced to negligible levels by a robust structure which completely avoids use of wire bonds through use of ball bonding and flip-chip manufacturing processes, possibly in combination with chip scale packaging and hourglass shaped stacked solder bumps of increased compliance and controlled height / shape. Turn-off voltage overshoot is reduced to about one-half or less than a comparable wire bond packaged power module. Hourglass shaped solder bumps provide increased compliance and reliability over much increased numbers of thermal cycles over wide temperature excursions.

Owner:VIRGINIA TECH INTPROP INC

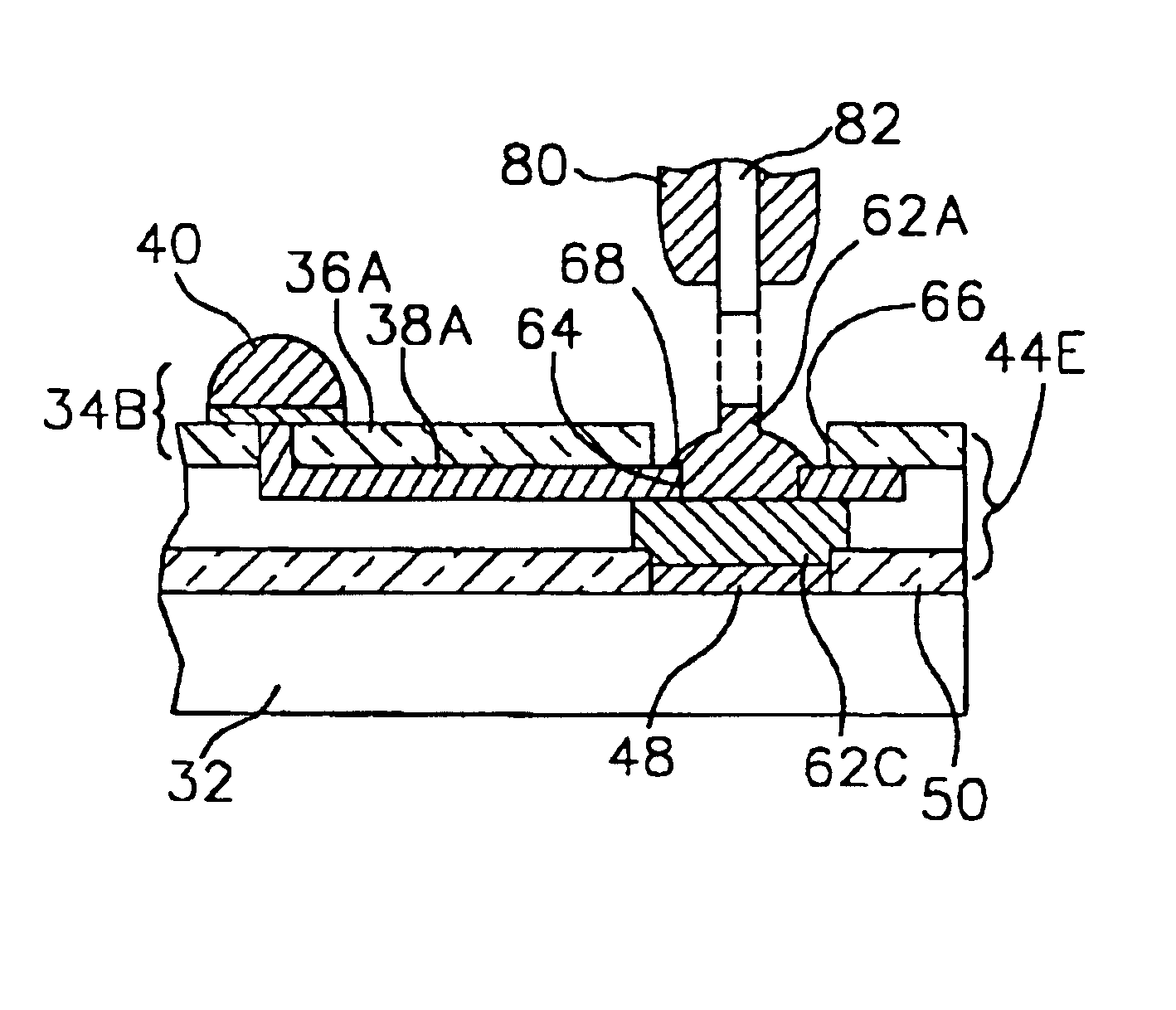

Semiconductor chip assembly with welded metal pillar that includes enlarged ball bond

InactiveUS7268421B1Enhancing mechanical supportImprove protectionThyristorSemiconductor/solid-state device detailsSemiconductor chipSealant

A semiconductor chip assembly includes a semiconductor chip that includes a conductive pad, a conductive trace that includes a routing line and a metal pillar, a connection joint that electrically connects the routing line and the pad, and an encapsulant. The chip and the metal pillar are embedded in the encapsulant, the routing line extends laterally beyond the metal pillar towards the chip, and the metal pillar is welded to the routing line.

Owner:BRIDGE SEMICON

Method of forming a structure for electronic devices contact locations

InactiveUS6722032B2Minimize electrical conductor lengthMinimizes potential for damagingPrinted circuit assemblingLine/current collector detailsContact padEngineering

Probes for electronic devices are described. The probe is formed by ball bonding a plurality of wires to contact locations on a fan out substrate surface. The wires are cut off leaving stubs. A patterned polymer sheet having electrical conductor patterns therein is disposed over the stubs which extend through holes in the sheet. The ends of the wires are flattened to remit the polymer sheet in place. The wire is connected to an electrical conductor on the polymer sheet which is converted to a contact pad on the polymer sheet. A second wire is ball bonded to the pad on the polymer sheet and cut to leave a second stub. The polymer sheet is laser cut so that each second stub is free to move independently of the other second studs. The ends of the second stubs are disposed against contact locations of an electronic device, such as an FC chip, to test the electronic device.

Owner:TOKYO ELECTRON LTD

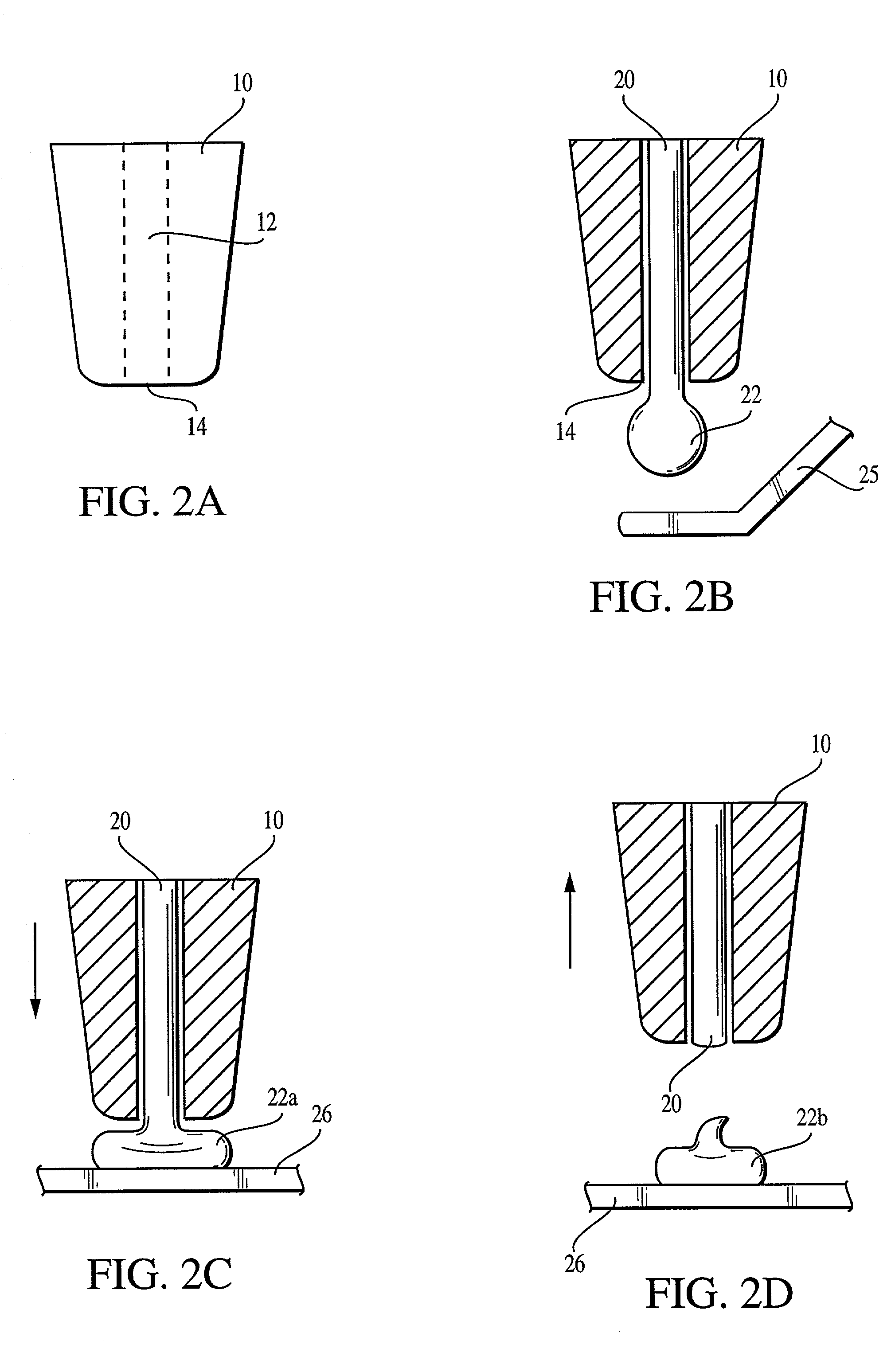

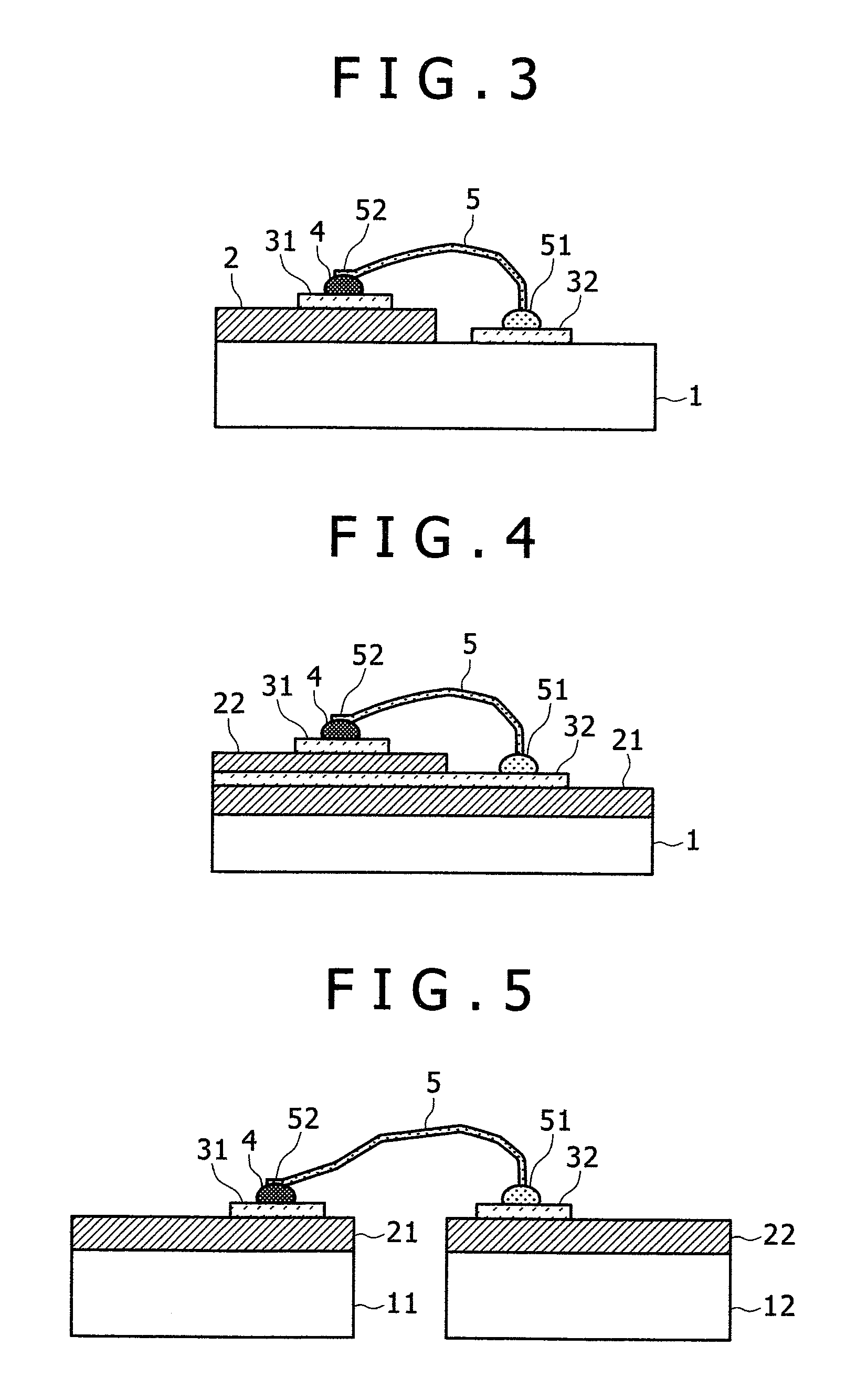

Wire bonding method

A ball is formed at the tip of a wire projecting from a capillary. The capillary is positioned above an interconnection, and ball bonding forms a bump on the interconnection. The capillary is then moved next to the bump and wedge bonding is carried out. Next, the capillary is moved upward and another ball is formed at the tip of the wire, and the wire is primary bonded to a bonding pad of a semiconductor chip. The wire is then looped and the capillary is positioned above the bump, and secondary bonding is carried out. As a result, the formation of tails on the bump is prevented.

Owner:DENSO CORP

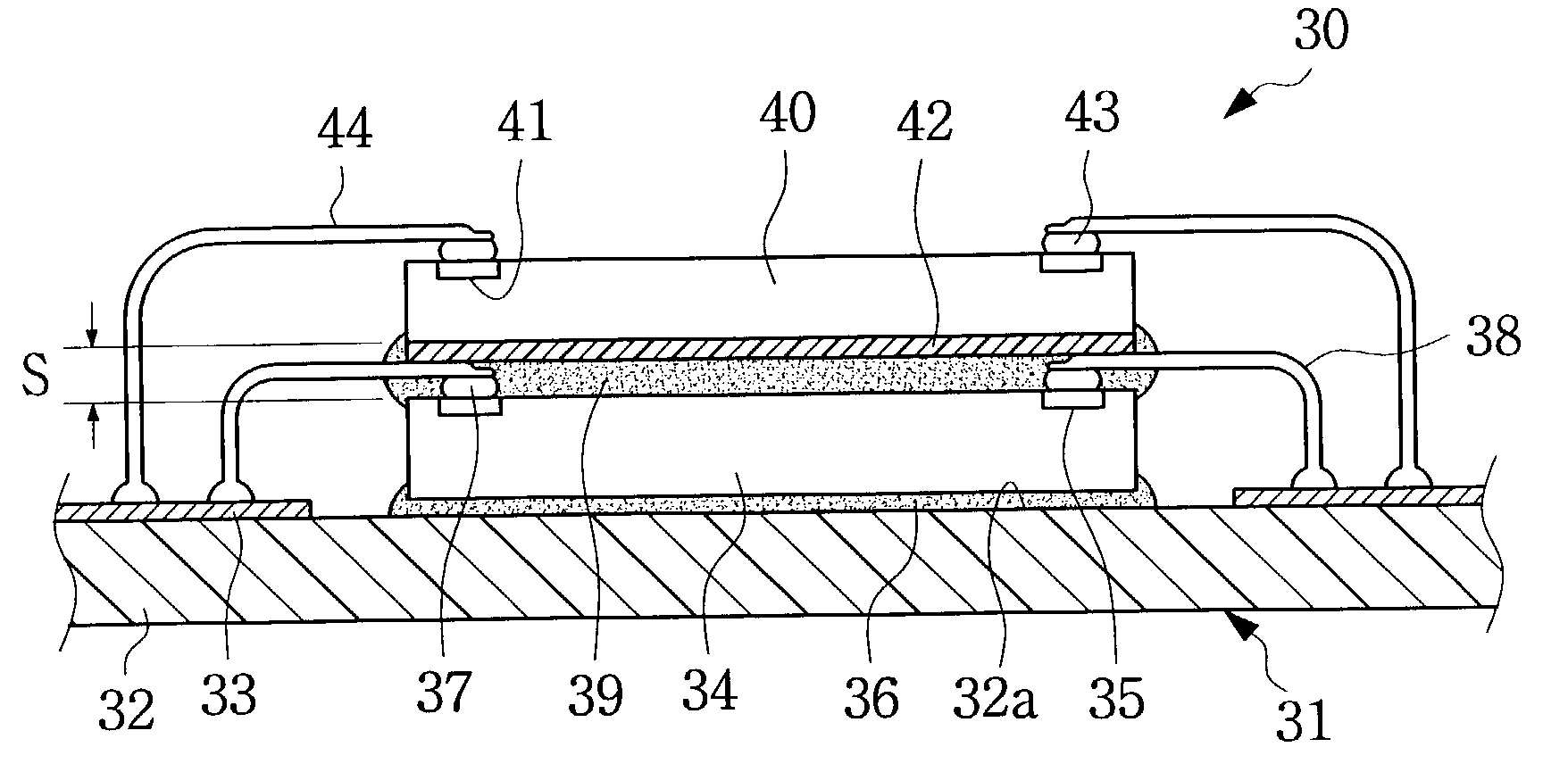

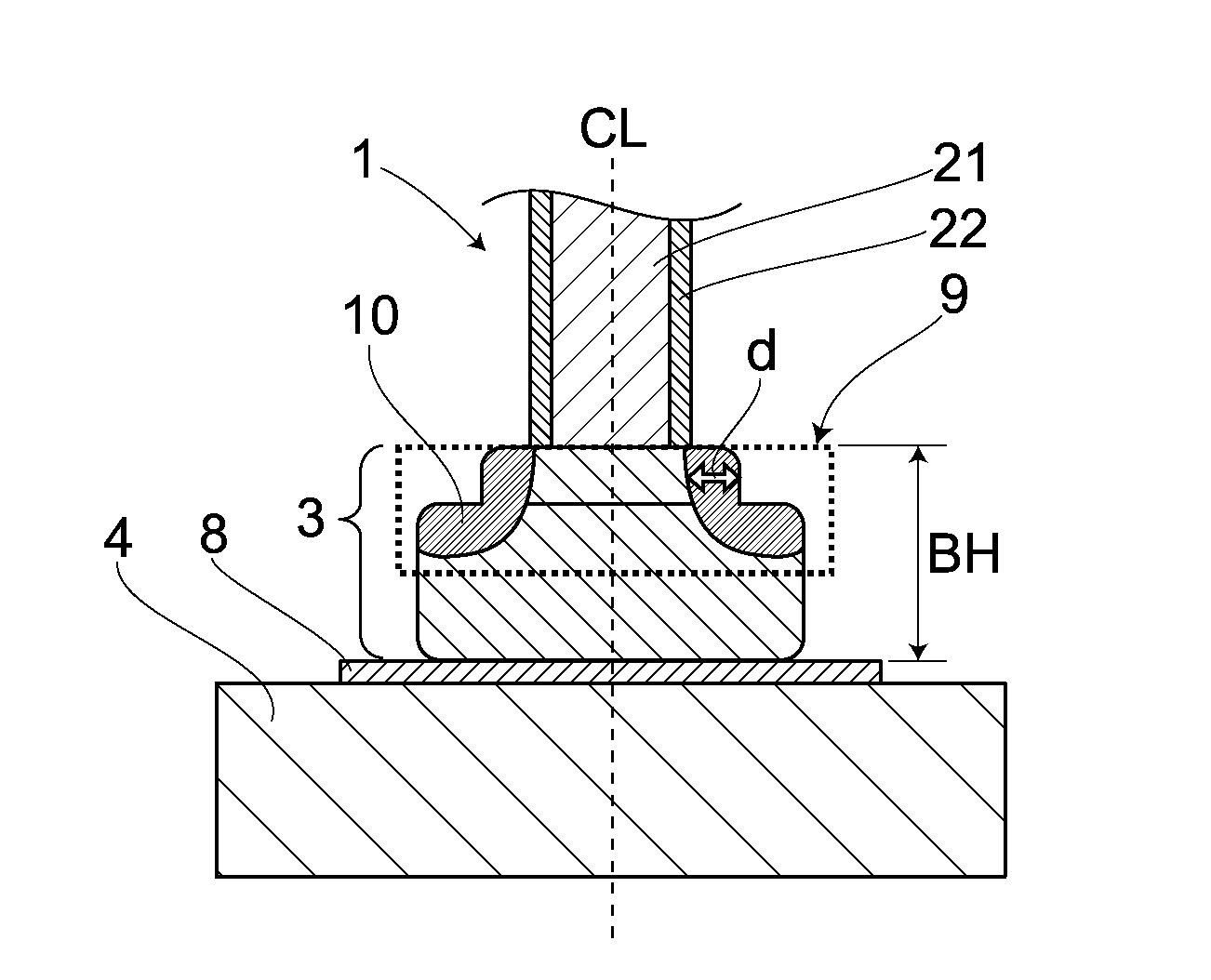

Semiconductor chip stack structure

InactiveUS6977439B2Reduce the overall heightSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipElectrical connection

Semiconductor chip stack structure and method are provided. A first chip has a first metal bump formed on a first electrode pad. The first chip is attached to and electrically connected to a substrate. The electrical connection is made by a bump reverse bonding method in which one end of a bonding wire is ball-bonded to the substrate and the other end is stitch-bonded to the metal bump. The second chip is stacked on the first chip. The bonding wire is substantially parallel with a top surface of the first chip. Accordingly, the chip stack structure and method minimize a space between the first chip and the second chip, thereby reducing the total height of semiconductor chip stack.

