Patents

Literature

8927 results about "Oxidation resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxidation Resistance. (resistance to sealing), the ability of metallic materials to resist chemical degradation of the surface caused by the action of air or other gaseous mediums at high temperatures. The oxidation resistance of a metal or alloy in an oxidizing atmosphere is determined by the properties of the oxide layer—scale—that forms on...

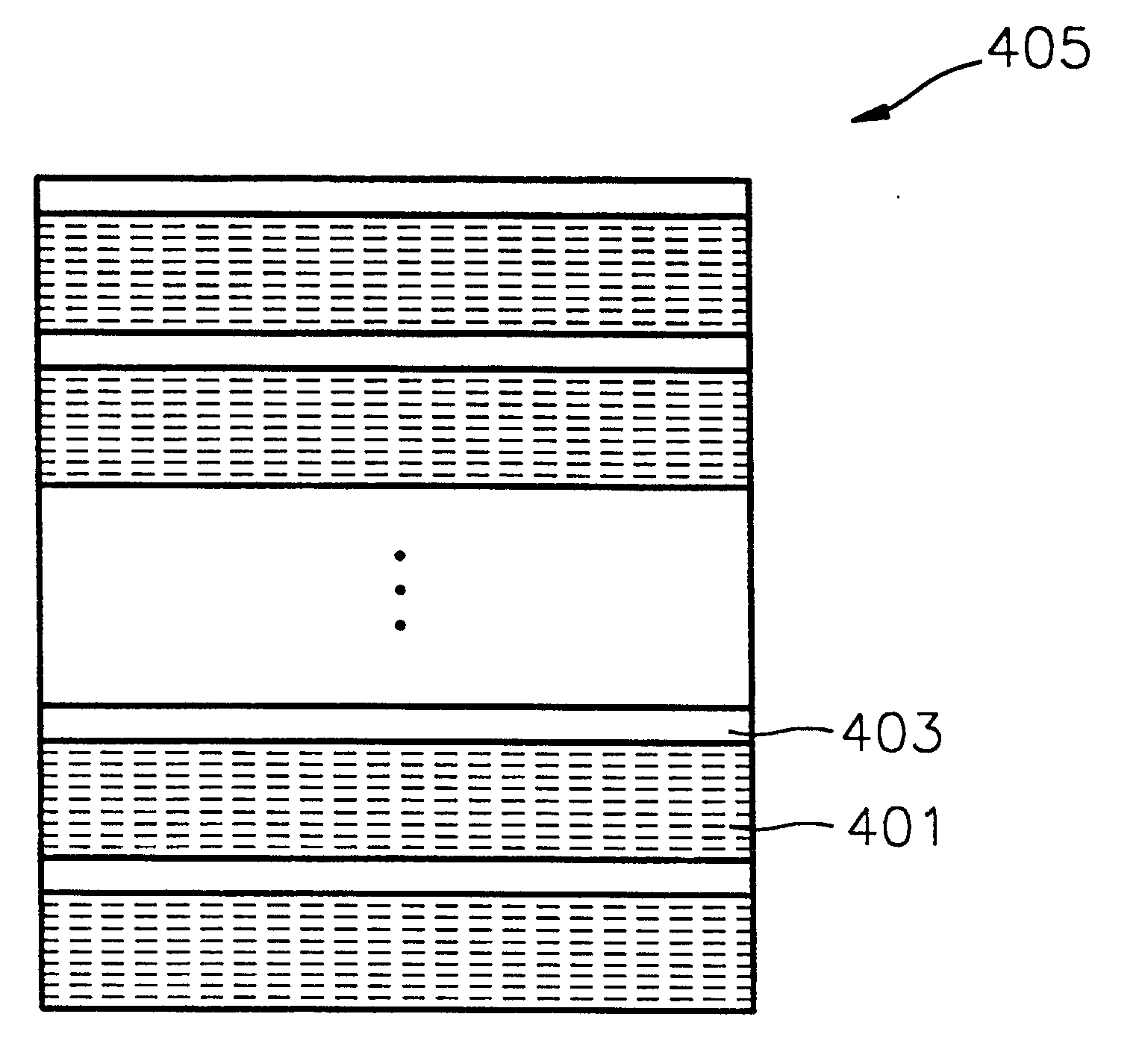

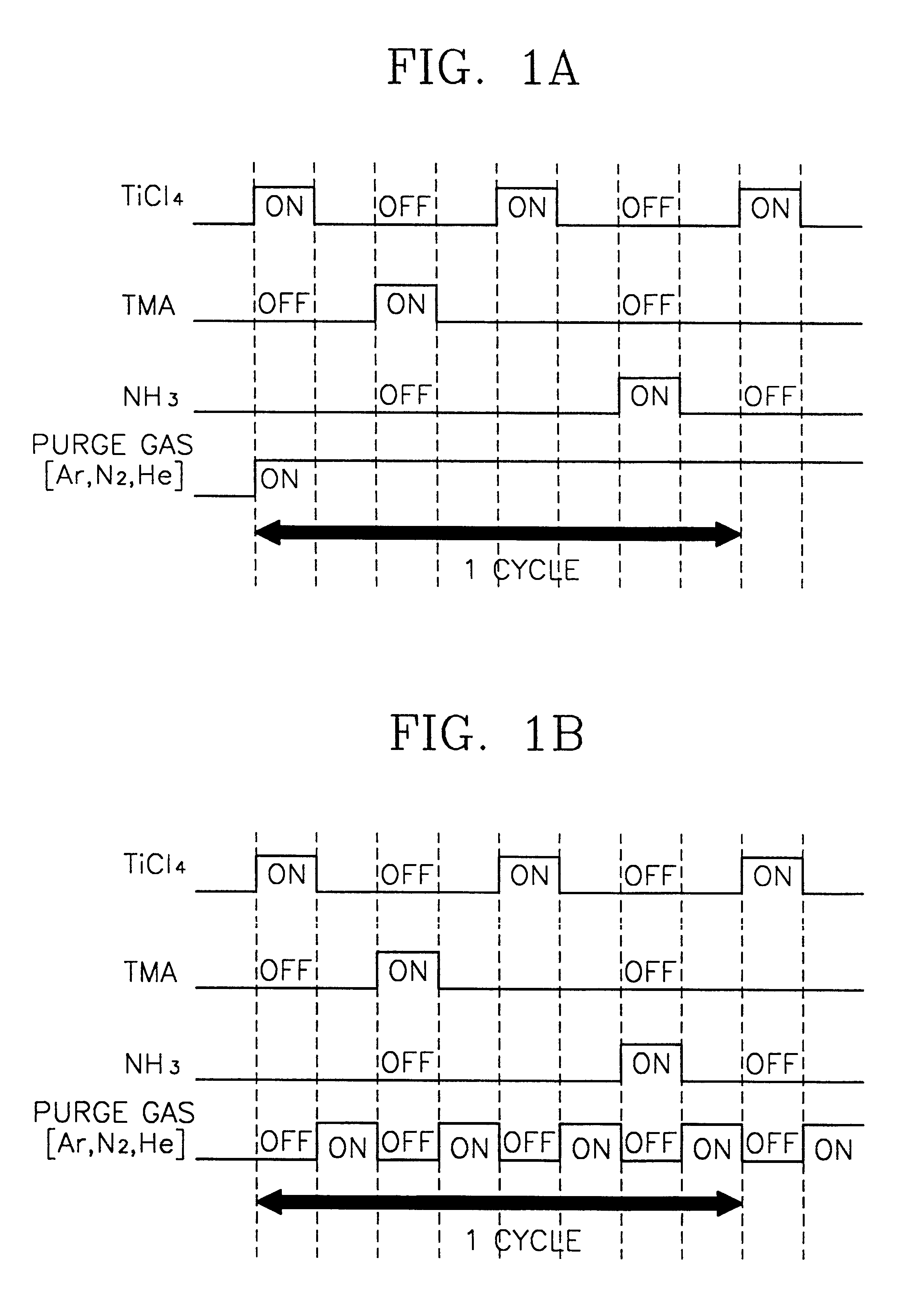

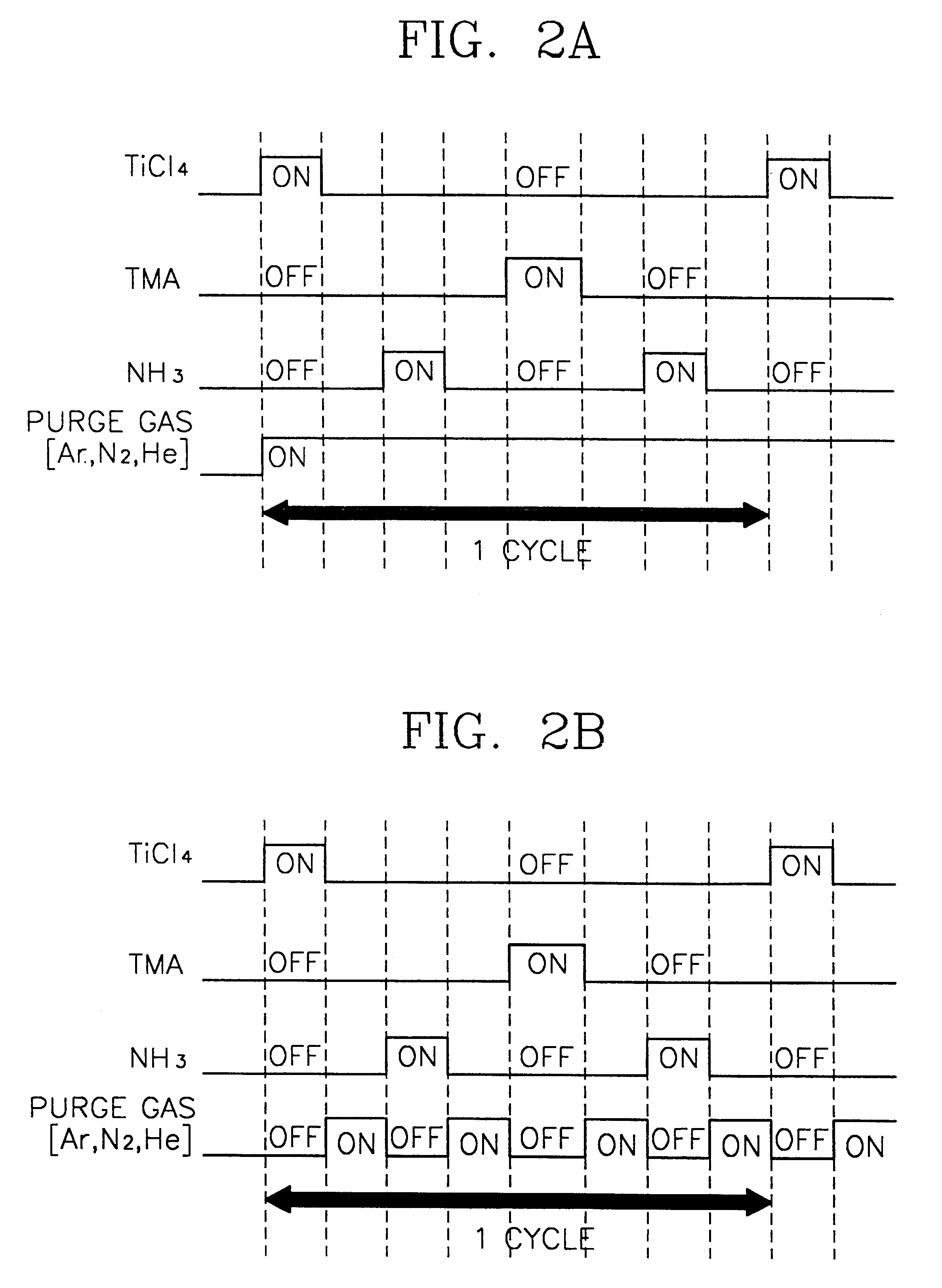

Method of forming metal layer using atomic layer deposition and semiconductor device having the metal layer as barrier metal layer or upper or lower electrode of capacitor

InactiveUS6287965B1High thermal resistantEasy to adjustSemiconductor/solid-state device manufacturingCapacitorsNiobiumDevice material

A method of forming a metal layer having excellent thermal and oxidation resistant characteristics using atomic layer deposition is provided. The metal layer includes a reactive metal (A), an element (B) for the amorphous combination between the reactive metal (A) and nitrogen (N), and nitrogen (N). The reactive metal (A) may be titanium (Ti), tantalum (Ta), tungsten (W), zirconium (Zr), hafnium (Hf), molybdenum (Mo) or niobium (Nb). The amorphous combination element (B) may be aluminum (Al), silicon (Si) or boron (B). The metal layer is formed by alternately injecting pulsed source gases for the elements (A, B and N) into a chamber according to atomic layer deposition to thereby alternately stack atomic layers. Accordingly, the composition ratio of a nitrogen compound (A-B-N) of the metal layer can be desirably adjusted just by appropriately determining the number of injection pulses of each source gas. According to the composition ratio, a desirable electrical conductivity and resistance of the metal layer can be accurately obtained. The atomic layers are individually deposited, thereby realizing excellent step coverage even in a complex and compact region. A metal layer formed by atomic layer deposition can be employed as a barrier metal layer, a lower electrode or an upper electrode in a semiconductor device.

