Bonding wire

A bonding wire and bonding technology, applied in the field of bonding wires, can solve the problems of hydrogen explosion and high cost, and achieve the effect of high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 3 and 15 and comparative example 1 to 3

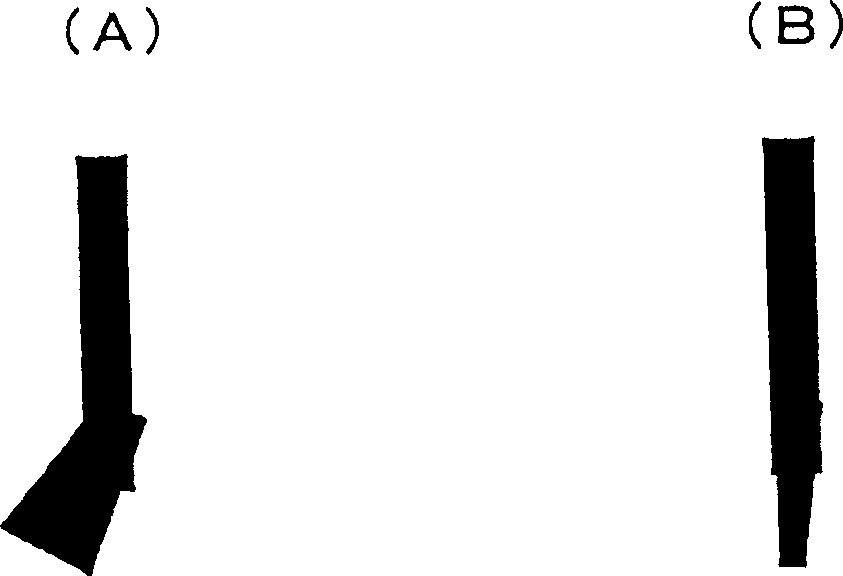

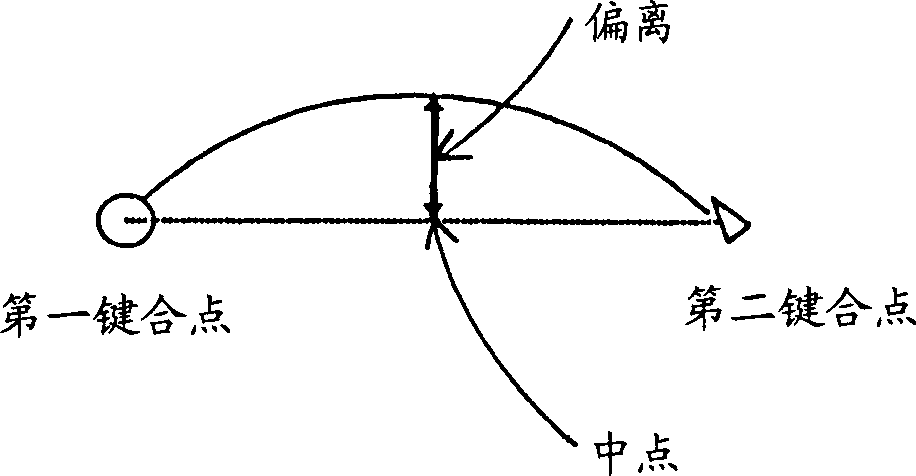

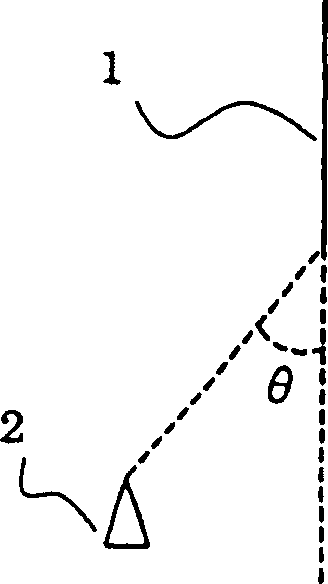

[0070] By using a copper bonding wire containing 0.05% by weight of impurities other than copper, the resulting diameter * 20μm leads, Pd plating thickness 0.1μm. During production, by varying the processing conditions and annealing conditions, leads with the stretches shown in Tables 1 and 2 were produced. In Example 15, intermediate annealing was performed. By using these lead wires, ball-forming properties and bond strength of balls with a diameter of 60 μm were evaluated. The results of the evaluation are listed in Tables 3 and 4.

[0071] ( * : Outer diameter of the lead wire with core and coating. )

Embodiment 4 to 6 and 16 and comparative example 4 to 6

[0073] By using a copper bonding wire containing 0.05% by weight of other impurities in addition to copper, a lead wire with a diameter of 25 μm was produced with a Pd plating thickness of 0.1 μm. During production, by varying the processing conditions and annealing conditions, leads with the stretches shown in Tables 1 and 2 were produced. In Example 16, intermediate annealing was performed. By using these lead wires, ball-forming properties and bond strength of balls with a diameter of 70 μm were evaluated. In addition, loop characteristics are evaluated. The results of the evaluation are listed in Tables 3 and 4.

Embodiment 7 to 8 and comparative example 7 to 9

[0075] By using a copper bonding wire containing impurities other than copper in a total weight ratio of 0.005%, a lead wire with a diameter of 25 μm was produced with a Pd plating thickness of 0.1 μm. During production, by varying the processing conditions and annealing conditions, leads with the stretches shown in Tables 1 and 2 were produced. By using these lead wires, ball-forming properties and bond strength of balls with a diameter of 70 μm were evaluated. The results of the evaluation are listed in Tables 3 and 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com