Owner:SAMSUNG ELECTRONICS CO LTD

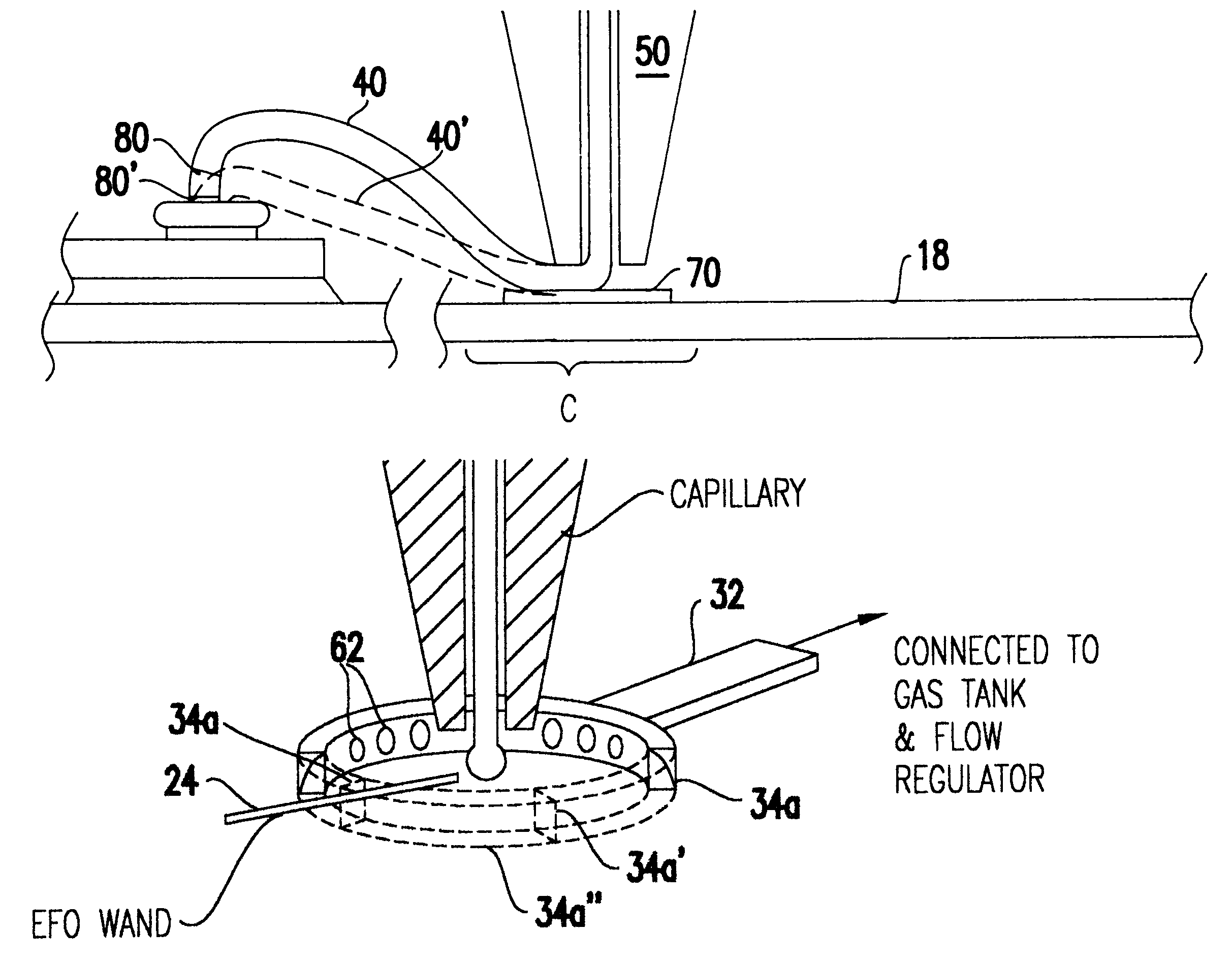

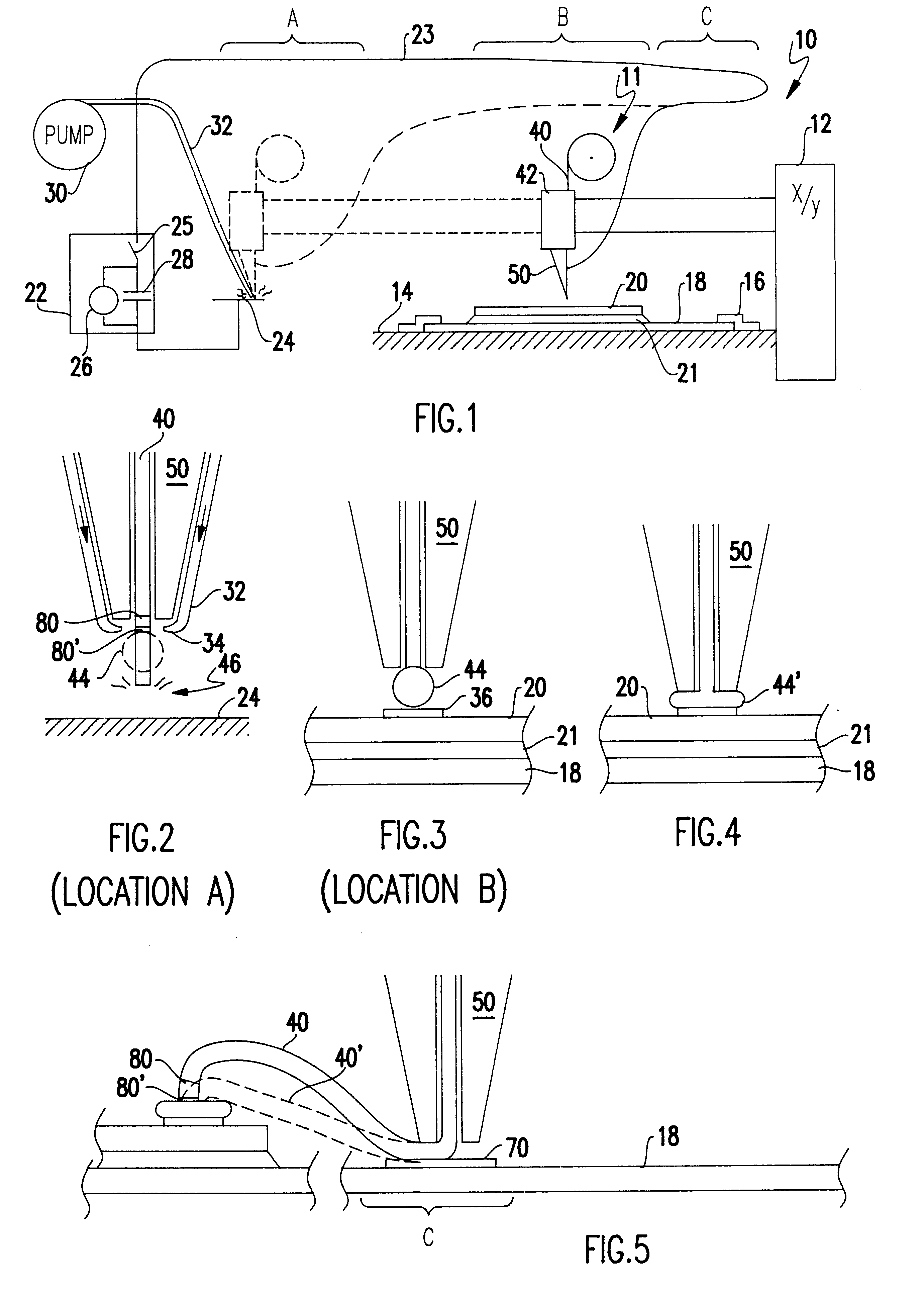

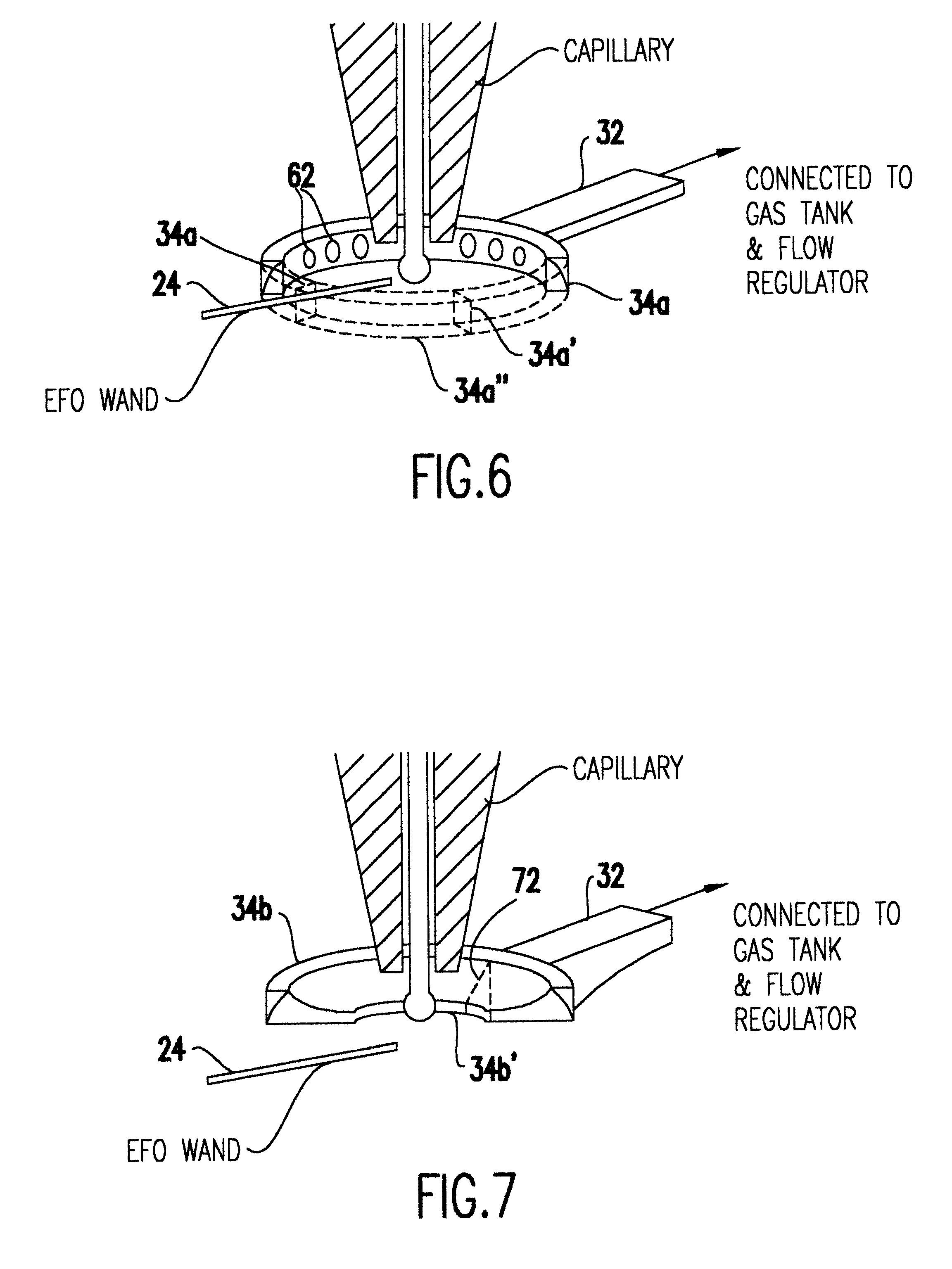

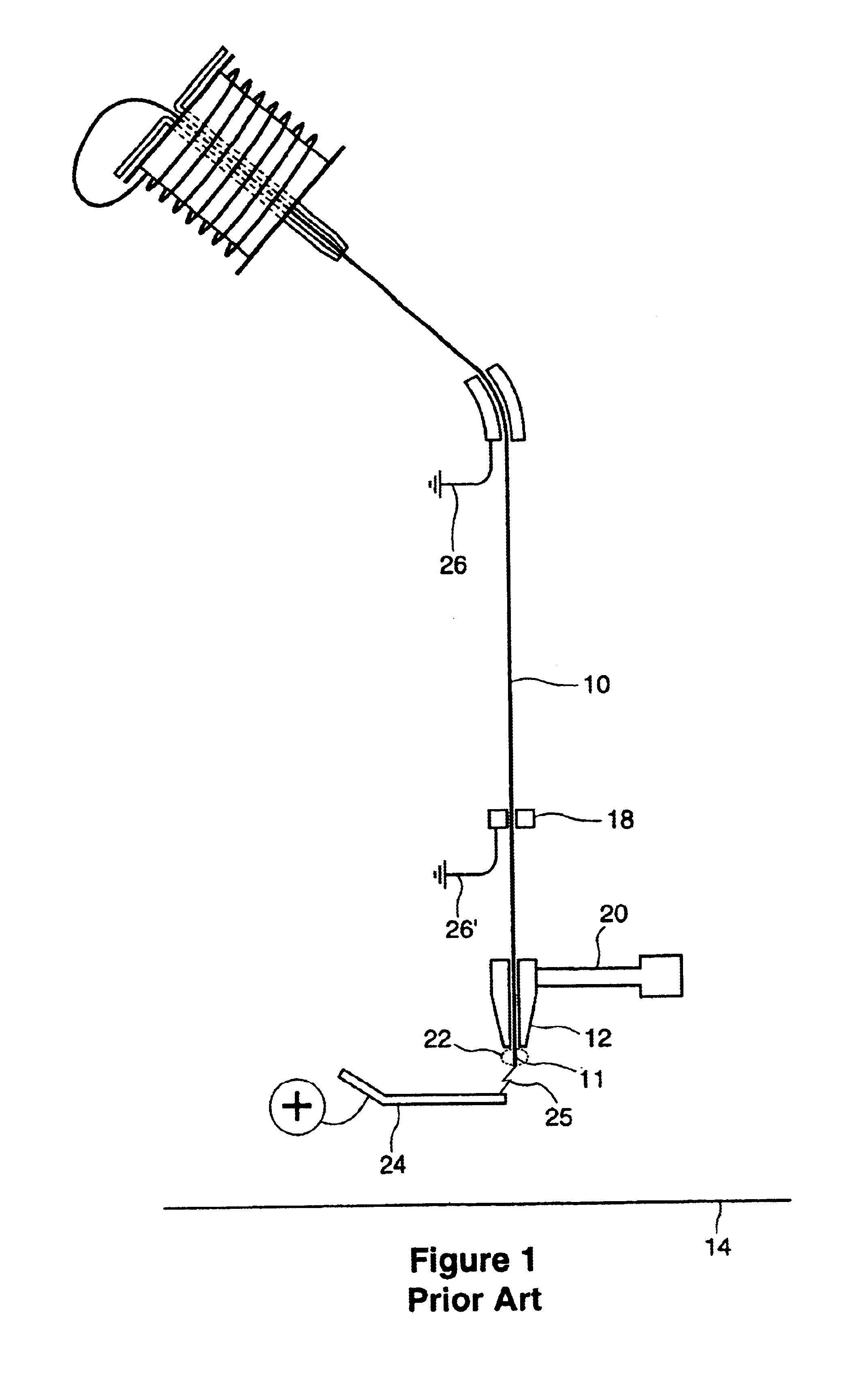

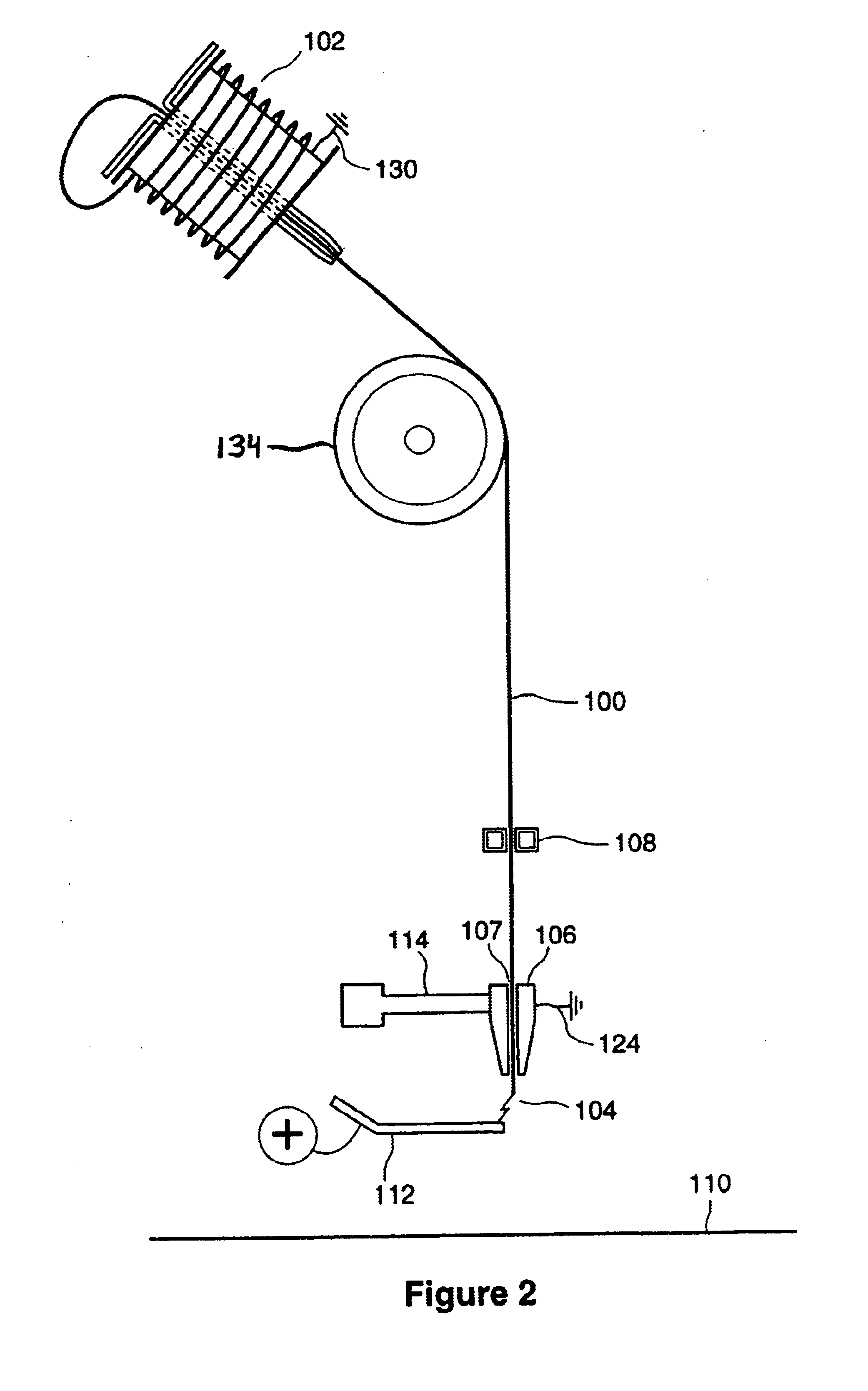

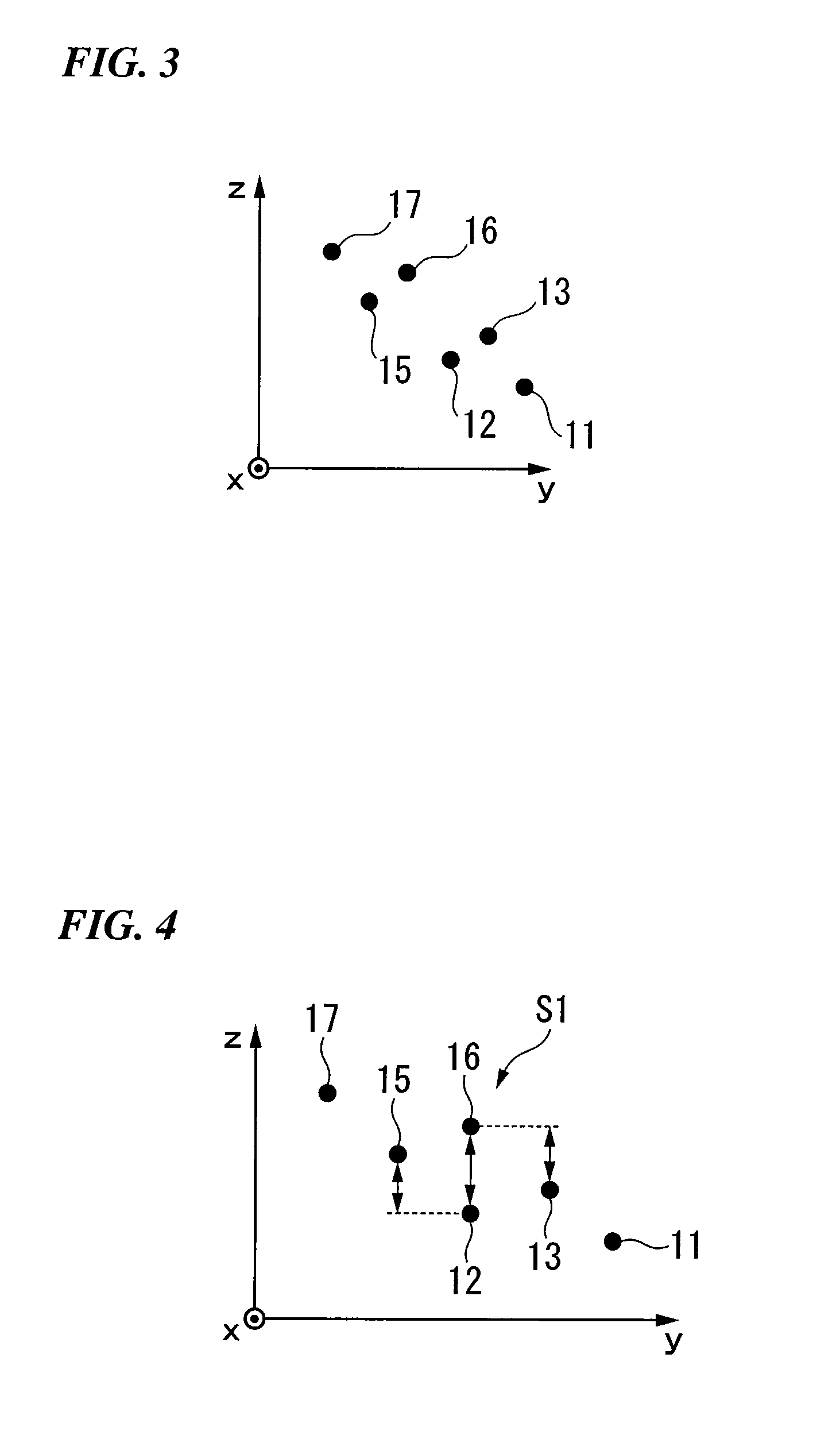

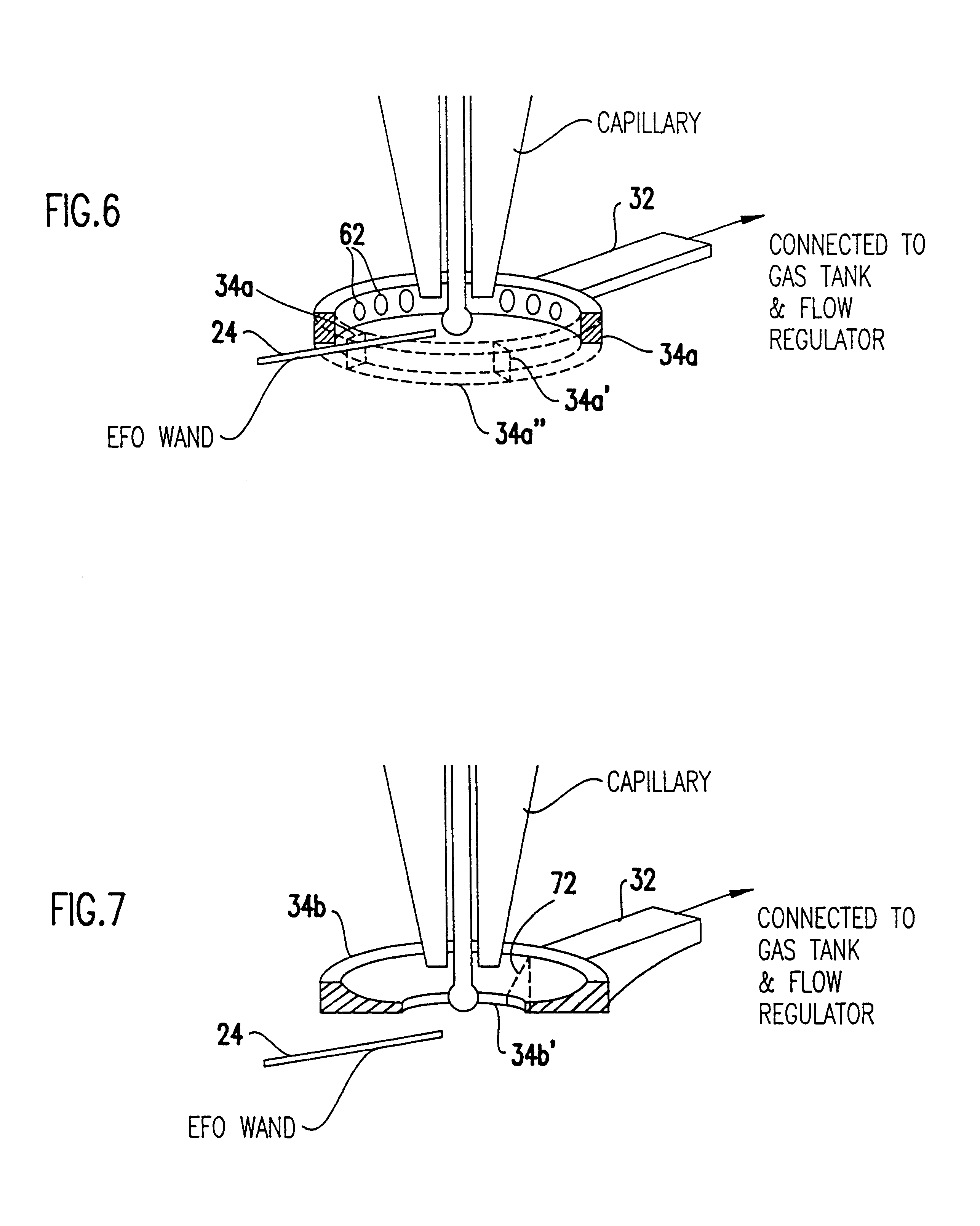

Wire bonder for ball bonding insulated wire and method of using same

InactiveUS6896170B2Easy to integrate into existing equipmentEasy to installSemiconductor/solid-state device detailsSolid-state devicesLead bondingEngineering

A wire bonder for bonding an insulated wire to a surface is disclosed. The bonder includes a bond head, having a bonding position adjacent to said surface and a wire preparation position spaced apart from the surface. There is a wire holder on the bond head, the wire holder being sized and shaped to permit a free end of the insulated wire to extend from the wire holder when the bond head is in the spaced apart position. A source of insulated wire for said bond head is provided as well as an electrical discharge wand positioned adjacent to said bond head when the bond head is in the spaced apart position. The wand directs sufficient electricity