Owner:SAMSUNG ELECTRONICS CO LTD

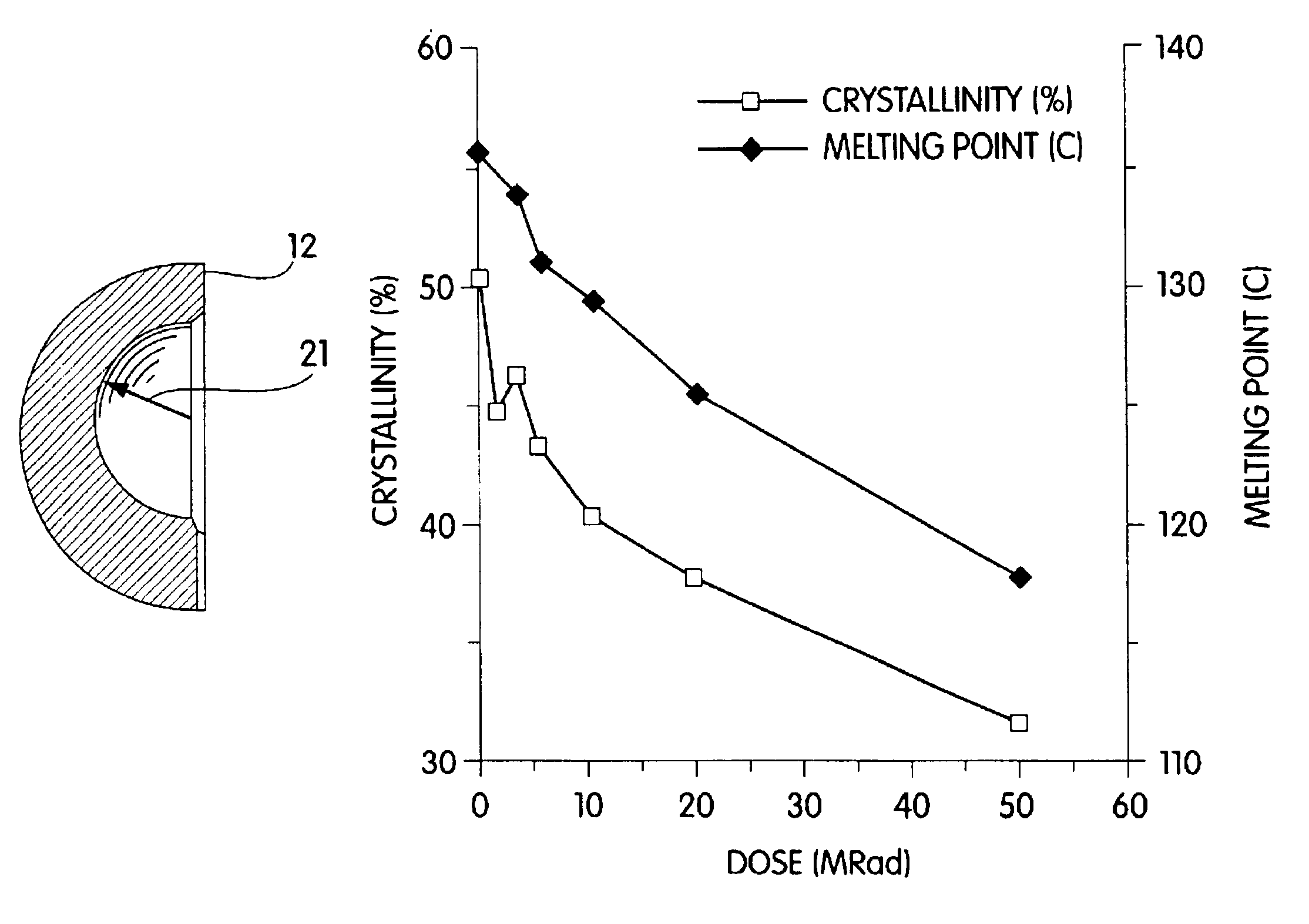

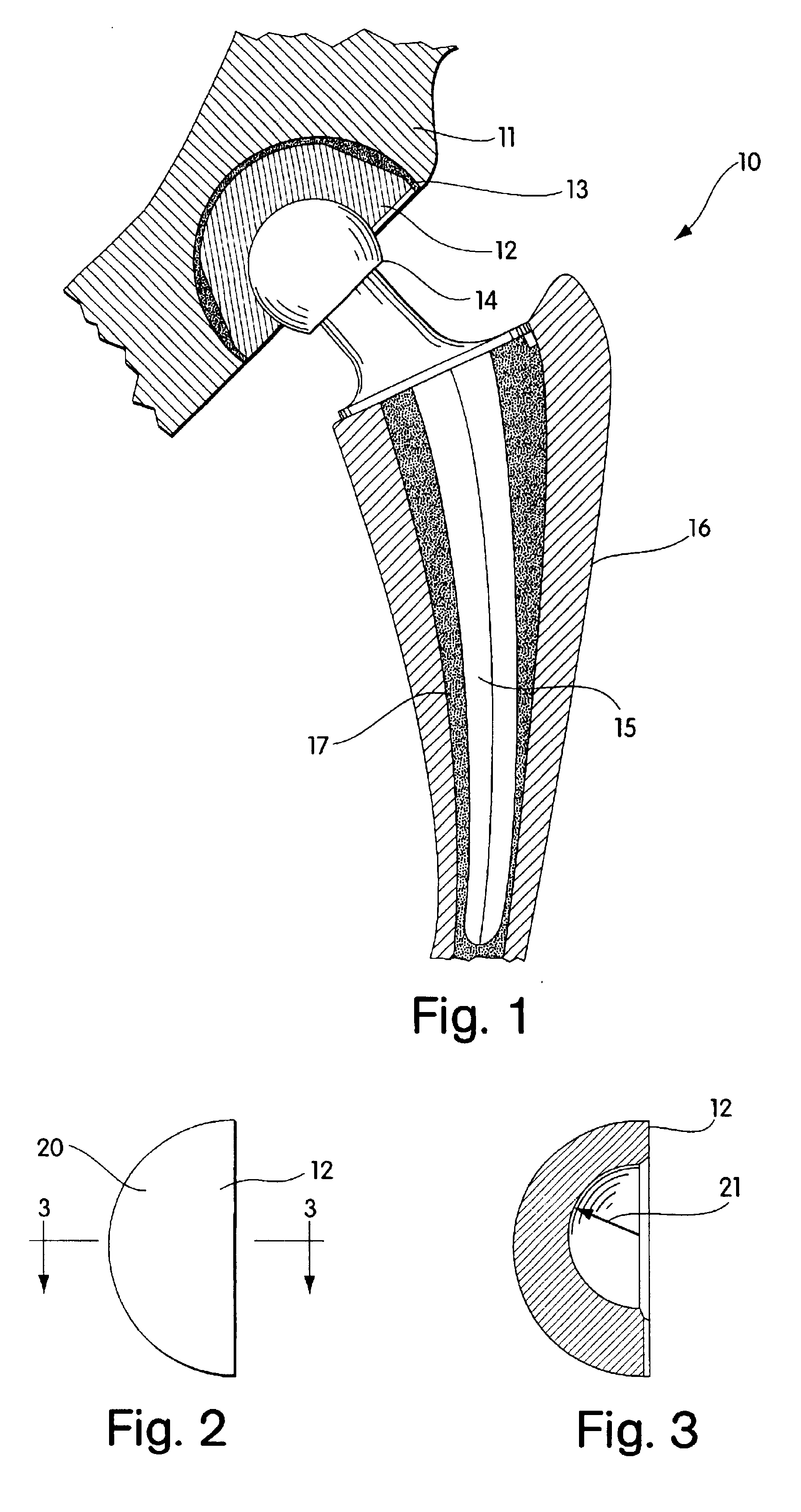

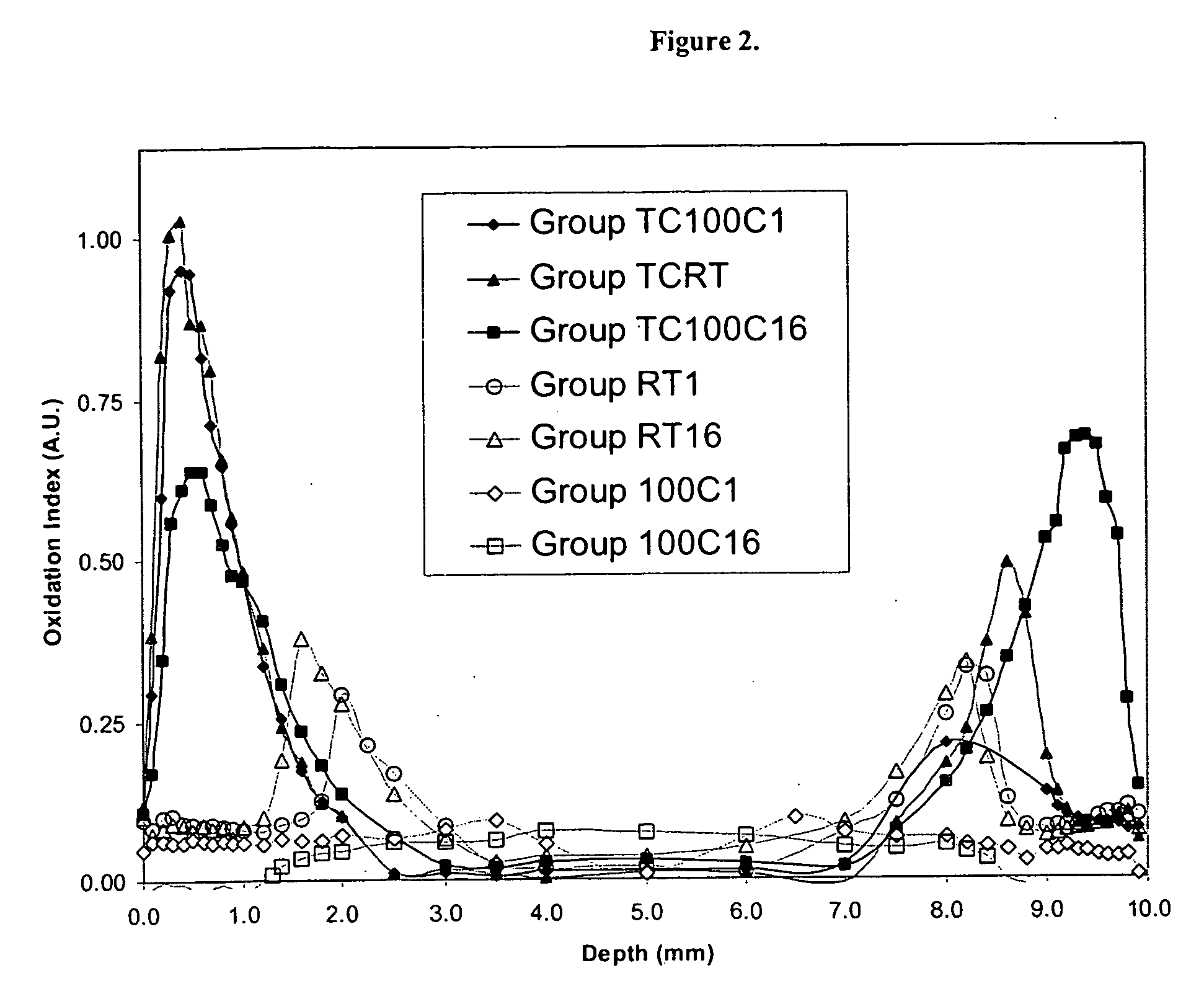

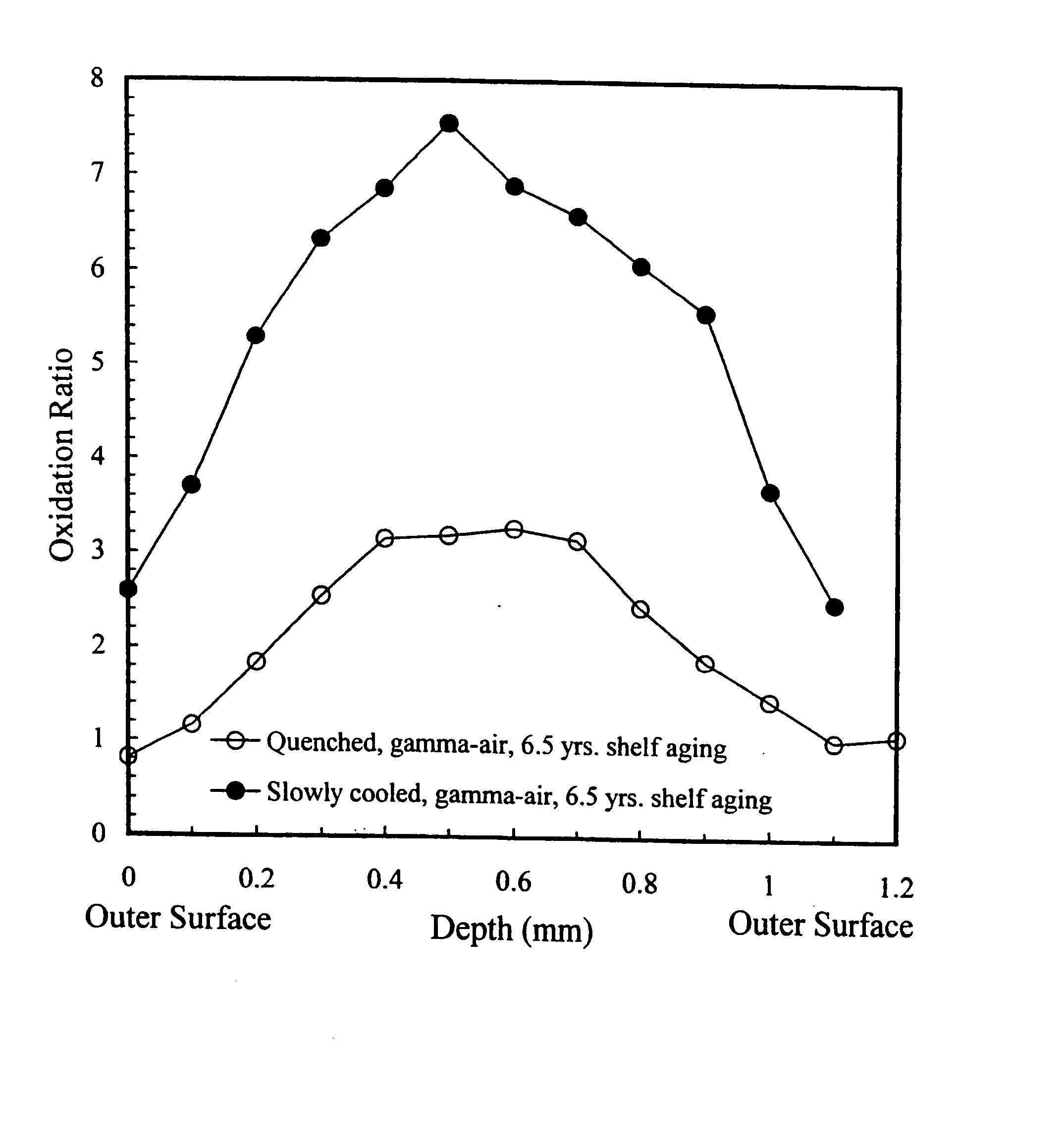

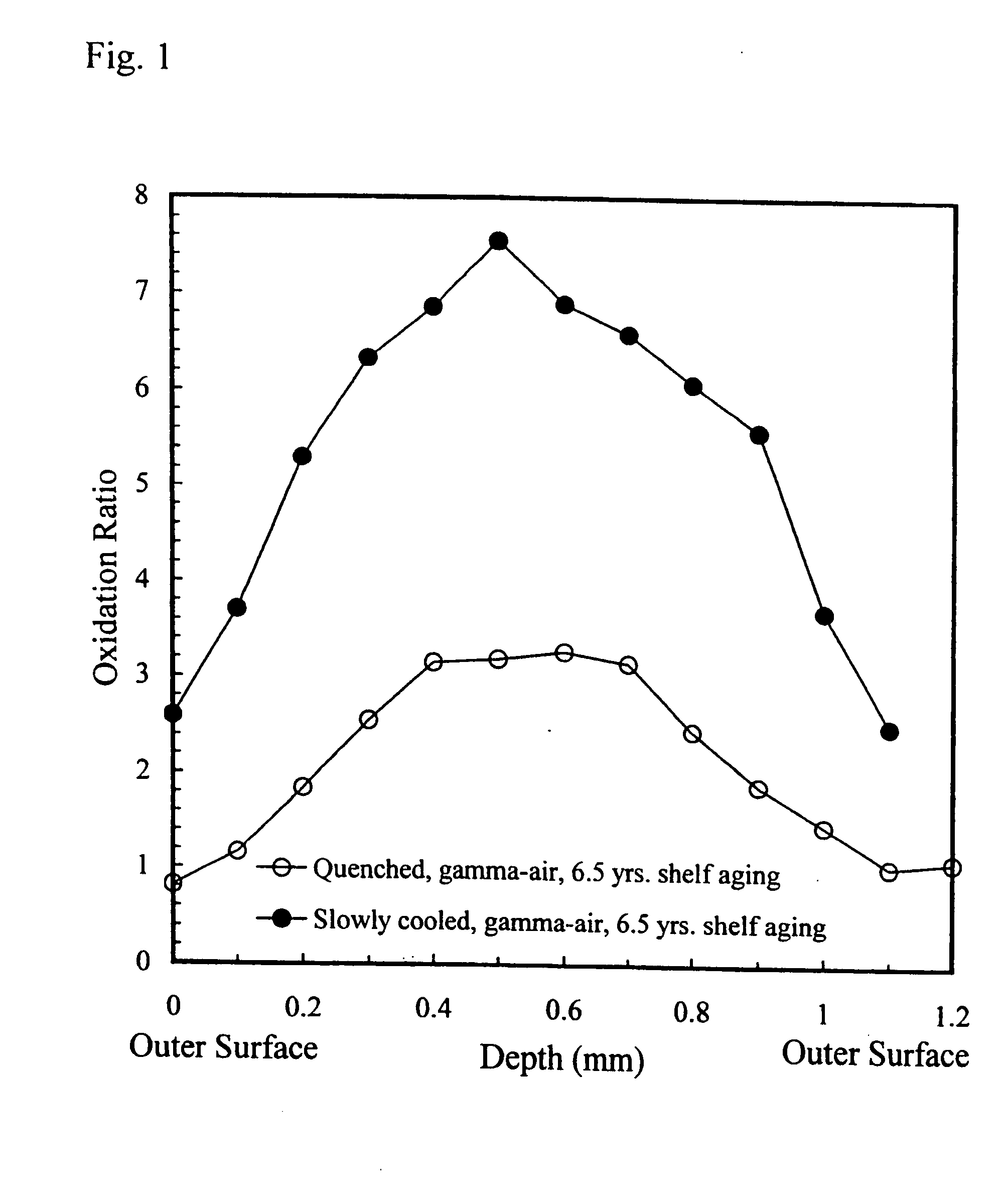

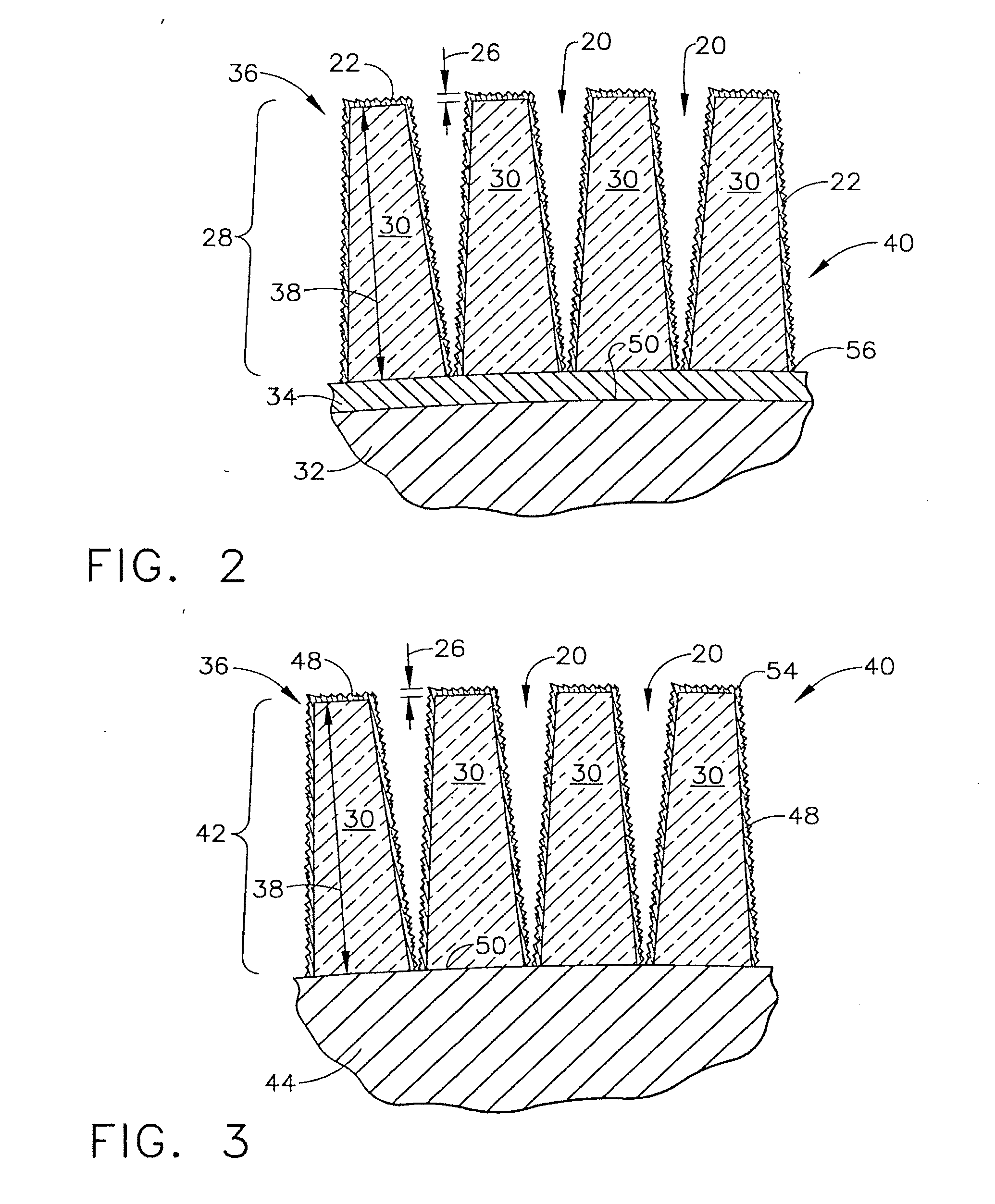

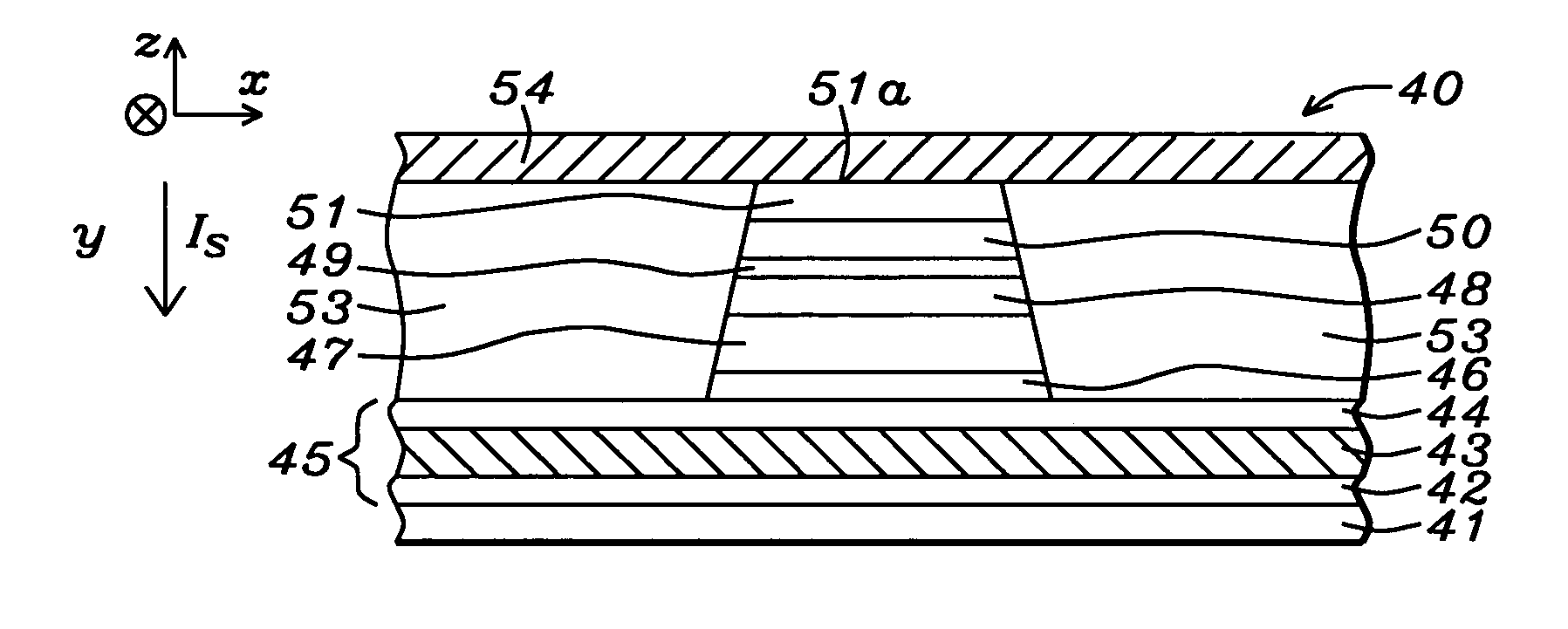

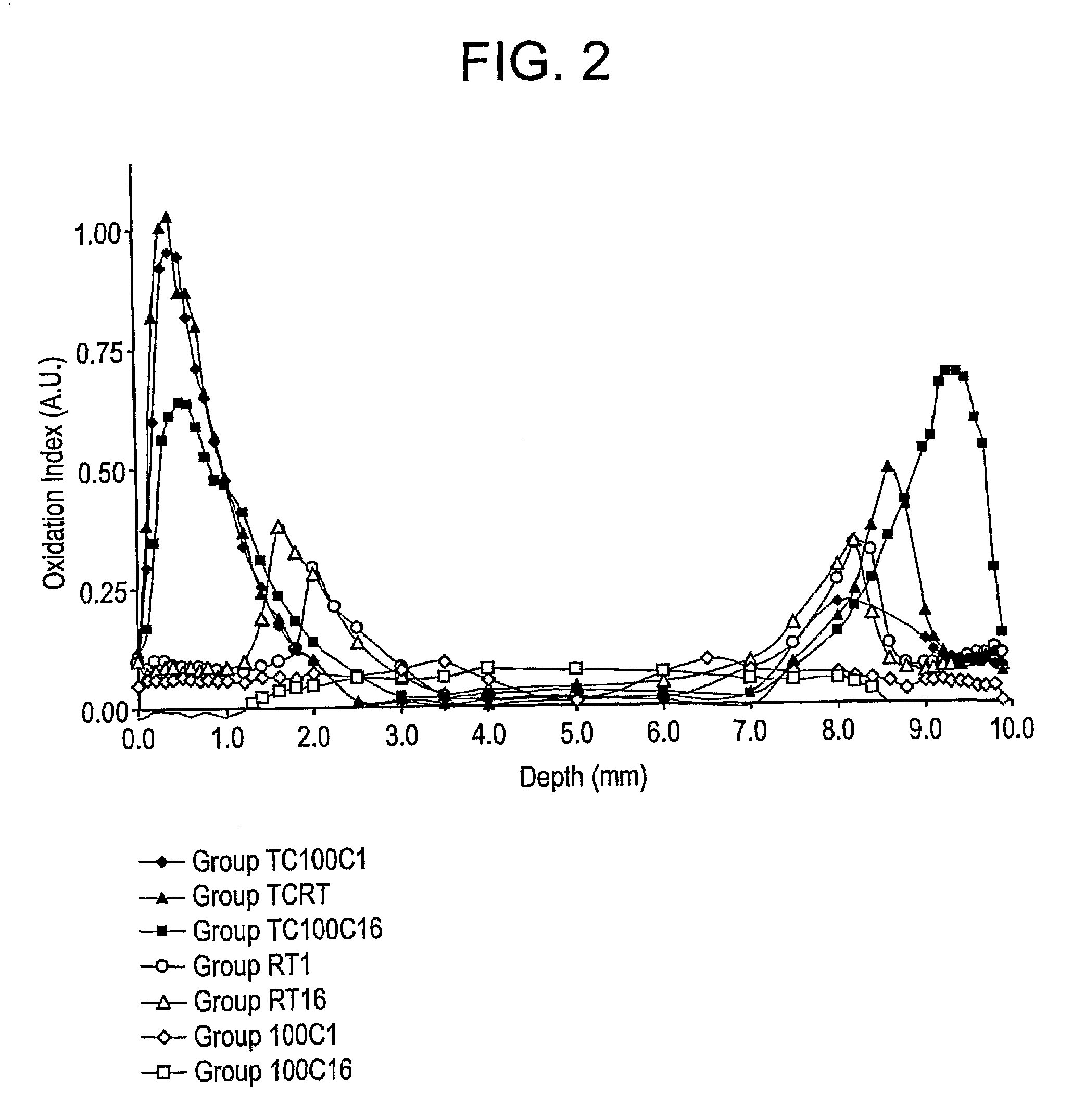

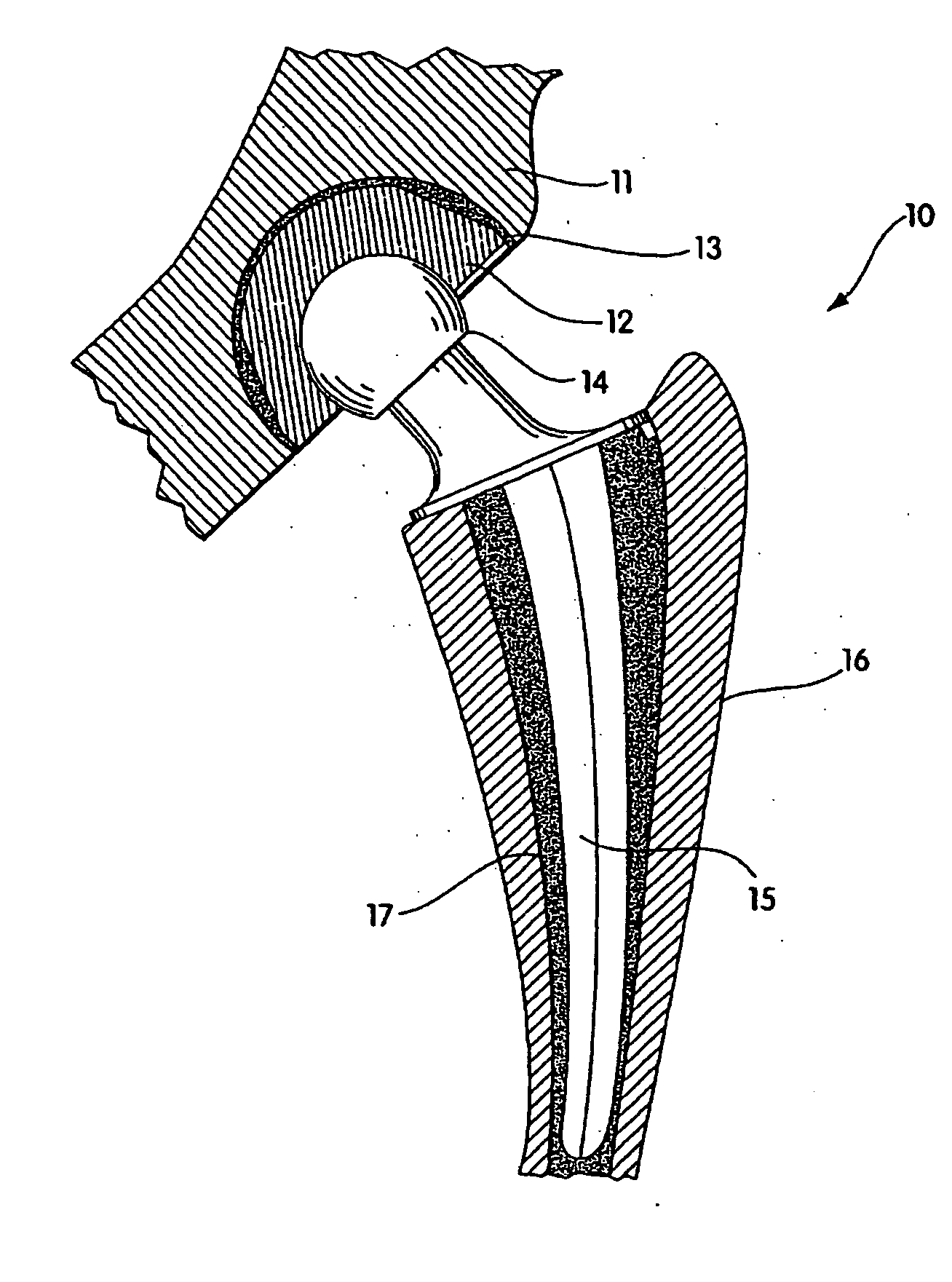

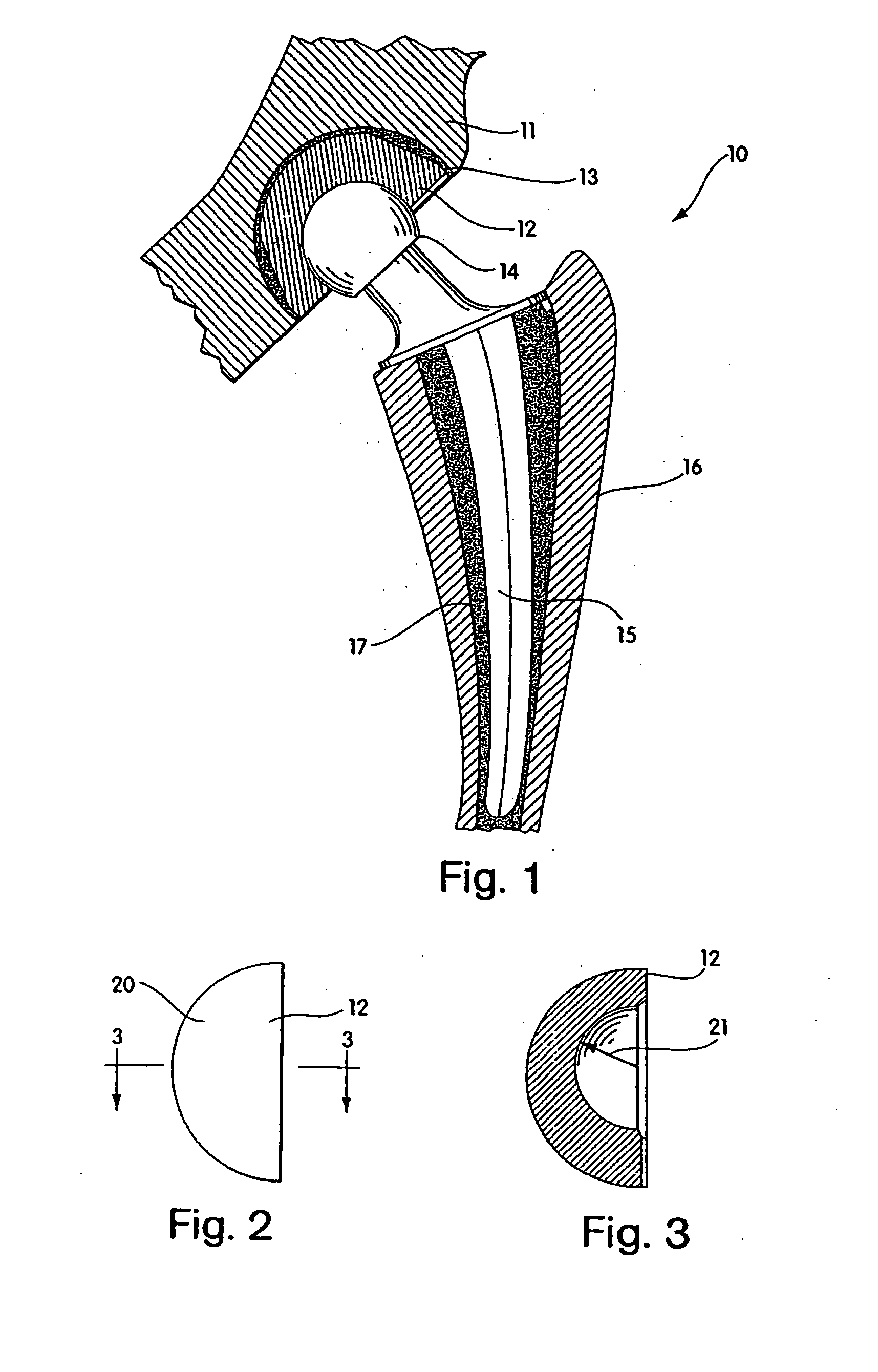

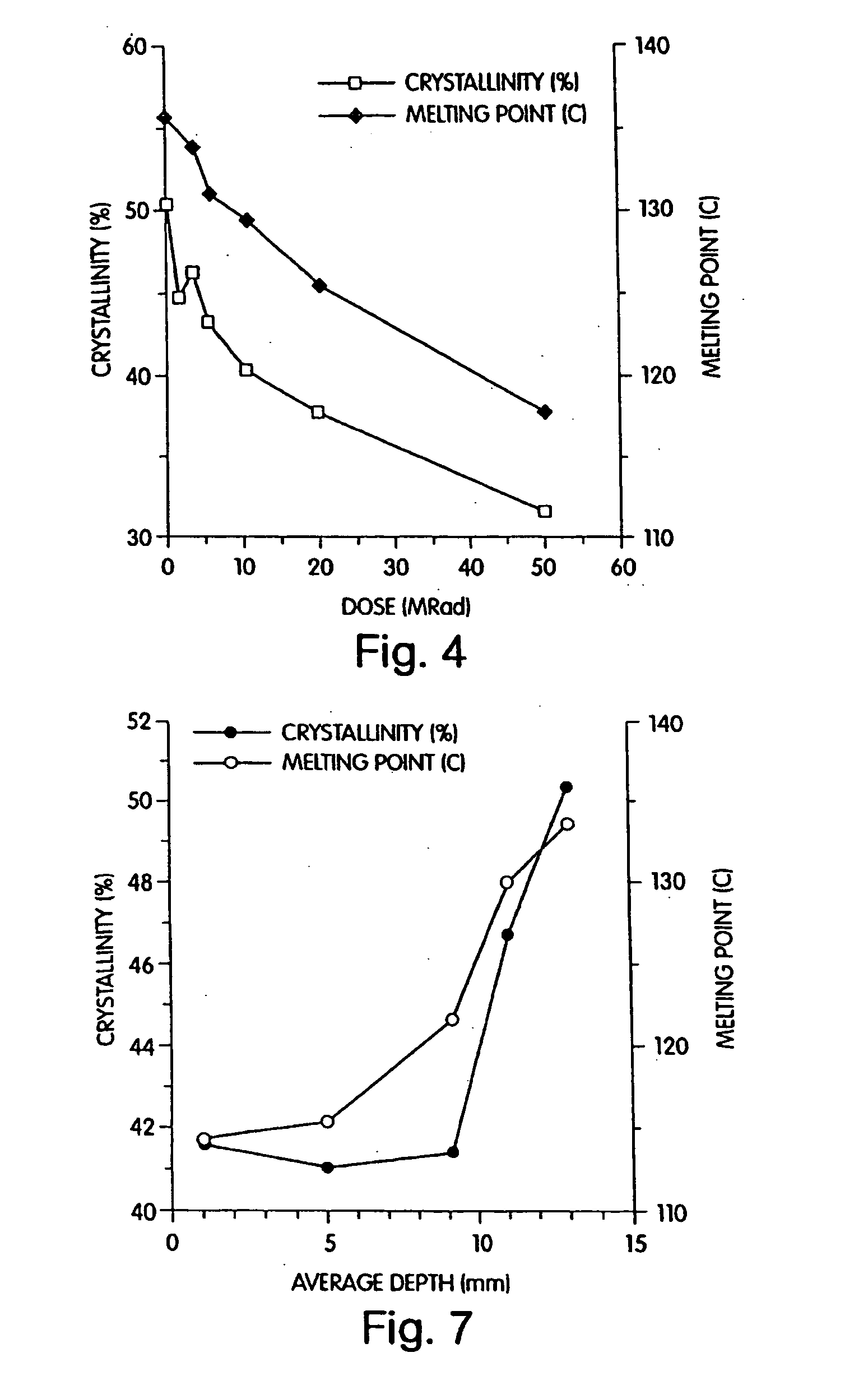

Radiation and melt treated ultra high molecular weight polyethylene prosthetic device and method

InactiveUS6641617B1Reduce productionReduce osteolysis and inflammatory reactionBone implantJoint implantsOxidation resistantPeriprosthetic

A medical prosthesis for use within the body which is formed of radiation treated ultra high molecular weight polyethylene having substantially no detectable free radicals, is described. Preferred prostheses exhibit reduced production of particles from the prosthesis during wear of the prosthesis, and are substantially oxidation resistant. Methods of manufacture of such devices and material used therein are also provided.

Owner:CENTPULSE ORTHOPEDICS +1

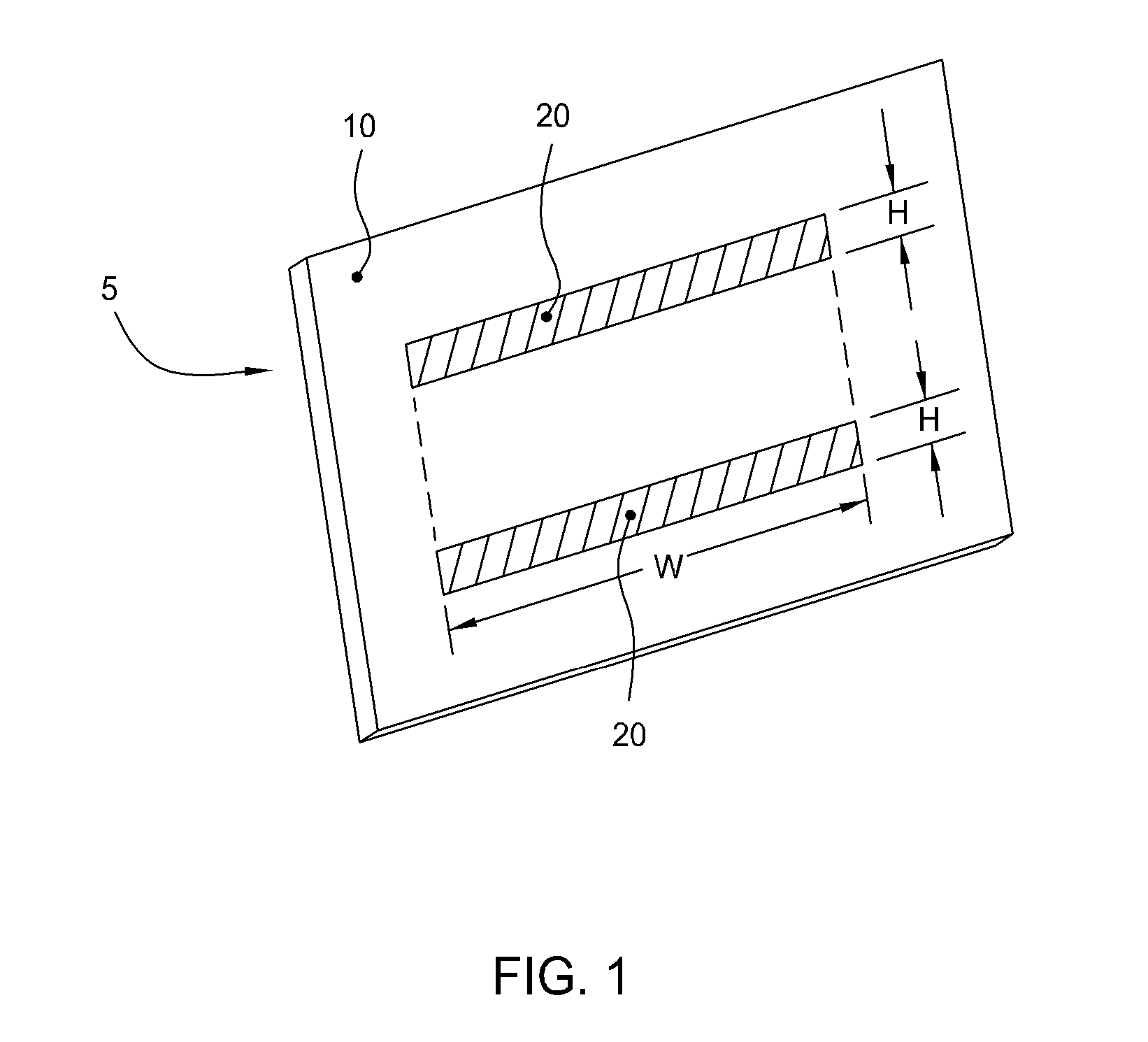

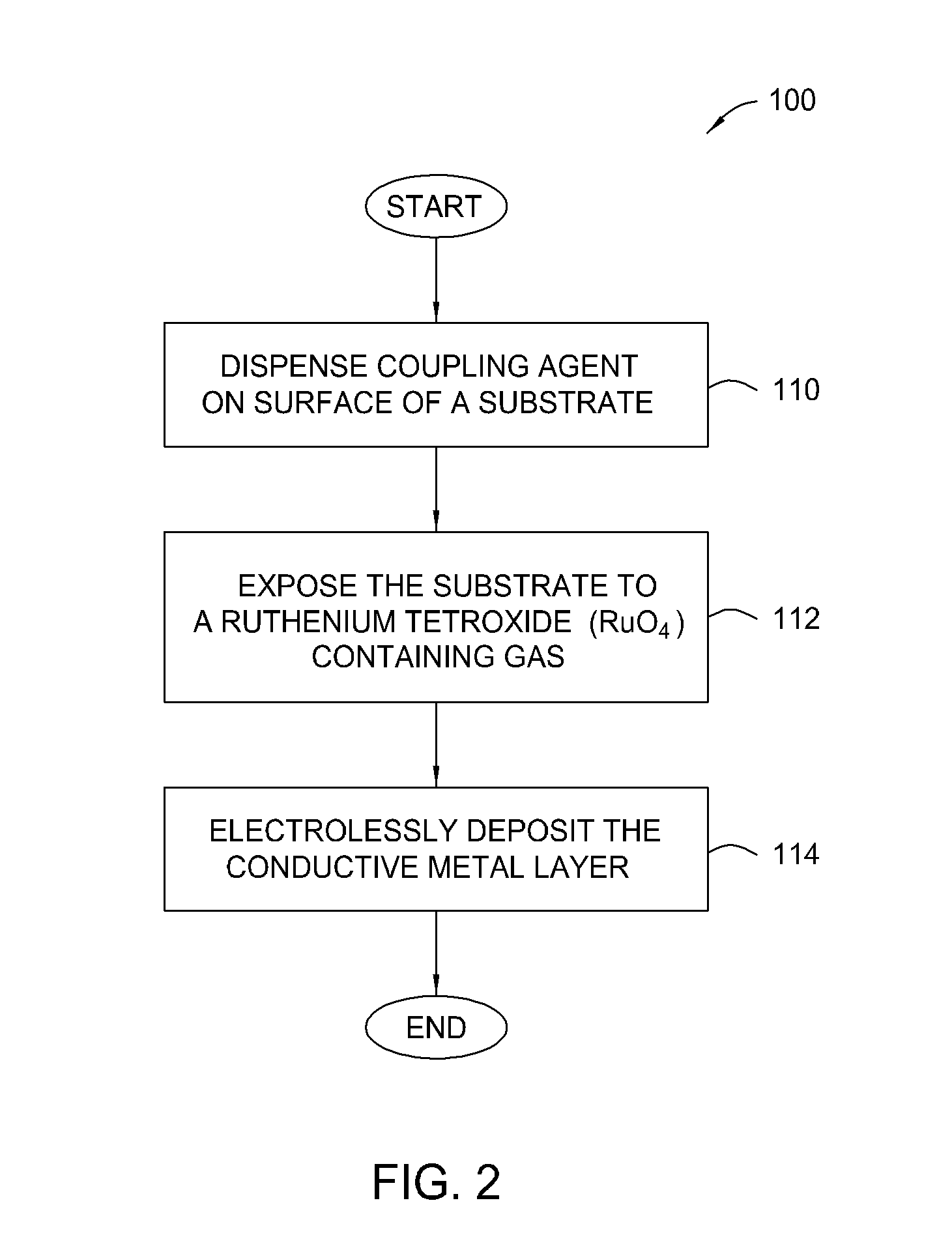

Patterned electroless metallization processes for large area electronics

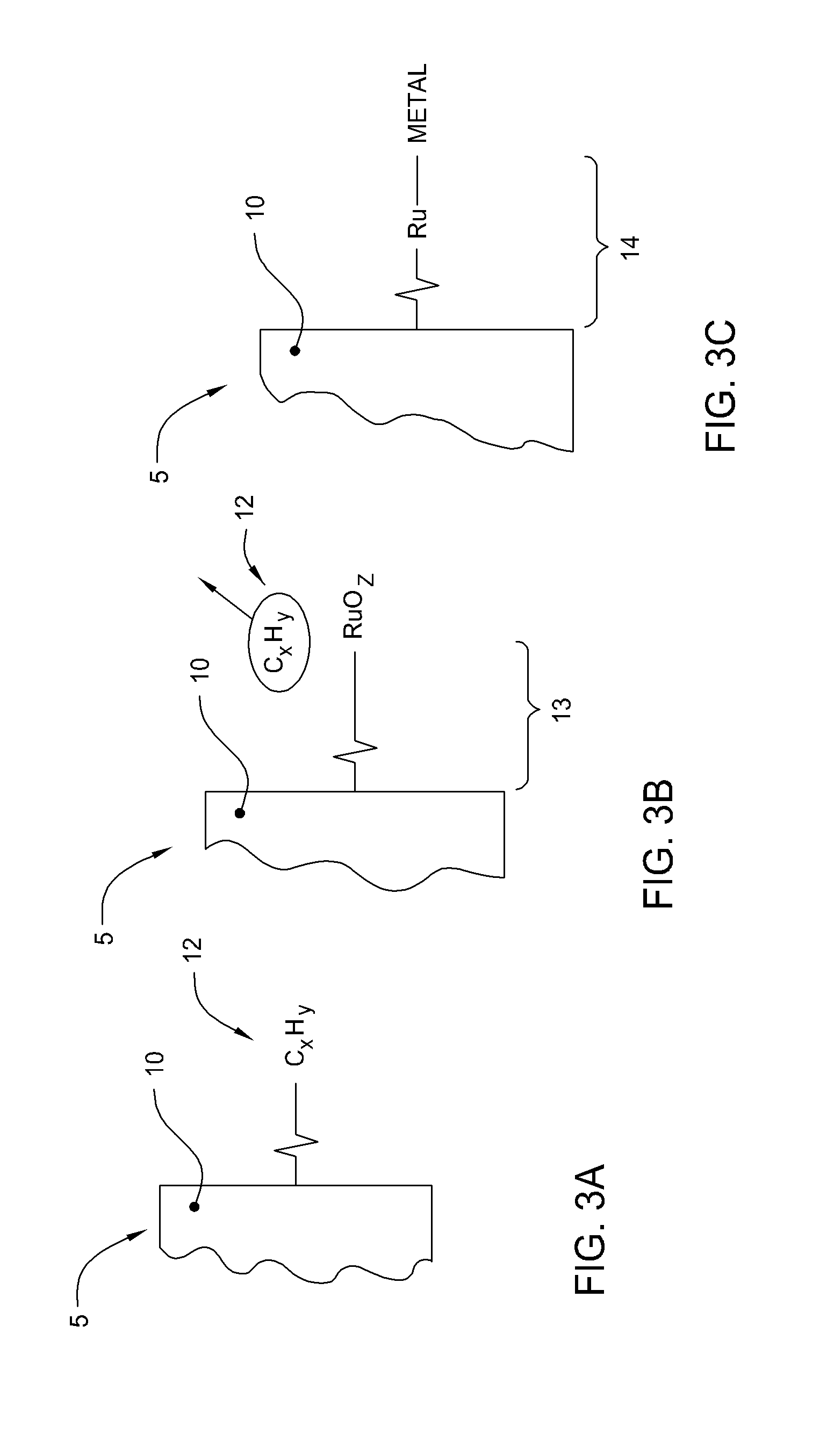

The present invention generally provides an apparatus and method for selectively forming a metallized feature, such as an electrical interconnect feature, on a electrically insulating surface of a substrate. The present invention also provides a method of forming a mechanically robust, adherent, oxidation resistant conductive layer selectively over either a defined pattern or as a conformal blanket film. Embodiments of the invention also generally provide a new chemistry, process, and apparatus to provide discrete or blanket electrochemically or electrolessly platable ruthenium or ruthenium dioxide containing adhesion and initiation layers. In general, aspects of the present invention can be used for flat panel display processing, semiconductor processing, solar cell device processing, or any other substrate processing, being particularly well suited for the application of stable adherent coating on glass as well as flexible plastic substrates. This invention may be especially useful for the formation of electrical interconnects on the surface of flat panel display or solar cell type substrates where the line sizes are generally larger than semiconductor devices or where the formed feature are not generally as dense.

Owner:APPLIED MATERIALS INC

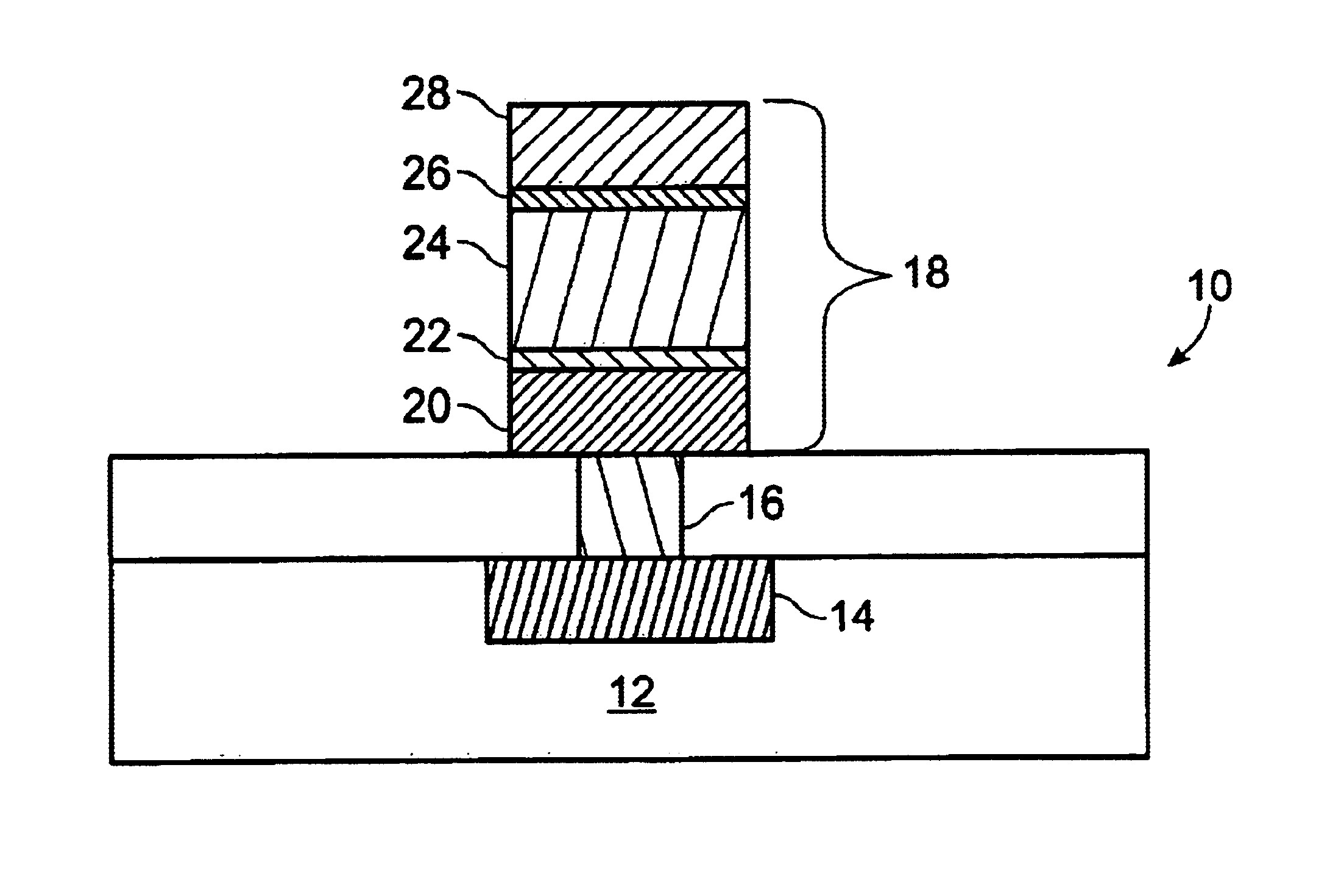

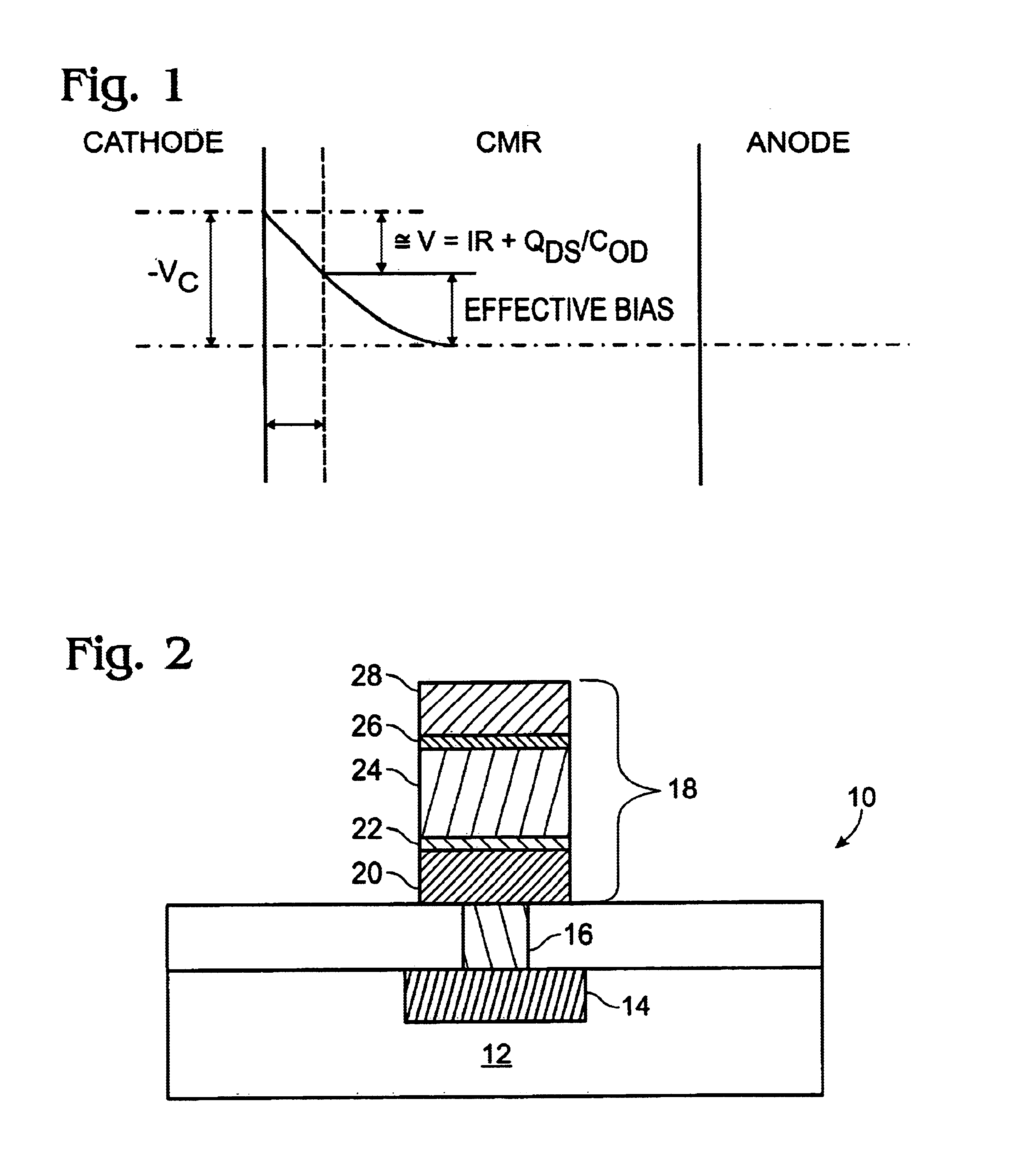

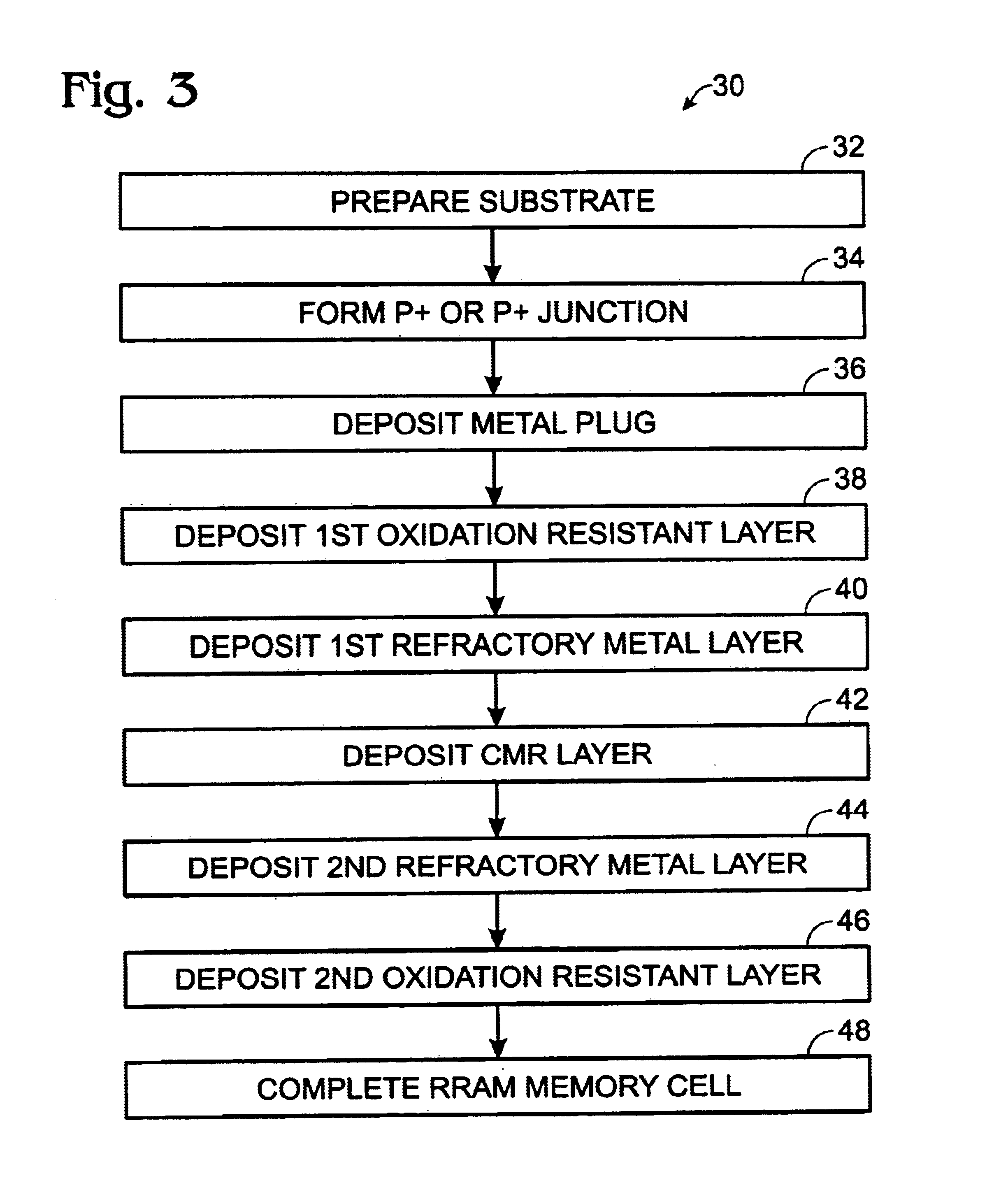

RRAM memory cell electrodes

ActiveUS6849891B1Improve device reliabilityImprove device device enduranceTransistorMagnetic-field-controlled resistorsOxidation resistantSilicon

A RRAM memory cell is formed on a silicon substrate having a operative junction therein and a metal plug formed thereon, includes a first oxidation resistive layer; a first refractory metal layer; a CMR layer; a second refractory metal layer; and a second oxidation resistive layer. A method of fabricating a multi-layer electrode RRAM memory cell includes preparing a silicon substrate; forming a junction in the substrate taken from the group of junctions consisting of N+ junctions and P+ junctions; depositing a metal plug on the junction; depositing a first oxidation resistant layer on the metal plug; depositing a first refractory metal layer on the first oxidation resistant layer; depositing a CMR layer on the first refractory metal layer; depositing a second refractory metal layer on the CMR layer; depositing a second oxidation resistant layer on the second refractory metal layer; and completing the RRAM memory cell.