at the extending free end of the insulated wire to form a bond ball on the free end. A ground associated with the insulated wire, is provided the ground being sized and positioned to conduct electrical energy away from the insulated bond wire to prevent the insulation on the bond wire remote from the free end from being damaged.

Owner:MICROBONDS INC

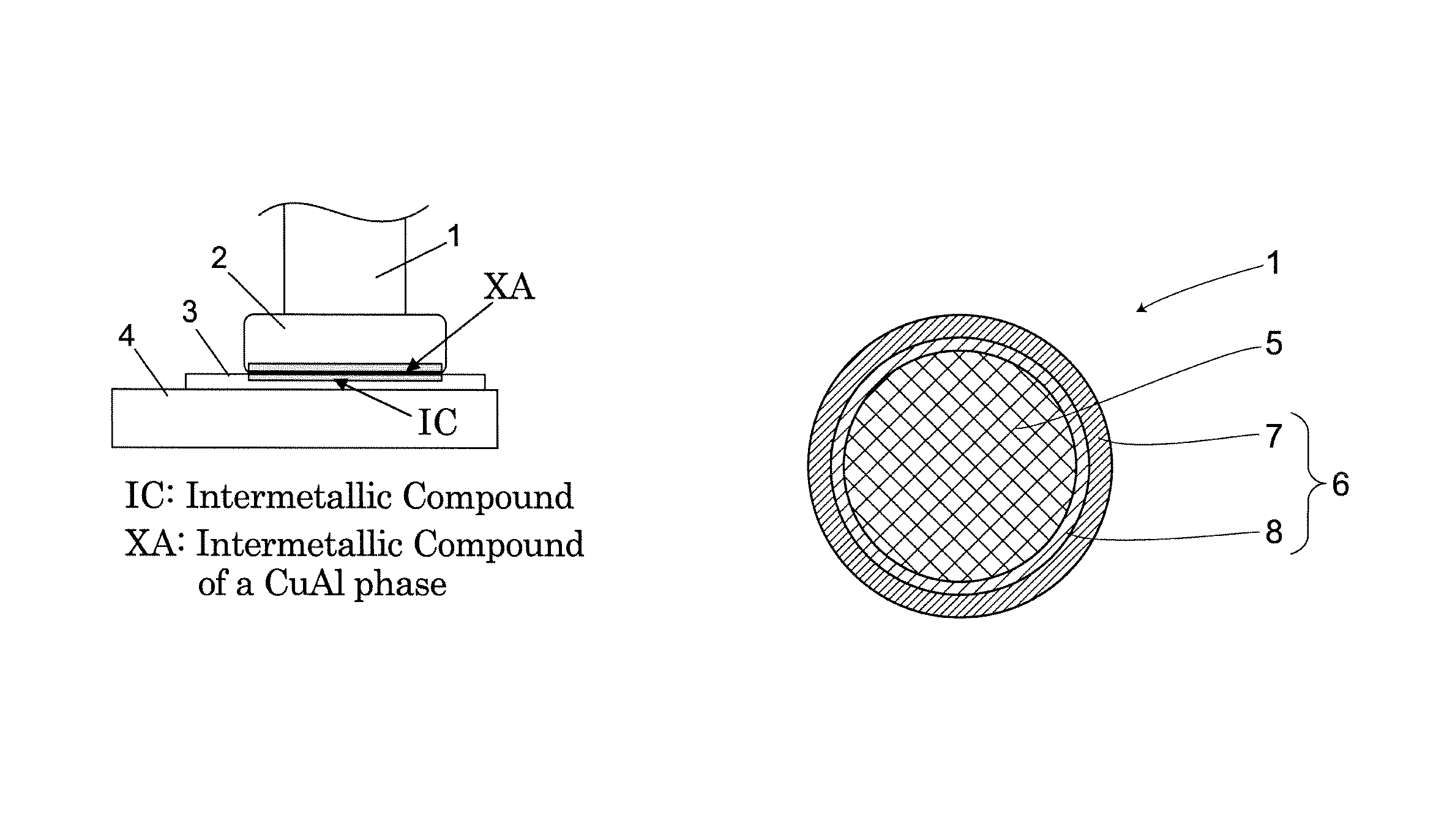

Copper bonding wire for semiconductor device and bonding structure thereof

ActiveUS8653668B2Reduce material costsImprove long-term reliabilitySemiconductor/solid-state device detailsSolid-state devicesCopperIntermetallic

A bonding structure and a copper bonding wire for semiconductor device include a ball-bonded portion formed by bonding to the aluminum electrode a ball formed on a front end of the copper bonding wire. After being heated at any temperature between 130° C. and 200° C., the ball-bonded portion exhibits a relative compound ratio R1 of 40-100%, the relative compound ratio R1 being a ratio of a thickness of a Cu—Al intermetallic compound to thicknesses of intermetallic compounds that are composed of Cu and Al and formed on a cross-sectional surface of the ball-bonded portion.