Owner:XENOGENIC DEV LLC

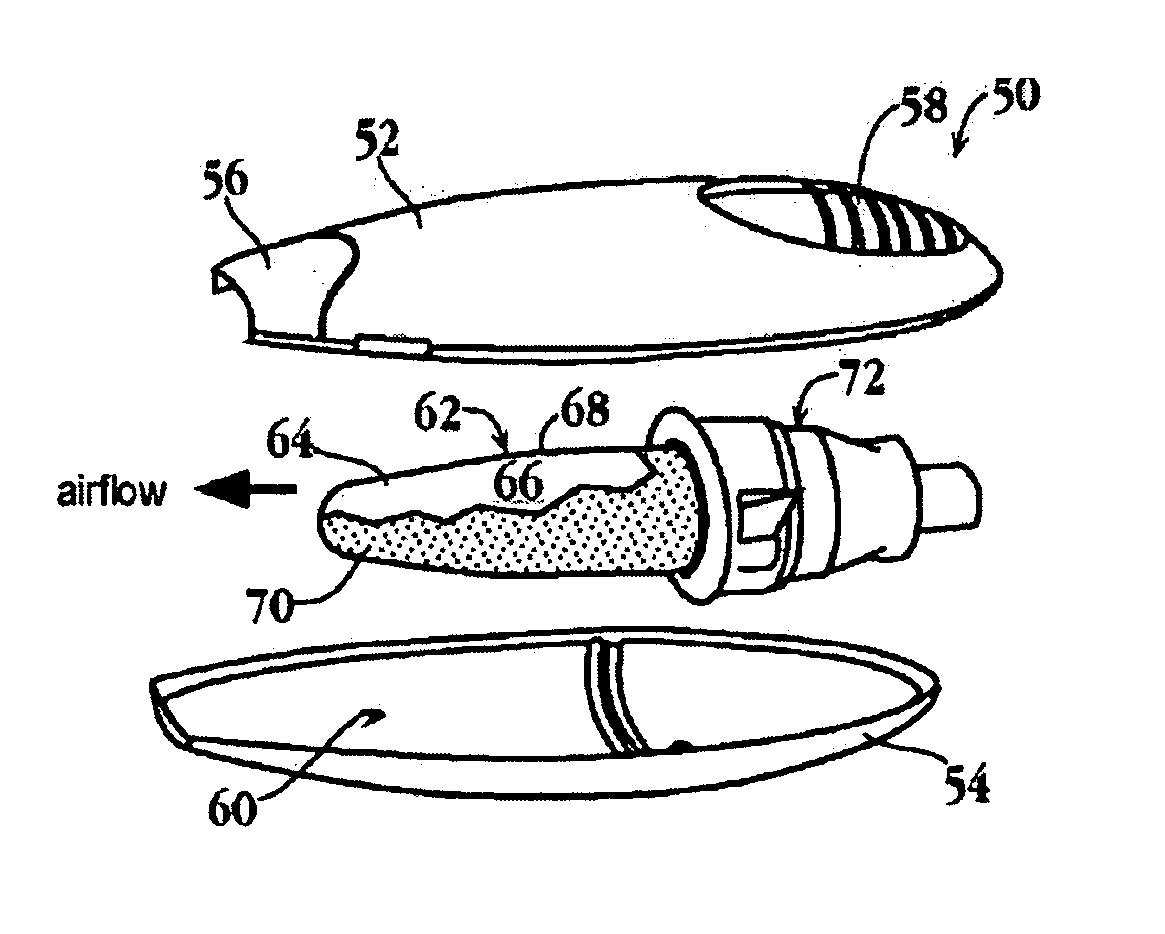

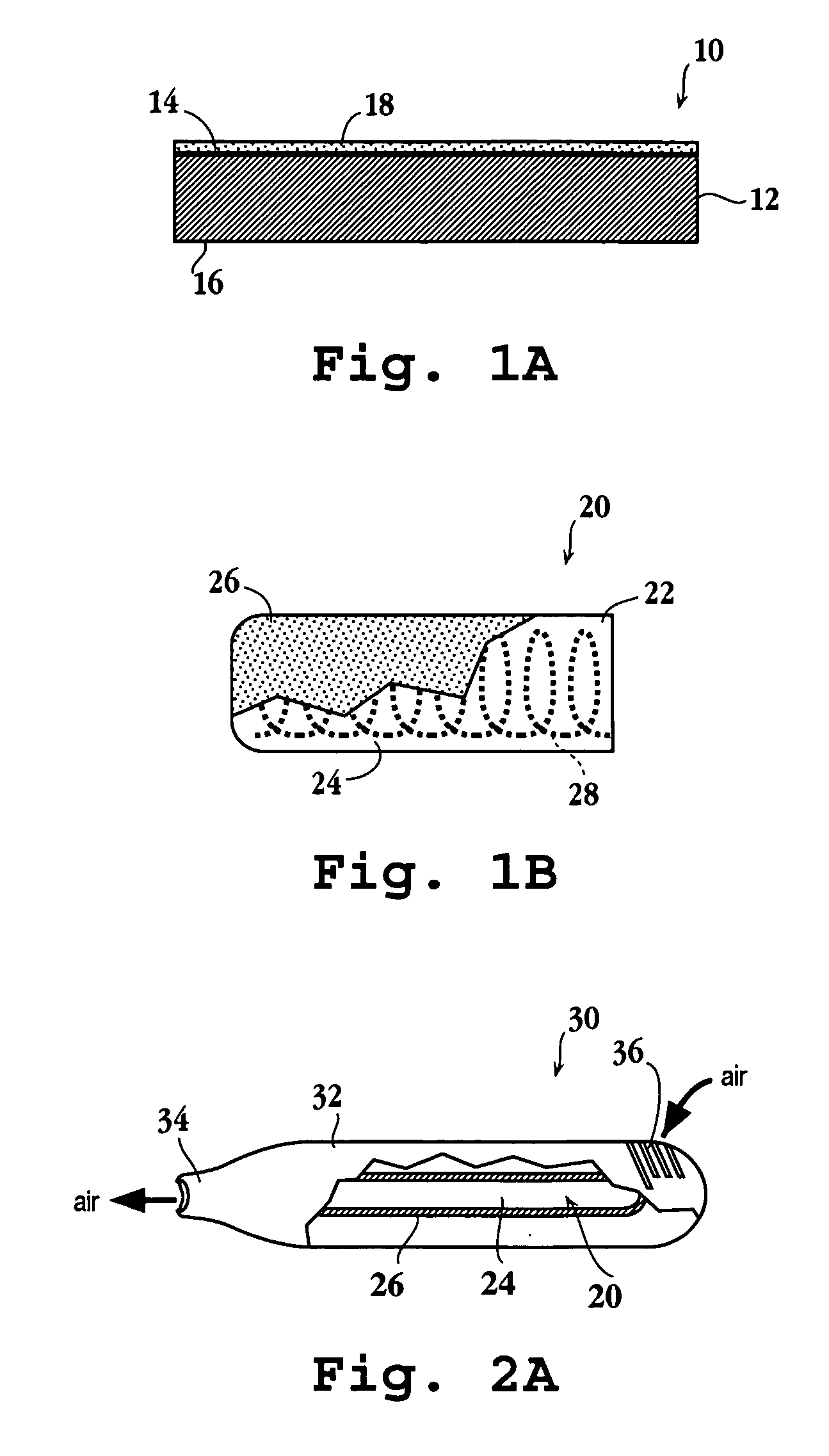

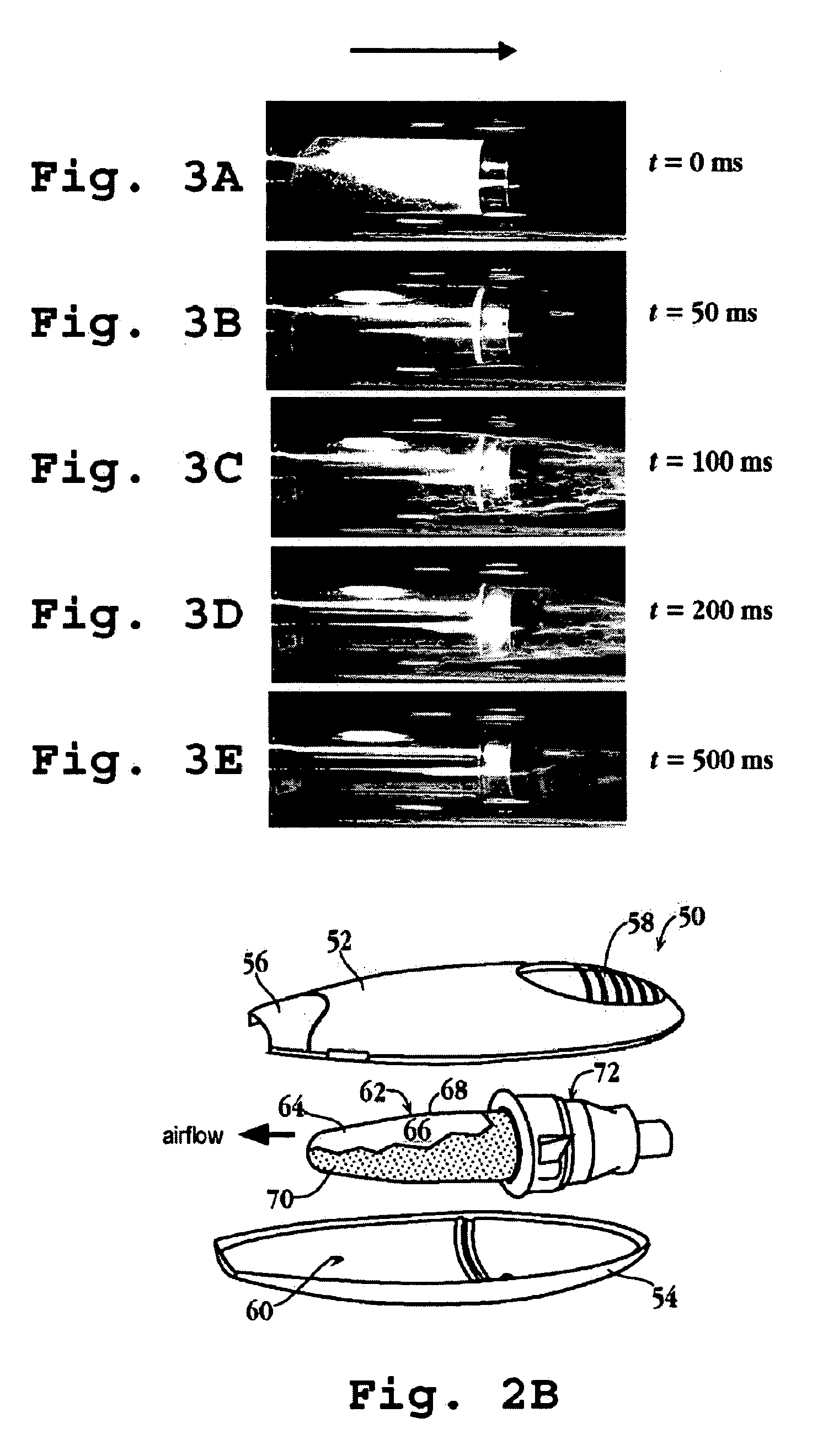

Substrates for drug delivery device and methods of preparing and use

An assembly and method for producing a condensation aerosol are disclosed. The assembly includes a heat-conductive metal substrate with an oxidation resistant exterior surface and a drug composition film on the exterior surface and is for use in an aerosol device. The thickness of the film and the surface of the substrate is such that the aerosol formed by vaporizing and condensing the drug composition the aerosol contain 10% by weight or less drug-degradation products and at least 50% of the total amount of the drug composition in the film. The methods for treating the exterior surface include heat and chemical treatment and formation of a protective overcoat.

Owner:ALEXZA PHARMA INC

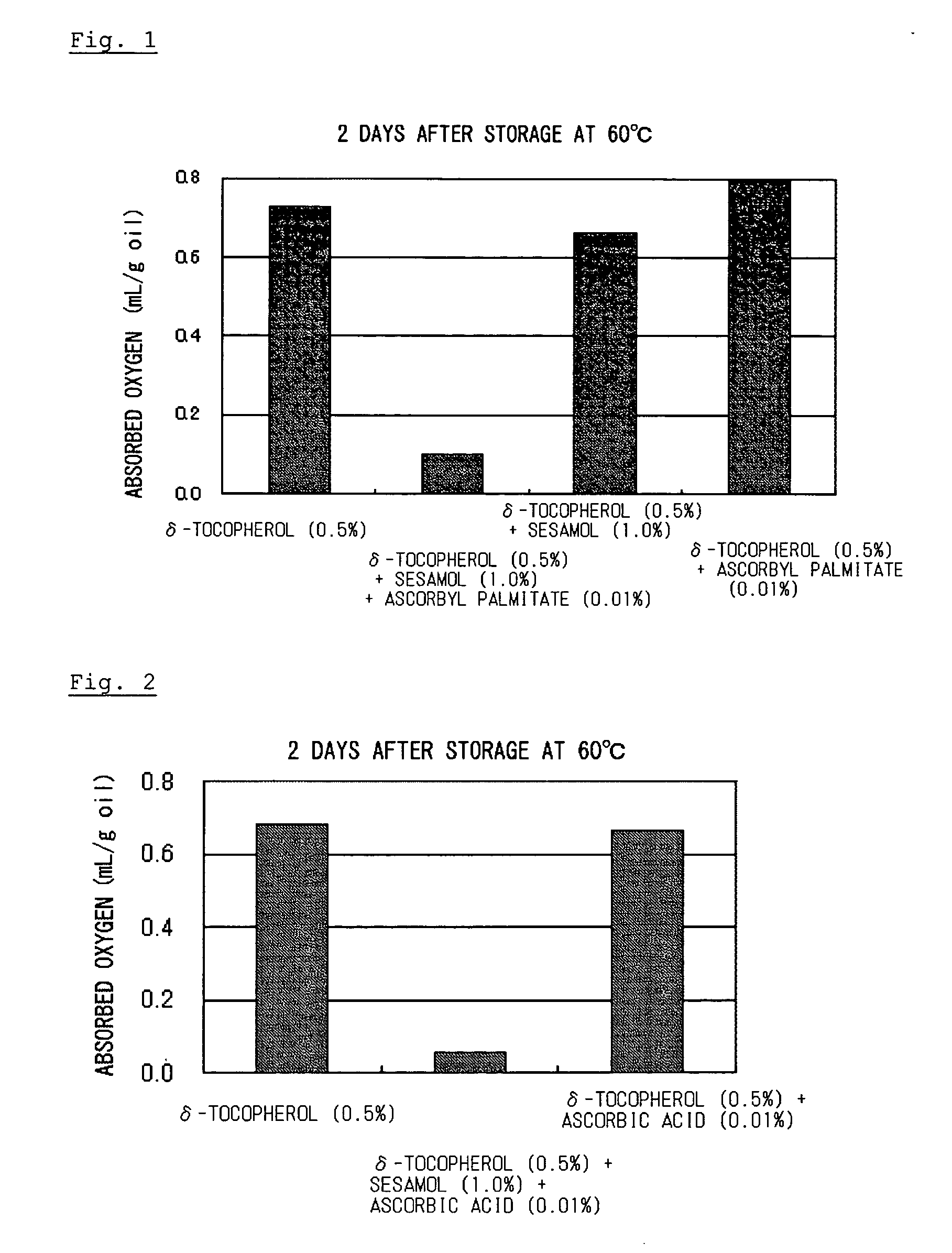

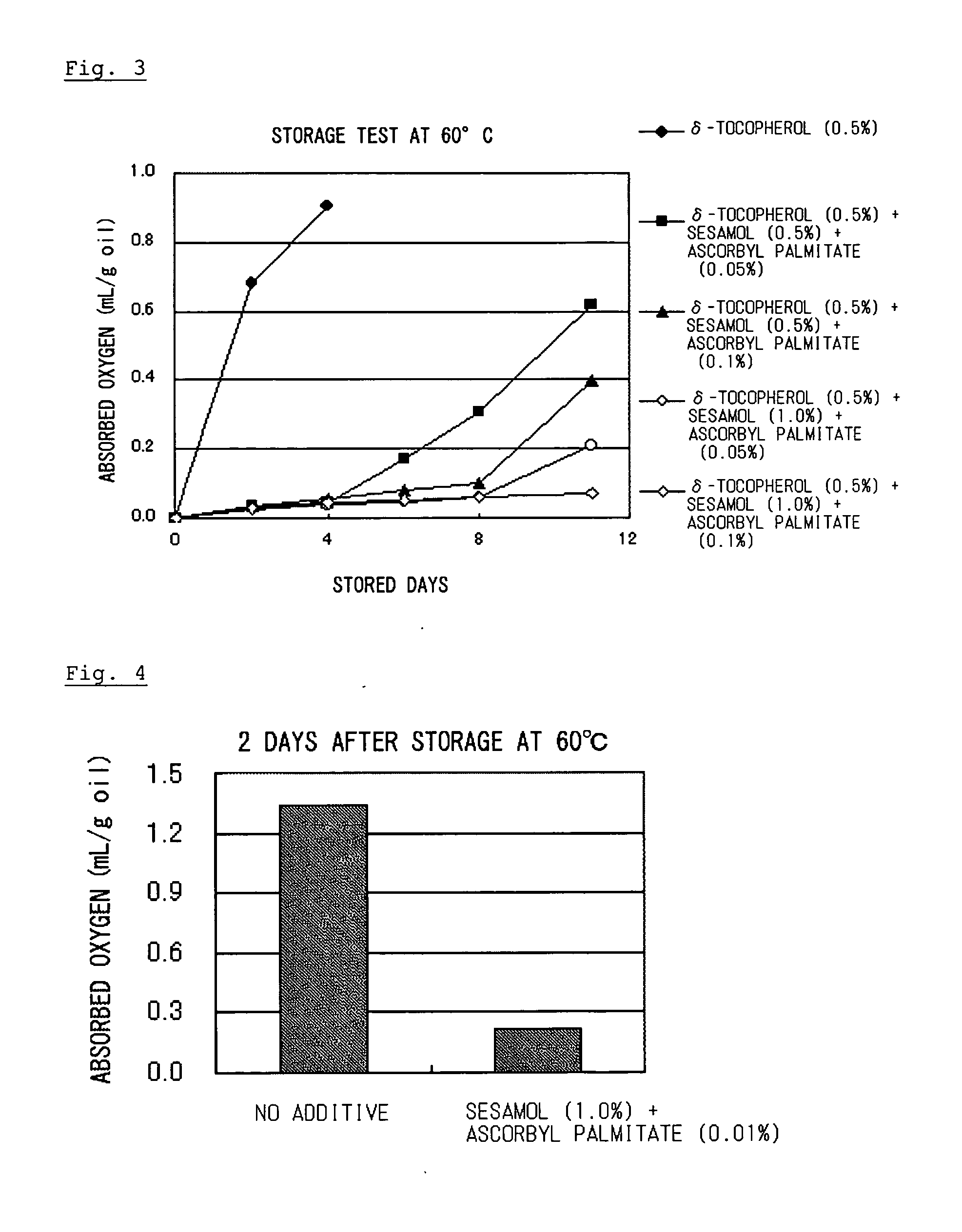

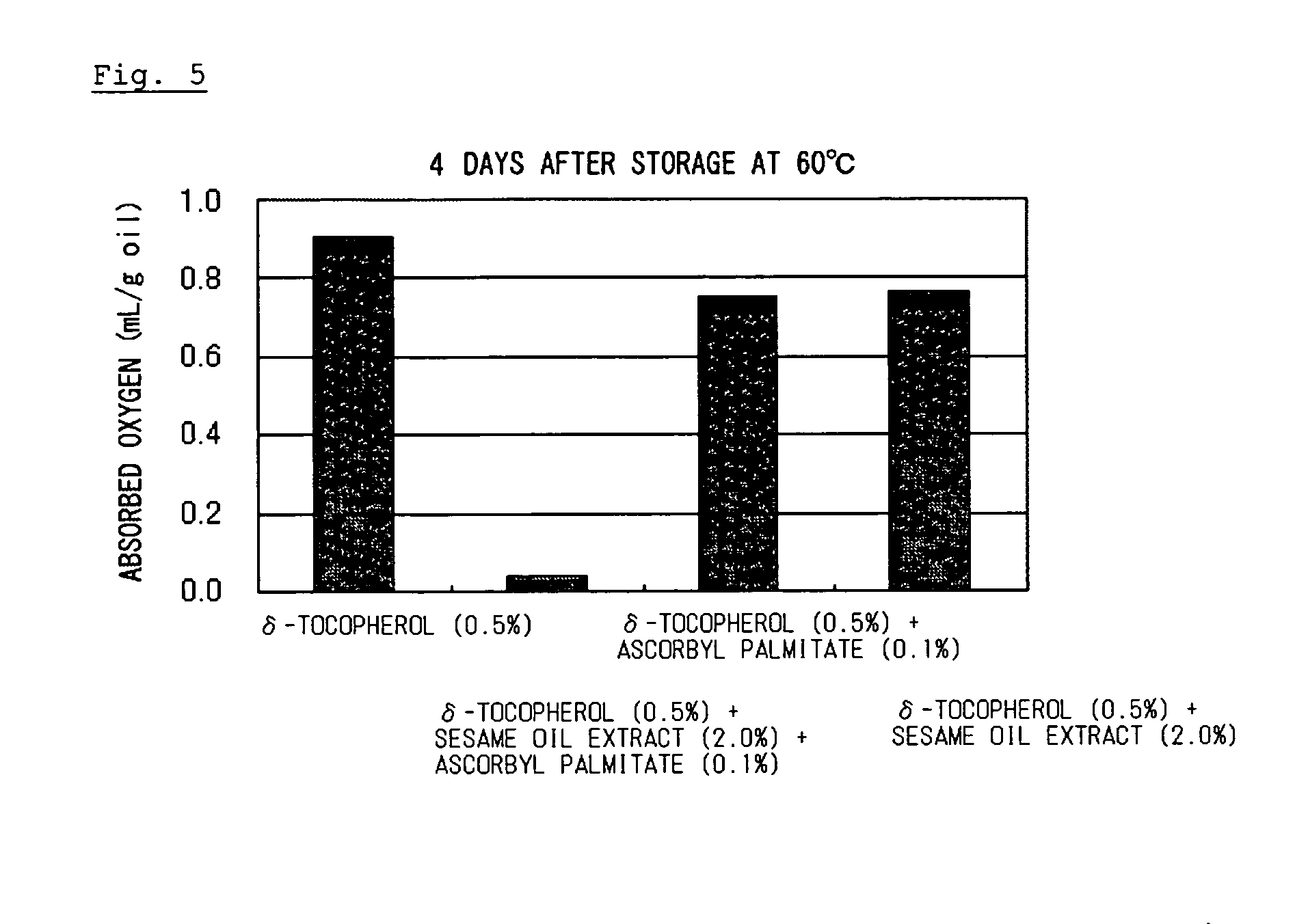

Composition containing organic substance having double bond with improved oxidative stability

ActiveUS20060134178A1Improve stabilitySafe antioxidantOrganic active ingredientsCosmetic preparationsSesamum orientaleGeneral purpose

To an organic substance having a double bond such as a polyunsaturated fatty acid was added an antioxidative component containing an antioxidative sesame component and ascorbic acid or an ascorbyl fatty acid ester. The above method provides a composition containing an organic substance having a double bond exhibiting enhanced oxidative stability. Particularly, it extremely improves oxidative stability of fat and oil which contains polyunsaturated fatty acid. General-purpose refined fish oil which is easy to handle can be provided for food, medicine or feed uses.

Owner:NIPPON SUISAN KAISHA LTD

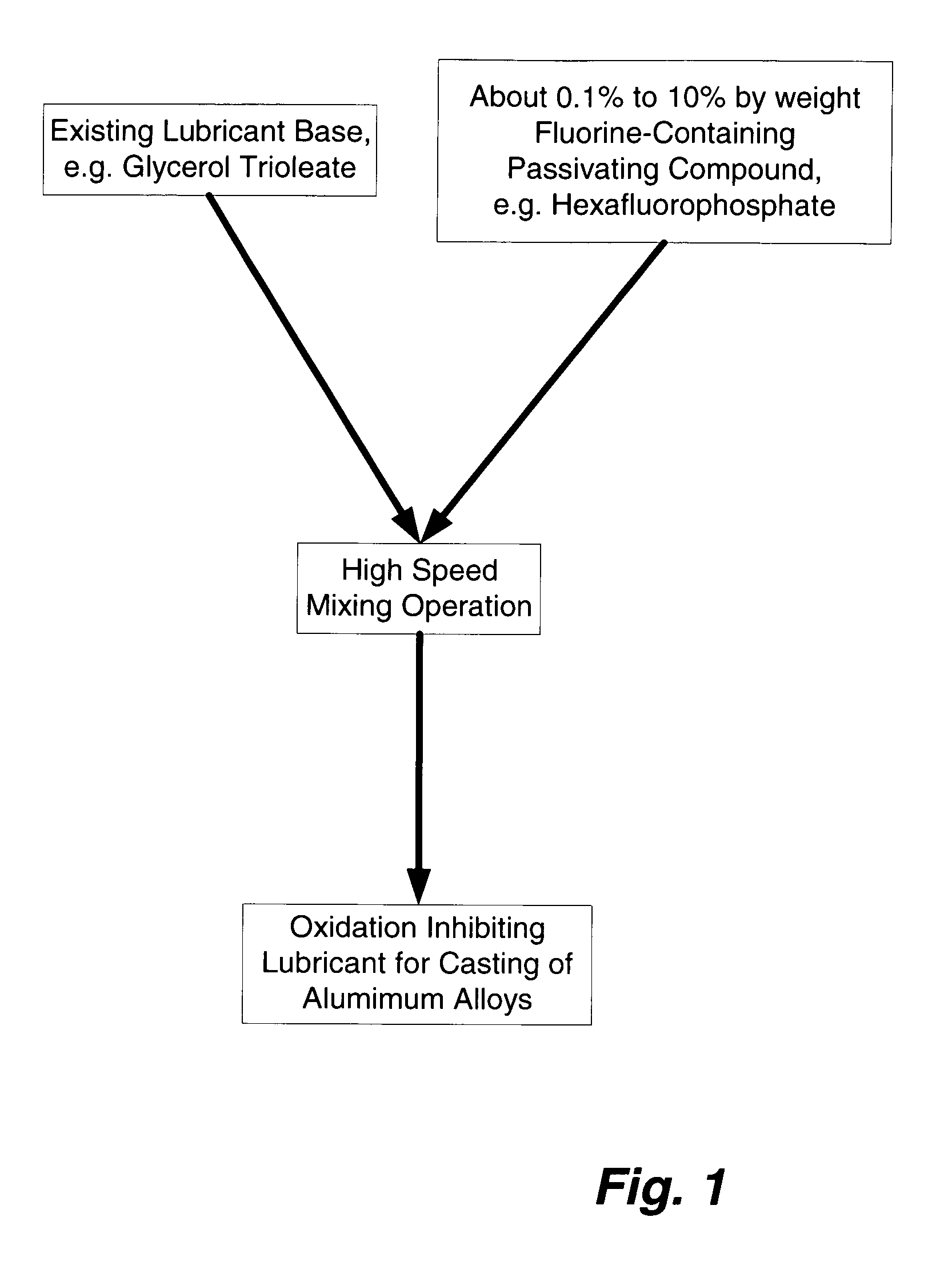

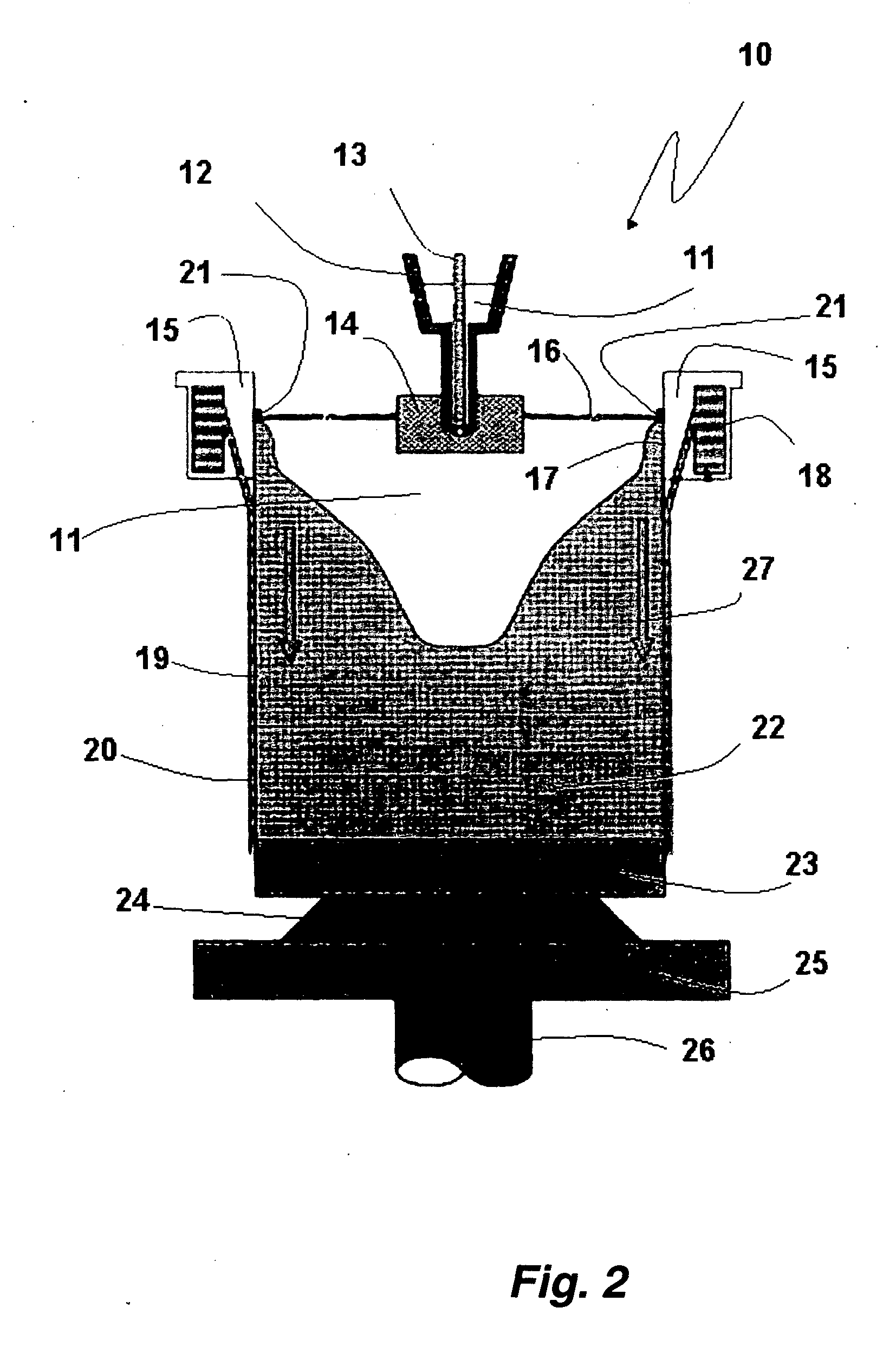

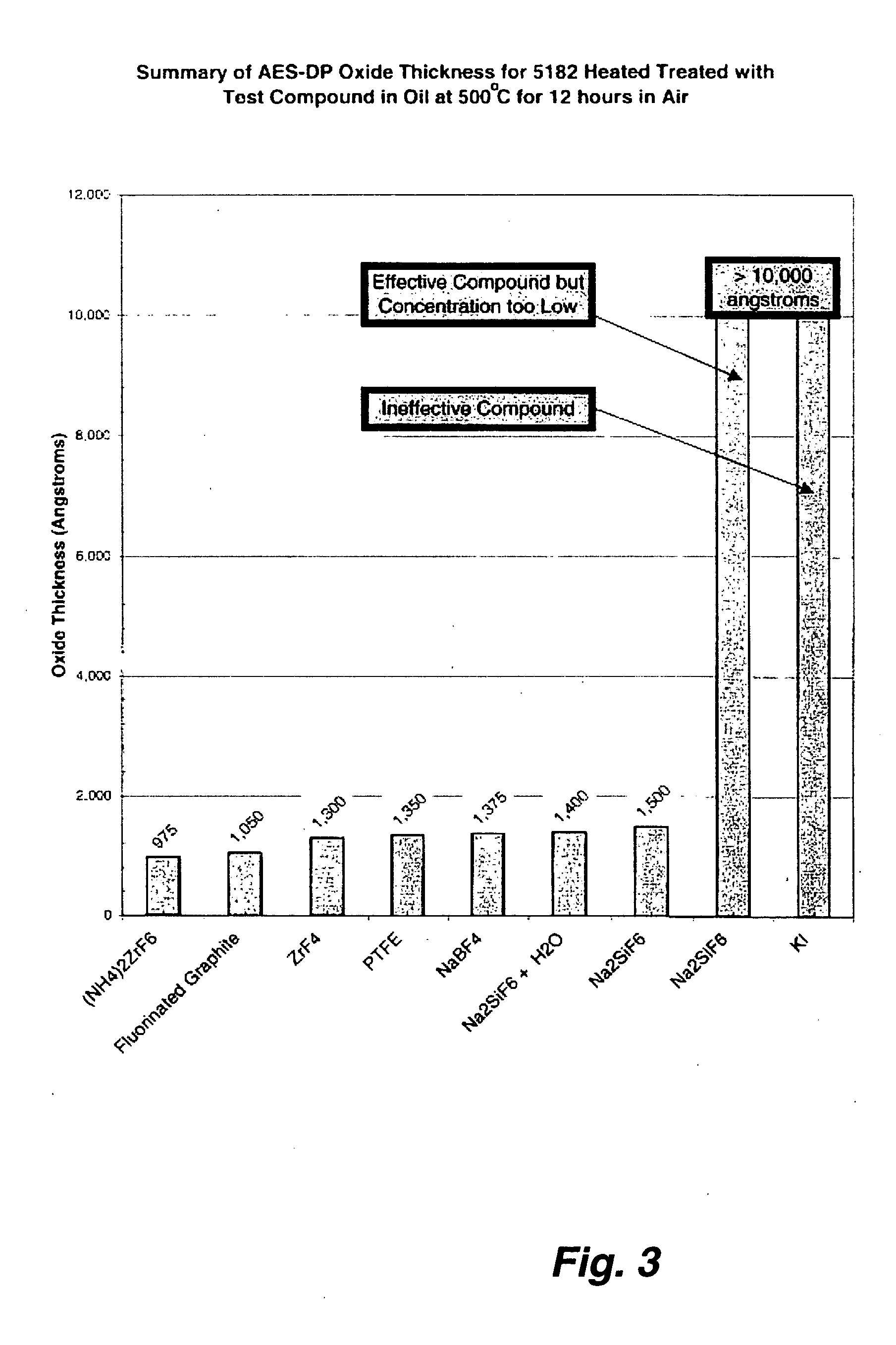

Lubricant for improved surface quality of cast aluminum and method

InactiveUS20050043189A1Reduce oxidationProtect the surfaceSnowboard bindingsSkisEmulsionOxidation resistant

In an oxidation inhibiting lubricant composition suitable for use in the manufacture of aluminum alloys comprising lubricant base selected from the group consisting of solid lubricants, liquid lubricants, grease lubricants, emulsion lubricants, and dispersion lubricants, the improvement wherein the lubricant composition further comprises: an effective amount of a fluorine-containing passivating compound.