Owner:NIPPON STEEL CHEMICAL CO LTD +1

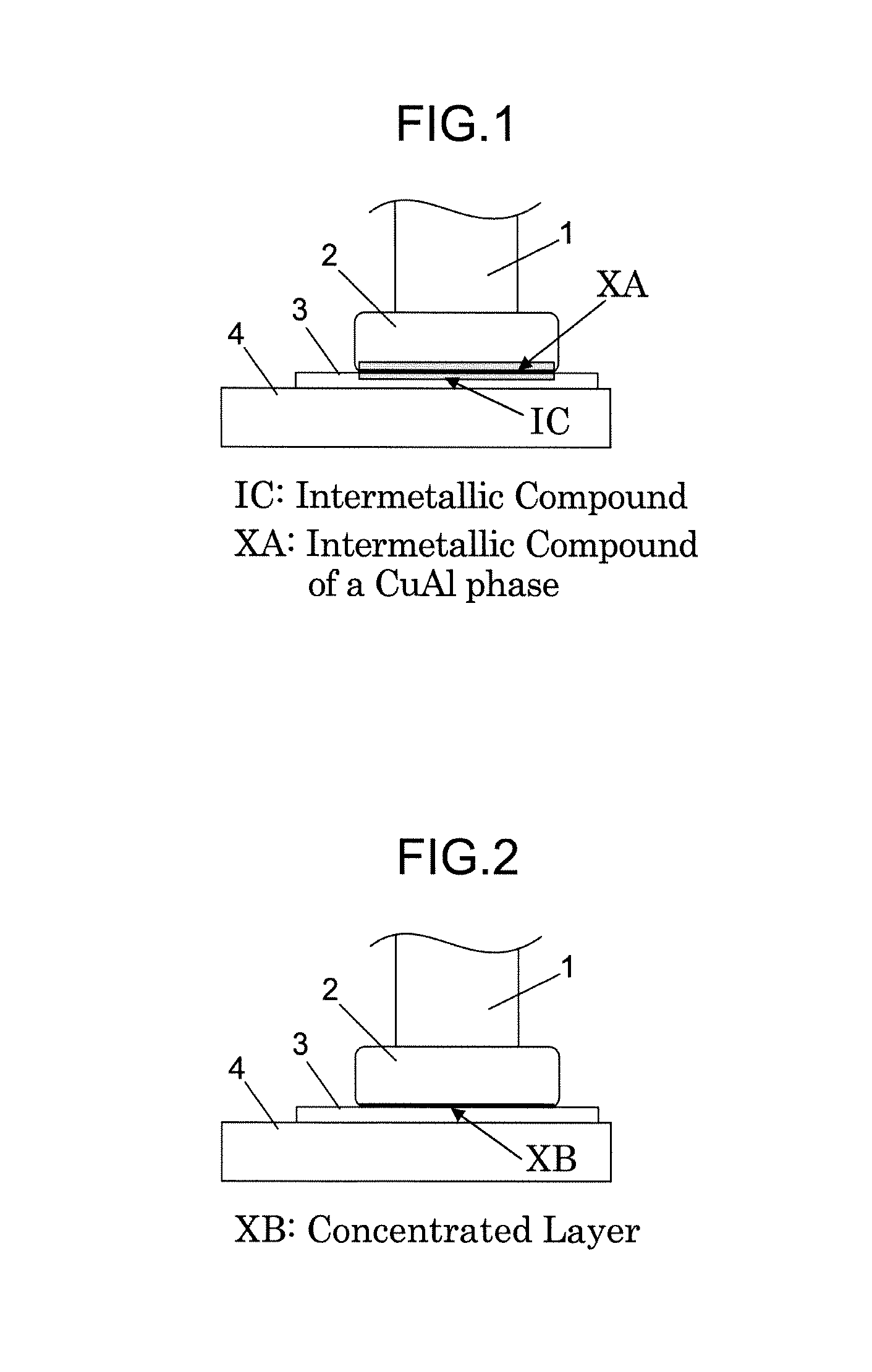

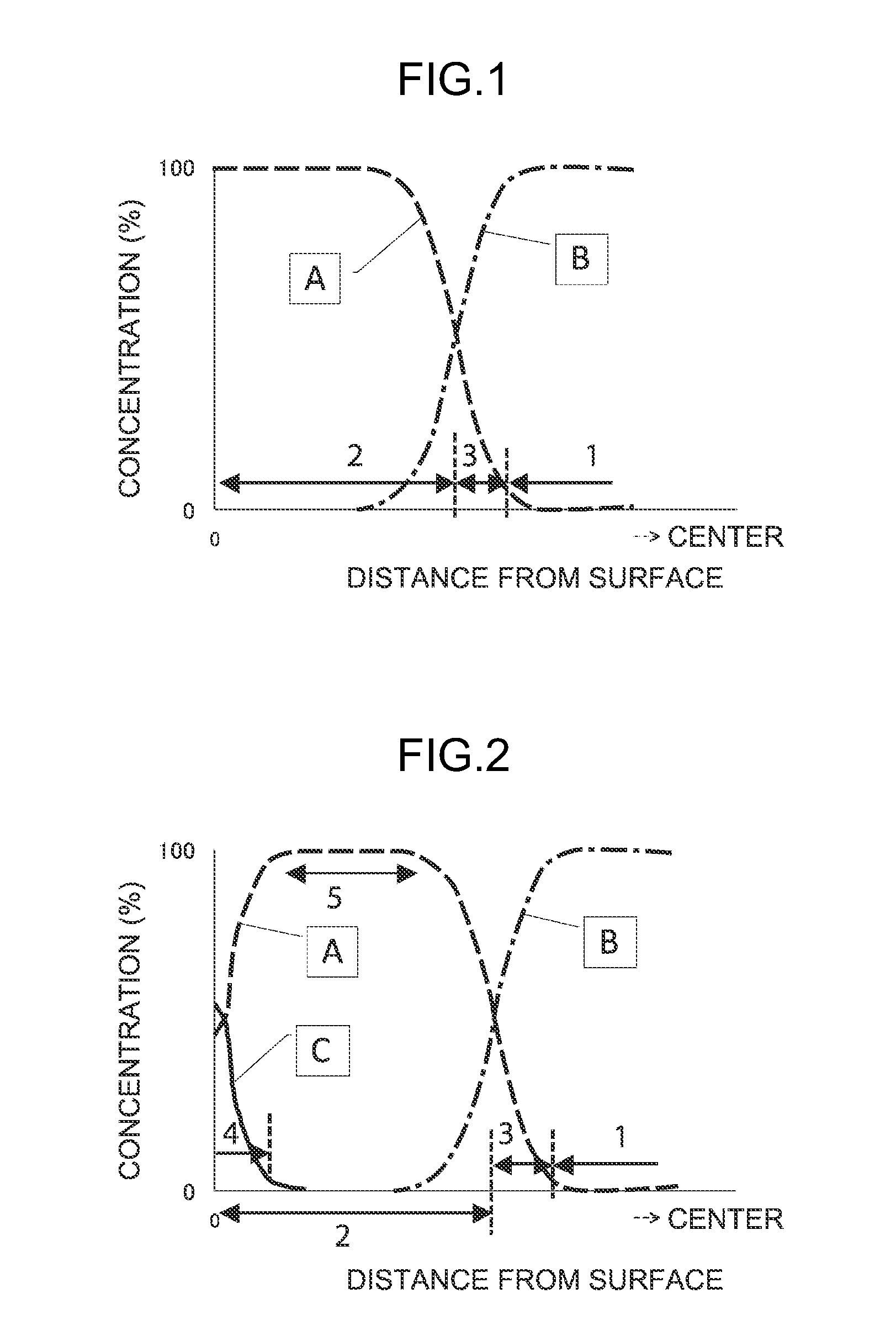

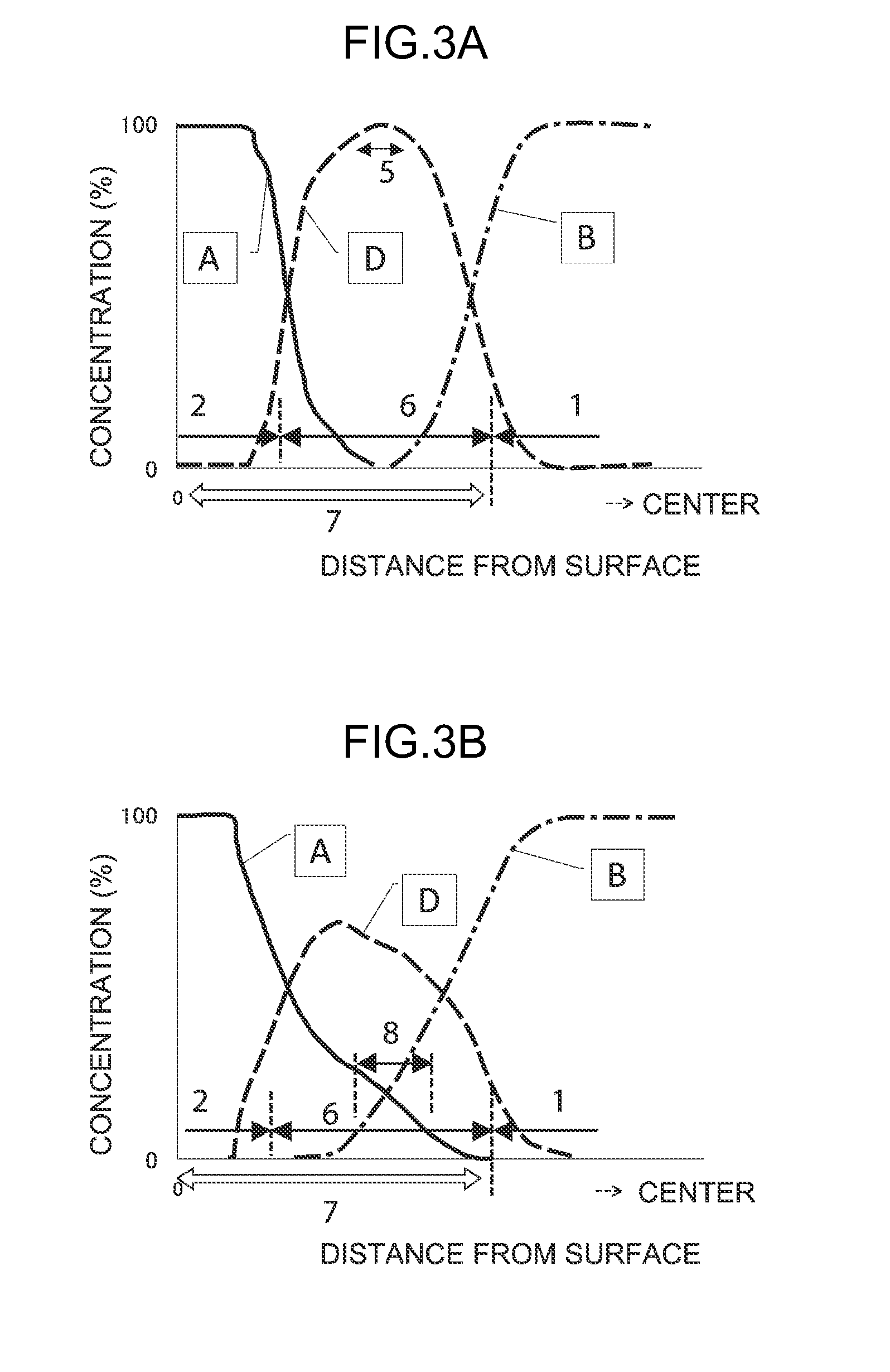

Bonding wire

InactiveUS20040245320A1Complex structureAvoid collisionSoldering apparatusSolid-state devicesWire rodStructural engineering

A bonding wire having a core mainly consisting of copper and a coating layer formed on the core, wherein the coating layer is made of an oxidation-resistant metal having a melting point higher than that of copper, and the elongation of this bonding wire per unit sectional area is 0.021% / mum<2 >or more; and a bonding wire having a core mainly consisting of copper and a coating layer formed on the core, wherein the coating layer is made of a metal having oxidation resistance higher than that of copper, and the relationship of 0.007<=X<=0.05 is satisfied wherein an area ratio X is (the area of the coating layer / the area of the core at the section of wire being cut vertically) are provided. The bonding wires thus provided are inexpensive and excellent in ball formation characteristic and bonding characteristic. Further, a ball bonding method characterized in using the above bonding wire is also provided.

Owner:SUMITOMO ELECTRIC WINTEC INC

Bonding structure of multilayer copper bonding wire

A bonding structure of a ball-bonded portion is obtained by bonding a ball portion formed on a front end of a multilayer copper bonding wire. The multilayer copper bonding wire includes a core member that is mainly composed of copper, and an outer layer that is formed on the core member and is mainly composed of at least one noble metal selected from a group of Pd, Au, Ag and Pt. Further, a first concentrated portion of such noble metal(s) is formed in a ball-root region located at a boundary with the copper bonding wire in a surface region of the ball-bonded portion.

Owner:NIPPON STEEL CHEMICAL CO LTD +1

Semiconductor package having flex circuit with external contacts

InactiveUS6911355B2Semiconductor/solid-state device detailsSolid-state devicesElectrical conductorFlexible circuits

A chip scale semiconductor package and a method for fabricating the package are provided. The package includes a semiconductor die and a flex circuit bonded to the face of the die. The flex circuit includes a polymer substrate with a dense array of external contacts, and a pattern of conductors in electrical communication with the external contacts. The package also includes interconnects configured to provide separate electrical paths between die contacts (e.g., bond pads), and the conductors on the flex circuit. Several different embodiments of interconnects are provided including: bumps on the die contacts, bonded to the flex circuit conductors with a conductive adhesive layer; polymer bumps on the conductors, or die contacts, applied in a semi-cured state and then fully cured; solder bumps on the die contacts and conductors, bonded to one another using a bonding tool; rivet-like bonded connections between the conductors and die contacts, formed using metal bumps and a wire bonding or ball bonding apparatus; single point bonded connections between the conductors and die contacts, formed with a bonding tool; and wire bonds between the conductors and die contacts.

Owner:ROUND ROCK RES LLC

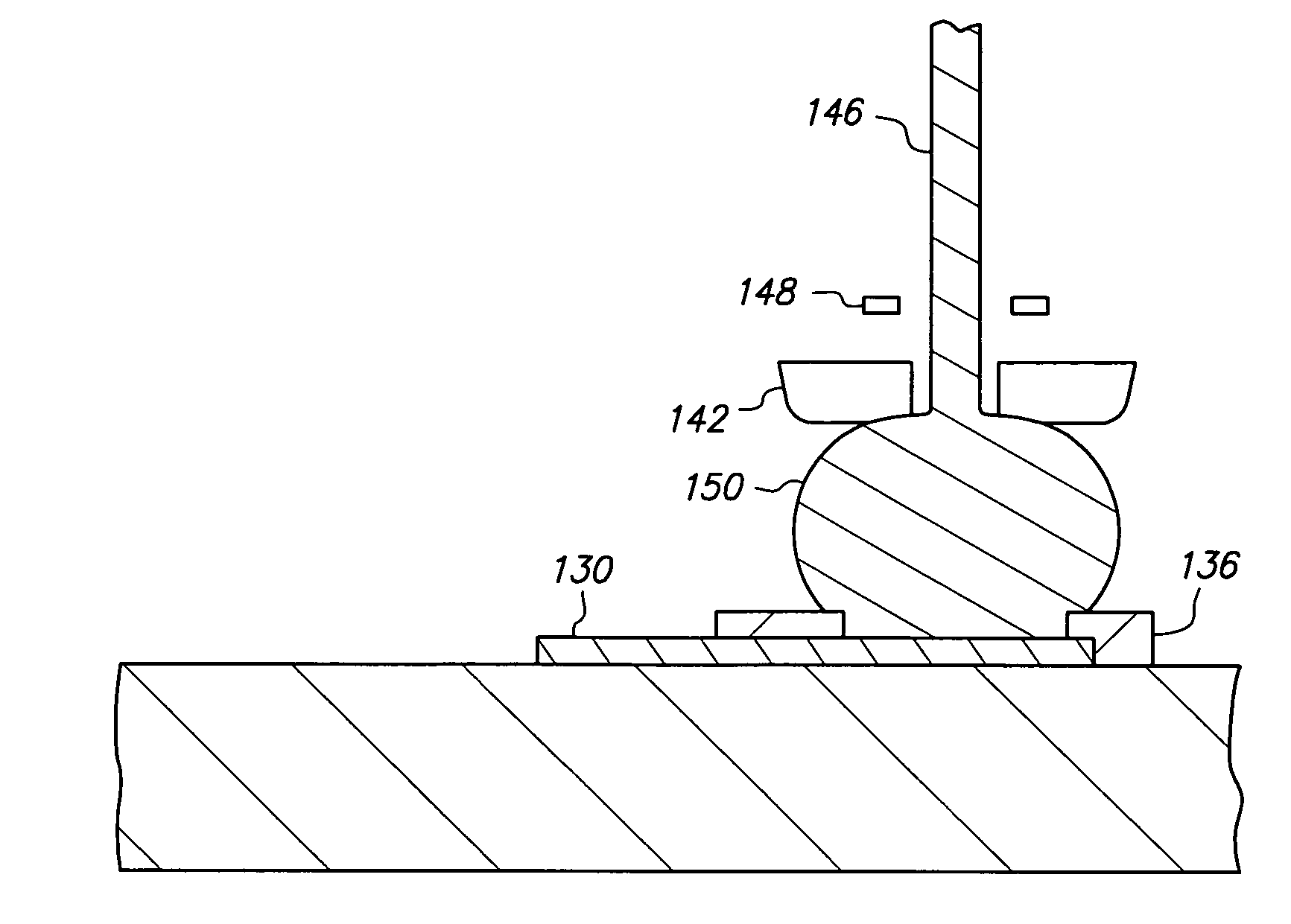

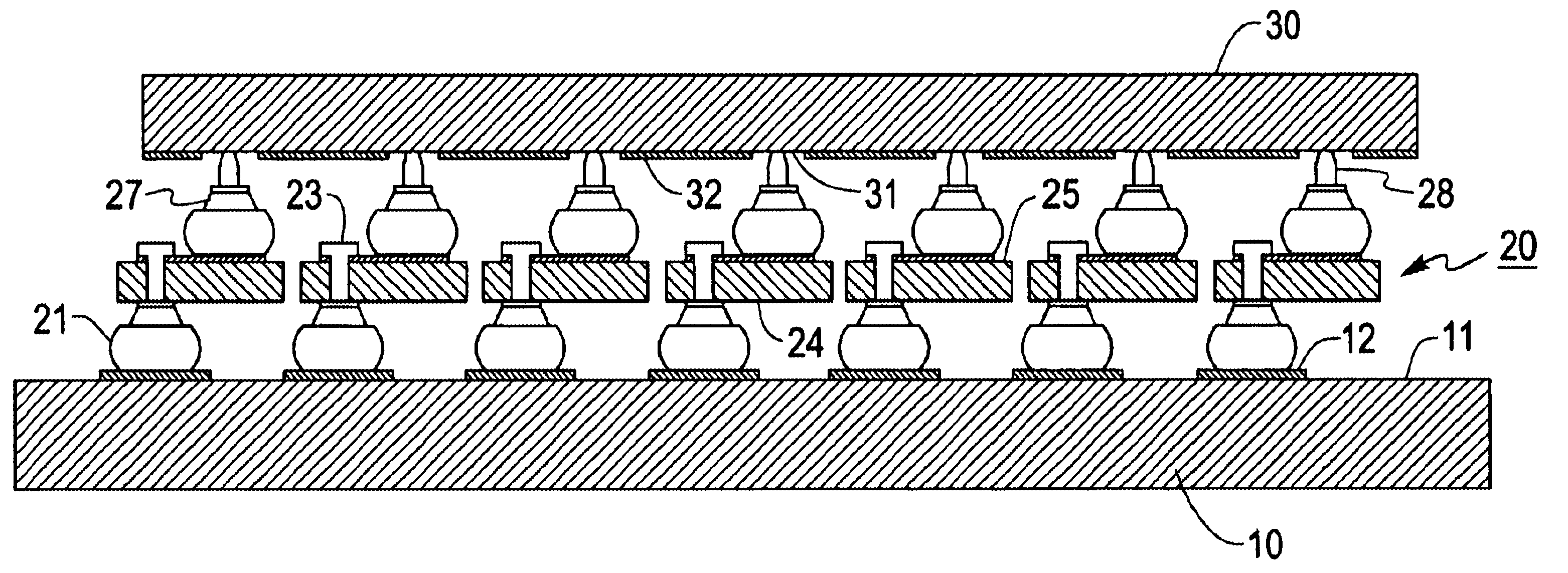

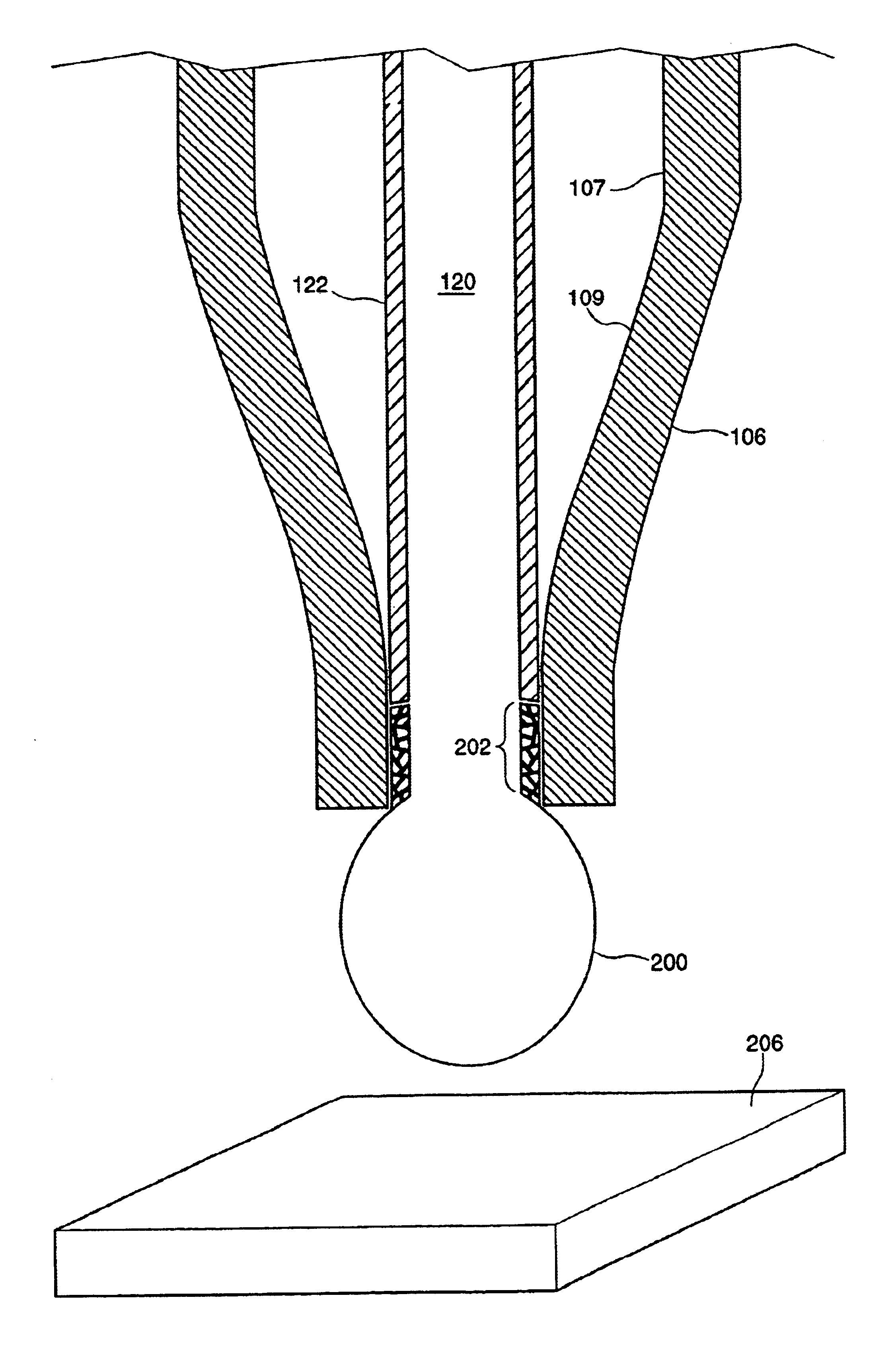

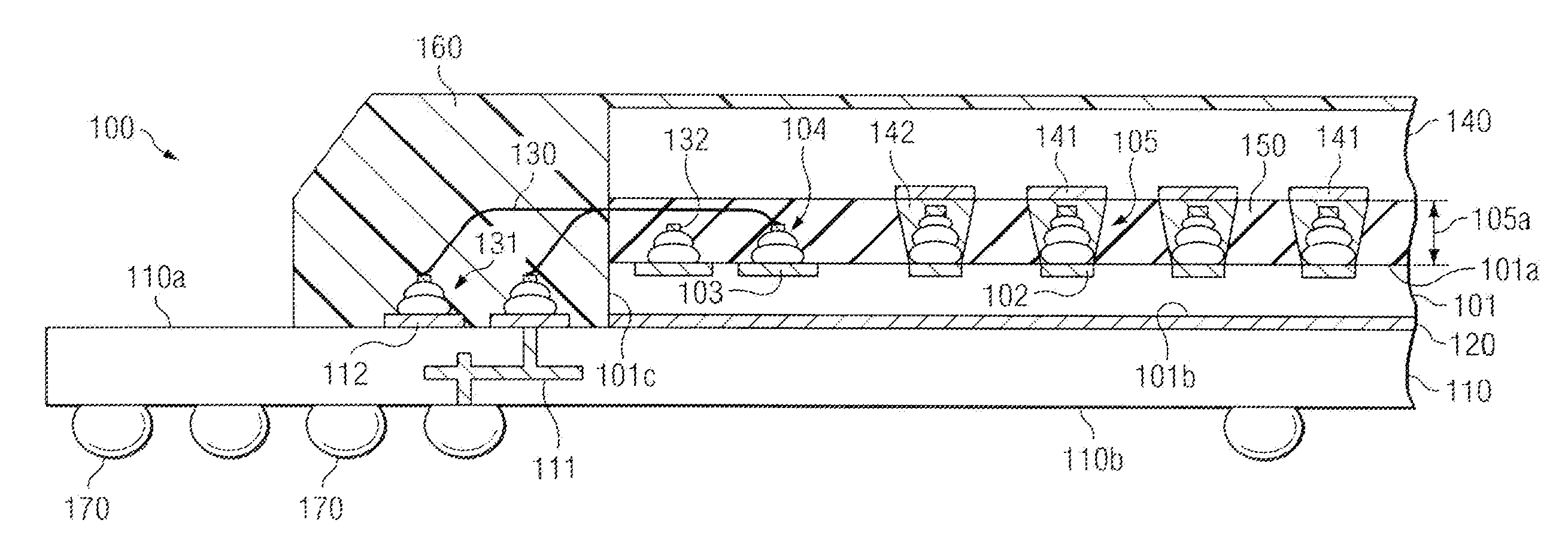

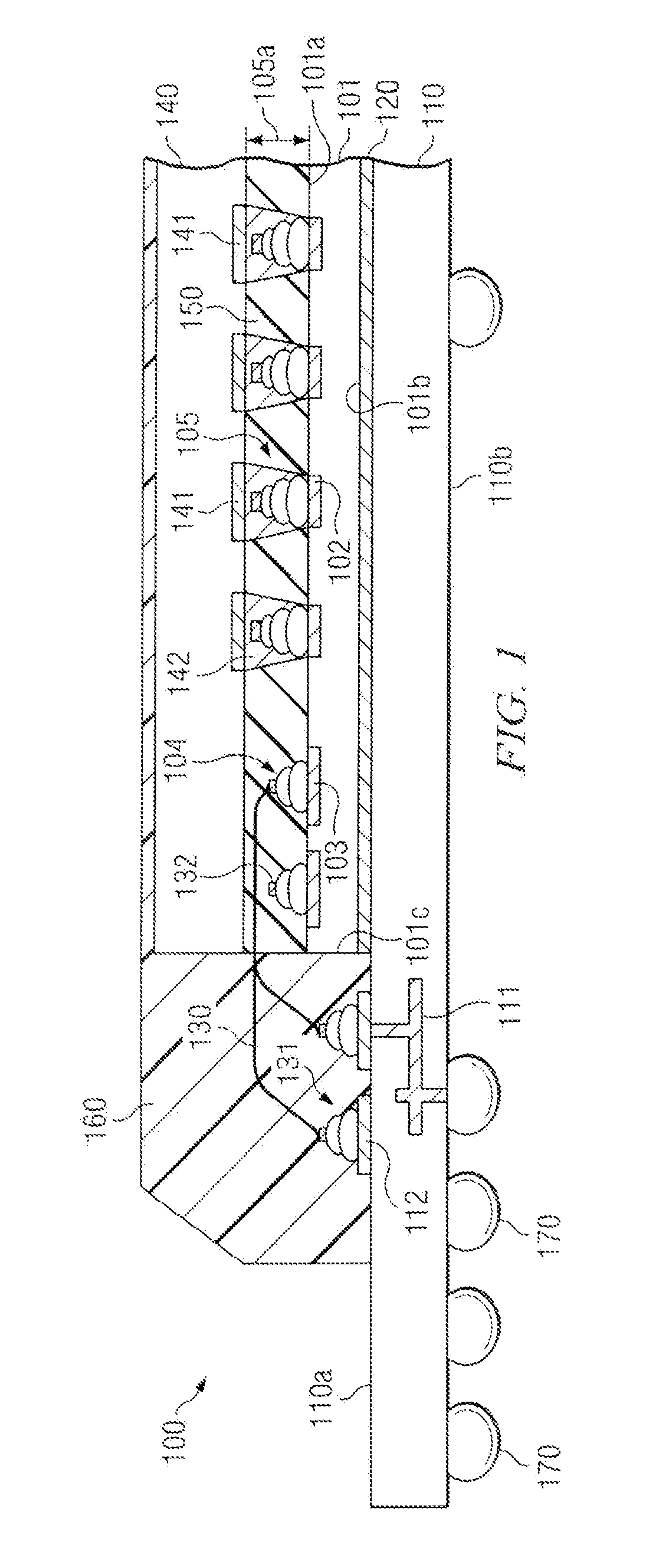

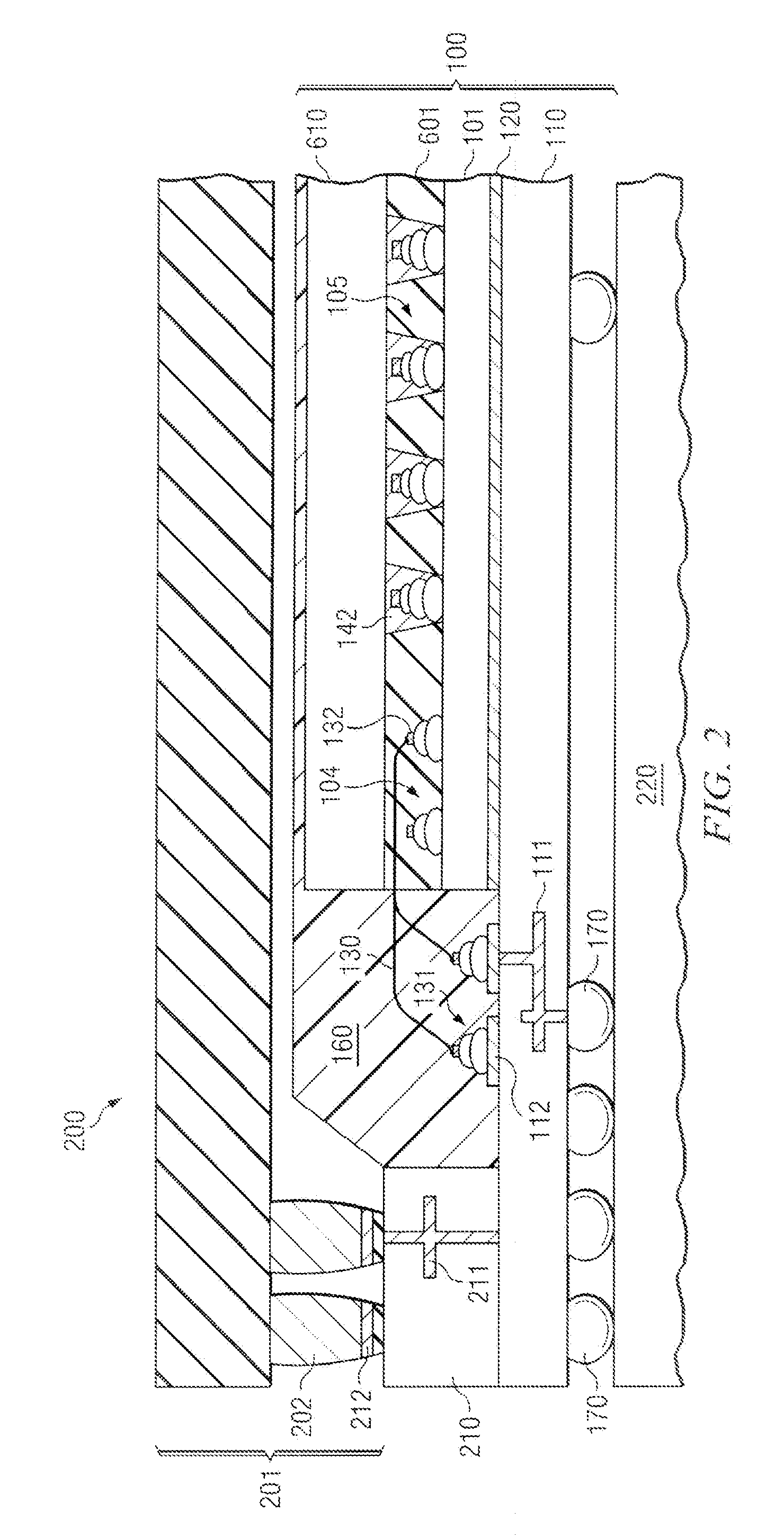

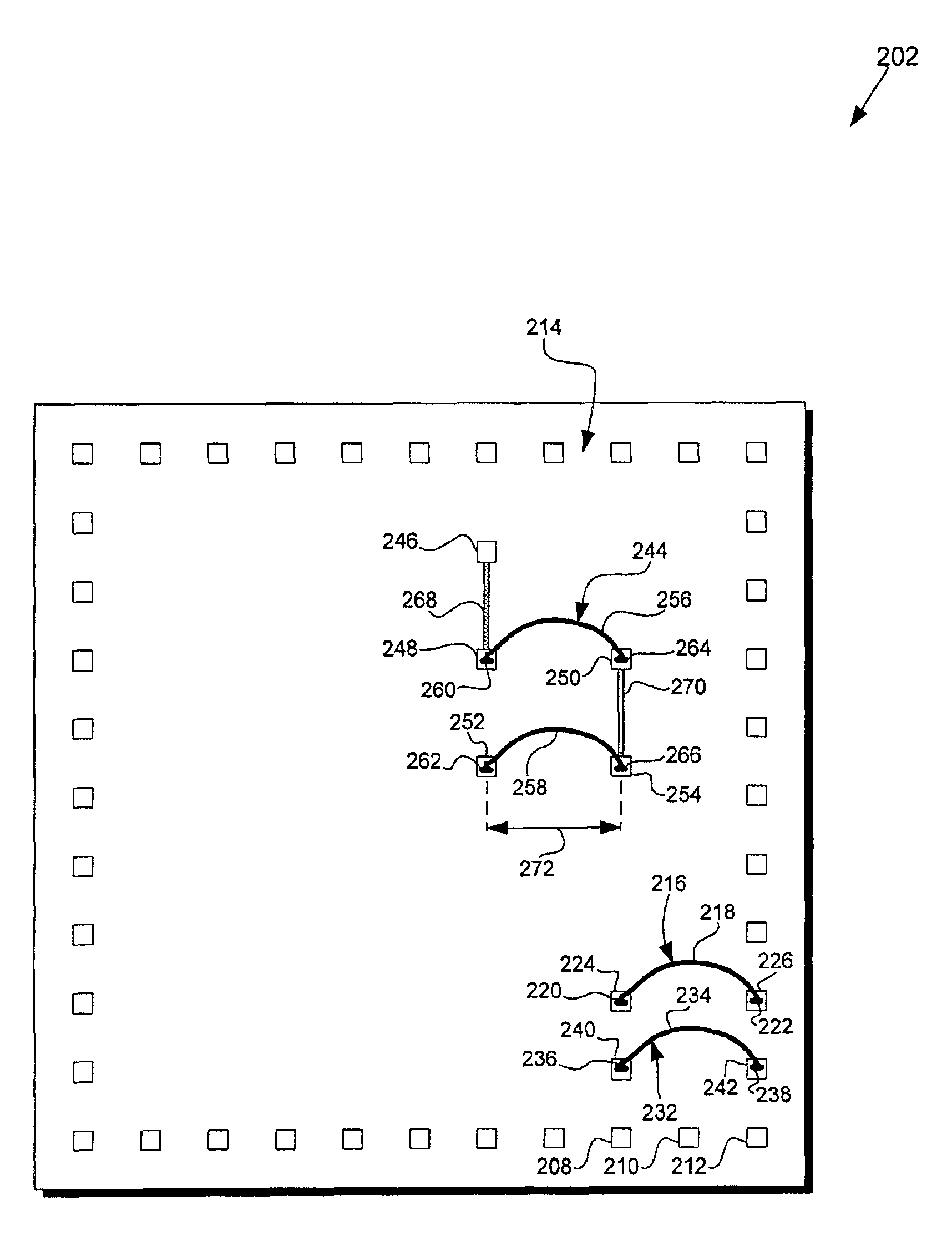

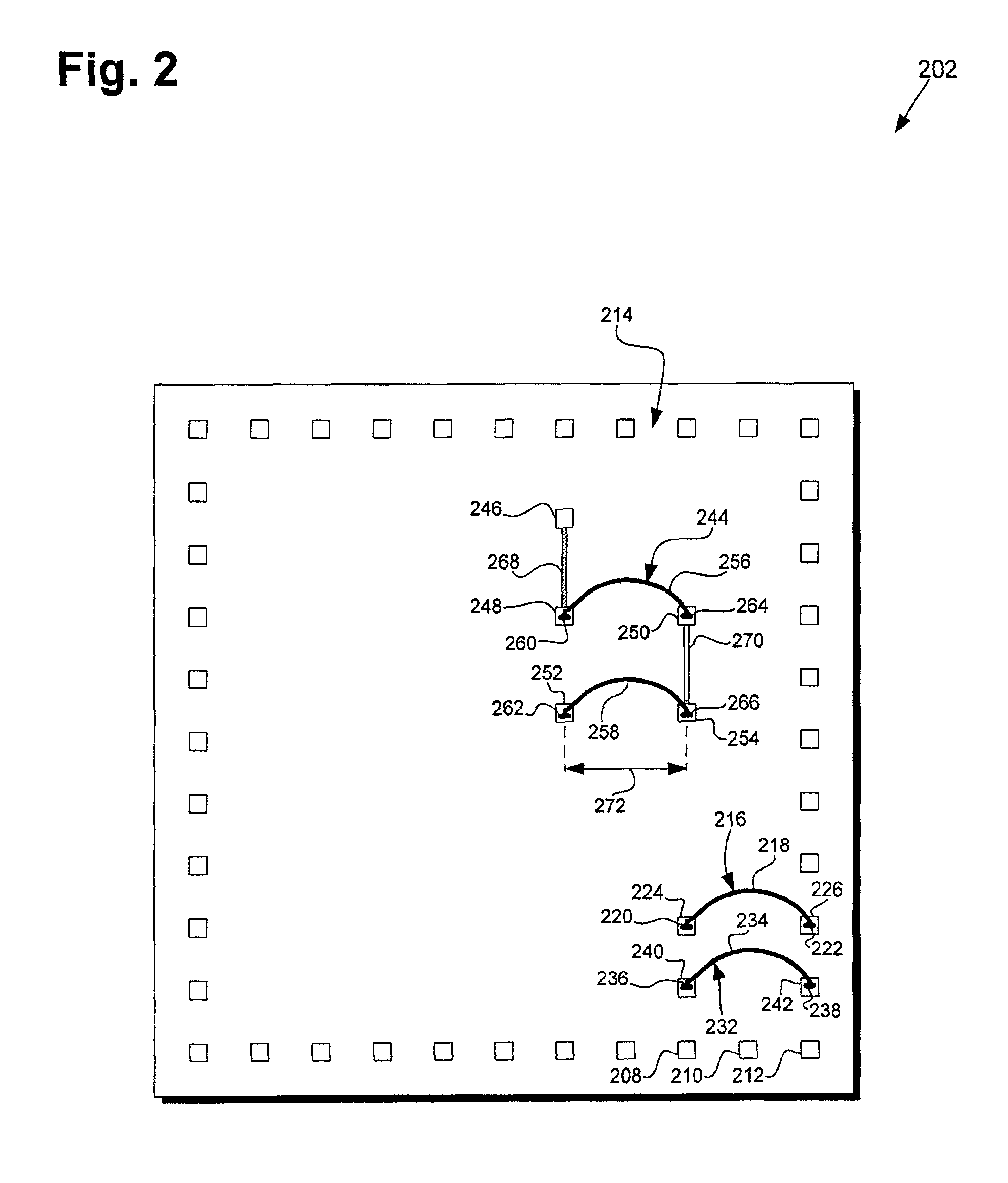

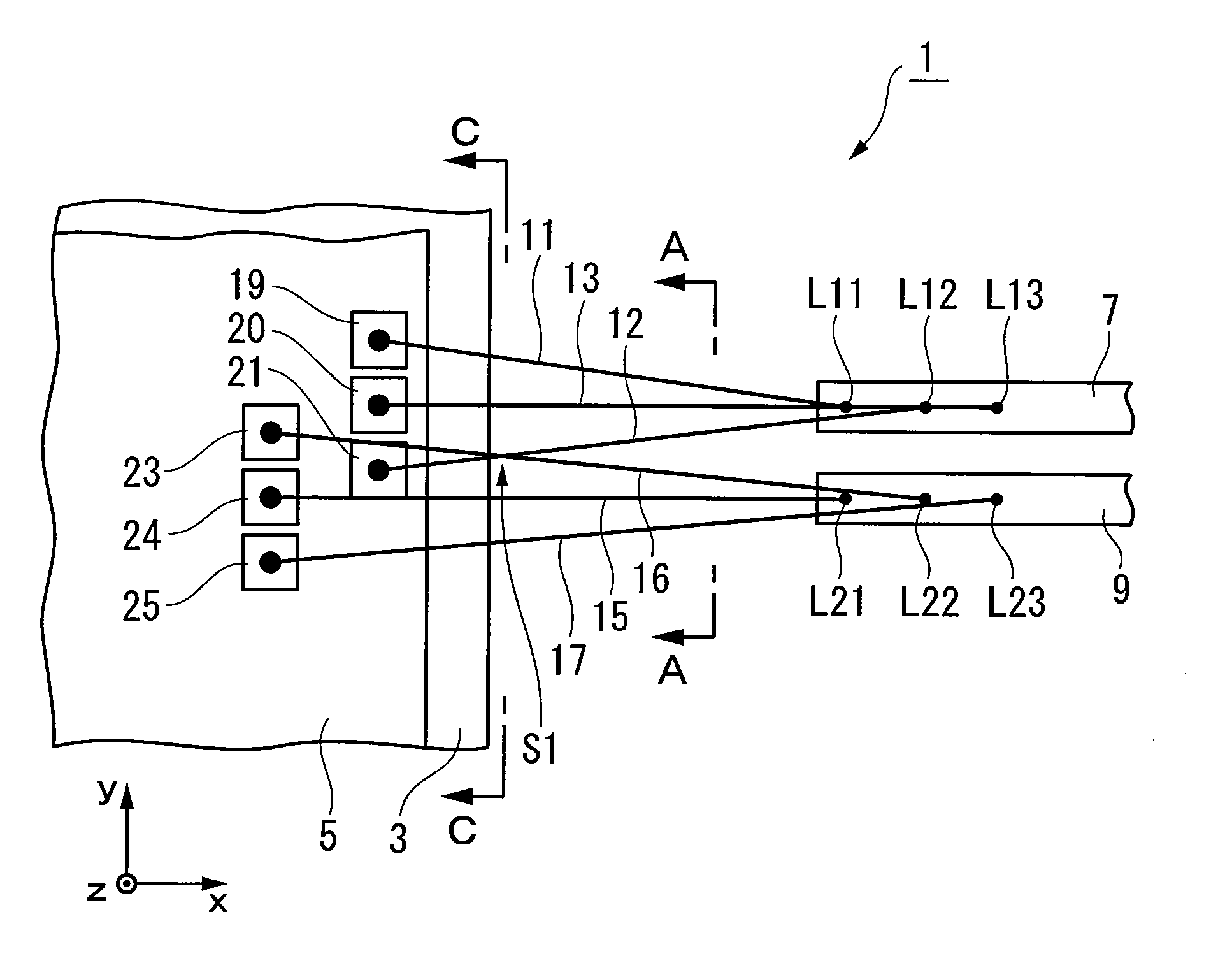

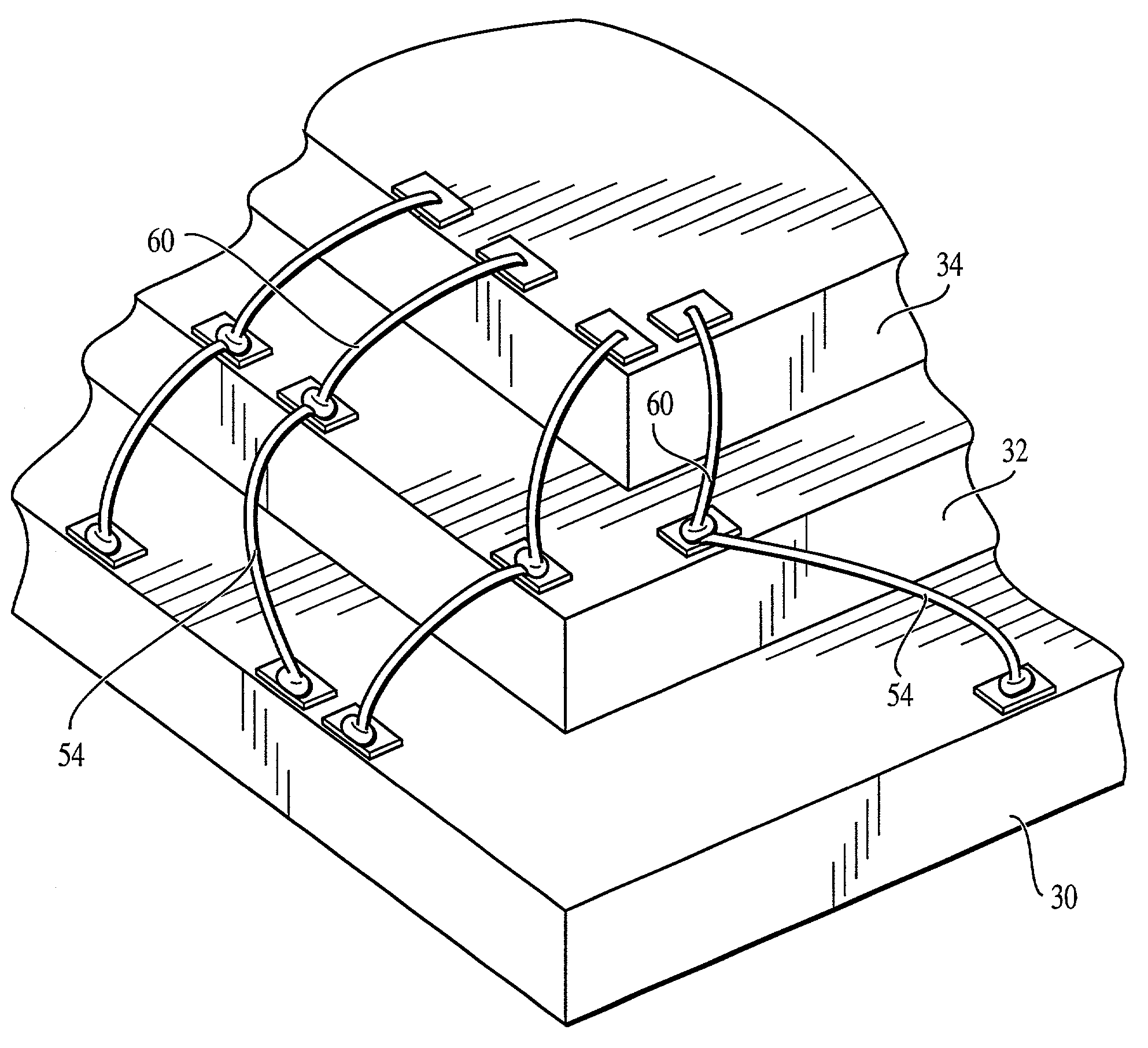

Controlling Flip-Chip Techniques for Concurrent Ball Bonds in Semiconductor Devices

ActiveUS20070228543A1Improve electrical performanceImprove mechanical stabilitySemiconductor/solid-state device detailsSolid-state devicesContact padSemiconductor chip

A device has a first semiconductor chip (101) with contact pads in an interior first set (102) and a peripheral second set (103). A deformed sphere (104) of non-reflow metal such as gold is placed on each contact pad of the first and second sets. At least one additional deformed sphere (105) is placed on the first set pads, forming column-shaped spacers. The first chip is attached to a substrate (110) with a chip attachment location and a third set of contact pads (112) near the location. Low profile bond wires (130) span between the pads of the third set and the second set. A second semiconductor chip (140) of a size has a fourth set of contact pads (141) at locations matching the first set pads. The second chip is placed over the first chip so that the fourth set pads are aligned with the spacers on the matching first set pads, and at least one edge of the second chip overhangs the sphere on at least one pad of the second set. A reflow metal (142) bonds the spacers to the second chip, while the spacers space the first and second chips by a gap (105a) wide enough for placing the wire spans to the second set pads.

Owner:TEXAS INSTR INC

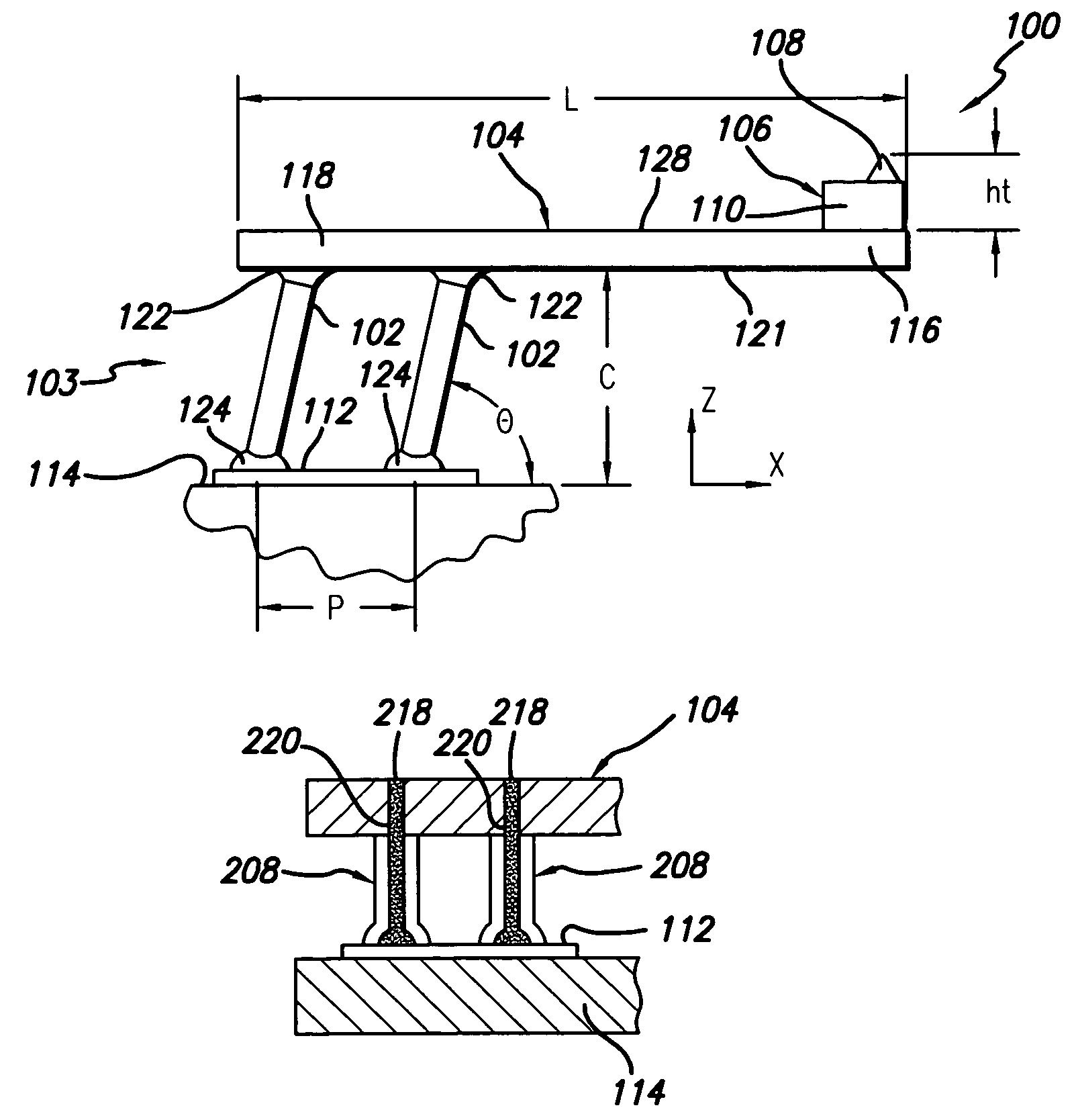

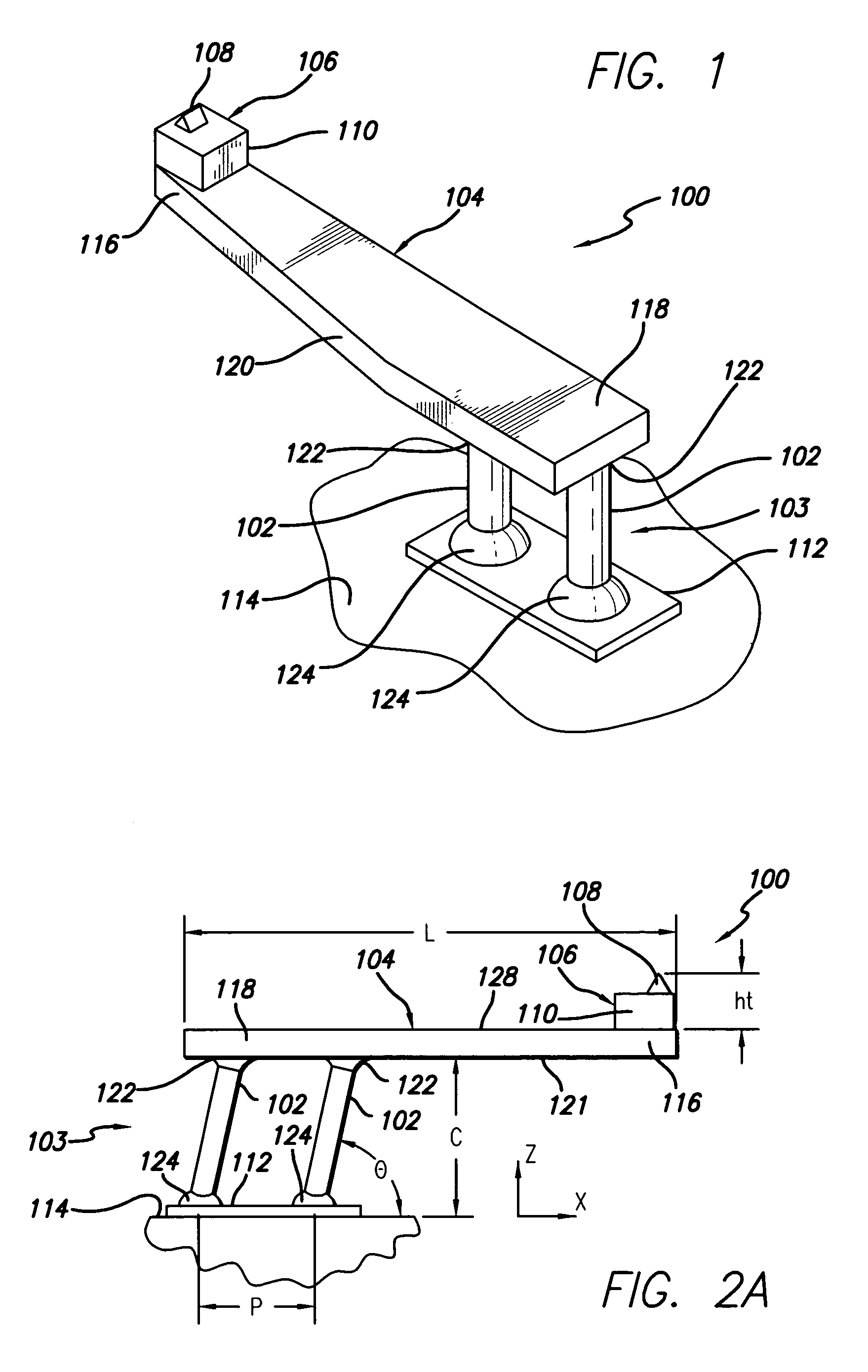

Composite microelectronic spring structure and method for making same

InactiveUS7063541B2Eliminate needLess timePrinted circuit assemblingElectronic circuit testingProbe cardInterposer