Owner:ARCONIC INC

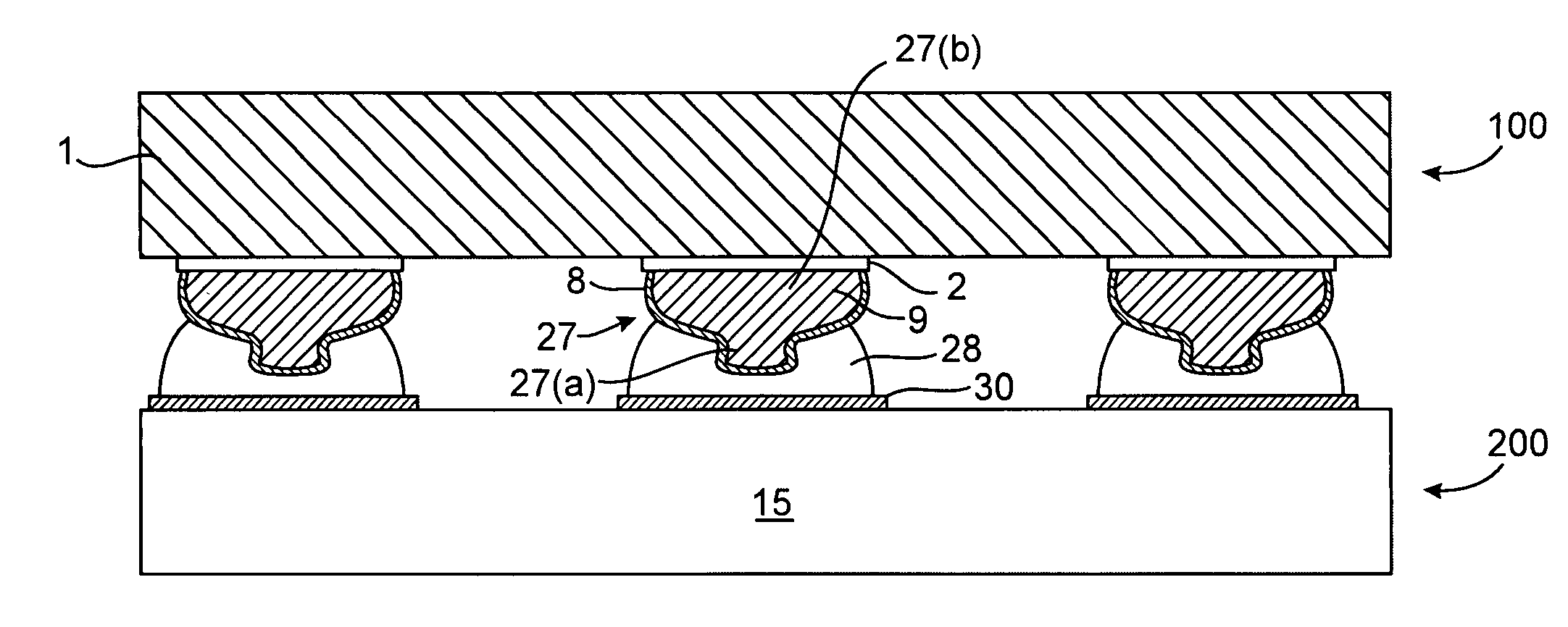

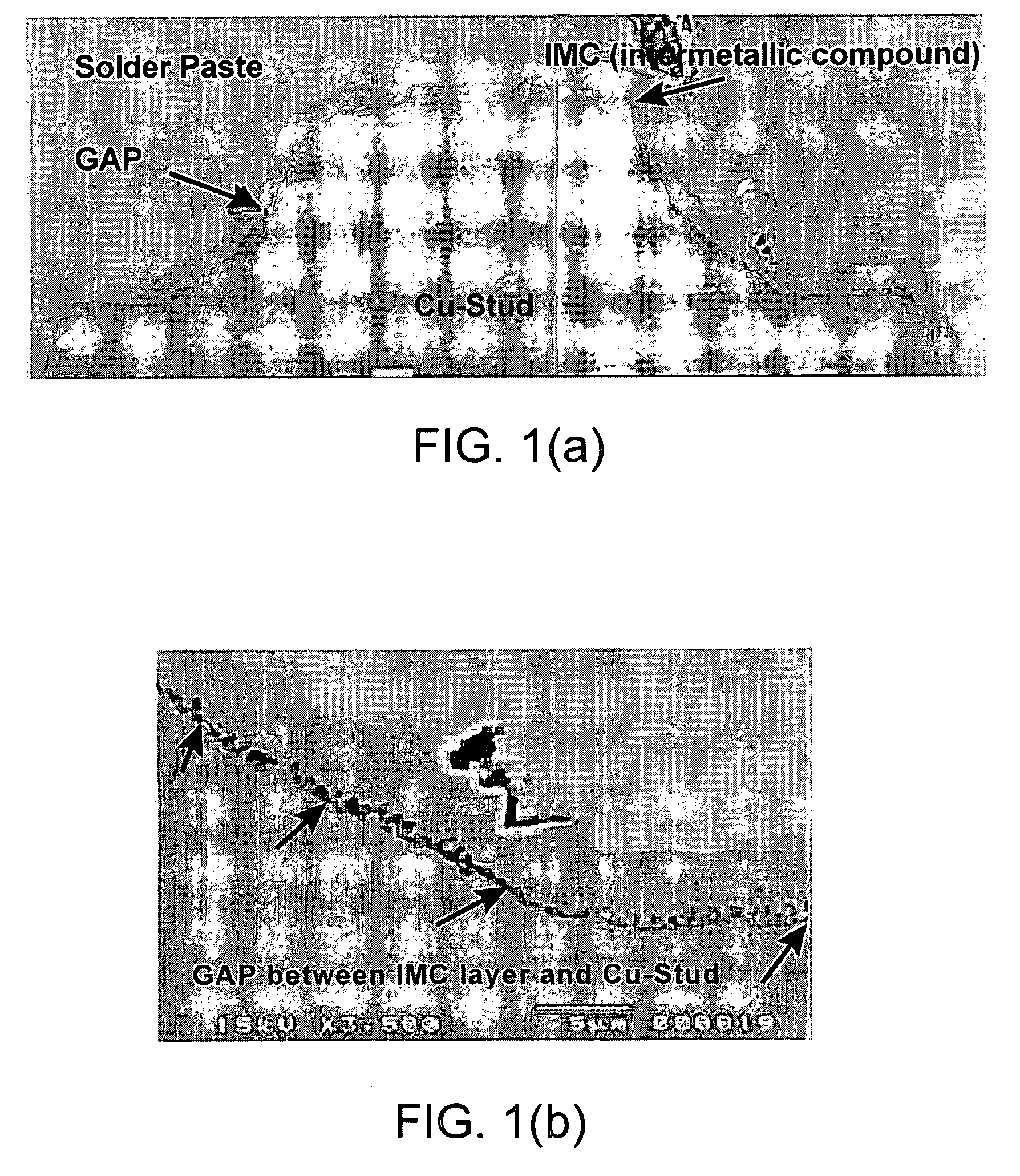

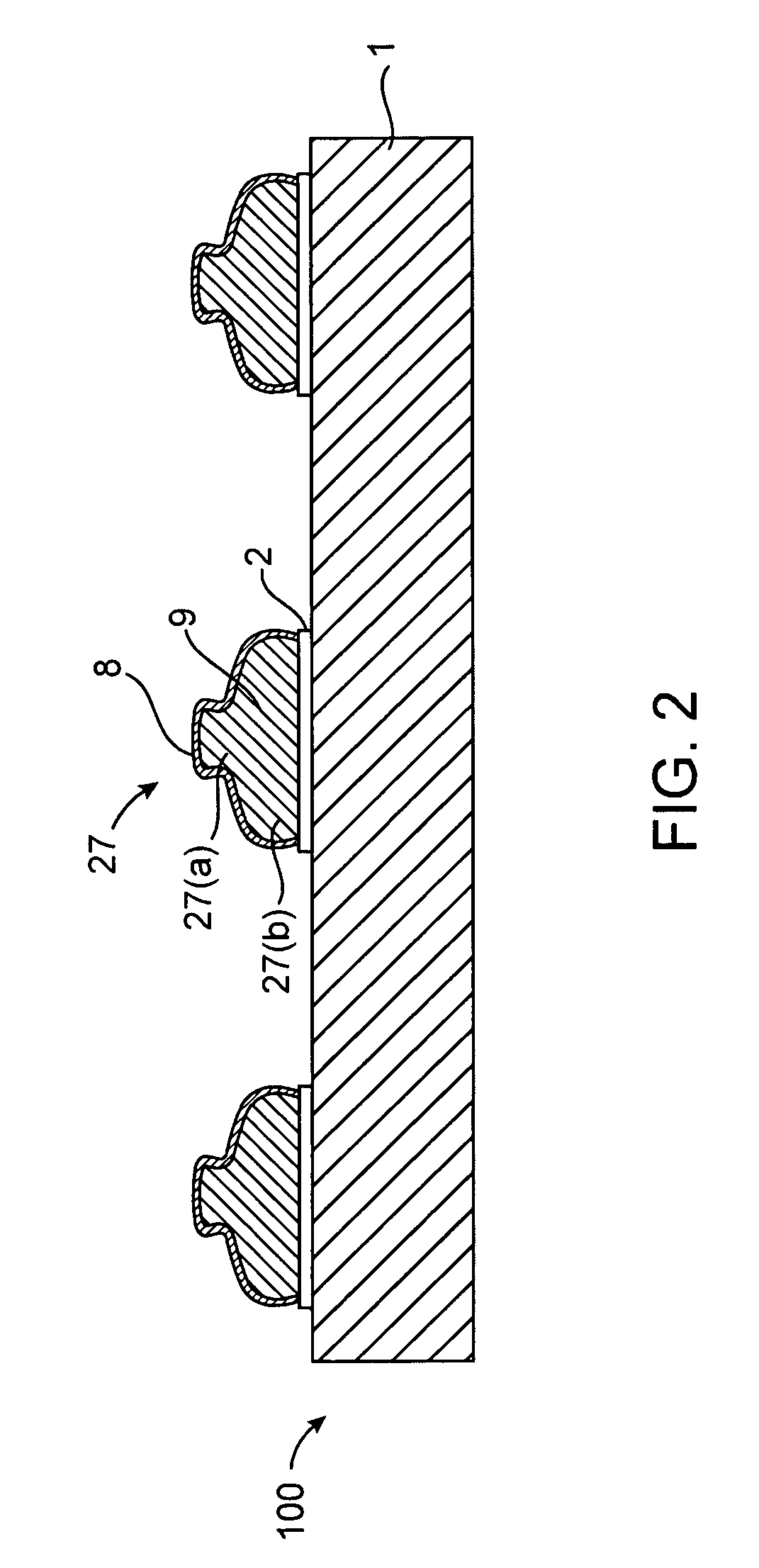

Dual metal stud bumping for flip chip applications

InactiveUS7271497B2ElectrotherapySemiconductor/solid-state device detailsOxidation resistantEngineering

A method for forming a stud bumped semiconductor die is disclosed. The method includes forming a ball at the tip of a coated wire passing through a hole in a capillary, where the coated wire has a core and an oxidation-resistant coating. The formed ball is pressed to the conductive region on the semiconductor die. The coated wire is cut, thereby leaving a conductive stud bump on the conductive region, where the conductive stud bump includes an inner conductive portion and an outer oxidation-resistant layer.