An improved microelectronic spring structure, and method of making the same, are disclosed. The improvement comprises, in a spring contact of the type comprising a beam attached to a post, of replacing the post with a plurality of column elements. The beam component is thus provided with one or more column elements which both structurally support and electrically connect one end of the beam to an electronic component. The column elements are preferably comprised of relatively straight segments of wire elements that are ball-bonded to a substrate and are over-coated with suitable structural and / or conducting materials. In the alternative, the improvement comprises a single column element comprised of a relatively straight segment of wire that is ball-bonded to a substrate and over-coated with suitable structural and conducting materials, wherein the column element is essentially rigid. The improved spring structures are especially useful for use as spring contacts on substrates such as probe cards, interposers, semiconductor devices, and other electronic components.

Owner:FORMFACTOR INC

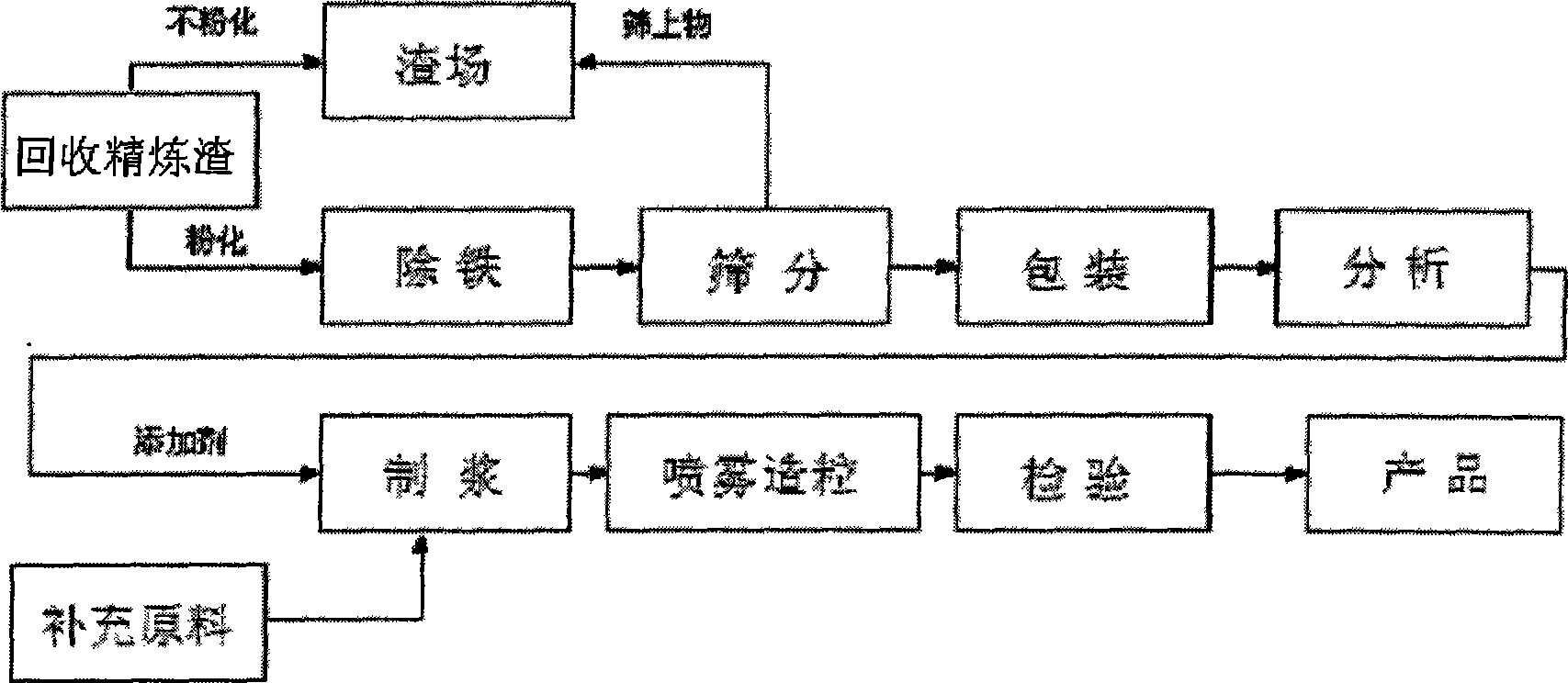

Method for preparing protecting residue from recovery refining slag

The invention relates to a method for preparing protecting slag from recovered refining slag remained in a ladle after continuous casting, which is characterized in that the recovered refining slag is natural cooled down, pulverized, subjected to iron removal and passes a 80-mesh screen; undersize is picked up and subjected to component analysis; according to the target component of the prepared protecting slag, if corresponding amount of natural mineral or fine powder of manually synthesized material containing the lacked components needs to be added, butane radical sodium xanthate and balling bonding agent in the general adding amount are added to prepare pulp with the solid content of between 50 and 70 weight percent, and the pulp is sprayed at the tower top at a hot air temperature of between 550 and 650 DEG C to prepare hollow micro balls. The invention has two characteristics: 1. the method has the simple recycling process, and the materials used to prepared the protecting slag are calculated and added only by the principle of adding what lacks and adding how much lacks, so that the component requirement on the protecting slag preparation is met; and 2. due to high added value of the product, the value of the recovered refining slag can be fully utilized.

Owner:JIANGSU JIANAI HIGH TEMPERATURE MATERIAL

High density integral test probe

InactiveUS7276919B1Minimized contact resistanceEasy alignmentElectrical measurement instrument detailsIndividual semiconductor device testingHigh densityContact position

Owner:GLOBALFOUNDRIES INC

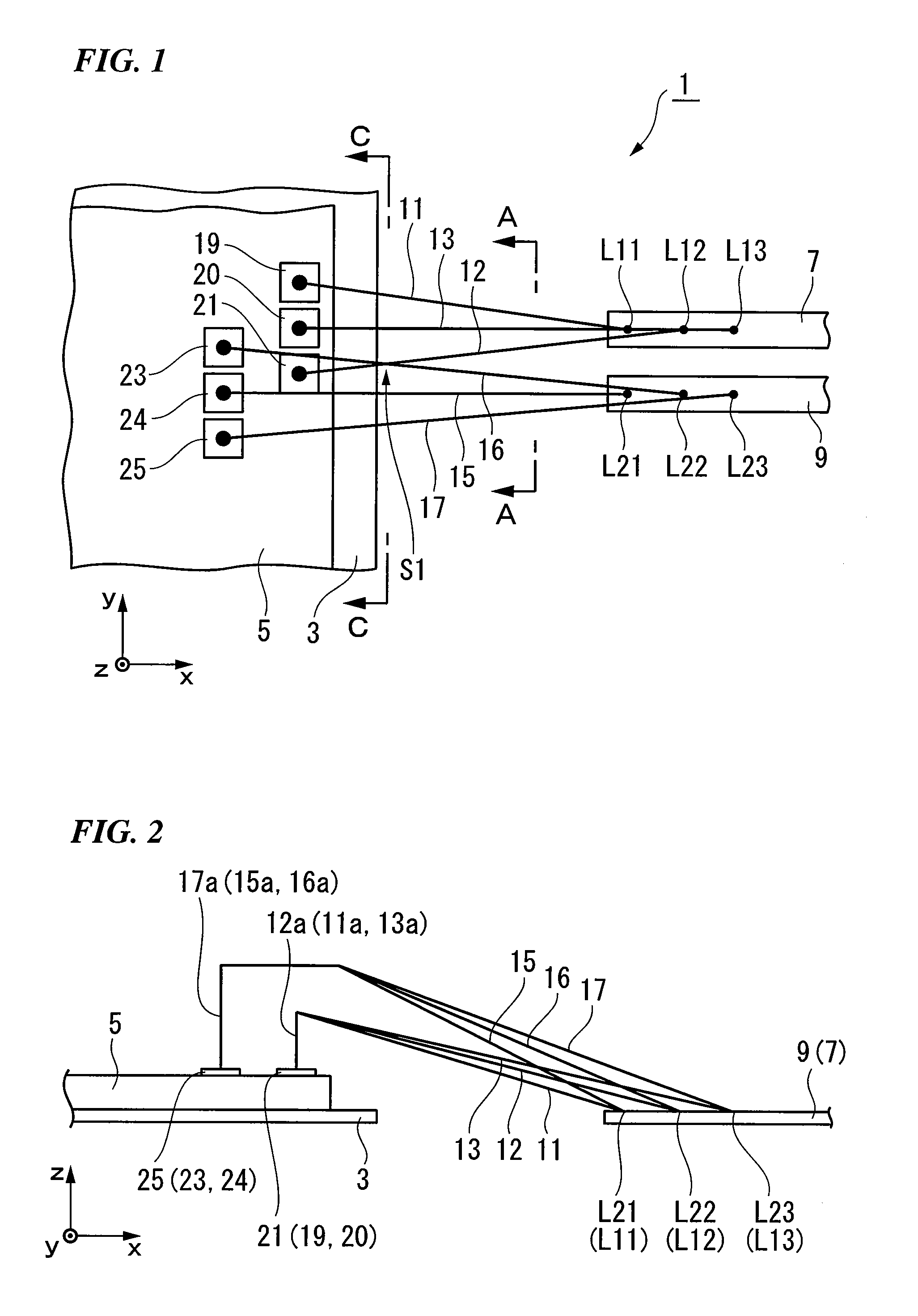

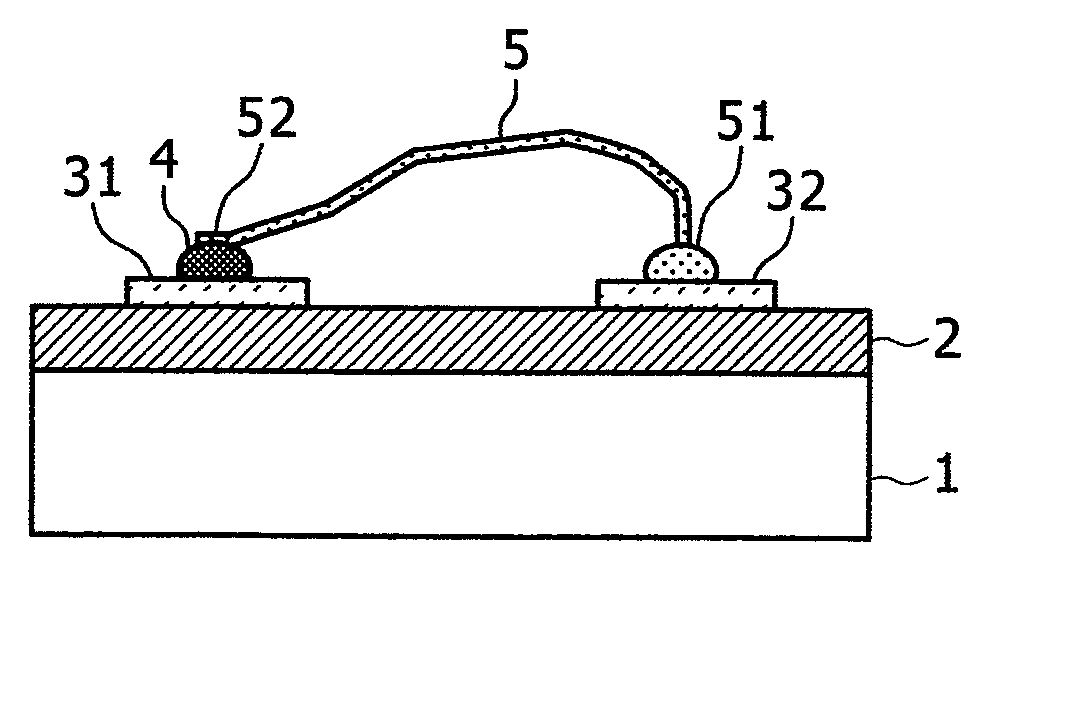

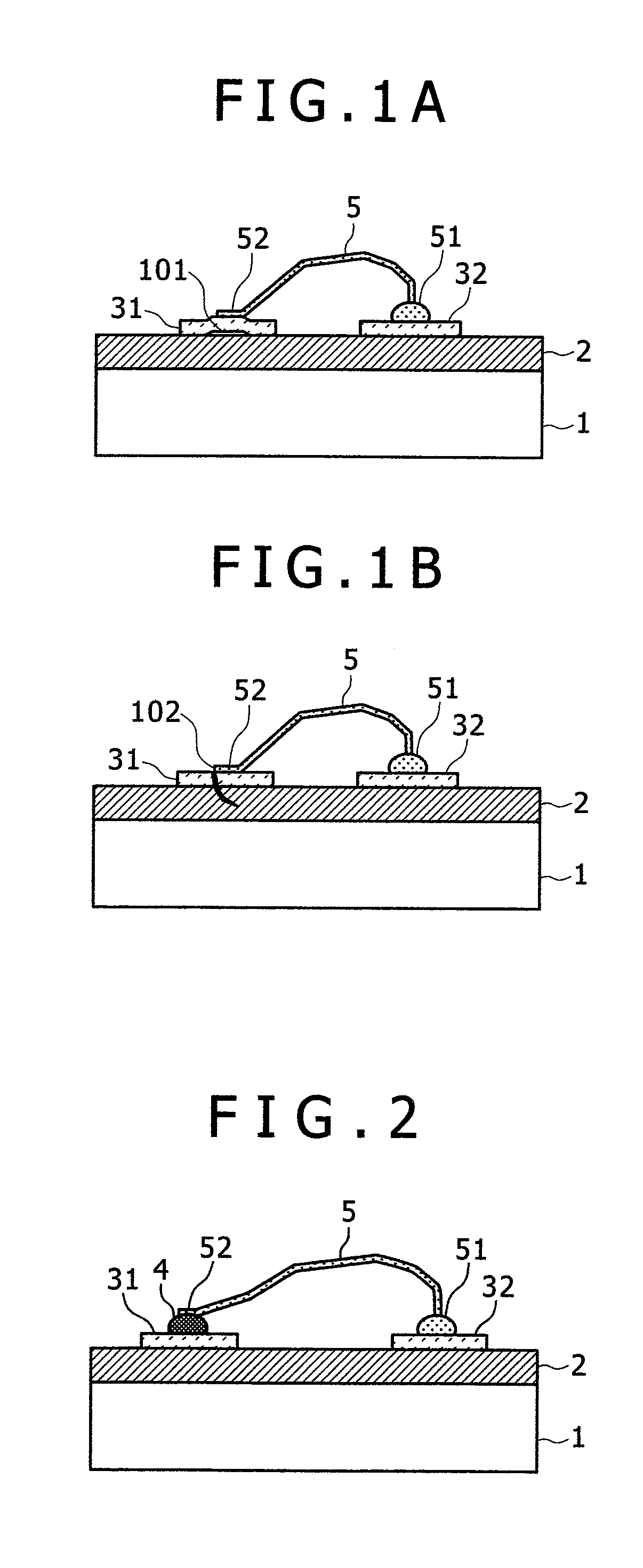

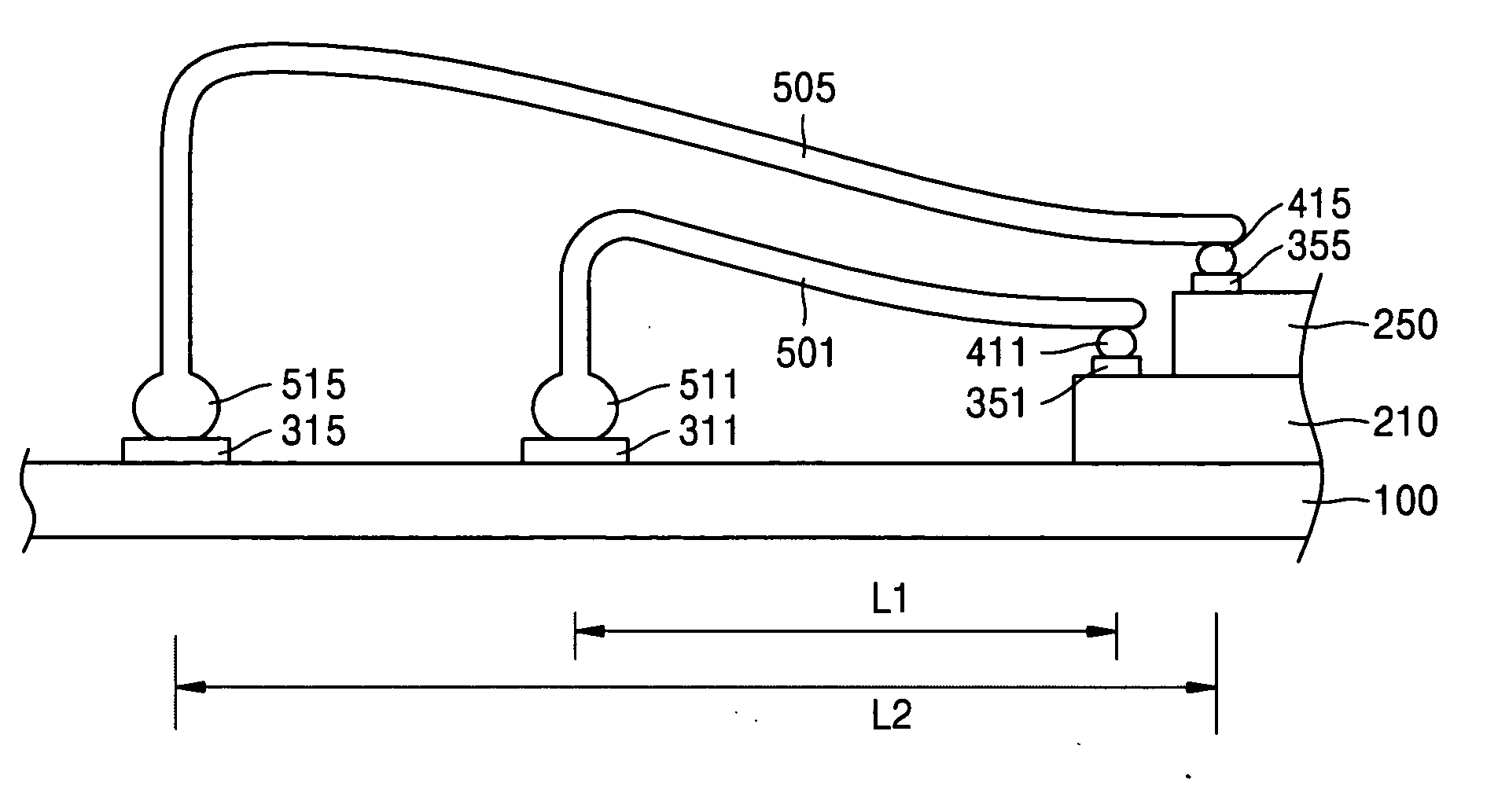

Wire loop, semiconductor device having same and wire bonding method

ActiveUS7815095B2Not easy to damageLow profileSemiconductor/solid-state device detailsSolid-state devicesLead bondingBall bonding

A wire loop comprises a wire connecting a first bonding point and a second bonding point therethrough, wherein the wire includes a ball bonded to the first bonding point, a neck portion adjacent to the ball and a major portion extending from the neck portion to the second bonding point. The neck portion includes a riser part which extends, from the bonded ball, obliquely upward in a direction toward the second bonding point, and the riser part is formed by a top portion of the ball which has entered an opening of a capillary and been shaped at the time of ball bonding. The riser part is formed by inclining the top portion of the ball, which enters the opening of the capillary at the time of ball bonding, which inclining is done by moving the capillary obliquely upward toward the second bonding point.

Owner:KAIJOO KK

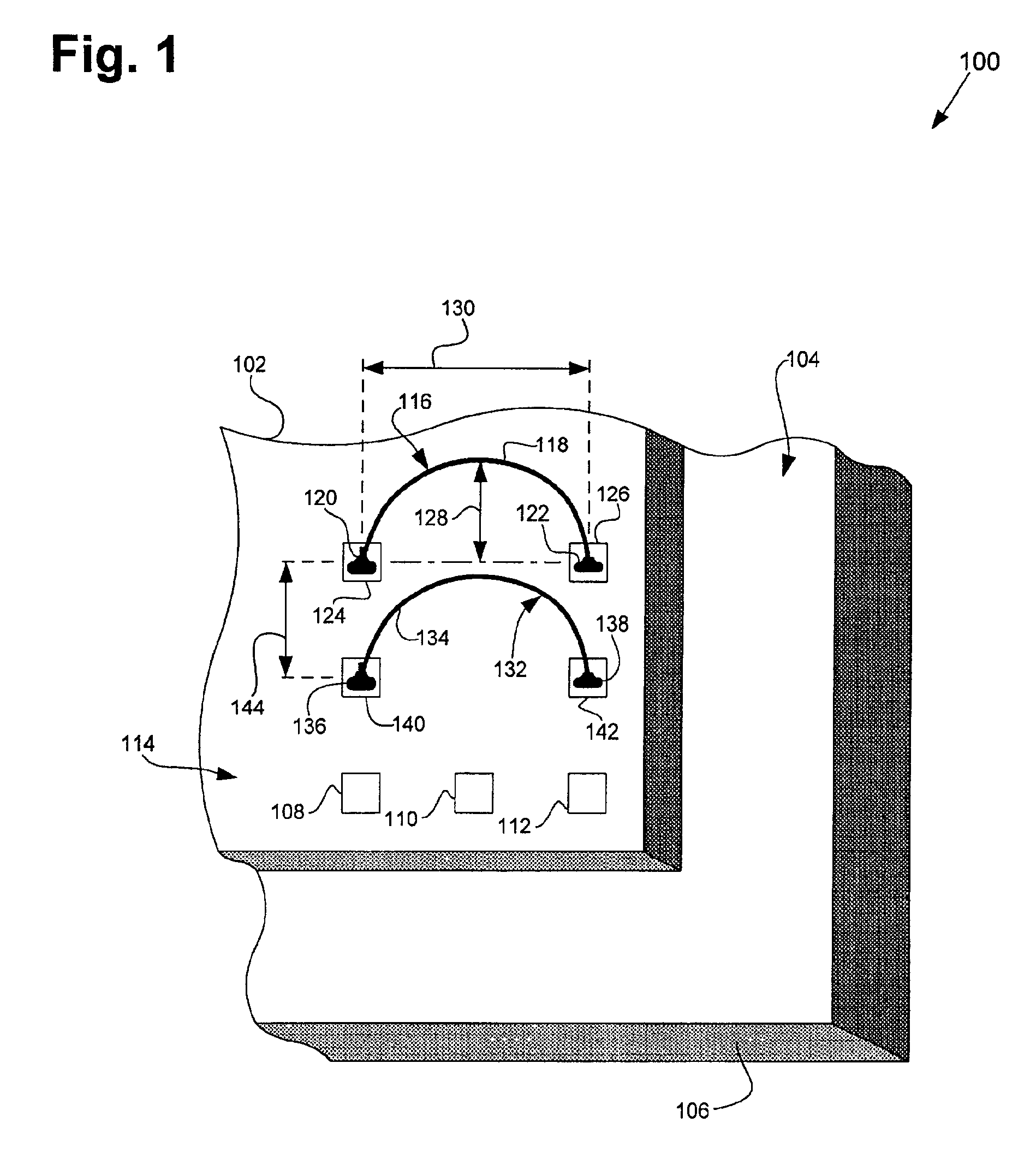

Off-chip inductor

InactiveUS6803665B1Semiconductor/solid-state device detailsSolid-state devicesElectrical conductorEngineering

According to an embodiment, a semiconductor die has a source bond pad and a destination bond pad attached to a top surface of the semiconductor die. A stud bump is situated on the destination bond pad. A bonding wire is then ball bonded to the source bond pad and thereafter stitch bonded to the stud bump on the destination bond pad. The bonding wire acts as an off-chip inductor or a portion of an off-chip inductor. In one embodiment a number of bonding-wires and on chip conductors are used to form an off-chip inductor. The inductance of the off-chip inductor can be adjusted or fine-tuned by adjusting a loop height of the one or more bonding wires used in the off-chip inductor. The inductance of the invention's off-chip inductor can also be adjusted by increasing or decreasing the number of bonding wires used to form the off-chip inductor.