Owner:SEMICON COMPONENTS IND LLC

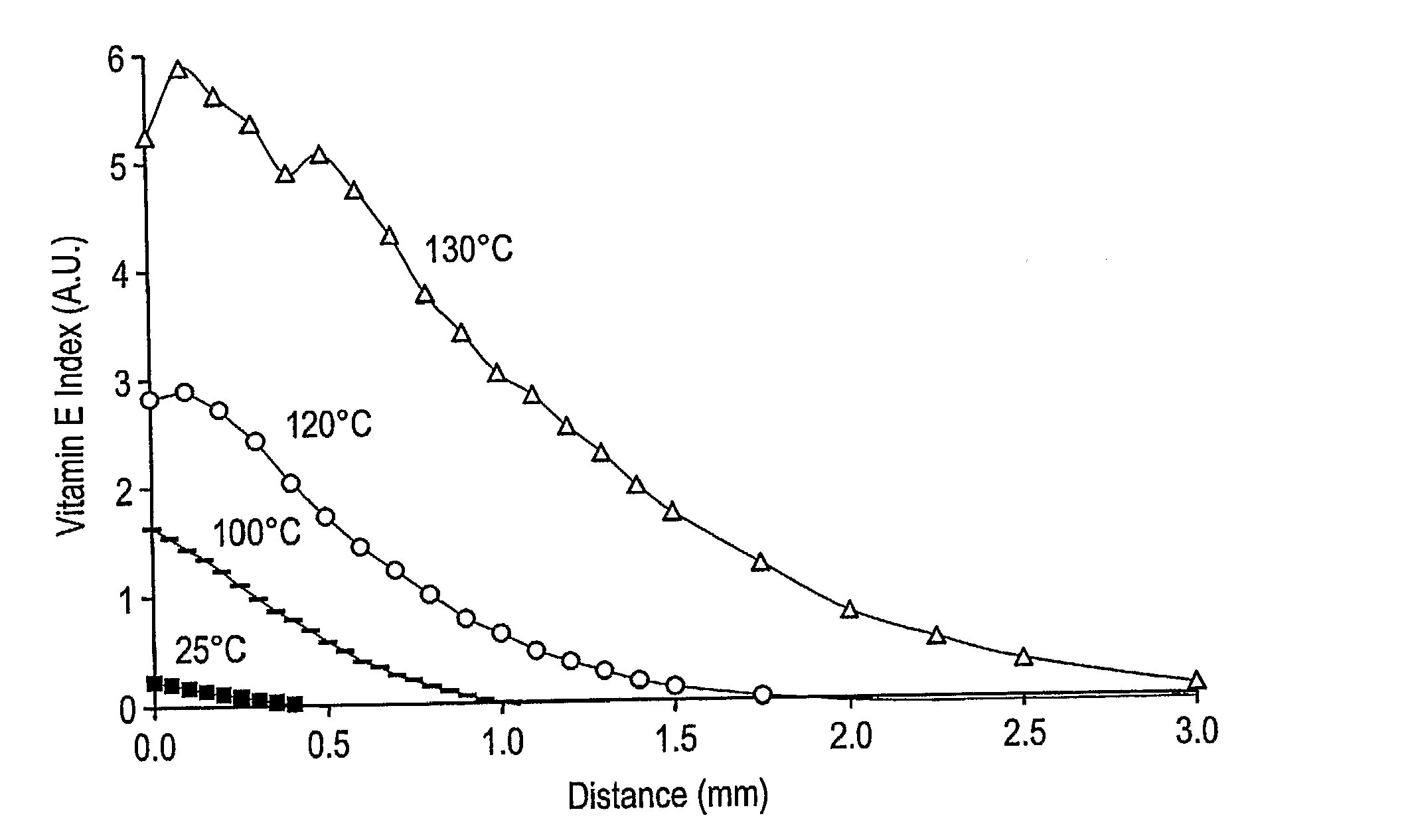

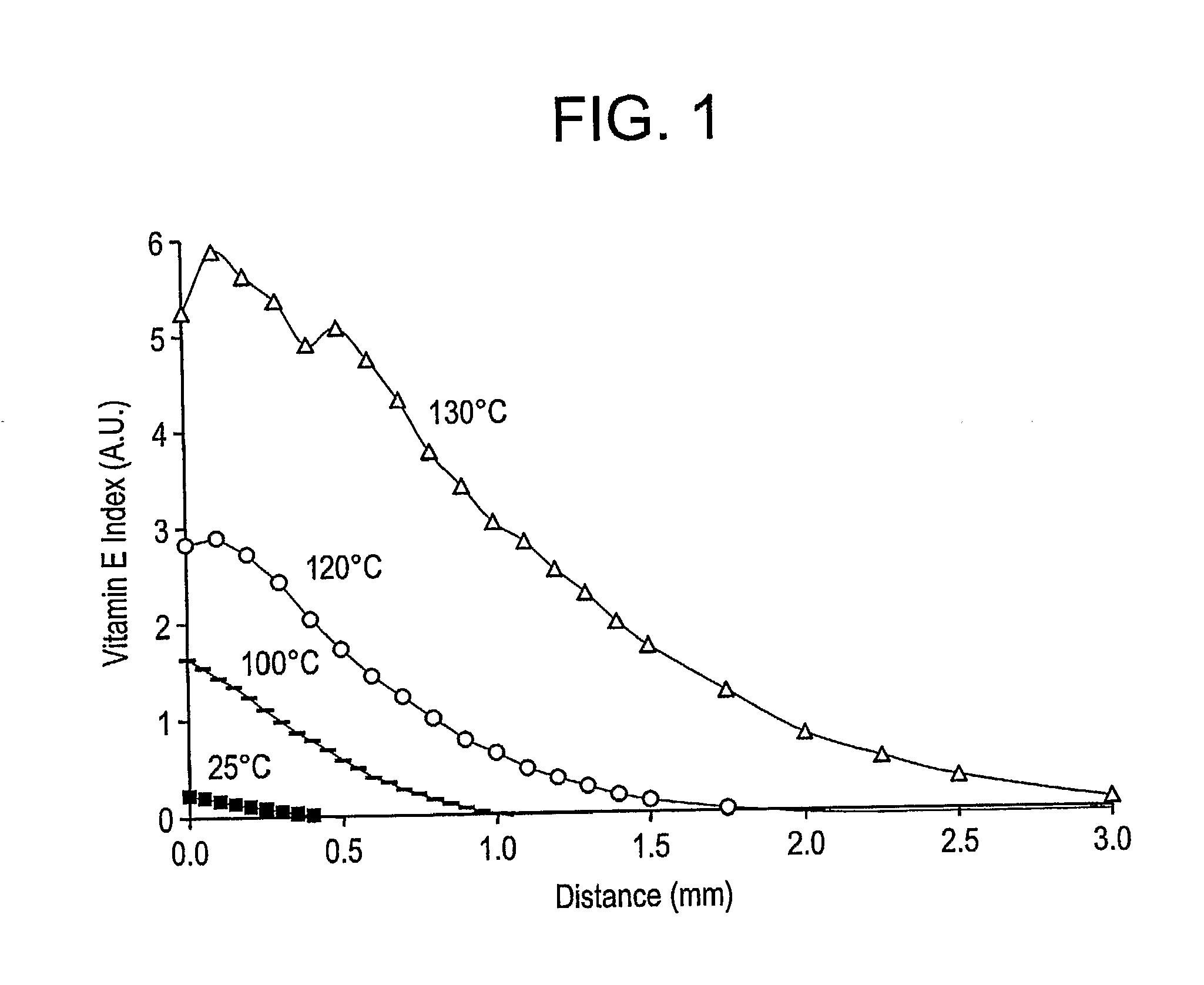

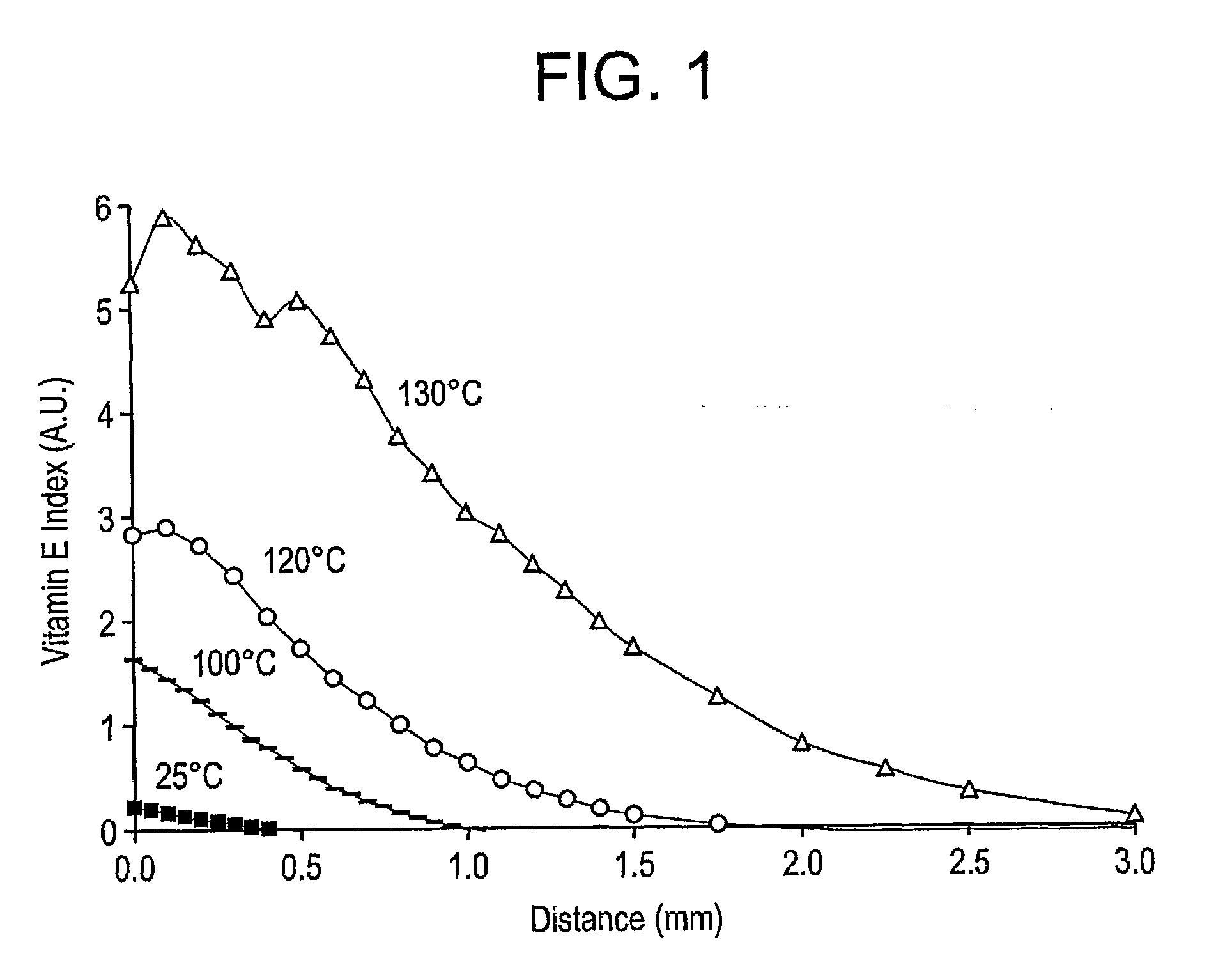

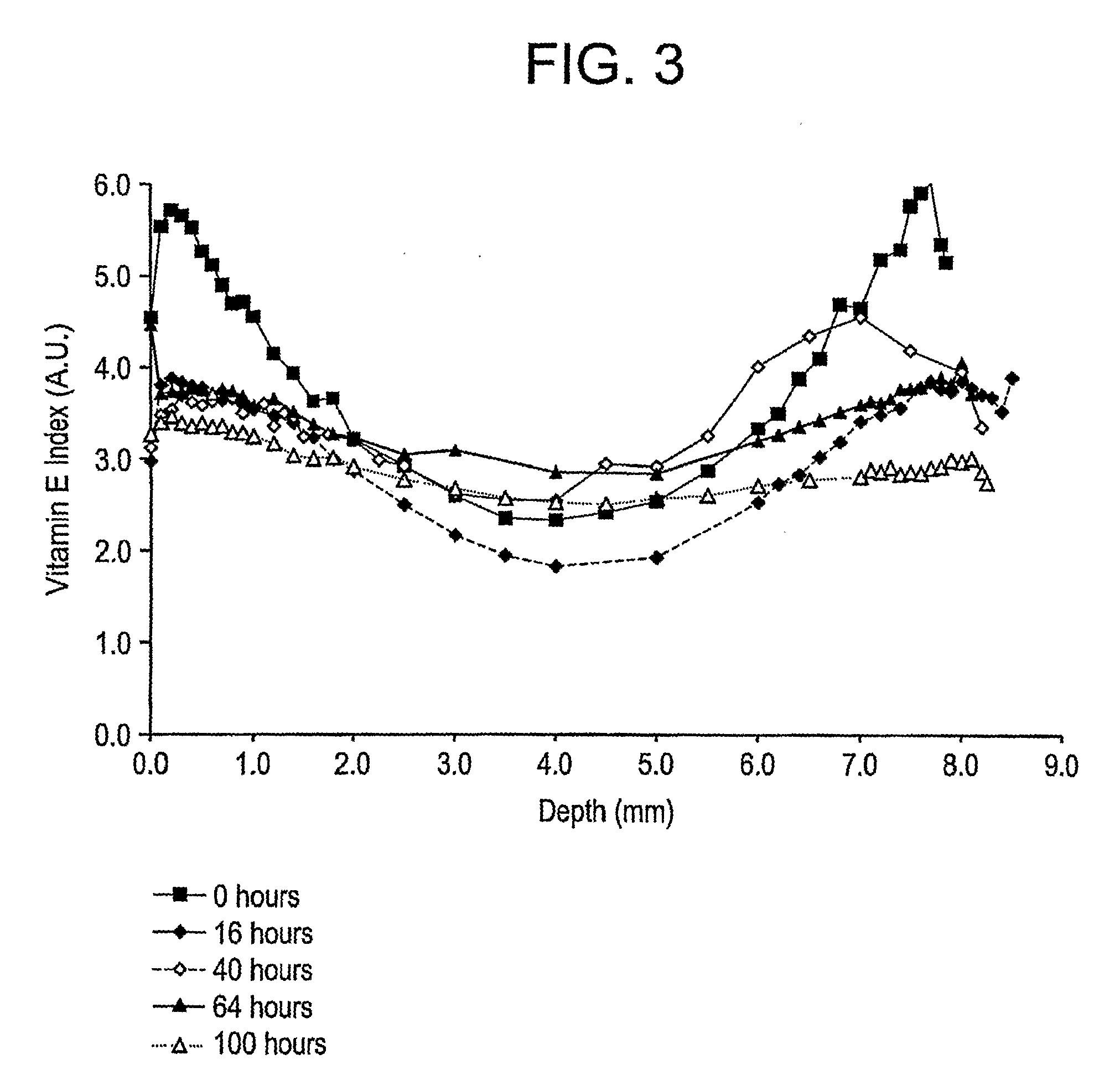

Methods for making oxidation resistant polymeric material

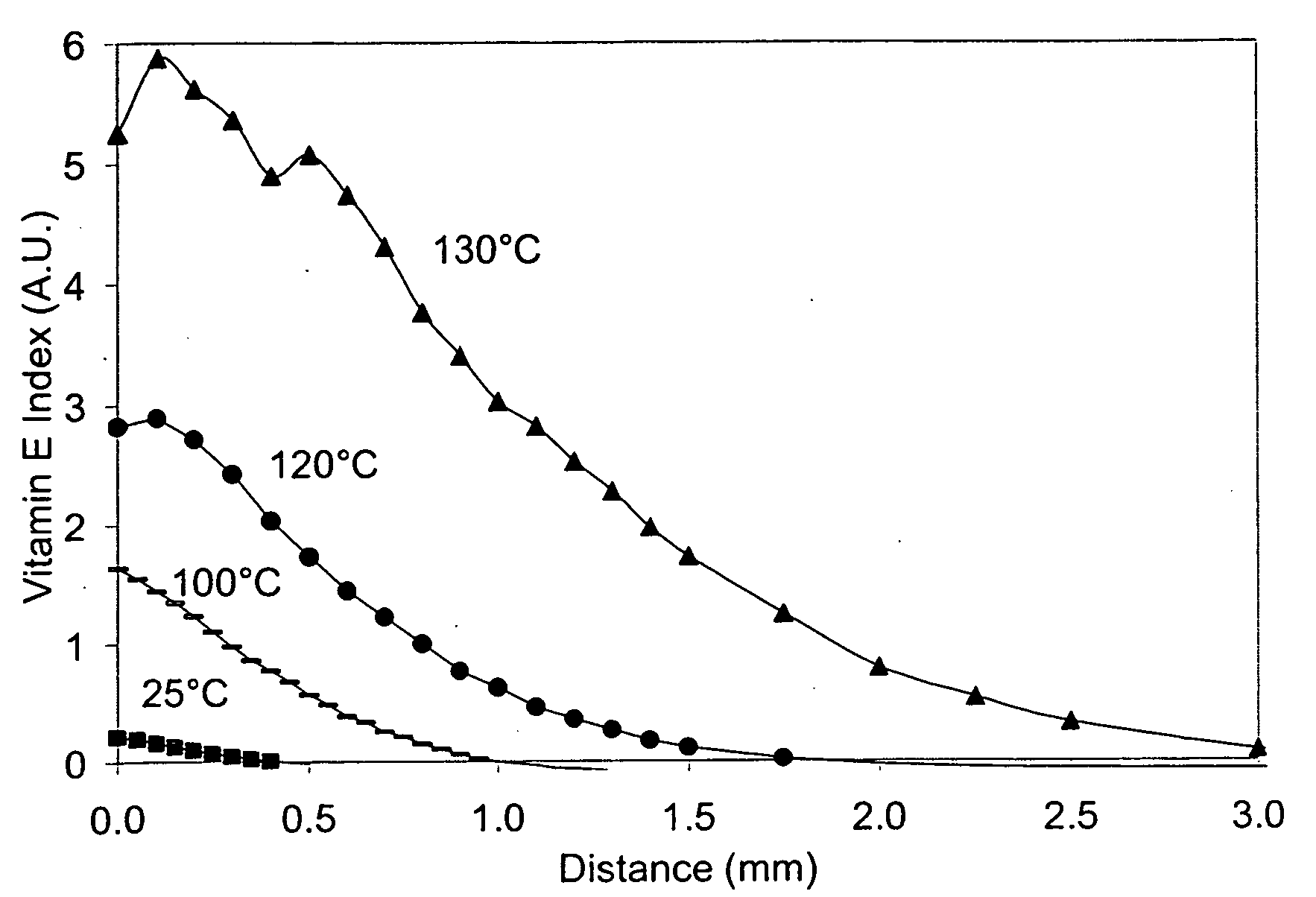

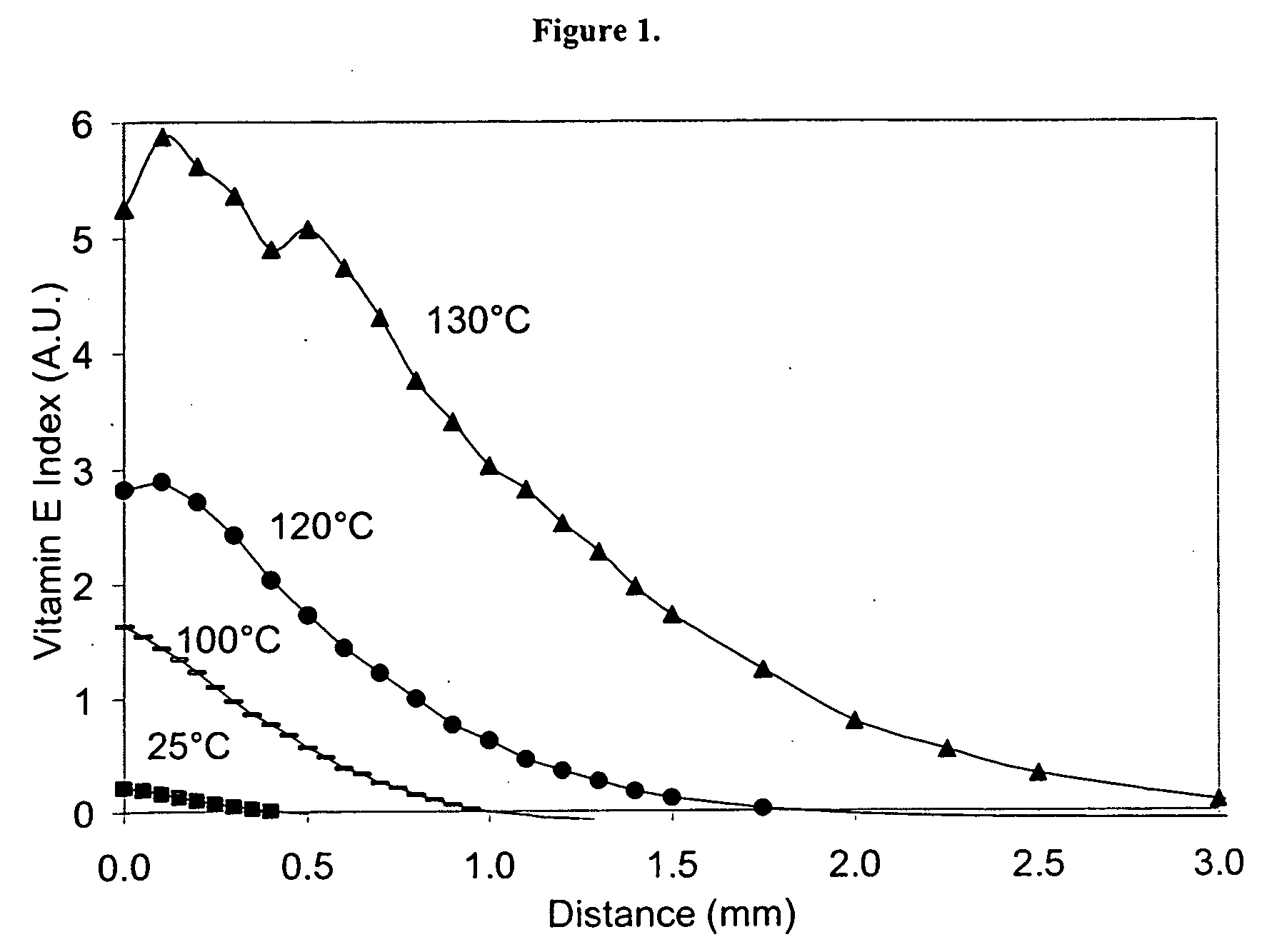

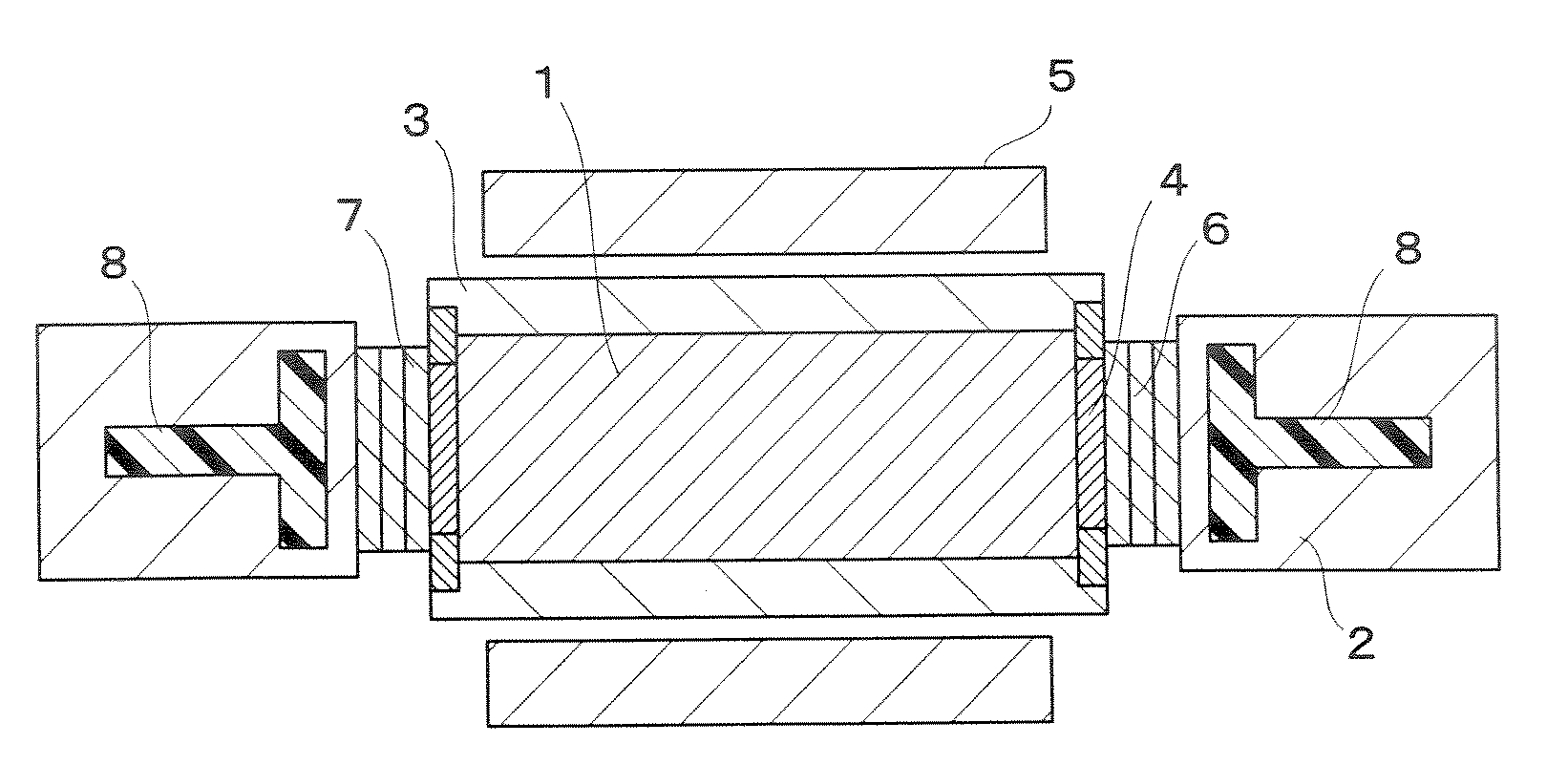

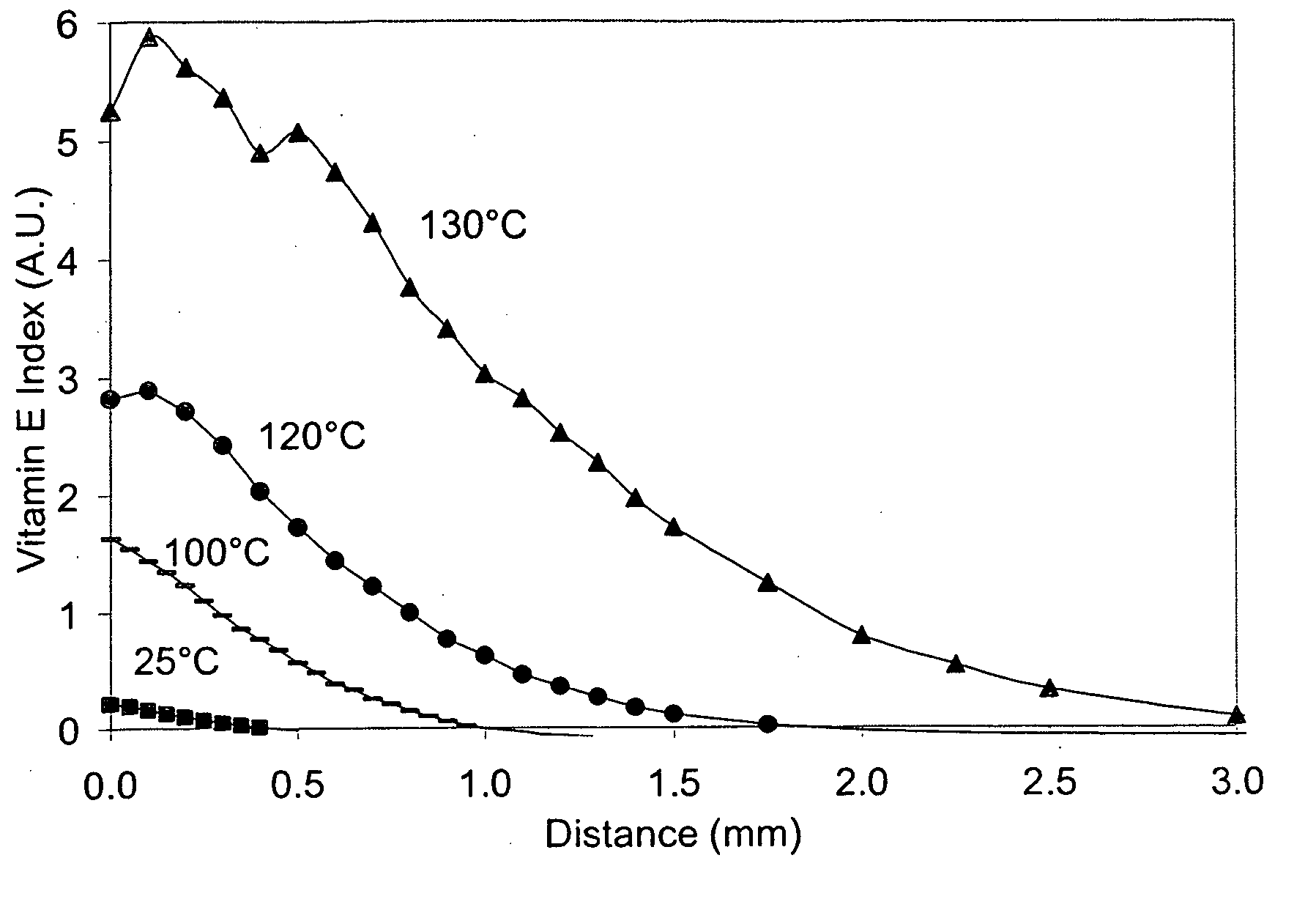

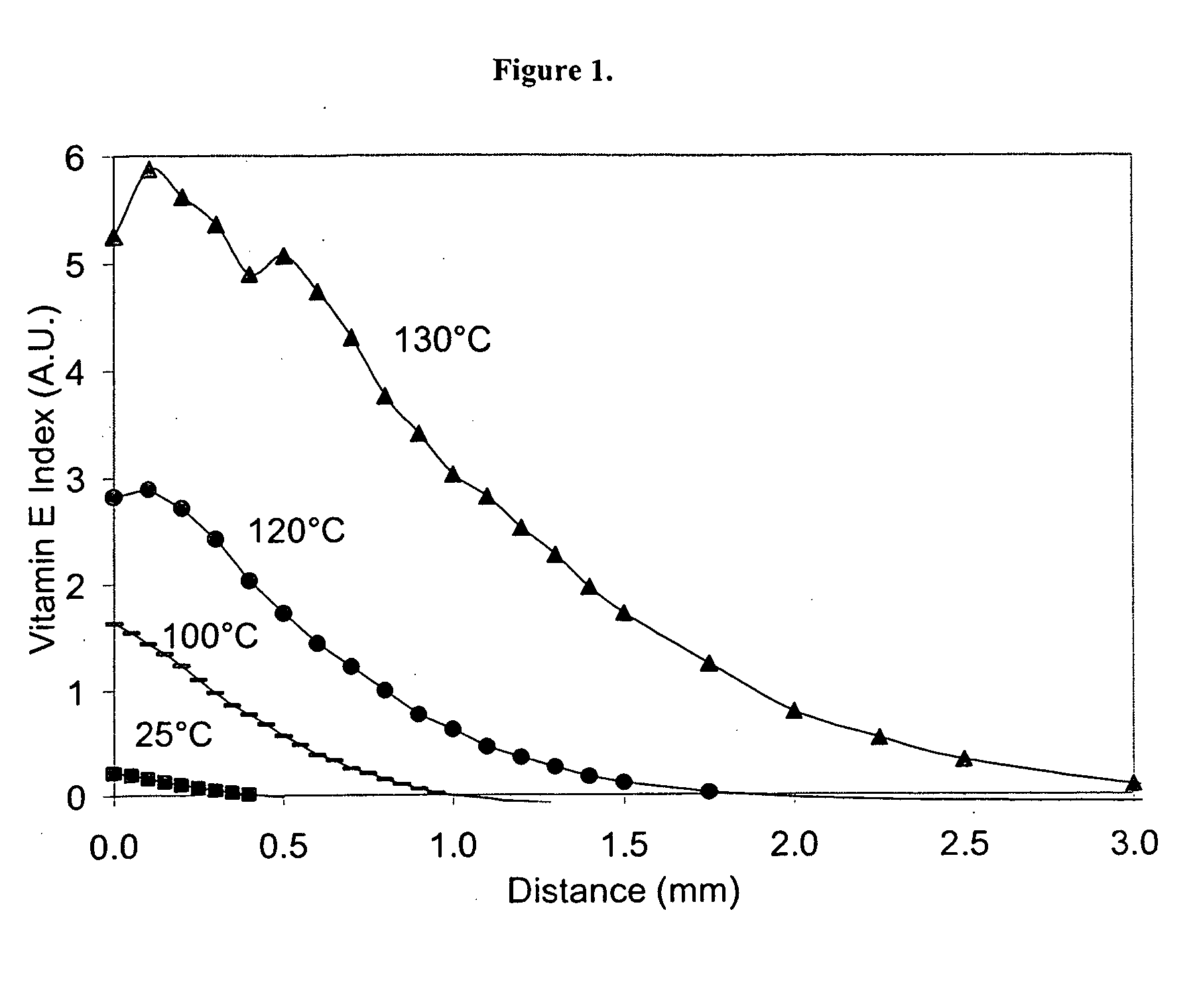

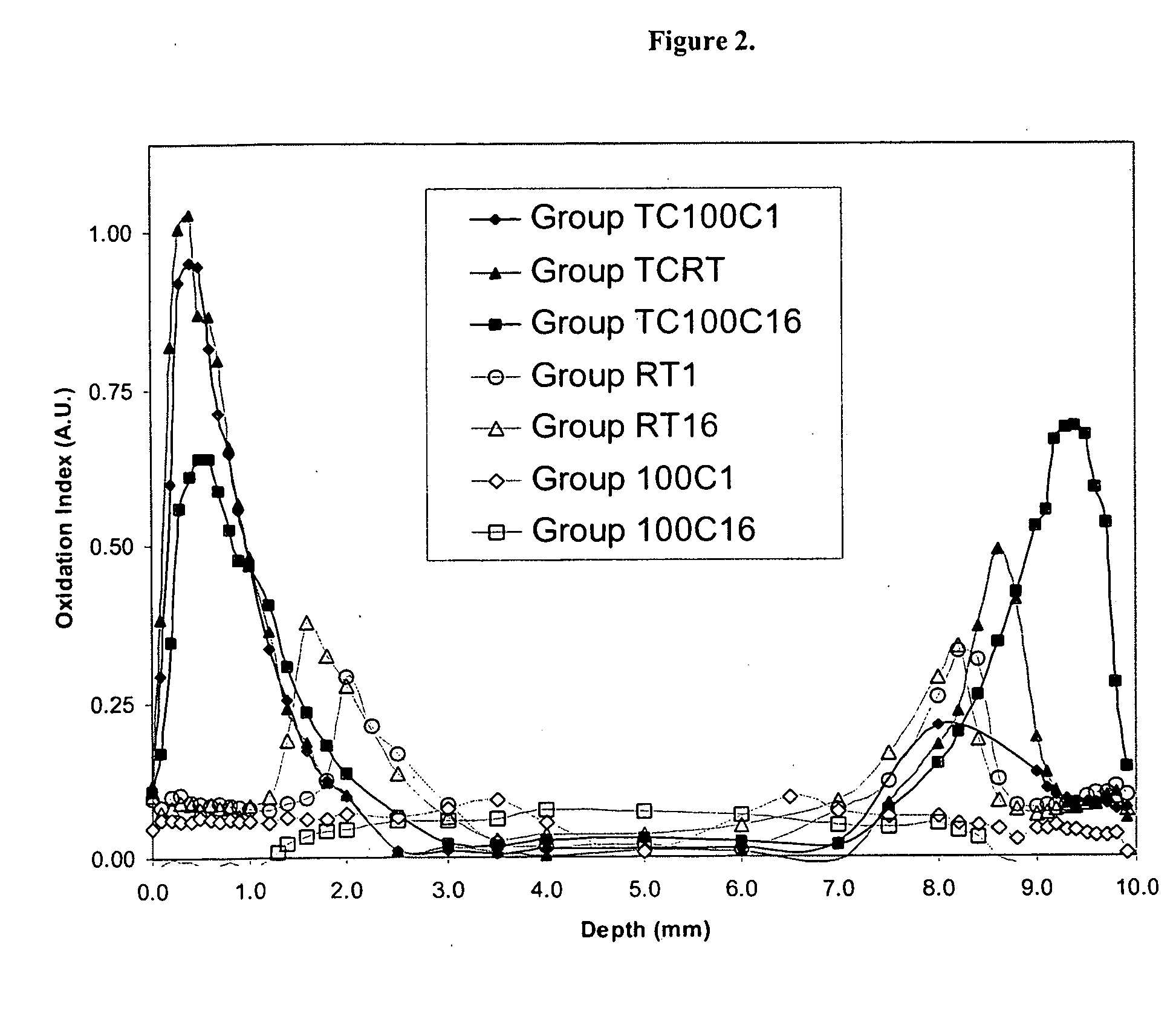

The present invention relates to methods for making oxidation resistant medical devices that comprise polymeric materials, for example, ultra-high molecular weight polyethylene (UHMWPE). The invention also provides methods of making antioxidant-doped medical implants, for example, doping of medical devices containing cross-linked UHMWPE with vitamin E by diffusion and materials used therein.

Owner:MURATOGLU ORHUN K +1

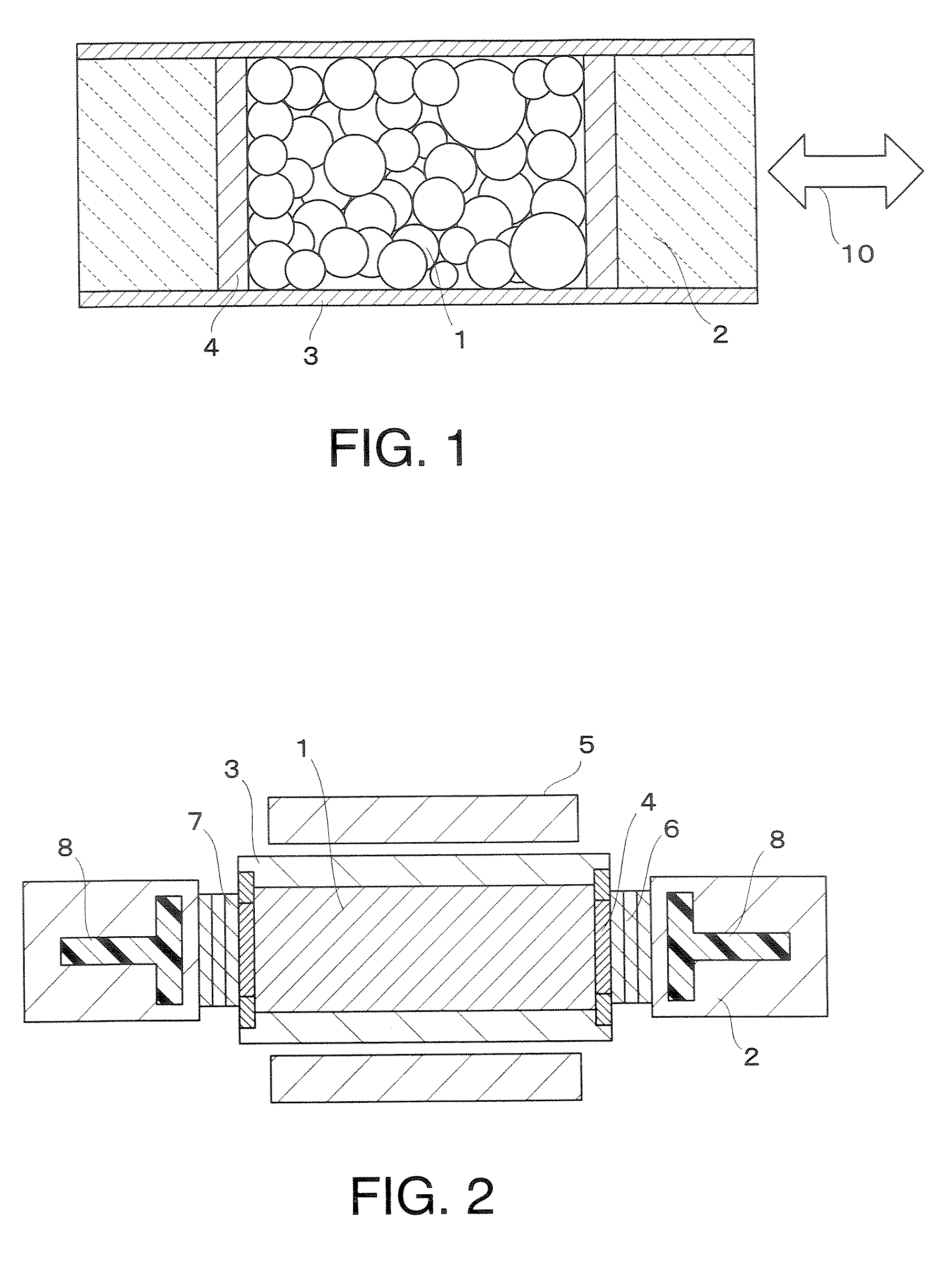

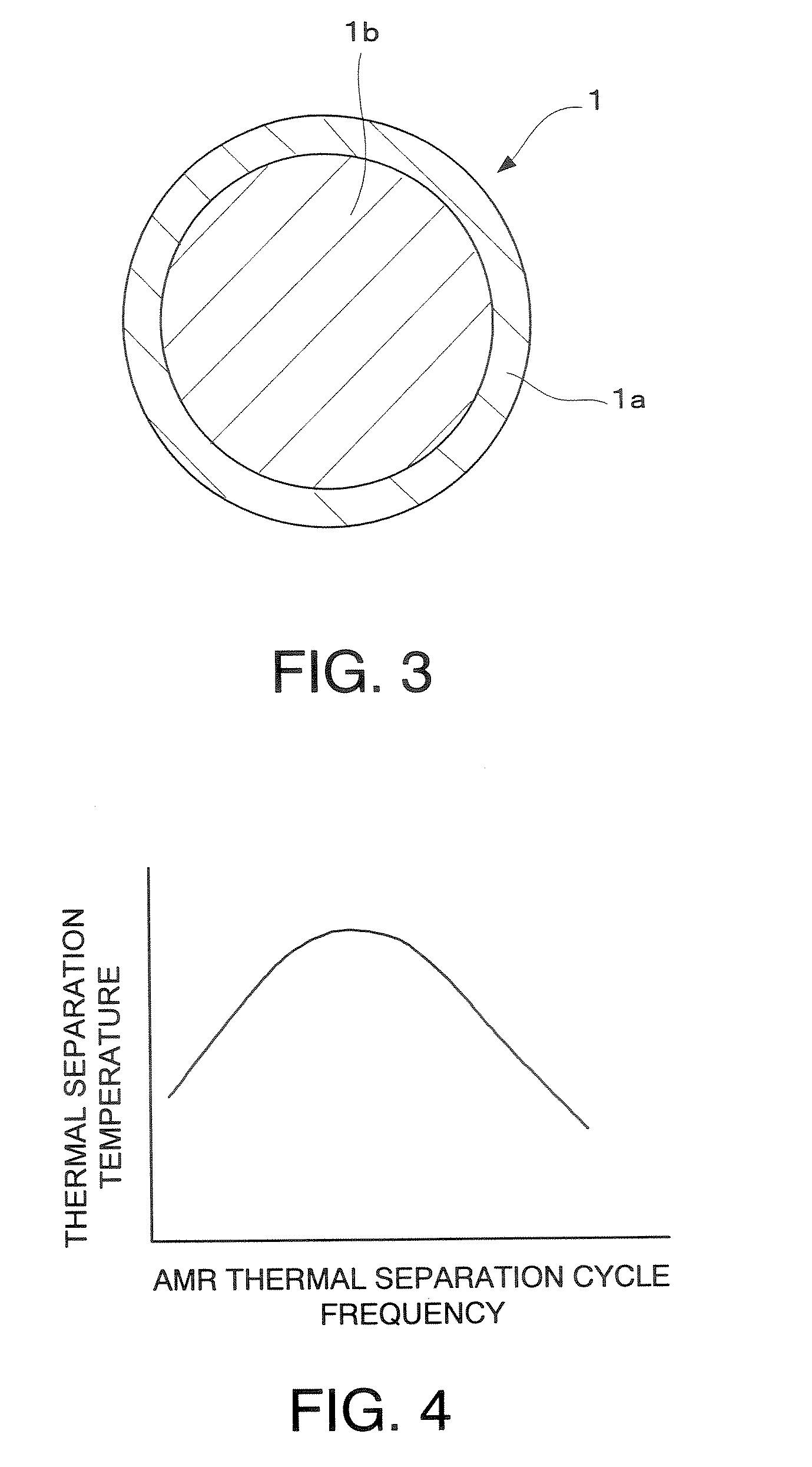

Magnetic refrigeration material and magnetic refrigeration device

InactiveUS20070220901A1Avoid Heat Exchange EfficiencyImprove heat transfer efficiencyTransportation and packagingEnergy efficient heating/coolingOxidation resistantMagnetic refrigeration

A magnetic refrigeration material has magnetic material particles with a magnetocaloric effect and an oxidation-resistant film formed on the surfaces of the magnetic material particles.

Owner:KK TOSHIBA

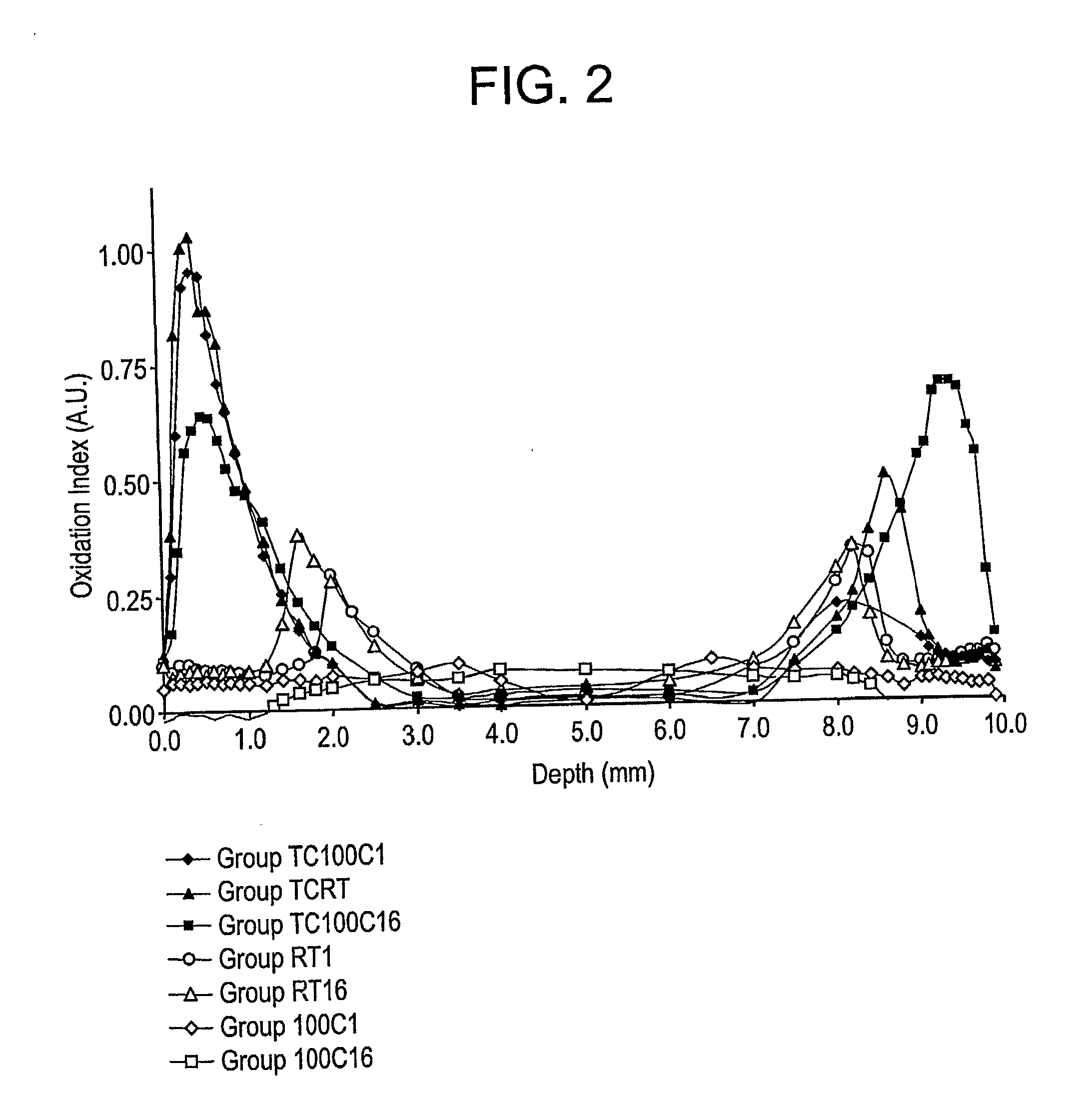

Oxidation-resistant and wear-resistant polyethylenes for human joint replacements and methods for making them

InactiveUS20070293647A1Improve wear resistanceImprove the immunitySurgeryPackage sterilisationPresent methodWear resistant

The present invention presents methods for making oxidation-resistant and wear-resistant polyethylenes and medical implants made therefrom. Preferably, the implants are components of prosthetic joints, e.g., a bearing component of an artificial hip or knee joint. The resulting oxidation-resistant and wear-resistant polyethylenes and implants are also disclosed.

Owner:THE ORTHOPAEDIC HOSPITAL

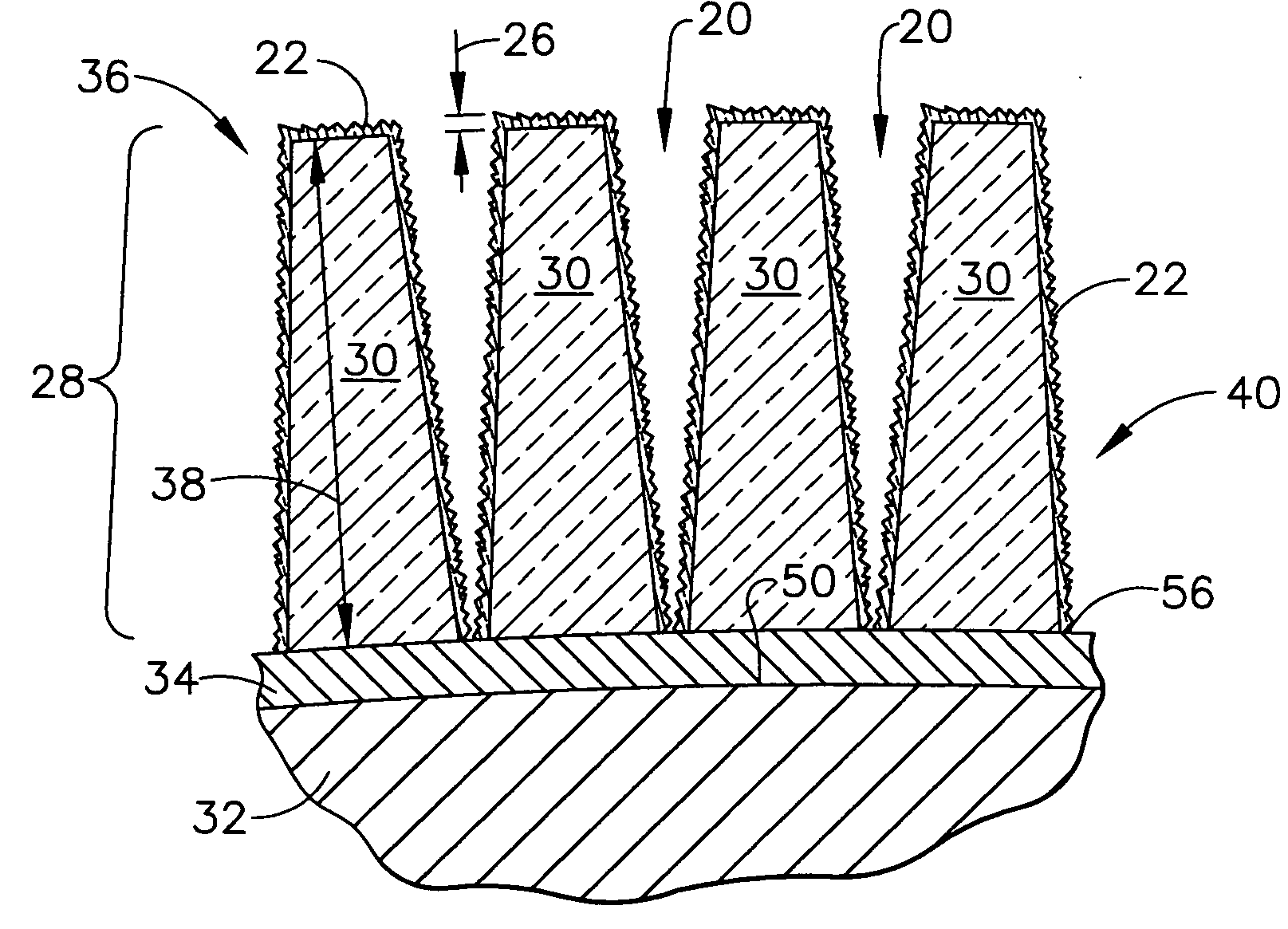

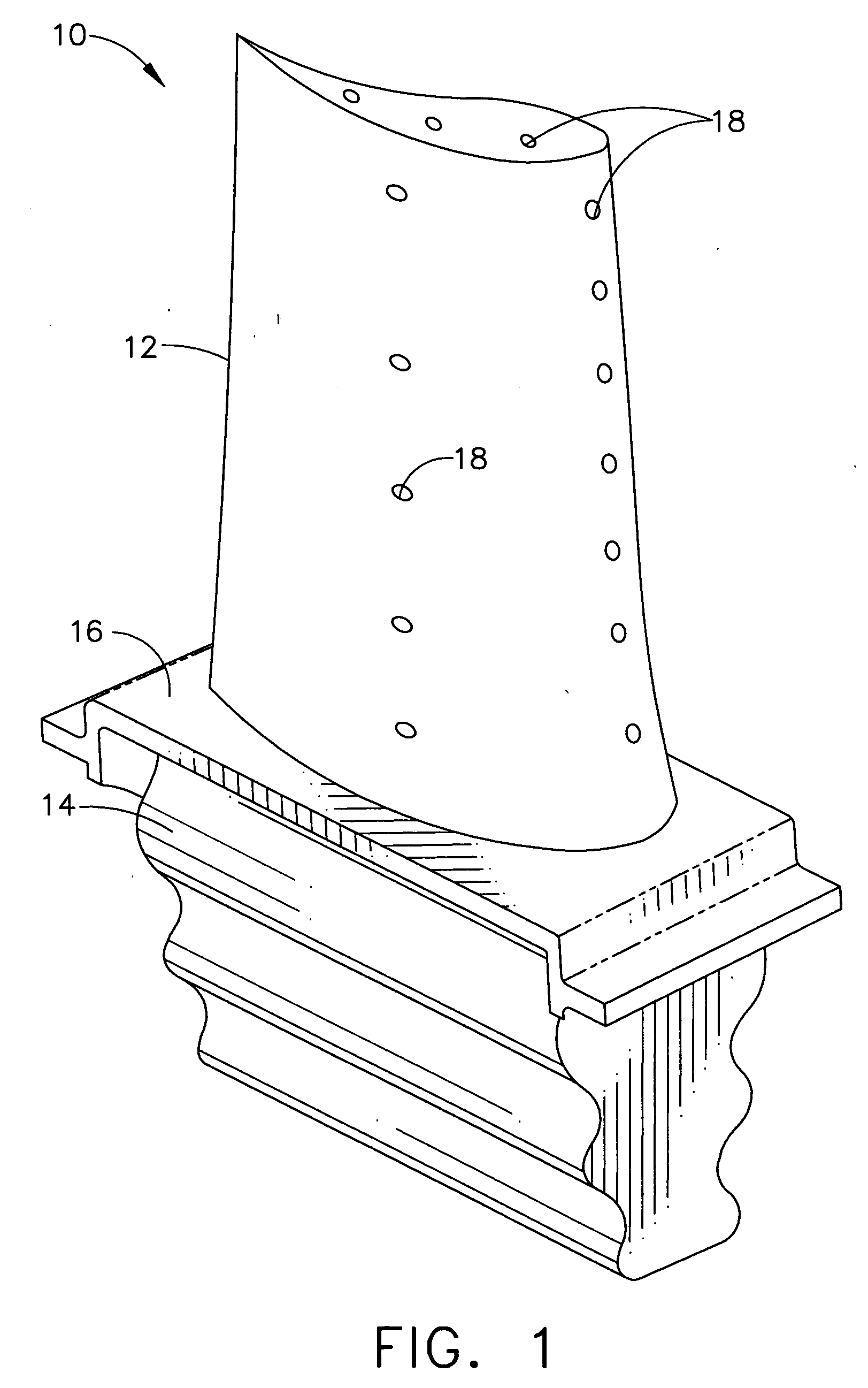

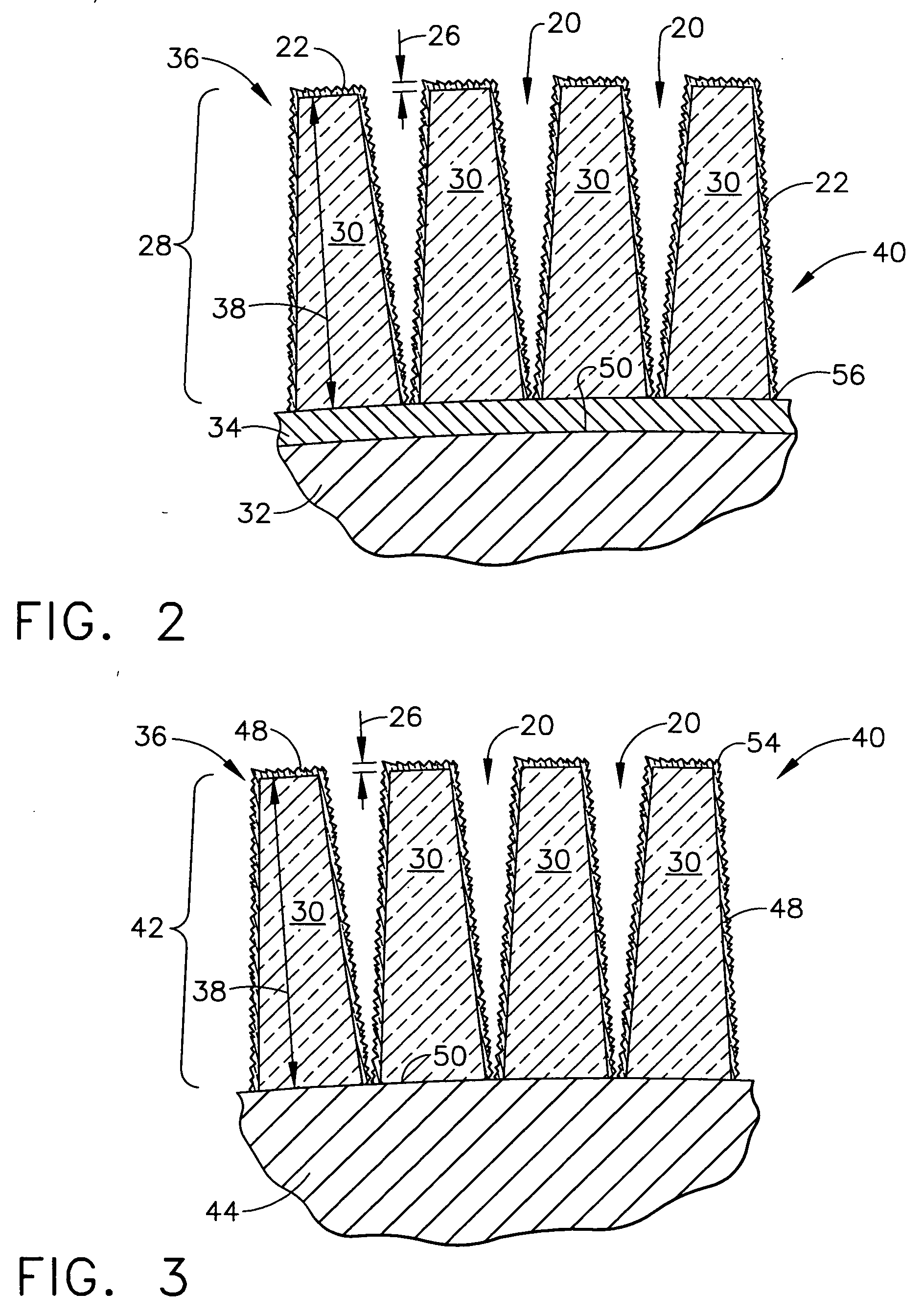

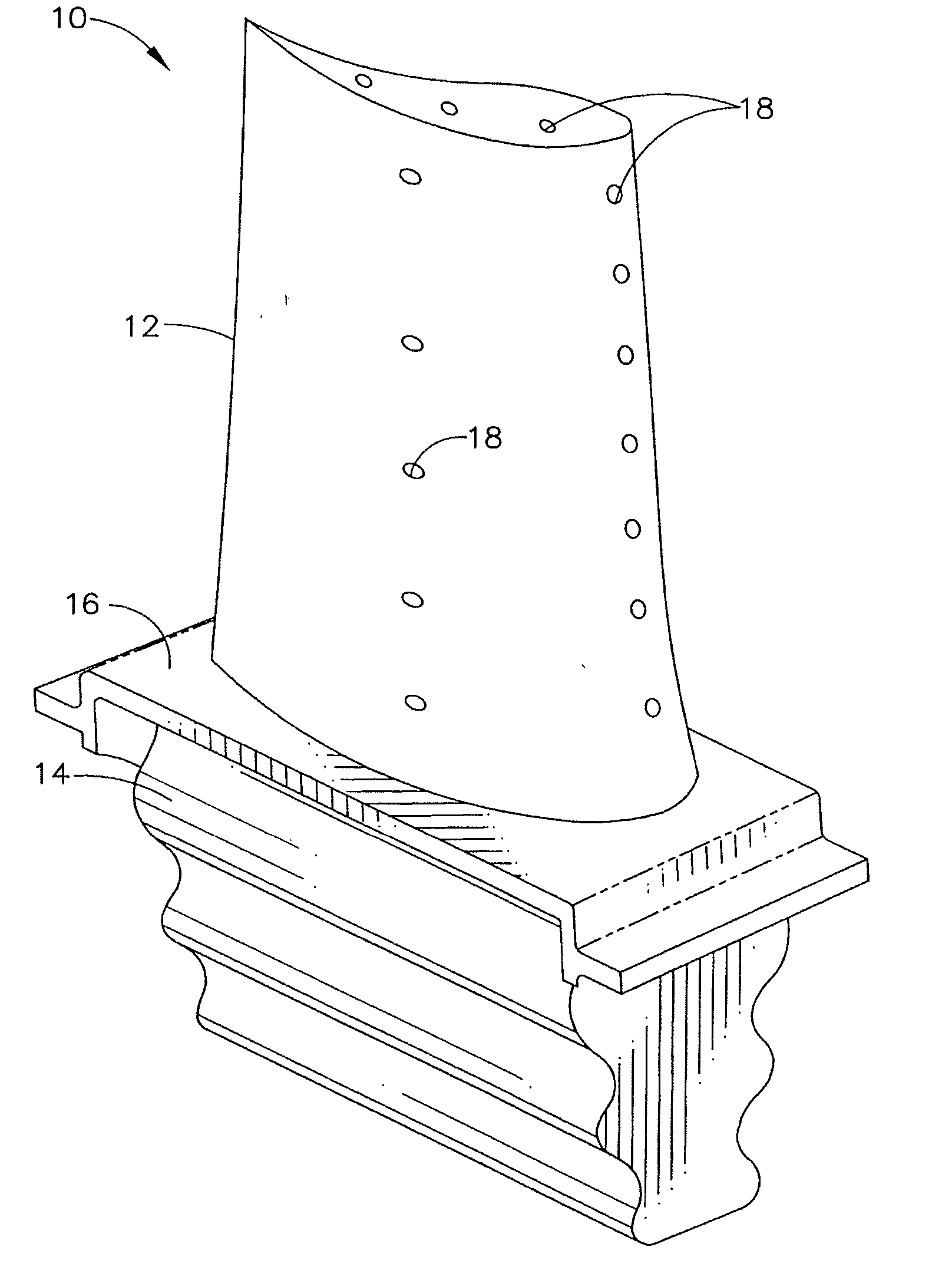

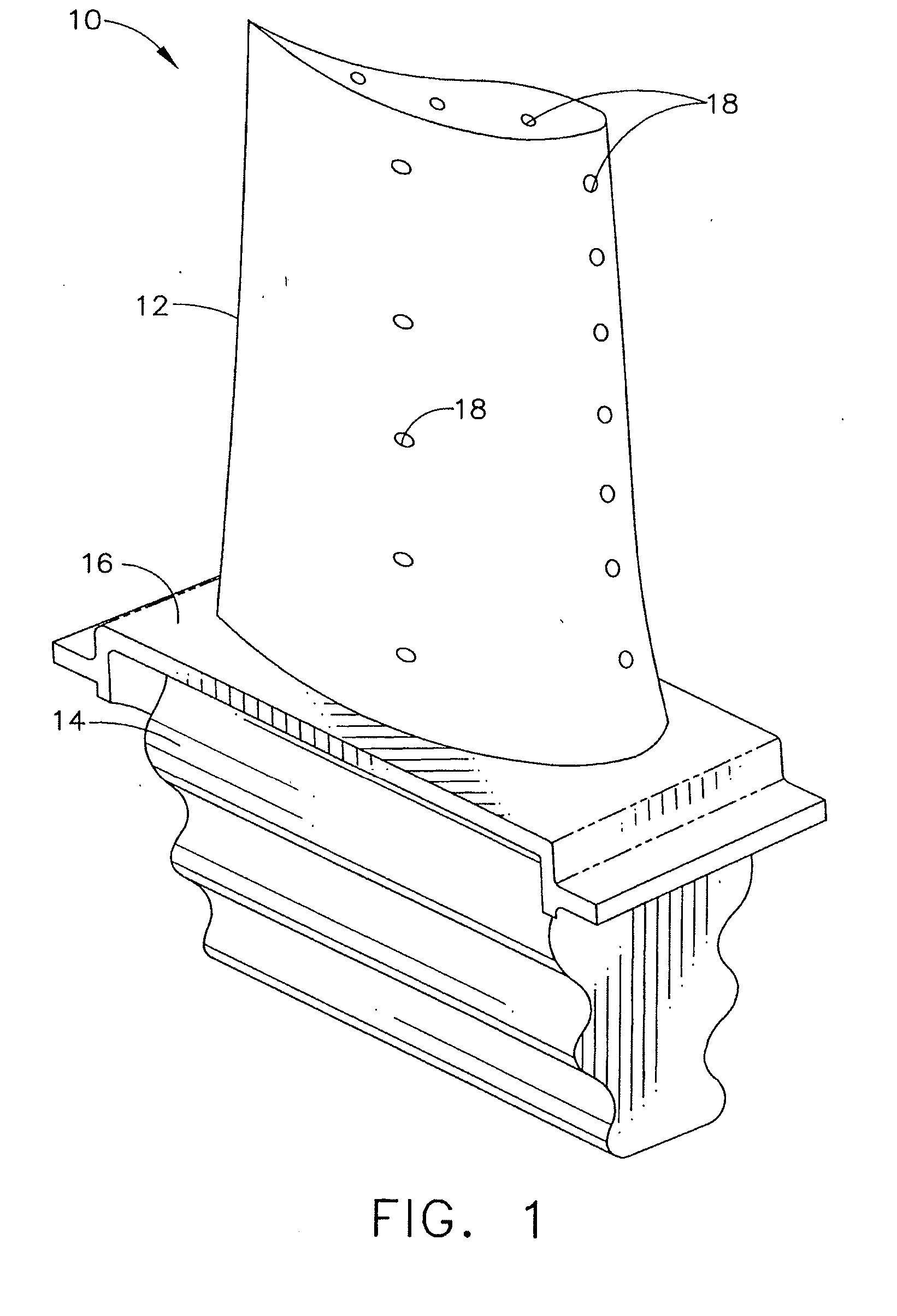

Atomic layer deposition for turbine components

A method and superalloy component for depositing a layer of material onto gas turbine engine components by atomic layer deposition. A superalloy component may have a ceramic thermal barrier coating on at least a portion of its surface, comprising a superalloy substrate and a bonding coat; and aluminum oxide (Al2O3) layer may be deposited on top of an yttria-stabilized zirconia layer and form a bonding coat by atomic layer deposition. The yttria-stabilized zirconia layer may have a plurality of micron sized gaps extending from the top surface of the ceramic coating towards the substrate and defining a plurality of columns of the yttria-stabilized zirconia layer. Also, atomic layer deposition may be used to lay an aluminum oxide (Al2O3) layer over a tantalum oxide (Ta2O5) layer on a silicon-based substrate. Using atomic layer deposition to coat the gas turbine engine components permits conformal coating of the columnar surface to permit gap expansion and contraction without sintering of the columnar surface or spalling of the coating, and form an oxidation resistant bonding coat.

Owner:HONEYWELL INT INC

Atomic layer deposition for turbine components

A method and superalloy component for depositing a layer of material onto gas turbine engine components by atomic layer deposition. A superalloy component may have a ceramic thermal barrier coating on at least a portion of its surface, comprising a superalloy substrate and a bonding coat; and aluminum oxide (Al2O3) layer may be deposited on top of an yttria-stabilized zirconia layer and form a bonding coat by atomic layer deposition. The yttria-stabilized zirconia layer may have a plurality of micron sized gaps extending from the top surface of the ceramic coating towards the substrate and defining a plurality of columns of the yttria-stabilized zirconia layer. Also, atomic layer deposition may be used to lay an aluminum oxide (Al2O3) layer over a tantalum oxide (Ta2O5) layer on a silicon-based substrate. Using atomic layer deposition to coat the gas turbine engine components permits conformal coating of the columnar surface to permit gap expansion and contraction without sintering of the columnar surface or spalling of the coating, and form an oxidation resistant bonding coat.

Owner:HONEYWELL INT INC

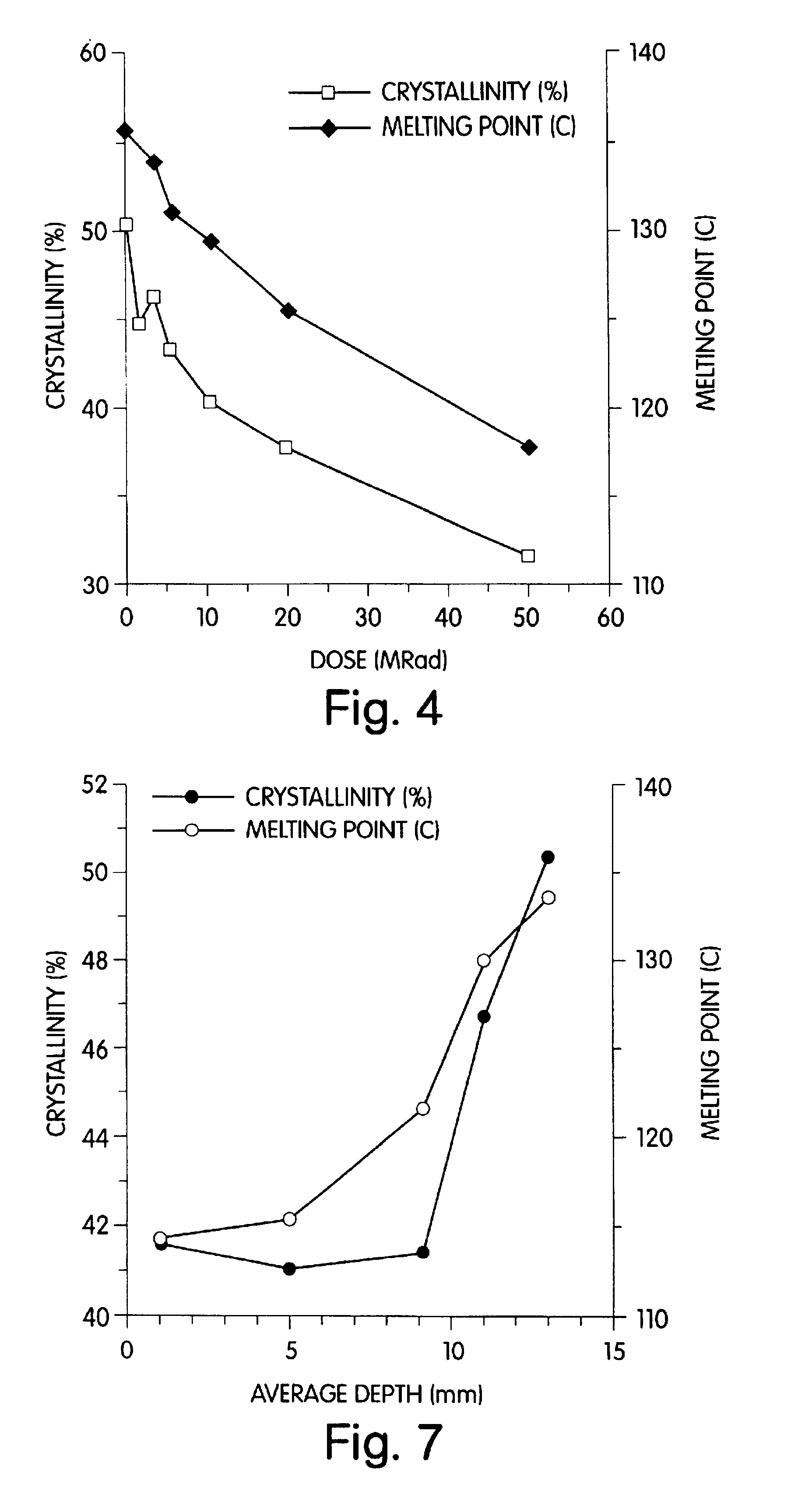

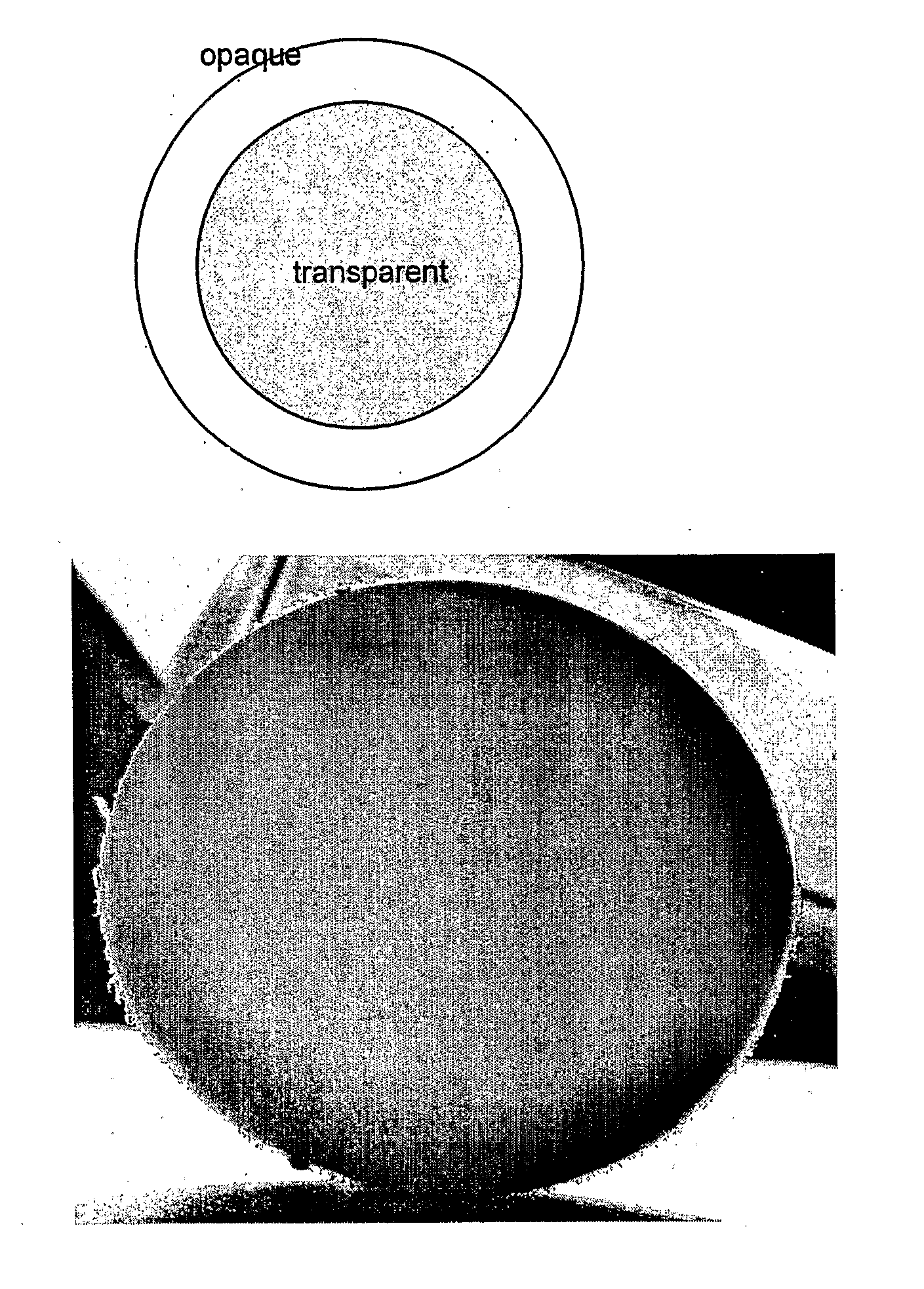

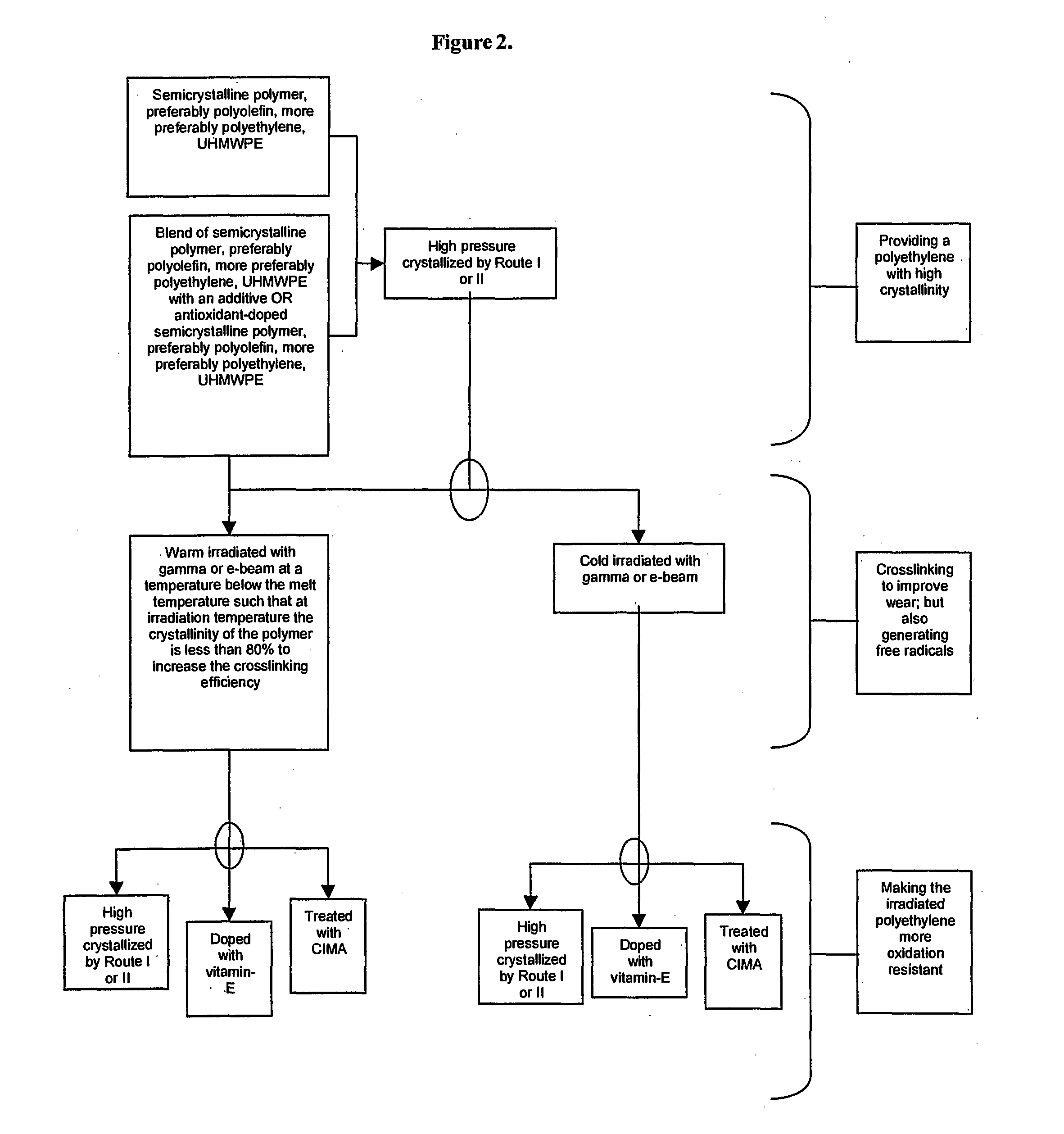

Highly Crystalline Cross-Linked Oxidation-Resistant Polyethylene

ActiveUS20070265369A1High crystallinityImprove the immunityPowder deliveryImpression capsCrystallographyCross-link

The present invention relates to methods for making highly crystalline cross-linked polymeric material, for example, highly crystalline cross-linked ultra-high molecular weight polyethylene (UHMWPE). The invention also provides methods of making antioxidant-doped highly crystalline cross-linked polymeric material using high pressure and high temperature crystallization processes, medical implants made thereof, and materials used therein.

Owner:THE GENERAL HOSPITAL CORP

Methods for making oxidation resistant polymeric material

The present invention relates to methods for making oxidation resistant medical devices that comprise polymeric materials, for example, ultra-high molecular weight polyethylene (UHMWPE). The invention also provides methods of making antioxidant-doped medical implants, for example, doping of medical devices containing cross-linked UHMWPE with vitamin E by diffusion, post-doping annealing, and materials used therein.

Owner:THE GENERAL HOSPITAL CORP +1

Methods for making oxidation resistant polymeric material

InactiveUS20050194722A1Improve uniformityFacilitated DiffusionStentsConductive materialCross-linkAntioxidant

The present invention relates to methods for making oxidation resistant medical devices that comprise polymeric materials, for example, ultra-high molecular weight polyethylene (UHMWPE). The invention also provides methods of making antioxidant-doped medical implants, for example, doping of medical devices containing cross-linked UHMWPE with vitamin E by diffusion and materials used therein.

Owner:CAMBRIDGE POLYMER GROUP

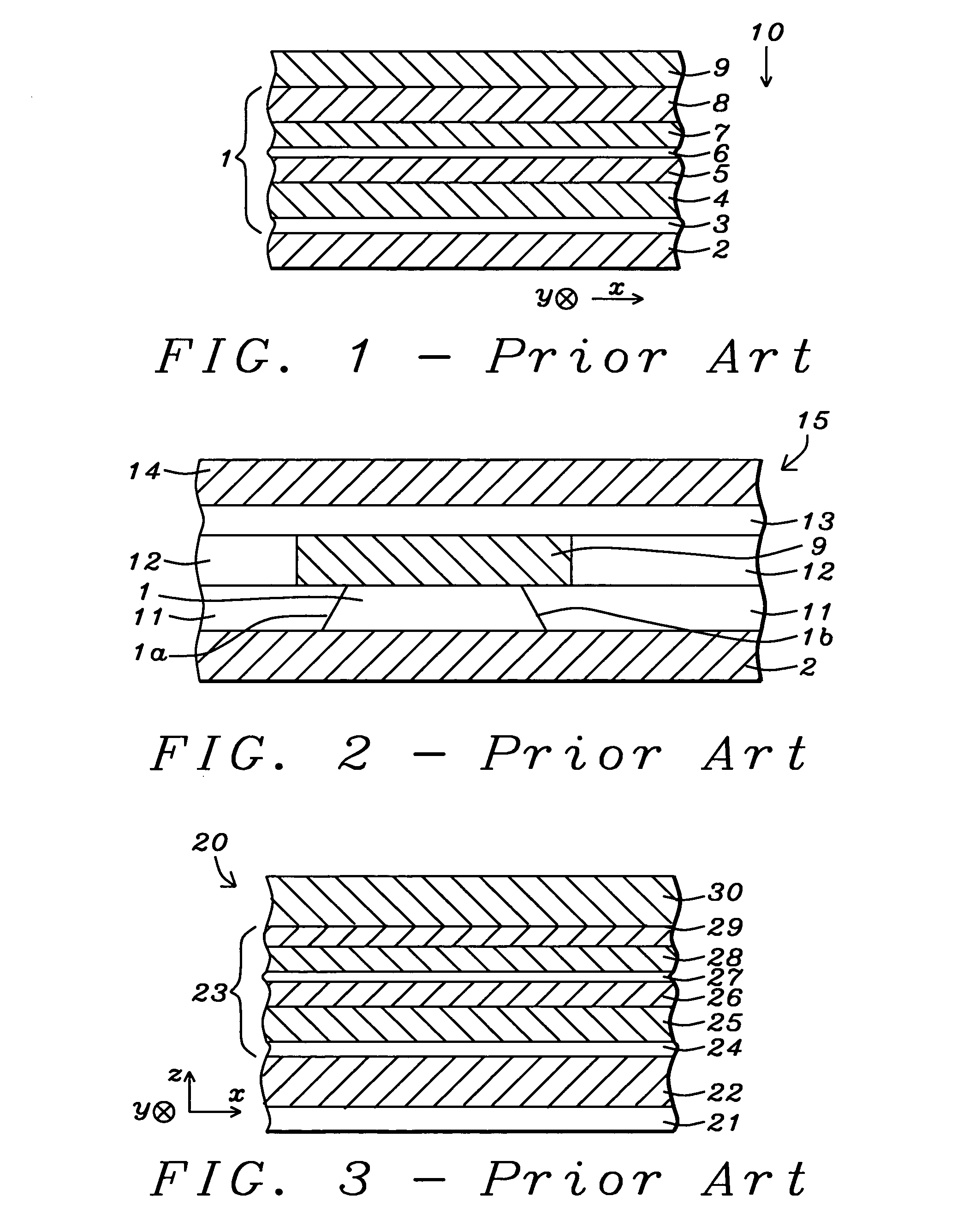

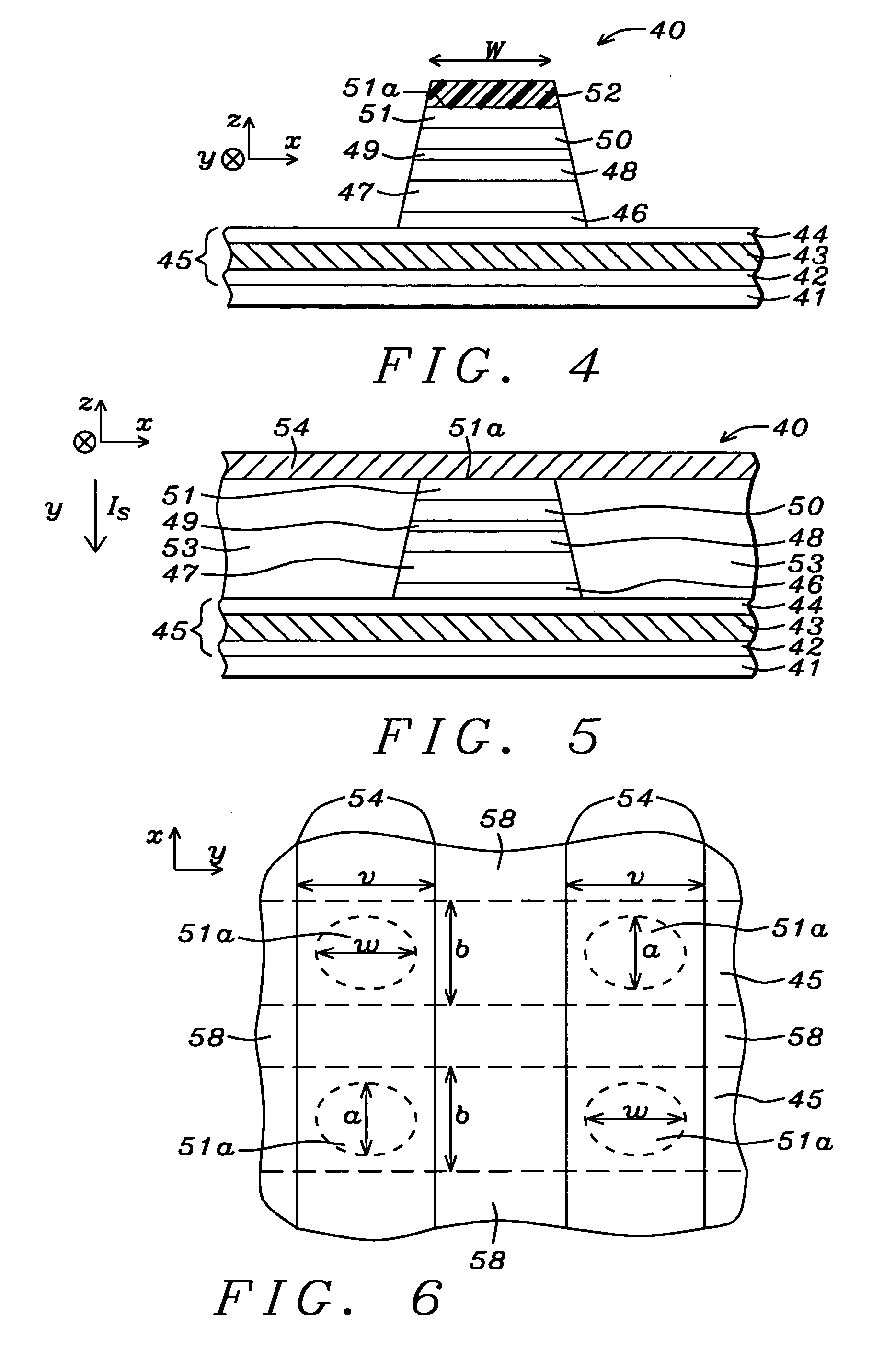

Novel underlayer for high performance magnetic tunneling junction MRAM

ActiveUS20060002184A1High resistivityConsistent growthNanomagnetismMagnetic measurementsOptoelectronicsHigh resistivity

An MRAM structure is disclosed in which the bottom electrode has an amorphous TaN capping layer to consistently provide smooth and dense growth for AFM, pinned, tunnel barrier, and free layers in an overlying MTJ. Unlike a conventional Ta capping layer, TaN is oxidation resistant and has high resistivity to avoid shunting of a sense current caused by redeposition of the capping layer on the sidewalls of the tunnel barrier layer. Alternatively, the α-TaN layer is the seed layer in the MTJ. Furthermore, the seed layer may be a composite layer comprised of a NiCr, NiFe, or NiFeCr layer on the α-TaN layer. An α-TaN capping layer or seed layer can also be used in a TMR read head. An MTJ formed on an α-TaN capping layer has a high MR ratio, high Vb, and a RA similar to results obtained from MTJs based on an optimized Ta capping layer.

Owner:APPLIED SPINTRONICS +1

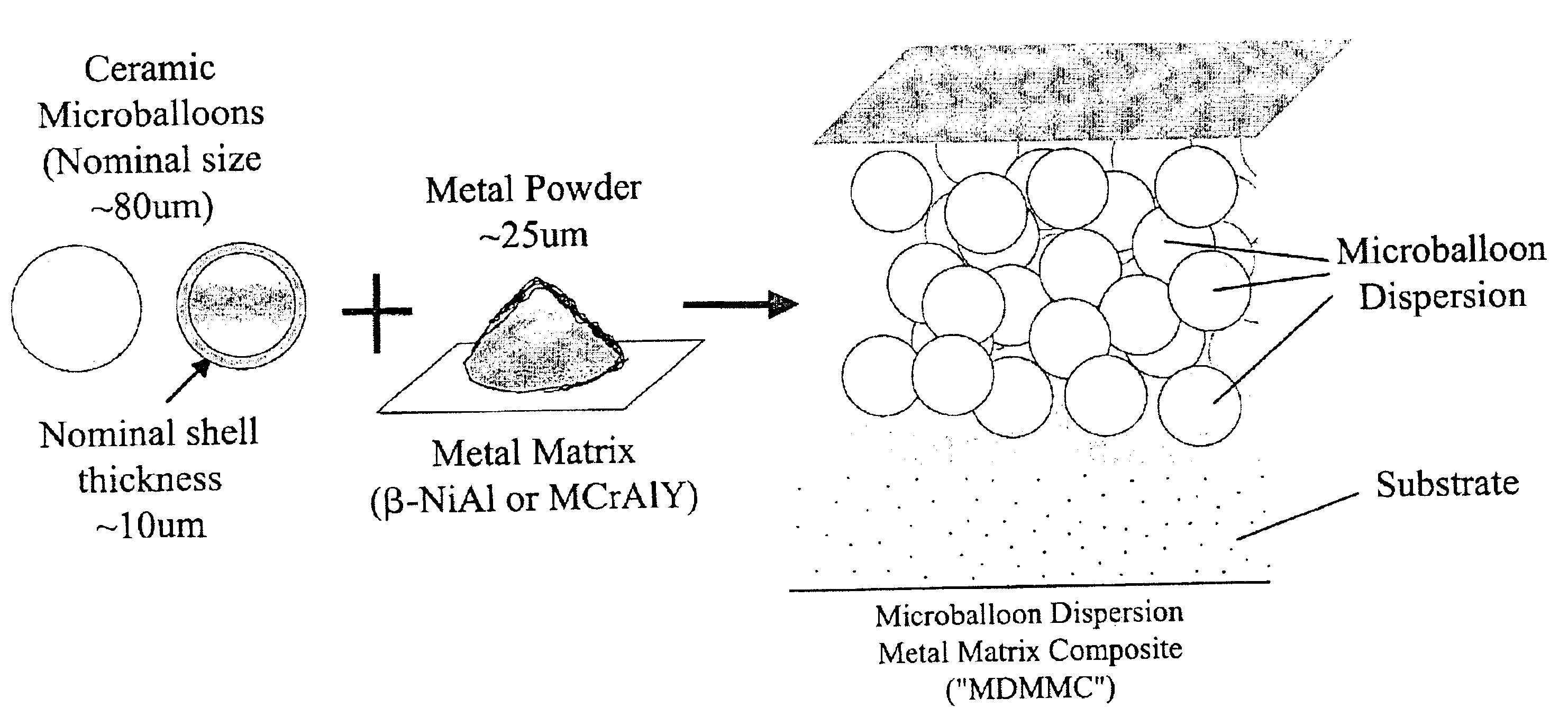

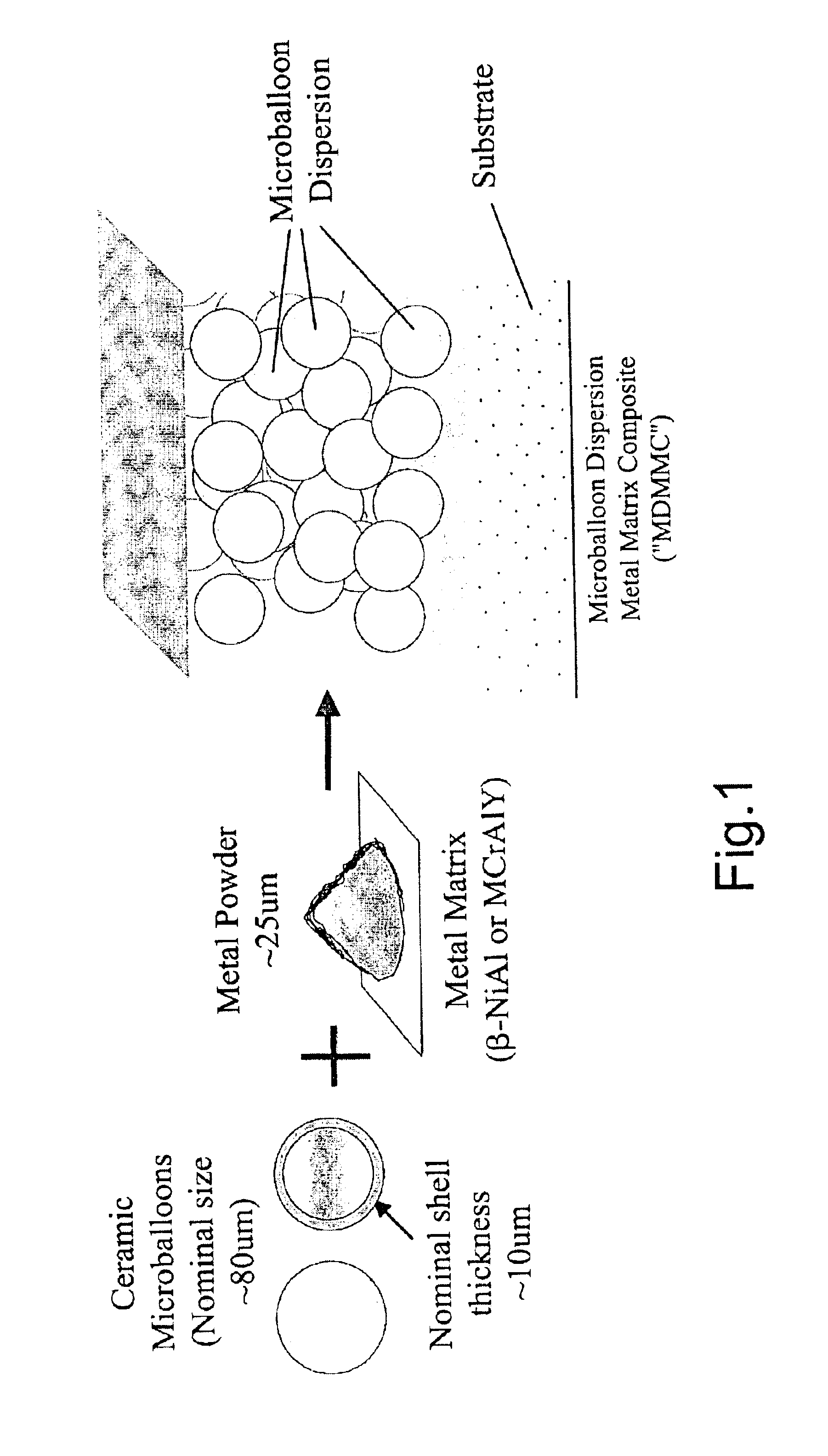

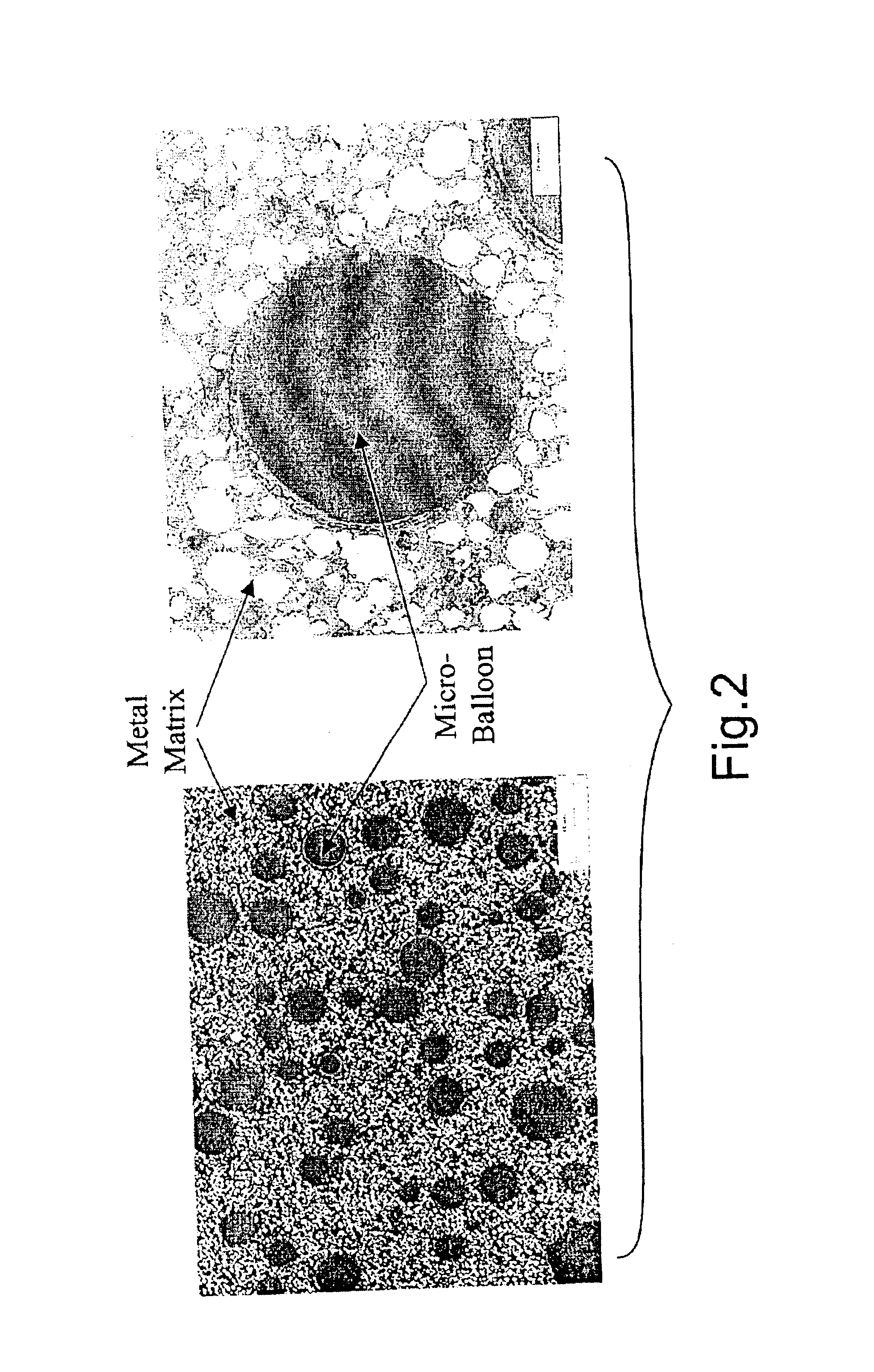

High temperature, oxidation-resistant abradable coatings containing microballoons and method for applying same