Owner:SKYWORKS SOLUTIONS INC

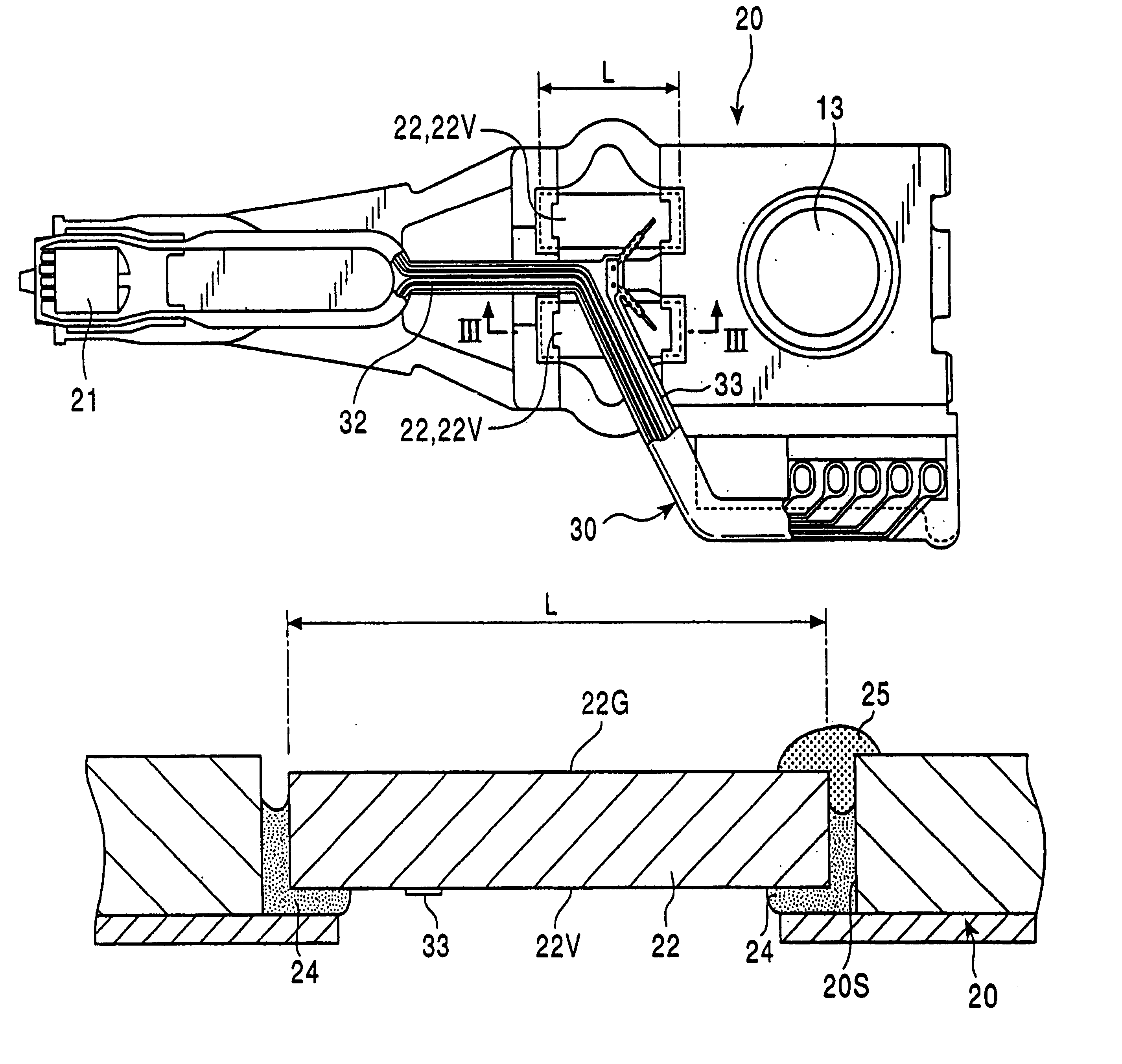

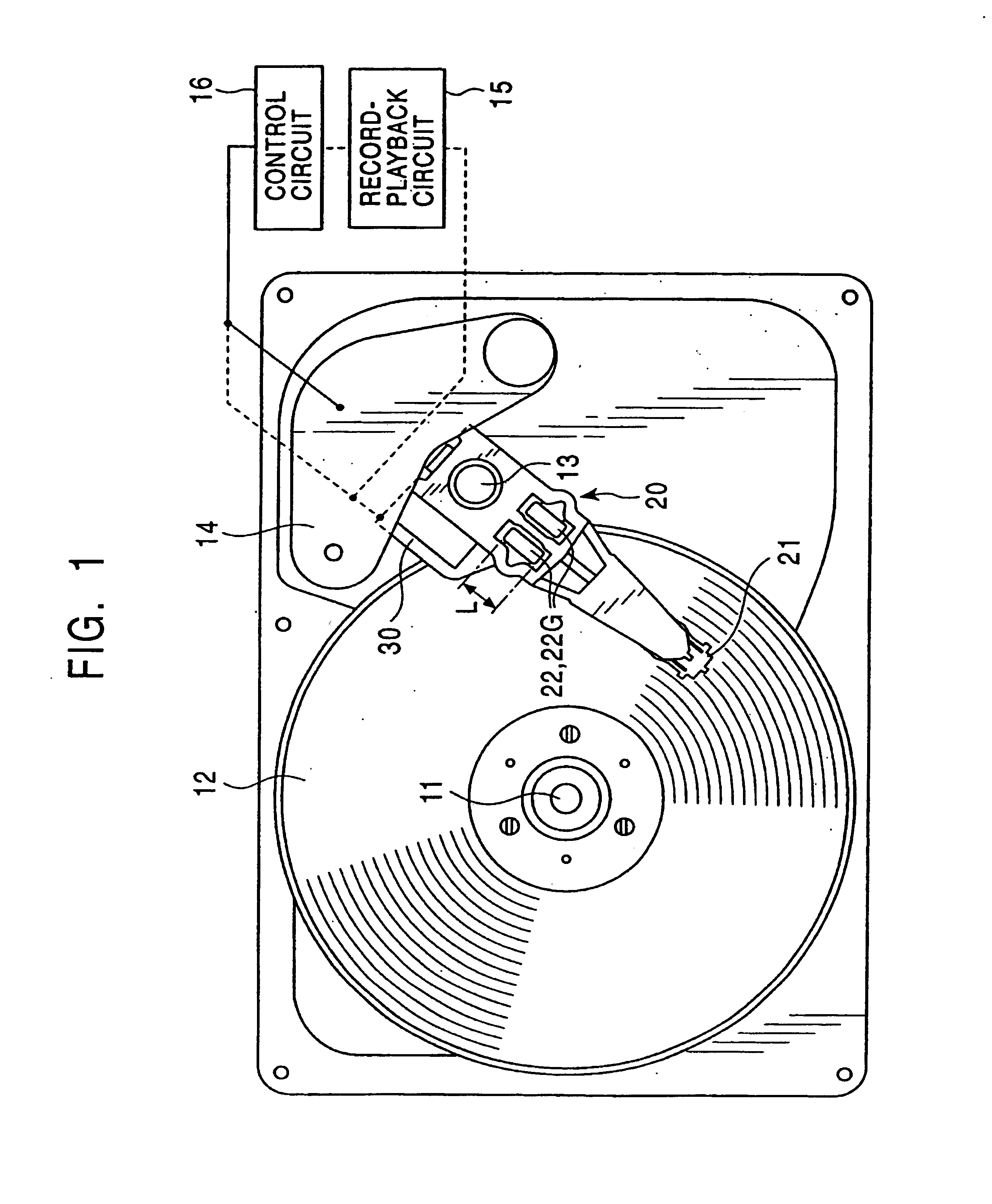

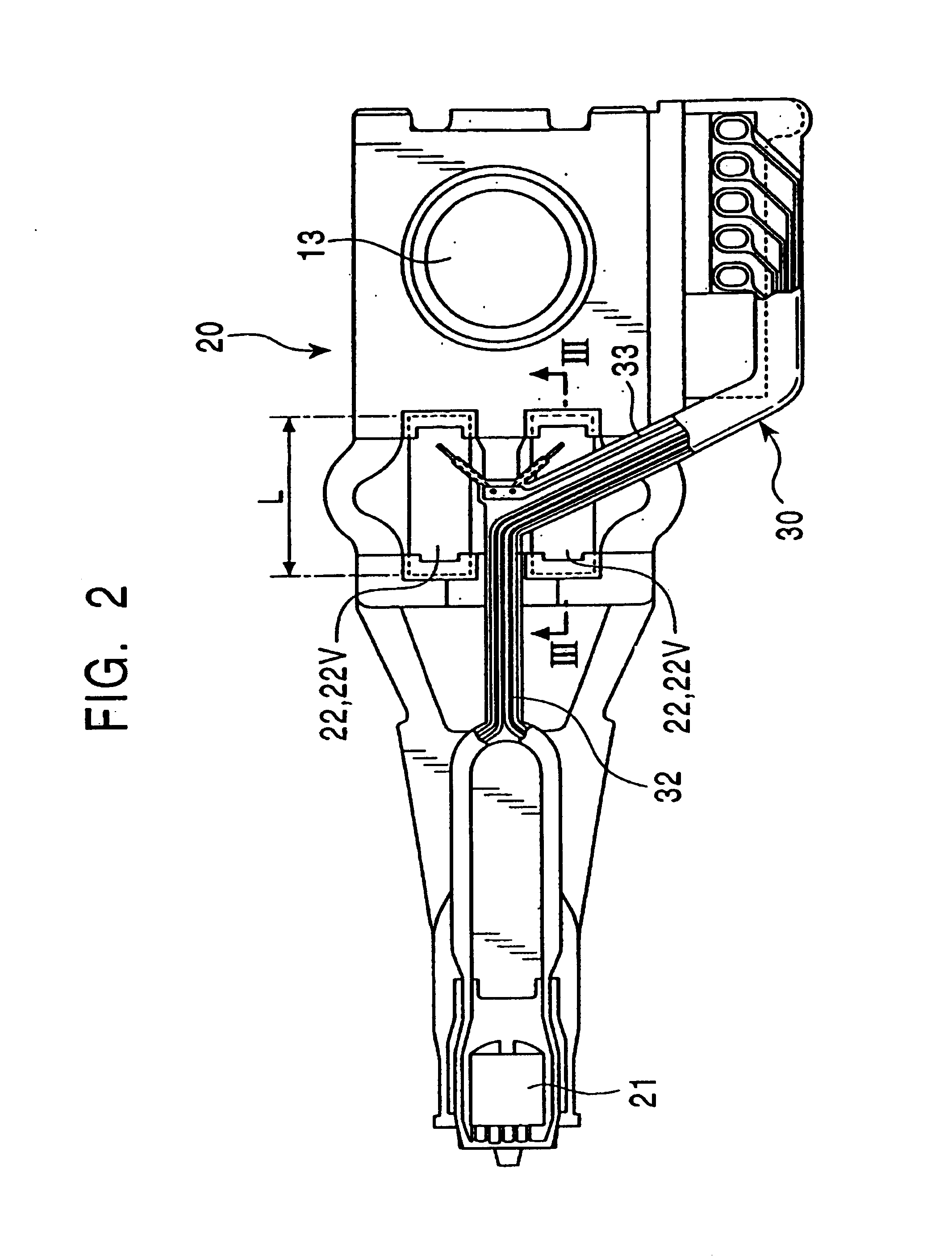

Magnetic head actuator having finely movable tracking device

InactiveUS7167344B2Easy wiringReduce breakagePrinted circuit assemblingTrack finding/aligningEngineeringActuator

A magnetic head actuator provided with a finely movable tracking device having a piezoelectric element is provided for easy wiring to the piezoelectric element and reducing problems such as wire breakage and continuity defects. In the magnetic head actuator, a portion of an FPC board resin base is removed to expose a portion of the feeding line that extends onto a voltage impressing electrode. An electrical and mechanical connection is made between the electrode and the exposed portion of the feeding line by ultrasonic bonding, Au ball bonding, or stud bumping.

Owner:TDK CORPARATION

Bonding wire

InactiveCN1575512AHigh bonding strengthEasy to moveSemiconductor/solid-state device detailsSolid-state devicesOxidation resistantCopper

A bonding wire having a core mainly consisting of copper and a coating layer formed on the core, wherein the coating layer is made of an oxidation-resistant metal having a melting point higher than that of copper, and the elongation of this bonding wire per unit sectional area is 0.021% / mu m<2> or more; and a bonding wire having a core mainly consisting of copper and a coating layer formed on the core, wherein the coating layer is made of a metal having oxidation resistance higher than that of copper, and the relationship of 0.007 < / = X < / = 0.05 is satisfied wherein an area ratio X is (the area of the coating layer / the area of the core at the section of wire being cut vertically) are provided. The bonding wires thus provided are inexpensive and excellent in ball formation characteristic and bonding characteristic. Further, a ball bonding method characterized in using the above bonding wire is also provided.

Owner:SUMITOMO ELECTRIC WINTEC INC

Semiconductor device and wire bonding method therefor

InactiveUS20080088012A1Reliably prevent electric short-circuiting from occurringSmall sizeSemiconductor/solid-state device detailsSolid-state devicesDevice materialLead bonding

In a semiconductor device, first wires each having a relatively low loop height are formed between a first lead and a plurality of first electrode pads aligned in a first line, and then second wires each having a relatively high loop height are formed between a second lead and a plurality of second electrode pads aligned in a second line, wherein the second line is distanced from the first line in view of the first and second leads. Wire bonding is sequentially performed so as to increase the height difference between the first wire and the second wire, thus avoiding the occurrence of electric short-circuiting between adjacently arranged wires. In wire bonding, a bump forming process, a ball bonding process, and a wedge bonding process are sequentially performed. It is preferable that the second lead be vertically distanced from the first lead in the thickness direction.

Owner:YAMAHA CORP

Control of size and heat affected zone for fine pitch wire bonding

InactiveUS6267290B1Solid-state devicesWelding/cutting auxillary devicesHeat-affected zoneLead bonding

Owner:INT BUSINESS MASCH CORP

Bonding wire for semiconductor

ActiveUS20110120594A1Reduce tensionLarge spanSolid-state devicesWelding/cutting media/materialsWire rodHydrogen concentration

It is an object of the present invention to provide a multilayer wire which can accomplish both ball bonding property and wire workability simultaneously, and which enhances a loop stability, a pull strength, and a wedge bonding property. A semiconductor bonding wire comprises a core member mainly composed of equal to or greater than one kind of following elements: Cu, Au, and Ag, and an outer layer formed on the core member and mainly composed of Pd. A total hydrogen concentration contained in a whole wire is within a range from 0.0001 to 0.008 mass %.

Owner:NIPPON STEEL CHEMICAL CO LTD +1

Stacked chip connection using stand off stitch bonding

InactiveUS7021520B2Semiconductor/solid-state device detailsSolid-state devicesLead bondingEngineering

The present invention provides a structure, apparatus, and method for wire bonding in which a first wire bond is formed between first and second components, a second wire bond is formed between the second component and a third component such that the second wire bond is in electrical communication with the first wire bond, wherein the first and second wire bonds are connected to said first and second components, respectively, using ball bonding.

Owner:ROUND ROCK RES LLC

Electronic circuit and method for manufacturing same

InactiveUS20090294158A1Solve problemsSemiconductor/solid-state device detailsPrinted circuit aspectsElectrical connectionSemiconductor chip

Owner:MATSUSHIMA NAOKI +1

Semiconductor device having semiconductor chips stacked and mounted thereon and manufacturing method thereof

ActiveUS7675153B2Semiconductor/solid-state device detailsSolid-state devicesLead bondingSemiconductor chip

Chips are stacked and mounted on a circuit board having external connection electrodes and mounted thereon by wire bonding. At least one of the chips stacked on the chip includes overhung portions each of which has a start point inside bonding pads, is made thinner in a direction towards the outer periphery to an end point reaching the side wall and forms a space used to accommodate ball bonding portions between the overhung portion and the main surface of the chip arranged in the lower stage on a backside corresponding in position to the bonding pads, and insulating members formed to cover the overhung portions and prevent bonding wires of the chip arranged in the lower stage from being brought into contact with the upper-stage chip.

Owner:KIOXIA CORP

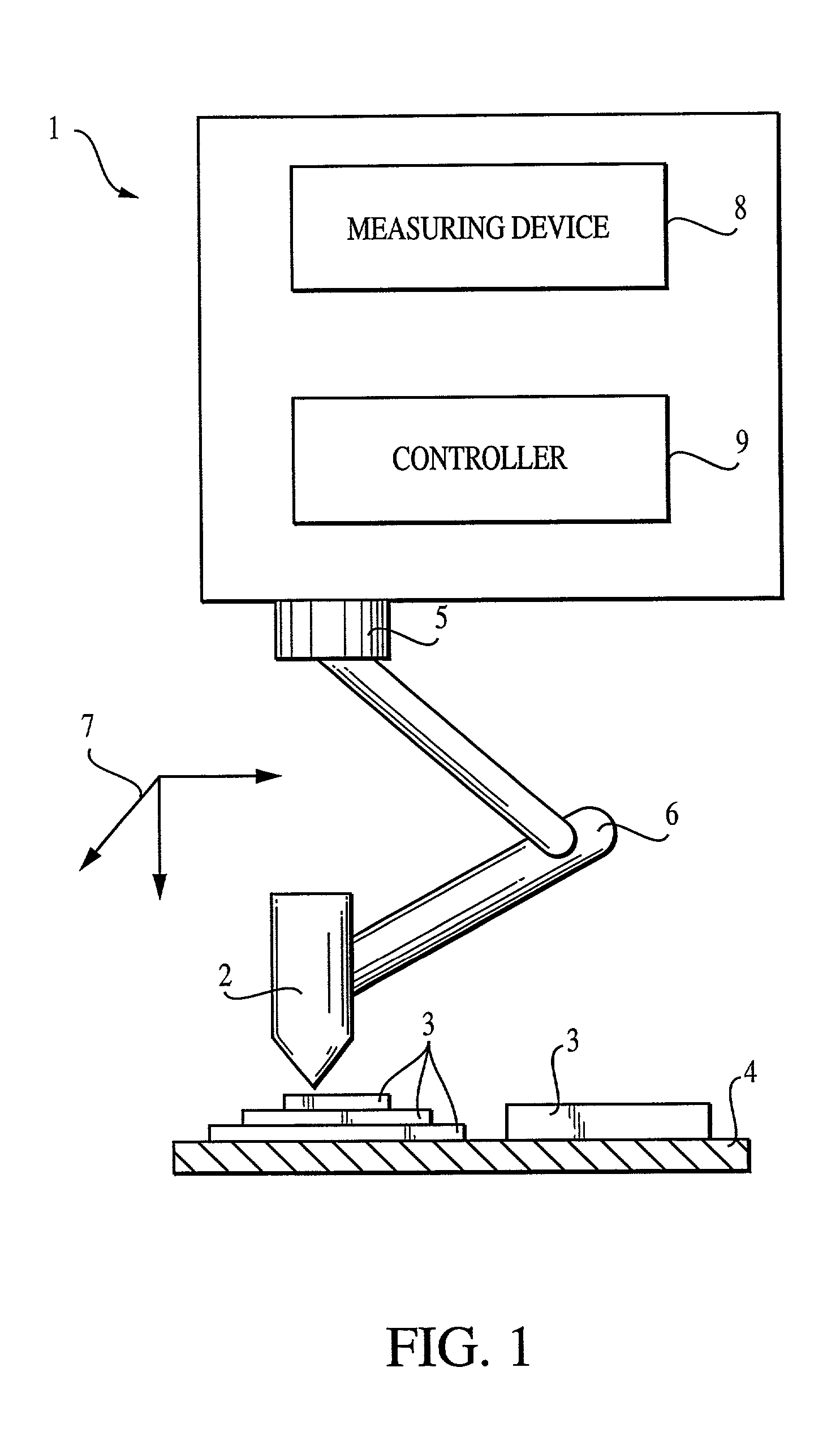

Method and apparatus for bonding a wire

InactiveUS20050200009A1Increase wire diameterSemiconductor/solid-state device detailsSolid-state devicesDevice formLead bonding

A method and apparatus for bonding a wire and a wire bond device formed by the same are disclosed. The method includes providing a carrier with at least a first pad, providing a semiconductor chip having at least the second pad, the at least second pad being smaller than the first a pad, forming a conductive stud bump on the second pad, and forming a bonding wire that has two terminal portions, which are respectively bonded to the first pad and the stud bump to electrically connect the first pad and the second pad. The stud bump is bonded to the second pad by a ball bonding method which uses a wire that has an approximately smaller diameter than the bonding wire. Further, a prominence formed on one end of the terminal portions is provided which has an approximately larger diameter than the stud bump.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com