InactiveUS6916529B2Effective timeReducing hot gas leakageMolten spray coatingPropellersThermal sprayingMicrosphere

An abradable coating composition for use on shrouds in gas turbine engines or other hot gas path metal components exposed to high temperatures containing an initial porous coating phase created by adding an amount of inorganic microspheres, preferably alumina-ceramic microballoons, to a base metal alloy containing high Al, Cr or Ti such as β-NiAl or, alternatively, MCrAlY that serves to increase the brittle nature of the metal matrix, thereby increasing the abradability and oxidation resistance of the coating at elevated temperatures. Coatings having a total open and closed porosity of between 20% and 55% by volume due to the presence of ceramic microballoons ranging in size from about 10 microns to about 200 microns have been found to exhibit excellent abradability for applications involving turbine shroud coatings. An abradable coating thickness in the range of between 40 and 60 ml provides improved performance for turbine shrouds exposed to gas temperatures between 1380° F. and 1800° F. Abradable coatings in accordance with the invention can be used for new metal components or to repair existing equipment. The coatings can be applied to the metal shroud using thermal spray, processes that integrate sintering and brazing, or direct write techniques.

Owner:GENERAL ELECTRIC CO

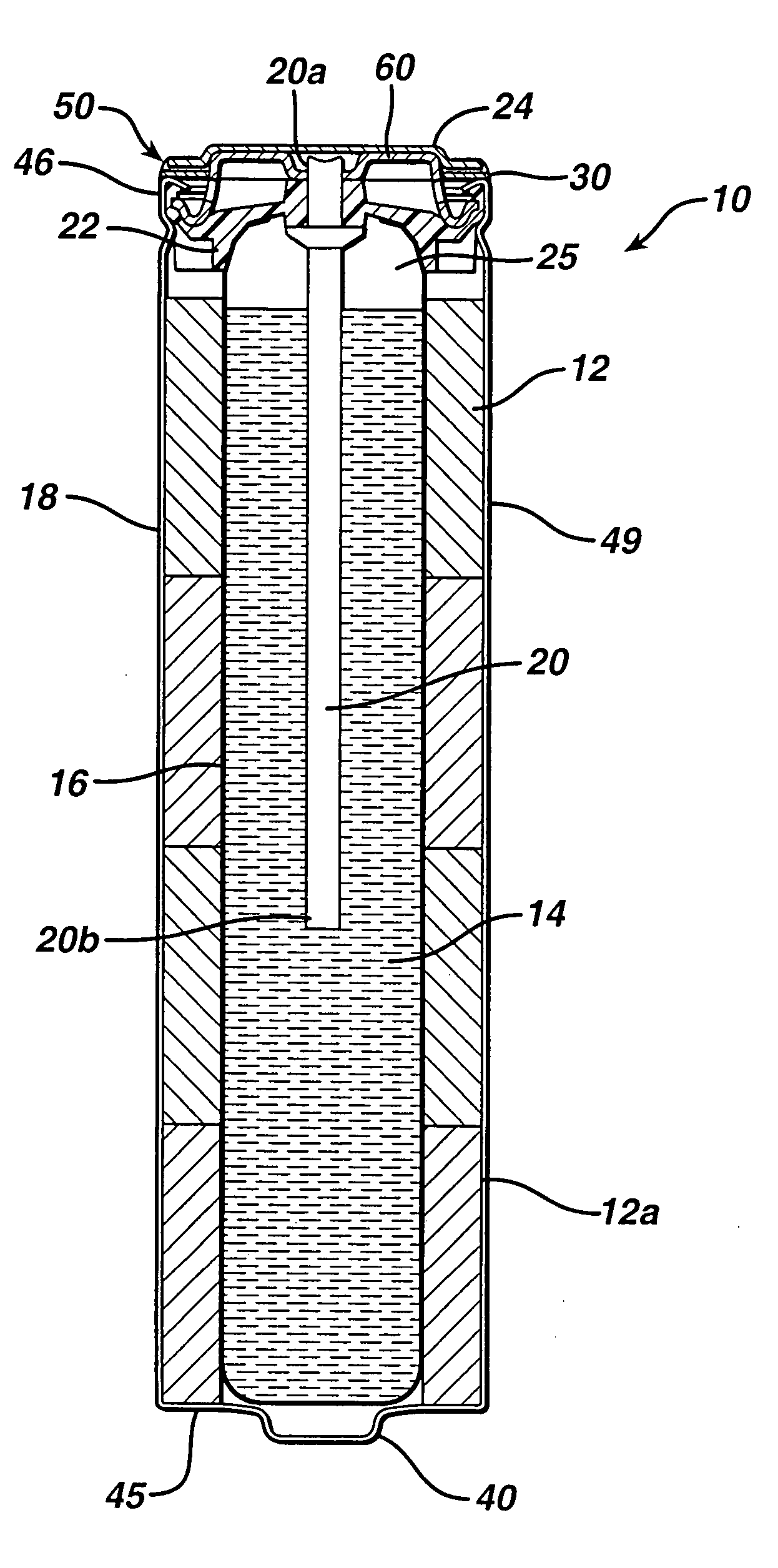

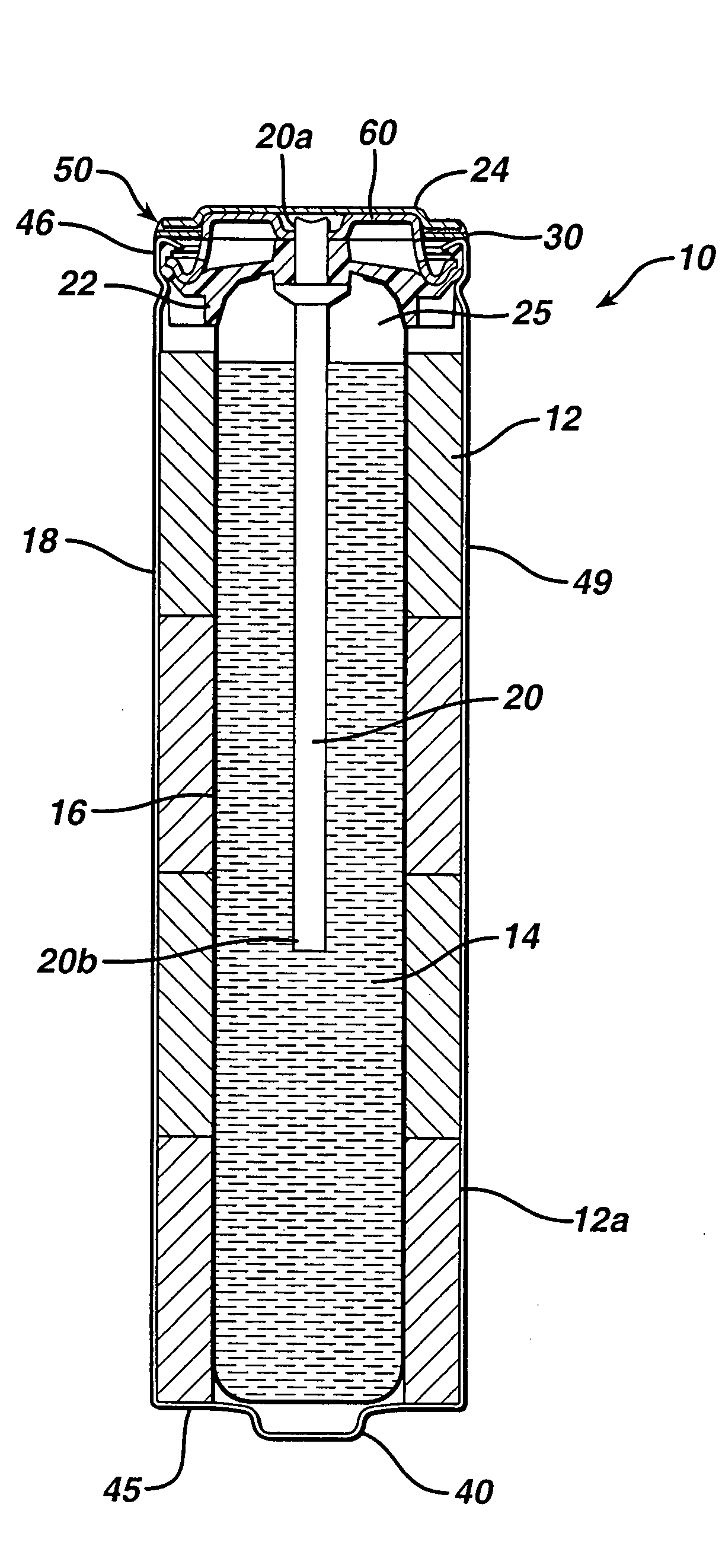

Alkaline battery including nickel oxyhydroxide cathode and zinc anode

InactiveUS20070248879A1Improve discharge performanceHigh capacity retentionActive material electrodesJackets/cases materialsConductive coatingZinc alloys

A primary alkaline battery includes a cathode including a nickel oxyhydroxide and an anode including zinc or zinc alloy particles. Performance of the nickel oxyhydroxide alkaline cell is improved by adding zinc fines to the anode and by including an oxidation resistant graphite in the cathode as well as in a conductive coating applied to the inside surface of the cell housing.

Owner:THE GILLETTE CO

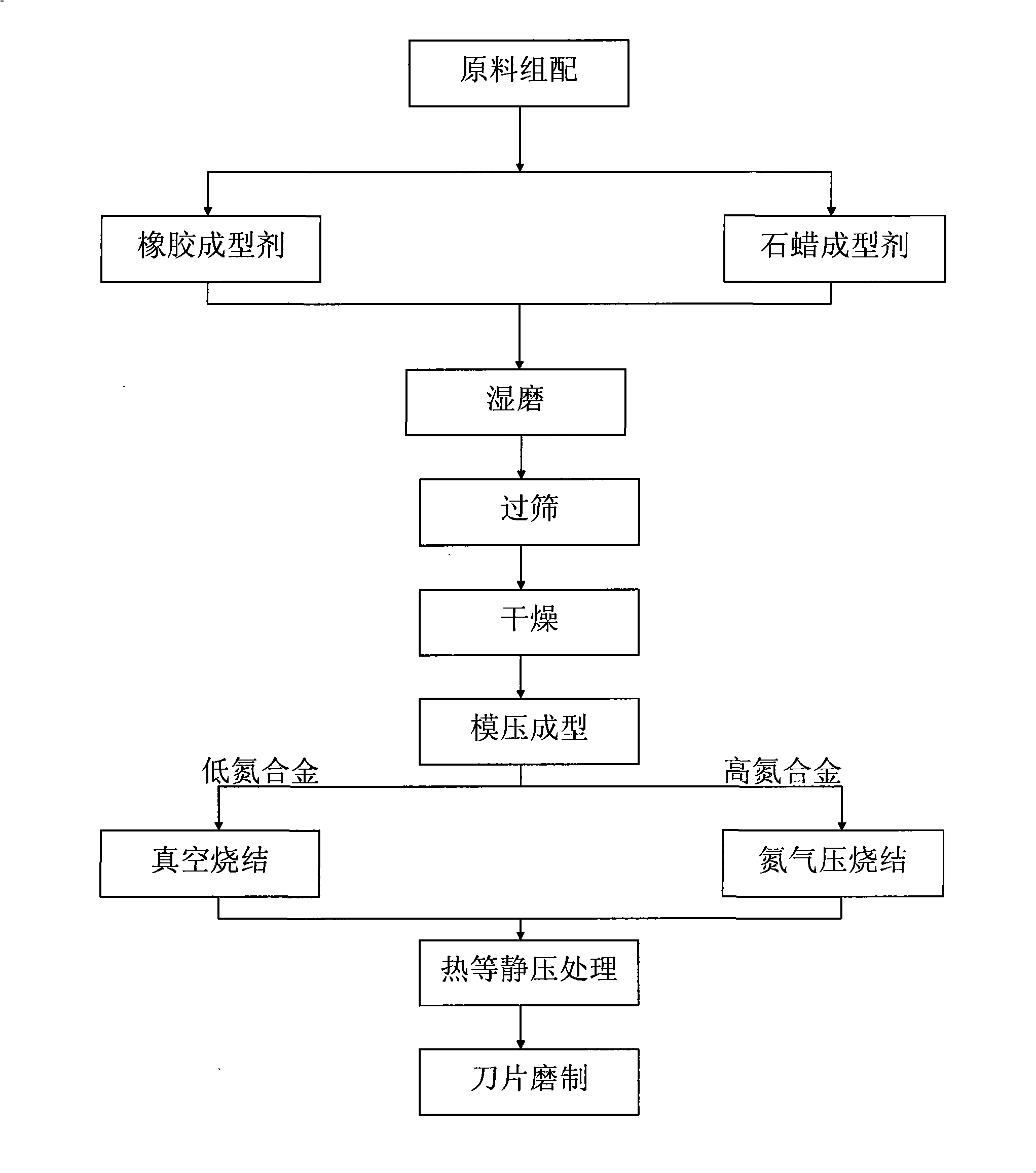

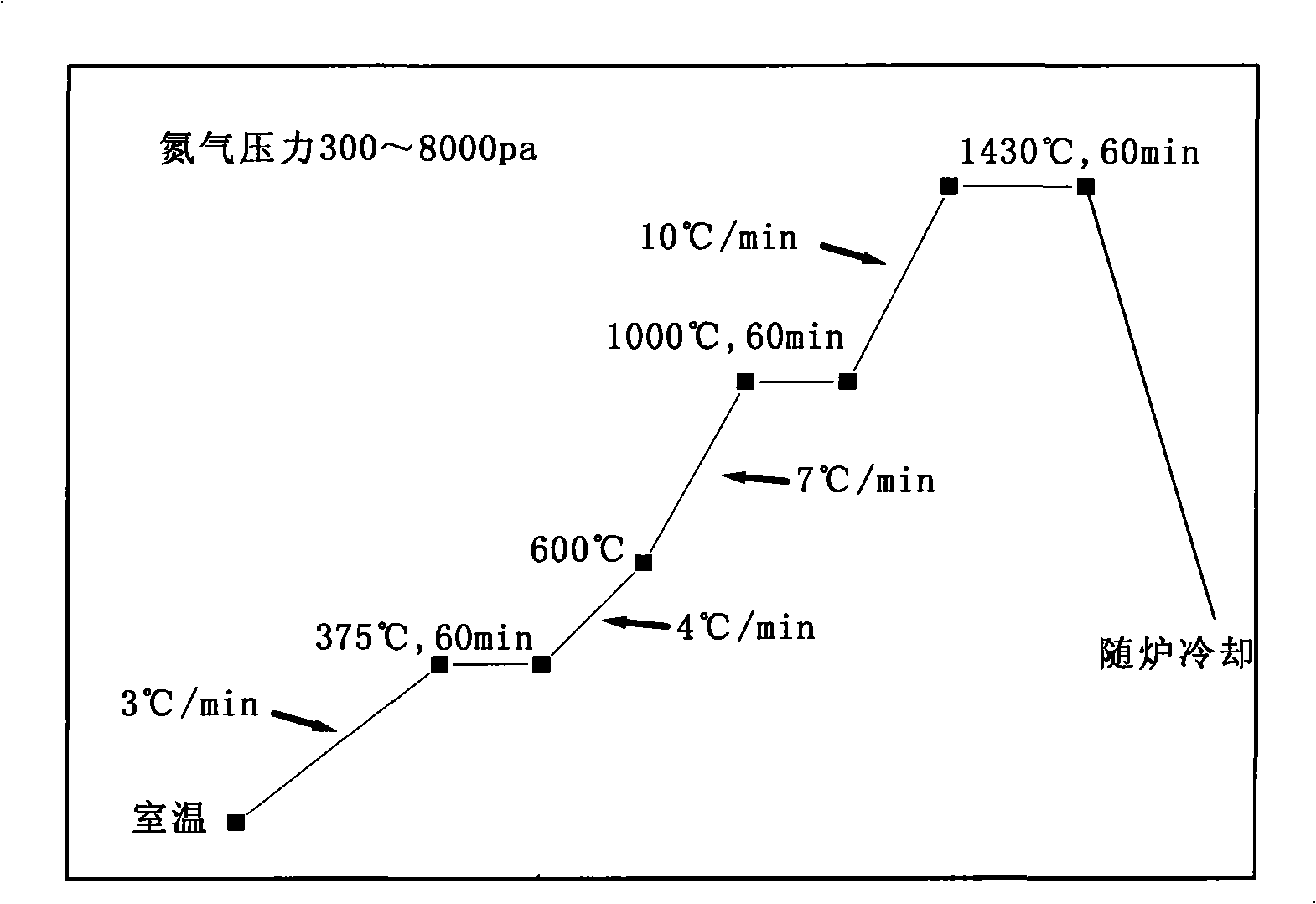

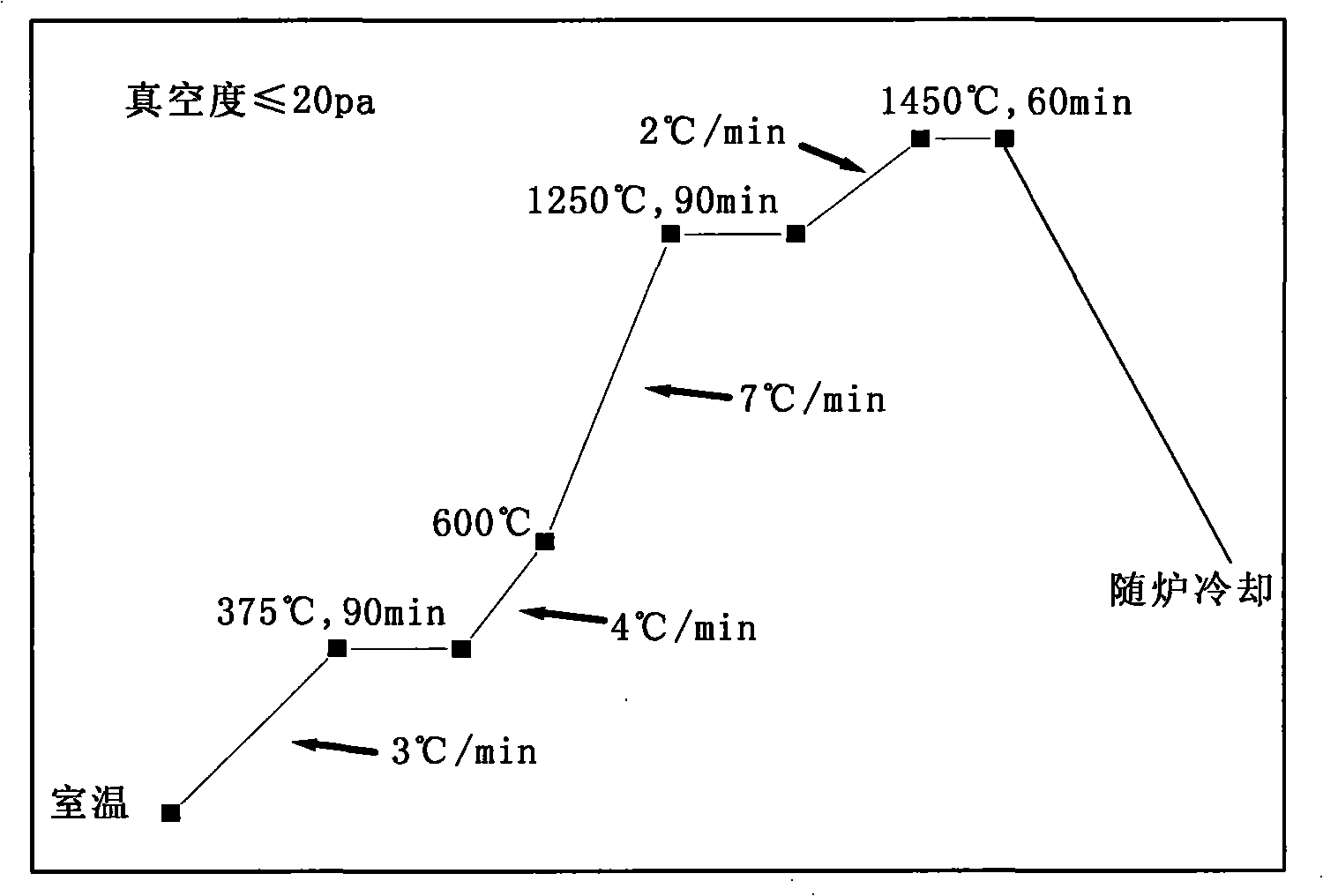

High-wear resistant Ti (C, N)-base ceramet tool bit and preparation thereof

InactiveCN101302595AReliable guarantee of high nitrogen-carbon ratioReliable Guarantee of HardnessLow nitrogenWear resistant

The invention provides a high-abrasion Ti(C, N) based metal ceramic tool and a preparation thereof. The Ti(C, N) based metal ceramic tool uses Ni and Co as a binder phase, is added with at least one carbonitride of Ti(Cx, N1-x) or (TiC)x plus (TiN)1-x as a basic batch, and consists of at least one composition of WC, Mo2C, Co, Ni, ZrC, Cr3C2, VC, TaC and NbC, and the balance being Ti(Cx, N1-x) or (TiC)x plus (TiN)1-x, wherein, an X value for adding the carbonitride of the Ti(C, N) based metal ceramic tool is as follows: X is less than or equal to 0.5 and more than or equal to 0.4, or the X is more than 0.5 and less than or equal to 0.7. The Ti(C, N) based metal ceramic tool is prepared according to the content of nitrogen by nitrogen pressure sintering or vacuum sintering combined with hot isostatic pressing treatment, thereby preventing nitrogen from escaping during the process of sintering high-nitrogen alloy, so that the high-nitrogen-carbon ratio in matrix and material hardness can be reliably guaranteed, and anti-oxidative abrasion property and anti-diffusive abrasion property of the material can be obviously increased through adding slight ZrC, Cr3C2, VC and other carbides into the basic batch; meanwhile, compactability and buckling strength of a low-nitrogen alloy structure can be obviously improved through optimally distributing each composition and content. The Ti(C, N) based metal ceramic tool is widely suitable for high-speed cutting tools of medium-low carbon steel and low alloy steel.

Owner:HUNAN UNIV OF SCI & TECH

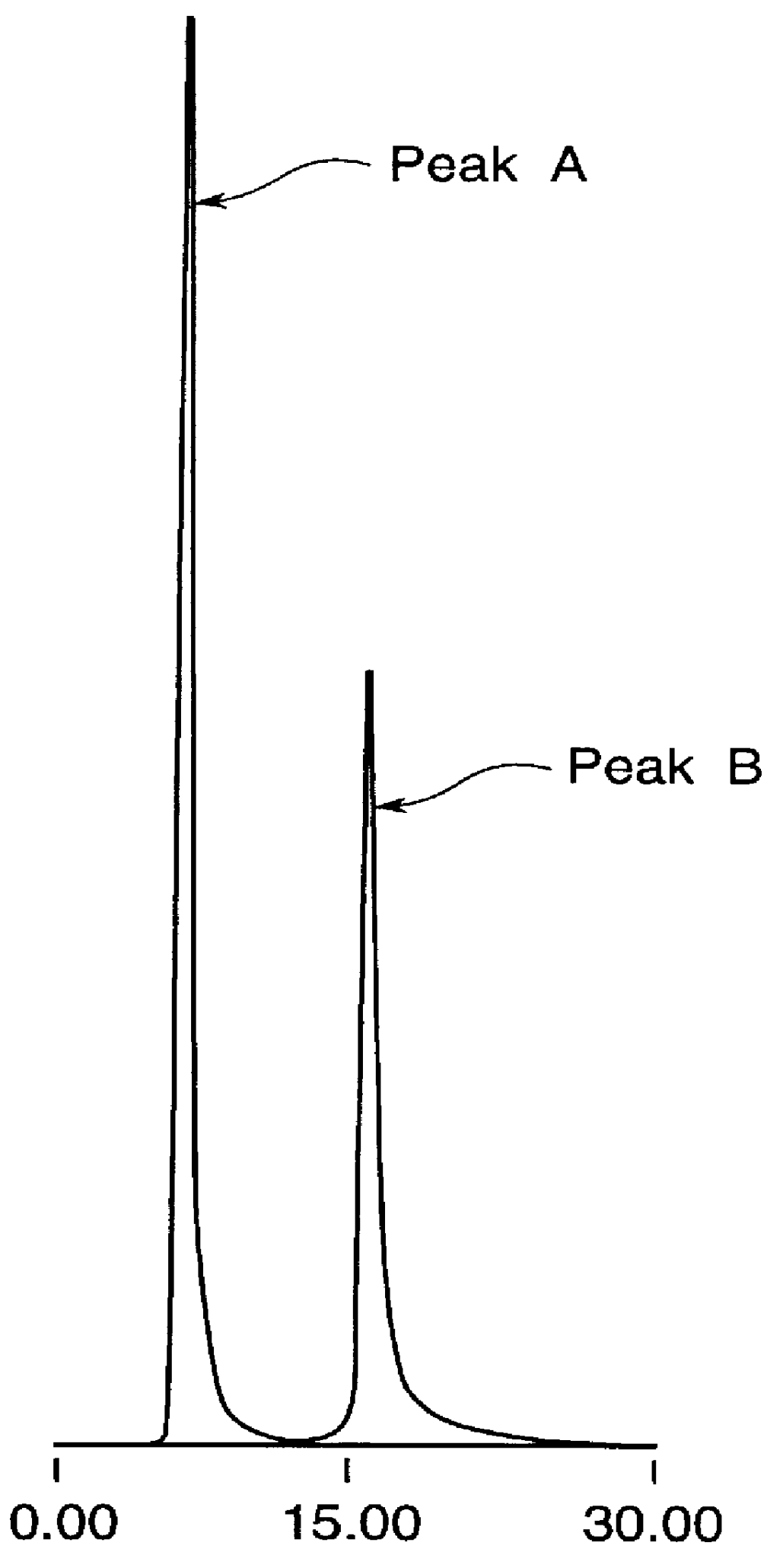

Highly purified tocopheryl phosphate, process for producing the same, analytical method therefor and cosmetic

InactiveUS6046181AGood water solubilityNo skin irritationOrganic active ingredientsCosmetic preparationsSolubilityCosmetic ingredient

Disclosed herein are a highly purified tocopheryl phosphate and / or a salt thereof (tocopheryl phosphates) wherein a P,P'-bistocopheryl hypophosphate and / or a salt thereof (P,P'-bistocopheryl diphoshates) is contained in a proportion of not higher than 3% by weight; a process for producing a highly purified tocopheryl phosphate and / or a salt thereof, which comprises the steps of reacting a tocopherol with an oxyphosphorus trihalide followed by treating with an acid or basic aqueous solution to thereby form tocopheryl phosphates (i) in which P,P'-bistocopheryl diphoshates (ii) formed as by-products are contained, hydrolyzing the P,P'-bistocopheryl diphoshates (ii) under acid condition, and, optionally, rendering the hydrolyzate neutral or basic under basic condition; and a method of analyzing tocopheryl phosphates, comprising analyzing a sample containing components (i) and (ii) with the use of a high-performance liquid chromatograph column packed with a gel of a polymethacrylate having, bonded thereto, long-chain alkyl groups. None or only an extremely minute amount of P,P'-bistocopheryl diphoshates are contained in the highly purified tocopheryl phosphates, so that the highly purified tocopheryl phosphates exhibit antioxidant and blood circulation promoting effects, have excellent water solubility, are powdery so that the handling thereof is extremely easy, are free from cutaneous irritation and allergenecity and ensure dermal safety. Therefore, the highly purified tocopheryl phosphates are useful as cosmetic ingredients. The amounts of components (i) and (ii) can be simply measured with high accuracy by the above method.

Owner:SHOWA DENKO KK

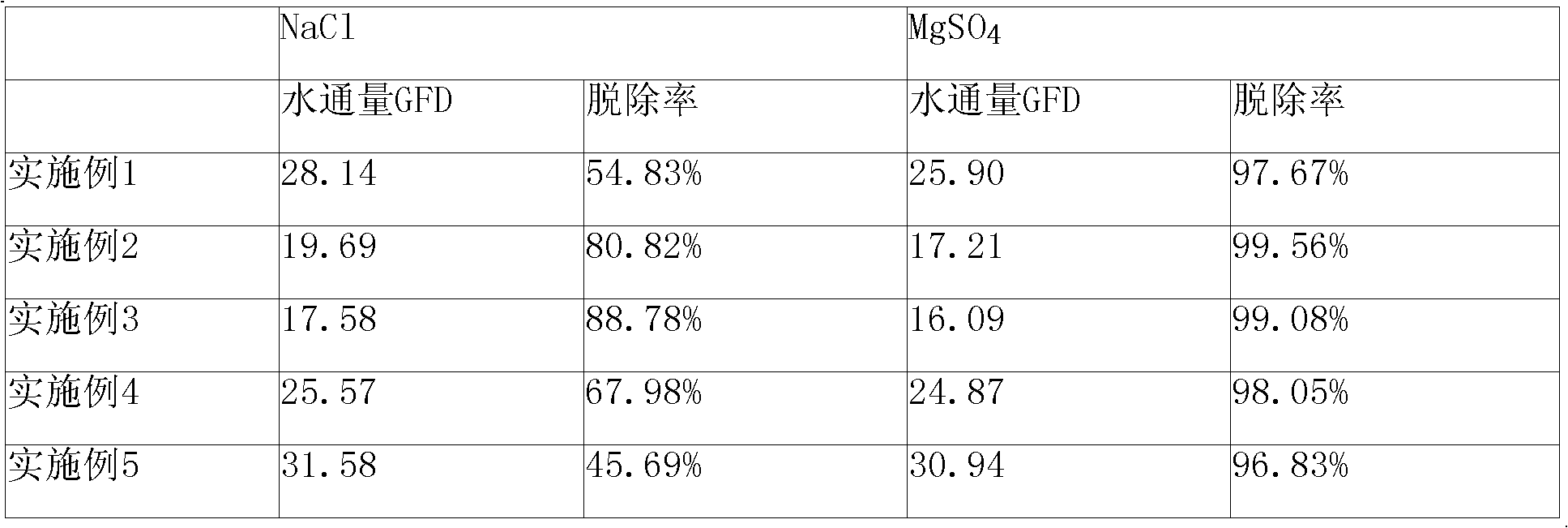

High-selectivity composite nanofiltration membrane and preparation method thereof

InactiveCN101934201AIncreasing the thicknessImproves stain resistanceSemi-permeable membranesPolyamideOxidation resistant

The invention discloses a high-selectivity composite nanofiltration membrane and a preparation method thereof. The high-selectivity composite nanofiltration membrane comprises a nonwoven layer and a polymer porous supporting layer; and the porous supporting layer is provided with one or two polyamide surface layers prepared by reacting polyamine and / or amine polyalcohol with chlorine polyacyl. Compared with the prior art, by forming one or two polyamide surface layers on the porous supporting layer through an interfacial polymerization method, the nanofiltration membrane has increased thickness of a surface layer, has more smooth, hydrolysis-resistant, oxidation-resistant and scratch-resistant surface, and improves pollution resistance; and the surface of the membrane can carry negative or positive charges, so that the composite nanofiltration membrane has a high-selectively functional desalting layer; besides, the method for preparing the composite nanofiltration membrane is simple to operate, high water flux and desalination rate are ensured under low pressure, and the service life of the membrane component is prolonged.

Owner:北京时代沃顿科技有限公司

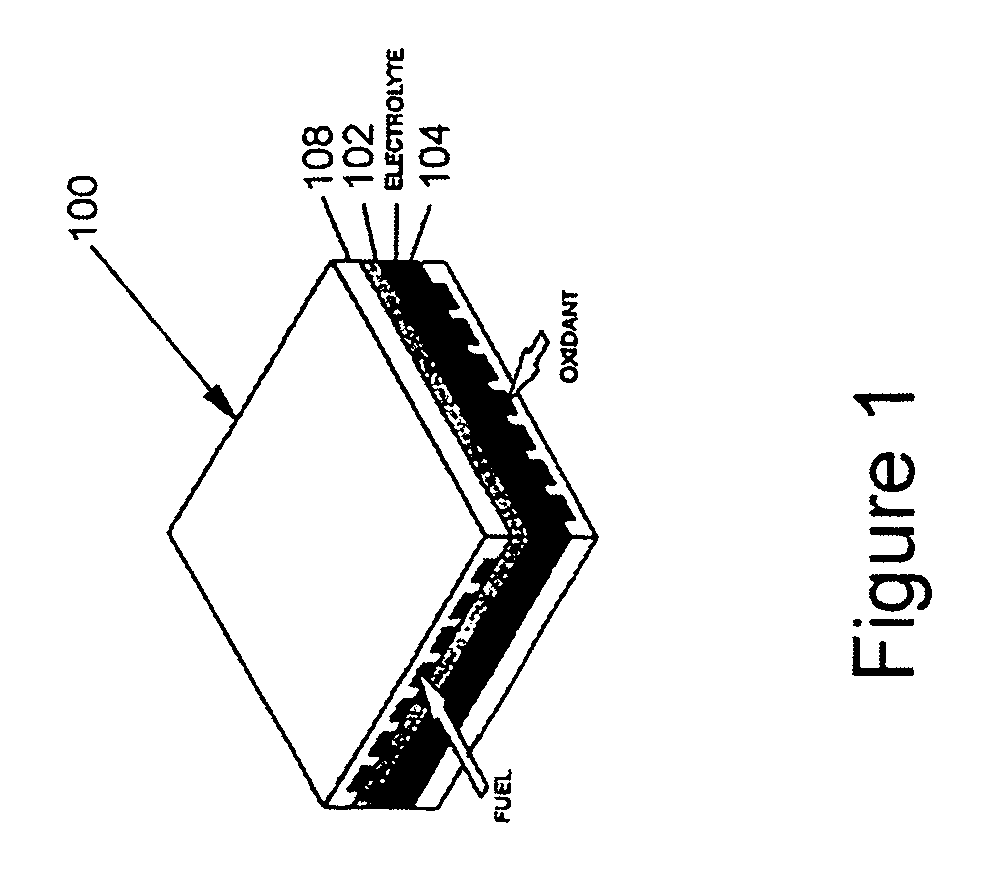

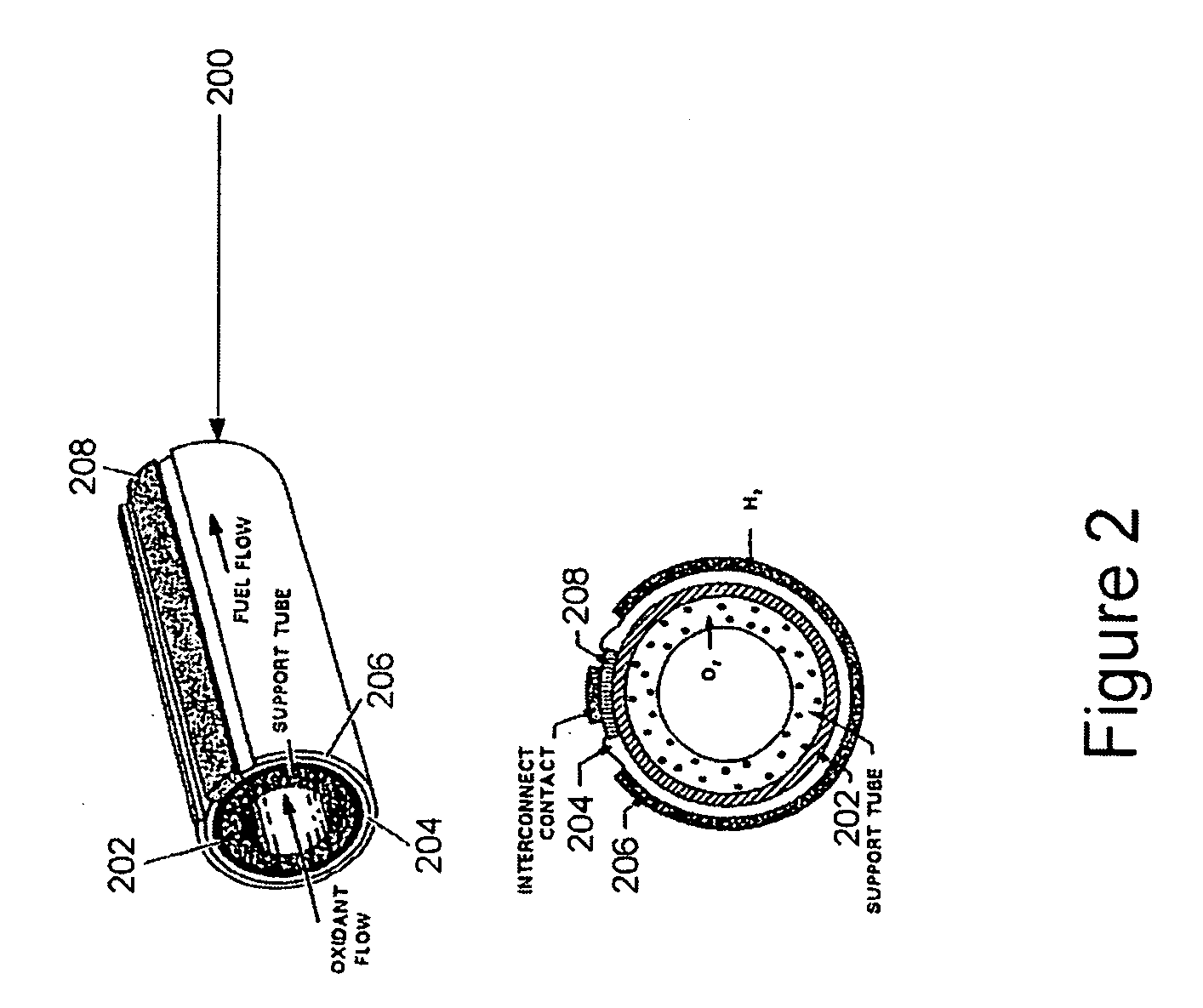

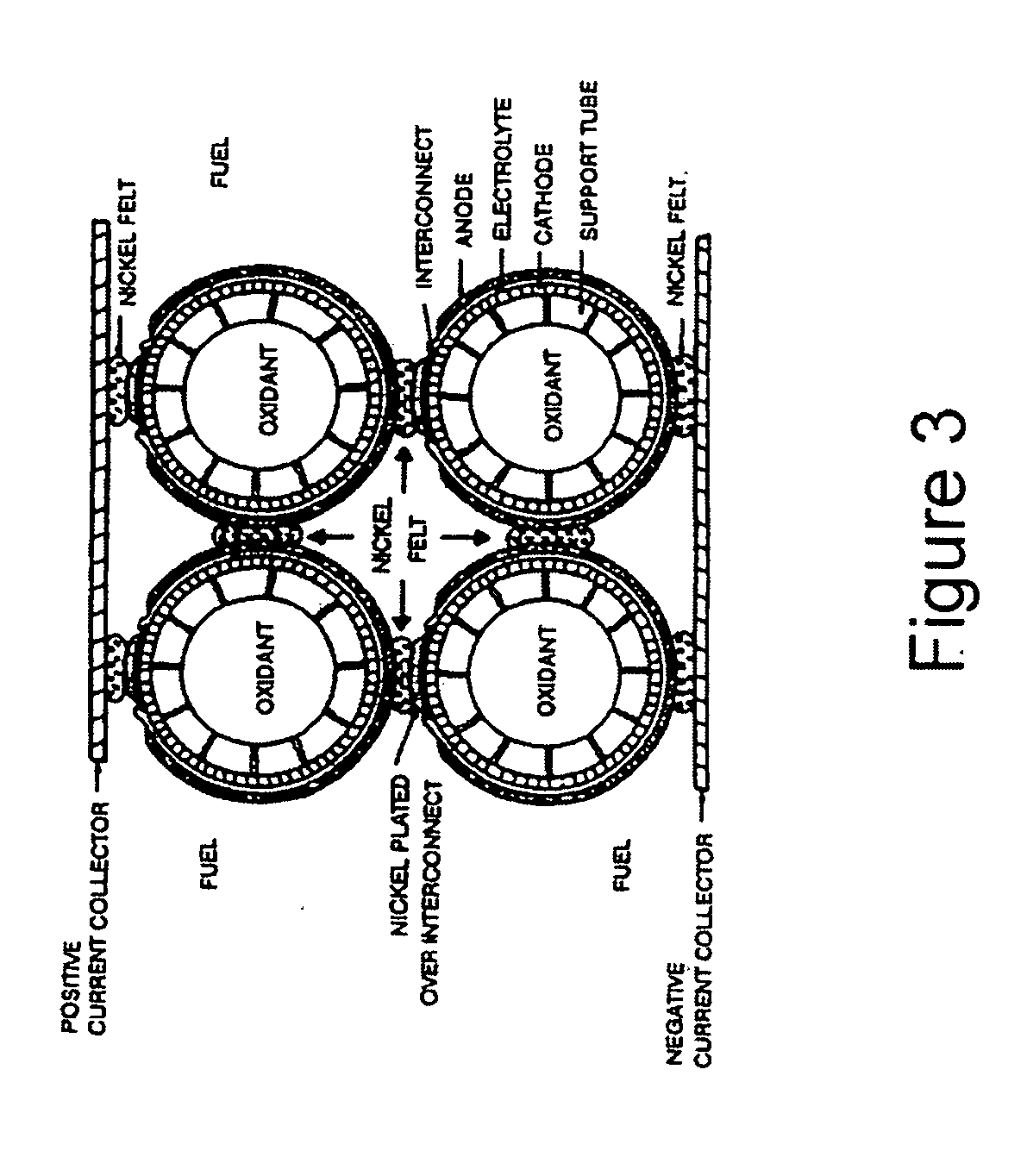

Tubular solid oxide fuel cells

InactiveUS20050037252A1Strong electrical contactImprove power densityFuel cells groupingCell electrodesFuel cellsThermal expansion

An anode-supported tubular fuel cell stack includes interconnect structures that are oxidation resistant at high temperature, flexible to accommodate thermal expansion stress and to provide strong electrical contact, have low electrical resistance, and are inexpensive and light weight. The interconnect structures may be formed out of metal sheet, which provide improved heat homogeneity throughout the fuel cell stack because of the high thermal conductivity of the metal. The interconnect structures are further shaped to provide resilience or spring-like features to allow movement between the tubular cells. Thus good electrical contact, thermal stress release, and shock absorption are simultaneously achieved.

Owner:EVOGY

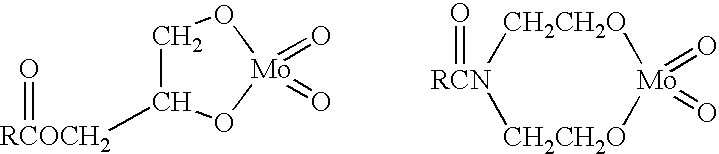

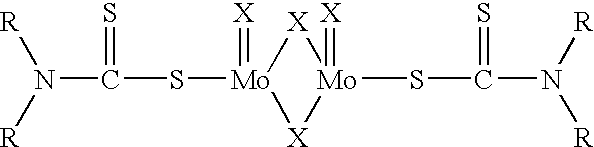

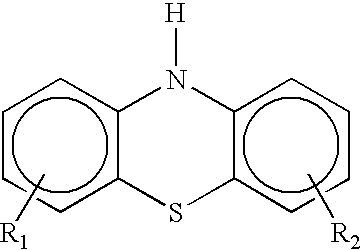

Antioxidant combination for oxidation and deposit control in lubricants containing molybdenum and alkylated phenothiazine

InactiveUS6797677B2Easy to controlPromote oxidationLiquid carbonaceous fuelsAdditivesAntioxidantOxidation resistant

The invention relates to a lubricating oil composition having improved antioxidant properties, and which contains a molybdenum compound and an alkylated phenothiazine. Further, it may also include a secondary diarylamine, preferably an alkylated diphenylamine. This combination of additives provides improved oxidation control and friction modifier performance to the lubricating oil. The composition is particularly suited for use as a crankcase lubricant, or a transmission lubricant, including low levels and zero levels of phosphorus.

Owner:AFTON CHEMICAL +1

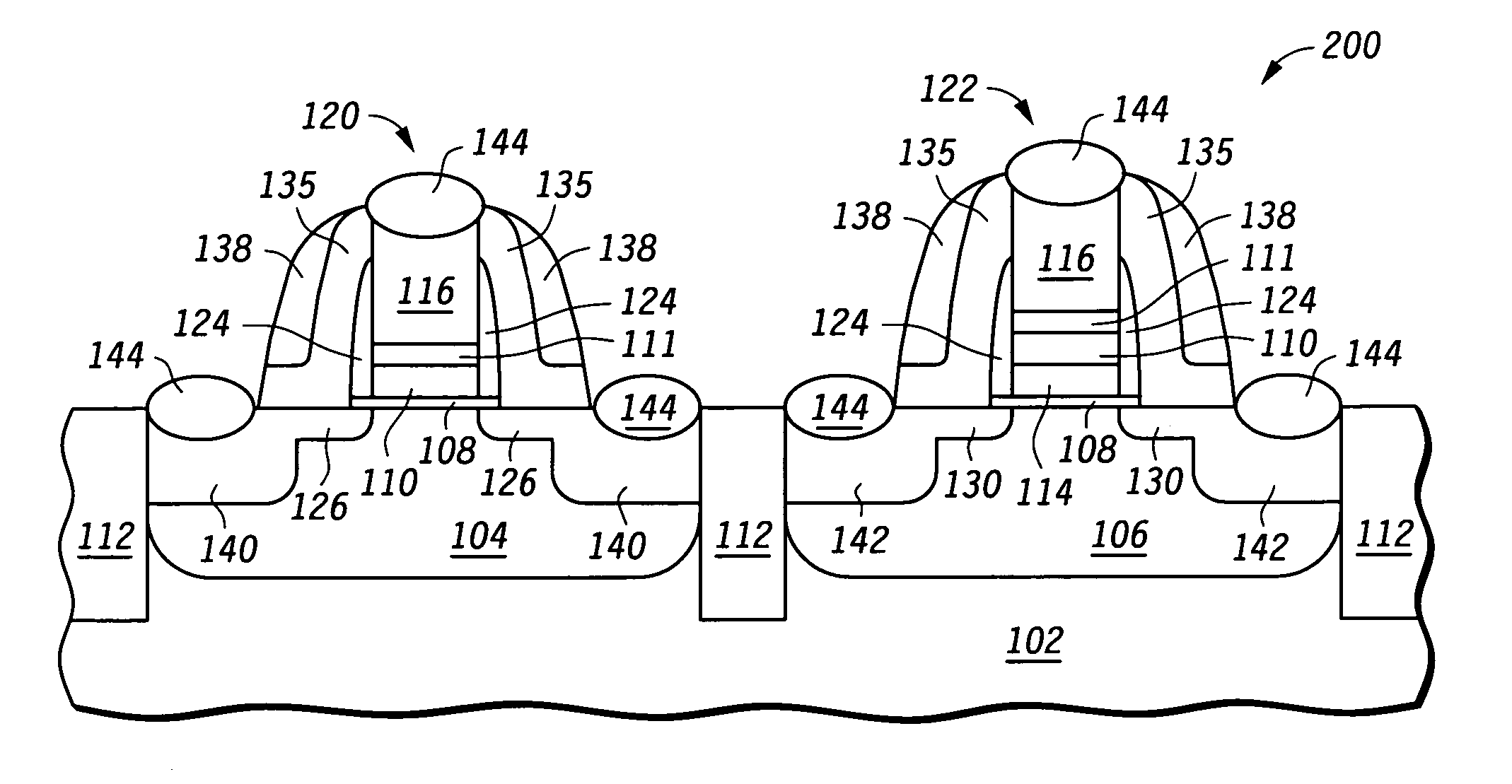

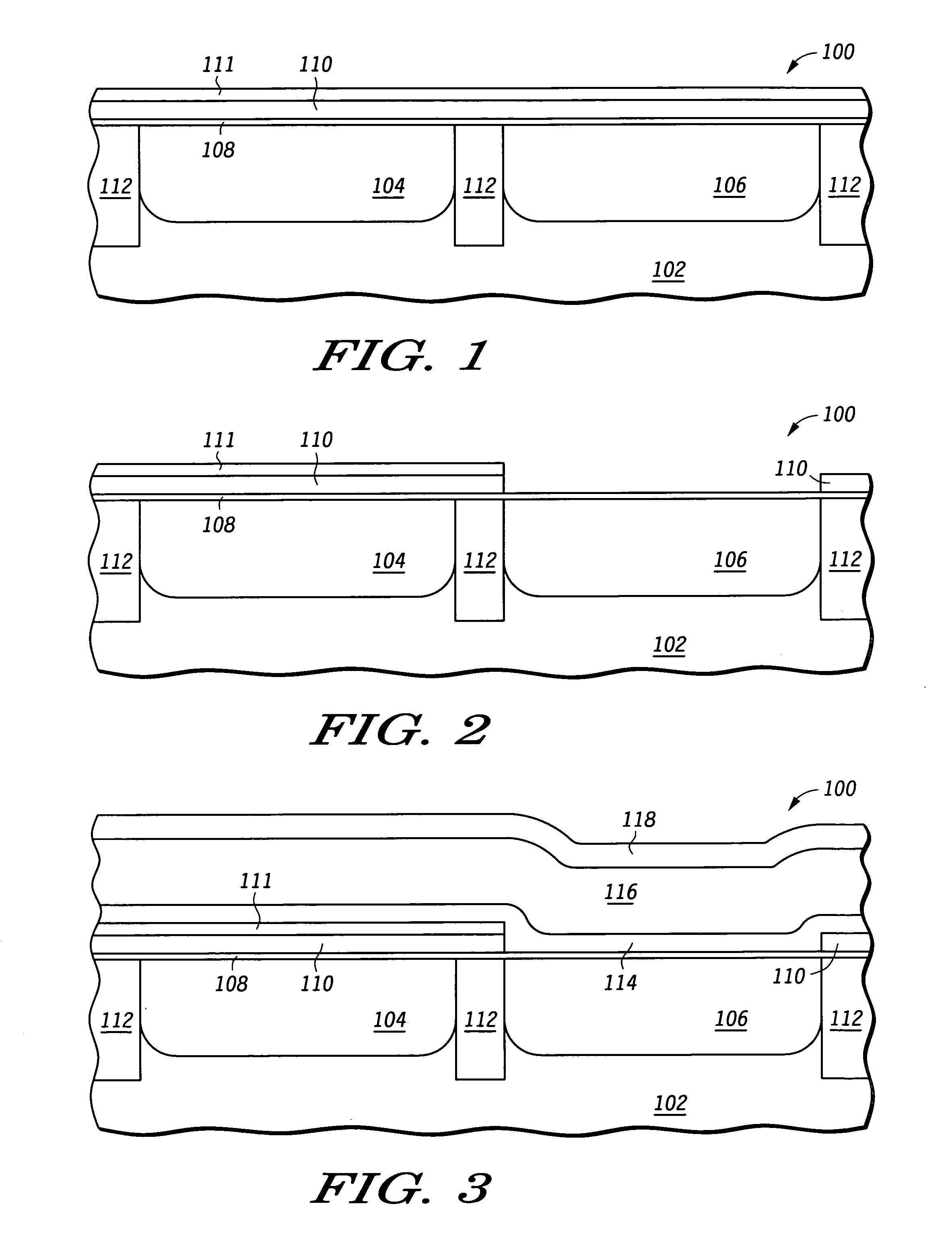

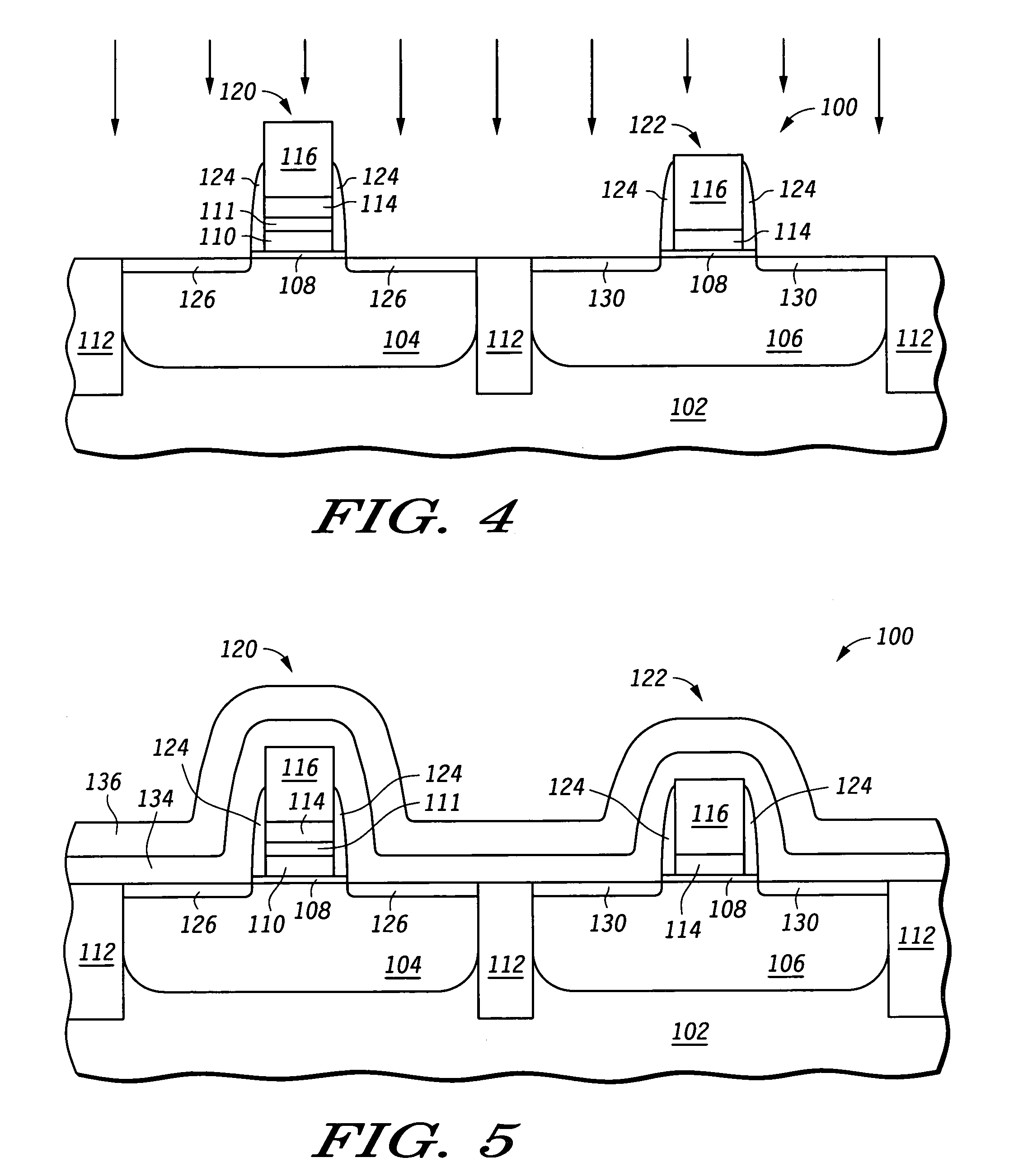

Metal gate transistor CMOS process and method for making

InactiveUS7109079B2TransistorSemiconductor/solid-state device manufacturingGate dielectricOxidation resistant

A method for forming a semiconductor device (100) includes a semiconductor substrate (102) having a first region (104), forming a gate dielectric (108) over the first region, forming a conductive metal oxide (110) over the gate dielectric, forming an oxidation resistant barrier layer (111) over the conductive metal oxide, and forming a capping layer over the oxidation resistant barrier layer. In one embodiment, the conductive metal oxide is IrO2, MoO2, and RuO2, and the oxidation resistant barrier layer includes TiN.

Owner:NORTH STAR INNOVATIONS

Method For Making Oxidation Resistant Polymeric Material

ActiveUS20080119582A1Facilitated DiffusionLavatory sanitoryJoint implantsCross-linkOxidation resistant

The present invention relates to methods for making oxidation resistant medical devices that comprise polymeric materials, for example, ultra-high molecular weight polyethylene (UHMWPE). The invention also provides methods of making antoxidant-doped medical implants, for example, doping of medical devices containing cross-linked UHMWPE with vitamin E by diffusion, post-doping annealing, and materials used therein.

Owner:THE GENERAL HOSPITAL CORP +1

Dietary supplements and prepared foods containing triglyceride-recrystallized non-esterified phytosterols

ActiveUS7575768B2Reduce fat oxidationReduce probabilityVitamin food ingredientsFatty substance preservation using additivesFood additiveDietary supplement

A nutritional supplement, prepared food product, or direct food additive for ingestion by mammals, and methods for preparing such products, are provided. Products of the invention comprise an oxidation-resistant fat-based composition substantially free of exogenous solubilizing and dispersing agents for phytosterols. The fat-based composition includes greater than 25% and less than 75% by weight of one or more triglyceride-based edible oil or fat, and greater than 25% and less than 75% by weight of one or more non-esterified phytosterols. The fat-based composition, when exposed to air, contains a reduced amount of oxidative by-products compared to a similar fat-based composition lacking non-esterified phytosterols. Also provided are methods for reducing plasma cholesterol in mammals, and methods for protecting plasma lipoproteins and cholesterol from oxidation by ingestion of products of the invention.

Owner:BRANDEIS UNIV

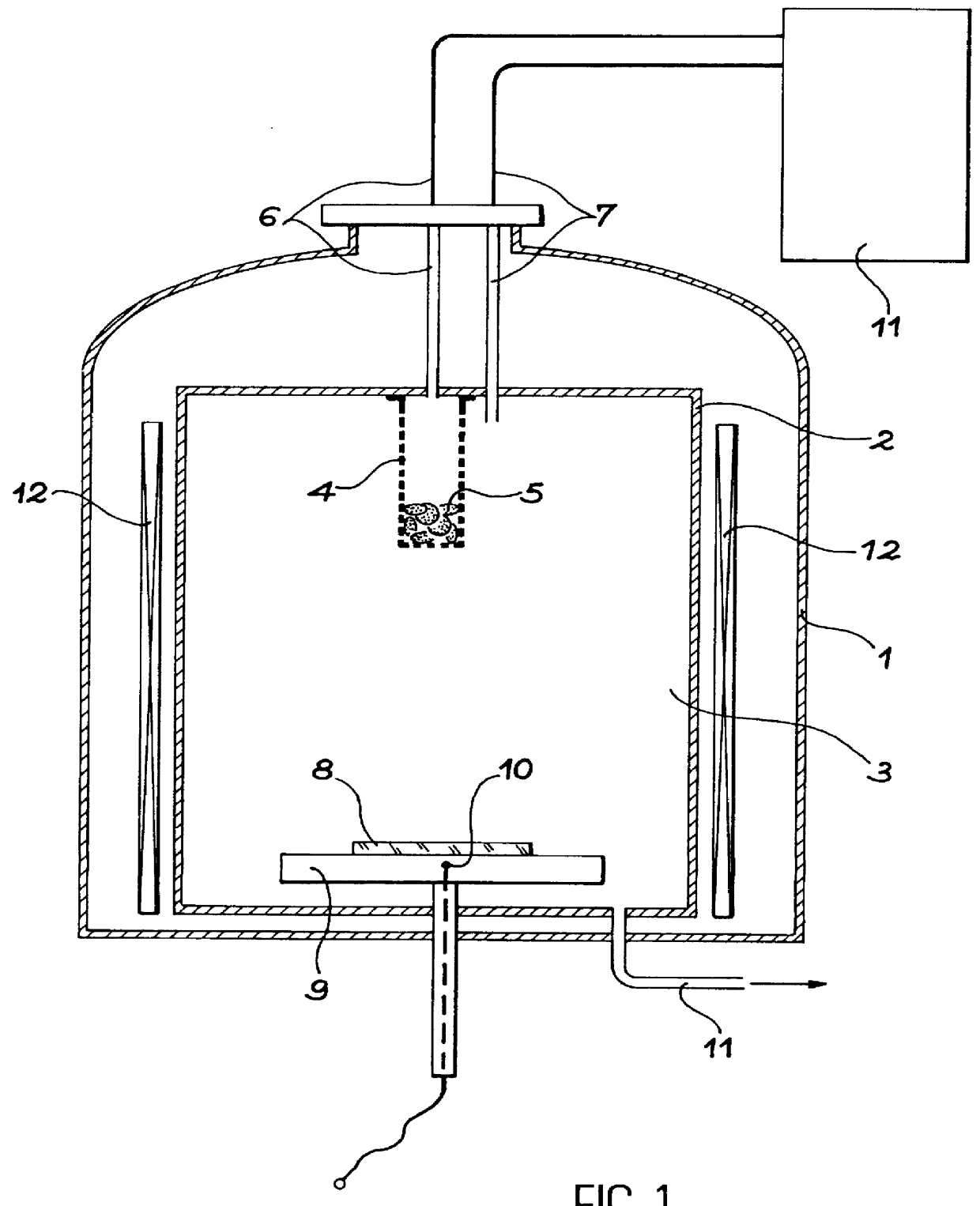

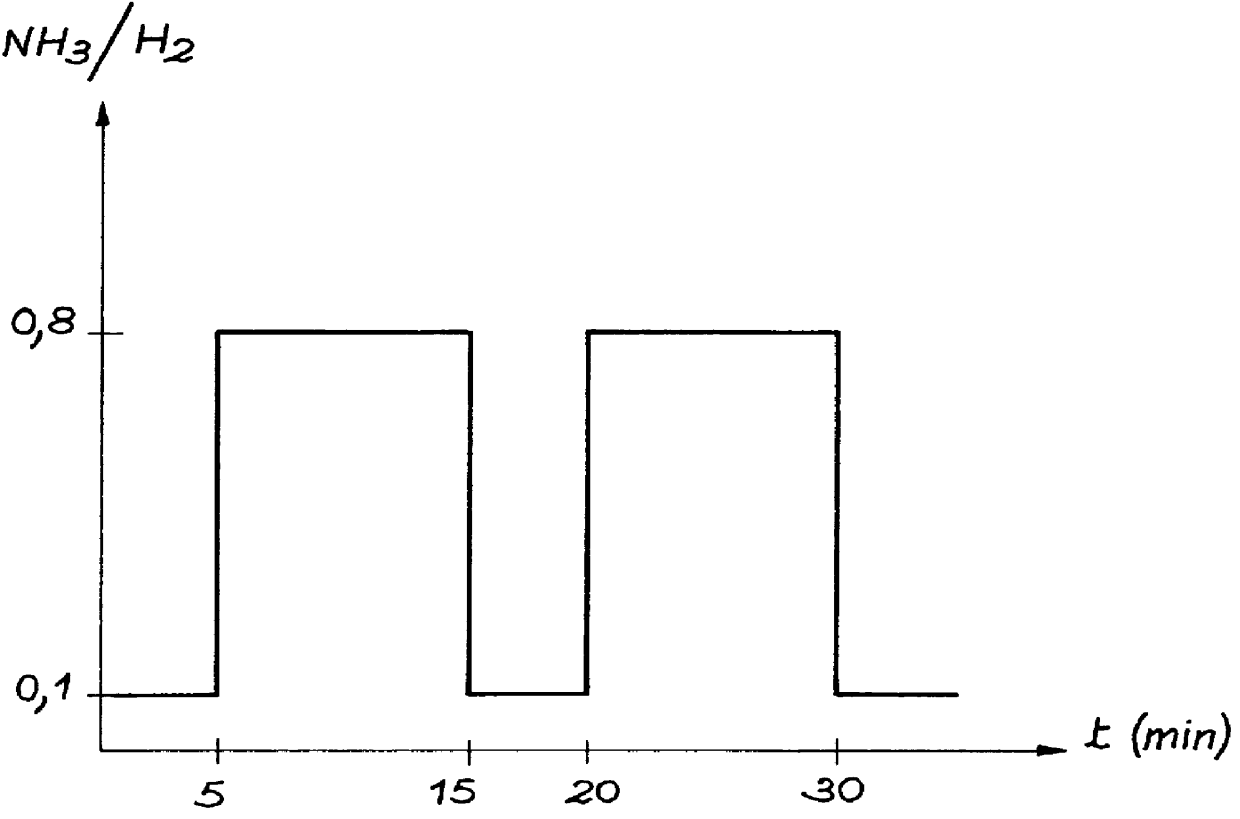

Process for the preparation by chemical vapor deposition (CVD) of a Ti-A1-N based multilayer coating

InactiveUS6040012AConsiderable flexibilityEasy to implementChemical vapor deposition coatingAluminium chlorideWear resistant

The invention relates to a process for the preparation of a multilayer coating, comprising a stack, on a substrate, of several layers chosen from among layers constituting by TiN and layers constituted by (Ti,Al)N, also known as Ti1-xAlxN, the entire coating being produced in a single, continuous operation by thermal chemical vapour deposition (CVD) from a gaseous mixture comprising a reducing gas, such as ammonia or nitrogen, hydrogen and titanium and optionally aluminium chlorides, the nature and / or composition of each deposited layer being instantaneously adjusted by modifying the reducing gas to hydrogen molar ratio in the gaseous mixture. The invention also relates to multilayer coatings comprising (Ti,Al)N layers of variable compositions and in particular with composition gradient. Application to wear-resistant or abrasion-proof coatings having a resistance to oxidation and corrosion, particularly at high temperatures.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Radiation melt treated ultra high molecular weight polyethylene prosthetic devices

InactiveUS20050165495A1Reduce productionReduce osteolysis and inflammatory reactionBone implantJoint implantsProsthesisOxidation resistant

A medical prosthesis for use within the body which is formed of radiation treated ultra high molecular weight polyethylene having substantially no detectable free radicals, is described. Preferred prostheses exhibit reduced production of particles from the prosthesis during wear of the prosthesis, and are substantially oxidation resistant. Methods of manufacture of such devices and material used therein are also provided.

Owner:THE GENERAL HOSPITAL CORP +1

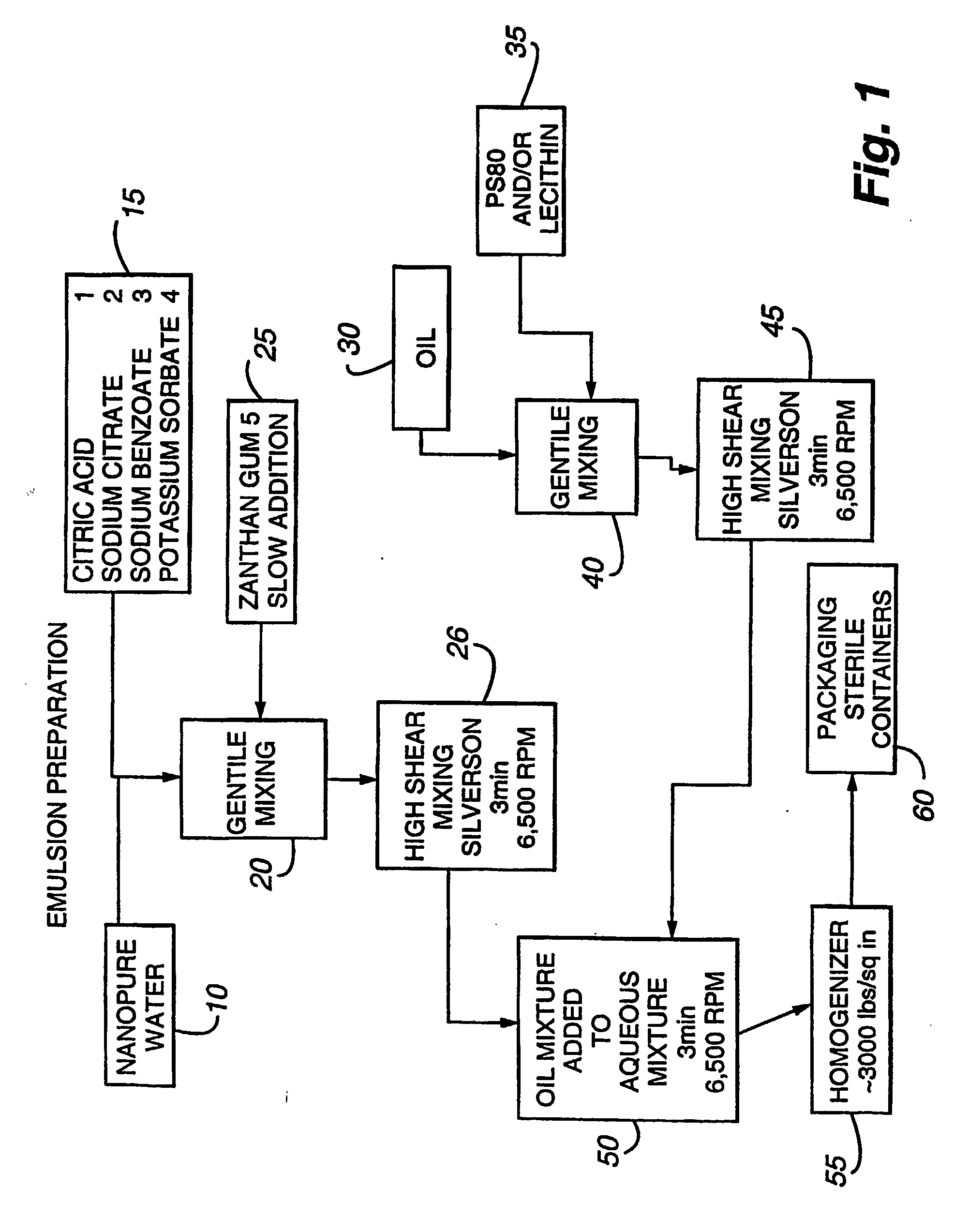

Stable emulsions of oils in aqueous solutions and methods for producing same

InactiveUS20060165735A1Physically and/orCosmetic preparationsToilet preparationsEmulsionOxidation resistant

Methods for making highly stable, oxidation-resistant emulsions comprising an oil, an emulsifier, an emulsion stabilizer and water are provided. The invention is particularly well suited for oils that are susceptible to oxidation, such as long chain polyunsaturated fatty acid oils. The resulting emulsion is highly stable and resistant to oxidation, and is useful in a number of products and as a stand-alone product.

Owner:MARTEK BIOSCIENCES CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com